Patents

Literature

113results about How to "Extend storage time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

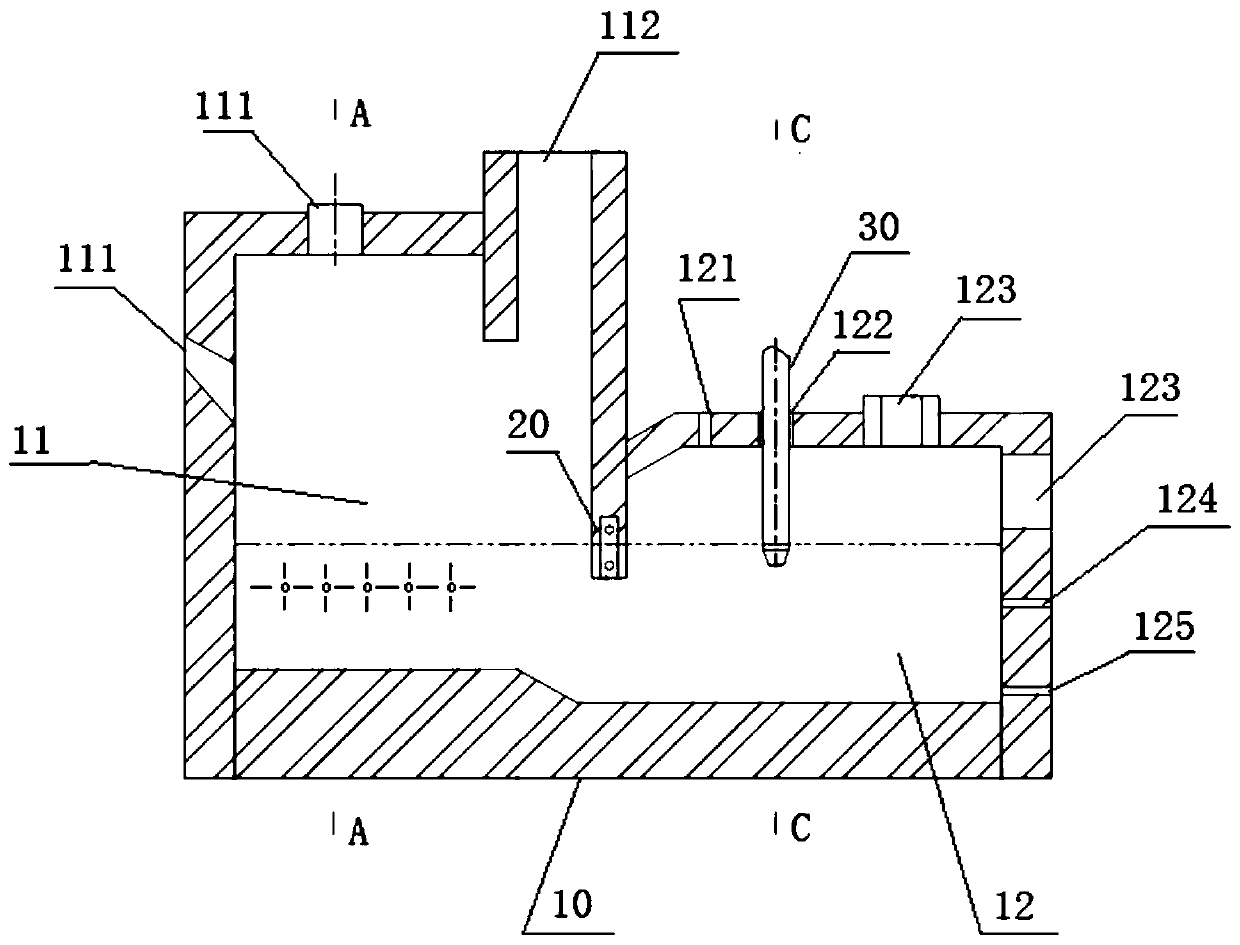

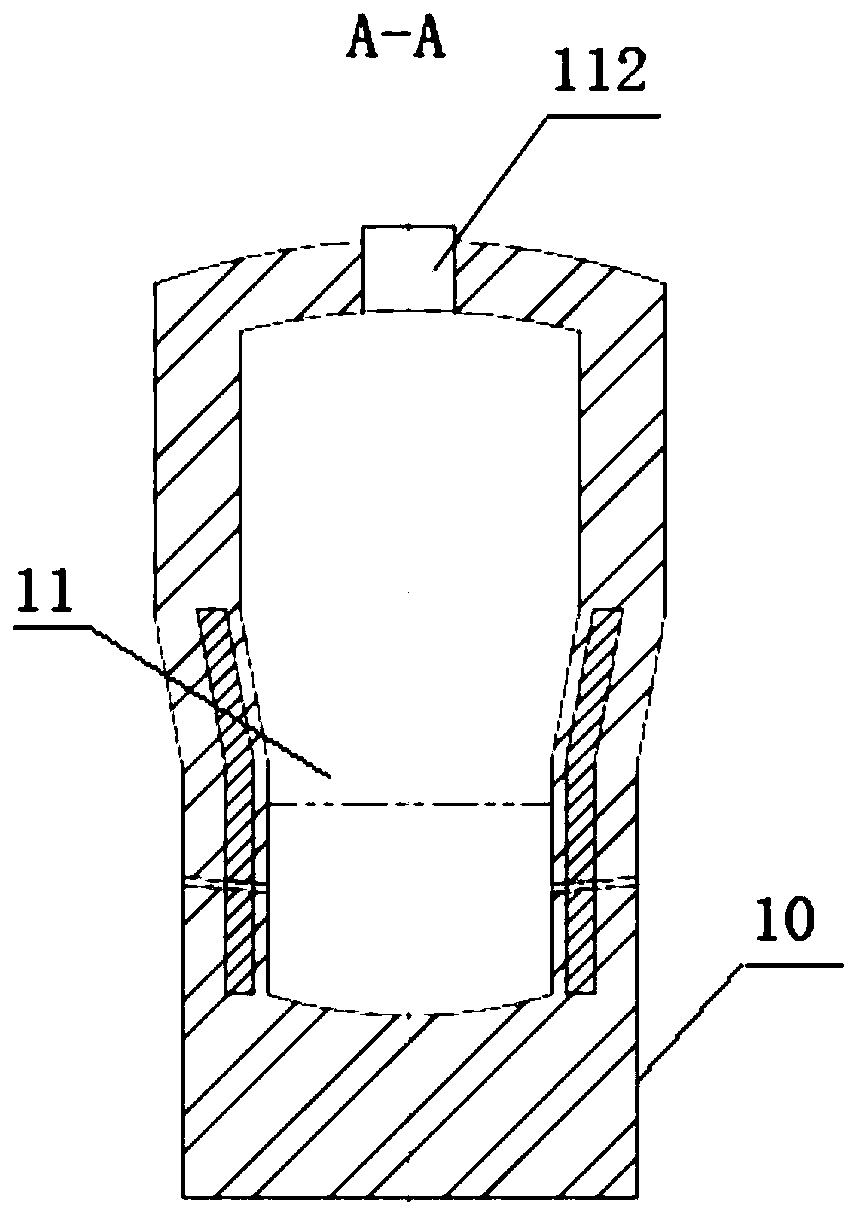

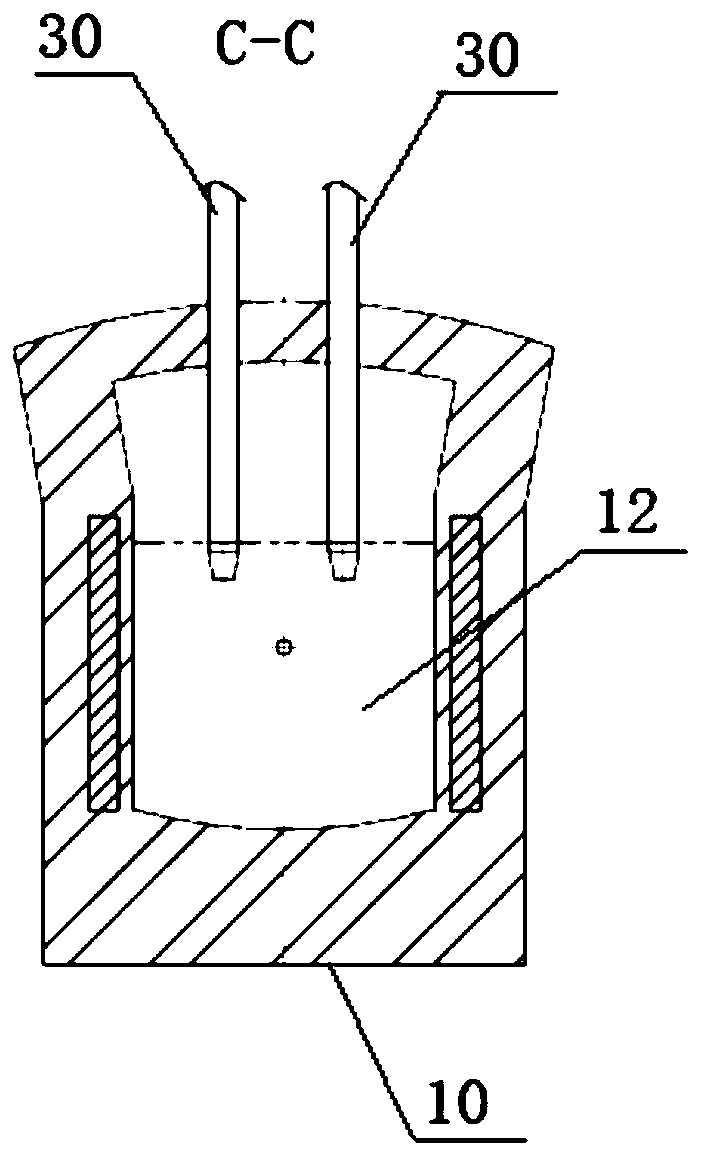

Ultra-long-term freshness preserving system

InactiveCN101766321AExtend storage timeImprove practicalityFood preservationEngineeringHigh concentration

The invention relates to an ultra-long-term freshness preserving system which can be applied to a refrigerator and installed in a refrigerating chamber of the refrigerator. The system comprises a freshness preserving box, an oxygen enriching membrane, a vacuum pump, a pressure sensor, a control plate and gas delivering pipes, wherein the oxygen enriching membrane is fixed in the freshness preserving box and connected with a gas sucking opening of the vacuum pump by the first gas delivering pipe penetrating through the wall of the freshness preserving box; an exhaust opening of the vacuum pump is led outside a box body for mounting the ultra-long-term freshness preserving system by the second gas delivering pipe; the pressure sensor is fixed to the first gas delivering pipe to sense the pressure in the freshness preserving box, and a signal line is connected with the control plate; and the control plate is connected with and controls the vacuum pump. The invention has ultrastrong freshness preserving function and can effectively improve the storing time of food stored in the refrigerator by being applied to the refrigerator; compared with the refrigeration of a common refrigerator, the invention is expected to be improved by 2-3 times. In addition, the invention can provide high-concentration oxygen for a room, has a plurality of advantages and practical values, and greatly improves the practicability and the healthy performance of the refrigerator.

Owner:SUZHOU SAMSUNG ELECTRONICS CO LTD

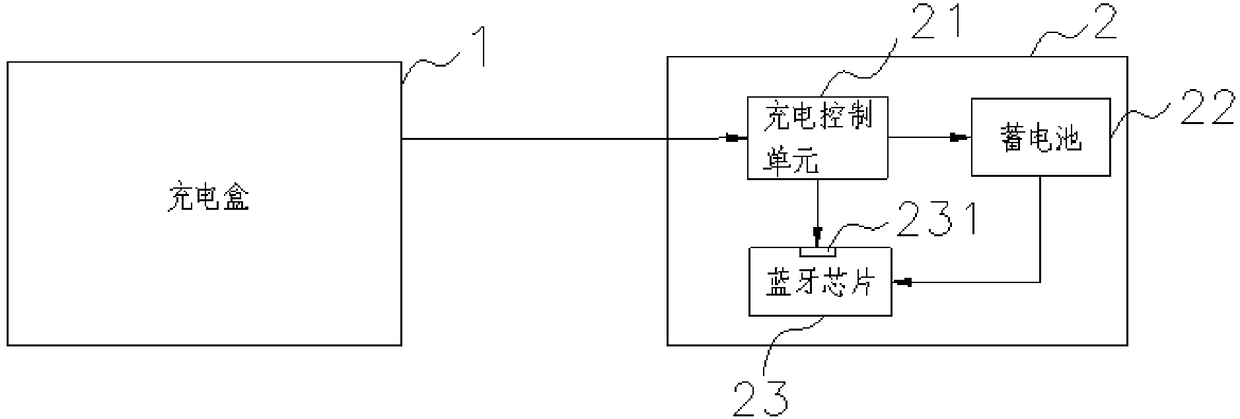

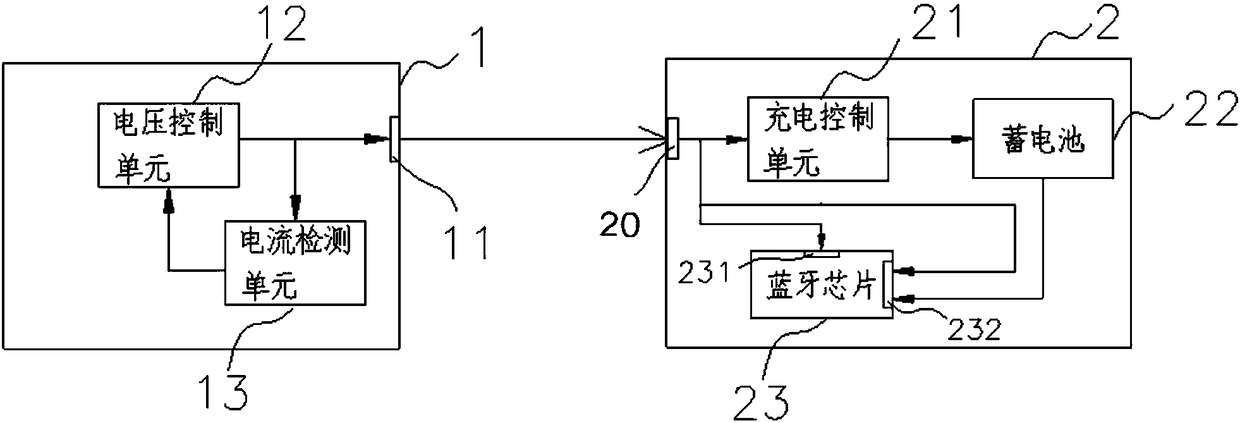

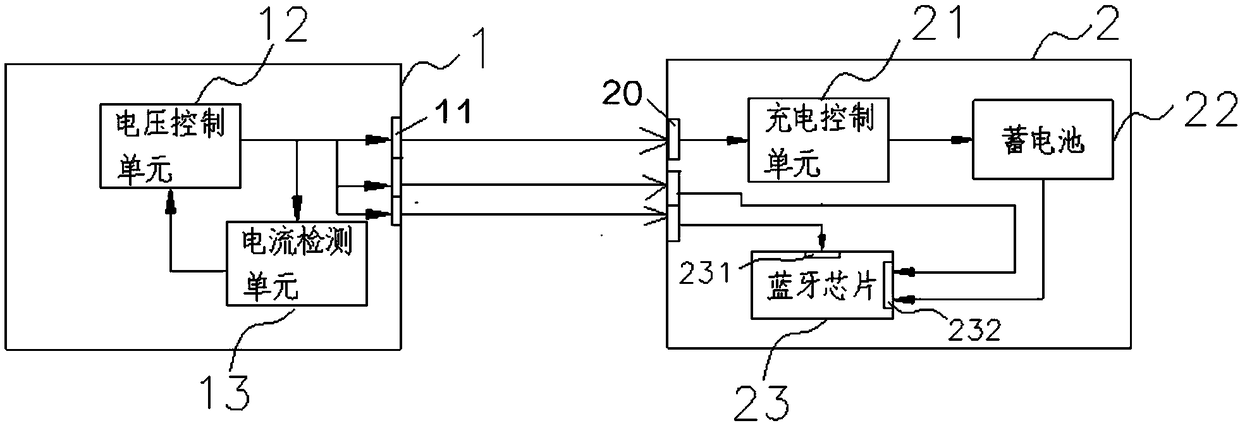

Wireless earphone charging system and wireless earphones in system

ActiveCN108242839AExtend storage timeSave powerElectric powerExchanging data chargerElectricityCharge control

The invention relates to the field of earphone charging, in particular to a wireless earphone charging system and wireless earphones in the system. When the wireless earphones are inserted into a charging box for charging, the charging box charges an energy storage unit in the wireless earphones, and during charging, a main chip in the wireless earphones is dormant to save power; after the energystorage unit is fully charged, a charging control unit in the wireless earphones also sleeps to avoid the power consumption caused by the converted voltage, and therefore the storage time of the powerin the charging box is prolonged; when the charging control unit is dormant, since a power supply terminal is electrically connected with a wake-up pin of the main chip, the level of the wake-up pinis kept at the non-awake level provided by the power supply terminal, so the main chip remains dormant; and when the earphones are removed from the charging box, the wake-up pin leaves the power supply terminal, the level thereof becomes a self-connected wake-up level, so that the main chip wakes up, the earphones are turned on, and the non-inductive operation of the user is completed.

Owner:广东思派康电子科技有限公司

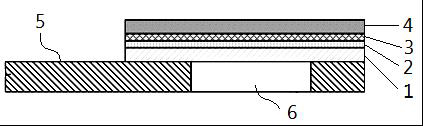

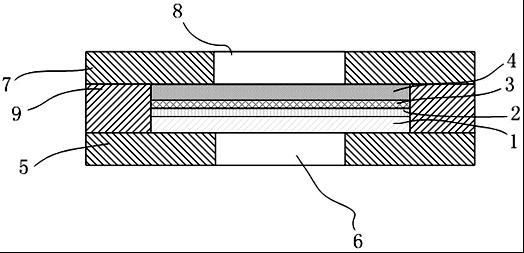

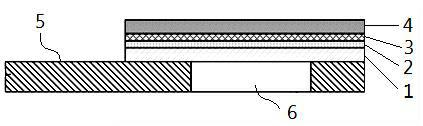

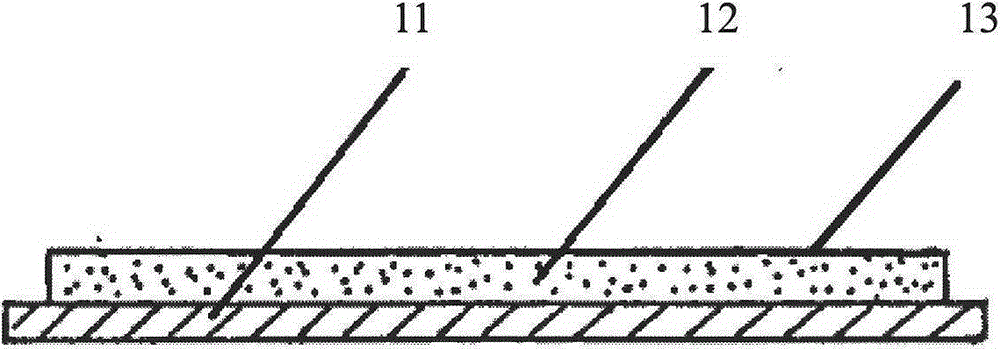

Multilayer film dry chemical reagent tablet for detecting alanine aminotransferase

InactiveCN102323399AExtend storage timeAccurate checkColor/spectral properties measurementsBiological testingChemistryBlood plasma

The invention discloses a multilayer film dry chemical reagent tablet for detecting alanine aminotransferase, which comprises a lower support layer; a test hole is disposed at one end of the lower support layer; the lower support layer is coated with a multilayer film; the multilayer film comprises an euphotic layer, a reagent layer, an auxiliary layer and a diffusion layer which are orderly superimposed from up to down; one side of the euphotic layer of the multilayer film is bonded and fixed at the test hole of the lower support layer. The multilayer film dry tablet for detecting alanine aminotransferase of the invention can rapidly and accurately detect alanine aminotransferase in serum and blood plasma, and can increase the preservation time of the dry tablet.

Owner:SUZHOU INST OF BIOMEDICAL ENG & TECH

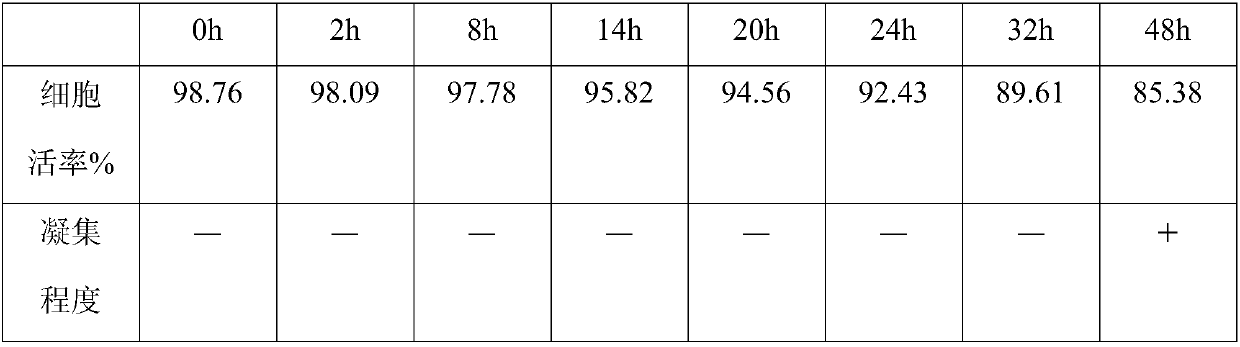

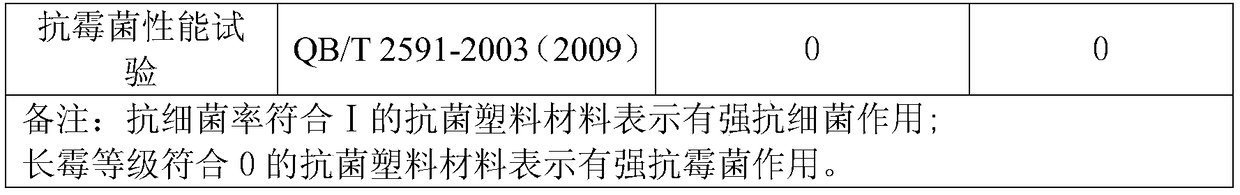

Mesenchymal stem cell preserving fluid for clinic local injection and method for preserving mesenchymal stem cell

ActiveCN109511648AImprove the living environmentMild living environmentDead animal preservationCell activityAntioxidant

The invention discloses mesenchymal stem cell preserving fluid for clinic local injection and a method for preserving mesenchymal stem cells. The preserving fluid contains the following components inpercentage by volume: 1%-5% of autologous plasma lysate, 1%-5% of an autologous stem cell conditional medium extract, 0.1%-1% of an antioxidant, 0.1%-0.4% of hyaluronic acid and the balance of a normal saline injection. By preserving the mesenchymal stem cells through the preserving fluid, the cell viability is high, the maintenance time of cell activity is long, and the preserving fluid foes notexogenous component and is high in safety.

Owner:CHENGDU QINGKE BIOTECH

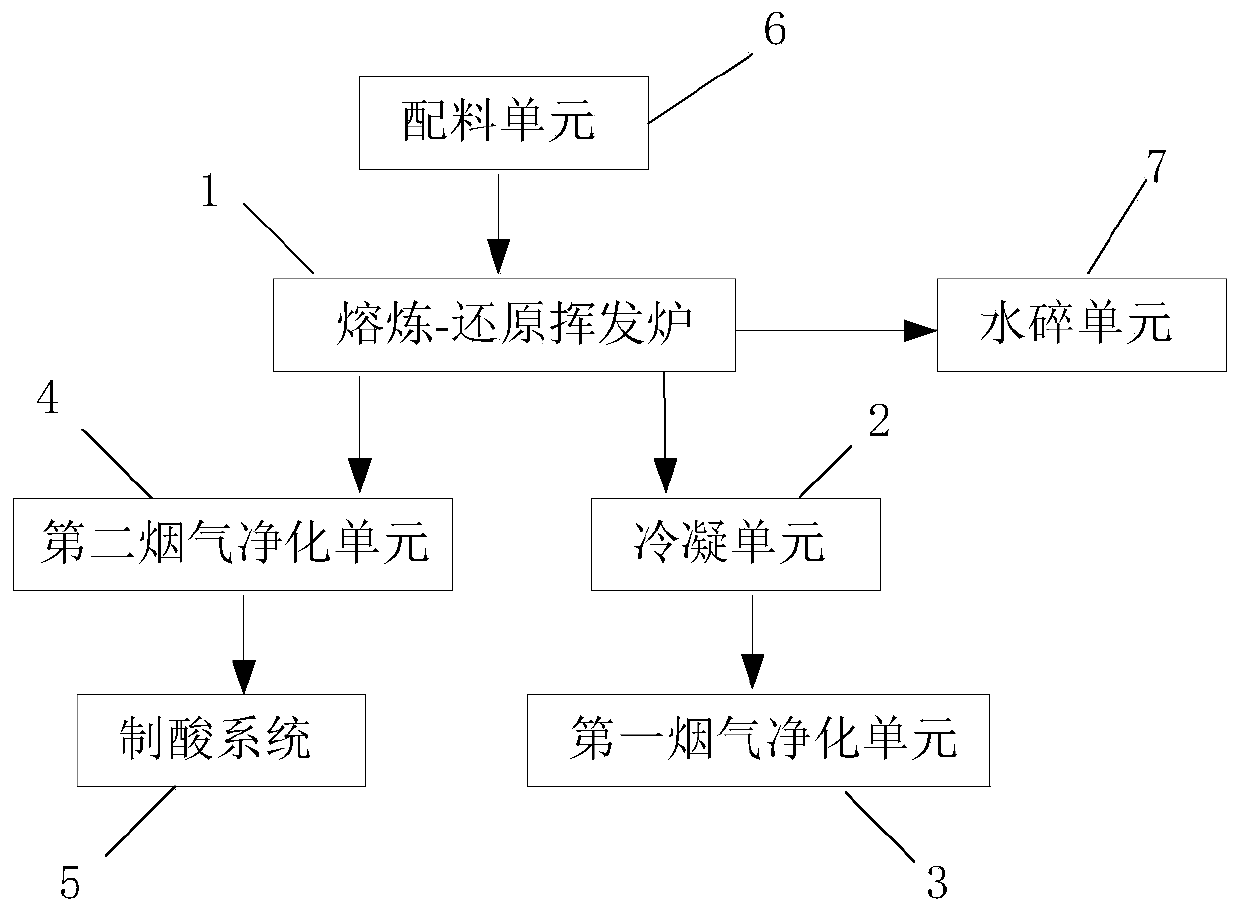

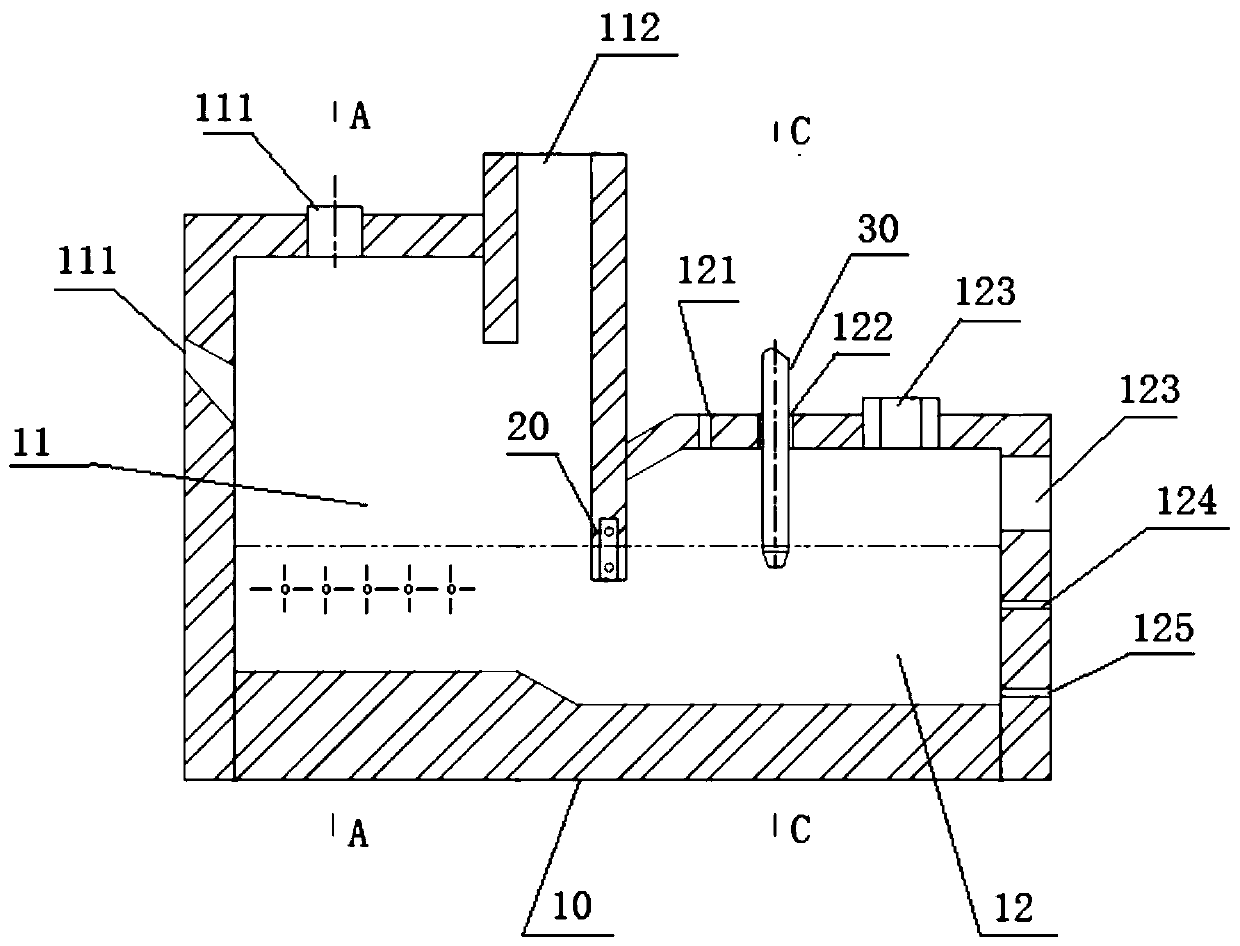

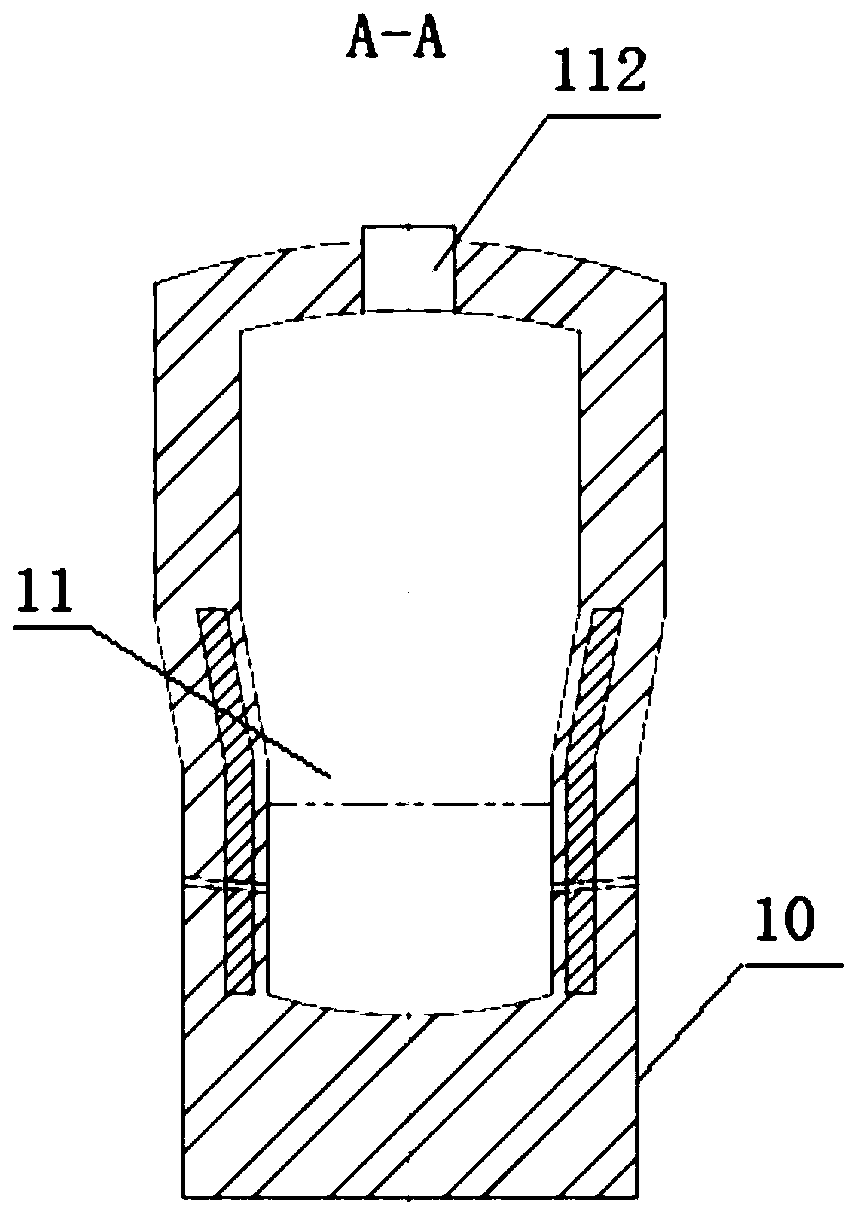

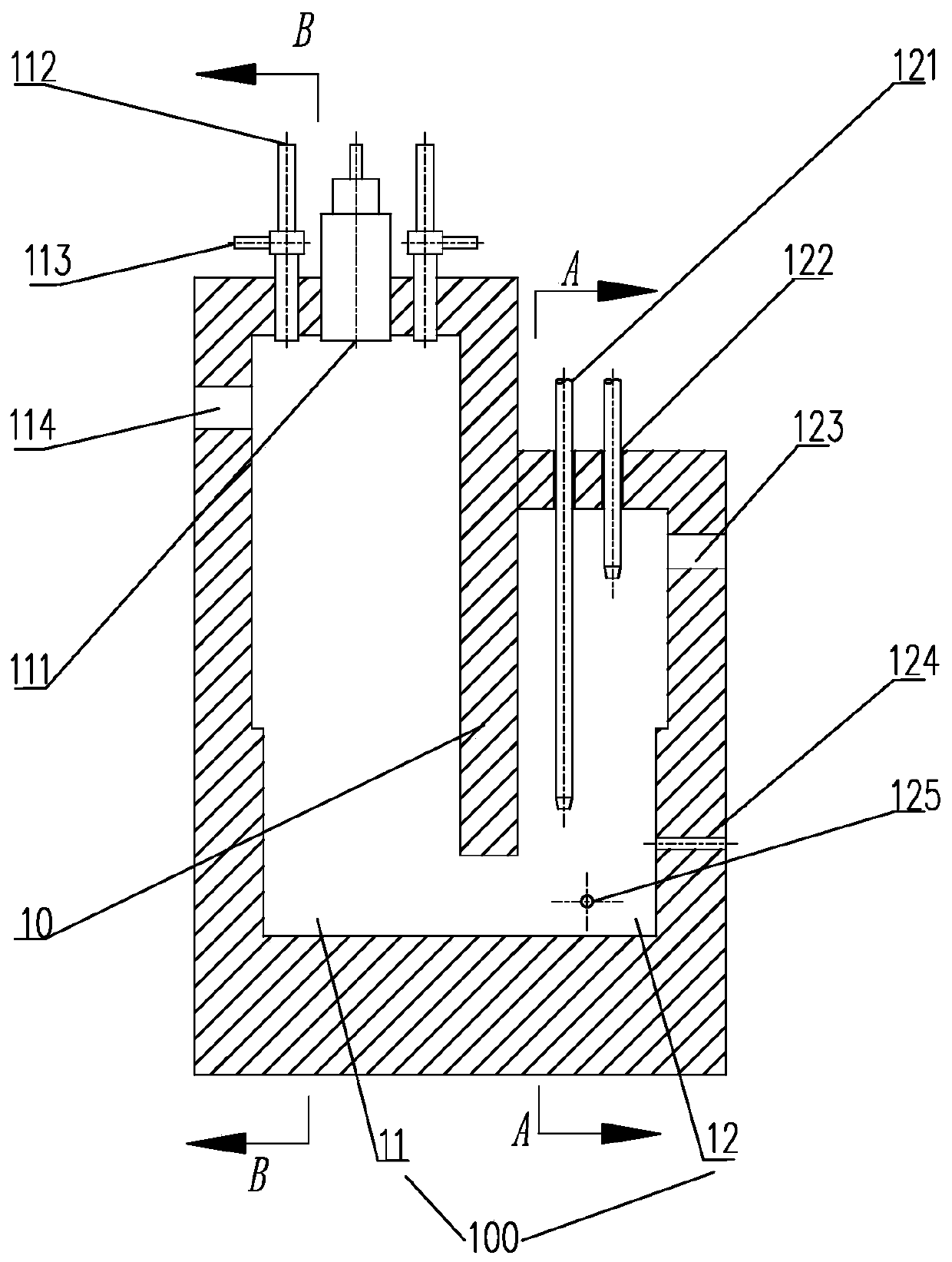

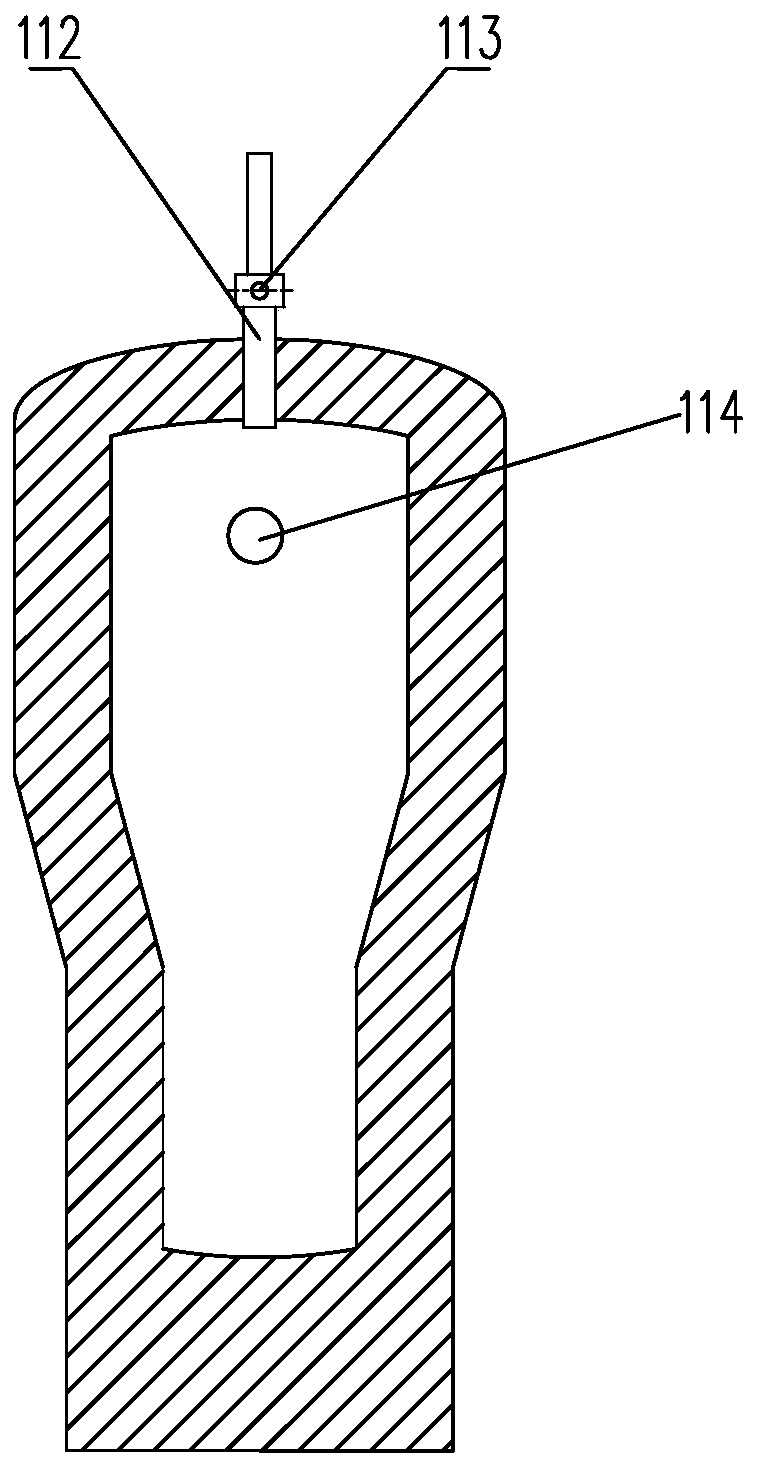

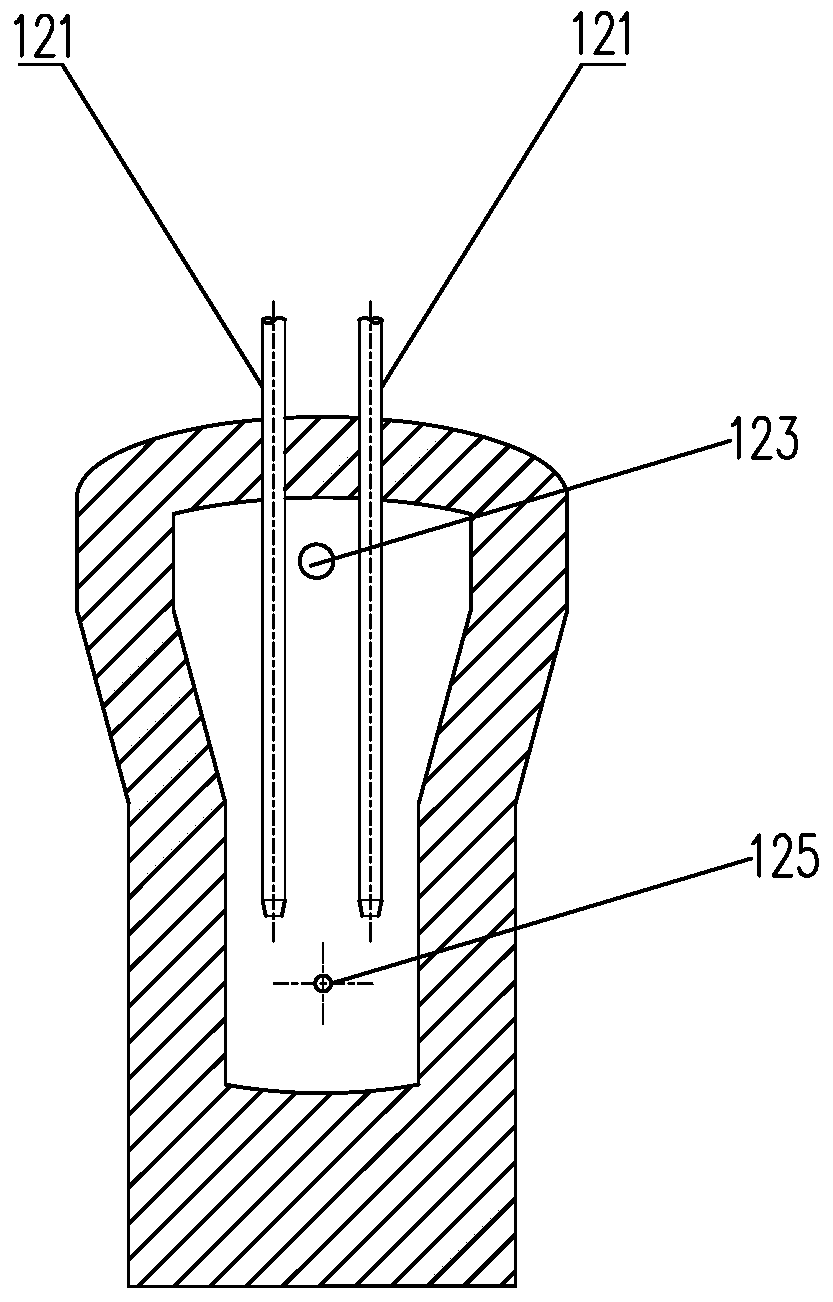

Pyrogenic process zinc smelting system

PendingCN110129583ASmall footprintReduce configuration height differenceProcess efficiency improvementFlueElectric heating

The invention provides a pyrogenic process zinc smelting system. The pyrogenic process zinc smelting system comprises a smelting-reducing volatilization furnace, a condensing unit and a first smoke purification unit, the smelting-reducing volatilization furnace comprises a furnace body, a partition wall and at least one heating electrode, the furnace body is provided with an inner cavity, the partition wall is arranged in the inner cavity, the partition wall divides the inner cavity into a smelting area and an electric heating reducing area in the horizontal direction, a communication channelis arranged below the partition wall and is used for communicating the smelting area and the electric heating reducing area, the smelting area is provided with a first feeding opening and a smelting area flue, the electric heating reducing area is provided with a second feeding opening, at least one electrode through hole and an electric heating reducing area flue, the second feeding opening is used for adding of a reducing agent, the heating electrode and the electrode through hole are in one-to-one corresponding, the heating electrode extends into the electric heating reducing area through the electrode through hole, the condensing unit is provided with a zinc steam inlet, the zinc steam inlet is connected with the electric heating reducing area flue, and the first smoke purification unit is connected with the condensing unit. The system is used for pyrogenic process zinc smelting, and the advantages of being simple in flow, low in energy consumption and high in zinc recycling rate are achieved.

Owner:CHINA ENFI ENGINEERING CORPORATION

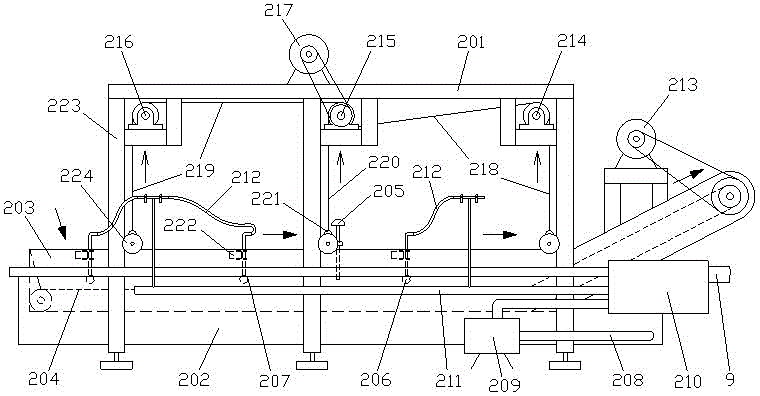

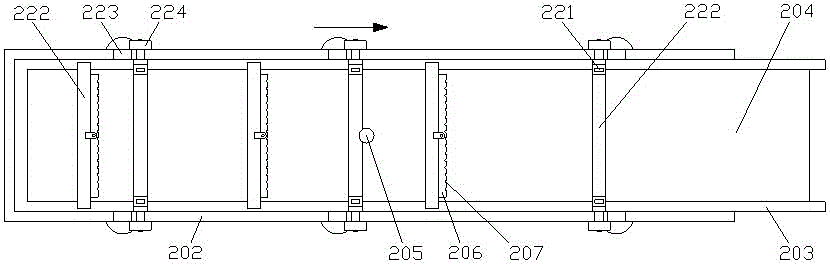

Fish ball product production device and process

InactiveCN104687103AUniform and aesthetically pleasingExtend storage timeFood preservationFood preparationEngineeringMechanical engineering

The invention relates to a fish ball product production device and process. The fish ball product production device comprises a fish ball forming machine. A conveying mechanism of the fish ball forming machine conveys formed raw fish ball products into a low-temperature boiling machine. A conveying mechanism of the low-temperature boiling machine conveys the fish ball products obtained after low-temperature boiling is conducted into a high-temperature boiling machine. A conveying mechanism of the high-temperature boiling machine conveys the fish ball products obtained after high-temperature boiling is conducted to a high-temperature cooking machine. The high-temperature cooking machine conveys the fish ball products obtained after high-temperature cooking is conducted into a cooling machine through a first elevator. The cooling machine conveys the cooled fish ball products into an instant freezer through a second elevator. The fish ball product production device is novel in structural design, reasonable in process design and high in production efficiency, energy is saved, emission is reduced, the formed fish ball products are even and attractive in form, and the appearance and taste of the products are guaranteed.

Owner:ZHEJIANG YUJI FOOD

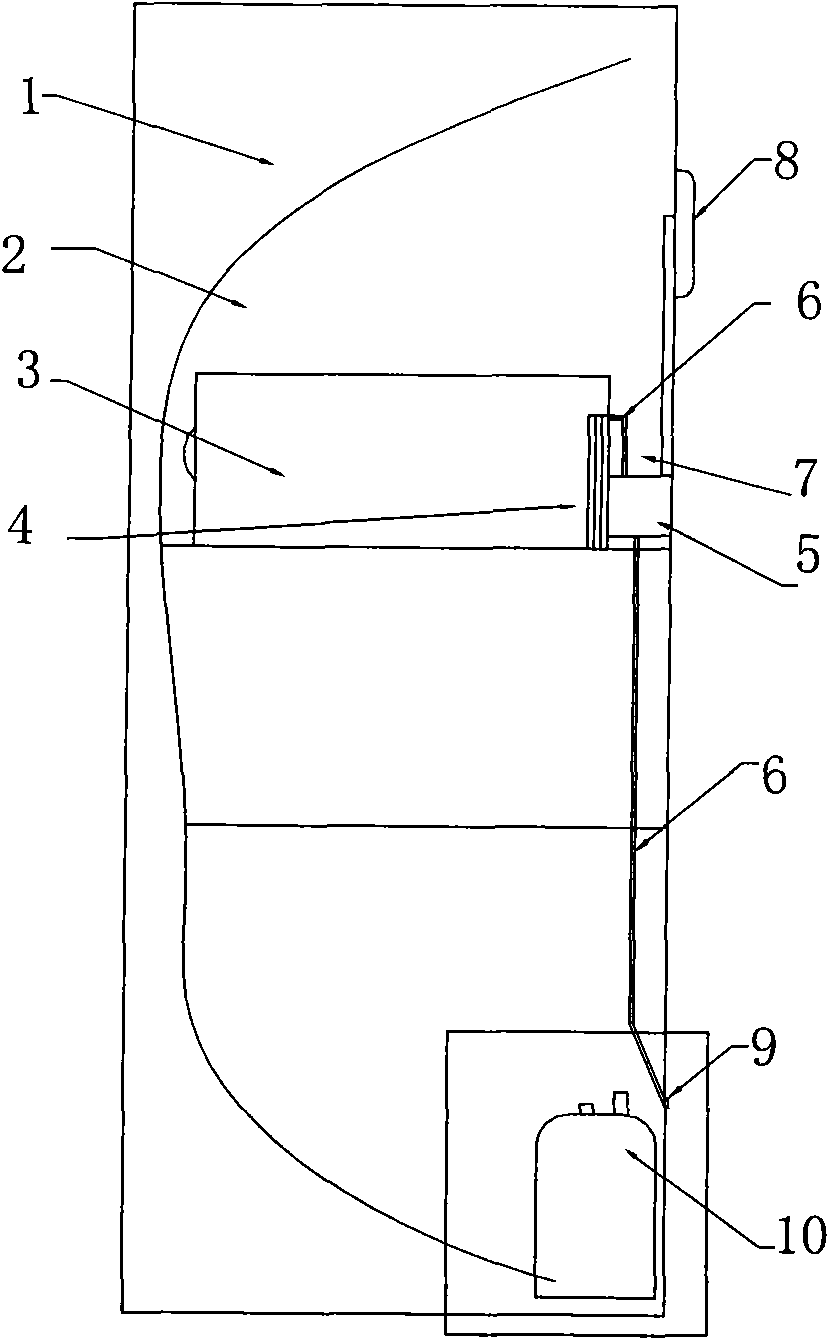

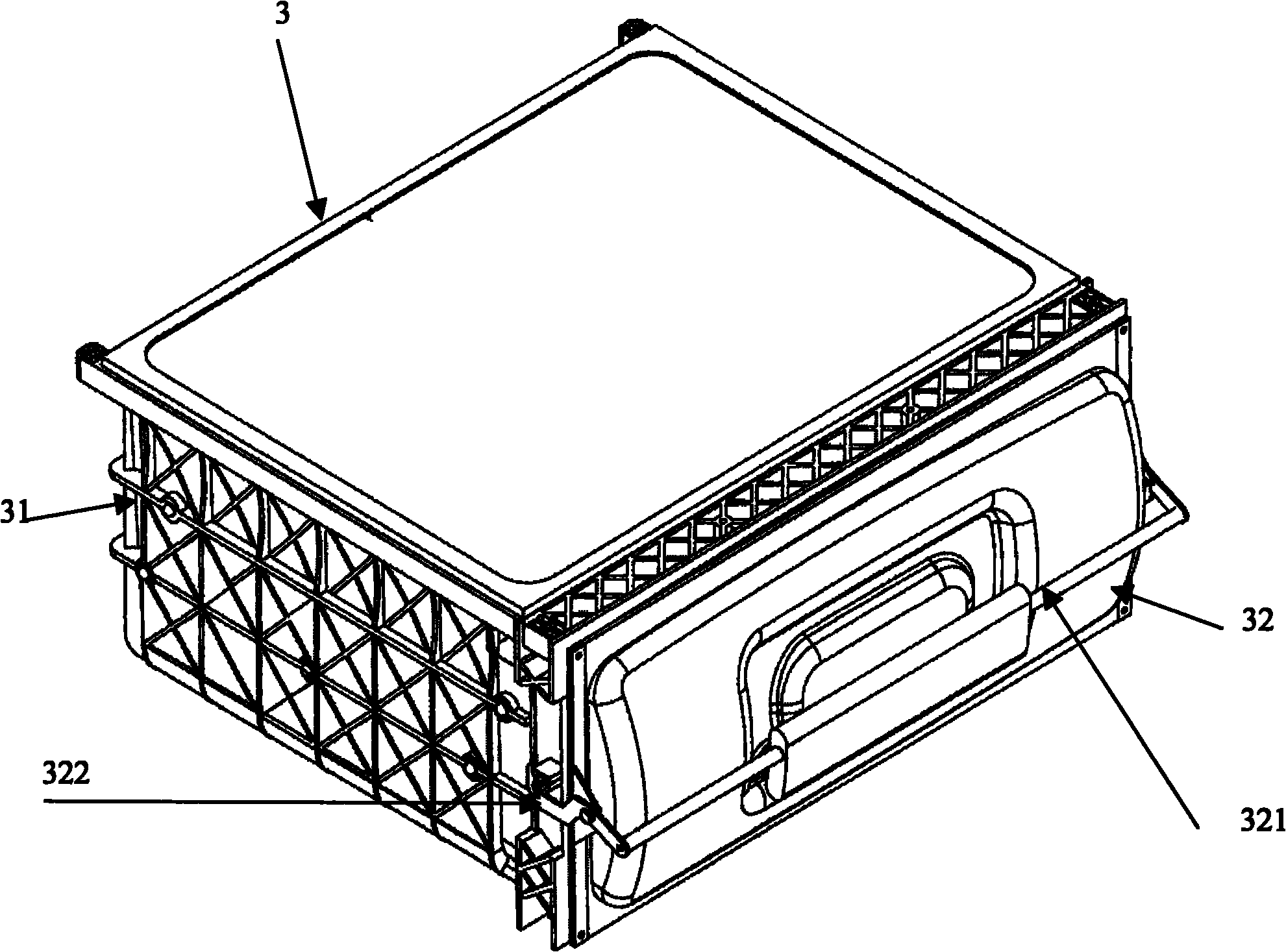

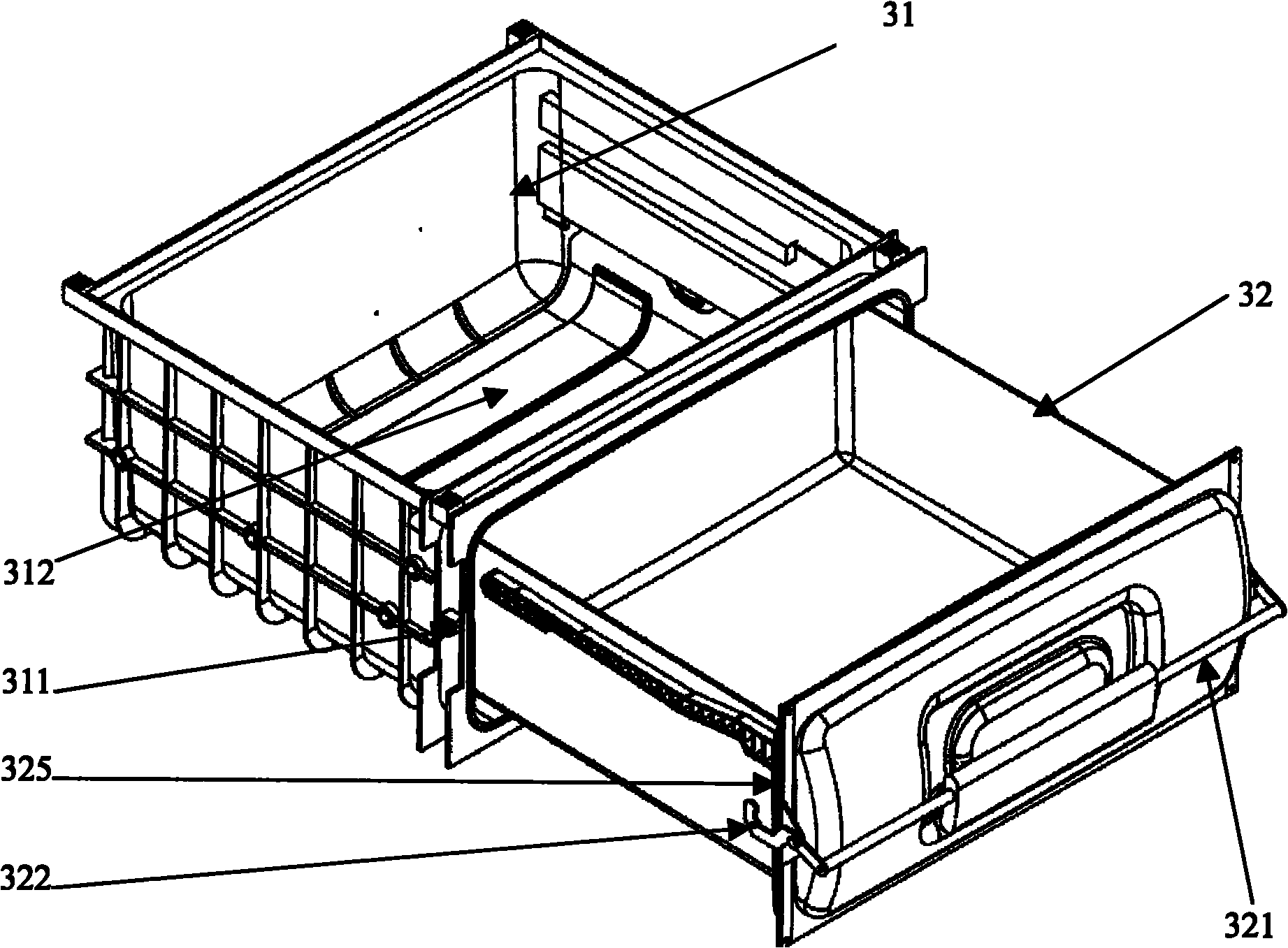

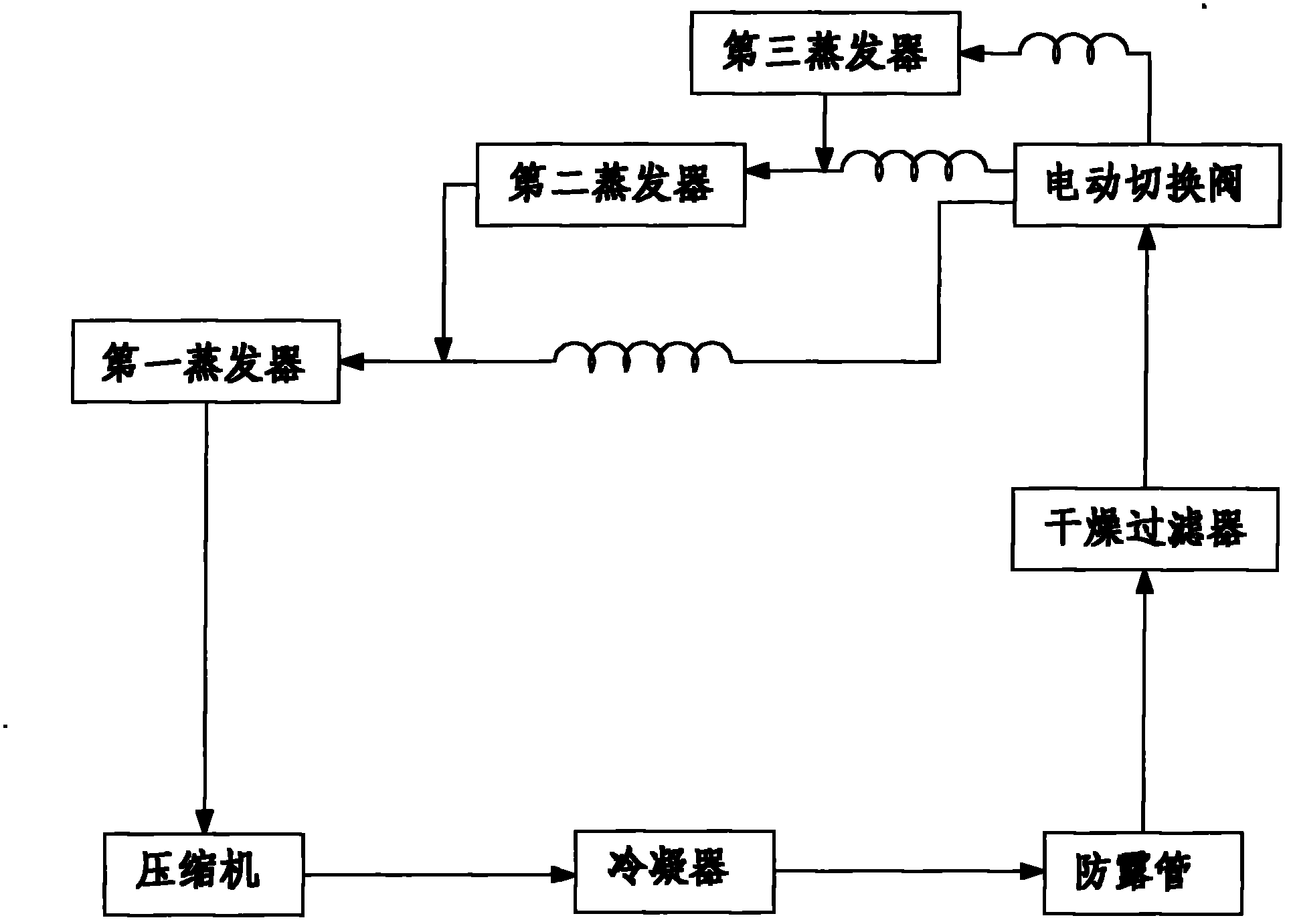

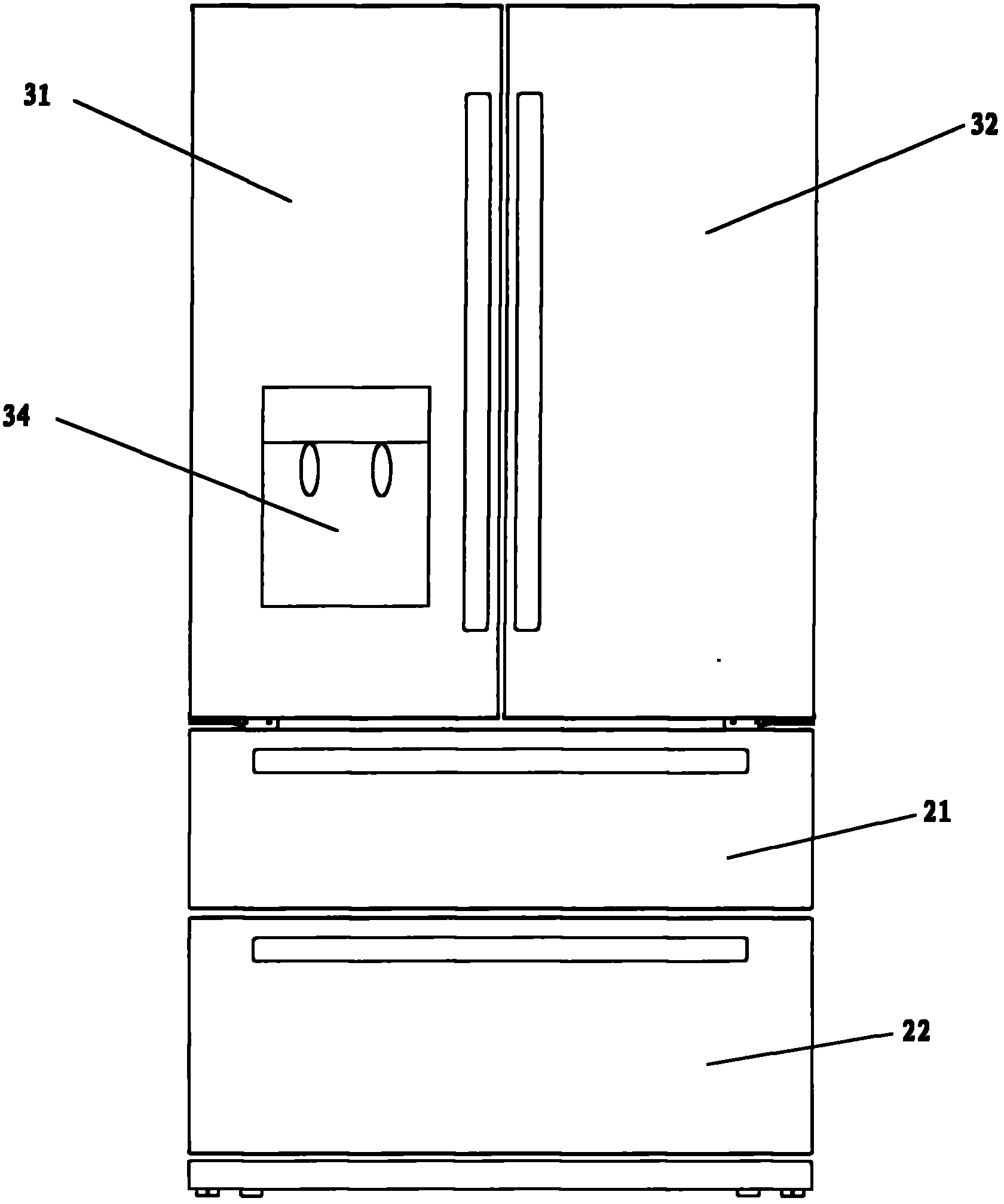

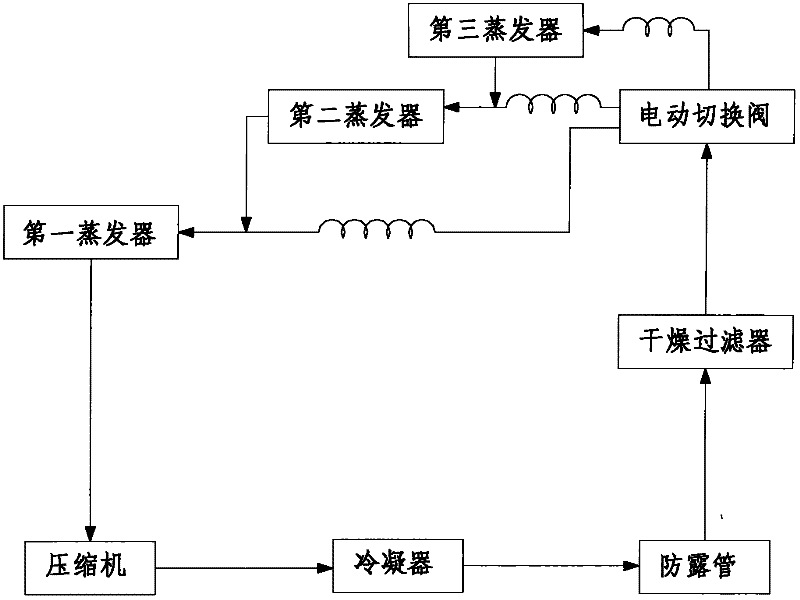

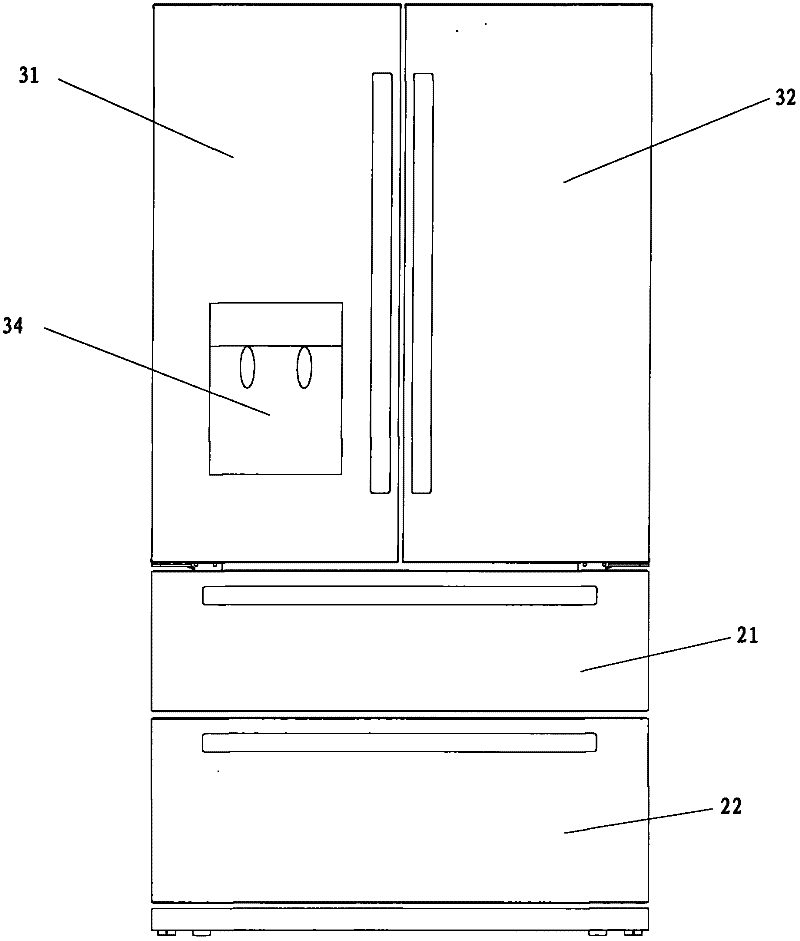

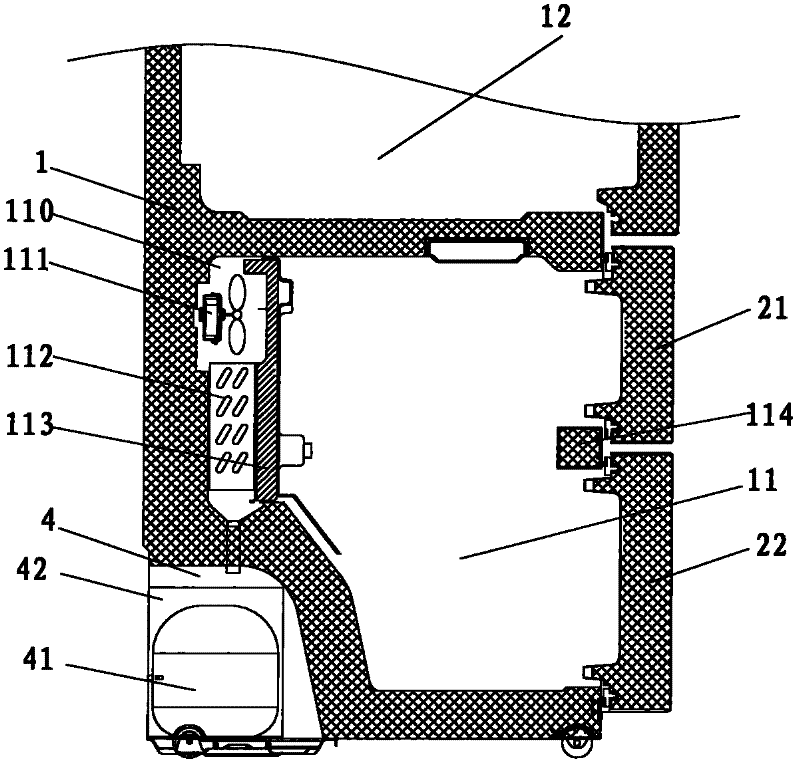

Refrigerator

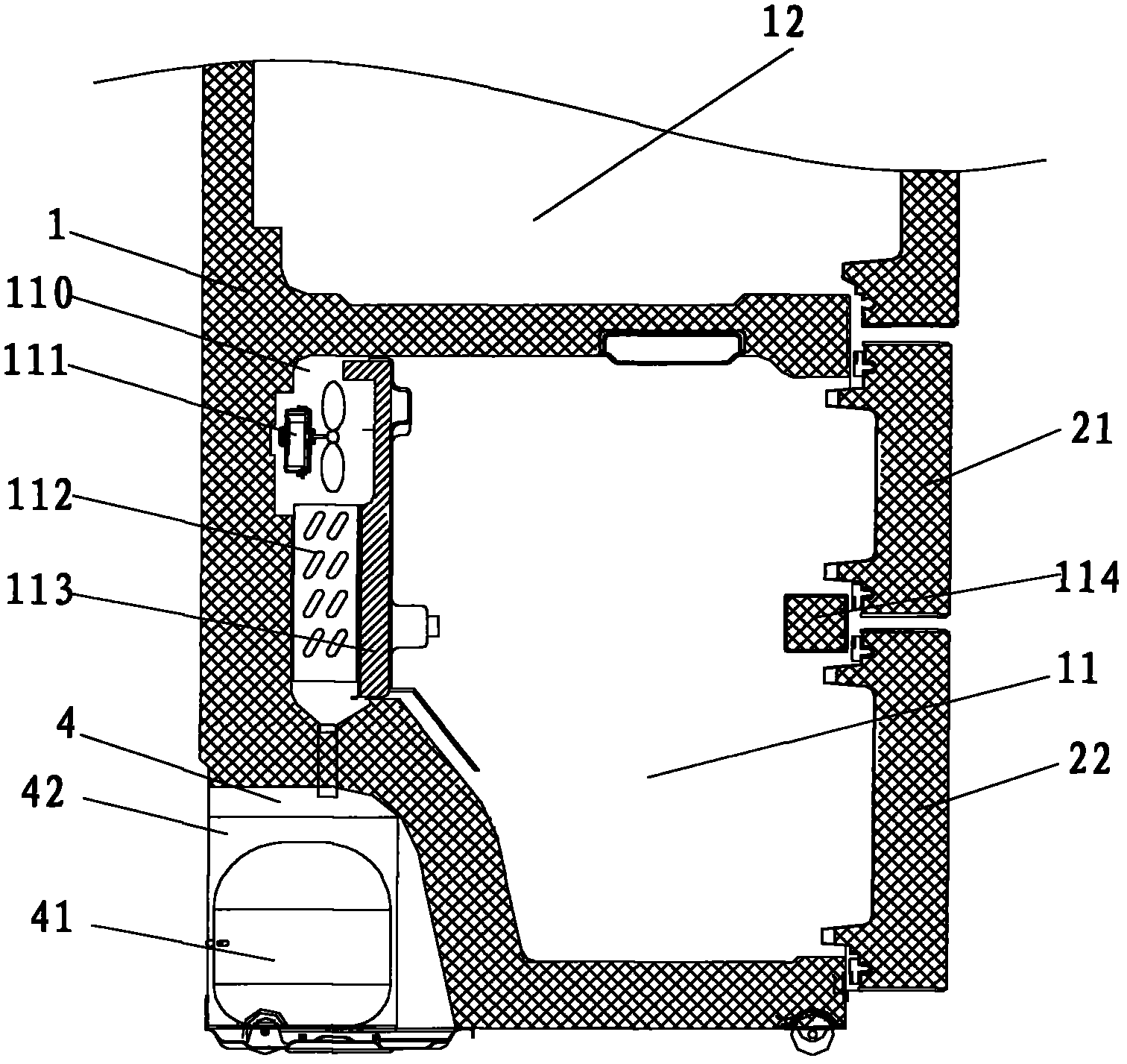

InactiveCN102213527AExtend storage timeEasy to useIce productionDomestic refrigeratorsFreezing chamberControl mode

The invention discloses a refrigerator, which comprises a refrigerator body, a door body of a freezing chamber, the door body of a refrigerating chamber, an ice maker and a refrigeration system, wherein the freezing chamber and the refrigerating chamber are formed in the refrigerator body; the refrigerating chamber is positioned above the freezing chamber; an ice-making chamber is arranged on an internal wall of the door body of the refrigerating chamber; an ice-taking groove which is connected with the ice-making chamber is arranged on an external surface of the door body of the refrigerating chamber; the ice maker is arranged in the ice-making chamber; the refrigeration system comprises a compressor, a condenser, a first evaporator, a second evaporator, a third evaporator and an electric switching valve; the compressor and the condenser are arranged in a compressor cabin which is positioned on the lower part of the rear side of the refrigerator body; the first evaporator is arranged in the freezing chamber and refrigerates the freezing chamber; the second evaporator is arranged in the refrigerating chamber and refrigerates the refrigerating chamber; the third evaporator is arranged in the ice-making chamber and refrigerates the ice-making chamber; the electric switching valve is connected with the first evaporator, the second evaporator and the third evaporator; and the first evaporator, the second evaporator and the third evaporator adopt a bypass control mode. The refrigerator provided by the embodiment of the invention has the advantages of good moisturizing effect, convenience for use, high refrigerating efficiency and low energy consumption.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

Short-process zinc pyrometallurgical device and method

The invention provides a short-process zinc pyrometallurgical device and method. The short-process zinc pyrometallurgical device comprises a furnace body, a partition wall and at least one heating electrode; the furnace body is provided with an inner cavity; the partition wall is arranged in the inner cavity of the furnace body, the inner cavity is divided into a smelting area and an electric heating reduction area by the partition wall in the horizontal direction, and a communication channel is arranged on the lower portion of the partition wall and used for communicating with the smelting area and the electric heating reduction area; the smelting area is provided with a first feeding inlet and a smelting area flue, and the first feeding inlet is used for allowing zinc concentrate and a fusing agent to be added; the electric heating reduction area is provided with a second feeding inlet, at least one electrode through hole and an electric heating reduction area flue, and the second feeding inlet is used for allowing a reducing agent to be added; and the heating electrodes correspond to the electrode through holes one by one and extend into the electric heating reduction area through the electrode through holes. According to the short-process zinc pyrometallurgical device provided by the invention, through the furnace body, the problems that in the prior art, a zinc pyrometallurgical mode is complex in process, high in energy consumption and the like are effectively solved, and the short-process zinc pyrometallurgical device has the advantages of being high in production efficiency, low in equipment cost, high in zinc recovery rate and the like.

Owner:CHINA ENFI ENGINEERING CORPORATION

System and method for smelting zinc concentrate and zinc-containing secondary material

The invention discloses a system and method for smelting zinc concentrate and a zinc-containing secondary material. The system comprises a mixing unit and a jet smelting and electric heating reductionfurnace. The mixing unit is provided with a zinc concentrate inlet, a zinc-containing secondary material inlet, a flux inlet and a mixed material outlet. A jet smelting area and an electric heating reduction area are defined in the jet smelting and electric heating reduction furnace, a partition wall is arranged between the jet smelting area and the electric heating reduction area, the bottom ofthe jet smelting area communicates with the bottom of the electric heating reduction area, the jet smelting area is provided with a material inlet, an oxygen-containing spray gun and a smelting smokeoutlet, the material inlet is connected with the mixed material outlet, and the electric heating reduction area is provided with an electrode, a reducing agent spray gun, a zinc-containing steam outlet, a slagging port and a metal melt outlet. By adopting the system, the zinc concentrate and the zinc-containing secondary material can be treated in a short process at low energy consumption, valuable metal such as lead, iron, silver, indium and germanium can be comprehensively recycled, and the zinc element has high direct recycle rate.

Owner:CHINA ENFI ENGINEERING CORPORATION

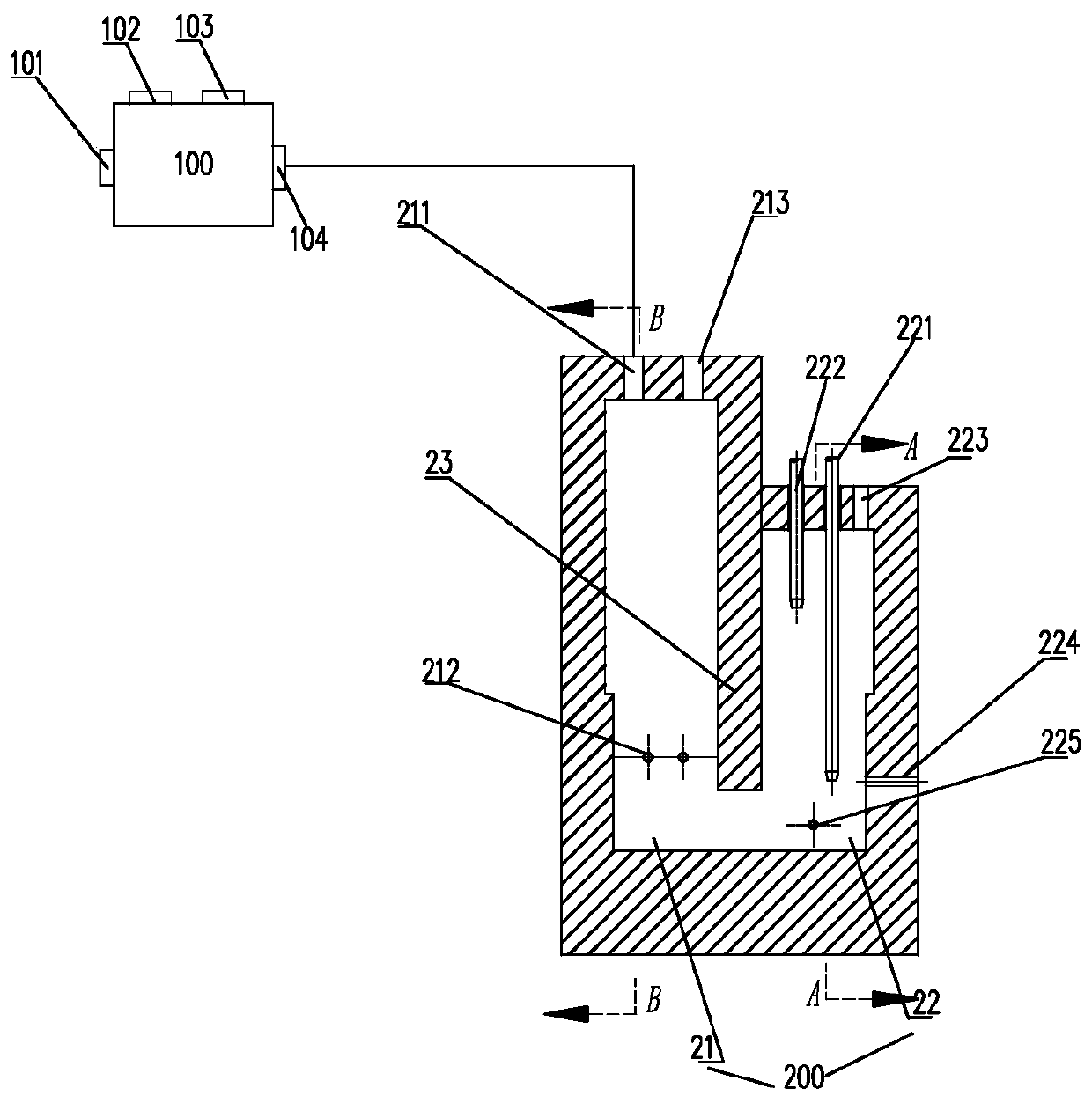

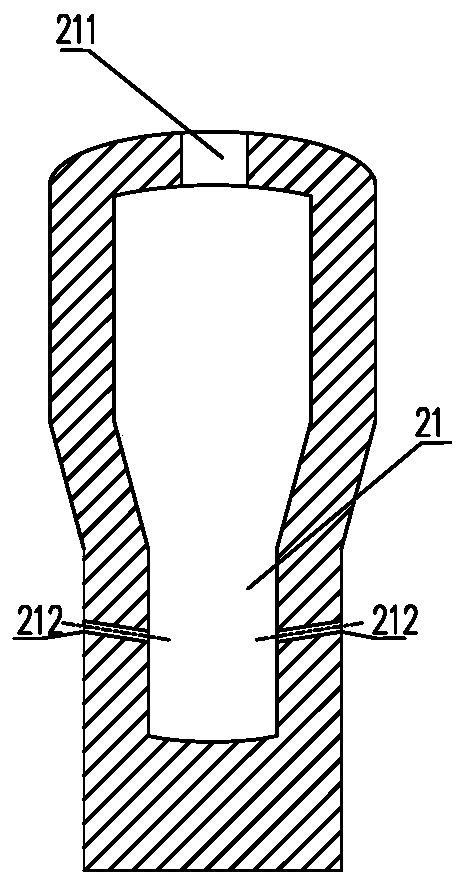

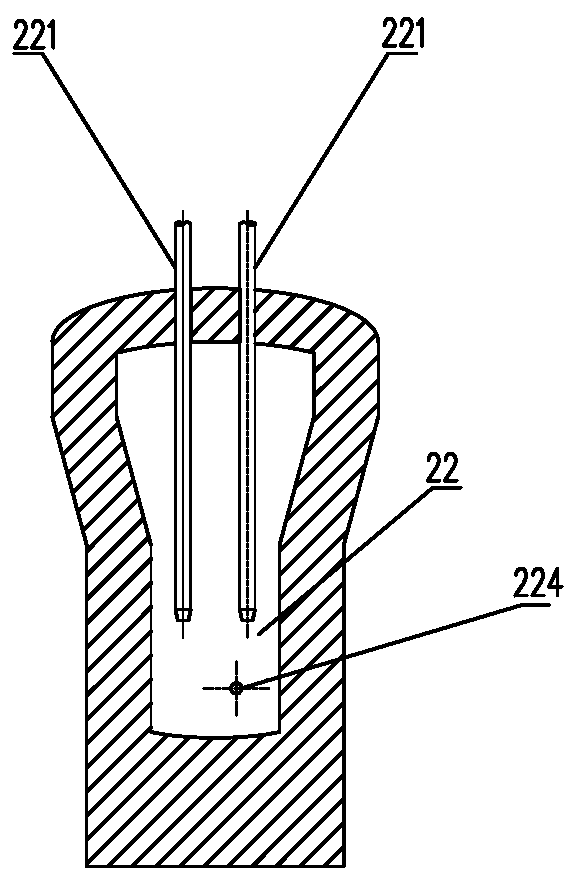

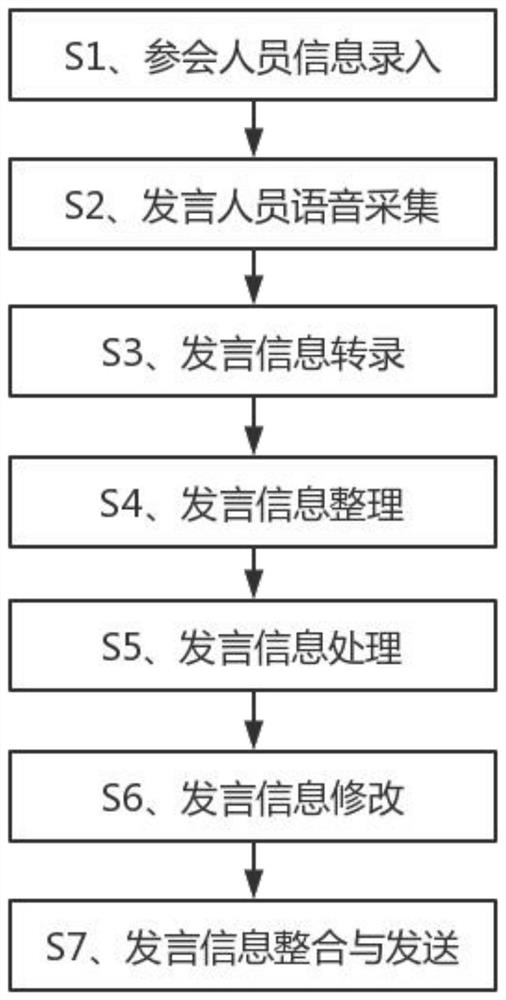

Intelligent paperless conference data information processing method based on artificial intelligence and big data analysis

PendingCN112712349ARealize processingImprove efficiencySemantic analysisDigital data protectionInformation processingEngineering

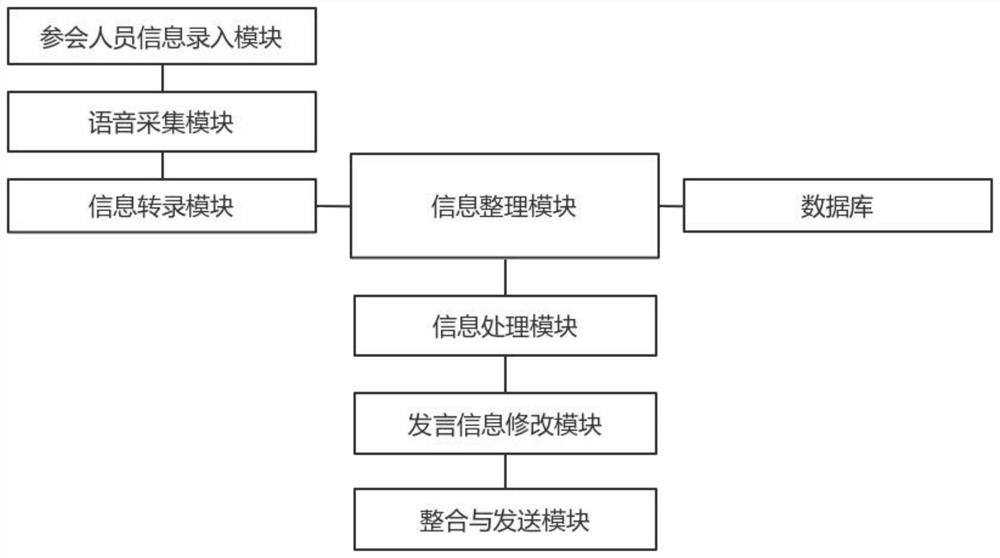

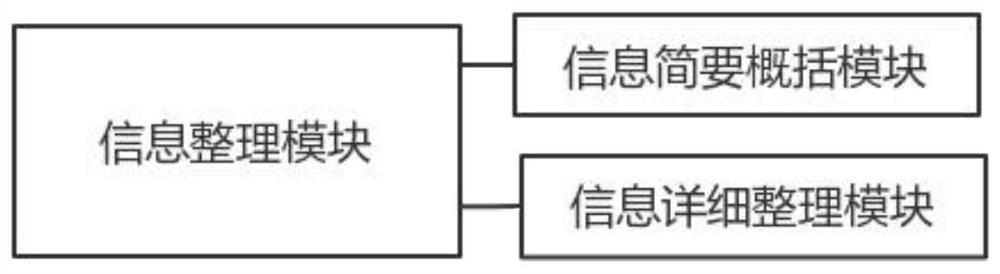

The invention discloses an intelligent paperless conference data information processing method based on artificial intelligence and big data analysis. An intelligent paperless conference data information processing system based on artificial intelligence and big data analysis needs to be used in specific implementation of the intelligent paperless conference data information processing method based on artificial intelligence and big data analysis. The system comprises a participant information input module, a voice acquisition module, an information transcription module, an information arrangement module, an information processing module, a speaking information modification module, an integration and sending module and a database. The collected voice information of each speaking person is converted into text information through the voice recognition technology; meanwhile, the speaking text information of each speaking person is sorted, processed, modified and integrated, so intelligent processing of conference data information is realized, the conference effect and the conference recording efficiency are effectively improved, and the conference processing time cost of conference participants is greatly reduced.

Owner:卓喜龙

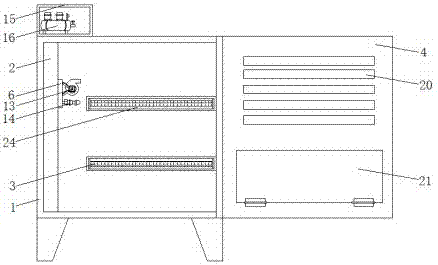

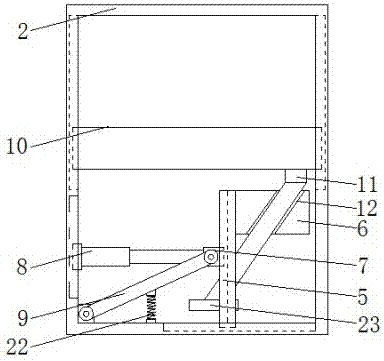

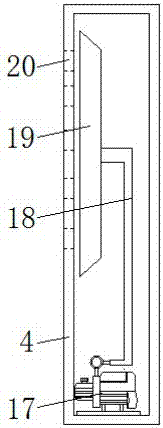

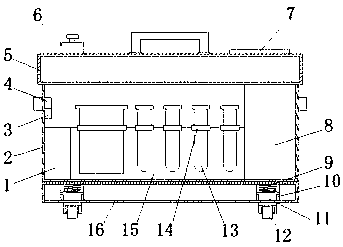

Dampproof file cabinet

ActiveCN107183949ASolve the problem of not having moisture protection functionKeep dryBook cabinetsFurniture partsStructural engineeringMechanical engineering

Owner:ANQING NORMAL UNIV

Suspension smelting electric heating reduction furnace and method for smelting zinc concentrate

PendingCN111411230ASmall footprintReduce configuration height differenceElectric furnaceSlagOre concentrate

The invention discloses a suspension smelting electric heating reduction furnace and a method for smelting zinc concentrate. The suspension smelting electric heating reduction furnace comprises a suspension smelting electric heating reduction furnace body, wherein a suspension smelting area and an electric heating reduction area are defined in the suspension smelting electric heating reduction furnace body, a separation wall is arranged between the suspension smelting area and the electric heating reduction area, and the bottom of the suspension smelting area is in communication with the bottom of the electric heating reduction area; an auxiliary burner, a material nozzle, an oxygen-containing gas spray gun and a smelting flue gas outlet are arranged on the smelting area; and an electrode,a reducing agent spray gun, a zinc-containing steam outlet, a slag discharge port and a metal melt outlet are arranged on the electric heating reduction area. Therefore, the suspension smelting electric heating reduction furnace can realize short flow and low energy consumption treatment of the zinc concentrate, and valuable metals such as lead, iron, silver, indium, and germanium are comprehensively recovered; moreover, the zinc element has the high direct yield rate; and meanwhile, obtained furnace slag has the low yield, and can be directly sold as general solid waste.

Owner:CHINA ENFI ENGINEERING CORPORATION

Maize seed storing method

InactiveCN106717600AEasy to operateExtend storage timeAgriculture tools and machinesHarvested fruit hanging devicesGerminationCarbon dioxide

Owner:安徽华安种业有限责任公司

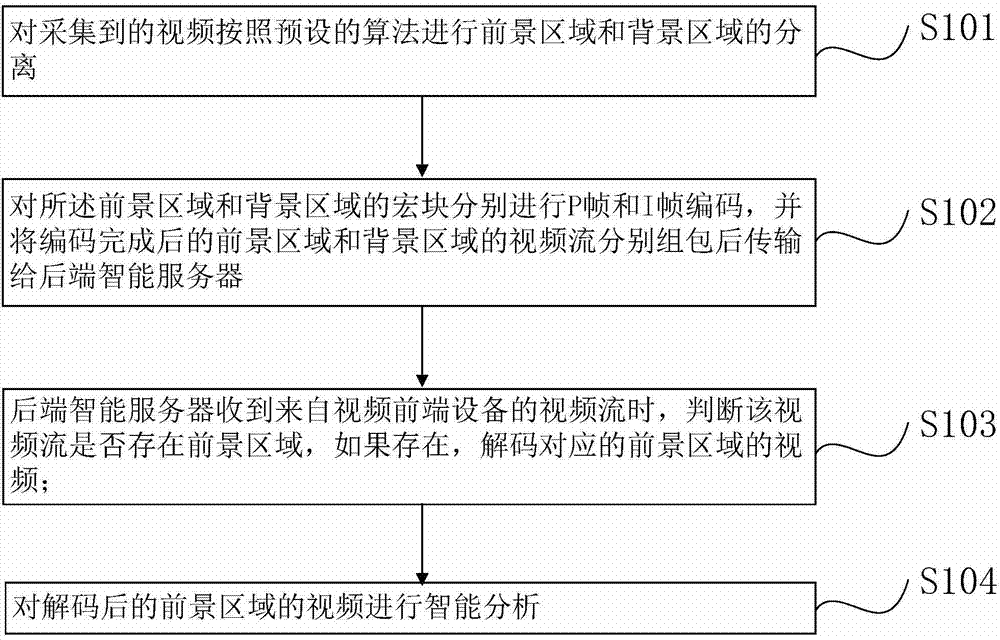

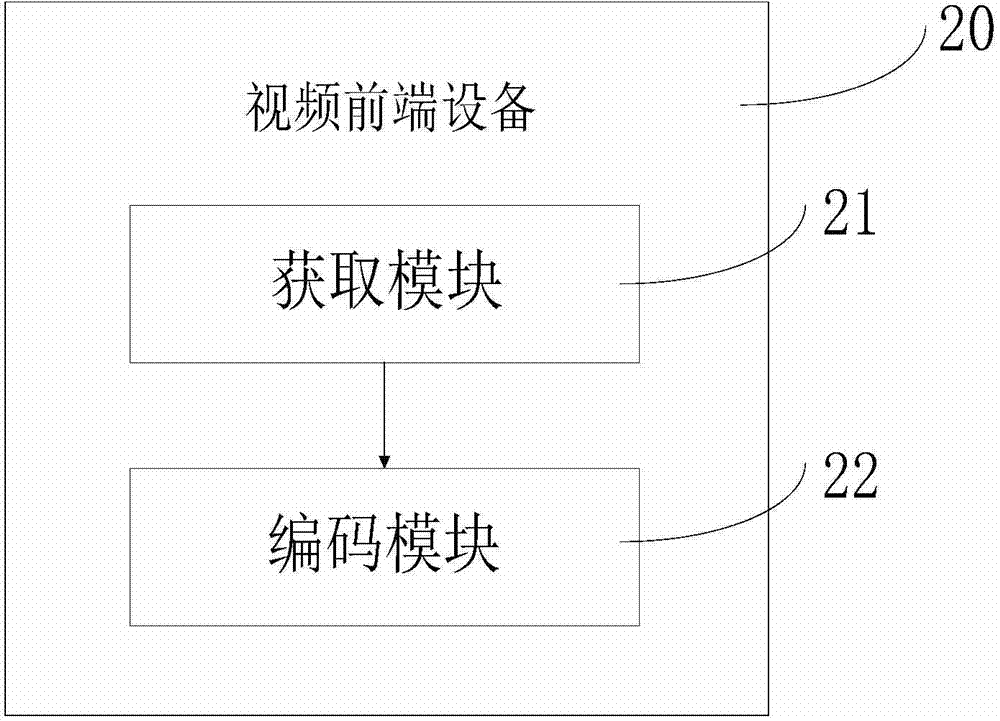

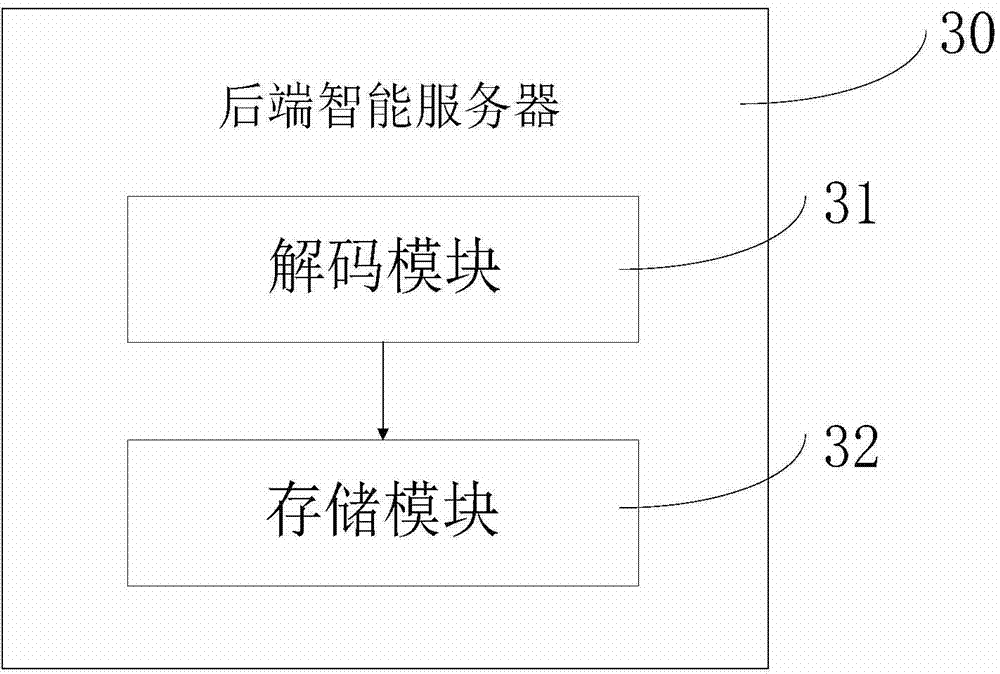

Video coding method, video processing method and equipment

ActiveCN103702123AIncreased network bandwidth consumptionQuality unchangedClosed circuit television systemsDigital video signal modificationVideo qualityComputer graphics (images)

The invention provides a video coding method and a video processing method, which are applied to an intelligent monitoring system. The intelligent monitoring system comprises front-end video equipment and a rear-end intelligent server. The video coding method comprises the following steps: separating a foreground area from a background area of an acquired video according to a preset algorithm; respectively performing P-frame and I-frame coding on macro blocks of the foreground area and the background area, respectively packaging video streams of the foreground area and the background area, which are coded, and transmitting the packaged video stream to the rear-end intelligent server; after the rear-end intelligent server receives the video stream from the front-end video equipment, judging whether the video stream has the foreground area; if so, decoding the video of the corresponding foreground area, and intelligently analyzing the decoded video of the foreground area. According to the methods, under the conditions that the quality of the video basically remains unchanged and the consumption of network bandwidth is slightly improved, the rear-end decoding capacity and the intelligent video analysis processing capacity can be remarkably improved, and the storage time of a storage server can be remarkably prolonged.

Owner:ZHEJIANG UNIVIEW TECH

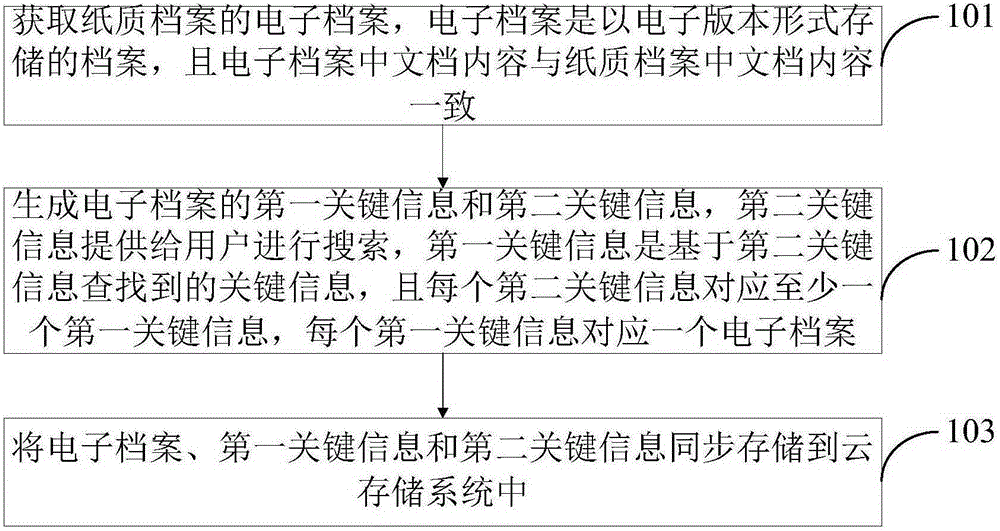

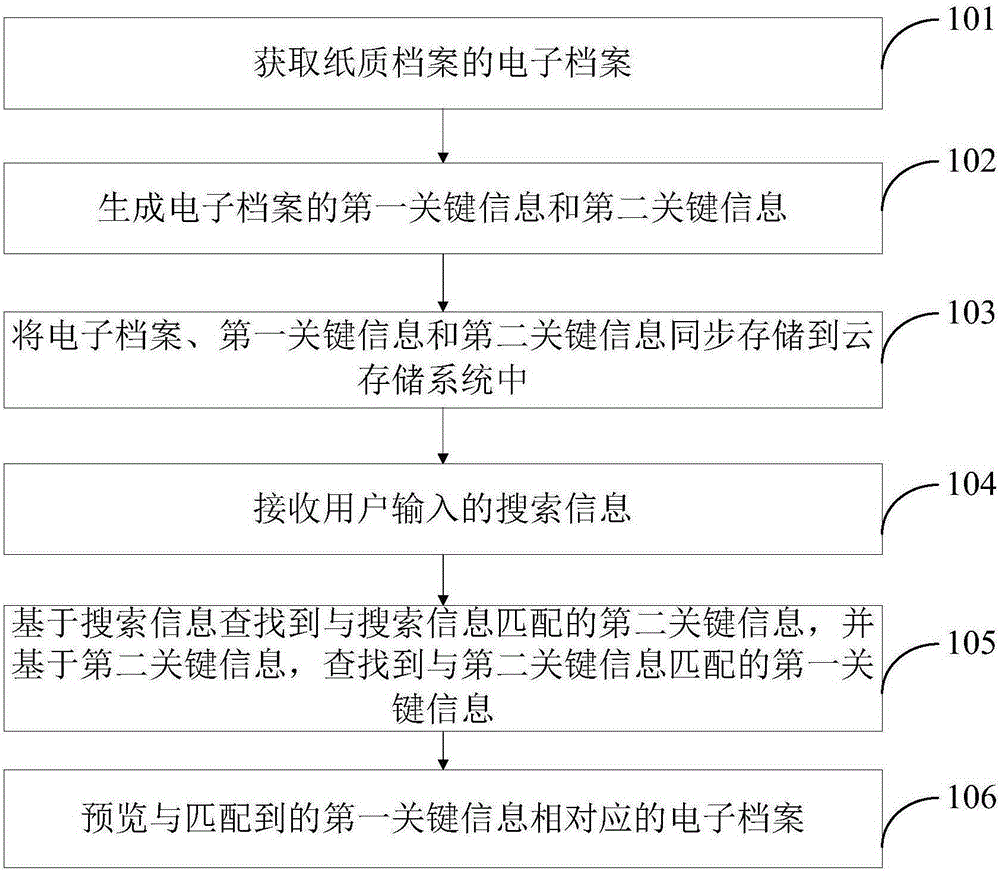

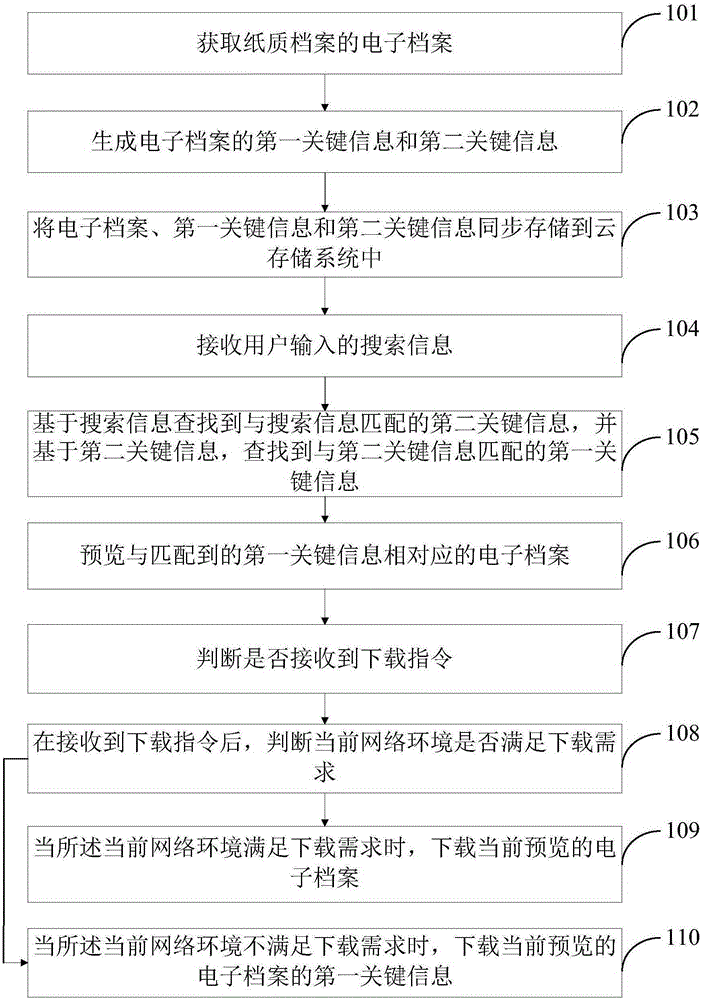

Archive management method and apparatus

InactiveCN105303321AExtend storage timeReduce storage costsResourcesCloud storage systemOperating system

The invention provides an archive management method and apparatus. The method comprises: obtaining electronic archives of paper archives, and generating first key information and second key information of the electronic archives; and then synchronously storing the electronic archives, the first key information and the second key information into a cloud computing system. The electronic management of the paper archives is realized, and the storage of the electronic archives is not influenced by the temperature and humidity of a storage environment, so that the storage time of the electronic archives can be prolonged; and the storage amount of the electronic archives is mainly determined by storage spaces of electronic storage devices such as a hard disk and the like, and the storage costs of the electronic storage devices are remarkably lower than the storage costs of sites, so that the storage costs can be reduced.

Owner:GUANGZHOU SALIAI STEMCELL SCI & TECH CO LTD

Refrigerator

ActiveCN102226615AExtend storage timeEasy to useLighting and heating apparatusDomestic refrigeratorsFreezing chamberControl mode

The invention discloses a refrigerator. The refrigerator comprises a body, freezing chamber door bodies, refrigerating chamber door bodies, an ice maker and a refrigerating system, wherein a freezing chamber and a refrigerating chamber arranged above the freezing chamber are formed in the body; an ice making chamber is arranged on the inner wall of one refrigerating chamber door body and an ice getting groove connected with the ice making chamber is arranged on the outer surface of the refrigerating chamber door body; the ice maker is arranged in the ice making chamber; the refrigerating system comprises a compressor, a condenser, a first evaporator, a second evaporator, a third evaporator and an electric changeover valve; the compressor and the condenser are arranged in a compressor cabin arranged on the lower part of the rear side of the body; the first evaporator is arranged in the freezing chamber and is used for refrigerating the freezing chamber; the second evaporator is arranged in the refrigerating chamber and is used for refrigerating the refrigerating chamber; the third evaporator is arranged in the ice making chamber and is used for refrigerating the ice making chamber;the electric changeover valve is connected with the three evaporators; and the three evaporators adopt the bypass type control mode. The refrigerator disclosed by the embodiment of the invention has the advantages of good moisturizing effect, convenience in use, high refrigerating efficiency and low energy consumption.

Owner:HEFEI MIDEA REFRIGERATOR CO LTD +1

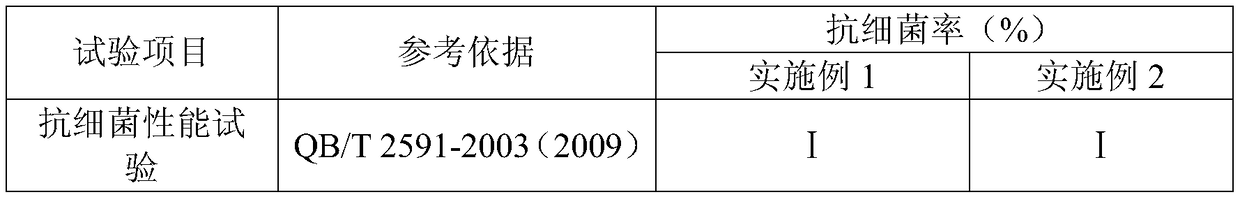

Mold-proof and antibacterial photovoltaic back plate and preparation method thereof

InactiveCN108659336AExtend storage timeReduce storage environmental conditionsSynthetic resin layered productsLaminationPolyethylene terephthalate glycolPolyolefin

The invention discloses a mold-proof and antibacterial photovoltaic back plate which sequentially comprises a weather-proofing fluorine membrane, an adhesive layer, PET (polyethylene terephthalate), an adhesive layer and a mold-proof and antibacterial membrane, wherein the mold-proof and antibacterial membrane comprises the following ingredients in parts by mass: 60-95 parts of polyolefin, 0.1-7 parts of a mold-proof and antimicrobial agent, 2-40 parts of inorganic fillers, 0.1-10 parts of an antioxidant, and 0.1-5 parts of an uvioresistant agent; and the mold-proof and antimicrobial agent istitanium dioxide and has a particle size of less than 100nm. Growth of mold and microorganisms in the back plate can be effectively inhibited, or killed by contact; the problems of performance degradation, an abnormal appearance and the like of the back plate due to reproduction of the mold and the microorganisms are avoided; and the long term performance stability of the back plate is ensured.

Owner:ZHONGTIAN PHOTOVOLTAIC MATERIALS

Waterproof gouache pigment composition and preparation method

The invention discloses a waterproof gouache pigment composition and a preparation method. The waterproof gouache pigment composition comprises pigments, aluminum stearate, sodium rosinate, epoxy resin, sodium dodecyl sulfate, polystyrene diol, sodium alkyl naphthalene sulfonate, styrene-acrylic emulsion, organic silicon, sodium benzoate, polyacrylamide dimethyl silicone oil, cellulose phthalate acid ester, tert-carboxylic acid and tetrafluoroethylene oil. Compared with the prior art, the composition is prepared by the aid of various chemical components and particularly has waterproof and moisture-proof effects, fading of a gouache is prevented, preservation time of the gouache is prolonged, and the composition has popularization and application values.

Owner:XINXIANG UNIV

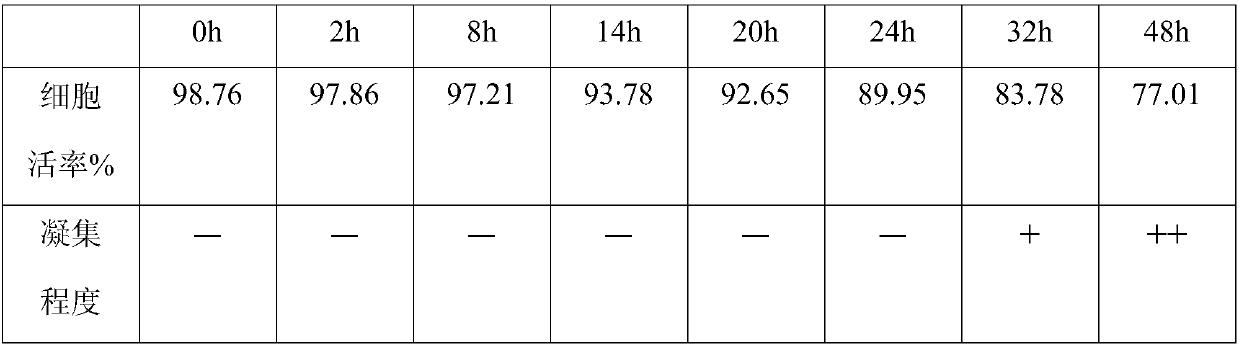

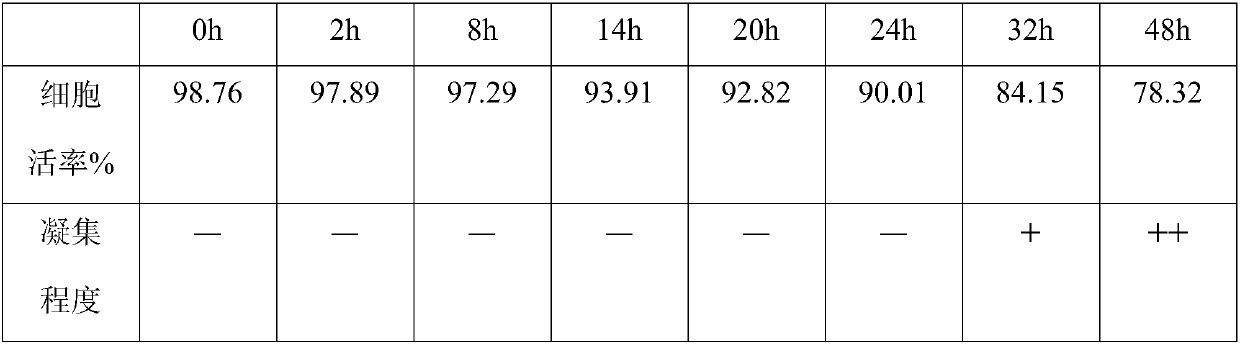

Mesenchymal stem cell preserving fluid for venous re-transfusion and preparation method of mesenchymal stem cell preserving fluid

The invention discloses a mesenchymal stem cell preserving fluid for venous re-transfusion and a preparation method of the mesenchymal stem cell preserving fluid. The preserving fluid comprises the following components in percentage by weight: 1-5% of an autologous plasma lysate mixed liquid, 1-5% of human albumin, 1-5% of a VC (Vitamin C) injection, 2-3% of a glucose injection, 23-30% of a compound electrolyte injection, 23-30% of a glucose salt injection and 23-30% of a compound amino acid injection. The preserving fluid disclosed by the invention is capable of achieving direct re-transfusion after temporary preservation of refrigeration, cell injury of cells preserved at a frozen state in a preparation process and a cell re-treatment process after anabiosis can be reduced, and the cellutilization rate can be increased.

Owner:CHENGDU QINGKE BIOTECH

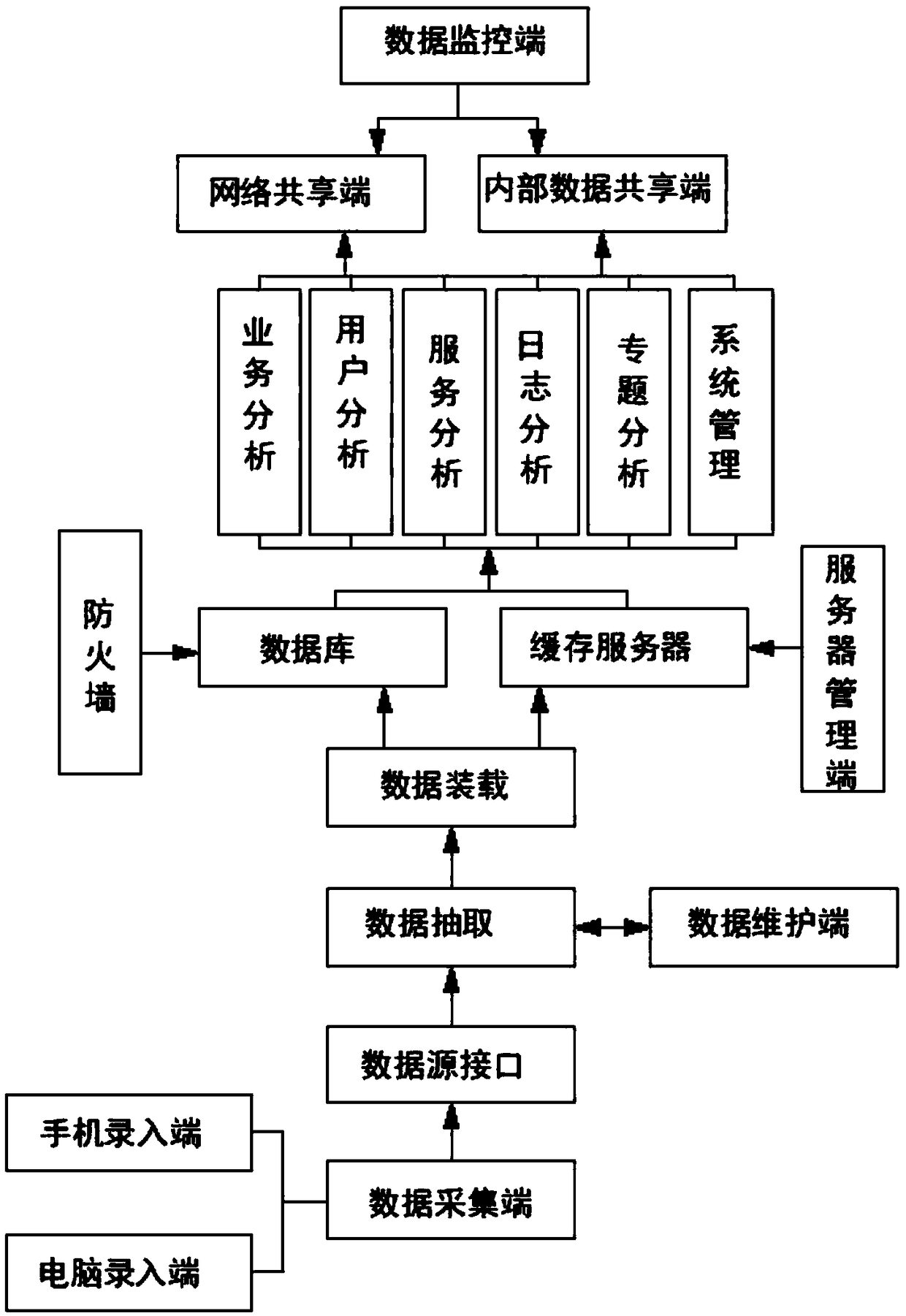

Data analysis and statistics system based on science and technology services

InactiveCN108764823AImprove input speedGuaranteed accuracyOffice automationData storage systemData processing

The invention discloses a data analysis and statistics system based on science and technology services. The data analysis and statistics system comprises a data acquisition system, a data storage system and a data processing system. The data analysis and statistics system is characterized in that the output end of the data acquisition system is connected with the input end of the data storage system; the output end of the data storage system is connected with the input end of the data processing system; the data acquisition system comprises a data acquisition end, a data source interface, dataextraction and data loading; the output end of the data acquisition end is connected with the input end of the data source interface; and the output end of the data source interface is connected withthe input end of the data extraction. The data acquisition system is arranged, so that the data acquisition can be more timely and accurate; a mobile phone input end and a computer input end are arranged, so that the input speed of data is increased; and a data maintenance end is arranged, so that the data can be screened, the wrong data can be deleted, and the accuracy of data input is guaranteed.

Owner:甘肃祥龙科技服务有限责任公司

Method for storing date as raw material for jujube juice

InactiveCN1689417AExtend storage timeLess loss of nutrientsFruits/vegetable preservation by freezing/coolingFood treatmentZiziphus jujubaChinese Jujube

The storing process of date as date juice material includes sorting and cleaning, high temperature sterilizing, packing and freezing, and features that cleaned date is sterilized at 85-100 deg.c for 10-25 min, sealed in plastic bag and maintained in cold storage warehouse at the temperature of -2 to -5 deg.c. The said technological scheme makes it possible for to prolong the date preserving period to over 12 months with less nutrients loss and the preserved date may be used in producing date juice beverage with the taste and nutrients similar to that of fresh date.

Owner:柳清伟

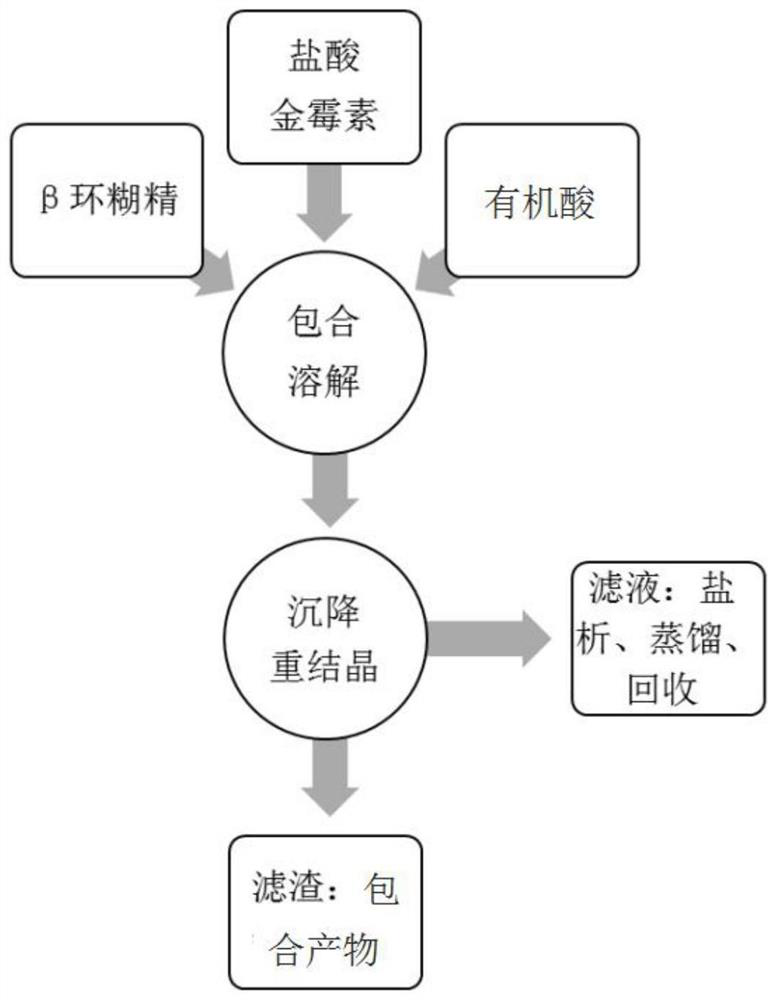

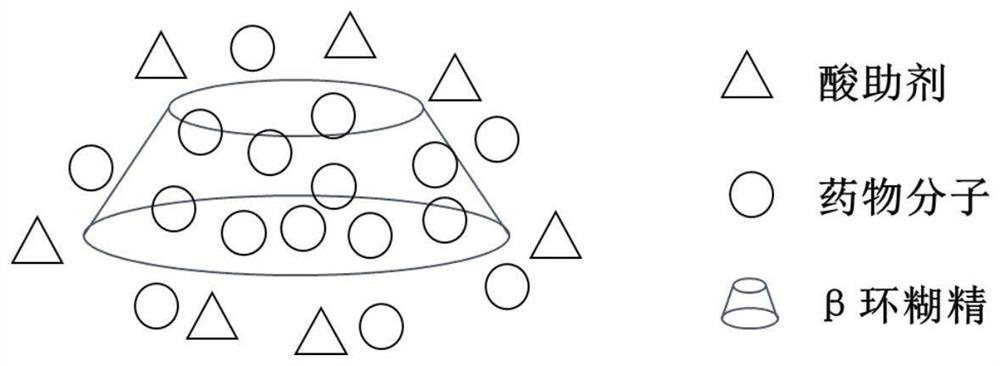

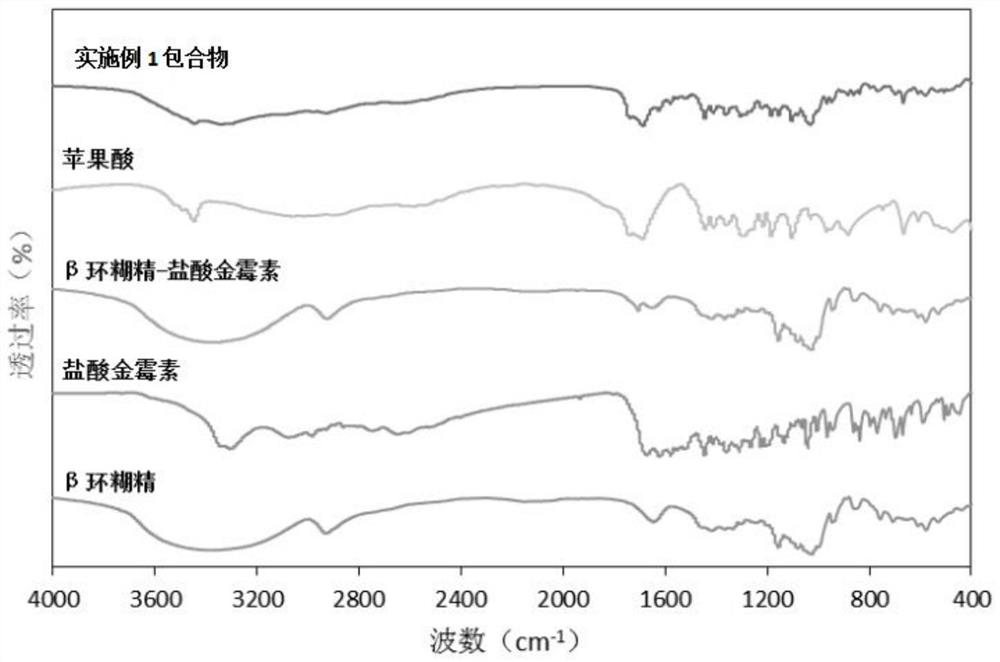

Indissolvable drug inclusion compound, inclusion method and chlortetracycline hydrochloride soluble powder

PendingCN112957481AImprove rapid dissolving abilityIncreased fast dissolving powerPowder deliveryTetracycline active ingredientsOrganic acidDrugs preparations

The invention provides an indissolvable drug inclusion method, and belongs to the technical field of biological medicines. The method comprises the following steps of stirring and dissolving beta-cyclodextrin in water, and preparing a beta-cyclodextrin solution; adding an indissolvable drug into the beta-cyclodextrin solution in batches, fully stirring, adding an organic acid, and stirring and mixing again to prepare an inclusion solution; and adding an organic solvent into the inclusion solution, stirring to separate out an inclusion product, standing at low temperature, and filtering out the product to obtain the inclusion product. The preparation method comprises the following steps of conducting inclusion of the water indissolvable drug raw material and beta-cyclodextrin with entrapment capacity by using an inclusion-hydrotropy-recrystallization process flow, assisting the hydrotropy effect of organic acid, and carrying out recrystallization precipitation to prepare the inclusion drug composition. The method is especially suitable for pharmaceutical preparations which are difficult in water solubility, not resistant to high temperature and unstable in aqueous solution.

Owner:FOSHAN NANHAI EASTERN ALONG PHARMA CO LTD

Method for extraction of Cornus walteri seed oil by combination of superhigh pressure treatment and subcritical double solvent extraction

ActiveCN105349253ASolving Grease ShortagesExtend storage timeFatty-oils/fats productionNutrientChemistry

The invention relates to a method for extraction of Cornus walteri seed oil by combination of superhigh pressure treatment and subcritical double solvent extraction. The method comprises 1, crushing Cornus walteri seeds, drying the crushed Cornus walteri seeds and carrying out pretreatment at a temperature of 30-40 DEG C under pressure of 300-350 MPa, 2, carrying out extraction on the Cornus walteri seeds pretreated by the step 1 in a subcritical fluid at a temperature of 120-180 DEG C under pressure of 3-7MPa to obtain extract, and 3, carrying out cooling and demulsification on the extract obtained by the step 2, carrying out standing layering, and taking a liquid in the upper layer, wherein the liquid in the upper layer is Cornus walteri seed oil. The superhigh pressure pretreatment is carried out prior to the subcritical fluid extraction and is carried out at a temperature of 30-40 DEG C under pressure of 300-350MPa for 10-15min so that lipoxidase and polyphenol oxidase in Cornus walteri seeds are passivated and even loses activity, microbes on Cornus walteri seeds are killed and a color, a fragrance, a taste, nutrients such as vitamins and local flavor substances of the food are not influenced and a recovery rate is obviously improved.

Owner:山东万路达园林科技有限公司 +1

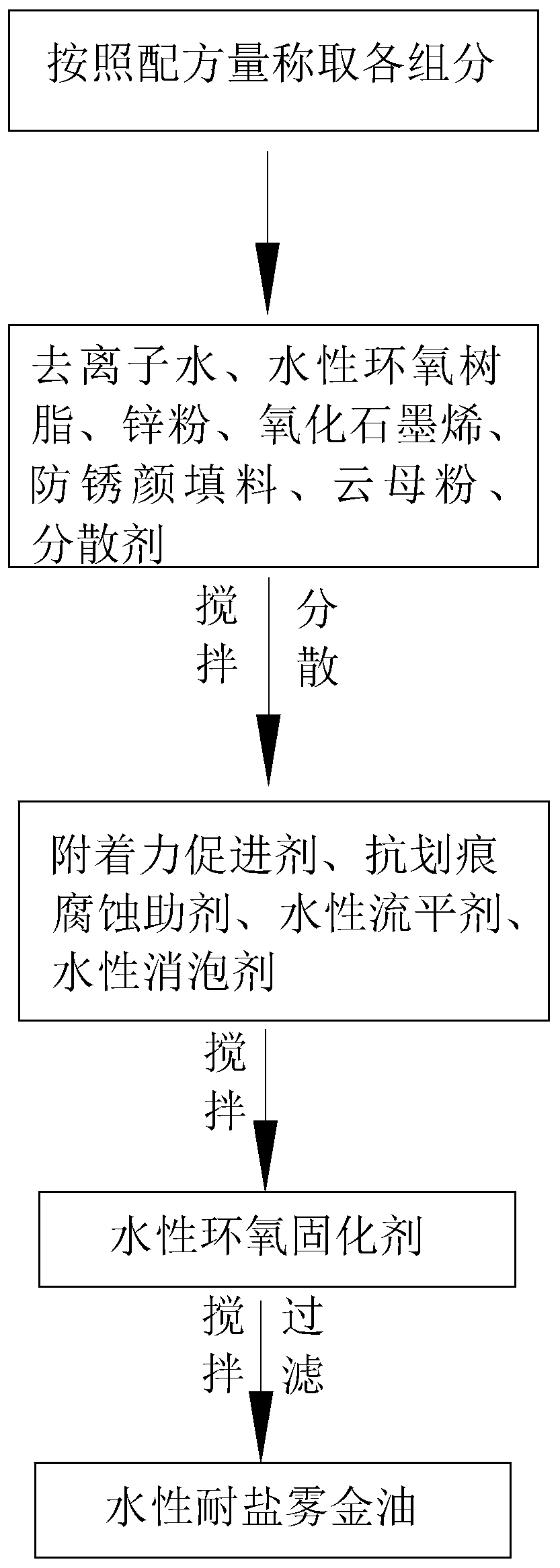

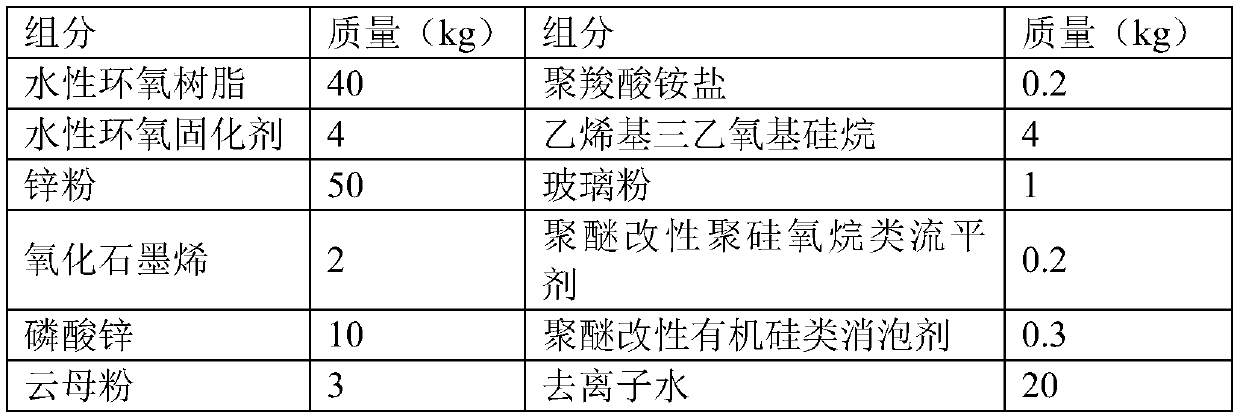

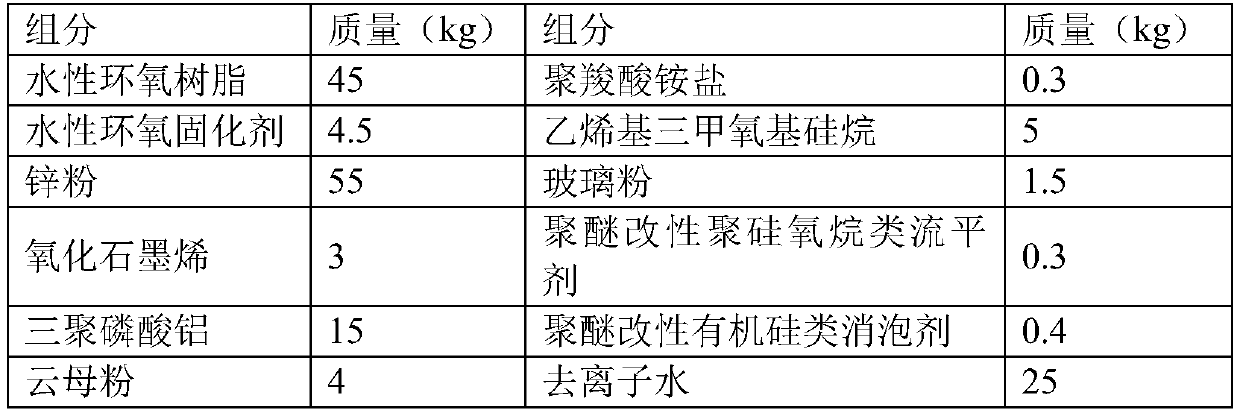

Water-based salt spray resistant gold oil and preparation method thereof

InactiveCN110330863ABlock throughAchieve protectionAnti-corrosive paintsEpoxy resin coatingsEpoxyWater based

The invention relates to water-based salt spray resistant gold oil and a preparation method thereof. The water-based salt spray resistant gold oil comprises the following components in parts by mass:40-50 parts of a water-based epoxy resin, 4-5 parts of a water-based epoxy curing agent, 50-60 parts of zinc powder, 2-5 parts of graphene oxide, 10-15 parts of rust-proof pigments and fillers, 3-5 parts of mica powder, 0.2-0.4 part of a dispersing agent, 4-6 parts of an adhesion promoter, 1-2 parts of an anti-scratch corrosion additive, 0.2-0.4 part of a water-based leveling agent, 0.3-0.5 part of a water-based antifoaming agent and 20-25 parts of deionized water. By improving the salt spray resistance of the water-based gold oil, the film sprayed onto protective metals is difficult to blister and drop, and the protection property of metals is prolonged.

Owner:福建省澳龙环保新材料有限公司

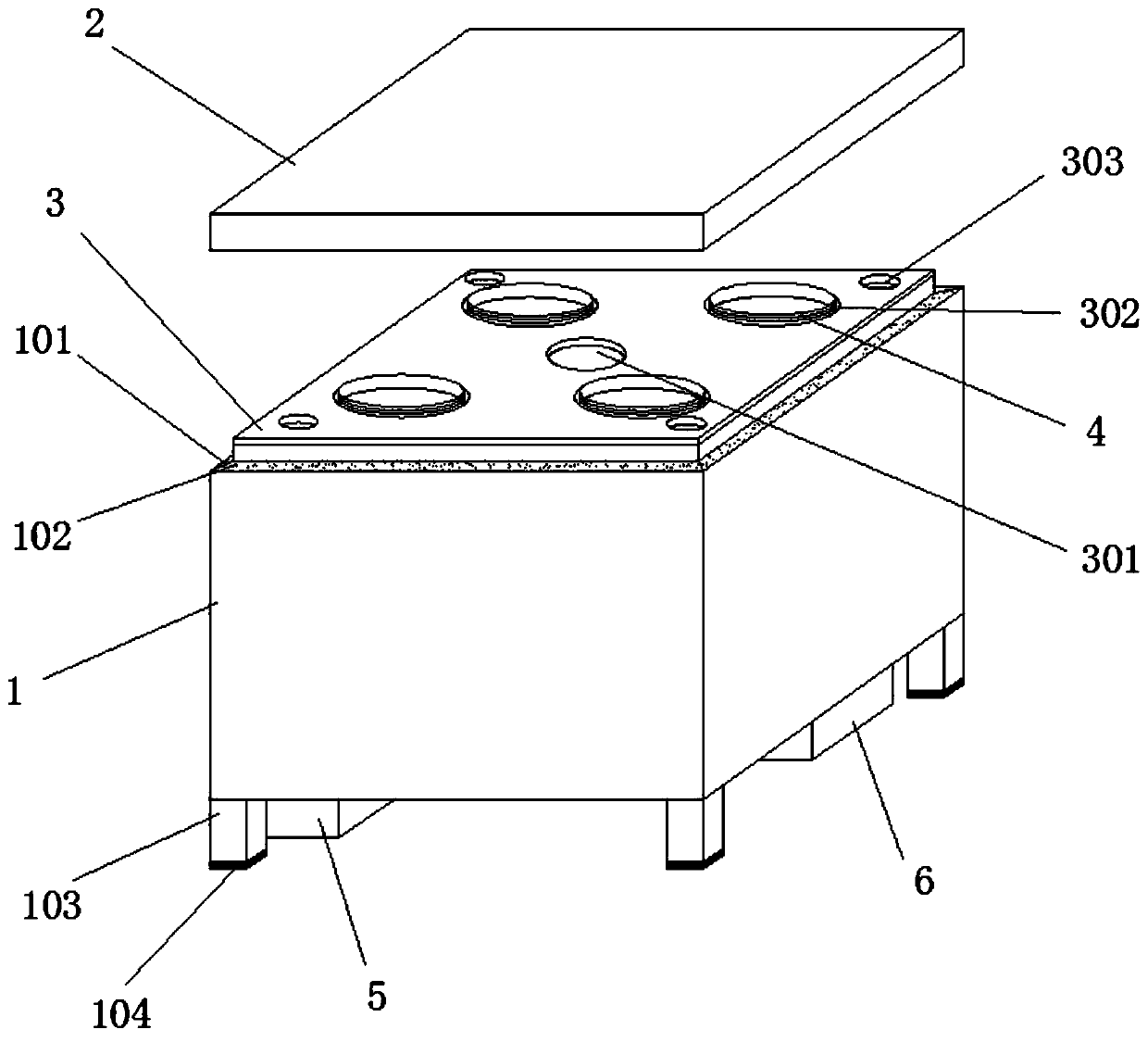

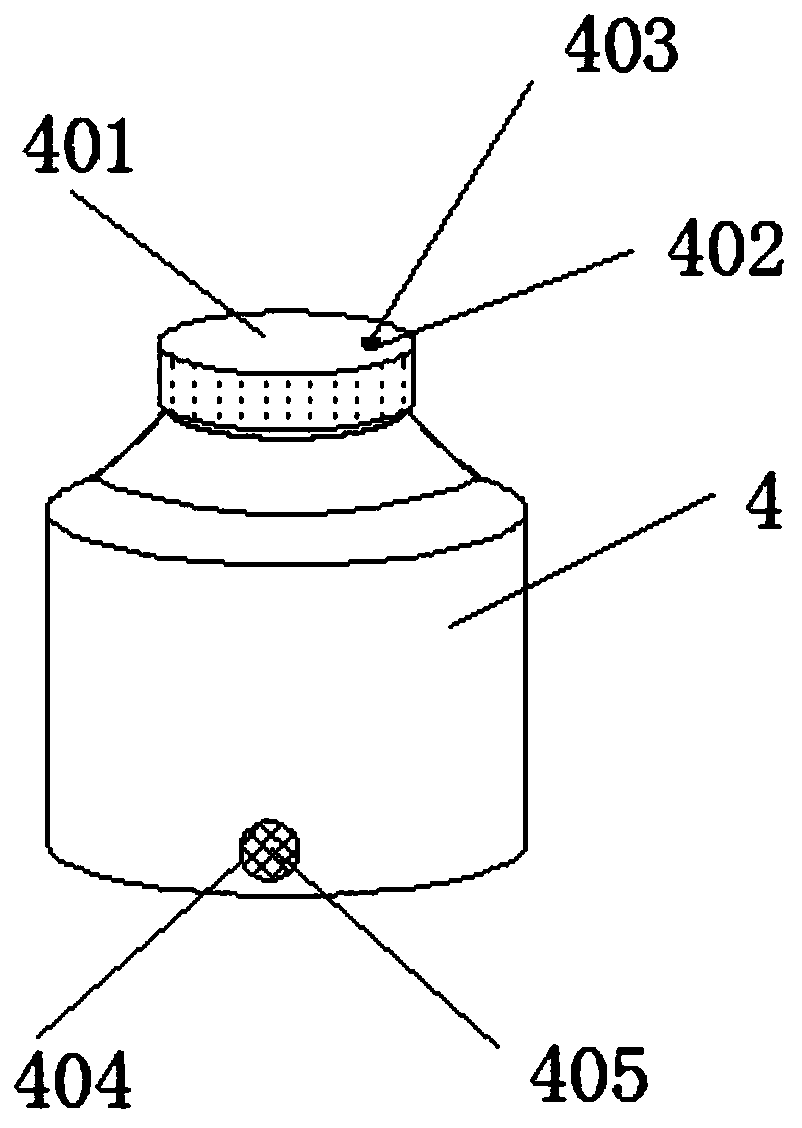

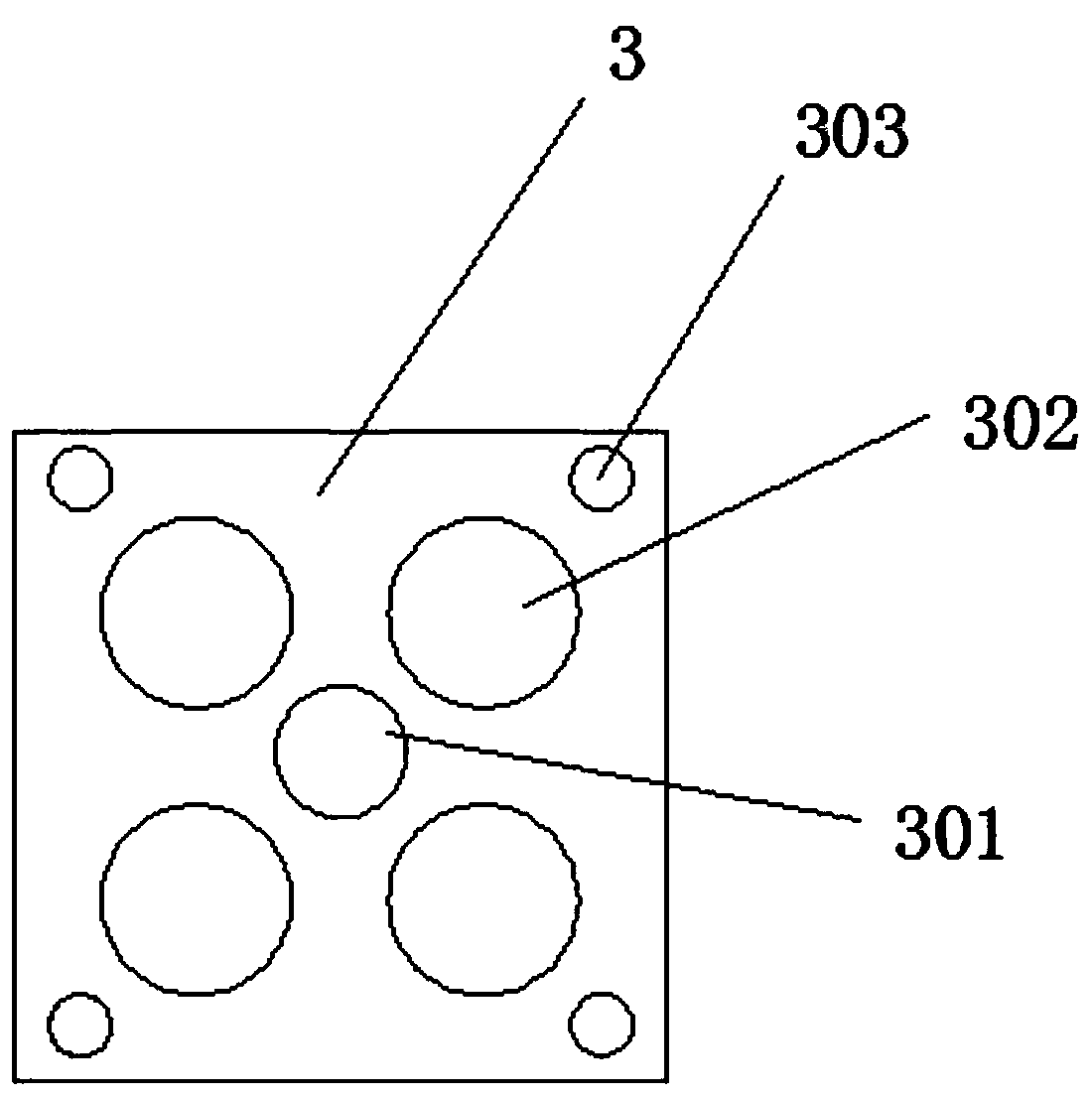

Deliquescence-prevention tea caddy

InactiveCN110668015AAvoid oxidation and yellowingGuaranteed tasteClosure with auxillary devicesPackaging under vacuum/special atmosphereUltraviolet lightsEngineering

The invention discloses a deliquescence-prevention tea caddy which comprises a storage box and tea caddies. The storage box is of a cavity box type structure; and the multiple tea caddies are fixedlyarranged in a cavity of the storage box. Through arranging the multiple tea caddies in the storage box, the storage box can store different species of tea leaves at the same time, so that the applicability is high; meanwhile, through the double-layer sealing arrangement of the storage box and the tea caddies, the sealing performance in the tea leaf storage process is further improved; through arranging a vacuum-pumping device, after the tea caddies are screwed down through covers, the vacuum-pumping device pumps out air in the tea caddies through an air conveying pipeline by a main vacuum-pumping pipeline, so that a vacuum degree in each tea caddy is ensured, the occurrence of the phenomenon that tea leaves in the tea caddies are oxidized and yellowed due to air in the caddies is effectively prevented, and the taste of the tea leaves is ensured maximally; and an ultraviolet lamp tube is arranged in a support cylinder and is used for sterilizing the storage box in real time, so that aninner environment of the storage box is guaranteed.

Owner:安徽花山街网络科技有限公司

Conveying device for raw materials for graphene production

ActiveCN108438035AImprove drynessExtend storage timeClosure with auxillary devicesVentilationPistonGraphite oxide

The invention discloses a conveying device for raw materials for graphene production. The conveying device for the raw materials for the graphene production comprises a base and a box body. Universalwheels are installed at the bottom of the base. The box body is fixed to the top end of the base. An air pump is installed on the inner wall of the box body. A fixed pad is fixed to the middle of thebox body. A vessel is connected to the top end of the fixed pad in a clamped mode. A compressor is installed on one side of the box body. An upper cover is connected with the top end of the box body through a hinge. An air pressure adjusting device is installed at the top end of the upper cover. The air pressure adjusting device comprises a rotary knob, a piston, a connecting rod, a shell and an air leakage hole. The shell is fixed at the top of the upper cover. The air leakage hole is formed in one side of the shell, and the piston is connected to the inner wall of the shell. The connecting rod is fixed to the middle of the piston. The rotary knob is fixed to the end, located at the outer side of the shell, of the connecting rod. According to the conveying device for the raw materials forthe graphene production, the dryness and air tightness of the box body are ensured, air in the box body is reduced, the storage time of graphite oxide is prolonged, the damage of the vessel in the conveying process is prevented, and the quality of the graphite oxide in the vessel is eneured.

Owner:嘉兴沃瑞科技有限公司

Clitopilus prunulus preserving method

ActiveCN106085865AExtend storage timeResearch and production promotionMicroorganism based processesMicroorganism preservationChemistryPleuromutilin

The invention relates to a clitopilus prunulus preserving method. The process includes the steps that clitopilus prunulus mycelia and a sodium alginate solution are mixed, the mixed solution is dripped into a calcium chloride solution to prepare small balls, and finally the small balls are put into pure water and preserved at the temperature of 0-4 DEG C. The clitopilus prunulus preserving method can greatly prolong the clitopilus prunulus preserving time while ensuring strain survival and has a positive acceleration effect on pleuromutilin and derivatives thereof.

Owner:宁夏泰瑞制药股份有限公司

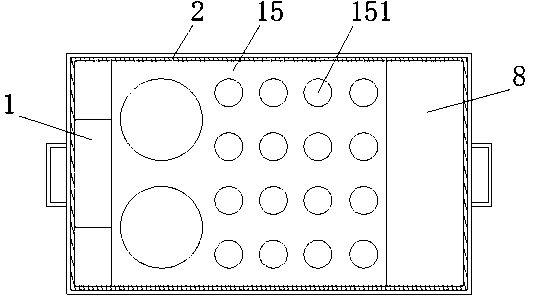

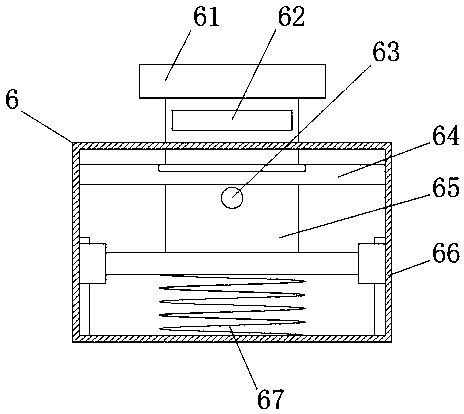

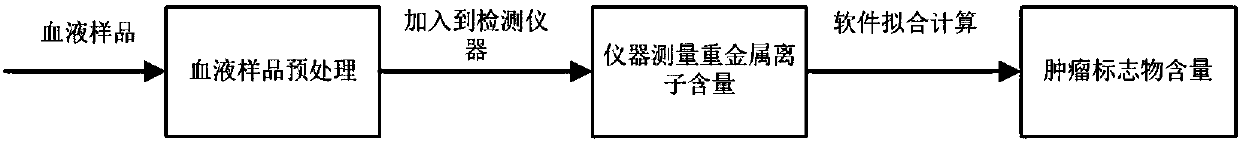

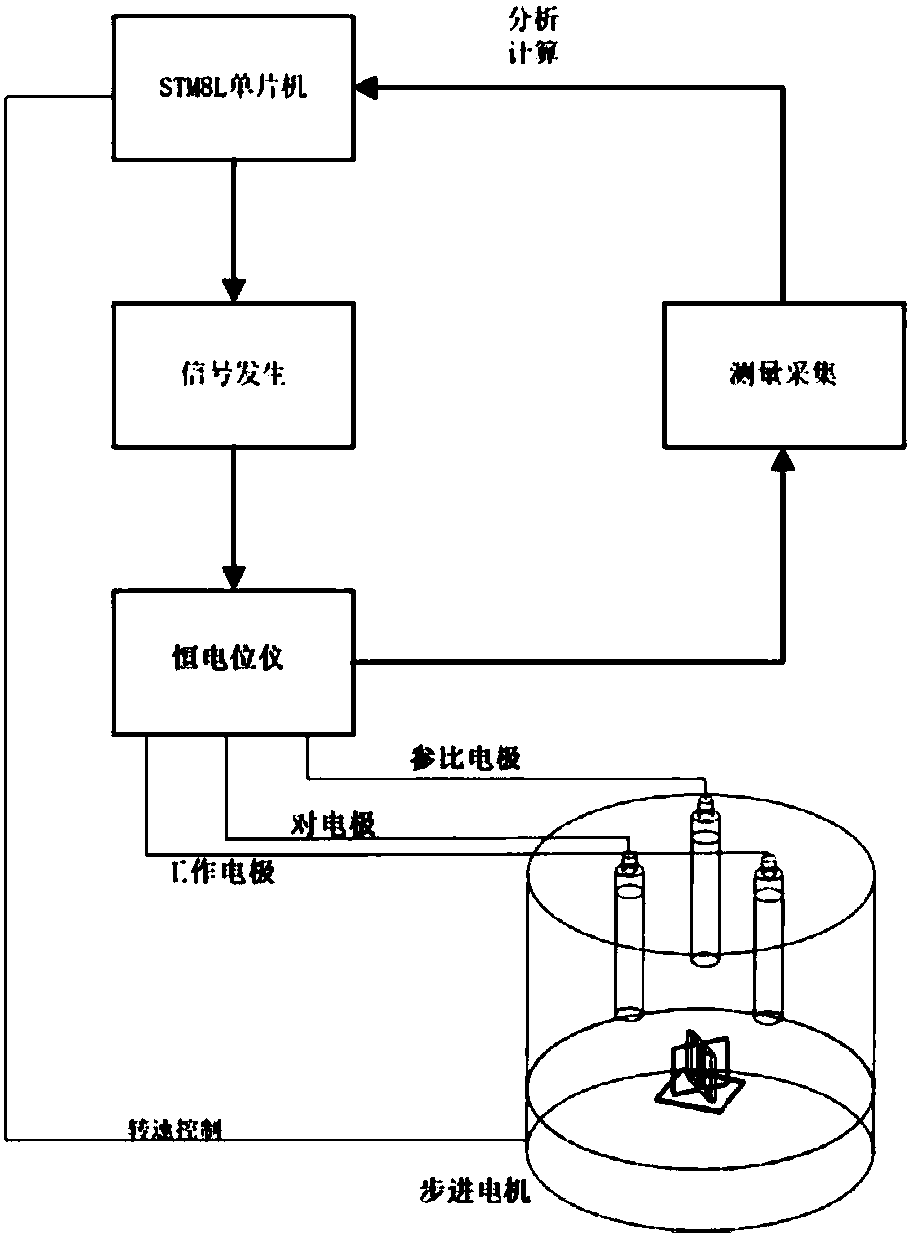

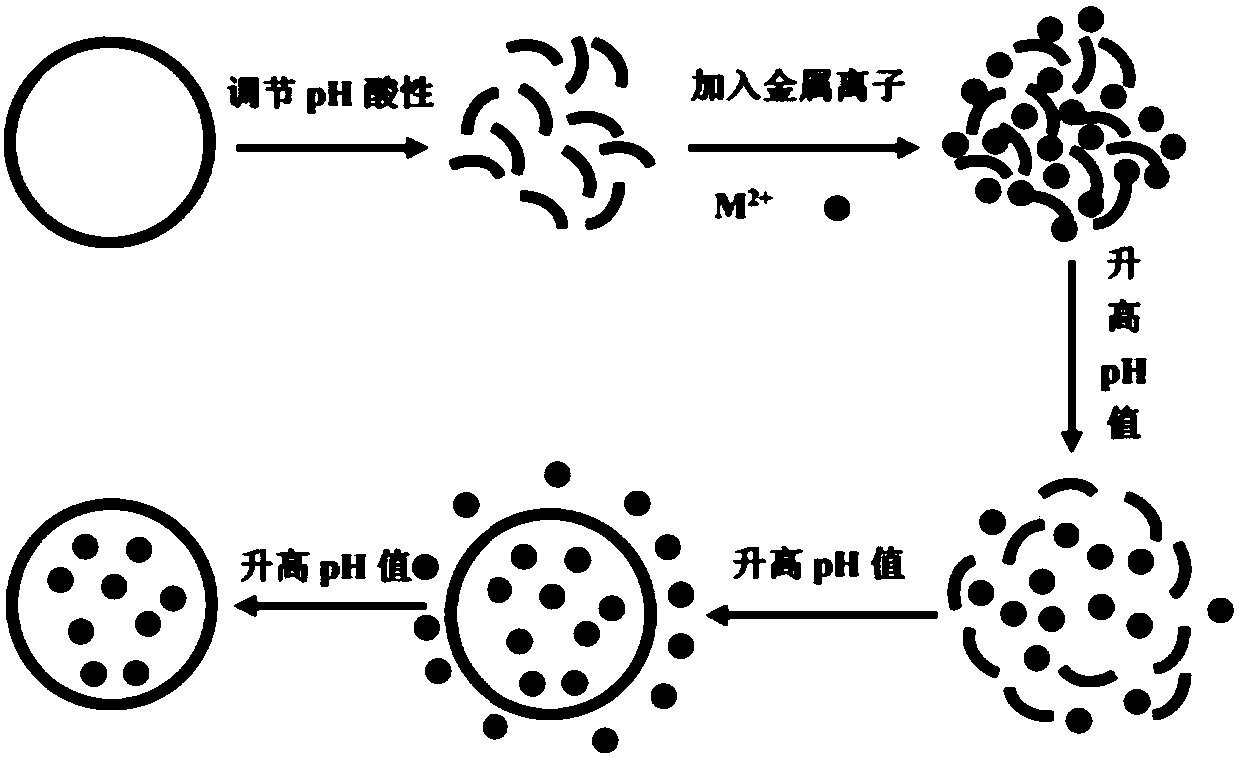

A combined detection instrument for multiple breast cancer tumor markers based on a nucleic acid aptamer

InactiveCN108519482AAchieving Simultaneous Joint DetectionReduce testing costsDisease diagnosisMaterial electrochemical variablesAptamerMagnetic bead

The invention discloses a combined detection instrument for multiple breast cancer tumor markers based on a nucleic acid aptamer. The combined detection instrument includes signal markers, magnetic bead-aptamer composite material, an electrolytic cell, a three-electrode measuring device and a measurement and analysis system based on a single-chip microcomputer STM8L. The signal markers include themarkers connected with the MUC 1 nucleic acid aptamer and HER-2 nucleic acid aptamer. The tradition protein antibody is replaced by adopting the multiple metal ion labels to mark the nucleic acid aptamer of different breast cancer tumor markers, the simultaneous combined detection for the multiple breast cancer tumor markers is realized, and the detection cost is reduced. The protein antibody isreplaced by adopting the nucleic acid aptamer, the requirements for the detection environment are reduced, and the storage time of the signal markers is improved.

Owner:HANGZHOU DIANZI UNIV

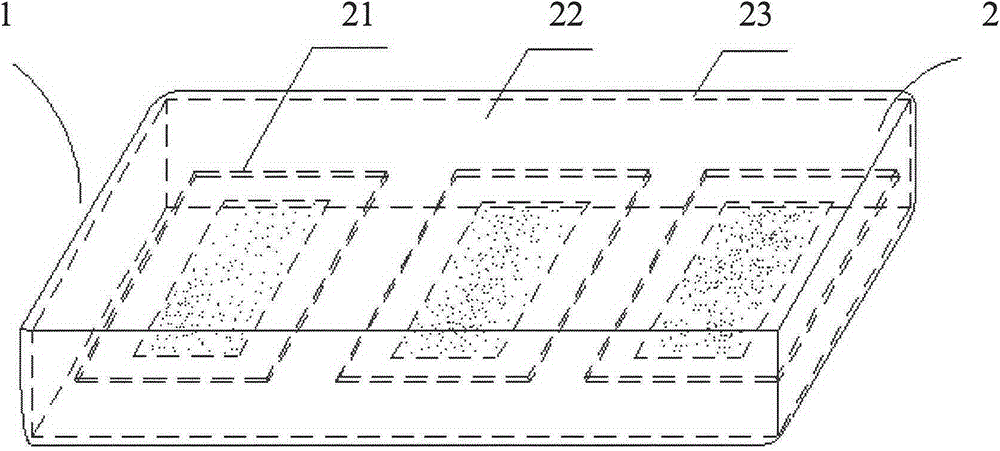

Agarose gel plate storage method

InactiveCN104597098AExtend storage timeReduce volumeMaterial analysis by electric/magnetic meansChemistryEngineering

The present invention provides an agarose gel plate storage method, wherein a sealed wrapping material is wrapped outside the agarose gel plate, and the method comprises film covering, single packaging, boxing and bagging. Compared with the method in the prior art, the method of the present invention has the following characteristics that: in order to ensure the long-term effectiveness of the kit, a purpose of the present invention is to provide a method for long-term storage of the agarose gel plate, the agarose gel prepared by the method has characteristics of no bacterial growth, strong antiseptic performance and easy storage, and the experiment results show that the storage time of the agarose gel plate stored by the agarose gel plate storage method in the 4 DEG C refrigerator is up to 6 months, such that the problem of the too short agarose gel plate storage time is solved, and the great market value is provided.

Owner:SHANGHAI DIAN CLINICAL TESTING CENT

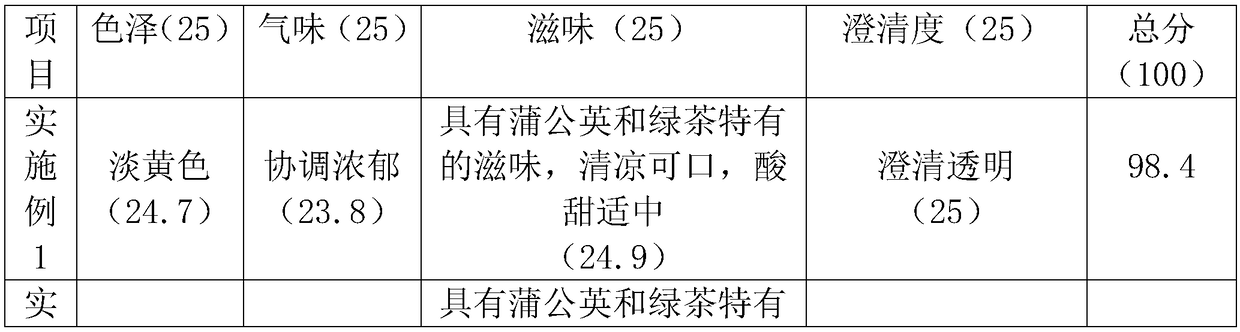

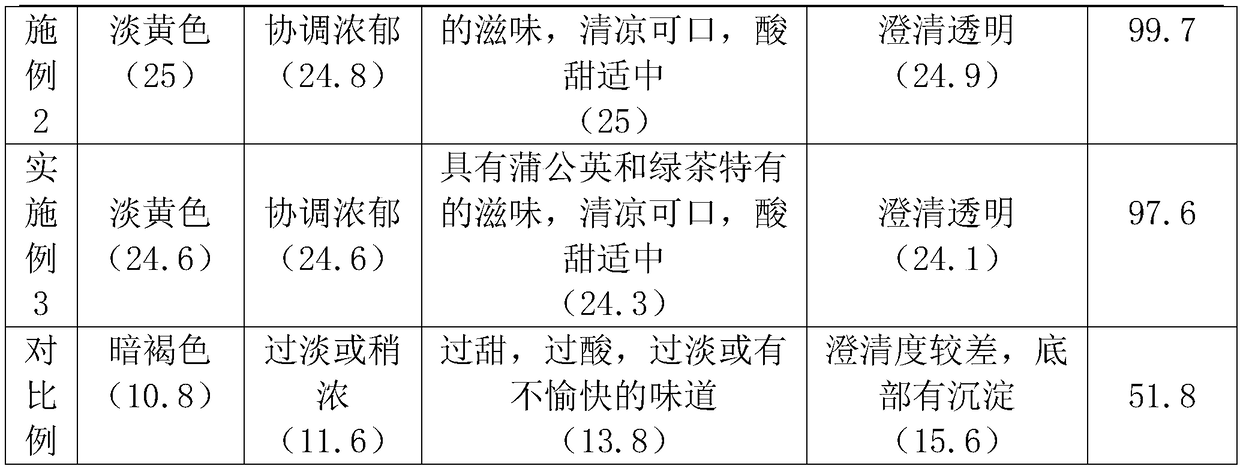

Dandelion tea processing method capable of increasing caffeic acid content

The invention discloses a dandelion tea processing method capable of increasing the caffeic acid content, and belongs to the technical field of processing of dandelion tea. The processing of the dandelion tea is realized through six steps of picking fresh leaves, performing maceration, performing microwave steam fixation, performing gradient temperature reduction and drying, performing alternativetwisting, and performing fermentation and shaping. According to the dandelion tea processing method disclosed by the invention, microwave steam fixation treatment, gradient temperature reduction anddrying treatment and alternate rolling treatment are adopted, so that effective components in the tea leaves can be extracted to the maximum extent, the effective components of the tea leaves are guaranteed not to be destroyed, and the preservation time of tea leaf finished products can be prolonged. Dandelion tea processed by the processing method disclosed by the invention is yellowish in color,harmonious and rich in smell, cool, refreshing and delicious, moderate in sour and sweet degree, clear and transparent, has peculiar taste of dandelions and green tea, and meets requirements of vastconsumers. In the dandelion tea processed by the processing method disclosed by the invention, the caffeic acid content is 0.478-0.486mg / g, the caffeic acid recovery rate is 97.2-98.1%, and the processing benefits are significant.

Owner:王斌

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com