Patents

Literature

2277results about "Packing paper" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

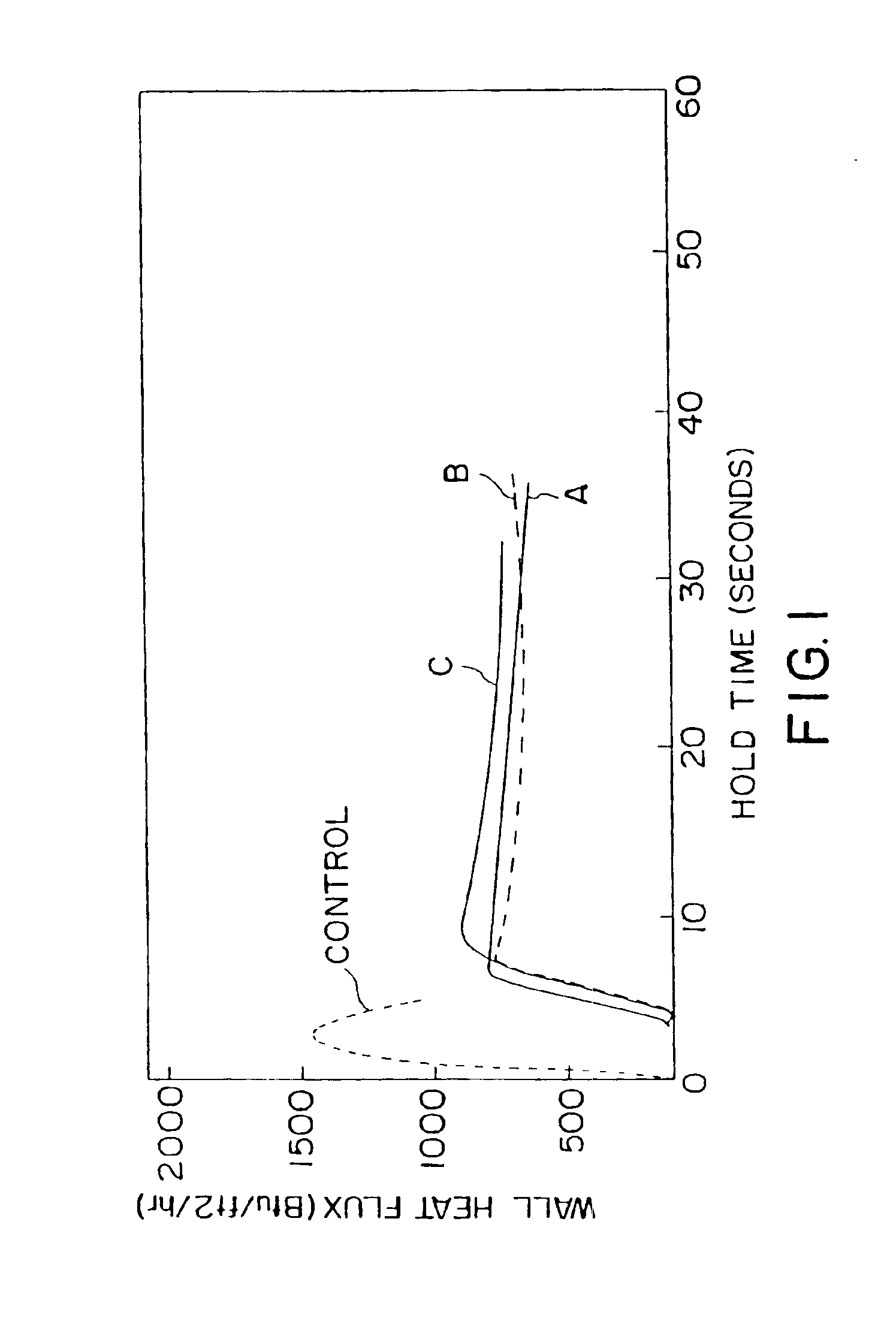

Bulk enhanced paperboard and shaped products made therefrom

An improved paperboard has been bulk enhanced by retaining a substantial portion of bulk-enhanced additives including expandable microspheres in a suitable distribution within the paperboard. The cellulosic paperboard web has an overall fiber weight (w) of at least 40 lbs. / 3000 square feet and at a fiber density of 3, 4.5, 6.5, 7, 8.3, and 9 pounds per 3000 square foot ream at a fiberboard thickness of 0.001 inch respectively, has a GM Taber stiffness of at least about 0.00716 w2.63 grams-centimeter / fiber mat density1.63 pounds per 3000 square foot ream at a fiberboard thickness of 0.001 inch, and a GM tensile stiffness of at least about 1890+24.2 w pounds per inch. The high retention of the bulk enhancing additives is believed to result from the incorporation of suitable retention aids. The resulting paperboard has better GM Taber stiffness values and GM tensile stiffness than prior art paperboards. The paperboard also has increased strain to failure and is able to be formed into suitable paperboard containers without loss of integrity. The resulting containers have increased hold times when they contain hot or cold food or drink.

Owner:DIXIE CONSUMER PROD

Coated paperboards and paperboard containers having improved tactile and bulk insulation properties

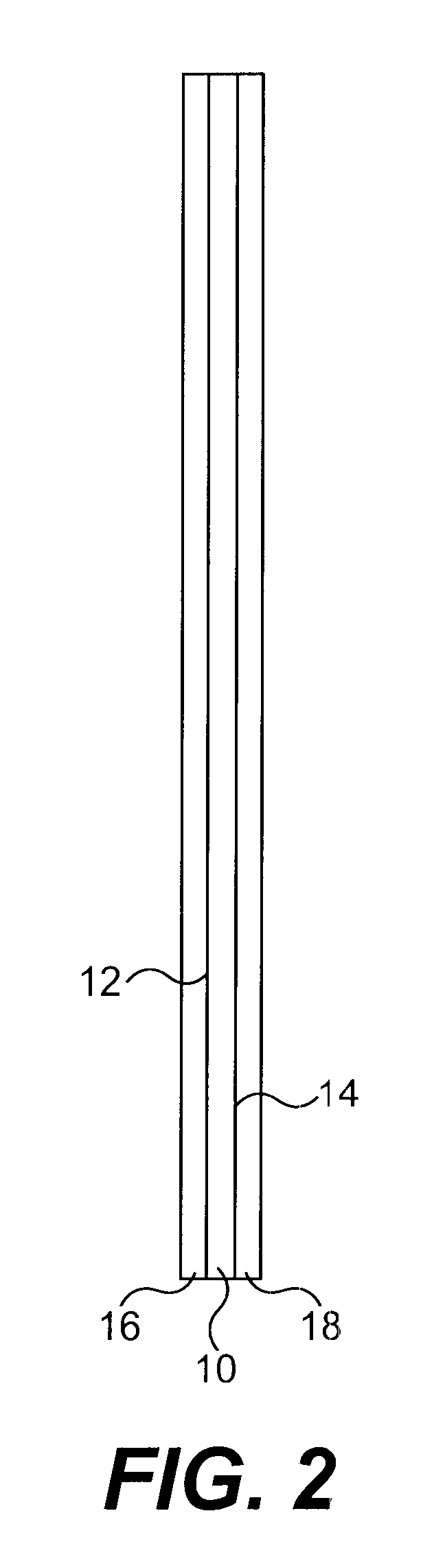

InactiveUS6919111B2Quality improvementImprove insulation performanceNon-fibrous pulp additionWrappersPaperboardEngineering

An improved paperboard has been bulk enhanced by retaining a substantial portion of bulk-enhanced additives including expandable microspheres in a suitable distribution within the paperboard. The cellulosic paperboard web has an overall fiber weight (w) of at least 40 lbs. per 3000 square feet and, at a fiber density of 3, 4.5, 6.5, 7, 8.3, and 9 pounds per 3000 square foot ream at a fiberboard thickness of 0.001 inches, has a GM Taber stiffness of at least about 0.00246 w2.63 grams-centimeter / fiber mat density1.63, and a GM tensile stiffness of at least about 615+13.18 w pounds per inch. The high retention of the bulk enhancing additives is believed to result from the incorporation of suitable retention aids. The resulting paperboard has better GM Taber stiffness values and GM tensile stiffness than prior art paperboards. The paperboard also has increased strain to failure and is able to be formed into suitable paperboard containers without loss of integrity. The resulting containers have increased hold times when they contain hot or cold food or drink.

Owner:DIXIE CONSUMER PROD

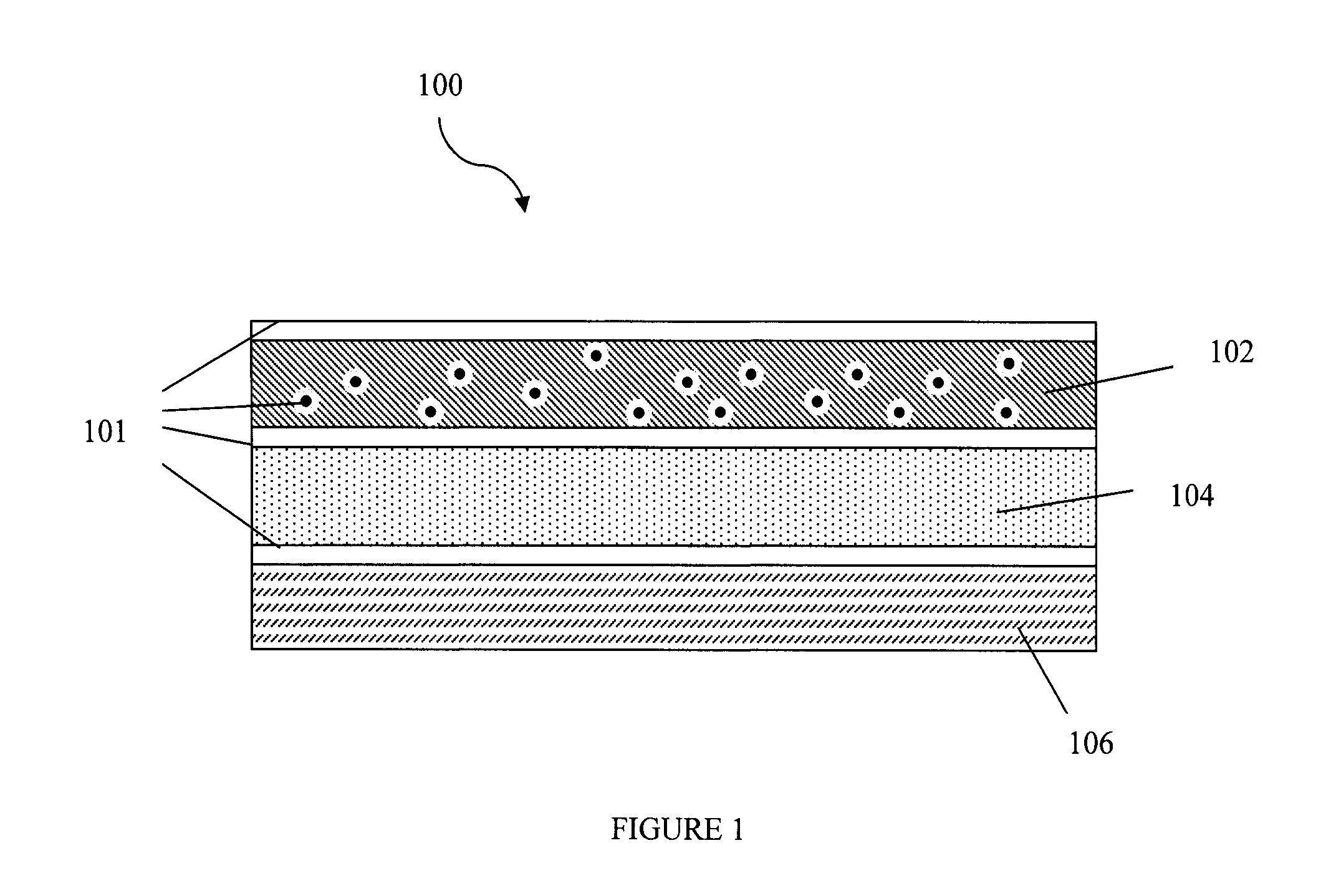

Paper or paperboard substrate, a process for production of the substrate and a package formed of the substrate

The present invention relates to a paper or paperboard substrate having barrier properties which substrate comprises a first fiber based layer, a second layer comprising microfibrillated cellulose and a third layer comprising a polymer. The invention further relates to a process for the production of said substrate and a package formed of said substrate.

Owner:STORA ENSO OYJ

Water stable fibers and articles comprising starch, and methods of making the same

Water stable fibers and articles made therefrom are formed from a thermoplastic composition comprising destructured starch, polyhydric alcohol, triglyceride, and optionally acid. Processes for making water stable compositions may comprise melt extruding a mixture of destructured starch, polyhydric alcohol, triglyceride, and optionally acid, to form an extrudate, and heating the mixture, extrudate, or both to provide a water stable article.

Owner:THE PROCTER & GAMBLE COMPANY

Moisture resistant container

A sheet of cellulose based material having enhanced strength, particularly the dry strength, substantially unaffected repulpability is disclosed. The sheet of cellulose based materials generally includes a first cellulose based material connected with a second cellulose base material element. The first cellulose based material is formed by separating a portion of the fiber from a furnish, treating the separated portion with a cationic wet strength resin which is allowed to bond to the fiber. The treated fiber is them mixed with the untreated balance of the fiber at some point before the paper machine. The fiber that is separated may be secondary fiber, virgin fiber or combinations thereof. The second cellulose base material element is substantially free from any treatment. The second cellulose base material element may be include substantially all untreated fibers.

Owner:INT PAPER CO

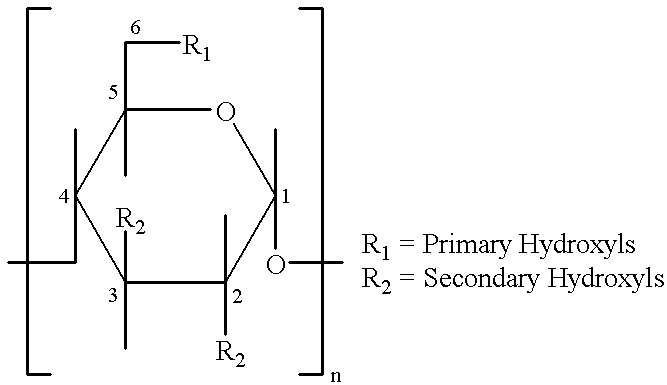

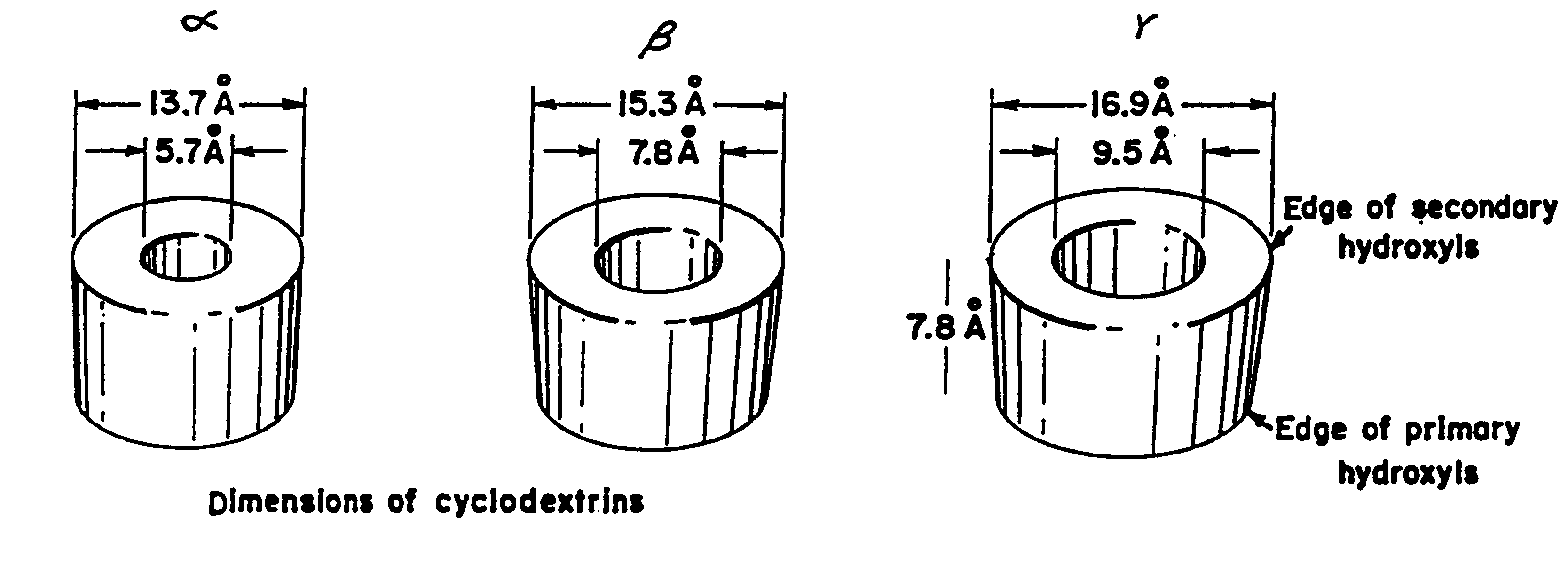

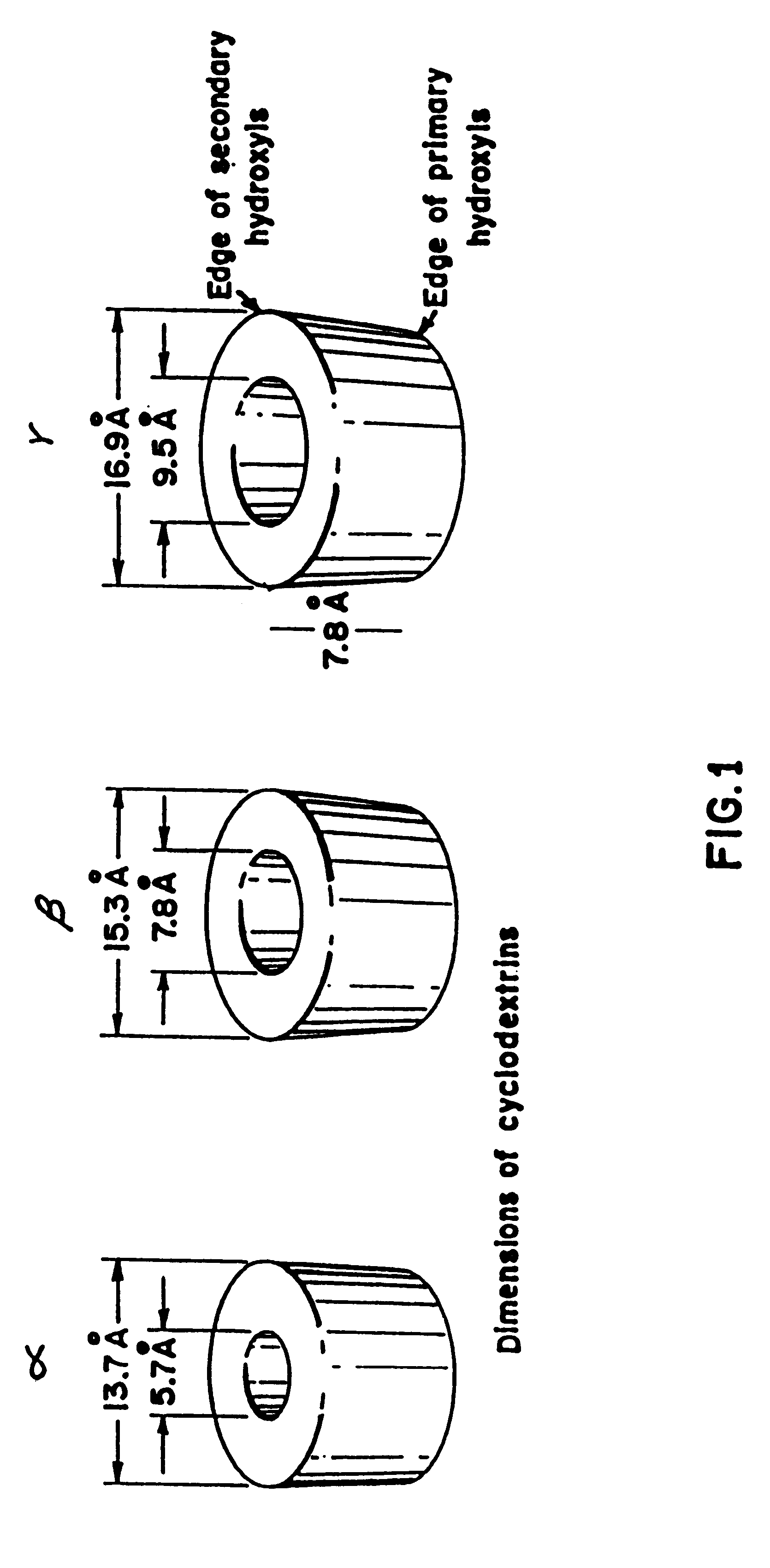

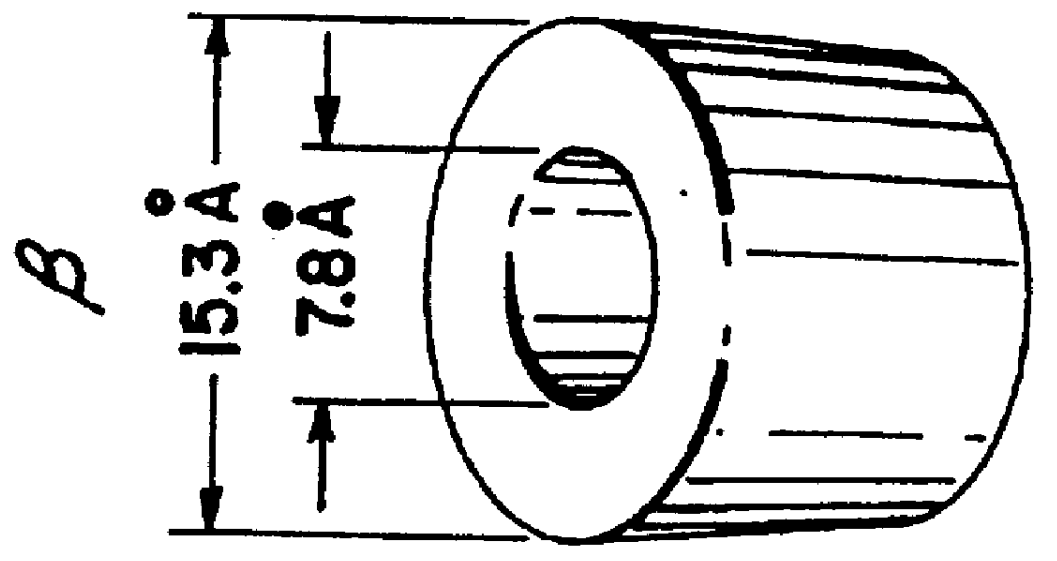

Barrier material comprising a thermoplastic and a compatible cyclodextrin derivative

InactiveUS6218013B1Easy to derivatizeImprove surface propertiesSemi-permeable membranesFlexible coversThermoplasticMoisture

A barrier film composition can comprise a thermoplastic web comprising a thermoplastic polymer and a dispersed cyclodextrin composition having substituents that compatibilize the cyclodextrin in the film. The thermoplastic / cyclodextrin film obtains substantial barrier properties from the interaction between the substituted cyclodextrin in the film material with a permeant. The substituents on the cyclodextrin molecule causes the cyclodextrin to be dispersible and stable in the film material resulting in an extrudable thermoplastic. Such materials can be used as a single layer film material, a multilayer film material which can be coated or uncoated and can be used in structural materials wherein the thermoplastic is of substantial thickness resulting in structural stiffness. The cooperation between the cyclodextrin and the thermoplastic polymer provides barrier properties to a web wherein a permeant can be complexed or entrapped by the cyclodextrin compound and held within the film preventing the permeant from passing through the film into the interior of a film, an enclosure or container. The permeant can comprise a variety of well known materials such as moisture, aliphatic or aromatic hydrocarbons, monomer materials, off flavors, toxic compounds etc.

Owner:CELLRESIN TECH

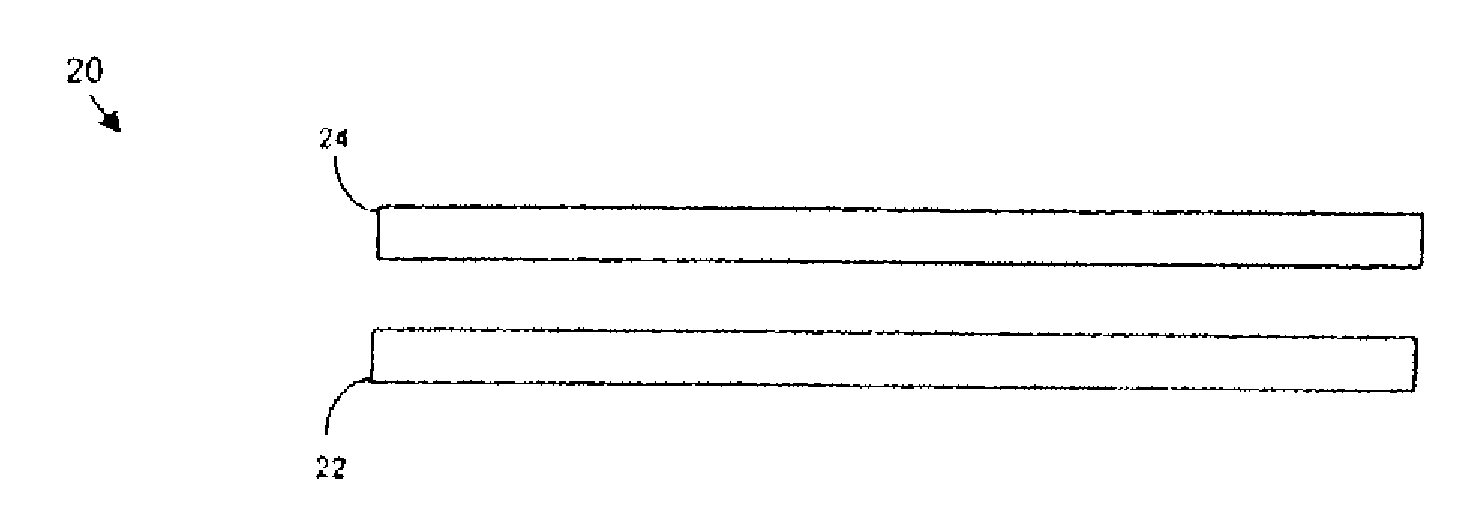

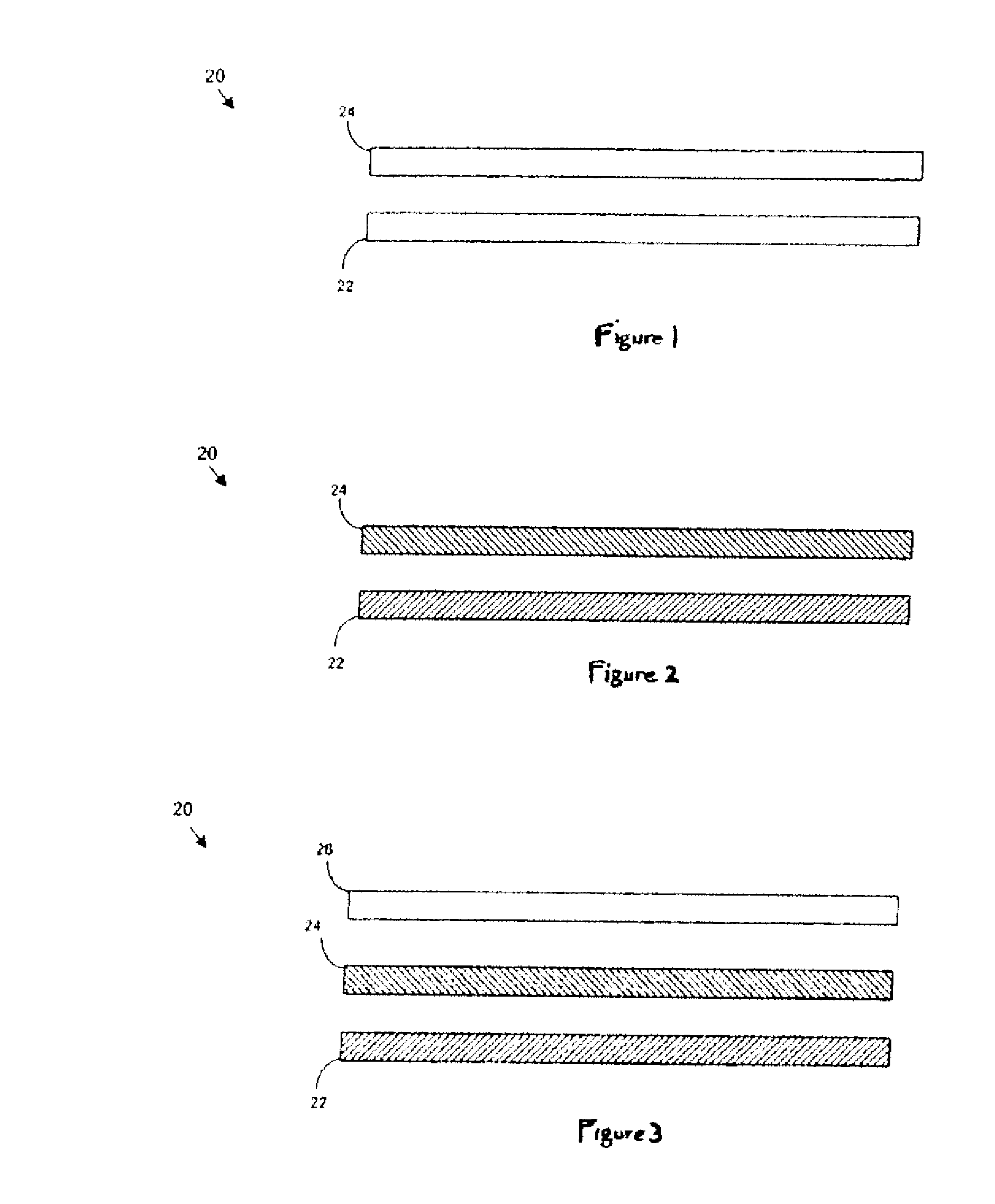

Paper or paperboard laminate and method to produce such a laminate

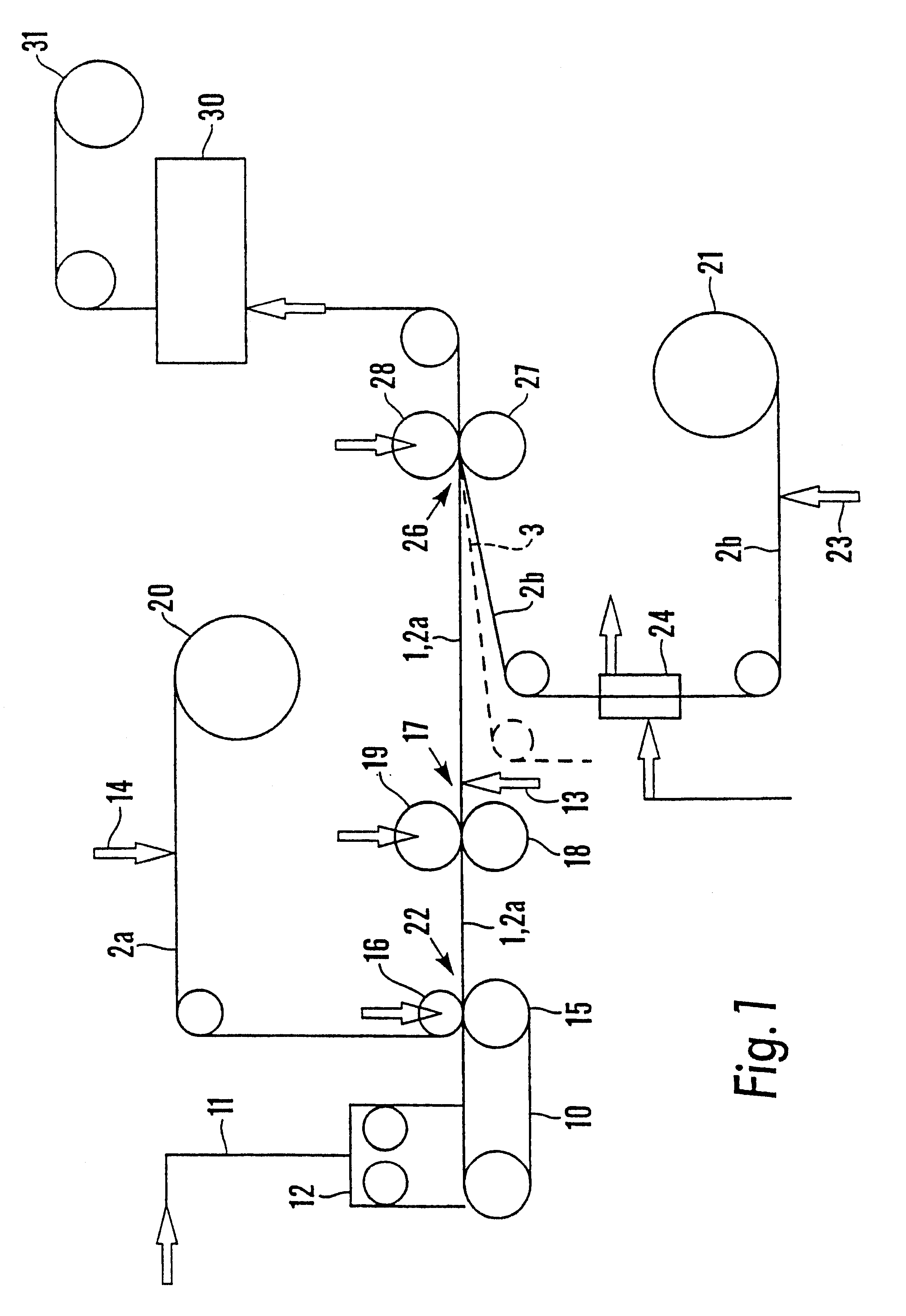

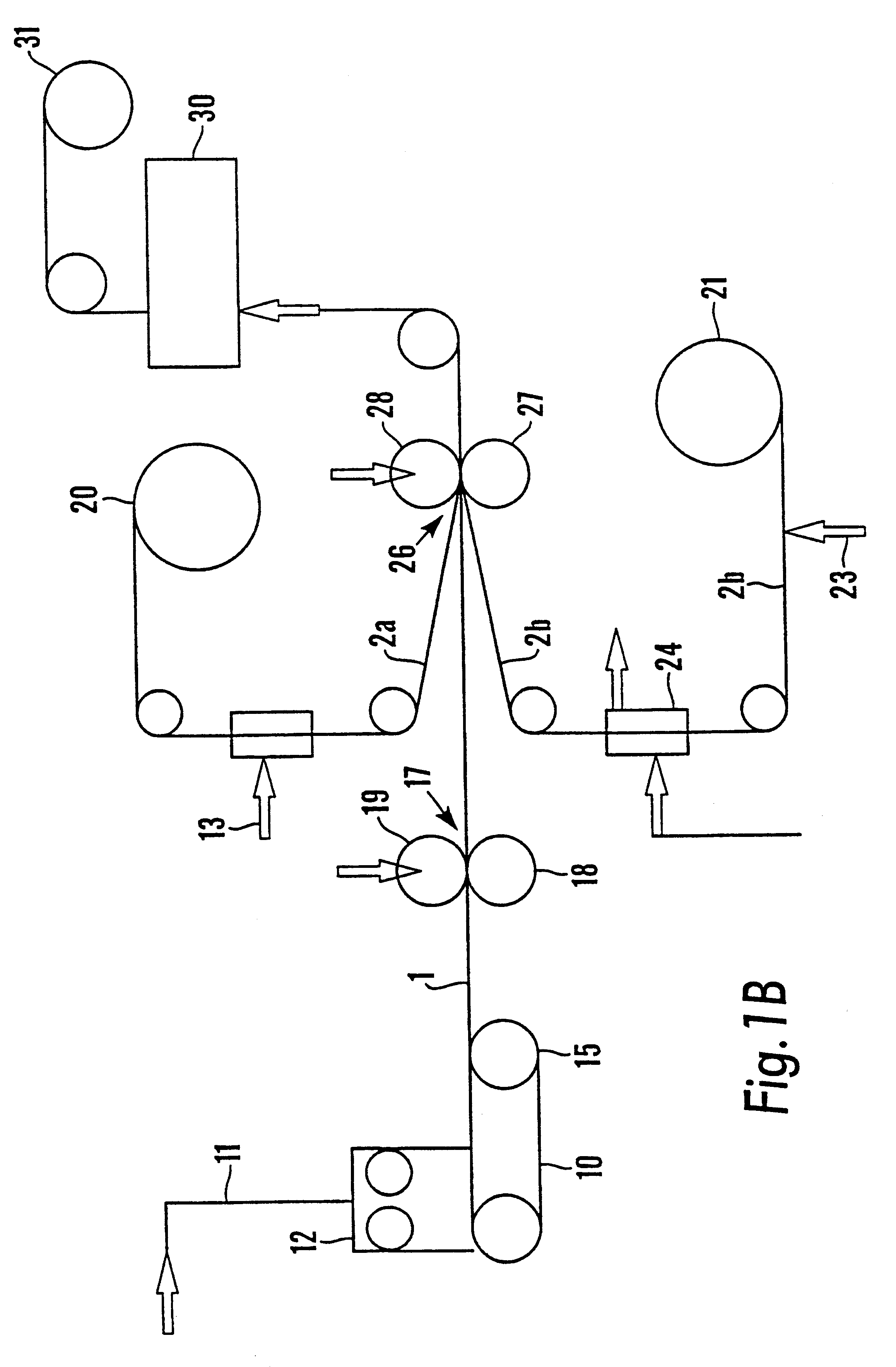

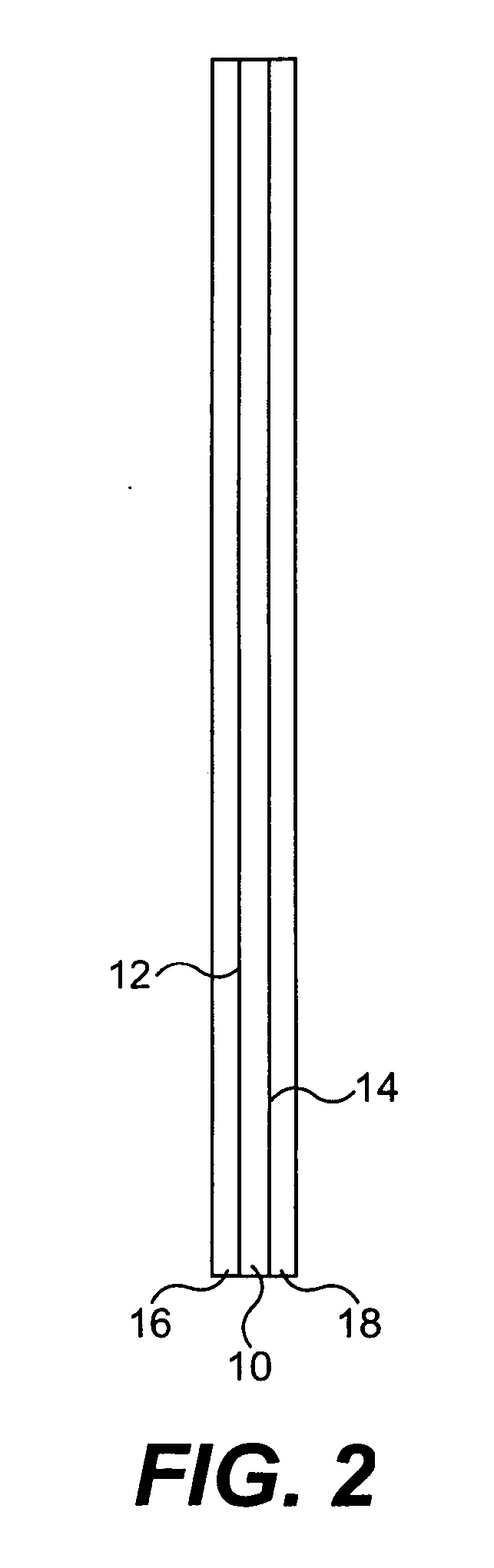

InactiveUS6537680B1Increase stiffnessFacilitate folding and subsequent creasingNon-fibrous pulp additionWrappersPaperboardCellulose fiber

Paper or paperboard laminate composed of at least one bulk-promoting layer, here termed the bulk layer, and on at least one side at the bulk layer at least one secondary layer, secondary layer and bulk layer being joined to one another directly or indirectly over basically the whole of their surfaces facing one another, 40-95% of the bulk layer consists of cellulose fibers with a freeness of 550-950 ml CSF, the secondary layer / layers has / have a greater density than the bulk layer, and the laminate has a bending stiffness index higher than 2.5 Nm7 / kg3, but less than 14 Nm7 / kg3, calculated as a geometric mean value for machine and transverse direction.

Owner:STORA ENSO AB

Aliphatic-aromatic polyetherester compositions, articles, films, coating and laminates and processes for producing same

Aliphatic-aromatic polyetherester compositions, articles made from the aliphatic-aromatic polyetherester compositions, and processes for producing the aliphatic-aromatic polyetherester compositions and articles are provided. Articles that can be made from the aliphatic-aromatic polyetherester compositions include films, coatings and laminates. Some of the compositions and articles are biocompostable. The films can further be used to form shaped articles such as sheets, food packaging such as sandwich wraps, thermoformed containers, and coatings for, for example, films and other substrates. The aliphatic-aromatic polyetheresters are based on copolyesters produced from a mixture of aromatic dicarboxylic acids, aliphatic dicarboxylic acids, poly(alkyene ether) glycols, and glycols.

Owner:DUPONT IND BIOSCIENCES USA LLC

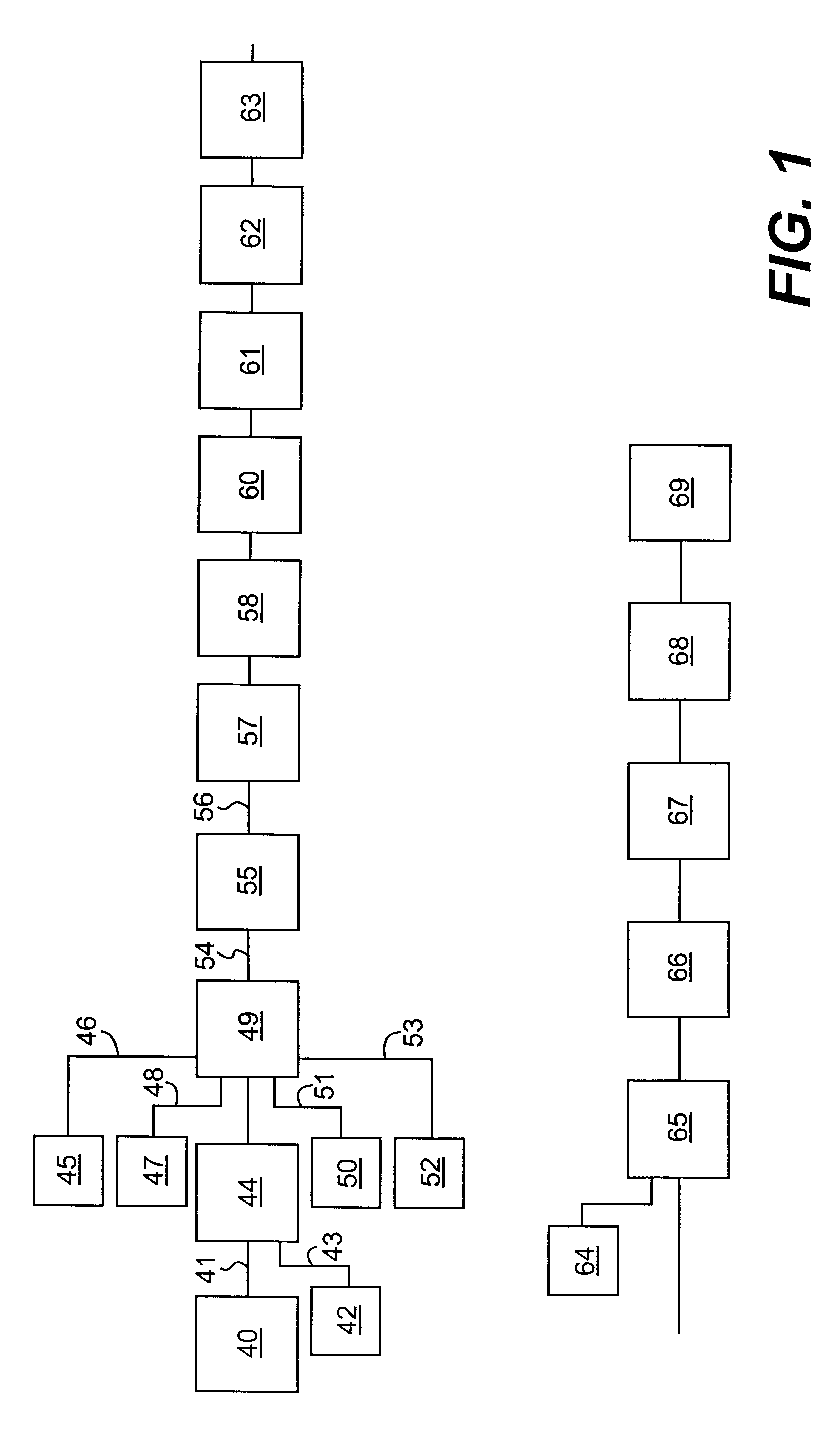

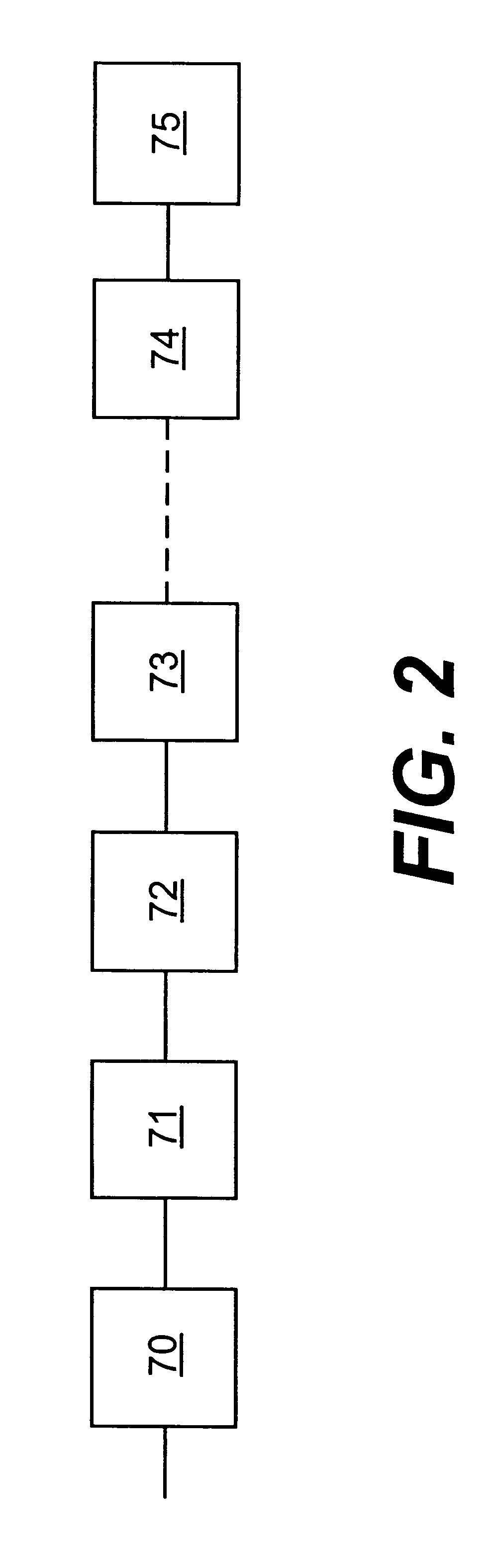

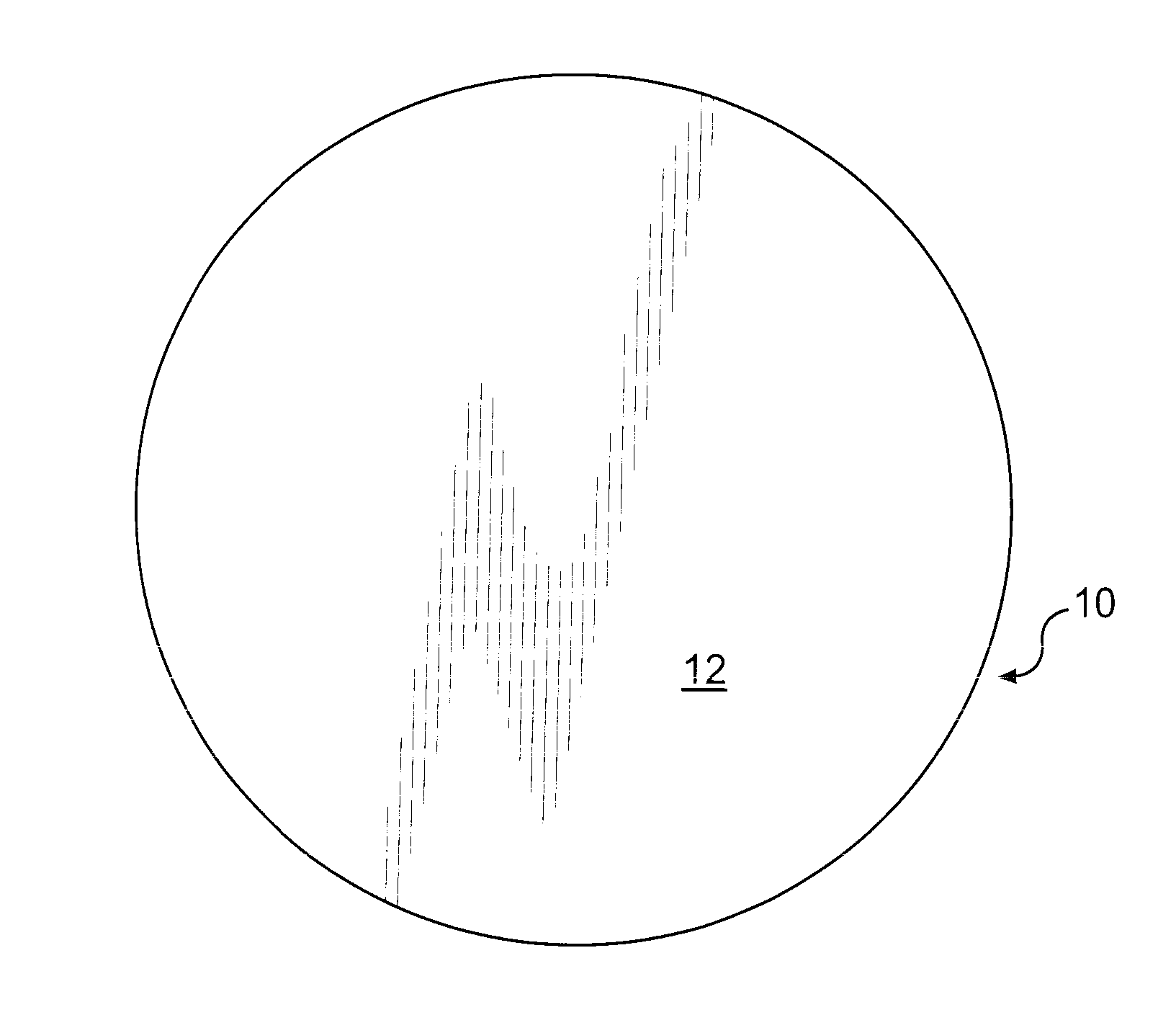

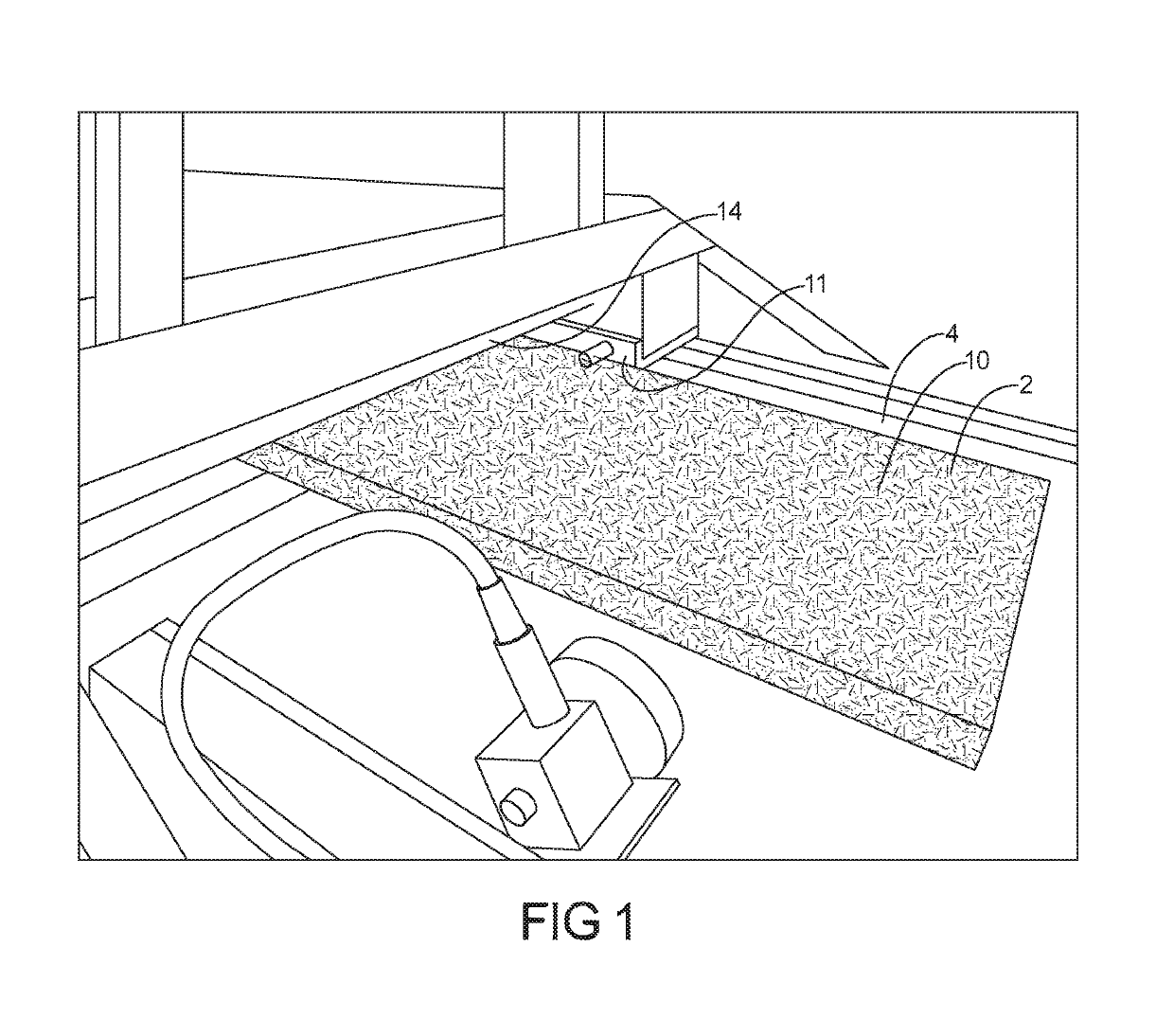

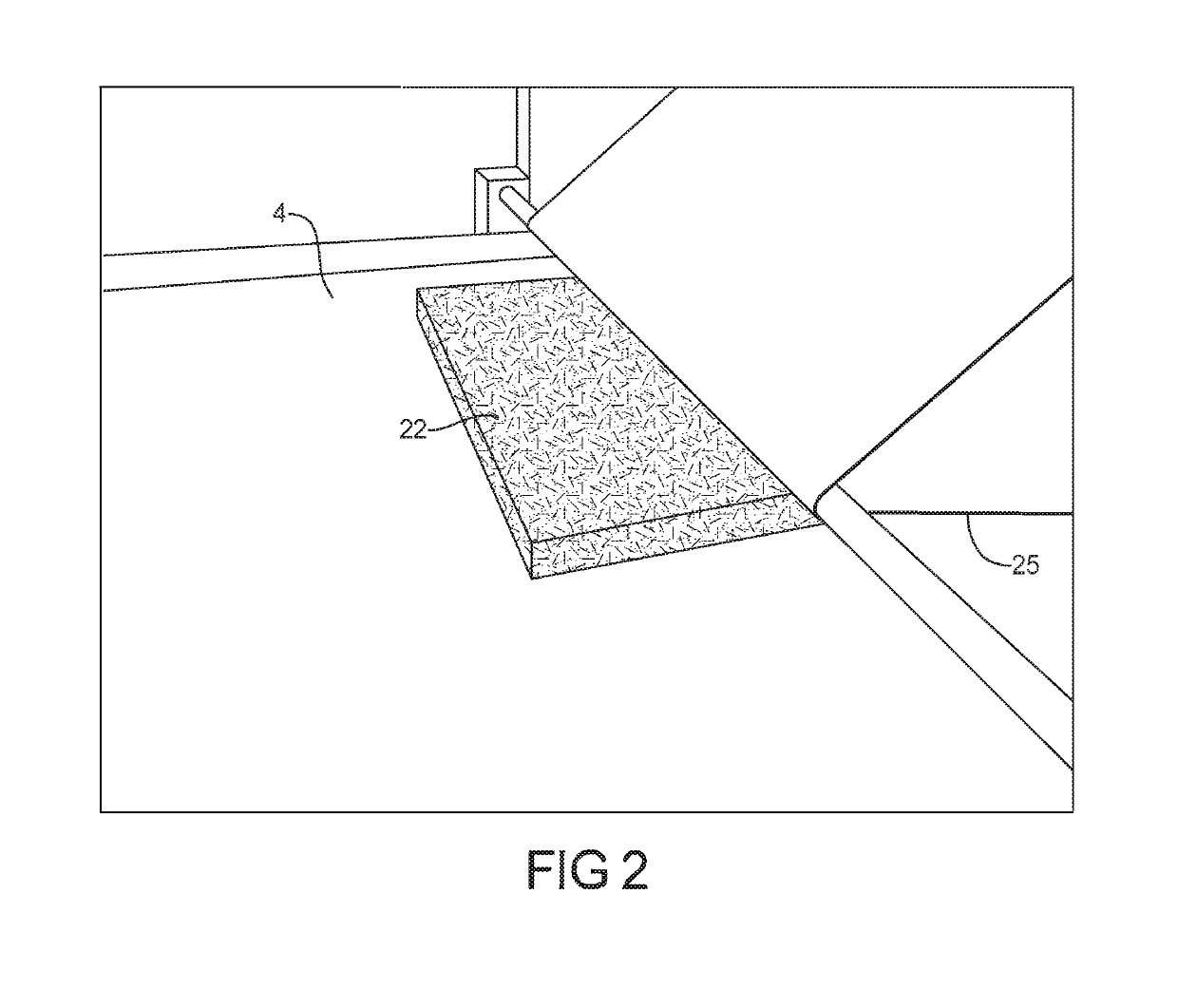

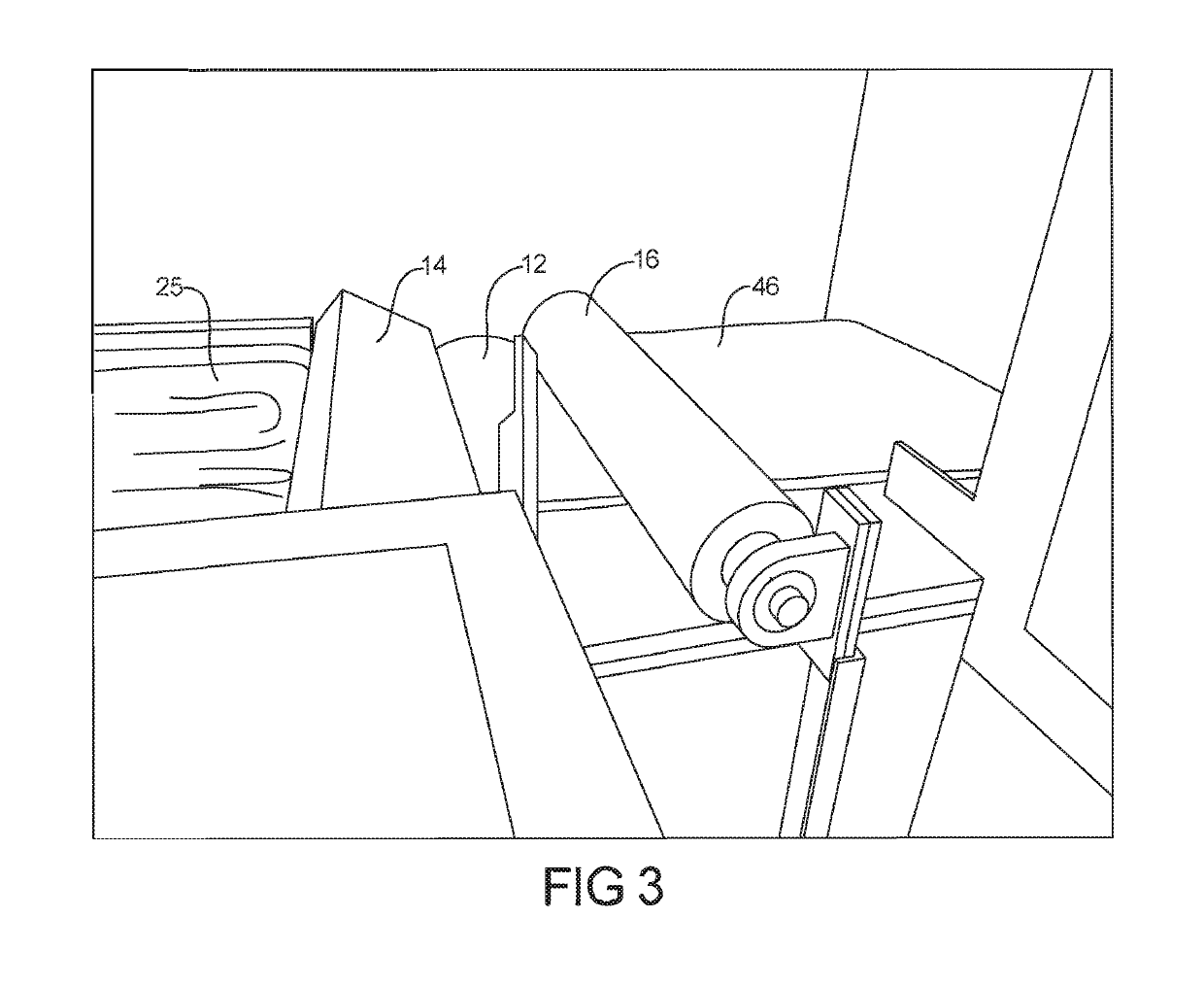

Low density paperboard articles

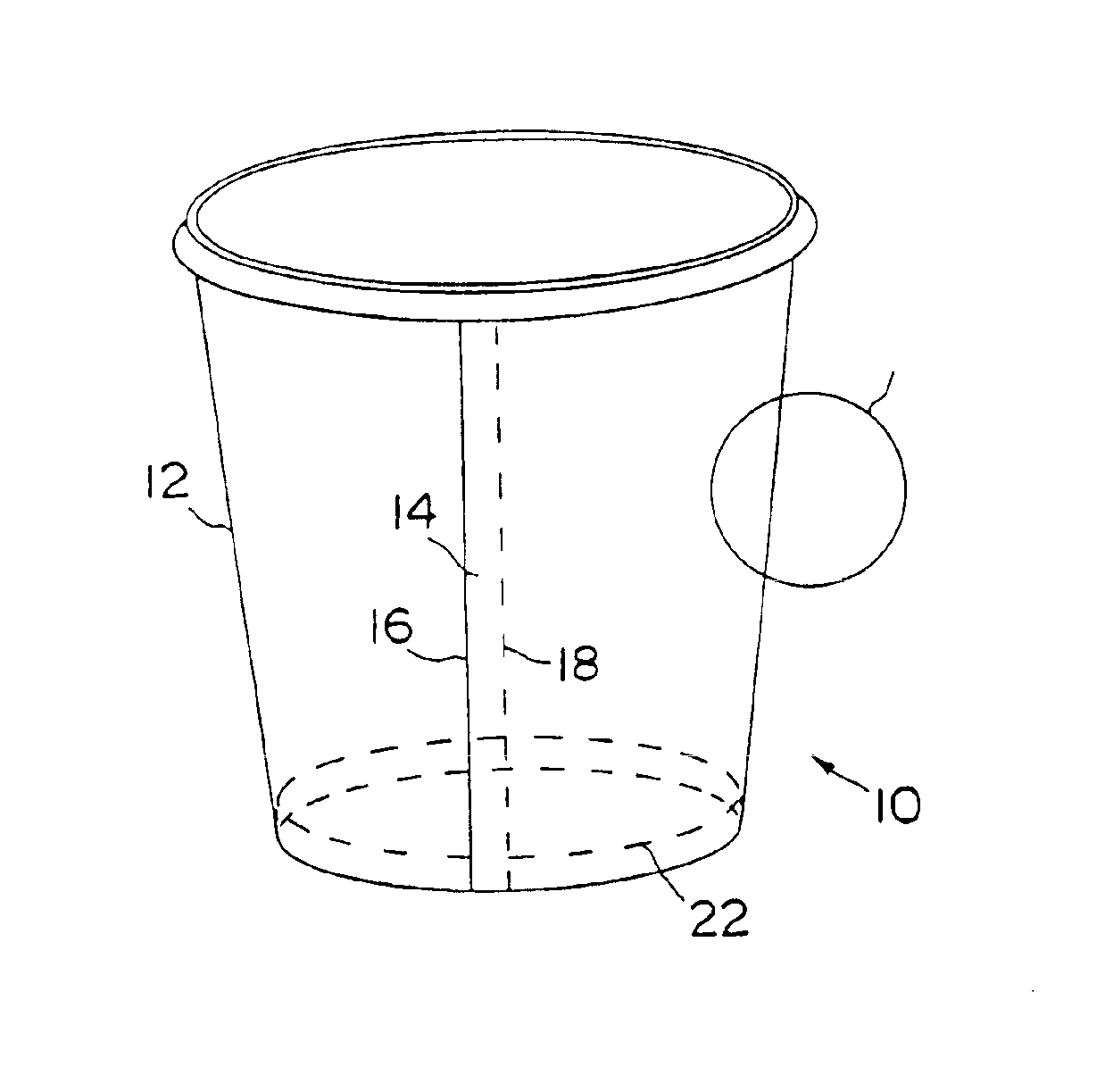

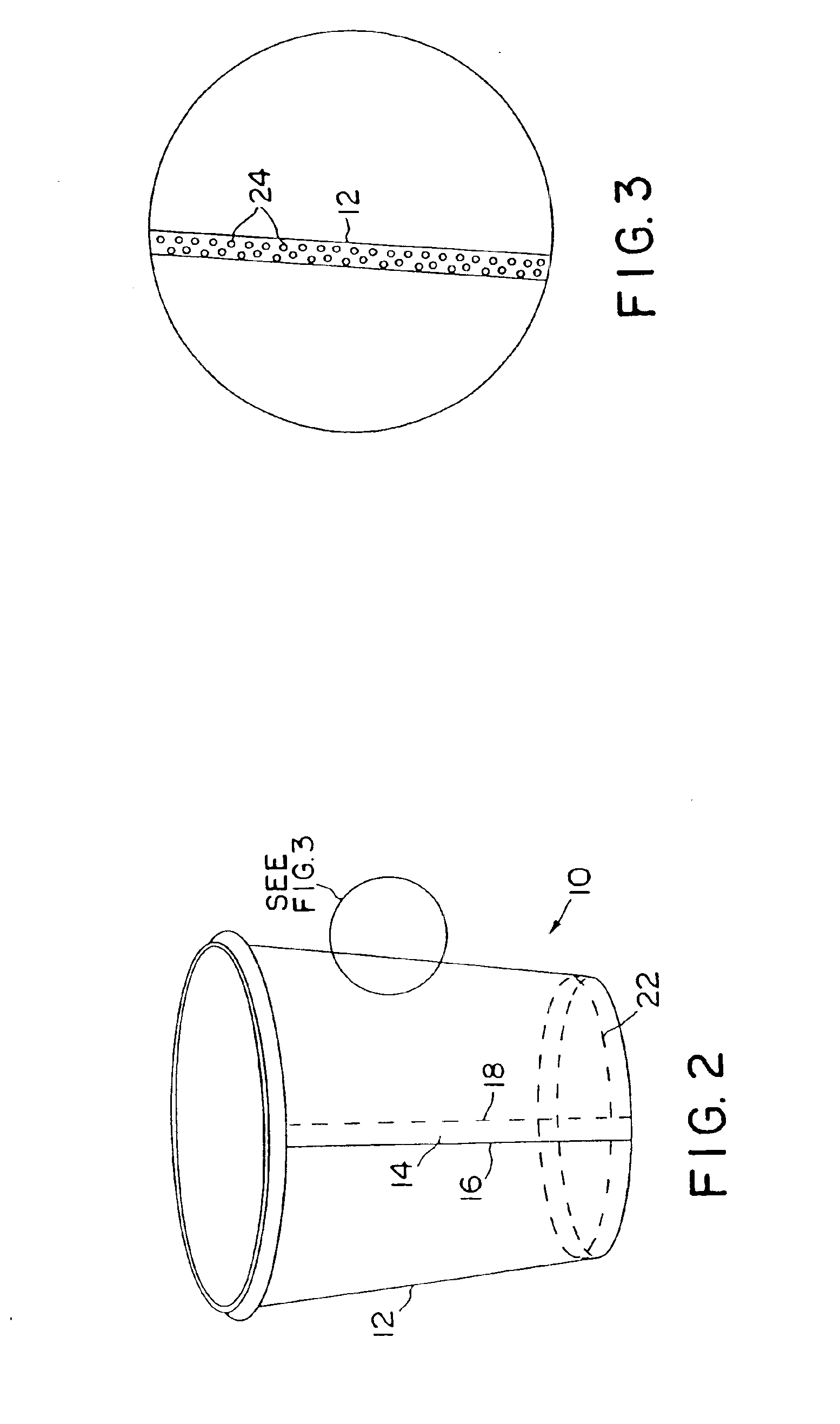

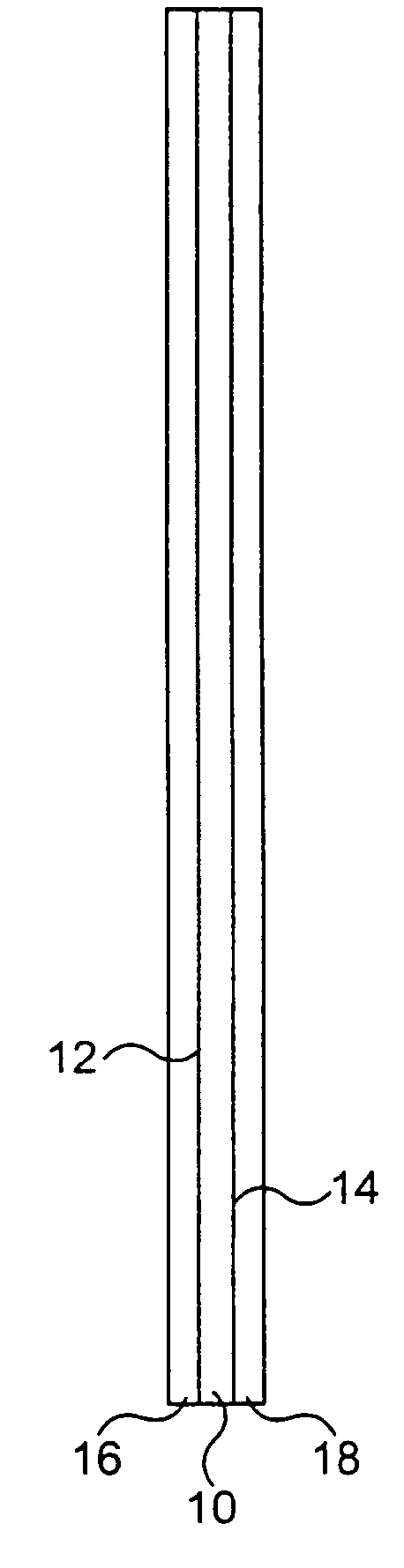

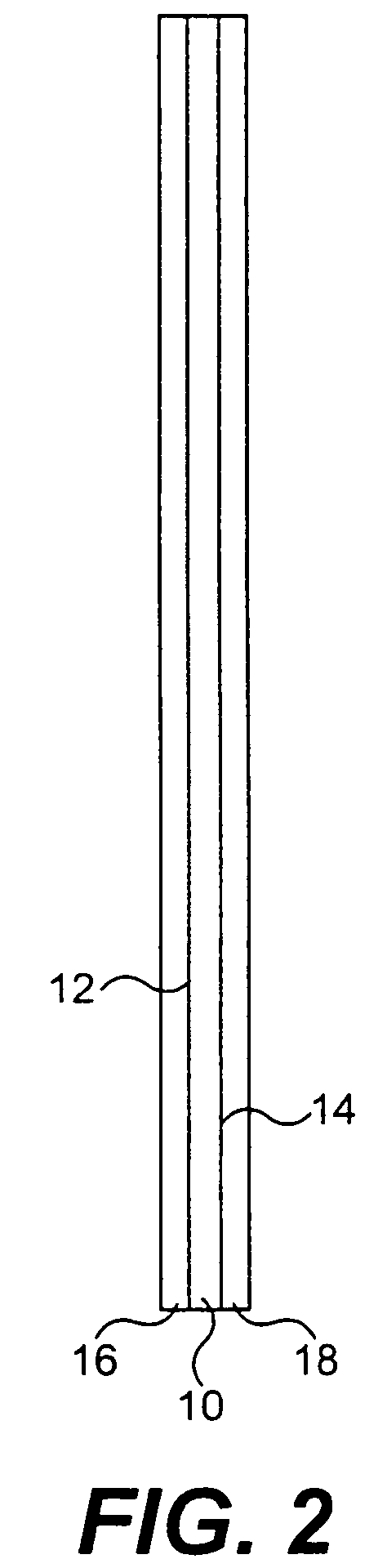

InactiveUS6846529B2Improve insulation performanceLess-expensive to produceNon-fibrous pulp additionNatural cellulose pulp/paperLow-density polyethyleneLinear low-density polyethylene

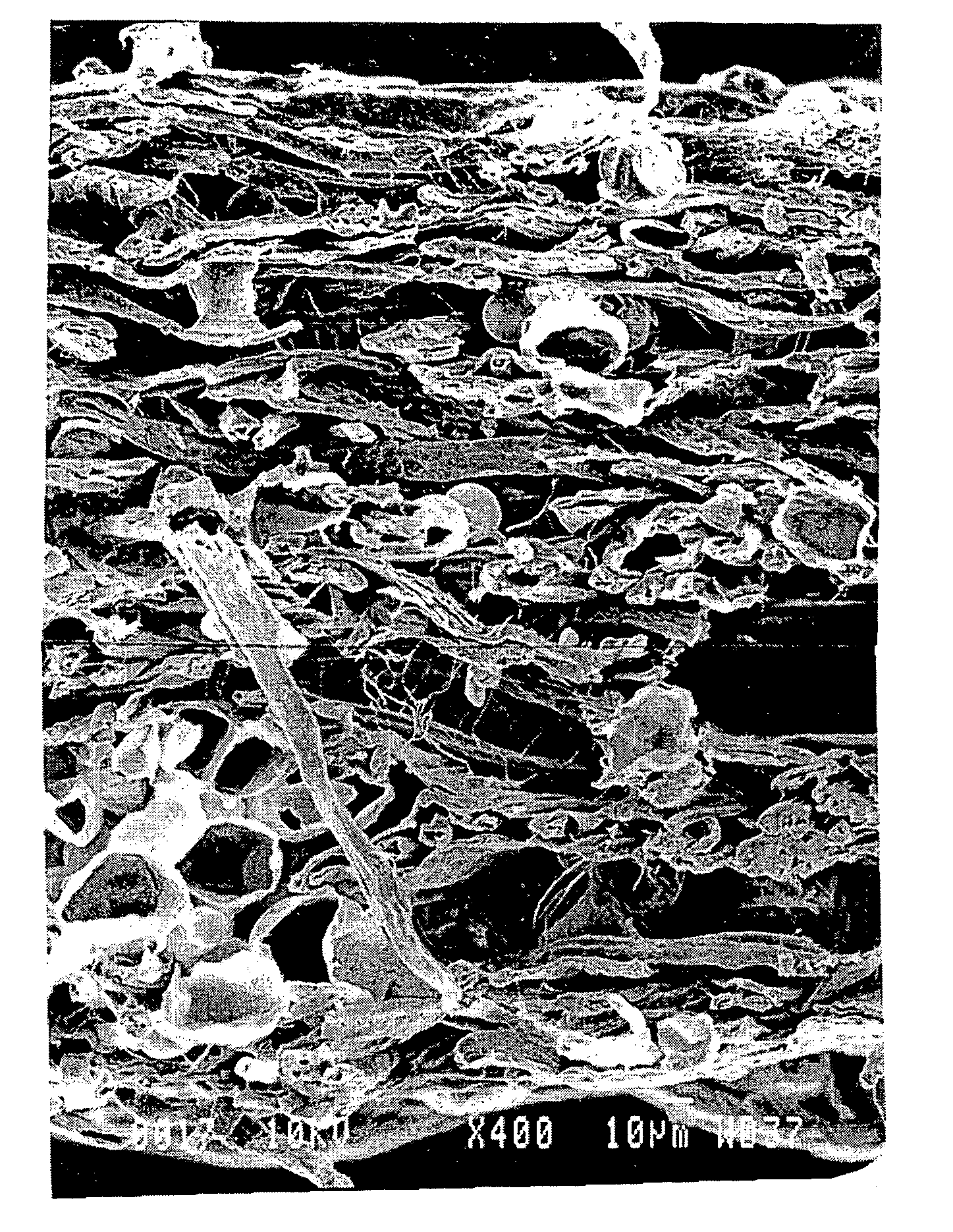

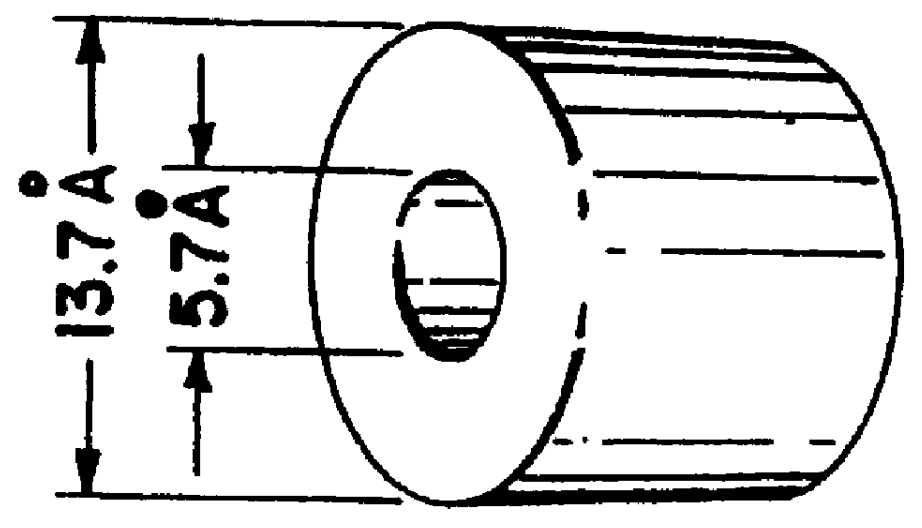

The invention provides a low density paperboard material for use in producing an insulated container, and is especially well-suited for making cups. The paperboard material comprises a paperboard web including wood fibers and expanded microspheres, and has a relatively low density ranging from about 6 to about 10 lb / 3MSF / mil, a relatively high caliper ranging from about 24 to about 35 mil, and an internal bond strength of at least about 80×10−3 ft-lbf preferably at least 100×10−3 ft-lbf. For applications such as cups the material is also coated on one or both sides with a barrier coating, preferably low density polyethylene, to limit liquid penetration into the web. The low density paperboard material of the invention is convertible for manufacture of containers, particularly cups, and the surface of the low density board may have a Sheffield smoothness of 300 SU or greater.

Owner:GRAPHIC PACKAGING INT

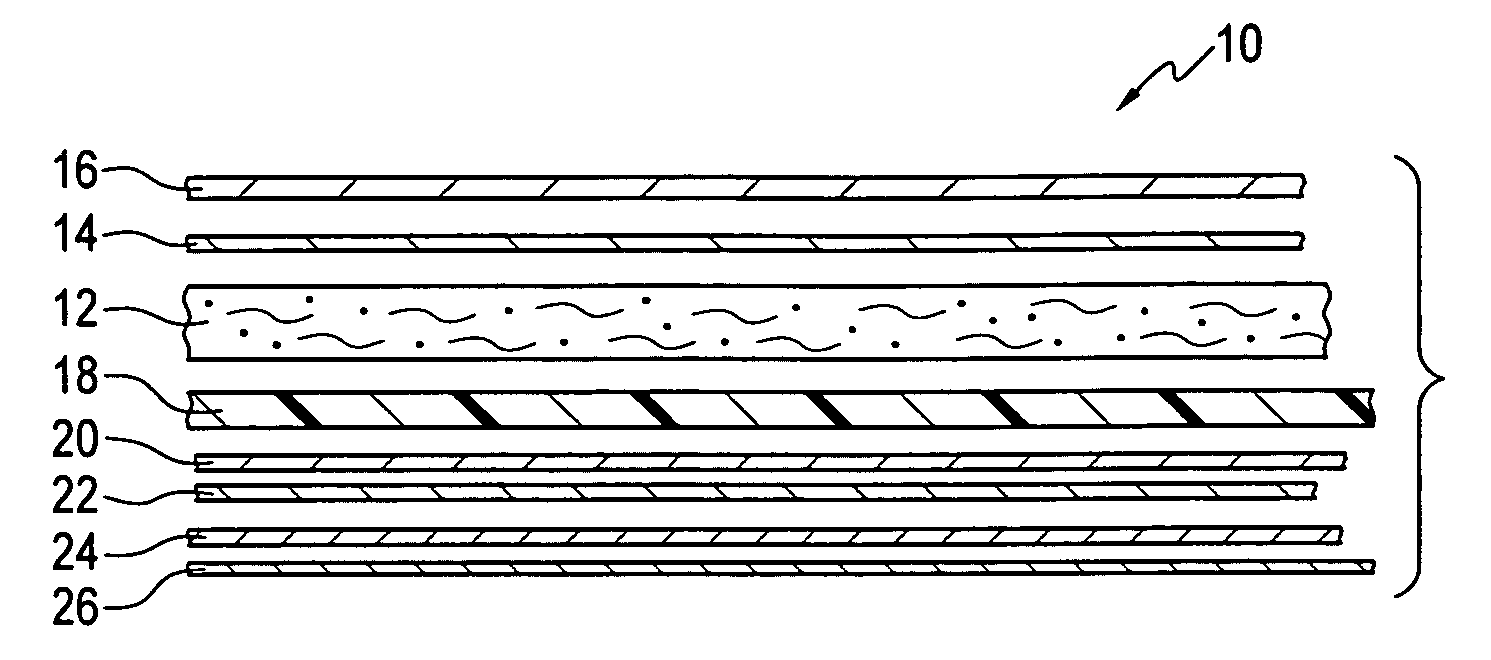

Coated paperboards and paperboard containers having improved tactile and bulk insulation properties

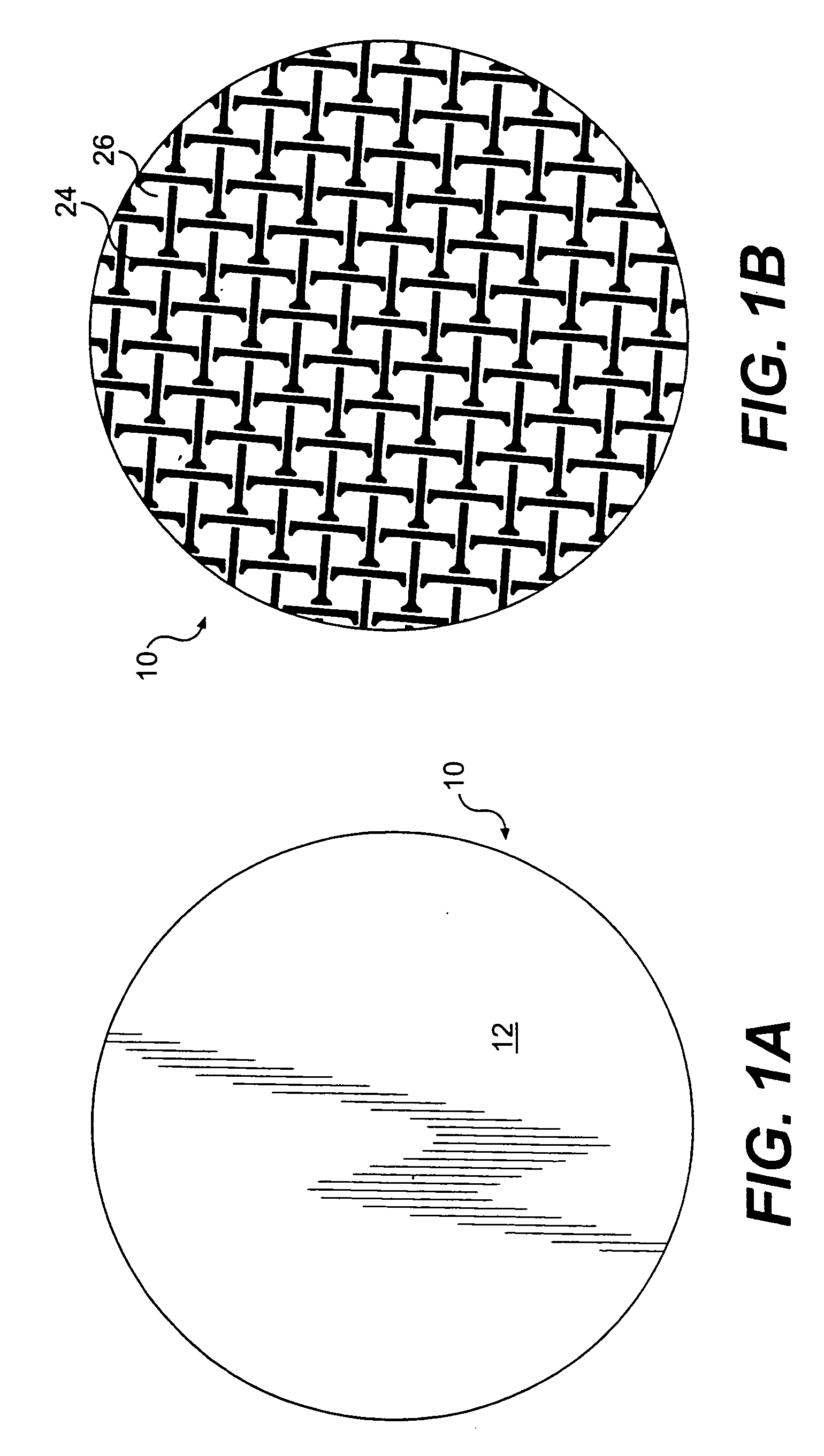

InactiveUS20060057365A1Improve insulation performanceIncrease stiffnessNon-fibrous pulp additionWrappersMicrospherePaperboard

An improved paperboard has been bulk enhanced by retaining a substantial portion microspheres in a suitable distribution within the paperboard. As in one embodiment, the high retention of the bulk enhancing additives is believed to result from the incorporation of suitable retention aids. The paperboard is able to be formed into suitable paperboard containers without loss of integrity. The resulting containers have increased hold times when they contain hot or cold food or drink.

Owner:DIXIE CONSUMER PROD

Coated paperboards and paperboard containers having improved tactile and bulk insulation properties

InactiveUS20050112305A1Improve insulation performanceIncrease stiffnessNon-fibrous pulp additionWrappersStatic friction coefficientPaperboard

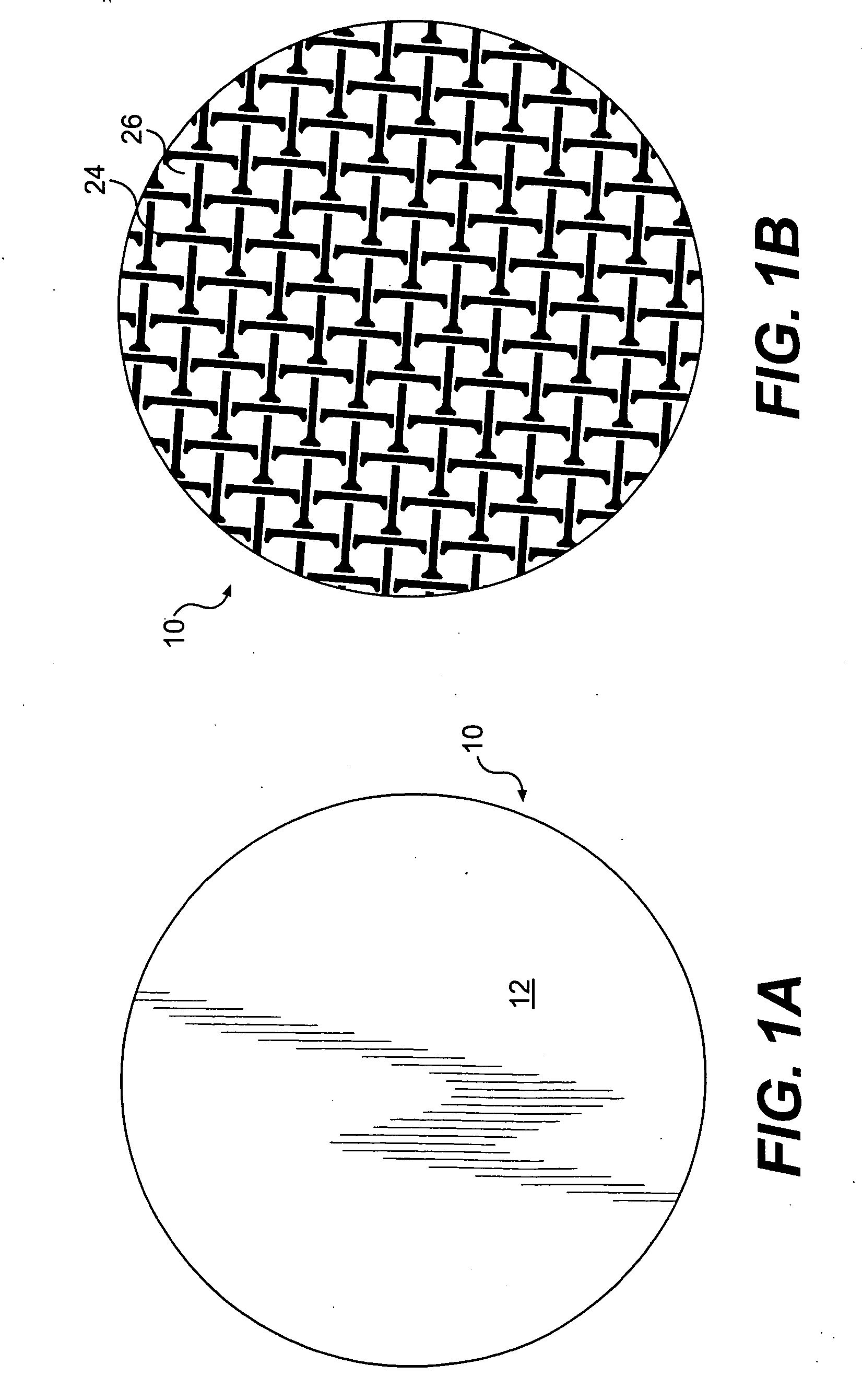

A method of making a texture-coated and / or insulation coated container from a flat paperboard blank in which a heat-hardenable liquid polymeric binder texturizing and / or insulating agent coating mixture is applied to one surface of the blank in a pattern of covered and open areas. This coating mixture is subjected to heat to cure the polymeric binder and expand the texturizing and / or insulating agent, optionally treated with moisture, and optionally heated to form the blank into the shape of a container, and the container produced by this method. The containers such as cups, plates, etc., are useful in food service. These containers have a coefficient of static friction which is about 0.2 to 2.0 and over and a kinetic coefficient of friction which is about 0.22 to 1.5.

Owner:DIXIE CONSUMER PROD

Method of producing a paper product

ActiveUS20100024998A1Protected contentNon-fibrous pulp additionPaper after-treatmentPolymer scienceCellulose fiber

The invention relates to a method of producing a laminate paper product comprising at least two layers, said method comprising (i) providing an aqueous suspension comprising cellulosic fibers (ii) adding to the suspension microfibrillar polysaccharide in an amount to yield from about 0.05 to about 50 wt % based on the weight of the cellulosic fibers (iii) dewatering the obtained suspension and forming a first layer having a density from about 150 to about 500 kg / m3 of said laminate paper product. The invention also relates to a method comprising (i) providing an aqueous suspension comprising cellulosic fibers (ii) adding to the suspension microfibrillar polysaccharide in an amount to yield from about 0.05 to about 50 wt % based on the weight of the cellulosic fibers (iii) dewatering the obtained suspension and forming at least a first and a second layer of said laminate whereby at least one of said at least first and second layer is formed from an aqueous suspension obtained in step (ii) containing microfibrillar polysaccharide; and joining said layers in such way that the laminate product obtains a density from about 150 to about 800 kg / m3. The invention also relates to a laminate paper product which can be obtained by the method and the use thereof.

Owner:KEMIRA OY

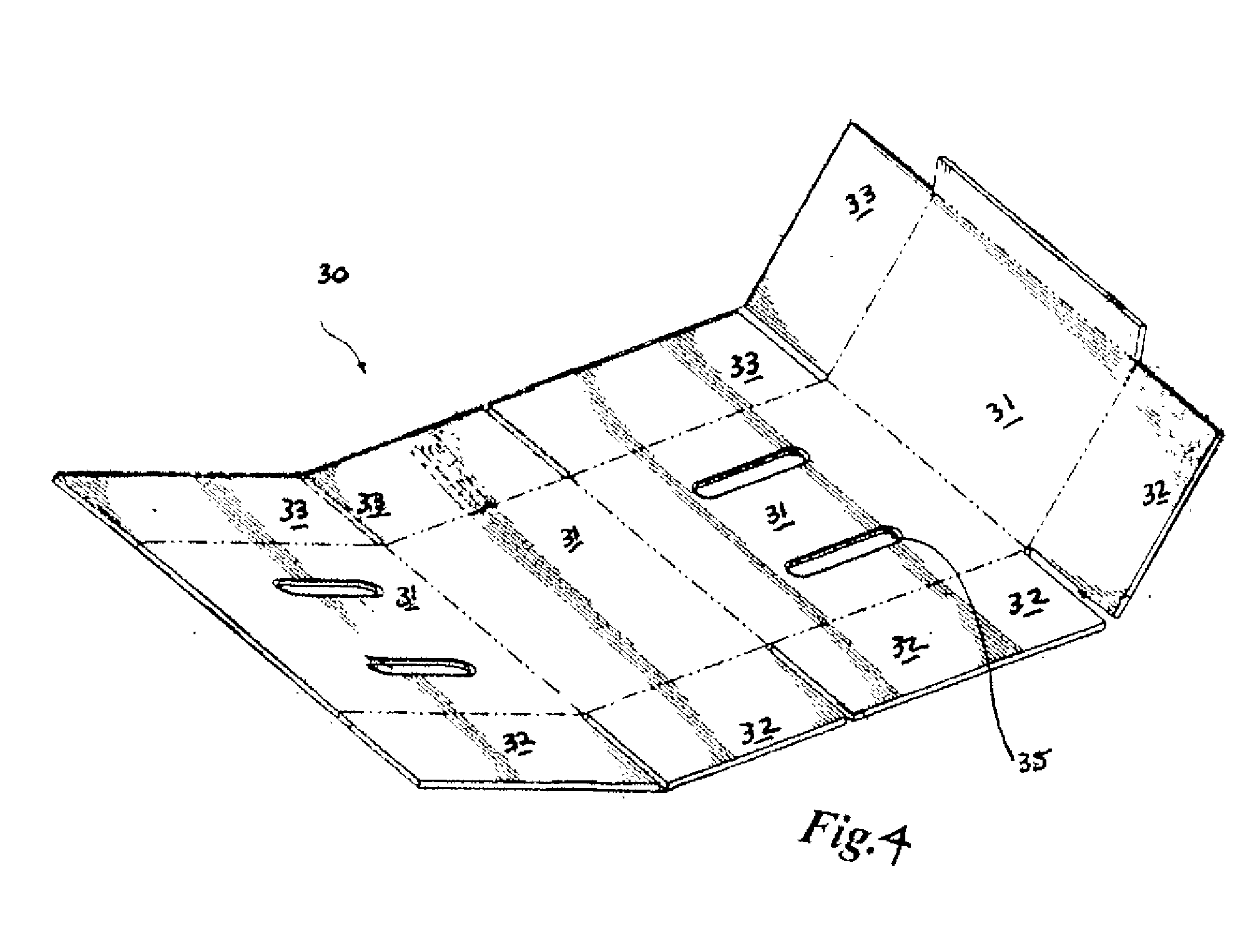

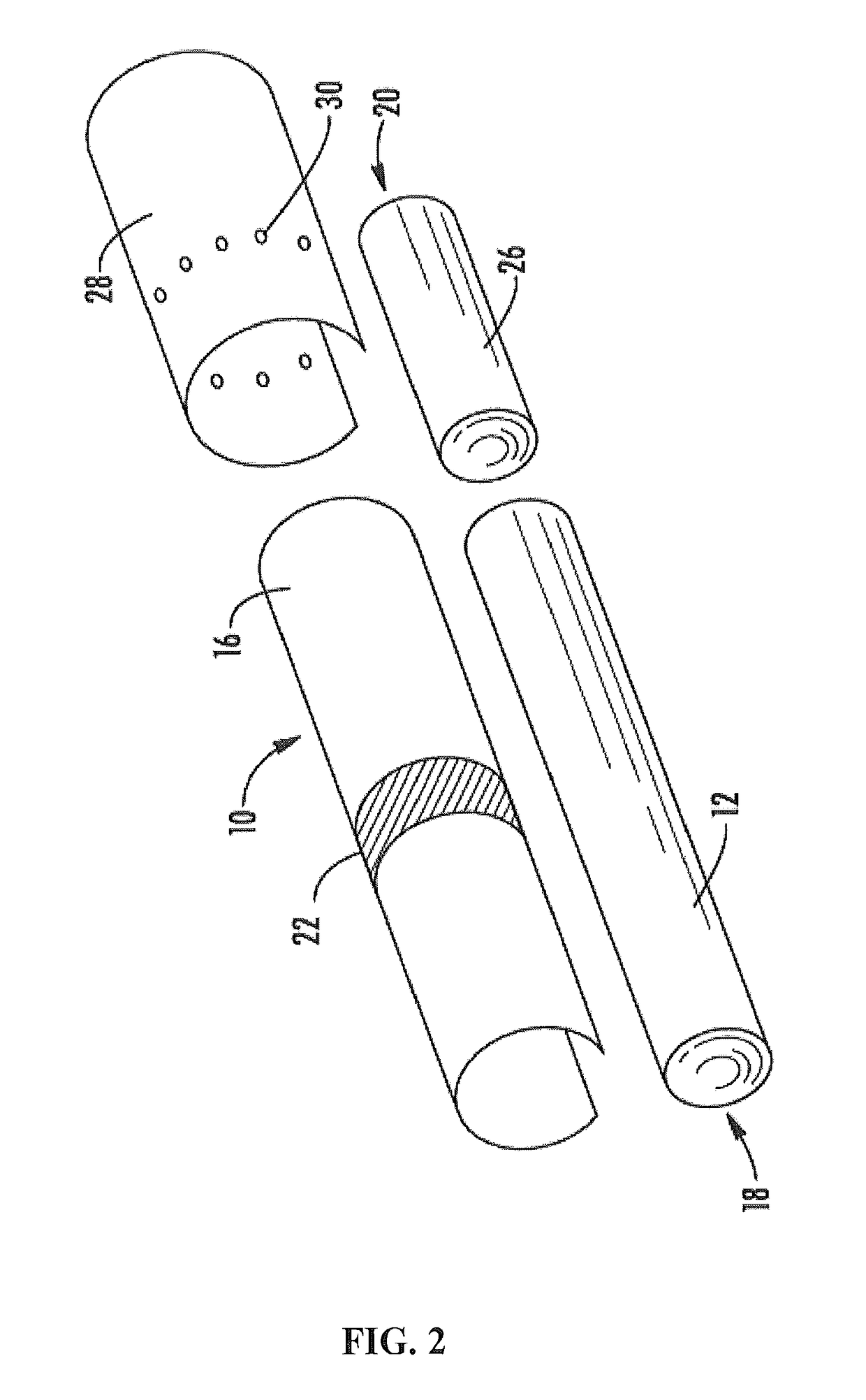

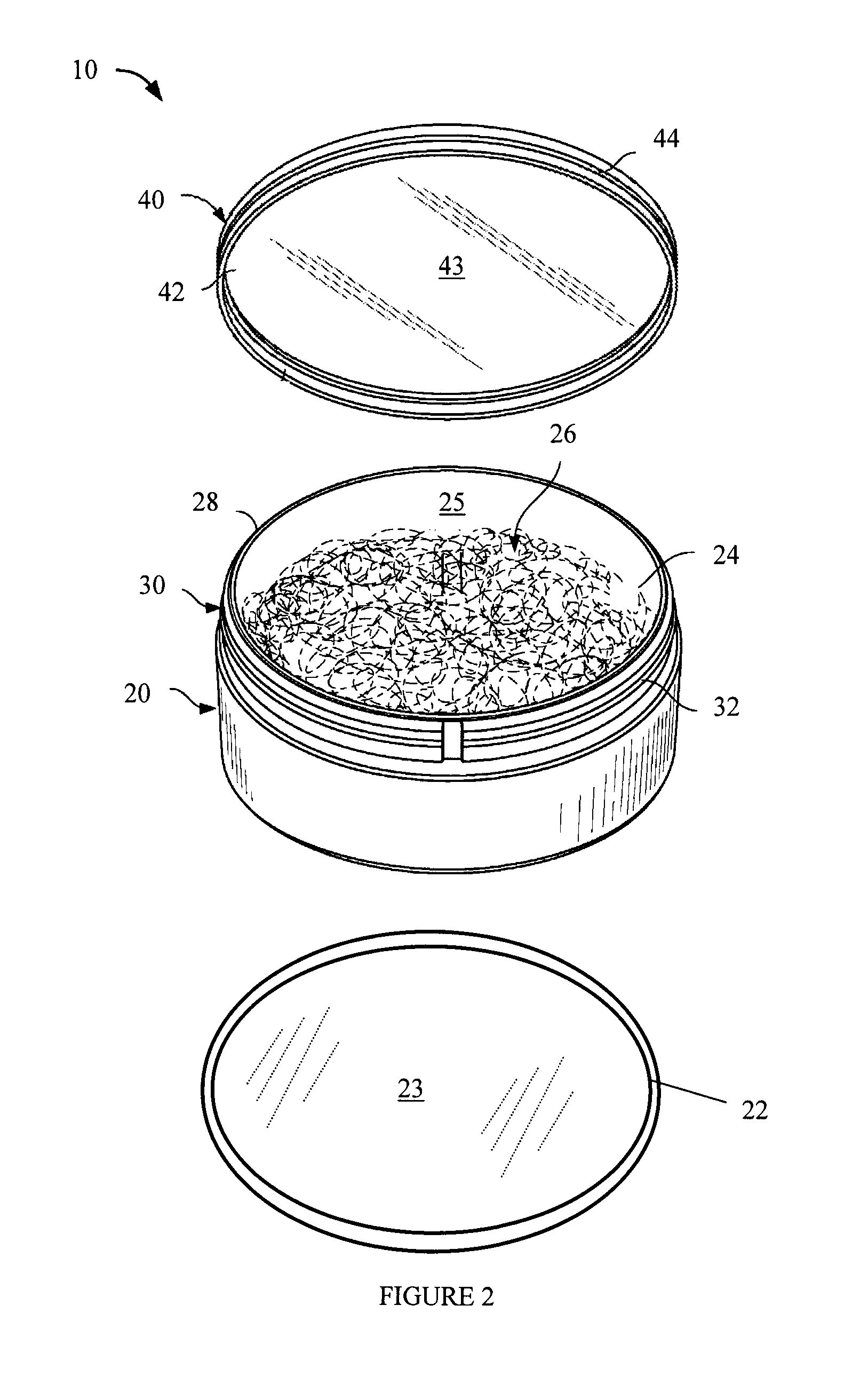

Repulpable container

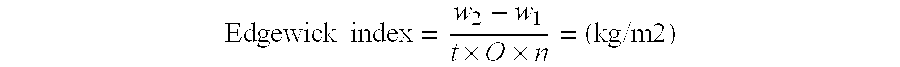

A repulpable insulated container assembly having a container formed of paper such as corrugated cardboard or varying paper materials and defining an interior; and a repulpable insert placed within the interior of the container and formed of a first paper layer; and a paper fiber pad coupled to the first paper layer.

Owner:PRATT RETAIL SPECIALTIES LLC

Sulfonated aromatic copolyesters containing hydroxyalkanoic acid groups and shaped articles produced therefrom

InactiveUS7358325B2Optimized balanceOptimized of dimensionalWrappers shrinkagePaper coatingPolymer scienceCopolyester

Owner:EI DU PONT DE NEMOURS & CO

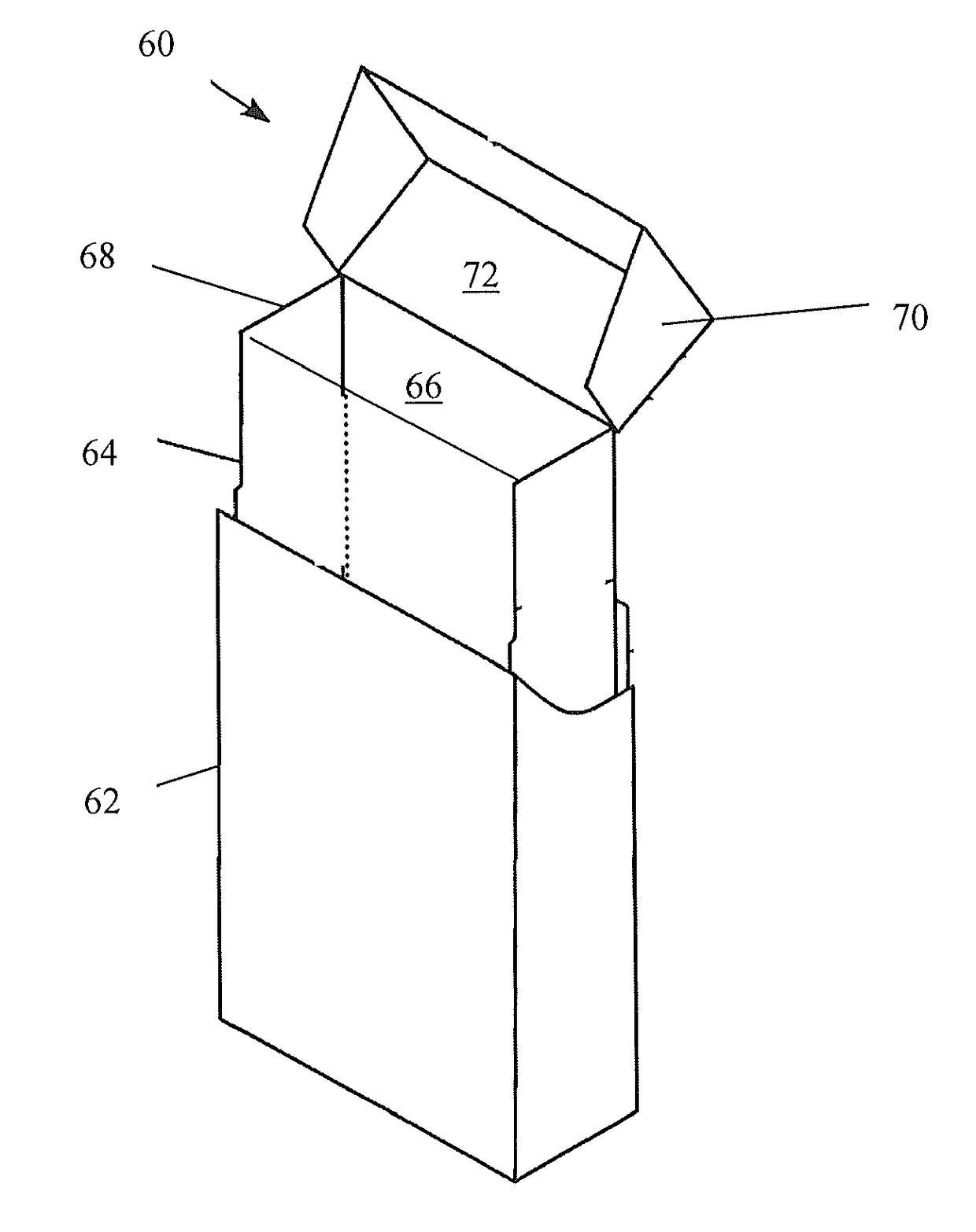

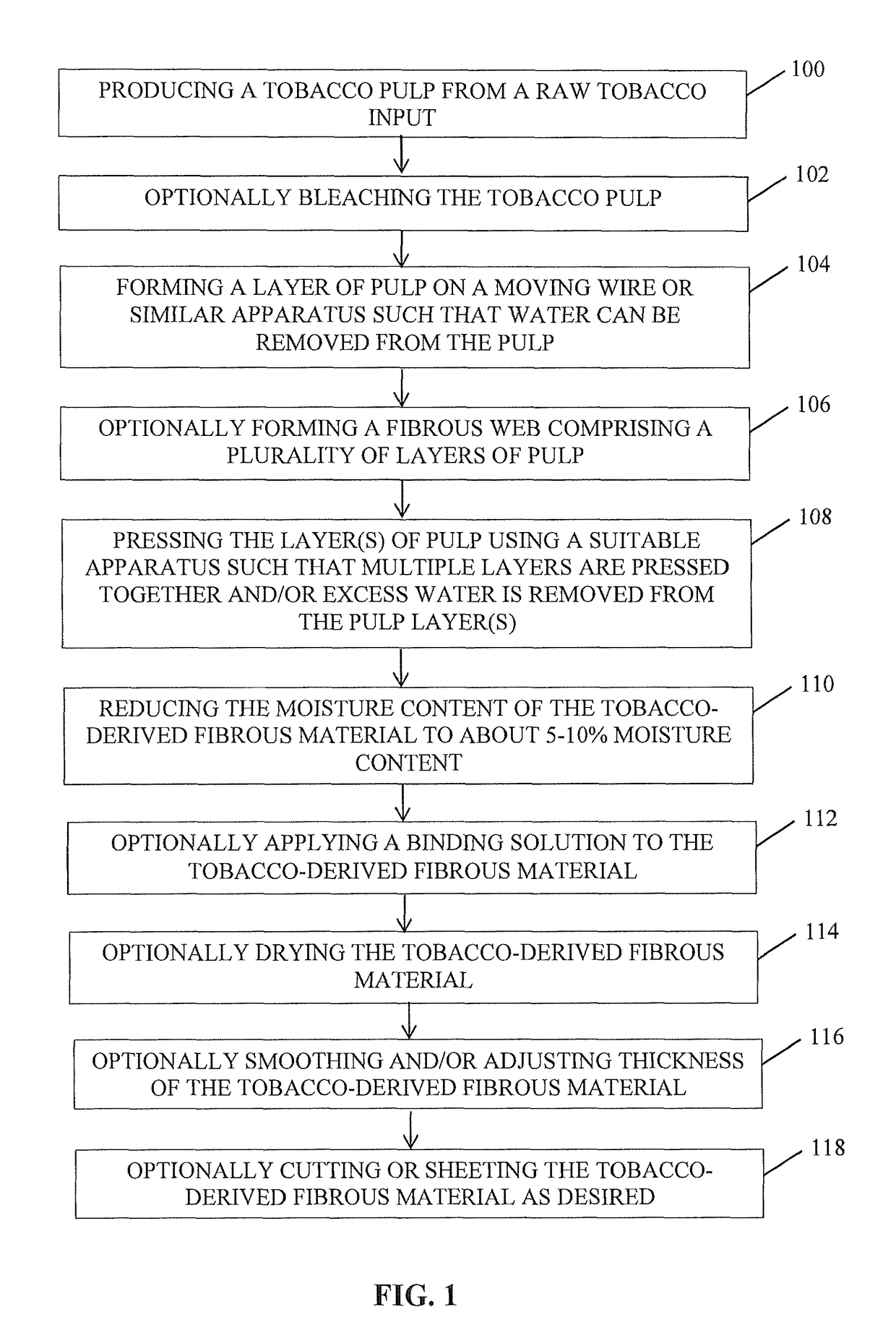

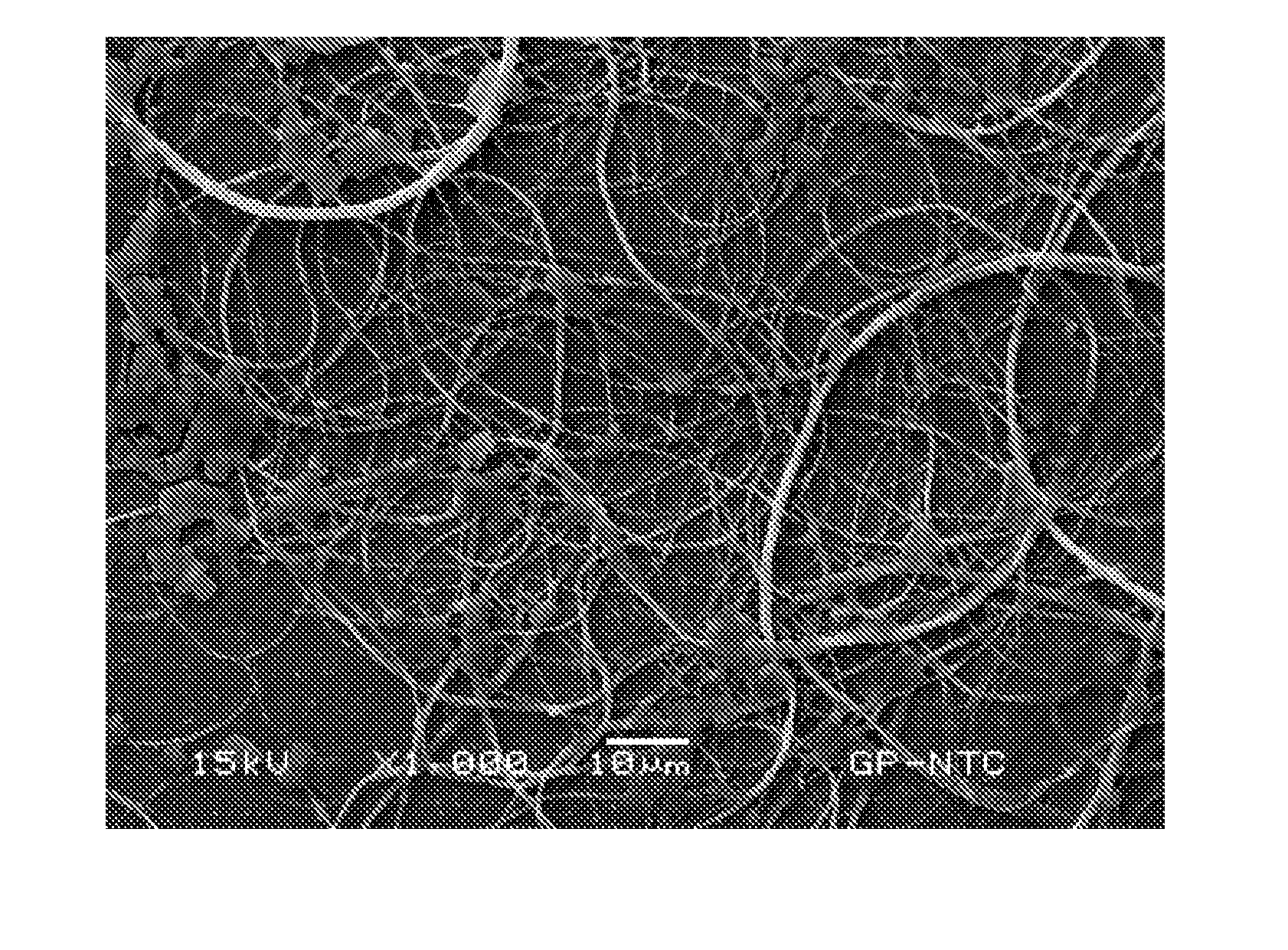

Tobacco-derived cellulose material and products formed thereof

A paper material is provided herein, wherein the paper material includes a fibrous material including at least 5 dry weight percent of fibers derived from a plant of the Nicotiana species; wherein the paper material has a basis weight ranging from about 5 g / m2 to about 450 g / m2; and wherein the paper material has a caliper ranging from about 0.01 mils to about 200 mils. The paper material can be suitable for use in a smoking article in the form of at least one of a tipping material, a plug wrap and a wrapping material. The paper material can be suitable for use in at least one of a soft carton container suitable to house smoking articles, a label, a paper substrate of a barrier layer, a hard carton suitable to house smoking articles and a container suitable to house smokeless tobacco products.

Owner:R J REYNOLDS TOBACCO COMPANY +1

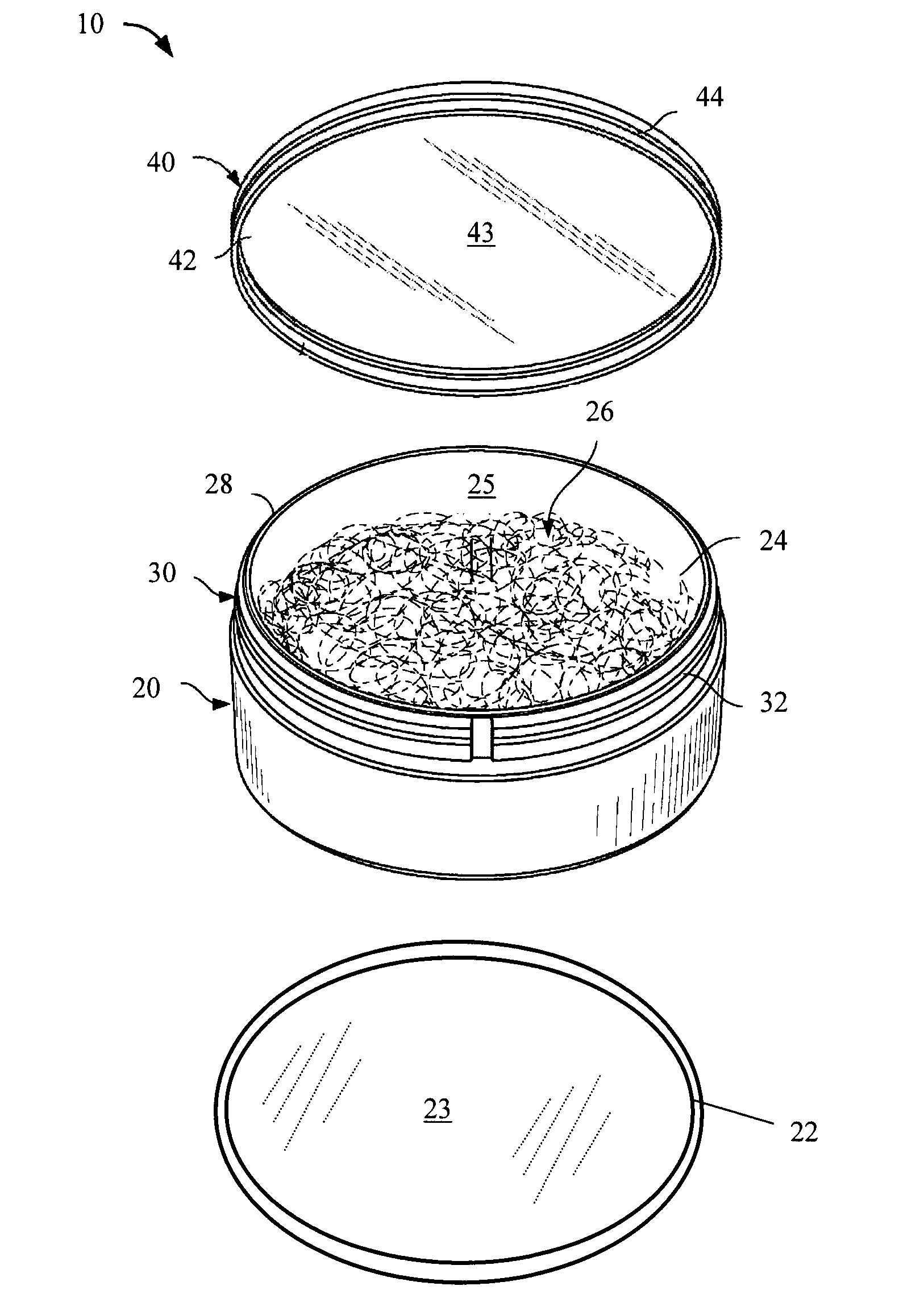

Transparent moisture barrier coatings for containers

Containers for smokeless tobacco products and other consumer and food products are provided. The containers include a layer of fibrous material, wherein the layer of fibrous material includes a moisture barrier layer imbedded within the layer of fibrous material or carried on an outer surface of the layer of fibrous material as a coating, the moisture barrier layer incorporating at least one of: (i) a triazine-containing compound; (ii) a nano-cellulose material; (iii) a nanoclay material; (iv) a polymer composition comprising one or more of a salt of one or more of myristic, palmitic and stearic acid, polyvinyl alcohol, and a C9-C18 fatty acid complex of a metal ion having an oxidation state of at least three; and (v) an inorganic oxide material.

Owner:R J REYNOLDS TOBACCO COMPANY

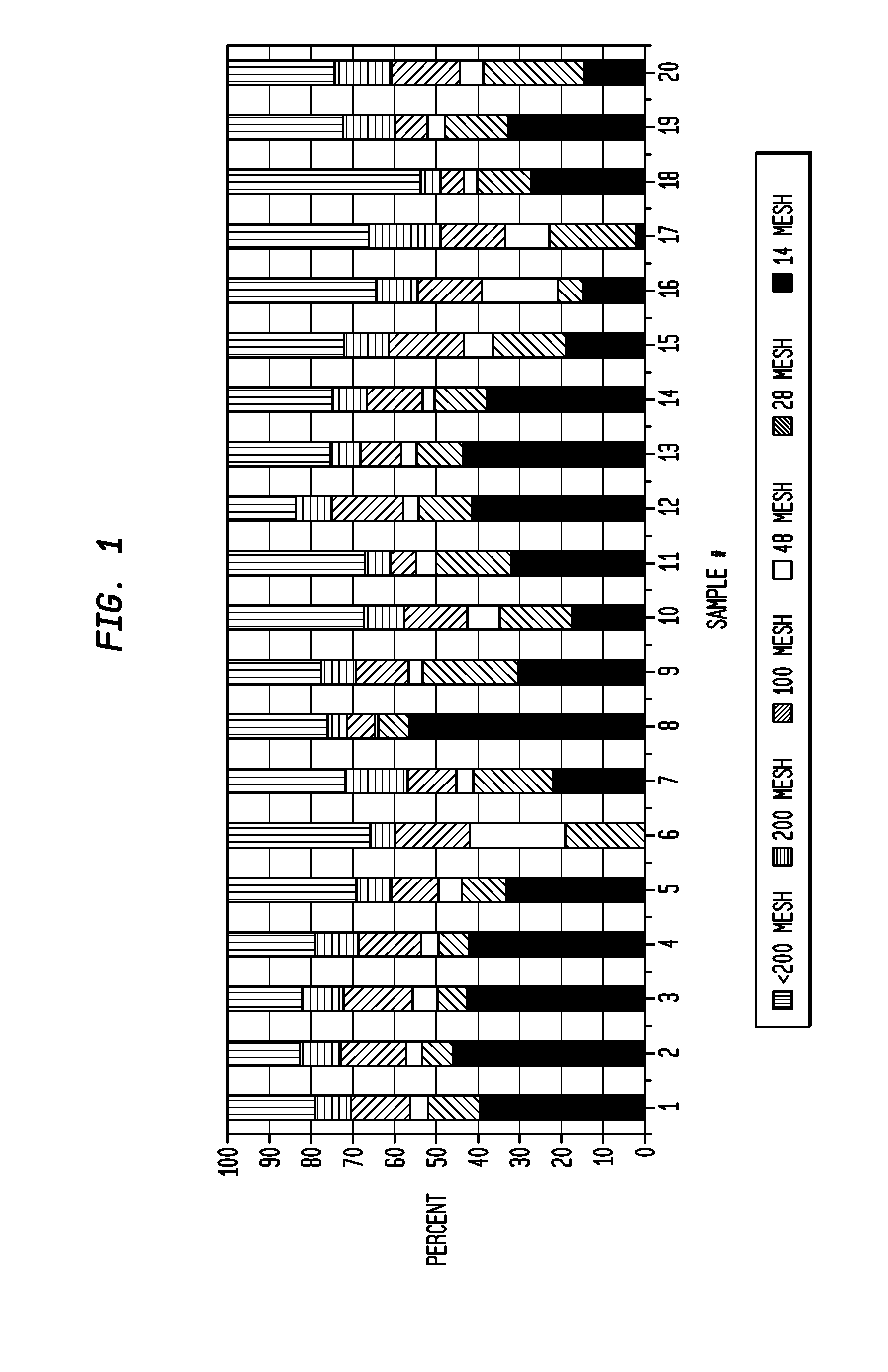

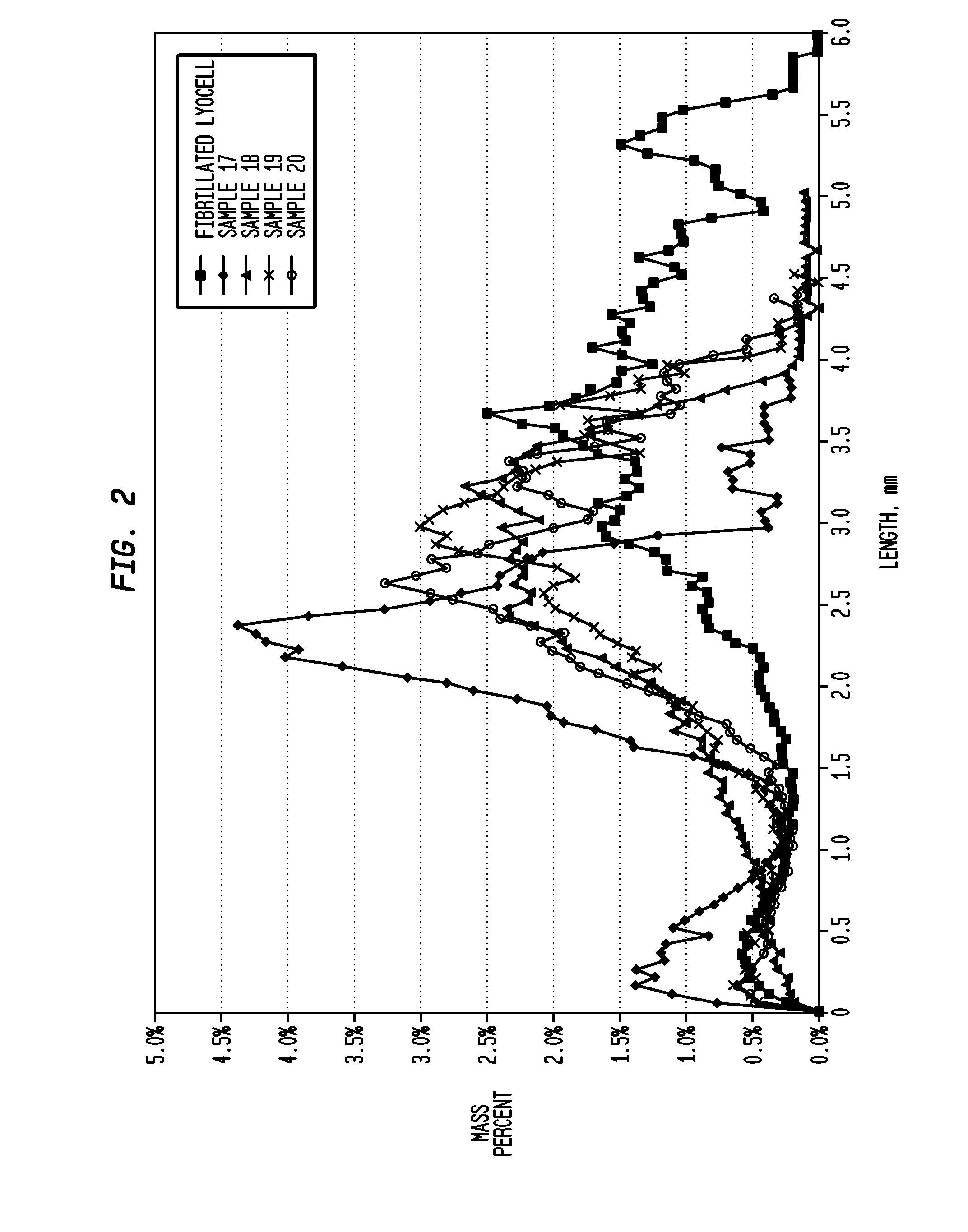

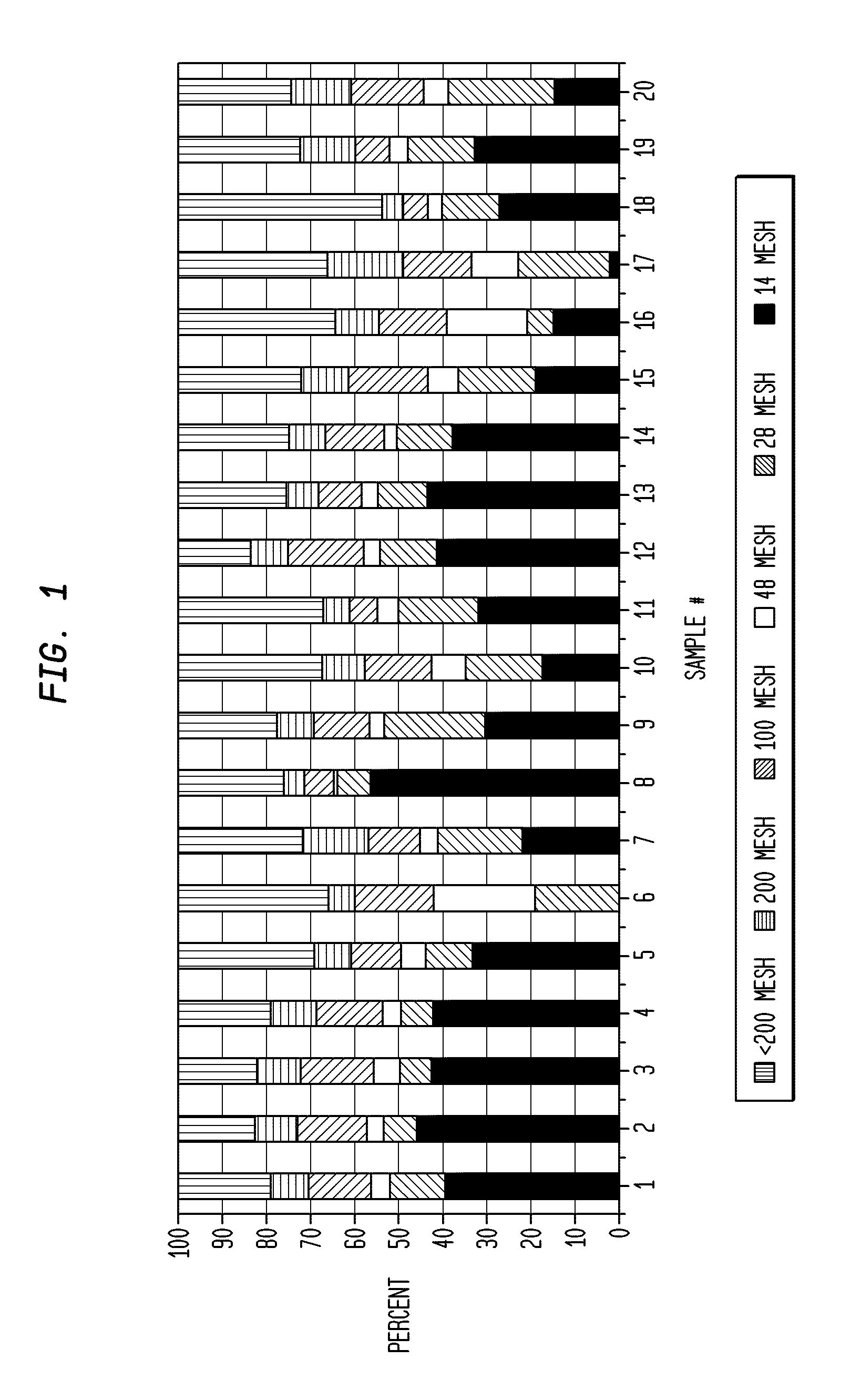

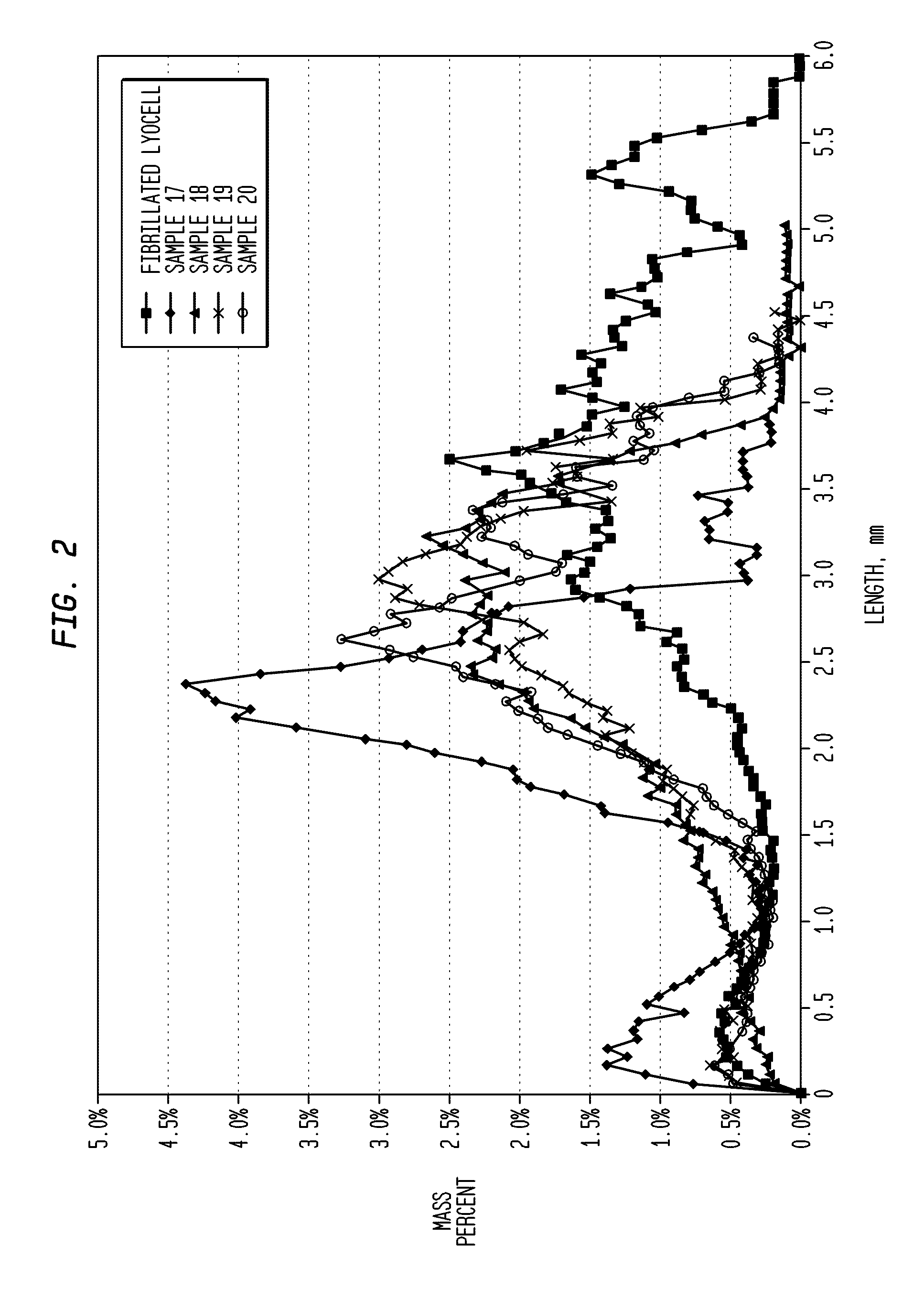

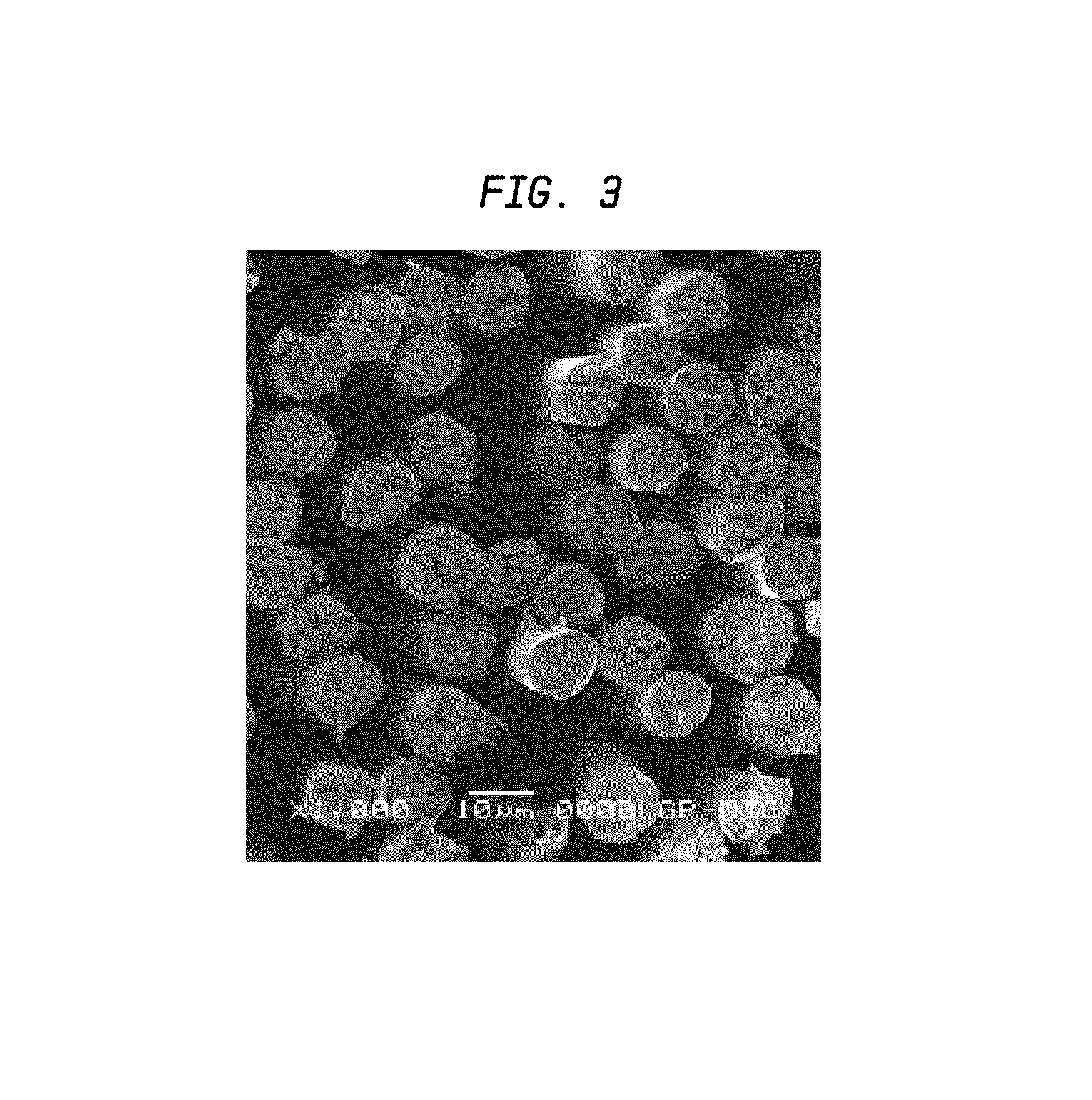

Food wrap base sheet with regenerated cellulose microfiber

A base sheet for food wrap products. The base sheet can include a pulp-derived papermaking fiber and a fibrillated regenerated cellulose microfiber having a CSF value of less than about 175 mL.

Owner:GPCP IP HLDG LLC

Porous fibrous sheets of nanofibers

Owner:DUPONT SAFETY & CONSTR INC

Water stable compositions and articles comprising starch and methods of making the same

Thermoplastic polymer compositions comprising starch and articles made therefrom are water stable or may be rendered so. One method of making water stable thermoplastic compositions comprises the steps of mixing destructured starch with polyhydric alcohol and acid, and forming an ester condensation reaction product from at least a portion of the polyhydric alcohol and acid. In some embodiments, a pre-polymer formed from the ester condensation reaction may be provided as a pre-polymer that is mixed with the starch.

Owner:THE PROCTER & GAMBLE COMPANY

Cellulosic product

InactiveUS20110088860A1Reduce liquid penetrationGood heat sealing performanceFibreboardCosmetic preparationsMicrosphereCellulose fiber

The present invention relates to a process of producing a cellulosic product comprising (i) providing an aqueous suspension of cellulosic fibers, (ii) adding microfibrillar polysaccharide, (iii) adding thermoplastic microspheres, (iv) dewatering the suspension and forming a cellulosic product. The invention also relates to a process of producing a single layer cellulosic product comprising (i) providing an aqueous suspension of cellulosic fibers, (ii) adding microfibrillar polysaccharide derived from softwood and / or hardwood and optionally adding thermoplastic microspheres to the suspension, (iii) dewatering the suspension and forming a cellulosic product. The invention further relates to a cellulosic product obtainable from said processes. The invention also relates to a composition comprising microfibrillar polysaccharide and thermoplastic microspheres and the use thereof.

Owner:AKZO NOBEL NV

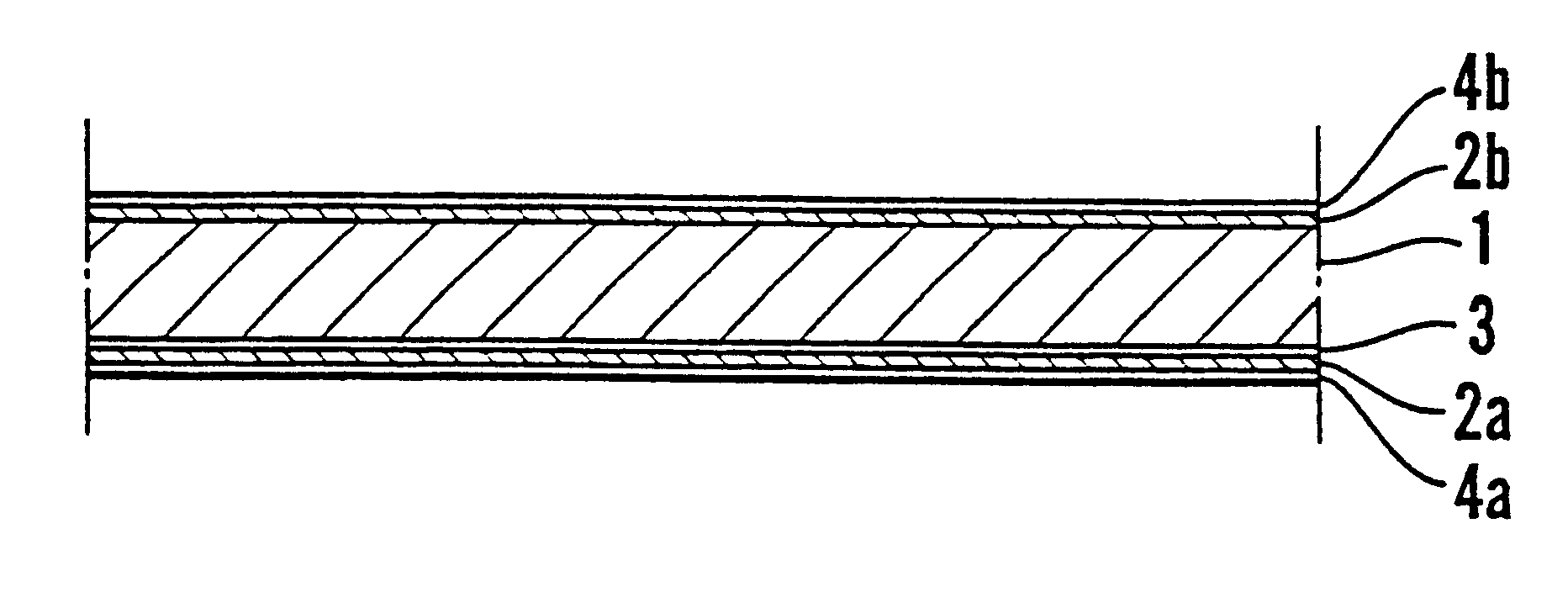

Multi-layer, high barrier packaging materials

InactiveUS20070087212A1Provide moisture resistanceProvide anti-wicking propertySynthetic resin layered productsCellulosic plastic layered productsPaper basedEngineering

A multi-layer, high barrier packaging lid material is adapted for releasably sealing to a plurality of containers including a first container comprised of one polymer and a second container comprised of another polymer. The packaging lid material comprises a paper base with an internal wet strength agent and an anti-wicking agent and having interior and exterior surfaces. A polymer oxygen barrier layer is bonded on the interior surface of the base. A tie layer is on the barrier layer, and a seal-peel layer is on the tie layer. The seal-peel layer is comprised of a blend of a first polymer and a second polymer. When the lid material is heat sealed to a first container the first polymer in the seal-peel layer bonds with the first container while the second polymer in said seal-peel layer functions as a contaminant to provide easy peeling. When the lid material is heat sealed to a second container the second polymer in the seal-peel layer bonds with the second container while the first polymer in the seal-peel layer functions as a contaminant to provide easy peeling.

Owner:STORA ENSO NORTH AMERICA

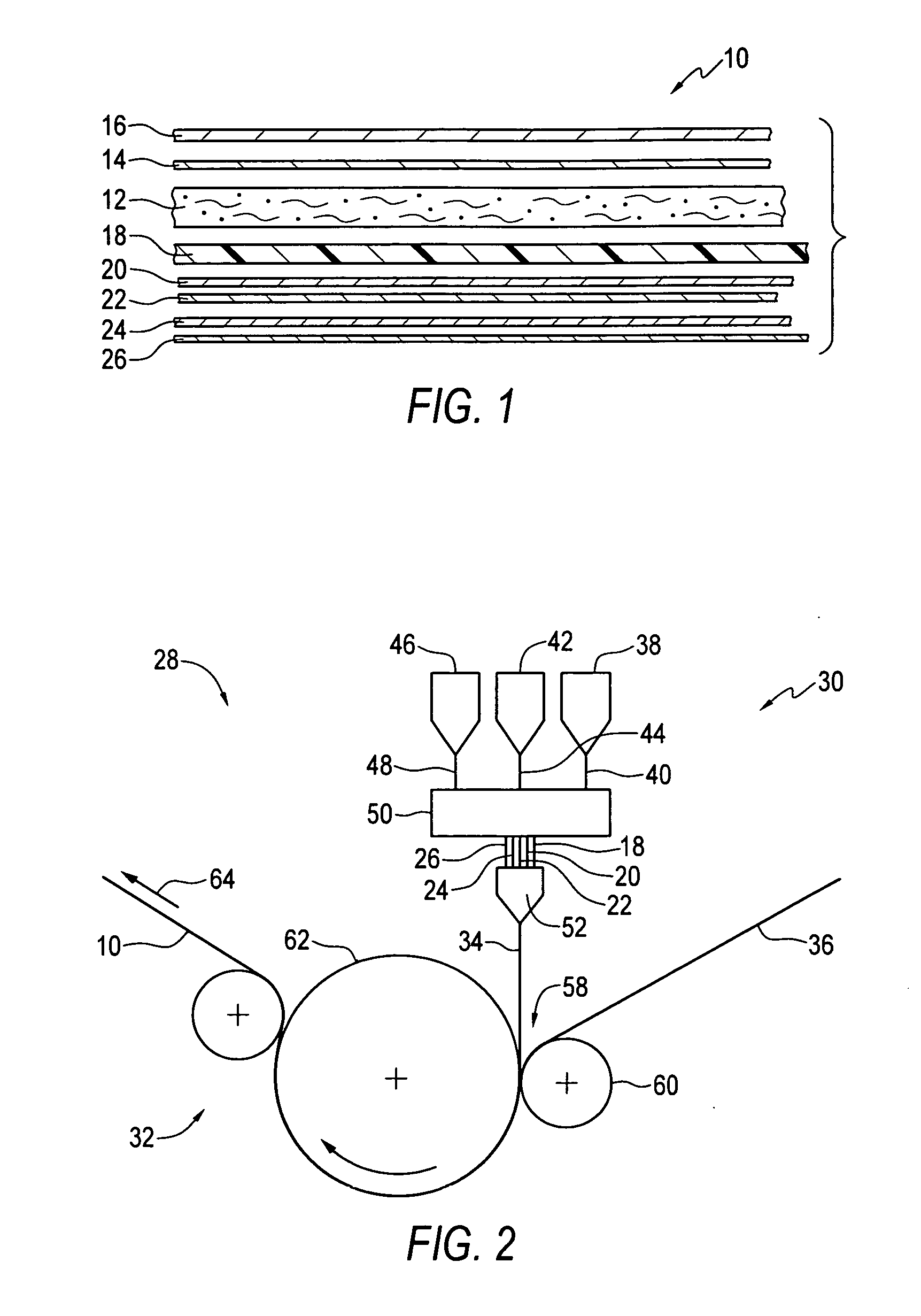

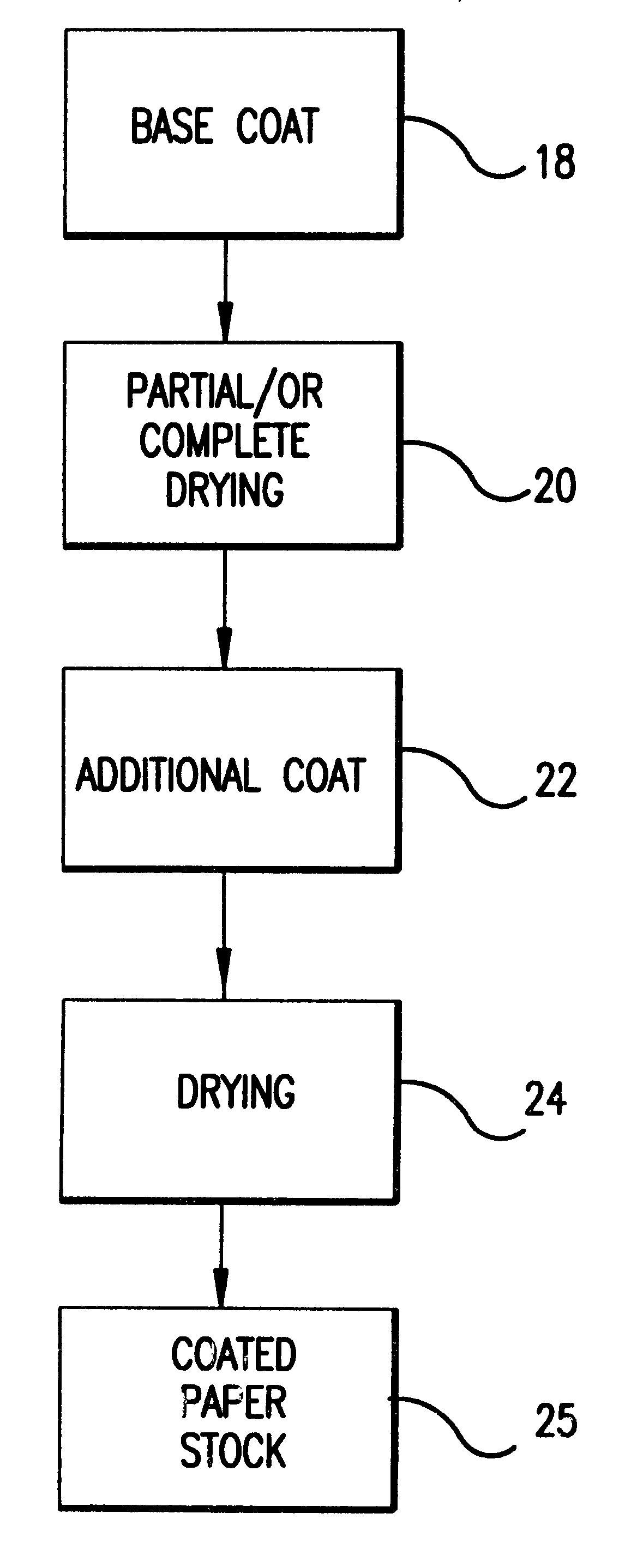

Recyclable and repulpable ream wrap and related methods of manufacture

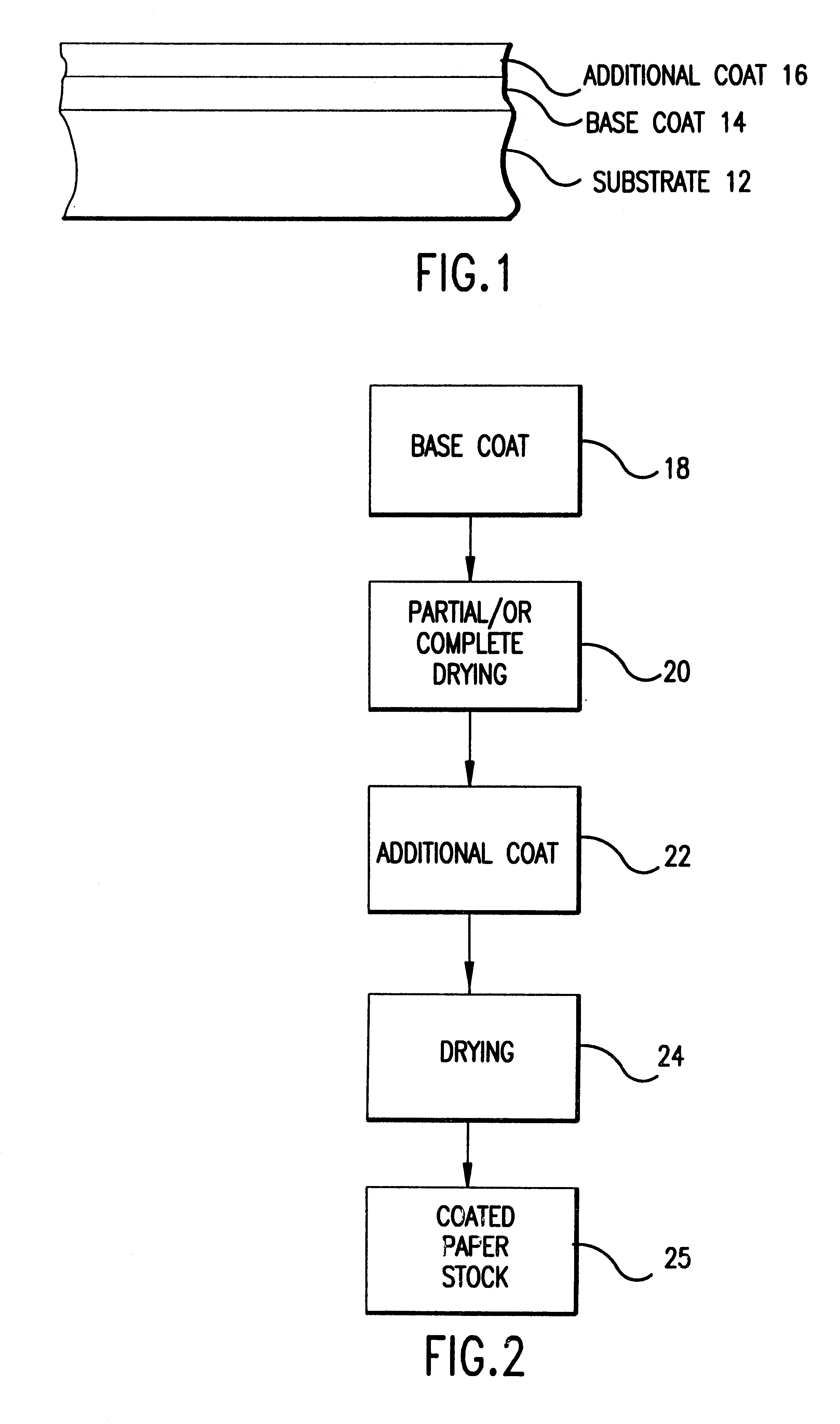

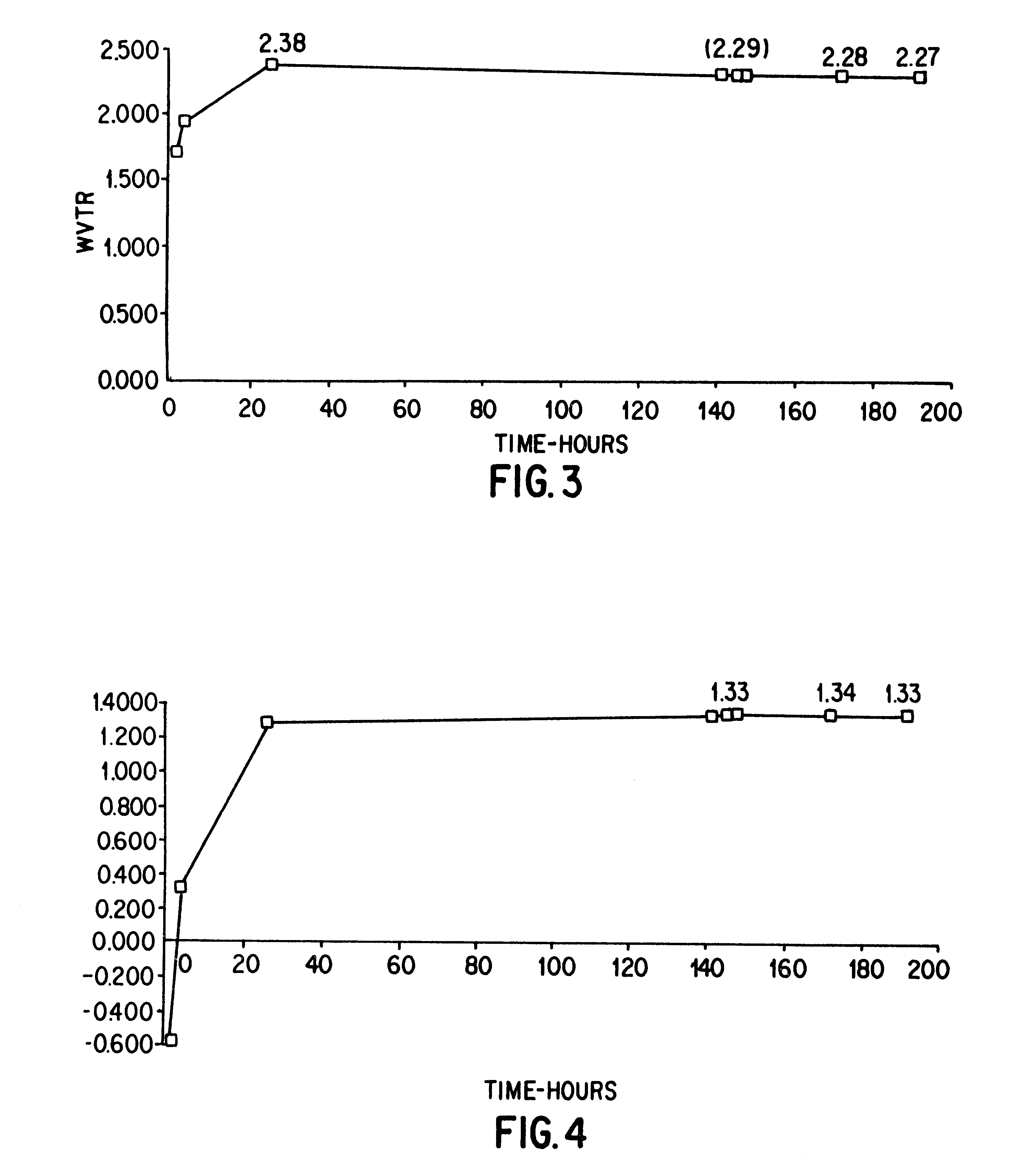

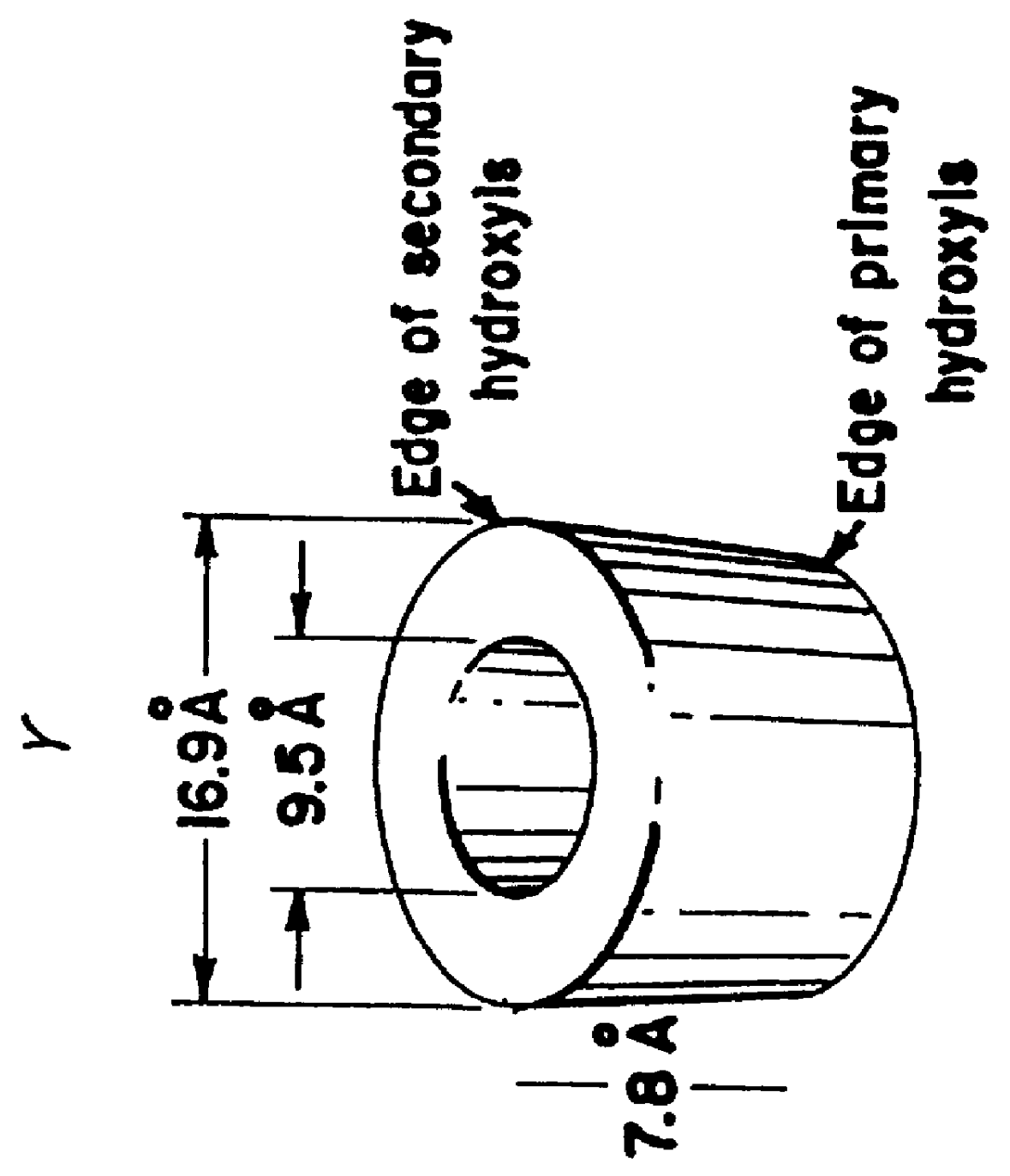

InactiveUS6548120B1Reduce penetrationReduce drying demandFlexible coversWrappersWater basedPolymer science

Recyclable and repulpable coated paper stock, preferably for use as ream wrap, comprising a substrate coated on at least one surface with a base coat and at least one additional coat over said base coat. Both coats are water based dispersions of a polymer selected from the group consisting of acrylic polymers, acrylic copolymers, polyvinyl acetate, polyvinyl alcohol, ethylene-vinyl acetate, polyvinyl chloride, styrene butadiene copolymers, polyvinylidiene chloride and its copolymers, or starch. The wax free coating forms a pin-hole free continuous film on the substrate which is resistant to water and water vapor. The invention also includes processes for making and recycling the invented coated paper stocks.

Owner:COATING EXCELLENCE INT

Rigid polymeric beverage bottles with improved resistance to permeant elution

InactiveUS6136354AImprove barrier propertiesImprove propertiesWrappersLarge containersThermoplasticPolyester

Carbonated beverages can have a substantially reduced concentration of water soluble materials derived from biaxially oriented thermoformed beverage containers. Such containers can comprise a permeant barrier and an active trap for water soluble materials that can be removed from the thermoplastic by extraction into the carbonated beverage. The improved container material comprises a blow molded thermoplastic polyester web comprising a compatible modified cyclodextrin material having pendent moieties or substituents that render the cyclodextrin material compatible with the container thermoplastic. The cyclodextrin material, after it is added to the polymer material, acts as a barrier and to trap extractable materials as they permeate through the thermoplastic polyester. The cyclodextrin molecule has a large center cavity having properties that increase the likelihood that organic molecules will be absorbed and trapped in the center pore. The resulting polyester is substantially resistant to any extraction of soluble materials from the polyester material by the carbonated beverage.

Owner:CELLRESIN TECH

Food wrap base sheet with regenerated cellulose microfiber

A base sheet for food wrap products. The base sheet can include a pulp-derived papermaking fiber and a fibrillated regenerated cellulose microfiber having a CSF value of less than about 175 mL.

Owner:GPCP IP HLDG LLC

Compositions

Compositions such as filled and coated papers may include microfibrillated cellulose and inorganic particulate material.

Owner:FIBERLEAN TECH LTD

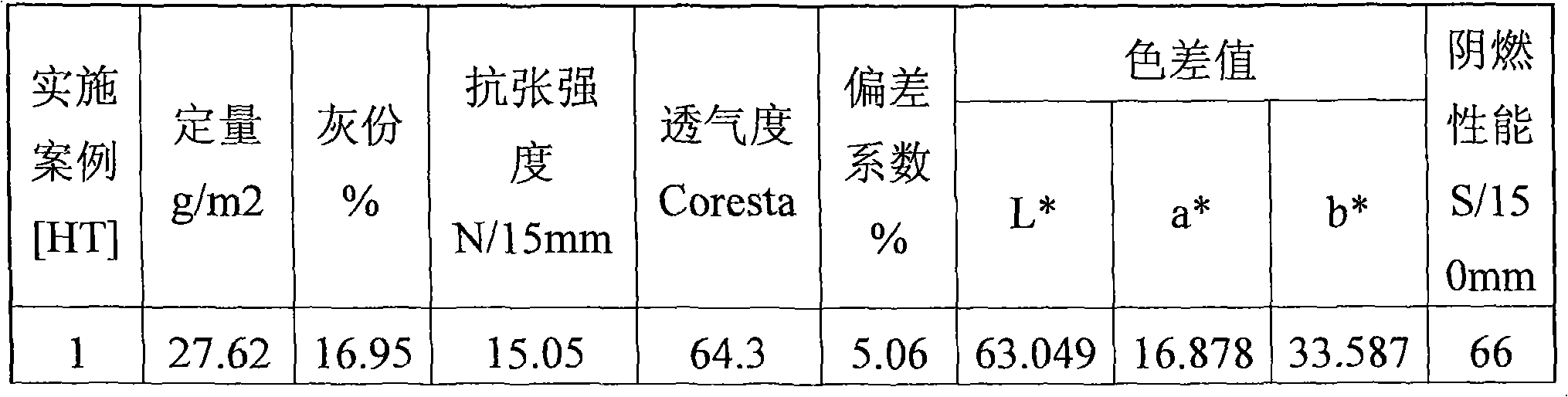

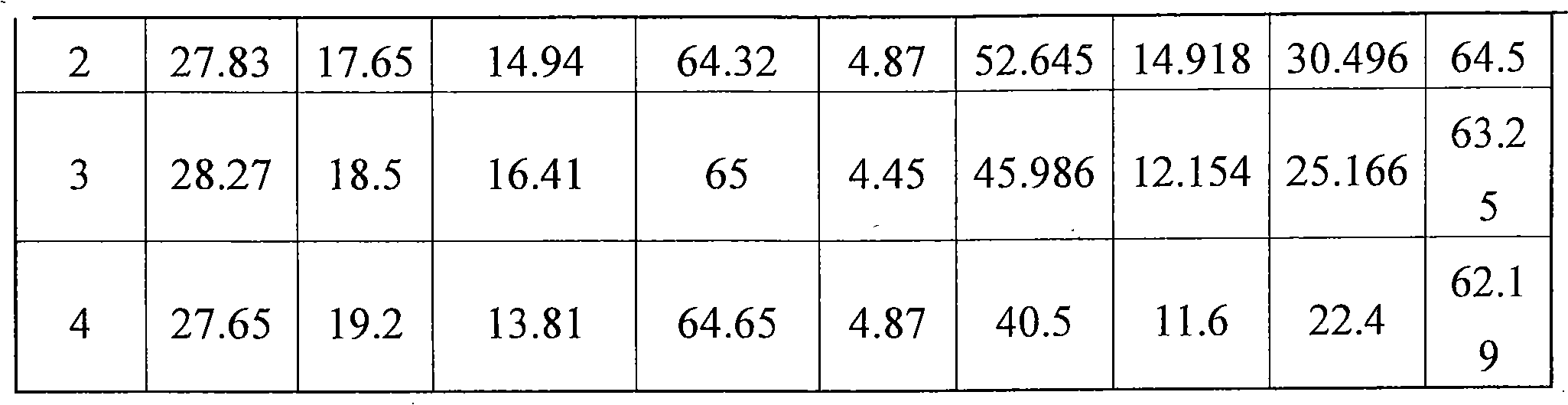

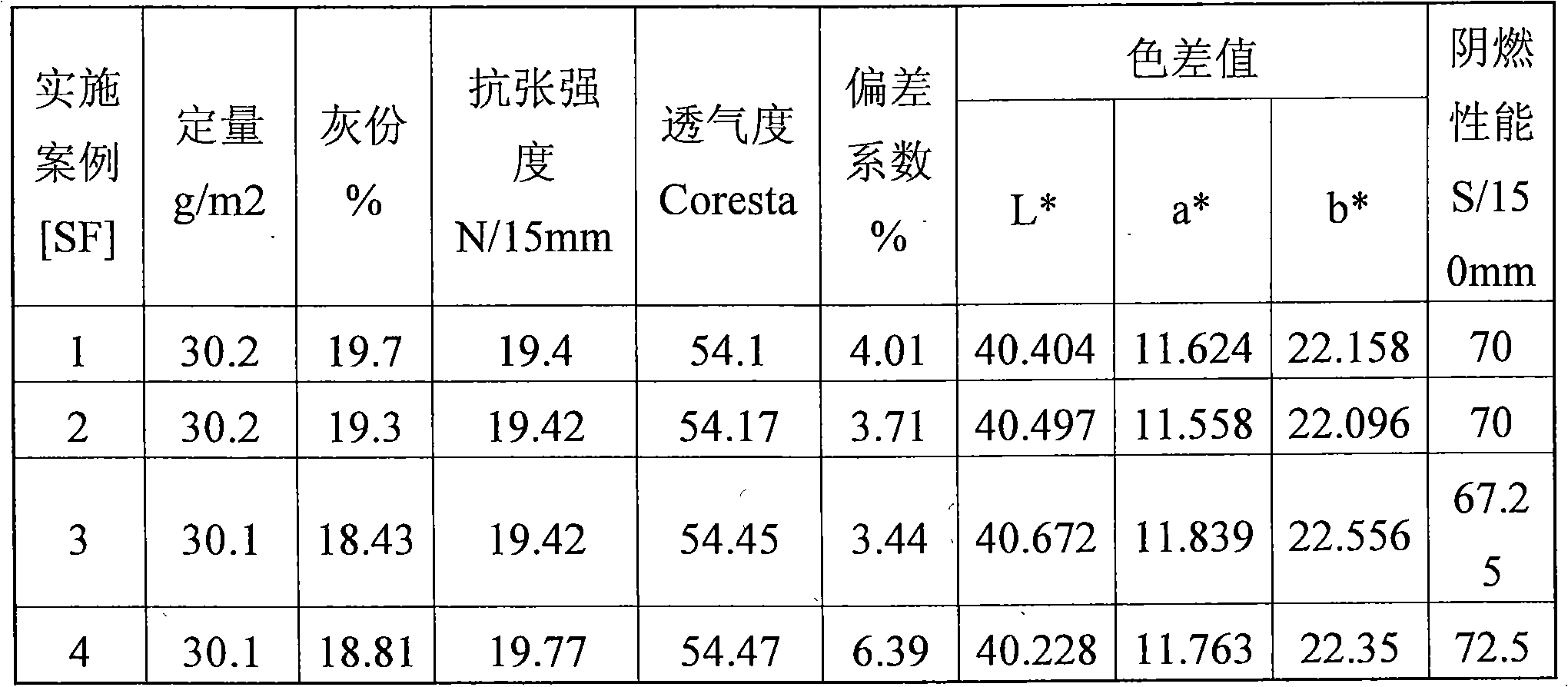

Colorized cigarette paper and preparation method

The invention discloses colorized cigarette paper, which mainly comprises the following components in part by weight: 55 to 70 parts of fiber, 30 to 45 parts of filler, 0.5 to 8 parts of combustion improver and 0.5 to 30 parts of cigarette paste, wherein the cigarette paste comprises the following components in part by weight: 1 to 8 parts of tobacco extract, 0.05 to 4.0 parts of natural extract, 0.001 to 0.05 part of edible pigment and the balance of water. The invention also discloses a preparation method for the colorized cigarette paper, which comprises the following steps of: (1) preparing combustion improver solution; (2) preparing dyeing solution; and (3) respectively adding the combustion improver solution and the dyeing solution prepared in the steps (2) and (3) into the cigarette paper by using a sizing machine for dyeing. The colorized cigarette paper and the preparation method thereof have the advantages that: the color of the cigarette paper is close to the original color of tobacco, so that the colorized cigarette paper has a more natural feel; and the preparation method can be used for production without any change of the production process for the conventional cigarette paper production equipment.

Owner:云南红塔蓝鹰纸业有限公司

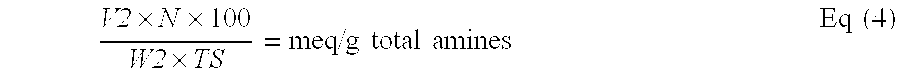

Reduced by product polyamine-epihalohydrin resins

Processes for rendering a polyamine-epihalohydrin resin storage stable, including processes that prepare a storage stable resin and / or processes that treat resins. A composition containing a polyamine-epihalohydrin resin which includes CPD-forming species can be treated with at least one agent under conditions to at least one of inhibit, reduce and remove the CPD-forming species to obtain a reduced CPD-forming resin so that a composition containing the reduced CPD-forming polyamine-epihalohydrin resin when stored for 2 weeks at 50° C., and a pH of about 2.5 to 3.5 contains less than about 250 ppm dry basis of CPD. The invention is also directed to a gelation storage stable reduced CPD-forming resin so that a composition containing the reduced CPD-forming polyamine-epihalohydrin resin, when stored at pH 1 for 24 hours at 50° C. and measured at 24 hours, produces less than about 1000 ppm dry basis of CPD. A paper product containing the storage stable polyaminopolyamide-epihalohydrin resin, when corrected for adding at about a 1 wt % addition level of the polyaminopolyamide-epihalohydrin resin, contains less than about 250 ppb of CPD. Moreover, a resin can be prepared starting from a prepolymer having a low acid number or low concentration of acid end groups. The invention is also directed to papers containing the resins.

Owner:SOLENIS TECH CAYMAN

Heat, grease, and cracking resistant release paper and process for producing the same

InactiveUS20100059191A1Natural cellulose pulp/paperPaper after-treatmentOil and greaseCrack resistance

Owner:COPAMEX DE C V

Board, packaging material and package as well as production and uses thereof

The invention relates to a process for producing board which comprises providing an aqueous suspension comprising cellulosic fibres; adding hydrotalcite to the suspension; dewatering the obtained suspension to provide a (i) single ply board. The invention further relates to board comprising one or more plies containing cellulosic fibres, wherein the board further comprises hydrotalcite distributed throughout at least one of said one or more plies.

Owner:AKZO NOBEL NV

Use of alkenyl succinic anhydride compounds derived from symmetrical olefins in internal sizing for paper production

A method of sizing paper for use in applications which require resistance to liquids comprising incorporating in the paper a size composition comprising one or more alkenyl succinic anhydride (ASA) compounds prepared from the reaction of maleic anhydride and one or more substantially symmetrical C20-C28 internal olefins.

Owner:ECOLAB USA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com