Patents

Literature

54results about How to "Improve frictional stability" patented technology

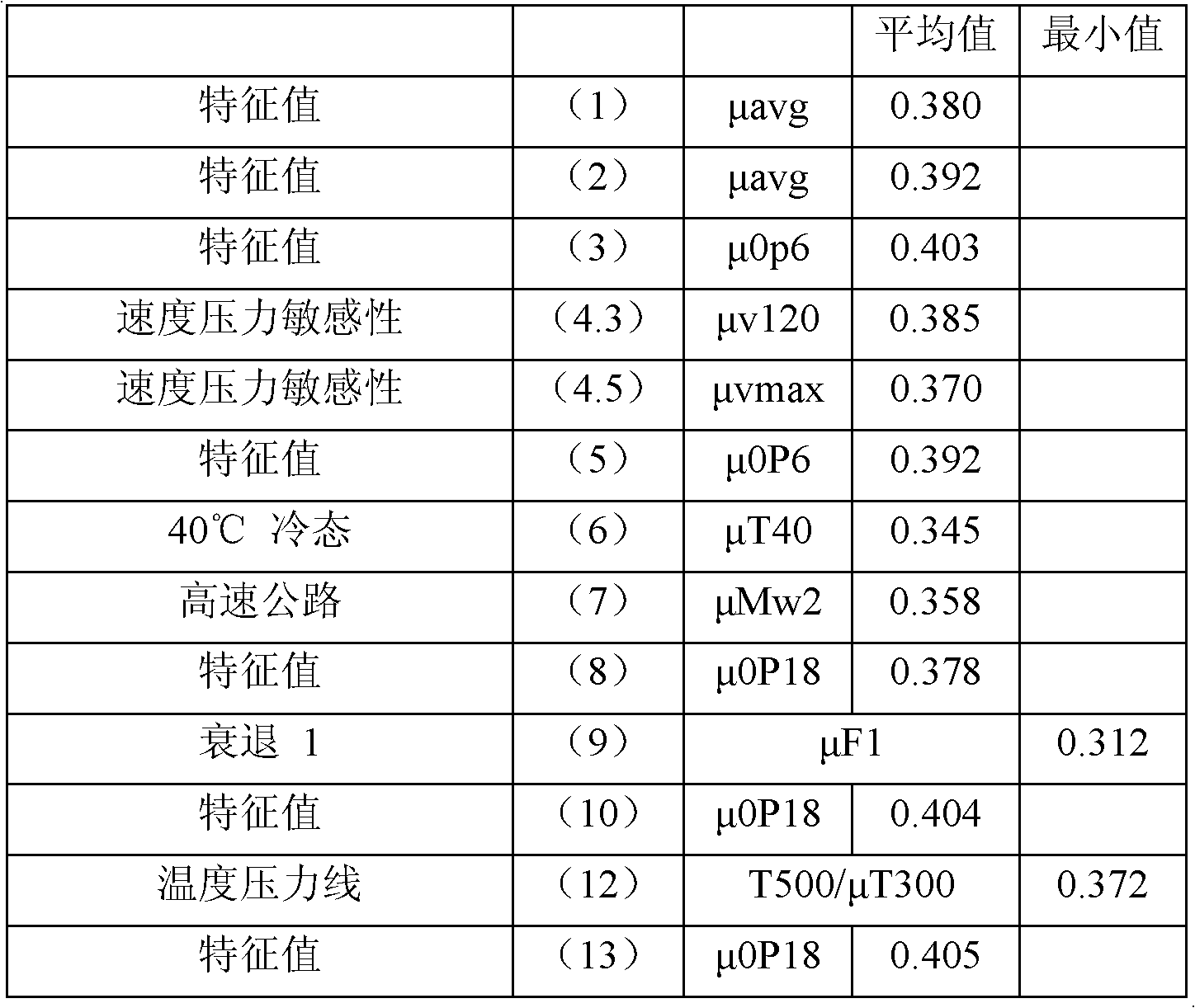

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

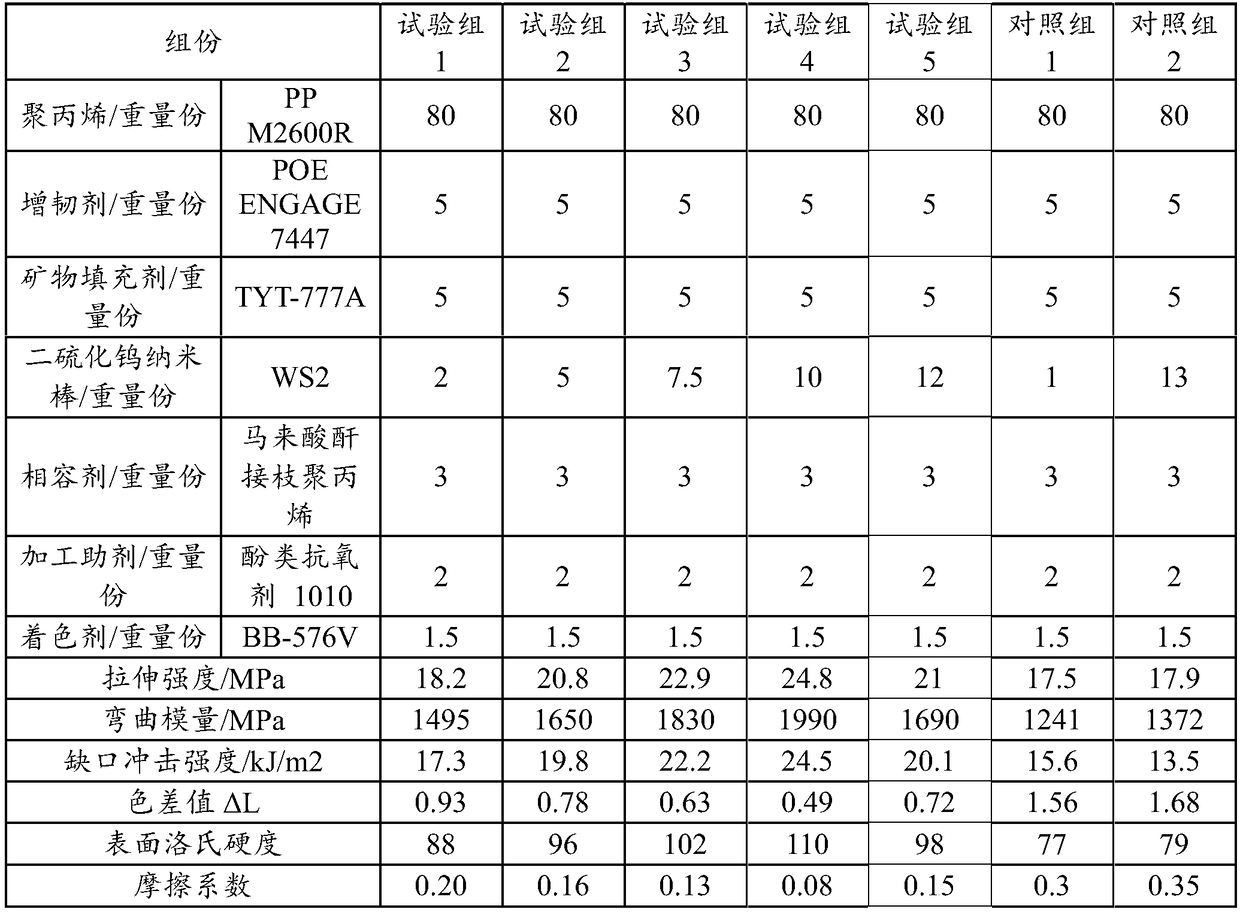

Formula and manufacturing method for car soft magnetic brake pad

ActiveCN103939511AEasy to prepareImprove braking effectOther chemical processesFriction liningFiberThermal treatment

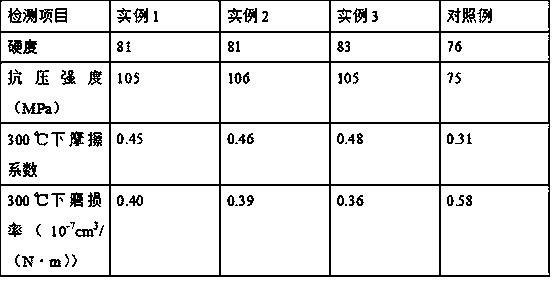

The invention discloses a formula and manufacturing method for a car soft magnetic brake pad. The formula comprises, by weight, 6-18 parts of organic binding agents, 15-45 parts of reinforced fibers, 10-50 parts of friction performance conditioners, 3-10 parts of packing and 5-30 parts of soft magnetic materials. The manufacturing method comprises porphyrization, material mixture, thermo-compression formation, thermal treatment, surface processing and other processes. The formula and manufacturing method for the car soft magnetic brake pad have the advantages that the soft magnetic materials are added into an original car brake pad, so that the friction coefficient is increased, the abrasion rate is lowered, friction stability is improved, and the car soft magnetic brake pad well adapts to various complex braking conditions of a car; as the added soft magnetic materials are ferromagnetic substances, the car soft magnetic brake pad has high magnetic conductivity and saturation magnetic induction intensity, and the most basic material conditions are provided for magnetic field control in the brake friction process. The manufacturing method for the car soft magnetic brake pad is simpler, magnetism does not need to be charged in advance, and the friction action can be regulated and controlled in the braking process by regulating the magnitude of the magnetism through an external magnetic field.

Owner:CHINA UNIV OF MINING & TECH

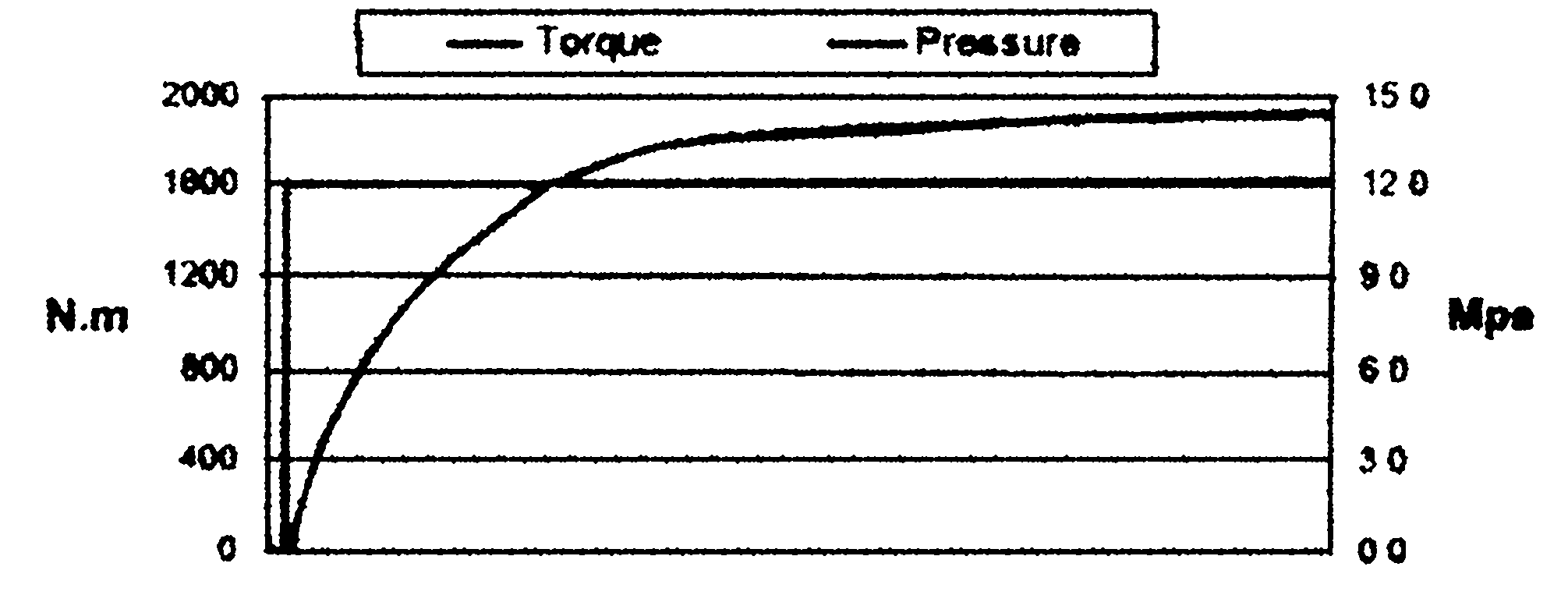

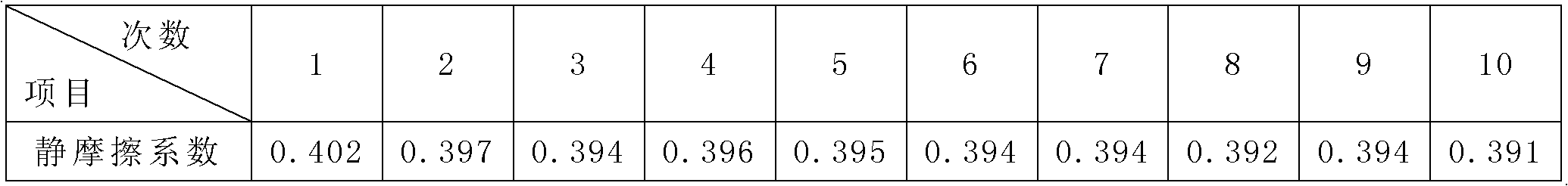

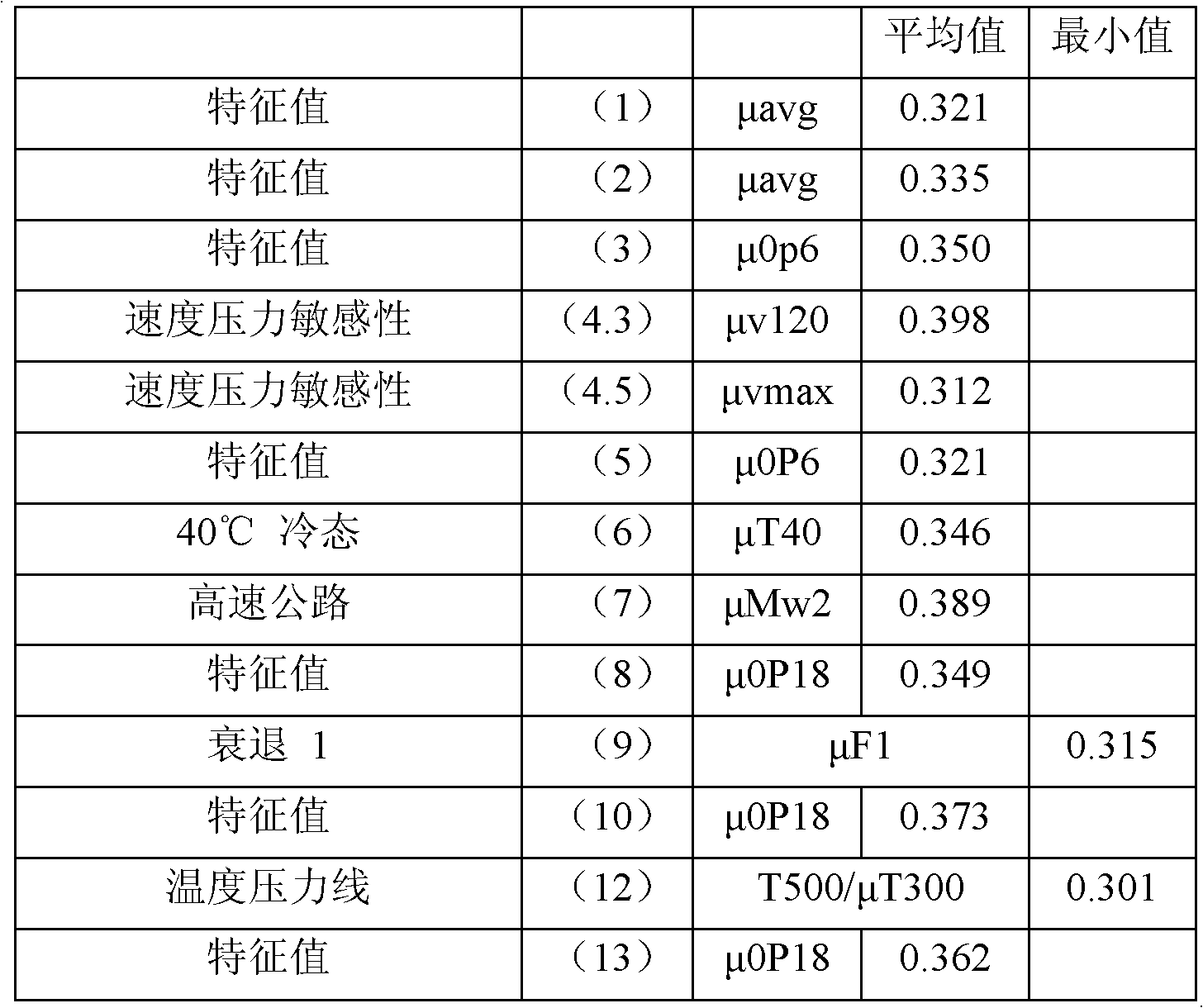

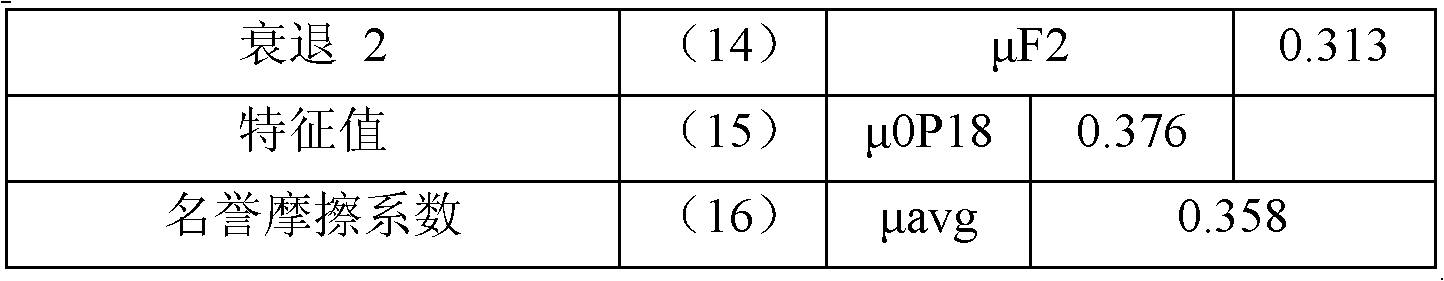

Resin-based yawing brake pad for wind-generated generator and preparation method thereof

InactiveCN101956775AMeet the requirements of yaw low speed brakingHigh coefficient of static frictionFriction liningLow speedAluminum silicate

The invention discloses a resin-based yawing brake pad for a wind-generated generator and a preparation method thereof. The resin-based yawing brake pad comprises phenolic resin, nitrile butadiene rubber, organic friction powder, chopped steel fiber, red copper fiber, aramid fiber, aluminum silicate / KFK fiber, graphite, barite and the like. The preparation method comprises the following steps of: weighing various components according to the formula; mixing the components by a plow harrow type blender mixer at high speed; ensuring that each fiber is fully dispersed uniformly; hot pressing forming at the temperature of 160-200DEG C; carrying out heat treatment in a heat treatment tank; cooling to the room temperature along the temperature of the furnace; and finally, machining to obtain the resin-based yawing brake pad. Compared with the general powder metallurgy brake pad, the yawing brake pad has the advantages of proper static friction coefficient, stable friction coefficient, low brake noise, smaller antithesis wear and lower manufacturing cost and can fully meet the yawing low-speed brake of the wind-generated generator.

Owner:HUNAN BOYUN AUTOMOBILE BRAKE MATERIALS +1

Multielement resin base carbon compound disc-type braking pad and preparation method thereof

ActiveCN102635653AImprove wear resistanceImprove high temperature resistanceFriction liningLow noiseSulfide

The invention discloses a multielement resin base carbon compound disc-type braking pad and a preparation method thereof. The braking pad is obtained by carrying out mould pressing and forming once on the following raw materials: unmodified phenolic resin, organosilicone modified phenolic resin, polyacrylate modified phenolic resin, polyacrylonitrile carbon fiber, artificial granular graphite, natural crystalline flake graphite, granular coke, silicon carbide, aramid pulp, compound mineral fiber, steel fiber, red copper powder, ferrous sulfide and barium sulfate. The product disclosed by the invention has the advantages of high temperature resistance, ablation resistance, small heat expansion coefficient, high specific strength, high specific modulus, good abrasion resistance, low noise, excellent initial performance, short breaking-in period, small heat fade, long service life, excellent pedal comfort degree, excellent high temperature and high speed performance and stable abrasion grade under different braking conditions, the effect on considering the good abrasion resistance and low noise is achieved, no dust is generated during braking, and various materials are all environment-friendly environment-protection materials. The multielement resin base carbon compound disc-type braking pad also has the function of automatically cleaning the braking disc.

Owner:JINAN GOLD PHOENIX BRAKE SYST

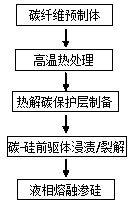

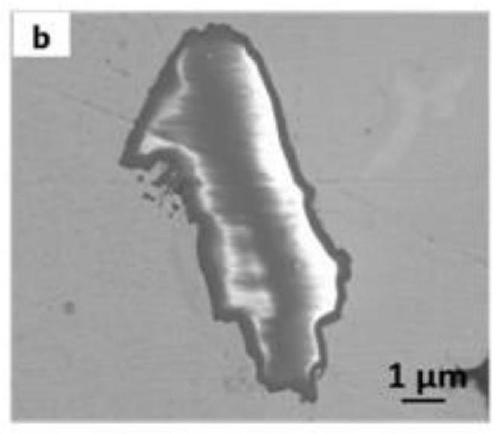

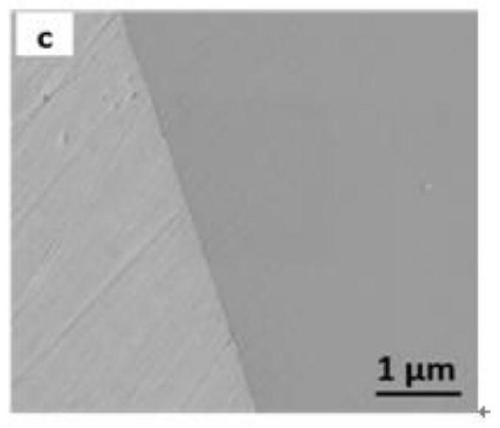

Carbon-silicon carbide double-ingredient substrate carbon fiber composite material as well as preparation method and application thereof

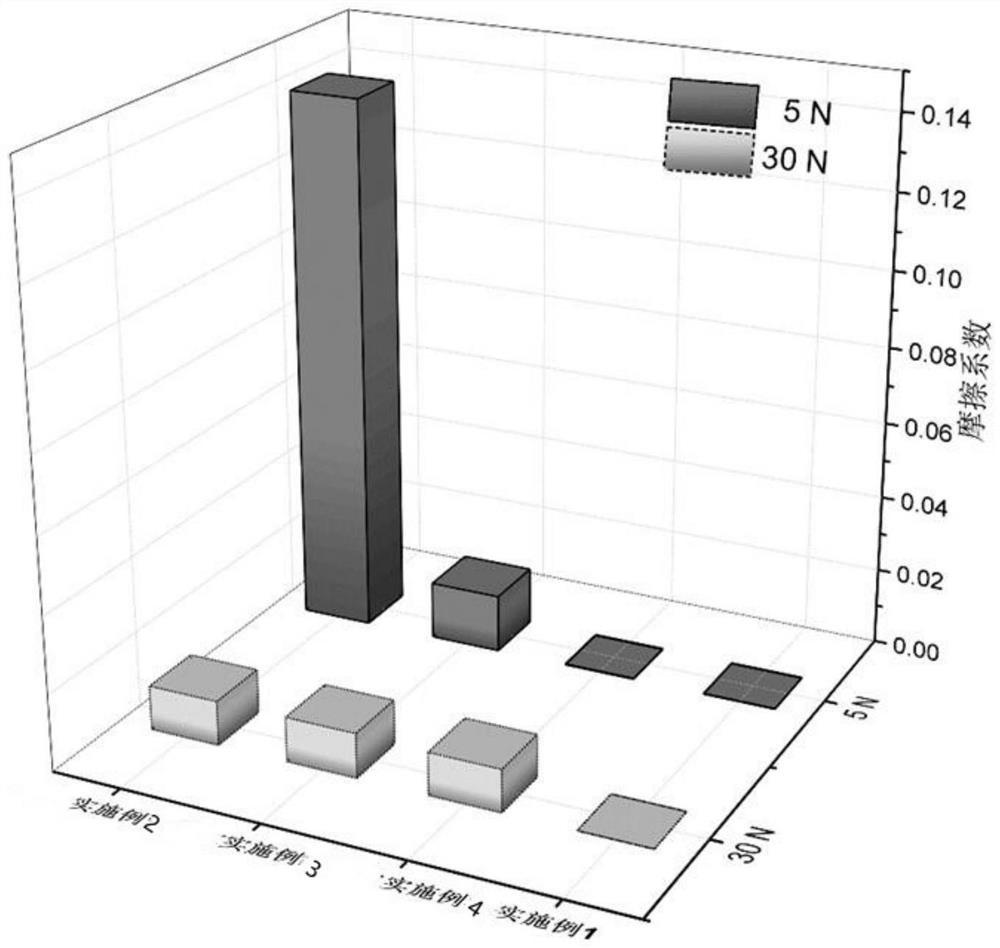

ActiveCN108516852AEvenly distributedImprove frictional stabilityBraking discsAdditive ingredientPorous carbon

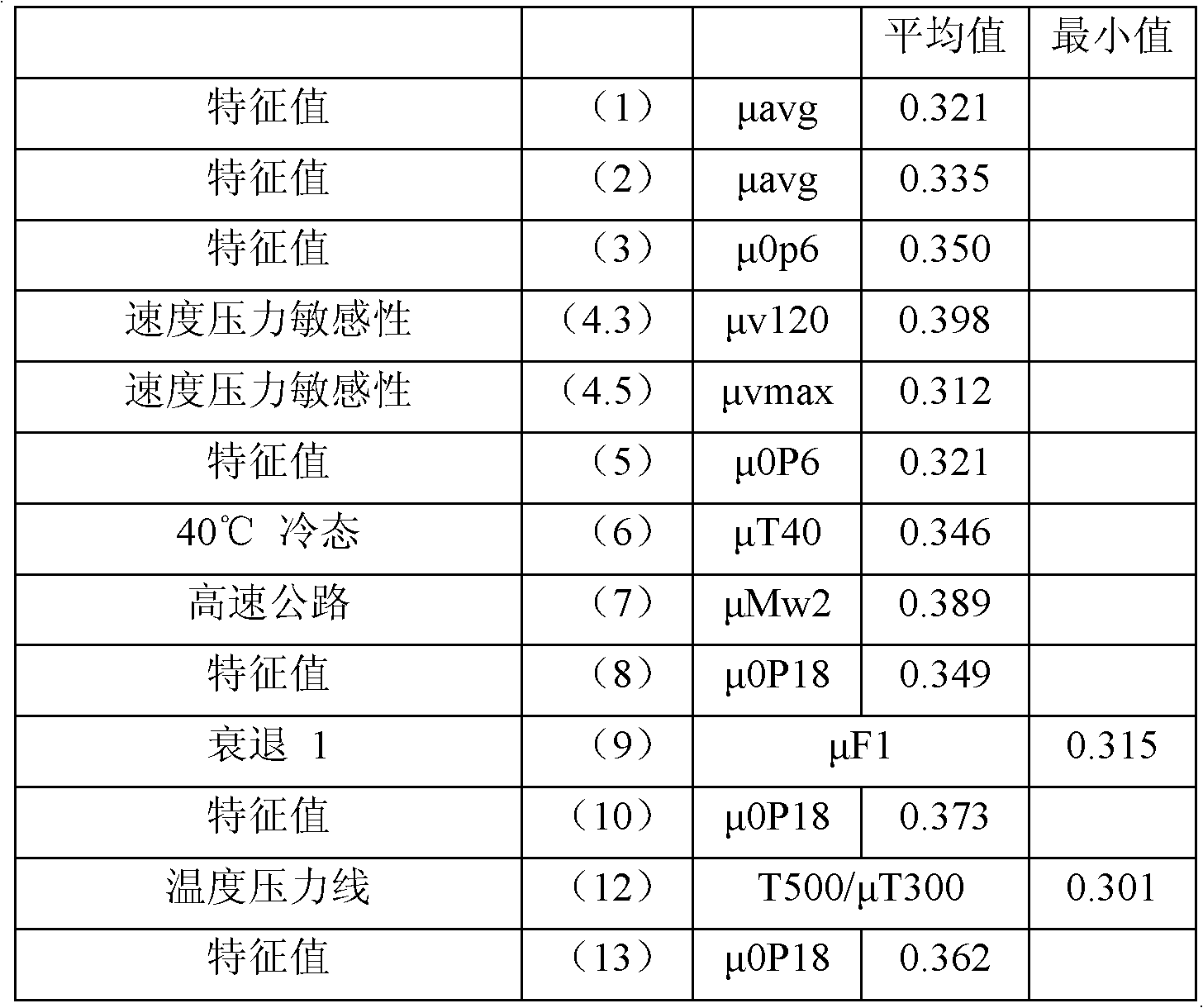

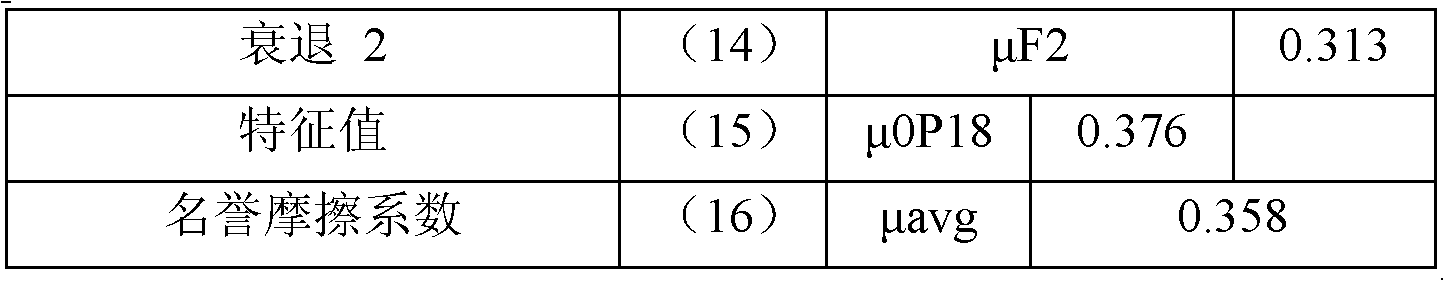

The invention discloses a carbon-silicon carbide double-ingredient substrate carbon fiber composite material as well as a preparation method and application thereof. The method comprises the followingsteps of (1) performing weaving and high-temperature heat treatment on a carbon fiber prefabricated body; (2) preparing a porous carbon / carbon blank body; (3) introducing carbon elements and siliconelements into the carbon / carbon blank body in an impregnating mode; after the soaking and pyrolysis circulation period, obtaining a Cf / Cm-Sim porous intermediate; (4) performing embedded fusion Si seeping on the Cf / Cm-Sim porous intermediate to obtain a Cf / Cm-SiCm composite material. The inside SiC distribution of the composite is uniform; the residue Si content is 1.2 to 3.3 percent; the bendingintensity is 236 to 275MPa; the compression intensity is 322 to 364MPa; the dynamic friction coefficient is 0.32 to 0.48; the mechanical / friction performance is excellent; the thermal stability and the environment applicability are high; the material is applicable to the manufacturing of automobile braking discs / sheets.

Owner:湖南金羽先进材料有限公司

Self-lubricated composite plating in multiple layers and preparation method

InactiveCN1727520AGood anti-frictionReduce internal stressVacuum evaporation coatingSputtering coatingSputteringUltimate tensile strength

A self-lubricating multi-layer coated layer is composed of several Mo layers and several IF-MoS2 layers, which are alternatively prepared. Its preparing process includes providing laminar MoS2 powder, S powder and Mo sheets and alternative magnetically controlled sputterings and multi-arc ionic platings. Its advantages are high stability, low friction coefficient, high antiwear nature and high adhesion.

Owner:ZHEJIANG UNIV +1

Metallic matrix spindle brake pad for wind driven generator and preparation method thereof

InactiveCN101660581AMeet the requirements of high-speed brakingImprove mechanical propertiesFriction liningFiberWind driven

The invention relates to a metallic matrix spindle brake pad for a wind driven generator and a preparation method thereof. The material comprises iron powder, copper powder, tin powder, sulphur, shortcut steel fiber, copper fiber, high alumina ceramic fiber, inorganic oxide, graphite, etc. The preparation method comprises: weighing the components of the material according to the formulation, stirring and mixing the components in a special dry-type mixer, and ensuring the fibers to be fully dispersed and even; pressing the mixture for molding at the normal temperature, then sintering at the certain pressure and temperature, and cooling along with a furnace; finally, machining to obtain the metallic matrix spindle brake pad. Compared with the common powder metallurgy brake pad, the frictionmaterial prepared by the method is added with metals and the ceramic fiber, so as to remarkably improve the mechanical properties of the material and the static friction torque; meanwhile, the product has the advantages of moderate and stable coefficient of dynamic friction, better wear resistance, low brake noise and less dual wear, can completely meet the requirement of the wind driven generator for high speed brake of a spindle, and realizes environmental protection in deed.

Owner:CENT SOUTH UNIV +1

Metal-based yaw brake block for wind-powdered generator and manufacture method thereof

InactiveCN101799053AReduce manufacturing costImprove mechanical propertiesFriction liningFiberMechanical property

The invention relates to a metal-based yaw brake block for a wind-powdered generator and a manufacture method thereof. The materials comprise iron powder, copper powder, tin powder, sulfur, chopped steel fiber, copper fiber, high-alumina ceramic fiber, inorganic oxides, graphite, and the like. The manufacture method comprises the following steps of: firstly, weighting all the component materials according to a prescription; stirring and mixing in a special dry-type mixer to fully and evenly disperse all the fibers; pressing and molding at room temperature; then, sintering at a certain pressure and temperature; cooling in a furnace; and finally, mechanically processing to obtain a material of the invention. Compared with a common metallurgic brake block, the friction material prepared by the method remarkably improves the mechanical properties and the static friction torque of the materials by adding metal and ceramic fibers. Meanwhile, the product has the advantages of suitable and stable dynamic friction coefficient, better wear resistance, smaller dual wear and low manufacture cost and can fully satisfy the yaw brake requirement of a wind-powdered generator.

Owner:CENT SOUTH UNIV +1

Preparation method of aluminum matrix composite material brake disc

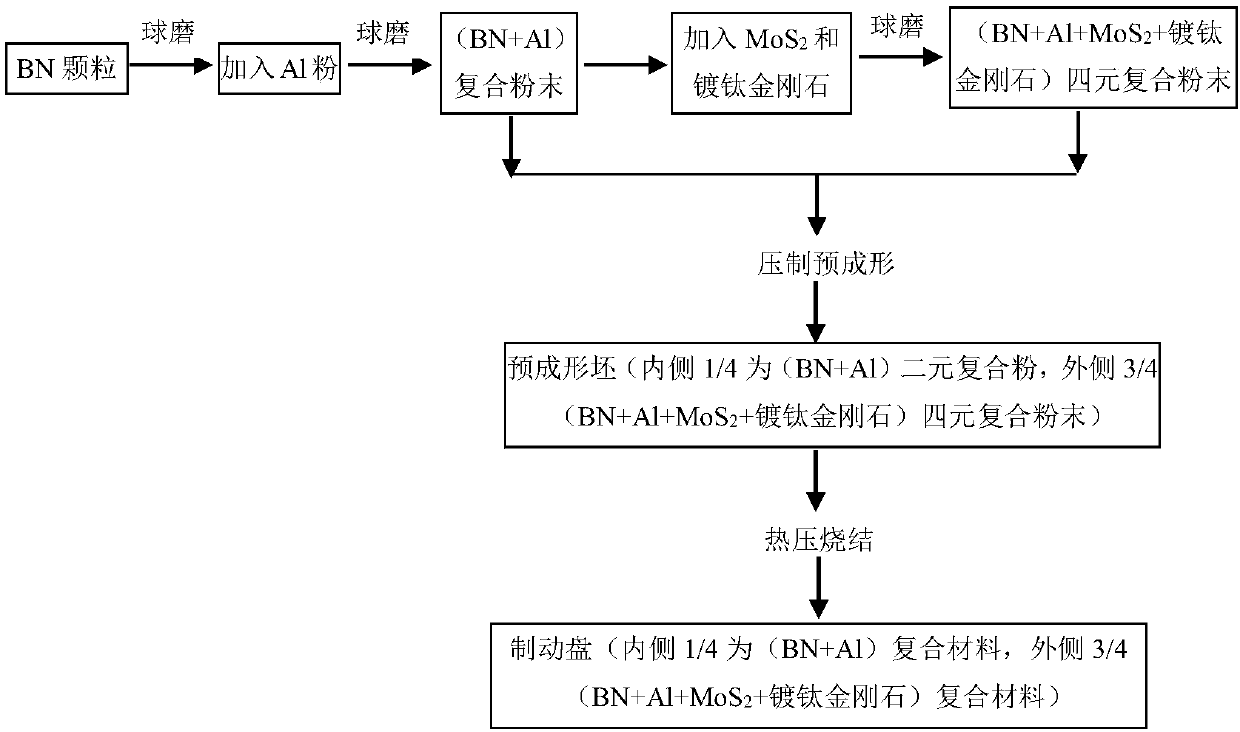

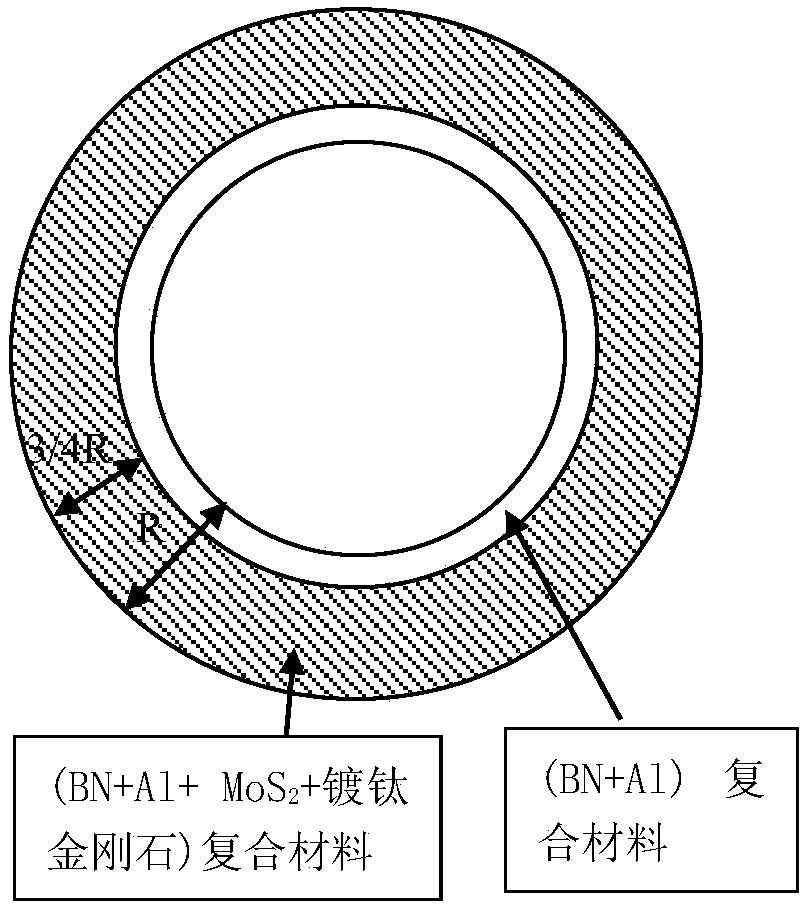

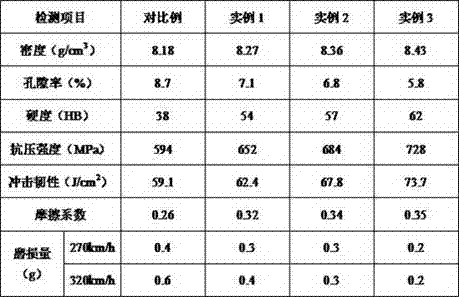

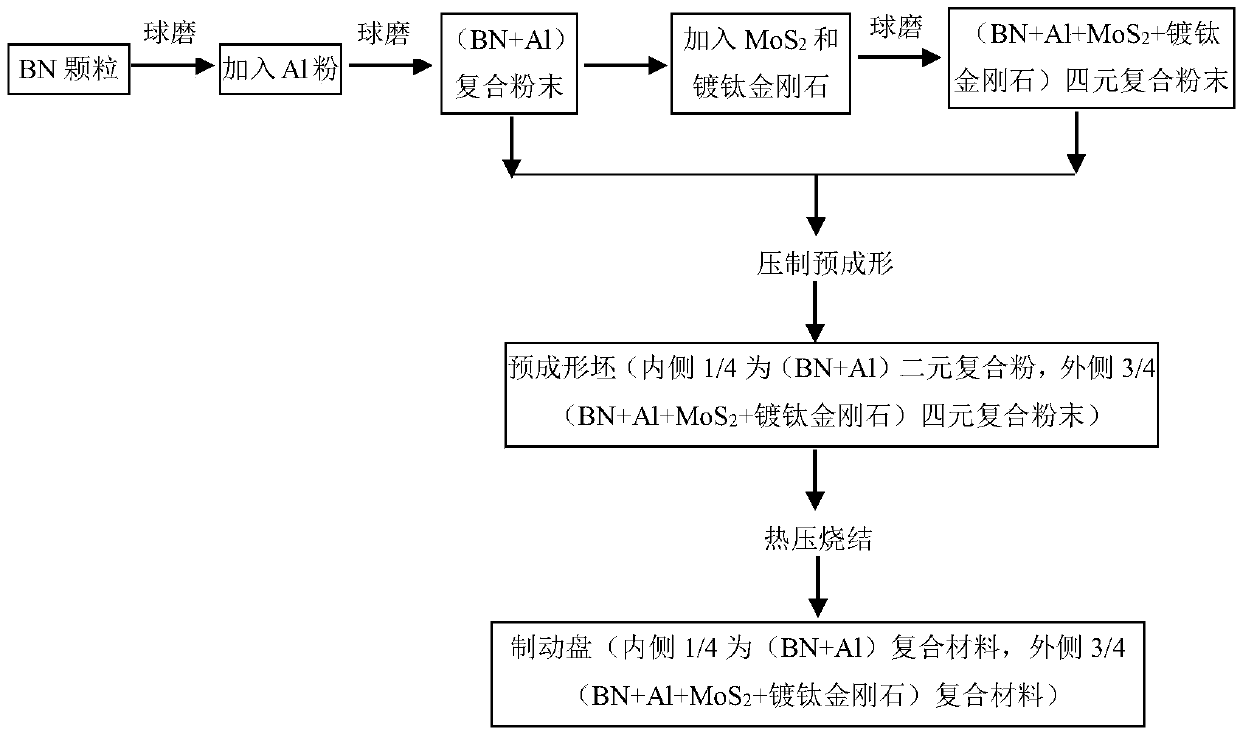

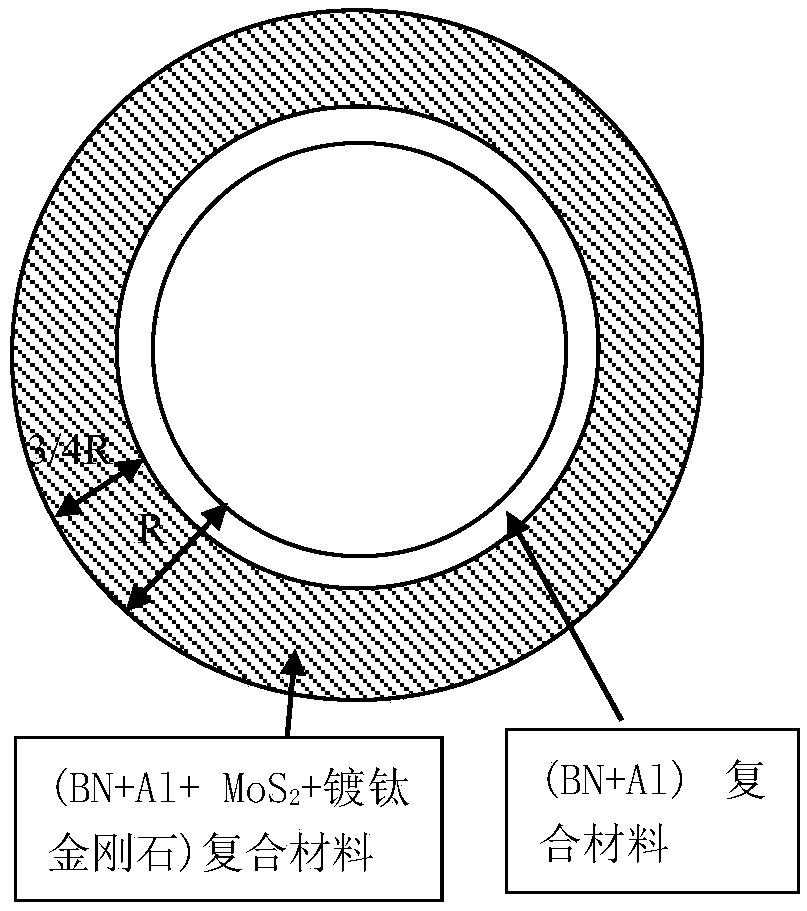

ActiveCN107598158AImprove wear resistanceGood dimensional stabilityBraking discsControl mannerTitanium

The invention relates to a preparation method of an aluminum matrix composite material brake disc, and belongs to the field of metal matrix composite materials. BN powder, MoS2 powder and titanium-plated diamond micro-powder are selected to serve as a reinforcement body, and pure aluminum serves as a matrix; through ball milling, the BN powder and Al powder are firstly mixed, and therefore the BNpowder is evenly distributed in the Al powder to form composite powder; then the composite powder, the MoS2 powder and the titanium-plated diamond micro-powder are mixed evenly according to a certainproportion, then pressing and pre-forming are carried out, in the pressing process, through a powder filling control manner, (BN+Al) composite powder is distributed to the 1 / 4 width position of the inner side of a pre-forming blank of an annular brake disc, and (BN+Al+MoS2+titanium-plated diamond) quaternary mixing powder is distributed to the outer side; and finally, the pressed and pre-formed blank is placed into a vacuum hot-pressing furnace for hot pressed sintering, and the composite aluminum matrix composite material brake disc is finally obtained. By means of the above method, the prepared motorbike brake disc is small in mass and better in radiating performance and wear-resisting property, and the working stability and reliability of the brake disc can be comprehensively improved.

Owner:山东银光钰源轻金属精密成型有限公司

Preparation method for high-speed rail brake powder metallurgy copper base friction material

InactiveCN107326248AImprove frictional stabilityReduce wearMolybdenum oxides/hydroxidesCopper nitrateHydrolysis

The invention discloses a method for preparing a high-speed rail brake powder metallurgy copper-based friction material, which belongs to the technical field of friction material preparation. The present invention oxidizes and modifies molybdenum trioxide by mixing potassium permanganate solution and glacial acetic acid, crystallizes it to form a rod-shaped structure, and disperses it in deionized water, and loads the copper hydroxide colloid formed by the hydrolysis of copper nitrate on the rod-shaped structure. The surface of molybdenum trioxide is mixed with flake graphite, atomized copper powder, iron powder, etc. by ball milling and sintered at high temperature to form a sintered material, which is crushed, milled and sieved to prepare a copper-based friction material. Molybdenum trioxide in rod-shaped composite particles The high-temperature stability performance of the copper-based friction material is effectively enhanced, and at the same time, the rod-shaped structure effectively enhances the friction force and improves the wear loss during its braking wear, and has broad application prospects.

Owner:常州市宝平不绣钢制品有限公司

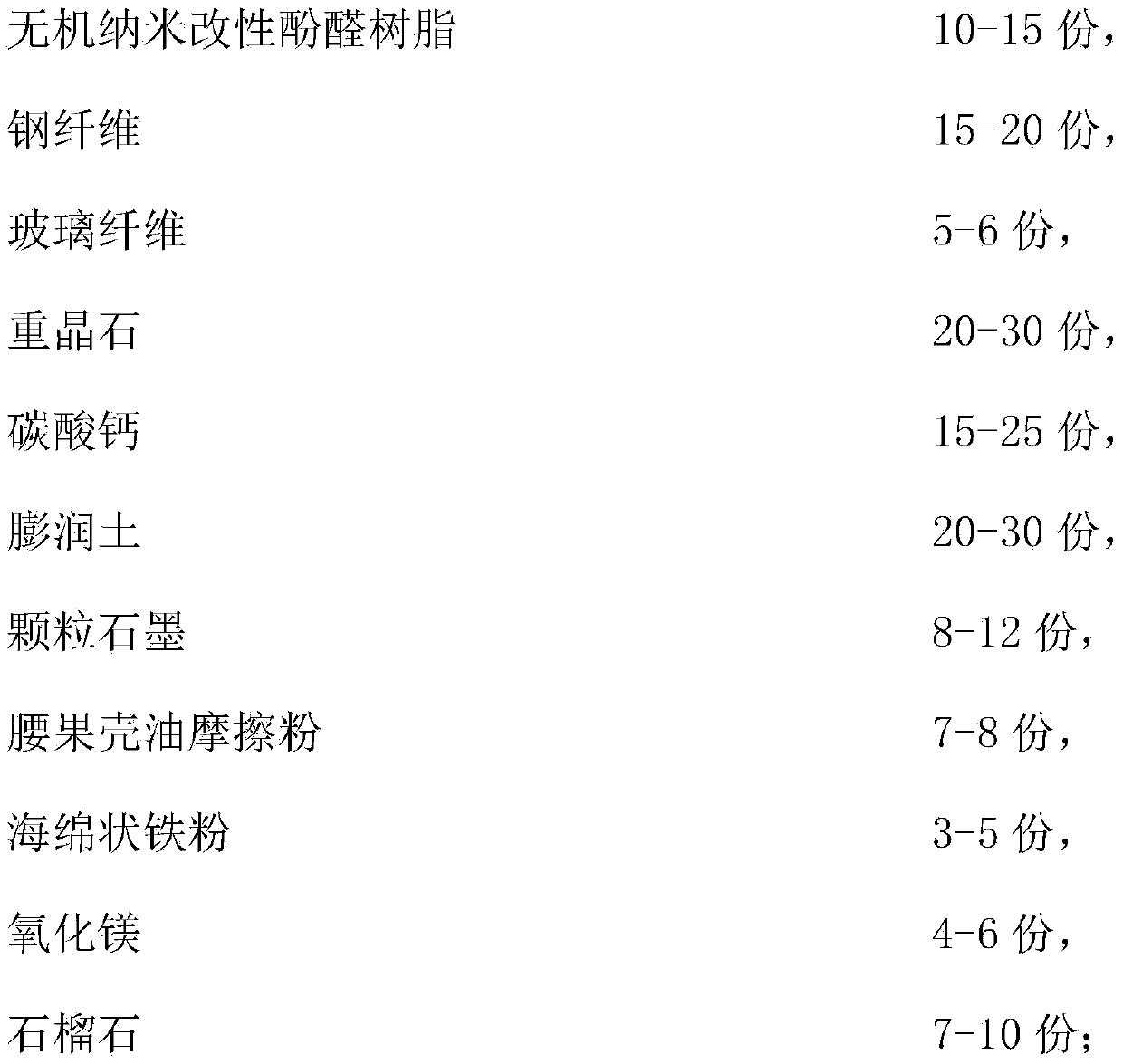

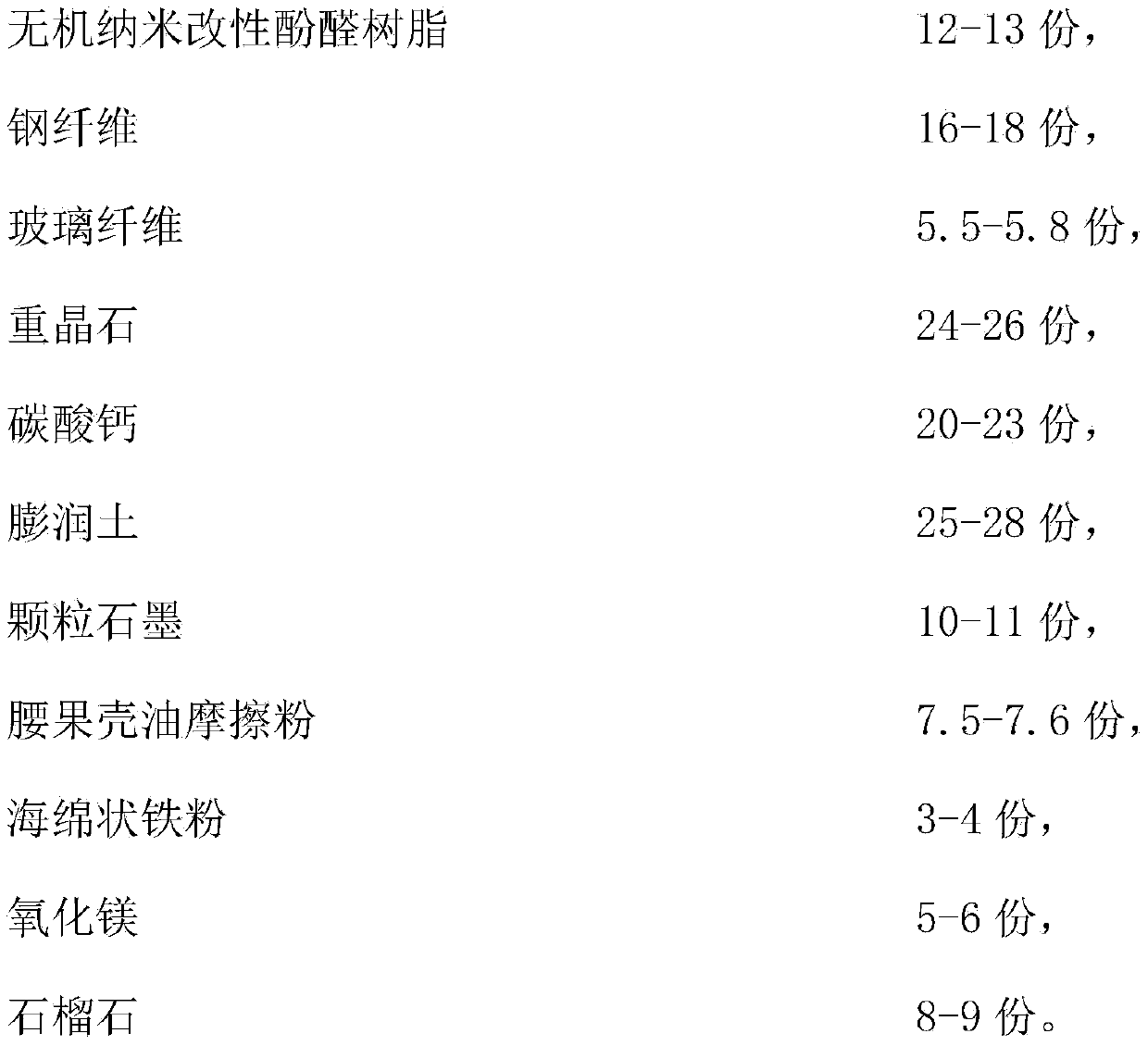

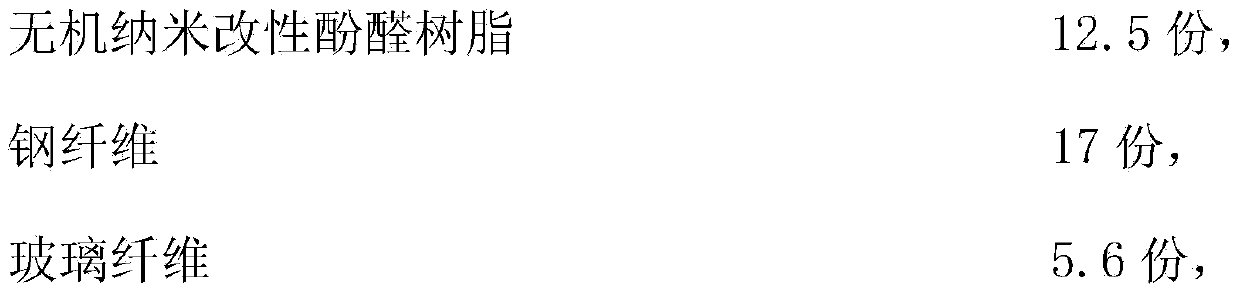

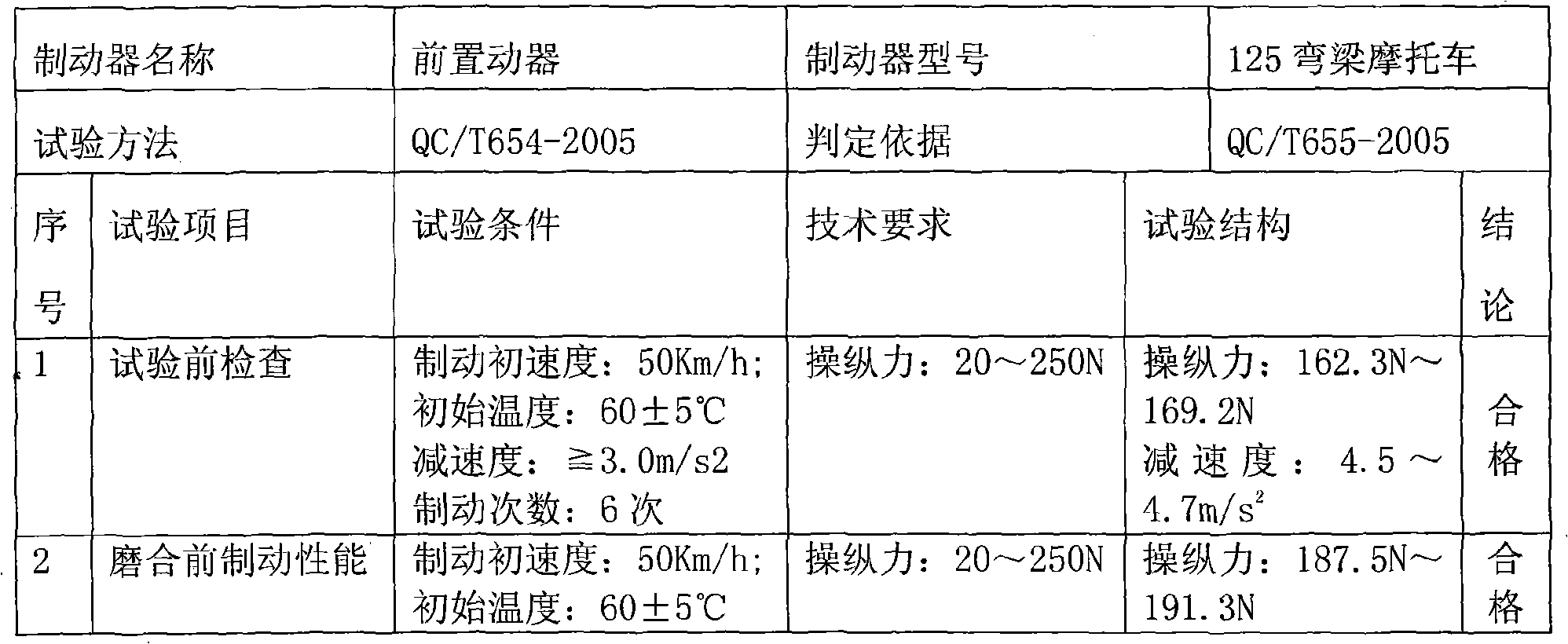

Inorganic nano modified phenolic resin brake pad and preparation process thereof

The invention discloses an inorganic nano modified phenolic resin brake pad which is prepared from the following raw materials in parts by weight: 10-15 parts of inorganic nano modified phenolic resin, 15-20 parts of steel fibers, 5-6 parts of glass fibers, 20-30 parts of barite, 15-25 parts of calcium carbonate, 20-30 parts of bentonite, 8-12 parts of granular graphite, 7-8 parts of cashew nut shell oil frictional powder, 3-5 parts of spongy iron powder, 4-6 parts of magnesium oxide and 7-10 parts of garnet, wherein the inorganic nano modified phenolic resin is obtained by adopting modified nano vermiculite to modify phenolic resin, the water content is 0.5-0.8wt% and the content of free phenol is 1.5-2wt%. The invention further discloses a preparation method of the inorganic nano modified phenolic resin brake pad. According to the invention, the inorganic nano modified phenolic resin brake pad is high in thermal stability, excellent in heat resistance, good in frictional stability and wear resistance, simple in preparation process and convenient for actual operation.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

Material for non-asbestos copper fibre brake disc

The invention relates to a non-asbestos copper fiber brake plate material, composed of phenolic resin, frication dust, butadiene acrylonitrile rubber, alumina, chromite, feldspar, cut copper fiber, needle shape wollastonite powder, tire powder, magnesia and lignin fiber; the weight percentages of the ingredients are as follow: phenolic resin 8-12%, frication dust5-15%, butadiene acrylonitrile rubber2-5%, alumina5-10%, chromite15-25%, feldspar5-8%, cut copper fiber6-8%, needle shape wollastonite powder10-15%, tire powder15-20%, magnesia2-5% and lignin fiber15-20%. The non-asbestos fiber brake plate with a copper substrate is of high brake performance, stable friction coefficient, high thermal conduction, good head dissipation performance in the rubbing process and good plasticity and has no harm to dualization; the copper substrate has small binding affinity to oxygen and is slow to oxidate in air.

Owner:重庆银角制动器有限公司

Automotive brake block made from modified thermoplastic phenolic resin material

InactiveCN104235243AHigh probability of bindingGood toughening effectFriction liningSilicon dioxideToughening

The invention discloses an automotive brake block made from a modified thermoplastic phenolic resin material. The brake block comprises the following raw materials in parts by weight: 15-20 parts of modified thermoplastic phenolic resin, 15-20 parts of nylon fiber, 8-10 parts of pitch-based carbon fiber, 5-10 parts of polypropylene fiber, 8-10 parts of lignin fiber, 3-5 parts of expanded vermiculite, 10-17 parts of barite, 12-15 parts of chromium iron powder, 8-10 parts of fluorite, 5-7 parts of crystalline flake graphite, 6-8 parts of nitrile rubber powder, 5-8 parts of tyre powder, 5-6 parts of iron powder and 10-13 parts of silicon dioxide. The automotive brake block made from the modified thermoplastic phenolic resin material provided by the invention is good in toughening effect and thermal stability, excellent in heat-resistant quality, and better in friction stability and wearable performance.

Owner:NINGGUO FEIYING AUTO SPARE PARTS

Method for preparing high-temperature-resistant friction material from modified ramie fibers

InactiveCN106220894ASimple preparation stepsImprove heat resistanceOther chemical processesPolymer scienceAcrylonitrile

The invention discloses a method for preparing a high-temperature-resistant friction material from modified ramie fibers and belongs to the technical field of friction material preparation. Raw ramie is weighed and soaked with a sodium chloride solution, after heating and heat preservation, the pH value is adjusted, filtering is carried out after heat preservation, a filtered material is obtained, after washing and air-drying, the material is mixed with phospholipase C and bakelite powder, and degummed modified ramie fibers are prepared through degumming modification; an ethyl orthosilicate ethanol solution, sodium dodecyl sulfate and other matter are taken and mixed to be prepared into a modified mixed solution, the modified mixed solution is mixed with the degummed modified ramie fibers, and the modified ramie fibers are prepared after ultrasonic oscillation and microwave reaction modification; the modified ramie fibers are mixed with butadiene-acrylonitrile rubber and other matter, and the high-temperature-resistant friction material is prepared through hot-press molding in a die. The method has the advantages that the preparation steps are simple, and the obtained product is good in heat resistance and can resist the temperature of 200-220 DEG C; the friction stability of the material is good, and the mechanical performance is improved by 45-48%.

Owner:仇颖莹

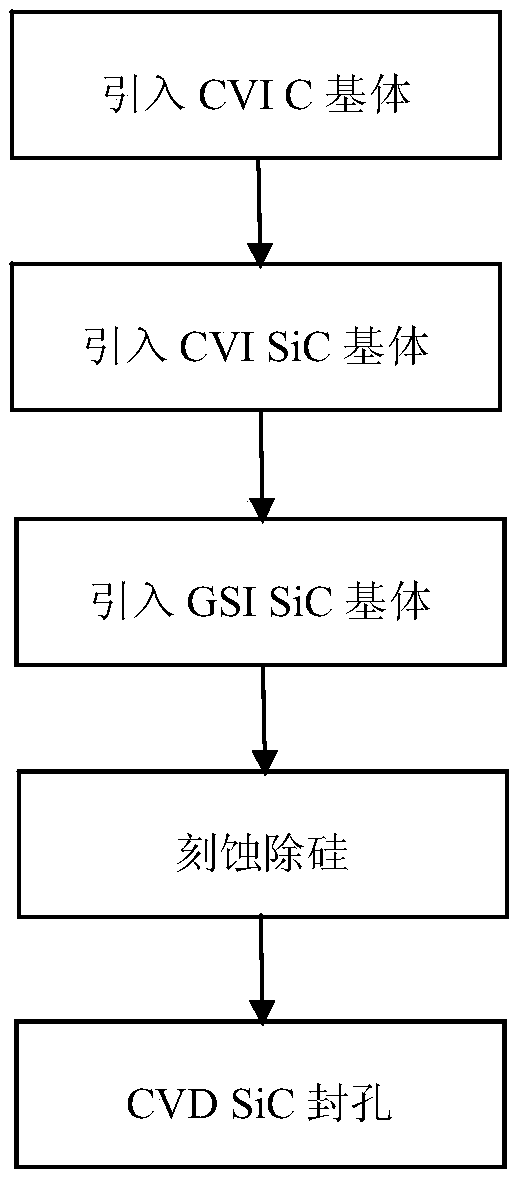

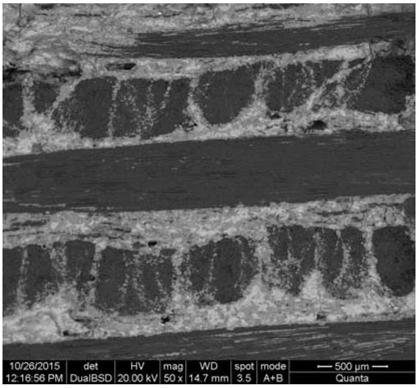

c/c-sic composite material and its preparation method and application

The invention discloses a C / C-SiC composite material, and a preparation method and an application thereof. The C / C-SiC composite material comprises a carbon fiber prefabricated part, a carbon matrix and a silicon carbide matrix, aperatures of the carbon fiber prefabricated part are filled with the carbon matrix and the silicon carbide matrix, the silicon carbide matrix comprises a first silicon carbide matrix and a second silicon carbide matrix, and the second silicon carbide matrix is introduced through a vapor silicon infiltration sintering technology. The preparation method comprises the following steps: 1, introducing the carbon matrix; and 2, respectively introducing the first silicon carbide matrix and the second silicon carbide matrix. The C / C-SiC composite material has the advantages of uniform components, high density, fine matrix particles, high friction stability, high heat conductivity and excellent mechanical performances. The preparation method is simple, and the composite material has excellent performances.

Owner:NAT UNIV OF DEFENSE TECH

Friction particles

The invention relates to a friction material to be mounted in brake components and other devices for producing friction, in particular a kind of friction particles comprising the following constituents (by weight percentage): artificial graphite 40-65%, fabric 20-40%, resin 2-15%, nano mortar 3-15%, latex 5-20%, rubbing agent 3-15%, sodium silicate 1-10% and hexamethylene tetramin 0.5-2%.

Owner:周惠昌

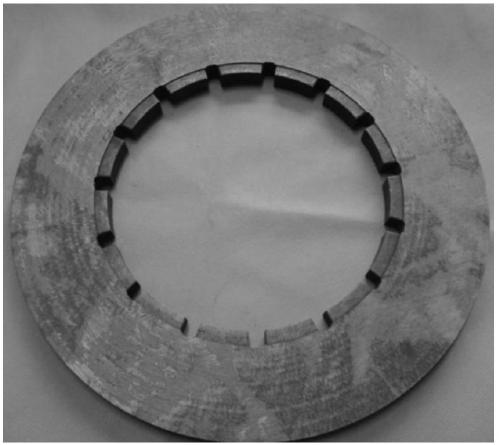

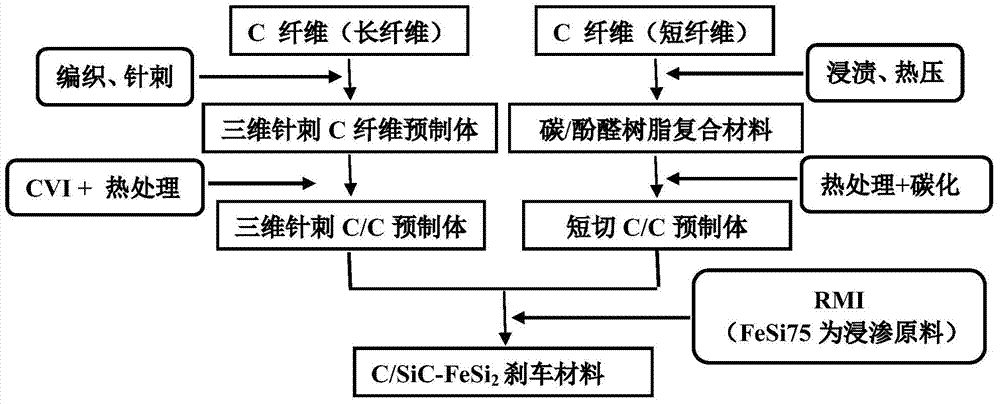

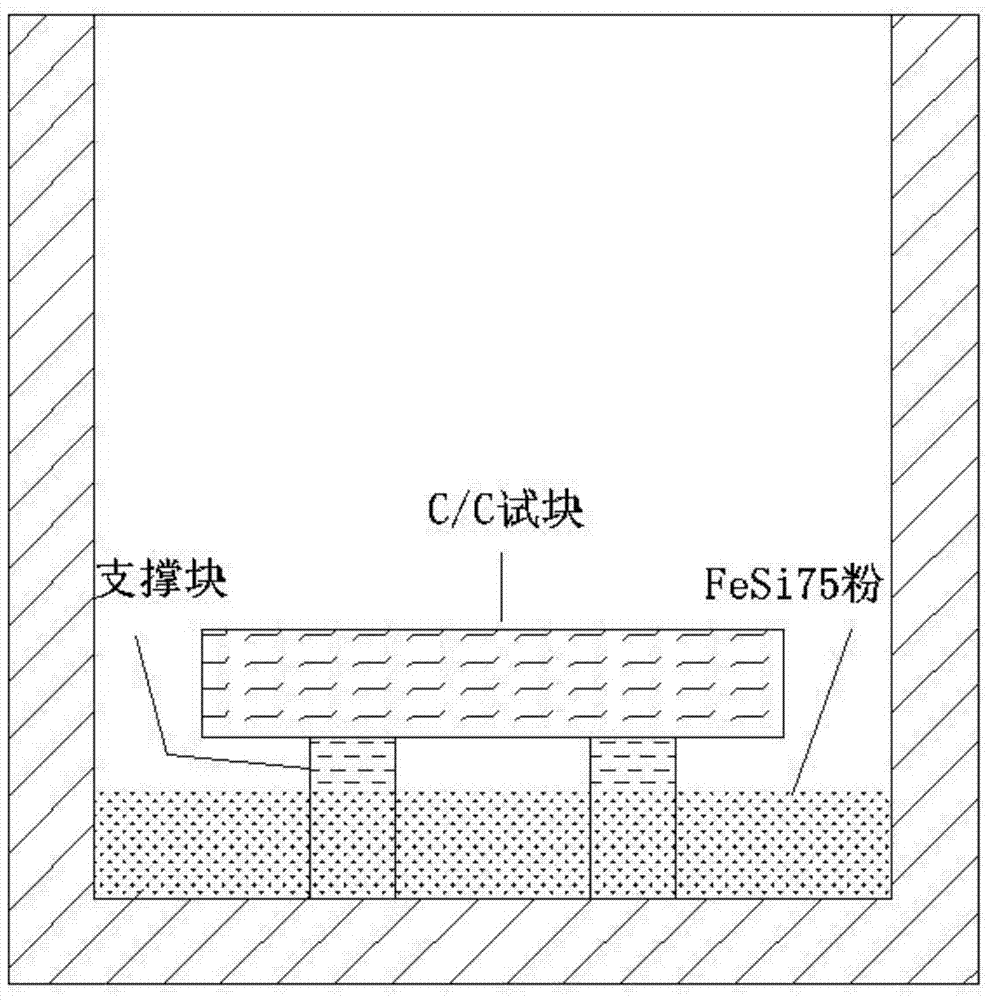

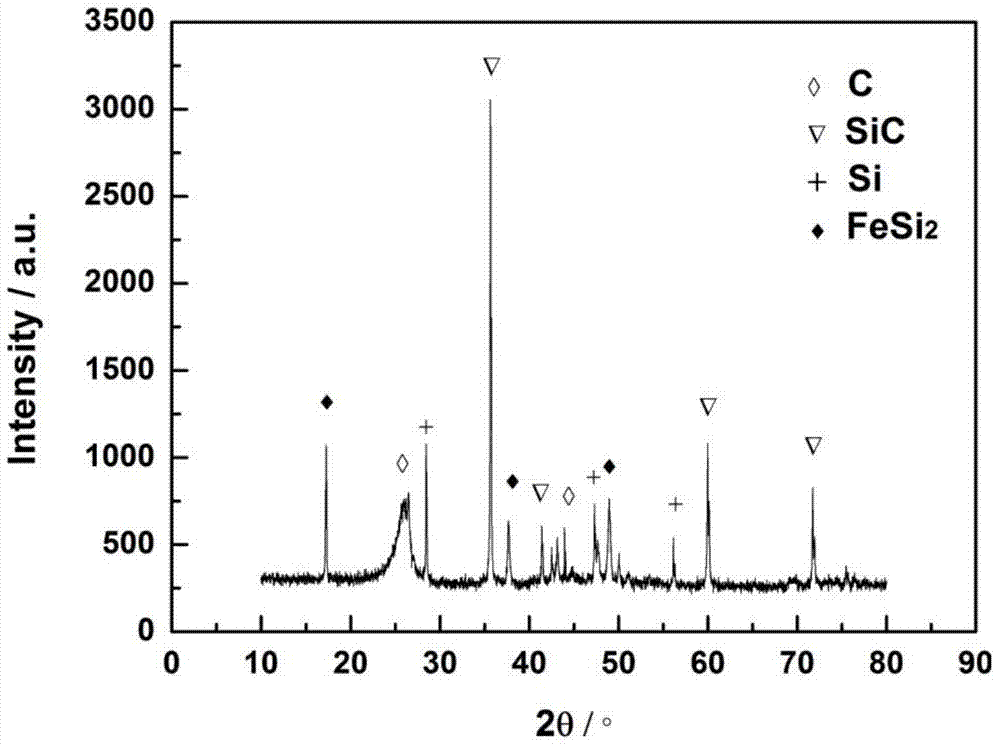

Preparation method of FeSi2 modified C/SiC braking material

InactiveCN104844243AImprove mechanical propertiesGood for heat dissipationRaw materialNanotechnology

The invention relates to a preparation method of a FeSi2 modified C / SiC braking material. A method combining CVI with RMI is adopted to prepare the FeSi2 modified three-dimensional needled C / SiC braking material. The preparation method includes: taking FeSi75 alloy powder as a RMI infiltration raw material; obtaining the FeSi2 modified C / SiC braking material through a reactive melt infiltration (RMI) process. By the preparation method, raw material cost is lowered remarkably, and RMI process temperature is lowered; a FeSi2 phase is introduced into a C / SiC composite material, so that strength and heat conductivity of the braking material are improved, friction stability is improved, and wear rate is lowered.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

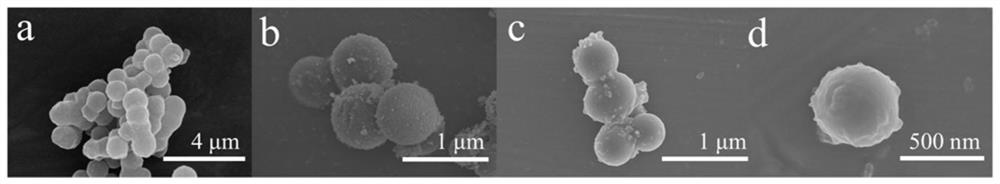

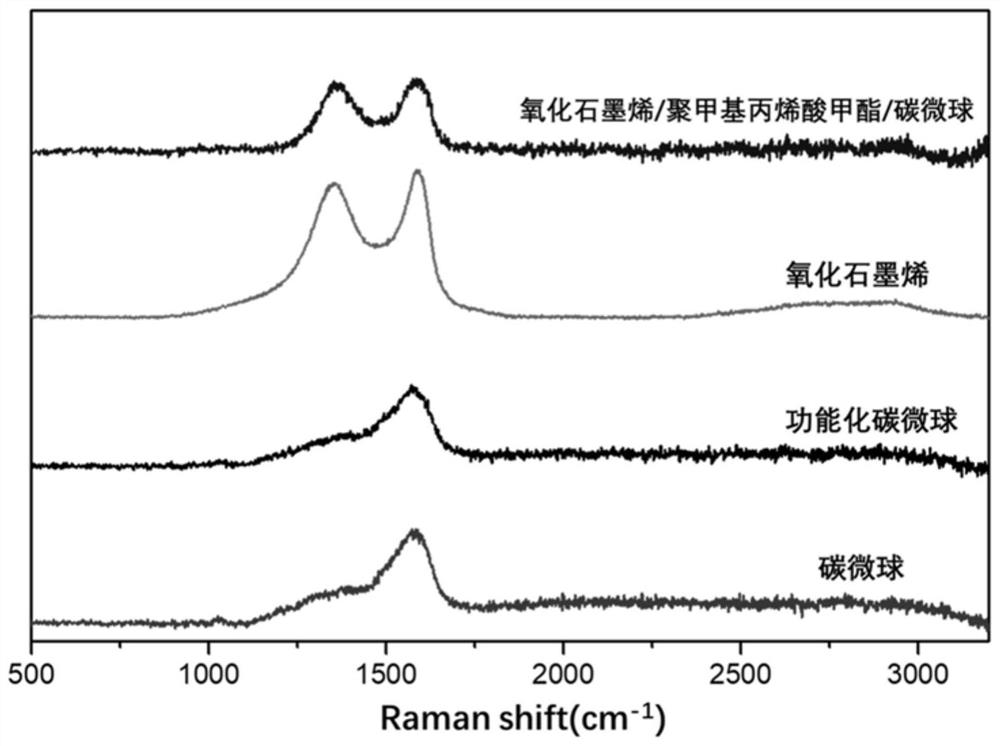

Preparation method of graphene oxide reinforced polymethyl methacrylate/carbon microsphere composite material

The invention discloses a preparation method of a graphene oxide reinforced polymethyl methacrylate / carbon microsphere composite material. The preparation method comprises the following steps: carrying out a hydrothermal reaction by using a glucose solution as a carbon source to obtain carbon microspheres; dissolving the carbon microspheres in a mixed solution of deionized water and anhydrous ethanol, adding a mixed solution of a silane coupling agent and anhydrous ethanol, carrying out a reaction under a condensation reflux heating condition to obtain modified carbon microspheres; preparing asolution from the modified carbon microspheres, water and methyl methacrylate, marking the solution as a solution A, introducing nitrogen, continuously stirring; preparing a graphene oxide water solution, marking the graphene oxide water solution as a solution B, continuously stirring; adding the uniformly stirred solution B into the uniformly stirred and mixed solution A to obtain a solution C,continuously stirring the solution C until the solution C is uniformly mixed; adding sodium dodecyl benzene sulfonate into the solution C, heating for reaction, and filtering, centrifuging, washing and drying the reaction product to obtain the graphene oxide reinforced polymethyl methacrylate / carbon microsphere composite material.

Owner:SHAANXI UNIV OF SCI & TECH

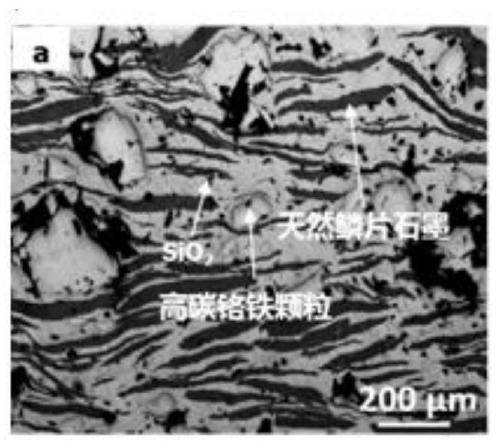

Copper-based composite material reinforced by double-size hard particles and preparation method thereof

InactiveCN110343899AImprove mechanical propertiesExcellent friction and wear resistanceFlake graphiteCeramic particle

The invention discloses a copper-based composite material reinforced by double-size hard particles. The copper-based composite material is prepared from, by mass, 1%-5% of ceramic particles, 6%-12% ofhigh-carbon ferrochromium particles, 8%-12% of natural flake graphite and the balance of electrolytic copper powder, wherein the ceramic particles are one or more of copper-plated SiC particles, copper-plated B4C particles, copper-plated TiC particles, copper-plated A1203 particles, copper-plated Cr203 particles, copper-plated SiO2 particles, copper-plated Si3N4 particles and copper-plated AlN particles. The invention also provides a preparation method of the copper-based composite material reinforced by the double-size hard particles.

Owner:CHANGCHUN UNIV OF TECH

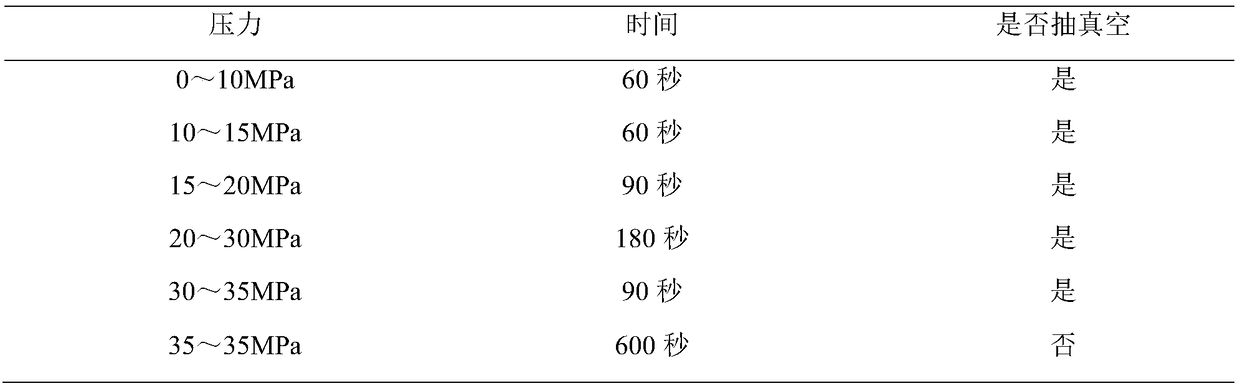

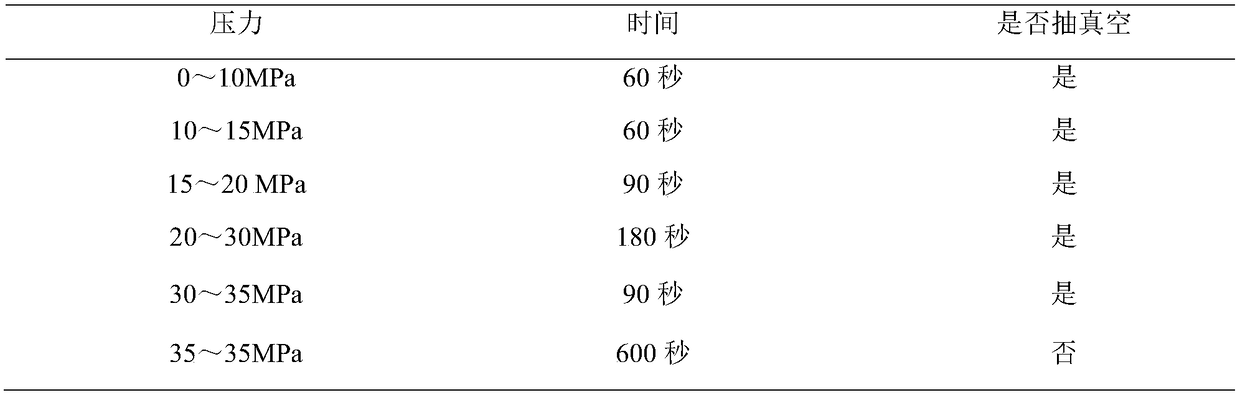

Ceramic matrix tread sweeper grinder and production method thereof

InactiveCN109336473AImprove high temperature resistanceHigh strengthVehicle cleaningSlagFerrosilicon

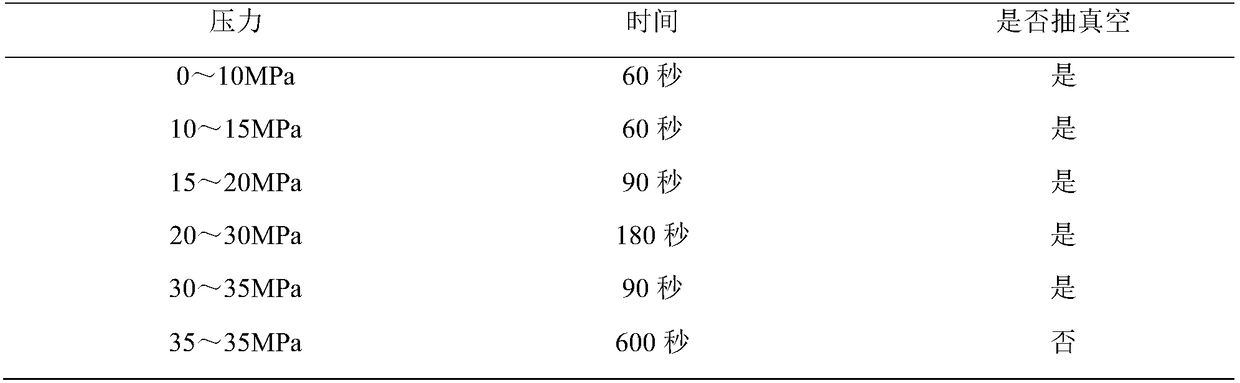

The invention discloses a ceramic matrix tread cleaner grinder and a production method thereof, and belongs to the field of urban rail transit equipment. The ceramic matrix tread cleaner grinder is prepared from the following ceramic raw materials: a silicon carbide whisker, ferrosilicon nitride, quartz powder, alumina powder, titanium oxide and zirconia powder. The production method comprises thefollowing steps: pouring the raw materials into a mixer, adding modified phenolic resin for premixing, then adding tetrahydrofuran and water for continuous mixing and producing particles with the diameter of about 2 to 3 mm, drying, carrying out vacuum hot-pressing molding and curing. According to the production method disclosed by the invention, hot-pressing molding is carried out on the grinderby improving a formula and a process and using modified phenolic resin as a binder; with reasonable hot pressing pressure and heat treatment time, the toughness and thermal stability of the grinder can be improved; in addition, slag is not easy to fall off and the service life can be effectively prolonged; besides, certain social benefits for environmental protection also can be played.

Owner:马鞍山市雷狮轨道交通装备有限公司

Preparation method of low-wear-type ceramic-based composite bake material

ActiveCN108191442AImprove thermal conductivityImprove stabilityFriction liningActuatorsMaterials preparationFiber bundle

The invention relates to the technical field of automobile brake material preparation and in particular to a preparation method of a low-wear-type ceramic-based composite bake material. The preparation method comprises the steps: adopting natural organic sponge with an abundant pore structure as a raw material, extracting moso bamboo fiber bundles from moso bamboo, and stacking the sponge and thefiber bundles at intervals; then, carrying out puncturing treatment by using a barbed needle to make the moso bamboo fiber bundles distributed among sponge blocks at a vertical angle to obtain a complex; carrying out carbonization treatment on the complex, then, carrying out vapour fumigation on the complex by using methyltrichlorosilane, and carrying out in-situ deposition under a thermal actionto generate a silicon carbide crystal; and then, soaking the silicon carbide crystal by using tetraethyl orthosilicate to increase the density, and carrying out high-temperature sintering to obtain silicon carbide ceramic brake material. The brake material prepared by using the preparation method is good in wear resistance, high in friction coefficient, not easy to exceed the rated brake power ina brake process and wide in application prospect.

Owner:HENGSHUI ZHONGCHENG FRICTION MATERIAL

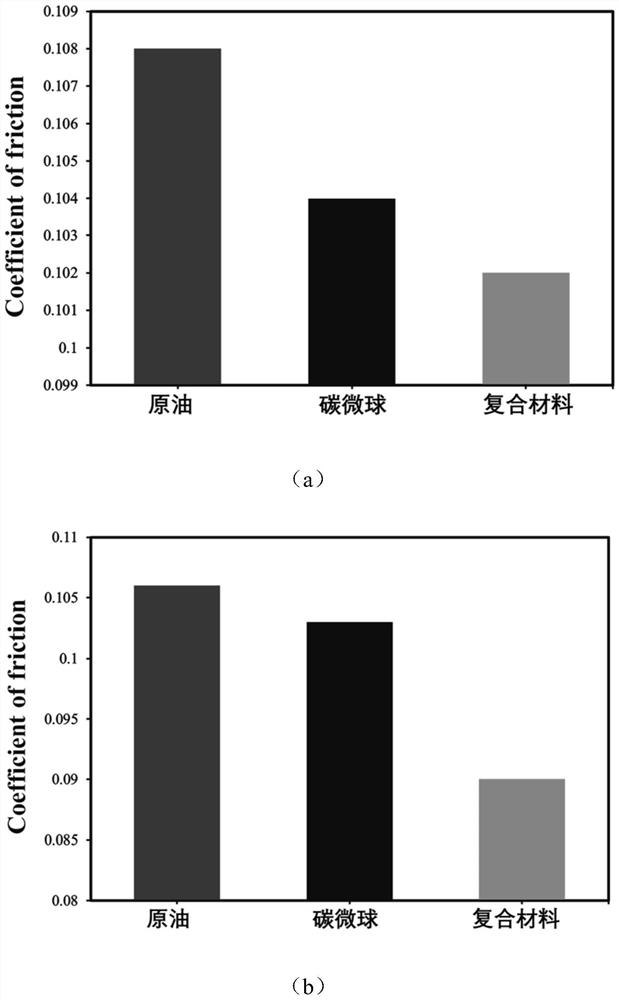

Gear oil and preparation method thereof

InactiveCN106893624APrevent oxidative deteriorationAvoid generatingAdditivesPolymethyl methacrylateCleansing Agents

The embodiment of the present invention discloses a gear oil, which comprises the following components by weight percentage: 1.5% polymethyl methacrylate, 0.3% V1156 pour point depressant, 0.3% di-tert-butyl-p-cresol, dialkyl dithio Zinc phosphate 2%, bis-succinimide 1%, friction system improver 0.5%; antifoaming agent 0.0001%, pigment 0.0001%, and the rest is base oil. A preparation method of the above-mentioned cleaning agent is also disclosed. The above raw materials are stirred and mixed evenly at room temperature; the gear oil and its preparation method of the embodiment of the present invention have excellent high temperature stability, prevent oil from oxidative deterioration and deposit formation, and keep the gearbox clean. Excellent anti-wear protection, effectively prolonging the service life of components. Excellent friction characteristics to ensure continuous, reliable and trouble-free operation of the transmission. Good friction stability and smoother gear shifting.

Owner:SHENZHEN PINGCHI IND

Multielement resin base carbon compound disc-type braking pad and preparation method thereof

ActiveCN102635653BImprove wear resistanceImprove high temperature resistanceFriction liningLow noiseTemperature resistance

The invention discloses a multielement resin base carbon compound disc-type braking pad and a preparation method thereof. The braking pad is obtained by carrying out mould pressing and forming once on the following raw materials: unmodified phenolic resin, organosilicone modified phenolic resin, polyacrylate modified phenolic resin, polyacrylonitrile carbon fiber, artificial granular graphite, natural crystalline flake graphite, granular coke, silicon carbide, aramid pulp, compound mineral fiber, steel fiber, red copper powder, ferrous sulfide and barium sulfate. The product disclosed by the invention has the advantages of high temperature resistance, ablation resistance, small heat expansion coefficient, high specific strength, high specific modulus, good abrasion resistance, low noise, excellent initial performance, short breaking-in period, small heat fade, long service life, excellent pedal comfort degree, excellent high temperature and high speed performance and stable abrasion grade under different braking conditions, the effect on considering the good abrasion resistance and low noise is achieved, no dust is generated during braking, and various materials are all environment-friendly environment-protection materials. The multielement resin base carbon compound disc-type braking pad also has the function of automatically cleaning the braking disc.

Owner:JINAN GOLD PHOENIX BRAKE SYST

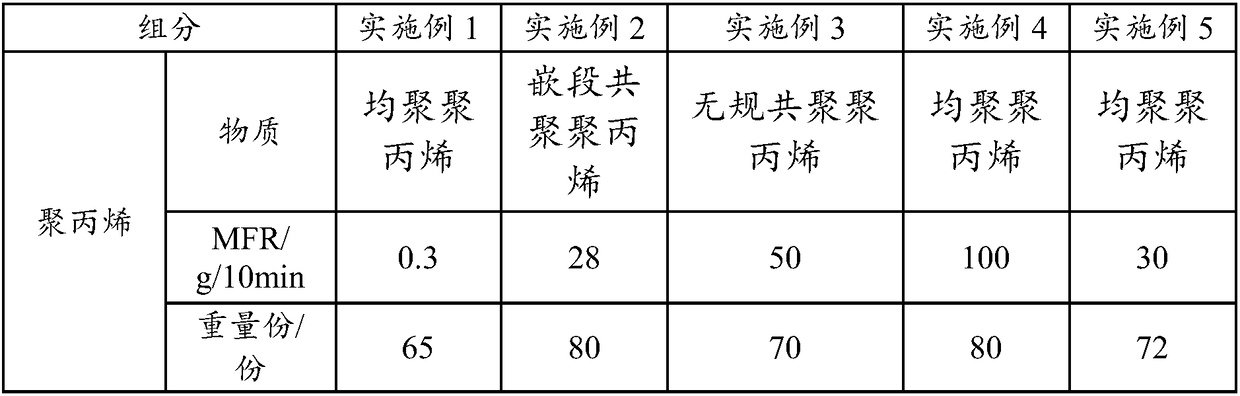

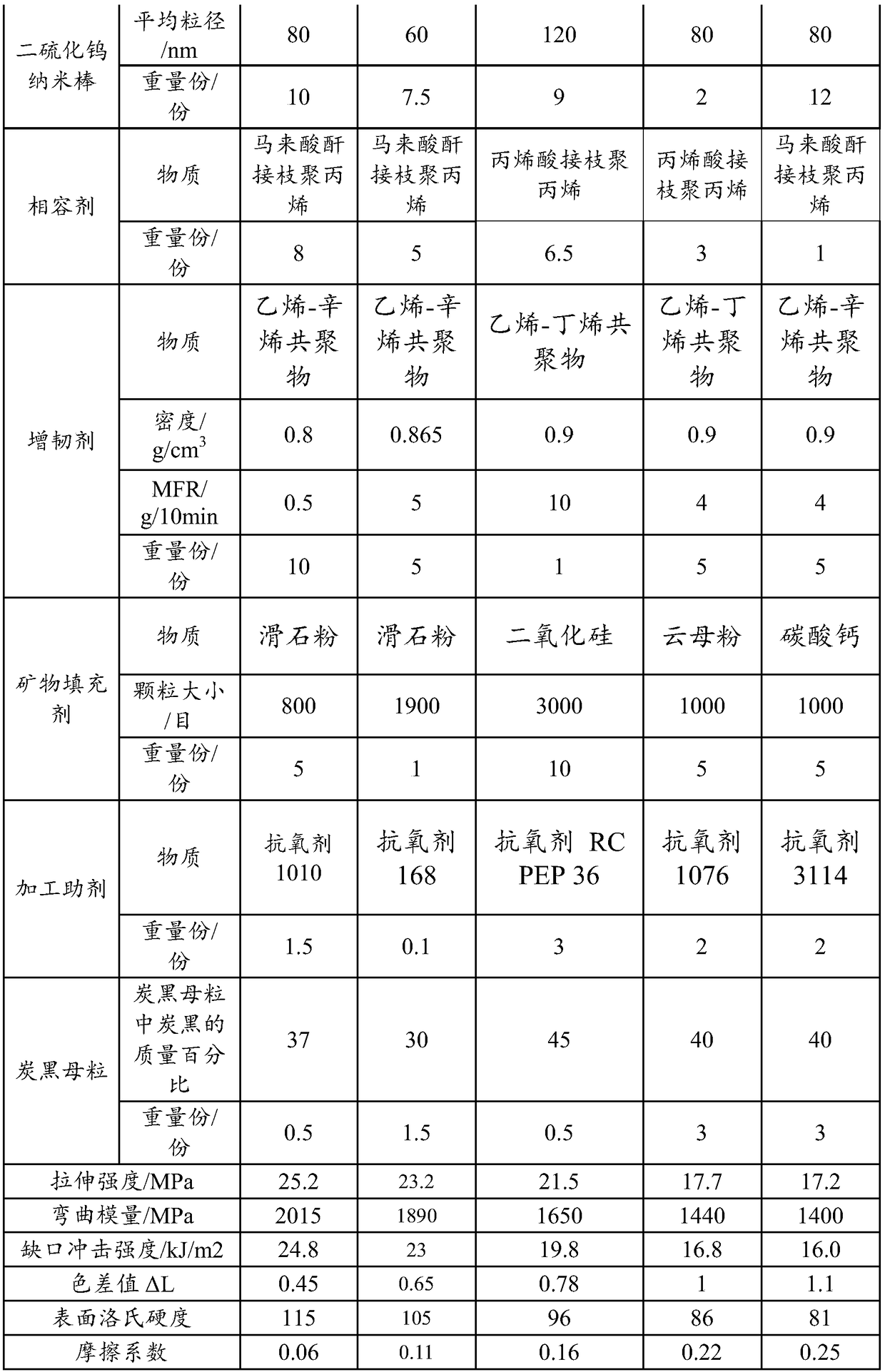

Polypropylene composite material and preparation method thereof

The invention relates to a polypropylene composite material and a preparation method thereof, and belongs to the technical field of a modified material. The polypropylene composite material is prepared from the following ingredients in parts by weight: 65 to 80 parts of polypropylene, 2 to 12 parts of tungsten disulfide nanometer rods and 1 to 8 parts of compatilizers. The specific content of tungsten disulfide nanometer rods are added into polypropylene substrates under the cooperated dispersion effect of the specific content of compatilizers, so that mutual friction is generated between WS2materials in the prepared polypropylene composite material; layered sliding is generated; the WS2 becomes thin and small through friction; small fragments fill the defects in the abrasion process, sothat the friction undulation is further reduced; the friction stability is enhanced. Therefore the anti-scratching performance and the intensity of the obtained polypropylene composite material are obviously improved.

Owner:WUHAN JINFA TECH CO LTD +1

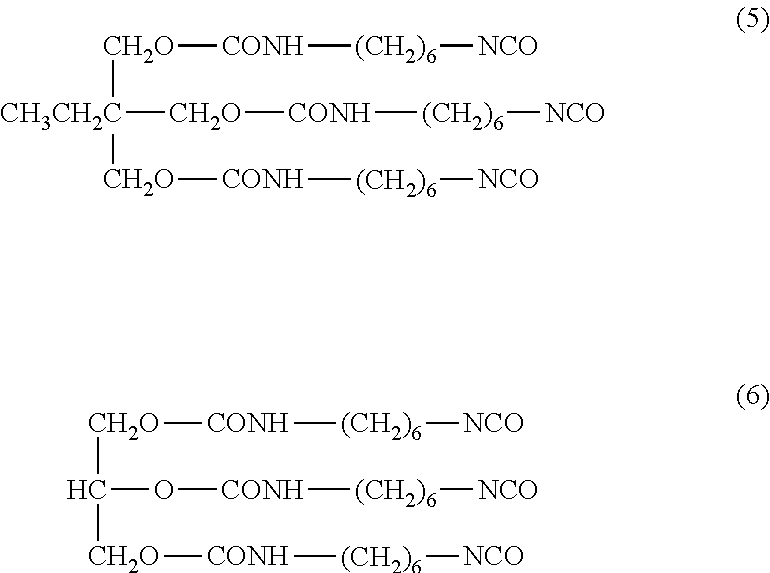

Cyclotriphosphazene ionic liquid used as lubricant and preparation method thereof

ActiveCN103571567ALow costGood friction stability and anti-wear and anti-friction performanceGroup 5/15 element organic compoundsSulfonic acids salts preparationPerylene derivativesImide

The invention discloses a cyclotriphosphazene ionic liquid used as a lubricant and a preparation method thereof. The ionic liquid is prepared by mixing the following components together: diglycol monomethyl ether, triglycol monomethyl ether, or tertglygol monomethyl ether derivatives of cyclotriphosphazene, lithium tetrafluoroborate, lithium hexafluorophosphate, and lithium trifluoromethanesulfonate or bis(trifluoromethane)sulfonimide lithium. The ionic liquid has a good chemical stability, thermal stability, and abrasion reducing and wear-resistant performance. The preparation method of the ionic liquid provided by the invention has the advantages of simple preparation process, low cost, excellent performance, and suitability for industrial application.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Cyclotriphosphazene ionic liquid used as lubricant and preparation method thereof

ActiveCN103571567BLow costImprove frictional stabilityGroup 5/15 element organic compoundsSulfonic acids salts preparationTetraglycolPhosphoric acid

The invention discloses a cyclotriphosphazene ionic liquid used as a lubricant and a preparation method thereof. This ionic liquid is composed of diethylene glycol monomethyl ether, triethylene glycol monomethyl ether or tetraethylene glycol monomethyl ether derivatives of cyclotriphosphazene and lithium tetrafluoroborate, lithium hexafluorophosphate, lithium trifluoromethanesulfonate or bis(three Fluoromethanesulfonyl)imide Lithium obtained after mixing. The ionic liquid has good chemical stability, thermal stability and anti-friction and anti-wear properties. The ionic liquid provided by the invention has simple preparation process, low cost and excellent performance, and is suitable for industrial application.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Adhesive Composition

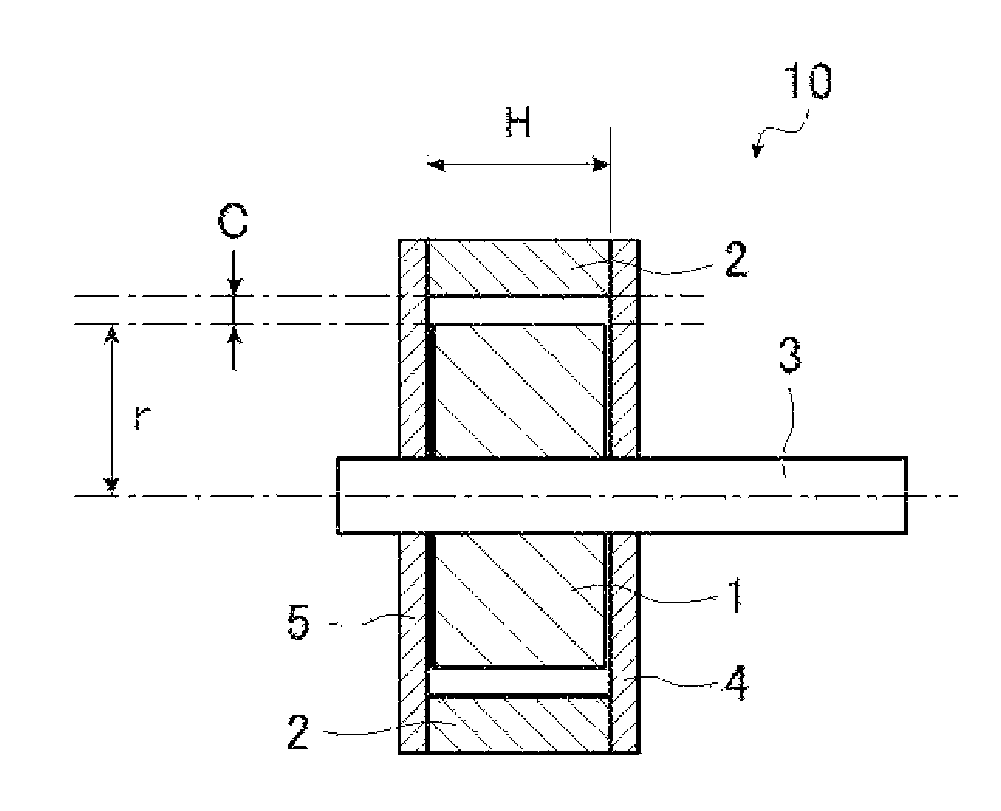

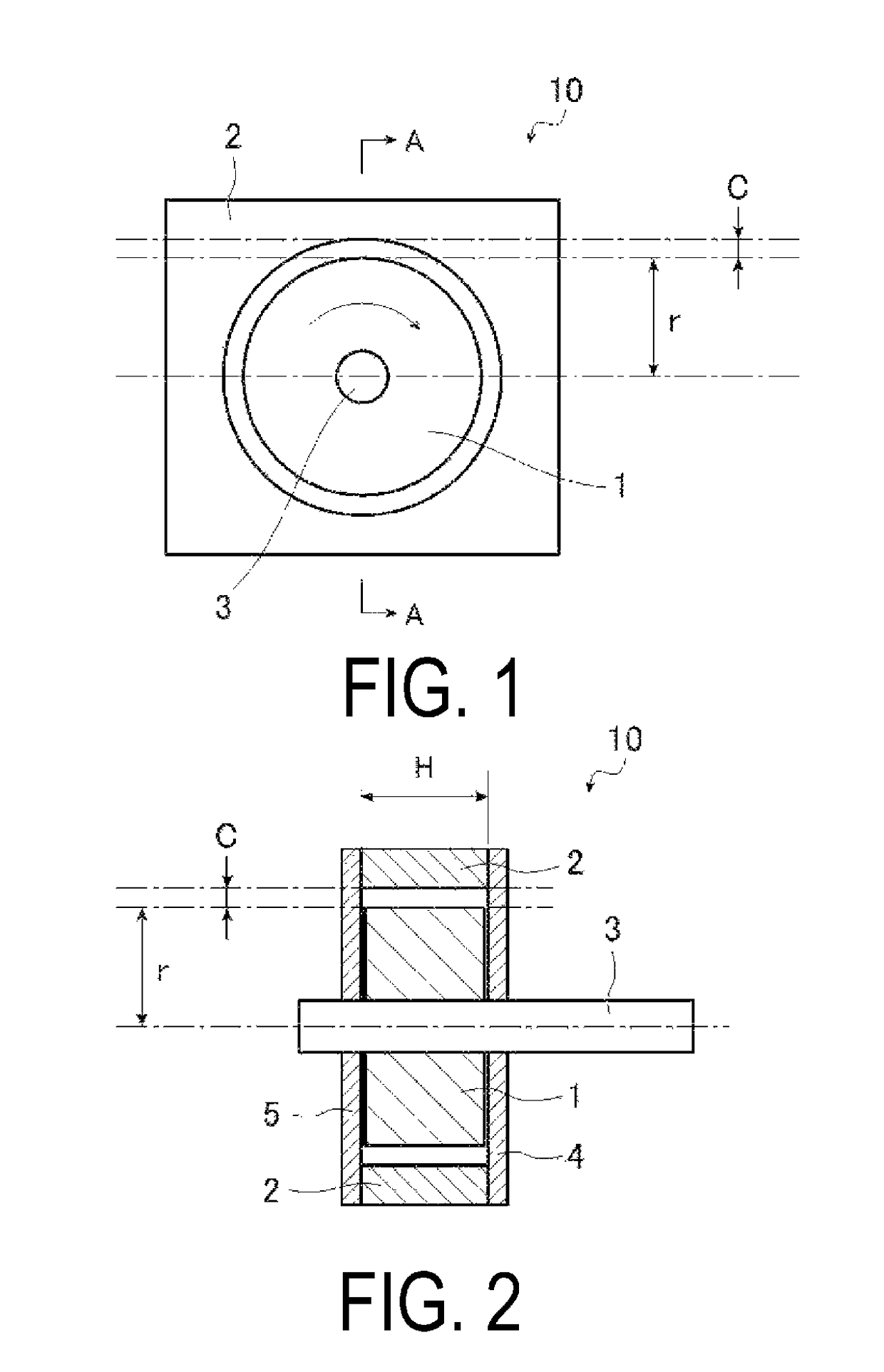

ActiveUS20180086956A1Improve frictional stabilityNon-macromolecular adhesive additivesOrganic-compounds/hydrides/coordination-complexes catalystsMetal catalystPrepolymer

The present technology provides an adhesive composition containing a urethane prepolymer (UP), plural types of carbon blacks (CB), calcium carbonate, aliphatic isocyanate, a metal catalyst, and an amine catalyst, wherein first and second CBs have dibutyl phthalate oil absorptions of from 23 to 40 cm3 / 100 g and from 85 to 120 cm3 / 100 g, respectively; contents 1 and 2 of the first and second CBs are respectively not less than 25 parts by mass and not less than 9 parts by mass per 100 parts by mass of the UP; a content of the calcium carbonate is from 5 to 30 parts by mass per 100 parts by mass of the UP, and from 5 to 50 parts by mass per 100 parts by mass of a sum of the contents 1 and 2.

Owner:SIKA HAMATITE CO LTD

Solid self-lubricating coating and preparation method thereof

ActiveCN114351088AHigh hardnessImprove wear resistanceVacuum evaporation coatingSputtering coatingGraphiteDiamond

The invention discloses a solid self-lubricating coating and a preparation method thereof.The coating is formed by compounding a hard diamond-like phase serving as an intrinsic supporting layer and a soft graphitization phase serving as a surface lubricating layer, the hard diamond-like phase is formed by mixing sp2 and sp3 hybrid carbon structures, and the atomic percentage content of sp3 is 25-70%; the soft graphitized phase is mainly composed of an sp2 hybrid carbon structure, the atomic percentage content of sp2 is 90% or above, and the content of a six-membered ring structure is 60% or above; the composite lubricating coating has the advantages of high hardness, high bearing capacity, low abrasion, super-lubricity and friction coefficient lt; 0.01, the solid self-lubricating coating material can provide wear-resistant lubricating protection for a matrix or a workpiece in various environments such as high load and high speed, the preparation method is simple, the operability is high, industrial production is easy, and the solid self-lubricating coating material is excellent in comprehensive performance, long in service life and high in reliability.

Owner:CHINA UNIV OF MINING & TECH

Lubricant compositions containing anti-corrosion ionic liquids

The invention discloses a lubricant composition containing a corrosion resistant ionic liquid. The composition comprises, by mass, 99.9%-98% of base oil and 0.1%-2% of the corrosion resistant ionic liquid, wherein the base oil is selected from multiply-alkylated cyclopentane with 2 to 5 alkyl chains, the corrosion resistant ionic liquid is obtained by compounding one of benzotriazole diglycol mono methyl ether, benzotriazole triglycol mono methyl ether and benzotriazole tetraglycol mono methyl ether with one of lithium tetrafluoroborate, lithium hexafluorophosphate, lithium trifluoromethanesulfonate and lithium bis(trifluoromethanesulphonyl)imide. The ionic liquid and the lubricant composition can be synchronously synthesized, the process is simple, and the lubricant composition has good corrosion resistance and excellent tribological properties.

Owner:YANTAI ZHONGKE RES INST OF ADVANCED MATERIALS & GREEN CHEM ENG

S-triazine ionic liquid used as lubricant and preparation method thereof

ActiveCN103571566BLow costImprove frictional stabilitySulfonic acids salts preparationSulfonic acid amide preparationTetraglycolIonic liquid

The invention discloses a s-triazine ionic liquid used as a lubricant and a preparation method thereof. This ionic liquid is composed of diethylene glycol monomethyl ether, triethylene glycol monomethyl ether or tetraethylene glycol monomethyl ether derivatives of s-triazine and lithium tetrafluoroborate, lithium hexafluorophosphate, lithium trifluoromethanesulfonate or bis(trifluoro Methylsulfonyl)imide obtained after mixing with lithium. The ionic liquid has good chemical stability, thermal stability and anti-friction and anti-wear properties. The ionic liquid provided by the invention has simple preparation process, low cost and excellent performance, and is suitable for industrial application.

Owner:中科润泉(烟台)工业科技有限公司

A kind of preparation method of aluminum matrix composite material brake disc

ActiveCN107598158BImprove wear resistanceGood dimensional stabilityBraking discsAl powderControl manner

The invention relates to a preparation method of an aluminum matrix composite material brake disc, and belongs to the field of metal matrix composite materials. BN powder, MoS2 powder and titanium-plated diamond micro-powder are selected to serve as a reinforcement body, and pure aluminum serves as a matrix; through ball milling, the BN powder and Al powder are firstly mixed, and therefore the BNpowder is evenly distributed in the Al powder to form composite powder; then the composite powder, the MoS2 powder and the titanium-plated diamond micro-powder are mixed evenly according to a certainproportion, then pressing and pre-forming are carried out, in the pressing process, through a powder filling control manner, (BN+Al) composite powder is distributed to the 1 / 4 width position of the inner side of a pre-forming blank of an annular brake disc, and (BN+Al+MoS2+titanium-plated diamond) quaternary mixing powder is distributed to the outer side; and finally, the pressed and pre-formed blank is placed into a vacuum hot-pressing furnace for hot pressed sintering, and the composite aluminum matrix composite material brake disc is finally obtained. By means of the above method, the prepared motorbike brake disc is small in mass and better in radiating performance and wear-resisting property, and the working stability and reliability of the brake disc can be comprehensively improved.

Owner:山东银光钰源轻金属精密成型有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com