Ultra-long-term freshness preserving system

A fresh-keeping box and vacuum pump technology, applied in food preservation, food science, application and other directions, can solve problems such as water loss, yellowing, decay, etc., and achieve the effect of improving storage time and improving practicability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

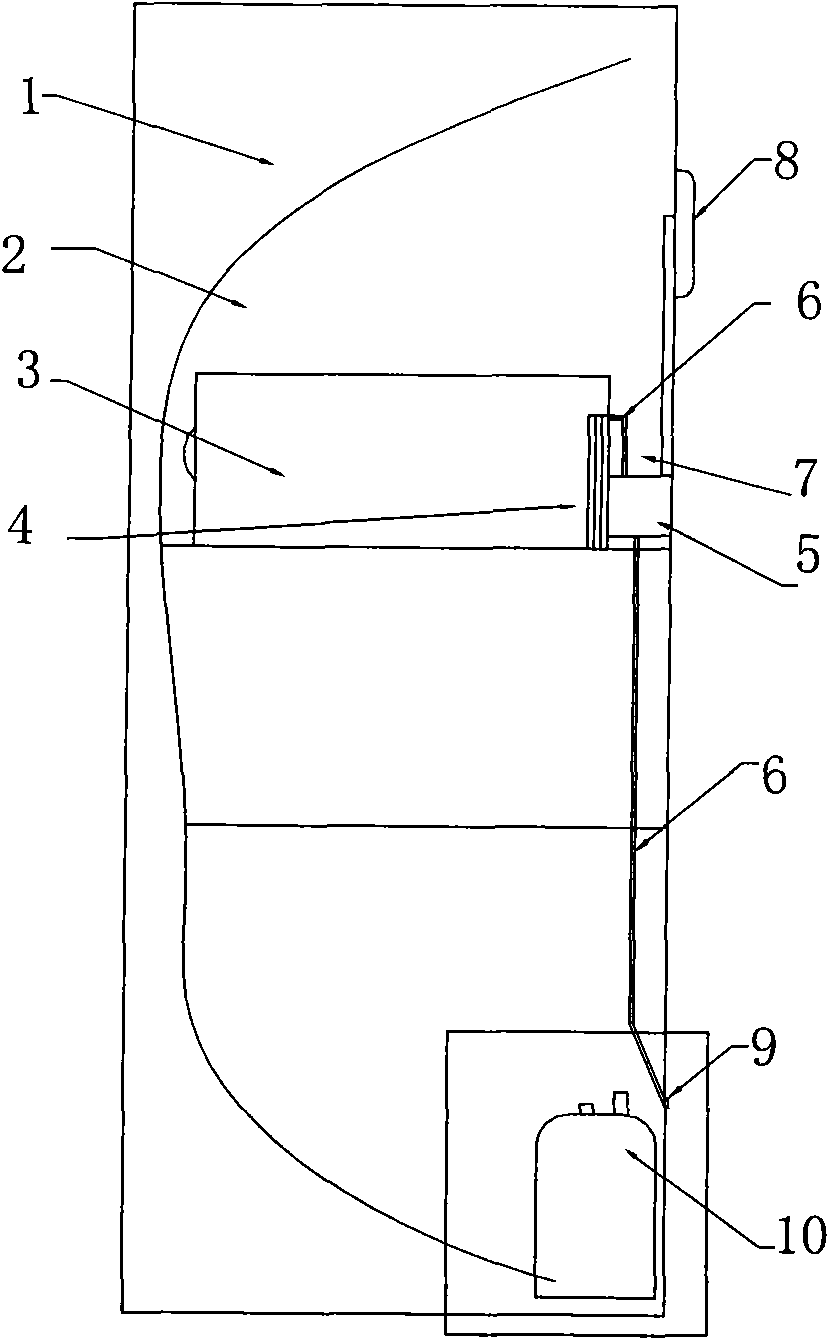

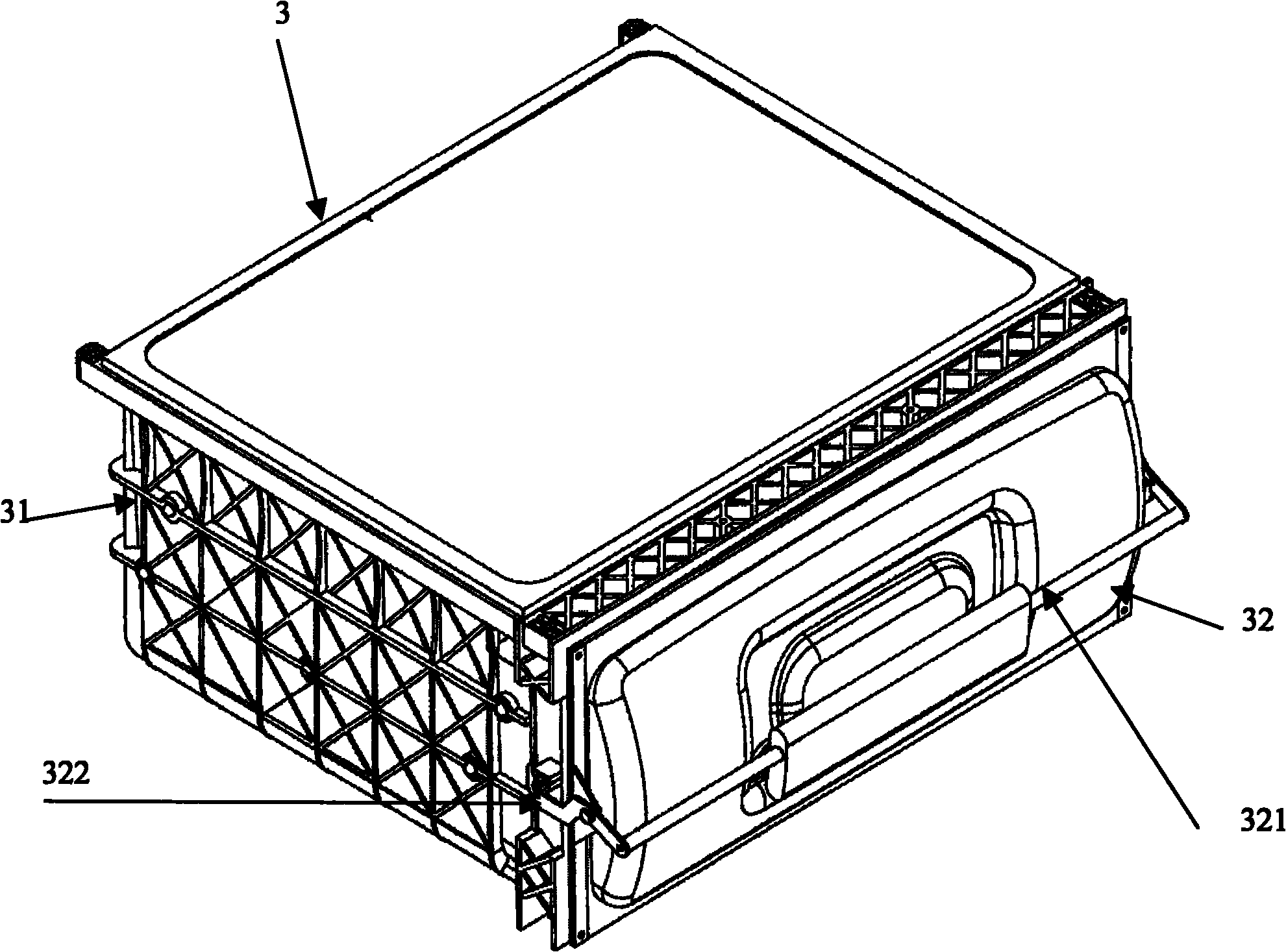

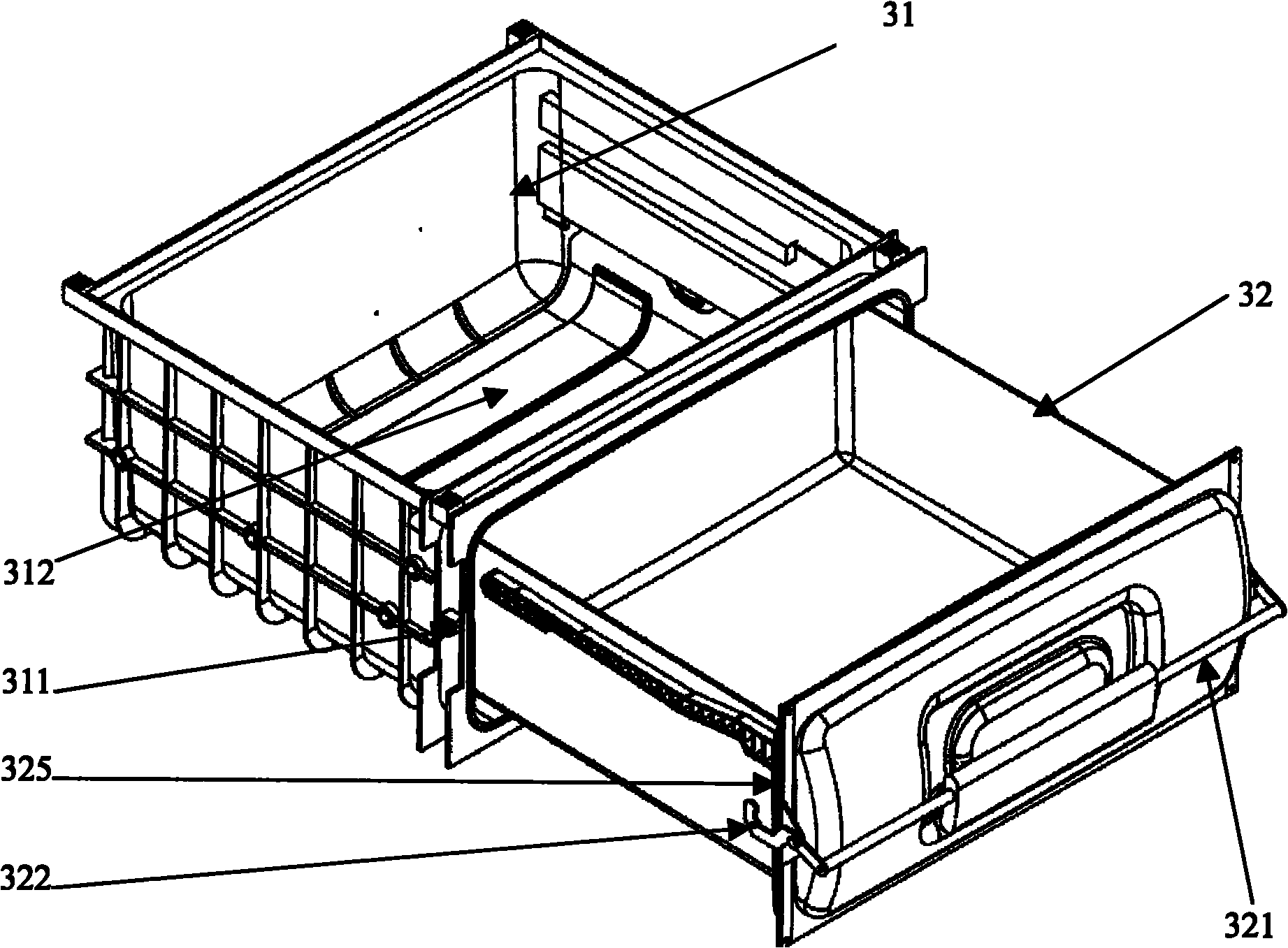

[0020] see figure 1 , The refrigerator body 1 of an embodiment of the present invention includes three parts: a refrigerating chamber 2, a freezing chamber, and a temperature-changing chamber. Wherein, there is a specific fresh-keeping system in the refrigerator room 2, and this system is made up of fresh-keeping box 3, oxygen-enriched film 4, vacuum pump 5, first air delivery pipe 6, pressure sensor 7, control board 8, second air delivery pipe 11. The fresh-keeping box 3 is fixed in the refrigerating chamber of the refrigerator. The fresh-keeping box 3 has an oxygen-enriched film 4 built in. In principle, in order not to hinder the placement of food, the oxygen-enriched film will be fixed on the inner wall of the fresh-keeping box. Except for the door, any wall surface Can. Oxygen-enriched film 4 passes through fresh-keeping box wall through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com