Double-head sewing machine for cement woven bag sheet

A technology for woven bags and sewing machines, which is applied to pocket sewing machines, sewing machine components, and thread-cutting mechanisms in sewing machines, etc., can solve the problems of low production efficiency and high labor intensity of workers, and achieve material saving, neat and beautiful finished products, and increased output. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The following examples are only used to illustrate the technical solutions of the present invention, but do not limit the present invention.

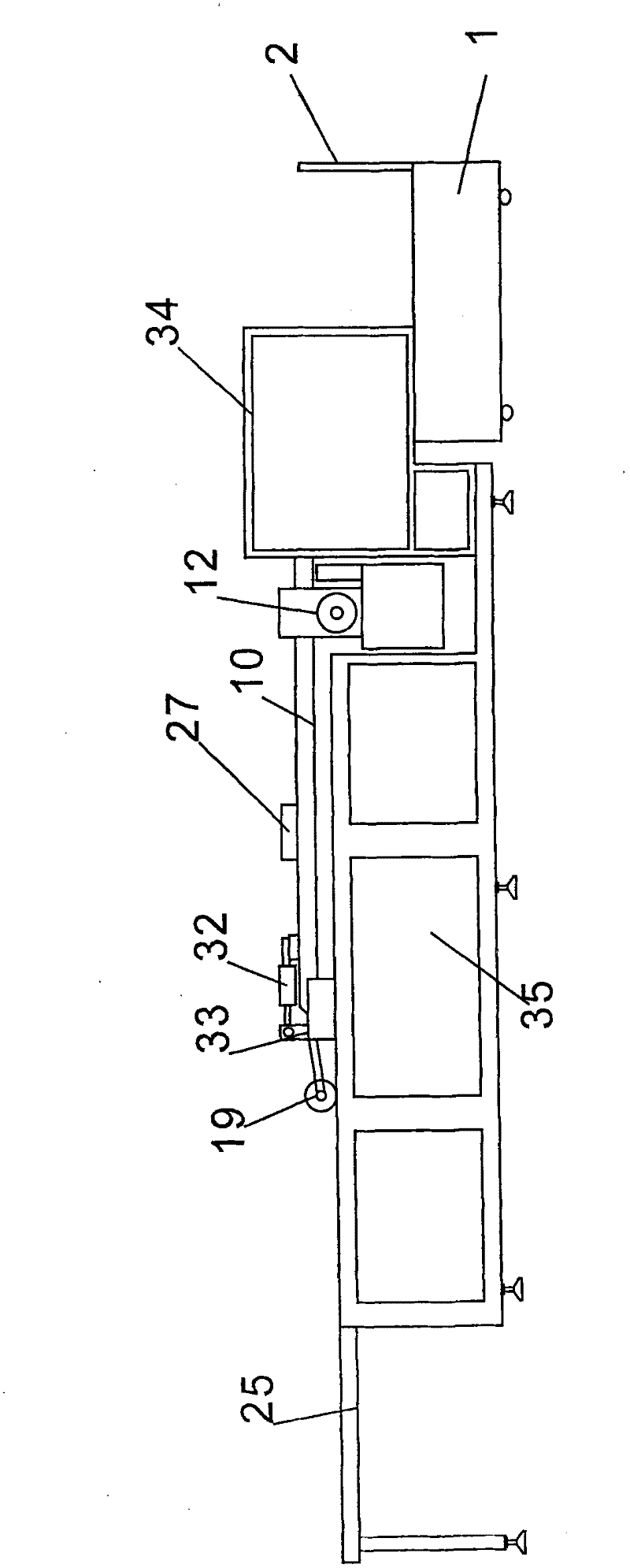

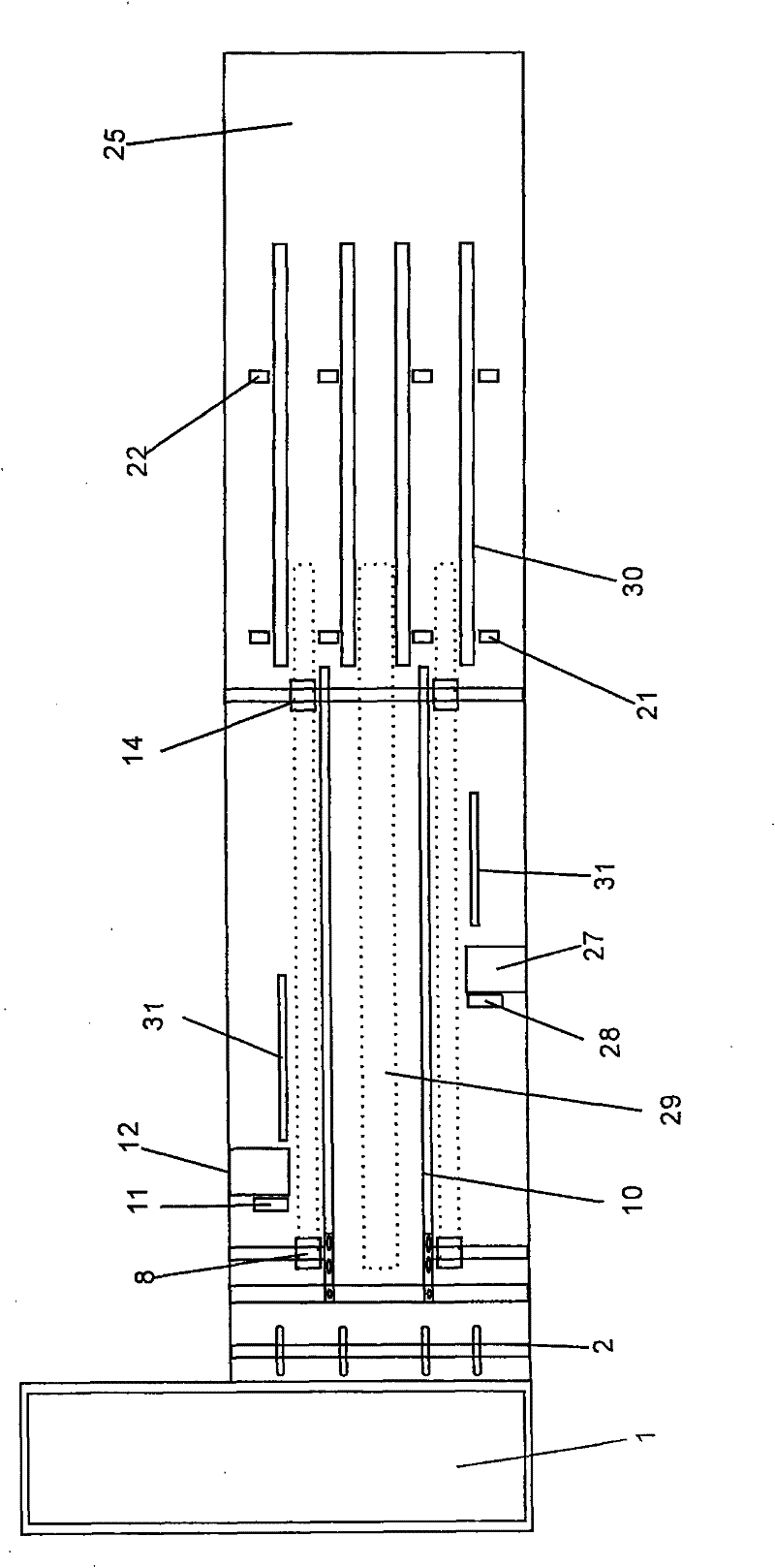

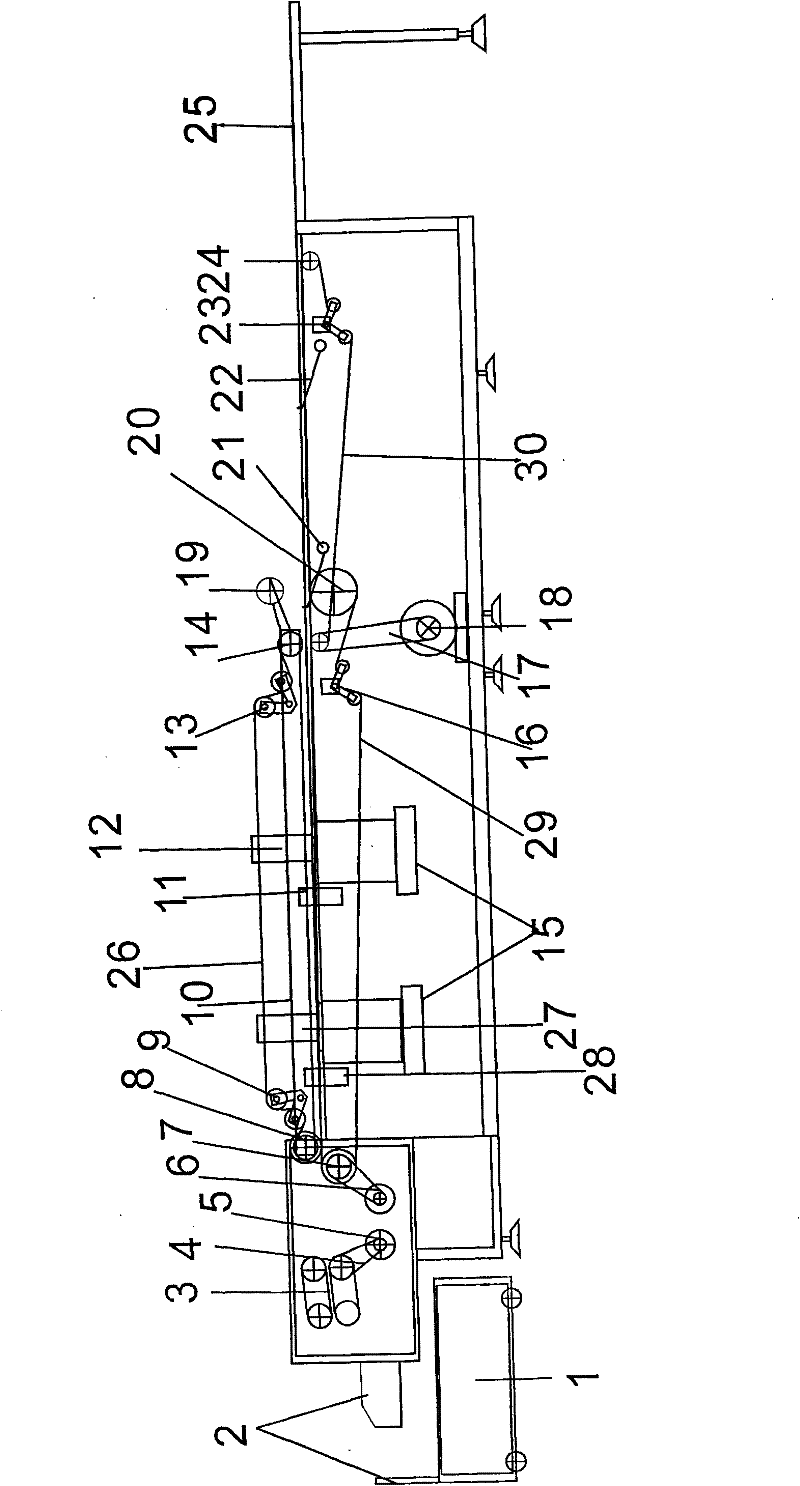

[0017] The double-head sewing machine for cement woven bags, viewed from the front view, is equipped with a rear bag stacking platform 25, a rear conveying mechanism 24, a pressure roller mechanism 19, a main conveying system, a fast conveying mechanism 3, and a bag collecting baffle plate 2 in sequence from left to right 1, bag collecting machine 1, control system 35 is contained in the below of press wheel mechanism 19; The effect of stacking bag table 25 is to put original bag piece on the workbench; Back conveying mechanism 24 plays bag piece, makes the bag piece arrange in sequence The function is composed of the rear transmission belt 30, the transmission wheel, the tensioner mechanism 23, the auxiliary transmission motor 18, and the belt 17; the pressure wheel mechanism 19 is composed of the pressure wheel, the pressure whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com