Patents

Literature

137results about "Lightening equipment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

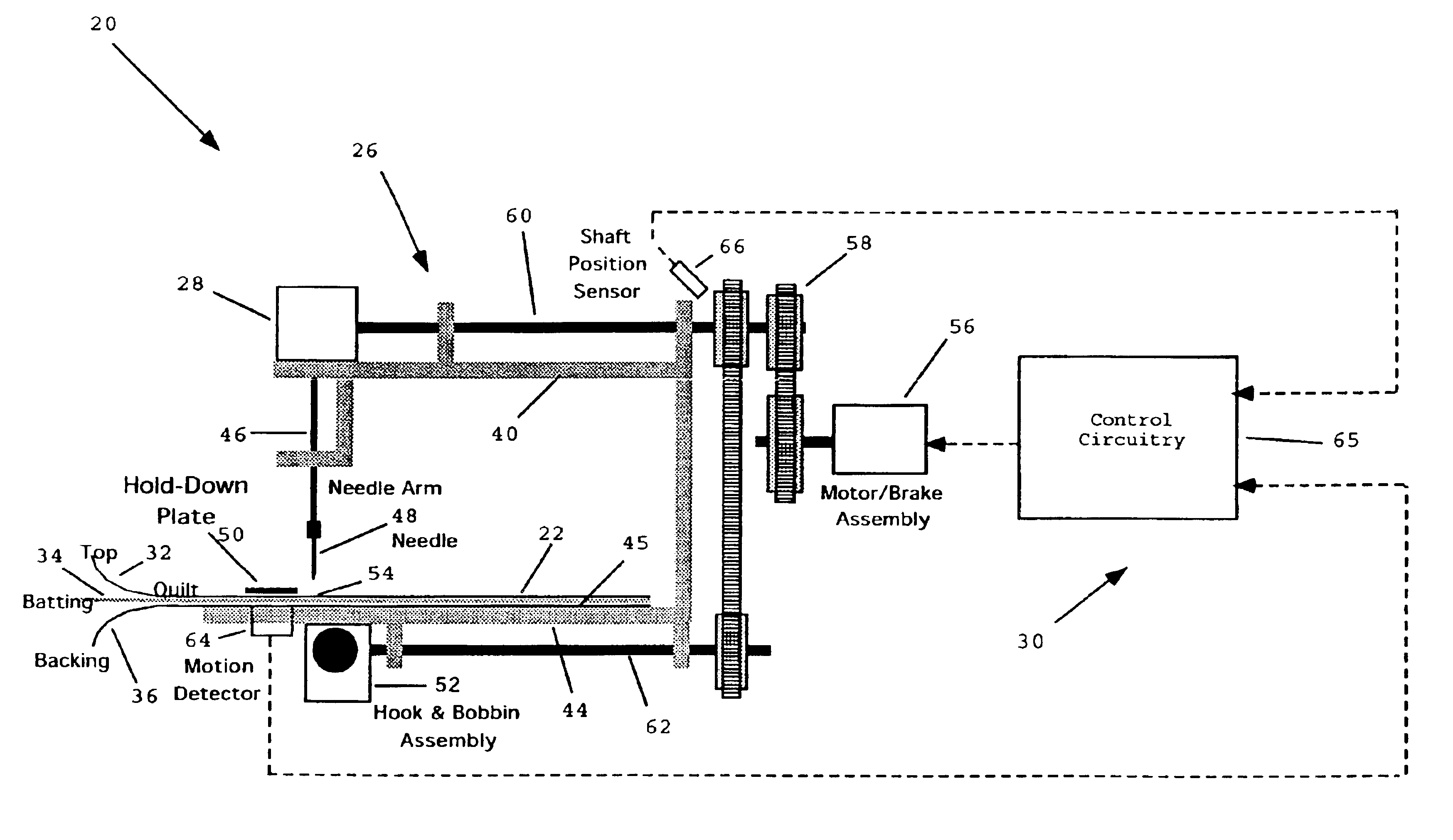

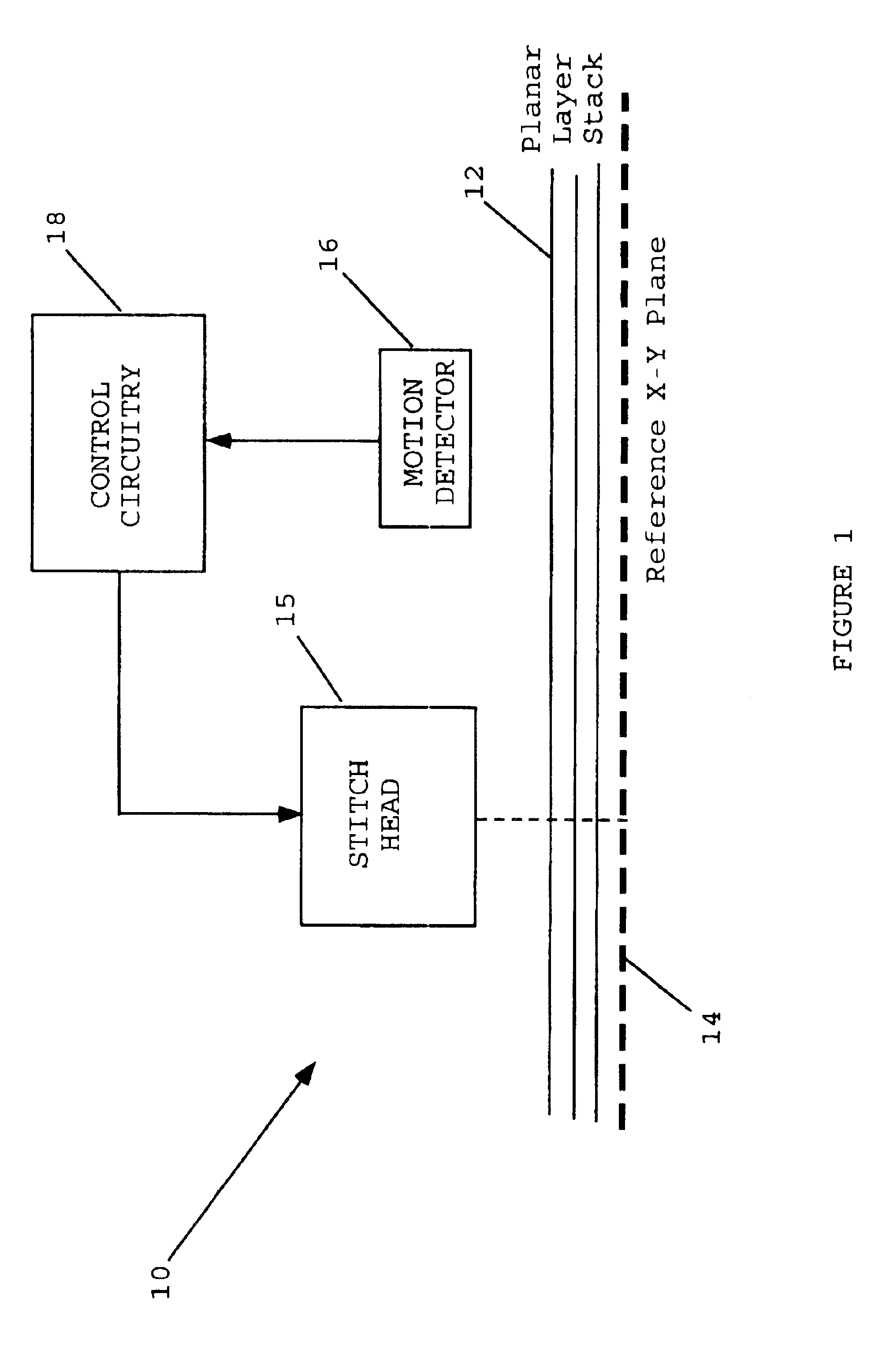

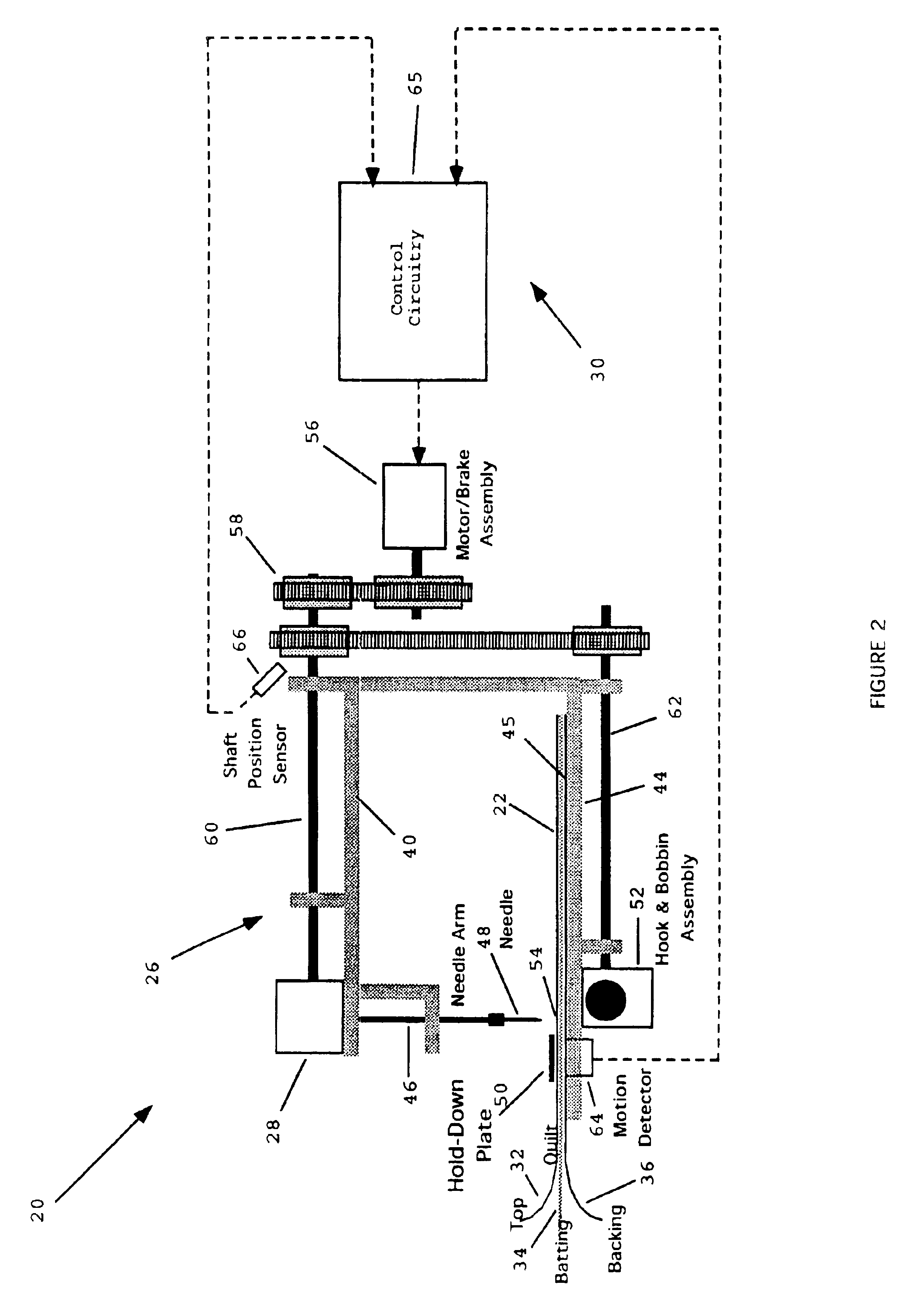

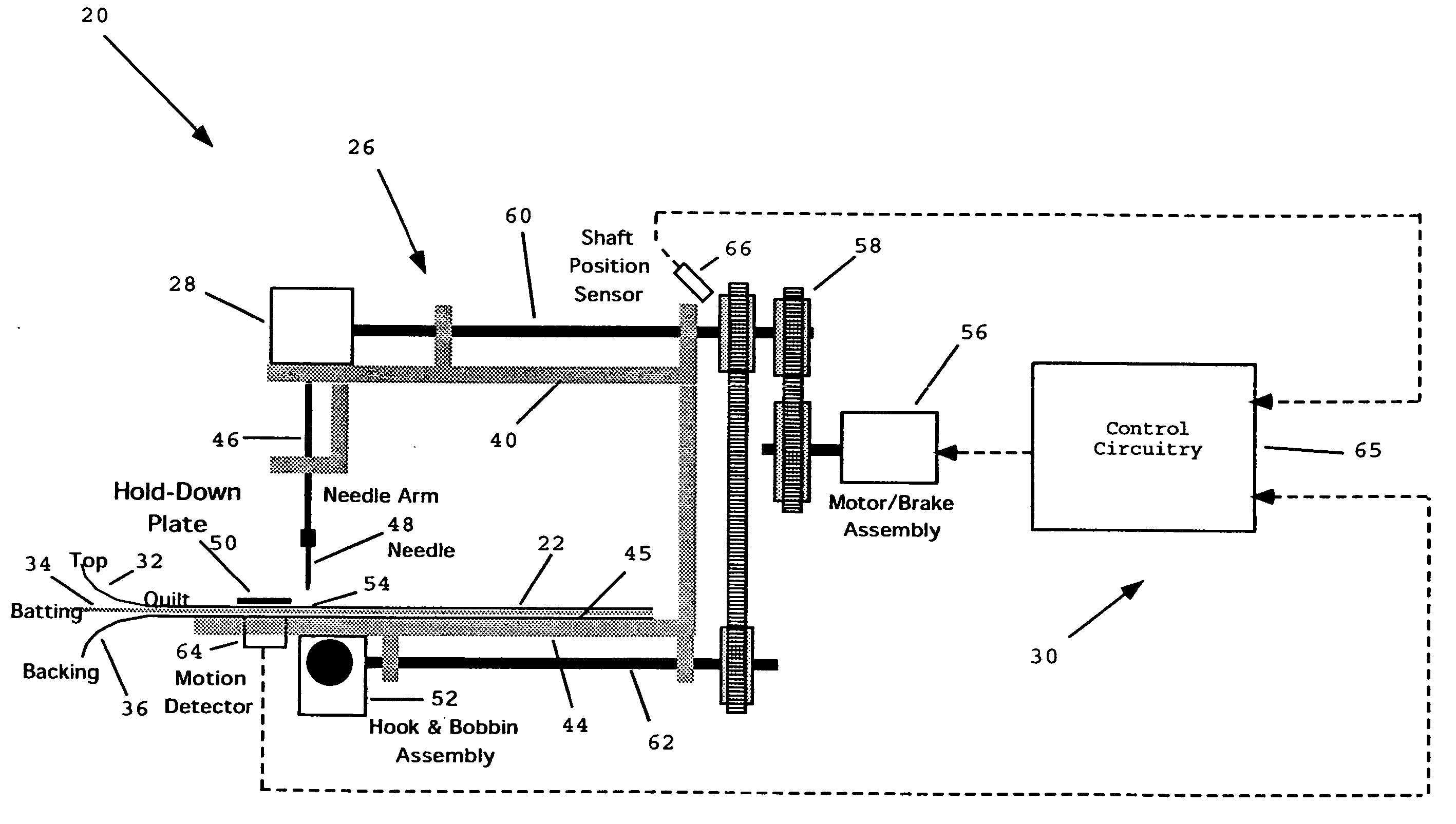

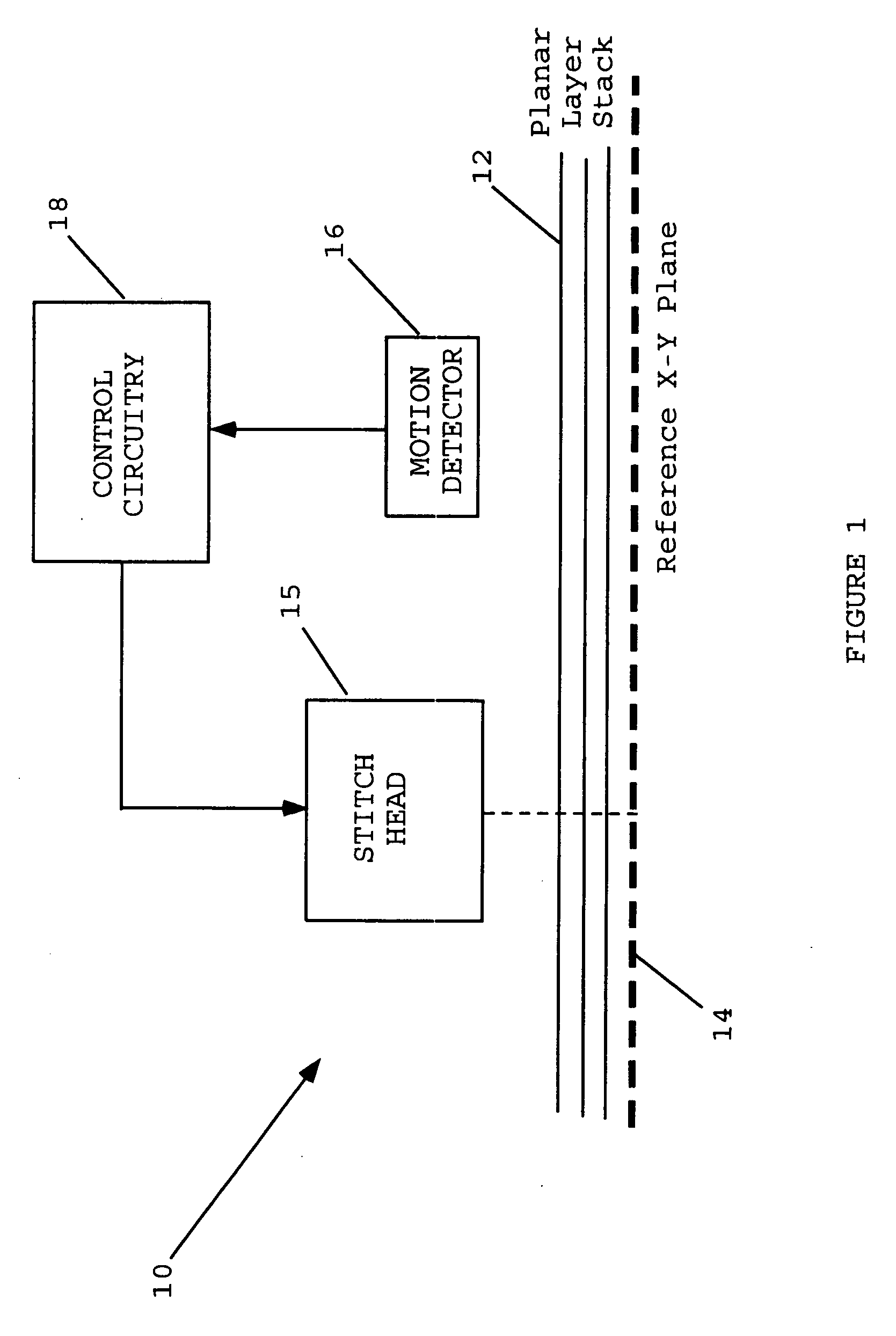

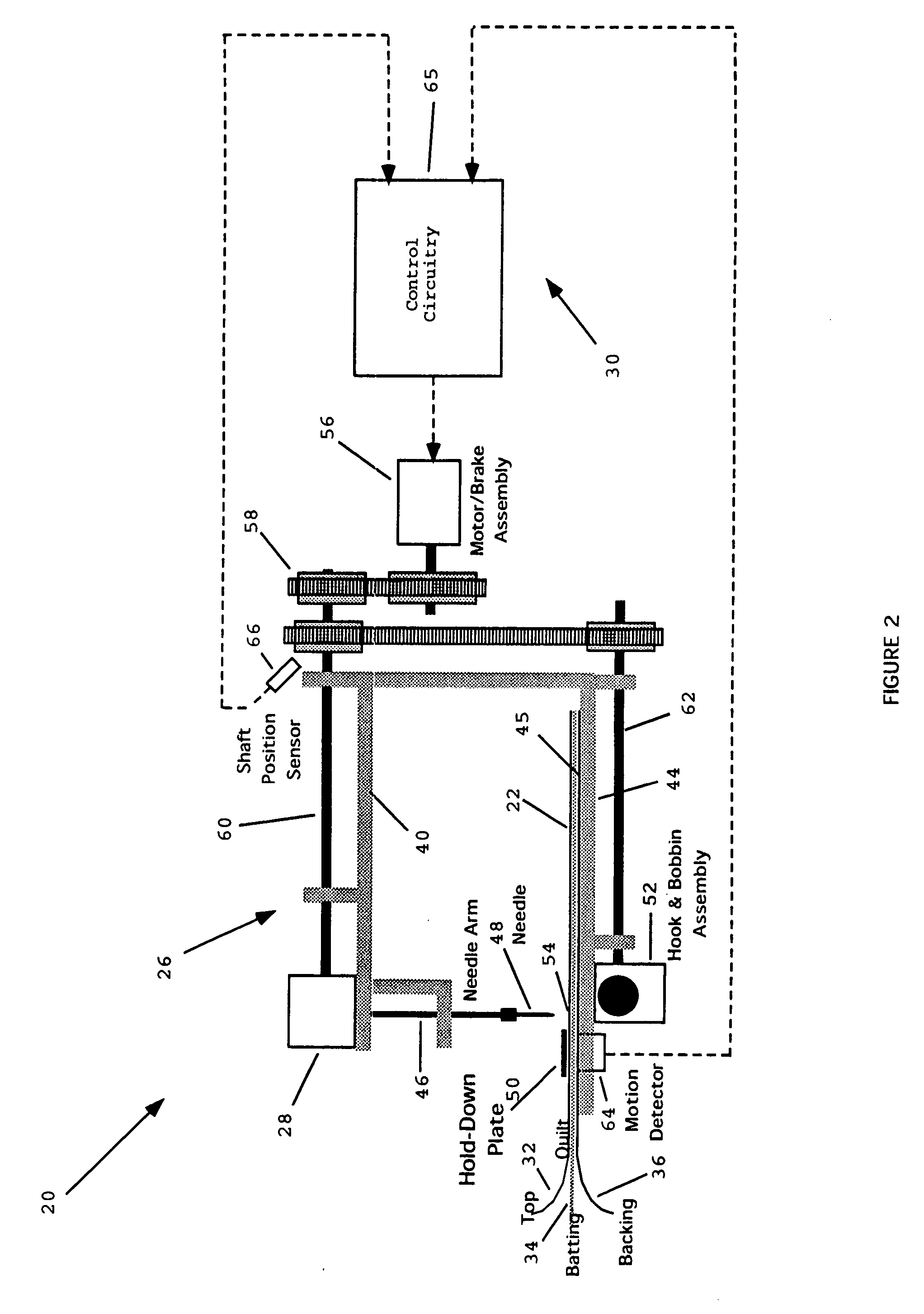

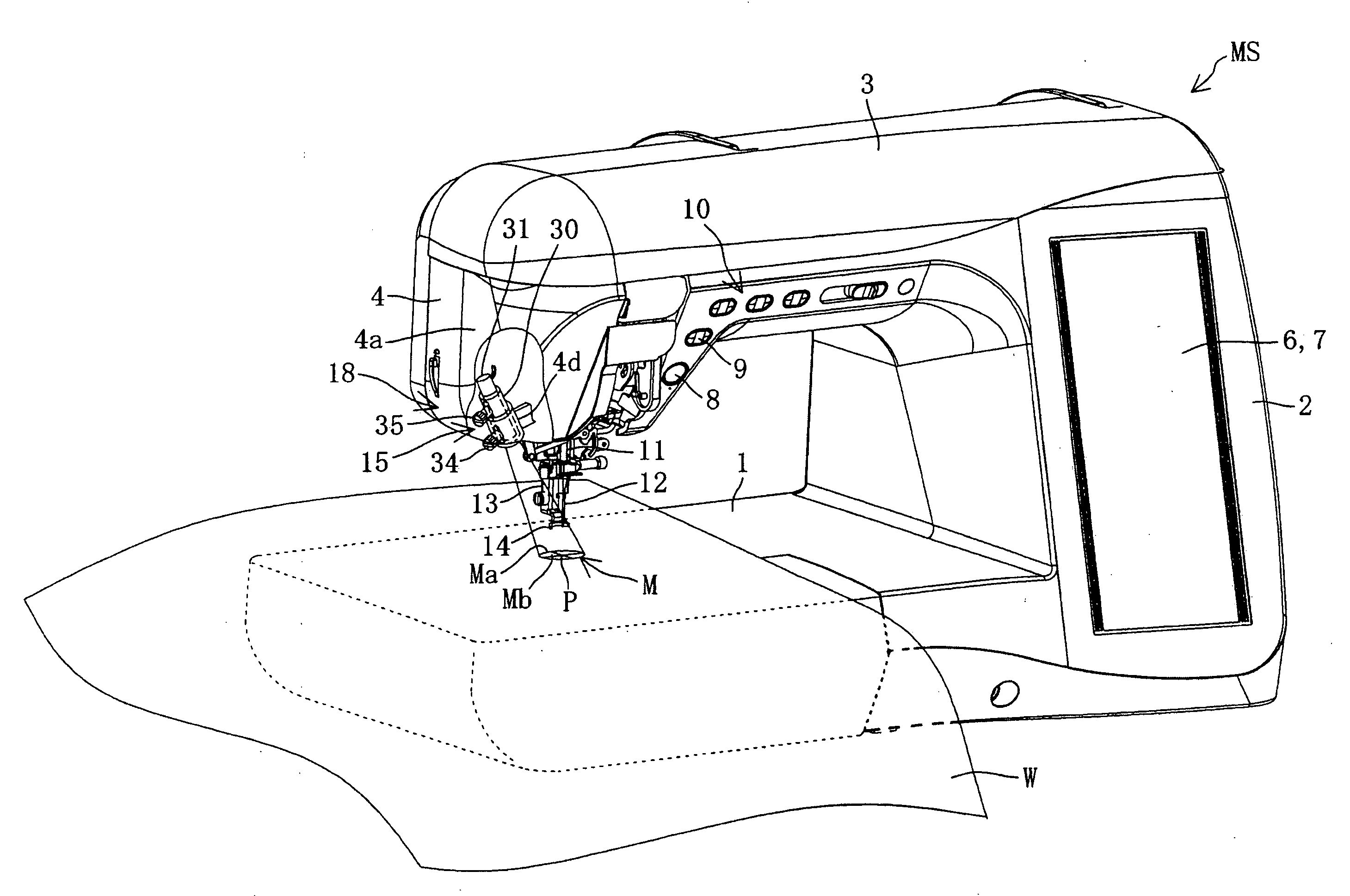

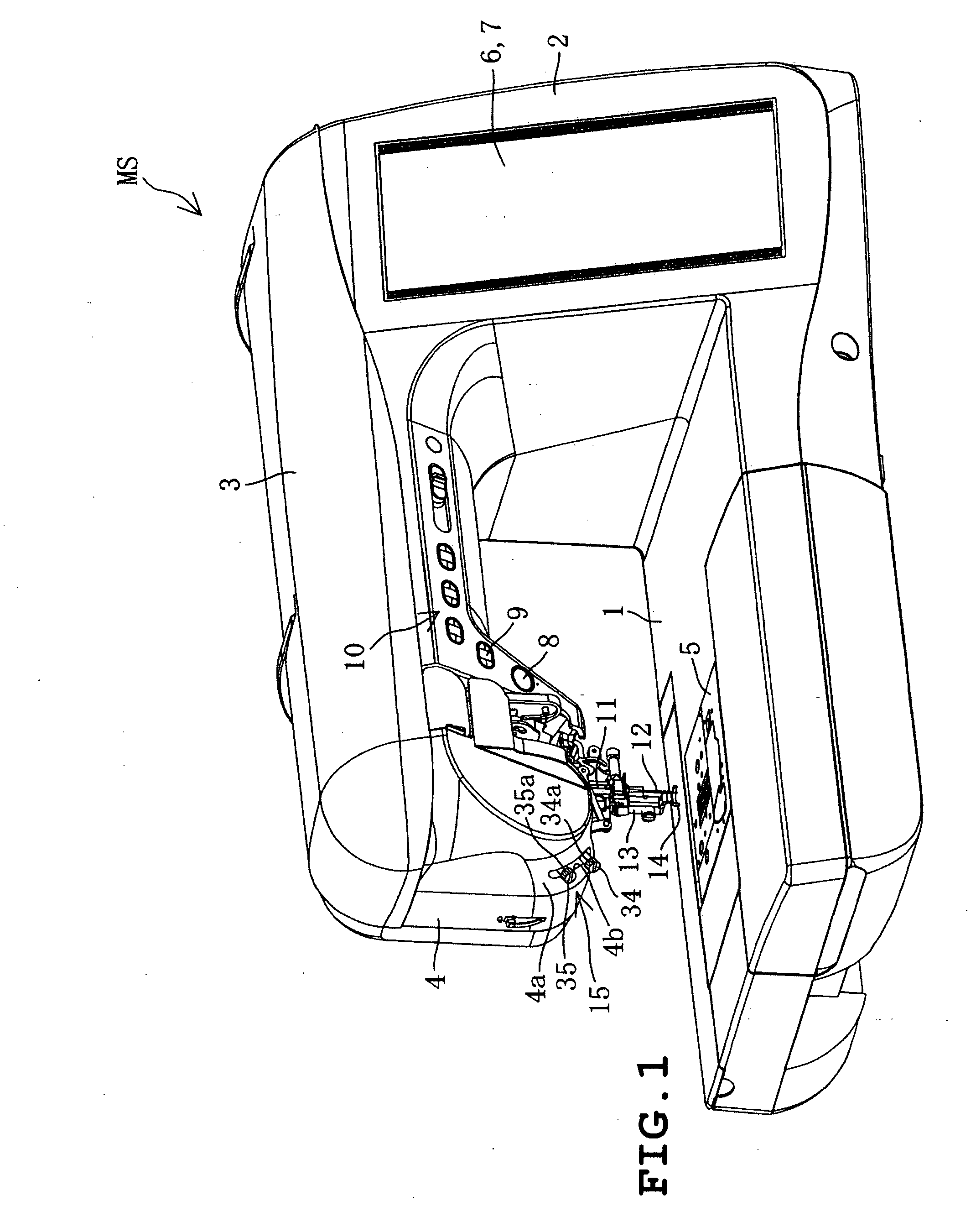

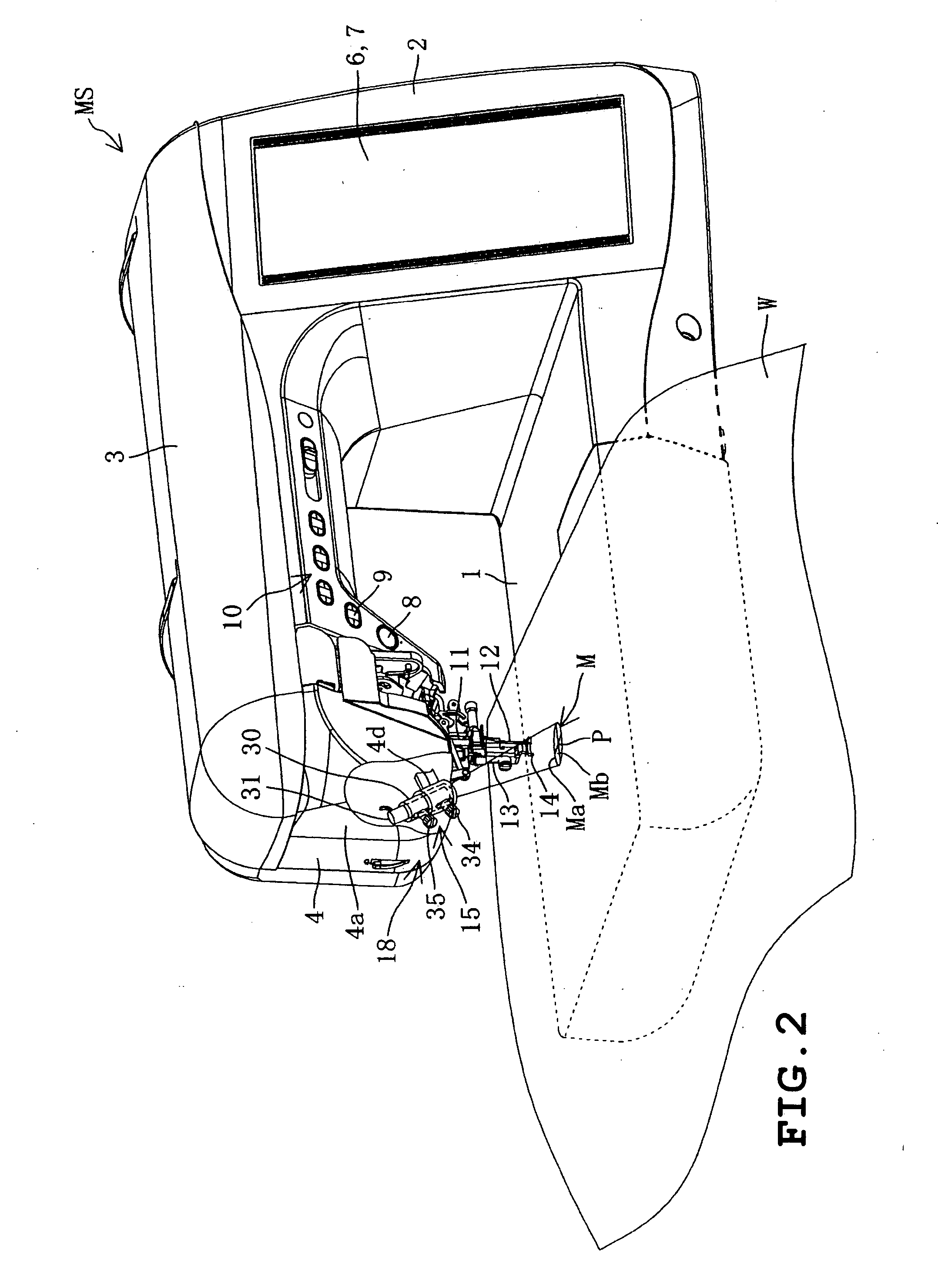

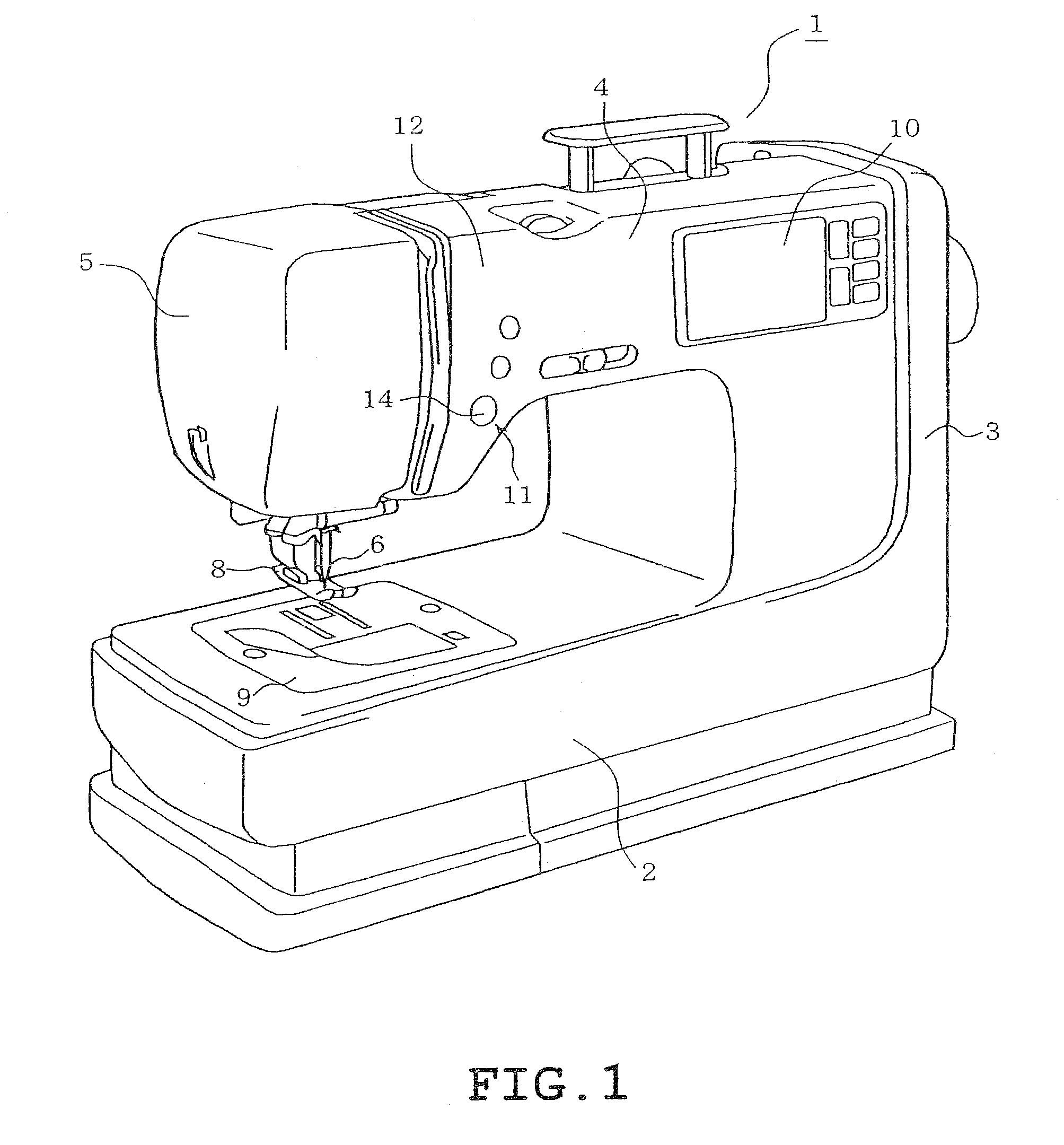

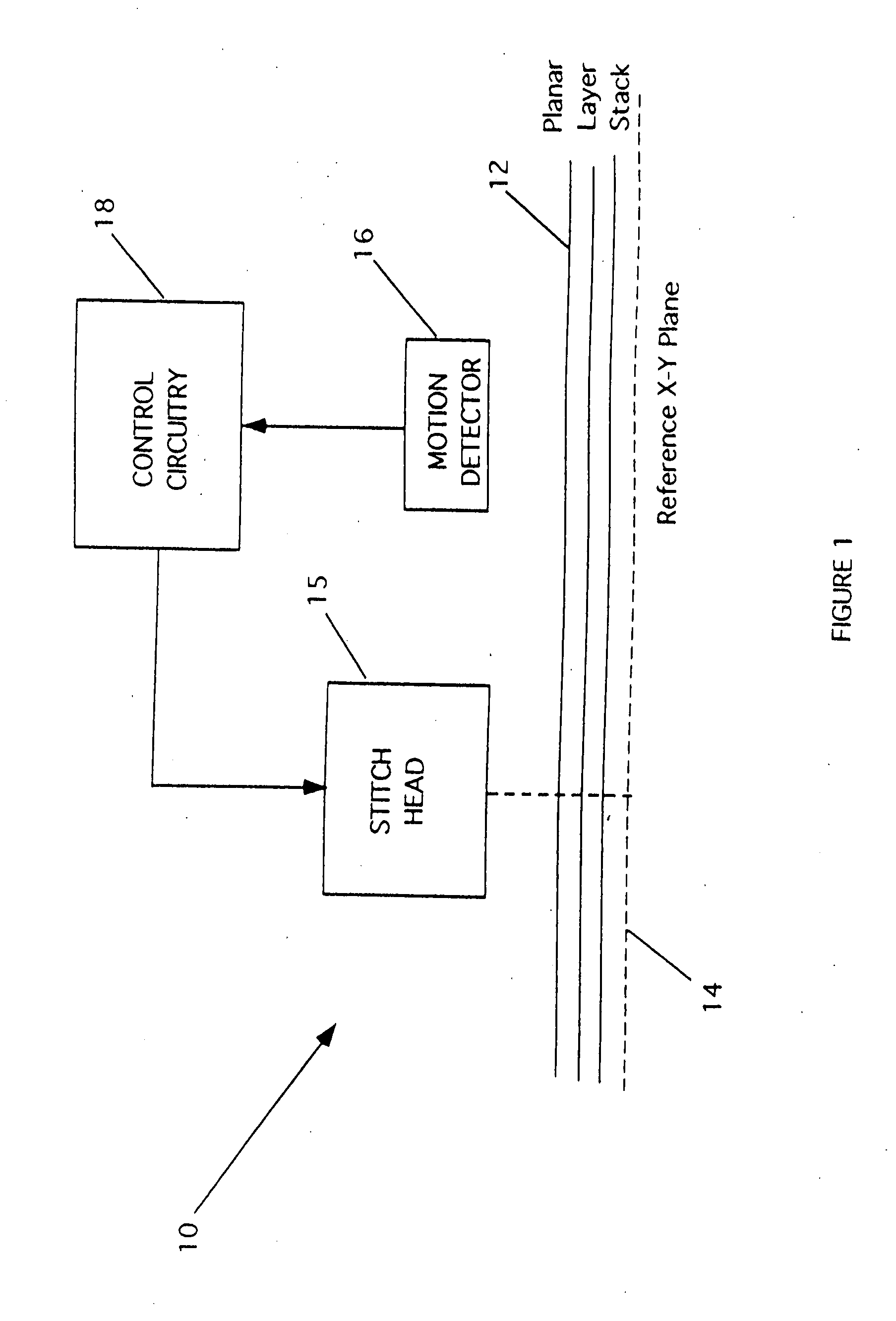

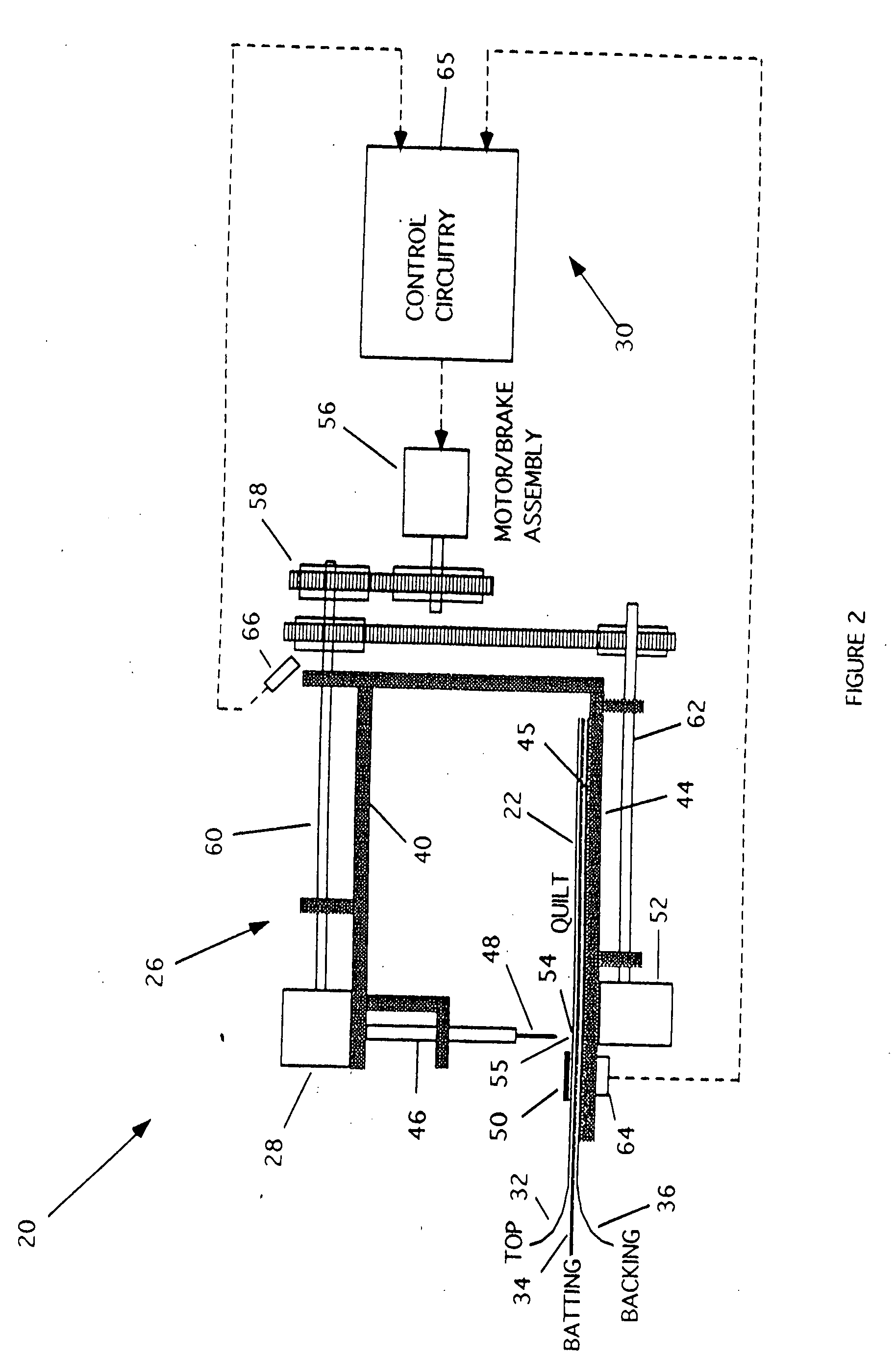

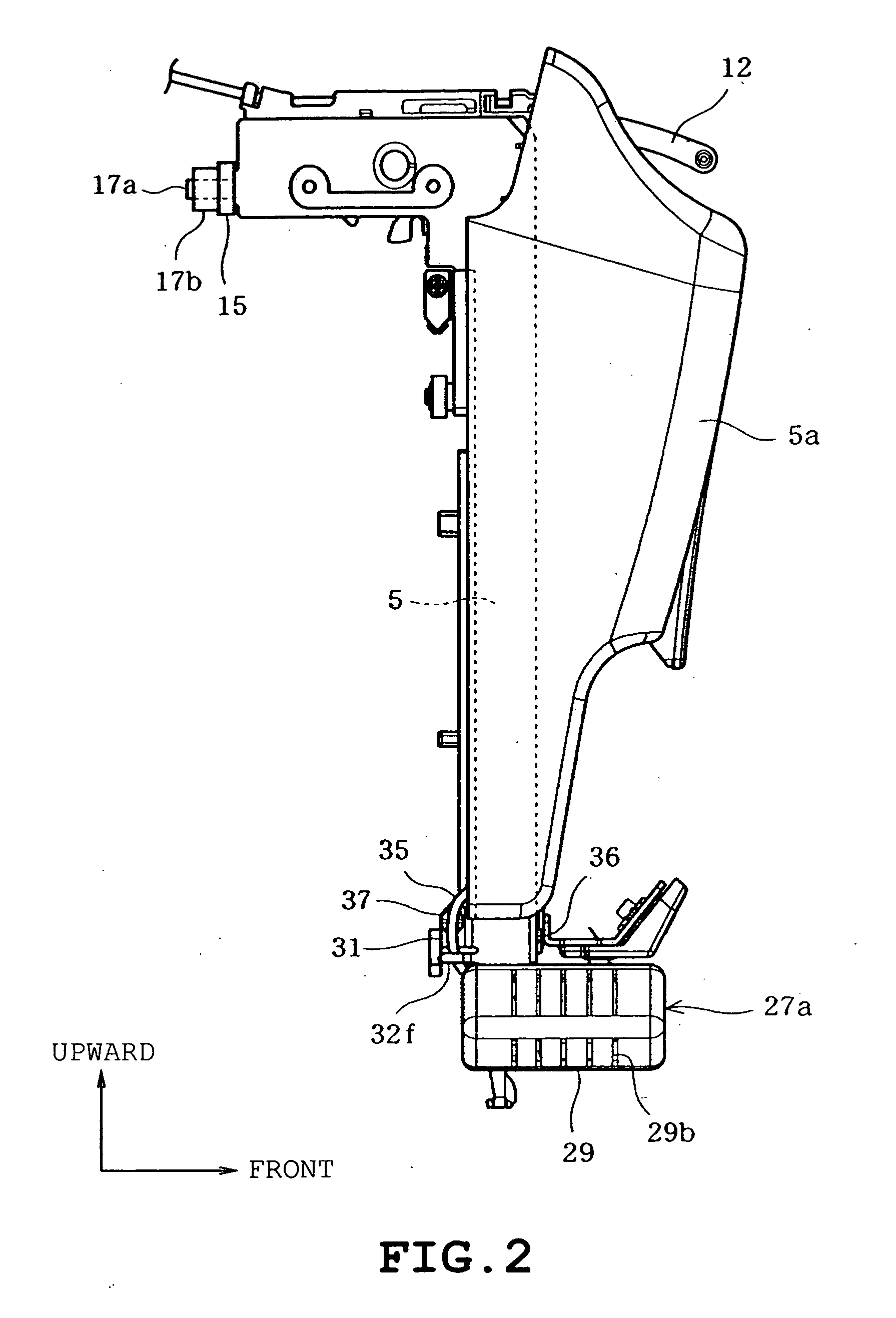

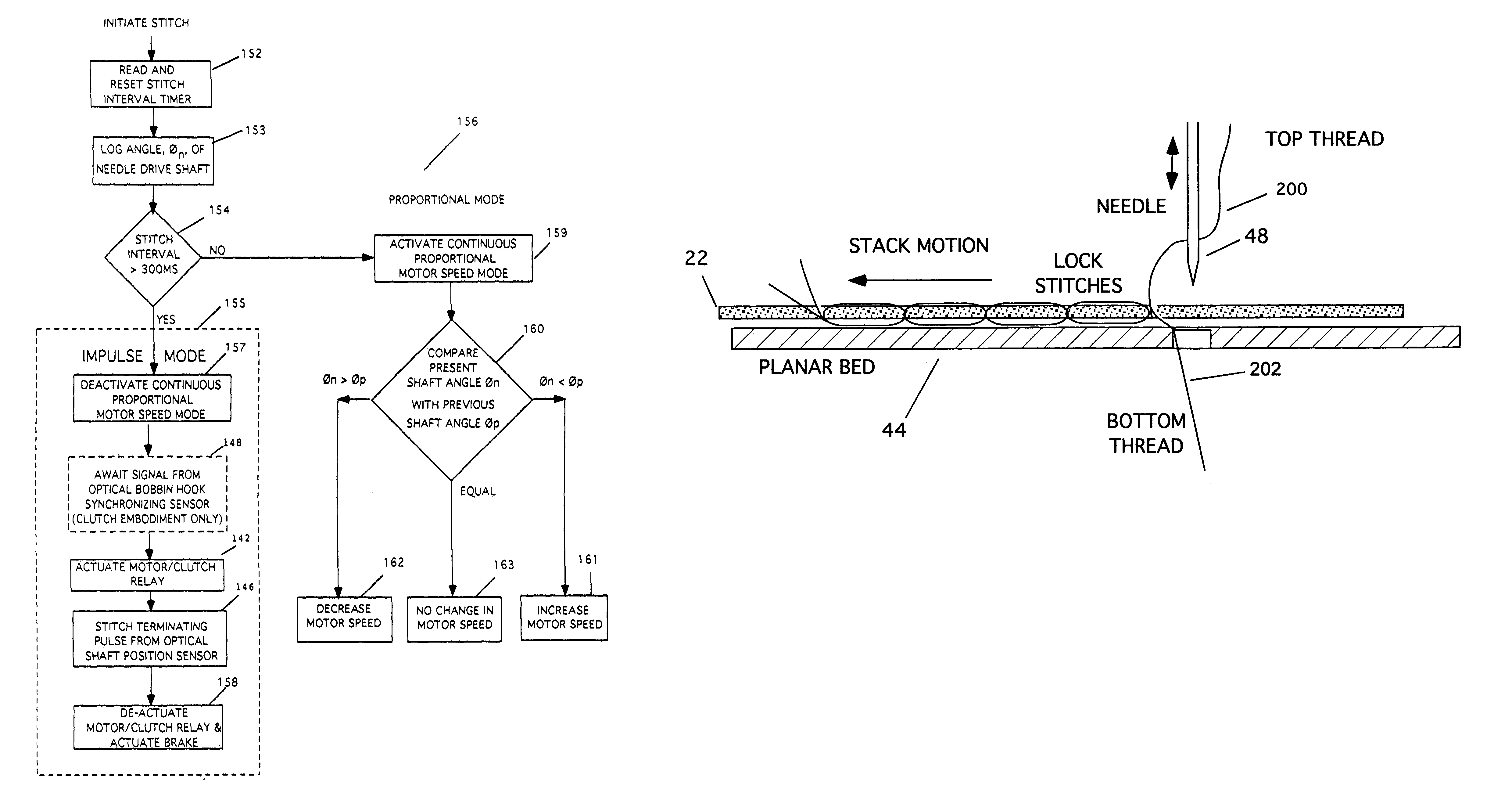

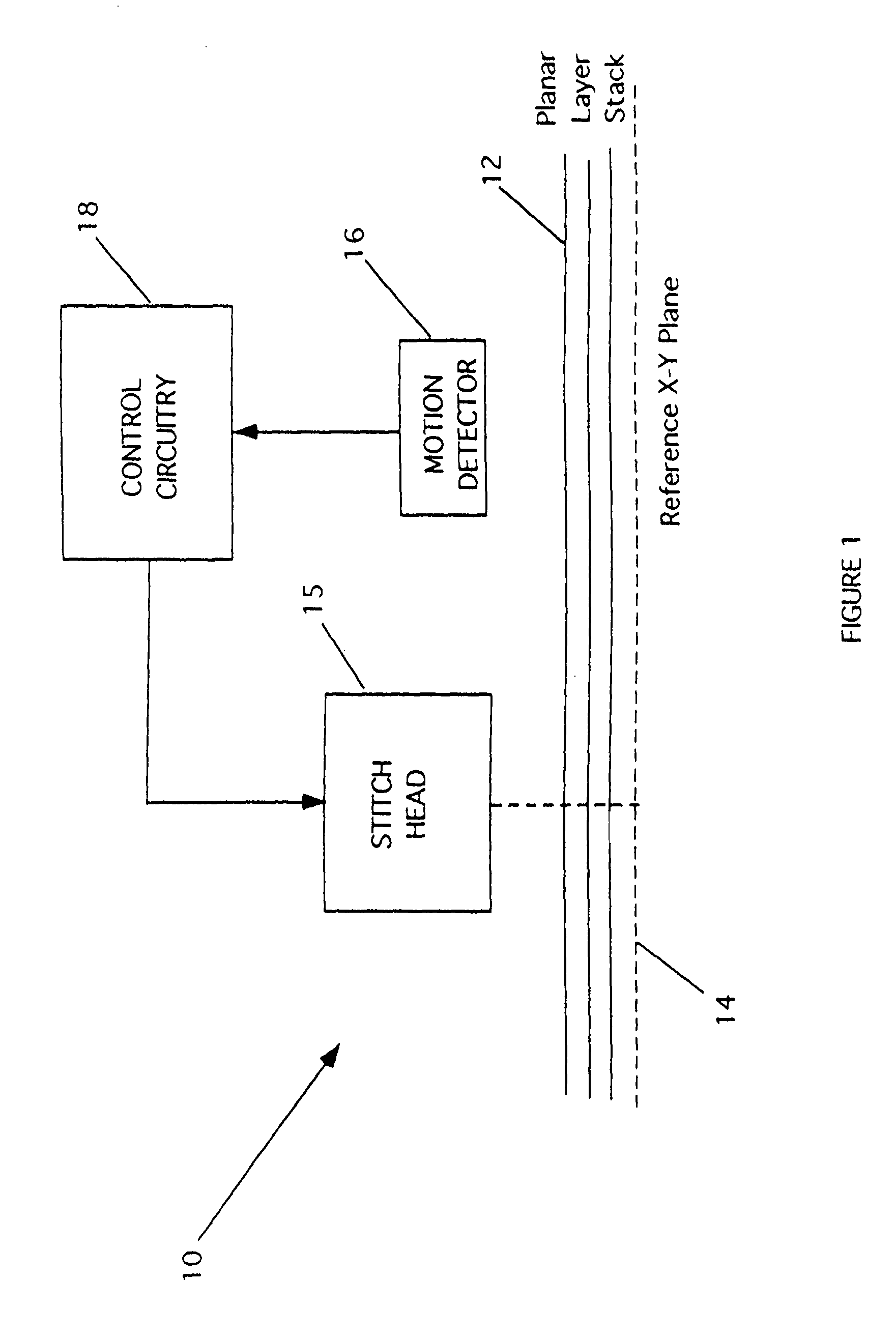

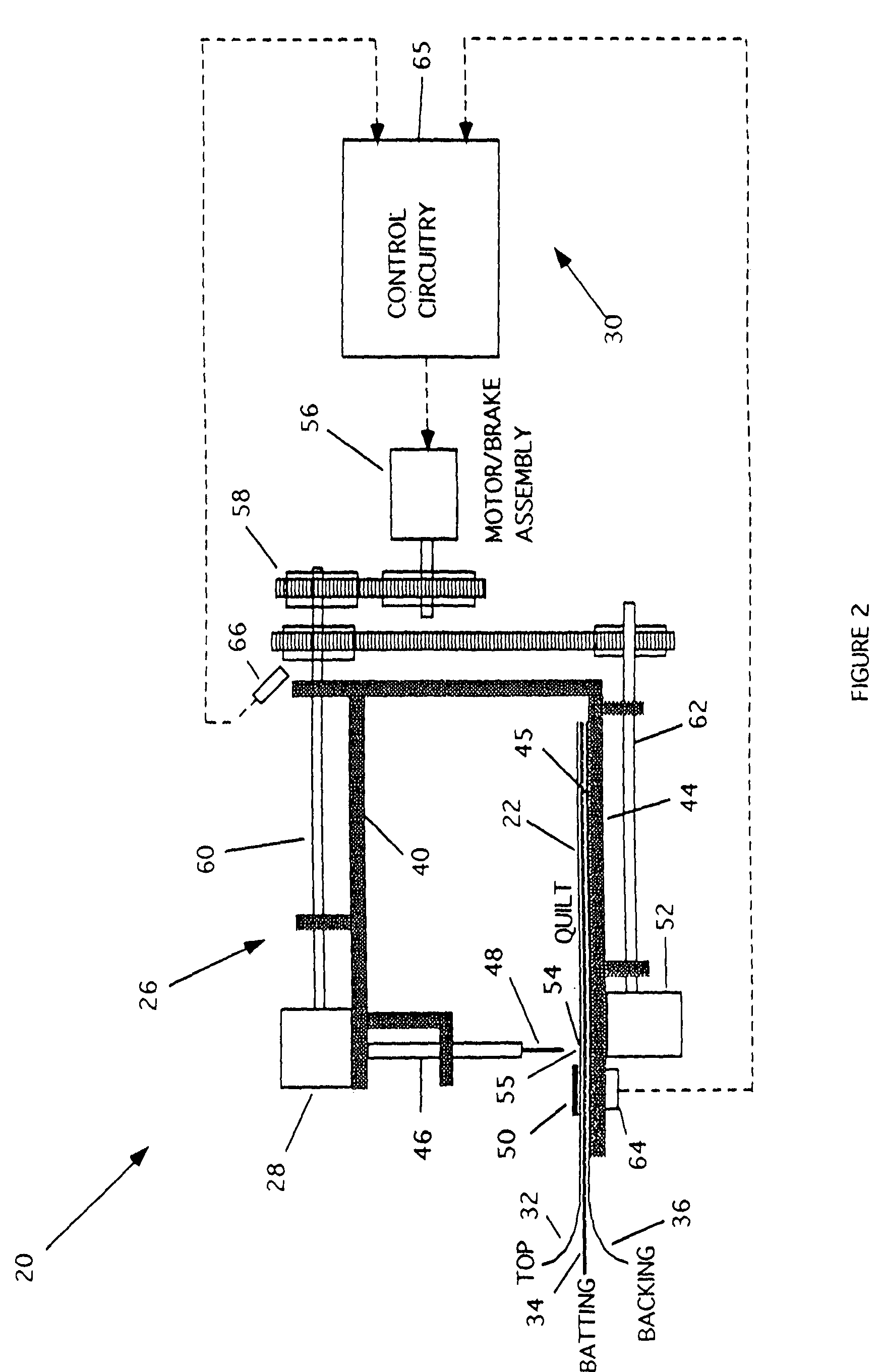

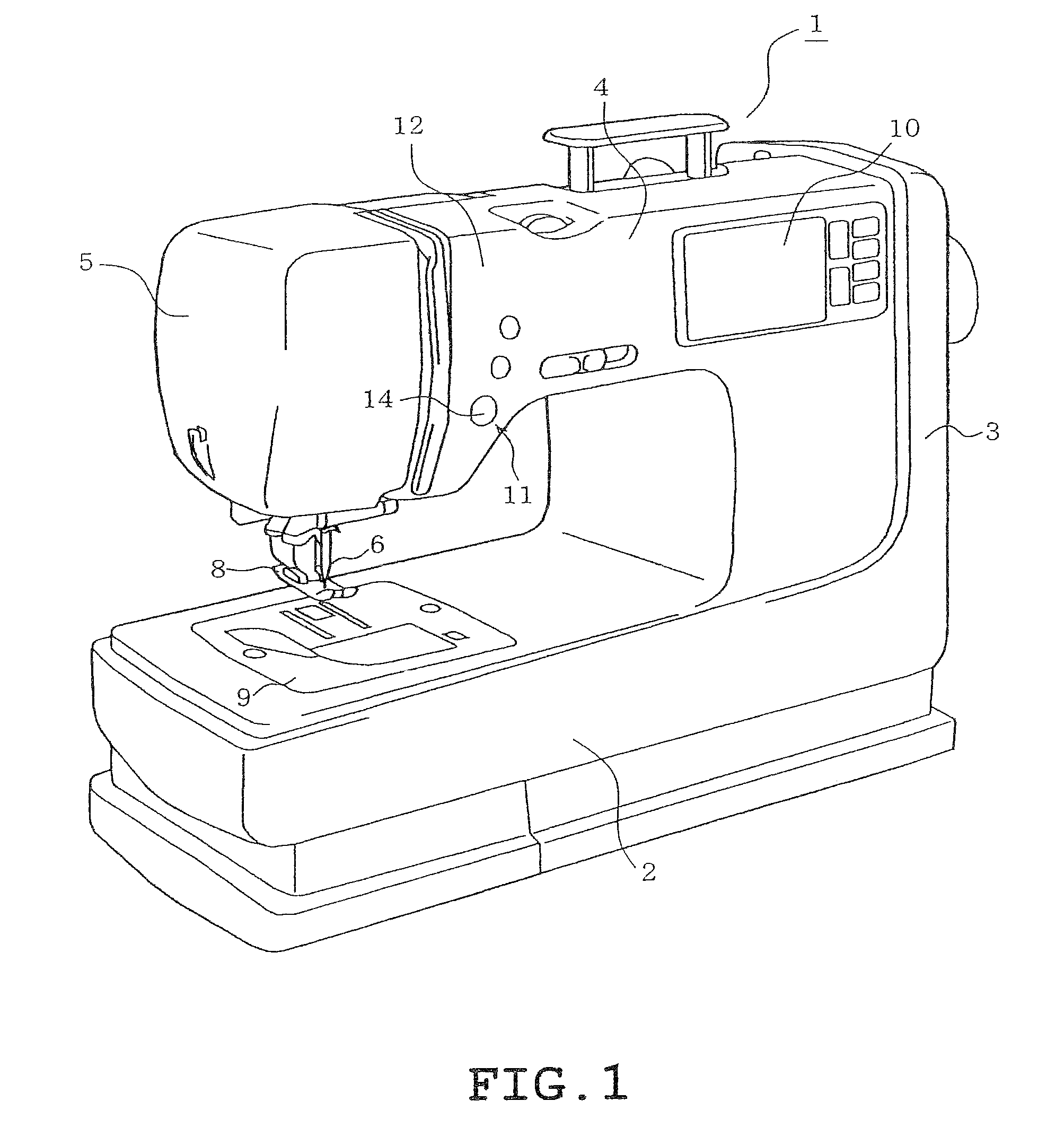

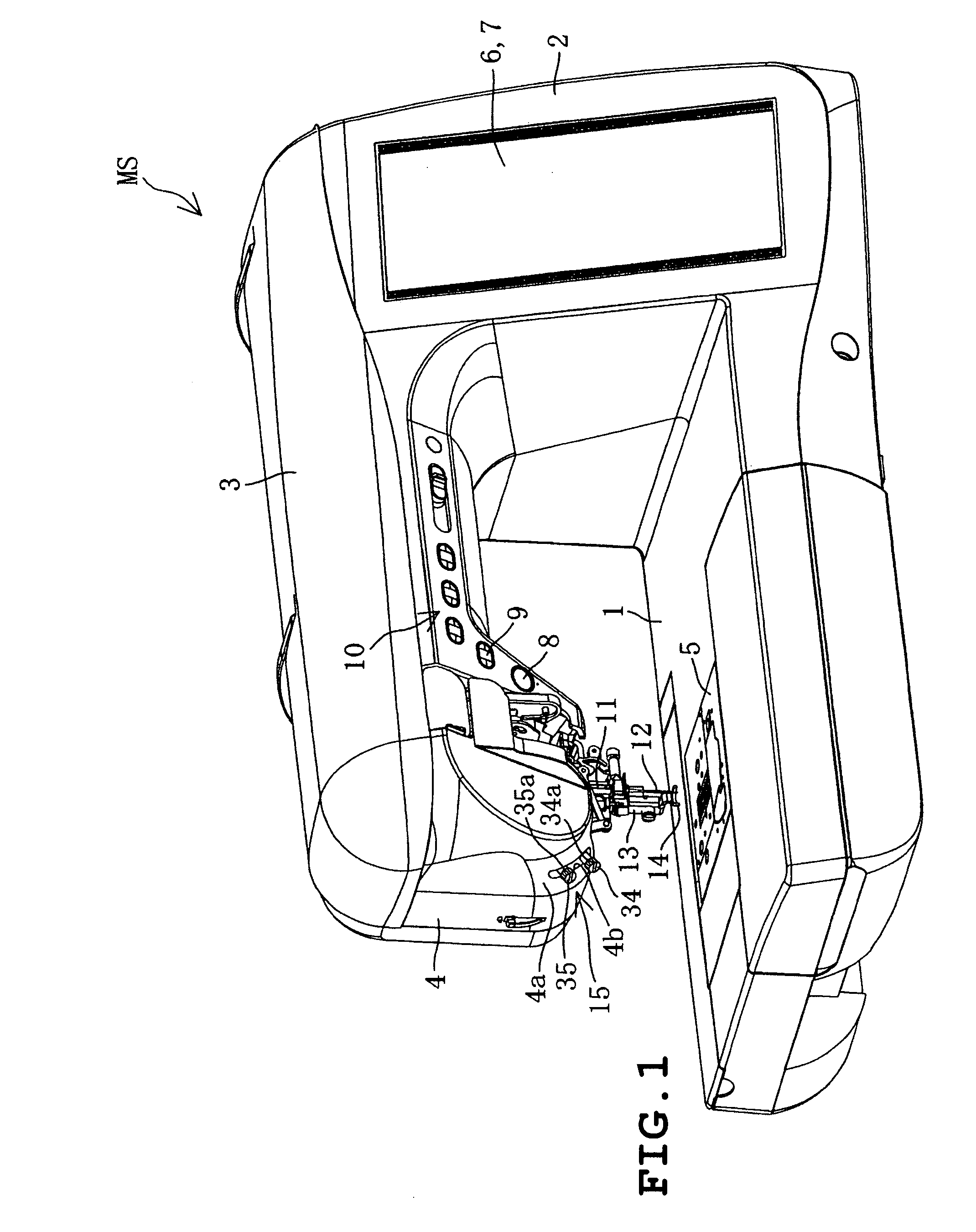

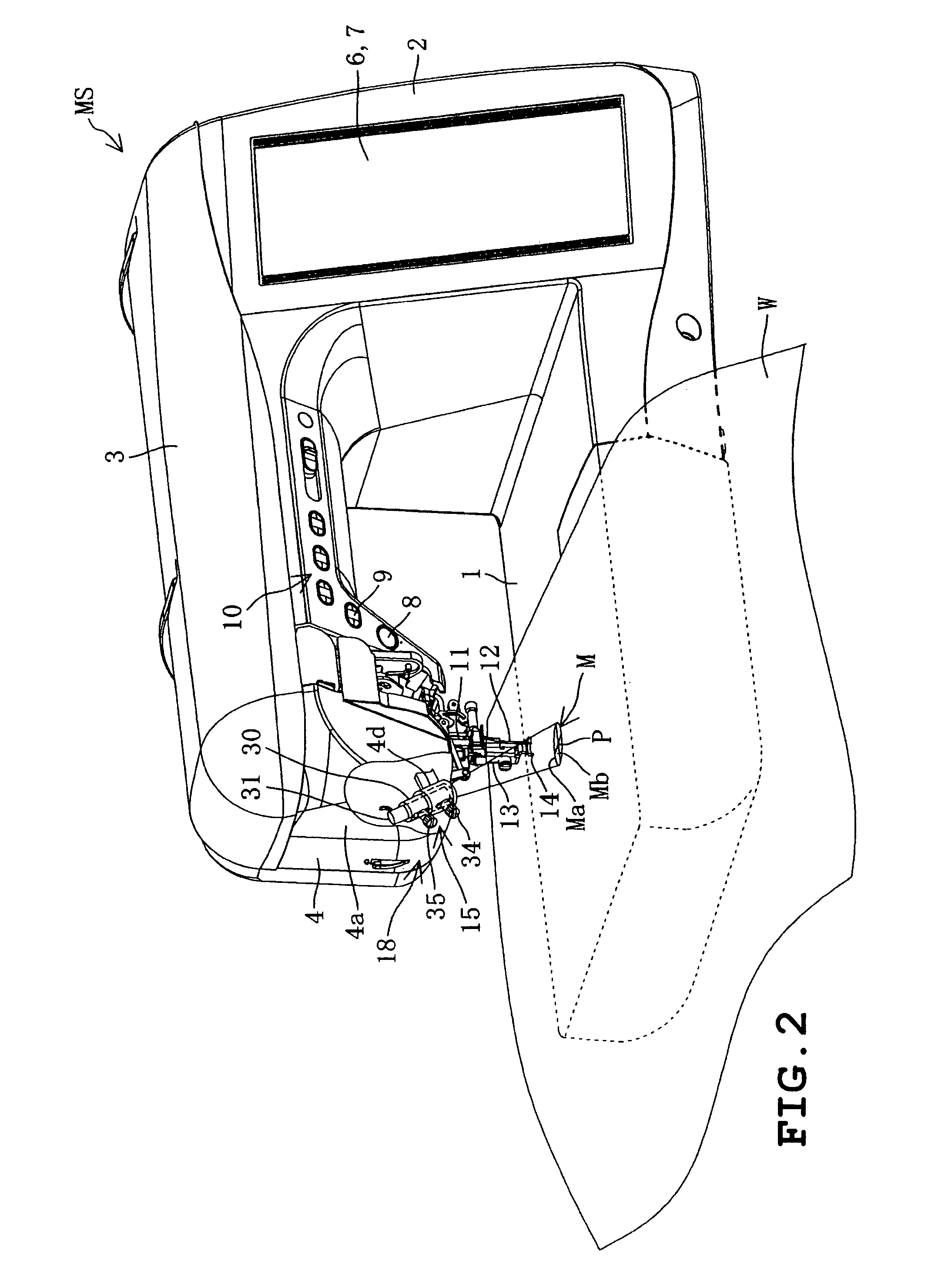

Quilting method and apparatus

ActiveUS6883446B2Easy to produceProgramme-controlled sewing machinesSewing-machine control devicesMotion detectorEngineering

A quilting apparatus for enabling a user to freely move a stack of fabric layers across a planar bed relative to an actuatable stitch head. The apparatus includes a motion detector which detects the movement of the stack and controls the actuation of the stitch head. Consequently, the apparatus functions to synchronize the delivery of stitch strokes by the head with the manually controlled movement of the quilt material stack. This frees the user to move the stack over a wide range of speeds, to start or stop movement at will, and to guide the stack in any direction across the planar bed.

Owner:BERNINA SEWING MACHINE

Quilting method and apparatus

ActiveUS20050016428A1Easy to produceProgramme-controlled sewing machinesSewing-machine control devicesMotion detectorEngineering

A quilting apparatus for enabling a user to freely move a stack of fabric layers across a planar bed relative to an actuatable stitch head. The apparatus includes a motion detector which detects the movement of the stack and controls the actuation of the stitch head. Consequently, the apparatus functions to synchronize the delivery of stitch strokes by the head with the manually controlled movement of the quilt material stack. This frees the user to move the stack over a wide range of speeds, to start or stop movement at will, and to guide the stack in any direction across the planar bed.

Owner:BERNINA SEWING MACHINE

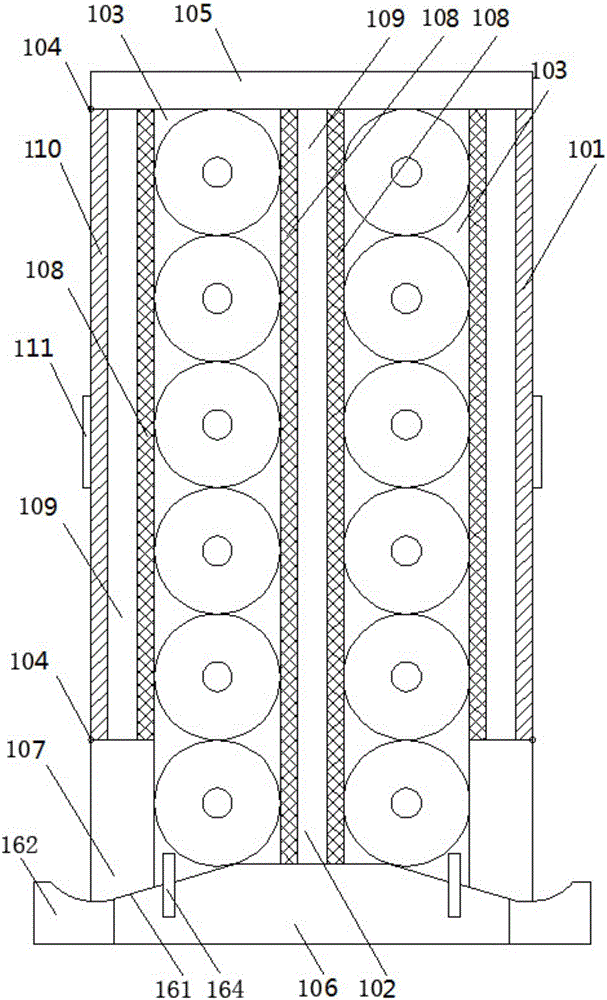

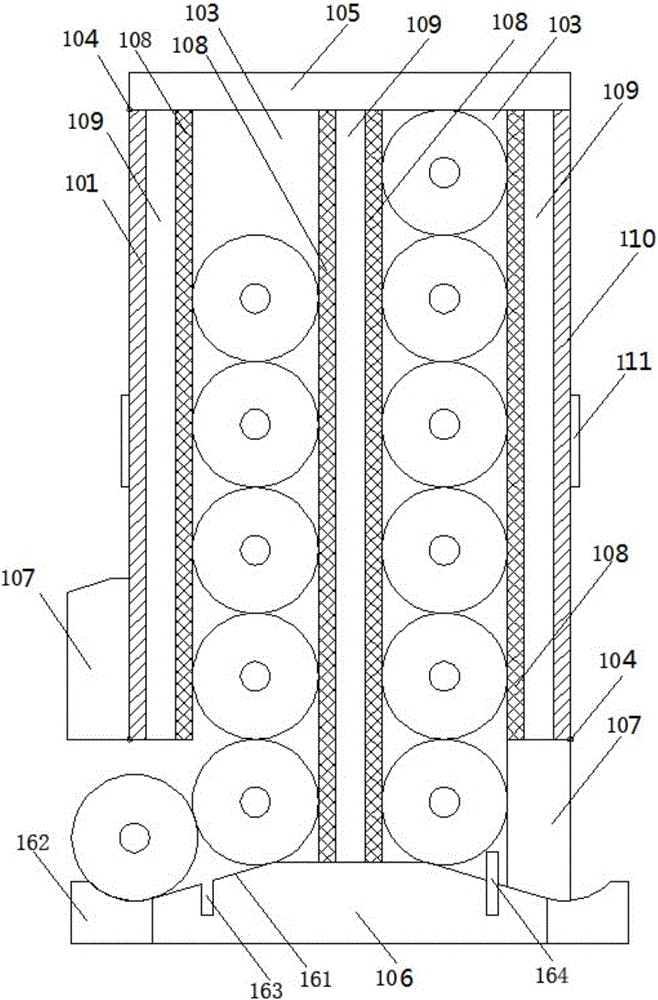

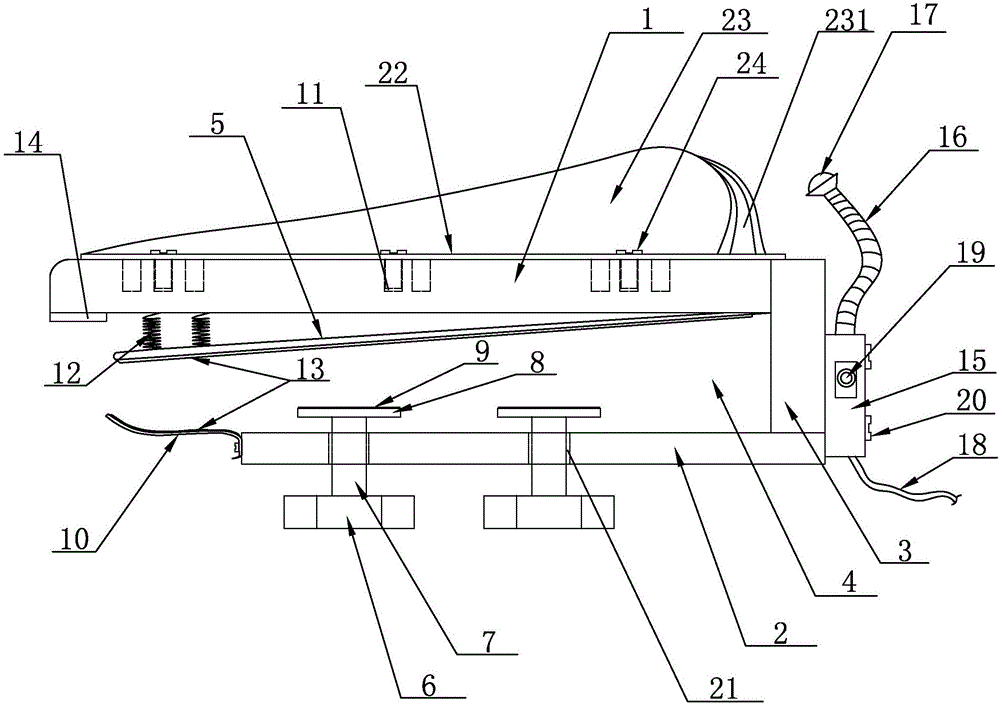

Complete equipment for tailoring

ActiveCN106367938AEasy to storeKeep drySevering textilesWork-collecting devicesEngineeringDrying Agents

The invention discloses complete equipment for tailoring. The complete equipment comprises a fabric storage cabinet, a fabric cutting machine, a sewing machine, a button sewing machine and an ironing machine, wherein the fabric storage cabinet comprises a cabinet body; the cabinet body is divided into left and right fabric accommodating cavities by virtue of a drying agent separator which is arranged at the center of the cabinet body, and the length of each fabric accommodating cavity is equal to the diameter of the fabric; the top end of the cabinet body is connected with a cover plate through a rotary hinge; a base is arranged at the bottom end of the cabinet body; and bottom ends of left and right side walls of the cabinet body are respectively connected with an upward lifting door through the rotary hinge. The fabric storage cabinet can be used for greatly reducing the time for searching fabrics, the dryness of the environment in the cabinet body is effectively maintained, and long-term fabric storage is facilitated.

Owner:MEISHENG CULTURE INNOVATION HLDG

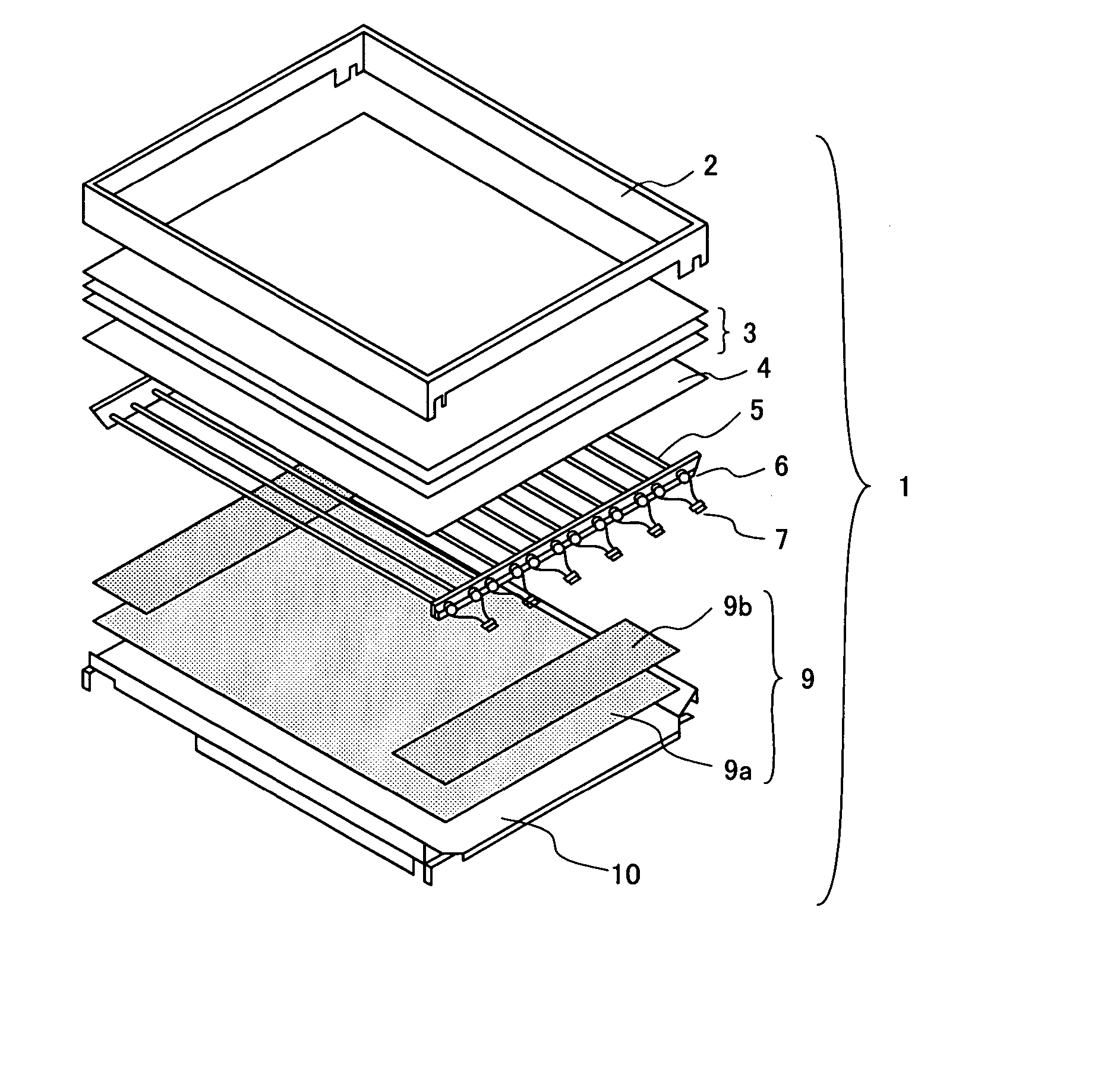

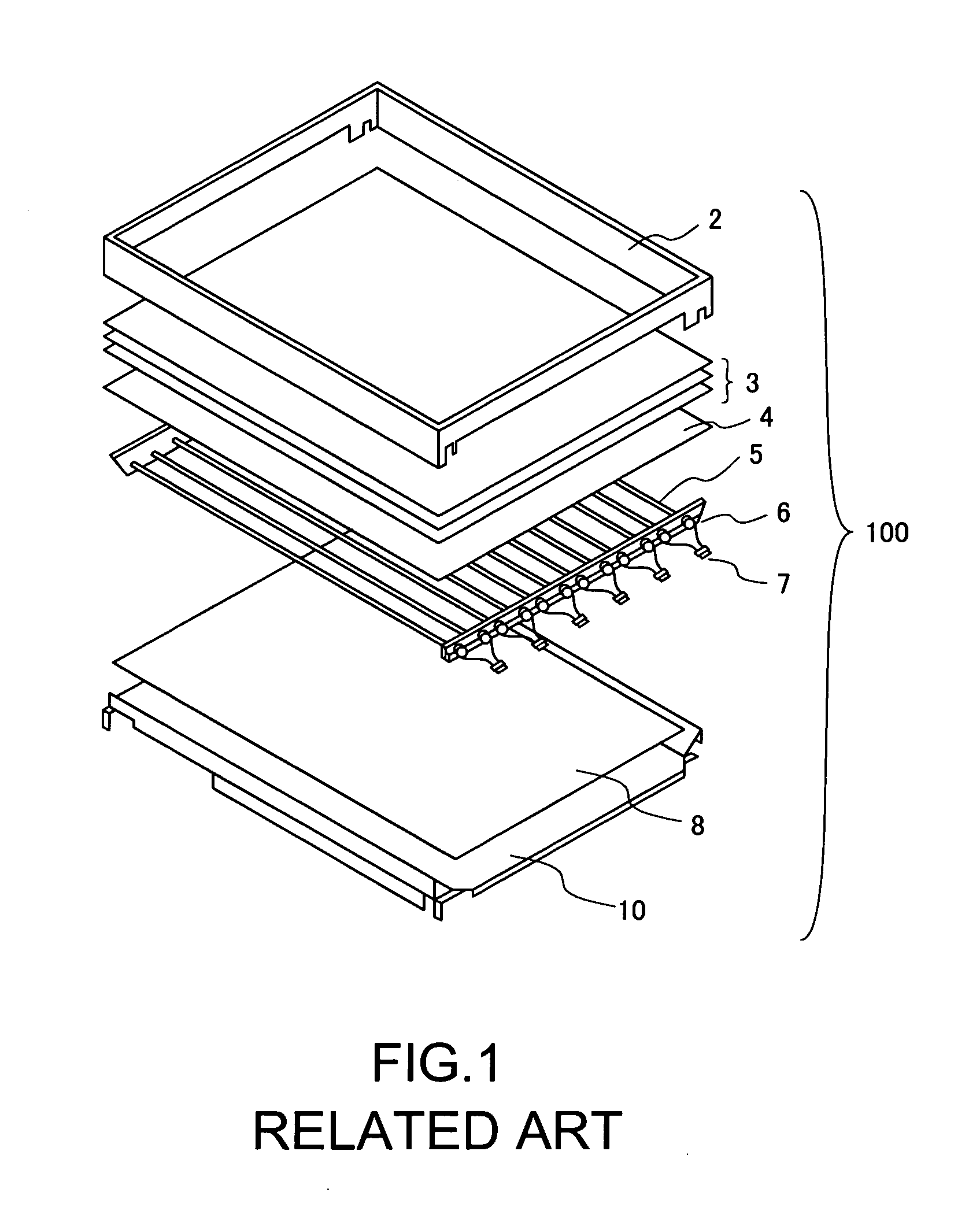

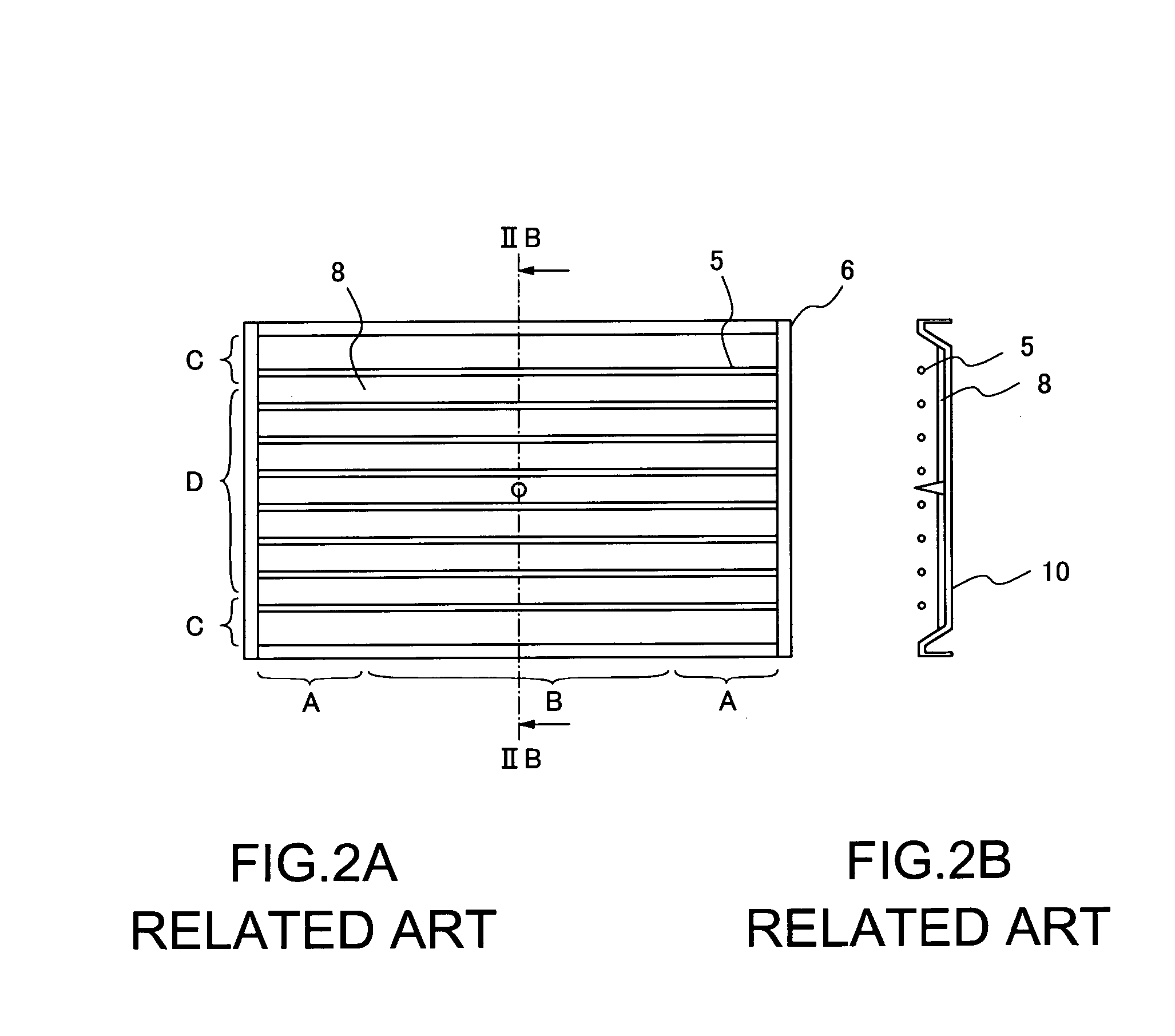

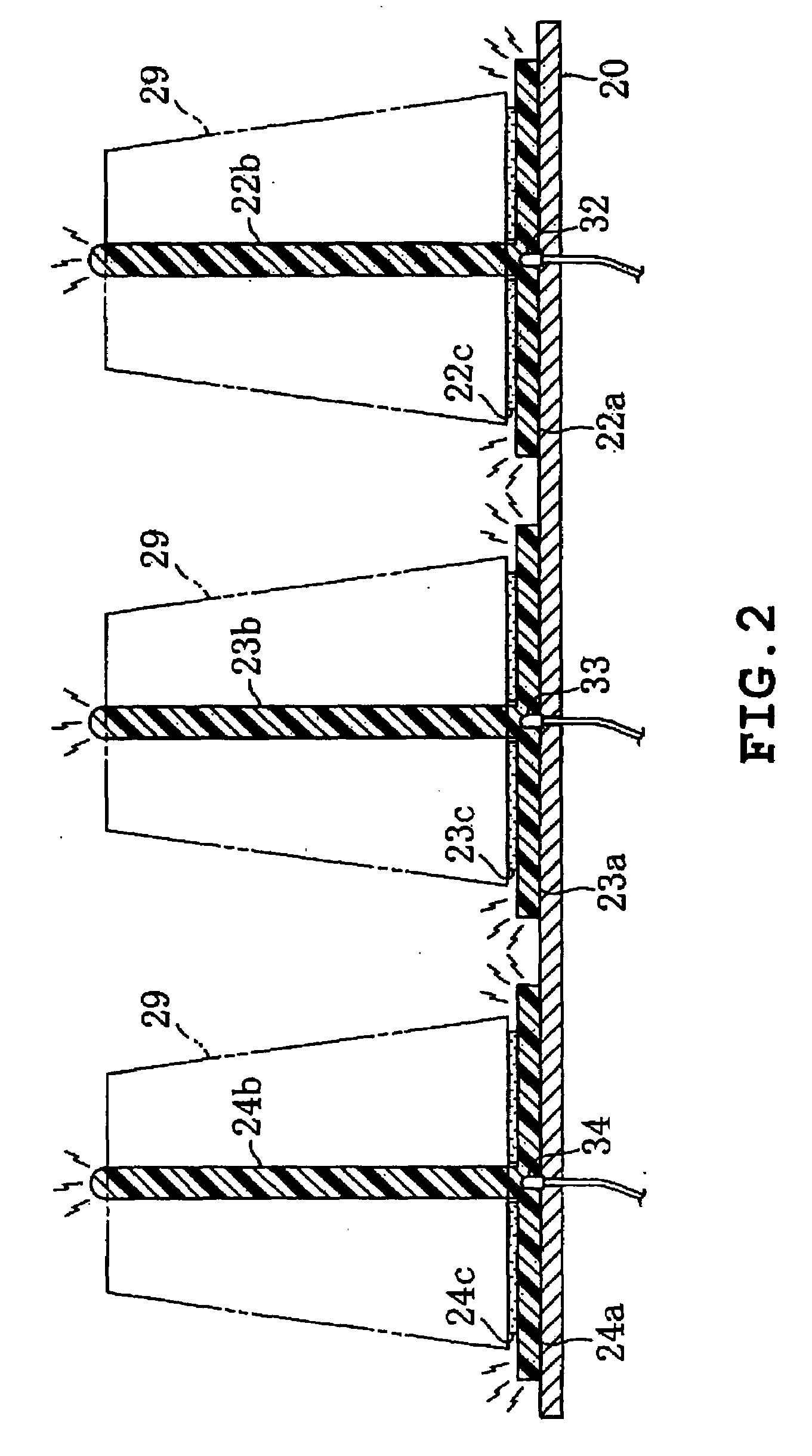

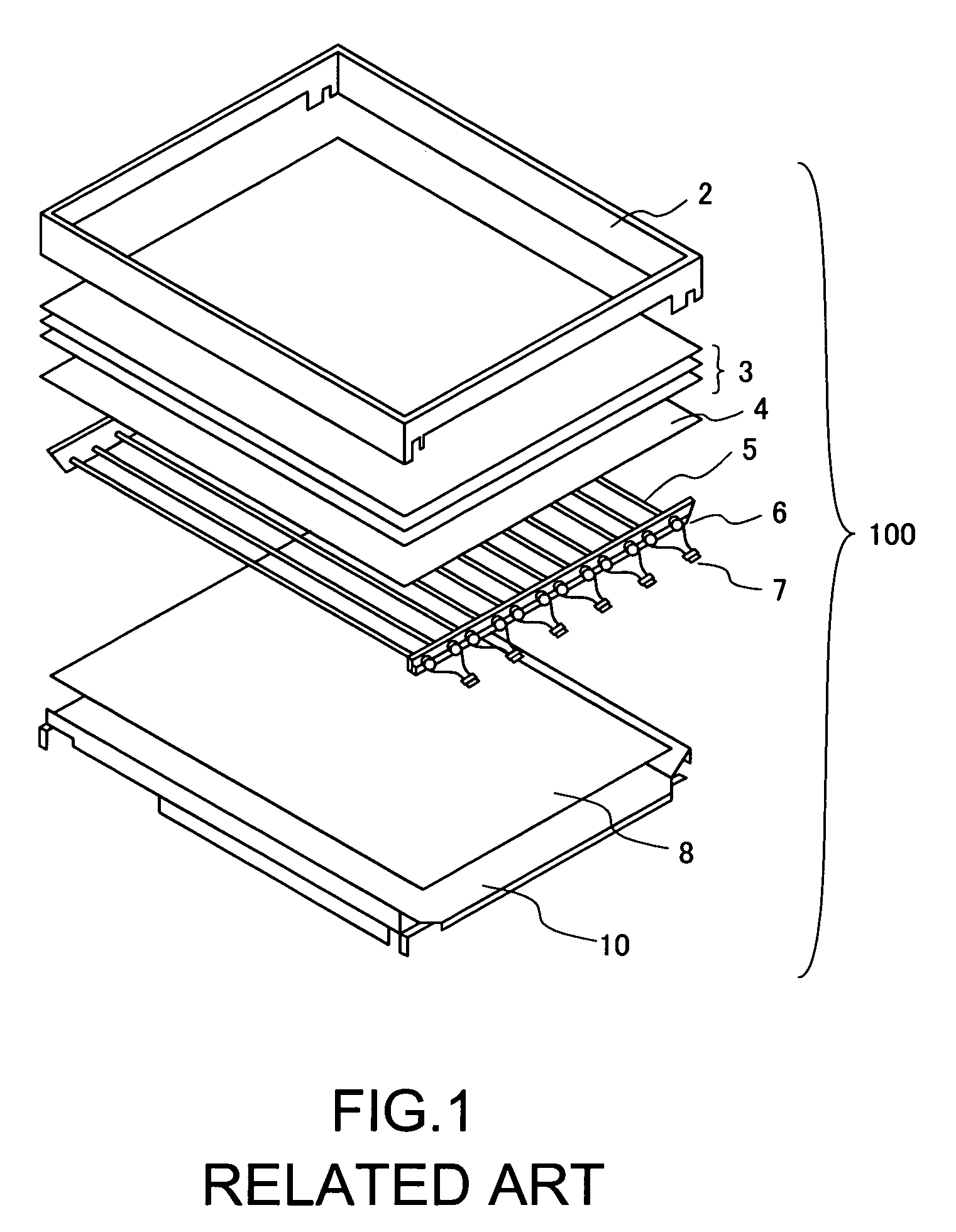

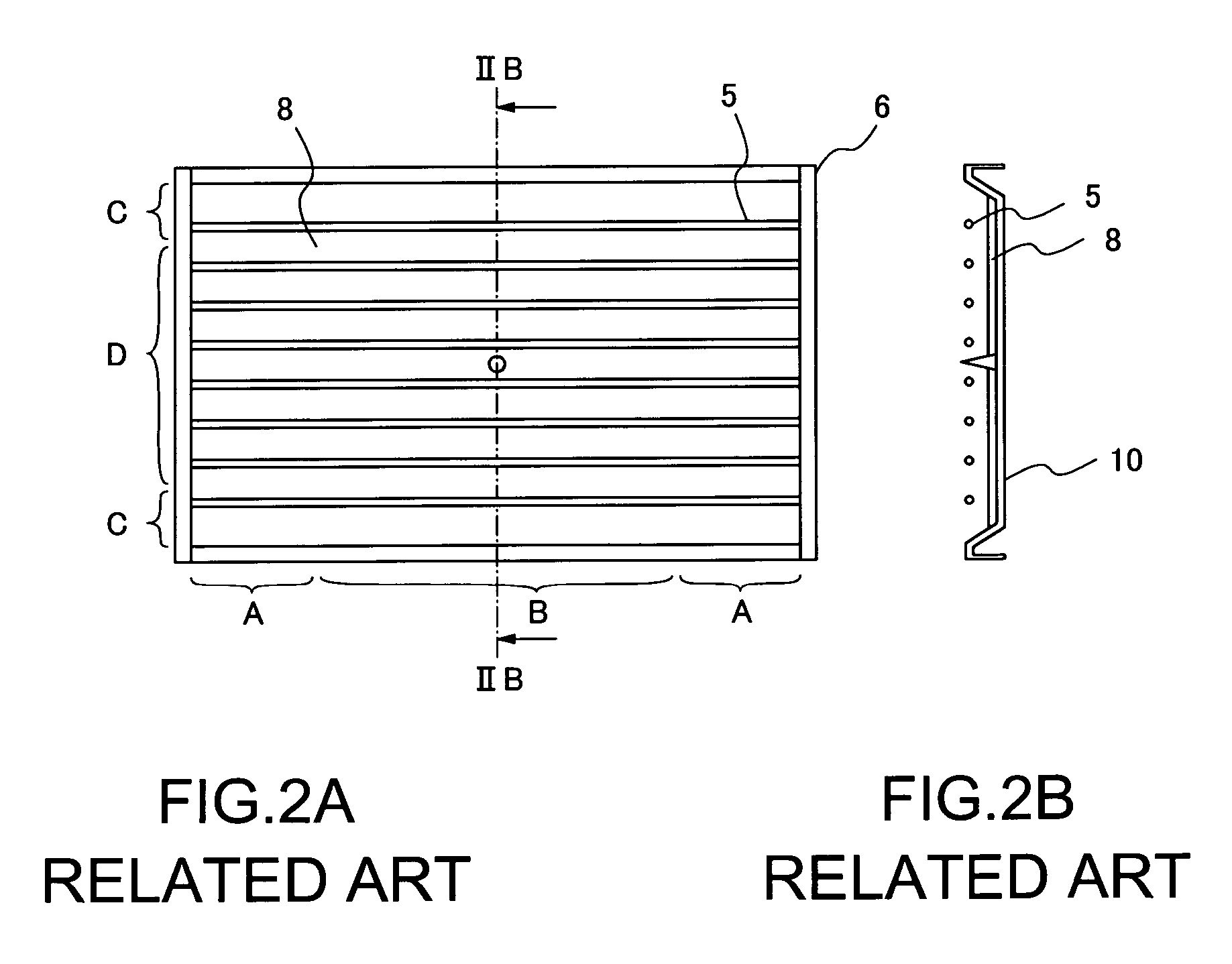

Backlight unit

ActiveUS20070058390A1Improve brightness uniformityNarrow display frameMeasurement apparatus componentsLighting support devicesEngineeringReflectivity

Disclosed is a backlight unit which illuminates a display panel from a rear surface thereof, including at least: tubular lamps arranged in parallel to the panel; and a reflecting member which reflects light from the lamps toward the panel, wherein the reflecting member is divided into a first region opposed to an area near an electrode provided in an end portion of the lamp and a second region nearer to a middle area than the first region, the first region having a higher reflectance than the second region. In another backlight unit, a reflecting member is divided, with respect to the arrangement direction of the lamps, into an end lamp near region which is opposed to a lamp arranged in end portion and a middle region which is nearer to a middle area than the end lamp region, the end lamp region having a higher reflectance than the middle region.

Owner:NEC LCD TECH CORP

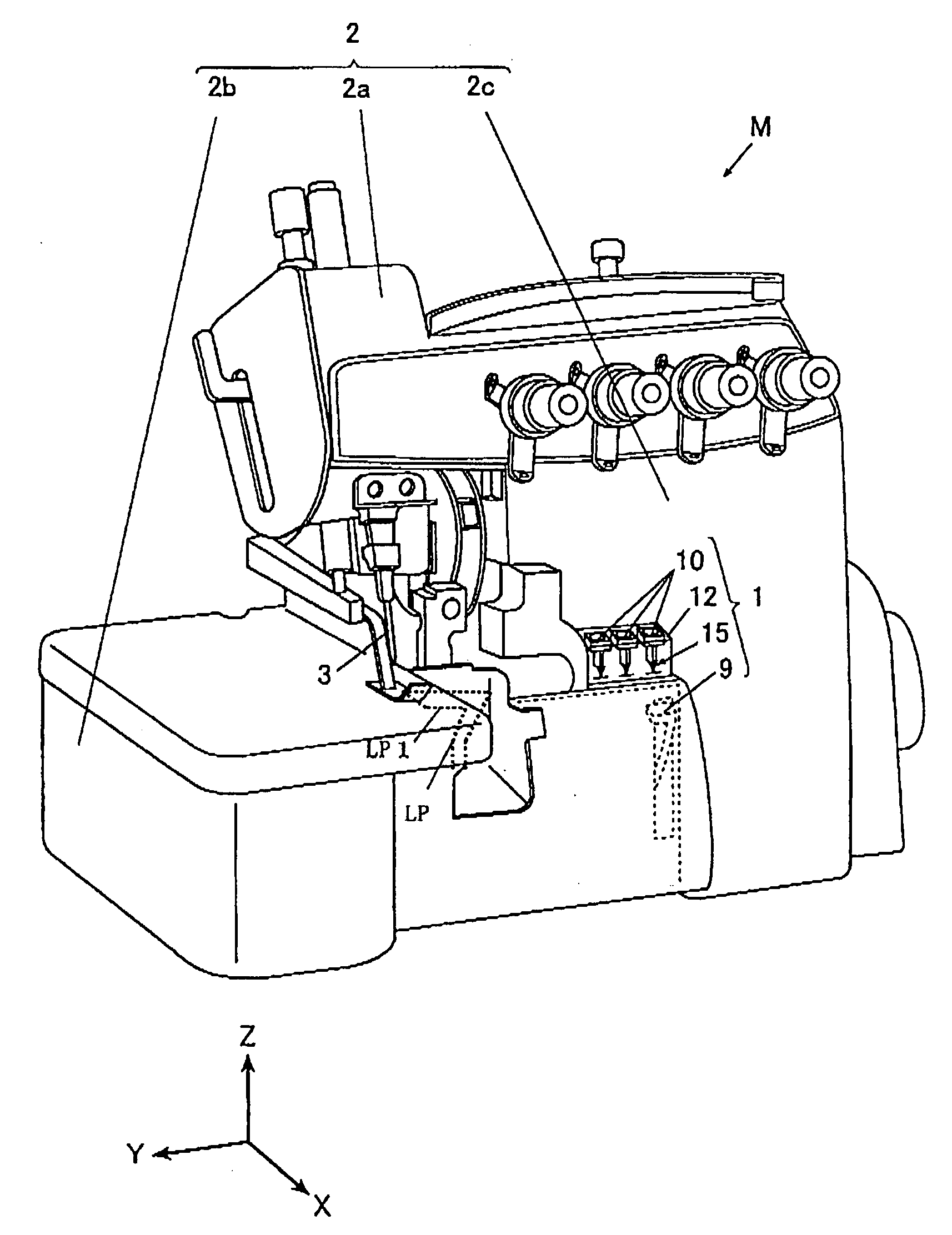

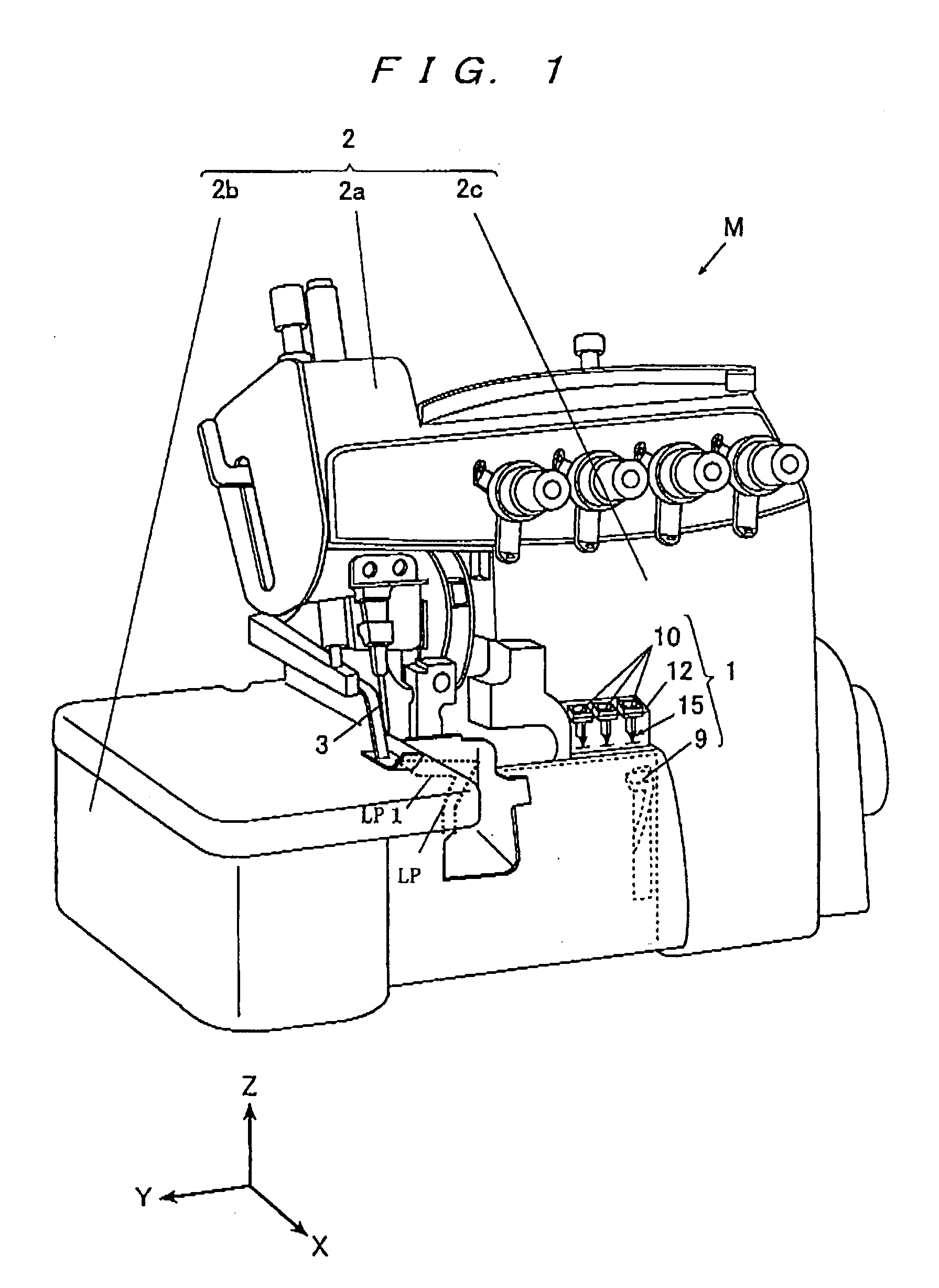

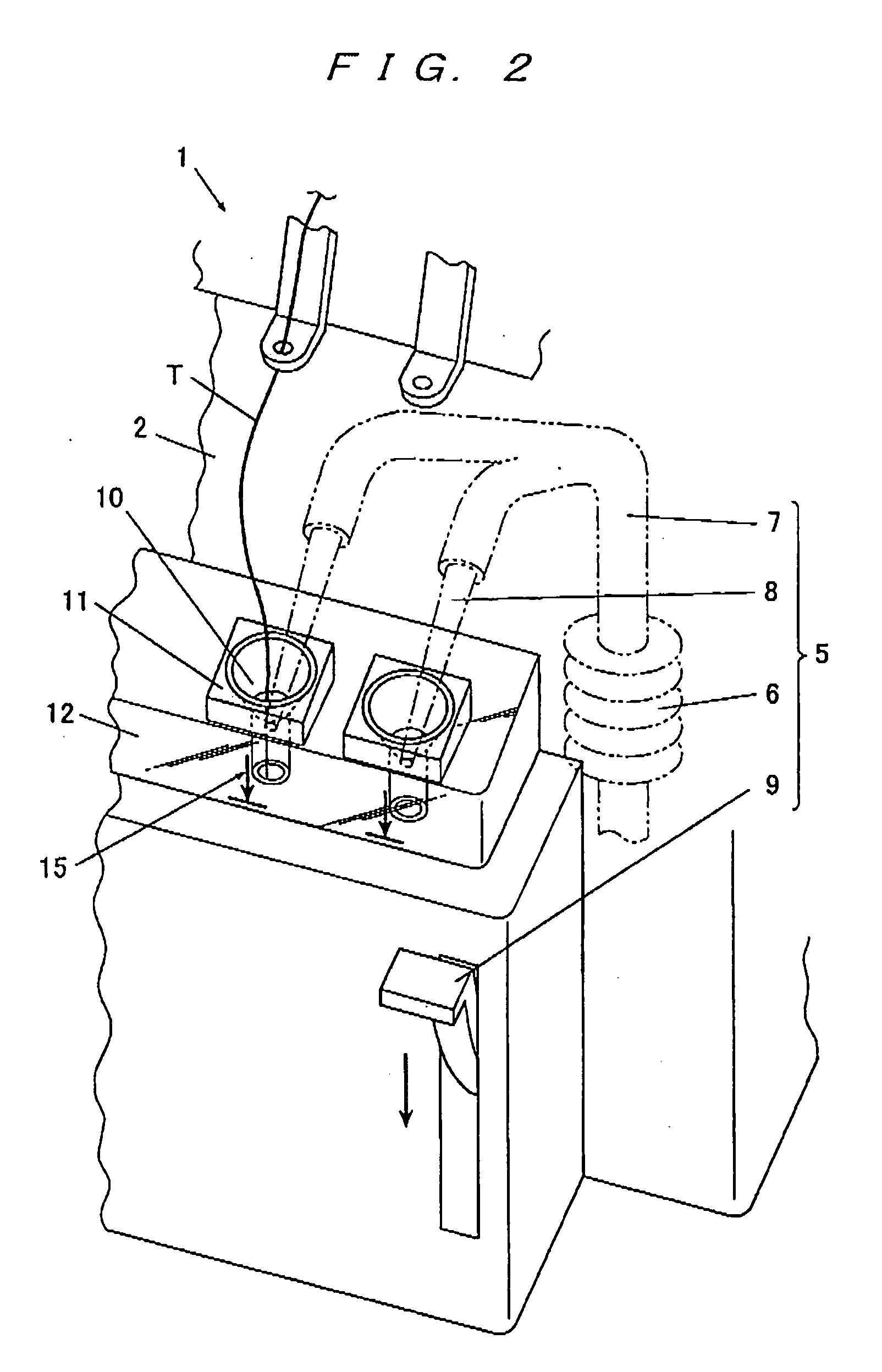

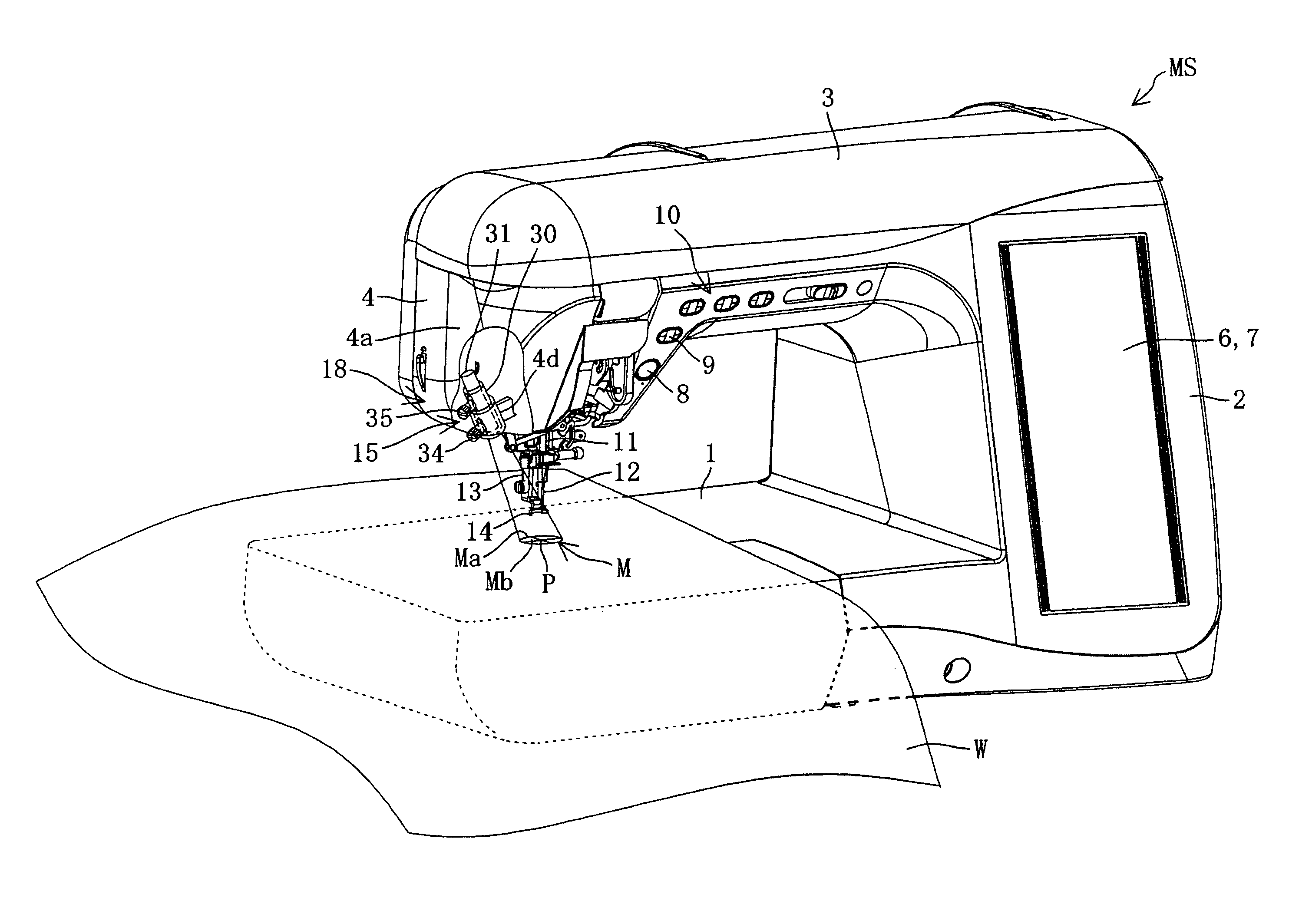

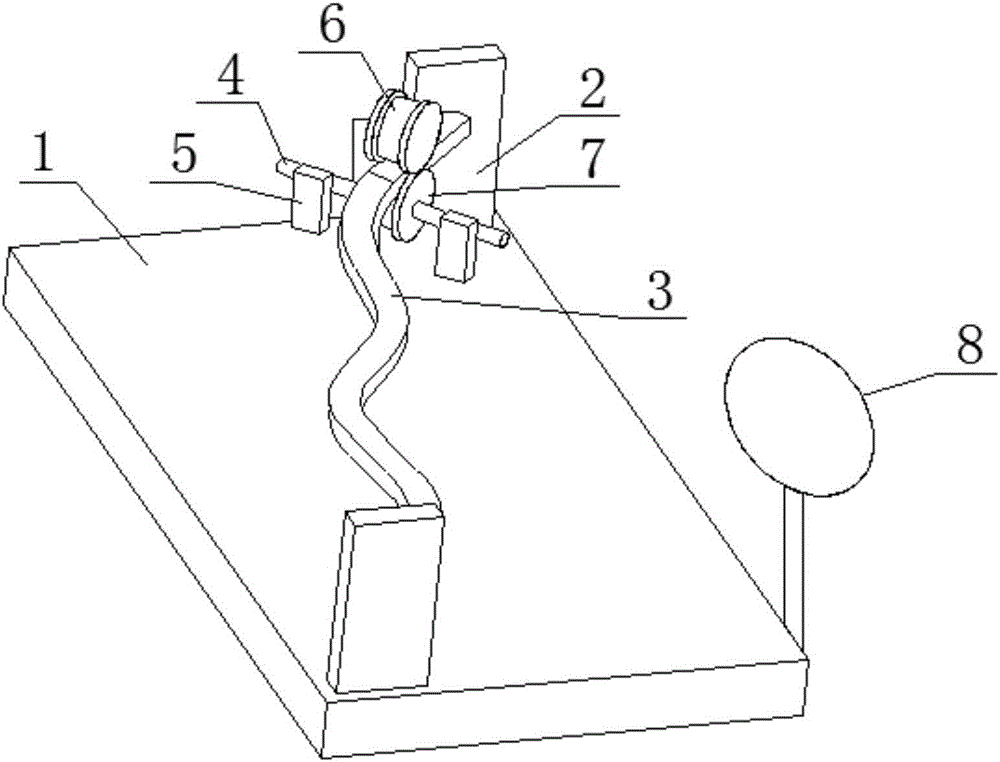

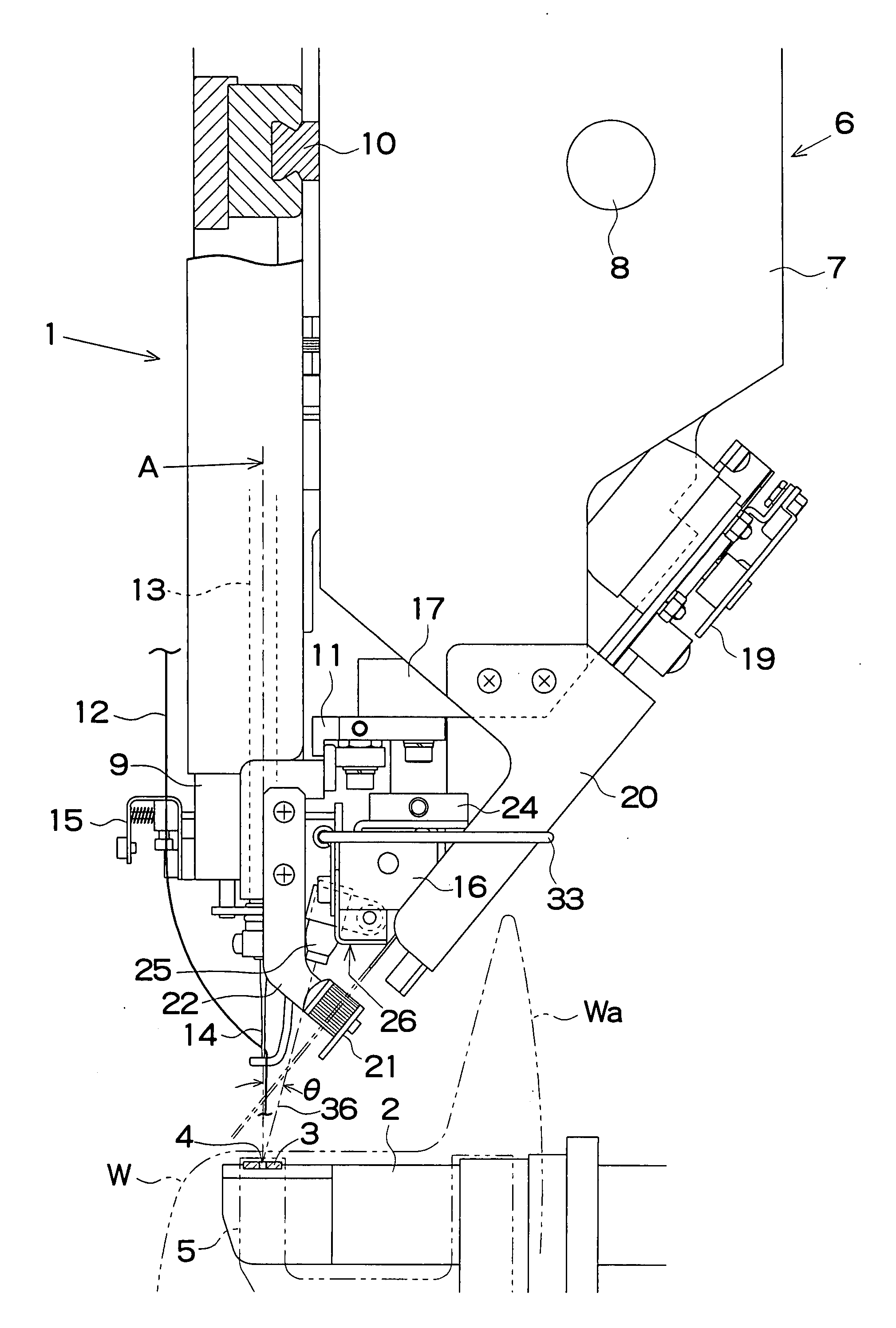

Workpiece cloth positioning guide device for sewing machine

A workpiece cloth positioning guide device for a sewing machine includes a projector which projects a sewing reference mark onto an upper side of workpiece cloth placed on a sewing bed of the sewing machine. The projector projects light emitted from the light source onto a needle drop reference point of the sewing needle of the sewing machine from obliquely above so that a sewing reference mark including a circle having a center at the needle drop reference point on the upper side of the workpiece cloth and the sewing reference mark guides the workpiece cloth when the workpiece cloth is positioned in sewing.

Owner:BROTHER KOGYO KK

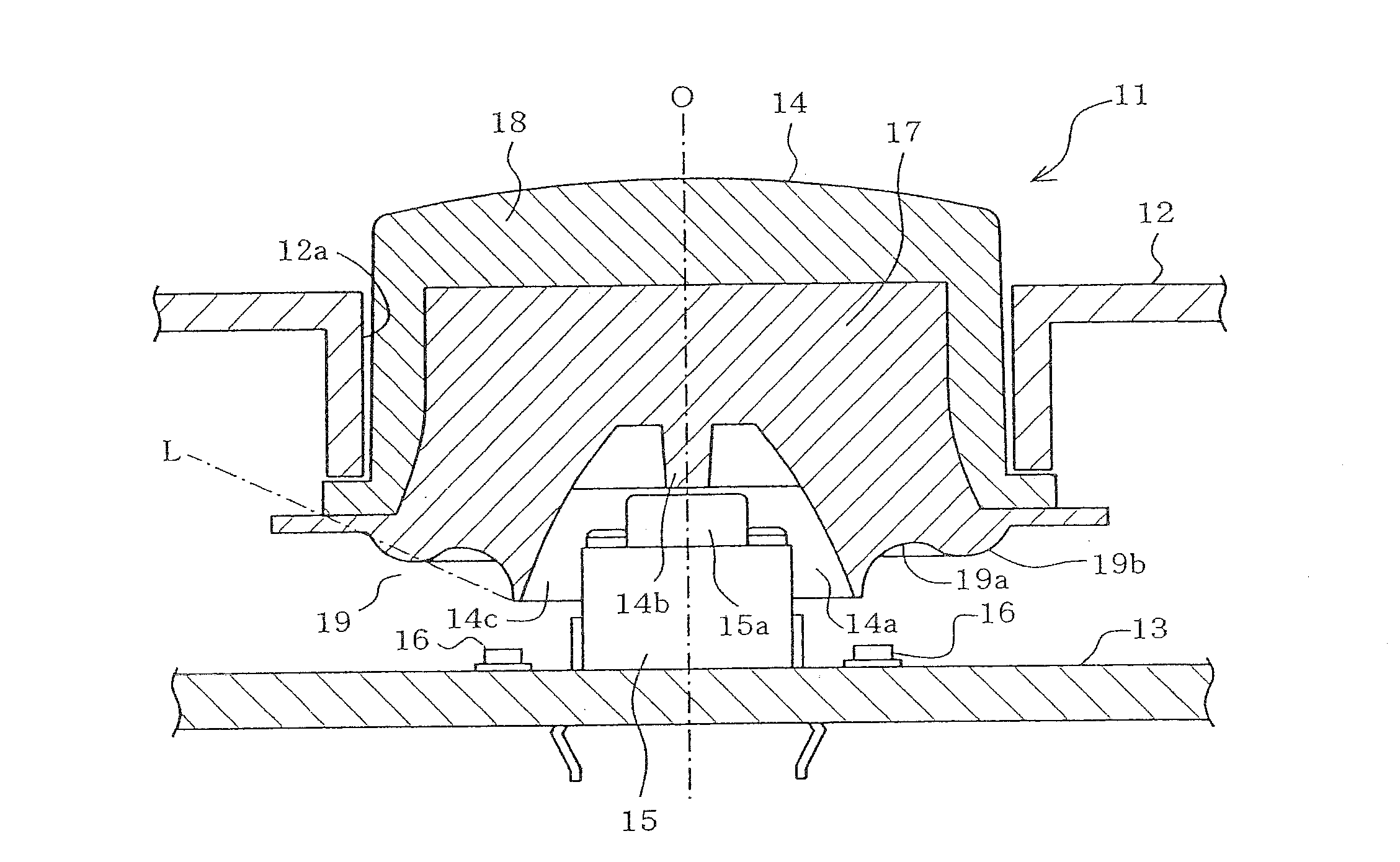

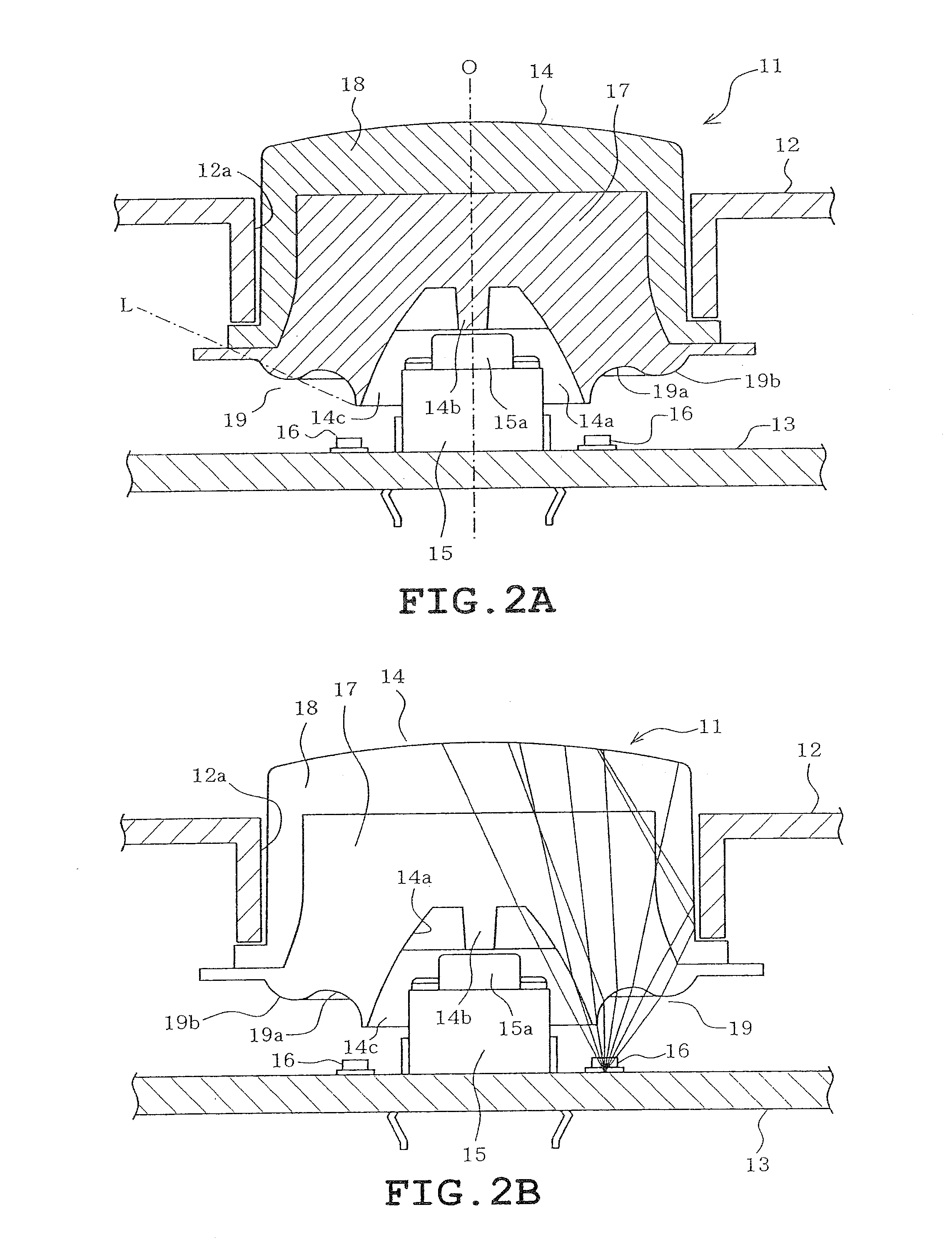

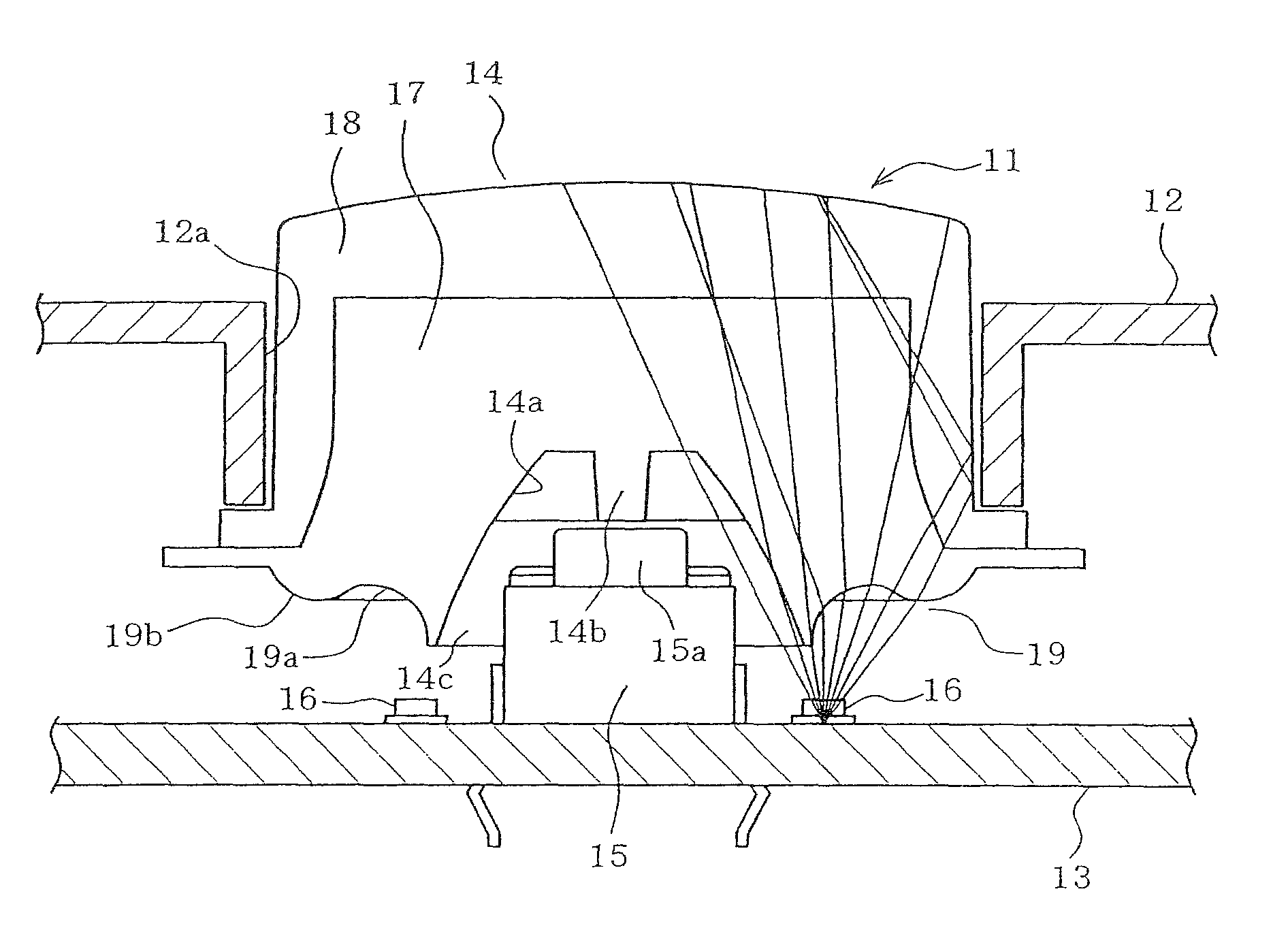

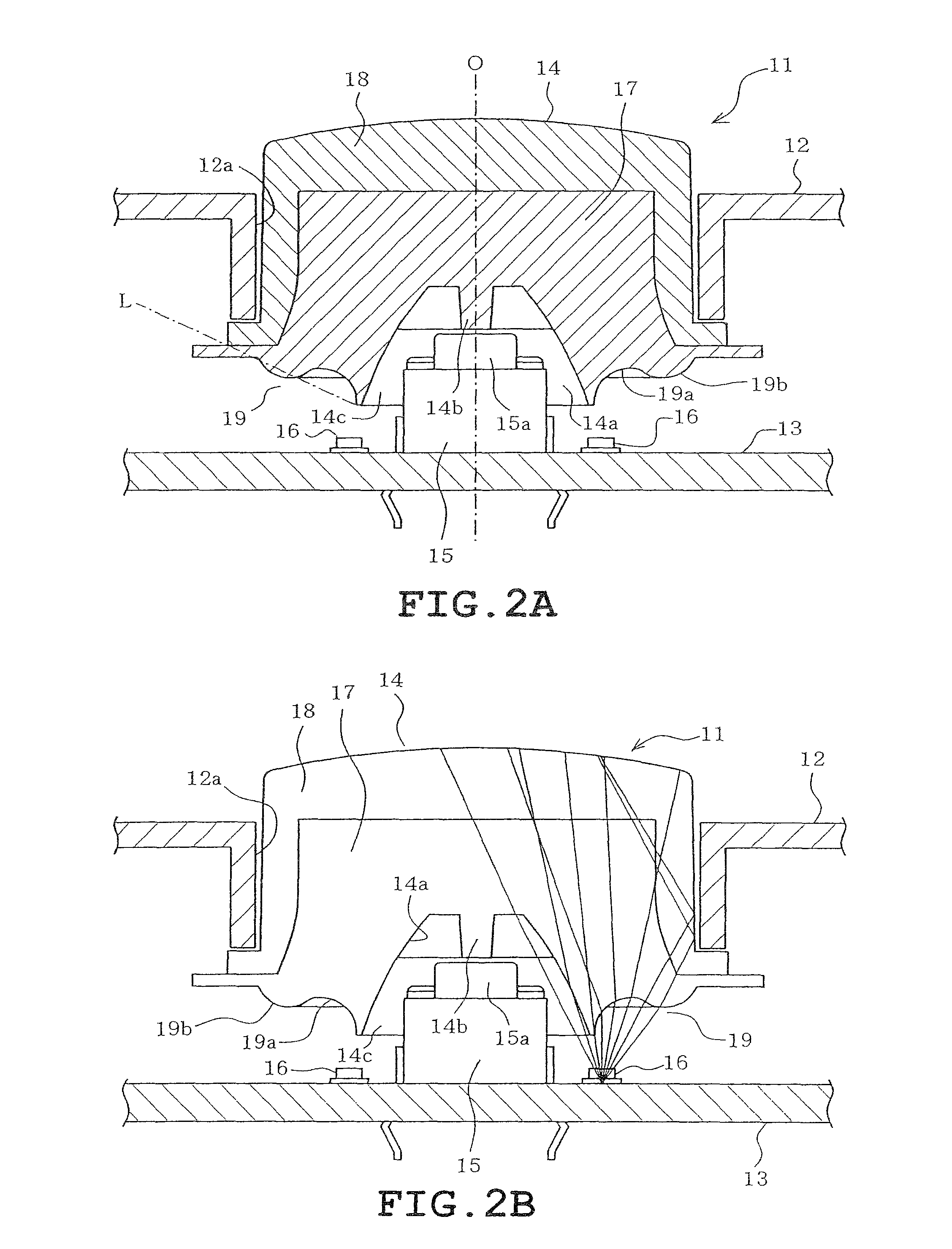

Push button switch device and sewing machine provided therewith

ActiveUS20100314229A1Improve the sense of operationUniform lightEmergency actuatorsSewing-machine control devicesEngineeringPush switch

A push button switch device mounted on an equipment body includes a push button member disposed on a cover constituting an outer surface of the equipment body, the push button member being configured to be light-transmissible, a switching element located behind the push button member so that its operation axis substantially corresponds with a central axis of the push button member, light sources disposed around the switching element to illuminate the outer surface of the push button member, the light sources being operated by the push button member, and an incidence plane located on a rear surface of the push button member so that light from the light sources is incident thereon, the incidence plane including a concave curved surface that is located so as to substantially face the light sources and a flat or convex curved surface located outside and is continuous to the concave curved surface.

Owner:BROTHER KOGYO KK

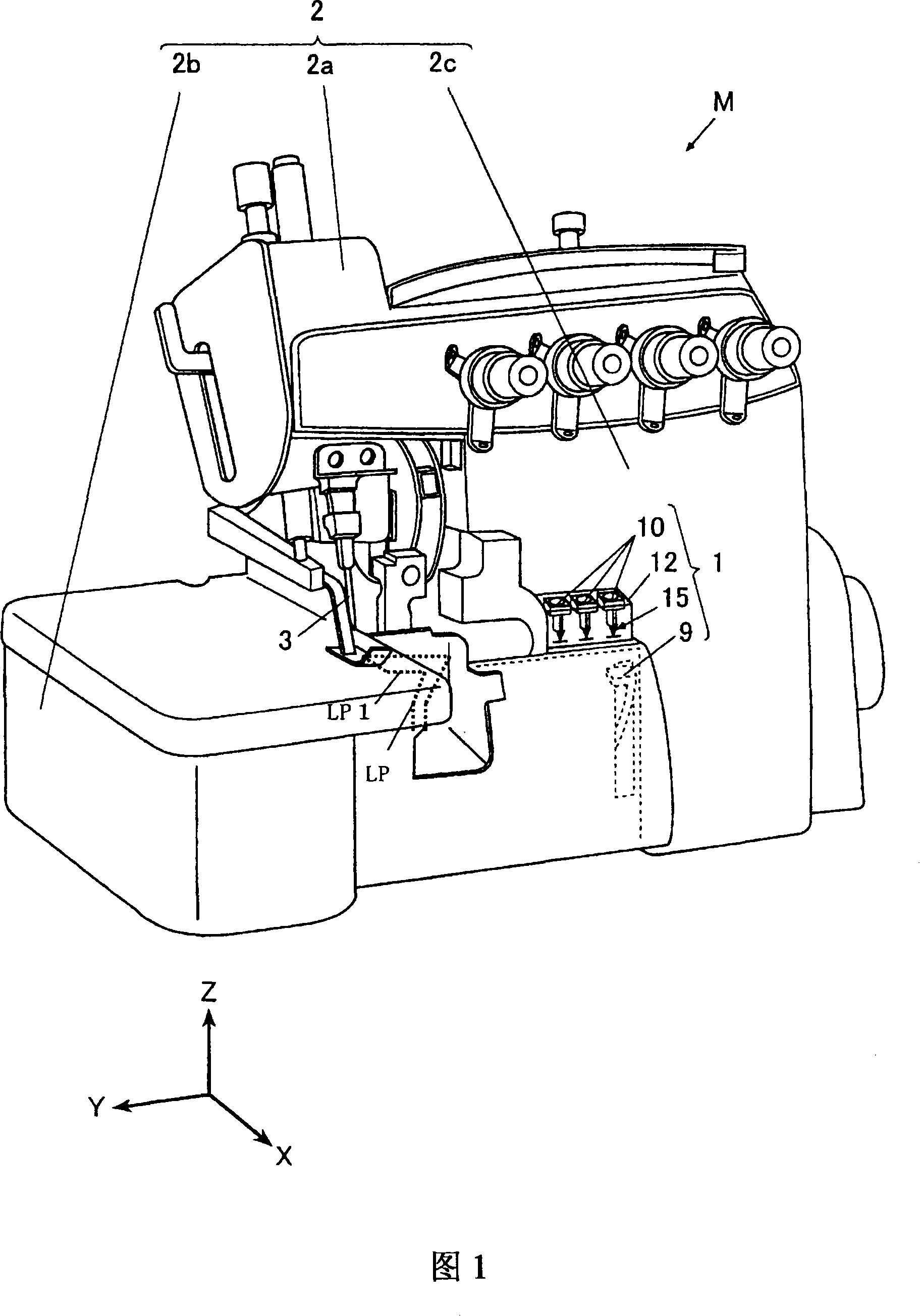

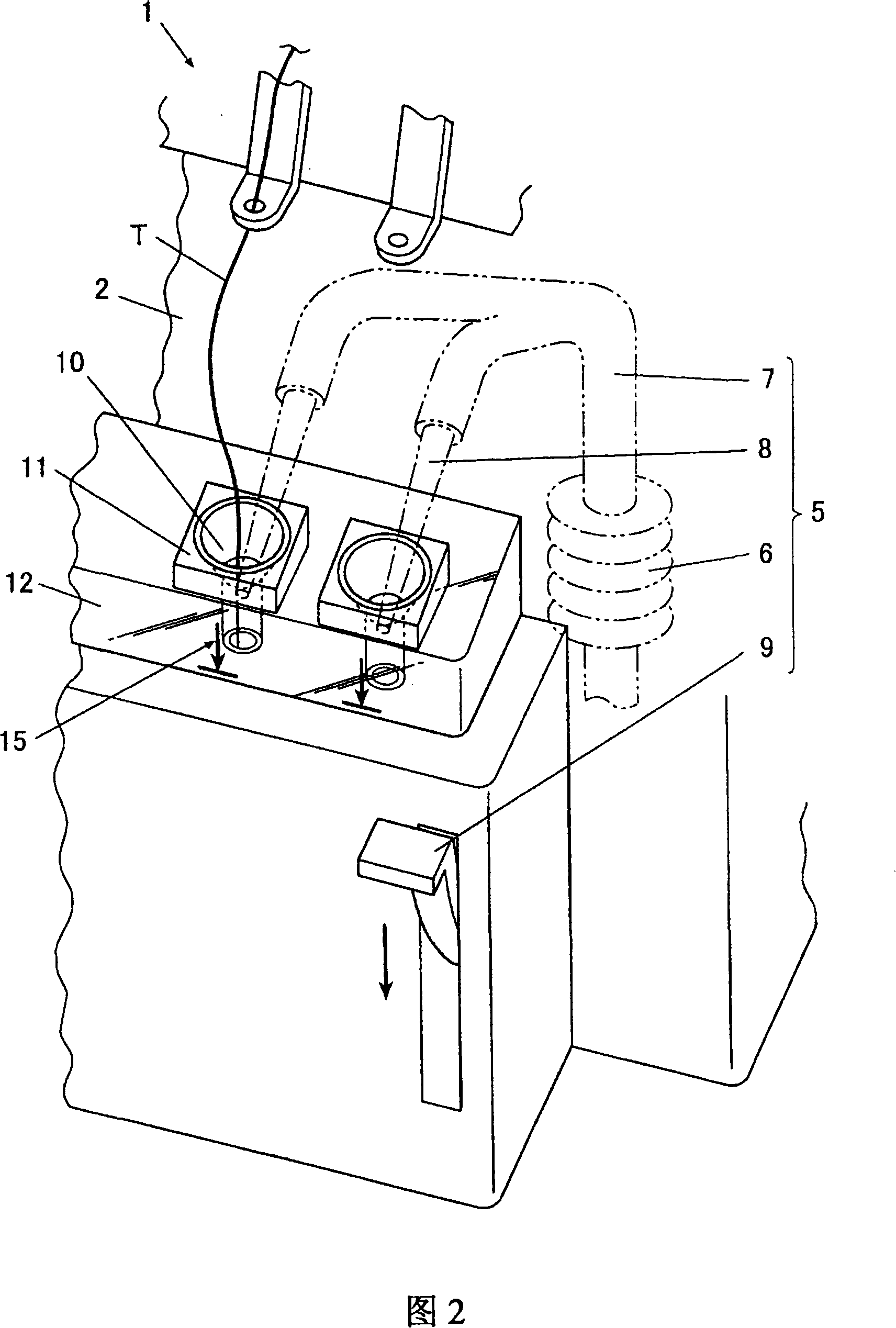

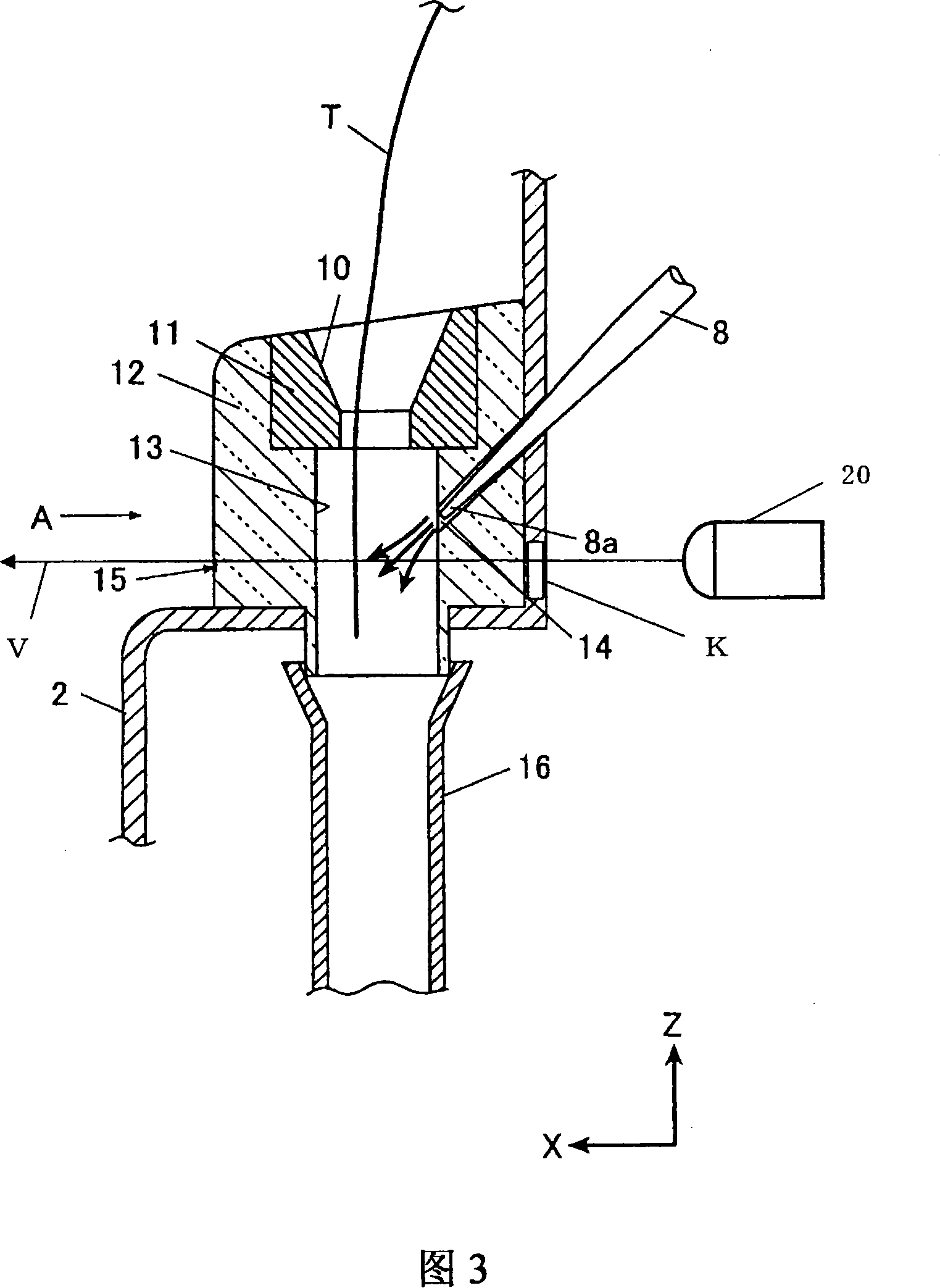

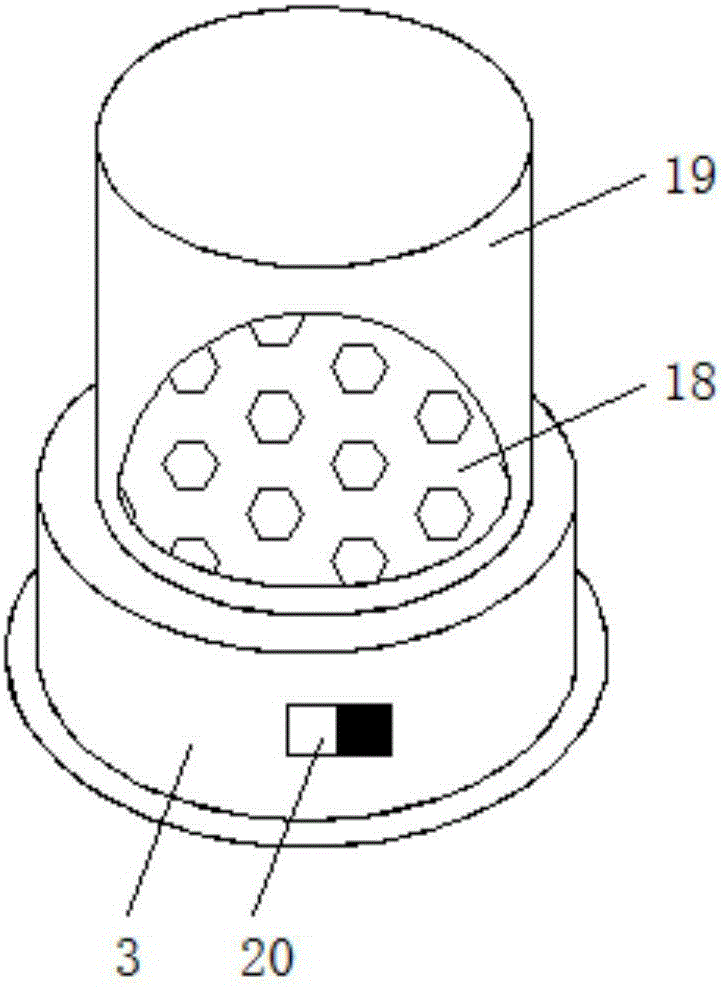

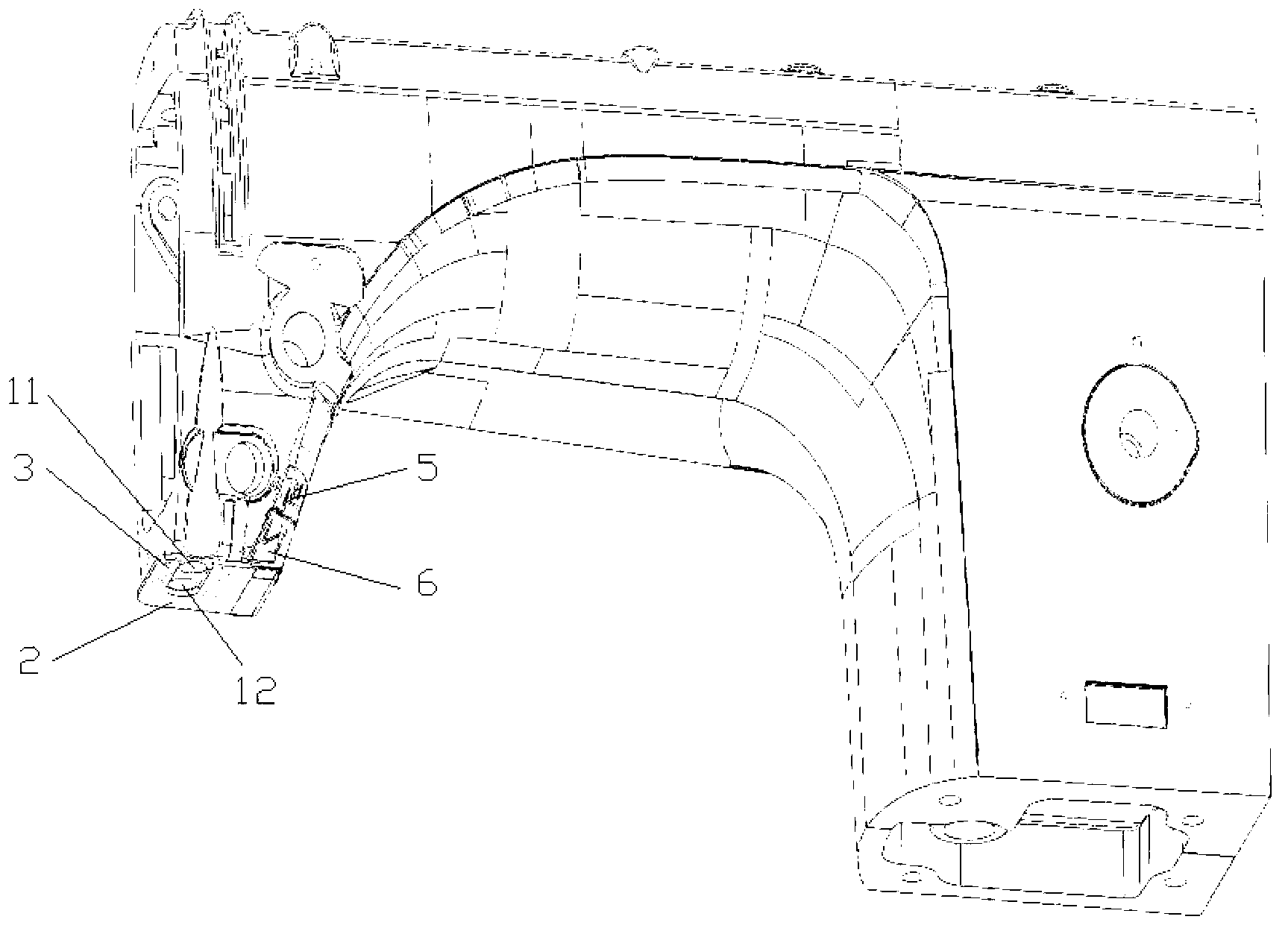

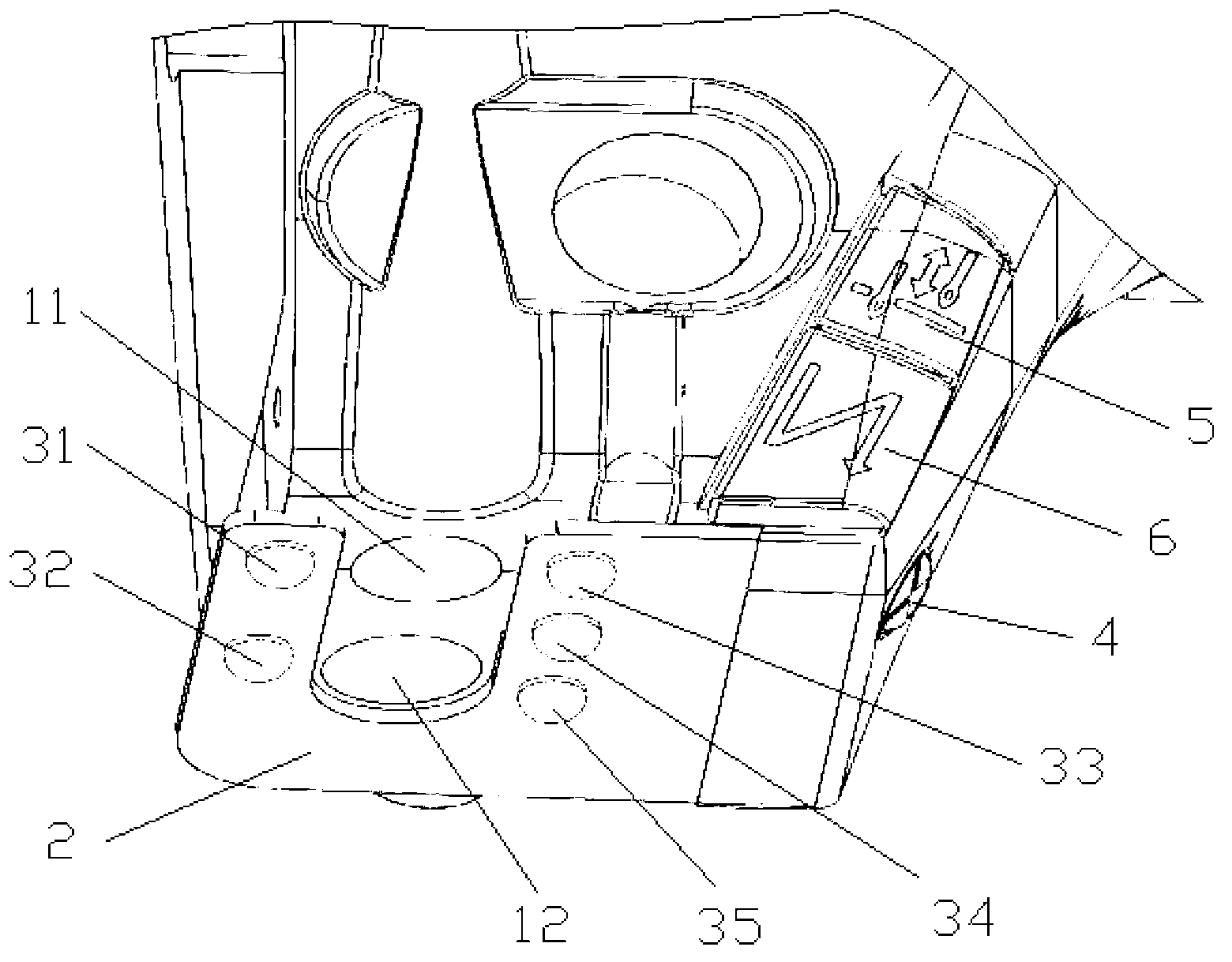

Threading device of sewing machine

InactiveUS20080257241A1Easily and visually recognizeReduce stepsFilament handlingLightening equipmentEngineeringScrew thread

A threading device of a sewing machine includes a thread inserting base formed with a thread path hole having a thread inserting port opened toward an outer side of a sewing machine frame, and further formed with an air path hole which joins the thread path hole in the vicinity of the thread inserting port, an air supply device coupled to the air path hole to supply compressed air, and illuminating means provided on the sewing machine frame to irradiate a joining portion of the thread path hole and the air path hole. The thread inserting base includes a transparent member through which at least the joining portion of the thread path hole and the air path hole can be visually recognized.

Owner:JUKI CORP

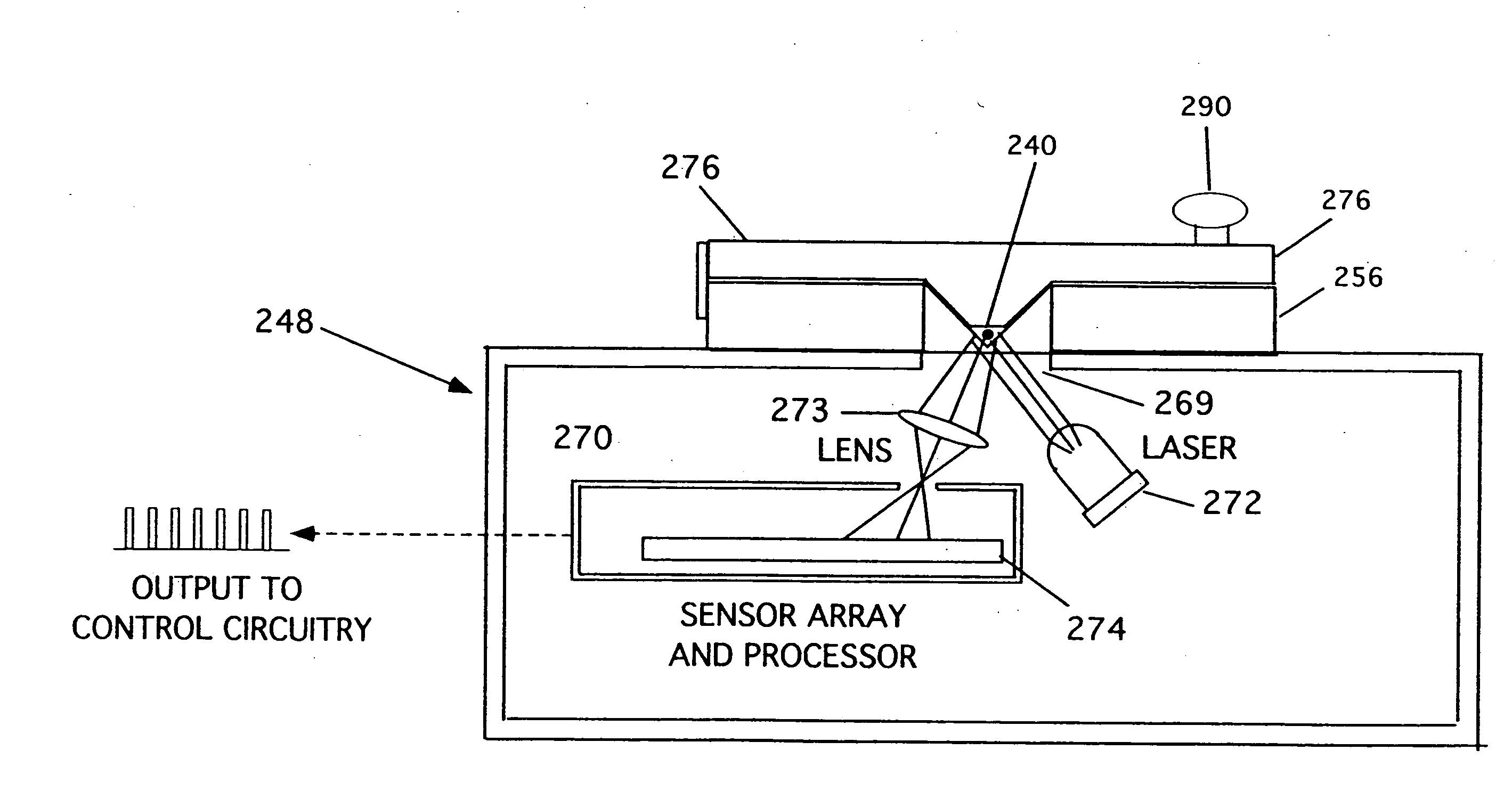

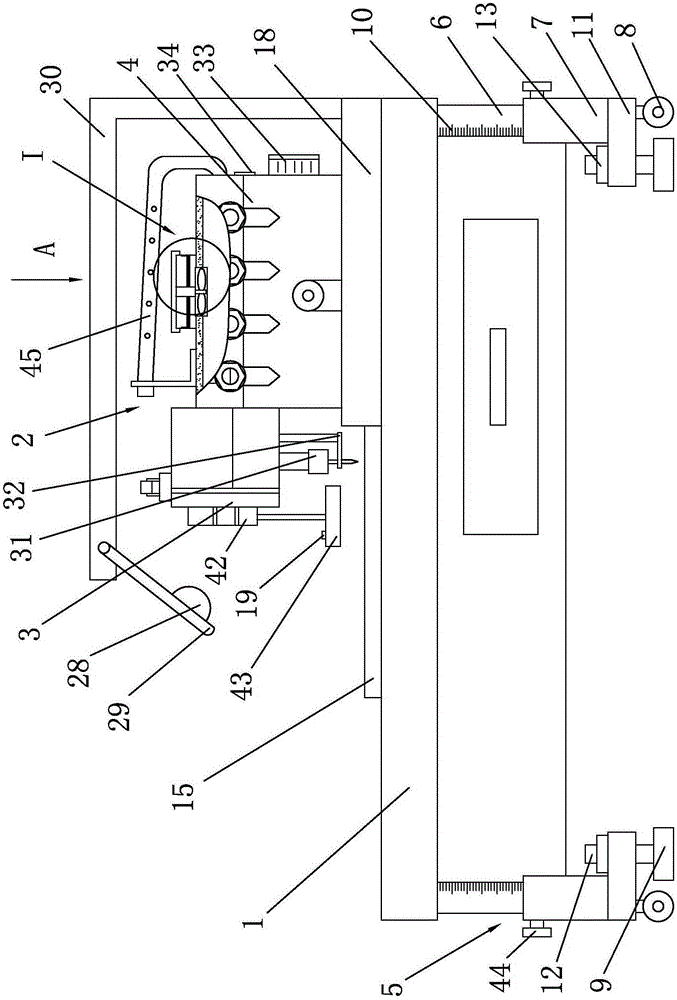

Stitching method and apparatus employing thread longitudinal movement detection

InactiveUS20070256619A1Readily move longitudinallyAvoiding lateral slackProgramme-controlled sewing machinesSewing-machine control devicesEngineeringSewing machine

A method and apparatus for detecting longitudinal thread motion in a quilting / sewing machine for controlling the actuation of a fixedly located stitch head. A preferred detector comprises an optical sensor which directly senses the longitudinal movement of a thread as it moves along a guide path from a supply source toward a stitch head needle.

Owner:KOEMER RALPH J

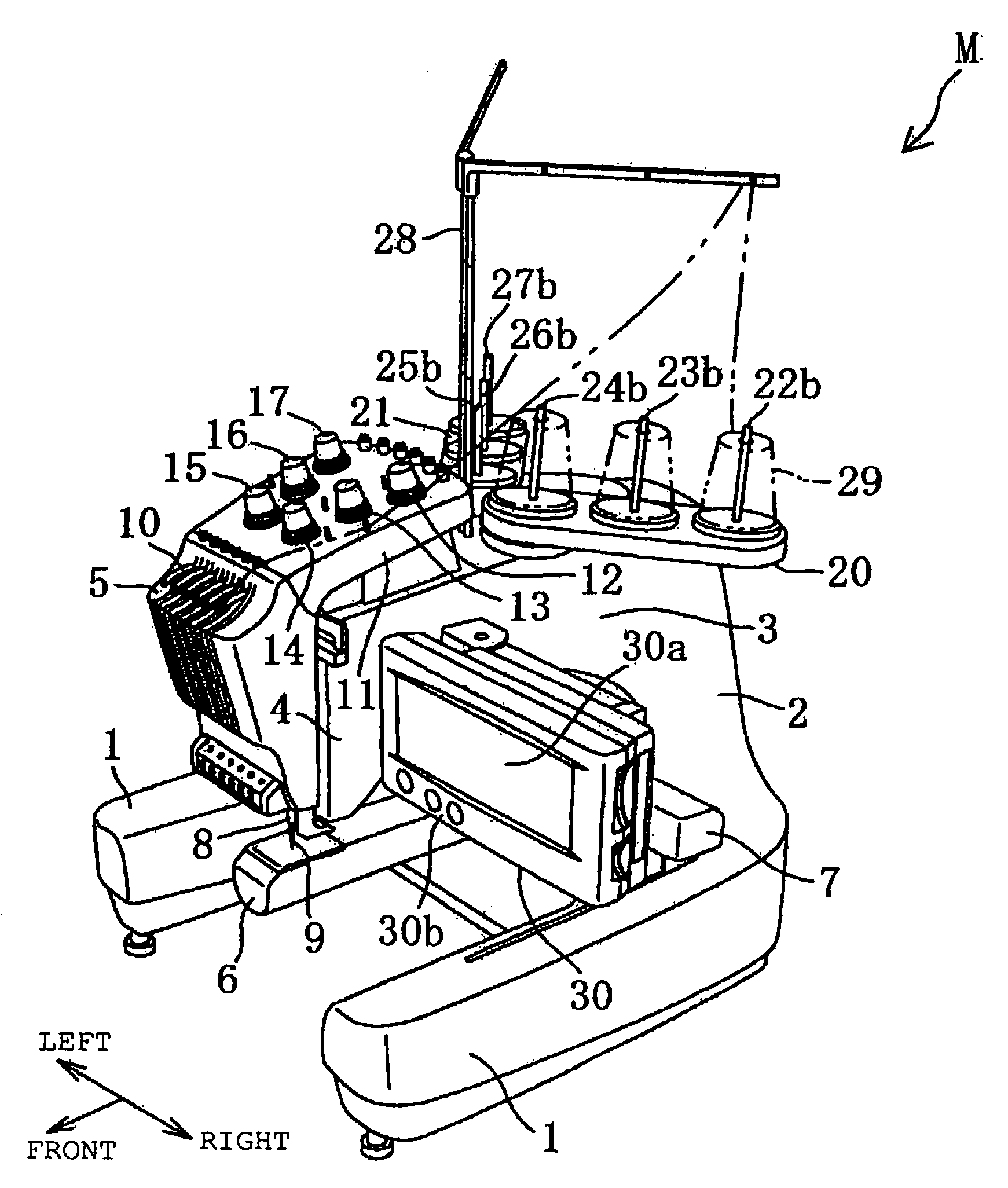

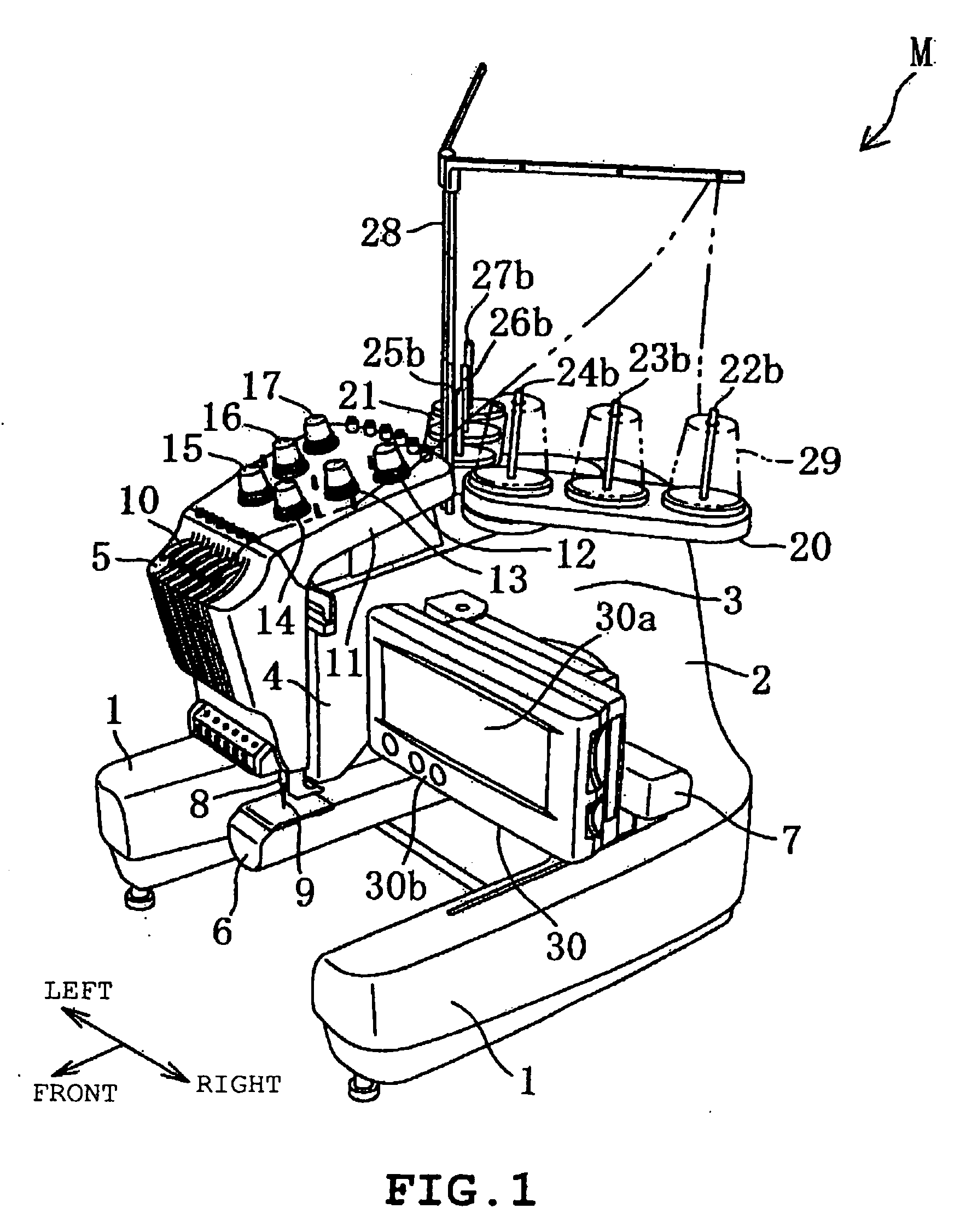

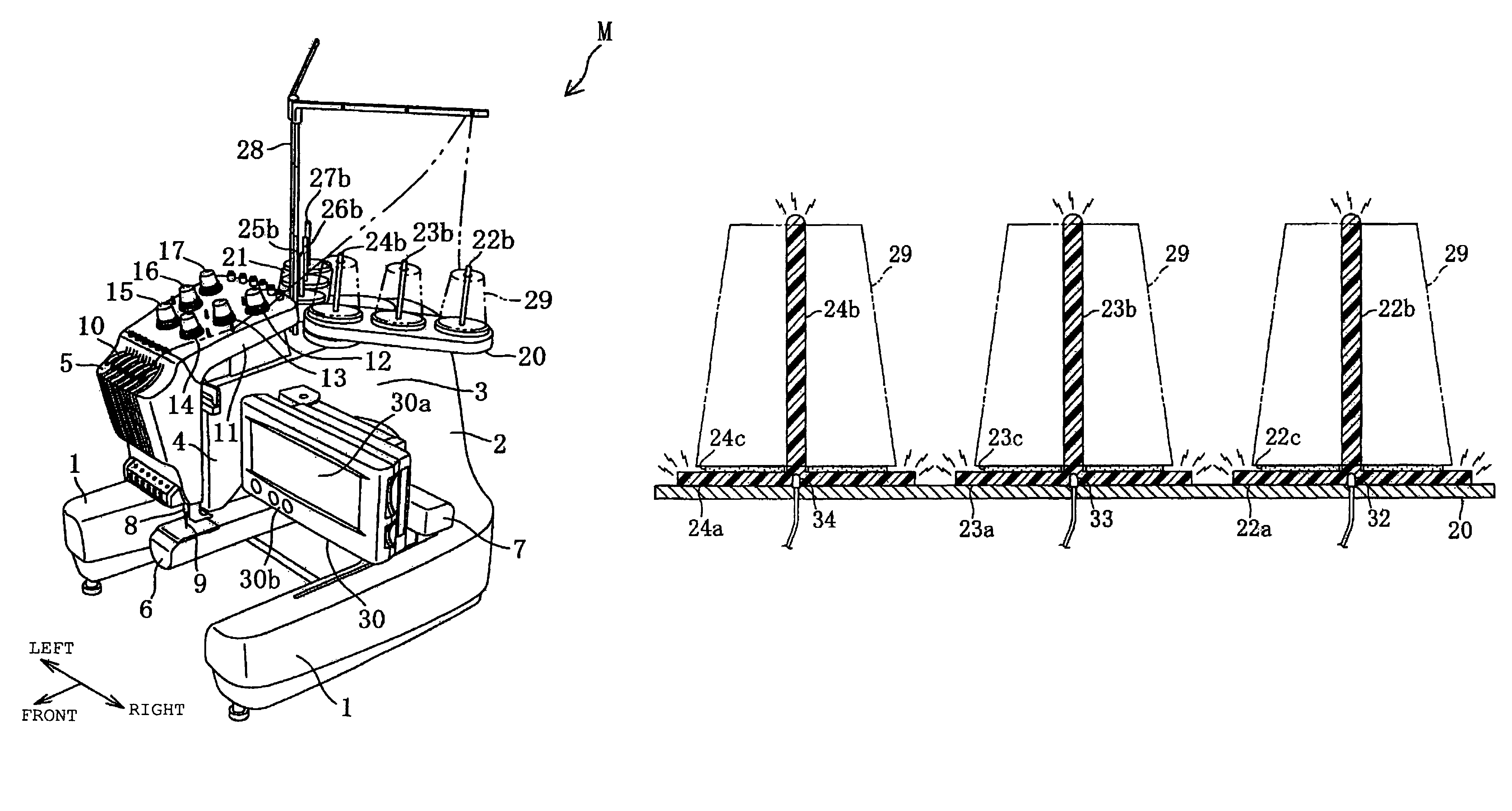

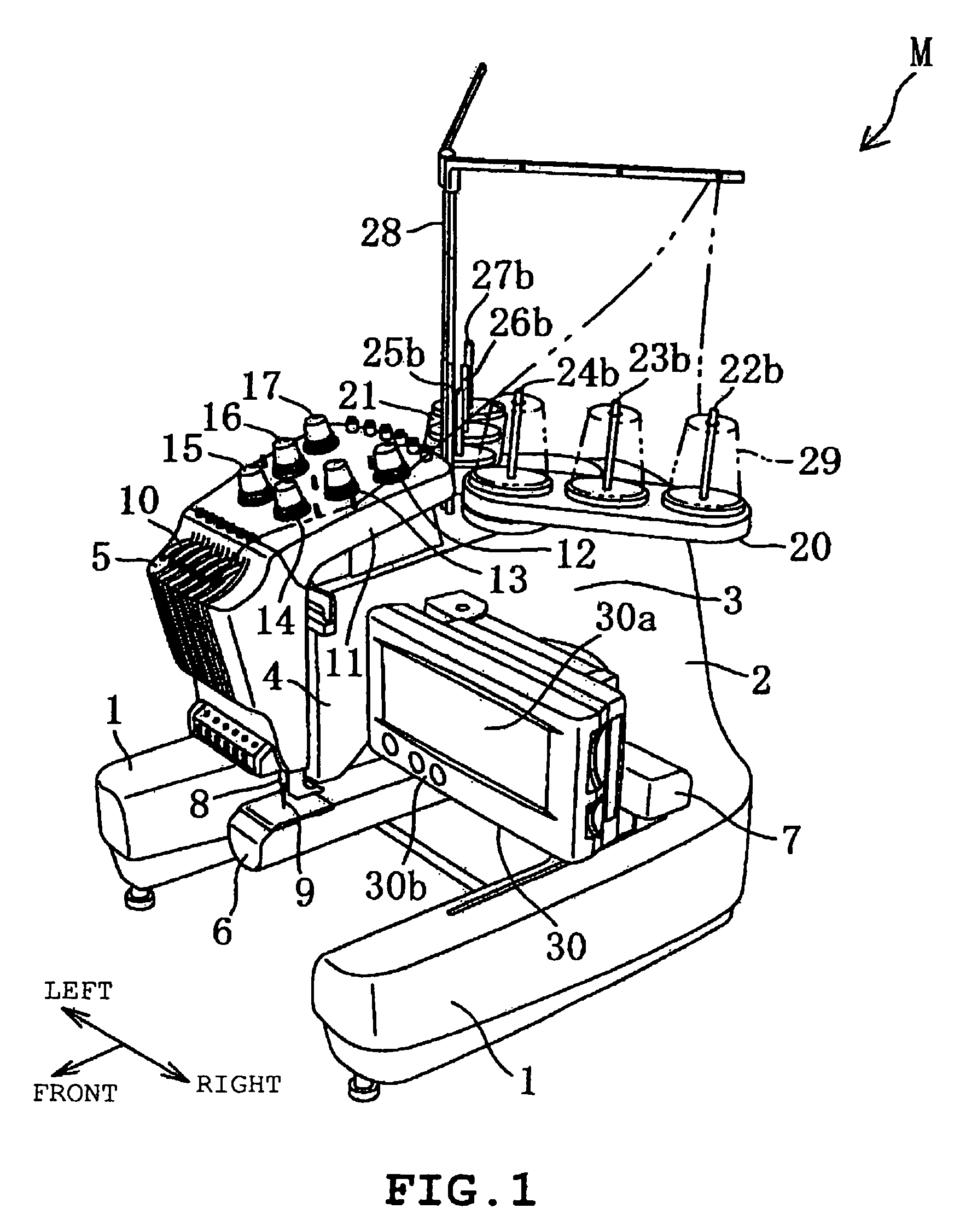

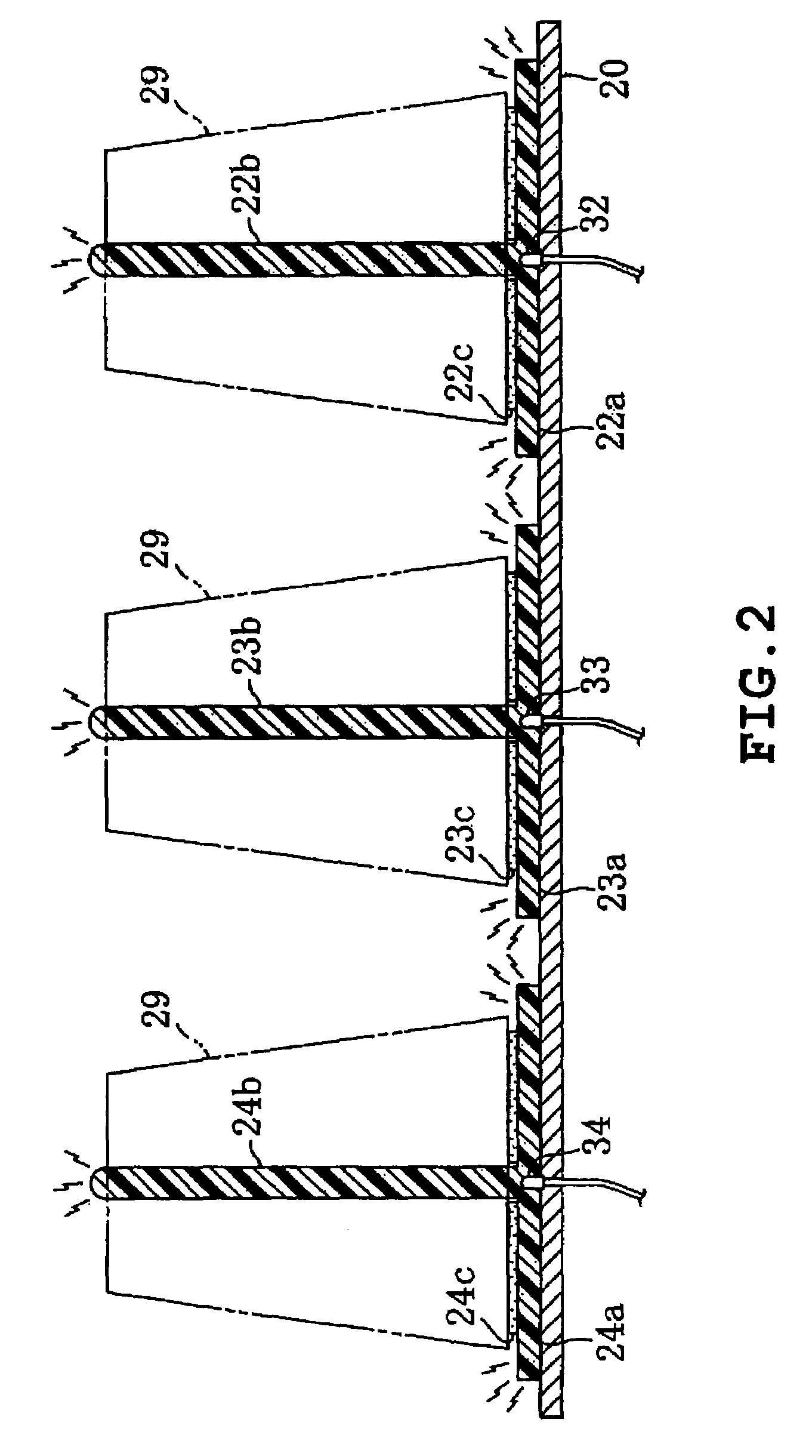

Sewing machine and spool pin stand therefor

A sewing machine includes needlebars for a sewing operation using a plurality of needle threads, a spool pin stand having a plurality of spool pins to which thread spools corresponding to the needlebars are attachable, respectively, thread passage defining members located on a thread passage extending from the spool pin stand to the needlebars, a storage unit storing sewing data including at least thread color information about colors of the needle threads, thread supply display units located on the spool pin stand so as to correspond to the spool pins respectively, the thread supply display units displaying the thread colors in a color-variable manner, respectively, and a thread color information display control unit controlling the thread supply display units based on the thread color information read from the sewing data storage unit, so that thread colors corresponding to the spool pins are displayed by the thread supply display units, respectively.

Owner:BROTHER KOGYO KK

Backlight unit

ActiveUS7641373B2Improve brightness uniformityNarrow display frameMeasurement apparatus componentsLighting support devicesLight reflectionEngineering

Disclosed is a backlight unit which illuminates a display panel from a rear surface thereof, including at least: tubular lamps arranged in parallel to the panel; and a reflecting member which reflects light from the lamps toward the panel, wherein the reflecting member is divided into a first region opposed to an area near an electrode provided in an end portion of the lamp and a second region nearer to a middle area than the first region, the first region having a higher reflectance than the second region. In another backlight unit, a reflecting member is divided, with respect to the arrangement direction of the lamps, into an end lamp near region which is opposed to a lamp arranged in end portion and a middle region which is nearer to a middle area than the end lamp region, the end lamp region having a higher reflectance than the middle region.

Owner:NEC LCD TECH CORP

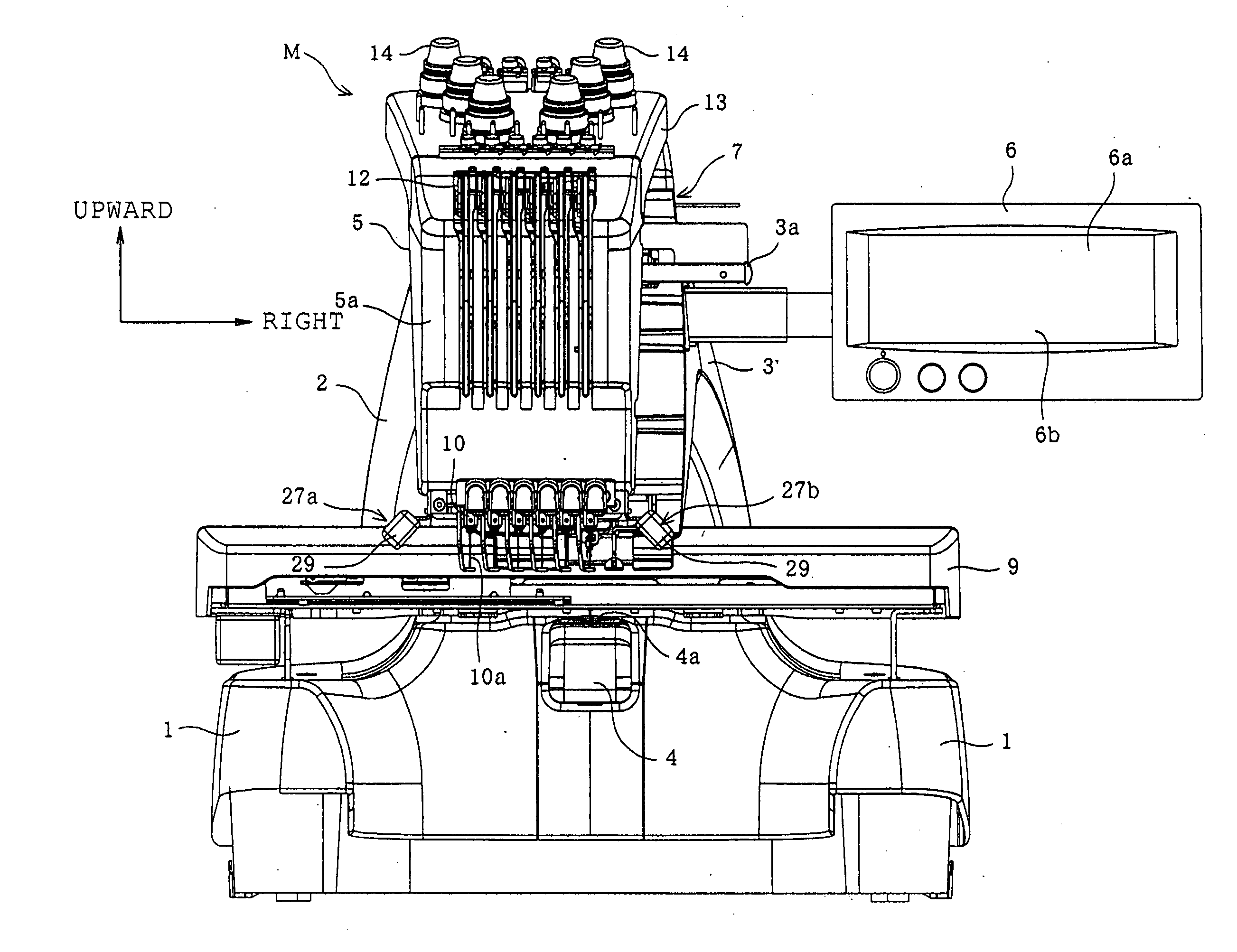

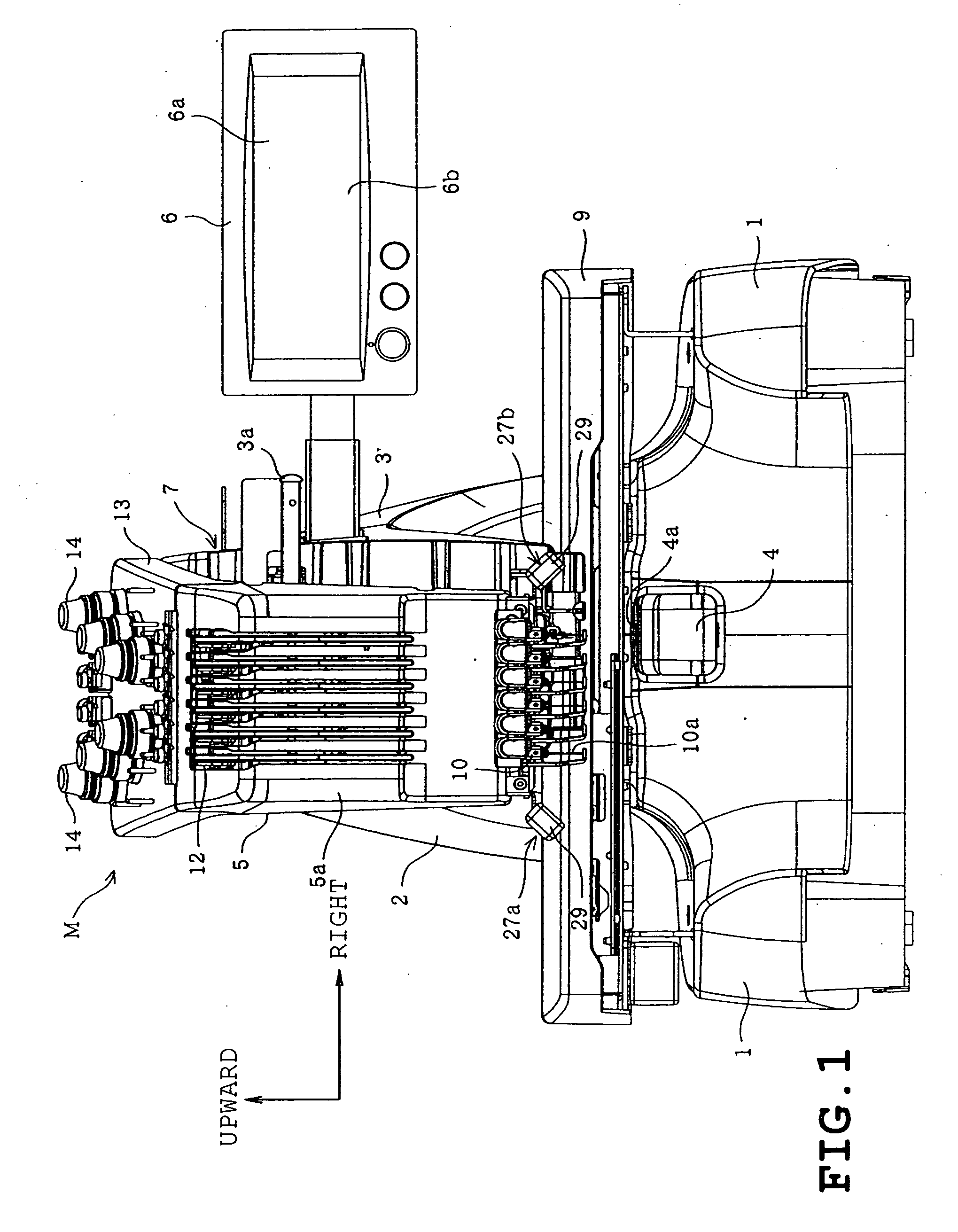

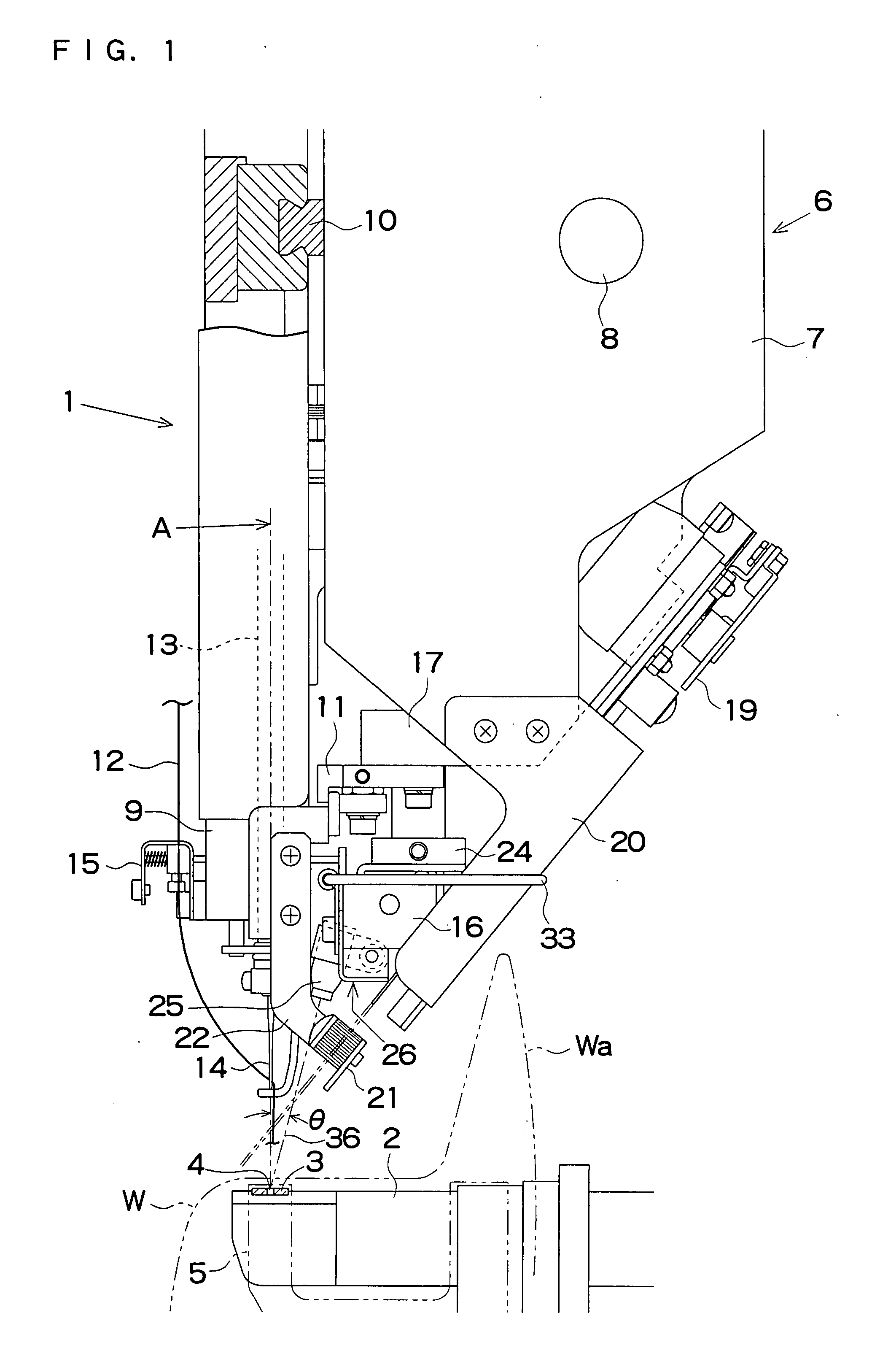

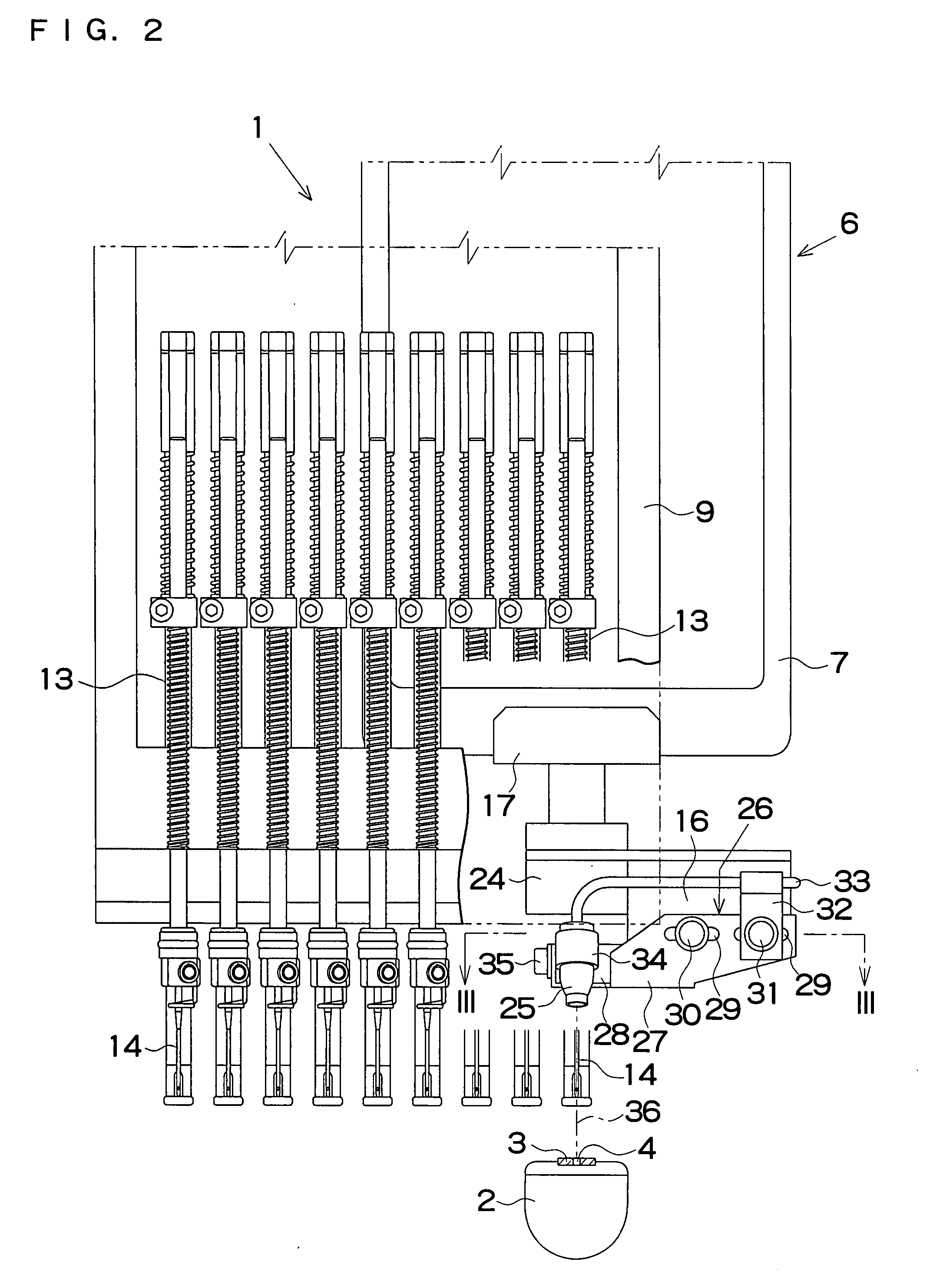

Illumination device for multineedle sewing machine and the multineedle sewing machine

An illumination device for a multineedle sewing machine includes an illuminating member which has a light source and located at a lateral side of a needle bar case and is disposed so as to open portions of needle bars and portions of needles, a light amount adjusting unit which adjusts an amount of light of the light source, and a control unit which controls the light amount adjusting unit with movement of the needle bar case by the needle bar case moving mechanism together with the illuminating member so that a predetermined illuminance is maintained at least in part of an illuminated area which is illuminated by the light source. The part of the illuminated area is located near the needle drop position.

Owner:BROTHER KOGYO KK

Stitching method and apparatus employing thread longitudinal movement detection

InactiveUS7793602B2Readily move longitudinallyAvoiding lateral slackProgramme-controlled sewing machinesSewing-machine control devicesEngineeringSewing machine

A method and apparatus for detecting longitudinal thread motion in a quilting / sewing machine for controlling the actuation of a fixedly located stitch head. A preferred detector comprises an optical sensor which directly senses the longitudinal movement of a thread as it moves along a guide path from a supply source toward a stitch head needle.

Owner:KOEMER RALPH J

Illuminated push button switch

ActiveUS8247722B2Improve the sense of operationUniform lightEmergency actuatorsSewing-machine control devicesEngineeringPush switch

Owner:BROTHER KOGYO KK

Workpiece cloth positioning guide device for sewing machine

ActiveUS7854209B2Programme-controlled sewing machinesWork-feeding meansEngineeringReference designator

Owner:BROTHER KOGYO KK

Sewing machine for clothes processing

The invention discloses a sewing machine for clothes processing. The sewing machine for clothes processing comprises support legs, a table surface, a rack, a top plate, a machine head, a working table, a goose neck tube, a fan, a lighting lamp, a cup holder, a dust collection hopper, a dust collection pump, a channel, a collection box and a drawer, wherein four support legs are uniformly arranged at the lower part of the table surface; the rack is fixedly and vertically arranged on the left side of the upper part of the table surface; the top plate is fixedly horizontally arranged at the upper end of the rack; the machine head is fixedly arranged at the lower part of the top plate; the working table is fixedly and horizontally arranged at the upper end of the rack; the machine head is fixedly arranged below the top plate; the working table which is fixedly mounted on the table surface is arranged right below the machine head; the fan is connected below the top plate and positioned on the left side of the machine head through the goose neck tube; the lighting lamp is arranged at the right side part of the rack. Compared with the prior art, the working performance of the sewing machine is improved, the adaptability of the sewing machine is improved, functions of the sewing machine are enriched, the working intensity of operators is alleviated, and great convenience is brought to clothes processing.

Owner:嘉兴永盛服饰有限公司

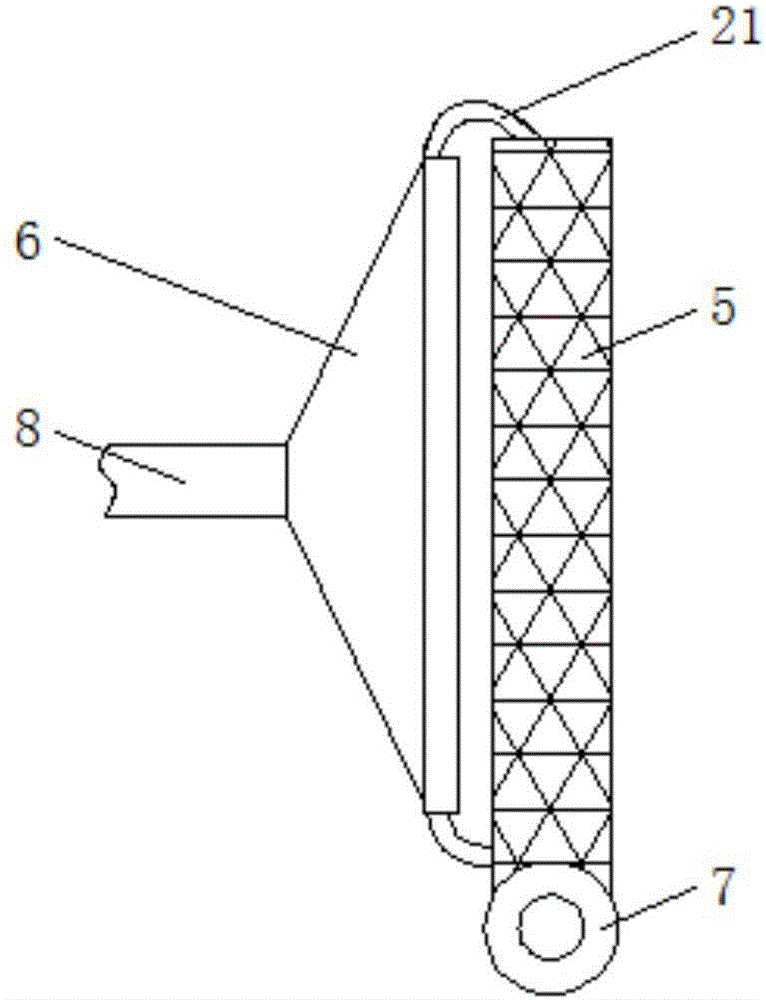

Quality- guaranteed over-lock sewing machine

InactiveCN106801299AGuarantee the need for lightQuality assuranceLightening equipmentLuminous intensityEngineering

The invention relates to a quality- guaranteed over-lock sewing machine. The quality- guaranteed over-lock sewing machine comprises a machine frame. Mounting bases are disposed in the two across corners on the upper terminal of the machine frame. A flexible track is arranged on the machine frame. The two mounting bases are connected with the two ends of the track respectively. An upper roller is disposed in the upper end of the track. A lower roller is disposed in the lower end of the track. A beam inserts through the middle part of the lower roller. The beam rotates along with the lower roller. The over-lock devices that conduct the over-lock operation on the cloth symmetrically placed on the machine frame. The over-lock devices move along the axial direction of the beam in sliding mode. A smart lamp capable of adjusting luminance according to outside luminous intensity is arranged on the machine frame. Compared with the prior art, the smart lamp is capable of adjusting luminance according to outside luminous intensity, which guarantees the luminance needs in over-lock operational procedure, the quality and the efficiency of over-lock.

Owner:广西柳州市诗彤贝儿婴幼儿用品制造有限公司

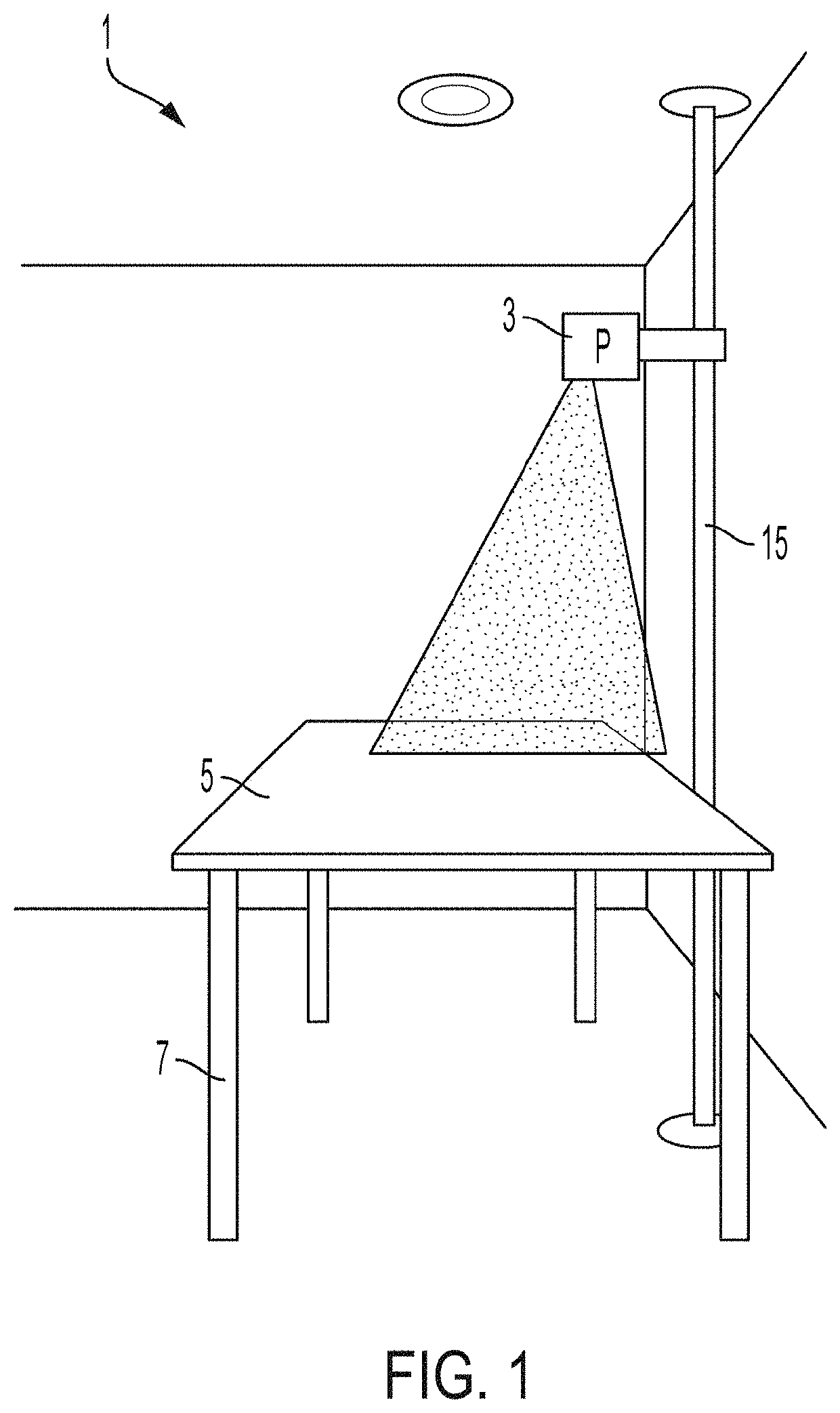

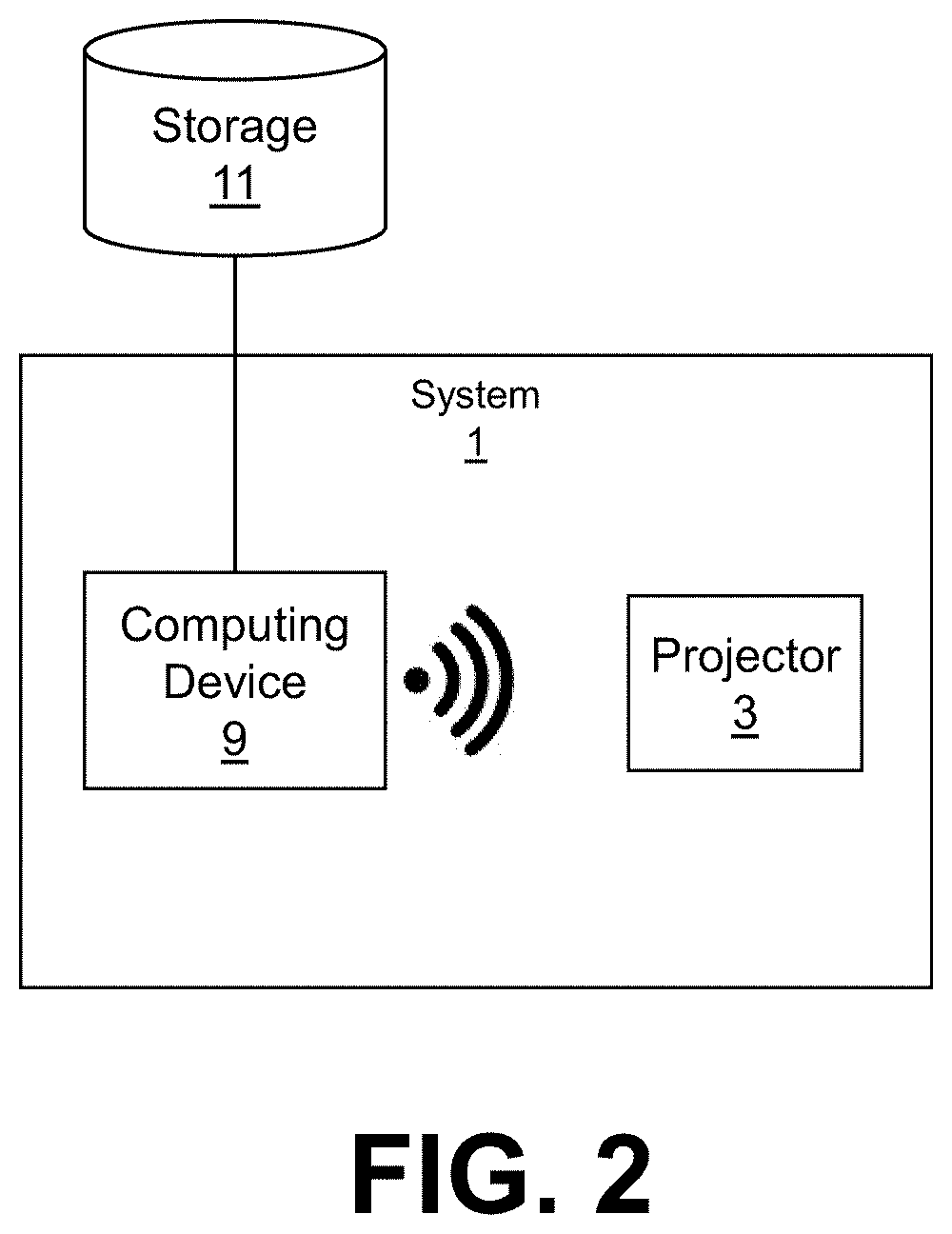

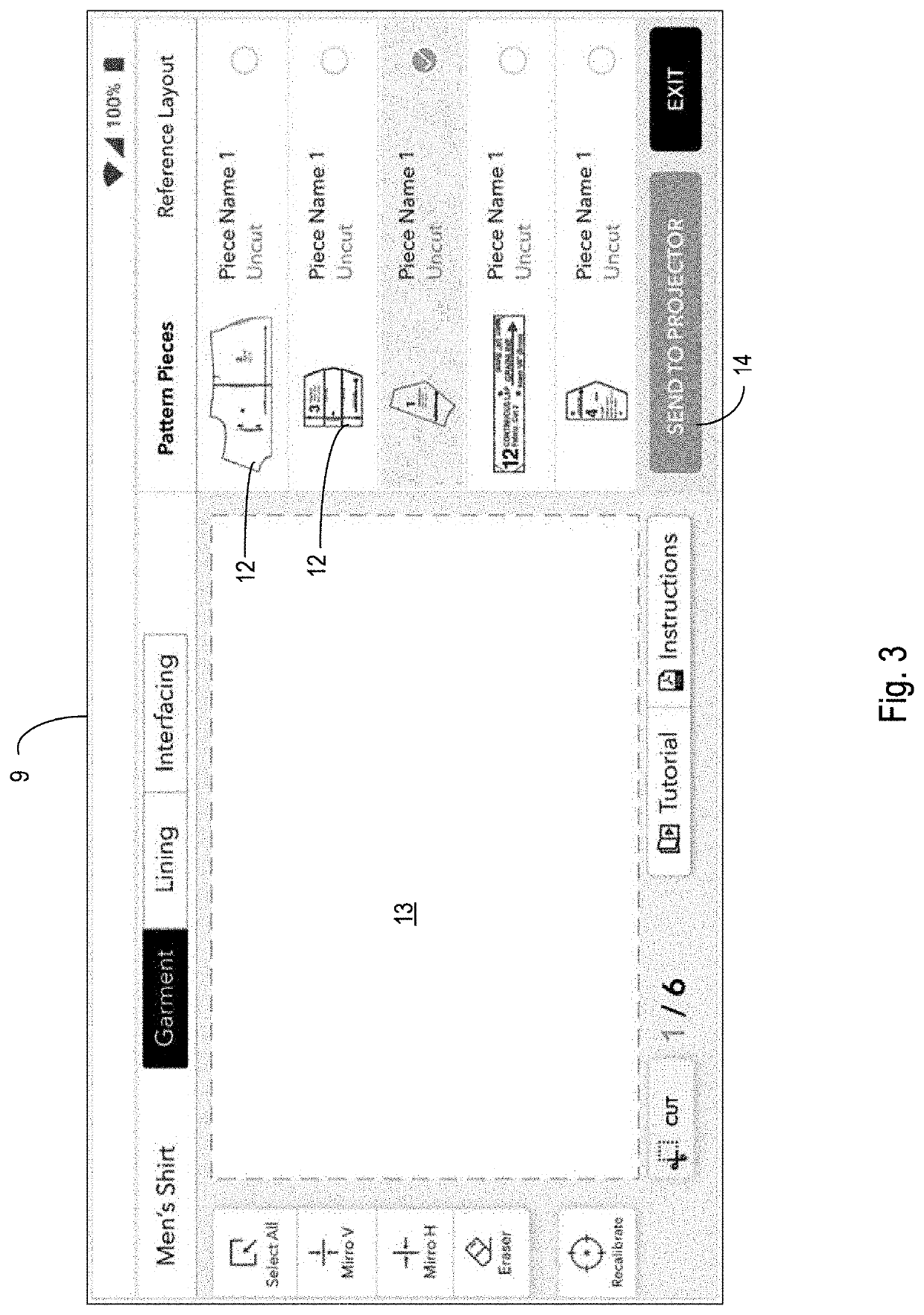

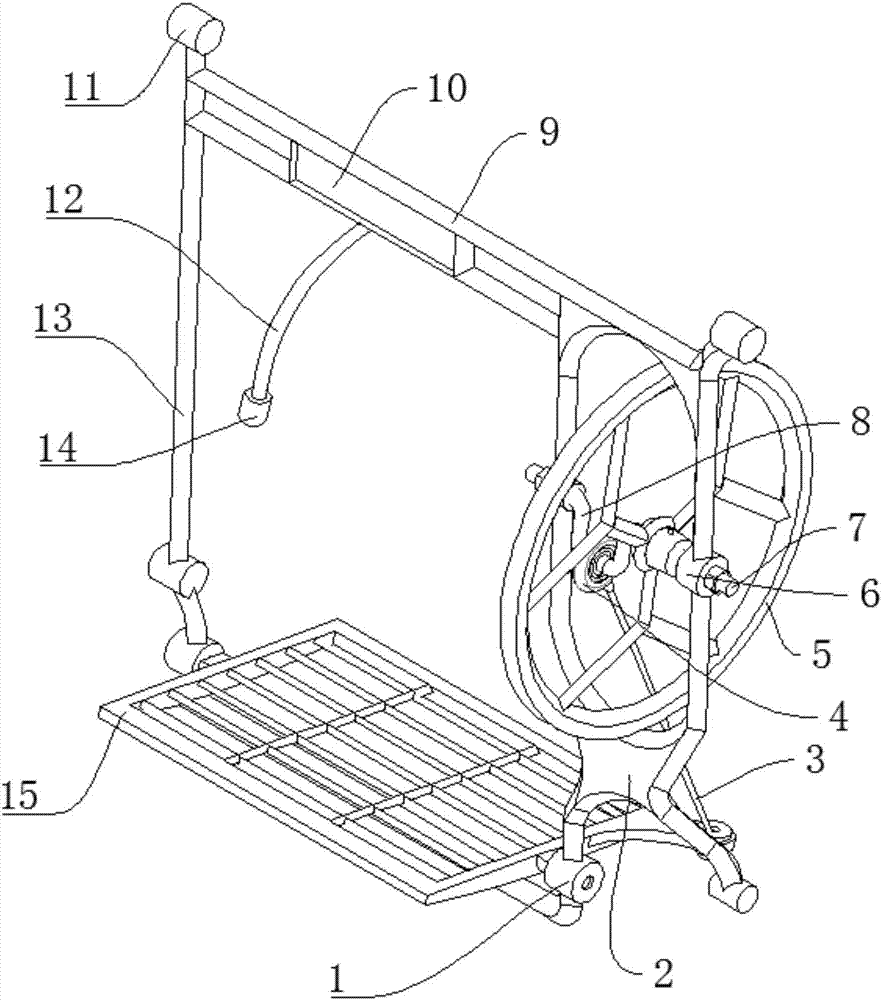

Image projecting systems and methods

PendingUS20210356849A1Easily digitally storableFully reusableWork-feeding meansProjectorsProjection systemMechanical engineering

A projection system for projecting sewing patterns onto a surface comprises a vertical beam, a projector, and a cart. The vertical beam includes (a) a floor engaging portion at a bottom end and (b) a ceiling engaging portion at a top end, the ceiling engaging portion being vertically movable with respect to the floor engaging portion such that, when in use, the floor engaging portion and the ceiling engaging portion engage a floor and a ceiling, respectively, to anchor the projection system adjacent the surface. The projector is configured to receive data representing the sewing patterns and to project the sewing patterns. The cart is operably attached to the projector and slidably attached to the vertical beam, wherein sliding the cart vertically adjusts a height of the projector above the surface.

Owner:DITTOPATTERNS LLC

Thread-through device for sewing machine

ActiveCN101168889AEasy to identifyEasy threading workLightening equipmentNeedle-threading devicesEngineeringTread

Owner:JUKI CORP

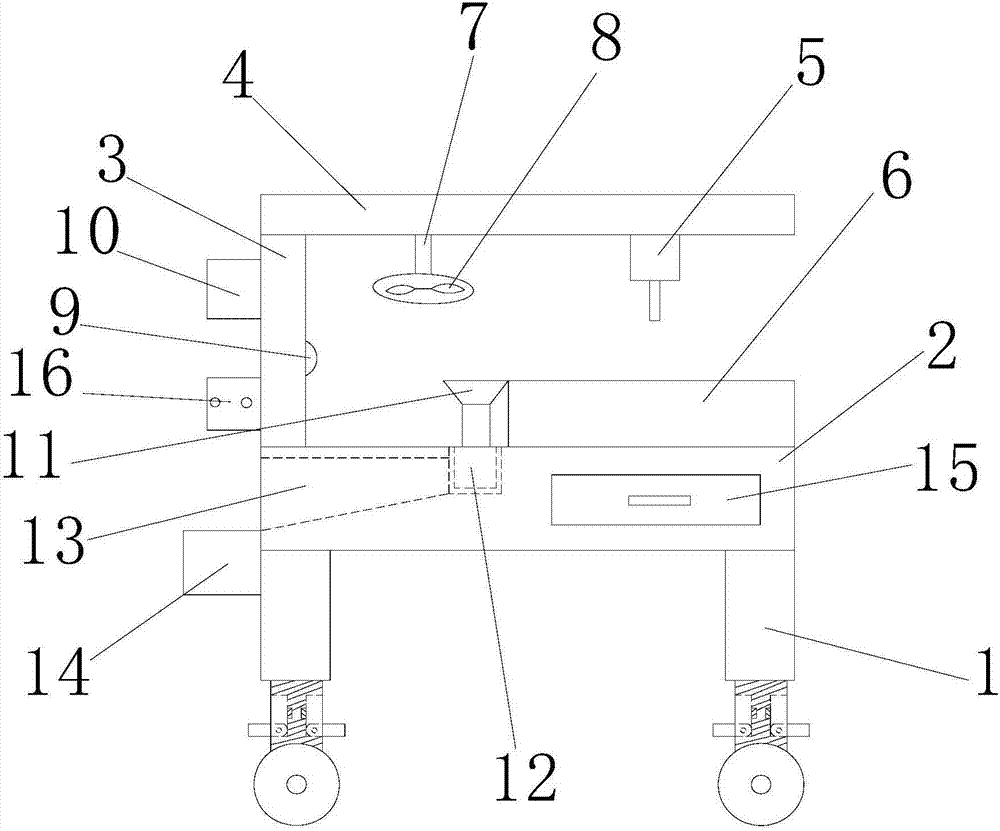

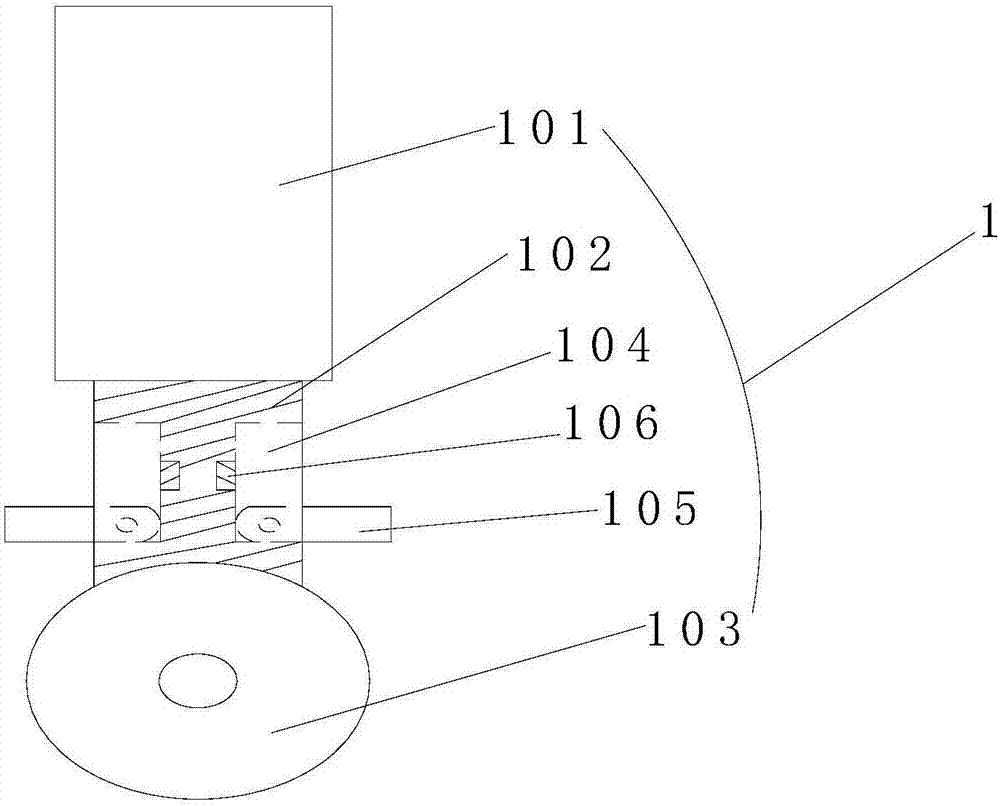

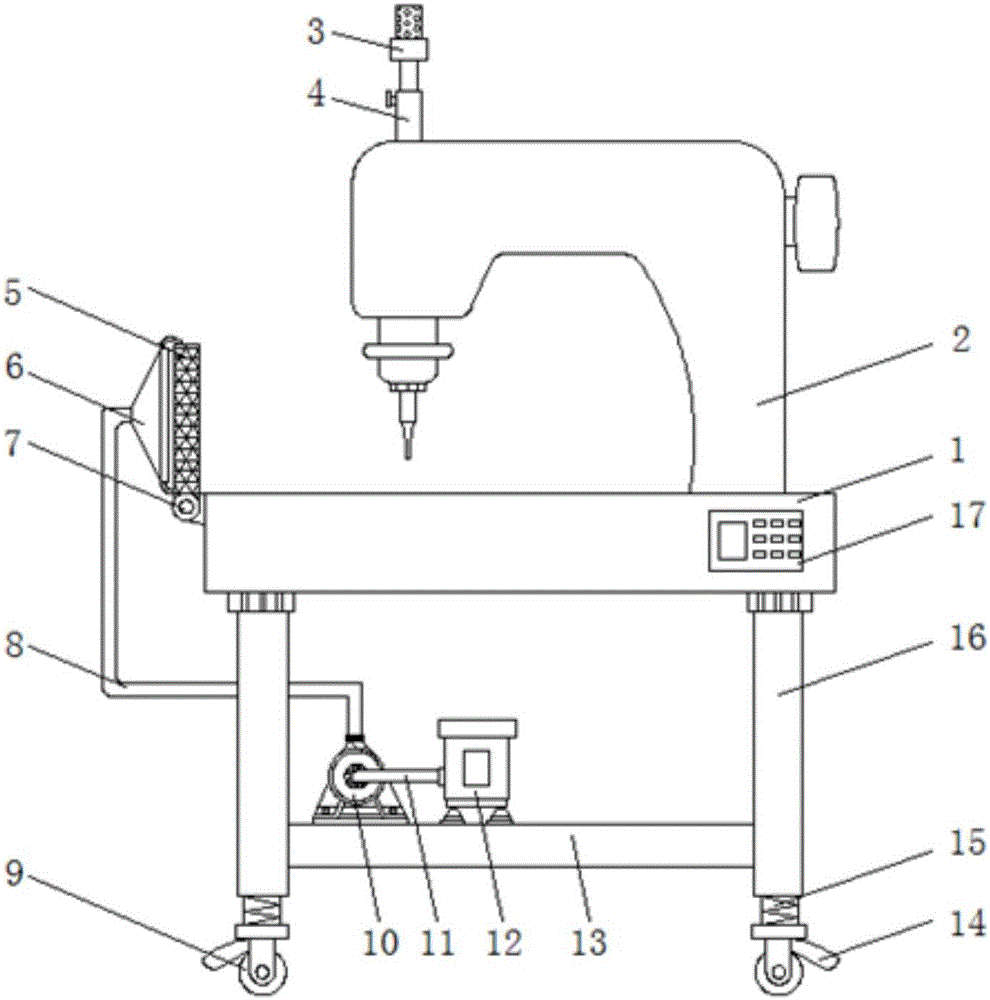

Serger for tie production

InactiveCN105177863AReduce wasteAvoid compromising qualityLubrication/cooling devicesSewing-machine casingsProcess engineering

The invention discloses a serger for tie production. The serger comprises a working table, serger bodies and an illuminating device. Each serger body comprises a handpiece and a machine box. A height adjusting device is arranged below the working table and comprises lifting columns, supporting columns, universal wheels and supporting feet. The serger bodies comprise a first serger body and a second serger body. A boss is arranged on the upper portion of each machine box. A heat dissipating device is arranged in each boss. The illuminating device comprises an illumination lamp and a moving plate. The serger is simple in structure and high in practicality; by means of the height adjusting device, the height of the working table can be adjusted according to the stature of an operator, use is more convenient, and operation is safer; by means of design of the illuminating device, when light is dark, brightness is improved, and the operator can continue working; by means of design of the heat dissipating devices, heat in the machine boxes can be dissipated faster, the service life of the serger is prolonged, the accident occurrence rate is reduced, and the comprehensive utilization efficiency is improved.

Owner:SHAOXING HENRY TIE FASHION

High-practicability sewing machine

InactiveCN106757864APlay a protective effectImprove protectionSewing-machine control devicesLightening equipmentPulp and paper industryClean environment

The invention discloses a high-practicability sewing machine which comprises an operation platform and a sewing machine body. An extensible rod is mounted on the sewing machine body, a lamp holder is mounted at the top end of the extensible rod, a lighting lamp is mounted on the lamp holder, a supporting leg is welded on each of two sides of the bottom of the operation platform, the two supporting legs are connected through a shelving plate, a traveling castor is mounted at the bottom end of each supporting leg, an induced draft fan and a dust collection box are arranged on the shelving plate, the induced draft fan is connected with a dust suction funnel through a dust suction hose, and one side of the operation platform is rotatably connected with a filter net through a rotating shaft. By mounting the lighting lamp on the lamp holder, the lighting lamp can provides lighting at dark places, so that convenience is brought to an operating worker to thread a needle eye of the sewing machine so as to improve product quality; the high-practicability sewing machine is simple in structure, flexible to move and capable of eliminating pollutants like dust and batting around the sewing machine, cleaning environment outside the sewing machine and bringing benefit to health of a user.

Owner:WUJIANG ZHENYU SEWING EQUIP

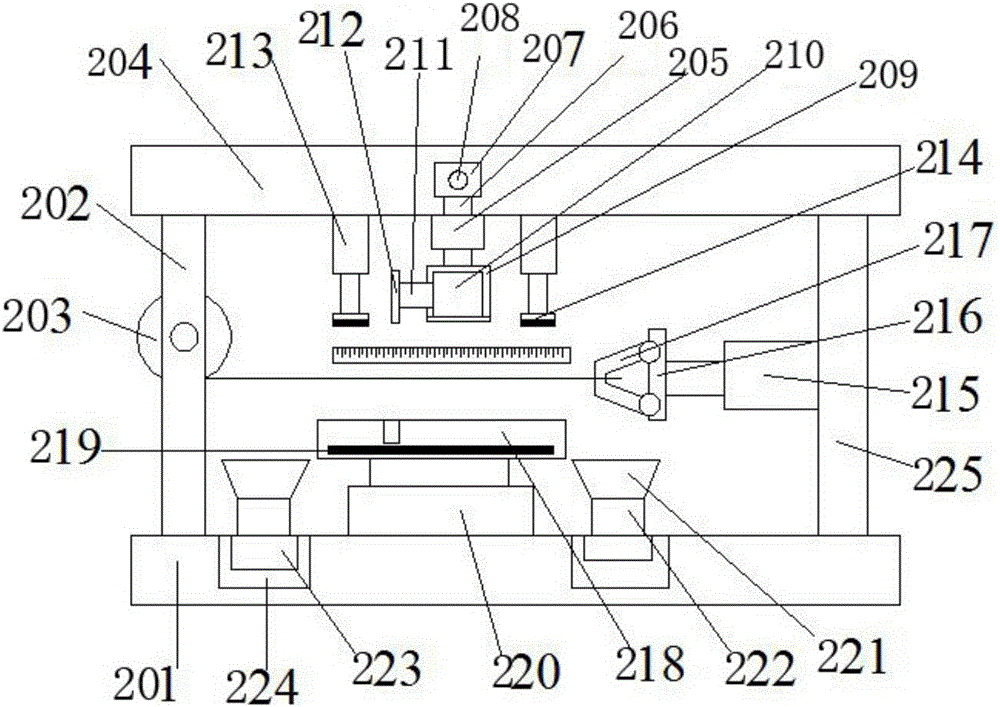

Automatic sewing and button sewing machine for garment making

The invention relates to the field of garment making mechanical equipment, in particular to an automatic sewing and button sewing machine for garment making. The machine comprises a feeding device, apushing device, a clamping device and a button sewing machine body; a button vibration plate of the feeding device conveys button workpieces to a button guide rail and pushes the button workpieces tothe pushing device, the pushing device sequentially conveys the button workpieces into the clamping device, garments to which buttons need to be sewn are placed below the clamping device, the button workpieces correspond to the garments in position, and the button sewing machine body drives a button sewing needle to sew the buttons; a garment box can contain the garments, and convenience is provided for workers to take and place the garments; in addition, the protection function is achieved when the machine works through the arrangement of a buffering device, a lighting lamp can provide convenience for work when light is insufficient, and a scale ruler can help the workers to carry out comparison; the machine is easy to operate, excellent in design, capable of achieving automatic button sewing in the field of garment making, and high in practicability.

Owner:ANHUI YICAINI FIBER MATERIALS TECH

Lockstitch sewing machine head

ActiveCN103243498AImprove work efficiencyProtect eyesightSewing-machine casingsElectric circuit arrangementsEngineeringLight source

The invention provides a lockstitch sewing machine head. The lockstitch sewing machine head is provided with a needle bar hole and a pressing bar hole. A mounting plate is arranged under the surface of the machine head, which is provided with the needle bar hole and the pressing bar hole, the mounting hole surrounds the needle bar hole and the pressing bar hole along the circumferential direction, and the mounting plate is provided with lighting lamps which illuminate downwards and are arranged around the needle bar hole and the pressing bar hole. According to the lockstitch sewing machine head, a needle bar and a press bar can be illuminated by a plurality of light sources to avoid shadows, so that the working efficiency of operators and the qualification rate of products can be improved and the eyesight of the operators can be protected; and meanwhile, the surface of a switch is smooth, so that the products or the operators can avoid being scraped by the protruded switch on a lockstitch sewing machine, and further the safety of the products and the operators can be guaranteed during the working process of the lockstitch sewing machine. Besides, the backstitch function and the complementary stitching function can be controlled by a backstitch function switch and a complementary stitching switch respectively, so that the usage of the operators can be facilitated. The switches can be mounted in a separate and independent mode or a combined and integrally-formed mode on the machine head according to product requirements.

Owner:JACK SEWING MASCH CO LTD

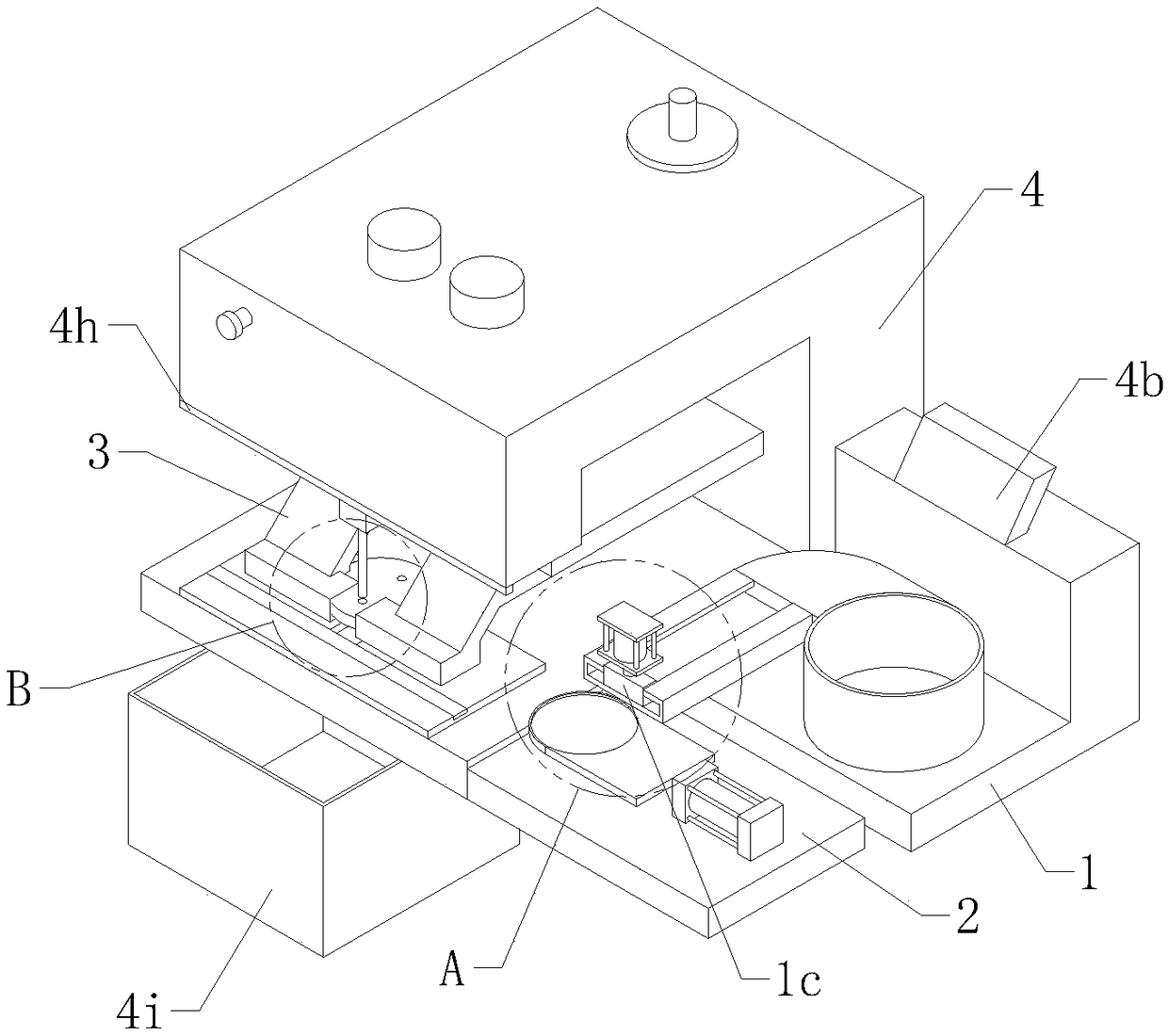

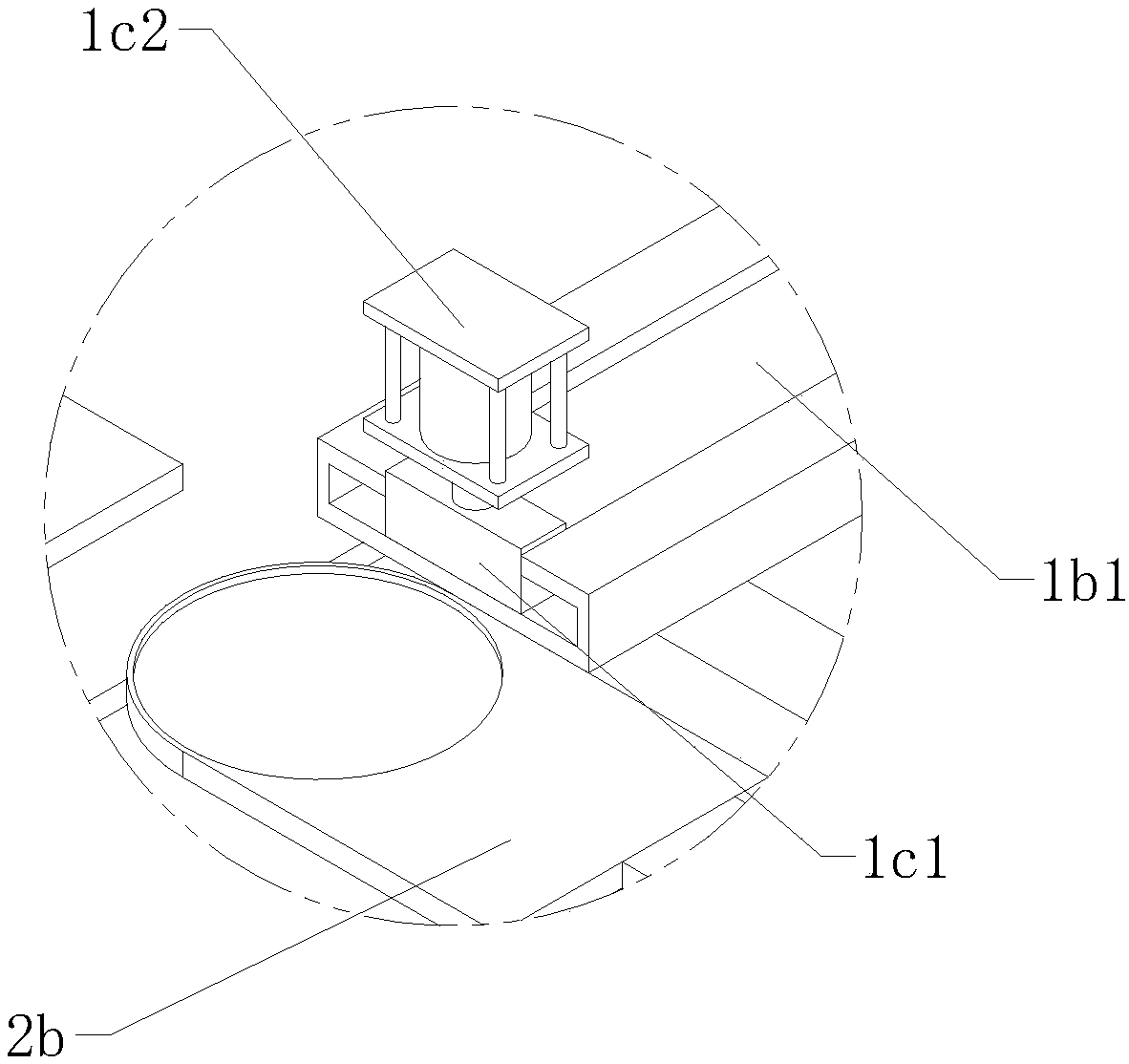

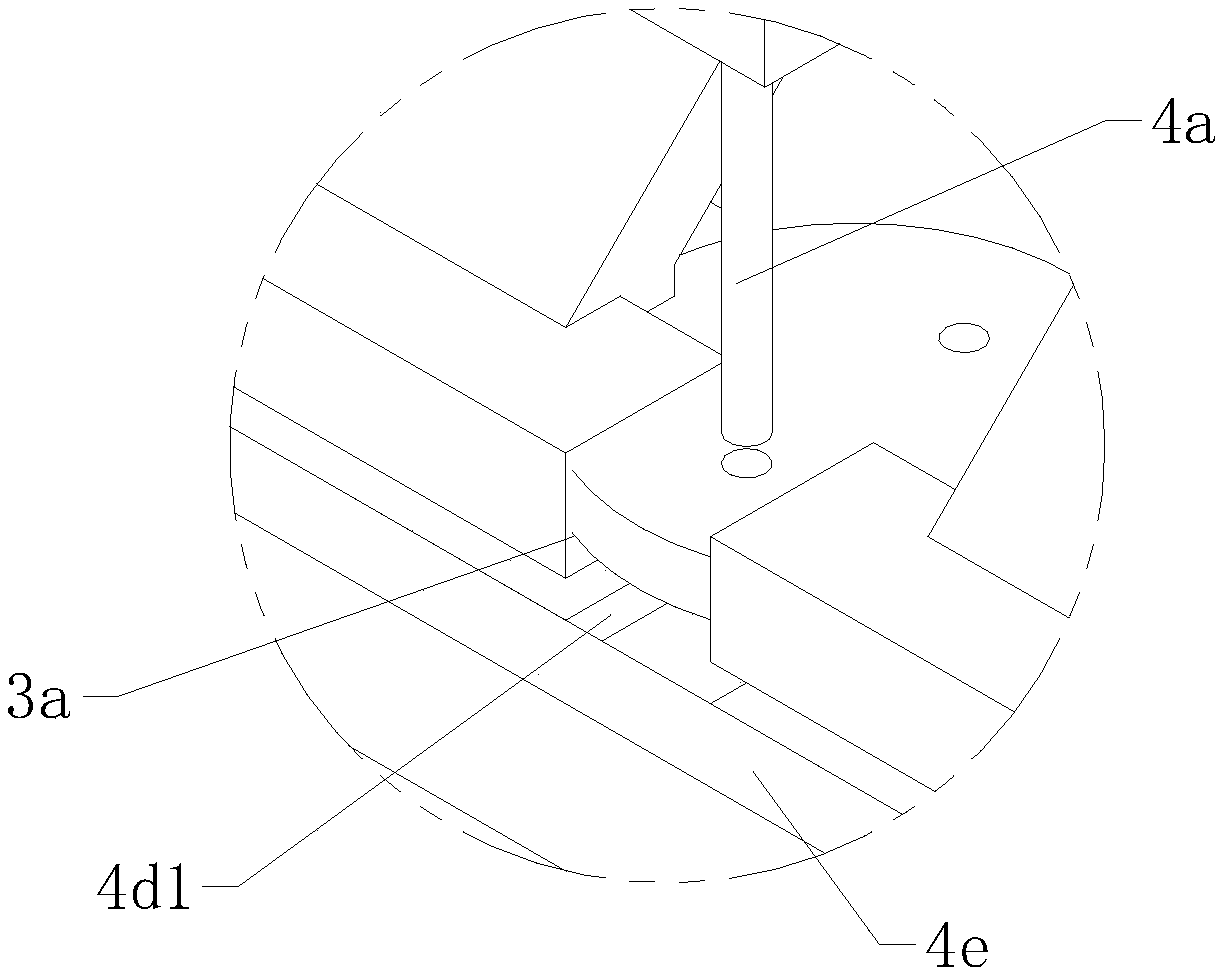

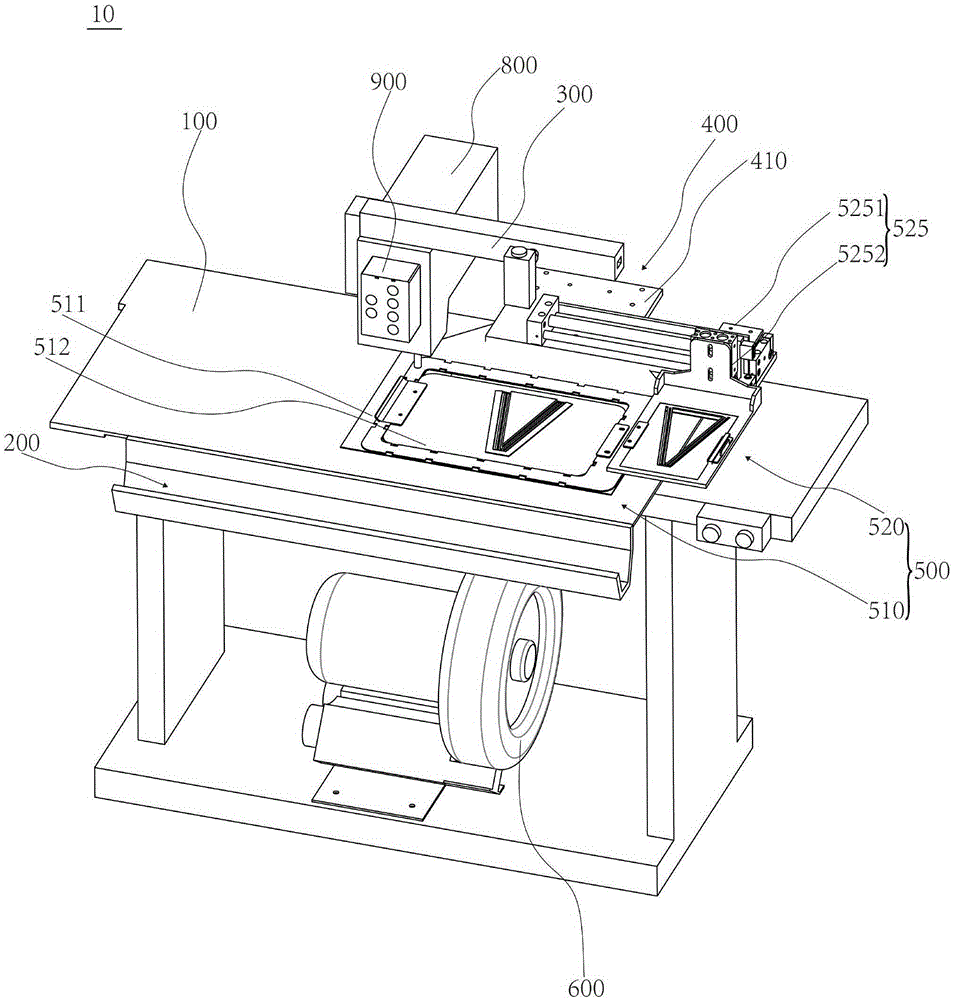

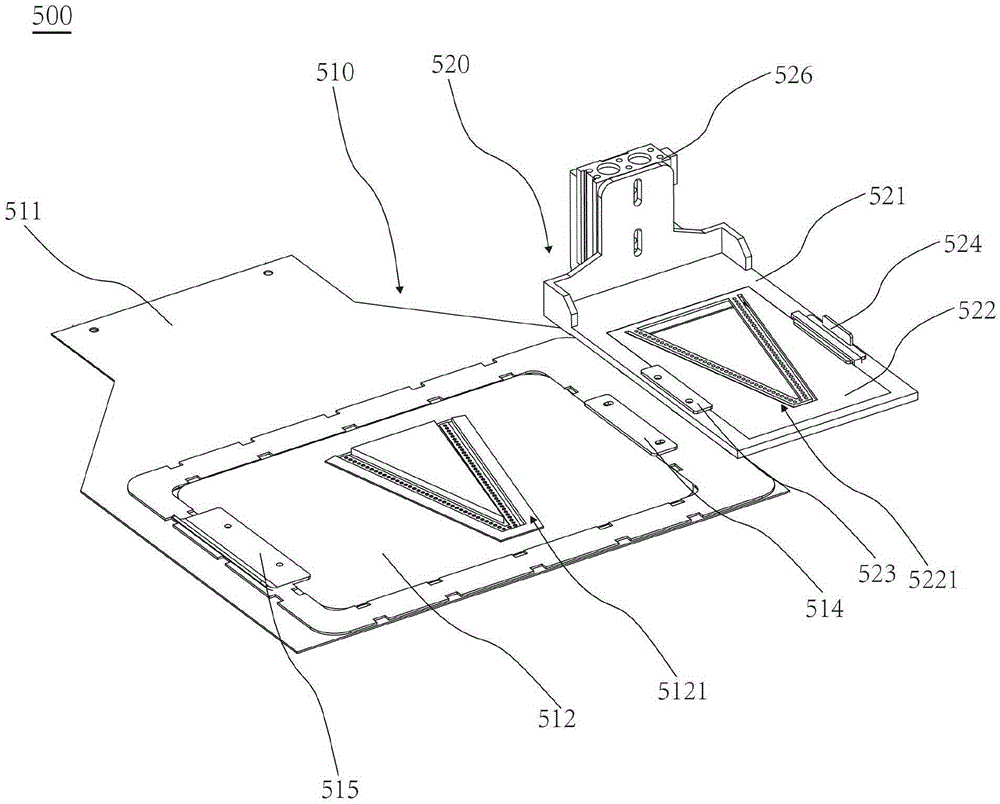

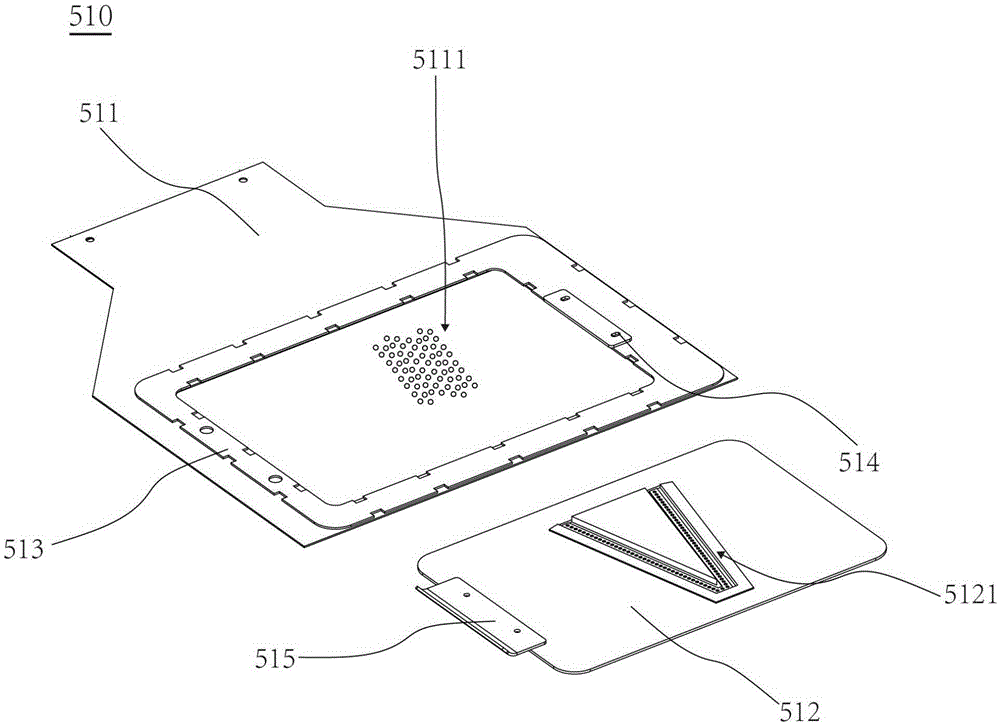

Automatic sewing object stitching system and method

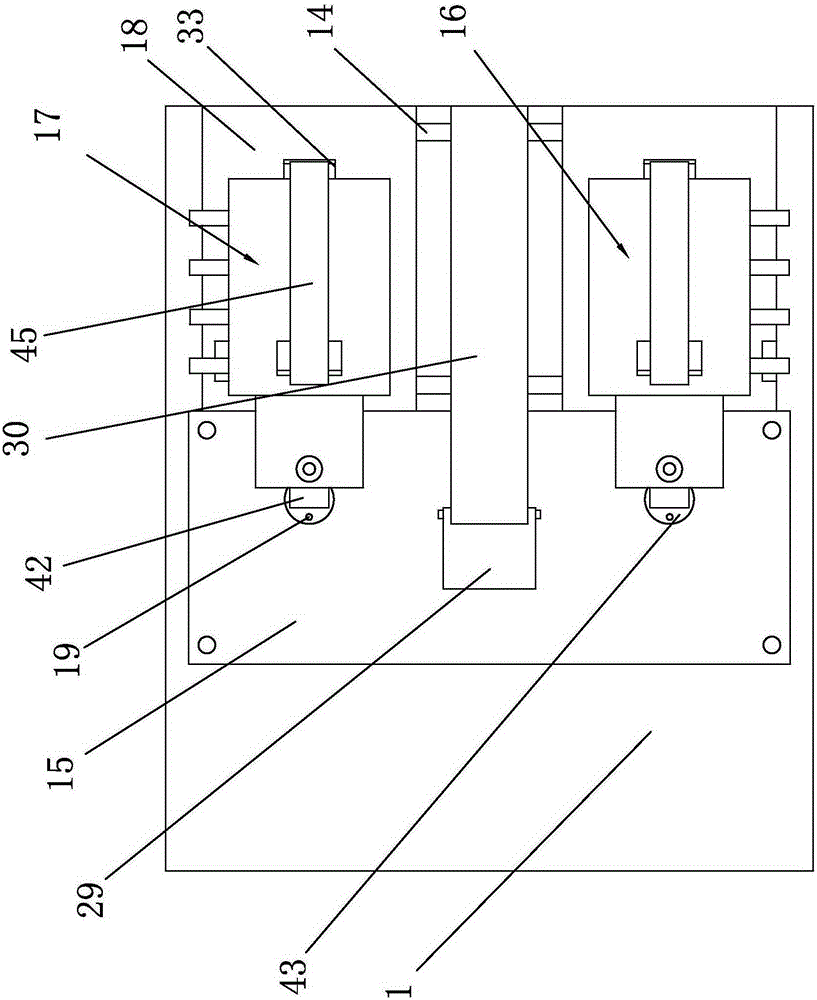

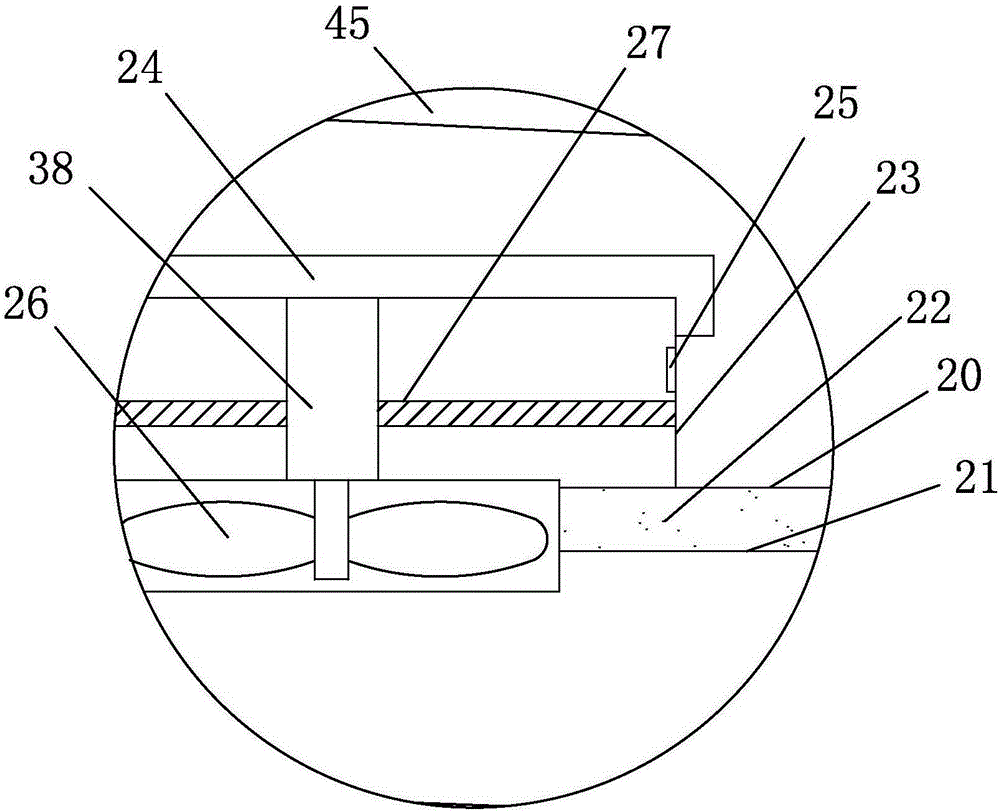

ActiveCN105256468ARealize layingAchieve overlappingWork-feeding meansPressersEngineeringMechanical engineering

The invention discloses an automatic sewing object stitching system and method. The automatic sewing object stitching system comprises a worktable, a material moving device, a material stacking device, an air draft device and a sewing device, wherein a plurality of suction holes are formed in the worktable; the material moving device is provided with a material moving board and a material moving board driving part used for driving the material moving board to move; the material stacking device comprises a first material stacking part and a second material stacking part; the first material stacking part is provided with a first core plate fixed on the material moving board; the first core plate is provided with a first sewing channel; the second material stacking part is provided with a material pressing part and a material stacking driving part arranged on the material moving board, connected to the material pressing part and used for driving the material pressing part to move so as to press sewing objects; the material pressing part is provided with a second sewing channel; the air draft device is communicated with the suction holes; the sewing device is used for sewing the sewing objects. The automatic sewing object stitching system saves time and is high in production efficiency.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

Sewing machine and spool pin stand therefor

A sewing machine includes a spool pin stand having spool pins to which thread spools are attachable and seats corresponding to the spool pins, respectively, thread passage defining members located on a thread passage, a sewing data storage unit storing sewing data including at least thread color information about colors of the needle threads, thread supply display units which are located on the spool pin stand so as to correspond to the spool pins respectively, the thread supply display units being configured to produce light which transmits through at least ones of the spool pins and the seats and displaying the thread colors in a color-variable manner, respectively, and a thread color information control unit controlling the thread supply display units based on the thread color information so that thread colors corresponding to the spool pins are displayed by the thread supply display units, respectively.

Owner:BROTHER KOGYO KK

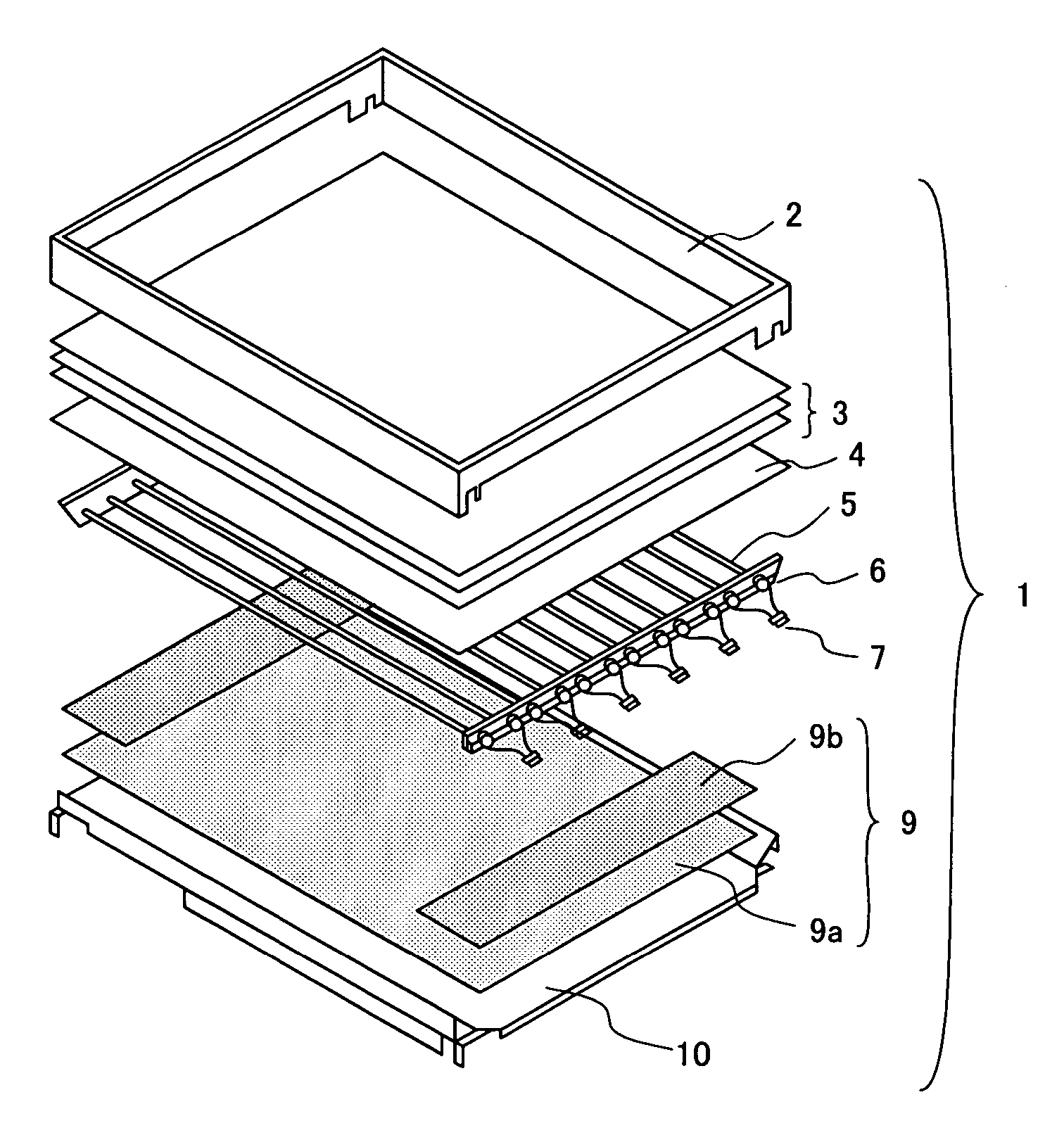

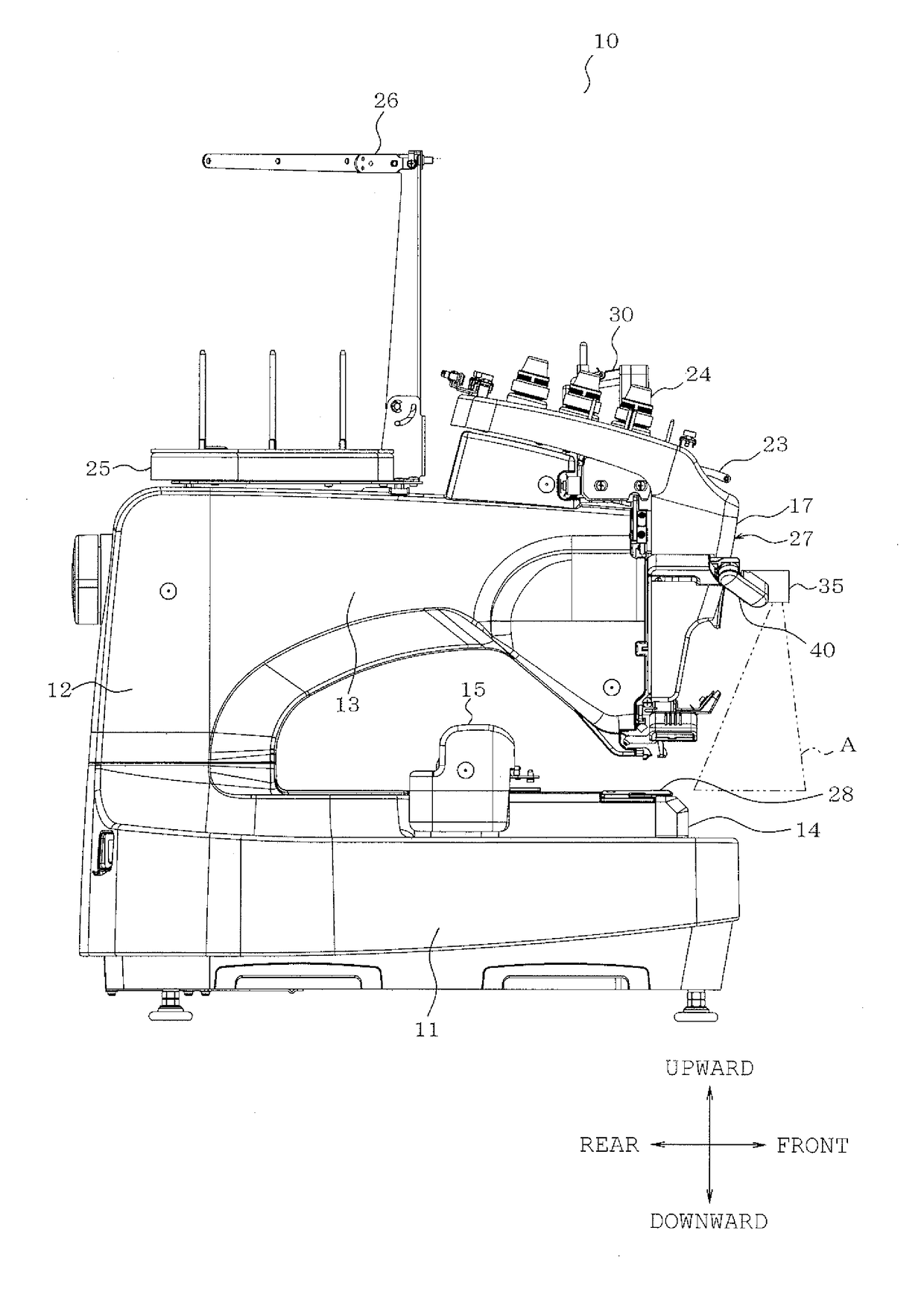

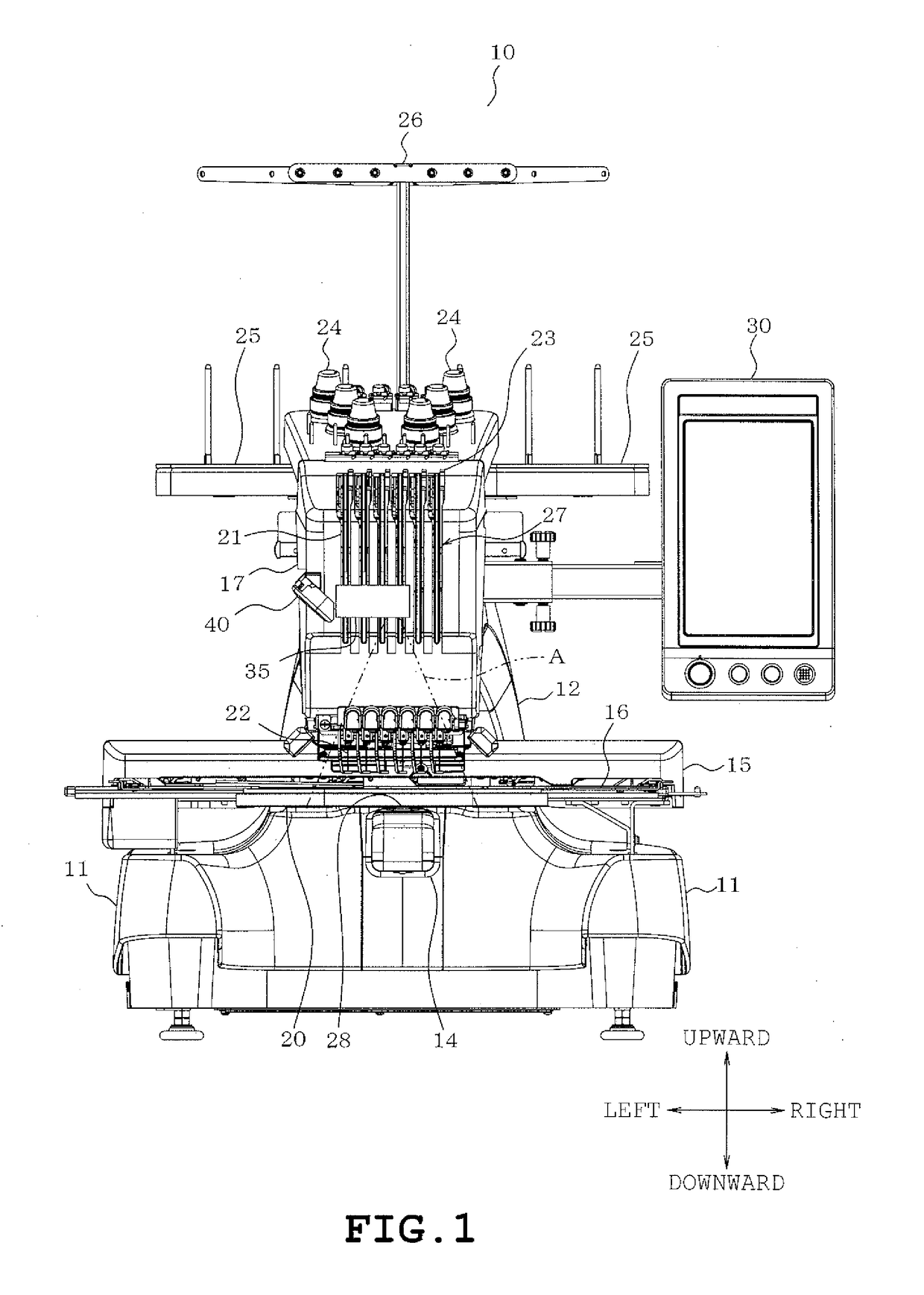

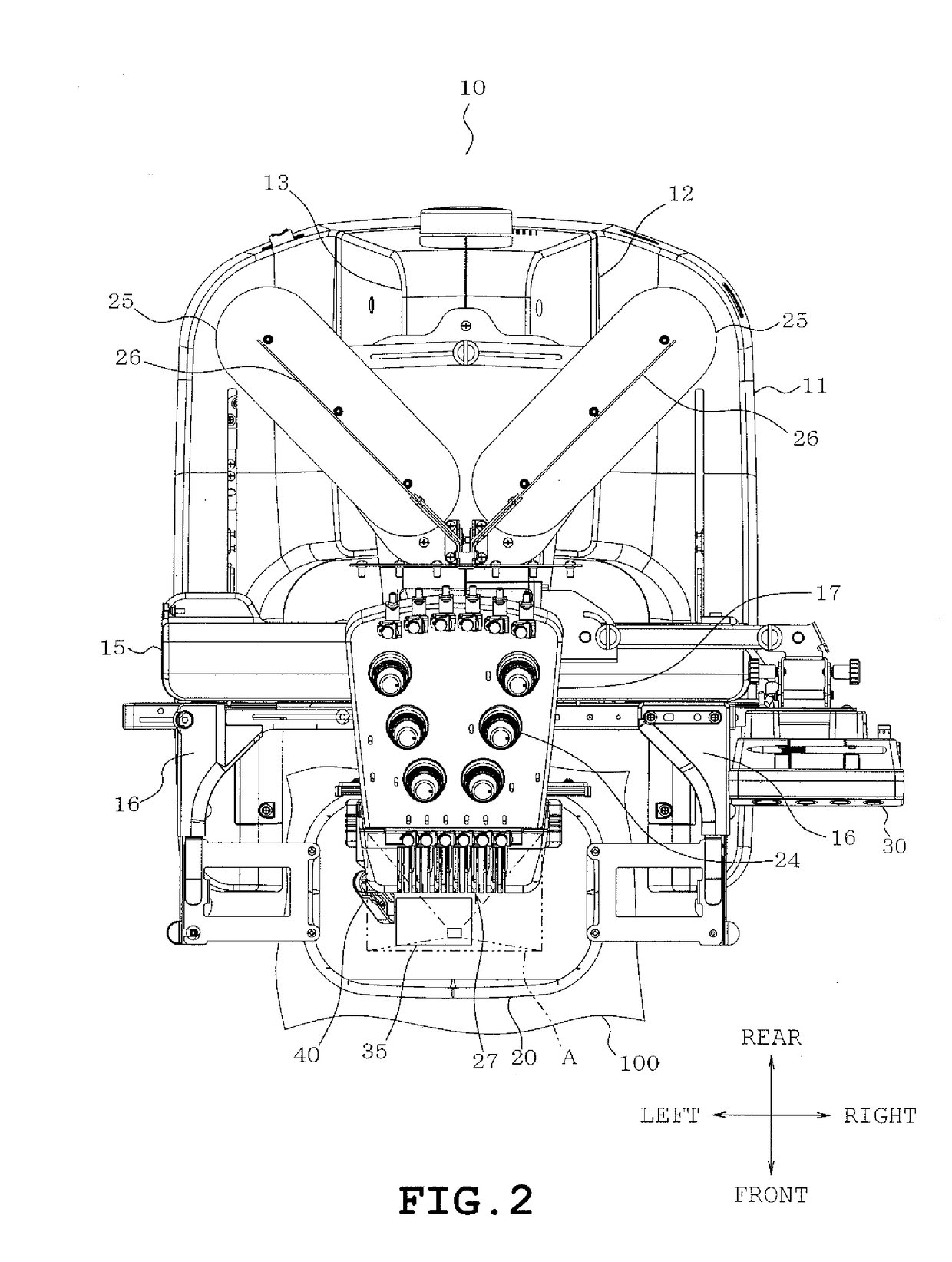

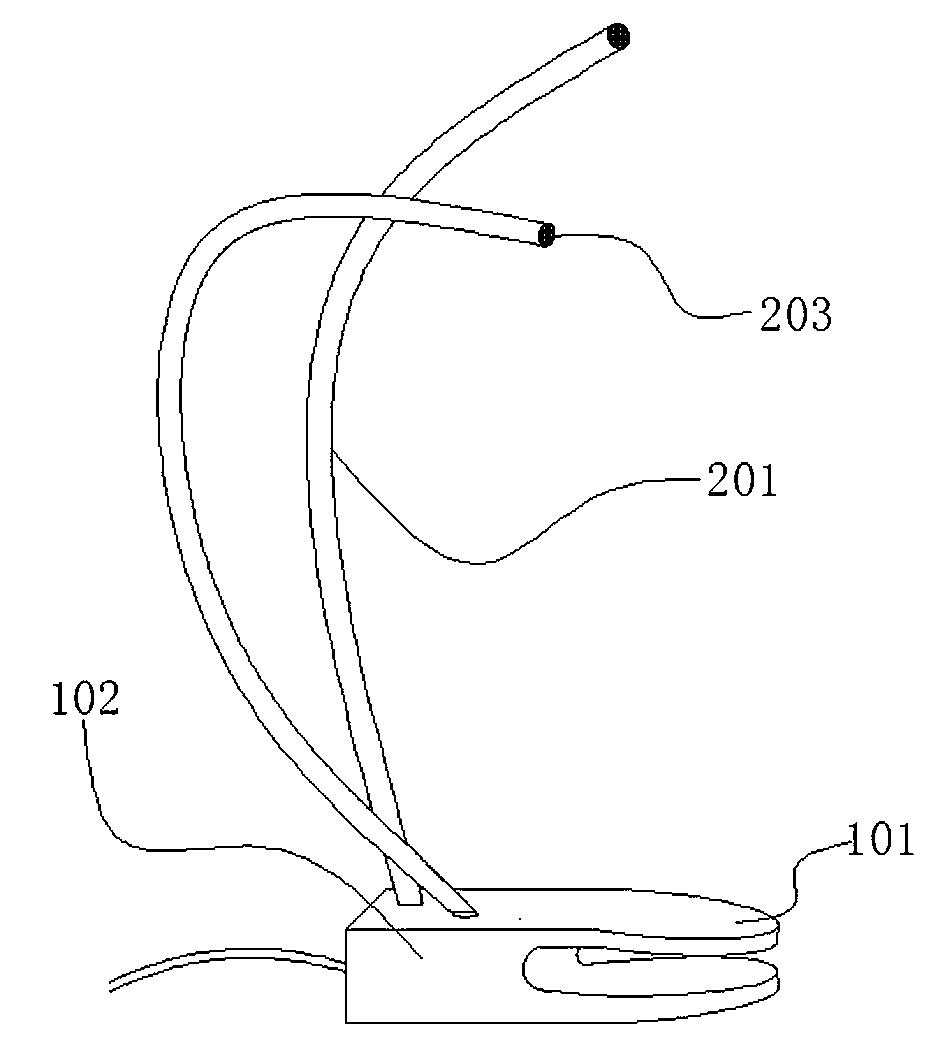

Multi-needle type embroidery sewing machine

InactiveUS20080223272A1Good adhesionGood effectWork-feeding meansLightening equipmentEngineeringLaser beams

The present invention provides a multi-needle type embroidery sewing machine which includes; a machine head having an arm unit, a needle bar support supported on the front face of the arm unit so as to be movable in a transverse direction, a plurality of needle bars supported by the needle bar support so as to be movable in a vertical direction, and needles individually attached to the needle bars, and is constituted such that the one needle bar is indexed to a sewing position by a movement of the needle bar support; and a laser marker for irradiating a needle drop point of the needle attached to the needle bar indexed to the sewing position, with a laser beam. The laser marker is attached to the arm unit so as to be arranged just behind of the needle bar indexed to the sewing position, and the angle of inclination of the laser beam with respect to the axis of the needle bar indexed to the sewing position is 5 degrees to 25 degrees.

Owner:BARUDAN KK

Sewing machine frame with real-time monitoring function used for necktie sewing

InactiveCN107574592AReduce labor intensityImprove work efficiencySewing-machine control devicesLightening equipmentDrive wheelEngineering

The invention discloses a sewing machine frame with a real-time monitoring function used for necktie sewing. The sewing machine frame comprises a seat body, a connecting rod, a transverse beam and a display screen. A support rack is arranged besides the seat body. The connecting rod is installed besides the support rack. A bearing seat is arranged besides the connecting rod. A main shaft is installed besides the bearing seat. A shaft sleeve is disposed besides the main shaft. A driving wheel is located besides the shaft sleeve. A driving rod is arranged besides the driving wheel. The transverse rod is installed besides the driving rod. The display screen is located besides the transverse beam. An adjustable rod is installed below the display screen. A probe is installed besides the adjustable rod. An LED lamp is arranged besides the probe. A support rod is disposed besides the LED lamp. A pedal is installed besides the support rod. The sewing machine frame with the real-time monitoringfunction used for necktie sewing has the following beneficial effects: the overall sewing process is displayed through the display screen; labor intensity of operation workers is reduced; and workingefficiency is improved.

Owner:SHENGZHOU BINGE CLOTHING CO LTD

Multi-needle sewing machine

Owner:BROTHER KOGYO KK

Sewing machine provided with light-emitting diode (LED) illuminating lamp

InactiveCN102936805AStrong bending resistanceImprove fatigue resistanceLightening equipmentLight pipeEngineering

The invention discloses a sewing machine provided with a light-emitting diode (LED) illuminating lamp. The sewing machine provided with the LED illuminating lamp is characterized in that the LED illuminating lamp is provided with a lamp holder placed or clamped on a working table of the sewing machine, the lamp holder is provided with more than two LED lamp tubes, LED lamp bulbs are arranged at the tops of the LED lamp tubes, tube bodies of the lamp tubes are goose necks, and a storage battery or a power line connected with a power supply is arranged in the lamp holder. A user can bend the lamp tubes at any angles according to the demands and enable light to be irradiated onto corners on the sewing machine. Compared with common fixed illuminating lamps, the LED illuminating lamp is flexible in use, avoids illuminating dead angles and improves the work efficiency.

Owner:WUJIANG RUNLEI TEXTILE

Multifunctional sewing machine overlapping fixture

InactiveCN105002667AEasy to fixReasonable structural designWork-feeding meansLightening equipmentEngineeringWorkbench

The invention discloses a multifunctional sewing machine overlapping fixture, comprising a base board. The base board is fixedly provided with an overlapping board. The overlapping board is provided with an overlapping channel. The lower end of the base board is detachably provided with a sewing machine fixing device. The sewing machine fixing device comprises an upper fixing board and a lower fixing board. The upper fixing board and the lower fixing board are arranged in parallel. The distance between the lower end face of the upper fixing board and the upper end face of the lower fixing board is 6 cm. The right end faces of the upper fixing board and the lower fixing board are fixedly provided with a connecting board. A workbench slot whose opening is toward the left is formed among the upper fixing board, the connecting board, and the lower fixing board. The upper end face of the upper fixing board is provided with a plurality of overlapping fixture fixing screw holes. The right end of the lower end face of the upper fixing board is welded with a positioning spring. The lower fixing board is at least provided with two locking screw holes. Each locking screw hole is provided with a locking device. The above technical scheme is reasonable in structural design, simple in structure, easy in installation, reliable in fixation, and convenient in use.

Owner:黄春根

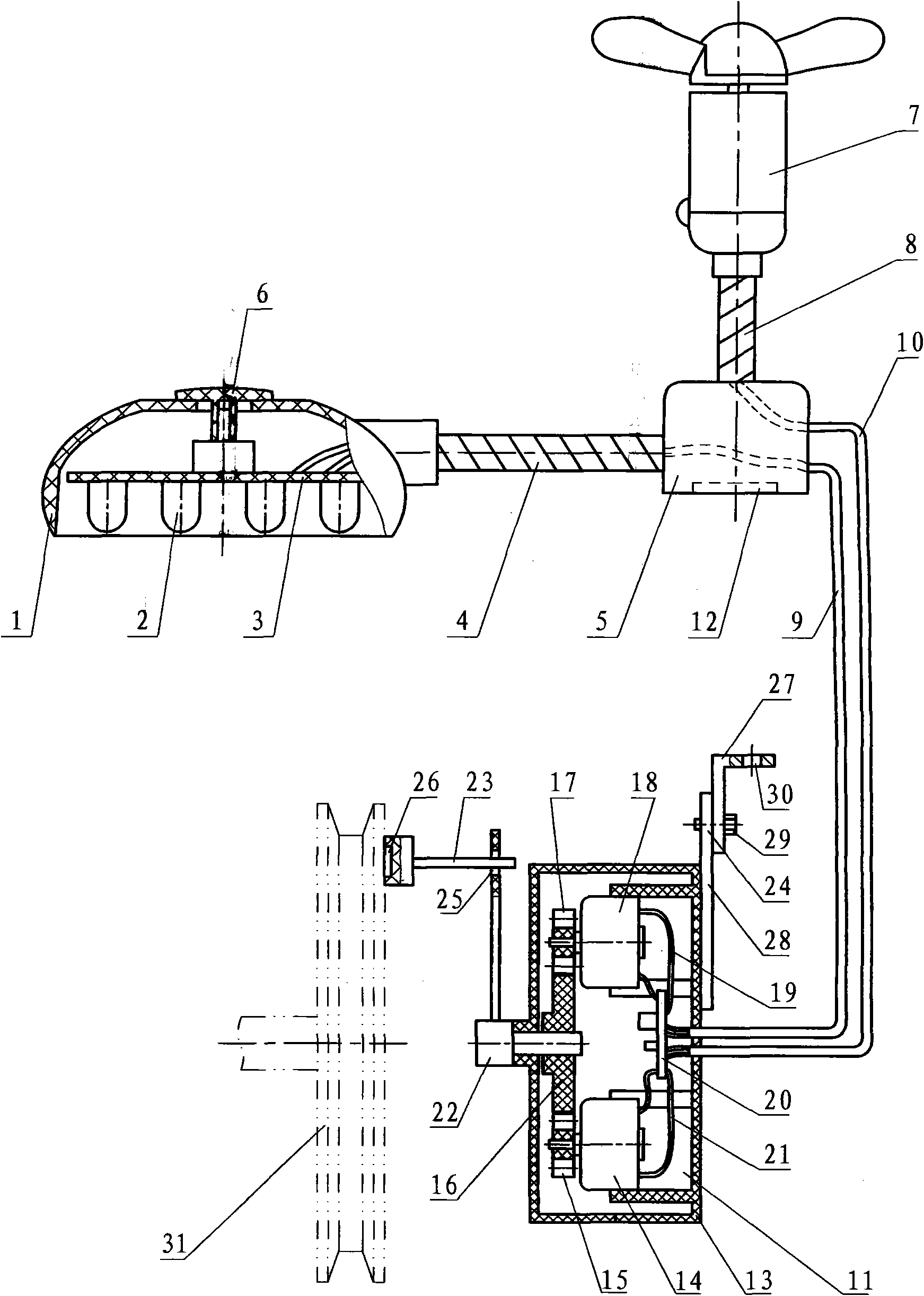

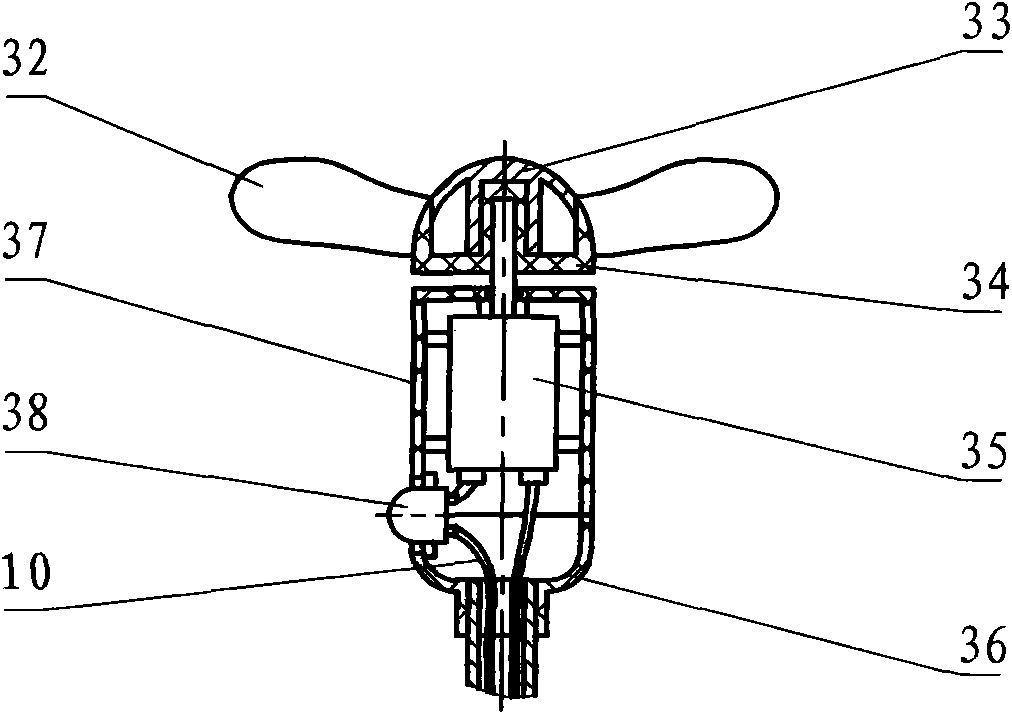

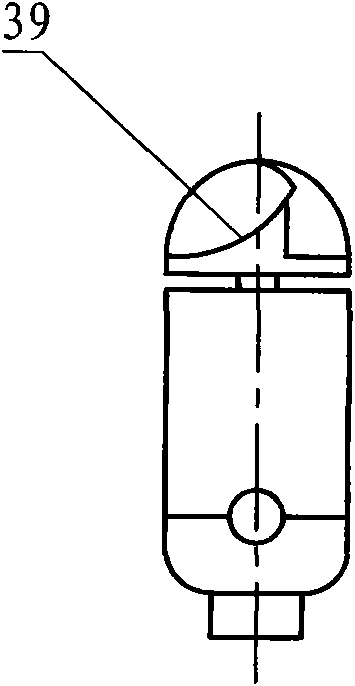

Fan lamp of self-generating sewing machine

InactiveCN101576225ASafe to useLess prone to failureLighting applicationsLighting support devicesWorking environmentMicro motor

A fan lamp of self-generating sewing machine comprises a lamp shell 1, a light-emitting diode group 2, a circuit board 3, a metal hose 4, a lamp pedestal 5, a fan 7, a metal hose 8, an electric wire 9 and an electric wire 10, wherein the circuit board 3 is arranged in the lamp shell 1, the light-emitting diode group 2 is arranged on the circuit board 3, a sliding switch 6 is arranged on the circuit board 3, the bottom of the lamp pedestal 5 is provided with a magnet 12, the metal hose 4 and the metal hose 8 are arranged on the lamp pedestal 5, one end of the electric wire 9 is connected with the light-emitting diode group 2, one end of the electric wire 10 is connected with a micro motor 35 in the fan 7; and the fan lamp is characterized in that the other end of the electric wire 9 and the electric wire 10 is provided with a generating device 11. The invention has the advantages of small volume, easy installation and good safety, achieves illuminating effect without affecting an operator to sew, and improves working efficiency; meanwhile the invention can radiate and lower temperature for the operator and improve workshop working environment.

Owner:叶信平

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com