Patents

Literature

121results about "Chloride preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Enhanced mercury control in coal-fired power plants

InactiveUS6808692B2Easy to captureEliminate dischargeChloride preparationUsing liquid separation agentPulverized fuel ashElemental mercury

A method of treating a coal combustion flue gas, which includes injecting a molecular halogen or thermolabile molecular halogen precursor, such as calcium hypochlorite, able to decompose to form molecular halogen at flue gas temperature. The molecular halogen converts elemental mercury to mercuric halide, which is adsorbable by alkaline solids such as subbituminous or lignite coal ash, alkali fused bituminous coal ash, and dry flue gas desulphurization solids, capturable in whole or part by electrostatic precipitators (ESPs), baghouses (BHs), and fabric filters (FFs), with or without subsequent adsorption by a liquid such as a flue gas desulphurization scrubbing liquor.

Owner:HAZELMERE RES

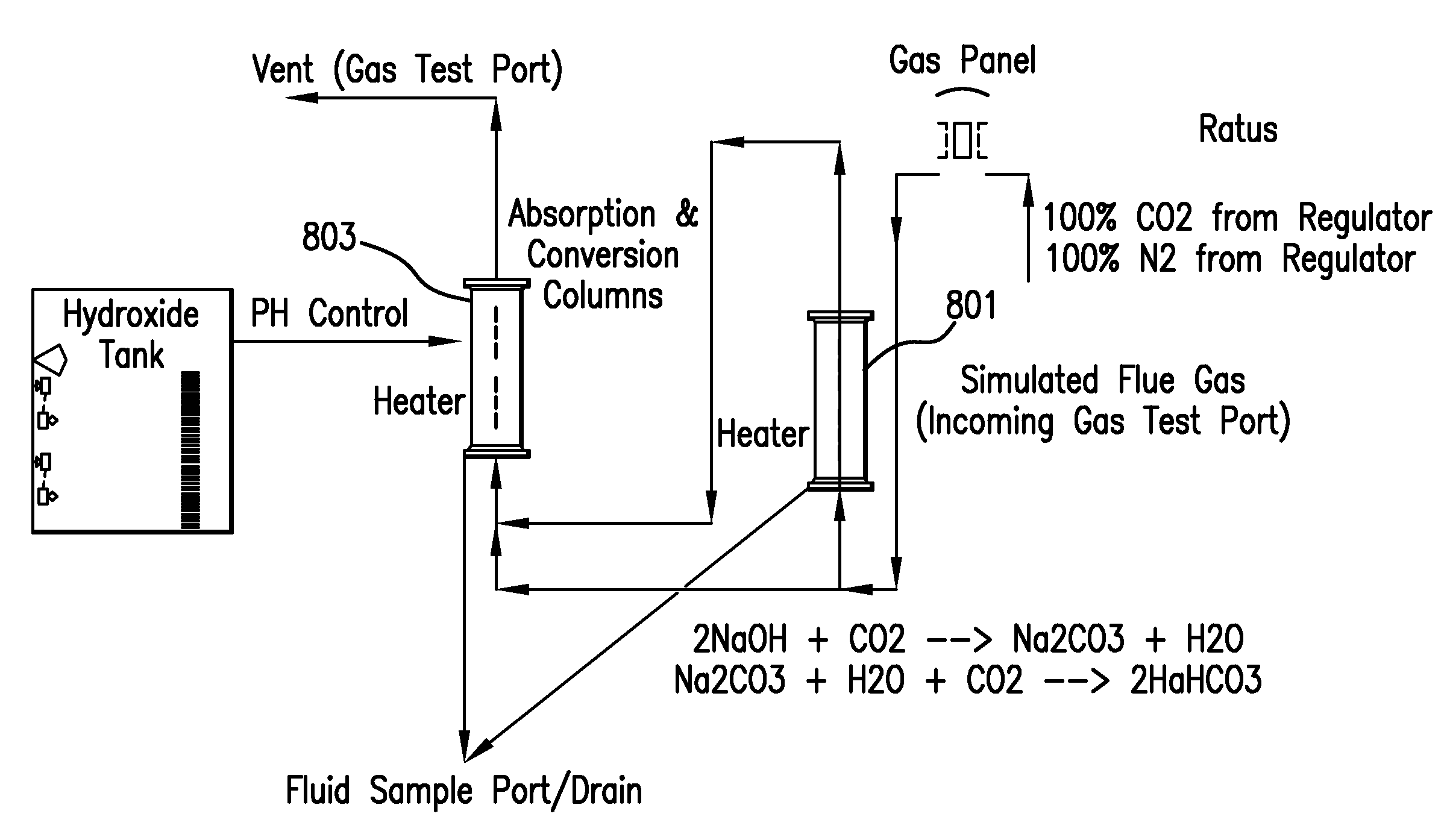

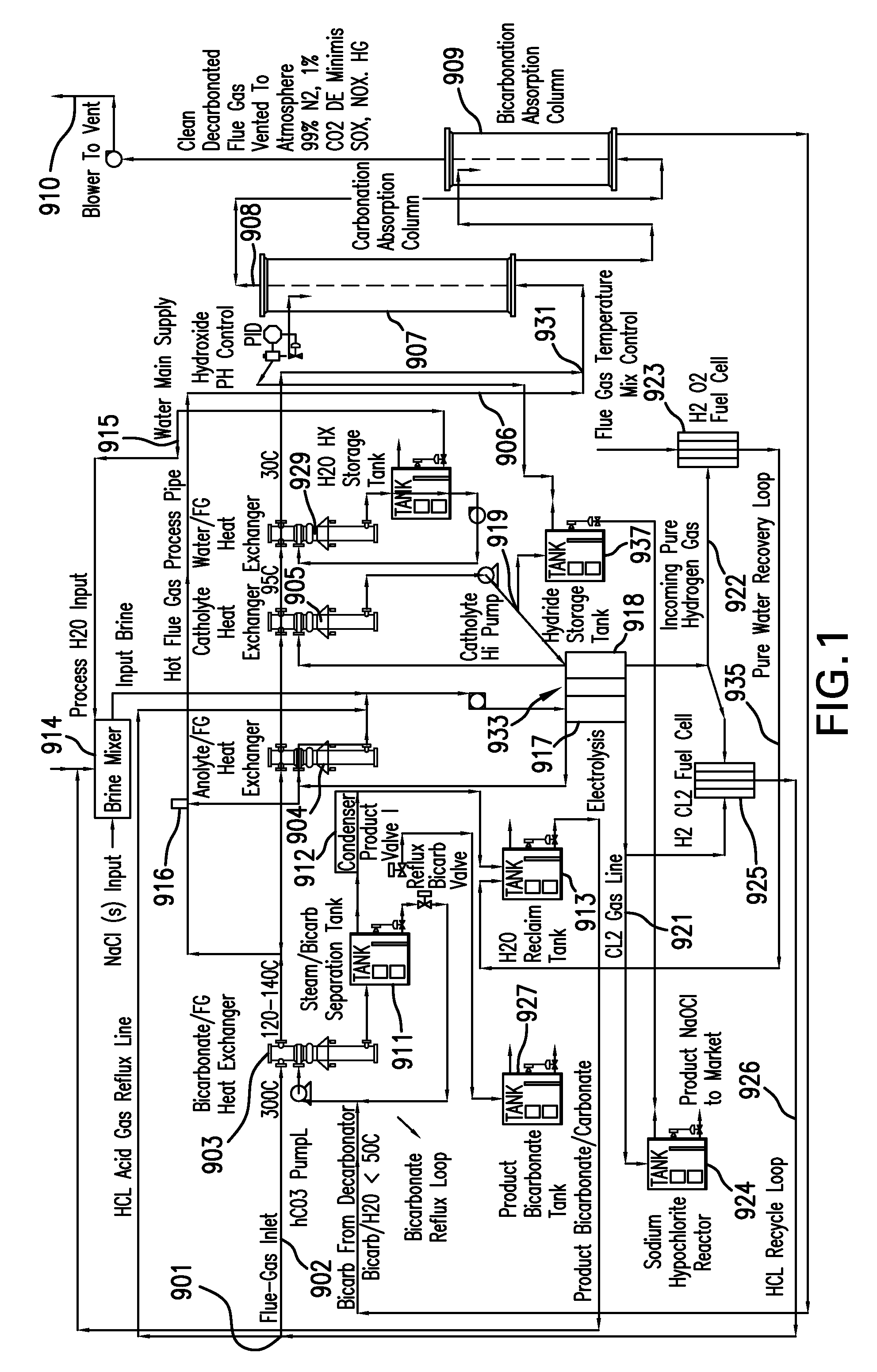

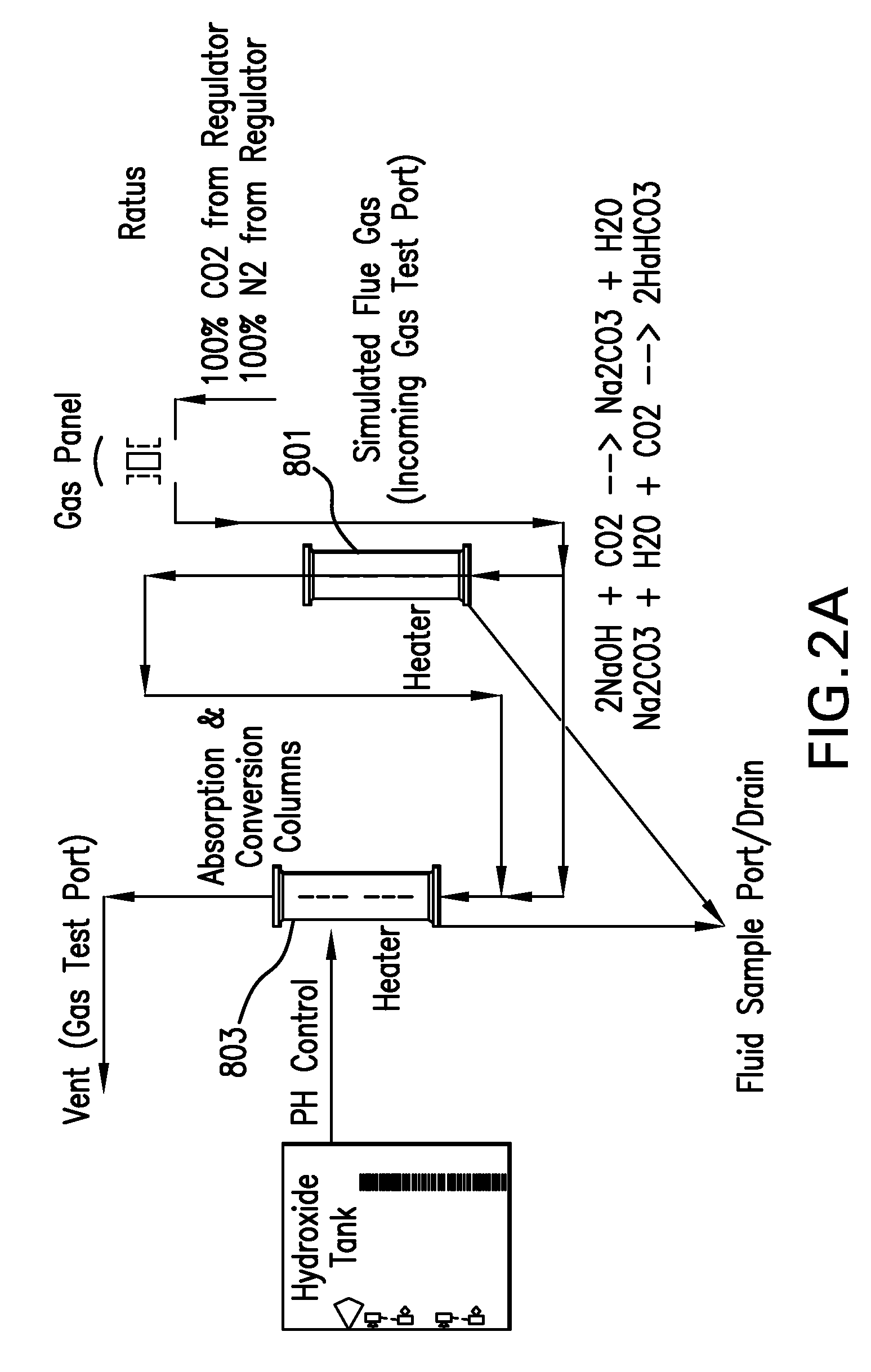

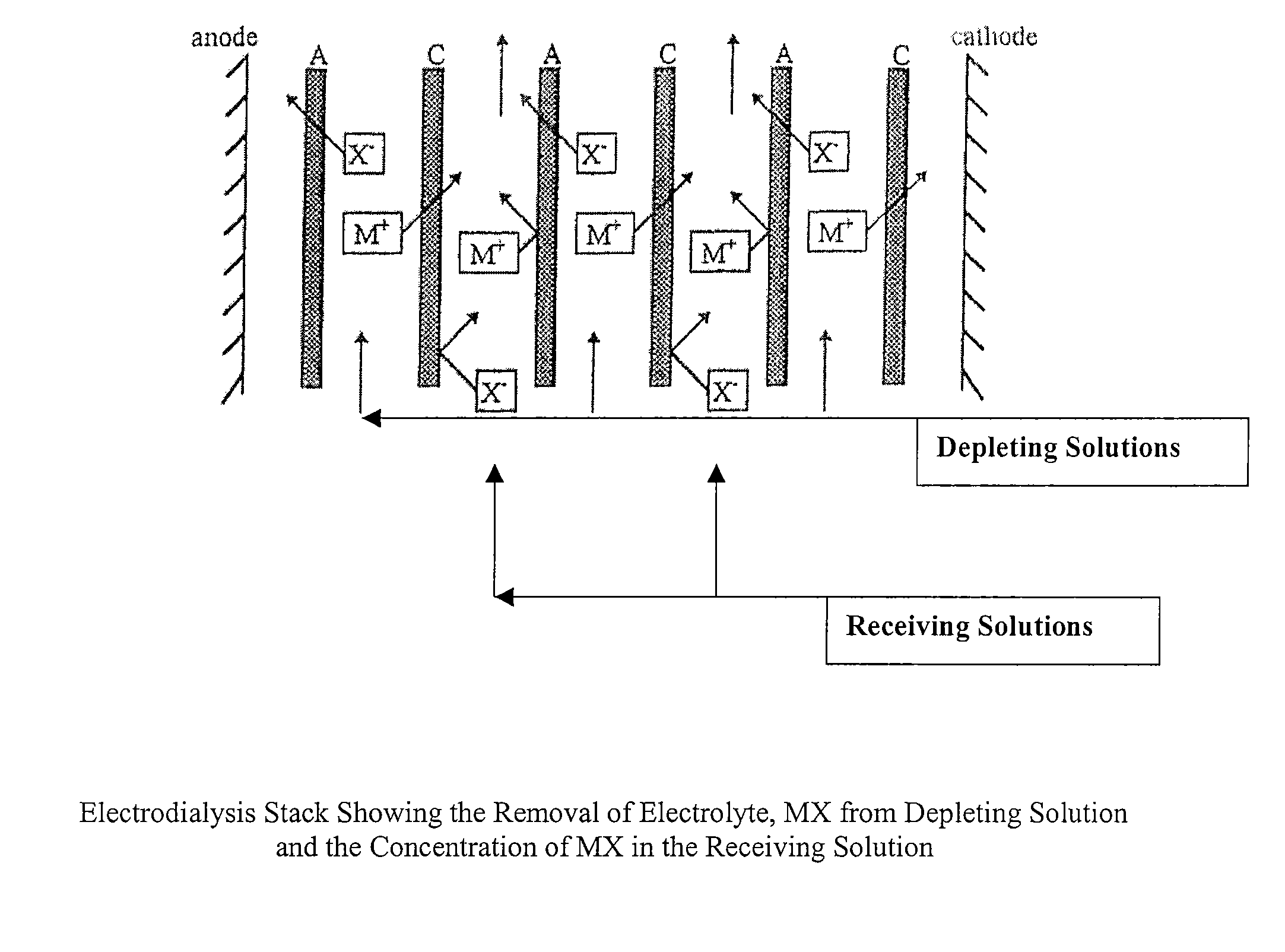

Removing Carbon Dioxide From Waste Streams Through Co-Generation of Carbonate and/or Bicarbonate Minerals

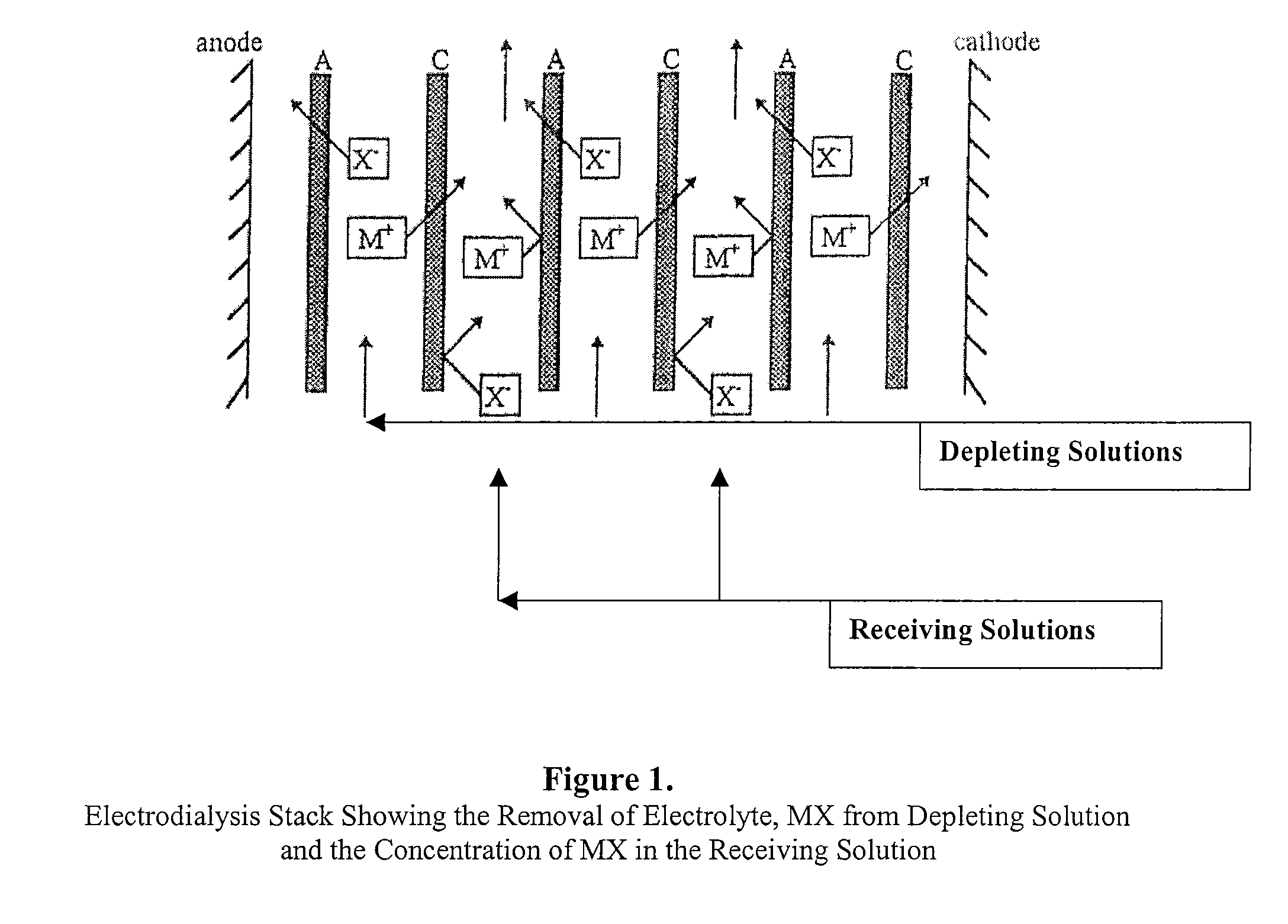

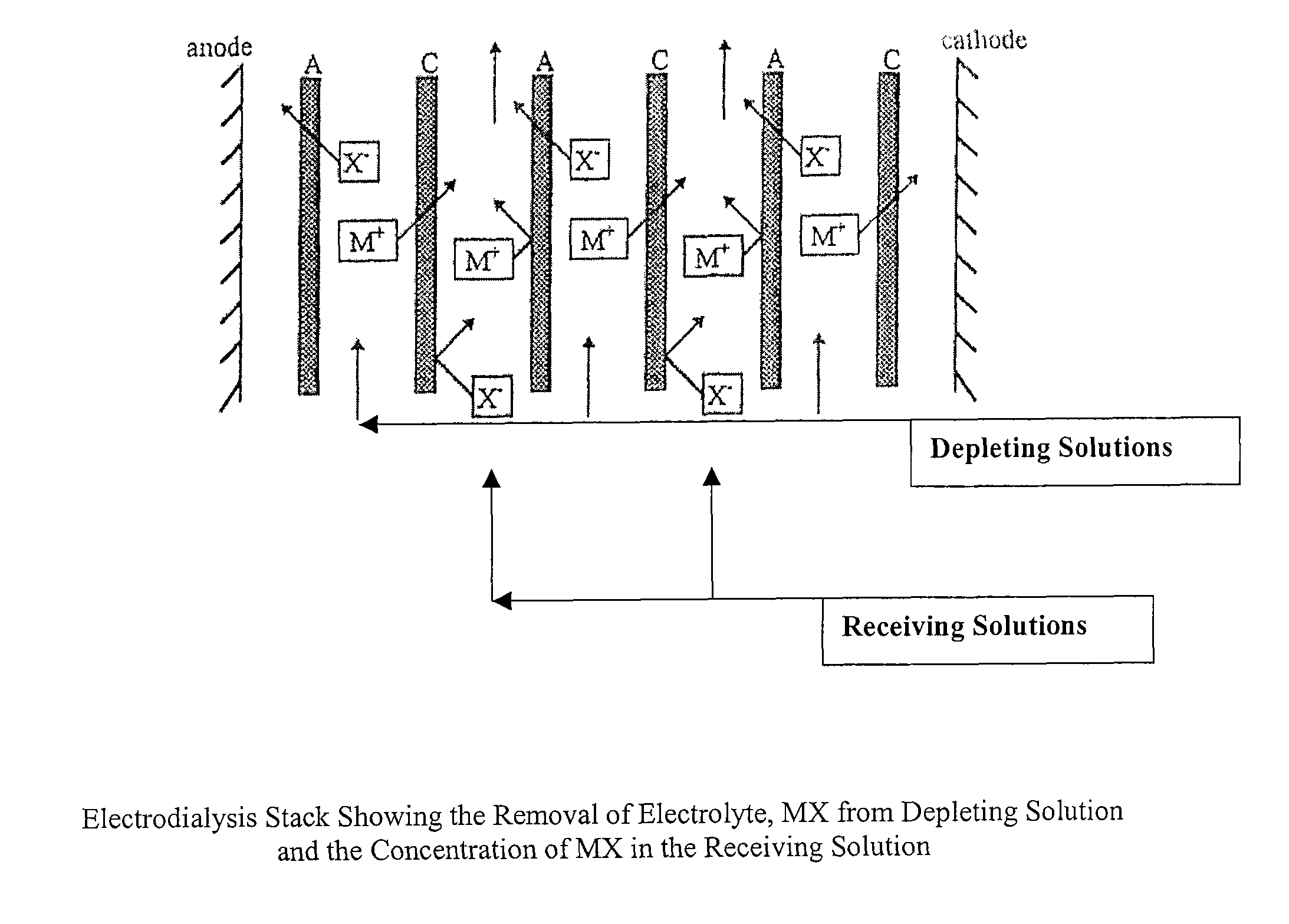

ActiveUS20090127127A1Prevent returnChloride preparationCalcium/strontium/barium chloridesDicarbonateElectrolysis

Apparatuses and methods for removing carbon dioxide and other pollutants from a gas stream are provided. The methods include obtaining hydroxide in an aqueous mixture, and mixing the hydroxide with the gas stream to produce carbonate and / or bicarbonate. Some of the apparatuses of the present invention comprise an electrolysis chamber for providing hydroxide and mixing equipment for mixing the hydroxide with a gas stream including carbon dioxide to form an admixture including carbonate and / or bicarbonate.

Owner:CARBONFREE CHEM HLDG LLC

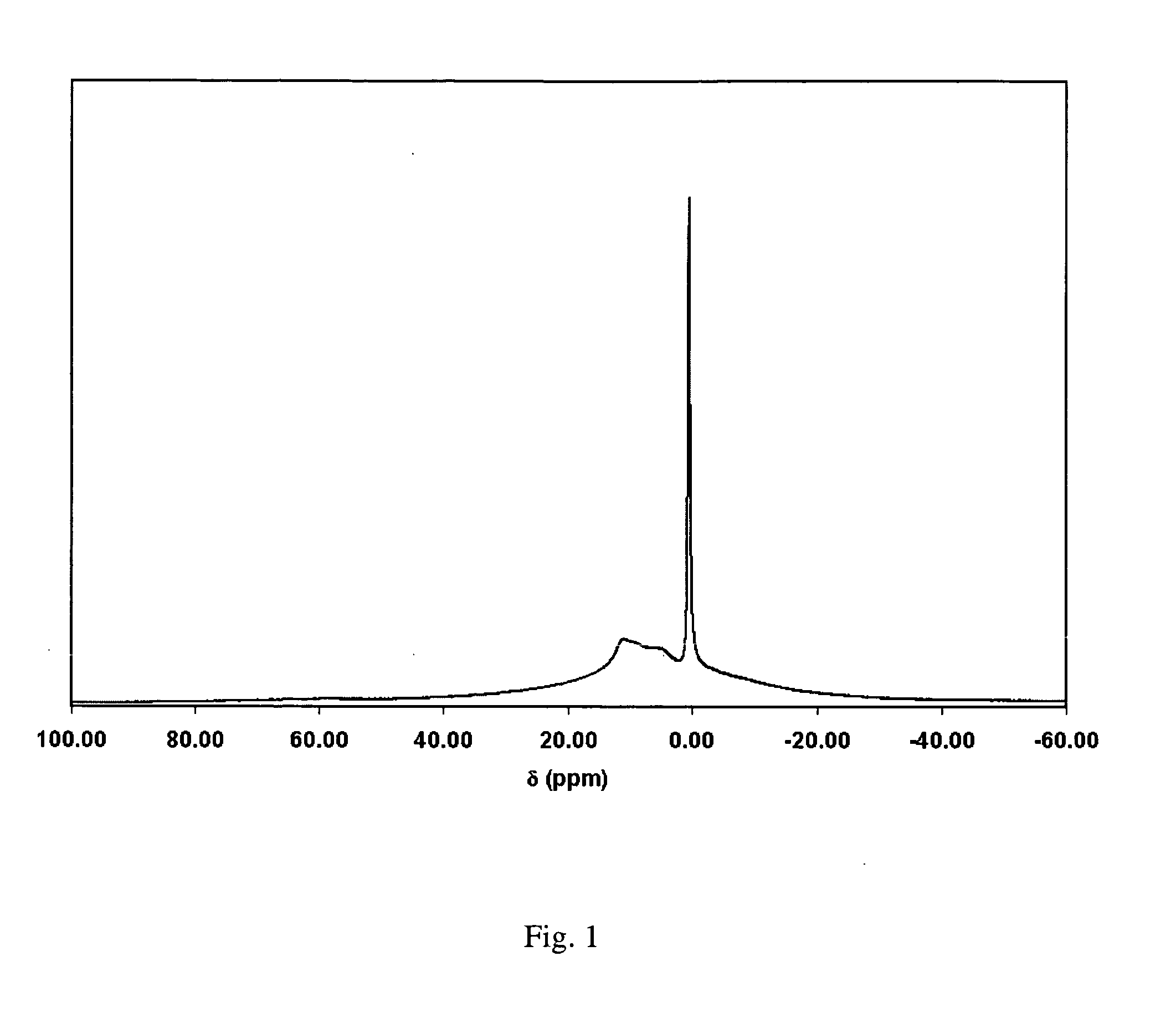

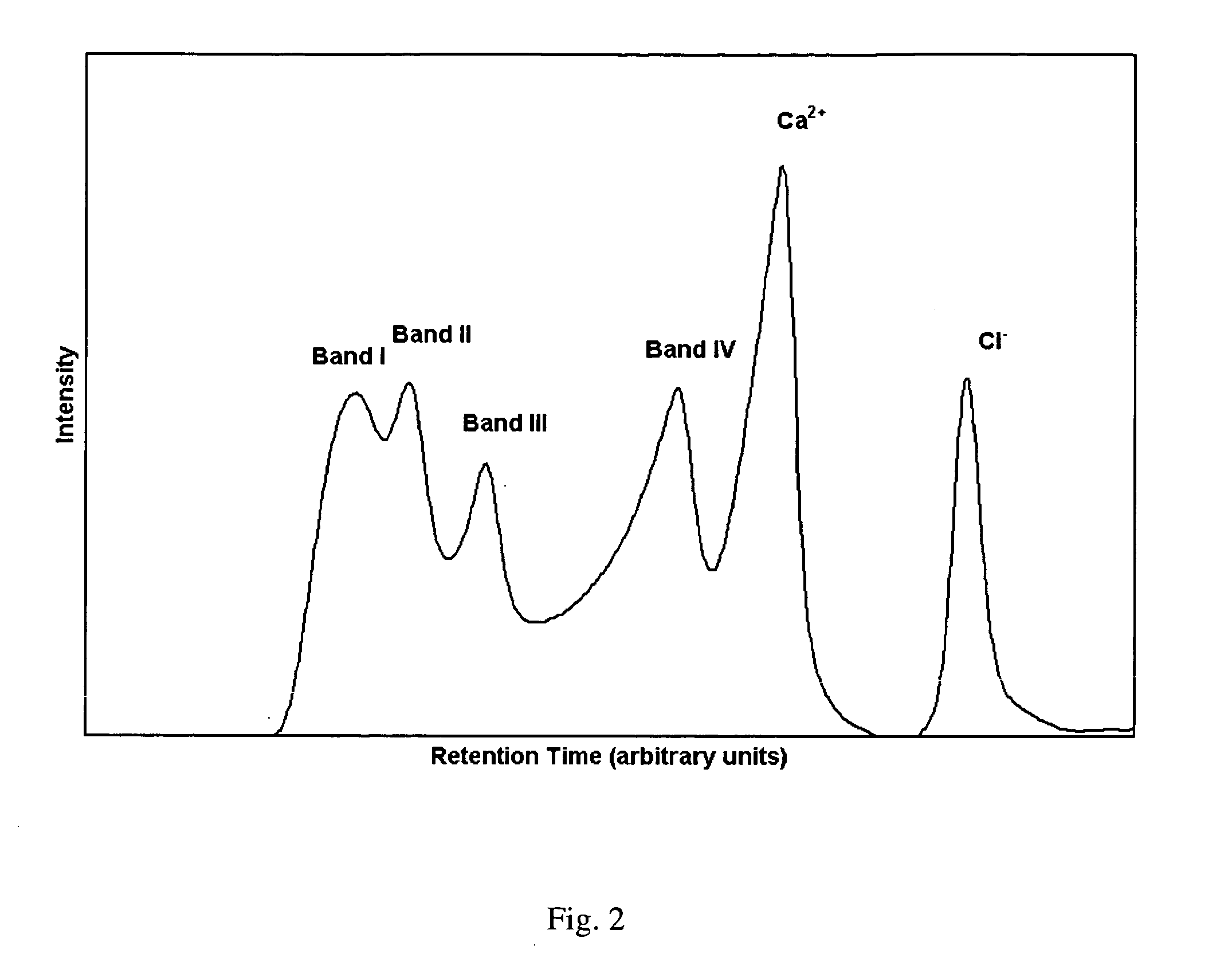

Polyaluminum calcium hydroxychlorides and methods of making the same

InactiveUS20080131354A1Improve efficiencyReduce sludge generationCosmetic preparationsChloride preparationAluminum hydrateHigh pressure

A process is provided for the preparation of a novel polyaluminum calcium hydroxychloride composition of enhanced efficiency for water treatment, paper sizing, and antiperspirant applications. The polyaluminum calcium hydroxychloride compositions are prepared via the acidification of higher basicity reaction products to form mid-to-high basicity final products. Two methods are provided for the preparation of higher basicity products, contemplated in the first, and an aqueous acid solution, such as hydrochloric acid, aluminum chloride, or a mixture thereof, is mixed with a strong alkaline calcium salt such as calcium oxide or calcium carbonate and aluminum powder at temperatures greater than 60° C. In a second method, bauxite, aluminum hydrate, or aluminum metal, and calcium aluminate are mixed with hydrochloric acid and are reacted at high temperatures and / or elevated pressures for a certain period of time whereby, when the reaction is complete, the mixtures are filtered to obtain clear solutions. The final PAC-Ca solutions may be dried to powder to have a wide range of basicities from about 40% to about 80%. At lower basicities, the polyaluminum calcium hydroxychloride sales are used preferably as antiperspirants, while at higher basicities, the solutions are used preferably as water treatment chemicals.

Owner:GENERAL CHEM LLC

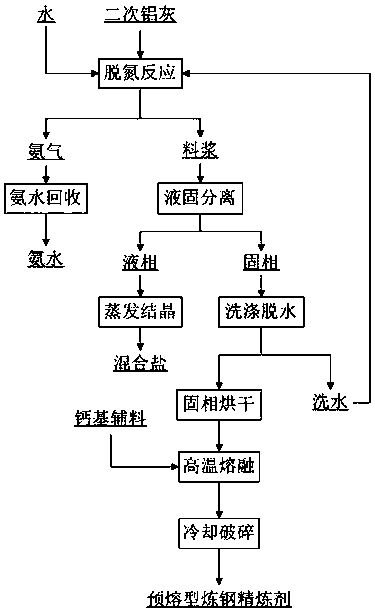

Harmless and comprehensive utilization method of secondary aluminum dross

InactiveCN107555447ARealize harmless treatmentTo achieve the purpose of "zero emission" utilizationChloride preparationFluoride preparationSlurryLiquid solid

The invention provides a harmless and comprehensive utilization method of secondary aluminum dross and relates to a harmless and comprehensive utilization method of secondary aluminum dross produced in an aluminum dross treating process. The harmless and comprehensive utilization method is characterized in that slurry is prepared from the secondary aluminum dross produced in the aluminum dross treating process and water, a stirring deamination reaction is performed, and ammonia gas formed through the reaction is condensed or absorbed by water; slurry after the reaction is subjected to liquid-solid separation, separated liquid phase is subjected to evaporative crystallization, and a chlorate and fluoride salt mixture is obtained; separated solid phase is used for producing a calcium aluminate material. With adoption of the method, the aluminum dross can be treated harmlessly, useful components in the aluminum dross are recovered efficiently, the harmless secondary aluminum dross can replace high-alumina bauxite for preparing a calcium aluminate product, production cost is reduced greatly, zero-release utilization of the aluminum dross is realized, the process is simple, the operation is convenient, the cost is low, environmental protection is realized, and the method has wide applicability.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

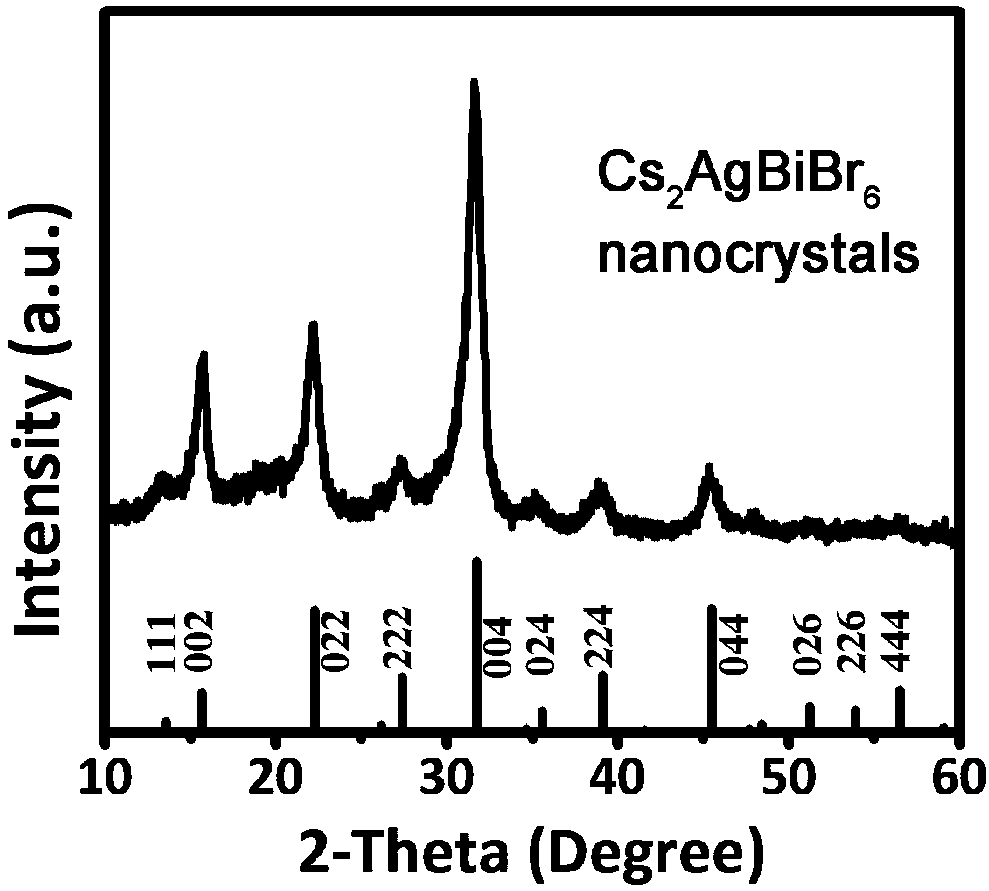

Preparation method of stable lead-free all-inorganic double perovskite A2BB'X6 nanocrystals

ActiveCN107934916AGood reproducibilityGood dispersionBromide preparationHydrocarbon from carbon oxidesReaction temperaturePhysical chemistry

The invention discloses a preparation method of stable lead-free all-inorganic double perovskite A2BB'X6 nanocrystals. The method adopts a thermal injection technology to synthesize the nanocrystals,and concretely comprises the following steps: mixing a metal precursor salt, a reaction solvent oleic acid, oleylamine, octadecene and other raw materials, carrying out vacuum heating and stirring ata certain temperature for a certain period of time, rising the temperature to a suitable reaction temperature under the protection of N2, rapidly injecting the obtained hot oleate solution of A into areaction system, and then rapidly cooling the system to room temperature by using ice bath to finally obtain the A2BB'X6 perovskite nanocrystals having a uniform size. The method has the advantages of simplicity, convenient, good reappearance and environmental protection, and the obtained product has the advantages of uniform size, good dispersion, high stability and excellent photocatalytic performance, and can be applied to the fields of photocatalysis, photodetectors, laser, solar cells and the like.

Owner:SUN YAT SEN UNIV

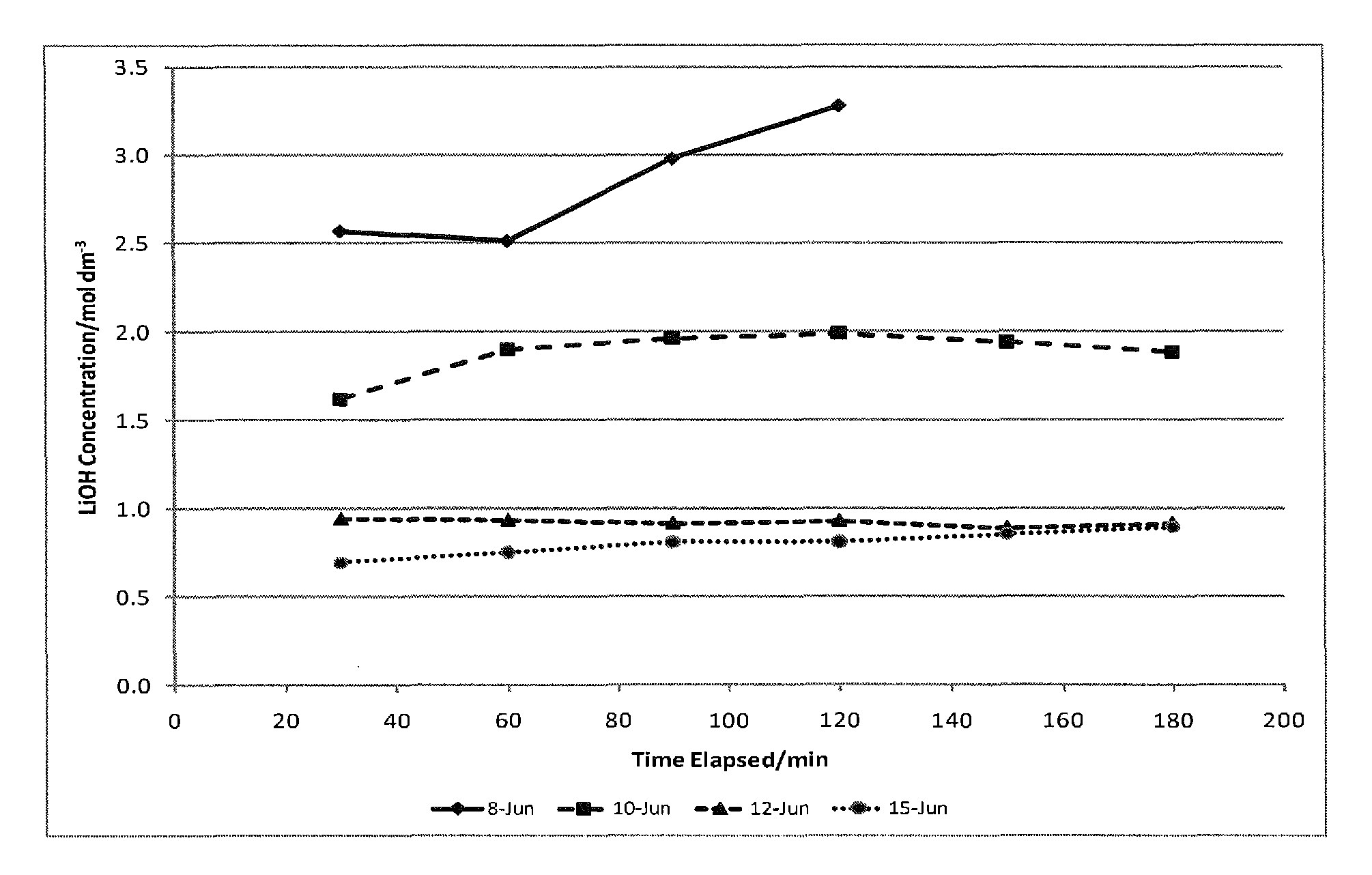

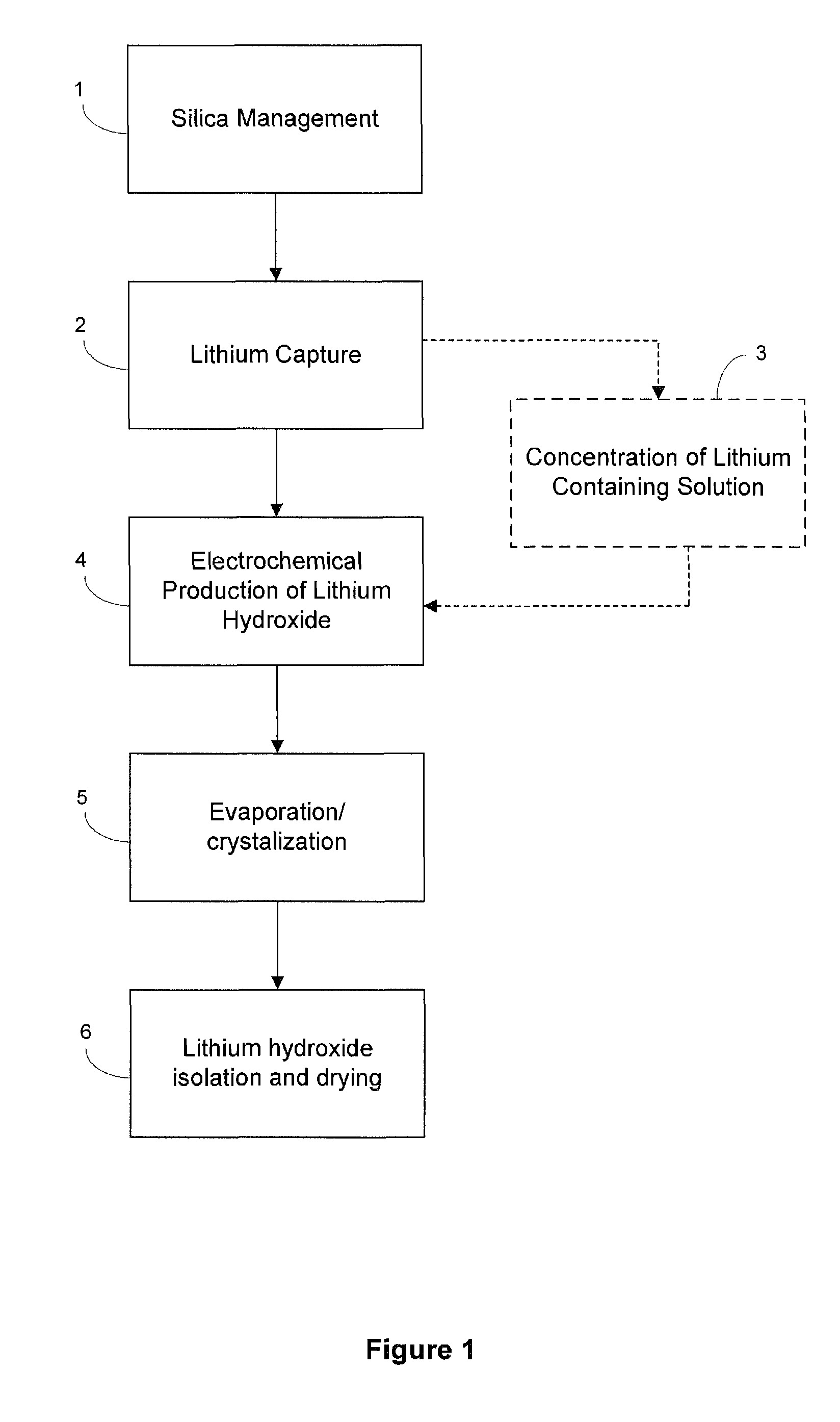

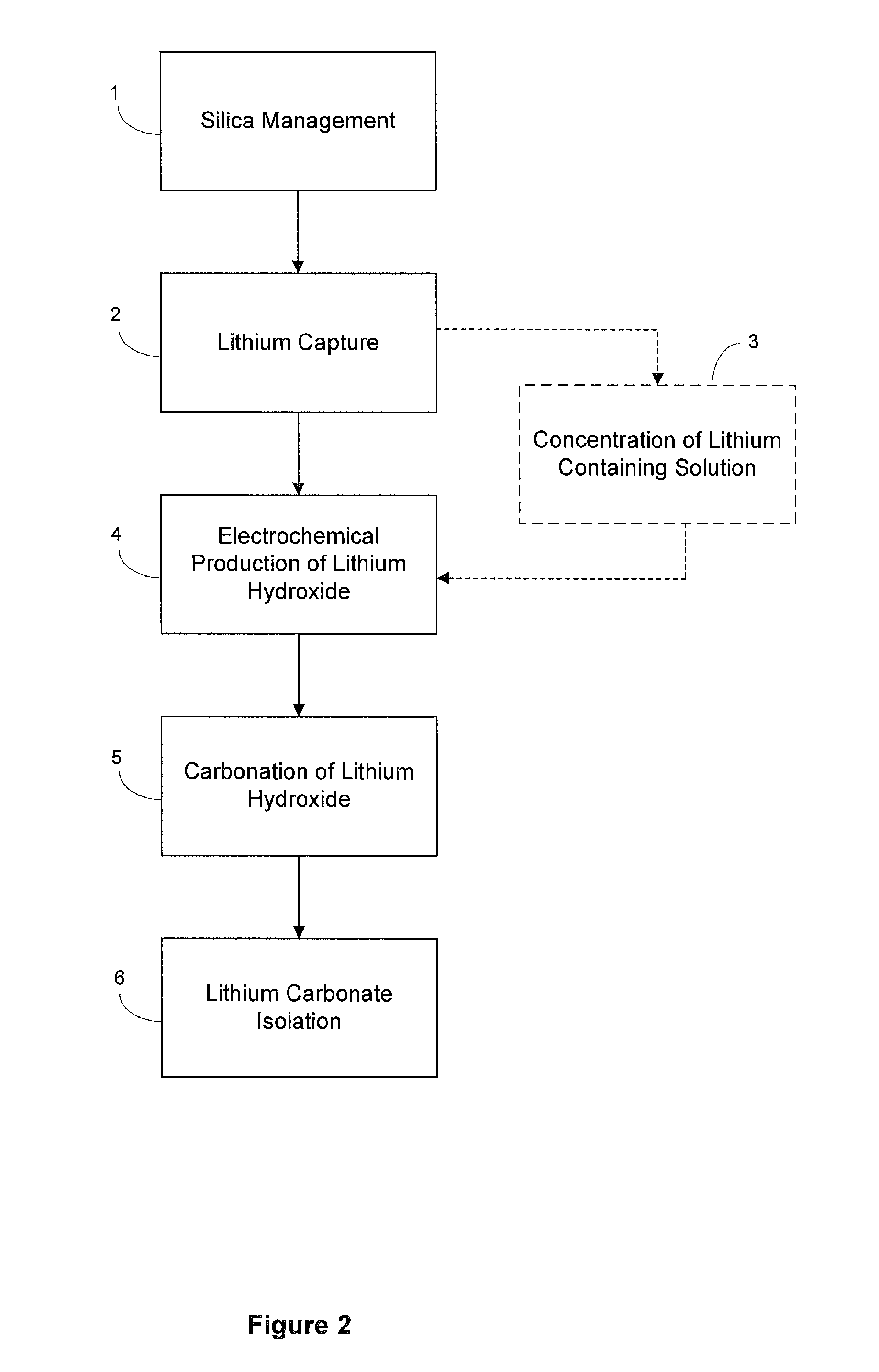

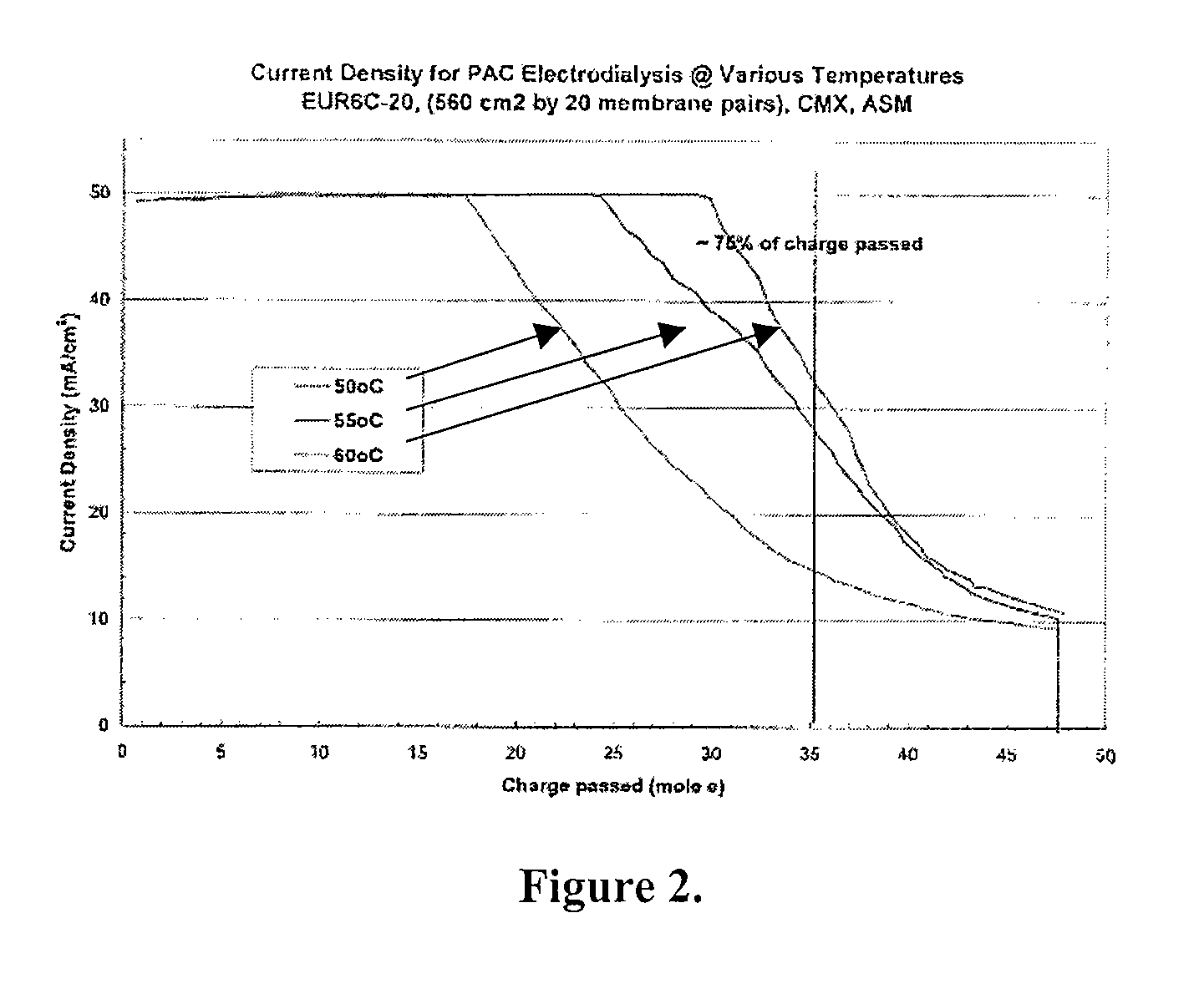

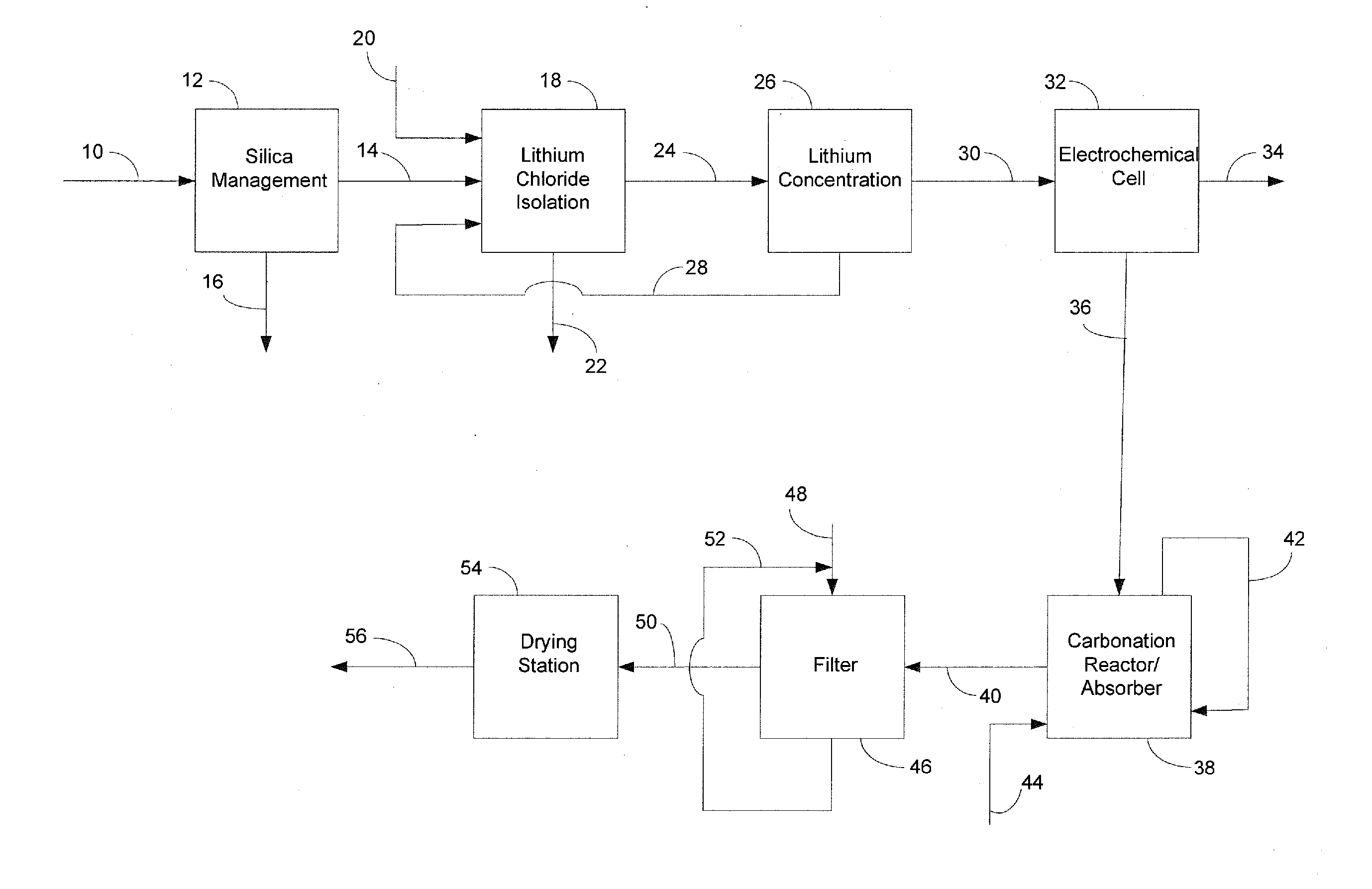

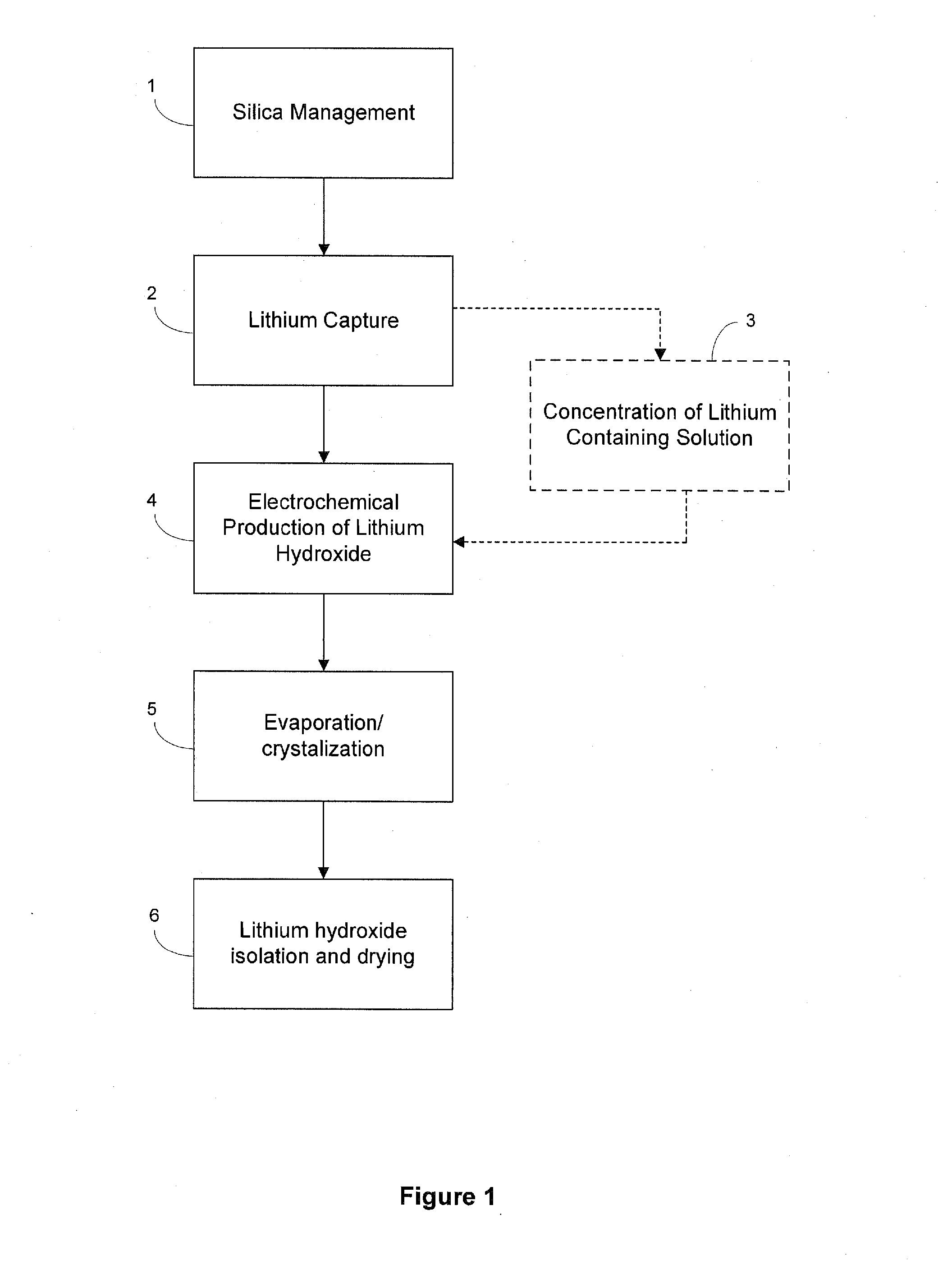

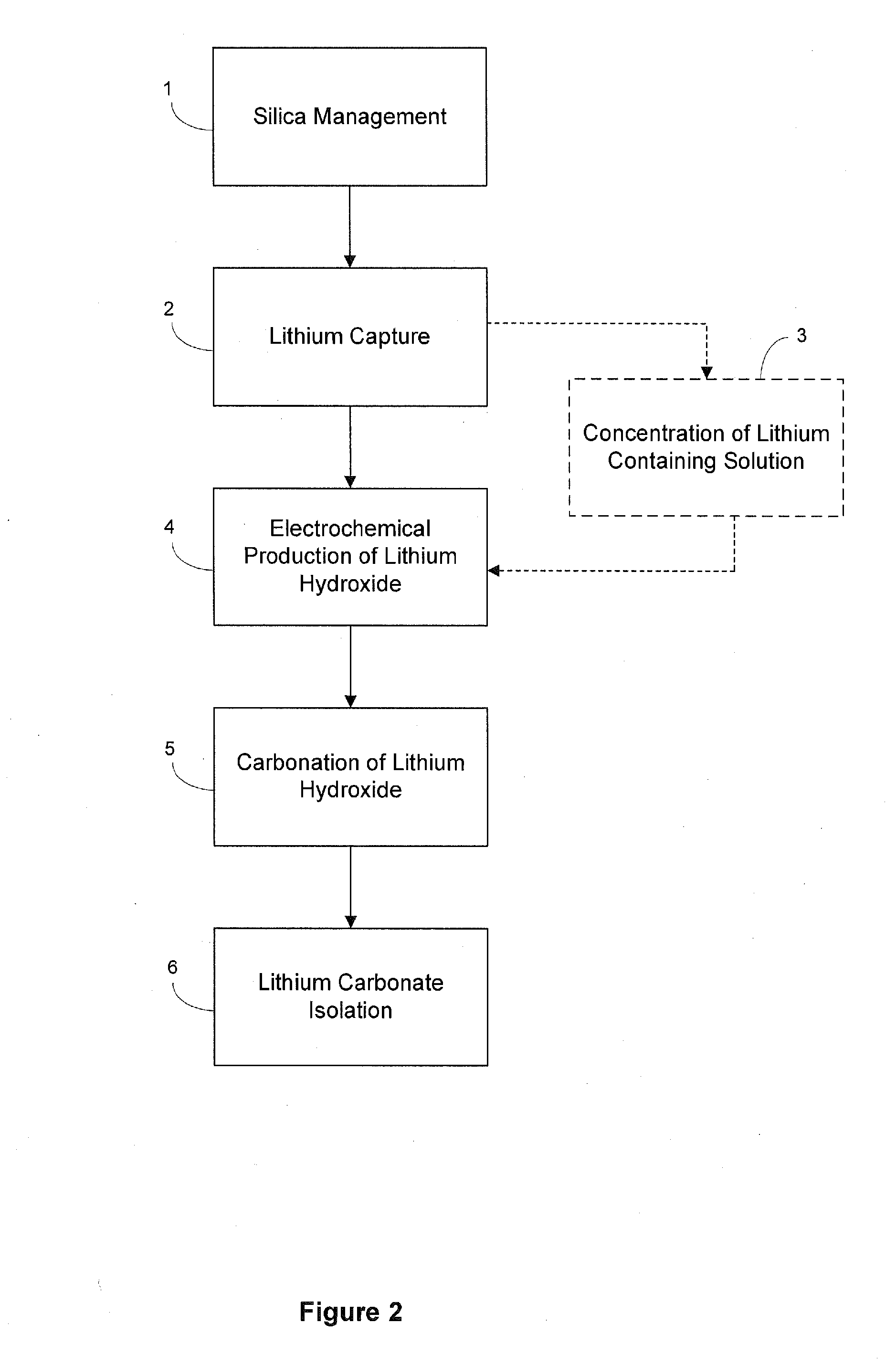

Preparation of lithium carbonate from lithium chloride containing brines

ActiveUS9034294B1Chloride preparationSolid sorbent liquid separationLithium carbonateLithium hydroxide

This invention relates to a method for the preparation of lithium carbonate from lithium chloride containing brines. The method can include a silica removal step, capturing lithium chloride, recovering lithium chloride, supplying lithium chloride to an electrochemical cell and producing lithium hydroxide, contacting the lithium hydroxide with carbon dioxide to produce lithium carbonate.

Owner:TERRALITHIUM LLC

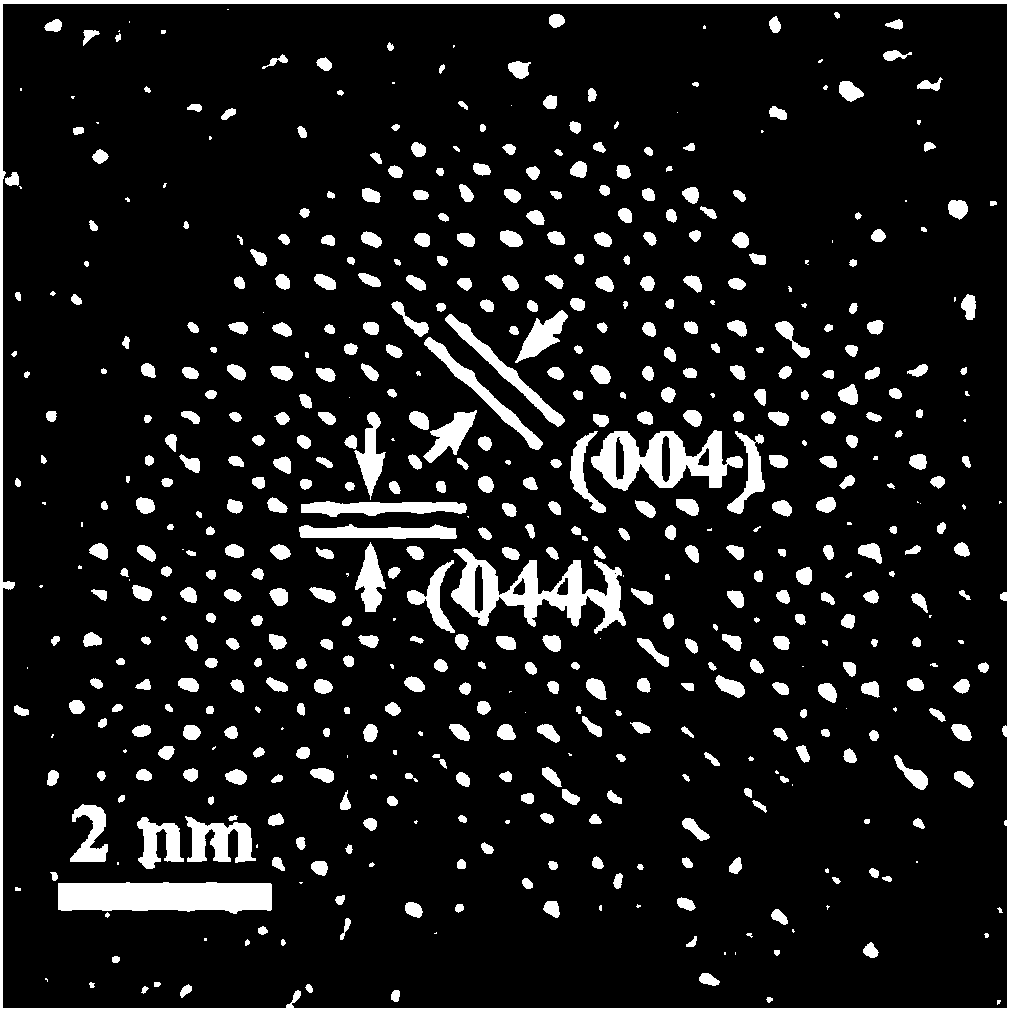

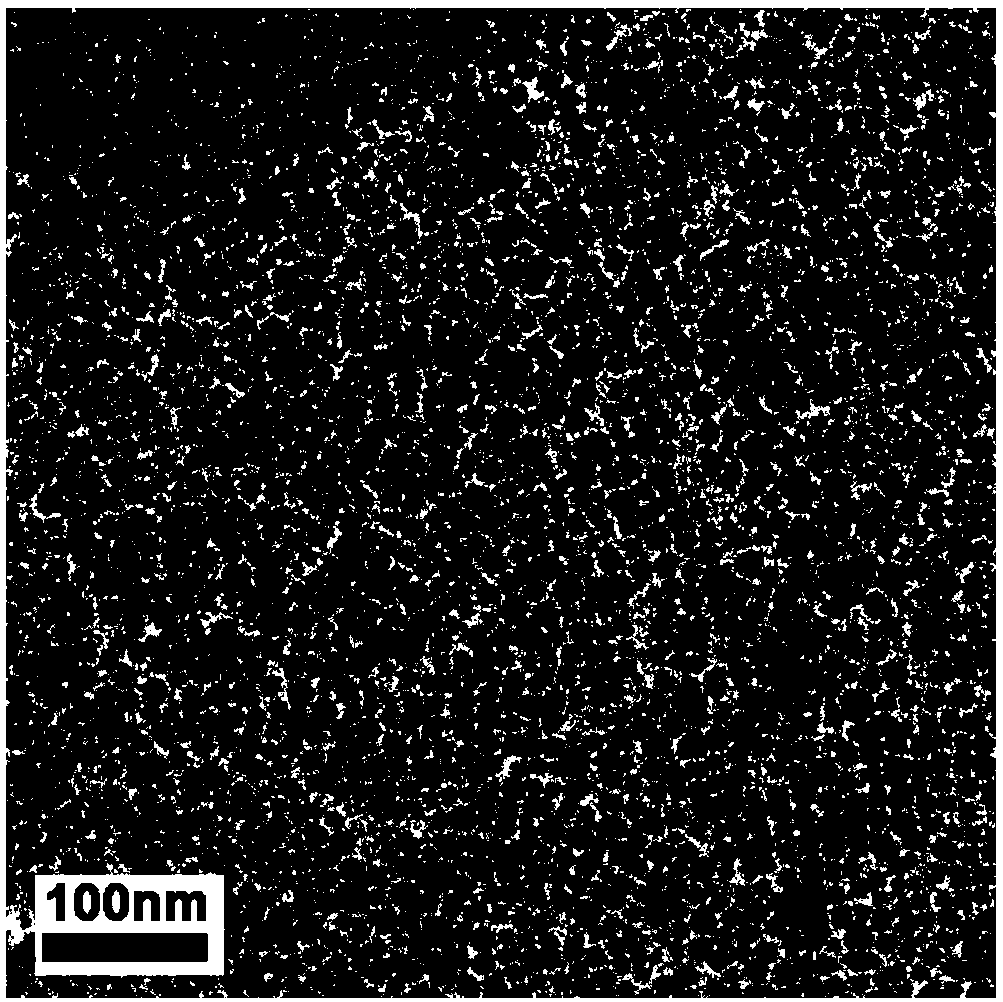

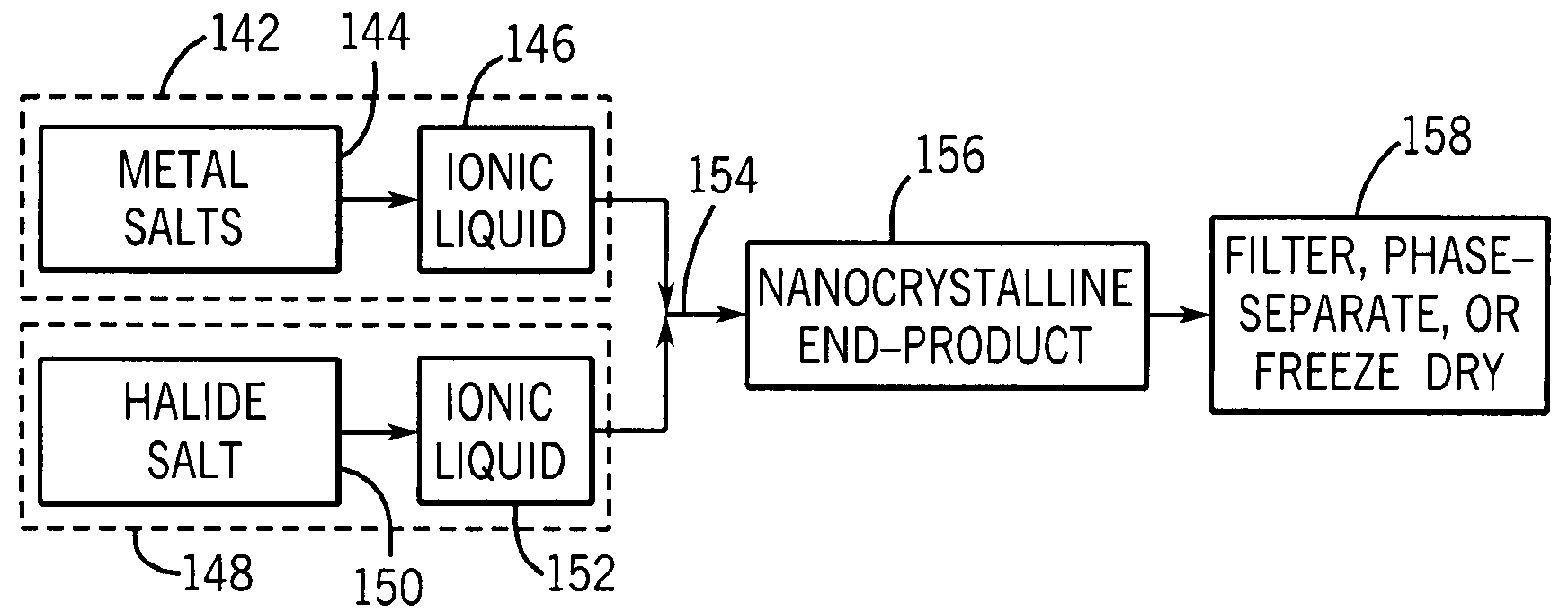

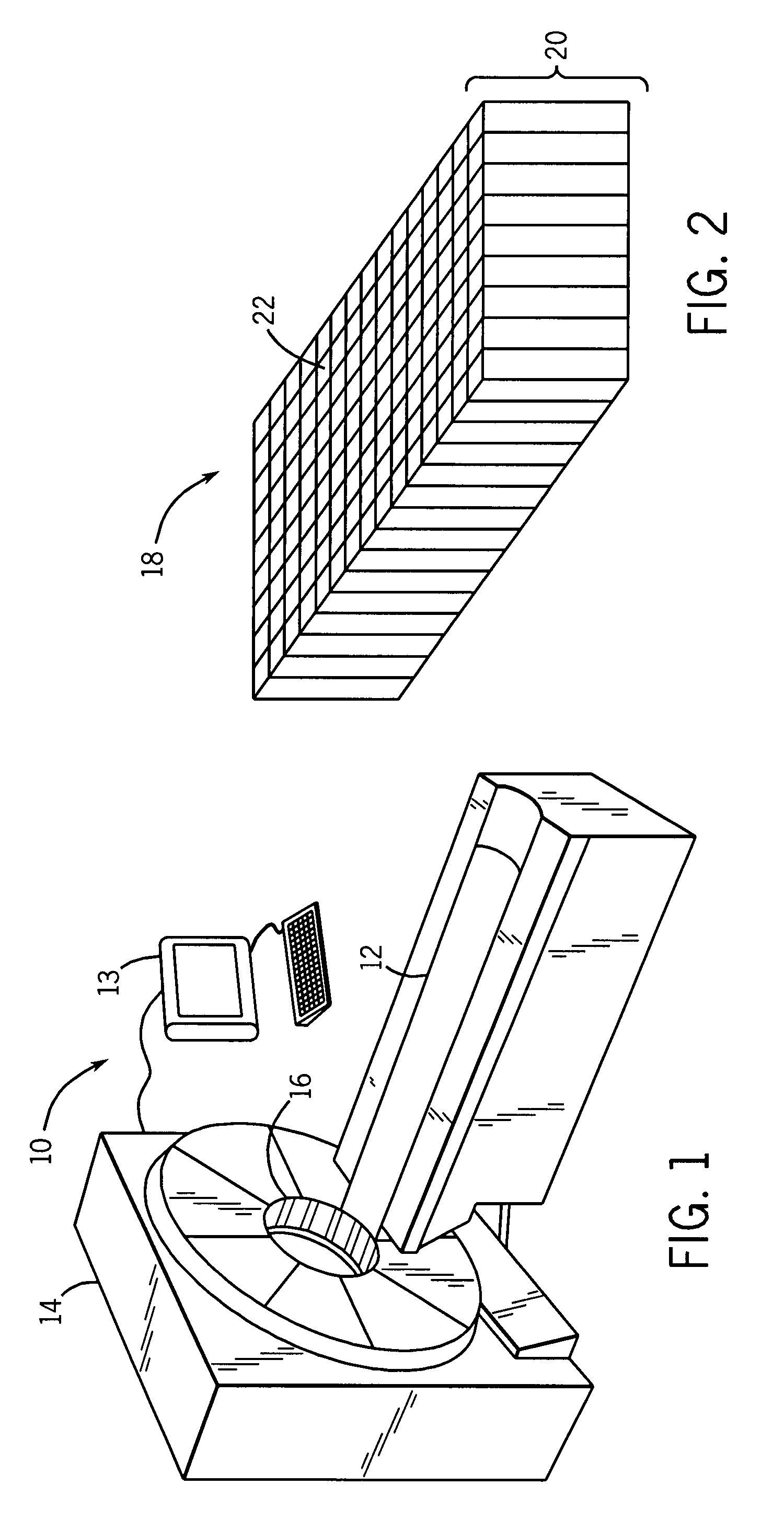

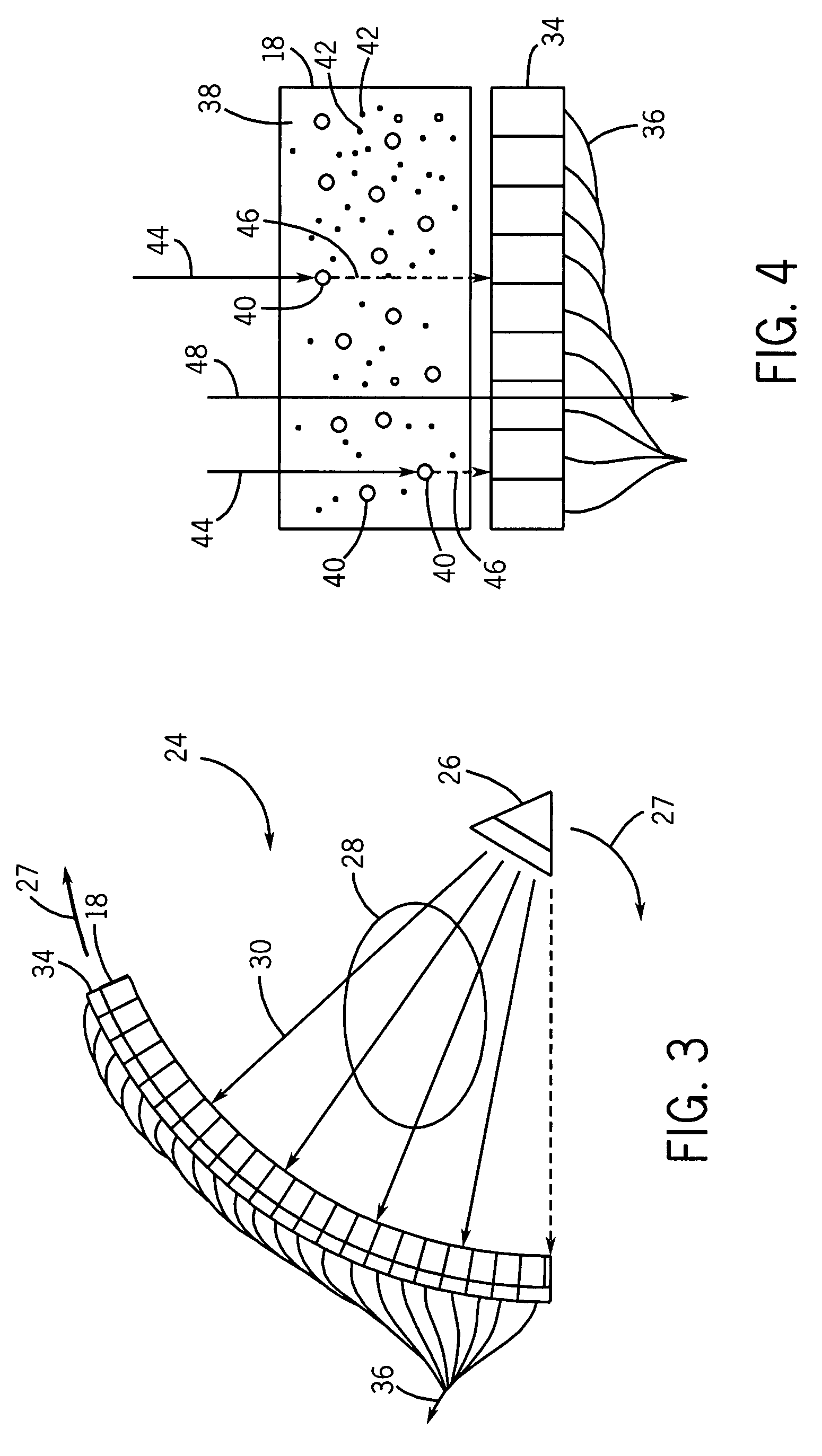

Nano-scale metal halide scintillation materials and methods for making same

Crystalline scintillator materials comprising nano-scale particles of metal halides are provided. The nano-scale particles are less than 100 nm in size. Methods are provided for preparing the particles. In these methods, ionic liquids are used in place of water to allow precipitation of the final product. In one method, the metal precursors and halide salts are dissolved in separate ionic liquids to form solutions, which are then combined to form the nano-crystalline end product. In the other methods, micro-emulsions are formed using ionic liquids to control particle size.

Owner:GENERAL ELECTRIC CO

Metal chlorides and metals obtained from metal oxide containing materials

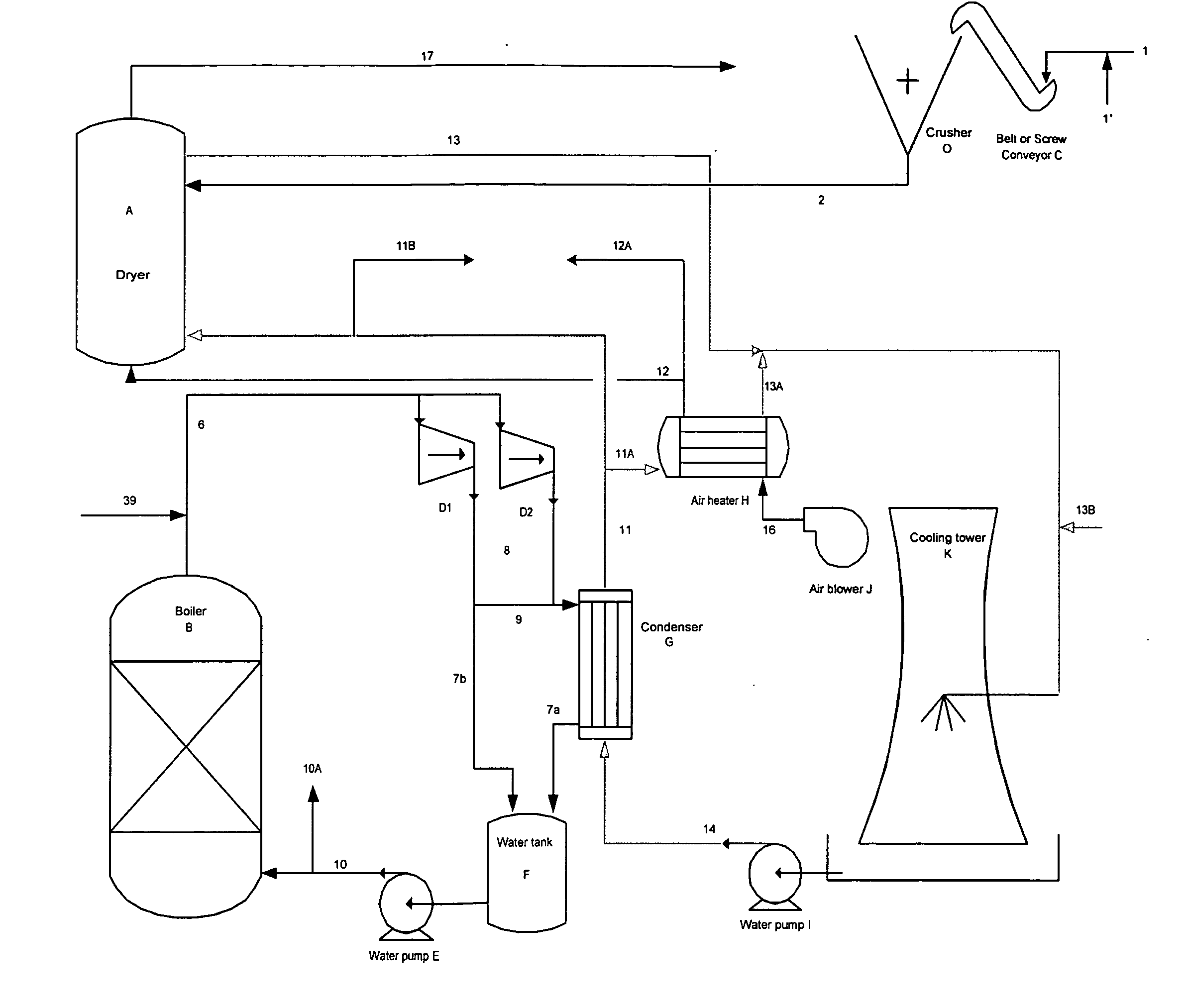

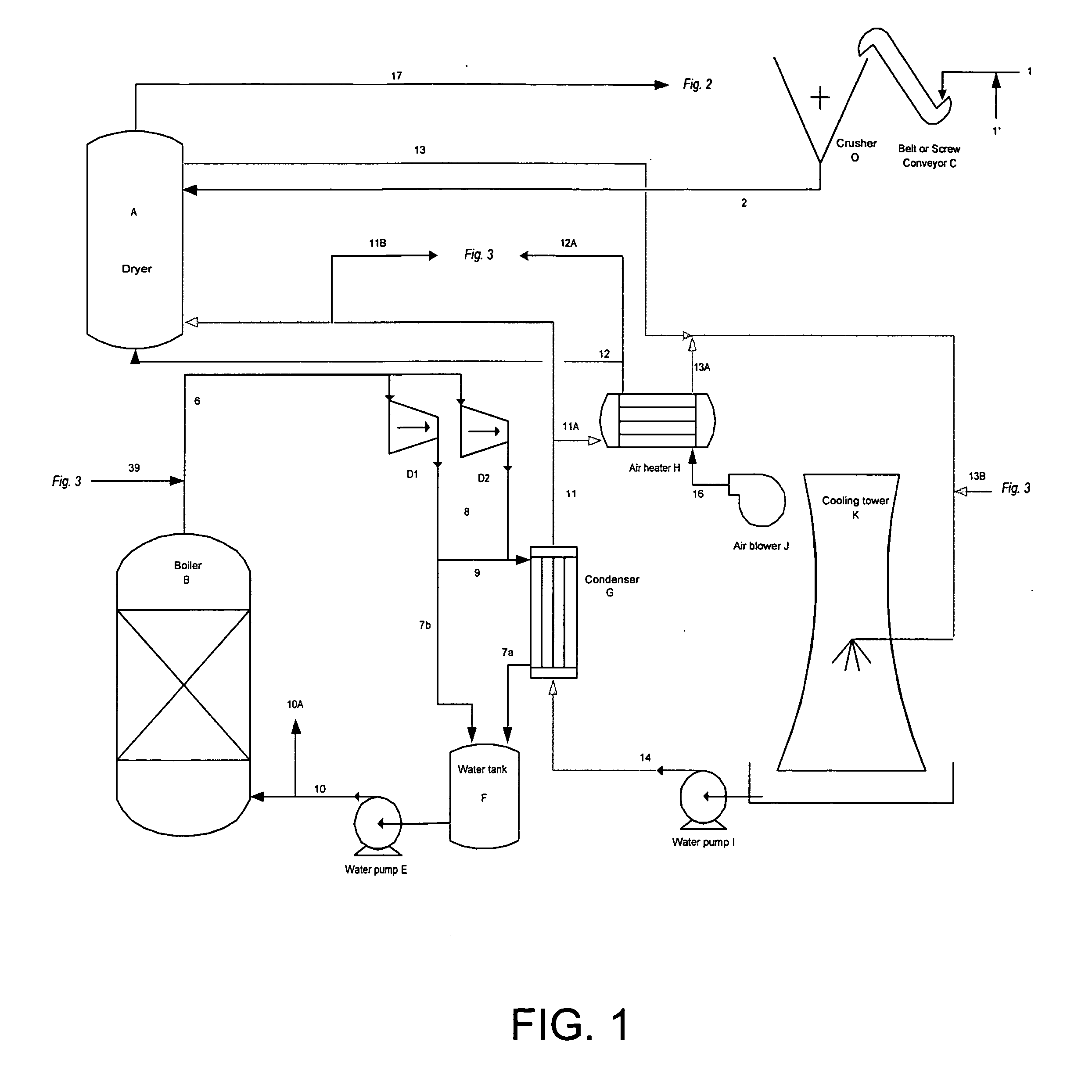

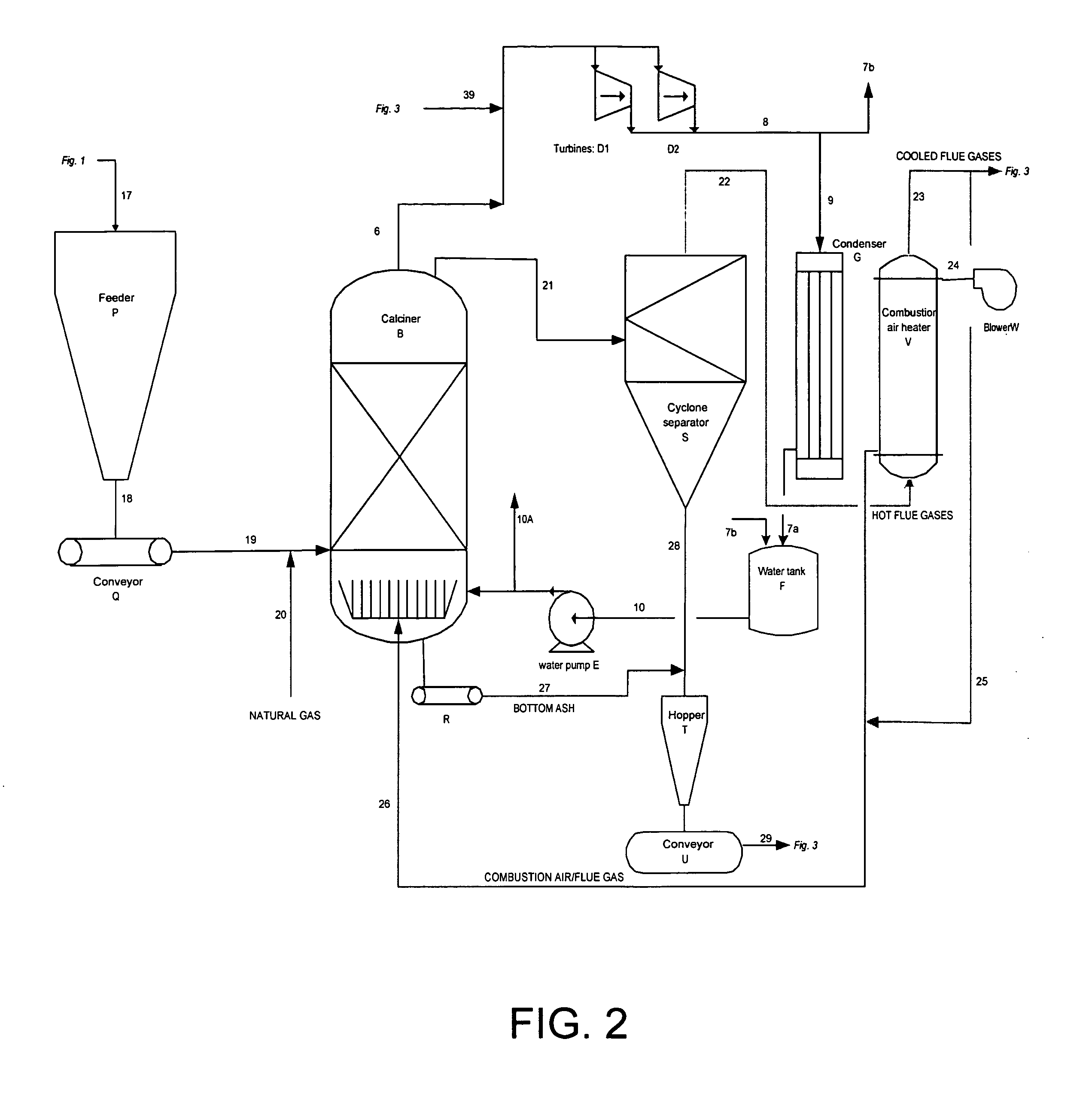

Method and apparatus for preparing at least one metal chloride from metal oxide containing material comprising calcining the metal oxide containing material under temperature conditions sufficient to obtain a calcined product comprising at least one metal oxide; and selectively chlorinating the calcined product to form at least one metal chloride.

Owner:KEYSTONE METALS RECOVERY

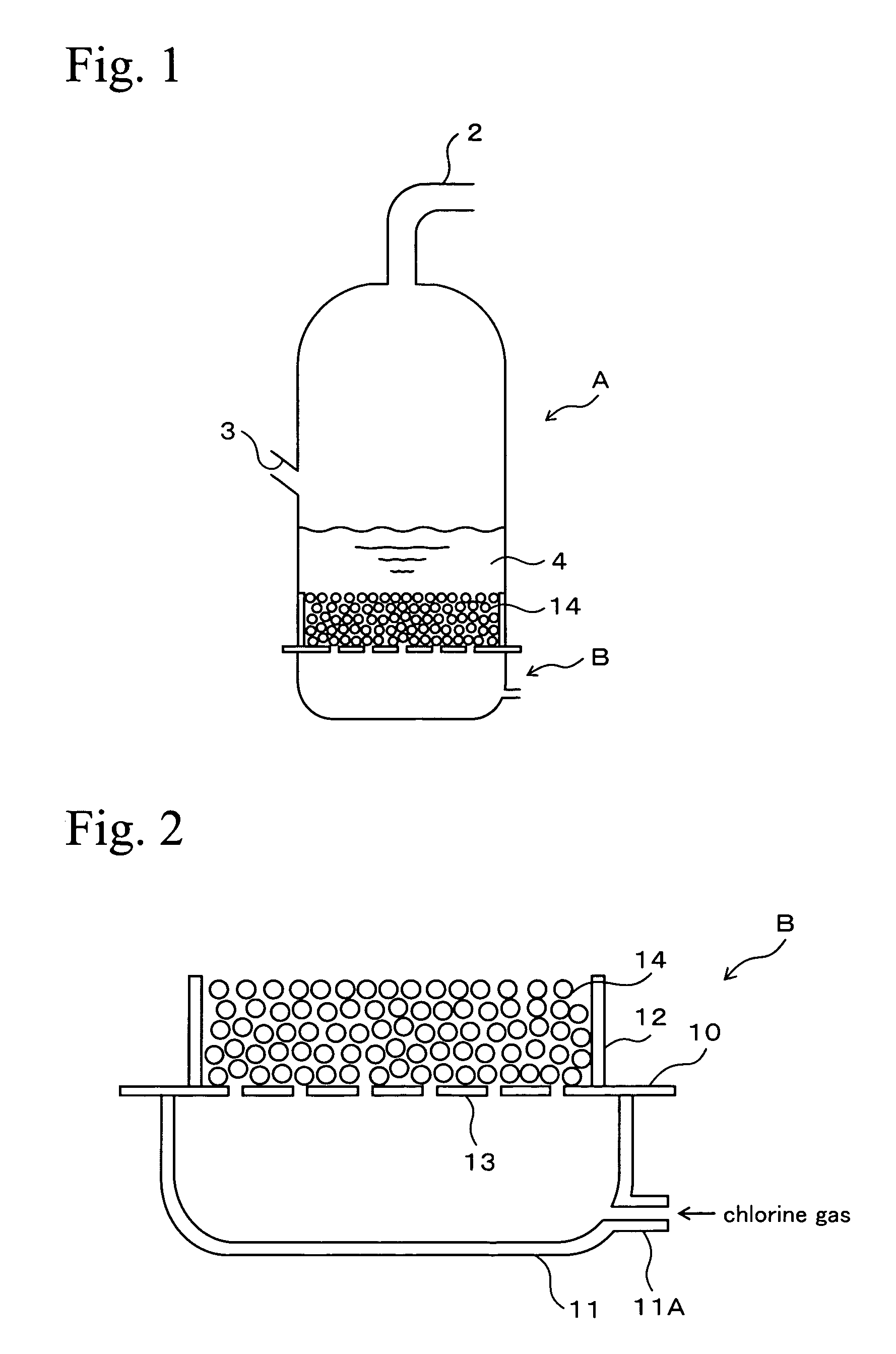

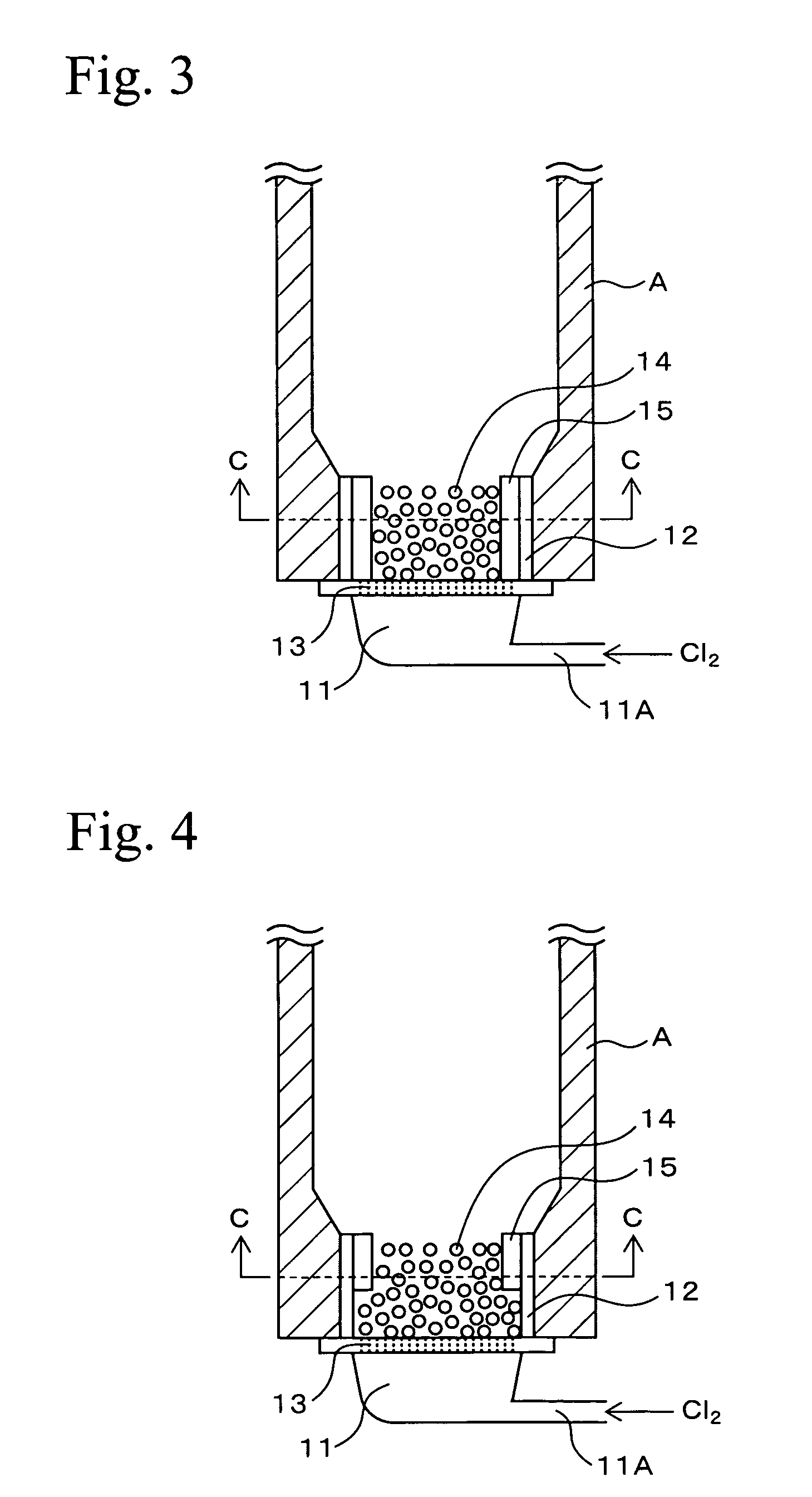

Apparatus for production of metal chloride

InactiveUS20070178028A1Increased durabilityEfficient productionPhysical/chemical process catalystsChloride preparationMetal chlorideFluidized bed

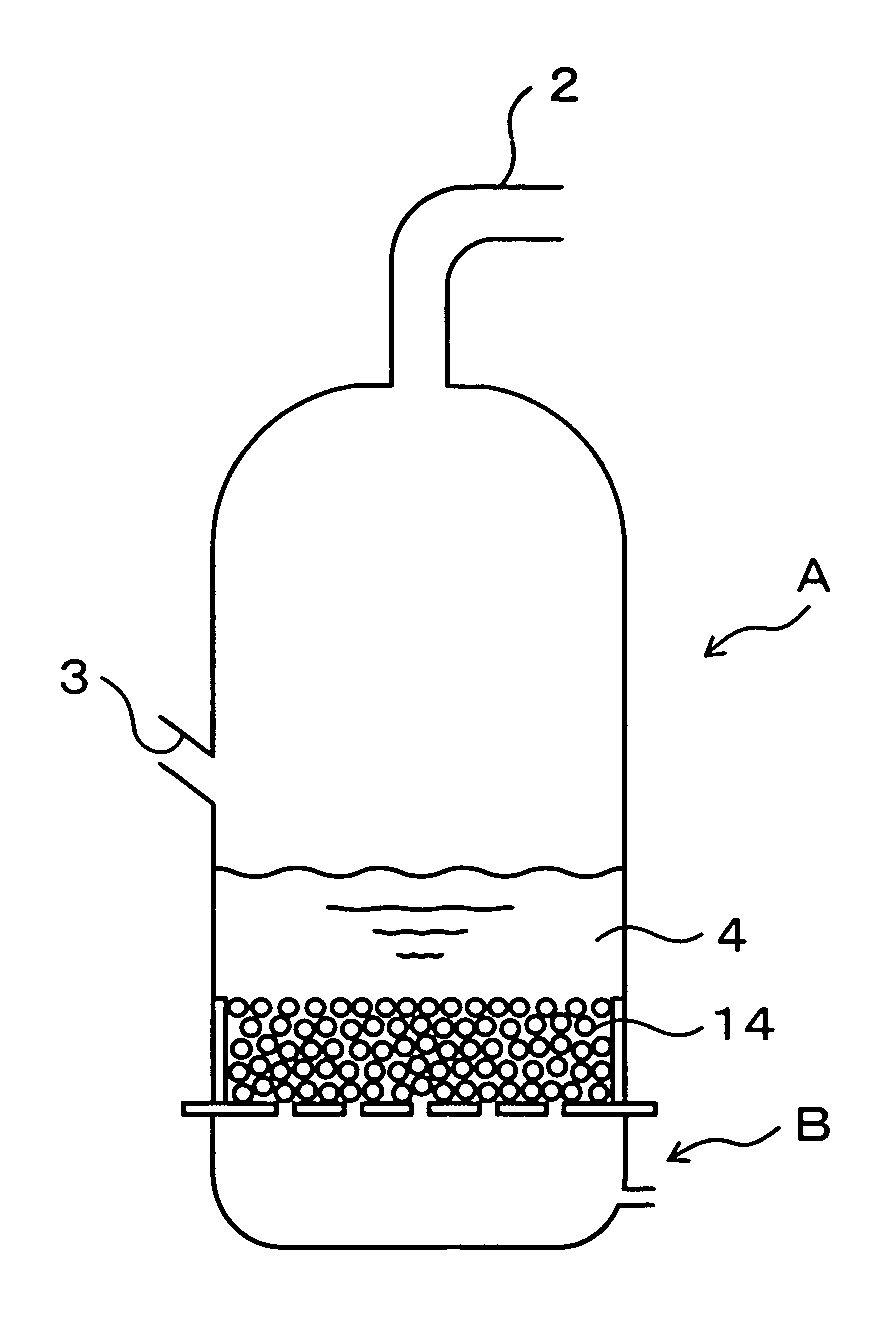

Porous plate 13 is disposed between wind box 11 of dispersion board B and cylindrical vessel wall 12. Filling layer 14 of a structure packed with ceramic particles such as those of fused silica is disposed on the porous plate 13 so as to fill the inside of the cylindrical vessel wall. The filling layer 14 is composed of ceramic particles, so that the corrosion wear by chlorine gas can be inhibited and the durability thereof enhanced. Furthermore, a chlorine resistant member is disposed in a form so as to adhere to the internal surface of the cylindrical vessel wall 12, so that the corrosion wear by chlorine gas of the cylindrical vessel wall 12 can also be effectively inhibited. As a result, damage to the internal wall of the chlorination furnace can be minimized, and the state of allowing chlorine gas to be uniformly dispersed and supplied to fluidized bed 4 containing titanium ore and coke can be maintained for prolonged periods.

Owner:TOHO TITANIUM CO LTD

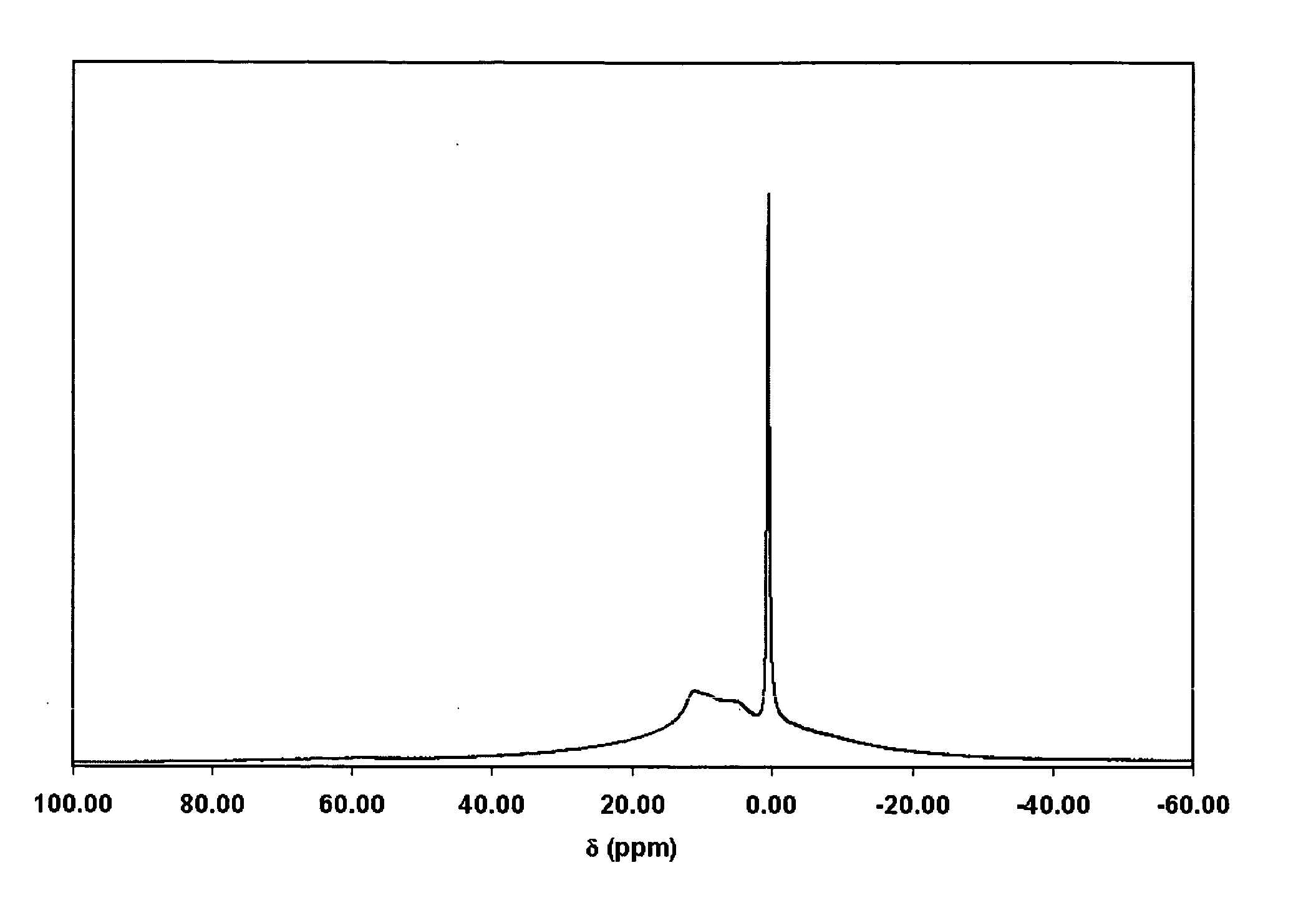

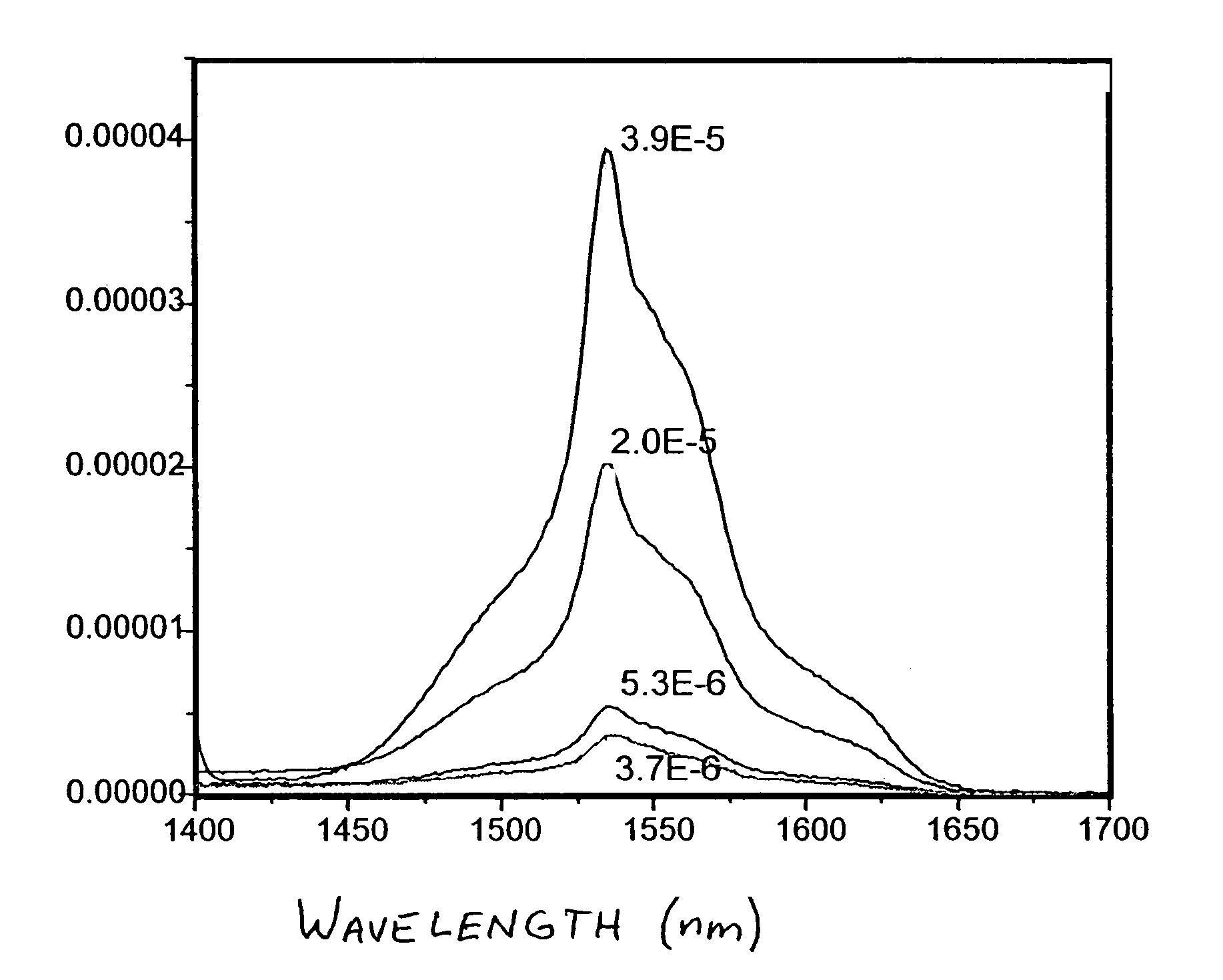

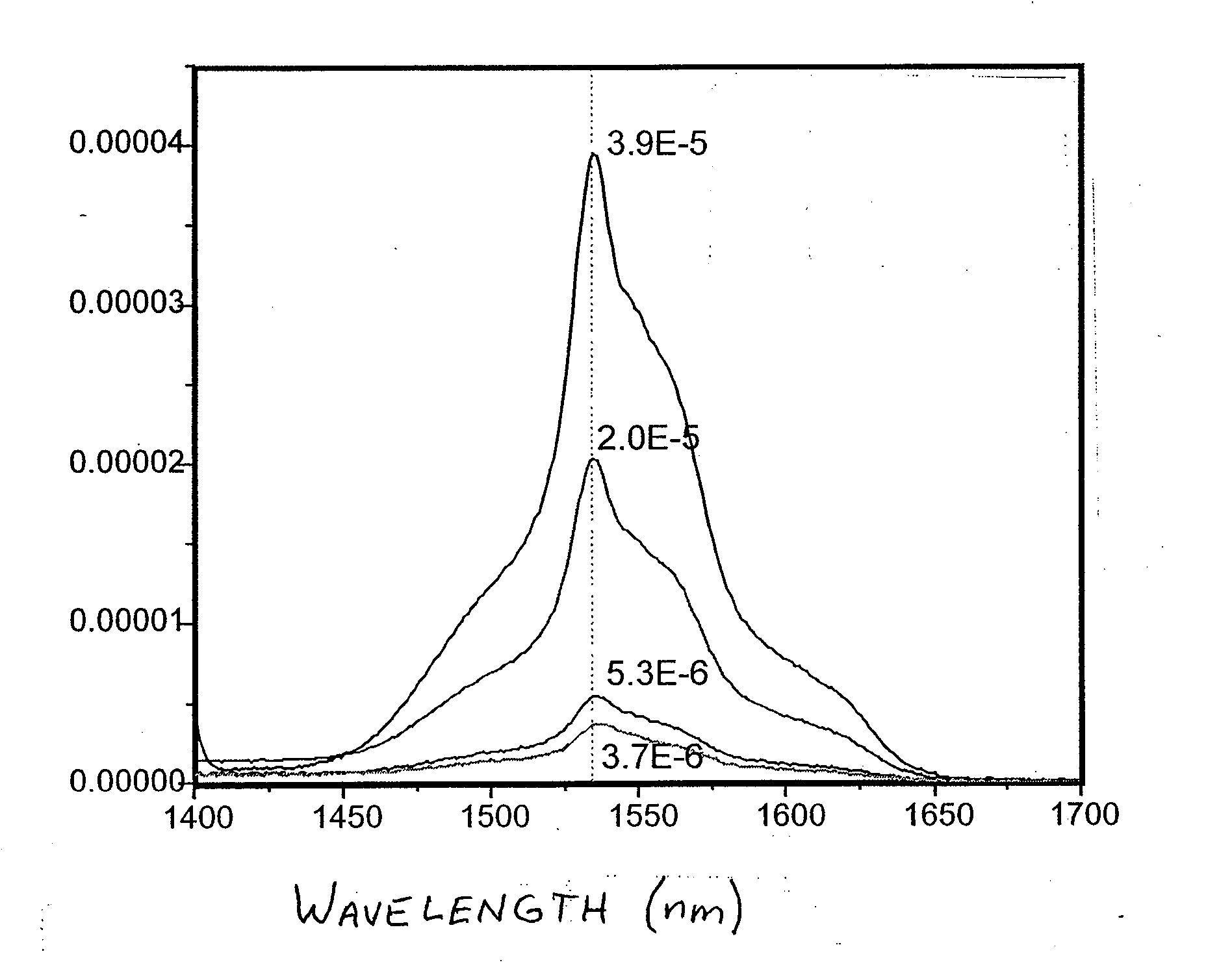

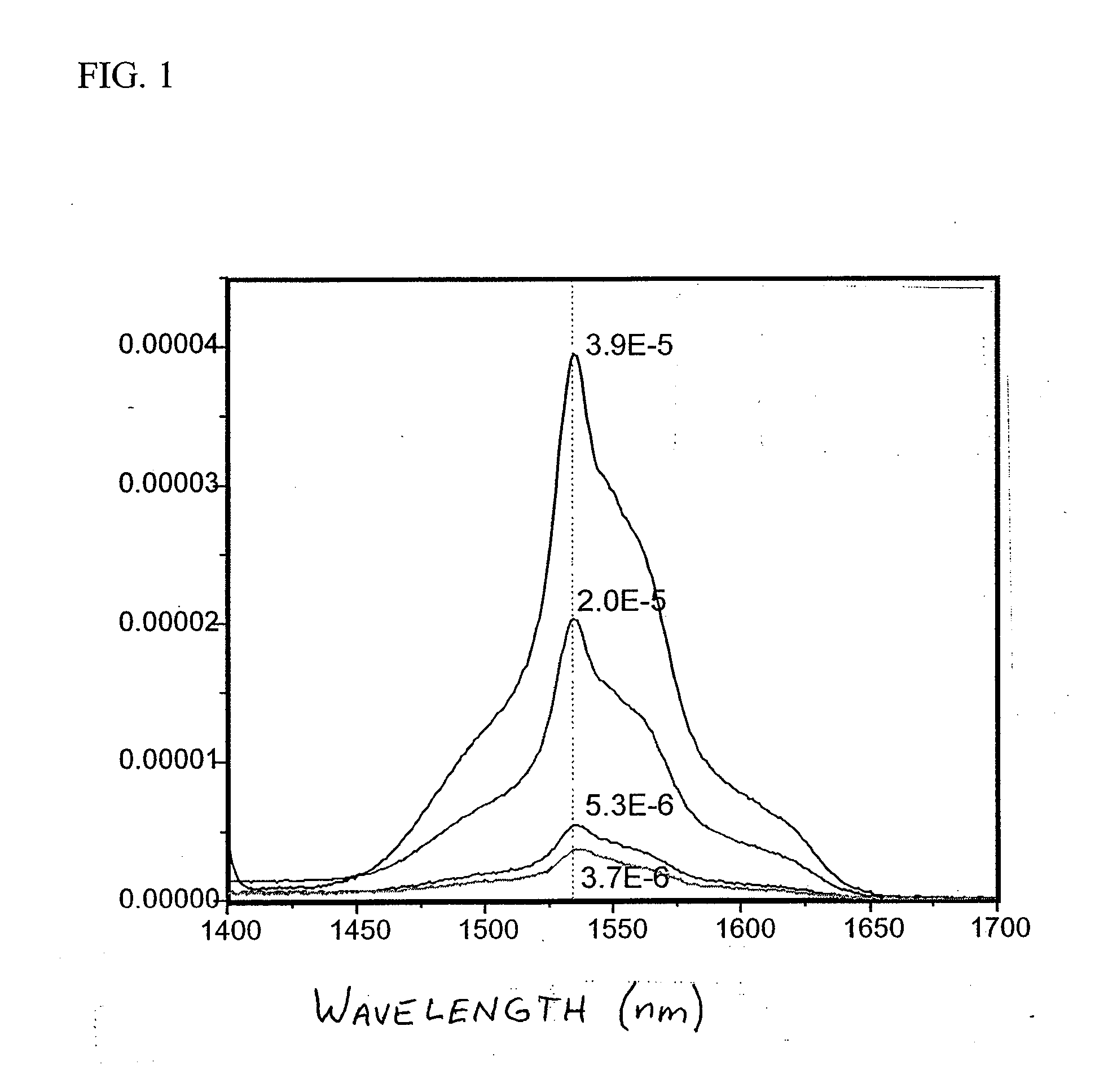

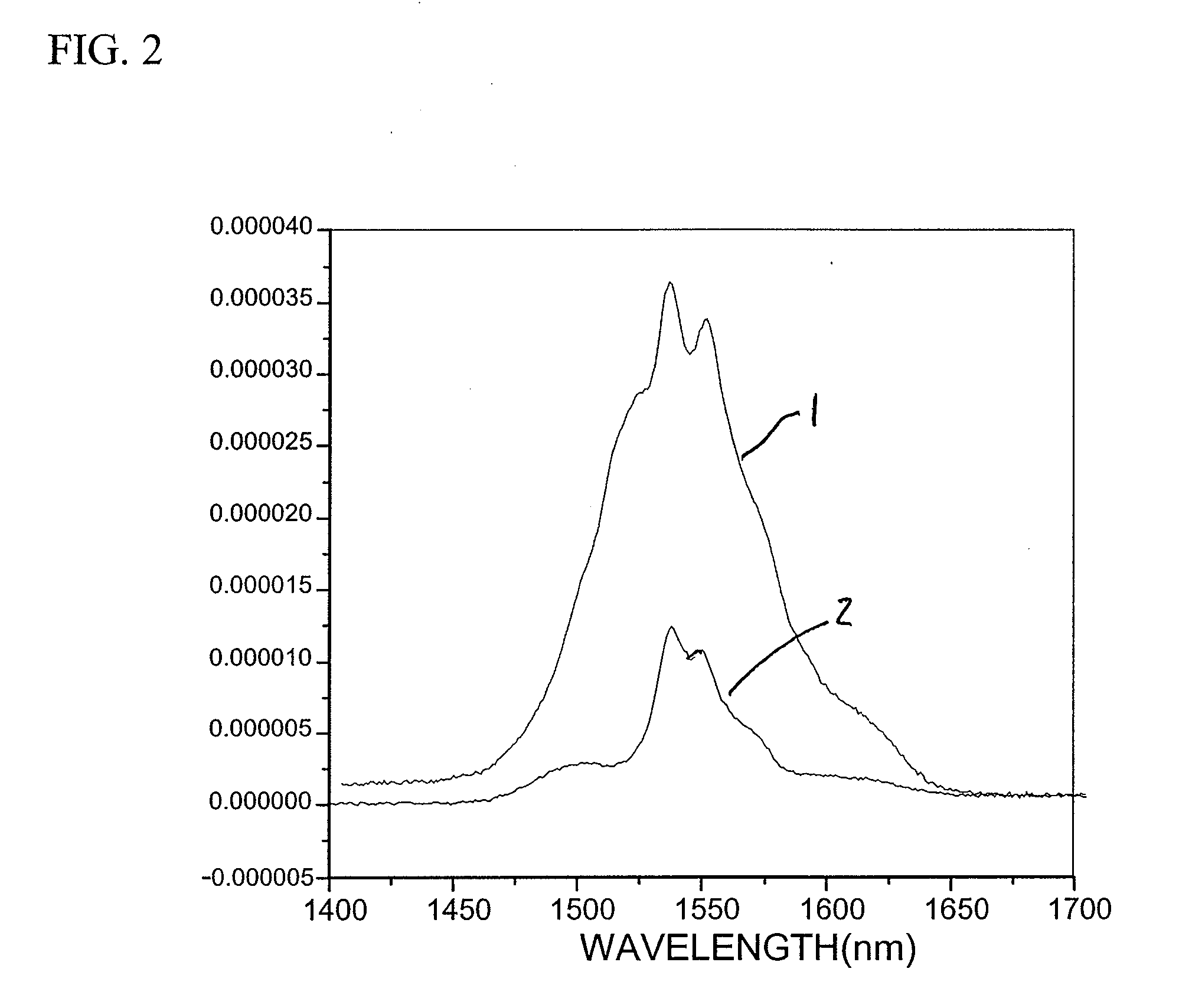

Optically transparent nanocomposite materials

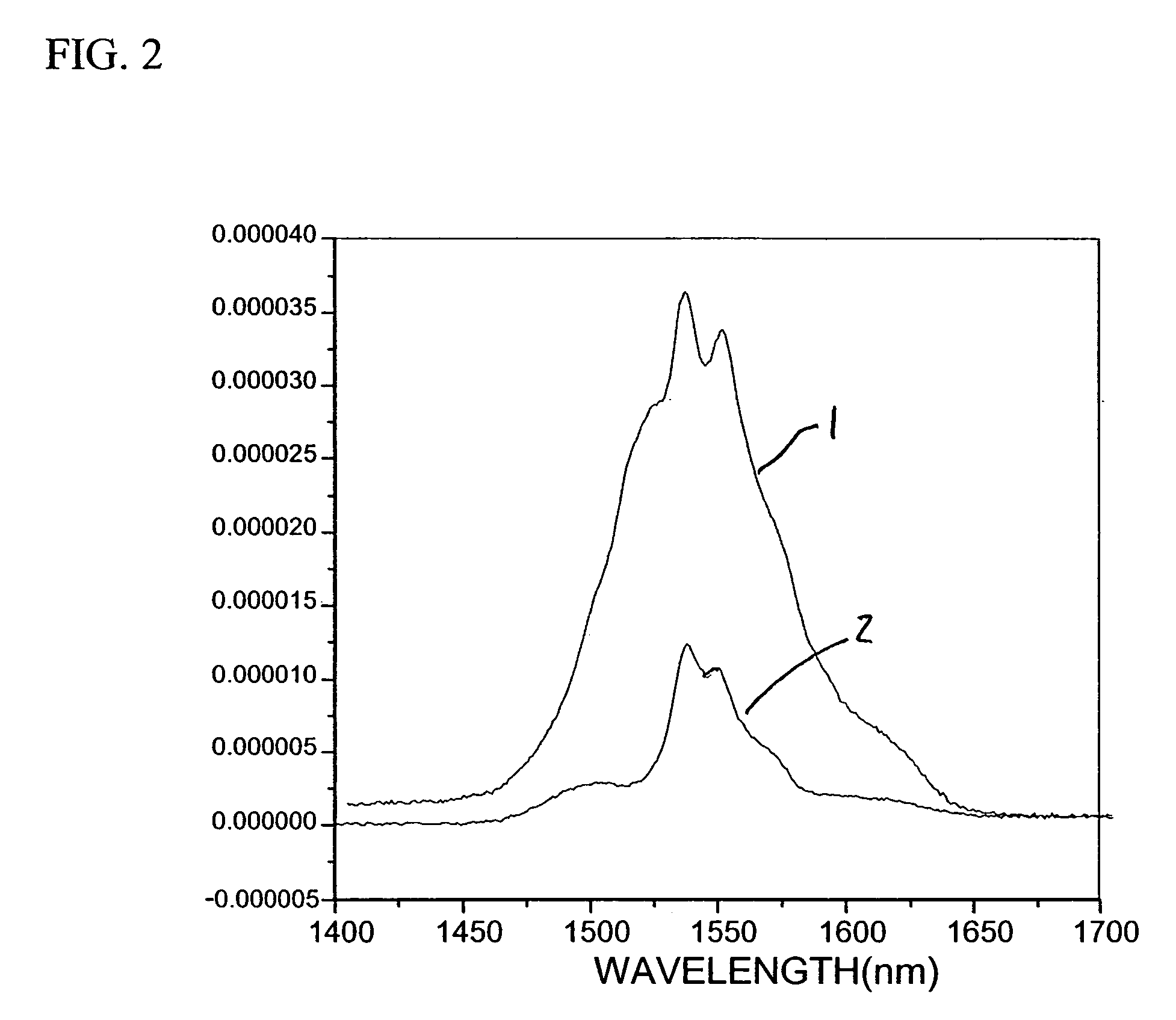

InactiveUS7094361B2Well formedReadily fiberizableMaterial nanotechnologyChloride preparationFluorescenceSolid solution

Optically transparent composite materials in which solid solution inorganic nanoparticles are dispersed in a host matrix inert thereto, wherein the nanoparticles are doped with one or more active ions at a level up to about 60 mole % and consist of particles having a dispersed particle size between about 1 and about 100 nm, and the composite material with the nanoparticles dispersed therein is optically transparent to wavelengths at which excitation, fluorescence or luminescence of the active ions occur. Luminescent devices incorporating the composite materials are also disclosed.

Owner:RUTGERS THE STATE UNIV

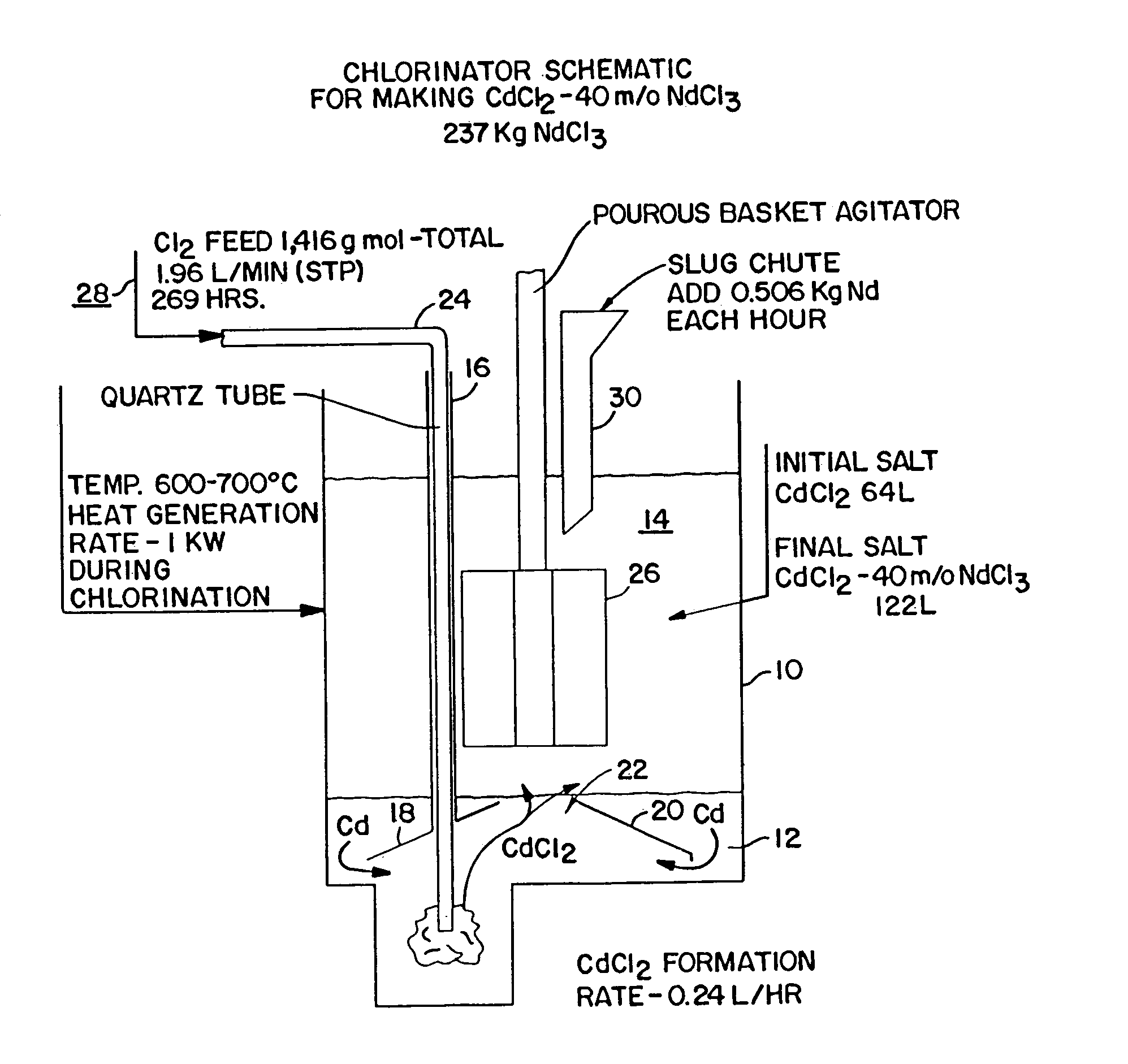

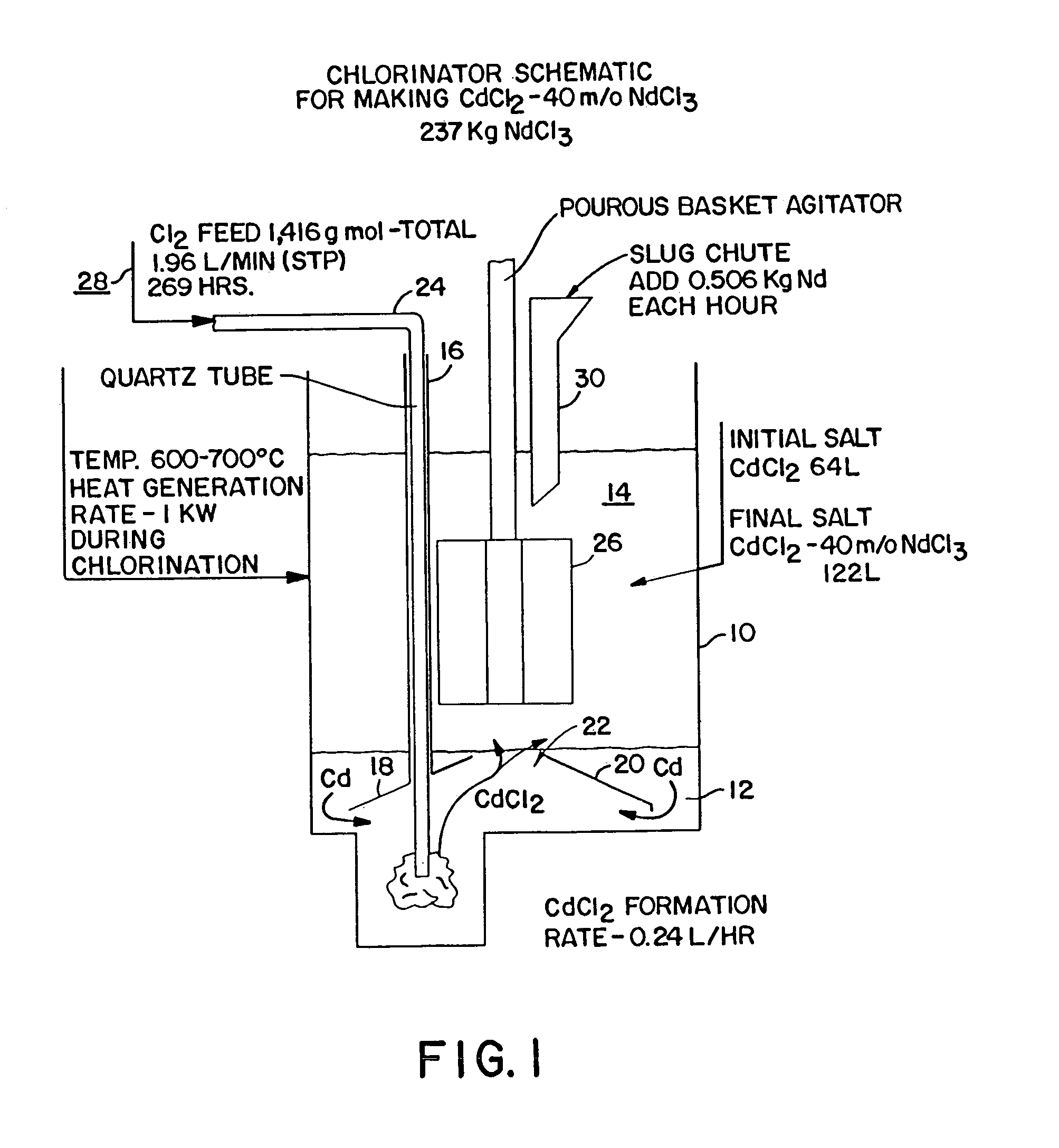

Apparatus and method for making metal chloride salt product

InactiveUS7217402B1Low densityRare earth metal chloridesChloride preparationMetal chlorideDistillation

A method of producing metal chlorides is disclosed in which chlorine gas is introduced into liquid Cd. CdCl2 salt is floating on the liquid Cd and as more liquid CdCl2 is formed it separates from the liquid Cd metal and dissolves in the salt. The salt with the CdCl2 dissolved therein contacts a metal which reacts with CdCl2 to form a metal chloride, forming a mixture of metal chloride and CdCl2. After separation of bulk Cd from the salt, by gravitational means, the metal chloride is obtained by distillation which removes CdCl2 and any Cd dissolved in the metal chloride.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

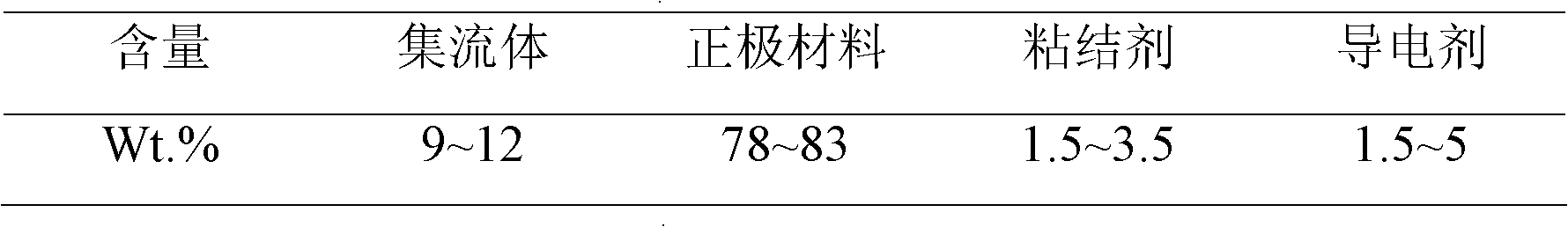

High-purity polymetallic-element solid mixed salt and preparation method and application thereof

InactiveCN102088124AMeet production requirementsIncrease productivityChloride preparationCell electrodesManganeseCobalt

The invention discloses a high-purity polymetallic-element solid mixed salt. The solid mixed salt is prepared from raw materials of waste secondary lithium batteries, the content of impurities such as calcium, magnesium, copper, zinc, ferrum, aluminum, lead, cadmium and chromium in the solid mixed salt is lower than 10 ppm respectively. The invention also discloses a preparation method and application of the high-purity polymetallic-element solid mixed salt. The nickel, cobalt and manganese in waste batteries are treated and prepared into high-purity polymetallic solid mixed salt which is then used for preparing the anode material and the front-body material of batteries, thus the non-ferrous metal resources are recycled, and the high-purity polymetallic-element solid mixed salt has higher economic benefit and social benefit.

Owner:GUANGDONG BRUNP RECYCLING TECH

Optically transparent nanocomposite materials

InactiveUS20060231797A1Reduce dispersionWell formedMaterial nanotechnologyChloride preparationFluorescencePhysical chemistry

Optically transparent composite materials in which solid solution inorganic nanoparticles are dispersed in a host matrix inert thereto, wherein the nanoparticles are doped with one or more active ions at a level up to about 60 mole % and consist of particles having a dispersed particle size between about 1 and about 100 nm, and the composite material with the nanoparticles dispersed therein is optically transparent to wavelengths at which excitation, fluorescence or luminescence of the active ions occur. Luminescent devices incorporating the composite materials are also disclosed.

Owner:RUTGERS THE STATE UNIV

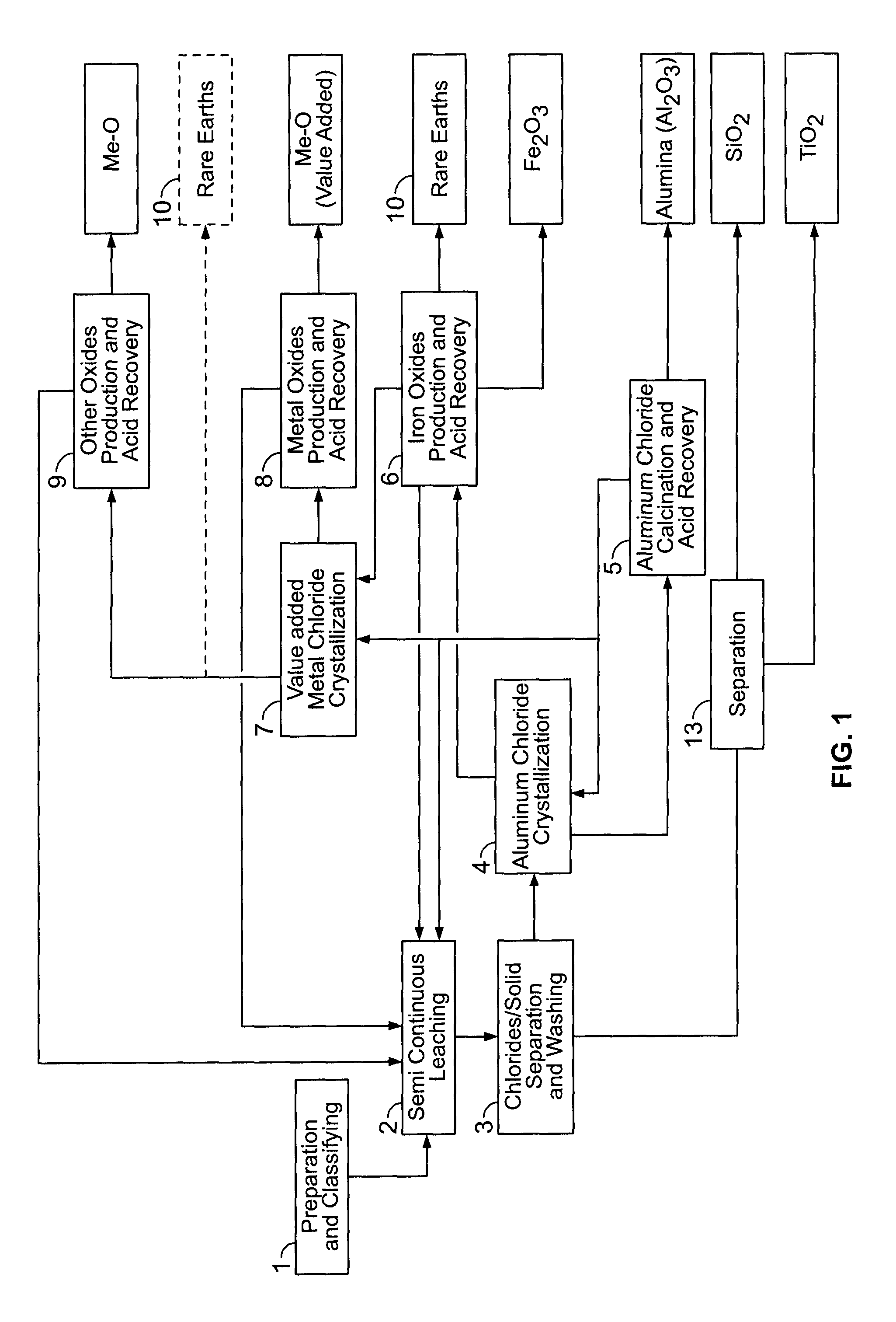

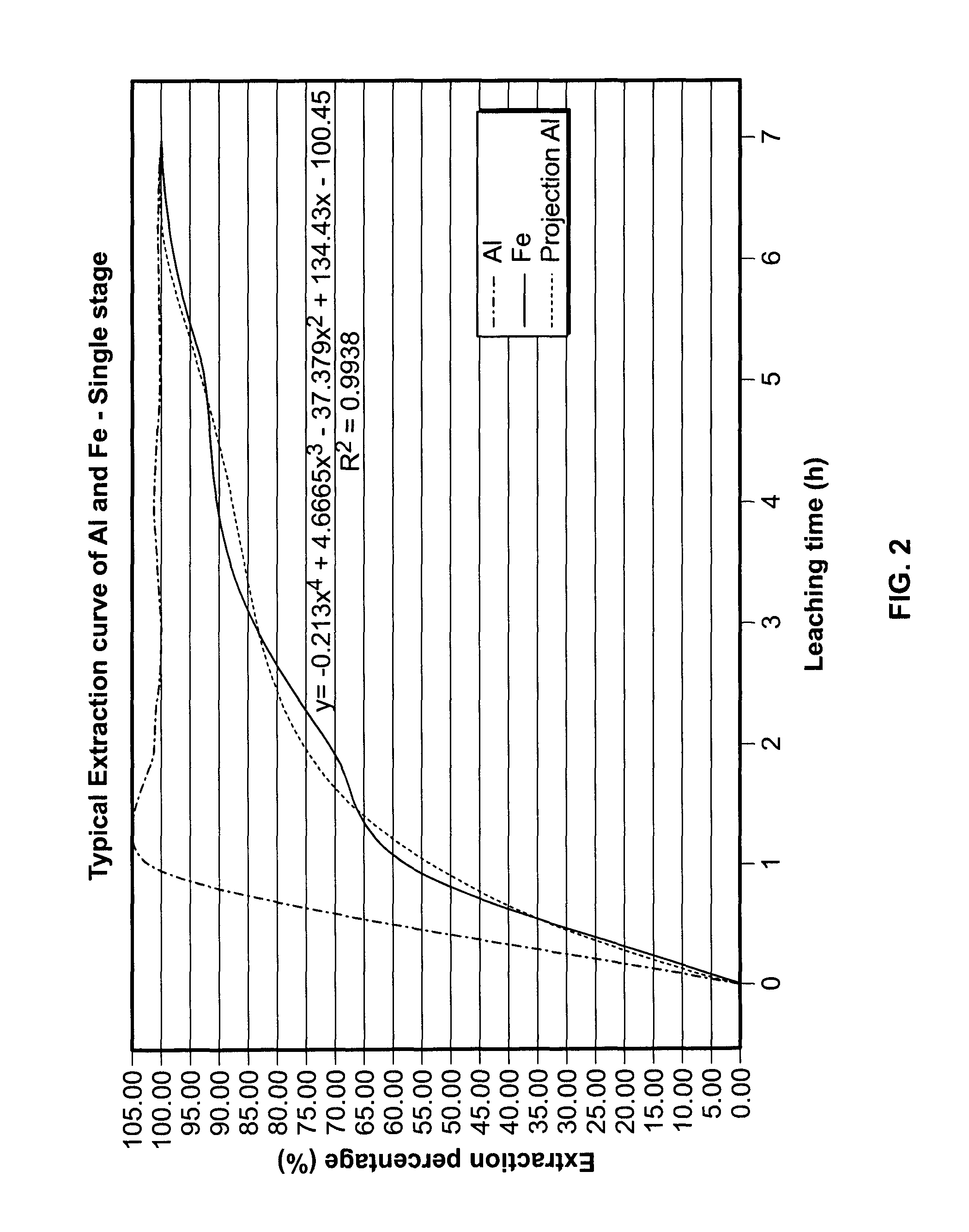

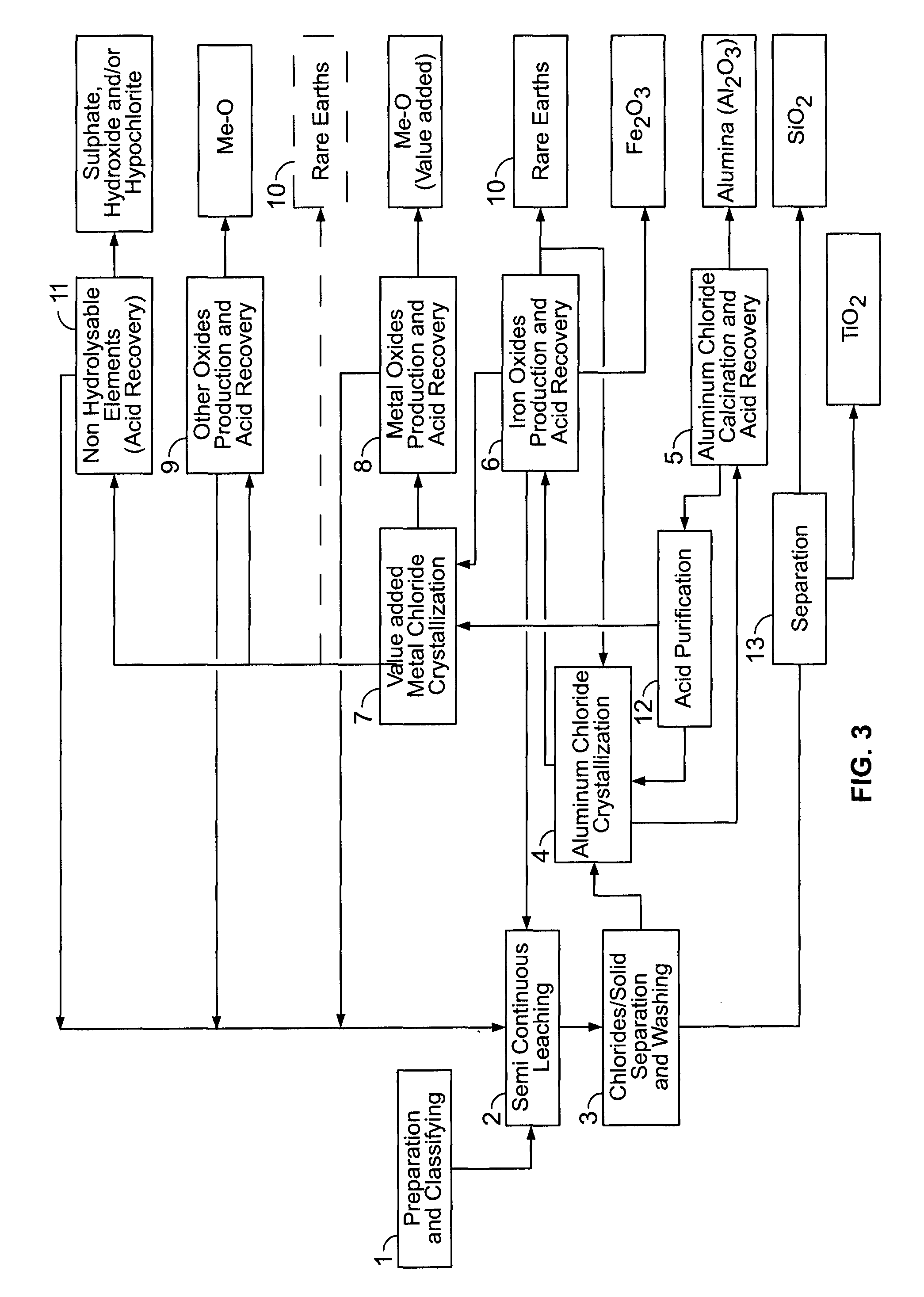

PROCESSES FOR PREPARING ALUMINA AND MAGNESIUM CHLORIDE BY HCl LEACHING OF VARIOUS MATERIALS

The disclosed processes can be effective for treating various materials comprising several different metals. These materials can be leached with HCl for obtaining a leachate and a solid. Then, they can be separated from one another and a first metal can be isolated from the leachate. Then, a second metal can further be isolated from the leachate. The first and second metals can each be substantially selectively isolated from the leachate. This can be done by controlling the temperature of the leachate, adjusting pH, further reacting the leachate with HCl, etc. The metals that can be recovered in the form of metal chlorides can eventually be converted into the corresponding metal oxides, thereby allowing for recovering HCl. The various metals can be chosen from aluminum, iron, zinc, copper, gold, silver, molybdenum, cobalt, magnesium, lithium, manganese, nickel, palladium, platinum, thorium, phosphorus, uranium, titanium, rare earth element and rare metals.

Owner:ORBITE ALUMINAE INC

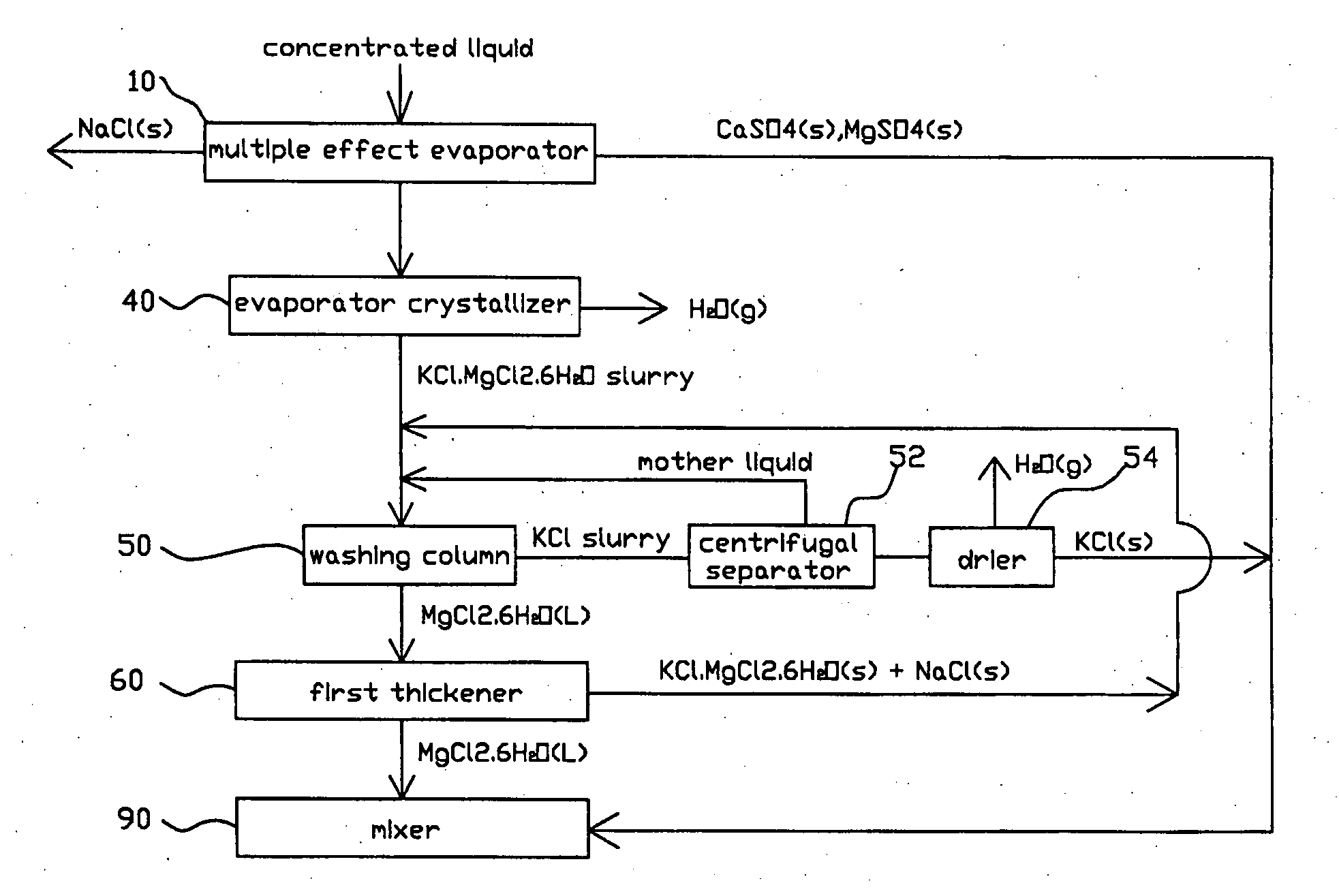

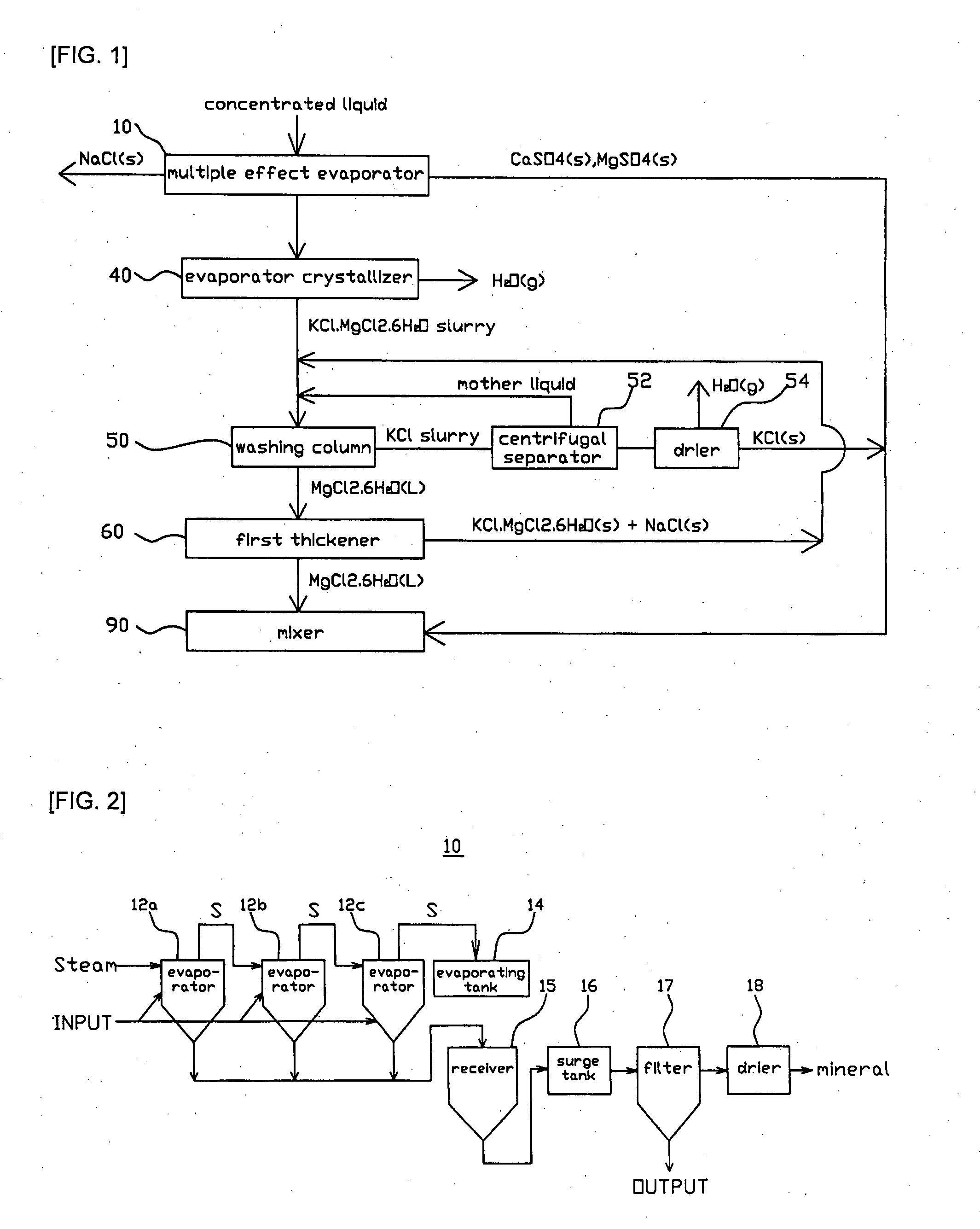

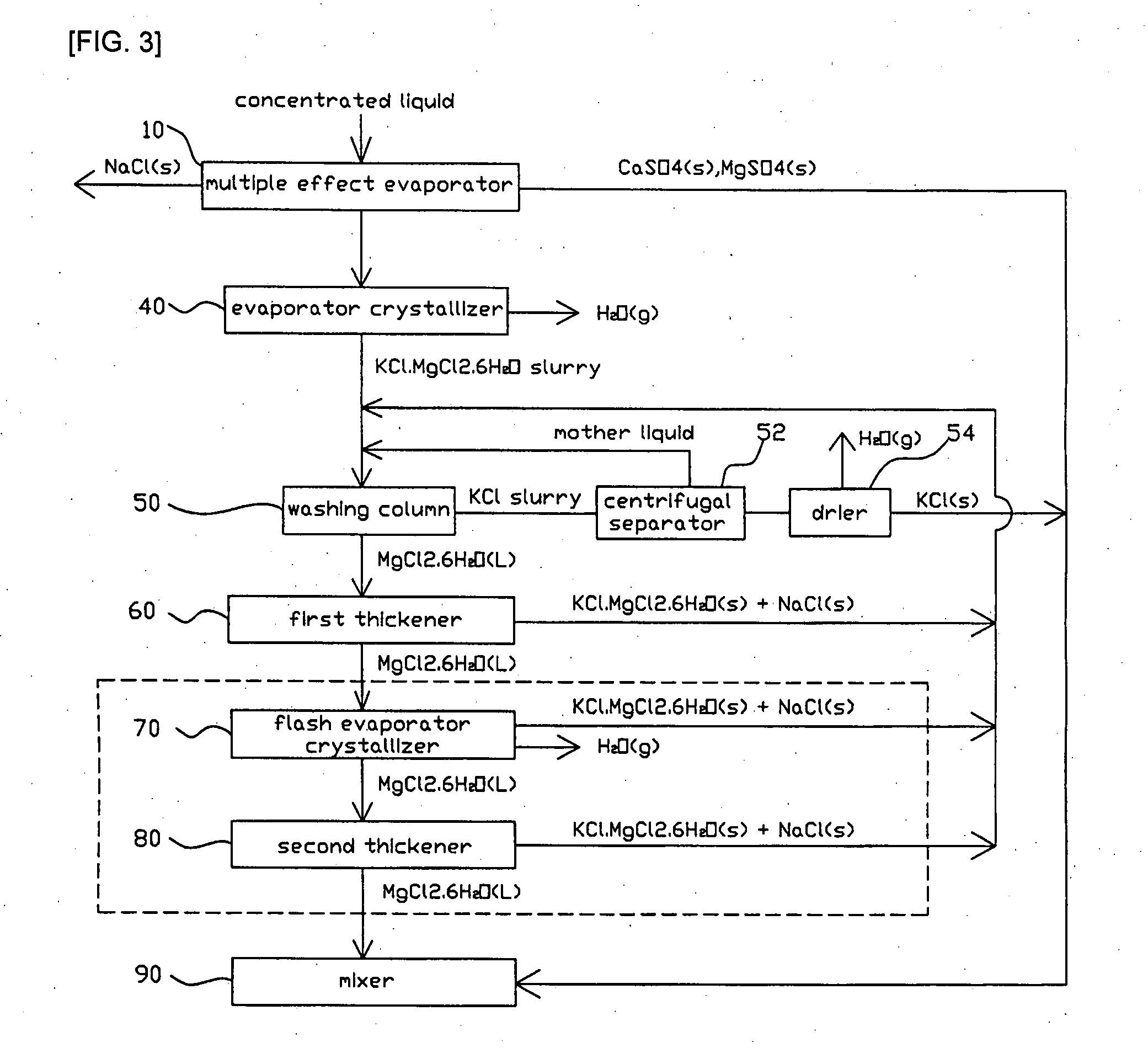

Method for extracting minerals with high purity from deep ocean water

A method for efficiently extracting minerals of high purity from deep ocean water by using low temperature vacuum crystal is disclosed. The method comprises the steps of: obtaining concentrated liquid containing ion components and fresh water without the ion components by freshening the deep ocean water; separating crystals of a calcium salt, a sodium salt, and a sulfate from the concentrated liquid by heat-concentrating and filtering the concentrated liquid; obtaining a mixed salt slurry of a potassium salt and a magnesium salt by concentrating the concentrated liquid from which a calcium salt, a sodium salt, and a sulfate are removed; obtaining a solution in which a magnesium salt is dissolved and a crystal of a potassium salt by washing the mixed salt slurry with water; and obtaining a mixed crystal of a potassium salt and a magnesium salt by concentrating the solution in which a magnesium salt is dissolved, and then separating a magnesium salt solution with improved purity by filtering the concentrated solution in which a magnesium salt is dissolved.

Owner:WATERVIS

Harmlessness treatment method for freon

InactiveCN103058190ASimple processImprove conversion efficiencyChloride preparationFluoride preparationInorganic saltsReaction temperature

The invention relates to a harmless treatment method for freon. The method comprises the steps of (1) dissolving an alkali in water to obtain an alkali aqueous solution, then conveying the alkali aqueous solution, the freon and an oxidizing agent into a hydrothermal reactor respectively; (2) preheating the mixed reactants, performing a hydrothermal oxidizing reaction, controlling a reaction temperature to be 200-300 DEG C and a reaction pressure to be 6-30 MPa, a harmless product is obtained after the hydrothermal reaction is carried out for 5-20 minutes; and (3) cooling a reaction product to obtain carbonate and inorganic salts of fluorine and chlorine. The hydrothermal condition is helpful for fully mixing of the reactants, and facilitates rapid reaction. Compared with a conventional method, the method provided by the invention has the advantages of high speed and high efficiency for the harmless treatment of the freon and has wide application prospects in the fields of waste treatment and waste recycle.

Owner:TONGJI UNIV

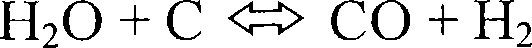

Deoxidation method for molten salt and deoxidated molten salt

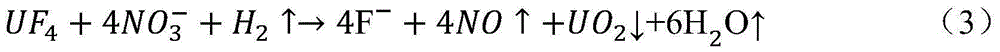

ActiveCN106517097ALess corrosiveImprove deoxidation efficiencyChloride preparationFluoride preparationSulfate radicalsWater vapor

The invention discloses a deoxidation method for a molten salt and a deoxidated molten salt. The method comprises the following steps: introducing carbon into the molten salt, carrying out first-time heating under vacuum conditions until the molten salt is molten, carrying out first-time heat preservation, carrying out first-time cooling, then, carrying out second-time heating until the molten salt is molten, carrying out second-time heat preservation, and carrying out second-time cooling, thereby obtaining the deoxidated molten salt, wherein the molten salt is a fluoride molten salt and / or chloride molten salt. The deoxidation method disclosed by the invention is high in deoxidation efficiency and simple and easy in operation and is safe, reliable and controllable, the carbon-reduction product is removed in the form of gas and does not deposit, and nitrate radicals, sulfate radicals, free oxygen and oxygen-derived free radicals are removed from the molten salt, so that industrial production is facilitated; and in case of later-stage molten-salt treatment by HF-H2, phenomena that pipelines are blocked up by the molten salt and the molten salt is lost due to acute boiling of the molten salt caused by water vapor expansion are absent.

Owner:上海联和日环能源科技有限公司

Process for preparing element halides

InactiveCN101061060AFast heating rateEfficient heatingBromide preparationChloride preparationTraffic accidentVehicle detection

To specify vehicles carrying persons who can be eyewitnesses in the event of a traffic accident. This vehicle detection apparatus is for detecting any vehicle located in the vicinity of an accident site at the time of occurrence of an accident and comprises a vehicle information storage part for storing vehicle identifiers; a one's own vehicle impact detection storage part for storing information about witnessing vehicles; a vehicle information reader part for obtaining vehicle identifiers from the vehicle information storage part of another vehicle detection apparatus; and an impact detection part for detecting impact and for obtaining the vehicle identifiers from the vehicle information reader part upon detection of the impact to store the vehicle identifiers as information about the eyewitnessing vehicles in the one's own vehicle impact detection storage part. Thus when detecting impact on a vehicle, the apparatus can obtain the identification numbers of nearby vehicles and specify any vehicles carrying persons who can be eyewitnesses of the traffic accident.

Owner:WACKER CHEM GMBH

Method for preparing polymerized iron chloride by using cinder of sulfur iron ore

InactiveCN101049978AEliminate pollutionTo achieve the goal of "using waste to make waste"Chloride preparationIron halidesCinderChemistry

This invention discloses a method for preparing poly (ferric chloride) from burnt troilite slag. The method comprises: (1) mixing burnt troilite slag and 15-30% HCl at a certain ratio, reacting at 60-95 deg.C for 1-4 h, and filtering; (2) dividing the leached solution into two parts; (3) adding NaOH to one part, and aerating to obtain Fe(OH)3 colloid; (4) adding an appropriate amount of oxidant to the other part, adding composite phosphate as the stabilizer, stirring vigorously, adding the Fe(OH)3 colloid, and aging for 1 h to obtain poly(ferric chloride) product. The method has such advantages as high ecological safety, high product stability and good flocculation effect.

Owner:NANKAI UNIV

Nano-scale metal halide scintillation materials and methods for making same

Crystalline scintillator materials comprising nano-scale particles of metal halides are provided. The nano-scale particles are less than 100 nm in size. Methods are provided for preparing the particles. In these methods, ionic liquids are used in place of water to allow precipitation of the final product. In one method, the metal precursors and halide salts are dissolved in separate ionic liquids to form solutions, which are then combined to form the nano-crystalline end product. In the other methods, micro-emulsions are formed using ionic liquids to control particle size.

Owner:GENERAL ELECTRIC CO

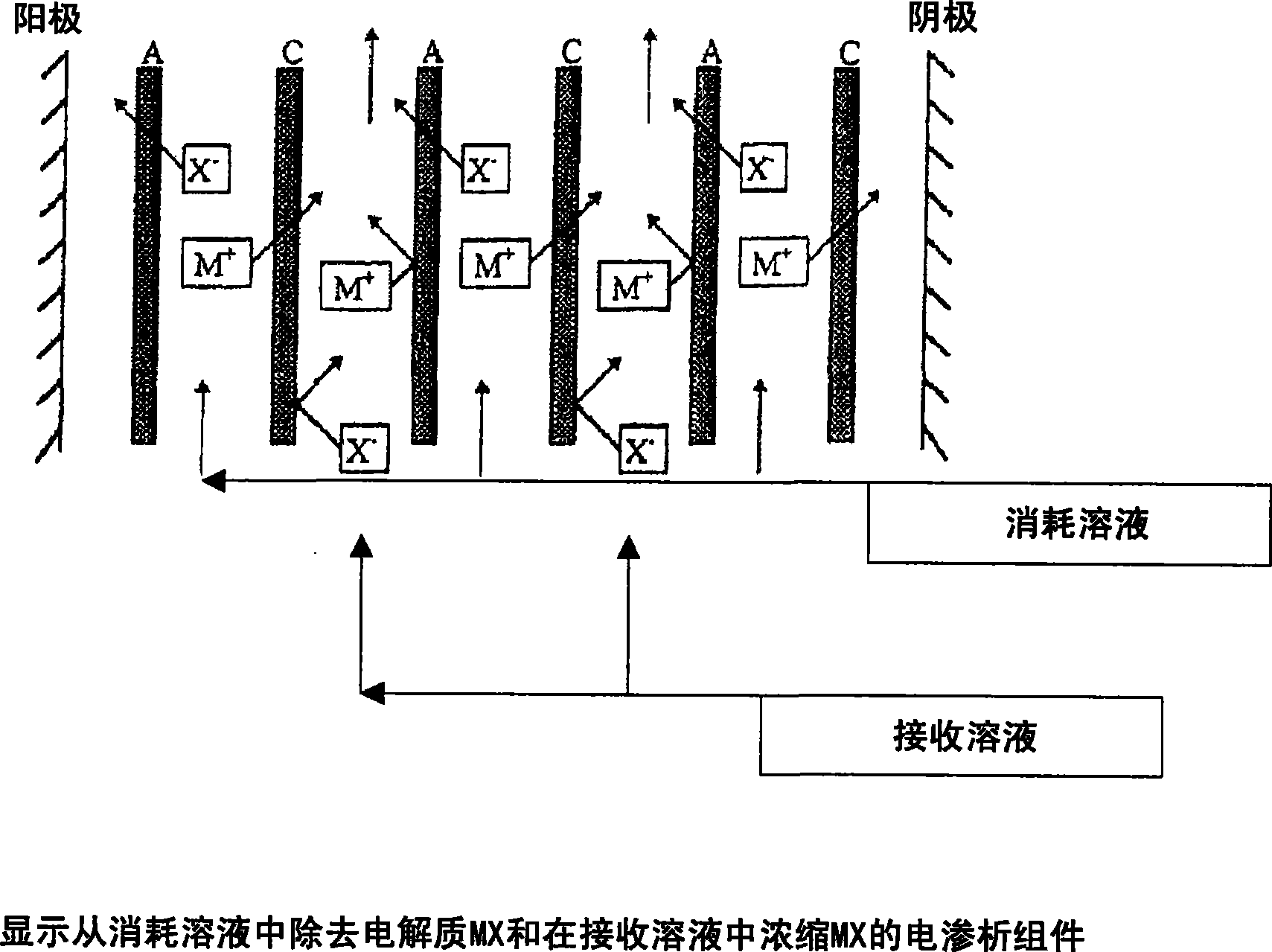

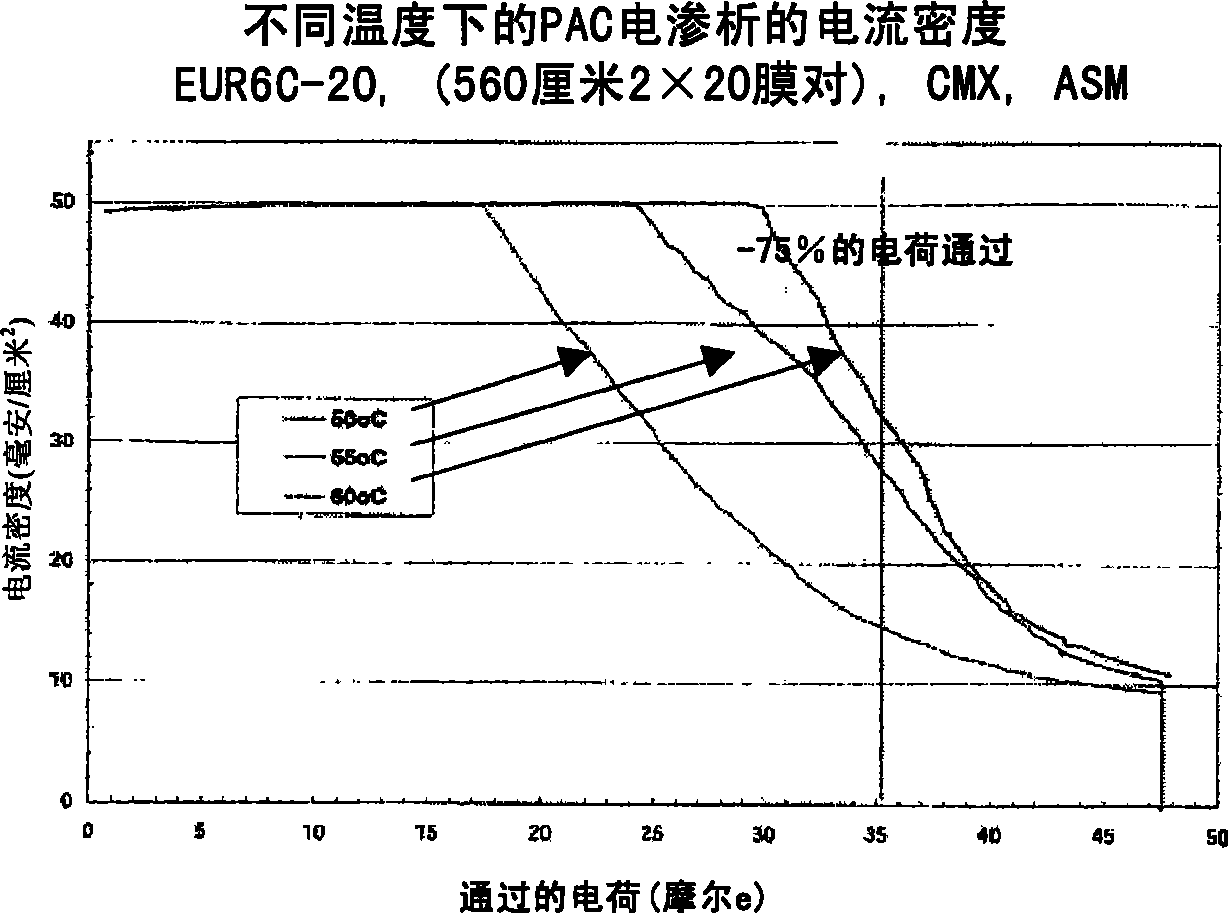

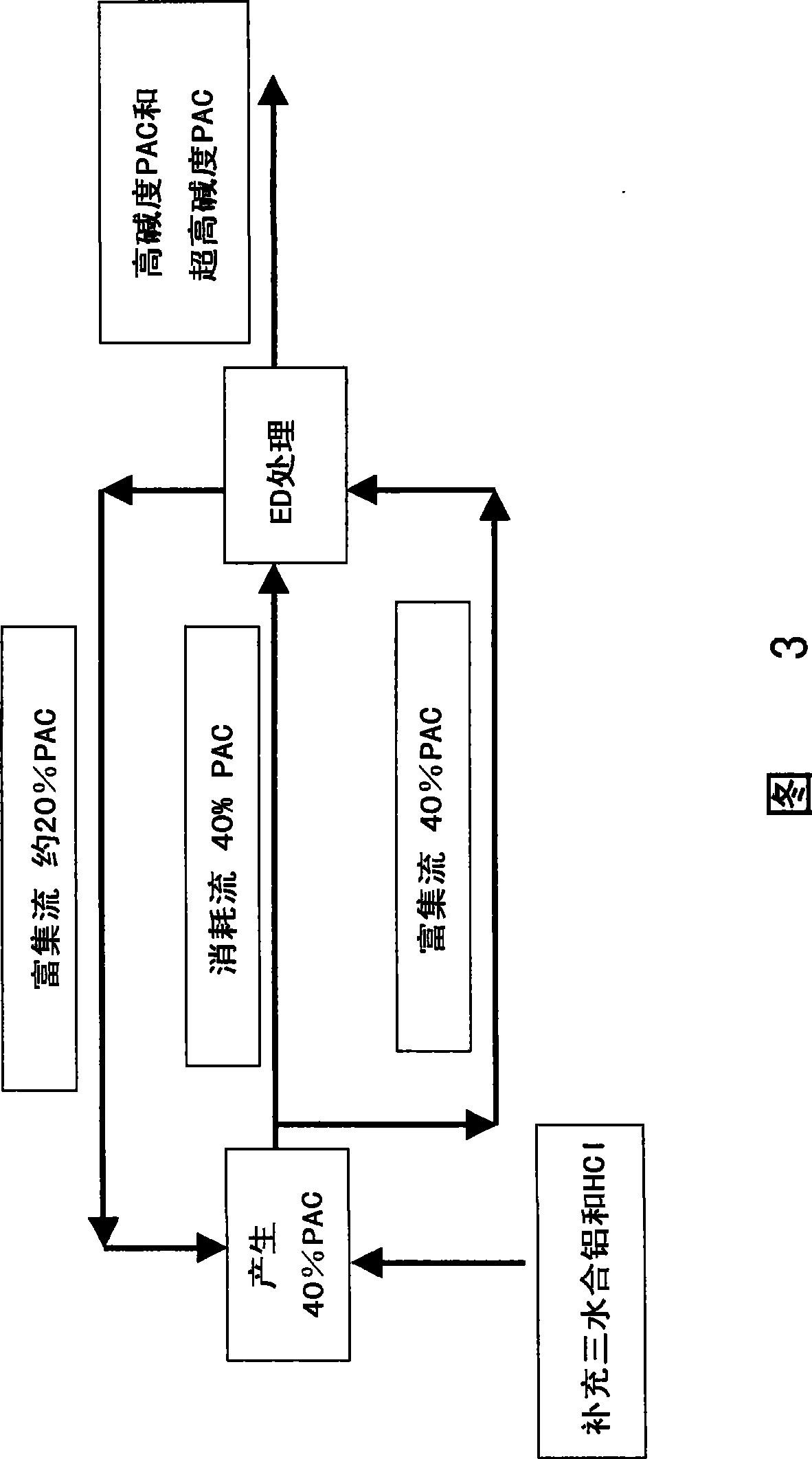

Polyaluminum Chloride and Aluminum Chlorohydrate, Processes and Compositions: High-Basicity and Ultra High-Basicity Products

ActiveUS20070187256A1Increase concentrationIncrease hydroxide contentCosmetic preparationsElectrolysis componentsAntiperspirantsAlkalinity

The invention relates generally to processes for the production of high-basicity and ultr-high basicity polyaluminum chlorides including aluminum chlorohydrate. The processes can produce products of a wide range of basicities and are particularly useful in producing high basicity products. The process can produce a wide range of solution concentrations and are particularly useful in producing high solution concentrations. The processes described generate high purity products, which are free of by-product salt(s). The processes described herein can also be utilized to produce enhanced efficacy polyaluminum chlorides including aluminum chlorohydrate. When compared to conventional processes for manufacturing these compounds the processes disclosed herein are unique in so far as the disclosed processes do not require aluminum metal as a starting material. The products of the processes are suitable in applications including water purification, catalysts, and antiperspirants. In addition, the invention is directed to the products prepared by the processes described herein.

Owner:NEXT CHEM LLC

Preparation Of Lithium Carbonate From Lithium Chloride Containing Brines

ActiveUS20150259215A1Photography auxillary processesChloride preparationLithium chlorideLithium hydroxide

This invention relates to a method for the preparation of lithium carbonate from lithium chloride containing brines. The method can include a silica removal step, capturing lithium chloride, recovering lithium chloride, supplying lithium chloride to an electrochemical cell and producing lithium hydroxide, contacting the lithium hydroxide with carbon dioxide to produce lithium carbonate.

Owner:TERRALITHIUM LLC

Polyaluminum chloride and aluminum chlorohydrate, processes and compositions: high-basicity and ultra high-basicity products

The invention relates generally to processes for the production of high- basicity and ultr- high basicity polyaluminum chlorides including aluminum chlorohydrate. The processes can produce products of a wide range of basicities and are particularly useful in producing high basicity products. The process can produce a wide range of solution concentrations and are particularly useful in producing high solution concentrations. The processes described generate high purity products, which are free of by-product salt(s). The processes described herein can also be utilized to produce enhanced efficacy polyaluminum chlorides including aluminum chlorohydrate. When compared to conventional processes for manufacturing these compounds the processes disclosed herein are unique in so far as the disclosed processes do not require aluminum metal as a starting material. The products of the processes are suitable in applications including water purification, catalysts, and antiperspirants. In addition,the invention is directed to the products prepared by the processes described herein.

Owner:NEXT CHEM LLC

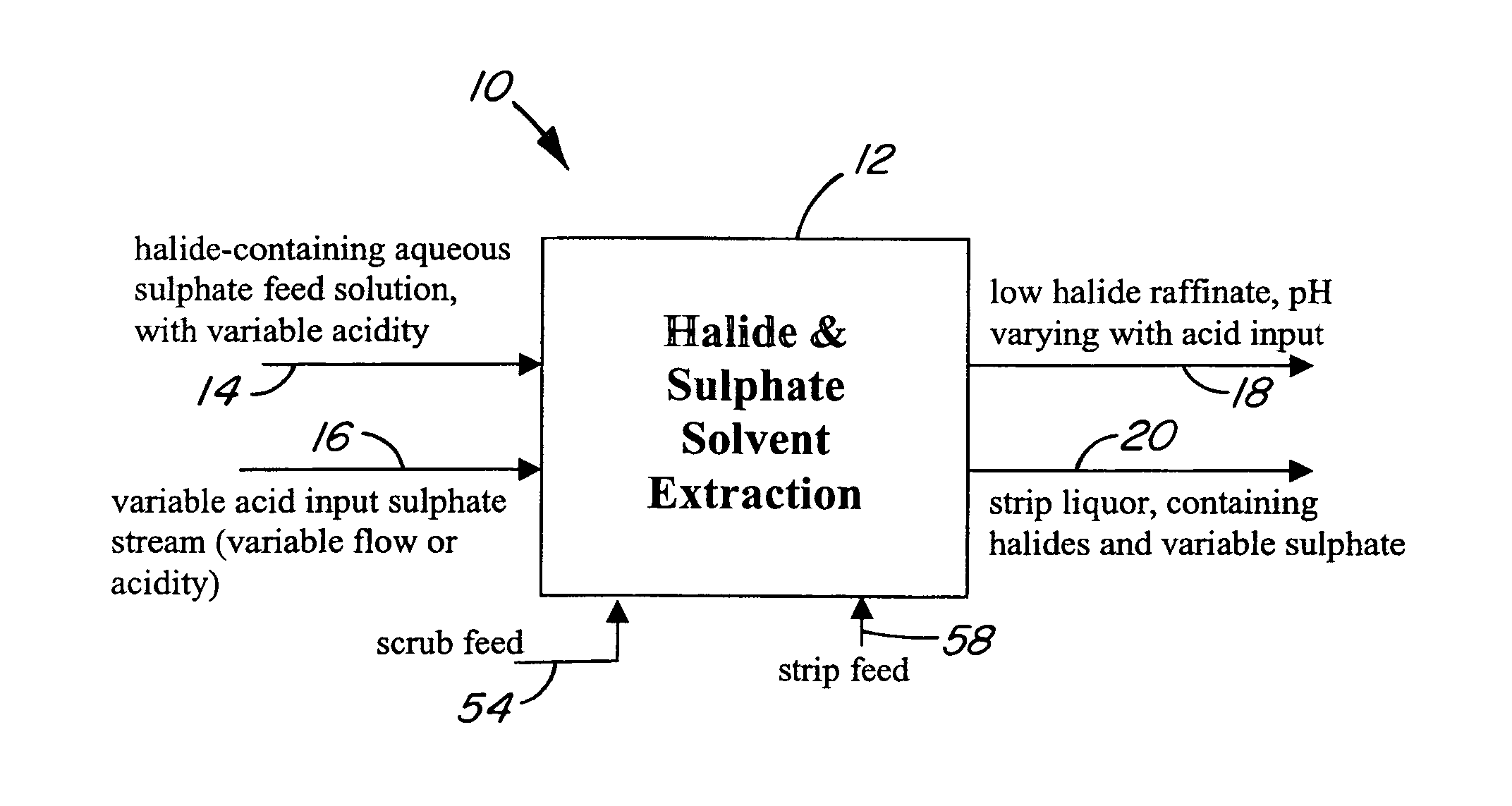

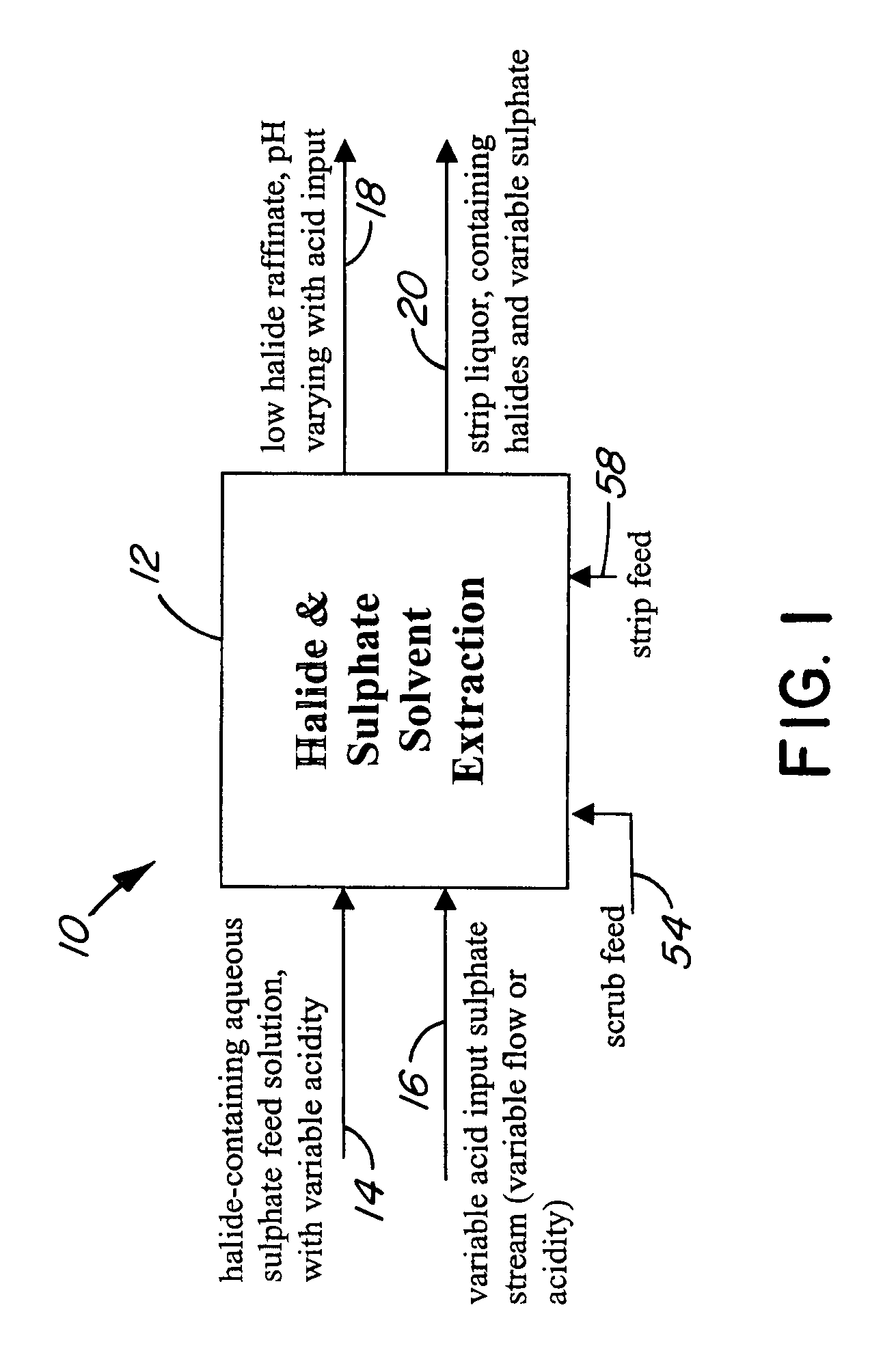

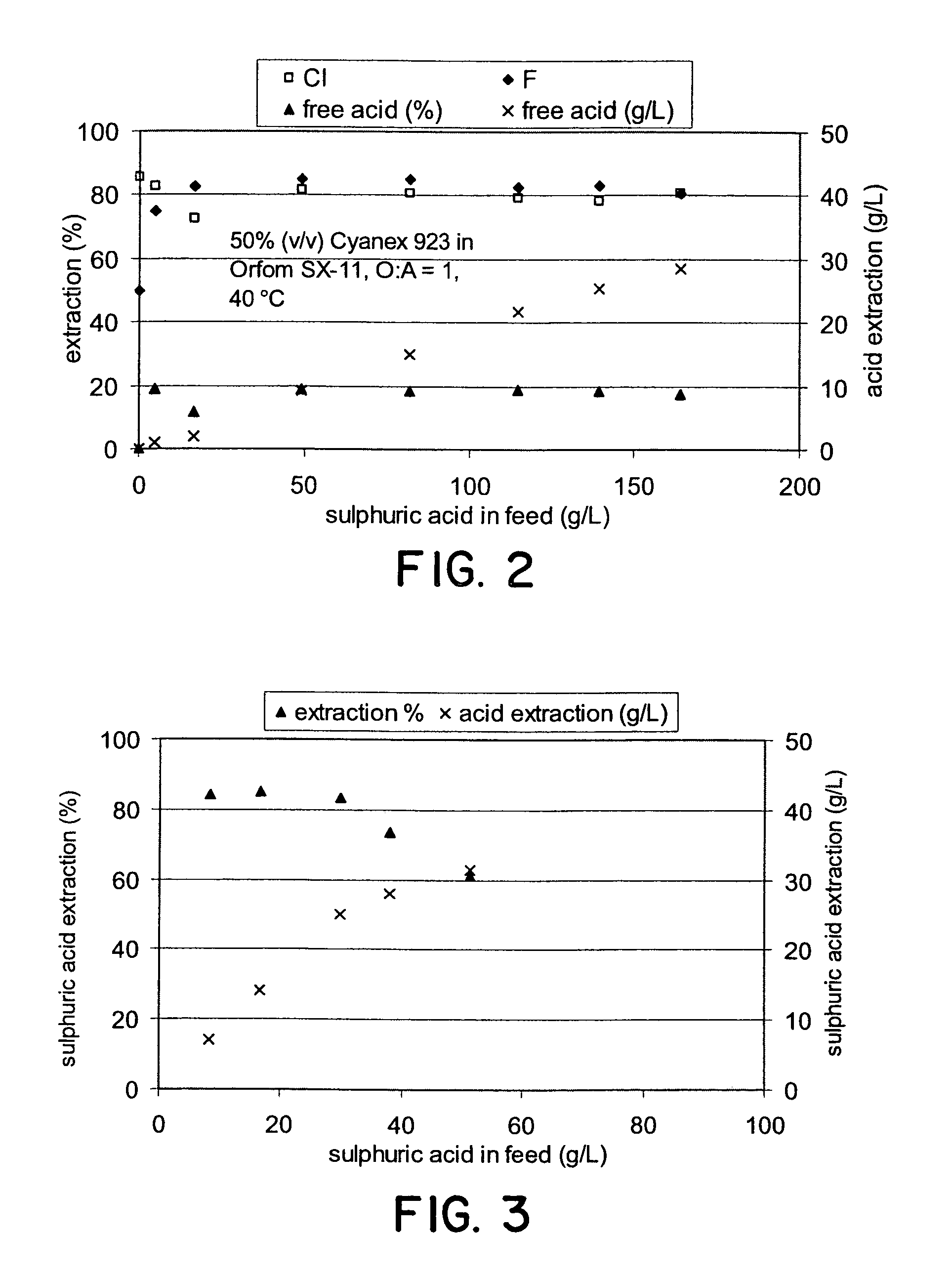

Solvent extraction of a halide from a aqueous sulphate solution

A method of extracting a halide and sulphate from an aqueous sulphate solution, such as a zinc sulphate solution, comprises subjecting the solution to solvent extraction to extract halide and sulphate from the solution and controlling the amount of sulphate extracted by selective adjustment of the acidity of the aqueous solution.

Owner:TECK METALS

Polyaluminum chloride and aluminum chlorohydrate, processes and compositions: high-basicity and ultra high-basicity products

ActiveUS7846318B2Increase hydroxide contentCosmetic preparationsChloride preparationAntiperspirantsAlkalinity

The invention relates generally to processes for the production of high-basicity and ultra-high basicity polyaluminum chlorides including aluminum chlorohydrate. The processes can produce products of a wide range of basicities and are particularly useful in producing high basicity products. The process can produce a wide range of solution concentrations and are particularly useful in producing high solution concentrations. The processes described generate high purity products, which are free of by-product salt(s). The processes described herein can also be utilized to produce enhanced efficacy polyaluminum chlorides including aluminum chlorohydrate. When compared to conventional processes for manufacturing these compounds the processes disclosed herein are unique in so far as the disclosed processes do not require aluminum metal as a starting material. The products of the processes are suitable in applications including water purification, catalysts, and antiperspirants. In addition, the invention is directed to the products prepared by the processes described herein.

Owner:NEXT CHEM LLC

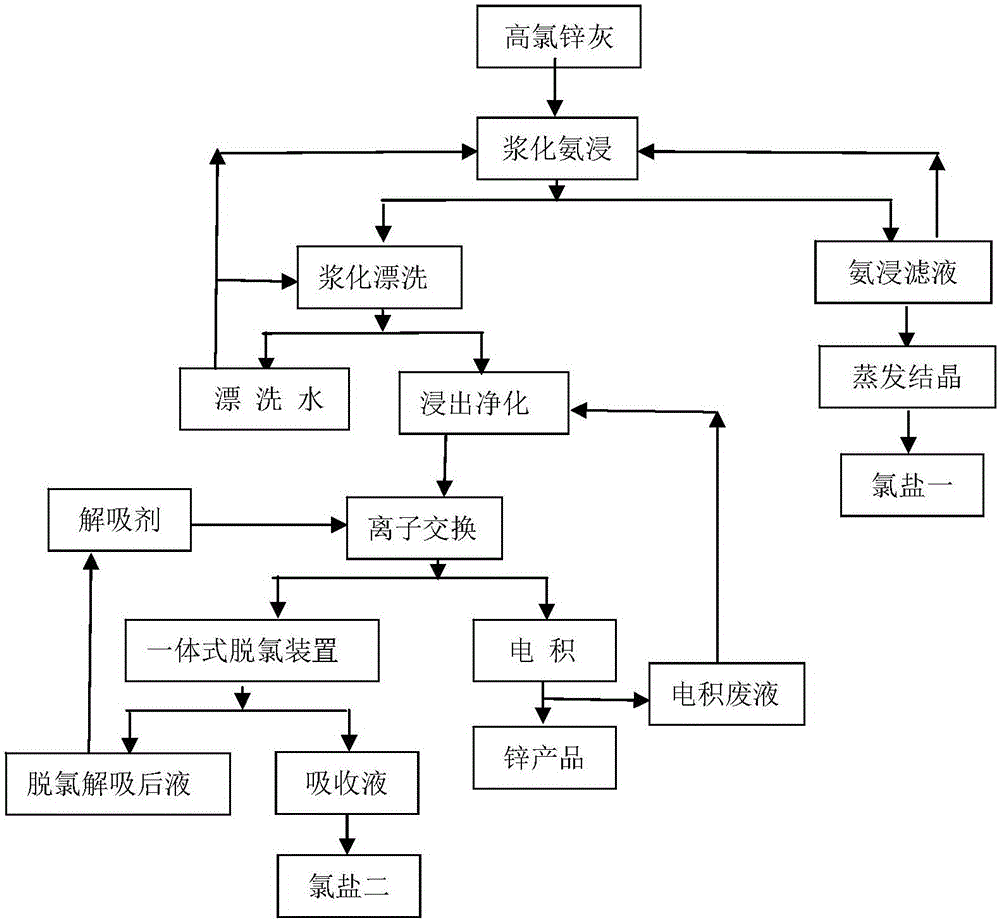

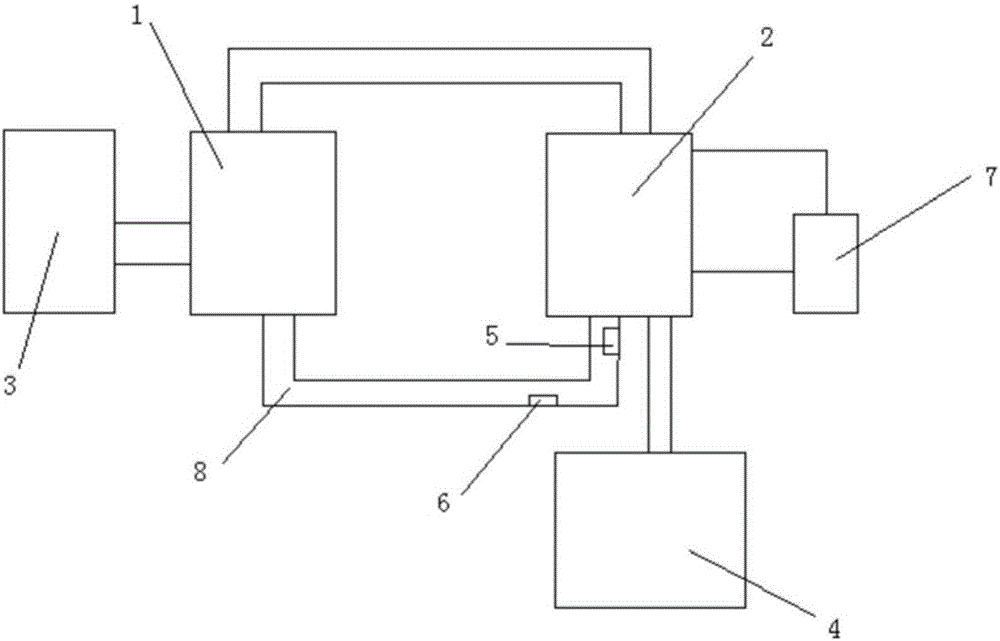

Method for producing electrolytic zinc through high-chloride zinc ash material ammonia leaching ion exchange combined process

InactiveCN106399715AIncreased concentration of chloride ionsReduce water volumeChloride preparationPhotography auxillary processesLiquid wasteFiltration

The invention discloses a method for producing electrolytic zinc through a high-chloride zinc ash material ammonia leaching ion exchange combined process. The method comprises the steps that (1) high-chloride zinc ash is made into slurry, ammonia is added to conduct ammonia leaching; ammonia leaching filter residues and ammonia leaching filtrate are obtained after filtration; if the concentration of chloride ions in the filtrate is less than 80 g / L, slurrying and ammonia leaching are conducted again; and if the concentration of chloride ions in the filtrate is greater than 80 g / L, a way is opened, and chlorine salt I is recovered; the ammonia leaching filter residues are rinsed to obtain rinsing water and after-rinsed zinc ash, the after-rinsed zinc ash is subjected to sulfuric acid leaching to obtain a zinc sulfate solution and leaching residues, and the leaching residues are used for recovery of zinc and lead; chloride ions are removed from the zinc sulfate solution by using ion exchange resin, the zinc sulfate solution is subjected to electrodeposition sending and zinc is recovered after dechlorination, and an ion exchange desorption after-solution is subjected to dechlorination to generate chlorine salt II and returns to the ion exchange resin as a desorption reagent. Through the method, high-efficiency and low-cost impurity removal and harm removal of high-chloride zinc ash with the treatment effect which is several times higher than the treatment limit effect obtained through an existing dechlorination process is realized; a new acceptable raw material source is provided for production of electrolytic zinc; emissions of waste liquor and waste residues are avoided, and the environmental protection effect and economic and social benefits are remarkable.

Owner:吉首市金湘资源科技开发有限公司

Method for preparing high-purity anhydrous indium trichloride

InactiveCN101254942AHigh yieldShorten the timeChloride preparationGallium/indium/thallium compoundsIndium TrichlorideProduction rate

The invention relates to a preparation method of high purity anhydrous indium trichloride, which belongs to the technology field of rare metal fine chemical industry. The preparation method includes: Using 99.99-99.999% Indium metal and 36% hydrochloric acid as the material and using organic solvents including n-butyl alcohol and n-heptane as the dehydrant, that is, using more unstable complex to replace more stable compound, the stable hydrated indium trichloride is replaced with the more unstable complex of the indium trichloride organic solvent; adopting a manner of microwave heating and gradually heating up including three steps of distillation dehydration at normal pressure, distillation de-reagent at reduced pressure and sublimation and purification of the anhydrous indium trichloride; and finally obtaining the high purity anhydrous indium trichloride (InCl3), which is white with a purity of up to 99.99-99.999% and a production rate of 97%-98%.

Owner:KUNMING UNIV OF SCI & TECH

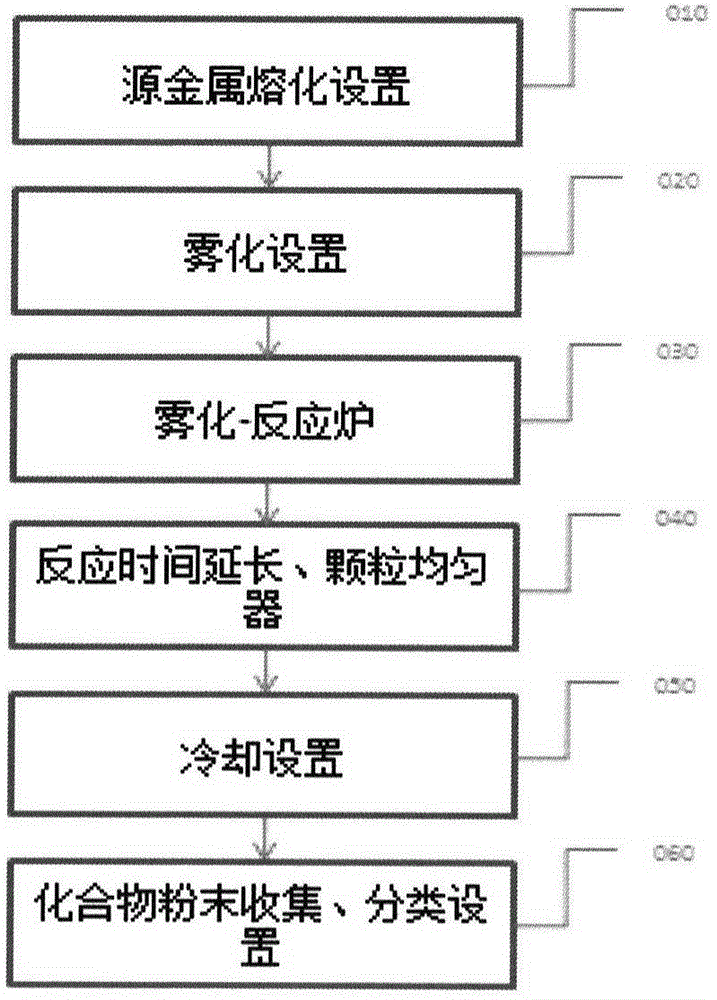

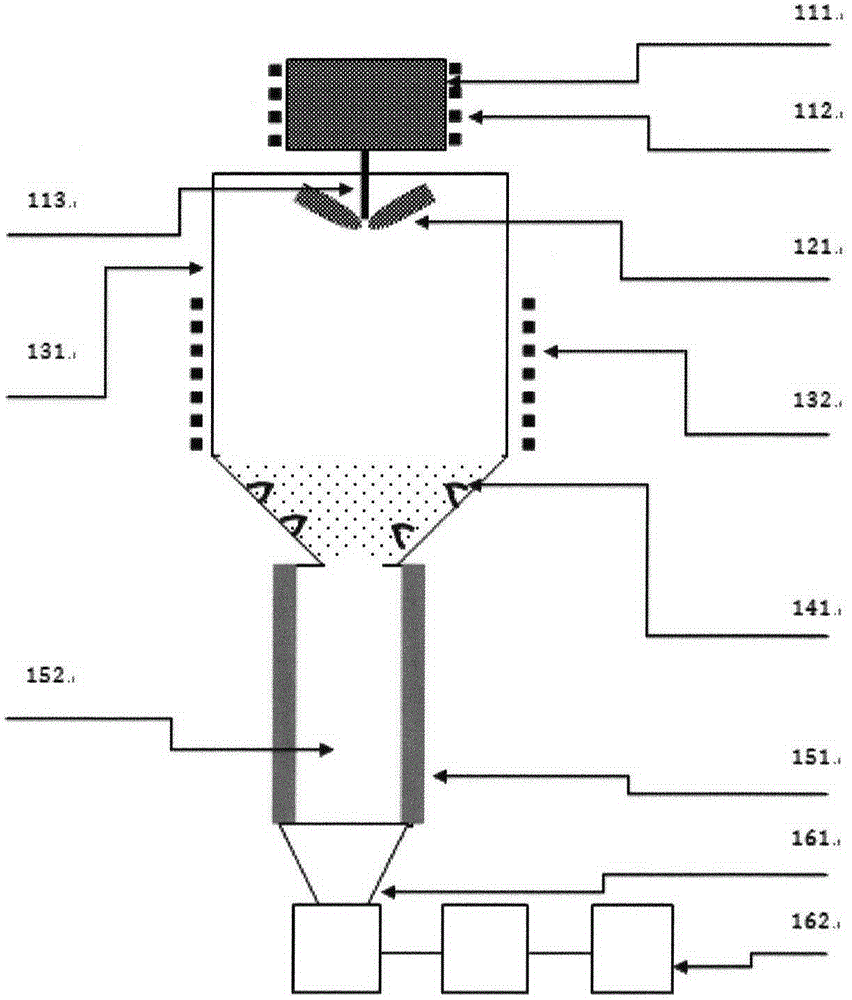

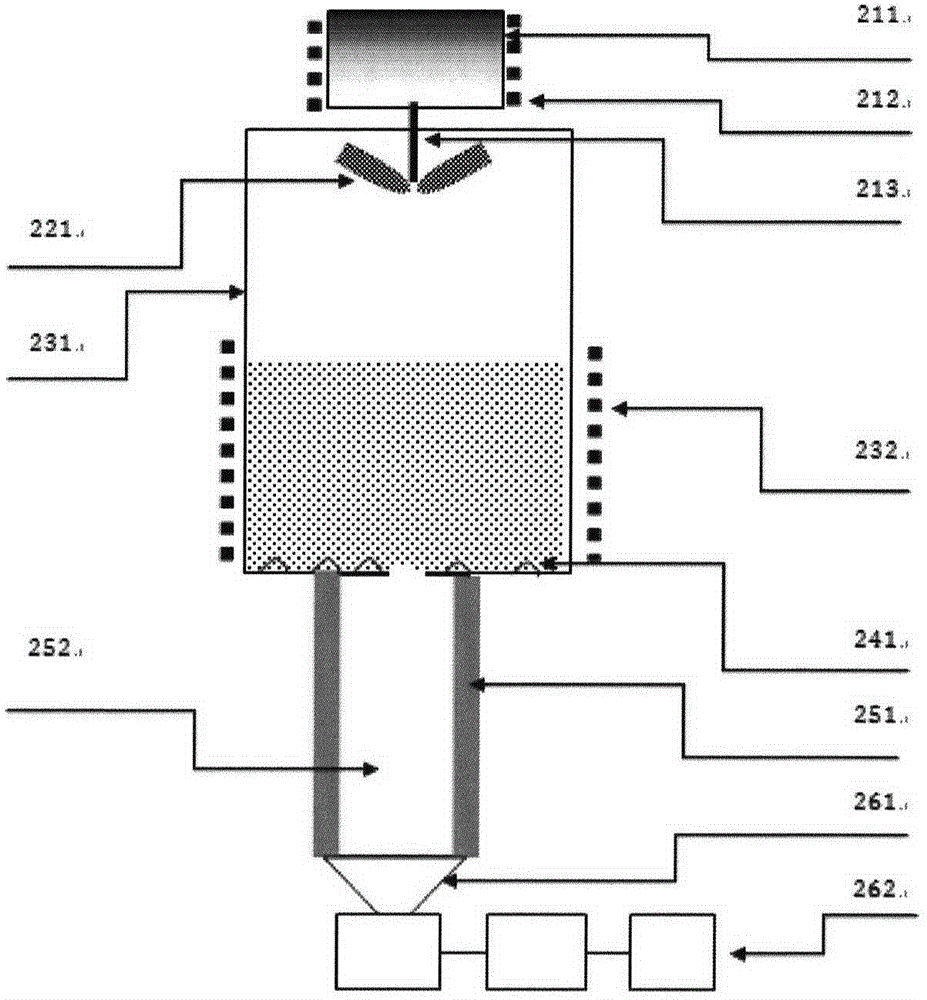

Refractory compound powder material preparation device and preparation method

InactiveCN106268543AHigh purityReduce the impactOxygen/ozone/oxide/hydroxideChloride preparationMaterials preparationEnvironment effect

The invention relates to a refractory compound powder material preparation device which comprises a source metal melting unit, an atomization-reaction furnace, a cooling unit and a refractory compound powder collection and classification unit. A source metal passes through the melting unit to form a liquid stream, the liquid flow enters the atomization unit, and the molten metal is atomized to form tiny liquid drops to react with reactant gas, so that the metal liquid drops are converted into refractory compound powder; and meanwhile, the metal liquid drops continuously react under the action of a grain homogenizer to form multielement refractory compound crystal grains. The crystal grains are cooled and subjected to grain collection and classification to obtain the refractory compound powder material. The device integrates the functions of melting, atomization, reaction, synthesis, cooling, collection and classification, and can be used for preparing the refractory compound powder material with high purity and uniform grains. The device has the advantages of high efficiency and small influence on the environment, and is suitable for popularization and application in the field of powder metallurgy.

Owner:南京科姆特新材料有限公司

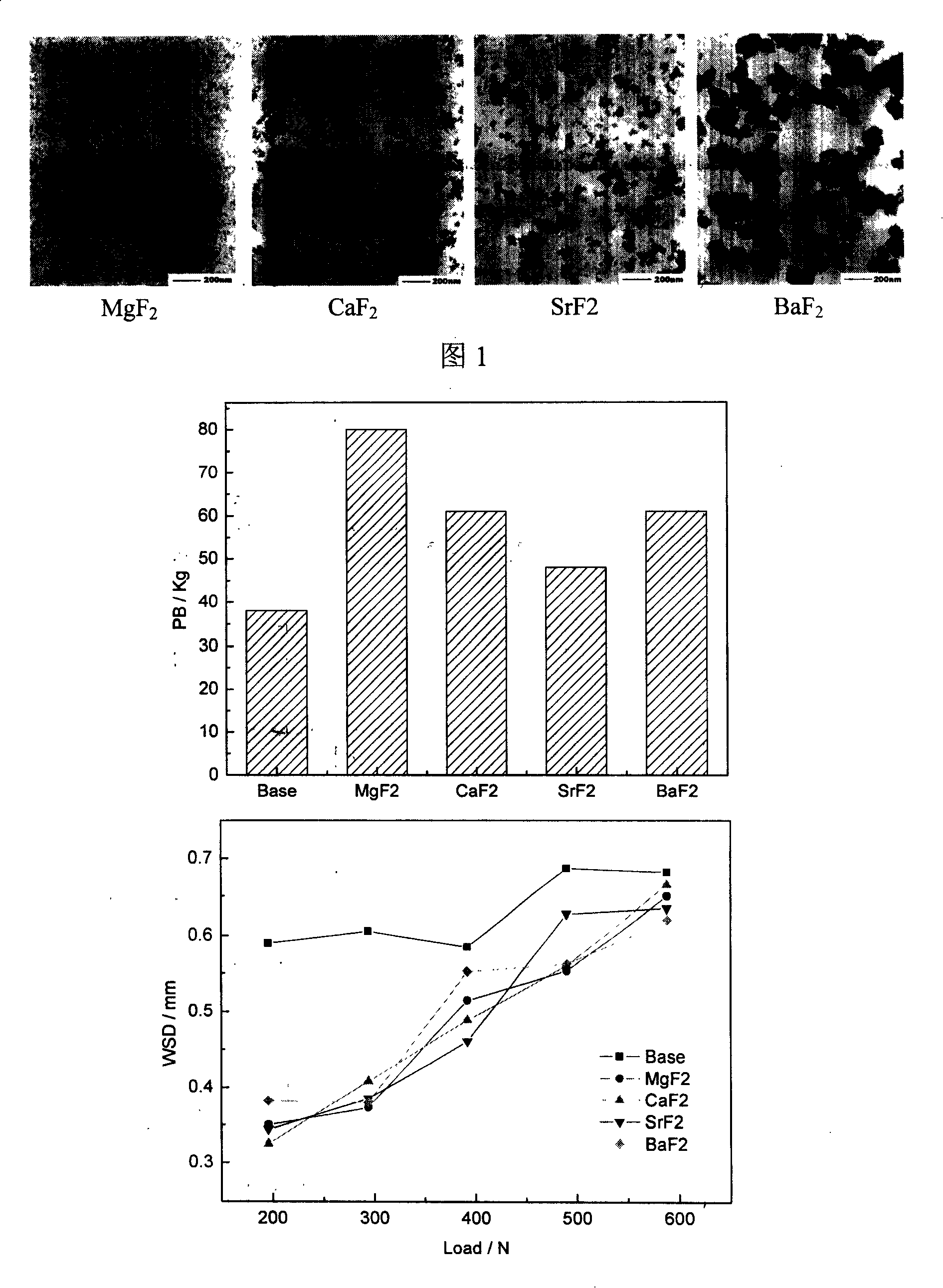

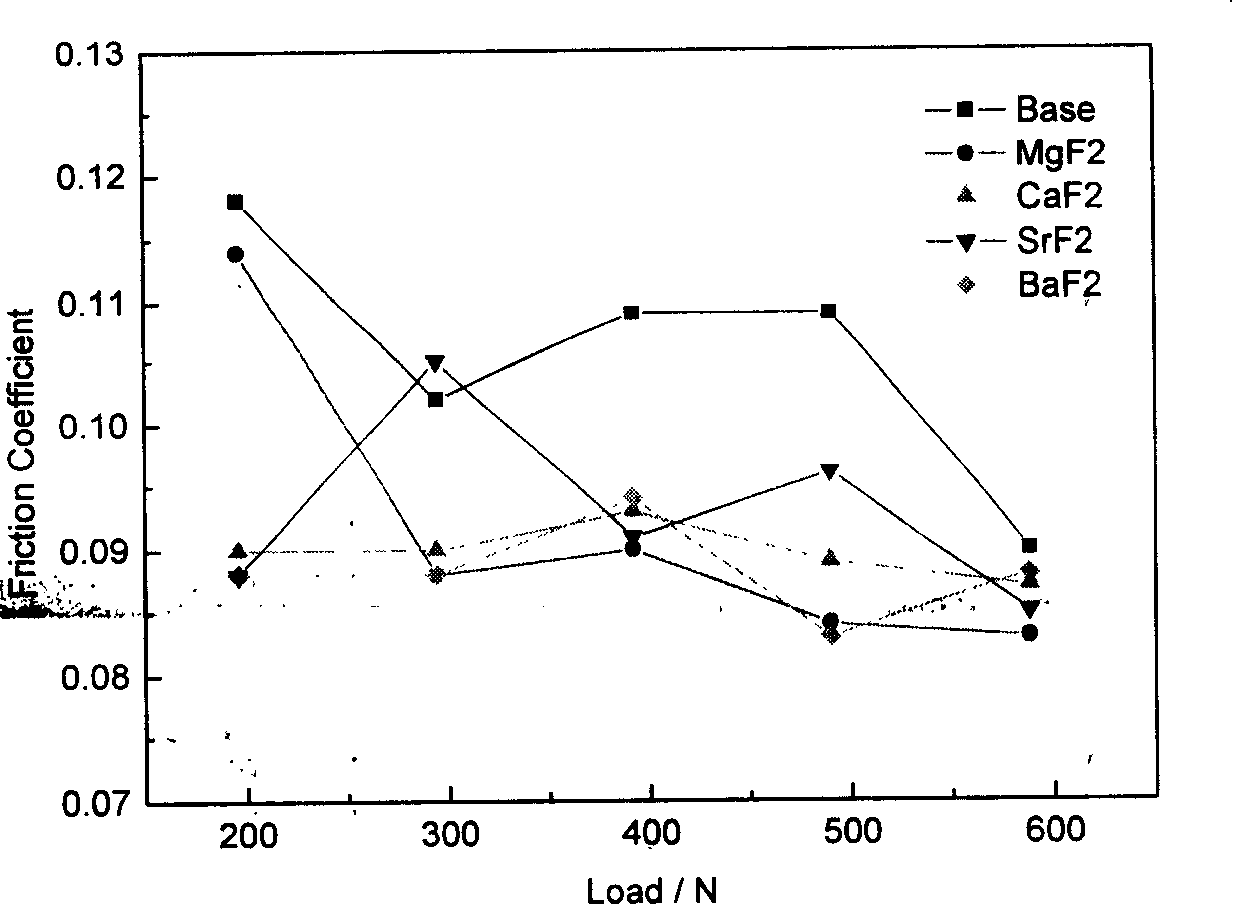

Alkaline earth fluoride nano granule preparation method

InactiveCN101190782AEasy to prepareExcellent anti-friction and anti-wearMagnesium fluoridesChloride preparationProcess equipmentAlkaline earth metal

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

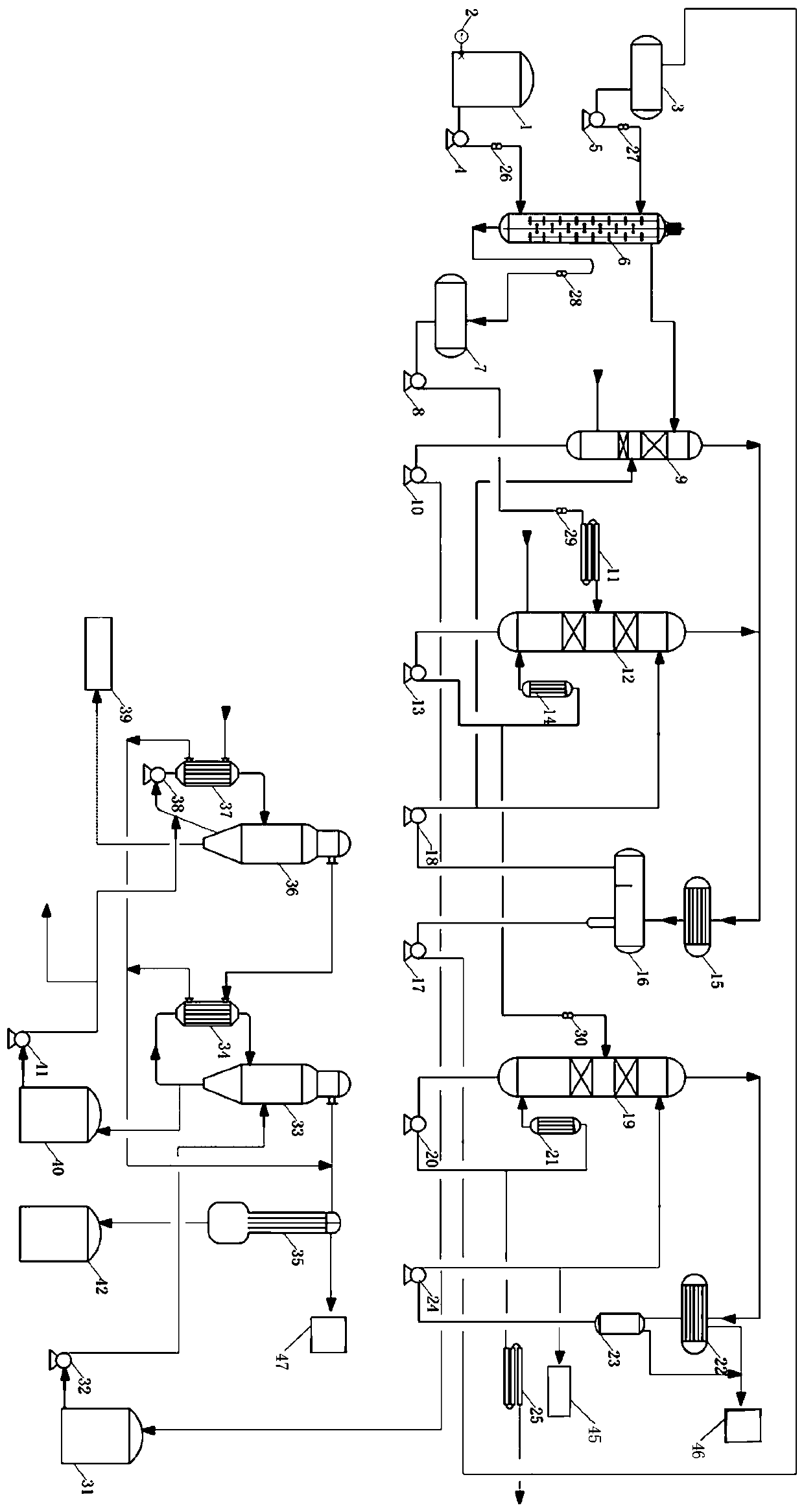

Separation and recycling system of NMP in salty solution

PendingCN109761425AAchieve separationReduce energy consumptionChloride preparationOrganic chemistryRoom temperatureSolvent

The invention belongs to the technical field of mixed solution recycling devices, and particularly relates to a separation and recycling system of NMP in a salty solution. The separation and recyclingsystem is mainly used for separation and recycling of NMP and salt in a solvent which is washed and neutralized, and comprises an extraction device, a stripping tower, an extraction agent removing device, an NMP purifying device and an evaporating device. The recycling system adopts dynamic extraction at room temperature, not only achieves separation of the solvent from water, but also greatly improves the recycling rate of the solvent, and the recycling rate of the solvent is as high as 99.95% or above; salt in a waste salty solution is recycled through the evaporating device, reuse of the salty solution is achieved, the cost is lowered, low emission of waste liquid is achieved, and the requirement of national environment protection is conformed.

Owner:河南神马芳纶技术开发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com