Patents

Literature

635 results about "Static friction coefficient" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

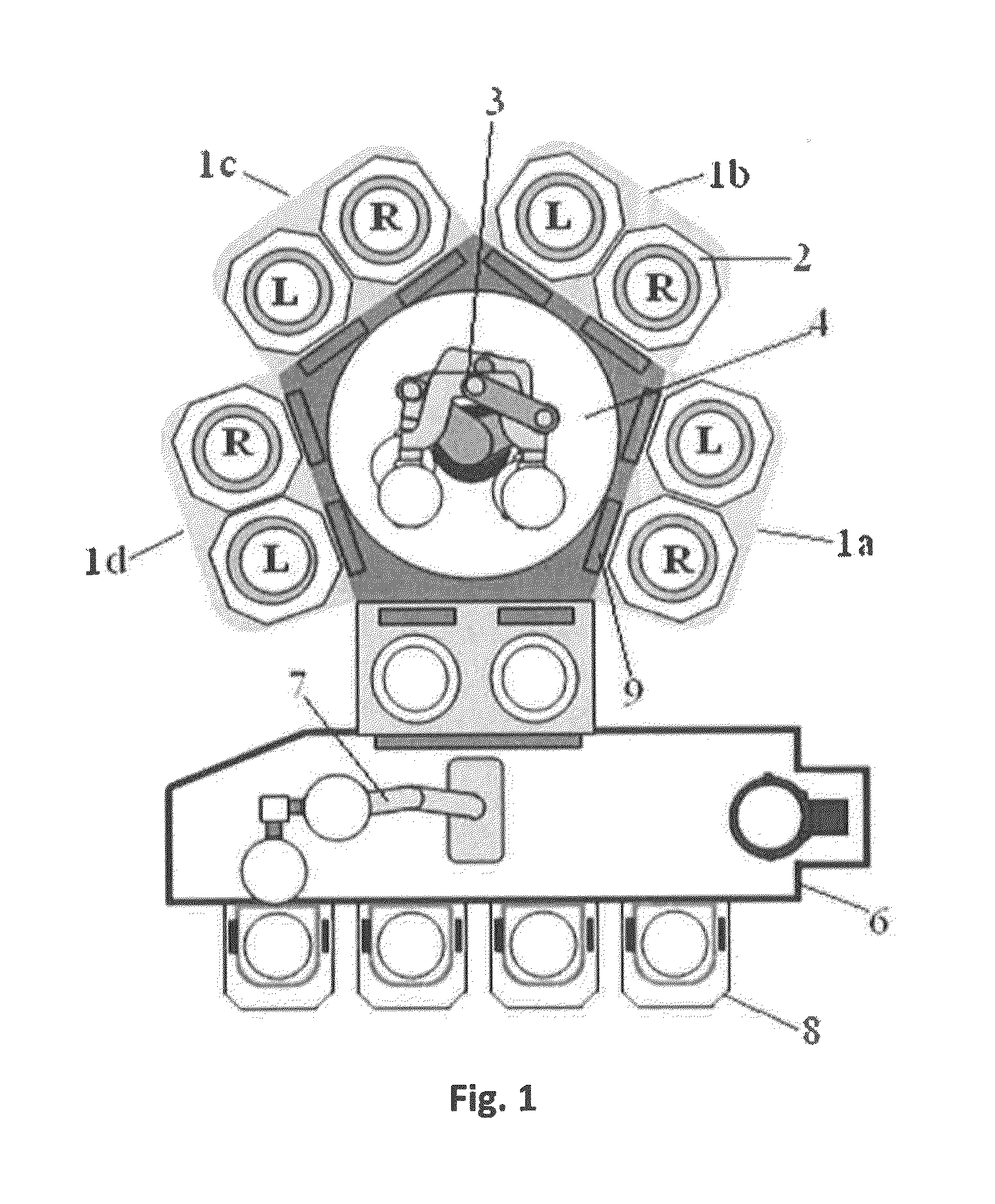

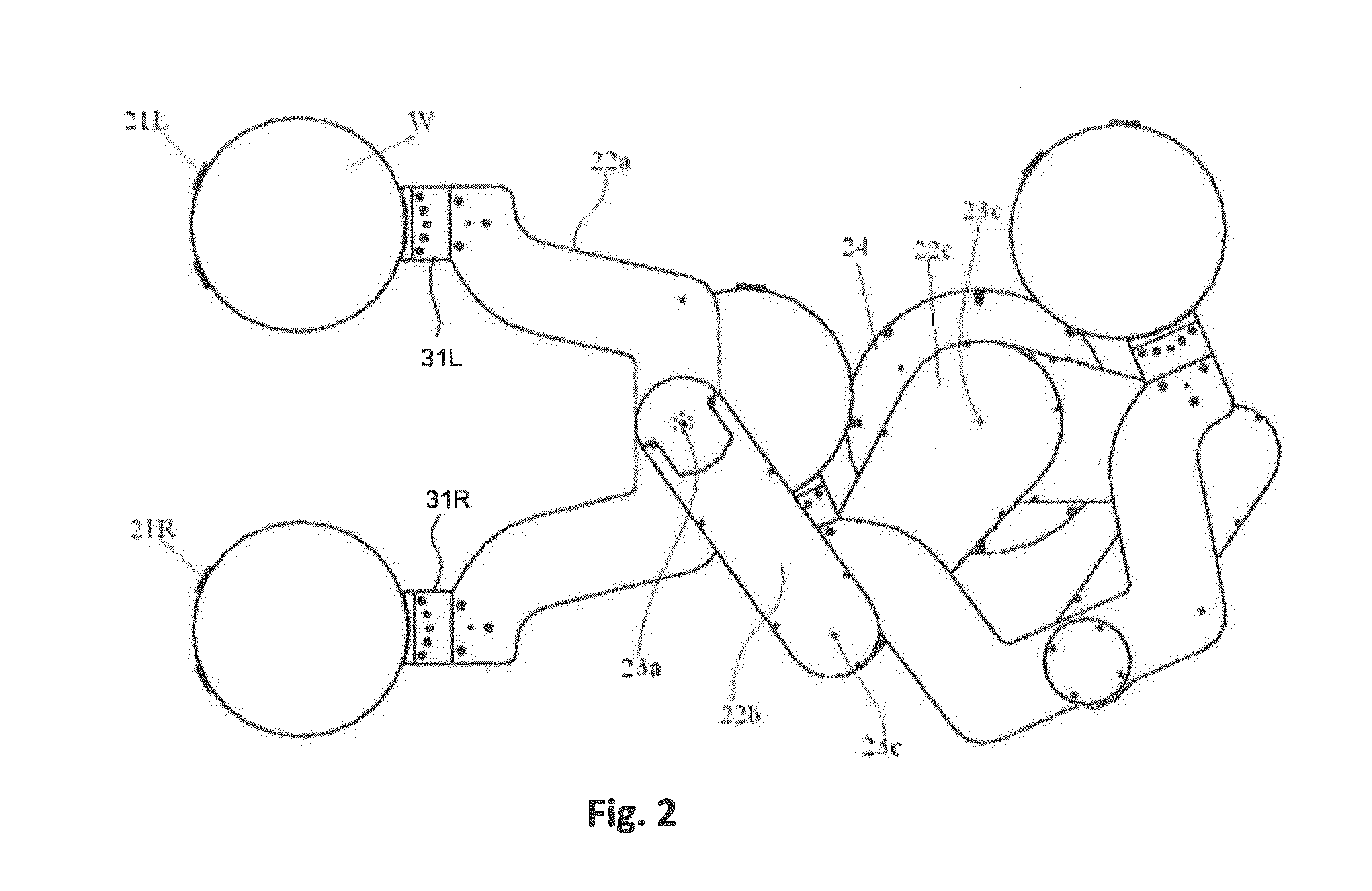

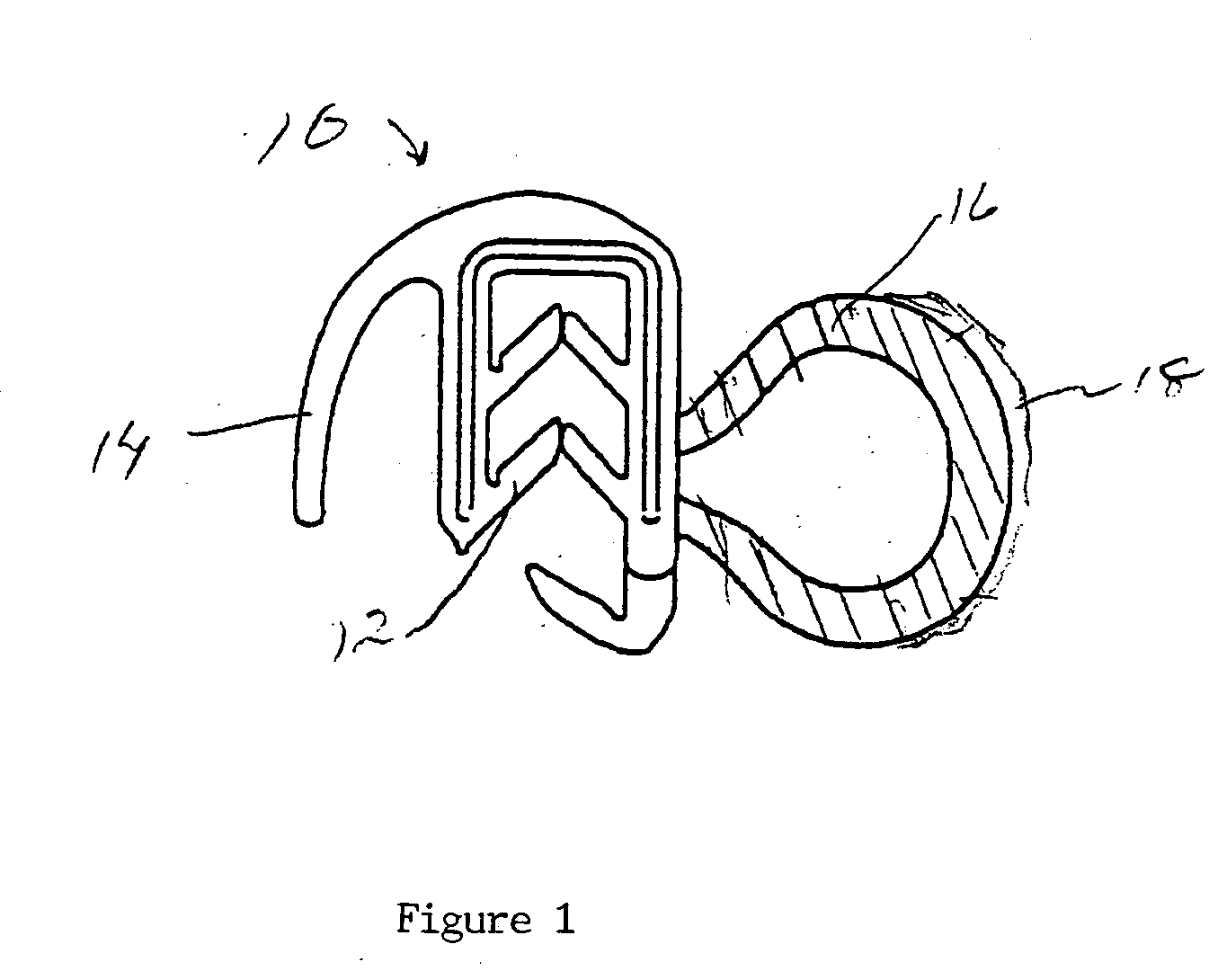

Anti-slip end-effector for transporting workpiece

ActiveUS20150217456A1Lamination ancillary operationsGripping headsStatic friction coefficientActuator

Owner:ASM IP HLDG BV

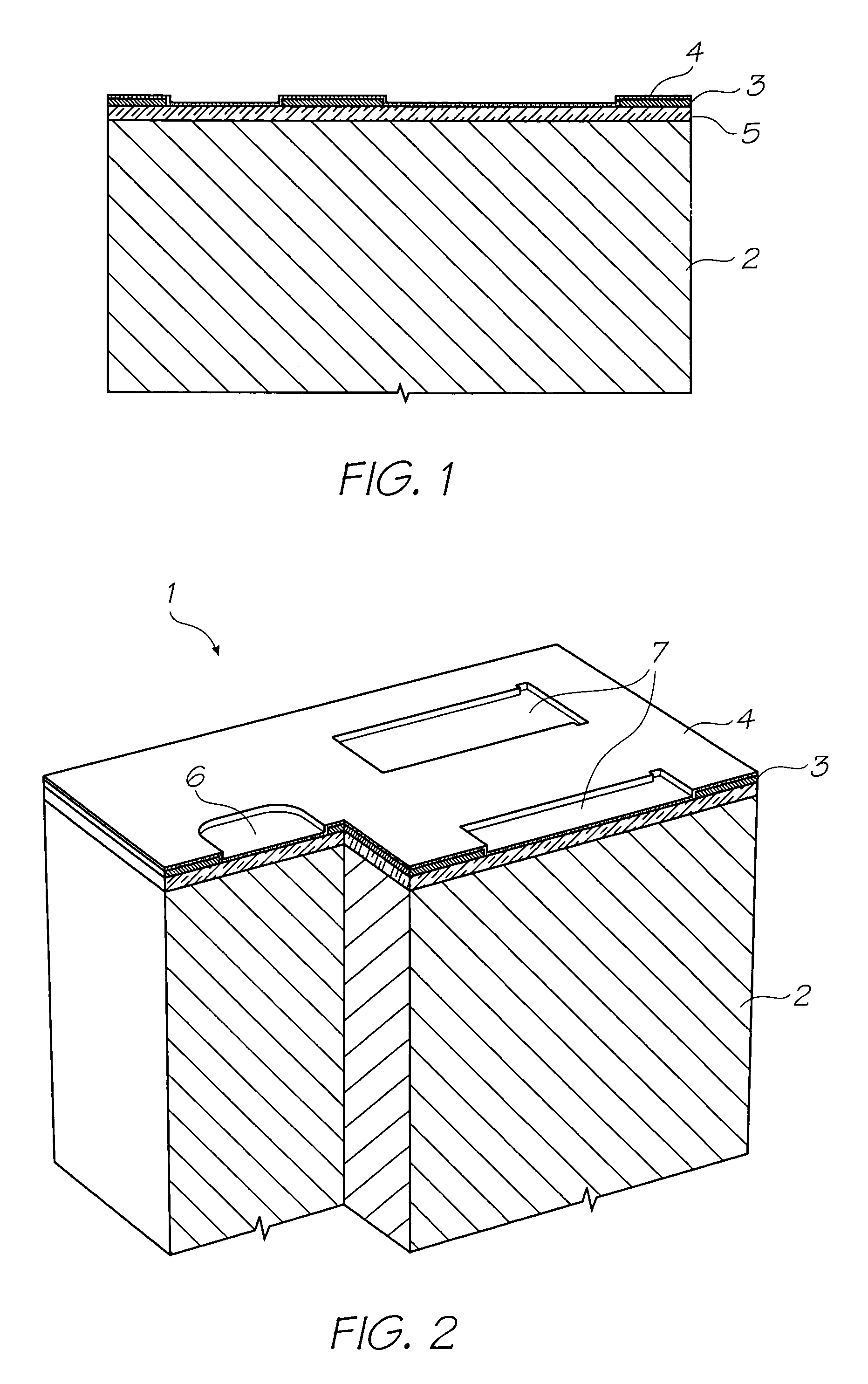

Anti-slip end-effector for transporting workpiece

ActiveUS9370863B2Gripping headsSemiconductor/solid-state device manufacturingStatic friction coefficientRobotic arm

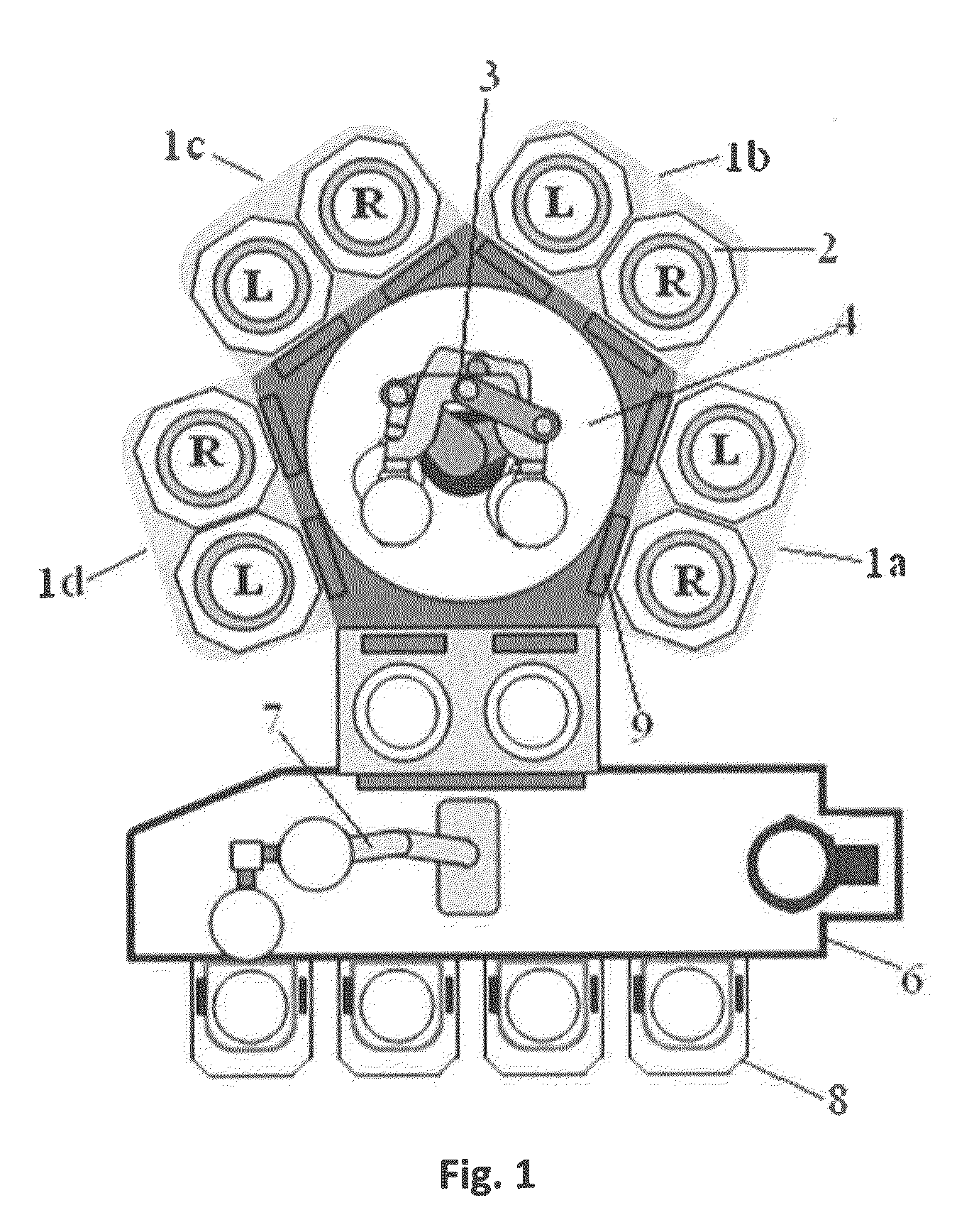

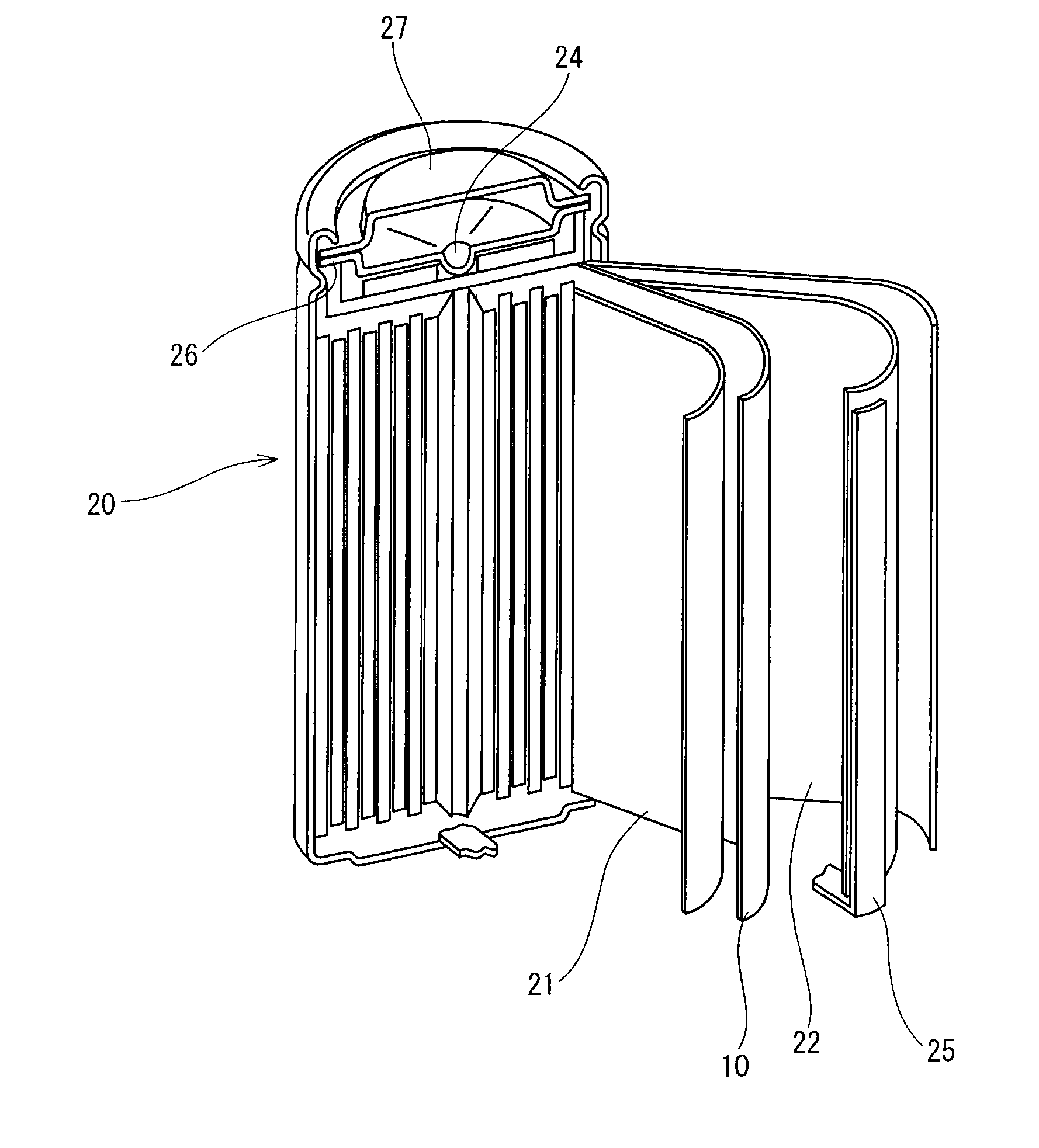

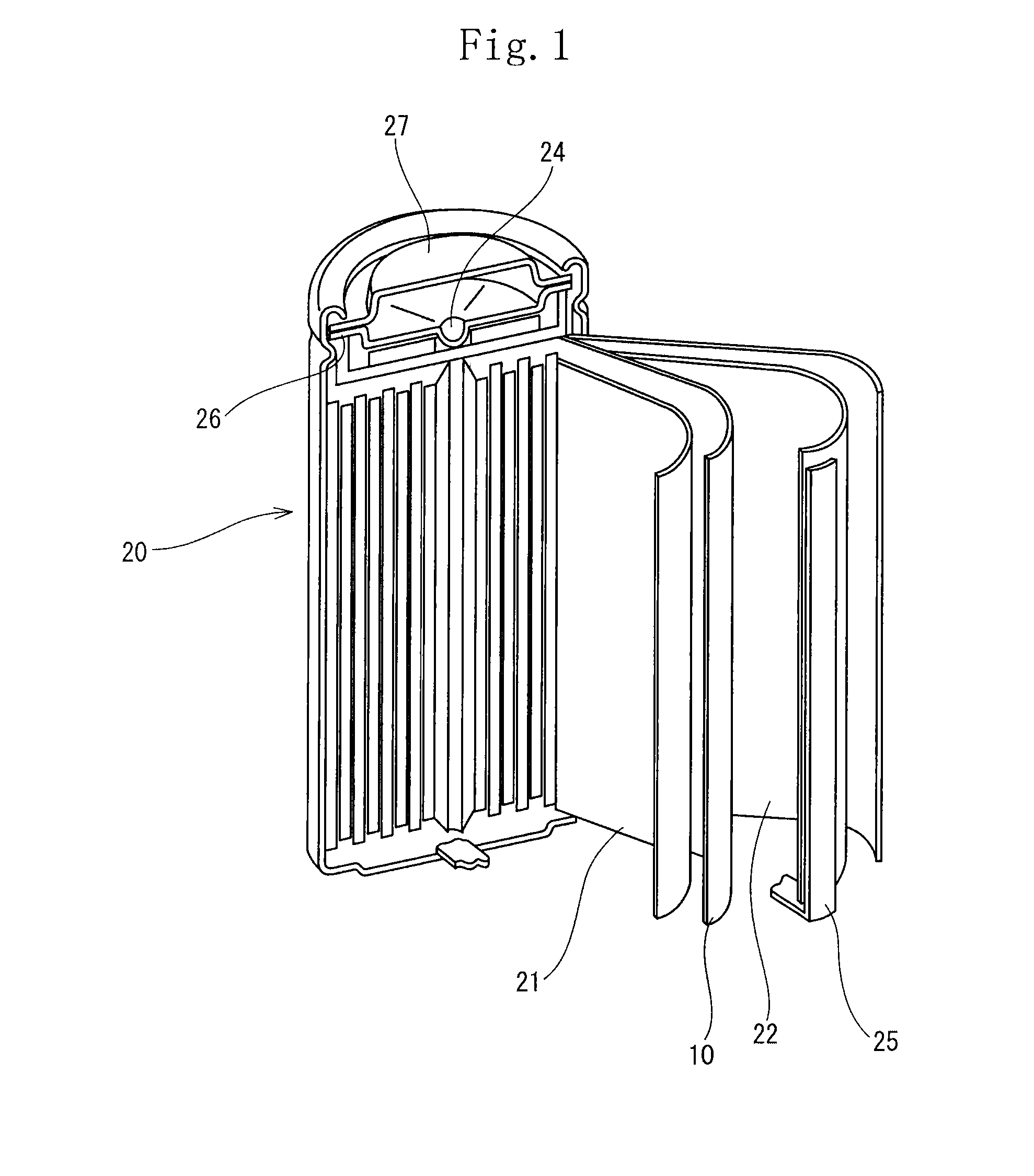

An anti-slip end-effector for transporting a workpiece, which is configured to be attached to a robotic arm, includes: a workpiece-supporting area for placing a workpiece thereon for transportation; at least one front protrusion disposed at a distal end of the workpiece-supporting area for engaging an edge of the workpiece to restrict movement of the workpiece placed on the workpiece-supporting area beyond the front protrusion; and at least one anti-slip protrusion disposed in the workpiece-supporting area for contacting and supporting the backside of the workpiece, said anti-slip protrusion having a top face having a static friction coefficient of 1.0 or more as measured against the backside of the workpiece, and having a surface roughness of less than 0.4 μm.

Owner:ASM IP HLDG BV

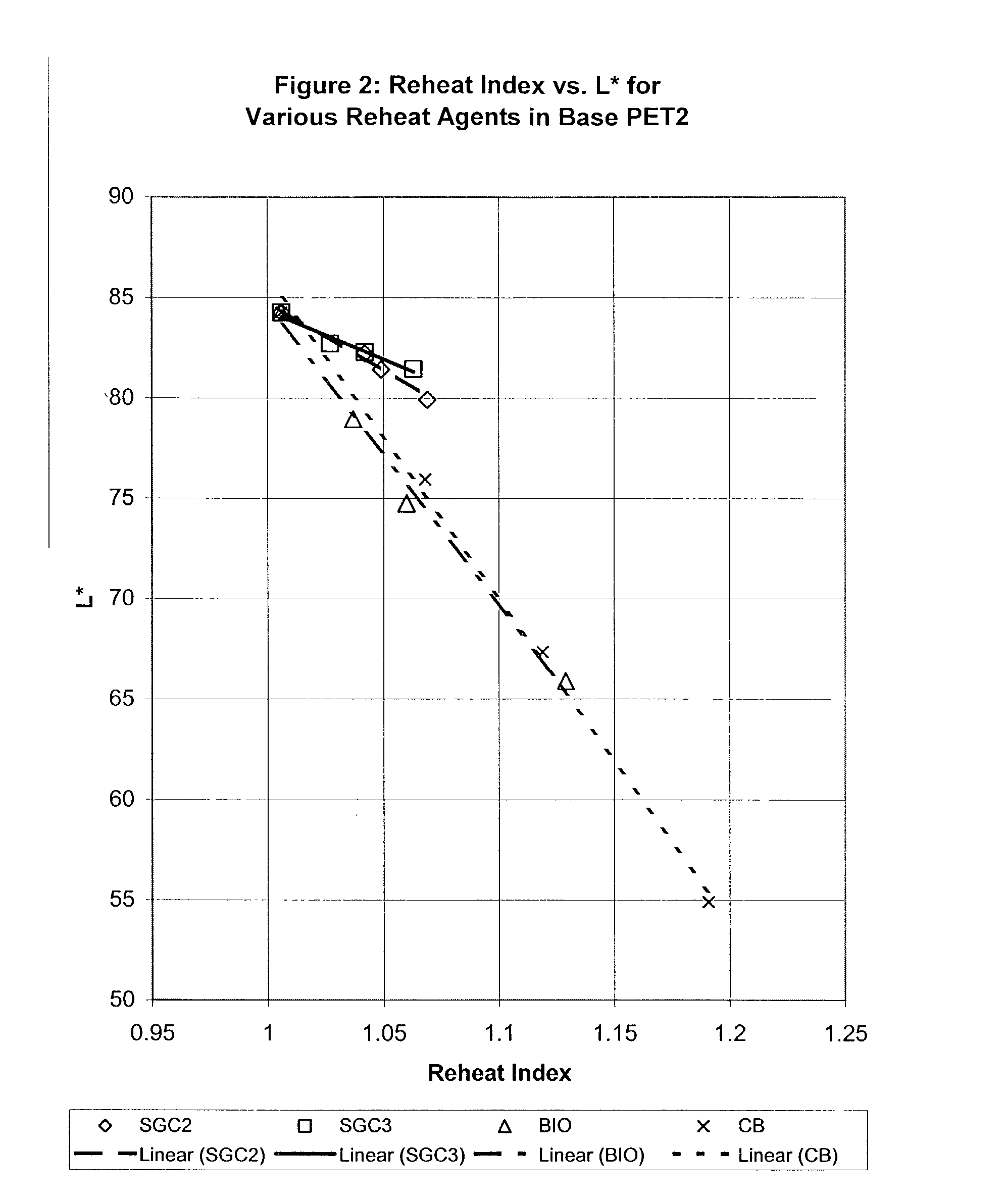

Glassy carbon thermoplastic compositions

InactiveUS20040101642A1Good reheat rateImproved * b * ratingSynthetic resin layered productsThin material handlingPolyesterStatic friction coefficient

A thermoplastic composition such as a polyester composition including polyethylene terephthalate polymers containing glassy carbon, and the preforms, bottles, sheets, rods, tubes, films and other articles made from these compositions. Also, polyester compositions are provided which have a certain individual or combination of properties, including low coefficient of static friction, low coefficient of static friction and low haze or high L* or low positive b* or a combination thereof, and those having low L* and low positive b* at given reheat rates.

Owner:EASTMAN KODAK CO

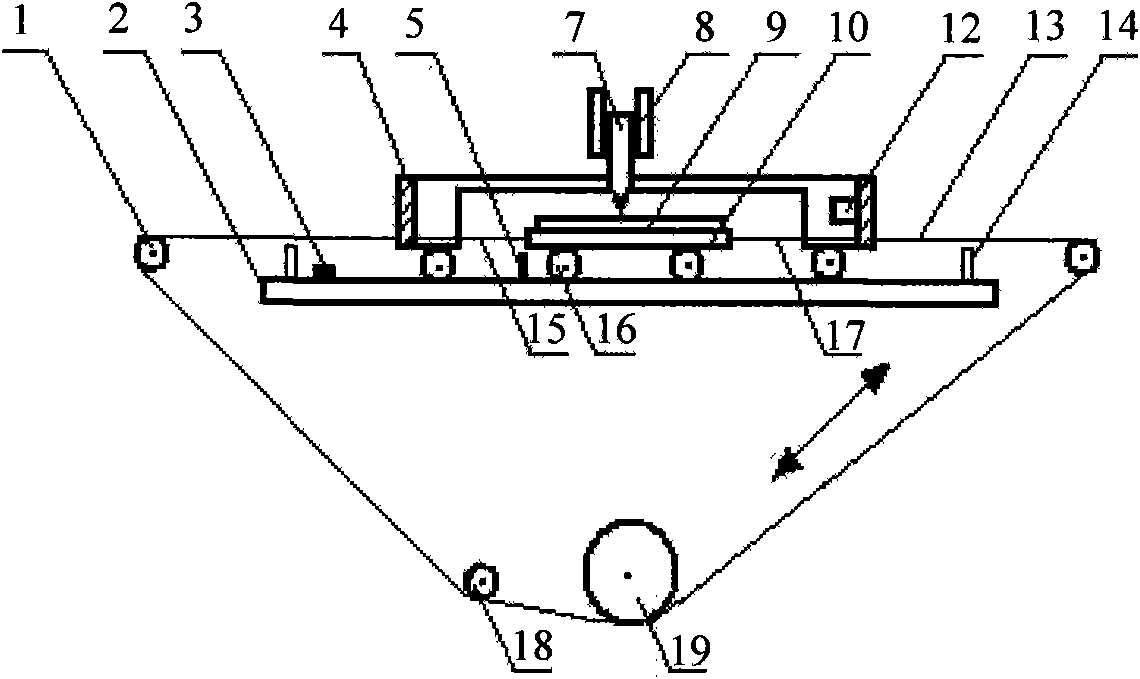

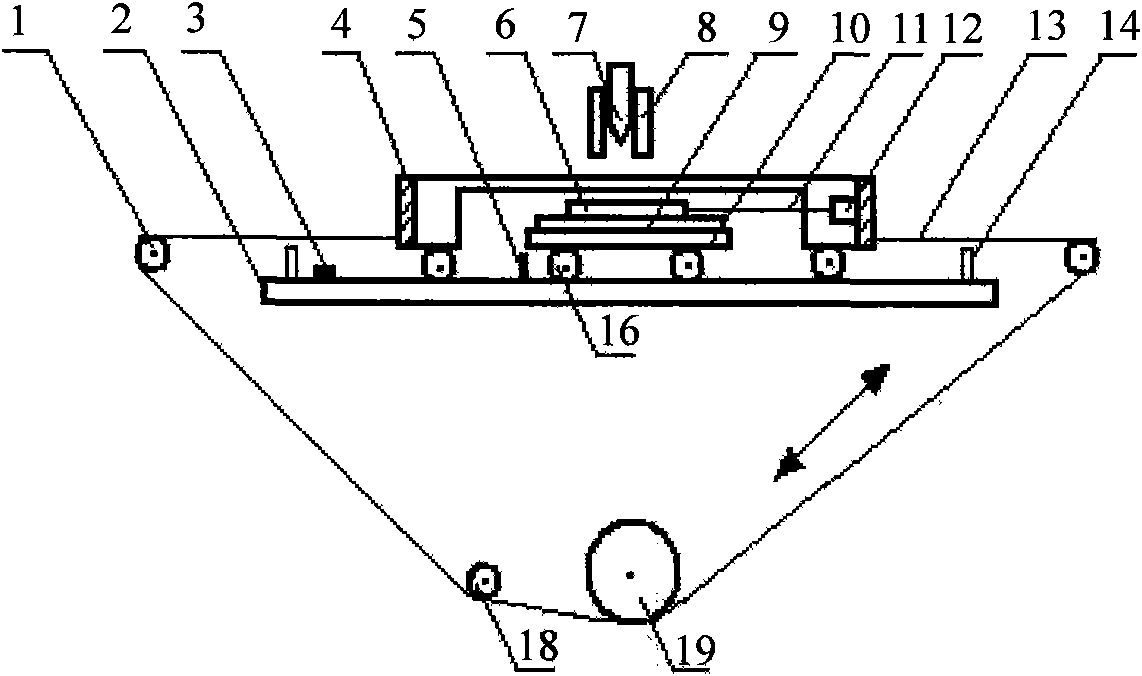

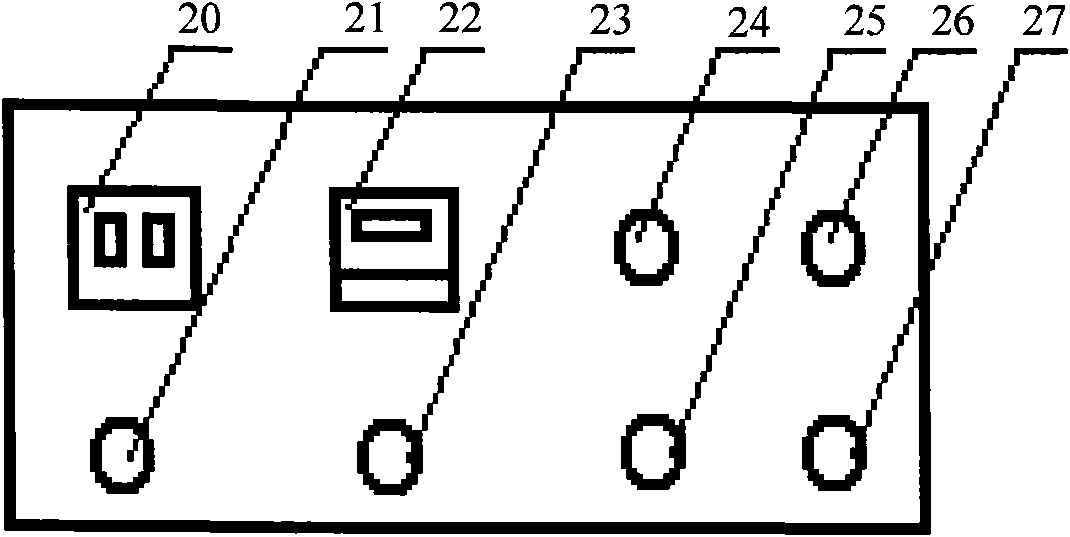

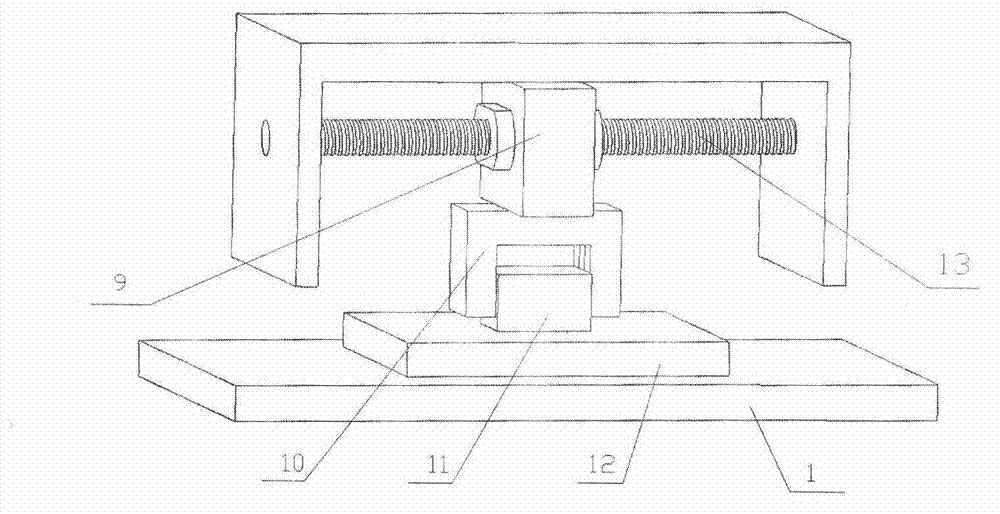

Device and method for testing linear reciprocating sliding friction and abrasion

InactiveCN101556238AAdjustable sliding speedAdjustable loadUsing mechanical meansMaterial weighingPositive pressurePeak value

The invention discloses a device and a method for testing linear reciprocating sliding friction and abrasion; the device consists of a transducer, a workbench, a sample table, a dragging frame, a force sensor, a changeover switch, a counter, a locking device, a guideway, a baffle, a cable wire, a reducer, a peak value stabilizer, a control part and an auxiliary component; the equipment can automatically complete the abrasion test of an arranged period and can manually complete the test to friction coefficient. The testing method comprises the following steps of: leading the friction block and the sample to reciprocate to slide horizontally with constant pressure, obtaining an abrasion weight loss rate after abrading, keeping a certain positive pressure and leading the sliding block to move from stillness to uniform movement, thus obtaining the maximum static friction coefficient and the sliding friction coefficient. The device and the method can realize uniformly linear and reciprocating relative sliding abrasion in long unidirectional journey, test the maximum static friction coefficient between two bodies and the maximum static friction coefficient, the speed, the load and the adjustable journey with other materials, and can be widely applied to the detection of various samples of different materials and different structural forms.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

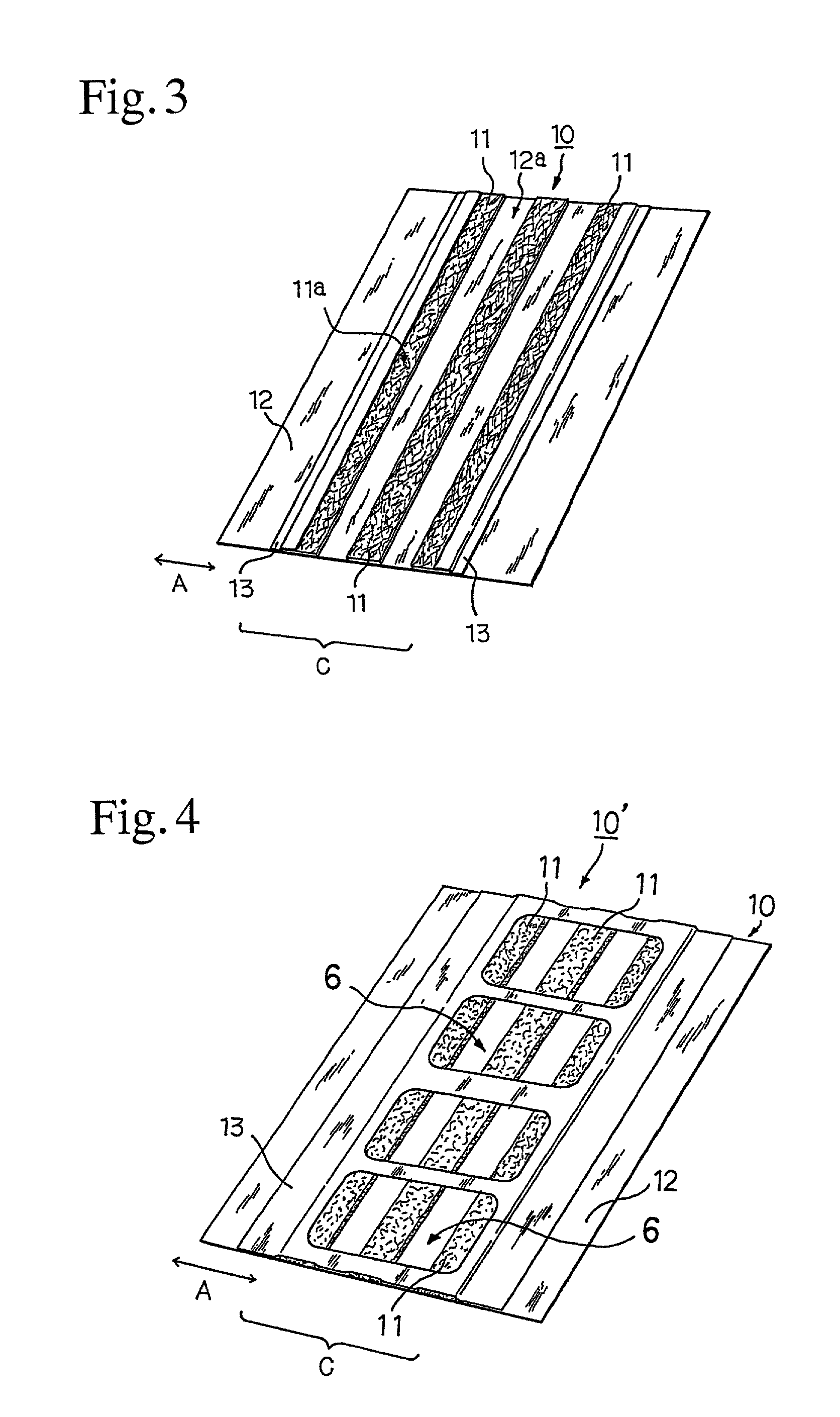

Coated paperboards and paperboard containers having improved tactile and bulk insulation properties

InactiveUS20050112305A1Improve insulation performanceIncrease stiffnessNon-fibrous pulp additionWrappersStatic friction coefficientPaperboard

A method of making a texture-coated and / or insulation coated container from a flat paperboard blank in which a heat-hardenable liquid polymeric binder texturizing and / or insulating agent coating mixture is applied to one surface of the blank in a pattern of covered and open areas. This coating mixture is subjected to heat to cure the polymeric binder and expand the texturizing and / or insulating agent, optionally treated with moisture, and optionally heated to form the blank into the shape of a container, and the container produced by this method. The containers such as cups, plates, etc., are useful in food service. These containers have a coefficient of static friction which is about 0.2 to 2.0 and over and a kinetic coefficient of friction which is about 0.22 to 1.5.

Owner:DIXIE CONSUMER PROD

Nonwoven fabric, process for producing the same, sanitary material and sanitary supply

InactiveUS20030157859A1Feel goodSuitable for useLayered productsAbsorbent padsStatic friction coefficientPolyolefin

Polyolefin resin-based non-woven fabric characterized by containing a fatty acid amide compound, and by having a static friction coefficient of 0.1 to 0.4. Production of such non-woven fabric is achieved by subjecting, for example, non-woven fabric containing 0.05 to 1 wt. % erucamide to an aging treatment at 30 to 60° C. for 5 to 50 hours.

Owner:IDEMITSU UNITECH CO LTD

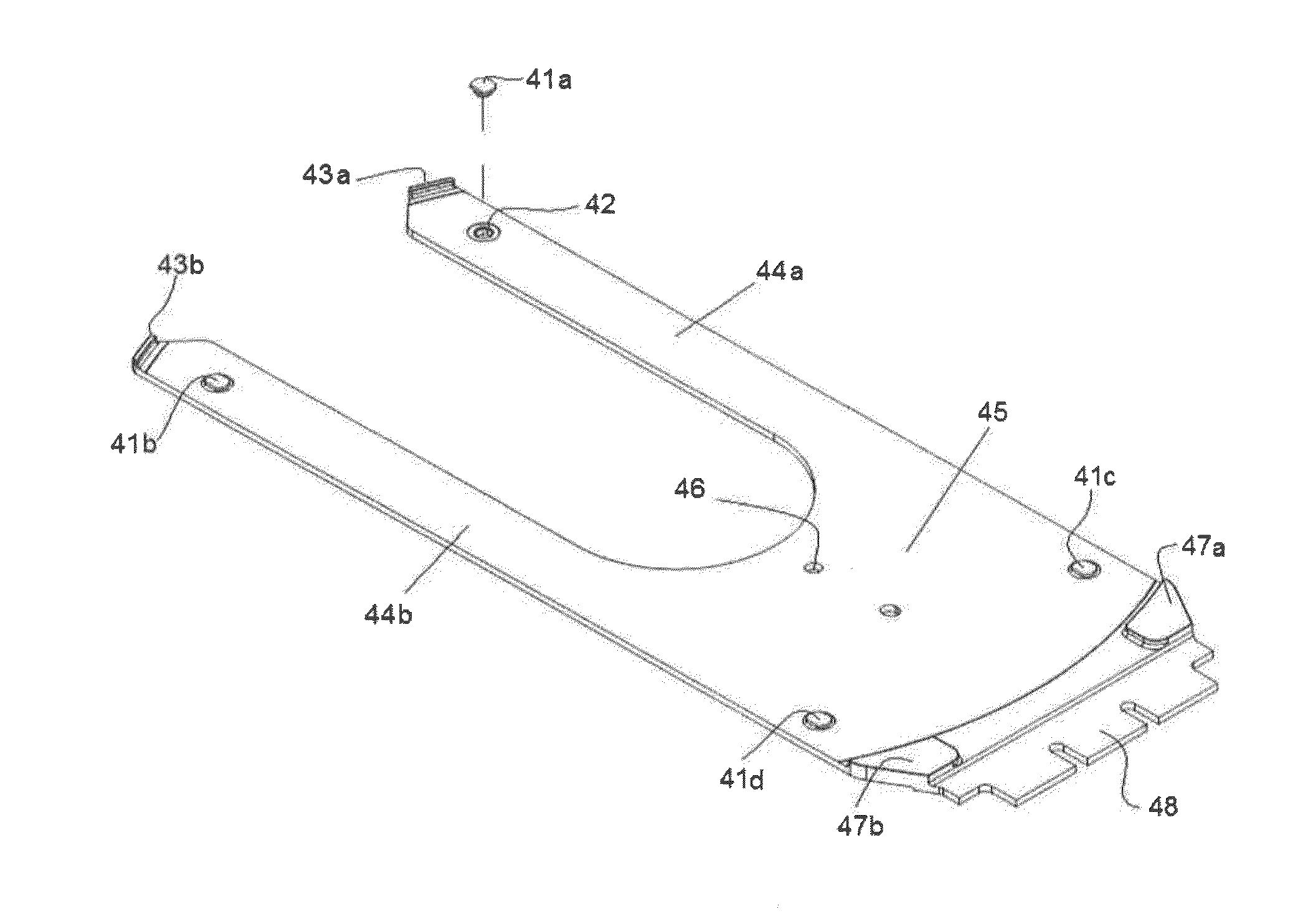

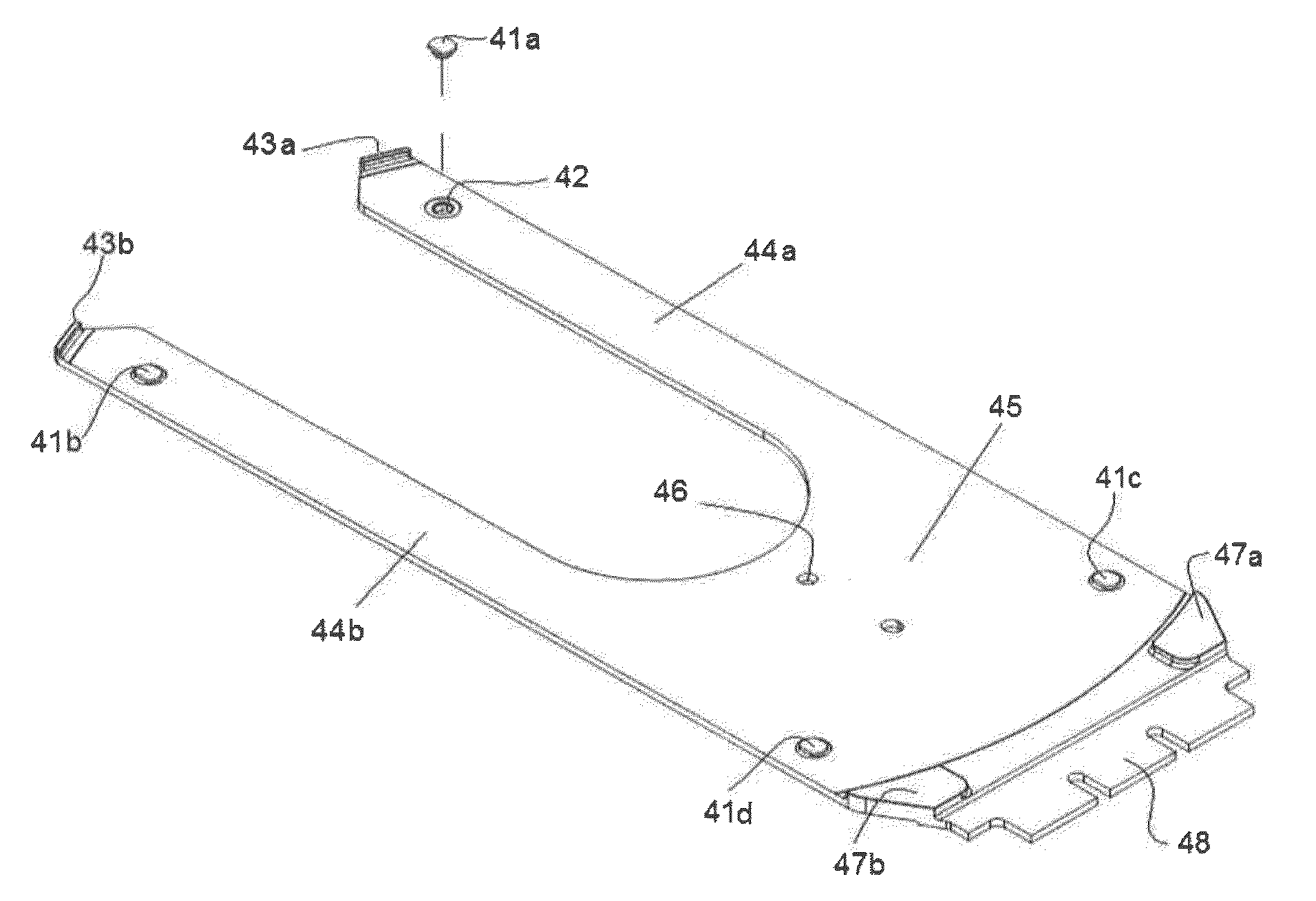

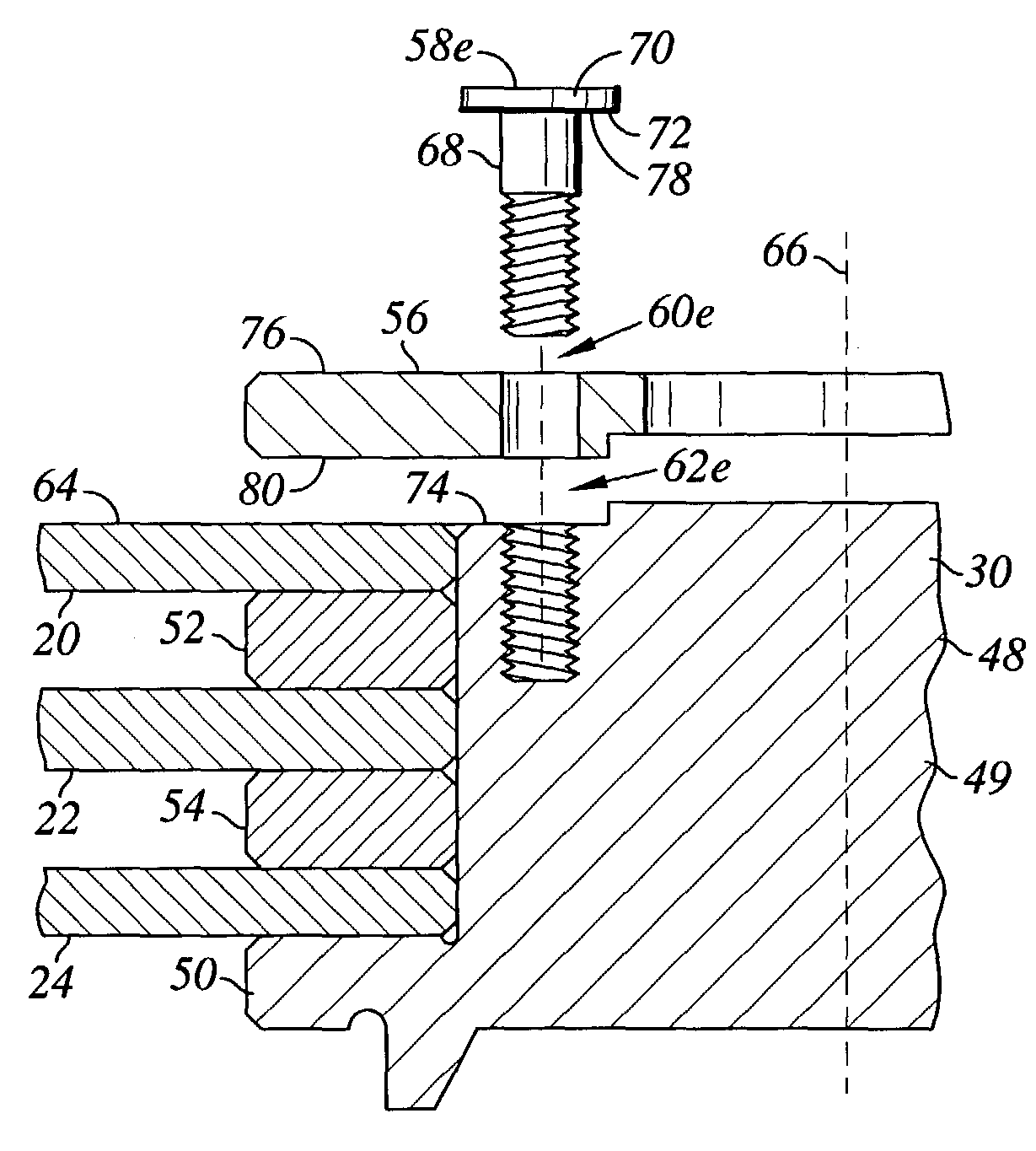

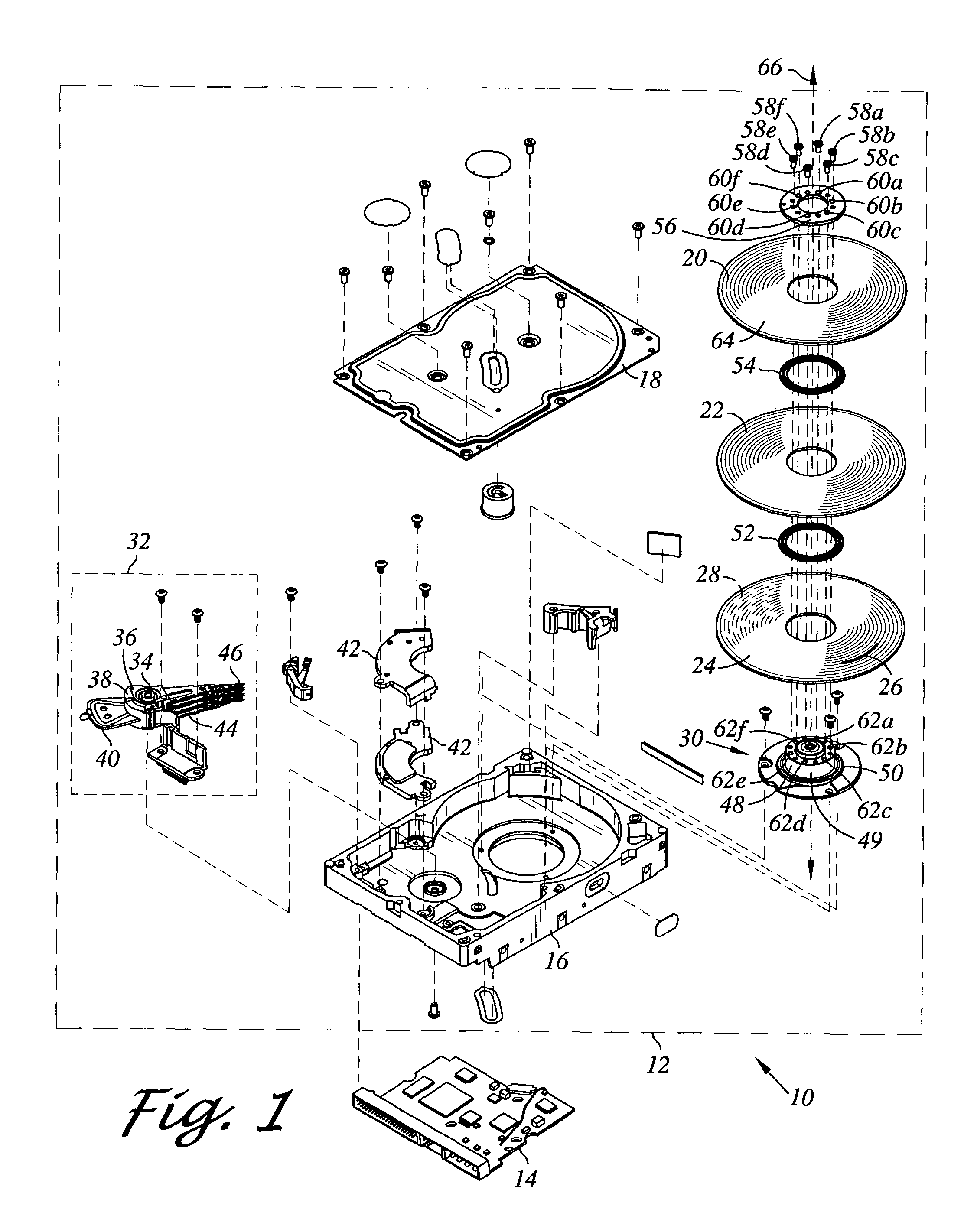

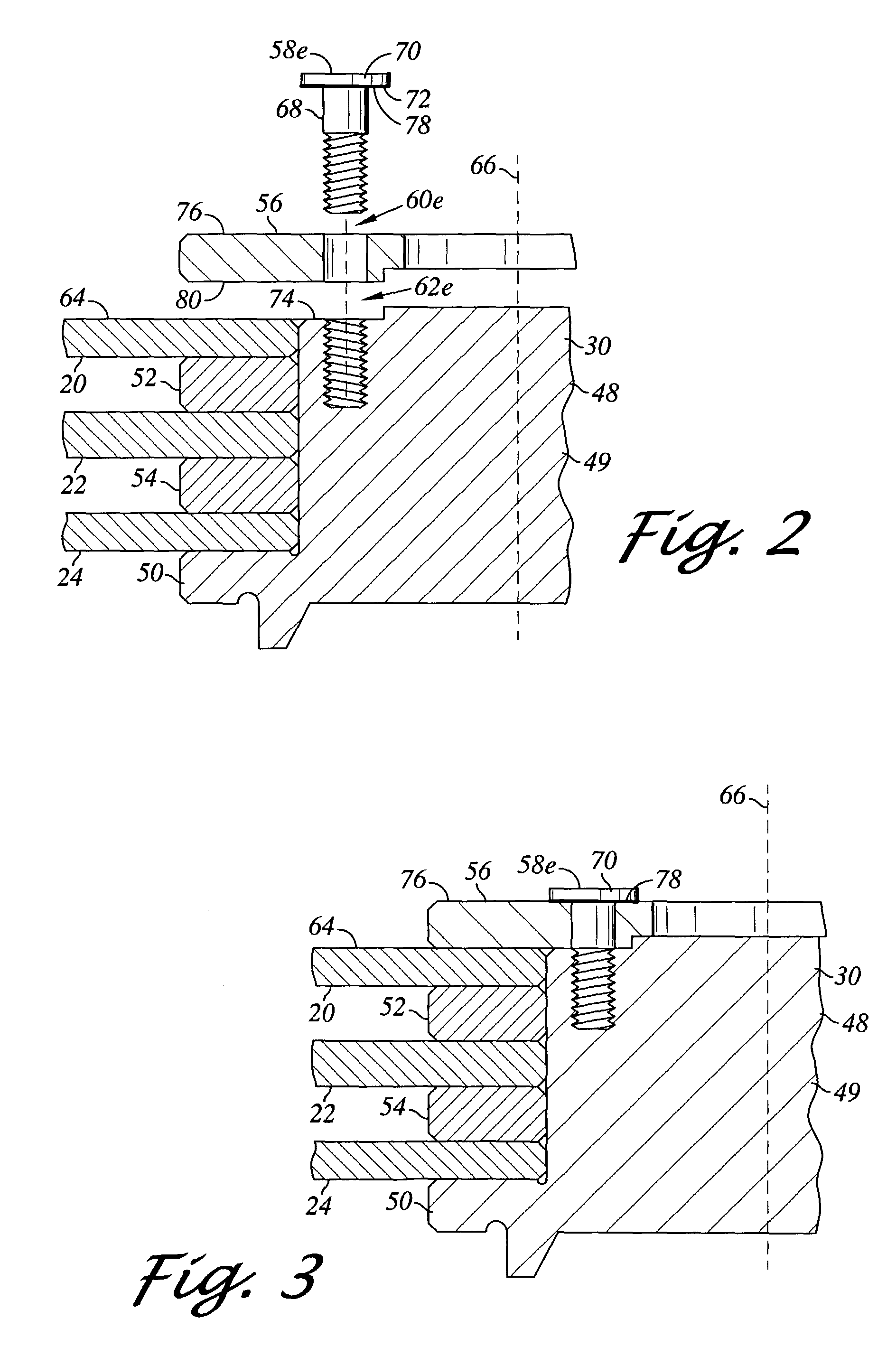

Disk drive including surface coated disk clamp screws with reduced coefficient of friction for mitigating disk clamp movement

InactiveUS7057852B1Record information storageRecord carrier accessoriesStatic friction coefficientEngineering

An aspect of the invention can be regarded as a disk drive that includes a disk drive base, a disk including disk surface, and a spindle motor including a spindle motor hub including a clamping surface with disk clamp holes. The disk drive includes a disk clamp disposed upon the disk surface. The disk clamp includes a screw head interface surface and screw openings. The disk drive includes disk clamp screws each including a shaft sized and configured to respectively engage the threaded disk clamp holes respectively through the screw openings. The screws each further include a screw head having a screw head clamping surface disposed against the screw head interface surface. The screws each further include a surface coating disposed upon the screw head clamping surface. The surface coating has a static coefficient of friction less than a static coefficient of friction of the screw head.

Owner:WESTERN DIGITAL TECH INC

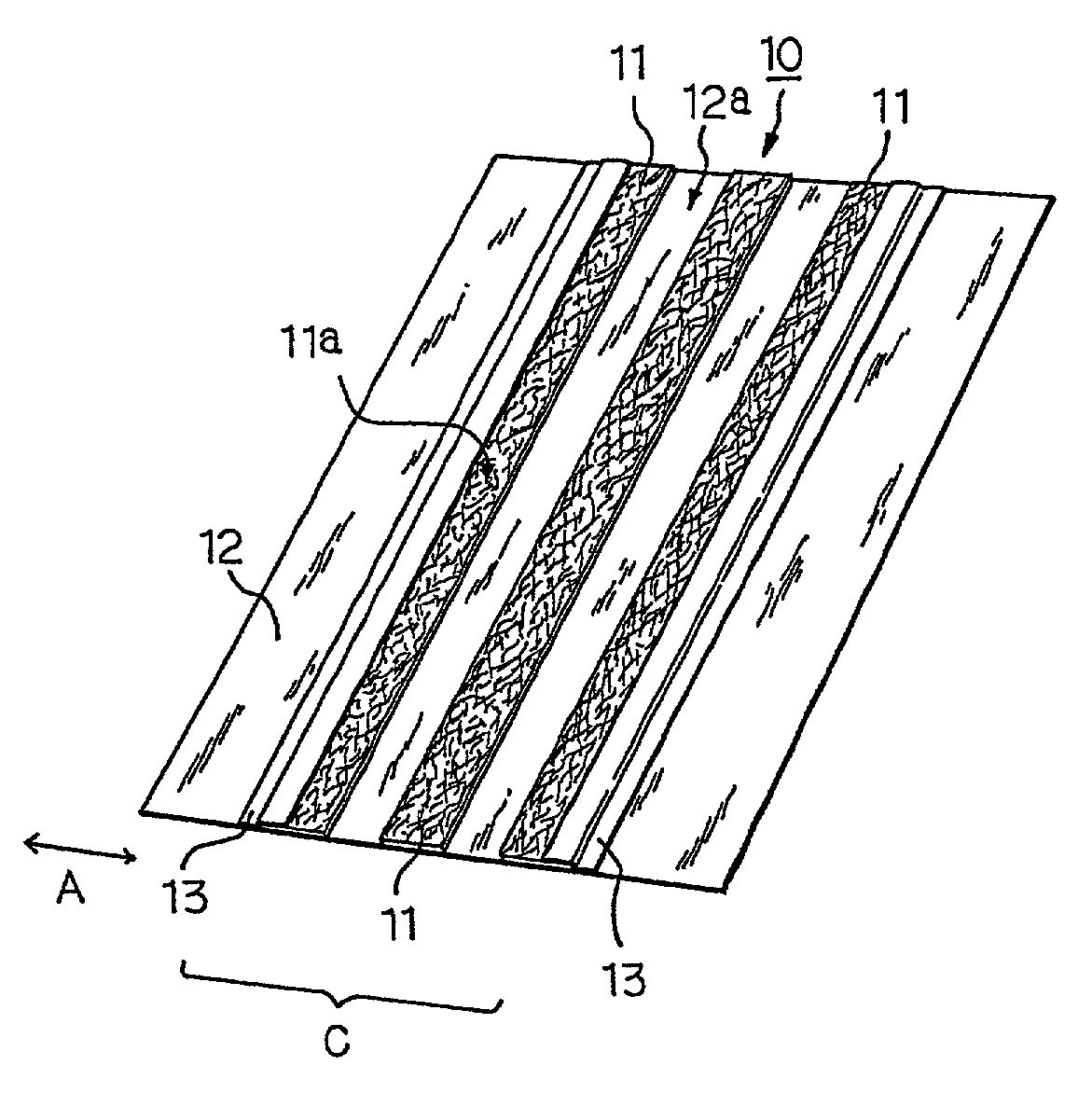

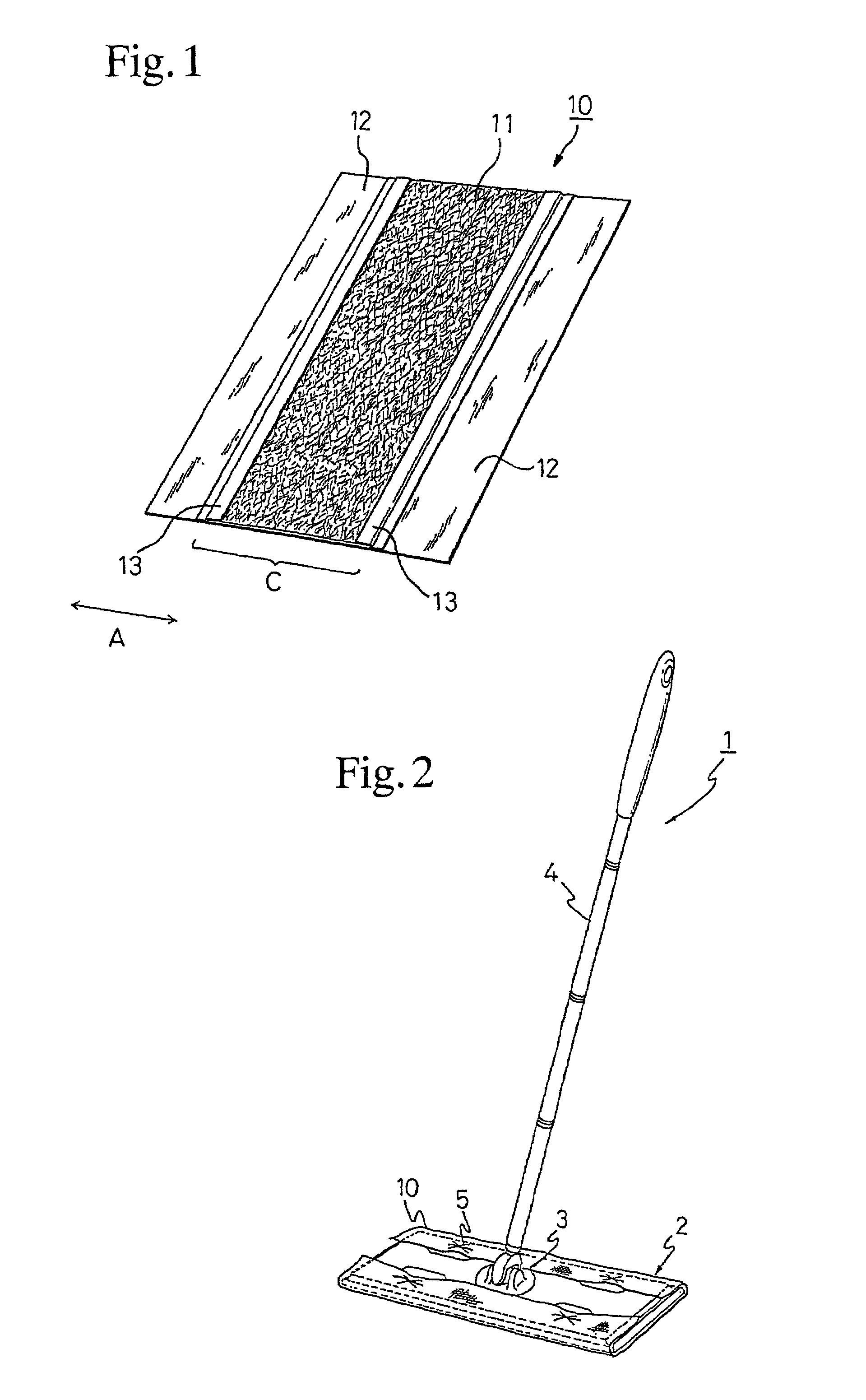

Cleaning Sheet

InactiveUS7033965B2Easy to cleanKitchenware cleanersBathroom accessoriesStatic friction coefficientStatic friction

A cleaning sheet having a cleaning surface comprising a cleaning area for cleaning a piled surface and a low-friction area which adjoins the cleaning area. The cleaning area has a coefficient of static friction of 0.1 to 4.0 against wool press felt (JIS L3201 R33W). The low-friction area comprises a film or nonwoven fabric and has a coefficient of static friction of 0.01 to 1.0 against wool press felt (JIS L3201 R33W).

Owner:KAO CORP

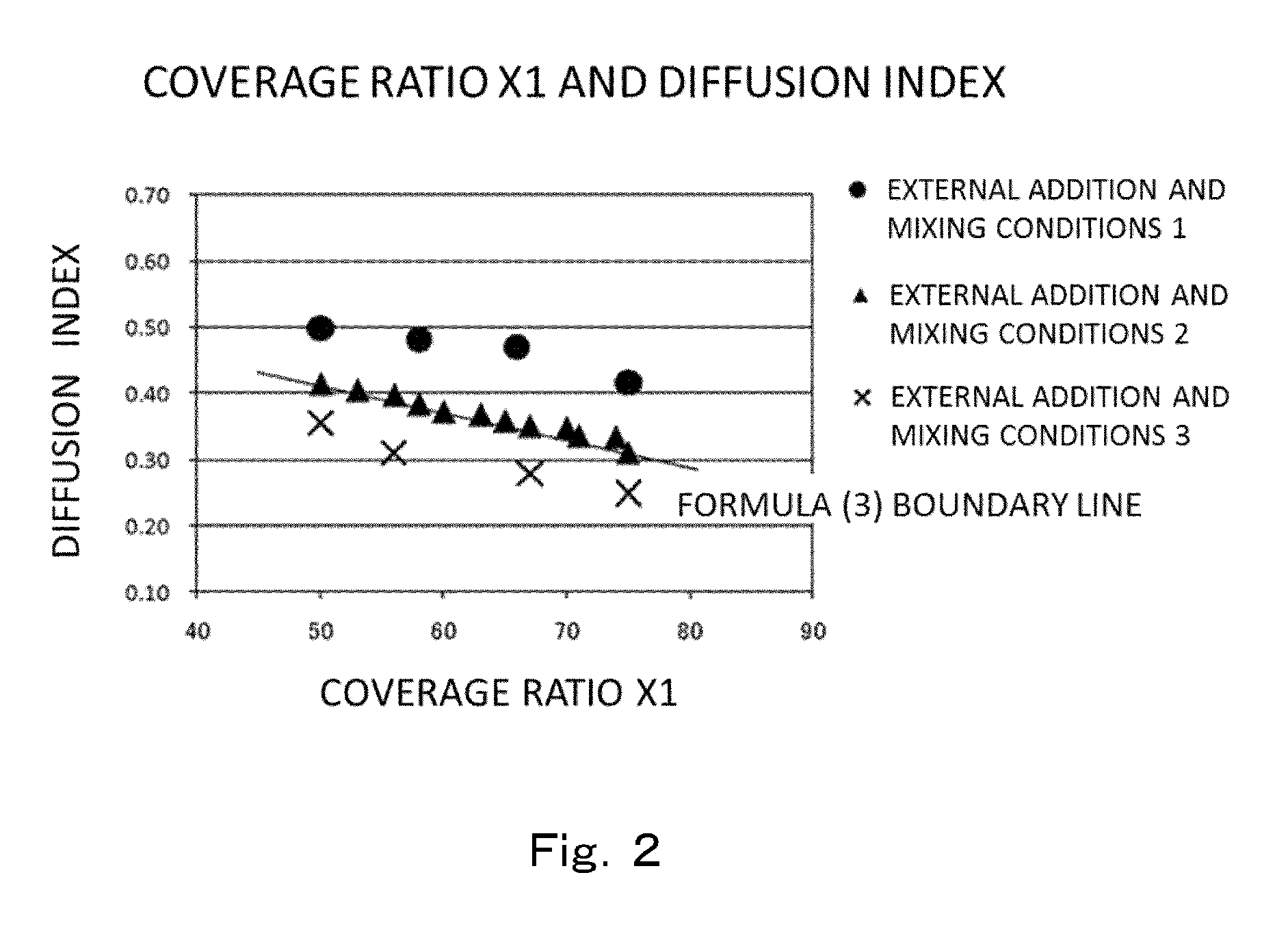

Toner

Owner:CANON KK

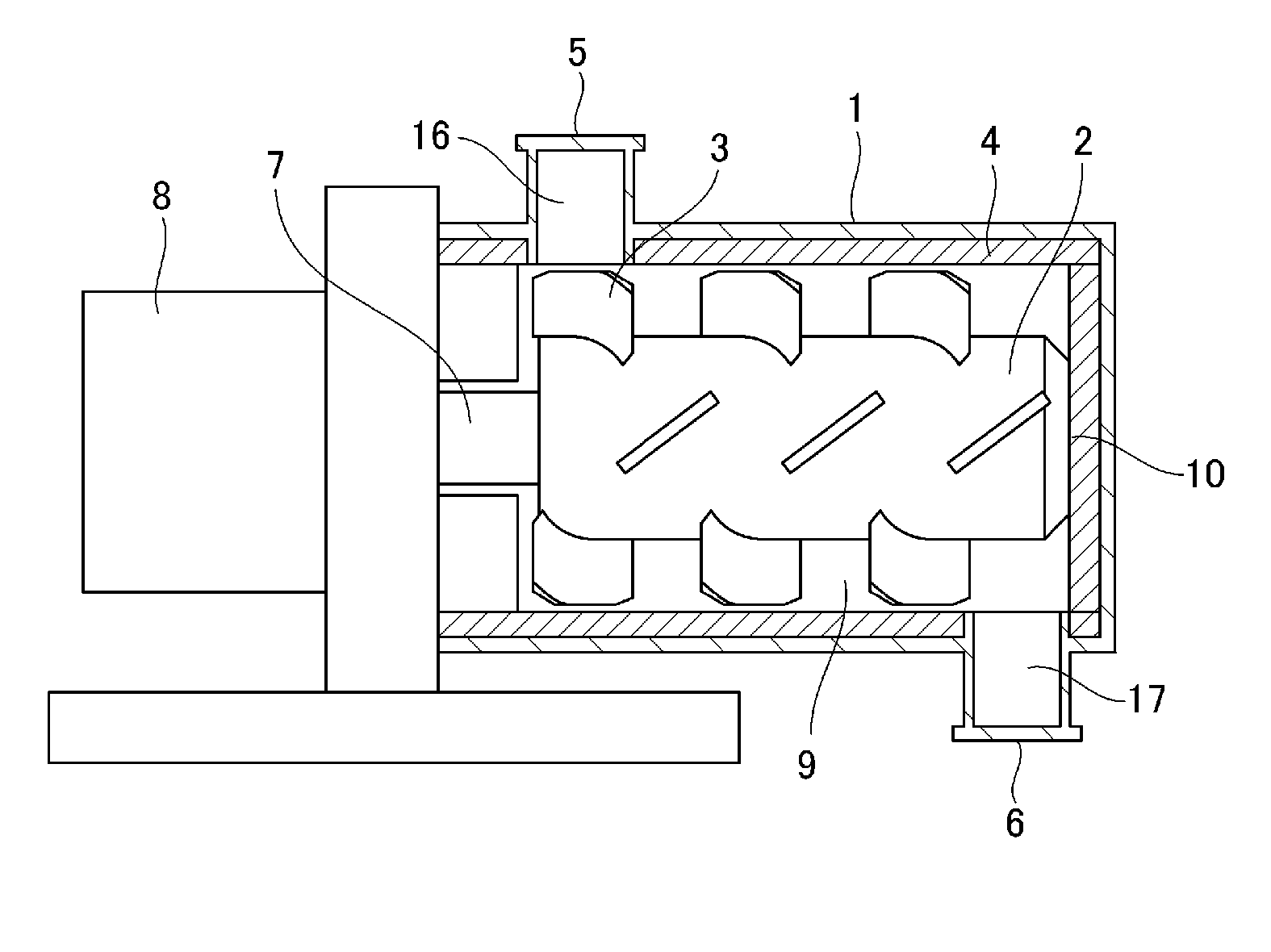

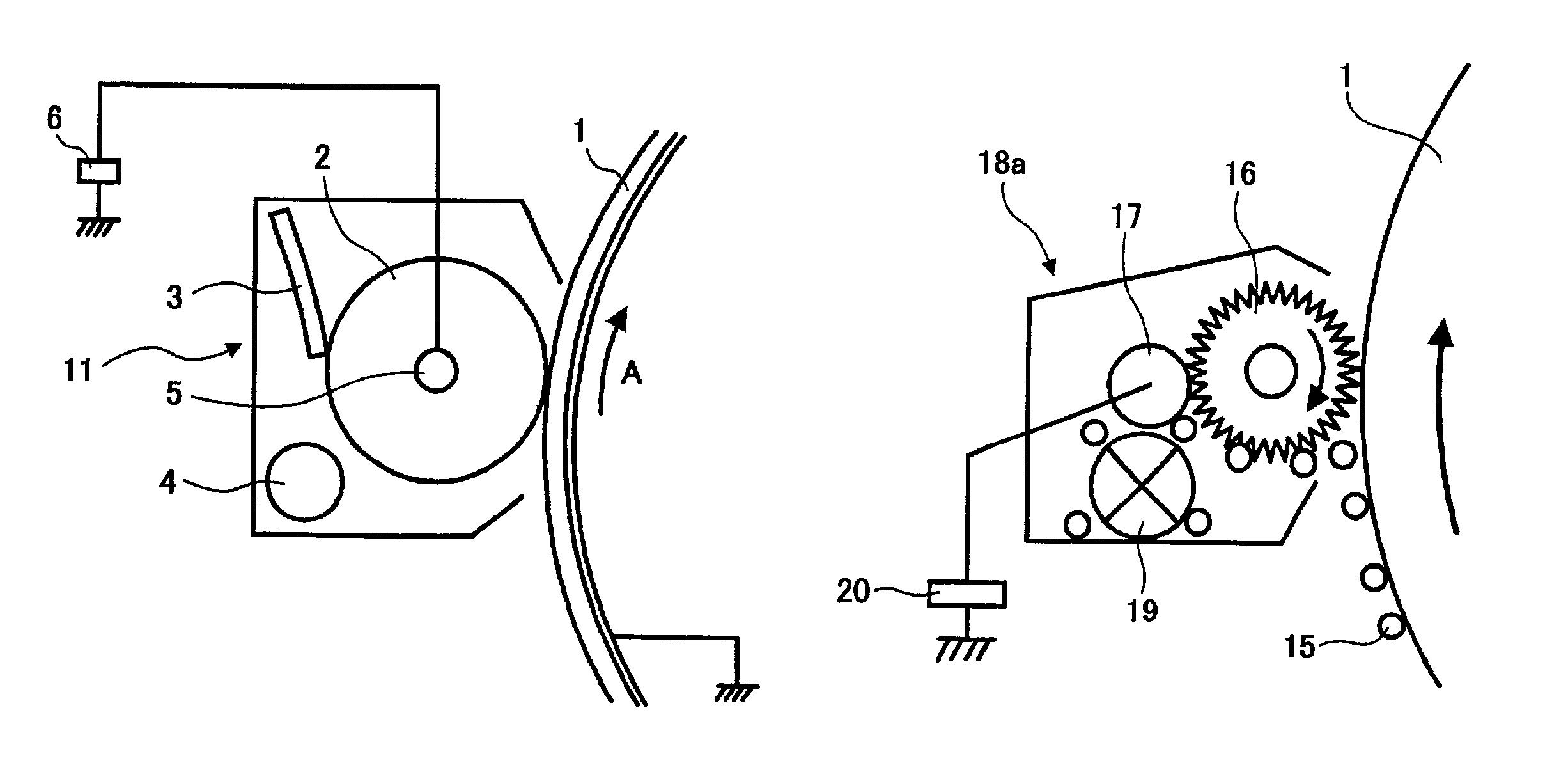

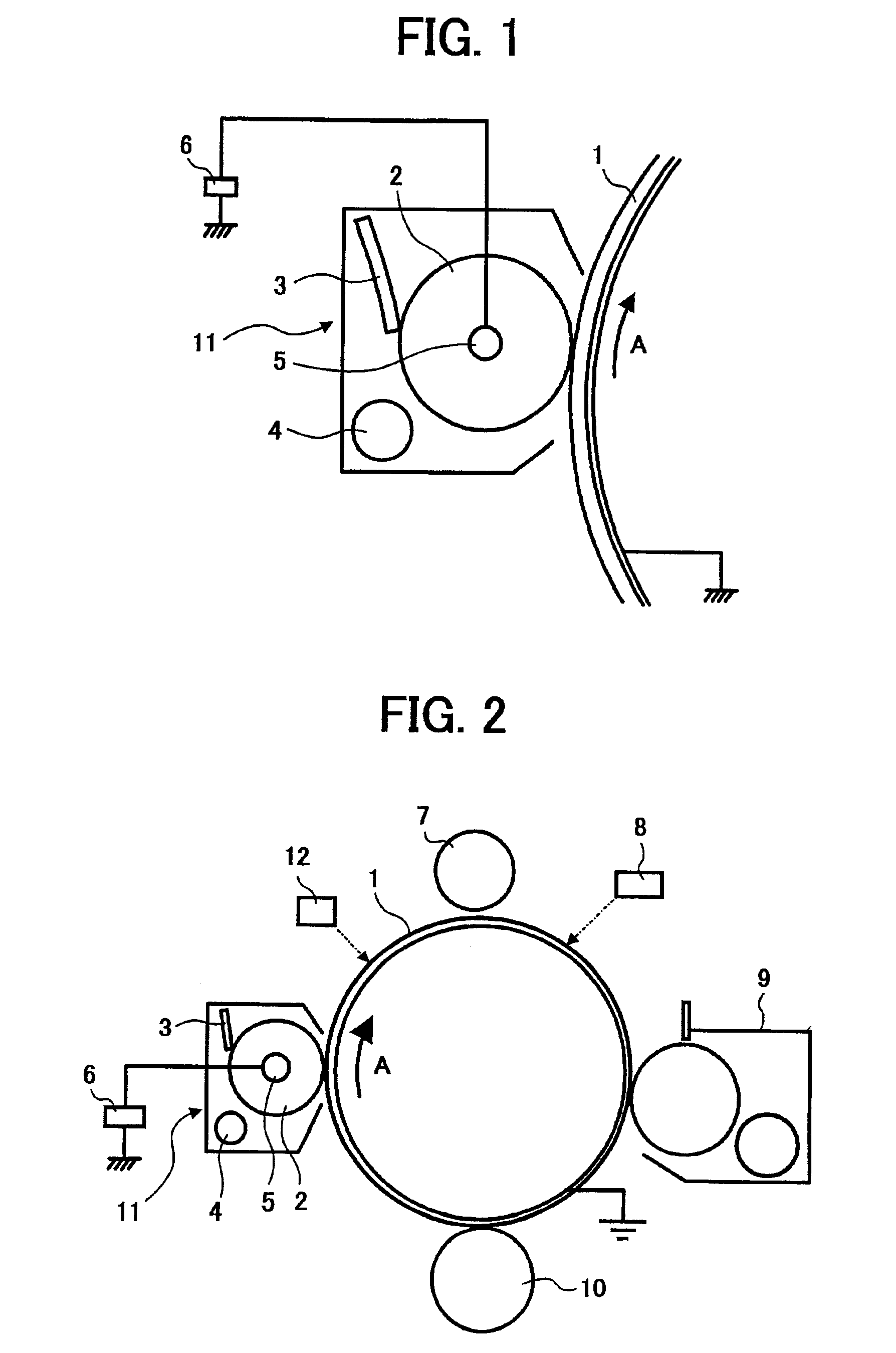

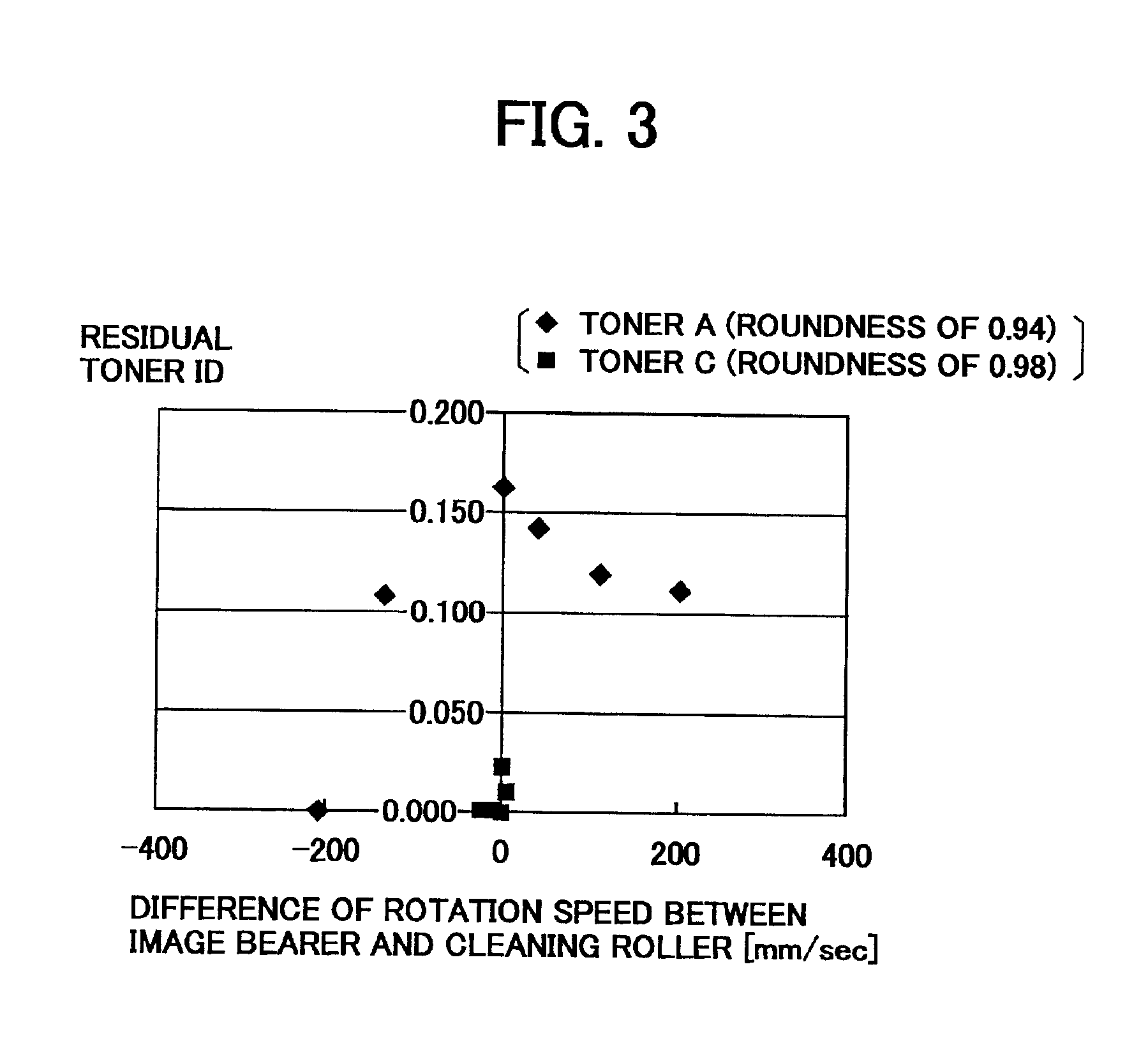

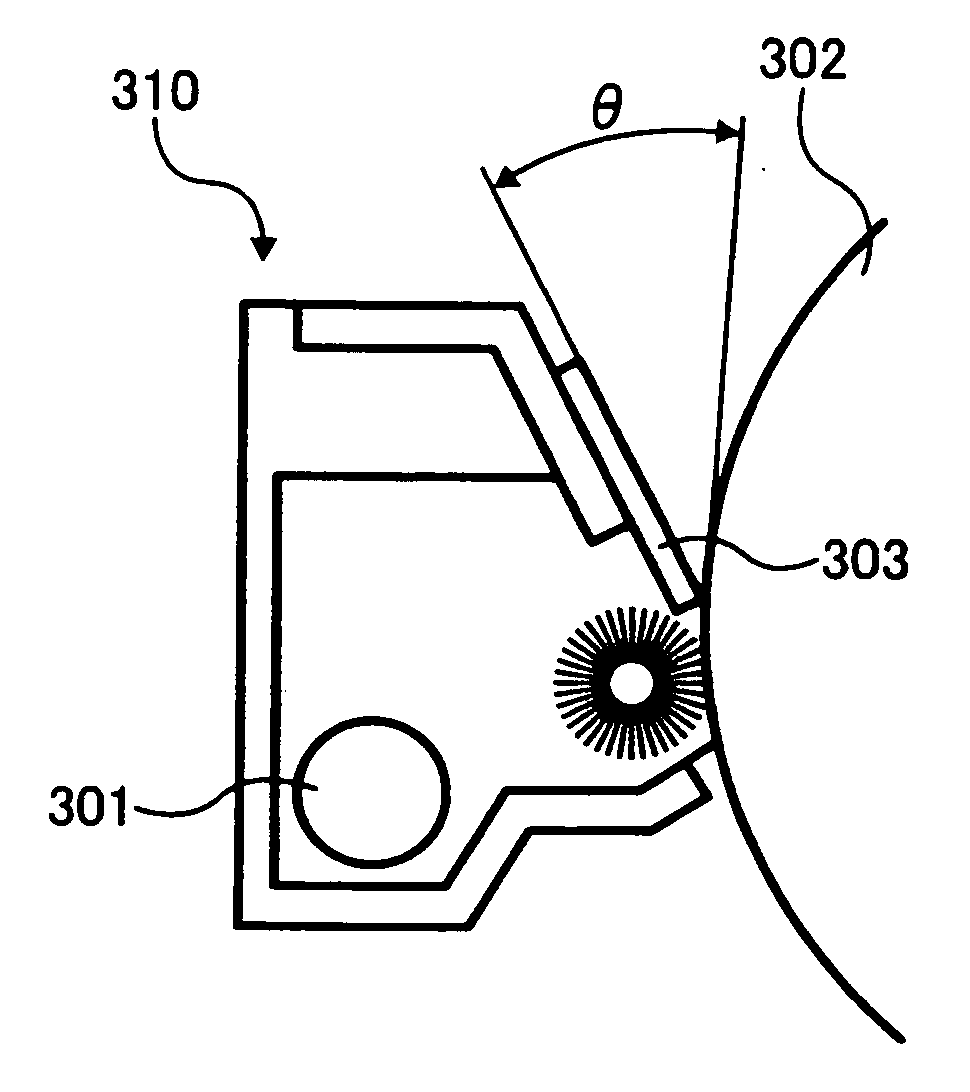

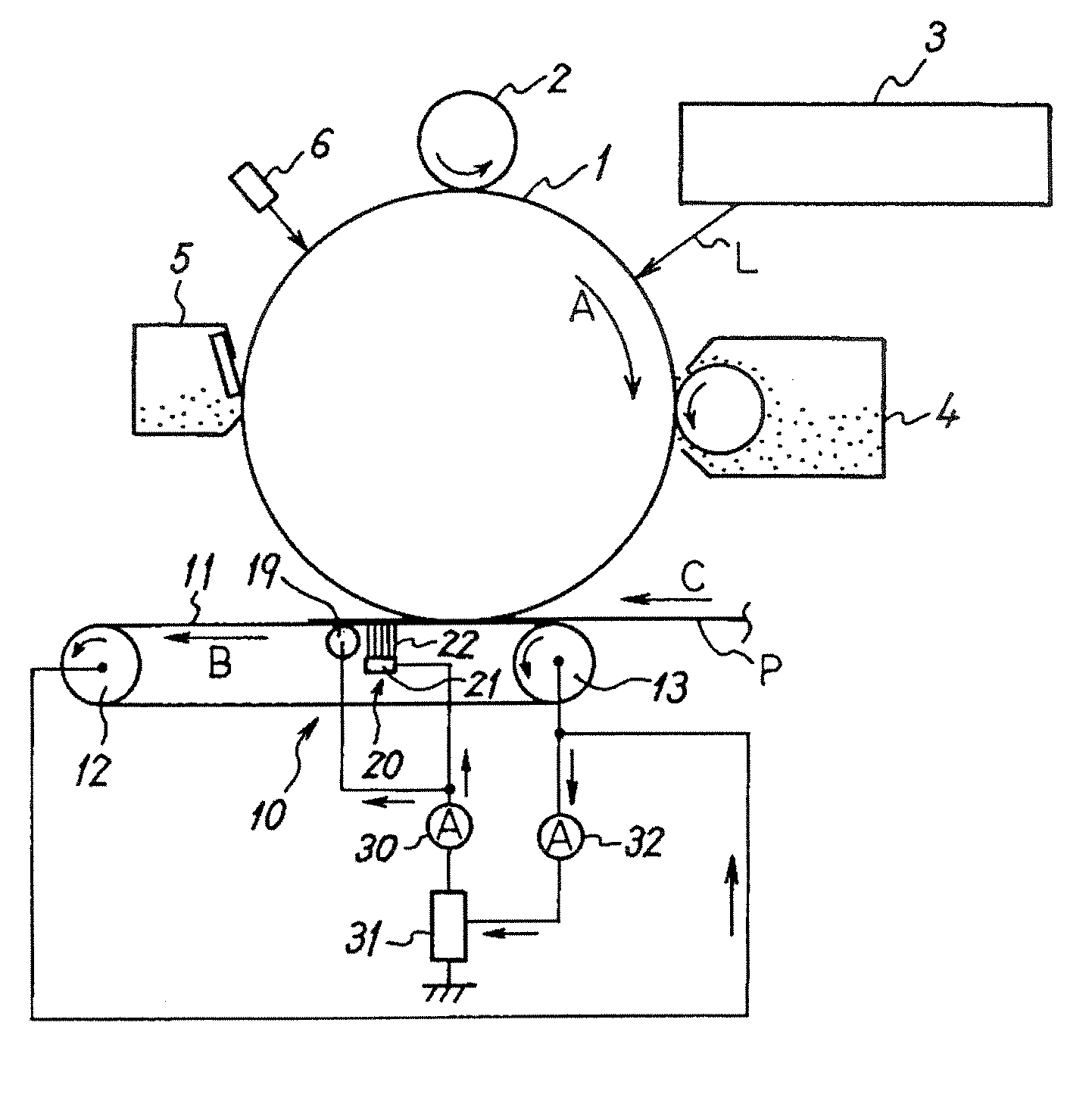

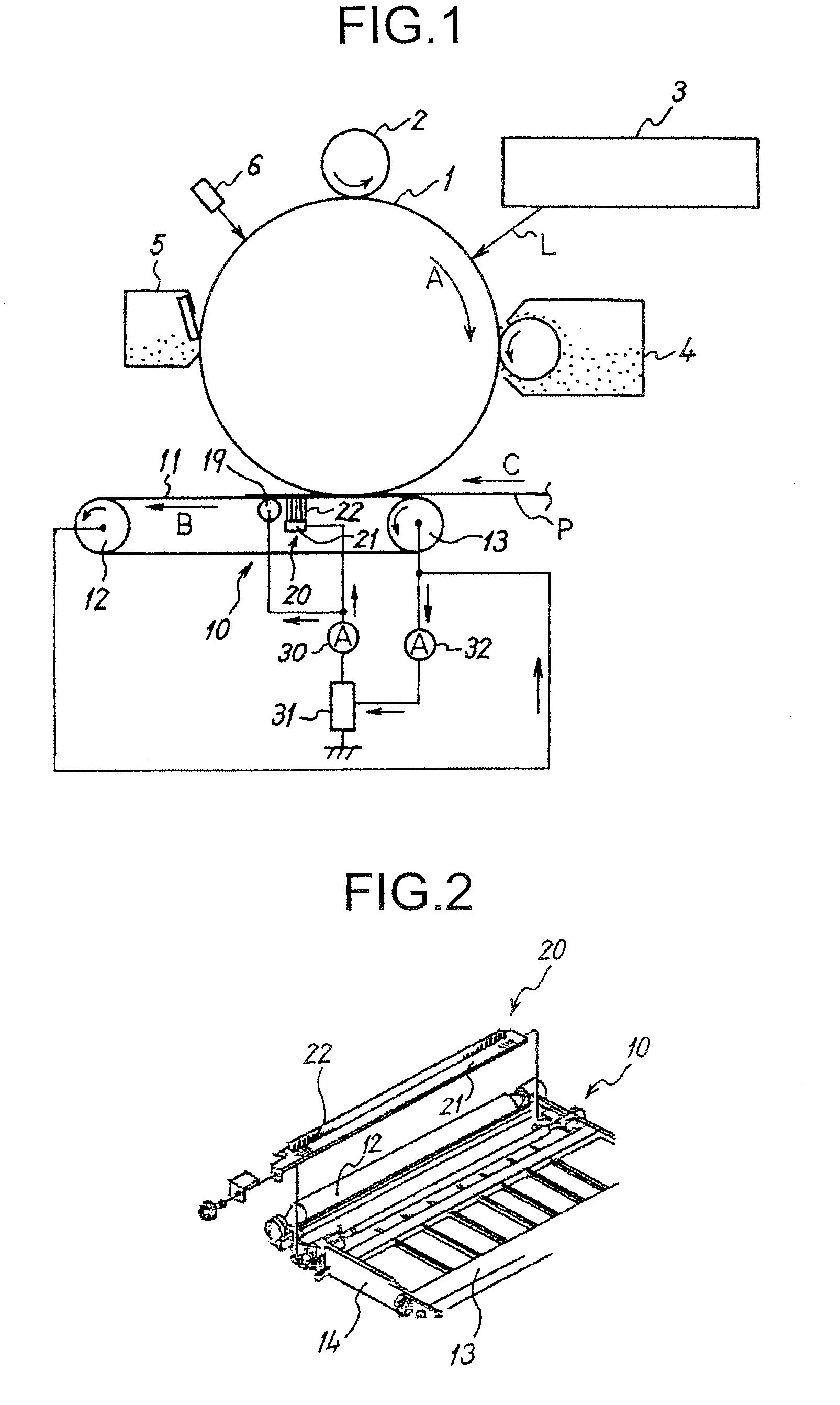

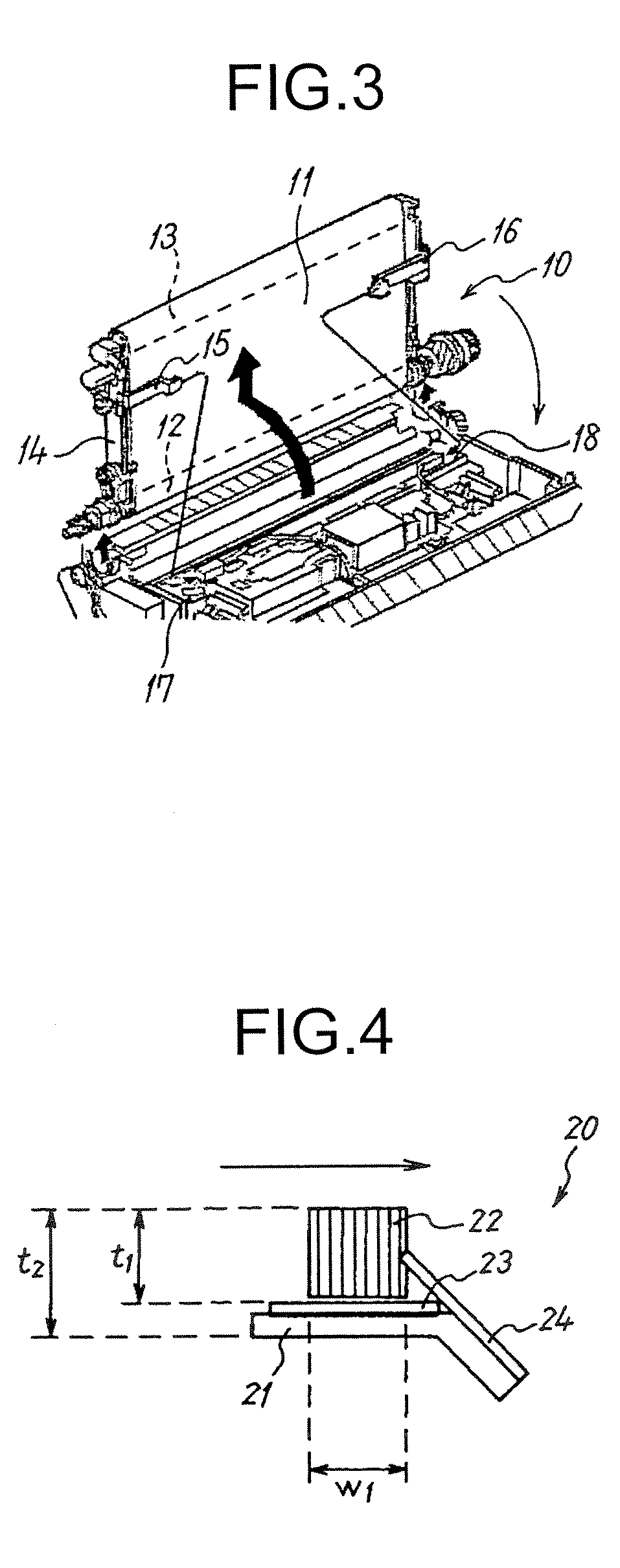

Cleaning device and image forming apparatus using the cleaning device

InactiveUS6987944B2Electrographic process apparatusCorona dischargeStatic friction coefficientBristle

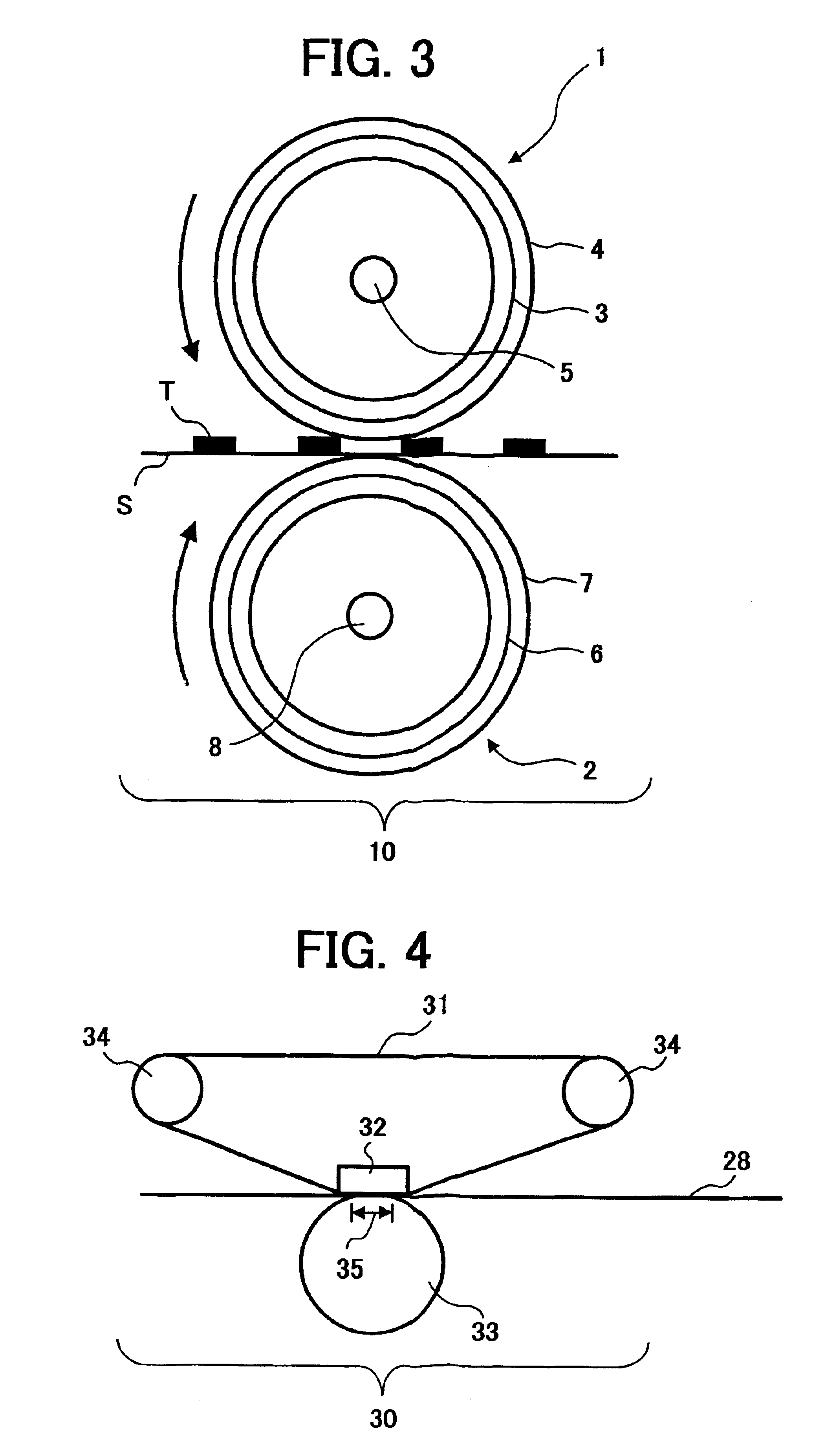

An image forming apparatus includes an image bearer, a charging device that charges a surface of the image bearer, a latent image forming device that forms a latent image on the image bearer, a developing device that develops the latent image on the image bearer with a spherical toner into a toner image, a transfer device that transfers the toner image to a transfer material, and a cleaning device that removes the spherical toner remaining on the image bearer after the toner image is transferred to the transfer material. The cleaning device including a cleaning roller that removes the spherical toner on the image bearer while rotating and contacting the image bearer and which has a greater coefficient of static friction than the surface of the image bearer. An electric field is formed between the cleaning member and the image bearer by applying a voltage to the cleaning member so that the spherical toner adhered onto the image bearer is electrostatically attracted to the cleaning member. The cleaning member may also include a brush roller having bristles planted in a specific configuration.

Owner:RICOH KK

High-wearing high-rigidity reinforced nylon 66 complexes and method for making same

ActiveCN101182388ALow surface energy activitySpherulite refinementStatic friction coefficientGlass fiber

The invention relates to a highly wear-resistant and high-rigidity reinforced nylon 66 compound. The invention is characterized in that the compound consists of materials of the following weight portions: 66 portions to 100 portions of nylon, 0.1 portions to 15 portions of nucleater, 5 portions to 30 portions of wear-resistant agent, 0.5 portion to 3 portions of heat stabilizer and processing aid, and 15 portions to 105 portions of glass fiber. The invention has the advantage that each index all reaches or surpasses the scheduled requirements; the bending modulus of the material reach above 11000MPa; the hardness reaches to 135 N / mm2. Under the condition of no lubrication, surface pressure of 1.5 kg / m2, speed of 29 m / min and a temperature of 23 DEG C, the maximum static friction coefficient is 0.11; the maximum dynamic friction coefficient is 0.07. Under the condition of no lubrication, surface pressure of 100kg / cm<2> and speed of 23m / min, the PV value reaches above 2270kg / cm<2> question mark m / min.

Owner:SHANGHAI KINGFA SCI & TECH +1

Aqueous dispersion coating composition having noise and/or friction abatement properties

InactiveUS20070134502A1Dry noise valueReduce interior noiseSynthetic resin layered productsPolyurea/polyurethane coatingsStatic friction coefficientPolymer science

An aqueous dispersion coating for rubber and polymer substrates comprises a blend of a polysiloxane and a curable polyurethane and various additives such as a urethane crosslinking agent, a heat resistant filler, and the like. The aqueous dispersion coating reduces the noise upon contact or movement of the coated substrate with an article and maintains the initial static coefficient of friction therewith over a period of time. A desired end use is as a coating on vehicle weatherstrips such as for doors, trunks, and other enclosing articles.

Owner:LORD CORP

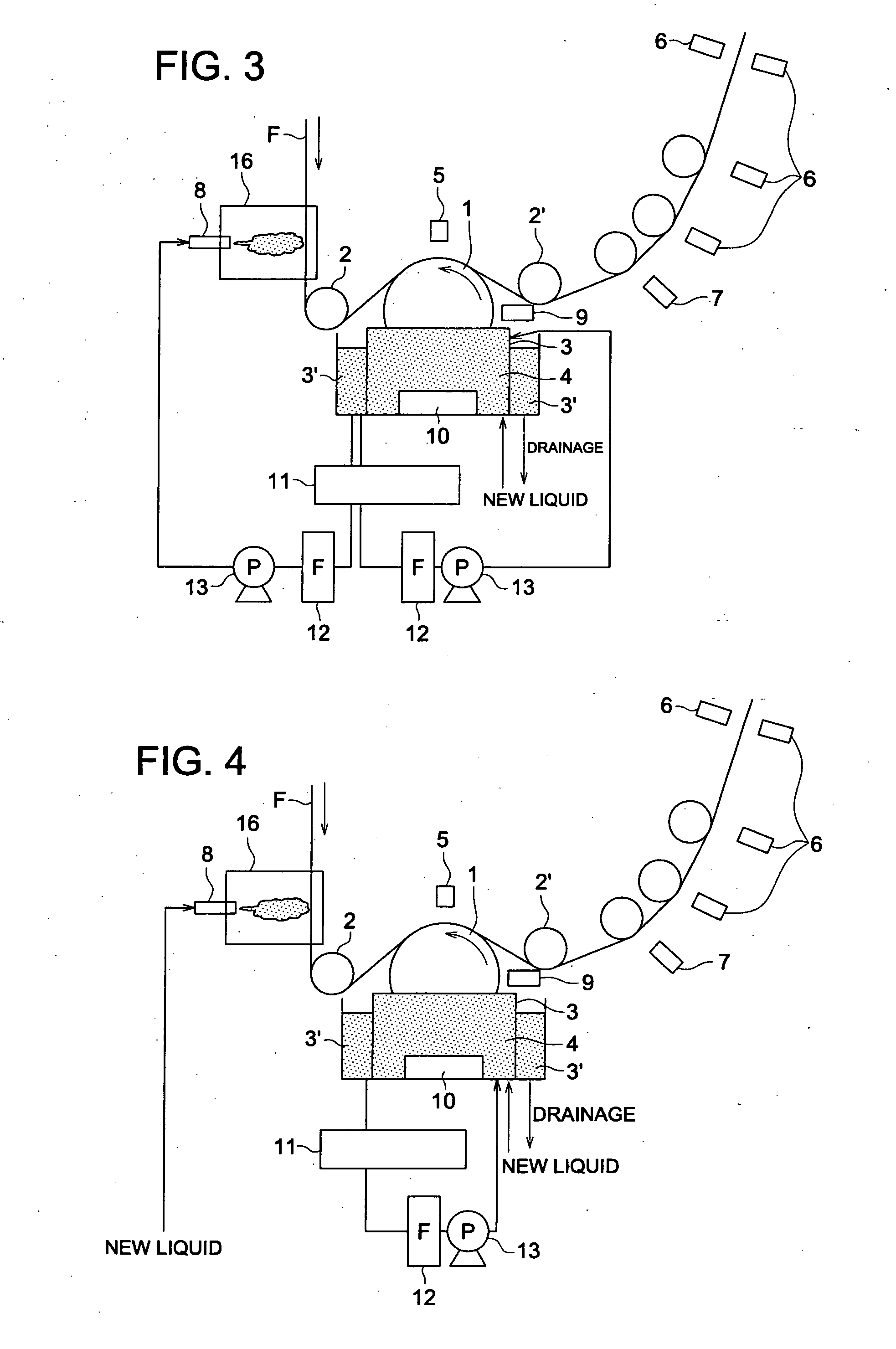

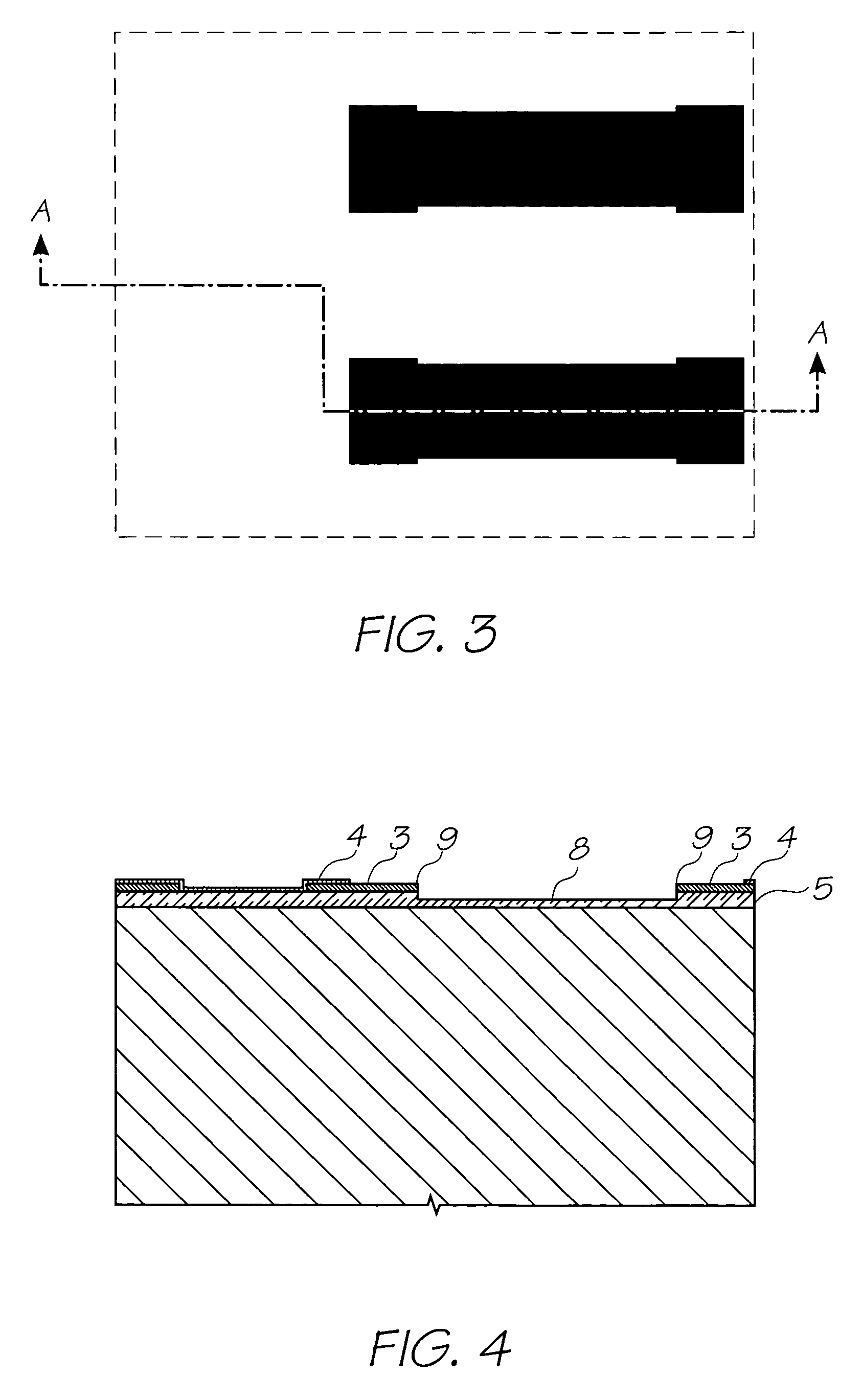

Optical Film Treating Method, Optical Film Treating Apparatus, and Optical Film Producing Method

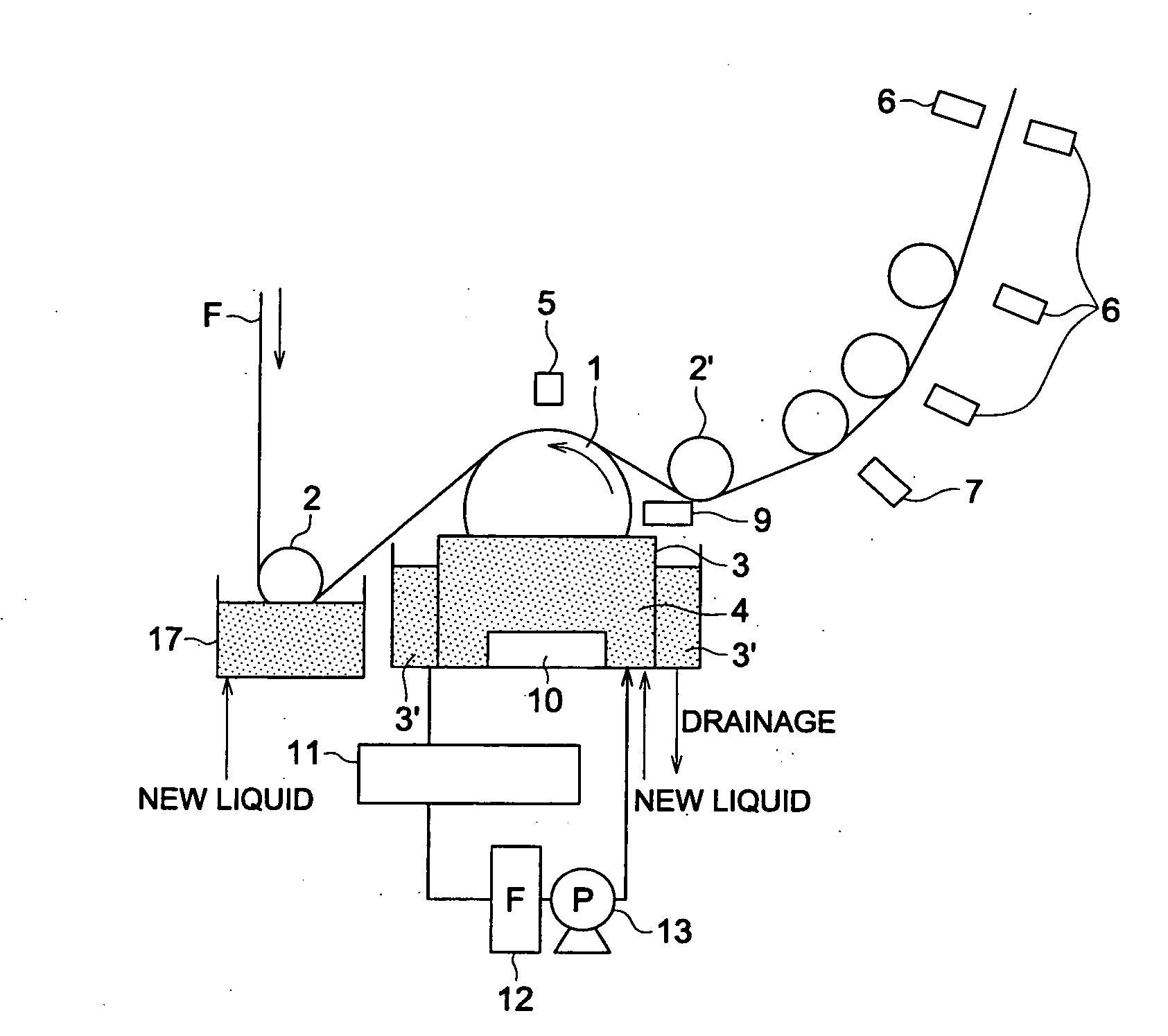

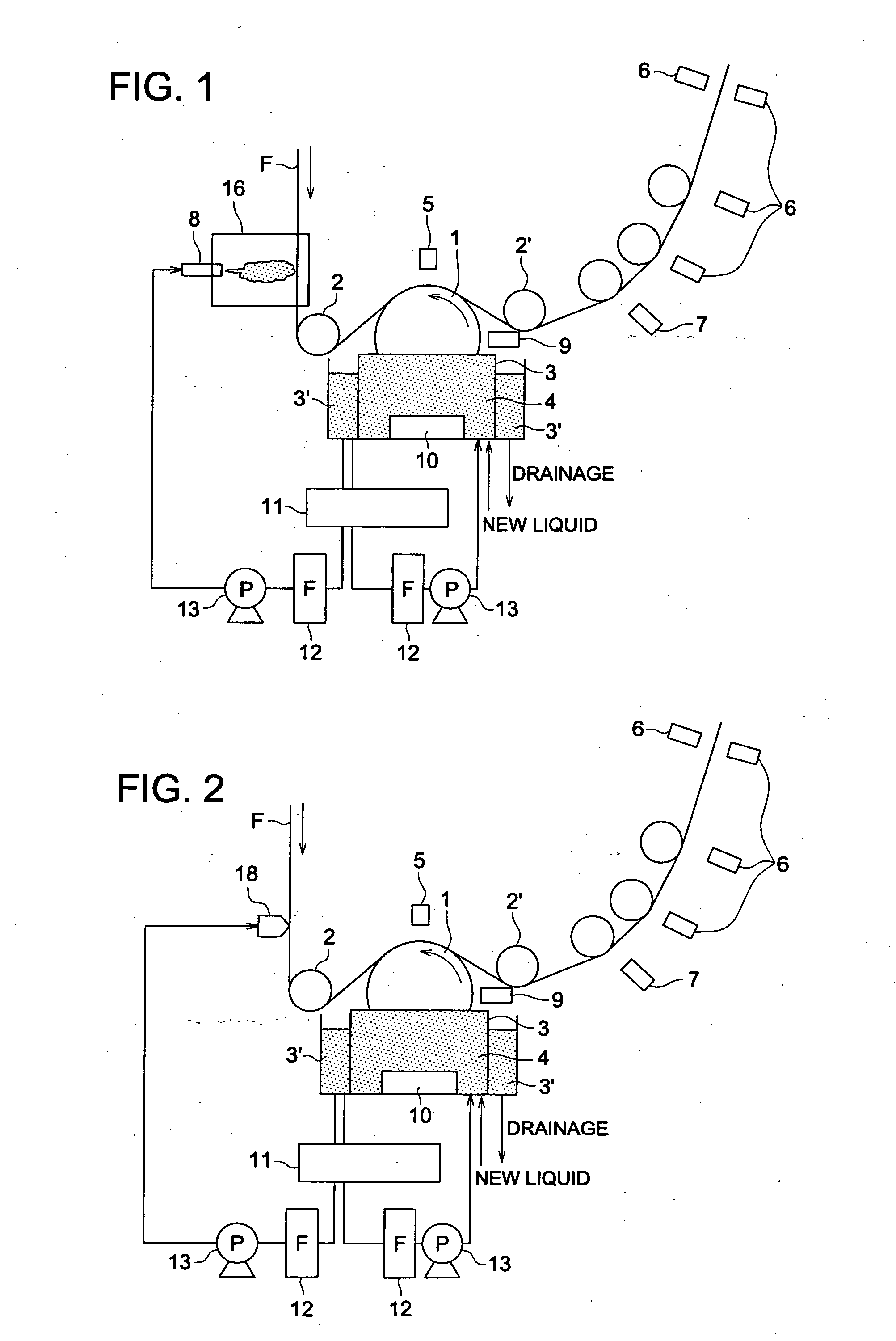

InactiveUS20090232977A1Improve unevennessTransversely streaked unevennessMechanical cleaningPressure cleaningStatic friction coefficientElastomer

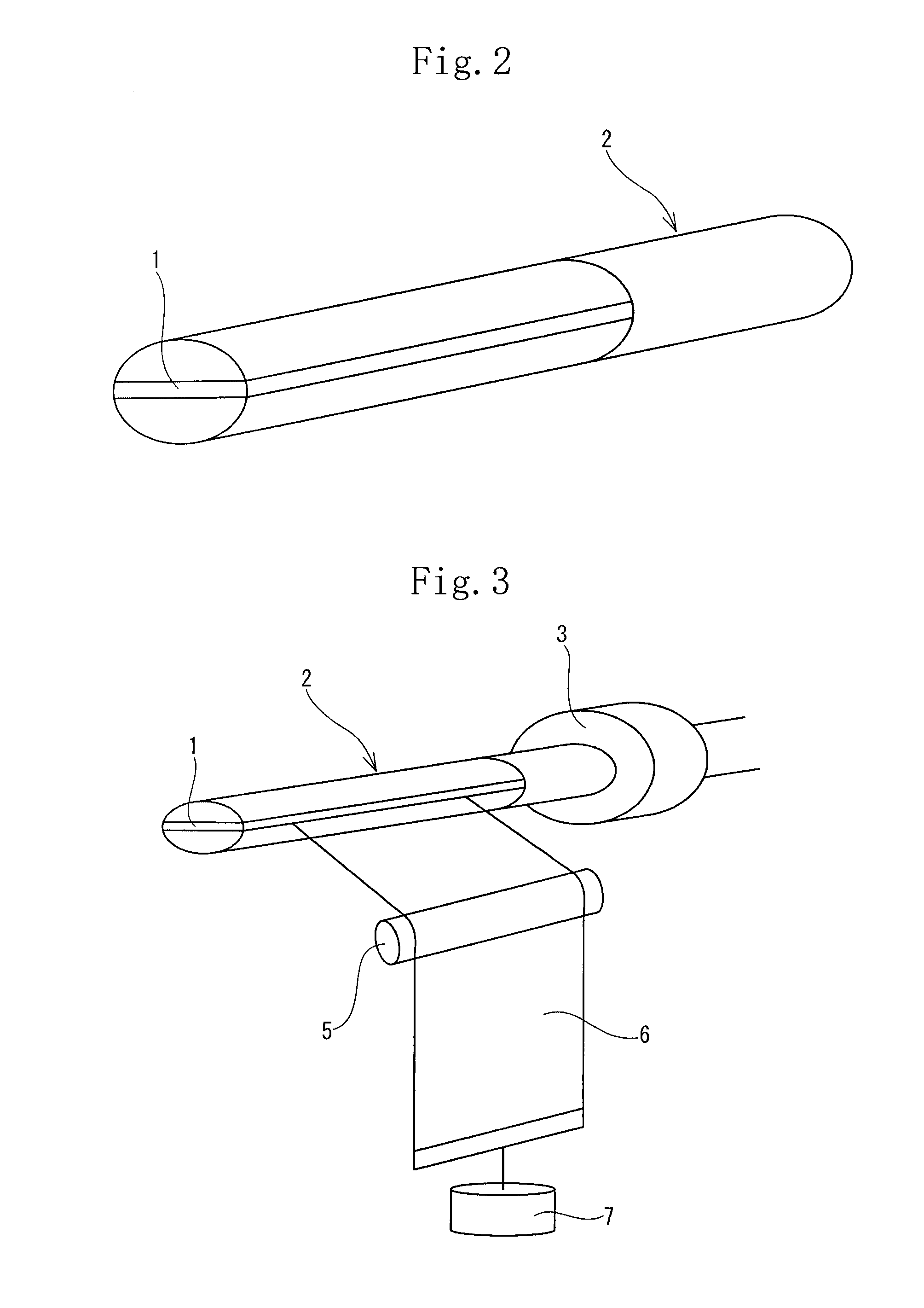

A method of optical-film treatment in which coating troubles apt to occur in the formation of a functional layer, e.g., an antireflection layer, on a continuous film by coating fluid application, such as transverse thickness-difference lines, coating streaks, and tailing, are diminished. The method of optical-film treatment comprises wetting with a liquid a continuous film which is being continuously conveyed, continuously rubbing the continuous film with an elastomer, and then removing the liquid from the continuous-film surface, and is characterized in that the surface of the elastomer has a coefficient of static friction of 0.2-0.9.

Owner:KONICA MINOLTA OPTO

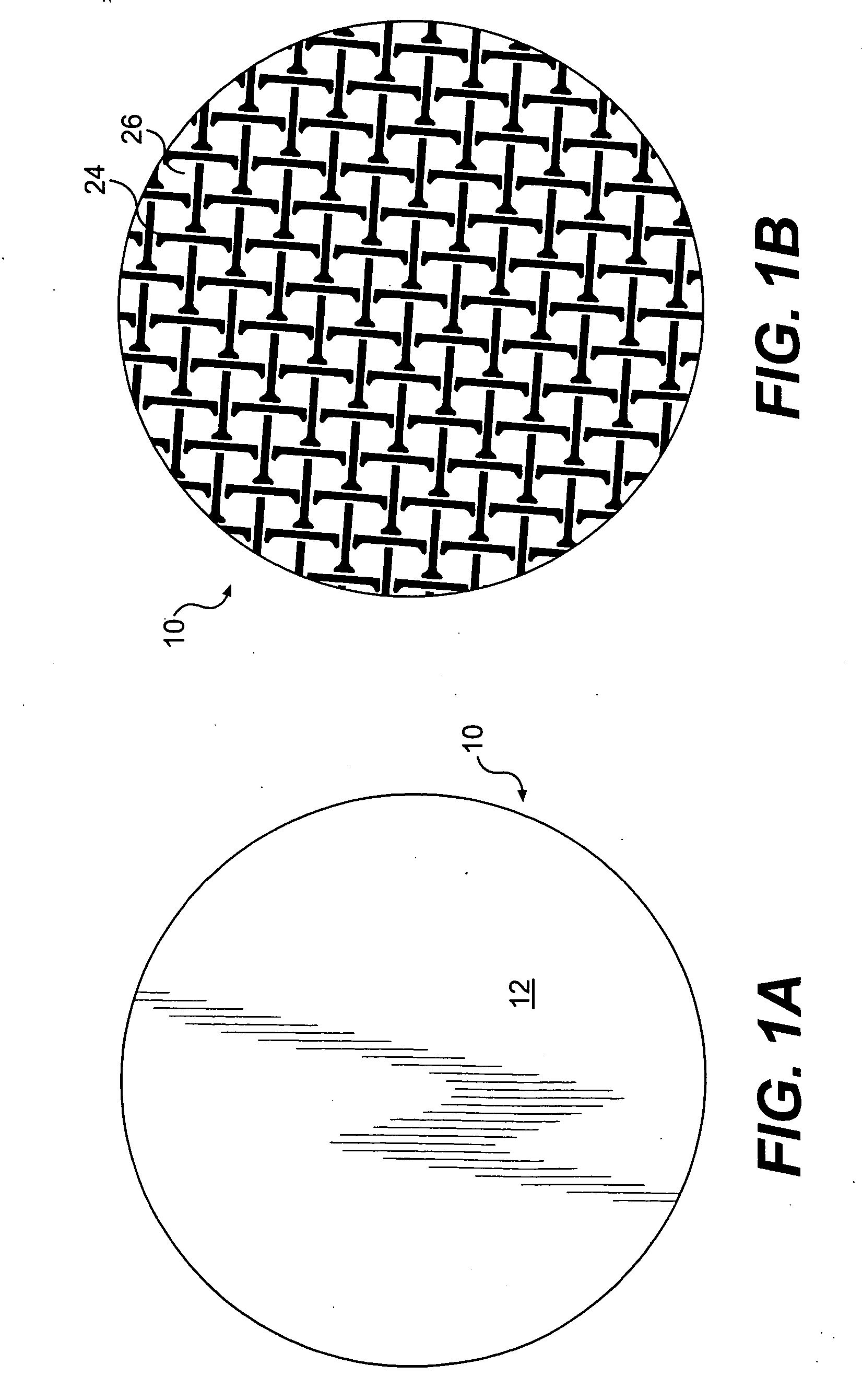

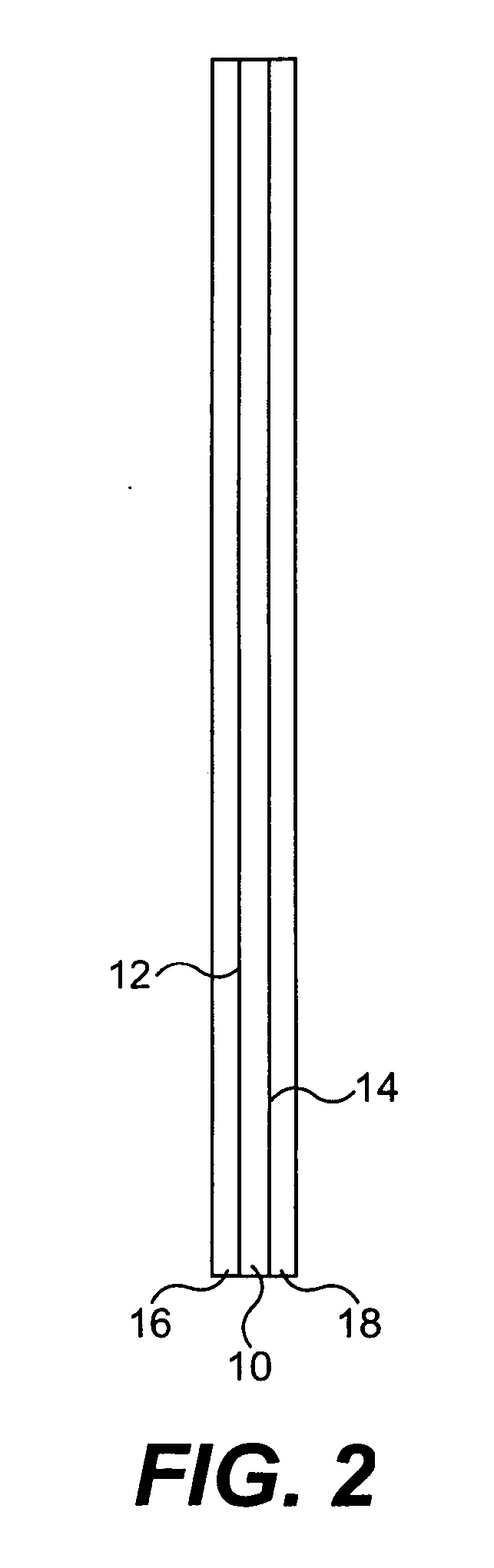

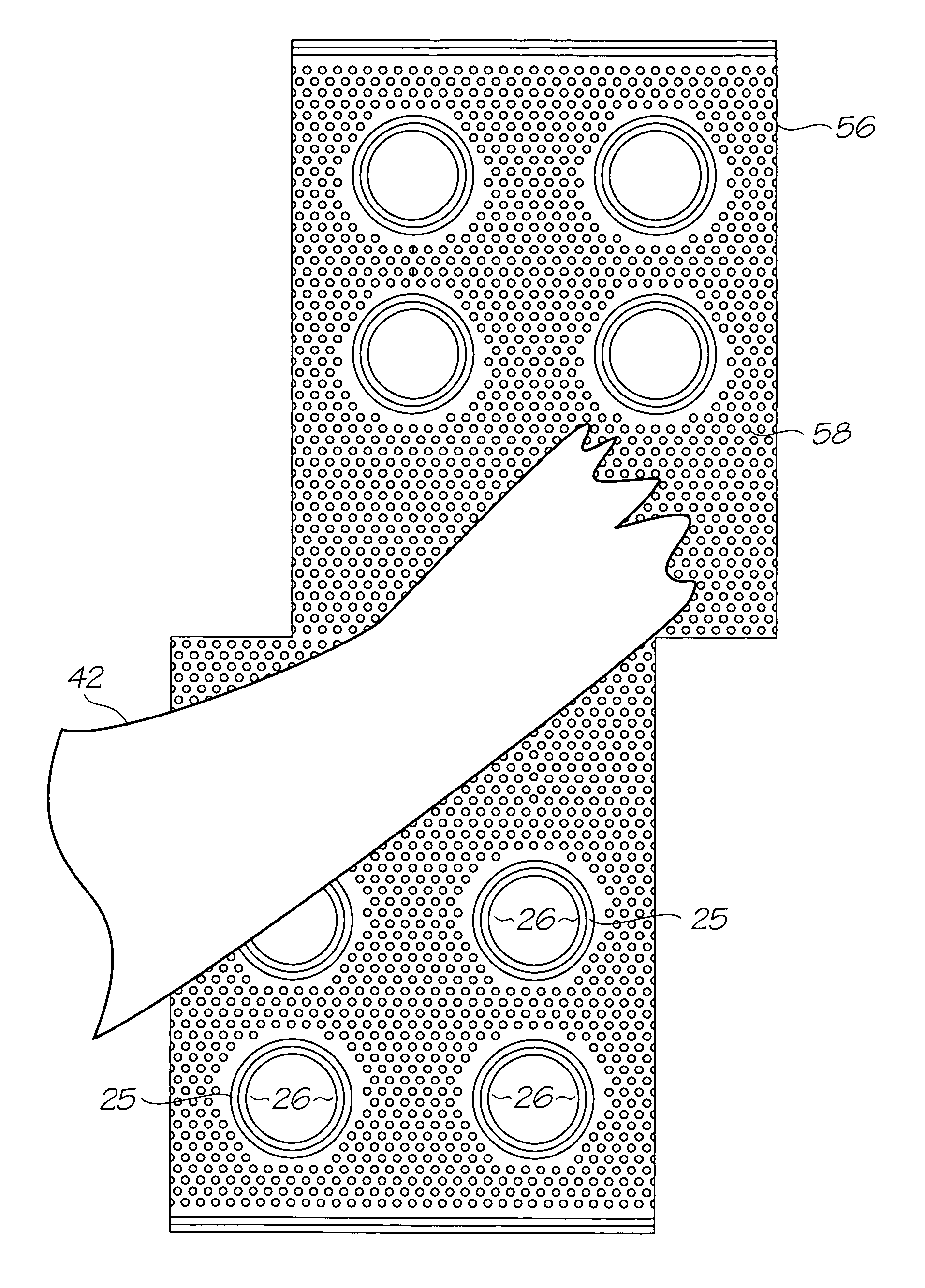

Reduced stiction printhead surface

ActiveUS7510267B2Reduction factorPrintingFlexible microstructural devicesStatic friction coefficientPaper dust

An inkjet printhead with a nozzle plate that has an exterior surface with formations for reducing its co-efficient of static friction. By reducing the co-efficient of static friction, there is less likelihood that paper dust or other contaminants will clog the nozzles in the nozzle plate. Static friction, or “stiction” as it has become known, allows dust particles to “stick” to nozzle plates and thereby clog nozzles. By patterning the exterior of the nozzle plate with raised formations, dust particles can only contact the outer extremities of each formation. This reduces friction between the particles and the nozzle plate so that any particles that contact the plate are less likely to attach, and if they do attach, they are more likely to be removed by printhead maintenance cleaning cycles.

Owner:SILVERBROOK RES PTY LTD +1

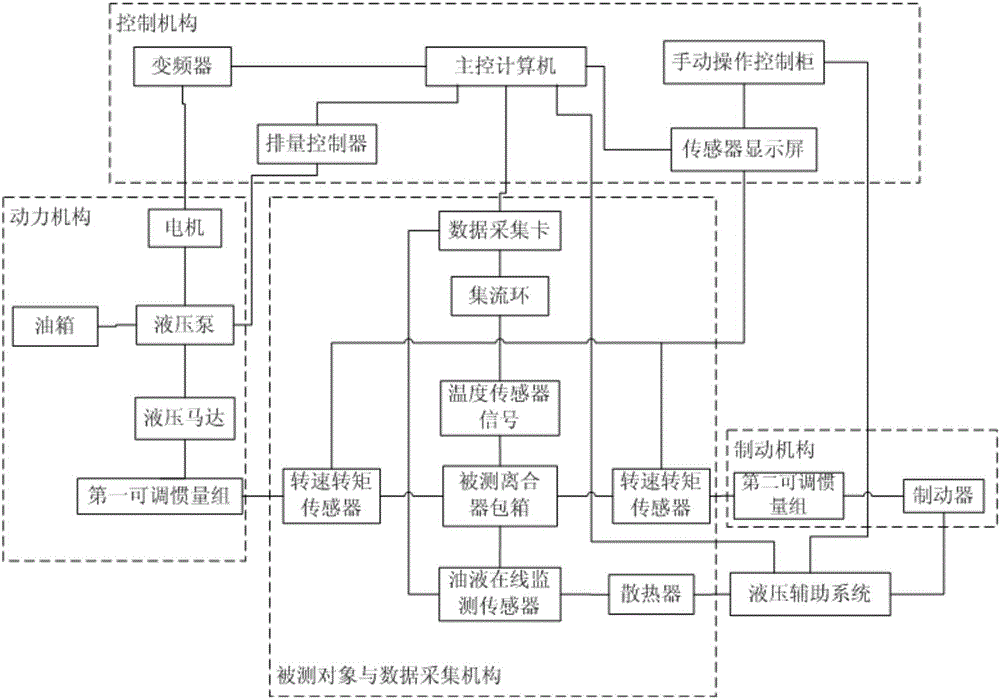

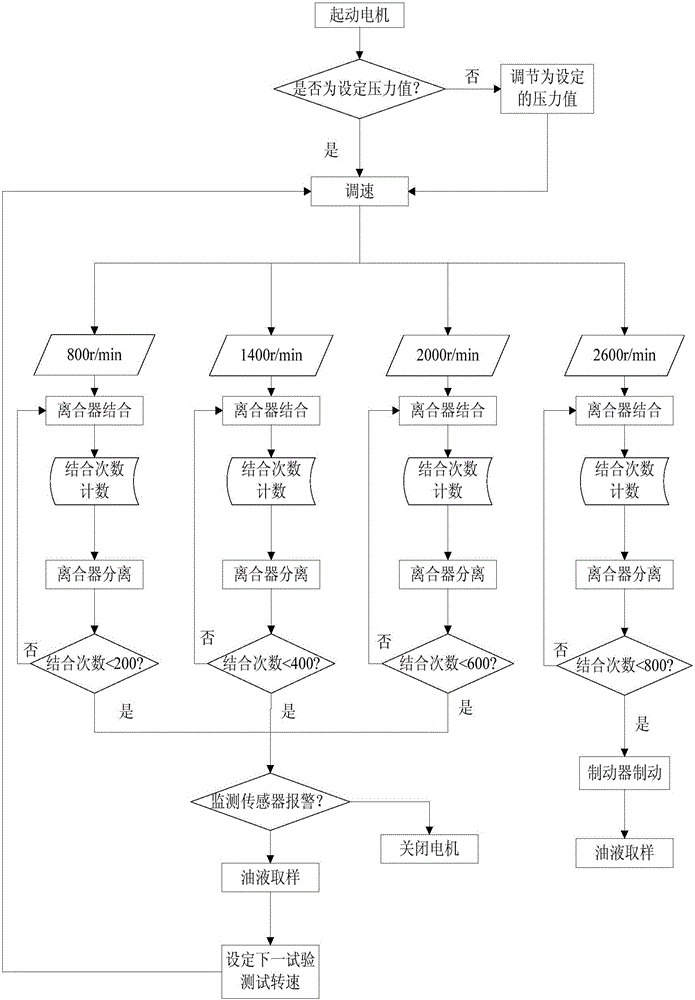

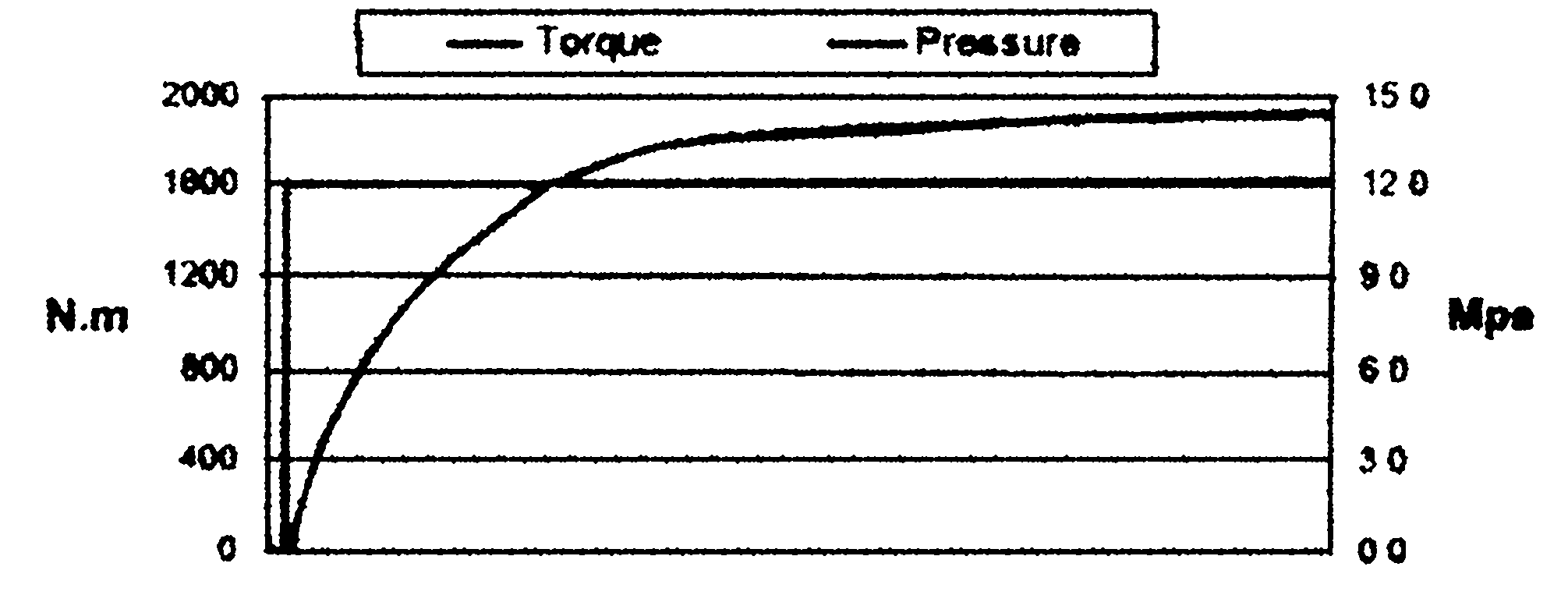

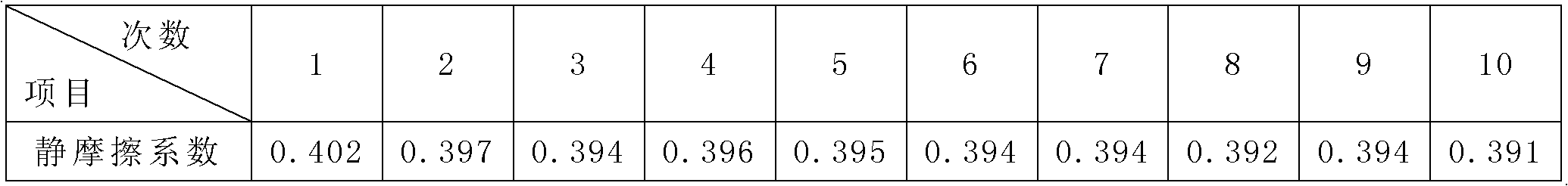

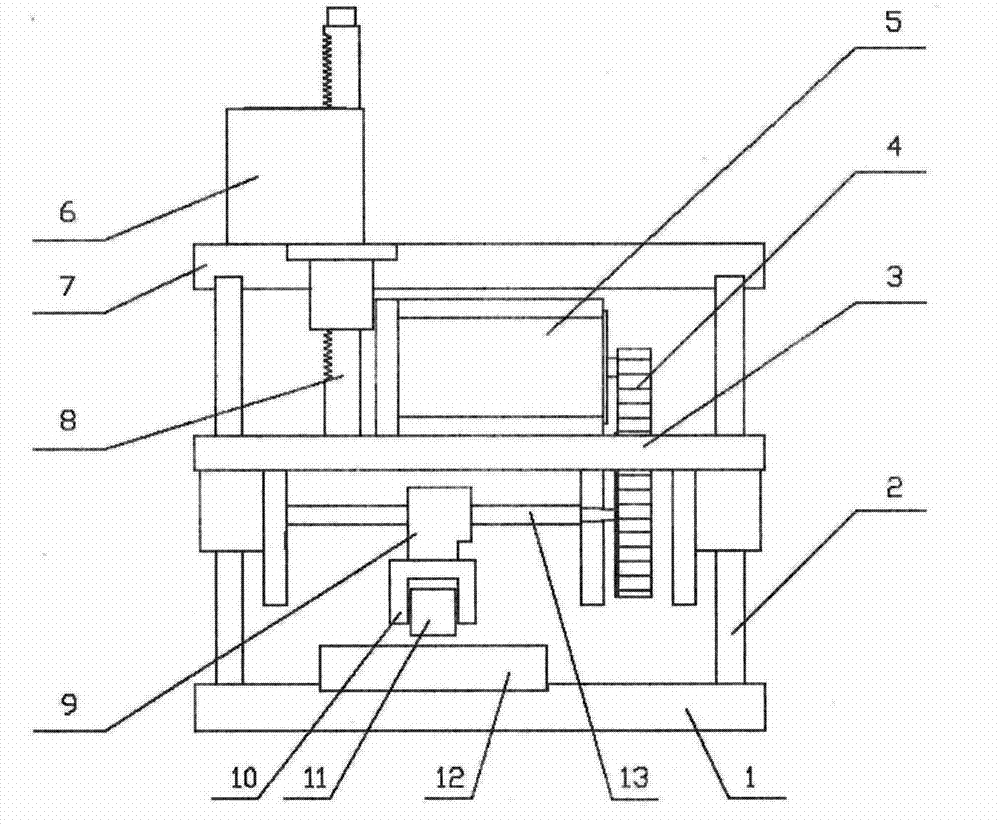

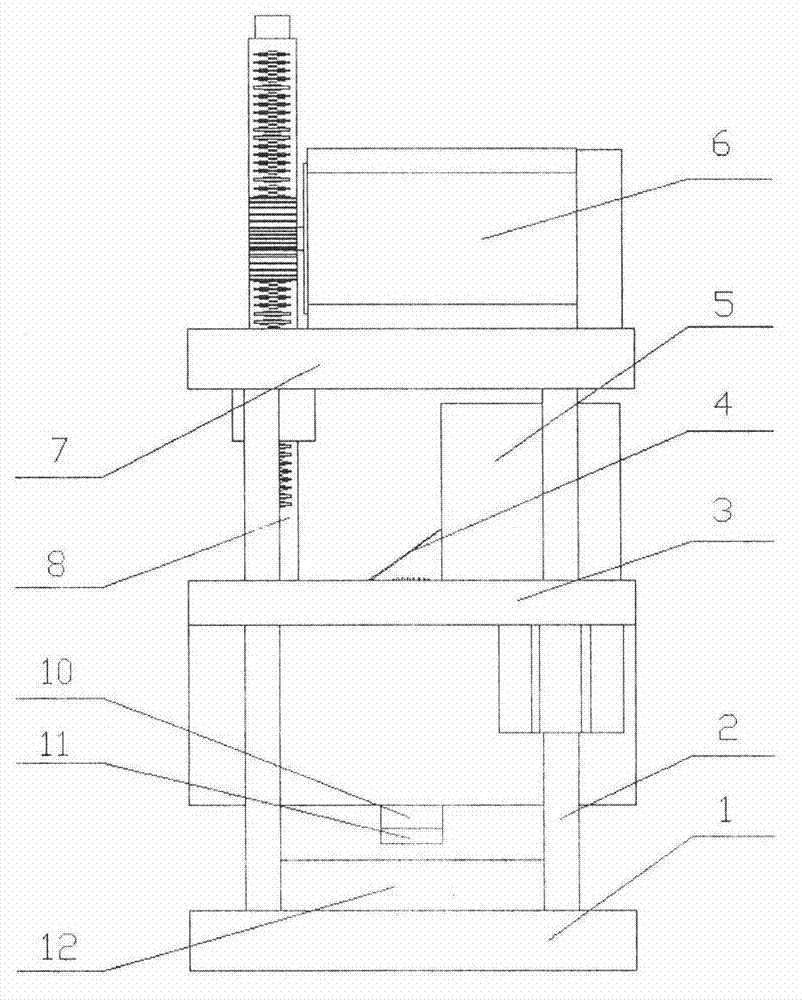

Wet-clutch friction plate's wear extent testing method and testing stand

ActiveCN105021483ASafe and reliable operationAvoid damageUsing mechanical meansInvestigating abrasion/wear resistanceStatic friction coefficientFriction torque

Owner:BEIJING INFORMATION SCI & TECH UNIV

Anti-corrosion copper-based brake material with high friction coefficient and preparation method of anti-corrosion copper-based brake material

The invention discloses an anti-corrosion copper-based brake material with a high friction coefficient. The anti-corrosion copper-based brake material is prepared from the following raw materials in percentage by weight: 34%-79% of copper, 6%-12% of carbon, 2%-6% of titanium, 2%-6% of nickel, 4%-10% of quartz sand, 3%-9% of silicon carbide, 2%-6% of mullite, 0-8% of molybdenum disulfide and 2%-9% of molybdenum trioxide, wherein the materials can be pressurized, sintered and molded in a protective atmosphere in a powder metallurgy manner; the sintering temperature is 800-890 DEG C; the sintering time is 100-200 minutes; and the exerted pressure is 1.9-3MPa. A Cu-Ni-Ti alloy component is adopted as a connecting phase, so that the problem that a common copper-based powder metallurgy brake material is poor in decay resistance in a marine environment is overcome; and the mullite is adopted as a friction phase, so that the problem that a common copper-based brake material is low in dynamic and static friction coefficient is solved.

Owner:贵州新安航空机械有限责任公司

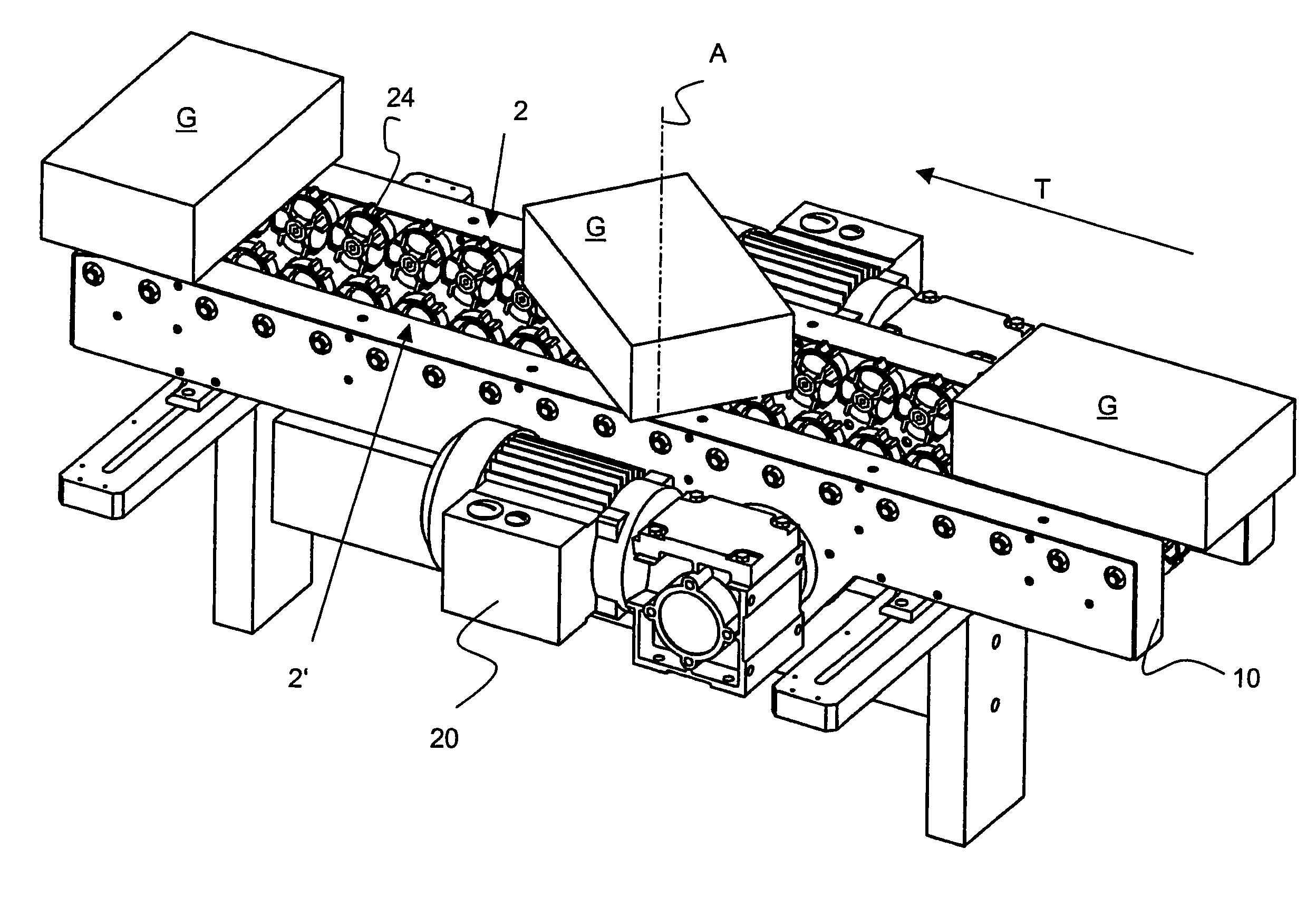

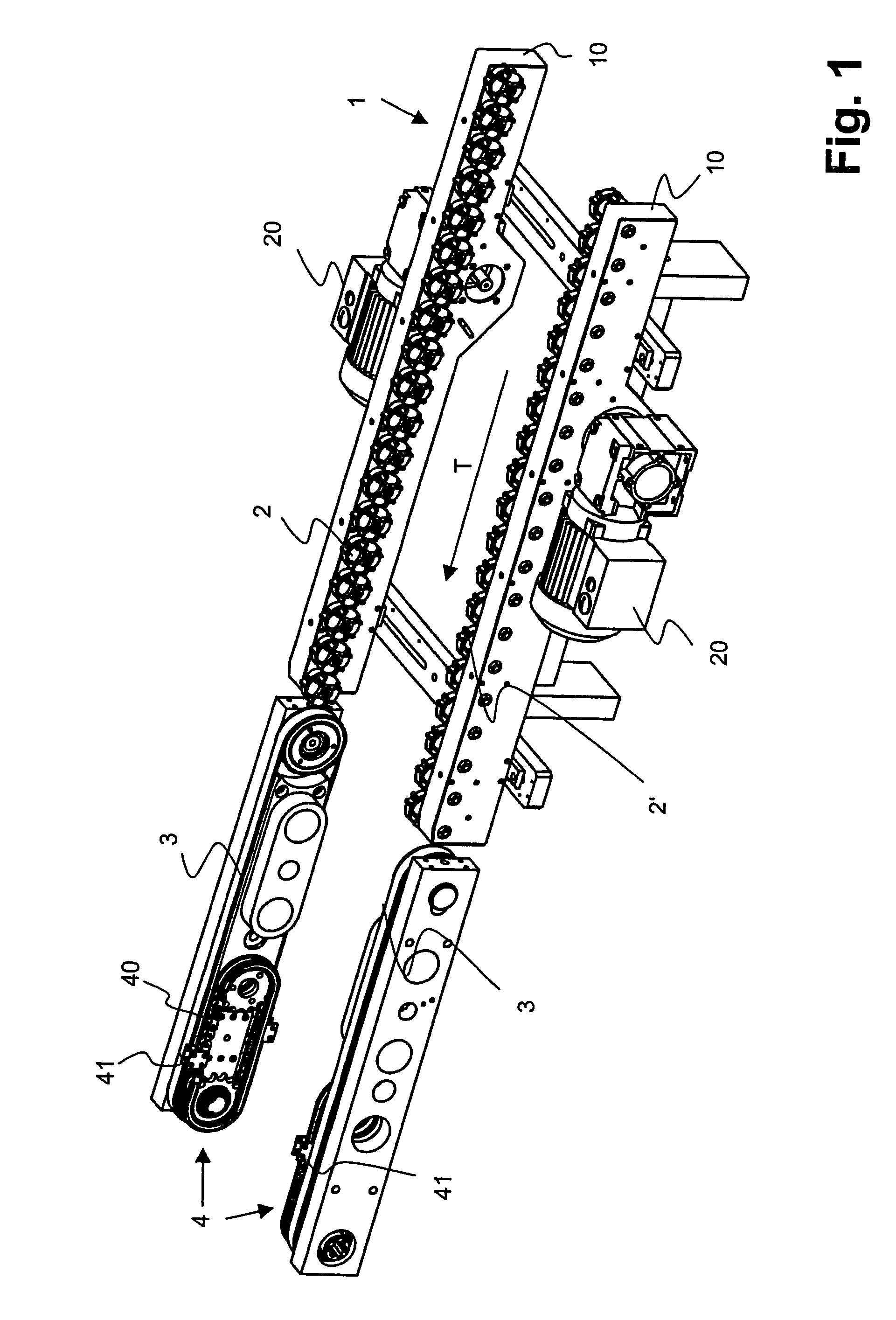

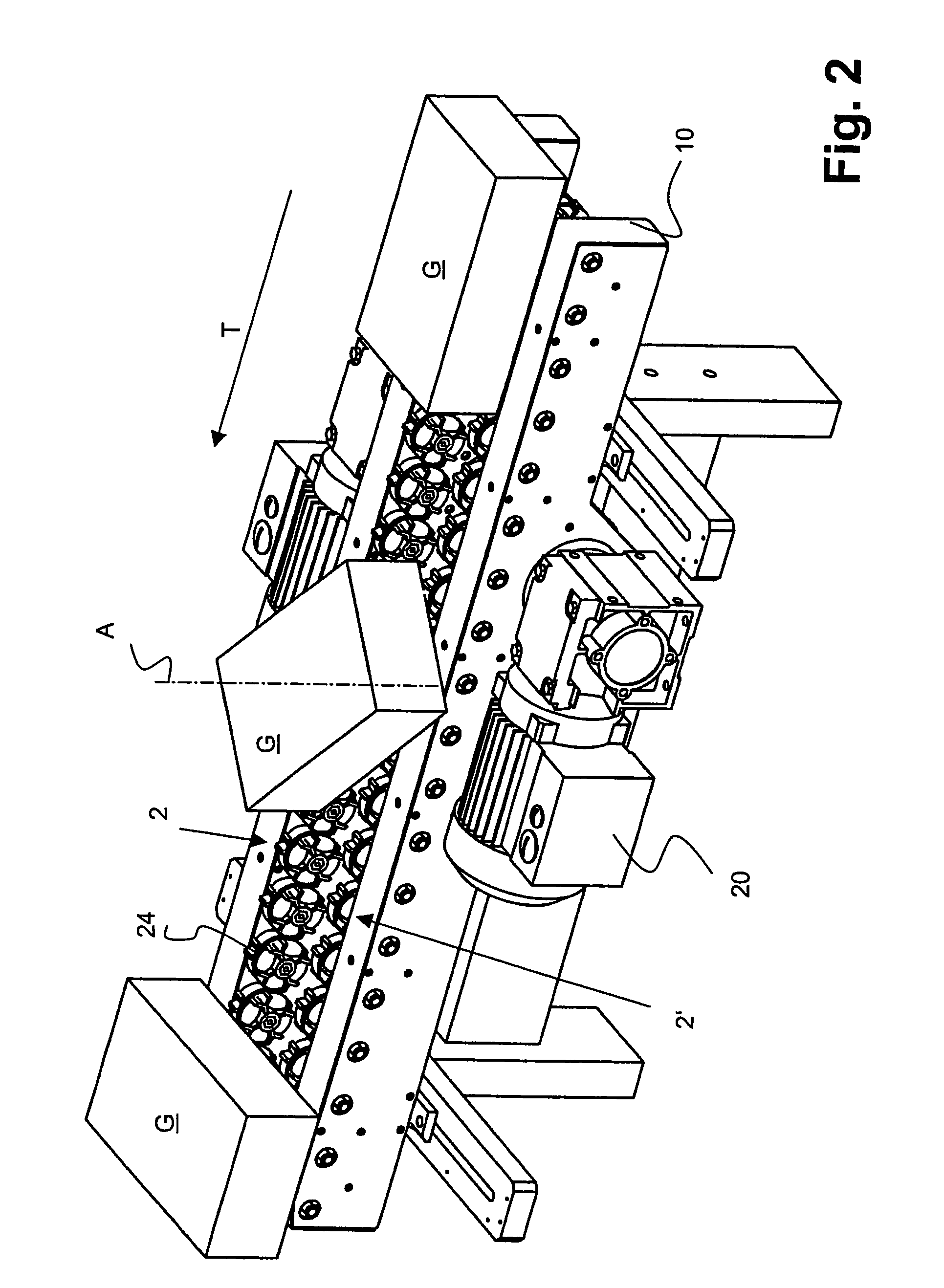

Apparatus for rotating an article

InactiveUS6981580B2Minimize forceStraightforward and cost-effective to produceConveyorsConveyor partsStatic friction coefficientCoefficient of friction

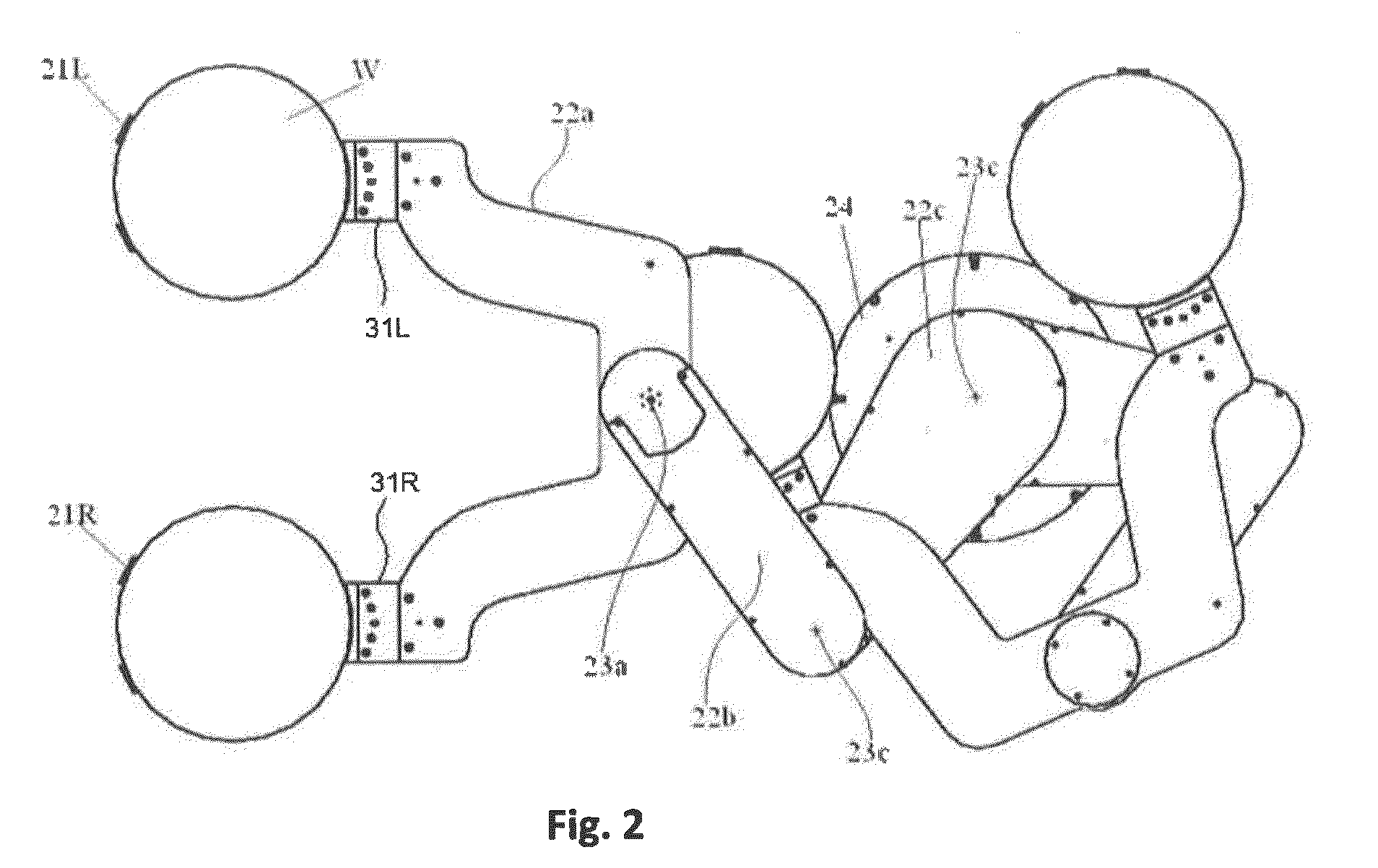

An apparatus having approximately parallel conveyors (2, 2′) for transporting and rotating an article (G) has multiple longitudinally arranged omnidirectional rollers (24), each omnidirectional roller (24) having multiple individual rollers (240) arranged about its periphery. The conveyors (2, 2′) extend in a transporting direction (T), bear against the bottom of the article (G), and rotate the article about an axis perpendicular to the article bearing plane. At least one conveyor can be driven at a speed different from the other conveyor to transport and rotate the article on the conveyor. The bearing portion of article (G) is subject to direction-dependent coefficients of friction with the transporting direction (T) having a static or sliding coefficient of friction that is higher than the rolling coefficient of friction in the direction perpendicular (S) to the transporting direction (T).

Owner:ROBERT BOSCH GMBH

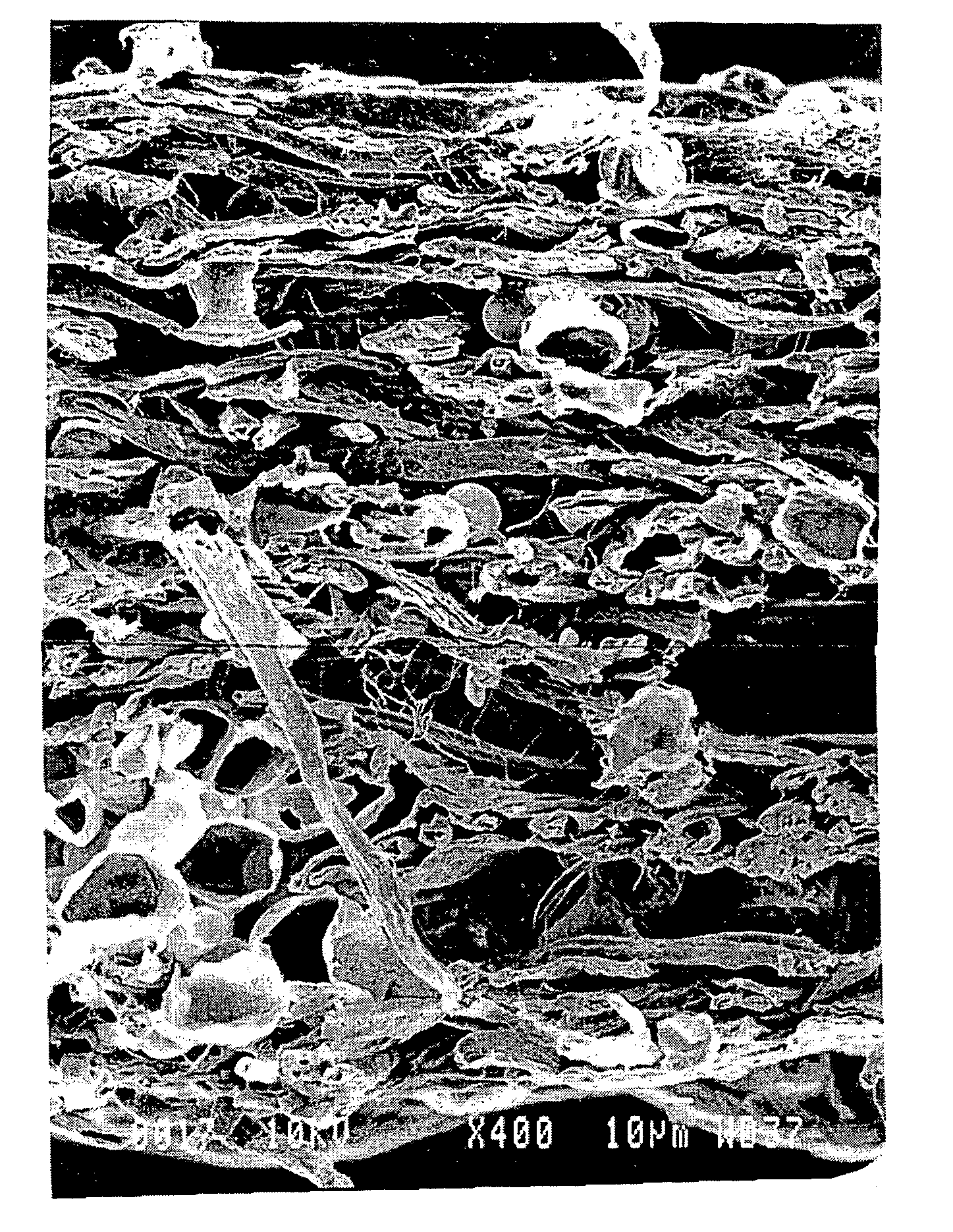

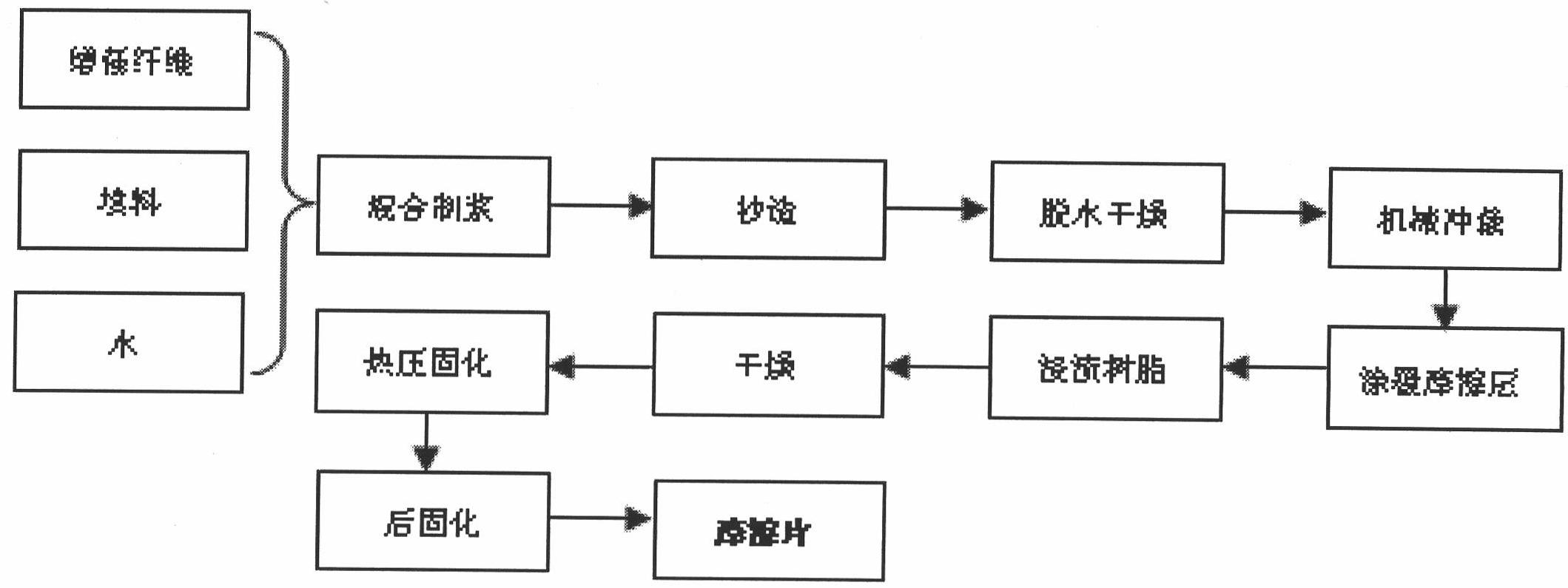

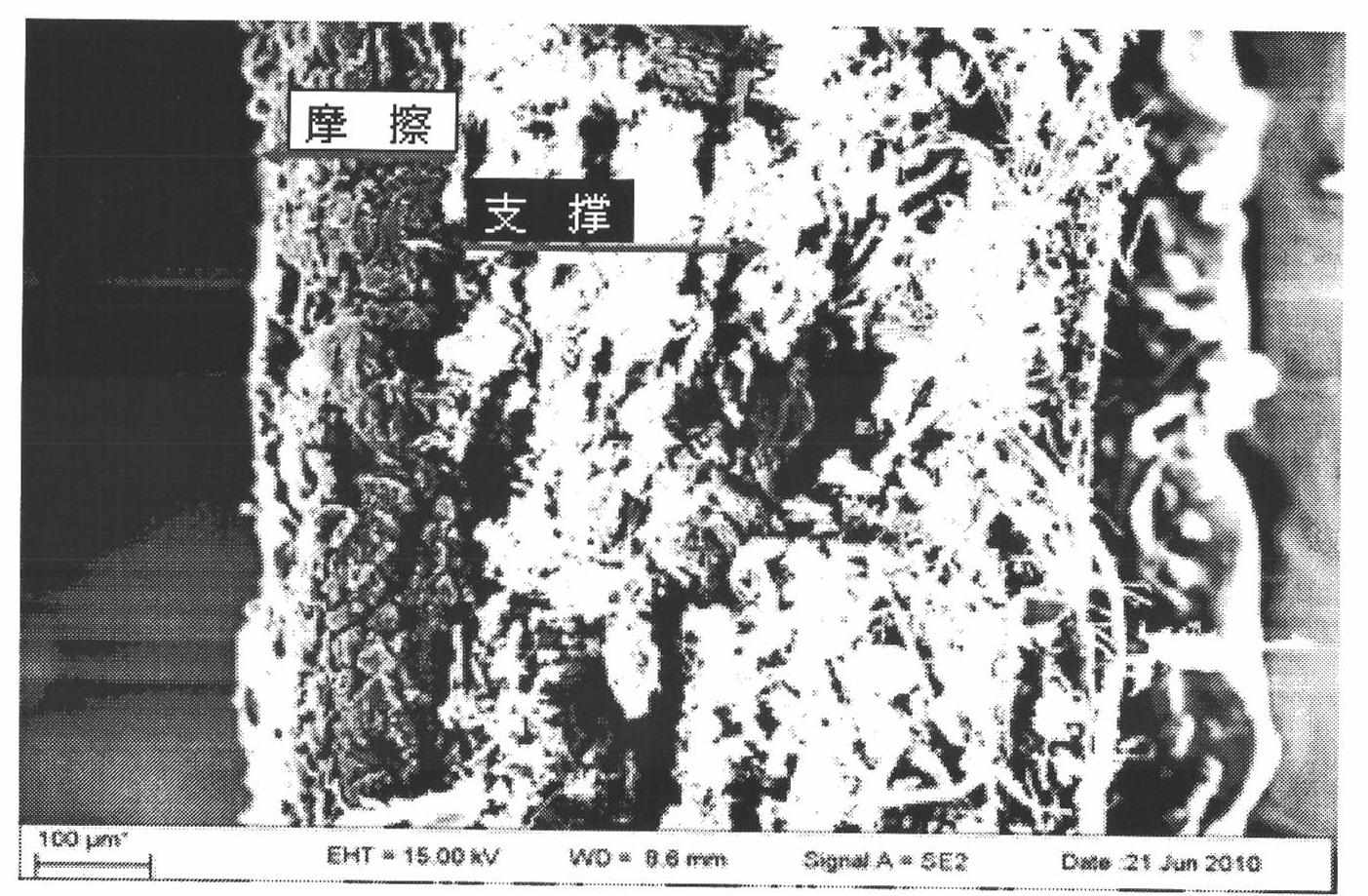

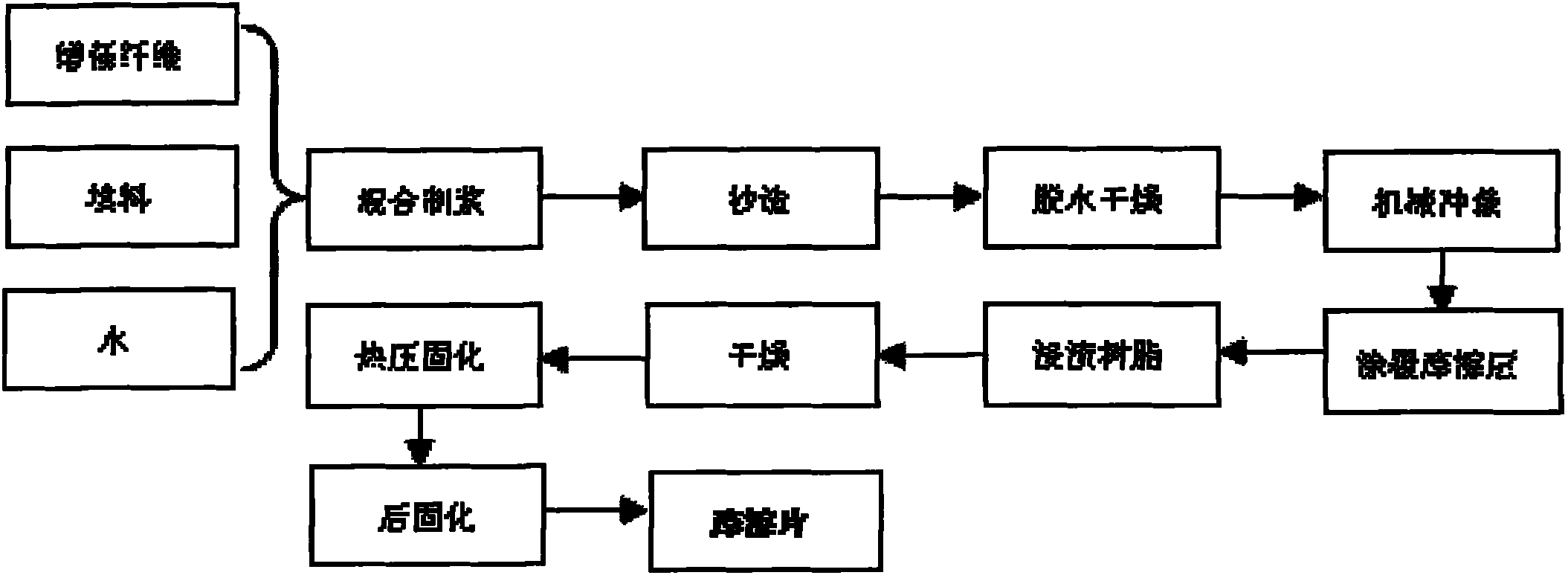

Carbonaceous double-layer paper-based friction material and preparation method thereof

InactiveCN102093842AIncrease coefficient of frictionCopy molding process is simpleOther chemical processesFiberStatic friction coefficient

The invention discloses a carbonaceous double-layer paper-based friction material and a preparation method thereof, aiming at solving the technical problem of low friction coefficient of the traditional double-layer paper-based friction material. According to the technical scheme, the carbonaceous double-layer paper-based friction material is prepared from 15-30% of reinforced fibre, 20-35% of filler, 5-15% of carbonaceous material, 5-10% of alumina and graphite and 25-35% of cashew nut shell oil modified phenolic resin. The preparation method comprises the following steps of: manufacturing and shaping a support layer in one time; and coating a friction layer on the surface of the support layer to obtain the carbonaceous double-layer paper-based friction material. Compared with the two-time manufacturing and shaping process in the background art, the preparation method is simpler. The coefficient of dynamic friction of the carbonaceous double-layer paper-based friction material is improved to 0.145-0.168 from 0.112-0.140 in the background art, and the coefficient of static friction is improved to 0.194-0.232 from 0.155-0.191 in the background art.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

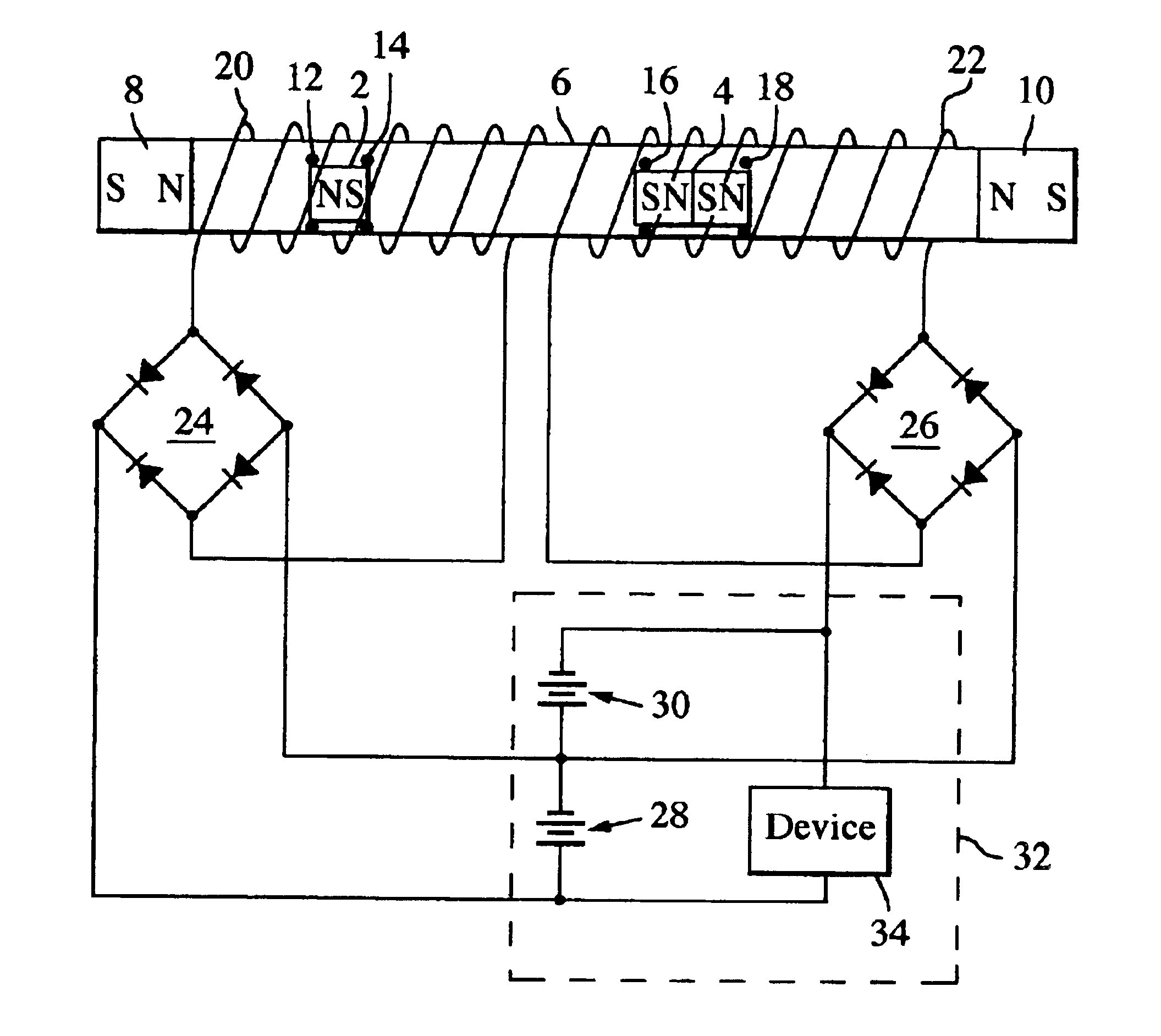

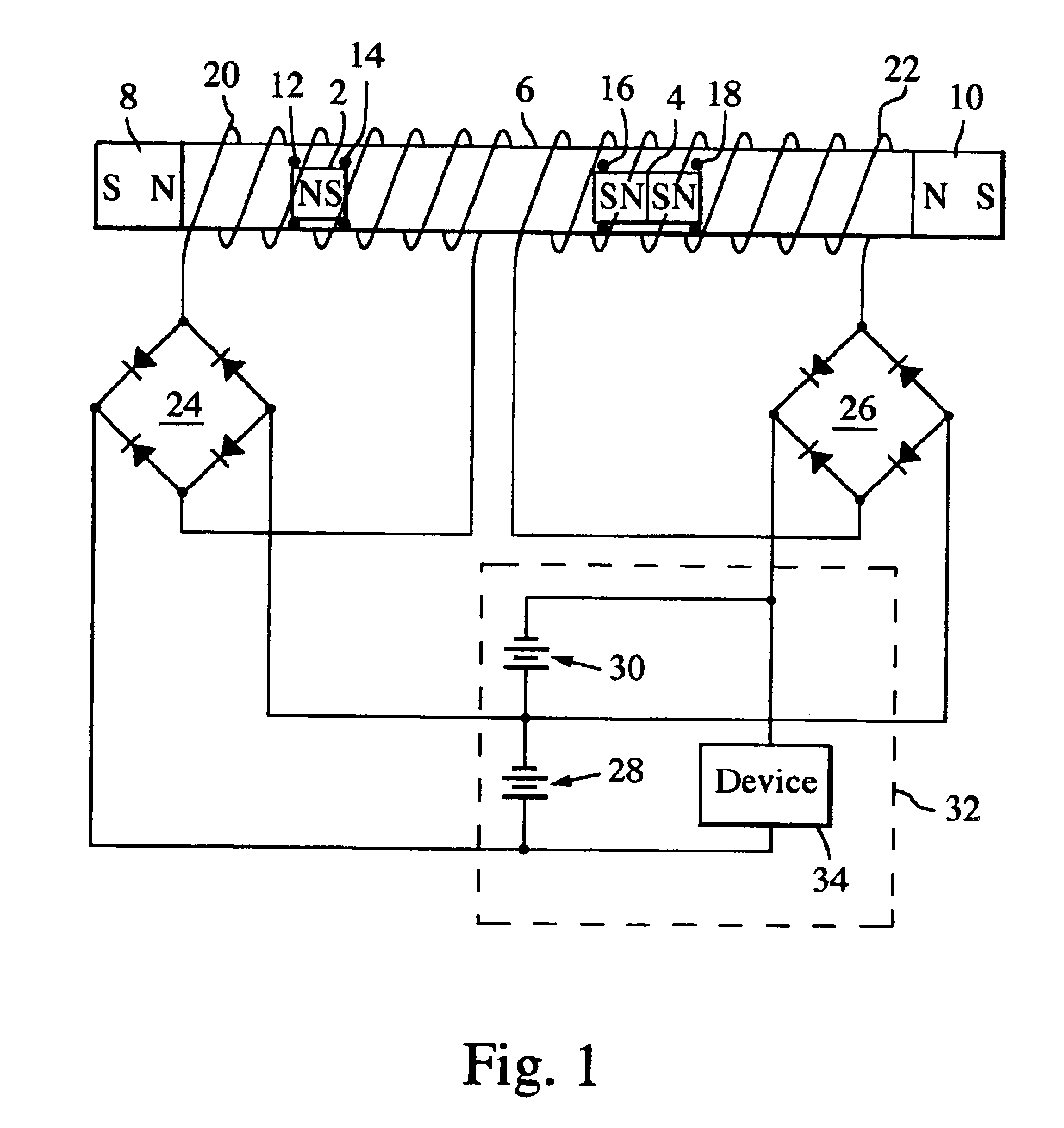

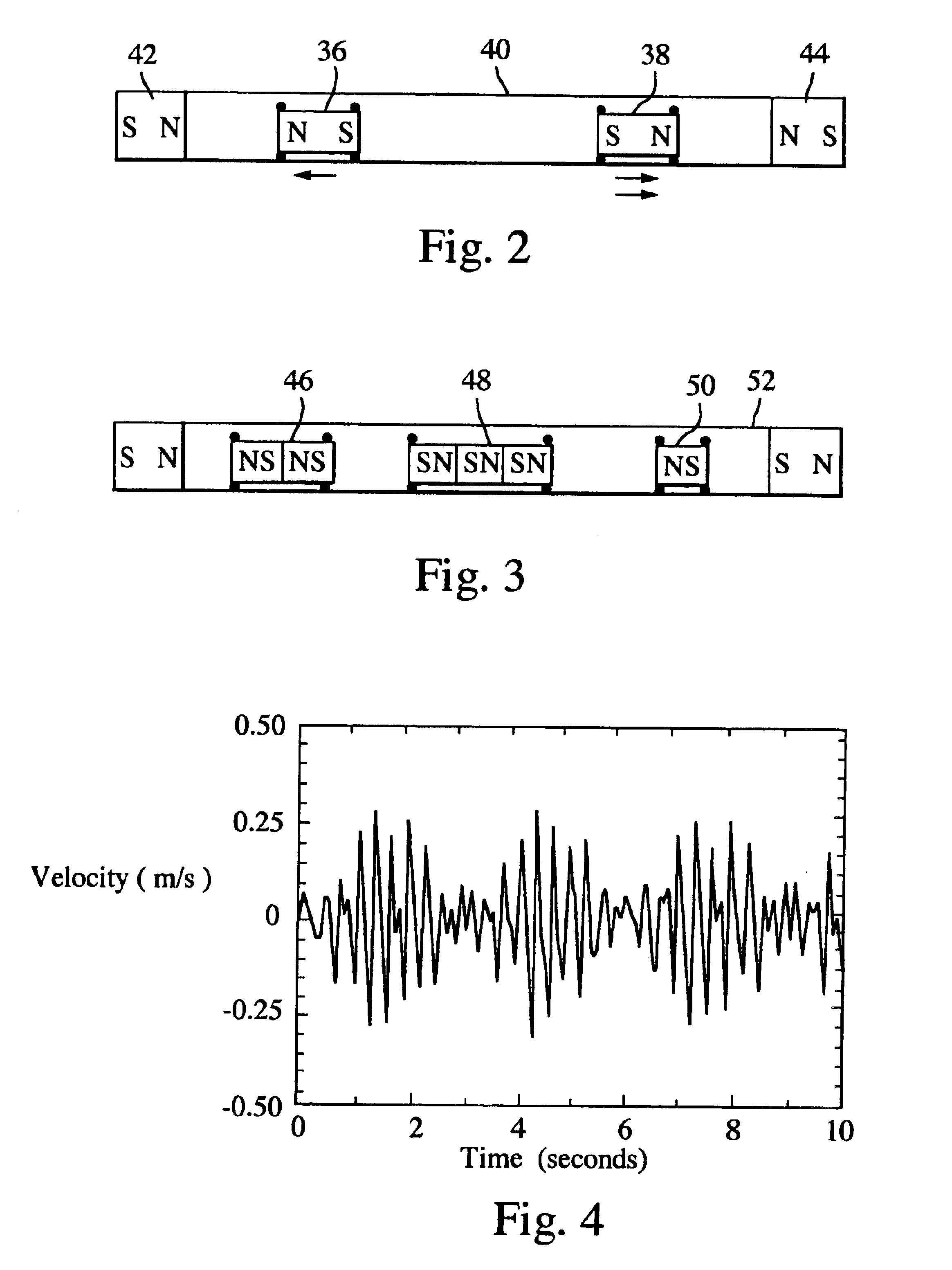

Multiple magnet system with different magnet properties

InactiveUS6861772B2Enhanced couplingHigh sensitivityMagnetic circuitMachines/enginesStatic friction coefficientElectricity

A dynamic magnet system, particularly useful for electrical generation, employs multiple magnets in polar opposition to each other for individual movement relative to a support structure. The magnets have a critical angle of displacement from a horizontal static position of less than 1 degree, with at least some of the magnets having mutually different properties. With different magnetic strengths, a greater movement is produced for both magnets in response to movements of the support structure, for particular ranges of magnetic strength ratios, than would be the case with equal magnets. The magnet movement can be translated into an electrical signal to power an operating system. Ultra low friction ferrofluid bearings can be used to establish static coefficients of friction between the magnets and support structure less than 0.02, enabling useful power generation from only slight movements of the support structure.

Owner:TELEDYNE SCI & IMAGING

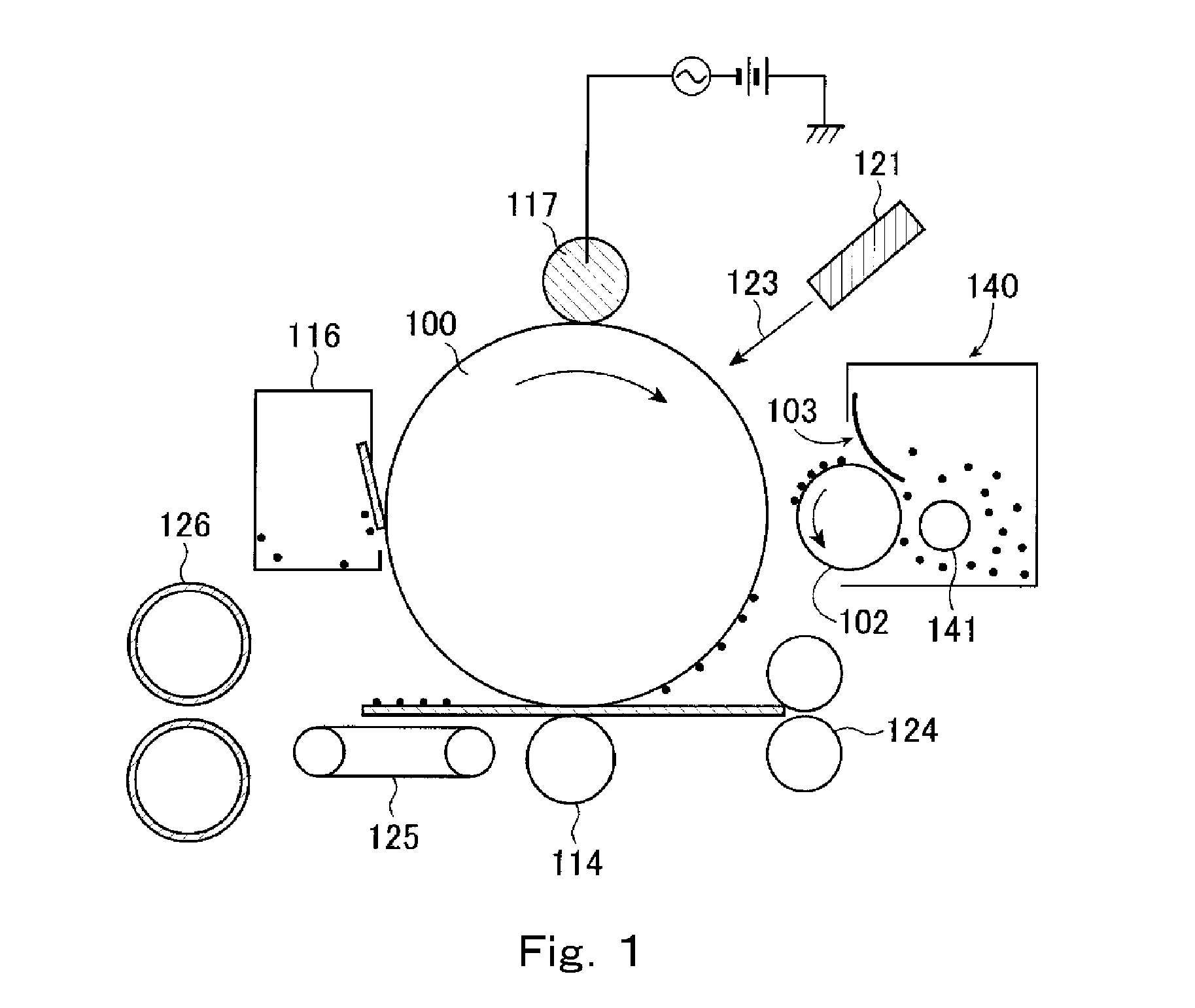

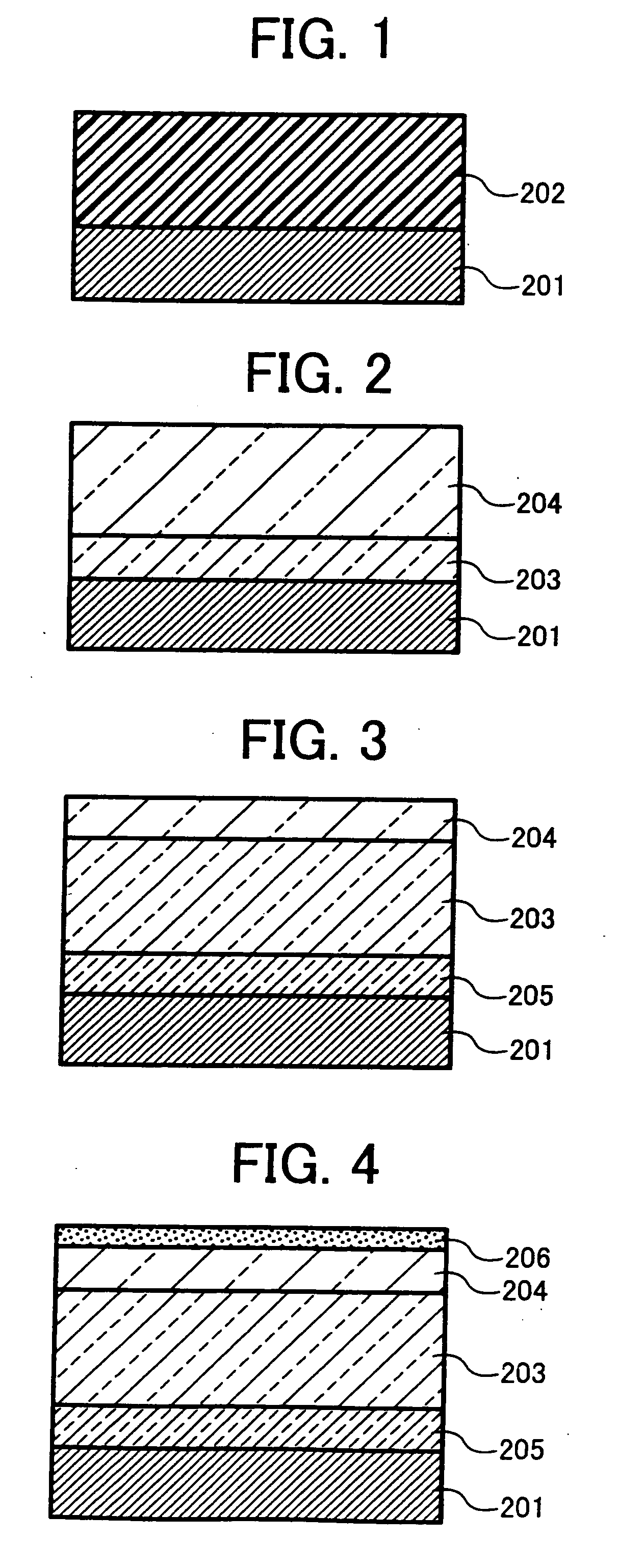

Toner, method for manufacturing the toner, and image forming method and apparatus using the toner

InactiveUS6911289B2Excellent thin line reproducibilityConducive to preservationDevelopersElectrographic process apparatusStatic friction coefficientStatic friction

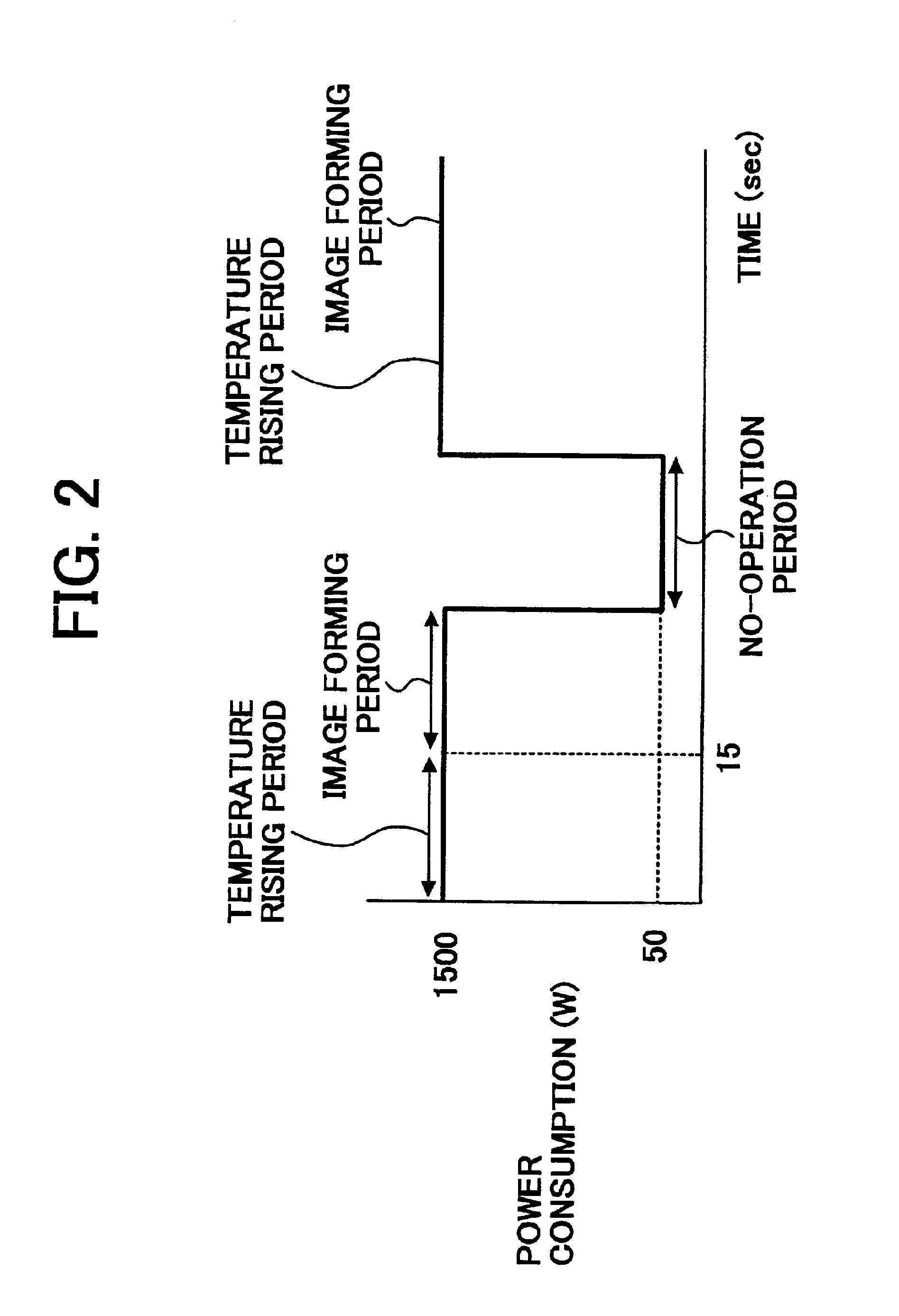

A toner including toner particles including a binder resin and a release agent, wherein when the toner is molded into a plate upon application of a pressure of 478 kg / cm2, the toner plate has a surface having a coefficient of static friction of from 0.20 to 0.40. An image forming apparatus including an image bearing member, an image developer to form a toner image on the image bearing member, an image transferer configured to transfer the toner image on a receiving material and a fixer configured to fix the toner image thereon, wherein the apparatus has a waiting time not longer than 15 seconds, and a maximum power consumption not greater than 1.5 KW and 30 W in an image forming state and in a standby state, respectively, wherein the toner is the toner mentioned above.

Owner:RICOH KK

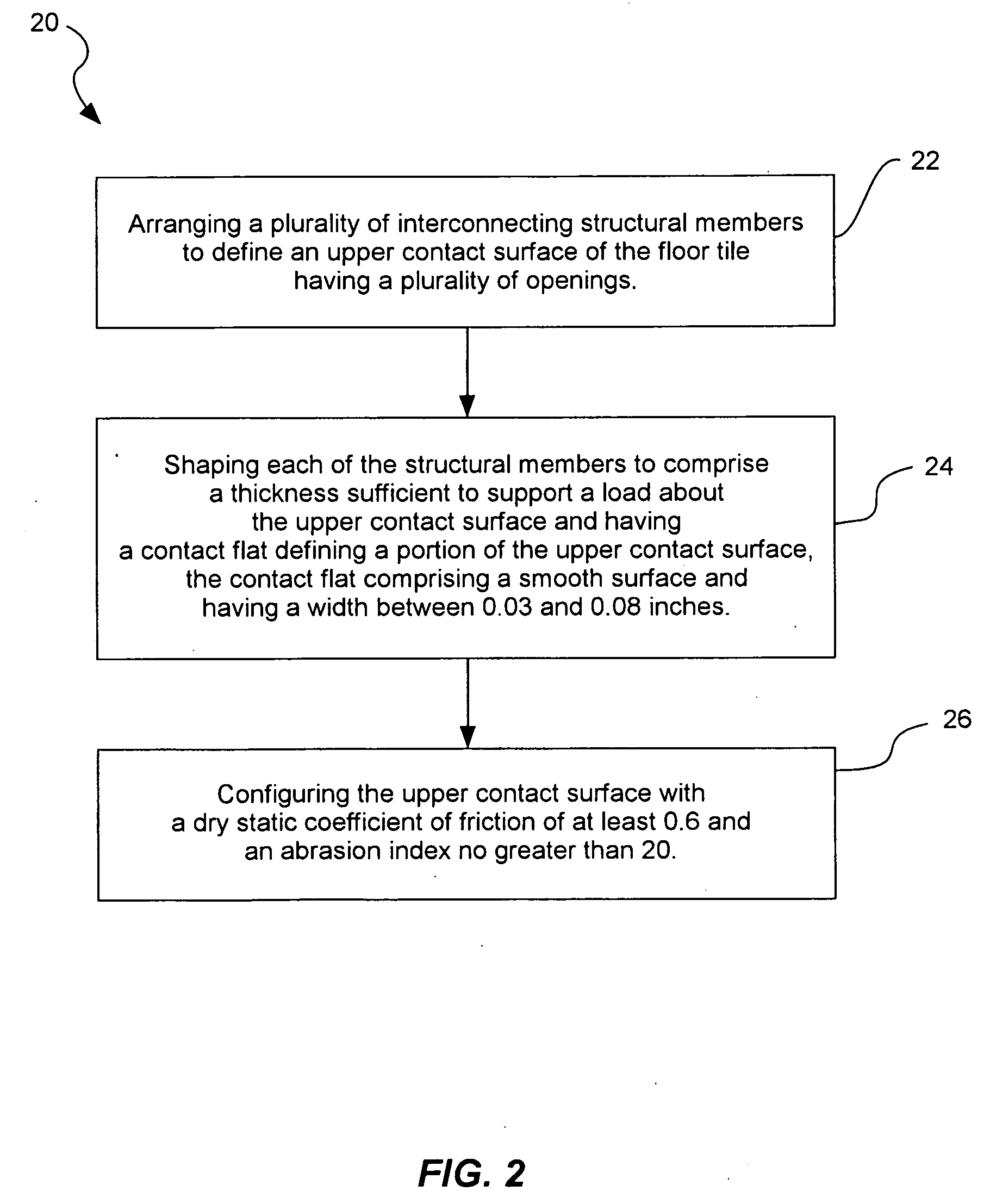

Method of Making A Modular Synthetic Floor Tile Configured For Enhanced Performance

InactiveUS20090235605A1Great tractionReduce abrasivenessSingle unit pavingsFloorsStatic friction coefficientEngineering

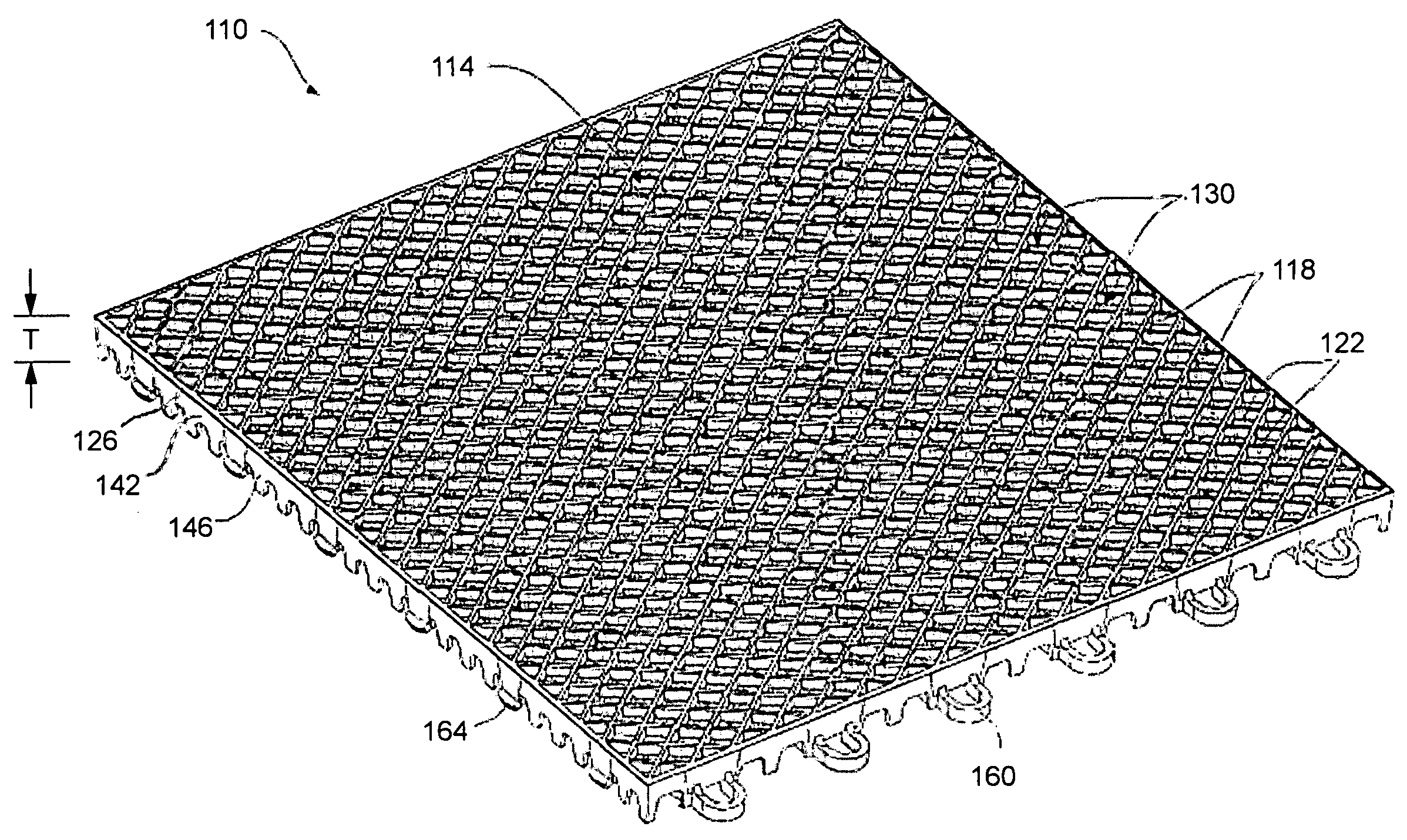

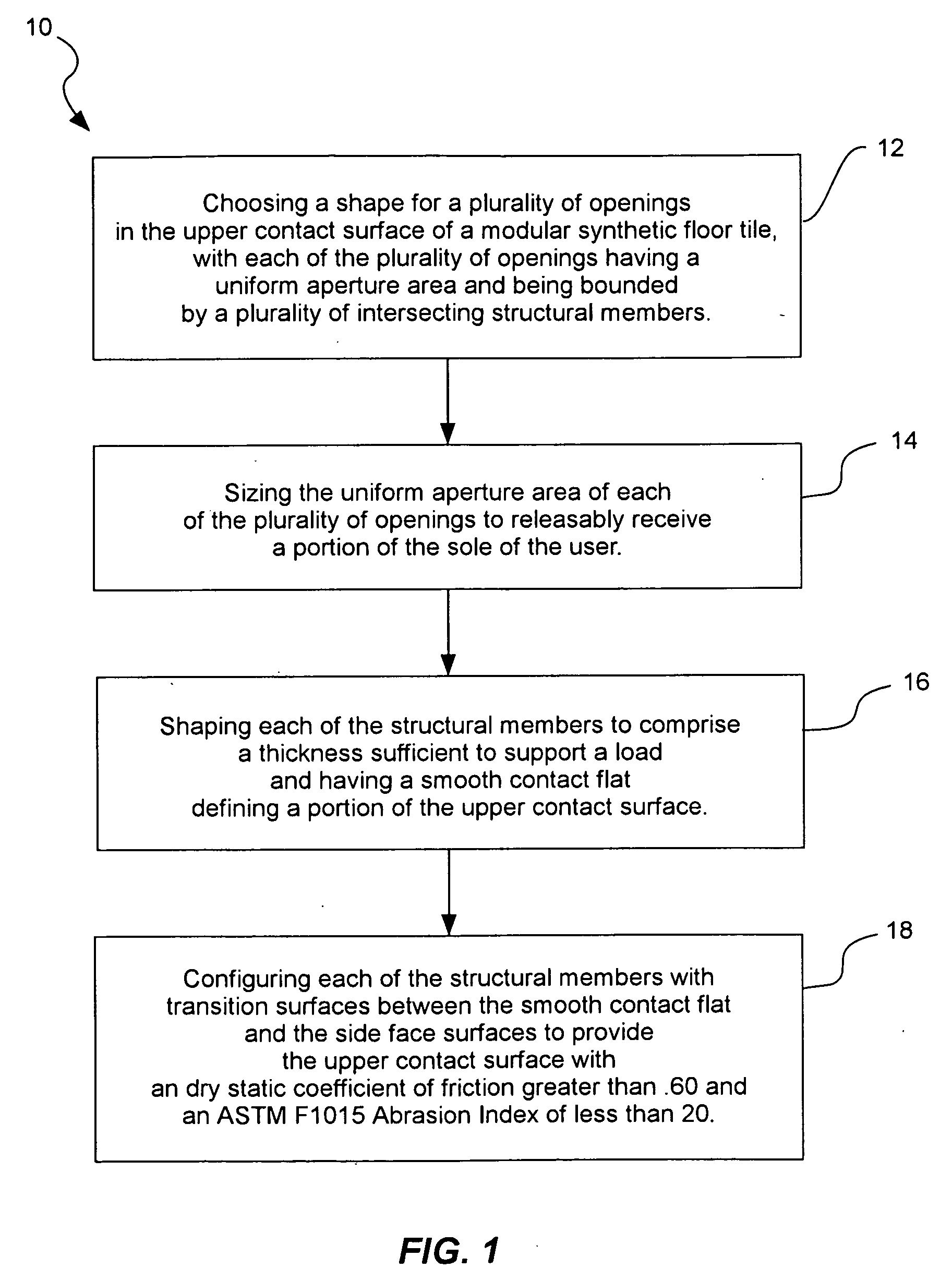

A method for enhancing the performance characteristics of a modular synthetic floor tile, which includes configuring a plurality of structural members to define an upper contact surface with a plurality of openings in the upper contact surface of the floor tile, configuring each of the structural members to comprise a thickness sufficient to support a load about the upper contact surface and with a contact flat having a smooth surface and a width between 0.03 and 0.08 inches, and configuring the upper contact surface with a dry static coefficient of friction of at least 0.6 and an abrasion index no greater than 20.

Owner:CONNOR SPORT COURT INT

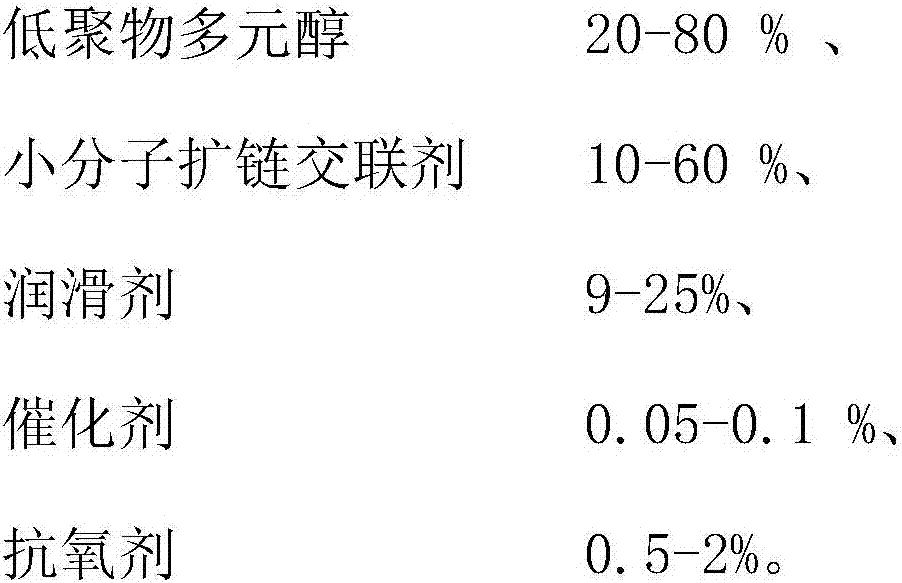

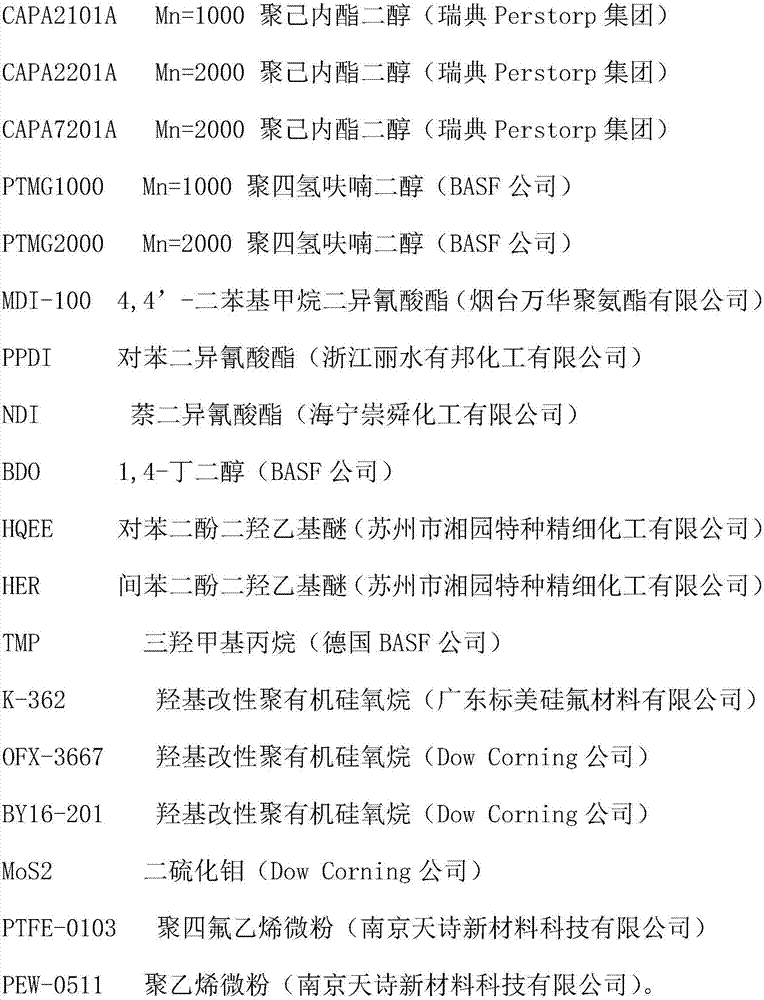

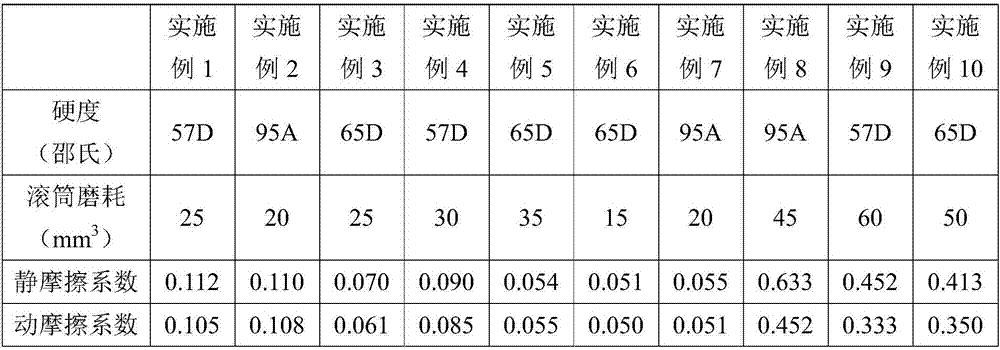

High-hardness self-lubricating polyurethane elastomer and preparation method thereof

The invention discloses a high-hardness self-lubricating polyurethane elastomer and a preparation method thereof. The polyurethane elastomer includes, by weight, 100 parts of polyurethane hemi-prepolymer and 30-100 parts of a polymer containing active hydrogen, wherein the content of free isocyanate in the polyurethane hemi-prepolymer is 9-16 wt% and water content in the polymer containing active hydrogen is less than 0.05 wt%. The polyurethane elastomer can reach up to 65D in hardness, has high mechanical strength and high wear resistance, is very low in friction coefficient which can be controlled to about 0.050, and is very small in difference between kinetic friction and static friction coefficients, so that the polyurethane elastomer can be widely applied in the fields in which reductions on abrasion and friction coefficient are required, especially in sealing members.

Owner:WINSIN MATERIALS INC

Heat-sensitive adhesive material

InactiveUS20060159913A1Improved delivery propertyHigh bonding strengthThin material handlingMetal layered productsStatic friction coefficientPolyethylene terephthalate

The object of the present invention is to provide a heat-sensitive adhesive material having improved delivery properties and a superior adhesive strength. The objective heat-sensitive adhesive material in which an adhesive layer comprising mainly an adhesive is coated over a support and a heat-sensitive adhesive layer having developed adhesion by heating and maintaining the developed adhesive strength is coated over the adhesive layer, has Clark stiffness set by JIS P-8143 of 30 m3 / 100 to 180 cm3 / 100 in a longitudinal direction and a coefficient of static friction between a heat-sensitive layer and a polyethylene terephthalate (PET) film of 0.90 or less.

Owner:RICOH KK

Apparatus for determining coefficients of friction

InactiveUS20140060149A1Readily apparentUsing mechanical meansInvestigating abrasion/wear resistanceStatic friction coefficientDisplay device

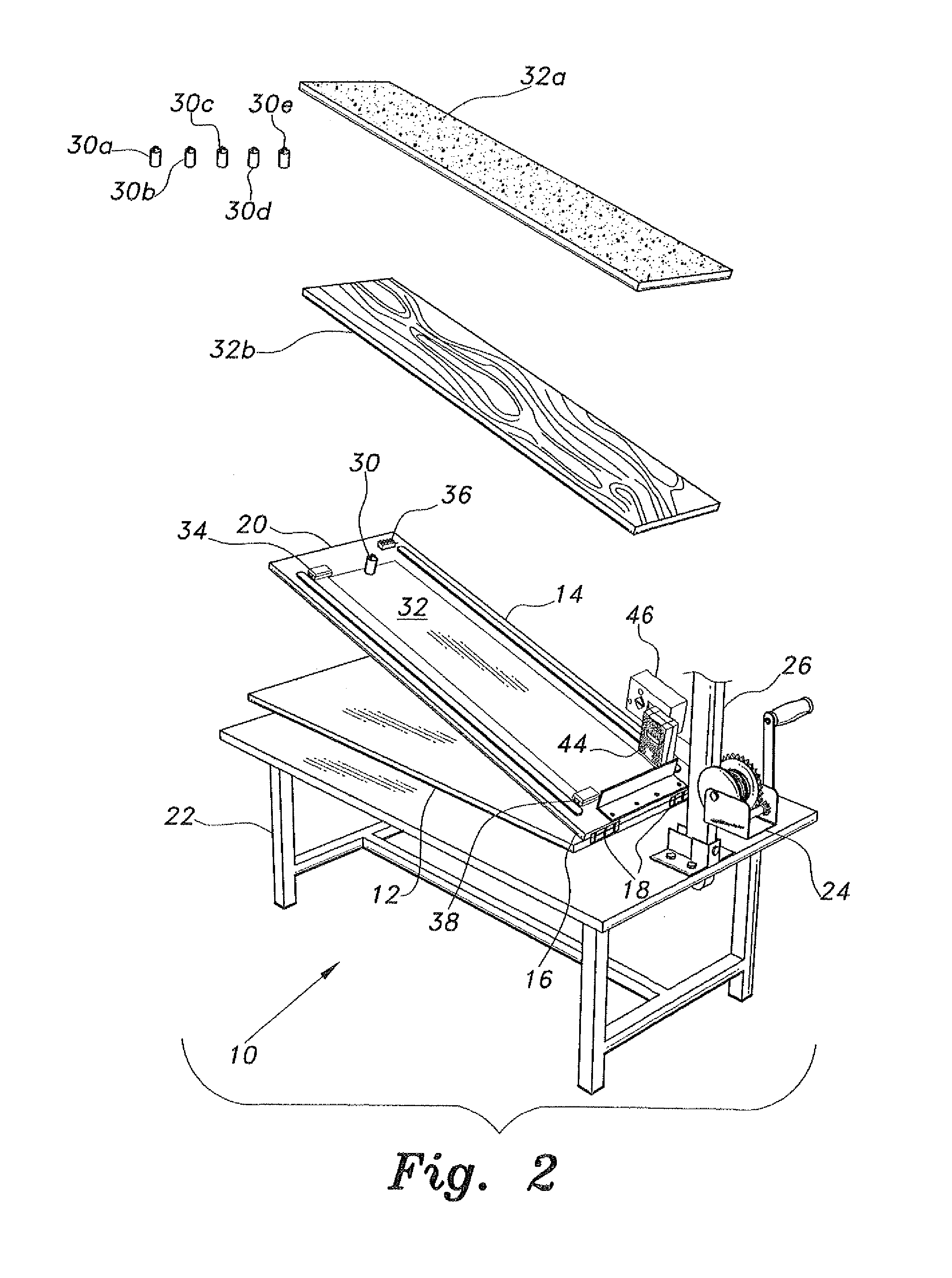

The apparatus for determining coefficients of friction collects data required for determining static and dynamic coefficients of friction between various materials. The apparatus includes a ramp with adjustable slope and a plurality of test masses for placement on the ramp. Upslope lights and sensors, downslope lights and sensors, and a digital angle meter are installed on the ramp. The apparatus has a timing device having a display to show the elapsed time between a test mass passing the upslope sensor and the downslope sensor. The operator can determine the static coefficient of fraction from the tangent of the angle displayed on the digital angle meter when a test mass first begins to slide, and can compute the kinetic coefficient of friction from the angle displayed on the digital angle meter and the elapsed time shown on the timing device.

Owner:KUWAIT UNIV

Laminated porous film, separator for battery, and battery

InactiveUS20120231323A1Improve slip performanceExcellent in its slip performance and performance of pullingFinal product manufactureSynthetic resin layered productsStatic friction coefficientPolyolefin

Disclosed is a laminated porous film which has both gas permeability and heat resistance and can exhibit excellent smoothness and excellent pin extraction properties when used as a separator for a battery. The laminated porous film is characterized by having a heat-resistant layer laminated on at least one surface of a polyolefin resin porous film, wherein the heat-resistant layer comprises a filler and a resin binder, and wherein the surface of the heat-resistant layer has a static friction coefficient of 0.45 or less, a gas permeability degree of 2000 sec / 100 ml or less and a tensile elastic modulus of 400 to 1000 MPa when the film is stretched in the lengthwise direction at a stretching rate of 3%.

Owner:MITSUBISHI PLASTICS INC

Biaxially oriented polyester film and flexible disk

InactiveUS6485810B1Dimensional stability is not deterioratedImprove adhesionRecord carriersMagnetic materials for record carriersStatic friction coefficientPolyester

A biaxially oriented polyester film which has a difference between refractive index on the front side and refractive index on the rear side of the film of 0 to 0.002, a heat shrinkage factor of 0 to 0.6% when it is heated at 105° C. for 30 minutes under no load, a Young's modulus of 4,609 MPa (470 kg / mm2) or more and a difference between the maximum value and the minimum value of Young's modulus on the film plane of 981 MPa (100 kg / mm2) or less, a center line average roughness on the film plane of 2 to 10 nm, and a static friction coefficient of 0.55 or less. A flexible disk having excellent electromagnetic conversion characteristics can be produced by forming an adhesive layer on both sides of the film and a magnetic layer on the adhesive layer.

Owner:TEIJIN LTD

Resin-based yawing brake pad for wind-generated generator and preparation method thereof

InactiveCN101956775AMeet the requirements of yaw low speed brakingHigh coefficient of static frictionFriction liningLow speedAluminum silicate

The invention discloses a resin-based yawing brake pad for a wind-generated generator and a preparation method thereof. The resin-based yawing brake pad comprises phenolic resin, nitrile butadiene rubber, organic friction powder, chopped steel fiber, red copper fiber, aramid fiber, aluminum silicate / KFK fiber, graphite, barite and the like. The preparation method comprises the following steps of: weighing various components according to the formula; mixing the components by a plow harrow type blender mixer at high speed; ensuring that each fiber is fully dispersed uniformly; hot pressing forming at the temperature of 160-200DEG C; carrying out heat treatment in a heat treatment tank; cooling to the room temperature along the temperature of the furnace; and finally, machining to obtain the resin-based yawing brake pad. Compared with the general powder metallurgy brake pad, the yawing brake pad has the advantages of proper static friction coefficient, stable friction coefficient, low brake noise, smaller antithesis wear and lower manufacturing cost and can fully meet the yawing low-speed brake of the wind-generated generator.

Owner:HUNAN BOYUN AUTOMOBILE BRAKE MATERIALS +1

Measuring method and measuring device of dynamic friction characteristics on textile surface

ActiveCN103163068AEasy to controlUsing mechanical meansMaterial analysisStatic friction coefficientLinear motion

The invention discloses a measuring method and a measuring device of dynamic friction characteristics on the textile surface. The measuring device comprises a measuring assembly, a reciprocated motion mechanism, a lifting mechanism and a machine frame, wherein the measuring assembly comprises a sliding block fixed sleeve and a sliding block, flanges arranged at two ends of the sliding block are installed in a groove of the sliding block fixed sleeve, the vertical direction of the sliding block is floating, and the measuring device can change the location of the machine frame through the lifting mechanism. According to the measuring method, the reciprocated uniform speed linear motion of the sliding block is achieved by means of the reciprocated mechanism, and therefore friction force born by the sliding block can be converted into side pressure of the sliding block on the sliding block fixed sleeve, and measurement of the dynamic friction coefficient and static friction coefficient on the textile surface can be achieved by means of measurement of dynamic change of the side pressure. Three friction characteristic indicators such as the dynamic friction coefficient, the static friction coefficient and the frictional work on the textile surface can be obtained by means of once measurement and calculation of the whole measuring device. The measuring method and the measuring device of the dynamic friction characteristics on the textile surface can be applied to textile detection industry and can achieve quick measurement of the friction characteristics on the textile surface.

Owner:CHINA JILIANG UNIV

Image forming apparatus, image forming method and process cartridge

InactiveUS20070019989A1Long durabilityEasy to cleanElectrographic process apparatusStatic friction coefficientLatent image

An image forming apparatus including an image bearing member having a static friction coefficient of from 0.1 to 0.3, a latent electrostatic image forming device, a developing device, and a cleaning device including a cleaning blade to remove remaining toner, in which the contact pressure of the cleaning blade to the image bearing member ranges from 1.5 to 10 g / cm, and the image bearing member and the cleaning blade satisfy the following relationships (1) and (2): 0.01 (kg)≦(Toff−T0) / r≦0.15 (kg) Relationship (1) 1.2≦(Ton−T0) / (Toff−T0)<3.8, Relationship (2) wherein T0 (kgcm) represents the rotation torque of the image bearing member when the cleaning blade is not in contact therewith, Toff, the rotation torque when the cleaning blade contacts the image bearing member and the toner is not thereon, Ton, the rotation torque when the cleaning blade contacts the image bearing member and the toner is thereon for development, and r represents the radius of the image bearing member.

Owner:RICOH KK

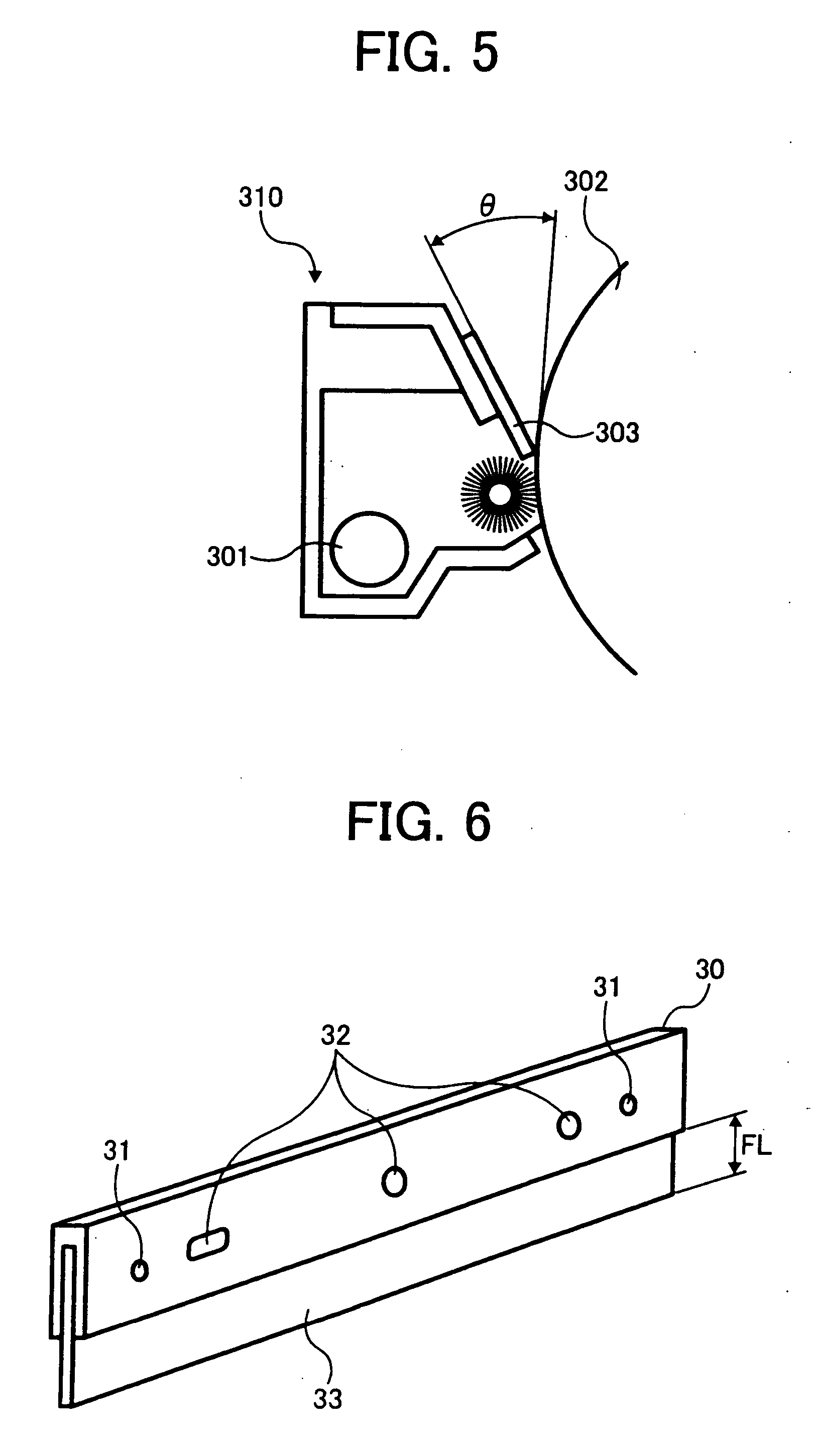

Brush member and transfer device and image forming apparatus using the same

InactiveUS20070014597A1Solve problemsElectrographic process apparatusReturned AmountStatic friction coefficient

In an image forming apparatus, a transfer brush with length of raised bristles on the surface of a metal holder equal to or smaller than 5.8 millimeters is used. Alternatively, a transfer brush with a maximum bristle inclination amount of raised bristles in a brush unit including a plurality of bristles equal to or smaller than 0.53 millimeter or a transfer brush with a maximum bristle inclination return amount of raised bristles in the brush unit equal to or smaller than 0.30 millimeter is used. An amount of biting into a paper conveyor belt in the brush unit is set to a value equal to or smaller than 2.5 millimeters. A paper conveyor belt with hardness of the rear side equal to or lower than 78 Hs is used. Alternatively, a paper conveyor belt with a coefficient of static friction on the rear surface equal to or lower than 0.75 is used.

Owner:RICOH KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com