Patents

Literature

1269results about "Needle severing devices" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

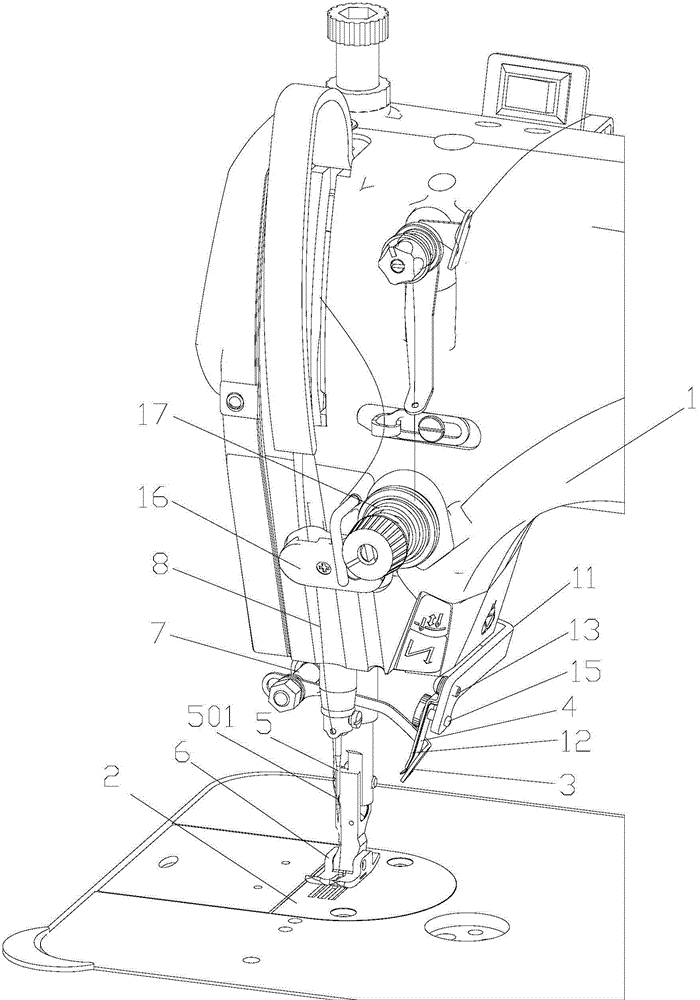

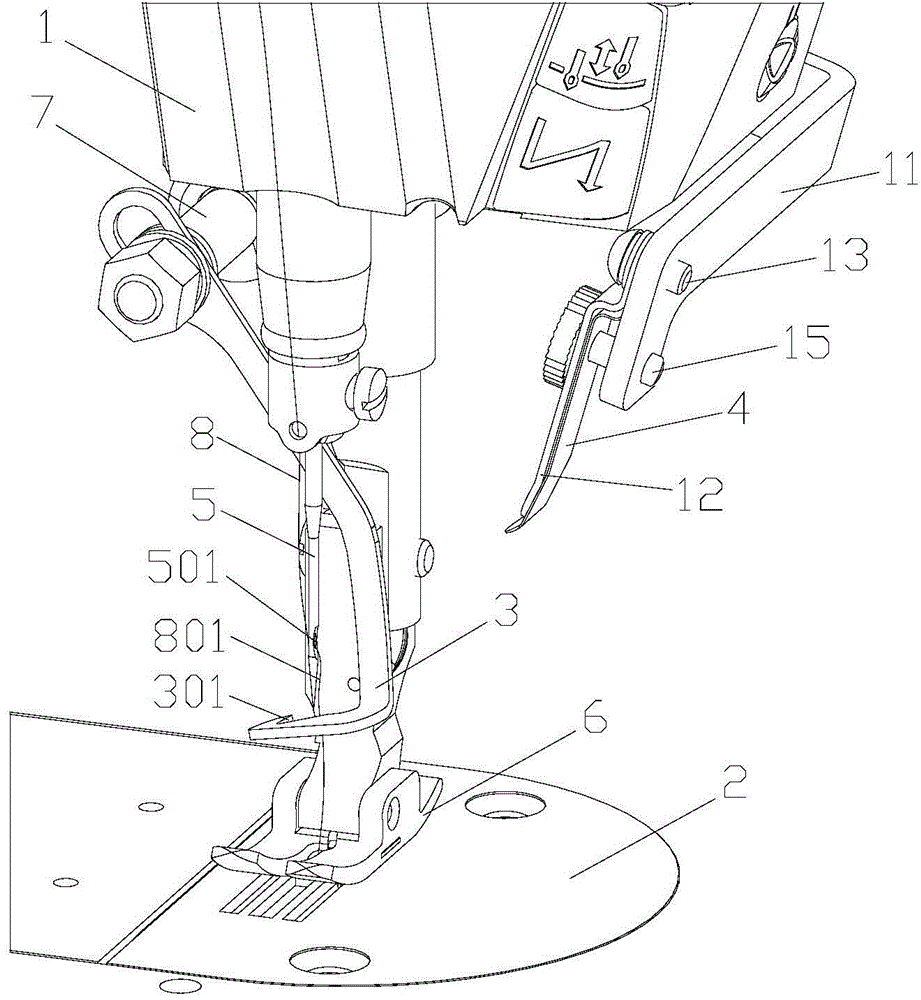

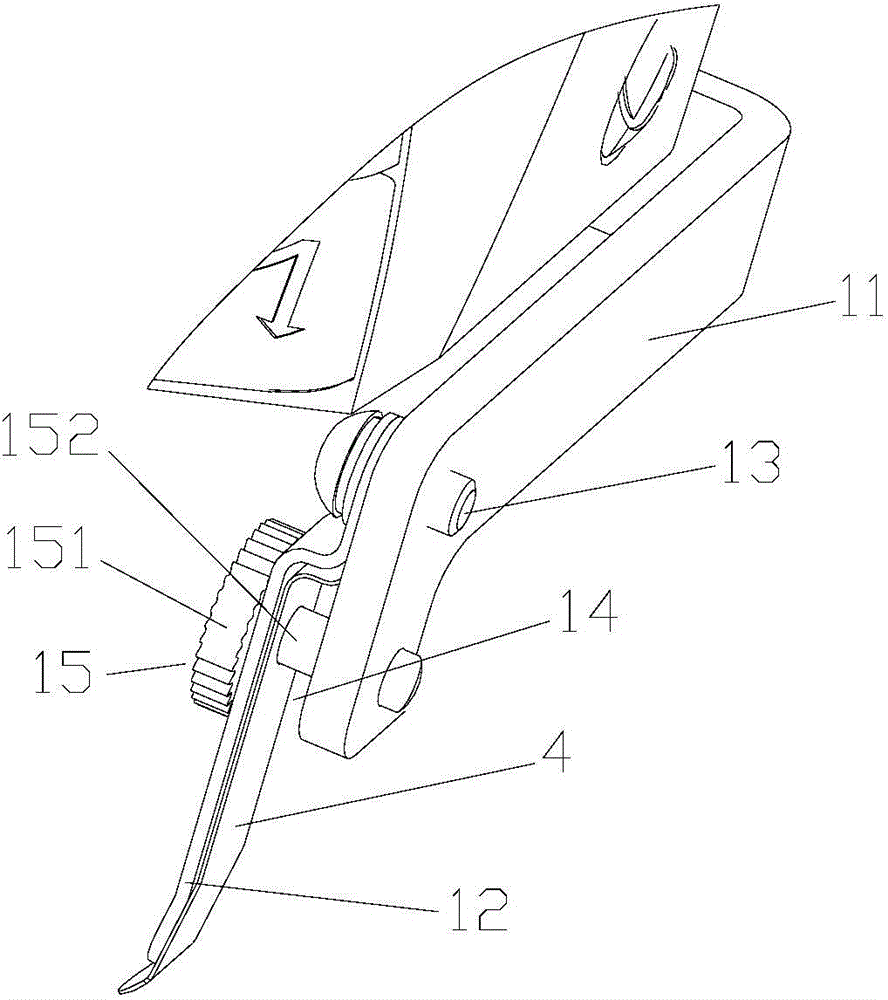

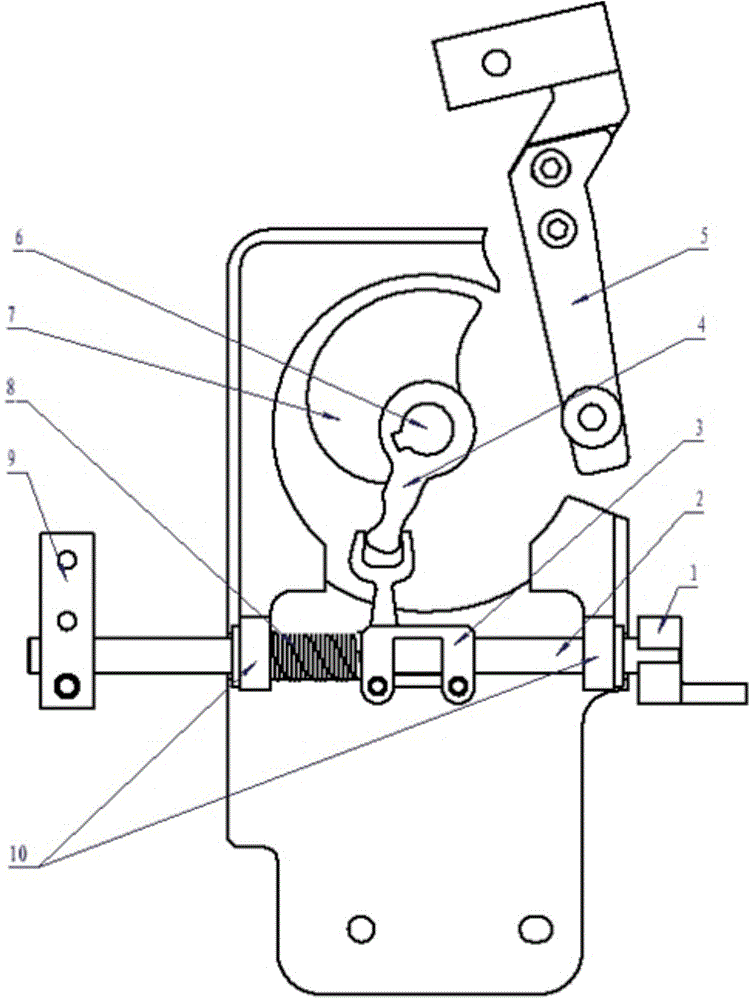

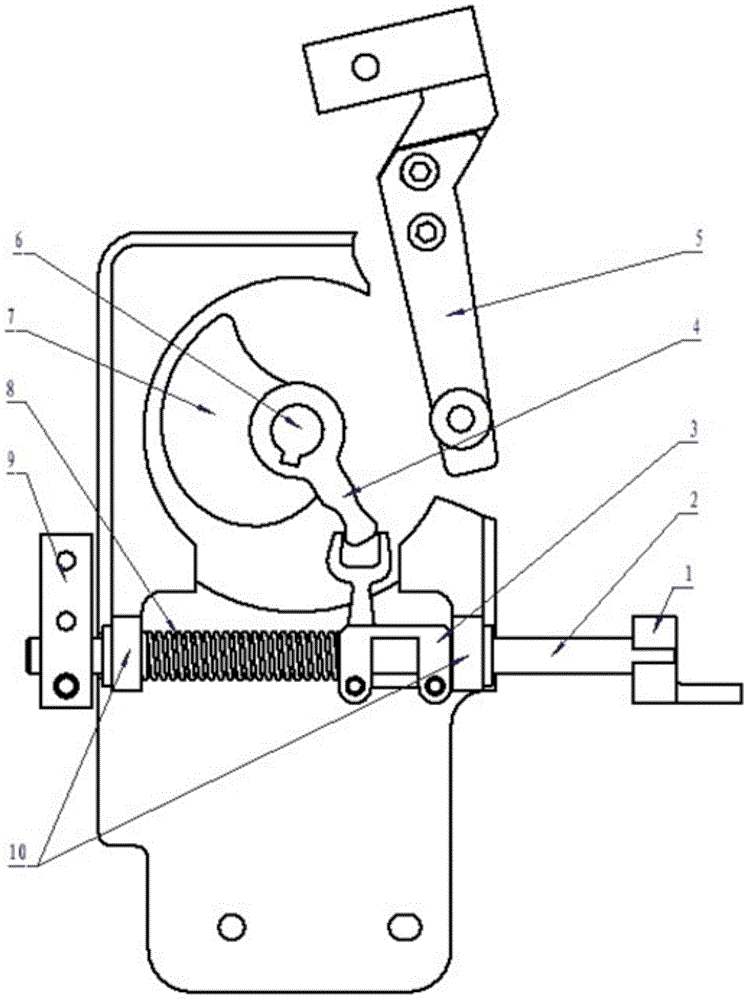

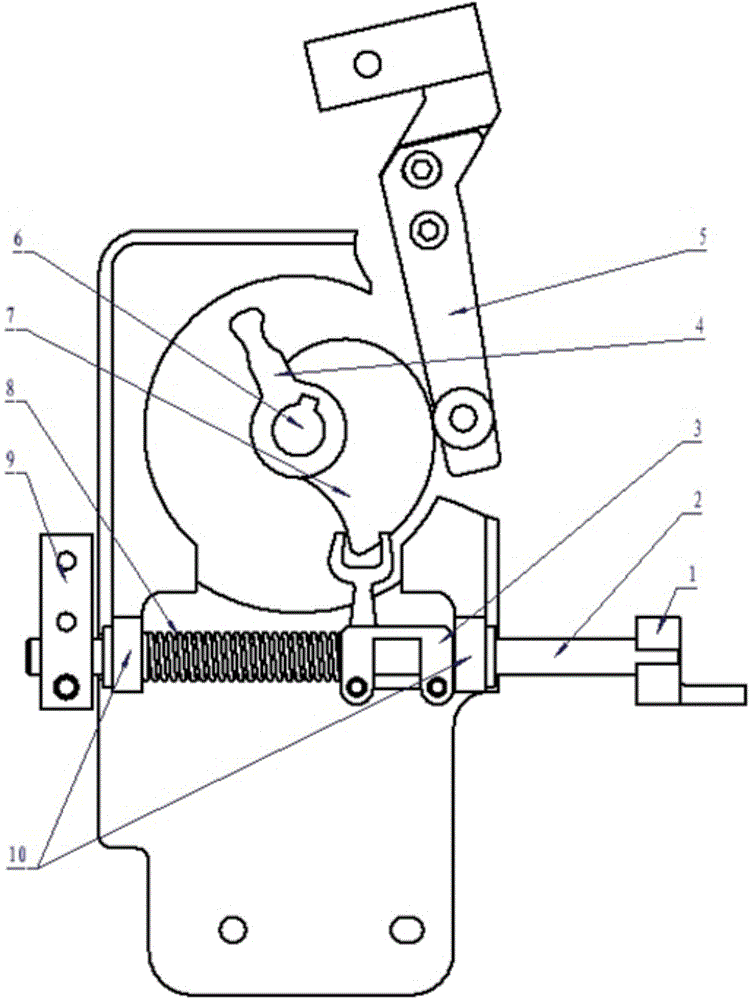

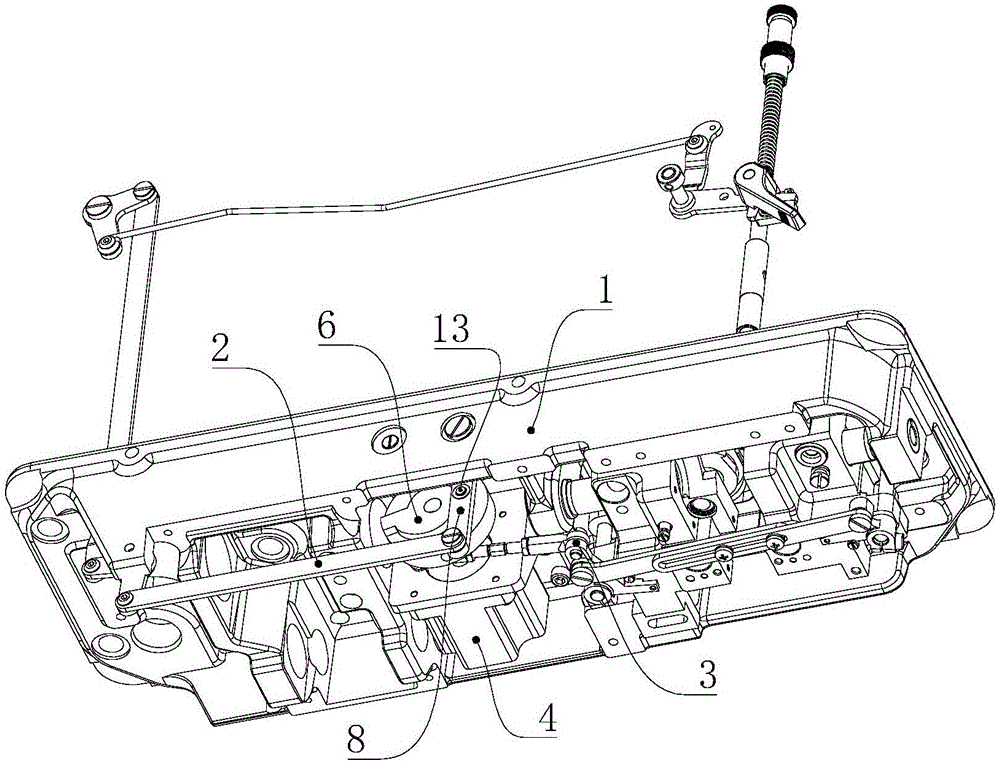

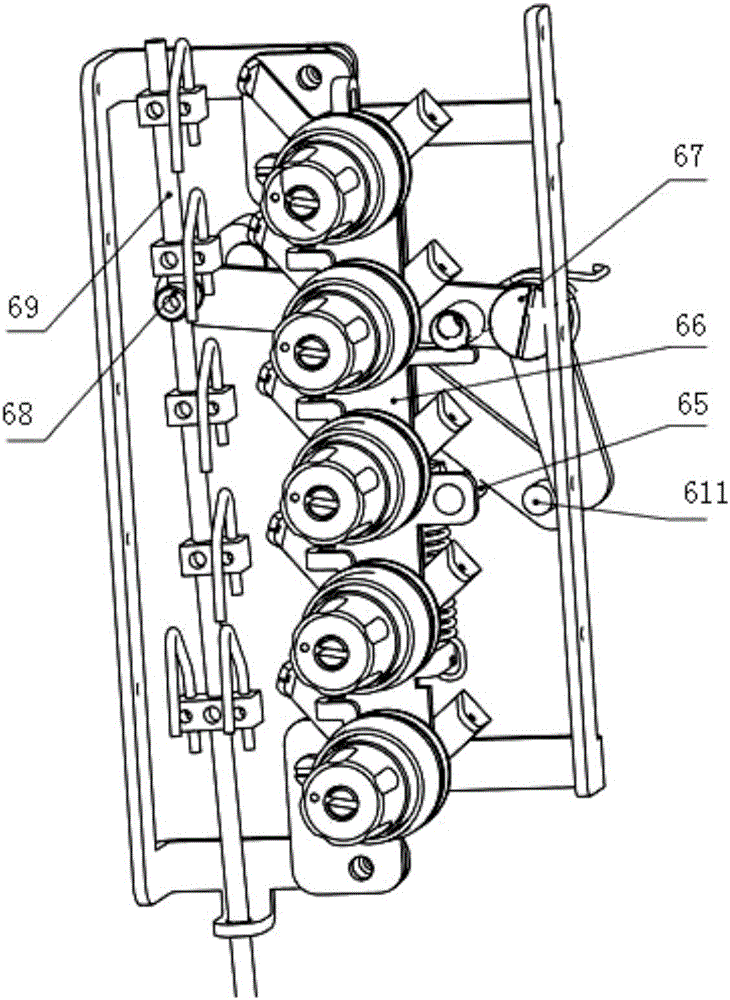

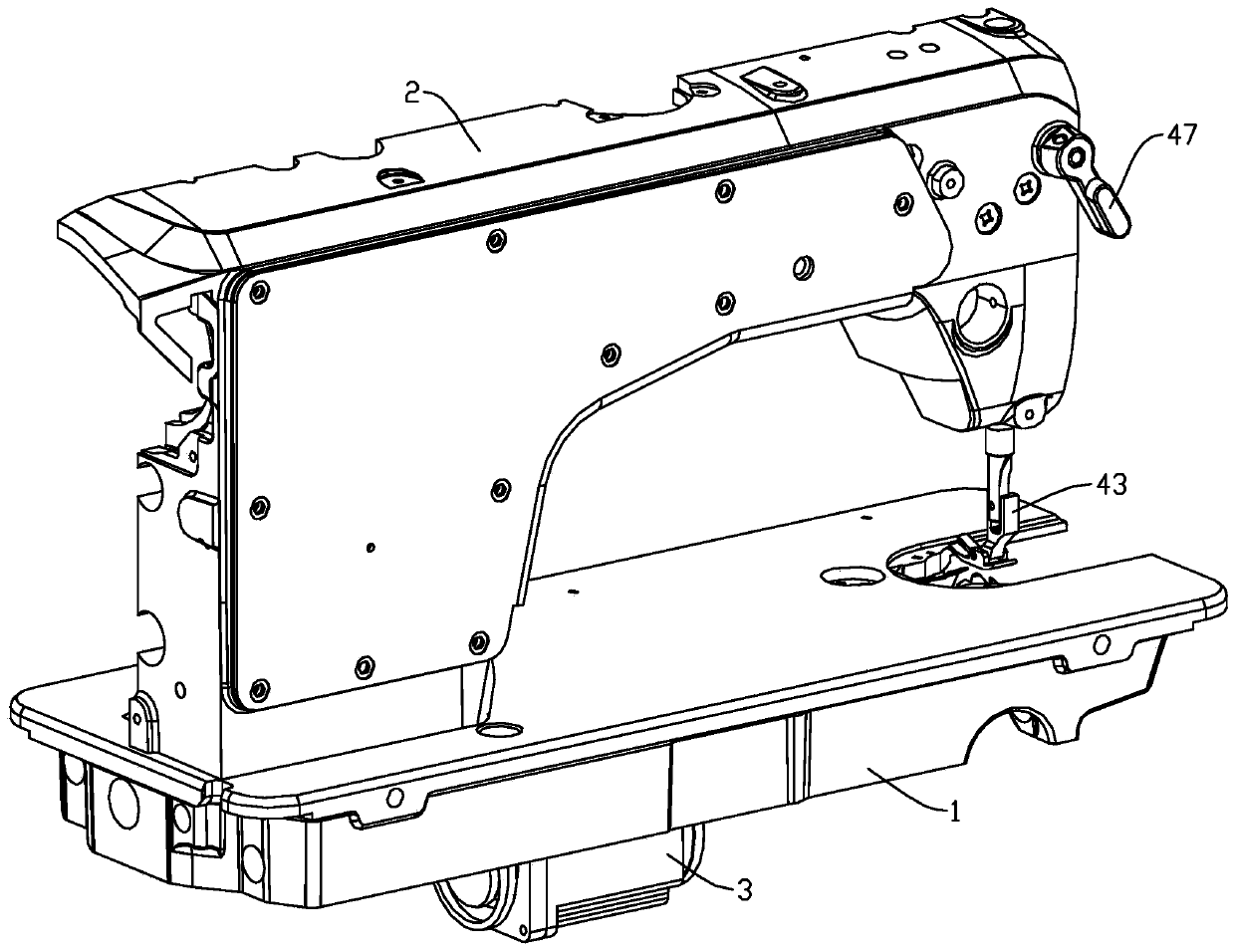

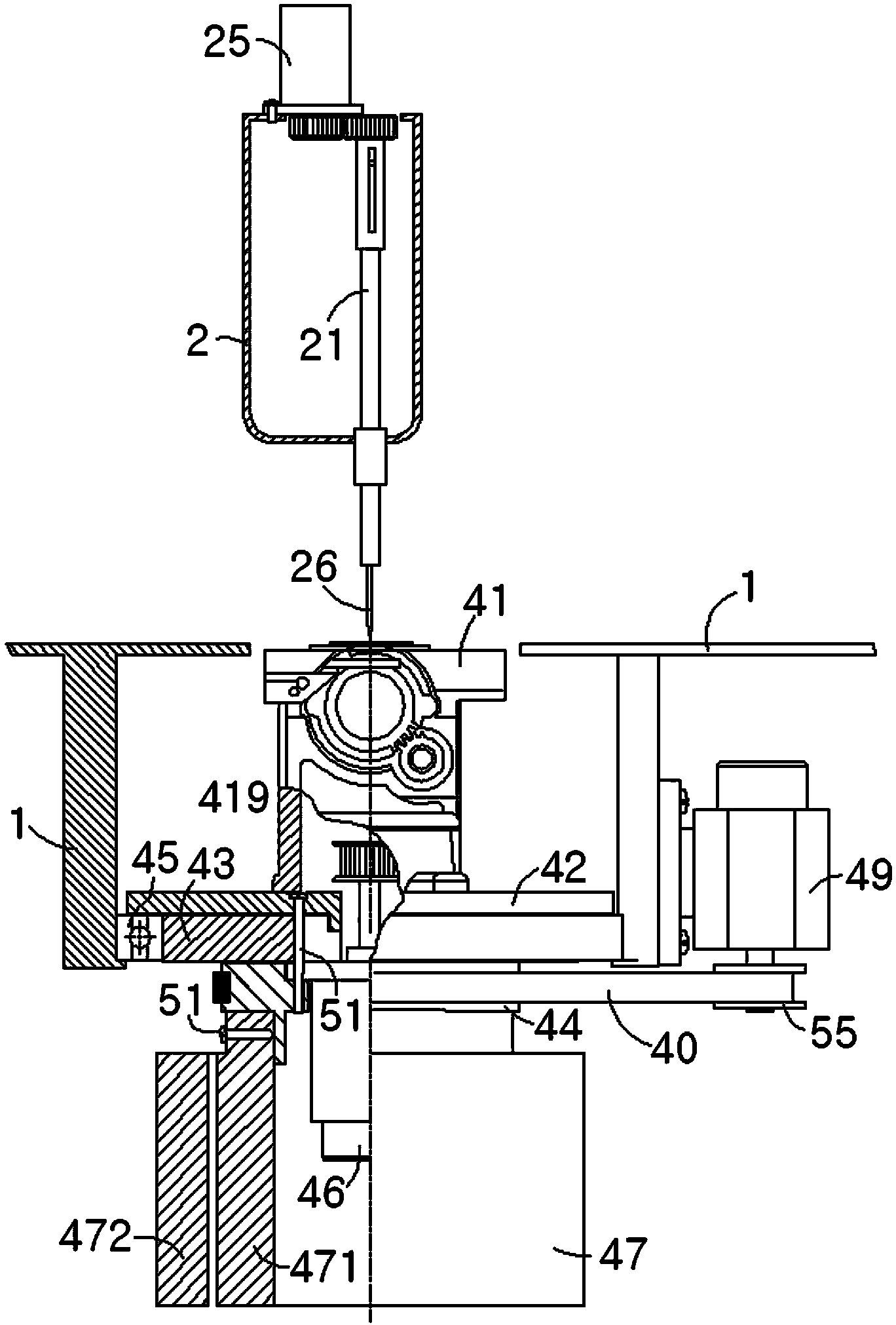

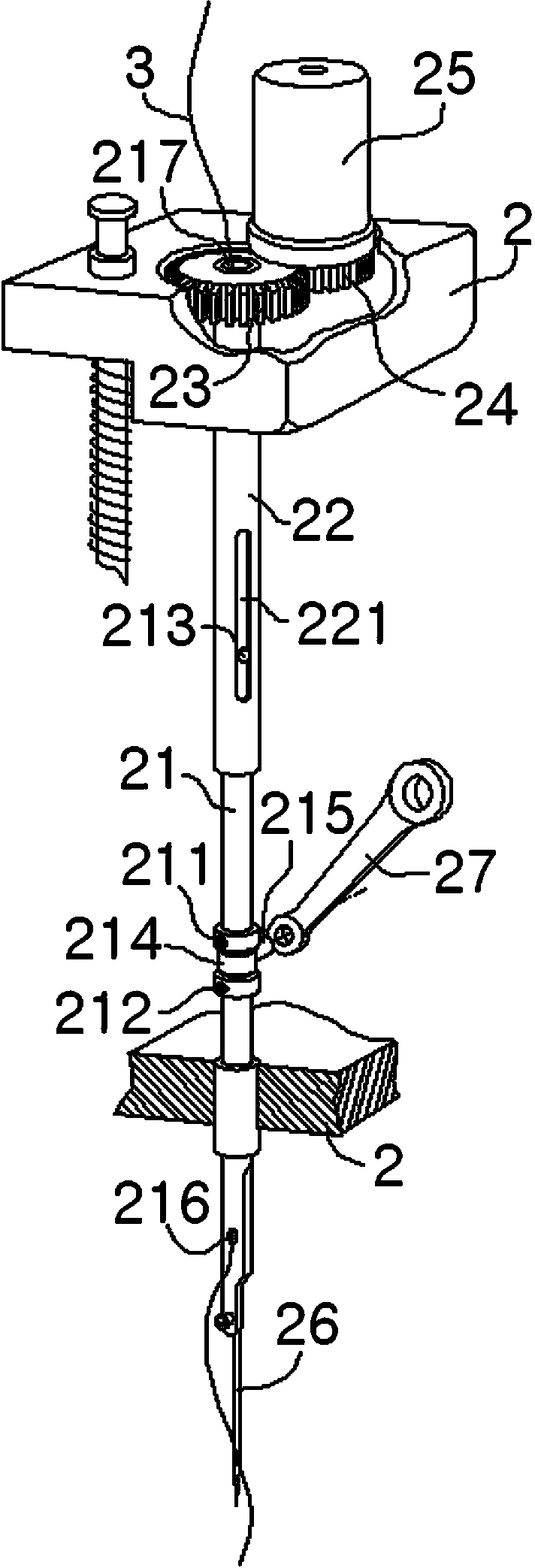

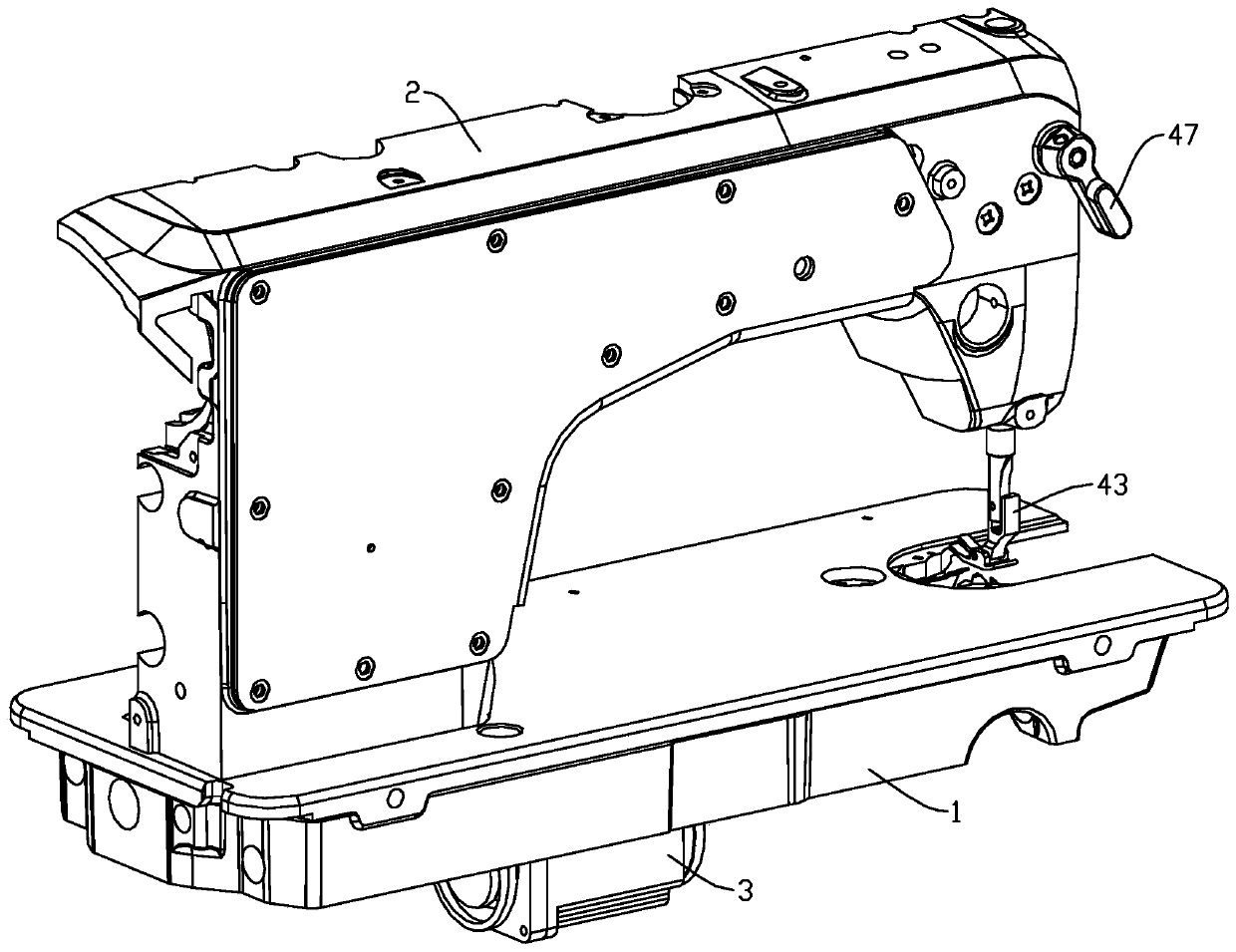

Bird nest removing device for sewing machine and using method thereof

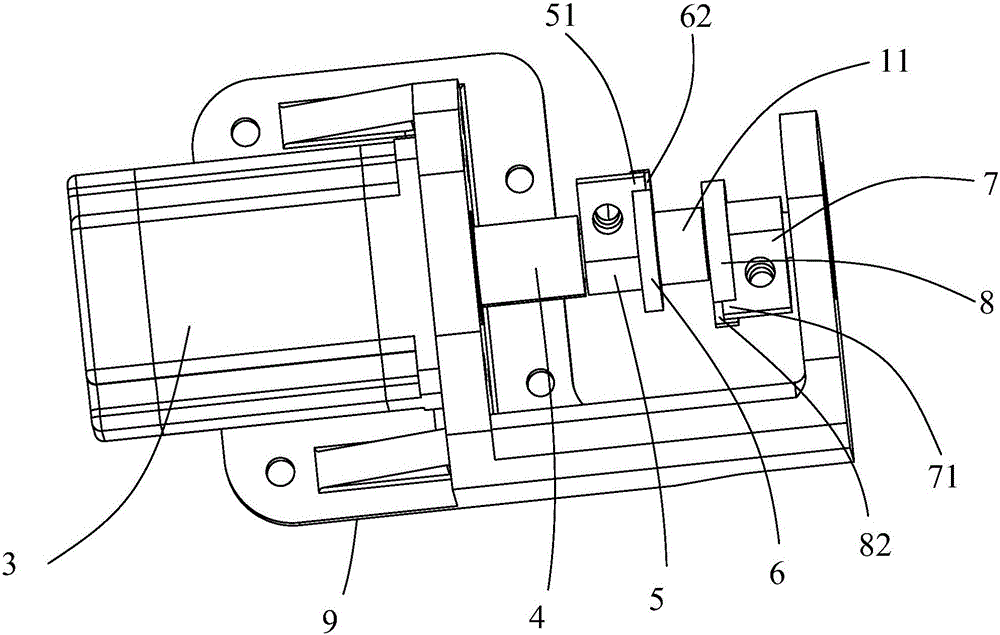

ActiveCN104911838AQuick tightenStable line amountNeedle severing devicesIndustrial engineeringSewing machine

The invention provides a bird nest removing device for a sewing machine and a using method thereof. The bird nest removing device comprises a pull hook, a thread clamping plate, a machine needle and a presser foot plate, wherein the pull hook, the thread clamping plate, the machine needle and the presser foot plate are located below a machine head. The drag hook is connected with the machine head through a rotating shaft, the machine needle is provided with a needle eye allowing threads to penetrate through, the presser foot plate is located on a needle plate, the presser foot plate is provided with a thread passing groove corresponding to the machine needle, the thread passing groove extends in the moving direction of a sewing material, and a thread cutter is arranged at the bottom of the thread passing groove. According to the bird nest removing device for the sewing machine and the using method thereof, an arc swing hook thread clamping device is used for clamping machine needle thread residues after thread trimming, the enough stable thread quantity is provided for starting sewing through thread clamping and loosening time coordination of two thread clamp holders in the seam starting process next time, seam starting upper threads can be tightened quickly under the condition that bottom threads do not exist, the clamped thread residues are cut off at the position close to the sewing material needle hole, the remaining thread residues are short, and the problem of bird nest thread residues is solved thoroughly.

Owner:JACK SEWING MASCH CO LTD

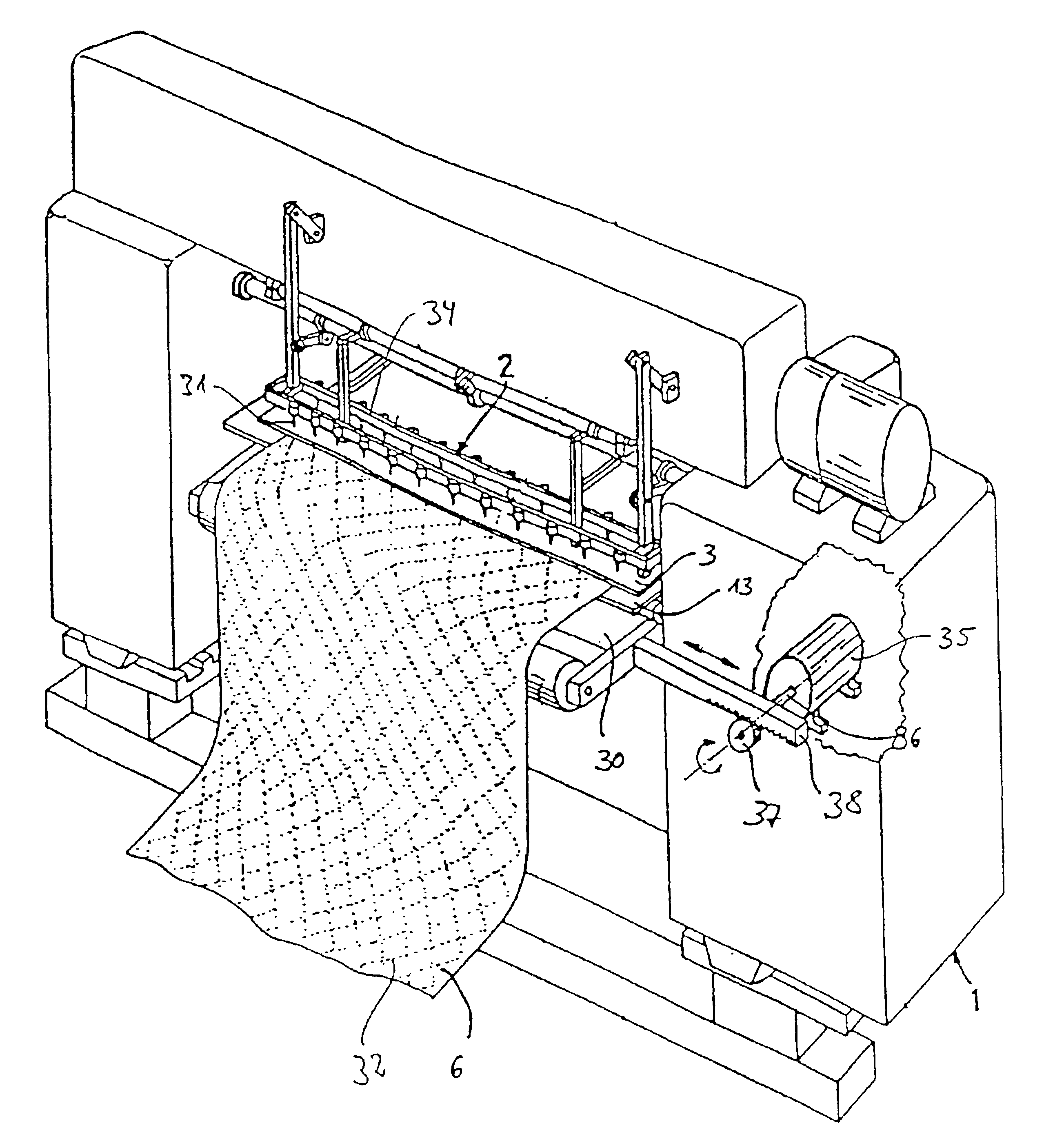

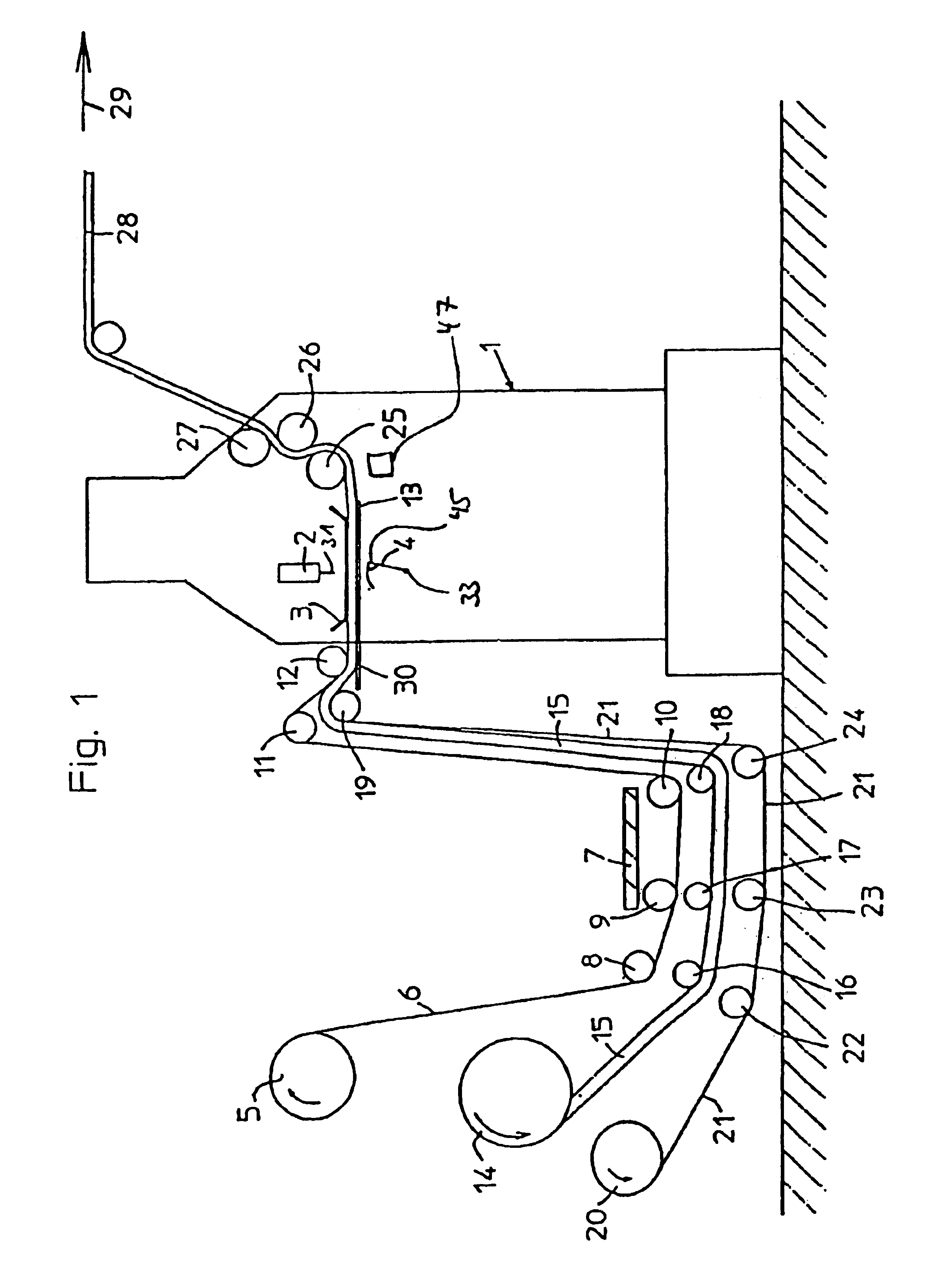

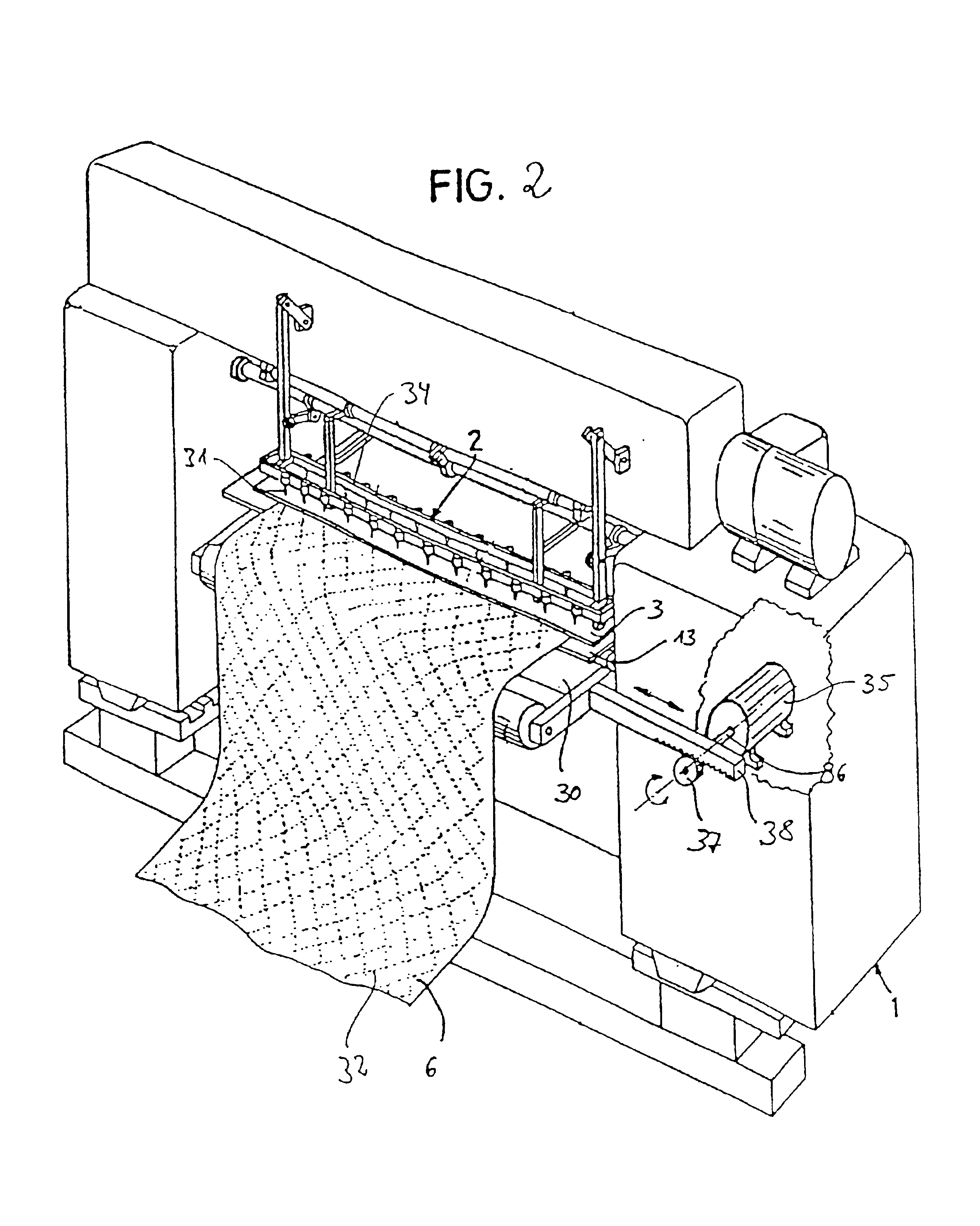

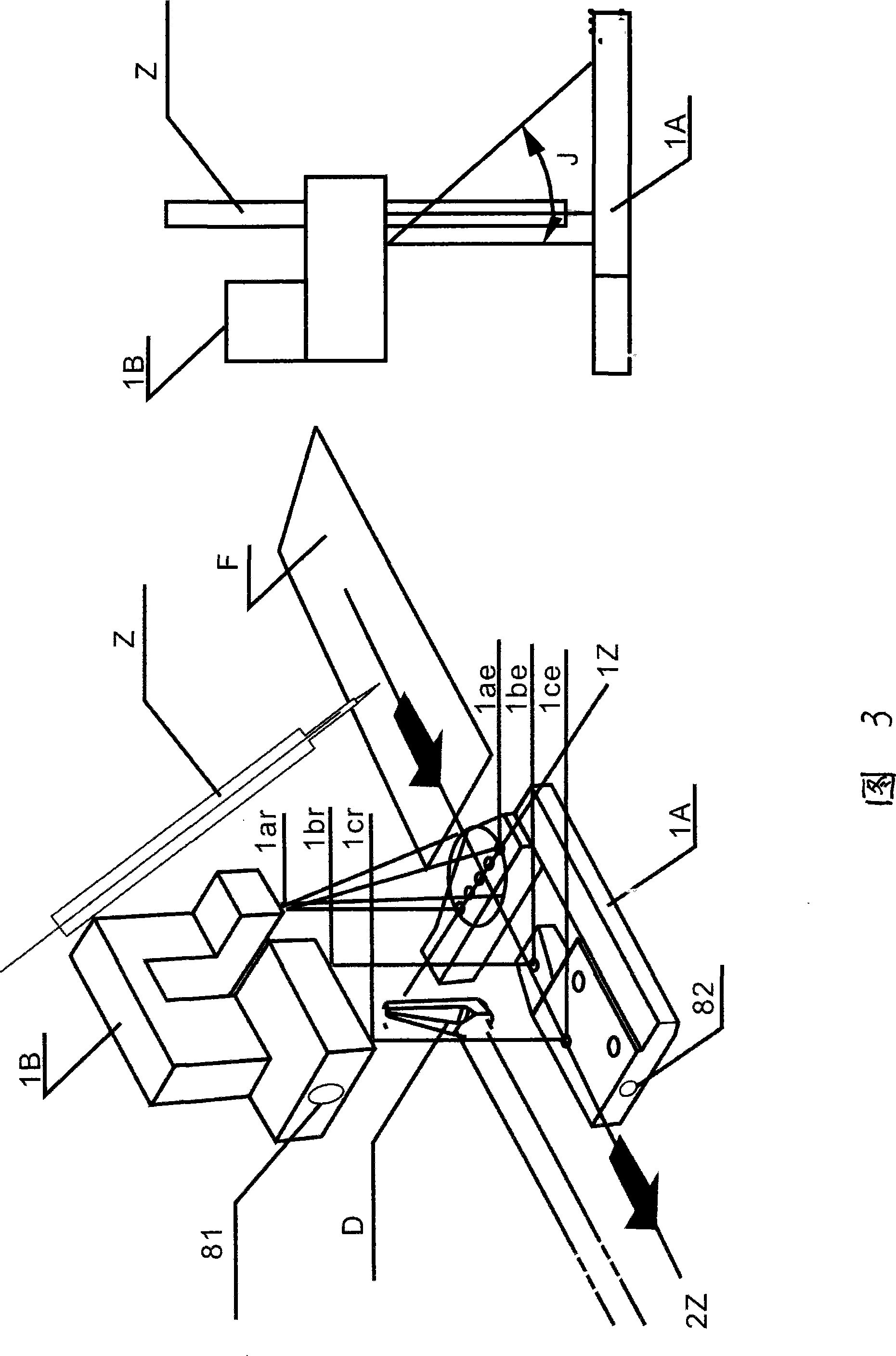

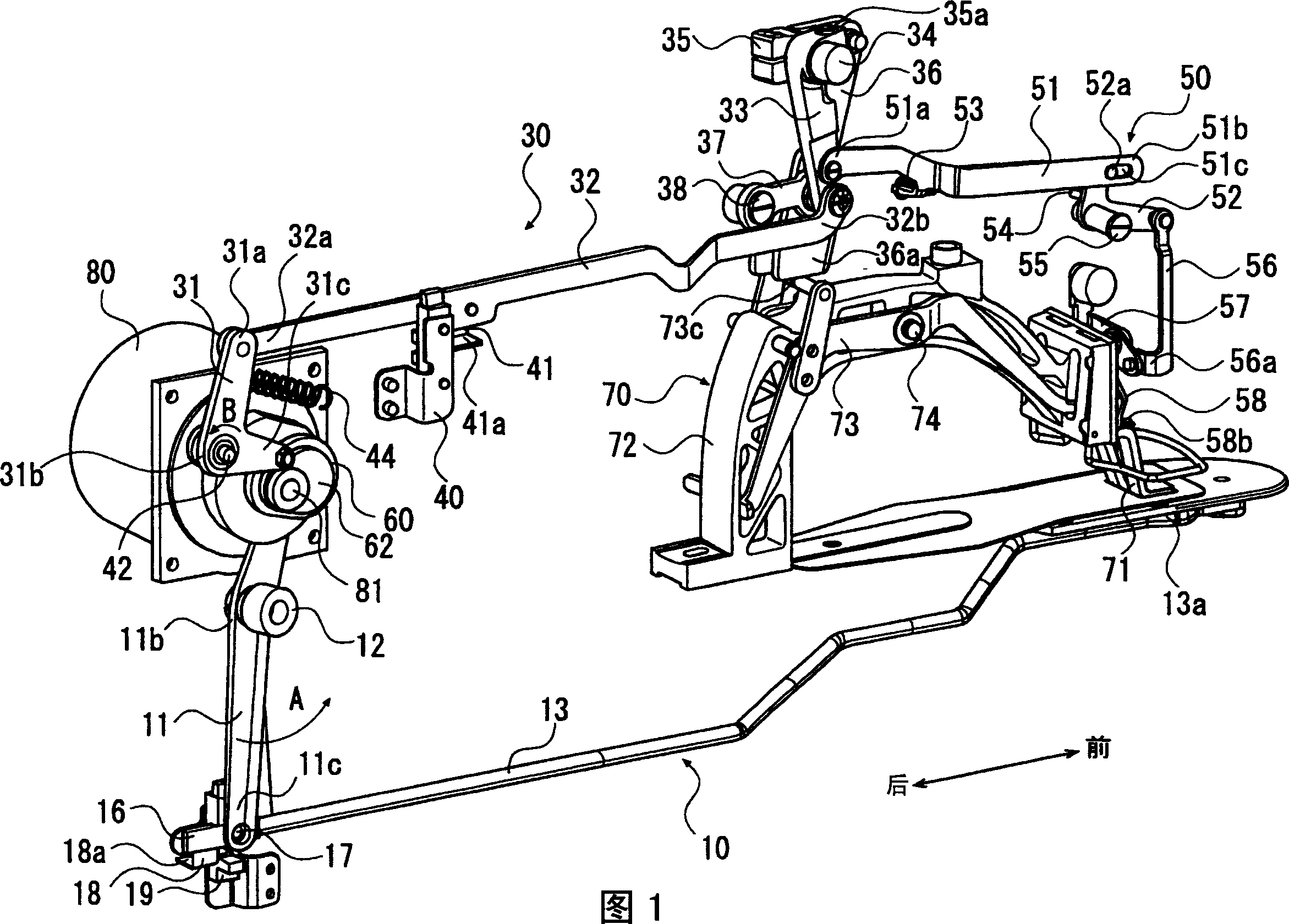

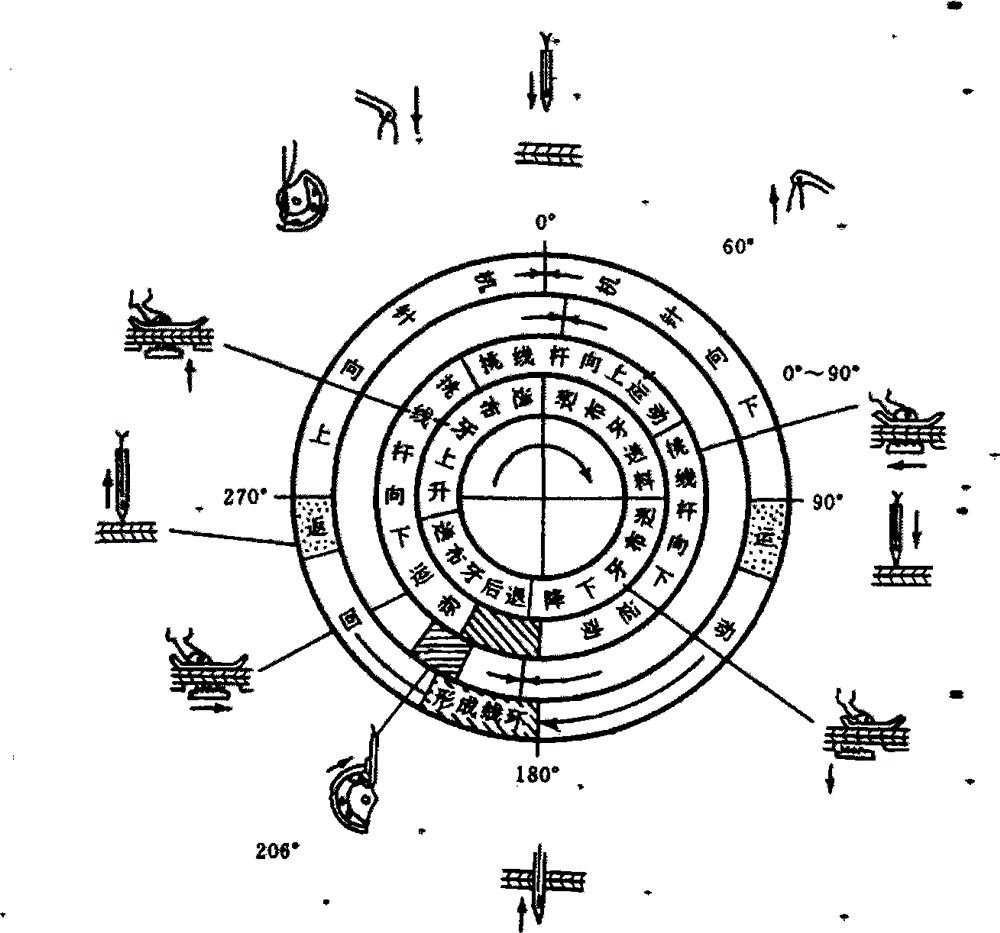

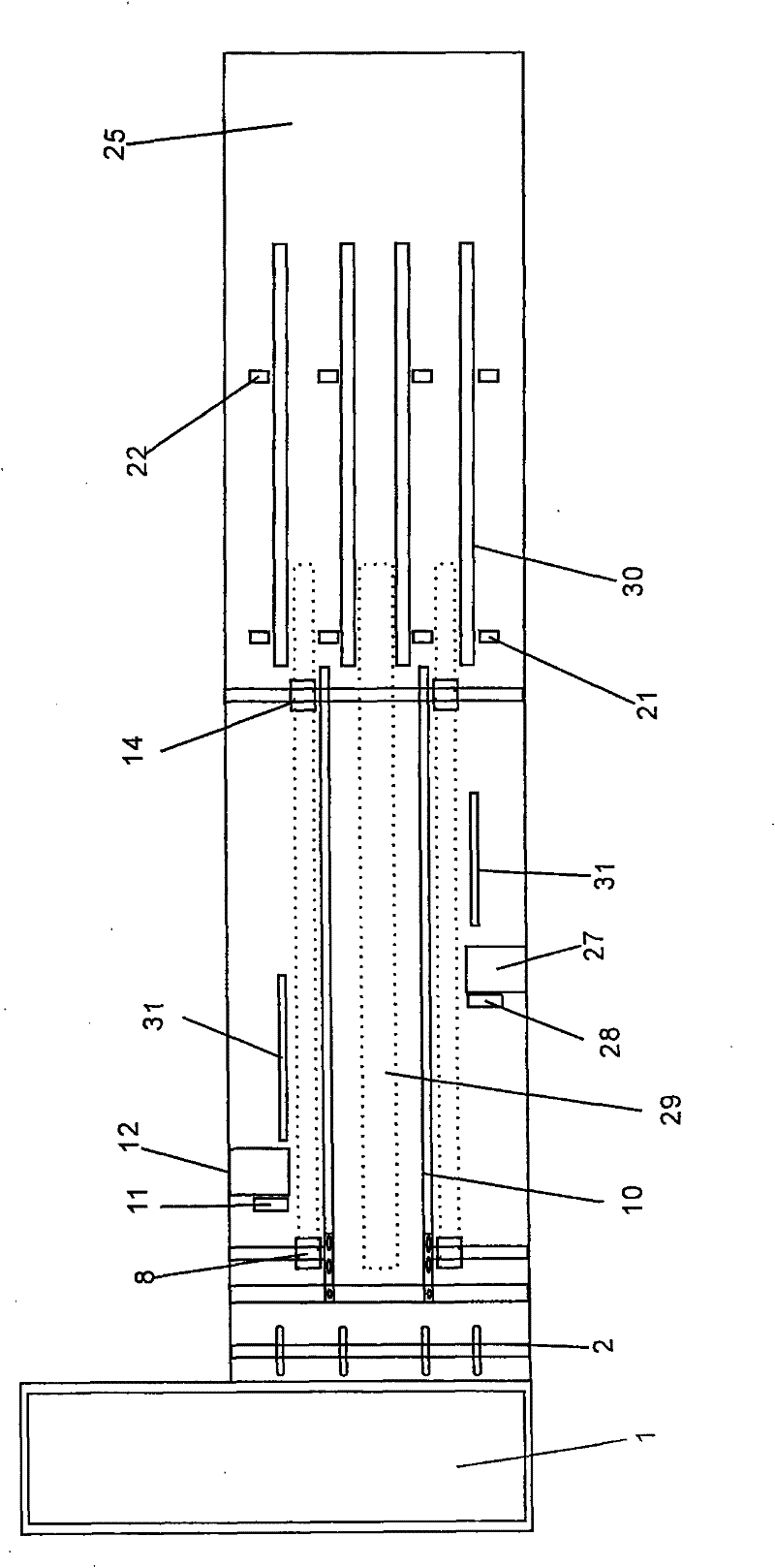

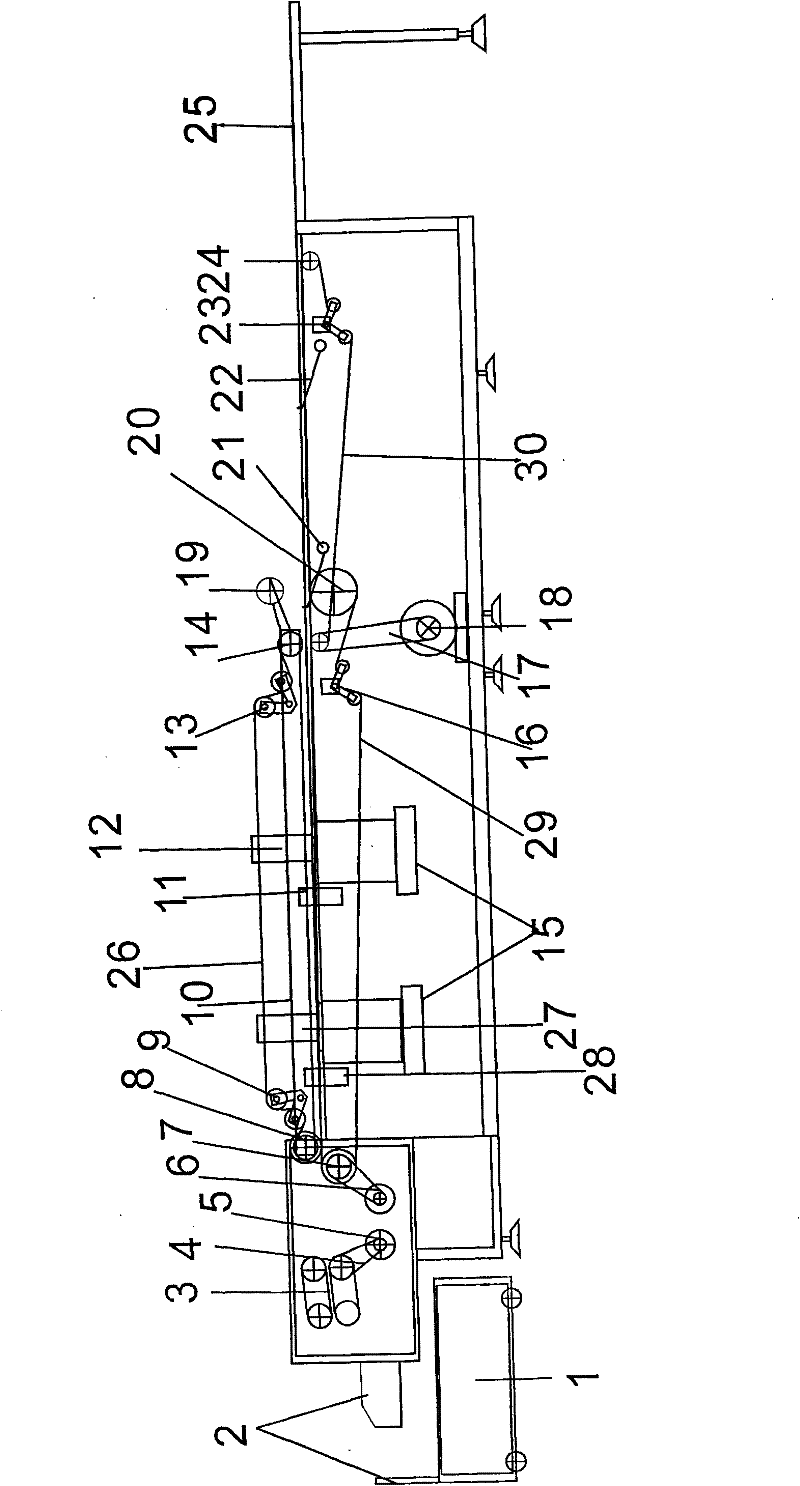

Chain stitch multi-needle quilting machine and method to create a pattern in a quilting material

InactiveUS6895878B2Cut shortAvoid insufficient lengthWork-feeding meansNeedle severing devicesEngineeringBiomedical engineering

The invention relates to a chain stitch multi-needle guilting machine with stitch-forming quilting elements and a method for creating a pattern in a guilting material. The elements of the quilting machine are comprised of at least one needle bar with attached needles and at least one looper shaft with attached loopers. Each of the needles and the loopers have a corresponding needle thread and looper thread associated therewith, form quilting element pairs, and are driven to build chain stitches in a quilting material. At least one of the needles is adjustable between two positions and participates in the quilting procedure in a first position and does not prick into the quilting material in the second position during the quilting procedure. The quilting machine can be made to have a device to knot the needle thread with the looper thread, or a device to cut the looper thread, or both.

Owner:NAHMASCHFAB EMIL STUTZNACKER

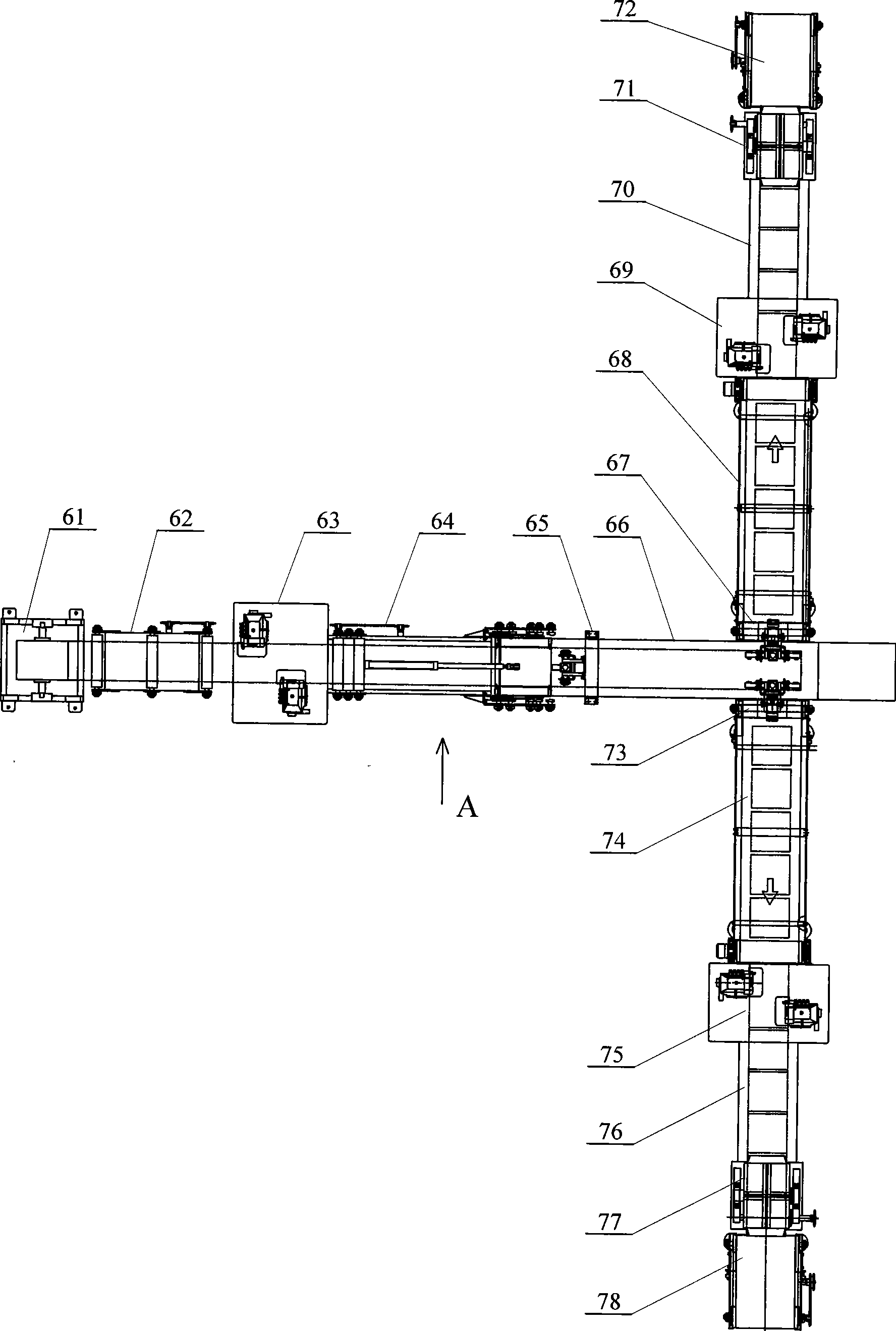

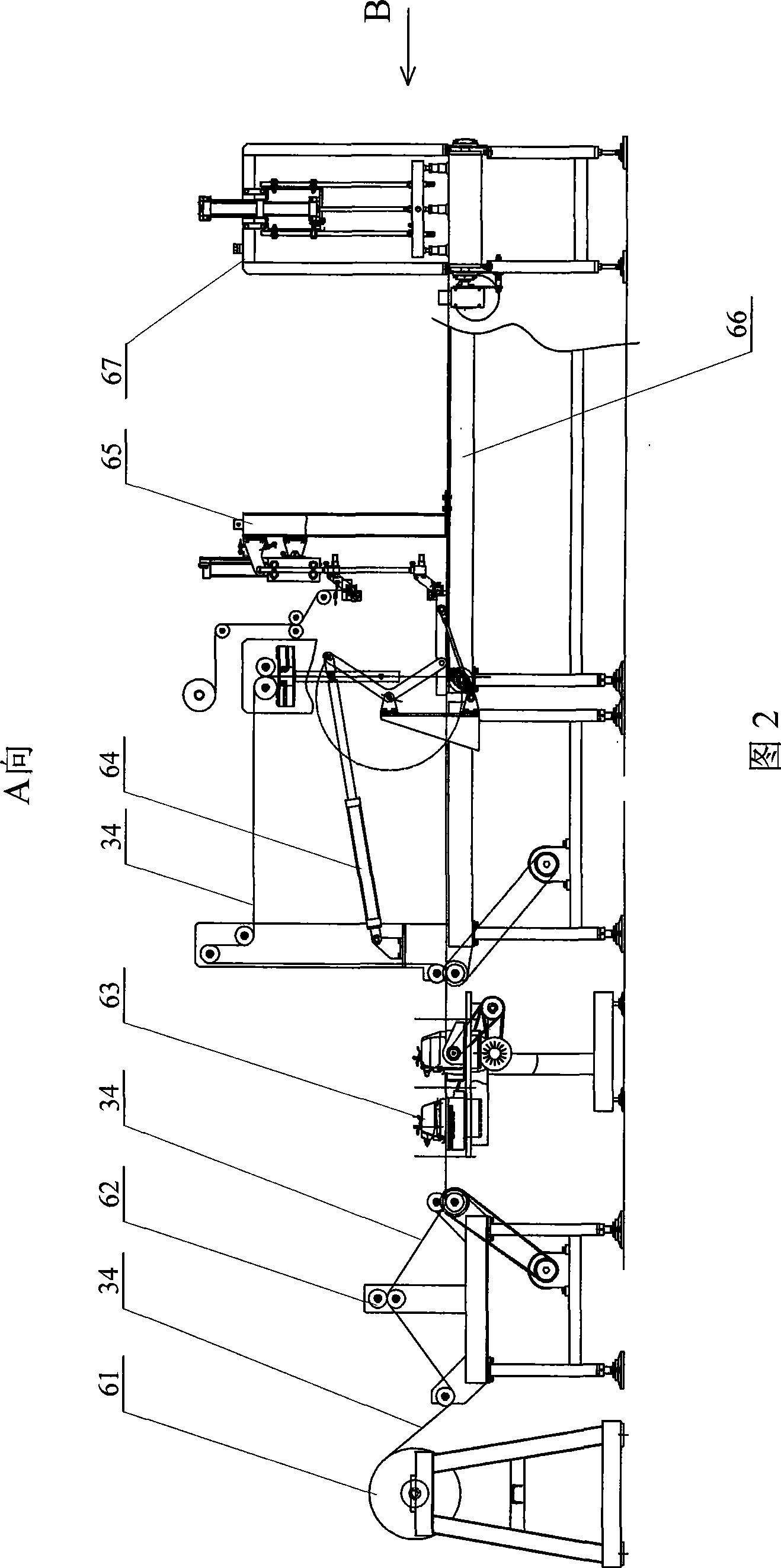

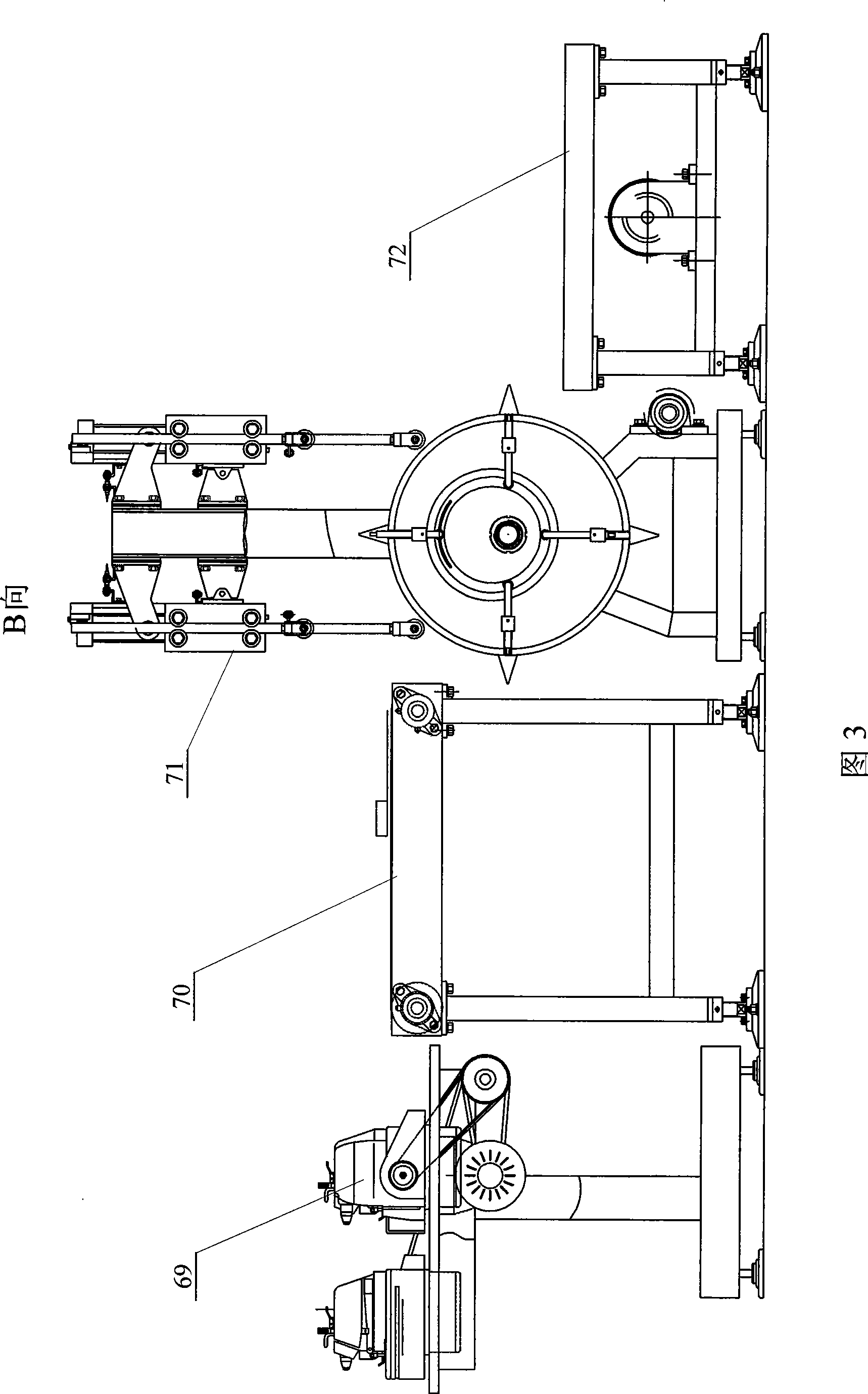

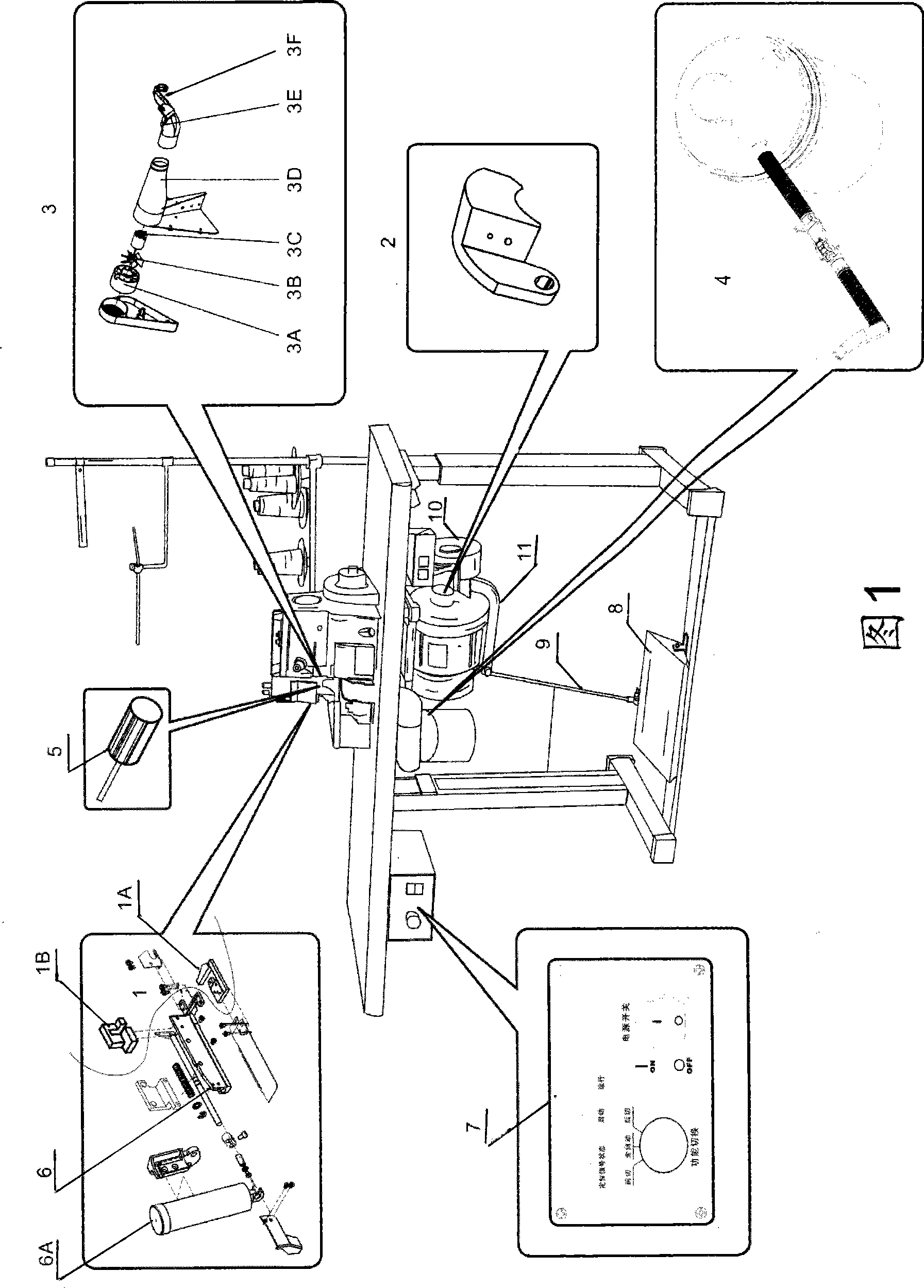

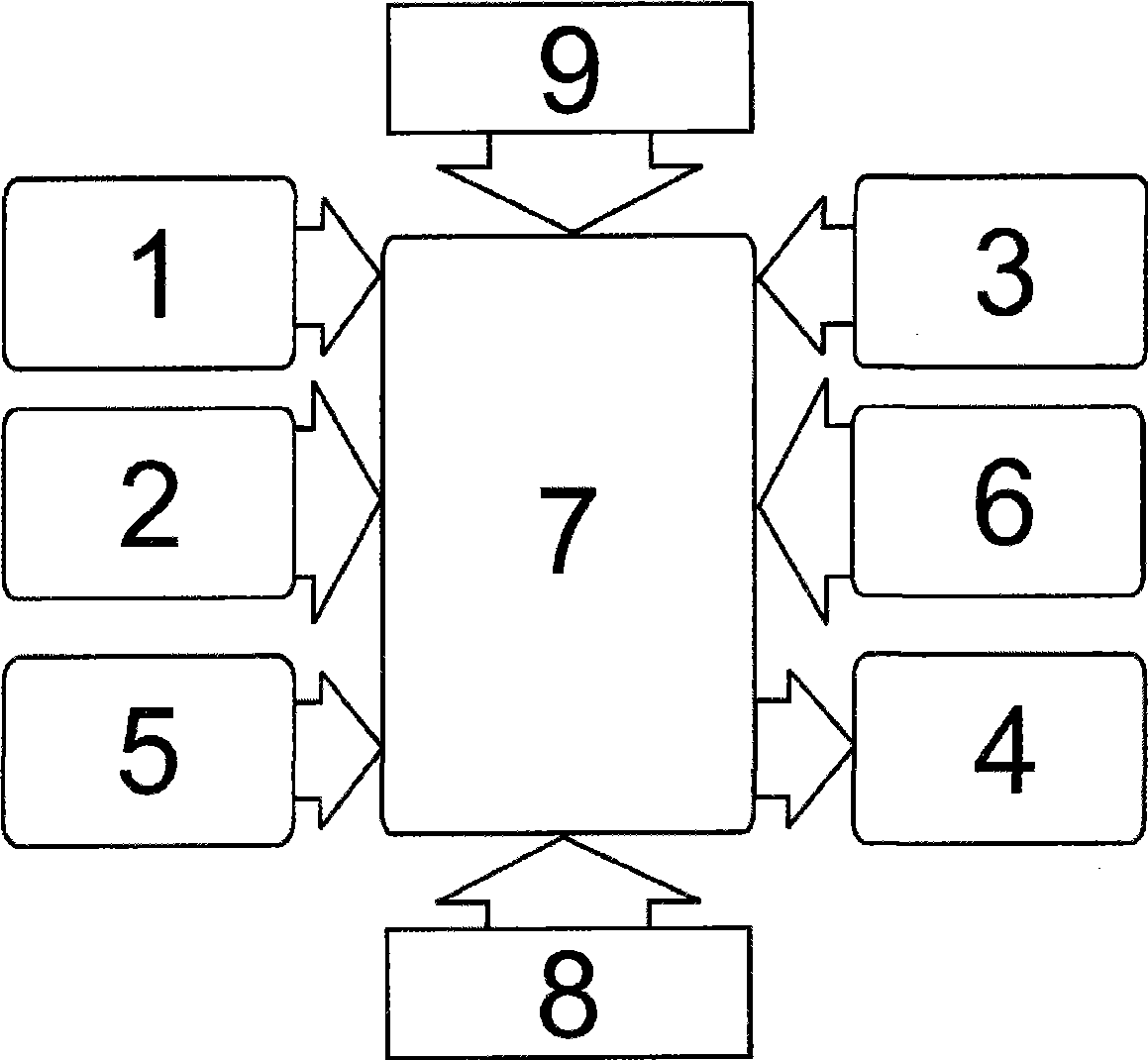

Hemming production line of face cloth

ActiveCN101392434ASimple structureReasonable designWorkpiece carriersWork-feeding meansProduction lineEngineering

The invention provides a kerchief hemming-stitch production line, and relates to a kerchief production line. The invention aims at solving the problems that the existing kerchief is produced by hand, the production efficiency is low and the production quality is difficult to be guaranteed. The invention includes a damping core arranging machine, a synchronous conveyer, a first double head overlock machine, a reclaiming conveyer and a first conveyer which are sequentially arranged; a first transverse reclaiming machine and a second transverse reclaiming machine are respectively arranged at both sides of the rear part of the first conveyer, and a second conveyer, a second double head ovelock machine, a third conveyer and a first end-cutting device are sequentially arranged behind the first transversal reclaiming machine; a fourth conveyer, a third double head overlock machine, a fifth conveyer and a second end-cutting device are sequentially arranged behind the second transversal reclaiming machine. The invention adopts the first double head overlock machine to overlock the two sides of the cloth and adopts the second or third double head overlock machine to overlock the other two sides of the kerchief, which can improve the production efficiency by 5-6 times compared with the manual operation.

Owner:张广生

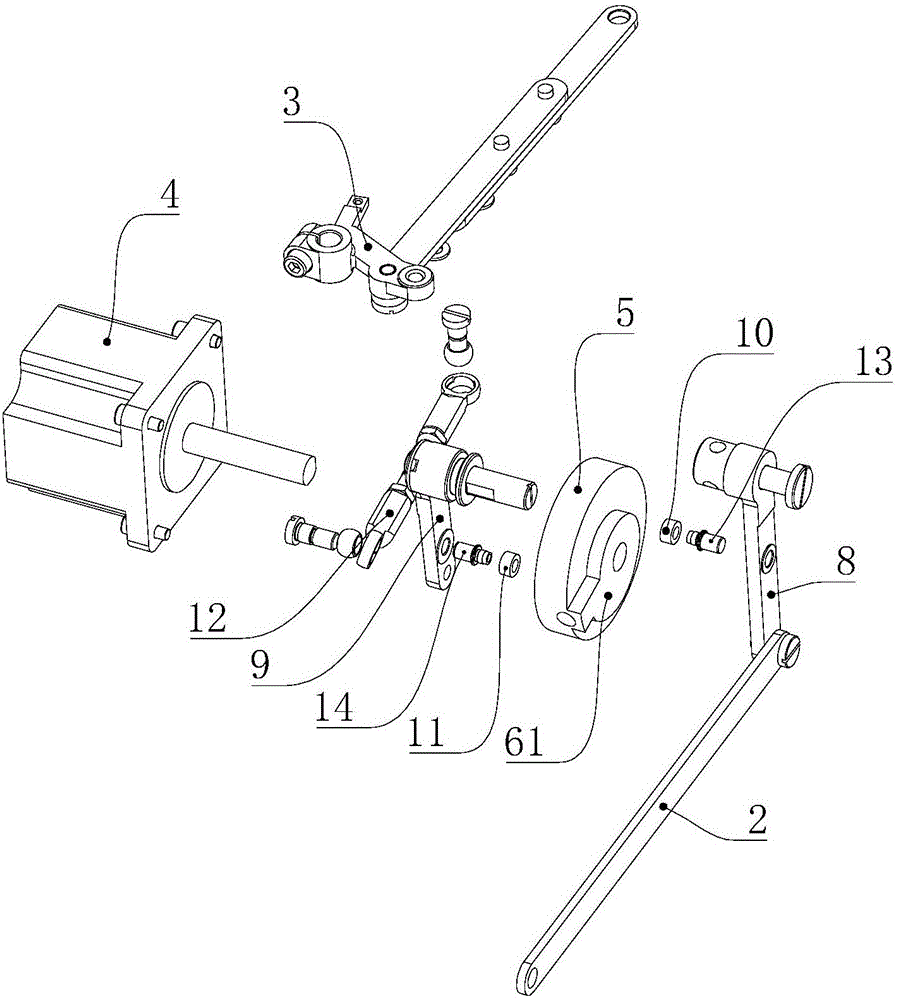

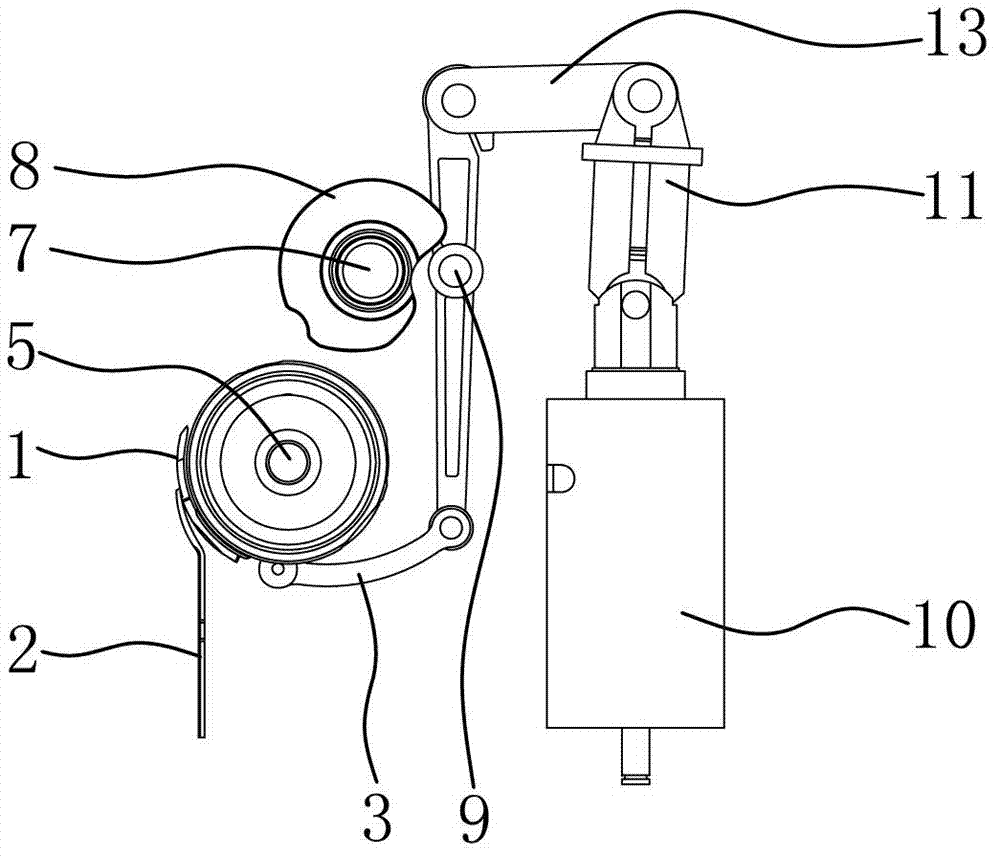

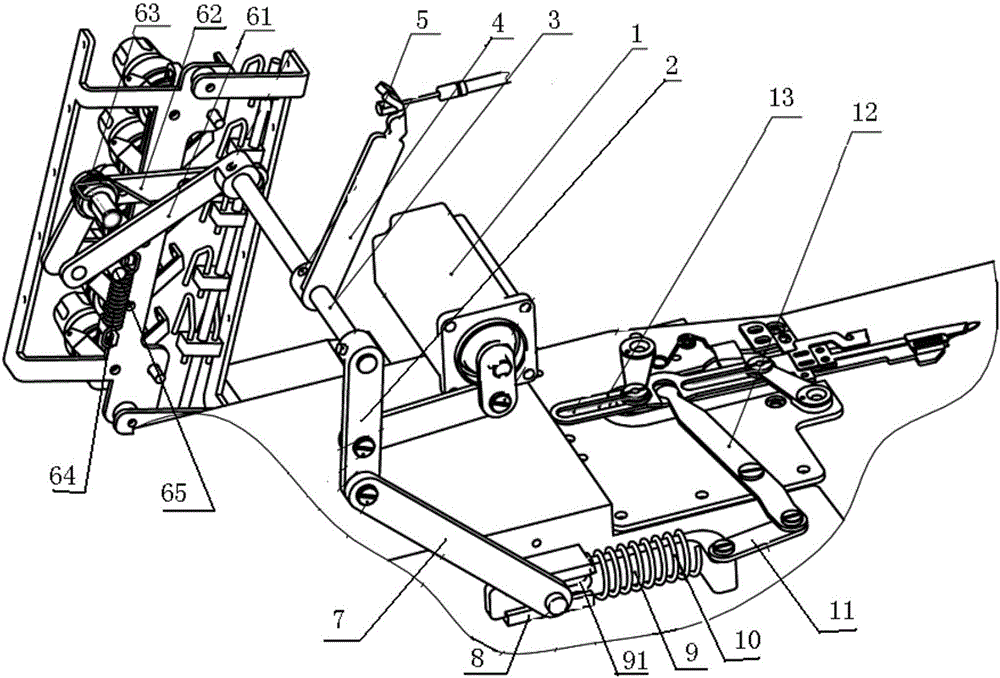

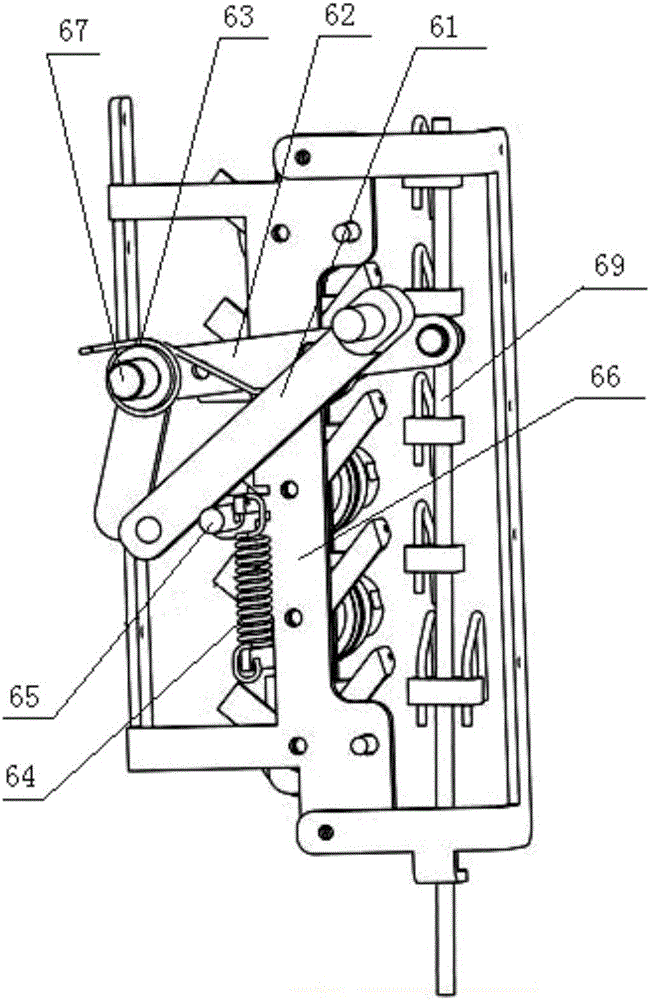

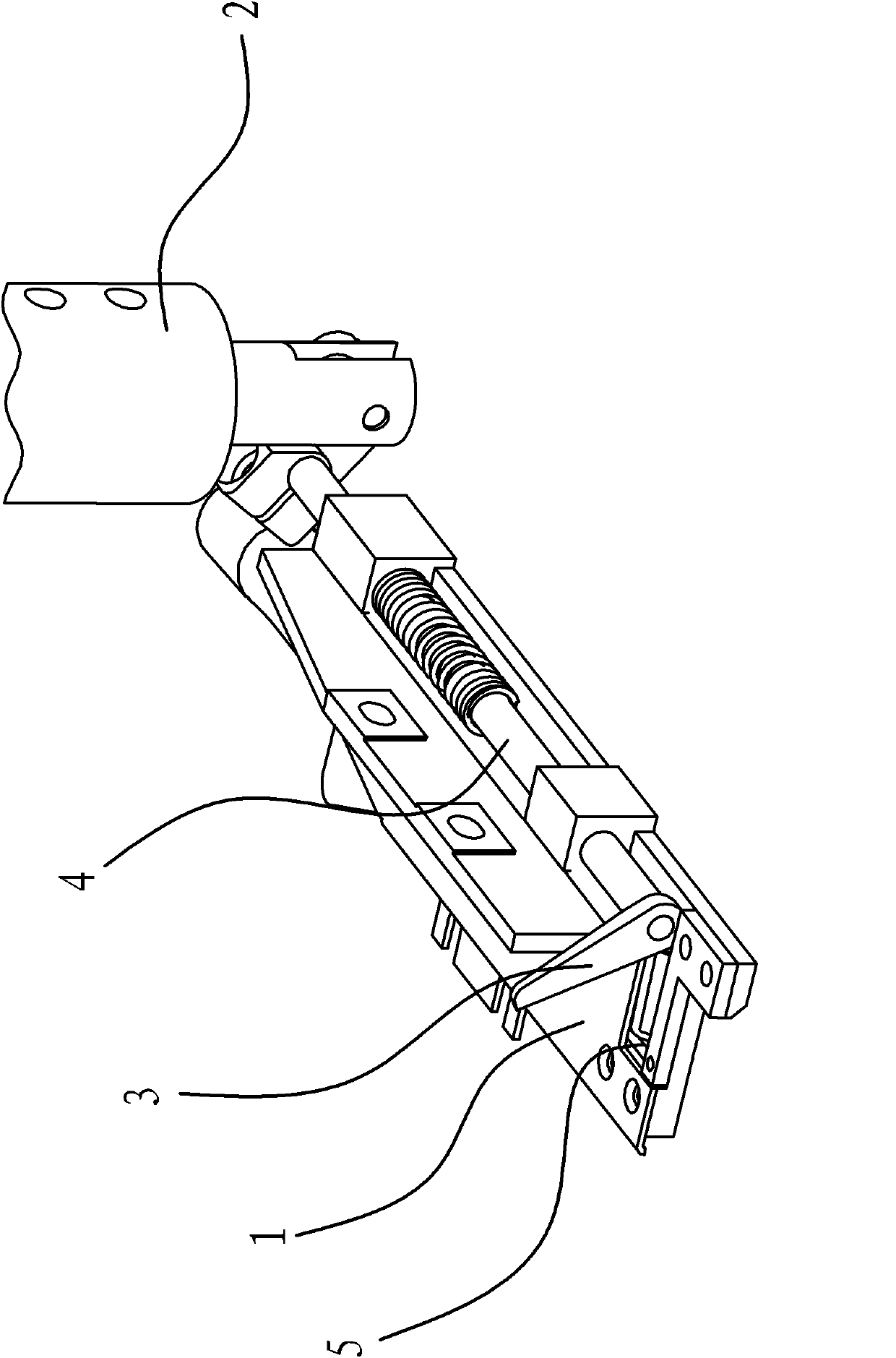

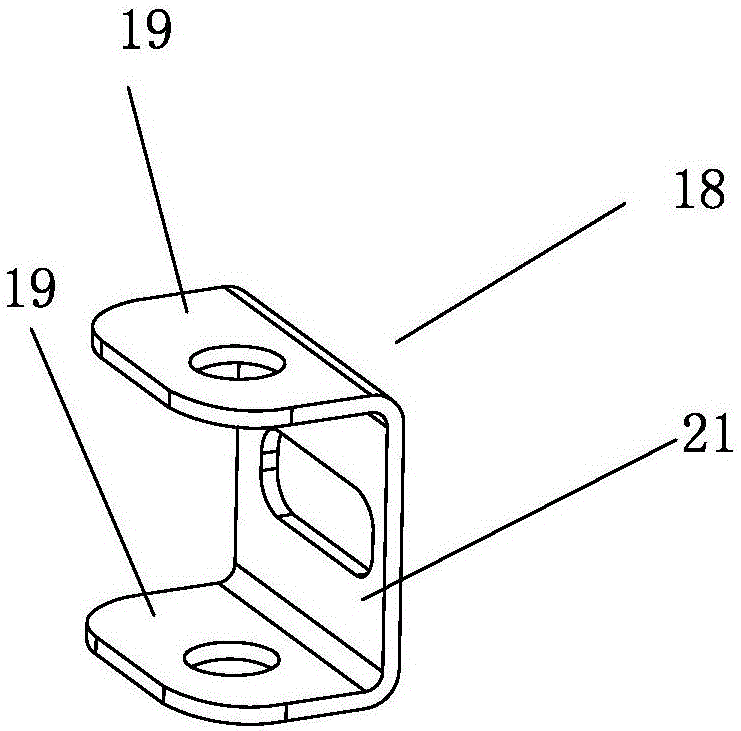

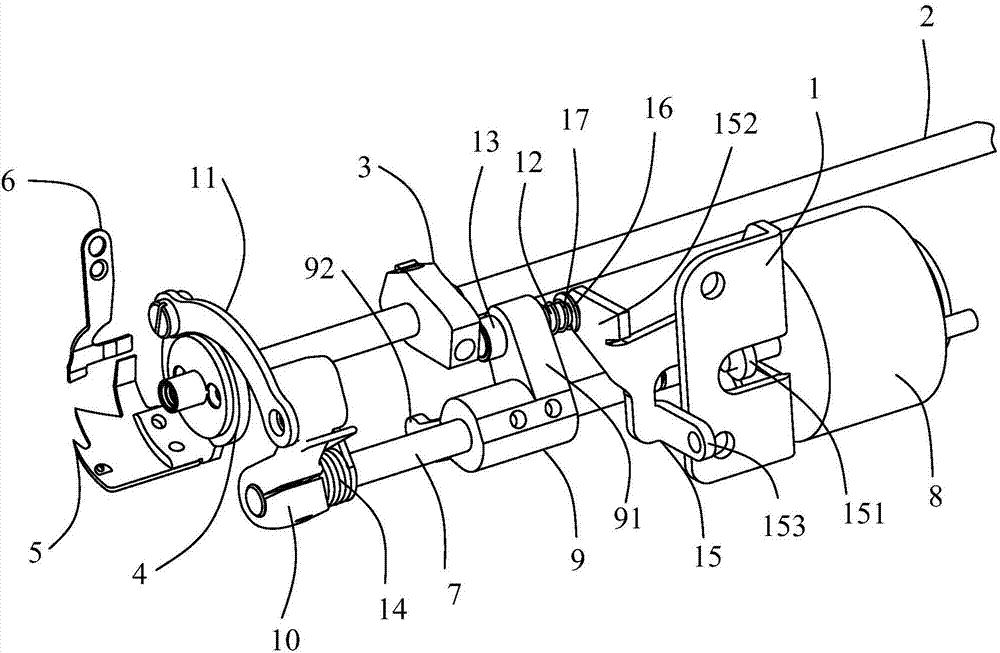

Thread trimming and presser foot raising driving device of sewing machine

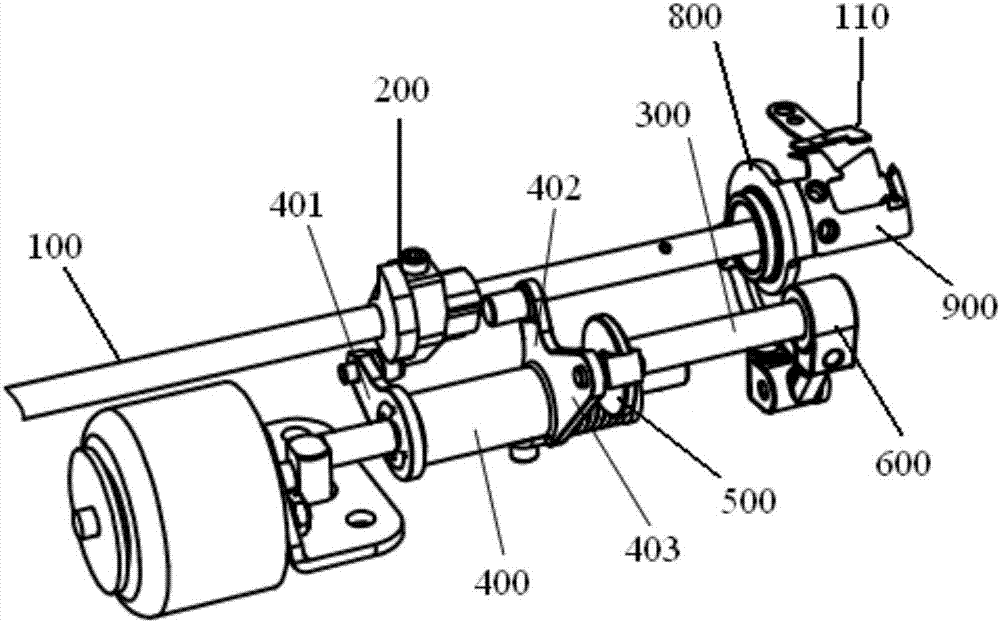

ActiveCN104878529AFew partsLow costNeedle severing devicesSewing-machine control devicesEngineeringCam

The invention provides a thread trimming and presser foot raising driving device of a sewing machine. The technical problems that thread trimming, thread loosening and presser foot raising are implemented by two existing thread trimming and presser foot raising driving devices, the cost is high, occupied space is large, noises are large, mounting time is long, and mounting is not facilitated are solved. The thread trimming and presser foot raising driving device of the sewing machine comprises a stepping motor, a shifting fork mechanism and a cam, wherein the shifting fork mechanism comprises a shifting rod, a fork rod, a sliding rod and at least two fixing rings; one end of the shifting rod and the cam are fixed on a spindle of the stepping motor; the other end of the shifting fork can extend in the fork rod and drives the fork rod to move; the fork rod is fixed on the sliding rod; the sliding rod is positioned in the two fixing rings and can slide in the fixing rings; and a movement trace of the cam and a free end of a presser foot raising connecting rod of the sewing machine are intersected. A lower thread trimming device and a thread slacking device are driven to perform thread trimming, thread clamping and thread slacking through the shifting fork mechanism, and presser foot raising is implemented through the cam.

Owner:STRONG H MACHINERY TECH

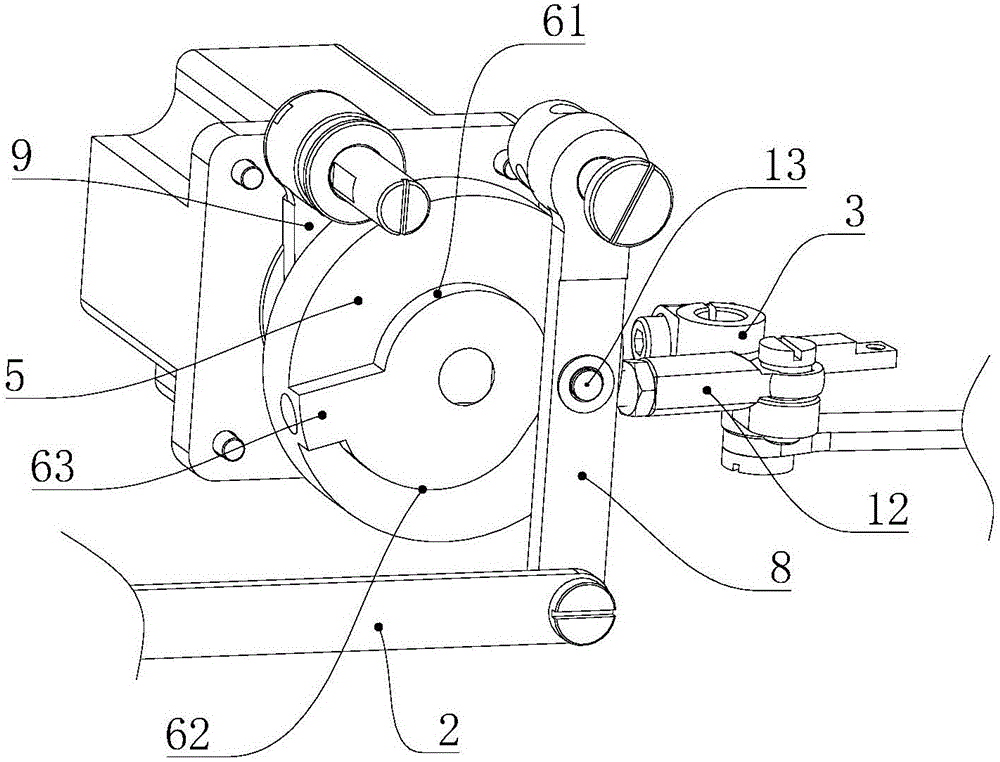

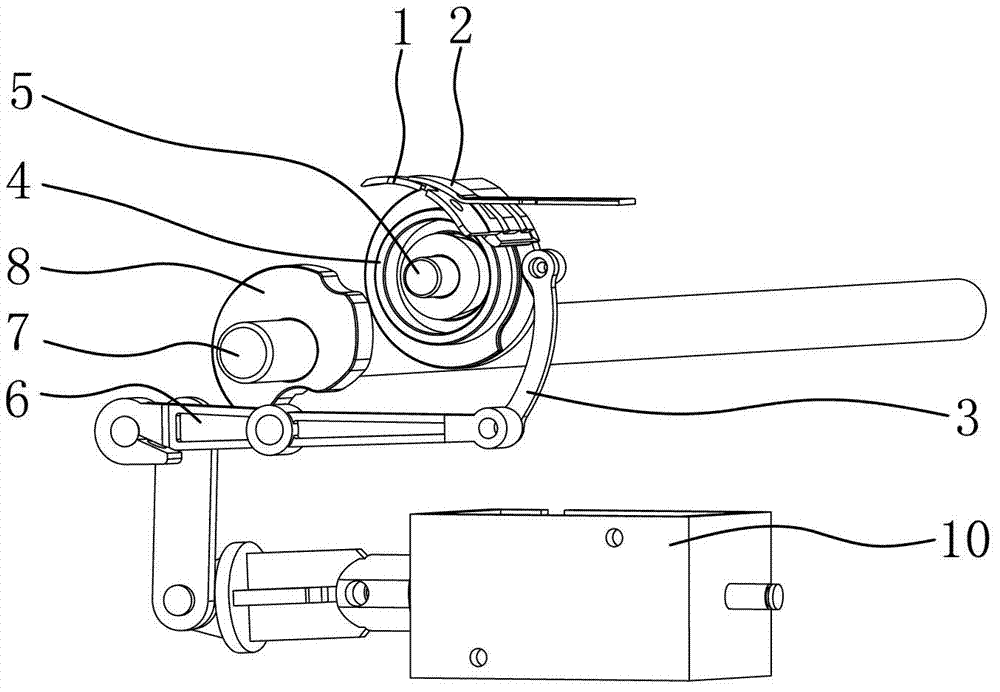

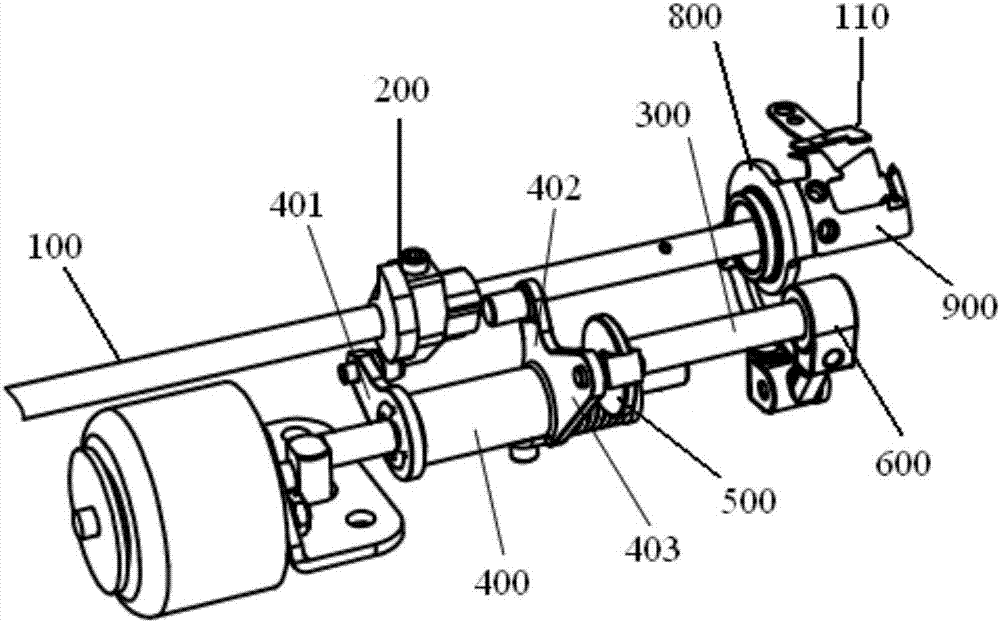

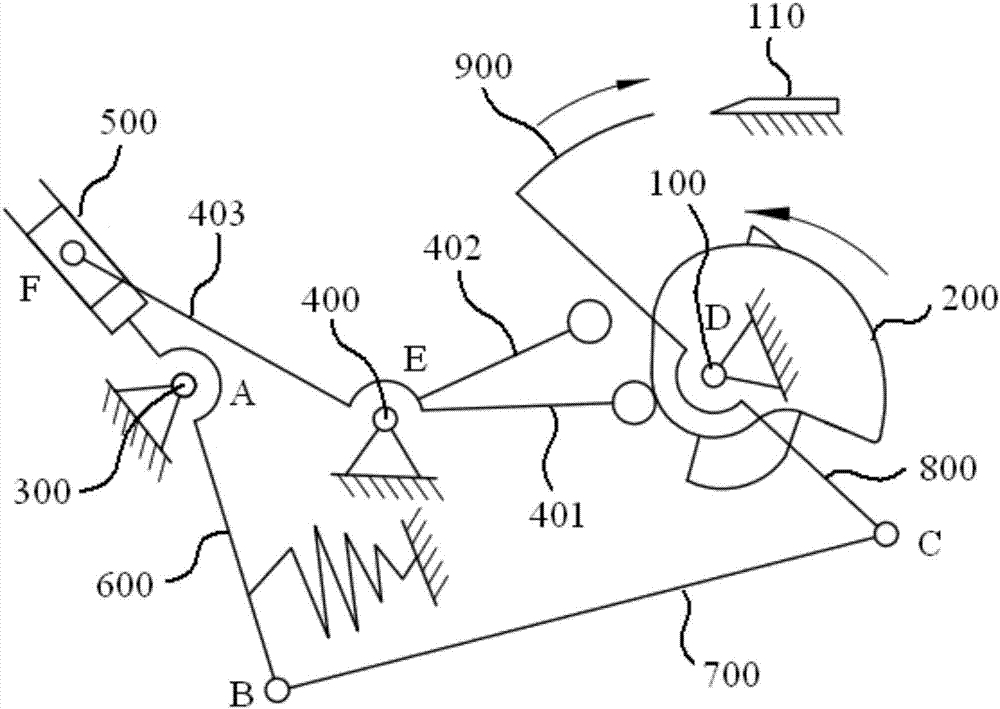

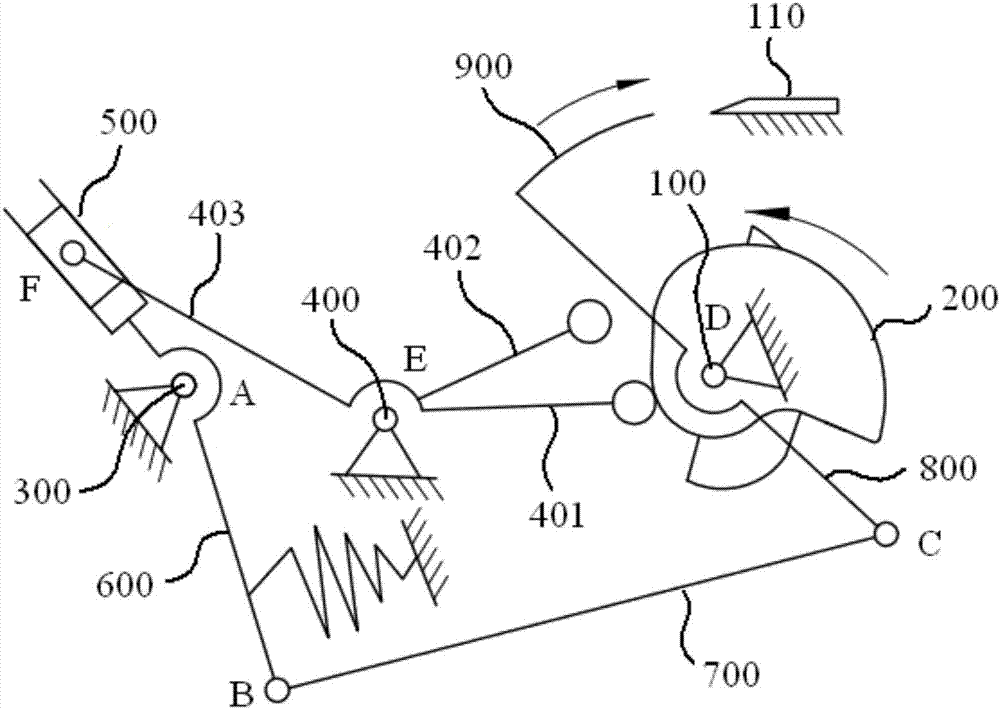

Driving device for automatic thread trimming and automatic presser foot lifting

ActiveCN106012323ACompact structureSame rotation speedNeedle severing devicesPressersMotor driveEngineering

The invention belongs to the technical field of sewing machines, and particularly discloses a driving device for automatic thread trimming and automatic presser foot lifting. The driving device is simple in structure and capable of guaranteeing stable operation of a sewing machine. The driving device comprises a presser foot lifting transmission rod, a thread trimming transmission rod, a stepping motor, a cam body arranged on the stepping motor, a pressure foot lifting connecting rod and a thread trimming connecting rod. The cam body is provided with a pressure foot lifting driving cam surface and a thread trimming driving cam surface, both of which comprise a base circle surface and a lift curved surface. The other end of the pressure foot lifting connecting rod is hinged to one end of the pressure foot lifting transmission rod, and the pressure foot lifting connecting rod is provided with a first driven pin. The thread trimming transmission rod is hinged to the other end of the thread trimming connecting rod, and the thread trimming connecting rod is provided with a second driven pin. When the stepping motor drives the cam body to rotate clockwise by a certain angle, one driven pin enters the lift curved surfaces from the base circle surfaces, and the other driven pin slides on the base circle surfaces; when the stepping motor drives the cam body to rotate anticlockwise, one driven pin slides on the base circle surfaces, and the other driven pin enters the lift curved surfaces from the base circle surfaces.

Owner:ZHEJIANG DUMA SEWING MACHINE

Sewing machine

ActiveCN1611650AFast and efficient sewingImprove efficiencyProgramme-controlled sewing machinesNeedle severing devicesSewing needleIndustrial engineering

The invention provided a sewing machine for improving the efficiency of sewing work and quickening it. The sewing machine is provided with a needle driving means 30, a cloth pressing means 40, a moving means 50 for positioning a sewing needle 11 to cloth, an input means 20 for inputting the setting relating to sewing, a storage means 103 for respectively storing sewing data and successive sewing data composed of two or more pieces of the sewing data, and an operation control means 100 for controlling respective parts on the basis of the respective stored sewing data. The order of sewing is specified for two or more pieces of sewing data and is inputted by the input means 20 and the storage means 103 stores it. The operation control means 100 makes the sewing of the sewing data or the successive sewing data be successively performed according to the stored order and waits for the detection of re-pressing by the cloth pressing means every time sewing is performed for the respective successive sewing data or sewing data for which the order is specified.

Owner:JUKI CORP

Thread cutting and presser foot lifting device of sewing machine and sewing machine

ActiveCN106948096ASimple structureSmall footprintNeedle severing devicesPressersElectric machineryEngineering

The invention belongs to the technical field of sewing machines and relates to a thread cutting and presser foot lifting device of a sewing machine and the sewing machine. The thread cutting and presser foot lifting device of the sewing machine comprises a double-end motor, a thread cutting cam assembly and a presser foot lifting crank assembly, wherein the thread cutting cam assembly comprises a thread cutting cam arranged on a motor shaft at one end of the double-end motor; a movement groove is formed in the thread cutting cam; one end of a thread cutting crank is connected with the thread cutting cam through a connecting pin; the connecting pin is arranged in the movement groove of the thread cutting cam; the other end of the thread cutting crank is connected with a thread cutting shaft; the thread cutting shaft is connected with a thread cutting mechanism; the presser foot lifting crank assembly comprises a presser foot lifting crank arranged on a motor shaft at the other end of the double-end motor; an abutting part is arranged on the presser foot lifting crank; the abutting part abuts against an ejection rod of a presser foot lifting mechanism. According to the thread cutting and presser foot lifting device of the sewing machine, one driving source is used for controlling movement of the thread cutting mechanism and the presser foot lifting mechanism; the driving source is reduced so that the structure is simpler and an occupied space is simple; the thread cutting and presser foot lifting device is convenient to mount and the cost is reduced.

Owner:JACK SEWING MASCH CO LTD

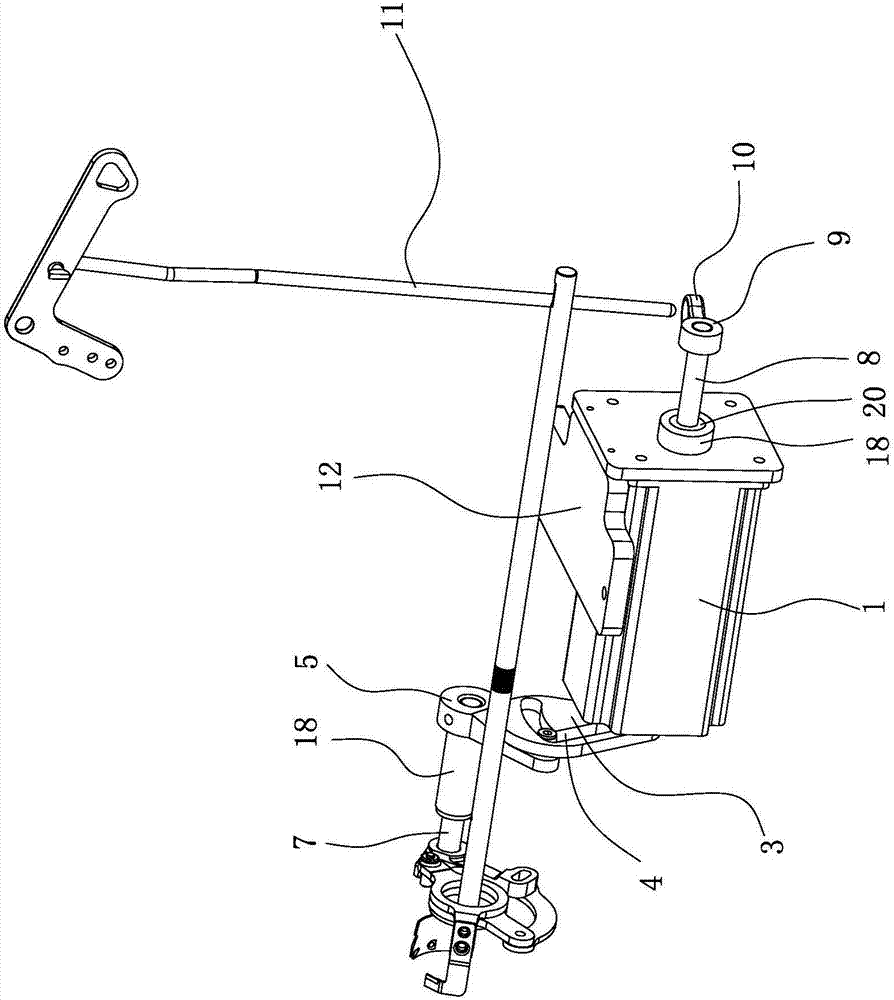

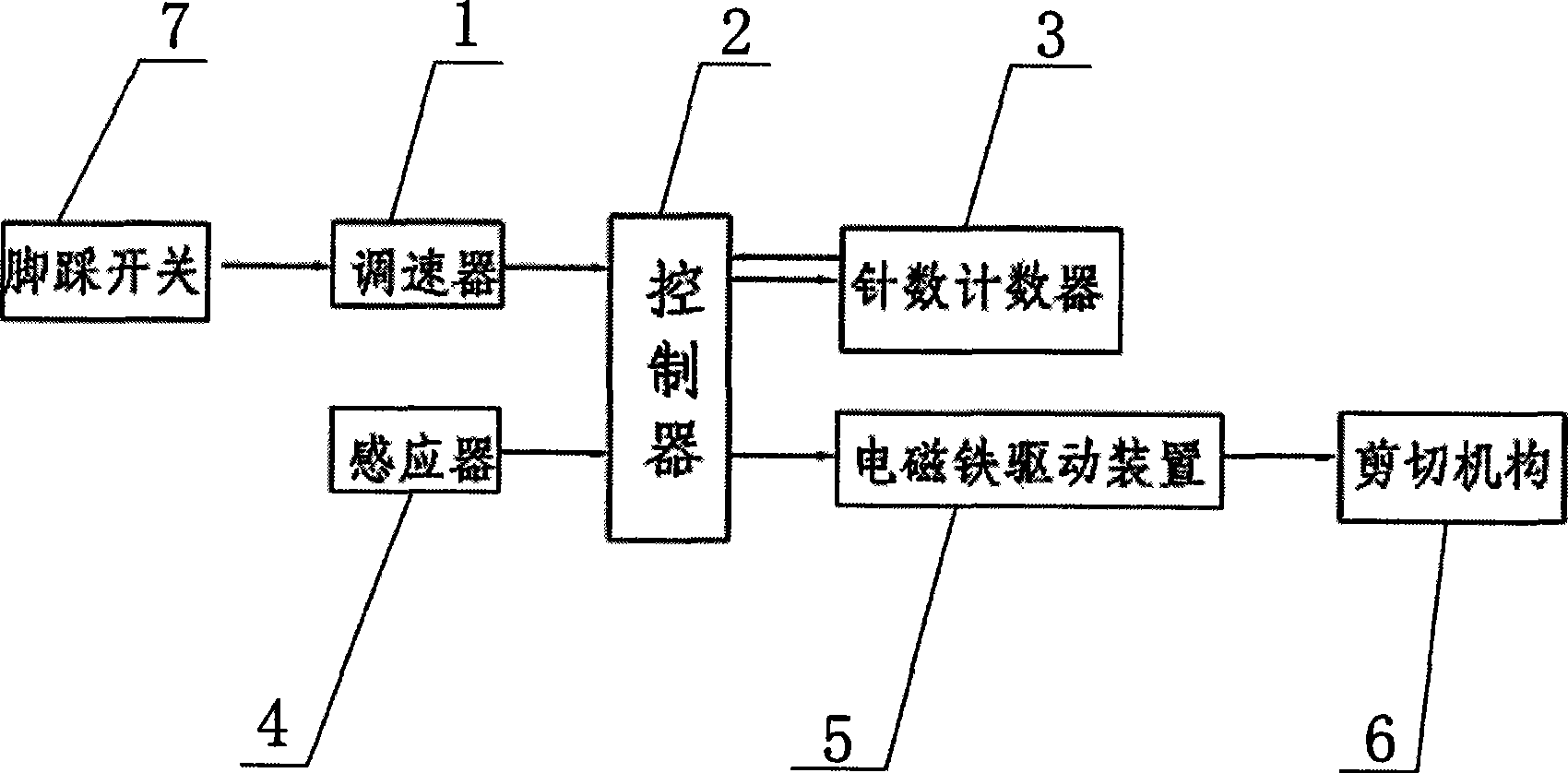

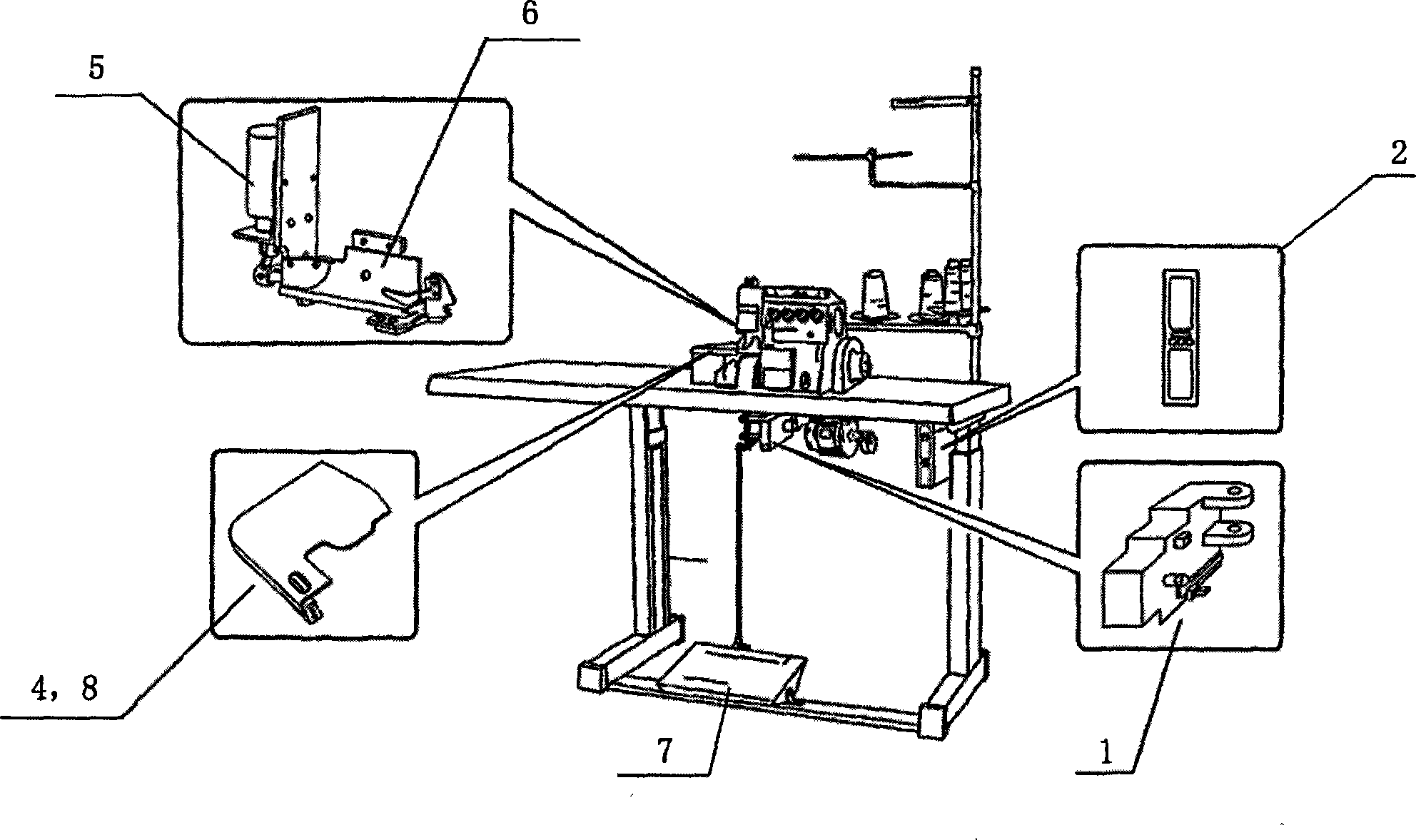

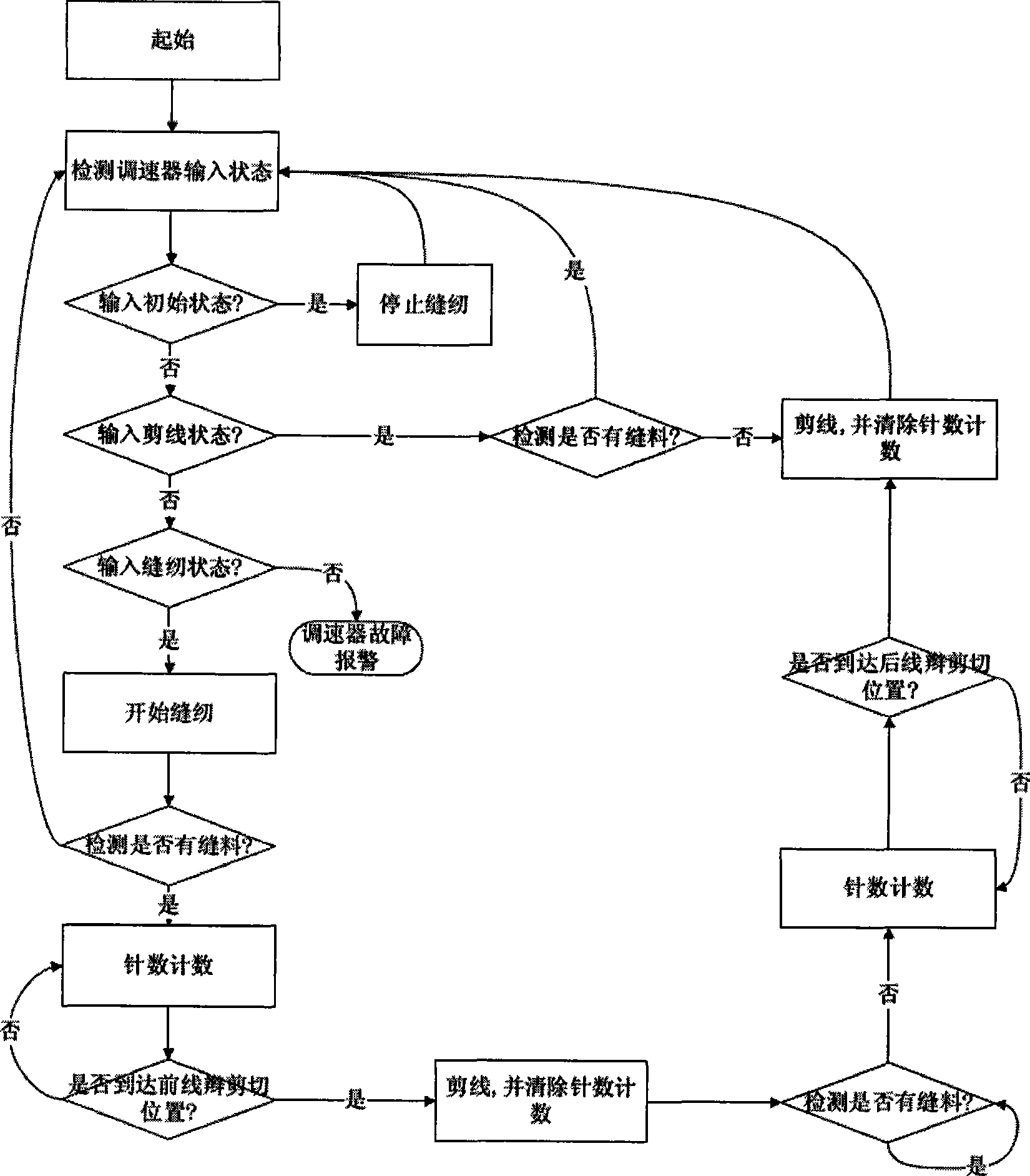

Automatic braid-cutting device and working method for sewing of overedging machine

ActiveCN101532223ASimple structureEasy to installNeedle severing devicesSewing-machine control devicesElectrical connectionInductor

The invention relates to an automatic braid-cutting device and a working method for sewing of an overedging machine. The prior industrial overedging machine basically completes the process of cutting remained thread-braids by a manually cutting mode; even if an automatic braid-cutting device is arranged, the machine is not suitable to be applied in large scale because of complicated structure, difficult operation, high cost, and the like. The automatic braid-cutting device comprises a controller, an inductor, a main shaft, an electromagnetic drive device and a cutting mechanism, wherein a stitching counter is arranged inside the controller; a speed regulator is arranged below a bedplate; the stitching counter and the main shaft are in electrical connection; the speed regulator and the inductor are connected into the controller in parallel; the controller is connected with the electromagnetic drive device; and the cutting of remained thread-braids can be realized by counting delay through the stitching counter, performing protection on a sewing material by the inductor and controlling the cutting mechanism by the controller. The device has a simple structure and convenient use, and can realize mutual conversion of automatic cutting and manual cutting.

Owner:XIAN TYPICAL IND

Automatic cutting device of sewing machine

InactiveCN102877230AAvoid hitting pinsGuaranteed stable workNeedle severing devicesEngineeringKnife holder

The invention provides an automatic cutting device of a sewing machine and belongs to the technical field of sewing machines. The device can solve the problems of discontinuous operation, affected production efficiency and the like caused by the needle-bumping phenomenon in the prior art. The device comprises a moving knife, a fixing knife, a connecting rod and a cutting electromagnet, which cooperate with each other to cut threads, wherein the fixing knife is fixed on a base of the sewing machine, the moving knife and one end of the connecting rod are fixed on a cutting knife holder, the cutting knife holder is sleeved on a lower shaft, the other end of the connecting rod is hinged with one end of a transmission rod, and the other end of the transmission rod is connected with a moving iron of the cutting electromagnet; and a feed lifting rock shaft is provided with a cutting cam, the cutting cam is positioned on the side of the transmission rod, and the transmission rod is fixedly provided with a cylindrical pin which is matched with the cutting cam to drive the transmission rod to move. The device provided by the invention has the advantages of high cutting accuracy, convenience in operation, simple structure and the like.

Owner:JACK SEWING MASCH CO LTD

Thread trimming mechanism of sewing machine

The invention provides a thread trimming mechanism of a sewing machine. A rotating shaft is arranged in a case of the sewing machine. The thread trimming mechanism comprises a main tool rest, an auxiliary tool rest and a driving mechanism which are arranged in the case, wherein a main moving cutter is mounted on the main tool rest; an auxiliary moving cutter is mounted on the auxiliary tool rest; an output end of the driving mechanism is connected with a main crank and an auxiliary crank, the main crank is connected with the main tool rest, and the auxiliary crank is connected with the auxiliary tool rest; the output end of the driving mechanism performs reciprocating rotation; the driving mechanism drives the main tool rest to perform reciprocating rotation around the rotating shaft through the main crank and drives the auxiliary tool rest to perform reciprocating rotation around the rotating shaft through the auxiliary crank, so that the main moving cutter and the auxiliary moving cutter move face to face to complete close cutting and move back to back to complete resetting. The driving mechanism is adopted to drive the main crank and the auxiliary crank simultaneously so as to drive the main moving cutter and the auxiliary moving cutter to move oppositely around the rotating shaft for engagement, trimming of opposite threads and bottom threads is completed, and the engaged position of trimmed threads is stable.

Owner:JACK SEWING MASCH CO LTD

Front and rear automatic shear line device of overedger sewing products

InactiveCN101446006AAccuratePrecise positioning in placeNeedle severing devicesSewing-machine control devicesYarnState of art

The invention discloses a front and rear automatic shear line device of overedger sewing products, which consists of a transmission-type synchronous scanning opto-electronic group, a blowing device, an enabling signal sensor, a front cut dust collecting device, a stepping sensor, an electromagnetic or pneumatic shear knife rest (an executing mechanism) and an electrical control box. A full-automatic shear line device which is provided with a front blade and a rear blade of the sewing products that are controlled by photoelectric detection; on the premise of no human intervention, the shear process of freely setting yarn at the front end and the rear end of the sewing products can be completed. As the device is not needed to be stopped for trimming, the sheared thrum is absorbed cleanly at the same time. As the device is not needed to be stopped for trimming, and the sheared thrum is absorbed cleanly at the same time, the working efficiency of the single device is increased by over 30% compared with the prior art; the efficiency and the reliability are high.

Owner:王国秋 +1

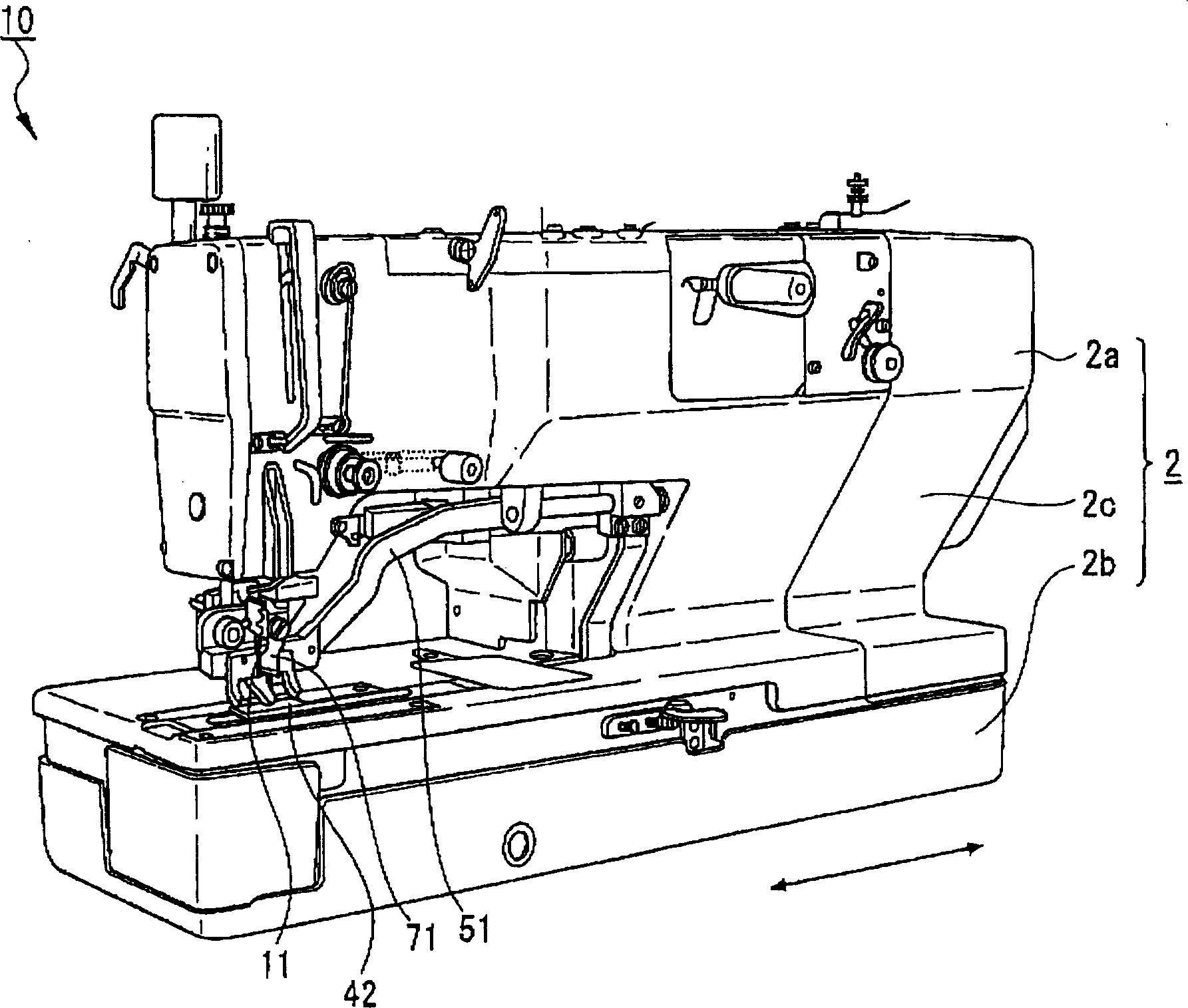

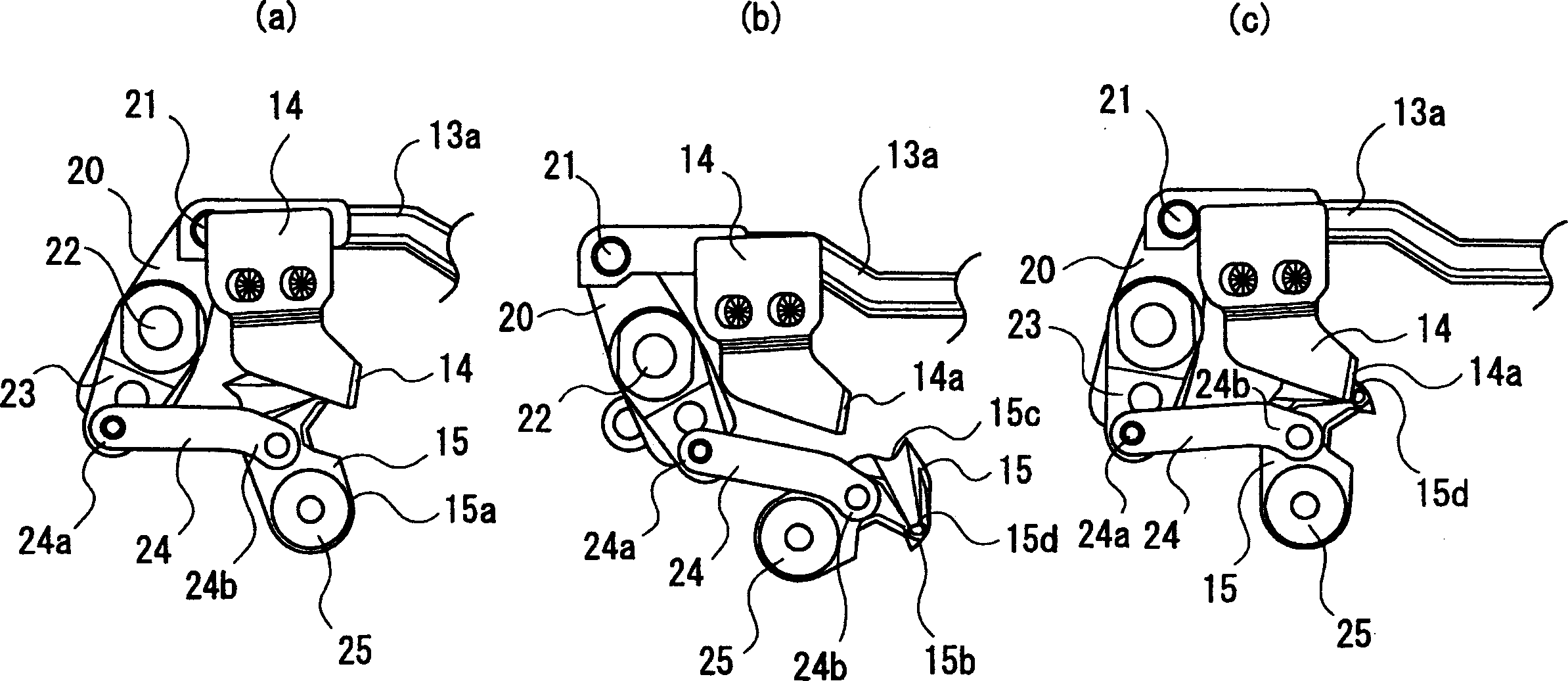

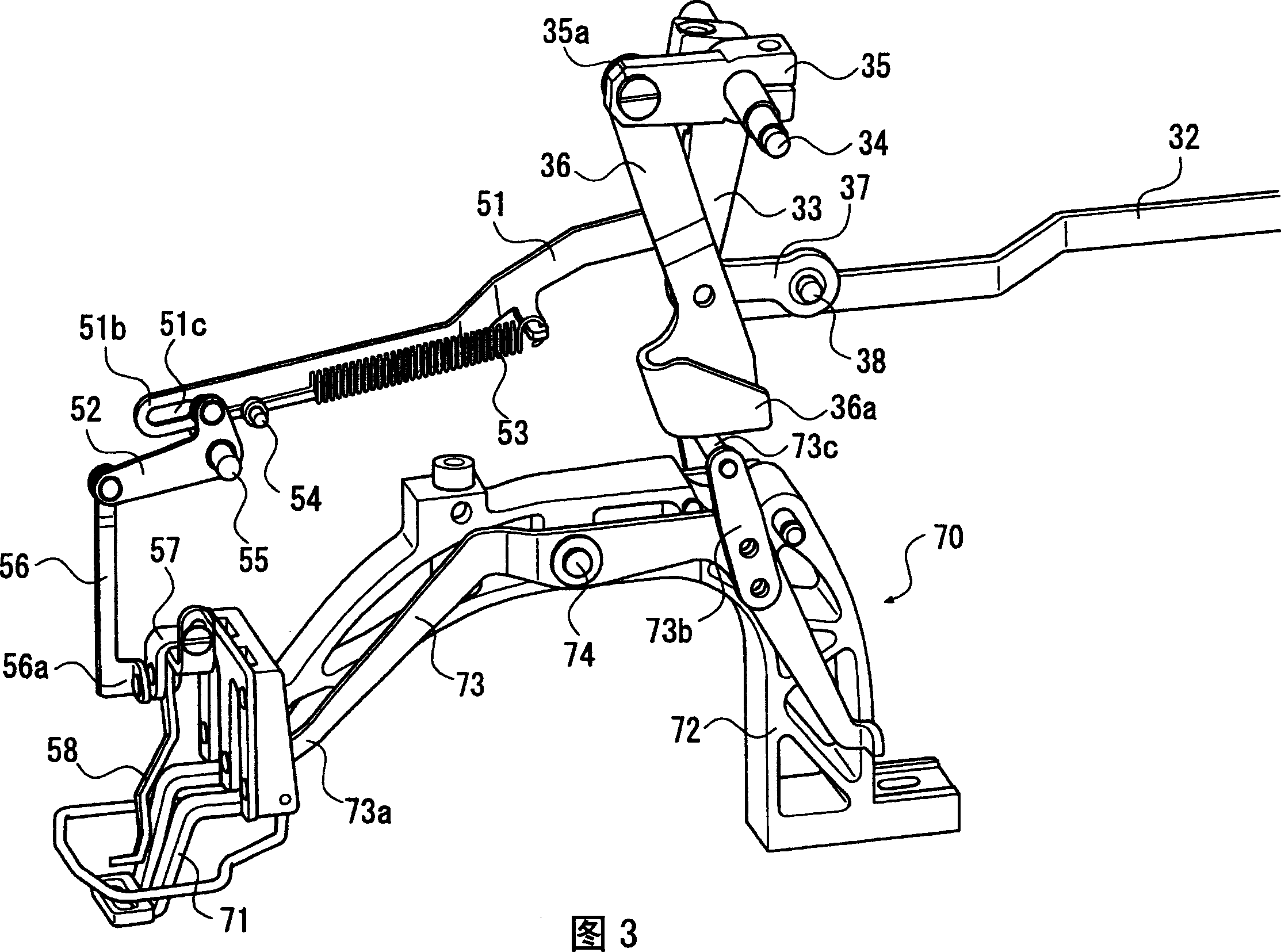

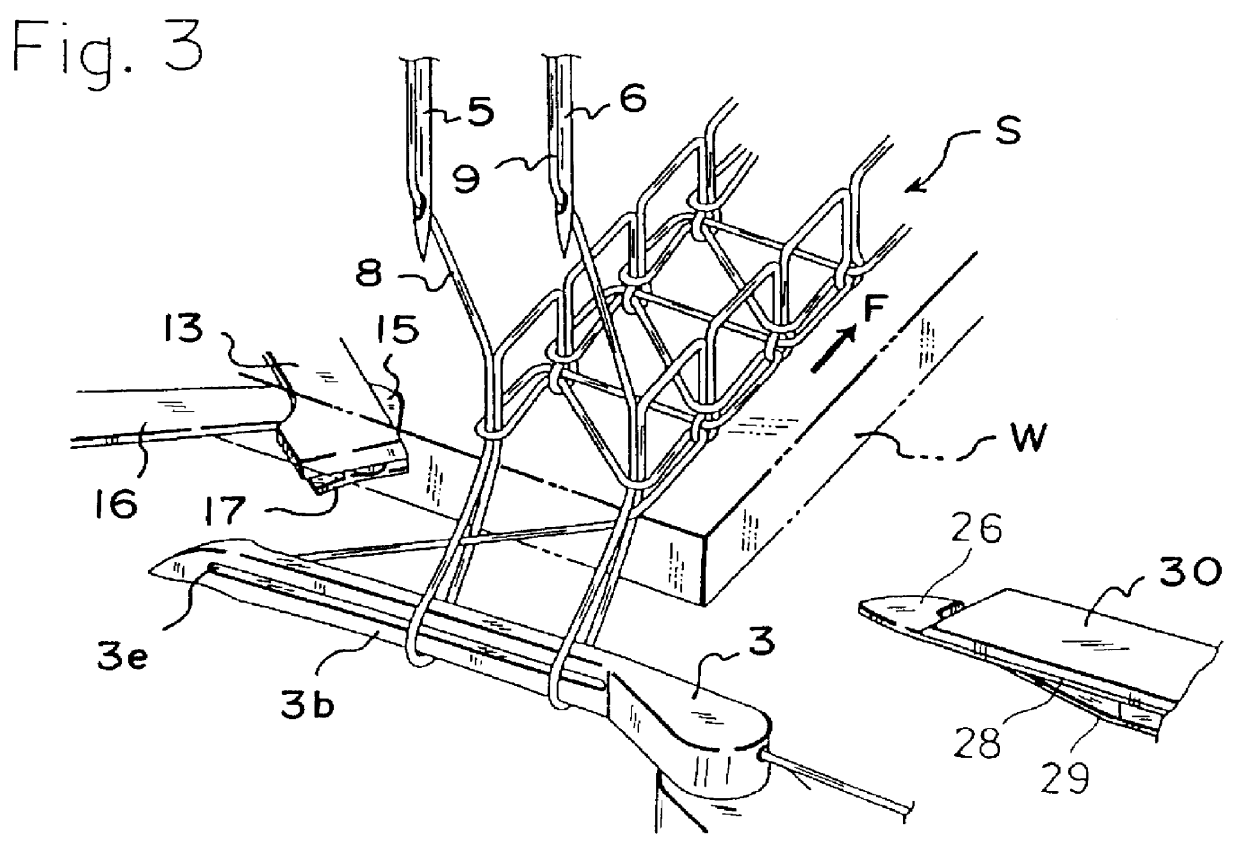

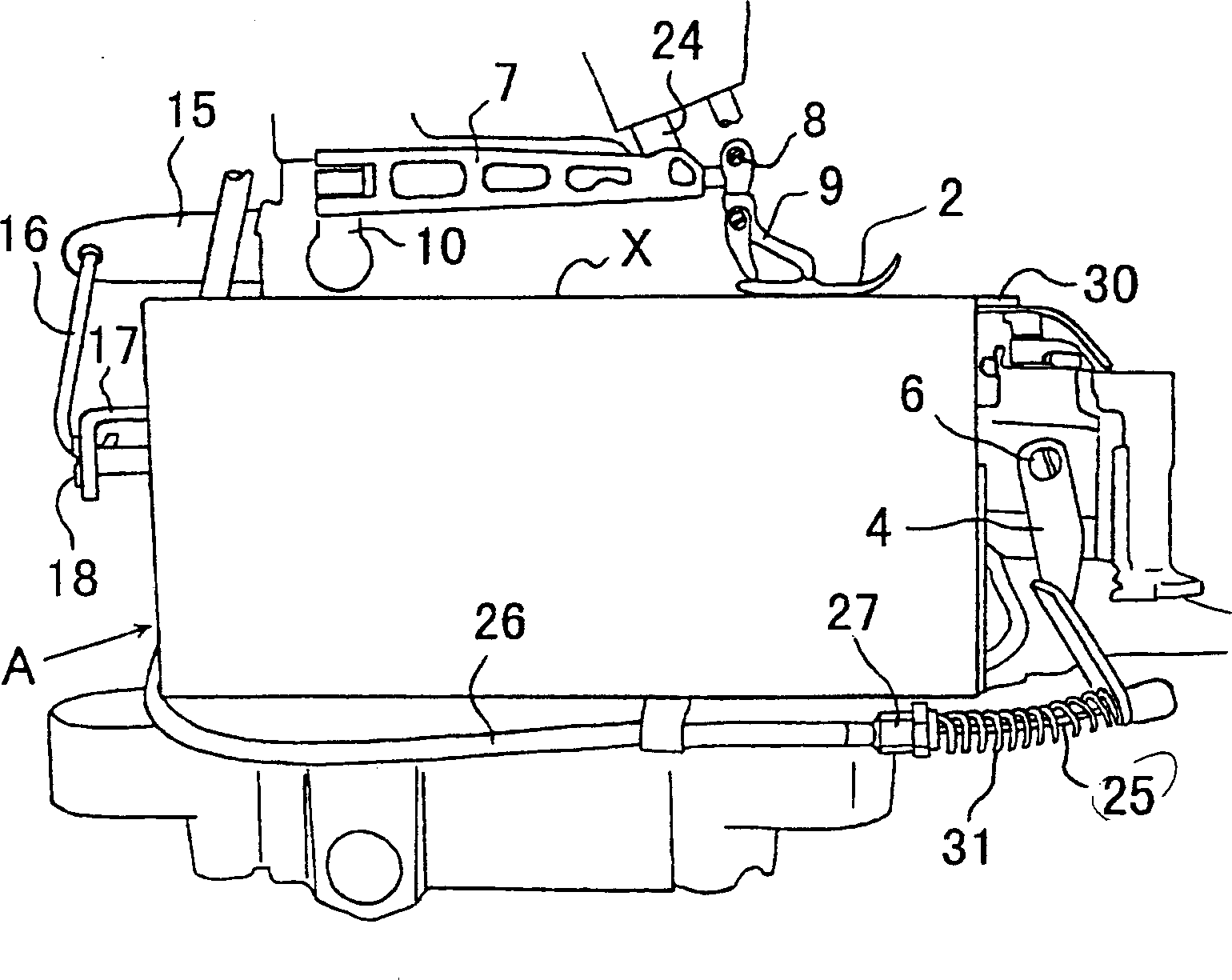

Sewing machine

InactiveCN1458327AReduce in quantityReduce weightProgramme-controlled sewing machinesNeedle severing devicesPhase differenceEngineering

To achieve the efficiency in the sewing work in a sewing machine having a thread cutting mechanism, a presser lifter mechanism and a thread sweeping mechanism by checking the operation of the presser lifter mechanism as required while preventing the delay in the cycle time simplifying the mechanisms and the controls. The sewing machine has the thread cutting mechanism 10, the presser lifter mechanism 30, the thread sweeping mechanism 50 and a drive means for driving the mechanisms is provided with the first cam 61 which has a thread cutting operation part for converting rotary driving forces of a single pulse motor 80 as the drive means to those to match the thread cutting mechanism 10 and the second cam 62 which has a thread sweeping operation part and a presser lifting operation part for converting rotary driving forces of the pulse motor 80 to those to match the thread sweeping mechanism and the presser lifter mechanism. The first cam and the second cam are arranged in such a phase difference as to operate the thread cutting mechanism, the thread sweeping mechanism and the presser lifter mechanism sequentially with the rotation of the pulse motor.

Owner:JUKI CORP

Airbag device

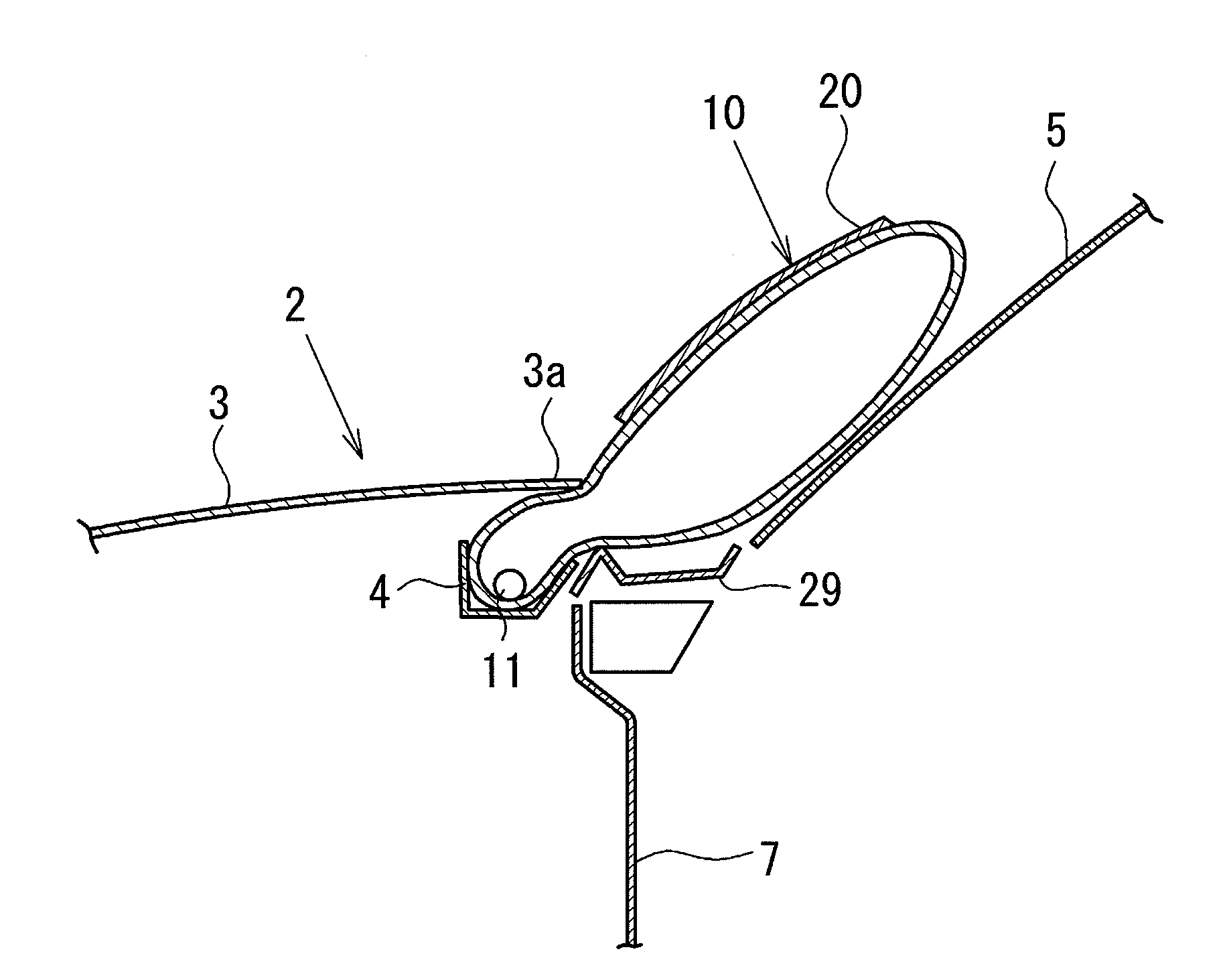

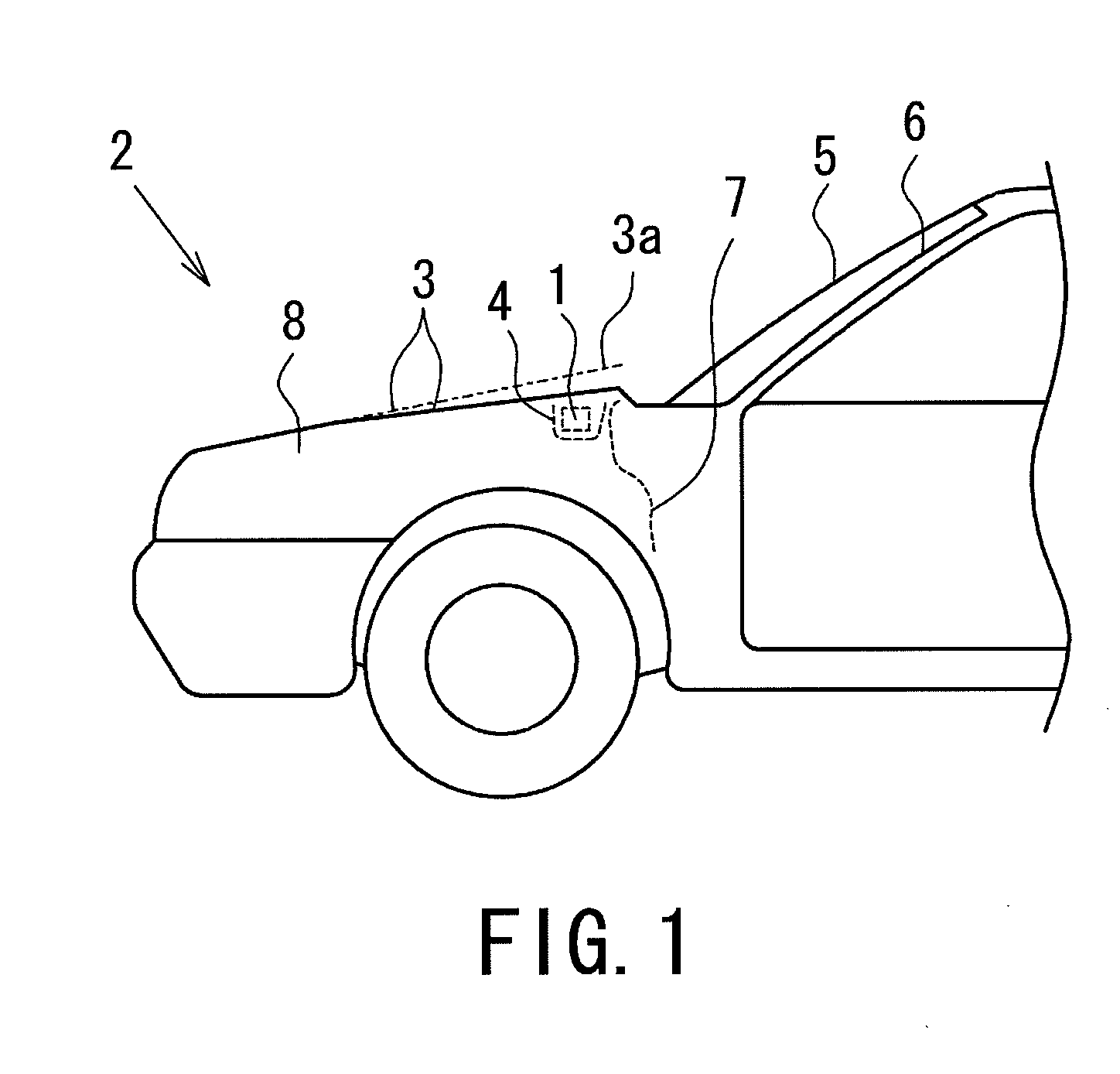

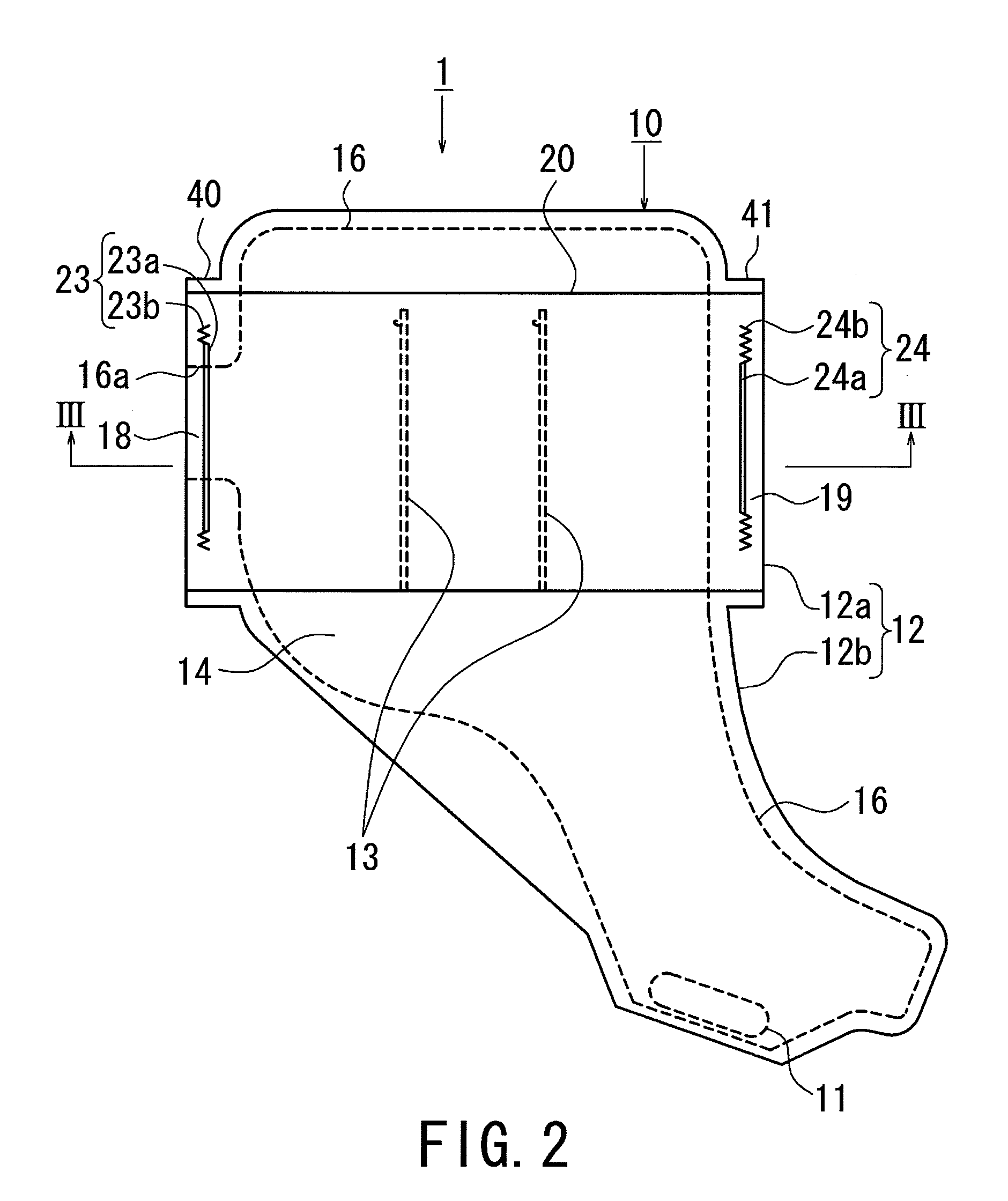

InactiveUS20090200778A1Improve securityLow costNeedle severing devicesPedestrian/occupant safety arrangementEngineeringAirbag

Intended is to always provide effective impact reduction by releasing gas at a timing of pushing into airbag.An airbag (10) has a vent hole (18) in one side end portion. One end of a third base fabric (20) is sewn to the airbag (10) through a first sewn portion (23) that closes the vent hole (18), and the other end of the third base fabric 20 is sewn to the other side end portion of the airbag (10) through a second sewn portion (24). The first sewn portion (23) has weaker binding force by sewing than the second sewn portion (24) so that the first sewn portion (23) is separated to open the vent hole (18) when tension force is applied from the third base fabric (20) to the first and second sewn portions (23) and (24).

Owner:MAZDA MOTOR CORP +1

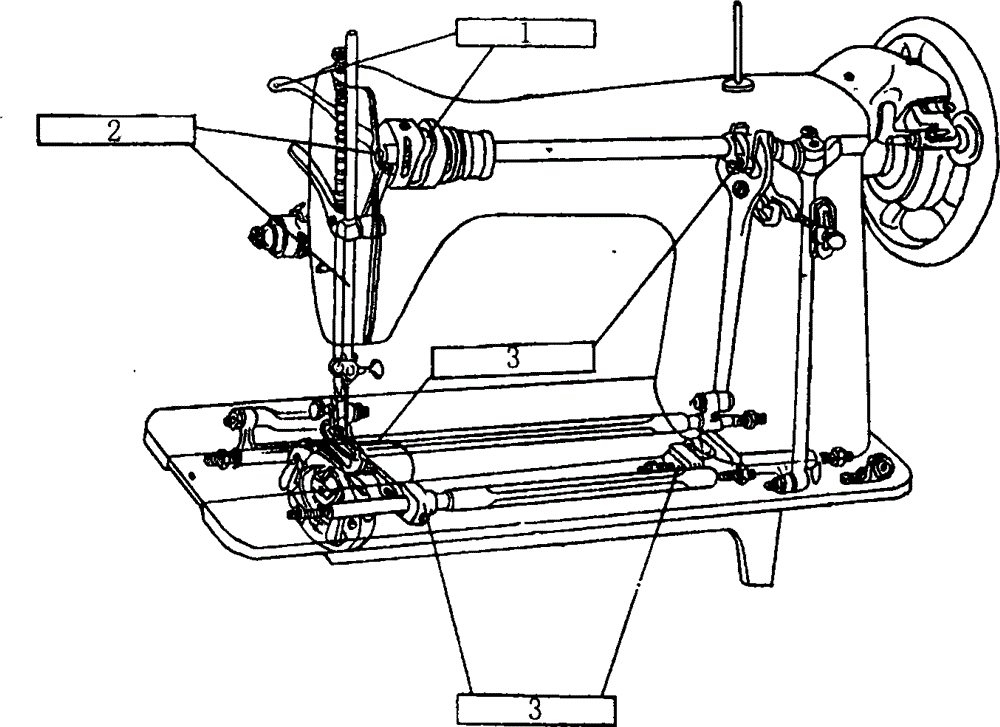

Thick stuff sewing machine

InactiveCN102943352ALarge capacityAutomatic replacementNeedle severing devicesSewing-machine control devicesClutchManipulator

The invention provides a thick stuff sewing machine which mainly comprises a needle bar mechanism, a thread hooking mechanism, a take-up mechanism and a feeding mechanism. A base thread detection device is mounted on a rotating shuttle; a sensor, a controller and a manipulator are arranged in the base thread detection device; the sensor is used for sensing the stock of base threads; the controller controls the manipulator to replace a bobbin; a lifting mechanism is mounted on a needle bar; the needle bar is connected with a draw bar through the lifting mechanism; a clutch I is arranged between the draw bar and the needle bar through the lifting mechanism; a clutch II is arranged between the needle bar and a needle bar crank connecting rod mechanism; a linkage curved bar is arranged between the clutch I and the clutch II; a servo control system is arranged on the thick stuff sewing machine; and a power module, a control module, a drive module and a servo motor are arranged in the servo control system. Through the invention, the structure and the control system are optimized, and the production efficiency is improved.

Owner:苏磊 +1

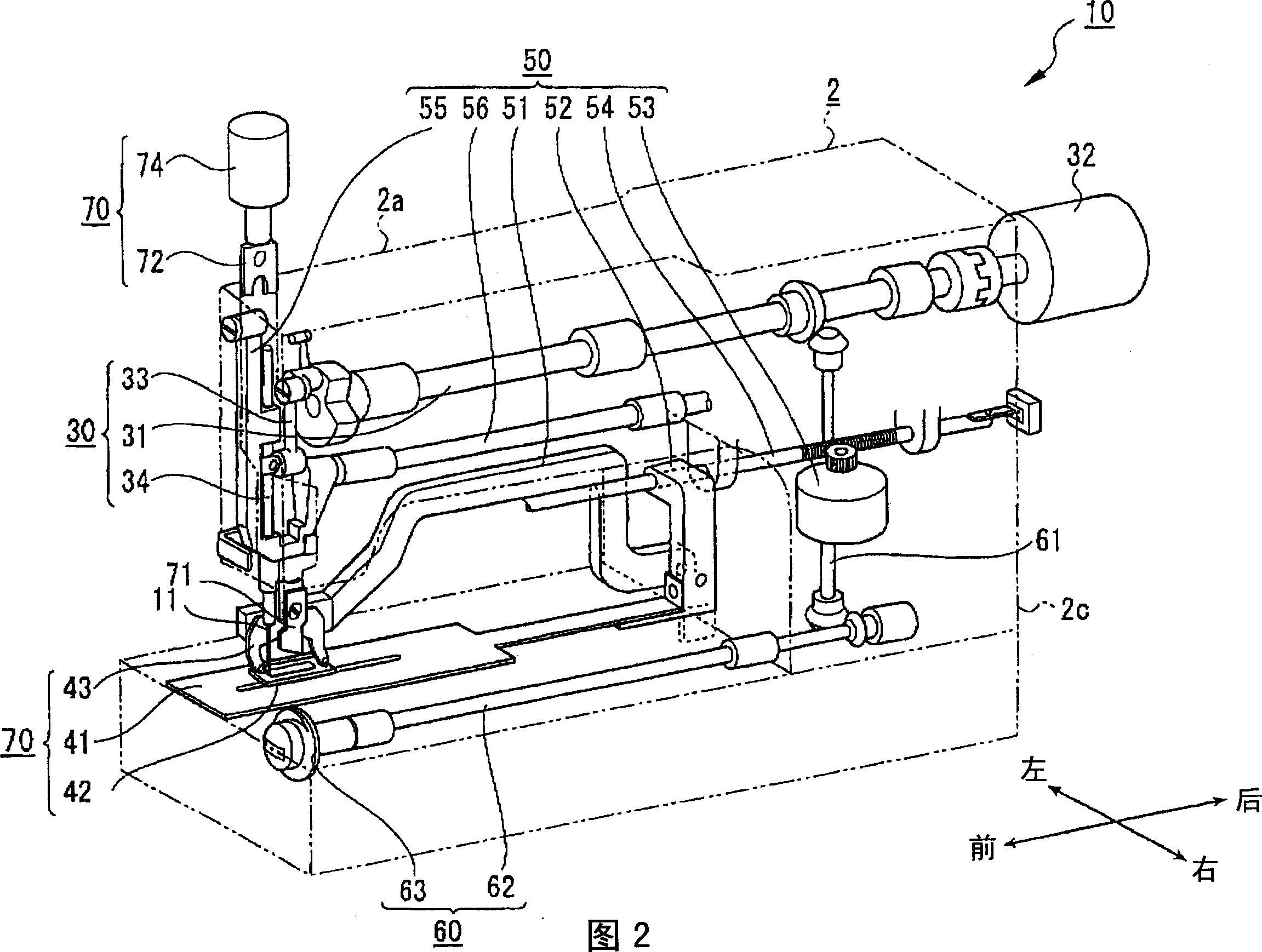

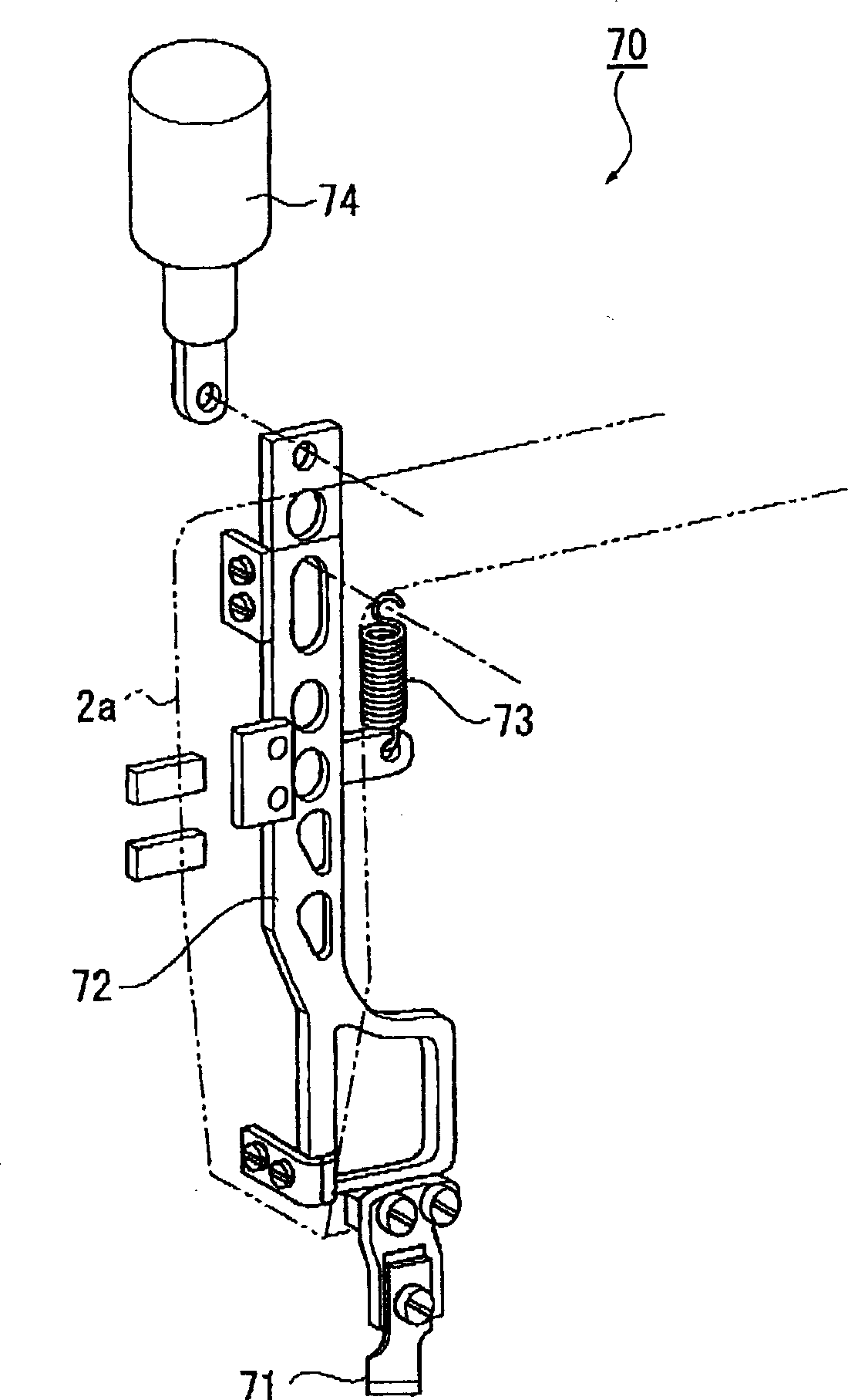

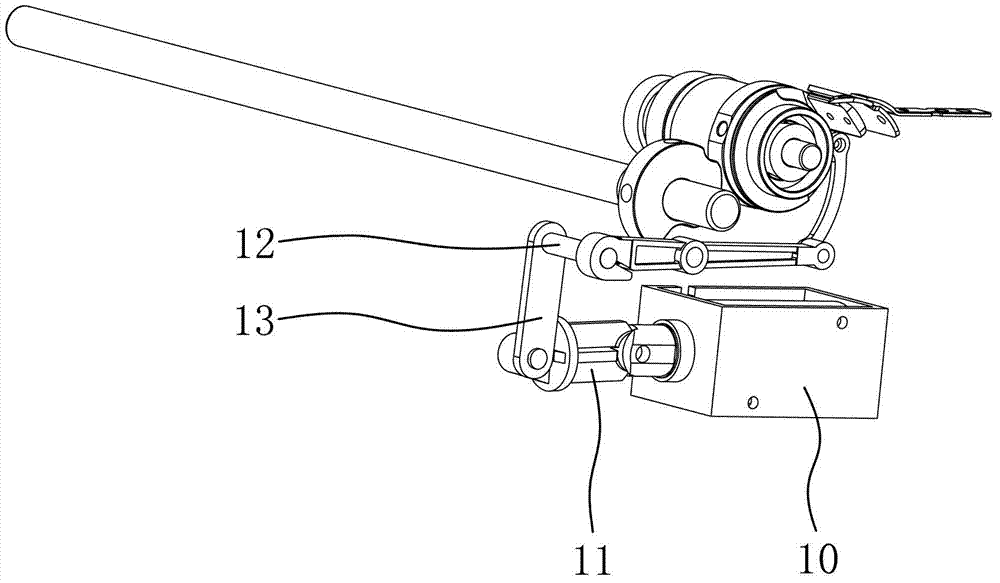

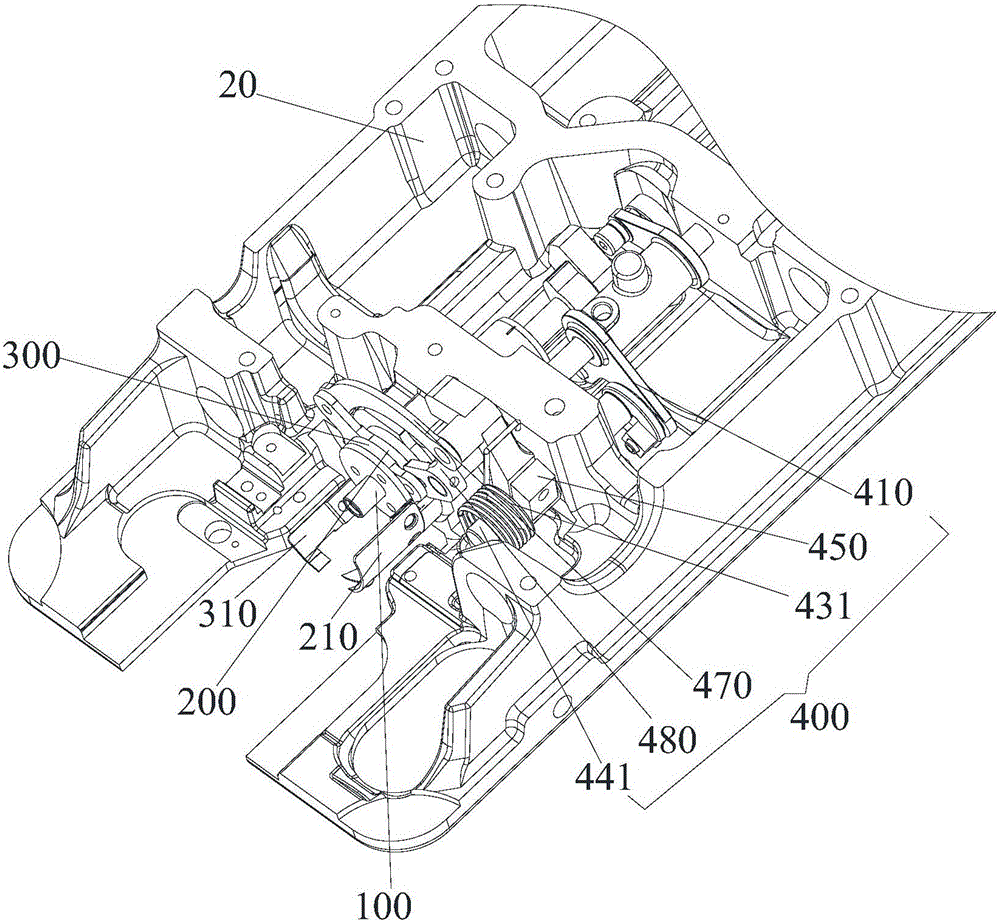

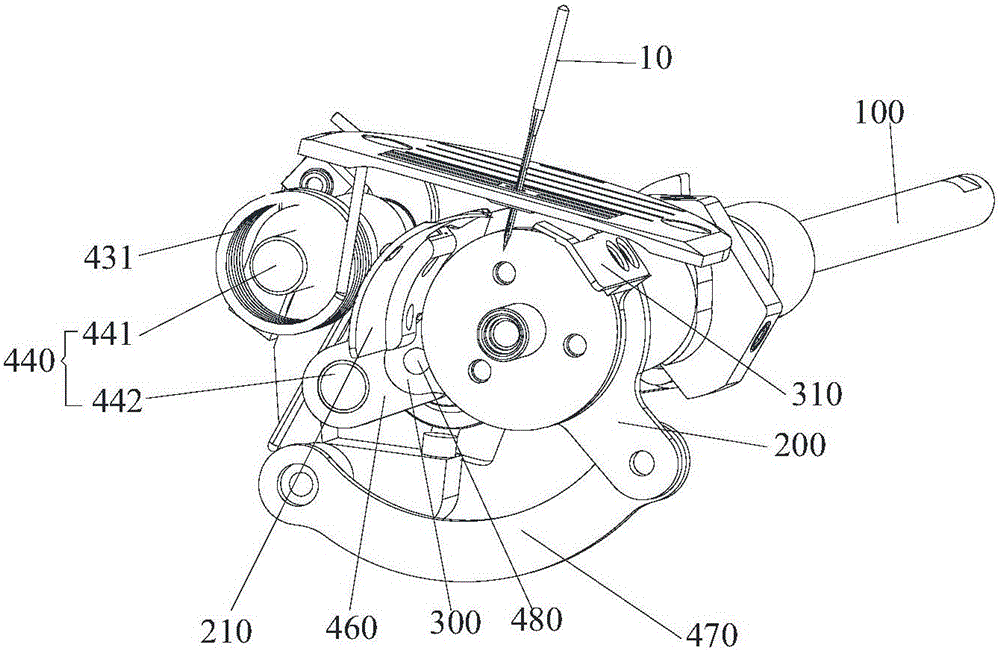

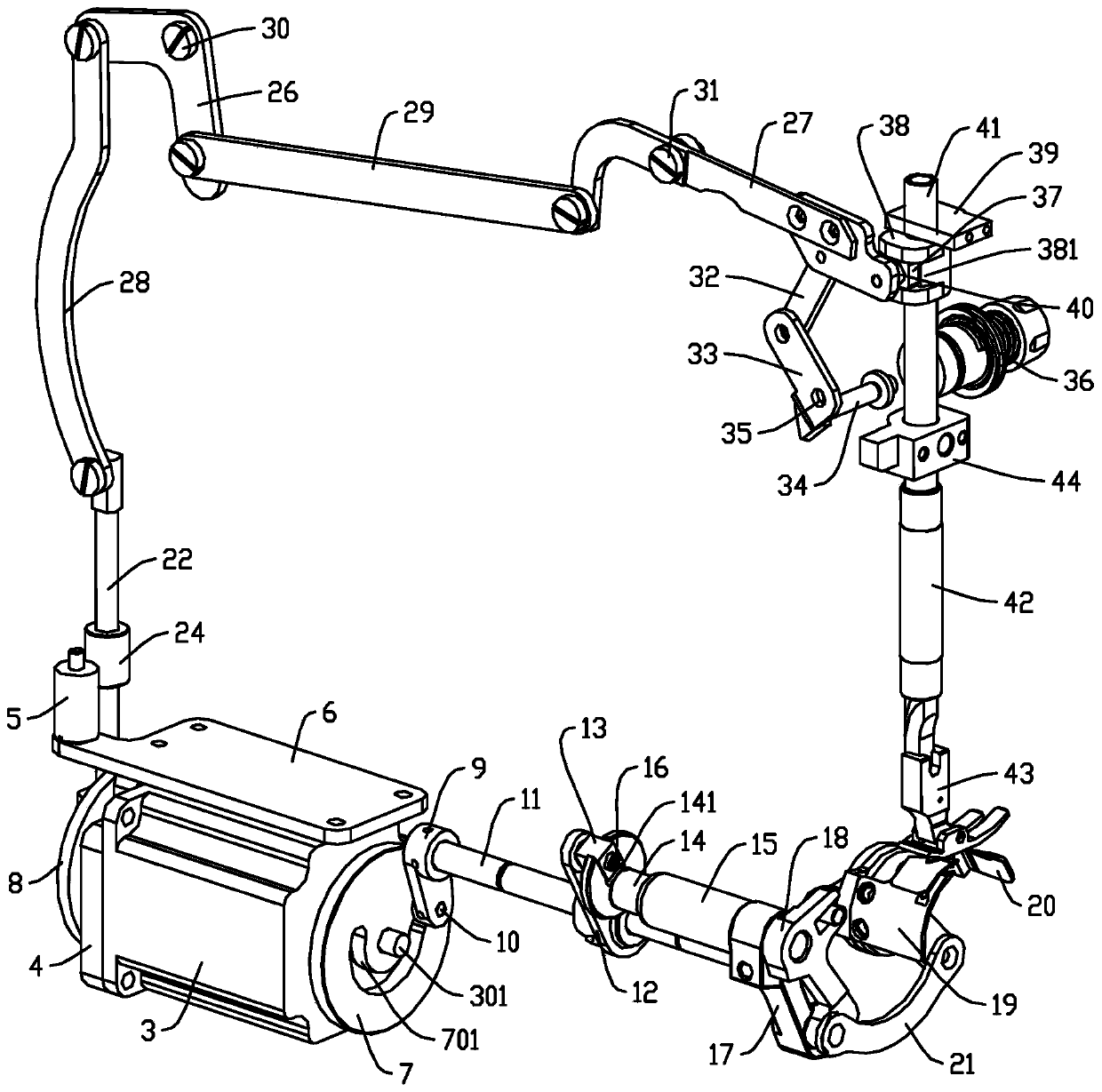

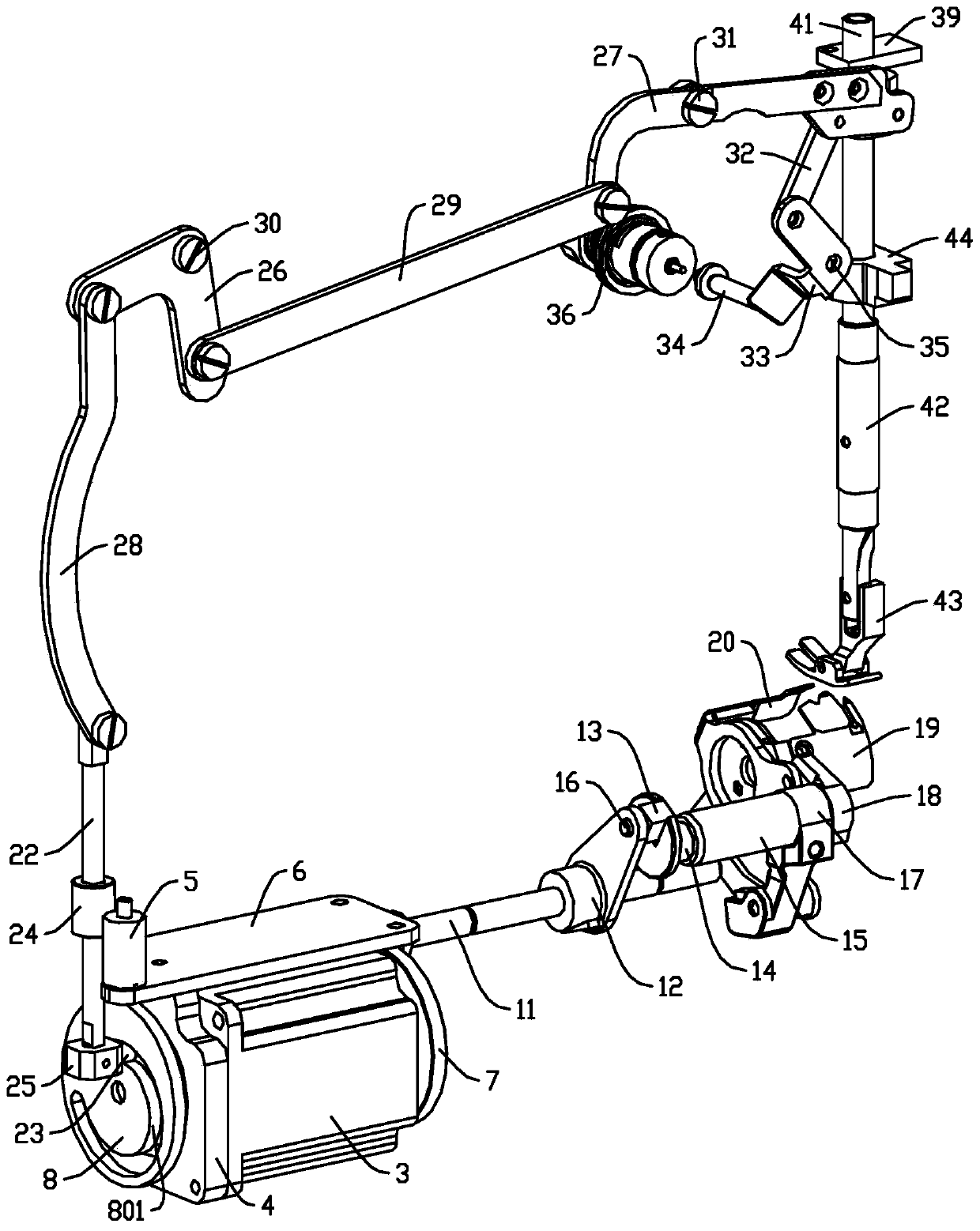

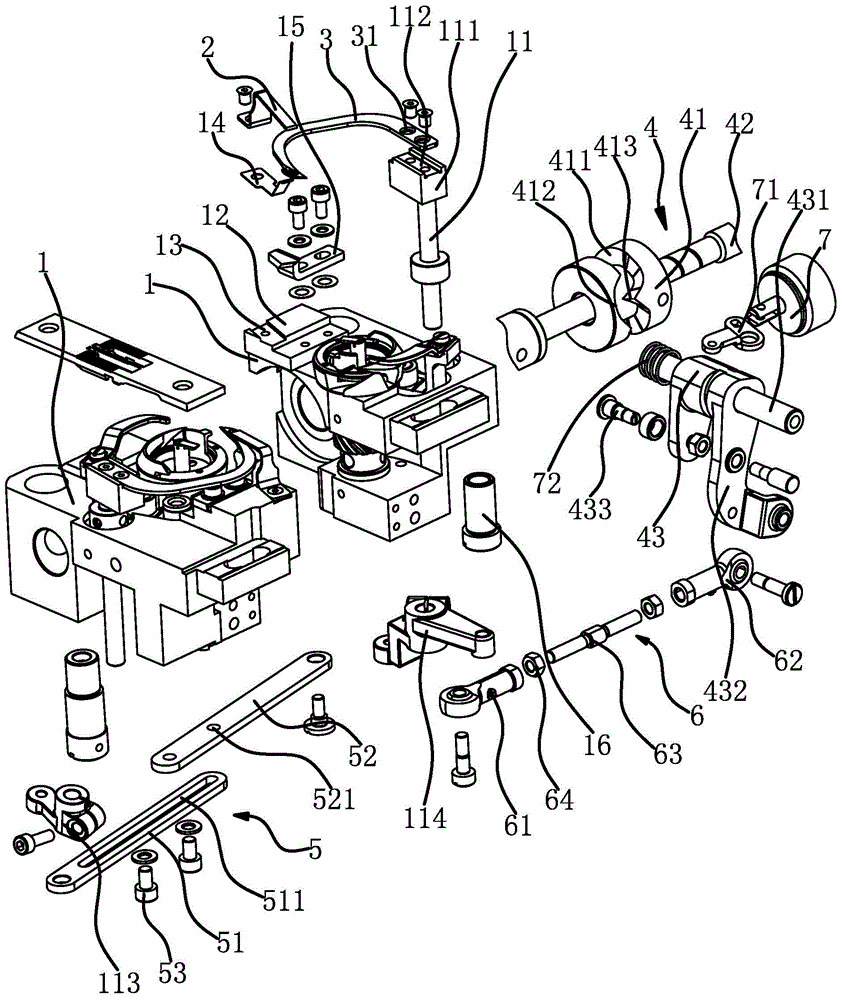

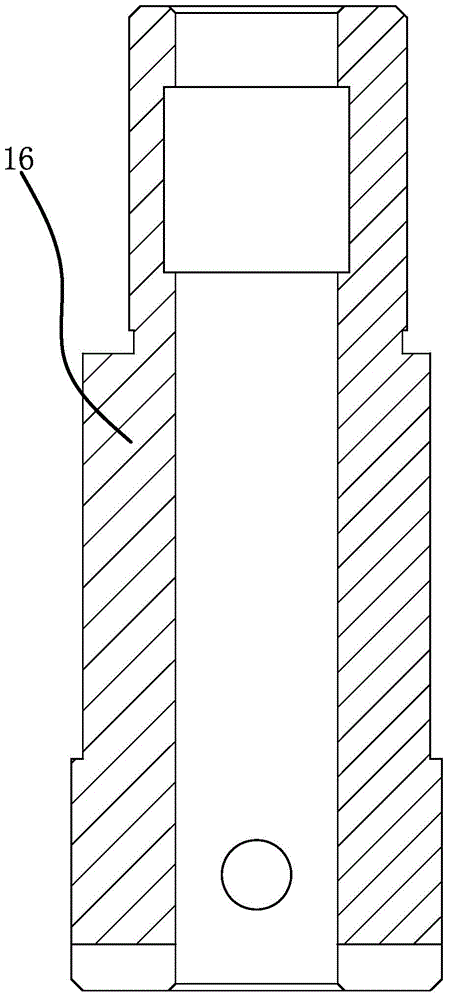

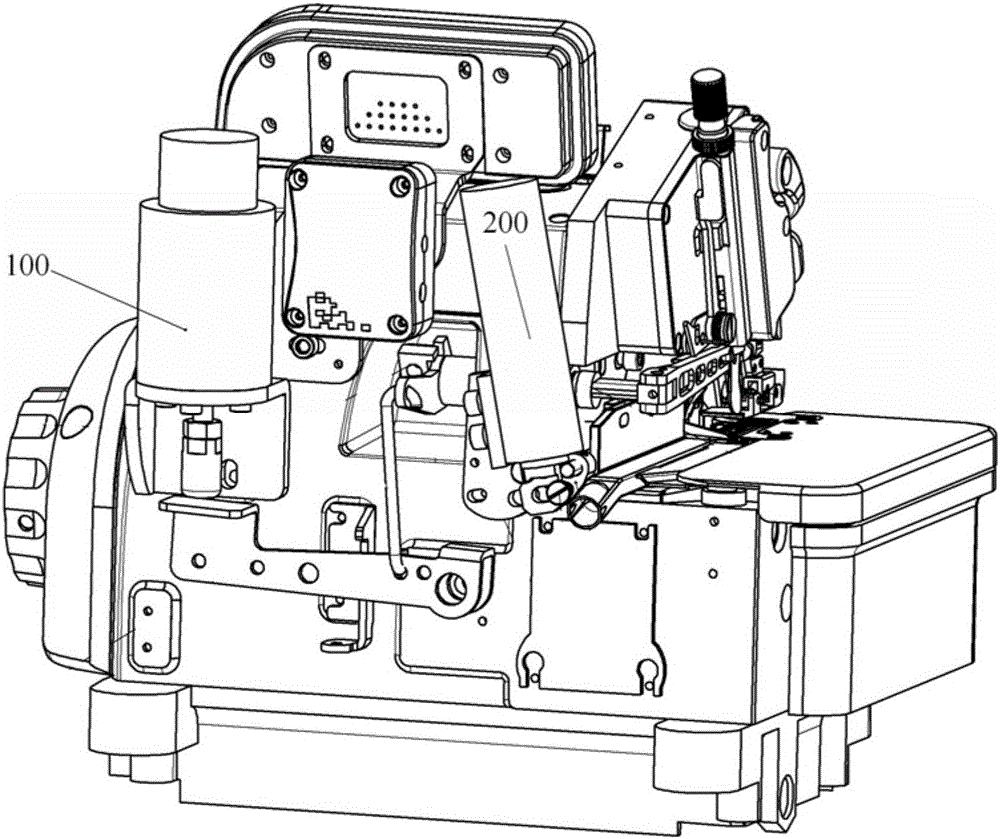

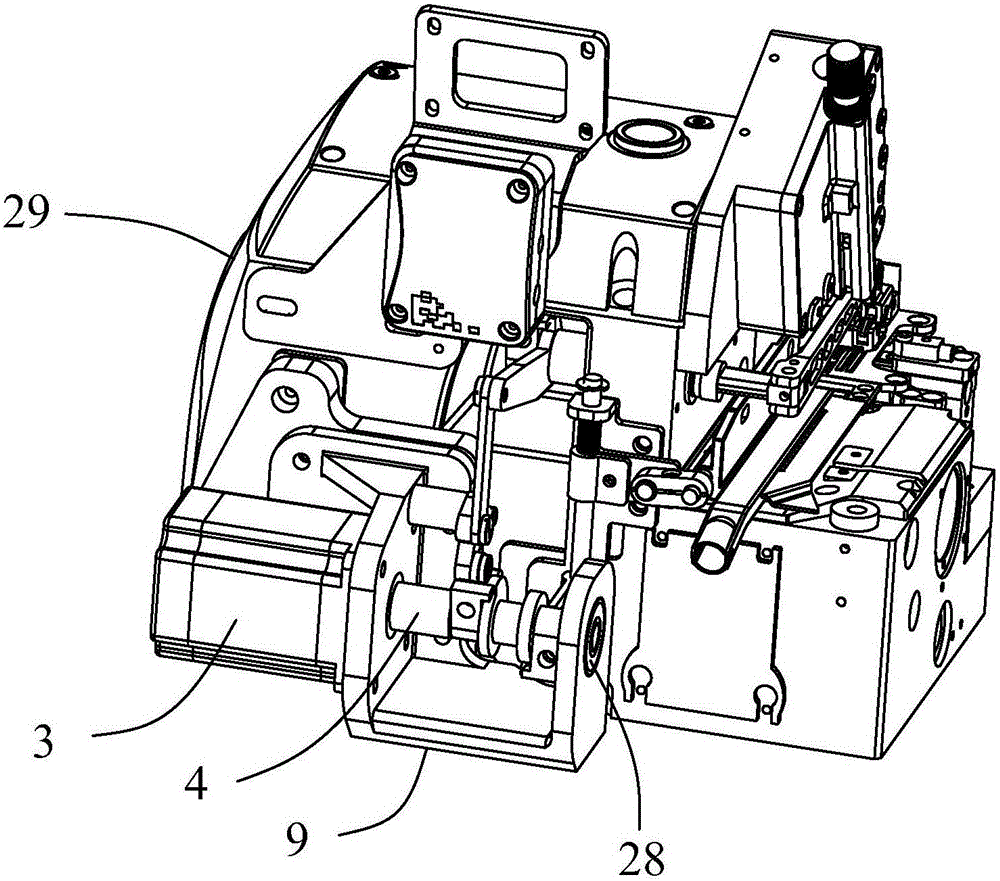

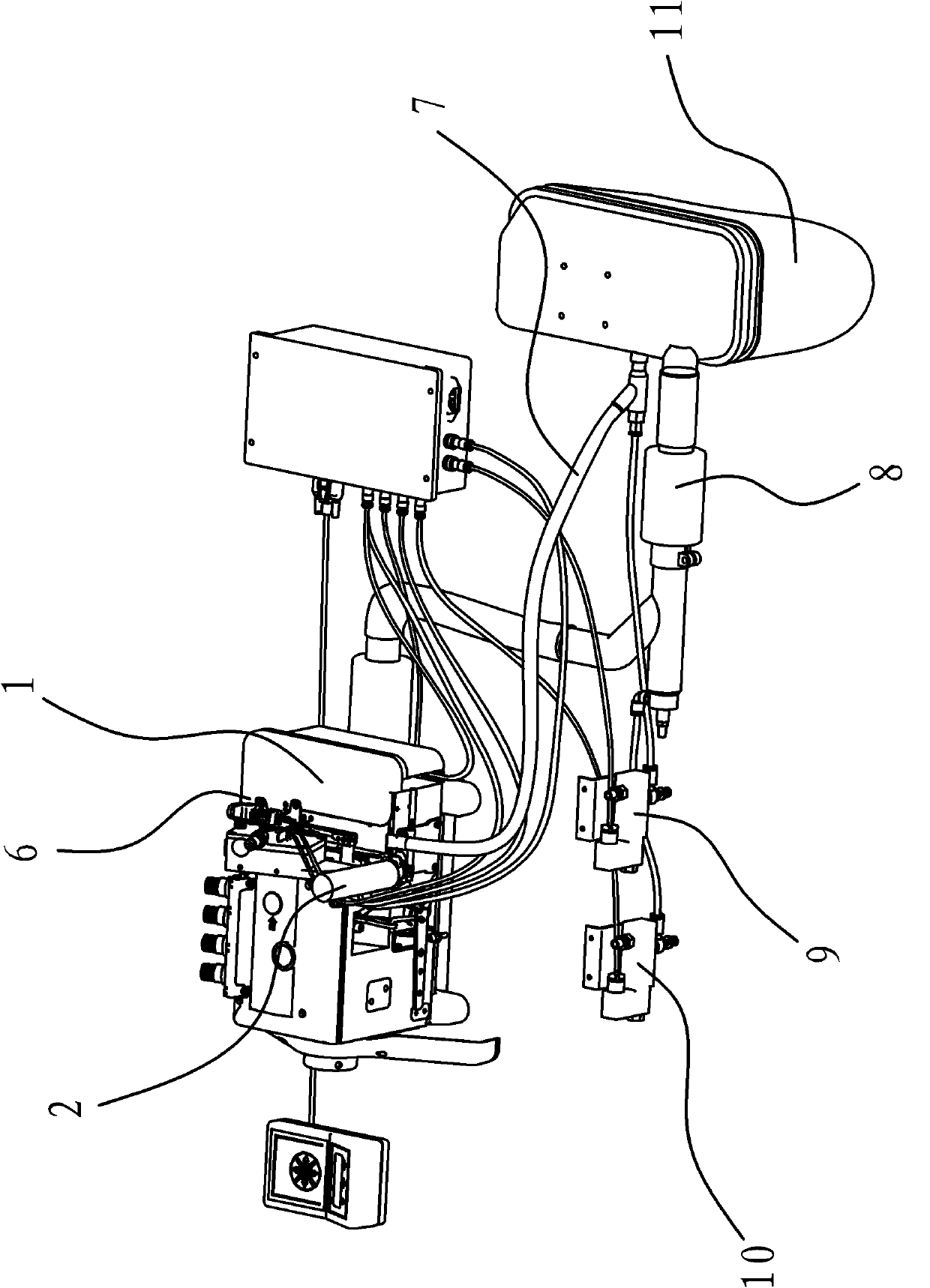

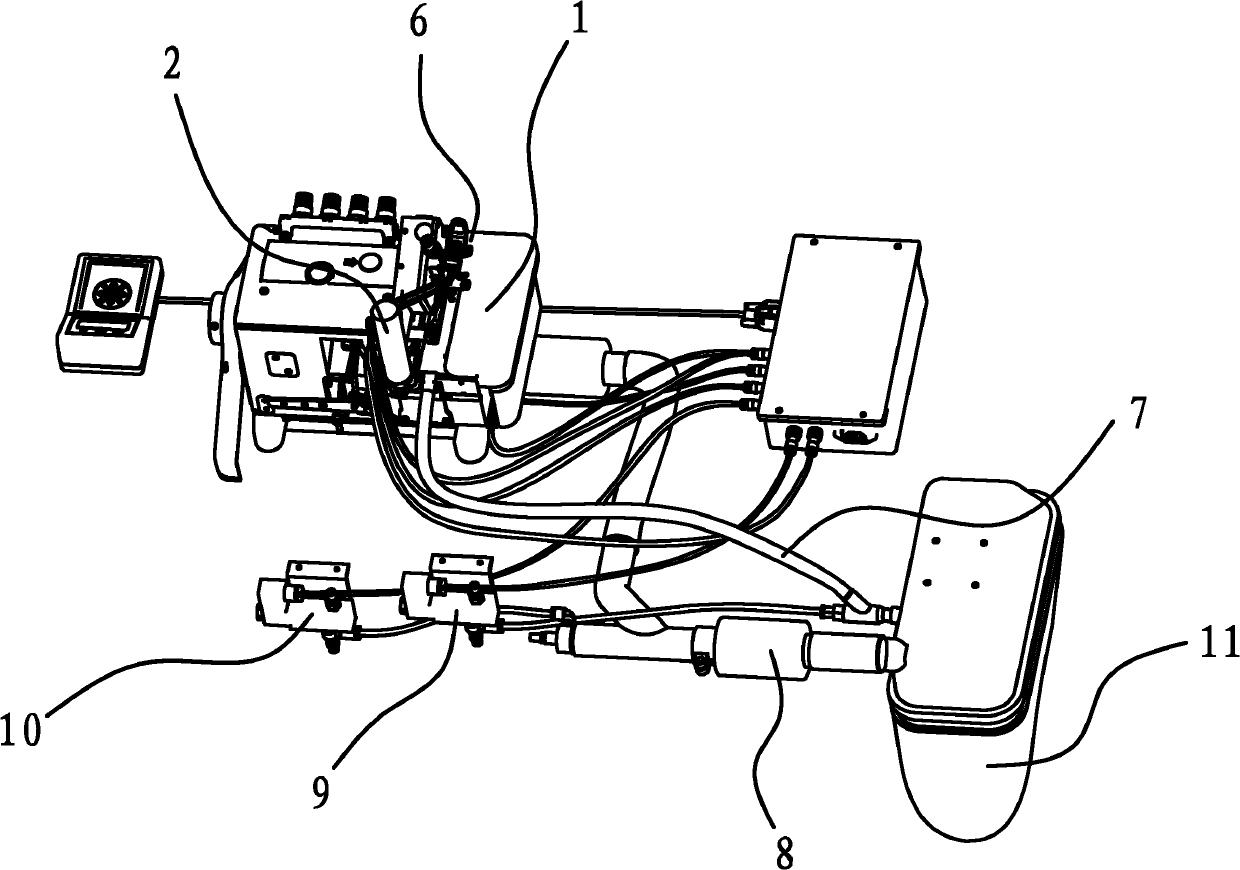

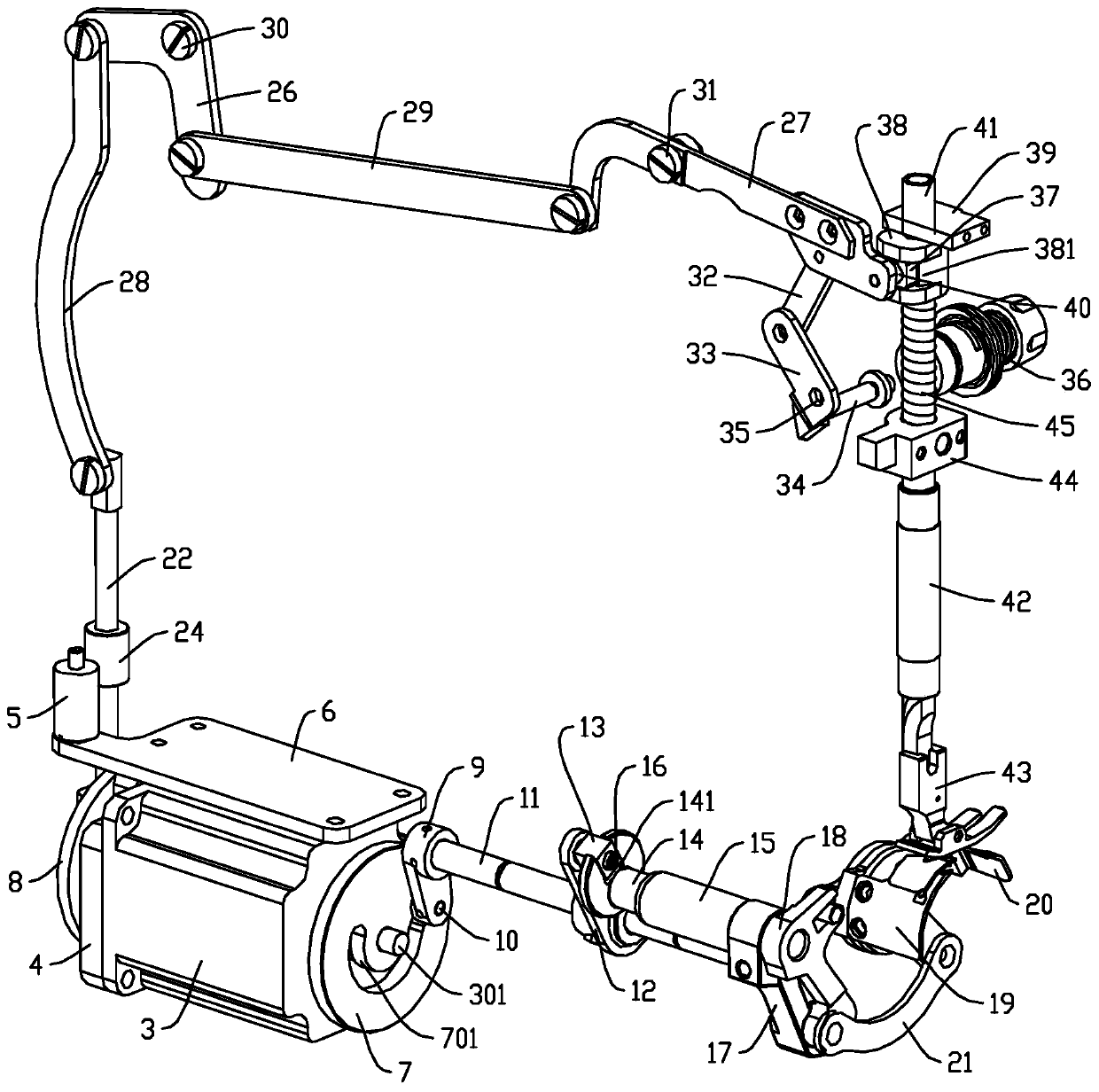

Drive mechanism integrating trimming, thread slacking, routing and presser foot lifting and sewing machine

ActiveCN105839300AEasy to controlMovement precisionNeedle severing devicesSewing-machine control devicesDrive motorEngineering

The invention provides a drive mechanism integrating trimming, thread slacking, routing and presser foot lifting and a sewing machine. The drive mechanism comprises a drive motor, a thread slacking shaft in transmission connection with the drive motor, a presser foot lifting transmission assembly connected with a presser foot lifting assembly, and a thread slacking transmission part connected with a thread slacking and routing assembly. The presser foot lifting transmission assembly comprises a presser foot lifting transmission rod and a presser foot lifting transmission part which are in sliding connection, the presser foot lifting transmission rod is fixedly connected with the thread slacking shaft, the presser foot lifting transmission part is connected with the presser foot lifting assembly, and the thread slacking transmission part is connected with the thread slacking shaft. One power source, namely the drive motor is adopted, so that the drive mechanism is simplified; meanwhile, the drive motor can control movement positions more accurately, routing and thread slacking actions and presser foot lifting and thread slacking actions are more accurate, and adjustment is more convenient.

Owner:JACK SEWING MASCH CO LTD

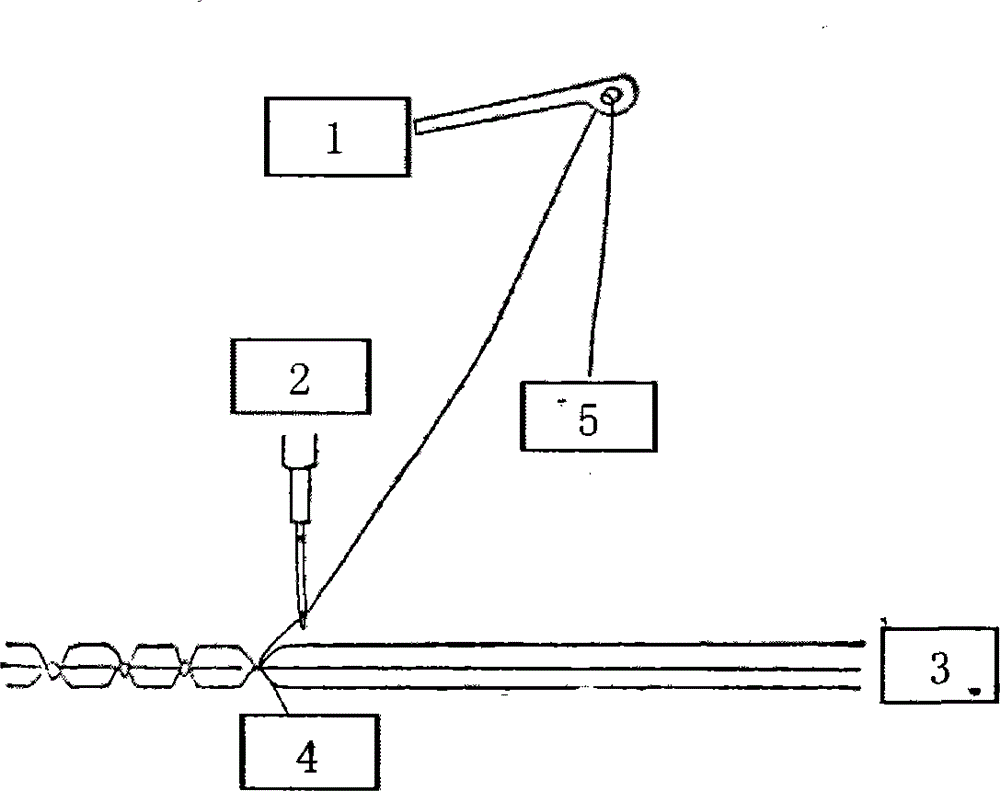

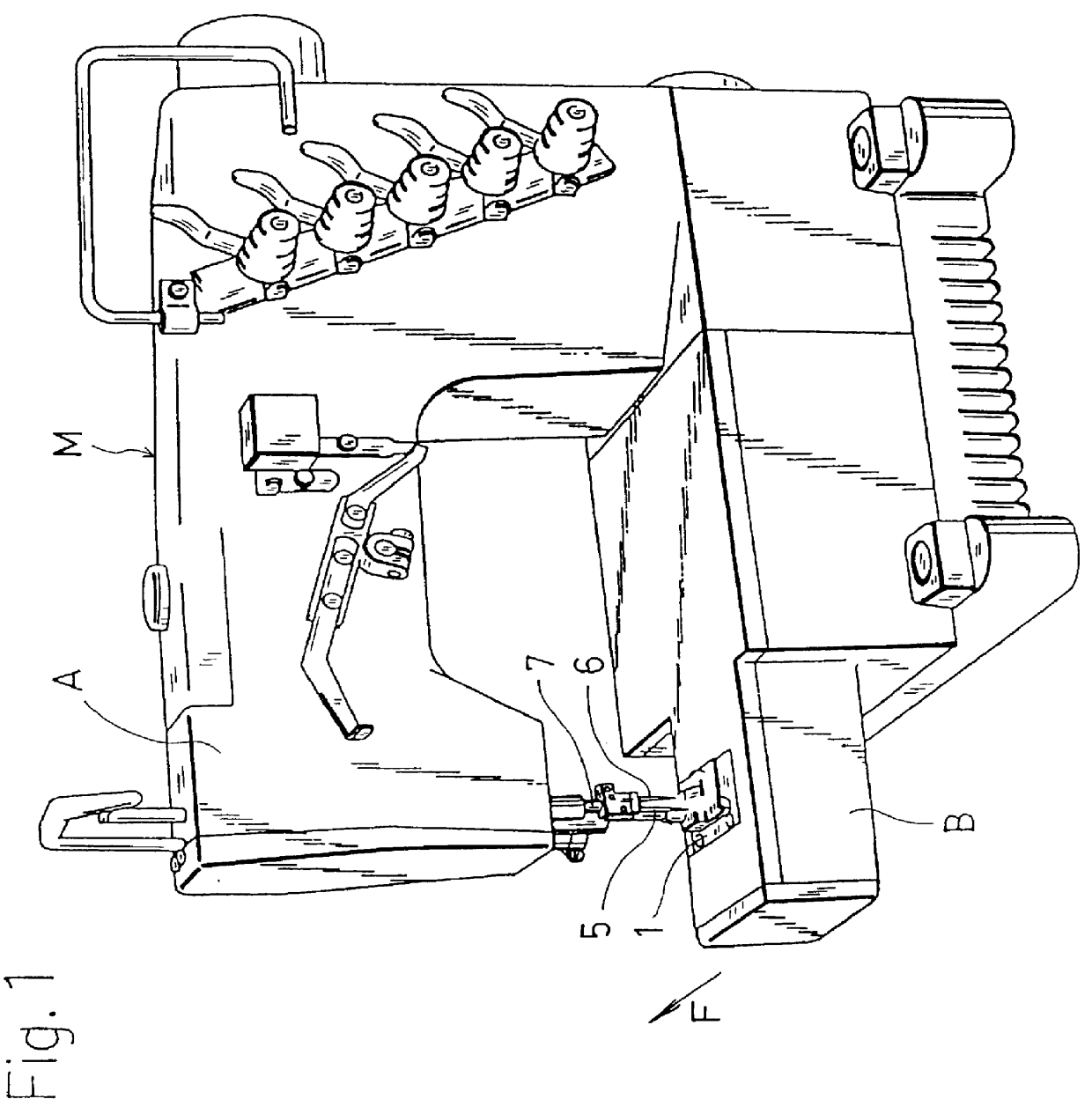

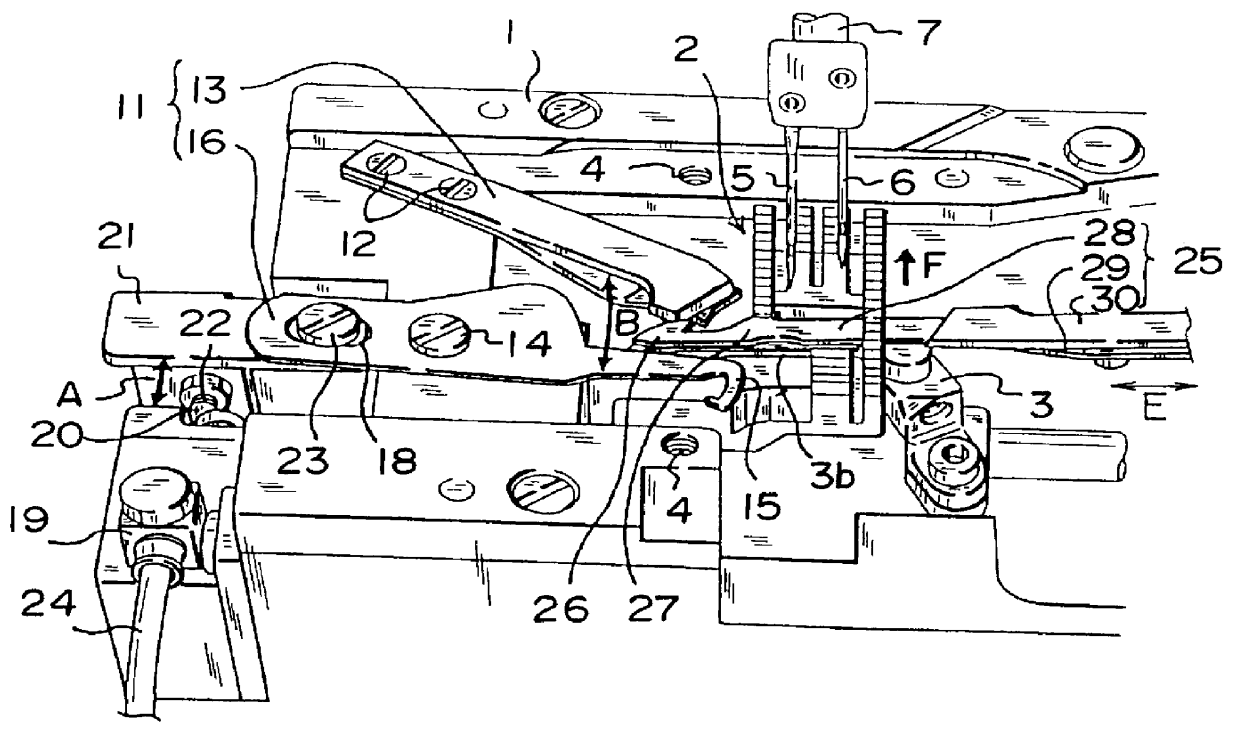

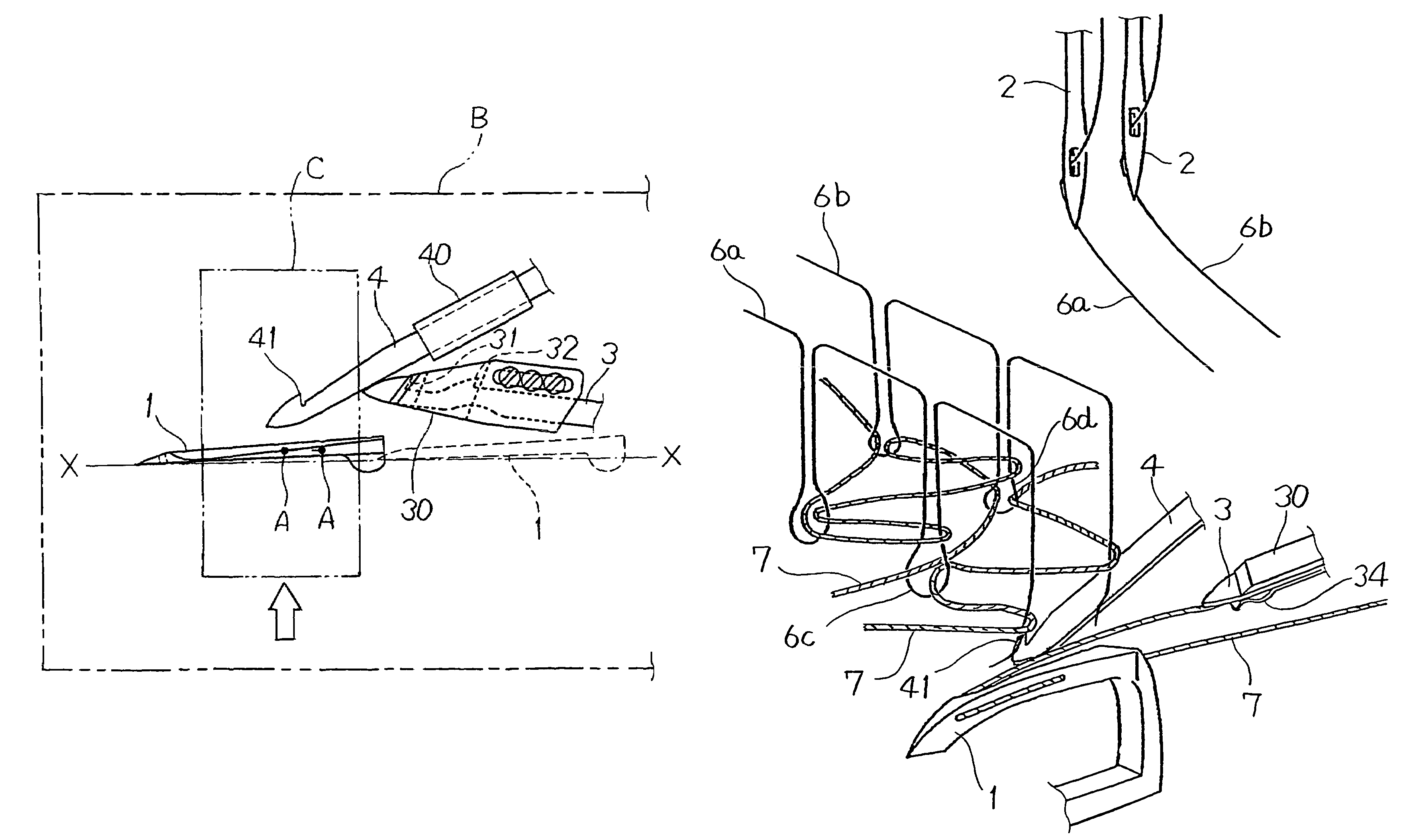

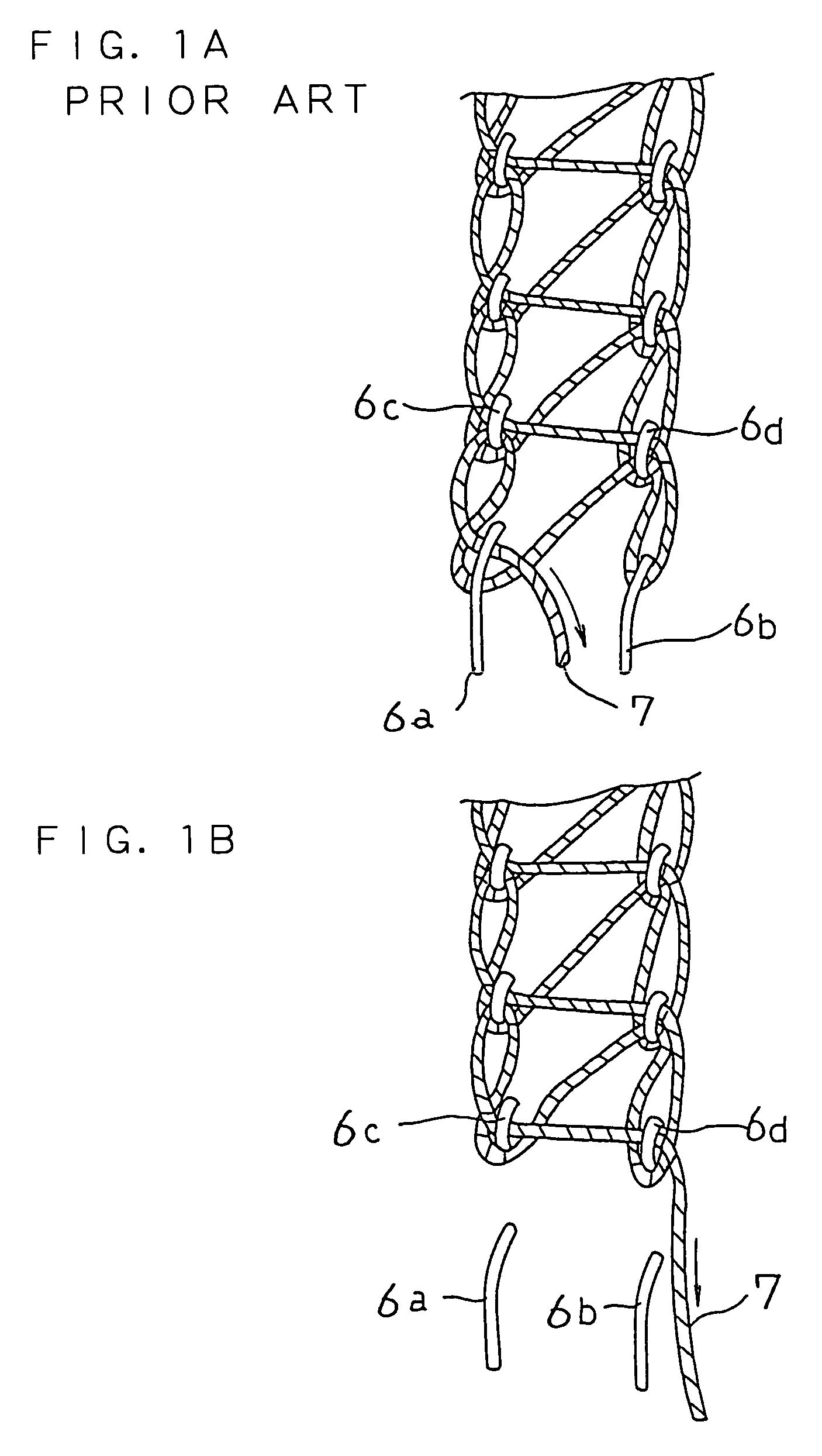

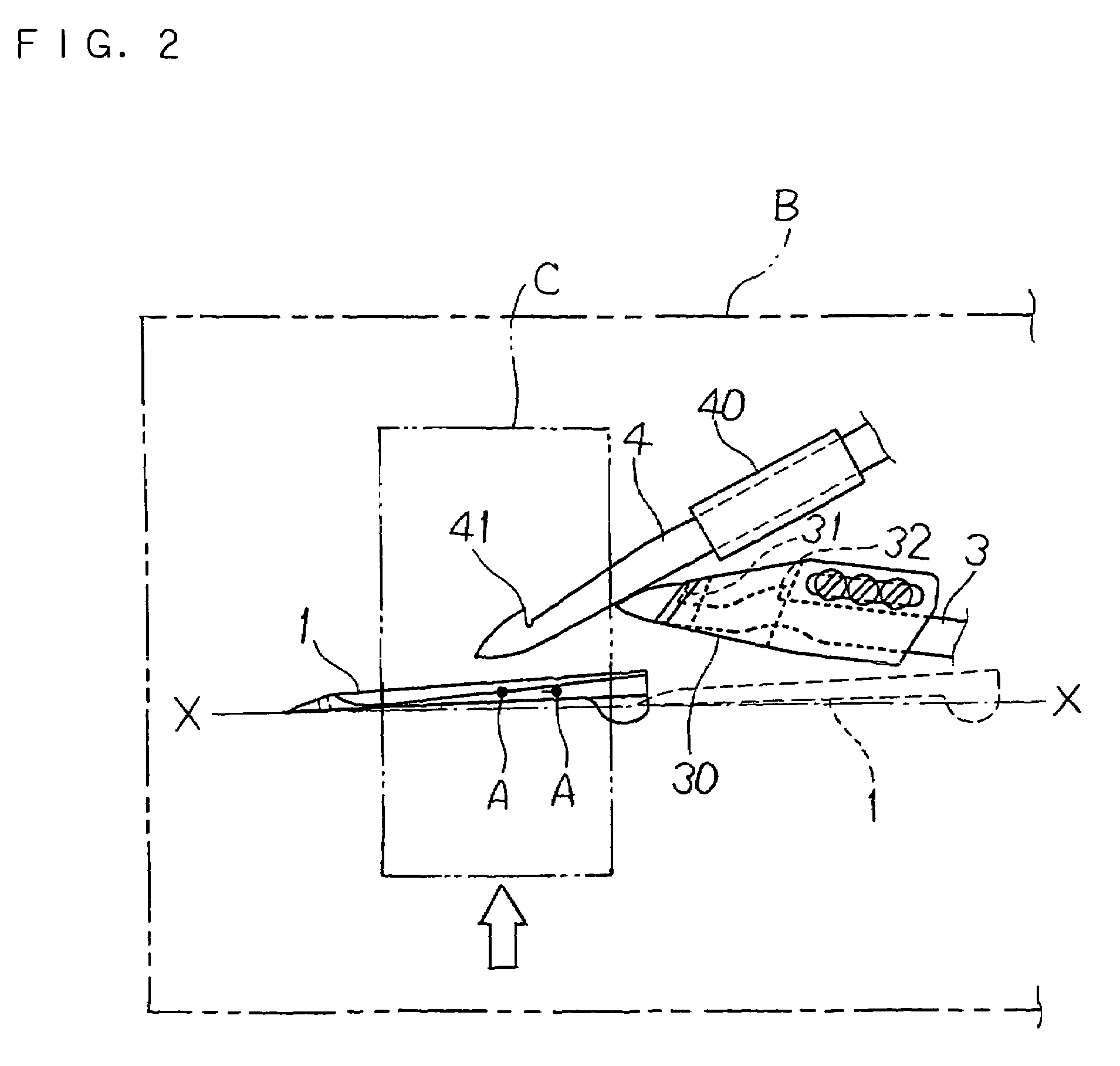

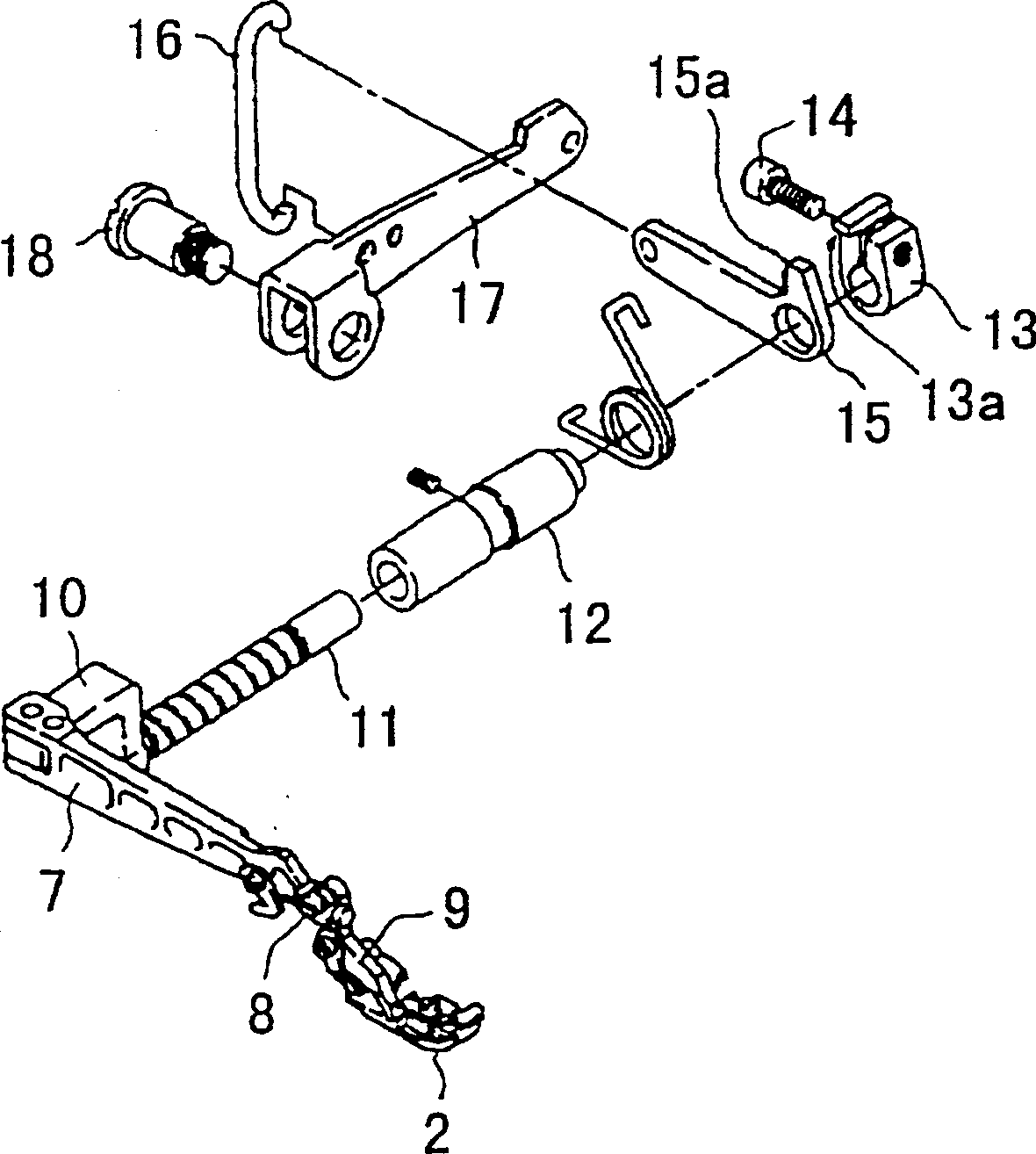

Method and apparatus for preventing a seam from raveling in double chain stitch sewing machine

InactiveUS6119613APreventing a seam from ravelingNeedle severing devicesLoop holdersEngineeringDouble chain

A method and apparatus for preventing a seam from raveling in a double chain stitch sewing machine according to the present invention are applied to sewing of cloth by a double chain stitch sewing machine. Near the sewing end point for forming a double chain stitch by collaboration of a plurality of needles and a looper, the looper thread consecutive to the looper from the cloth is hooked and engaged on the hook at the left side of the needles. After driving the sewing machine for a half stitch or one stitch in this state, the looper thread hooked on the hook is cut off. Simultaneously with this cutting or before or after the cutting, the needle thread loop consecutive to the needles from the sewing end of the cloth through the looper is cut off between the looper and the cloth. Further, capturing the cut looper thread consecutive to the looper from the cloth, the end of the cut looper thread is pulled out from the final needle thread loop at the end of sewing. Therefore, raveling of thread from the sewing end point is prevented, and the length of the thread end consecutive to the sewing end point is short, so that sewn products of good appearance may be obtained.

Owner:PEGASUS SEWING MACHINE MFG

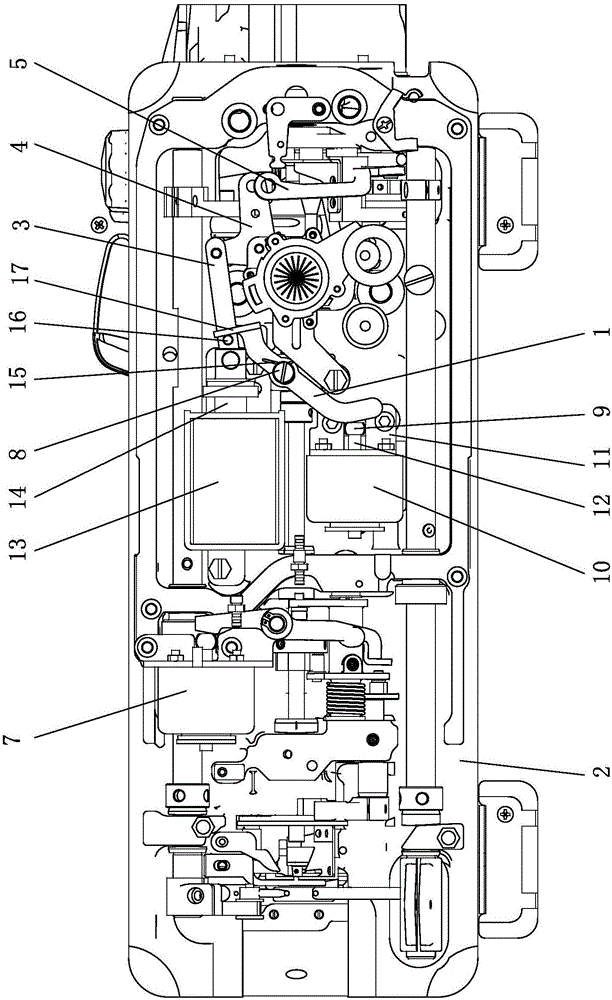

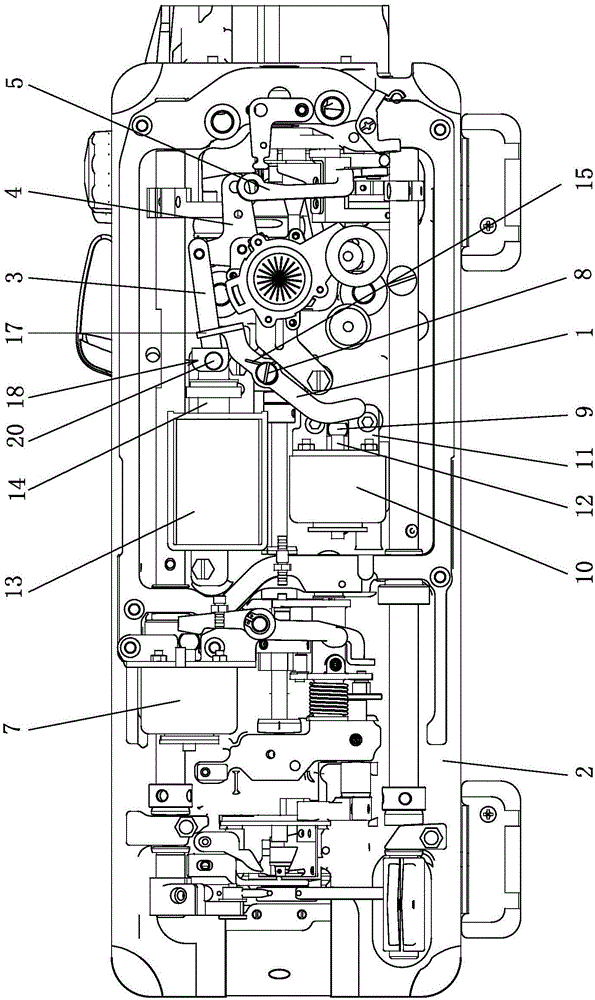

Thread trimming/loosening foot-lifting/pressing device for sewing machine, and sewing machine

ActiveCN110923967ASignificant progressSimple structureNeedle severing devicesPressersDrive wheelCrank

Owner:浙江杰克智能缝制科技有限公司

Thread trimming mechanism for two-needle sewing machine

InactiveCN104532491AImprove work efficiencyReduce adjustmentNeedle severing devicesEngineeringSewing machine

The invention provides a thread trimming mechanism for a two-needle sewing machine, and belongs to the technical field of sewing machine equipment. The problem that it is difficult for the current sewing machine to trim two stitches simultaneously is solved. The thread trimming mechanism for the two-needle sewing machine comprises two hook tables, the two hook tables are both fixedly connected with fixed blades, and are both rotatably connected with moving blade shafts, the upper end of each moving blade shaft is fixedly connected with a moving blade, the surfaces of the moving blades are attached to and abut against the surfaces of the fixed blades, a driver is arranged in a machine shell, and a connecting rod structure which can drive the two moving blade shafts to conduct reciprocating rotation along the opposite direction in a set angle is arranged between the driver and the two moving blade shafts. According to the thread trimming mechanism for the two-needle sewing machine, the installation and debugging are more convenient, the reliability of the thread trimming is high, a bottom thread and an upper thread can be hooked and trimmed simultaneously at one time, and two stitches can be trimmed simultaneously.

Owner:ZHEJIANG SHANGGONG GEM SEWING TECH CO LTD

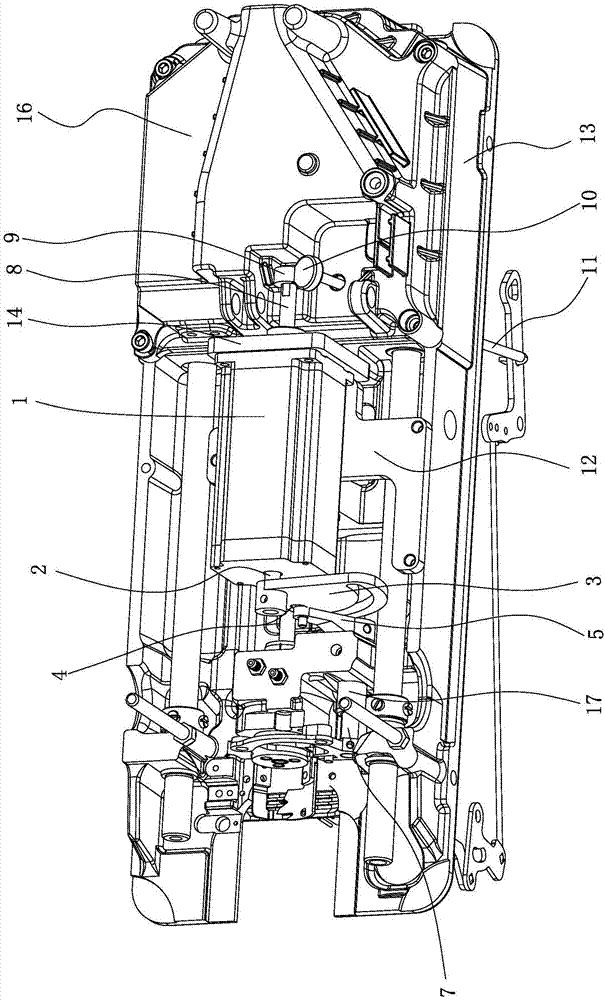

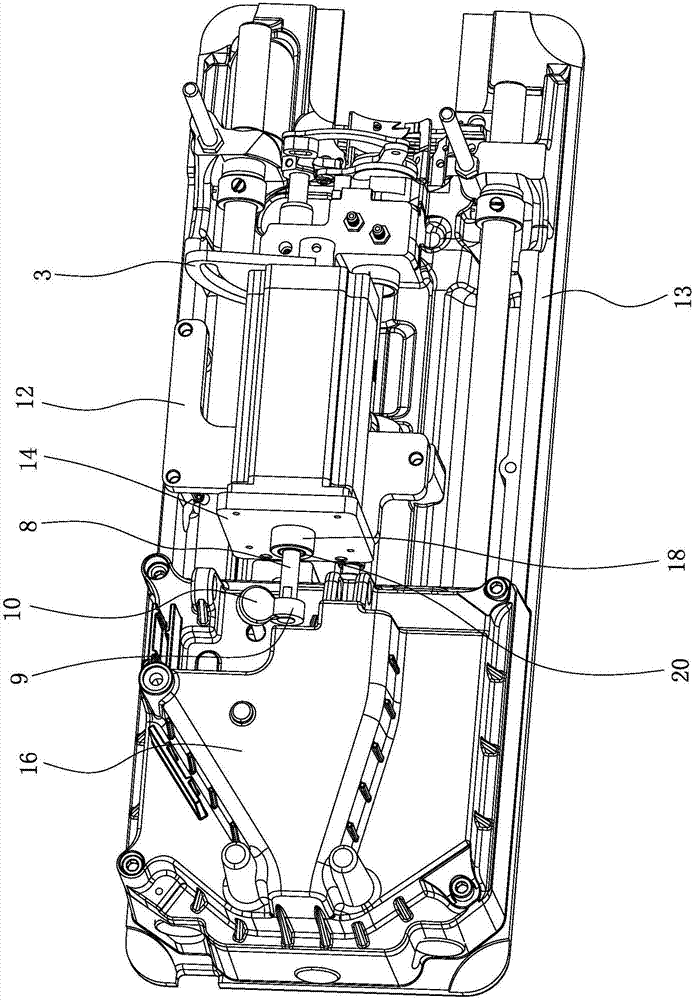

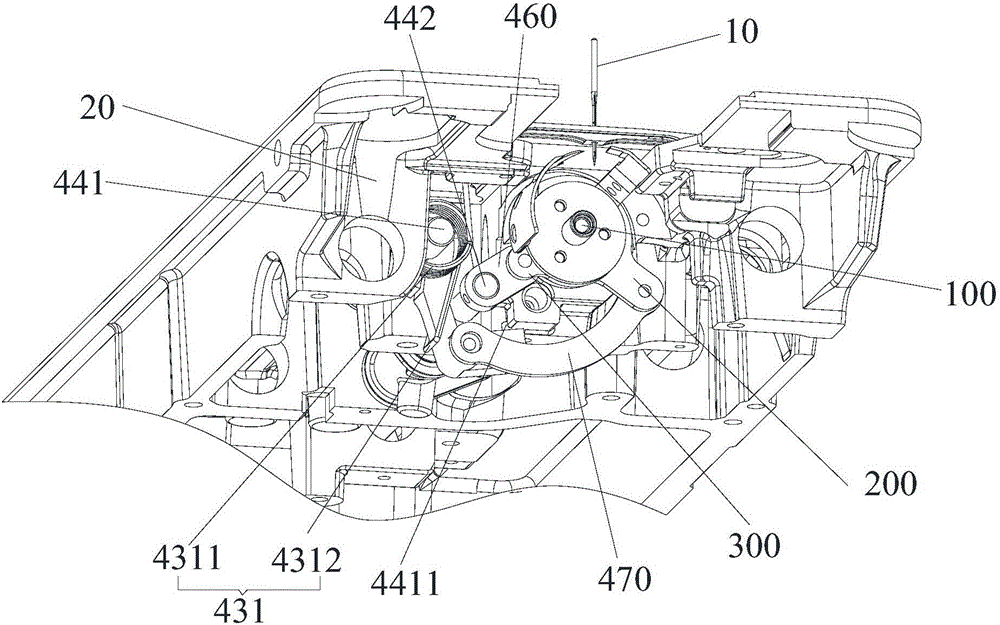

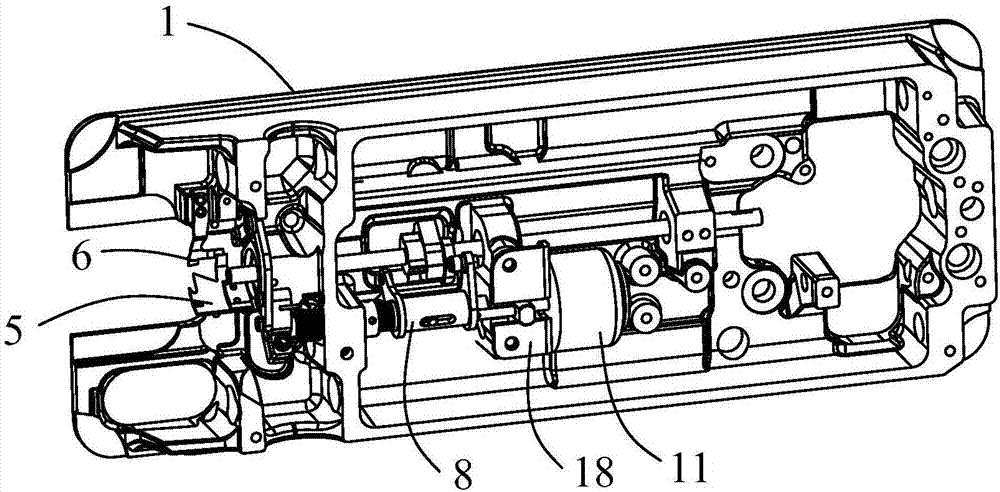

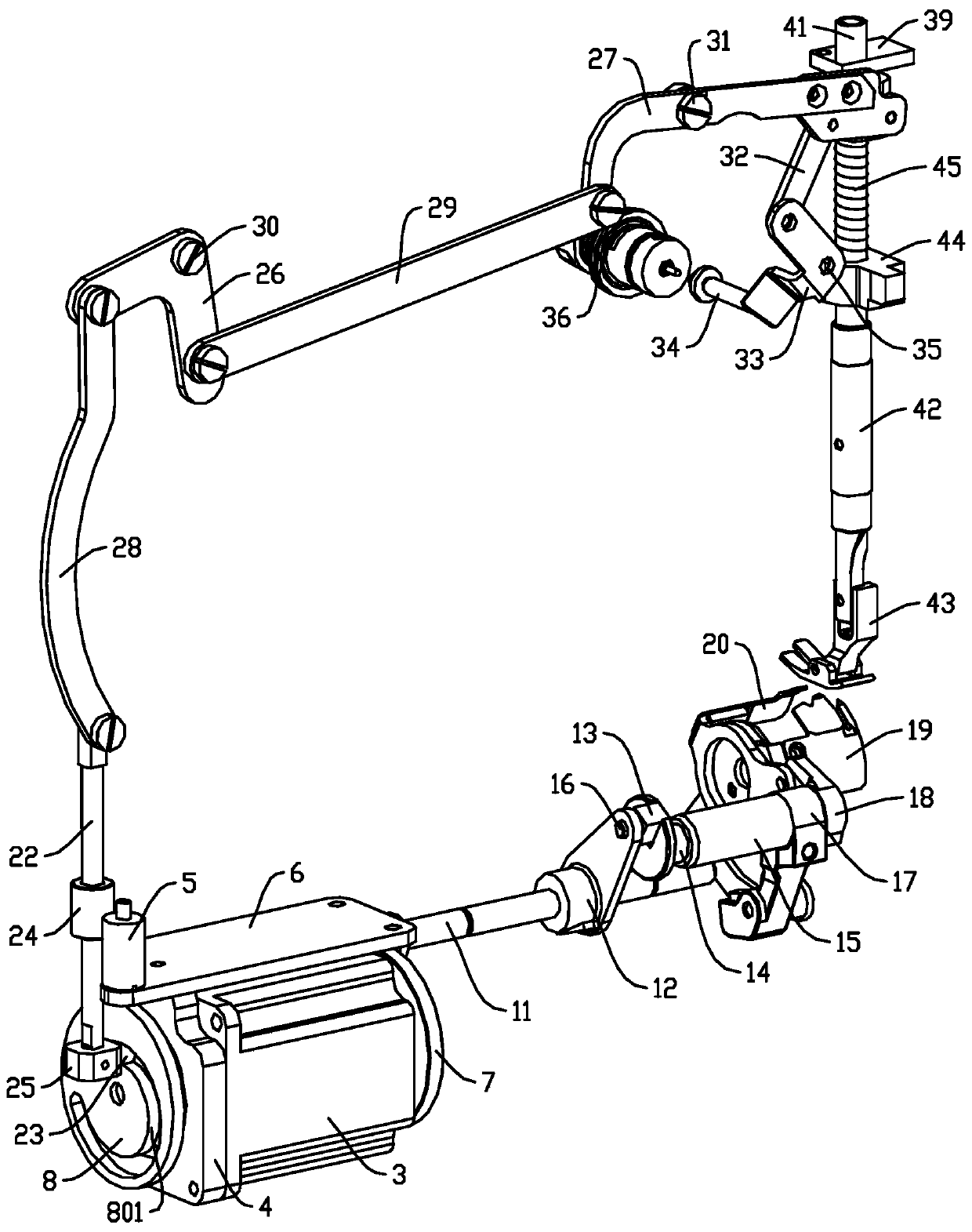

Integrated presser foot lifting and thread trimming device and sewing machine

The invention provides an integrated presser foot lifting and thread trimming device. The integrated presser foot lifting and thread trimming device comprises a presser foot lifting drive mechanism, a thread trimming drive mechanism, a power source, a rotatable coupling shaft, a presser foot lifting driving assembly, a presser foot lifting drive wheel connected with the presser foot lifting drive mechanism, a thread trimming driving assembly as well as a thread trimming drive wheel connected with the thread trimming drive mechanism; when the power source drives the coupling shaft to rotate forwards, the presser foot lifting driving assembly is abutted against the presser foot lifting drive wheel and drives the presser foot lifting drive wheel to rotate to enable the presser foot lifting drive mechanism to act, and the thread trimming driving assembly is separated from the thread trimming drive wheel; when the power source drives the coupling shaft to rotate reversely, the presser foot lifting driving assembly is separated from the presser foot lifting drive wheel, and the thread trimming driving assembly is abutted against the thread trimming drive wheel and drives the thread trimming drive wheel to rotate to enable the thread trimming drive mechanism to act. According to the integrated presser foot lifting and thread trimming device, a foot lifting action and a thread trimming action can be realized in a time-sharing manner only through one power source, so that the overall structure is more compact, the cost of a sewing machine is reduced effectively, and the attractiveness of the sewing machine can be improved.

Owner:JACK SEWING MASCH CO LTD

Automatic thread trimmingmechanism of sewing machine and sewing machine

ActiveCN106894175AReduce in quantityReduce assembly man-hoursNeedle severing devicesSewing-machine control devicesEngineeringCam

The invention provides a sewing machine automatic thread trimming mechanism. The mechanism includes a lower shaft, a thread trimming drive cam, a moving cutter assembly, a crankshaft, a thread trimming drive assembly, a thread trimming crank and a thread trimming connecting rod, wherein the thread trimming drive cam is fixed on the lower shaft, the moving cutter assembly can swing around the lower shaft and includes at least one moving cutter and a moving cutter frame, the thread trimming drive assembly is installed at one end of the crankshaft, and the thread trimming crank is fixed at the other end of the crankshaft; the thread trimming drive assembly includes a first extending arm, the end portion of the first extending arm is connected with a rotor, the two ends of the thread trimming connecting rod are hinged to the thread trimming crank and the moving cutter frame respectively, the distance between the crankshaft and the hinged point of the thread trimming crank and the thread trimming connecting rod is L1, the distance between the lower shaft and the hinged point of the moving cutter frame and the thread trimming connecting rod is L2, the ratio of the L1 to the L2 is not smaller than 2.5, and the transmission angle gamma of the thread trimming connecting rod relative to moving cutter frame is not smaller than 40 degrees; during thread trimming, the rotor is matched with a thread trimming contact surface on the periphery of the thread trimming drive cam. The structure and transmission chains of the sewing machine automatic thread cutting mechanism are simplified, the number of complicated parts in an original mechanism is reduced, the cost is reduced, and the assembling time is reduced.

Owner:JACK SEWING MASCH CO LTD

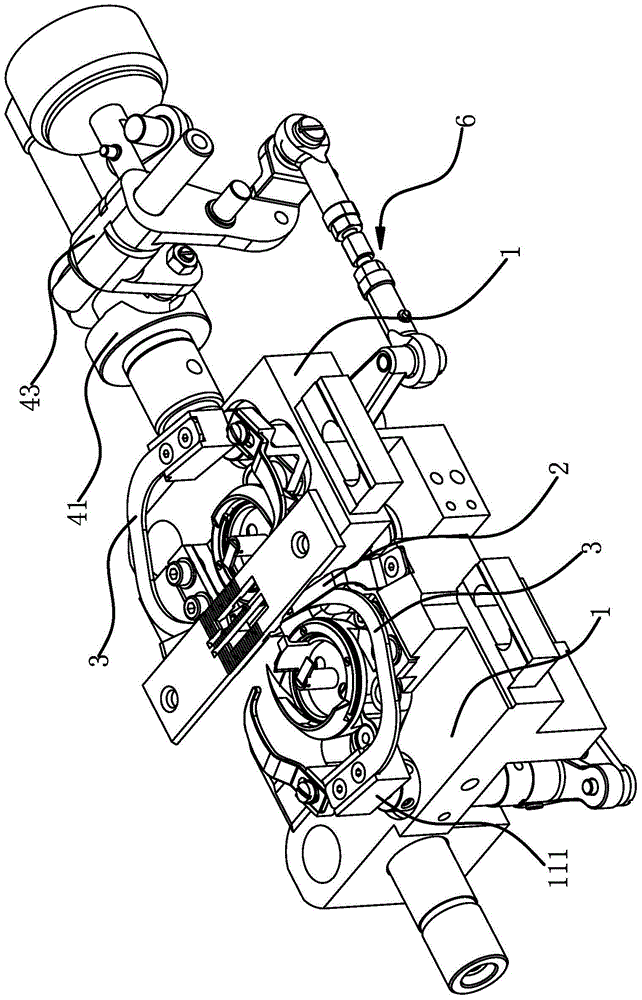

Industrial sewing machine

ActiveCN104141201ASuitable for sewingThe stitches are strong and beautifulProgramme-controlled sewing machinesNeedle severing devicesProgrammable logic controllerReciprocating motion

The invention belongs to the technical field of machinery and discloses an industrial sewing machine. A needle holder is driven to do vertical reciprocation by a swing rod and is driven to rotate around the needle holder axis by a needle holder rotation motor. A rotary hook and a hook carrier are mounted on a hook carrier assembly which comprises a shell, a rotary disc, a circular rotary seat, a belt pulley ring, a rotary hook motor, an assembly bearing and a slip ring. The rotary hook assembly is driven to do horizontal rotation by a rotary hook motor. Cloth to be sewn is clamped by a cloth feeding mechanism to do plane moving between the needle holder and the rotary hook. The needle holder rotation motor, the rotary hook carrier motor and the rotary hook motor are connected to a programmable logic controller on a table through the slip ring. The programmable logic controller drives the needle holder and the rotary hook carrier assembly to do rotation with same phase and same angular velocity. Products sewn by the industrial sewing machine have stable and firm stitches, and the industrial sewing machine is particularly suitable for sewing leather / cloth products in variable curved shapes.

Owner:广州明志电脑花样缝纫机械有限公司

Thread cutting mechanism in sewing machine

InactiveCN102002829AEasy to controlEasy to sewWorkpiece carriersNeedle severing devicesEngineeringDriven element

The invention provides a thread cutting mechanism in a sewing machine, which belongs to the technical field of machinery. The invention solves the problem that the traditional thread cutting mechanism can not absorb waste materials in a feeding position of the sewing machine. The thread cutting mechanism in the sewing machine is arranged at a needle plate of the sewing machine; the mechanism comprises a drive element and a cutter which is connected with the drive element and used for cutting threads; the cutter is provided with a sucking opening I; the feeding position of the needle plate is provided with a sucking opening II; and the lower part of the needle plate is provided with a pump sucking assembly which is connected with the sucking opening I and the sucking opening II. Both the cutter and the feeding position of the sewing machine are provided with the sucking openings for sucking the waste materials, and the two sucking openings are convenient for screwing a long sewing material.

Owner:ZHEJIANG ZOJE SEWING MACHINE

Sewing machine

ActiveCN106637733AFirmly connectedNot easy to fall offNeedle severing devicesSewing-machine control devicesState of artEngineering

The invention belongs to the technical field of sewing equipment and relates to a sewing machine. The sewing machine comprises a first driver and a first connection rod, the first connection rod is rotationally connected to a machine shell bottom plate, one end of the first connection rod is connected with a movable part of the first driver, the other end of the first connection rod is connected with a movable part of a second driver, the movable part of the second driver is also connected with a second connection rod, the second connection rod is driven by the first driver to rotate so that the other end of the first driver can drive the second connection rod to move to adjust to a corresponding stitch length for dense sewing, and the action of the first driver is controlled by a controller. The sewing machine can solve the problems that in the prior art, after thread cutting, thread ends are not attractive due to different lengths, and the thread ends are too long after thread cutting, and the stitch length during sewing can be adjusted through a mechanical structure. Before thread cutting, a small segment of dense sewing or variable-stitch-length sewing is conducted, so that the thread ends become short after thread cutting, the left thread ends are firmly connected and not likely to fall off after being torn, the sewing effect is improved, and attractiveness is improved.

Owner:JACK SEWING MASCH CO LTD

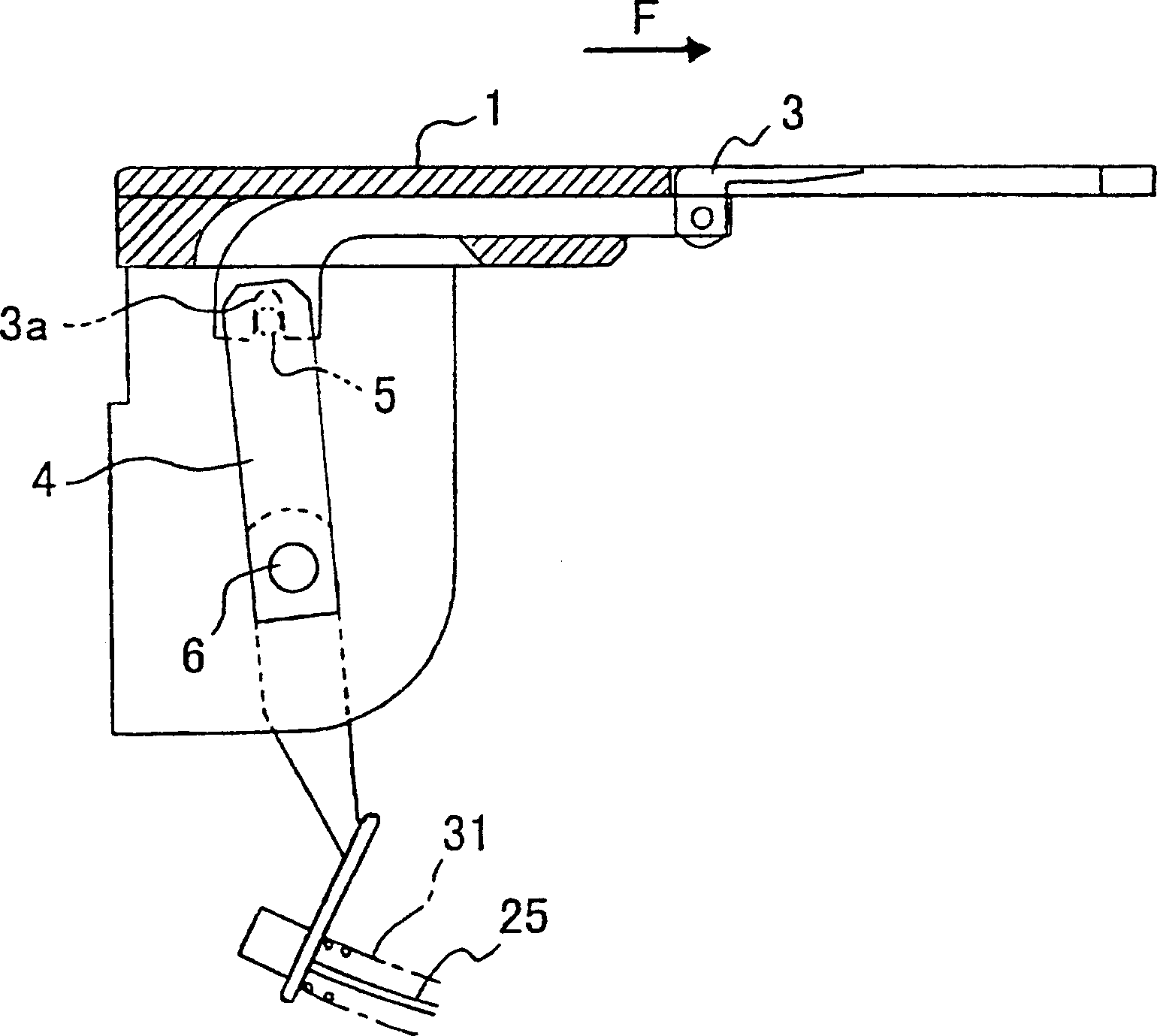

Seam ravel preventing apparatus and ravel preventing method

InactiveUS7497177B2Stable executionPreventing ravelingNeedle severing devicesLoop takersEngineeringScrew thread

A looper is brought into an advance state at the end of sewing, and a looper thread hanging hook arranged on the right rear side of a needle drop position is forced to advance and retreat to catch a looper thread running to the rear side of the looper and hold it on the rear side of the needle drop position. After performing sewing for one stitch in this state, the thread cutting hook arranged on the right side of the needle drop position is forced to advance and retreat to catch the looper thread running to the rear side of the looper with a first hold section and catch needle threads and the looper thread held by the looper thread hanging hook with a second hook section, and then these threads are collectively cut by bringing them into slide-contact with a thread cutting knife.

Owner:YAMATO SEWING MASCH MFG CO LTD

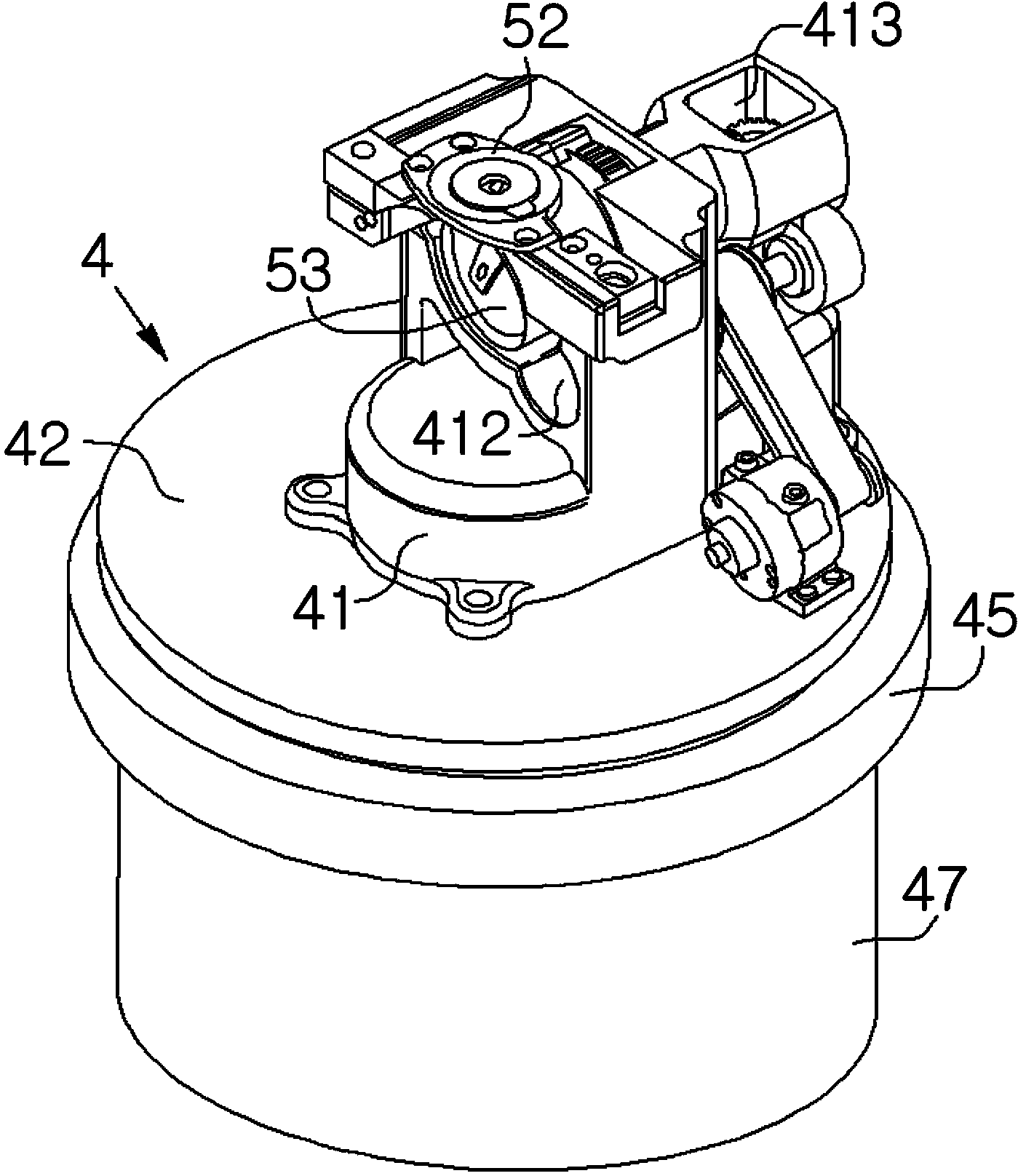

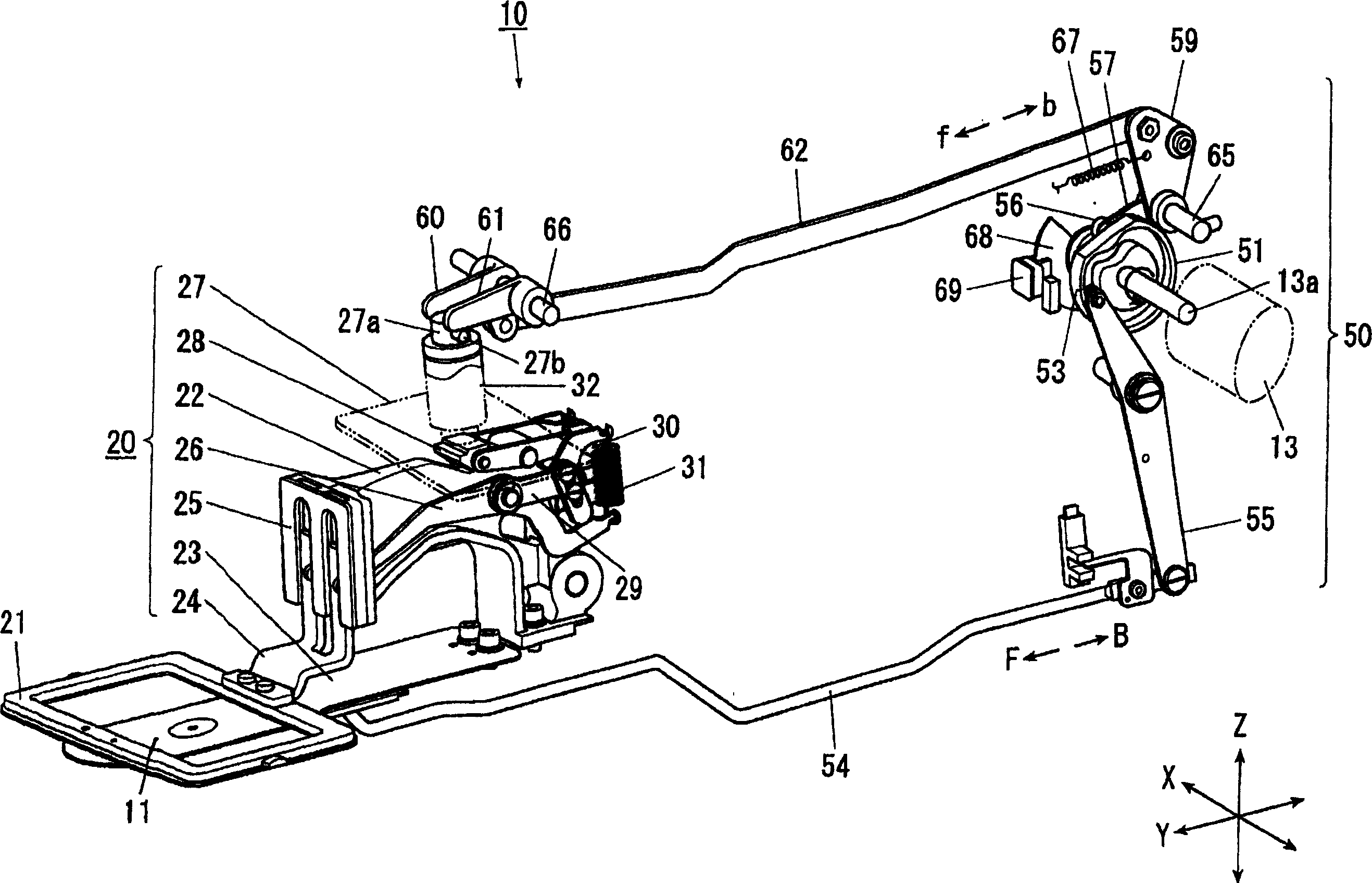

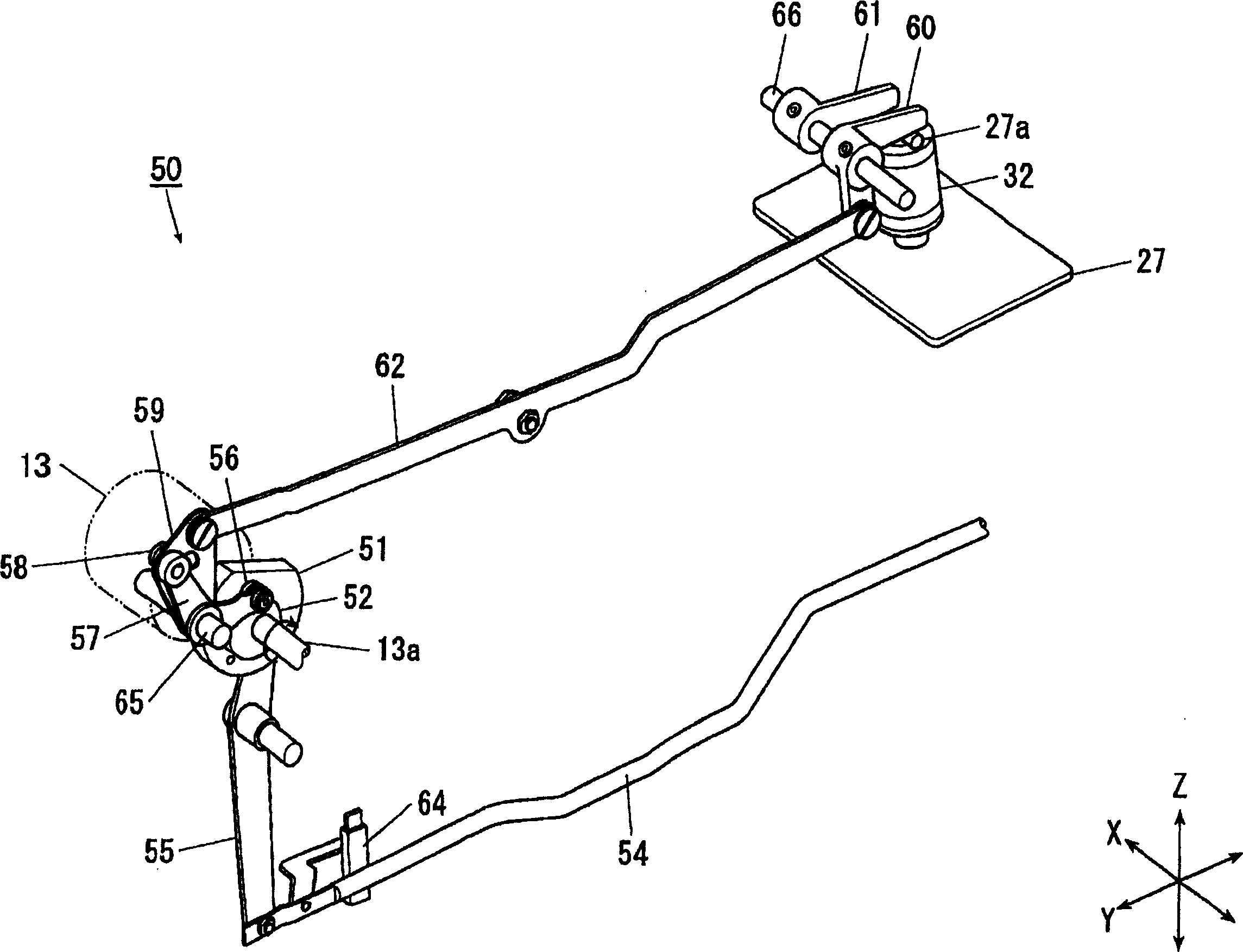

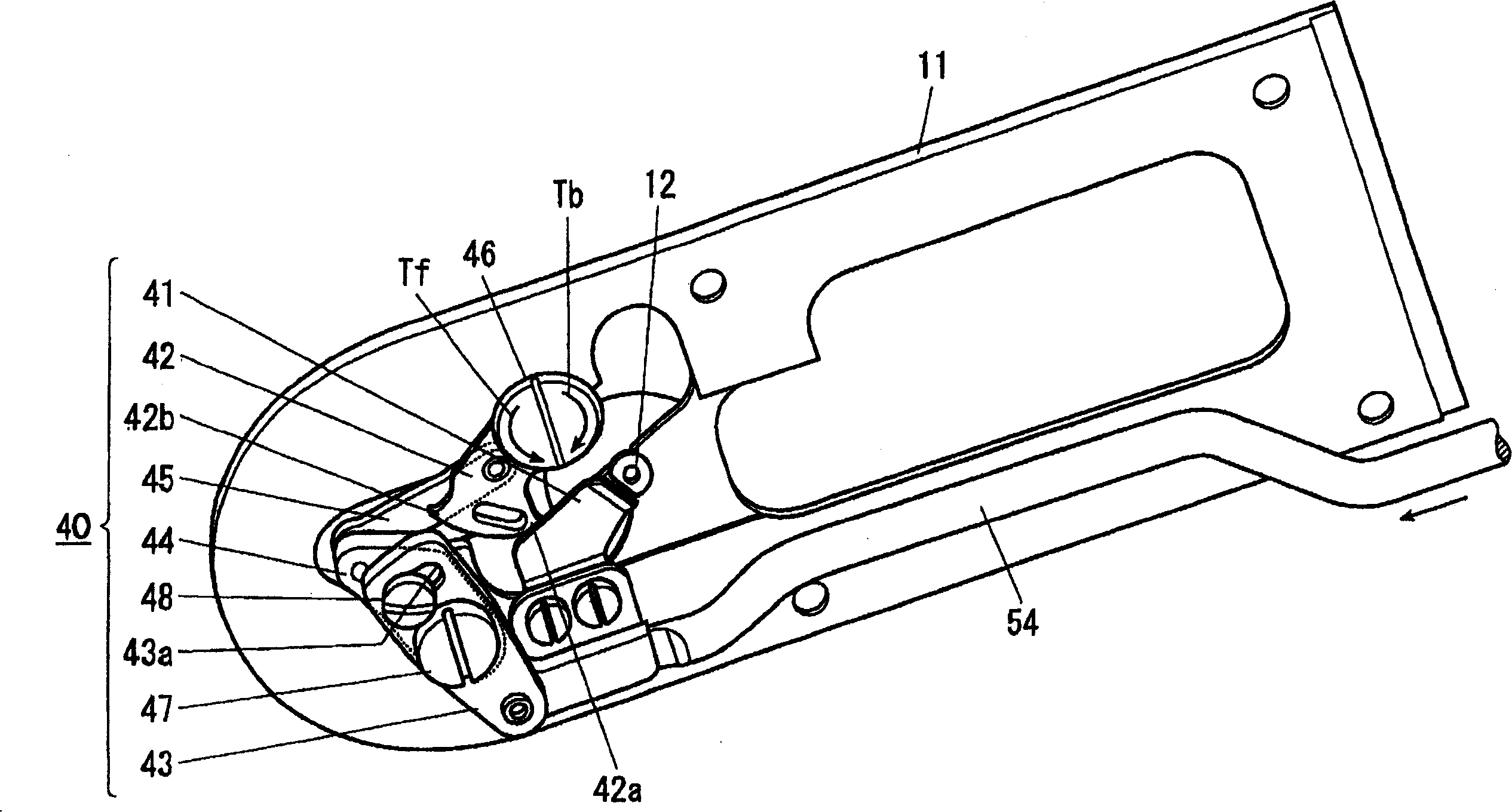

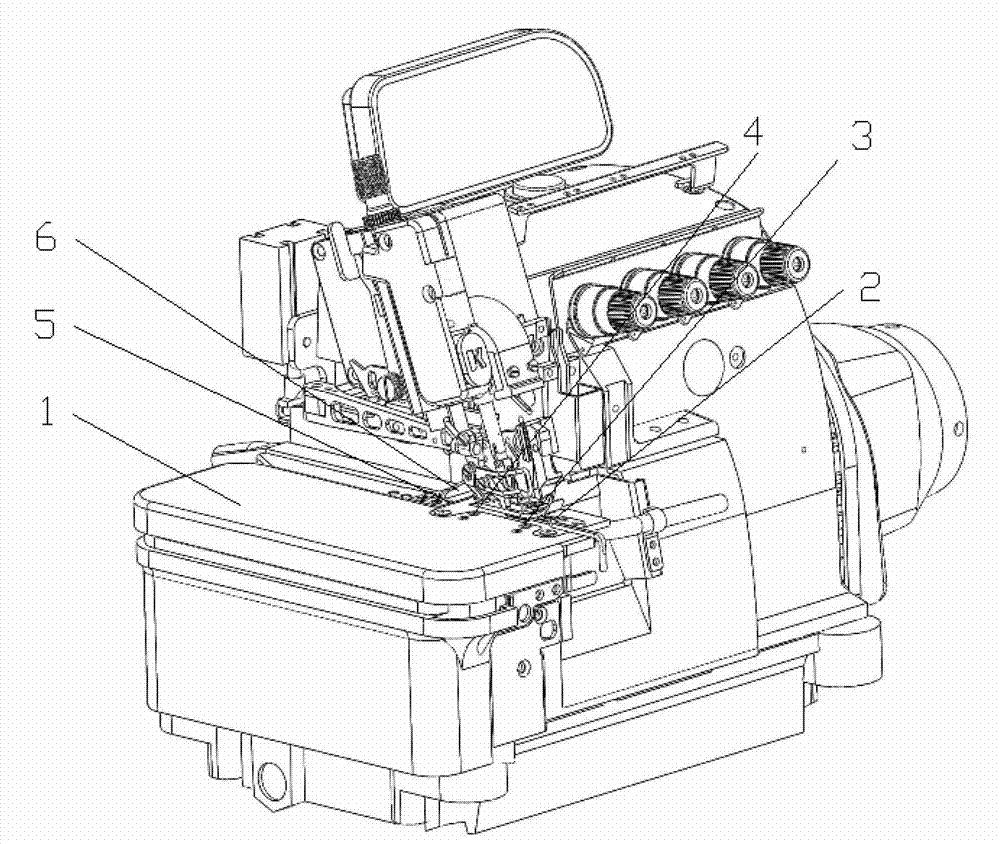

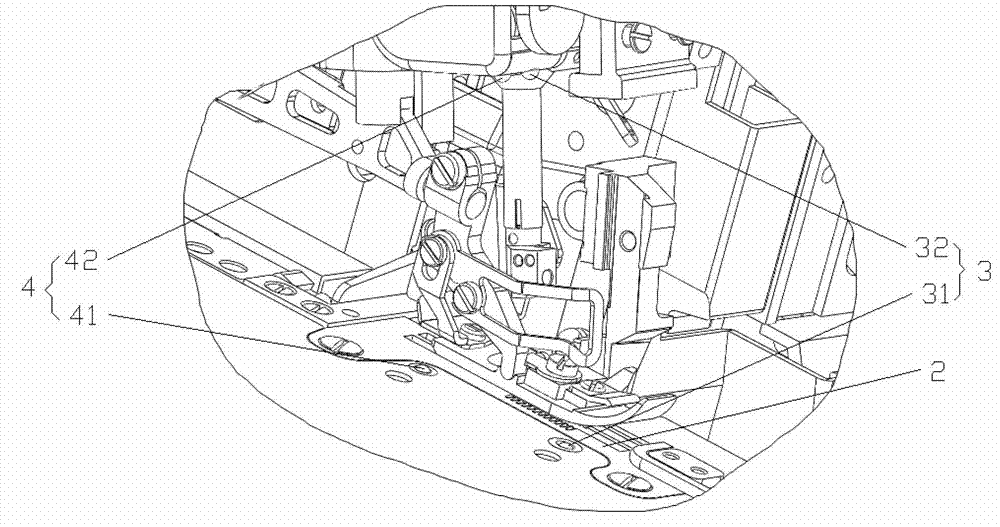

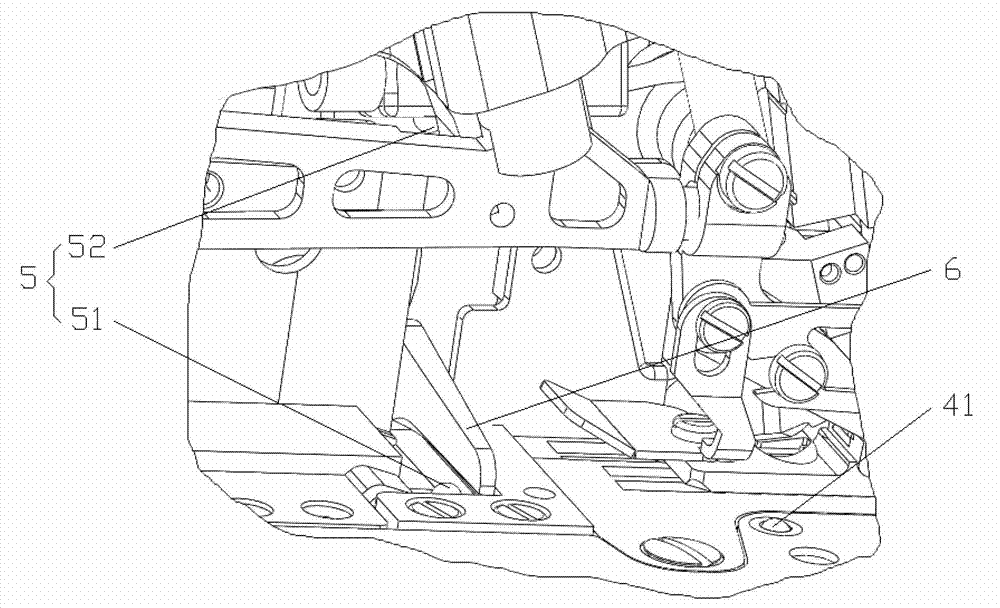

Sewing machine

InactiveCN1757812AAvoid burdenThe state that hinders the rotationWorkpiece carriersNeedle severing devicesTransmitterSewing machine

A seaming machine comprises a cloth press (20) capable of lifting up and down to support a press stand (21), a cutter (40) arranged under a needle plate (11) and provided with a fixed blade (41) and a movable blade (42), a step motor (13) as the drive source of the cloth press (20) and the cutter (40), and a power transmitter (50) for transmitting rotary drive force of the step motor (13) to each mechanism, wherein the power transmitter is provide with two rotary cams (51, 52) driven by the step motor, while the cams can transmit drive force on each mechanism. And an actuating quantity adjuster (59) is arranged between the cloth press and the rotary cams to adjust the driving quantity. The seaming machine can realize optimized rotation of step motor.

Owner:JUKI CORP

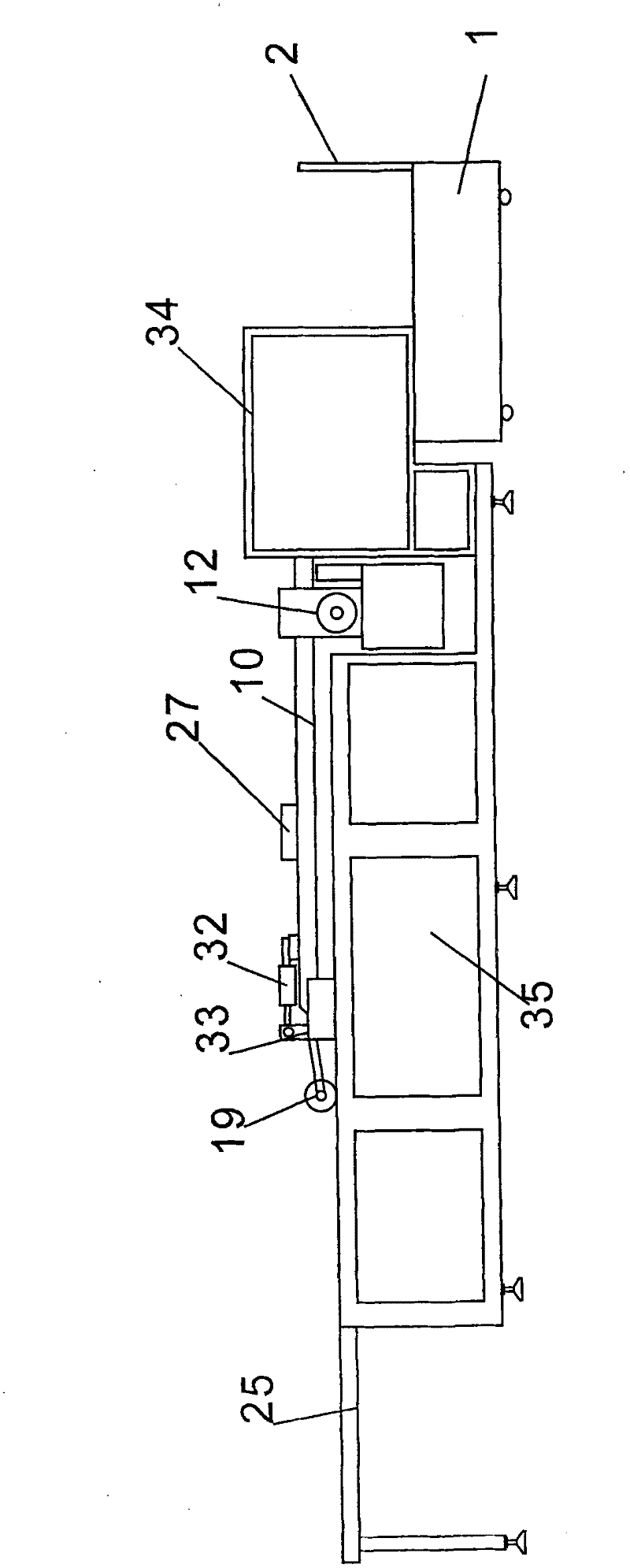

Double-head sewing machine for cement woven bag sheet

InactiveCN102242469AQuality improvementIncrease productionWork-feeding meansNeedle severing devicesDrive wheelControl system

The invention relates to a double-head sewing machine for a cement woven bag sheet, comprising a back bag piling platform (25), a back transmitting mechanism (24), a pressing wheel mechanism (19), a main transmitting mechanism, a quick conveying mechanism (3), a bag collecting baffle plate (2) and a bag collecting machine (1) which are sequentially arranged; wherein the back transmitting mechanism (24) comprises a back transmitting belt (30), a driving wheel, a tension wheel mechanism (23), an auxiliary driving motor (18) and a belt (17); the pressing wheel mechanism (19) comprises a pressingwheel, a pressing wheel support (33) and a pressing wheel cylinder (32) and is controlled by a control system (35); the main transmitting mechanism comprises a main driving motor (6), a main driving wheel mechanism (7), an auxiliary driving wheel mechanism (8), an auxiliary driving wheel mechanism (14), a tension mechanism (9), a tension mechanism (13), a tension mechanism (16), a main driving auxiliary mechanism (20), a main transmitting belt (29), an auxiliary transmitting belt (26) and a pressing mechanism (10); and the quick conveying mechanism (3) comprises a conveying motor (5), a belt (4) and an auxiliary wheel. The double-head sewing machine provided by the invention has the advantages of increasing the yield, saving the material and improving the finished product quality.

Owner:ZHEJIANG QICAI PACKING

Double-needle cup seaming machine

InactiveCN1381625AOptimize the extraction processSewing-machine casingsNeedle severing devicesEngineeringSewing machine

A double-needle overlock sewing machine, comprising: an outer claw formed as a part of a needle plate and extending along the feeding direction, a middle claw parallel to the outer claw and slidably arranged along the extending direction thereof, and an outer claw arranged on the needle plate The empty wire loop holder and cutter at the front. The sewing machine has: a presser foot disposed above the needle plate, an urging member for urging the presser foot toward the needle plate, and a rotatably supported back surface of the sewing machine frame against the urging force of the urging member. Presser foot lifter that raises the presser foot from the needle plate. The middle claw is connected with the presser foot handle, and when the presser foot is raised by the operation of the presser foot handle, the front end of the middle claw is hidden by the open pinhole of the needle plate. Accordingly, it is possible to provide a double-needle overlock sewing machine capable of operating the middle claw with a low-cost structure and without impairing the operator's workability of the material.

Owner:PEGASUS SEWING MACHINE MFG

Overedger automatically-inductive sewing system and method

InactiveCN103088560ARealize automatic thread trimmingSolve manual pulling clothProgramme-controlled sewing machinesNeedle severing devicesInductorEngineering

The invention provides an overedger automatically-inductive sewing system and a method. A starting inductor and a front thread trimming inductor transmit signals to a controller, the controller controls an overedger to work, and then automatic sewing for cloth is achieved; and a back thread trimming inductor detects time when the cloth leaves and transmits signals to the controller, the controller controls a thread trimmer to trim thread, and then automatic thread trimming is achieved. By means of the overedger automatically-inductive sewing system and the method, the problem that manual cloth spreading is inconsistent with mechanical thread trimming is solved, the thread trimmer can not trim the cloth, and therefore product percent of pass is guaranteed, and working efficiency is improved.

Owner:JACK SEWING MASCH CO LTD

Thread trimming, thread loosening, presser foot lifting and presser foot pressure adjusting device of sewing machine and sewing machine

ActiveCN110983644ASimple structureCompact structureNeedle severing devicesSewing-machine control devicesCrankEngineering

The invention relates to the technical field of sewing machines, in particular to a thread trimming, thread loosening, presser foot lifting and presser foot pressure adjusting device of a sewing machine and the sewing machine comprising the device. The device comprises a power piece, a cam structure, a thread trimming driving crank connected with a thread trimming mechanism and an ejector rod connected with a thread loosening mechanism, a presser foot lifting mechanism and a presser foot pressure adjusting mechanism, a first transmission pin on the thread trimming driving crank is matched witha first driving contour face of the cam structure, and the first driving contour face is provided with a thread trimming driving section for driving the thread trimming mechanism to execute thread trimming action; and a second transmission pin on the ejector rod is matched with a second driving contour face of the cam structure, and the second driving contour face is provided with a thread loosening driving section for driving the thread loosening mechanism to execute thread loosening action, a presser foot lifting driving section for driving the presser foot lifting mechanism to execute presser foot lifting action and a presser foot pressure adjusting driving section for driving the presser foot pressure adjusting mechanism to execute presser foot pressure adjusting action. The four functions of thread trimming, thread loosening, presser foot lifting and presser foot pressure adjusting are achieved through the driving of one power piece.

Owner:JACK SEWING MASCH CO LTD

Sewing machine thread trimming device and sewing machine

ActiveCN106948103ASimple structureImprove transmission efficiencyNeedle severing devicesSewing-machine control devicesDrive shaftEngineering

The invention provides a sewing machine thread trimming device, comprising a lower shaft, a thread trimming cam fixed on the lower shaft, a moving cutter assembly which can swing around the lower shaft, a thread trimming driving shaft, a thread trimming power source, and a thread trimming driving crank and a thread trimming crank fixed on the thread trimming driving shaft, and a driving assembly. The moving cutter assembly comprises at least a moving cutter. The outer peripheral surface of the thread trimming cam is provided with a thread trimming driving cam surface. The thread trimming driving crank is provided with a crank arm. A movable roller pin shaft passes through the crank arm. The roller pin shaft is provided with a roller. When the device trims a thread, the thread trimming power source drives the roller pin shaft to move, so the roller moves to the direction close to the thread trimming cam and cooperates with the thread trimming driving cam surface. The thread trimming crank is connected with the moving cutter assembly through the driving assembly, and drives the moving cutter assembly to swing. The thread trimming driving crank in the device has and only has one crank arm, so the device is simplified in structure, and a transmission chain of the sewing machine thread trimming device is simplified, so as to improve transmission efficiency and transmission reliability and reduce production cost.

Owner:JACK SEWING MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com