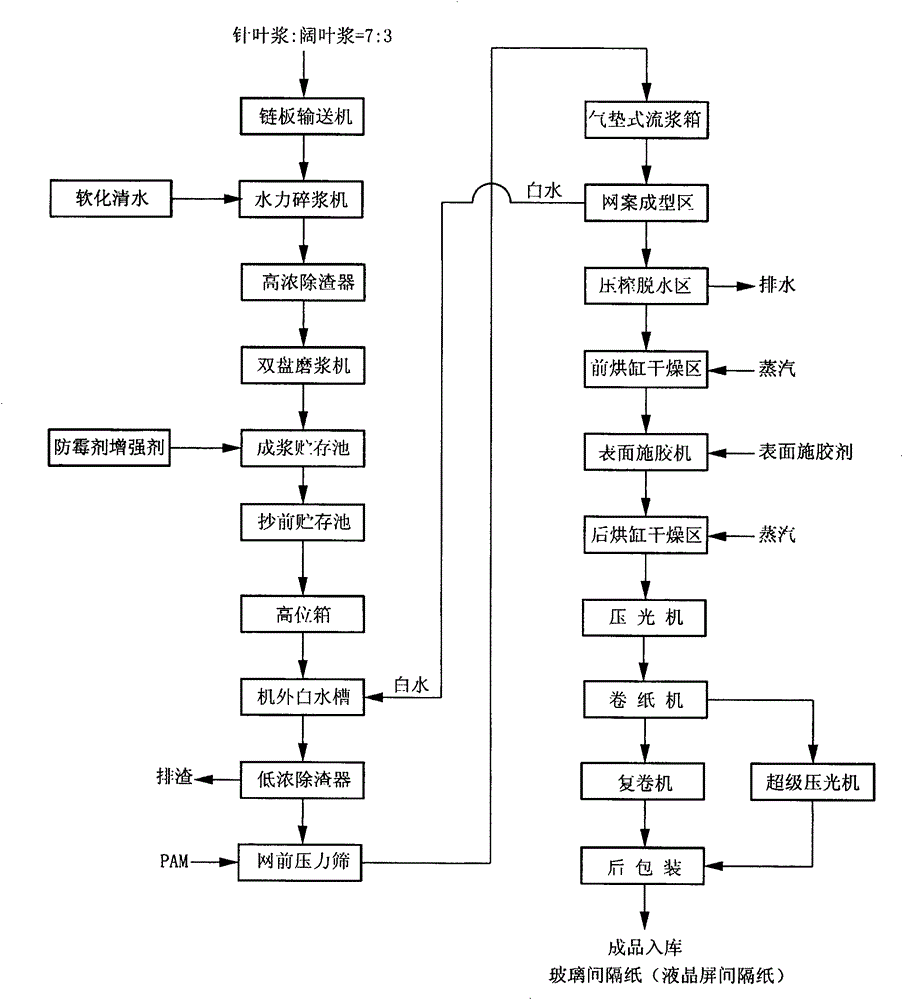

Glass backing paper production process

A technology of glass spacer paper and production process, which is applied in the directions of wrapping paper, wrapping paper, flexible covering, etc., to achieve the effect of moderate cost, stable quality and improved smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with specific examples.

[0011] Bleached softwood pulp and bleached hardwood pulp with low dust and low ash content are transported by chain plate at a ratio of 7:3 and pulped with softened water, deslagged by high-consistency slag remover, and beaten by double-disc refiner Finally, the slurry is stored in the slurry tank, and antifungal agent and reinforcing agent are added to it; the slurry passes through the high-level box, the low-concentration slag remover (slag removal), adds polyacrylamide and passes through the front pressure screen, and then The slurry is distributed on the net through the air-cushion headbox, pre-dehydrated by using ceramic dehydration chopping boards and vacuum couch rolls, and further processed by a vacuum pre-pressing roll, a four-roller three-nip composite press roll, a vacuum suction roll, and a glossy press roll. Dehydration; 5 groups of 36 Φ1500mm drying cylinders are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com