Patents

Literature

145results about "Spool-pin assemblies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Embroidery machine and embroidery system

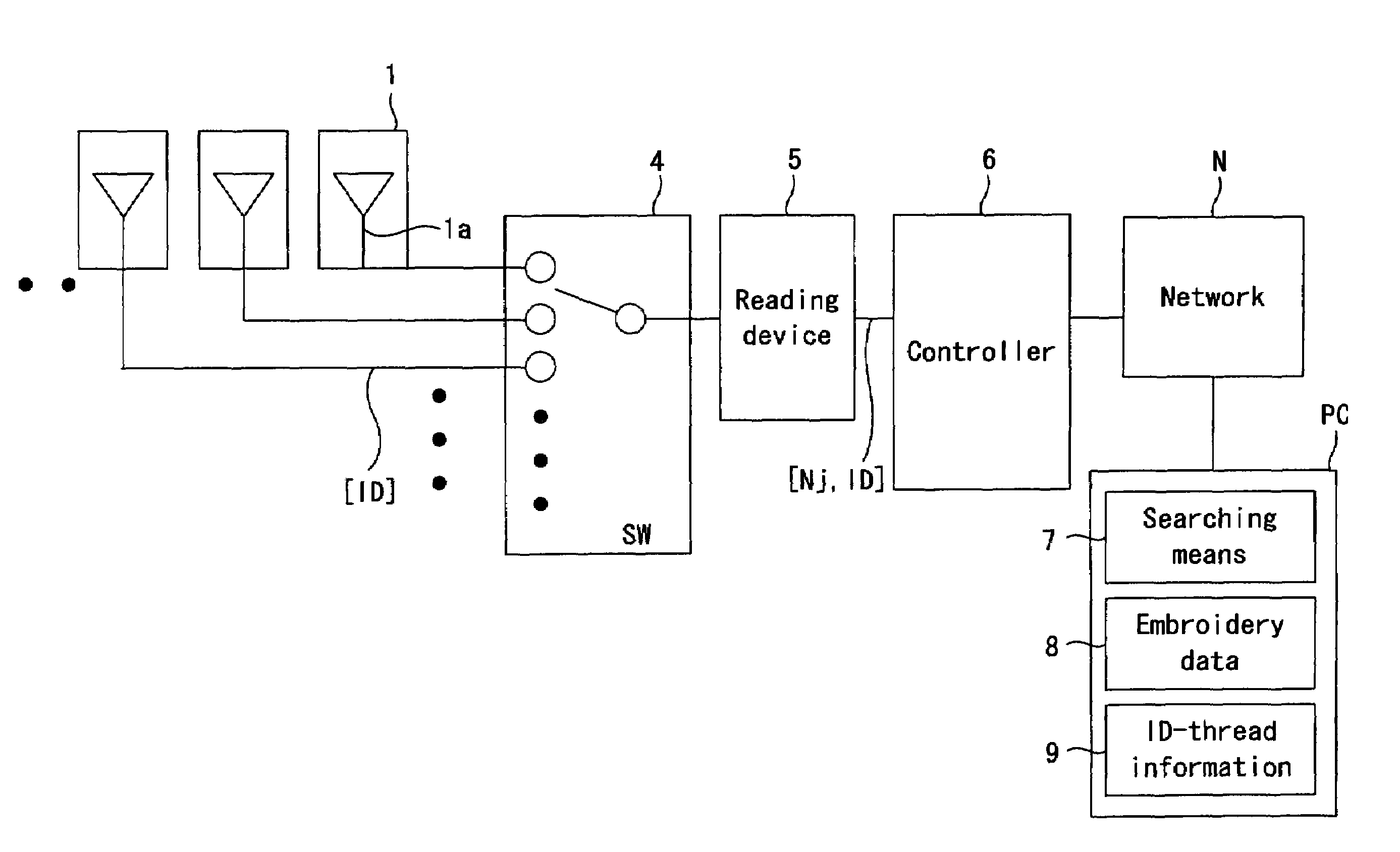

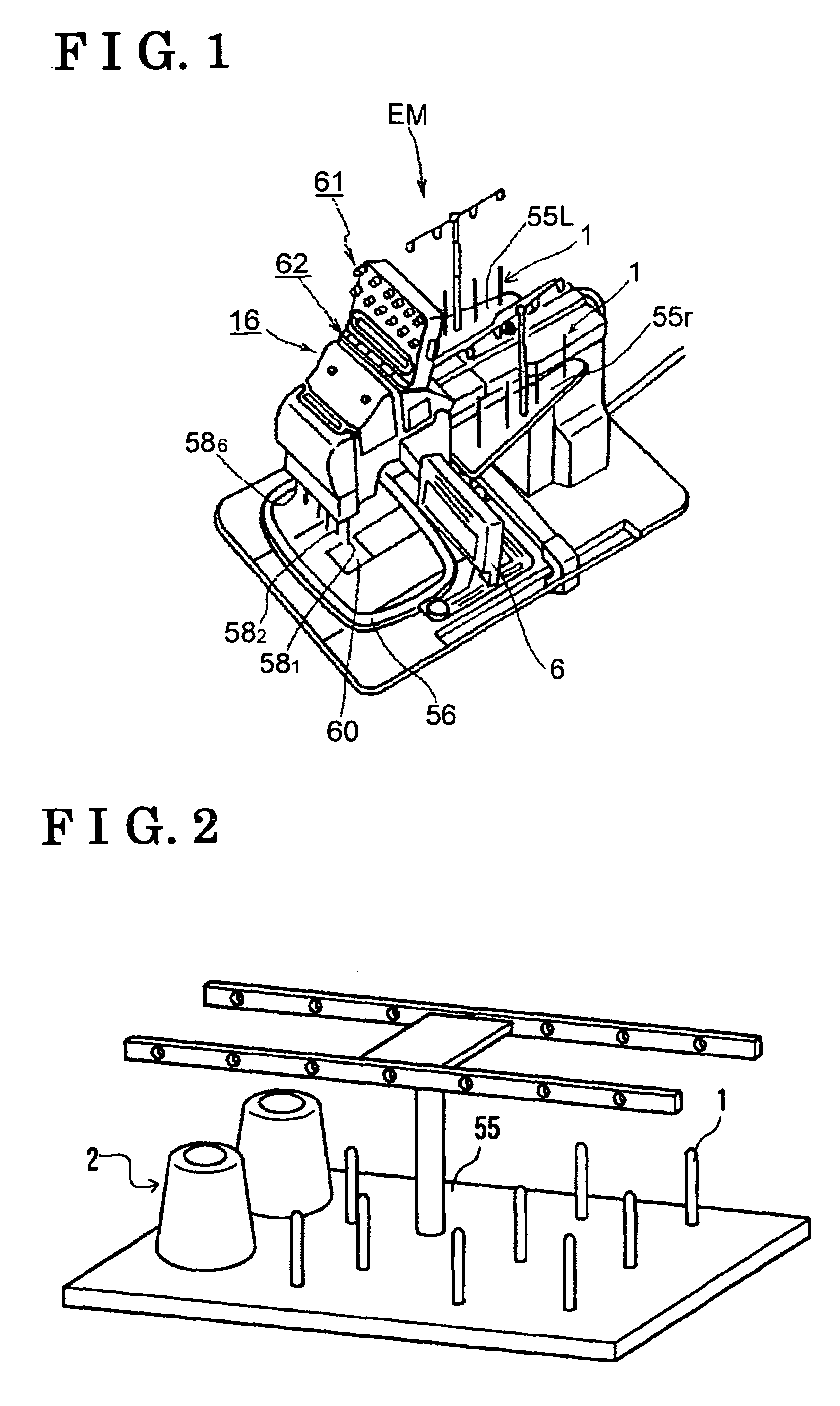

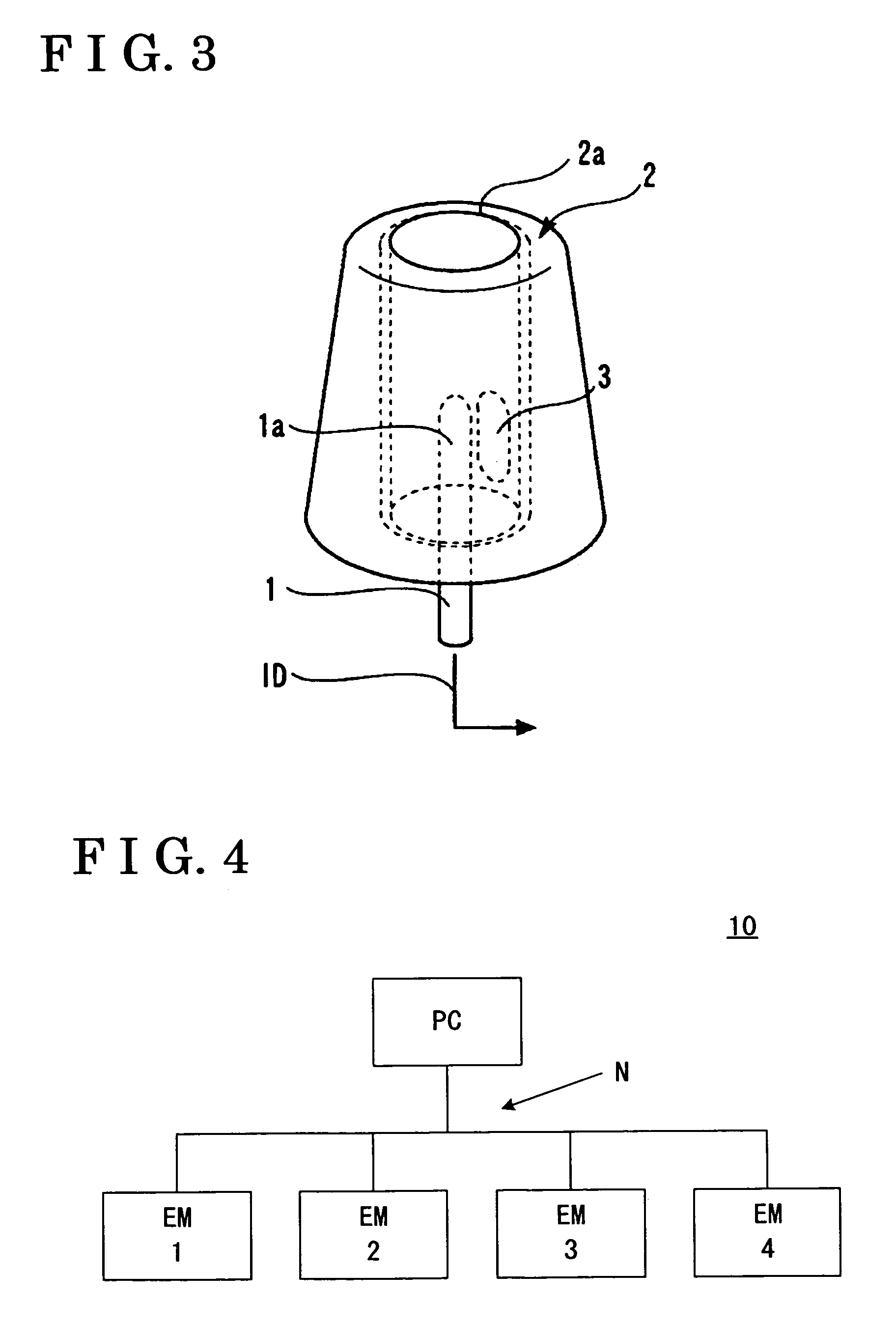

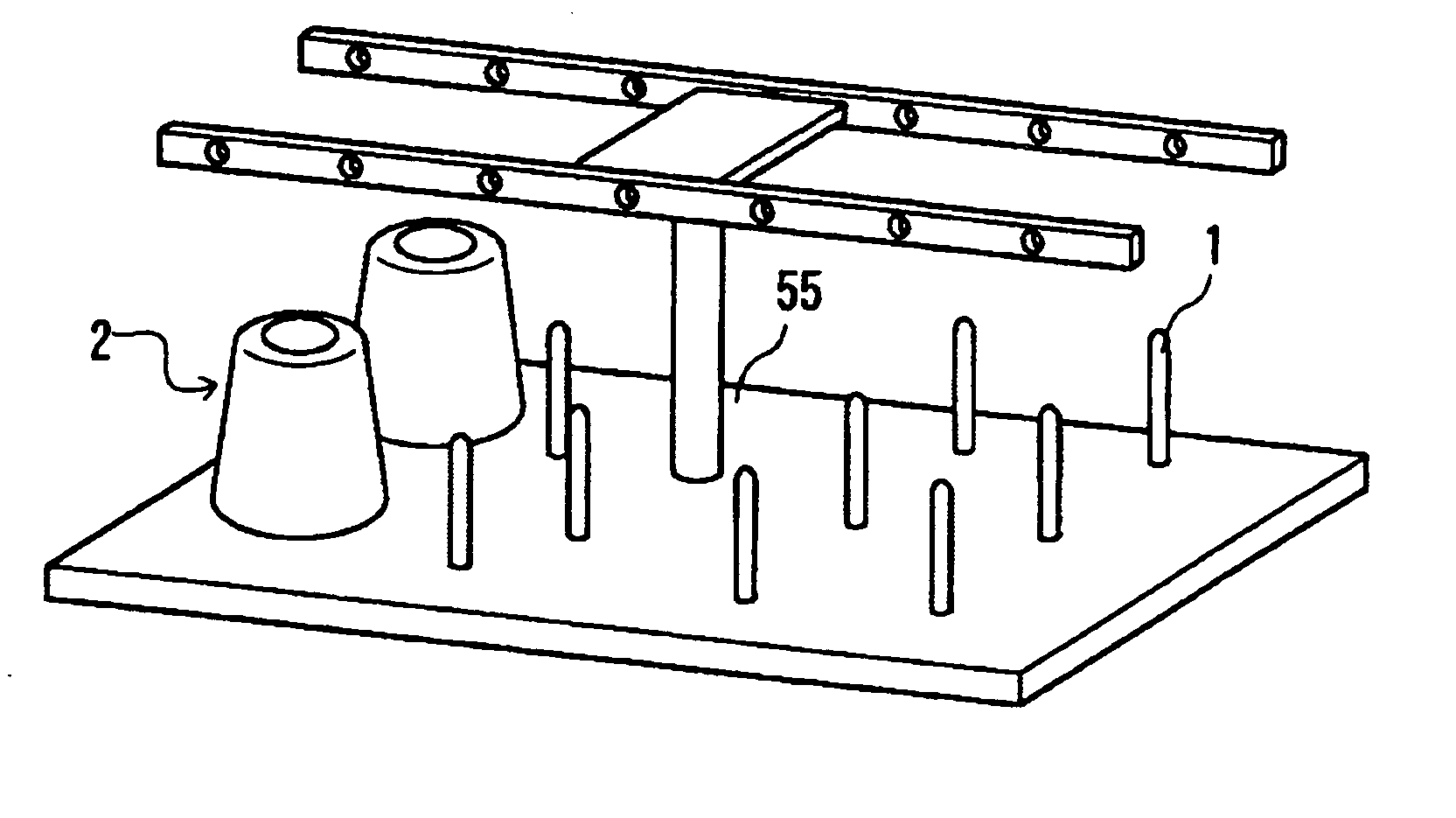

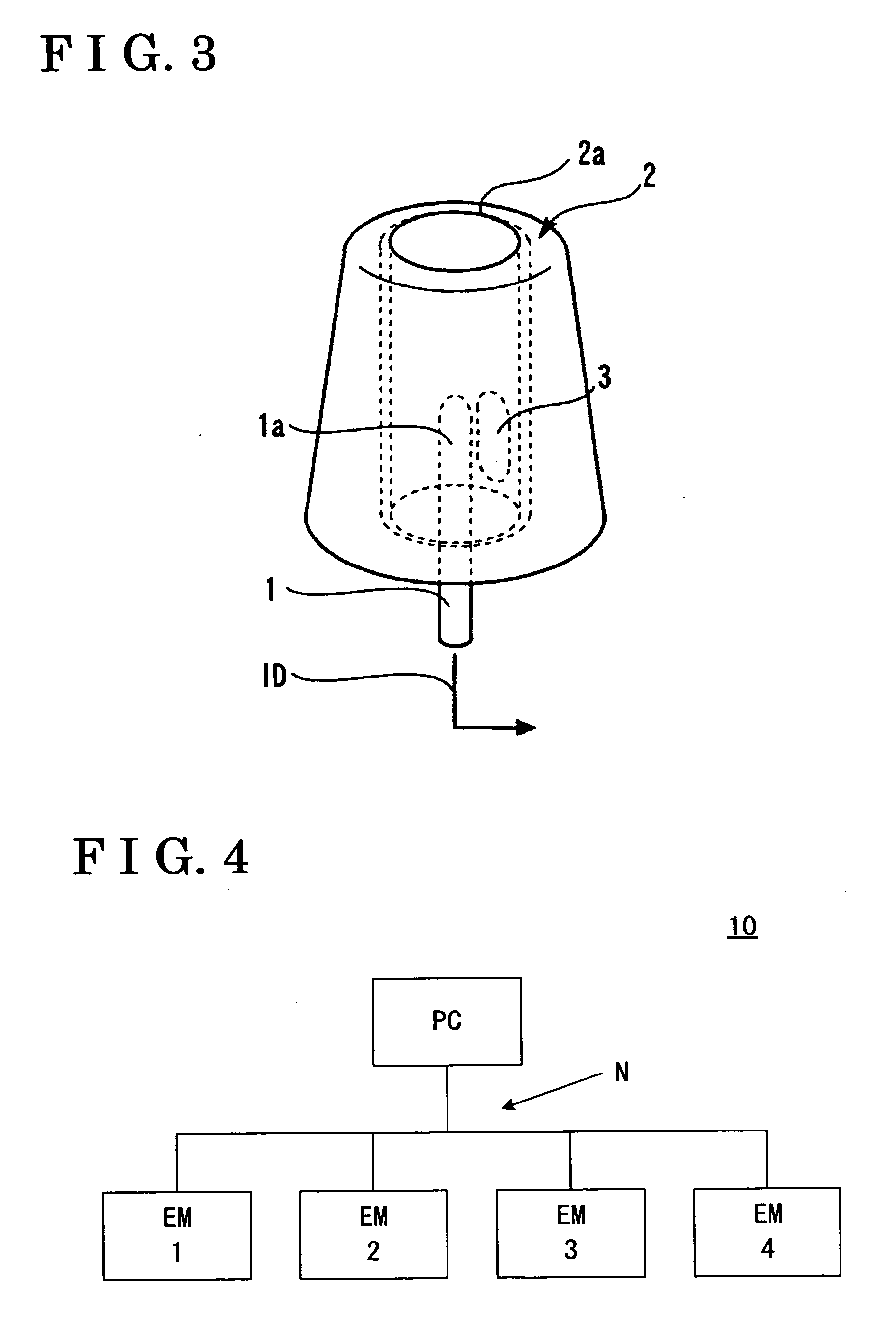

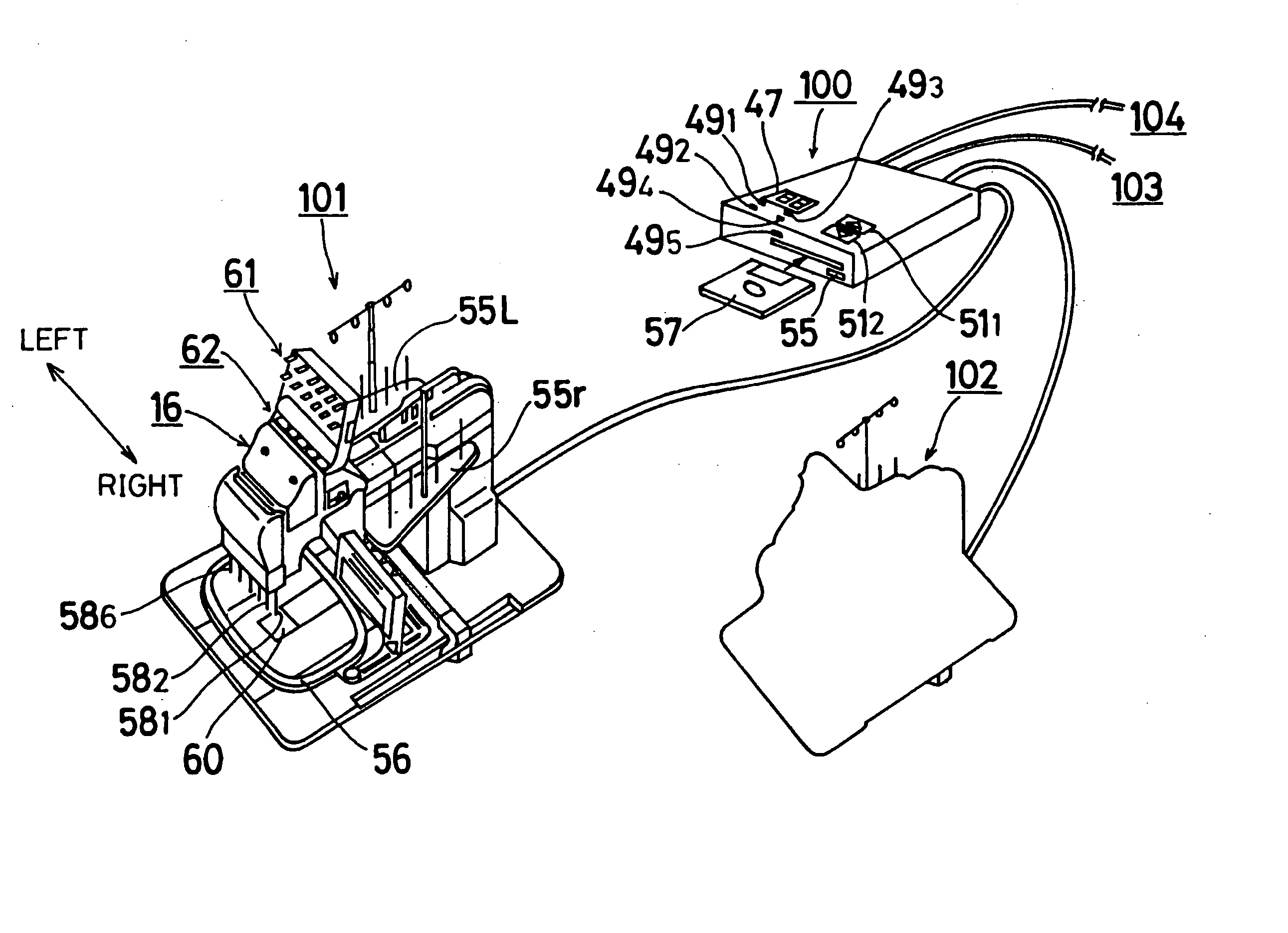

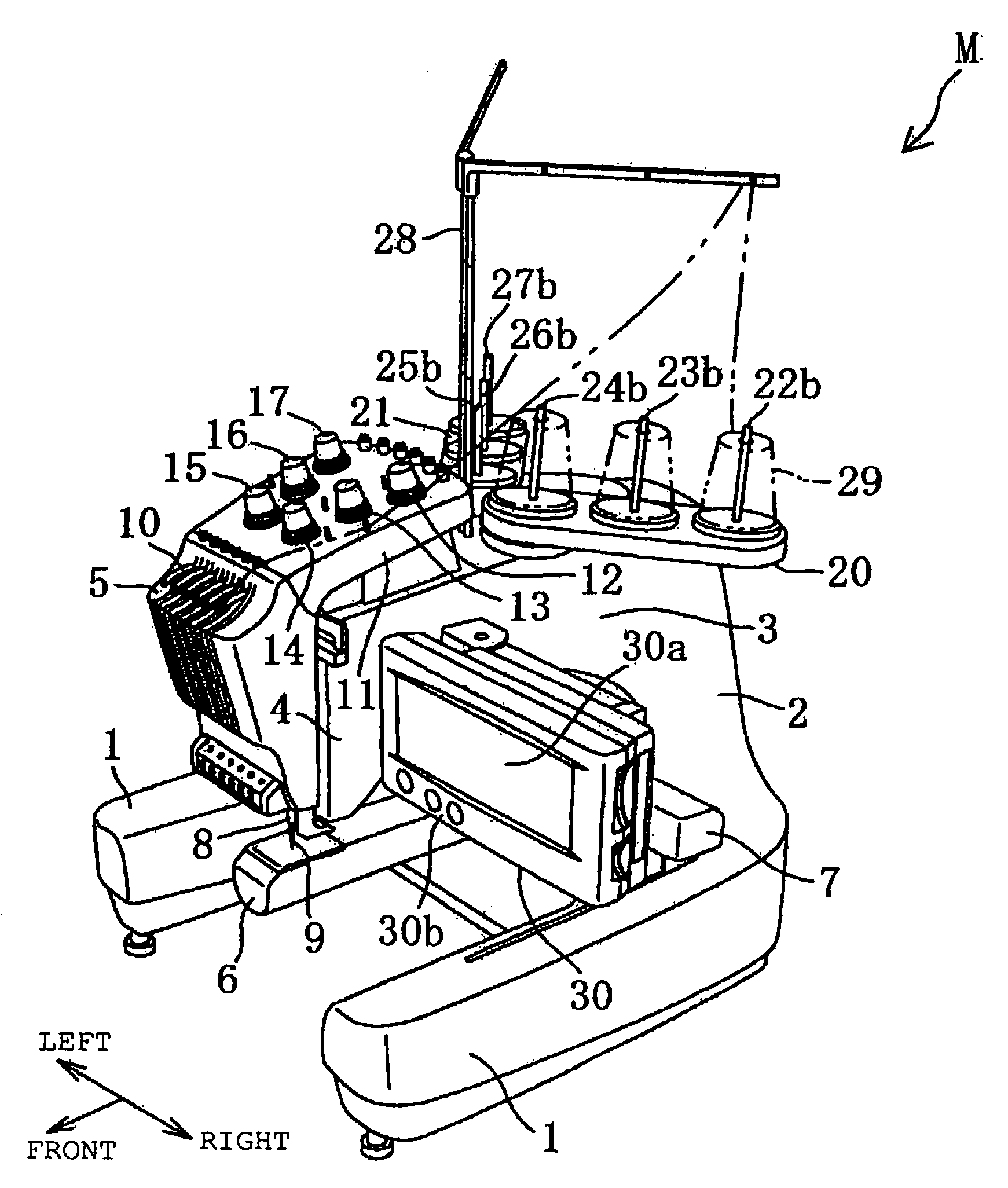

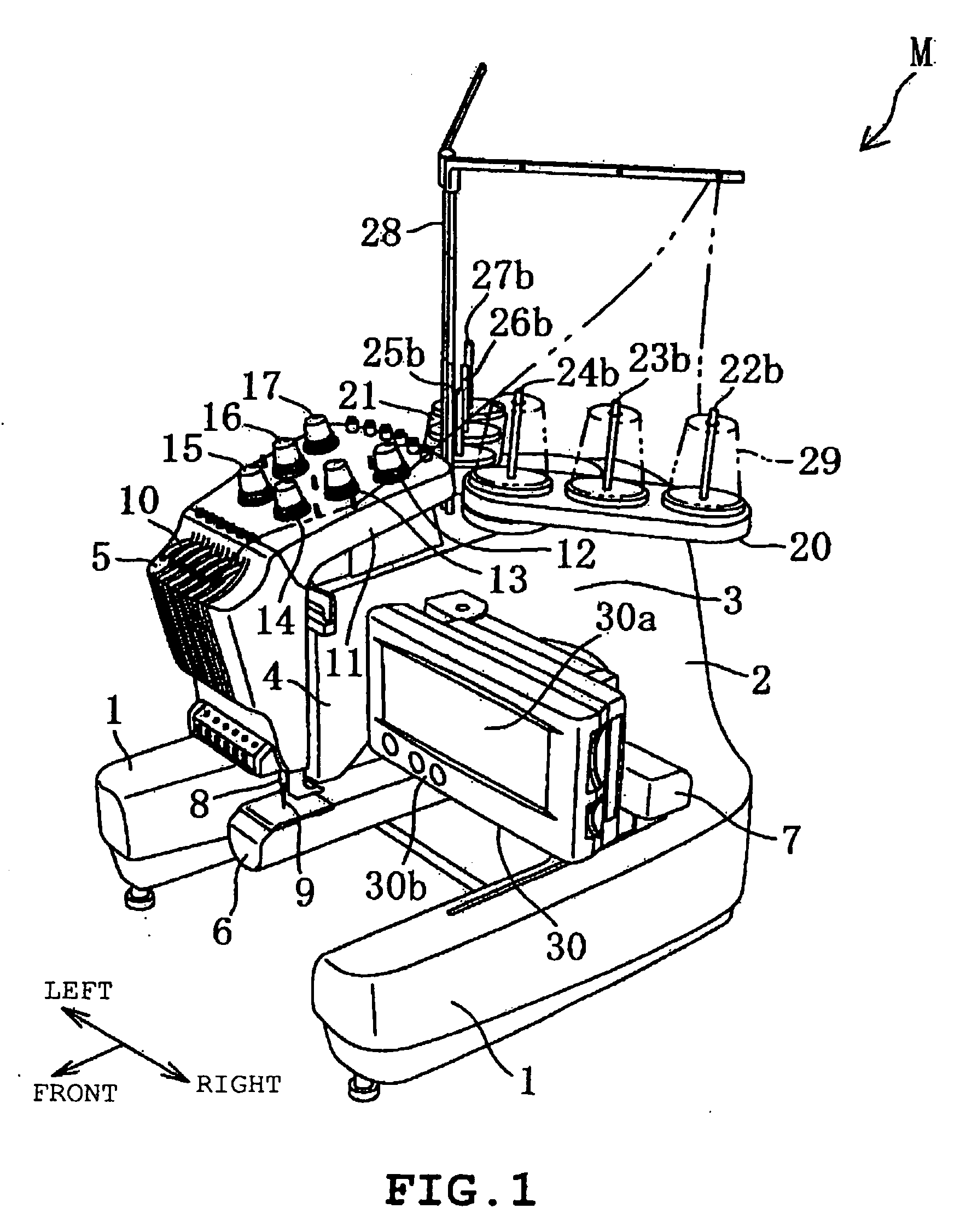

An embroidery machine includes a plurality of thread reel stand bars, a plurality of thread reels installed to the thread reel stand bars, respectively, a plurality of needles to which threads are supplied from the respective thread reels, at least two of the needles being selected to operate, on the basis of an embroidery data, in order for forming a stitch pattern of multiple colors, a wireless tag attached to each of the thread reels an having information related to the thread wound therearound, and a receiving device, for reading the information in the wireless tag, provided at each of the thread reel stand.

Owner:AISIN SEIKI KK

Embroidery machine and embroidery system

An embroidery machine includes a plurality of thread reel stand bars, a plurality of thread reels installed to the thread reel stand bars, respectively, a plurality of needles to which threads are supplied from the respective thread reels, at least two of the needles being selected to operate, on the basis of an embroidery data, in order for forming a stitch pattern of multiple colors, a wireless tag attached to each of the thread reels an having information related to the thread wound therearound, and a receiving device, for reading the information in the wireless tag, provided at each of the thread reel stand.

Owner:AISIN SEIKI KK

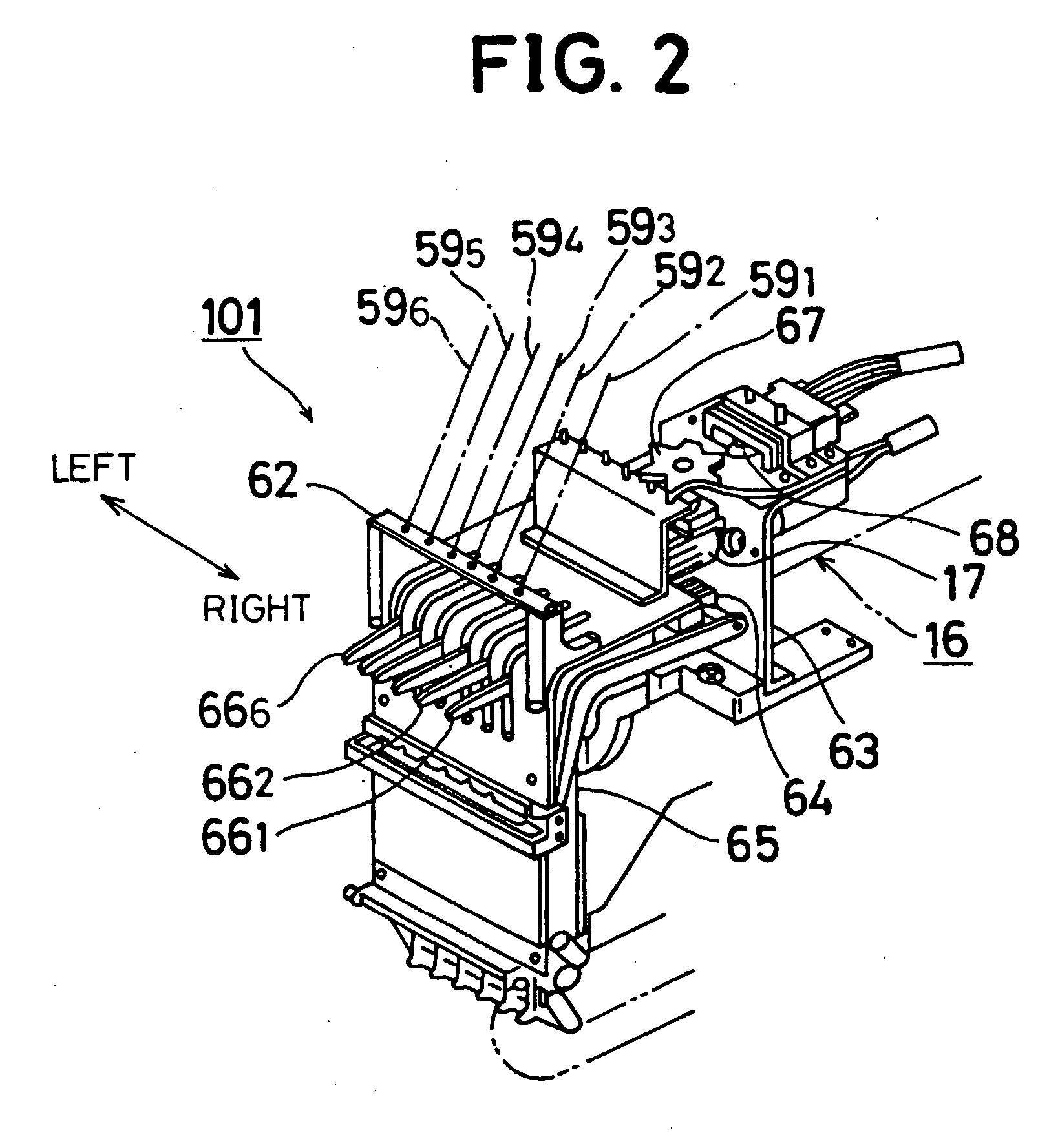

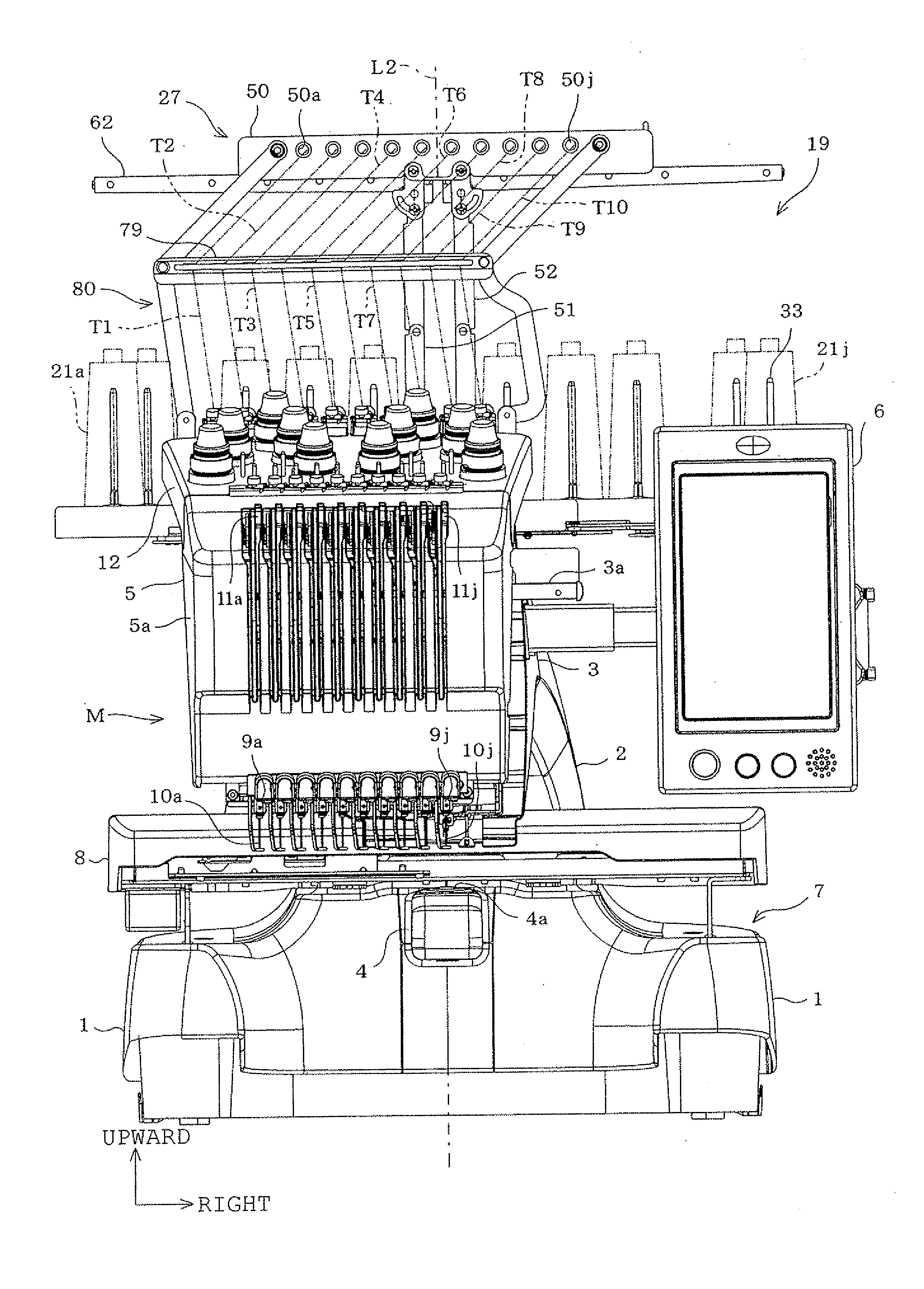

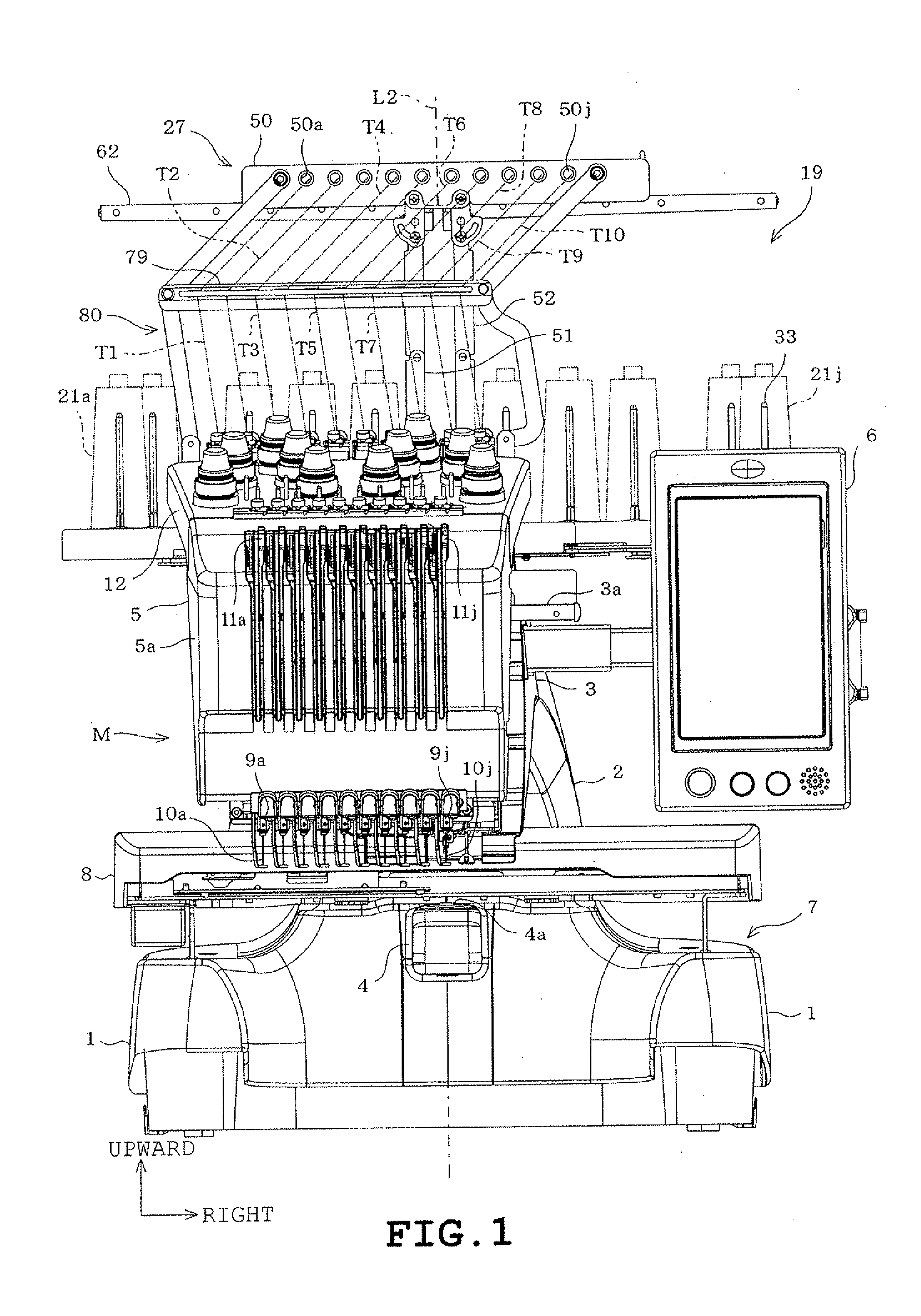

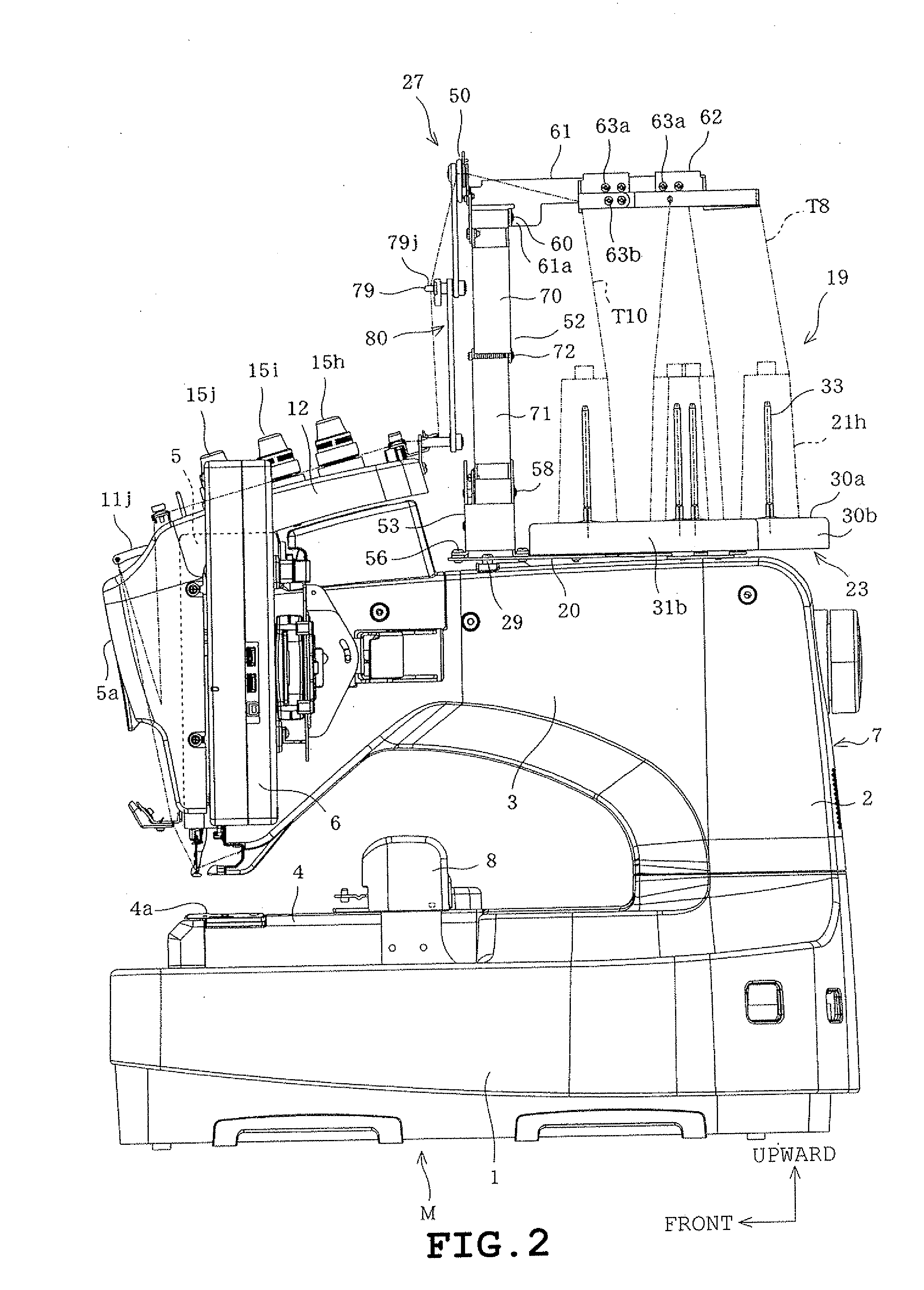

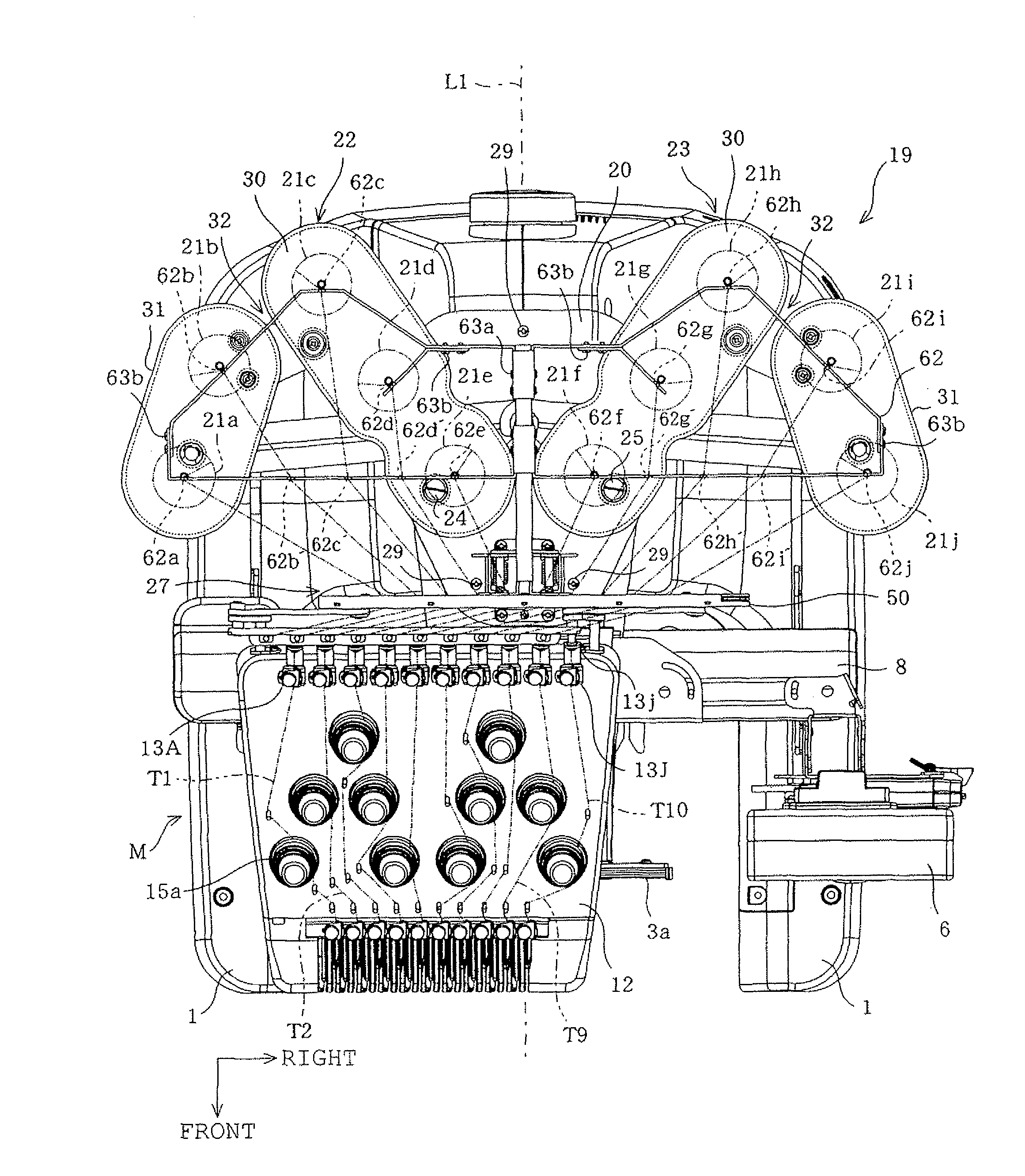

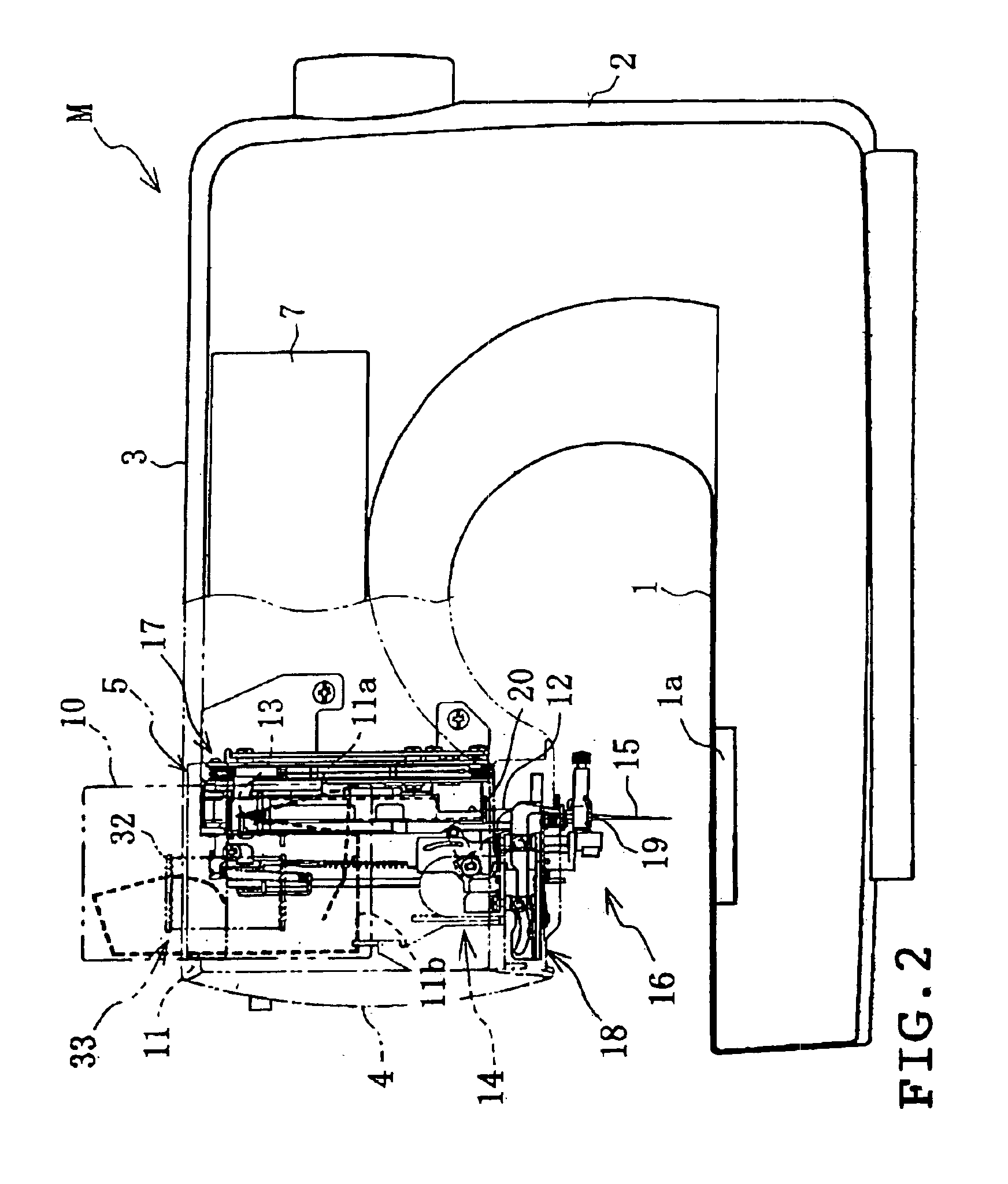

Embroidering machine

InactiveUS20050188906A1Avoid enteringProgramme-controlled sewing machinesSpool-pin assembliesLight beamComputer science

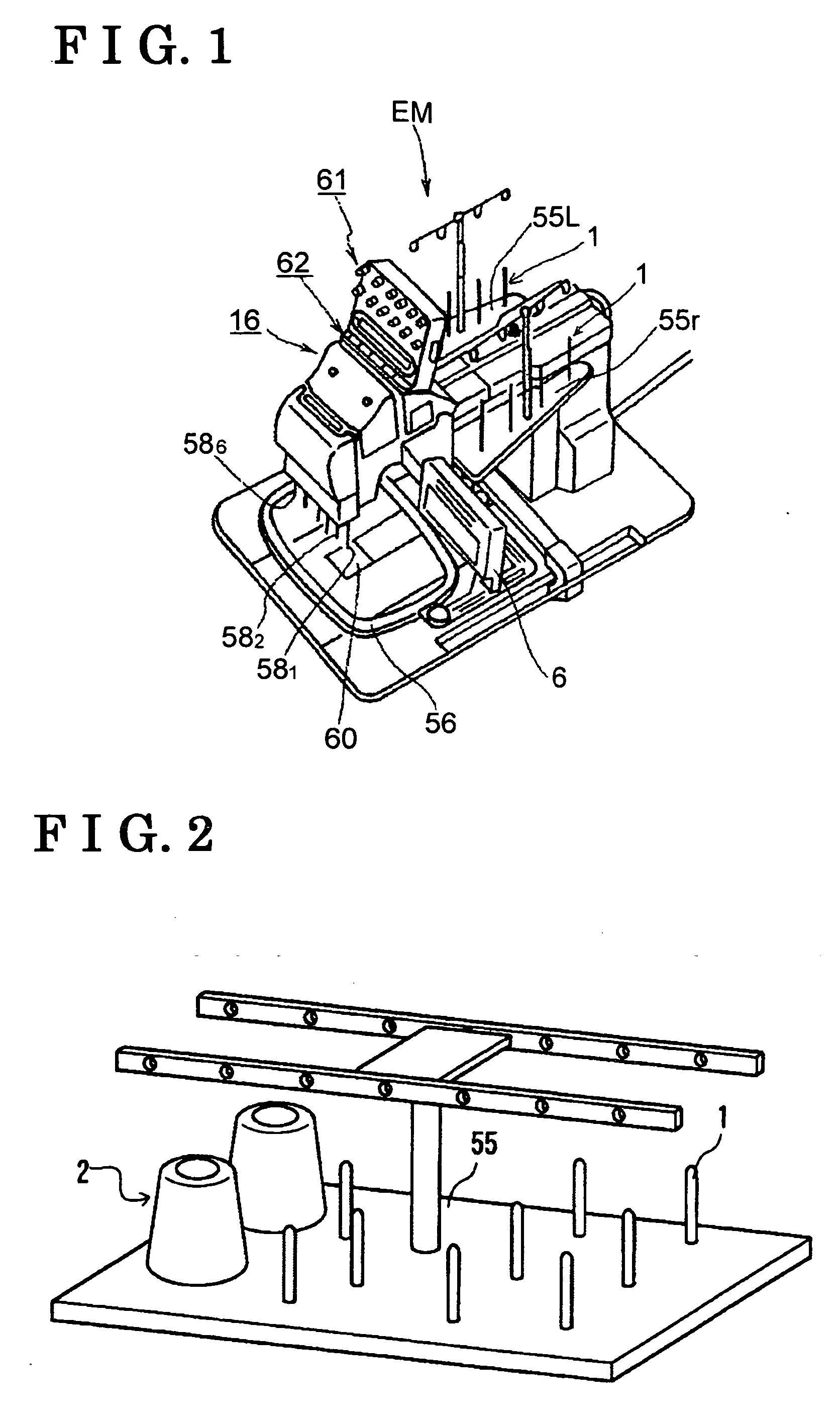

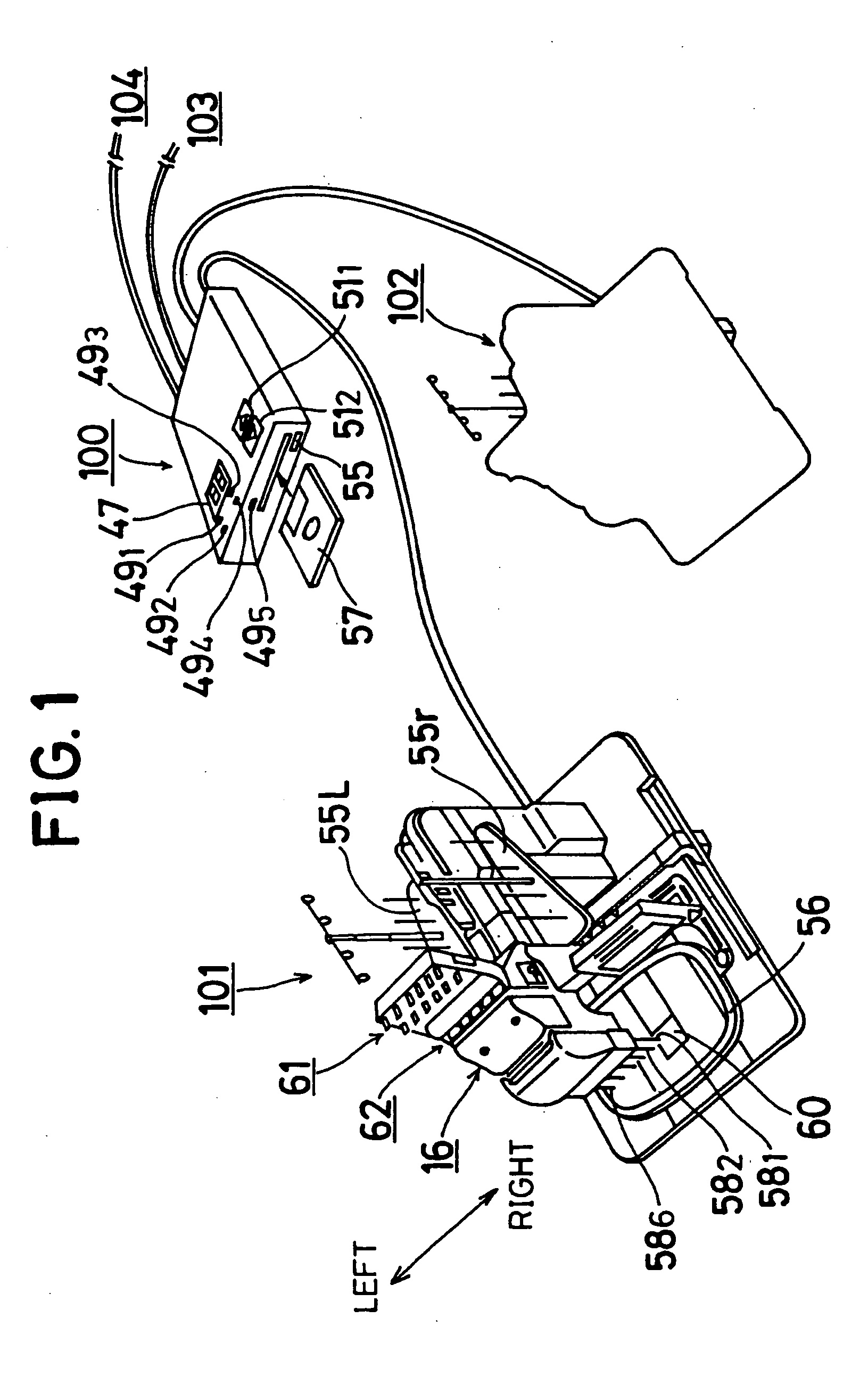

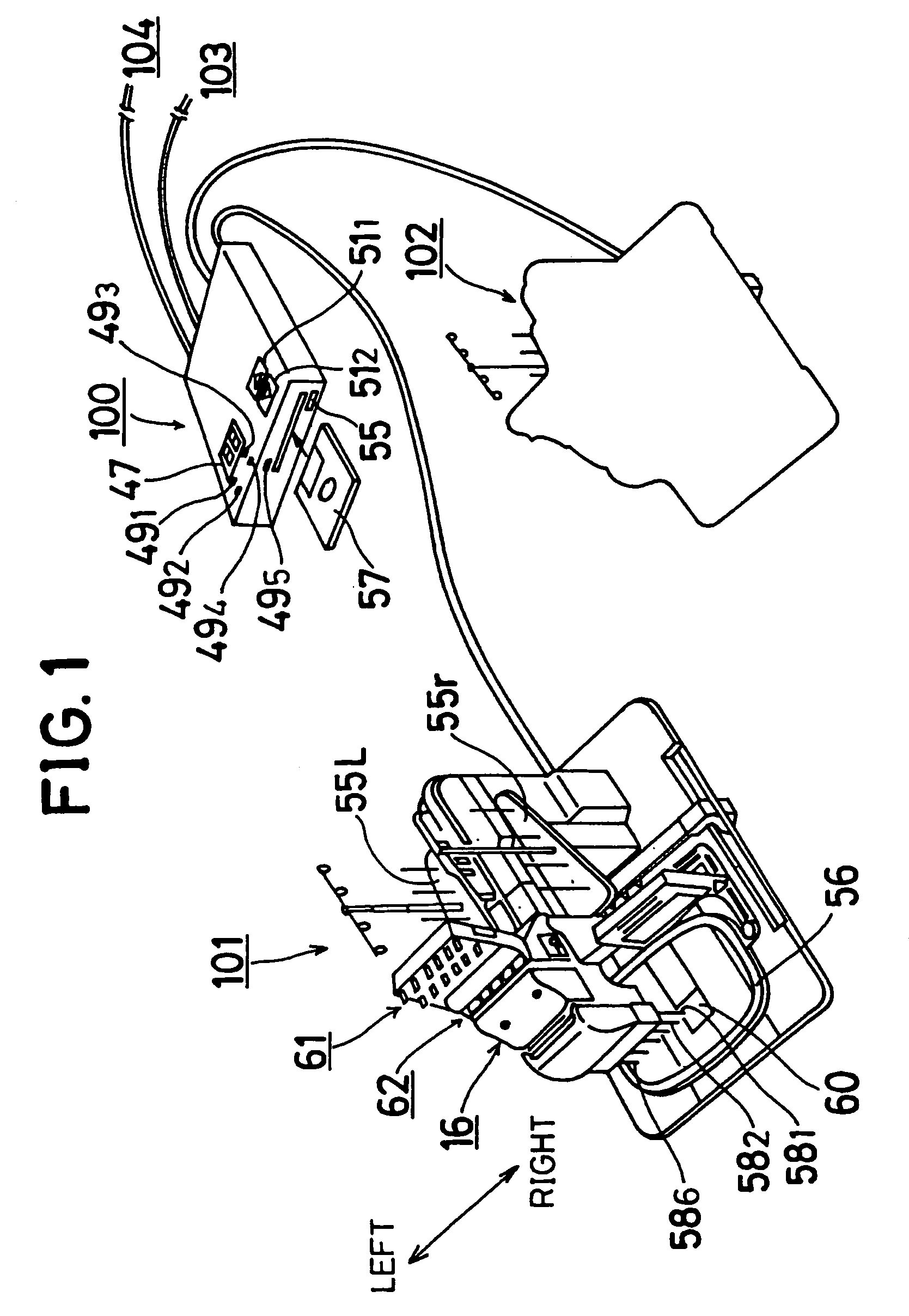

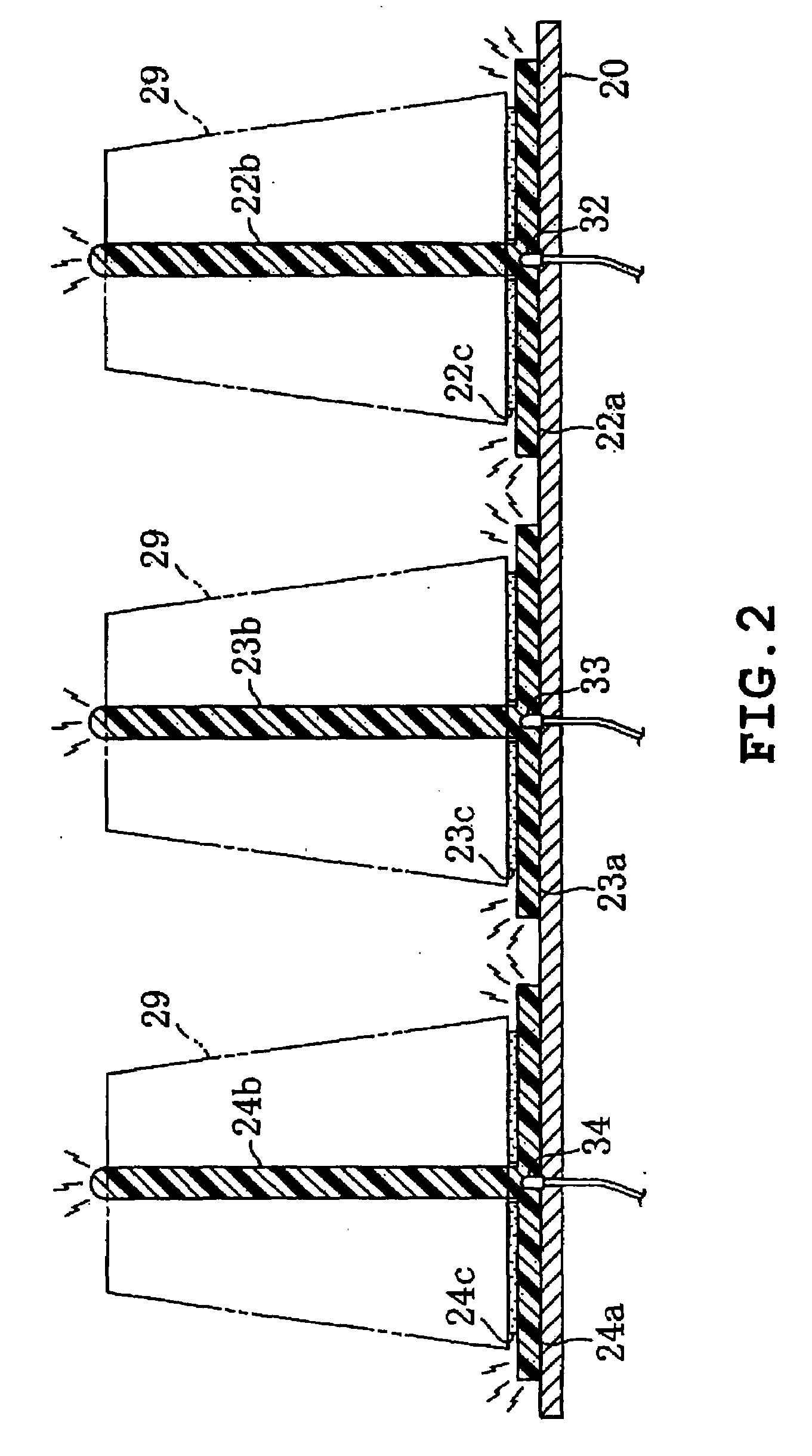

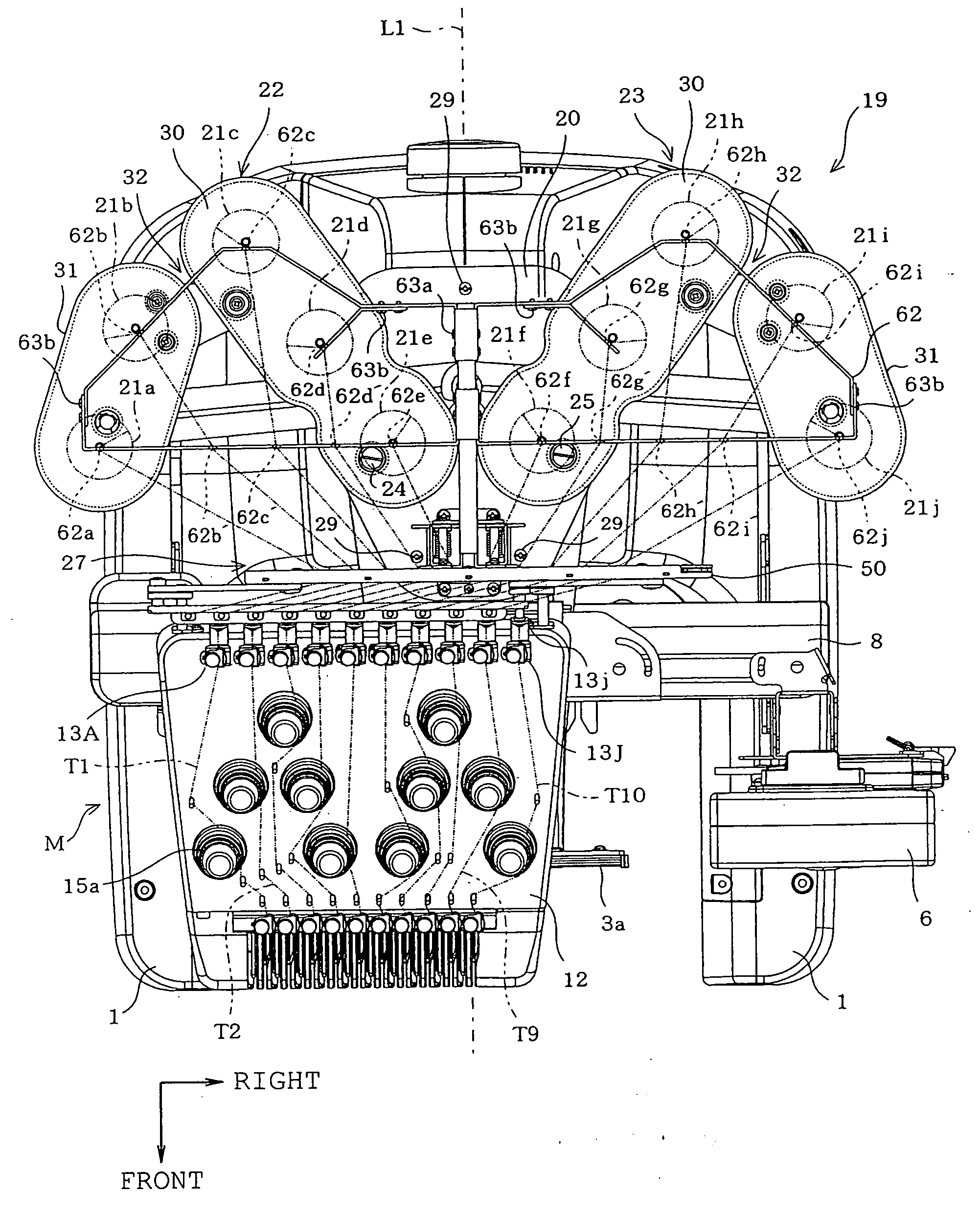

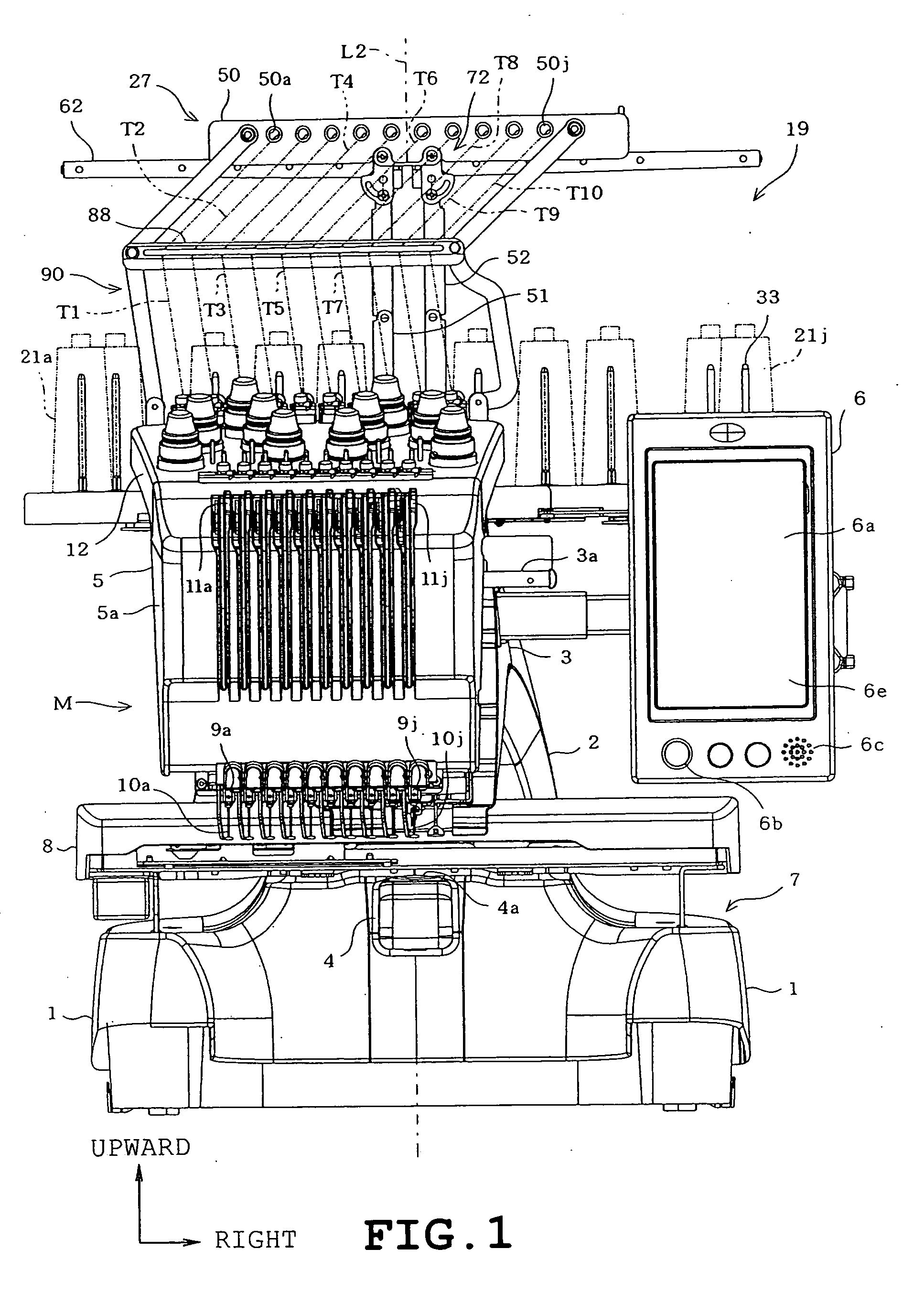

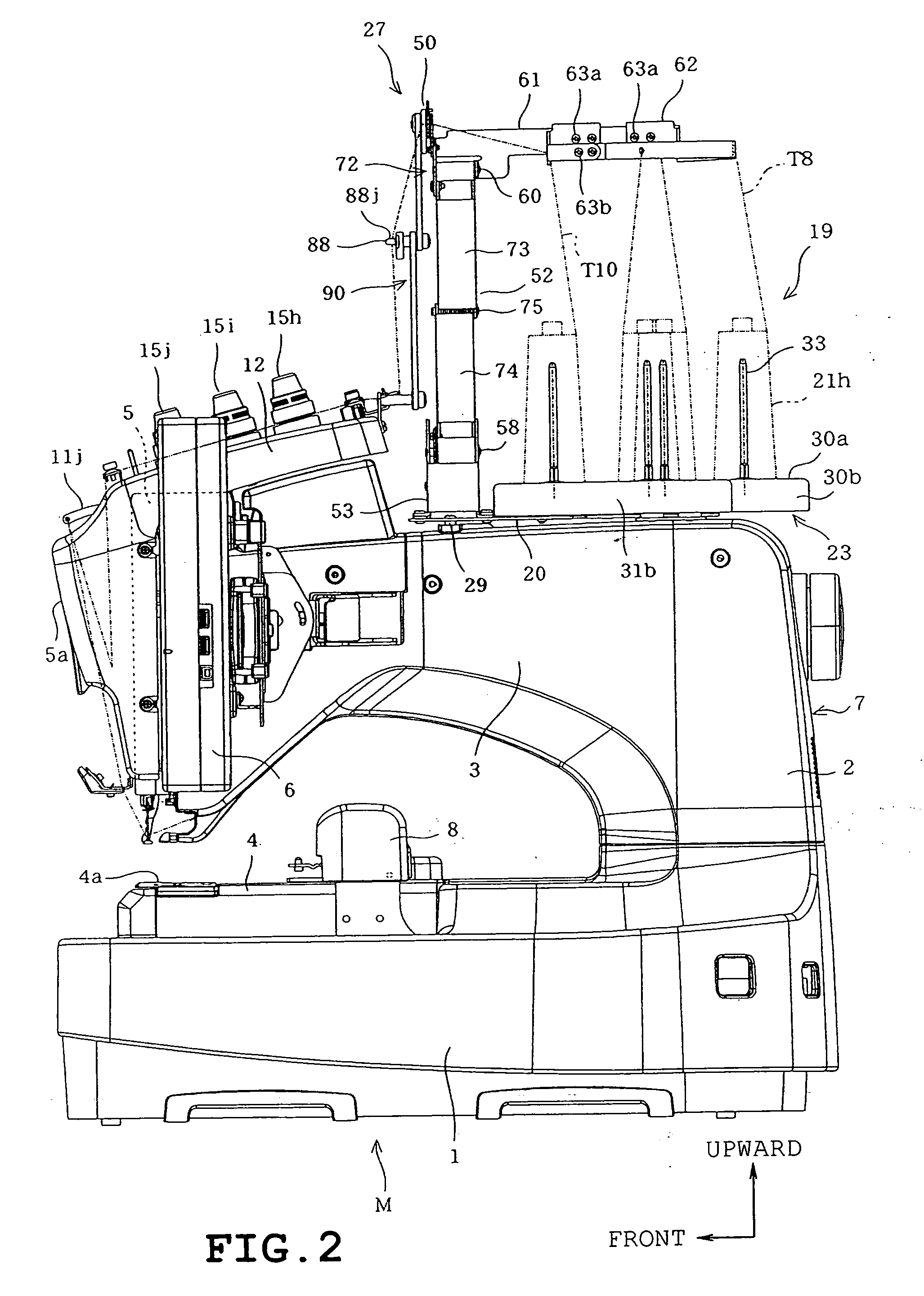

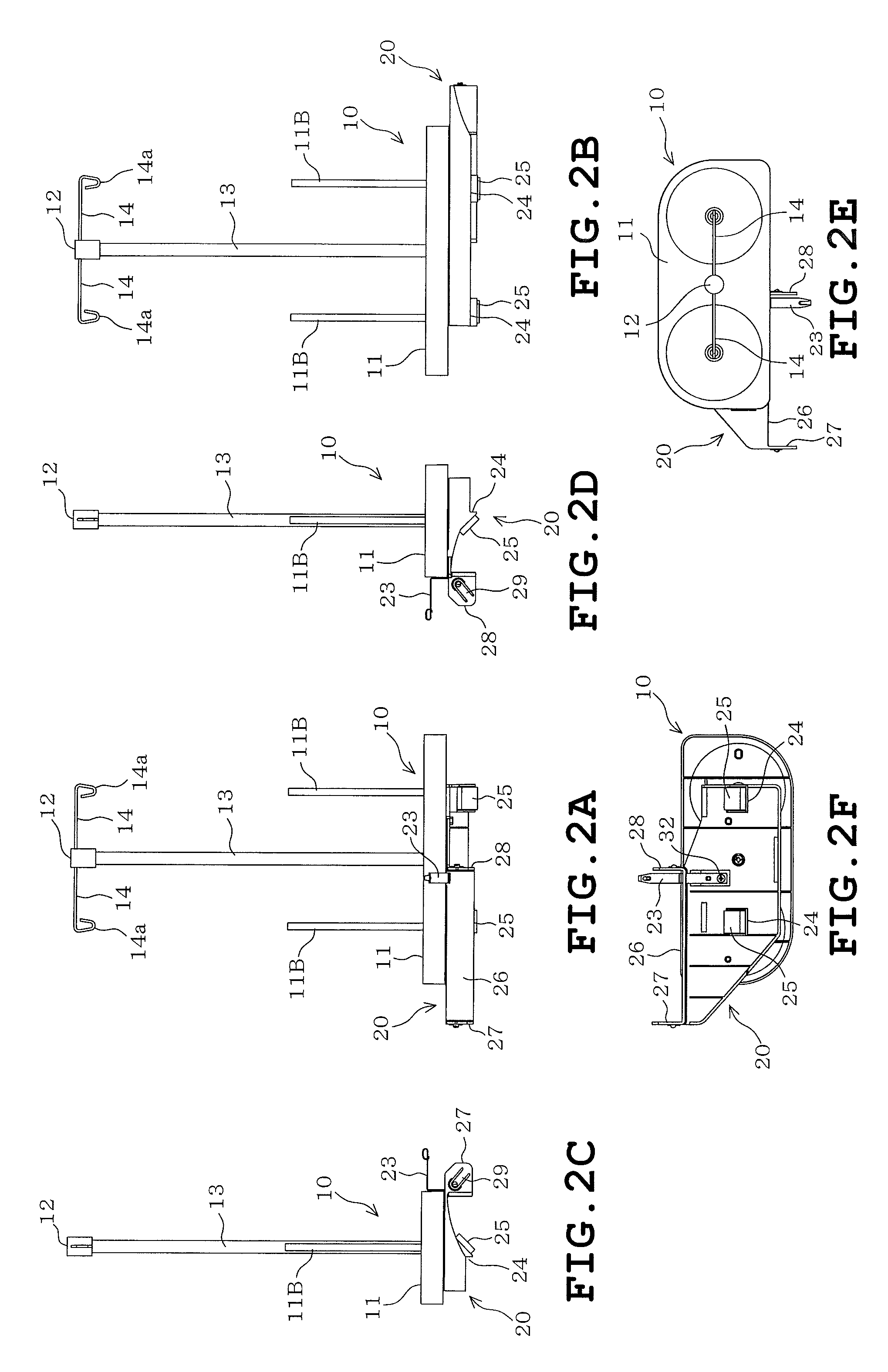

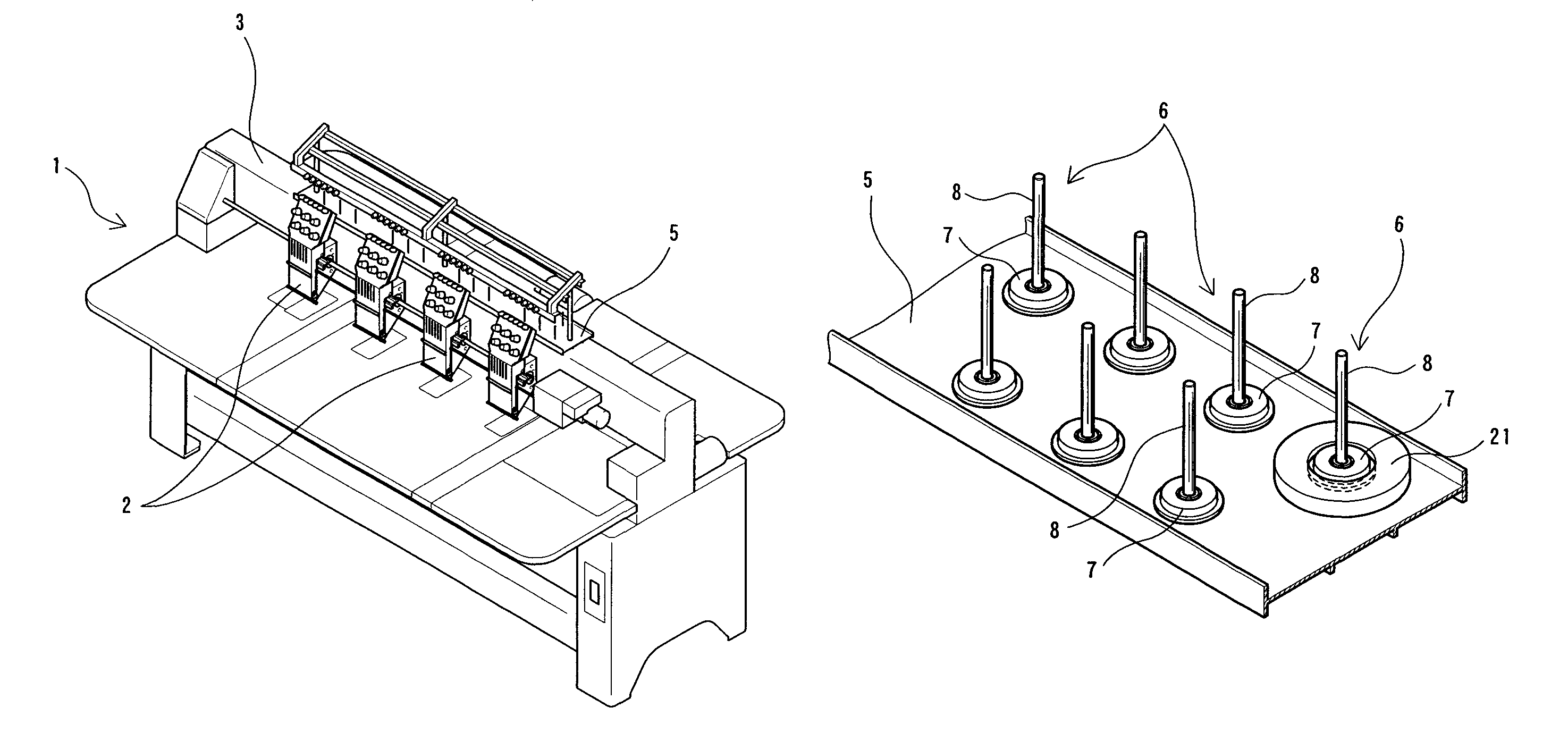

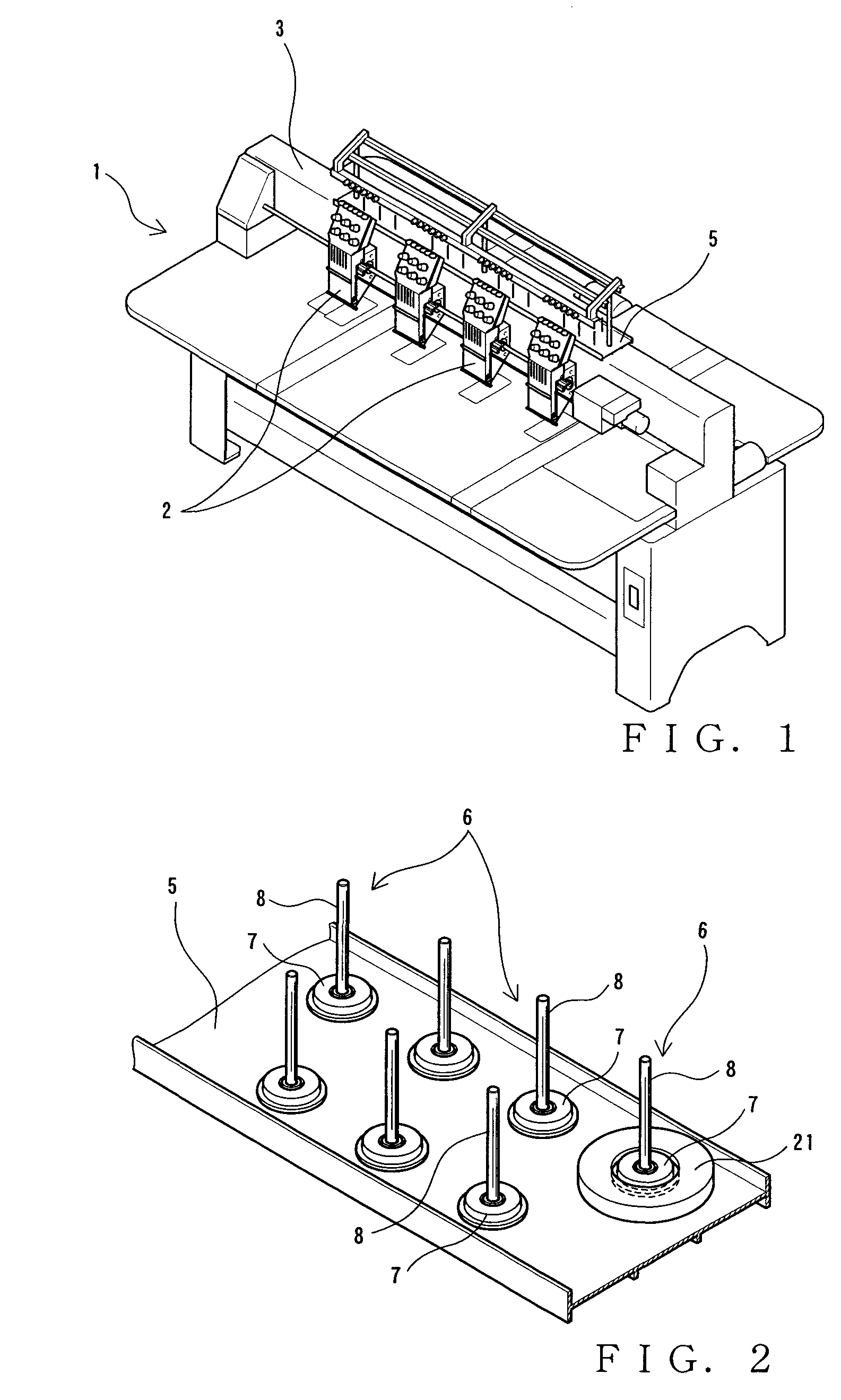

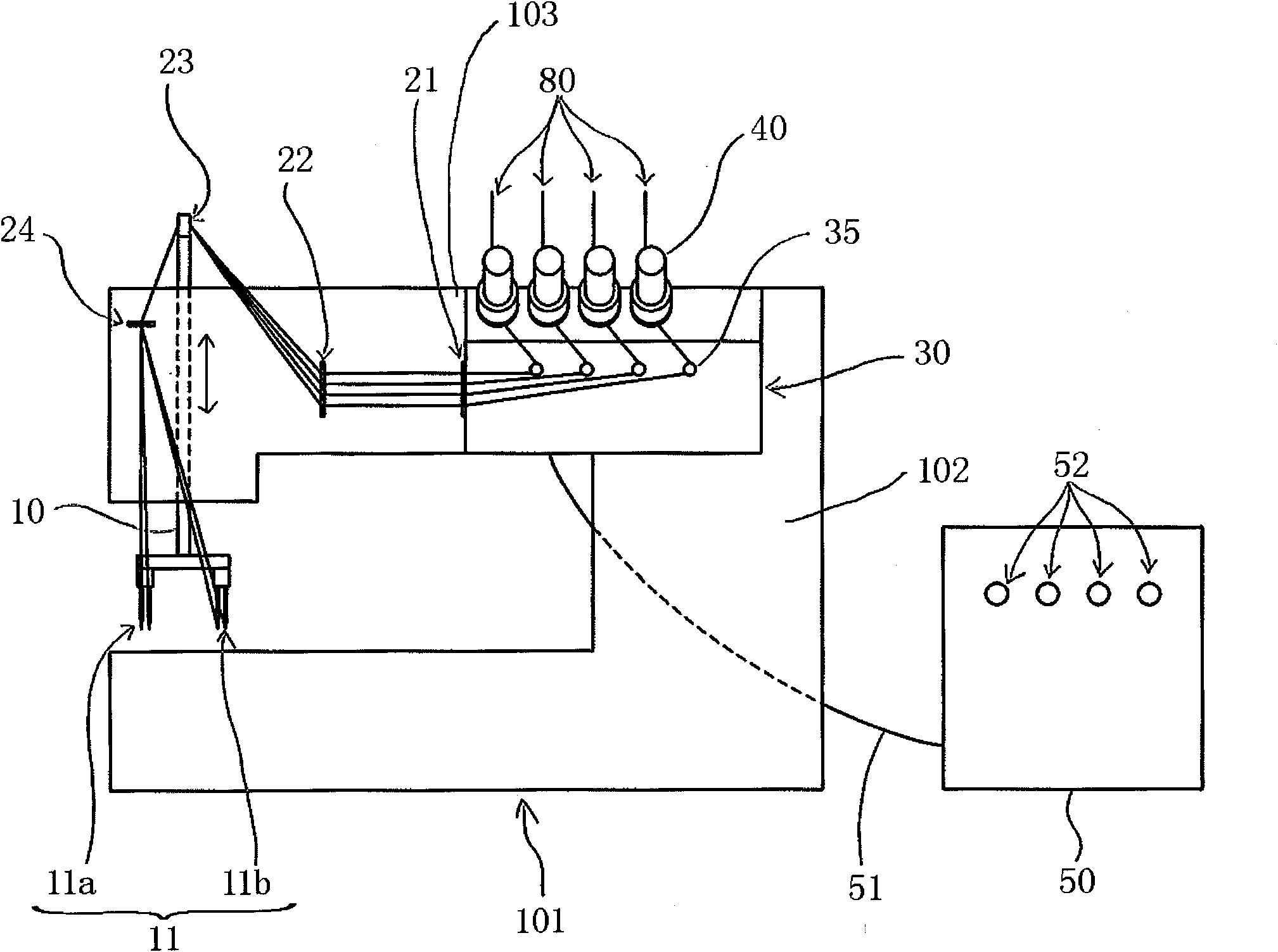

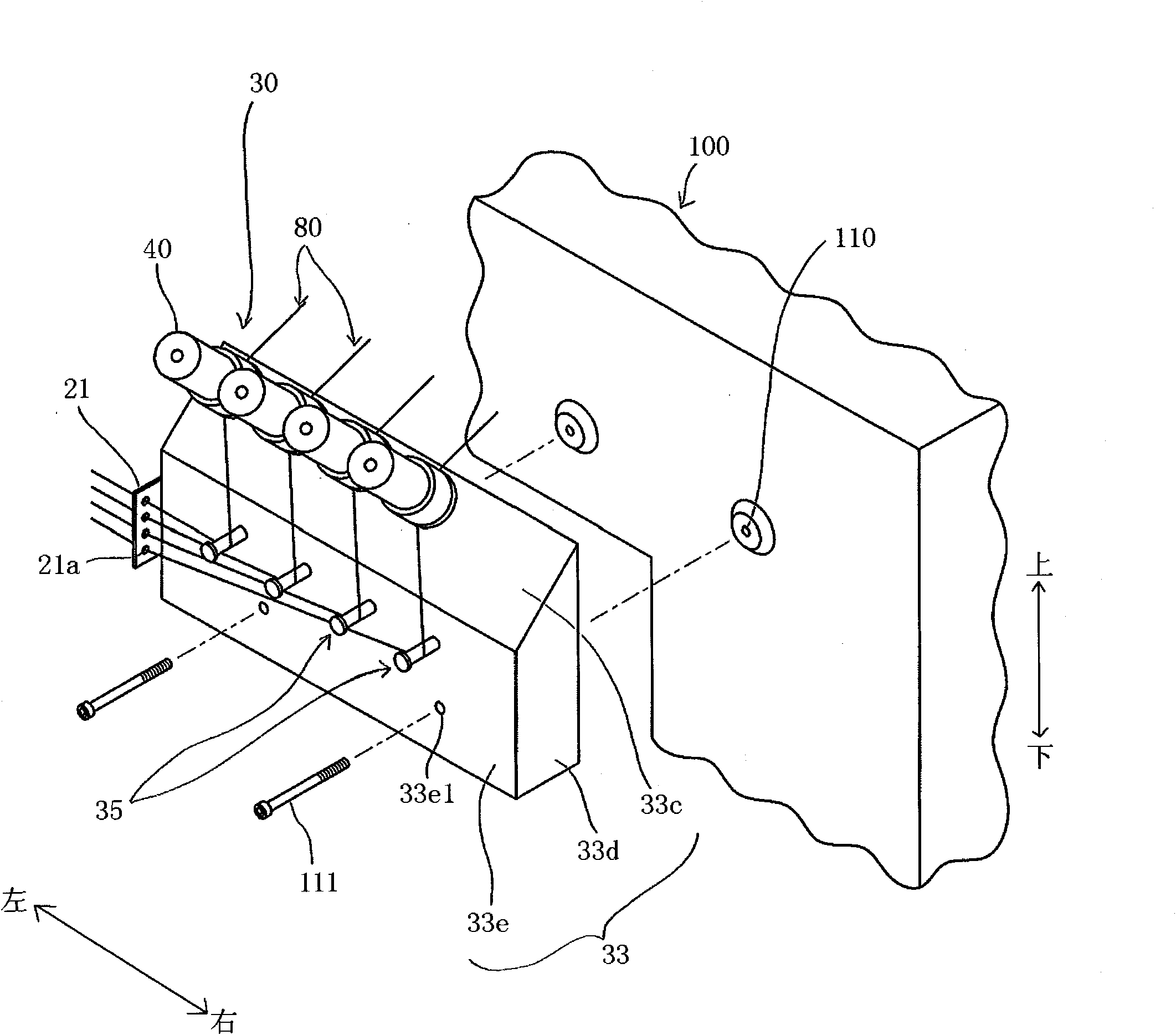

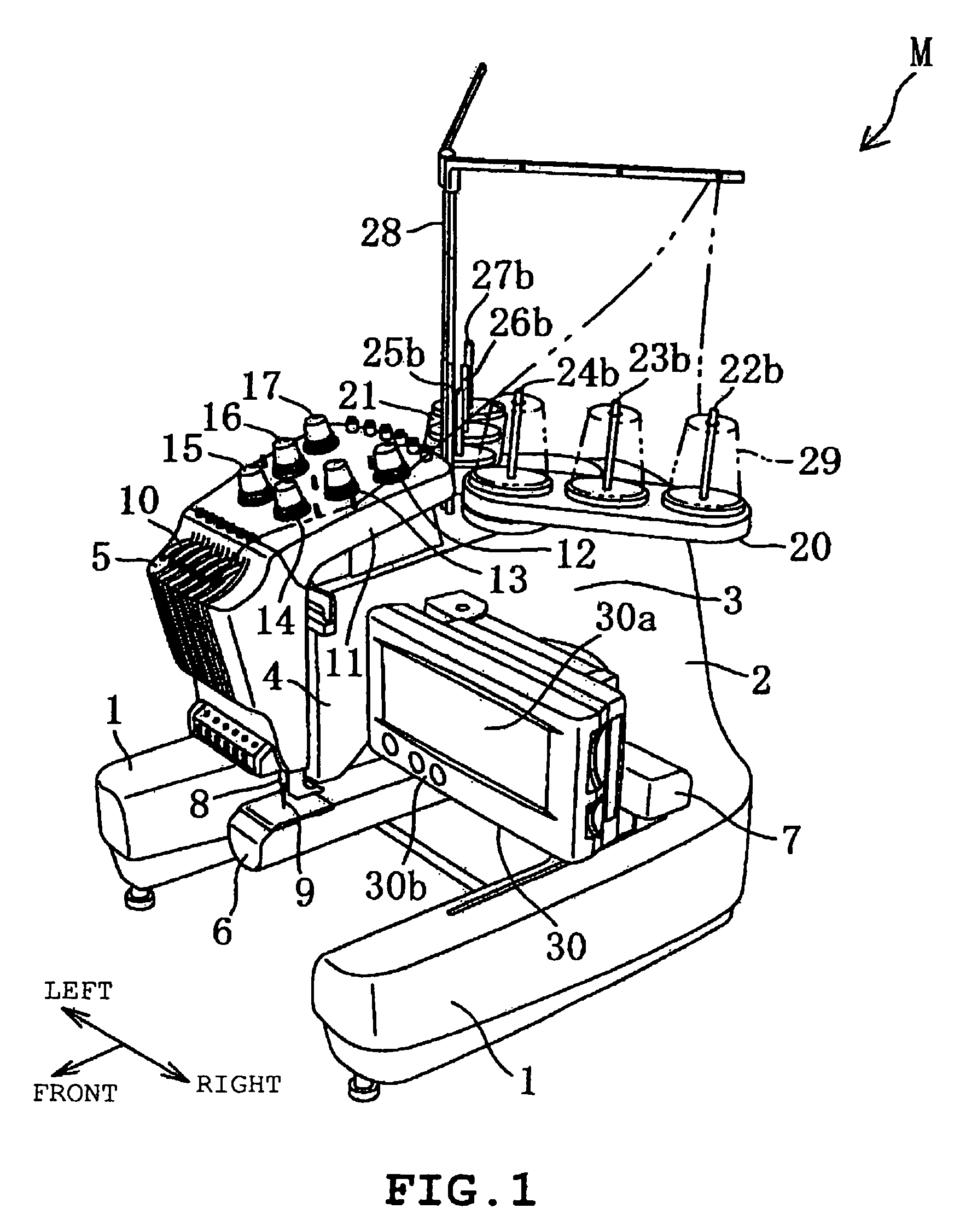

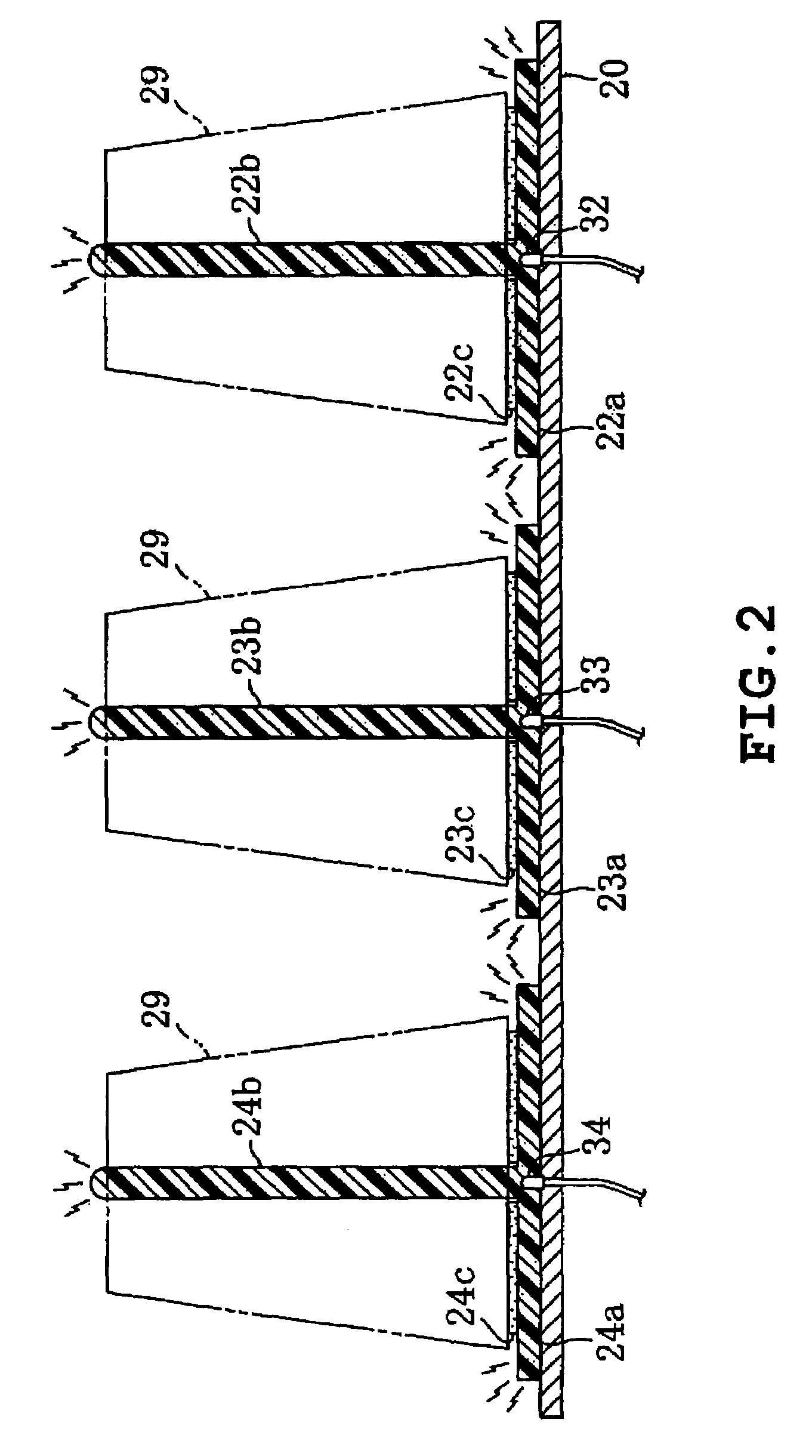

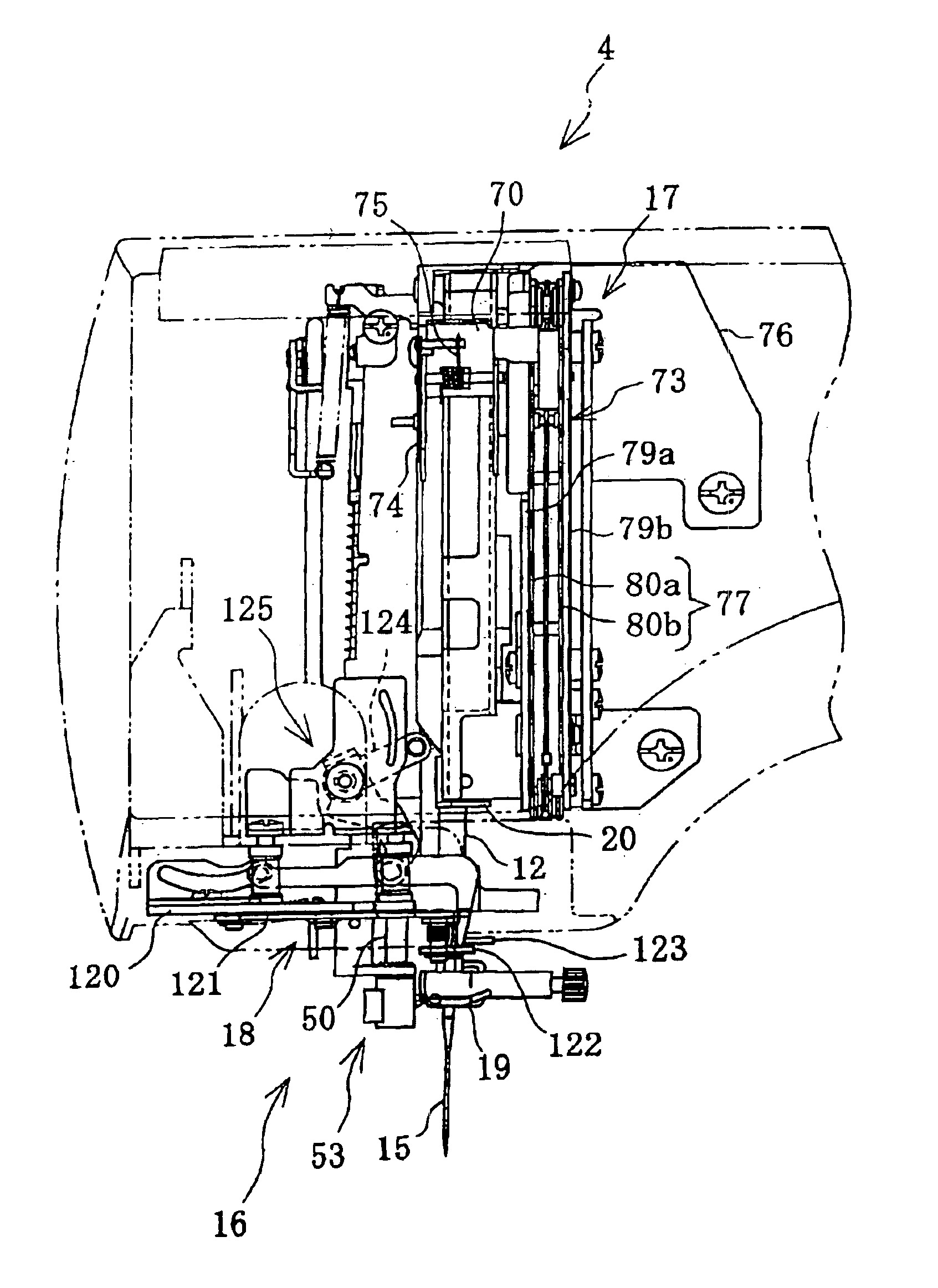

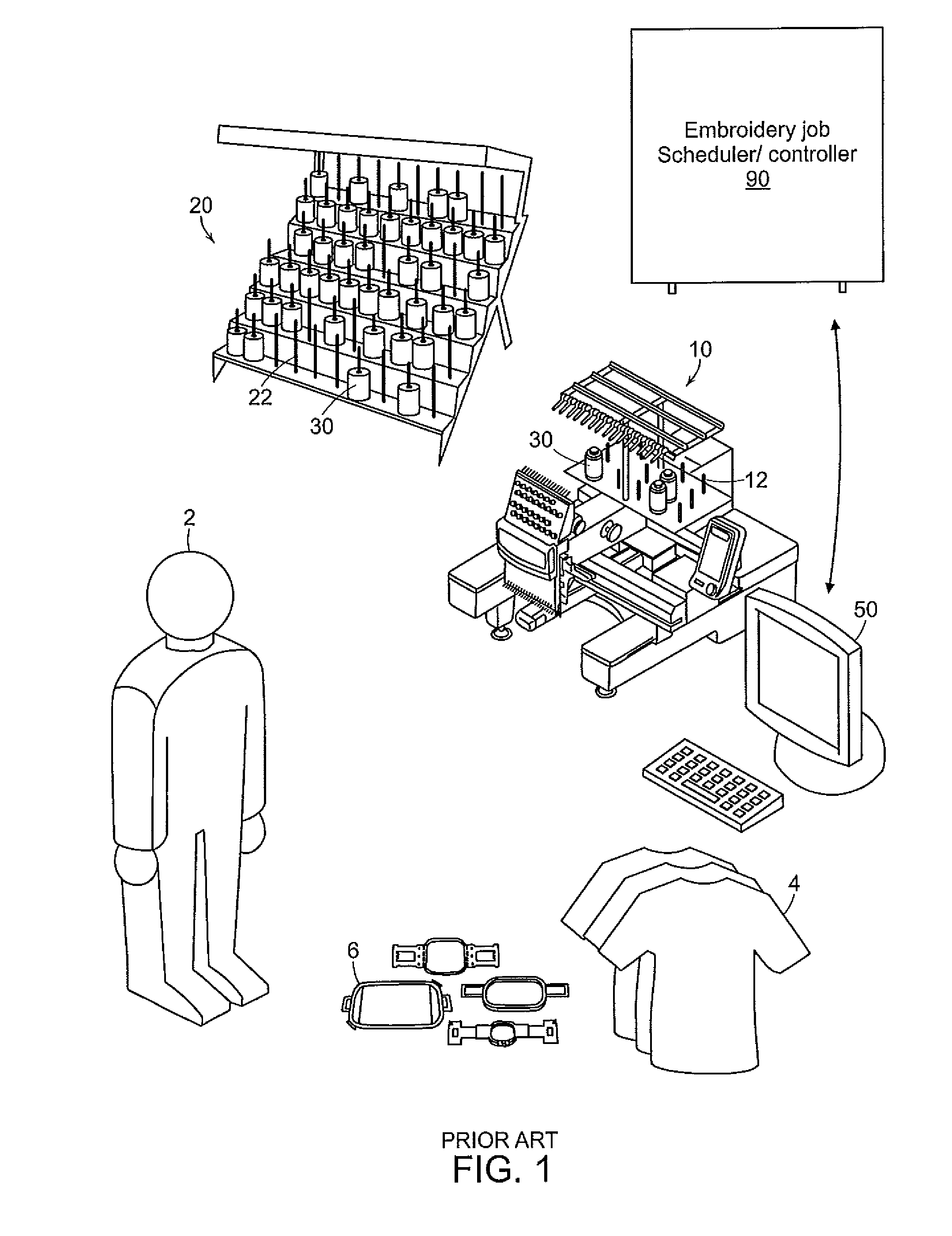

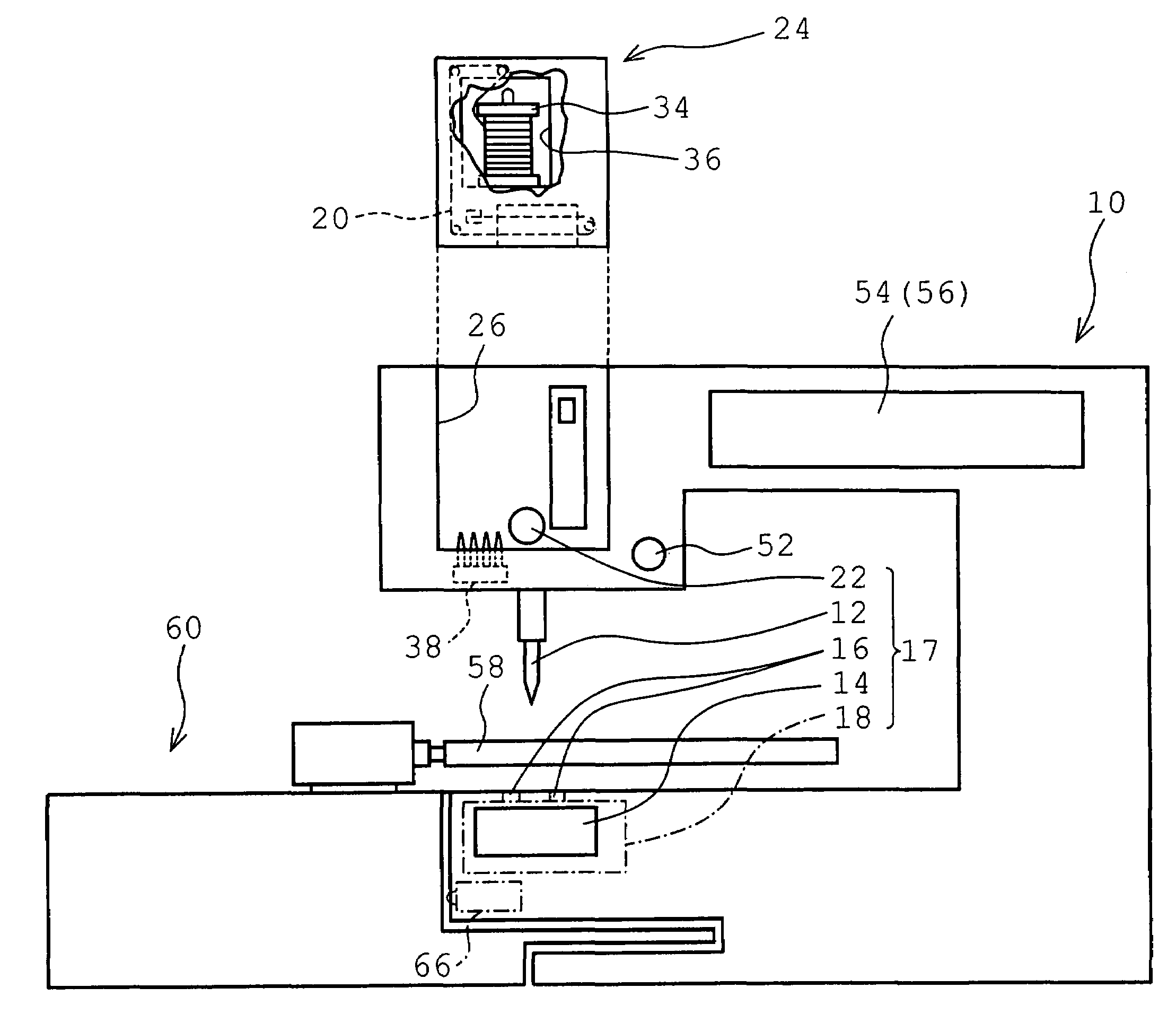

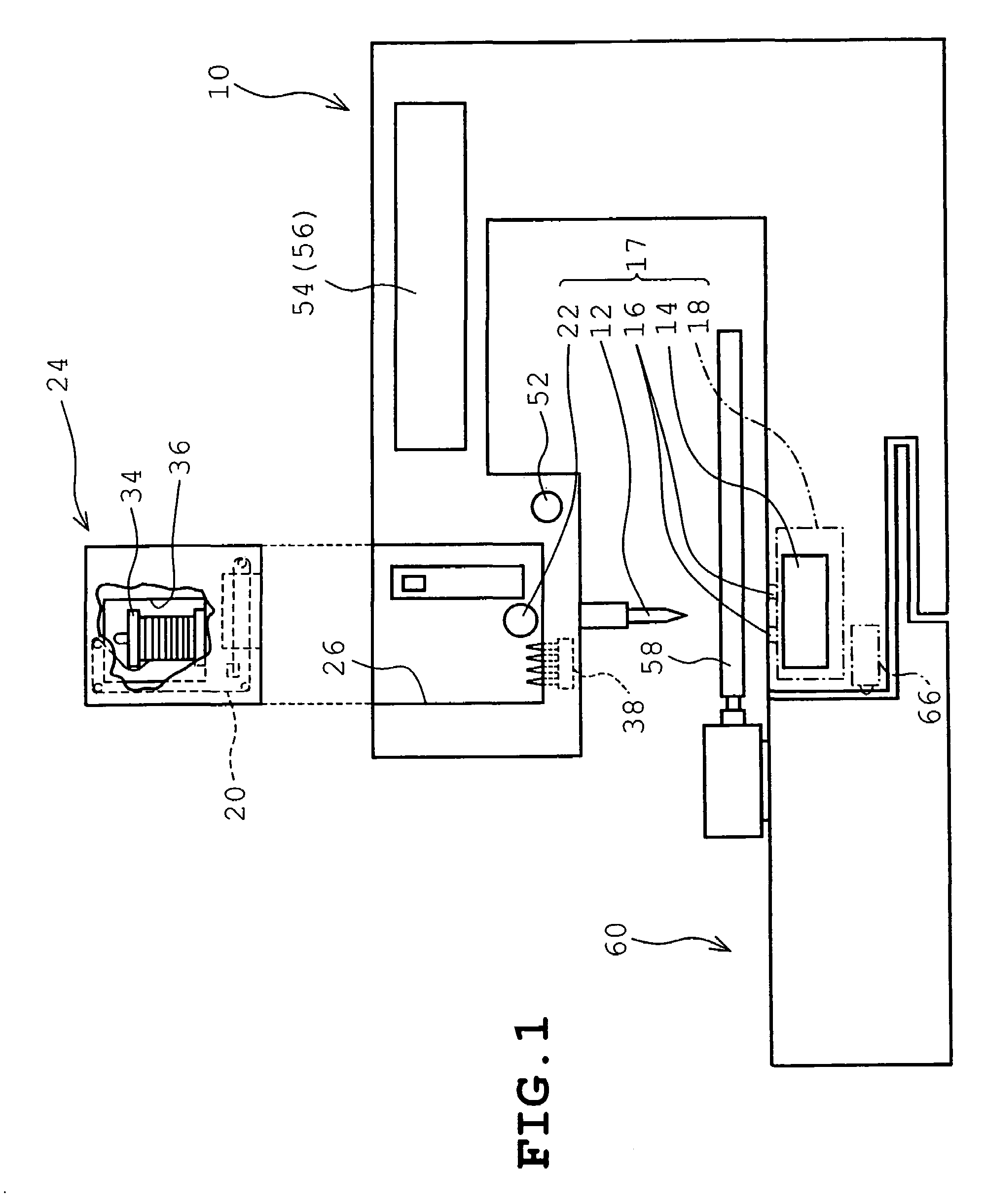

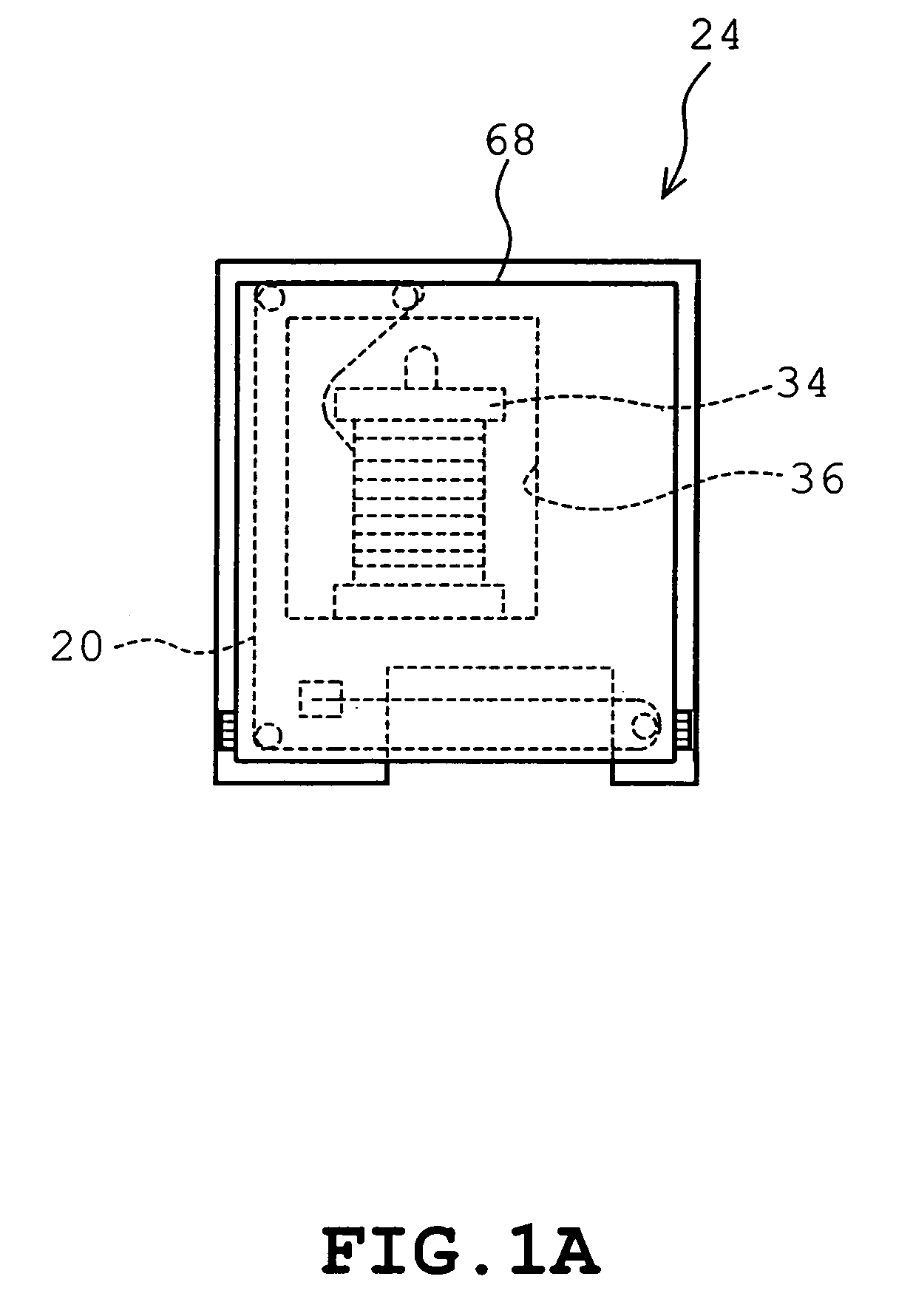

The present invention provides an embroidering machine which is made up of a thread station at which a plurality of spools of different colored threads are installed; a frame on which a work-piece is carried in tension mode; an embroidery stitching mechanism having a plurality of needles to which the colored threads are routed, respectively, and stitching the work-piece with the colored thread routed to a selected needle; a color recognizing device for recognizing the color of each of the threads routed to the respective needles; data reading means for reading embroidering data relating to the embroidering pattern; a comparing device matching a color indication included in the embroidering data with the color of each of the threads which is recognized by the color recognizing device, the comparing device selecting one of the threads to which the thread of the matched color is routed for determining the selected needle; and a control device for controlling the selected needle of the embroidery stitching mechanism and the frame to produce an embroidering pattern on the work-piece with the matched color thread. The color recognizing device includes an emitting portion from which a beam of light is emitted to the corresponding thread, a receiving a reflection beam of light reflected from the thread, and a light shielding device provided between the emitting portion and the receiving portion for the prevention of an entrance of light into the receiving portion except for the reflection beam of light.

Owner:AISIN SEIKI KK

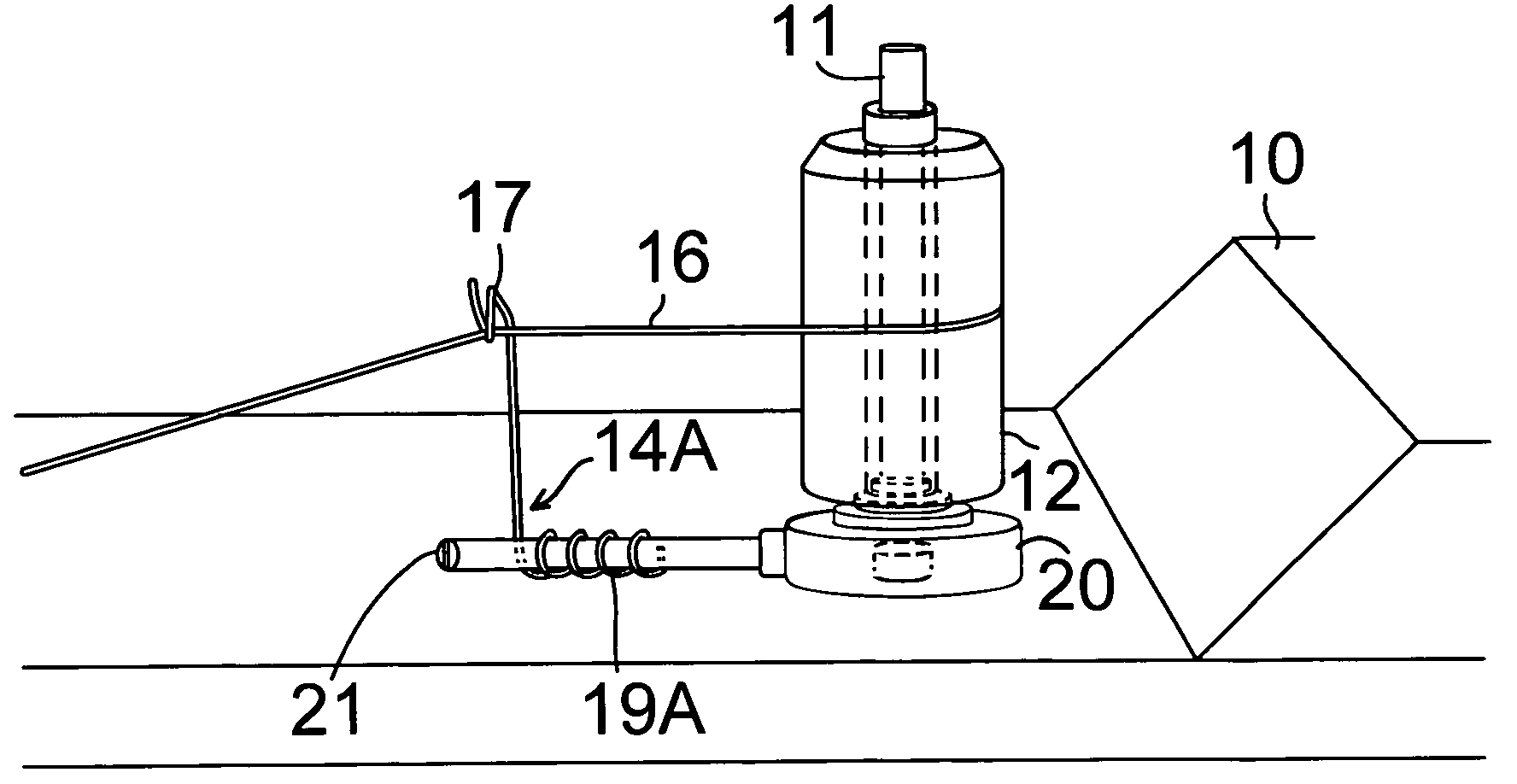

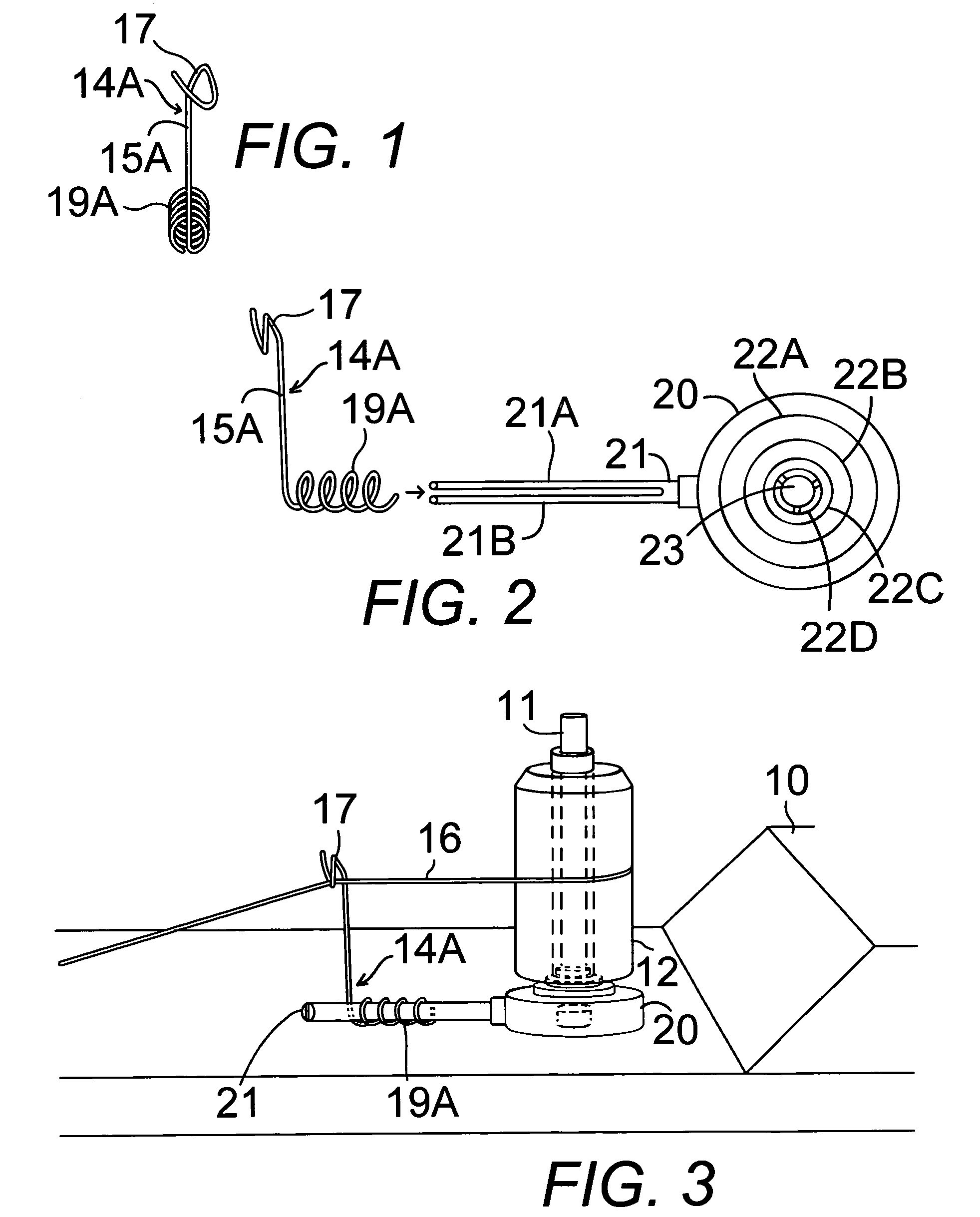

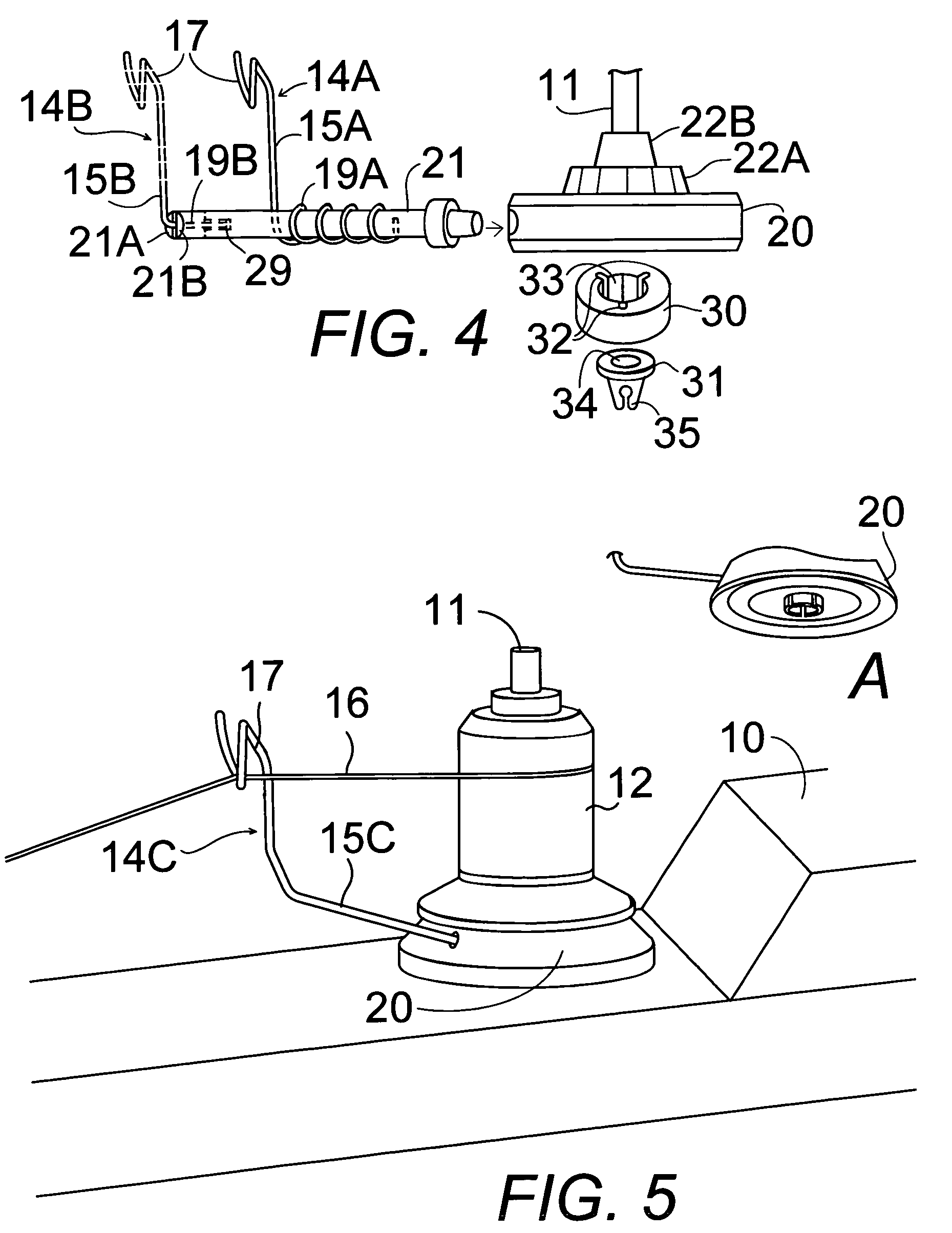

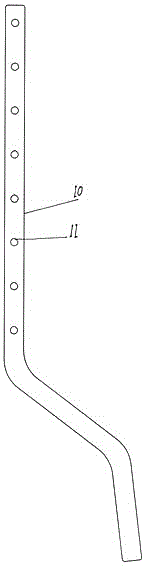

Sewing machine embroidery thread guide

InactiveUS7219611B1Easy thread loading and tangle-free feeding of threadEvenly distributedFilament handlingSpool-pin assembliesEngineeringGuide wires

A bent embroidery thread guide wire is attached to a base mount releasably attachable to a spool pin rod of an embroidery and sewing machine. An open spiral bent loop end of the upwardly bent wire adjusts to a position spaced slightly apart from and approximately centered on an embroidery thread spool mounted on the machine. The embroidery thread feeds from the spool through the open looped end, through the normal threading procedure of the machine, to the thread consuming needle apparatus under tension. A transverse bar extending from the base mount allows the guide wire to slide adjustably thereon to move toward or away from the spool. A stepped base mount receives embroidery thread spools of different diameters.

Owner:TRONCOSO EVA G +1

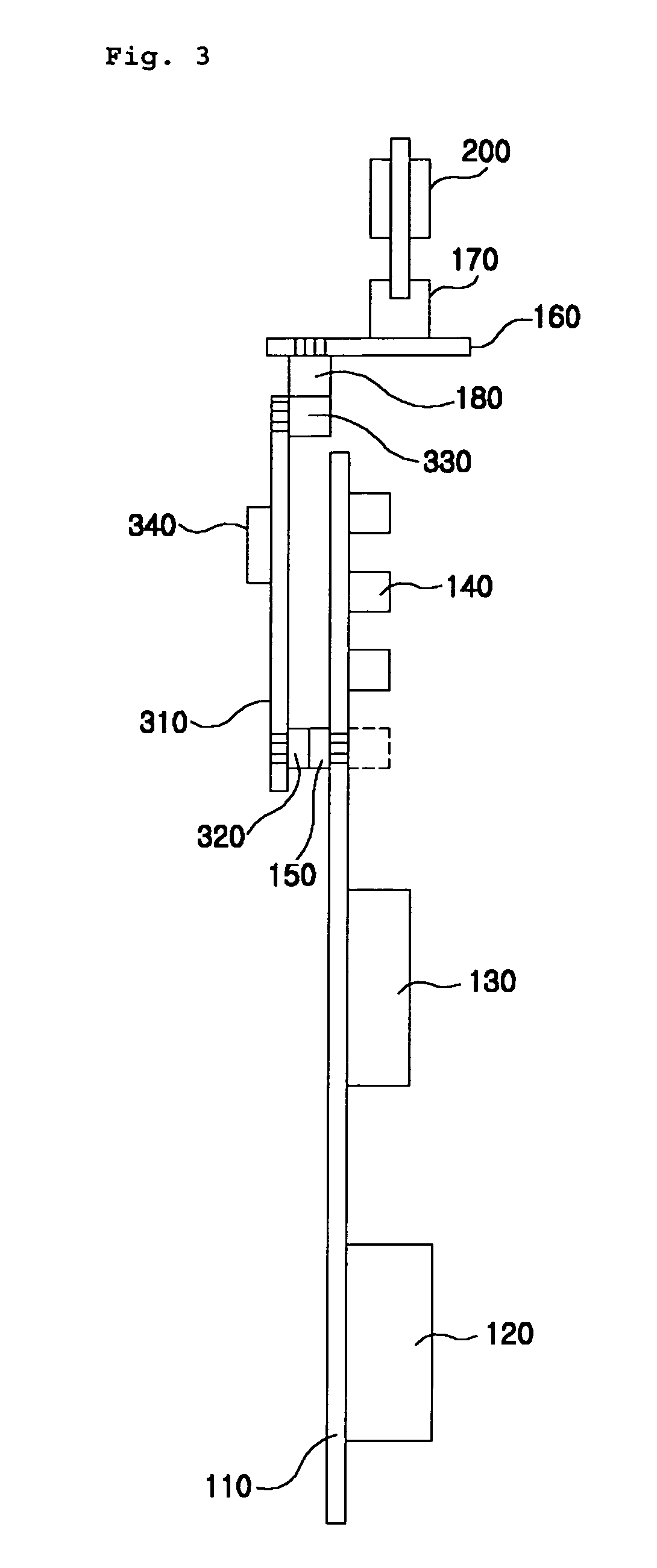

Integrated sock making machine with binding-off function

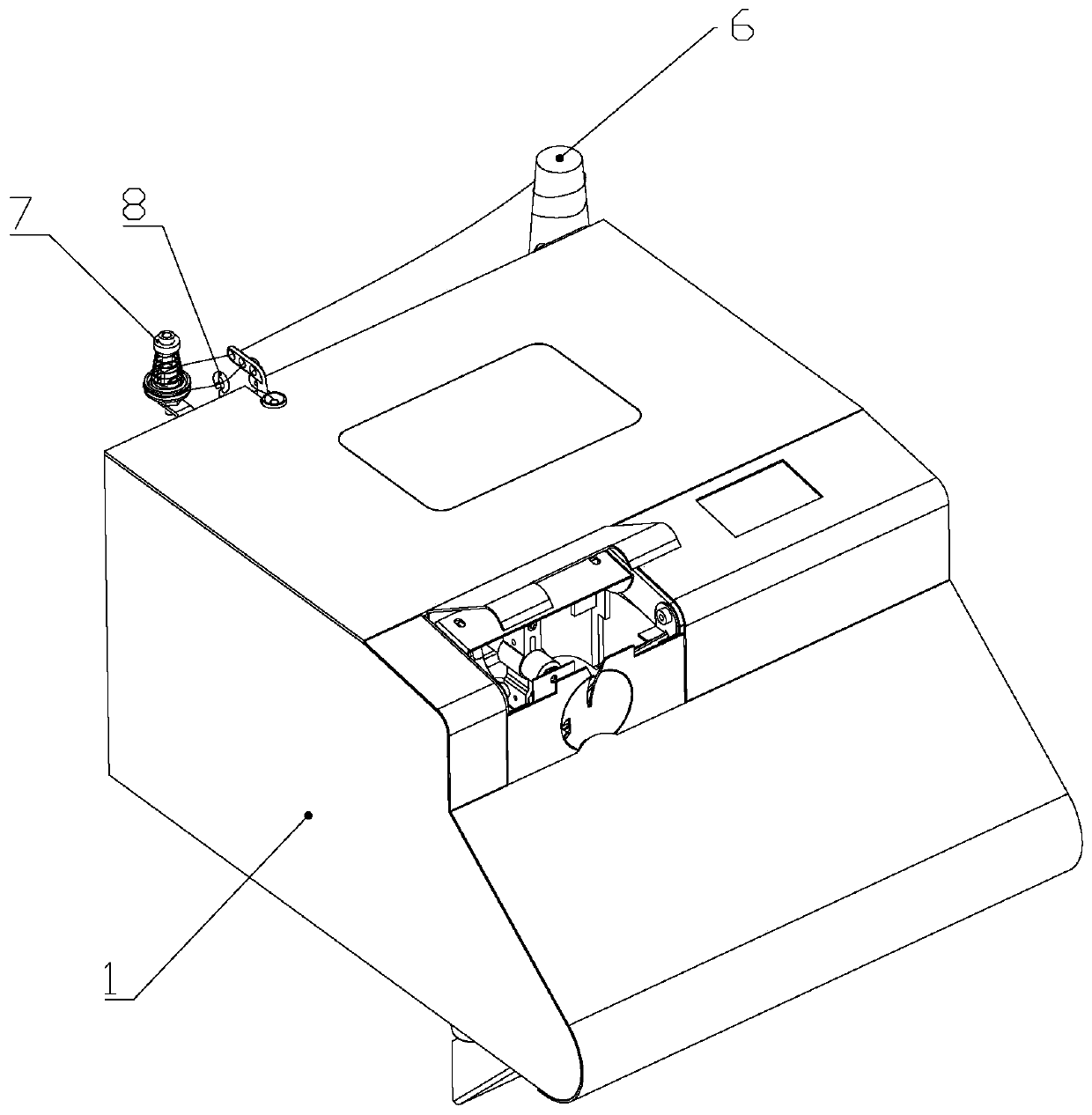

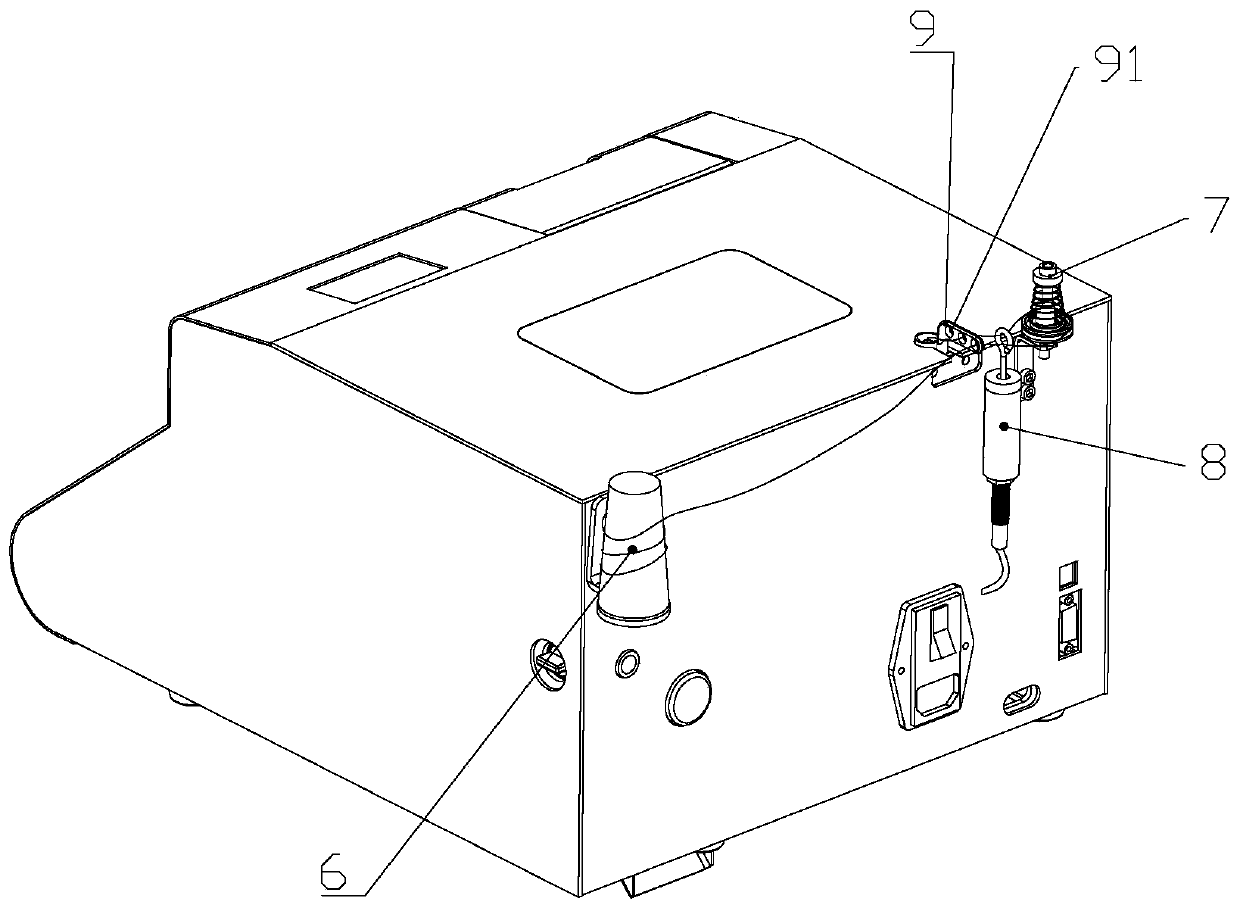

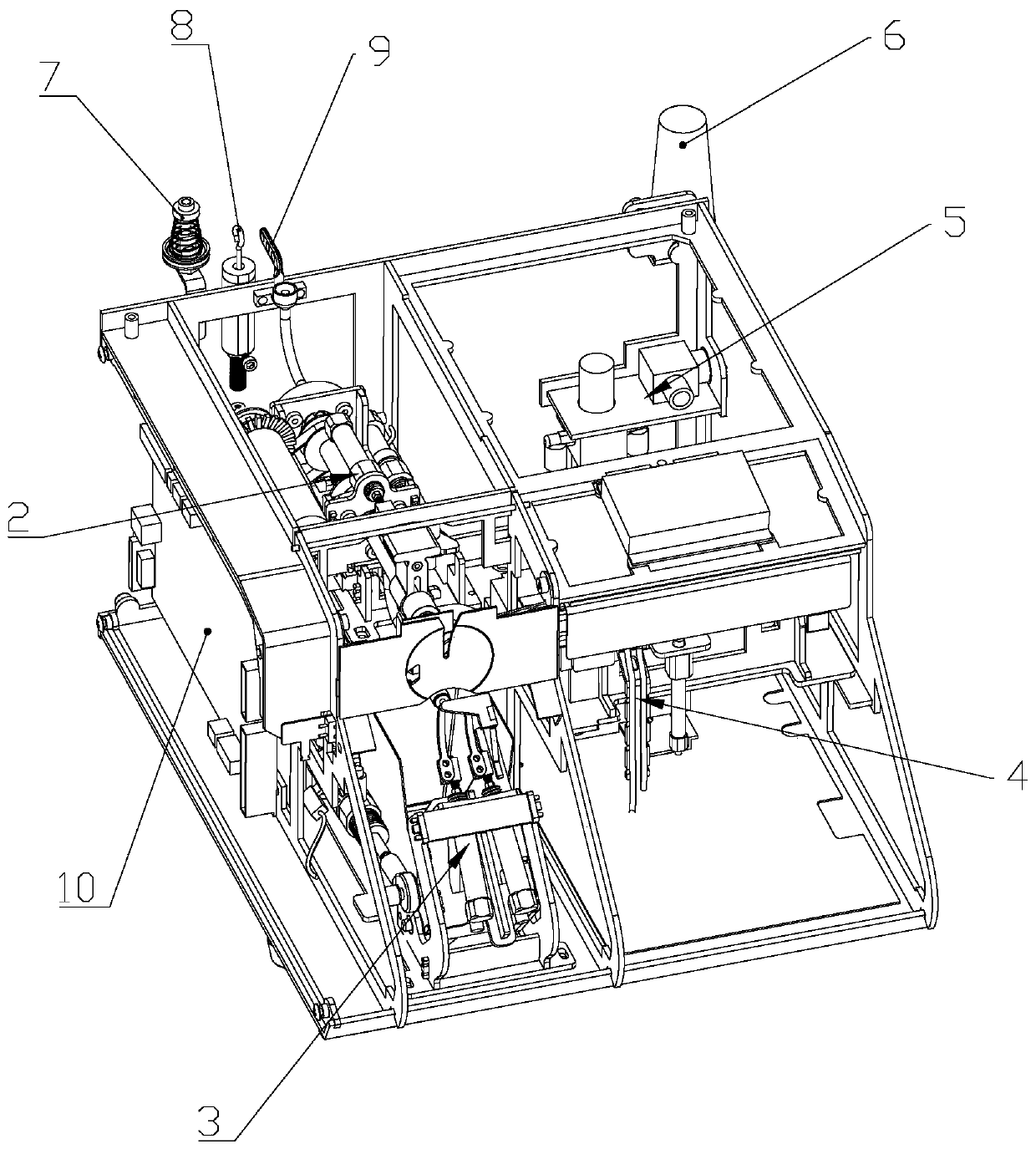

ActiveCN103966760AWith sock sewing functionIncrease productivityLinking machinesSpool-pin assembliesMagnetic valveManufacturing engineering

The invention discloses an integrated sock making machine with a binding-off function. The integrated sock making machine comprises a work table and a sock weaving machine installed on the work table, the work table is further provided with a binding-off machine, a rotary stand column, a work plate, a sock discharging platform and an electromagnetic control box, a sock turning ejecting rod is matched with the work plate, a sock discharging cylinder is matched with the sock discharging platform, and the sock weaving machine, the binding-off machine, the rotary stand column, a sock absorbing cylinder, the sock turning ejection rod and the sock discharging cylinder are all connected with the electromagnetic control box. The integrated sock making machine has a sock sewing function and has the advantages that only one work procedure is needed from sock production to a finished product, production efficiency is effectively improved and labor and materials are saved.

Owner:浙江海润精工机械有限公司

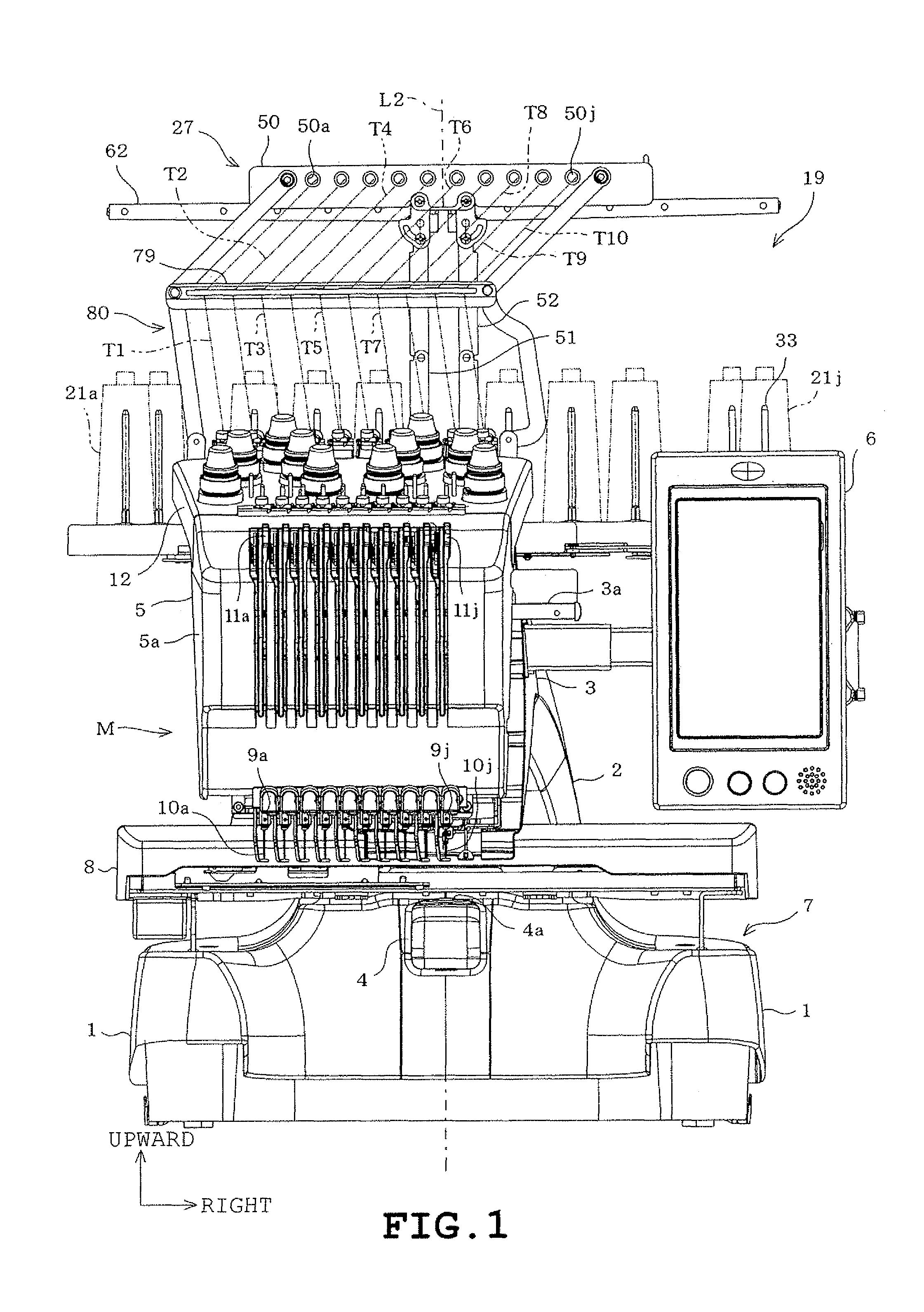

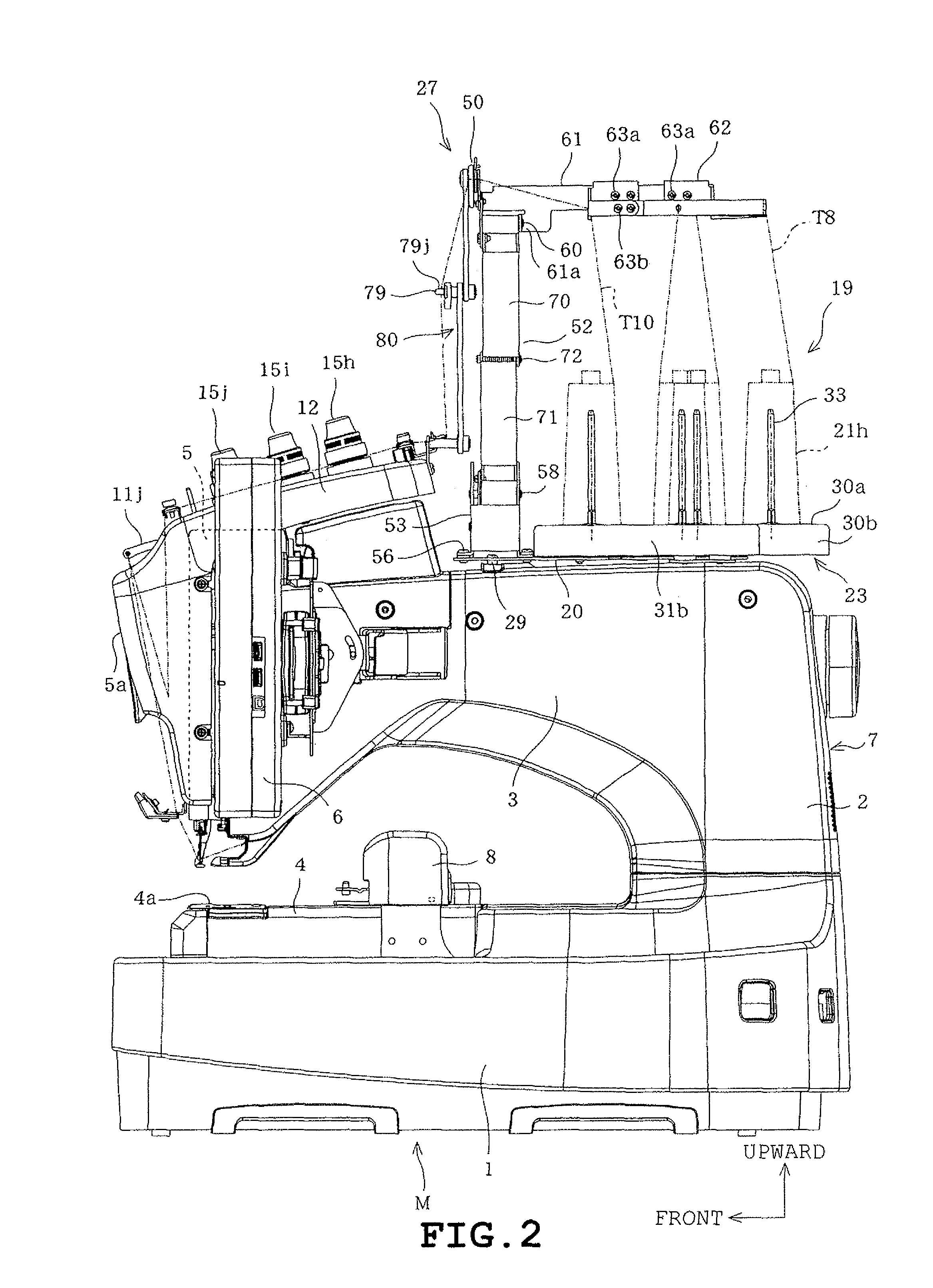

Embroidering machine

InactiveUS7055443B2Avoid enteringProgramme-controlled sewing machinesSpool-pin assembliesLight beamComputer science

The present invention provides an embroidering machine which is made up of a thread station at which a plurality of spools of different colored threads are installed; a frame on which a work-piece is carried in tension mode; an embroidery stitching mechanism having a plurality of needles to which the colored threads are routed, respectively, and stitching the work-piece with the colored thread routed to a selected needle; a color recognizing device for recognizing the color of each of the threads routed to the respective needles; data reading means for reading embroidering data relating to the embroidering pattern; a comparing device matching a color indication included in the embroidering data with the color of each of the threads which is recognized by the color recognizing device, the comparing device selecting one of the threads to which the thread of the matched color is routed for determining the selected needle; and a control device for controlling the selected needle of the embroidery stitching mechanism and the frame to produce an embroidering pattern on the work-piece with the matched color thread. The color recognizing device includes an emitting portion from which a beam of light is emitted to the corresponding thread, a receiving a reflection beam of light reflected from the thread, and a light shielding device provided between the emitting portion and the receiving portion for the prevention of an entrance of light into the receiving portion except for the reflection beam of light.

Owner:AISIN SEIKI KK

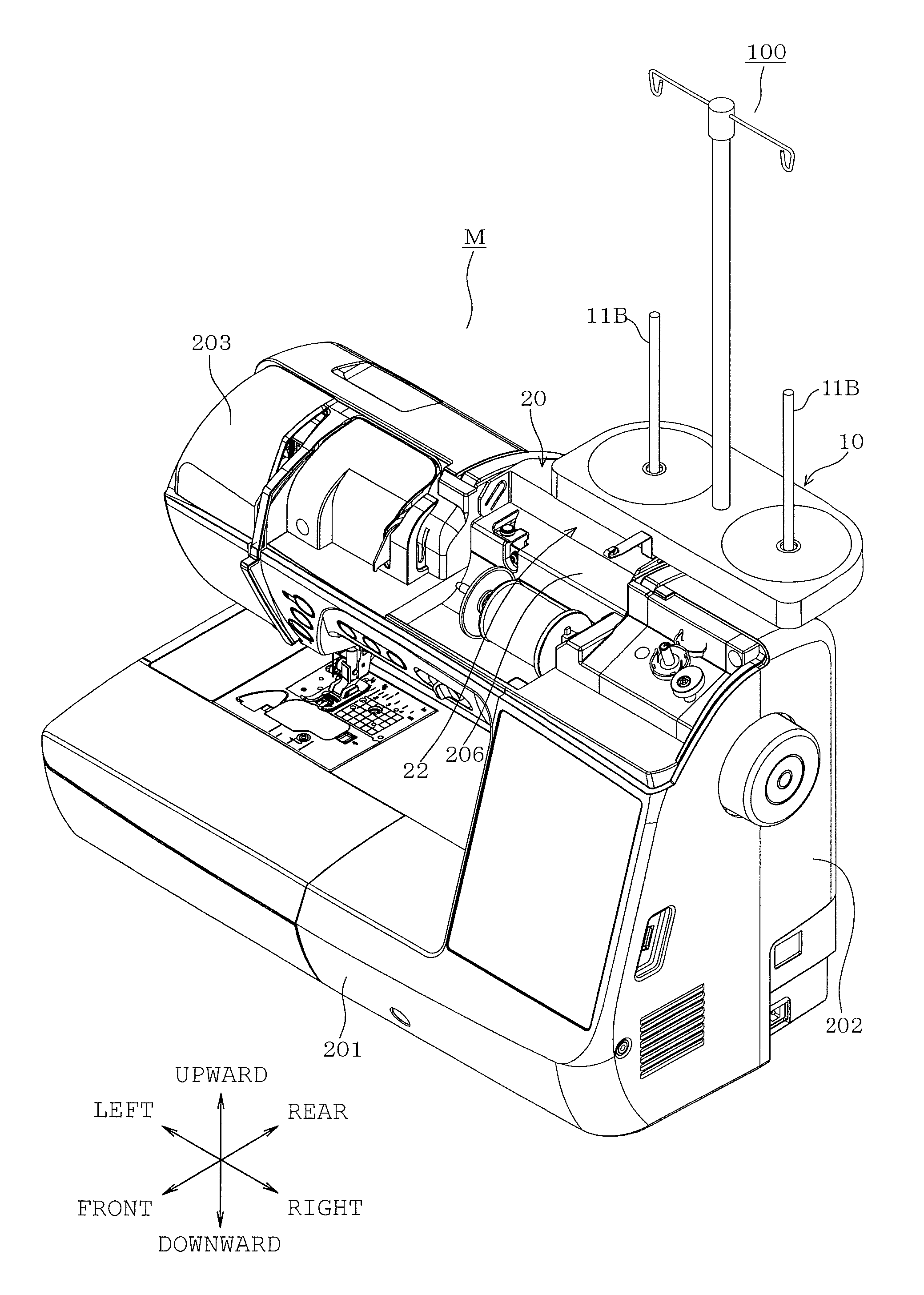

Sewing machine and spool pin stand therefor

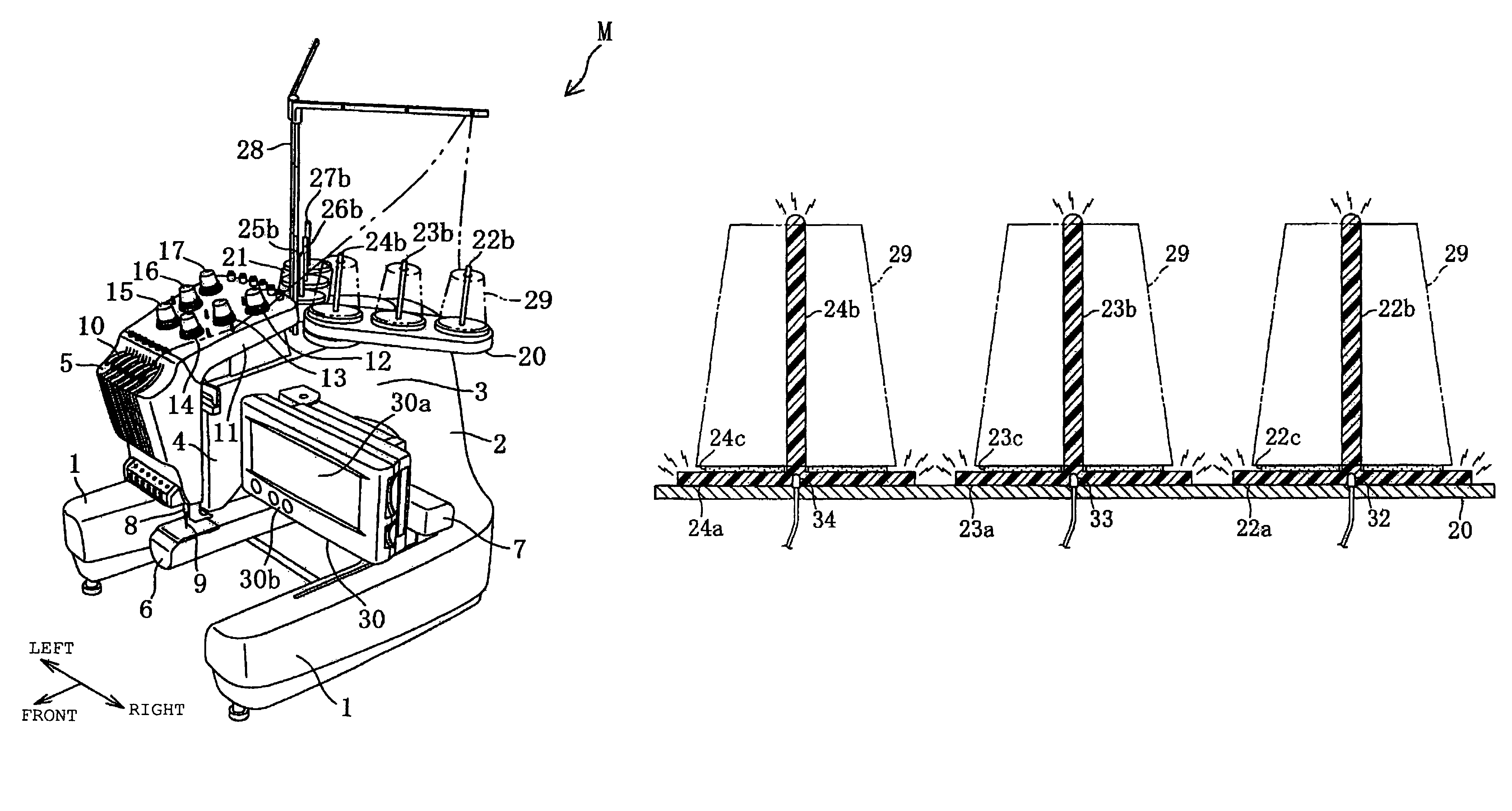

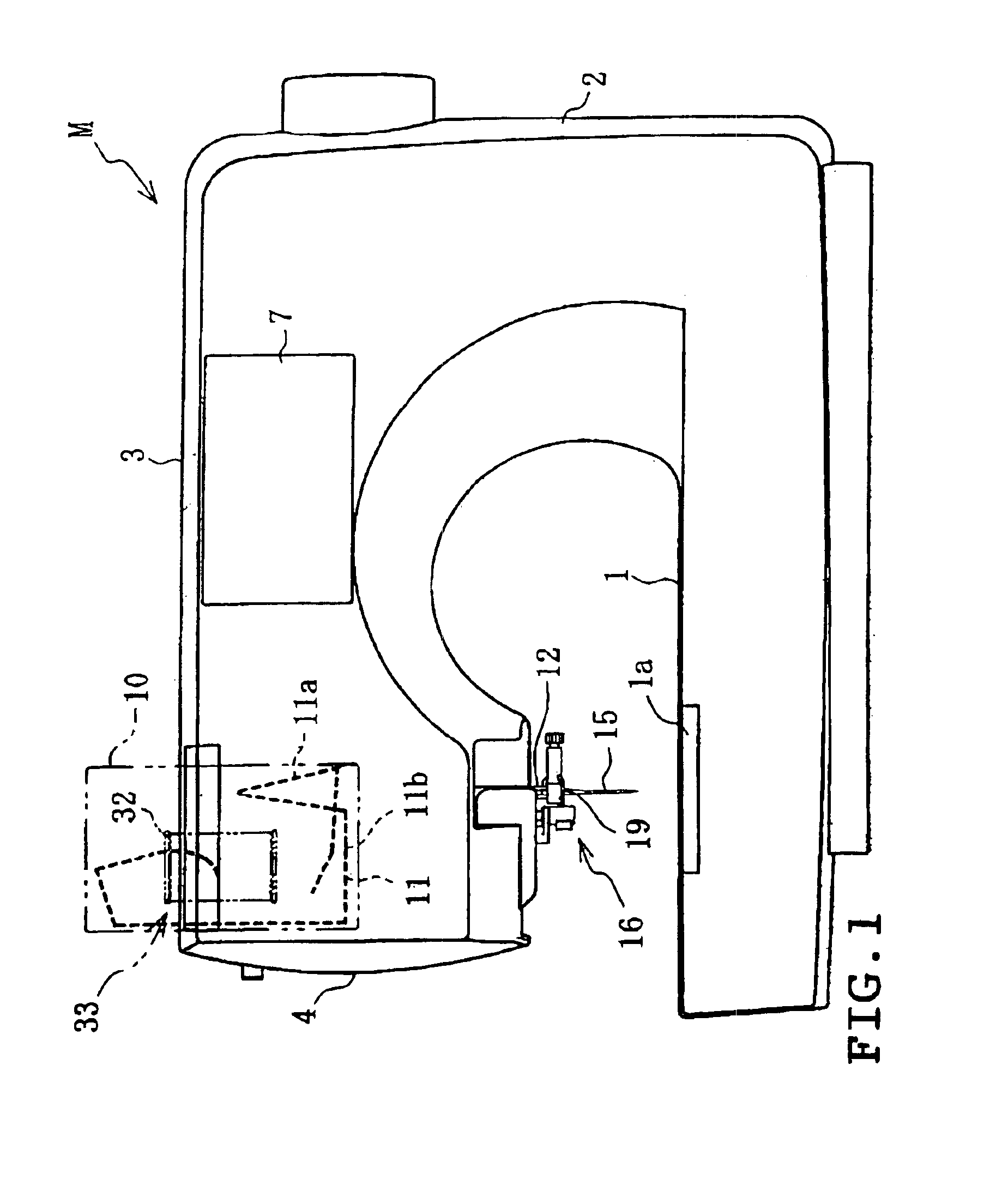

A sewing machine includes needlebars for a sewing operation using a plurality of needle threads, a spool pin stand having a plurality of spool pins to which thread spools corresponding to the needlebars are attachable, respectively, thread passage defining members located on a thread passage extending from the spool pin stand to the needlebars, a storage unit storing sewing data including at least thread color information about colors of the needle threads, thread supply display units located on the spool pin stand so as to correspond to the spool pins respectively, the thread supply display units displaying the thread colors in a color-variable manner, respectively, and a thread color information display control unit controlling the thread supply display units based on the thread color information read from the sewing data storage unit, so that thread colors corresponding to the spool pins are displayed by the thread supply display units, respectively.

Owner:BROTHER KOGYO KK

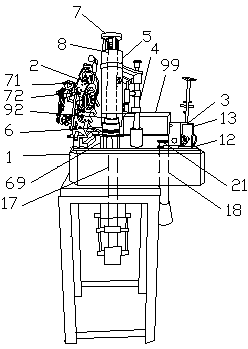

Intelligent full-automatic hot-melting button wrapping machine

PendingCN110820187AAvoid wastingAvoid pulling out and droppingSewing-machine control devicesSpool-pin assembliesWinding machineControl system

The invention discloses an intelligent full-automatic hot-melting button wrapping machine. The intelligent full-automatic hot-melting button wrapping machine comprises a frame and is characterized inthat a winding mechanism, a thread pulling and breaking mechanism, a thread melting and fixing mechanism and a drive device are arranged in the frame, a control system in control connection with the drive device is arranged on the frame, a spool seat for mounting a spool is arranged on the frame, a button wrapping thread tightness adjuster is arranged between the spool seat and the winding mechanism, a thread breaking detecting alarm device is arranged between the button wrapping thread tightness adjuster and the winding mechanism, and the output end of the thread breaking detecting alarm device is connected with the control system. The intelligent full-automatic hot-melting button wrapping machine the thread breaking detecting alarm device is arranged on the frame, the thread breaking detecting alarm device transmits thread breaking information to the control system when the button wrapping thread entering the winding mechanism breaks to guarantee that the machine stops working duringthread breaking, the thread breaking detecting alarm device can also emits notification to notify staff immediately after the thread breaking occurs, and manpower and material resource waste can be avoided.

Owner:谭英

Spool holder and sewing machine provided therewith

ActiveUS20110011319A1Light weightImprove refining effectSewing-machine control devicesFilament handlingEngineeringSewing machine

Owner:BROTHER KOGYO KK

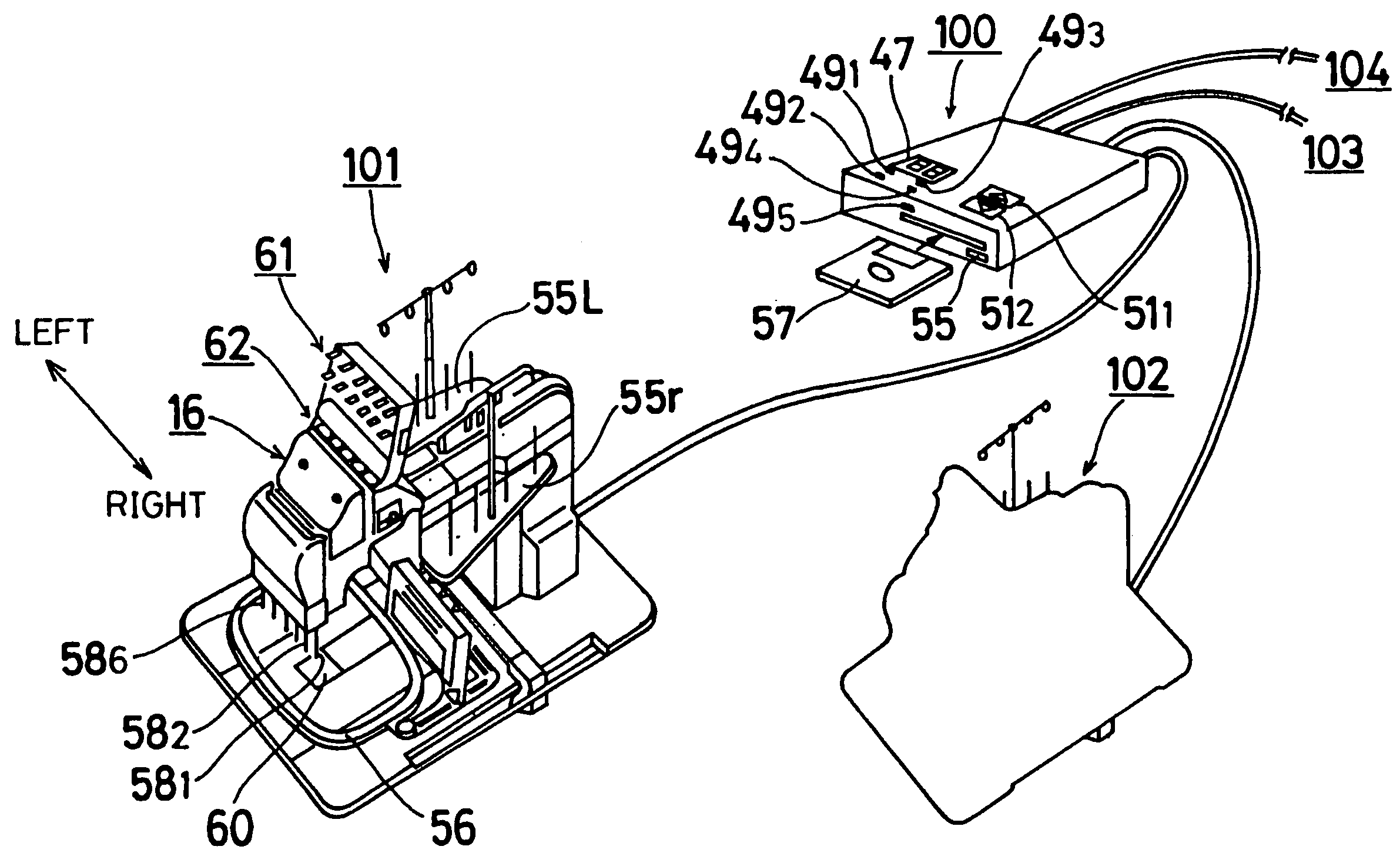

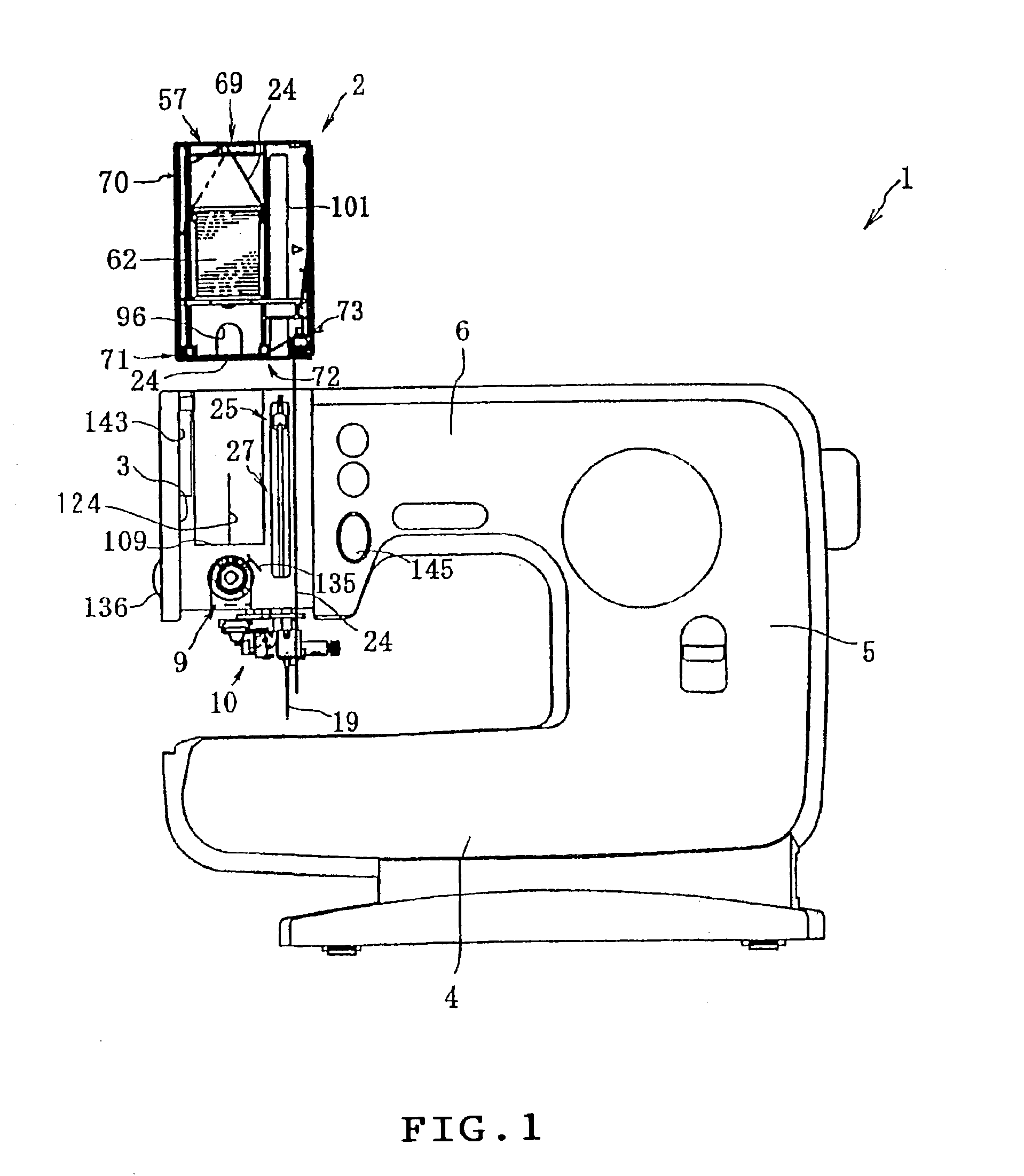

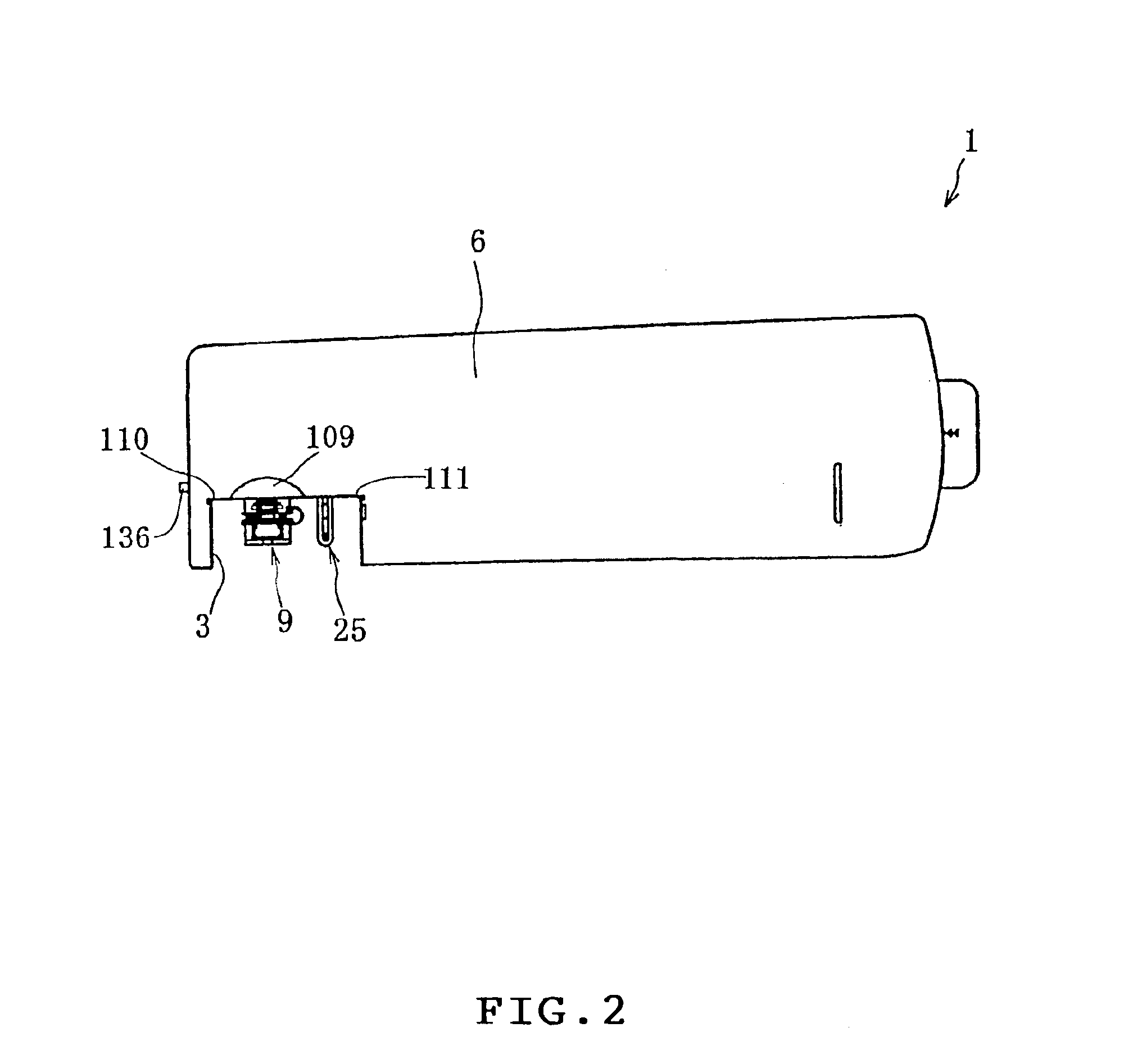

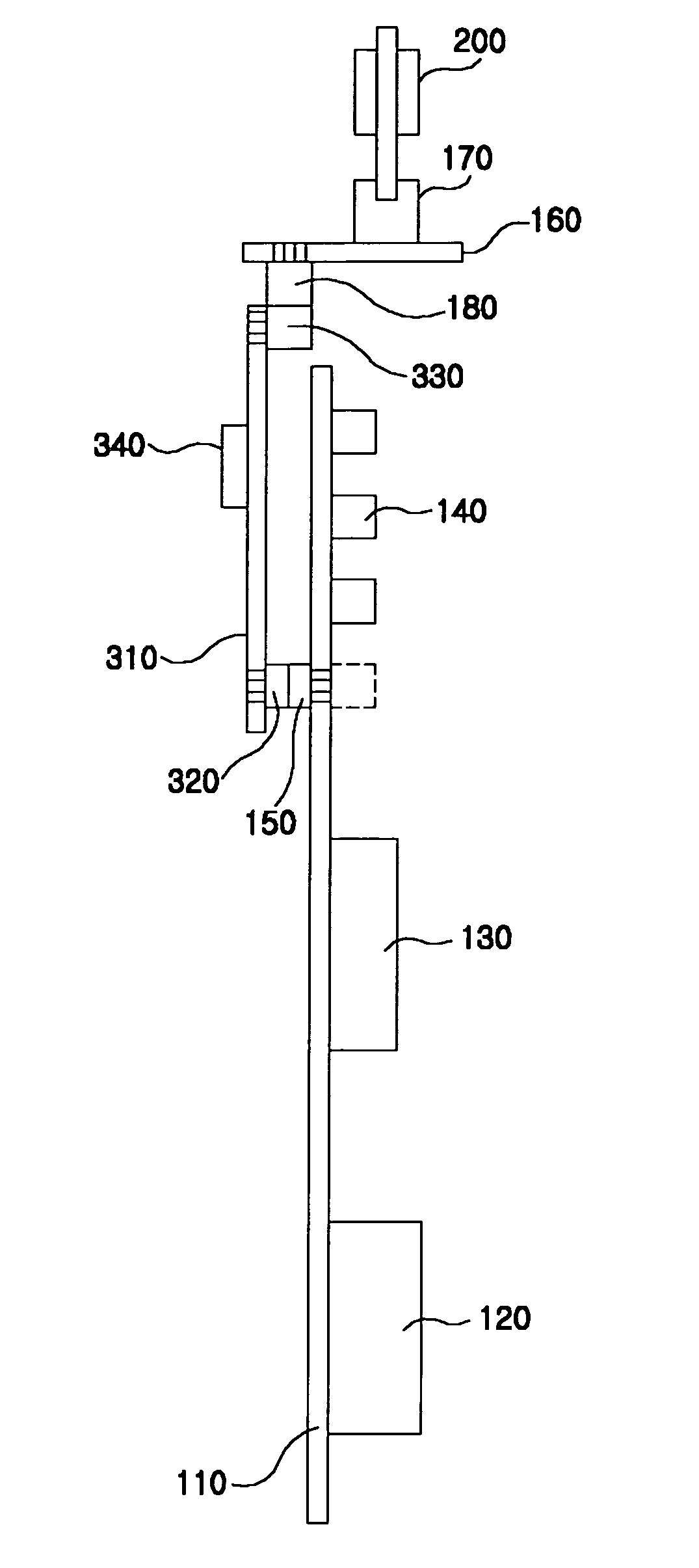

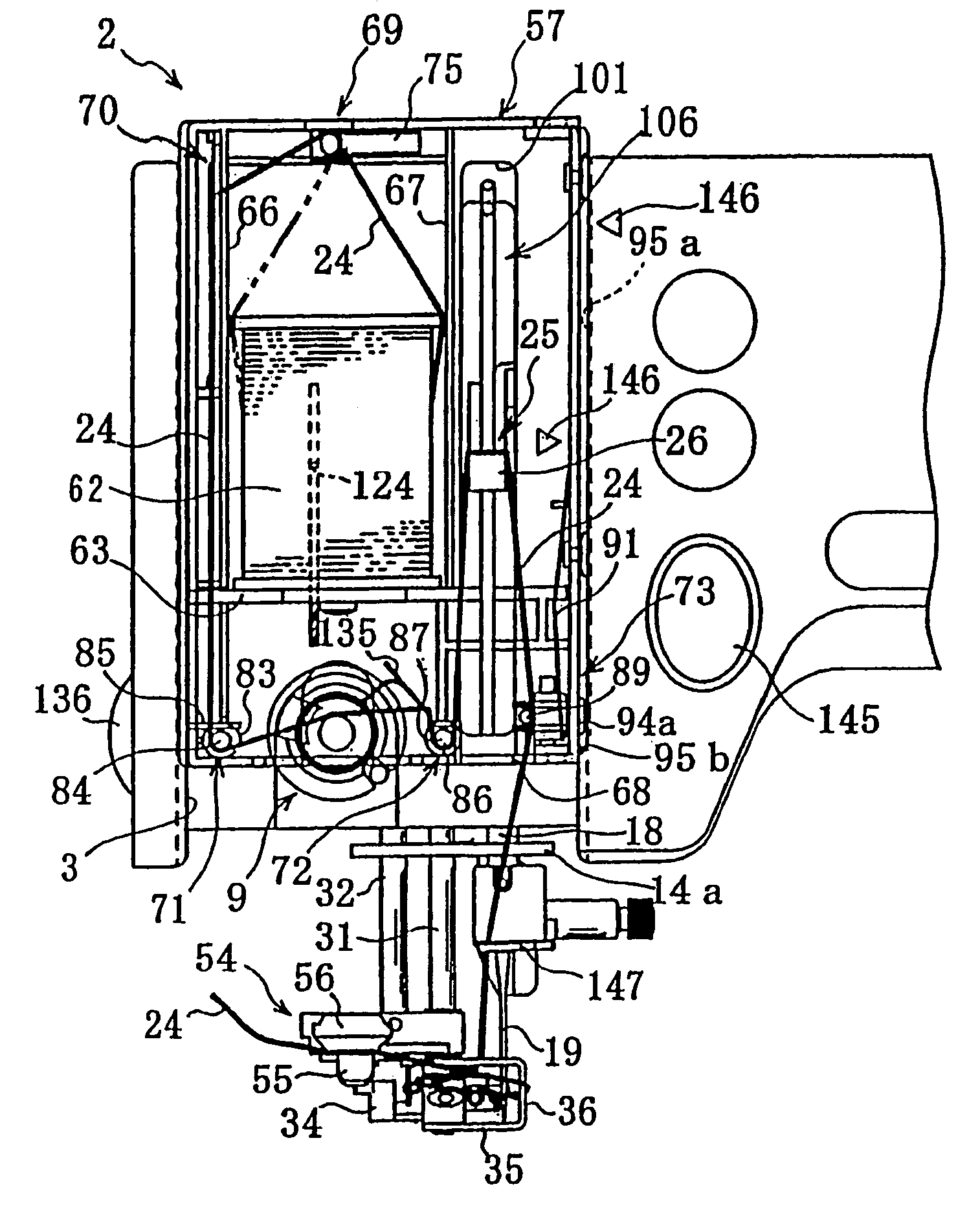

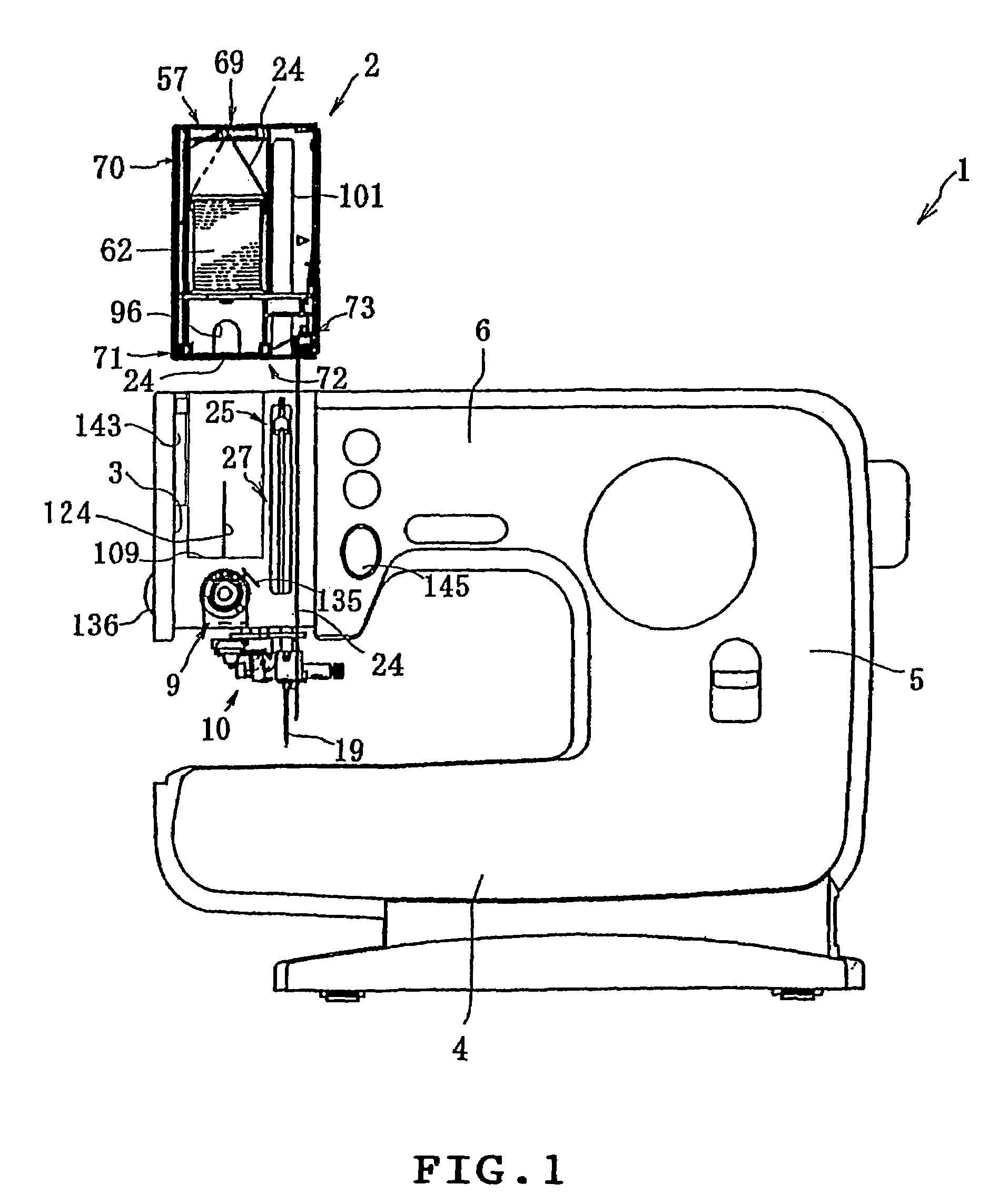

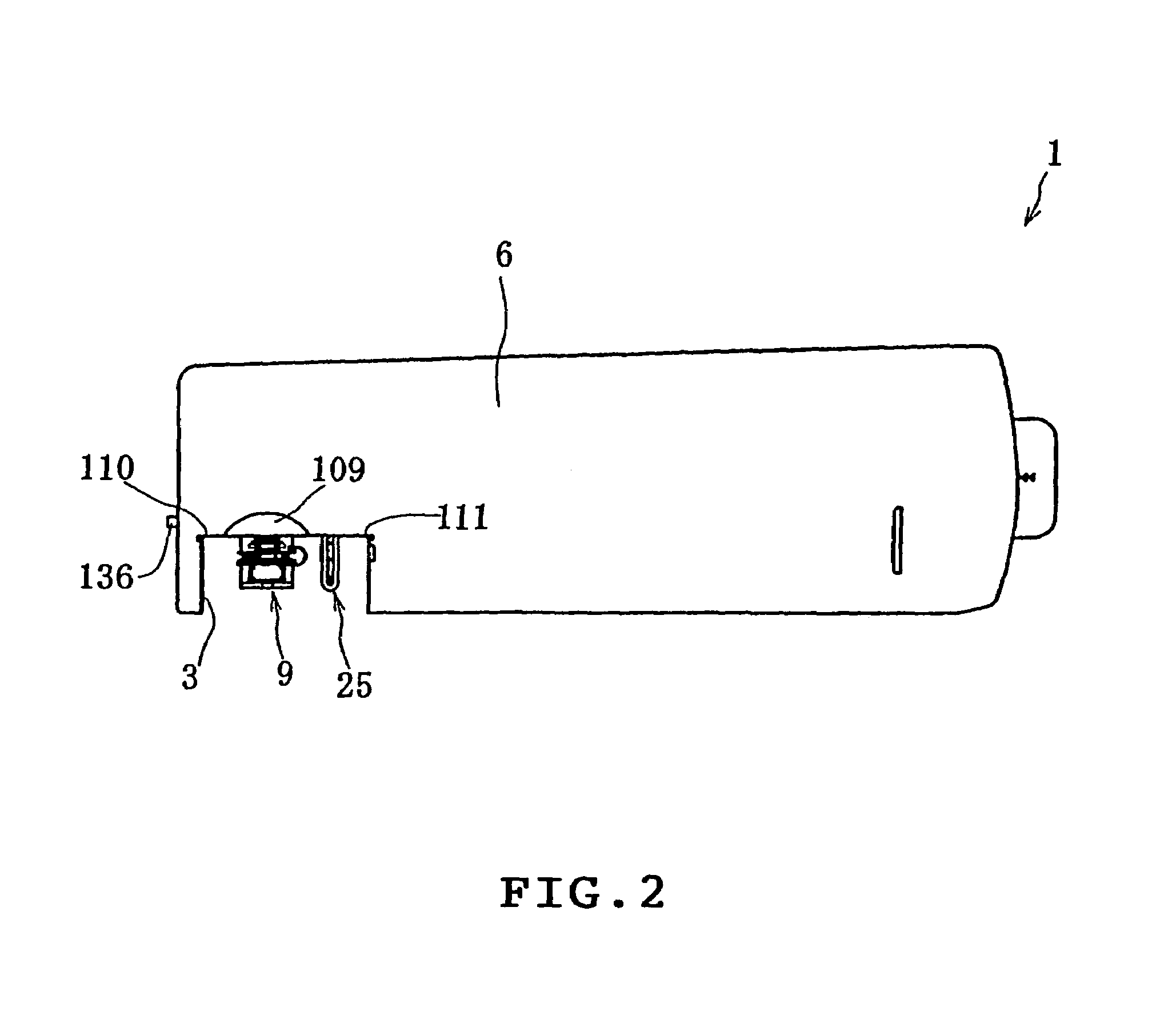

Sewing machine with needle thread cassette and needle thread cassette

InactiveUS6883447B1Improve handlingEasy to operateSewing-machine casingsFilament handlingBobbinEngineering

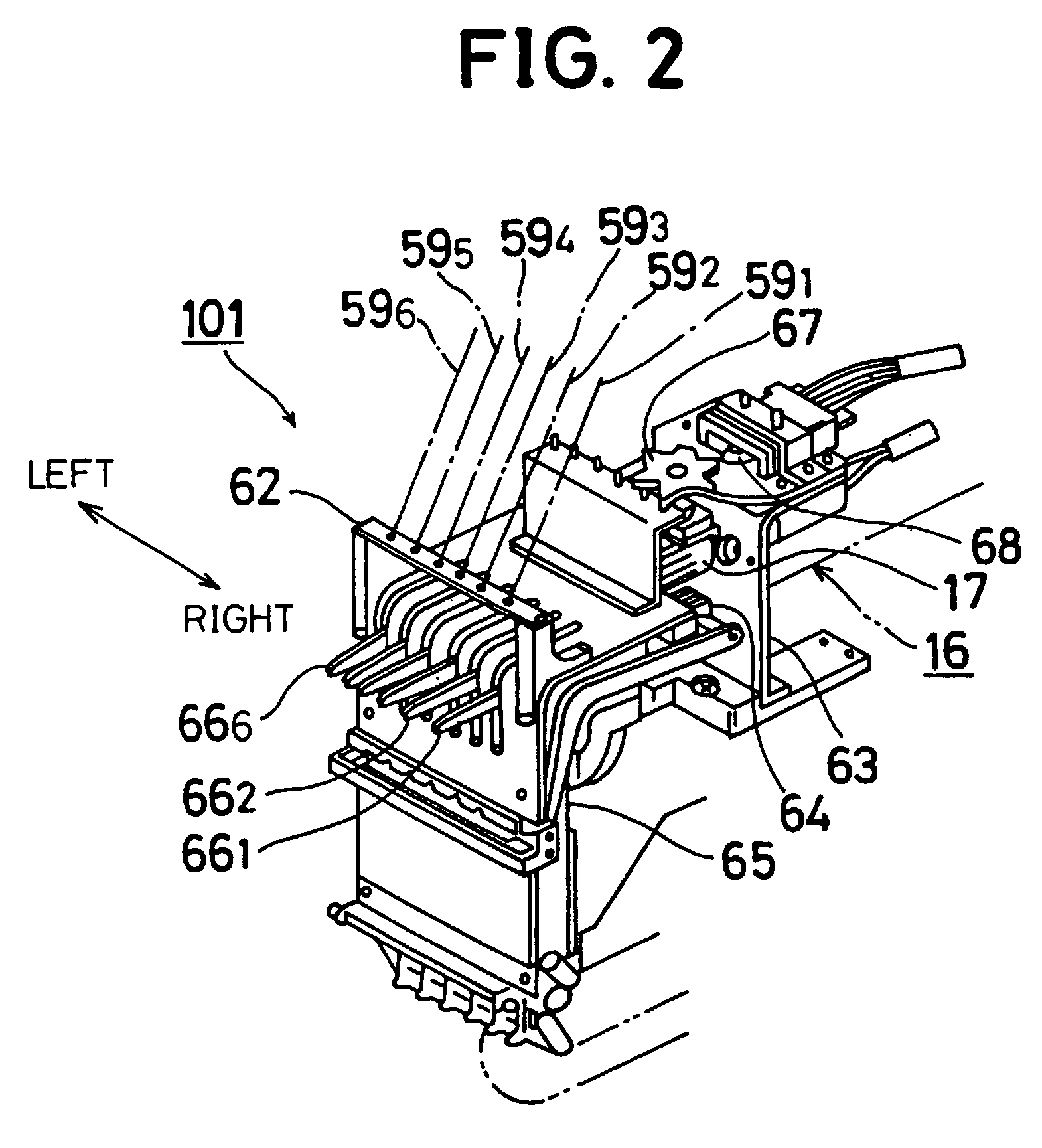

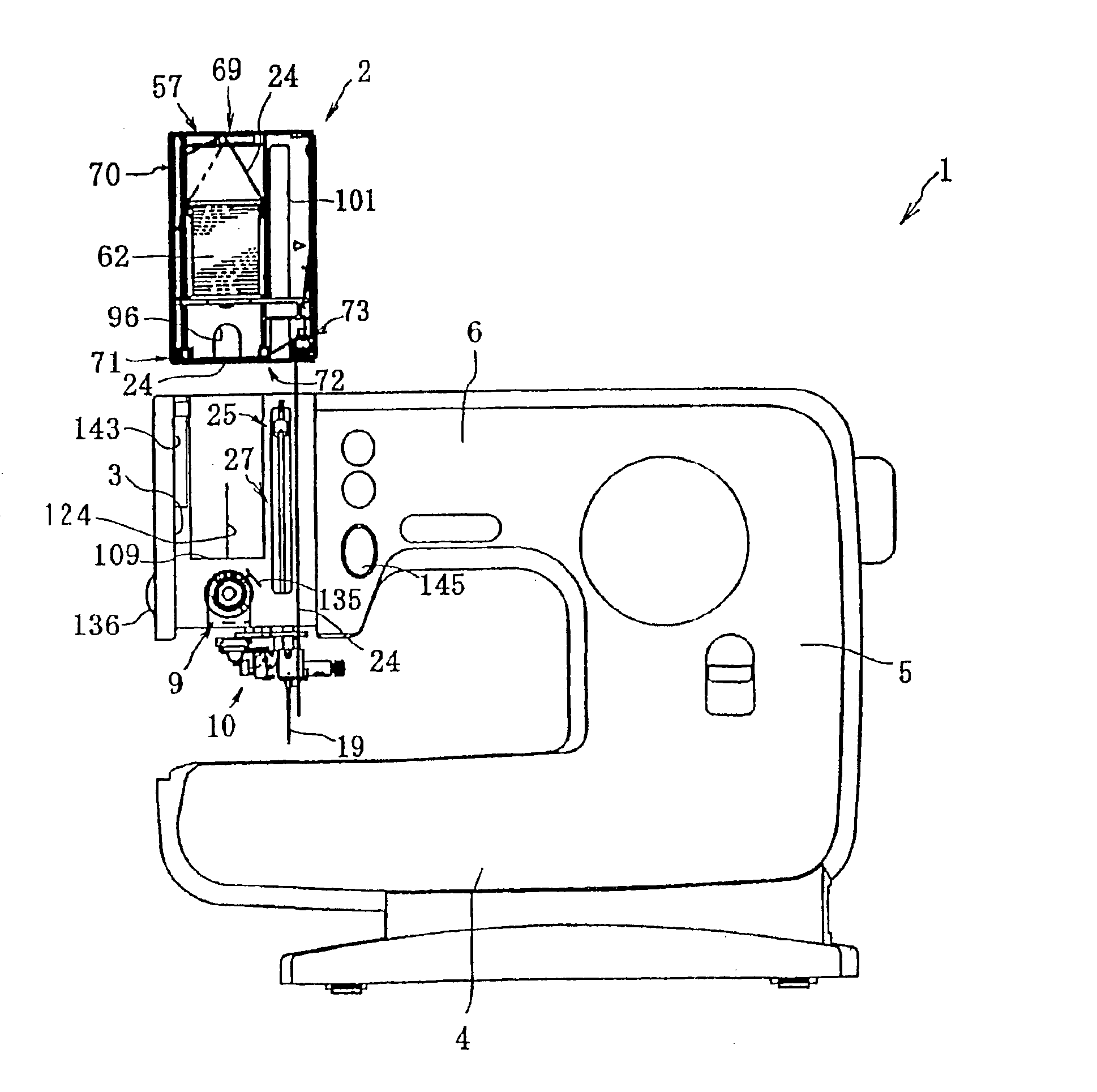

A sewing machine with a needle thread cassette, wherein a cassette mount (3) is reduced in size. The cassette mount (3) including a thread take-up lever travel region is formed in the form of a vertical groove in the arm head of the sewing machine. A needle thread cassette (2) having a thread bobbin (62) vertically received therein is removably mounted on the cassette mount (3) vertically from above. With a thread take-up lever (25) stopped in a position corresponding to a needle top stop position, the needle thread cassette (2) is mounted on the cassette mount (3), whereby the thread is engaged with the thread guard of the thread take-up lever (25) and a thread tension regulator (9).

Owner:BROTHER KOGYO KK

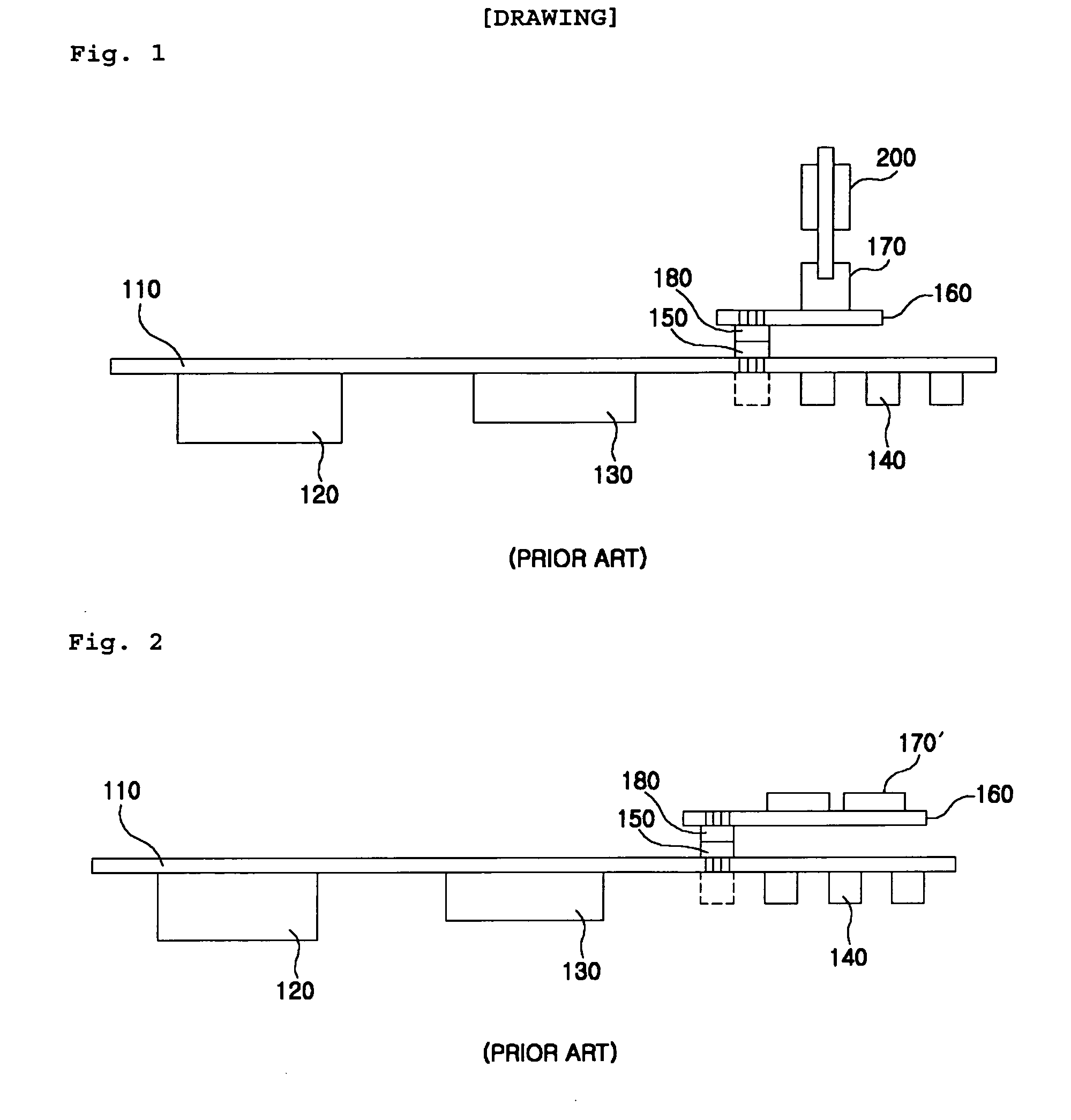

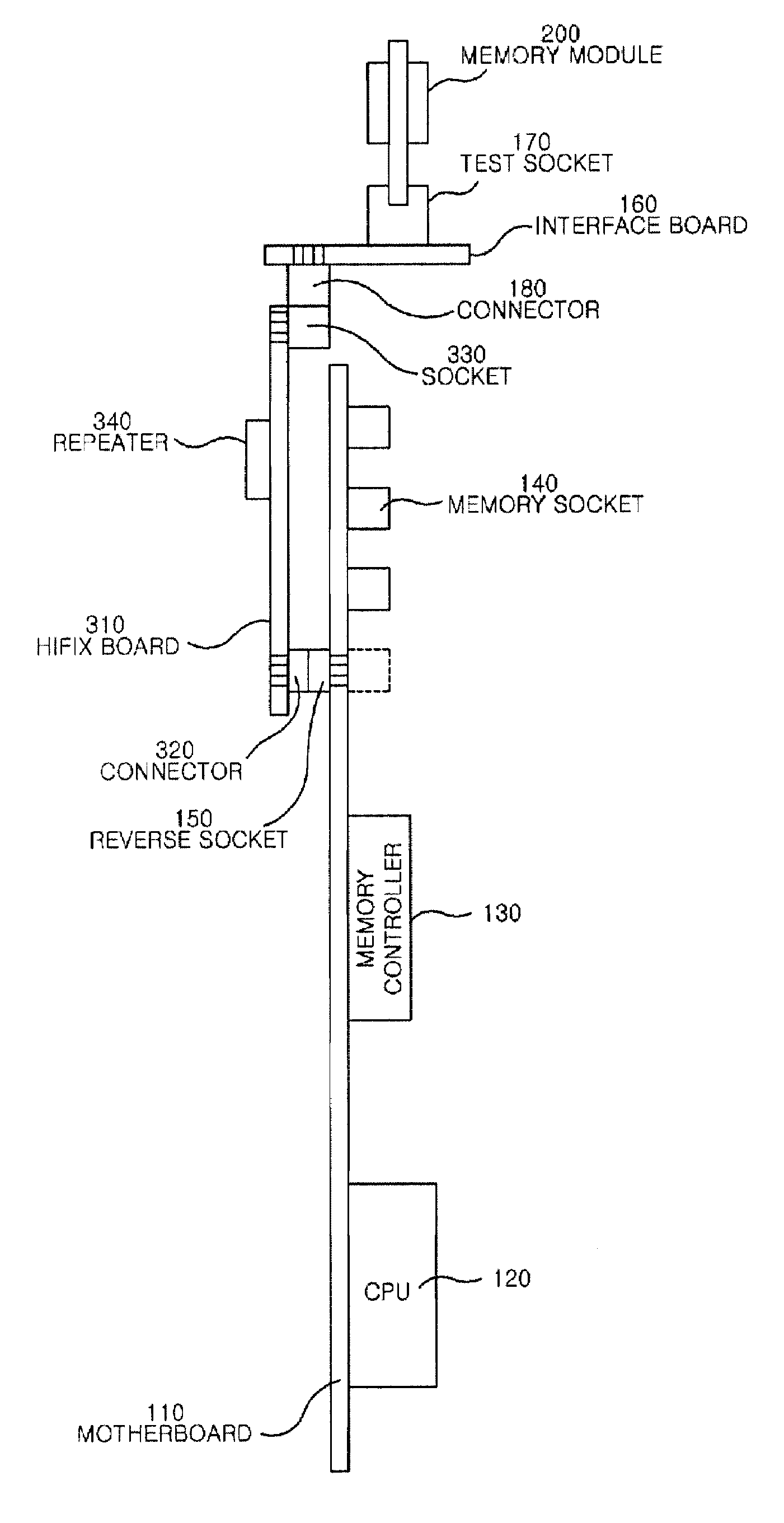

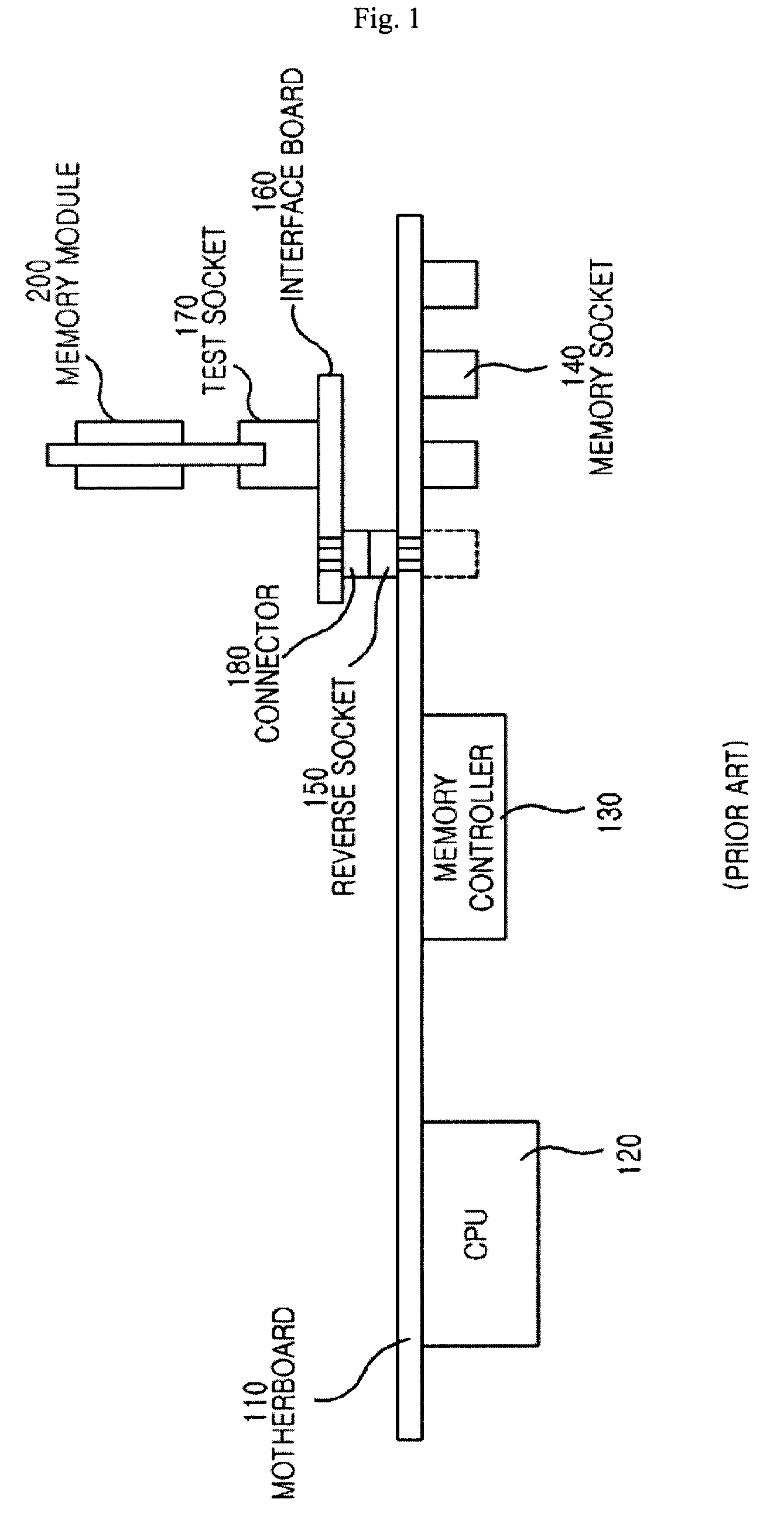

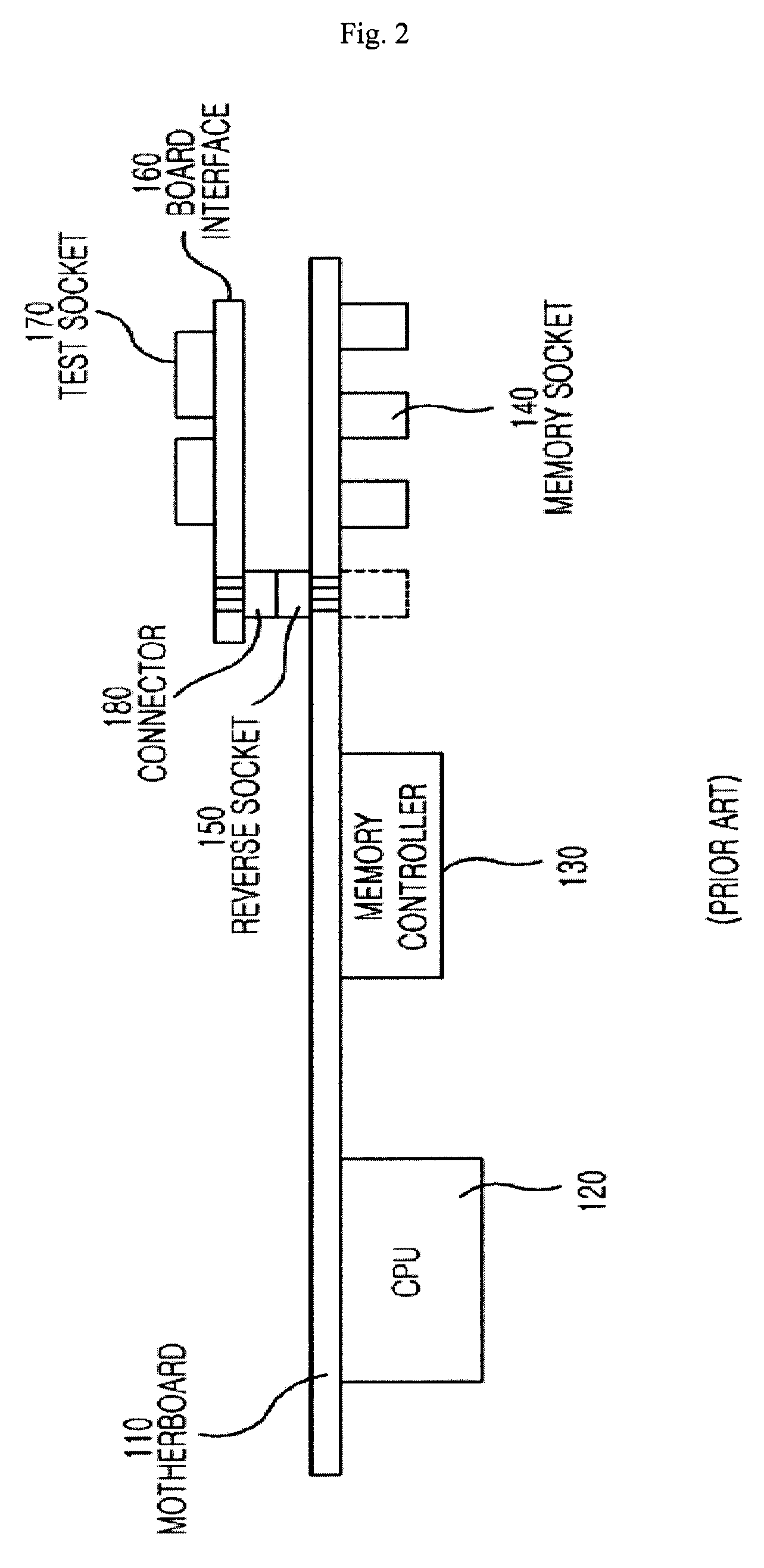

Memory application tester having vertically-mounted motherboard

ActiveUS20060242468A1Limit in trace lengthControl lengthError detection/correctionSpool-pin assembliesSemiconductorMotherboard

The present invention relates to a memory application tester for testing a semiconductor memory device comprising a plurality of motherboards having a memory socket. The motherboards are vertically mounted and effectively integrated so that a memory application tester may test more memory device simultaneously, and a limit in the trace length due to the integration of the motherboards is effectively solved.

Owner:UNITEST

Spool holder and sewing machine provided therewith

InactiveUS20110011318A1Easy to replaceCompact storageSewing-machine control devicesFilament handlingSewing machine

Owner:BROTHER KOGYO KK

Sewing machine

InactiveUS6981459B2Operation efficiency can be improvedSimple engagementSewing-machine casingsFilament handlingBobbinEngineering

A sewing machine includes a thread take-up lever and a thread tension regulator each disposed along a predetermined needle thread passage from a thread bobbin to a needle, an arm having a front face, and a movable controller disposed in the front of the arm so as to be movable at least within a predetermined range. The movable controller does not protrude out of the front face of the arm when moved in the predetermined range. The needle thread is engaged with at least one of the thread take-up lever and the thread tension regulator when the movable controller is moved within the predetermined range while the needle thread has been drawn from the thread bobbin near to the needle substantially along the predetermined needle thread passage.

Owner:BROTHER KOGYO KK

Spool holder and sewing machine provided therewith

InactiveUS8251000B2Easy to replaceCompact storageSewing-machine control devicesFilament handlingEngineeringSewing machine

Owner:BROTHER KOGYO KK

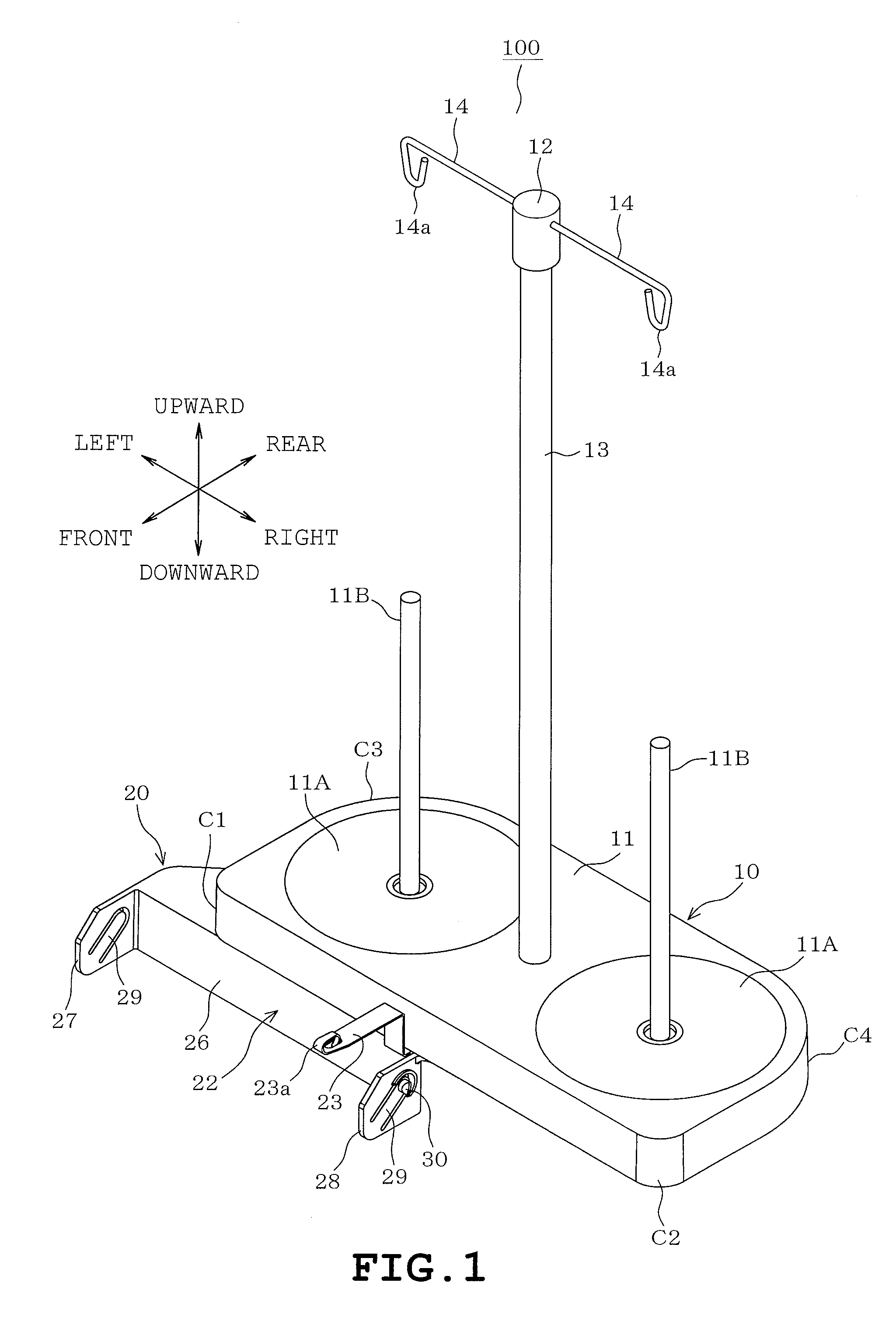

Spool holder and sewing machine

A spool holder on which a thread spool is placeable includes an engagement part detachably engaging a mount which is located on an arm of a sewing machine. In the spool holder, a support located on a rear end of a cover member is detachably attached to the mount. The cover member covers an upper side of a front of the arm and a front side of an upper surface of the arm so that the cover member is capable of opening and closing the upper side of the front of the arm and the front side of the upper surface of the arm. The spool holder is attached to the sewing machine by inserting the engagement part rearward from a front side of the sewing machine into the mount from which the cover member has been detached.

Owner:BROTHER KOGYO KK

Thread stand for sewing machine

InactiveUS7793603B2Good adhesionImprove stabilityWork-feeding meansFilament handlingEngineeringScrew thread

Owner:TOKAI IND SEWING MACH CO LTD

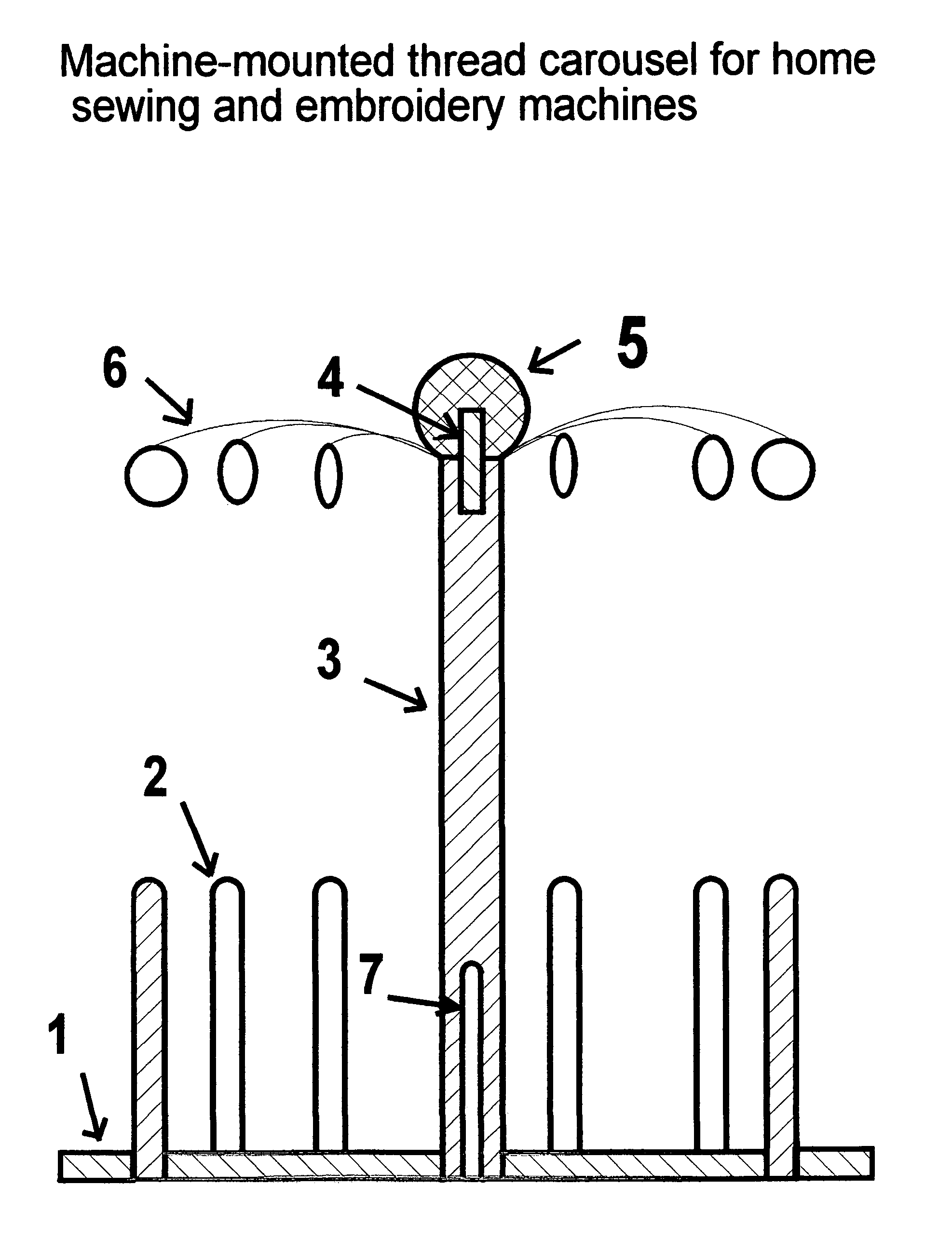

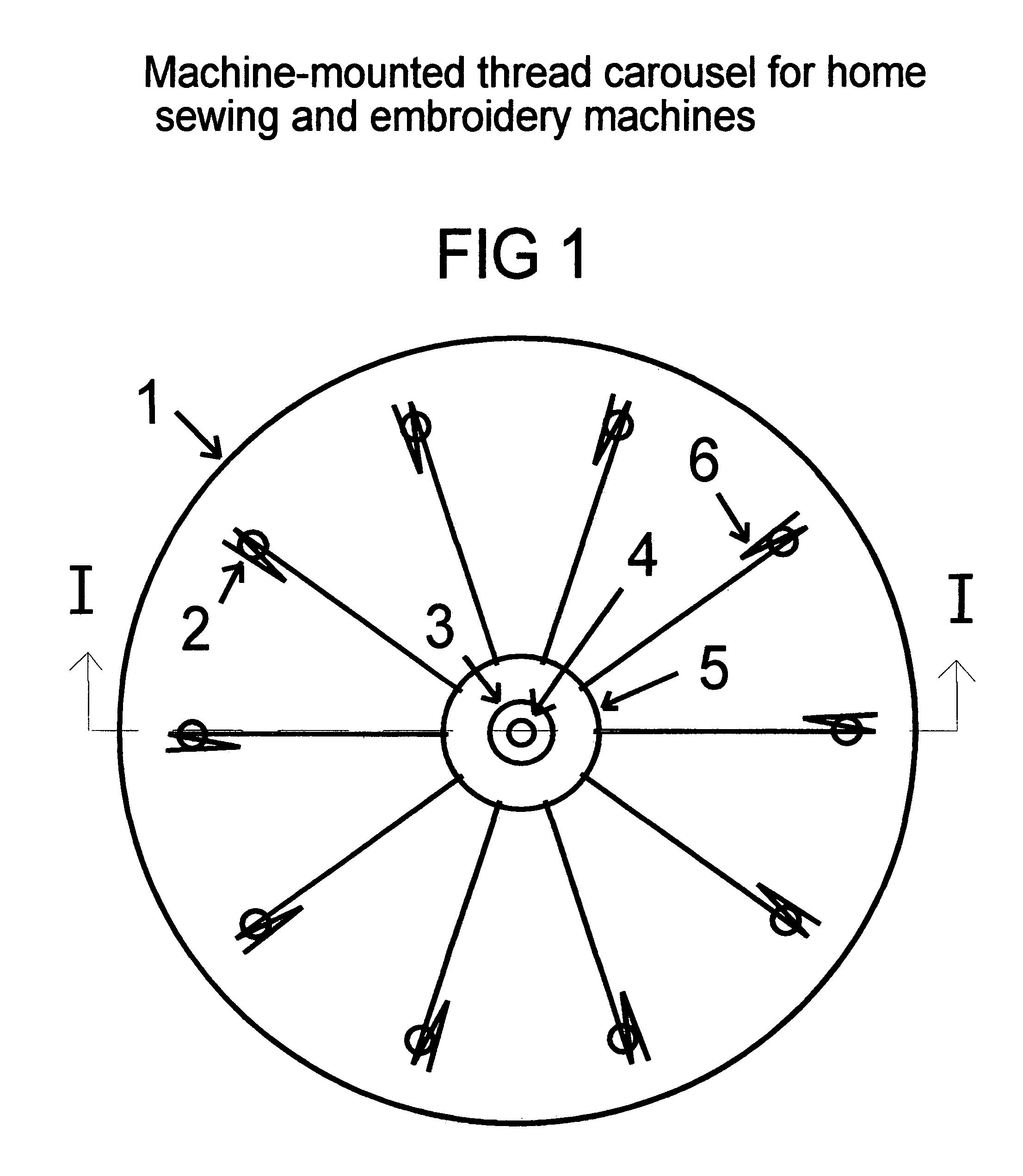

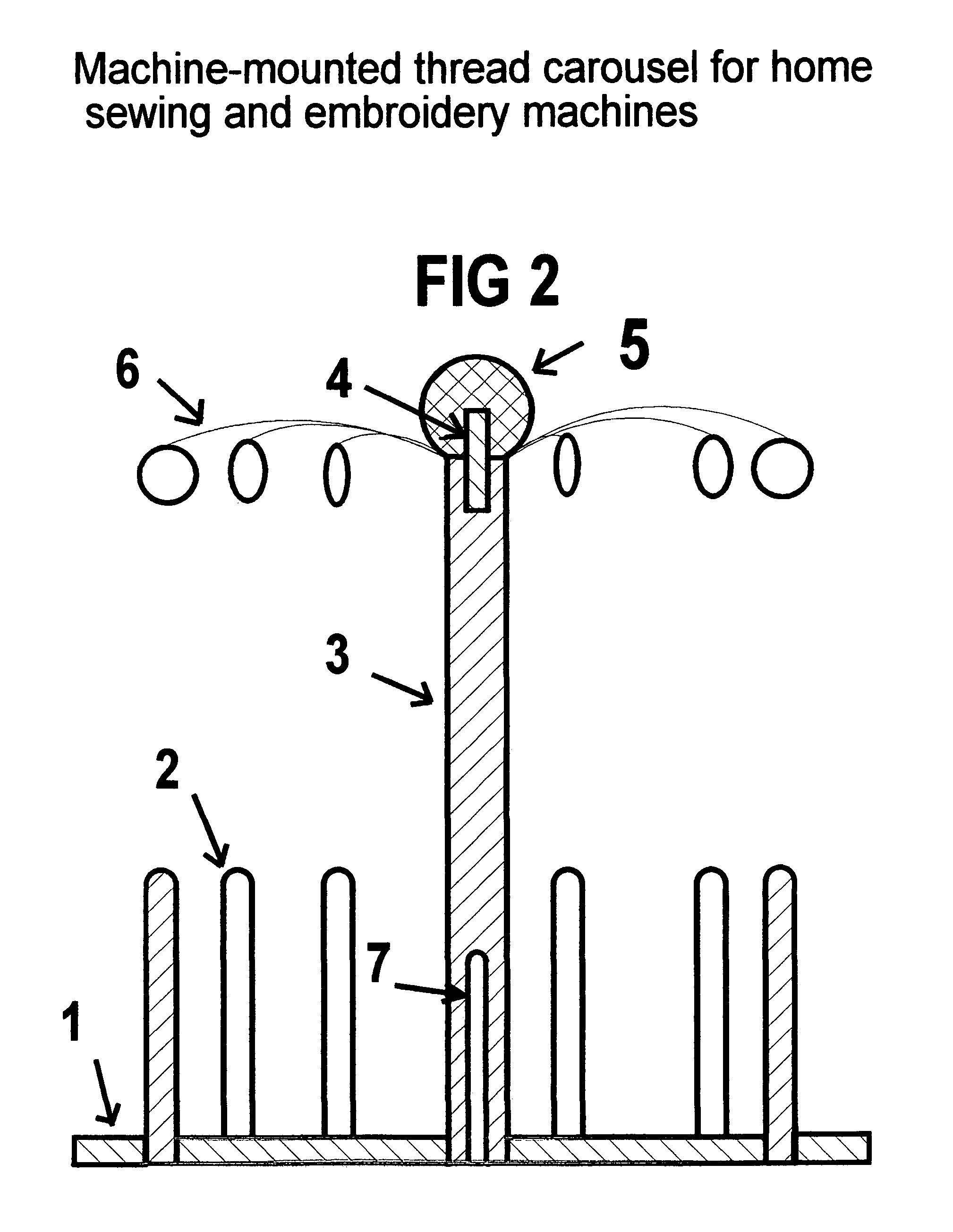

Machine-mounted thread carousel for home sewing and embroidery machines

InactiveUS7025302B1Thread changeEqual effectivenessFilament handlingSpool-pin assembliesCircular discEngineering

This invention is a device for transporting, holding and feeding a plurality of spools of level-wound or cross-wound thread on a home sewing and / or embroidery machine. This device fits over the vertical spindle of the machine if so equipped, or over a spindle devised for the intended machine so as to provide the same function if not so equipped. It consists of a disk with a flat base, free to rotate about its vertical axis, with provisions for accepting spools of thread of various standard sizes. It can be made of any material suitable for the purpose and embodies a thread guide for each spool when used to feed cross-wound thread. It also embodies a knob, pin, ring, or other feature to enable it to be installed / removed from the machine manually without tools.

Owner:MORKOVSKY HENRY

Memory application tester having vertically-mounted motherboard

ActiveUS7327151B2Control lengthEfficient solutionSpool-pin assembliesHand sewing toolsSemiconductorMotherboard

Owner:UNITEST

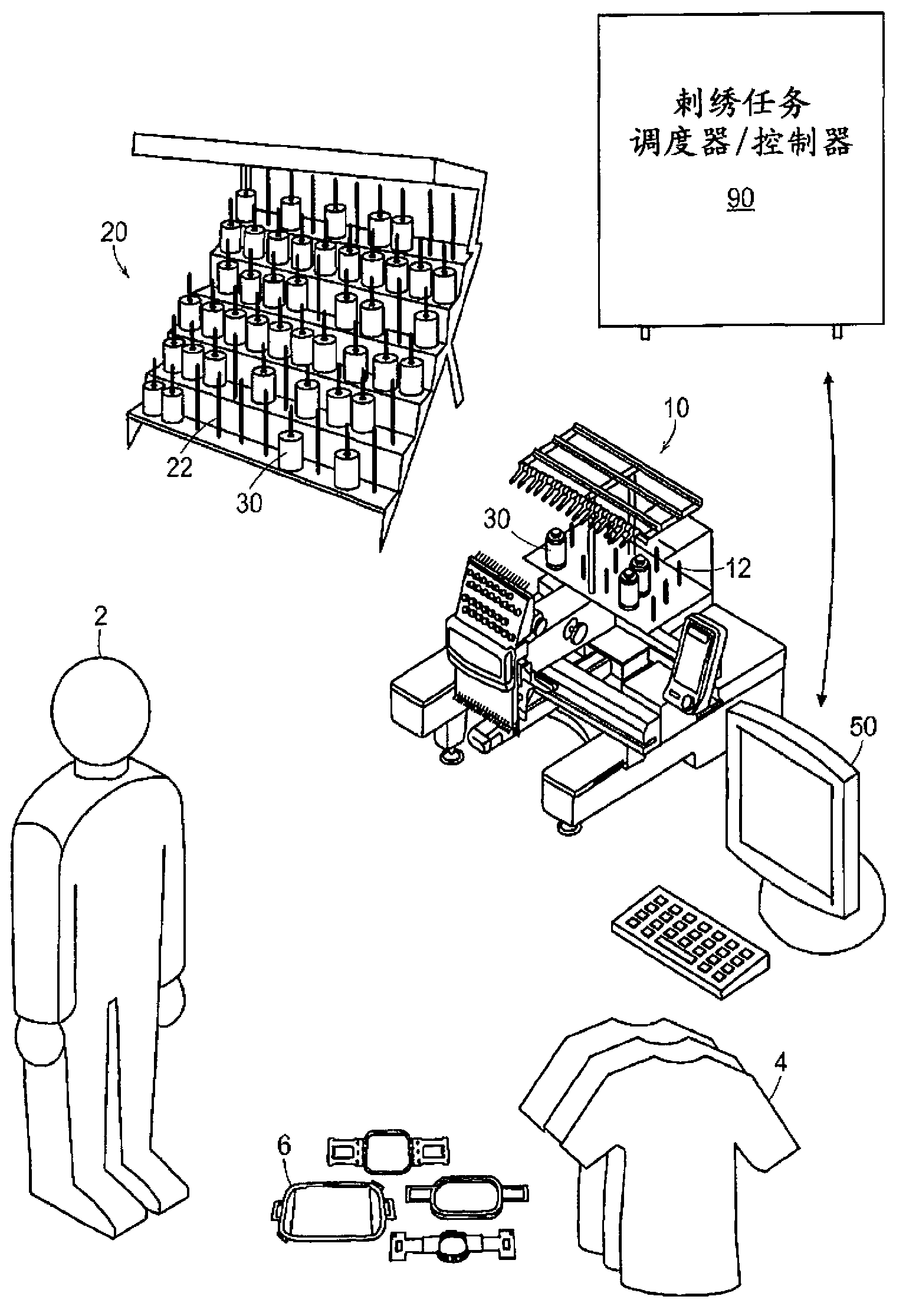

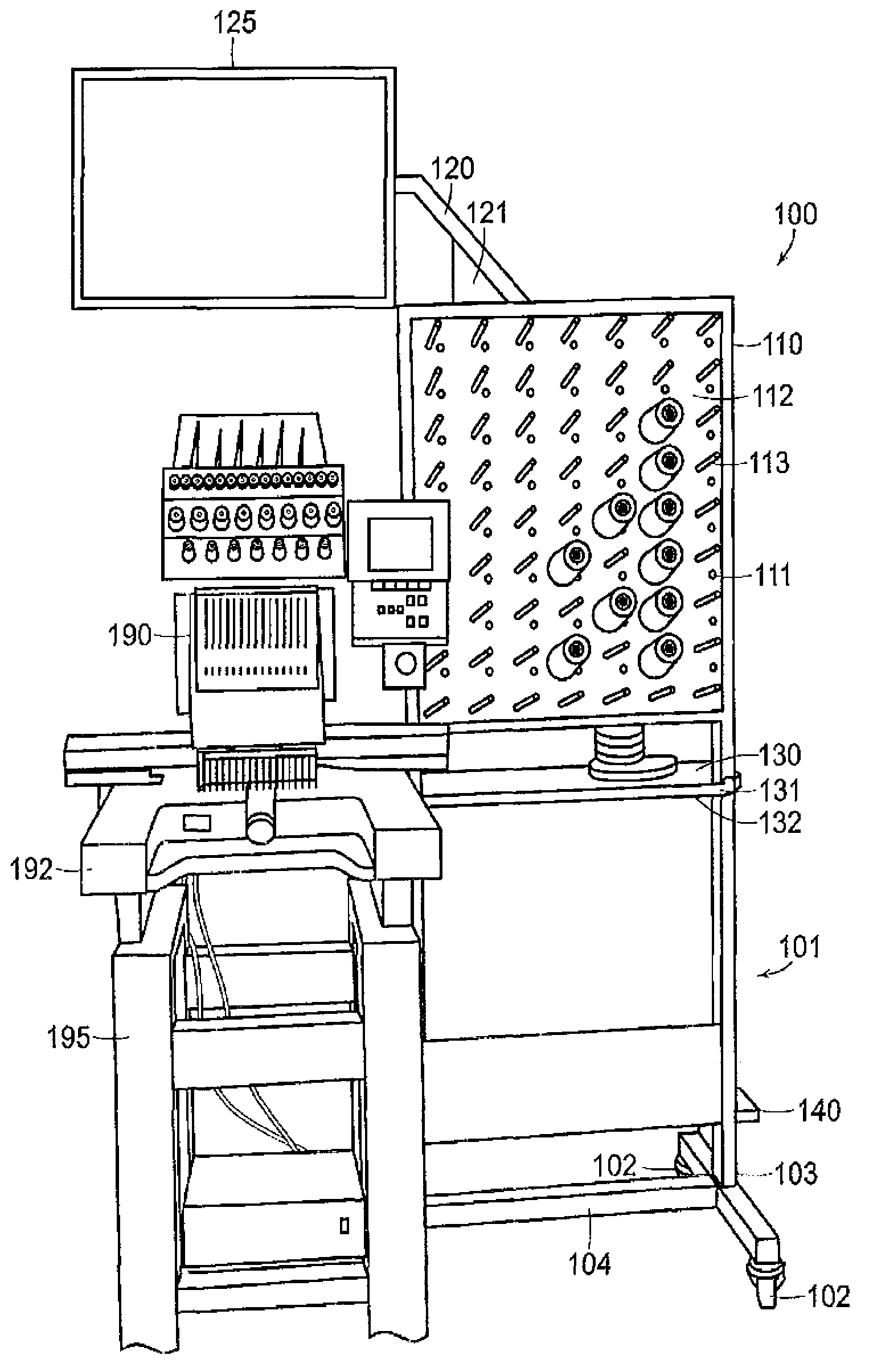

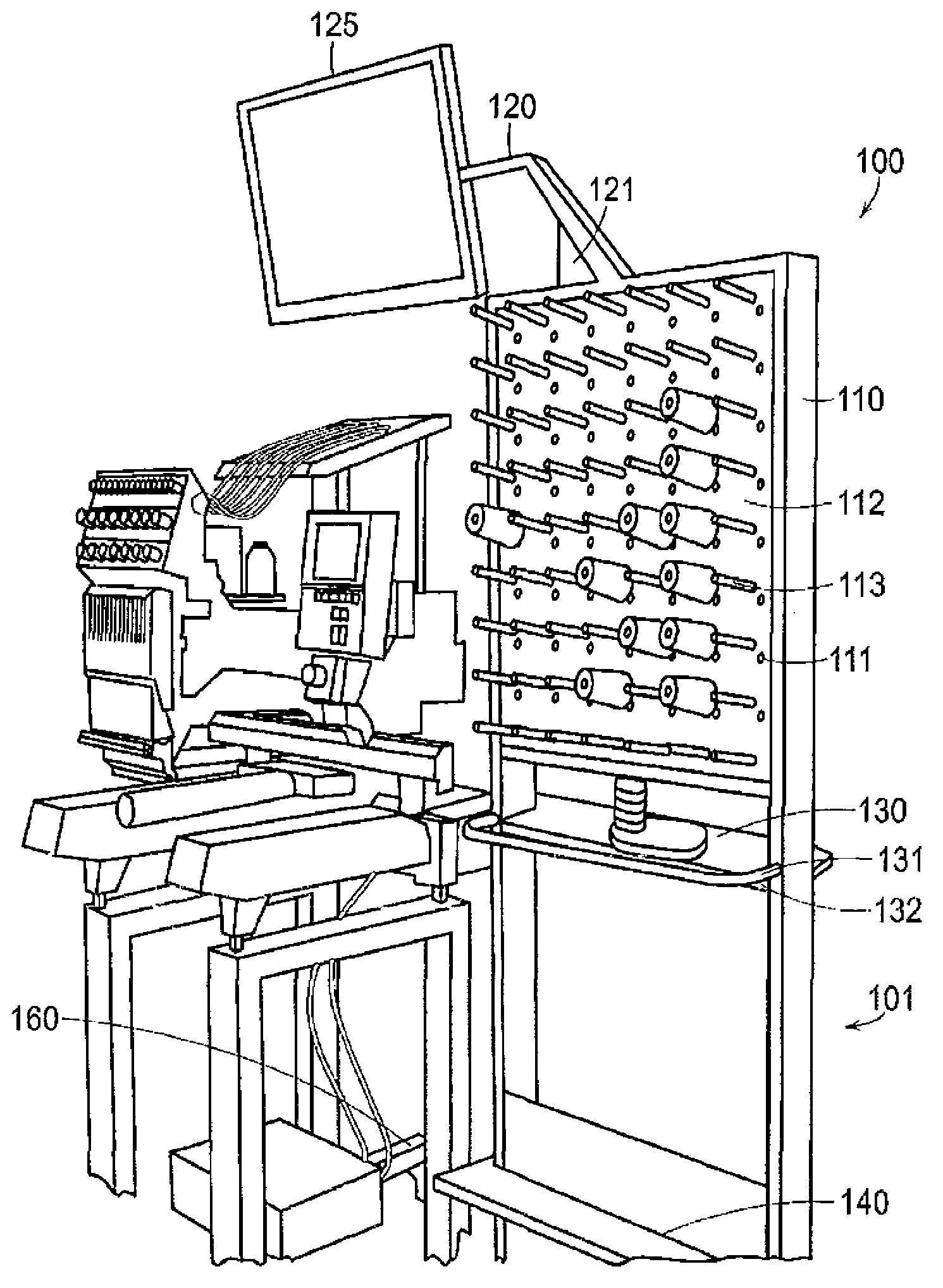

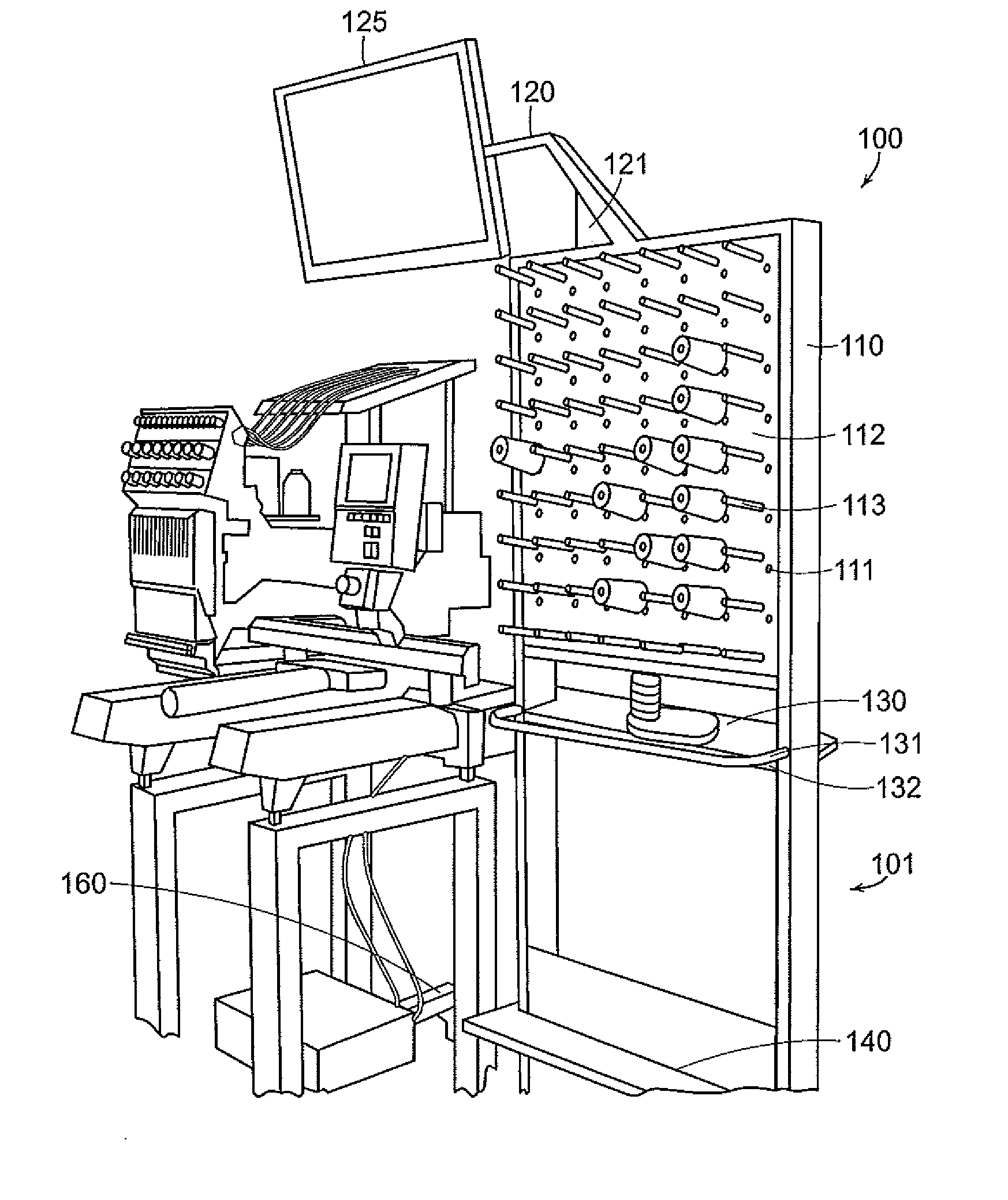

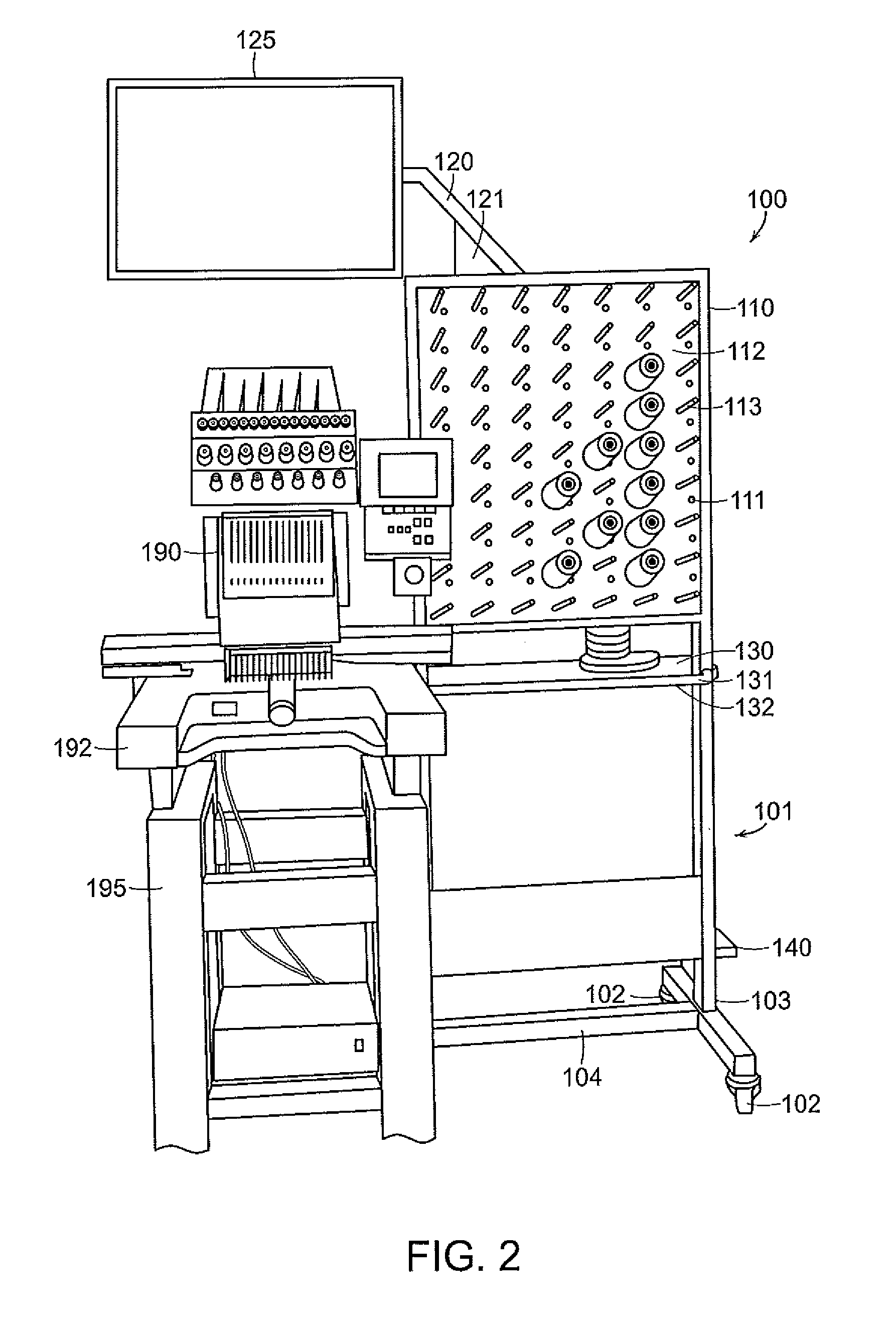

Embroidery workstation utility cart

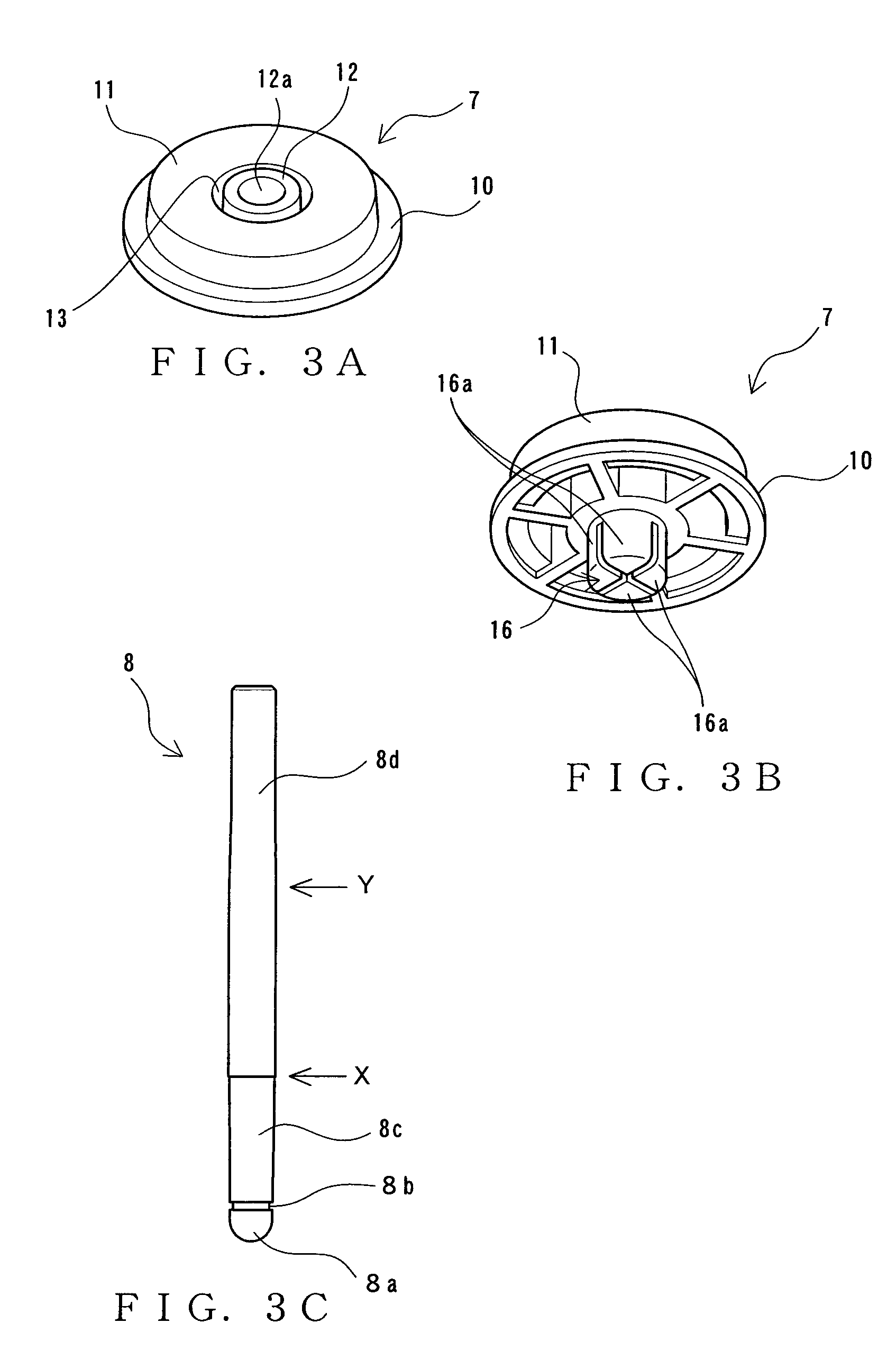

An embroidery workstation utility cart for optimizing the positioning of supports for the embroidery machine, thread spool rack, monitor, workpiece queue, and other accessories desired for optimal embroidery processing.

Owner:VISTAPRINT TECH

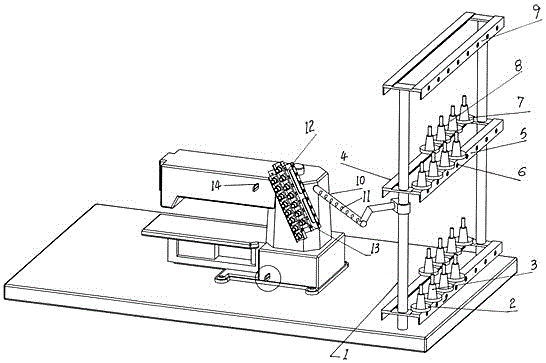

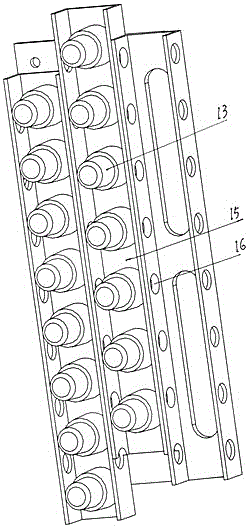

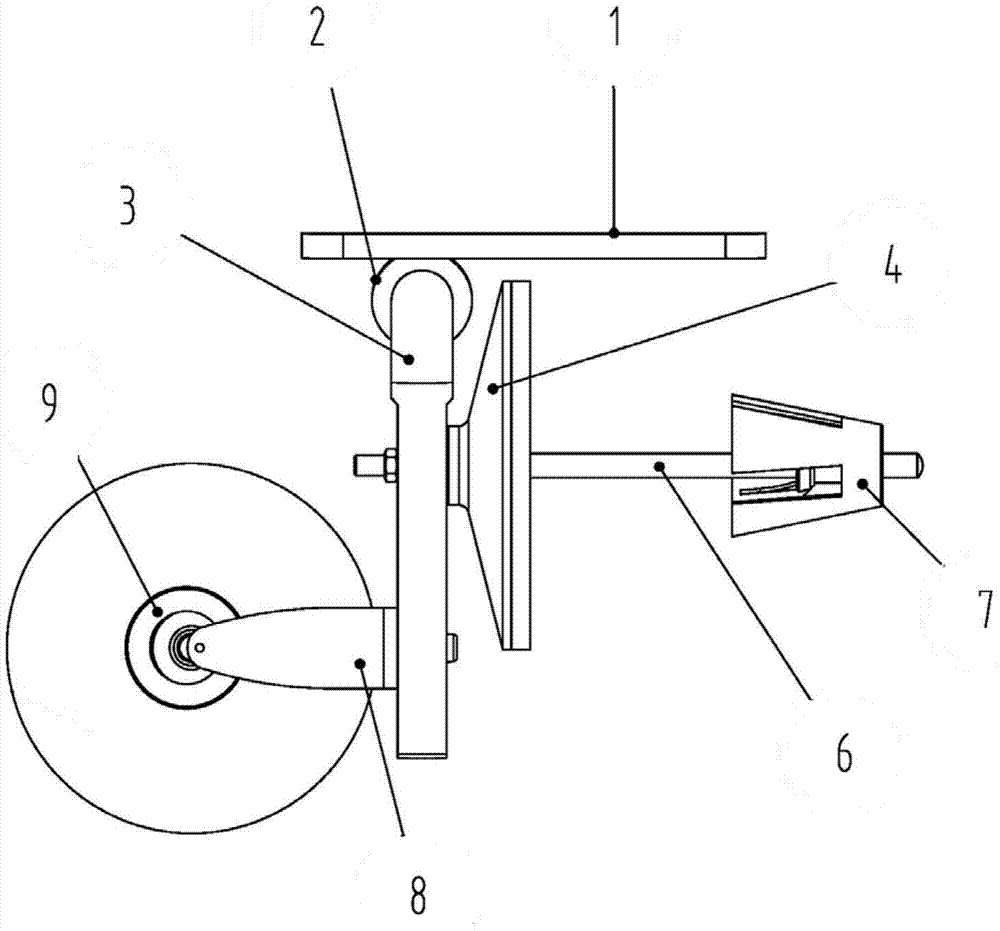

Thread bracket for sewing reflective stripes

InactiveCN106120185AImprove securityImprove bindingSpool-pin assembliesThread-break detectorsArchitectural engineeringSewing needle

The invention discloses a thread bracket for sewing reflective stripes. The thread bracket comprises thread rollers. A rack is formed by two round steel pipes which are spaced by a distance and fixed to one end of a sewing machine. An inner threading plate and an outer threading plate are arranged in the middle of the rack, a top layer threading plate is fixed to the head of the rack, a lower thread tray is arranged below the inner threading plate and the outer threading plate, an upper thread tray is arranged between the inner threading plate and the outer threading plate, the upper thread rollers are arranged on the upper thread tray, the lower thread rollers are arranged on the lower thread tray, threading holes are formed in the plate surfaces of the inner threading plate and the outer threading plate, a thread adding device is fixed to a machine head at one end of the sewing machine, a thread guide pipe is arranged in a suspended mode at the position above the thread adding device and in the middle of the inner threading plate, thread guide holes are formed in the thread guide pipe, thread separating rollers are arranged on the thread adding device, a thread distribution plate is fixed to the part, blow the thread separating rollers, of the sewing machine, two sets of threads are arranged in thread outlet holes of the thread distribution plate respectively in a penetrating mode, and the four threads in each set are threaded into a sewing needle to carry out sewing along the two sides of each reflective stripe.

Owner:新乡市新科防护科技有限公司

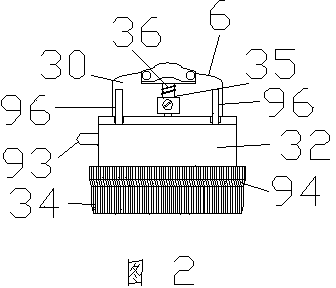

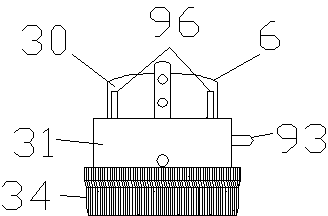

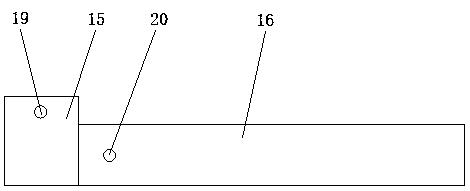

Facial line detection mechanism, facial line detection device and sewing machine provided with facial line detection device

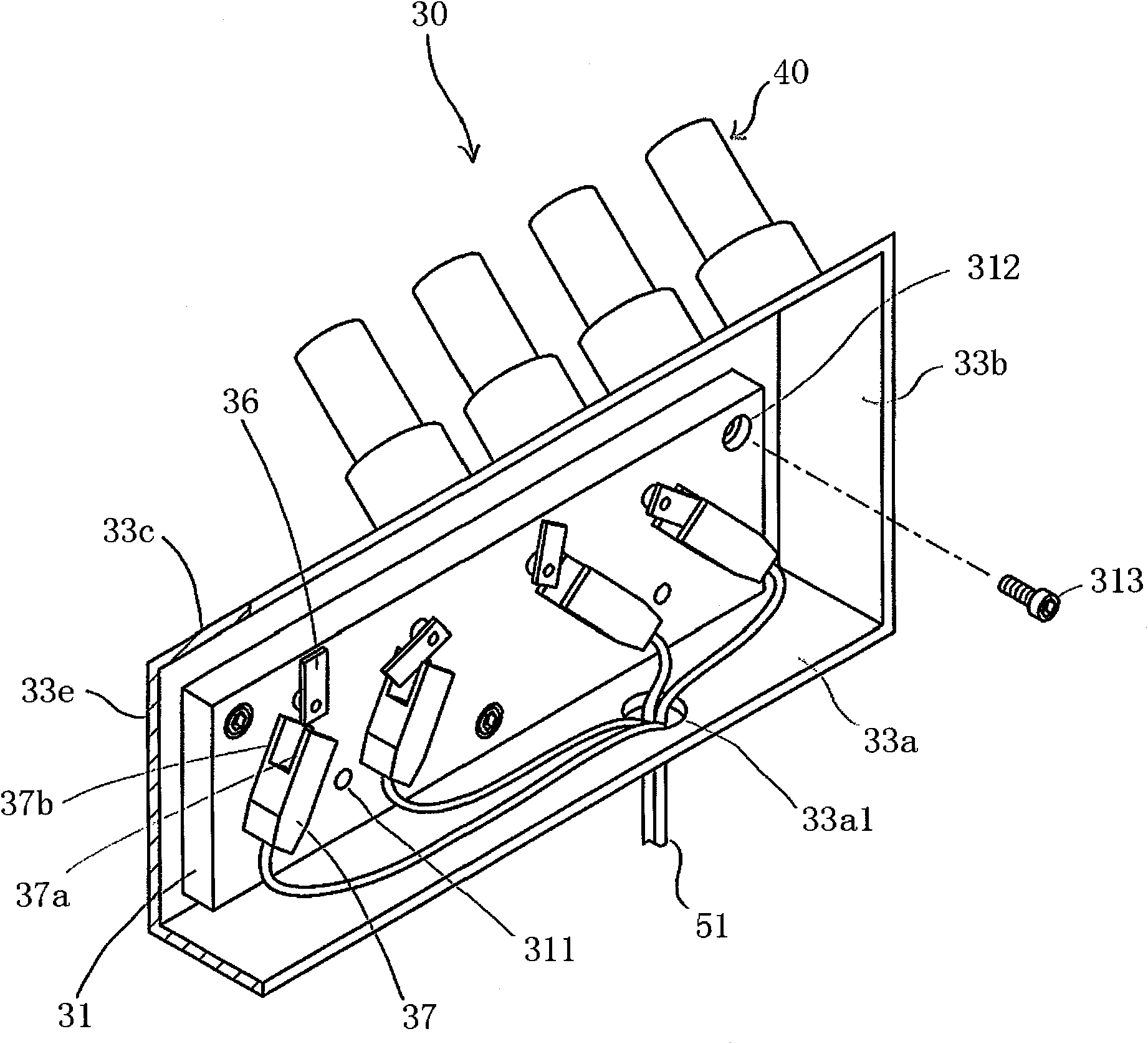

The invention aims at providing a facial line detection mechanism capable of monitoring the supply condition of facial lines, a facial line detection device provided with the mechanism and a sewing machine provided with the device. The facial line detection mechanism is characterized by comprising a base (31), a rotating shaft (38), a line roller (35), a detected component (36) and a detection component (37), wherein the base (31) is arranged on the sewing machine; the rotating shaft (38) passes through the base (31); the line roller (35) is fixed at one end of the rotating shaft (38) in a manner of being prominent from the first face of the base (31); the detected component (36) is fixed at the other end of the rotating shaft (38) in a manner of being prominent from the second face of the base (31) at the opposite side of the first face; and the detection component (37) is applied to detecting the rotation of the detected component (36).

Owner:YKK CORP

Sewing machine and spool pin stand therefor

A sewing machine includes a spool pin stand having spool pins to which thread spools are attachable and seats corresponding to the spool pins, respectively, thread passage defining members located on a thread passage, a sewing data storage unit storing sewing data including at least thread color information about colors of the needle threads, thread supply display units which are located on the spool pin stand so as to correspond to the spool pins respectively, the thread supply display units being configured to produce light which transmits through at least ones of the spool pins and the seats and displaying the thread colors in a color-variable manner, respectively, and a thread color information control unit controlling the thread supply display units based on the thread color information so that thread colors corresponding to the spool pins are displayed by the thread supply display units, respectively.

Owner:BROTHER KOGYO KK

Thread holding mechanism and sewing machine provided therewith

InactiveUS6880473B2Increase passionReliable holdFilament handlingSpool-pin assembliesScrew threadSewing needle

A thread holding mechanism for sewing machines is disclosed holding a thread when the thread is passed through an eye of a sewing needle. The mechanism includes a thread holding member including a thread holding portion capable of holding the thread, an operating force transmitting member to which an external force is applied, a moving member to which the operating force transmitting member transmits the force, moving the thread holding member near the eye of the needle, and a thread nipping member provided in the thread holding member for releasably nipping the thread, a switching member provided near a movement path of the thread holding member for switching the thread nipping member to an interposition releasing side temporarily prior to thread holding in synchronization with a predetermined stage of a step of moving the thread holding member.

Owner:BROTHER KOGYO KK

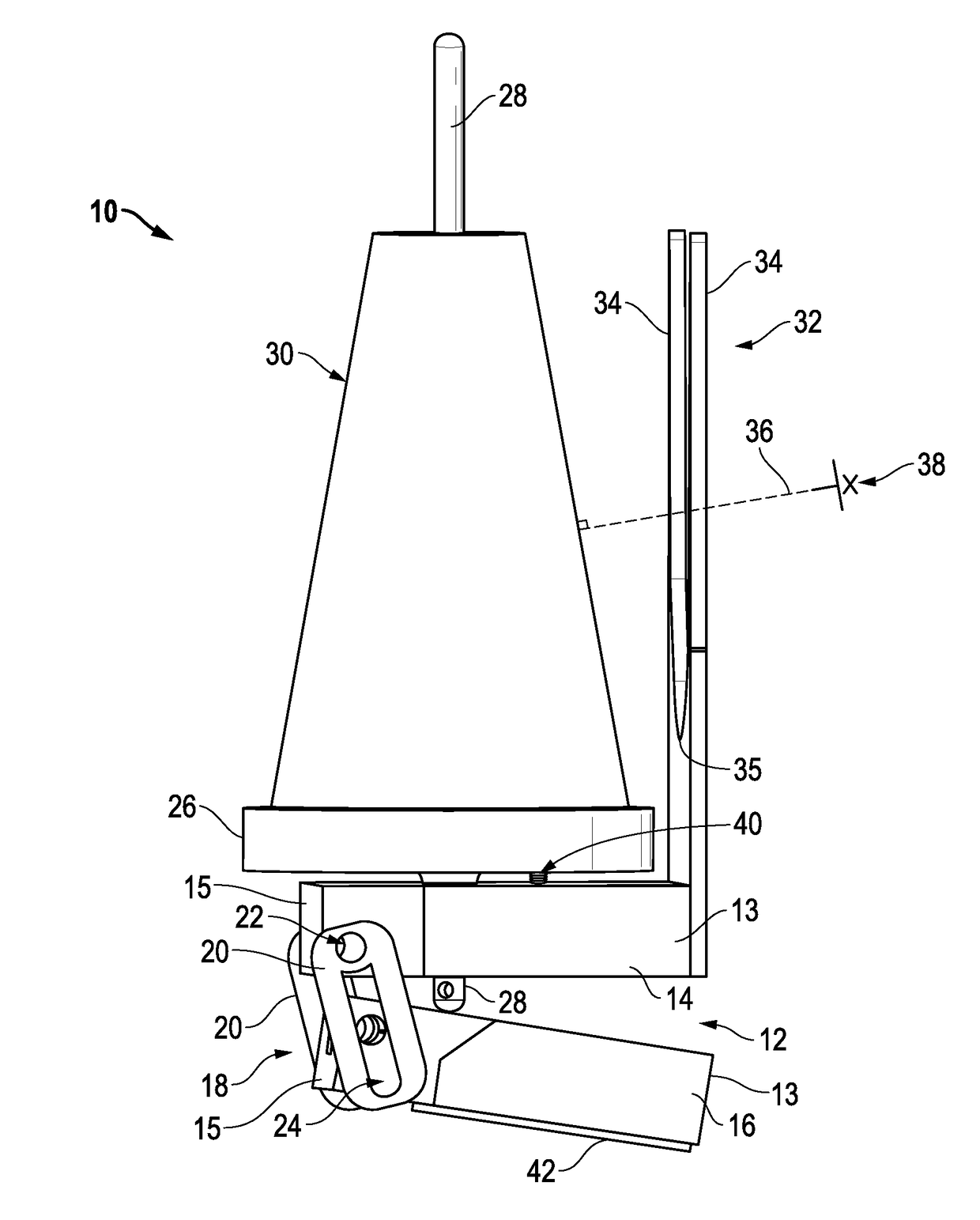

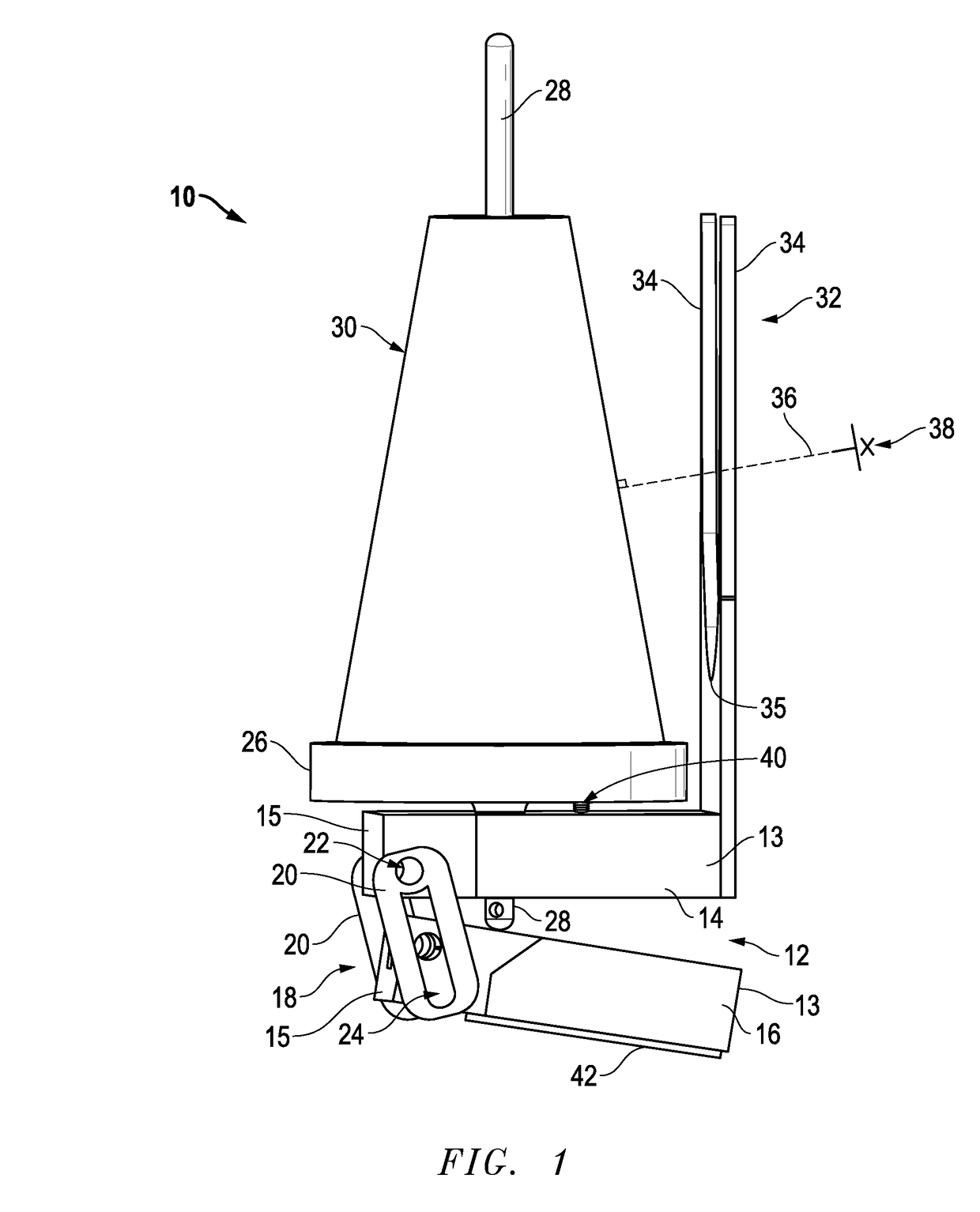

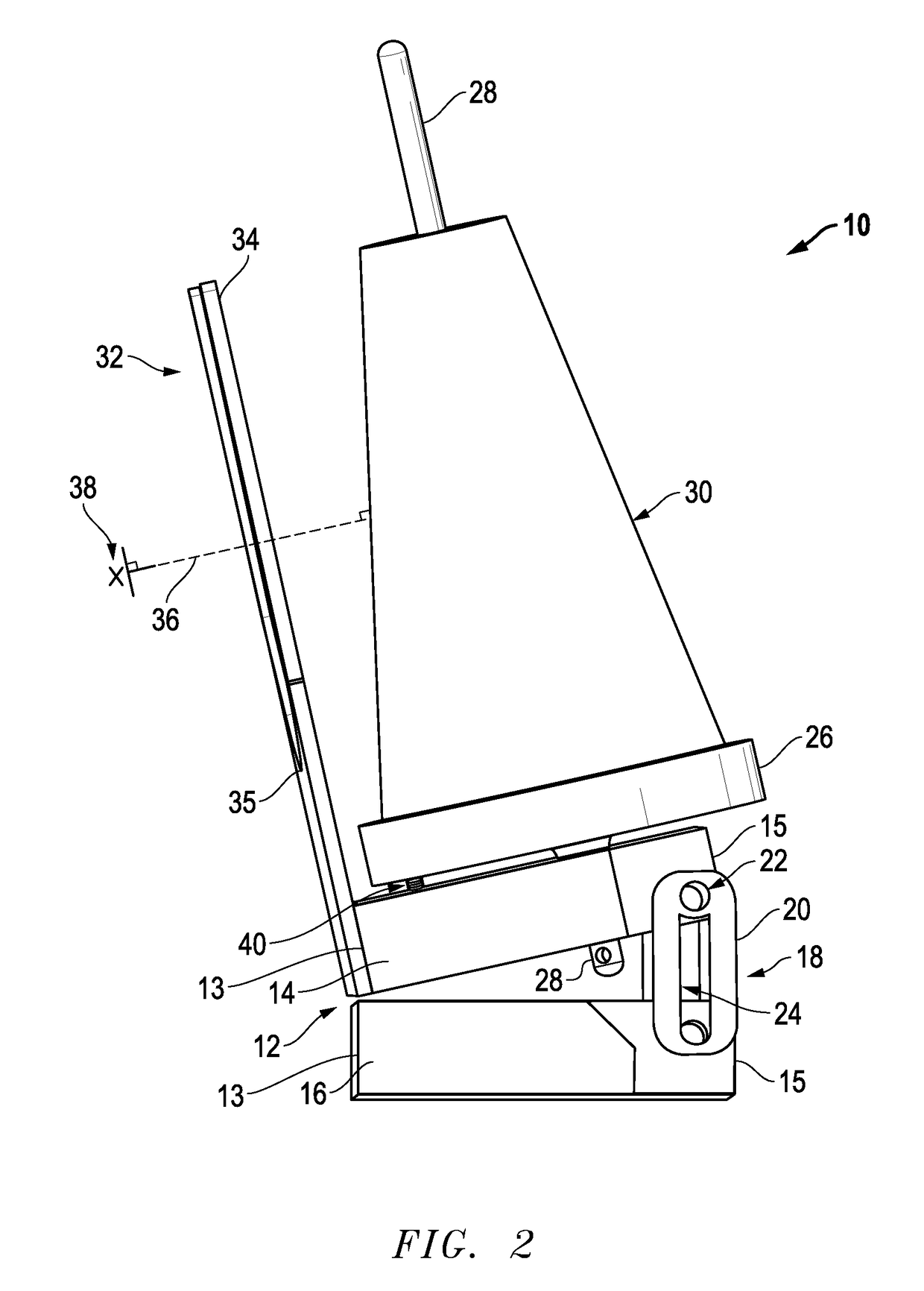

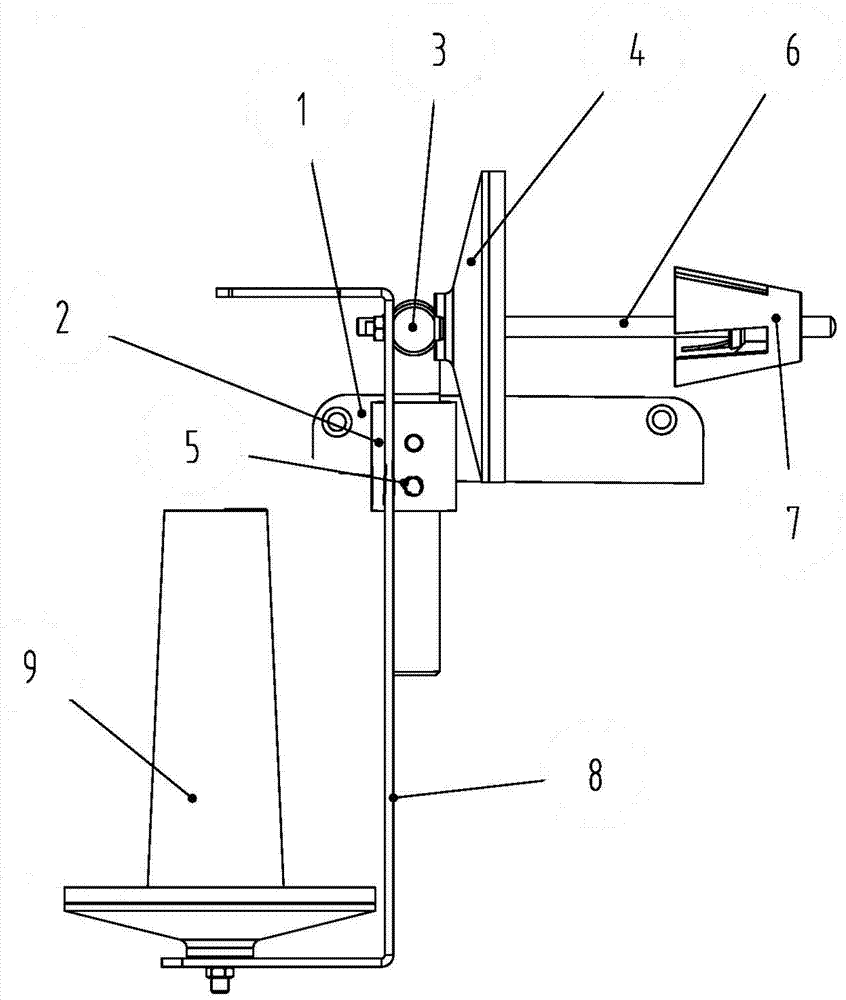

Quick spinner thread alignment apparatus and method

A quick spinner thread alignment apparatus consists of a two part adjustable mounting block comprised of an upper block and a lower block. An angle adjustment device is connected to the upper block and the lower block where the angle adjustment device adjustably secures the upper block at selected angles relative to the lower block. A thread support disk is rotatably connected with the mounting block. A thread saver is connected with the mounting block. A thread pole is connected with the thread support disk and a brake is connected with the thread support disk and the mounting block.

Owner:MARTELLI JOHN D

Embroidery workstation utility cart

InactiveUS20120097081A1Convenience to workCreelsSpool-pin assembliesWorkstationIndustrial engineering

An embroidery workstation utility cart for optimizing the positioning of supports for the embroidery machine, thread spool rack, monitor, workpiece queue, and other accessories desired for optimal embroidery processing.

Owner:VISTAPRINT SCHWEIZ

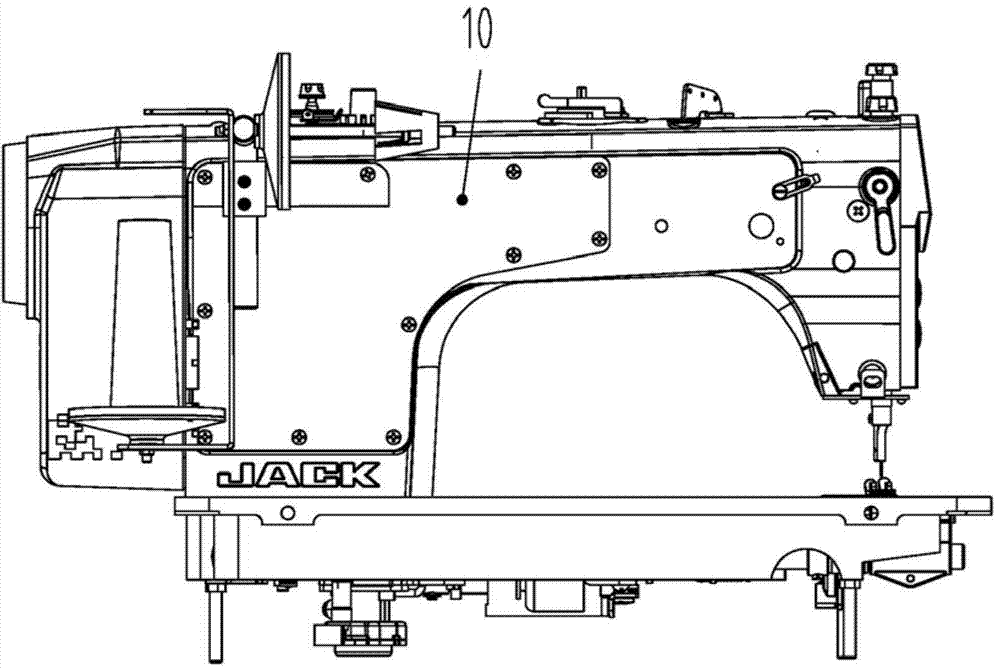

Sewing machine and thread stand thereof

The invention discloses a thread stand of a sewing machine. The thread stand comprises at least two pay-off devices and connecting devices, wherein the at least two pay-off devices are respectively used for accommodating wound upper threads (12) and accommodating wound bottom threads (13); the connecting devices are used for connecting the pay-off devices and the sewing machine. By utilizing the connecting devices, the pay-off devices are installed on a machine body of the sewing machine, that is, the thread stand is installed on the machine body of the sewing machine. The thread stand is simple in structure, and is convenient to install; the existing installation mode is changed, the thread stand is close to users; threads are relatively convenient to change and adjust, and the thread stand is convenient to operate by users, and is fixedly connected so as to prevent from being knocked off effectively, and further the working efficiency is improved. The invention also discloses the sewing machine comprising the thread stand.

Owner:JACK SEWING MASCH CO LTD

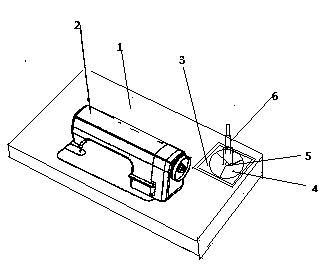

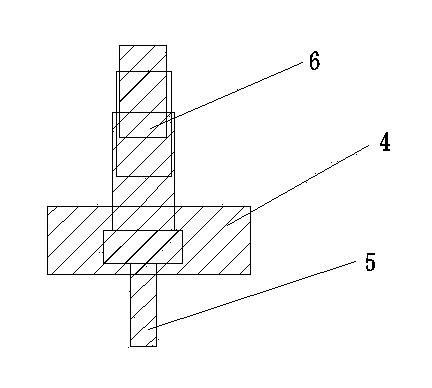

Sewing machine

The invention discloses a sewing machine which comprises a sewing machine body and a workbench. The sewing machine body is placed on the workbench which is provided with a groove. A tray for containing wires is placed in the groove. The tray can rotate freely. The wires needed for sewing are placed in the tray, the wires can rotate along with the tray, so that wire feeding is smooth during a sewing process, and the phenomenon that the wires are broken by pulling, or a cylinder wound with the wires topples is avoided.

Owner:SUZHOU JIALUO GARMENT

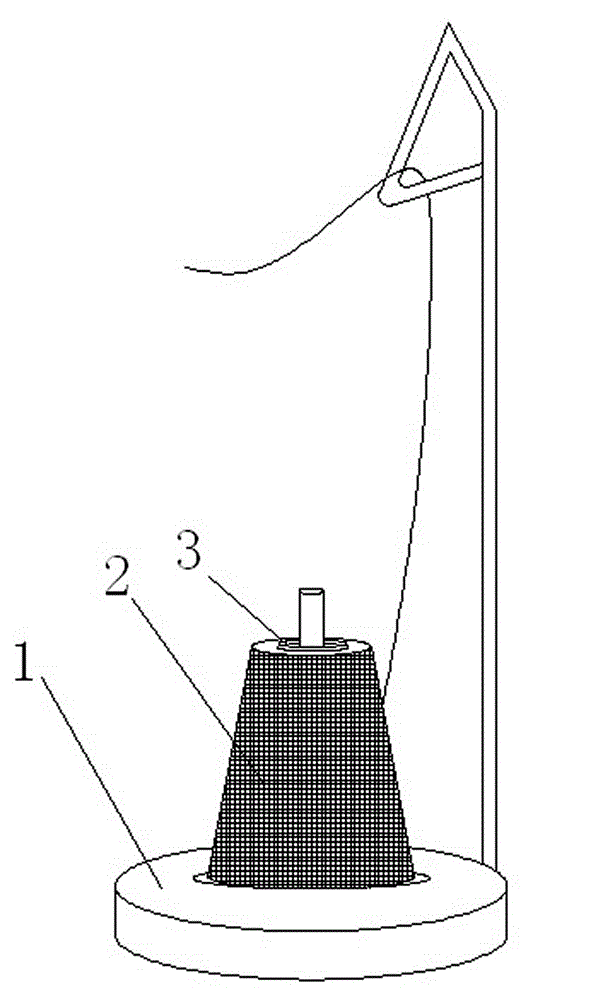

Spool sleeve piece

The invention discloses a spool sleeve piece which is characterized by comprising a spool body for coiling lines and a spool support. The bottom of the spool is provided with an annular magnet coil, and the spool support comprises a spool base and an inserting rod arranged on the spool base. The inserting rod comprises a line take-up rod and a spool positioning rod. A magnet block is arranged in the spool base. The sleeve piece can adsorb and fix the spool and the spool base through magnetic force, prevents the spool from shaking on spool base when lines are pumped too fast.

Owner:WUJIANG RUNLEI TEXTILE

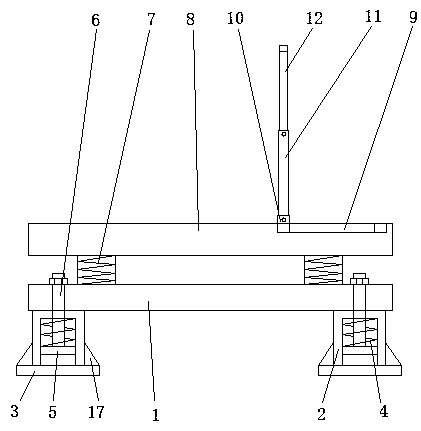

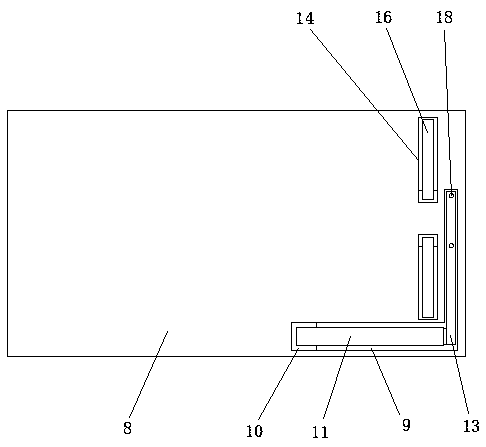

Sewing machine base

InactiveCN108796867AImprove vibration damping effectAffect normal operationNon-rotating vibration suppressionSpool-pin assembliesEngineeringChassis

The invention relates to a sewing machine base. The sewing machine comprises a pedestal, wherein support columns are connected to four corners of the bottom of the pedestal in an adhesion manner, chassises are fixedly connected to the bottoms of the support columns, damping springs I are fixedly connected to the tops of inner cavities of the support columns, support discs are fixedly connected tothe bottoms of the damping springs I, and connecting rods are fixedly connected to the centers of the tops of the support discs, penetrate through the tops of the support columns and are connected with the pedestal. The sewing machine base is simple in structure and convenient to use, the damping effect of a sewing machine can be improved, the situation that support legs of the sewing machine or afloor is damaged due to the vibration caused during the working of the sewing machine is avoided, the loosening of internal parts of the sewing machine is avoided, and even the influence on the normal working of the sewing machine is avoided; by combining forward damping with backward damping, vibration caused during the working of the sewing machine can be furthest reduced; and by combining a thread frame with the sewing machine base, the space is reasonably utilized, the space occupied by the thread frame is reduced, and the use space of a user is increased.

Owner:SUZHOU KAICHENG SEWING EQUIP

Sewing apparatus using thread cassette

InactiveUS7028626B2Suitable for operationImprove convenienceProgramme-controlled sewing machinesSewing-machine control devicesEngineeringClosed state

A sewing apparatus such as a sewing machine includes a sewing mechanism in which a needle thread is used, a cassette mount to which a thread cassette, while in a closed state, holding the needle thread used in the sewing mechanism is detachably attached, a determining unit determining a type of the thread cassette attached to the cassette mount, and a control device controlling the sewing mechanism according to the type of the thread cassette determined by the determining unit.

Owner:BROTHER KOGYO KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com