Zero thread ring holder for chain type stitch sewing machine

A technology of holding device and chain stitch, which is applied in the sewing machine to cut off the thread mechanism, sewing machine components, sewing machine housing, etc., which can solve the problems of unstable continuous empty thread loop, low efficiency of sewing operation, and deterioration of fabric positioning and other problems, to achieve stable and continuous formation, good packing performance, and good packing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Refer to the following Figure 1 to Figure 6 Examples of the present invention will be described.

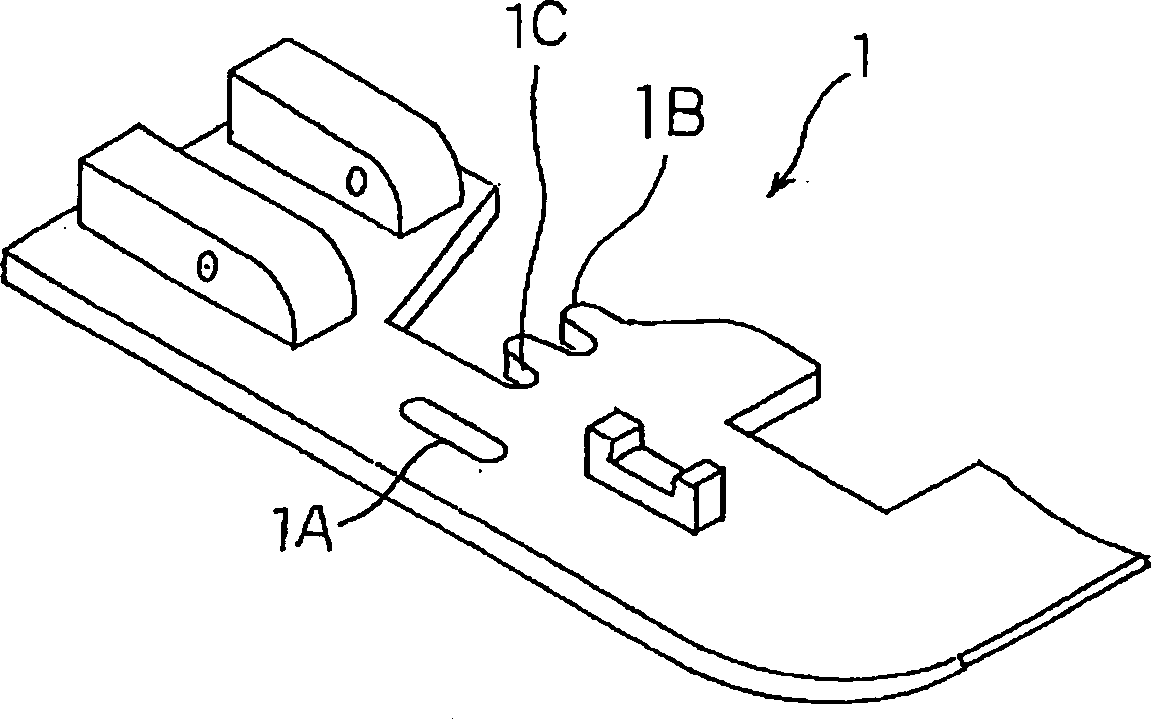

[0034] figure 1 It is a perspective view of the presser foot 1, which has a long needle hole 1A along the cloth feeding direction and a needle hole 1C with two sliding thread pieces 1B as well known.

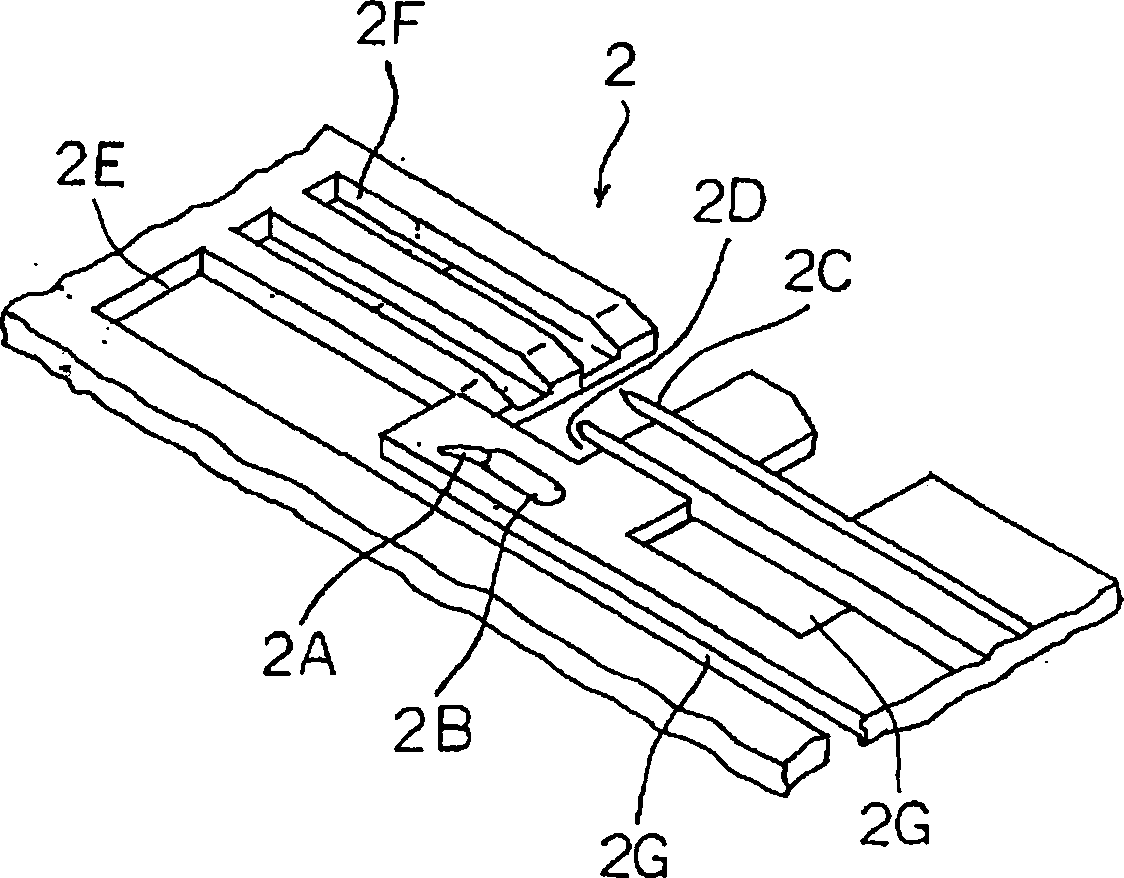

[0035] figure 2 is a perspective view of the needle plate 2 on which the corresponding figure 1 The needle hole 1A is formed with a needle hole 2B whose length is along the cloth feeding direction and has an empty thread loop guide groove 2A in front of the cloth feeding direction.

[0036] In addition, on this needle plate 2, two thread slide pieces 2C and needle holes 2D corresponding to the two thread slide pieces 1B of the above-mentioned presser foot 1 are formed, and a needle hole 2C located in the needle hole 2C forming the empty thread loop guide groove 2A is formed. The wide main feed hole 2E in front of the feed direction and the narrow main feed hole 2F in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com