Dog lifting feeding mechanism of sewing machine and sewing machine

A technology of feeding mechanism and sewing machine, applied in the direction of feeding mechanism, sewing machine components, sewing equipment, etc., can solve the problems of broken needles, short service life of synchronous belts, inconvenient maintenance, etc., to ensure synchronization, low failure rate, Avoid offset effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

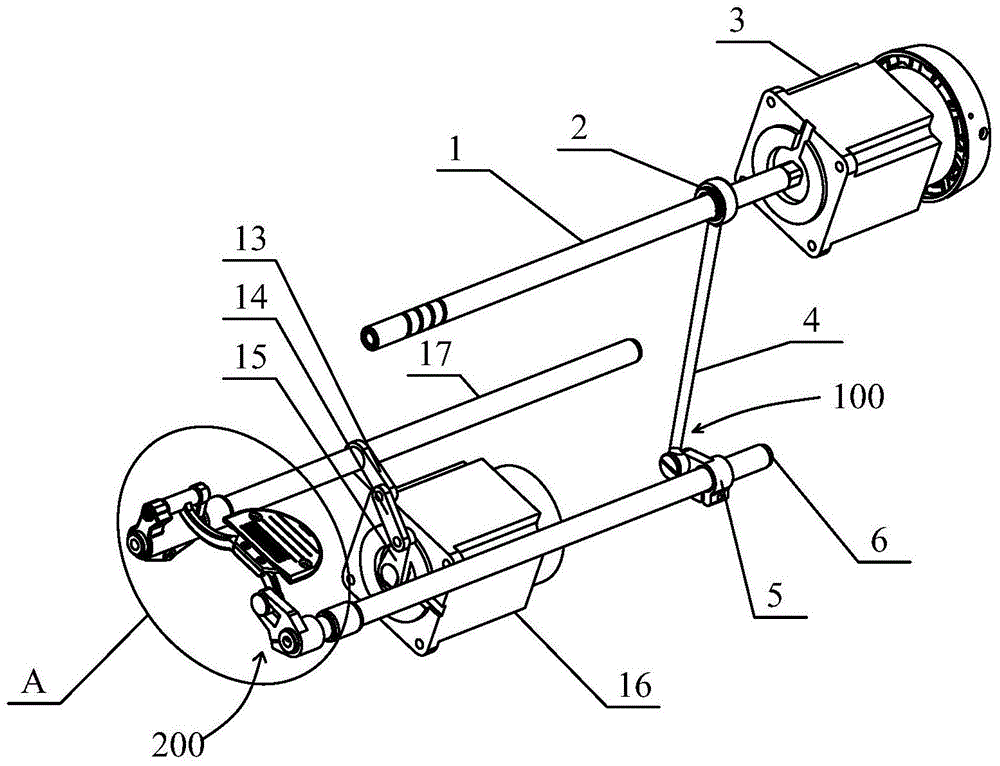

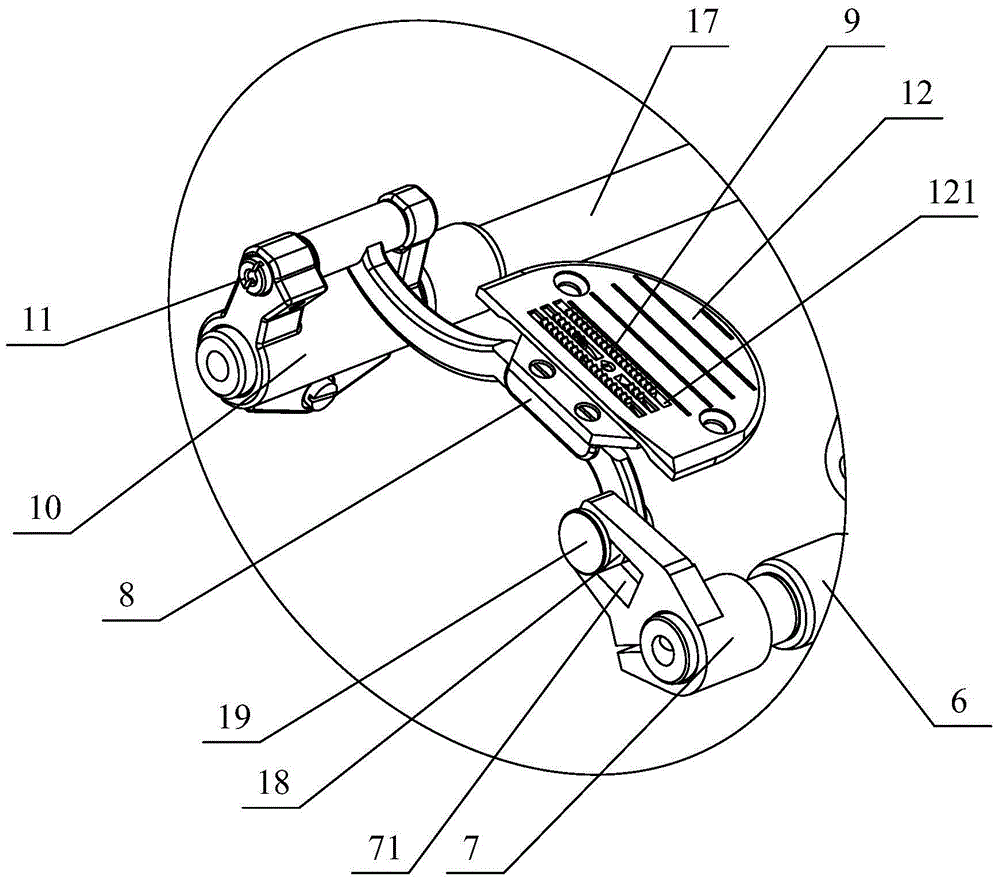

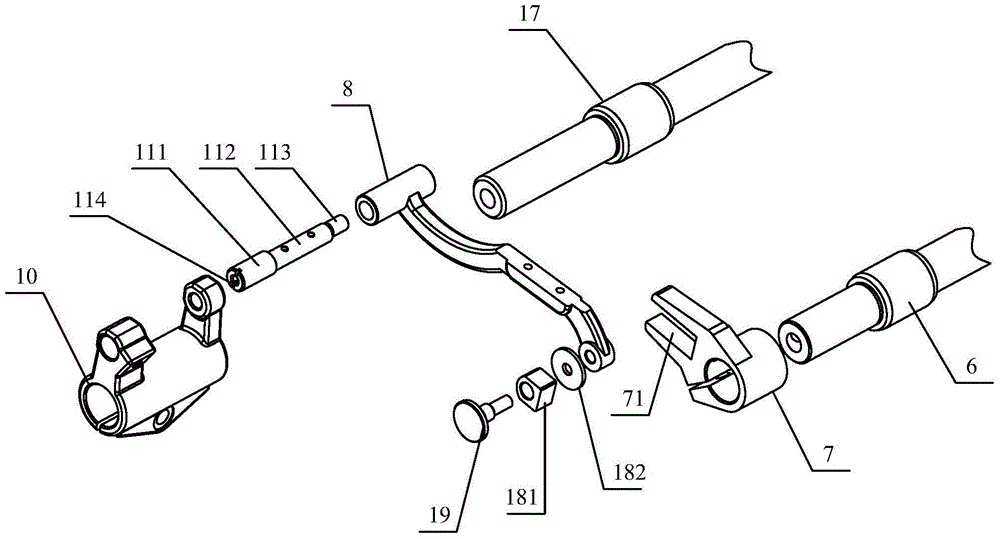

[0072] Embodiment one, as figure 1 As shown, the first transmission unit 100 includes a first eccentric cam 2 or an eccentric bearing fixed on the upper shaft 1, a tooth-lifting rear crank 5 fixed at one end on the tooth-lifting shaft 6, and a tooth-lifting connecting rod 4. The upper end of the tooth lifting connecting rod 4 is rotatably matched with the first eccentric cam 2 or the eccentric bearing, and the lower end of the tooth lifting connecting rod 4 is hinged with the other end of the tooth lifting rear crank 5 . In the present application, the first eccentric cam 2 is fixed on the upper shaft 1; the first eccentric cam 2 includes a first connection part connected with the upper shaft 2 and a second connection part connected with the teeth lifting link 4 , the first connecting part and the second connecting part are arranged eccentrically, so that the center of the upper end of the lifting link 4 does not coincide with the center of the upper shaft 1, so when the first...

Embodiment 2

[0073] Embodiment two, such as Figure 4 As shown, the first transmission unit 100 includes a first connecting rod 20, a second connecting rod 21 and a first slider 22, one end of the first connecting rod 20 is fixed on the upper shaft 1, and the second connecting rod 20 is fixed on the upper shaft 1. One end of the rod 21 is fixed on the lifting shaft 6, the first slider 22 is hinged to the other end of the first connecting rod 20, and is slidably sleeved on the second connecting rod 21, and the second connecting rod 21 Extend along the radial direction of the lifting tooth shaft 6. The upper shaft 1 drives the upper end of the first connecting rod 20 to rotate, so the lower end of the first connecting rod 20 swings back and forth with the axis of the upper shaft 1 as the center line, and is moved by the sliding of the first slider 22 on the second connecting rod 21. Drive the second connecting rod 21 to swing back and forth with the axis of the tooth lifting shaft 6 as the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com