Large-sized vacuum hotpressing stove

A vacuum hot pressing furnace, a large-scale technology, applied in furnaces, muffle furnaces, cooking furnaces, etc., can solve the problem of broken graphite tubes, damage, difficult control of the lifting platform, the accuracy of the working material table, the flatness of the working material table and the furnace body Vacuum sealing performance and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

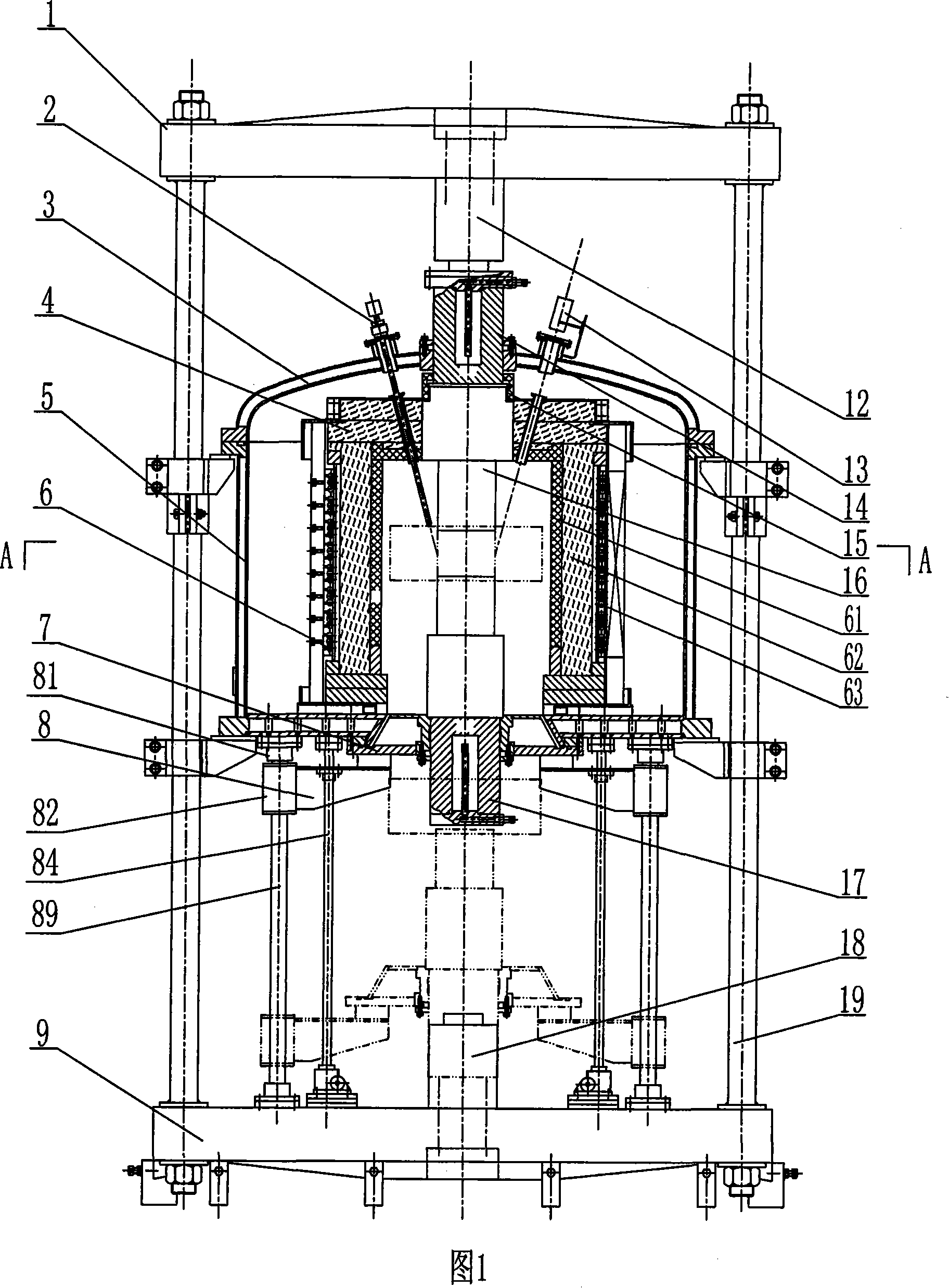

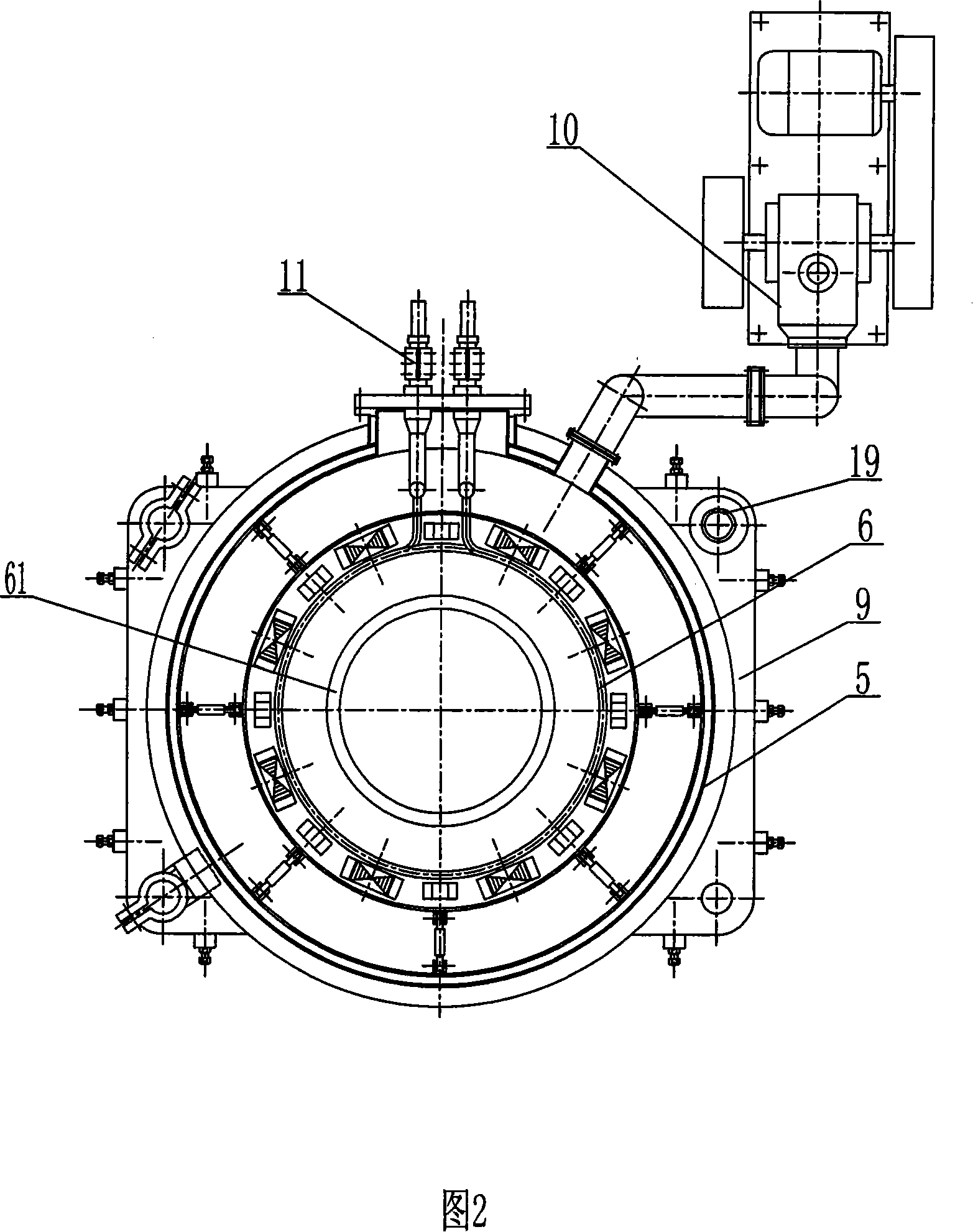

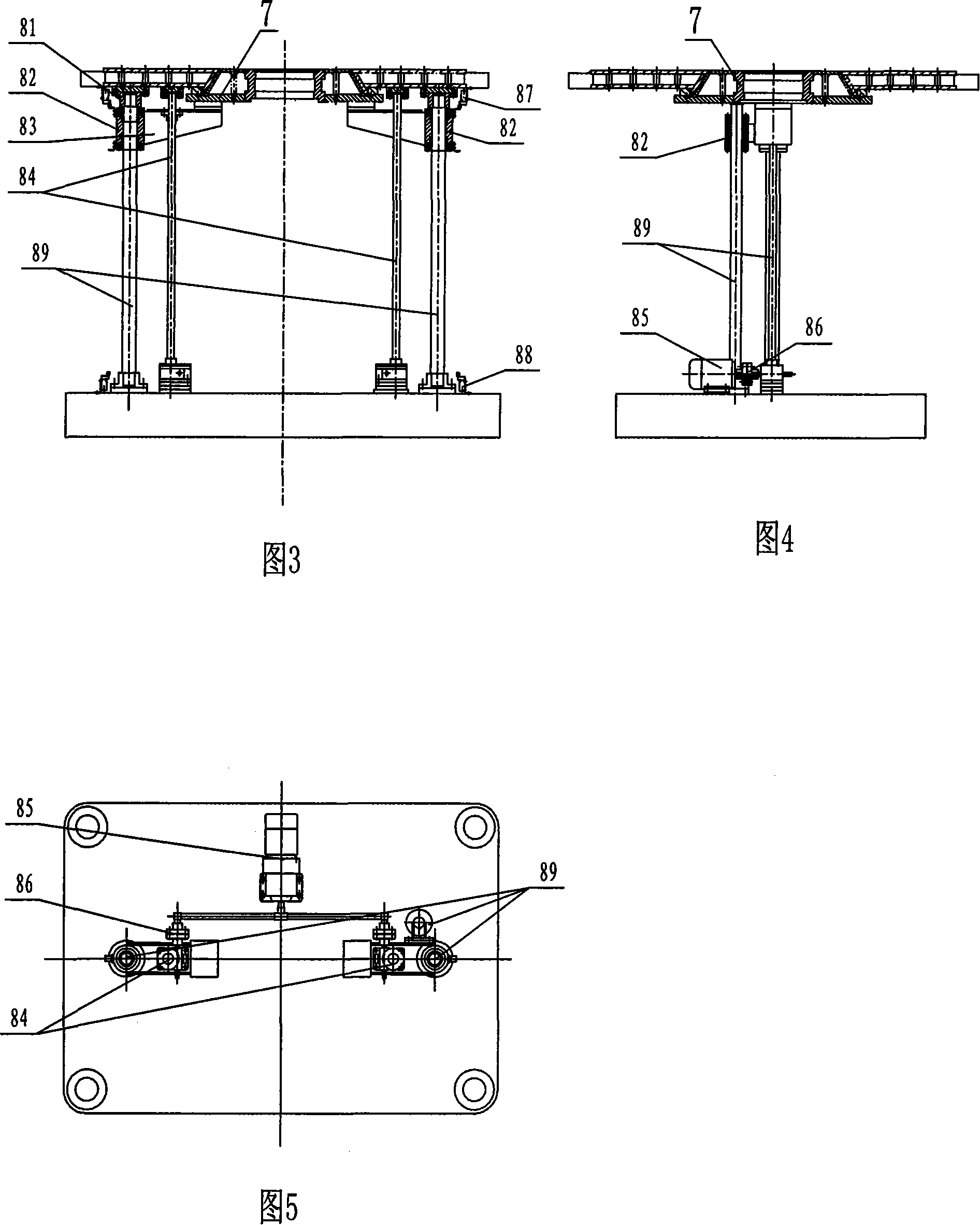

[0069] The vacuum hot-pressing furnace of the present invention shown in Figures 1 and 2 is a periodic electric furnace that adopts a medium-frequency induction method to heat in a vacuum (or protective atmosphere) state. It includes upper and lower mounting seats 1 and 9 supported by four columns 19. The main body of the electric furnace is fixedly connected with the four columns 19 through connectors. The main body of the electric furnace mainly includes a furnace cover 3, a furnace lining 4, a furnace shell 5, and the bottom of the furnace shell. The lifting device 8, the induction heating device in the furnace shell 5. The hot-pressing mold that has been filled with powder adopts the bottom charging method, and is loaded into the furnace through the bottom feeding platform 7, so that the hot-pressing mold is located in the middle of the graphite heating element. Furnace shell 5, vacuum system 10 and gas charging system can keep the furnace chamber under vacuum or protectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com