Preparation method of carbon fiber electrode efficiently producing hydrogen peroxide to treat organic wastewater

A carbon fiber electrode, hydrogen peroxide technology, applied in oxidation water/sewage treatment, chemical instruments and methods, water/sewage treatment, etc., can solve the problems of restricted application, low output, etc., achieve high-efficiency treatment, simple operation, increase reaction The effect of the active site

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

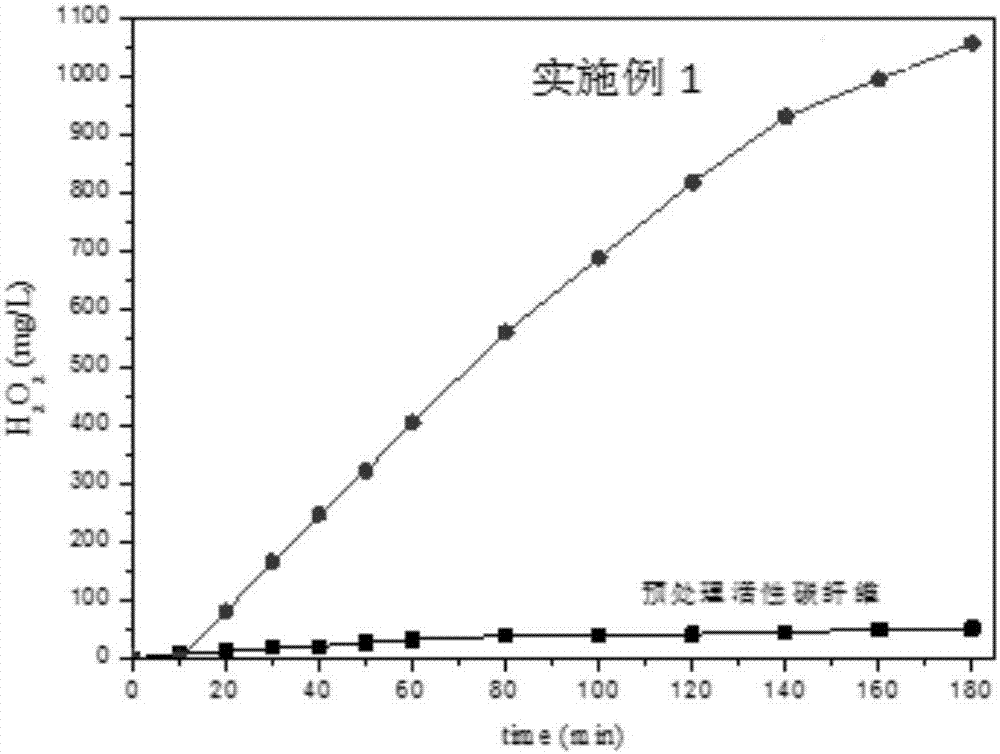

Embodiment 1

[0027] step one;

[0028] Mix 0.2g of carbon nanotube particles and 0.2g of polytetrafluoroethylene into 15ml of deionized water, then add 1ml of isopropanol, and ultrasonically mix the solution for 10 minutes to obtain a mixed solution A;

[0029] Step two;

[0030] Apply the mixed solution A evenly on both sides of the cleaned and degreased carbon fiber material to obtain a pretreated carbon fiber material

[0031] Step three;

[0032] The pretreated carbon fiber material obtained in step 2 was placed in an oven at a temperature of 40° C. for 4 hours, and then placed in a muffle furnace for annealing treatment at 300° C. for 1 hour to obtain the carbon fiber material.

Embodiment 2

[0034] step one;

[0035] Mix 0.2g of carbon nanotube particles and 0.6g of polytetrafluoroethylene into 20ml of deionized water, then add 2ml of isopropanol, and mix the solution evenly by ultrasonication for 15min to obtain a mixed solution A;

[0036] Step two;

[0037] Apply the mixed solution A evenly on both sides of the cleaned and degreased carbon fiber material to obtain a pretreated carbon fiber material;

[0038] Step three;

[0039] The pretreated carbon fiber material obtained in step 2 was placed in an oven at 60° C. for 6 hours, and then placed in a muffle furnace for annealing at 360° C. for 1 hour to obtain the carbon fiber material.

Embodiment 3

[0041] step one;

[0042] Mix 0.2g of carbon nanotube particles and 1.4g of polytetrafluoroethylene into 30ml of deionized water, then add 3ml of isopropanol, and mix the solution uniformly by ultrasonication for 20min to obtain a mixed solution A;

[0043] Step two;

[0044] Apply the mixed solution A evenly on both sides of the cleaned and degreased carbon fiber material to obtain a pretreated carbon fiber material;

[0045] Step three;

[0046] The pretreated carbon fiber material obtained in step 2 was placed in an oven at 80° C. for 8 hours, and then placed in a muffle furnace for annealing treatment at 360° C. for 1 hour to obtain the carbon fiber material.

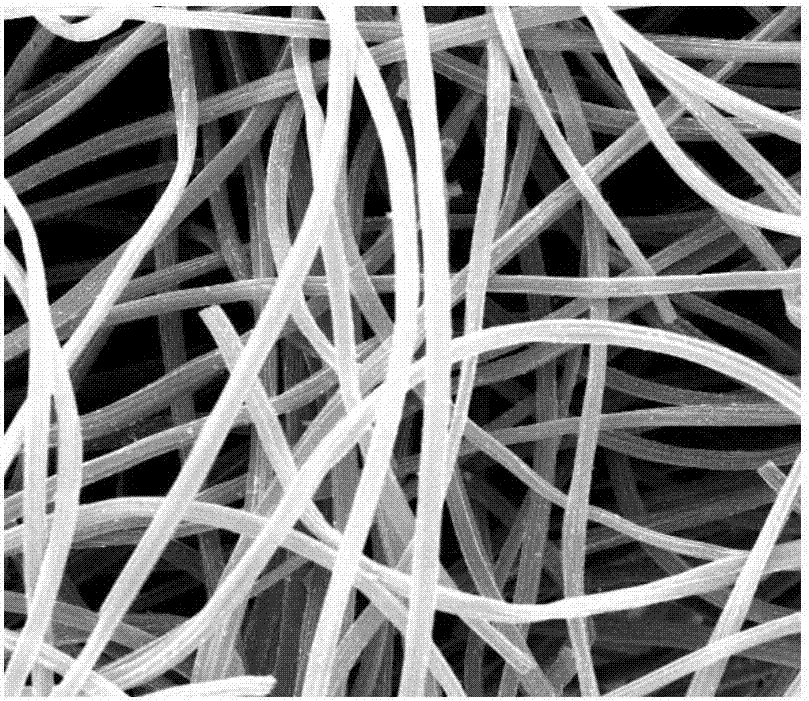

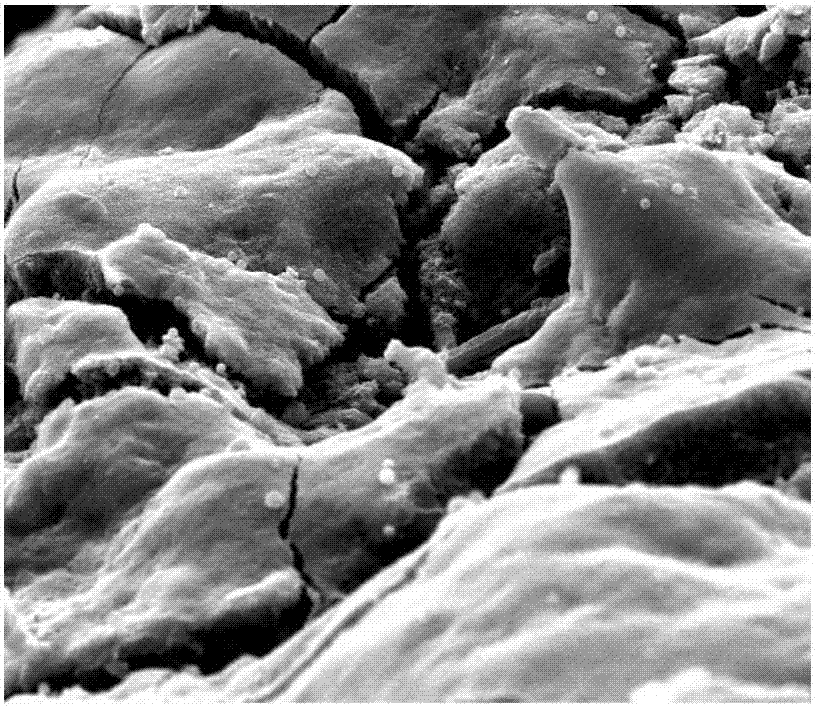

[0047] The SEM figure of the carbon fiber obtained in embodiment 1 is as figure 1 As shown, as a control, the SEM image of the pretreated carbon fiber is shown in figure 2 As shown, it can be seen that the surface of the material obtained in the example is loaded with a large number of nano-carbon particles and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com