Patents

Literature

82results about How to "Realize laying" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

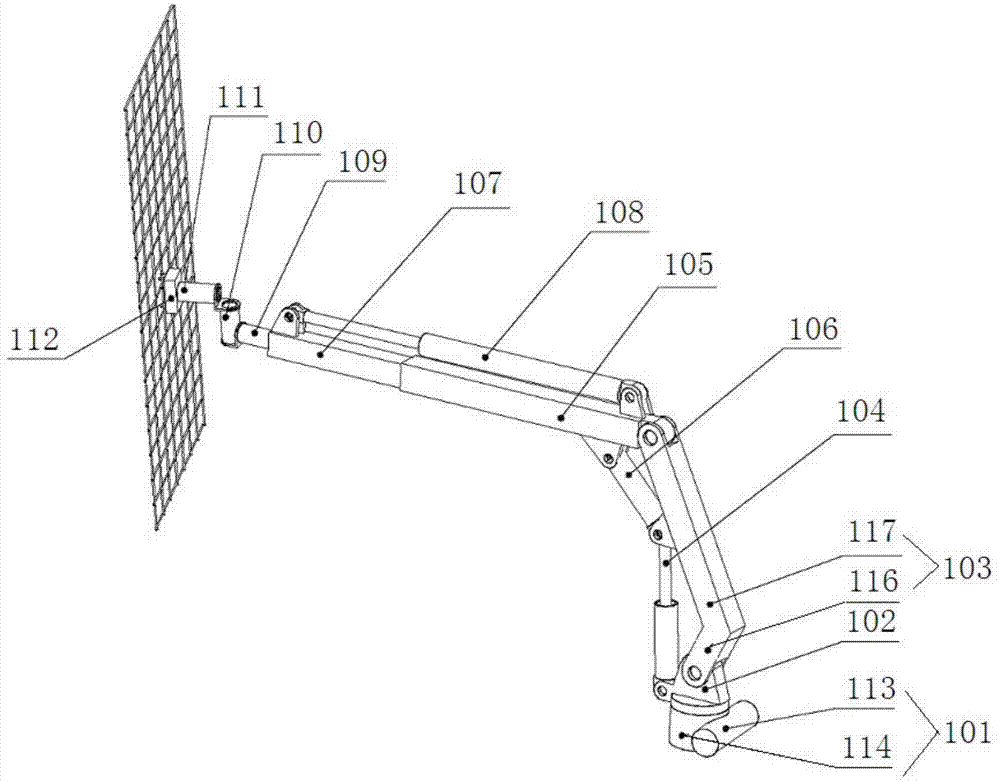

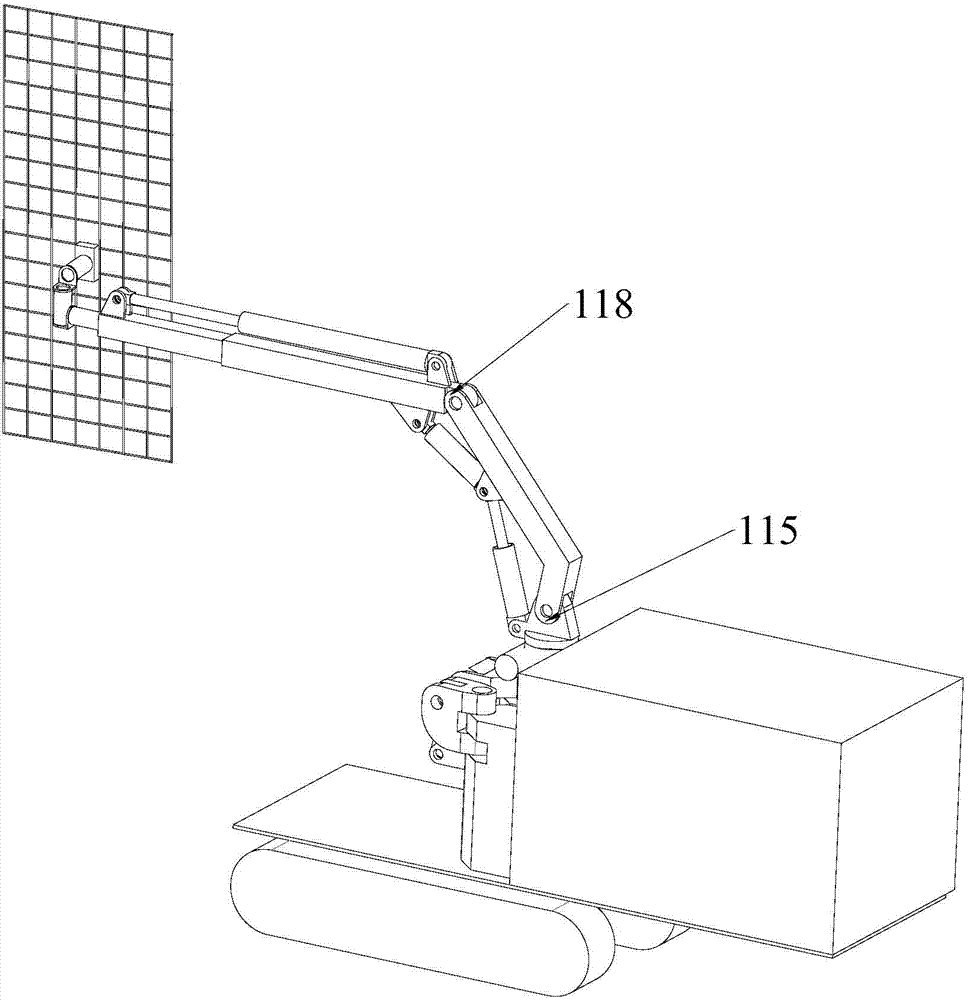

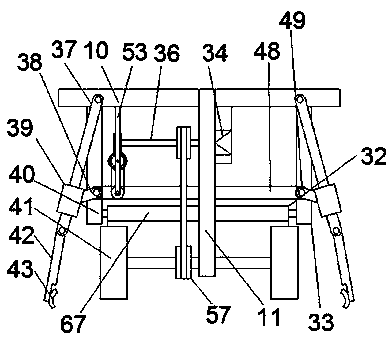

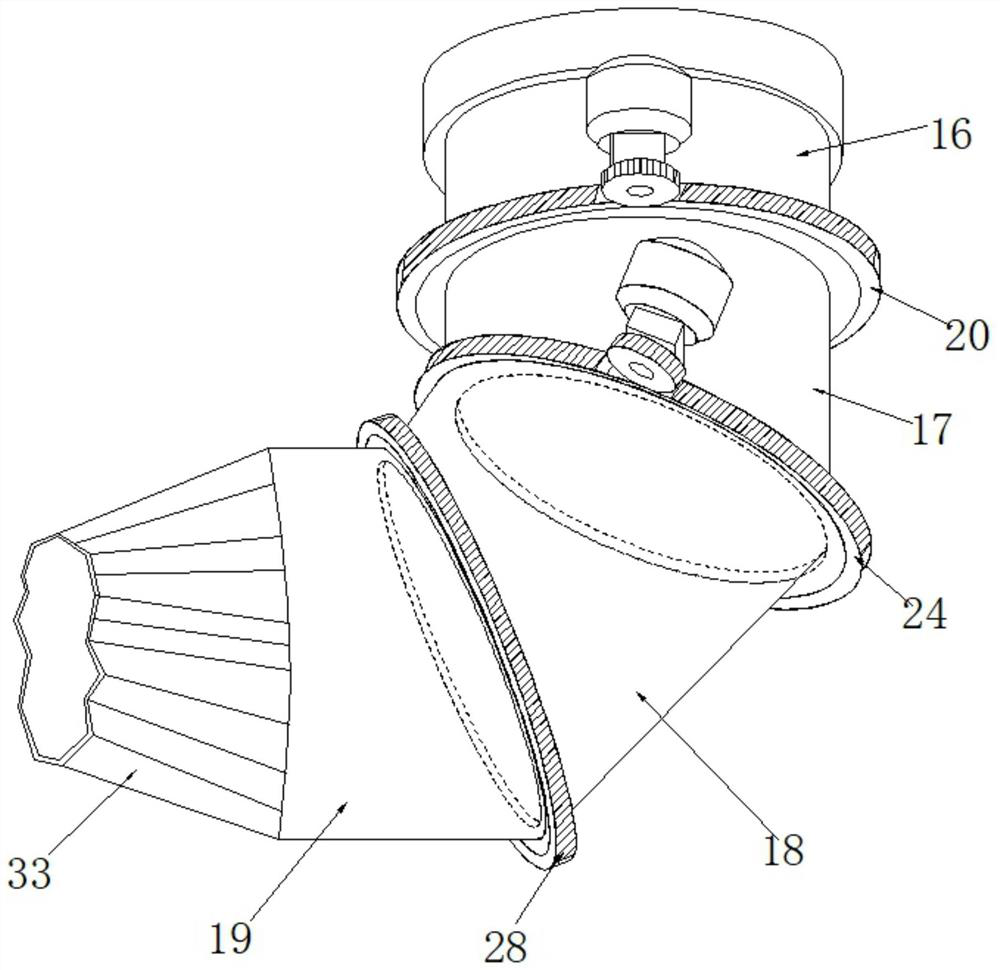

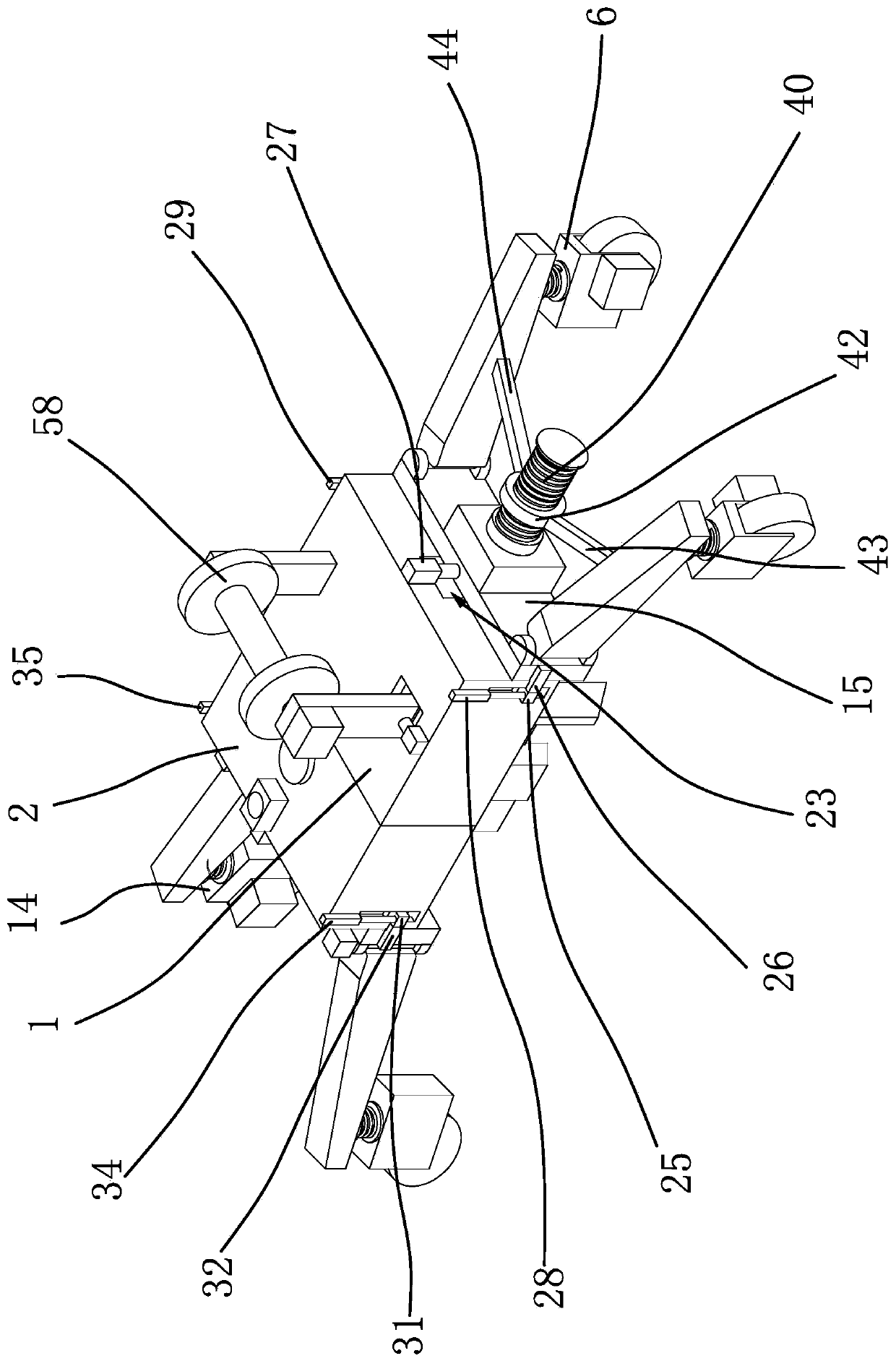

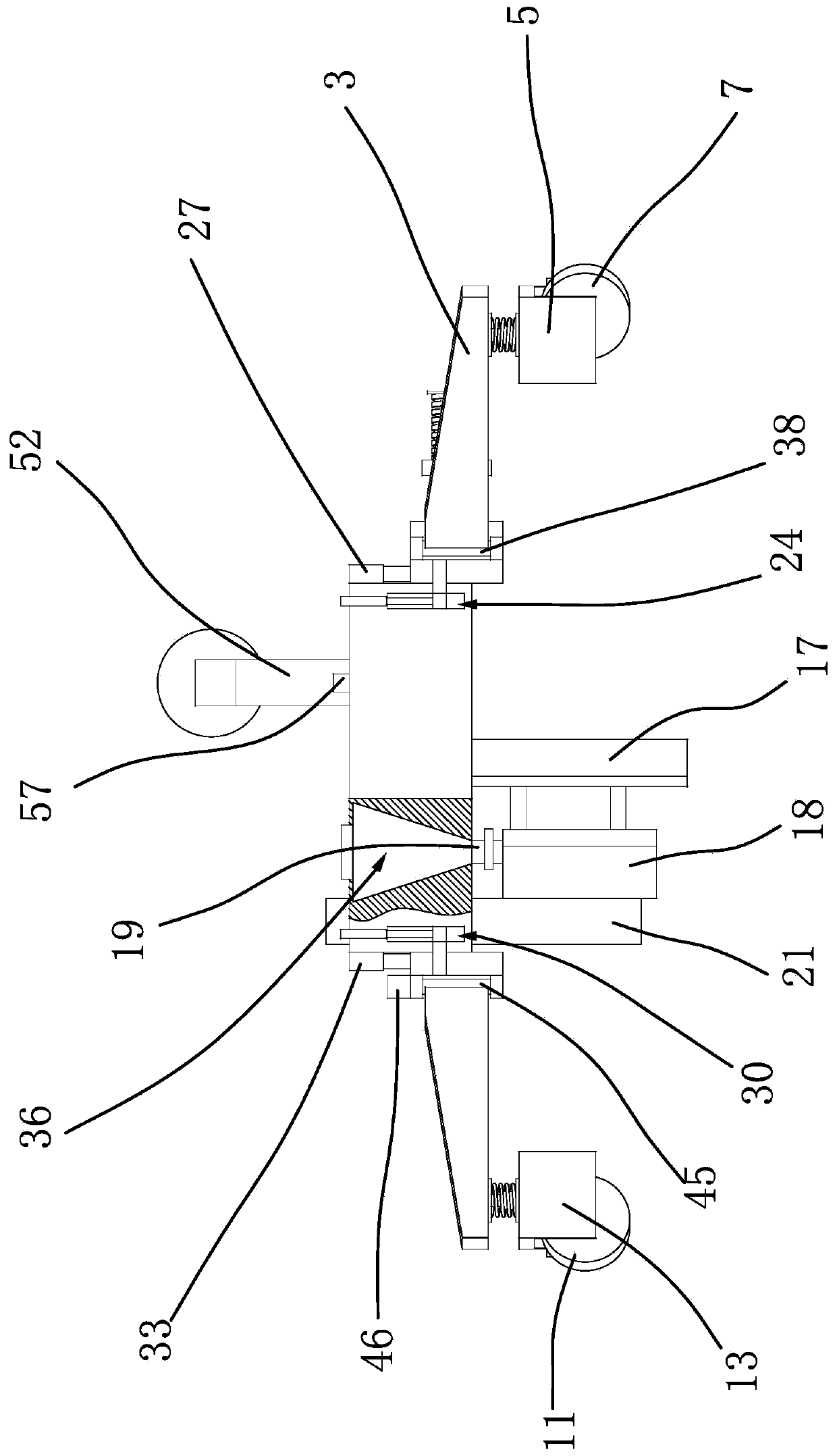

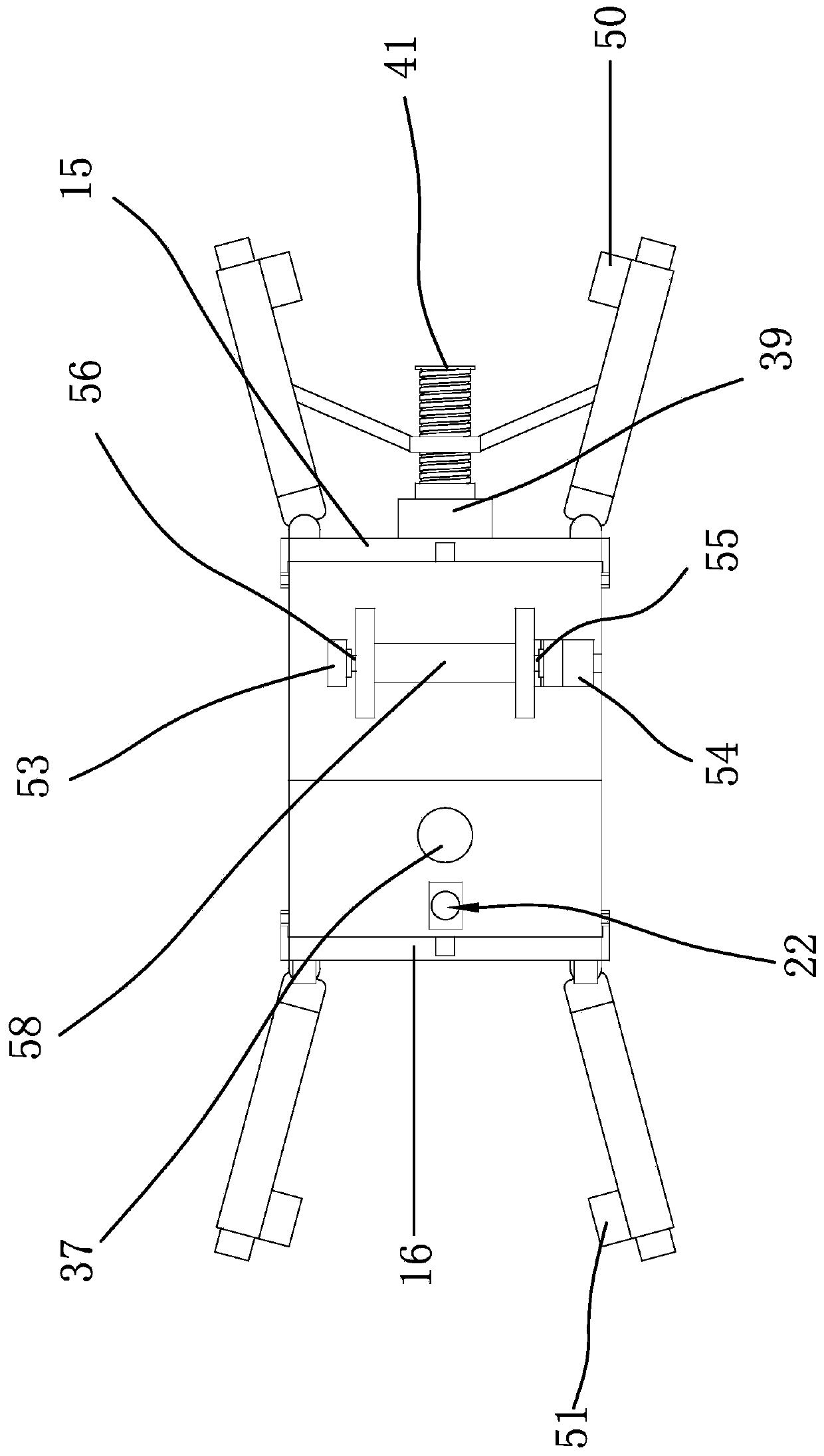

Automatic net paving device of anchor rod drill carriage for coal mine

InactiveCN104847386AAchieve left and right translationRealize up and down translationDerricks/mastsDrilling machines and methodsRotational degrees of freedomRock bolt

The invention discloses an automatic net paving device of an anchor rod drill carriage for a coal mine. The device comprises a rotating base, a lug base, a first arm, a first oil cylinder, a second arm, a second oil cylinder, a third arm, a third oil cylinder, a first spiral swing cylinder, a second spiral swing cylinder, a third spiral swing cylinder and a magnetic manipulator. The automatic net paving device of the anchor rod drill carriage for the coal mine realizes horizontal translation of the magnetic manipulator through the rotation of a worm wheel of the rotating base, realizes vertical translation of the magnetic manipulator through the telescopic motions of the first oil cylinder and the second oil cylinder, realizes front-back translation of the magnetic manipulator through the telescopic motion of the third oil cylinder, and realizes three degrees of rotating freedom of the magnetic manipulator through the rotation of the three spiral swing cylinders; and the magnetic manipulator realizes the grabbing and the pavement of reinforcement meshes, so that the automatic net paving device of the anchor rod drill carriage for the coal mine can realize automatic pavement of the reinforcement meshes so as to improve the paving efficiency of the reinforcement meshes.

Owner:王发秀

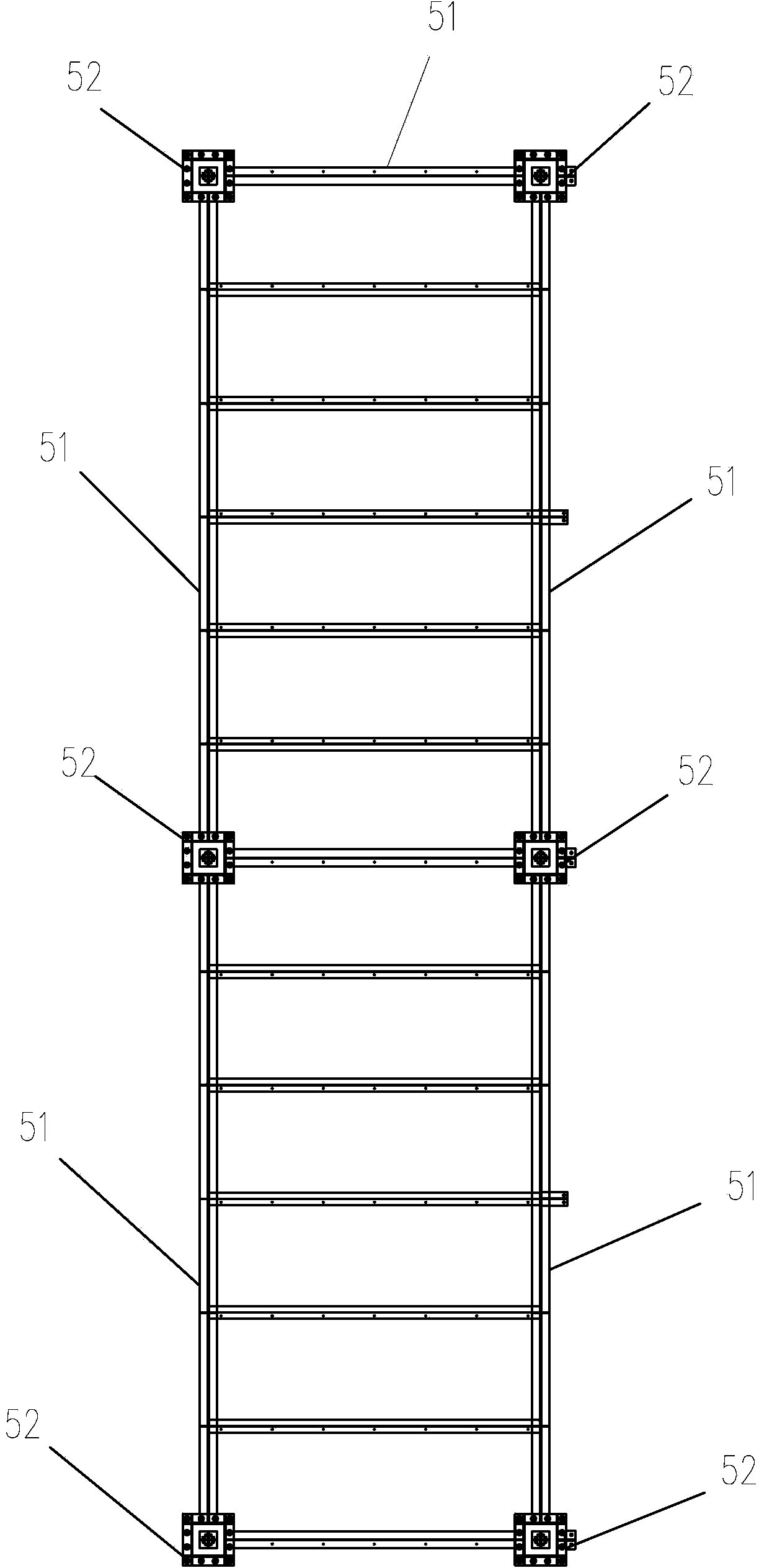

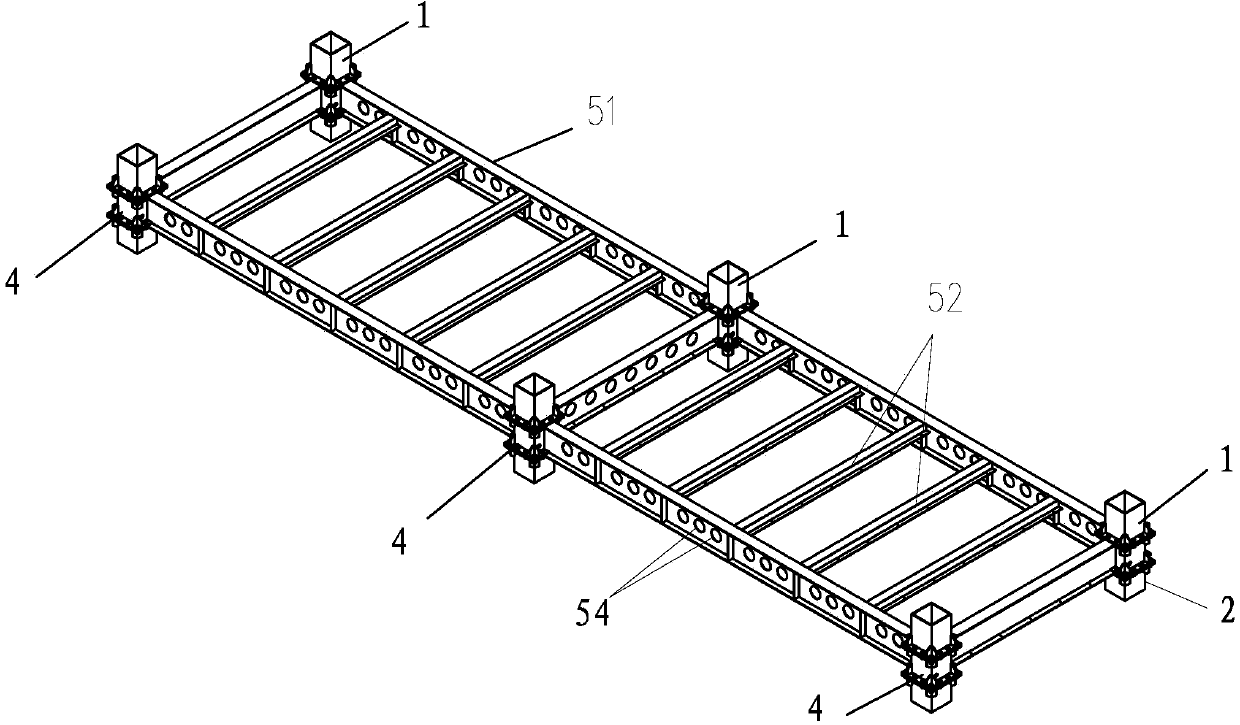

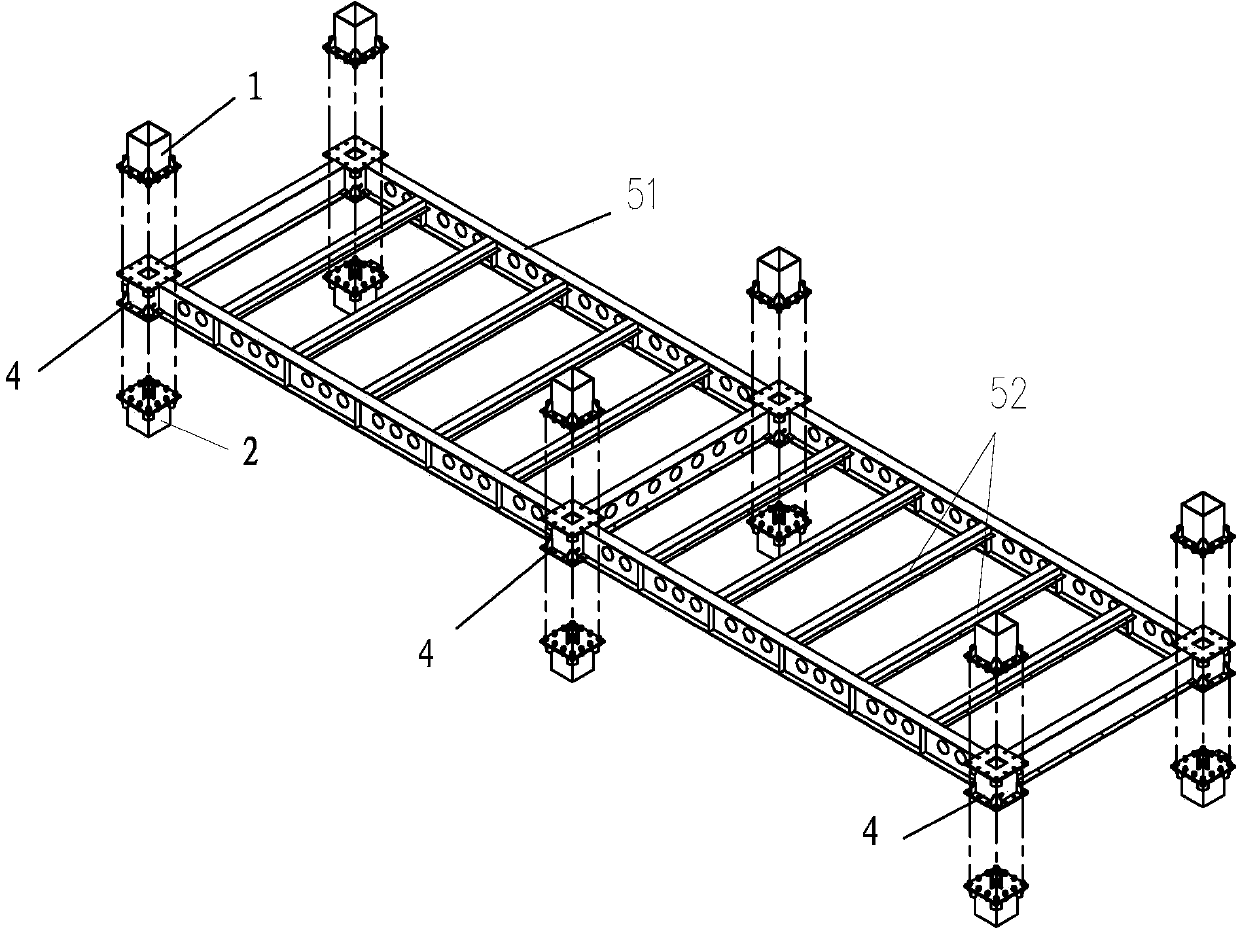

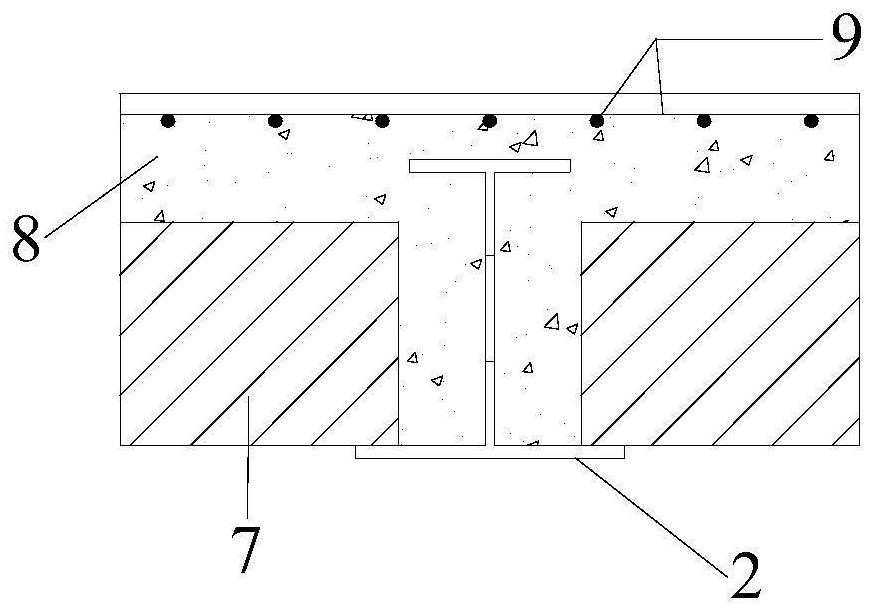

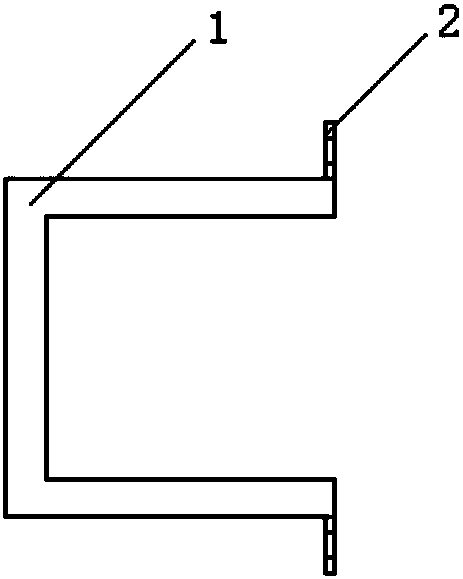

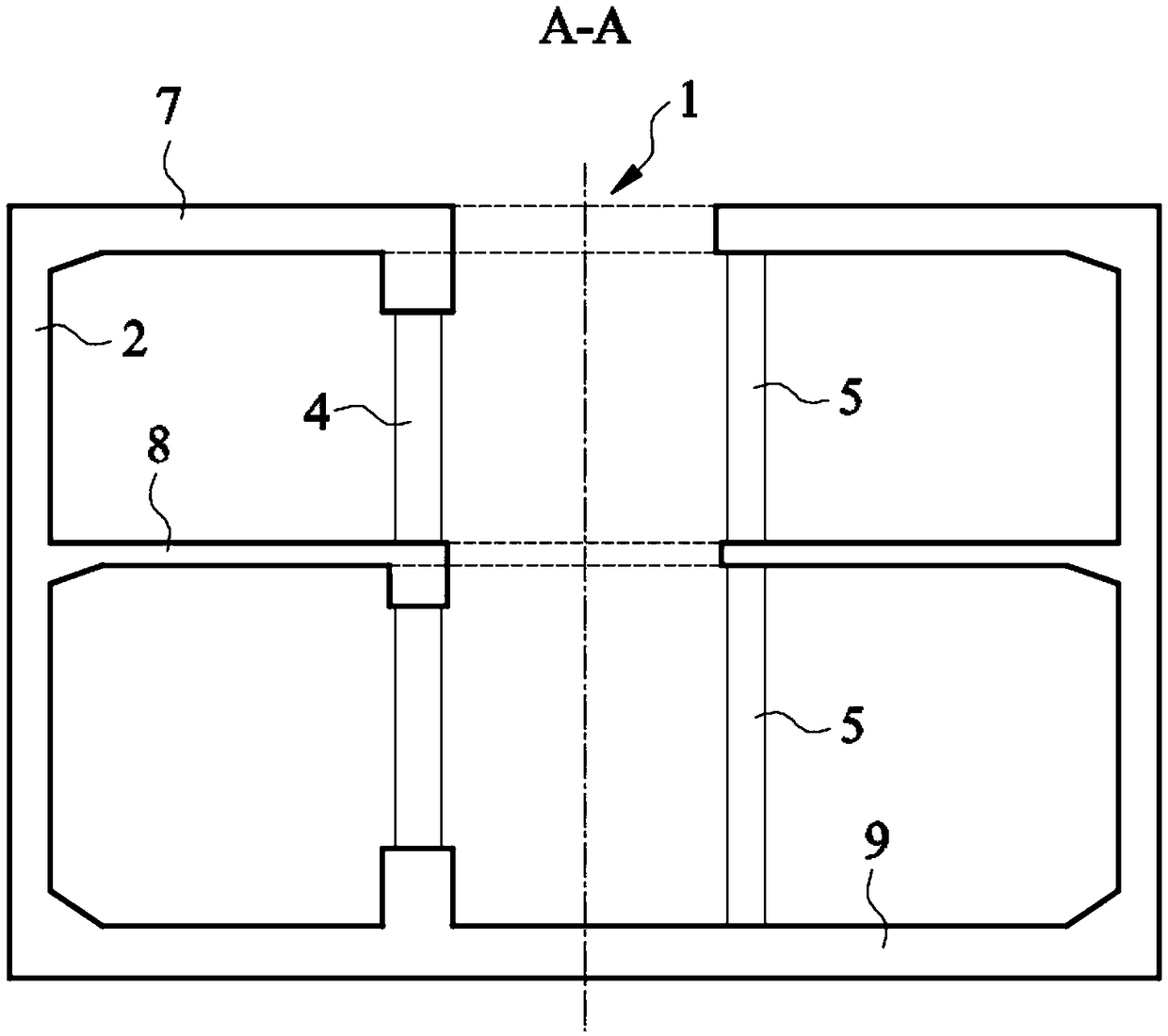

Floor structural modules and assembling method thereof

ActiveCN103993659ARealize industrial productionImprove on-site construction efficiencyBuilding constructionsStructural unitBuilding construction

The invention mainly discloses an assembling method of floor structural modules. Each floor structural module comprises a plurality of main beams, secondary beams and a plurality of box-type components, the main beams are connected to form an outer frame with the box-type components as unit connecting points, and the secondary beams are arranged in the outer frame defined by the main beams. The assembling method includes the steps that first, the structural modules are prefabricated in a factory; second, the finished structural modules are carried to a construction site, and the structural modules and on-site square columns are fast assembled and connected. According to the method, structural units for the floor modules are formed in the factory, welding is reduced, the quality of machining in the factory is improved, and the industrial degree of steel components is improved.

Owner:ZHEJIANG GREEN BUILDING INTEGRATION TECH CO LTD

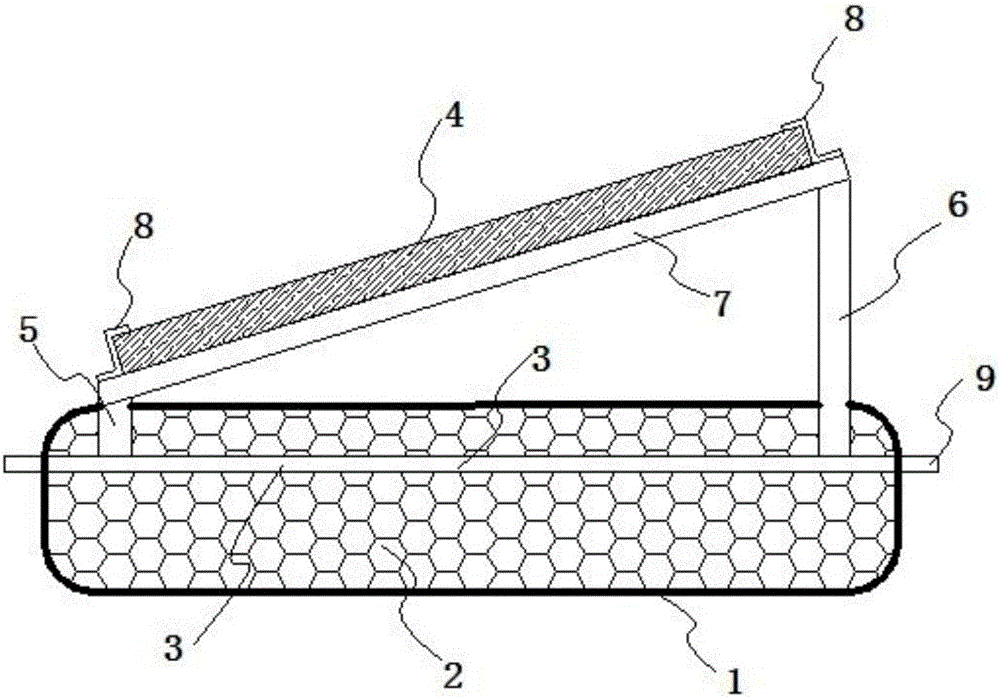

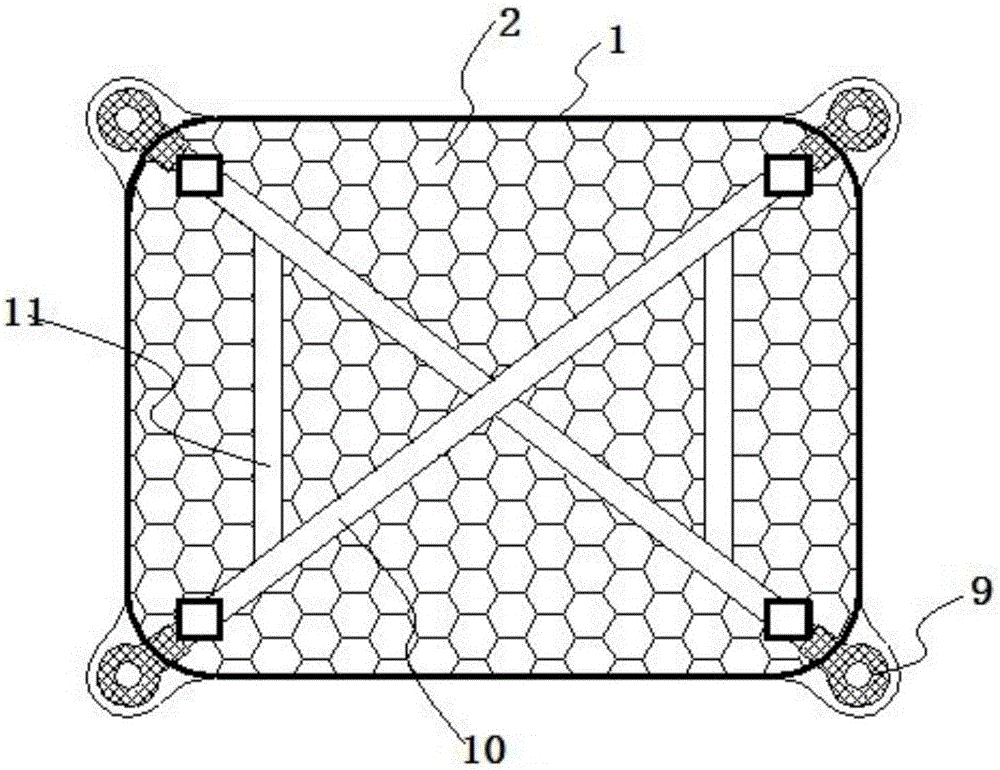

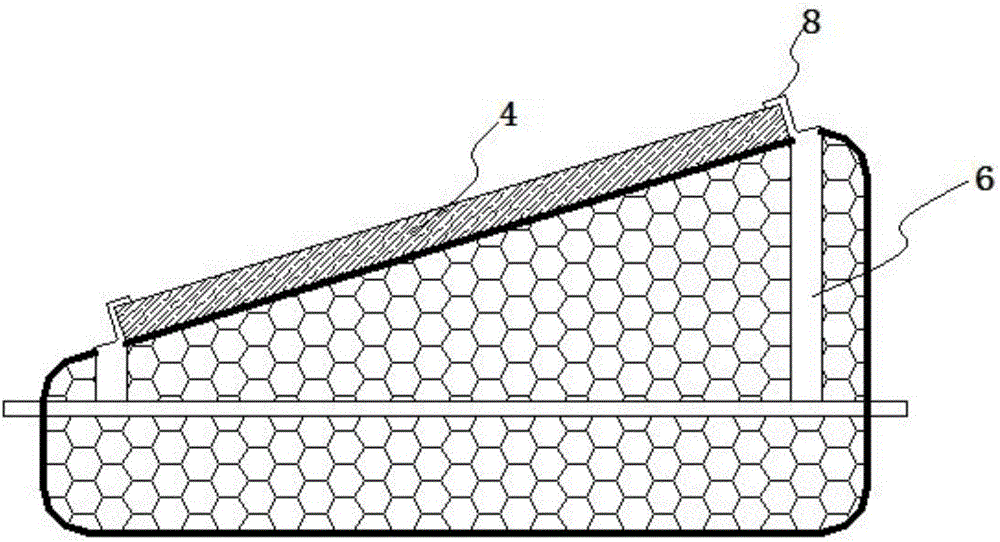

Integral photovoltaic panel water surface floating table and floating table array

InactiveCN105932936ARealize layingSimple structurePhotovoltaic supportsWaterborne vesselsStructural engineeringPaddy field

The invention discloses a photovoltaic panel water surface floating table and a floating table array. The floating table comprises foam, a lining plate, a bracket and a photovoltaic panel, wherein the lining plate is arranged in the foam; the bracket passes through the foam, and is fixed to the lining plate; and four corners of the foam are provided with connection joints which are fixedly connected with the lining plate. The photovoltaic panel water surface floating table has a simple structure. A foam float bowl is combined with a lining framework, so that the cost is reduced greatly on the premise of ensuring certain mechanical strength. Moreover, construction and installation become convenient, and solar assembly pavement in water areas such as paddy fields, and surfaces of rivers and lakes is realized.

Owner:YANGZHOU XILAI SOLAR ENERGY TECH

Energy-saving environment-friendly building bricklaying device

ActiveCN110374343AMake sure the tiles are neatPrevent cement leakage from polluting the environmentBuilding material handlingHydraulic pressureBrick

The invention discloses an energy-saving environment-friendly building bricklaying device. The device comprises a bearing base, a lifting disc combination, a positioning plate combination and a control box. The bearing base is composed of a bottom plate, a bearing oil cylinder, a hydraulic pup and a hydraulic oil tank. The bearing oil cylinder is mounted on the side wall of the top of the bottom plate through a bolt, and guide cylinders are welded to the positions, on the two sides of the bearing oil cylinder, of the top side wall of the bottom plate. Outer bricks can be manually and evenly placed on a supporting pressing plate in a brick arranging combination, a bricklaying oil cylinder pushing stroke pushes the bricks to a limiting plate on the positioning plate combination in order, animpact sleeve on the vibration position is manually held and exerts force to the left side, the supporting pressing plate rotates clockwises, the bricks slide to the pre-laid cement in order, a bricklaying oil cylinder is adjusted, one side of the supporting pressing plate falls on the bricks, the impact sleeve is manually held, and carries out circular impact on a T column, a connecting frame drives the supporting pressing plate to frequently impact the bricks, the bricks are flat, and in-batch bricklaying operated by a single person can be achieved.

Owner:中乐建业集团有限公司

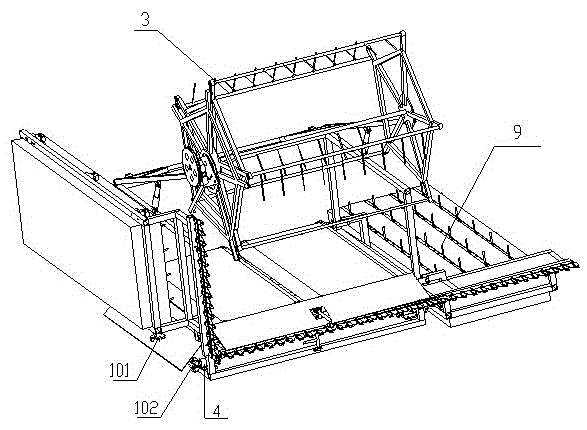

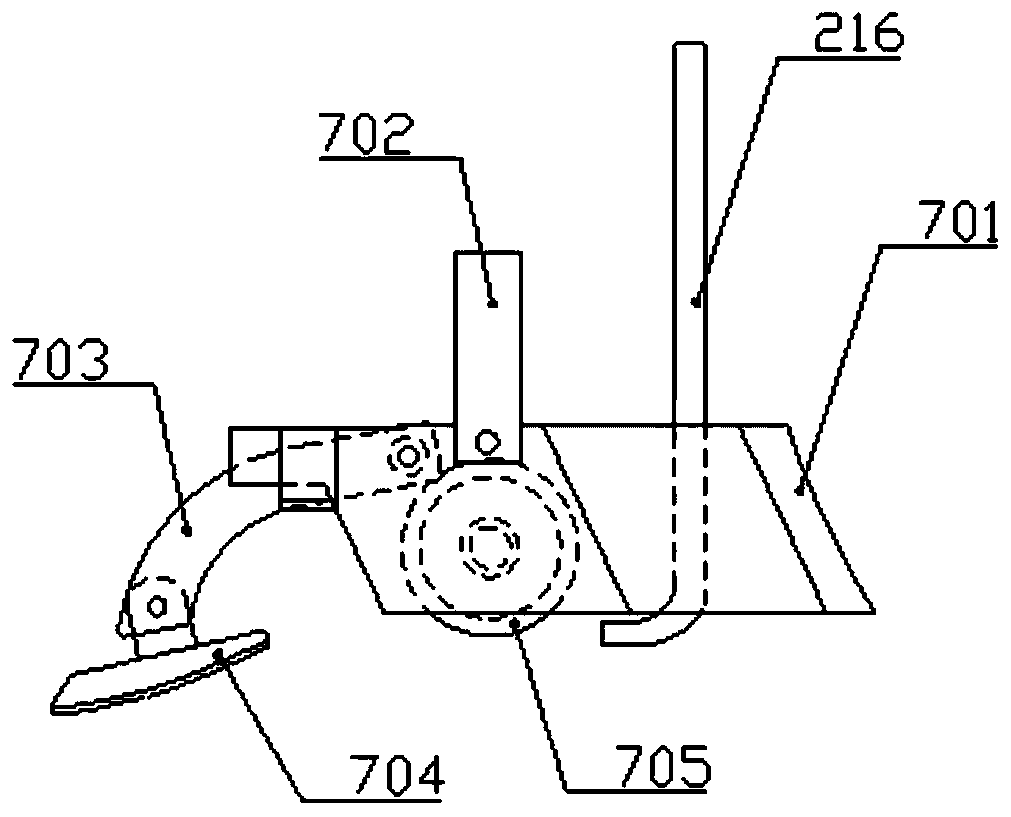

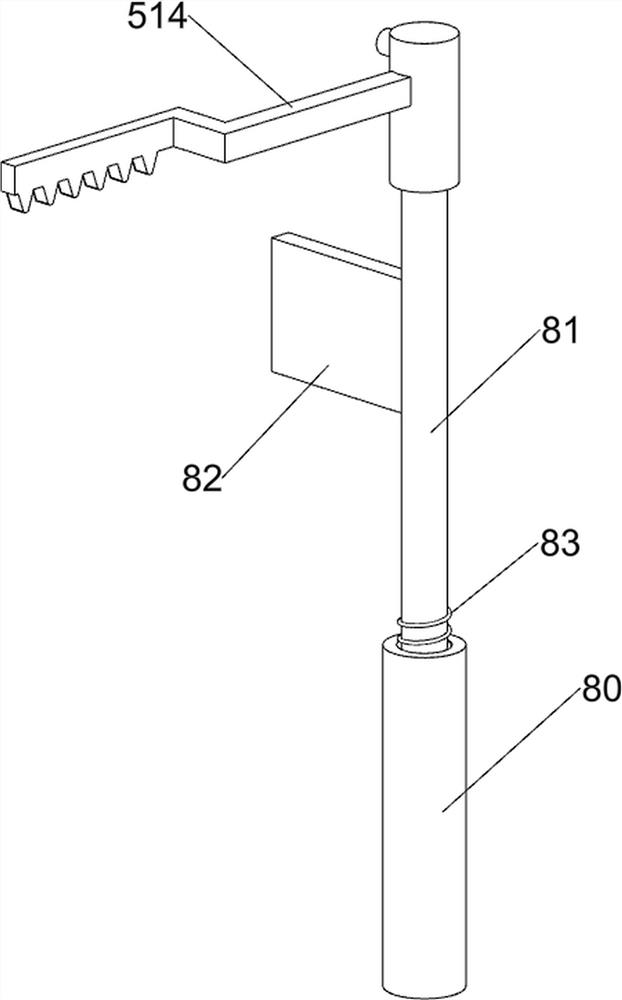

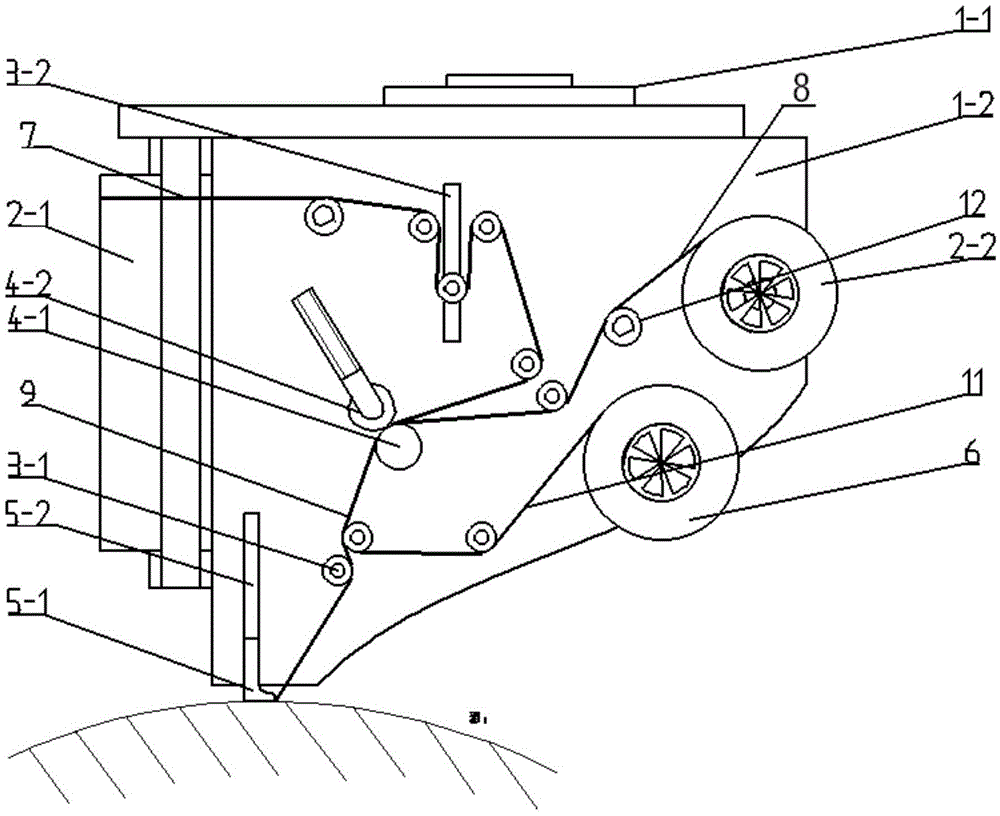

Oilseed rape two-side and rear laying cutter-rower

The invention discloses an oilseed rape two-side and rear laying cutter-rower which comprises a main cutting table. A hanging device capable of being connected to a walking chassis in a hung mode is arranged on the rear side of the main cutting table. A reel capable of ascending and descending is arranged on the top of the main cutting table. A main cutter is arranged in the front of the bottom. A transverse conveying device is arranged behind the bottom. The left side and the right side are each hinged to an auxiliary cutting table through a cylindrical hinge. Each auxiliary cutting table is provided with a longitudinal transmission sprocket conveying device. The reel, the main cutter, the transverse cutting device and the longitudinal transmission sprocket conveying devices are connected to a power transmission system in power connection with the walking chassis. According to the oilseed rape two-side and rear laying cutter-rower, the hanging device and the walking chassis can be rapidly connected in the hung mode, and the transverse and longitudinal combined conveying way is adopted, so that a space is reserved for turning of the cutter-rower in the field, no material laying space needs to be independently reserved for a first-compartment cutting-rowing operation, the problems that the way needs to be cleared in advance and blockage and accumulation are likely to be caused in the oilseed rape cutting-rowing process are solved, and the cutter-rower has the advantages of being small in vibration, small in energy consumption, high in efficiency and the like.

Owner:HUNAN AGRICULTURAL UNIV

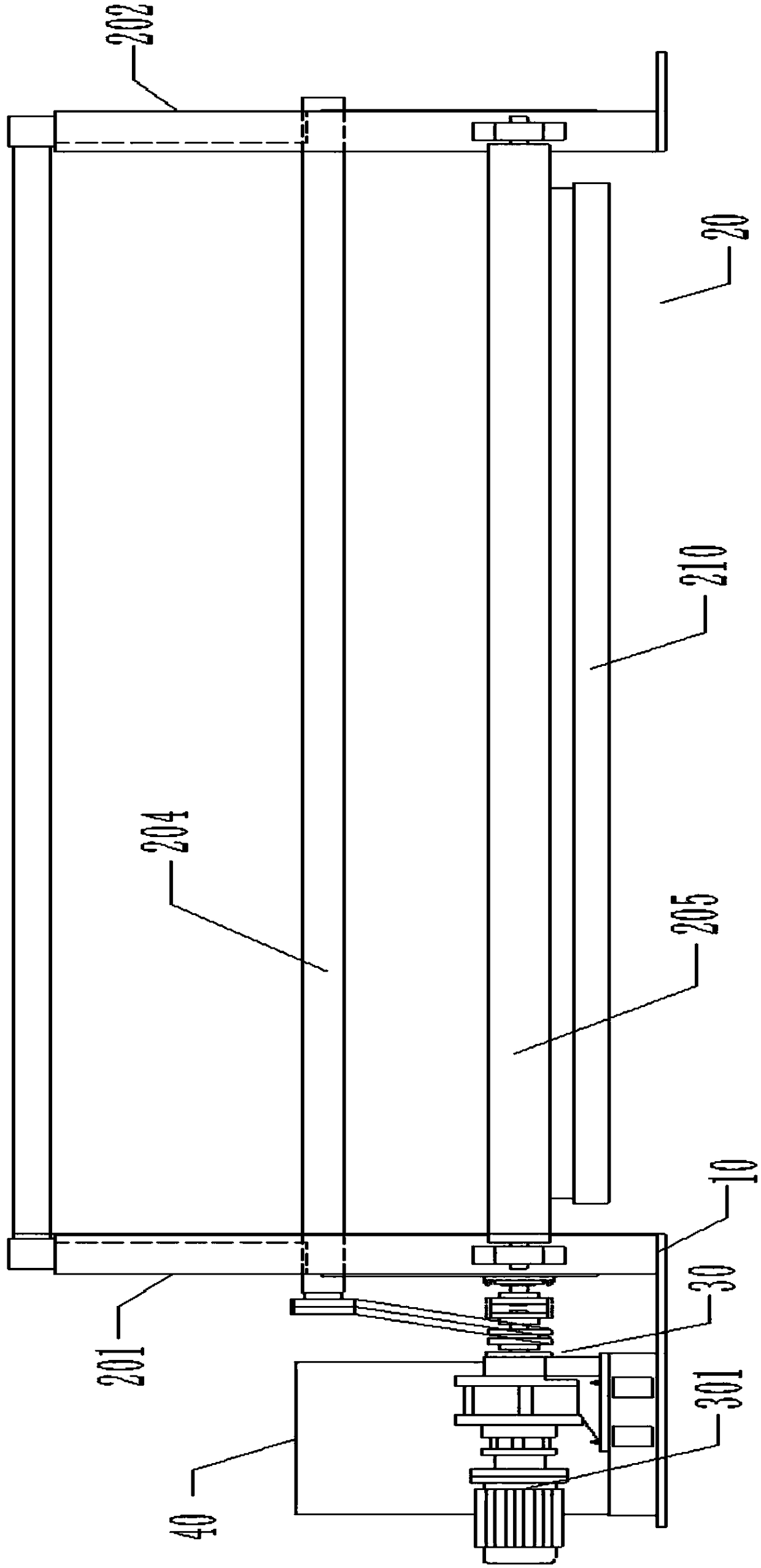

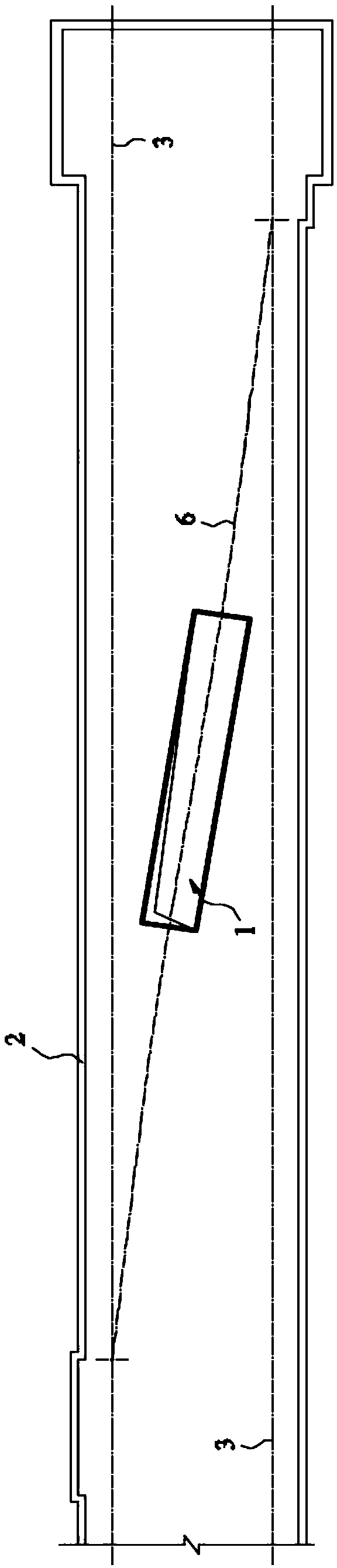

Perpendicular paving device for flexible coiled materials

ActiveCN108222078AGuarantee the quality of vertical layingSimple, safe and practical operationProtective foundationCivil engineering

The invention provides a perpendicular paving device for flexible coiled materials. The perpendicular paving device for the flexible coiled materials comprises a base, an auxiliary coiled material paving part, a power part and a control part. The auxiliary coiled material paving part, the power part and the control part are arranged on the base; an input end of the auxiliary coiled material pavingpart is connected with an output end of the power part; the power part is arranged to be an electrical connecting control part; the auxiliary coiled material paving part comprises an installation base I, an installation base II, a connecting beam, a steel rolling shaft I, a groove detecting and leveling mechanism and a cloth guiding roller; the power device comprises a variable-frequency and variable-speed motor and a transmission mechanism; and the control part comprises an electric cabinet body and a wireless remote controller. The perpendicular paving device for the flexible coiled materials provided by the invention is convenient to transfer, and simple, safe and practicable to operate; and the flexible coiled materials can be paved on a wall of a groove in a clinging way when being paved, so that the paving quality is ensured, meanwhile, the perpendicular paving construction efficiency is improved, and the construction difficulty is simplified.

Owner:TIANJIN ZHONGLIANGELIN SCI & TECH DEV CO LTD

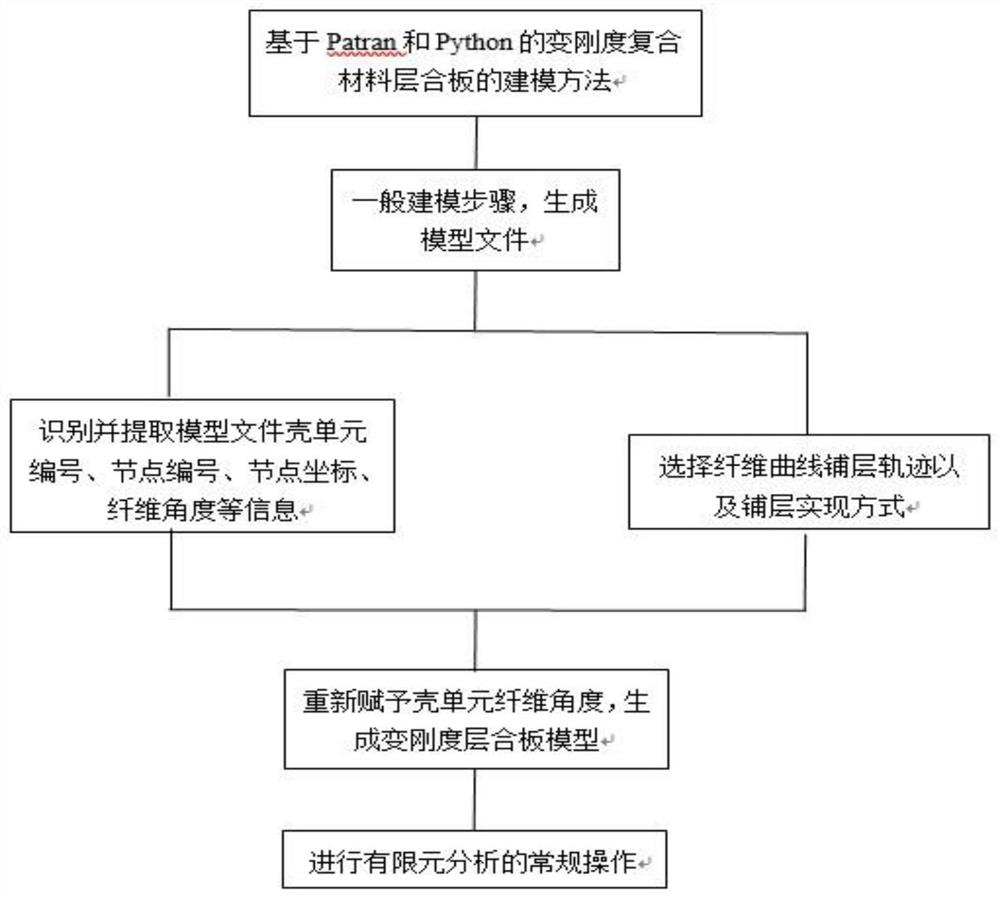

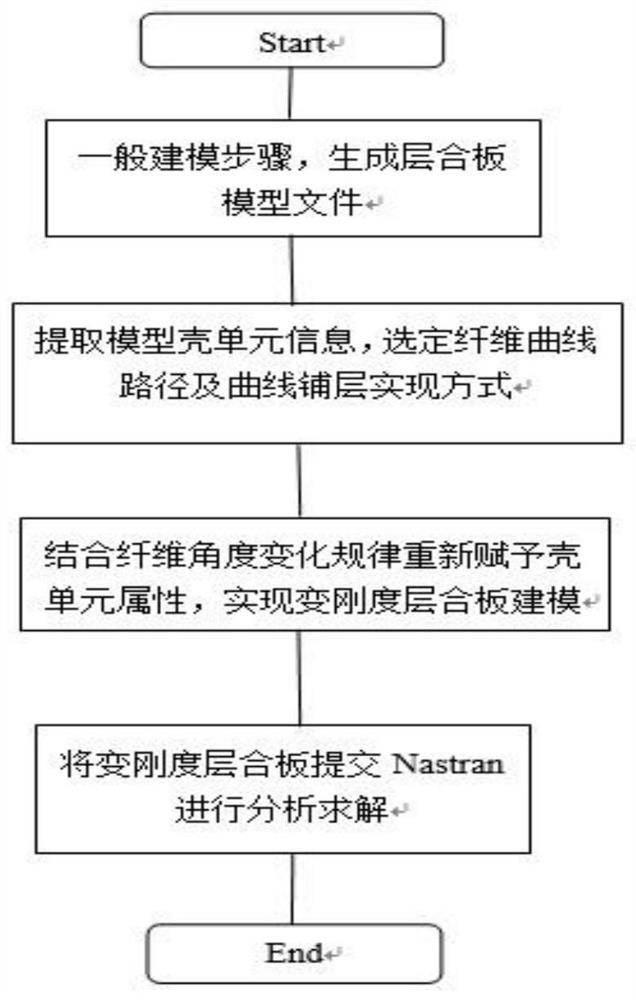

Finite element modeling method for variable stiffness composite laminate

InactiveCN111898295AFinite element modeling implementationRealize layingDesign optimisation/simulationSpecial data processing applicationsPython (programming language)Fiber

The invention discloses a finite element modeling method for a variable stiffness composite laminate. The method includes performing programming through Python and a PCL language; directly extractingthe fiber angle and node information of a laminated plate shell unit in a finite element model established by a Patran finite element through an operation file; calculating a central node coordinate of each shell unit, if the size of the shell unit is relatively small, approximately regarding the fiber angle of the point as the fiber angle of the unit, and finally re-endowing the fiber angle of each shell unit with the attribute of the shell unit according to a set curve track, thereby realizing fiber curve laying of the laminated plate. A variable stiffness laminate model is obtained by combining Patran and Python, then the model is submitted to Nastran to be solved and analyzed, and visualization processing is carried out through Patran import. According to the method, two programming languages of Python and PCL are combined, other platforms are not needed, and finite element modeling of the variable-rigidity laminated plate can be achieved through Patran.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

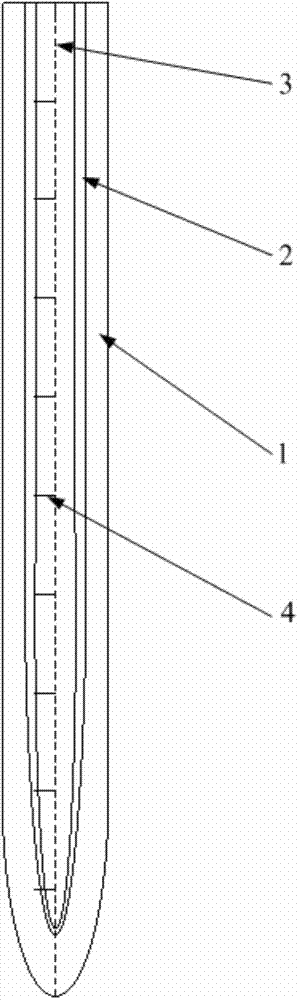

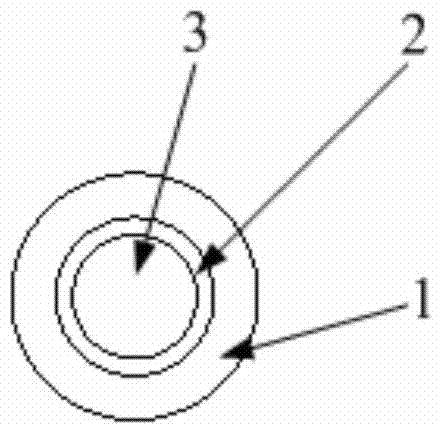

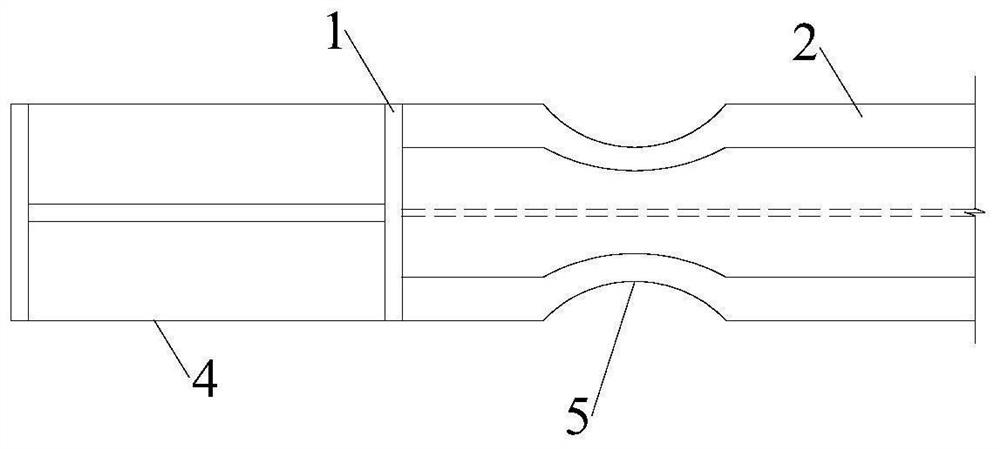

Power cable wire passing device

InactiveCN105226576ARealize layingImprove the pulling effectApparatus for laying cablesPower cableDrive shaft

The invention discloses a power cable wire passing device, comprising a rack; a wire rolling shaft is installed behind the rack; the wire rolling shaft is provided with a wire roller; the rack is connected to two lower part driving shafts which are arranged in parallel; one of the lower part driving shafts is driven by a power device; the lower part driving shaft is provided with a lower part driving roller; two upper part driving rollers which are arranged in parallel and are corresponding to the lower part driving shafts are rotatably connected to the rack; the upper part driving shafts are provided with upper part driving rollers; opposite grooves are arranged on the corresponding upper part driving rollers and the lower part driving rollers; the groove is provided with antiskid patterns; and grooves between the upper part driving roller and the lower part driving roller form a through hole for the power cable to pass through. The power cable wire passing device is good in drawing effect and high in efficiency of laying the cable.

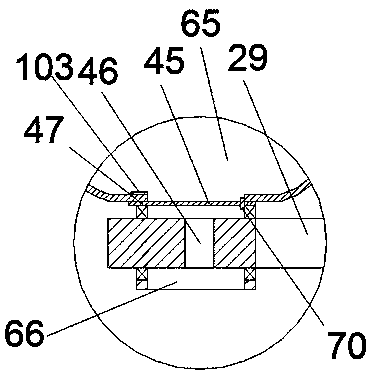

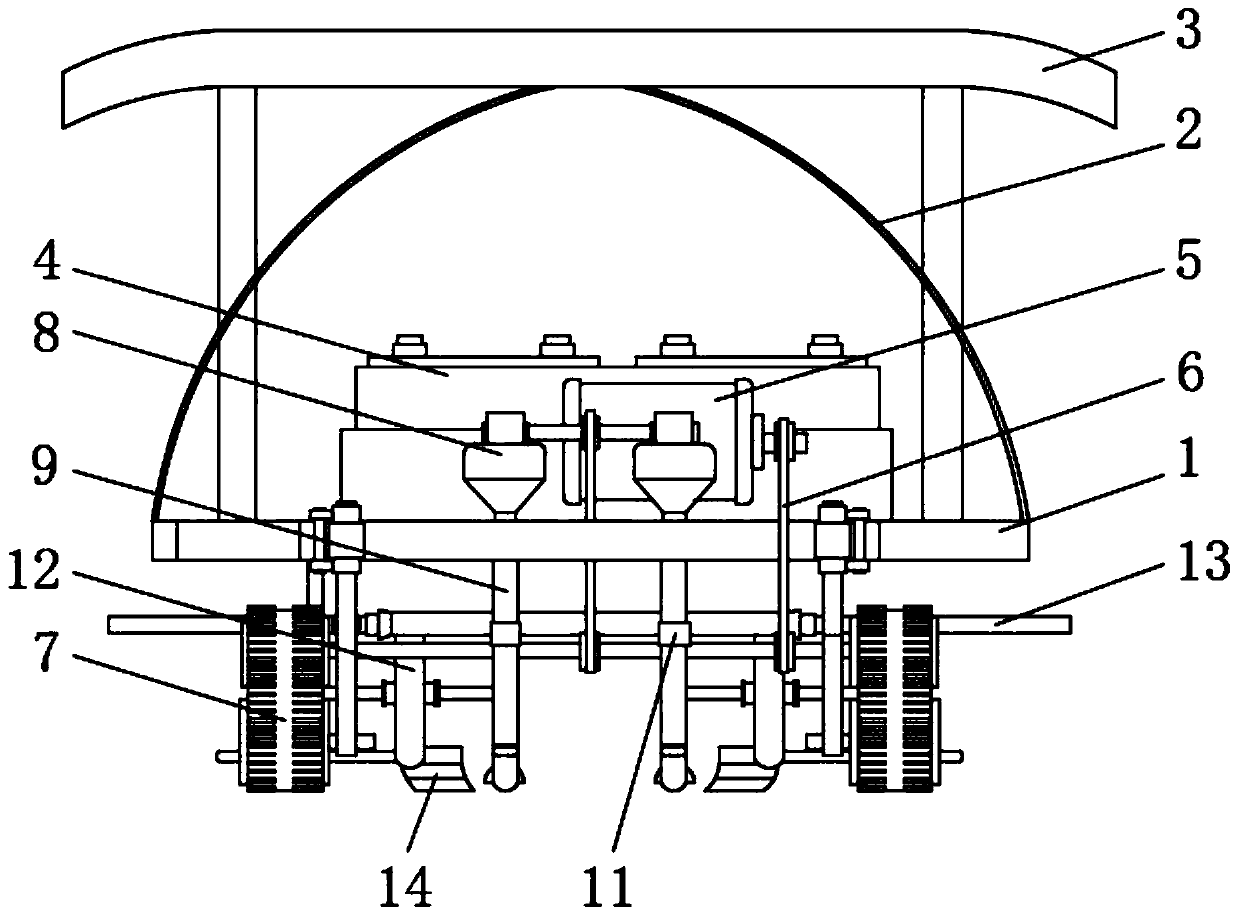

Owner:STATE GRID SHANDONG GAOMI POWER SUPPLY +1

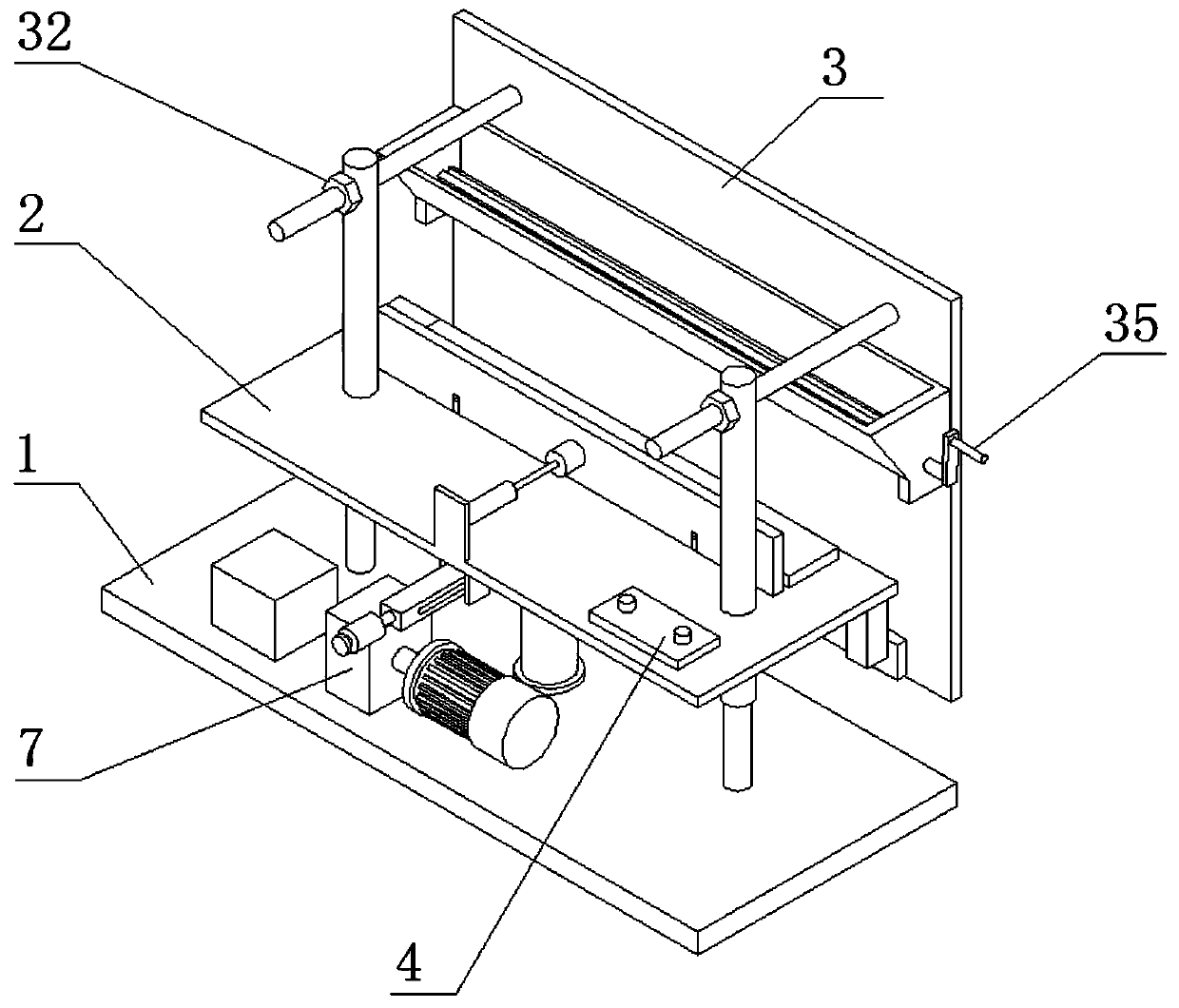

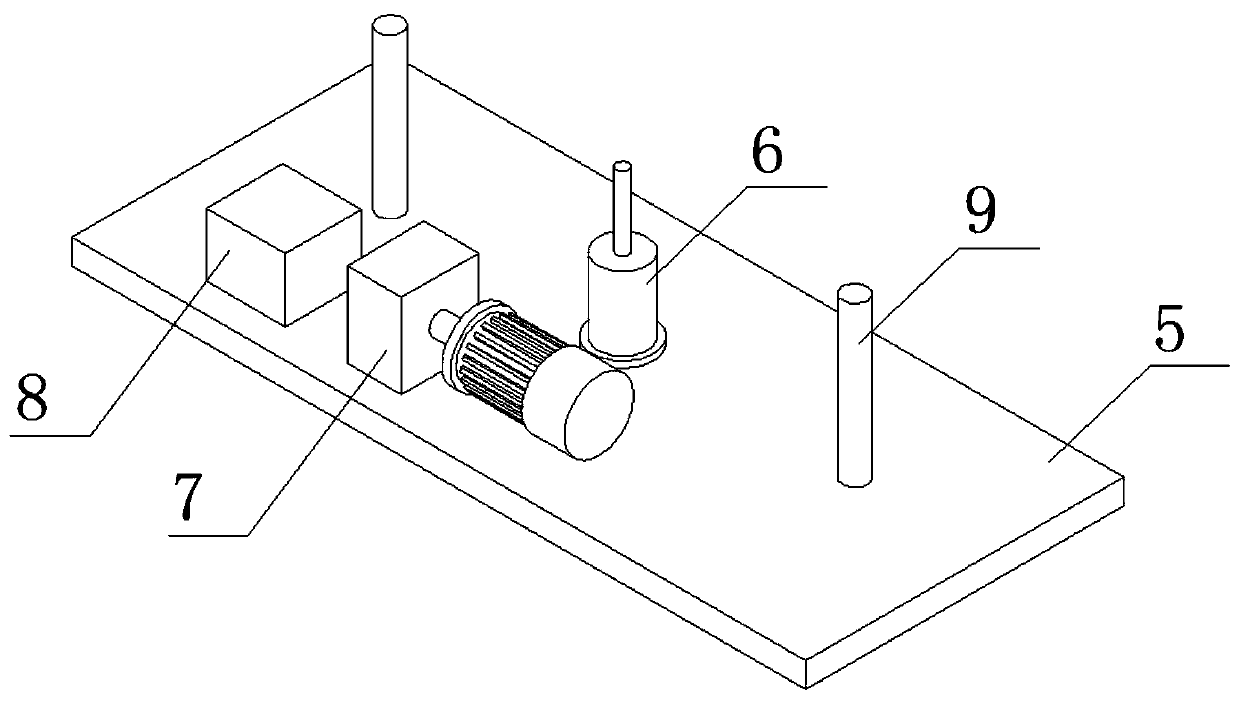

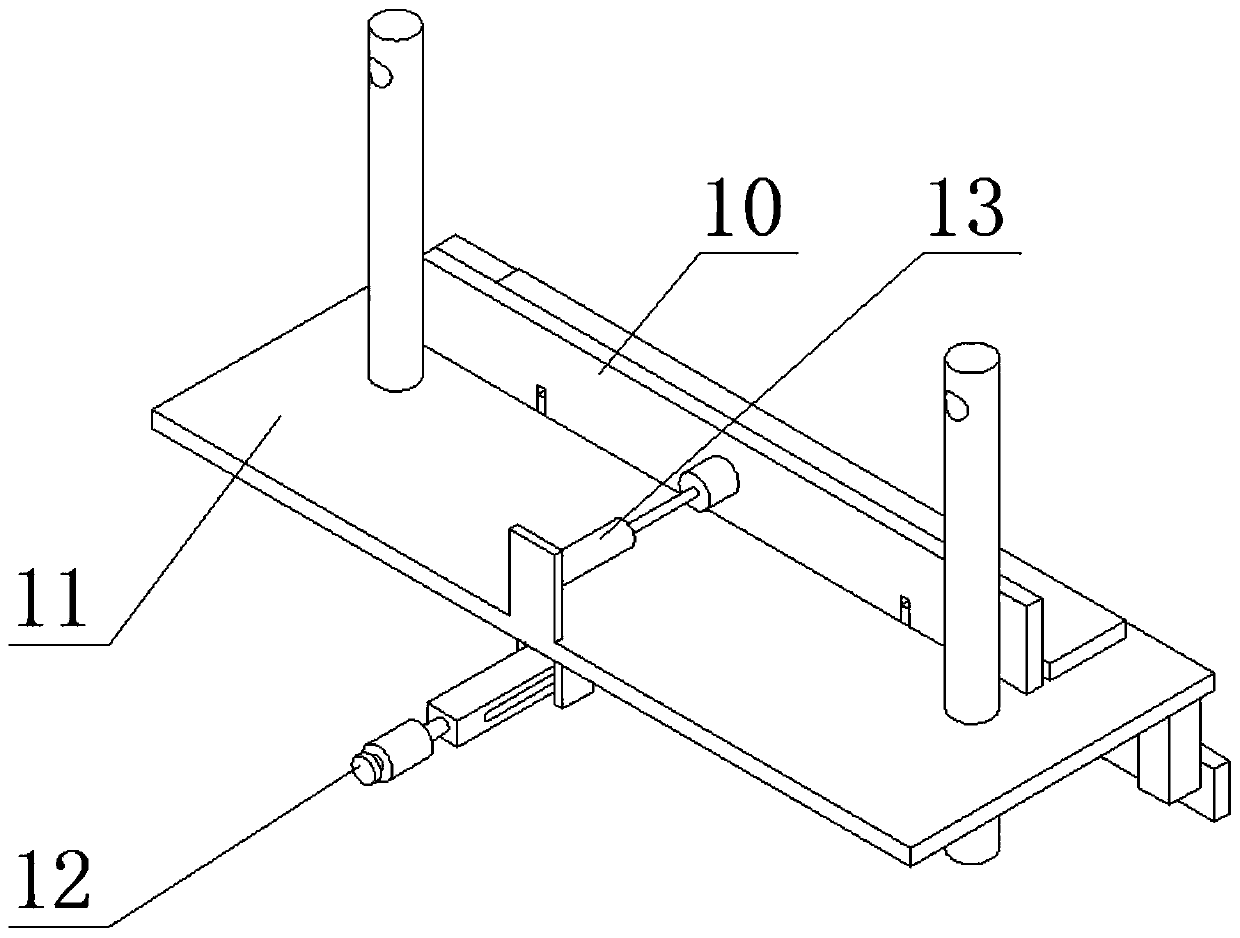

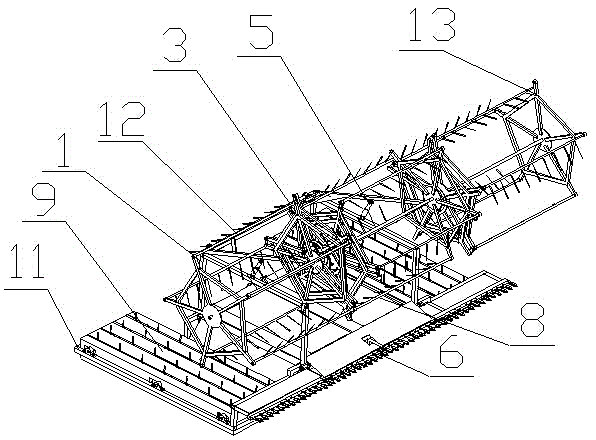

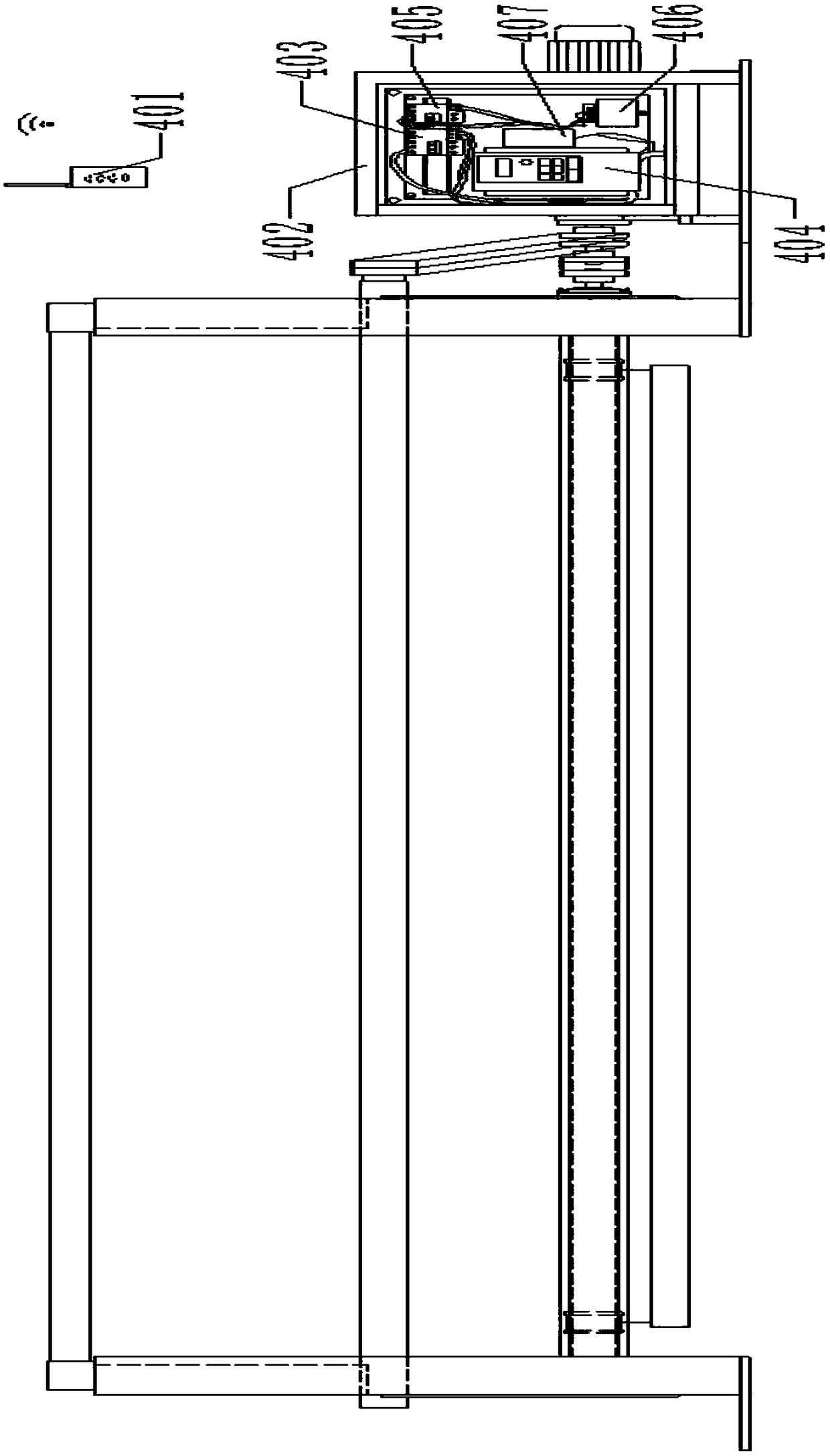

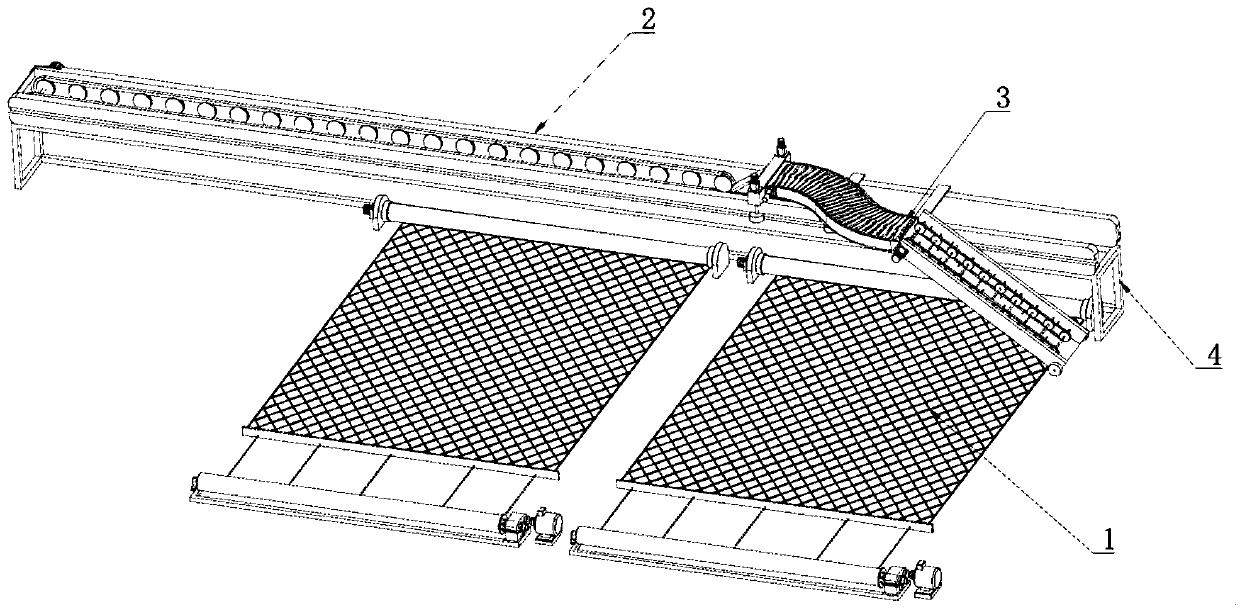

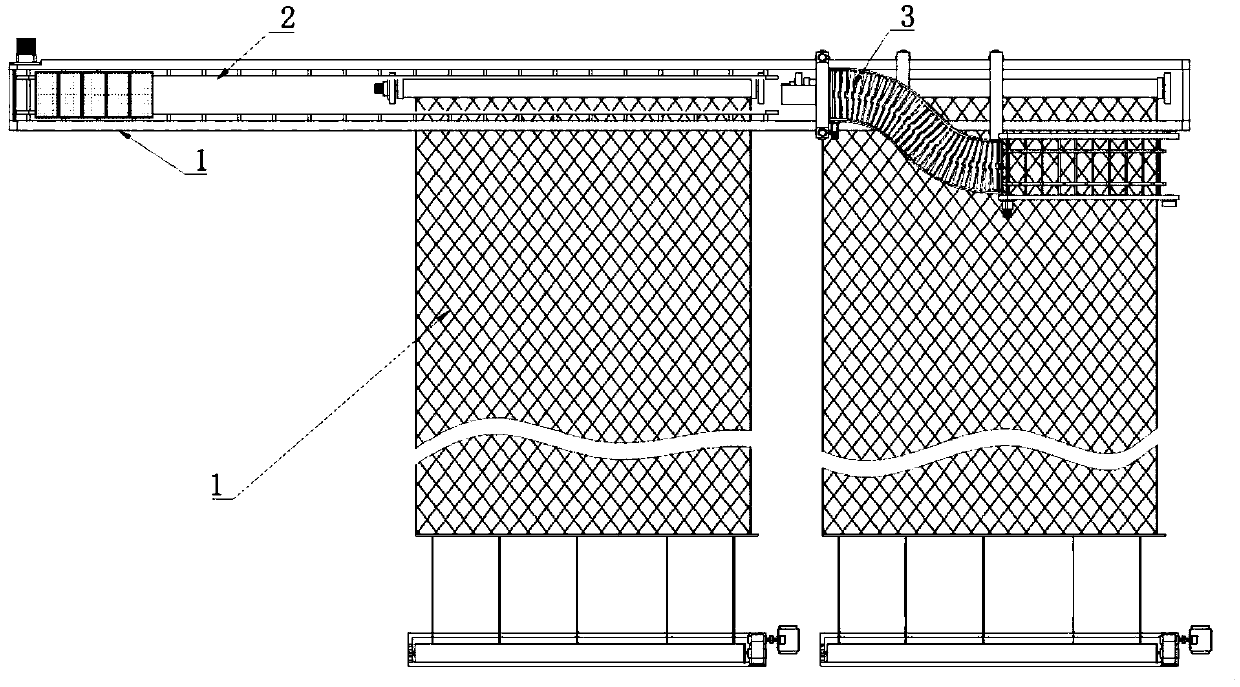

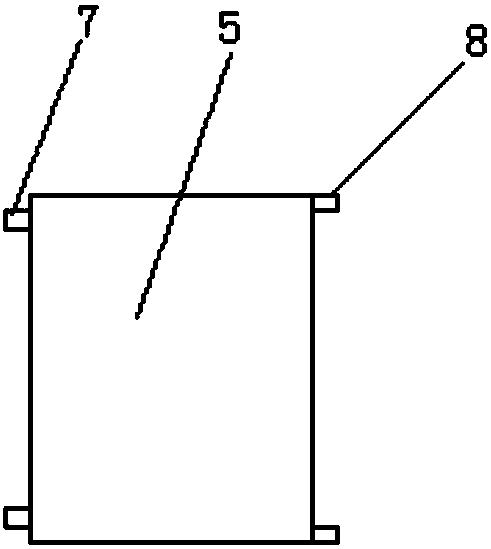

Full-automatic field tray-paving device and tray-paving method thereof

ActiveCN109548522AReduce laborRealize the function of fixed-point loadingCultivating equipmentsPlant protective coveringsFilm coatingFilm-coated tablet

The invention discloses a full-automatic field tray-paving device and a tray-paving method thereof. The present tray-paving device is capable of finishing a seedling tray paving operation but the position of tray loading needs to be continuously changed following the proceeding of tray paving operation. The full-automatic field tray-paving device disclosed by the invention comprises a seedling tray output device and n film tray-paving devices; each film tray-paving device comprises a tray-paving winding component and a film-reeling winding component; the seedling tray output device comprises ahorizontal tray conveying mechanism, a rail-exchanging tray conveying mechanism and a support frame; the horizontal tray conveying mechanism comprises a horizontal tray conveying motor, a first driving shaft and a unilateral horizontal tray conveying component; the rail-exchanging tray conveying mechanism comprises a rail-exchanging component and an inclined tray conveying component; the rail-exchanging component comprises an advancing motor, a power advancing frame, a tray-shoveling block and an S-shaped conveyor. According to the invention, the seedling tray is driven by the film, and meanwhile, the operations of film coating and tray paving can be simultaneously realized, so that the position of tray-paving mechanism need not be changed, the function of loading trays on a fixed site can be achieved and the labor force of workers is greatly reduced.

Owner:浙江德菲洛智能机械制造有限公司

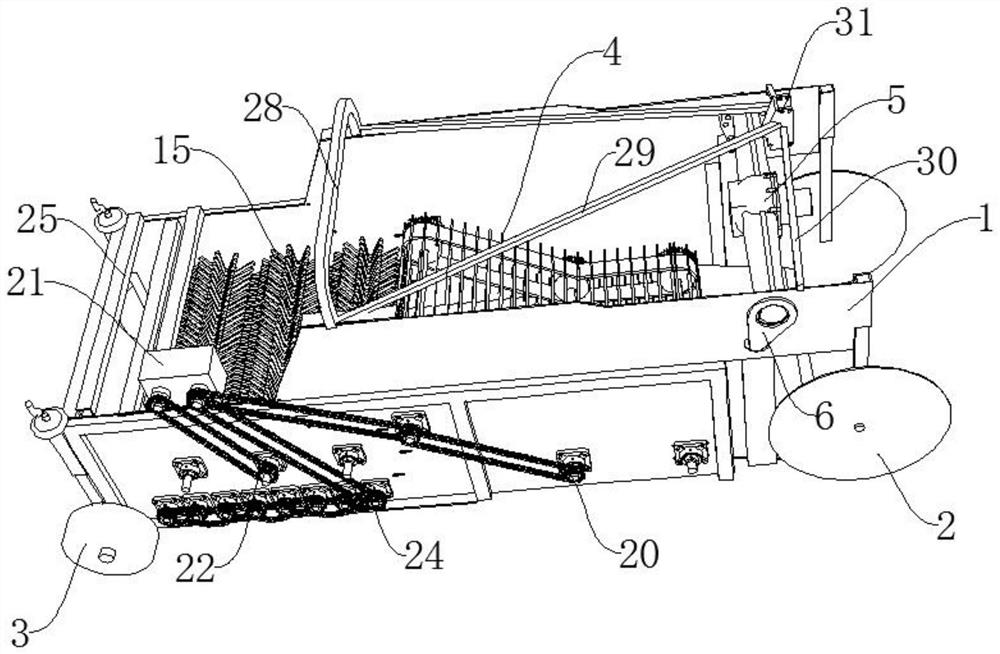

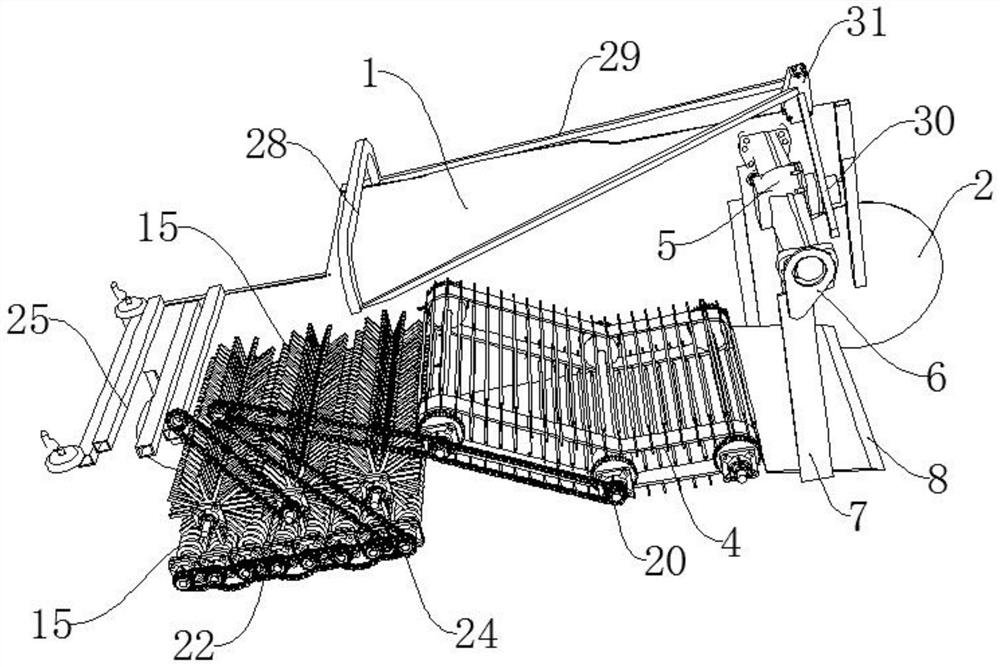

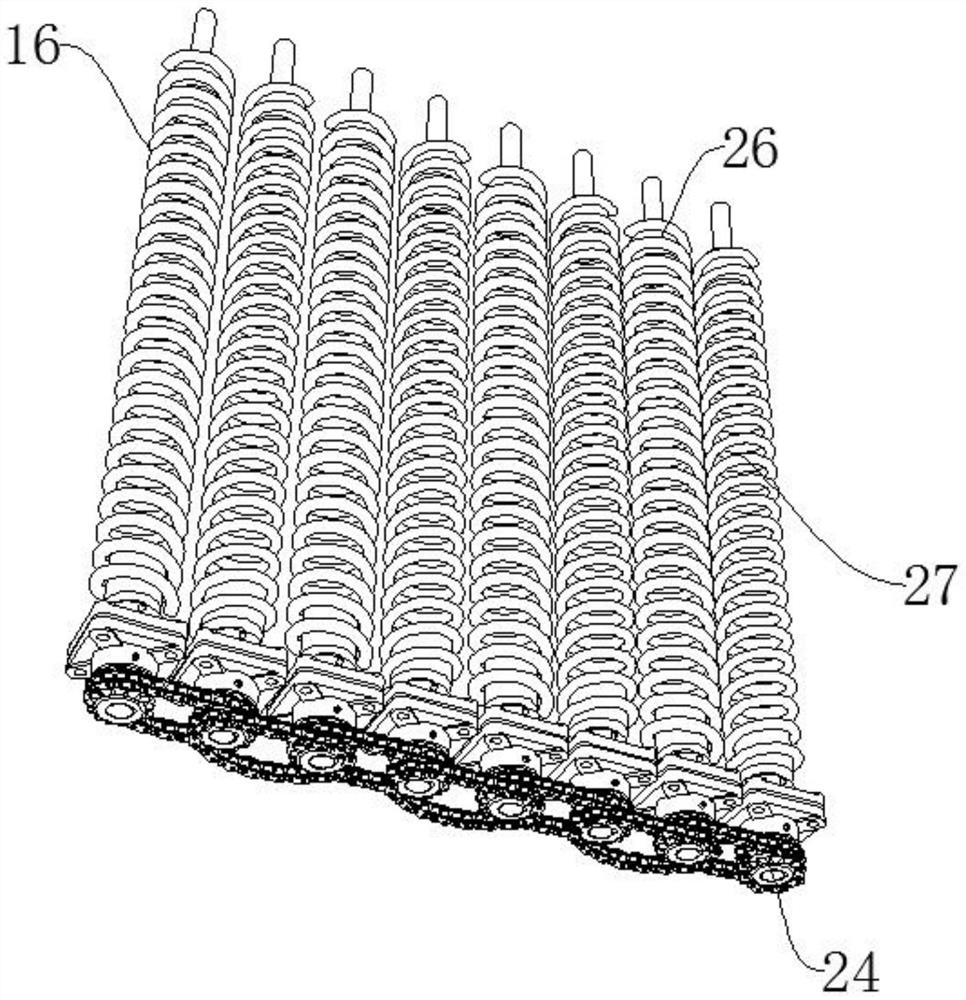

Suspension type water chestnut digging machine

PendingCN114158346APower transmission is simpleRealize transmissionDigger harvestersSoil scienceGeotechnical engineering

The invention discloses a suspension type water chestnut digging machine which comprises a machine frame, two sets of depth limiting wheels, a lifting chain component, a rubber tooth roller, a positive and negative spiral spring shaft and two sets of land wheels. The digging shovel is driven to advance, the digging shovel is driven by the eccentric wheel to vibrate to shovel upturned soil, the upturned soil is subsequently shaken by the lifting chain component to be split into soil blocks, and then the soil blocks fall onto a spring screen surface formed by alternately arranging positive and negative spiral spring shafts after being hit and extruded by the rubber tooth roller to be crushed; large soil blocks fall on the surface of the spring screen and then are beaten and extruded by the two rubber tooth rollers to be further crushed, meanwhile, the positive and negative spiral spring shafts synchronously rotate backwards to rub a mixture of the soil blocks and the water chestnuts and drive the mixture of the water chestnuts and the soil to rotate, and the soil adhering to the water chestnuts is further removed; soil blocks fall on the ground through gaps between the positive and negative spiral spring shafts and gaps of the springs, and large soil blocks and water chestnuts are conveyed to the rear end of the machine through a rolling screen face composed of the positive and negative spiral spring shafts and laid on the ground.

Owner:HUAZHONG AGRI UNIV

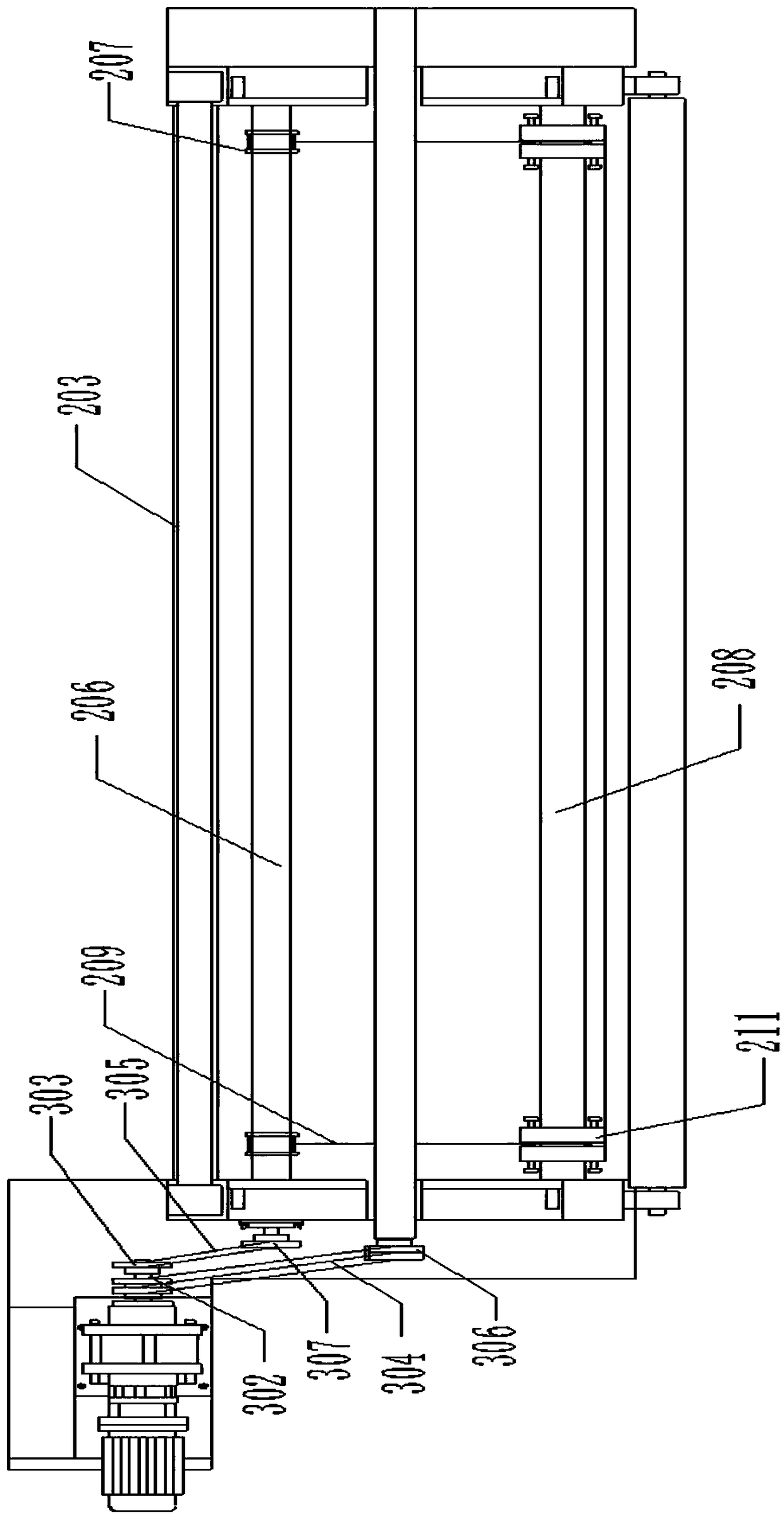

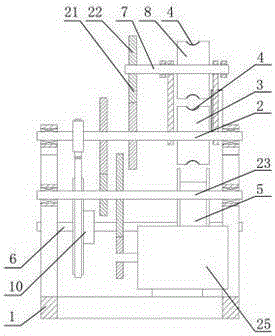

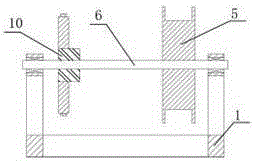

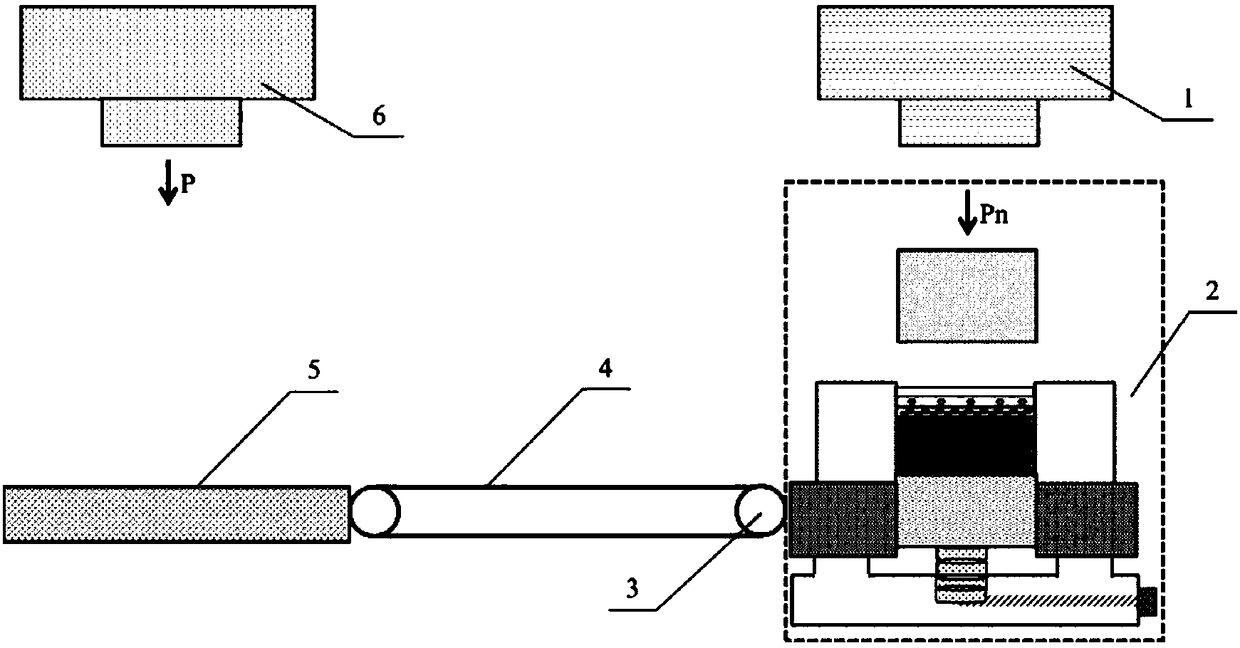

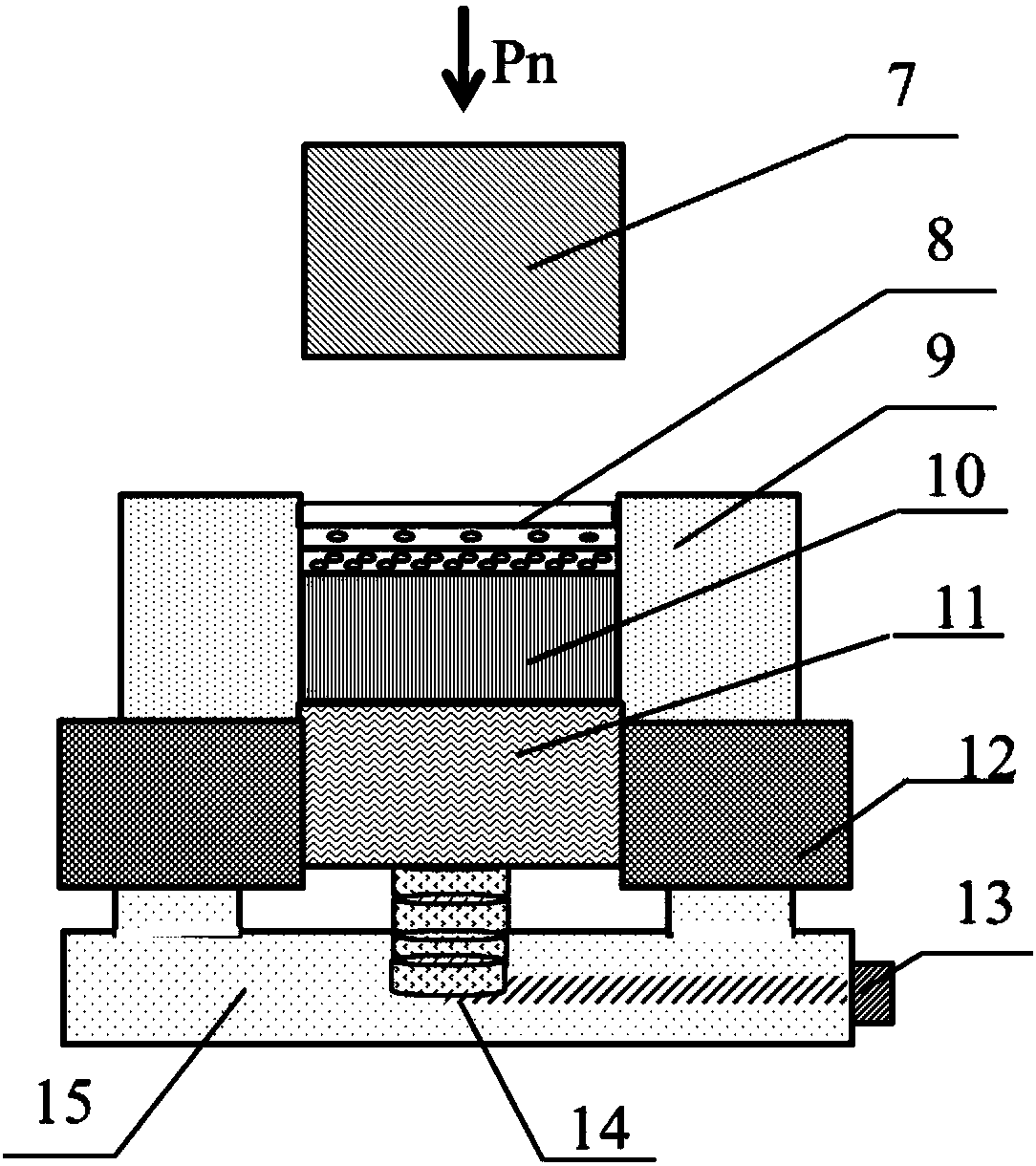

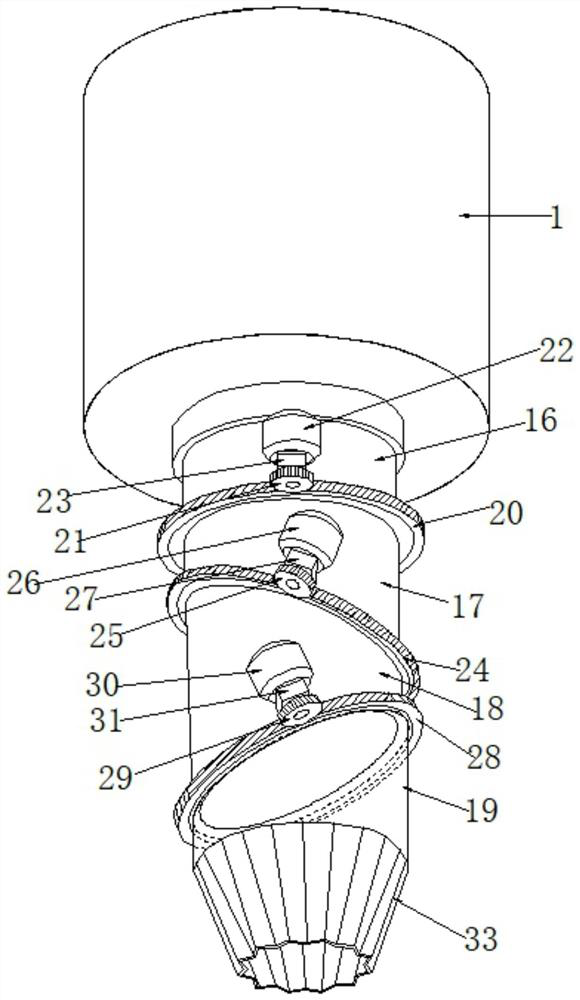

Forming device and application of large-size ultra-thin powder metallurgy gradient material

PendingCN108326297AImprove bindingPrecise control of lifting heightGradient materialMeasuring instrument

The invention belongs to the field of powder metallurgy forming equipment, and particularly relates to a forming device and application of a large-size ultra-thin powder metallurgy gradient material.The forming device of the large-size ultra-thin powder metallurgy gradient material comprises a pre-pressing forming system and a laminating powder laying forming system; and the laminating powder laying forming system is composed of a mold upper pressing head, a mold sleeve, a mold lower pressing head, a spiral height control instrument lifting table, a spiral height control instrument platform,a spiral rotary knob, a lifting screw rod and a height control instrument base. The laminating powder laying forming system of the forming device of the large-size ultra-thin powder metallurgy gradient material organically combines a spiral height measuring instrument and mold pressing forming, laminating powder laying with the descending height at the micron level is achieved, laying uniformity of each layer of power is guaranteed, and due to the fact that a mold can be replaced at any time, it can be achieved that sample forming blank bodies in different sizes are prepared. The forming device of the large-size ultra-thin powder metallurgy gradient material achieves integration of multi-layer powder laying, prefabricating forming and final forming in the powder metallurgy technology, thepressing forming performance is good, and thickness control of each layer is accurate.

Owner:CENT SOUTH UNIV

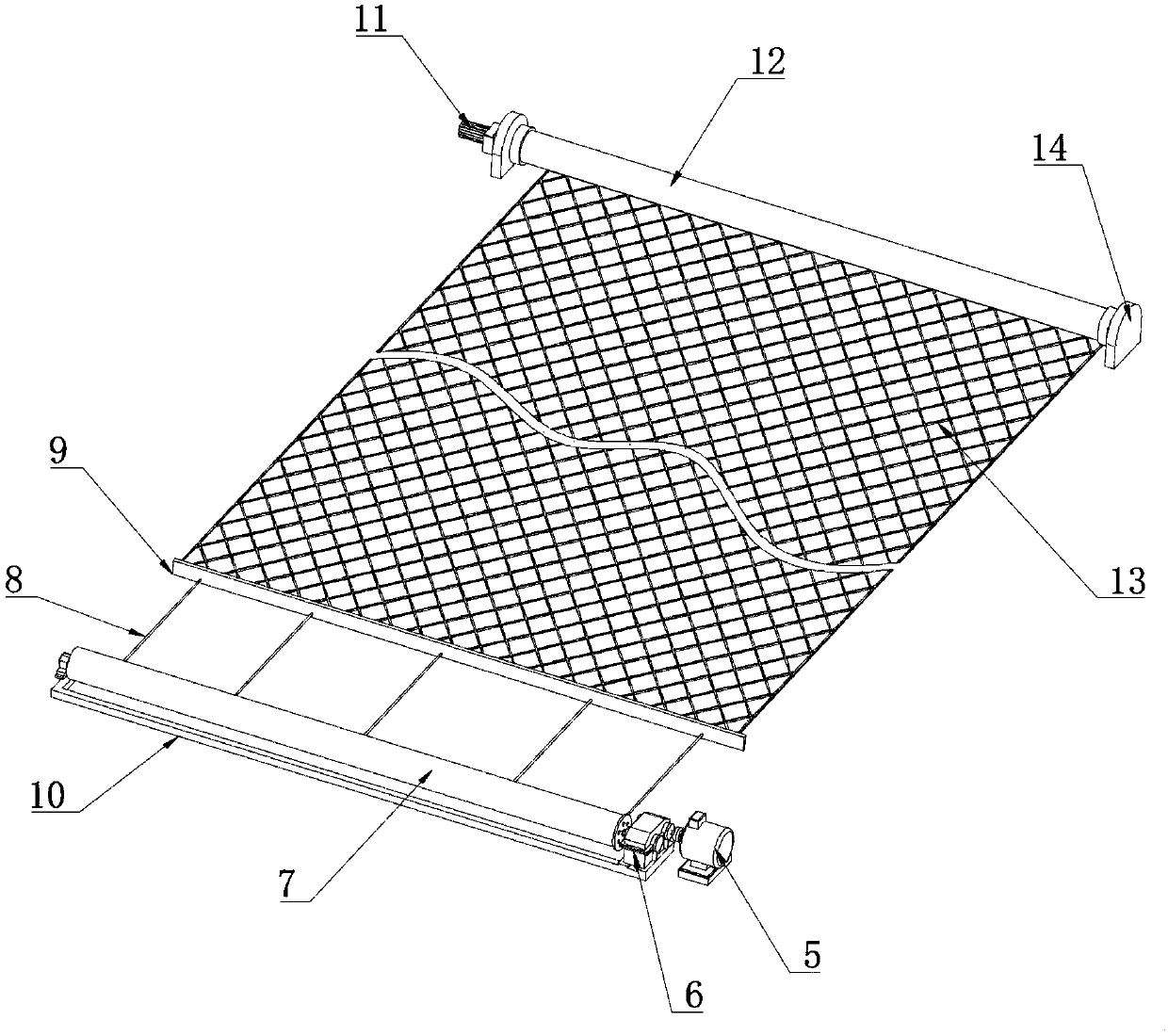

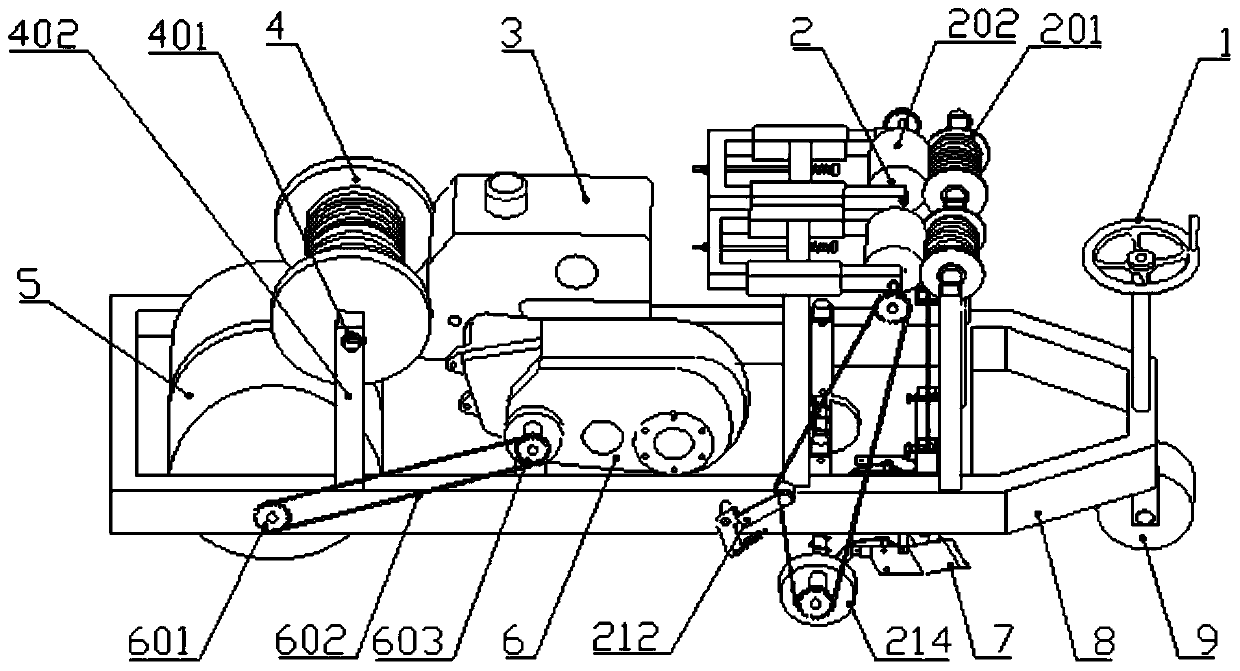

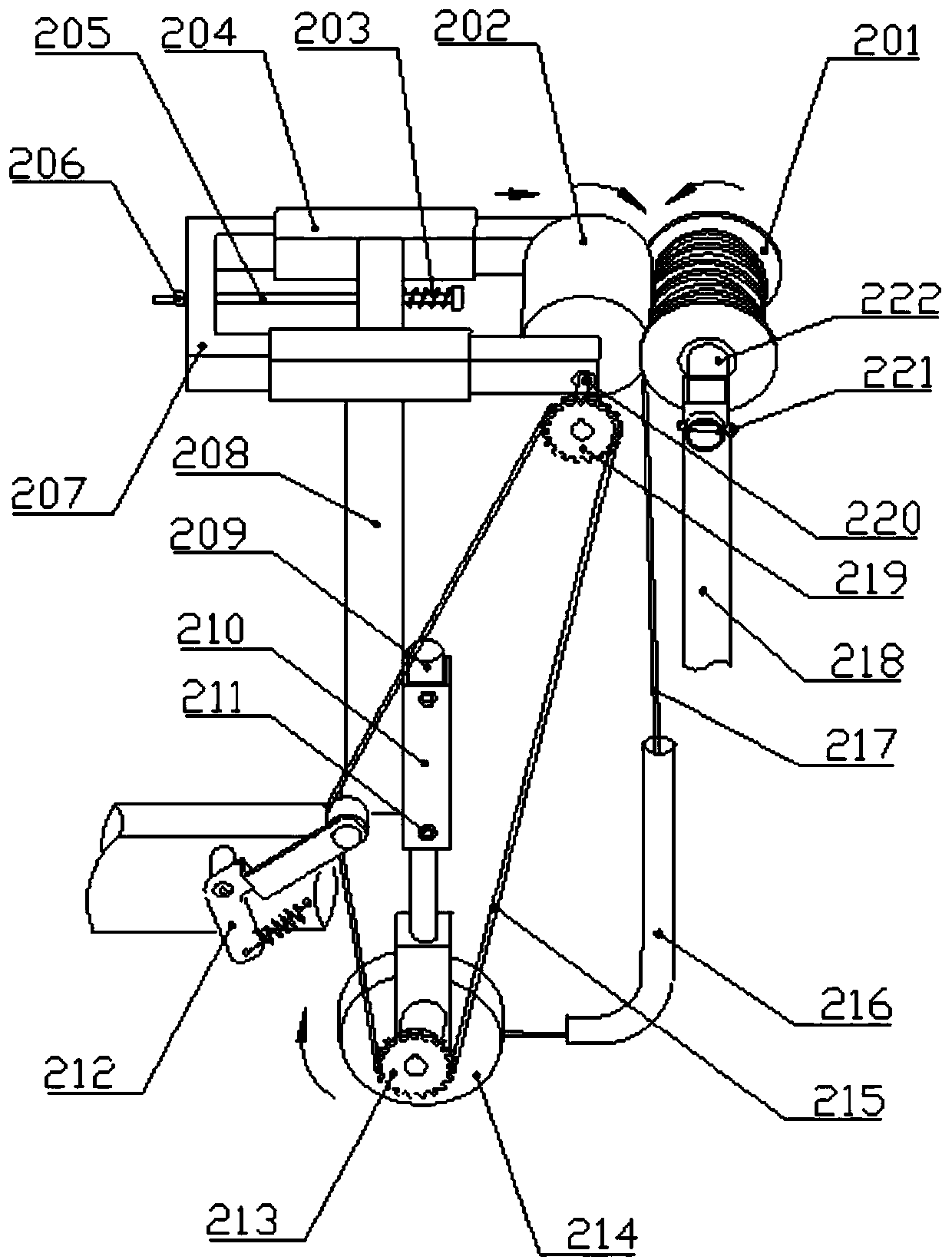

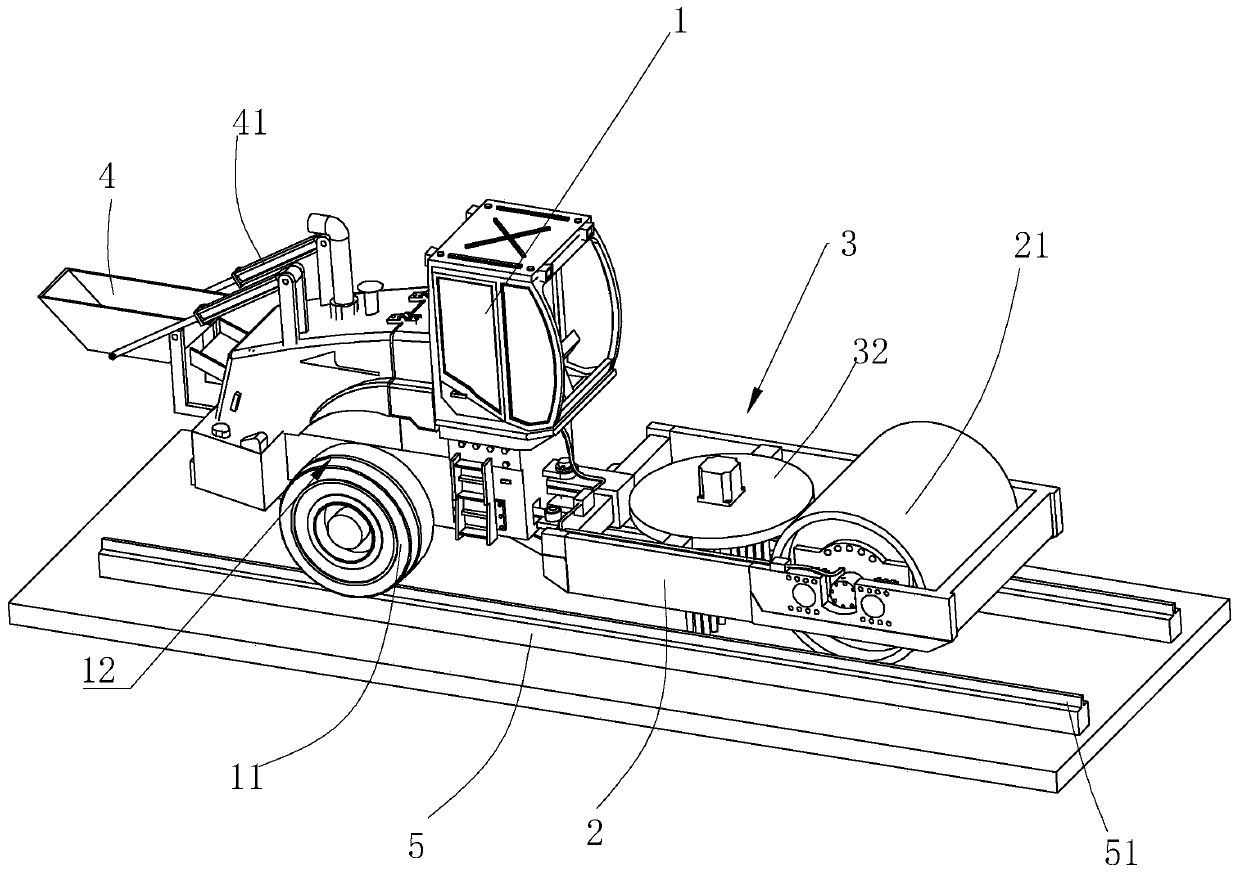

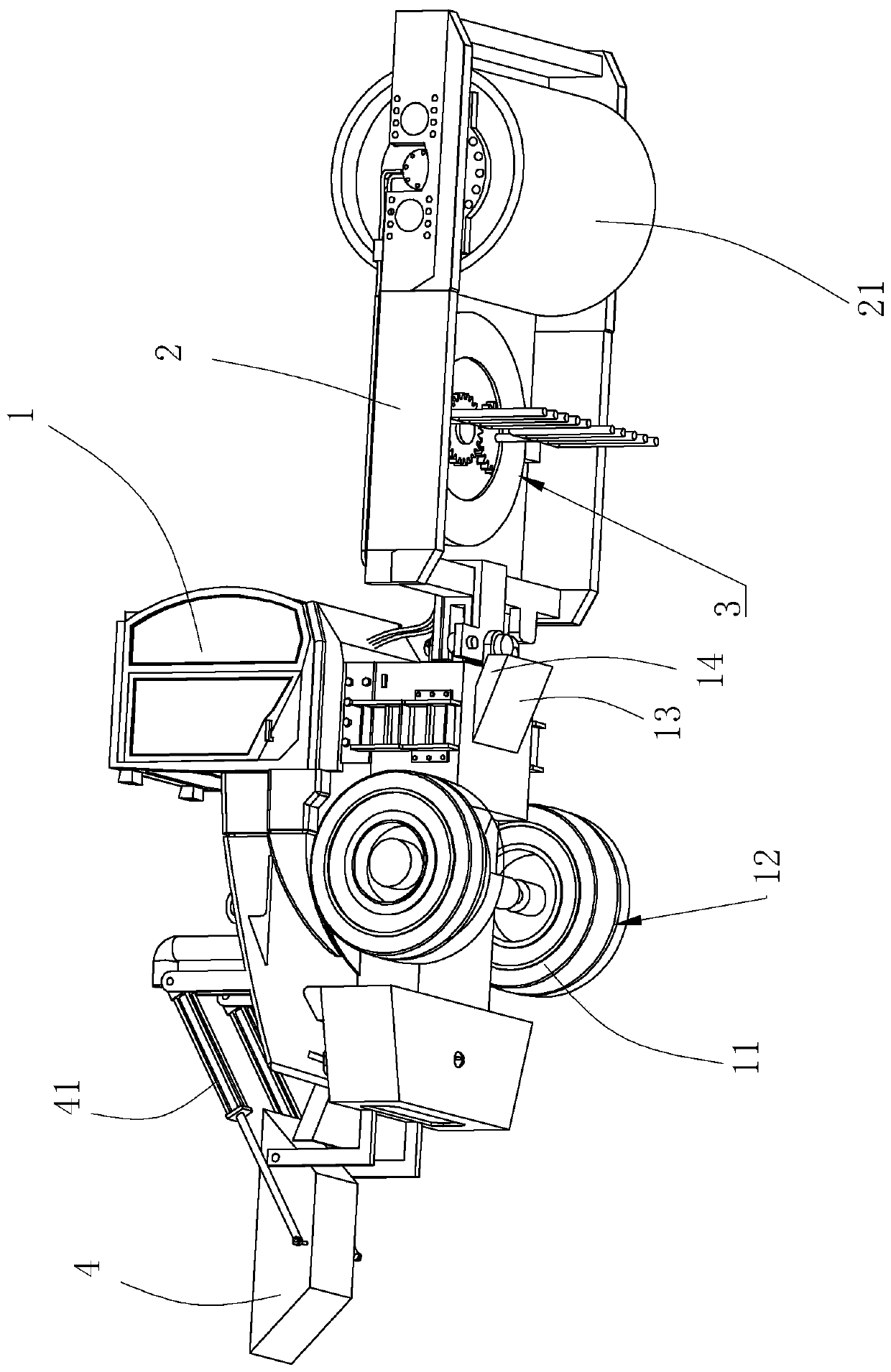

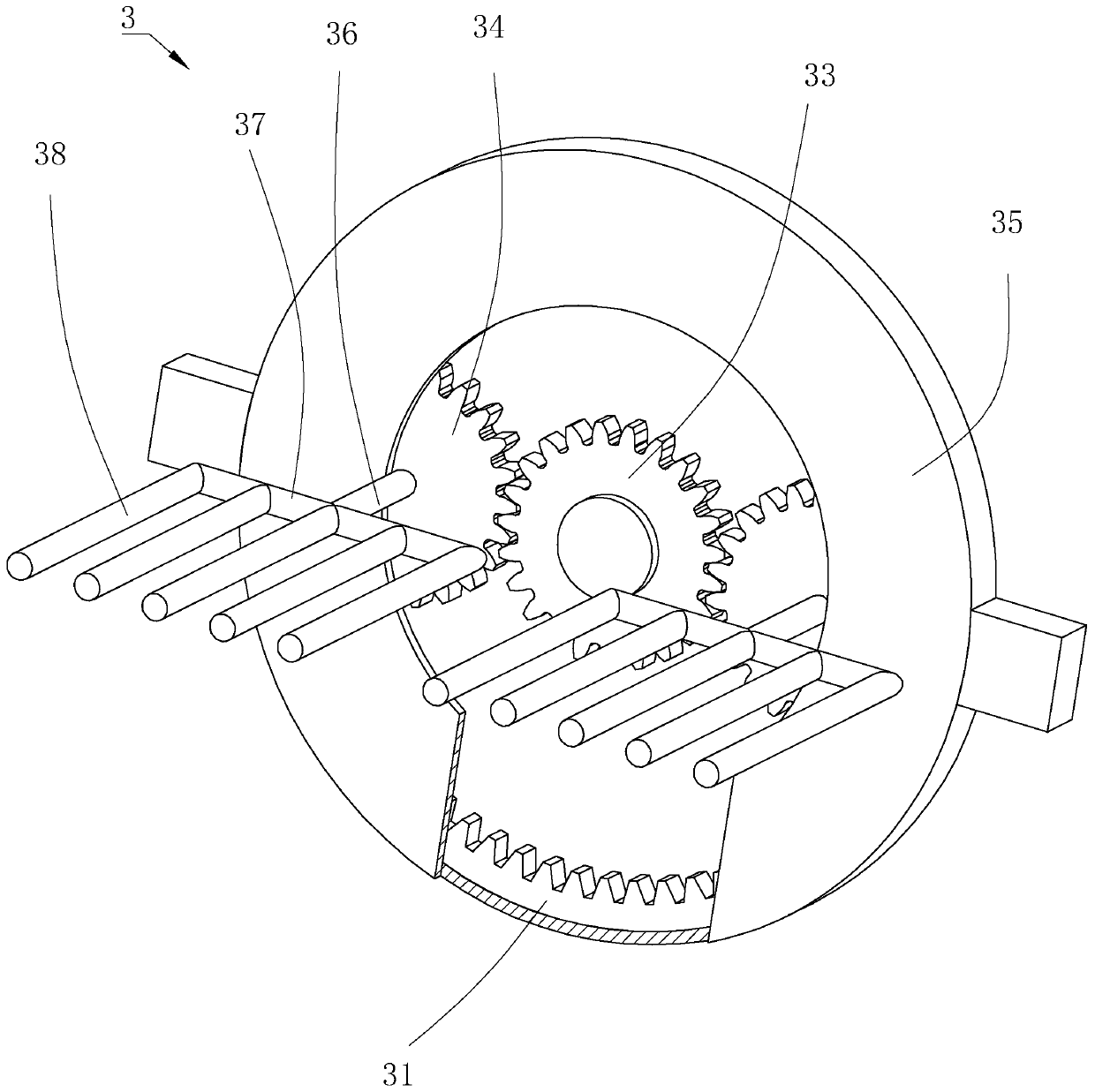

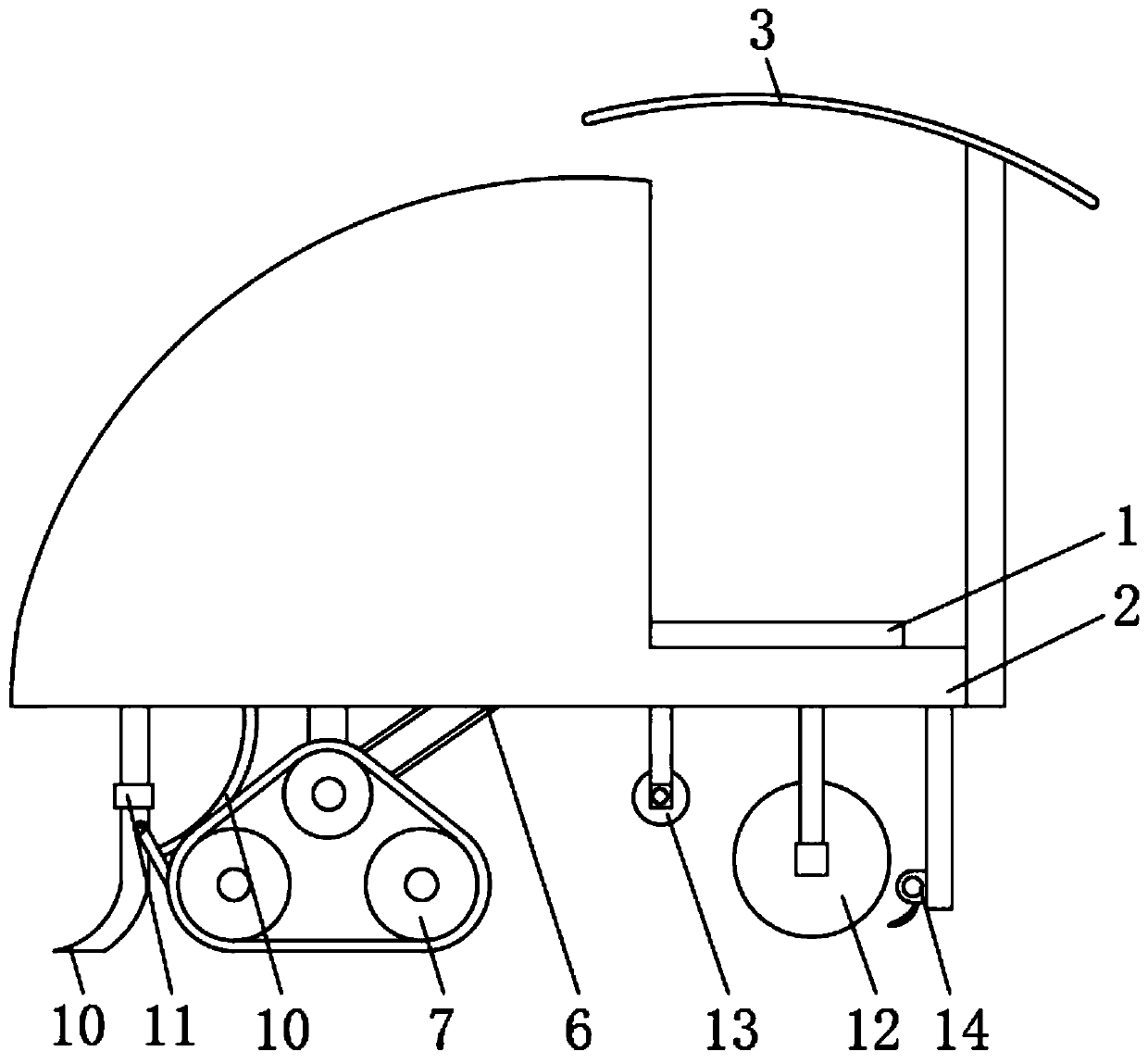

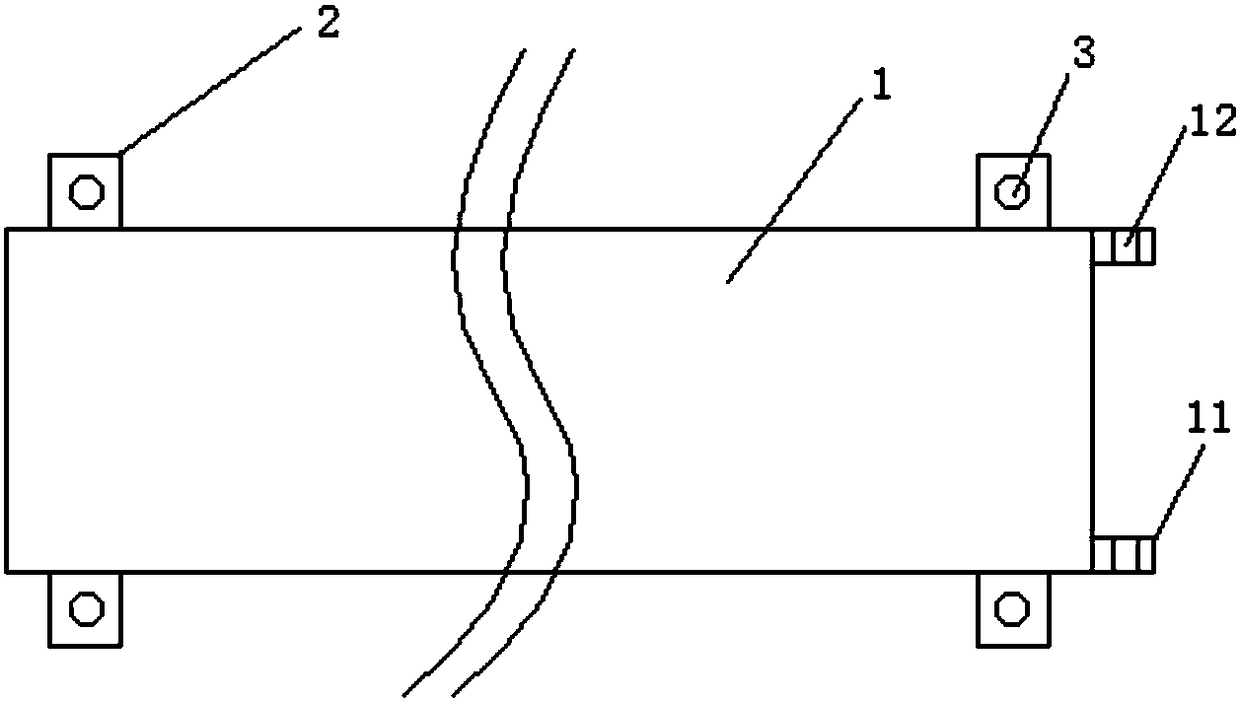

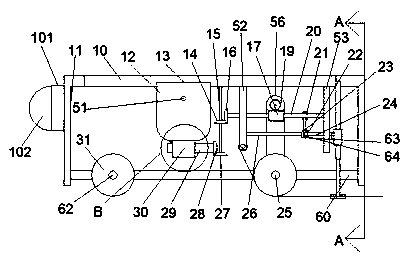

Self-propelled carrot seed-rope seeding machine

PendingCN109997455ARealize trench layingRealize layingPlantingClimate change adaptationDrip irrigationAgricultural engineering

The invention relates to agricultural machinery, in particular to a self-propelled carrot seed-rope seeding machine. The self-propelled carrot seed-rope seeding machine comprises a frame, furrowers, an elastic roller seed rope synchronous laying device, a drip irrigation belt roller, a rear roller and a chain transmission device. The elastic roller seed rope synchronous laying device, the drip irrigation belt roller and the rear roller are arranged on the frame sequentially from front to back, and the rear roller is mounted at the rear end of the frame. The elastic roller seed rope synchronouslaying device comprises two elastic roller seed rope synchronous laying device bodies, and the bottom of the frame is provided with the furrowers under the elastic roller seed rope synchronous layingdevice bodies. The drip irrigation belt roller is positioned between the two elastic roller seed rope synchronous laying device bodies, and a drip irrigation belt is wound on the drip irrigation beltroller which is connected with the frame through a drip irrigation belt roller rotating shaft. The rear roller is arranged behind the drip irrigation belt roller, the middle of the rear roller is provided with an annular groove, and the drip irrigation belt is arranged in the annular groove. The problem that the seed rope is broken when the machine is in operation is effectively solved.

Owner:QINGDAO AGRI UNIV

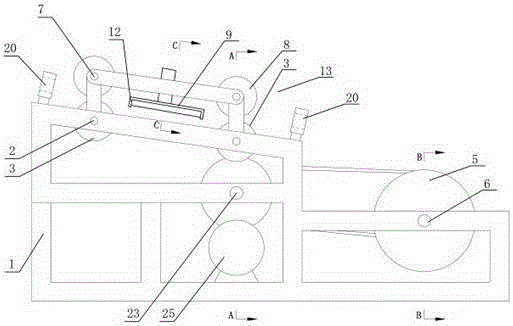

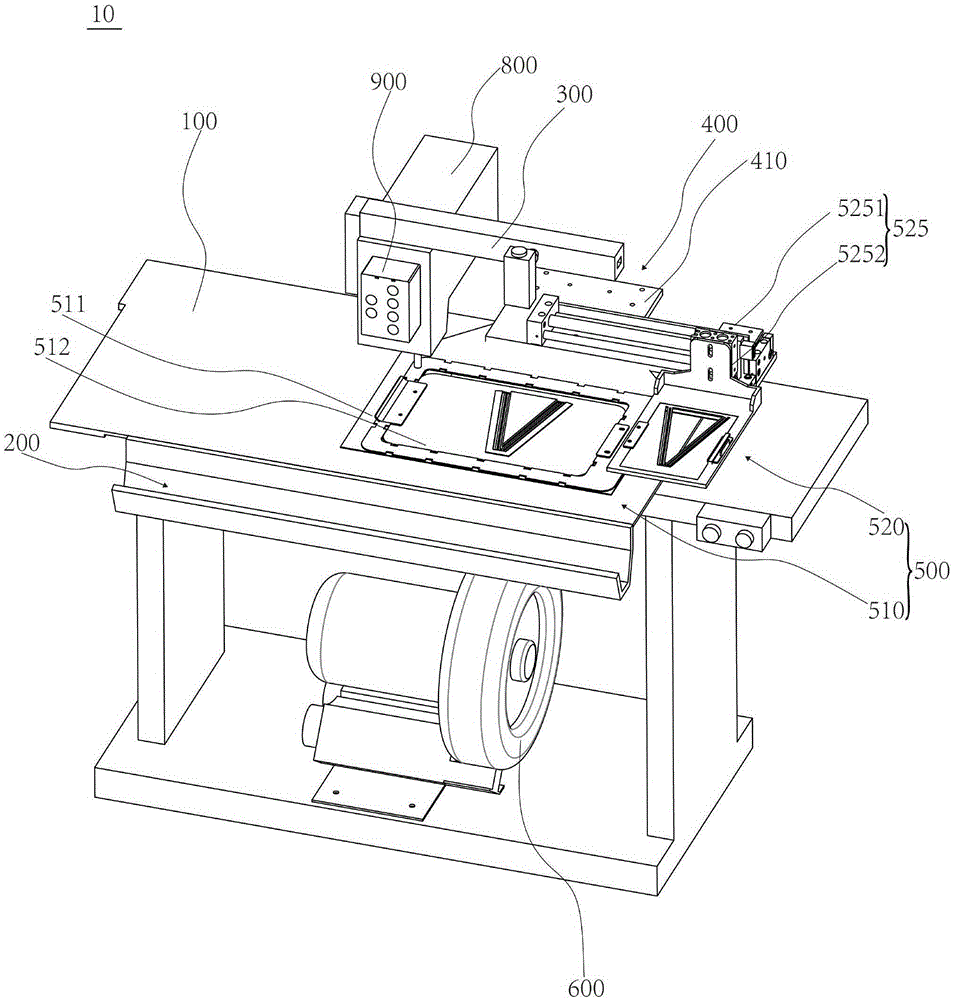

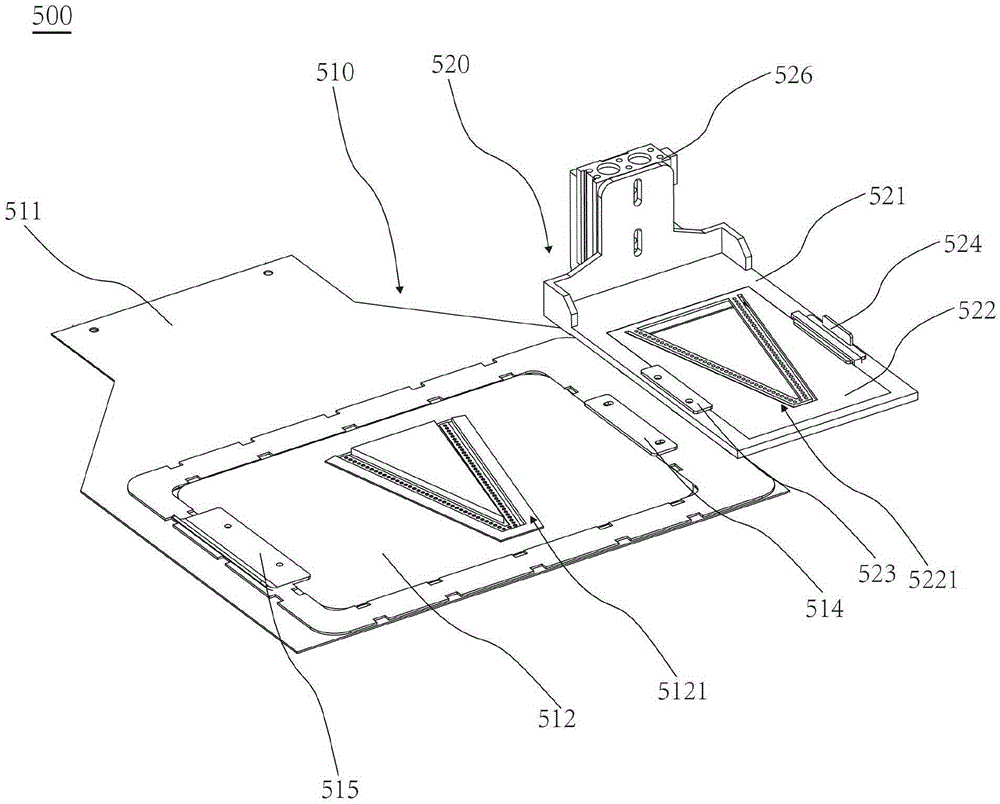

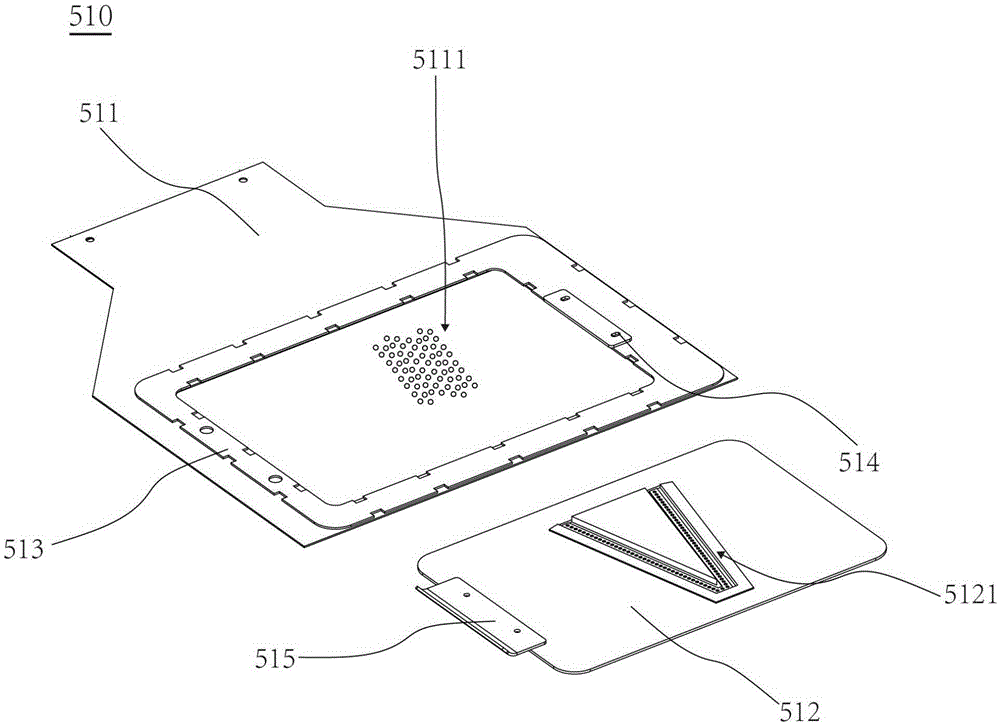

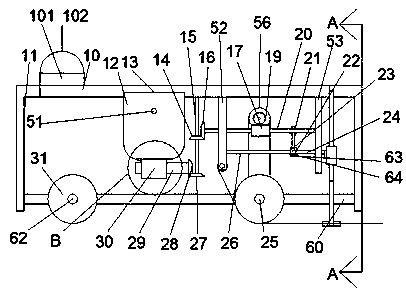

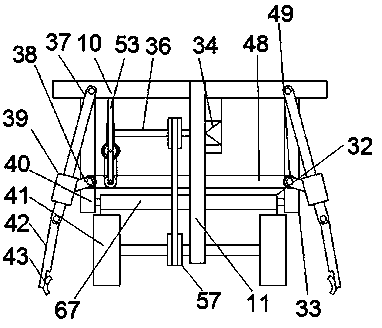

Automatic sewing object stitching system and method

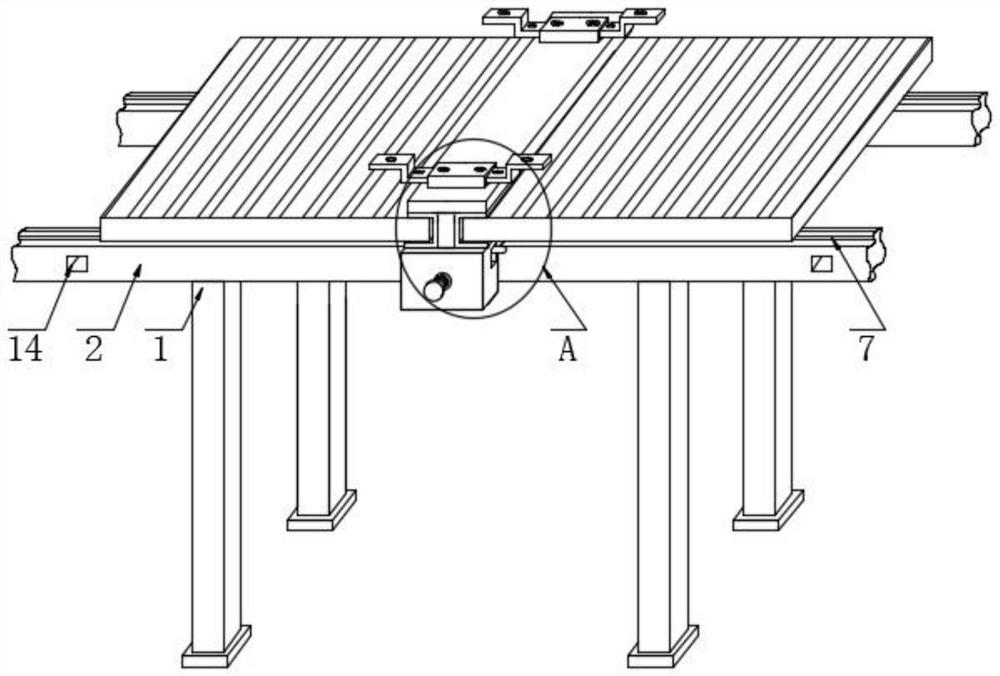

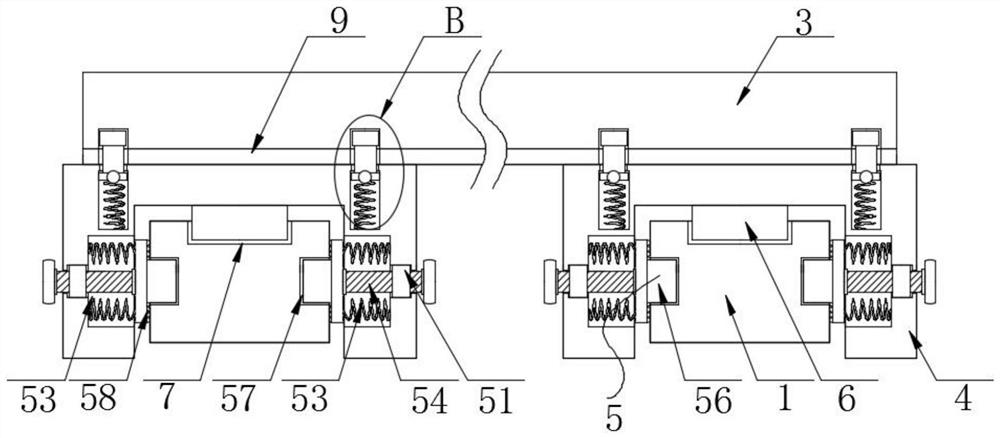

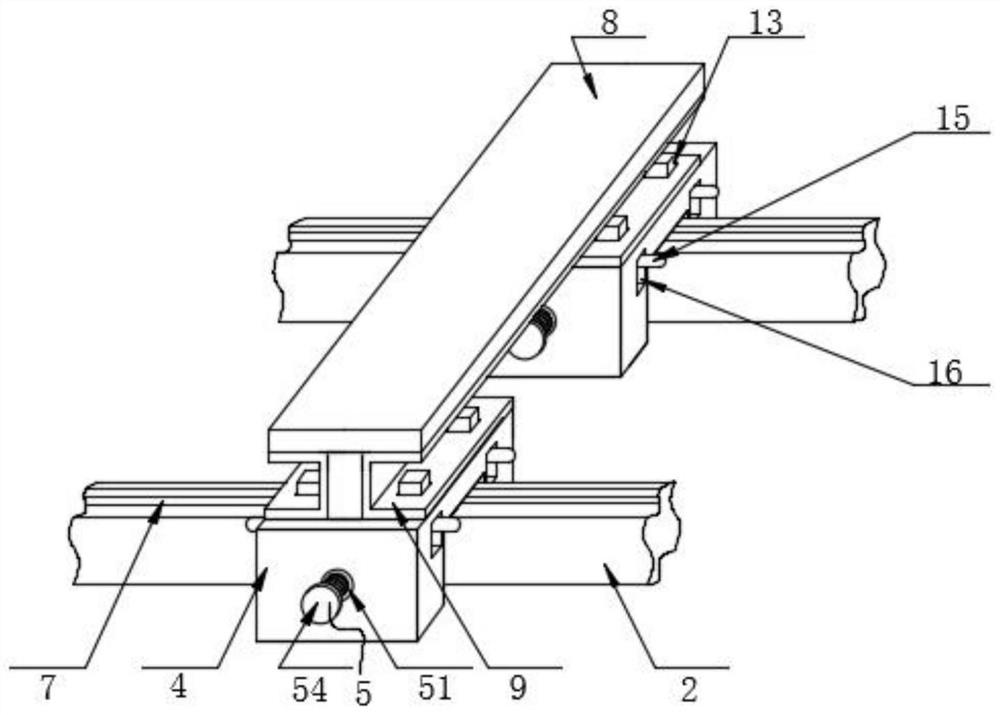

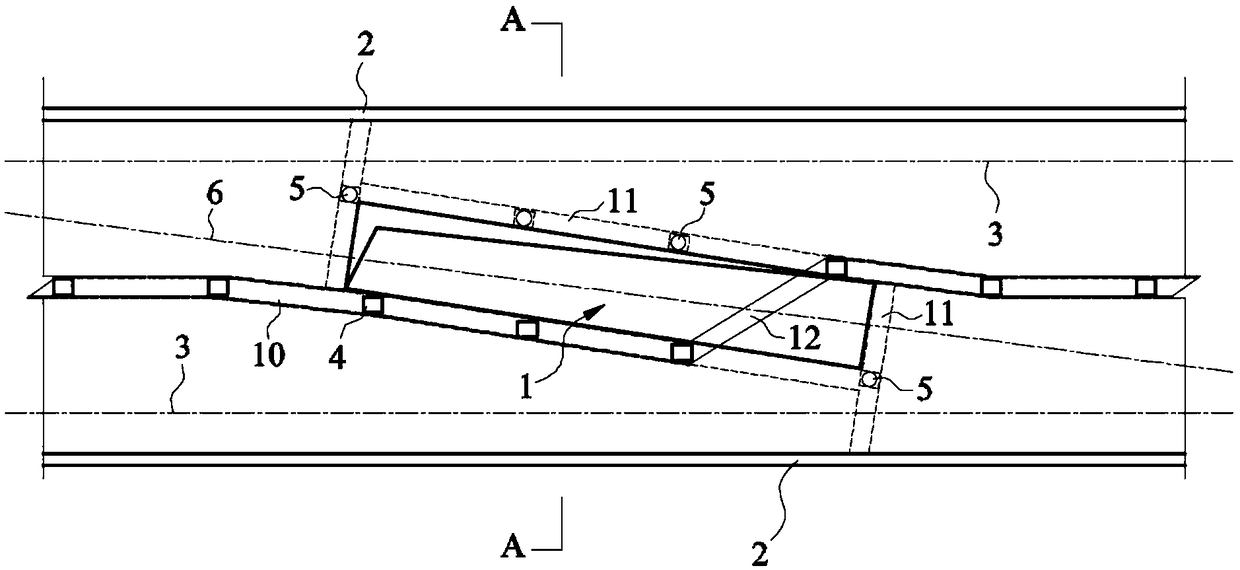

ActiveCN105256468ARealize layingAchieve overlappingWork-feeding meansPressersEngineeringMechanical engineering

The invention discloses an automatic sewing object stitching system and method. The automatic sewing object stitching system comprises a worktable, a material moving device, a material stacking device, an air draft device and a sewing device, wherein a plurality of suction holes are formed in the worktable; the material moving device is provided with a material moving board and a material moving board driving part used for driving the material moving board to move; the material stacking device comprises a first material stacking part and a second material stacking part; the first material stacking part is provided with a first core plate fixed on the material moving board; the first core plate is provided with a first sewing channel; the second material stacking part is provided with a material pressing part and a material stacking driving part arranged on the material moving board, connected to the material pressing part and used for driving the material pressing part to move so as to press sewing objects; the material pressing part is provided with a second sewing channel; the air draft device is communicated with the suction holes; the sewing device is used for sewing the sewing objects. The automatic sewing object stitching system saves time and is high in production efficiency.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

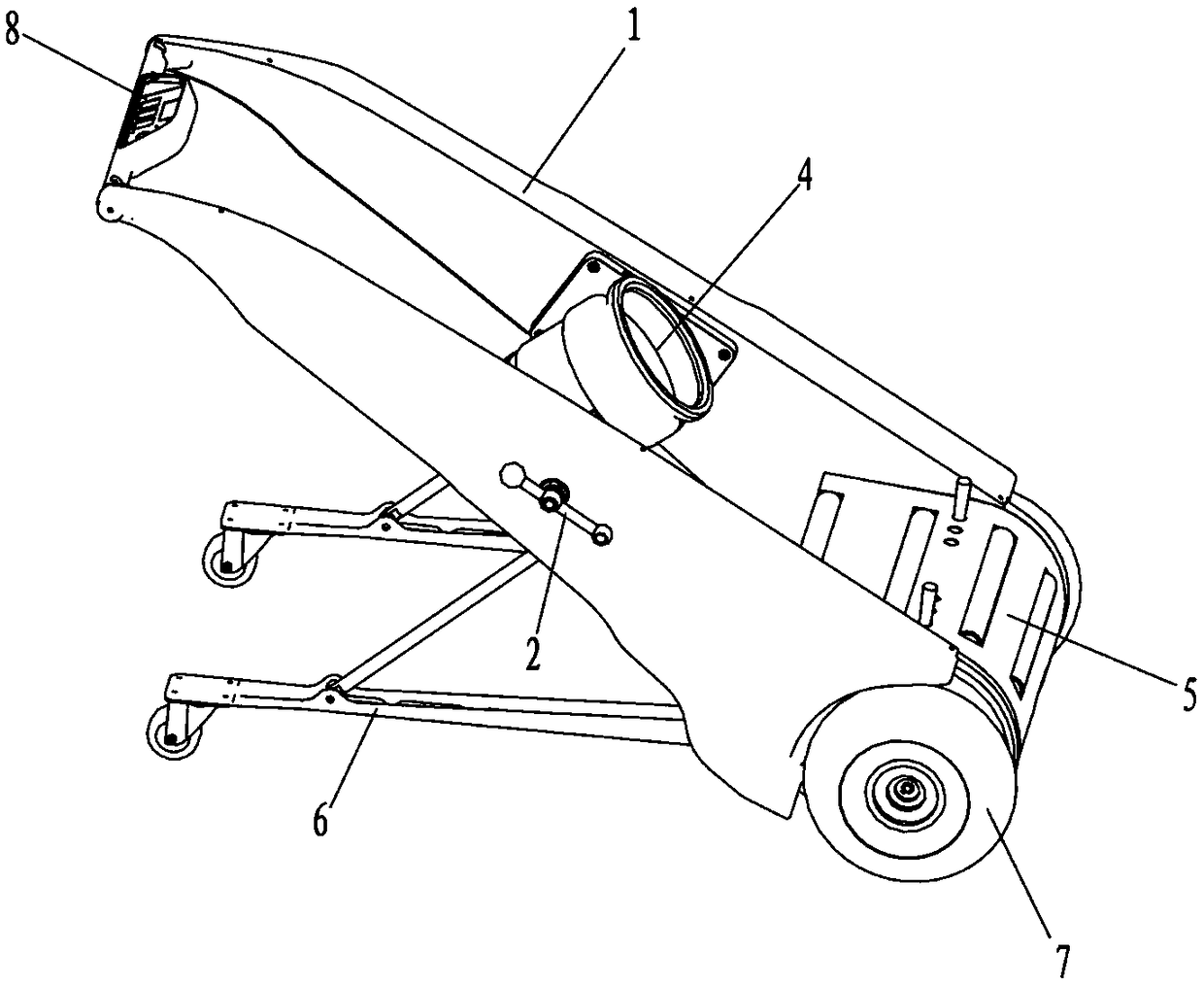

A municipal road construction device and a construction method

InactiveCN110344309AEvenly distributedFast layingRoads maintainenceArchitectural engineeringRoad construction

The invention relates to a municipal road construction device comprising a body with moving wheels mounted on both sides; the body is hinged with a support frame; and the support frame is rotatably connected with a rolling wheel; the axis of the rolling wheel is parallel to the axes of the moving wheels; and the support frame is provided with a stirring device between the body and a rolled road. Afeeding hopper is hinged at one end, away from the support frame, of the body, and a driving device for driving the rotation of the feeding hopper is mounted on the body. The body is provided with aninclined guide chute in a penetrated mode. A feeding end of the guide chute extends to a position below the feeding hopper, and a discharge end of the guide chute extends between the body and the stirring device. With the above arrangement, the concrete is guided to flow between the body and the stirring device via the guide chute, and finally falls between formworks pre-installed on the ground.When the body moves towards the direction of the feeding hopper, the stirring device and the rolling wheel move toward the concrete falling on the ground, and a relatively long and complete road can be continuously laid, which greatly reduces the construction period and labor cost.

Owner:广东隆建工程有限公司

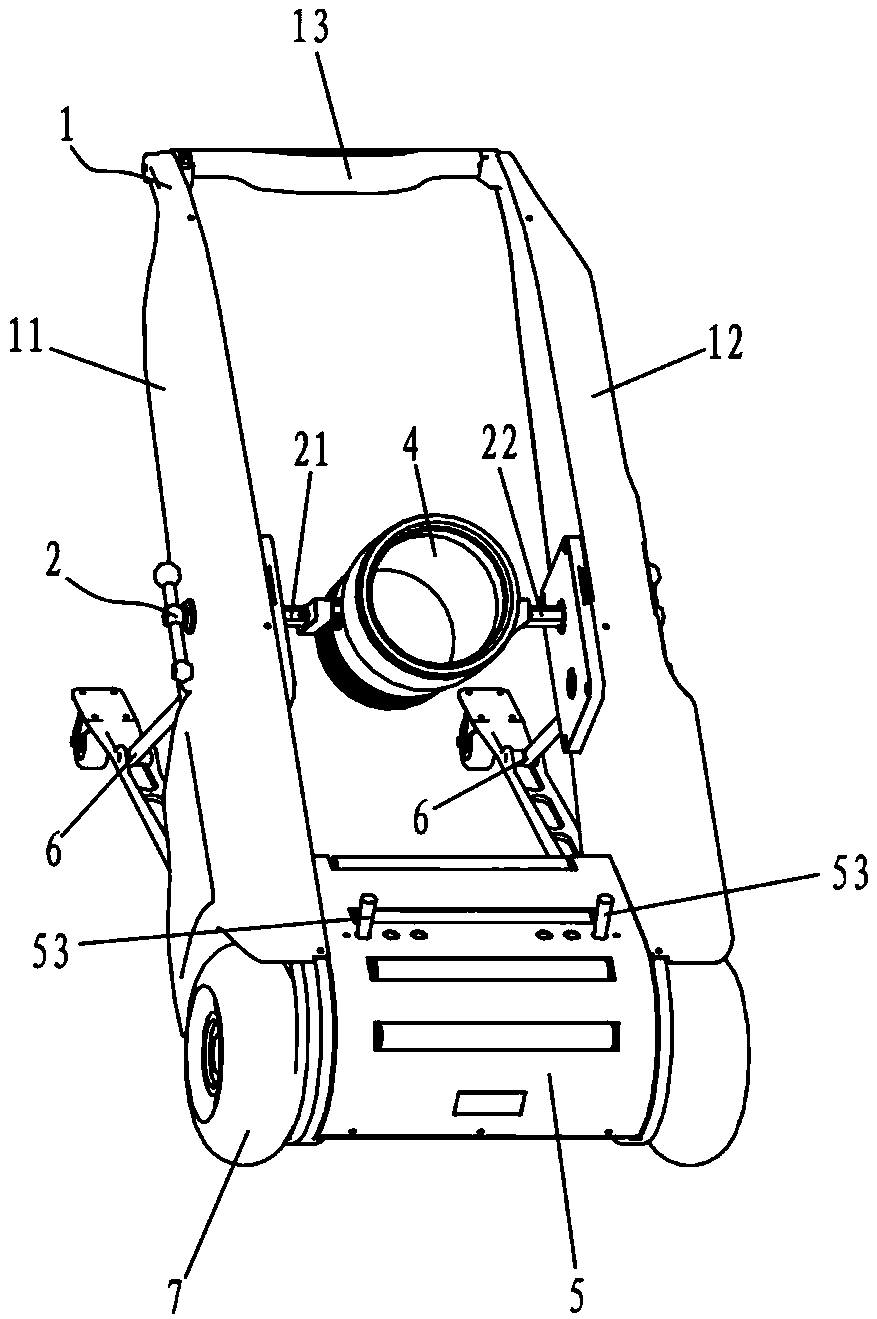

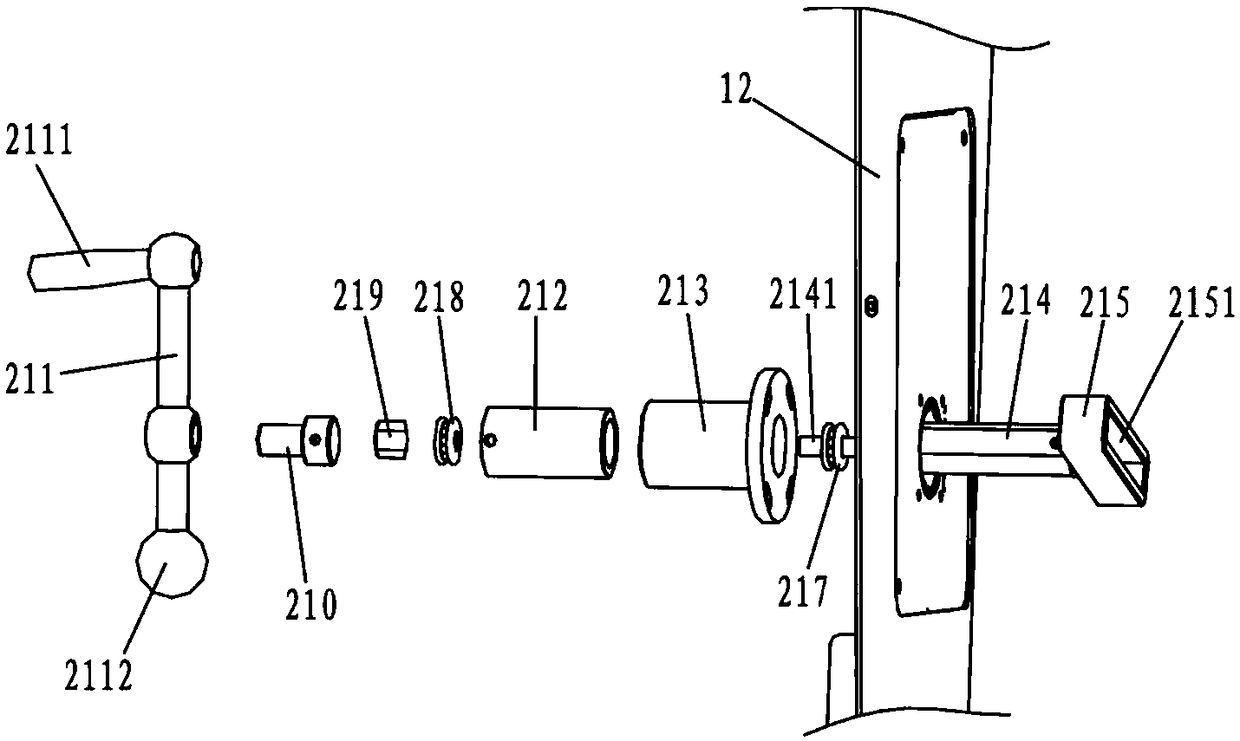

Water band laying and recovering device

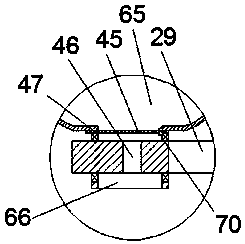

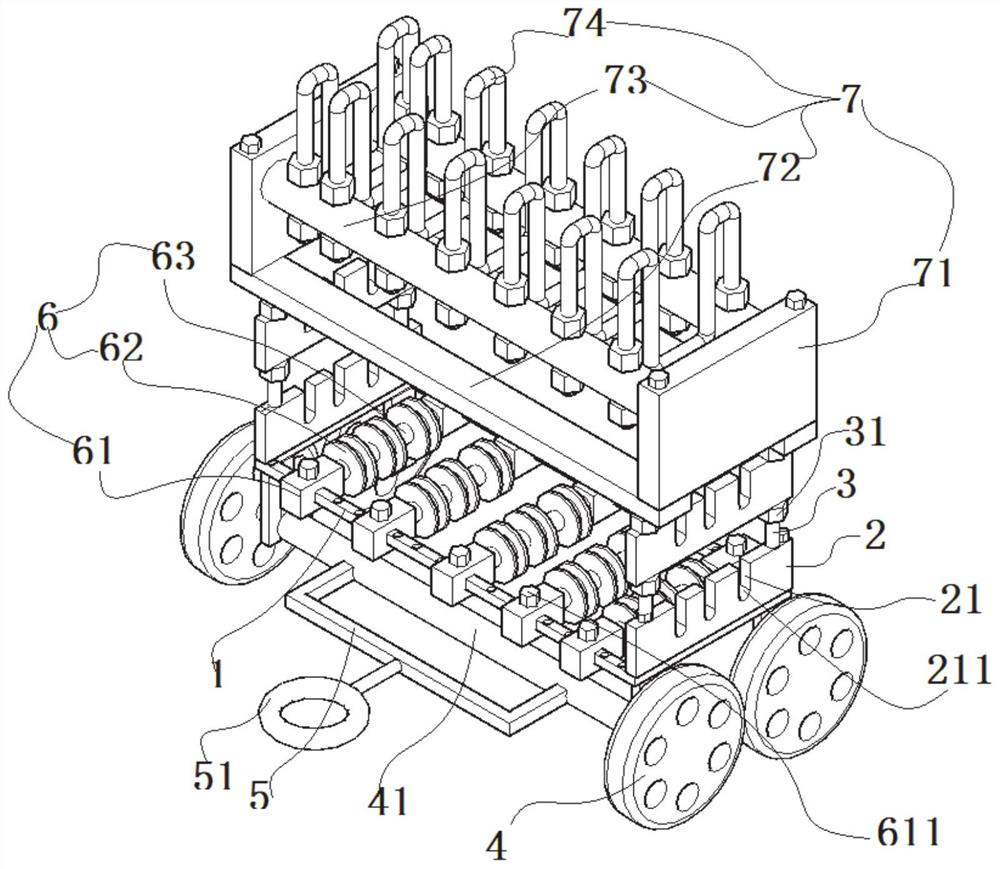

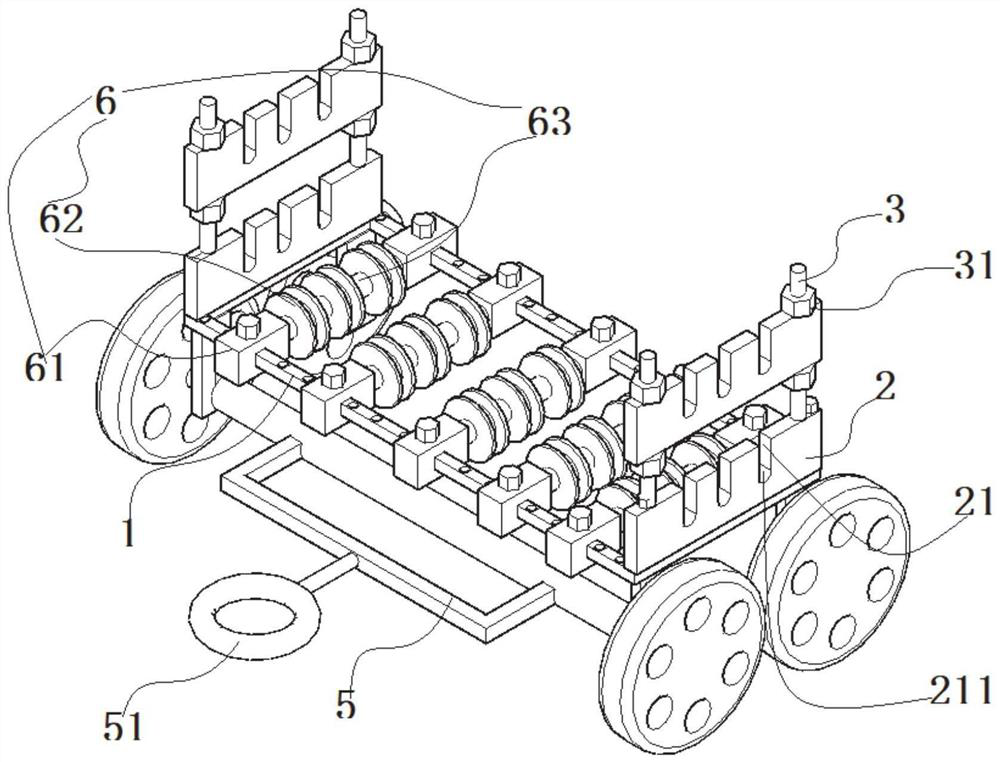

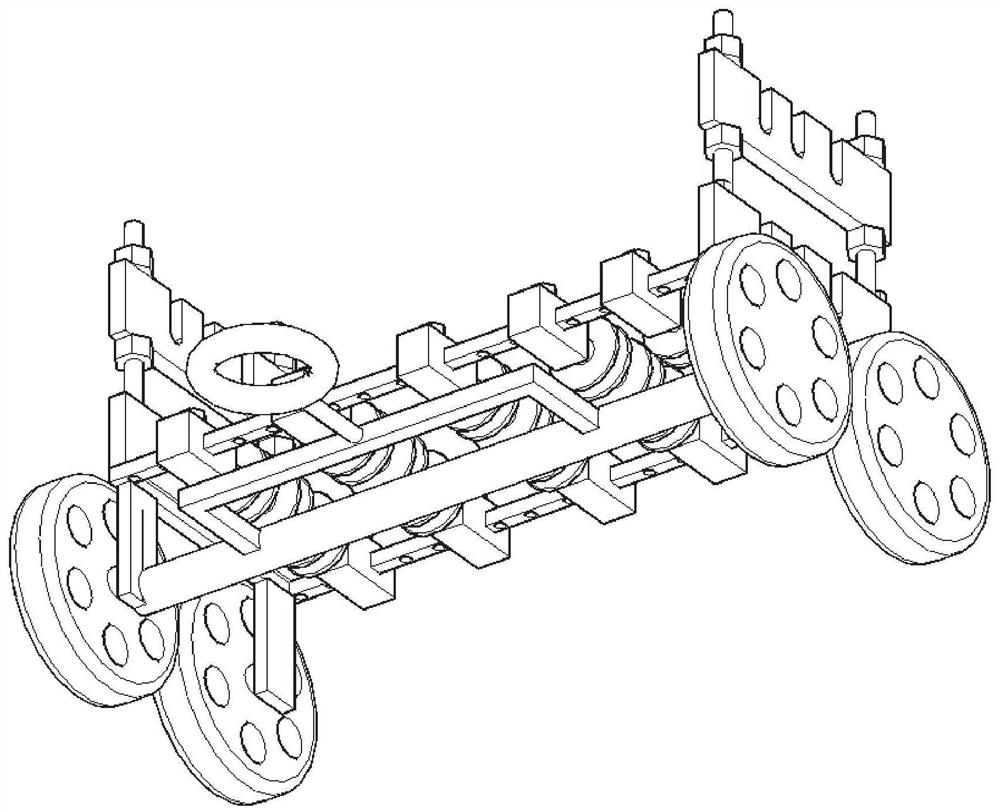

The invention relates to the field of fire-fighting emergency devices, and particularly discloses a water band laying and recovering device which comprises a frame component, a self-locking clamping mechanism, a take-up mechanism, a rapid connector, a water extrusion guide mechanism, traveling mechanisms and a water band lifting and loading mechanism. The self-locking clamping mechanism and the take-up mechanism are arranged in the middle of the frame component, the rapid connector is connected with the self-locking clamping mechanism, a water extrusion guide mechanism is arranged on the lowerportion of the frame component, the traveling mechanisms are arranged on two sides of the bottom of the frame component, the water band lifting and loading mechanism is connected with the middle of the frame component, the water band lifting and loading mechanism and the frame component form a triangle supporting structure, the self-locking clamping mechanism comprises a left clamping arm and a right clamping arm, clamping heads are arranged at the opposite ends of the left clamping arm and the right clamping arm, the rapid connector is clamped between the clamping heads, the take-up mechanism comprises a take-up driving motor and a transmission component, the transmission component comprises a driving part and a driven part, the driving part is arranged on an output shaft of the take-updriving motor, the driven part is arranged on the self-locking clamping mechanism, the take-up driving motor drives the driving part to rotate, so that the driven part drives the rapid connector to rotate, and take-up and pay-off of a water band is completed.

Owner:广州多钛克机械科技有限公司

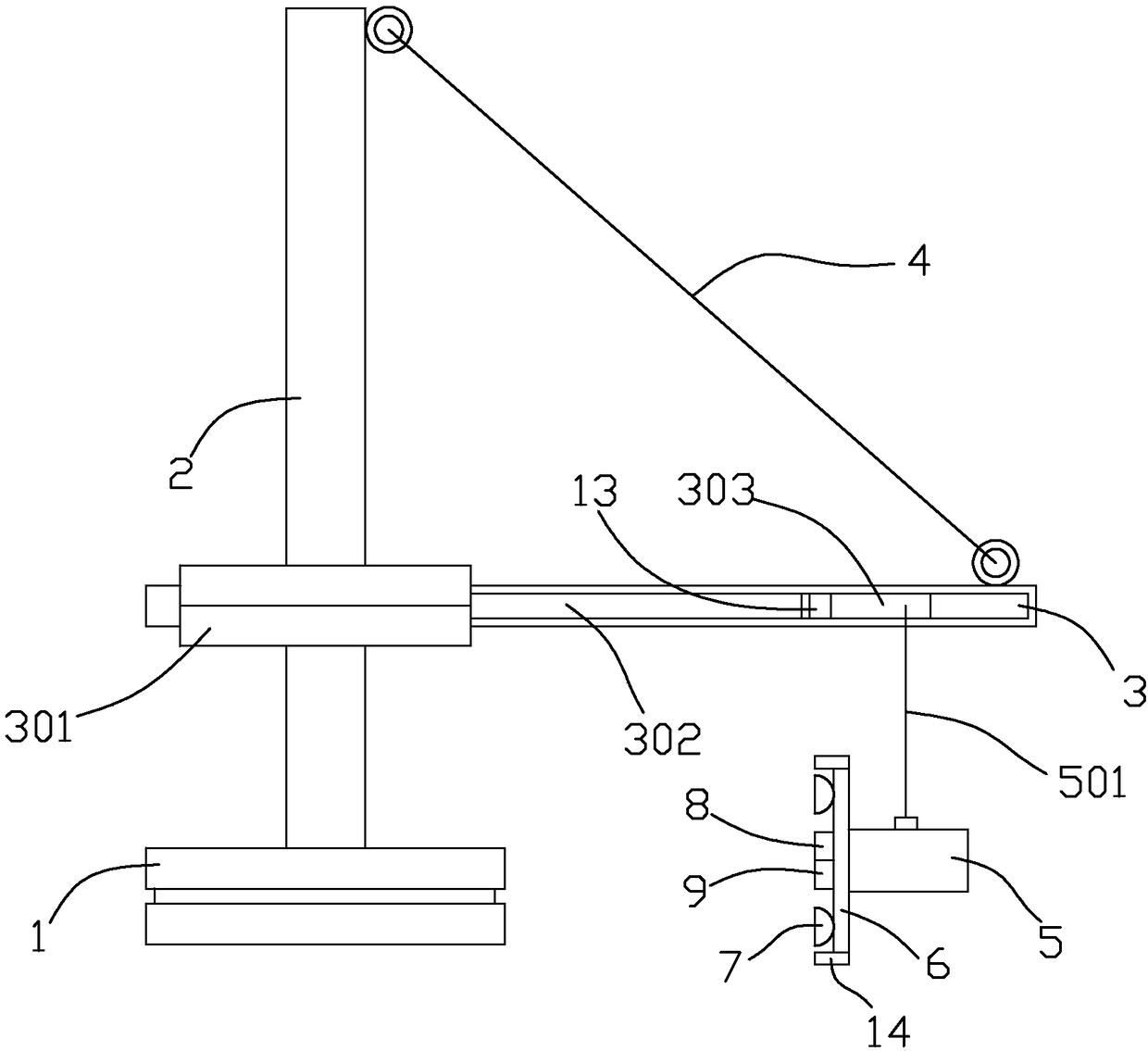

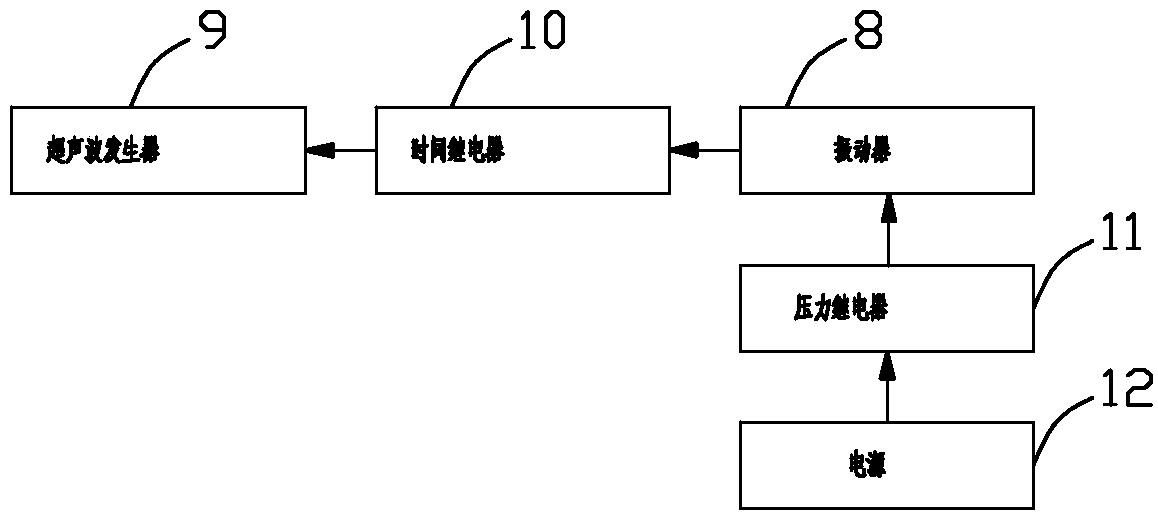

Tiling device

The invention relates to a tiling device which comprises a positioning base, a supporting shaft and a telescopic rod. The supporting shaft is vertically arranged at the upper end of the positioning base; one end of the telescopic rod is connected with the supporting shaft through a positioning bushing; the telescopic rod is connected with the supporting shaft through a stay cord capable of being rolled up; the telescopic rod is provided with a slide slot provided with a slider inside; a winch is arranged below the slider, and is connected with the slider through a load-bearing rope; a tiling plate is arranged at one side of the winch and is fixedly connected with the winch; two suckers are arranged at the side, away from the winch, of the tiling plate; a vibrator and an ultrasonic wave generator are arranged between the two suckers; a power input end of the ultrasonic wave generator is connected with a power input end of the vibrator through a time relay, and a power input end of the vibrator is connected with a power source through a pressure relay. Compared with the prior art, the tiling device has the advantages of realizing tiling on wall surfaces and improving tiling quality.

Owner:荣达新型建材(福建)集团有限公司

Cable threading device

The invention provides a cable threading device. The cable threading device comprises a hard penetrating rod and a cylindrical extrusion buffer part, wherein the hard penetrating rod can penetrate into a fireproof sealing material; a fixing hole for a cable to be laid to penetrate is formed in the tail end of the hard penetrating rod; the cylindrical extrusion buffer part is used for fixing the cable in the fixing hole, is arranged in the fixing hole and is in contact with the hole wall of the fixing hole; the inner hole diameter of the cylindrical extrusion buffer part is smaller than the outer diameter of the cable. The cable is directly driven to penetrate the fireproof sealing material together through the hard penetrating rod, the condition that the cable cannot penetrate caused by the shrinkage of the fireproof sealing material can be avoided, the cable is convenient to penetrate, and the cable can penetrate after once puncturing of the hard penetrating rod, so that the wok efficiency of laying the cable later is improved.

Owner:STATE GRID CORP OF CHINA +1

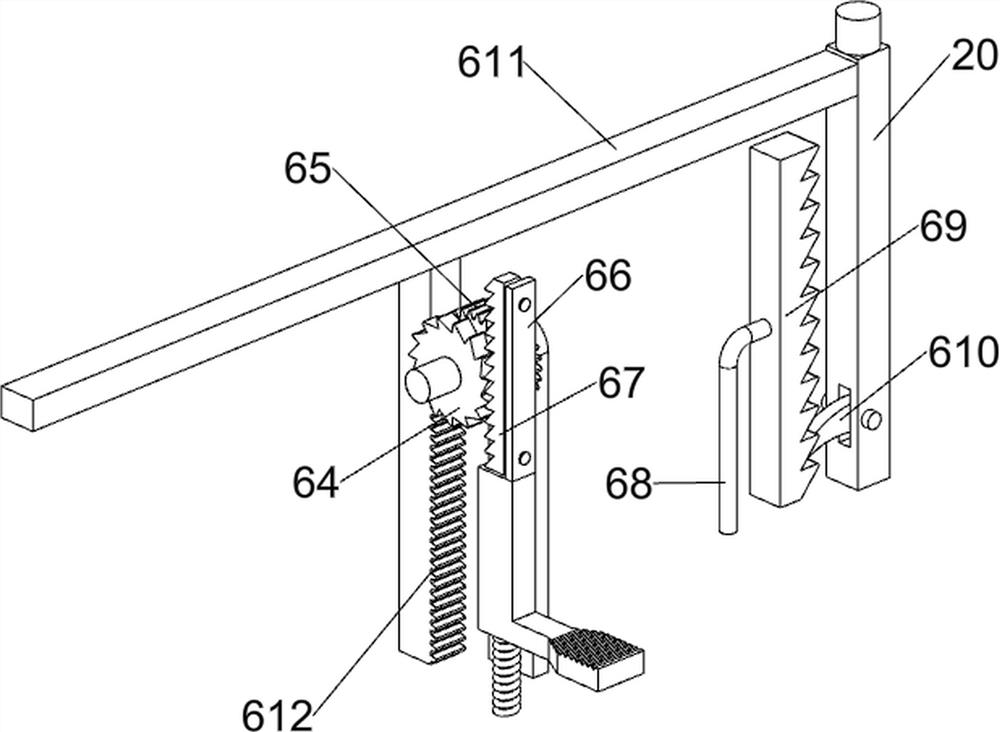

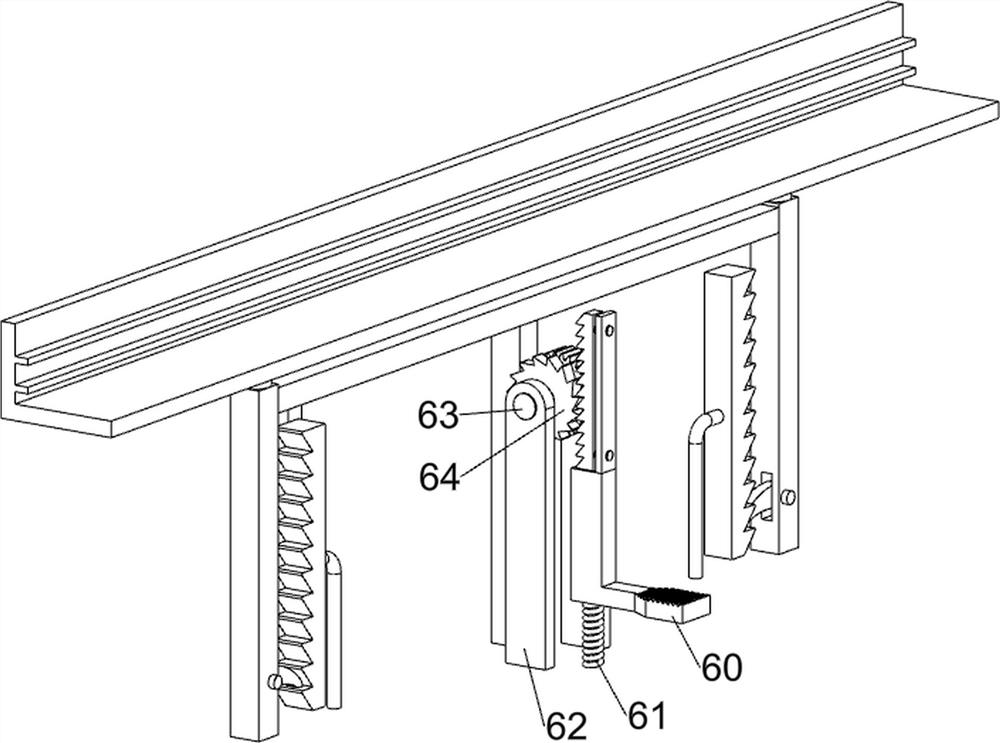

Automatic bricklaying trolley for building construction

ActiveCN112538977AAchieving continuous laying to the rightRealize layingBuilding material handlingBrickArchitectural engineering

The invention relates to a bricklaying trolley, in particular to an automatic bricklaying trolley for building construction. The automatic bricklaying trolley for the building construction is convenient to operate, brick plates do not need to be laid manually, and bricklaying can be conducted at different heights. The automatic bricklaying trolley for the building construction comprises bases anda brick conveying mechanism, wherein a moving mechanism is arranged between the bases, and the brick conveying mechanism is arranged on the moving mechanism. According to the trolley, intermittent laying and intermittent conveying of the brick plates are achieved through the brick conveying mechanism, then continuous rightward laying of the brick plates is achieved under cooperation of the movingmechanism, cement is laid through arrangement of a material laying mechanism, then, under the cooperation of the brick conveying mechanism, the brick plates are conveyed to the material laying mechanism, the material laying mechanism operates to enable the brick plates to stably fall onto the cement, and therefore bricklaying can be better conducted.

Owner:天长市石梁建设工程有限公司

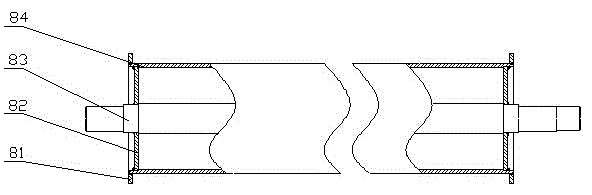

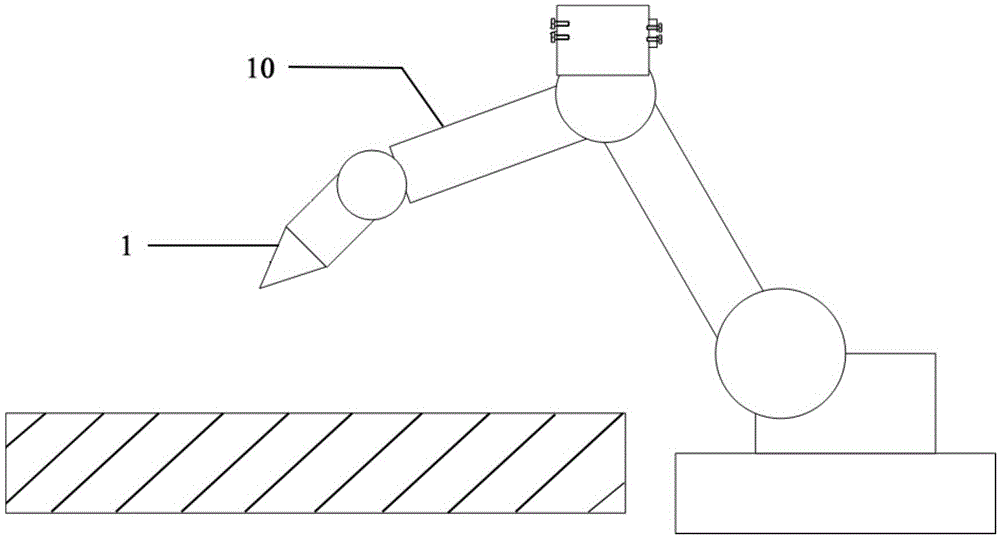

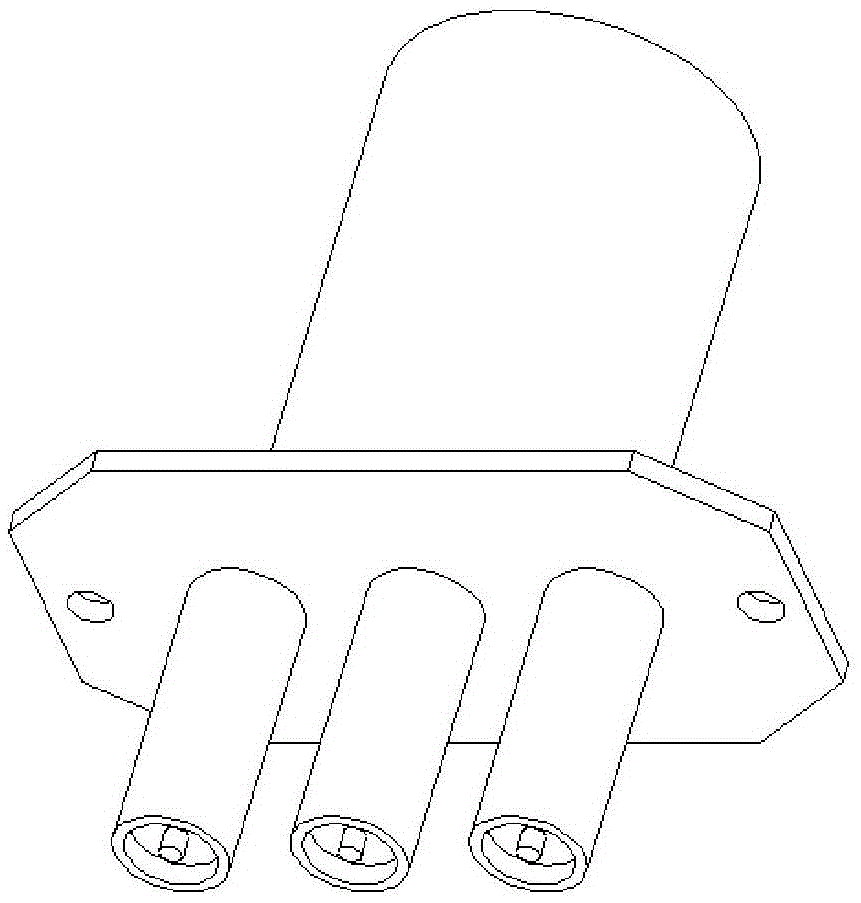

A device and method for automatic film laying of composite material preforms

The invention discloses a device and method for automatically laying a composite preformed body in a film-mounting manner. The device is characterized in that a supply system, a hot press roll system, a laying compression and pressure adjusting device and a conveying guide wheel are arranged on a rack. The method comprises the following steps: conveying fibers and resin films supplied by the supply system to the hot press roll system for pressing the fibers and the resin films into half prepreg tapes, conveying the half prepreg tapes to the laying compression and pressure adjusting device, enabling a laying arm of a robot to drive the rack for driving the laying compression and pressure adjusting device to lay the half prepreg tapes on a core mold, and adjusting the laying pressure and the laying path in real time as needed to obtain the preformed body. According to the device and the method, the fiber laying angle can be changed according to the needs of the laying path, the fiber-resin ratio of the composite preformed body can be accurately controlled, the subsequent processing processes of the preformed body and the material waste are reduced, the laying quality of the preformed body is high, the compatibility between the preformed body and other composite material forming process is good, and various preformed bodies with different fiber / resin systems can be formed.

Owner:陕西普立通复材科技有限公司

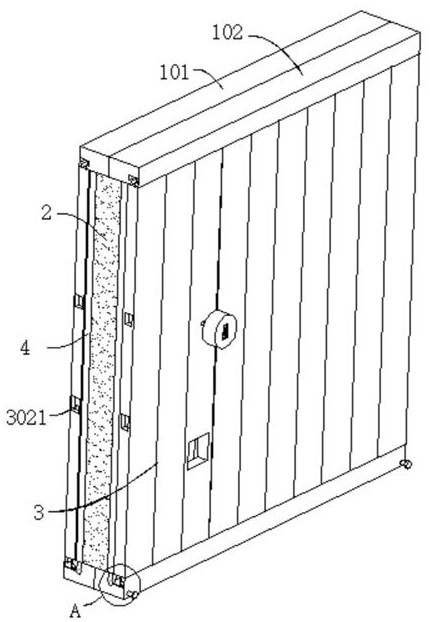

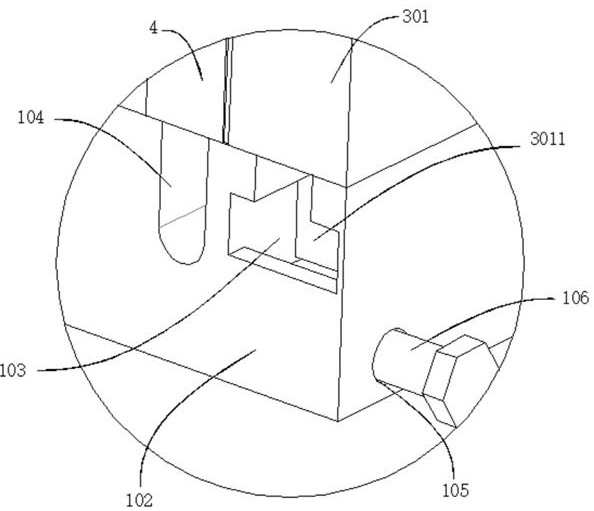

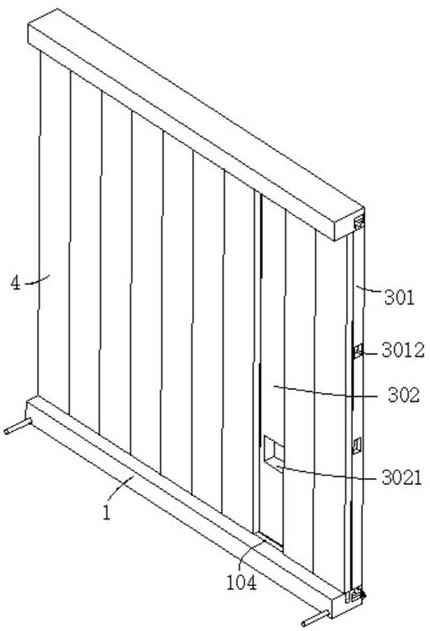

Prefabricated building partition wall structure based on BIM technology

ActiveCN112196145AImprove on-site construction efficiencyRealize layingWallsConstruction engineeringMechanical engineering

The invention discloses a prefabricated building partition wall structure based on a BIM technology, and belongs to the technical field of building partition walls. The prefabricated building partition wall structure based on the BIM technology comprises two fixing bases, a partition wall body and two decorative wallboards are connected between the two fixing bases, the two decorative wallboards are connected to the outer walls of the two sides of the partition wall body respectively, the decorative wallboards comprise the first wallboard and the second wallboard, and moving blocks are fixedlyconnected to the top and the bottom of the first wallboard. Moving grooves matched with the moving blocks are dug in the outer walls of the fixing bases, a socket groove is dug in the outer wall of the second wallboard, and a positioning mechanism is arranged in the second wallboard. The prefabricated building partition wall structure is simple in structure and convenient to assemble and disassemble, after factory prefabrication, a partition wall and a circuit pipeline can be laid at a time on site, on-site slotting is not needed, dust is avoided, the construction period is short, the comprehensive cost of prefabricated assembly is effectively reduced, and meanwhile the on-site construction efficiency of the partition wall is improved.

Owner:深圳市利德行投资建设顾问有限公司

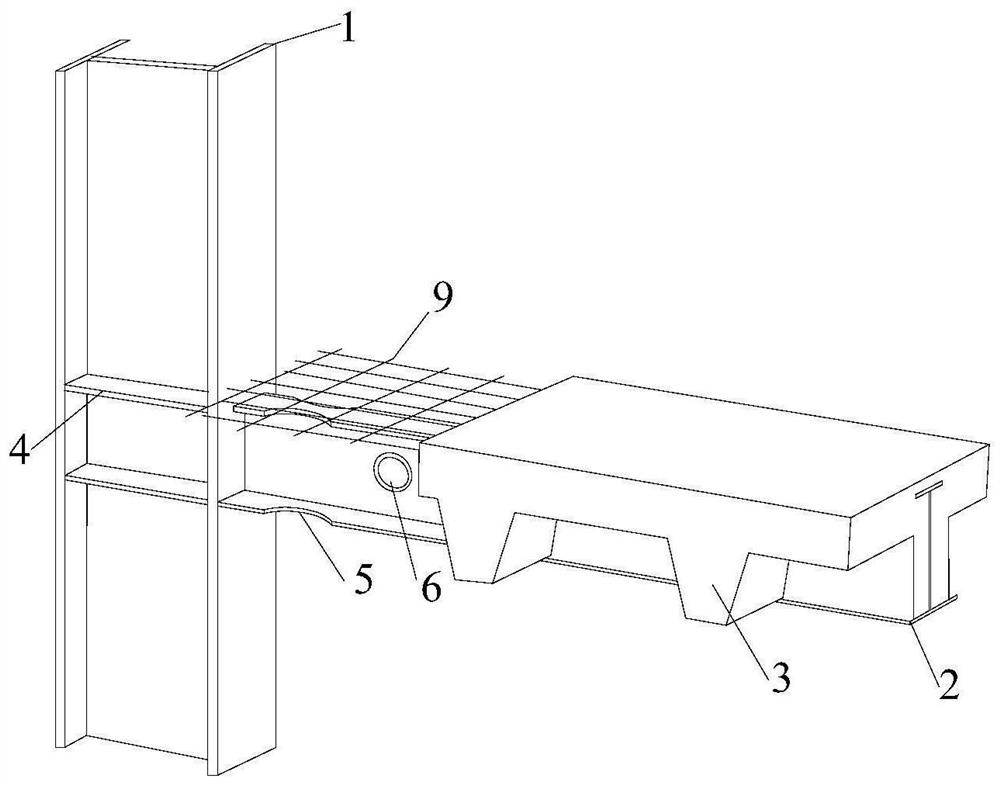

Canine bone-honeycomb type combined flat beam connecting joint

The invention discloses a canine bone-honeycomb type combined flat beam connecting joint, and relates to the technical field of building structures. The canine bone-honeycomb type combined flat beam connecting joint comprises a profile steel component and a profiled steel plate-concrete combined floor slab, wherein the profile steel component is an I-shaped steel column, and the left flange and the right flange of the I-shaped steel column are equal in width; the I-shaped steel column is perpendicular to an I-shaped steel beam, the middle of the right flange of the I-shaped steel column is fixed to the left end of the I-shaped steel beam, the lower flange of the I-shaped steel beam is wider than the upper flange, the upper flange and the lower flange are equal in thickness, and the lower flange and the right flange of the I-shaped steel column are equal in width; and the profiled steel plate-concrete combined floor slab comprises a profiled steel plate which is welded to the lower flange of the I-shaped steel beam in a lap joint mode, a concrete floor slab is arranged above the profiled steel plate, and a reinforcing mesh penetrates through the concrete floor slab. The canine bone-honeycomb type combined flat beam connecting joint has the advantages that the end flanges of the I-shaped steel beam are weakened in a canine bone mode, stress concentration of a honeycomb type combined flat beam joint welding seam area is relieved, the risk of brittle fracture of the joint area under the action of cyclic load is avoided, outward movement of a plastic hinge is realized, and the anti-seismic property is good.

Owner:CHANGAN UNIV

Plastic film laying and compacting device

InactiveCN108834532AHigh degree of automationLabor savingPressurised distribution of liquid fertiliserPlant protective coveringsPlastic filmTurbine

The invention discloses a plastic film laying and compacting device. The plastic film laying and compacting device comprises a main machine frame and a fertilizing device arranged on the lower side ofthe main machine frame, wherein first machine frames are symmetrically arranged on the left and right end surfaces of the main machine frame; a second machine frame is in rotational fit with the lower side of the first machine frame; a front wheel shaft is rotationally connected to the left side of the second machine frame; front wheels in front-and-back symmetry are fixedly arranged on the frontwheel shaft; a back wheel shaft is rotationally connected to the back side of the second machine frame; back wheels in front-and-back symmetry are fixedly arranged on the back wheel shaft; a first driven belt wheel is fixedly arranged between the second machine frame and the back wheel on the front side; a motor is fixedly arranged on the lower end surface of the main machine frame; a power shaftis in power connection with the front side of the motor; a first driving belt wheel is fixedly connected to the power shaft; the first driving belt wheel and the first driven belt wheel are connectedthrough a belt; and a turbine is fixed to the front end of a rotating shaft.

Owner:YICHANG HUIYIXING NEW ENERGY TECH CO LTD

Energy-saving automatic sowing and film mulching device

PendingCN110731142ARealize layingImprove battery lifePlantingClimate change adaptationGreenhouseAgricultural engineering

The invention belongs to the technical field of agricultural machinery and discloses an energy-saving automatic sowing and film mulching device. The energy-saving automatic sowing and film mulching device comprises a frame, a solar panel is fixedly arranged on the upper surface of the frame, and a motor is arranged on the upper surface of the frame, and a top plate is arranged on the upper surfaceof the frame. The energy-saving automatic sowing and film mulching device has advantages that by cooperation of a sowing device, film pressing wheels, furrowers, seeding apparatuses, traveling devices, covering devices and sensing devices, mulch films are pressed to the ground by the film pressing wheels, and soil on two sides can be turned to the surfaces of the mulch films by the covering devices, so that sowing and film mulching processes can be carried out at the same time, simple positioning of the mulch films can be realized by soil covering through the covering devices, and operating efficiency can be greatly improved. In addition, by adoption of solar energy as driving force, cleanness and environmental friendliness are realized, and production cost is reduced. Due to a battery pack carried on the device, endurance of the energy-saving automatic sowing and film mulching device is greatly improved, and the energy-saving automatic sowing and film mulching device can be used outdoors and greenhouses.

Owner:DEZHOU VOCATIONAL & TECHN COLLEGE

Mining cable protection device

InactiveCN108666939AAvoid damageIncrease capacityElectrical apparatusEngineeringElectrical and Electronics engineering

Owner:ZIBO HUAYUAN MINING CO LTD

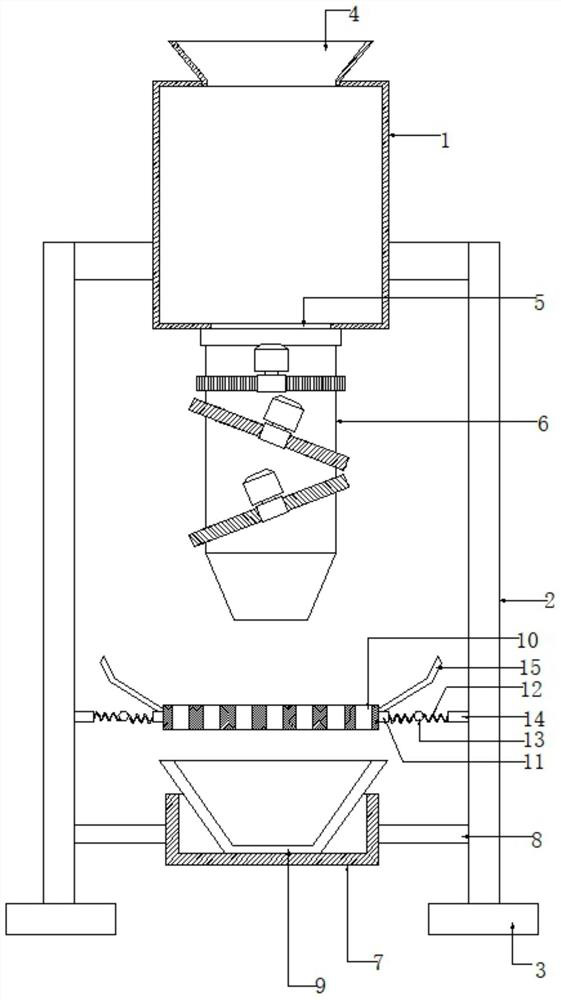

Rolling type small flowerpot soil spreading device used for garden for simulating of running robot

InactiveCN113079874AAvoid affecting transplanting workRealize the rolling functionSievingScreeningAgricultural engineeringEnvironmental geology

The invention discloses a rolling type small flowerpot soil spreading device used for a garden for simulating of a running robot. The rolling type small flowerpot soil spreading device comprises a box body, wherein the bottom parts of two sides of the box body are independently provided with supporting frames; the bottom of each supporting frame is provided with a supporting foot; the top of the box body is provided with a material feeding hopper; the bottom of the box body is provided with a material outlet; a material discharging part is arranged below the material outlet; a rolling device is arranged in the box body; the lower part between the supporting frames on two ends is provided with a fixing frame; in addition, two sides of the fixing frame are independently fixedly connected with the lower parts of the corresponding side edges of the supporting frames through a horizontal plate; and a flowerpot body is arranged in the fixing frame. The rolling type small flowerpot soil spreading device has the beneficial effects that the rolling device capable of simulating the structural form of the running robot is adopted to roll soil to avoid a phenomenon that caking soil directly falls into the flowerpot to affect subsequent transplantation work, meanwhile, working labor force of a manual operation is reduced, and working efficiency is improved.

Owner:夏爱莲

Optical cable laying construction vehicle suitable for stony soil

ActiveCN110989120ARealize layingEasy outflowOptical fibre/cable installationAgricultural engineeringStructural engineering

The invention provides an optical cable laying construction vehicle suitable for stony soil, and belongs to the field of telecommunication engineering. The optical cable laying construction vehicle suitable for stony soil comprises a vehicle body, a first wheel, a second wheel, a third wheel and a fourth wheel. The vehicle body comprises a front vehicle body and a rear vehicle body; a first mounting plate is arranged on the front vehicle body, a first support and a second support are rotationally arranged on the first mounting plate, the first wheel and the second wheel are rotationally arranged on the first support and the second support respectively, a second mounting plate is arranged on the rear vehicle body, a third support and a fourth support are rotationally arranged on the secondmounting plate, and the third wheel and the fourth wheel are rotationally arranged on the third support and the fourth support respectively; a primary furrowing coulter is fixed on the front vehicle body, a secondary furrowing coulter is arranged on the rear vehicle body, a wire guide plate is fixed on the secondary furrowing coulter, the upper end of the wire guide plate penetrates out of the upper surface of the rear vehicle body, and a wire guide through hole is vertically formed in the wire guide plate. The optical cable laying device has the advantage that optical cable laying at different depths can be achieved more flexibly according to complex terrains.

Owner:QUZHOU UNIV

Guide-rail-free color steel tile clamp structure and using method thereof

ActiveCN114525892AImprove practicalityAchieve installationPhotovoltaic supportsRoof covering using slabs/sheetsEngineeringStructural engineering

Owner:XIAMEN ANTAI NEW ENERGY TECH

Track panel well system based on subway station with single cross line

PendingCN109339108AAvoid Cantilevered SituationsEnsure structural stabilityArtificial islandsUnderwater structuresSubway stationCantilever

The invention discloses a track panel well system based on a subway station with a single cross line, and belongs to the technical field of track traffic construction. A track panel well is arranged on the subway station with the single cross line, so that the track panel well is arranged directly above the single cross line, the situation that station side walls in a track panel well range are located in a cantilever state in the construction of a traditional track panel well can be effectively avoided, and under the circumstance of ensuring the structural safety of the subway station, a function of track panel well hoisting track panels is realized. According to the rack panel well system based on the subway station with the single cross line, the structure is simple, the arrangement issimple and convenient, hoisting and laying of the track panels can be effectively realized, a large-range cantilever of the station side walls when the traditional track panel well is established is avoided, the structural stability and safety of the subway station in the establishment process of the track panel well are ensured, the construction period of subway engineering is shortened, the construction cost is reduced, and the rack panel well system based on the subway station with the single cross line has larger popularization and application value.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

Plastic thin film laying device

InactiveCN108934655AHigh degree of automationLabor savingFertiliser distributersPlant protective coveringsEngineeringPlastic film

The invention discloses a plastic thin film laying device. The device comprises a main rack and a fertilization device arranged on the lower side of the main rack, first racks are symmetrically arranged on the left end face and the right end face of the main rack, a second rack is rotationally cooperatively arranged on the lower side of the first rack, a front axle is rotationally connected to theleft side of the second rack, front wheels which are symmetrical front and back are fixedly arranged on the front axle, a rear axle is rotationally connected to the rear side of the second rack, rearwheels which are symmetrical front and back are fixedly arranged on the rear axle, and a first driven belt pulley is fixedly arranged between the second rack and the rear wheel on the front side; a motor is fixedly arranged at the lower end of the main rack, a power shaft is in power connection with the front side of the motor, a first driving belt pulley is fixedly connected to the power shaft and connected with the first driven belt pulley through a belt, and a turbine is fixedly arranged at the front end of a rotating shaft.

Owner:YICHANG HUIYIXING NEW ENERGY TECH CO LTD

High-voltage power cable laying device

ActiveCN112520487AAchieve installationRealize layingFilament handlingApparatus for laying cablesPower cableStructural engineering

The invention discloses a high-voltage power cable laying device. The high-voltage power cable laying device comprises a rectangular frame rod, wherein a plurality of cable unwinding parts arranged atintervals on the left side and the right side are connected to the rectangular frame rod in a sliding mode; each cable unwinding part comprises bearing mounting seats which are connected to the frontside and the rear side of the rectangular frame rod in a sliding mode; an unwinding shaft is rotatably connected between the bearing mounting seats; each unwinding shaft is fixedly connected with a plurality of unwinding wheels which are arranged at intervals in a direction from front to back; a winding groove is formed in each unwinding wheel; cable guide grid plate parts are fixedly connected to the left end and the right end of the rectangular frame rod; each cable guide grid plate part comprises two cable guide grid plates which are arranged at intervals at the upper part and the lower part; each cable guide grid plate is provided with a plurality of cable guide openings matched with the corresponding winding grooves; and two height adjusting parts which are arranged at intervals in adirection from front to back are used for adjusting the height between the cable guide grid plates. Through adoption of the part design of the device, the laying and mounting efficiency of the cablesis effectively improved.

Owner:国网山东省电力公司曲阜市供电公司 +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com