Patents

Literature

312 results about "Feed dogs" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

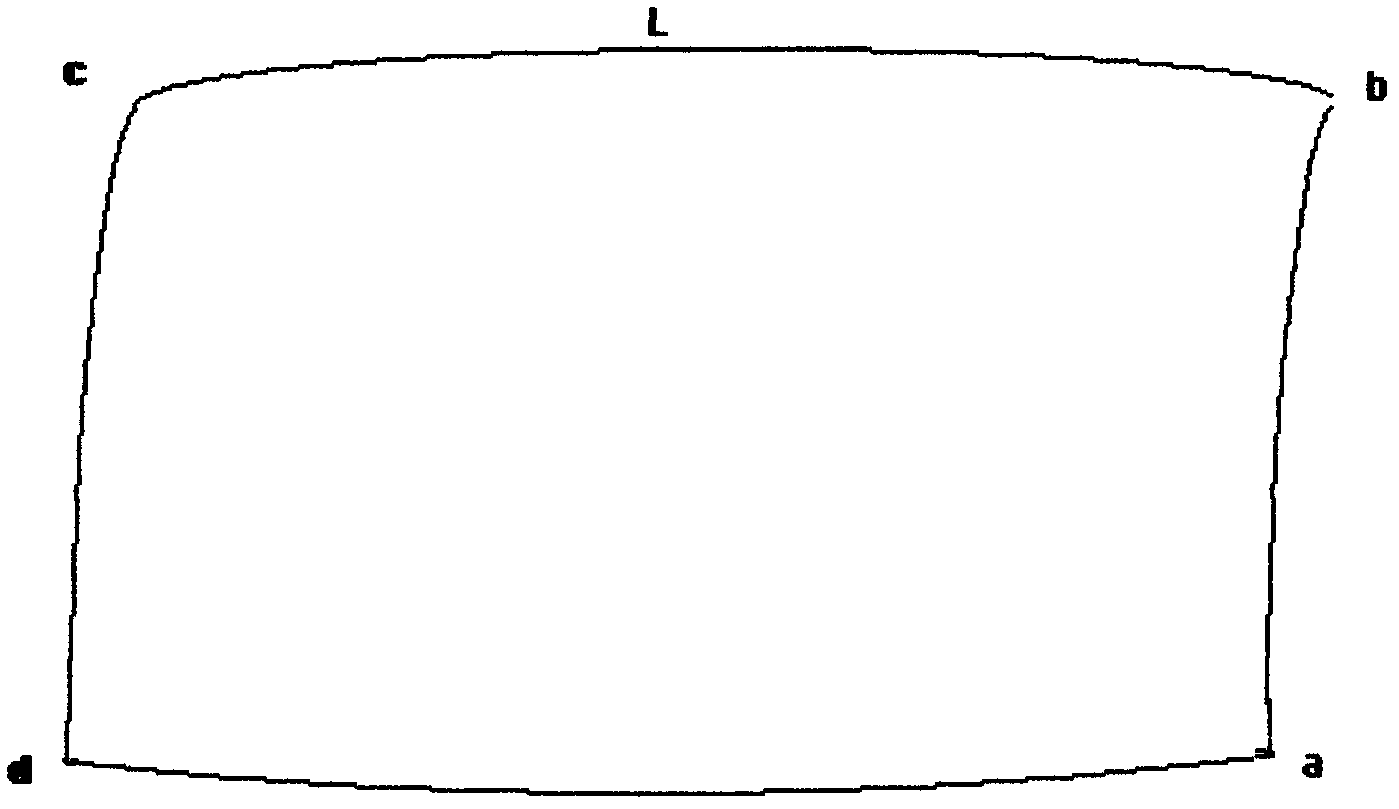

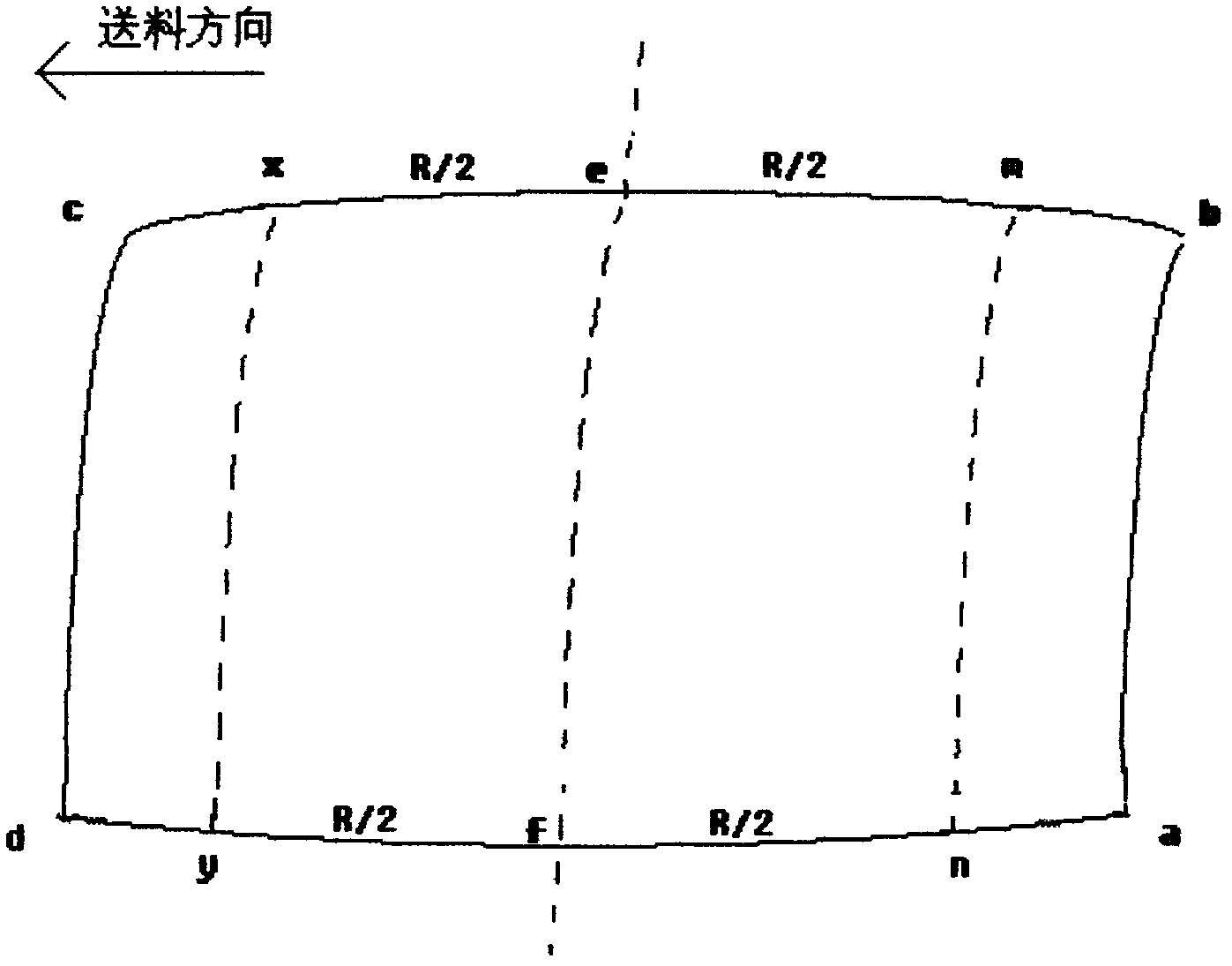

Feed dogs are the critical component of a "drop feed" sewing machine. A set of feed dogs typically resembles two or three short, thin metal bars, crosscut with diagonal teeth, which move back and forth in slots in a sewing machine's needle plate. Their purpose is to pull ("feed") the fabric through the machine, in discrete steps, in-between stitches.

Sewing machine

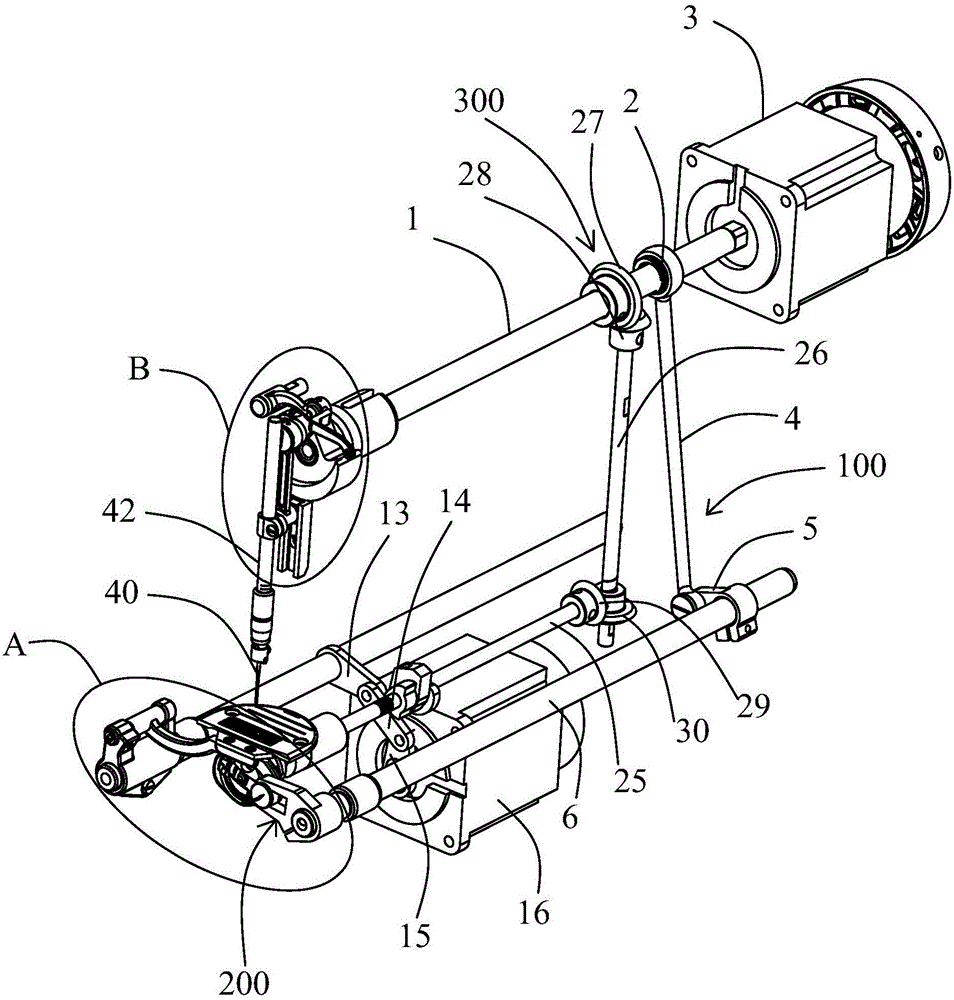

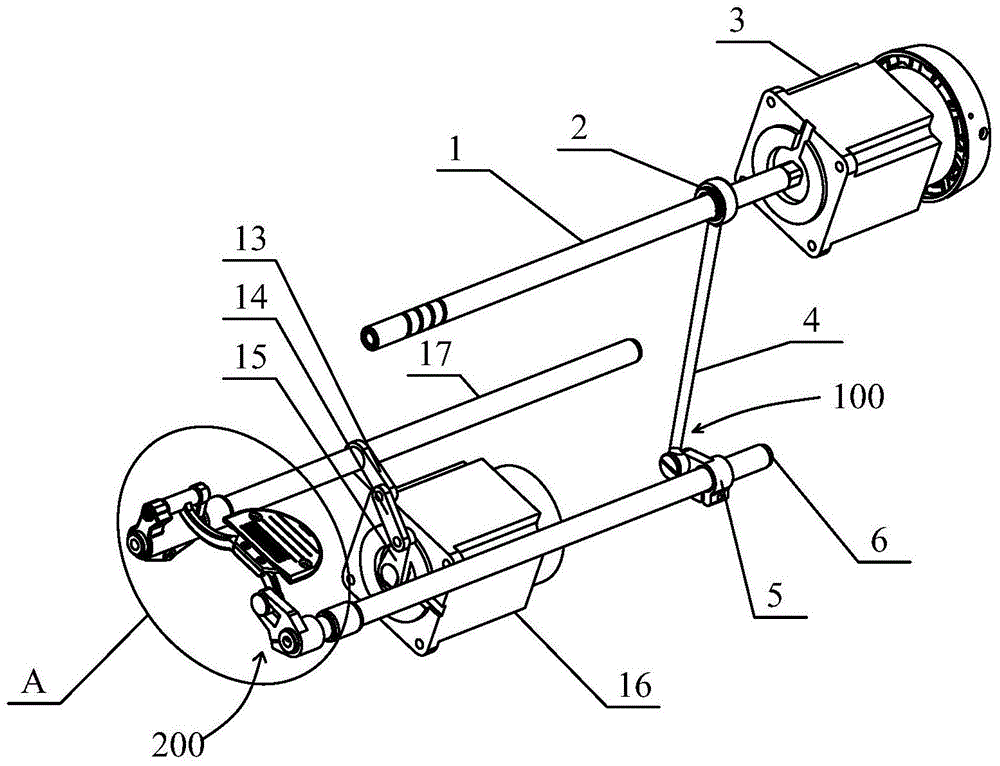

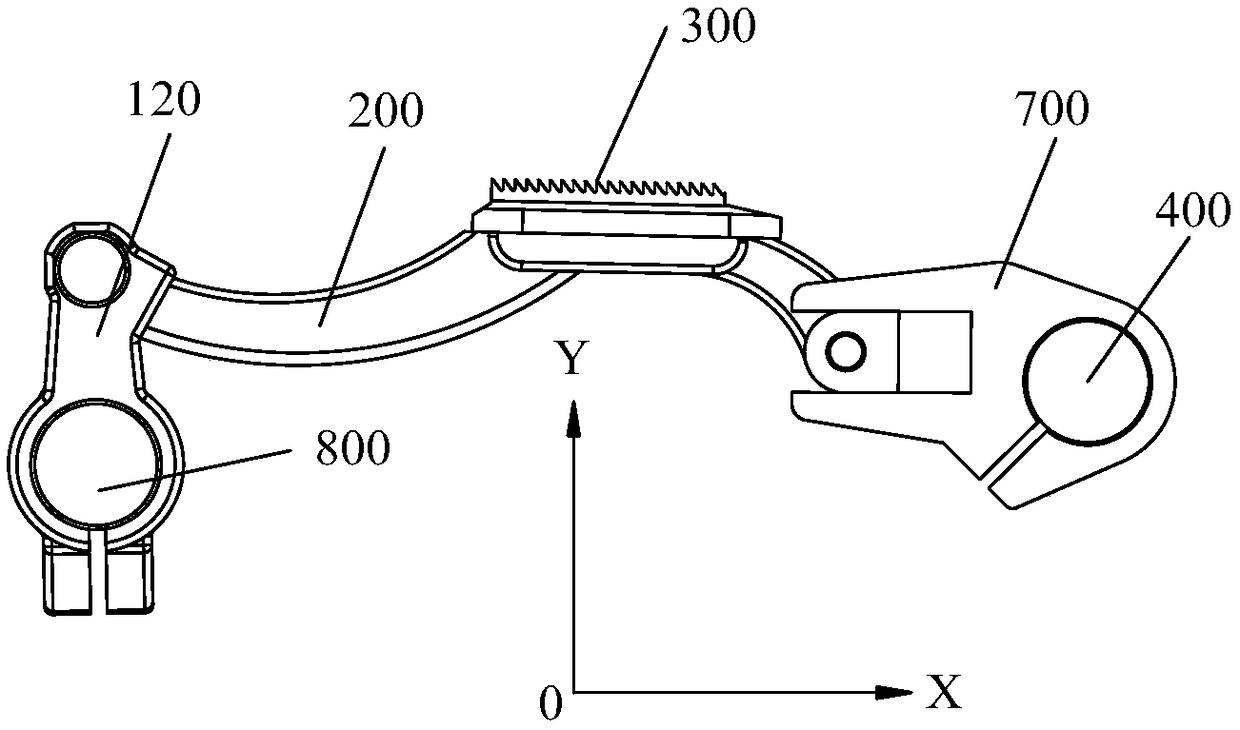

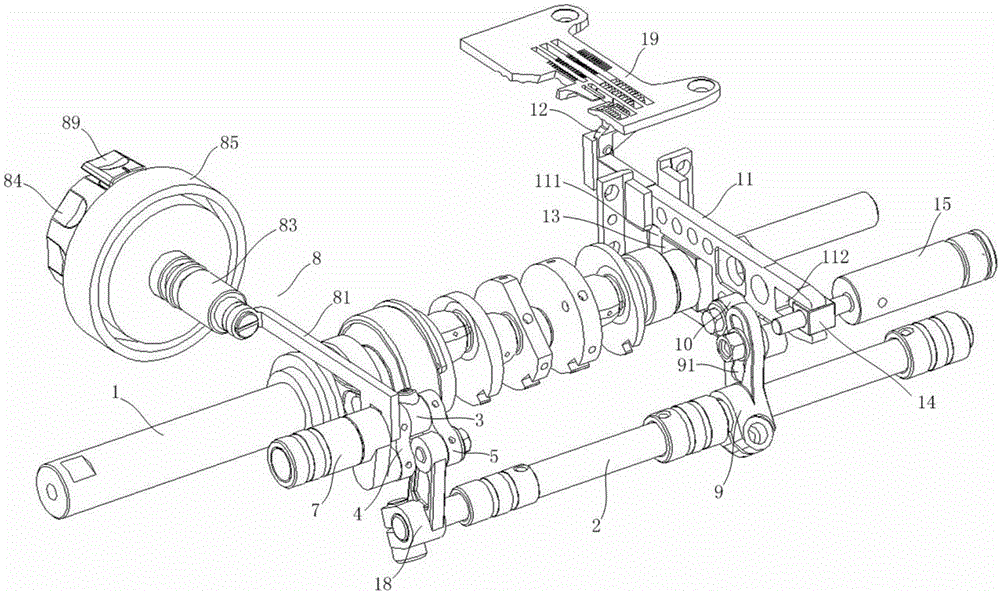

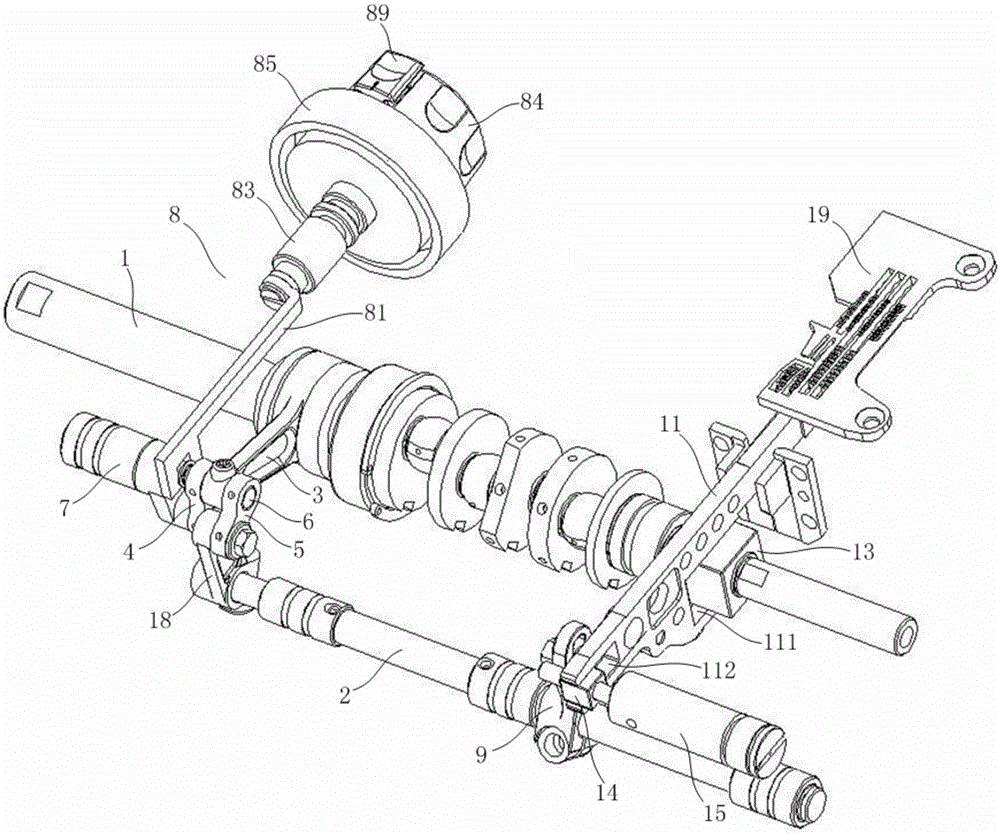

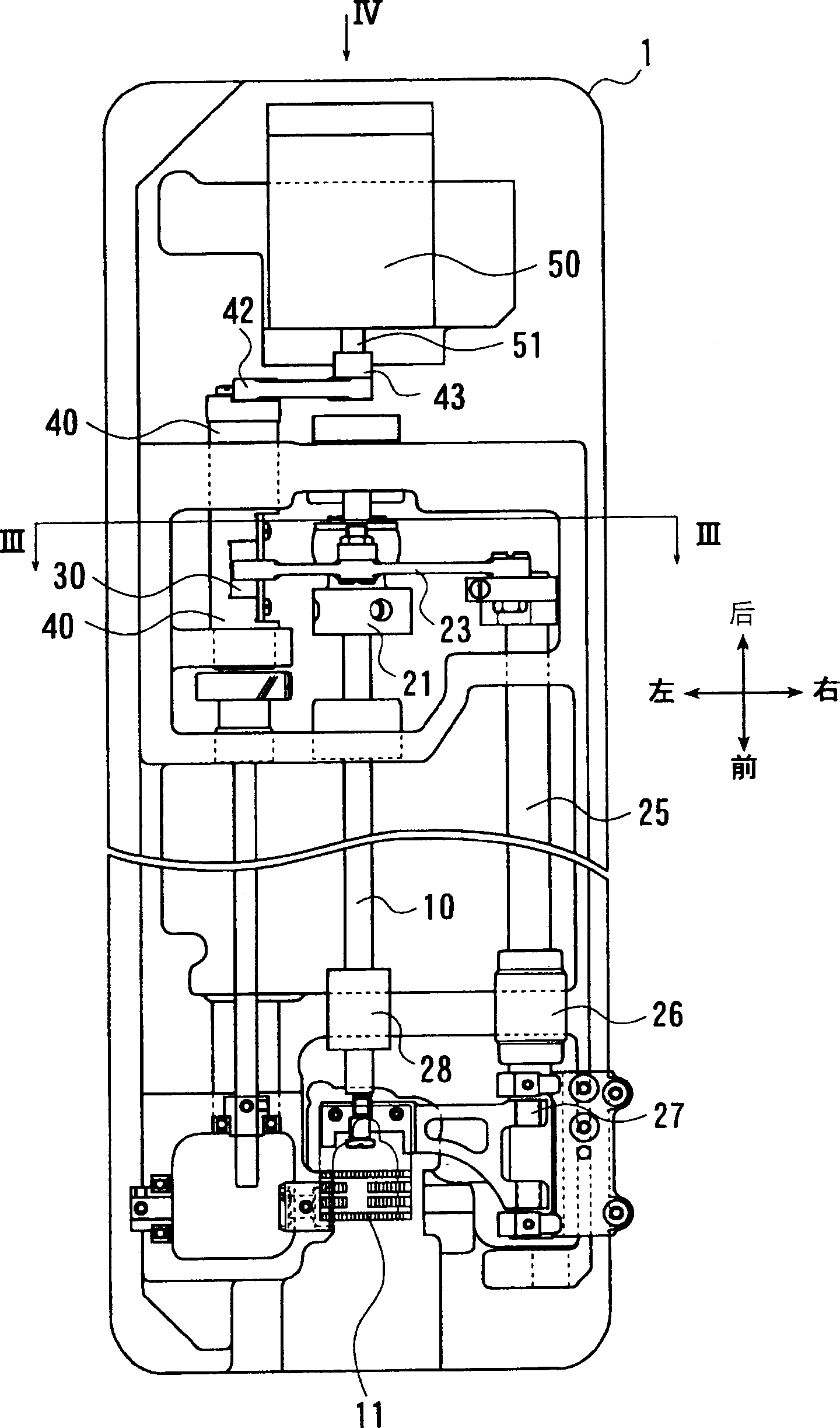

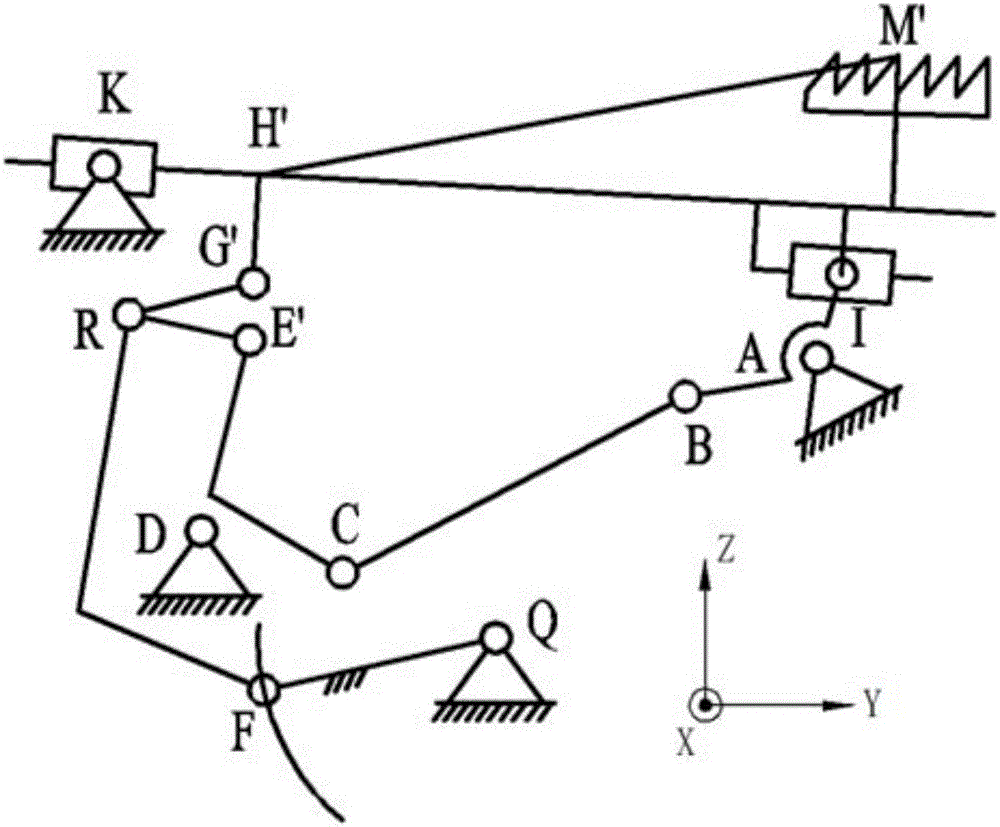

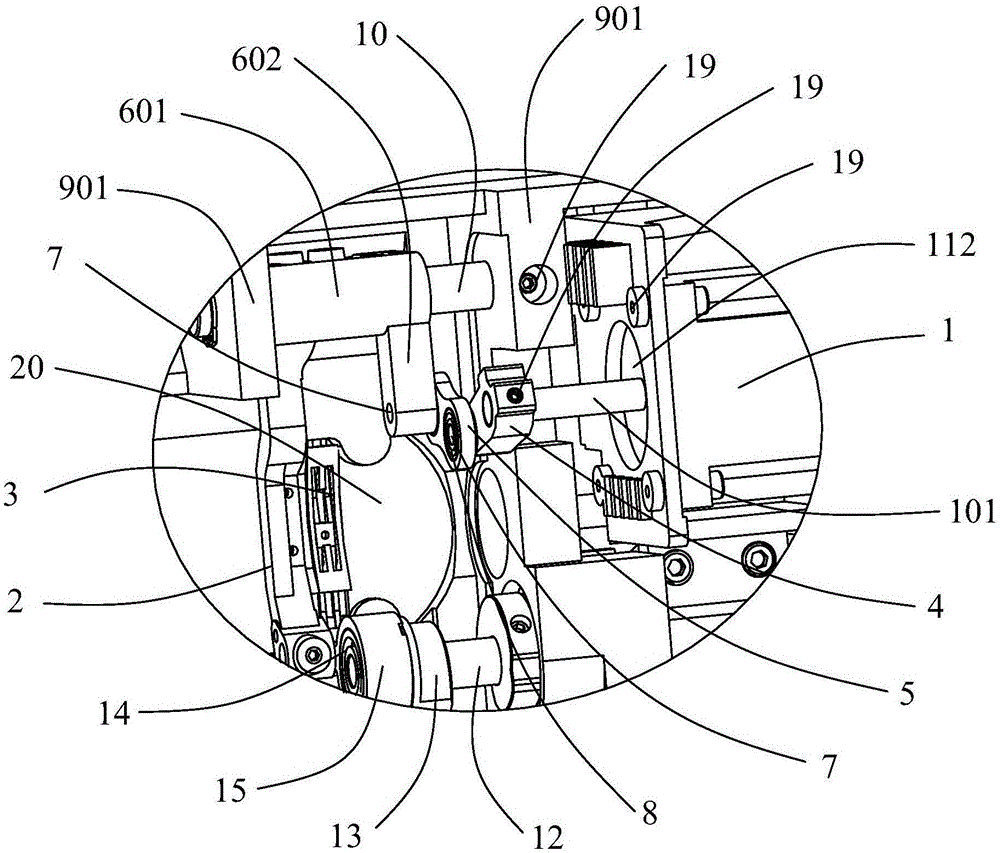

ActiveCN105113152AChange trajectoryAchieve sewingWork-feeding meansSewing-machine control devicesEngineeringFeed dogs

The invention provides a sewing machine. The sewing machine comprises an upper shaft driven by a first motor, a needle bar take-up mechanism arranged at one end of the upper shaft, a lower shaft parallel to the upper shaft, a thread take-off mechanism arranged at one end of the lower shaft, a feed dog frame and a feed dog fixed to the feed dog frame. The upper shaft is connected with the lower shaft through a drive unit. The upper shaft is connected with one end of the feed dog frame through a feed dog lifting mechanism. The sewing machine further comprises a second motor connected with the other end of the feed dog frame through a cloth feed mechanism. The feed dog lifting mechanism and the cloth feed mechanism which form a feed mechanism are driven by the two motors respectively, and therefore the output amount of the cloth feed mechanism can be regulated by regulating the output amount of the second motor, the movement tracks of the feed dog frame and the feed dog can be conveniently changed, and sewing of various patterns can be achieved.

Owner:JACK SEWING MASCH CO LTD

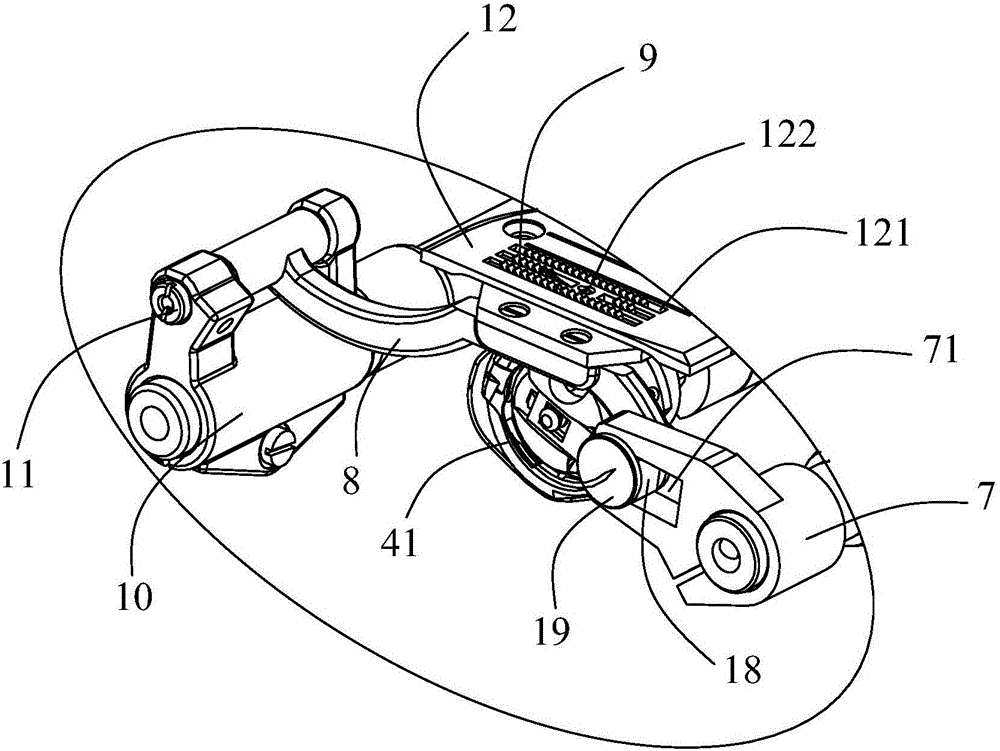

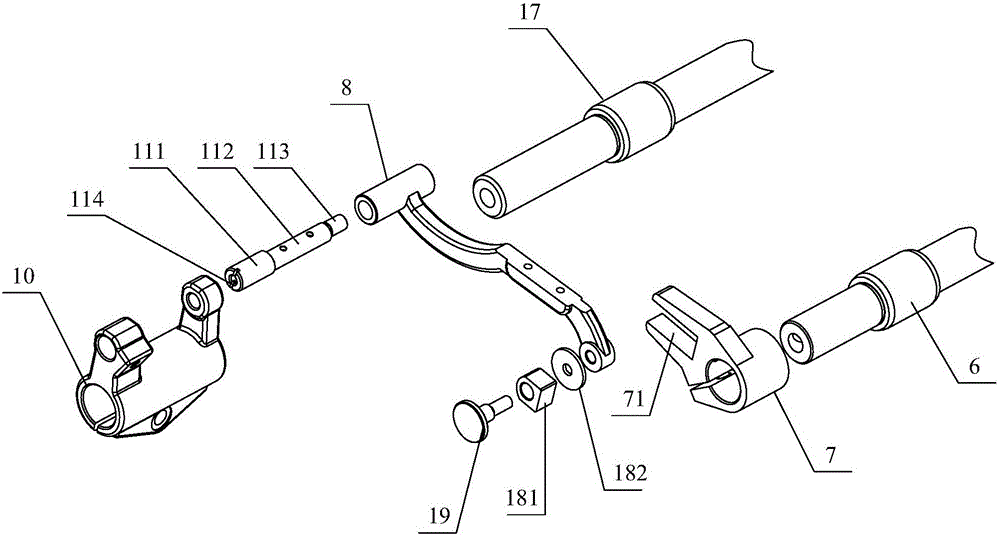

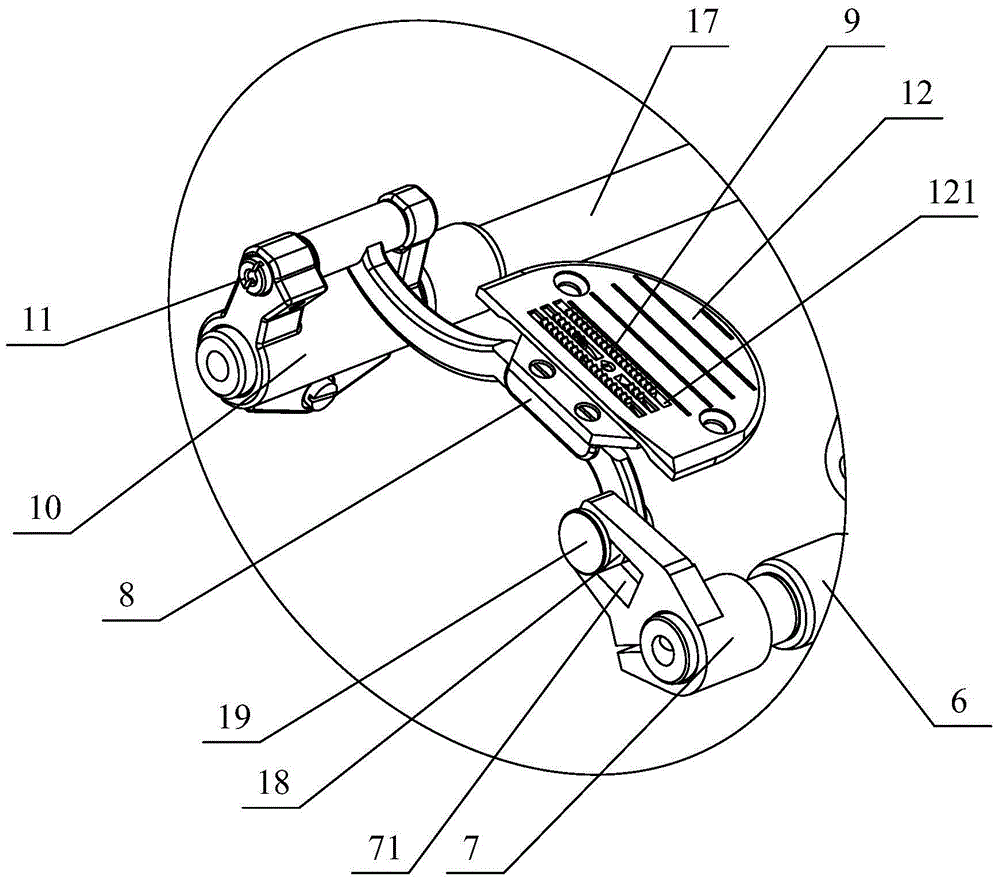

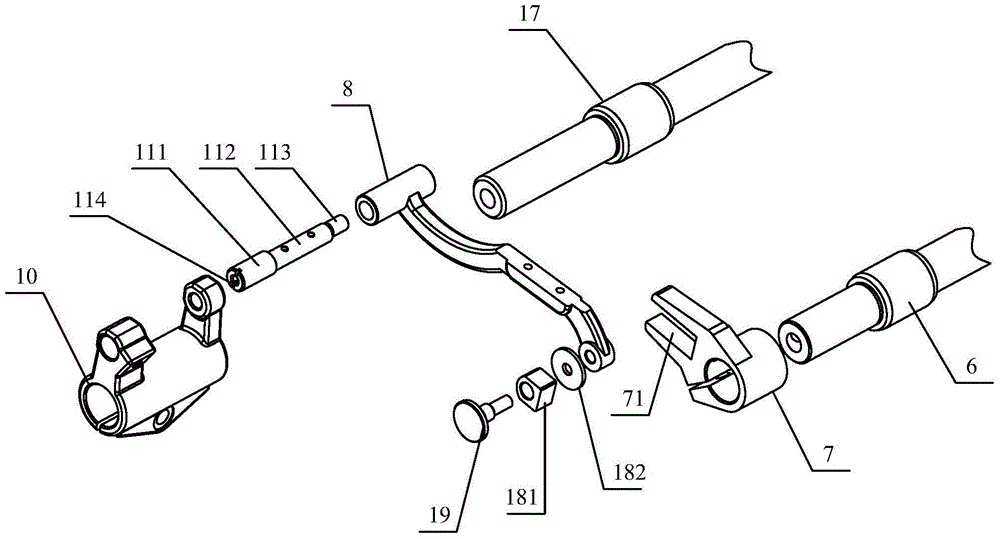

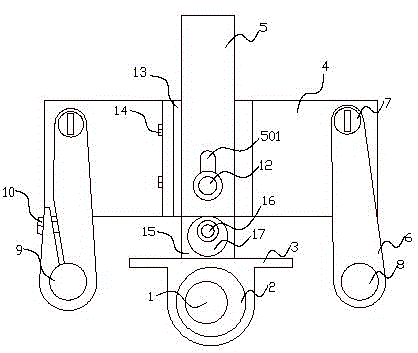

Dog lifting feeding mechanism of sewing machine and sewing machine

The invention provides a dog lifting feeding mechanism of a sewing machine. The mechanism comprises a first motor, a second motor, a dog rack and feed dogs fixed on the upper end surface of the dog rack, wherein the first motor is connected with the dog rack through a dog lifting mechanism; the second motor is connected with the dog rack through a cloth feeding mechanism; the dog lifting mechanism comprises an upper shaft and a dog lifting shaft which are arranged in parallel; the upper shaft is connected with the dog lifting shaft through a first transmission unit and drives the dog lifting shaft to swing back and forth with own axis as a center line; the dog lifting shaft is connected with the dog rack through a second transmission unit and drives the dog rack to reciprocate up and down. According to the dog lifting feeding mechanism of the sewing machine and the sewing machine, synchronism between rotation of the first motor and vertical movement of the dog rack can be guaranteed, deviation of a feeding time point is effectively avoided, and the noise is greatly reduced. According to the dog lifting feeding mechanism of the sewing machine and the sewing machine, synchronism between rotation of the first motor and vertical movement of the dog rack can be guaranteed, and deviation of a feeding time point is effectively avoided.

Owner:JACK SEWING MASCH CO LTD

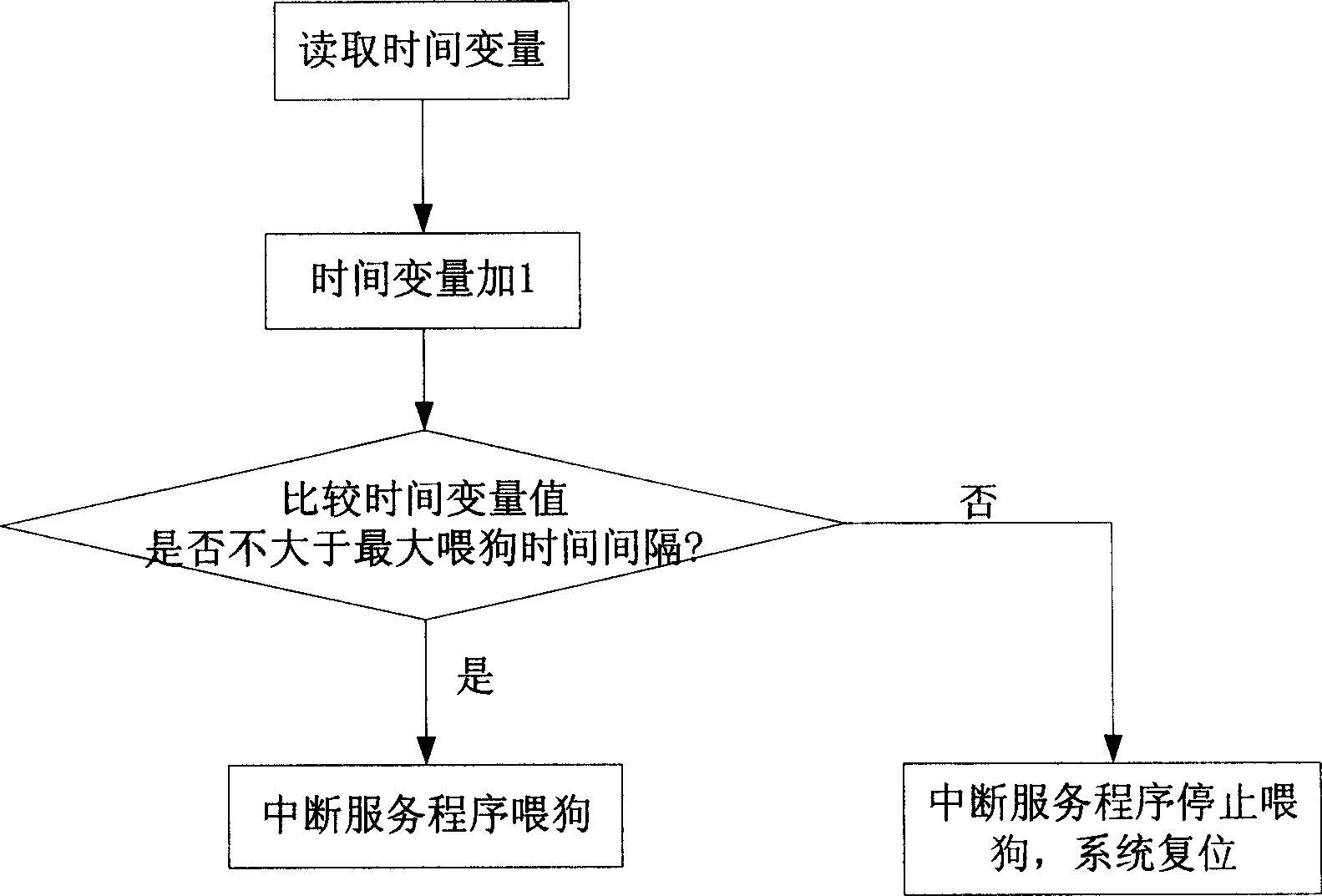

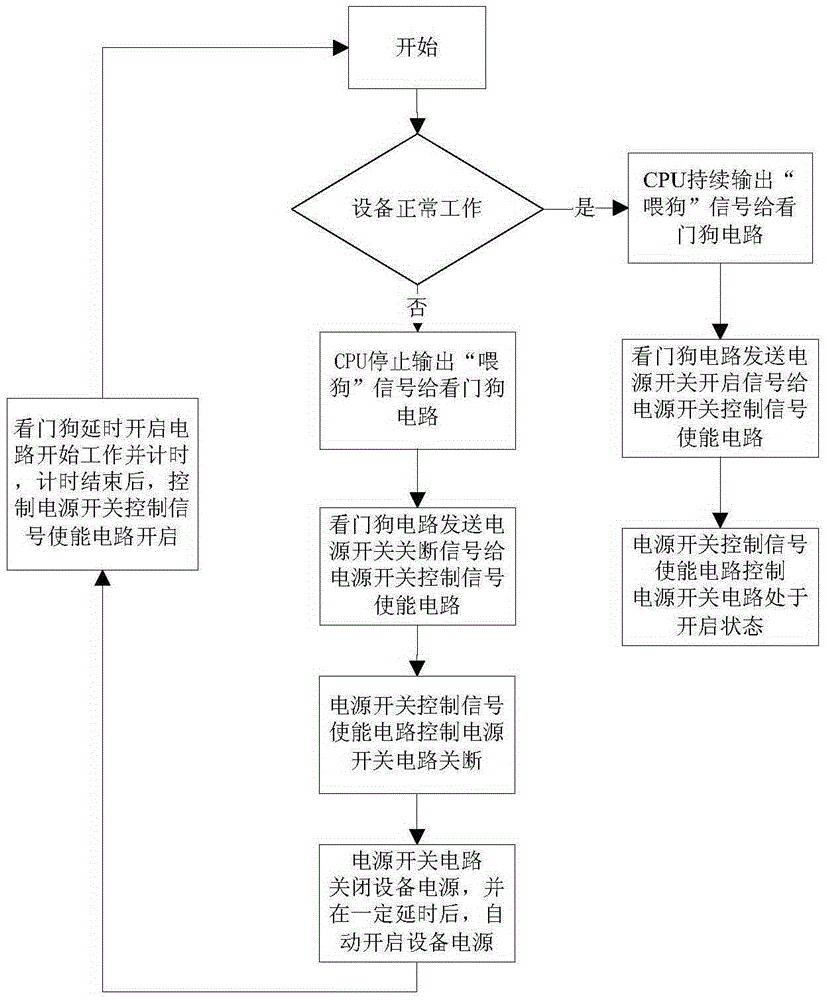

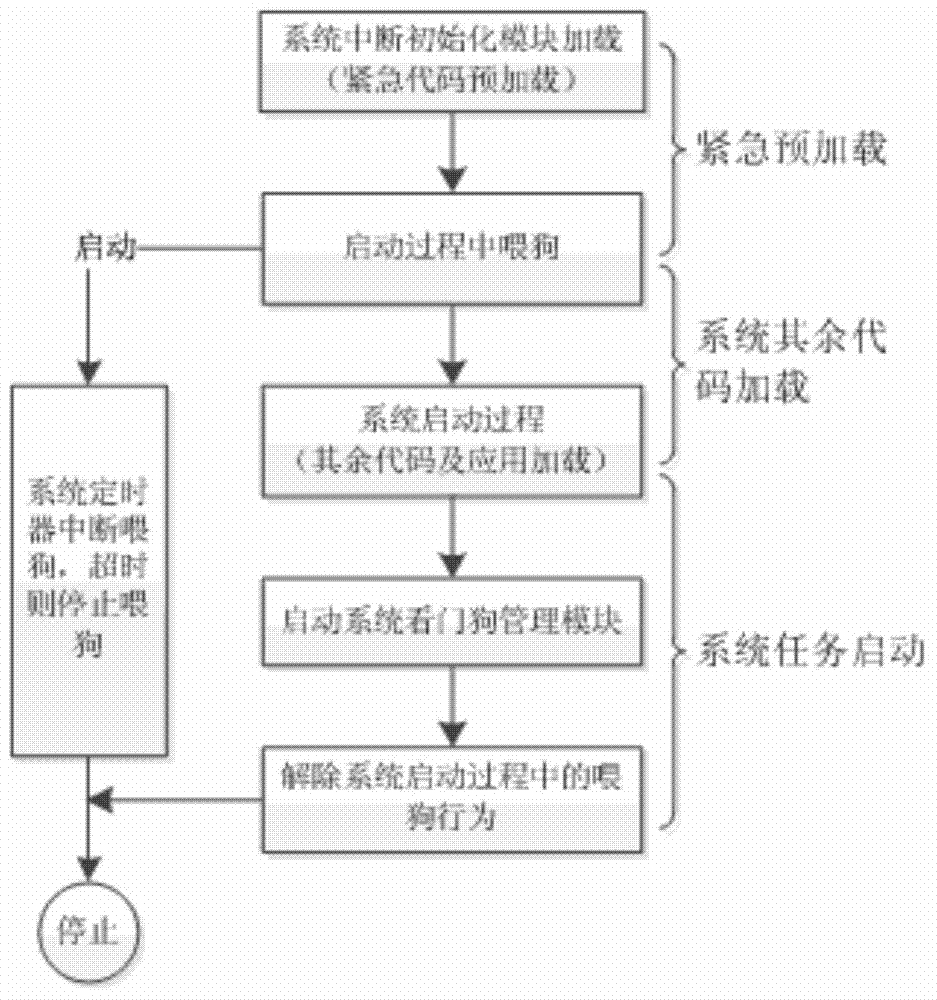

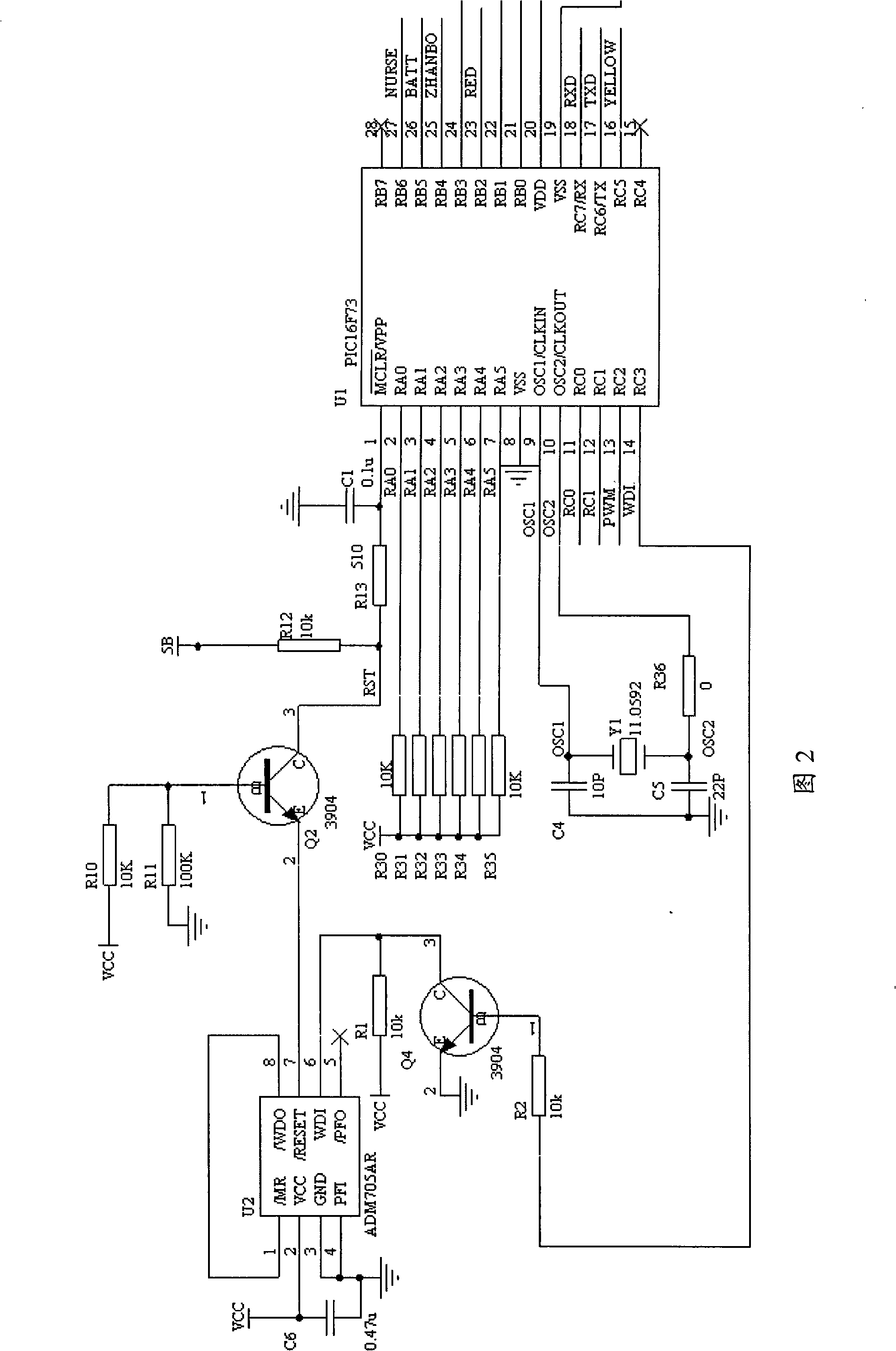

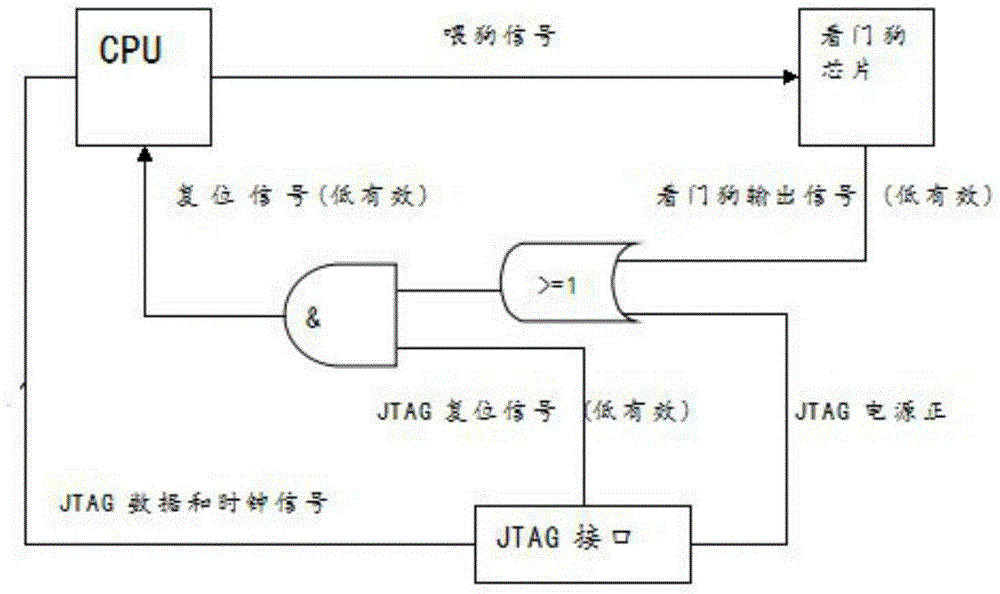

Watchdog control method

The disclosed watchdog control method includes processes: (1) according to interruption time interval, the system generates interrupt, which triggers interrupt service routine; (2) reading out time variable; the time variable adds an interruption time interval when each interrupt takes place in the system; (3) comparing value of time variable with maximal time interval for feeding dog setup in system; when value of time variable is not larger than maximal time interval for feeding dog, the interrupt service routine feeds dog; when value of time variable is larger than maximal time interval, the interrupt service routine stops feeding dog, and the watchdog module resets system; (4) when application program feeds dog, the value of time variable is reset. Since maximal time interval for feeding dog can be set based on condition, longer time interval is allowed so as to prevent issue of resetting system caused by feeding dog not in time since application program for feeding dog is blocked.

Owner:航天智讯新能源(山东)有限公司

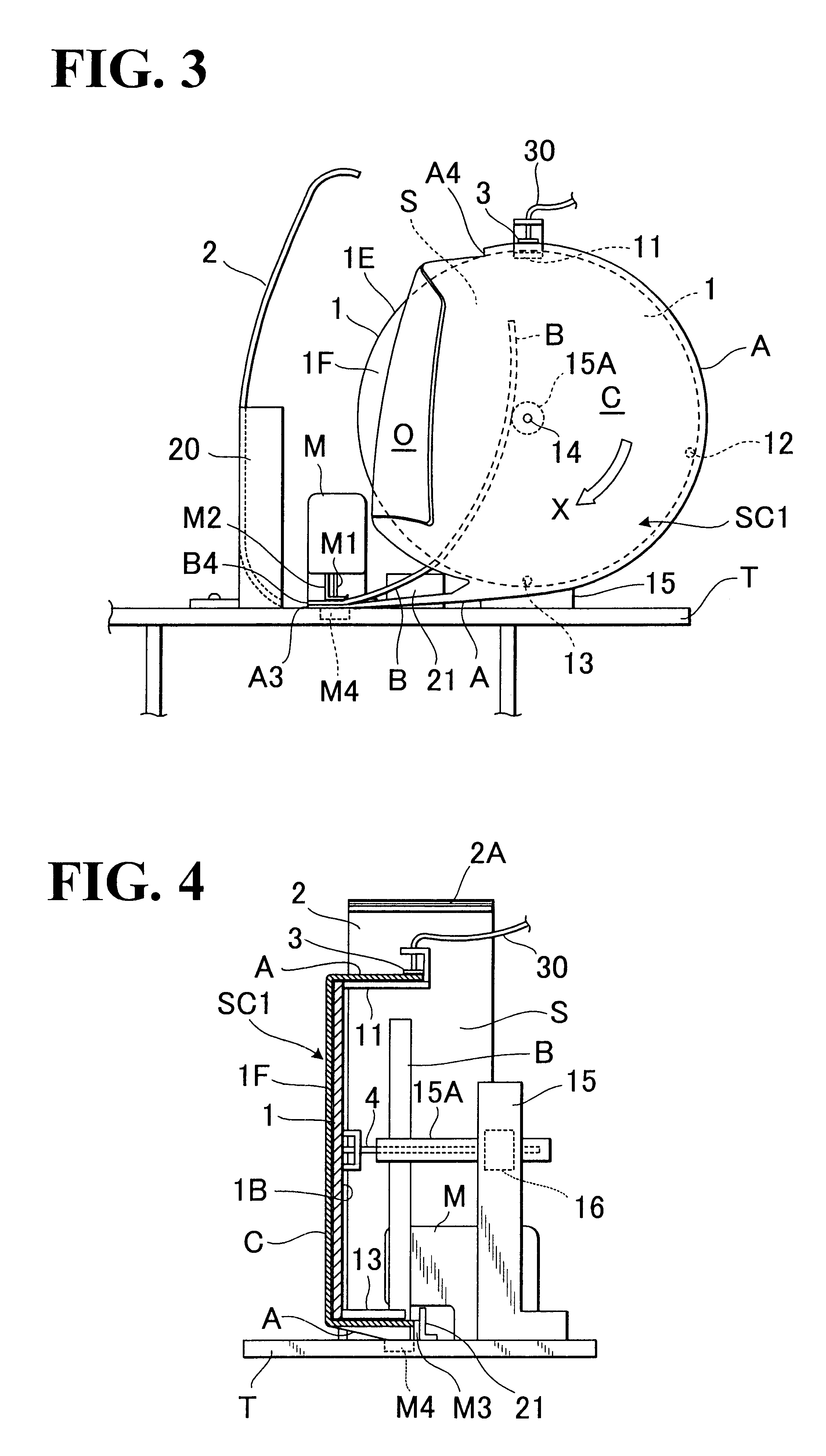

Cloth feeding mechanism for automatically improving coiling

ActiveCN108998899ADifferent take-up effectDifferent degrees of tighteningWork-feeding meansReciprocating motionElectric machinery

The invention provides a cloth feeding mechanism for automatically improving coiling. The mechanism comprises a tooth frame, a feed dog fixed at an upper end of the tooth frame, a lifting assembly which is connected with one end of the tooth frame and is used for driving the tooth frame to reciprocate down and up, and a feeding assembly which is connected with the other end of the tooth frame andis used for driving the tooth frame to reciprocate back and forth and further includes a lifting driving motor which is independent of a main motor of a sewing machine, wherein the lifting driving motor is connected with the lifting assembly to drive the lifting assembly to move. The cloth feeding mechanism is advantaged in that the phase of the lifting assembly can be adjusted, a main shaft driven by the main motor in the sewing machine and a threading and needling mechanism connected with an end portion of the main shaft can be in the non-synchronous relationship, so the time point t1 at which the feed dog emerges upward from a needle plate and the time point t2 at which the feed dog sinks down into the needle plate can be changed, that is, cloth can be delivered in advance or delayed, suture tightening degrees are different, so the sewing machine has different tightening effects, and the sewing machine can be well adapted to sewing materials having different thicknesses.

Owner:JACK SEWING MASCH CO LTD

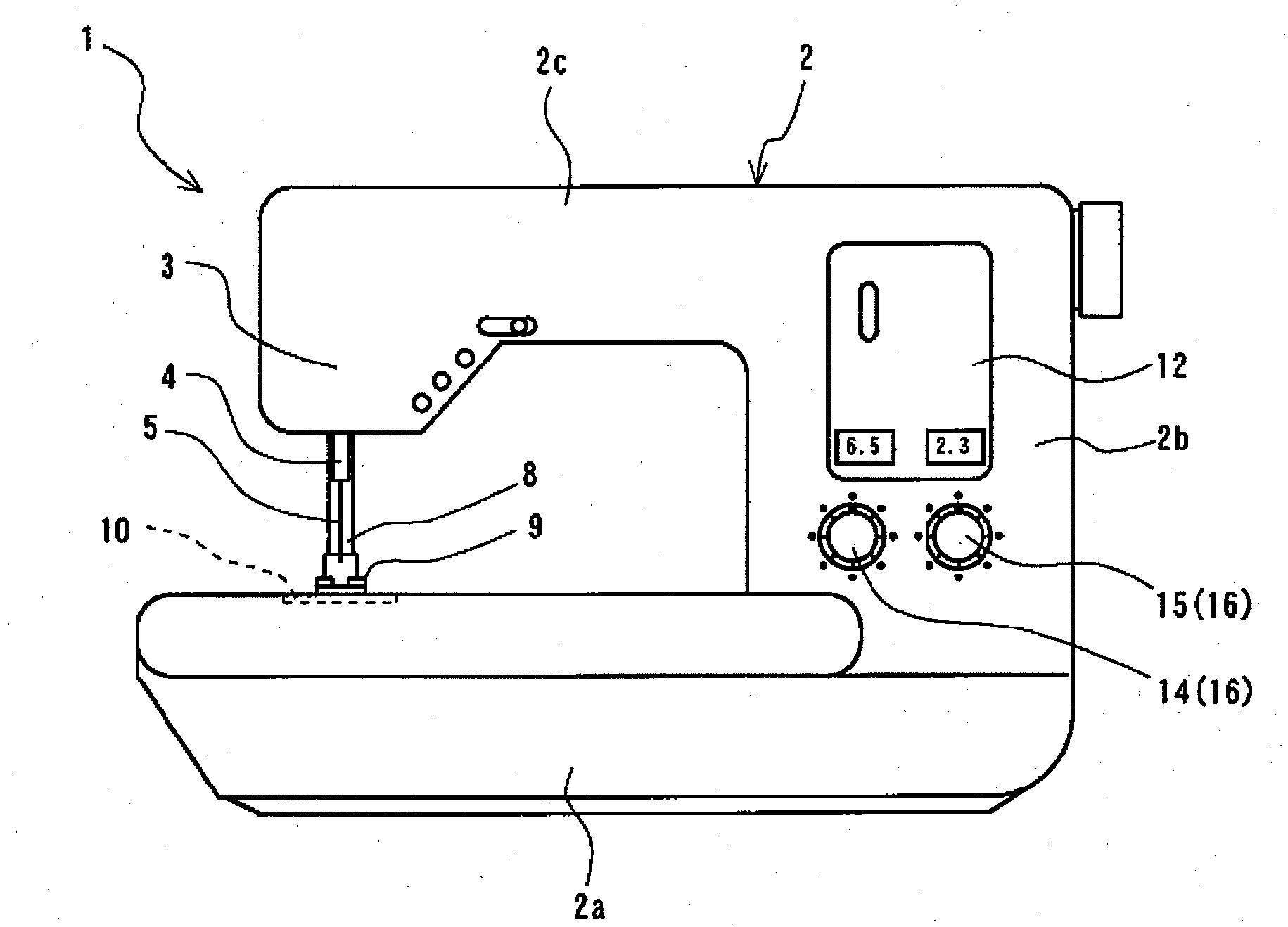

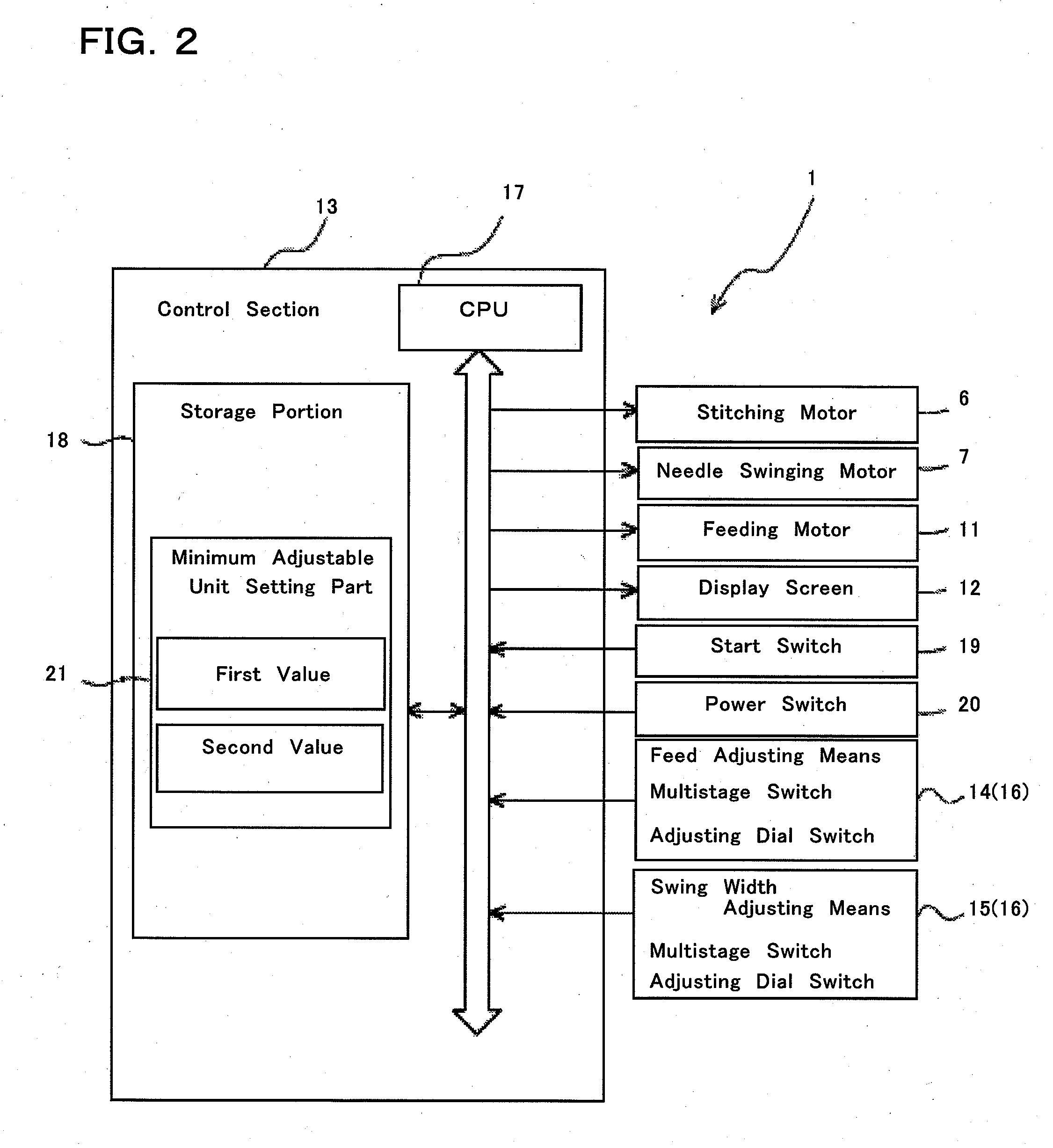

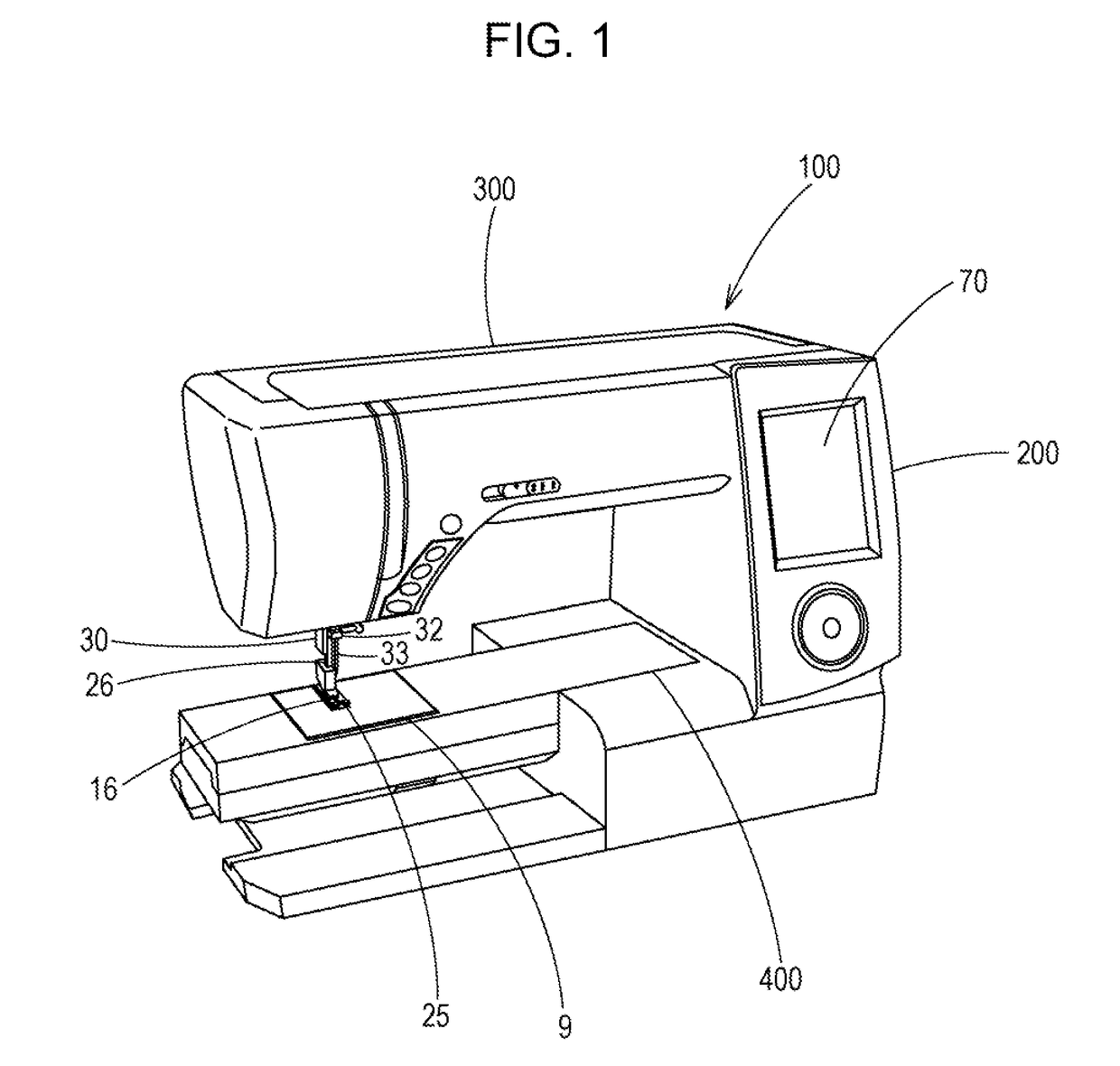

Zigzag sewing machine

A zigzag sewing machine is provided. The zigzag sewing machine includes a stitching motor which moves a needle, a feeding motor which moves a feed dog to feed a cloth, a needle swinging motor which swings the needle, a multistage-operating portion operable to adjust at least one of a feed amount of the cloth and a swing amount of the needle in a minimum adjustable unit, and a control section which controls the stitching motor, the feeding motor and the needle swinging motor to carry out a zigzag sewing in accordance with the at least one of the feed amount and the swing amount adjusted by the multistage-operating portion. The control section is configured to selectively assign a first value and a second to the minimum adjustable unit depending on whether the stitching motor is in operation or not.

Owner:JUKI CORP

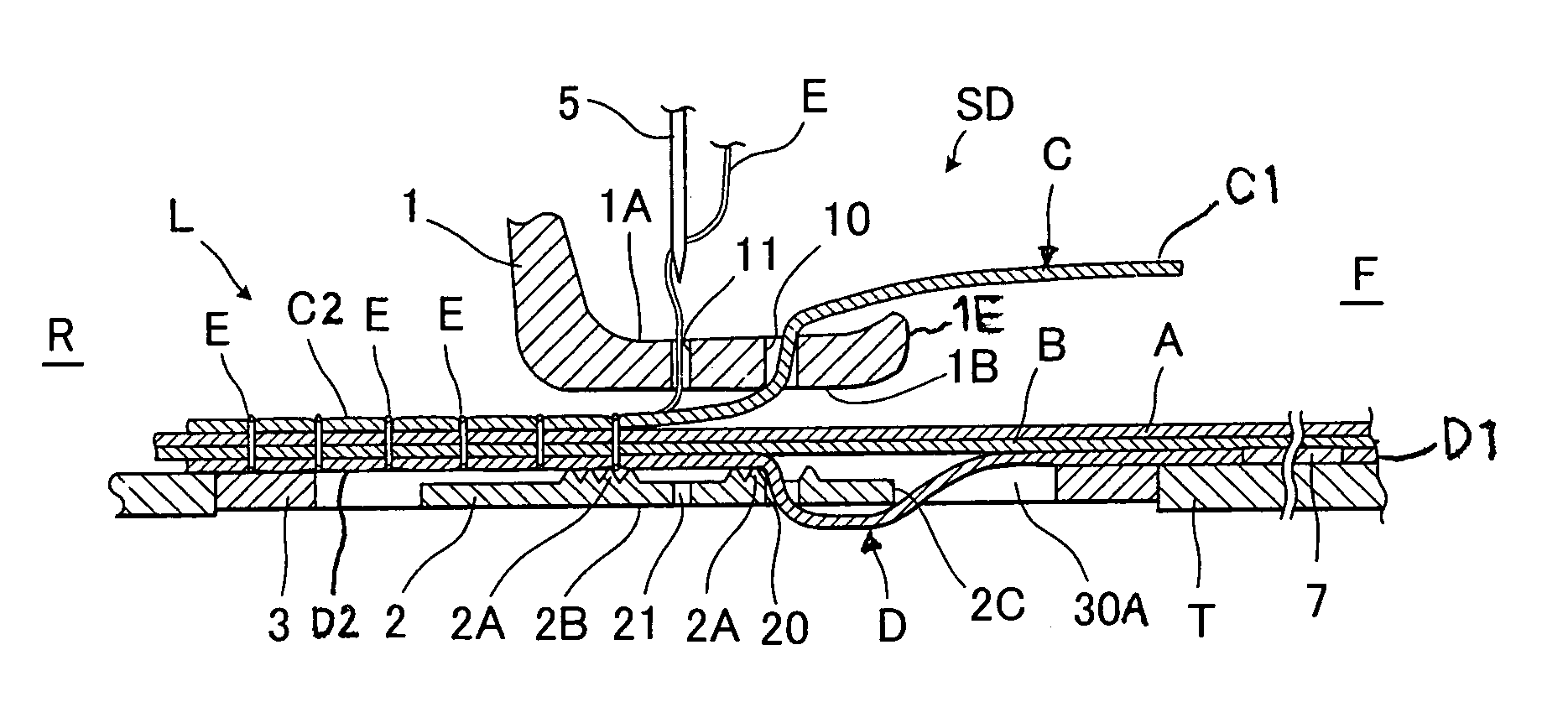

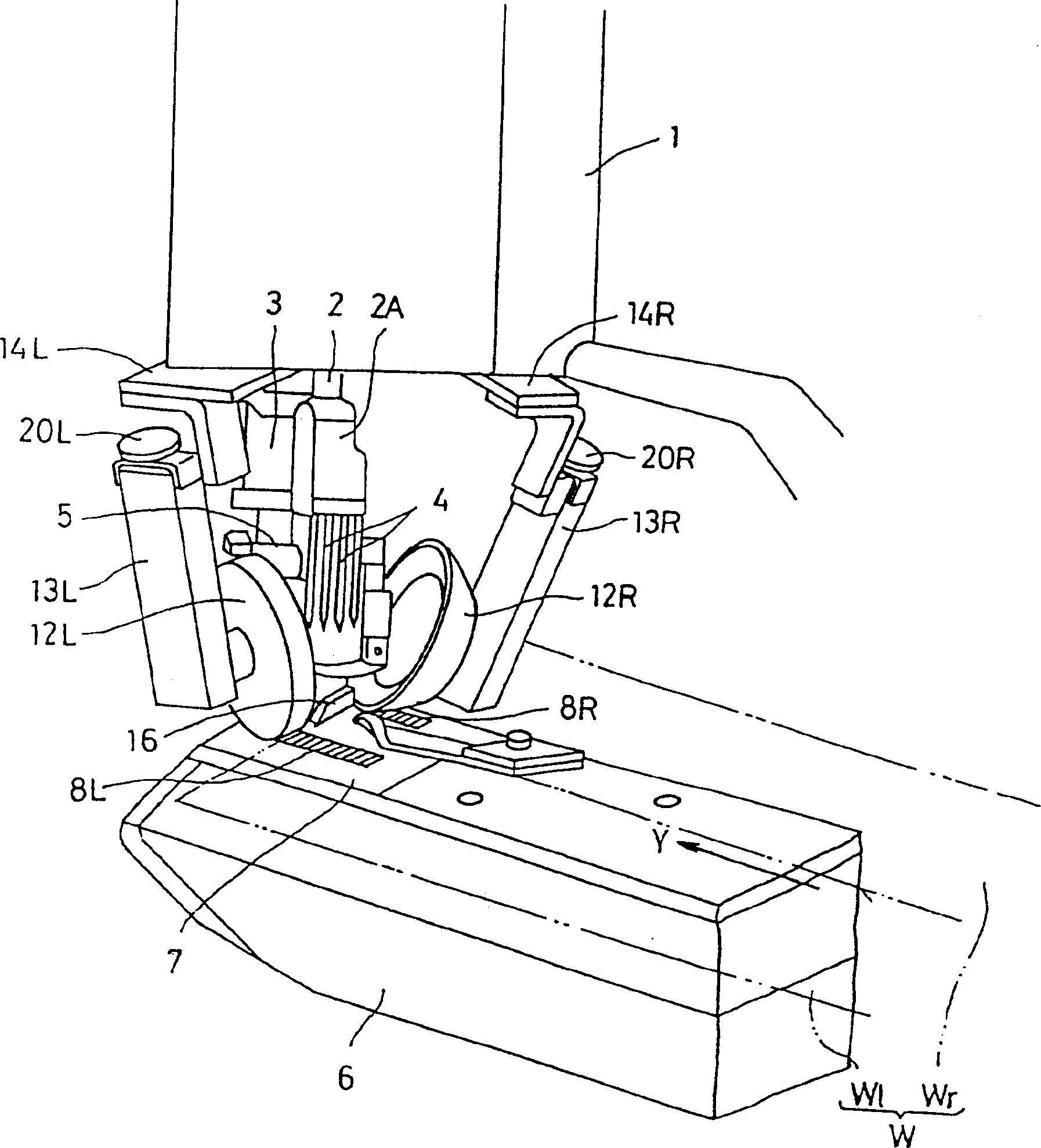

Sewing device for sewing sealing material with base materials

Owner:TACHI S CO LTD

Cloth feeding mechanism with stitch length adjusting function

ActiveCN106120172AWith stitch length adjustment functionSimple structureWork-feeding meansSewing-machine control devicesCanis lupus familiarisMechanical engineering

The invention provides a cloth feeding mechanism with a stitch length adjusting function. The cloth feeding mechanism comprises a main shaft and a cloth feeding shaft parallel to the main shaft. The main shaft is eccentrically sleeved with a cloth feeding connecting rod, and the end, away from the main shaft, of the cloth feeding connecting rod is hinged to the end of a first small connecting rod and the end of a second small connecting rod through a cloth feeding connecting rod pin. The end, away from the cloth feeding connecting rod pin, of the first small connecting rod is hinged to one end of a stitch length swing rod, a rotating shaft parallel to the main shaft is arranged in the middle of the stitch length swing rod, the stitch length swing rod is further connected with a stitch length adjusting component, and the stitch length adjusting component drives the stitch length swing rod to rotate around the rotating shaft of the stitch length swing rod. The end, away from the cloth feeding connecting rod pin, of the second small connecting rod is hinged to the end of a cloth feeding swing rod, the cloth feeding swing rod is fixed to the cloth feeding shaft, the cloth feeding shaft is further fixedly sleeved with a cloth feeding crank, the cloth feeding crank is connected with a main cloth feeding dog frame through a connecting rod, and the main cloth feeding dog frame is fixedly connected with a main cloth feeding dog and moves back and forth in the direction parallel to the extending direction of the main cloth feeding dog under driving of the cloth feeding crank.

Owner:JACK SEWING MASCH CO LTD

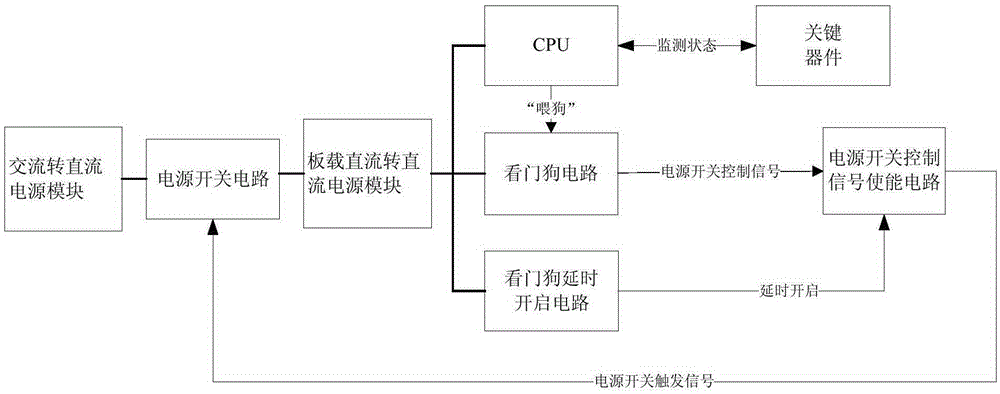

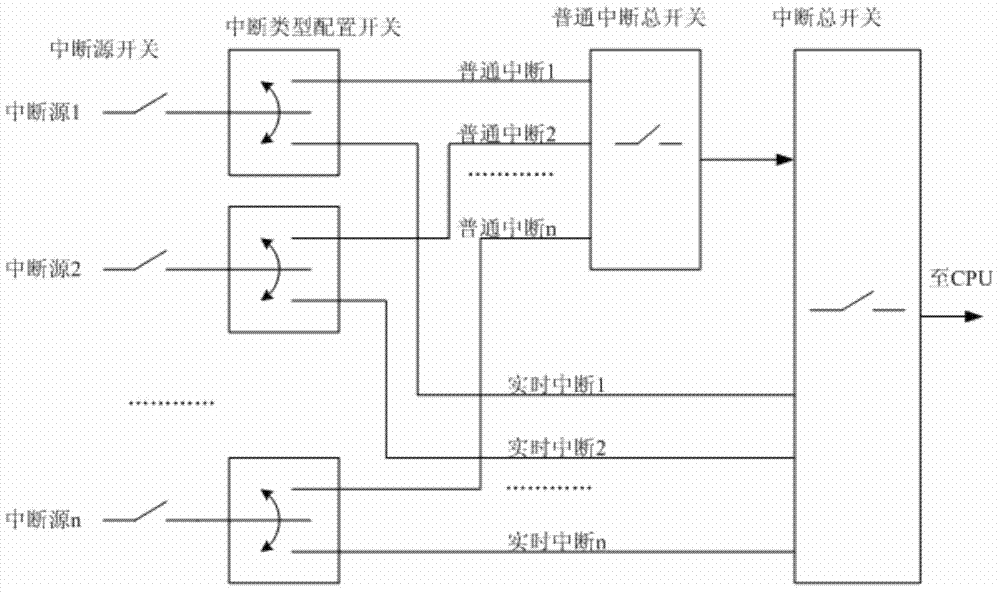

Circuit with automatic power-off restarting function in equipment failure

InactiveCN105302263ASolve unsolvable problemsA state that prevents repeated restartsFault responseData resettingPower switchingControl signal

The invention provides a circuit with an automatic power-off restarting function in equipment failure. A CPU of the equipment is connected with a key device of the equipment and the CPU is capable of monitoring the working state of the key device; when the equipment has hardware damage-free failure, the CPU stops outputting a feeding-dog signal, a watchdog circuit does not trigger the system hardware reset any more, and outputs a power switch control signal; a power switch circuit turns off the direct-current power supply of the equipment after being triggered; and after certain time delay, the power switch circuit automatically starts the direct-current power supply of the equipment to ensure that the equipment is restarted to restore the normal work. According to the circuit provided by the invention, the failure problems of all the hardware damage-free units can be solved; no matter whether the units with failures have hardware reset functions or not, the adopted power-off restarting manner is more thorough than the traditionally adopted hardware reset manner.

Owner:中电科网络安全科技股份有限公司

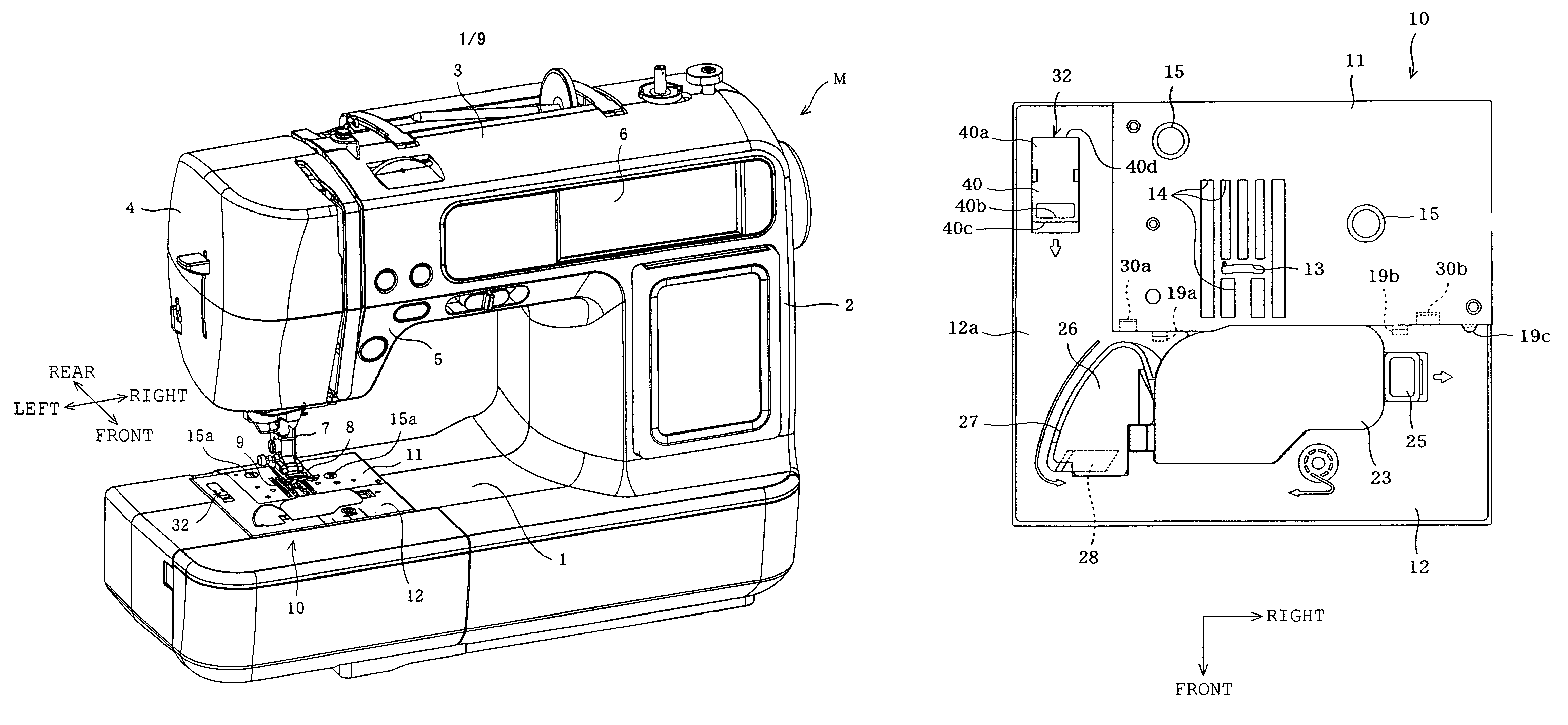

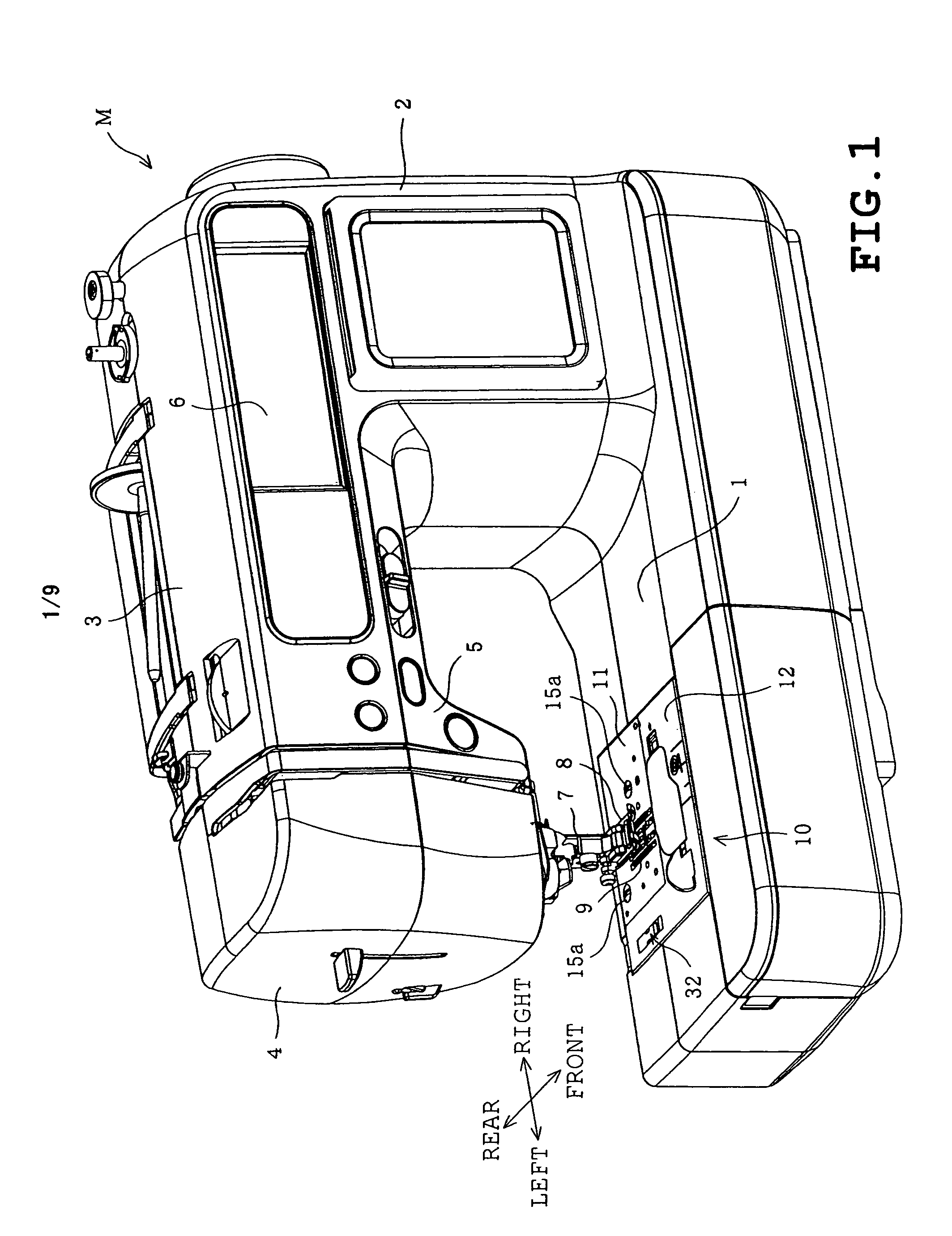

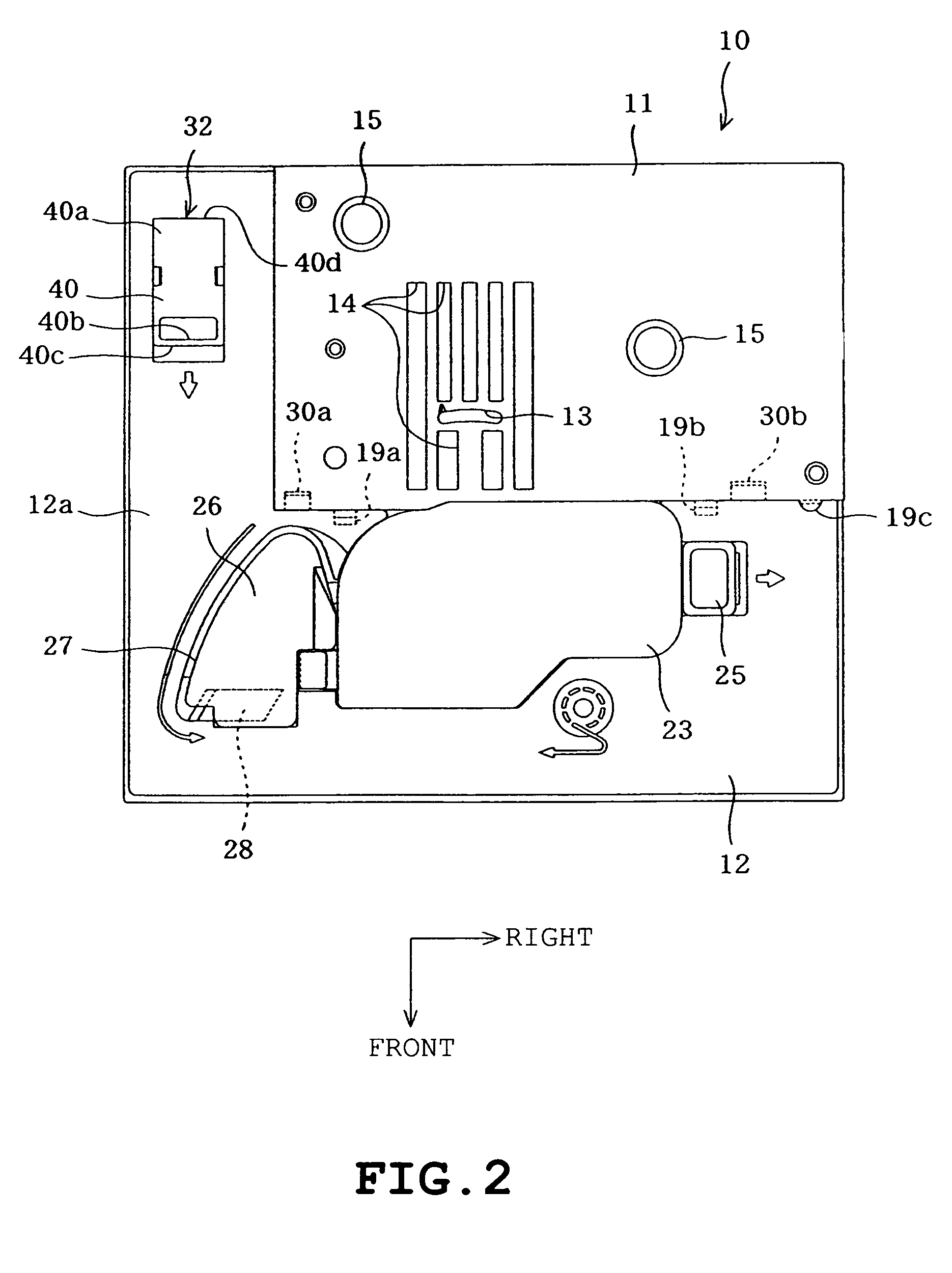

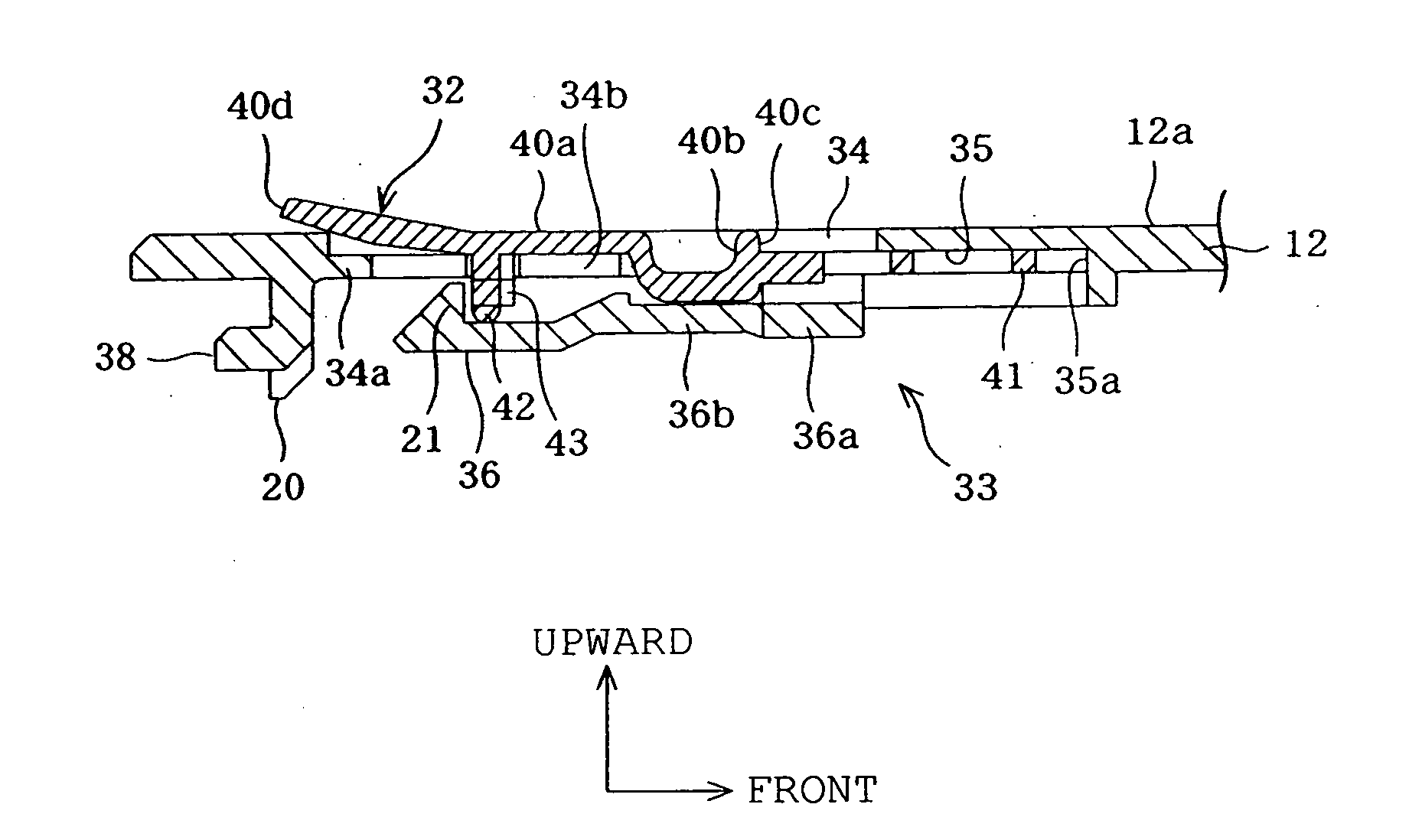

Needle plate and sewing machine provided therewith

A needle plate for a sewing machine includes a first needle plate fixed to a sewing machine bed and formed with a needle hole through which a needle passes and a rectangular hole through which a feed dog appears, a second needle plate disposed in front of the first needle plate and detachably attached to the first needle plate, an engagement mechanism sliding the second needle plate rearward from a front side of the first needle plate, thereby engaging the second needle plate with the first needle plate, and a disengagement operating member located on the second needle plate so as to operate the engagement mechanism so that the second needle plate is disengaged from the first needle plate. The disengagement operating member is moved frontward from a rear side of the first needle plate thereby to disengage the second needle plate from the first needle plate.

Owner:BROTHER KOGYO KK

Needle plate and sewing machine provided therewith

A needle plate for a sewing machine includes a first needle plate fixed to a sewing machine bed and formed with a needle hole through which a needle passes and a rectangular hole through which a feed dog appears, a second needle plate disposed in front of the first needle plate and detachably attached to the first needle plate, an engagement mechanism sliding the second needle plate rearward from a front side of the first needle plate, thereby engaging the second needle plate with the first needle plate, and a disengagement operating member located on the second needle plate so as to operate the engagement mechanism so that the second needle plate is disengaged from the first needle plate. The disengagement operating member is moved frontward from a rear side of the first needle plate thereby to disengage the second needle plate from the first needle plate.

Owner:BROTHER KOGYO KK

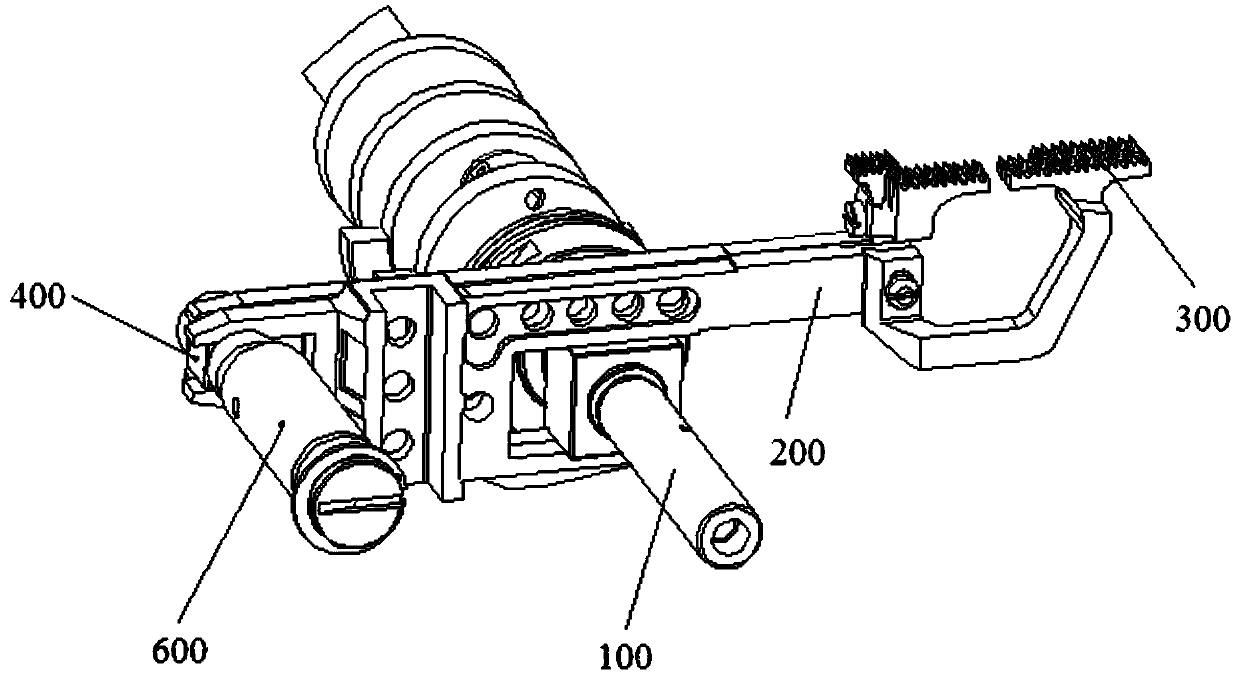

Cloth feed dog frame for sewing machine

The invention relates to the sewing machinery field, in particular to a cloth feed dog frame for a sewing machine. The cloth feed dog frame for the sewing machine comprises a frame body and a feed dog installed on the frame body, and further comprises a rocking arm mechanism which is connected with the frame body and enables the frame body to move left and right, and a dog lifting mechanism which moves the feed dog up and down, wherein a slide chute is formed in the front side of the middle of the frame body, a slide block is matched in the slide chute, the feed dog is fixed on the slide block through a second locking bolt, an adjustment groove matched with the second locking bolt is formed in the feed dog, one side of the feed dog is attached to the frame body, a cushion plate is further arranged between the other side of the feed dog and the frame body, and the cushion plate is fixed on the frame body through a fixing bolt. The cloth feed dog frame for the sewing machine can adjust the height of the feed dog so as to meet different demands, and simultaneously can further reduce abrasion rate of the feed dog, and prolongs use life of the feed dog.

Owner:陈贤德

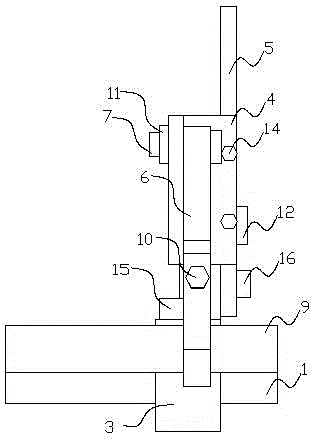

Method for rotating fan of server at full-speed after BMC (Baseboard Management Controller) fails

InactiveCN105278644AAchieve controllable speedGuaranteed cooling effectDigital data processing detailsPump controlState of artMicrocontroller

This invention discloses a method for rotating a fan of a server at full-speed after BMC (Baseboard Management Controller) fails. The method specifically comprises the following steps: the BMC is used as a controller of the rotating speed of the fan in the server; periodic pulse signals are output as feeding-dog signals when the BMC works normally, and a chip of the BMC is connected with a single chip; the single chip is used as a monitoring unit of the working state of the BMC; through monitoring the feeding-dog signals sent out by the BMC, the single chip monitors whether the BMC works normally or not; and after the BMC fails, the rotating speed of the fan is regulated to ensure normal heat dissipation of the system. Compared with the prior art, the method for rotating the fan of the server at full-speed after the BMC fails monitors the working state of the BMC; through detecting the working state of the MBC, when the failure of the BMC and the abnormal working situation are found, a gating line gates high-level signals to control the rotating speed of the fan; thus, the server can work normally; the method has strong practicality, and is easy to popularize.

Owner:LANGCHAO ELECTRONIC INFORMATION IND CO LTD

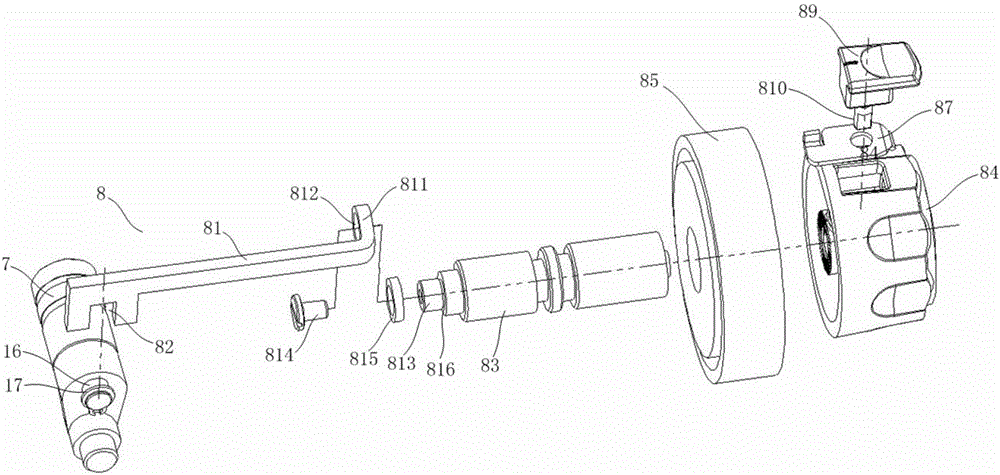

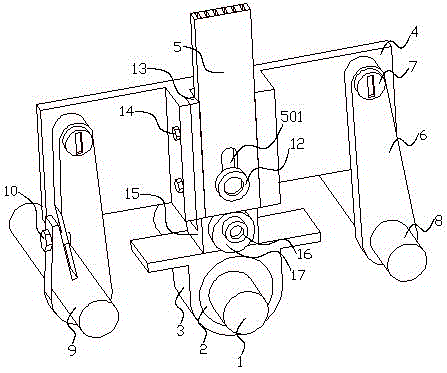

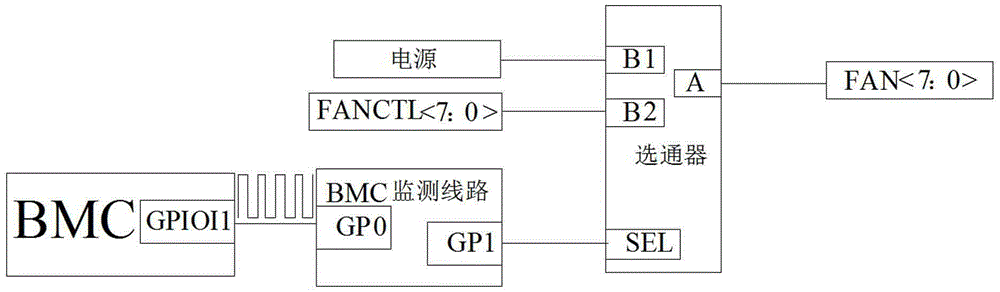

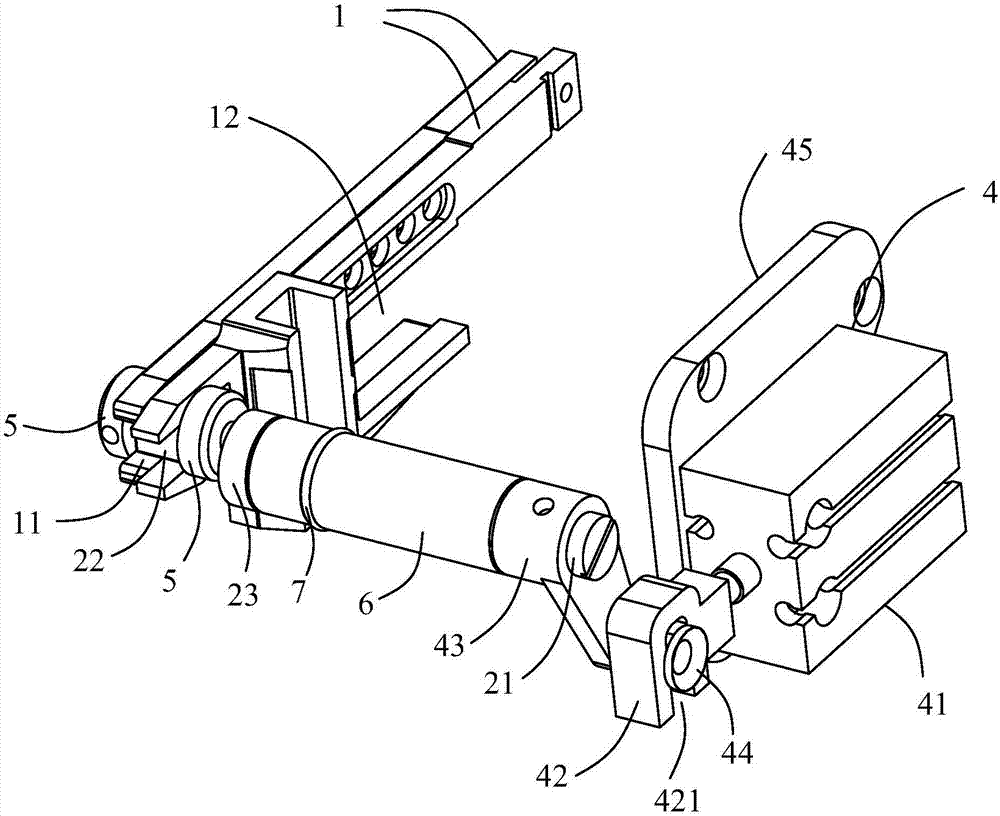

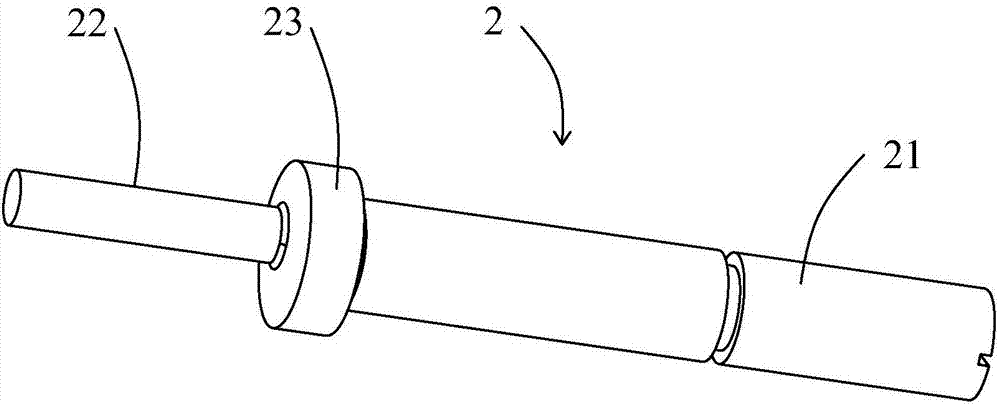

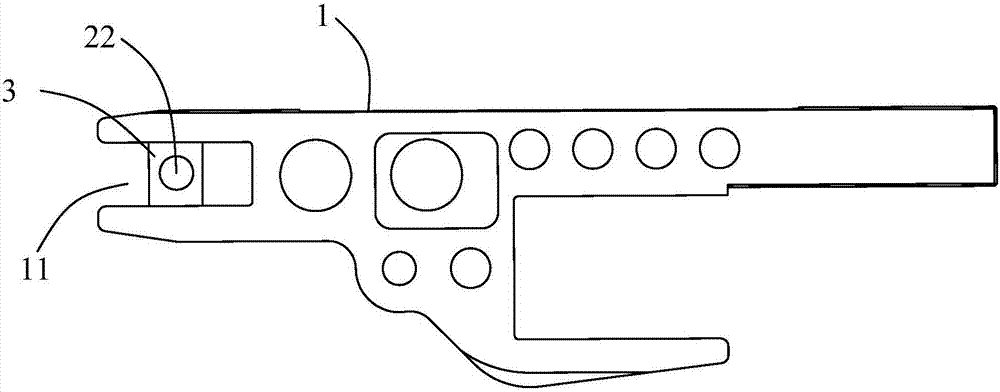

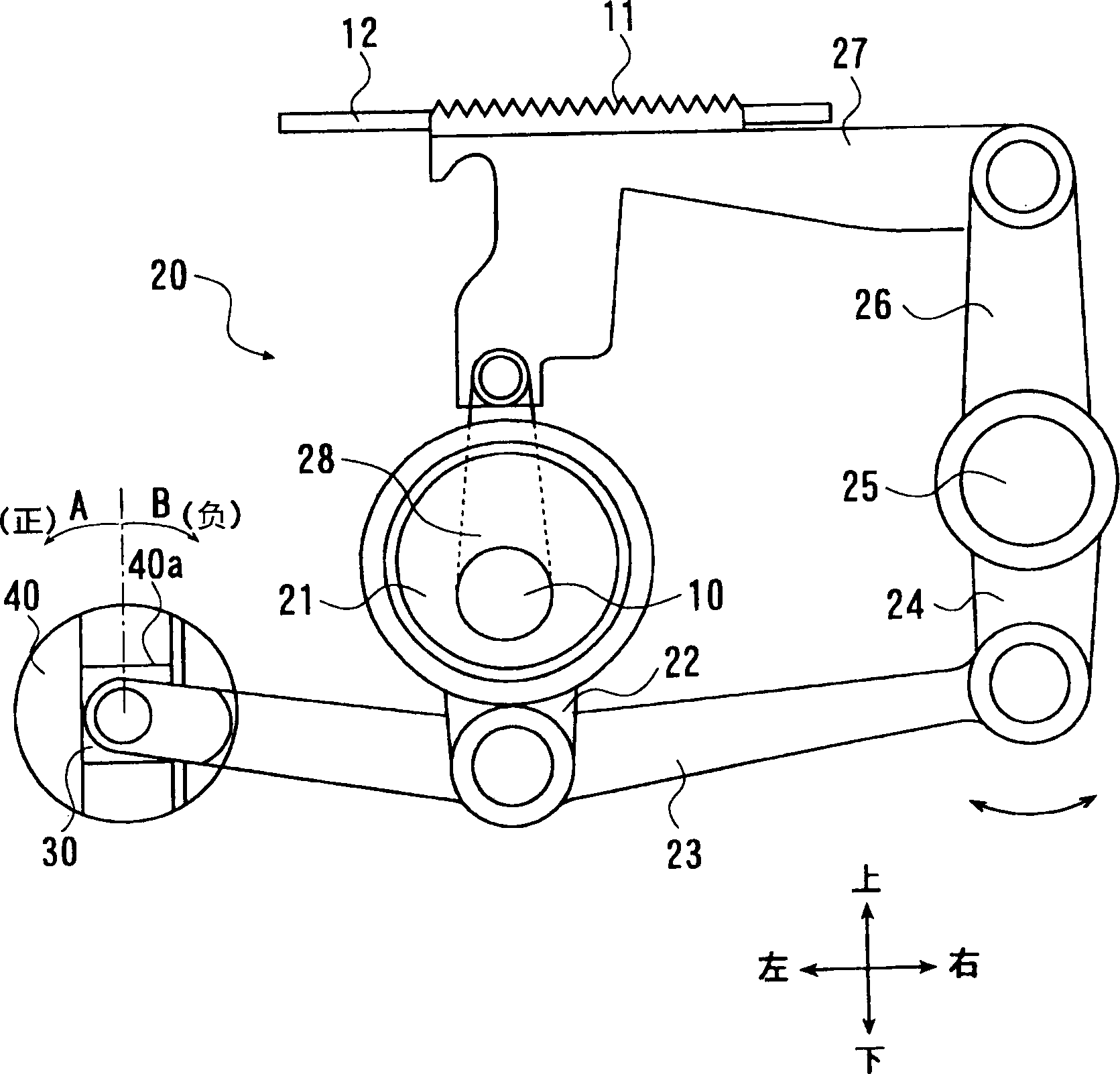

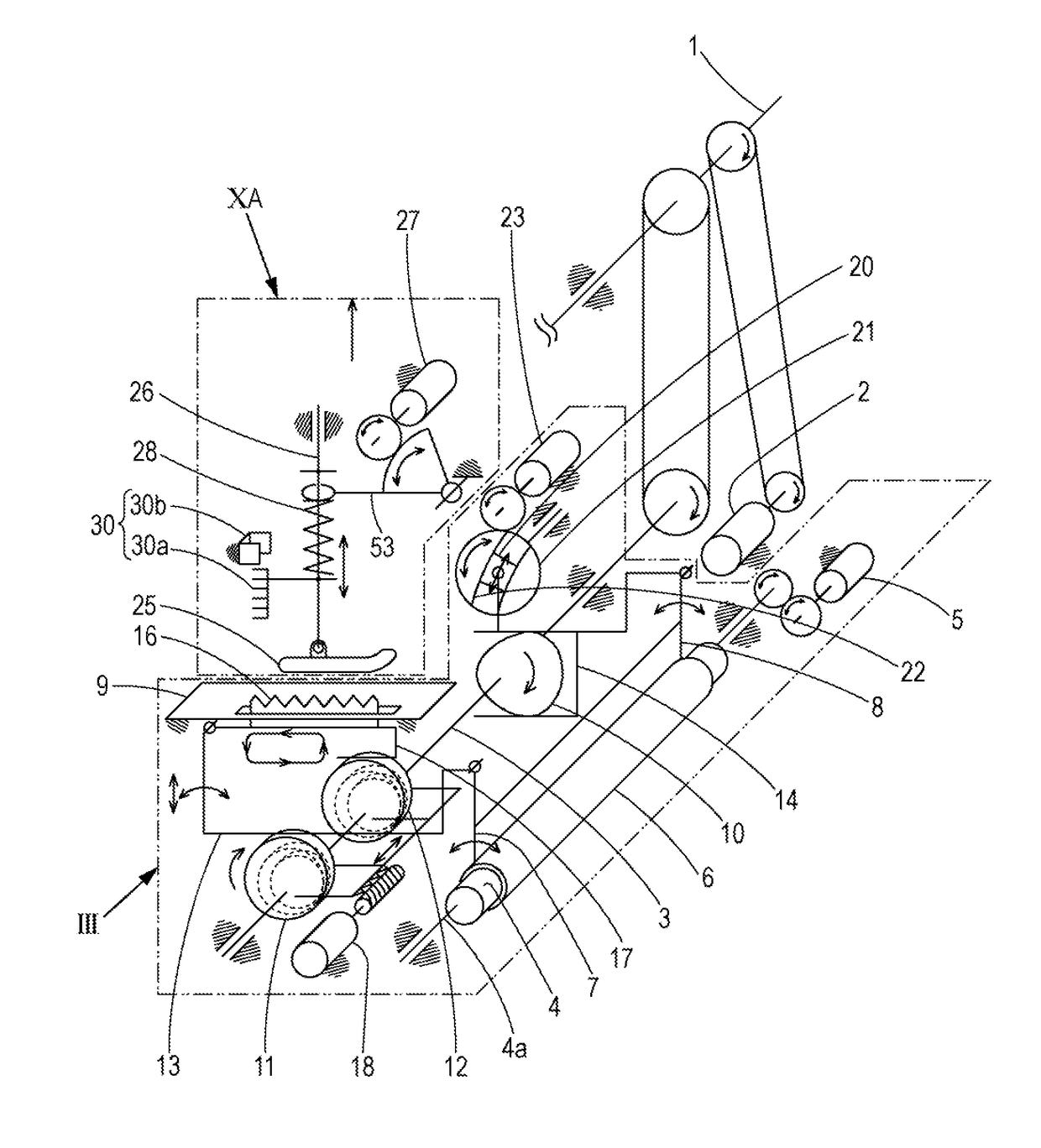

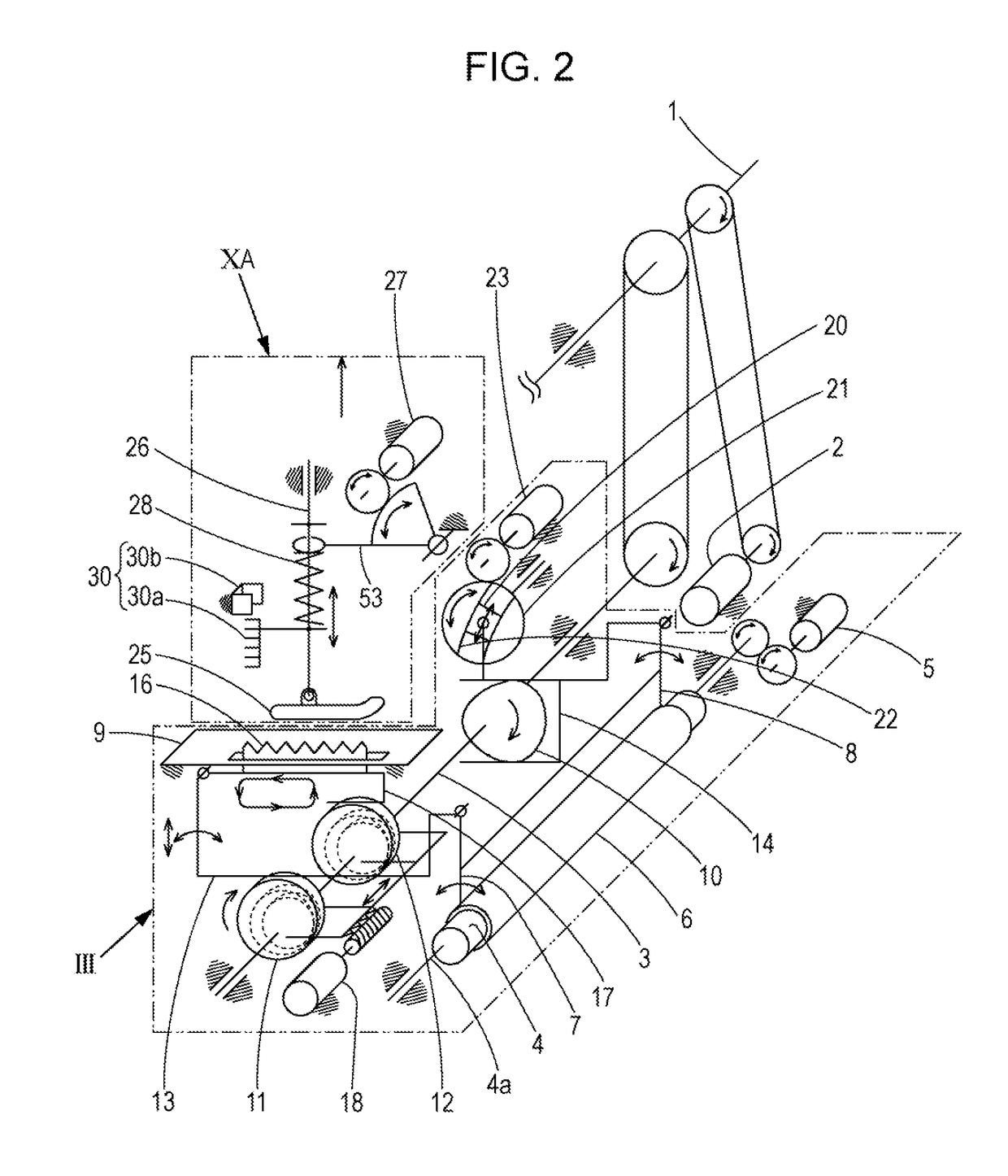

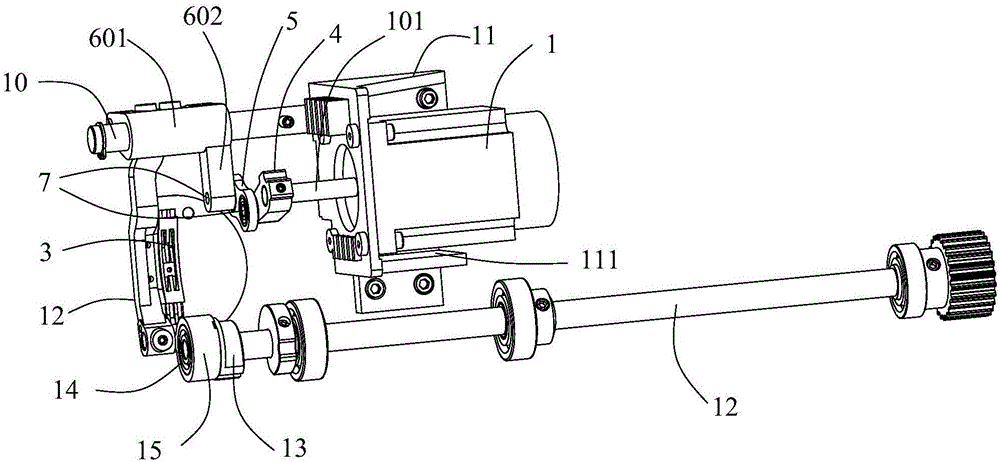

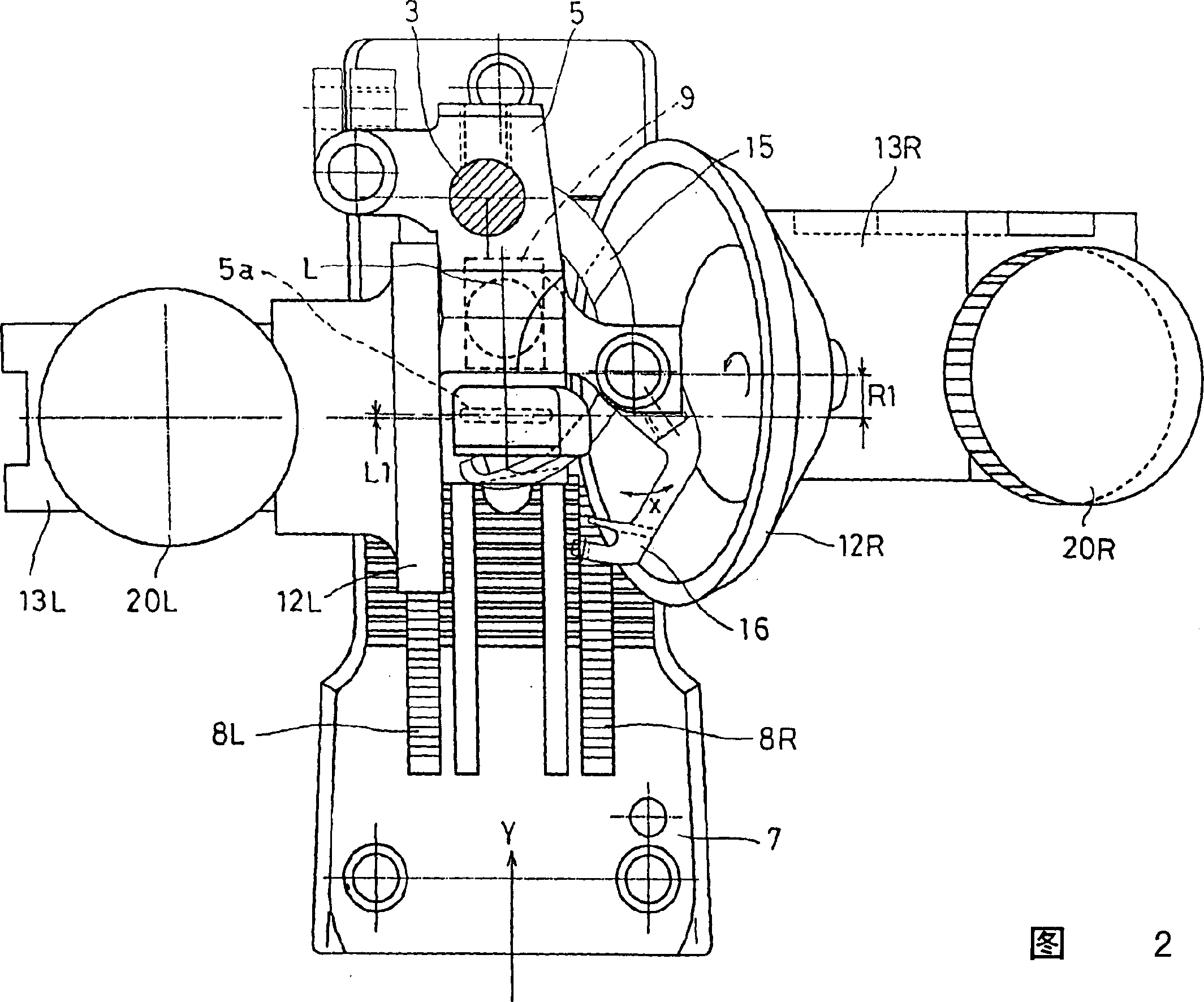

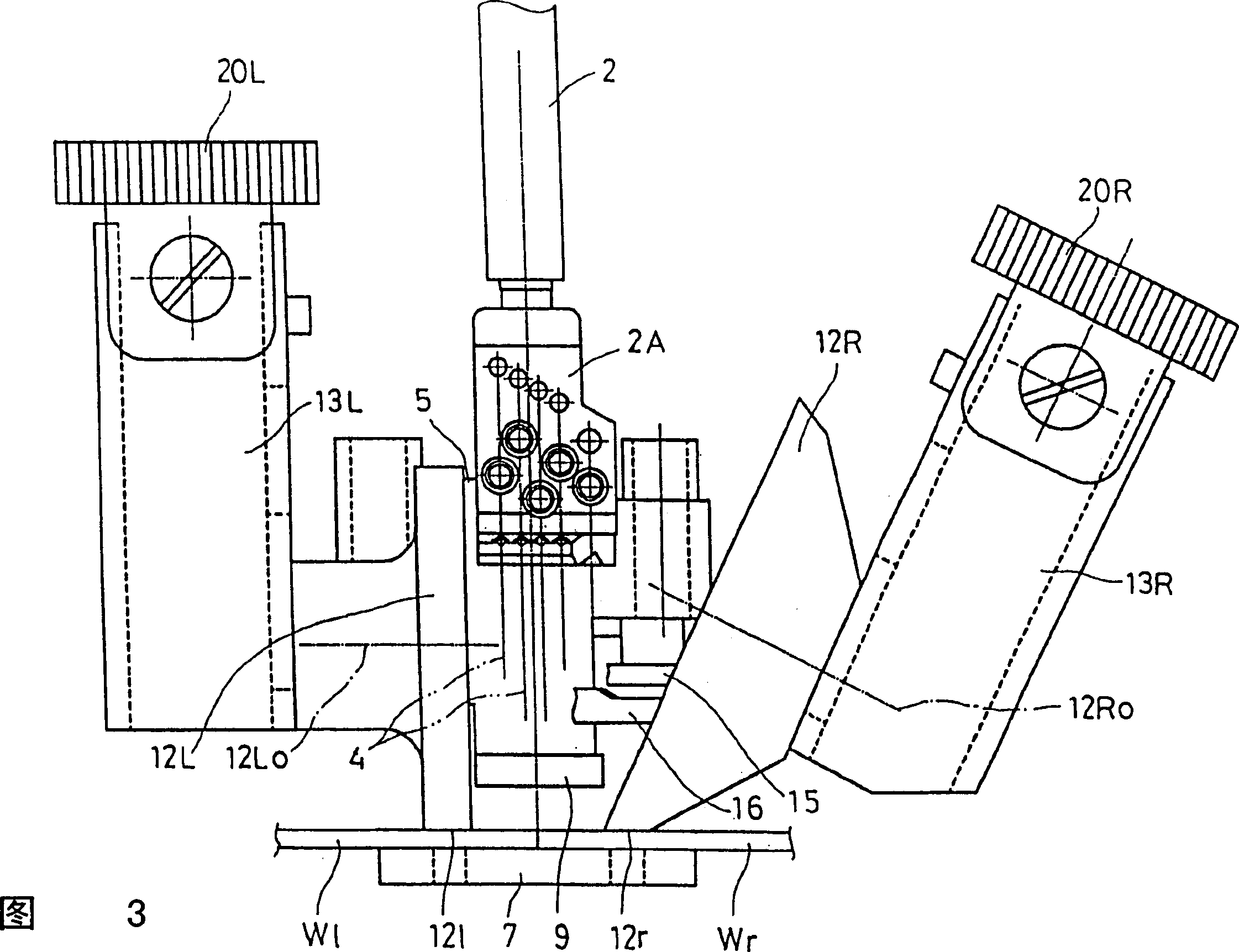

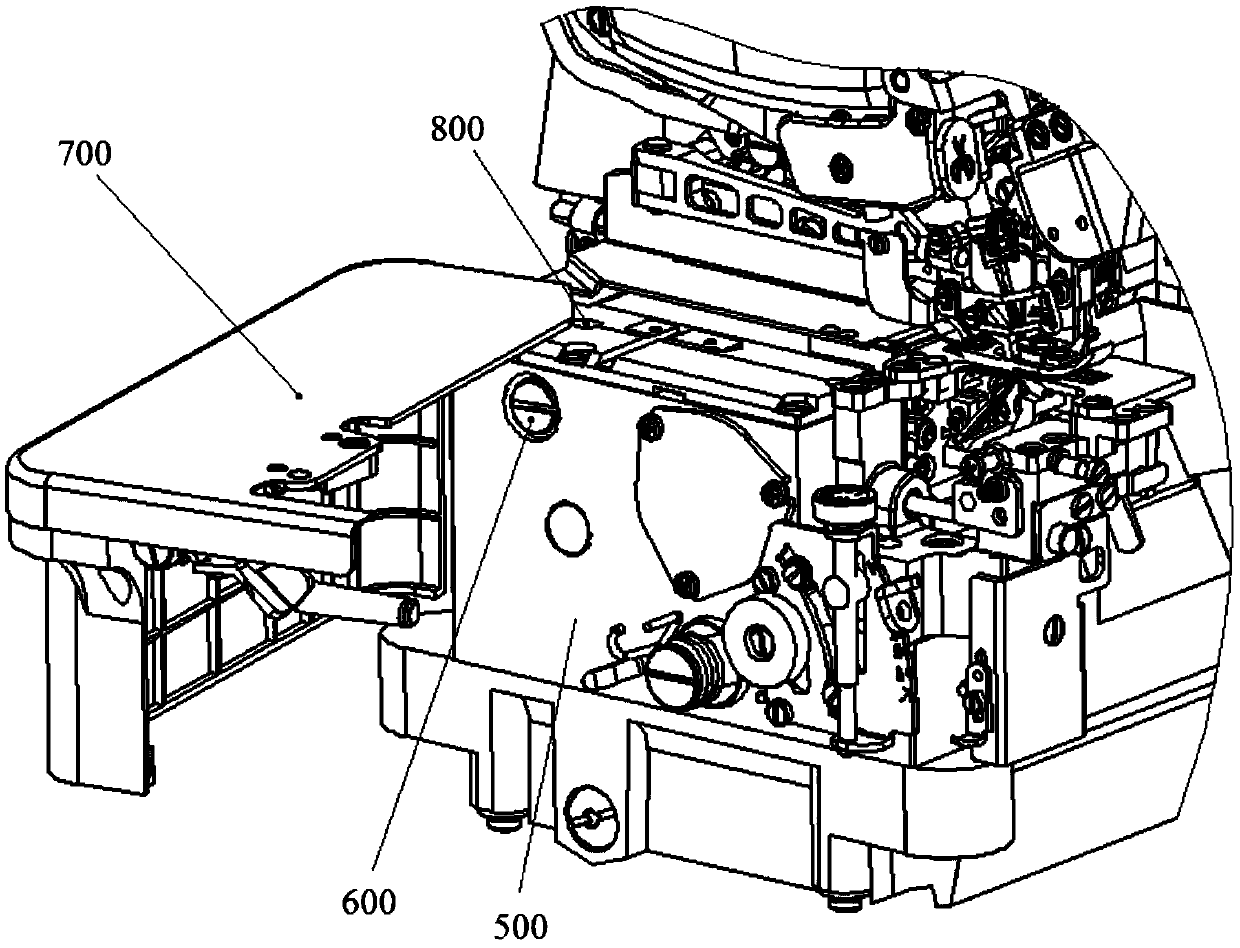

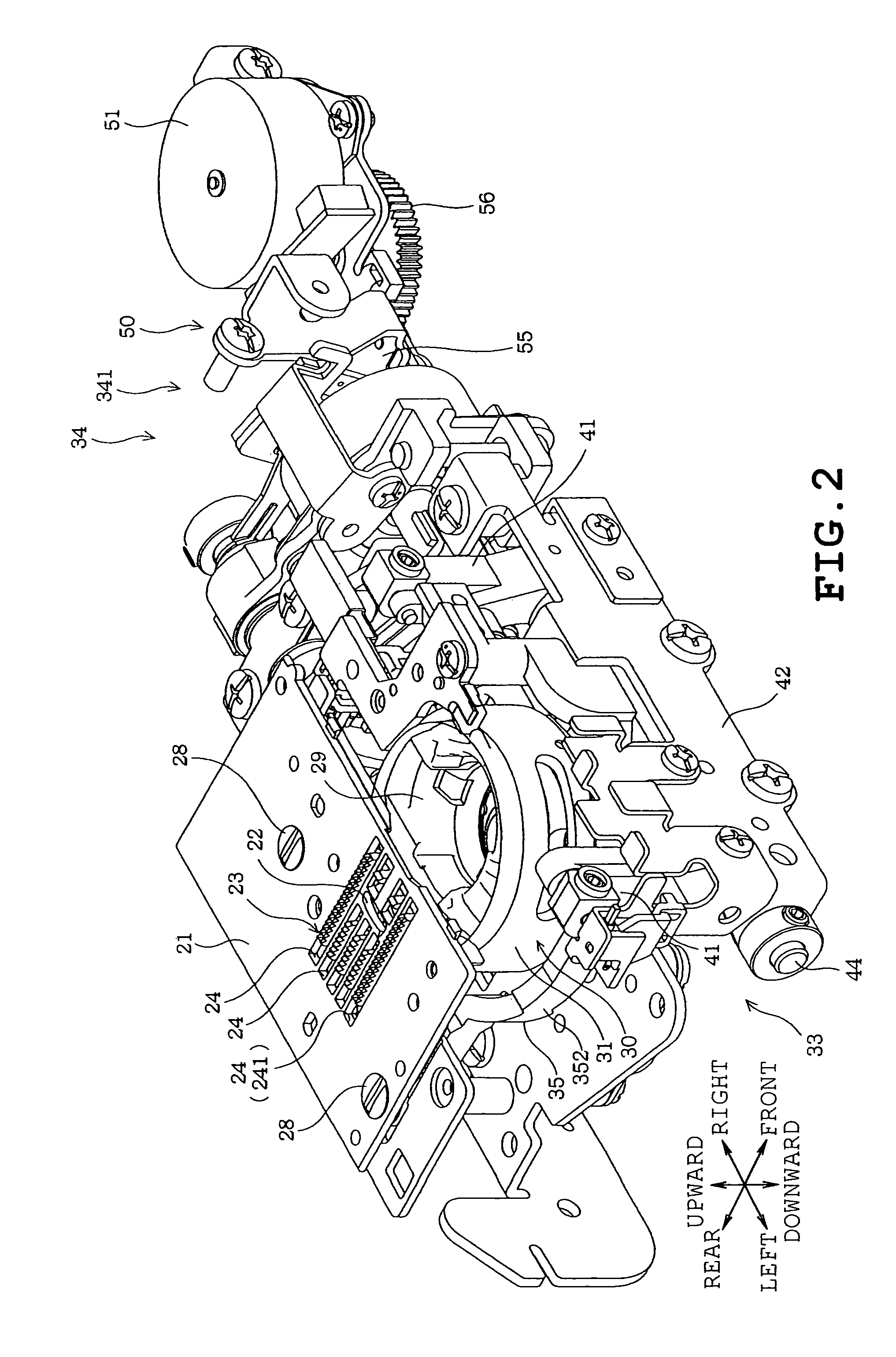

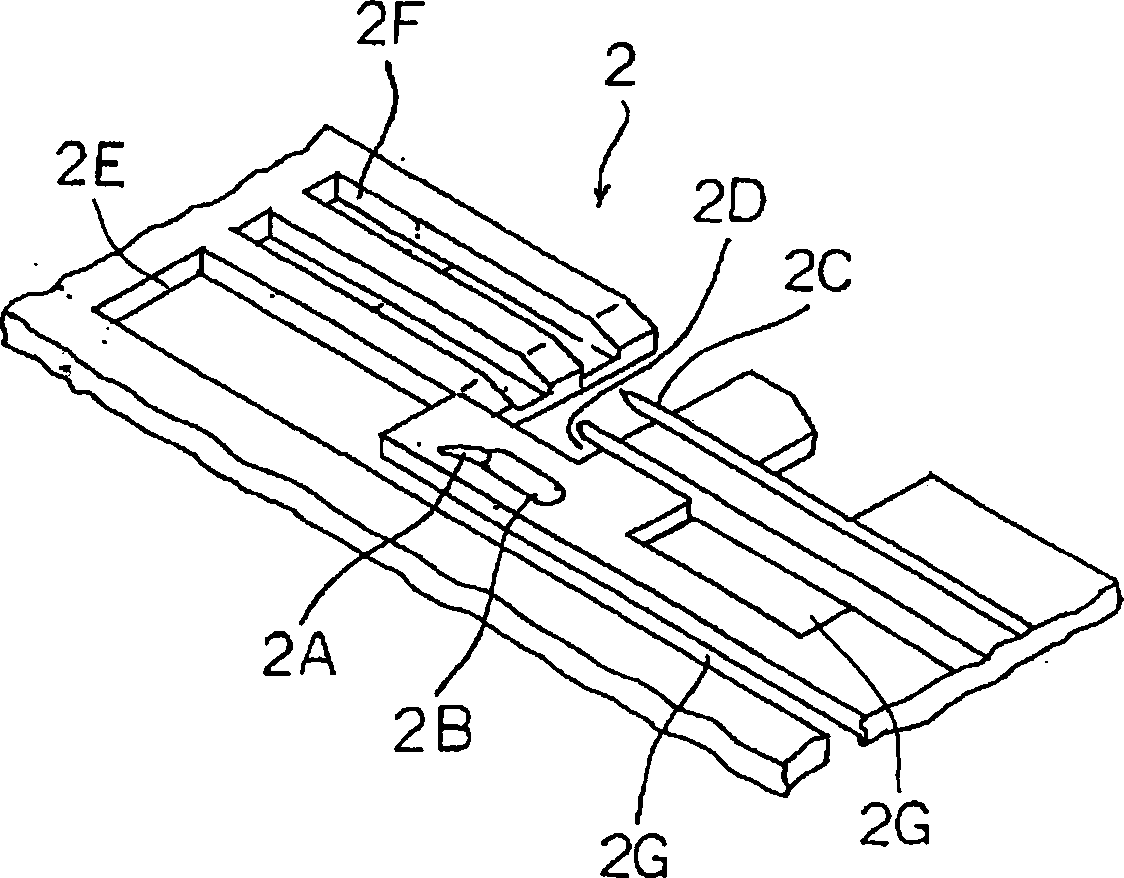

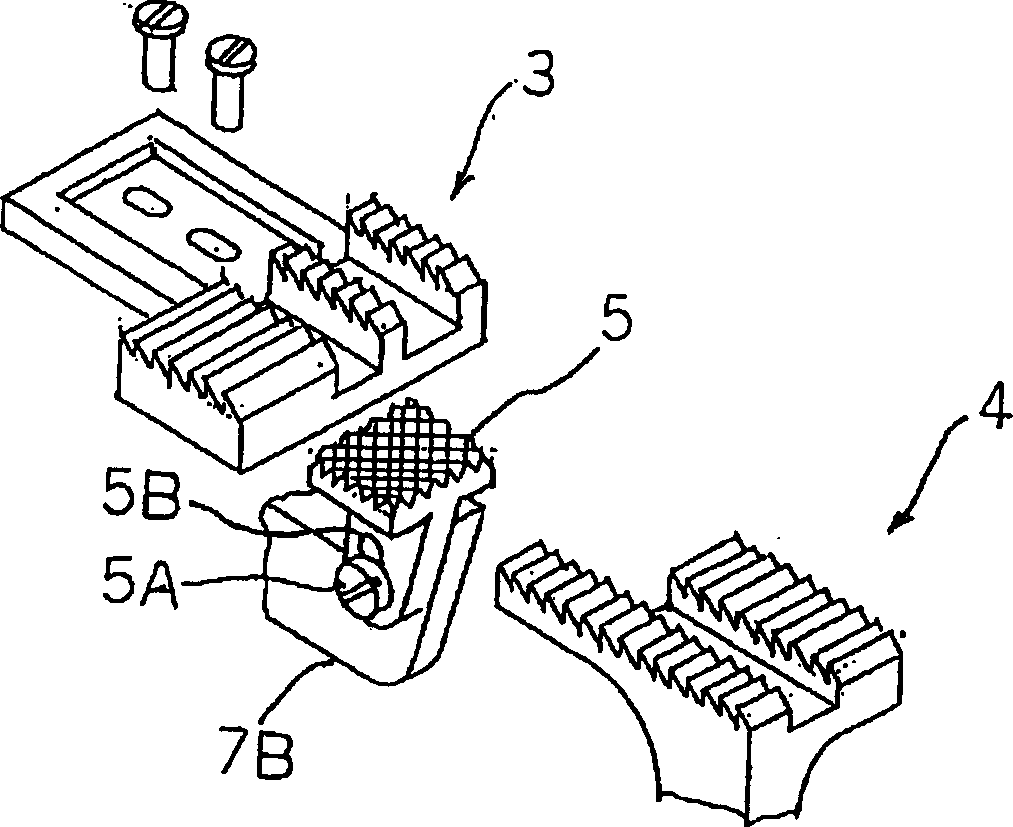

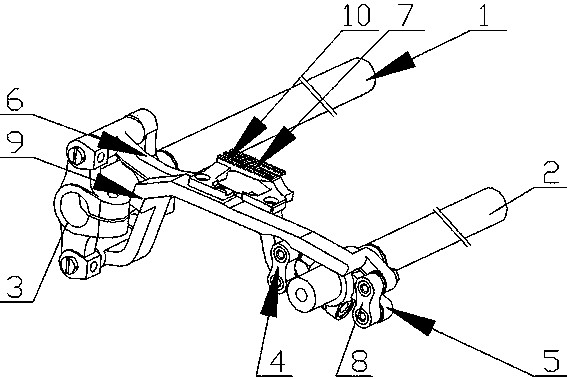

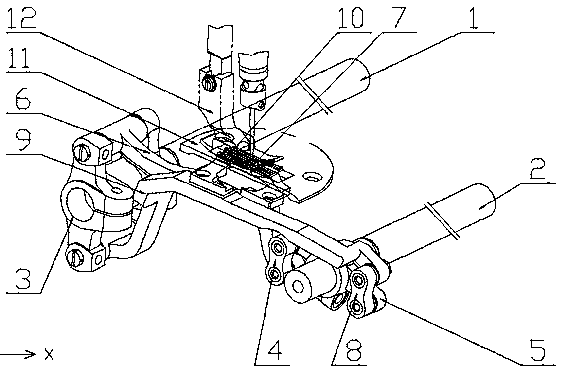

Motor control sewing machine feeding mechanism

The invention provides an improved sewing machine direct-driving feeding mechanism. The mechanism comprises a motor, a horizontal feeding shaft (1), a vertical feeding shaft (2), a feed dog pickup fork (3), a small assembly (4) for a feed dog frame and a feed dog (5), wherein the feed dog pickup fork (3) is arranged on the vertical feeding shaft (2); the small assembly (4) for the feed dog frame is arranged on the horizontal feeding shaft; and the feed dog (5) is installed on the small assembly (4) for the feed dog frame. In the mechanism, the horizontal feeding shaft (1) is directly driven by a motor, and the vertical feeding shaft is driven by the main shaft motor of the sewing machine. The two motors both can be connected to a computer and are directly programmed to control so as to change the feeding track and parameter of the feed dog. The mechanism has the advantages of stable feeding effect, accurate feeding displacement and convenience in control.

Owner:SUZHOU HAOJIE MACHINERY ELECTRONICS EQUIP

Staggering preventing device of sewing material and overlock sewing machine

Owner:JACK SEWING MASCH CO LTD

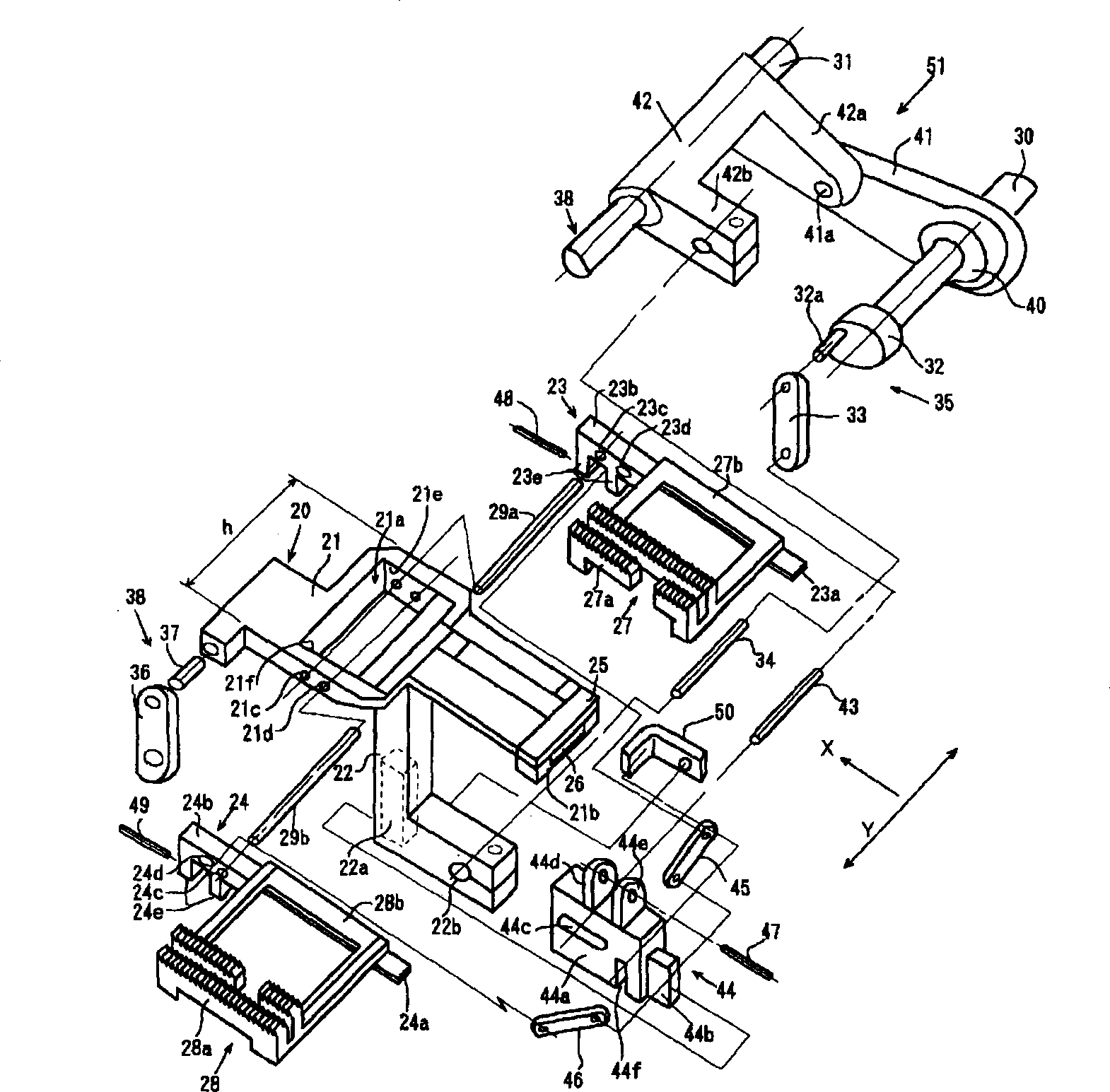

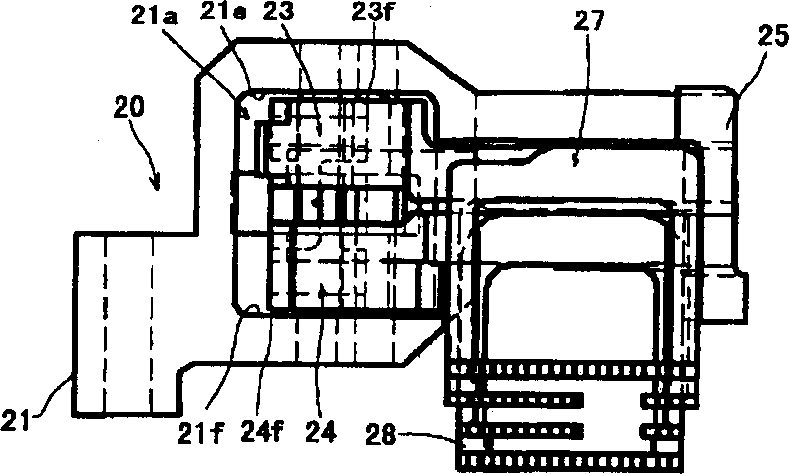

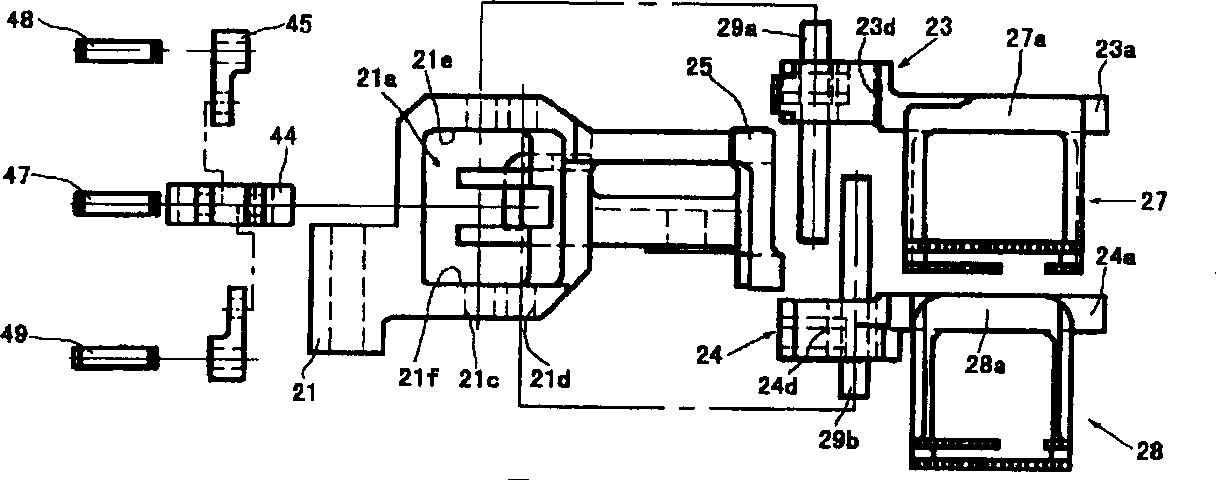

Cloth feeder of sewing machine

InactiveCN1376820AQuality improvementWork-feeding meansSewing-machine control devicesEngineeringActuator

PURPOSE: Provided is a cloth feeding device which is compact and performs precise movement when moved in a sliding direction. CONSTITUTION: In the sewing machine cloth feeding device comprises left and right feed dogs(27, 28) consisting of right and left feed dogs which are divided along a cloth feeding direction, a feed bar(20) for supporting the left and right feed dogs to be movable in a direction crossing the cloth feed direction, a vertical driving means(35) for giving a vertical motion to the left and right feed dogs, a horizontal driving means(38) or giving a horizontal motion to the feed dogs and left and right driving means(63, an actuator) for giving a motion in a sliding direction which crosses the cloth feeding direction to the feed dogs, the device comprises a plurality of support shafts(29a) which are individually fixed to the left and right feed dogs and arranged along the sliding direction and a plurality of support holes(21c, 21d) which are formed at both ends of the feed bar in the sliding direction in order to support the support shafts so as to be independently movable along the sliding direction.

Owner:JUKI CORP

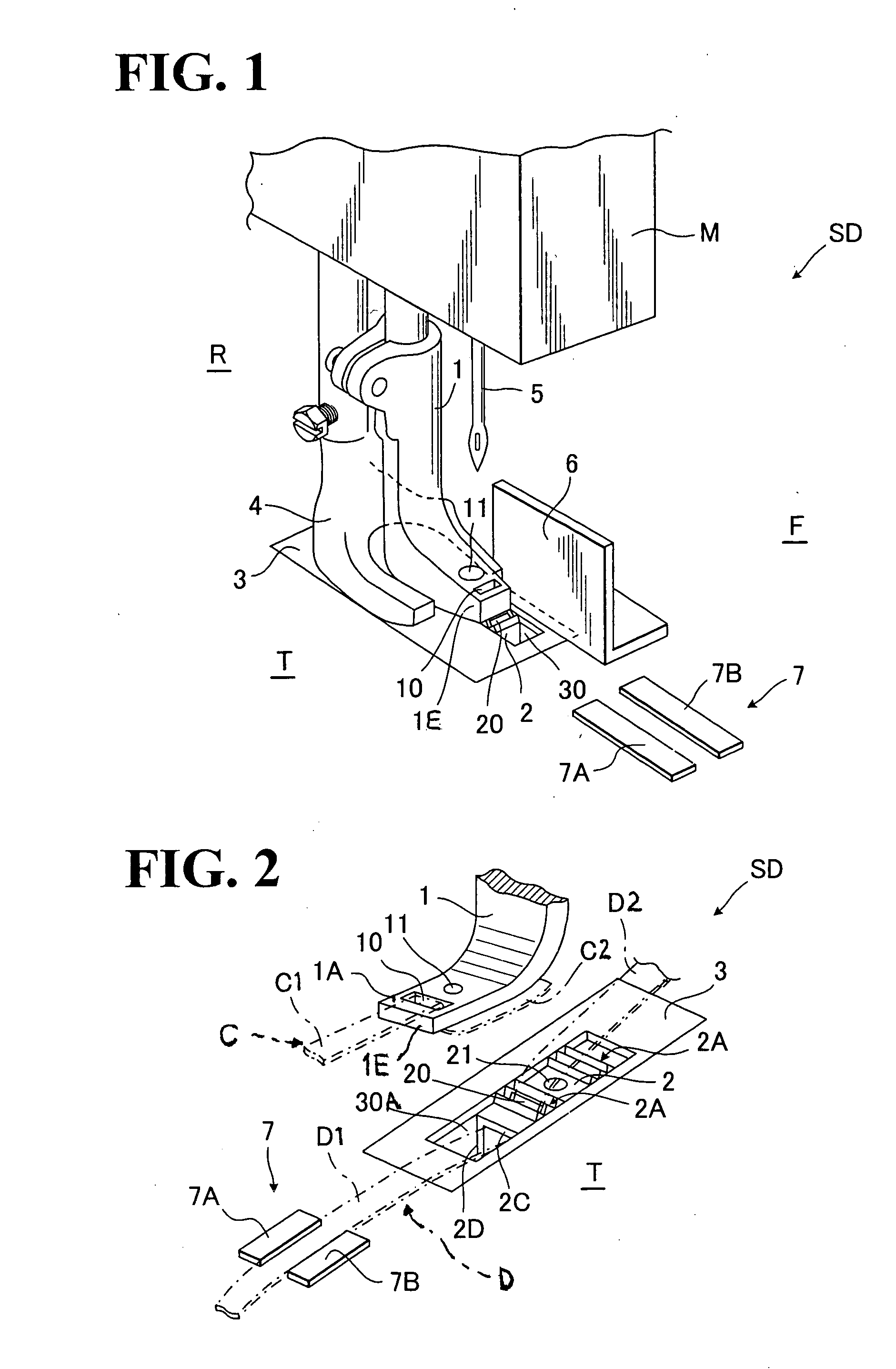

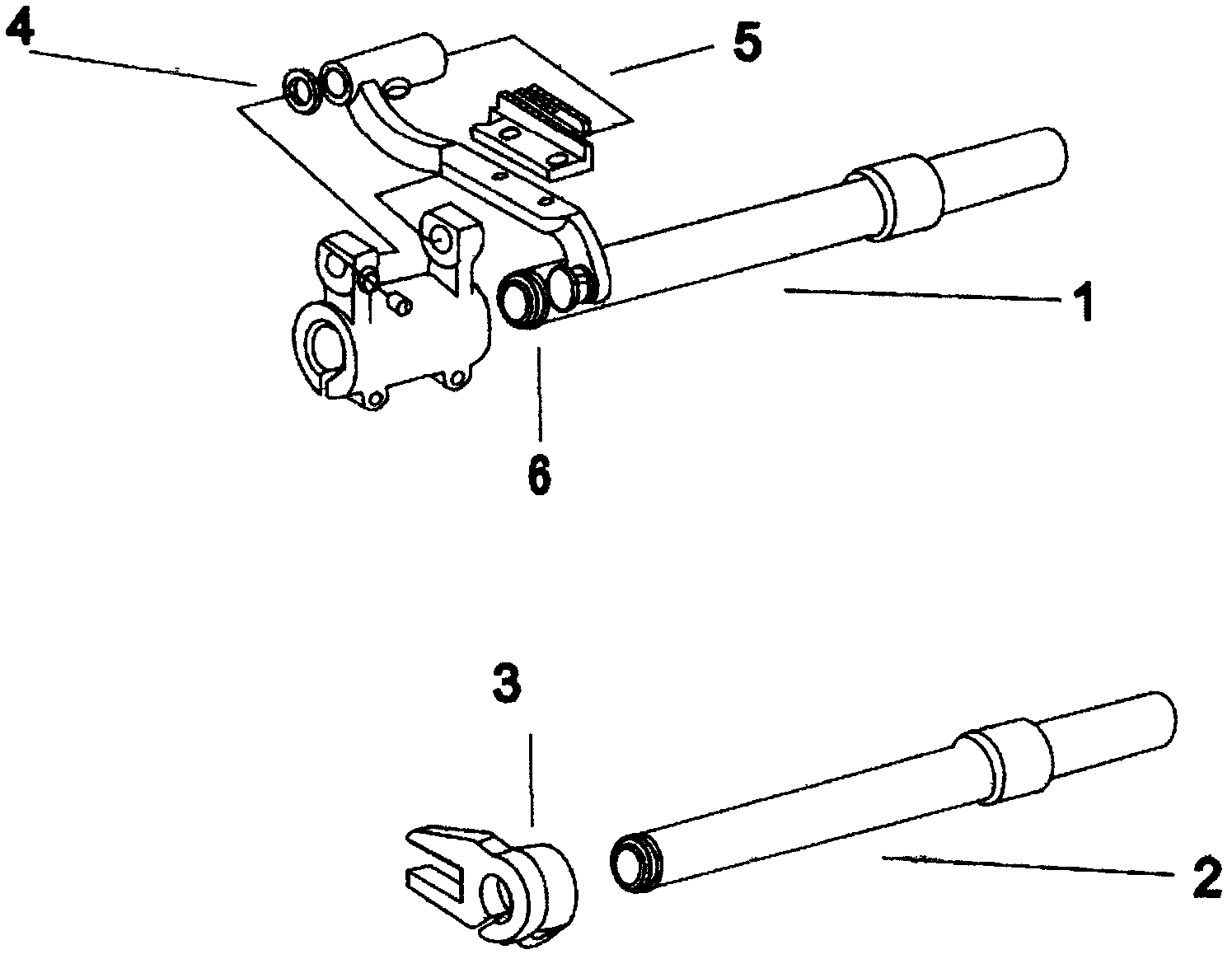

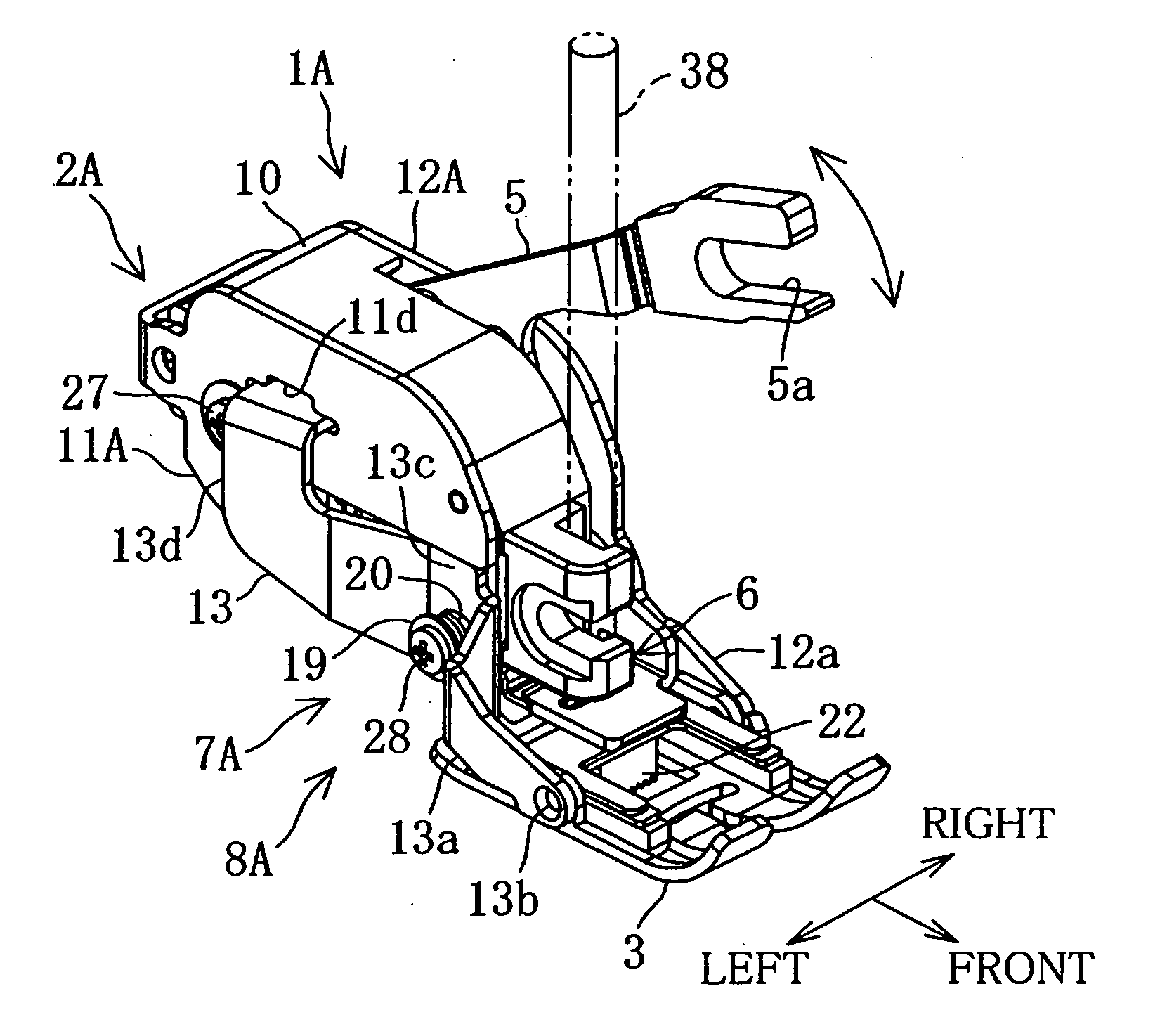

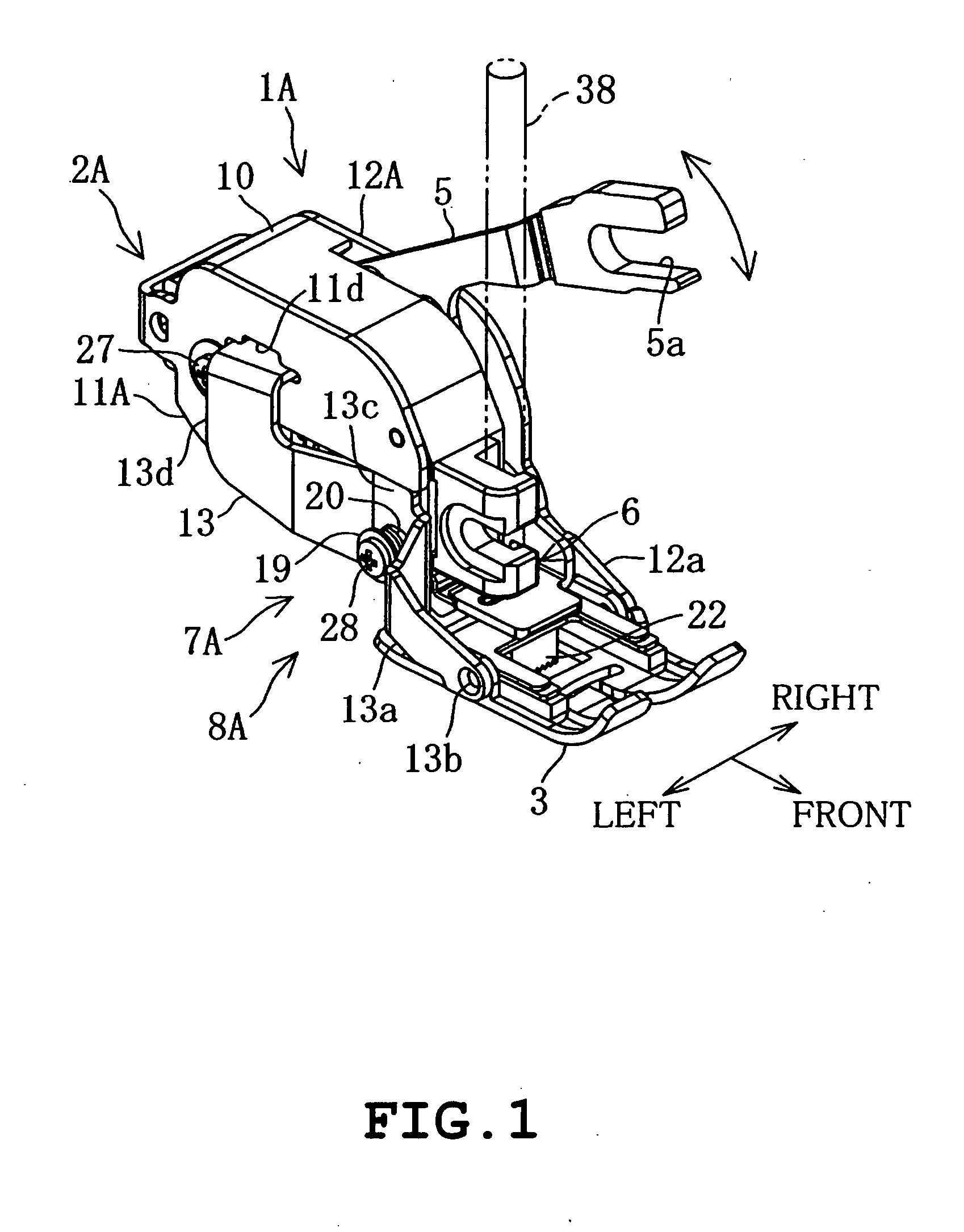

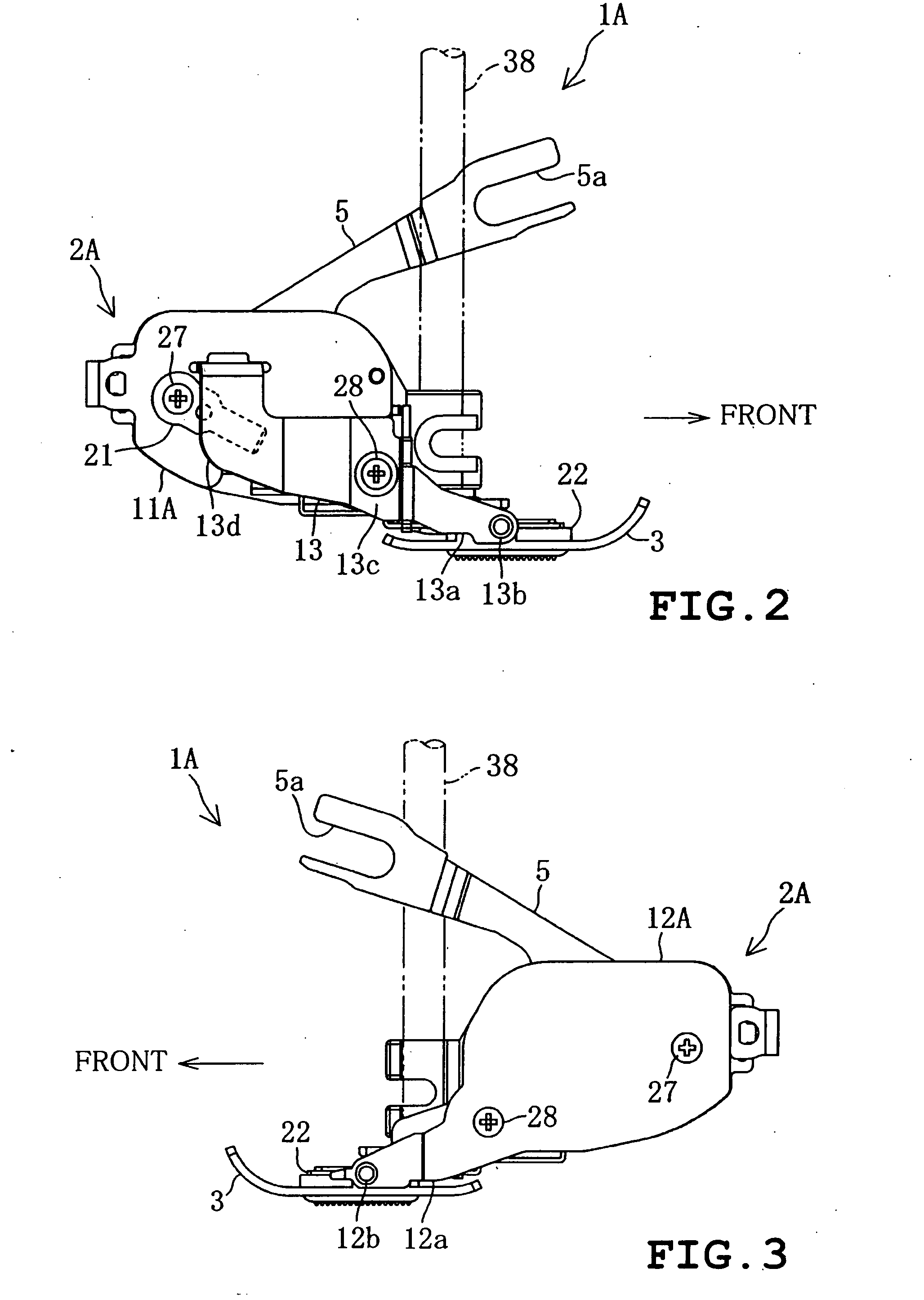

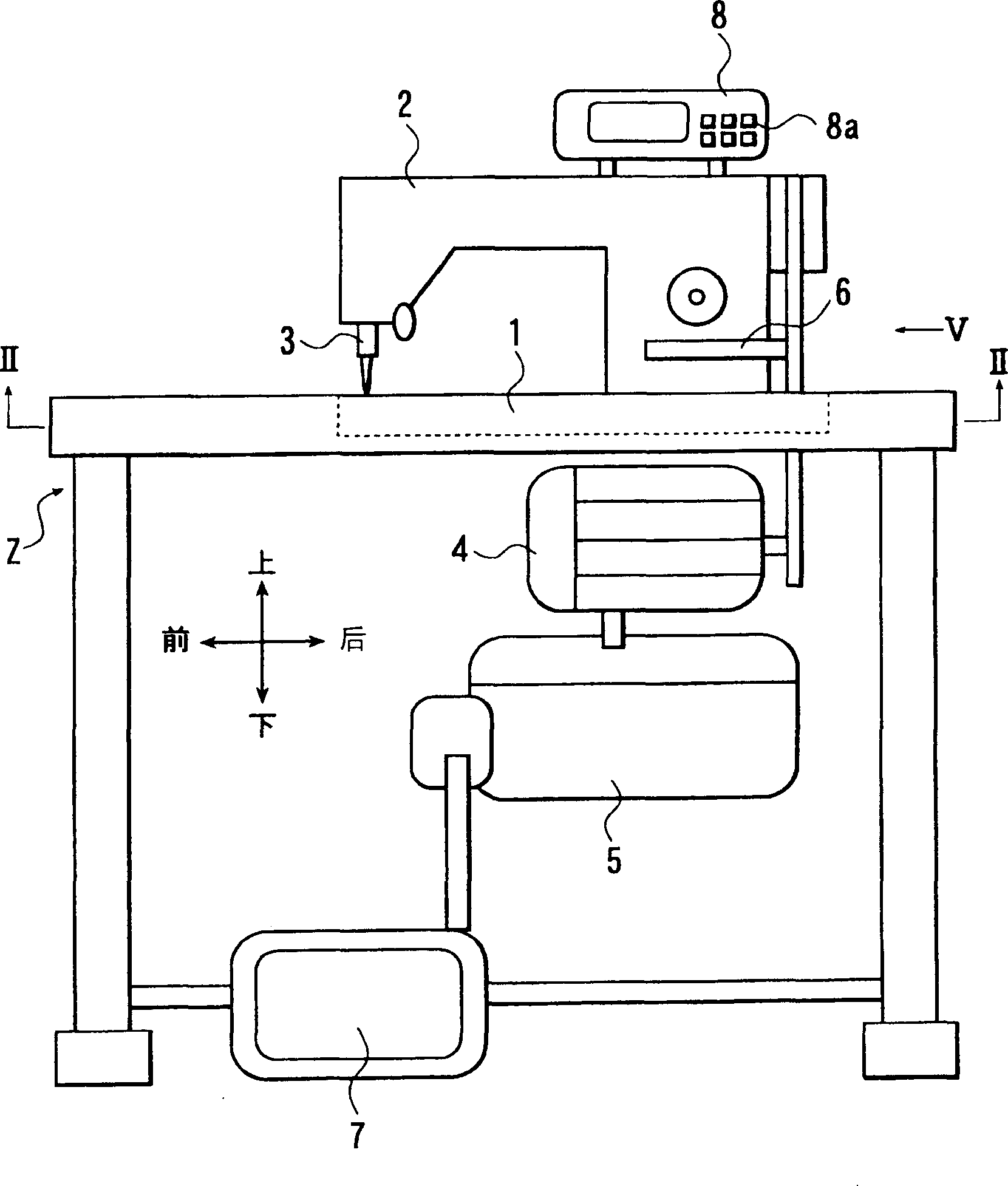

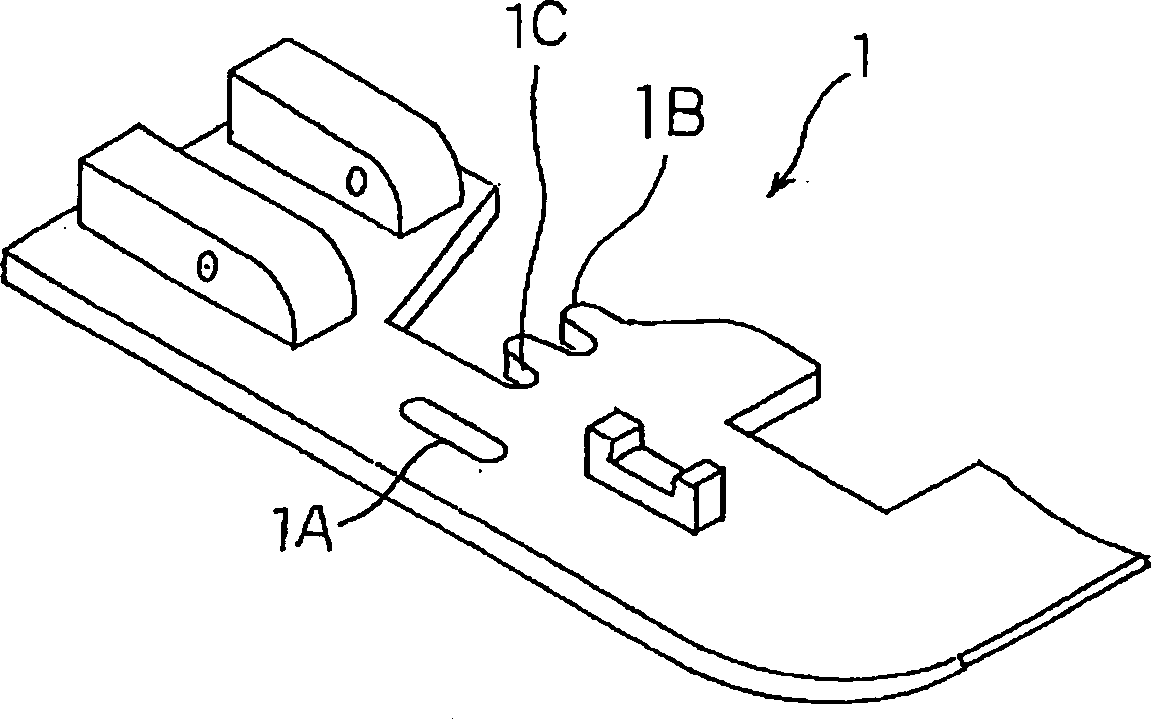

Walking foot for sewing machine

A walking foot for a sewing machine includes a presser foot having a pair of supported portions, an upper feed dog feeding workpiece cloth in synchronization with vertical movement of a needlebar, a supporting member fixed to a lower end of the presser bar and having a pair of engagement supporting portions supporting the presser foot, a swinging supporting mechanism engaging the engagement supporting portions with the supported portions from horizontally outside respectively so that the presser foot is supported on the supporting member so as to be swingable, and a disengaging mechanism moving at least one of the engagement supporting portions horizontally outward from an engagement position where the engagement supporting portion is in engagement with the supported portion of the presser foot, thereby being capable of switching the engagement supporting portion to a disengagement position where the engagement supporting portion is disengaged from the supported portion.

Owner:BROTHER KOGYO KK

Cloth feeding mechanism of sewing machine

InactiveCN1542193AEasy to useEasy to adjustProgramme-controlled sewing machinesWork-feeding meansEngineeringFeed dogs

The feeding device for the sewing machine is provided with: a feeding transmission mechanism 20 for transporting fabrics in a prescribed direction by swinging a feed dog 11 so as to come in contact with and leave the fabrics; an angle piece 30 for changing the amount of feeding of the feeding transmission mechanism; a stepping motor 50 for driving the angle piece; and a CPU 80 for controlling the amount of driving of the stepping motor so as to change the amount of feeding. The feeding device is further provided with: an operation lever 6 having a prescribed operable range Sa; a potentiometer 70 for detecting the amount of operation of the operation lever; and a program 110 for setting the amount of feeding for setting the correspondence relation between the amount of operation of the lever and the amount of feeding. The CPU controls the amount of driving of the stepping motor so as to change the amount of feeding corresponding to the amount of operation of the lever on the basis of the correspondence relation set by the program for setting the amount of feeding. To provide an easily operable feeding device for a sewing machine wherein the amount of feeding can be freely adjusted according to various kinds of sewing situations and the skill / liking of an operator.

Owner:JUKI CORP

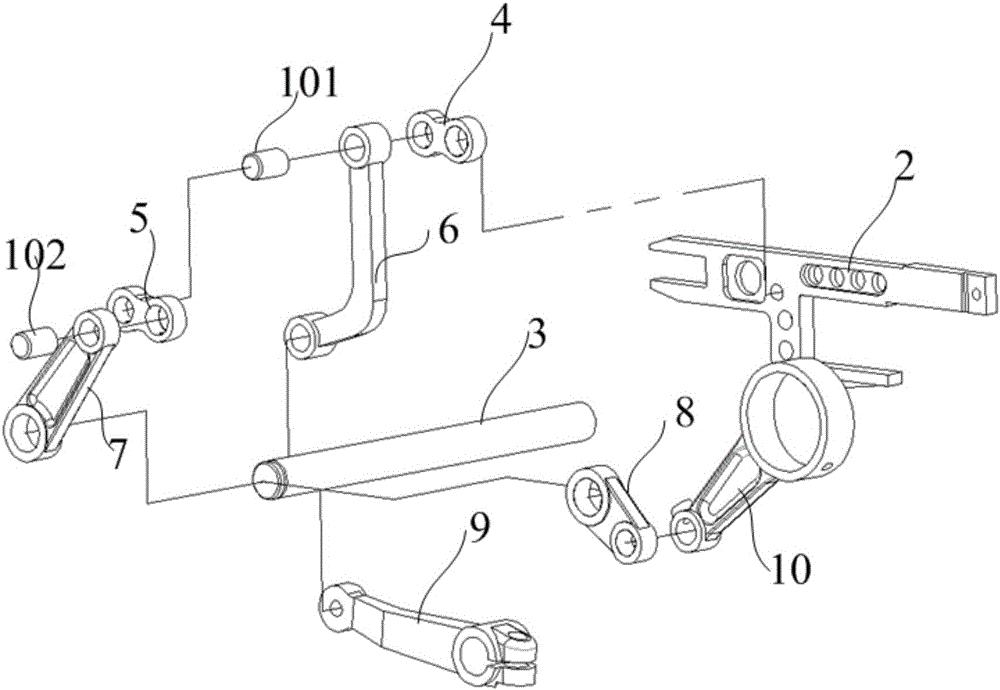

Differential cloth-feed adjusting structure and sewing machine

ActiveCN106012321AEasy to processEasy to installWork-feeding meansSewing-machine control devicesControl theoryFeed dogs

The invention provides a differential cloth-feed adjusting structure and a sewing machine. The differential cloth feed adjusting structure comprises a differential ratio adjusting part and a driving part, wherein the differential ratio adjusting part comprises a manual adjusting component, a differential connecting piece and a cloth-feed connecting rod; the manual adjusting component is in transmission connection with the differential connecting piece; one end of the cloth-feed connecting rod is hinged to the differential connecting piece and a differential connecting rod, so as to form a differential hinge point; the manual adjusting component is used for changing the position of the differential hinge point through the differential connecting piece; the differential connecting rod is connected to a differential feed dog rack; the differential feed dog rack is connected with a differential feed dog; the driving part comprises a feed connecting rod arranged on a spindle of the sewing machine, a cloth-feed shaft, a cloth-feed crank and a differential swing rod; the cloth-feed crank and the differential swing rod are fixed on the cloth-feed shaft in such a manner that preset included angles are formed between the cloth-feed crank and the differential swing rod; the feed connecting rod is connected with the cloth-feed crank; the differential swing rod is hinged to the other end of the cloth-feed connecting rod. According to the differential cloth-feed adjusting structure and the sewing machine, all the parts are easy to machine, and simple to mount, and the precise adjustment of the differential ratio is guaranteed.

Owner:JACK SEWING MASCH CO LTD

Feed dog adjustment device and sewing machine including same

The feed dog adjustment device, includes a feed rock shaft, rotatably attached to a sewing machine frame with an eccentric shaft provided at an eccentric position with respect, to a center, a feed rock shaft crank that, slides about the feed rock shaft, a feed bar rotatably attached to the feed rock shaft, crank, a feed dog provided on the feed bar, an actuator for inclination adjustment that rotates the eccentric shaft, and a controller that drives the actuator for inclination adjustment to adjust an inclination of the feed dog on a basis of data related to a type and stretchability of fabric.

Owner:JANOME CORP

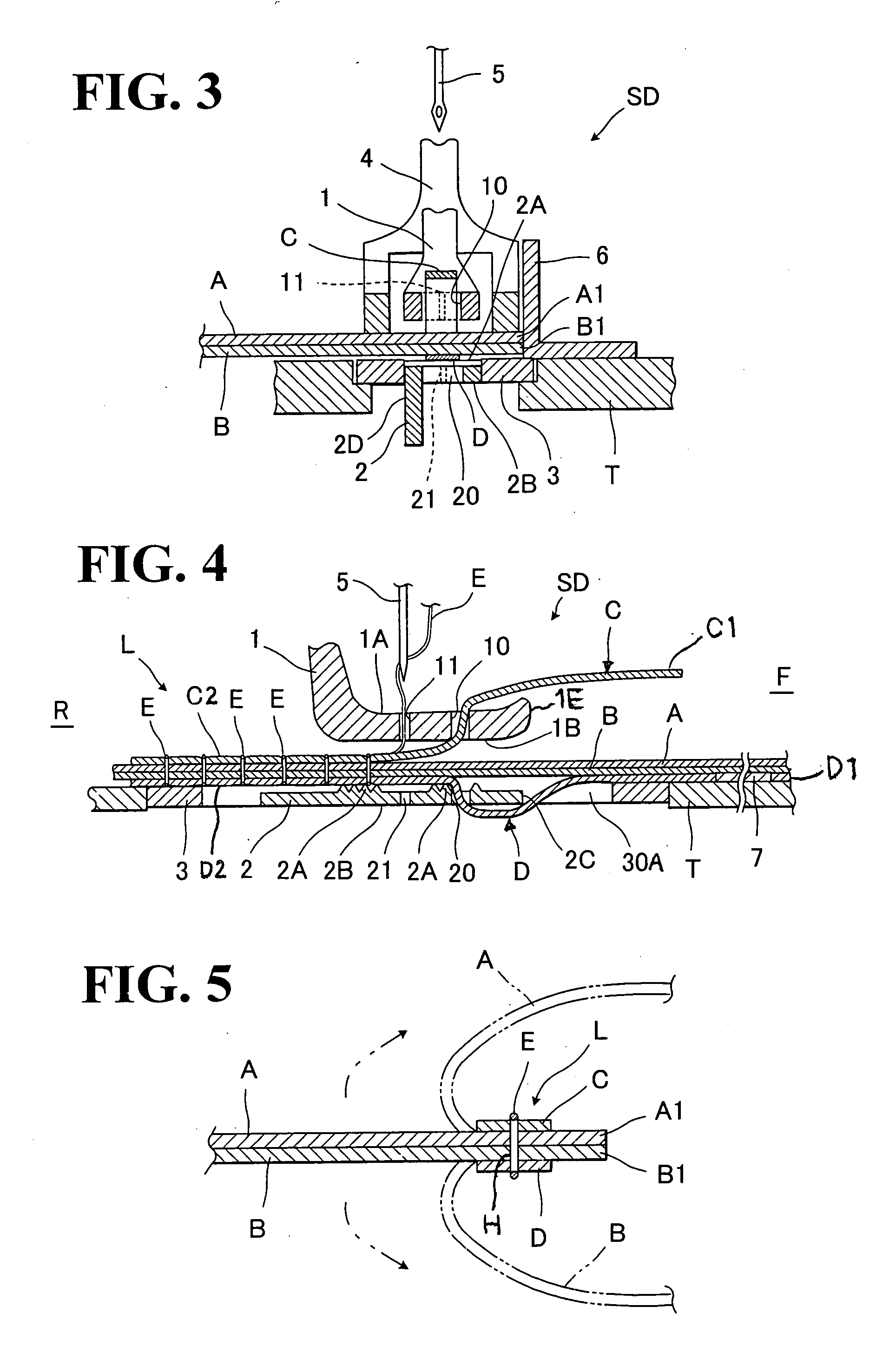

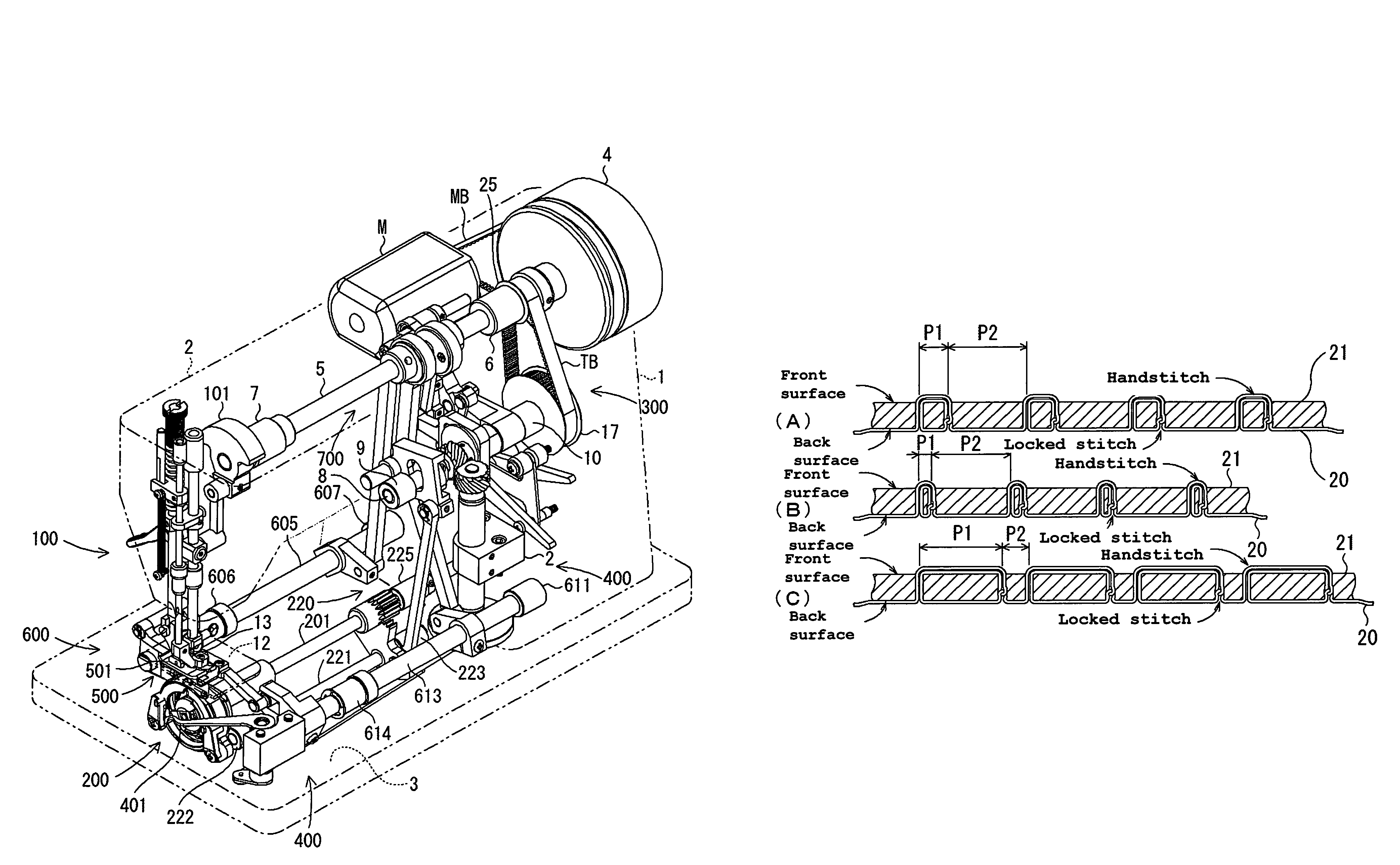

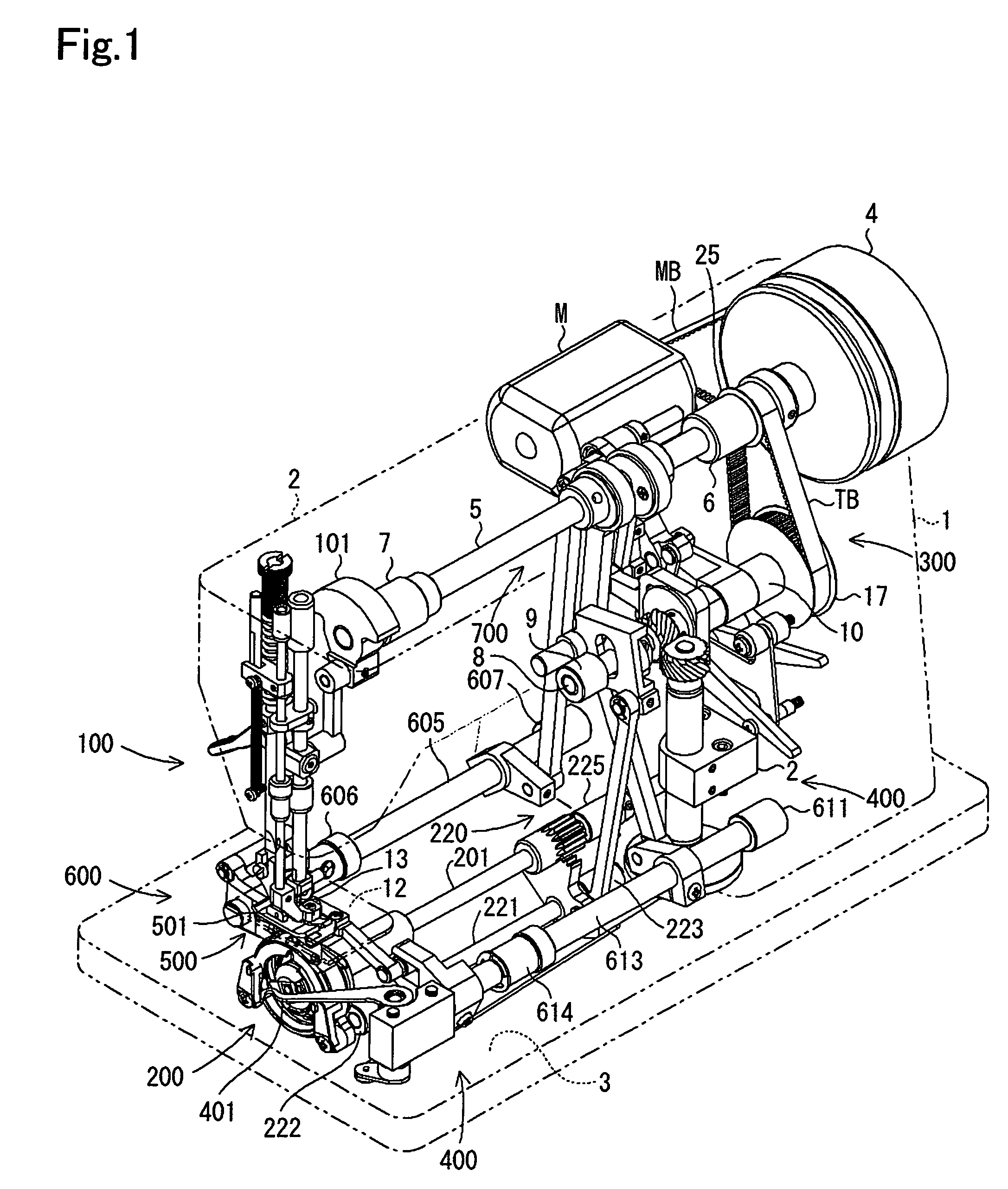

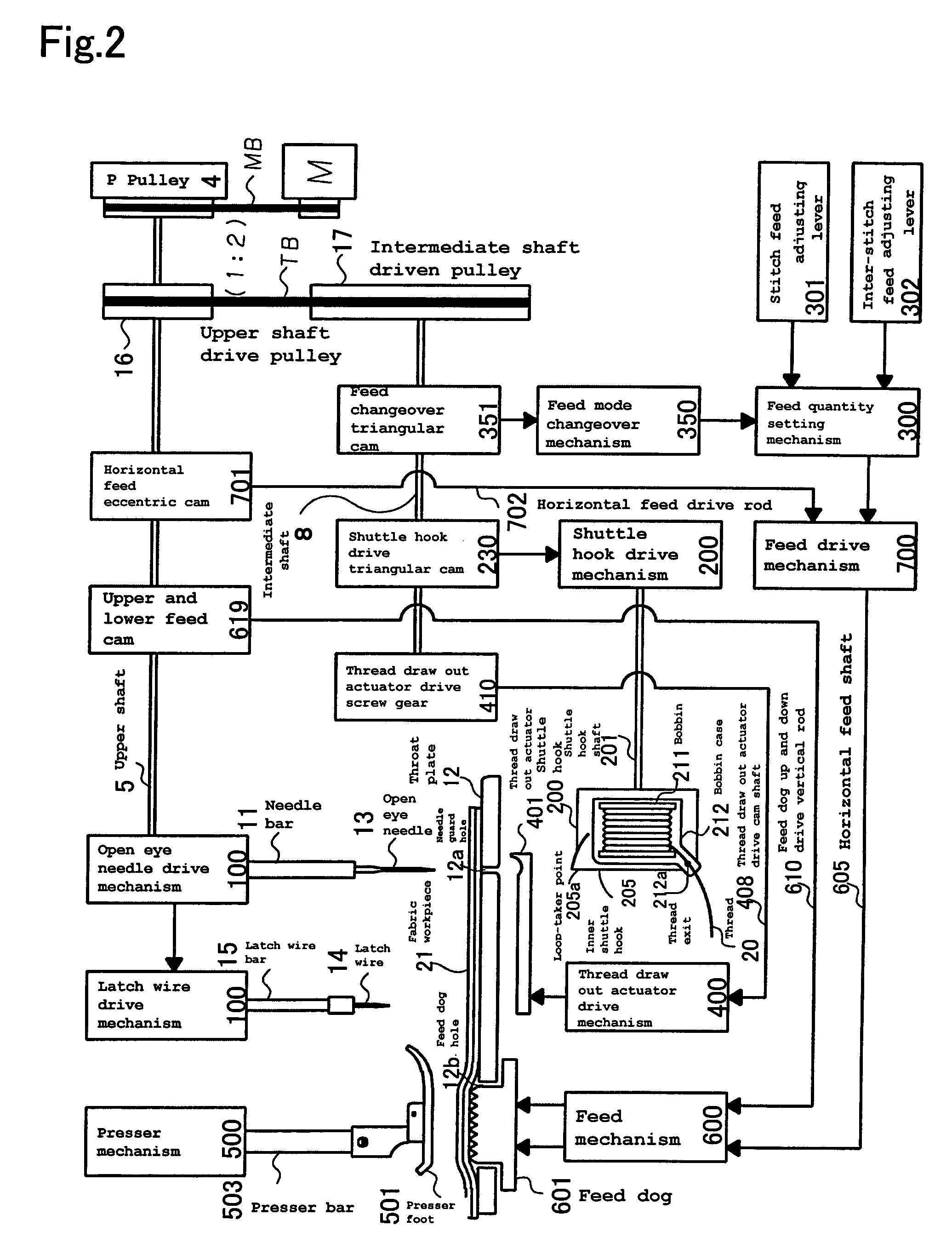

Method and sewing machine for forming single-thread locked handstitches

ActiveUS7891307B2Confirm positionAccurate sewingProgramme-controlled sewing machinesWork-feeding meansEye needlesEngineering

A sewing thread (20) can be captured certainly with a thread capturing open eye (13a) of an open eye needle (13) and the stitches are formed in the inner space of a sewing machine bed (3). A handstitch and a locked stitch are formed, respectively, on the front surface and the back surface of a fabric workpiece (21) as a skip stitch set through cooperation of the open eye needle (13), a shuttle hook (200) and a thread draw out actuator (401). A feed dog (601) feeds the fabric workpiece by a stitch length (P1) for handstitch during a first stroke of the open eye needle (13), and feeds the fabric workpiece by an inter-stitch pitch (P2) between the handstitches during a second stroke of the open eye needle (13).

Owner:SUZUKI MFG CO LTD

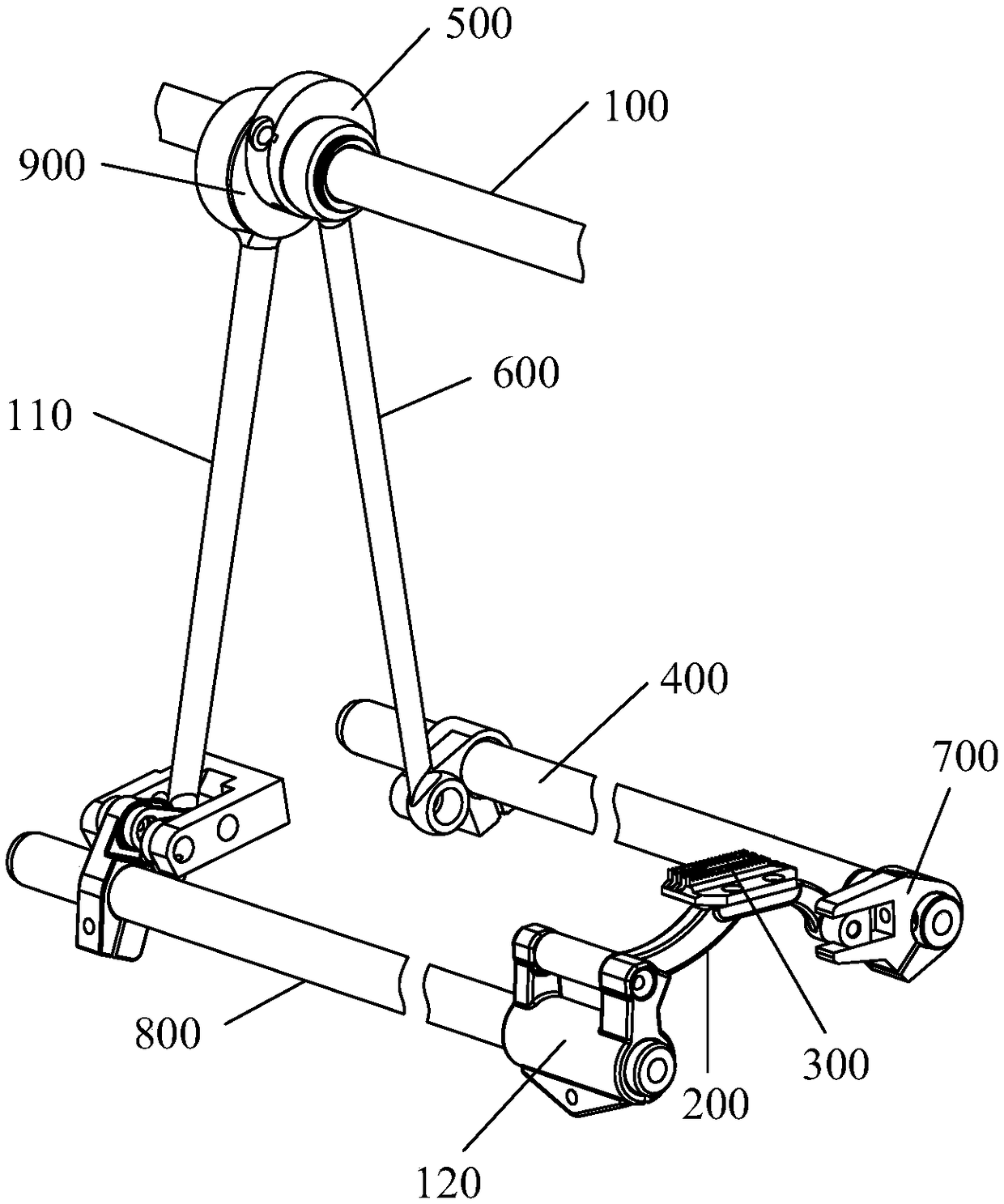

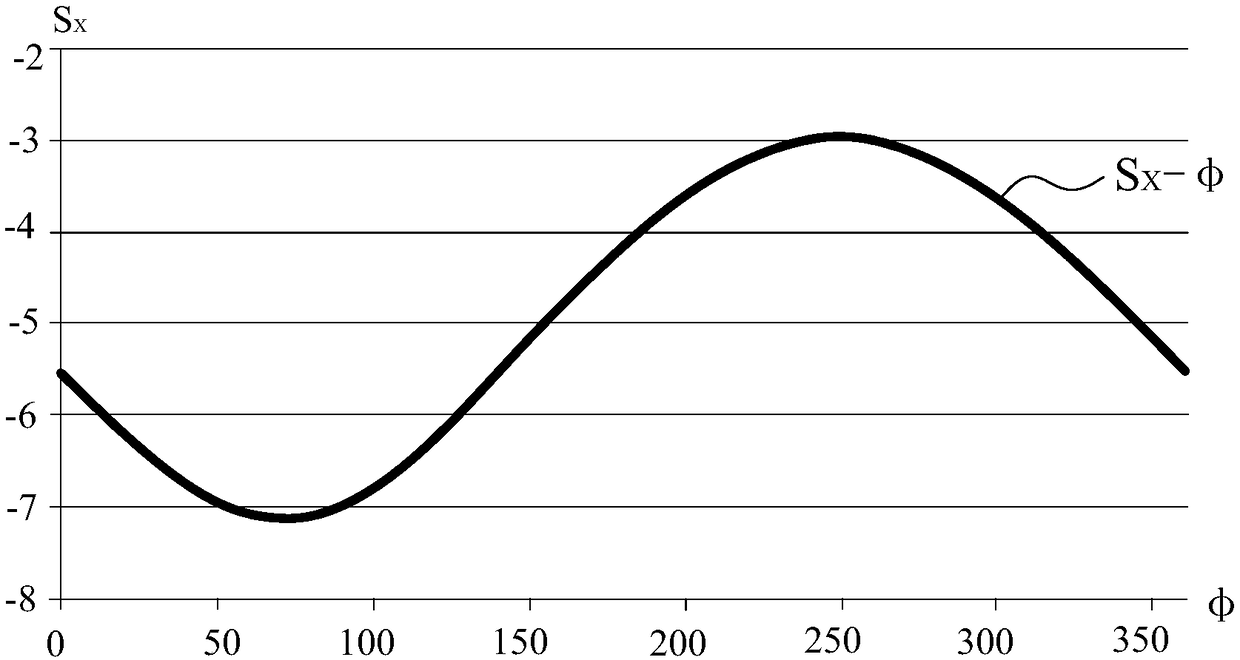

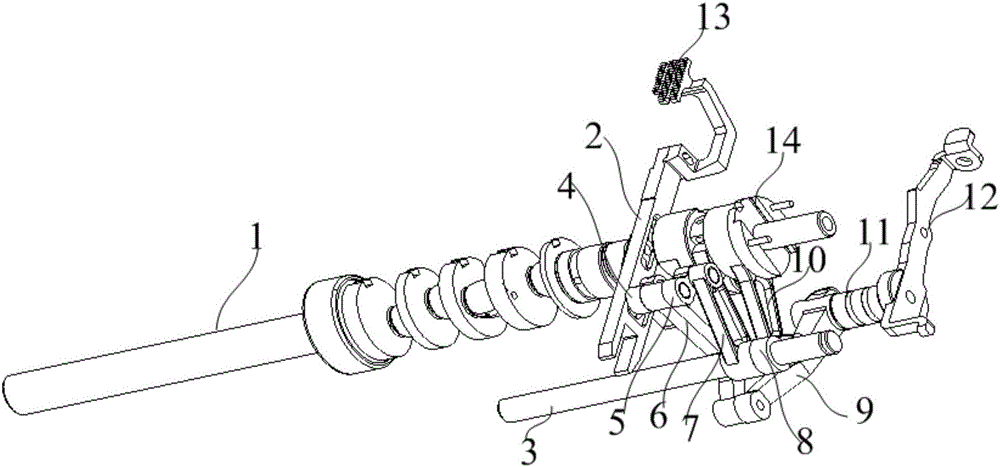

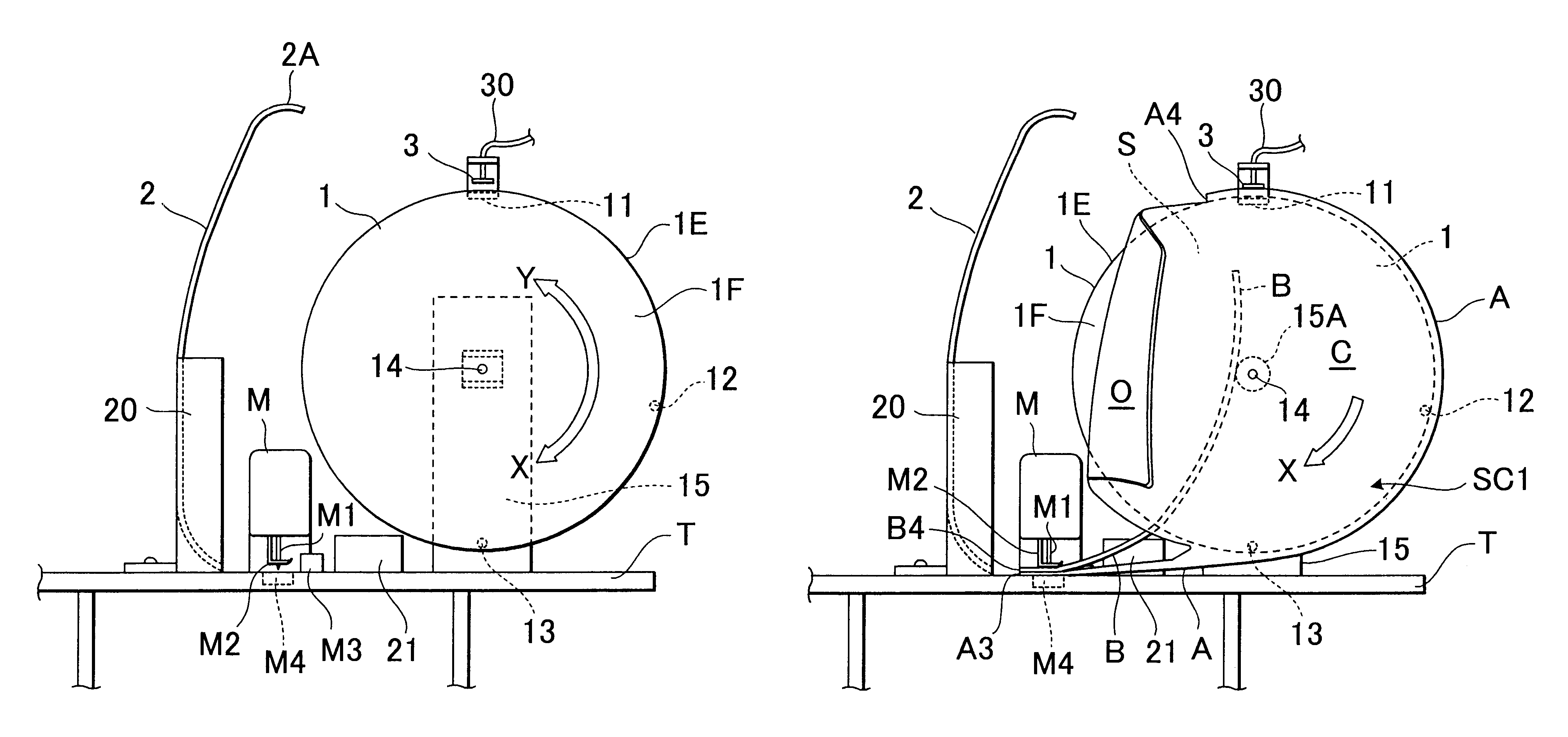

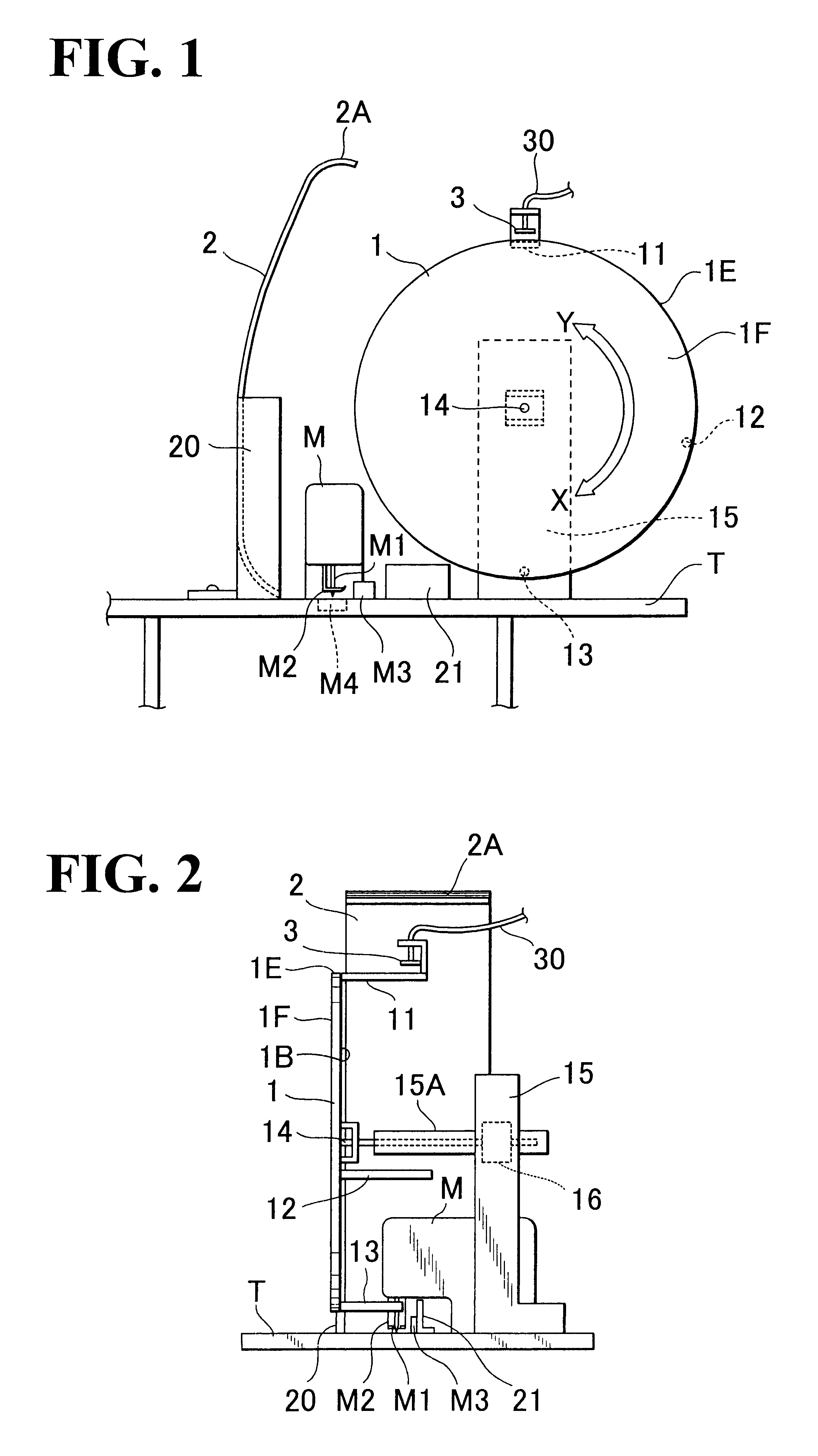

Feed mechanism of sewing machine and sewing machine

ActiveCN105113136AReduce loadCompact structureWork-feeding meansSewing-machine control devicesEngineeringAngle alpha

The invention provides a feed mechanism of a sewing machine. The feed mechanism comprises a main motor, a cloth feed motor, a feed dog frame and a feed dog fixed to the feed dog frame. The main motor is connected with the feed dog frame through a feed dog lifting mechanism. The cloth feed motor is connected with the feed dog frame through a cloth feed mechanism. The cloth feed mechanism comprises a drive connection rod, a swing connection rod and a feed dog base supported in a bottom plate of the sewing machine in a rotatable mode. One end of the drive connection rod is fixedly connected with an output shaft of the cloth feed motor, and the other end of the drive connection rod is hinged to one end of the swing connection rod. The other end of the swing connection rod is hinged to the feed dog base. The feed dog base is hinged to one end of the feed dog frame. In the feed process, the output shaft of the cloth feed motor swings once in a reciprocating mode within the regulated angle alpha, the feed dog frame and the feed dog can reciprocate twice in a front-back mode together relative to the bottom plate, and therefore the rotation direction switching frequency of the output shaft of the cloth feed motor is greatly decreased, the synchronism between drive of the main motor and drive of the cloth feed motor is ensured, and the sewing quality is improved.

Owner:JACK SEWING MASCH CO LTD

Method for monitoring computer operating system in starting process

InactiveCN104503859AAvoid changeDifficulty of SimplificationFault responseElectricityOperational system

The invention discloses a method for monitoring a computer operating system in the system starting process without increasing hardware cost or influencing system starting time. The method comprises the following steps of (1) after the system is powered on and started, opening real-tine interruption, and pre-loading an interruption module code of the system and a dog feeding scheme code in the system starting process as an emergency loading part into the system; (2) executing the dog feeding scheme code in the emergency loading part, and completing dog feeding by periodically triggering the real-tine interruption with an appointed timer by means of the opened real-time interruption; (3) appointing a counter in a dog feeding function to judge whether system start is overtime or not, and if the system start is overtime, not feeding dog and reloading by using a hardware watchdog rest system; (4) after the start is completed, relieving the appointed timer in a system task, and submitting a hardware watchdog to software of the system for arrangement. The method can solve the problem that the system start fails because the dog cannot be fed in the system starting process.

Owner:长园深瑞继保自动化有限公司

Cloth pressuring device of sewing machine

InactiveCN1397673AAvoid damageReduce frictional resistanceWork-feeding meansPressersEngineeringFeed dogs

In this invention, a small presser foot elastically pressing a fabric on the downstream side of a sewing direction of a needle location hole against moveable feed dogs on the top face side of a needle plate is mounted, a pair of right and left rotors and elastically pressing the fabric against the moveable feed dogs by the peripheral lower ends and are provided, and the straight line distance along the sewing direction between the peripheral lower ends and of the pair of right and left rotors and the pressing portion of the small presser foot is reduced as much as possible to the extent that there is no interference with operation. Accordingly, this invention is able to reliably, smoothly and uniformly feed fabric without necessitating the trouble of applying oil when sewing the less smooth fabric and easily carrying out a curve stitch and a fancy stitch.

Owner:YAMATO SEWING MASCH MFG CO LTD

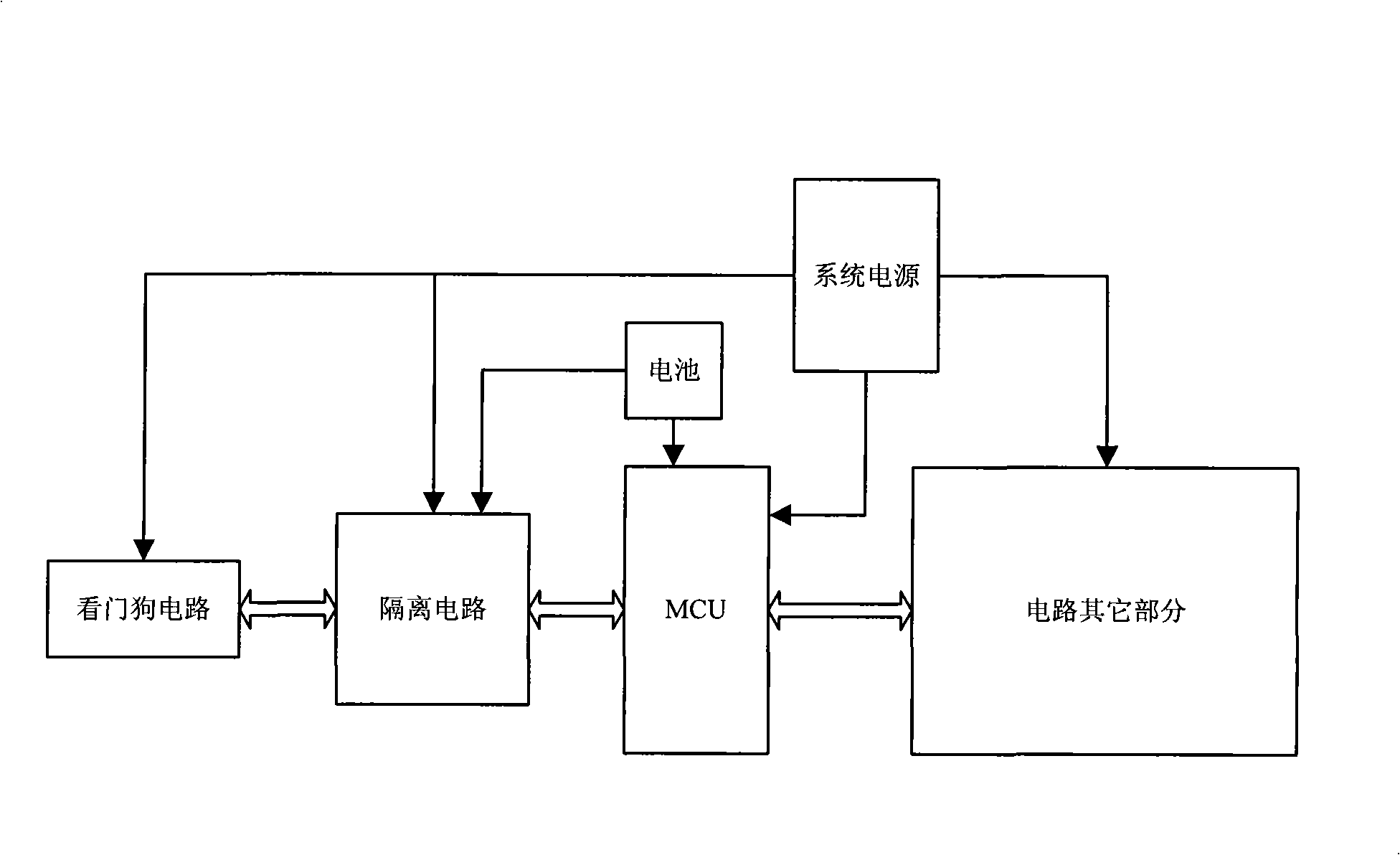

Controllable watchdog replacement system

ActiveCN101281414AEasy to implementLow costError detection/correctionData resettingCanis lupus familiarisFeed dogs

The invention relates to a controllable watchdog reset system, comprising a watchdog circuit and a microprocessor, and a system power supplying power for the watchdog circuit and the microprocessor. An isolation circuit is connected between the watchdog circuit and the microprocessor. When the system power normally supplies power, the isolation circuit transmits a reset signal of a reset pin of the watchdog circuit to a reset terminal of the microprocessor, and transmits a feeding-dog signal of I / O pin of the microprocessor to a feeding-dog pin of the watchdog circuit; when the system power is outage, the isolation circuit stops to cut off the contact between the watchdog circuit and the microprocessor. The invention has the effects of reducing system power dissipation, improving the service life of battery, and at the same time precluding a system reset problem caused by working wrongly of the watchdog circuit, and greatly improving reliability of the system.

Owner:SHENZHEN MINDRAY BIO MEDICAL ELECTRONICS CO LTD +1

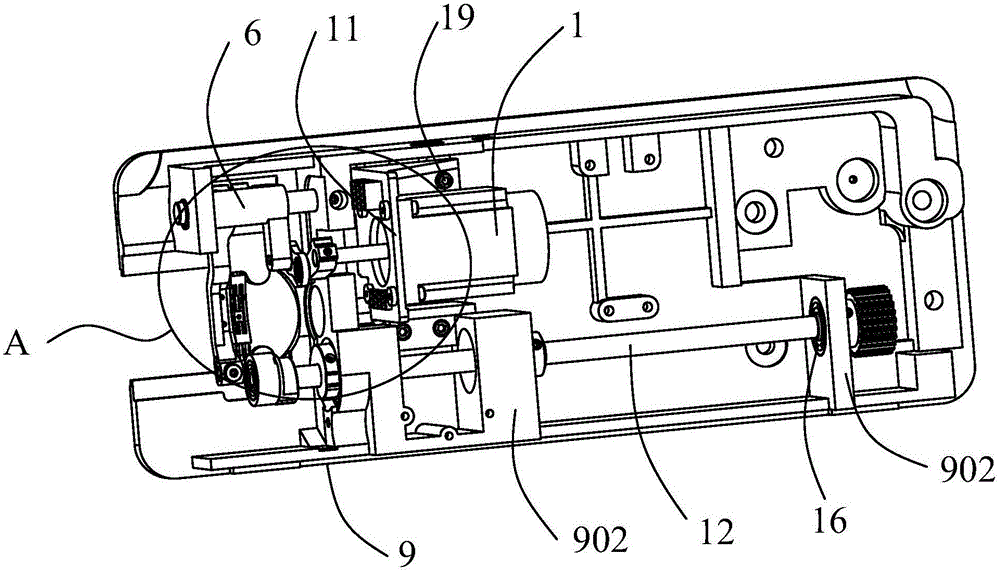

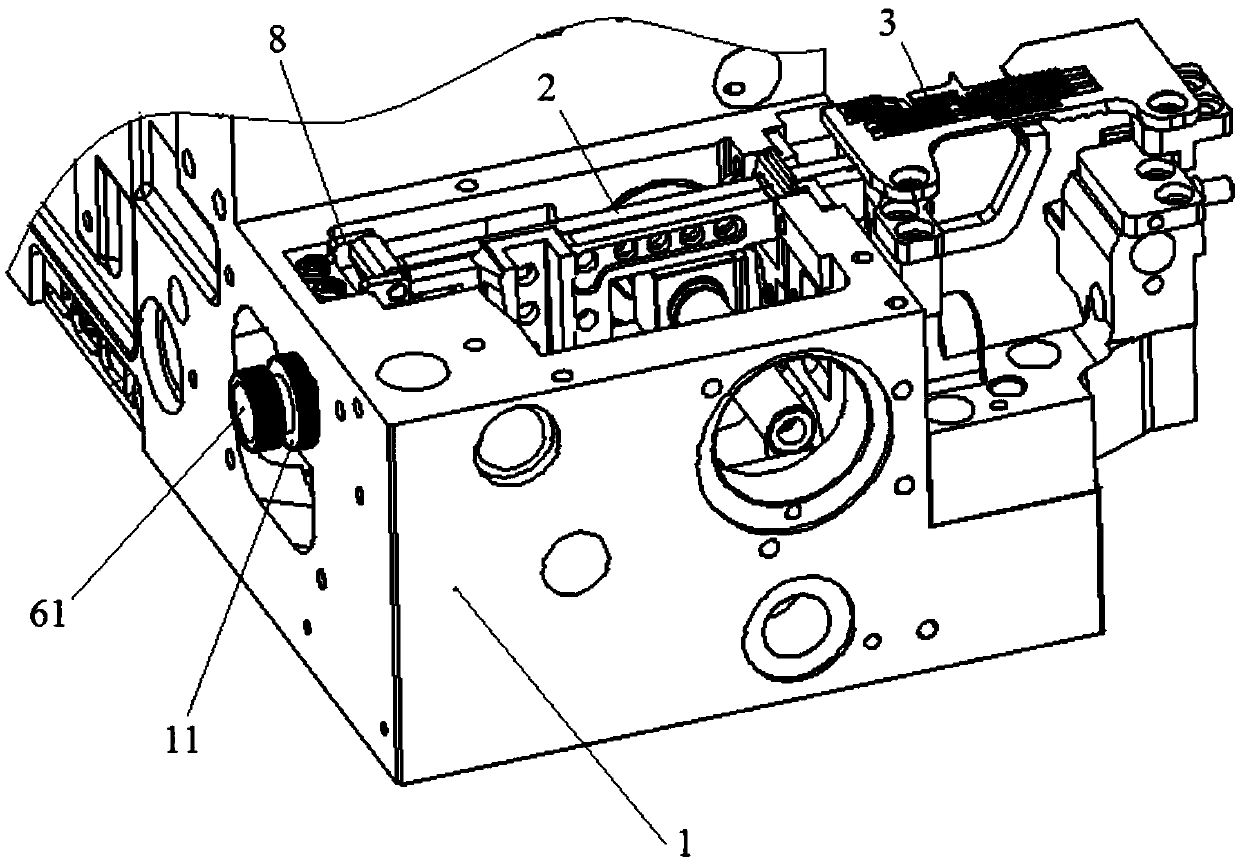

Feed dog inclination adjusting mechanism and sewing machine

ActiveCN109537181AEasy to operateWork-feeding meansSewing-machine control devicesEngineeringFeed dogs

The invention provides a feed dog inclination adjusting mechanism. The feed dog inclination adjusting mechanism comprises a feed dog holder, a feed dog mounted at one end of the feed dog holder, a slide block in sliding fit with the other end of the feed dog holder, and an eccentric shaft, and further comprises an adjusting shaft rotatably mounted inside a shell of the sewing machine, wherein theeccentric shaft comprises a first shaft part and a second shaft part which are in eccentric arrangement; the first shaft part is rotatably inserted into the slide block; a rotating operation part positioned outside the shell is arranged at one end of the adjusting shaft; the other end of the adjusting shaft is connected with the second shaft part of the eccentric shaft through a transmission assembly; when the rotating operation part of the adjusting shaft is rotated, the adjusting shaft drives the second shaft part of the eccentric shaft to rotate through the transmission assembly. In the feed dog inclination adjusting mechanism, through the rotation of the rotating operation part of the adjusting shaft, the eccentric shaft can be driven to rotate so as to adjust the inclination of the feed dog; the rotating operation part of the adjusting shaft is positioned outside the shell, so that during operation, the operation of opening a sewing table, unscrewing fixing bolts and the like is not required and only direct rotation of the rotating operation part is required, and the operation is very convenient, fast and efficient.

Owner:JACK SEWING MASCH CO LTD

Automated feeding mechanism for sewing machine

Owner:TACHI S CO LTD

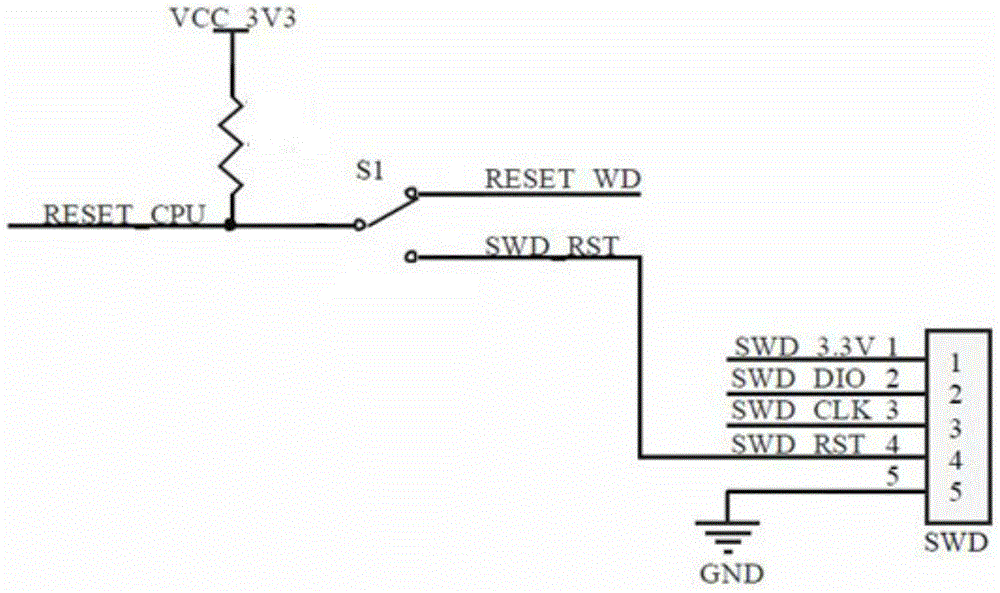

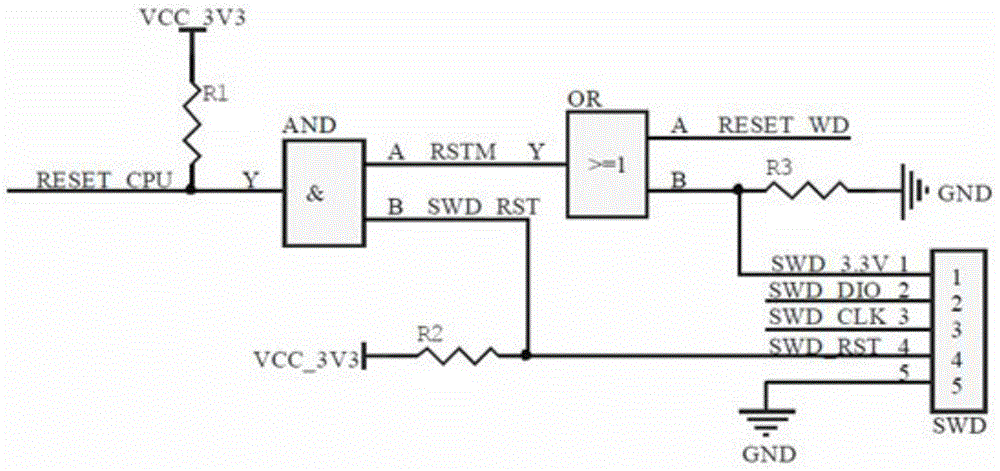

Jumper-free circuit for program running and JTAG program downloading

ActiveCN105224372ASave download timeSave debugging timeFault responseProgram loading/initiatingEngineeringJoint Test Action Group

The invention provides a jumper-free circuit for program running and JTAG program downloading. The jumper-free circuit comprises a CPU, a watchdog chip and a JTAG writer, wherein the CPU outputs a feeding-dog signal to the watchdog chip; a first signal RSTM is output by a watchdog reset signal RESET-WD output by the watchdog chip and a power supply signal SWD-3.3V of the JTAG writer through a 'or' logic; a second signal RESET-CPU is output by the first signal RSTM and a JTAG reset signal SWD-RST output by the JTAG writer through an 'and' logic; the signal is input into the CPU as a CPU reset signal; and the JTAG writer interacts with the CPU through data, clock and reset signals. The jumper-free circuit has the advantage that circuit switching devices such as a change-over switch and a dial switch are avoided, and is free of a jumper, high in reliability and low in cost; the JTAG program downloading and debugging time is greatly shortened; the area of a printed circuit board (PCB) is reduced; the production efficiency is improved; and meanwhile, the product running reliability is also increased.

Owner:INTEGRATED ELECTRONICS SYST LAB

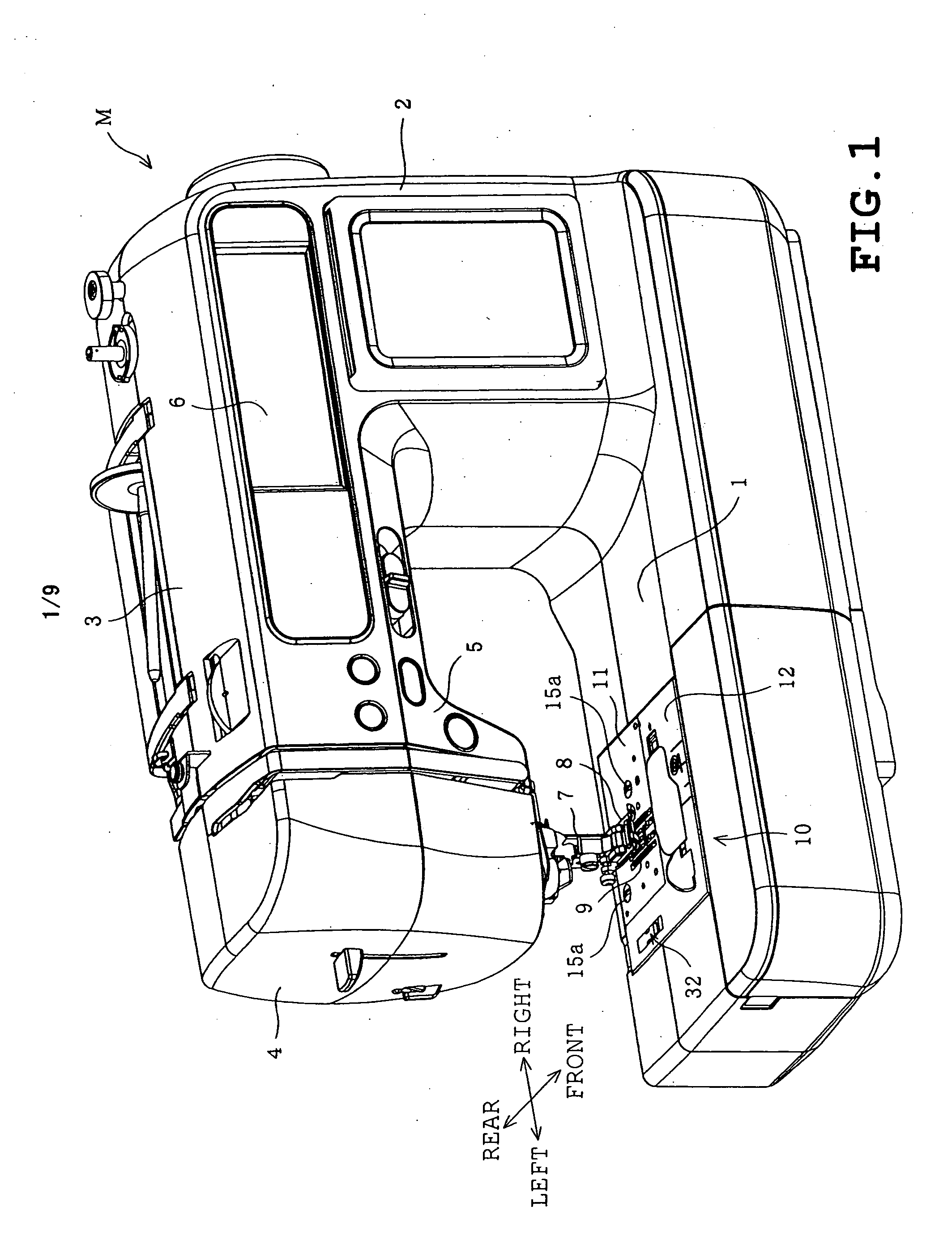

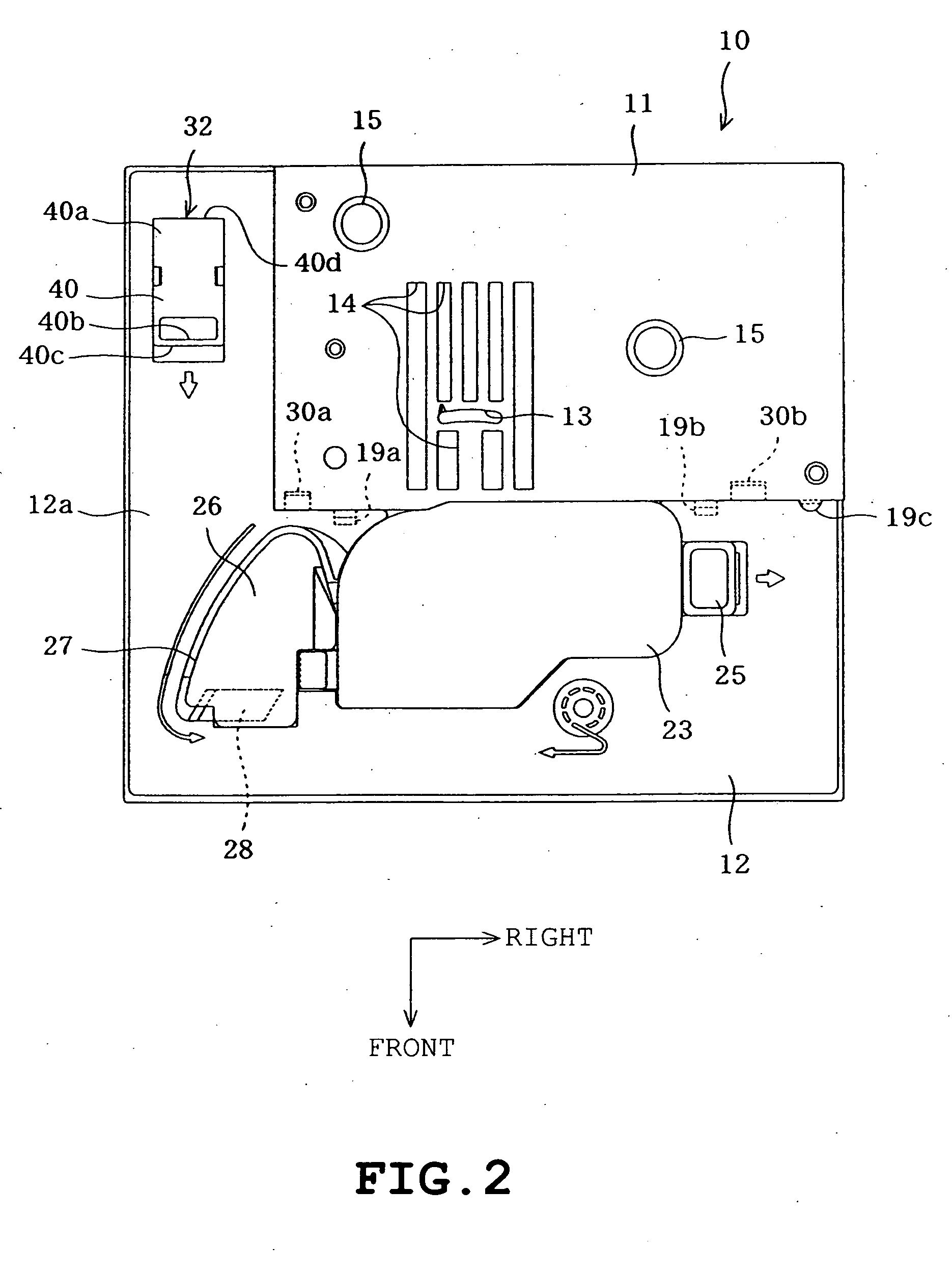

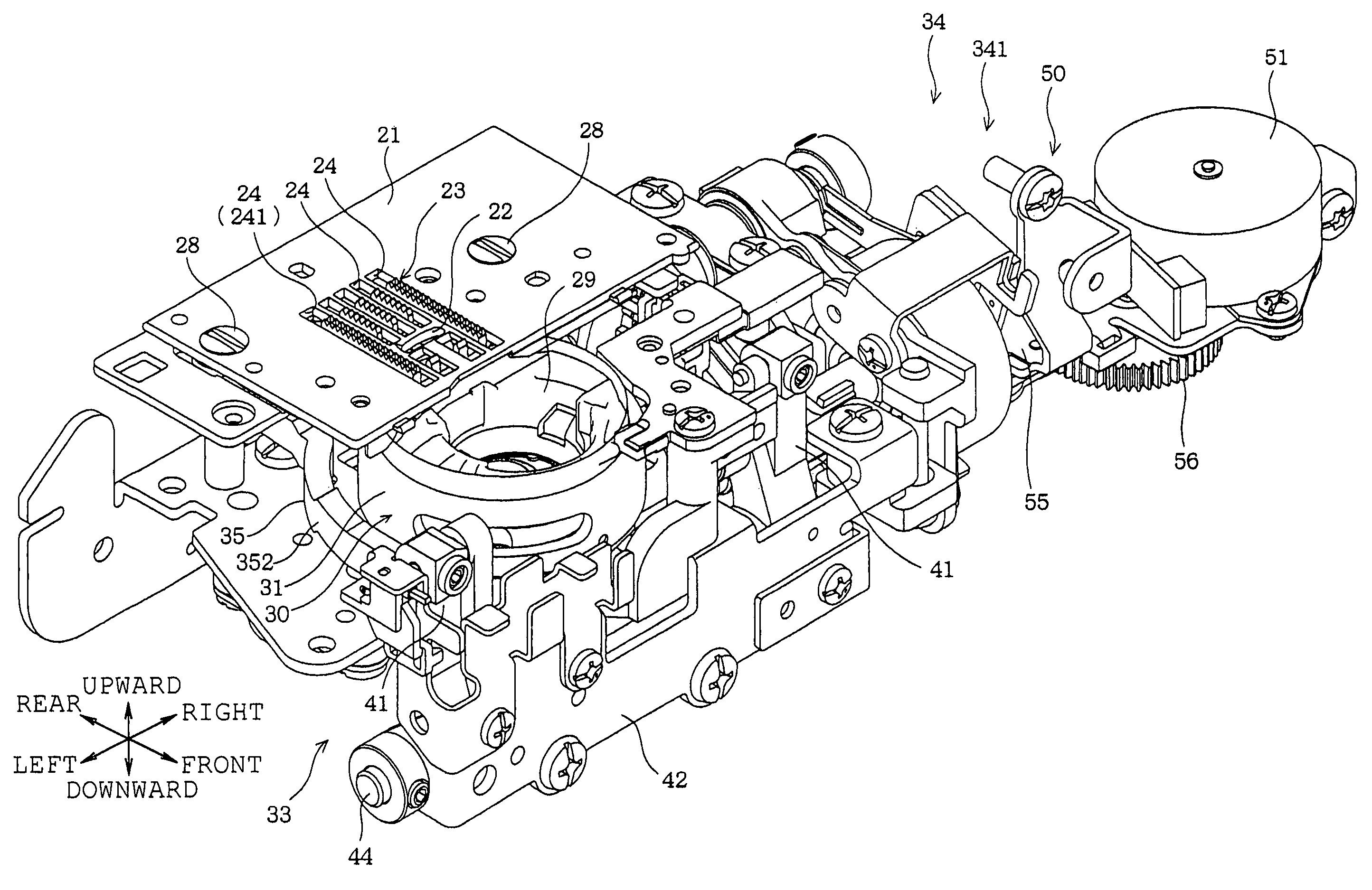

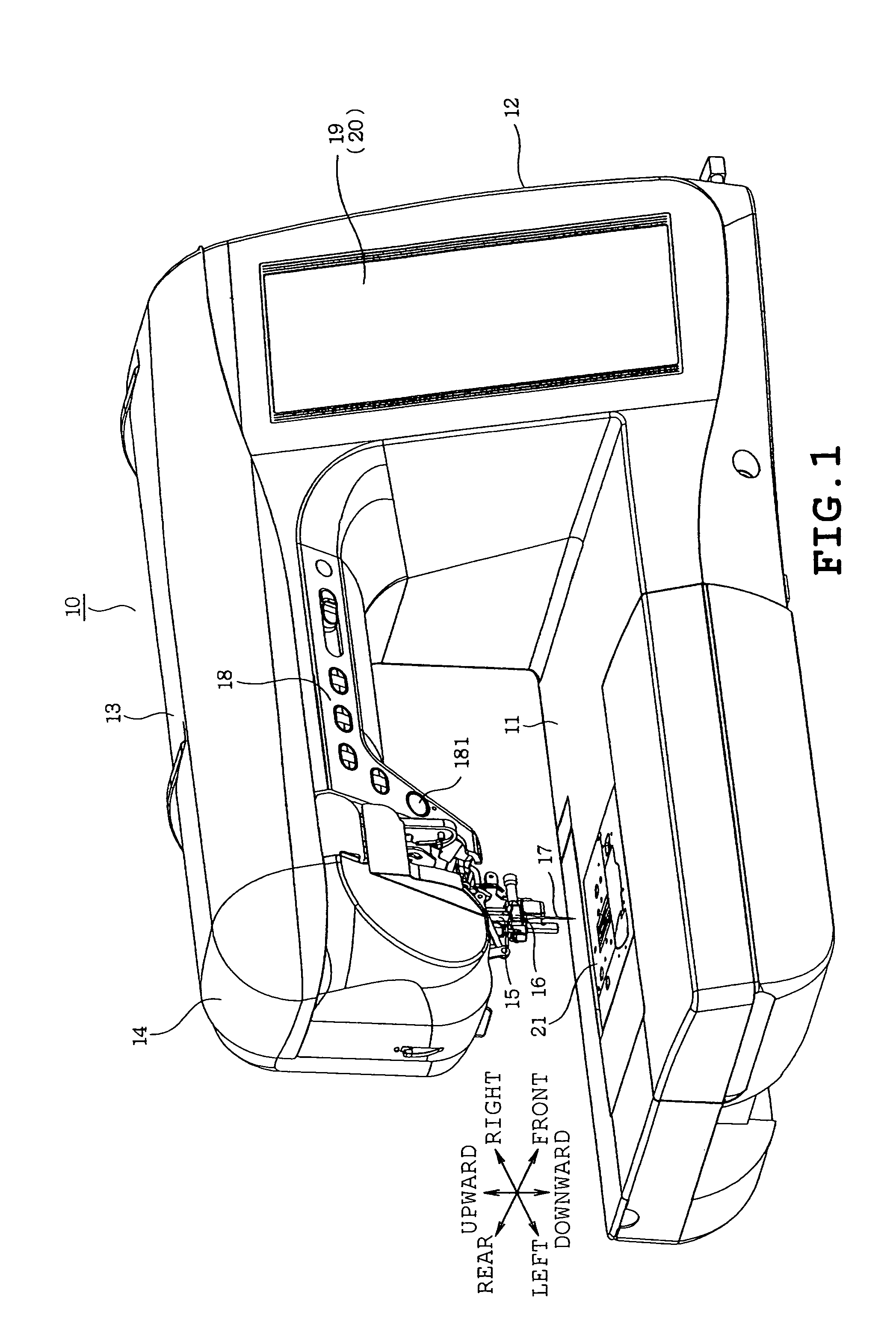

Sewing machine with detachable needle plate

InactiveUS8250999B2Simplify workAccurately determineSewing-machine casingsWork-feeding meansEngineeringFeed dogs

A sewing machine includes a feed dog which transfers workpiece cloth, a needle plate having a first hole through which a needle is passed and a second hole through which a feed dog is movable upward and downward, a bed to which the needle plate is detachably attachable, a feeding mechanism which drives the feed dog in a front-back direction and in an up-down direction, an engaged portion formed in the needle plate, an engaging portion formed in the feed dog or the feeding mechanism, and a switching unit which switches the feed dog or the feeding mechanism between a transfer position where the feed dog transfers the workpiece cloth and a needle plate adjusting position which differs from the transfer position and where the engaging and engaged portions are engaged with each other thereby to determine a fixing point of the needle plate on the bed.

Owner:BROTHER KOGYO KK

Zero thread ring holder for chain type stitch sewing machine

InactiveCN1392300AFit closelyImprove efficiencySewing-machine casingsWork-feeding meansReciprocating motionEngineering

An empty chain locking member is mounted on a chain stitch sewing machine comprising a needle for penetrating through a cloth on a throat plate to be vertically moved interlockingly with a main spindle of the sewing machine, thereby holding a needle thread, a cloth presser mounted on the throat plate and serving to press the cloth, a looper having a looper thread for reciprocating in such a direction as to cross a cloth feeding direction below the throat plate interlockingly with the main spindle of the sewing machine, a main feed dog for feeding a loop formed by the needle thread and the looper thread in cooperation of the needle and the looper rearward in the cloth feeding direction, and a loop engagement member for protruding from an upper surface of the throat plate and engaging the loop with the cloth presser when the main feed dog is descending from the upper surface of the throat plate. The present invention aims to facilitating setting of cloth between a cloth presser and a throat plate and to surely form an empty chain.

Owner:JUKI CORP

Cloth feed mechanism for sewing machine

InactiveCN103710890ACloth feeding is smooth and continuousImprove feeding qualityWork-feeding meansEngineeringFeed dogs

The invention relates to the technical field of mechanisms of sewing machines, in particular to a cloth feed mechanism of a sewing machine. The cloth feed mechanism of the sewing machine aims to solve the problems that potential safety hazard exists, cost is high and working efficiency is low in the prior art. The cloth feed mechanism for the sewing machine comprises a cloth feed shaft, a feed lifting rock shaft, a cloth feed crank, a feed frame, a second frame, a first cloth feed dog and a second cloth feed dog, wherein the cloth feed crank is provided with double-end drive ends which are perpendicularly and symmetrically arranged by 180 degrees. The cloth feed mechanism of the sewing machine is characterized by further comprising a feed lifting rock shaft crank, the cloth feed shaft and the cloth feed crank connected with the cloth feed shaft are located at the front portion in the cloth feed direction, the feed lifting rock shaft is a swinging shaft and located at the rear portion in the cloth feed direction, the feed lifting rock shaft crank is of a double-crank structure arranged in the cloth feed direction by 180 degrees, the middle of the feed lifting rock shaft crank is connected with the feed lifting rock shaft, the end of the first feed frame is connected with the crank structure at the front portion through a first feed lifting connection rod, and the end of the second feed frame is connected with the crank structure at the rear portion through a second feed lifting connection rod.

Owner:XIAN TYPICAL IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com