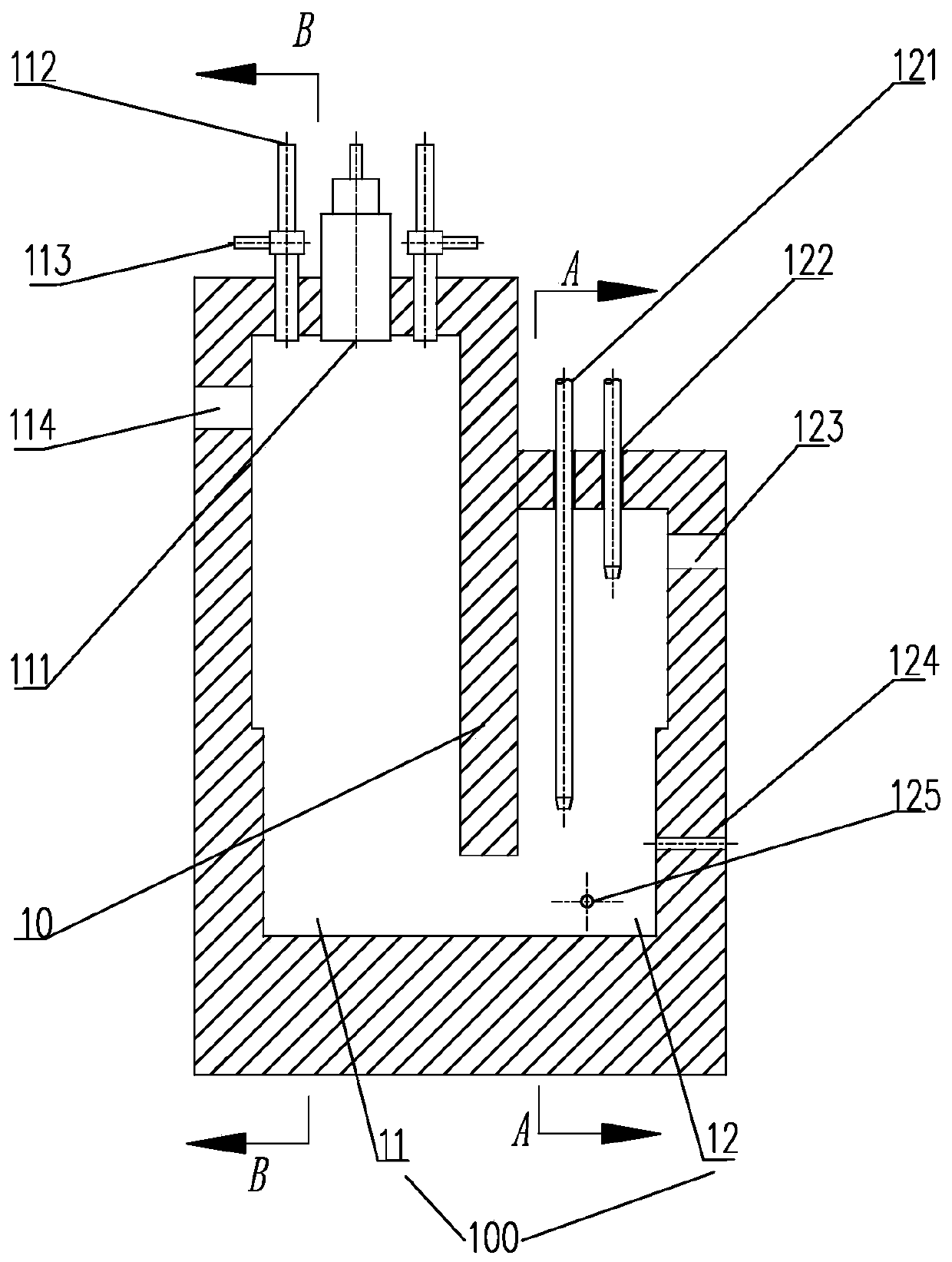

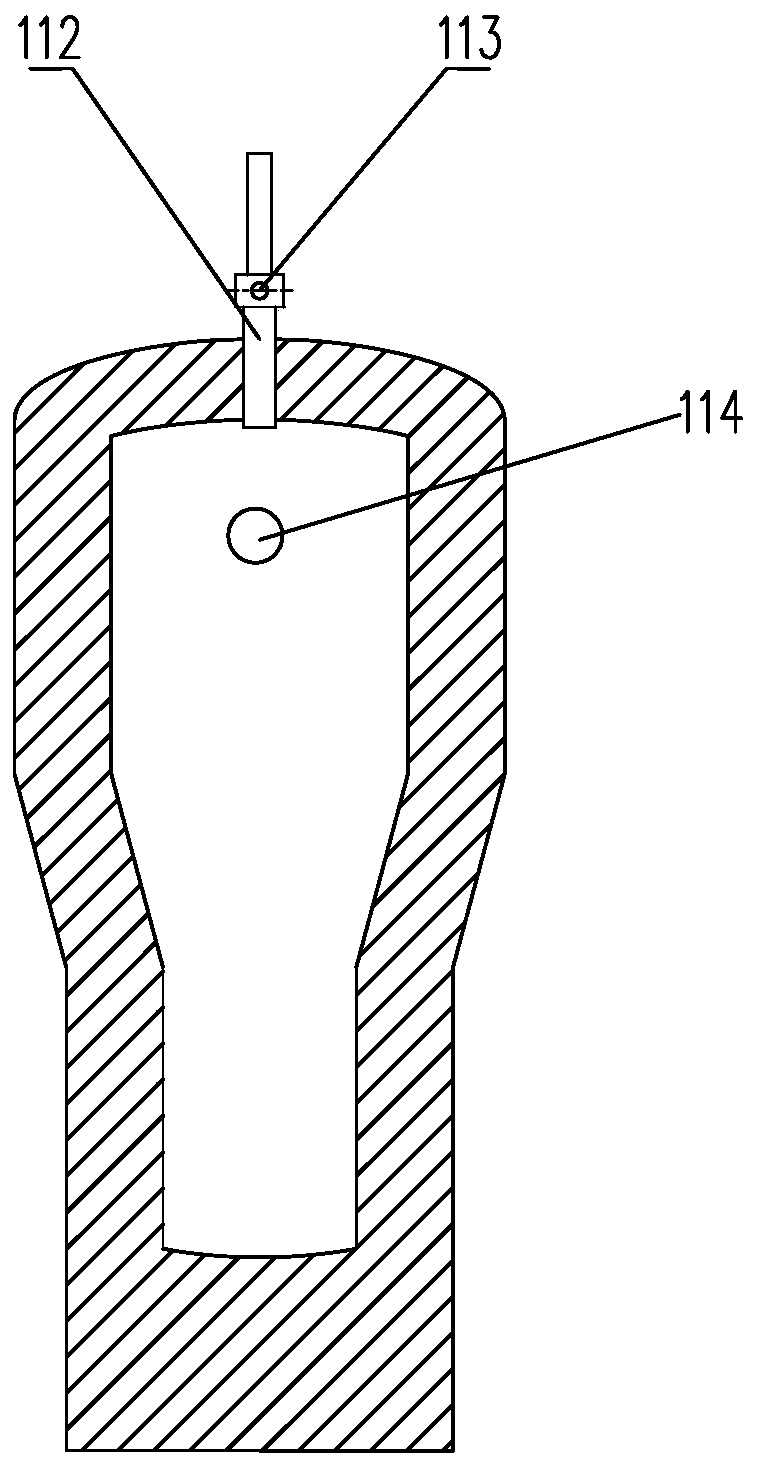

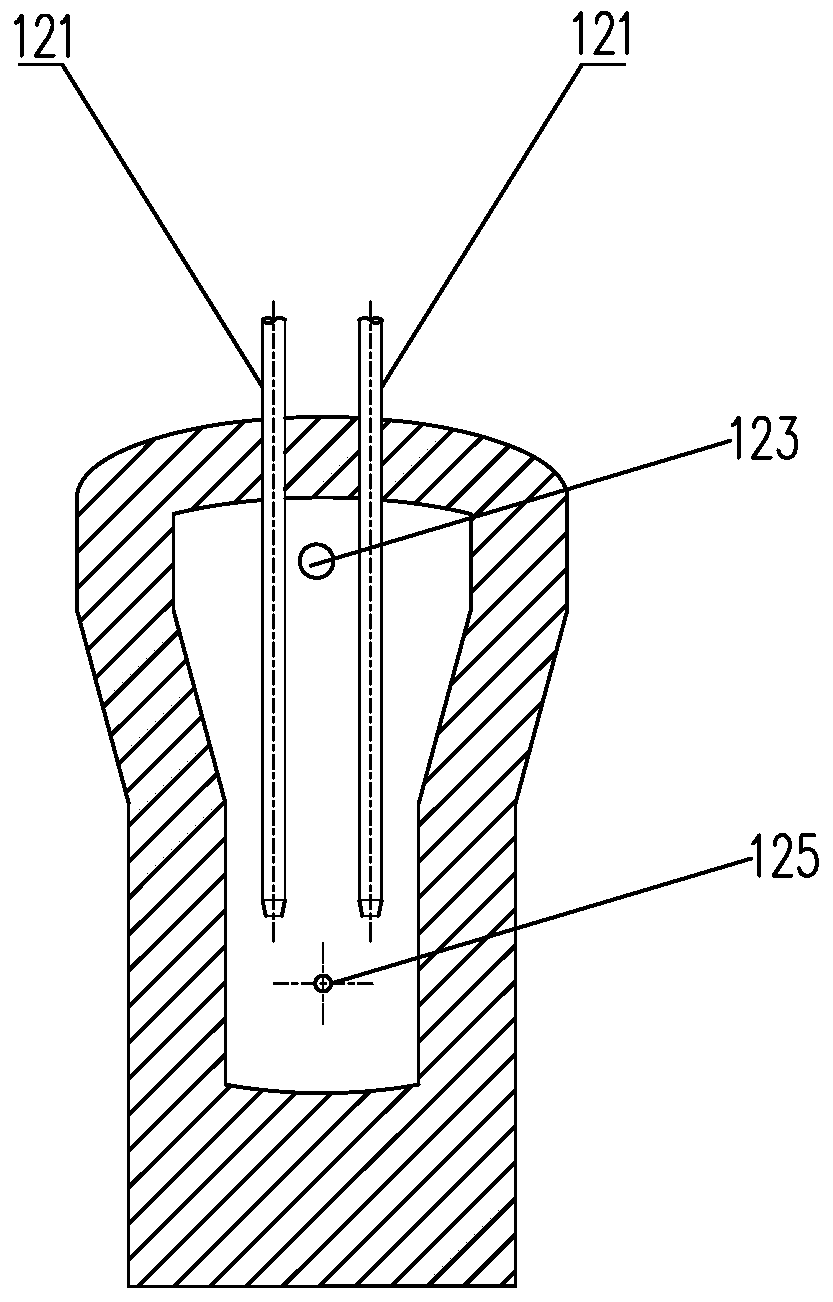

Suspension smelting electric heating reduction furnace and method for smelting zinc concentrate

A suspension smelting and reduction furnace technology, applied in the field of metallurgy, can solve the problems of inability to meet the requirements of modern large-scale industrial production, blast furnace, electric furnace slag with high zinc content, and high raw material composition requirements, so as to reduce the operation and occupation of melt discharge and addition. The effect of small land area and reduced tool consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0075] refer to Figure 7 , zinc concentrate (containing Zn: 50.1wt%), solvent (FeO, SiO 2 and CaO) and zinc slag (containing Zn: 19.7wt%) according to the mass ratio of 7:1:2 and then dried and sieved. The material nozzle is sprayed into the suspension smelting area, and then the zinc concentrate is contacted with oxygen-enriched air for oxidation smelting (smelting temperature is 1200°C), and sulfur-containing smelting flue gas and high-zinc slag are obtained. The gas is cooled by the waste heat boiler, dust is collected by the electrostatic precipitator, and the flue gas is sent to make acid. The slag type of the obtained high-zinc slag is ZnO-FeO-SiO 2 Type, ZnO-FeO-SiO 2 -CaO type, ZnO-FeO-SiO 2 -CaO-ZnO type, the above-mentioned high-zinc slag is put into the electrothermal reduction zone of the suspension smelting electrothermal reduction furnace through the communication channel between the partition wall and the bottom wall of the furnace body, and at the same time...

Embodiment 2

[0077] The difference from Example 1 is that the smelting temperature in the electrothermal reduction zone of the suspension smelting electrothermal reduction furnace is 1300°C.

Embodiment 3

[0079] The difference from Example 1 is that the smelting temperature in the electrothermal reduction zone of the suspension smelting electrothermal reduction furnace is 1450°C, and the electrothermal reduction zone of the suspension smelting electrothermal reduction furnace obtains zinc-containing steam, slag, and lead-containing iron melt.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com