Patents

Literature

9521 results about "Sewing machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

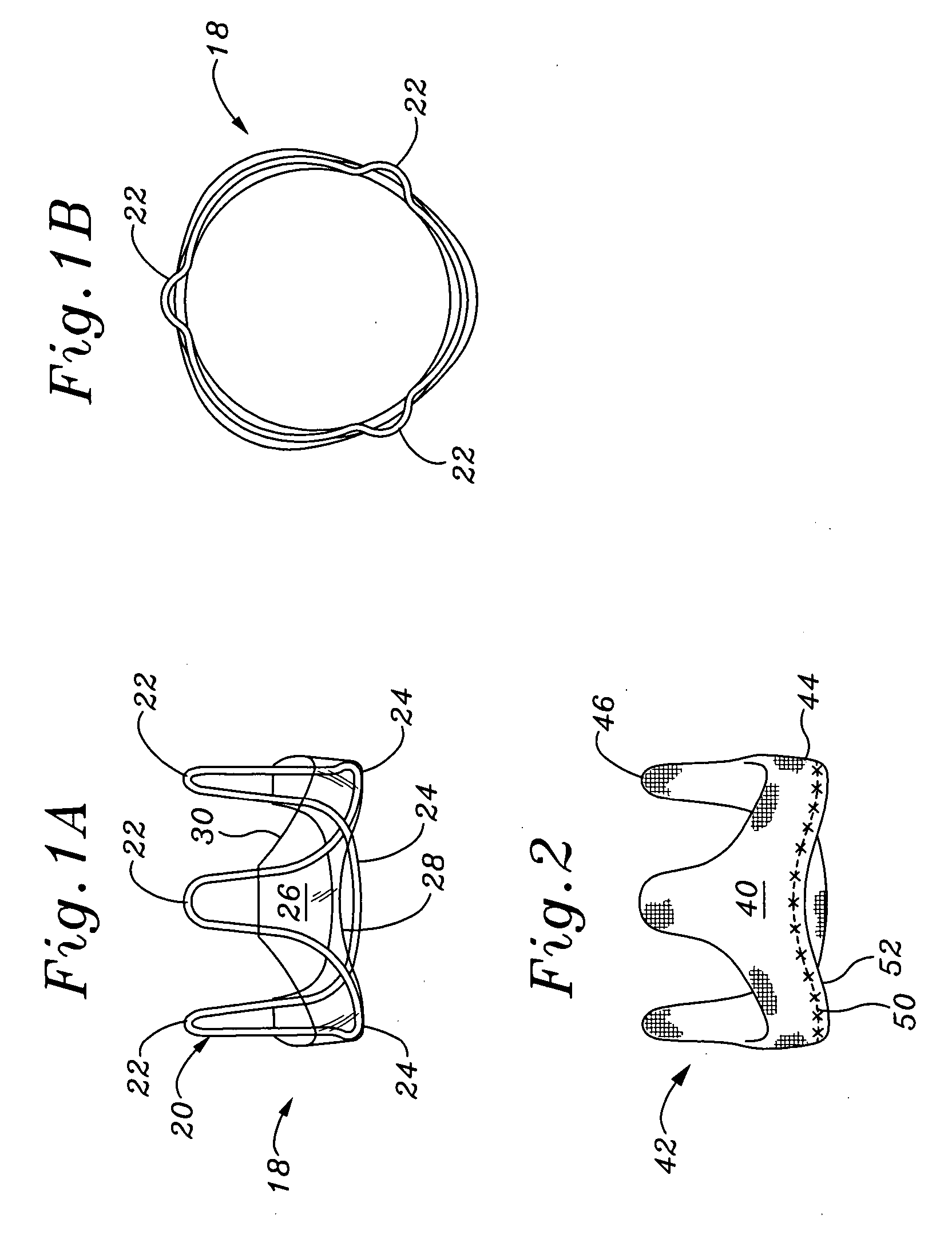

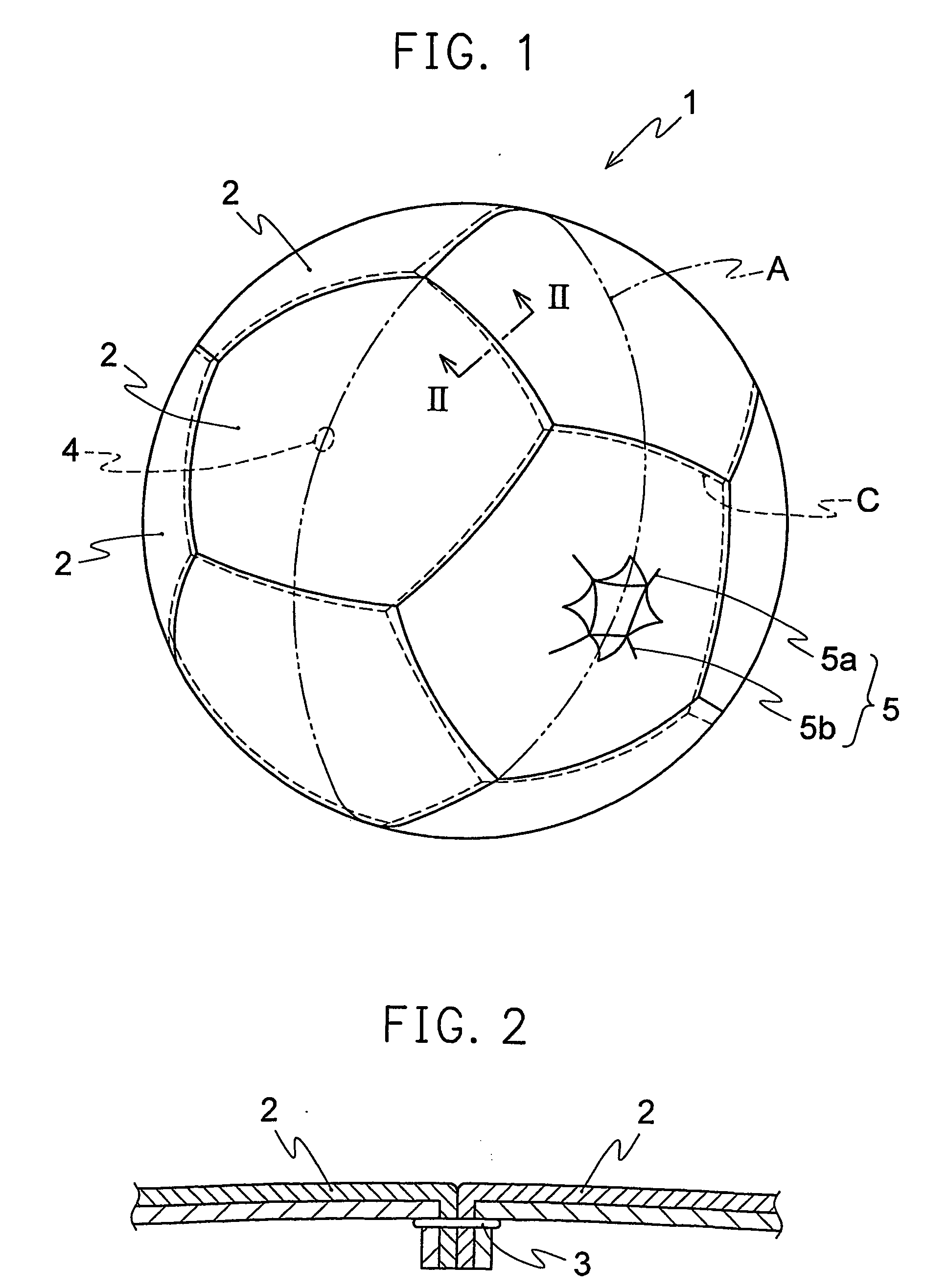

Ball for ball game and method for manufacturing the same

InactiveUS6971965B1Increase the number ofMaintain tensile strengthHollow inflatable ballsHollow non-inflatable ballsBall gameSpherical shaped

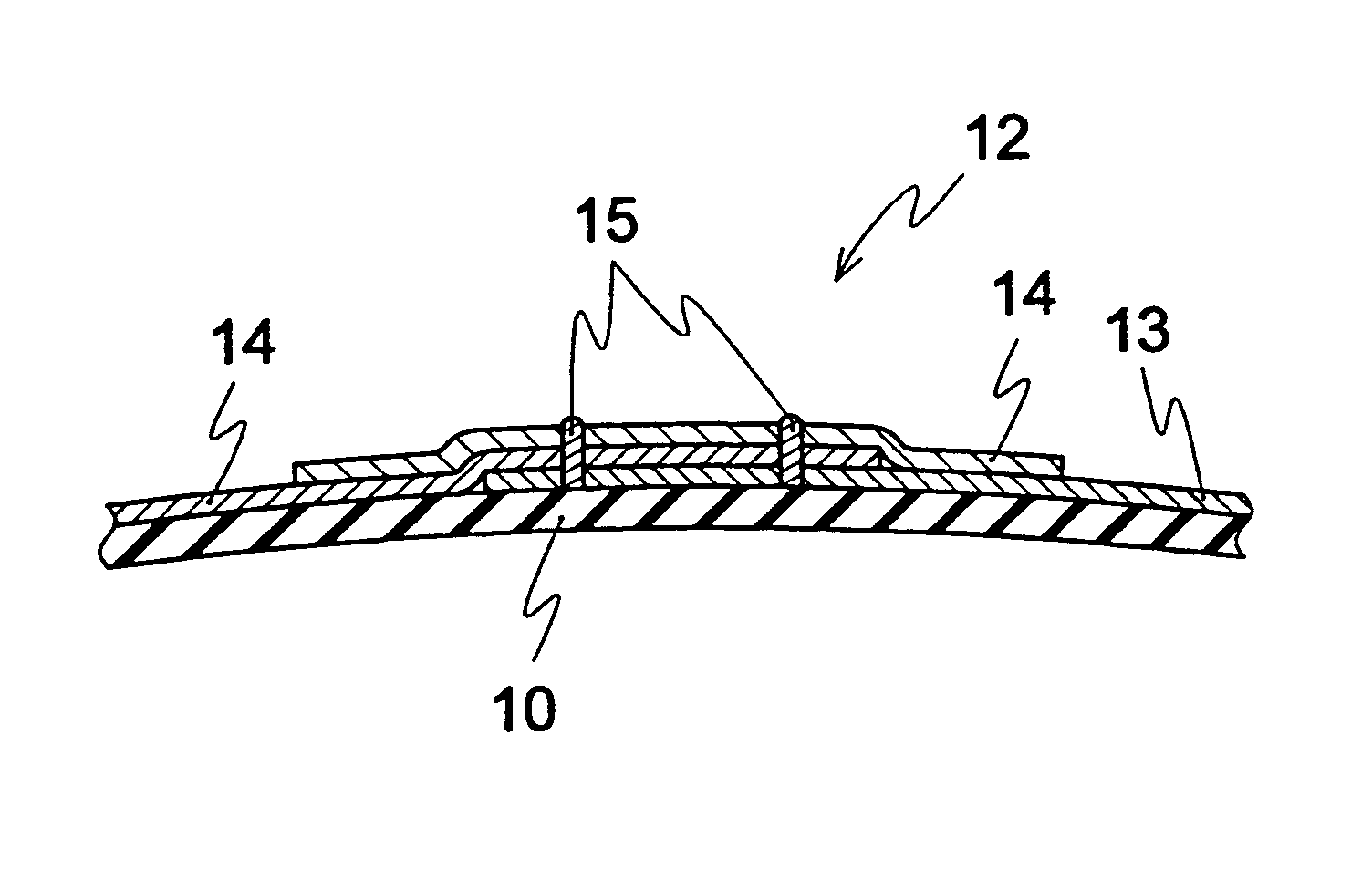

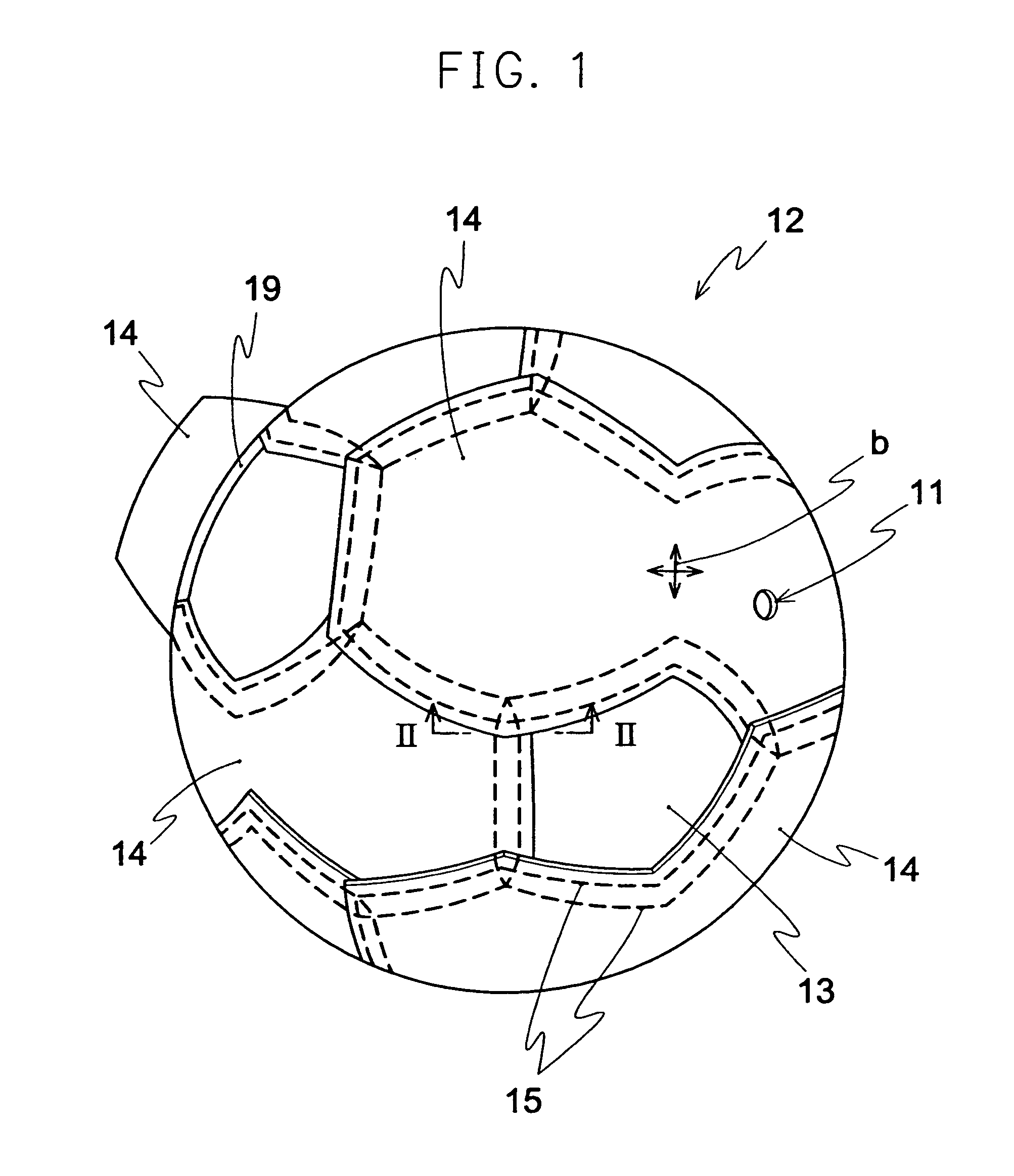

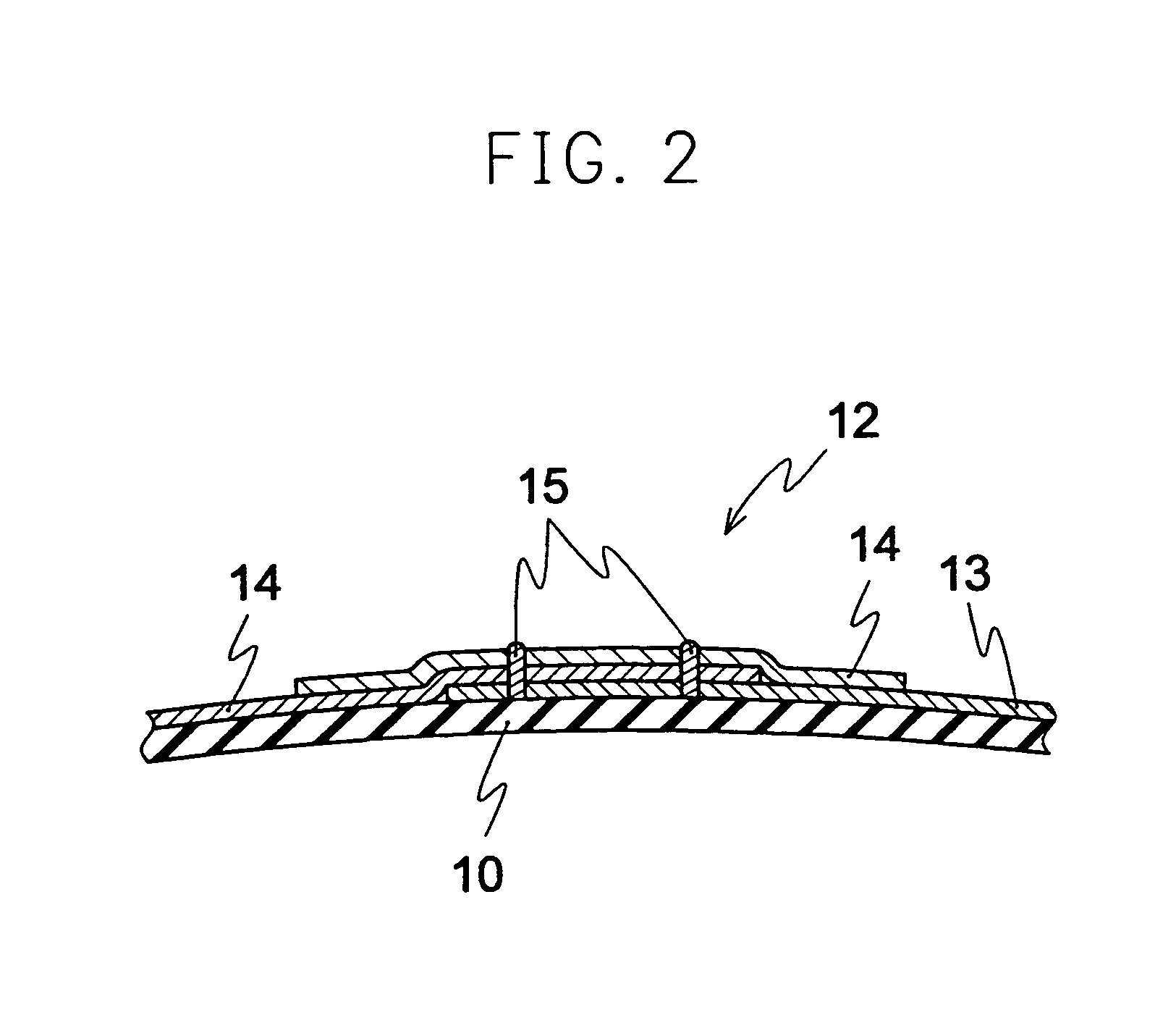

To provide a ball for ball game and a method for manufacturing the ball having superior sphericity, an ability to retain its original shape, durability, and soft feel. The fabric layer (12) is formed by sewing with a sewing machine for instance pentagonal first fabric pieces (13) together with composite shaped second fabric pieces (14) in which two hexagons are connected with each other, so that a spherical shape is formed. The marginal edge of the first and second fabric pieces are superimposed in the spherical surface direction, so that corner portions thereof are temporarily attached. Temporary attachment is achieved by inserting the needle into the needle through hole formed in the corner of the first and second fabric pieces, and welding by means of ultra sonic wave, such that the first and second fabric pieces (13, 14) are accurately aligned. The temporarily attached fabric pieces sewn together using a sewing machine along the guiding line (17) for sewing printed beforehand on the surface of the fabric pieces (13, 14).

Owner:MOLTEN CORPORATION +1

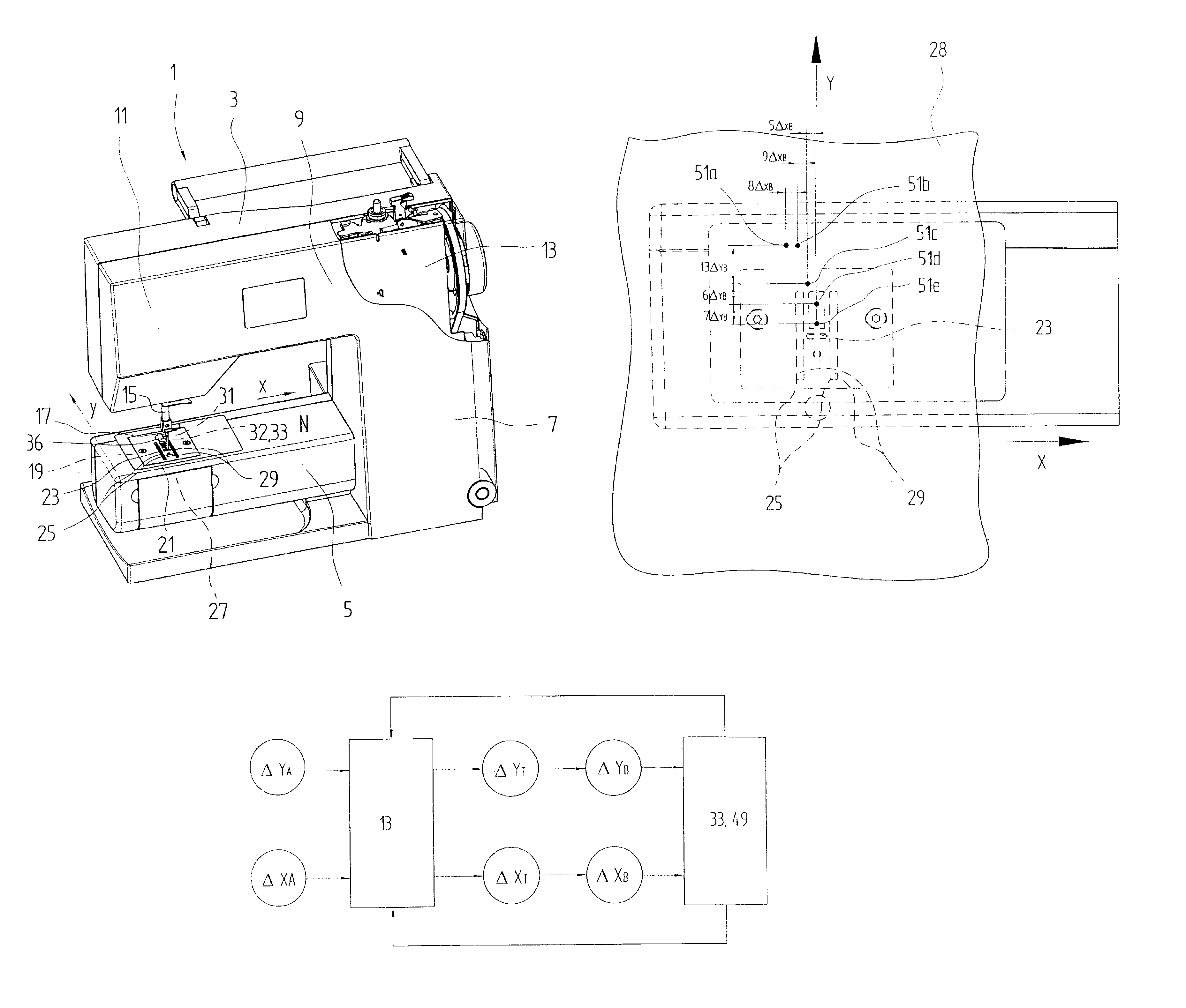

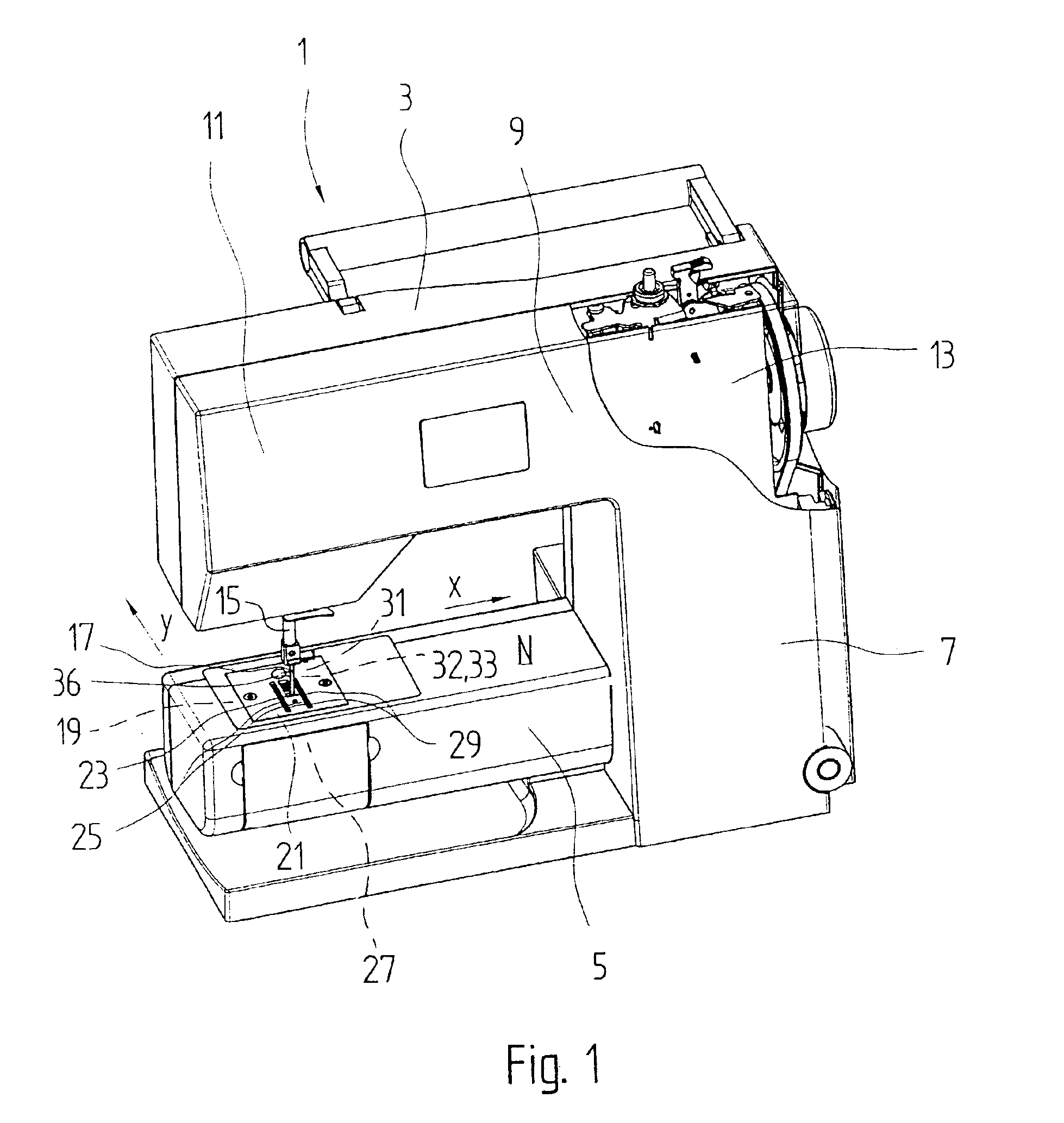

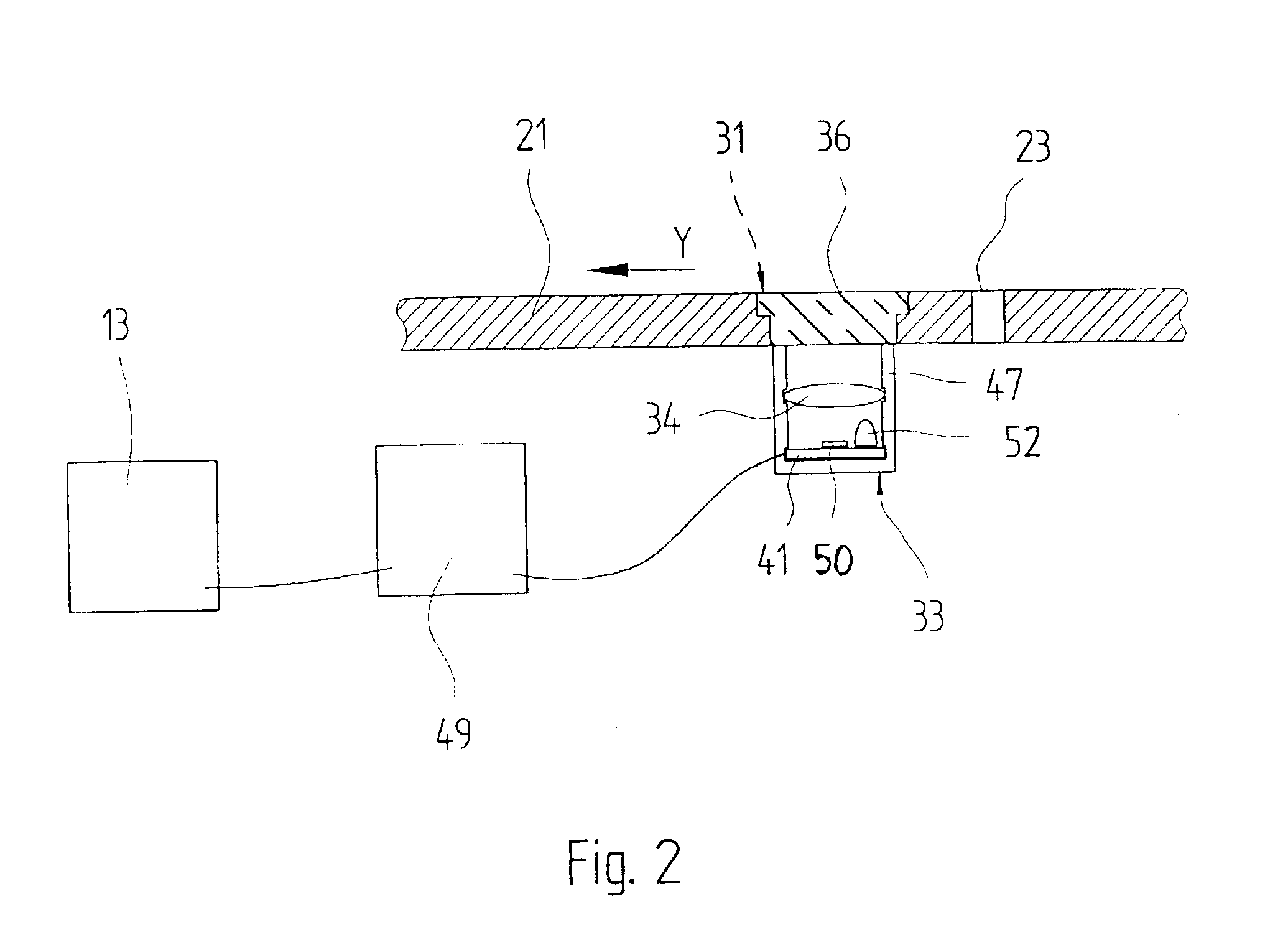

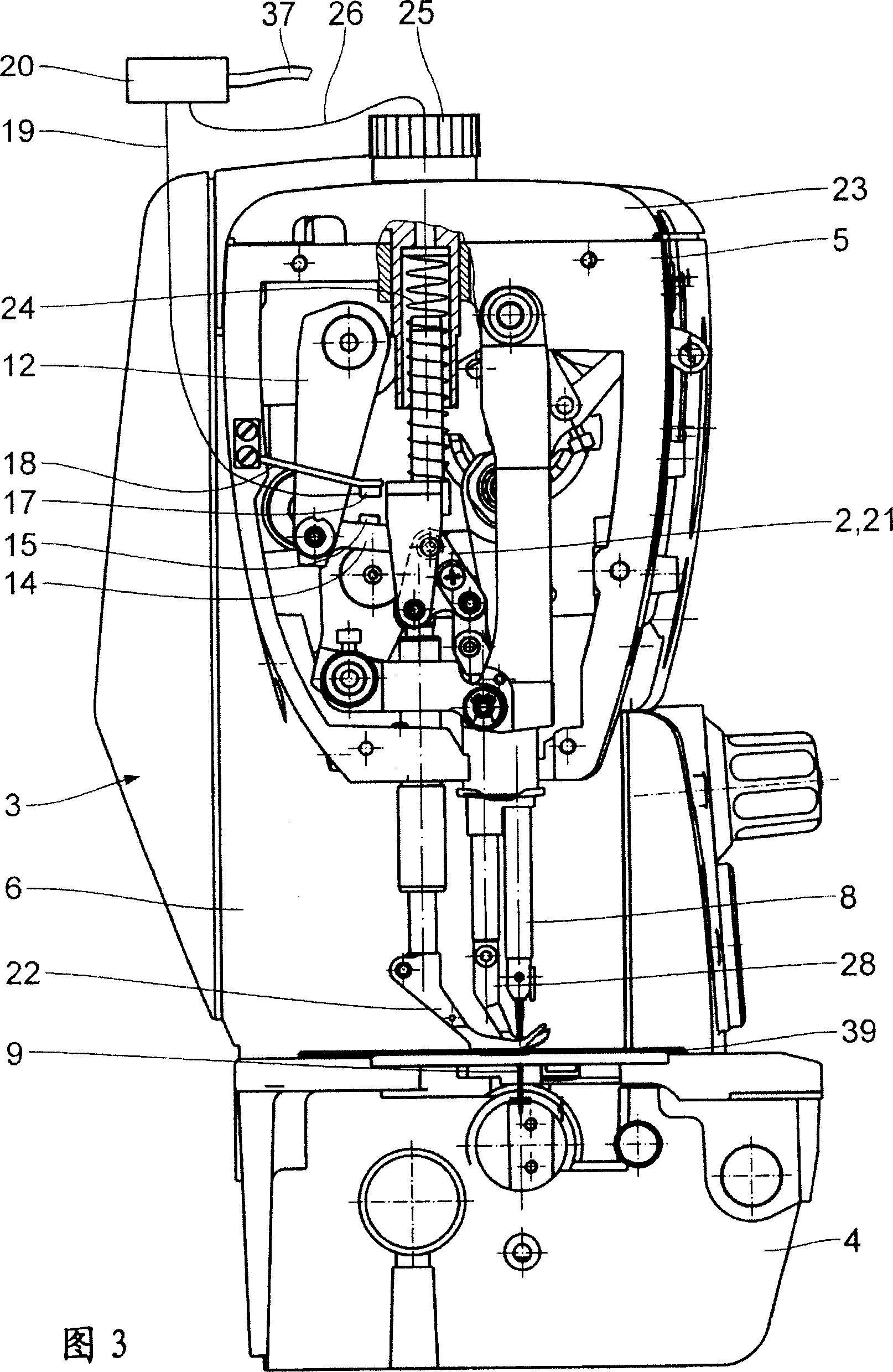

Method and device for regulating material transport in a sewing or embroidery machine

InactiveUS6871606B2Quickly and accurately calculated and compensatedImprove scanning rateProgramme-controlled sewing machinesWork-feeding meansMaterial transportMotion sensors

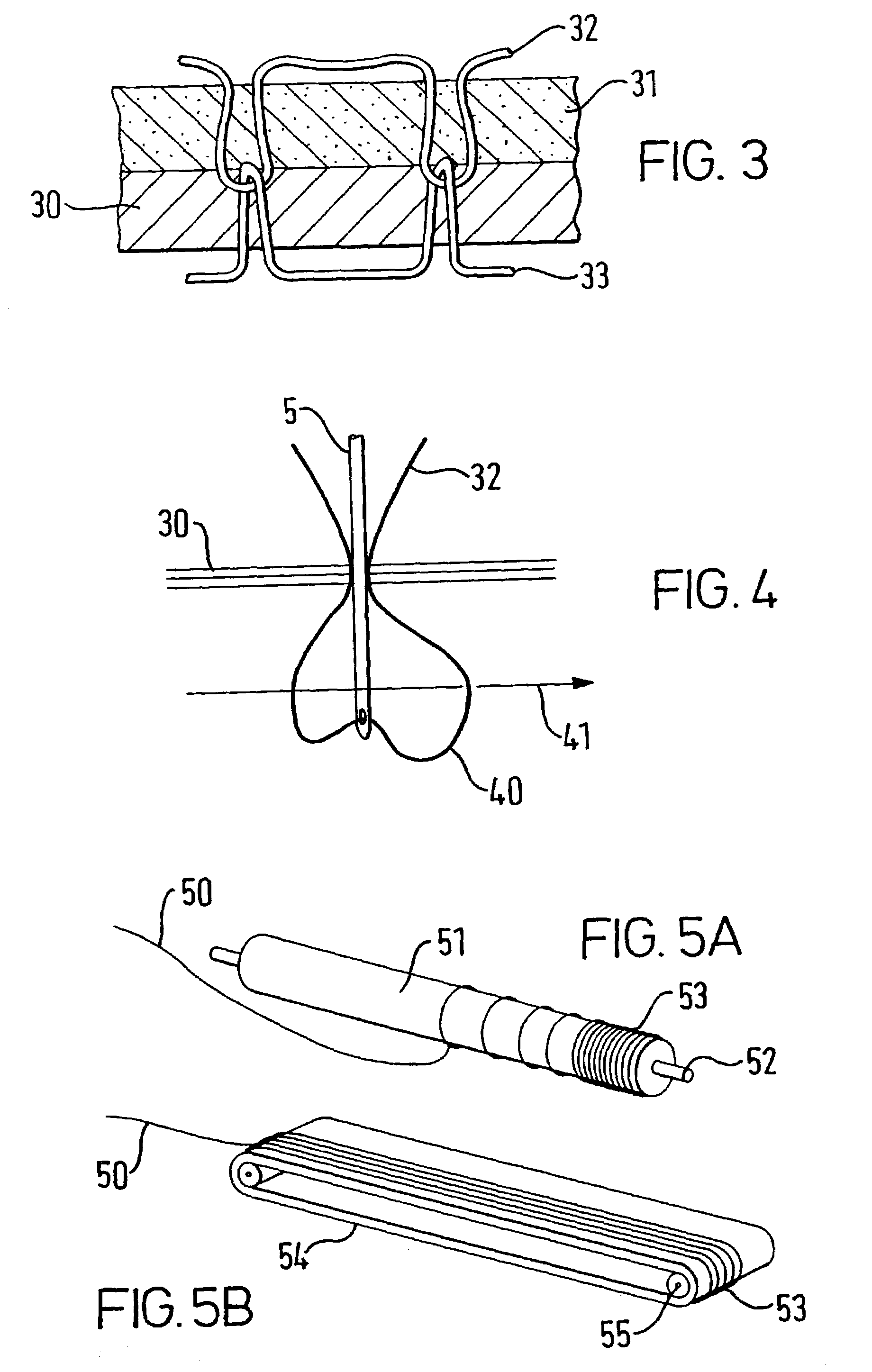

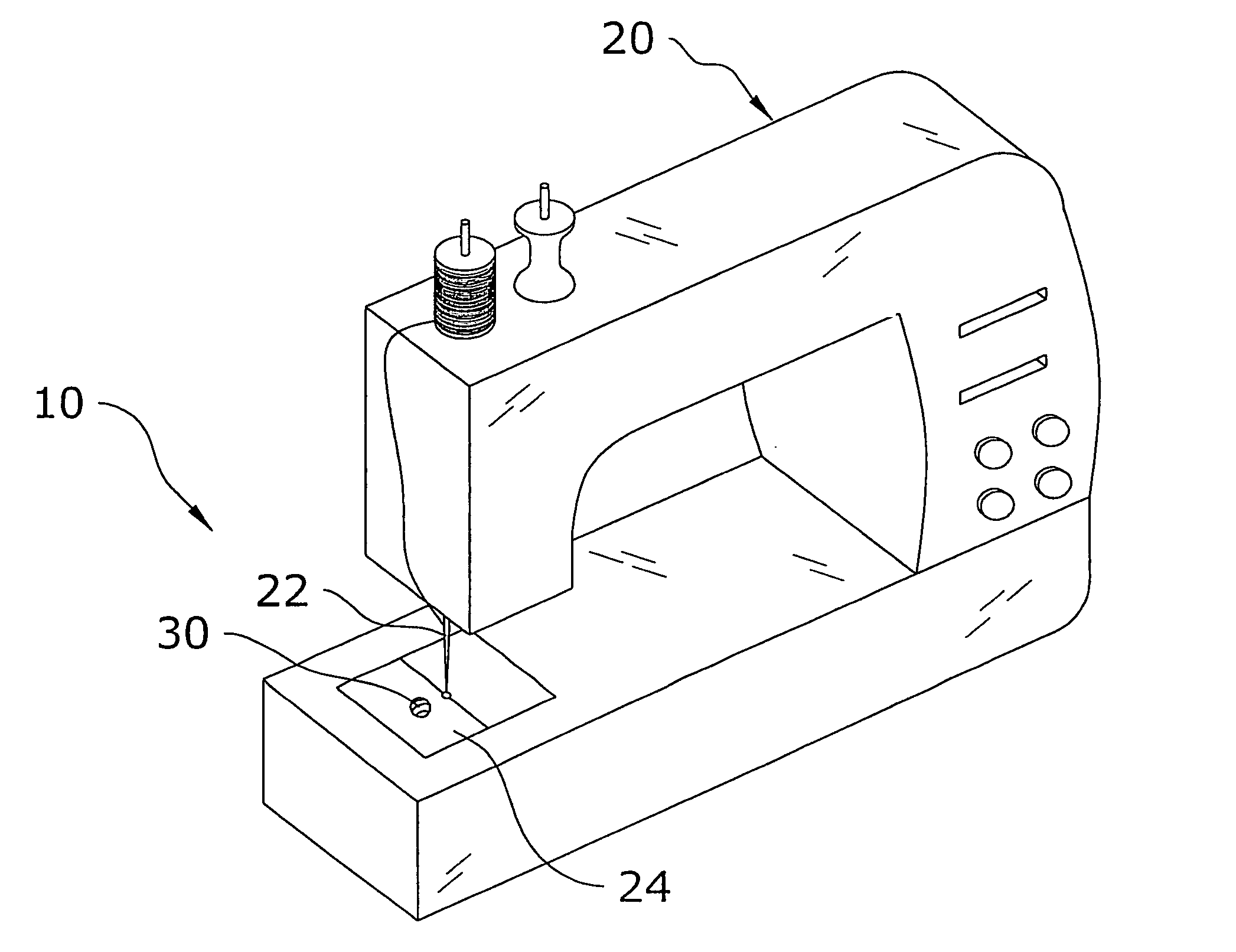

A method and device for regulating the transport of material in a sewing or embroidery machine (1) that uses information from a position or movement sensor (33) located underneath the throat plate (21). The controls for the sewing machine (1) calculate deviations of the actual feeding increments of the article to be sewn from the corresponding target values from the periodically read sensor signals. With this information, the feeding increments are regulated in such a way that the deviations are cancelled out by averaging.

Owner:FRITZ GEGAUF AKTIENGES BERNINA NAHMASCHFAB

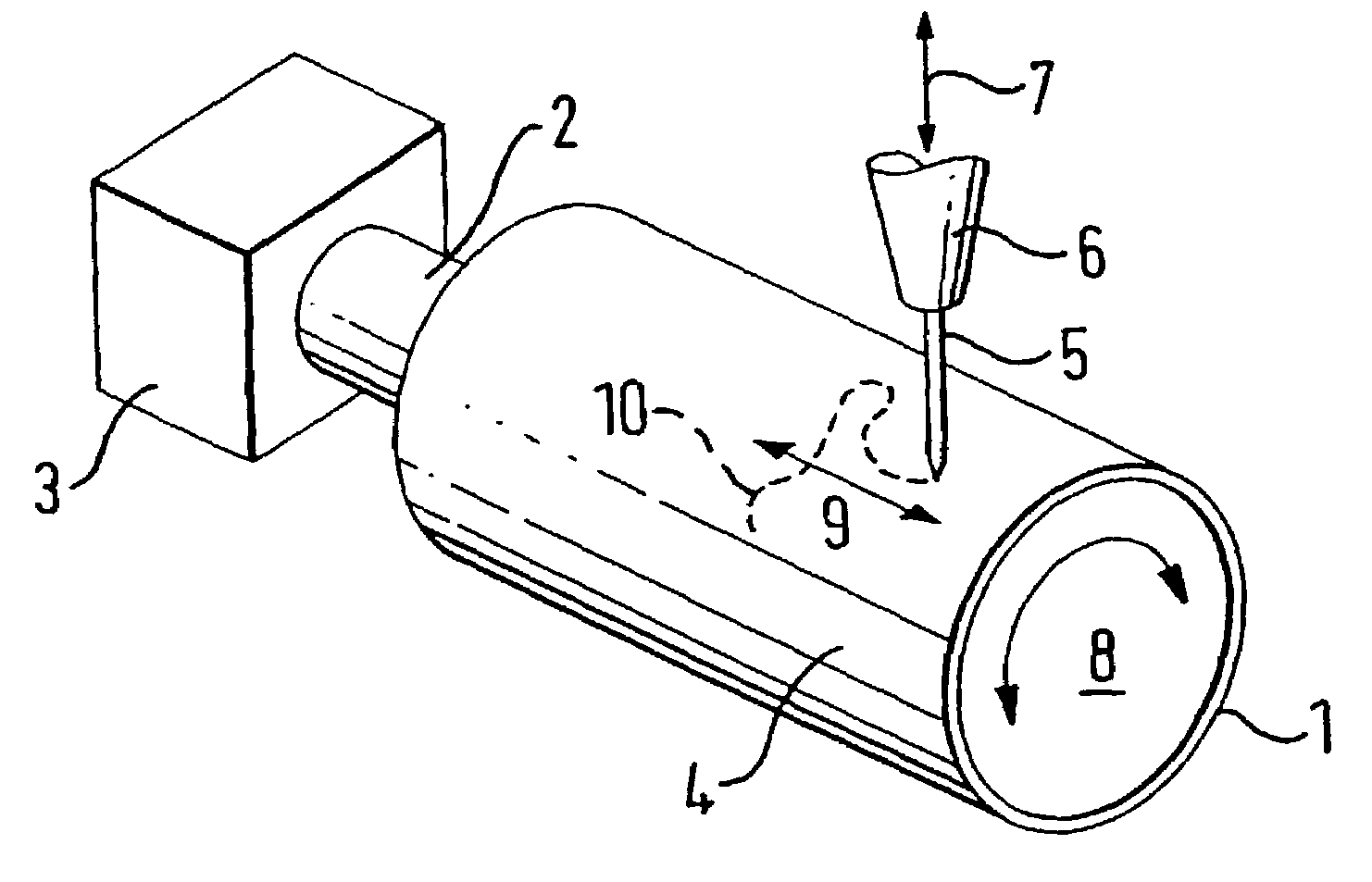

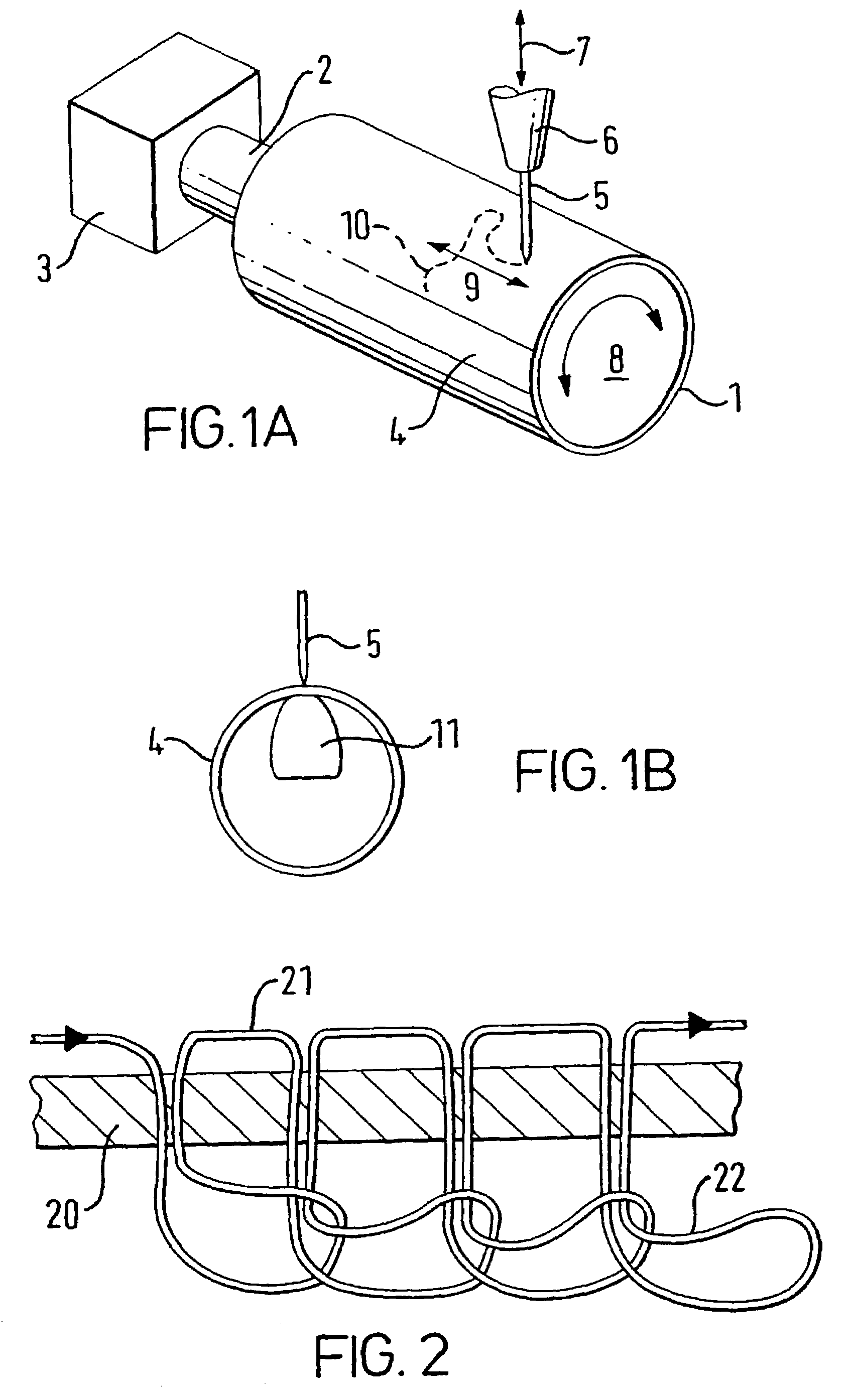

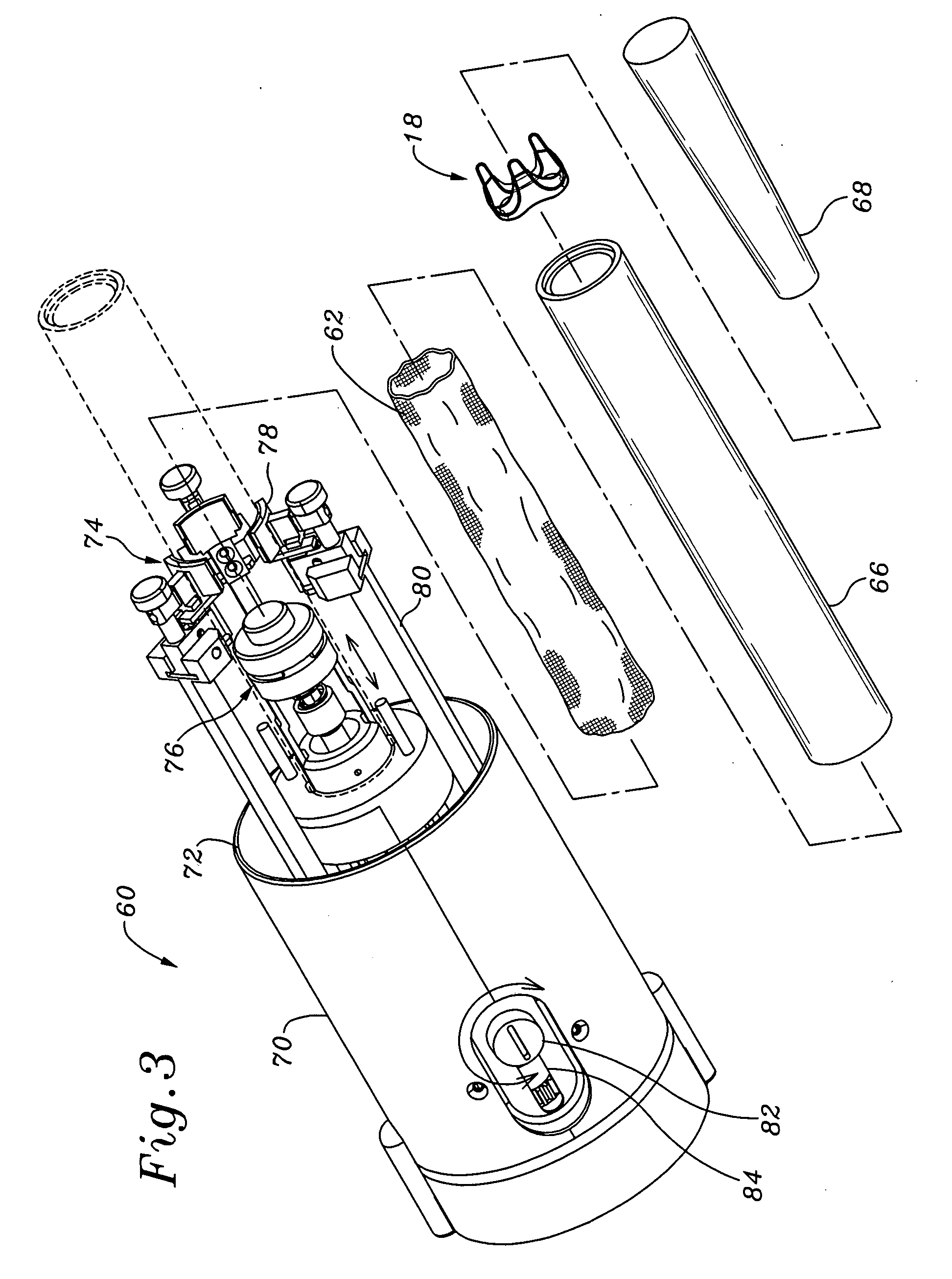

Method for manufacturing a medical implant

A method for stitching thread onto the wall of a tubular medical implant (preferably a graft) employs a sewing machine with an elongate bobbin or a needle on an elongate element, depending on whether it is desired to sew from the outside-in or the inside-out. A motor rotates and translates the implant, which is mounted on a hollow drum, relative to the needle.

Owner:ANSON MEDICAL LTD

Optical stitch regulator system

InactiveUS6959657B1Effective supervisionProgramme-controlled sewing machinesSewing-machine casingsEngineeringControl unit

An optical stitch regulator system for efficiently regulating the stitch length and stitch frequency of a sewing machine. The optical stitch regulator system includes at least one optical sensor within or external of the sewing platform of a sewing machine for sensing the motion of the fabric being sewn. The motion data is communicated to a control unit which communicates with the sewing machine for controlling the stitch length and frequency.

Owner:DUVAL RICHARD J

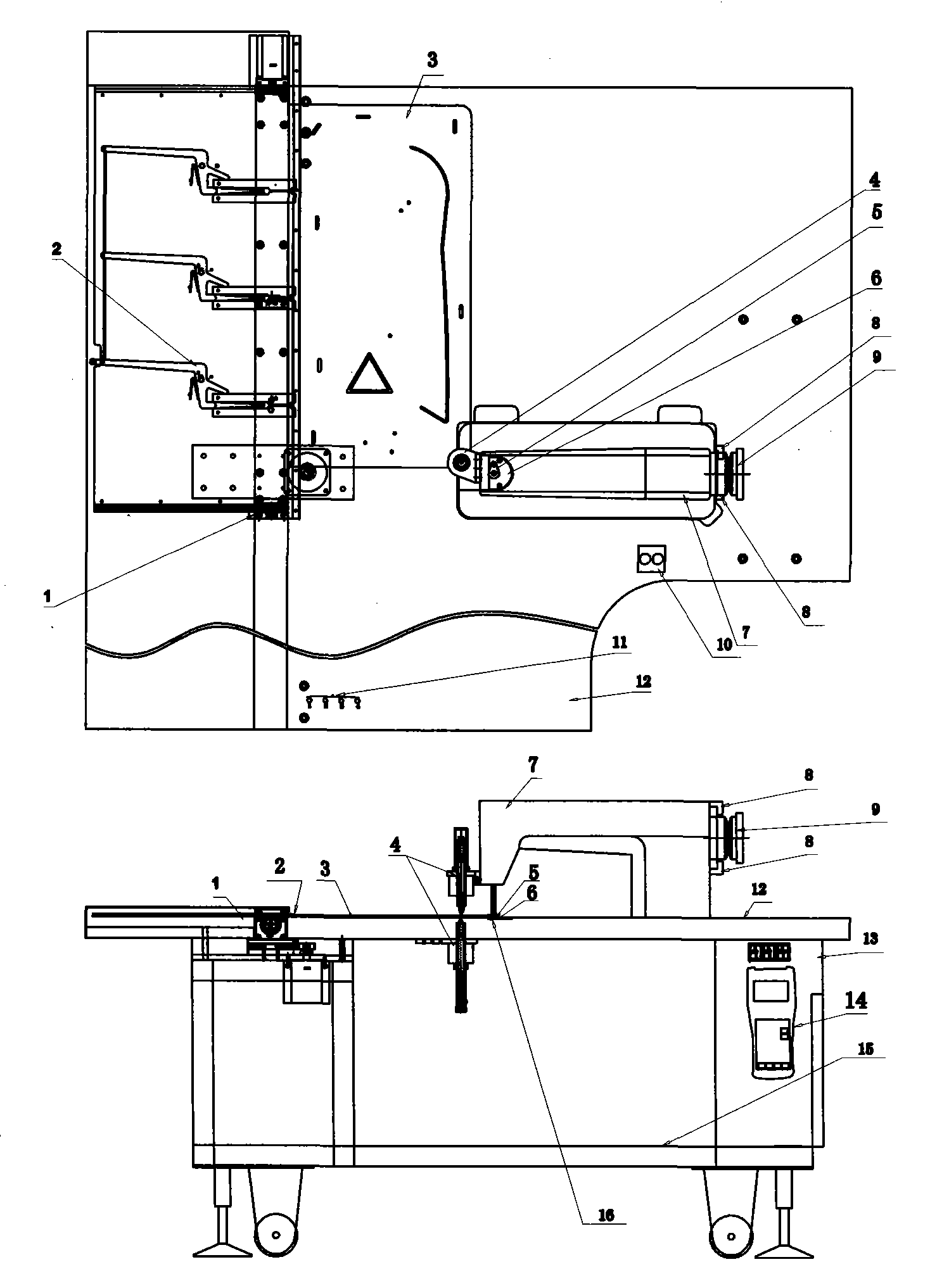

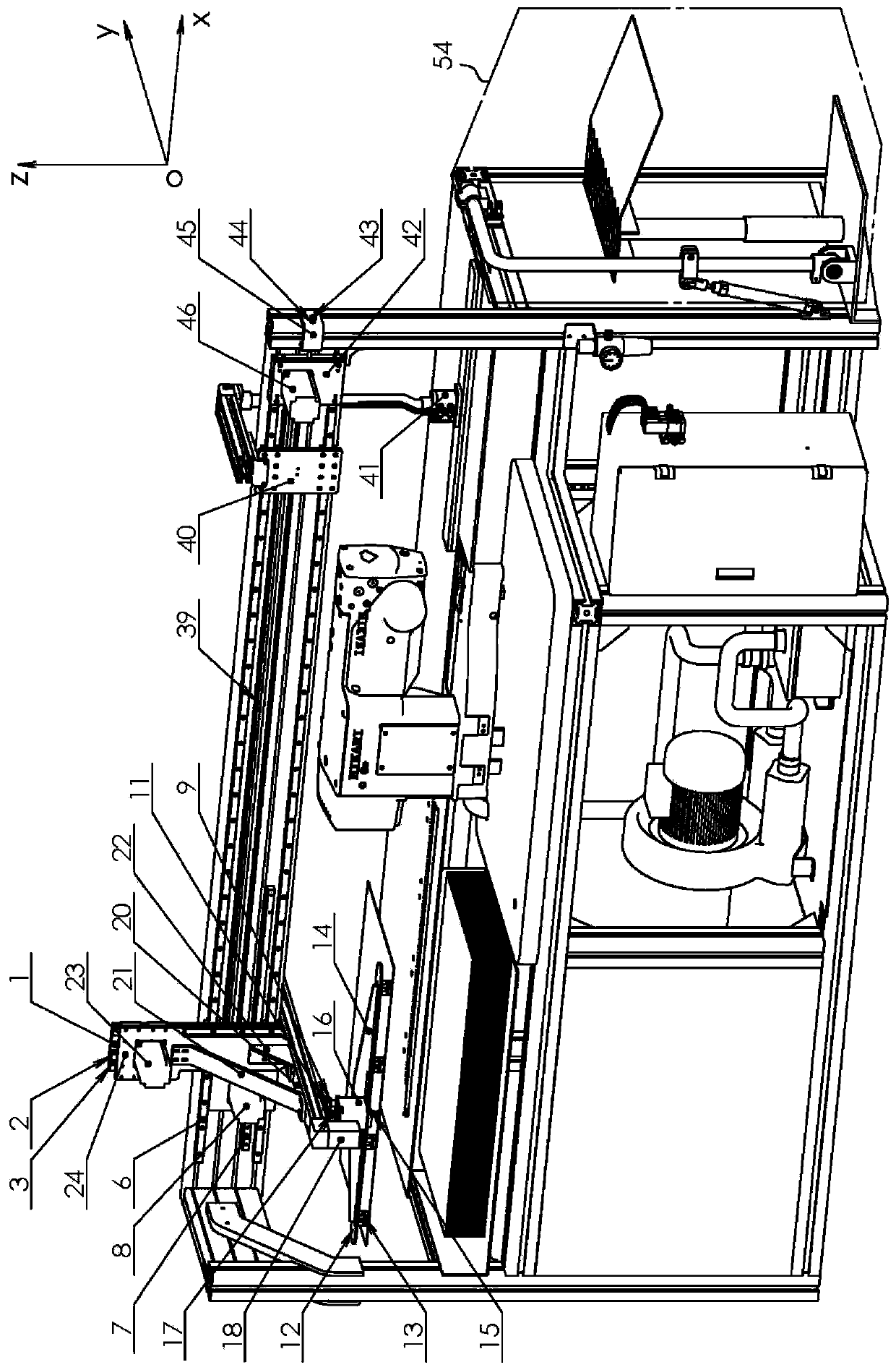

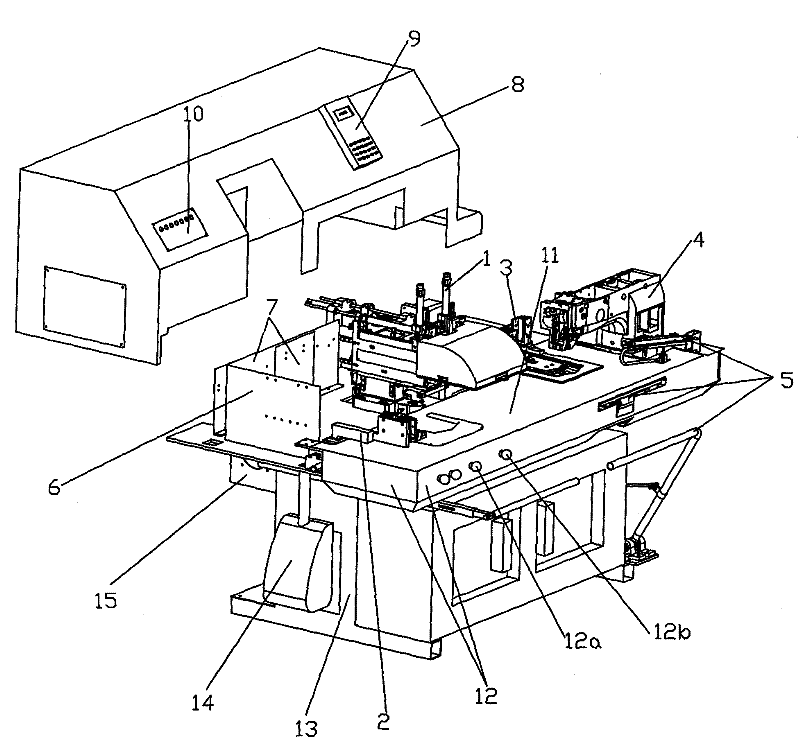

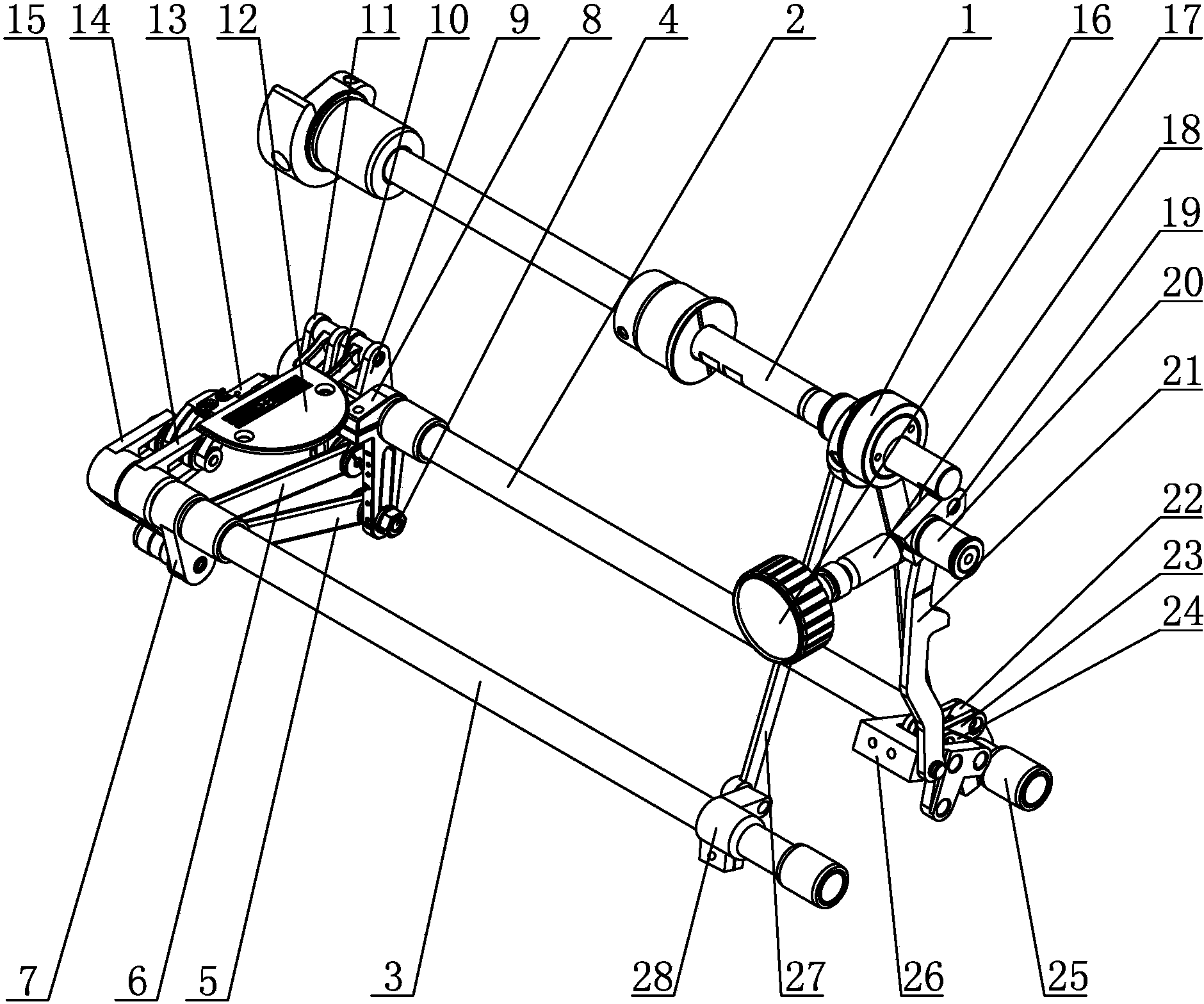

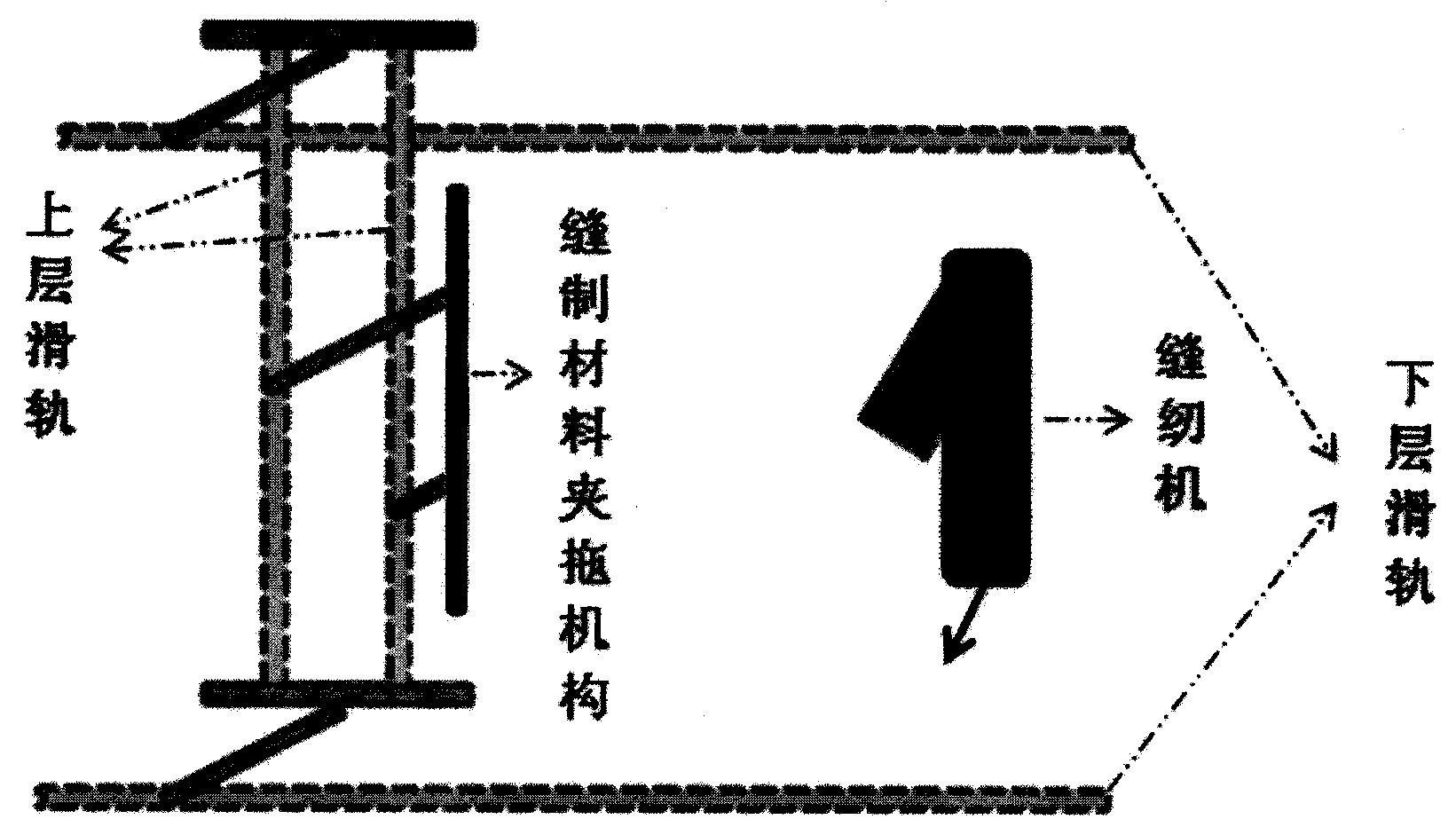

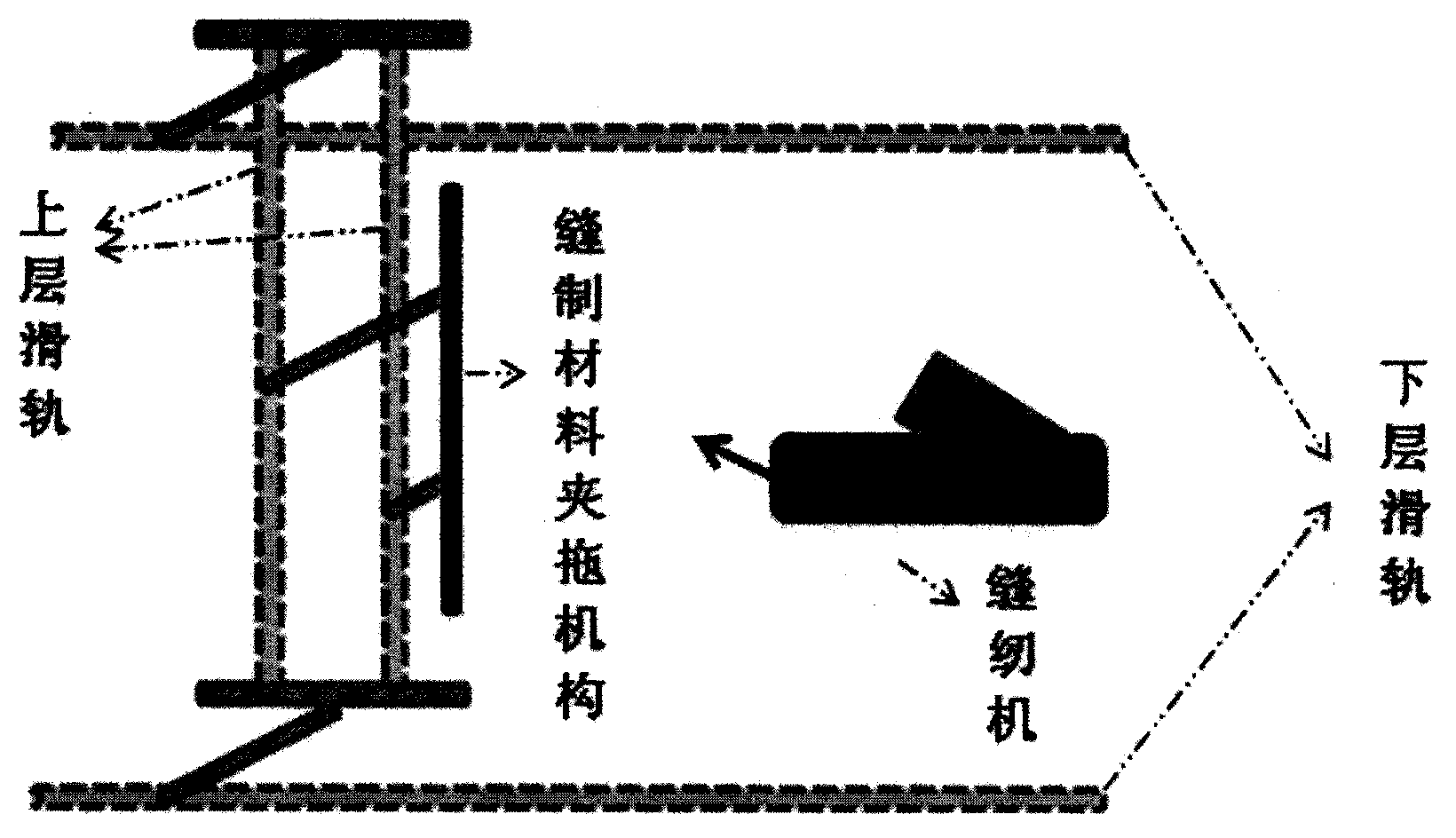

Multifunctional digital control sewing machine for feeding by clamping cloth sheets through template

InactiveCN101775712ALow costSimple structureProgramme-controlled sewing machinesControl systemElectric control

The invention discloses a multifunctional digital control sewing machine for feeding by clamping cloth sheets through a template, which comprises X and Y moving devices, a template automatic clamping mechanism device, a sewing template, a stippling marking device, a rotary core sleeve need board device, a sewing operation wood table board, a Z axial rotary speed regulation device, an electric cabinet, an electric control system and a sewing digital control programming system, a simply-modified common computer flat sewing machine head (7), a control system and a stander (15). The multifunctional digital control sewing machine for feeding by clamping the cloth sheets through the template has the advantages of low cost, simple structure, simple operation, and greatly improved production efficiency and product quality.

Owner:苏运松

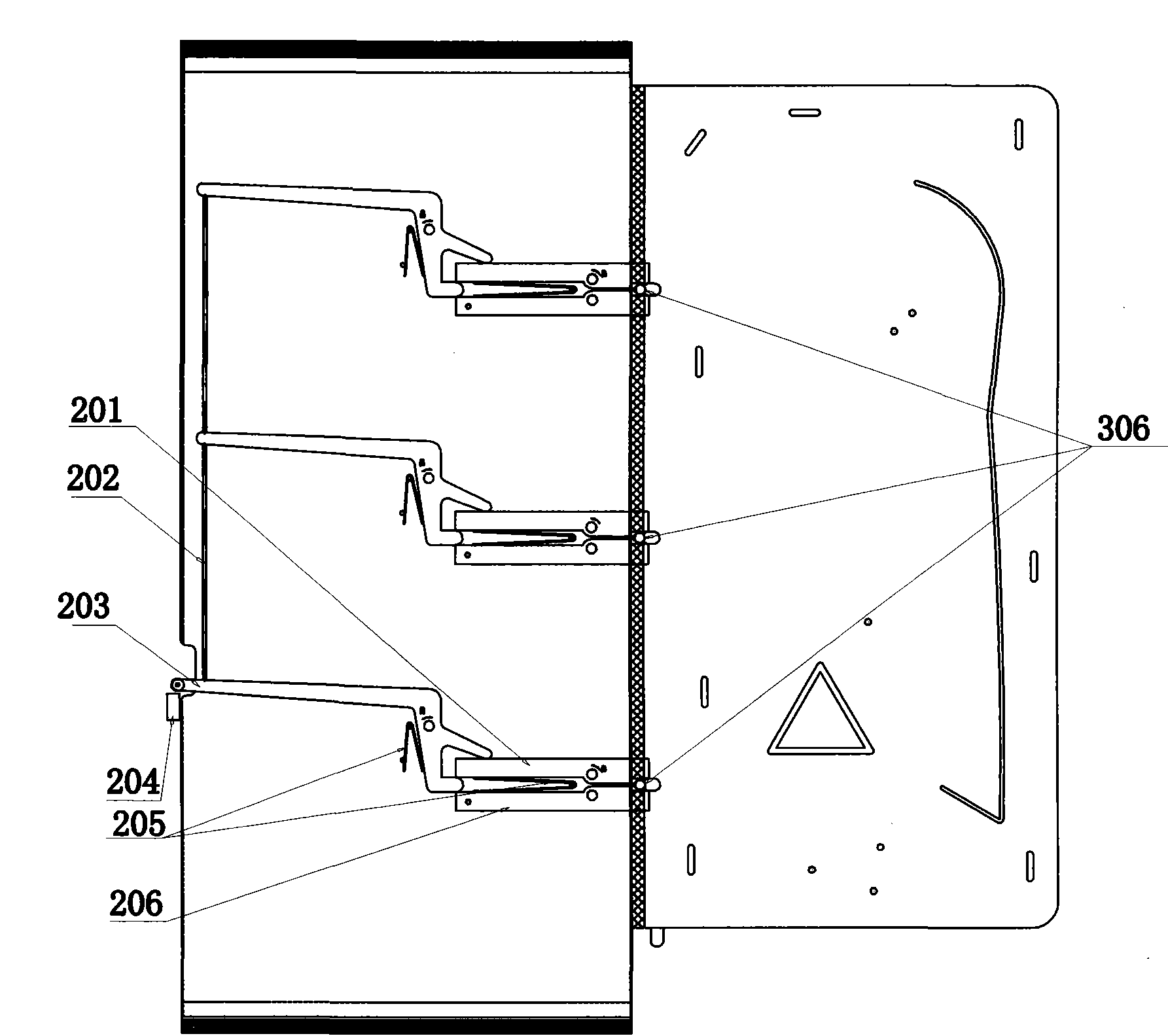

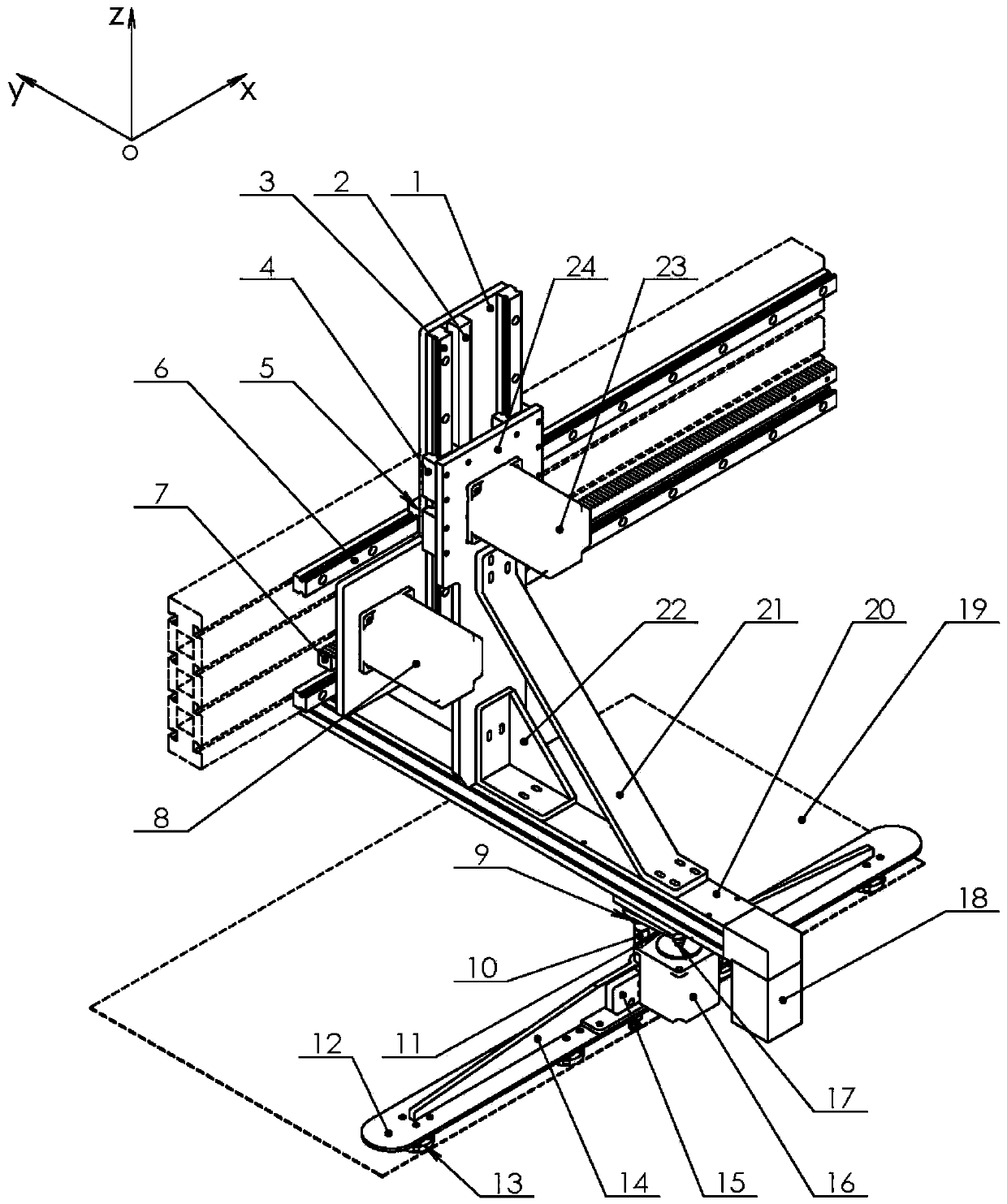

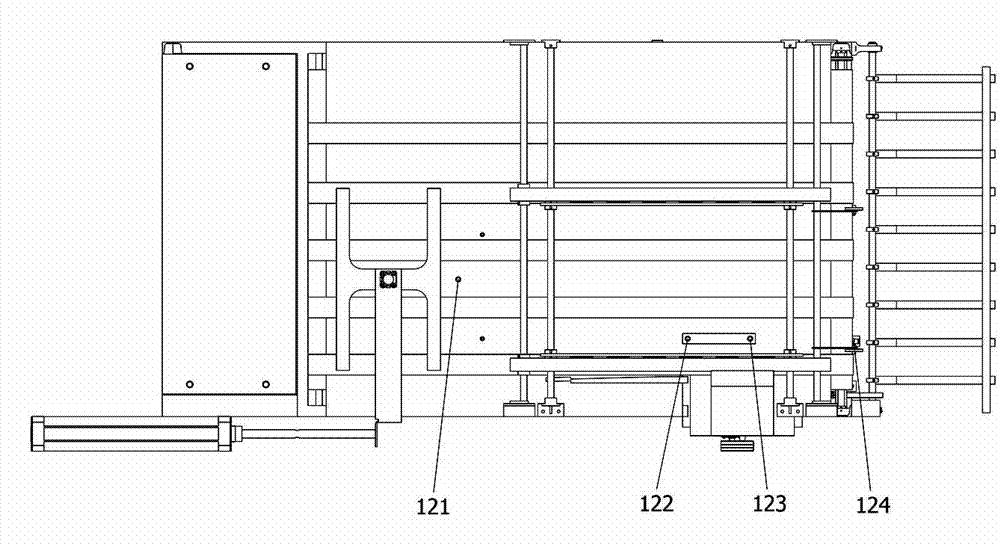

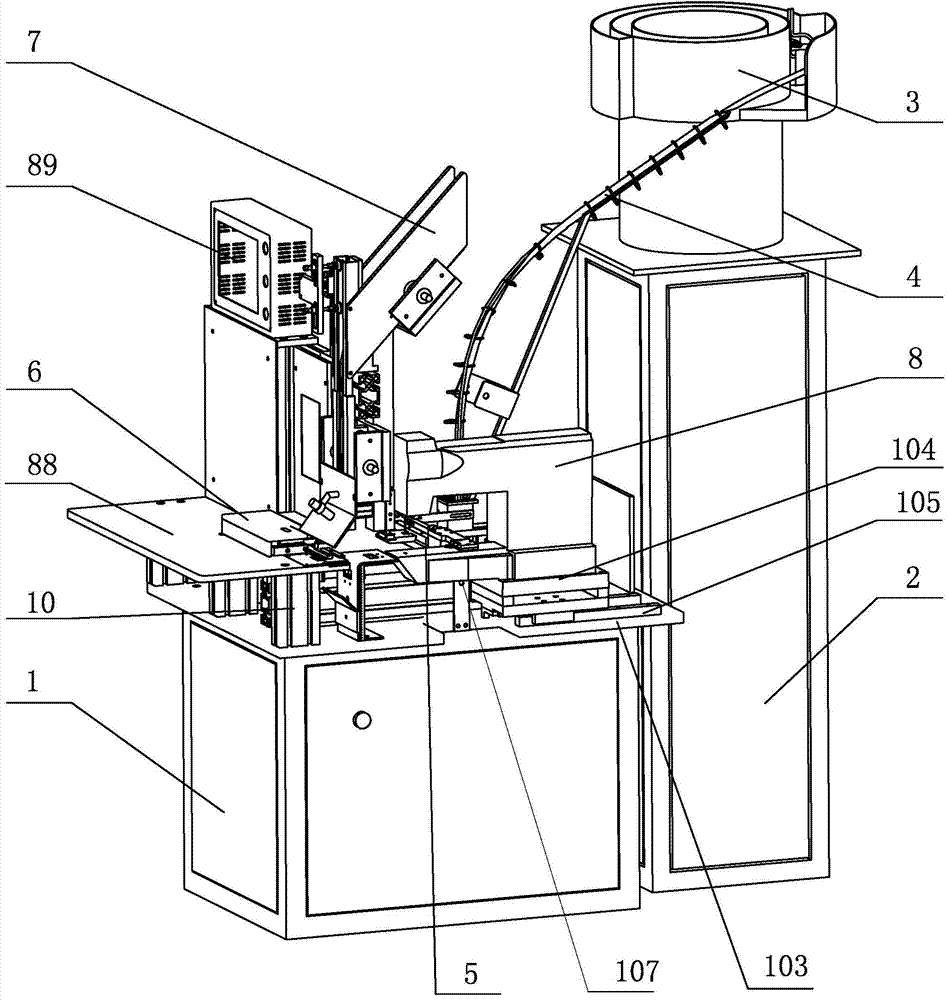

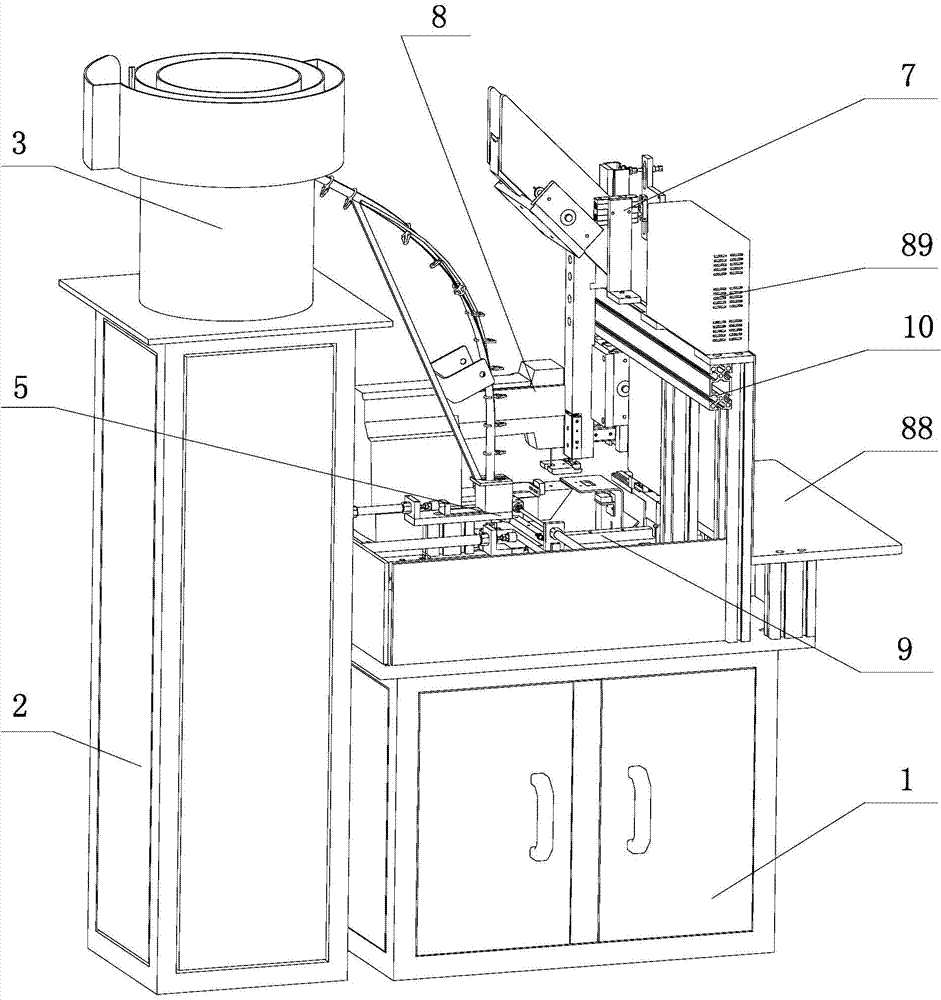

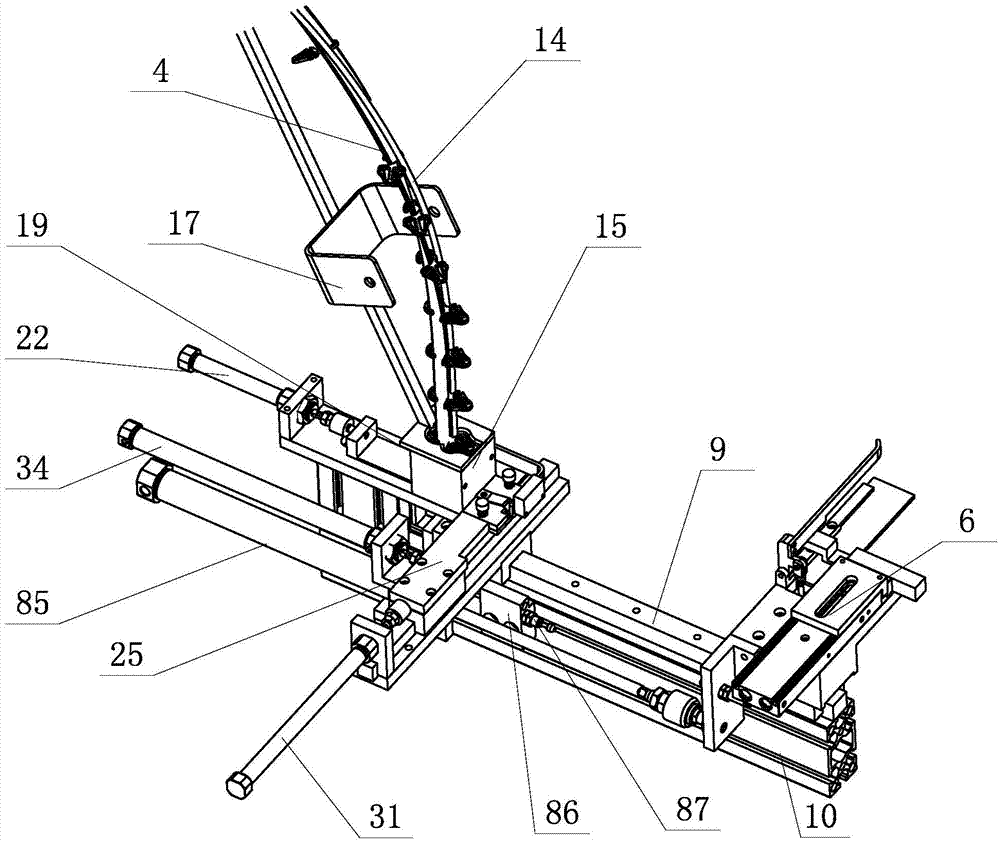

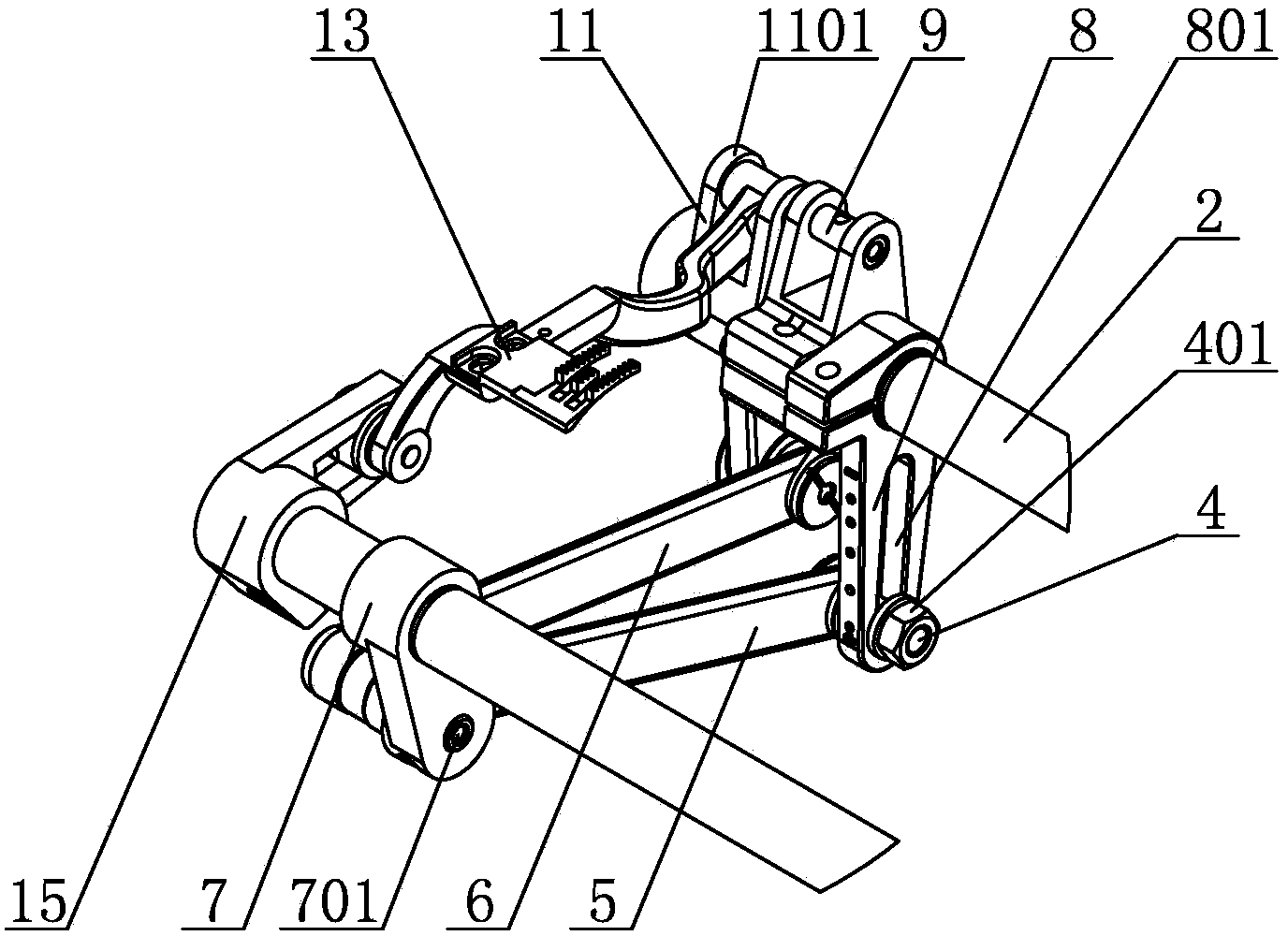

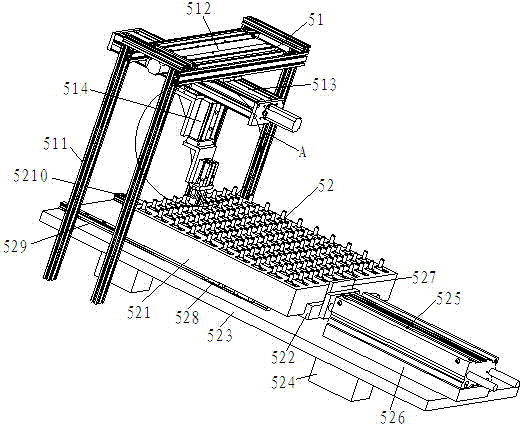

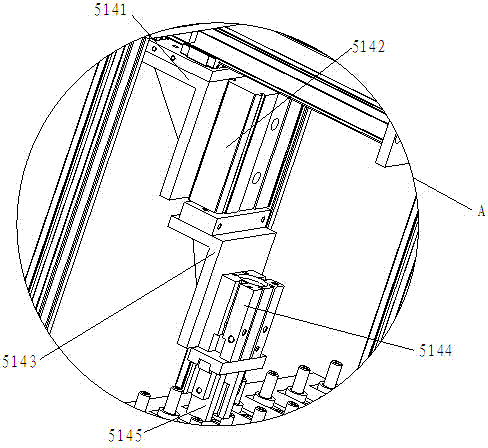

Full-automatic material taking and material feeding sewing machine

The invention relates to a full-automatic material taking and material feeding sewing machine. The full-automatic material taking and material feeding sewing machine comprises a fabric taking device, a fabric position correction system, an air pump system and a sewing material pressing and feeding device, wherein a horizontal guide rail is arranged in the X direction above a machine frame; the entire fabric taking device can conduct movement in X direction along the horizontal guide rail and can further conduct movement in Z direction on the horizontal guide rail; a linear module in a Y direction is arranged at the lower part of the fabric taking device; a rotating and regulating mechanism is arranged at the lower part of the linear module in the Y direction; a sucking disc fixing plate is arranged at the lower part of the rotating and regulating mechanism; the fabric position correction system comprises a fabric position sensing device; the fabric position sensing device comprises at least three sensors and a driving system that monitors the position of the fabric and transmits the signals of the fabric position deviation to the fabric taking device; the driving system corrects the placing position of the fabric through adjusting the global movement of the fabric taking device in the X direction, the Y-direction movement of the linear module in the Y direction and the rotating angles of the rotating and regulating mechanism.

Owner:上海富山精密机械科技有限公司

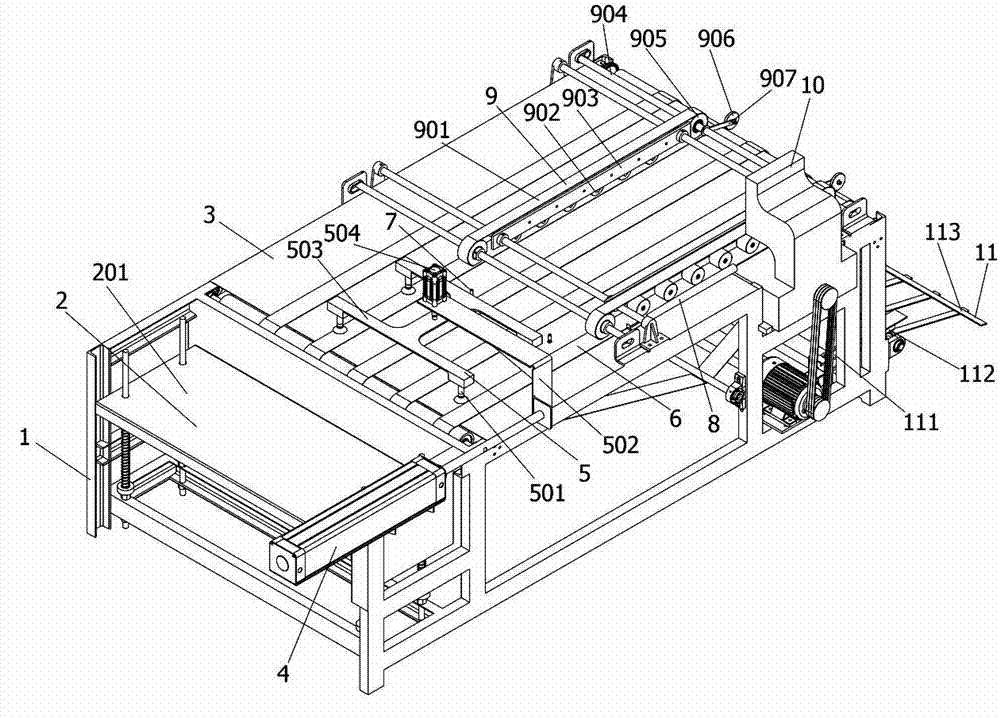

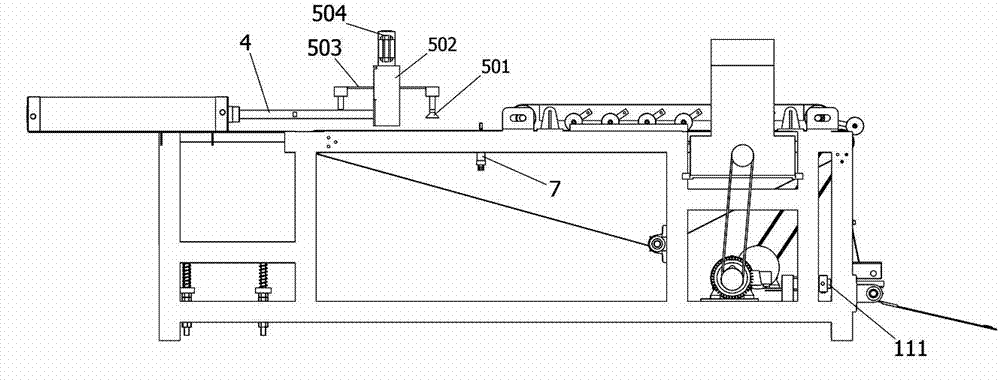

Automatic bag sewing machine

InactiveCN103882629AReduce labor costsShorten the lengthWork-feeding meansWork-collecting devicesReciprocating motionAutomation

The invention discloses an automatic bag sewing machine which comprises a rack assembly, a conveying assembly, a suction cup feeding assembly and a pressing wheel assembly. The rack assembly is located at the feeding end of the conveying assembly, and woven bags to be sewn are placed on the rack assembly. The suction cup feeding assembly is installed above the conveying assembly and the rack assembly and can reciprocate above the conveying assembly and the rack assembly so that the woven bags to be sewn can be moved from the rack assembly onto the conveying assembly. The pressing wheel assembly is installed on the conveying assembly so that the woven bags moving on the conveying assembly can be tightly attached to the conveying assembly to be flattened. A hemmer and a sewing machine body are installed on at least one side of the conveying assembly. The automatic bag sewing machine has the advantages of being simple and compact in structure, high in automation degree, good in consistency of sewn products, capable of reducing the labor cost and the like.

Owner:重庆市巨恒塑料有限公司

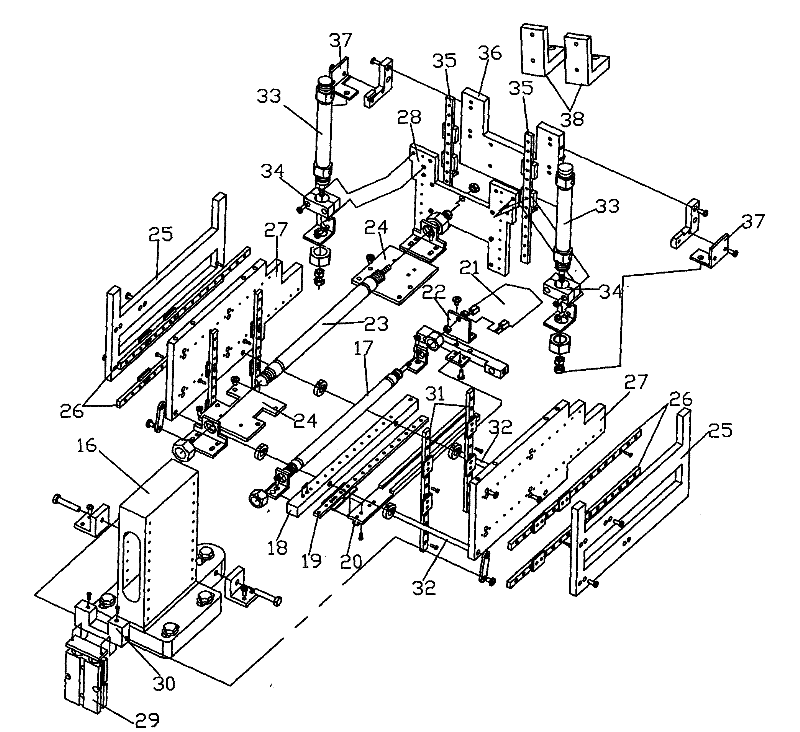

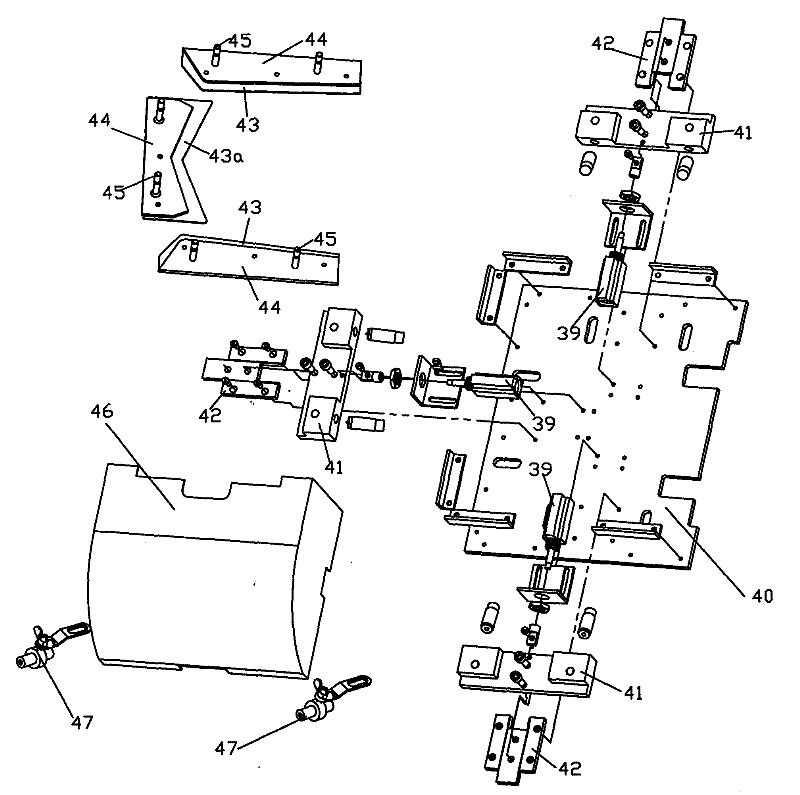

Pneumatic full-automatic pocket patching machine

InactiveCN102191633AReasonable structureEasy to operateWork-feeding meansSewing-machine control devicesManufacturing cost reductionSolenoid valve

The invention discloses a pneumatic full-automatic pocket patching machine. The machine comprises a rack steel plate, a pneumatic automatic non-ironing and folding mechanism and the like, wherein the pneumatic automatic non-ironing and folding mechanism is arranged above the rear part of the rack steel plate; a pneumatic automatic feeding mechanism is transversely arranged in front of the pneumatic automatic non-ironing and folding mechanism; a coordinate pattern transmission mechanism is arranged on the left of the pneumatic automatic non-ironing and folding mechanism; a rotating shuttle type pattern sewing machine sewing head is arranged in front of the rack steel plate on the right and is transversely arranged; an air pressure adjusting mounting plate is arranged at the left rear end of the rack steel plate; solenoid valve mounting plates are arranged on the right of the air pressure adjusting mounting plate; a shield is arranged on the rear half part of the whole rack steel plate; stainless steel coamings are arranged below a stainless steel working table; a first starting switch and a second starting switch are arranged above one stainless steel coaming; a dust collector is arranged on the left of a rack; and an electrical appliance control box is arranged behind the rack and on the lower part of the rack steel plate. The machine has the effects of lowering the manufacturing cost and realizing automatic programs such as non-ironing programs and the like.

Owner:SHANGHAI GUIYI SEWING EQUIP MFG

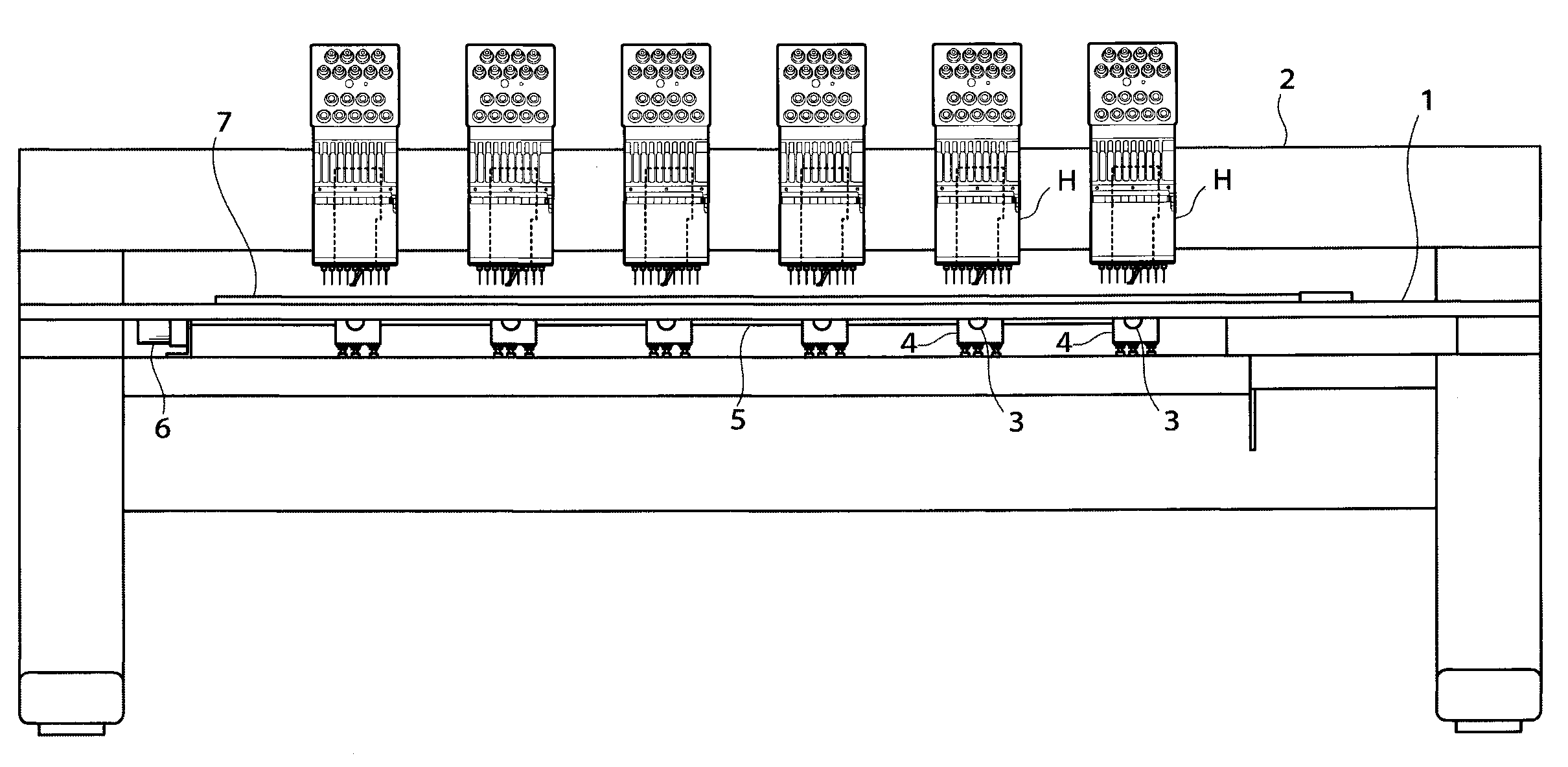

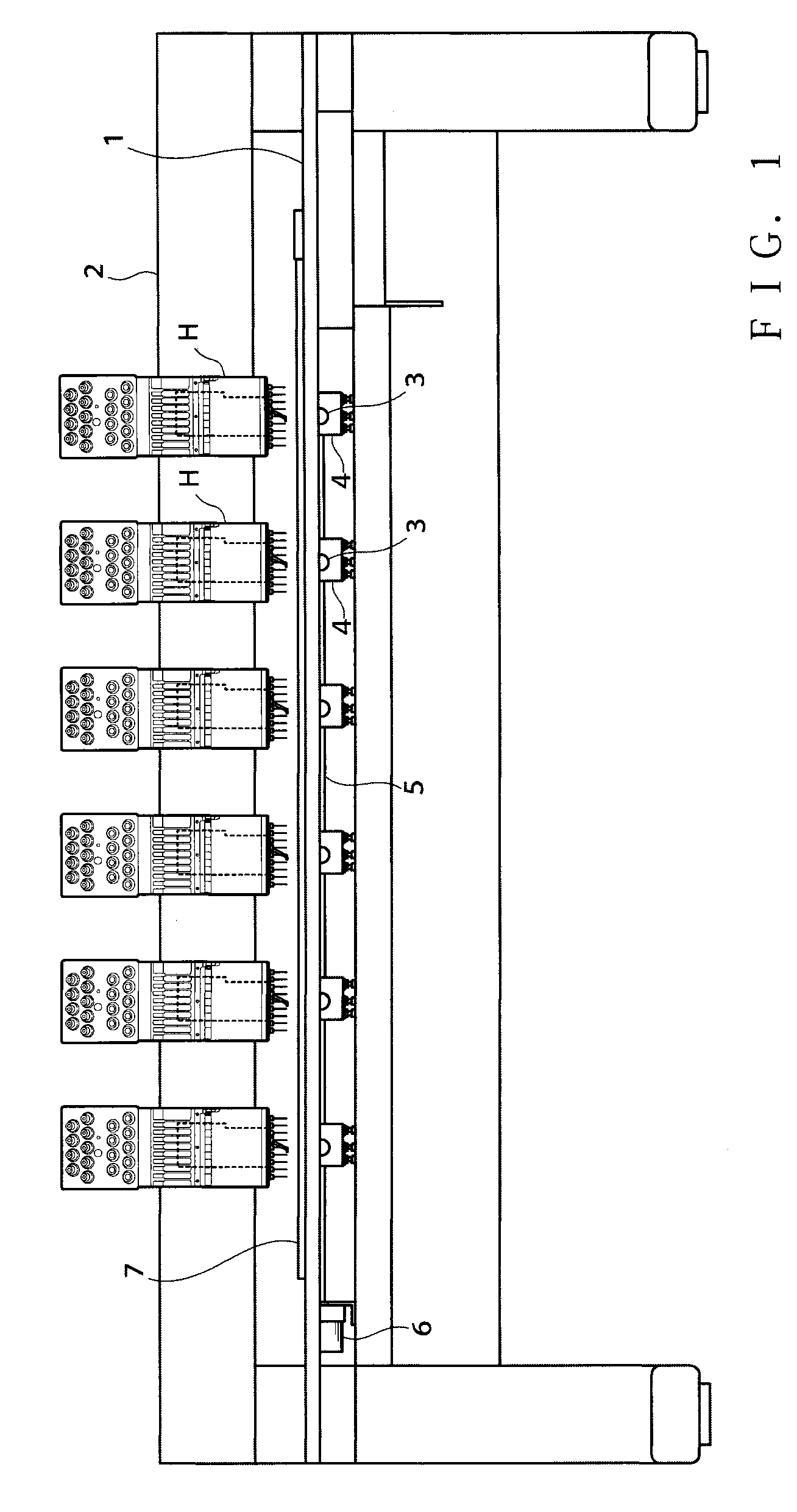

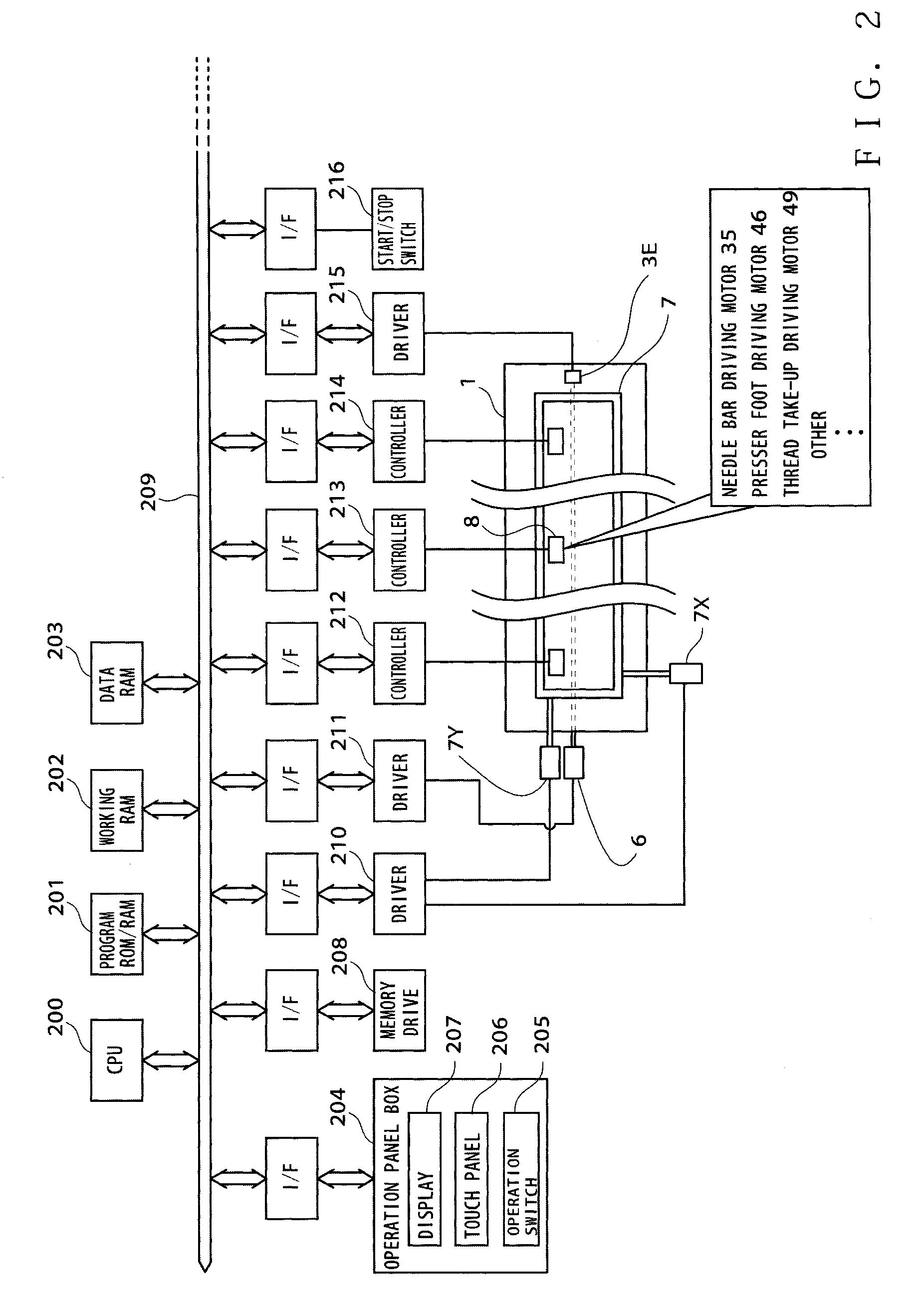

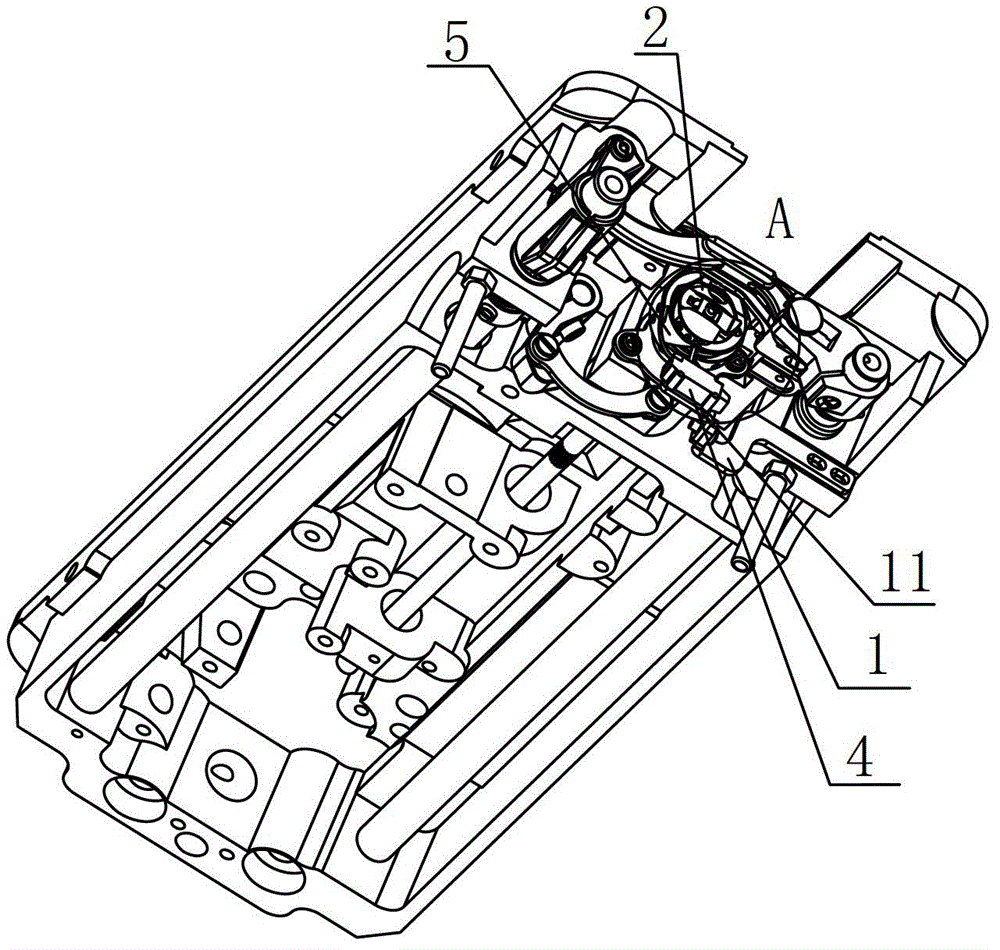

Multi-head embroidery sewing machine

InactiveUS20070261621A1Avoid unevennessEasy to switchPressersSewing-machine control devicesMechanical componentsEngineering

Individual motors in a sewing machine of the invention are provided, for each of a plurality of machine heads, for individually driving respective mechanical components, such as a needle bar driving mechanism, thread take-up lever and presser foot mechanism. A plurality of rotary hooks are driven by a common motor. Even in a case where embroidering workpieces set on the individual machine heads differ in material between the heads and upper threads used for the machine heads differ in characteristic between the heads, the sewing machine can make, in a concurrent, parallel fashion, embroidery products of different texture suited for the respective materials, characteristics, etc., by setting independent stitch formation per machine head.

Owner:TOKAI IND SEWING MACH CO LTD

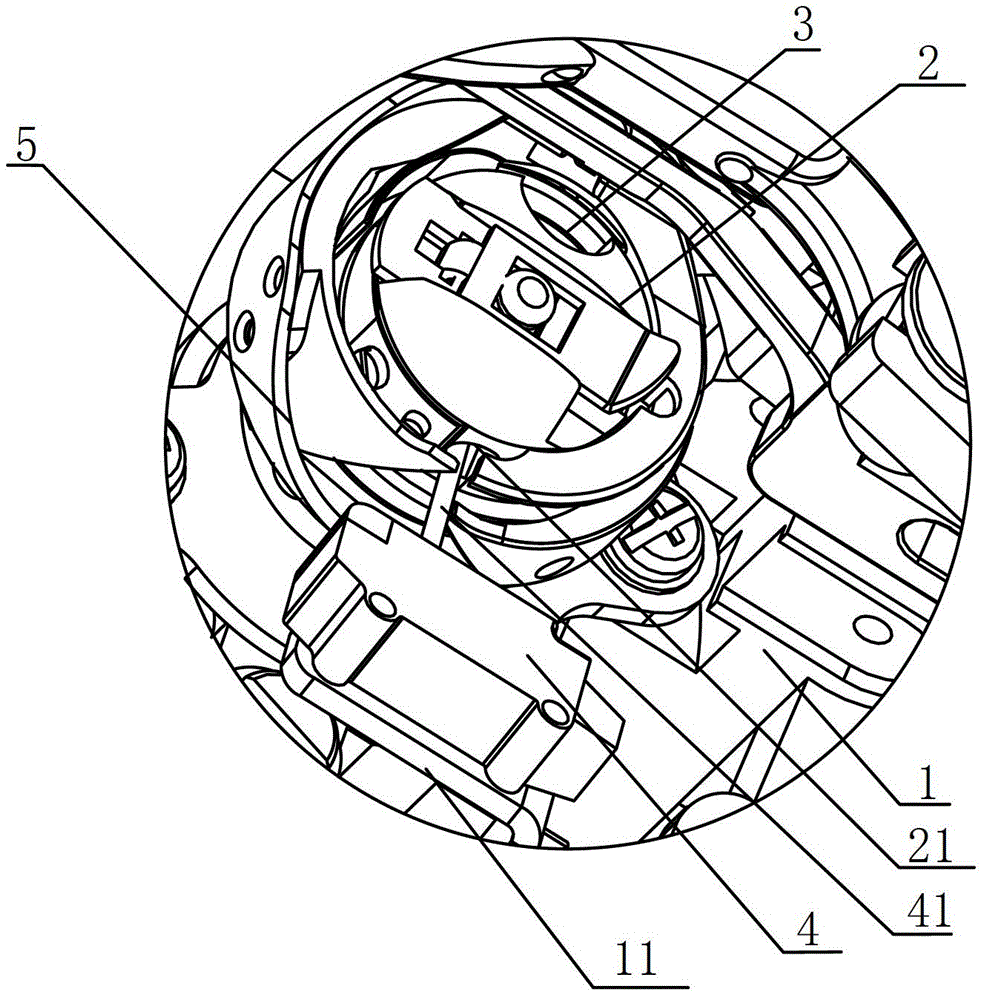

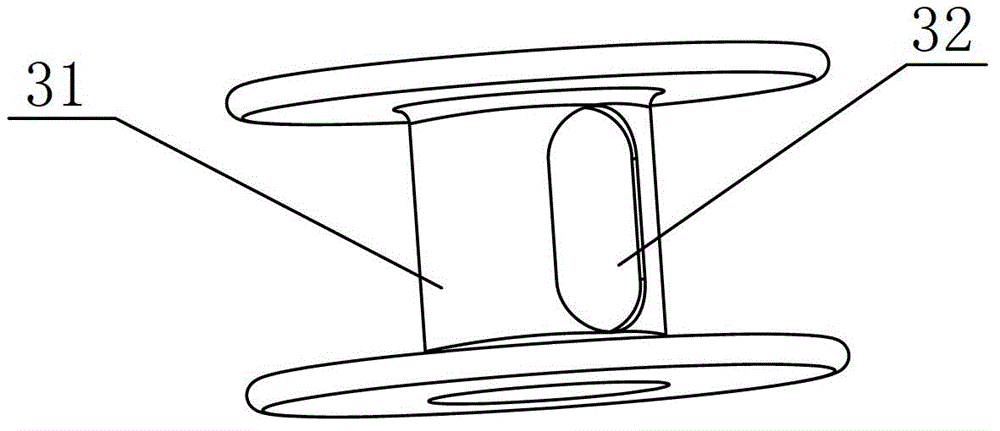

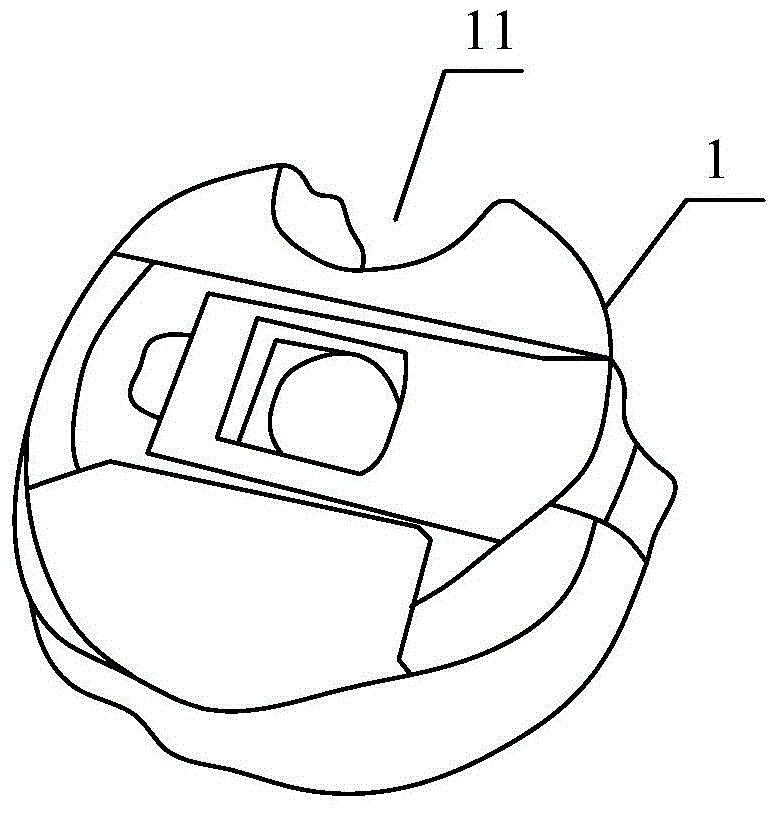

Base thread monitoring device for sewing machine

The invention provides a base thread monitoring device for a sewing machine. The sewing machine comprises a base plate, a bobbin case and a bobbin core which is filled with base thread in a winding mode, wherein the bobbin core is completely contained in the bobbin case, a thread winding column of the bobbin core is provided with a light reflecting surface, a light transmitting hole is formed in the side wall of the bobbin case, a photoelectric sensor is installed on the base plate, the photoelectric sensor is arranged on the outer side of the bobbin case, and is arranged opposite to the light transmitting hole, and the photoelectric sensor is composed of a receiver and a emitter. When the base thread on the thread winding column is large in amount, the base thread can shield the light reflecting surface. When the base thread is almost used out, the light reflecting surface is gradually exposed, the light reflecting surface can receive a signal which is given out by the emitter and enters through the light transmitting hole, and can reflect the signal to the receiver, the receiver gives out a signal after receiving the signal to have control over the sewing machine, and achieves the objective that the sewing machine cannot carry out sewing of the next time after finishing the current sewing, and therefore the phenomenon that the quality of a sewing product is influenced by lack of the base thread can be avoided.

Owner:JACK SEWING MASCH CO LTD

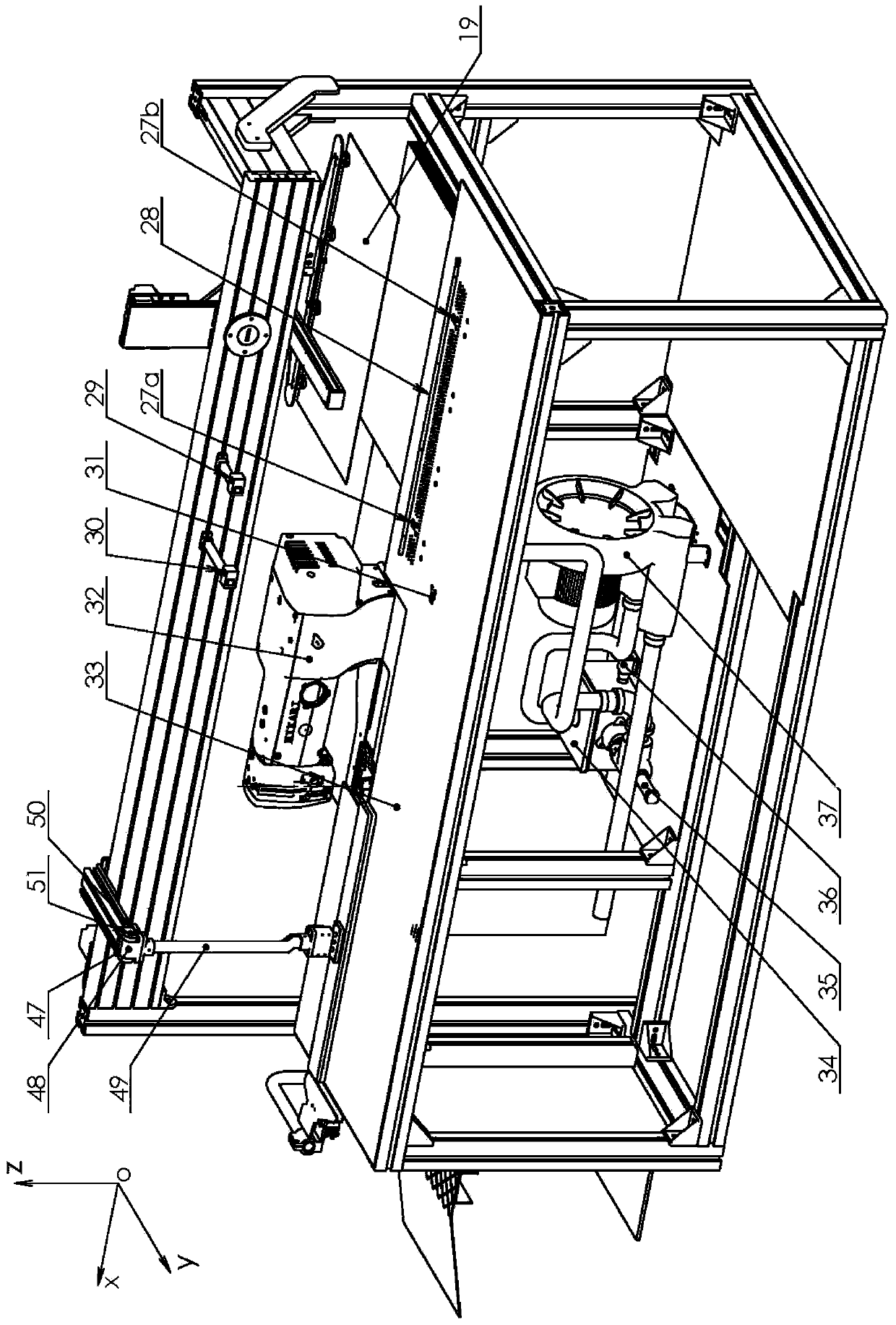

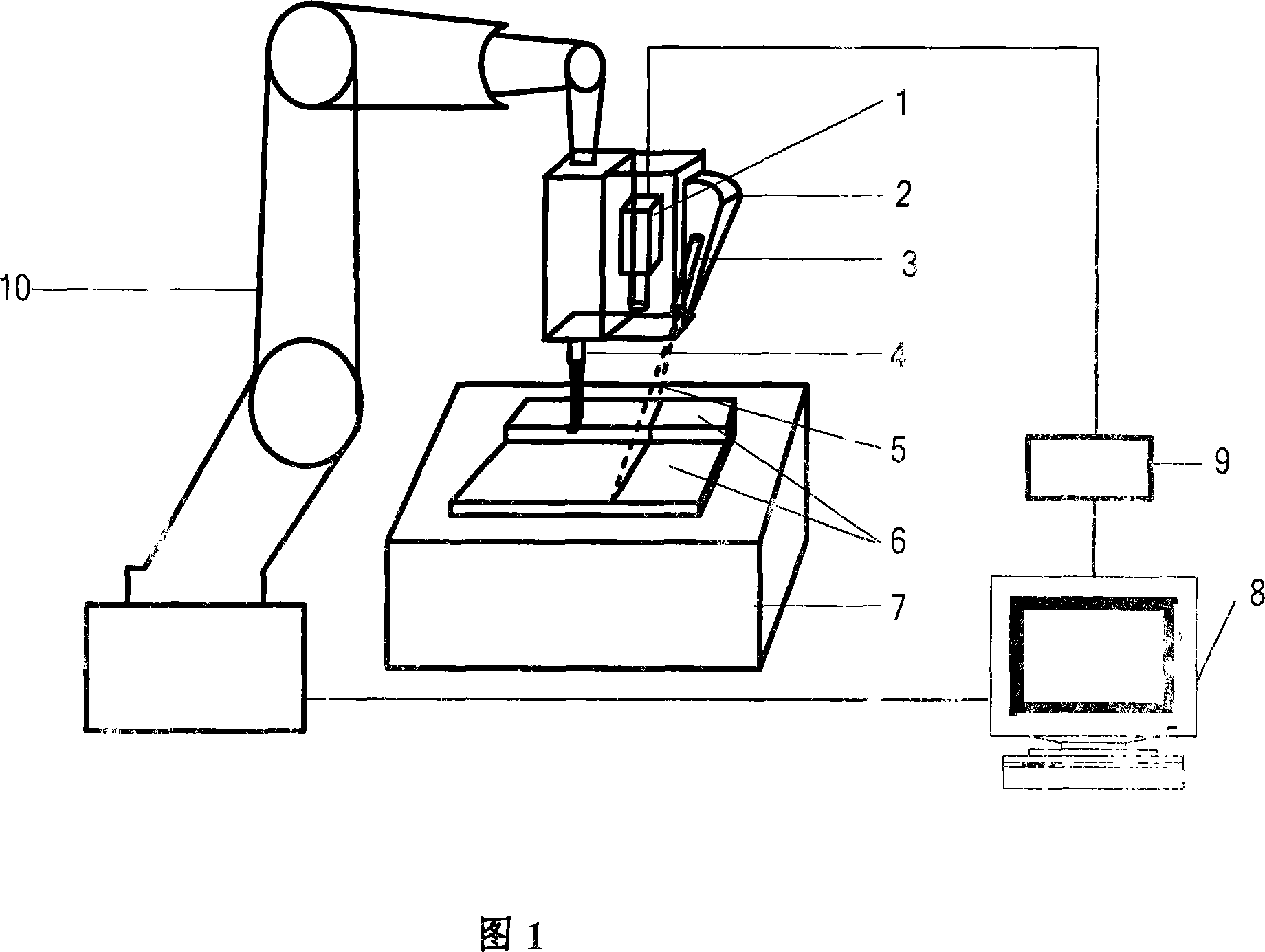

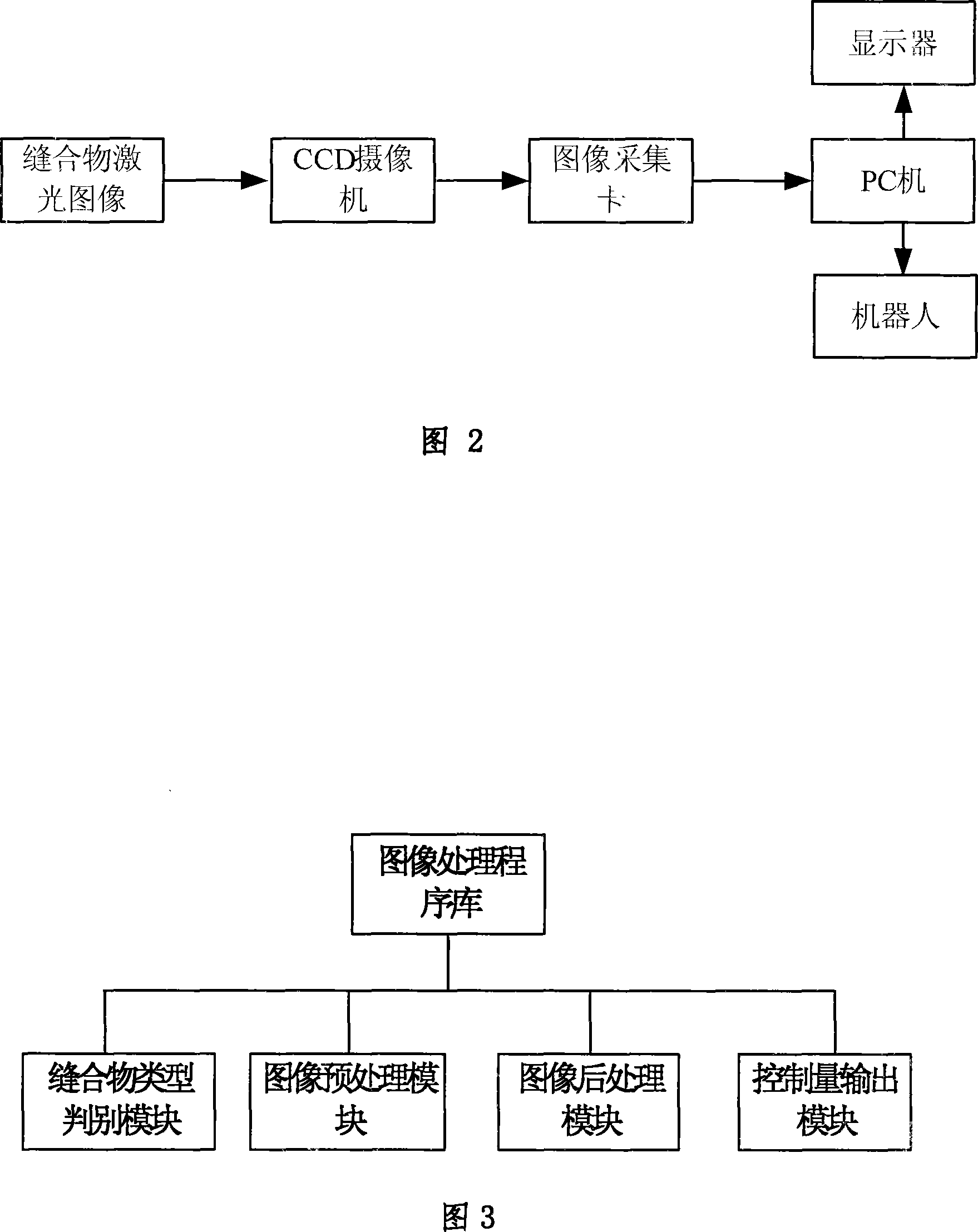

Robot sewing system for three-dimensional composite material perform

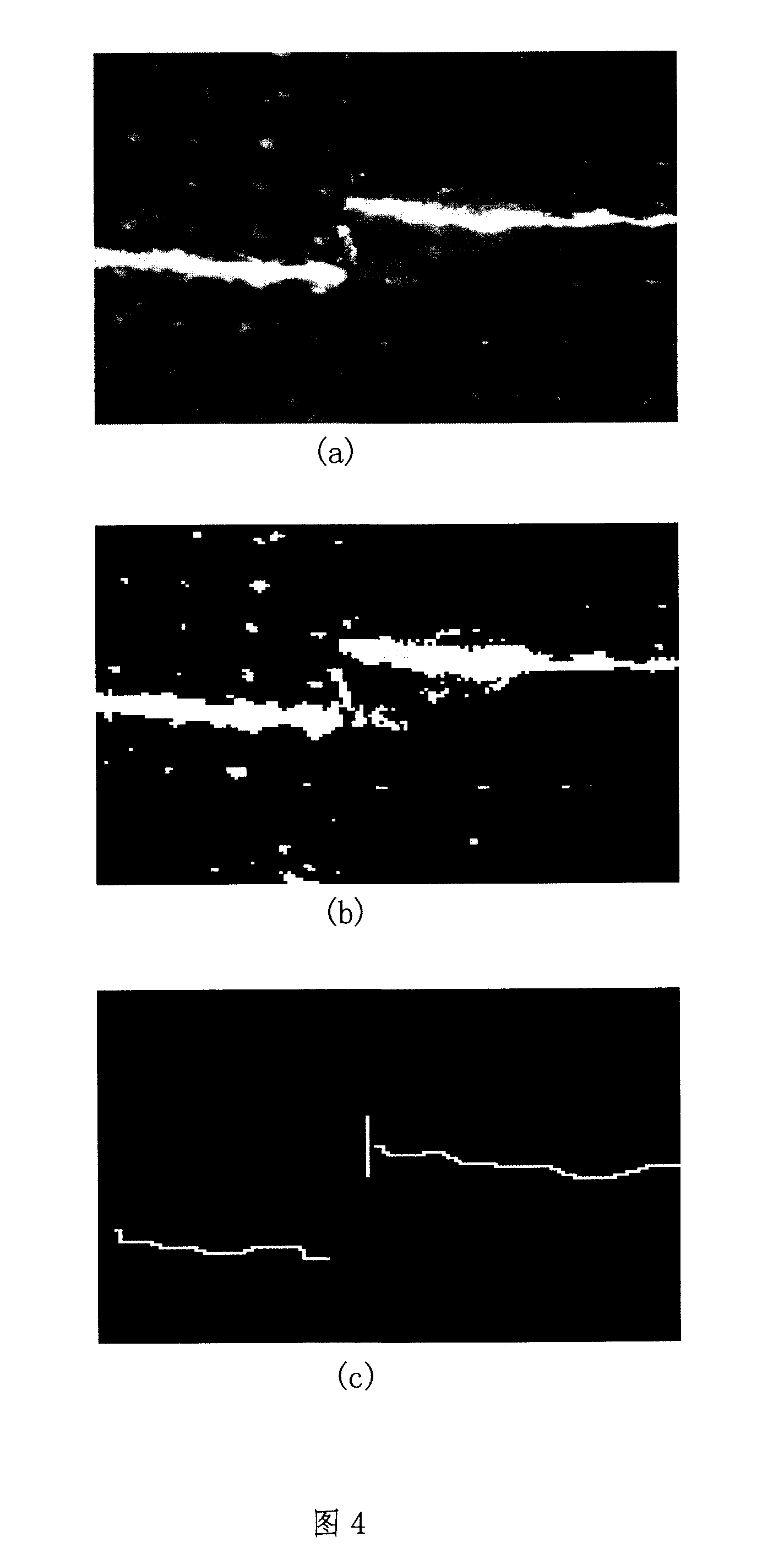

InactiveCN101205662AOvercome flexibilityOvercome errorProgramme-controlled manipulatorSewing apparatusImage post processingEngineering

The invention relates to a 3D composite material prefabrication piece robot sewing system, which comprises a robot, a single-face sewing machine, a structured light vision sensor and an image processing unit; the single-face sewing machine is connected with a shell of the structure light vision sensor and fixed at the tail end of an arm of the robot; the structured light vision sensor comprises a laser and a CCD video camera which are respectively fixed inside an shell of the structured light vision sensor, the included angle of a light axis centerline of the CCD video camera and a laser structure light surface of the laser is 30 to 60 degrees, which is perpendicular with the work-piece surface of a sewing material; the image processing unit comprises an image acquisition card, a PC machine and an image processing program library, the image processing program library comprises a sewing material type identification module, an image pre-processing module, an image post-processing module and a control capacity output module; the CCD video camera is connected with the image acquisition card through an video data line, the image acquisition card is arranged inside a main board slot of the PC machine, the PC machine is connected with the robot through a serial port.

Owner:TIANJIN POLYTECHNIC UNIV

Label sewing fully automatic socks packaging machine

ActiveCN103482108ARealize automatic delivery hookRealize automatic sewingPackagingArticle feedersSOCKSEngineering

The invention discloses a label sewing fully automatic socks packaging machine. The label sewing fully automatic socks packaging machine comprises a vibrating disk bracket, wherein the vibrating disk bracket is provided with a vibrating disk; a spiral material passage is arranged on the outer side of the vibrating disk; the lower end of the spiral material passage is connected with a hook mounting component; a socks feeding component is arranged in front of the hook mounting component; a vertical paper card bin component is arranged between the hook mounting component and the socks feeding component; a label sewing machine is arranged behind the socks feeding component; the hook mounting component and the socks feeding component are arranged on a same longitudinally arranged linear guide rail. The label sewing fully automatic socks packaging machine has the advantages that (1) the vibrating disk is arranged, so that automatic hook feeding can be realized, (2) the hook mounting component is arranged, so that automatic hook mounting can be realized, (3) the paper card bin component is arranged, so that automatic paper card feeding can be realized, (4) the socks feeding component is arranged, so that automatic socks feeding can be realized, and (5) the label sewing machine is arranged, so that automatic sewing can be realized.

Owner:佛山市南海大欣针织业有限公司

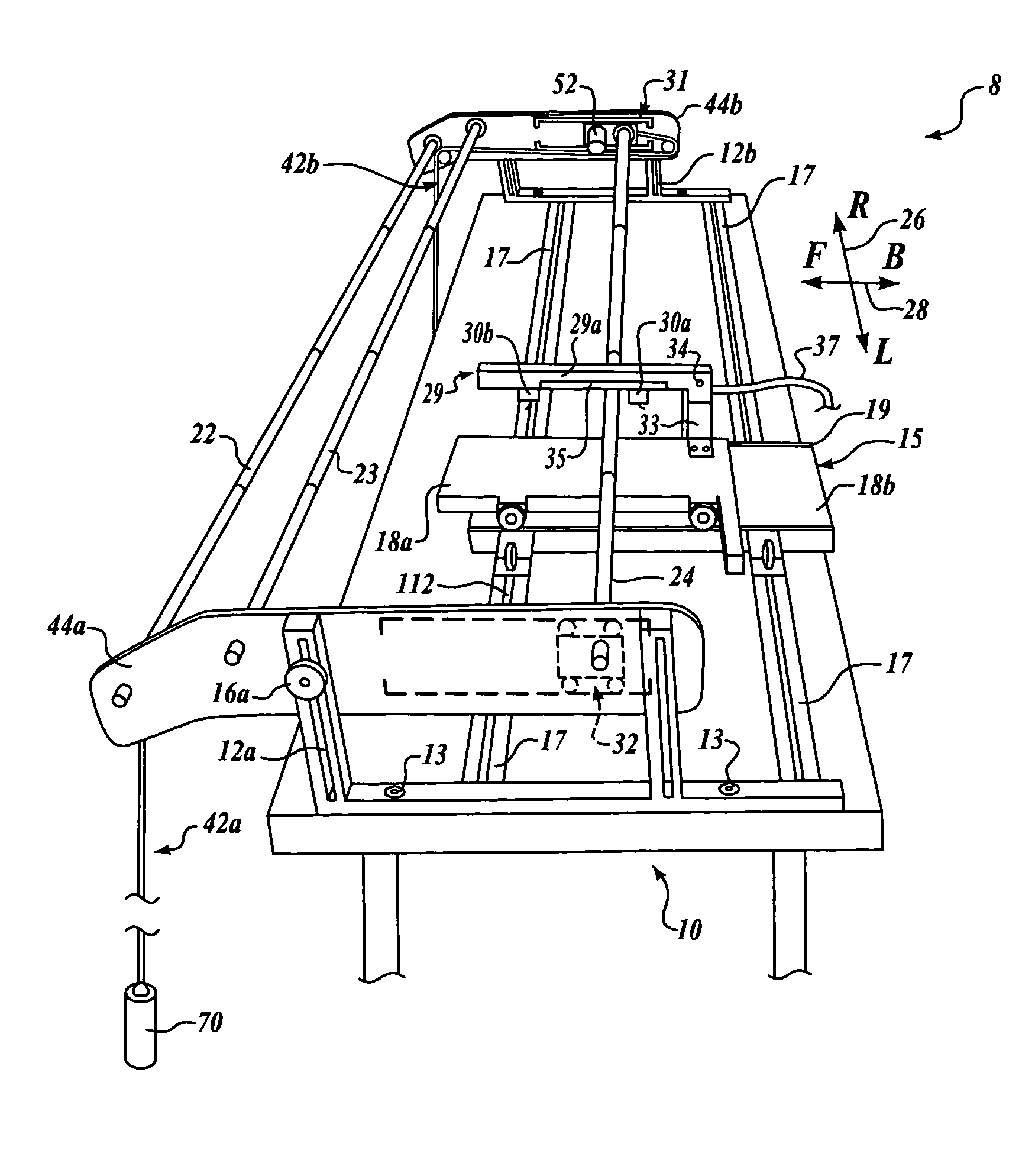

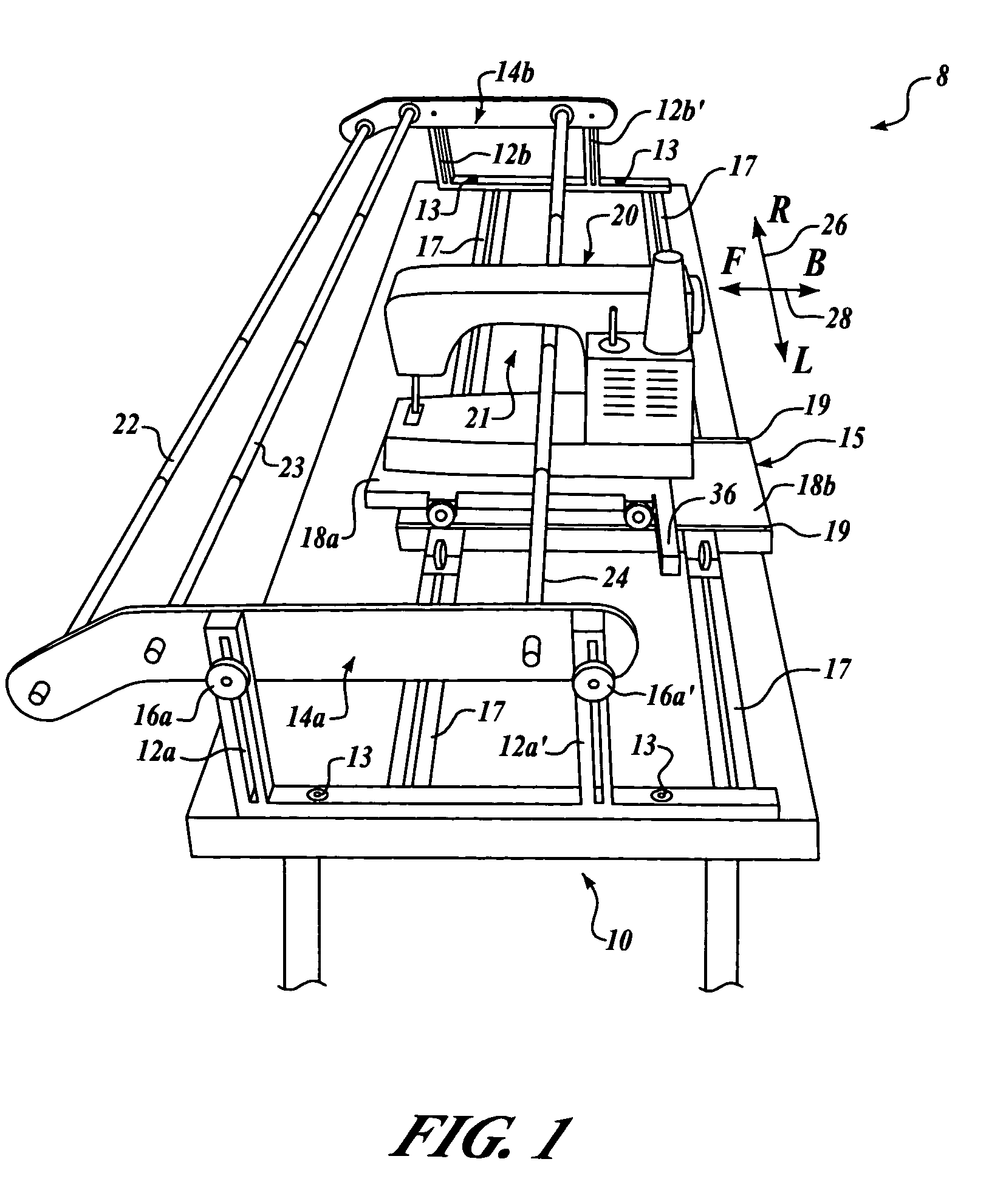

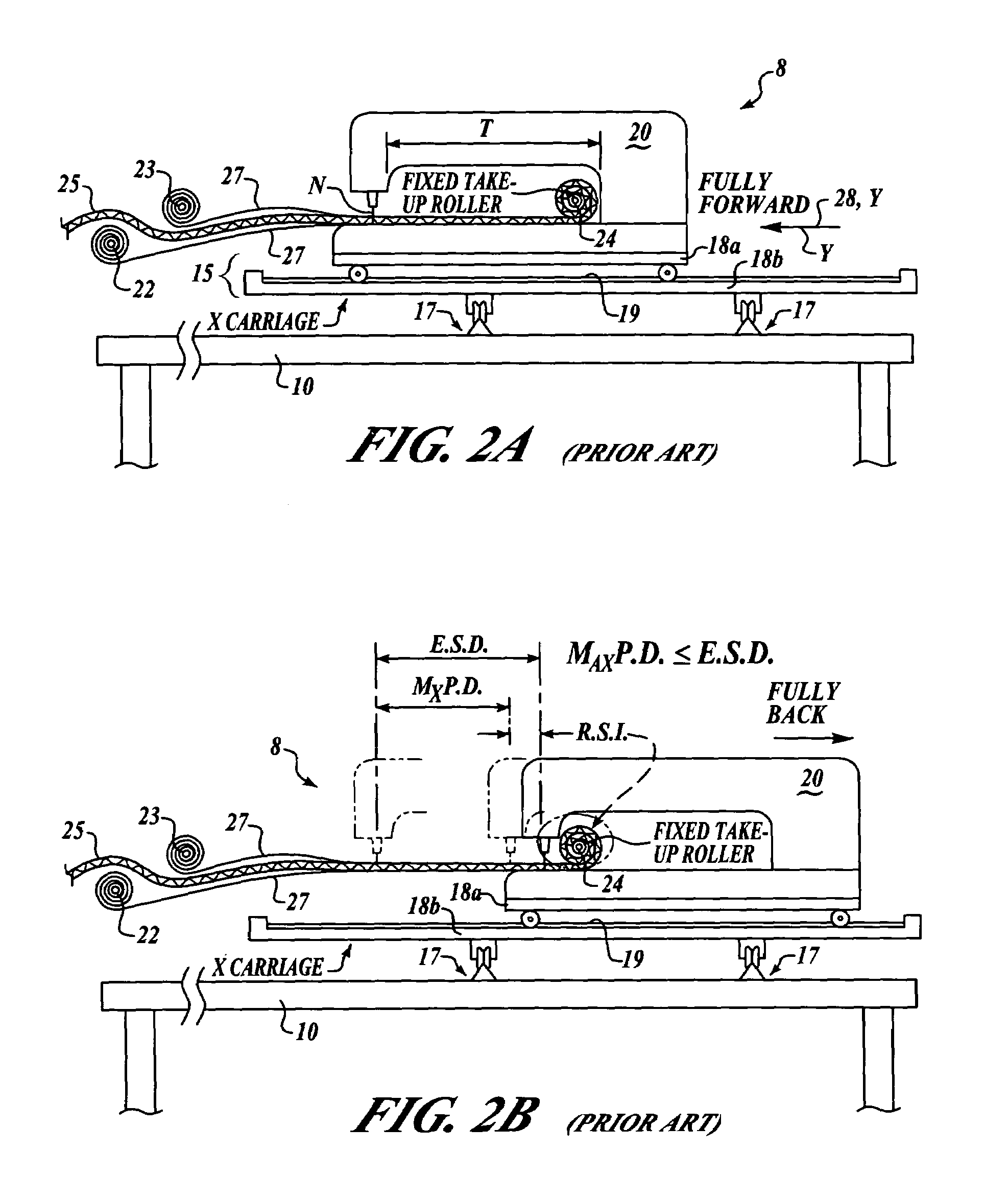

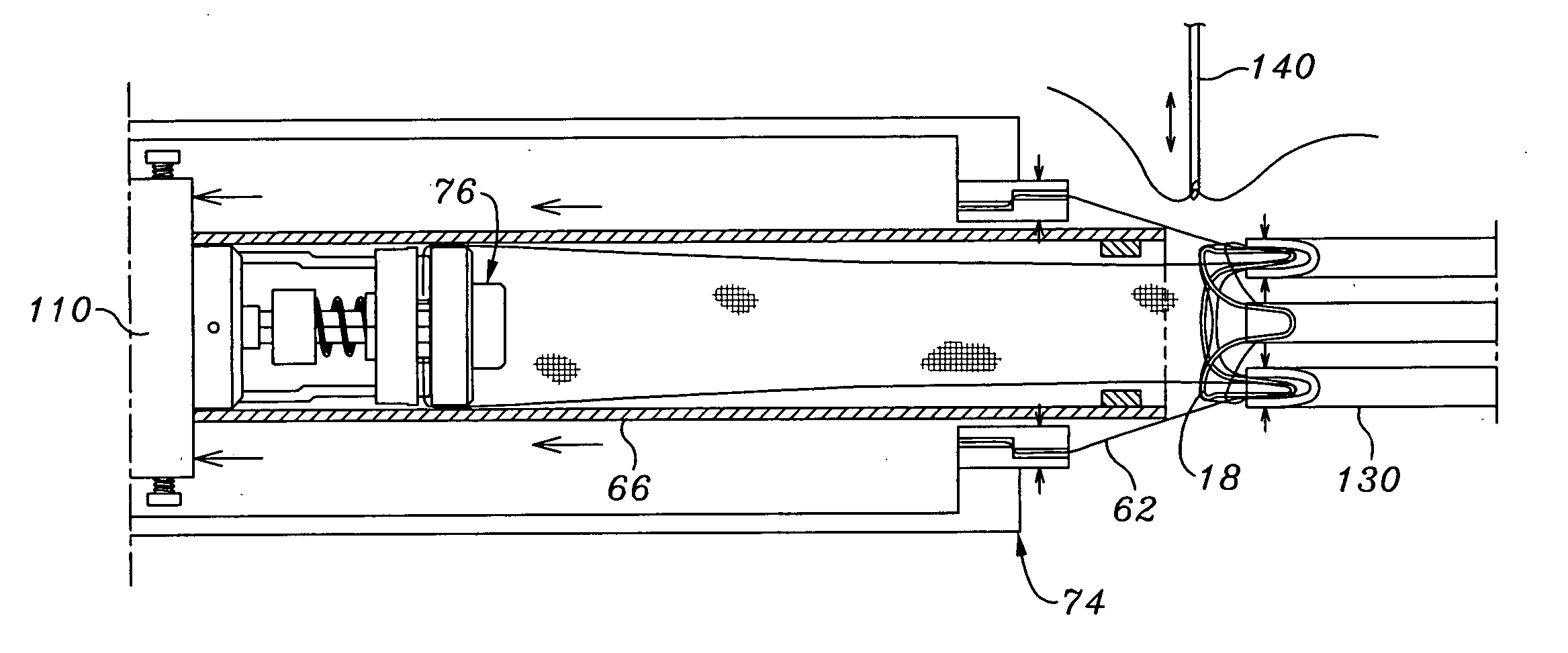

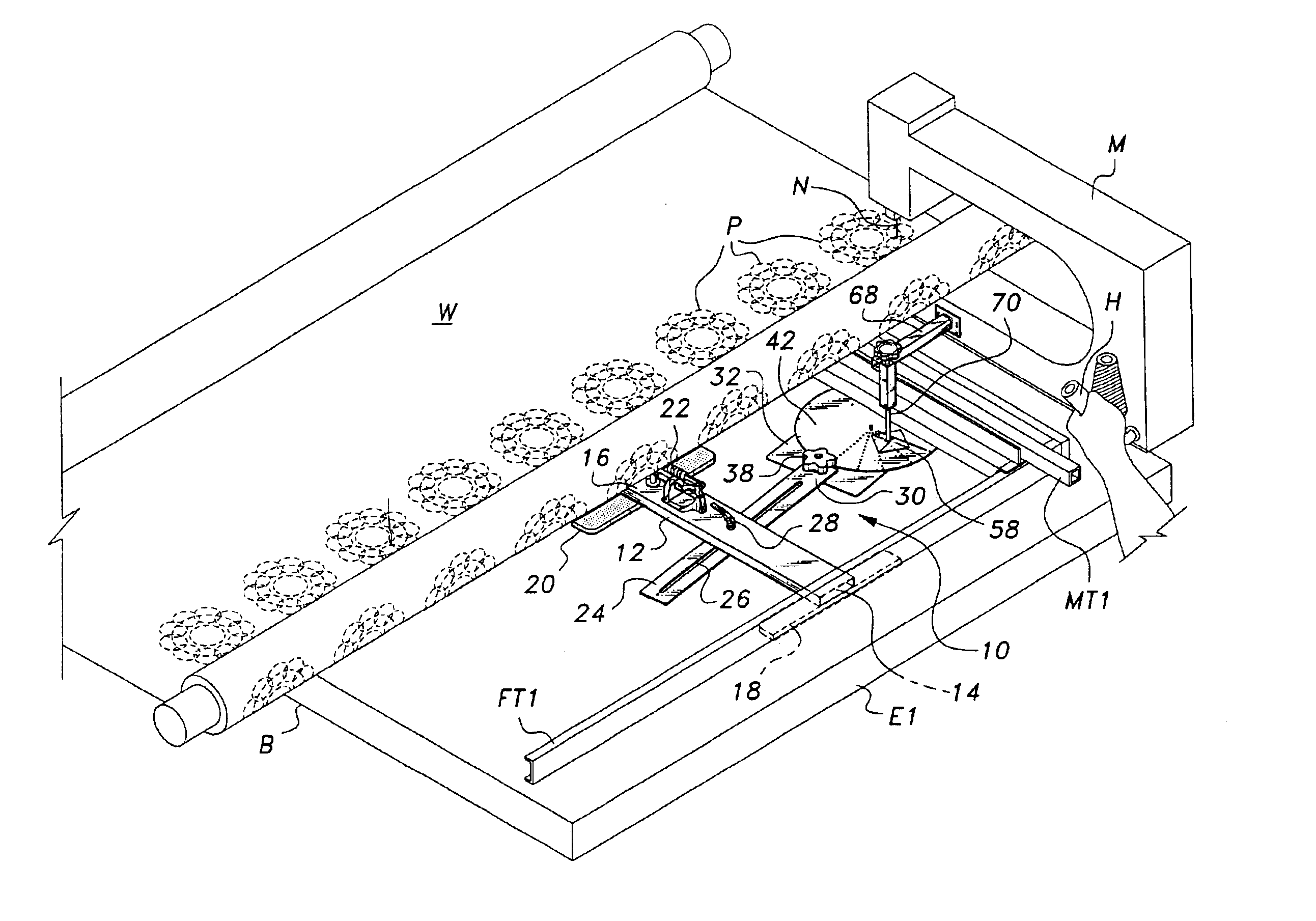

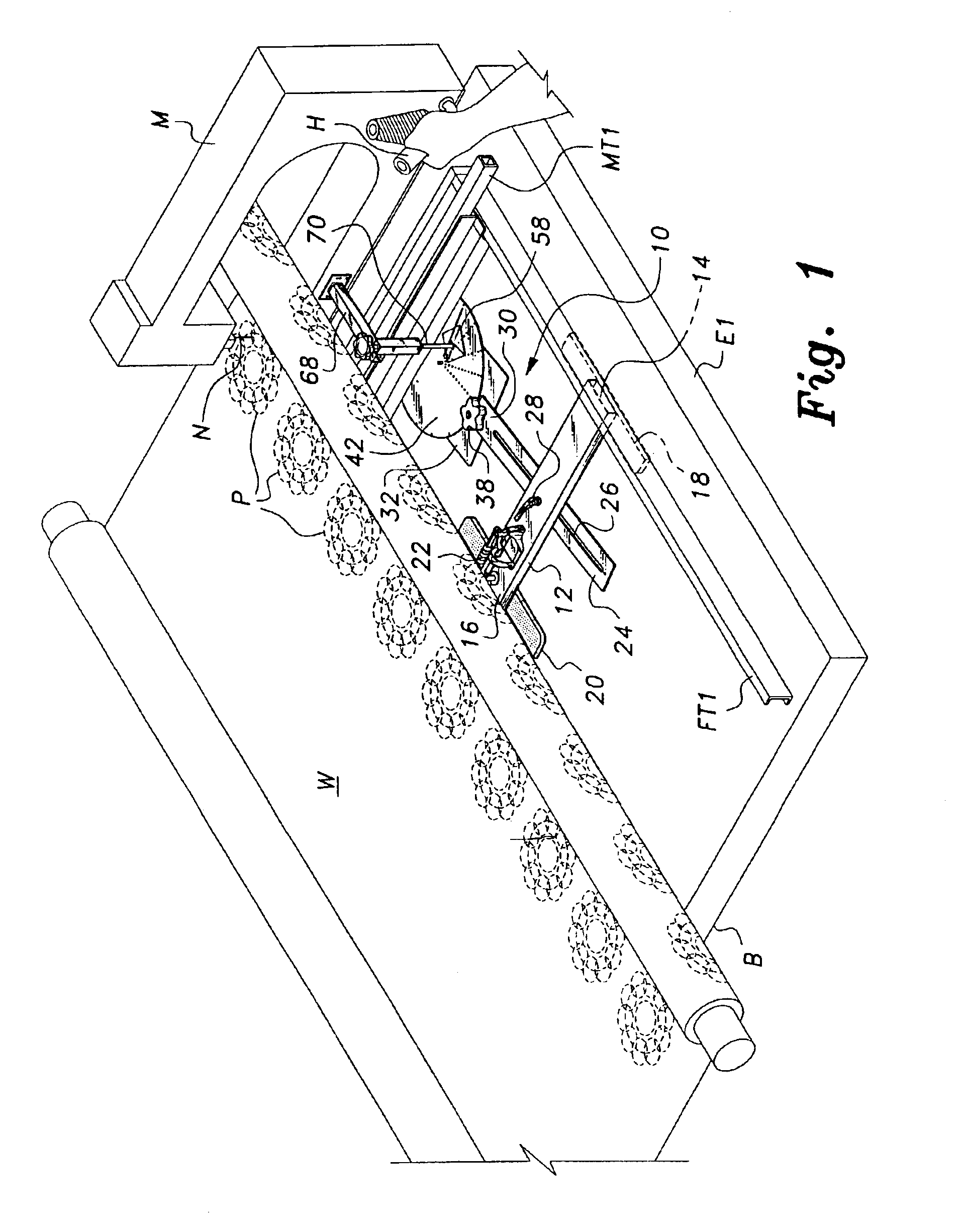

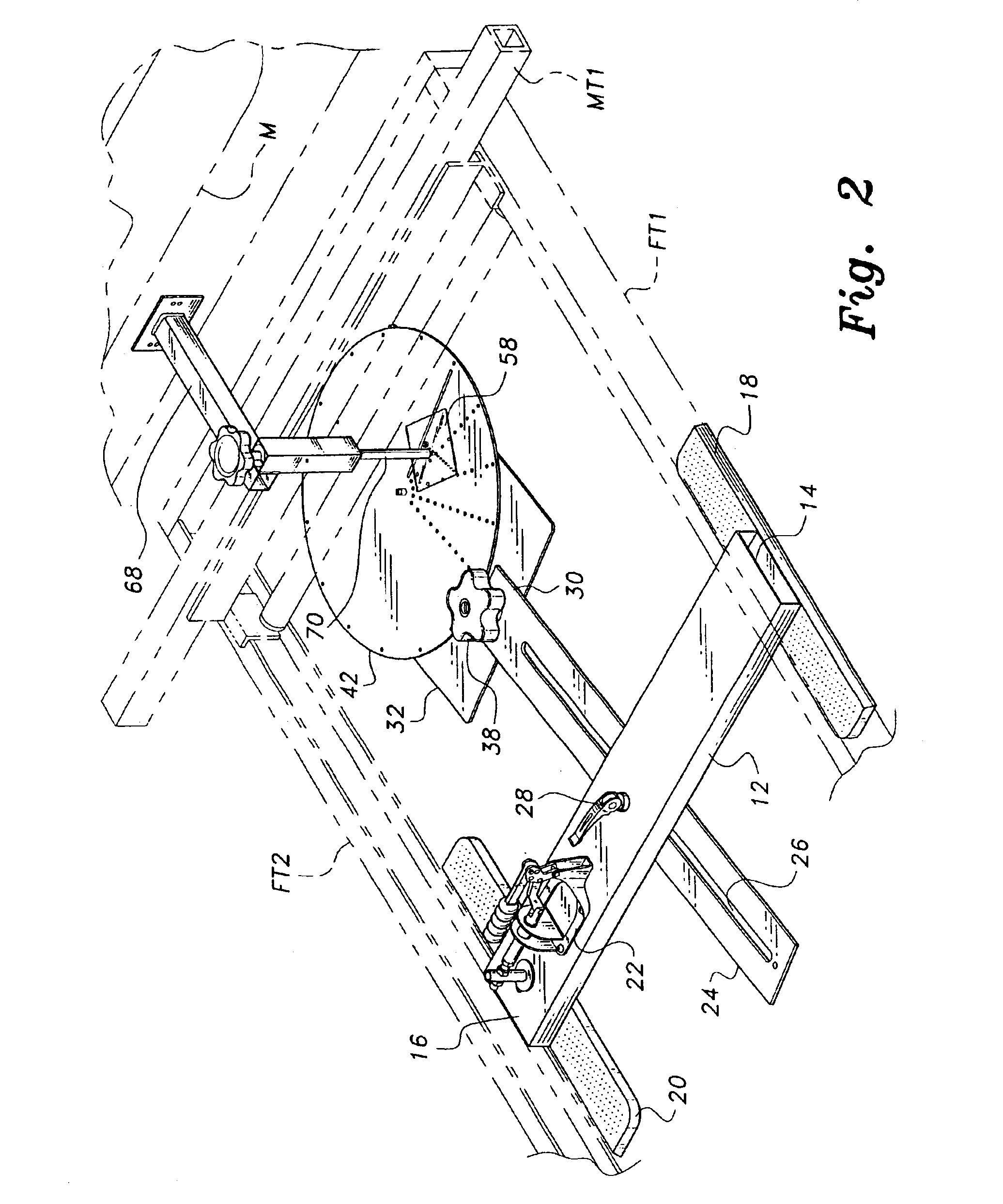

Movable quilting work area system and method

InactiveUS6990914B2Maintain tensionRestrict movementWork-feeding meansMattress sewingEngineeringMicroprocessor

An improved quilting apparatus and method for automatically providing a variable sewing area (VSA) independent of the throat depth of the sewing machine used and X / Y carriages on which the sewing machine is mounted, comprising a rotatably-powered take-up roller mounted on laterally movable carriages, a tension system for continuous tension on fabric and batting, arm-mounted or sewing machine-mounted sensors that detect proximity or engage fabric on the take-up roller and cause rotation of the take-up roller so that it is out of the way of the advancing or returning sewing machine. The inventive VSA system includes a microprocessor-based controller for automatic operation, which controller interfaces with PC operated quilting programs that drive powered X / Y carriage systems to allow sewing of quilting patterns much larger than the throat depth of conventional sewing machines.

Owner:MCMUFFIN & SNUFFLES

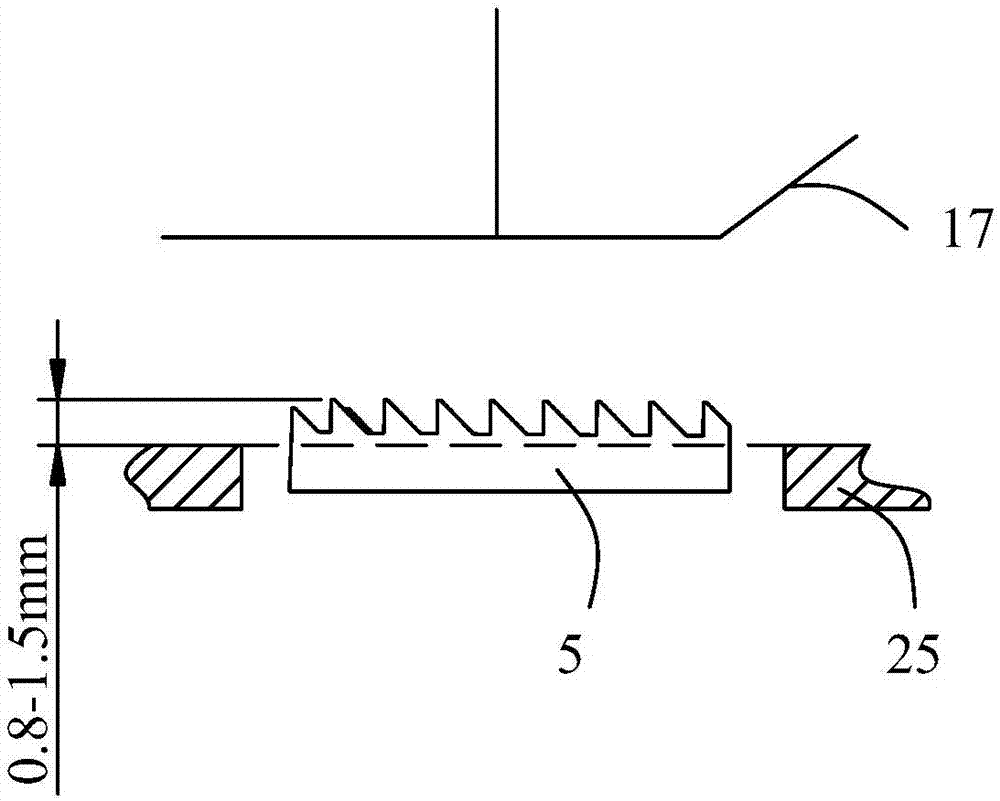

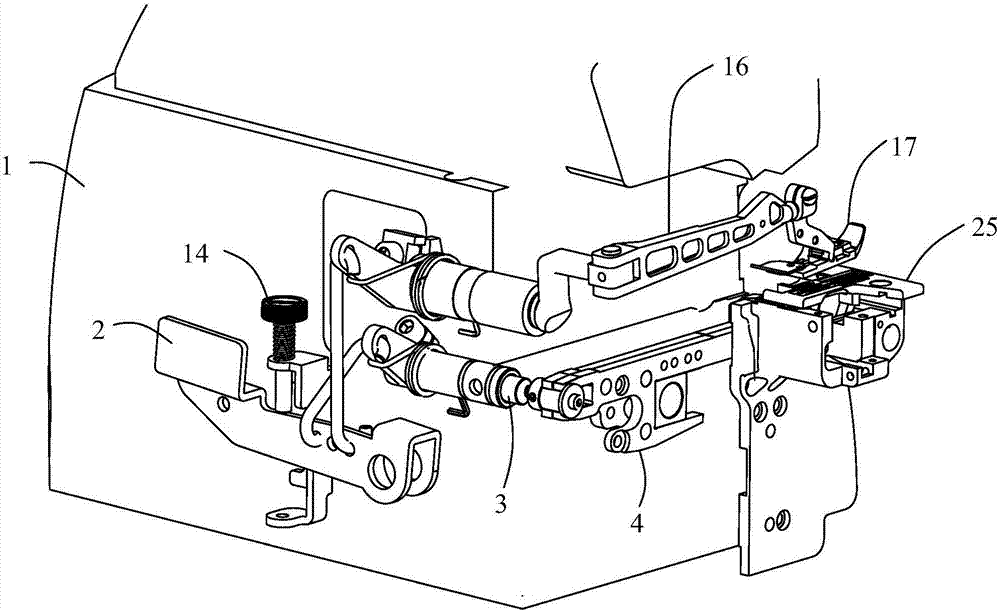

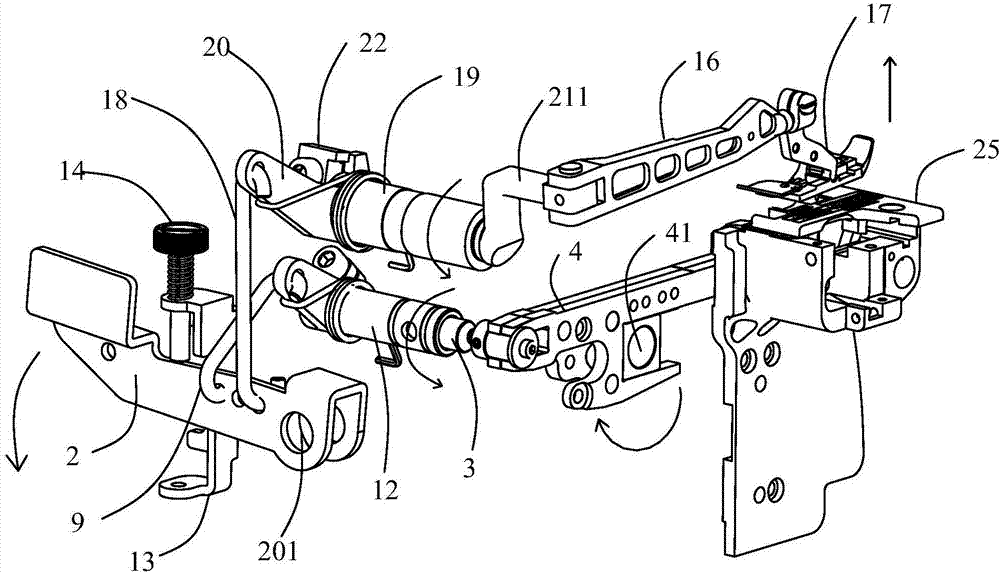

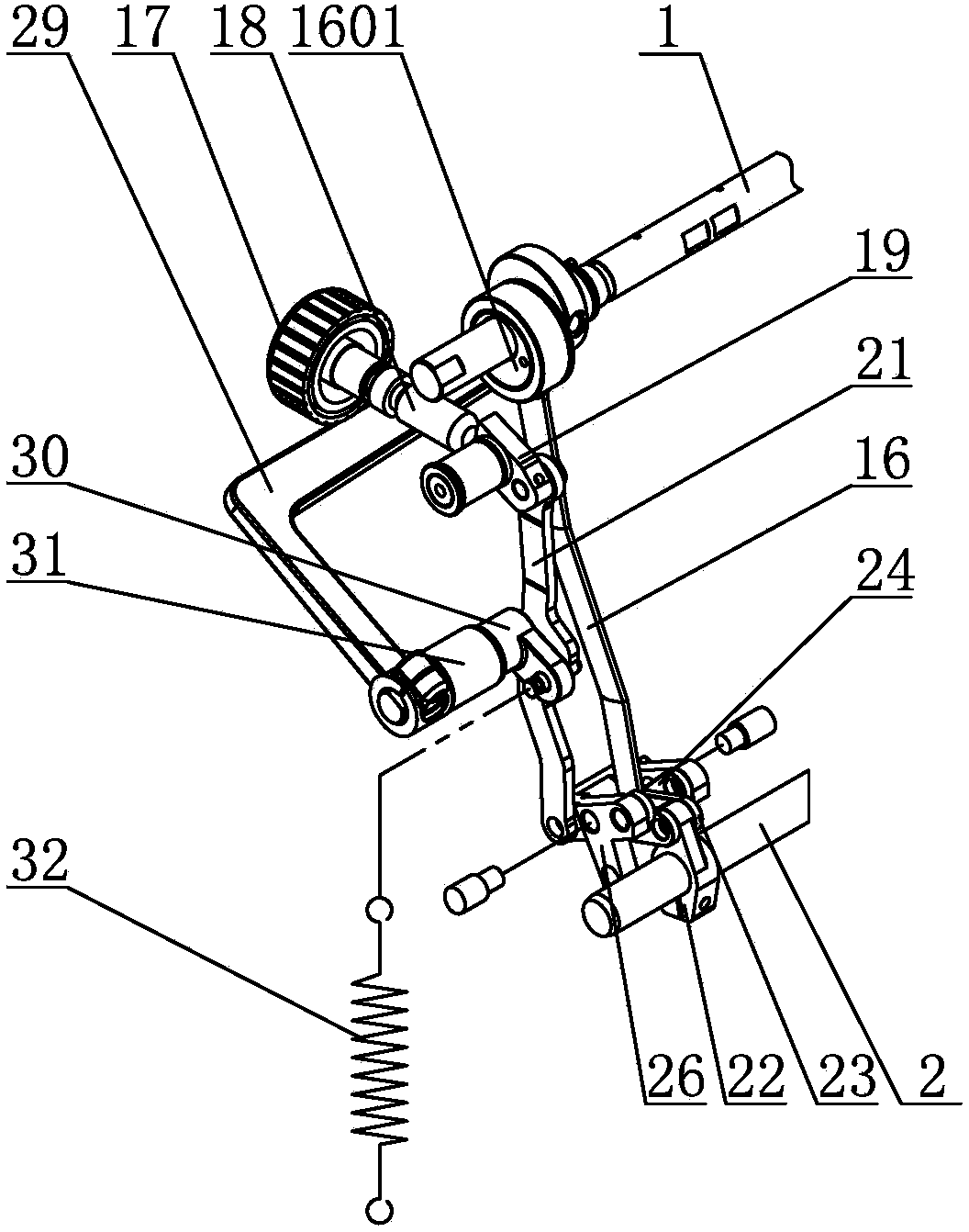

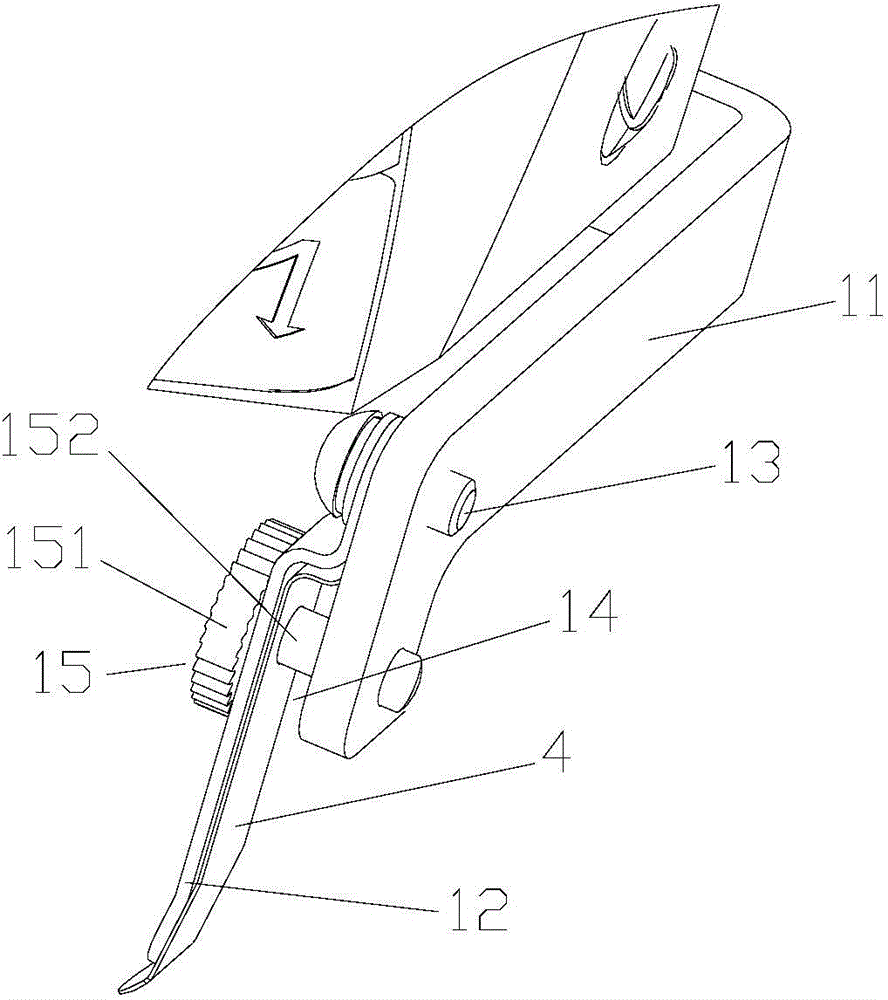

Feeding mechanism downward movement structure controlled by presser foot lifting mechanism and sewing machine

ActiveCN106988030AGuaranteed effective heightEasy to feedWork-feeding meansPressersDental ArticulatorsEffective height

The invention provides a feeding mechanism downward movement structure controlled by a presser foot lifting mechanism and a sewing machine. The feeding mechanism downward movement structure includes a presser foot lifting wrench, an eccentric shaft rotatably installed in a machine housing, a dental articulator having a second swinging supporting point, and a feeding tooth installed at one end of the dental articulator; a sliding groove is formed in the dental articulator, the eccentric shaft has a shaft body part and a shaft eccentric part eccentrically arranged on the shaft body part, the presser foot lifting wrench is connected with the shaft body part of the eccentric shaft through a first transmission mechanism, and the shaft eccentric part of the eccentric shaft can be rotatably installed in the sliding groove of the dental articulator and cooperated with the sliding groove in a sliding mode; when a presser foot is lifted, the presser foot lifting wrench swings around a first swinging supporting point and swings around the second swinging supporting point through a first transmission mechanism and an eccentric shaft driven dental articulator, so that the end, provided with the feeding tooth, of the dental articulator moves downward to the upper surface of a needle plate, the effective height between the presser foot and the needle plate after the presser foot is lifted is ensured, and therefore a to-be-sewed material is easily delivered between the presser foot and the needle plate before sewing is started.

Owner:JACK SEWING MASCH CO LTD

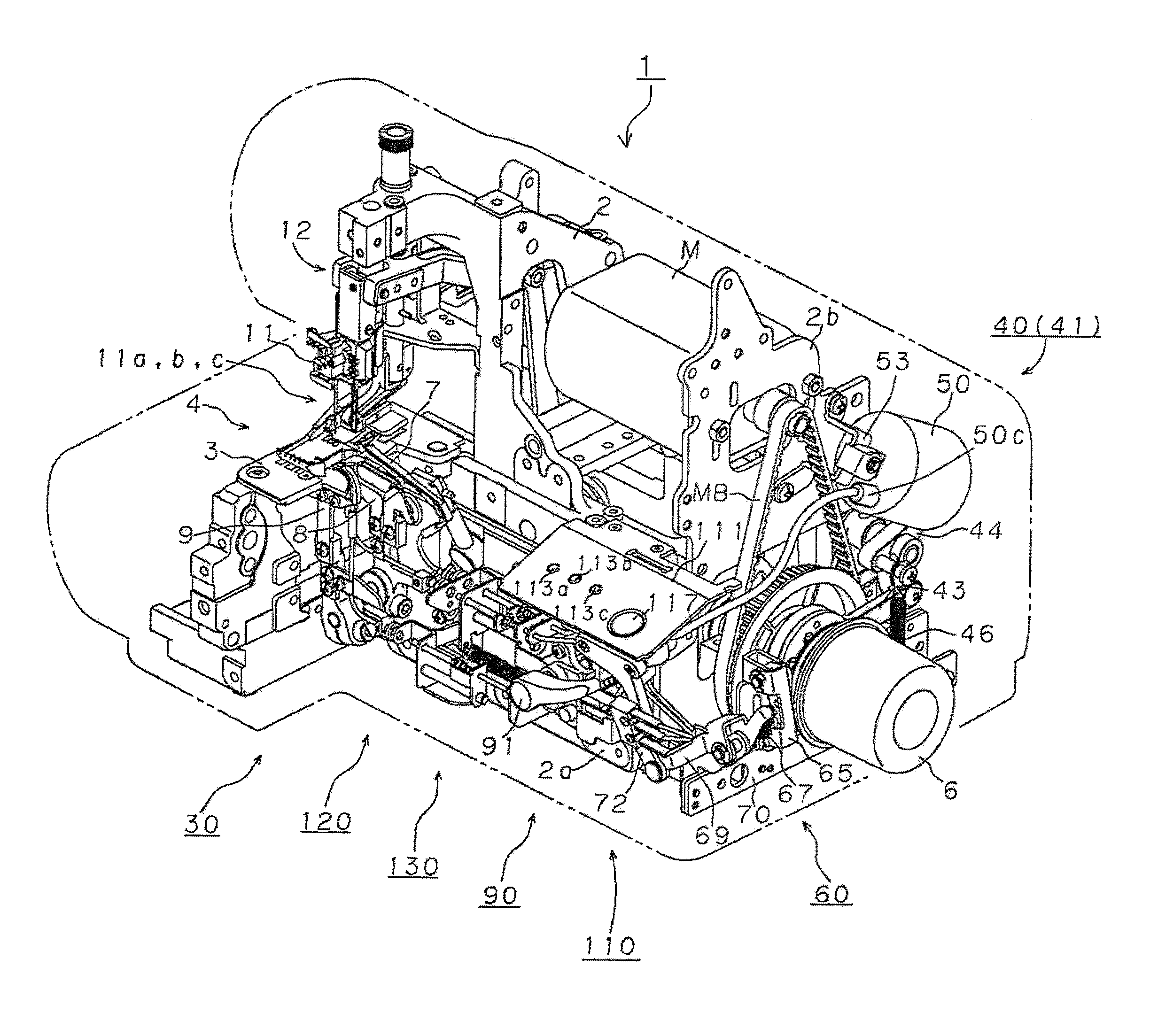

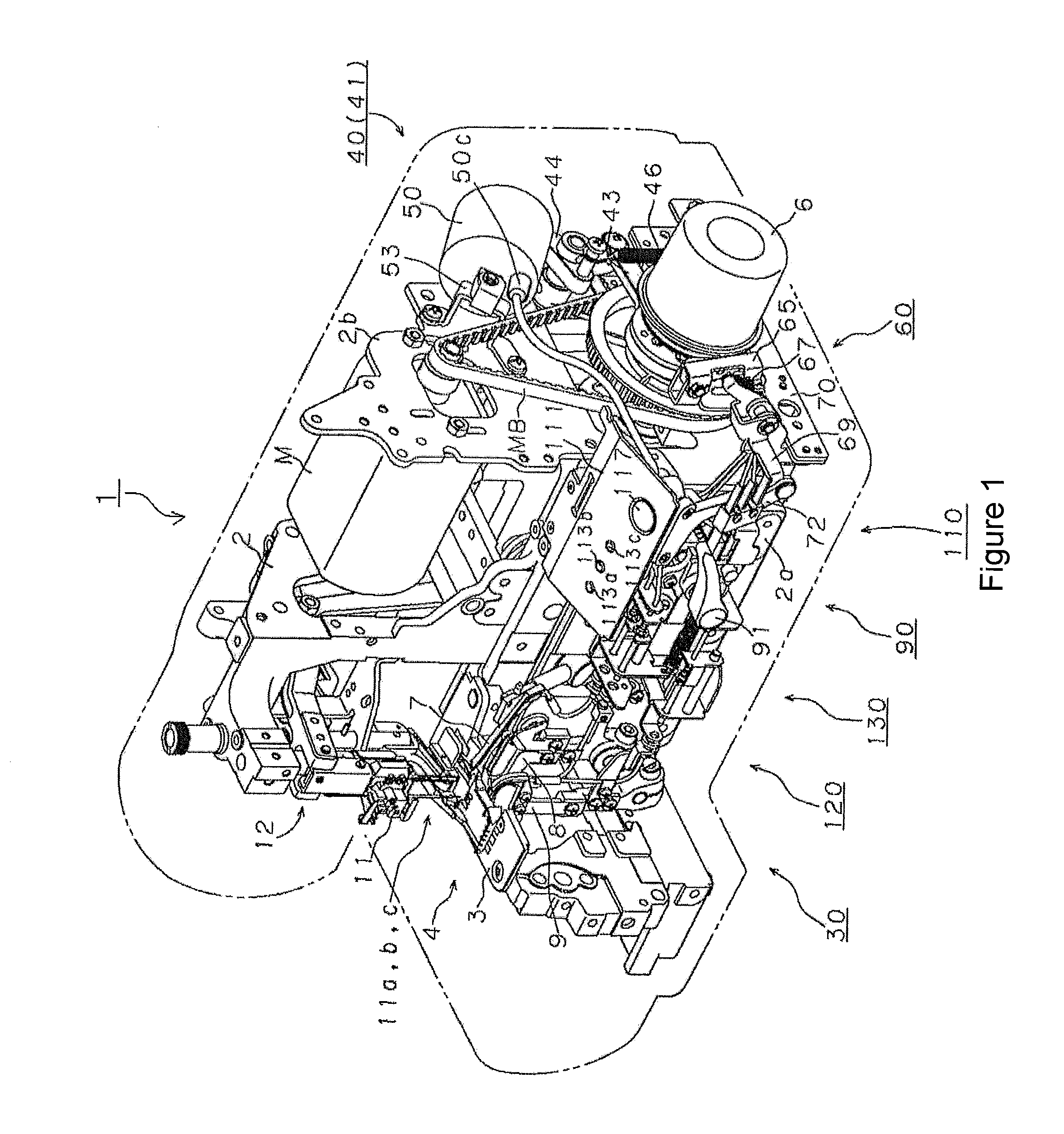

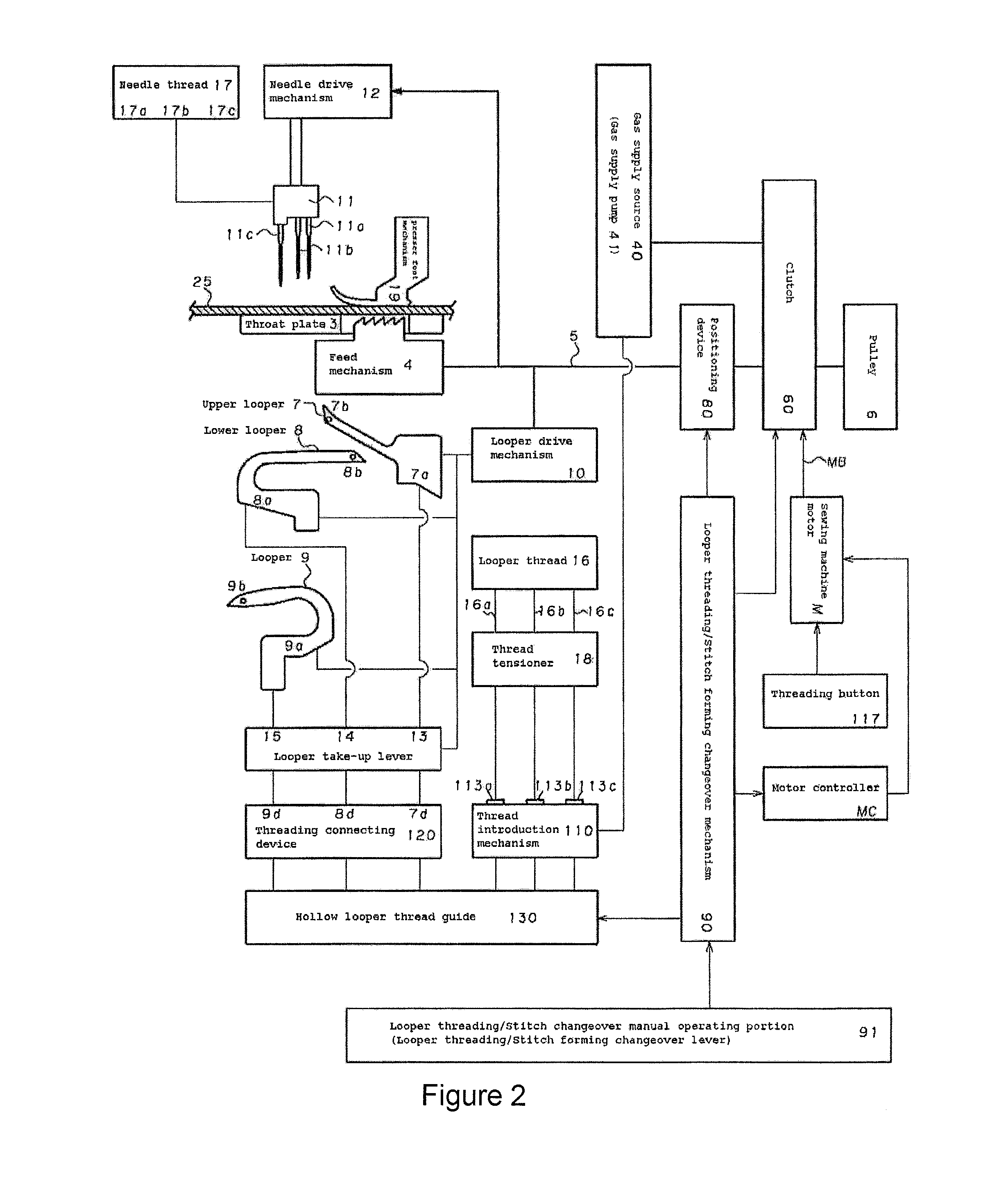

Gas Carrying Threading Device of Sewing Machine

ActiveUS20120210922A1Easy to handleEasy to operateThread-break detectorsNeedle-threading devicesTransmitted powerDrive shaft

Pressurized gas for carrying looper thread by gas is generated by gas supply pump operated by changing over a sewing-machine motor, which drives stitch forming device, looper threading is performed through loopers by one-touch operation. Gas carrying threading device of sewing machine, comprising: looper thread introduction mechanism inserts looper thread guided to loopers; hollow looper thread guide extends from looper thread introduction mechanism to looper thread inlets and has looper thread guide outlets; gas supply pump for performing looper threading by carrying looper thread by gas from looper thread introduction area through hollow looper thread guide to looper thread loop-taker point outlets; clutch for transmitting power from sewing machine motor M to drive shaft which drives stitch forming device including loopers at time of stitch formation or to gas supply pump at time of looper threading.

Owner:SUZUKI MFG CO LTD

Sewing machine for up-down differential feeding

ActiveCN104233644ASimple structureCombined design is reasonableWork-feeding meansSewing-machine control devicesCrankControl engineering

The invention relates to a sewing machine for up-down differential feeding. The sewing machine comprises a secondary feeding adjusting mechanism, a feeding shaft and a feed lifting rock shaft, wherein the secondary feeding adjusting mechanism comprises a lower differential feeding adjusting crank and a first tooth frame seat which are fixed on the feeding shaft, a lower differential feeding crank which movably sleeves the feeding shaft and a lower differential transmission crank which movably sleeves the feed lifting rock shaft; the first tooth frame seat is connected with a feeding tooth; the lower differential feeding crank is connected with a lower differential feeding tooth; the lower differential feeding adjusting crank, a first lower differential feeding connecting rod, the lower differential transmission crank, a second lower differential feeding connecting rod and the lower differential feeding crank are hinged and linked in sequence; the hinging position between the lower differential feeding adjusting crank and the first lower differential feeding connecting rod is adjustable. The hinging position is adjusted so that a force arm relation between the lower differential feeding adjusting crank and the first lower differential feeding connecting rod is changed and a relation of swinging and transferring the feeding shaft to the feeding tooth and the lower differential feeding tooth is changed, namely the lower differential feeding adjustment is realized.

Owner:宁波新三合自动化有限公司

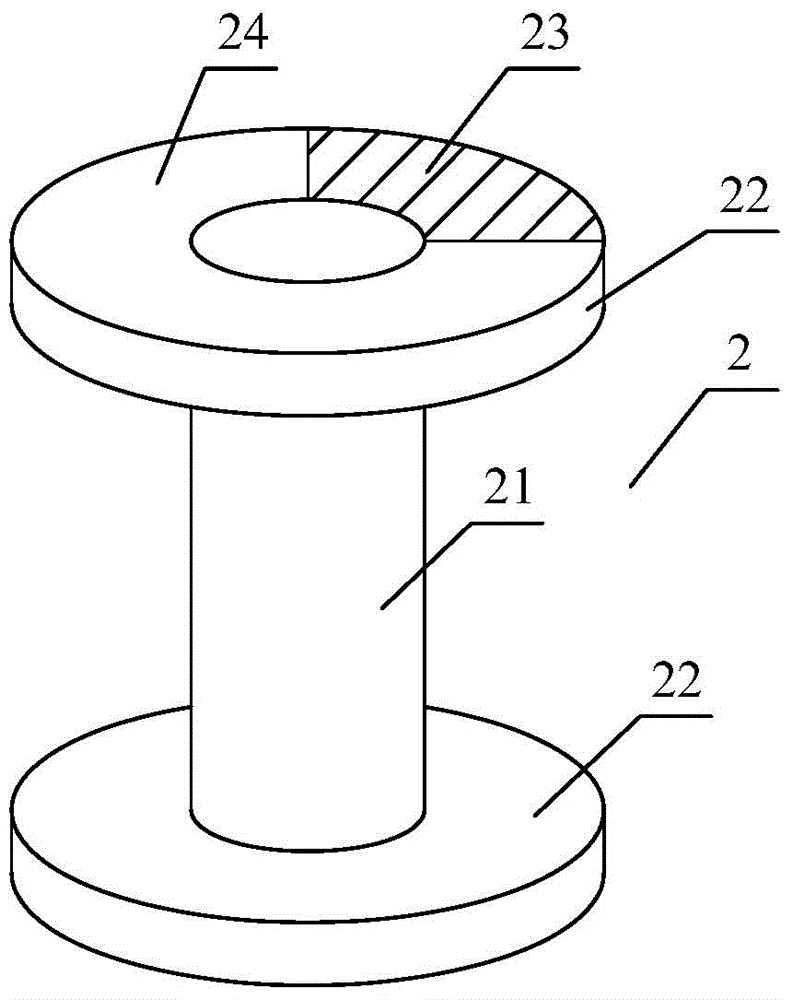

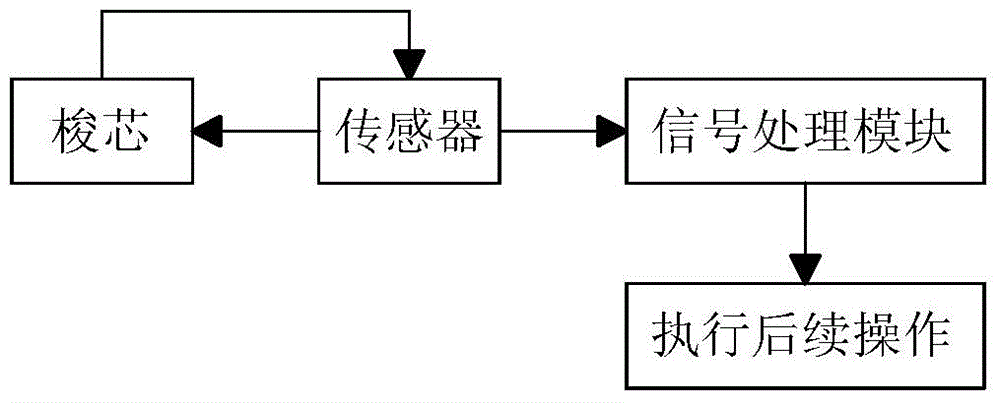

Device and method for detecting amount of bottom thread of sewing machine

The invention provides a device for detecting the amount of bottom thread of a sewing machine. The sewing machine comprises a bottom plate, a rotating shuttle and an electronic control module, wherein the rotating shuttle comprises a shuttle shell and a shuttle core; the shuttle core comprises a winding post and two flanges; at least one flange in the two flanges is provided with a first surface part and a second surface part on the outer surface; a light hole is formed on the outer wall of the shuttle shell; the first surface part or the second surface part is exposed outside from the light hole; the sewing machine also comprises a sensor fixed in the bottom plate; the sensor comprises a transmitter used for transmitting light, and a receiver used for receiving light; the receiver and the transmitter of the sensor just face to the first surface part or the second surface part exposed outside from the light hole, and the light reflection capabilities of the first surface part and the second surface part are different from each other; the sensor is connected with a signal processing module; the signal processing module is connected with the electronic control module. The device for detecting the amount of the bottom thread of the sewing machine is capable of timely detecting whether the bottom thread is used up or not in real time.

Owner:JACK SEWING MASCH CO LTD

Systems and methods for assembling components of a fabric-covered prosthetic heart valve

Owner:EDWARDS LIFESCIENCES CORP

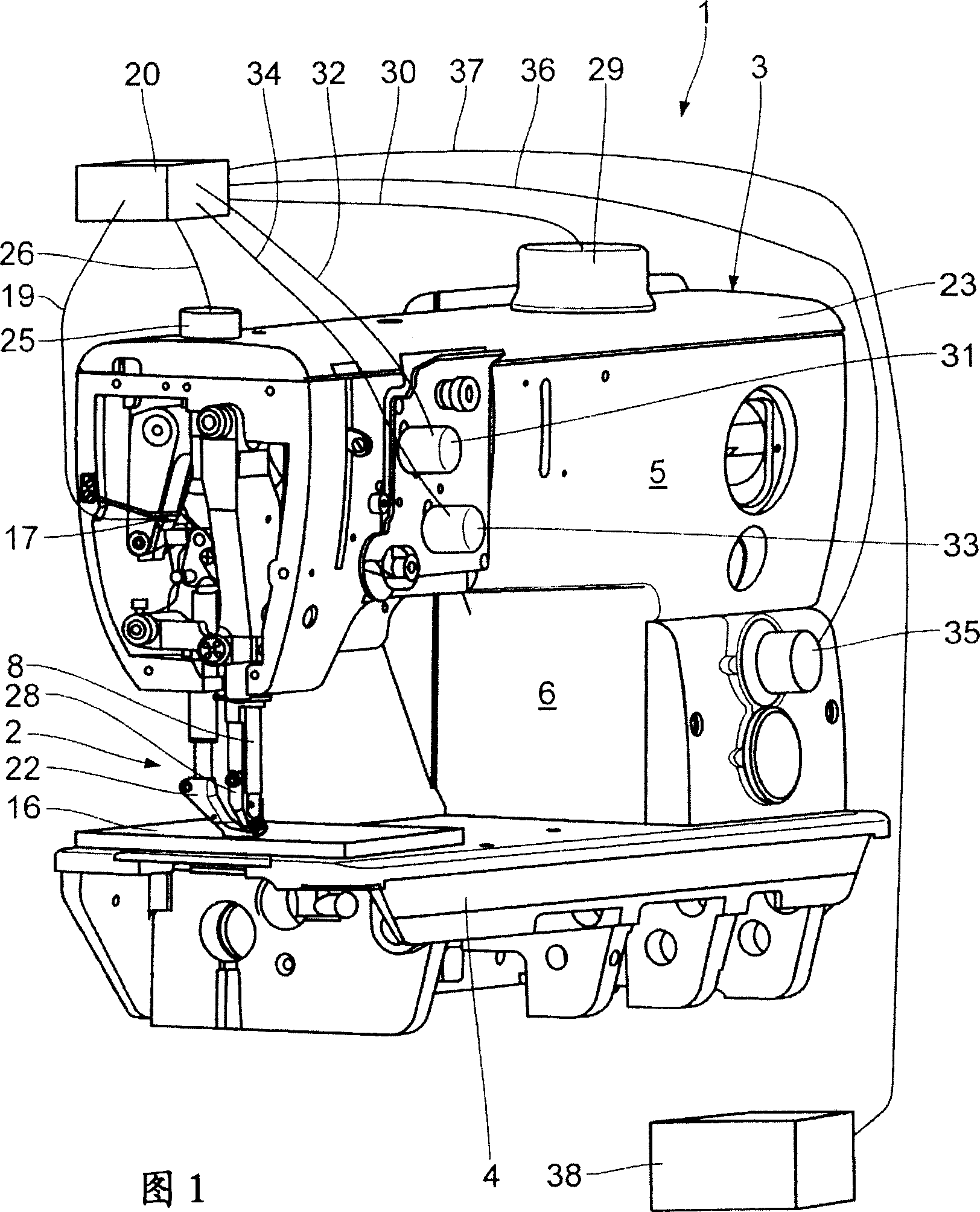

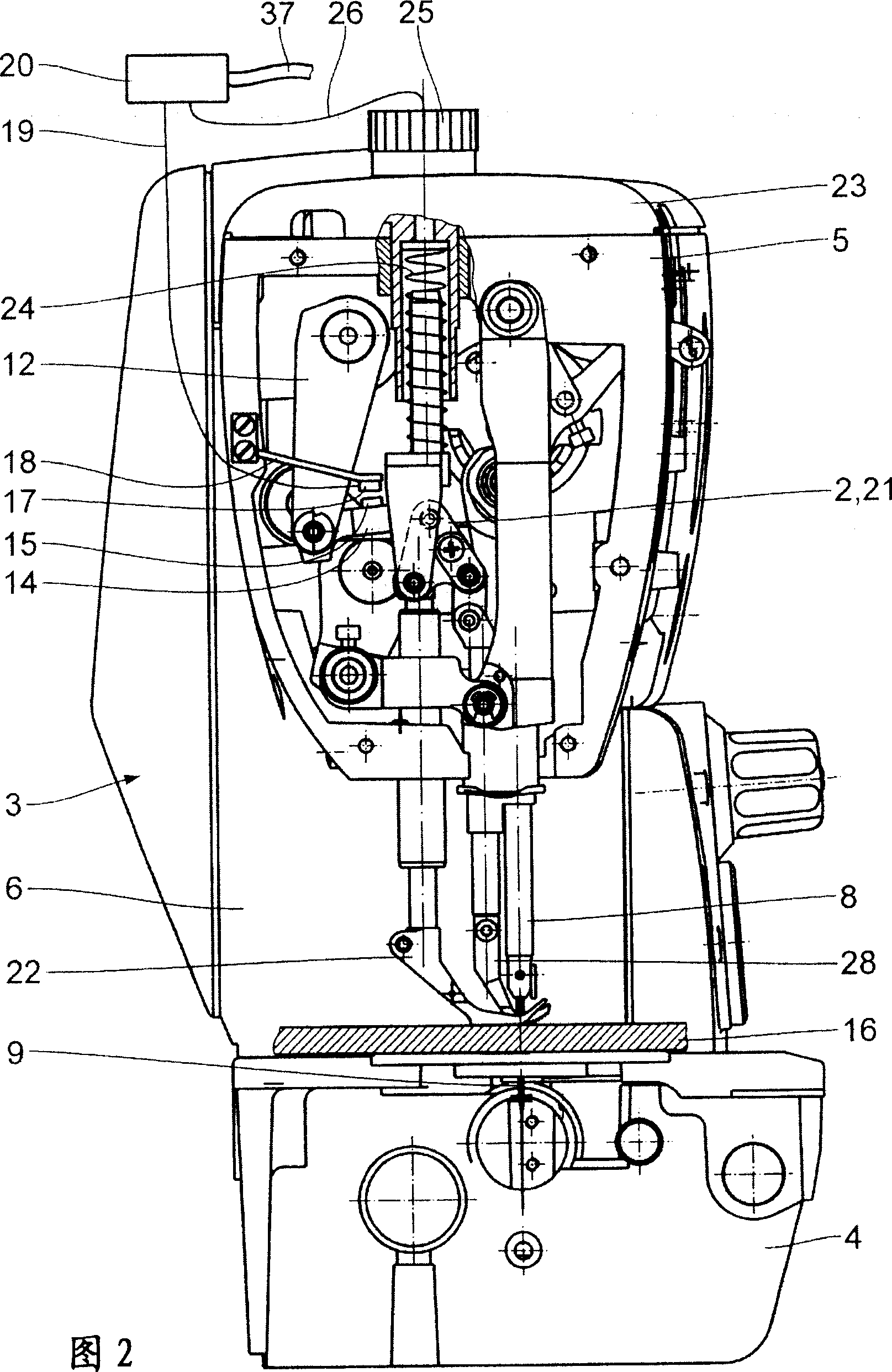

Sewing machine

InactiveCN1891887AReduce setup timeAvoid misadjustmentProgramme-controlled sewing machinesWork-feeding meansControl systemEngineering

The invention provided a sewing machine, improved to automatically switch the sewing machine to the thickness of cloth. This sewing machine includes: a housing having a base plate; a top arm; and a strut for integrating the base plate with the top arm. A metallic presser presses a cloth piece near a stitch forming position. The metallic presser driven by a movable rod is capable of moving between the lift position for releasing the cloth piece and the pressing position for the cloth piece to be pressed. When the metallic presser moves between these positions, the distance of at least one movable rod part from a reference structure fixed to the housing stably changes. The position sensor detects the position of the metallic presser in the pressing position. A control system makes signal connection thereto. The system sets an adjustment variable for the sewing machine depending upon the output value of the position sensor. As a result, the obtained sewing machine automatically performs switching to the thickness of variable cloth piece.

Owner:DURKOPP ADLER AG

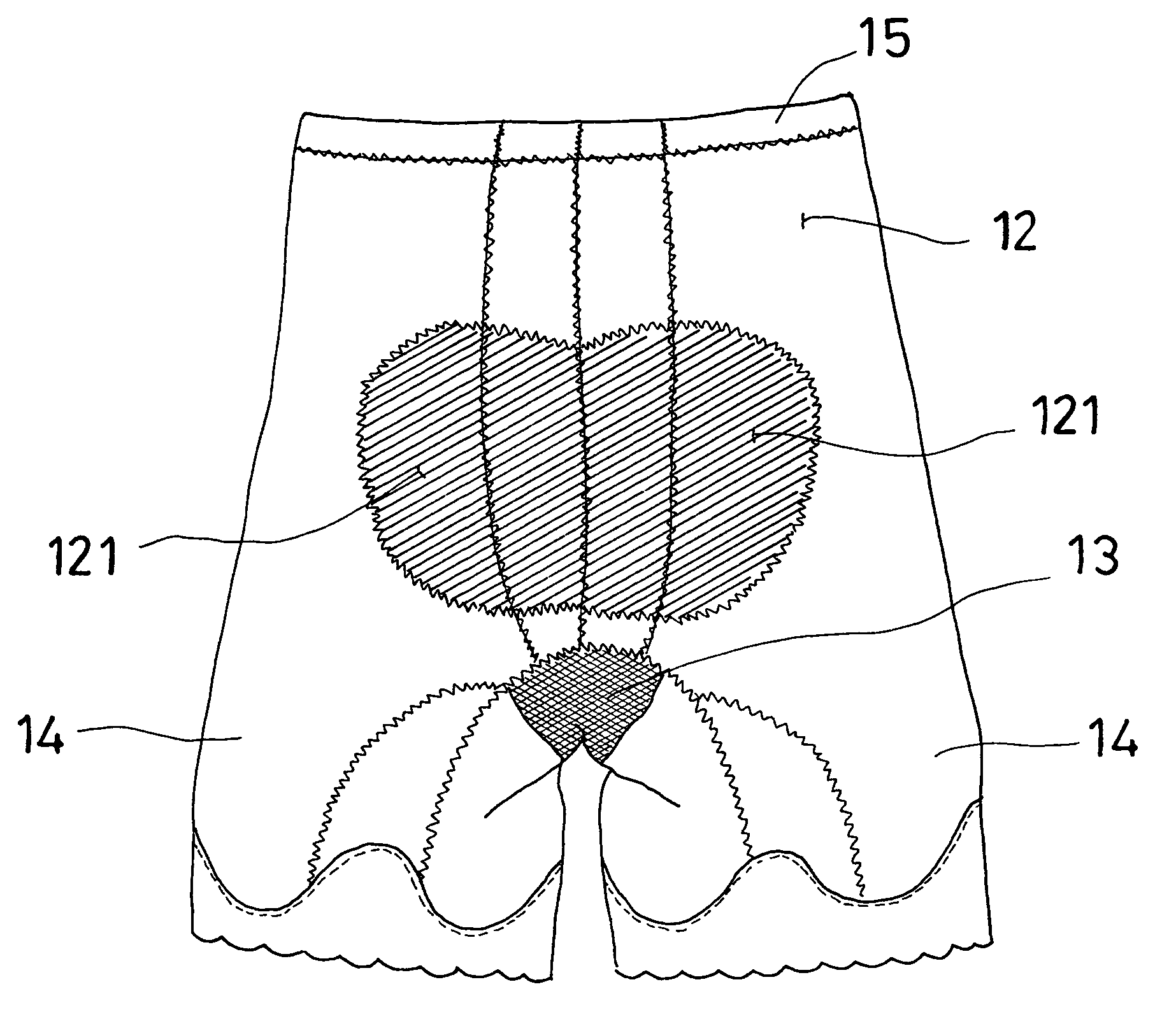

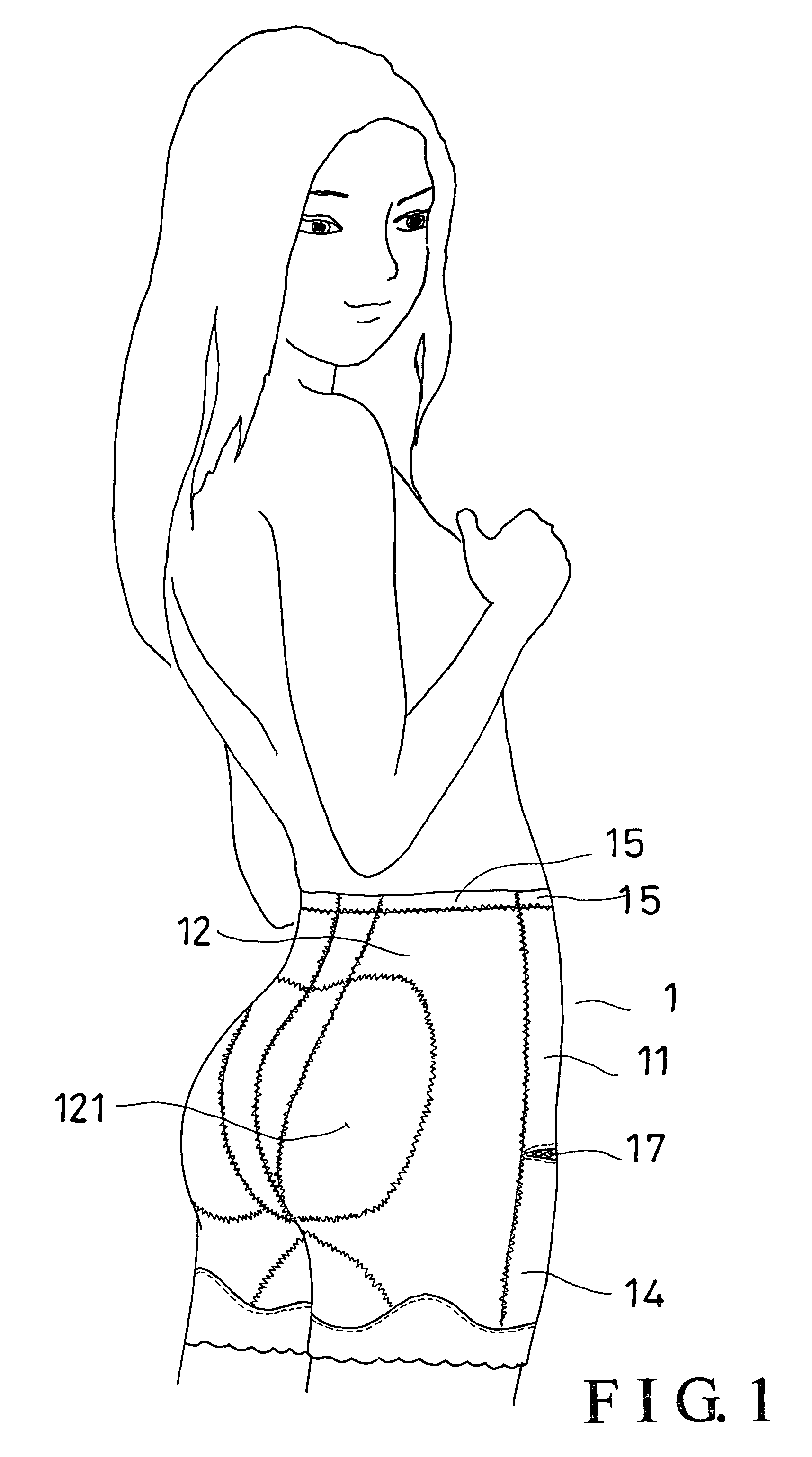

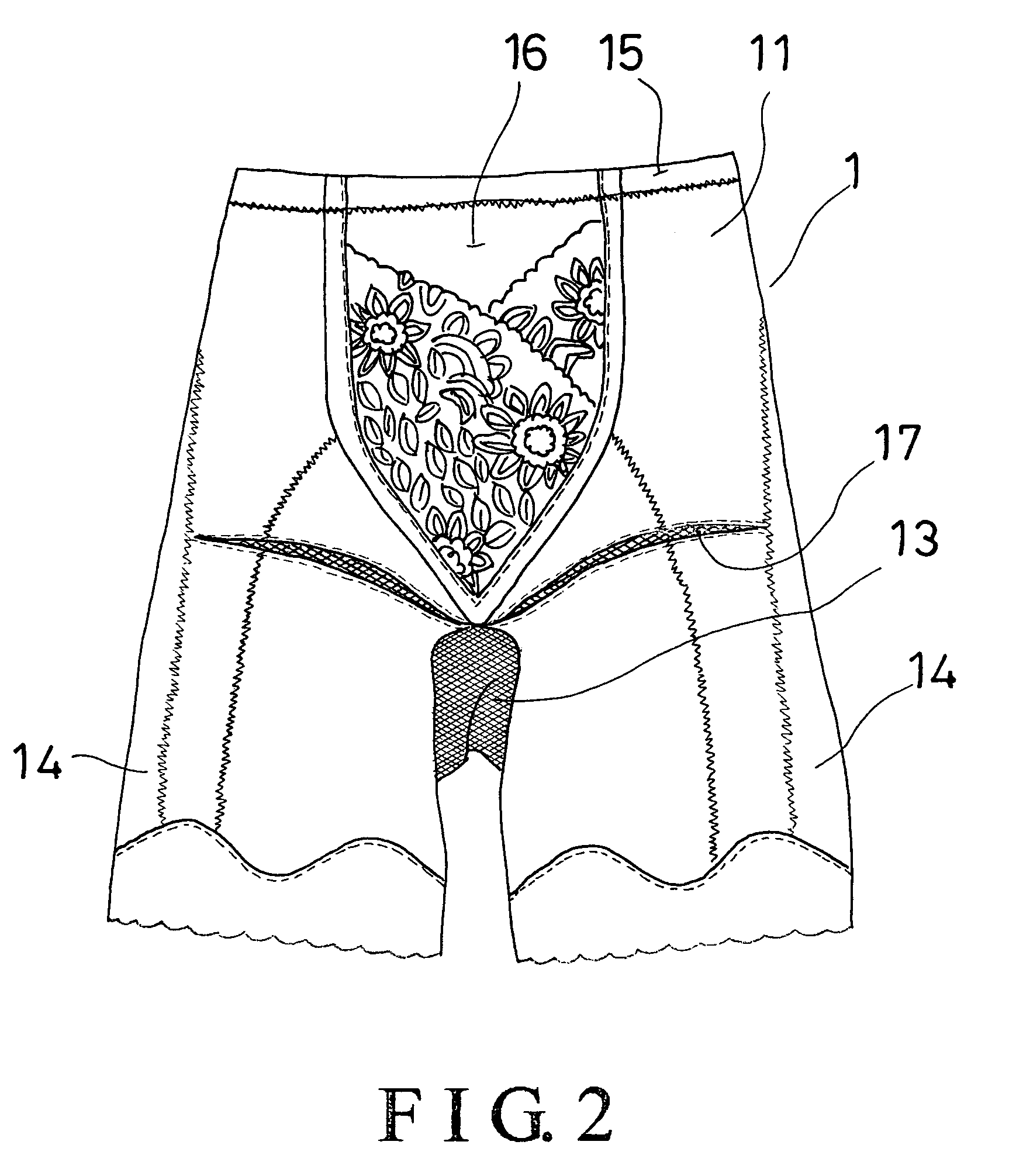

Shaping pant

A shaping pant is made of tailored inner and outer layers of elastic clot, which are sewn together by using sewing machines; the shaping pant includes a front, a bottom, and a rear; the rear has a single-layer gathering portion at a middle thereof, which is substantially in the shape of a heart, curving and symmetric about a central line of the shaping pant; the single-layer gathering portion is sewn in position at edges thereof; therefore, air will travel through the single-layer gathering portion easily, and the wearer's butt will be lifted and shaped, looking rounder.

Owner:SO ROSE CORP

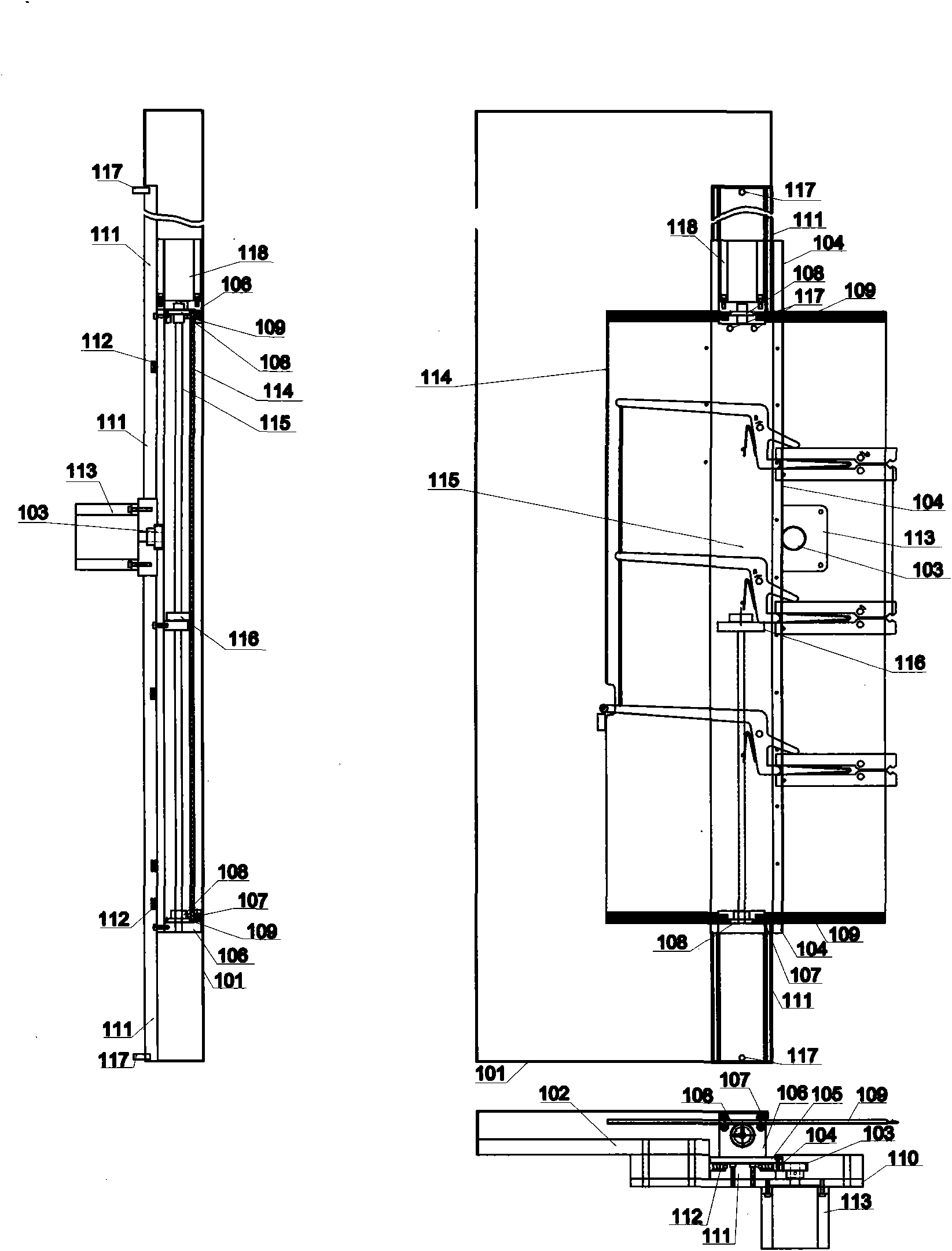

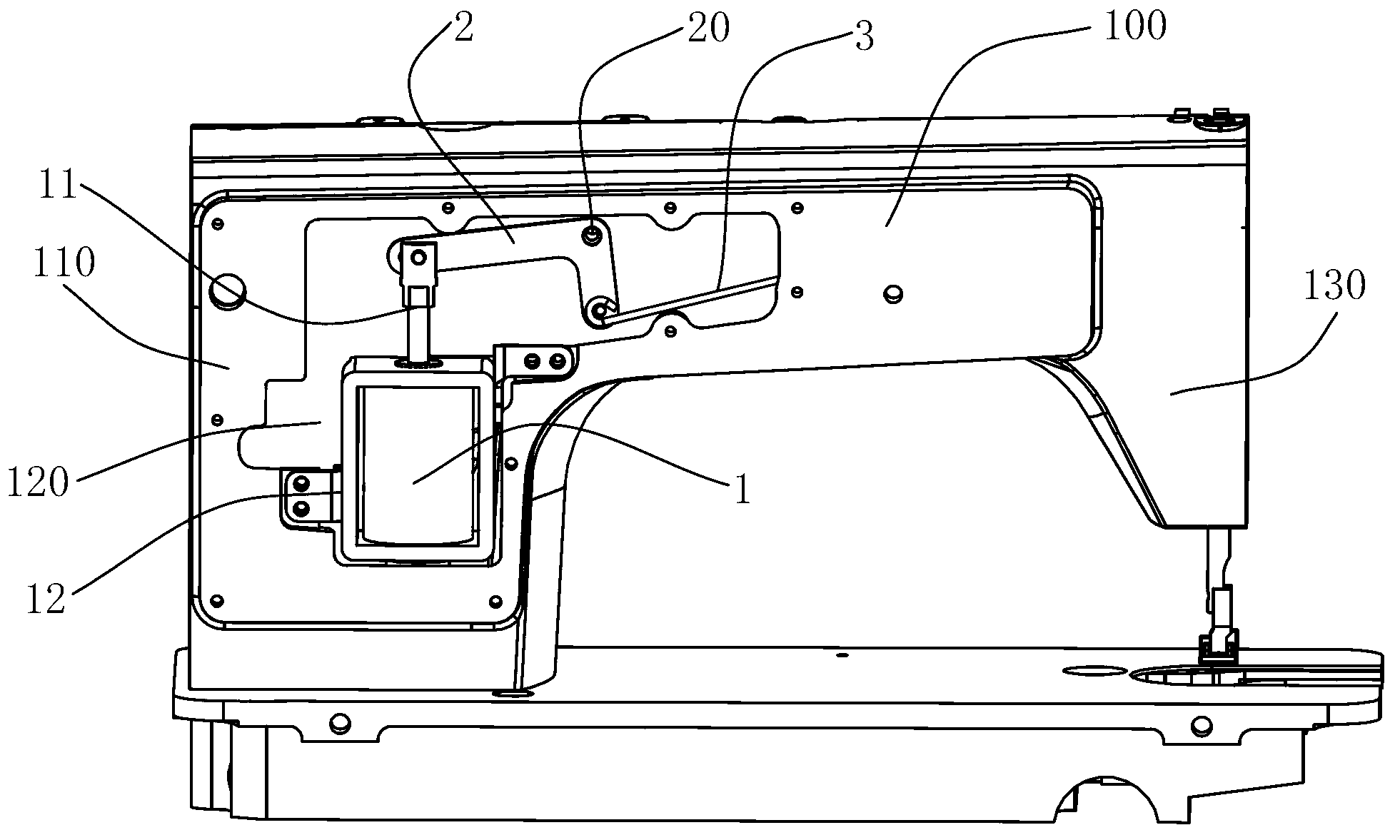

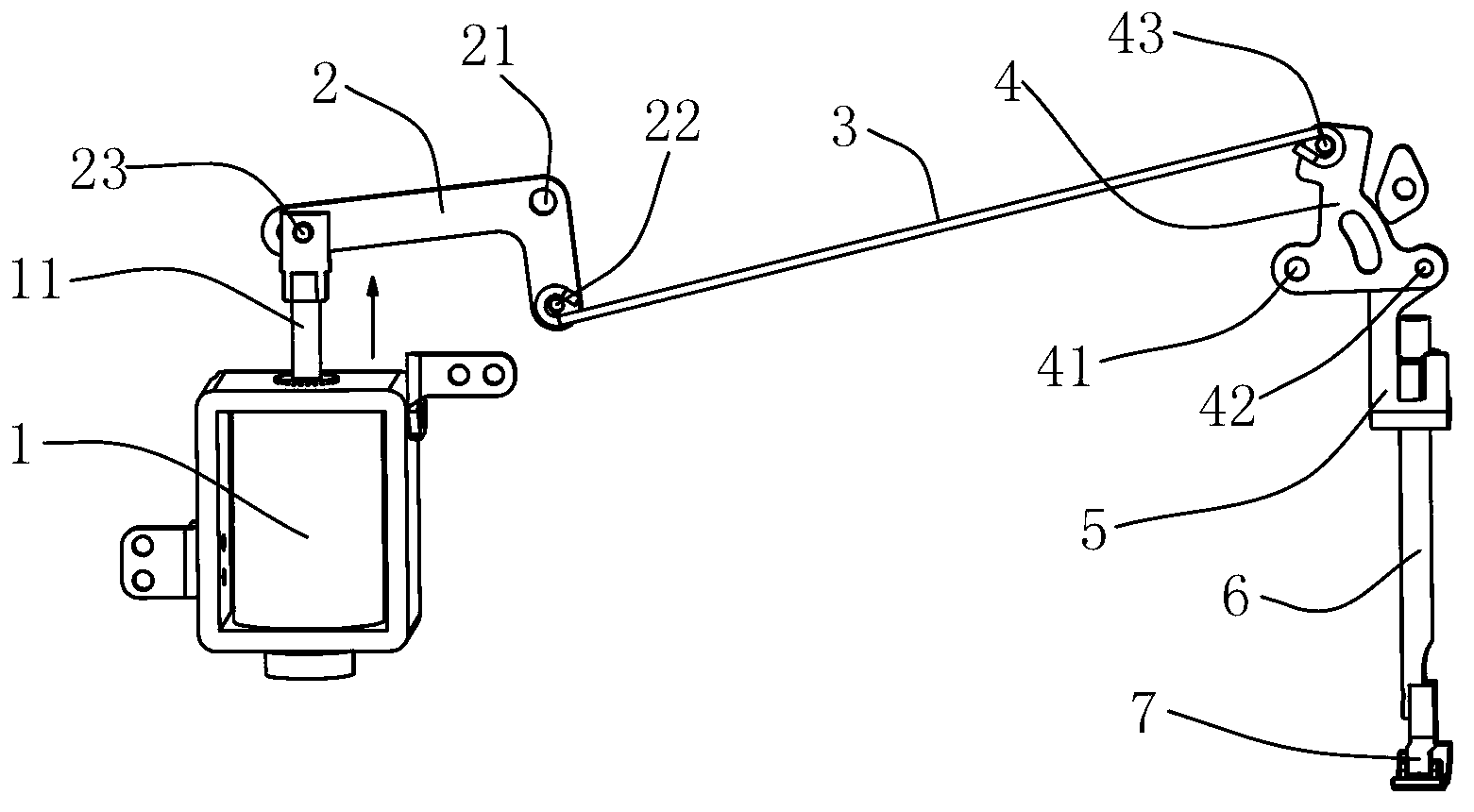

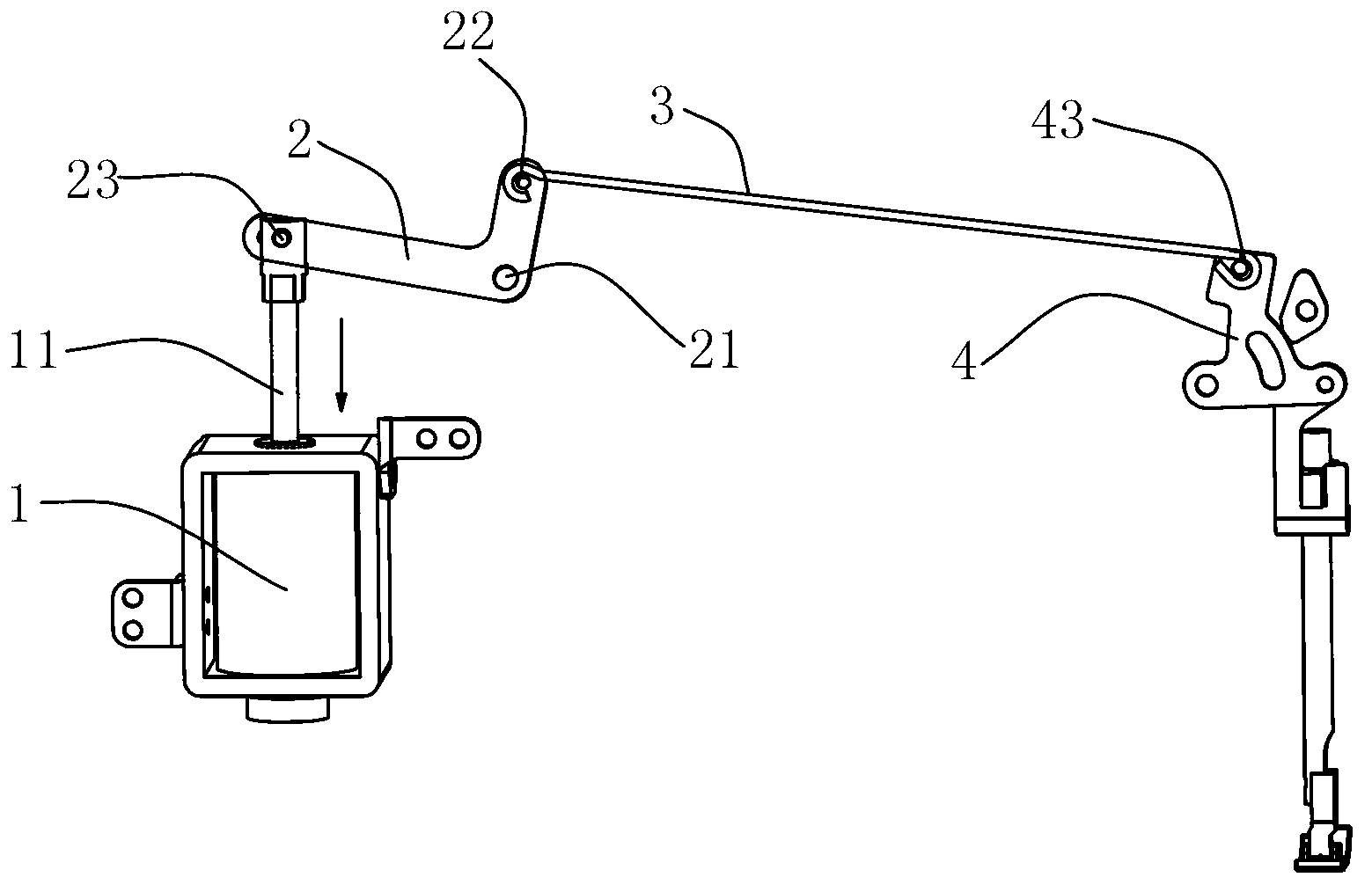

Built-in type automatic pressure foot lifting mechanism of sewing machine

The invention discloses a built-in type automatic pressure foot lifting mechanism of a sewing machine. The built-in type automatic pressure foot lifting mechanism comprises a housing, a linear driver, a back lever, a front lever and a pull rod, wherein the housing comprises an upright column part; a cavity is formed in the upright column part; the linear driver is fixedly mounted in the cavity and comprises a drag rod which is capable of linearly moving in a reciprocating manner; a back pin hole of the back lever is hinged with one end part of the drag rod, a first front pin hole of the back lever is rotationally connected onto the housing through a pin shaft, and the distance from the back pin hole to the first front pin hole is greater than the distance from a second front pin hole to the first front pin hole; the front lever comprises three pin holes, the first pin hole is rotationally connected onto the housing through a pin shaft, and the second pin hole is hinged with a pressure foot lifting plate; and the back end of the pull rod is hinged with the second front pin hole of the back lever, and the front end of the pull rod is hinged with the third pin hole of the front lever. According to the built-in type automatic pressure foot lifting mechanism, the linear driver is arranged in the housing, so the structure of the whole mechanism is more compact, the appearance of the mechanism is more attractive, and vibration and noise produced when the automatic pressure foot lifting device works are also reduced.

Owner:JACK SEWING MASCH CO LTD

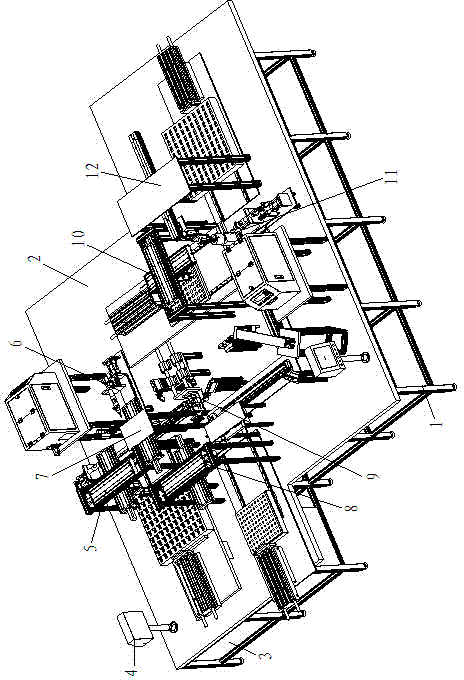

Sewing machine part assembler

ActiveCN104741922AIncrease productivityReduce manufacturing costAssembly machinesMetal working apparatusMan machineAlloy

The invention discloses a sewing machine part assembler. The sewing machine part assembler comprises an aluminum alloy rack, a working platform, a main electric control cabinet, man-machine controllers, a cam shaft feeding mechanism, a cam shaft screw screw-in mechanism, a cam shaft transposition manipulator, a lining feeding mechanism, a lining screw-in transposition mechanism, a driving sleeve feeding mechanism, a driving sleeve screw screw-in mechanism and a finished product unloading mechanism, wherein two man-machine controllers are arranged on the upper plane of the working platform; the lower plane of the working platform is fixedly arranged on the aluminum alloy rack; the main electric control cabinet, the cam shaft feeding mechanism, the cam shaft screw screw-in mechanism, the cam shaft transposition manipulator, the lining feeding mechanism, the lining screw-in transposition mechanism, the driving sleeve feeding mechanism, the driving sleeve screw screw-in mechanism and the finished product unloading mechanism are all arranged on the working platform. Through the mode, the assembler can be used for assembling sewing machine parts in place of a worker, so the production efficiency is greatly improved and the production cost is reduced.

Owner:JIANGSU CHENGYI INTELLIGENT TECH CO LTD

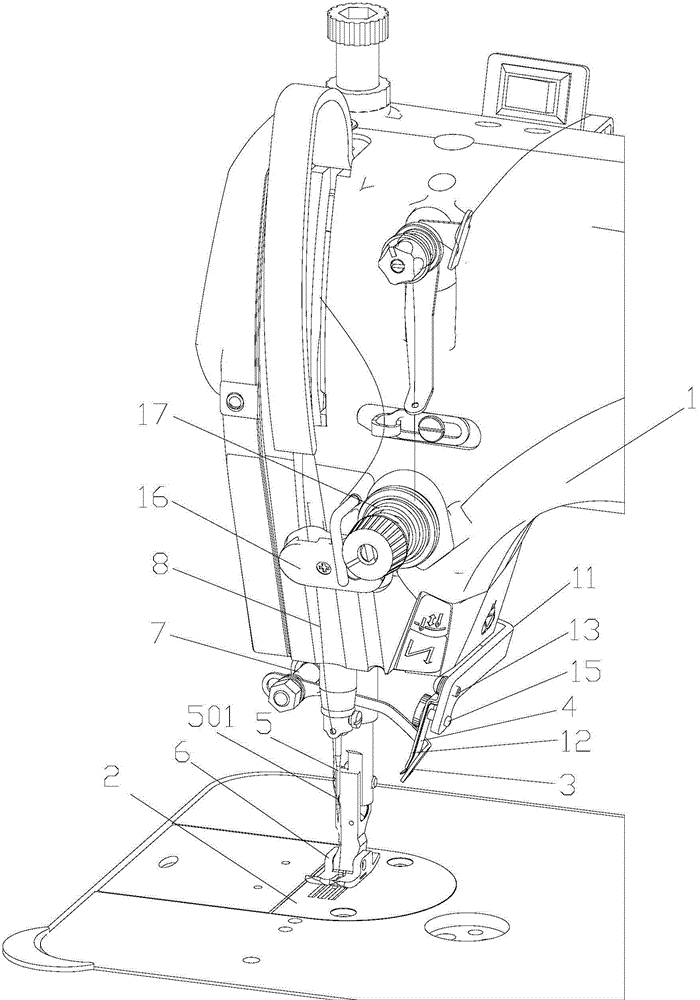

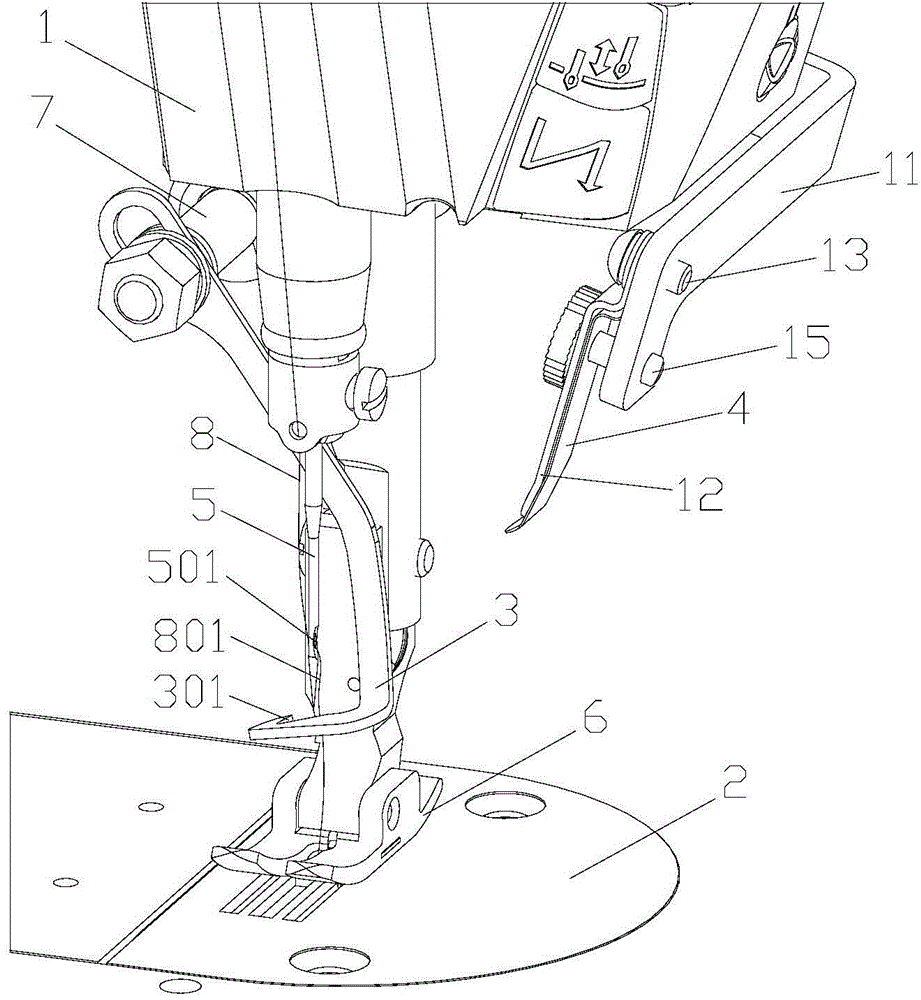

Bird nest removing device for sewing machine and using method thereof

ActiveCN104911838AQuick tightenStable line amountNeedle severing devicesIndustrial engineeringSewing machine

The invention provides a bird nest removing device for a sewing machine and a using method thereof. The bird nest removing device comprises a pull hook, a thread clamping plate, a machine needle and a presser foot plate, wherein the pull hook, the thread clamping plate, the machine needle and the presser foot plate are located below a machine head. The drag hook is connected with the machine head through a rotating shaft, the machine needle is provided with a needle eye allowing threads to penetrate through, the presser foot plate is located on a needle plate, the presser foot plate is provided with a thread passing groove corresponding to the machine needle, the thread passing groove extends in the moving direction of a sewing material, and a thread cutter is arranged at the bottom of the thread passing groove. According to the bird nest removing device for the sewing machine and the using method thereof, an arc swing hook thread clamping device is used for clamping machine needle thread residues after thread trimming, the enough stable thread quantity is provided for starting sewing through thread clamping and loosening time coordination of two thread clamp holders in the seam starting process next time, seam starting upper threads can be tightened quickly under the condition that bottom threads do not exist, the clamped thread residues are cut off at the position close to the sewing material needle hole, the remaining thread residues are short, and the problem of bird nest thread residues is solved thoroughly.

Owner:JACK SEWING MASCH CO LTD

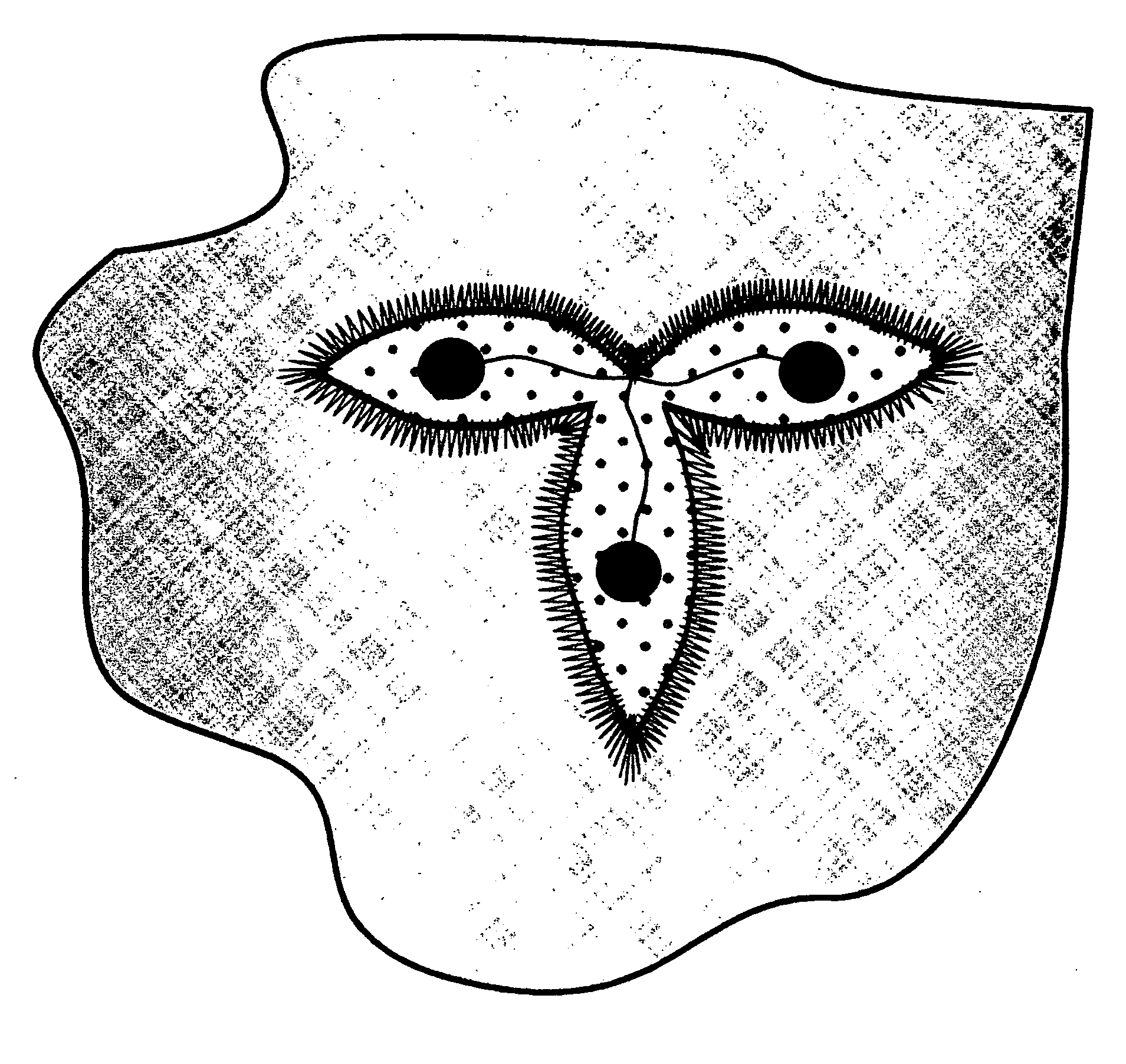

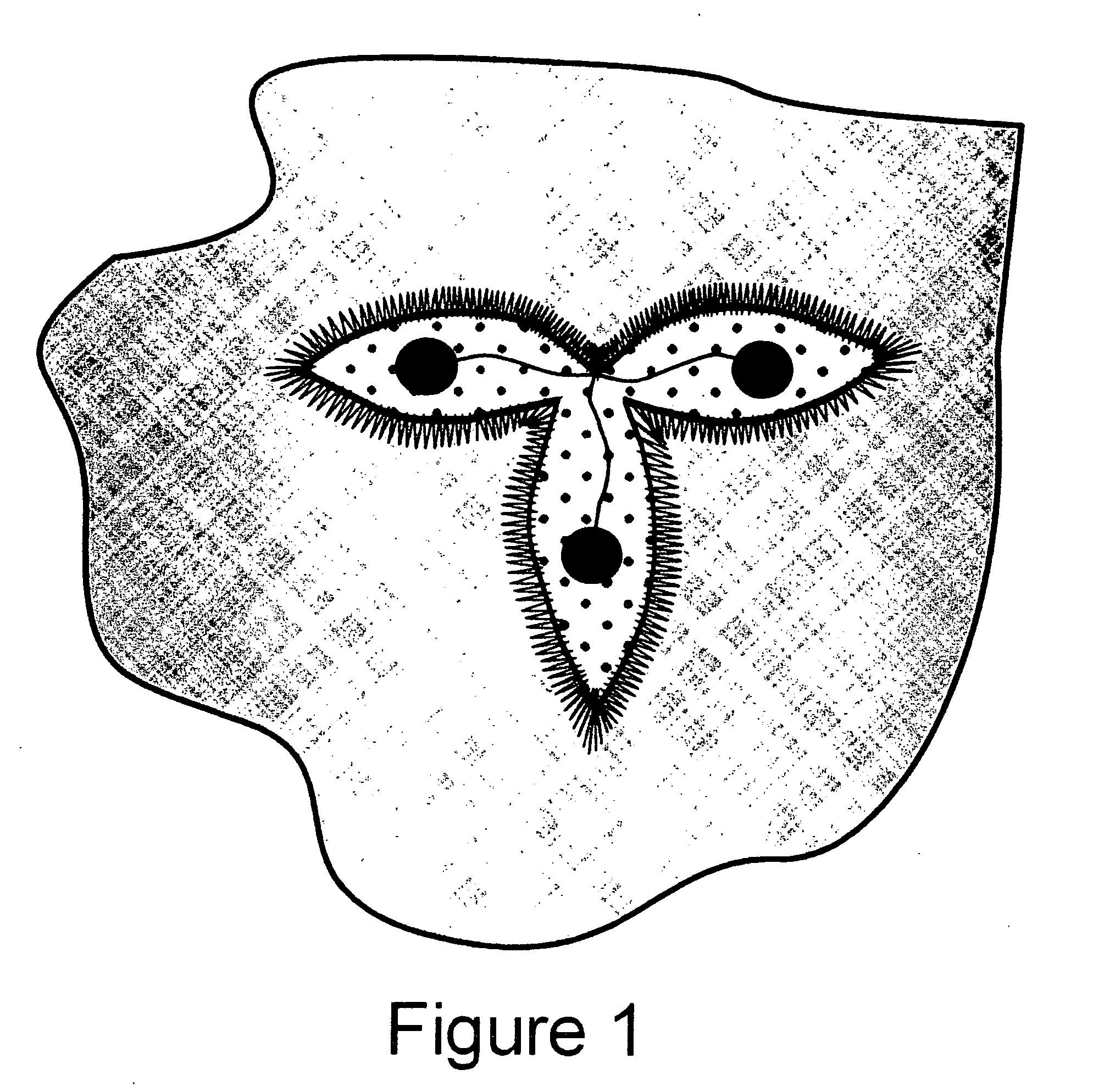

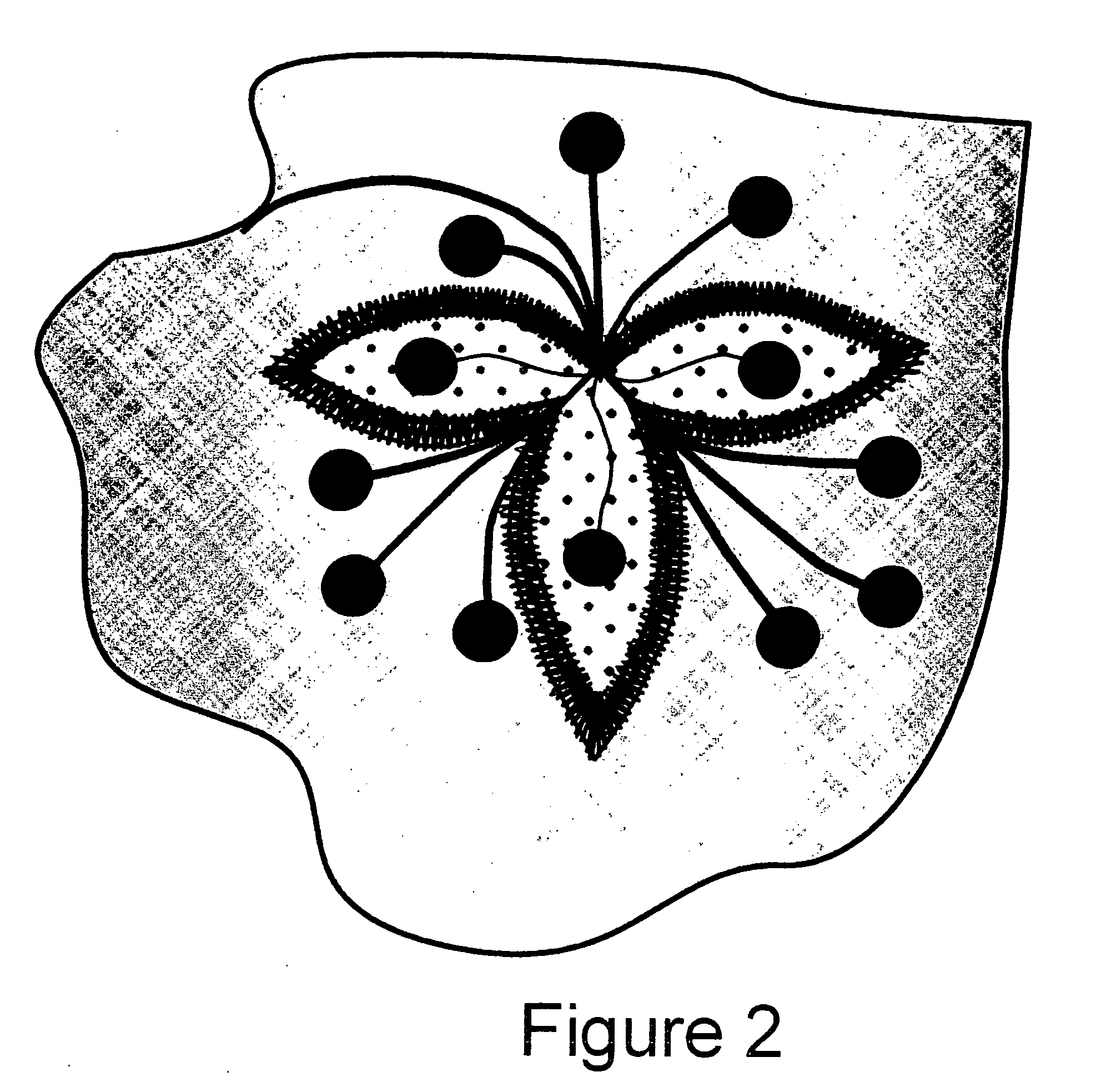

Translucent applique cutwork machine embroidery and method

InactiveUS20050211147A1Duplicates appearanceEnhanced and perfectly stitched appearanceEmbroidering machines apparatusSewing machineCivil engineering

Translucent applique cutwork embroidery designs can be performed by a sewing machine, preferably a computerized machine with digitized design embroidery patterns. The method employs a foundation fabric 11 and a removable stabilizer 12. Once a cutwork section 14 in an applique cutwork embroidery design is defined with a set of concentric underlay stitches 13 that bind said foundation fabric to removable stabilizer, said foundation fabric is removed from said cutwork section. An applique fabric 16 is then stitched in place over the cutwork section with another set of concentric underlay stitches 13 that are sewn in approximately the same location as the first set of concentric underlay stitches. Excess applique fabric 16 is cut away. The applique cutwork seam 18 joining applique fabric to foundation fabric is finished with zigzag stitches 17 that overcast all said concentric underlay stitches. Where appropriate, a machine embroidery design 19 is stitched on top of said applique fabric, cascading onto said foundation fabric. Said applique cutwork seam is concealed with satin stitches, or similar concealing stitches 20. The balance of the embroidery design is stitched onto said foundation fabric. When said removable stabilizer is removed, no further trimming of fabrics or threads is required.

Owner:WATERFIELD LAURA M

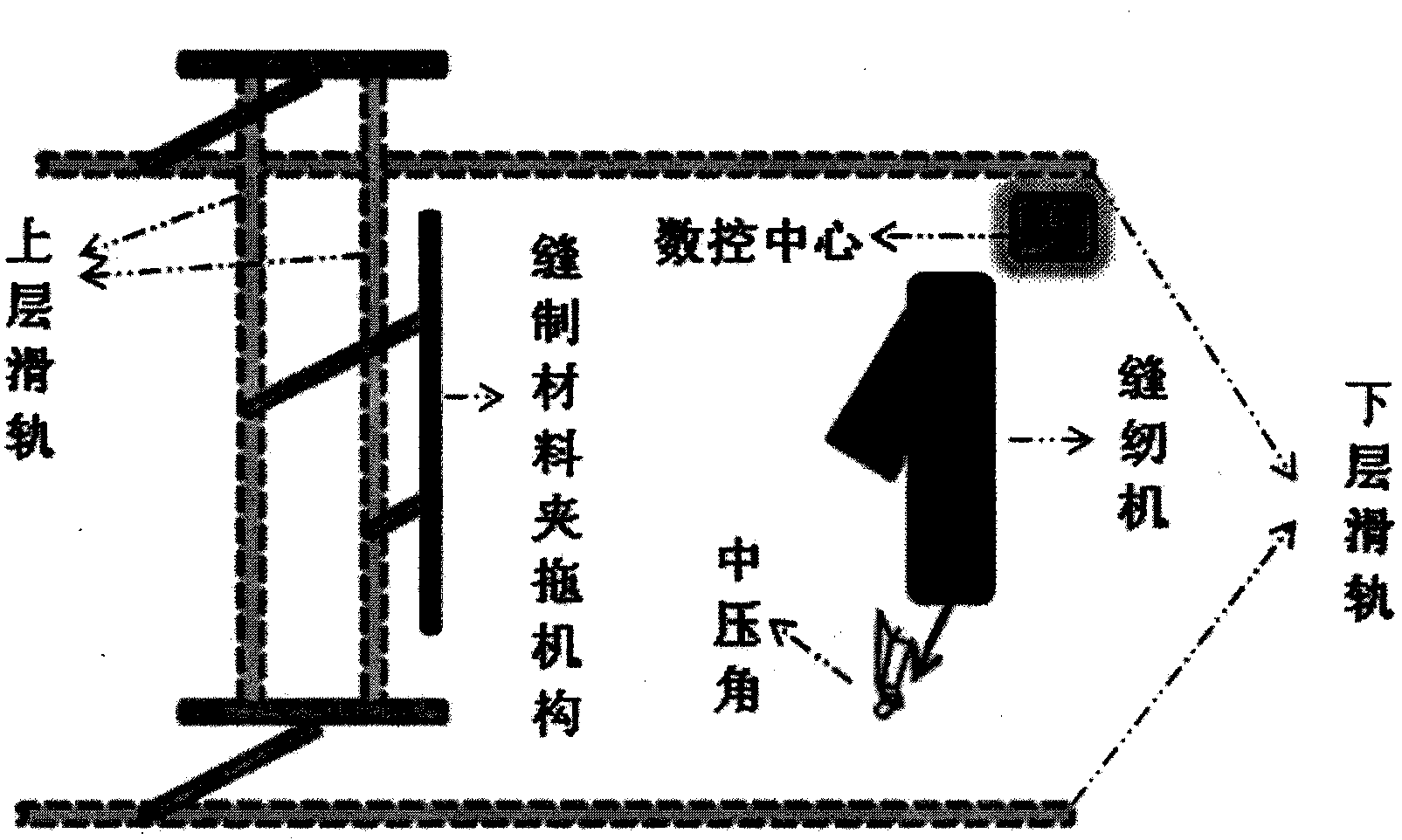

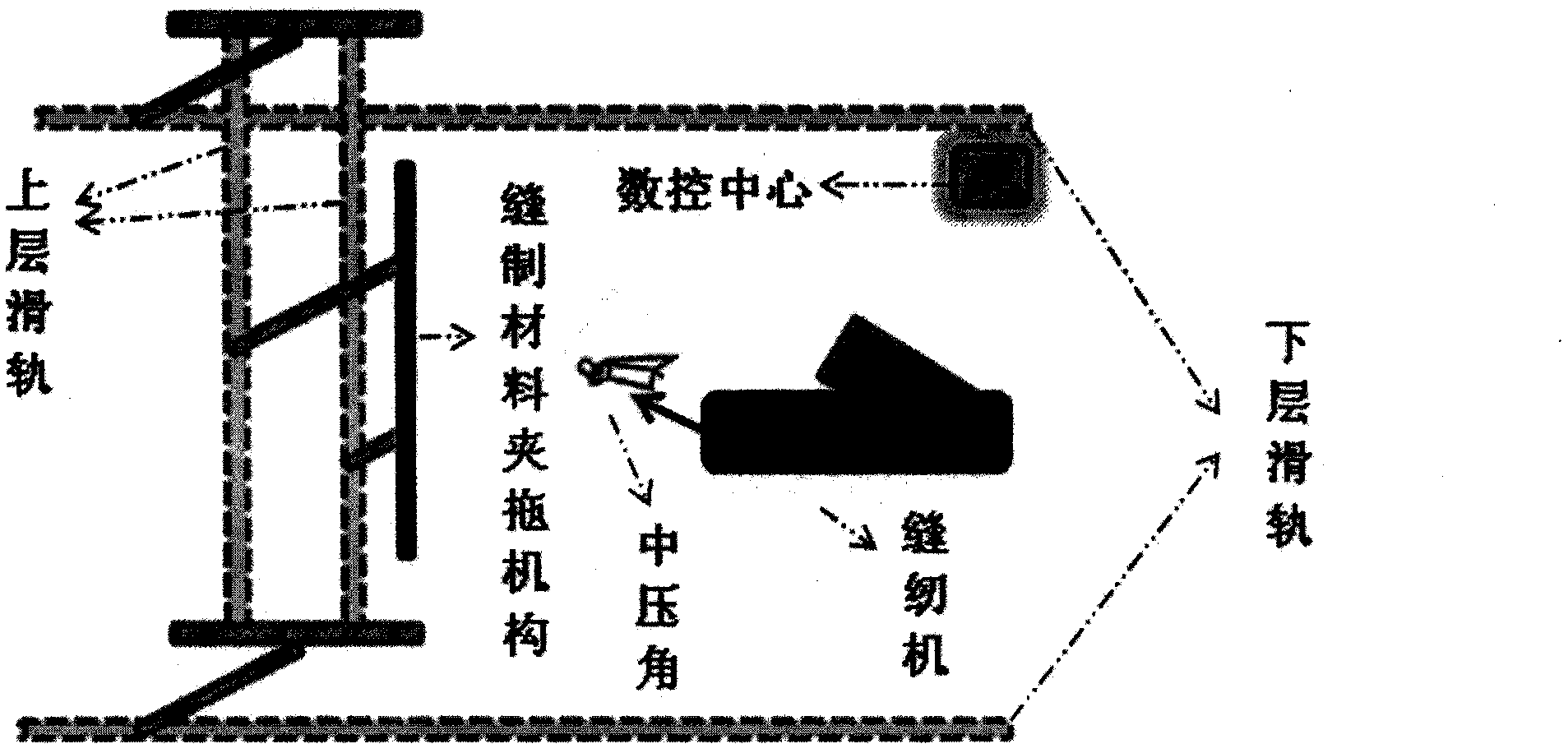

Sewing processing equipment

InactiveCN104233642AGuaranteed independenceAvoid broken needleSewing apparatusEngineeringSewing machine

The invention provides sewing processing equipment, which comprises a sewing machine, a sewing material clamping and dragging mechanism, two parallel slide rails at the upper layer and two parallel slide rails at the lower layer. The sewing processing equipment has the advantages that the sewing of various stitches and various pattern layer patterns can be realized, the work efficiency is improved, in addition, the production cost is lower, the installation and the debugging are simple, and the repair and the maintenance of the sewing machine can be easily carried out.

Owner:王艳玲

Guide for making non-linear patterns using a long arm quilting machine

A guide for making non-linear patterns using a long arm quilting machine is used to form a variety of different non-linear stitching patterns in a quilt or other workpiece. The mechanism includes a crossmember which locks adjustably between the fixed tracks of a conventional quilting machine bed or table, and an arm adjustably secured to the crossmember. The arm is slotted to provide both radial and linear adjustment relative to the crossmember. The guide attachment end of the arm provides for the selective attachment of any of a series of different templates thereto. The templates include guide slots or passages therein, with a guide pin or stylus engaging the template slots or passages. The stylus is in turn affixed to the sewing machine, causing the machine to form a stitching pattern according to the specific pattern of the selected template as the stylus travels in the selected slot or passage.

Owner:VALERIOTE MICHAEL A +1

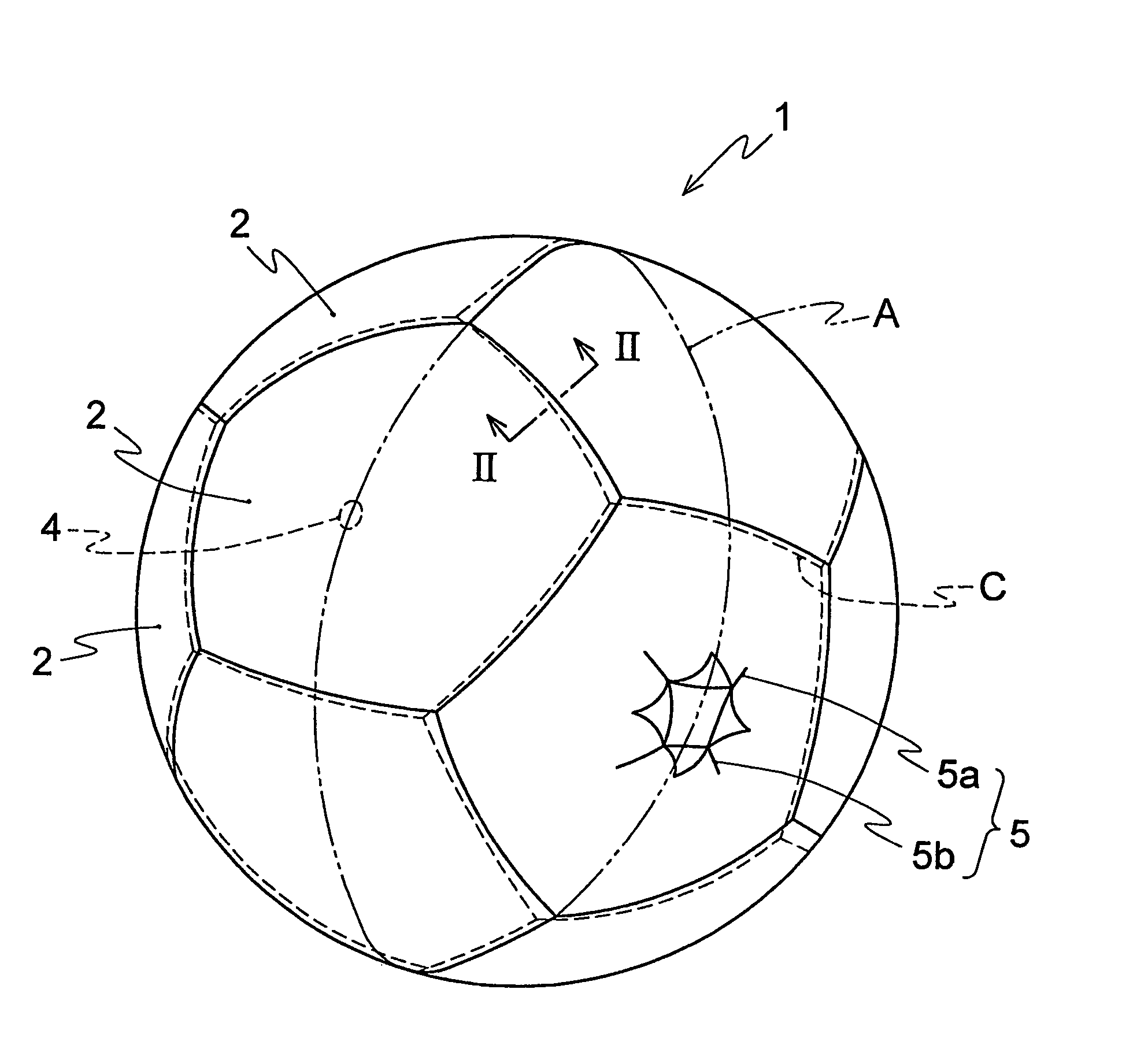

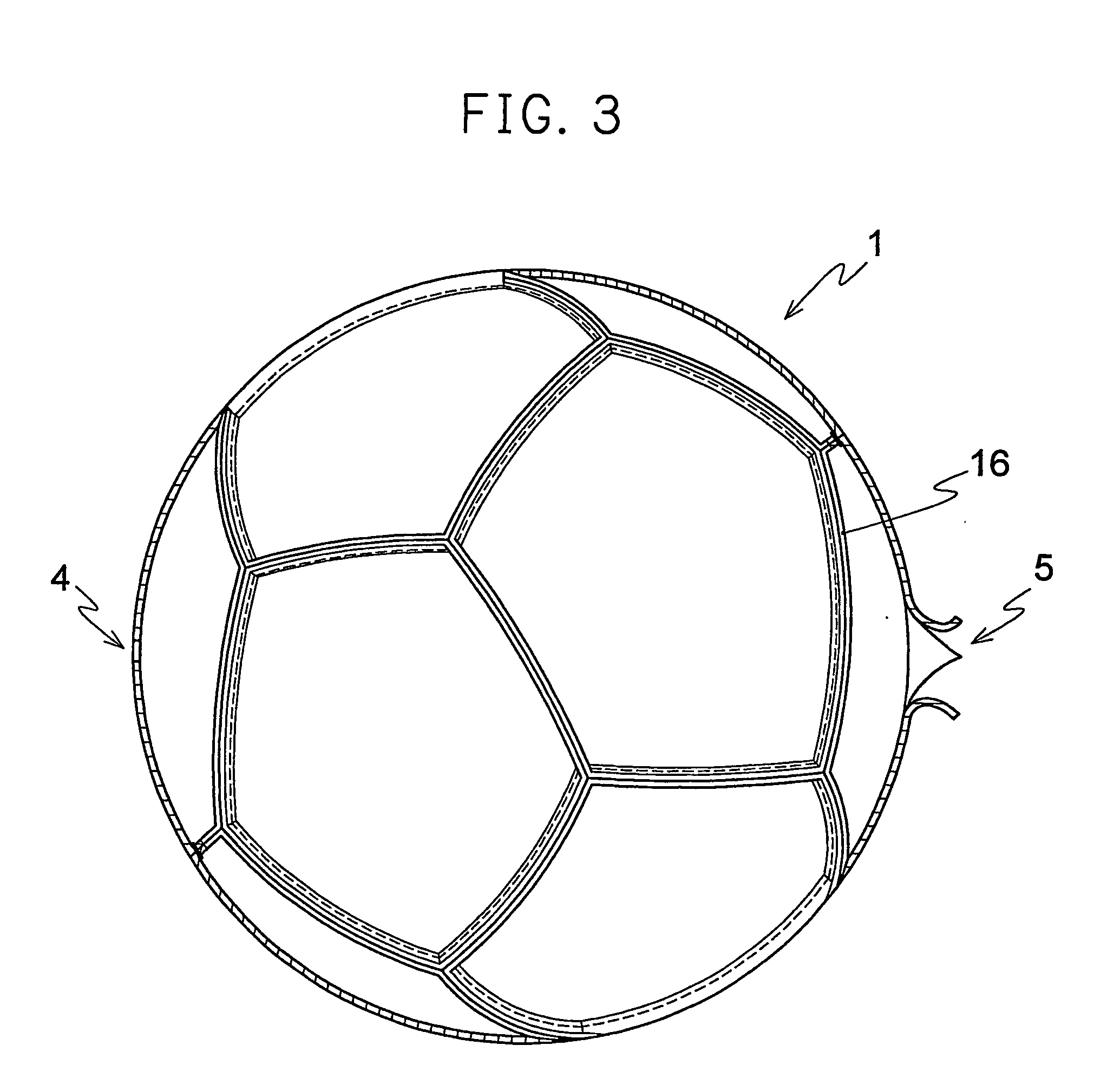

Ball for ball game and method for manufacturing the same

ActiveUS20060084536A1Improve accuracyHollow inflatable ballsHollow non-inflatable ballsEngineeringBall game

The ball for a ball game of the invention includes a fabric layer (1) having a spherical 12-hedron where twelve right pentagonal fabric pieces (2) are sewn together. The marginal edges of the fabric piece being folded by 90 degrees, and the marginal edges are sewn together with a sewing machine. The fabric layer is then reversed through cross-like slits (5a, 5b) formed in the fabric layer in a location opposite to a valve opening (5) (also formed in the fabric layer) in such a manner that the marginal edges are located on an inner side of the fabric layer. After the bladder is accommodated within the fabric layer through the closure hole (5), the hole (5) is closed by a patch. Onto a surface of the fabric layer, there is adhered the panels. Thereby, the ball for a ball game having no unevenness and soft feeling is attained.

Owner:MOLTEN CORPORATION +1

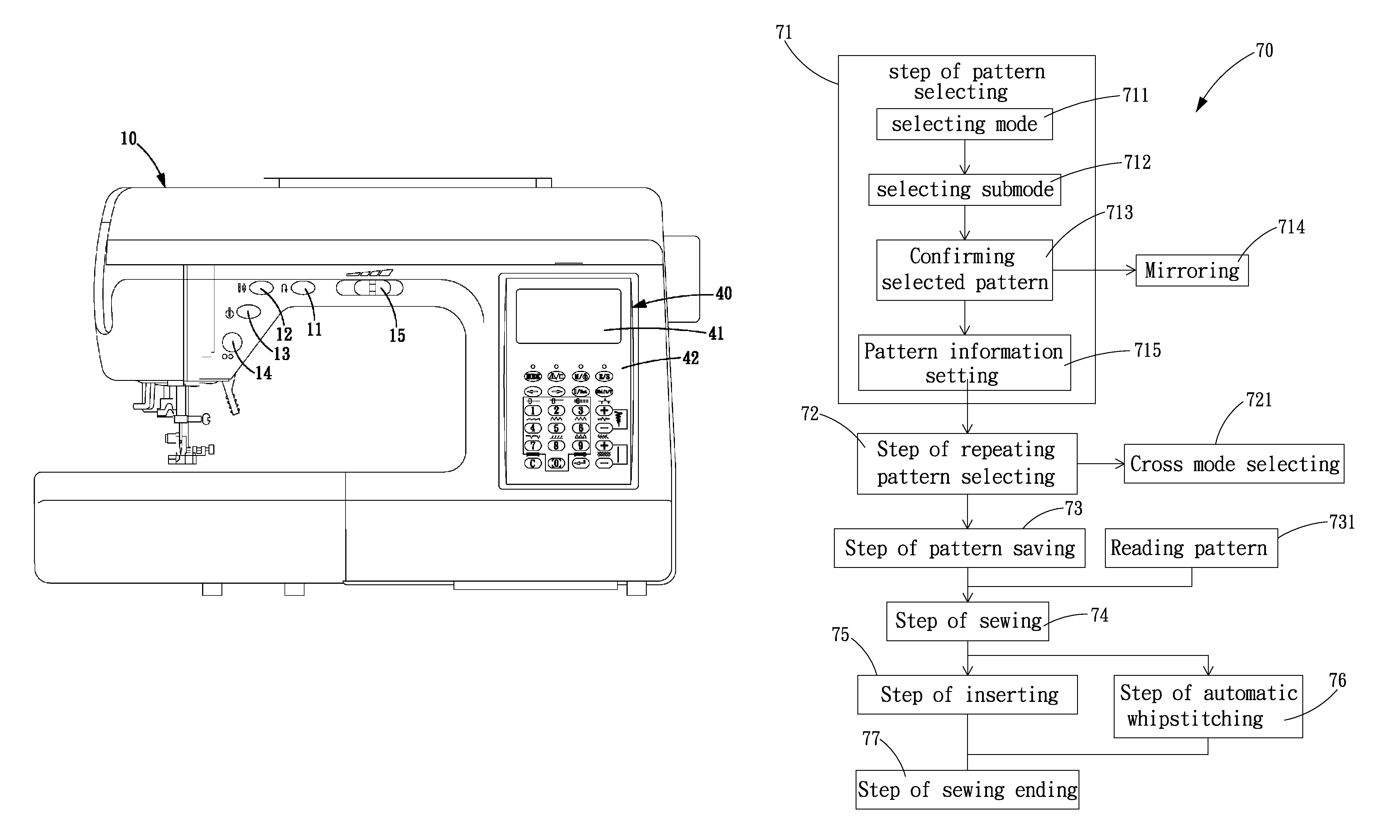

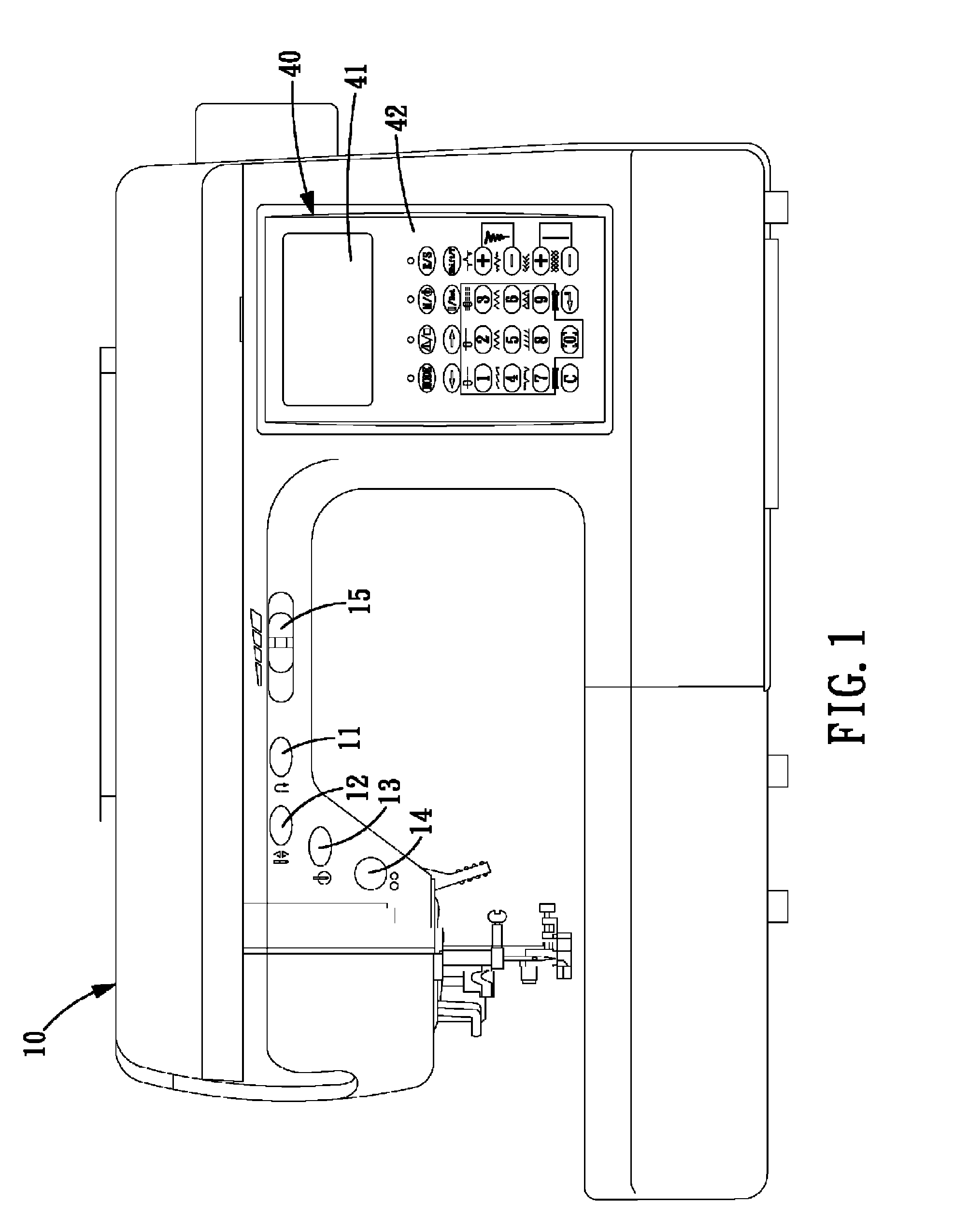

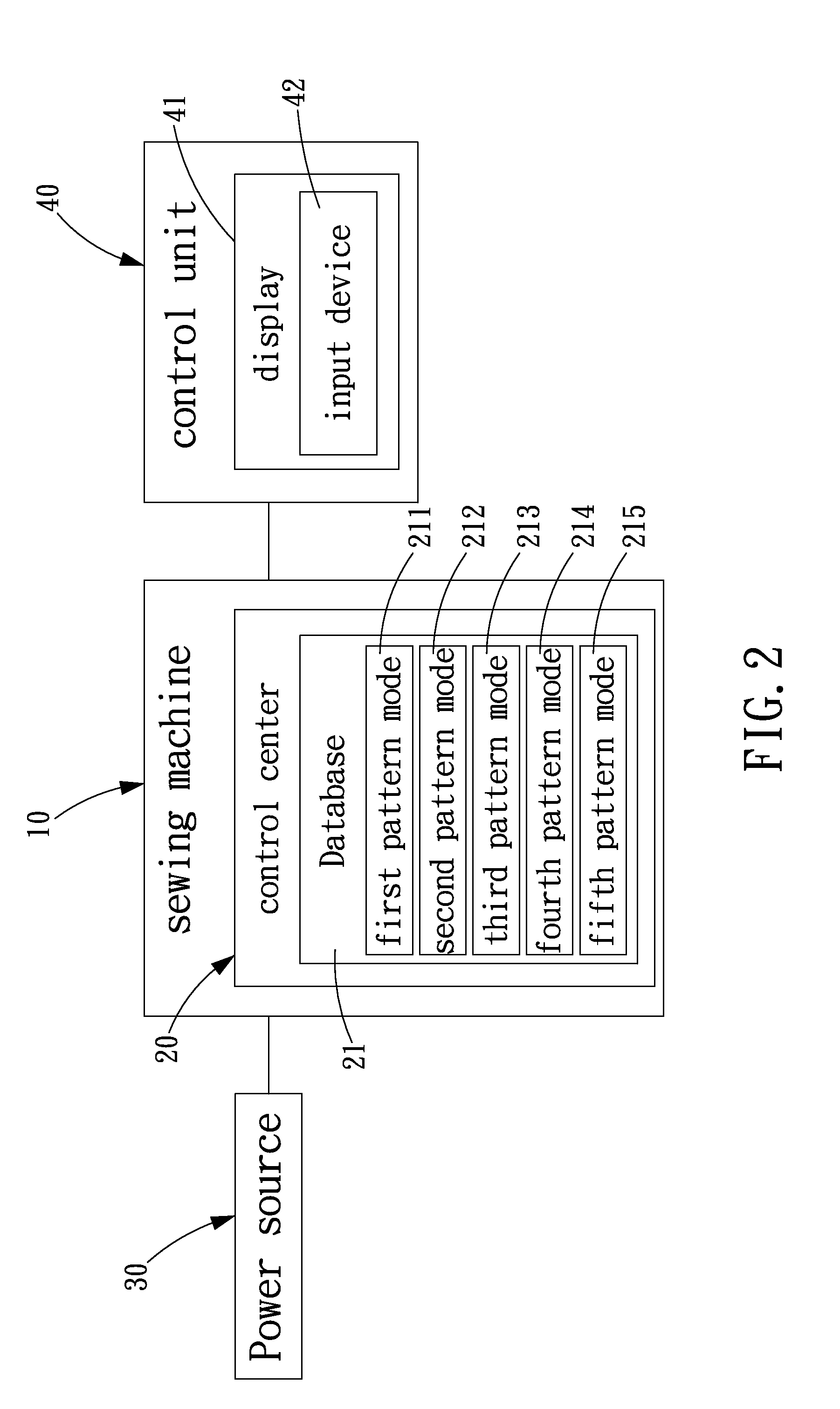

Method and device for controlling sewing patterns of a sewing machine

InactiveUS8763545B2Better satisfy userProgramme-controlled sewing machinesAutomatic machinesEngineeringSewing machine

A method and device for controlling sewing patterns of a sewing machine allows the user to edit the patterns or pattern strings saved in the database, and to mirror the patterns, or control the respective data of sewing. The sewing pattern can be easily and freely edited, and the information of all the sewing operations is clearly displayed on the display.

Owner:TSENG HSIEN CHANG

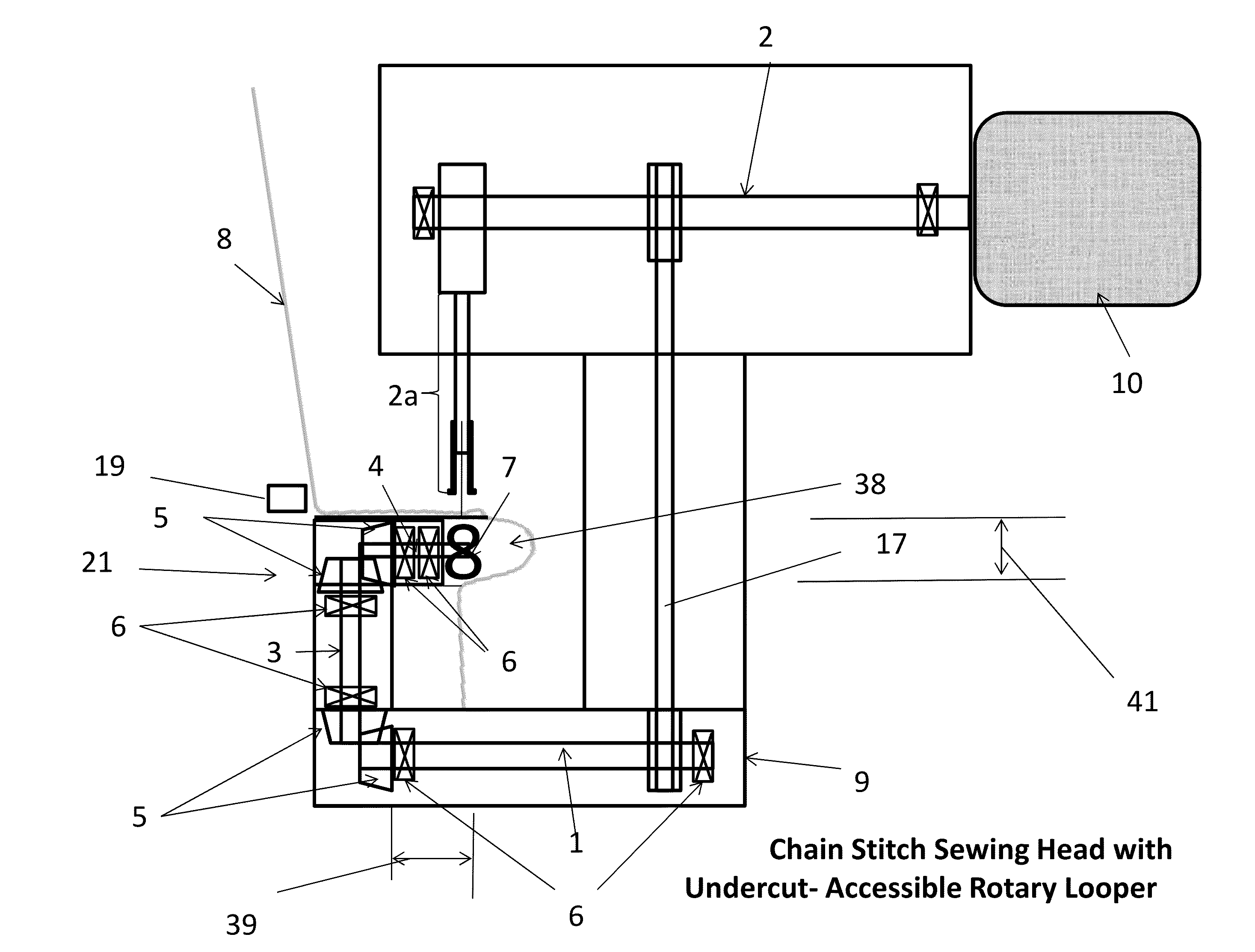

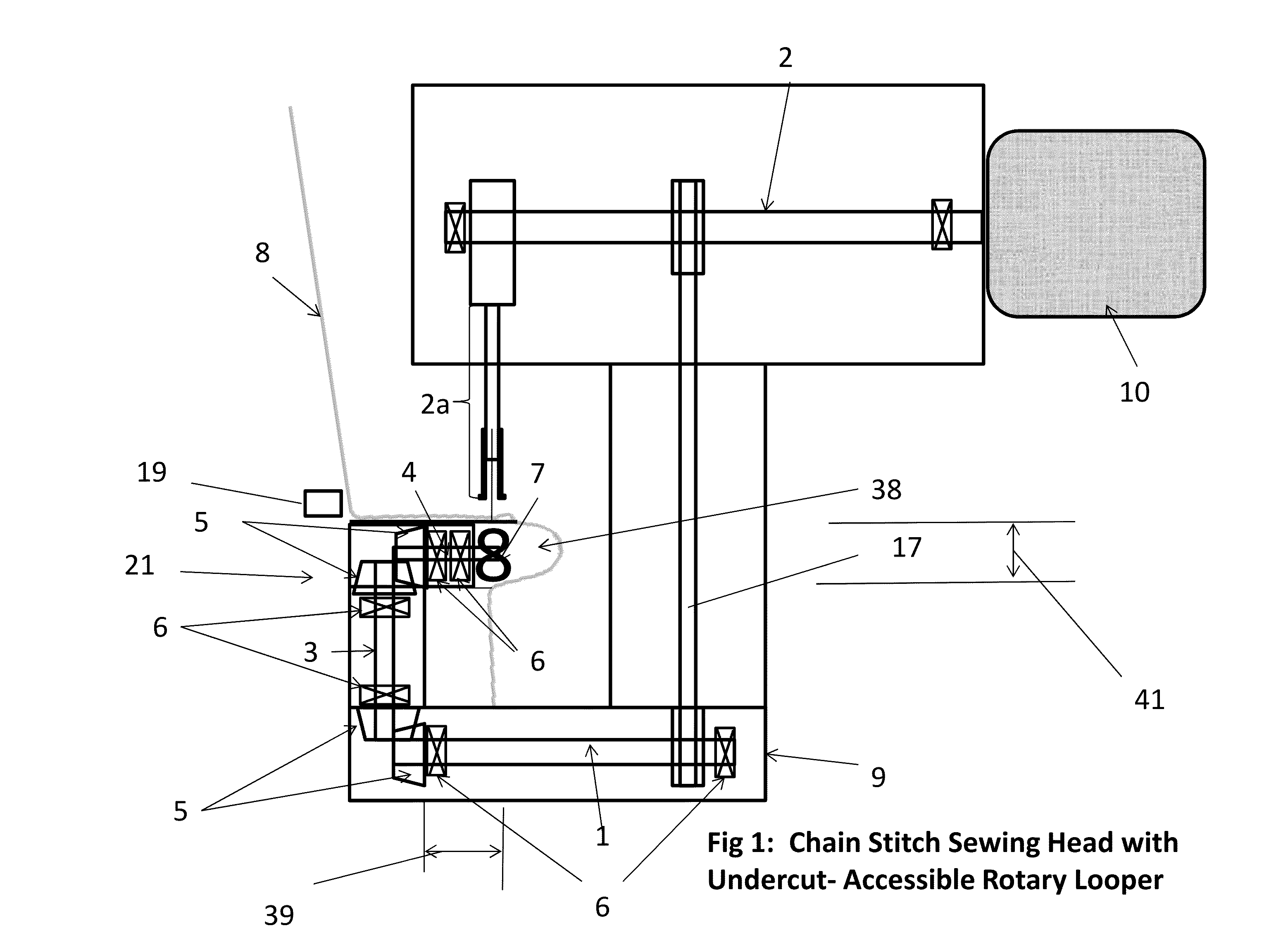

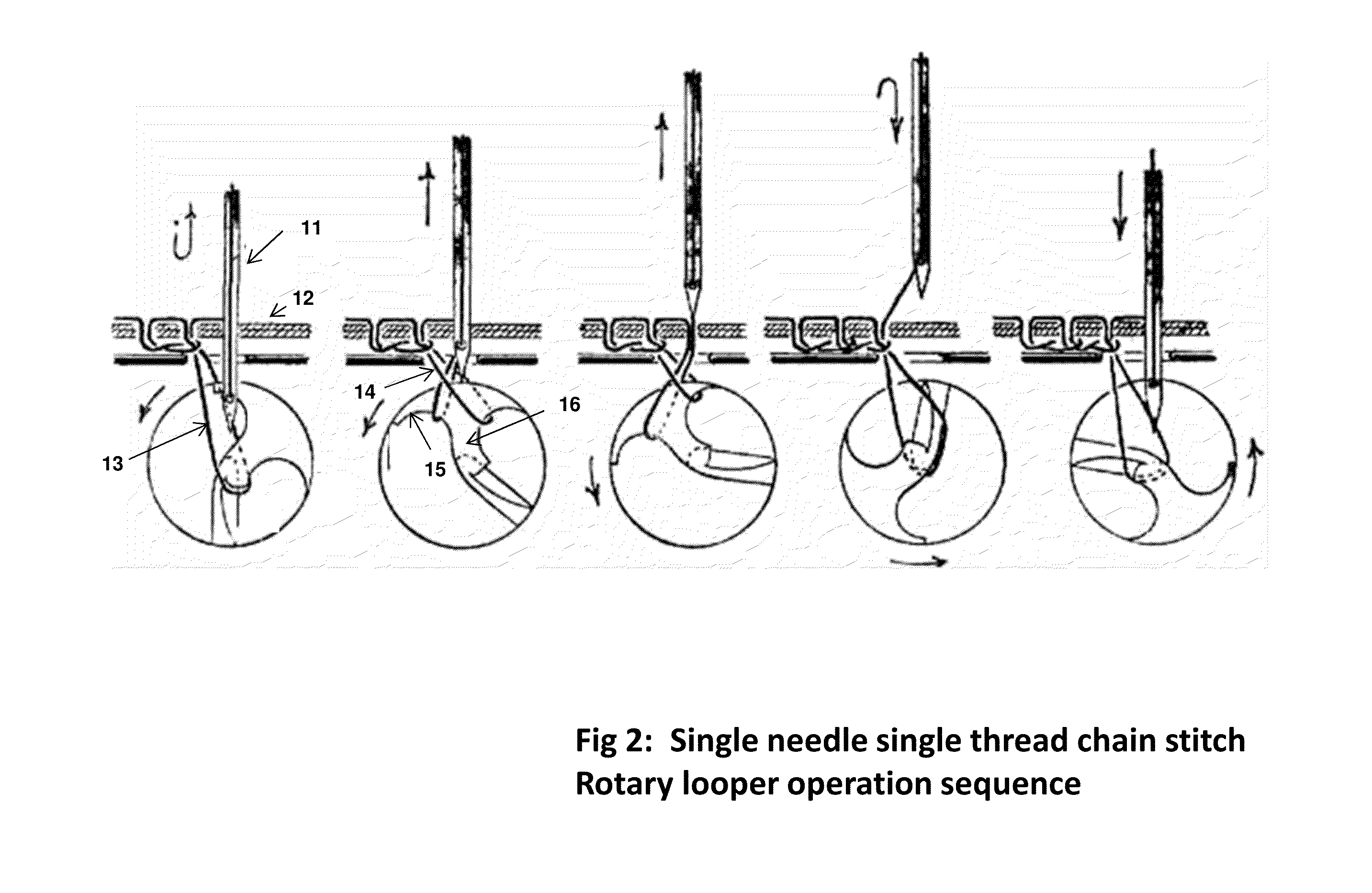

Apparatus for stitching vehicle interior components

An apparatus for stitching an interior component is disclosed herein. The component having an outer skin layer and the apparatus is a single needle chain stitch machine with a rotary looper and wherein a needle of the apparatus descends through the interior component and a hook of the rotary looper engages a thread loop formed during retraction of the needle after it has descended through the interior component; and wherein the apparatus further includes a mechanism for moving the interior component relative to the needle and looper to establish a stitch length.

Owner:INTEVA PRODUCTS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com