Guide-rail-free color steel tile clamp structure and using method thereof

A technology of color steel tiles and no guide rails, which is applied to the supporting structure of photovoltaic modules, roofs using tiles/slate tiles, roofs using flat panels/curved panels, etc., which can solve the problems of water leakage at splicing joints and adaptive adjustment of photovoltaic modules , It is difficult to complete the rapid splicing of two or two color steel tiles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

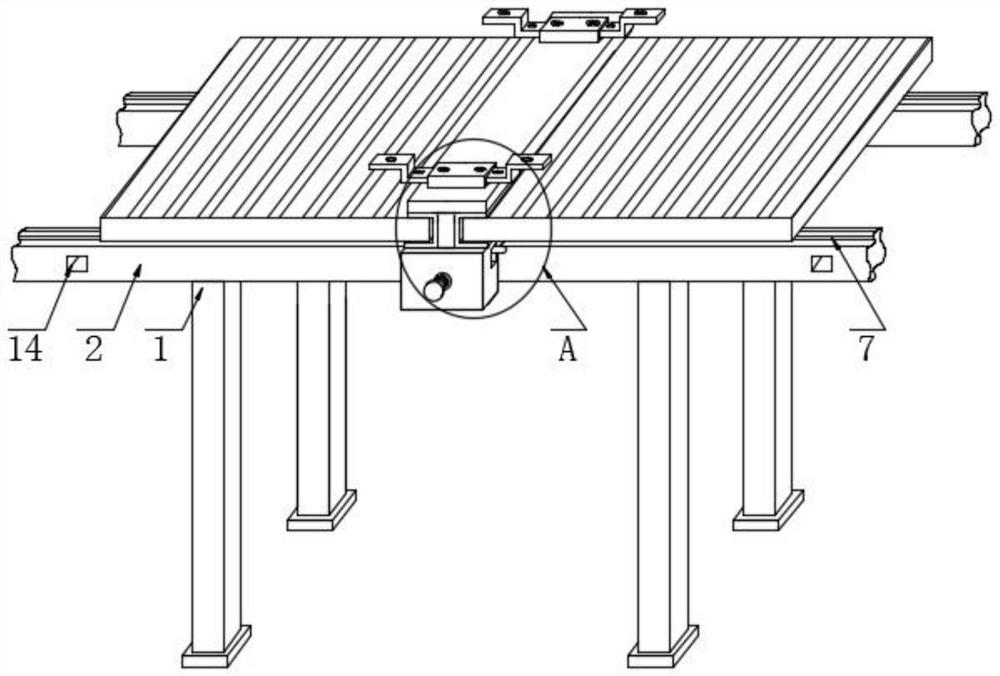

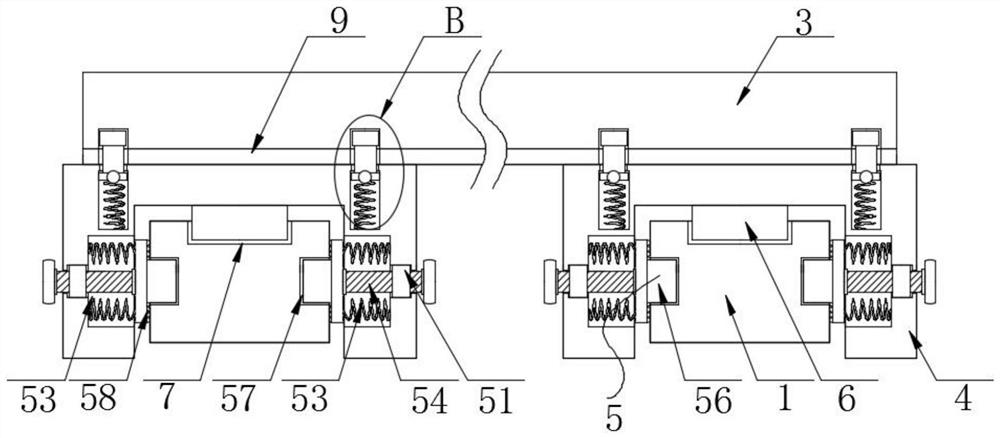

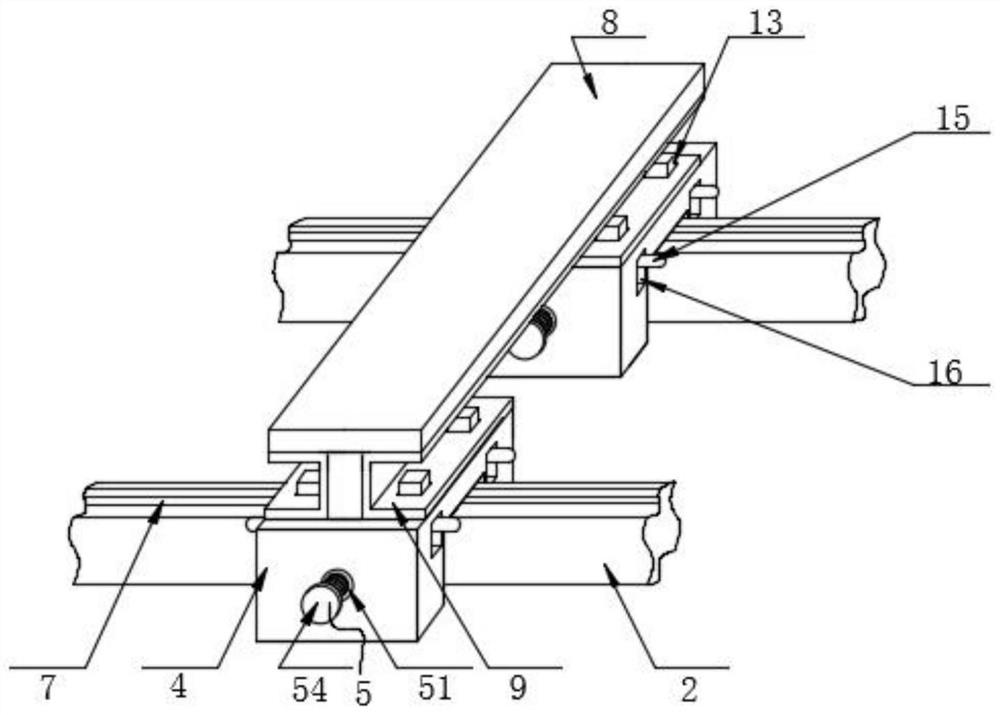

[0034]A rail-free color steel tile clamp structure, comprising a bracket 1 and a beam 2 fixedly connected to the top of the bracket 1, the color steel tiles 3 are movably connected to both sides of the top of the beam 2, and the top of the beam 2 is slidably connected with a mounting block 4. , the front and back sides of the mounting block 4 are provided with movable grooves 10, and the bottom of the inner wall of the movable groove 10 is fixedly connected with a clamping spring 11, the top of the clamping spring 11 is fixedly connected with a sliding plate 12, and the top of the sliding block 6 is fixedly connected A plug-in block 13 is fixedly connected. The top movable groove 10, the sealing gasket 9 and the color steel tile 3 of the plug-in block 13 extend to the interior of the color steel tile 3. The front and back of the bottom side of the color steel tile 3 are provided with plug-in sockets. The slot 14 that the block 13 is adapted to, one side of the sliding plate 12 ...

Embodiment 2

[0036] A rail-free color steel tile clamp structure, comprising a bracket 1 and a beam 2 fixedly connected to the top of the bracket 1, the color steel tiles 3 are movably connected to both sides of the top of the beam 2, and the top of the beam 2 is slidably connected with a mounting block 4. , a T-shaped plate 8 is fixedly connected between the tops of the two mounting blocks 4, and a sealing gasket 9 is fixedly connected to the inner wall of the T-shaped plate 8. The setting of the sealing gasket 9 can prevent the connection between the two color steel tiles 3 There is a problem of water leakage, the front and back of the top of the T-shaped plate 8 are fixedly connected with a fixed frame 17, and both sides inside the fixed frame 17 are movably connected with a connecting plate 18. The top of the connecting plate 18 and the two sides of the top of the fixed frame 17 Corresponding threaded holes 19 are provided on both sides, and a clamping mechanism 5 is arranged inside the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com