Patents

Literature

67results about How to "High coefficient of static friction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lubricating oil composition

ActiveUS20090082233A1Excellent friction propertyExcellent fuel saving propertyLiquid carbonaceous fuelsAdditivesMagnesiumStatic friction coefficient

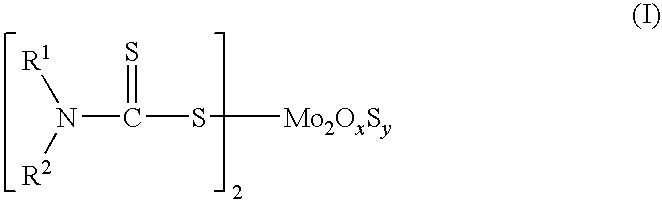

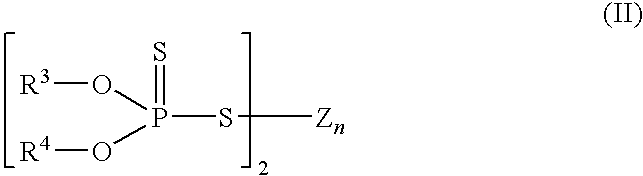

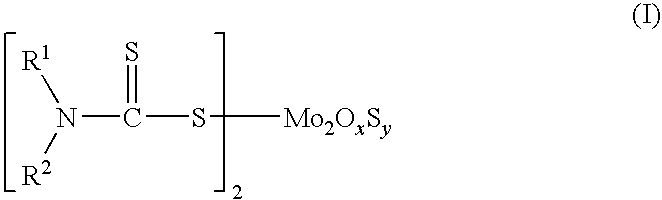

A lubricating oil composition includes lubricating oil base oil, an organic molybdenum compound (A), zinc dialkyl dithiophosphate (B), at least one compound (C) selected from calcium sulfonate, calcium phenate, and magnesium sulfonate and having a base number of 230 mgKOH / g or more, and an ashless dispersant containing boron or a mixture of an ashless dispersant containing boron and an ashless dispersant containing no boron (D) in predetermined ratios, in which: a mass ratio (P / Mo) of the P content to the Mo content in the composition is 1.5 or more; a mass ratio (CaMg / Mo) of a total content of the Ca and Mg derived from the component (C) to the Mo content in the composition is 3 or more; and a mass ratio (B / N) between B and N derived from the component (D) in the composition is 0.5 or more. The lubricating oil composition of the present invention has a high static friction coefficient of wet clutch, has excellent frictional property in a power transmission mechanism, has excellent fuel saving property, and is suitably used for power transmission lubricating oil and engine lubricating oil.

Owner:IDEMITSU KOSAN CO LTD

Resin-based yawing brake pad for wind-generated generator and preparation method thereof

InactiveCN101956775AMeet the requirements of yaw low speed brakingHigh coefficient of static frictionFriction liningLow speedAluminum silicate

The invention discloses a resin-based yawing brake pad for a wind-generated generator and a preparation method thereof. The resin-based yawing brake pad comprises phenolic resin, nitrile butadiene rubber, organic friction powder, chopped steel fiber, red copper fiber, aramid fiber, aluminum silicate / KFK fiber, graphite, barite and the like. The preparation method comprises the following steps of: weighing various components according to the formula; mixing the components by a plow harrow type blender mixer at high speed; ensuring that each fiber is fully dispersed uniformly; hot pressing forming at the temperature of 160-200DEG C; carrying out heat treatment in a heat treatment tank; cooling to the room temperature along the temperature of the furnace; and finally, machining to obtain the resin-based yawing brake pad. Compared with the general powder metallurgy brake pad, the yawing brake pad has the advantages of proper static friction coefficient, stable friction coefficient, low brake noise, smaller antithesis wear and lower manufacturing cost and can fully meet the yawing low-speed brake of the wind-generated generator.

Owner:HUNAN BOYUN AUTOMOBILE BRAKE MATERIALS +1

Carbon fiber and ceramic fiber reinforced wet paper-based friction sheet and manufacturing method thereof

ActiveCN103438127AGuaranteed stabilityGood physical and mechanical propertiesOther chemical processesNon-macromolecular organic additionStatic friction coefficientCarbon fibers

The invention relates to a carbon fiber and ceramic fiber reinforced wet paper-based friction sheet and a manufacturing method thereof. The wet paper-based friction sheet provided by the invention has the characteristics of high friction coefficient, stable friction performance, good wear resistance, adjustable dynamic / static friction coefficient ratio and high energy absorption capacity; the manufacturing method has the characteristics of simple working procedure and convenience and easiness in manufacture. The technical scheme is as follows: the carbon fiber and ceramic fiber reinforced wet paper-based friction sheet comprises ingredients including a substrate material, a friction performance regulator and a forming binder and further comprises an appropriate amount of polyacrylamide, an appropriate amount of polyoxene and an appropriate amount of sodium dodecylbenzene sulfonate; the manufacturing method of the carbon fiber and ceramic fiber reinforced wet paper-based friction sheet comprises the following steps of preparing base paper of a carbon fiber and ceramic fiber reinforced wet paper-based friction material; manufacturing the carbon fiber and ceramic fiber reinforced wet paper-based friction sheet.

Owner:杭州汉乐科新材料科技有限公司

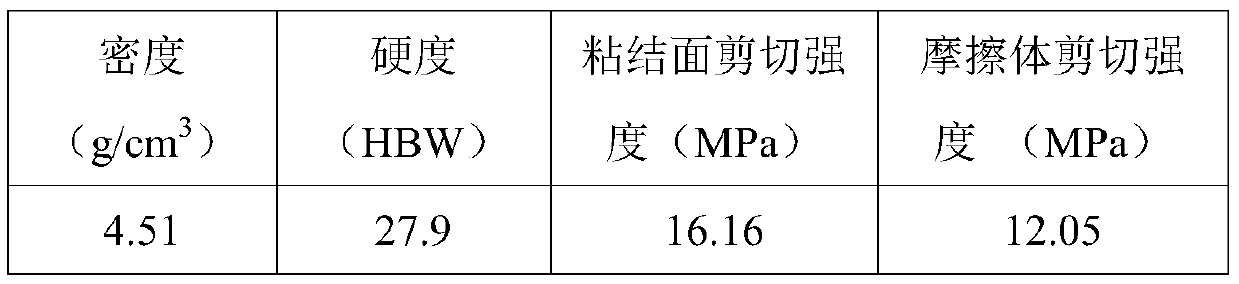

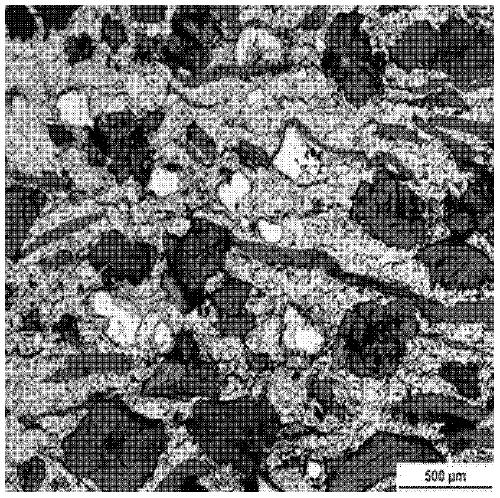

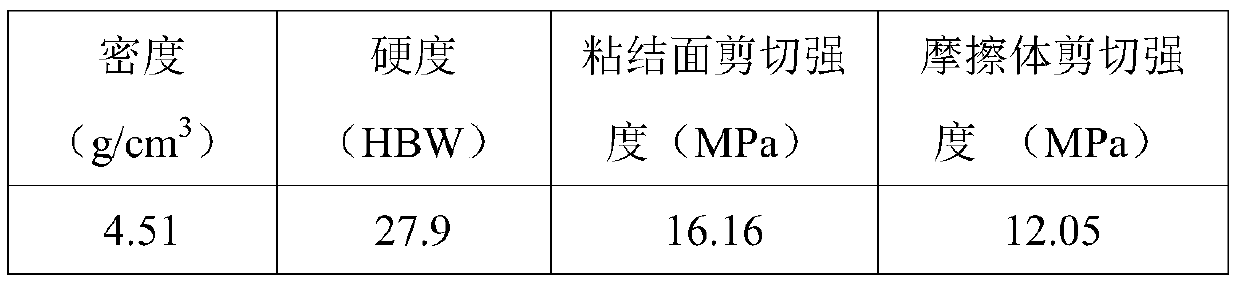

Copper-based powder metallurgy friction material for dry clutch of heavy-duty vehicle and preparation method thereof

ActiveCN110102754AHigh and stable coefficient of frictionHigh coefficient of static frictionTransportation and packagingMetal-working apparatusCopper platingGraphite particle

The invention discloses a copper-based powder metallurgy friction material for a dry clutch of a heavy-duty vehicle and a preparation method thereof. The matrix component of the friction material is copper and iron; the lubricating component is graphite particles, crystalline flake graphite, molybdenum disulfide and petroleum coke; the friction component is ferrochrome, zirconia and silicon dioxide; and the strengthening component is tin. The friction material comprises the following, by weight 50%-60% of copper powders, 1%-10% of iron powders, 5%-20% of graphite particle powders, 1%-5% of flake graphite, 1%-6% of molybdenum disulfide powders, 1%-15% of petroleum coke powders, 3%-9% of ferrochrome powders, 3%-9% of the zirconia, 1%-5% of the silicon dioxide, and 1%-4% of tin powders. The preparation method of the friction material comprises the following steps of mixing a mixture according to the composition of the powder metallurgical friction material; mixing the mixture in a V-shaped mixer evenly and pressing; and then sintering together with a copper-plated steel back to obtain the copper-based powder metallurgical friction material. The copper-based powder metallurgy frictionmaterial has high and stable friction coefficients and excellent wear resistance.

Owner:CENT SOUTH UNIV

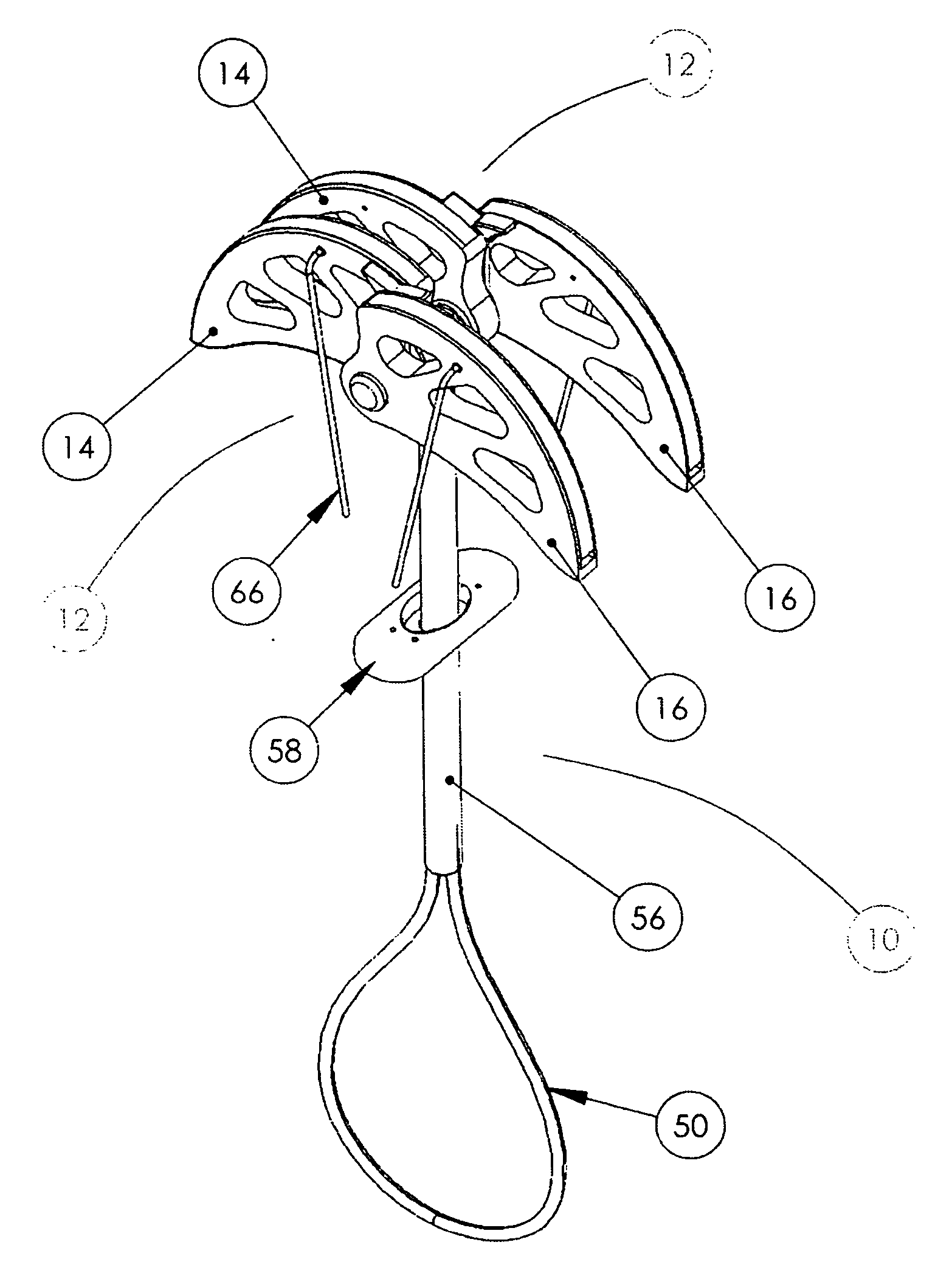

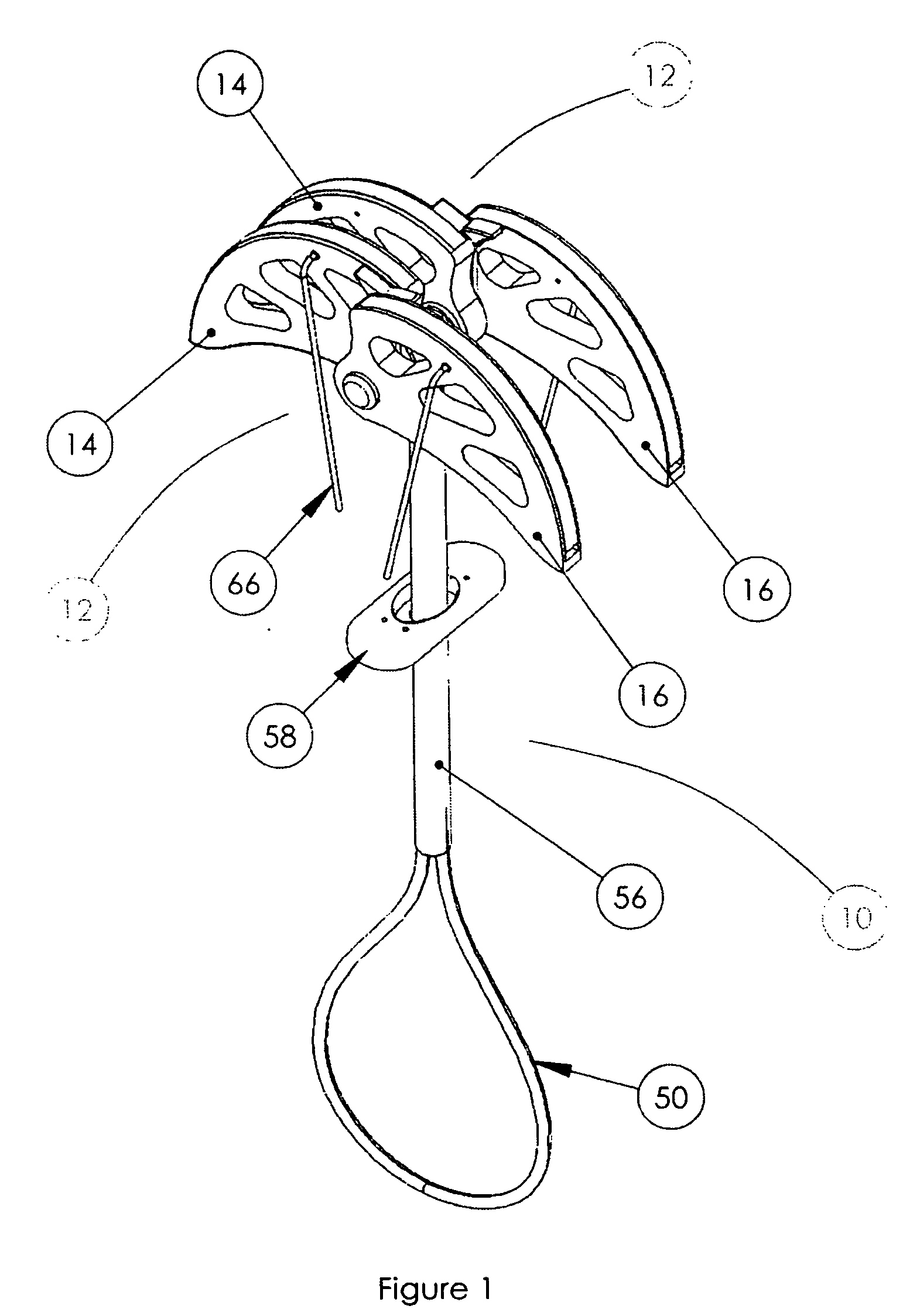

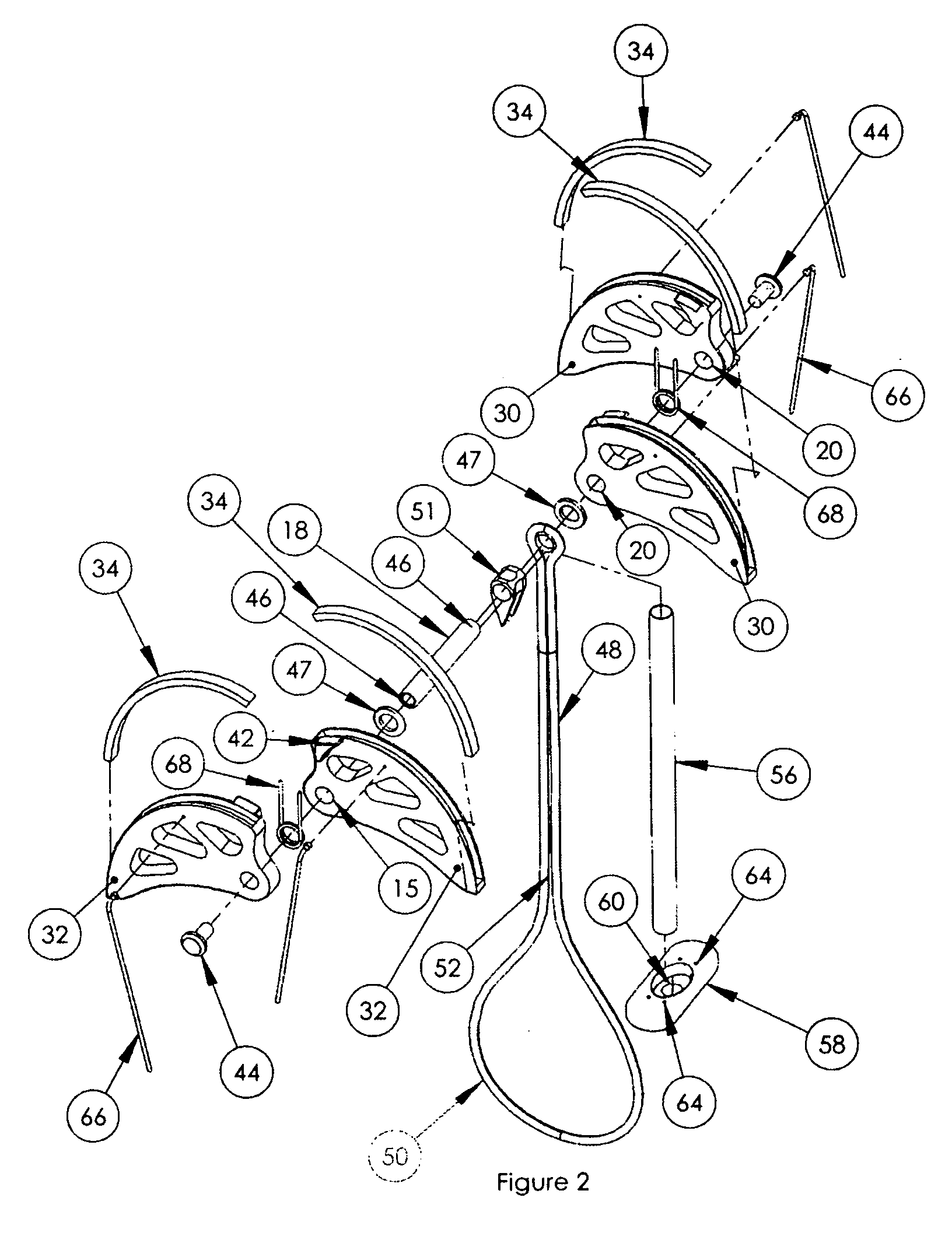

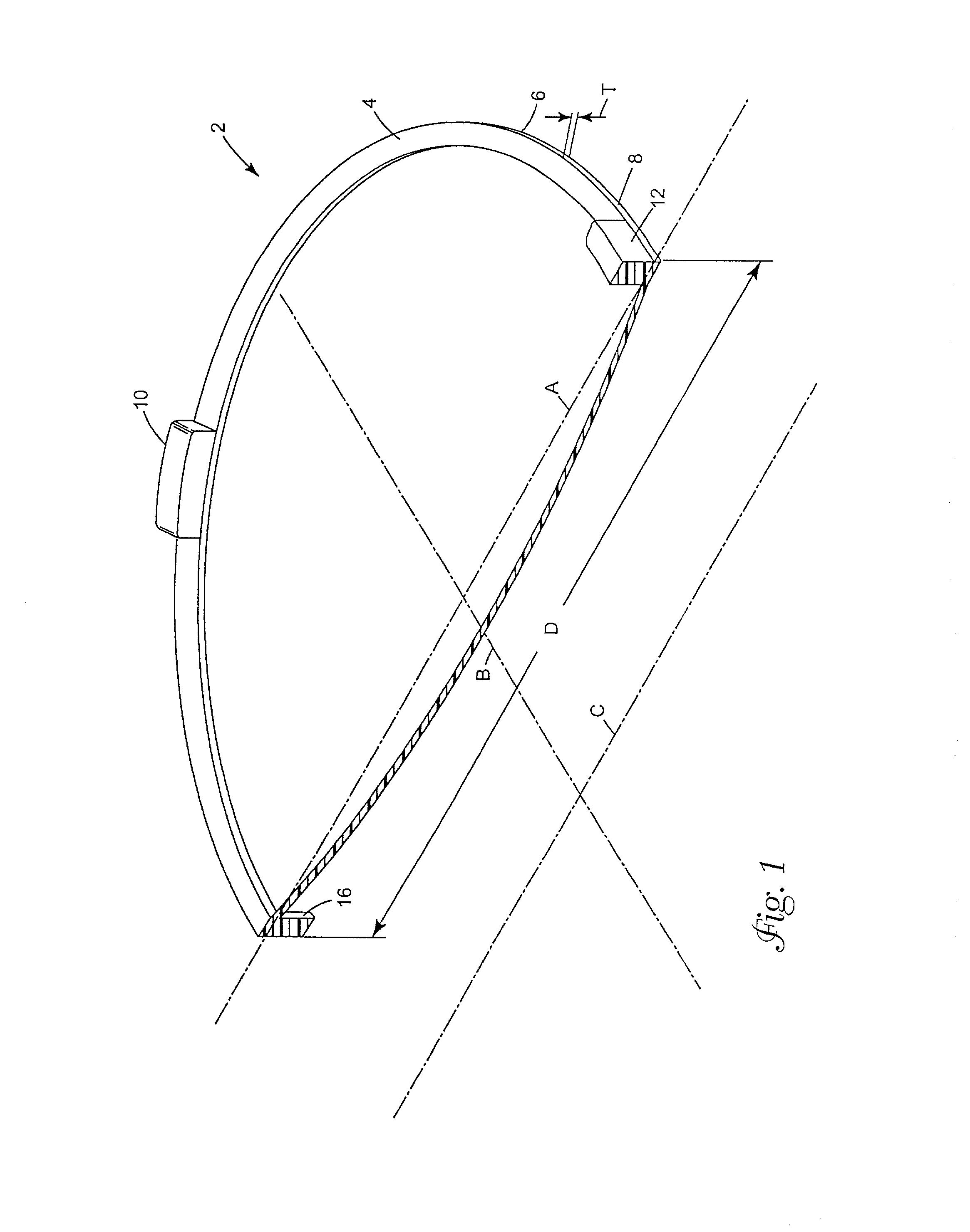

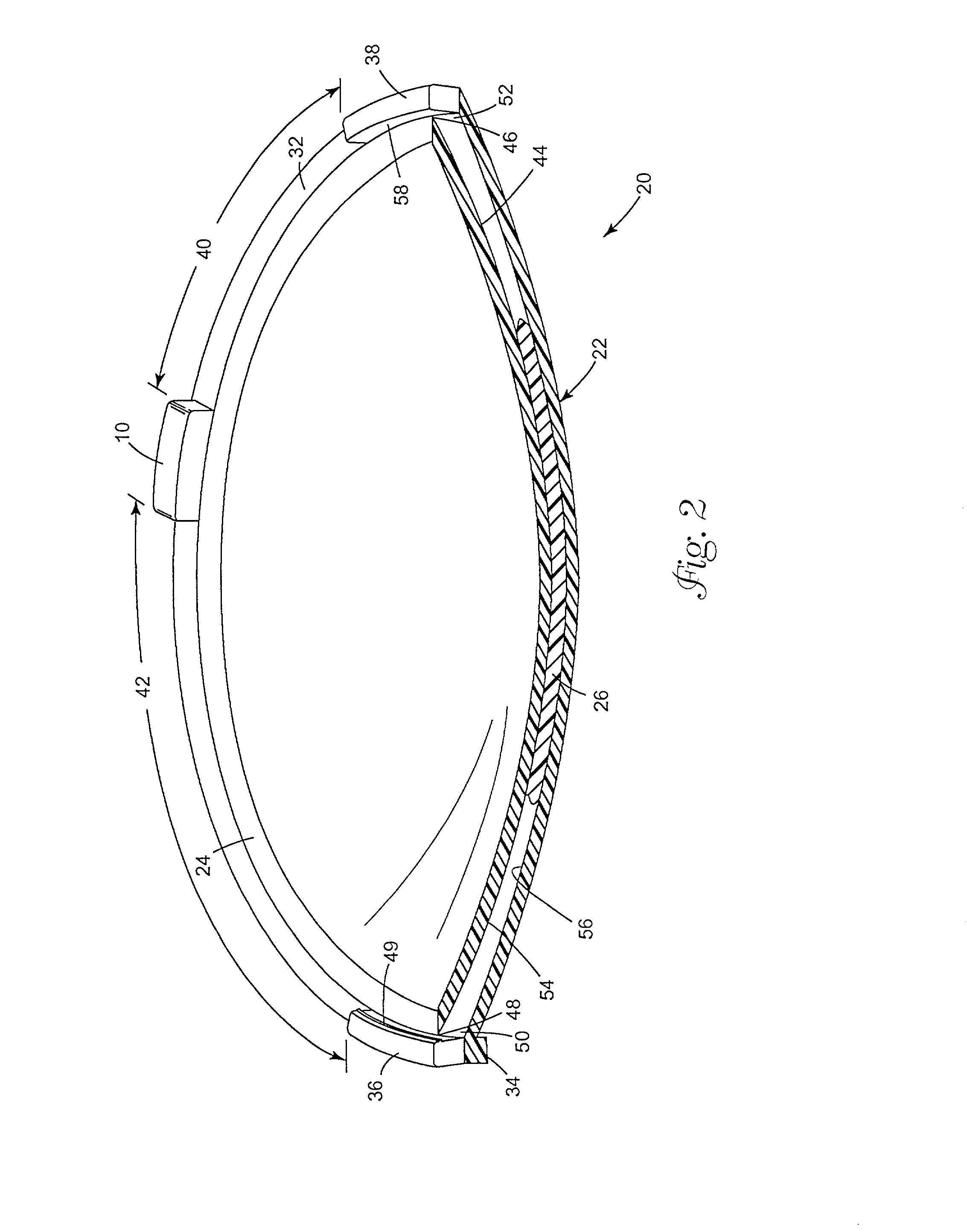

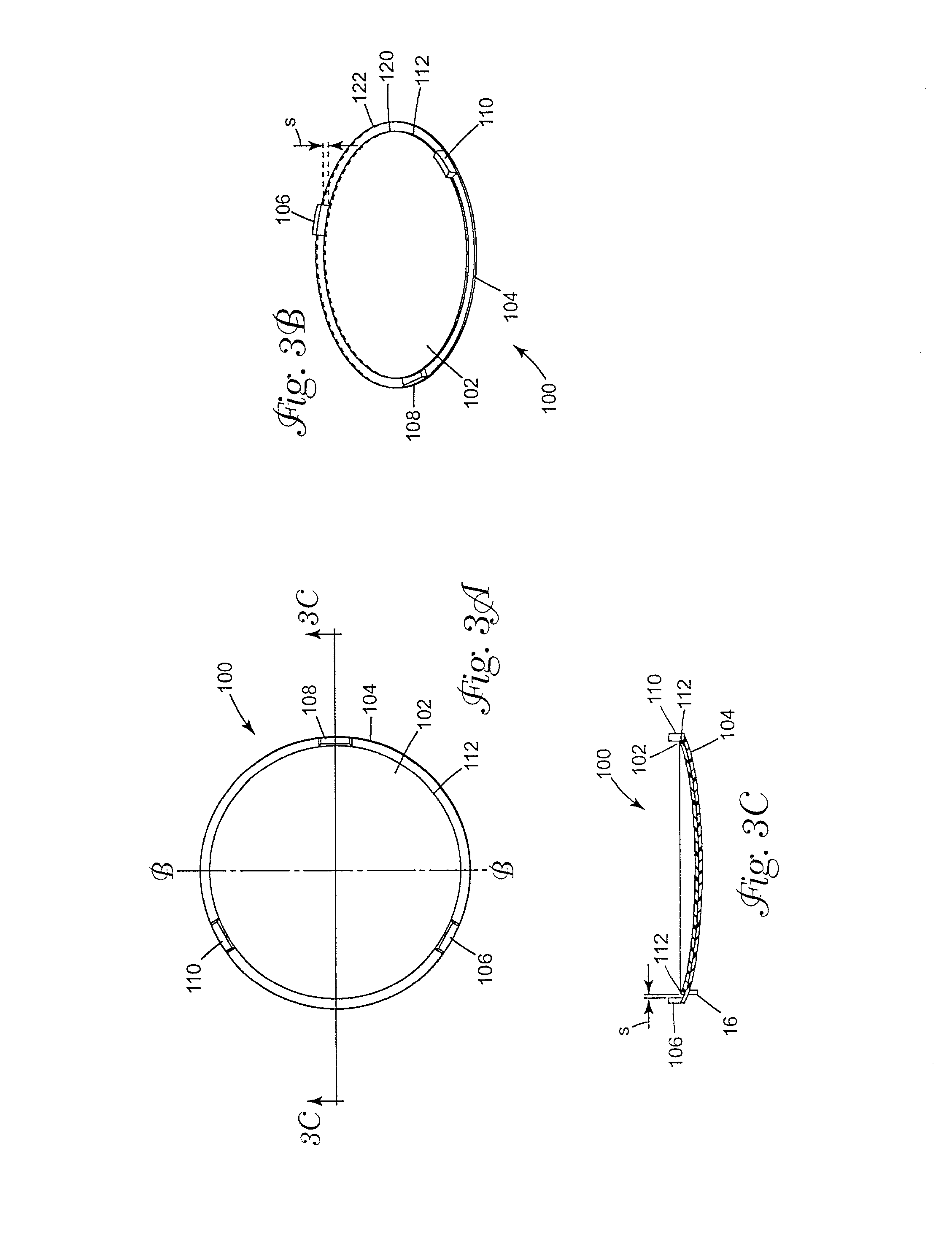

Camming device for climbing or use thereof

InactiveUS20060231708A1High coefficient of static frictionEasy to manufactureMountaineeringStands/trestlesFall protectionEngineering

A camming device is provided that has a superior range of operation, is lighter and has lower internal compressive forces. The improvement is a result of using a composition having a co-efficient of friction ranging between 0.35-0.55 affixed to the contact area, for example, a semi-metallic composition. An improved method of fall protection is also provided, as is a method of manufacture.

Owner:ROBERTSON BRYSON DAVID ROSS +2

Lubricating oil composition

ActiveUS7820599B2High coefficient of static frictionImprove fuel saving effectLiquid carbonaceous fuelsAdditivesStatic friction coefficientSulfonate

A lubricating oil composition includes lubricating oil base oil, an organic molybdenum compound (A), zinc dialkyl dithiophosphate (B), at least one compound (C) selected from calcium sulfonate, calcium phenate, and magnesium sulfonate and having a base number of 230 mgKOH / g or more, and an ashless dispersant containing boron or a mixture of an ashless dispersant containing boron and an ashless dispersant containing no boron (D) in predetermined ratios, in which: a mass ratio (P / Mo) of the P content to the Mo content in the composition is 1.5 or more; a mass ratio (CaMg / Mo) of a total content of the Ca and Mg derived from the component (C) to the Mo content in the composition is 3 or more; and a mass ratio (B / N) between B and N derived from the component (D) in the composition is 0.5 or more. The lubricating oil composition of the present invention has a high static friction coefficient of wet clutch, has excellent frictional property in a power transmission mechanism, has excellent fuel saving property, and is suitably used for power transmission lubricating oil and engine lubricating oil.

Owner:IDEMITSU KOSAN CO LTD

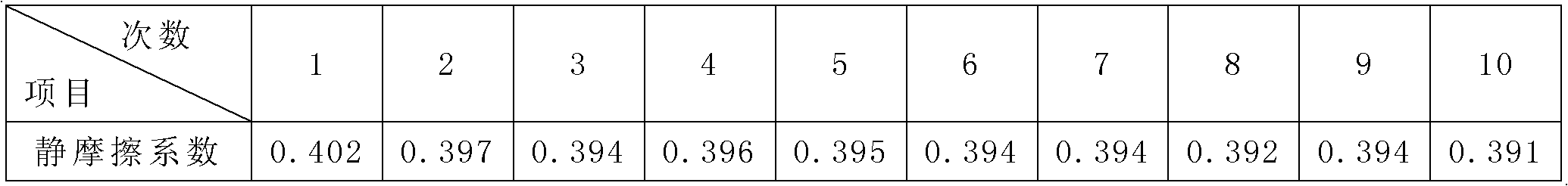

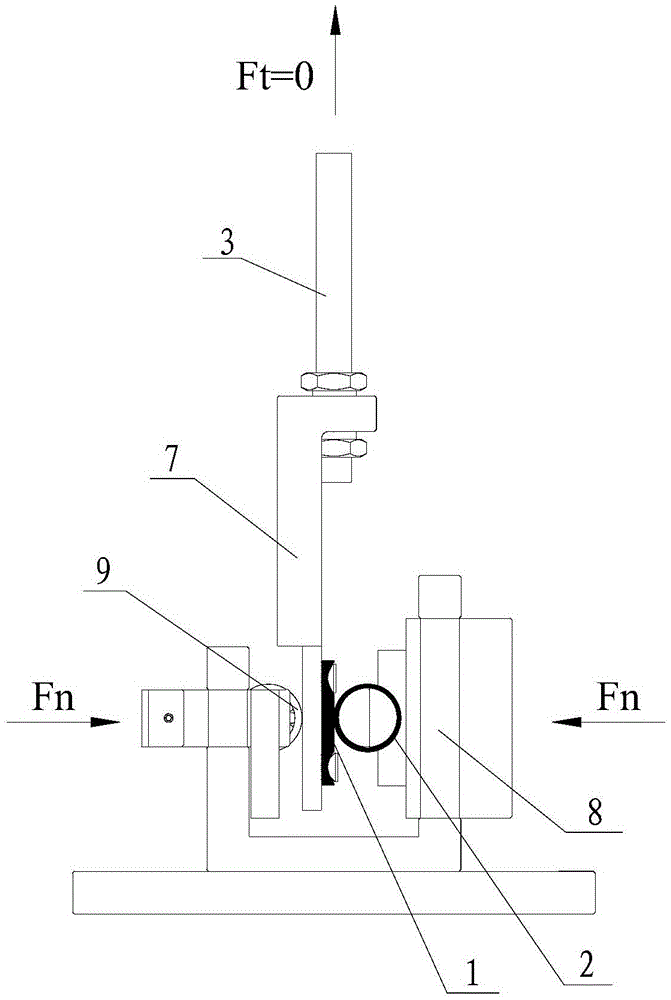

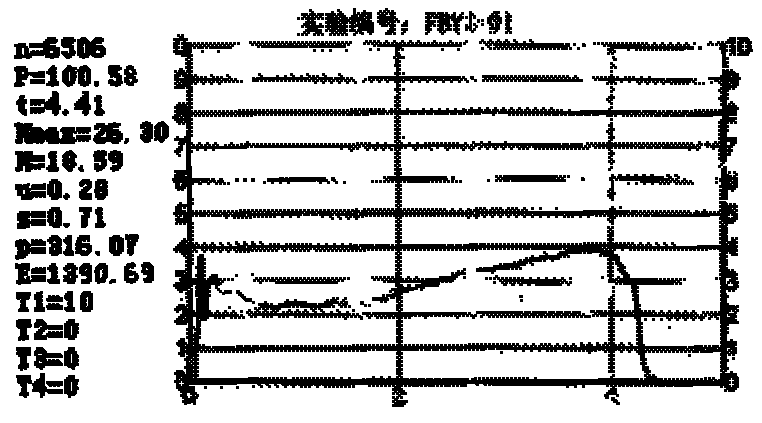

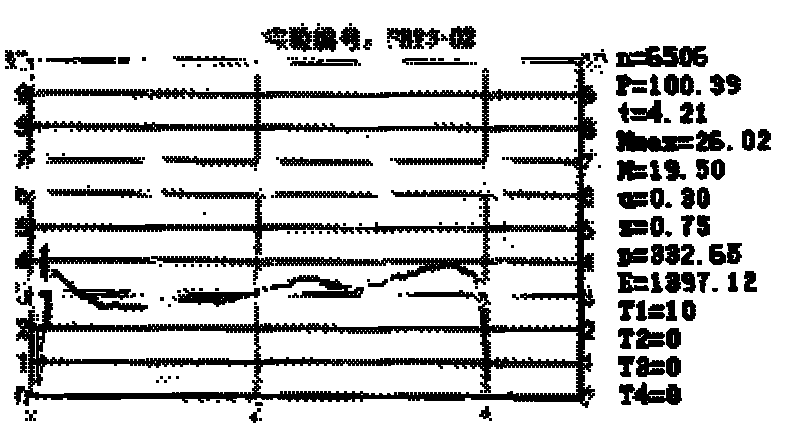

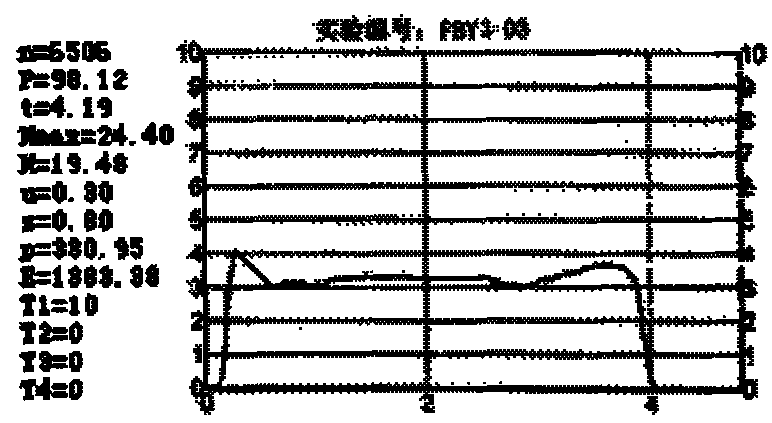

Test method applicable to measurement of static friction coefficient of engineering components

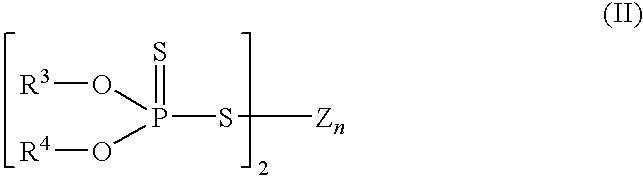

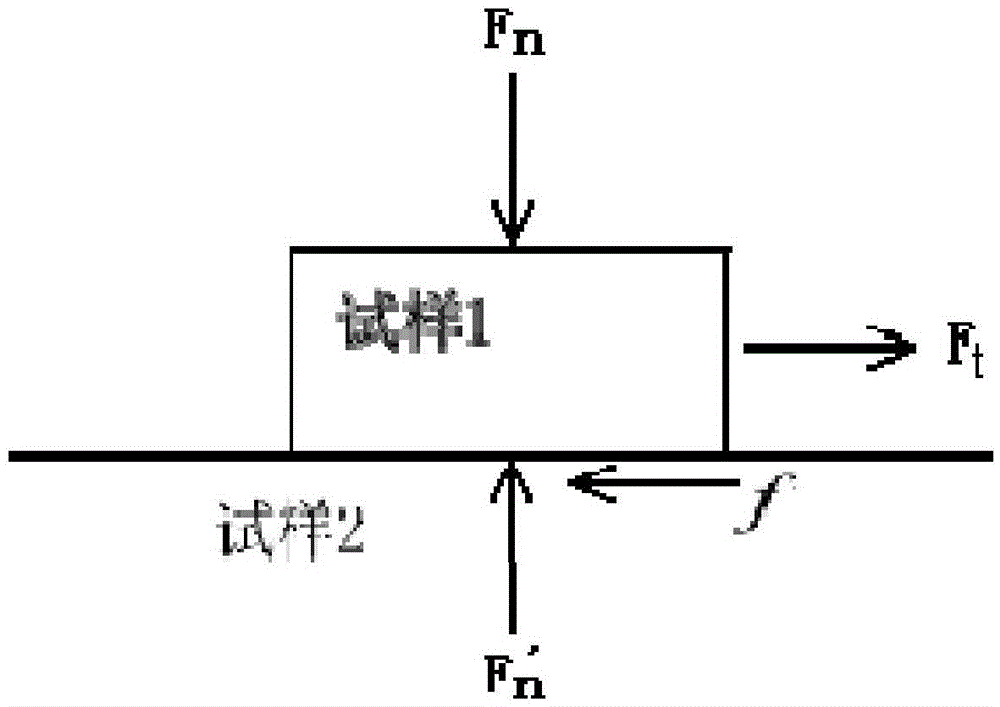

InactiveCN105606527AEfficient collectionValid recordUsing mechanical meansMaterial analysisStatic friction coefficientConstant force

The invention discloses a test method applicable to measurement of a static friction coefficient of engineering components. The test method especially aims at measuring the static friction coefficient of a case having smaller contact area between components; the test method is designed from a static friction basic definition, specimens are dragged at a constant force loading speed until the specimens are developed into a state of sliding relative to each other from a state of relative motion tendency, and an Ft-t relation curve can be effectively collected and recorded, so that a maximum static friction force is obtained, and then the static friction coefficient of the components is obtained. The method adopting the static friction coefficient obtained by the method for design and evaluation of component structure stability is conservative, has more security, and has application value in engineering. The test method is simple, has reliable results, and can be widely applied in measurement of the static friction coefficient between the two components under various complex work conditions.

Owner:SUZHOU NUCLEAR POWER RES INST +2

Metal-based yaw brake block for wind-powdered generator and manufacture method thereof

InactiveCN101799053AReduce manufacturing costImprove mechanical propertiesFriction liningFiberMechanical property

The invention relates to a metal-based yaw brake block for a wind-powdered generator and a manufacture method thereof. The materials comprise iron powder, copper powder, tin powder, sulfur, chopped steel fiber, copper fiber, high-alumina ceramic fiber, inorganic oxides, graphite, and the like. The manufacture method comprises the following steps of: firstly, weighting all the component materials according to a prescription; stirring and mixing in a special dry-type mixer to fully and evenly disperse all the fibers; pressing and molding at room temperature; then, sintering at a certain pressure and temperature; cooling in a furnace; and finally, mechanically processing to obtain a material of the invention. Compared with a common metallurgic brake block, the friction material prepared by the method remarkably improves the mechanical properties and the static friction torque of the materials by adding metal and ceramic fibers. Meanwhile, the product has the advantages of suitable and stable dynamic friction coefficient, better wear resistance, smaller dual wear and low manufacture cost and can fully satisfy the yaw brake requirement of a wind-powdered generator.

Owner:CENT SOUTH UNIV +1

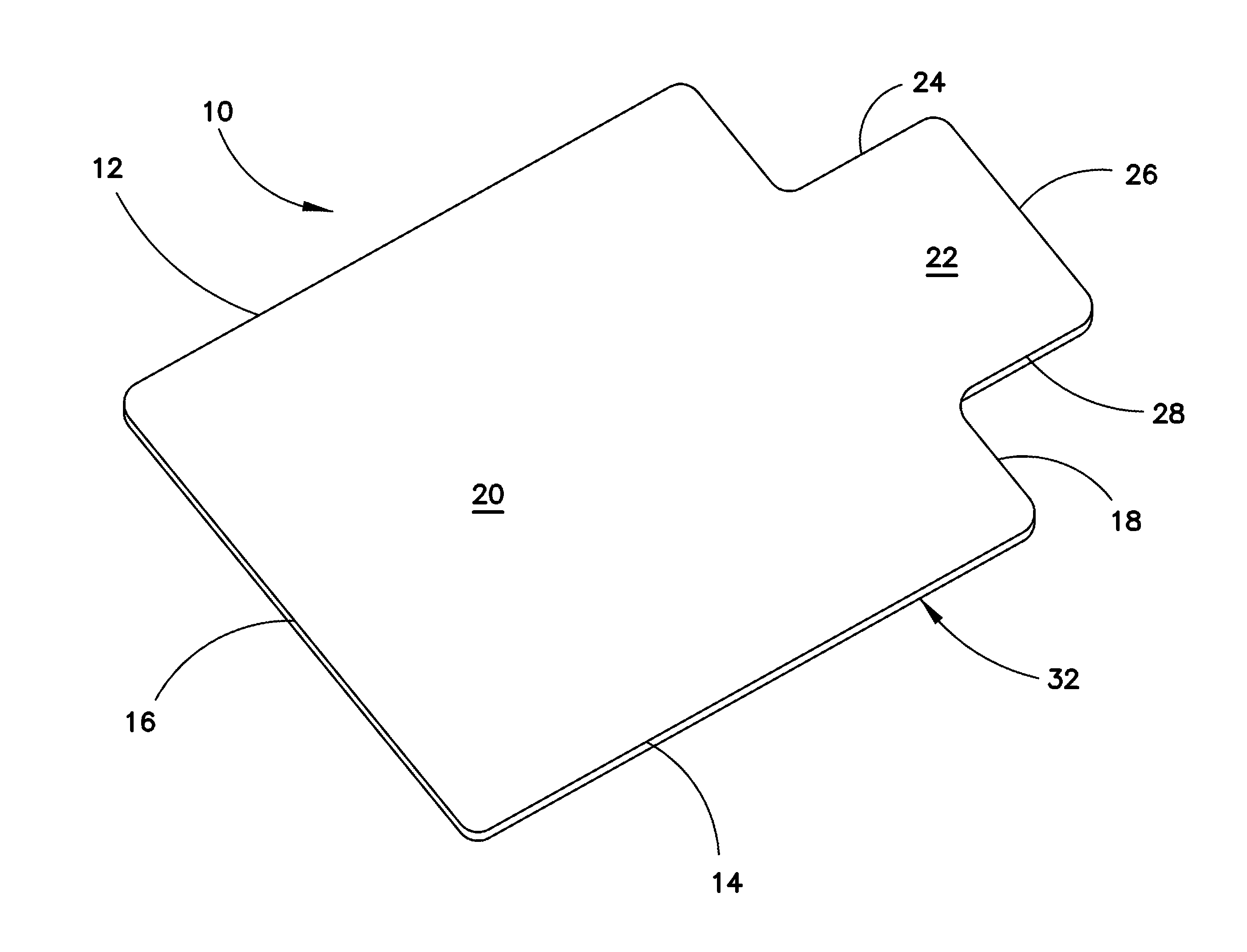

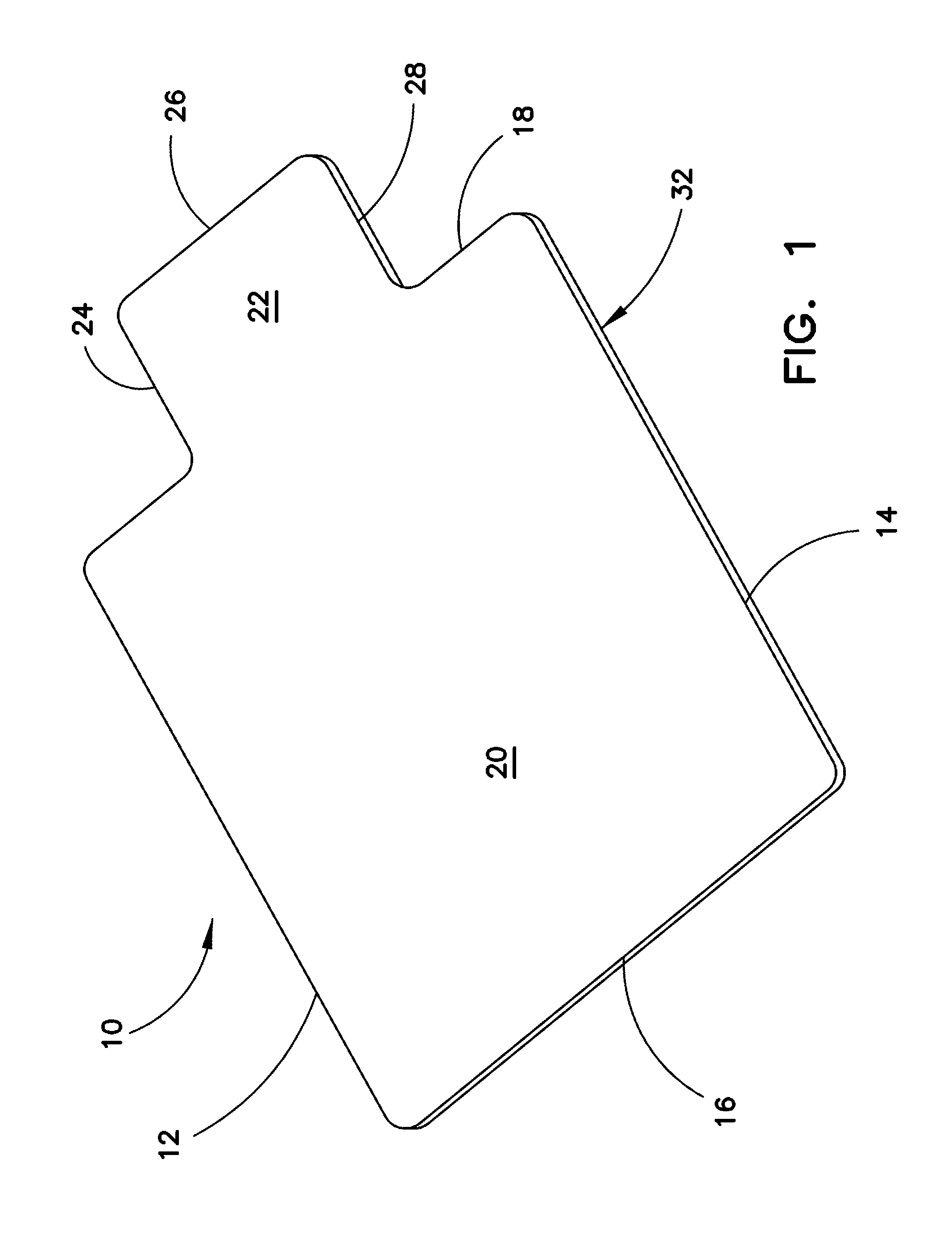

Lens blanks for ophthalmic elements

A polymeric front optical element blank is provided which may be laminated to a rear optical element blank. The polymeric front blank comprises an optical element having an exterior convex surface and an interior concave surface, with an edge between the exterior convex surface and the interior concave surface. The optical is provided with at least two projections which extend away from and higher than the edge on a side of the optical element having the concave surface. These projections assist in aligning an back optical element during lamination so that the two lenses will not move out of optical registry during lamination, especially where centrifugal forces are used to spread an adhesive between the front and rear lenses. It is preferred that there are at least three projections extending away from and higher than the edge on a side of the optical element having the concave surface. A particularly desirable and preferred process for using these lenses comprises the steps of: a) positioning a first optical element blank according to the invention having an interior surface and an exterior surface, b) applying a photopolymerizable adhesive composition on the interior surface of the optical element blank, the photopolymerizable adhesive composition being curable by UV radiation having a wavelength of between 385 and 410 nm, and the maximum spectral sensitivity of the photopolymerizable composition being within 15 nm of said UV radiation having a wavelength of between 385 and 410 c) positioning a second optical element blank having an interior surface and an exterior surface on the polymerizable adhesive composition with an interior face in contact with the polymerizable adhesive composition to form a prelaminated association, wherein at least one of the first and second optical element blanks absorbing at least 95% of any ultraviolet radiation component between 180 and 380 nm of incident radiation and allows at least 30% transmittal of at least one wavelength of ultraviolet radiation between 385 and 410 nm, and d) irradiating the prelaminated association with UV radiation having a significant component between 385 and 410 nm through at least one of the first and second optical element blanks to cure the adhesive and to laminate the first and second optical elements.

Owner:VISION EASE LENS

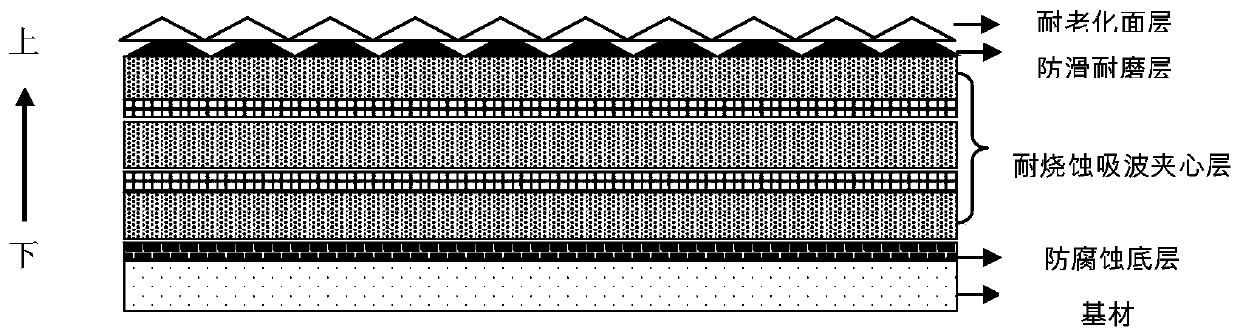

Ablation-resistant, wave-absorbing, antiskid and wear-resistant composite coating and preparation method thereof

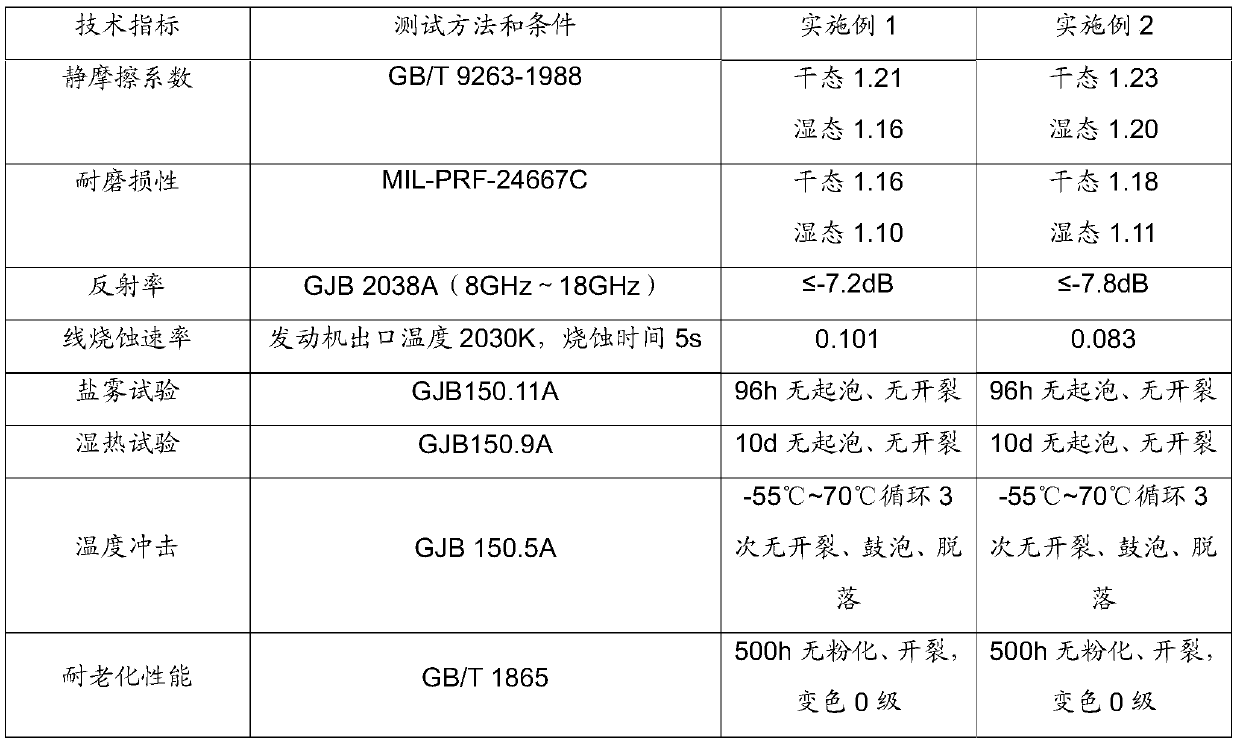

ActiveCN110885583AThe need for multifunctional integrationReduced viewing distanceFireproof paintsAnti-corrosive paintsStatic friction coefficientComposite coating

The invention provides an ablation-resistant, wave-absorbing, antiskid and wear-resistant composite coating and a preparation method thereof, and belongs to the field of special functional coatings. The composite coating comprises an anticorrosion bottom layer, an ablation-resistant wave-absorbing sandwich layer, an antiskid and wear-resistant layer and an anti-aging surface layer, and the composite coating is designed through collaborative matching of interlayer thickness to form a multifunctional compatible integrated coating. Compared traditional antiskid coatings, the coating of the invention has the following advantages: the process is simple, the reflectivity of the composite coating is smaller than or equal to -7 dB in a frequency band of 8-18 GHz, the composite coating has a low linear ablation rate and a good anti-aging performance, the static friction coefficient before and after abrasion is larger than or equal to 1.10, the composite coating can pass GJB150 environment testassessment, and the coating design scheme has remarkable technical advancement.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

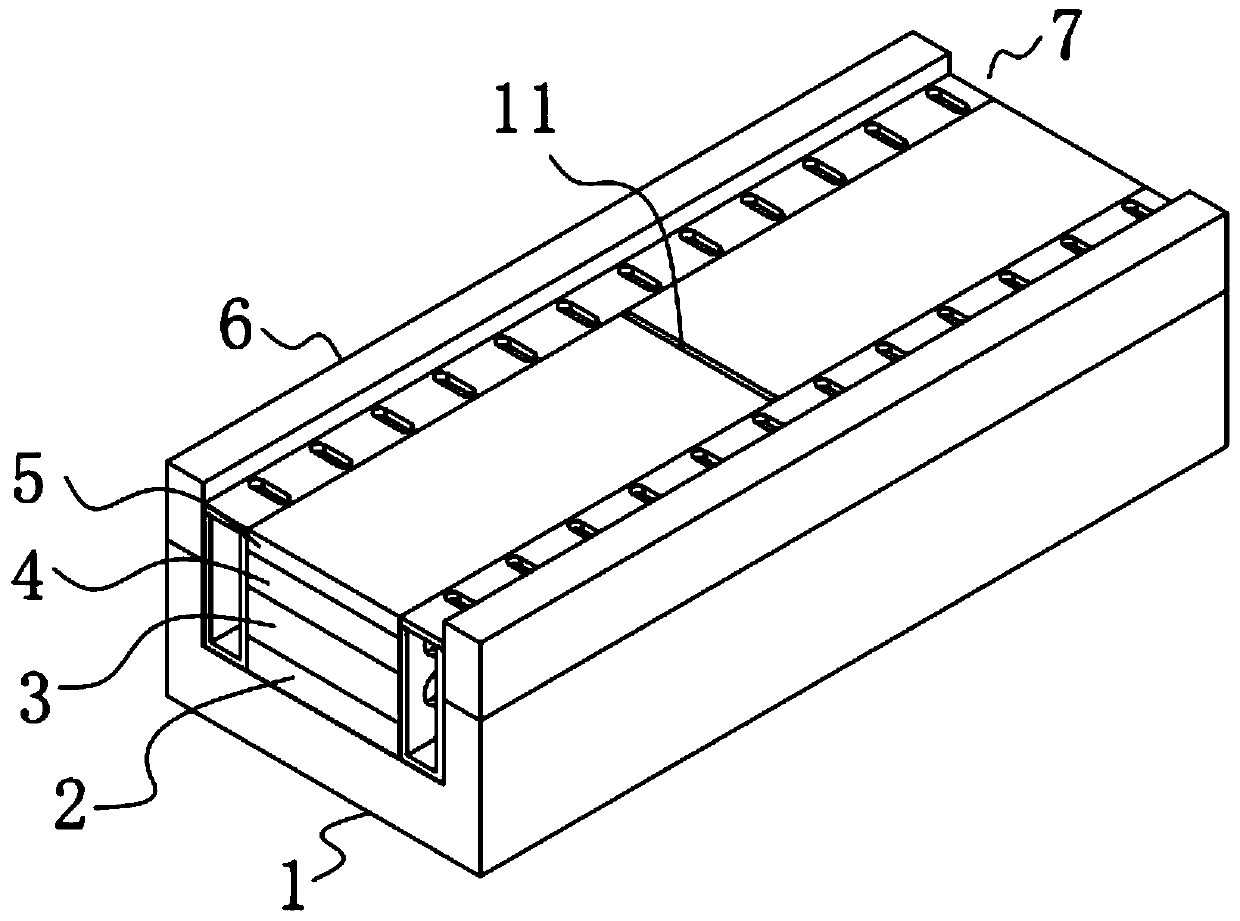

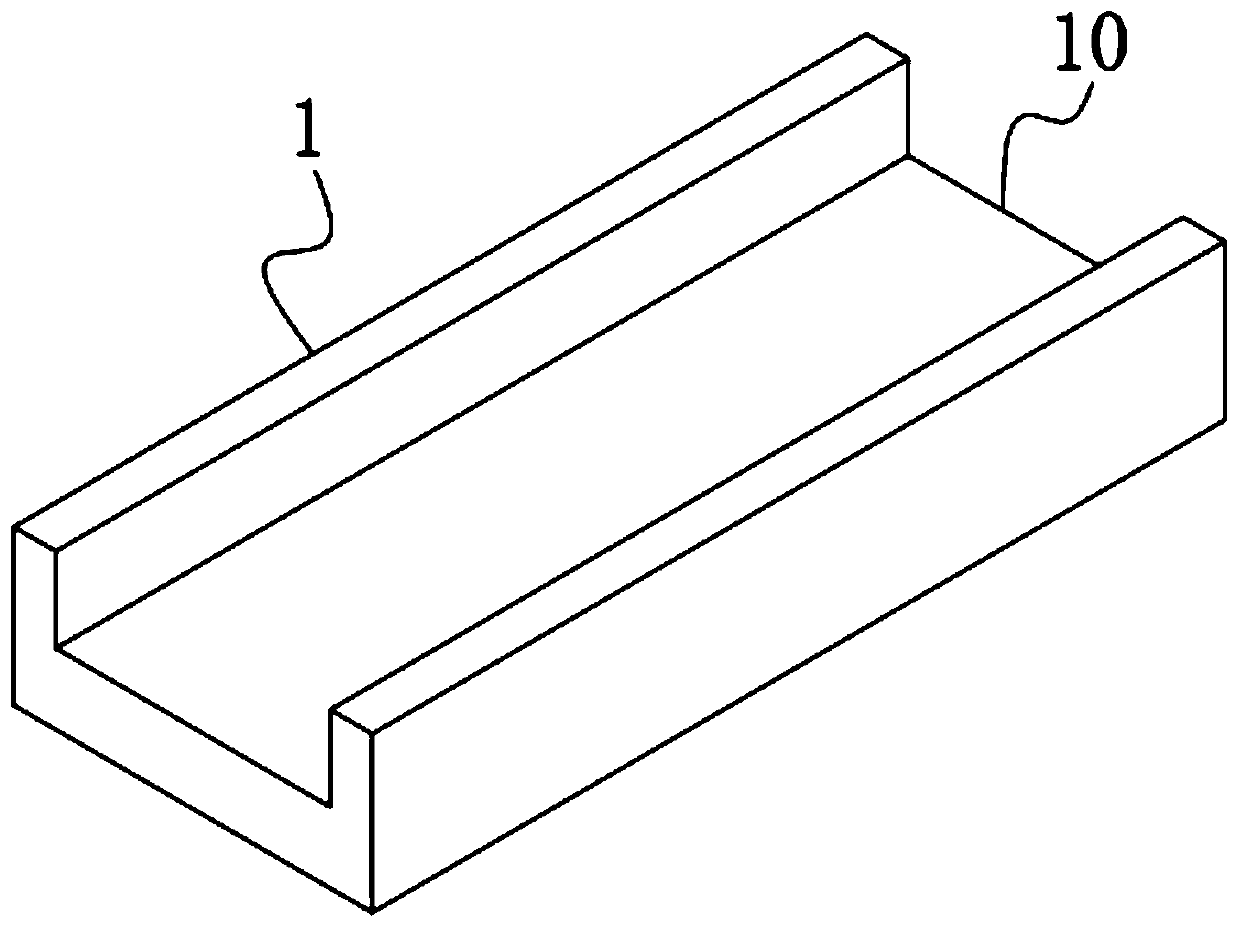

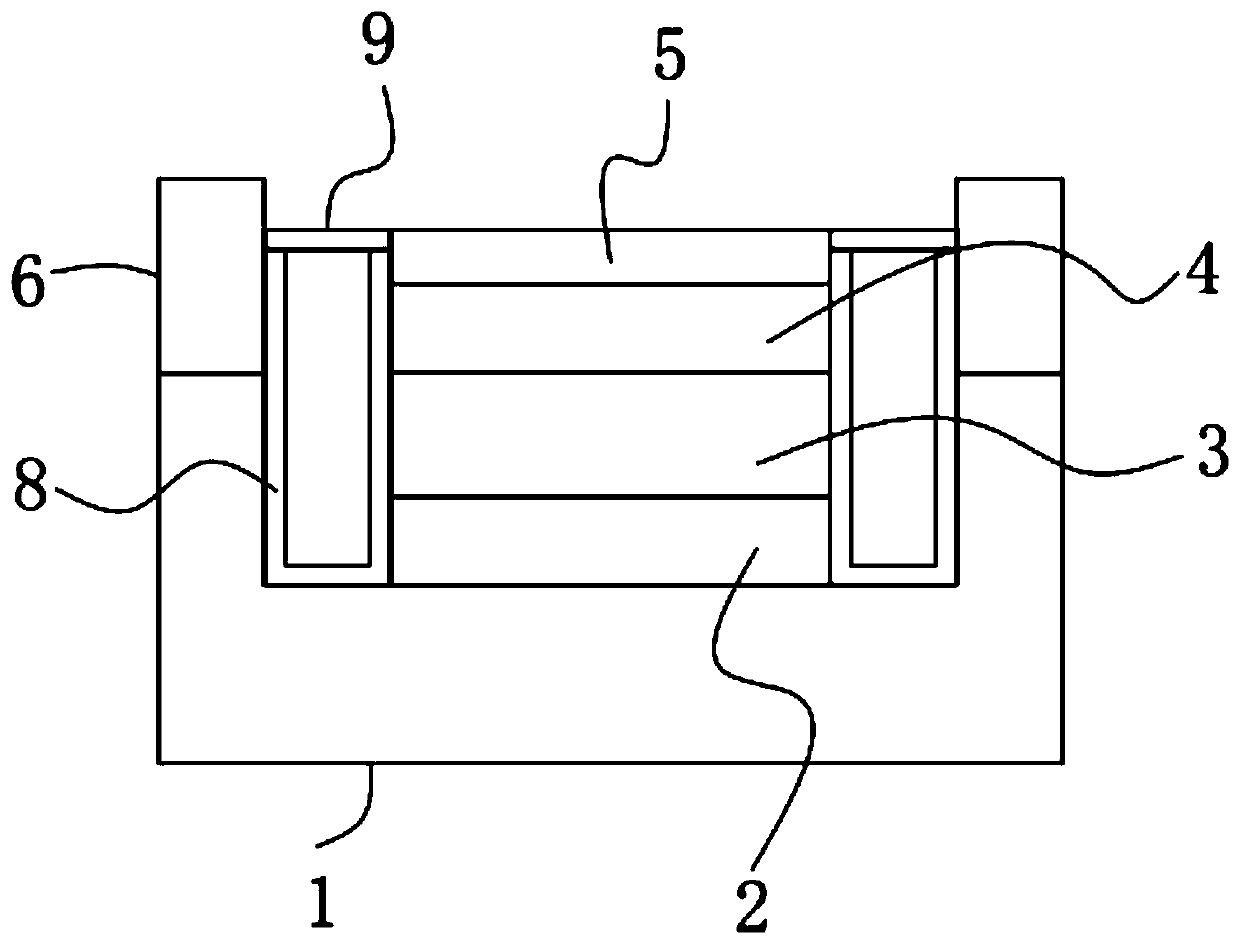

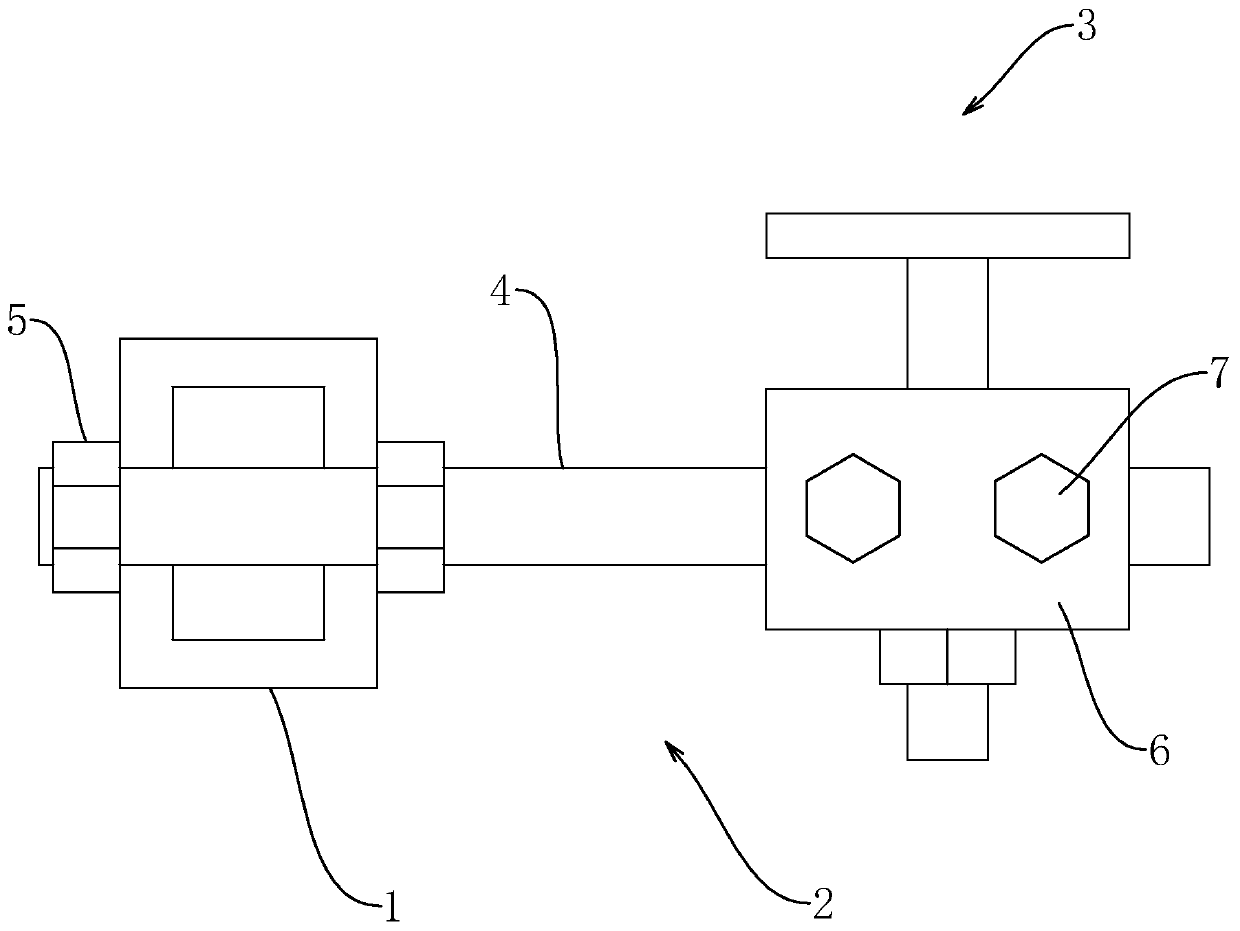

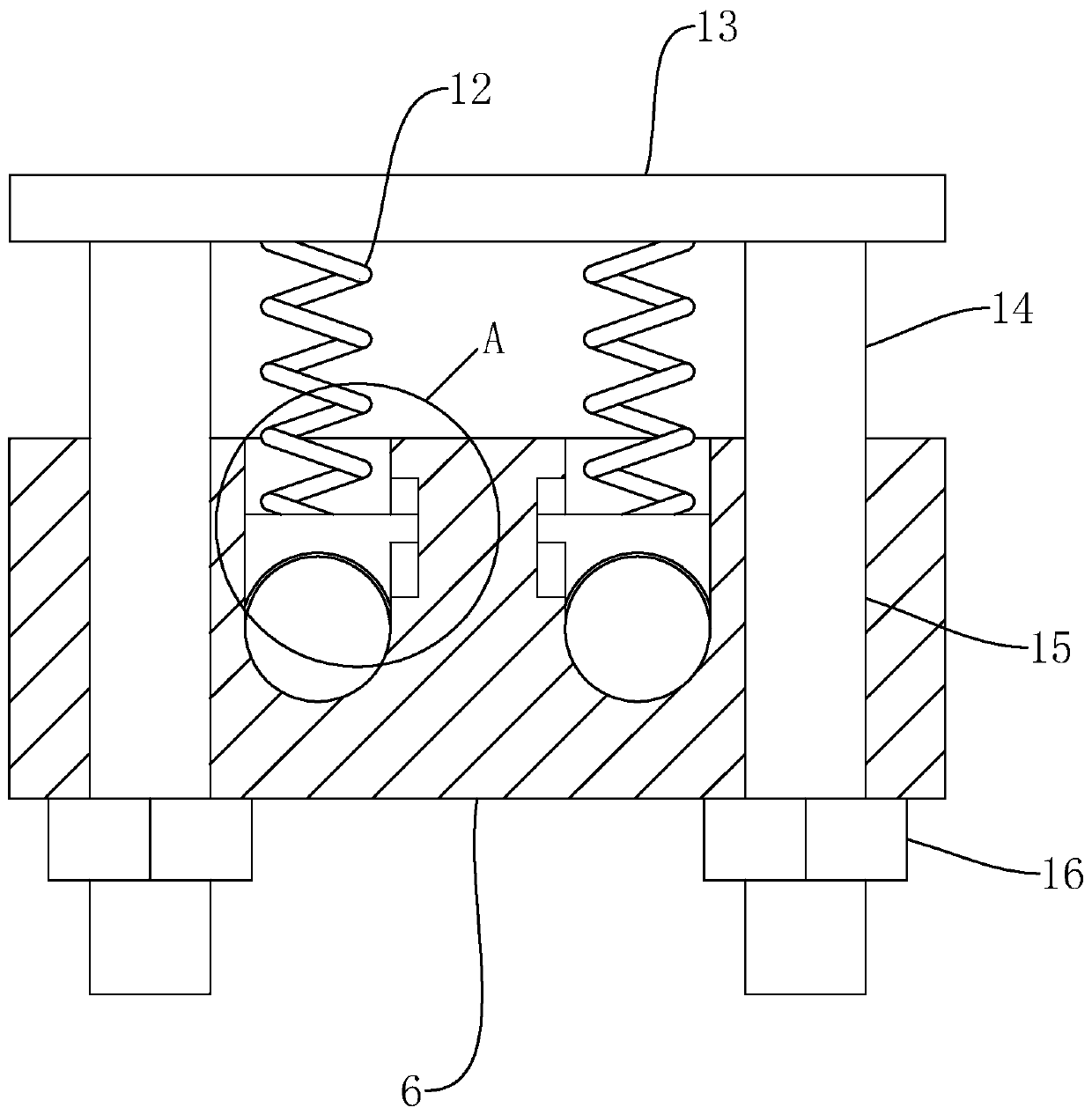

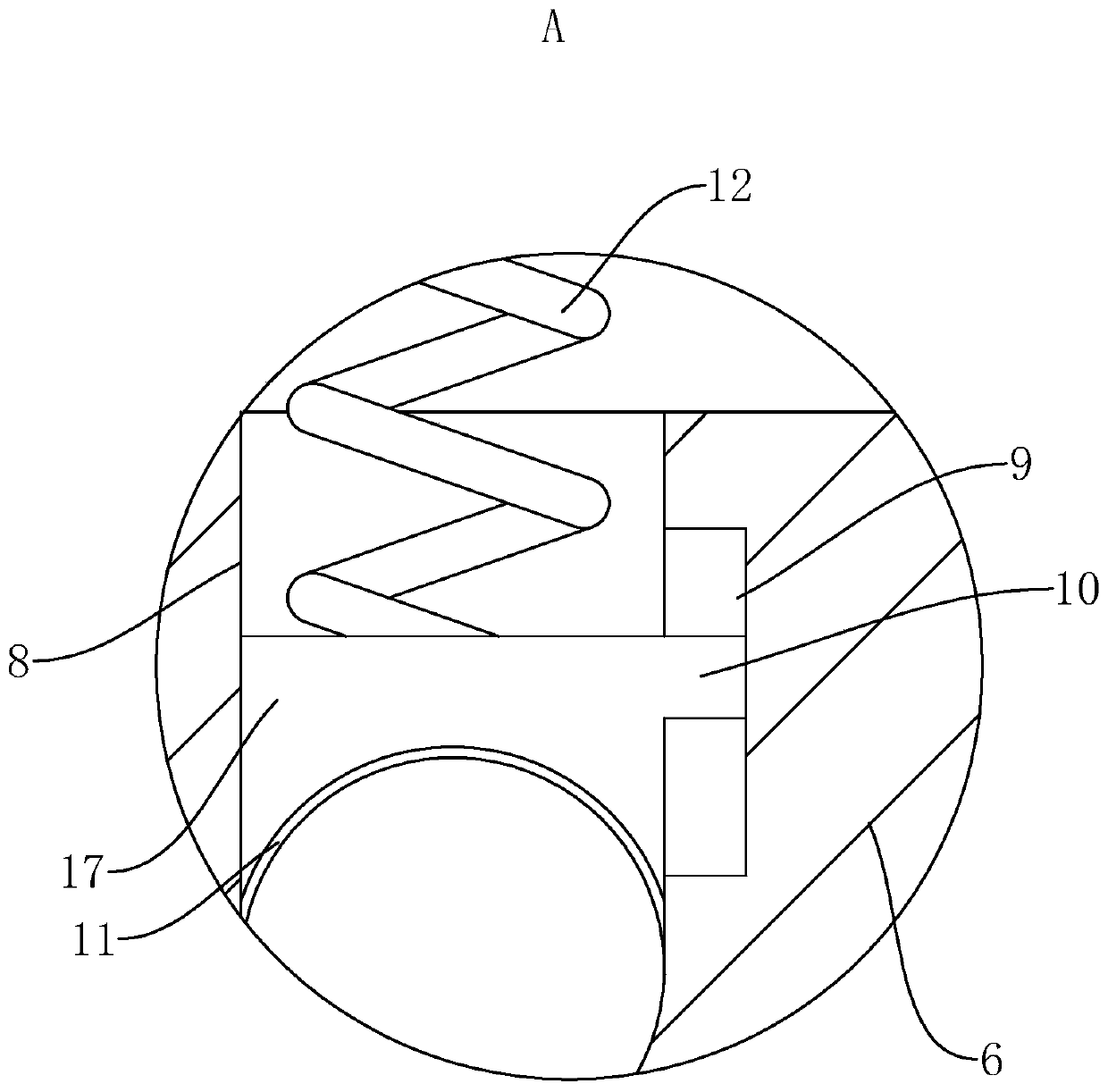

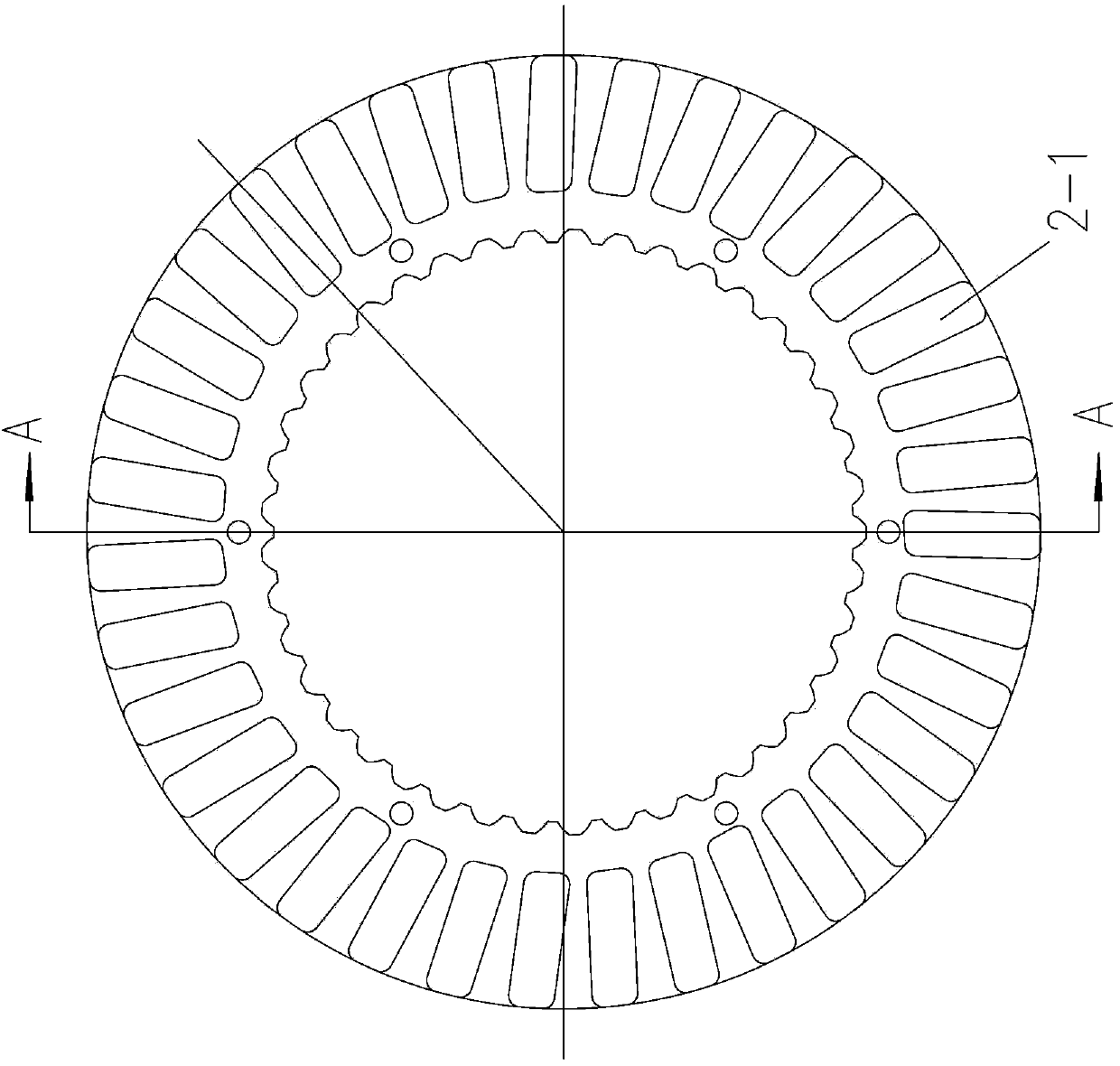

Full-automatic template foot pier nailing and cutting machine

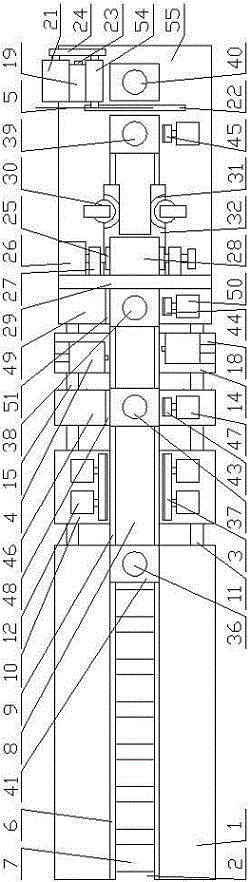

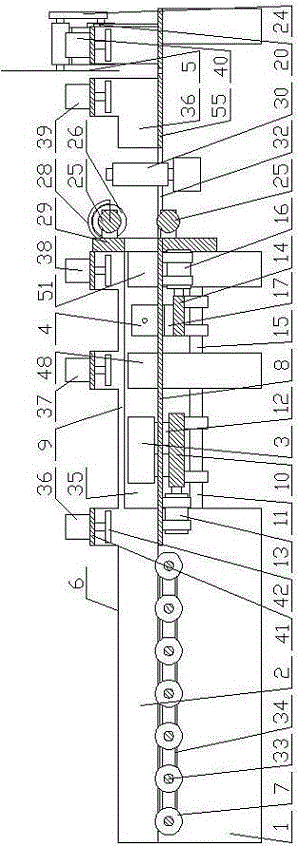

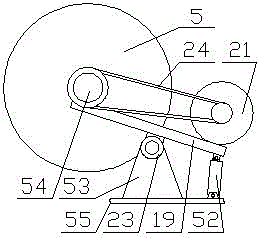

PendingCN106625969AIncrease productivityRapid automated productionStapling toolsWood feeding arangementsNail device

The invention discloses a full-automatic template foot pier nailing and cutting machine. The full-automatic template foot pier nailing and cutting machine comprises a chute feeder, and further comprises a loading device, a feeding device, a nailing device and a cutting device which are sequentially arranged along the chute feeder, wherein the loading device is arranged at one end of the chute feeder; the feeding device and the nailing device are sequentially arranged on two sides of the chute feeder; and the cutting device is arranged at the other end of the chute feeder. Known from the structure, the full-automatic template foot pier nailing and cutting machine realizes one-line quick and automatic production of foot piers by templates, improves the production efficiency of the foot piers by the templates, and is simple in equipment structure and smaller in area occupation.

Owner:金湖县唐港秦庄木材加工厂

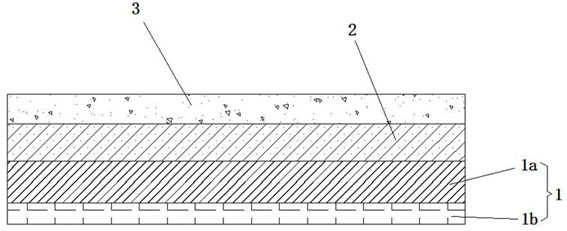

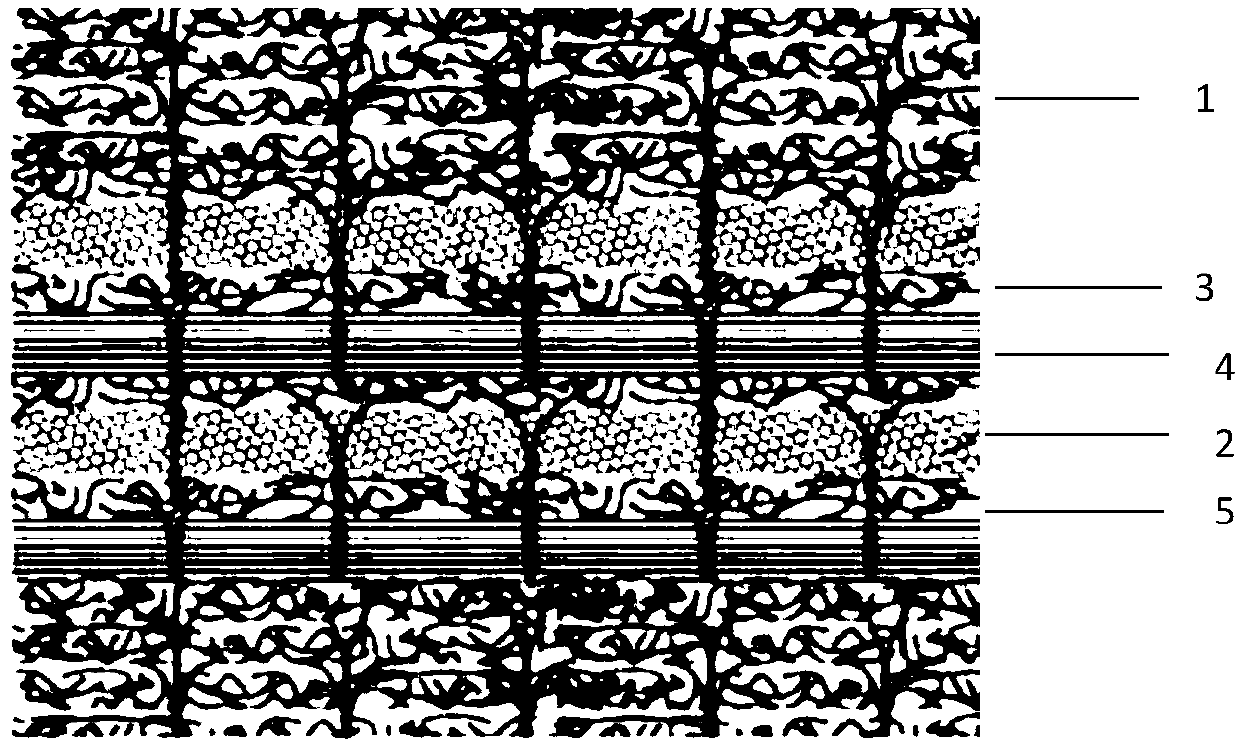

Pre-paved waterproof coiled material with high slippage resistance and preparation method of pre-paved waterproof coiled material

ActiveCN112976745AHigh coefficient of static frictionImprove slip resistanceUnderground chambersSynthetic resin layered productsElastomerStatic friction coefficient

The invention relates to a high anti-slip pre-paved waterproof coiled material and a preparation method thereof.The pre-paved waterproof coiled material comprises a base material layer, an adhesive layer and an anti-sticking layer which are sequentially arranged in a stacked mode, the base material layer comprises an upper layer and a lower layer, and the upper layer and the lower layer are prepared by co-extrusion molding of a first material and a second material; the raw material formula of the first material comprises matrix resin and a polyolefin elastomer; the raw material formula of the second material comprises a polyolefin elastomer. The base material layer is arranged to be of a two-layer structure including the upper layer and the lower layer; the upper layer and the lower layer are prepared through co-extrusion, and the lower layer is prepared by taking the polyolefin elastomer as a main raw material, so the pre-laid waterproof roll has a high static friction coefficient, an excellent anti-sliding effect is provided for the pre-laid waterproof roll, and construction is convenient and fast; and the adhesive also has excellent mechanical properties and relatively large bonding force with a lap joint edge. The upper layer and the lower layer of the base material layer are prepared through co-extrusion, and the processing technology of the pre-laid waterproof roll is simple.

Owner:JIANGSU CANLON BUILDING MATERIALS

Detergent for ceramic tiles of toilet

InactiveCN102703262AHigh coefficient of static frictionEnsure safetySurface-active non-soap compounds and soap mixture detergentsStatic frictionPyrophosphate

The invention discloses a detergent for ceramic tiles of a toilet. The detergent comprises the following raw materials in part by mass: 10 to 12 parts of citric acid, 5 to 7 parts of sodium carbonate, 1 to 3 parts of laurinol polyoxyethylene ether, 5 to 8 parts of sodium citrate, 2 to 3 parts of alkyl benzene sulfonic acid, 0.5 to 1 part of acidic sodium pyrophosphate, 3 to 5 parts of sodium chloride and 50 to 55 parts of water. By the detergent, dirt on the ceramic tiles can be removed, and static friction coefficients of slipping of the wet ceramic tiles can also be improved, so that the ceramic tiles are not damaged while the safety of personnel who walk on the ceramic tiles is ensured.

Owner:桑达化工(南通)有限公司

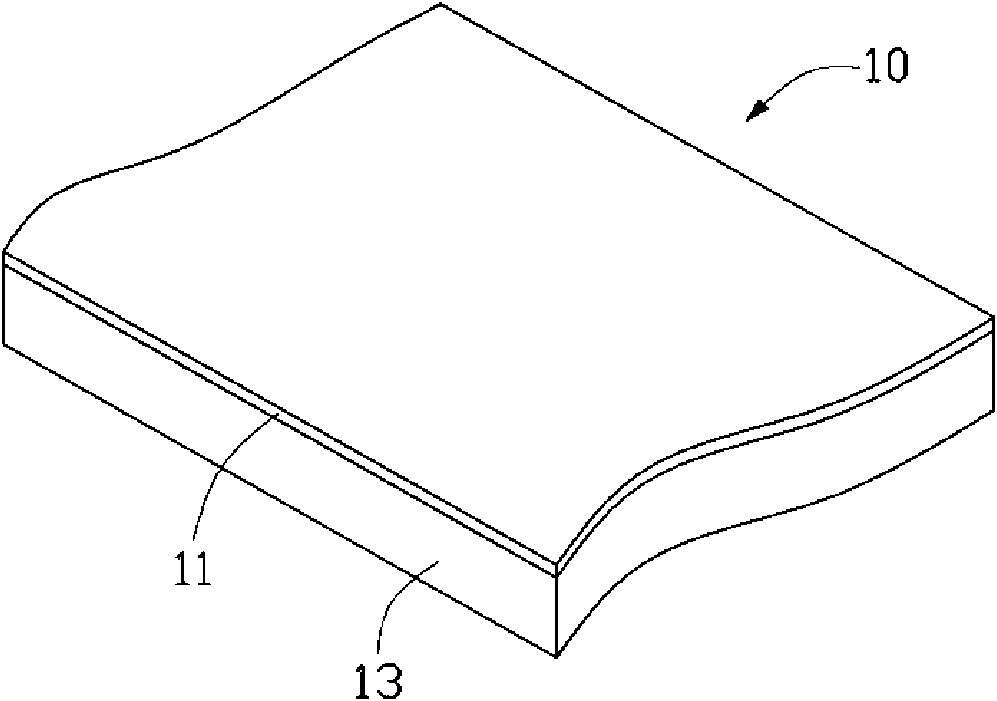

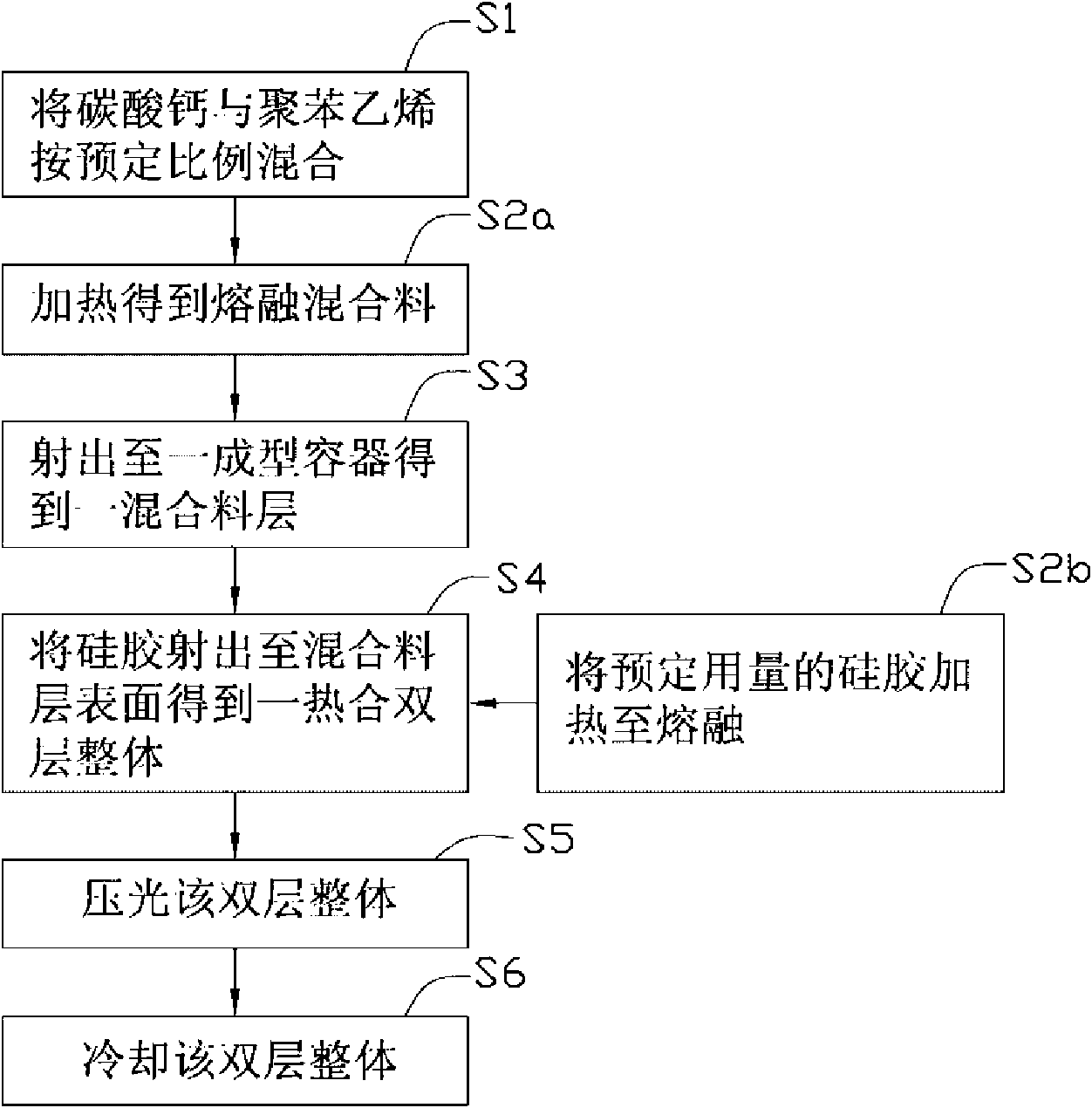

Packing material and preparation method thereof

InactiveCN101585435AGood shock absorbing functionImprove impact resistanceSynthetic resin layered productsDomestic articlesDamping functionPolystyrene

The invention provides a packing material, which comprises a base layer and a buffer layer formed on a surface of the base layer; the base layer consists of polystyrene and additives; and the buffer layer is made of a silica gel material. The packing material has good buffer and damping function. The invention also provides a preparation method for the packing material and a packing product made of the packing material.

Owner:JIANGSU YONGJIA ELECTRONICS MATERIALS

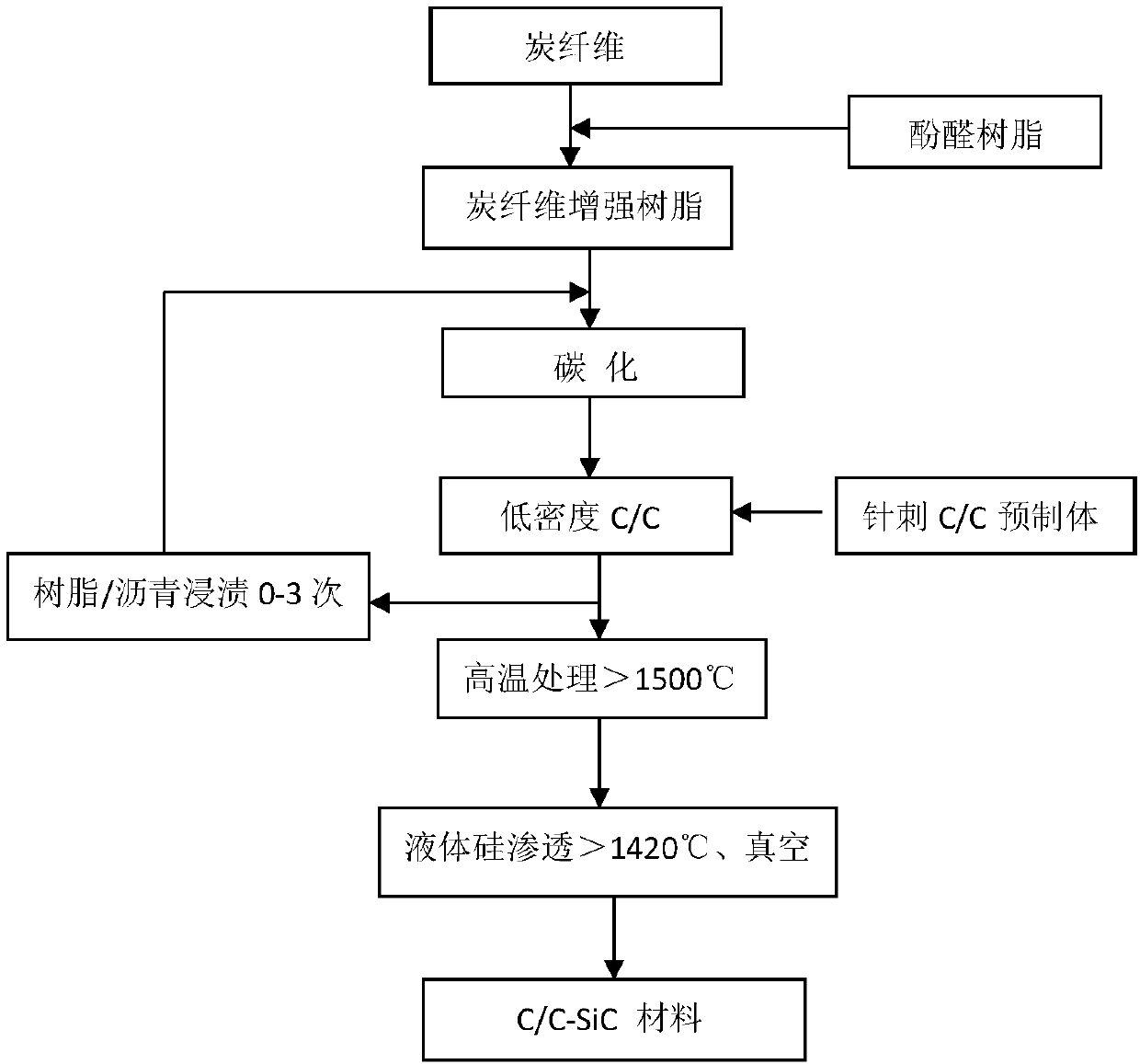

Novel modified prefabricated body carbon ceramic brake pad material and manufacturingmethod thereof

InactiveCN110345183AImprove antioxidant capacityImprove stabilityFriction liningActuatorsStatic friction coefficientFiber

The invention aims at solving the problems that existing brake pad materials are unstable in frication performance, high in hardness, high in oscillation frequency, poor in automatic performance, uneven in frication and the like, and provides a novel modified prefabricated body carbon ceramic brake pad material and a manufacturingmethod thereof. The manufacturingmethod of the novel modified prefabricated body carbon ceramic brake pad material includes the steps ofusing a novel carbon fiber prefabricated body of a sandwich structure, preparing and processing fibers of a needled structure, manufacturing C / C porous bodies by adopting a slurry infiltration process, and introducing SiC-based, Si-based and B-based compounds into the carbon / ceramic porous prefabricated bodies;the puzzle that theresidual amount of Si is uncontrollable is effectively solved. According to the sandwich-shaped C / SiC brake material, stability of dry state frication performance is improved, the static friction coefficient is improved, and friction performance under a wet state condition does not attenuate.

Owner:SHEN ZHEN QIANHAI SCICORE 3D TECH CO LTD

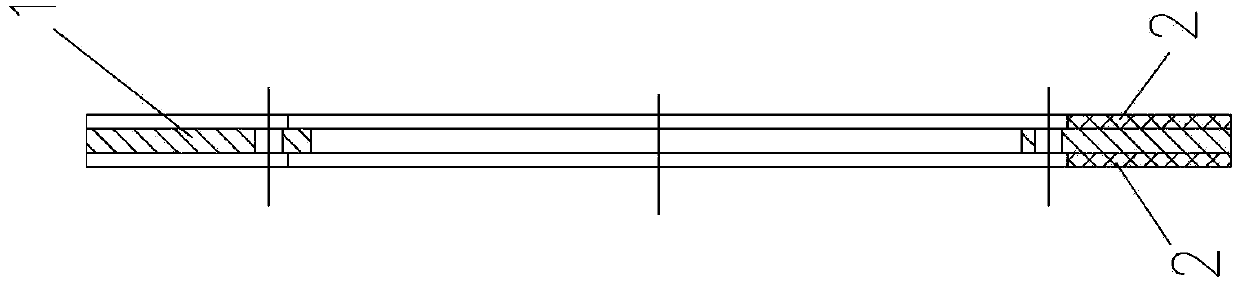

Production method of titanium steel composite wire material

ActiveCN103817167AHigh strengthHigh coefficient of static frictionMetal rolling arrangementsStatic frictionOil production

A production method for a titanium steel composite wire material is used for producing a titanium steel composite wire rope which is not only as high as an alloy steel wire in strength, but also as excellent as titanium in corrosion resistance and static friction coefficient. Metal wire rope producing equipment is used for producing the titanium steel composite wire rope with the titanium steel composite wire material in such a manner that 12 titanium steel composite wires are produced into a strand; 12 strands are twisted into the titanium steel composite wire rope. The composite wire material is high in strength because the grain size of the material is refined during the rolling process and cold hardening is formed during the drawing process. The titanium steel composite wire rope can meet the special requirements of ocean transportation, ocean engineering, oil production, elevator transmission dry friction pair and the like, for example, the titanium steel composite wire rope can be used as an aircraft catching cord of an aircraft carrier, or a hauling rope of a car lifting system of a high-speed elevator; the static friction force of the titanium steel composite wire rope can be improved by at least five times when the titanium steel composite wire rope is matched with a titanium traction sheave, so as to greatly improve the safety factor of the elevator and prolong equipment maintenance cycle.

Owner:沈阳和世泰通用钛业有限公司

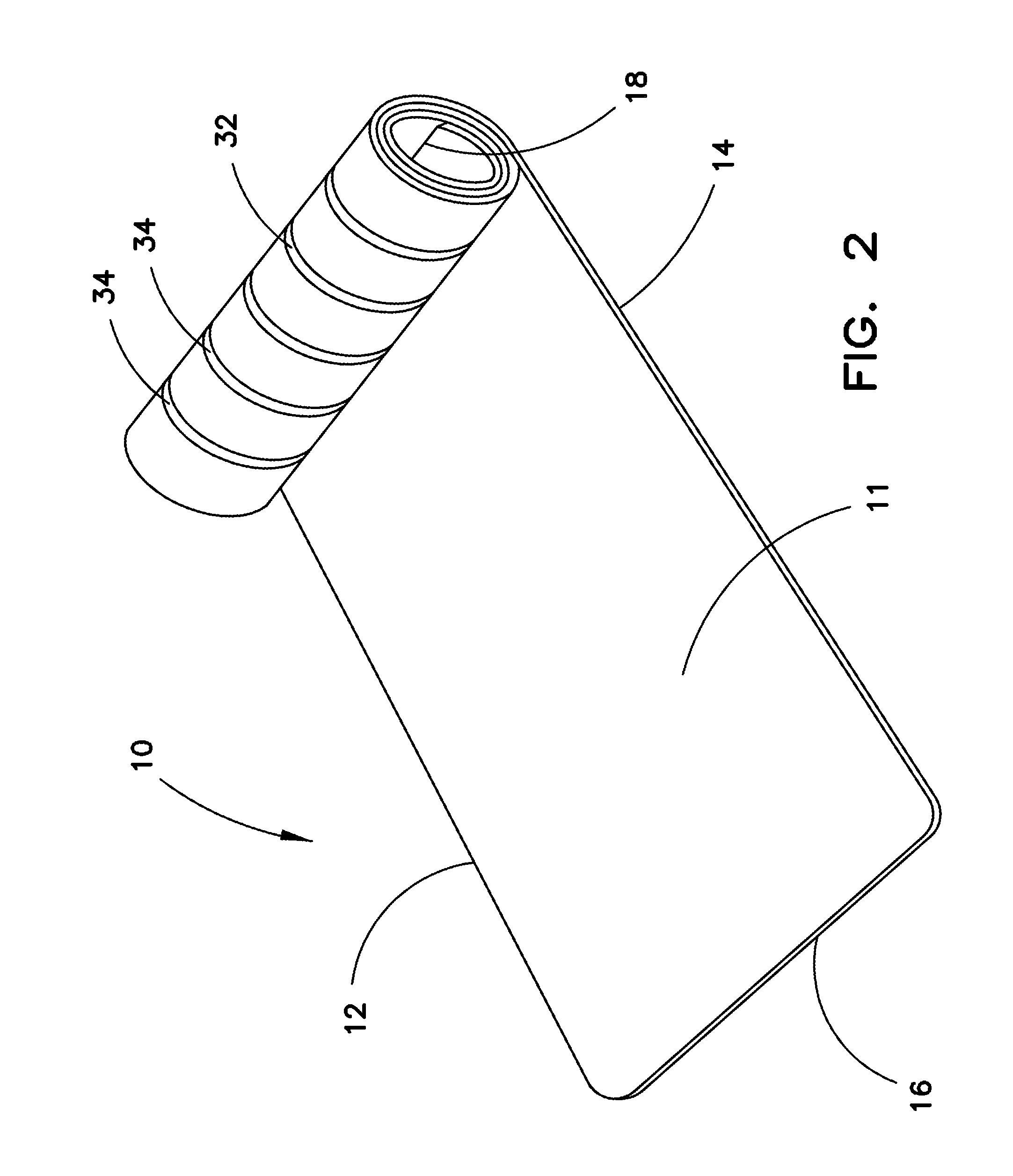

Protective mat with bottom surface having enhanced coefficient of friction

InactiveUS20150093548A1Reduce chanceSmall deflectionDecorative surface effectsDuplicating/marking methodsEntire lower bodyEngineering

A mat is provided for use on a carpeted floor surface, a hard floor surface, or both, and can have a substantially planar upper body surface suitable for interaction with a chair or other support structure. A slip-resistant layer can be bonded to a substantially planar lower body surface of the mat. The slip-resistant layer can be in the form of strips or coextensive with the entire lower body surface. The slip-resistant layer can allow placement in applications requiring simultaneous placement on both carpeted and hard floor surfaces, yet facilitating stable placement on both surfaces.

Owner:ROBBINS EDWARD S III

Modification method of easily-to-grab anti-skid swim ring

InactiveCN110791191AGood wear resistanceEvenly dispersedLiquid surface applicatorsPolyurea/polyurethane coatingsCalcium carbonateGlycerol

The invention discloses a modification method of an easily-to-grab anti-skid swim ring. The modification method comprises the following steps: mixing graphene oxide and modified molybdenum disulfide,adding deionized water, sealing, carrying out ultrasonic stirring, adding ammonia water to adjust the pH value to be neutral, adding waterborne polyurethane, and uniformly mixing to obtain pretreatedwaterborne polyurethane; adding modified nano calcium carbonate and modified silicon dioxide into the obtained pretreated waterborne polyurethane, heating and magnetically stirring, adding plasticizerglycerol, continuously stirring, standing and degassing to obtain an antiskid wear-resistant coating; and uniformly coating the surface of a swim ring with the obtained antiskid wear-resistant coating by using a coating rod, naturally drying, and carrying out rewetting treatment in a constant-temperature and constant-humidity box to obtain the antiskid wear-resistant swim ring.

Owner:界首市睿阳塑胶科技有限公司

High-performance permeable concrete system prepared by construction wastes and preparation method thereof

InactiveCN109722968AImprove bearing strengthPrevent slippingIn situ pavingsPaving gutters/kerbsEngineeringSubgrade

The invention discloses a high-performance permeable concrete system prepared by construction wastes and a preparation method thereof. The high-performance permeable concrete system prepared by the construction wastes comprises a foundation pit excavated in the ground; a roadbed is laid in the middle in the foundation pit; a stable base course, a concrete course and a high-performance permeable surface course are laid at the upper part of the roadbed in the foundation pit in sequence; clearances are reserved between the internal walls of the two sides of the foundation pit and the edge of theroadbed; and flow guide units are arranged in the clearances. According to the high-performance permeable concrete system prepared by the construction wastes, the bearing strength, the tensile strength, the elongation at break and the impact strength are better; high water permeability and higher safety performance are realized; slipping of pedestrians and sideslip of a vehicle can be effectivelyprevented; the frequency of occurrence of traffic accidents can be greatly reduced; the service life is long; a cracking phenomenon of the high-performance permeable surface course caused by a factorof geological subsidence variation or cold shrinkage and thermal expansion can be effectively prevented; and the provided preparation method has the advantages of scientific and reasonable construction steps, short construction period, high construction efficiency and good construction quality.

Owner:IANGSU COLLEGE OF ENG & TECH

Co-Ni-Fe-Cu nanometer coating and preparation method thereof

InactiveCN106086529AHigh bonding strengthImprove gripMolten spray coatingStatic friction coefficientHardness

The invention relates to a Co-Ni-Fe-Cu nanometer coating and a preparation method thereof. The Co-Ni-Fe-Cu nanometer coating comprises the components in parts by mass: 35-55 parts of Co, 45-65 parts of TiO2, 24-39 parts of Ni, 5-15 parts of Fe, 3-9 parts of Cu, 1-3 parts of Al2O3 and 0.11-0.68 part of microelements. The preparation method comprises the following steps of (1) preparing a Co-Ni-Fe-Cu nanometer sphere by using a dry crushing method; (2) mixing the nanometer sphere prepared in the step (1) with W, Mn, Al, Zn and Al2O3 by using a surfactant protection method to prepare nanometer powder; and (3) preparing the nanometer coating on an iron-based workpiece by using the nanometer powder prepared in the step (2) through a plasma spraying process. The Co-Ni-Fe-Cu nanometer coating not only has the high strength of ally steel, but also has the characteristics of excellent corrosion resistance, high static friction coefficient and the like, and the hardness of the prepared welding layer can reach to HRC37.

Owner:安徽鼎恒再制造产业技术研究院有限公司

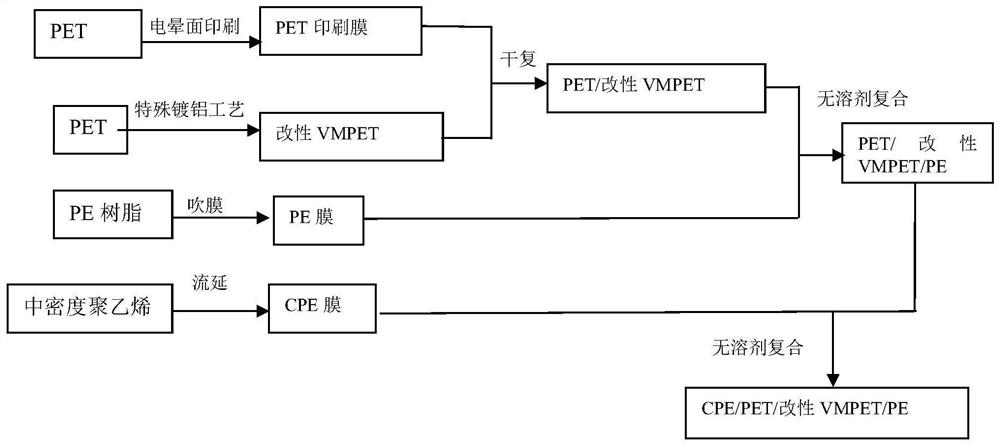

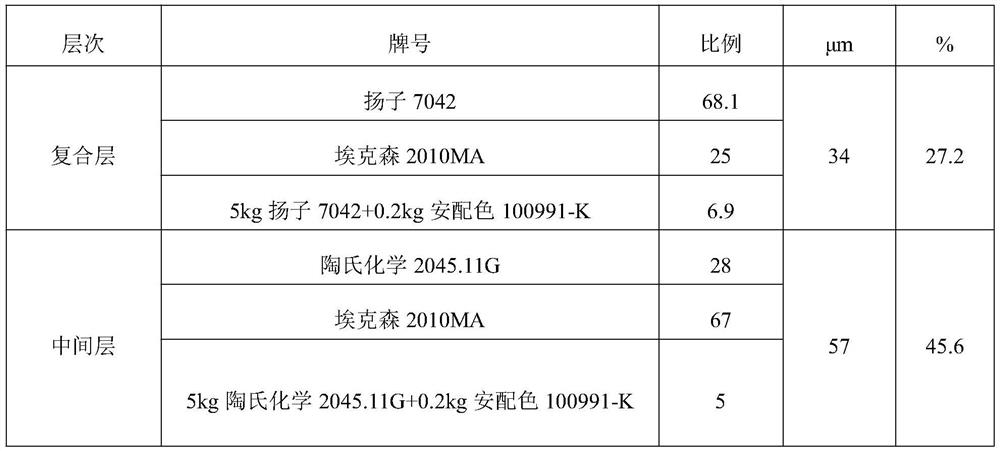

High-barrier antiskid packaging film and preparation method thereof

PendingCN113829707AGood lookingImprove stiffnessFlexible coversWrappersPolymer sciencePolyethylene terephthalate

The invention relates to the technical field of packaging materials, in particular to a high-barrier antiskid packaging film and a preparation method thereof. The packaging film is composed of a CPE film, a PET film, a modified VMPET film and a PE film which are sequentially layered, the CPE film and the PE film are prepared in a three-layer co-extrusion forming mode, and one face of the VMPET film is reversely plated with an aluminum-plated layer formed by metal aluminum, so that the barrier property, the aluminum layer adhesive force and the corona value attenuation period are all obviously improved, and under the severe high-humidity and high-temperature conditions, the interface of the packaged PET / VMPET aluminum plating layer is not layered, so that the integrity of the package is ensured, and the contents are not deteriorated; the packaging material with the CPE (heat-resistant) / PET (polyethylene terephthalate) / modified VMPET / PE (low-temperature) composite structure has the characteristics of balanced internal and external structures, flat bag shape, soft buffering of the outer-layer CPE, puncture and falling resistance, high static friction and good stacking and transporting effect, the problems of stacking slipping and unsmooth transportation are solved, and the whole large package is high in tearing strength and puncture resistance, and can resist falling and impact bag breaking.

Owner:HUANGSHAN NOVEL

Ceramic friction material mixture and mixing method thereof

ActiveCN105112016AReduce wear rateImprove quality and performanceOther chemical processesFriction liningSODIUM DODECYL BENZENE SULFONATEGraphite

The invention relates to the technical field of ceramic friction materials, particularly a ceramic friction material mixture and a mixing method thereof. Silicon dioxide, molybdenum disulfide, diesel, manganese carbonate ore, phosphorite, graphite, diatomite, ceramic fibers, carbon fibers, a phenolic resin and sodium dodecyl benzene sulfonate used as raw materials are selected and proportioned to prepare the ceramic friction material. The kinetic friction coefficient of the ceramic friction plate prepared from the ceramic friction material is 0.22-0.23, the static friction coefficient is 0.24-0.25, the kinetic / static friction ratio is 0.88-0.955, and the wear rate is 7.5*10<-6>mm<3>.J<-1>-9*10<-6>mm<3>.J<-1>. By combining the raw material proportioning and adding the manganese carbonate ore and phosphorite, the properties of the ceramic friction material mixture are improved, so that the frictional properties (especially stability, oil conductivity and physical and mechanical properties) of the ceramic friction material are improved.

Owner:贵州领想科技制造有限公司

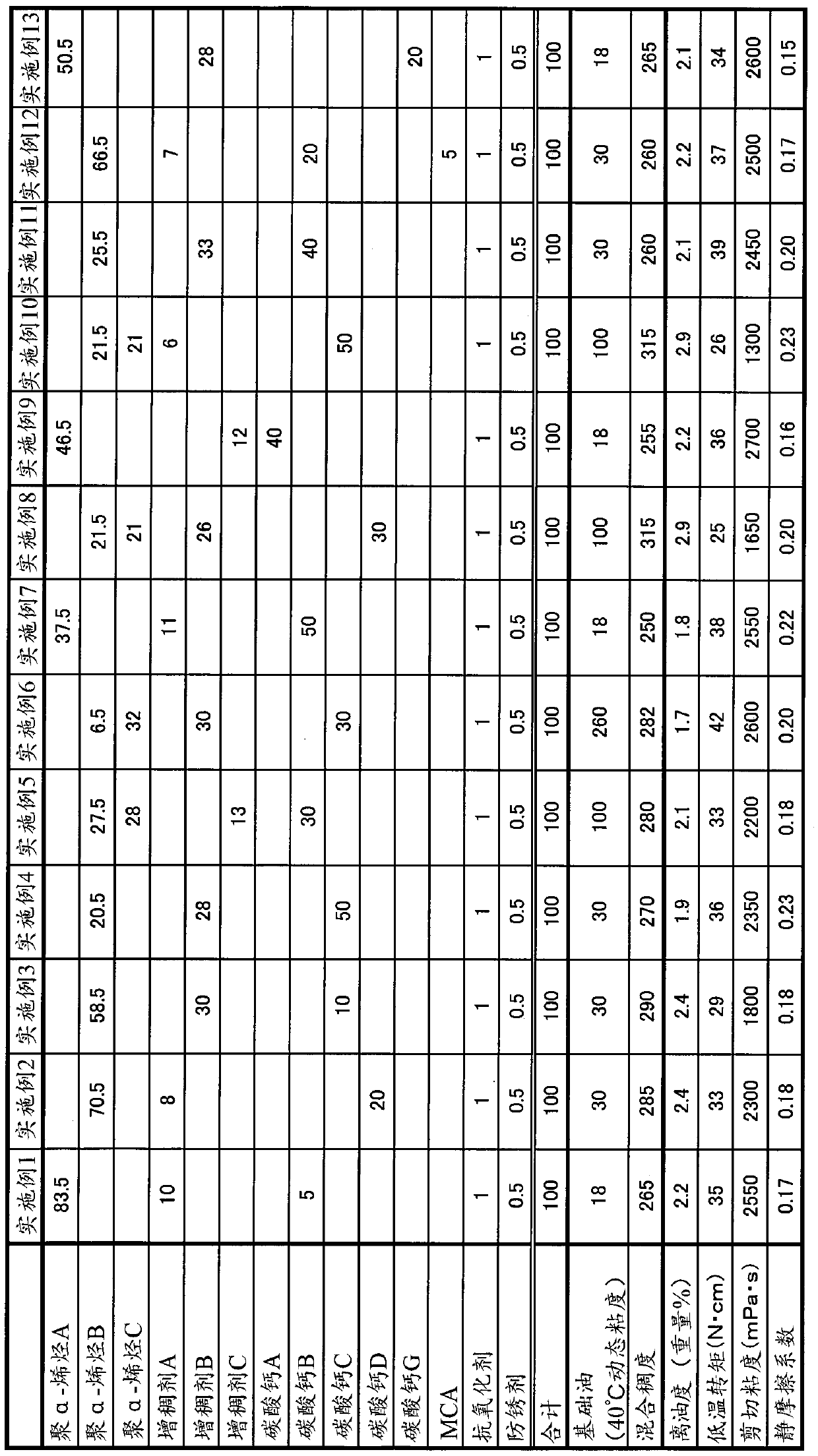

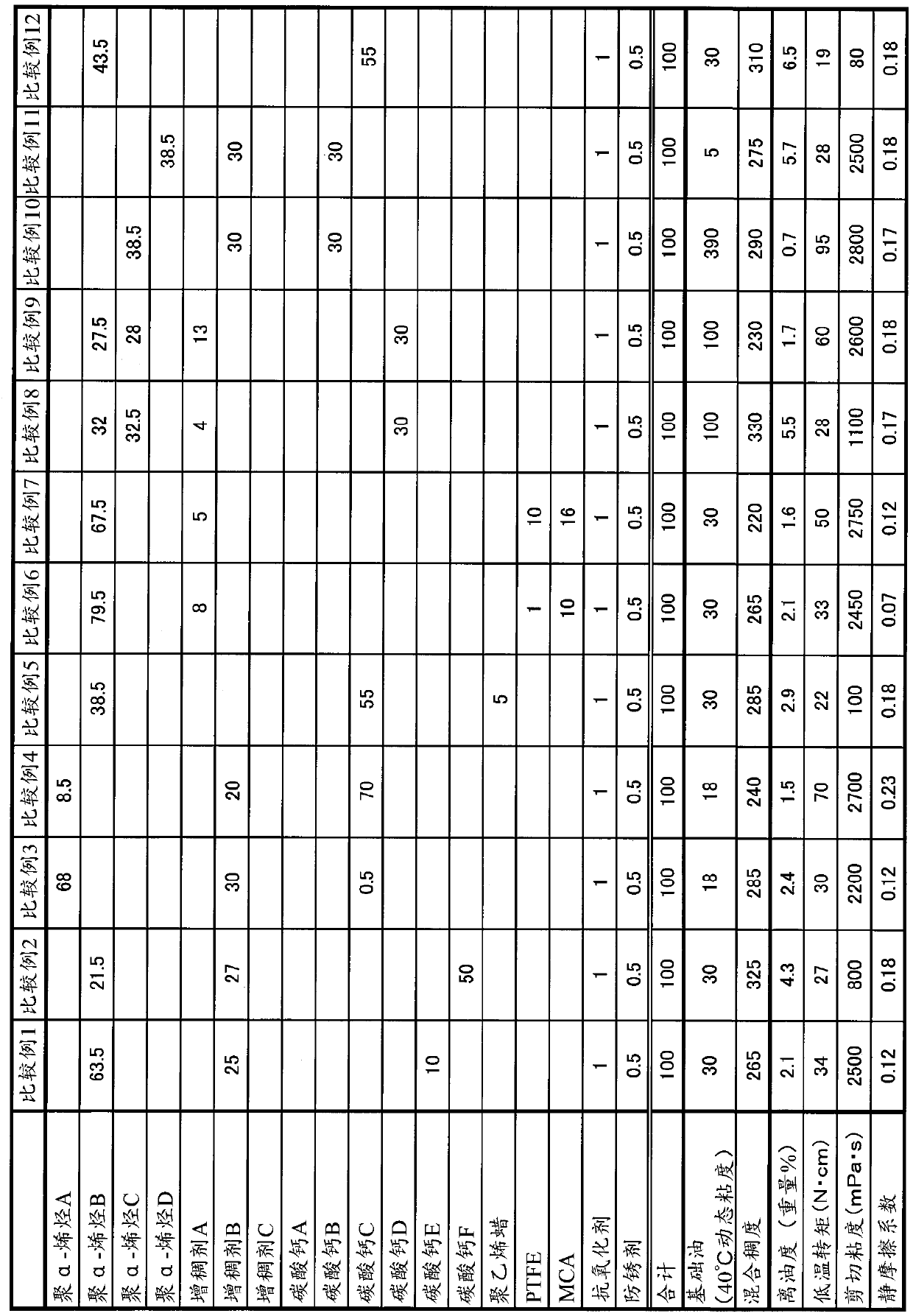

Lubricating grease composition

PendingCN109563429AExcellent low temperature torque characteristicsHigh coefficient of static frictionThickenersAdditivesPhysical chemistryOil separation

The purpose of the present invention is to provide a lubricating grease composition which has a high coefficient of static friction, while maintaining excellent torque characteristics at low temperatures, shear stability at high temperatures and oil separation characteristics at high temperatures. A lubricating grease composition according to the present invention contains a base oil, a thickeningagent and a solid lubricant, and is characterized in that: the solid lubricant is composed of calcium carbonate; the blending amount of the calcium carbonate is 1-60% by weight relative to the totalweight of the lubricating grease composition; the calcium carbonate has an average particle diameter of 0.1-30 Mum; the base oil has a kinematic viscosity of 18-300 mm2 / s at 40DC; and the lubricatinggrease composition has a worked penetration of 240-320.

Owner:NOK KLUEBER CO LTD

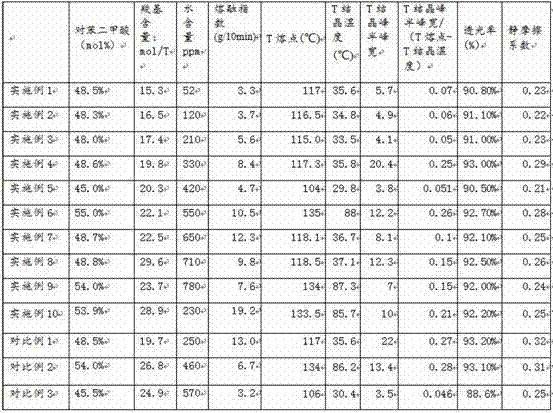

Polyester terphthalate-sebate resin and preparation method thereof

The invention discloses a polyester terphthalate-sebate resin and a preparation method thereof. The polyester terphthalate-sebate resin is formed by polymerization of dibasic acid and diol. By mole percent, the diol is formed by 45-55 mol% of terephthalic acid and 45-55 mol% of sebacic acid. The diol is 1,4-butanediol, thermal performance parameters of the polyester terphthalate-sebate resin meet the following relational expression: T crystal peak width at half height / (T melting point-T crystallization temperature)=0.05-0.26; when the polyester terphthalate-sebate resin is used to manufacture a film with a thickness of 25+ / -1 [mu]m, the static friction coefficient is 0.2-0.3, the light transmittance is 90% or above, the light transmittance and the static friction coefficient of the film are balanced, the film also has a low static friction coefficient while maintaining high light transmittance performance, processing can also be performed smoothly without an opening agent or a compatilizer, and the prepared polyester terphthalate-sebate resin has good transparency and processing performance.

Owner:KINGFA SCI & TECH CO LTD +1

Glass pedal connection device and mounting method thereof

ActiveCN109763612ALow construction precision requirementsEasy to installTreadsEngineeringToughened glass

The invention relates to the technical field of glass pedals, in particular to a glass pedal connection device and a mounting method thereof. The glass pedal connection device comprises a supporting frame, a movable frame connected with the supporting frame, and a supporting piece connected to the upper end of the movable frame and abutted with toughened glass; the movable frame comprises two parallel horizontal rods and a horizontal seat slidably connected to the horizontal rods; vertical guide holes are formed in the horizontal seat; the supporting piece comprises a pressure spring with oneend matched with the horizontal seat, and a supporting disk fixedly connected to the upper end of the pressure spring; at least two guide columns vertically passing through the guide holes are weldedto the supporting disk; the parts, passing through the horizontal seat, of the lower ends of the guide columns are in threaded connection with second adjustment nuts. After the glass pedal is mountedon the supporting disk, the glass pedal is leveled by rotating the second adjustment nuts. Since the pressure spring enables the supporting disk to be abutted with the glass pedal, several errors alsocan be compensated under the action of the pressing spring by timely adjustment.

Owner:深圳市极尚建设集团股份有限公司

Ceramic-fiber-paper-based friction plate and production method thereof

ActiveCN102878232BGuaranteed stabilityImprove toughnessNon-macromolecular organic additionPaper/cardboardAdhesiveBoron carbide

The invention relates to a ceramic-fiber-paper-based friction plate and a production method thereof and aims to provide the friction plate which is high in friction coefficient and fine in wear resistance and the production method which is simple in procedure and easy and convenient for production. According to the technical scheme, the ceramic-fiber-paper-based friction plate comprises ceramic fiber, carbon fiber, aramid pulp fiber, long staple cotton paper, diatomite, cashew shell oil friction powder, calcium carbonate whisker, boron carbide, potassium feldspar powder, rubber granule, iron sulfide, mica, alum, magnesia, cashew shell oil modified phenolic resin, powdered fluorine rubber, butyronitrile rubber latex, boron-tung oil modified phenolic resin and moderate additives. The production method includes the steps of firstly, producing pretreatment material, mixing material and size and performing papermaking to produce raw paper of ceramic-fiber-paper-base friction material; and secondly, soaking the raw paper in adhesive, cutting into strips after hot-pressing solidification, and adhering to a friction plate core plate to obtain the ceramic-fiber-paper-based friction plate.

Owner:杭州克尔菲利科技有限公司

Enameled wire surface treatment agent and preparation method thereof

InactiveCN105567395AImprove pressure resistanceHigh coefficient of static frictionLubricant compositionStatic friction coefficientSilicone oil

The invention discloses an enameled wire surface treatment agent and a preparation method thereof; the enameled wire surface treatment agent comprises the components in parts by mass: 90-99 parts of 3GS refrigerant oil, 1-6 parts of paraffin, 0.5-4 parts of silicone oil, and 0.03-0.5 part of tetrabutyl titanate. After an enameled wire is treated by the enameled wire surface treatment agent, the enameled wire can have smaller static friction coefficient so as to be in favor of high-speed wire wrapping and avoid air pollution and safety hazards.

Owner:先登高科电气股份有限公司

Copper-based powder metallurgy friction material for heavy-duty vehicle dry clutch and preparation method thereof

ActiveCN110102754BGood application effectGive full play to the synergistic effectTransportation and packagingMetal-working apparatusGraphite particleFerrochrome

A copper-based powder metallurgy friction material for a dry clutch of a heavy-duty vehicle and a preparation method thereof. The matrix components of the friction material are copper and iron, and the lubricating components are graphite particles, flake graphite, molybdenum disulfide and petroleum coke. The friction components are ferrochromium, zirconia and silicon dioxide, and the strengthening components are tin. The weight percent of the friction material composition is: copper powder 50%-60%, iron powder 1-10%, graphite particle powder 5-20%, flake graphite 1-5%, molybdenum disulfide powder 1-6%, petroleum Coke powder 1‑15%, ferrochrome powder 3‑9%, zirconia 3‑9%, silicon dioxide 1‑5%, tin powder 1‑4%. The preparation method of the friction material is as follows: preparing a mixture according to the composition of the powder metallurgy friction material, mixing the mixture evenly in a V-type mixer and pressing it into shape, and then sintering together with a copper-plated steel back to obtain a copper-based powder Metallurgical friction materials. The copper-based powder metallurgy friction material has a high and stable friction coefficient and excellent wear resistance.

Owner:CENT SOUTH UNIV

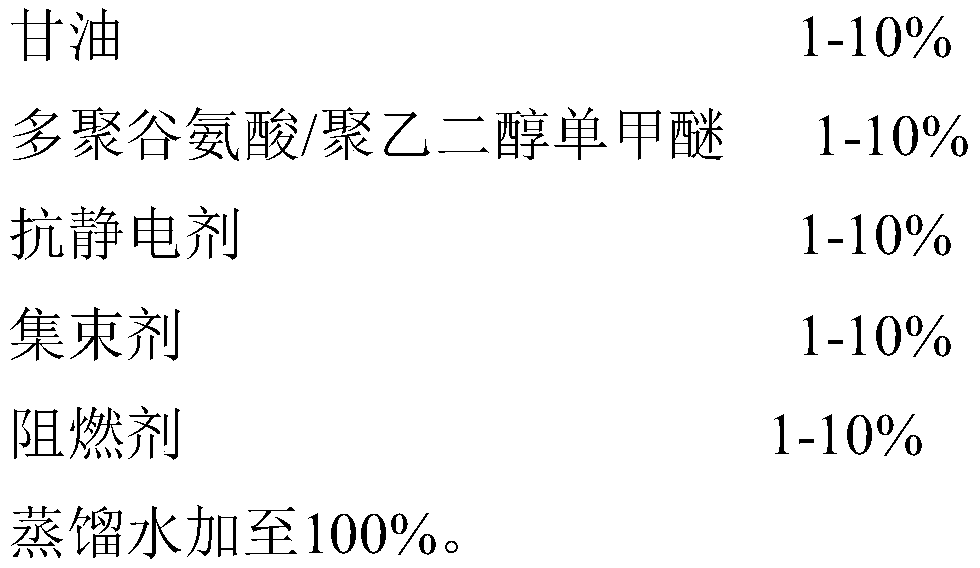

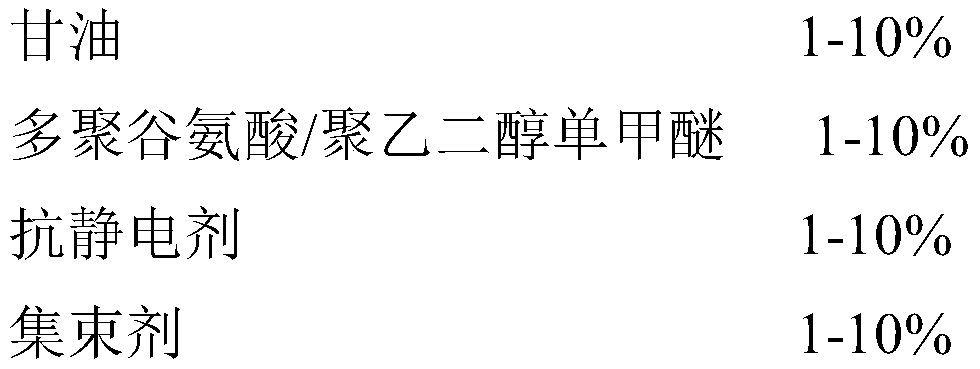

Spinning oil for processing regenerated polyester fiber

InactiveCN110241485AImprove smoothnessGood flexibilityHeat resistant fibresGrip property fibresPolyesterFiber

The invention discloses spinning oil for processing regenerated polyester fiber, and relates to the technical field of regenerated polyester fiber processing. The spinning oil is formed by mixing, by weight, 1-10% of glycerin, 1-10% of polyglutamic acid / polyethylene glycol monomethyl ether, 1-10% of an antistatic agent, 1-10% of a custer agent, 1-10% of fire retardant and the balance distilled water. By means of the spinning oil, the smoothness and softness of the polyester fiber can be remarkably improved, the kinetic friction coefficient between the fiber and metal is reduced, the static friction coefficient between the fiber is increased, and static electricity is reduced.

Owner:ANHUI SHUANGFAN HIGH FIBER CO LTD

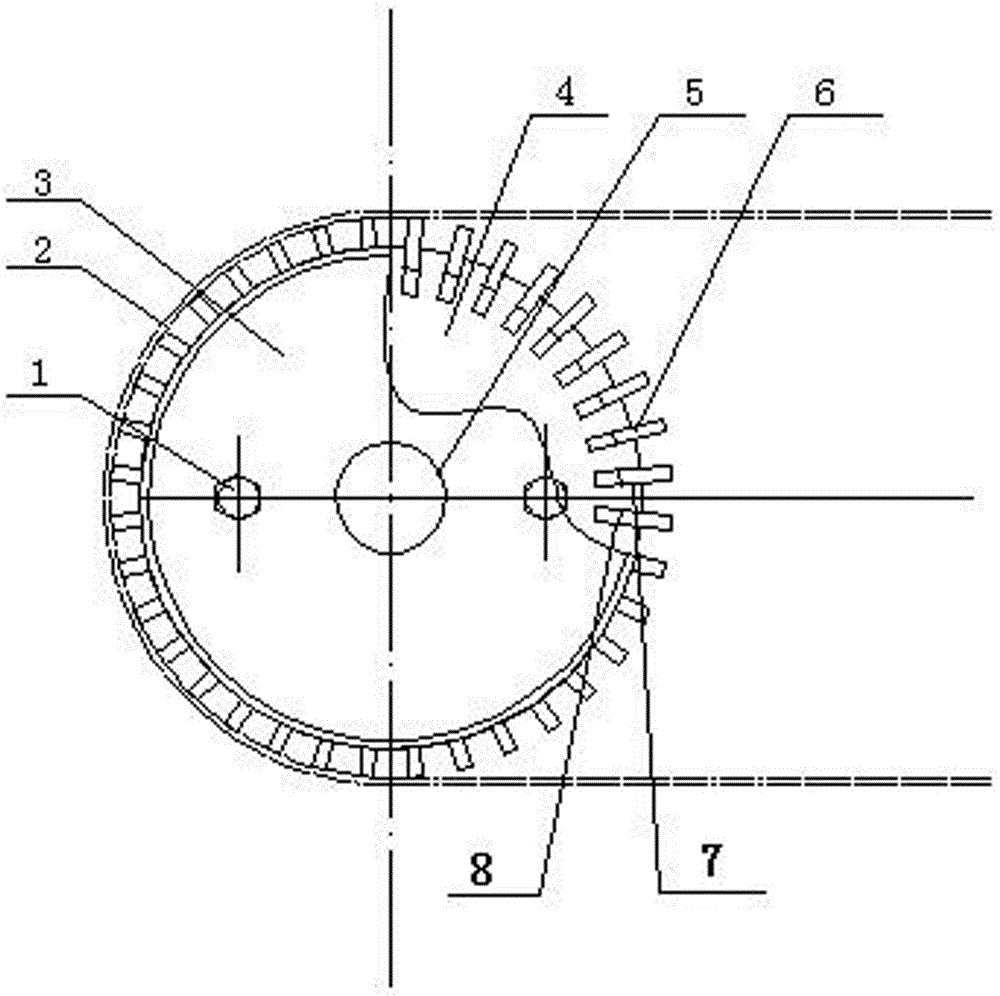

Antiskid, wear-resistant and temperature-resistant net belt driving wheel and preparation method thereof

ActiveCN105645044AImprove skid resistanceSolution to short lifeConveyorsRollersStatic friction coefficientDrive wheel

The invention discloses an antiskid, wear-resistant and temperature-resistant net belt driving wheel and a preparation method thereof. The driving wheel comprises a wheel body; axial grooves are uniformly distributed in the peripheral cylindrical surface of the wheel body; the depths of the axial grooves are larger than the widths of the axial grooves by 1.25 times; red copper flat strips are embedded in the all the axial grooves; the widths of the red copper flat strips are smaller than the widths of the axial grooves by 0.1-0.5 mm; the exposed heights of the red copper flat strips are smaller than 50 mm, and are larger than or equal to the thicknesses of the red copper flat strips; the two ends of the red copper flat strips exceed the two ends of the wheel body by 10-50 mm; positioning steps are turned at the two ends of the red copper flat strips; and the two ends of the red copper flat strips are positioned on the wheel body through matching between positioning rings and the positioning steps. The antiskid, wear-resistant and temperature-resistant net belt driving wheel has high static friction coefficient, can prevent a net belt from sliding, and has such advantages as wear resistance, long service life and high-temperature resistance.

Owner:LEIYANG YANXIN NON FERROUS METALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com