Process for preparing element halides

A technique for halides, halogen compounds, used in the manufacture of elemental halides

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0095] Due to the availability and heat resistance of fumed silica, devices and reaction supports comprising this material were used. It is not affected under the reaction conditions. In order to protect the glass device from reaction and thermal stress, the reactants are introduced into the reactor on a fumed silica support, which consists of a fumed silica tube with feet cut longitudinally in half. Thus, due to the small surface area and significantly lower temperature compared to pulverized or granular reaction mixtures, the reaction rate of the outer walls of the reactor was significantly reduced, and no rupture of the outer walls of the reactor was observed during a single reaction.

[0096] 1 to 1.5 g of a mixture of the listed materials and the likewise listed carbonaceous materials are placed on a fumed silica support (a tube of fumed silica cut in half, 13 mm in diameter, approximately 100 mm in length, fumed silica foot 5mm). The fumed silica carrier was introduced...

Embodiment 2

[0121] Desert sand with a maximum particle size of 0.5mm and SiO composed of activated carbon with a particle size of 2 to 2.5 mm in a ratio of 1:4 2 / C mixture 1 to 1.5 g. Fumed silica carrier is packed in reaction tube (glass tube, diameter is 30mm, has two chimneys, downcomer and upper conduit, average distance is 100mm), this reaction tube is packed into microwave reactor (Panasonic Household Appliances ) within the hot spot. A stream of chlorine diluted with argon (chlorine 40 liters / hour, argon 10 liters / hour) was passed through the reaction tube. After heating by activation of the microwave apparatus, the reaction product was condensed in a cold trap filled with pentane with an ethanol cold bath below -30°C. Carry out quantitative and qualitative analysis. The resulting reaction product is SiCl 4 .

[0122] Convert 50 to 60% of desert sand within a reaction time of 15 to 20 minutes, in which SiO 2 +2C+2Cl 2 → SiCl 4 +2CO is then calculated from the weight devia...

Embodiment 3

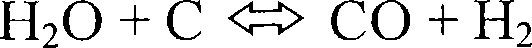

[0124] A mixture of hydrogen chloride (60 liters / hour) and nitrogen (40 liters / hour) was passed through the test apparatus described in Example 1. Convert 50 to 60% of desert sand within a reaction time of 15 to 20 minutes, in which SiO 2 +2C+2Cl 2 → SiCl 4 +2CO is then calculated from the weight deviation of the sample. If no further weight loss was observed after 5 minutes of continued irradiation, the experiment was stopped. Considering SiO in sand 2 The content is about 80% and CO is formed from CO in it 2 And in the case of the influence of Boudouard equilibrium of C, the SiO 2 actual conversion rate. Therefore, based on SiO x The source can achieve substantially quantitative yields.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com