Patents

Literature

1315results about "Automatic machines" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

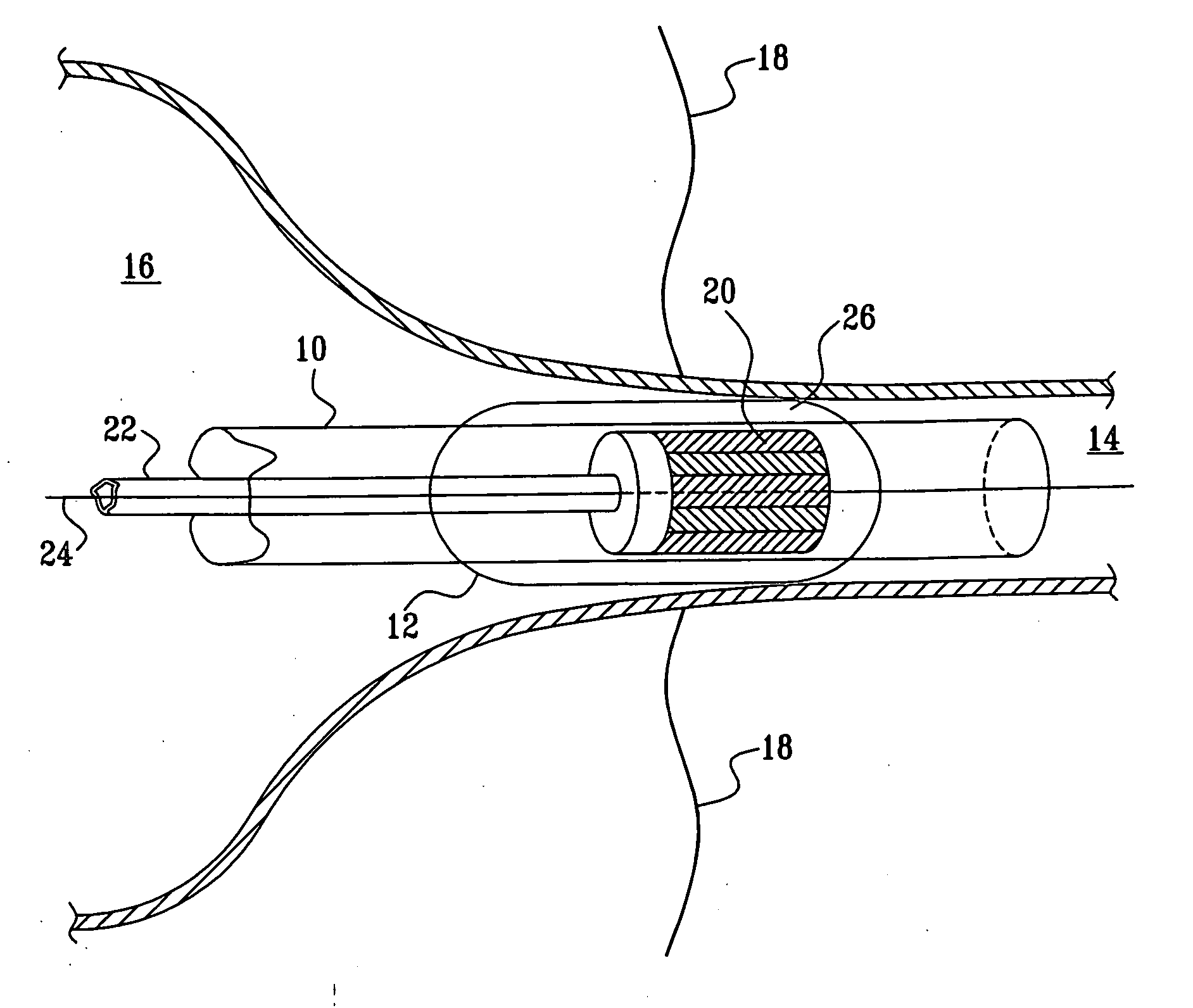

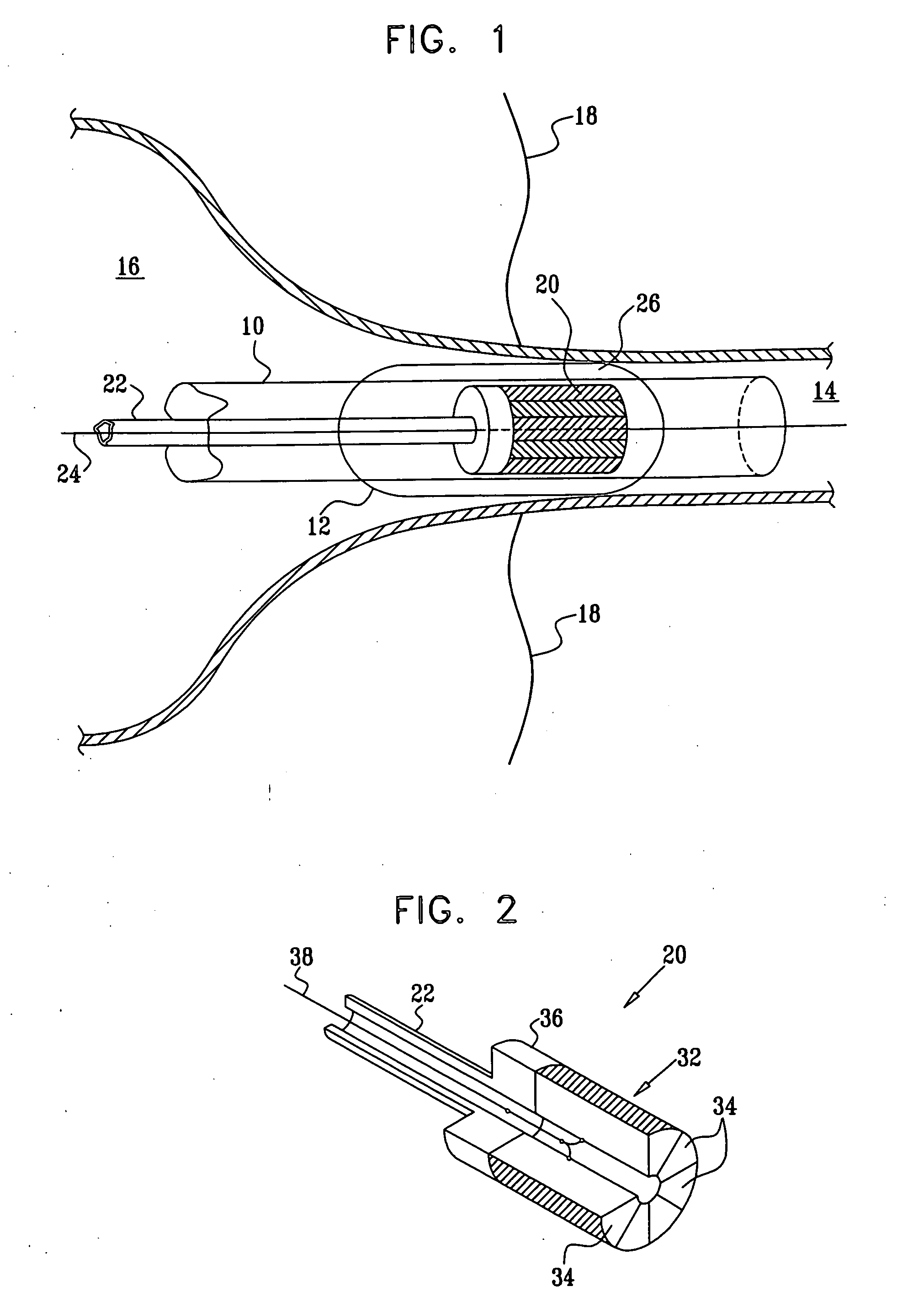

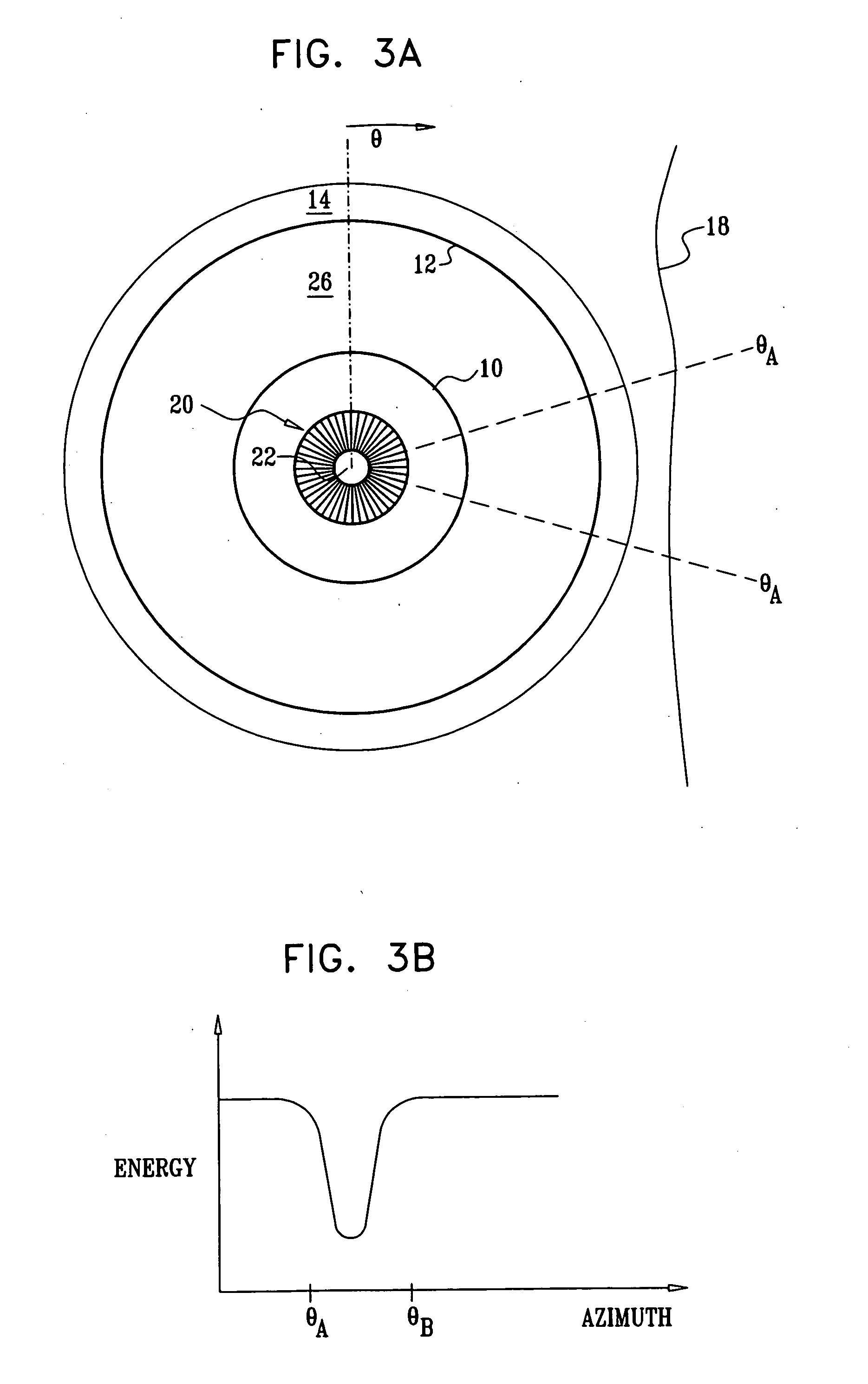

Phased-array for tissue treatment

ActiveUS20050215990A1Convenient treatmentWeaken energyUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyTarget tissuePhased array

Apparatus is provided for ablating tissue of a patient by applying ultrasound energy to the tissue. The apparatus is typically delivered to the targeted tissue via a catheter and includes an ultrasound array, which is adapted to be driven as a phased array to concentrate the ultrasound energy on the targeted tissue while avoiding surrounding tissue.

Owner:BIOSENSE WEBSTER INC

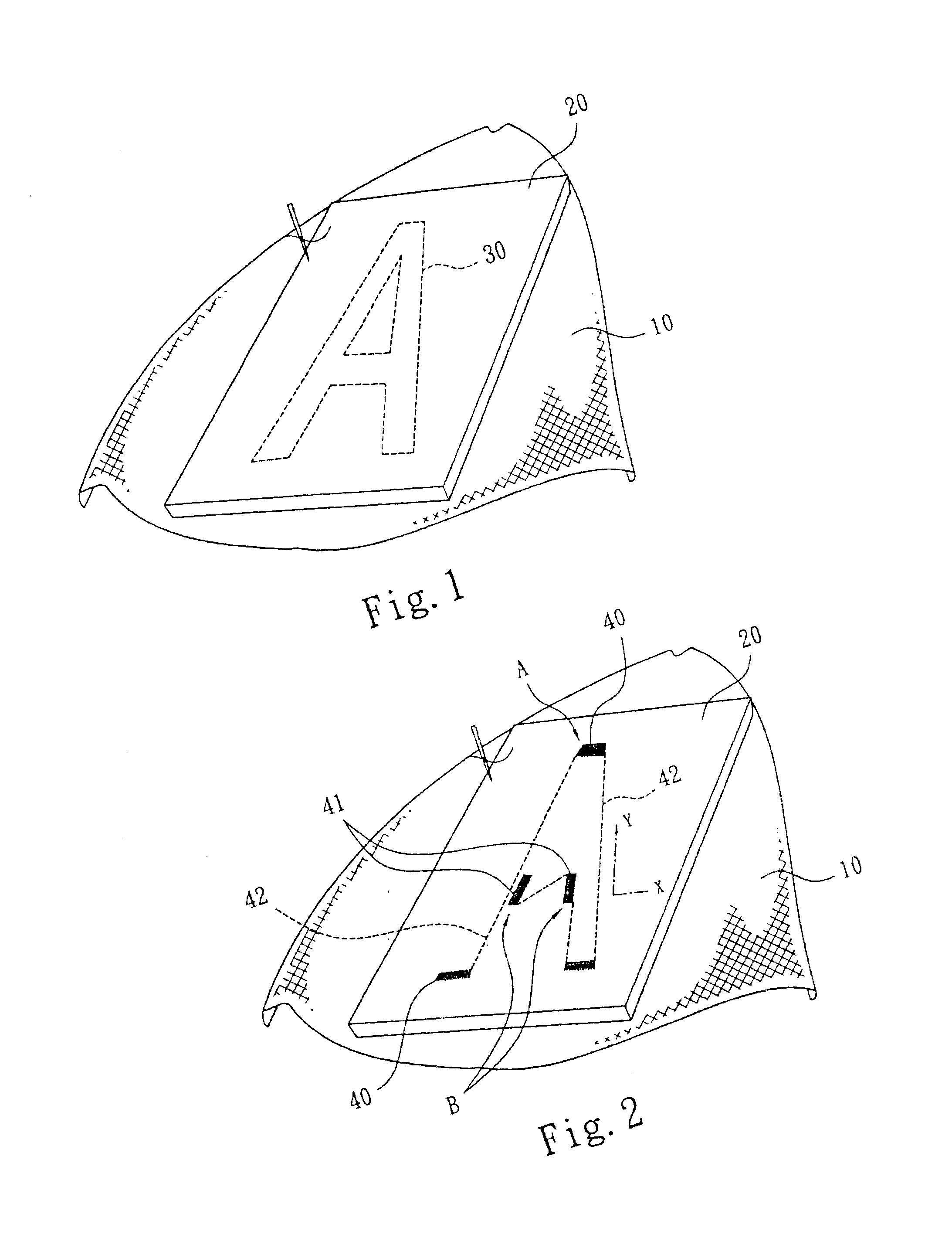

Raised embroidery process

Owner:WANG TAI KUANG

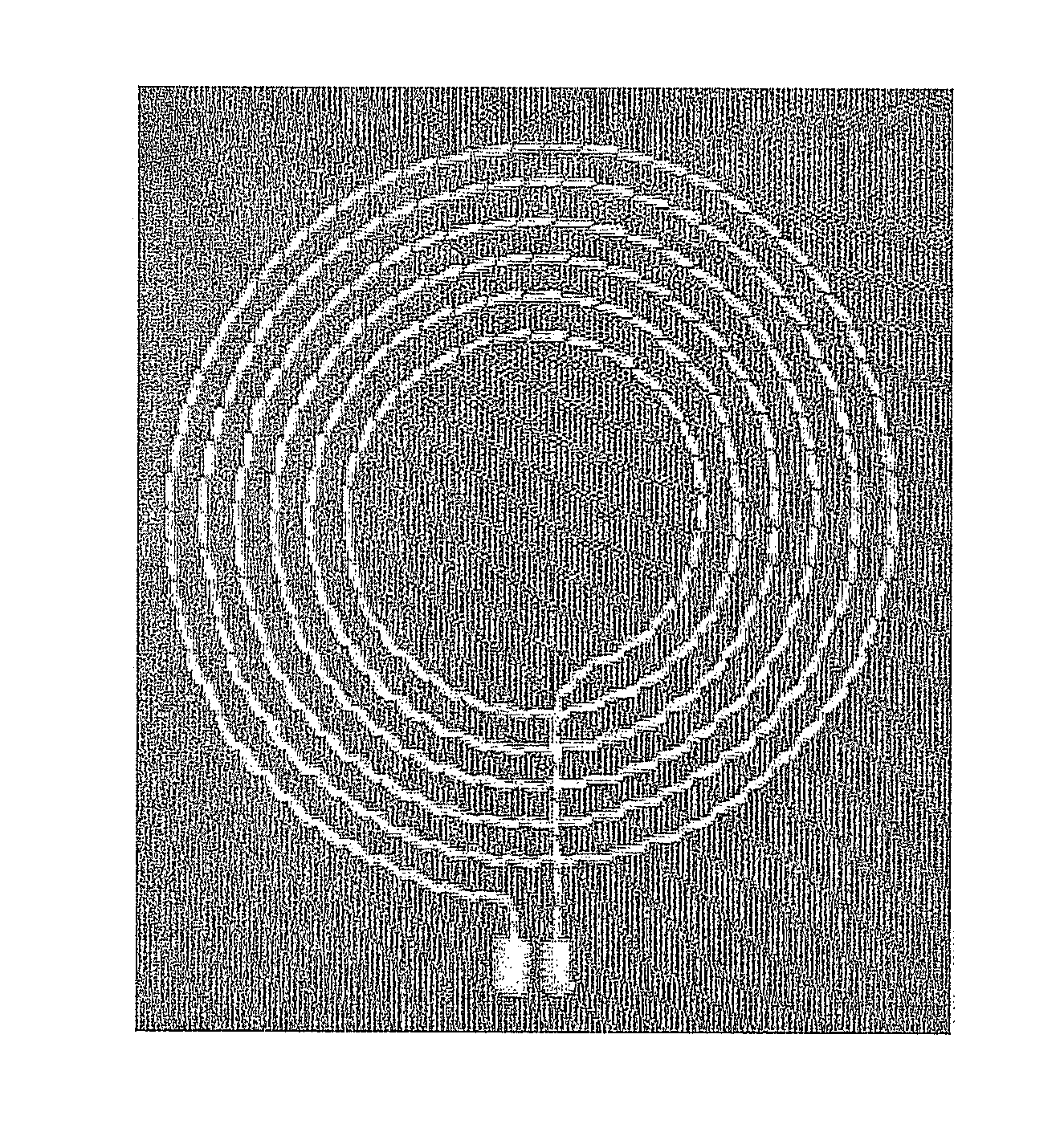

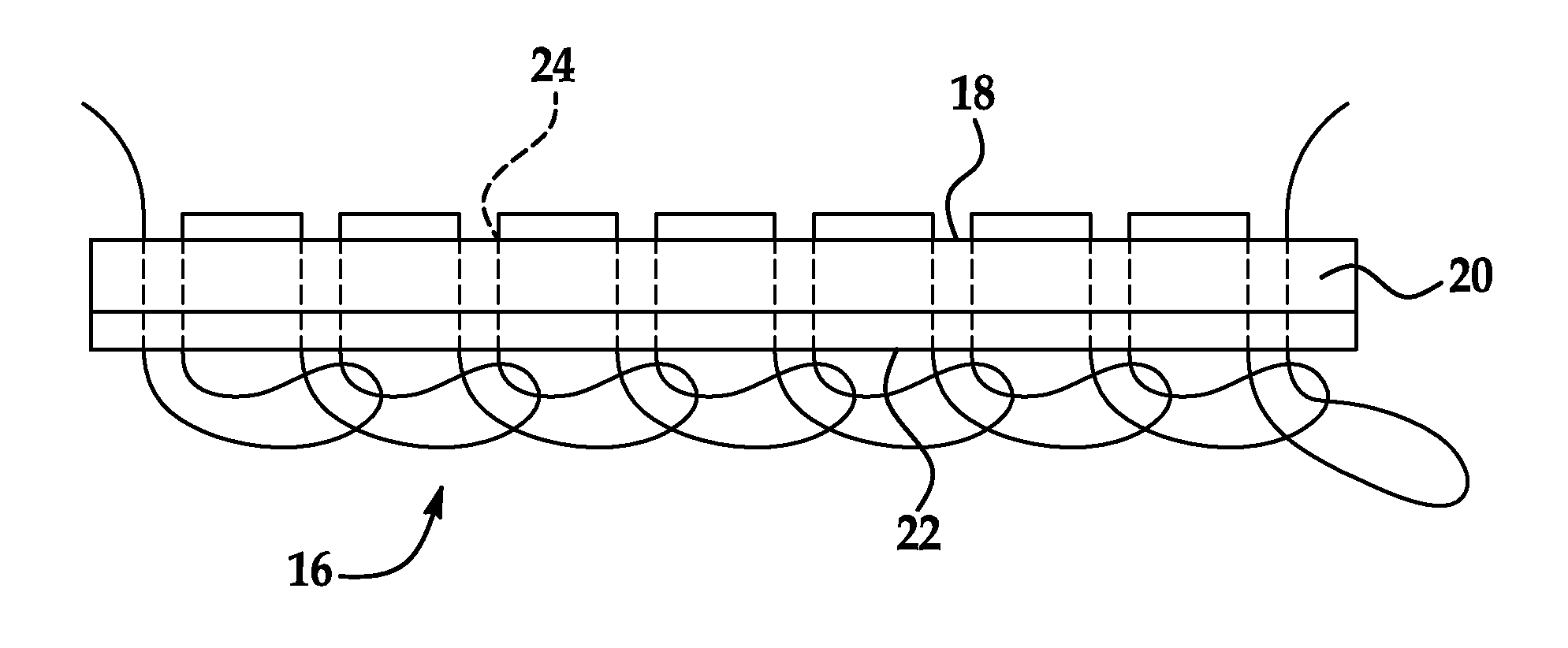

Electrically conductive metal composite embroidery yarn and embroidered circuit using thereof

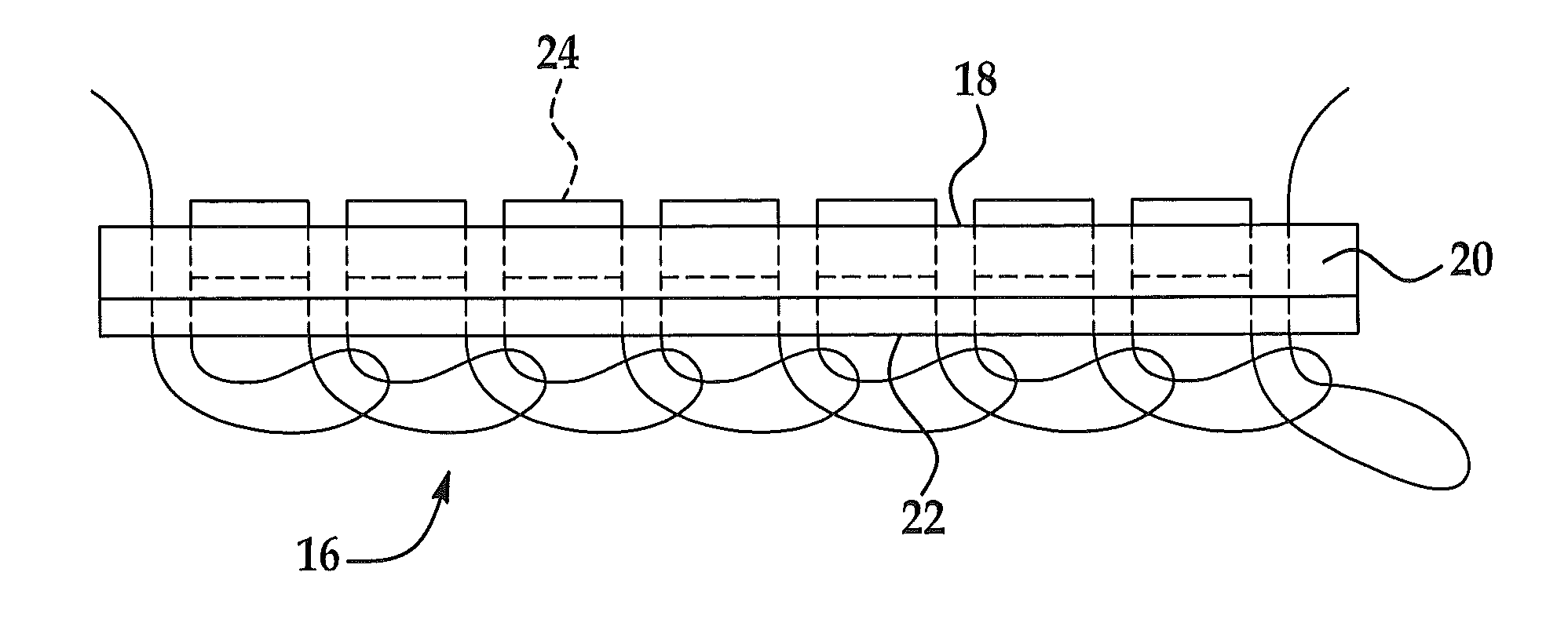

ActiveUS8505474B2Improve shortcomingsImprove conductivityGarmentsPrinted circuit aspectsYarnEngineering

The present invention relates to an electrically conductive metal composite embroidery yarn and embroidered circuit using thereof which may be applicable to smart textiles. More particularly, this invention relates to an electrically conductive metal composite embroidery yarn and embroidered circuit for smart textiles which can be used as power supply and signal transmission lines. The present invention provides an embroidered circuit which consists of a metal composite embroidery yarn and a dielectric fabric substrate, wherein the electrically conductive metal composite embroidery yarn is embroidered on the dielectric fabric substrate to form a circuit.

Owner:SEOUL NAT UNIV R&DB FOUND

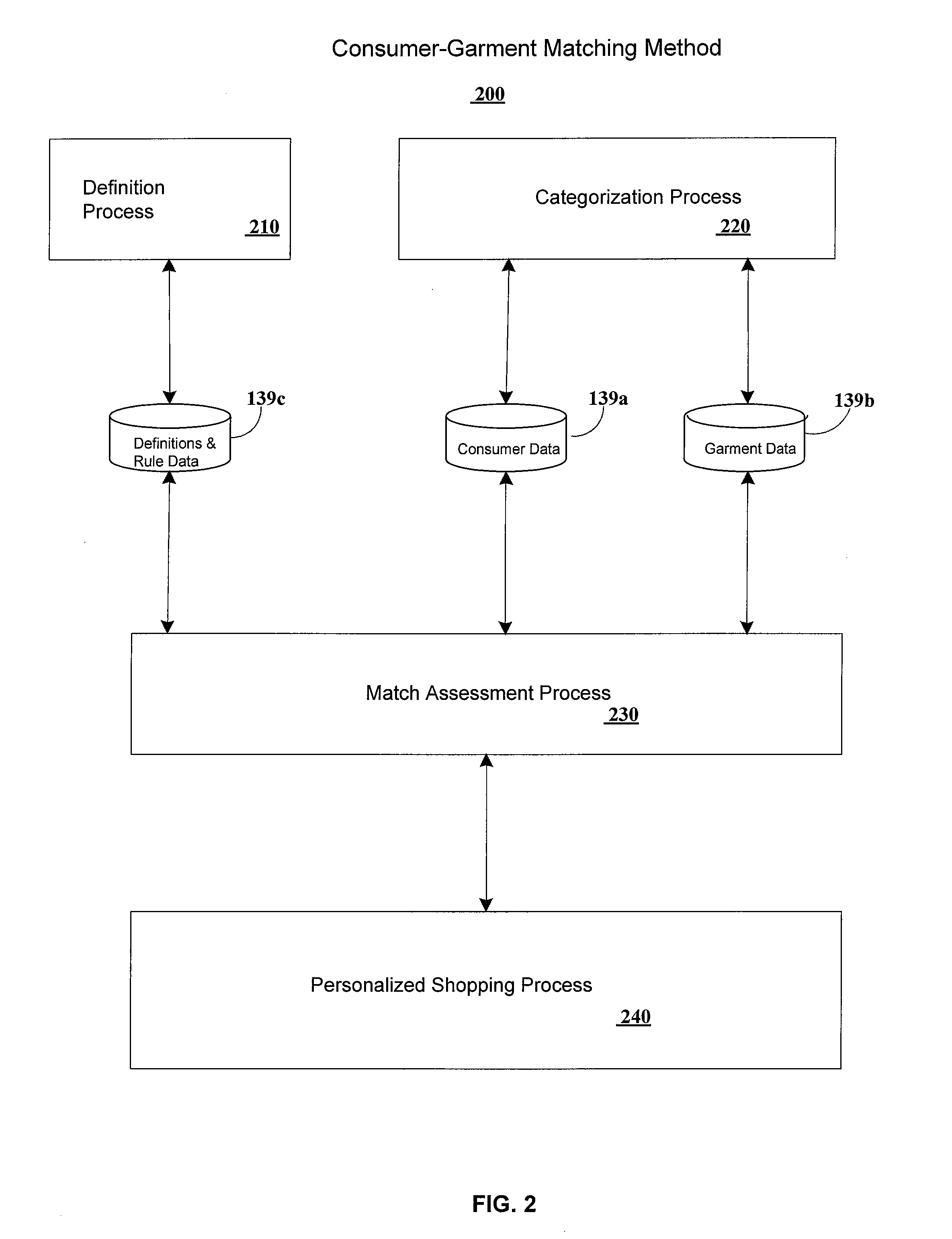

Computer system for rule-based clothing matching and filtering considering fit rules and fashion rules

InactiveUS20070198120A1Increase probabilityBuying/selling/leasing transactionsSpecial data processing applicationsData miningComputer generation

Owner:MIPSO

Method and system for automatically deriving stippling stitch designs in embroidery patterns

ActiveUS6968255B1Accurate and convenient to useProgramme-controlled sewing machinesSpecial data processing applicationsData formatComputer science

The invention pertains to a method of applying a stippling stitch design to an area defining an asymmetrical polygon in a coordinate planar display format, involving: defining a pathway, which may be based on a fractal design, within a geometrically symmetrical boundary, the pathway comprising a single non-intersecting line; conforming the pathway to an asymmetrical polygon area substantially disposed within the geometrically symmetrical boundary; deriving a plurality of coordinate points representative of the pathway; and passing the points to a data storage medium in a pre-determined embroidery data format.

Owner:TAJIMA SOFTWARE SOLUTIONS INC

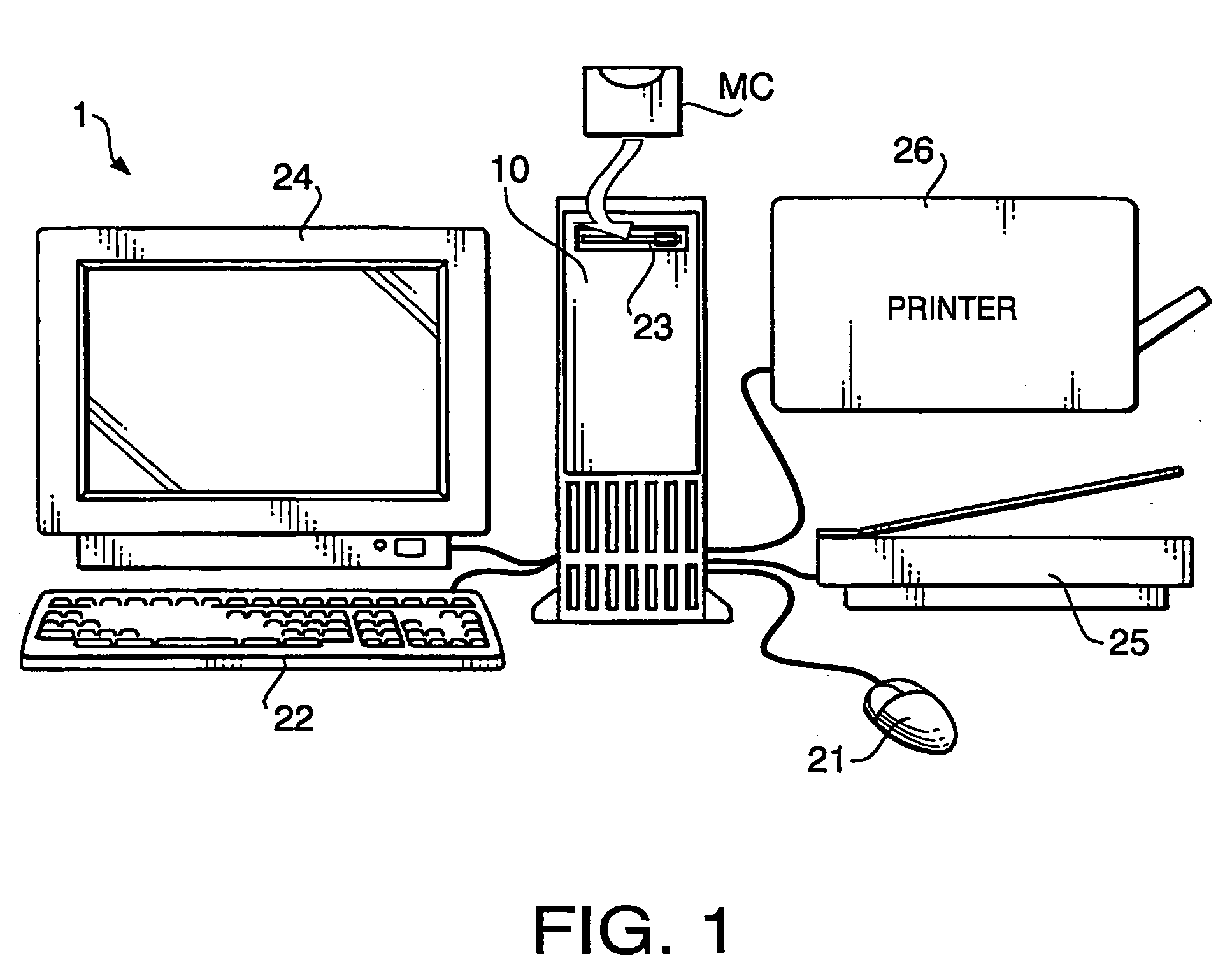

Image editing device and print/embroidery data creating device

ActiveUS20050182508A1Ink ejection amount can be controlledDifferent permeability characteristicProgramme-controlled sewing machinesAutomatic machinesComputer printingImage editing

A print / embroidery data creating device is provided with a usable color designating system, an output information setting system, a pixel examining system, an area setting system that sets a pixel area determined to correspond to the usable color as a usable color area and sets an area which does not correspond to the usable color area as a print area, an embroidery data creating system. The usable color area is output with the size set by the output information setting system at the position set by the output information setting system by the embroidering machine, and a print data creating system that creates print data such that a pixel area set as the print area by the area setting system is output as printed area with a color corresponding to the pixel color, the print area being output with the size set by the output information setting system at the position set by the output information setting system by the printer.

Owner:BROTHER KOGYO KK

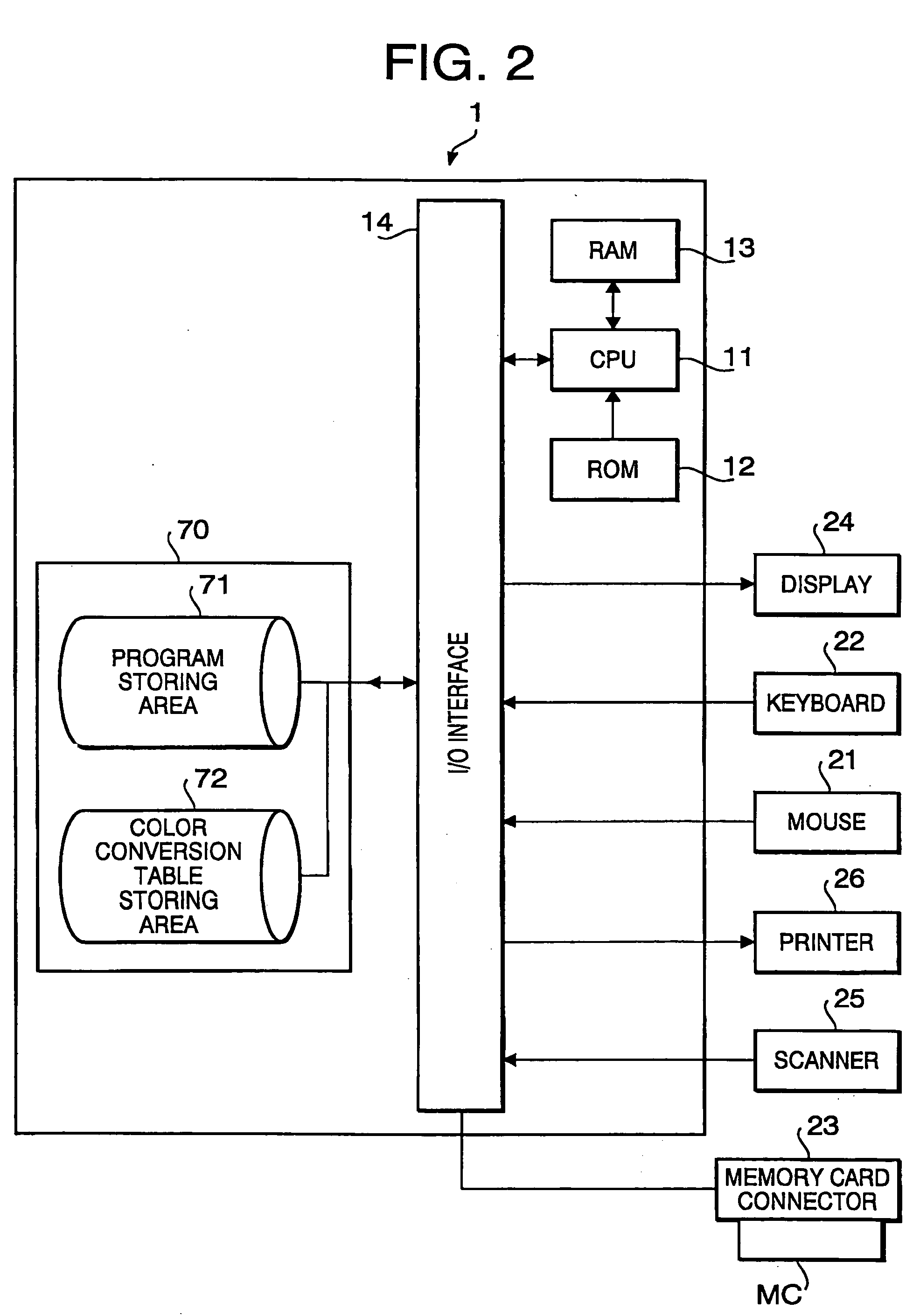

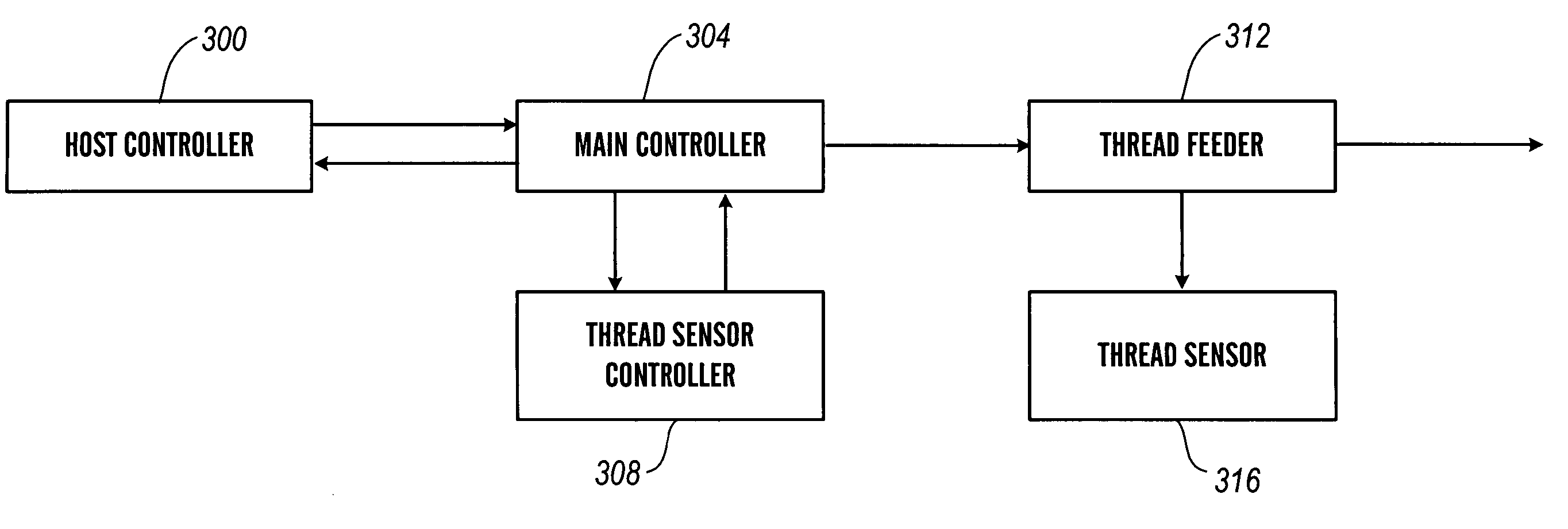

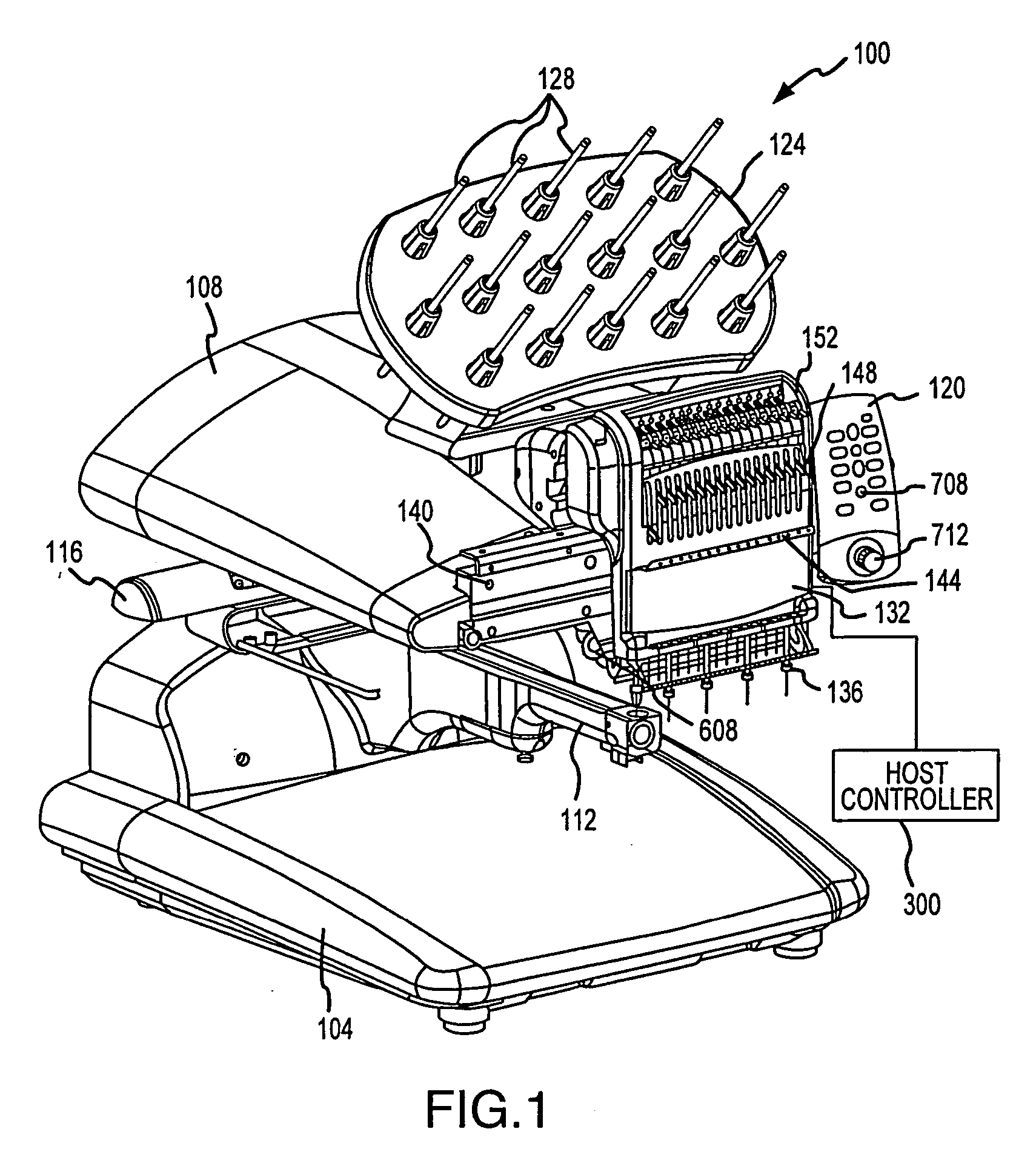

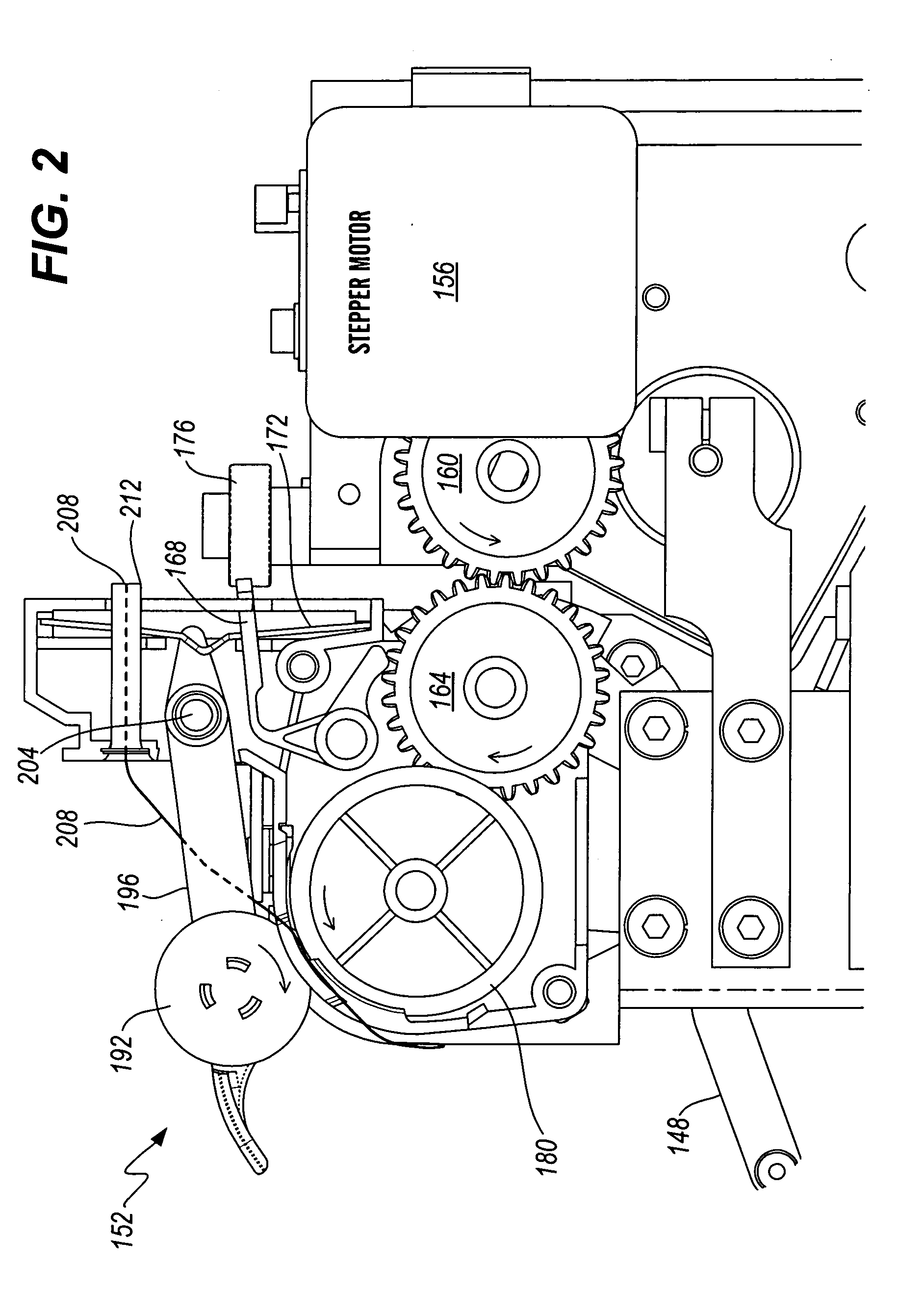

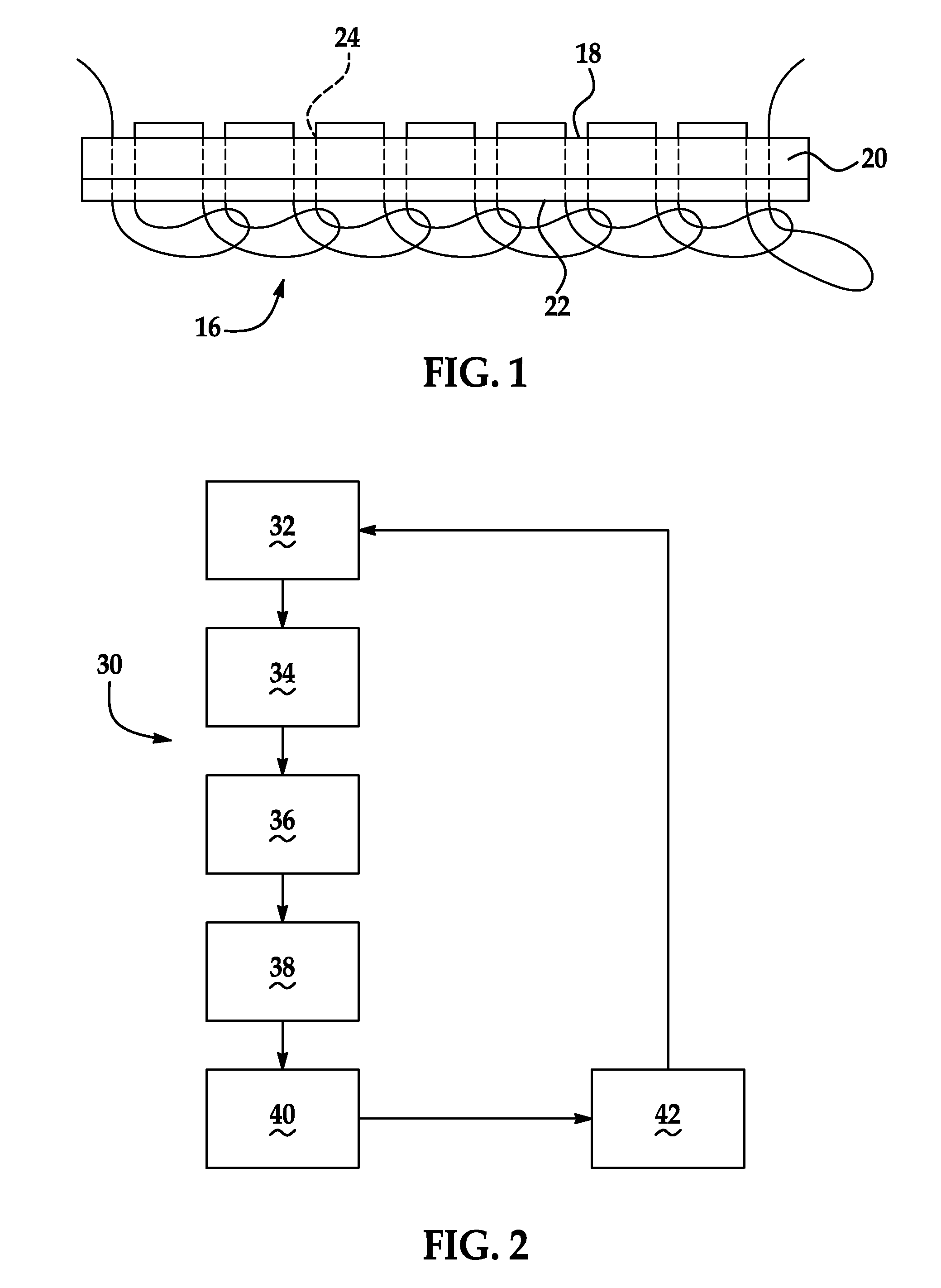

Computerized stitching including embroidering

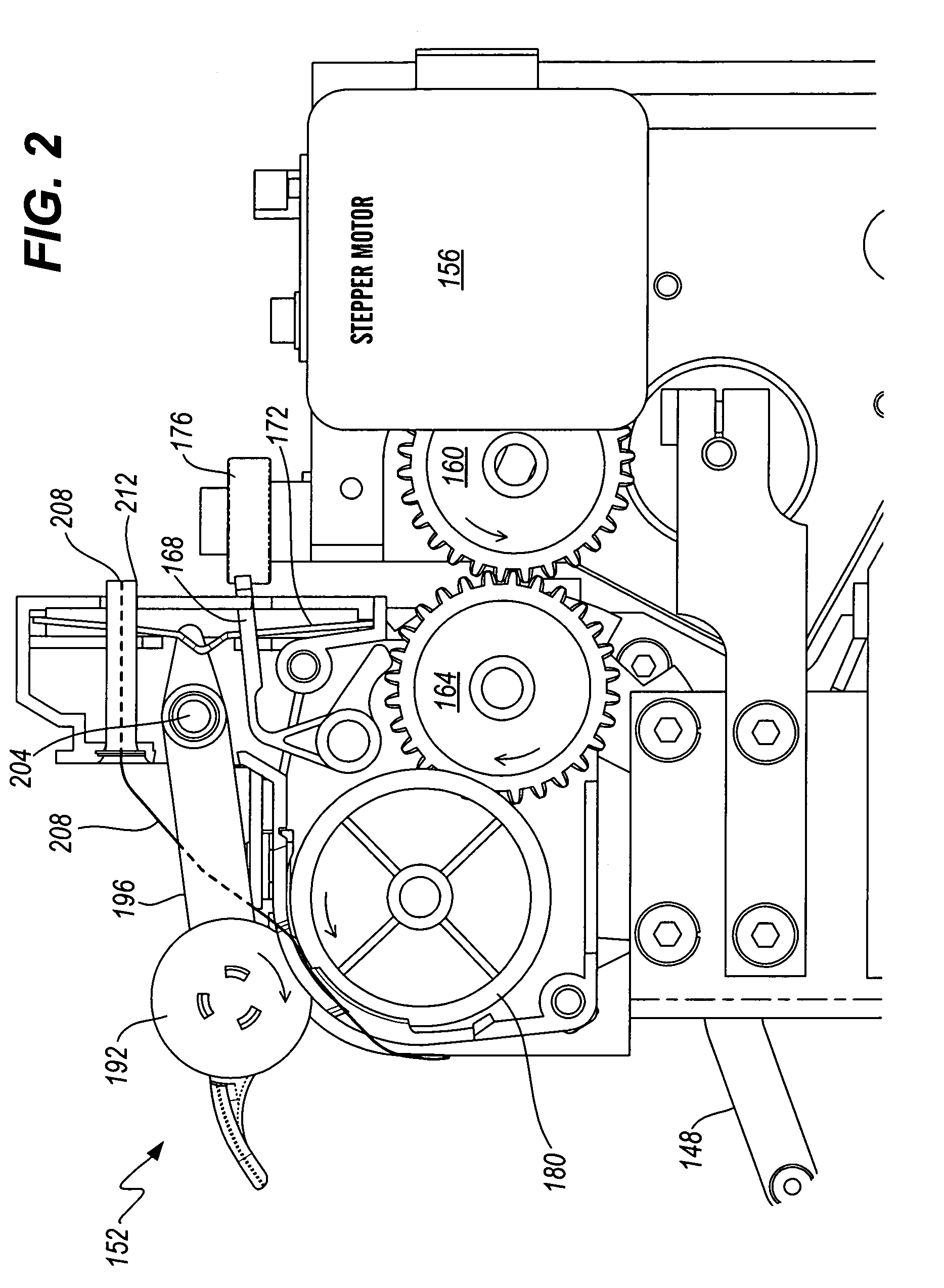

InactiveUS7308333B2Easy to controlProgramme-controlled sewing machinesPressersAnomaly detectionRemedial action

A stitching apparatus with thread tension control is provided. Tension in a thread is monitored during stitching apparatus operations, and remedial action is taken in response to the detection of an anomaly in the thread tension profile. The remedial action can include altering a feed rate of the thread in order to adjust the thread tension, and / or repeating a previous operation. Anomaly detection can be performed with respect to stitching or sewing operations, and also with respect to trim operations performed in connection with moving between elements and / or thread color changes.

Owner:MELCO INT

Method for stitching vehicle interior components and components formed from the method

A method of applying stitching to an interior component is provided herein. The method including the steps of: a) penetrating an outer skin layer, a substrate layer and an intermediary layer of the interior component with an awl to form a piercing therethrough; b) retracting the awl from the outer skin layer, the substrate layer and the intermediary layer; c) inserting a needle through the piercing through the substrate layer, the intermediary layer and the outer skin layer to grasp a thread positioned on the outer skin layer; d) pulling the thread through the outer skin layer, the intermediary layer and the substrate layer; e) looping the thread with a previous stitch passed through the outer skin layer, the intermediary layer and the substrate layer; f) advancing the interior component to another position; and g) repeating steps a-f until a predetermined amount of stitches are applied to the interior component.

Owner:INTEVA PRODUCTS LLC

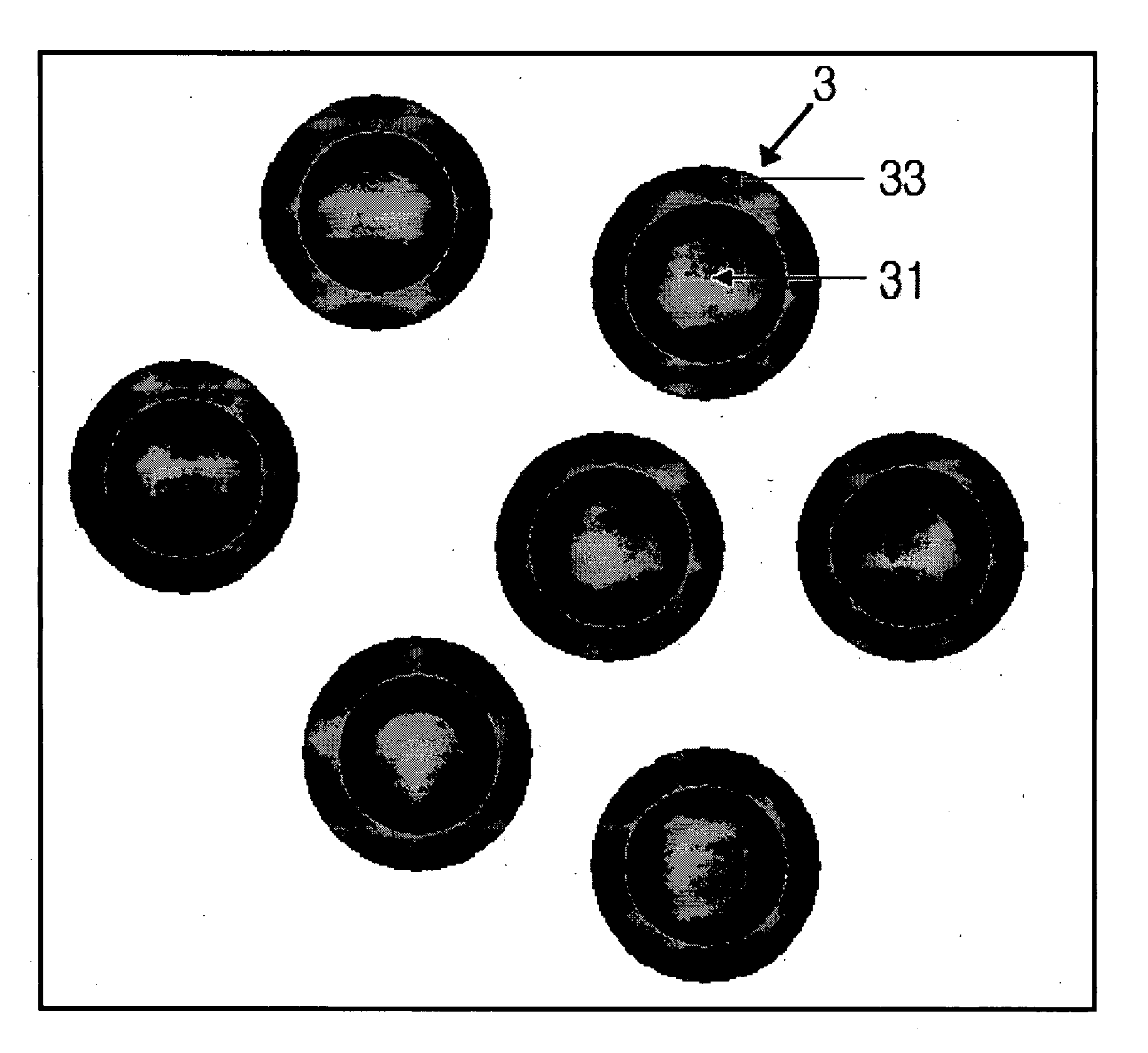

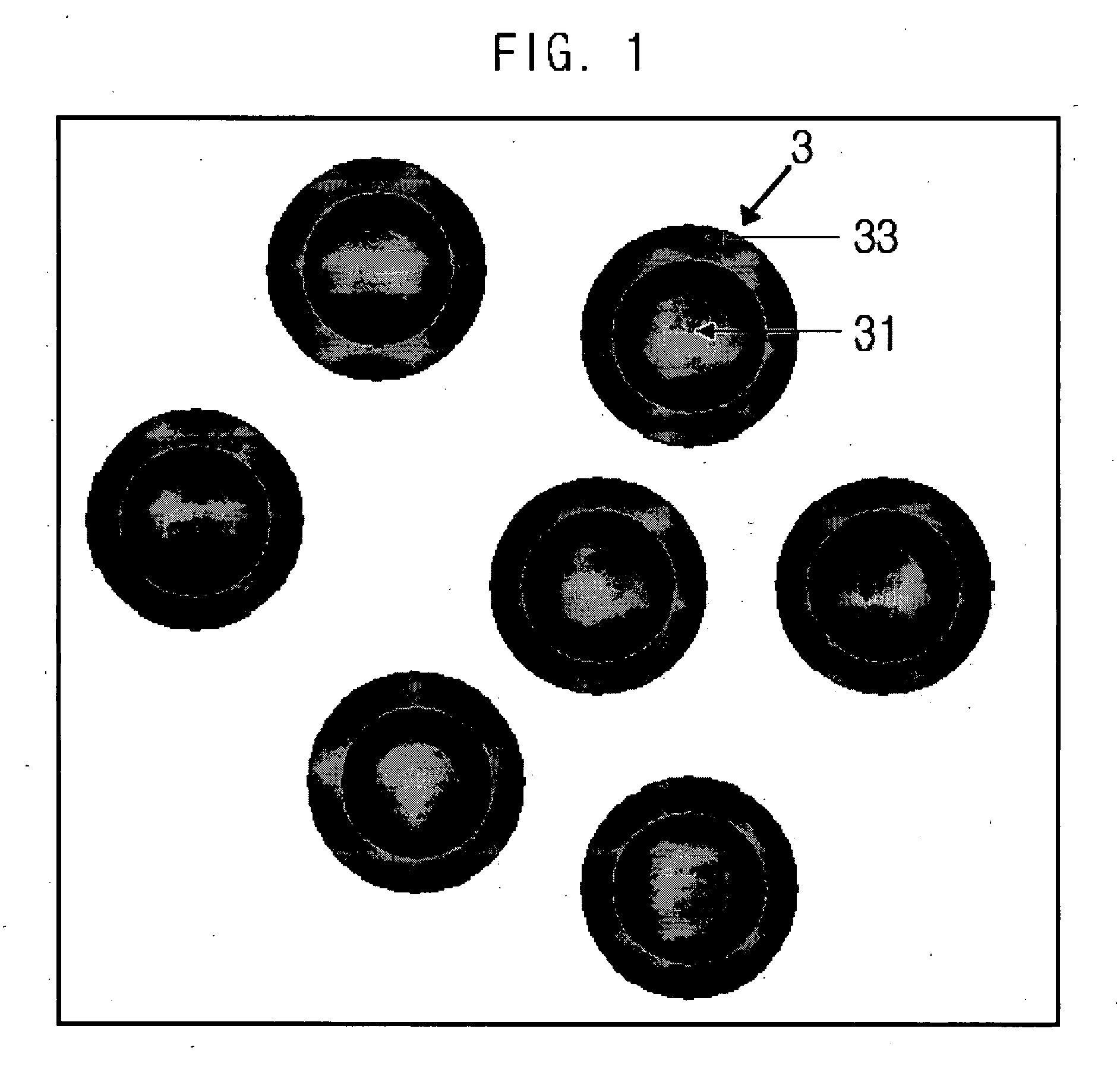

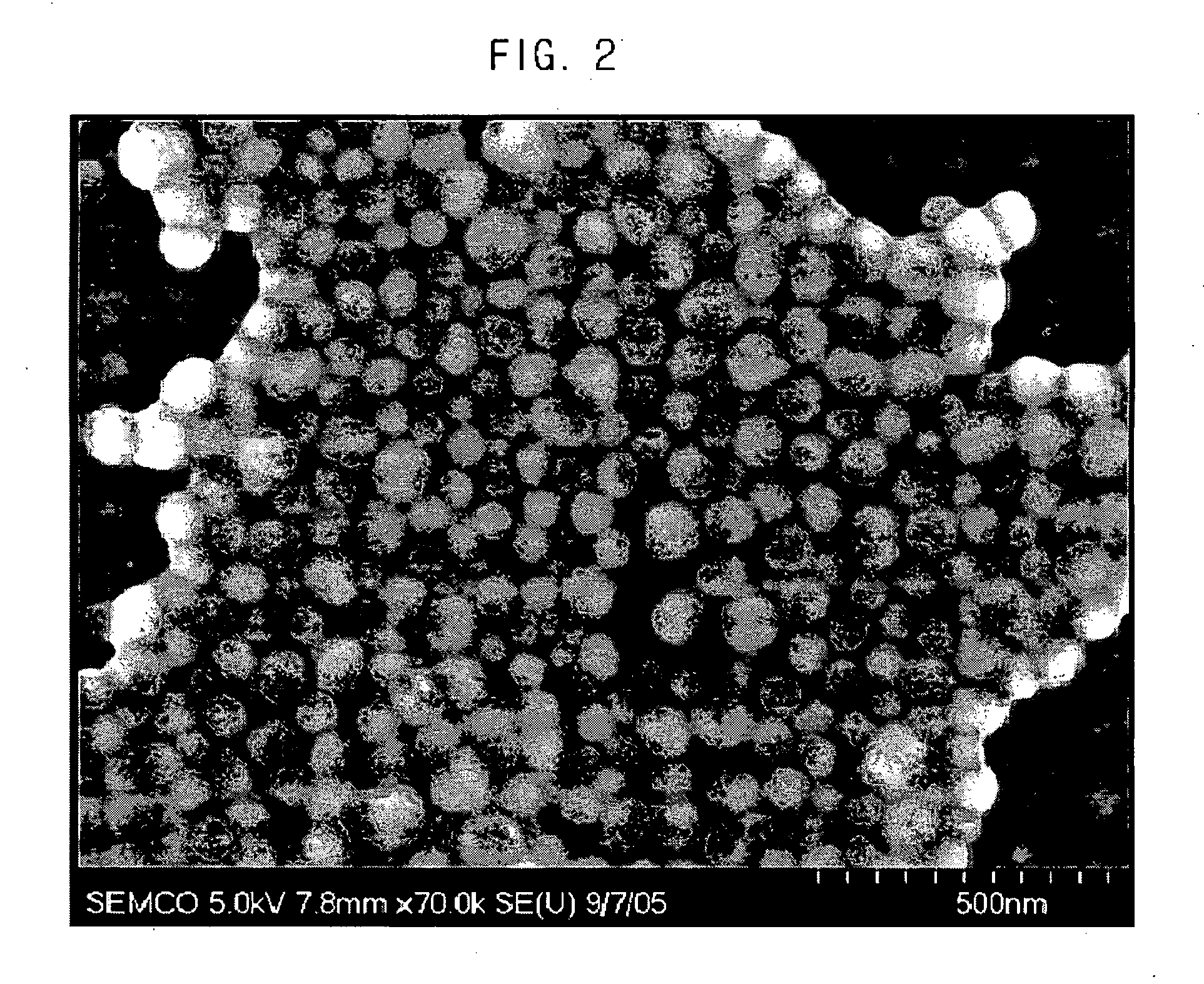

Core-shell structure metal nanoparticles and its manufacturing method

InactiveUS20070212562A1Prevent oxidationEconomical efficiencyMaterial nanotechnologyNon-insulated conductorsThin layerCore shell

The present invention provides metal nanoparticles, containing copper core and thin layer of precious metals enclosing the core to prevent oxidization of copper, in which manufacturing the metal nanoparticles is economical efficiency because of increased copper content and since such metal nanoparticles contain a metal having high electrical conductivity such as silver for a thin layer, they can form a wiring having better conductivity than copper and there is little concern that silver migration may occur.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

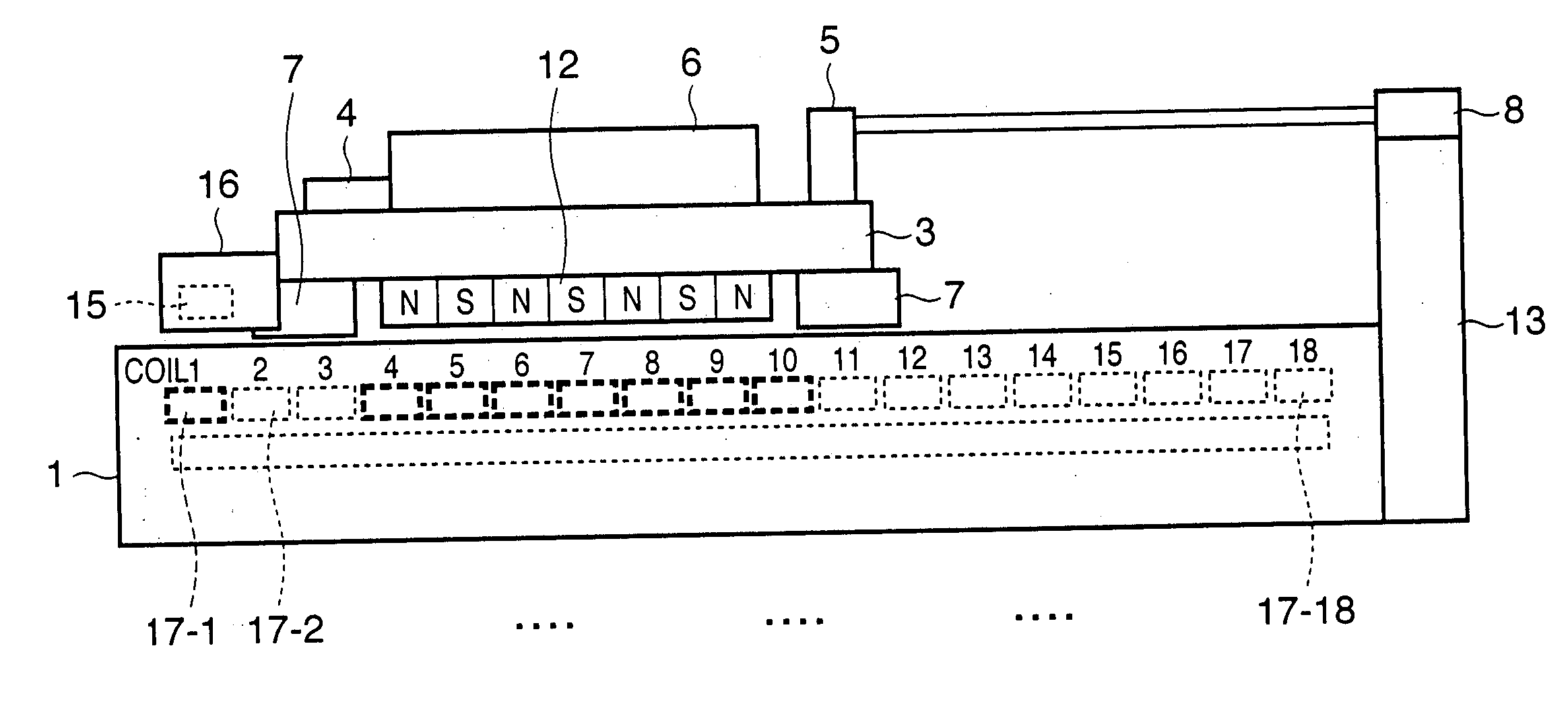

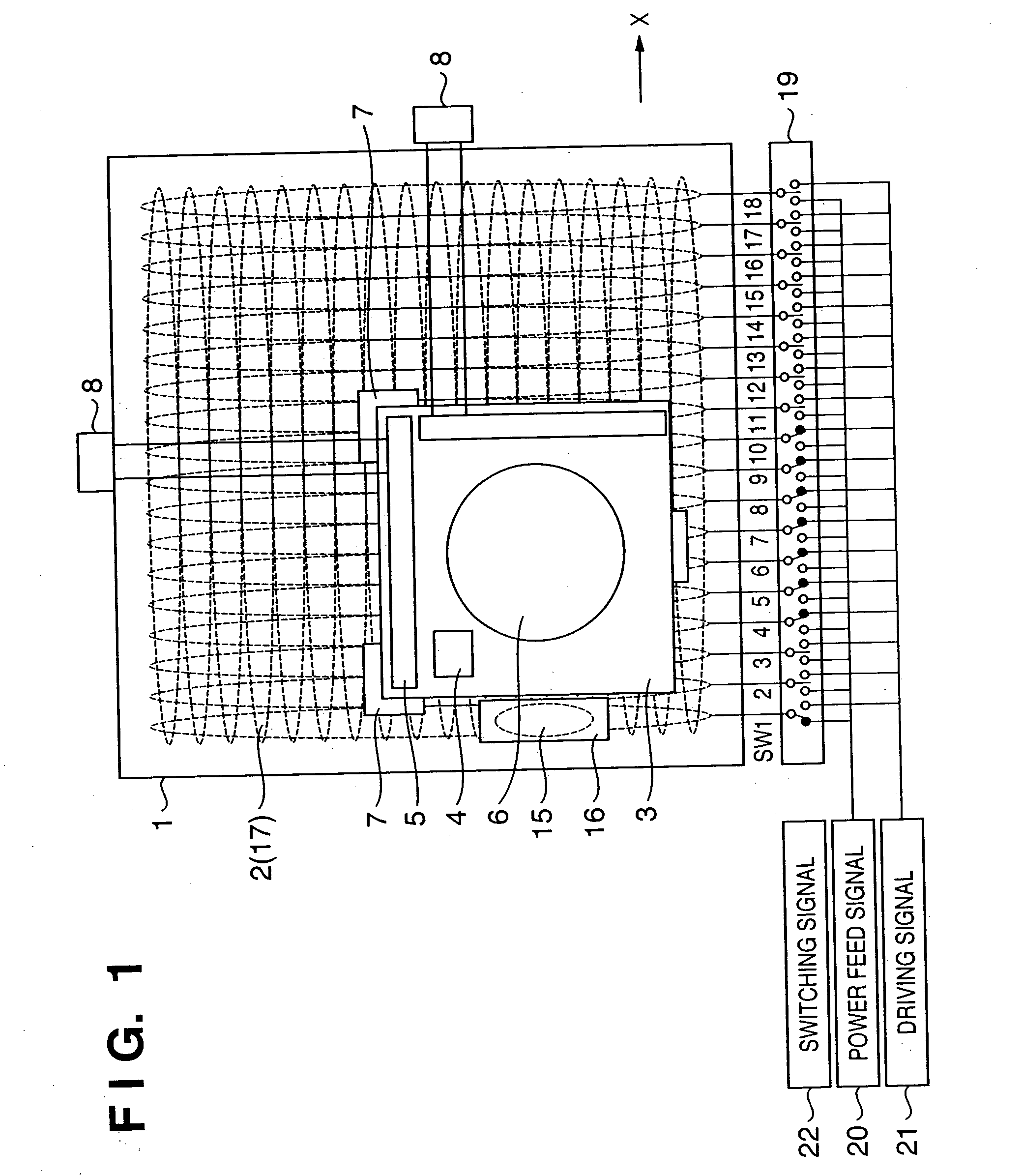

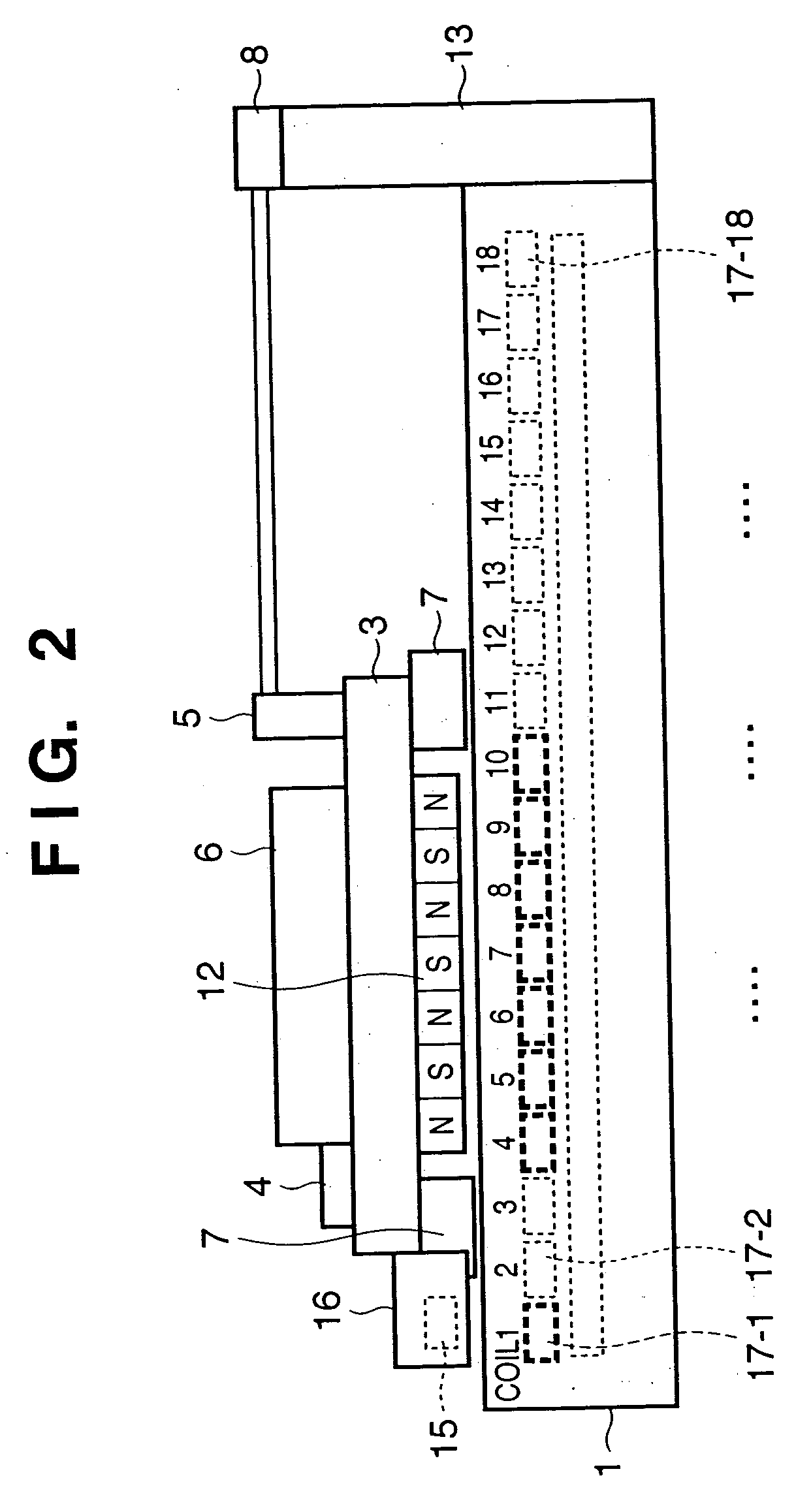

Alignment stage apparatus

InactiveUS20050093378A1Improve throughputIncrease speedDC motor speed/torque controlSemiconductor/solid-state device manufacturingElectric power transmissionElectricity

Power is supplied at an arbitrary position of a movable stage main body or arbitrary timing by downsizing or removing a battery mounted on a movable stage main body, in a non-contact manner without using any electrical cable. In an alignment stage having a power reception coil to which an AC magnetic field is supplied to obtain power in a non-contact manner, a plurality of power transmission coils which supply power are buried in a base structure. An unit for sequentially switching the power transmission coils in accordance with a position of the stage is provided. The power reception coils on the stage include a plurality of power transmission coils arranged to be phase-shifted from the power transmission coils. The frequency of the AC magnetic field is set at a resonance frequency determined by a load and the mutual inductance of the power transmission coils and power reception coils.

Owner:CANON KK

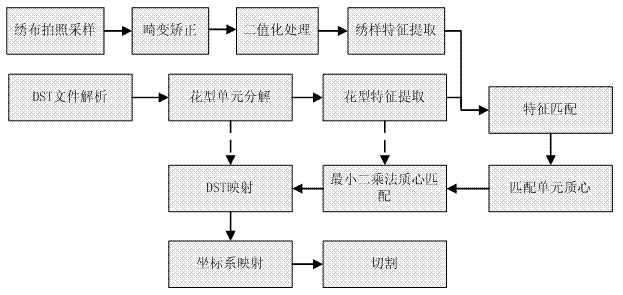

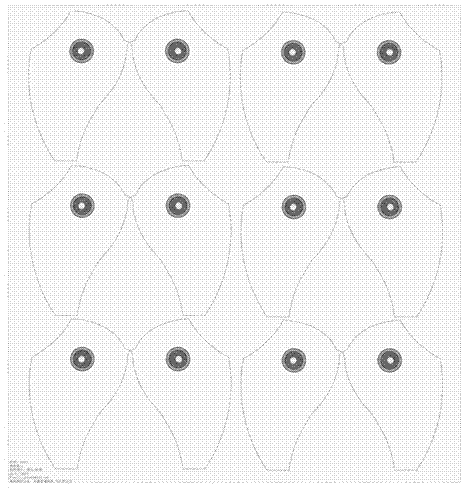

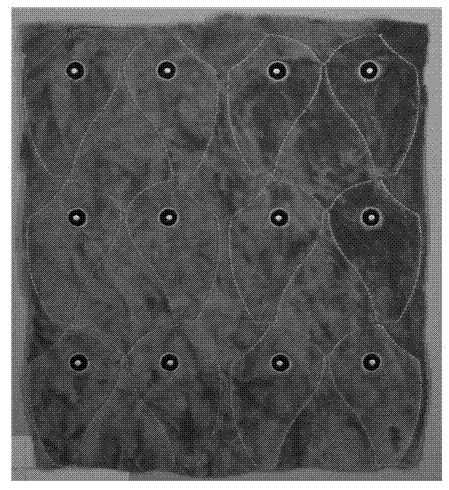

Automatic cutting method of embroidery cloth based on combination of DST file parsing and machine vision

InactiveCN102704215AIncrease profitReduce dependencyCharacter and pattern recognitionAutomatic machinesMachine visionLaser cutting

The invention discloses an automatic cutting method of embroidery cloth based on combination of DST file parsing and machine vision. In wool toy manufacturing industry, the profile and pattern of the wool toy are processed by adopting an embroidery machine, and the whole embroidery piece is cut one by one by adopting a laser cutter. The method comprises the steps of: firstly parsing a DST file (embroidery file) into an image file, selecting cutting units from the image file, and extracting the information of the cutting units to obtain the inside parameter of the unit; and carrying out correlated processing according to the image of cut sample obtained by camera shooting, matching the obtained cutting unit information with the processed sample, finally determining the cutting line position, generating a PLT file and cutting by a cutter. Different from other laser cutting methods based on machine vision, the method can finish cutting of the whole embroidery sample just by once shooting; and the method has the characteristics of high working efficiency and low unqualified rate, and has very strong cutting capability on the complicated embroidery sample.

Owner:SOUTHEAST UNIV

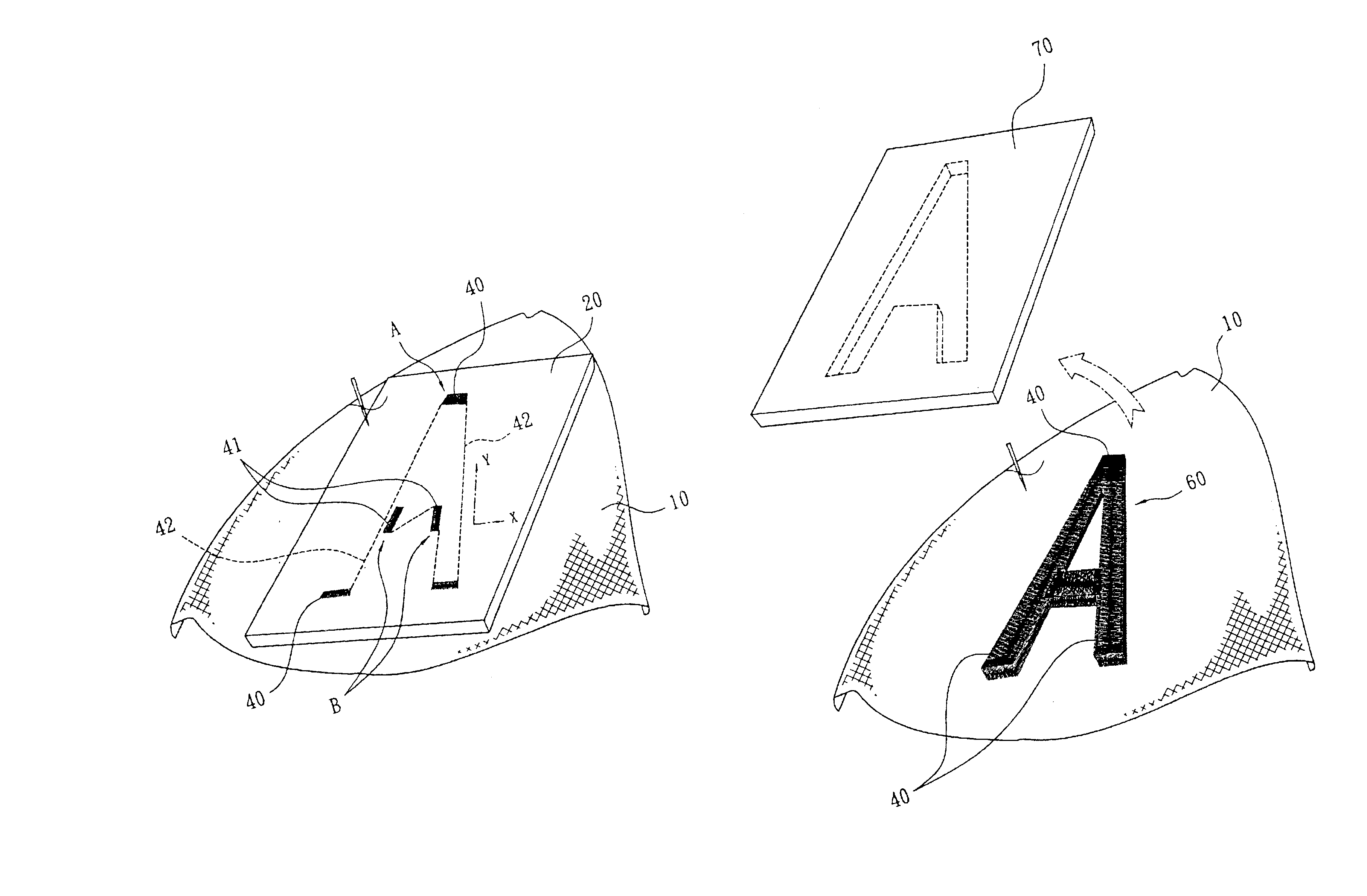

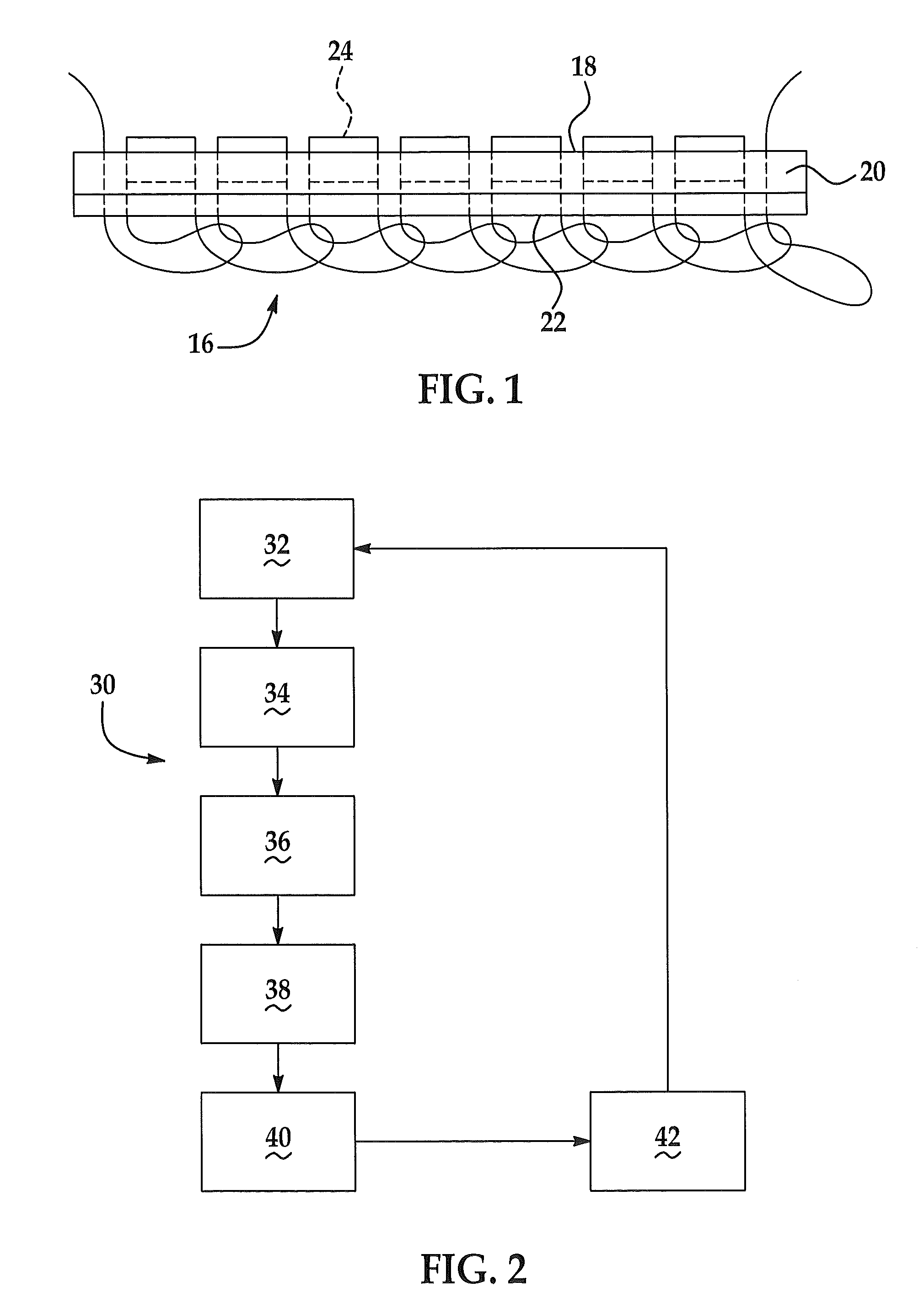

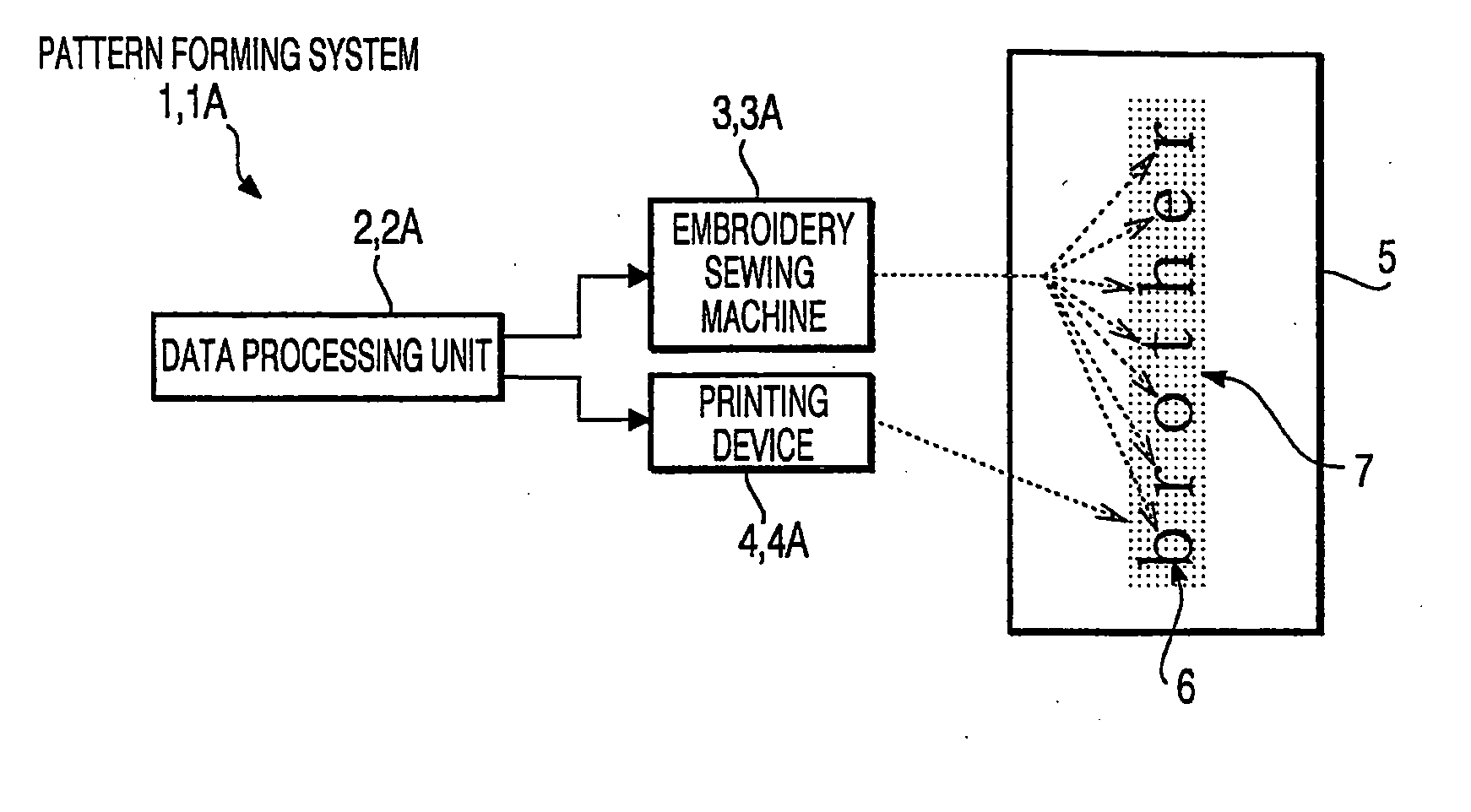

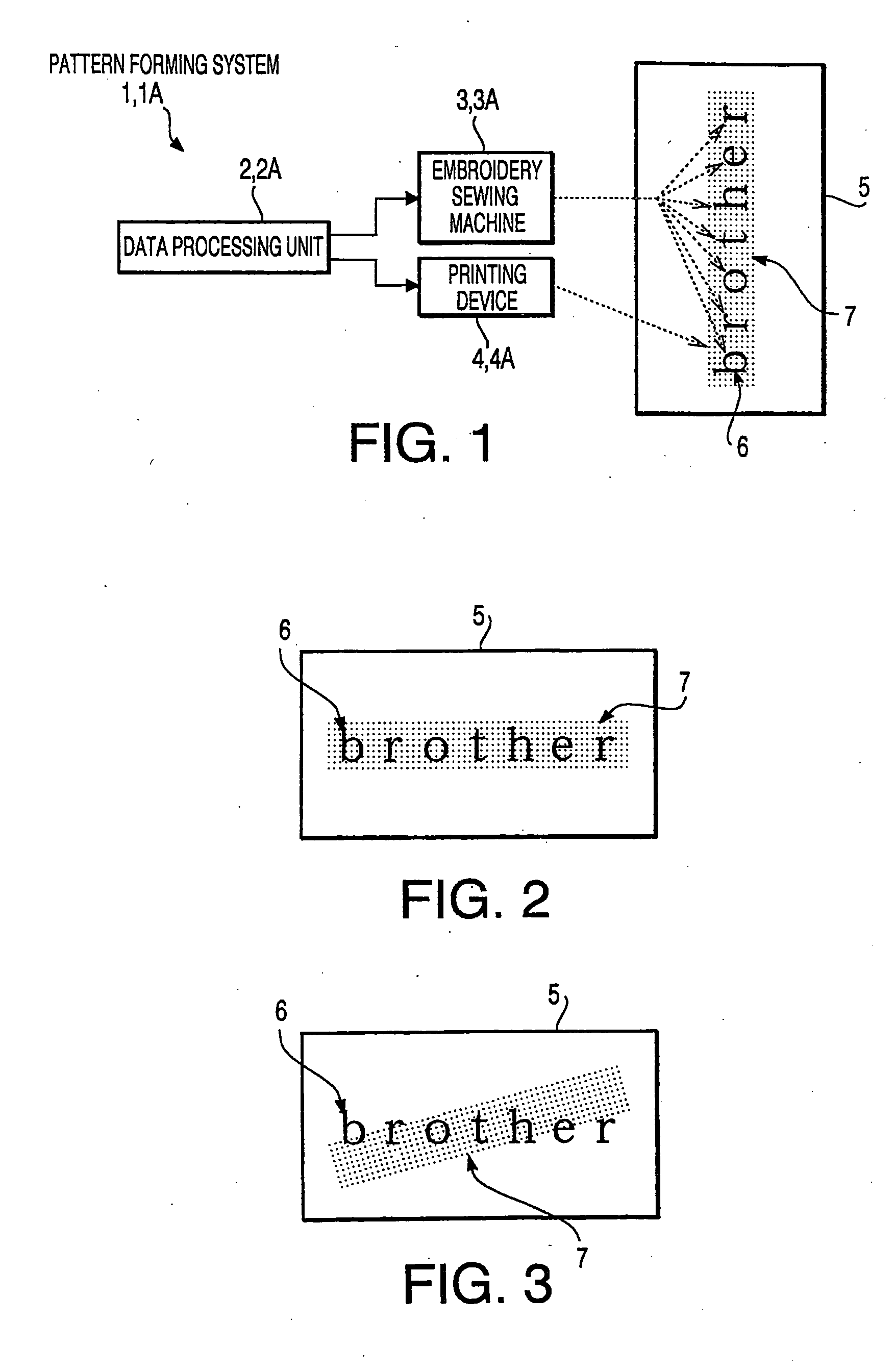

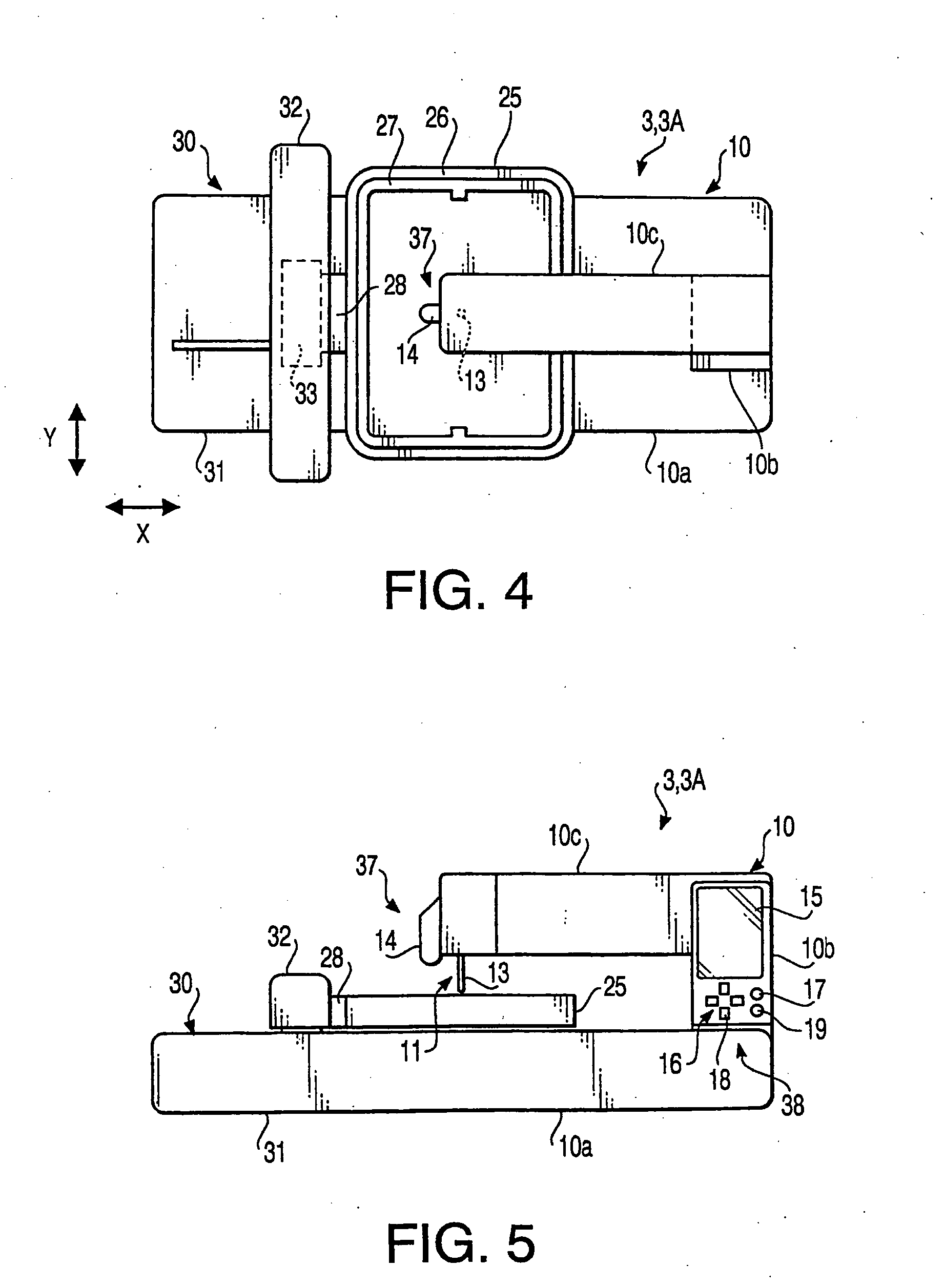

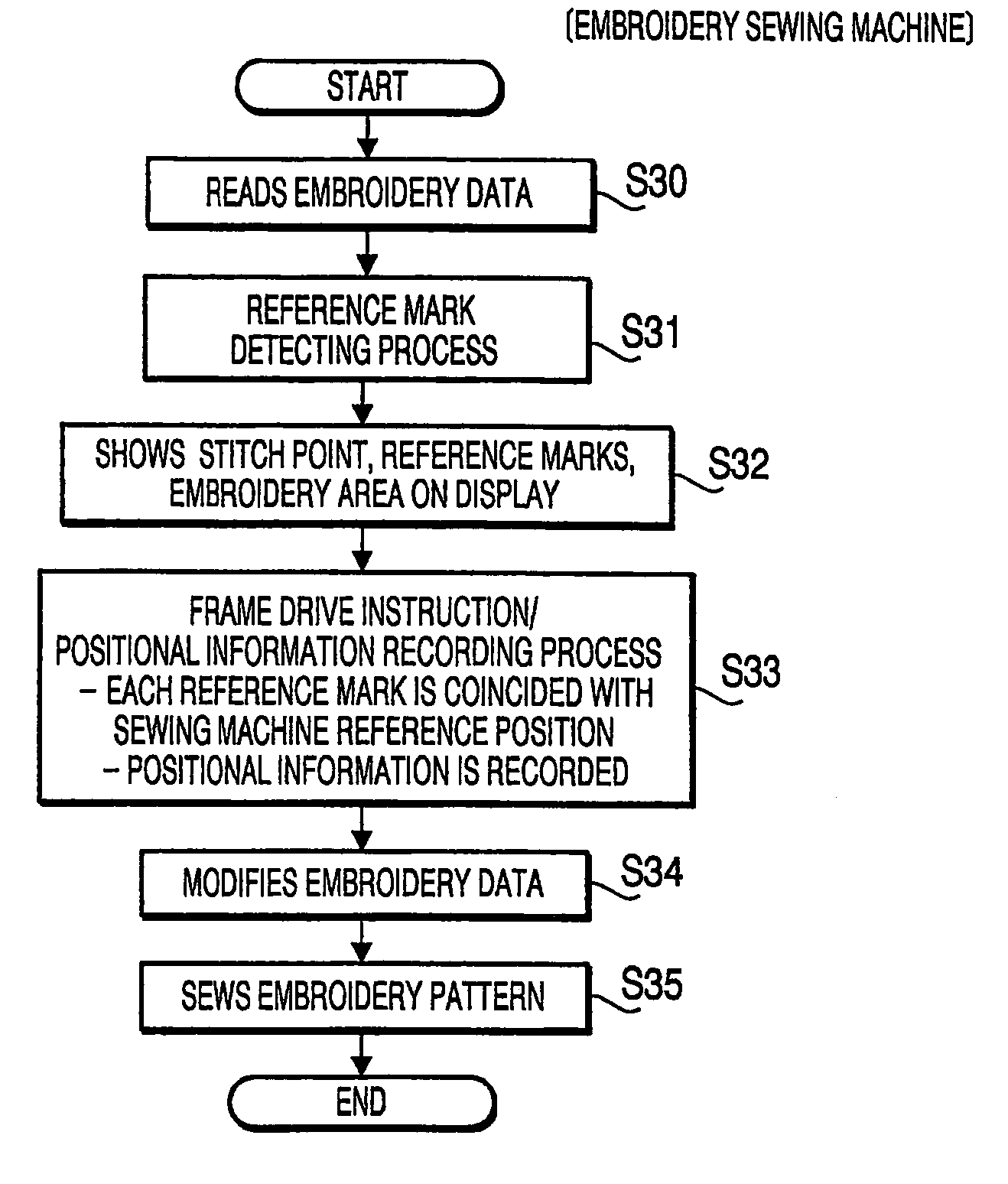

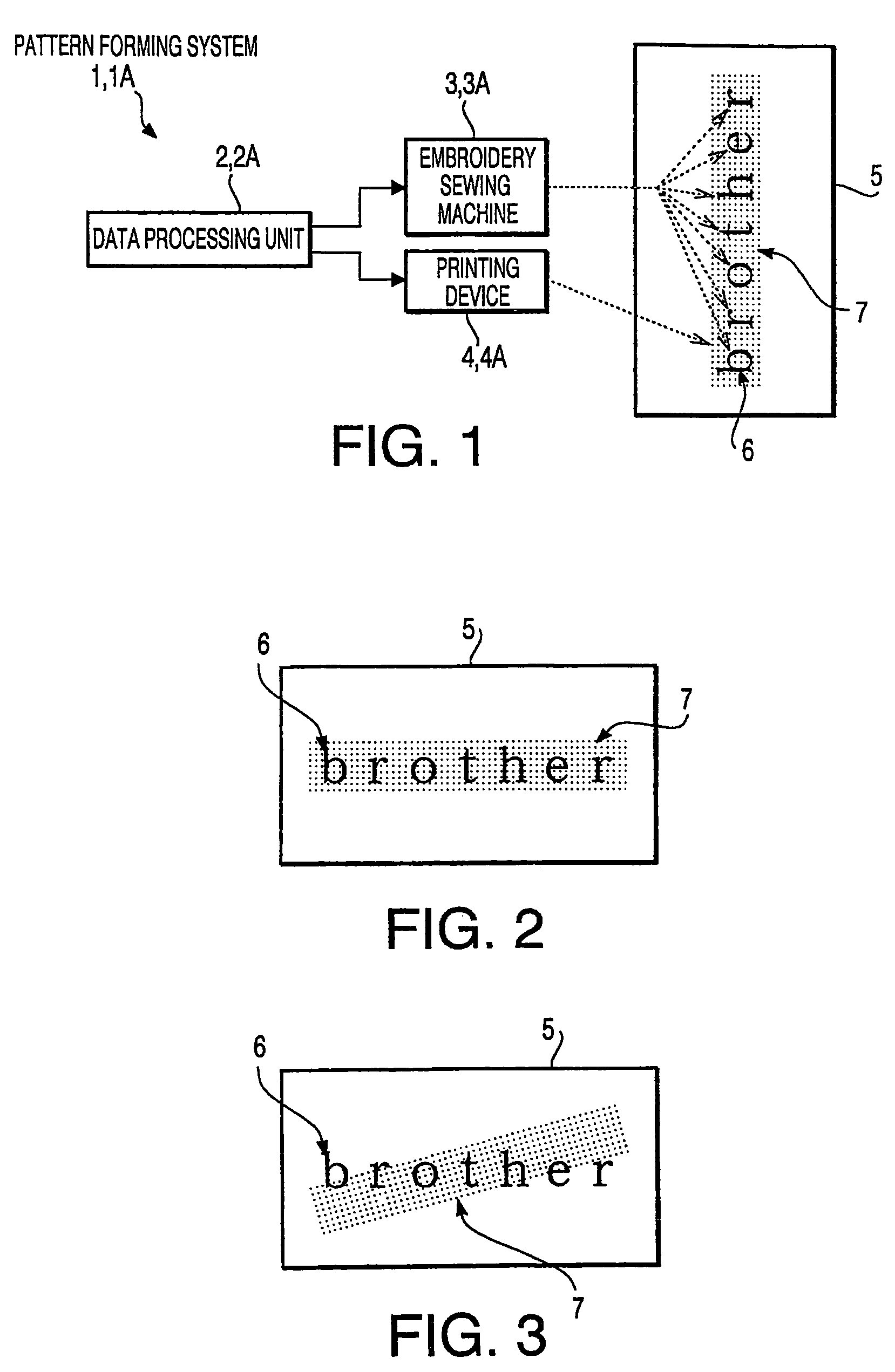

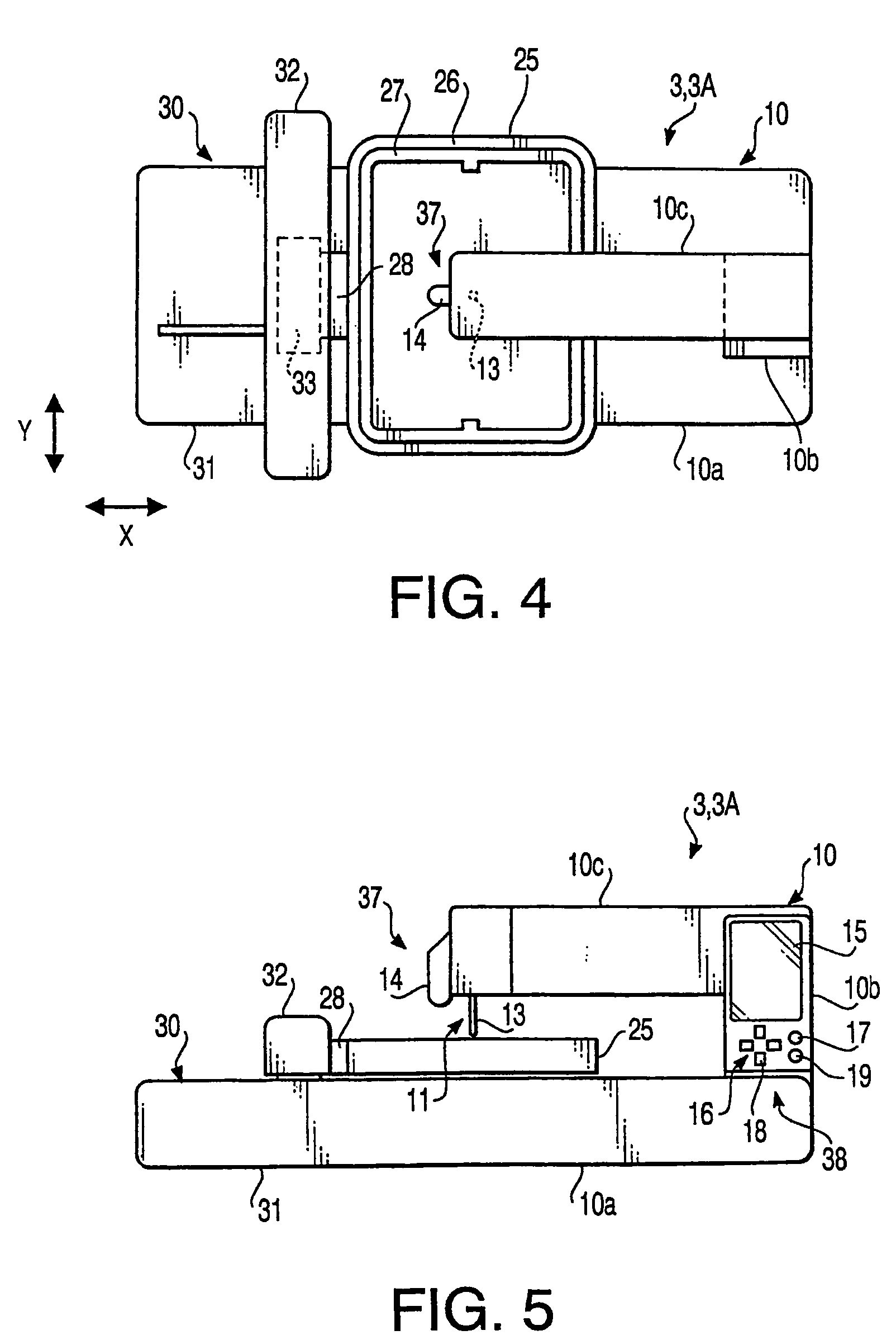

Data processing unit and pattern forming method

ActiveUS20060096510A1Quality improvementProgramme-controlled sewing machinesDigital differential analysersComputer graphics (images)Imaging data

A printing and embroidering system having a positional data appending system that is adapted to append positional data indicating positions of a first image and a second image with respect to each other to first image data representing the first image to be formed by one of printing and embroidering and second image data representing the second image to be formed by the other one of printing and embroidering, a first image forming unit with a first fabric holding member, which is adapted to form the first image based on the first image data on a fabric being held by the first fabric holding member, and a second image forming unit with a second fabric holding member, which is adapted to form the second image based on the fabric being held by the second fabric holding member, wherein the first image forming unit is provided with a mark forming system, which is adapted to form a predetermined mark represented by the positional data on the fabric, and wherein the second image forming system is provided with a misalignment eliciting system, which is adapted to elicit a misalignment between a position of the predetermined mark formed on the fabric held by the second fabric holding member and a position represented by the positional data appended to the second image data prior to forming the second image.

Owner:BROTHER KOGYO KK

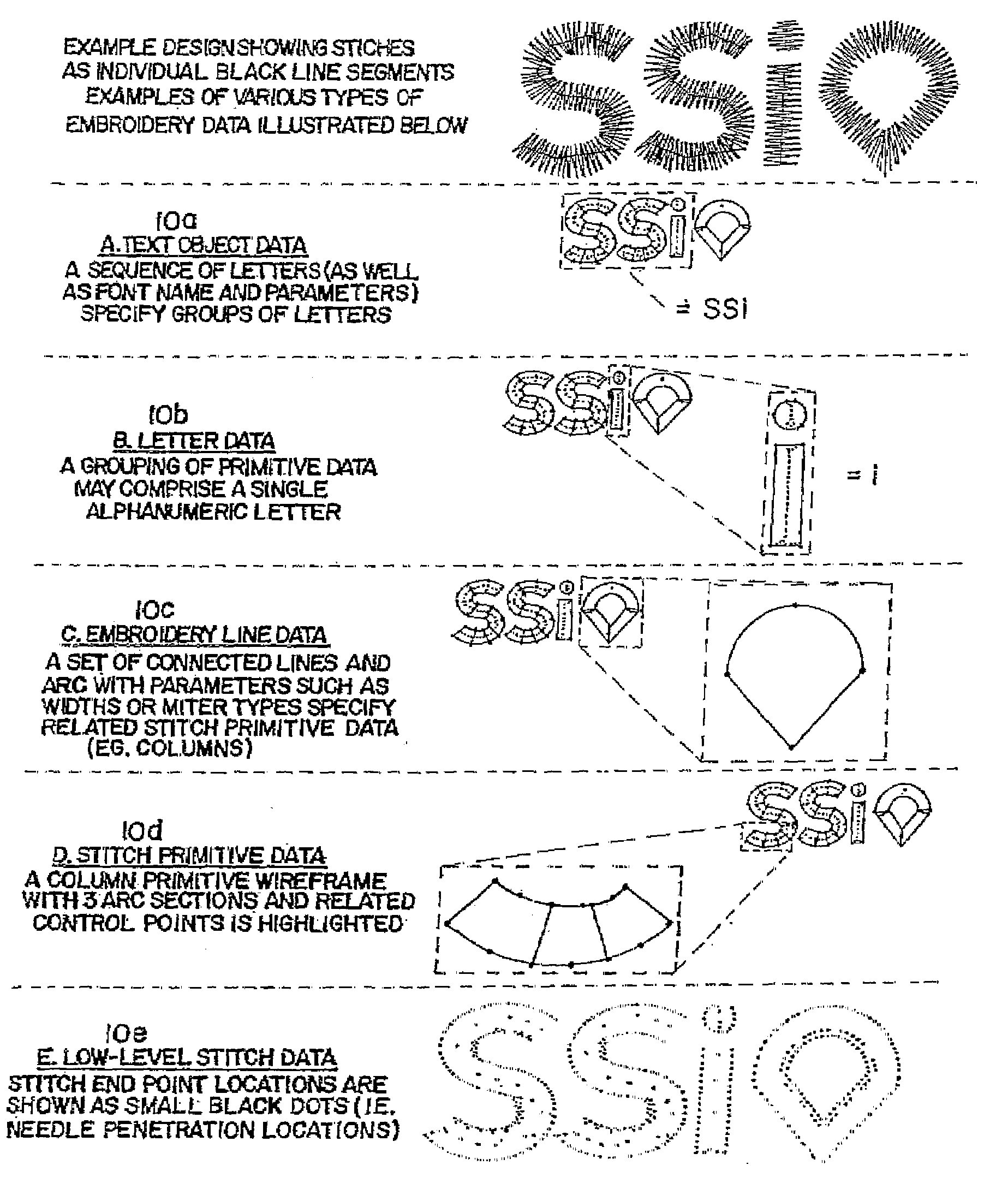

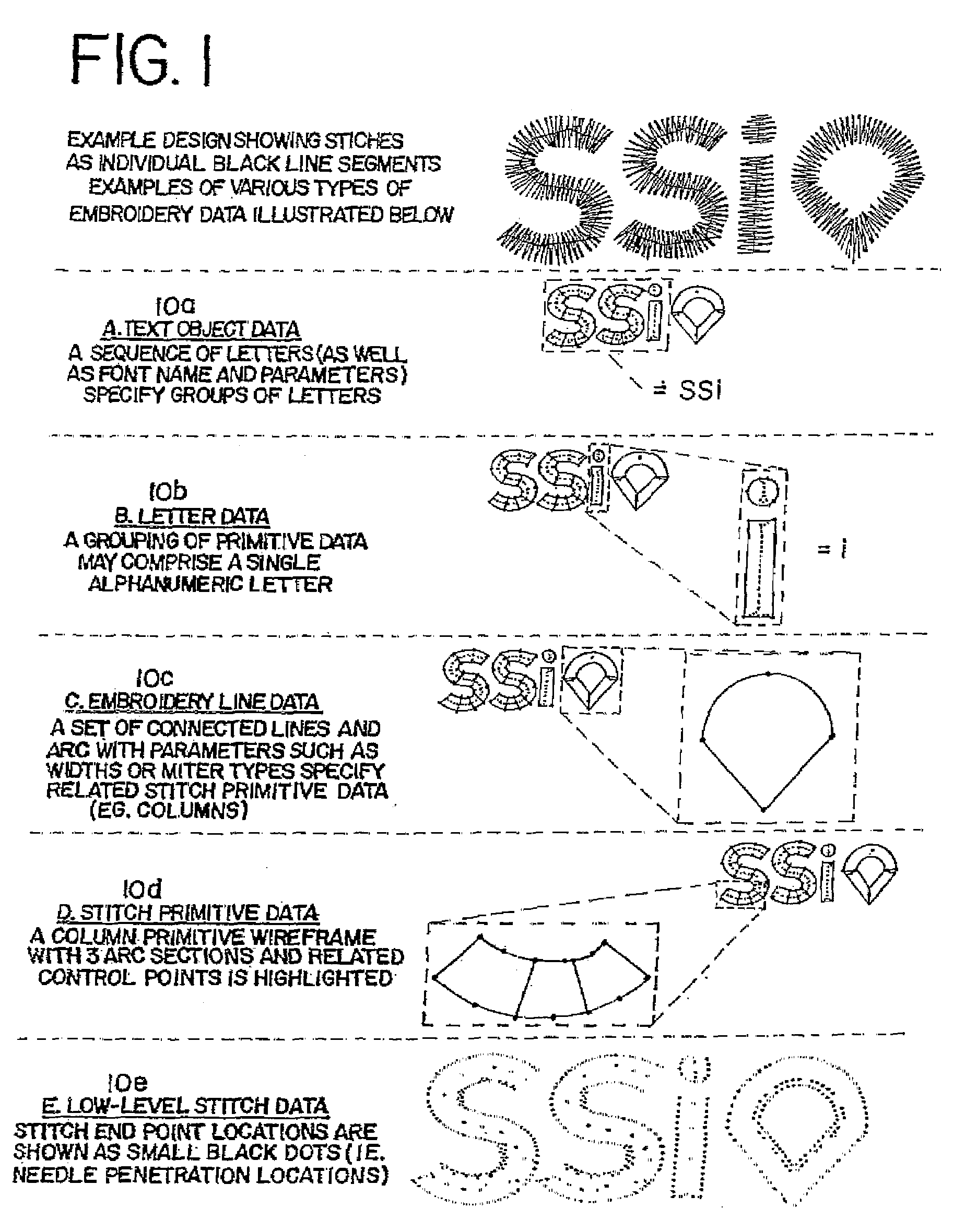

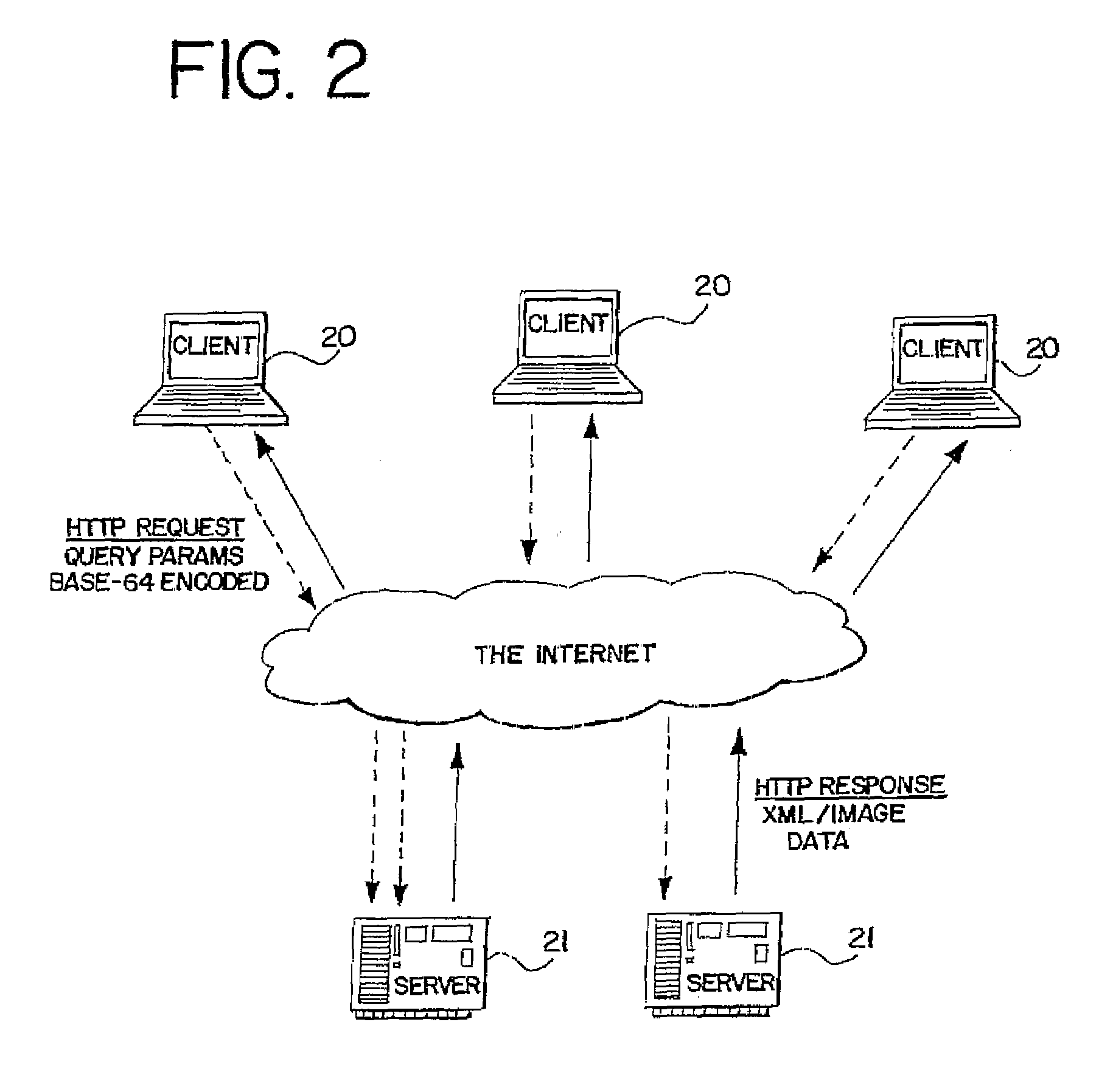

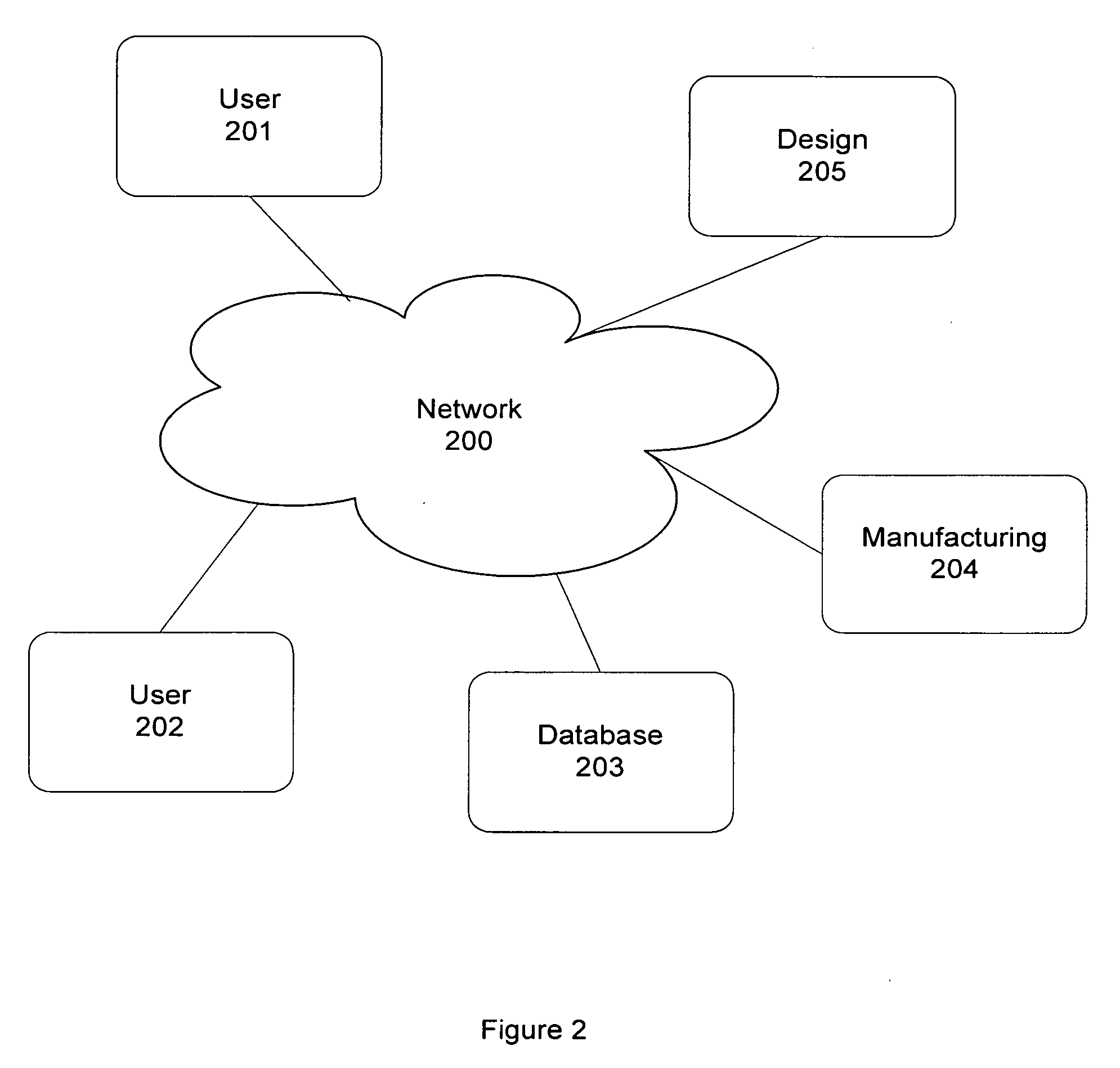

Method and System for Creating and Manipulating Embroidery Designs Over a Wide Area Network

ActiveUS20080079727A1Easy to displayDrawing from basic elementsImage data processing detailsClient-sideUser interface

A method and system are disclosed for creating and manipulating embroidery designs over a wide area network. The method includes steps to transmit various embroidery design data over a wide area network between a client and a server The manner in which the embroidery design data is created, manipulated, and transmitted allows a user to preview photo realistic renderings of possible finished products, and more precisely adjust interpretations through a provided user interface with minimum latency.

Owner:CIMPRESS SCHWEIZ

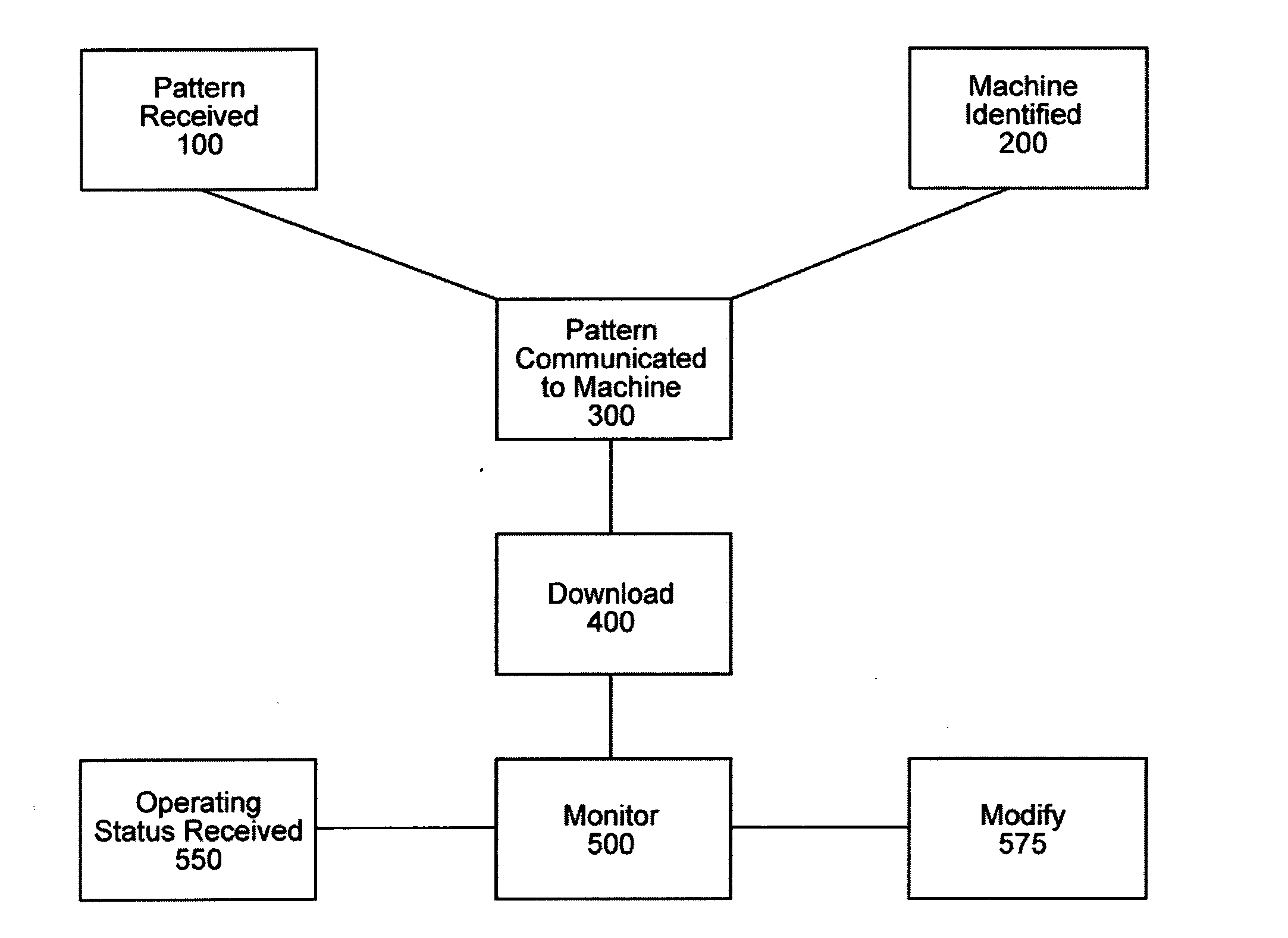

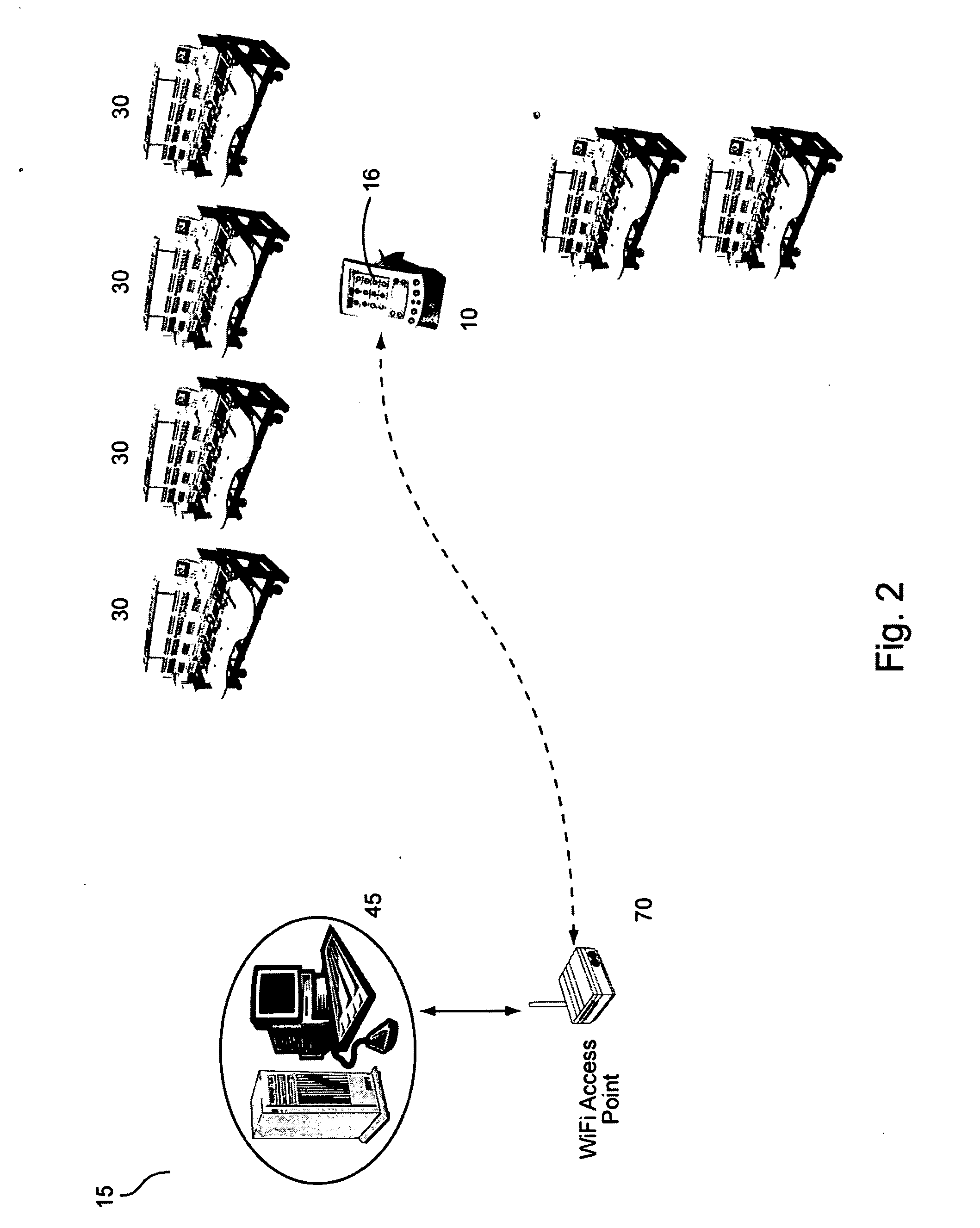

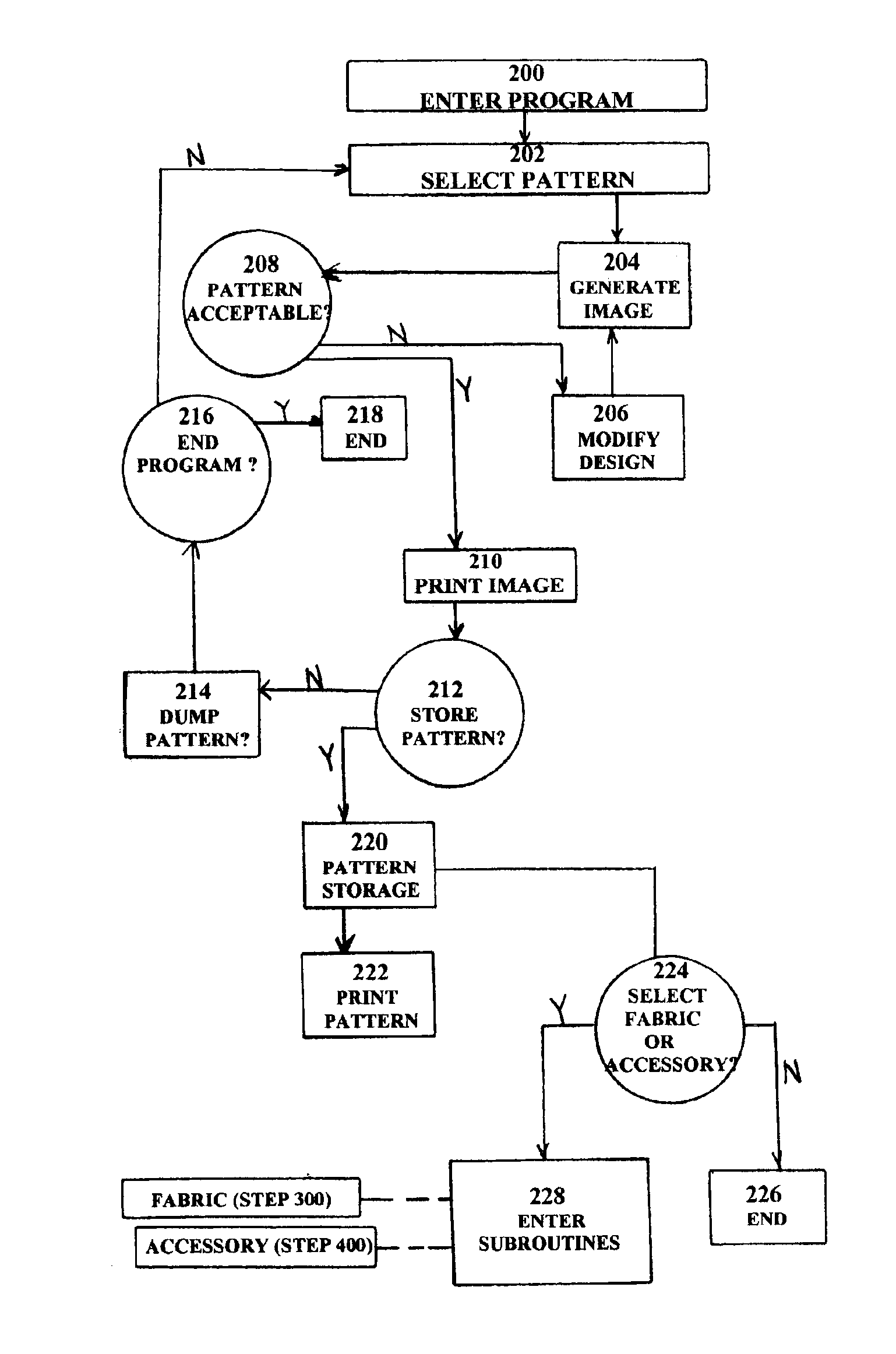

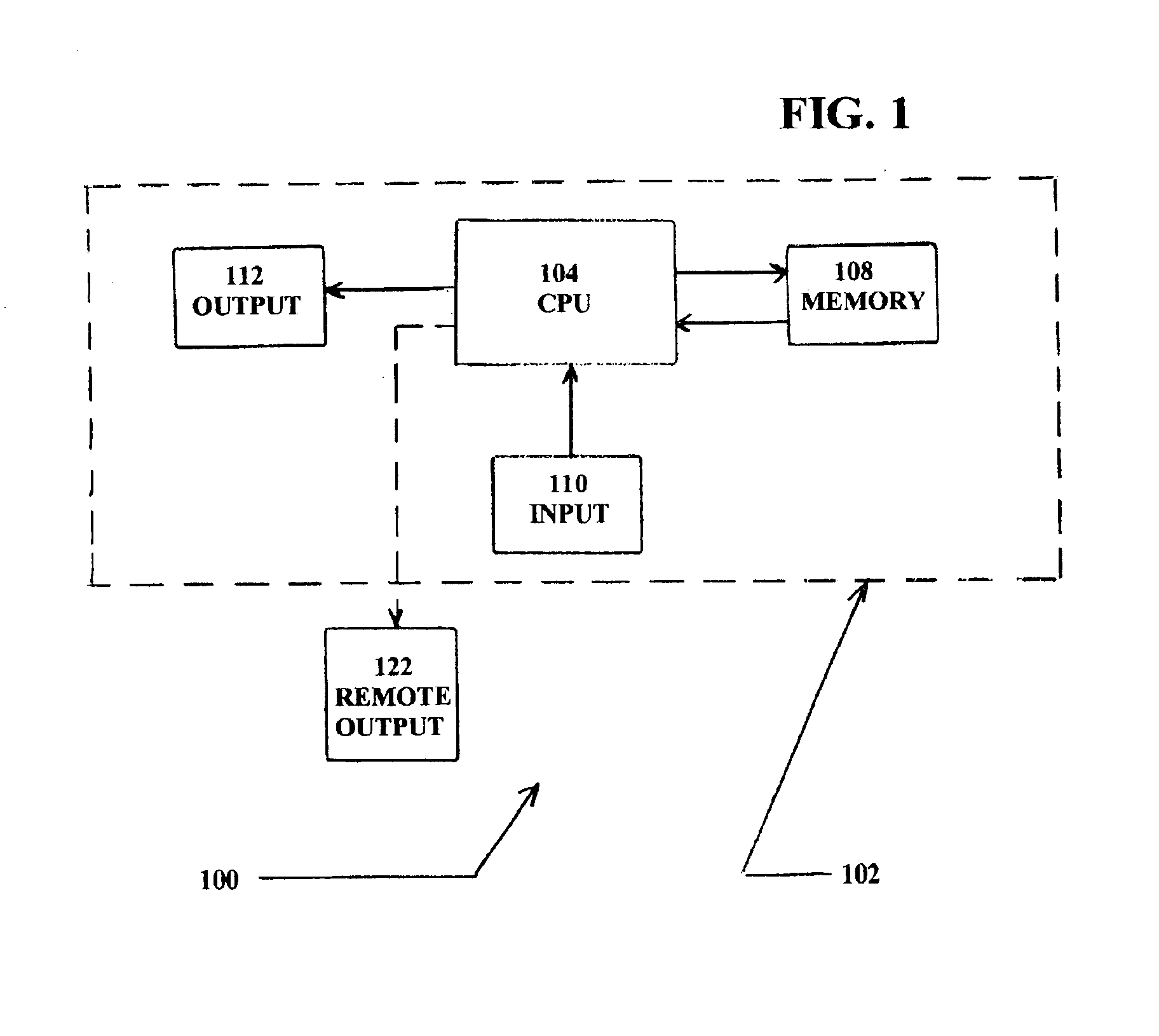

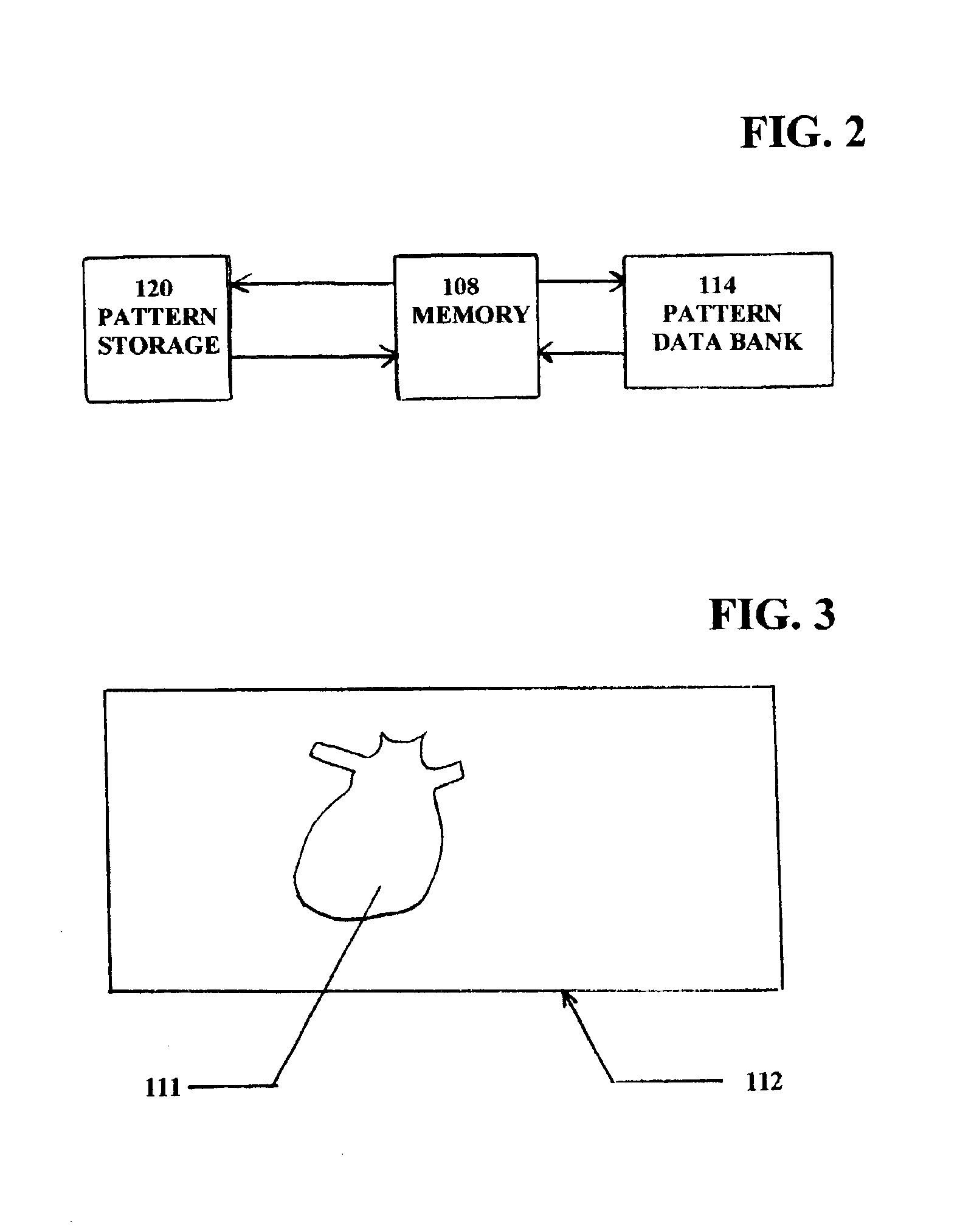

Embroidery network control system and method

InactiveUS20050060058A1Easy to operateExpand accessProgramme-controlled sewing machinesSpecial data processing applicationsGraphicsGraphical user interface

A method and system of remotely communicating embroidery pattern data to embroidery machines involving providing an embroidery pattern in response to a pattern selection input from a remote user at a local node, the input communicated through a communications connection between the local node and a server, receiving an identification address for an embroidery machine, communicating the embroidery pattern to the embroidery machine for application of the embroidery pattern to a work piece. The system includes a server having circuitry for receiving wireless electronic communications, a local node having a graphical user interface for receiving input from a remote user, the local node in wireless electronic communication with the server, a database of electronically encoded data, the data comprising embroidery patterns, the database in communication with the server, and responsive to the local node input, to retrieve embroidery patterns and to display the embroidery patterns through the server to the remote user, and an embroidery machine in communication with the server, the embroidery machine receiving embroidery patterns from the database through the server.

Owner:CAMERON MARION +7

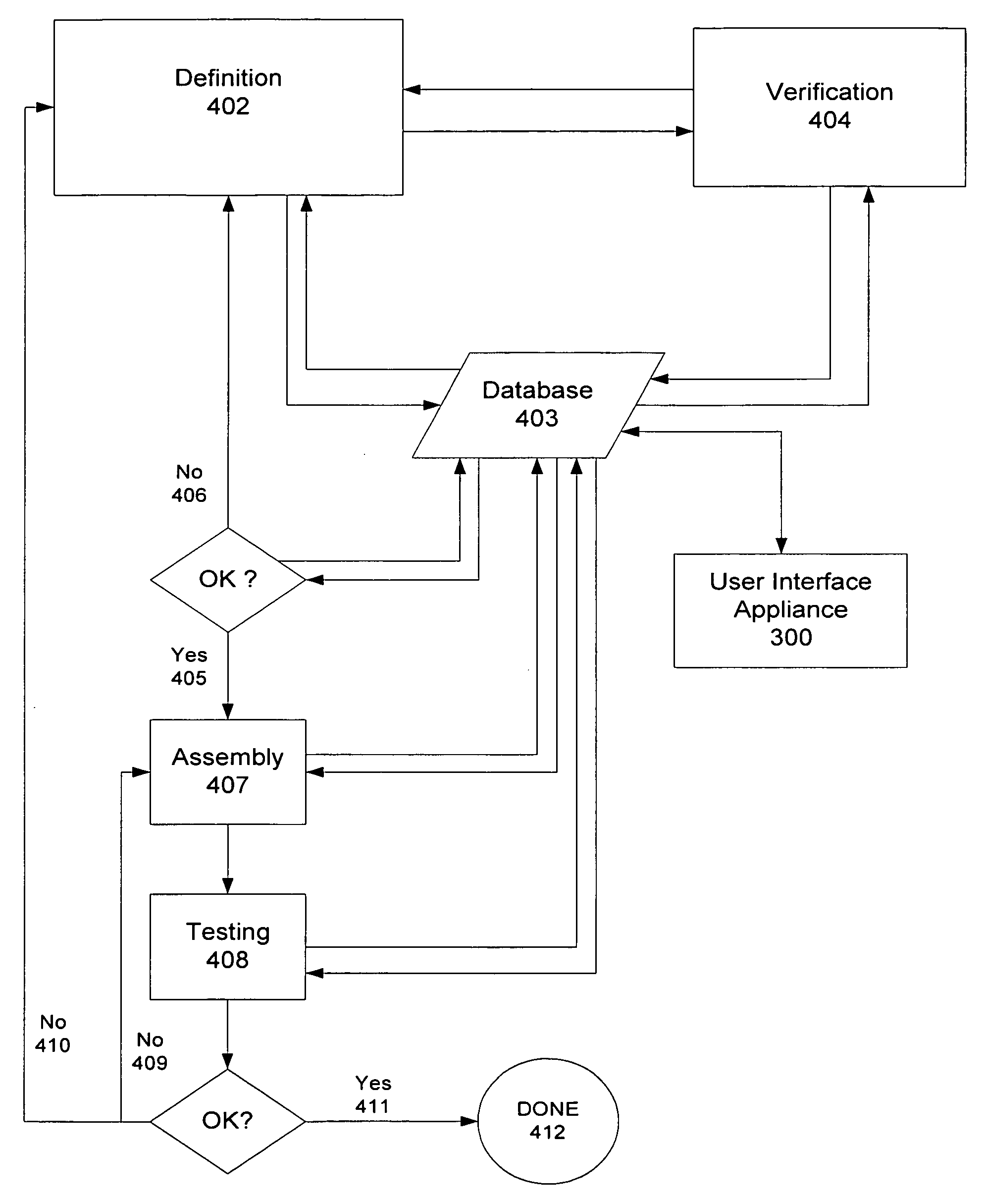

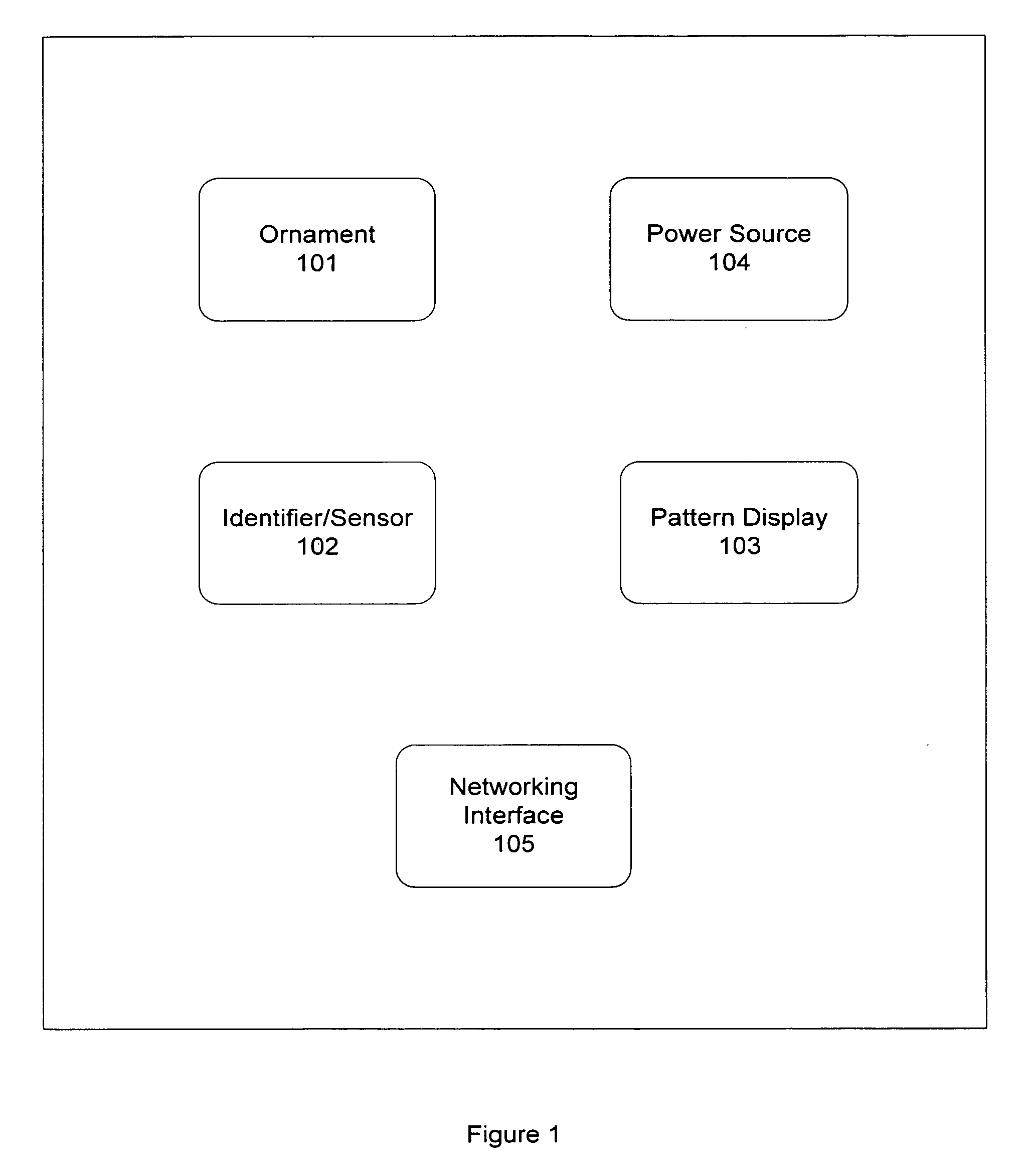

Reconfigurable garment definition and production method

InactiveUS20080147231A1Efficient integrationSimple designGarmentsSurgeryLine sensorComputer Aided Design

Computer-aided design and manufacture software and hardware automate garment and fashion definition and production. Configurable garment includes ornamental element, pattern display, and personal identifier and wireless sensor electronics.

Owner:FERNANDEZ DENNIS S

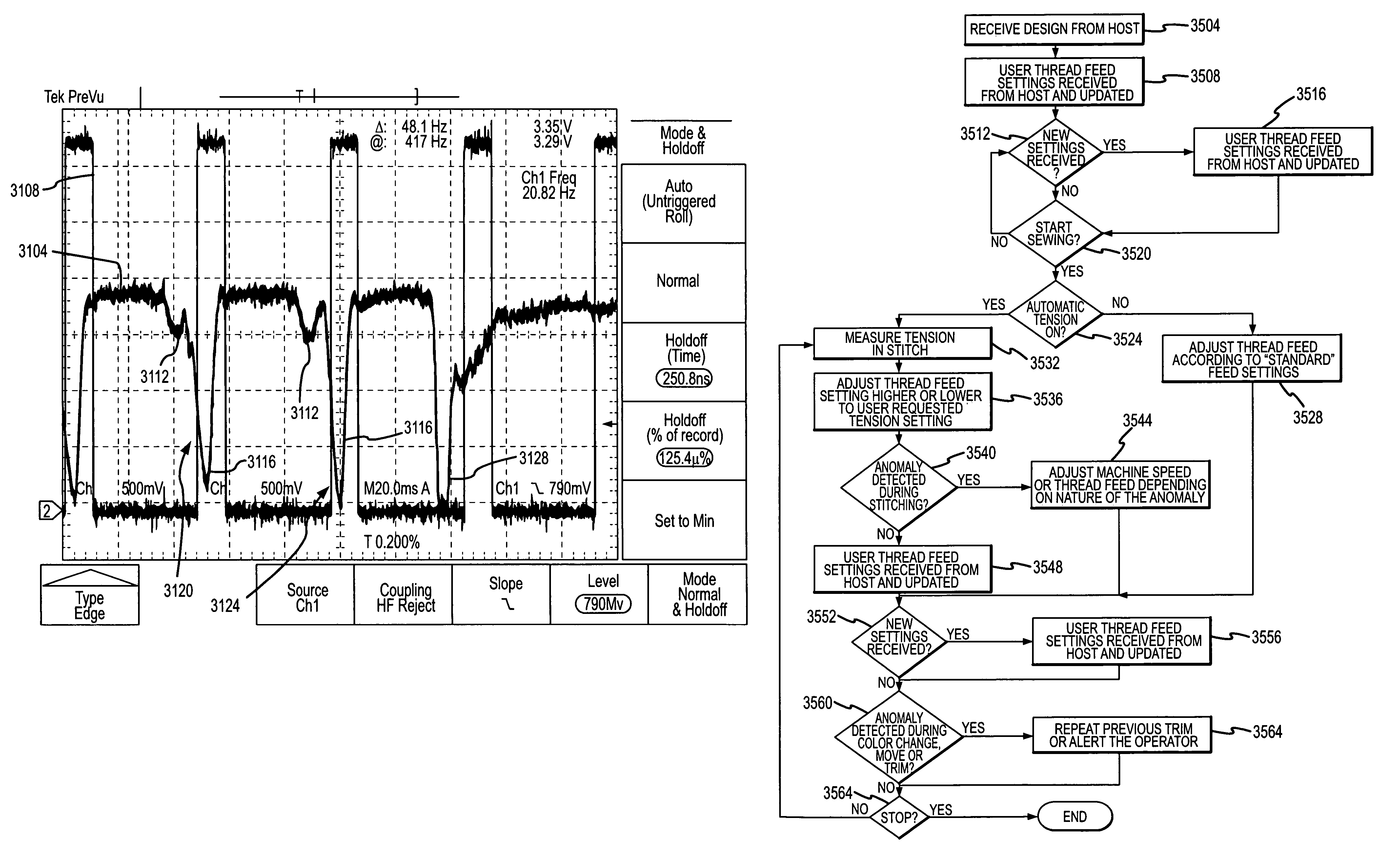

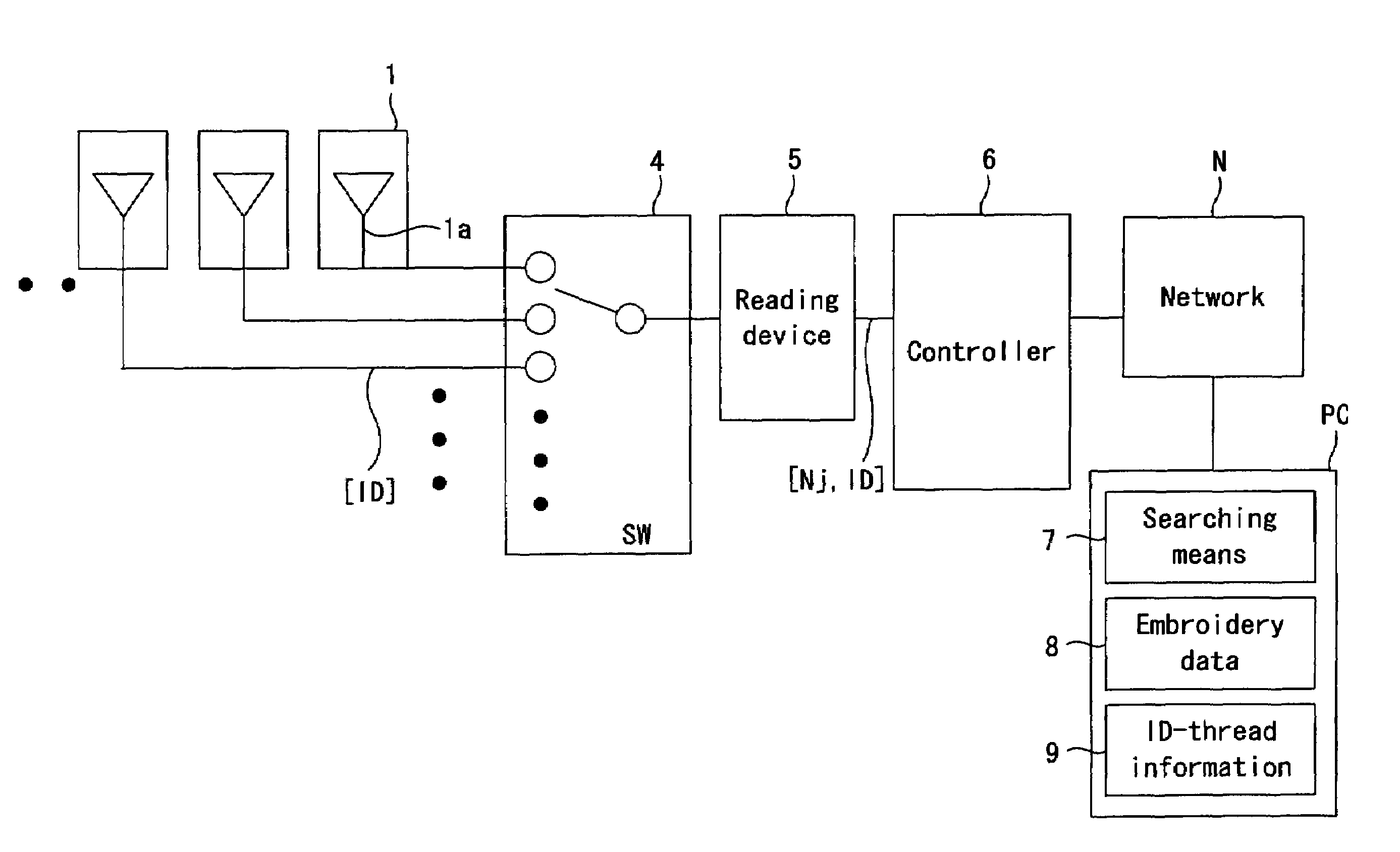

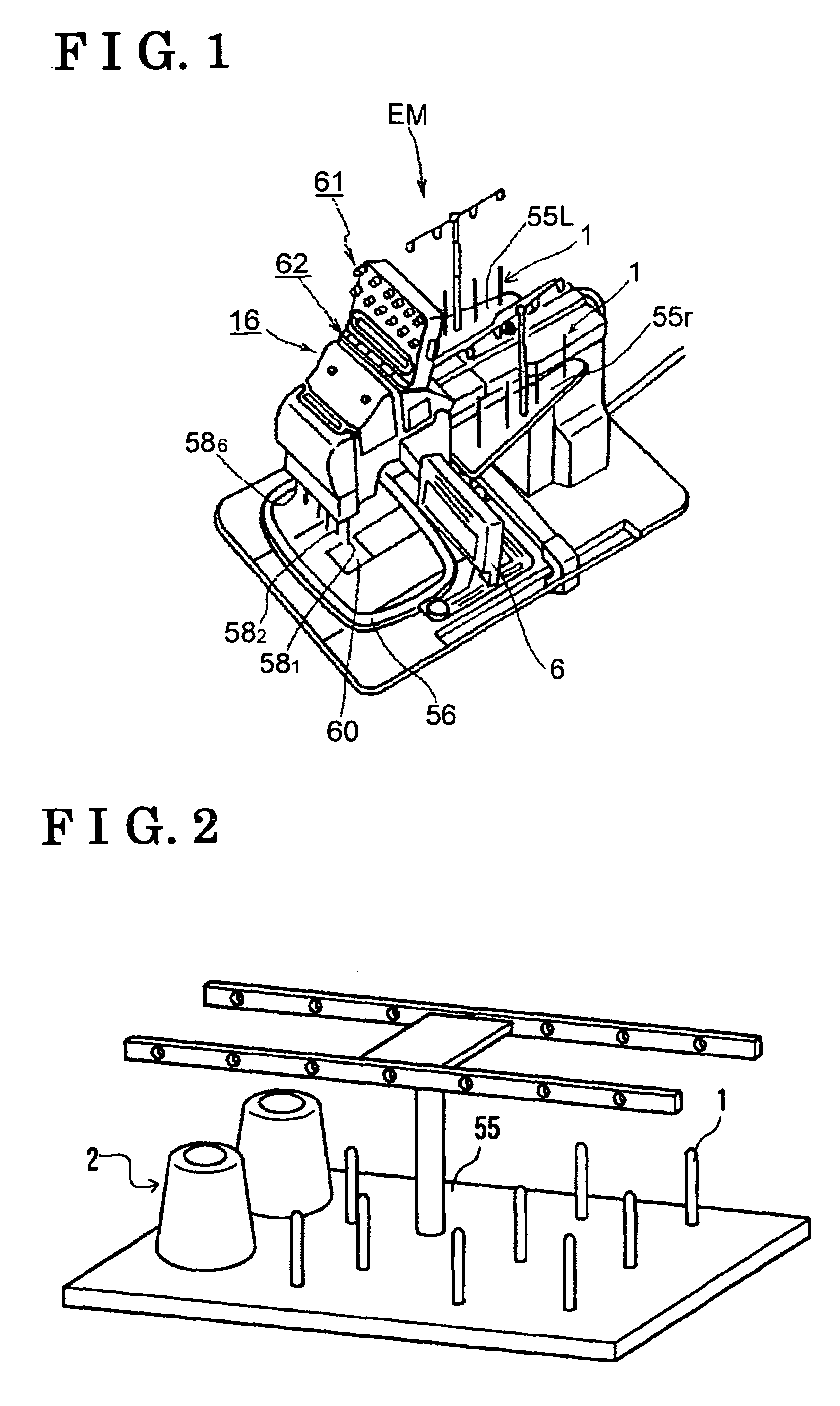

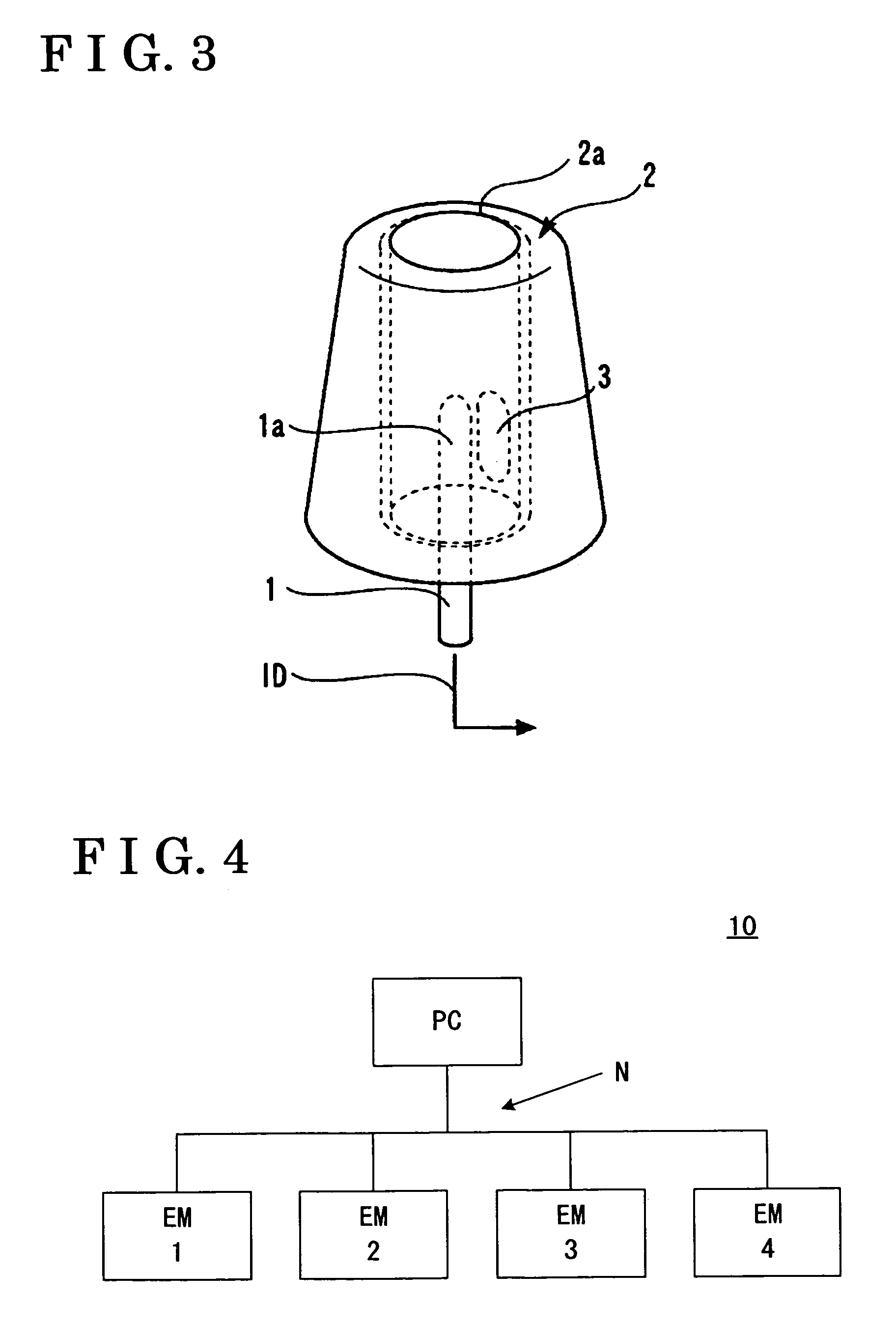

Embroidery machine and embroidery system

An embroidery machine includes a plurality of thread reel stand bars, a plurality of thread reels installed to the thread reel stand bars, respectively, a plurality of needles to which threads are supplied from the respective thread reels, at least two of the needles being selected to operate, on the basis of an embroidery data, in order for forming a stitch pattern of multiple colors, a wireless tag attached to each of the thread reels an having information related to the thread wound therearound, and a receiving device, for reading the information in the wireless tag, provided at each of the thread reel stand.

Owner:AISIN SEIKI KK

Data processing unit and pattern forming method

ActiveUS7854207B2Quality improvementProgramme-controlled sewing machinesDigital differential analysersComputer graphics (images)Computer science

A printing and embroidering system having a positional data appending system that is adapted to append positional data indicating positions of a first image and a second image with respect to each other to first image data representing the first image to be formed by one of printing and embroidering and second image data representing the second image to be formed by the other one of printing and embroidering, a first image forming unit with a first fabric holding member, which is adapted to form the first image based on the first image data on a fabric being held by the first fabric holding member, and a second image forming unit with a second fabric holding member, which is adapted to form the second image based on the fabric being held by the second fabric holding member, wherein the first image forming unit is provided with a mark forming system, which is adapted to form a predetermined mark represented by the positional data on the fabric, and wherein the second image forming system is provided with a misalignment eliciting system, which is adapted to elicit a misalignment between a position of the predetermined mark formed on the fabric held by the second fabric holding member and a position represented by the positional data appended to the second image data prior to forming the second image.

Owner:BROTHER KOGYO KK

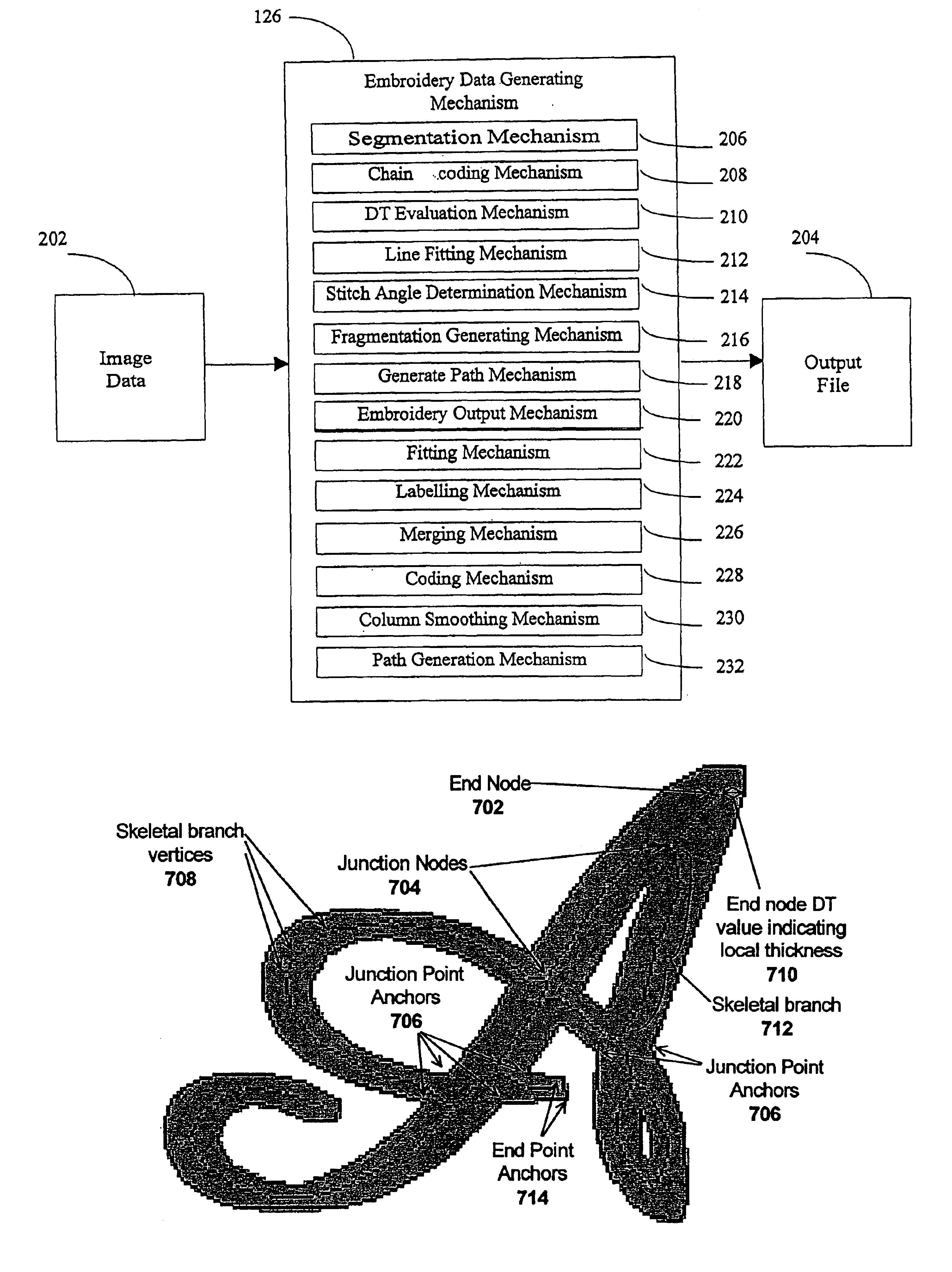

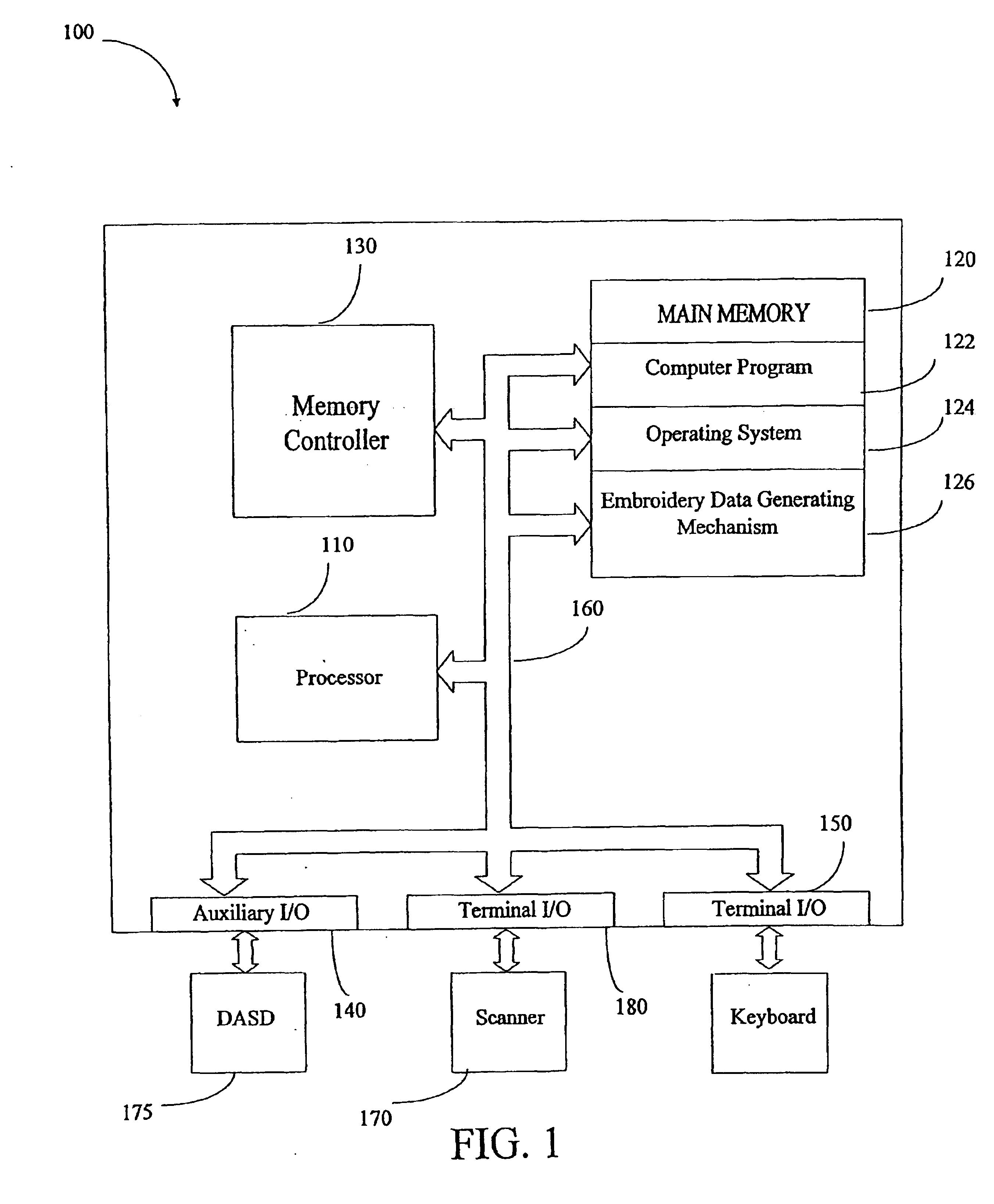

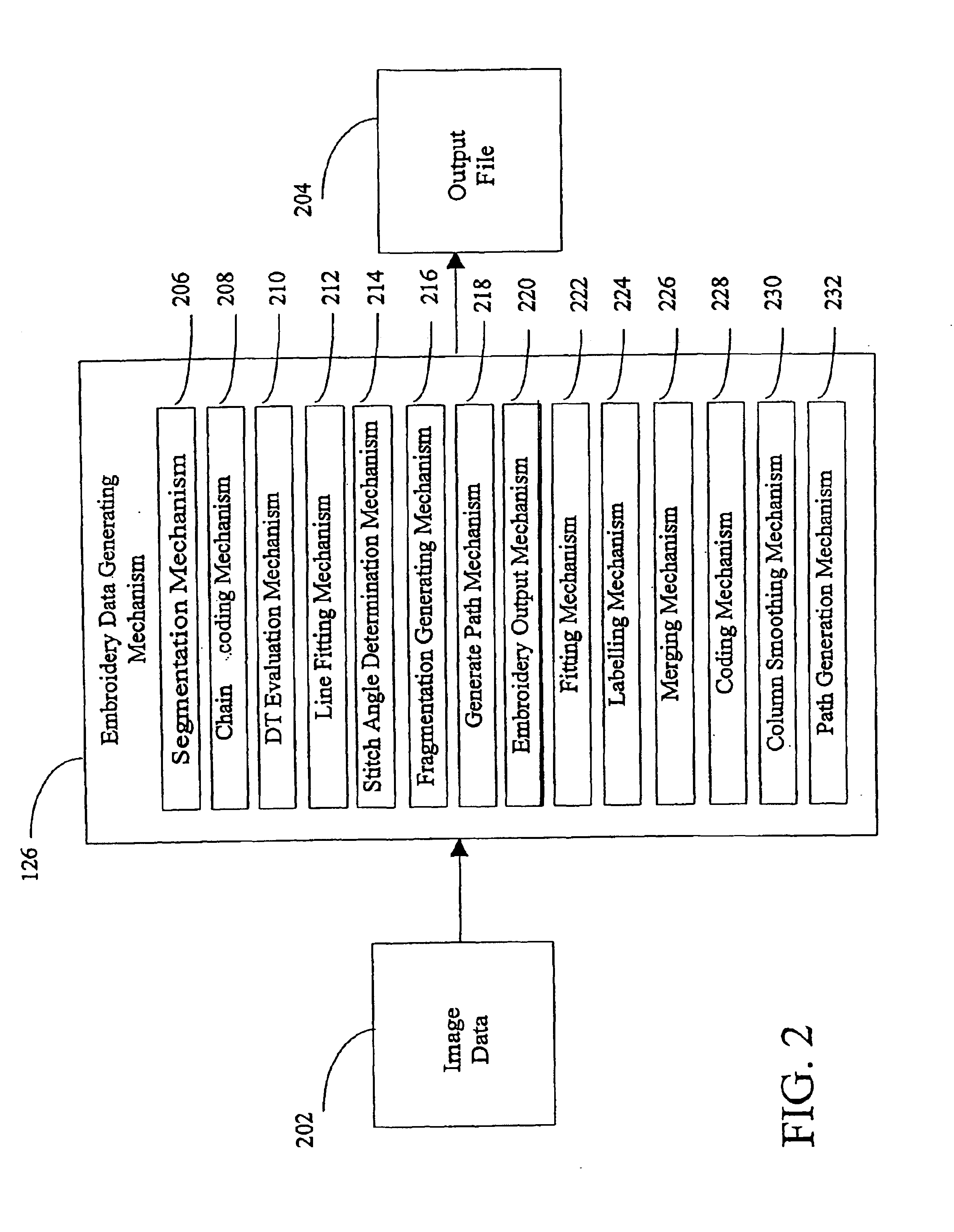

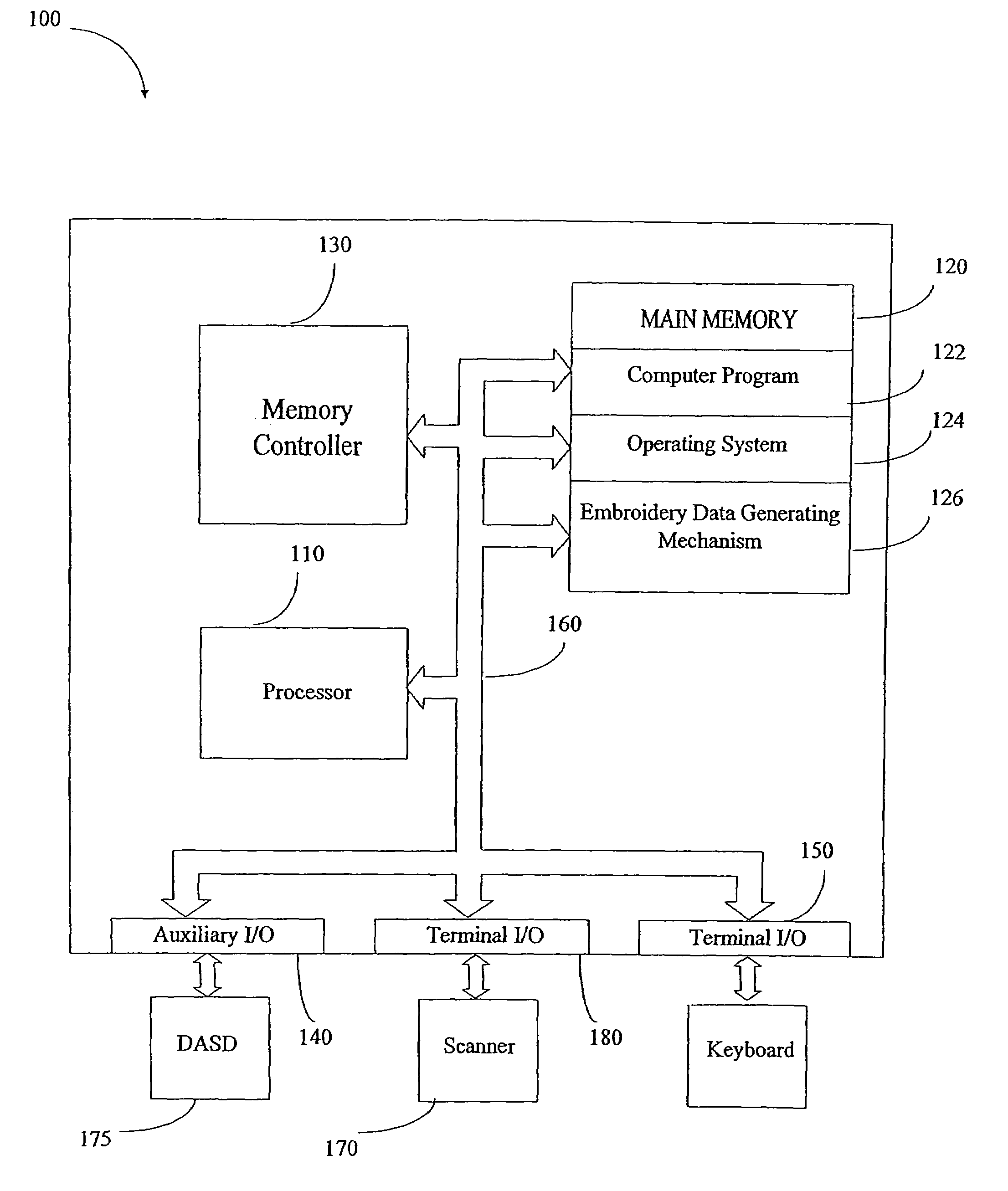

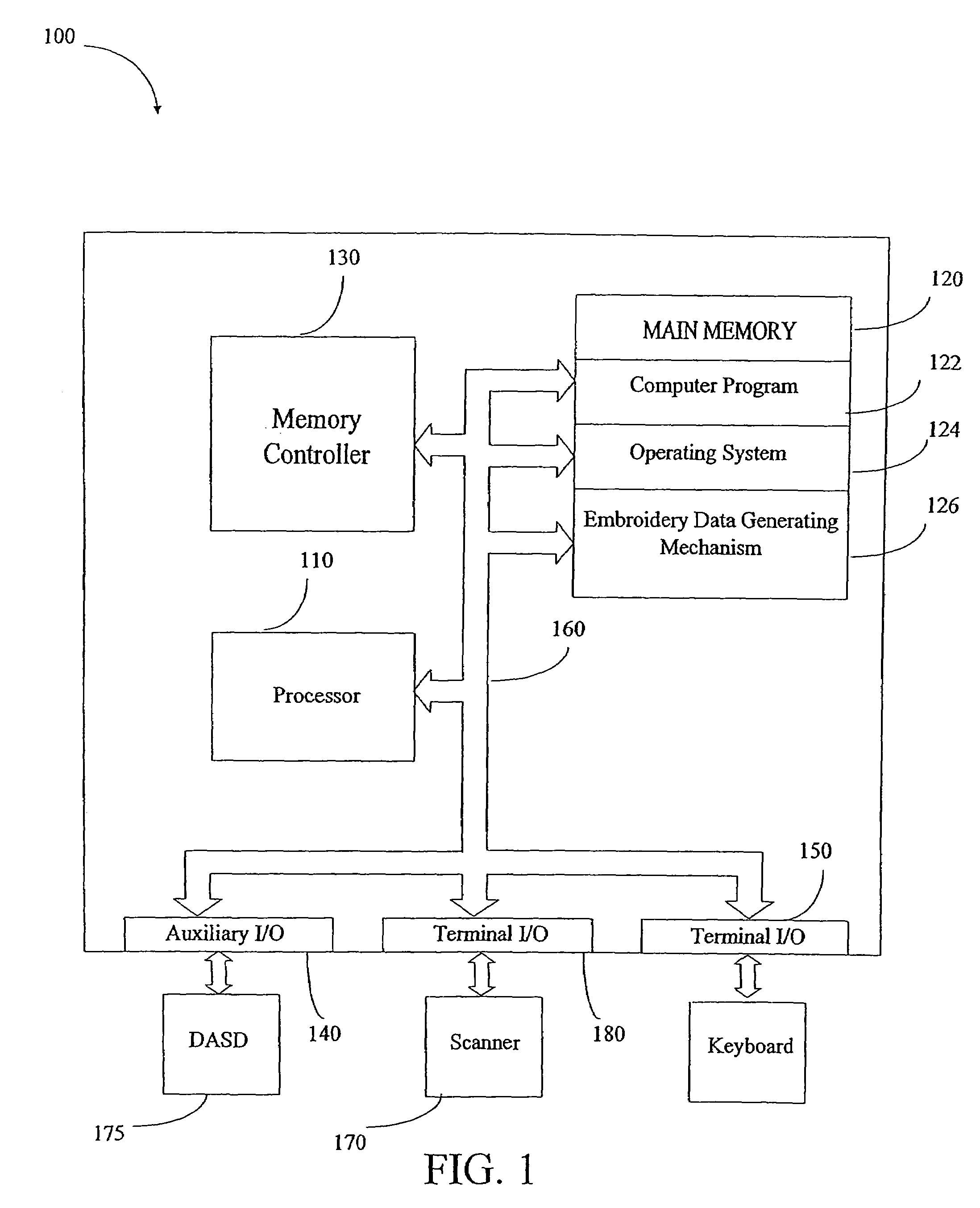

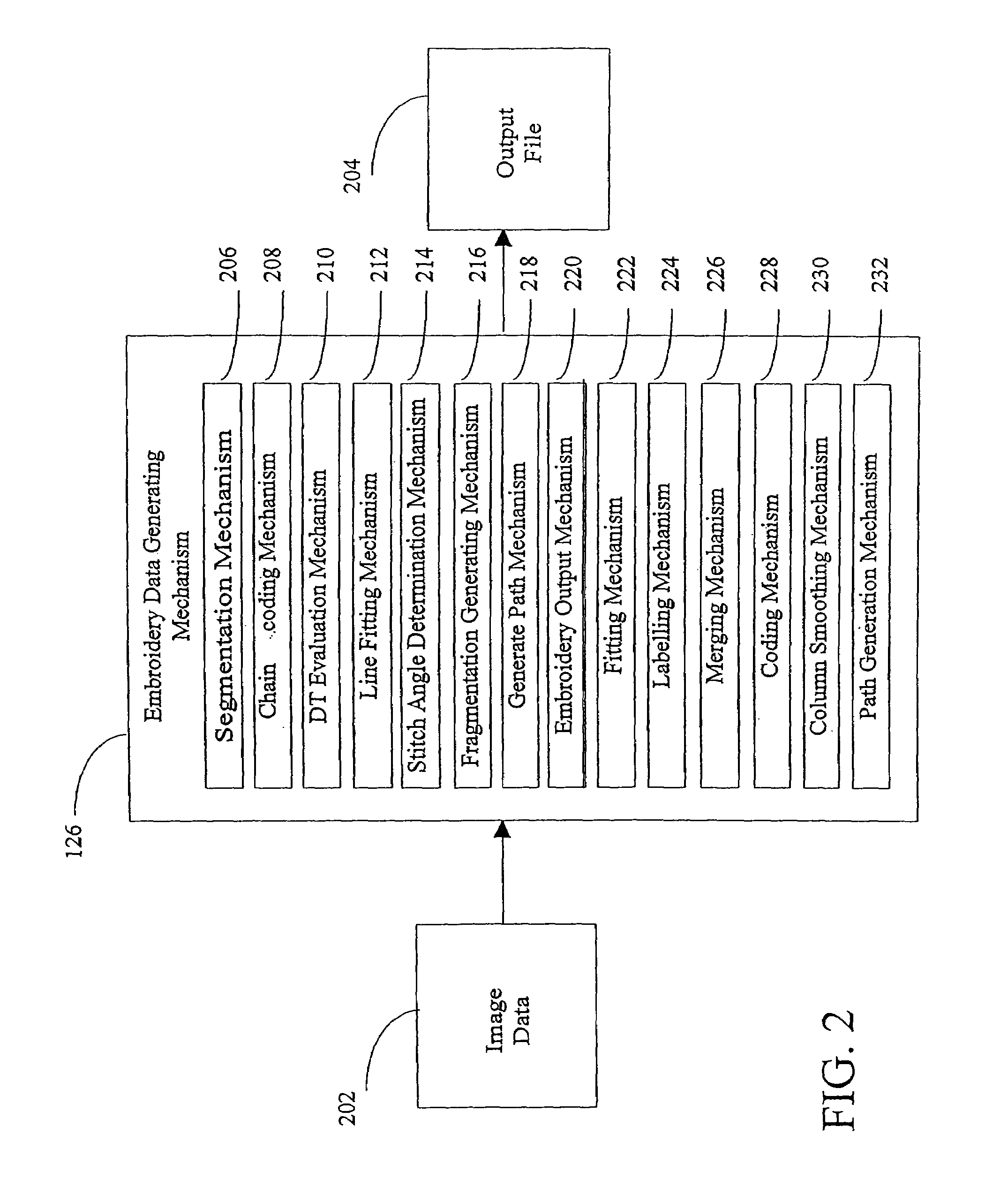

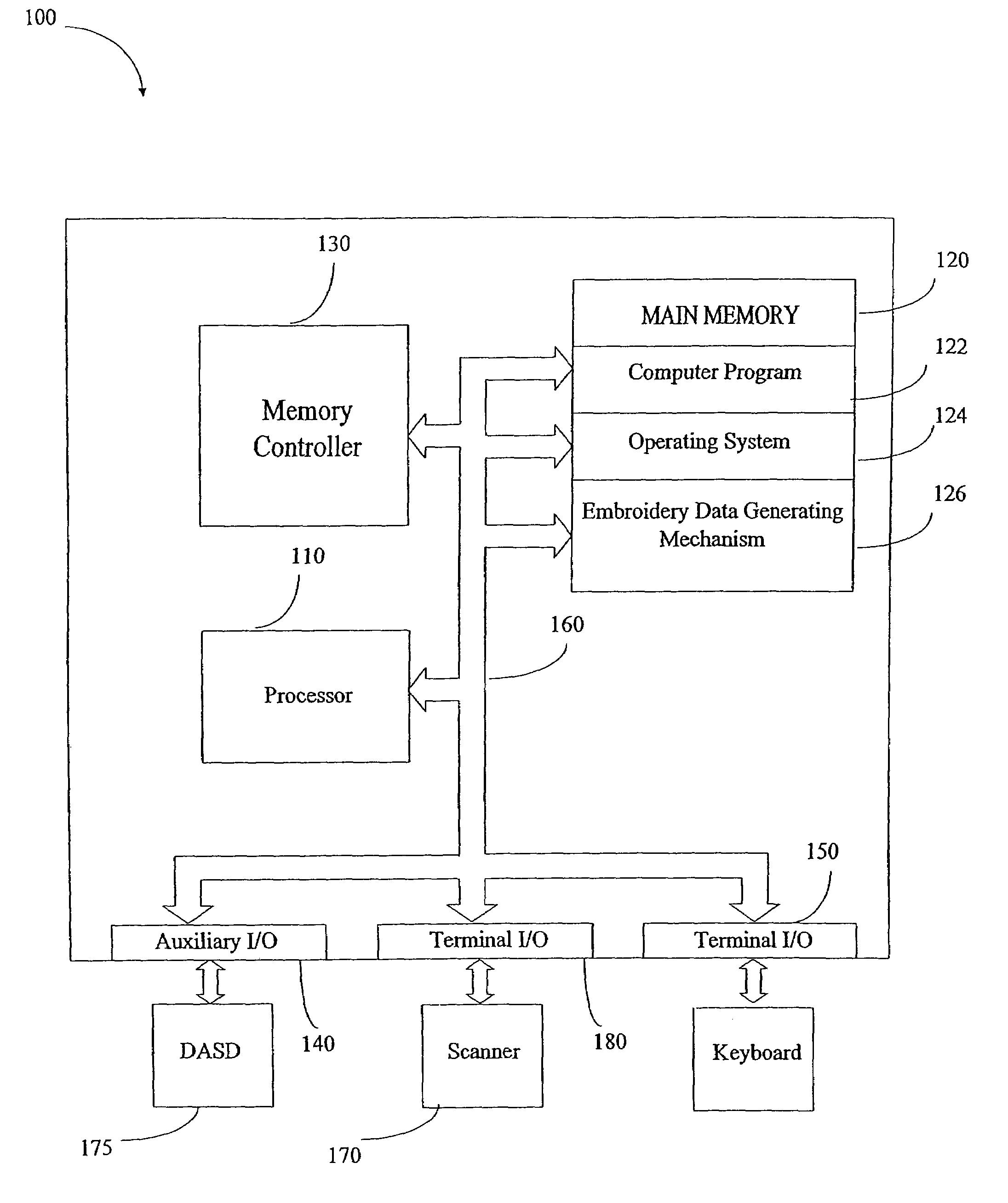

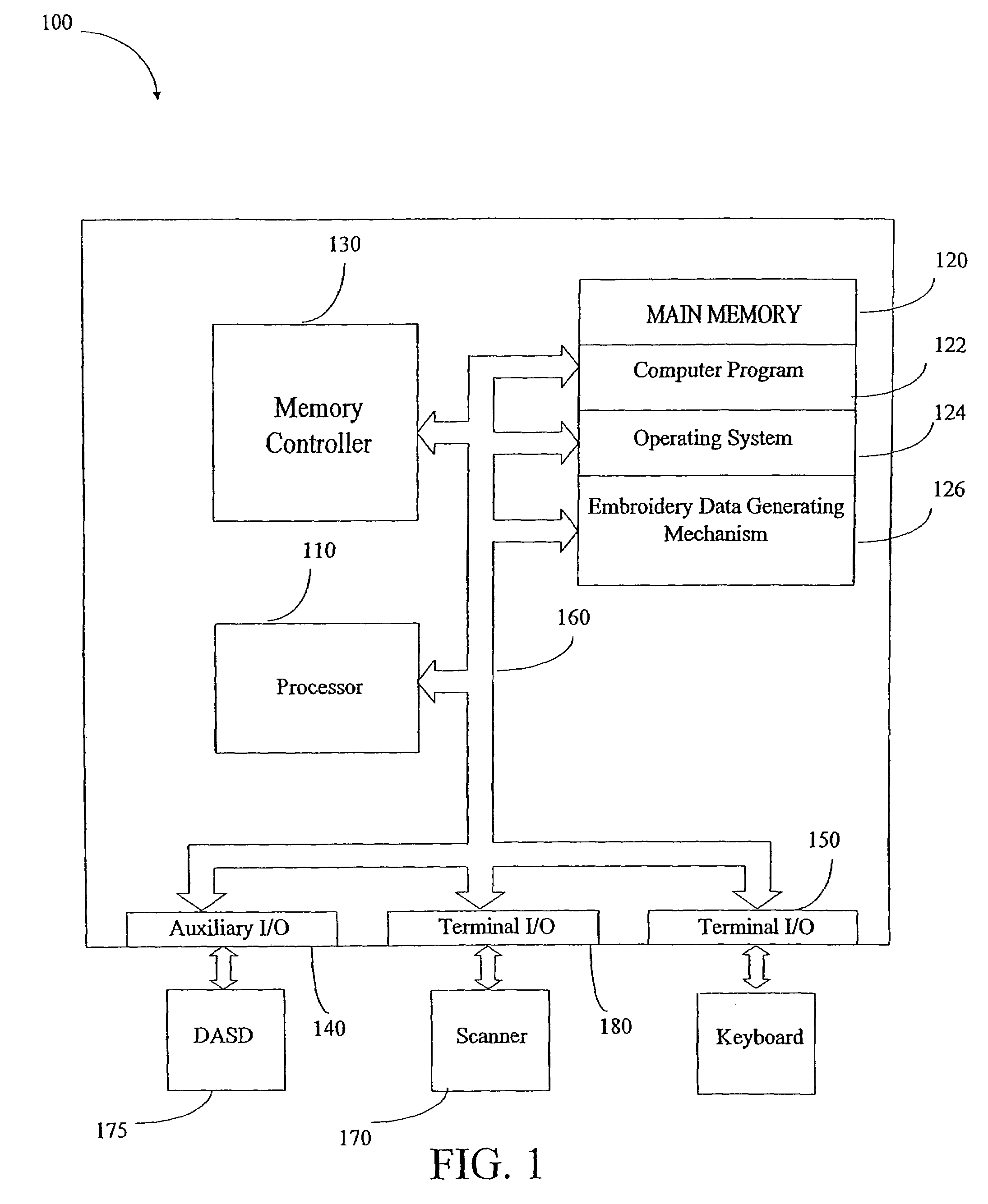

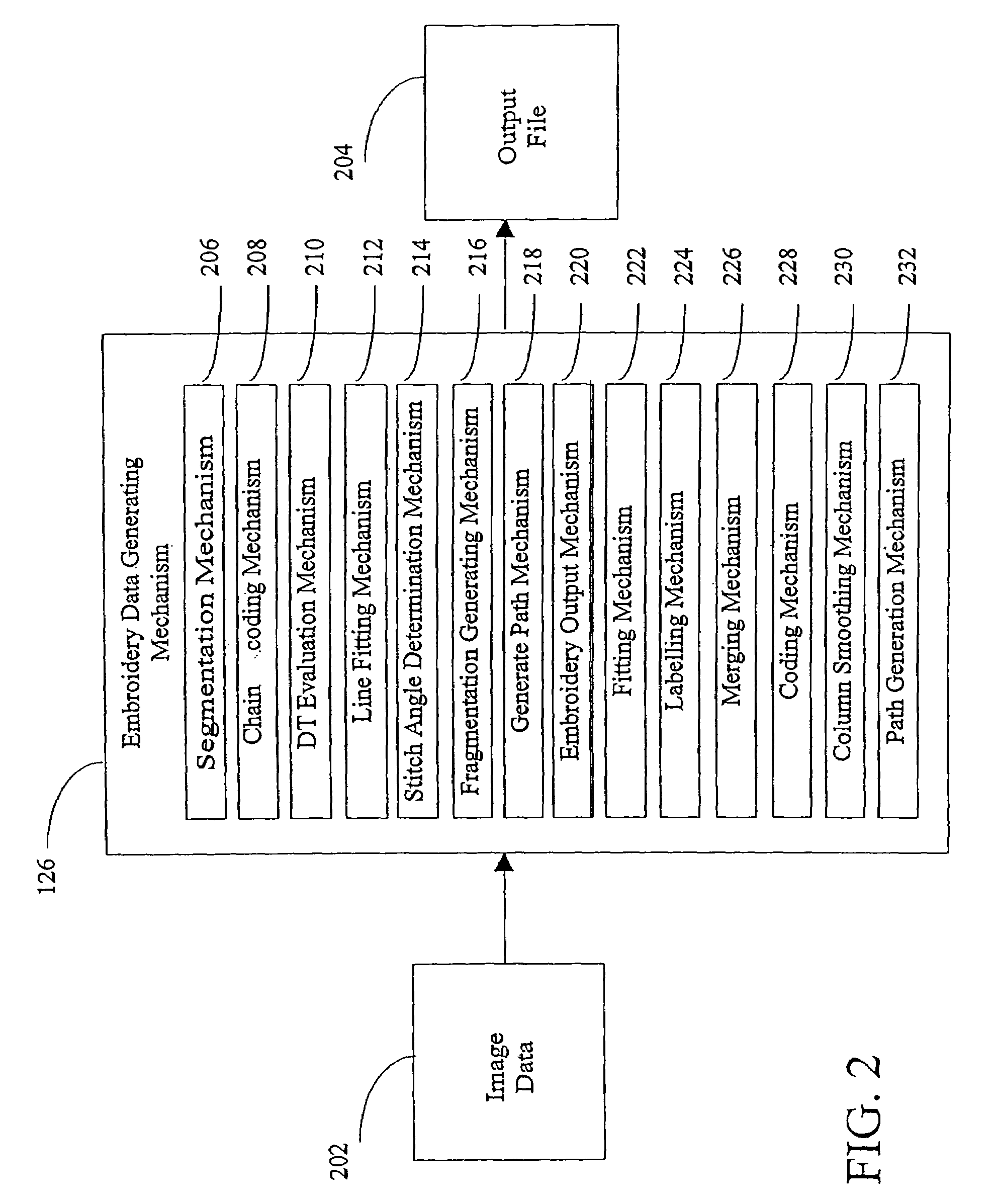

Automatically generating embroidery designs from a scanned image

InactiveUS6947808B2Automatically and efficiently generates accurate embroidery design dataEfficient and accurateProgramme-controlled sewing machinesTotal factory controlData fileComputer science

A method and system are disclosed for automatically generating embroidery designs from a scanned image. An embroidery data generating mechanism generates accurate embroidery designs. The embroidery data generating mechanism first reads an image data file, which contains bitmapping information generated from a software scanning tool, the information being related to an embroidery pattern that has been scanned. The scanned pattern is broken up into pixels, each pixel in the scanned image having a bitmap associated with the color of the pattern. Each unique color in the scanned pattern has its own unique bitmap. The embroidery generating mechanism also includes a segmentation mechanism and a chain-encoding mechanism which perform operations to enhance the quality of the bitmapped information and to separate regions of the scanned image into objects. A distance transform evaluation mechanism classifies each object as being either a thick object or a thin, predominantly regular object. Additional mechanisms further interpret the objects into entities such as regular and singular regions and compute optimum sewing paths for embroidery data generation.

Owner:CIMPRESS SCHWEIZ

Method and apparatus for producing a sewing pattern

InactiveUS6859679B1Programme-controlled sewing machinesAnalogue computers for control systemsEngineering

Owner:SMITH ALEXANDRA K +1

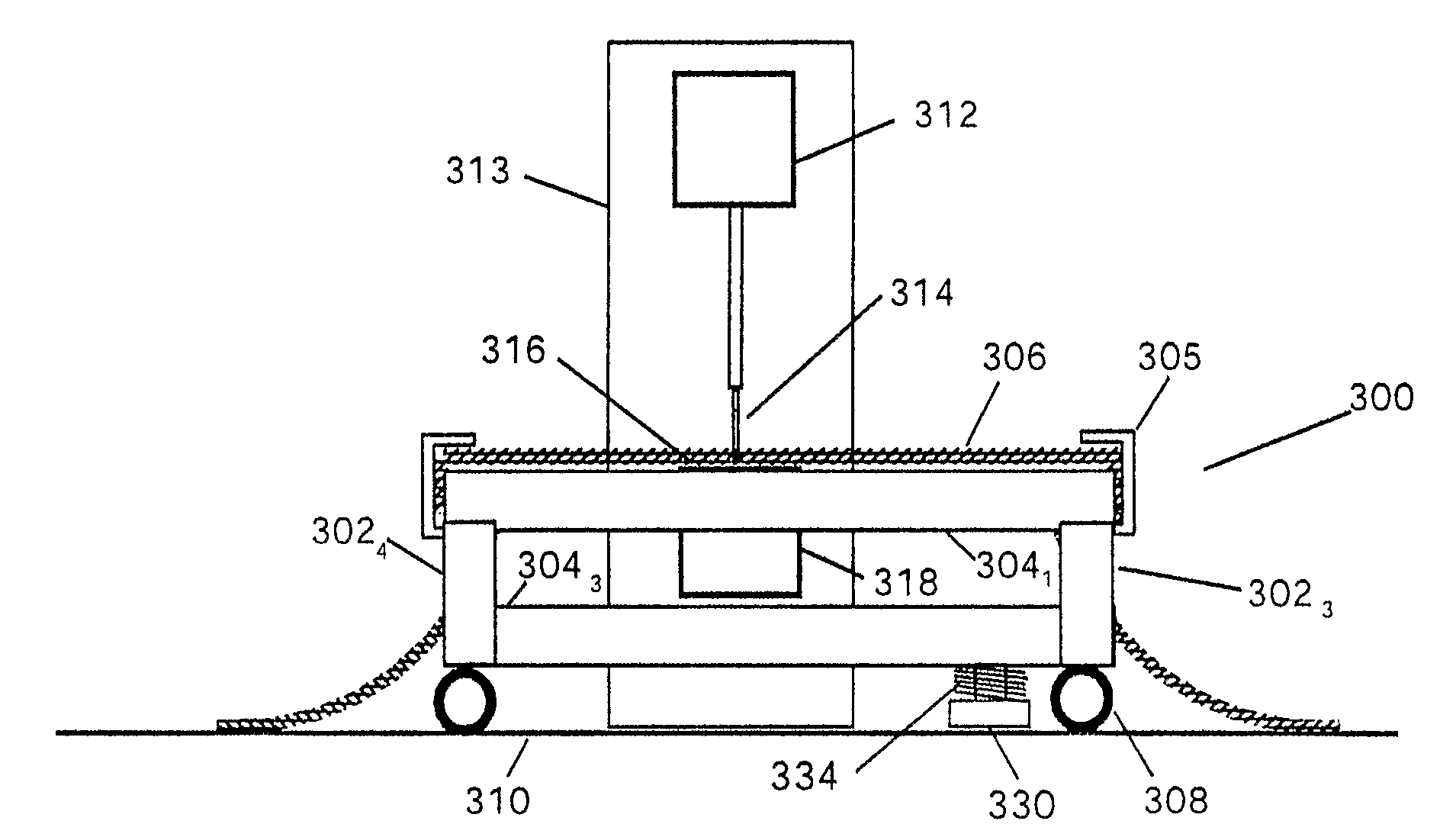

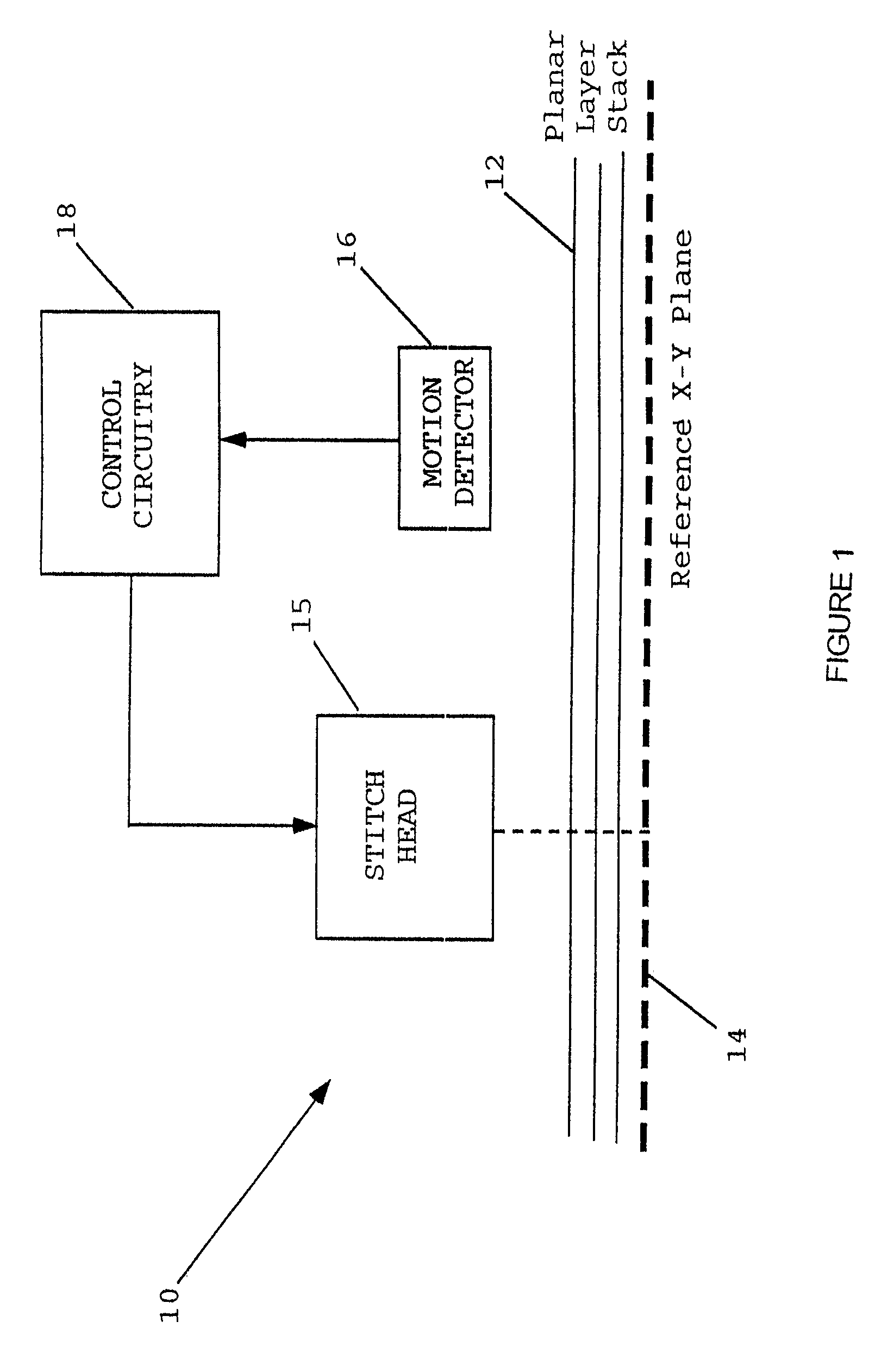

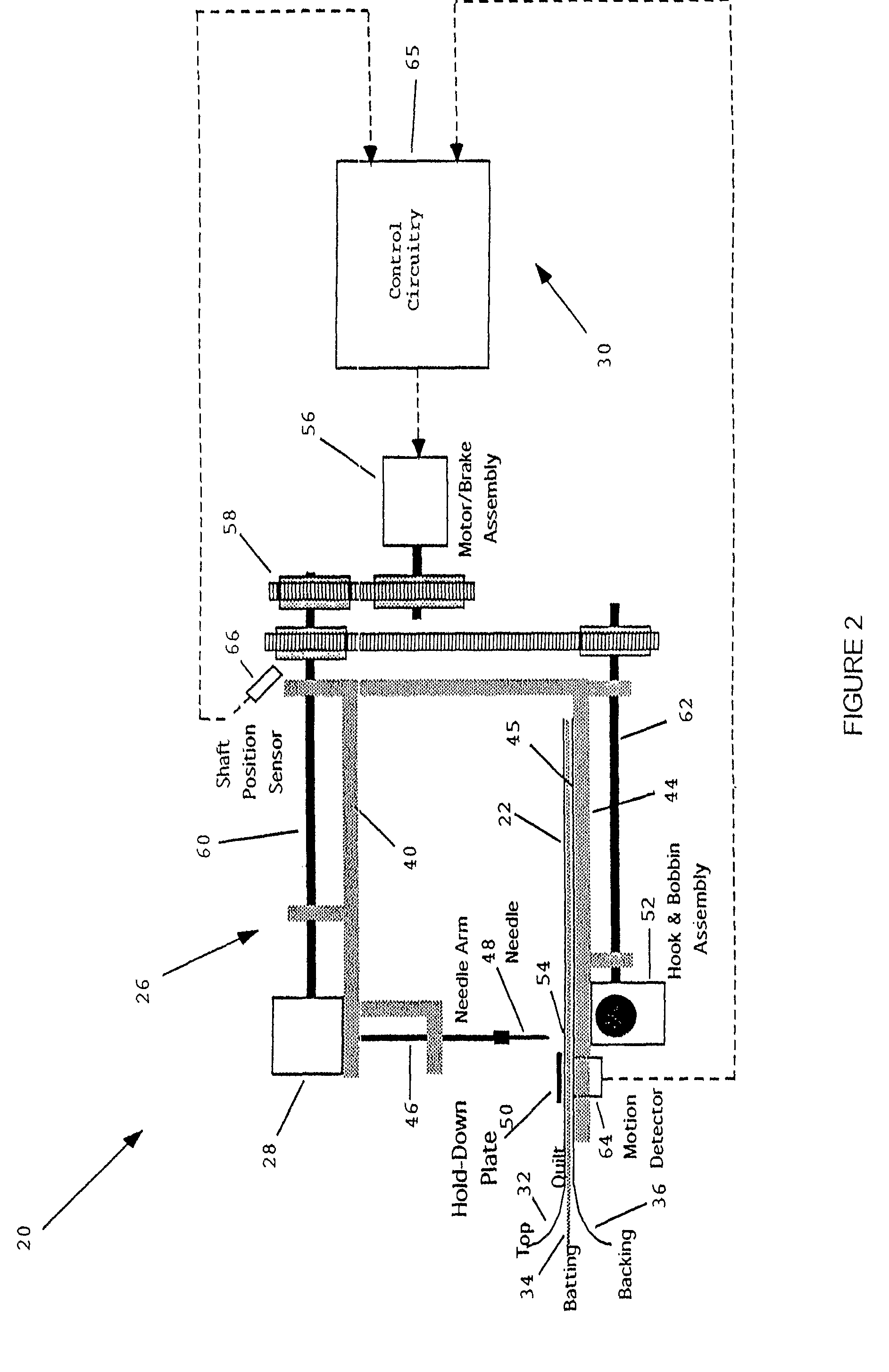

Quilting method and apparatus using frame with motion detector

Owner:KOERNER RALPH J

Computerized stitching including embroidering

InactiveUS20060064195A1Easy to controlProgramme-controlled sewing machinesPressersAnomaly detectionRemedial action

A stitching apparatus with thread tension control is provided. Tension in a thread is monitored during stitching apparatus operations, and remedial action is taken in response to the detection of an anomaly in the thread tension profile. The remedial action can include altering a feed rate of the thread in order to adjust the thread tension, and / or repeating a previous operation. Anomaly detection can be performed with respect to stitching or sewing operations, and also with respect to trim operations performed in connection with moving between elements and / or thread color changes.

Owner:MELCO INT

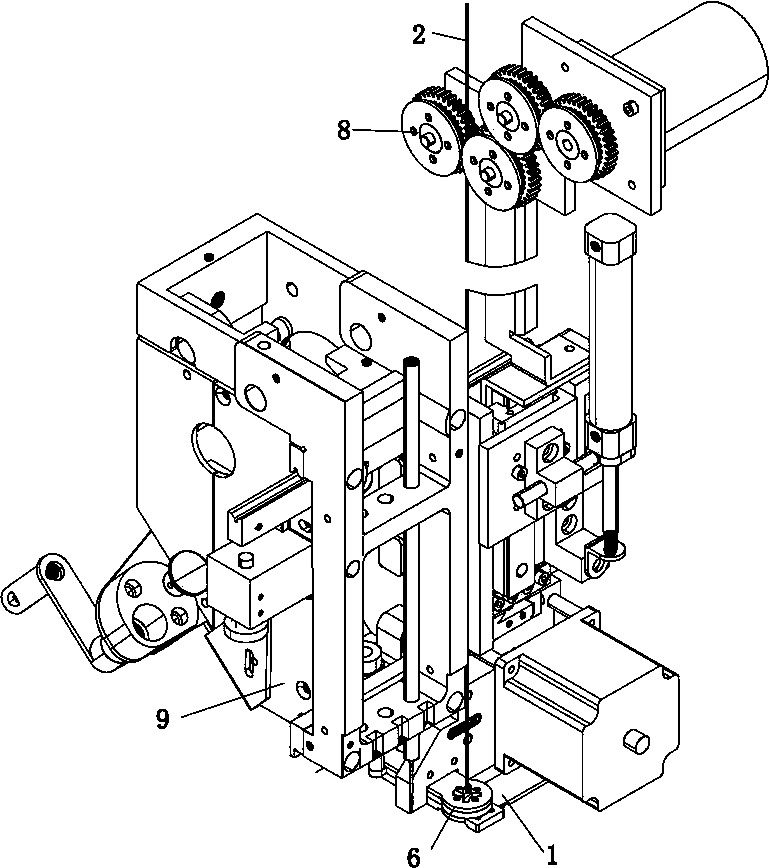

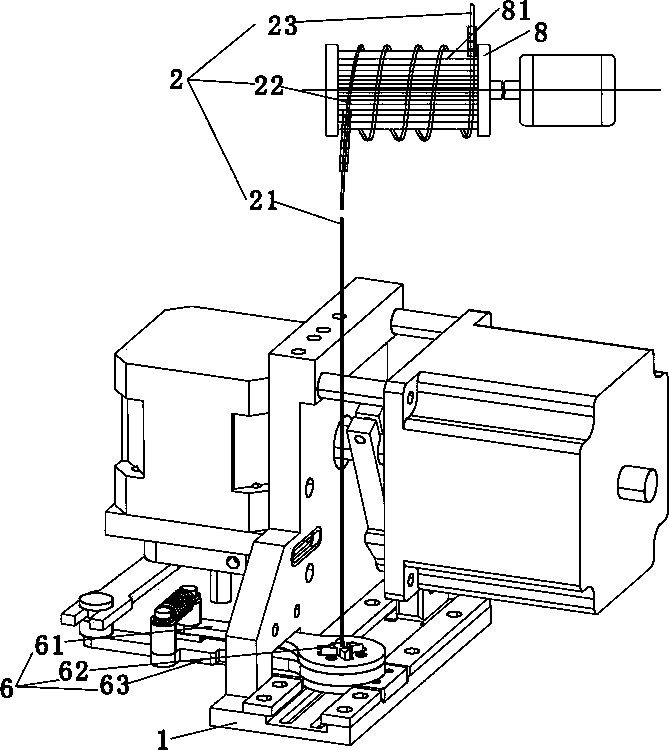

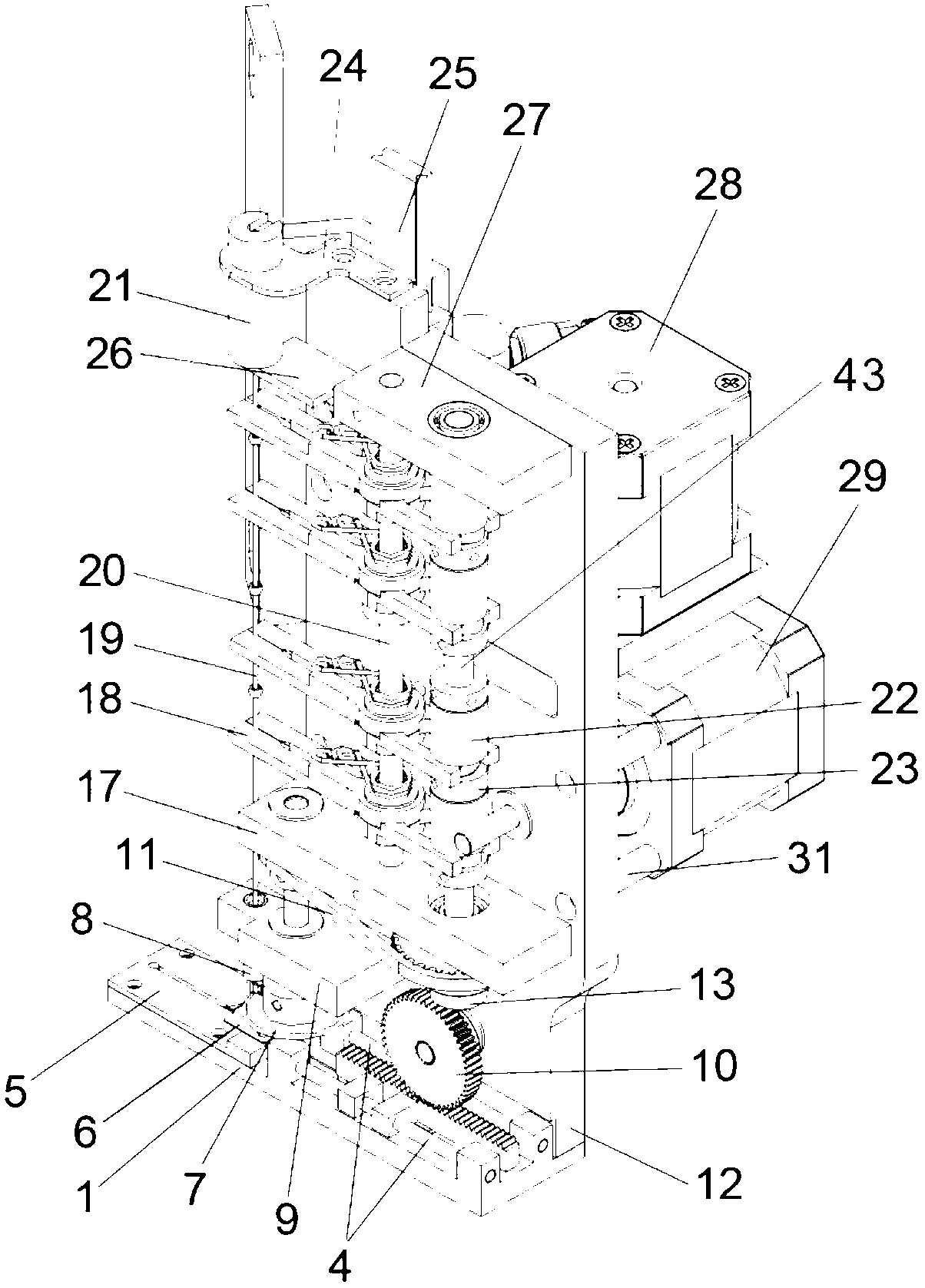

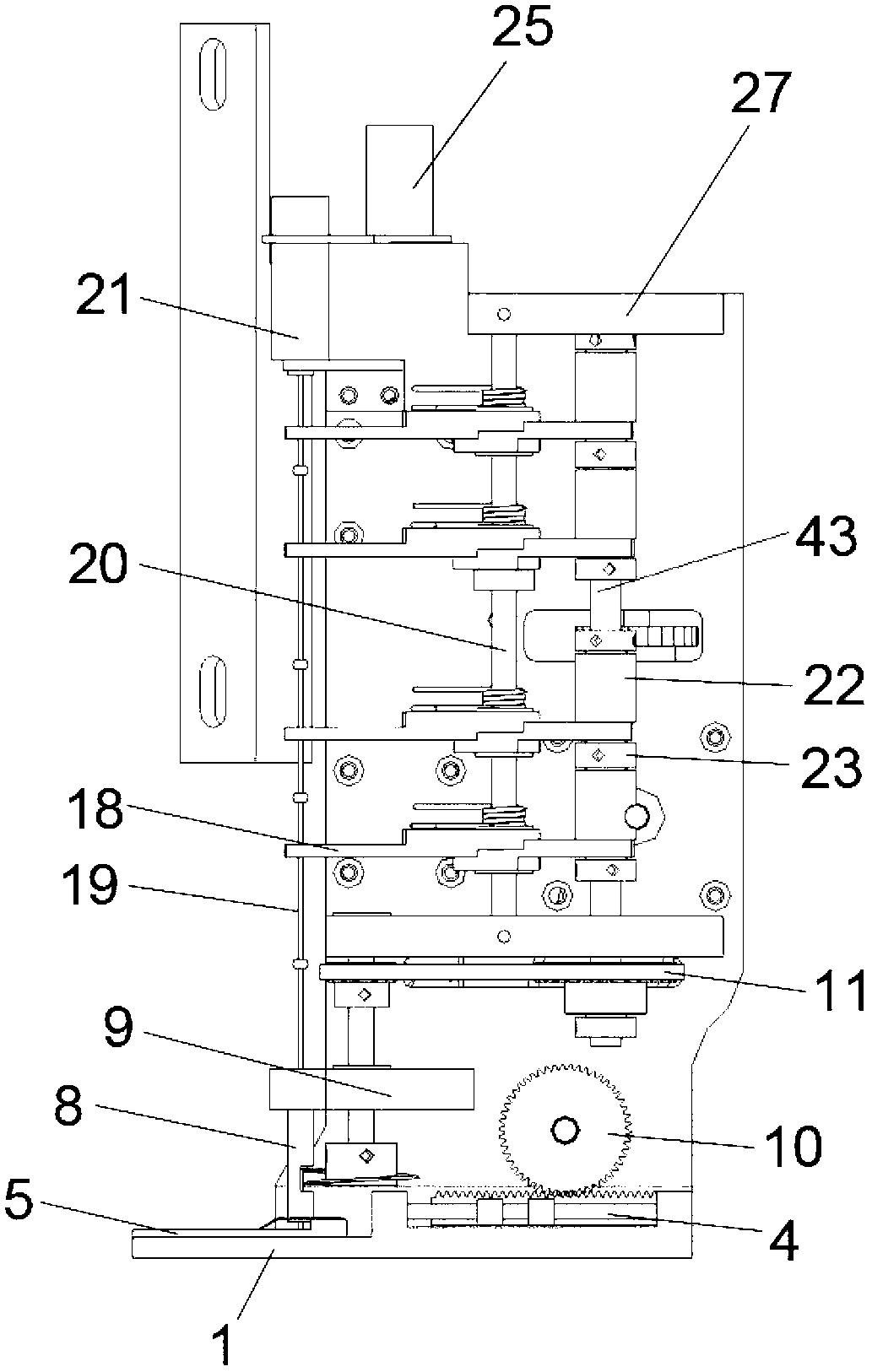

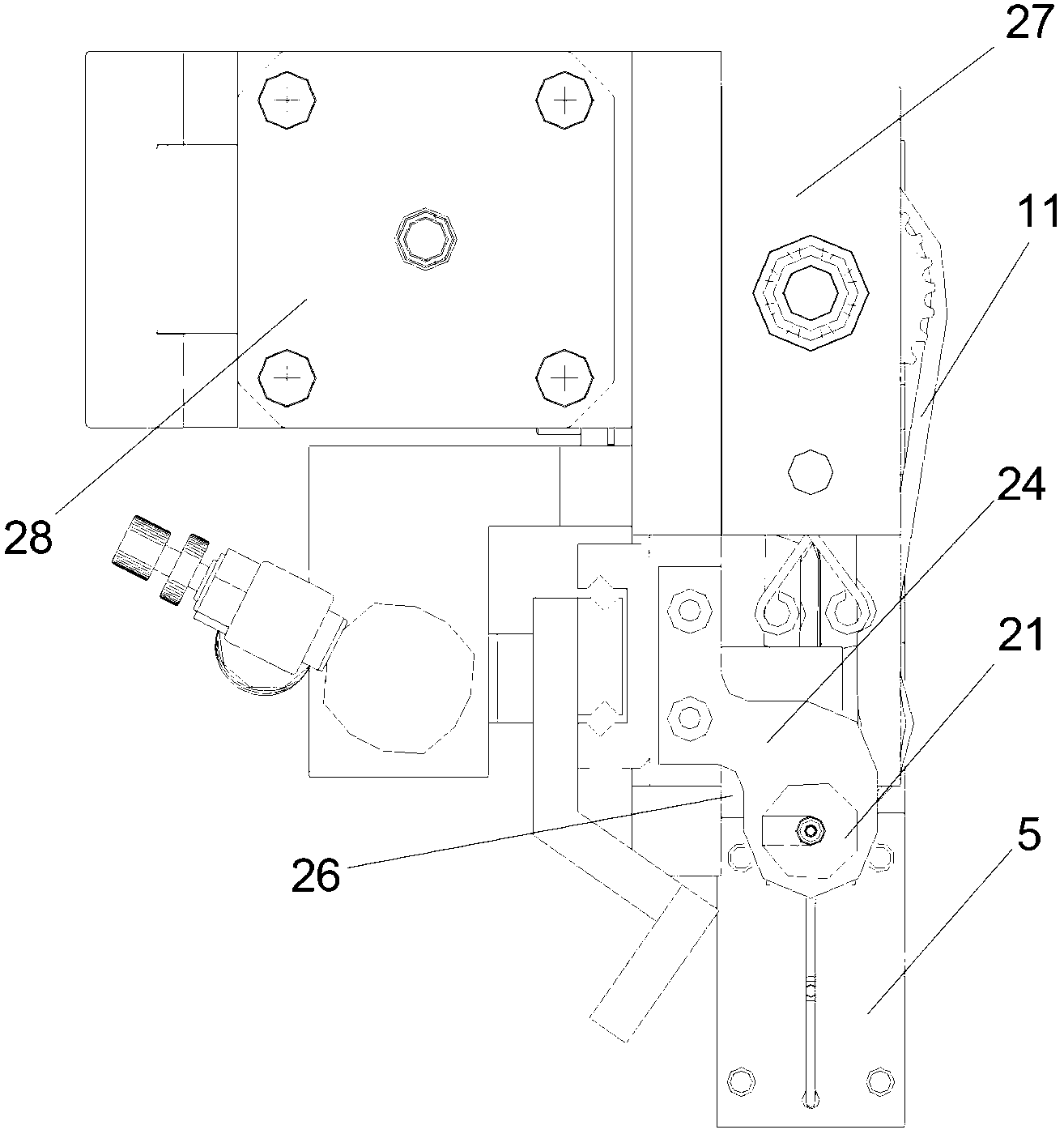

Bead embroidery embroidering machine and bead feeding method

ActiveCN103866501APrecisely throughPrecise positioningAutomatic machinesAuxillary devicesMechanical engineeringBead embroidery

The invention discloses a bead embroidery embroidering machine. The bead embroidery embroidering machine comprises an engine body, wherein the engine body is provided with one or more than one machine head; the machine head is connected with a feeding mechanism for gradually conveying embroidery beads to a position right below an embroidering needle of the embroidering machine one by one; the feeding mechanism is provided with a clamping opening for clamping and positioning the embroidery beads; a bead guide rod for supplying the embroidery beads to the feeding mechanism is suspended above the feeding mechanism; the embroidery beads are threaded on the bead guide rod to form a bead cluster; a positioning structure for positioning the embroidery beads which need to slide to corresponding feeding positions of the feeding mechanism from the bead guide rod is further arranged above the feeding mechanism; the positioning center of the positioning structure and the positioning center of the clamping structure are concentric. The bead guide rod is provided with the bead cluster formed by the embroidery beads and the bead cluster can be continuously fed to the feeding mechanism; the bead guide rod and the positioning structure can be used for accurately positioning the embroidery beads so that the embroidery beads accurately slide into the corresponding parts of the feeding mechanism according to requirements and the embroidery beads are conveniently and accurately positioned and conveyed, and furthermore, the embroidering needle can accurately penetrate through needle holes in the embroidery beads to embroider the embroidery beads on a textile.

Owner:诸暨市化工机械厂

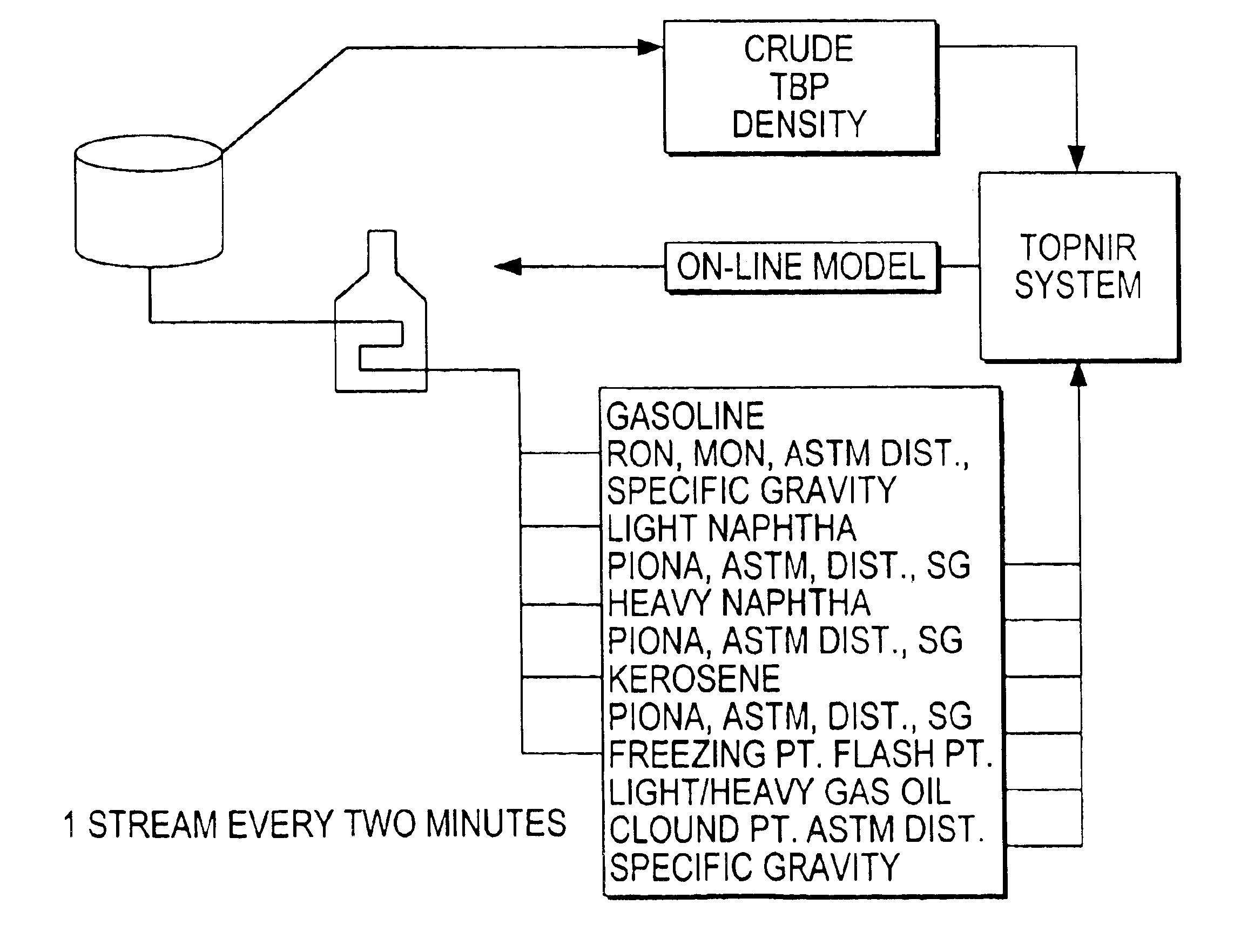

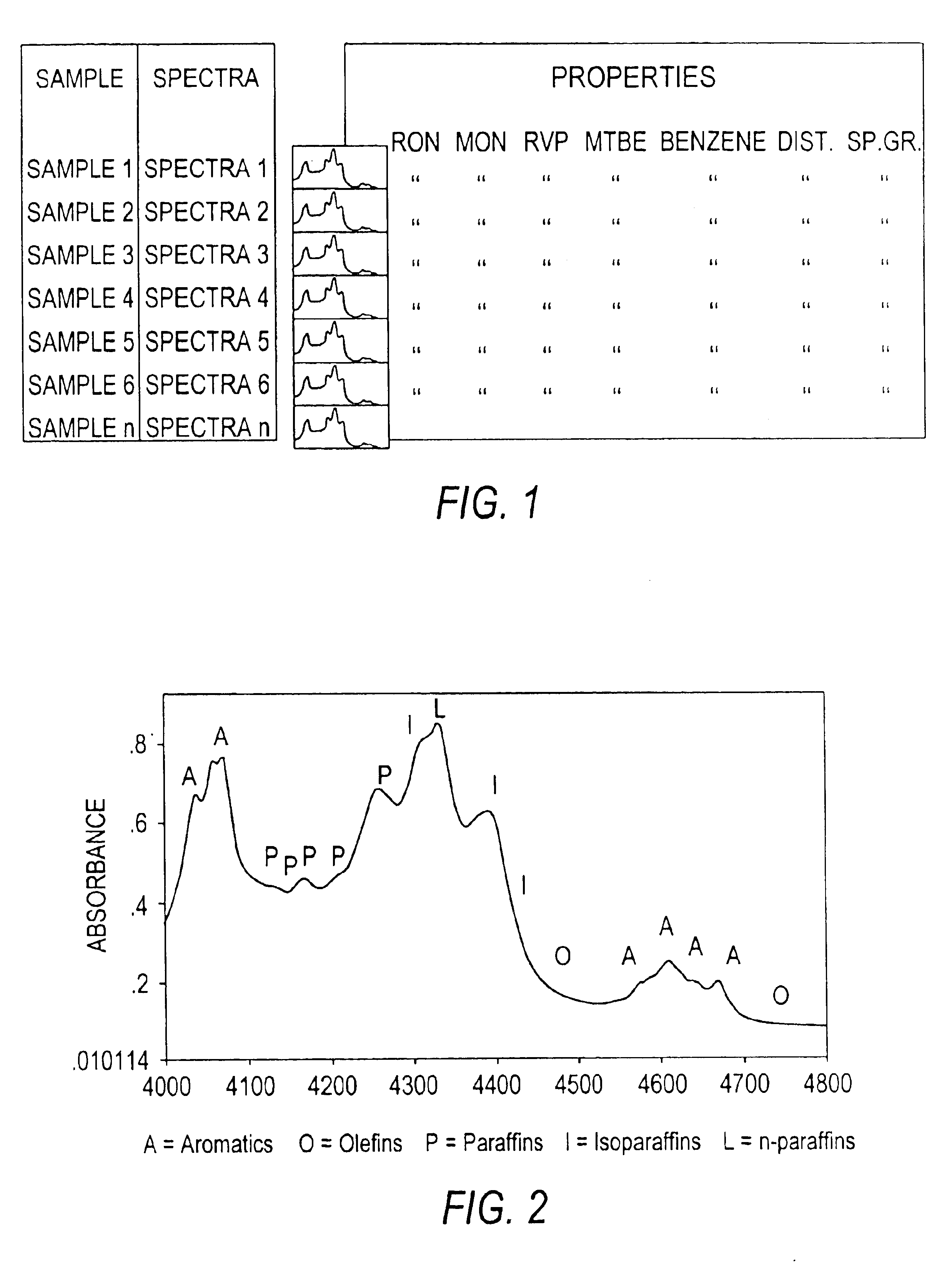

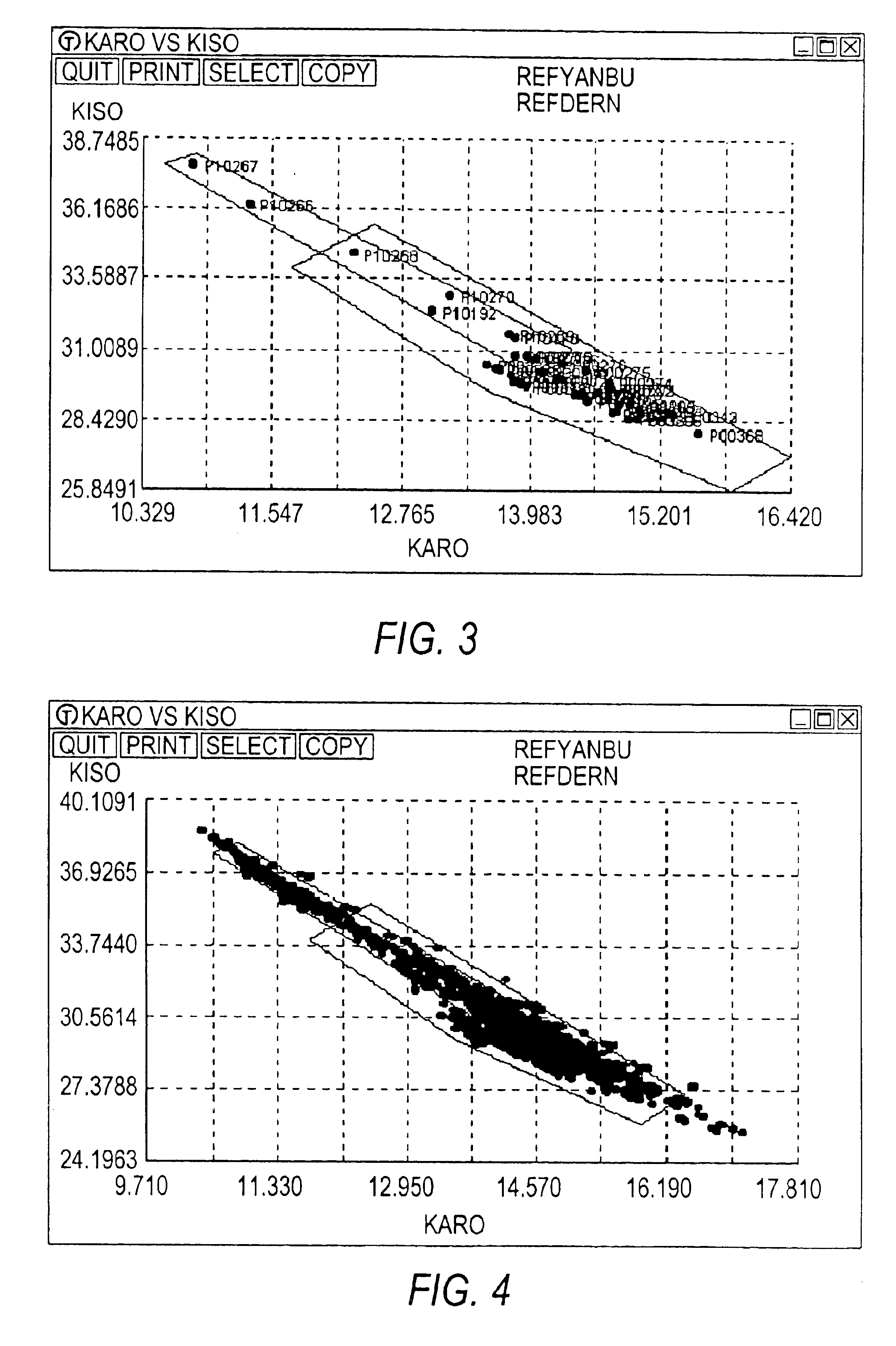

Topological near infrared analysis modeling of petroleum refinery products

InactiveUS6897071B2Promote resultsConfidenceRadiation pyrometryEarth material testingSpectroscopyPetroleum

A method of analyzing a substance exhibiting absorption in the near infrared (NIR) region subjects the substance to NIR spectroscopy, processes the data using a partial least squares (PLS) technique and identifies a component of the substance by performing a topological near infrared (TOPNIR) analysis on the processed data.

Owner:SAUDI ARABIAN OIL CO

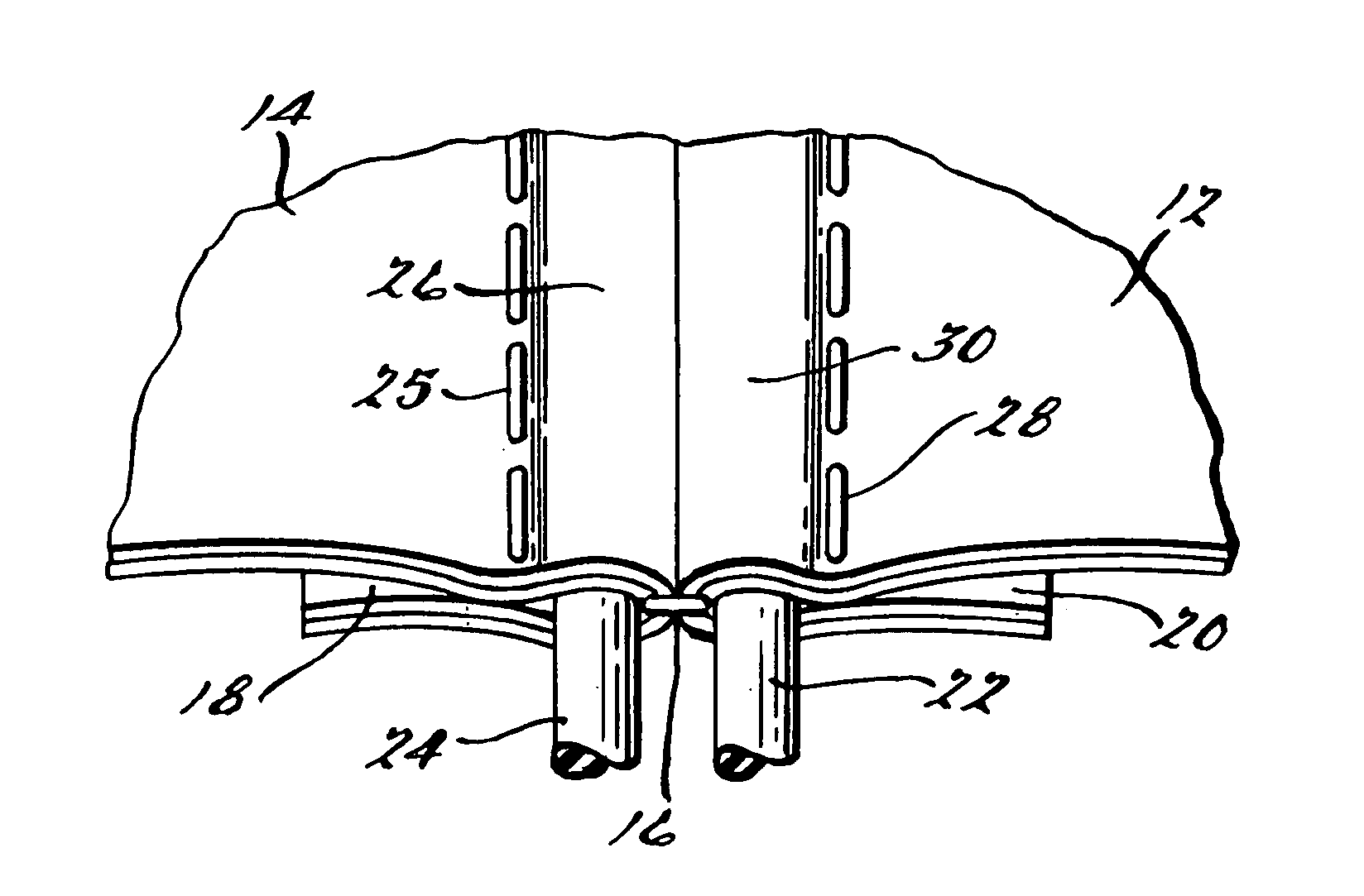

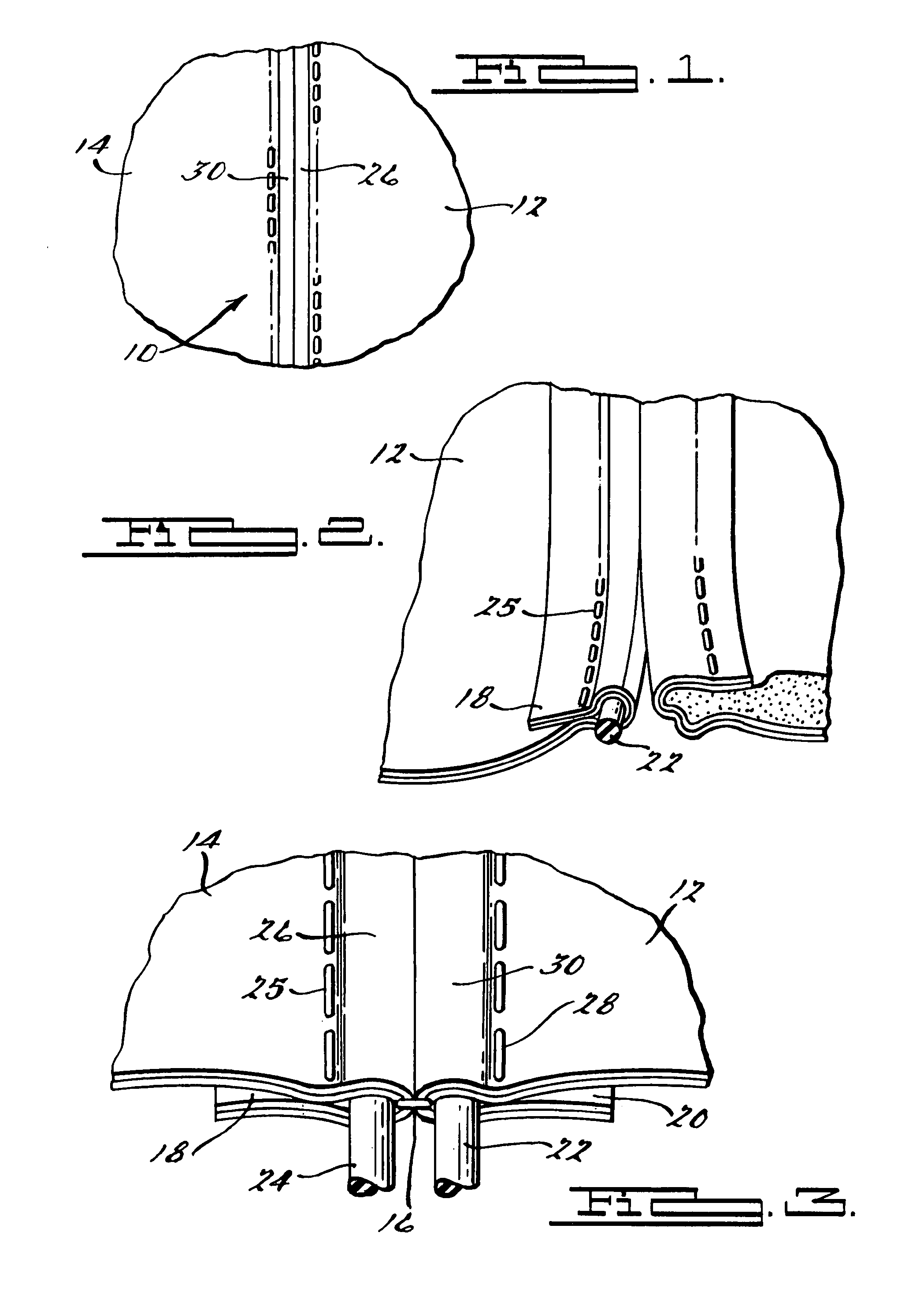

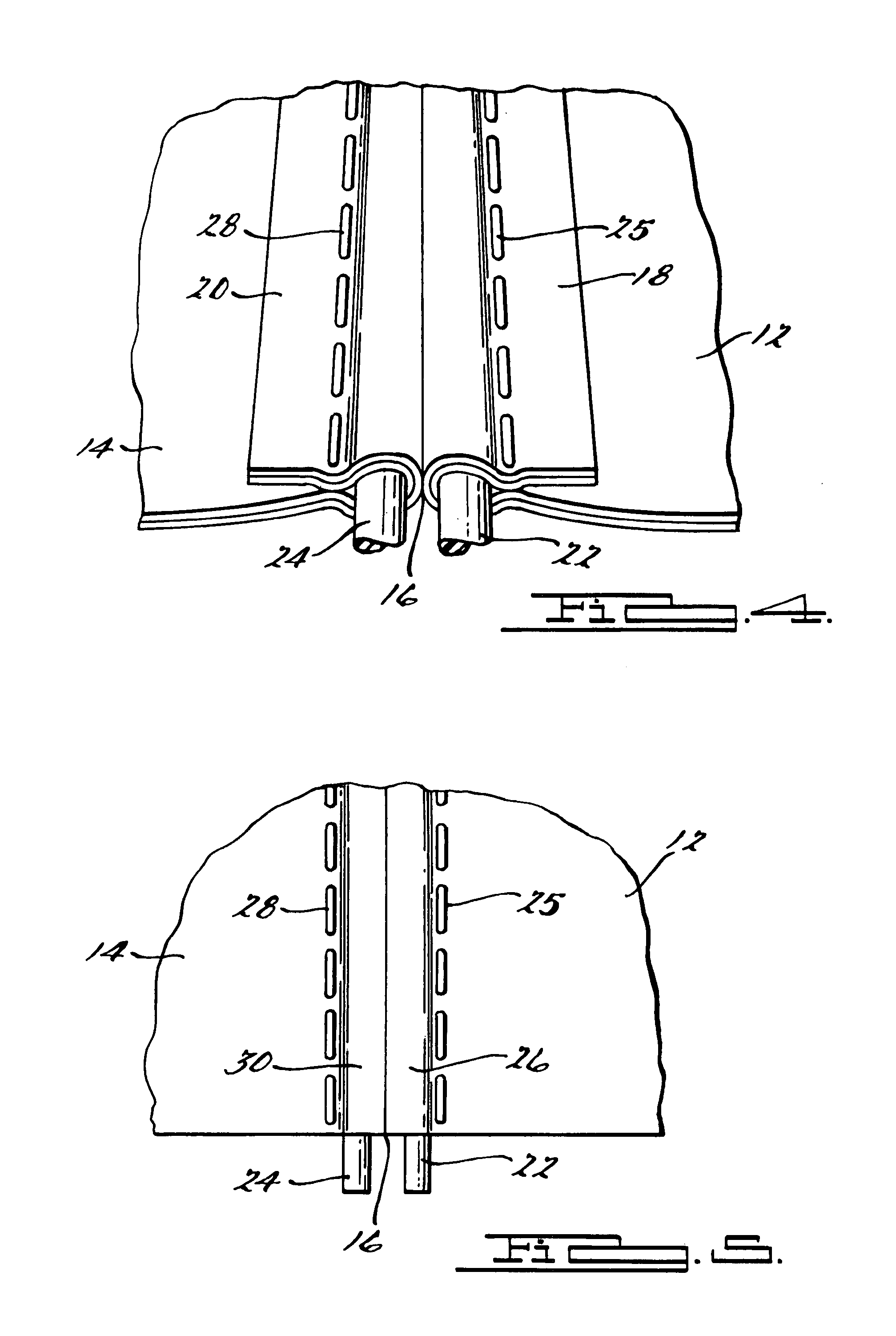

Non-laminate seam

ActiveUS7278363B2Cleaner lookLow costUpholstery manufactureVehicle seatsEngineeringMechanical engineering

Owner:IRVIN AUTOMOTIVE PROD LLC

Automatically generating embroidery designs from a scanned image

InactiveUS7016756B2Automatically and efficiently generates accurate embroidery design dataEfficient and accurateProgramme-controlled sewing machinesTotal factory controlData fileComputer vision

A method and system are disclosed for automatically generating embroidery designs from a scanned image. An embroidery data generating mechanism generates accurate embroidery designs. The embroidery data generating mechanism first reads an image data file, which contains bitmapping information generated from a software scanning tool, the information being related to an embroidery pattern that has been scanned. The scanned pattern is broken up into pixels, each pixel in the scanned image having a bitmap associated with the color of the pattern. Each unique color in the scanned pattern has its own unique bitmap. The embroidery generating mechanism also includes a segmentation mechanism and a chain-encoding mechanism which perform operations to enhance the quality of the bitmapped information and to separate regions of the scanned image into objects. A distance transform evaluation mechanism classifies each object as being either a thick object or a thin, predominantly regular object. Additional mechanisms further interpret the objects into entities such as regular and singular regions and compute optimum sewing paths for embroidery data generation.

Owner:CIMPRESS SCHWEIZ

Automatically generating embroidery designs from a scanned image

InactiveUS7016757B2Automatically and efficiently generates accurate embroidery design dataEfficient and accurateProgramme-controlled sewing machinesTotal factory controlData fileSoftware

A method and system are disclosed for automatically generating embroidery designs from a scanned image. An embroidery data generating mechanism generates accurate embroidery designs. The embroidery data generating mechanism first reads an image data file, which contains bitmapping information generated from a software scanning tool, the information being related to an embroidery pattern that has been scanned. The scanned pattern is broken up into pixels, each pixel in the scanned image having a bitmap associated with the color of the pattern. Each unique color in the scanned pattern has its own unique bitmap. The embroidery generating mechanism also includes a segmentation mechanism and a chain-encoding mechanism which perform operations to enhance the quality of the bitmapped information and to separate regions of the scanned image into objects. A distance transform evaluation mechanism classifies each object as being either a thick object or a thin, predominantly regular object. Additional mechanisms further interpret the objects into entities such as regular and singular regions and compute optimum sewing paths for embroidery data generation.

Owner:CIMPRESS SCHWEIZ

Method for stitching vehicle interior components and components formed from the method

Owner:INTEVA PRODUCTS LLC

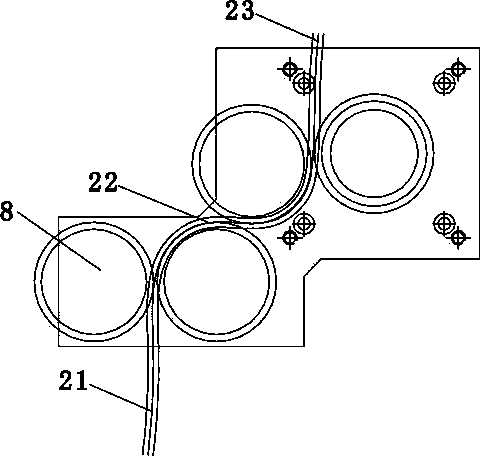

Embroidery bead feeding apparatus and method

ActiveCN103266434ARealize automatic feedingIngenious structureAutomatic machinesProduction rateElectric machinery

The invention discloses an embroidery bead feeding apparatus, which comprises a bead guiding pipe for guiding embroidery beads to fall down, a time sharing clamping mechanism, an embroidery bead separation mechanism, a feeding mechanism and an automatic feeding mechanism, wherein the time sharing clamping mechanism comprises a plurality of clampers, and a one-way sleeve drives the mutually-spaced clampers to carry out time sharing separation and enclosing under clamping motor driving, such that the bead guiding pipe is always positioned on a fixation position. The present invention further provides an embroidery bead feeding method. According to the present invention, the embroidery beads are conveyed to processing positions one by one through the time sharing clamping mechanism, the embroidery bead separation mechanism and the automatic feeding mechanism so as to achieve automatic embroidery bead feeding. The apparatus has characteristics of ingenious structure, high production rate, high automation degree, easy installation and maintenance, low processing cost and high practical values.

Owner:WENZHOU OULUOHUA INDAL

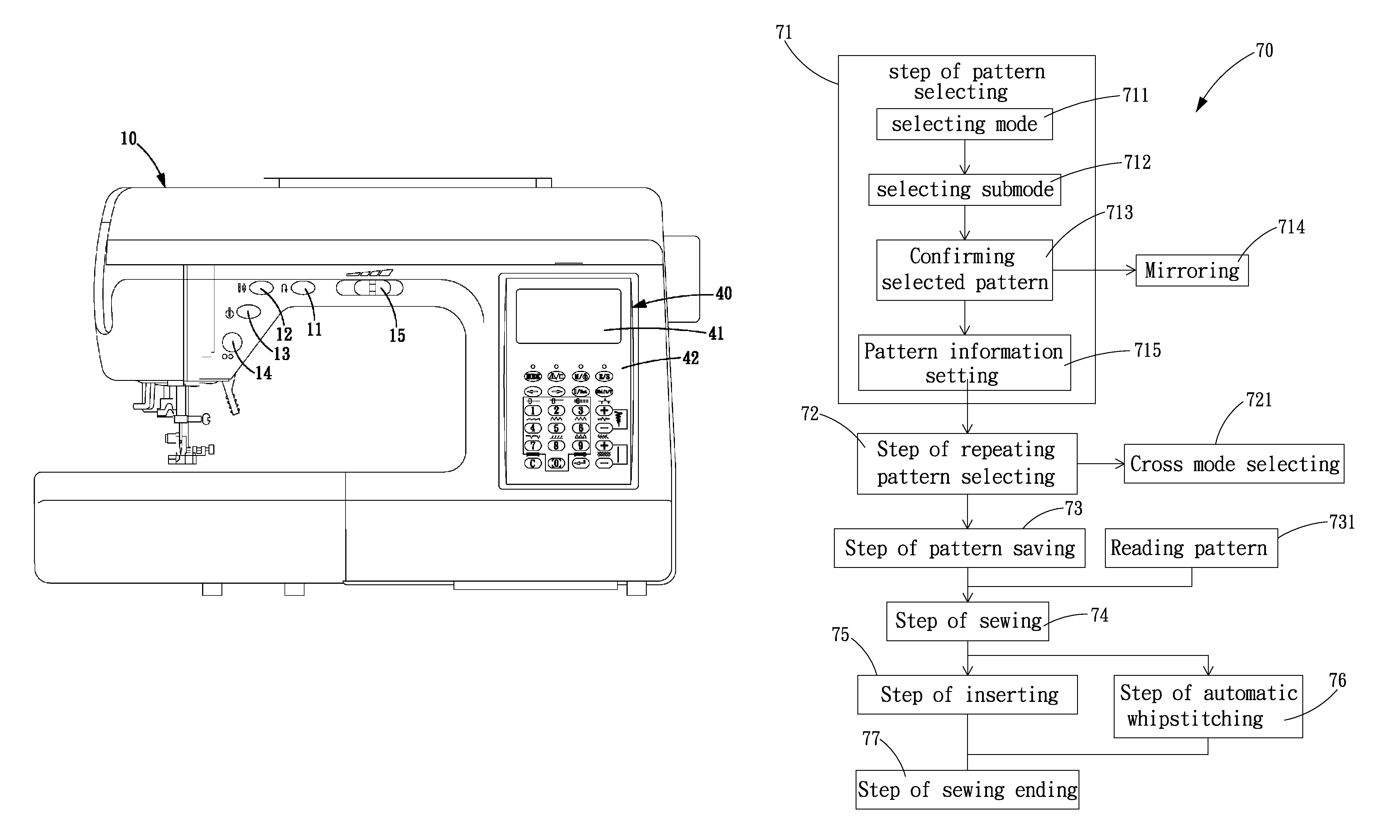

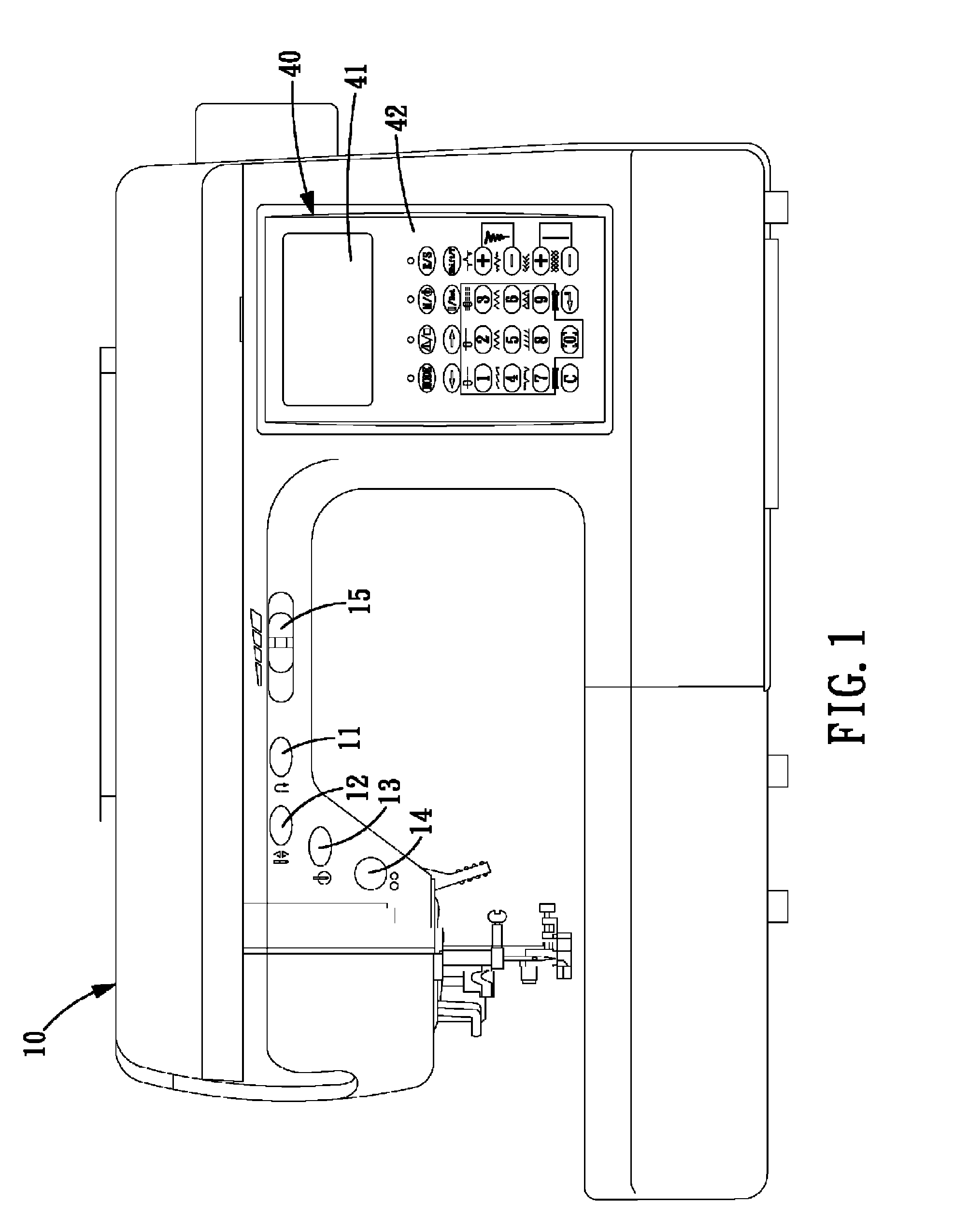

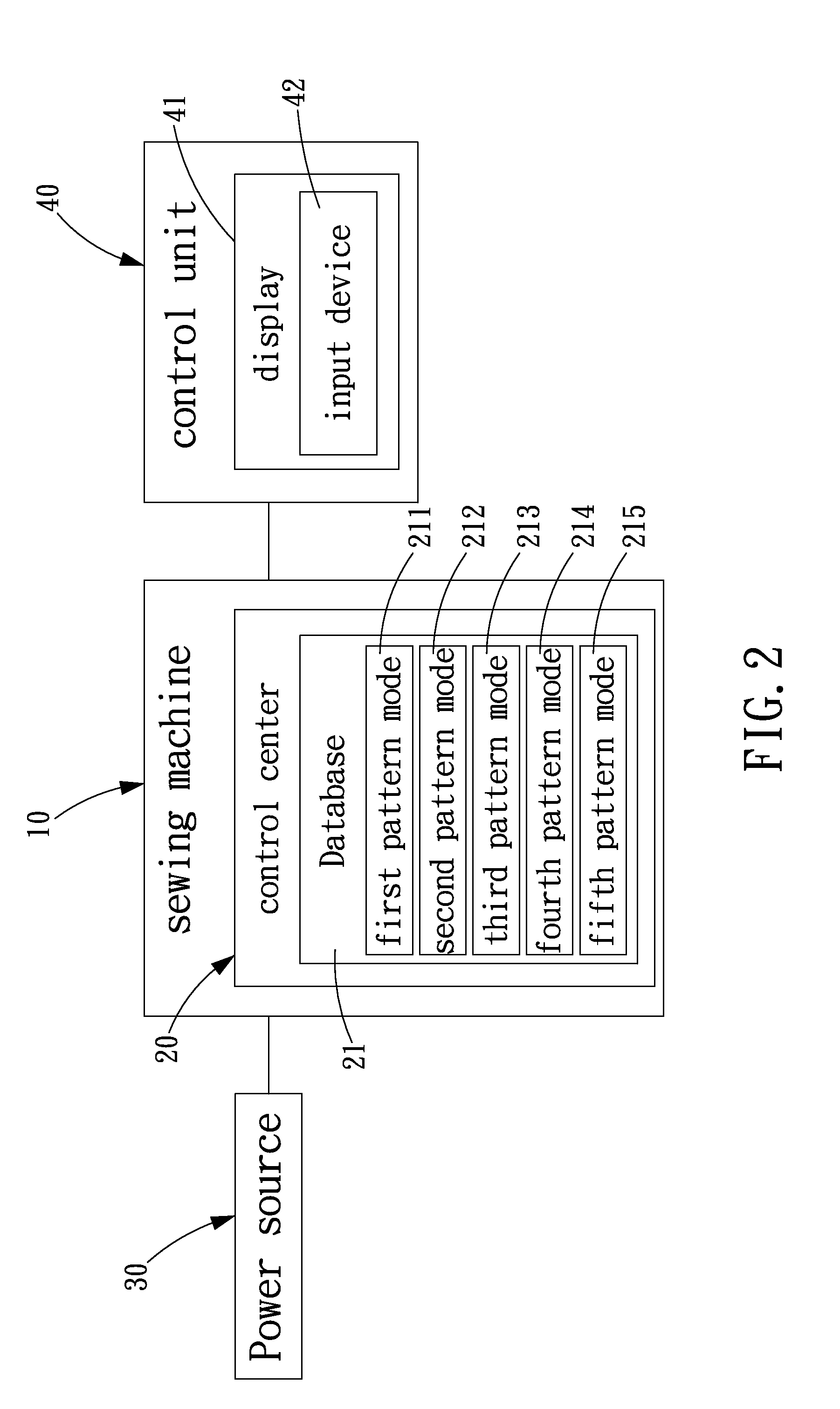

Method and device for controlling sewing patterns of a sewing machine

InactiveUS8763545B2Better satisfy userProgramme-controlled sewing machinesAutomatic machinesEngineeringSewing machine

A method and device for controlling sewing patterns of a sewing machine allows the user to edit the patterns or pattern strings saved in the database, and to mirror the patterns, or control the respective data of sewing. The sewing pattern can be easily and freely edited, and the information of all the sewing operations is clearly displayed on the display.

Owner:TSENG HSIEN CHANG

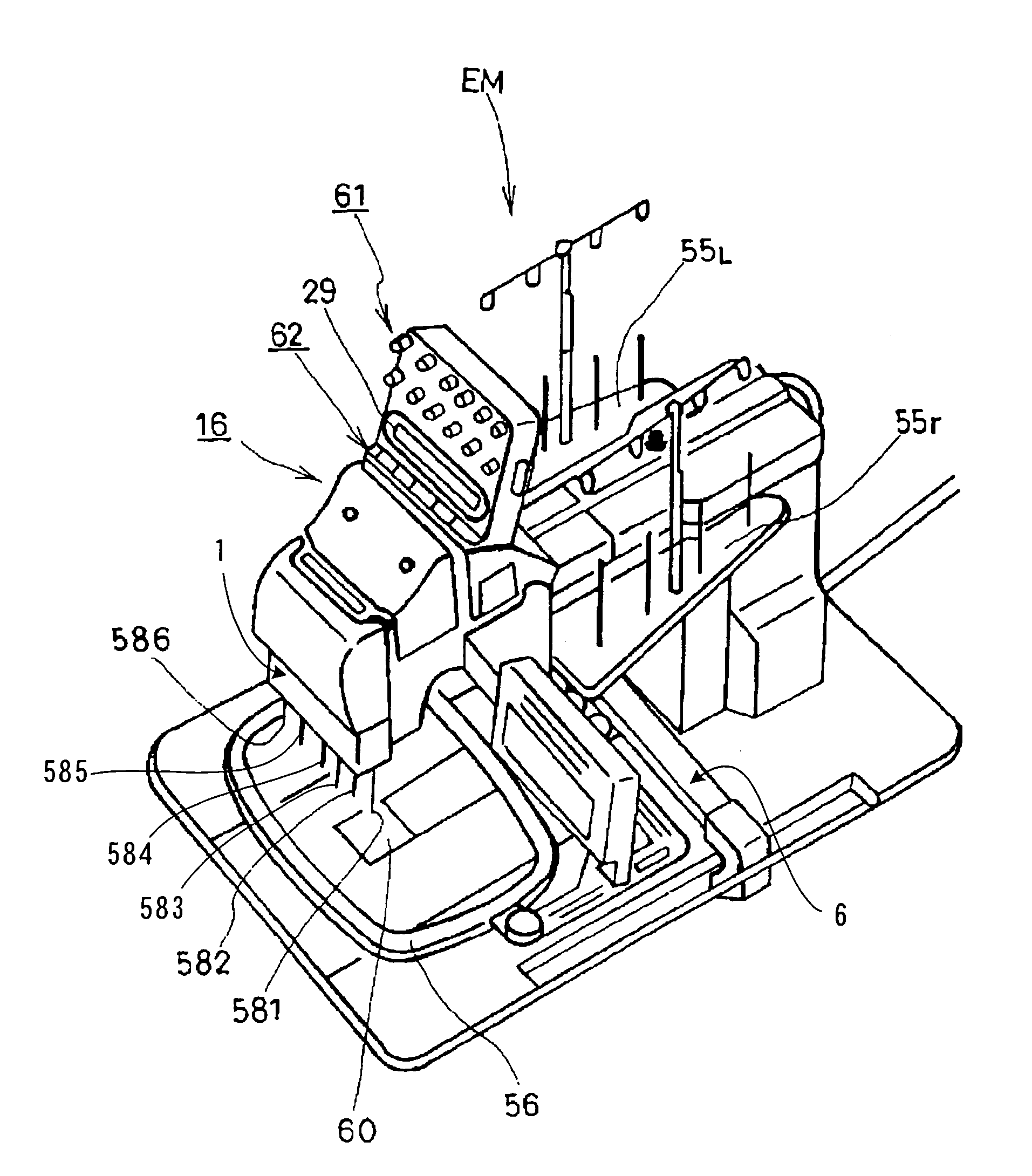

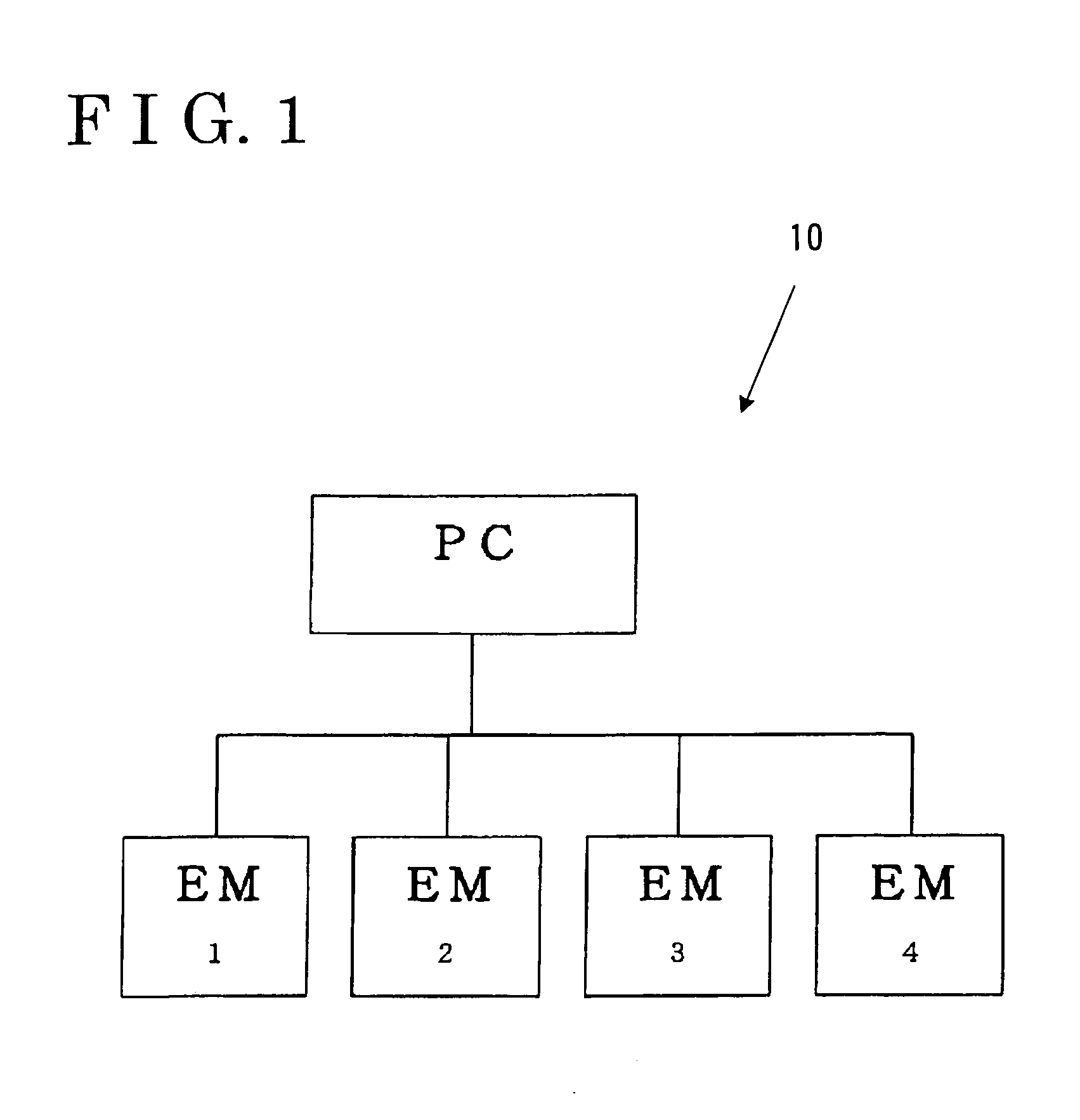

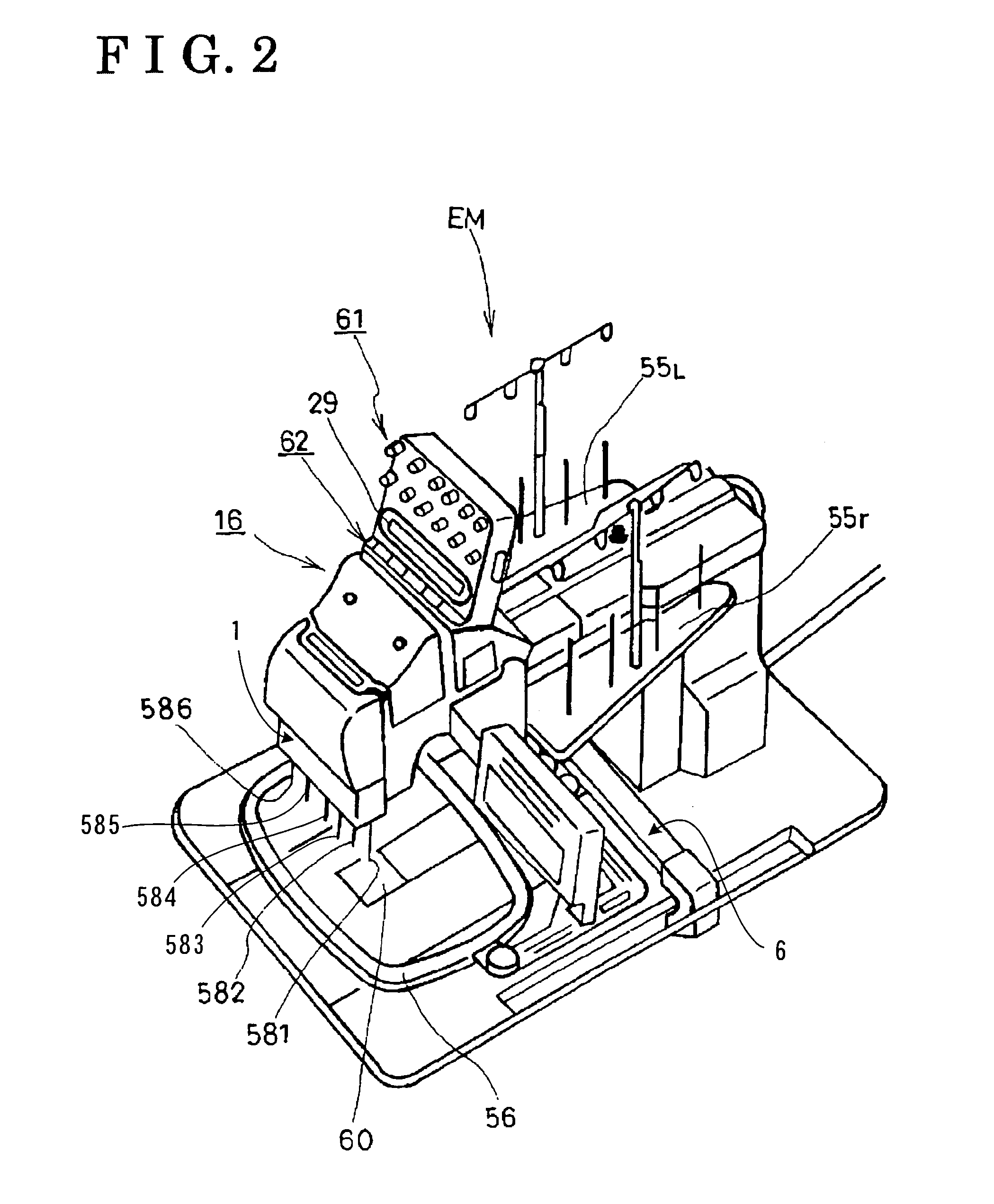

Embroidering system

An embroidering system includes at least one embroidering machine having plural needles supplied with threads having different colors, and a control device for transmitting an embroidery data to the at least one embroidering machine so as to selectively drive the plural needles. The embroidery data is generated and memorized in the control device prior to being transmitted to the at least one embroidering machine. The embroidery data is corrected as required. It is preferable that the embroidery data is corrected as the basis for needle numbers for the respective needles and the colors of the threads supplied to the respective needles.

Owner:AISIN SEIKI KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com