Conveying device for raw materials for graphene production

A transportation device and graphene technology, applied in transportation and packaging, capping with auxiliary devices, sealing parts with auxiliary devices, etc., can solve the problem of lack of storage and transportation of graphene raw materials, affecting the quality and sealing of graphene production Limited and other problems, to achieve the effect of increasing storage time, slowing down oxidation, and improving dryness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

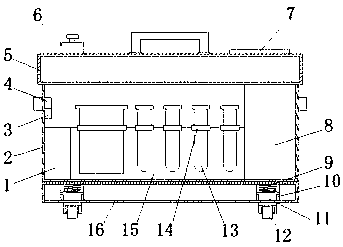

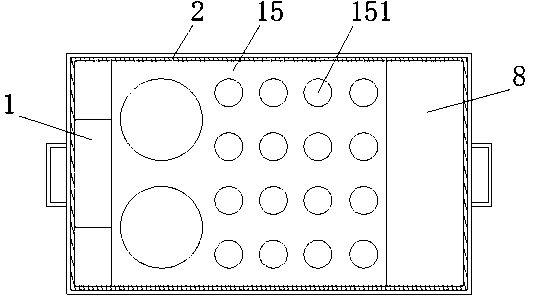

[0027]In Embodiment 1, the user puts the extracted graphite oxide into the vessel 13, and inserts the vessel 13 into the draw-in slot 151. There are various specifications of the draw-in slot 151, which is convenient for fixing and fixing vessels 13 of different sizes. The material of the pad 15 is silica gel, and the buffer pad 14 on the side wall of the slot 151 can play a good buffering effect, preventing the container 13 from colliding with the cabinet 2 and being broken when the cabinet 2 is shaken, and the upper cover 5 is closed. And lock and fix the upper cover 5 and the box body 2 through the lock, start the heater at the bottom of the box body 2 to heat the inside of the box body 2, so that the internal temperature of the box body 2 is 45 to 65 degrees Celsius, and start the air pump 1 at the same time. Accelerate the gasification speed of the moisture in the box body 2, and the air pump 1 discharges the gasified water out of the box body 2. At this time, under the ac...

Embodiment 2

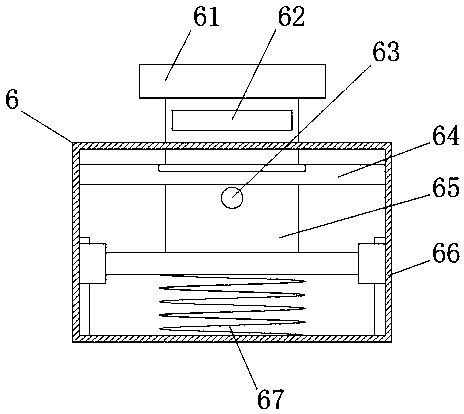

[0028] In Embodiment 2, the outer side of the connecting rod 65 is vertically fixed with the limiting rod 62. When the gaseous water heated in the box body 2 is discharged from the box body 2 by the air pump 1, the limiting bar 62 is located at the top of the housing 66 and is in contact with the housing. 66 clamped, and the vent hole 63 plays the role of auxiliary air circulation. When the temperature and humidity value does not change within half an hour, the knob 61 is pressed down, so that the limit rod 62 passes through the limit hole 68 and is located in the housing 66. Inside, turn the knob 61 again, so that the limit rod 62 is engaged with the housing 66. At this time, the piston 64 is located at the bottom of the vent hole 63, and the air pump 1 is started to work to form a negative pressure in the box body 2. The remaining steps are the same as those in the embodiment 1 is the same.

Embodiment 3

[0029] In embodiment 3, when the box body 2 is moved, a pull ring is fixed on the outside of the box body 2, which is convenient to connect with the power device through a connecting rope, and the top of the upper cover 5 is connected to the wristband through a hinge, which is convenient for lifting and moving. Vibration is generated in the middle, and the second spring 9 can play a very good buffering effect, reducing the collision strength between the container 13 inside the box body 2 and the fixed pad 15.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com