Patents

Literature

39results about How to "Improve service life effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

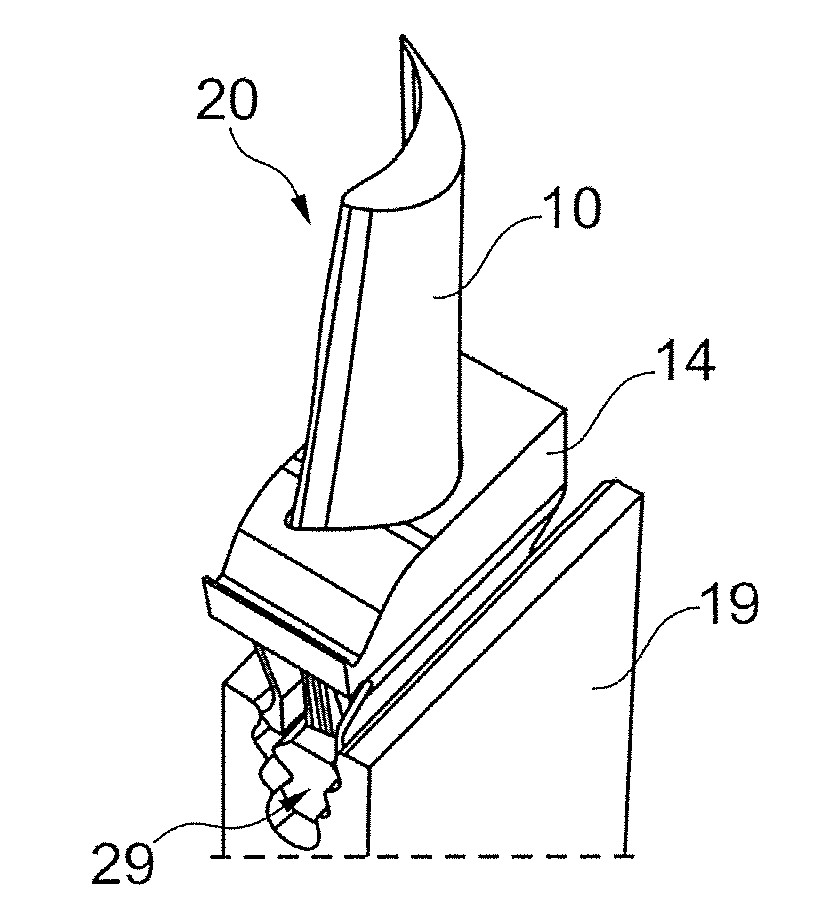

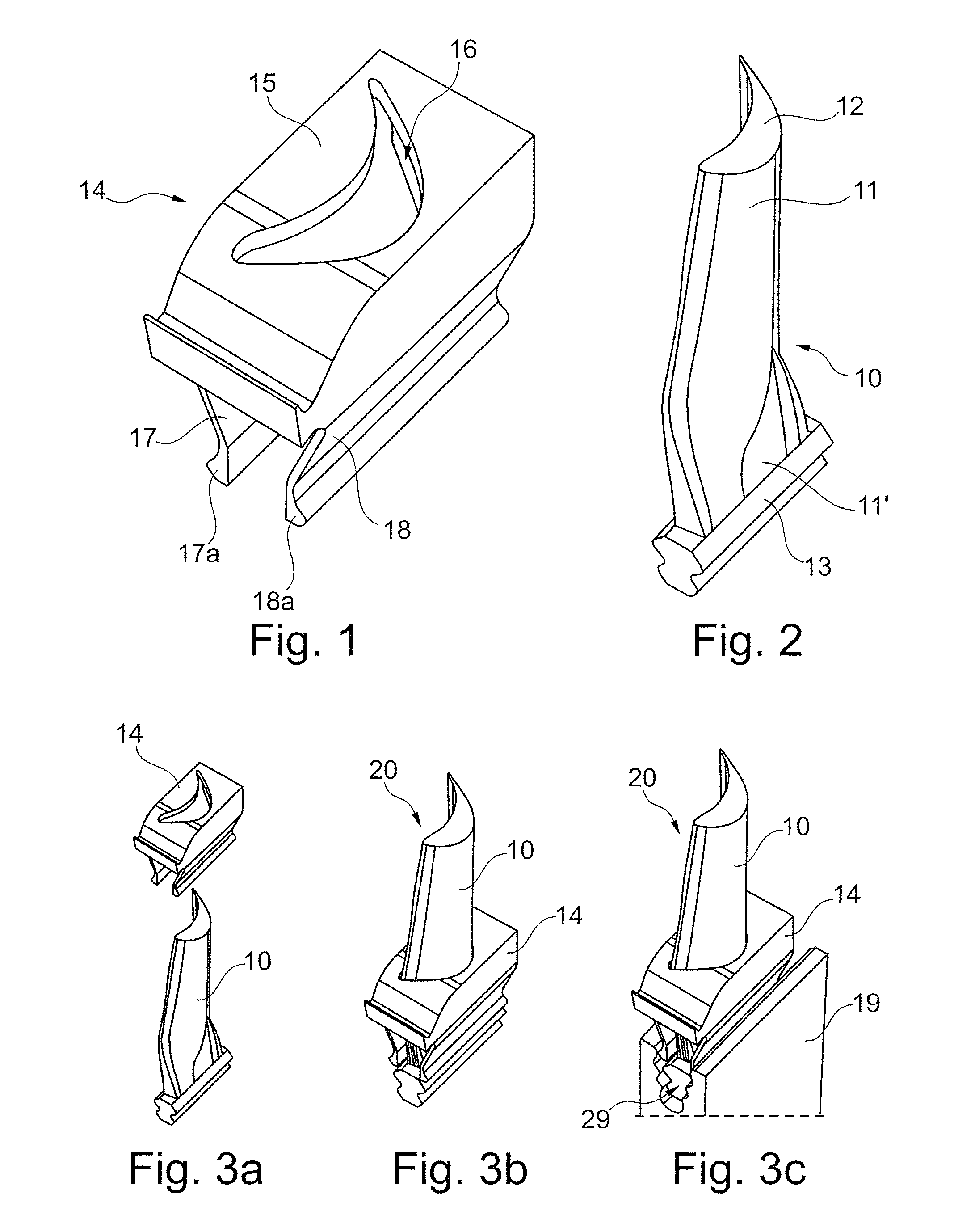

Rotor blade arrangement and gas turbine

InactiveUS20100124502A1Simple producibilityHigh deformationEngine fuctionsBlade accessoriesGas turbinesEngineering

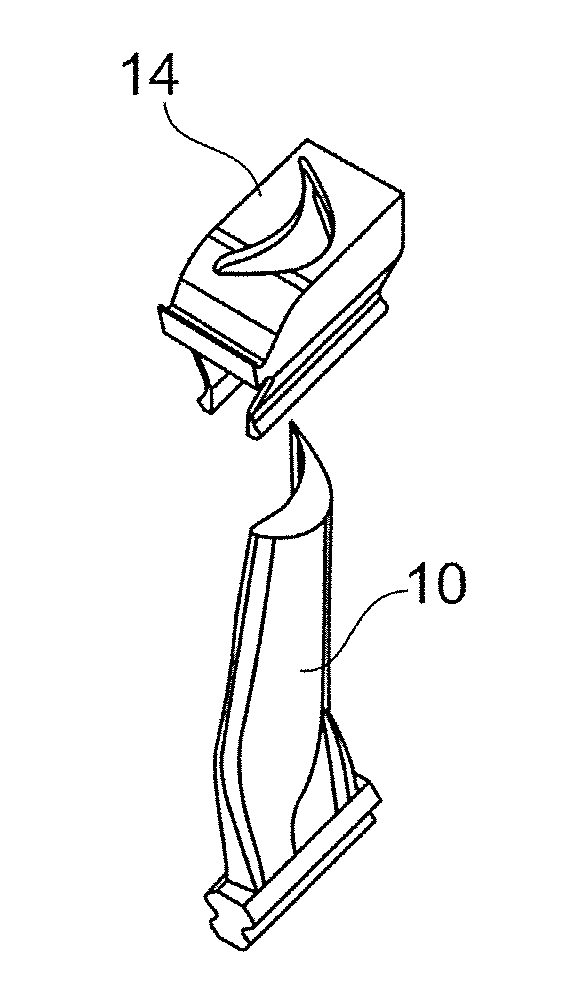

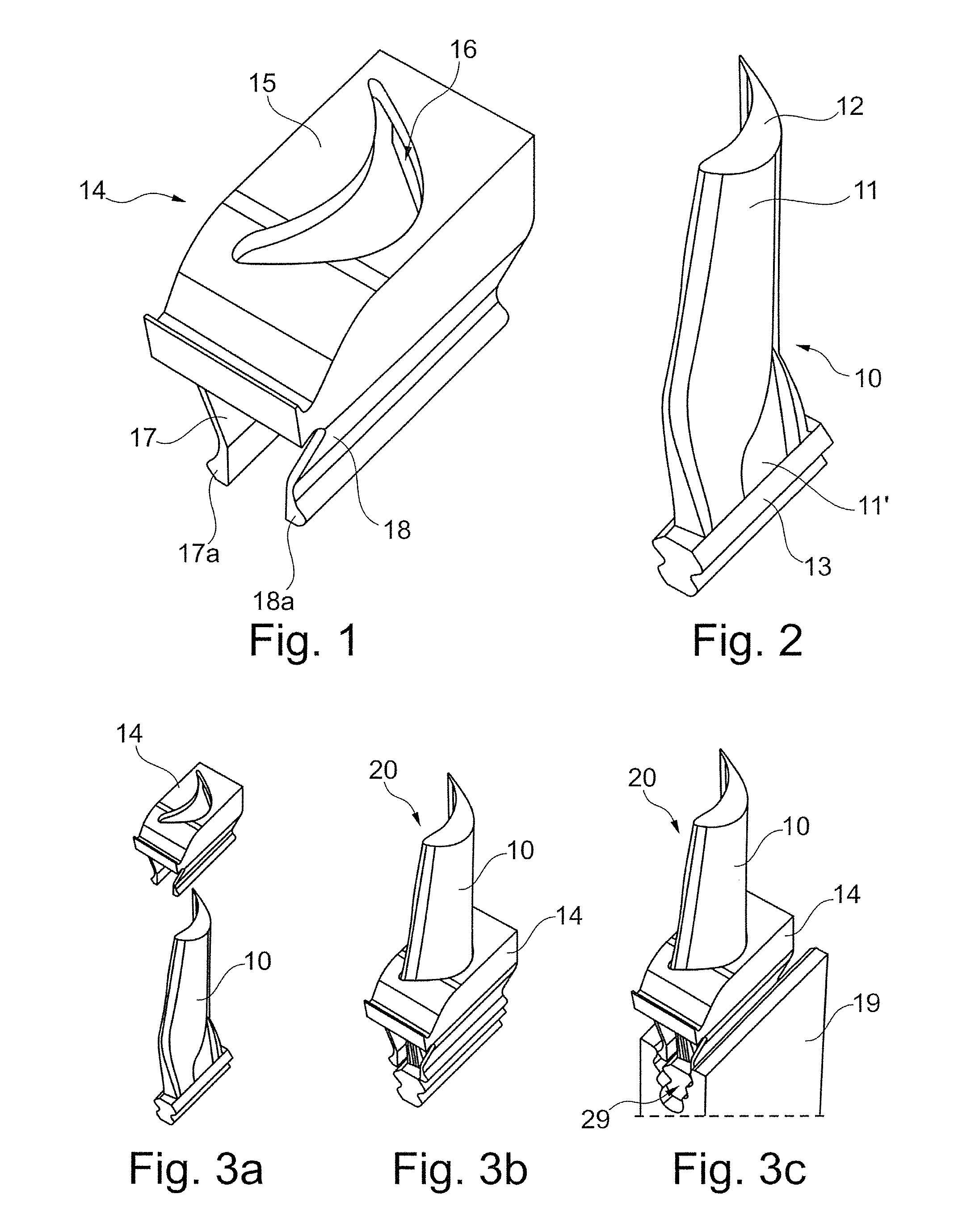

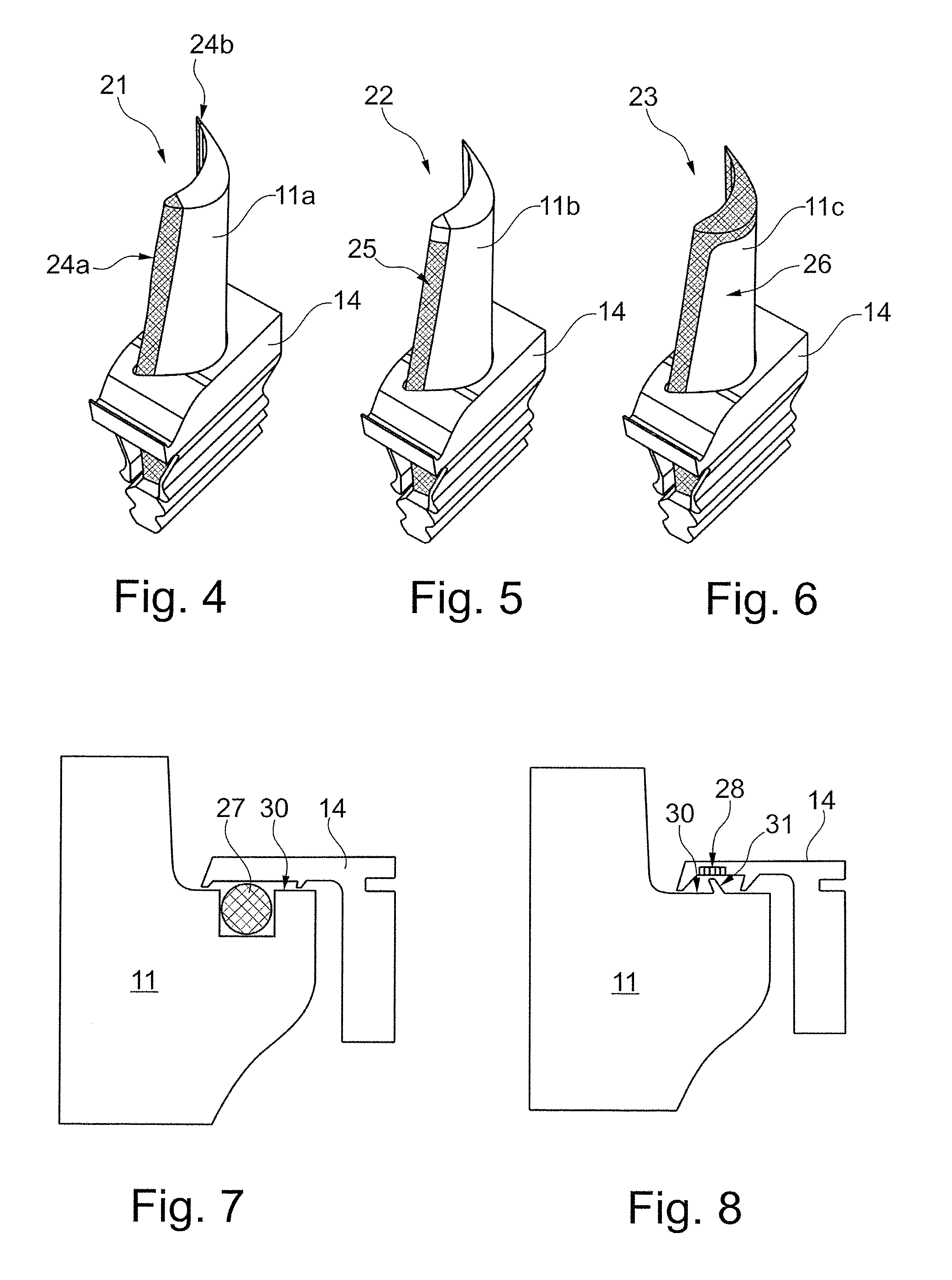

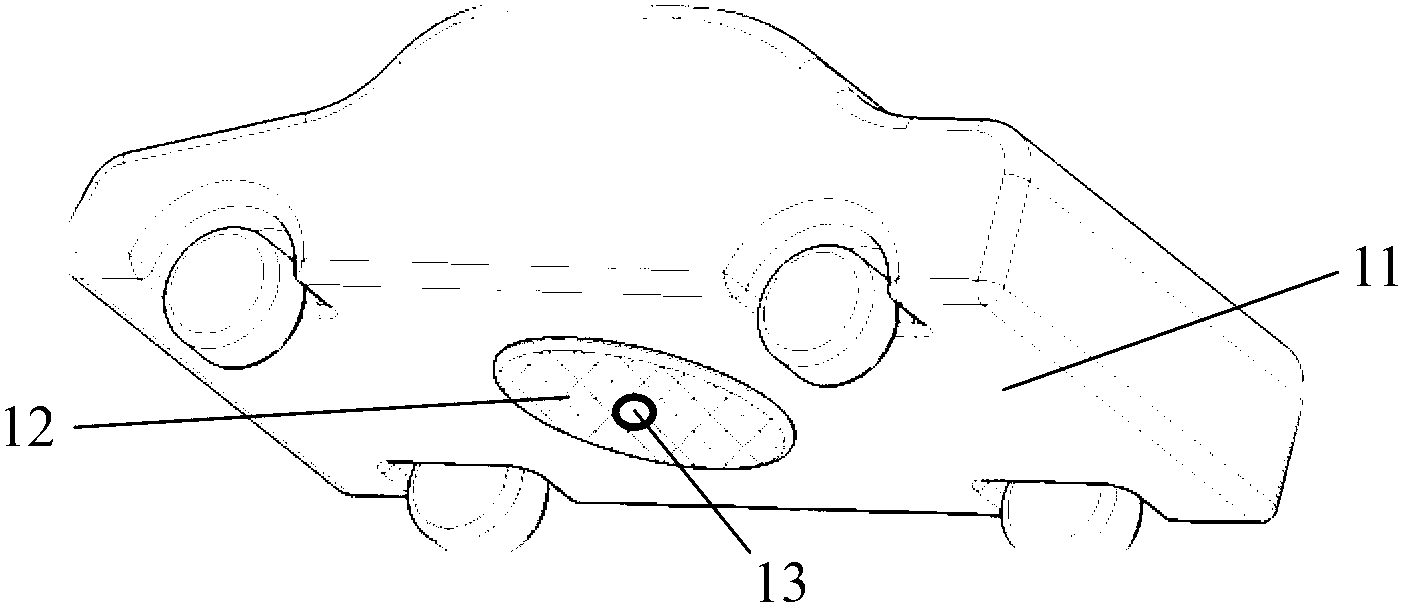

A rotor blade arrangement (20), especially for a gas turbine, which can be fastened on a blade carrier (19) and includes in each case a blade aerofoil element (10) and a platform element (14), wherein the platform elements (14) of a blade row form a continuous inner shroud. With such a blade arrangement, a mechanical decoupling, which extends the service life, is achieved by the blade aerofoil element (10) and the platform element (14) being formed as separate elements and by being able to be fastened in each case separately on the blade carrier (19).

Owner:ANSALDO ENERGIA IP UK LTD

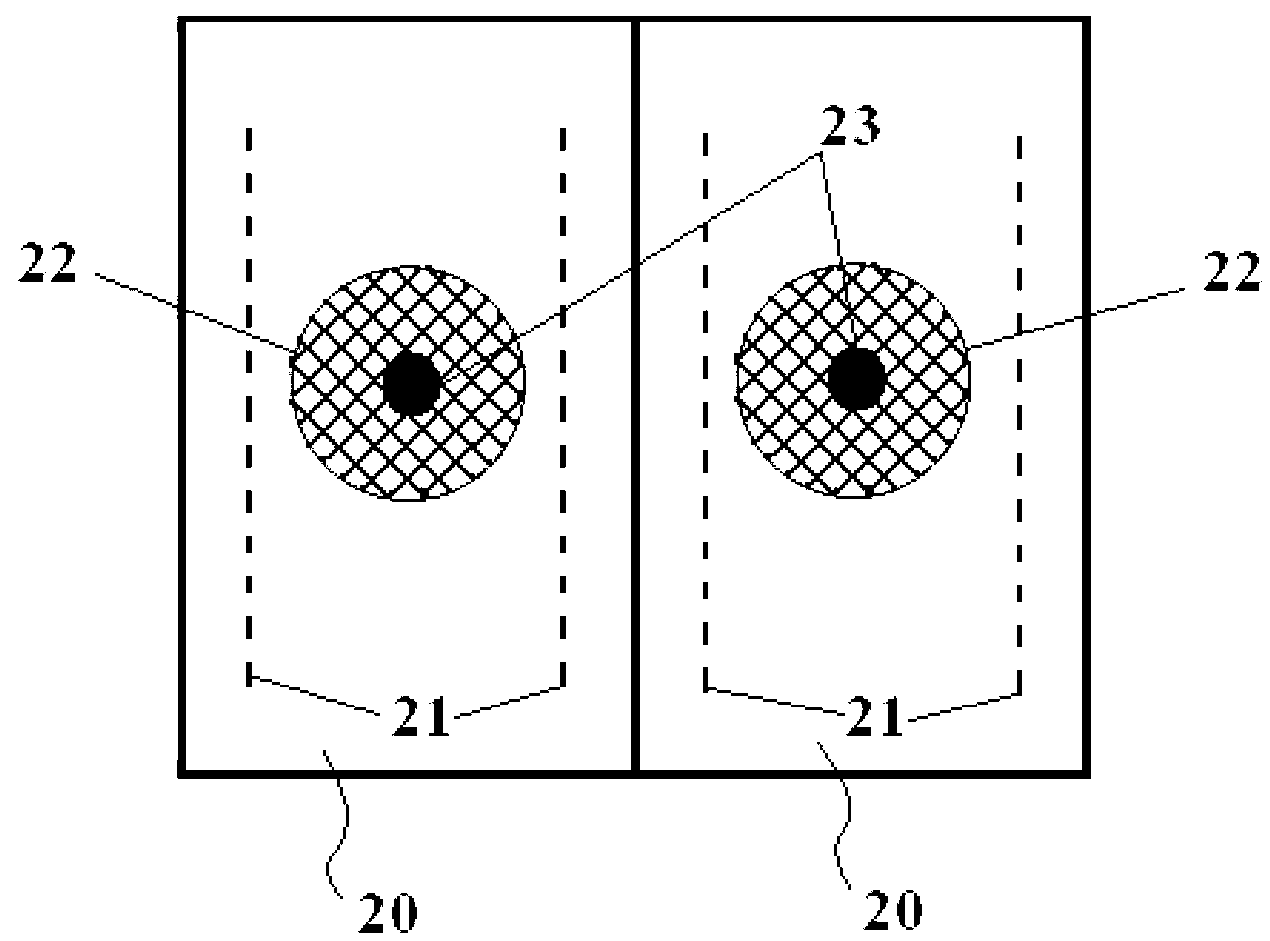

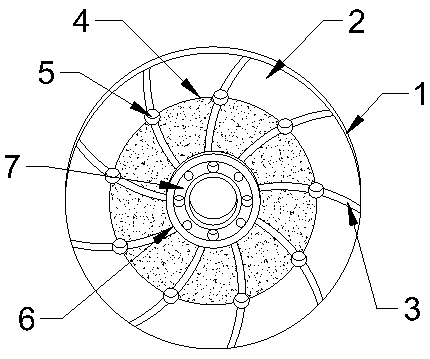

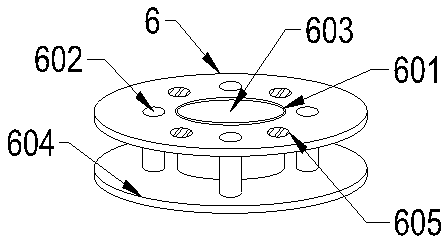

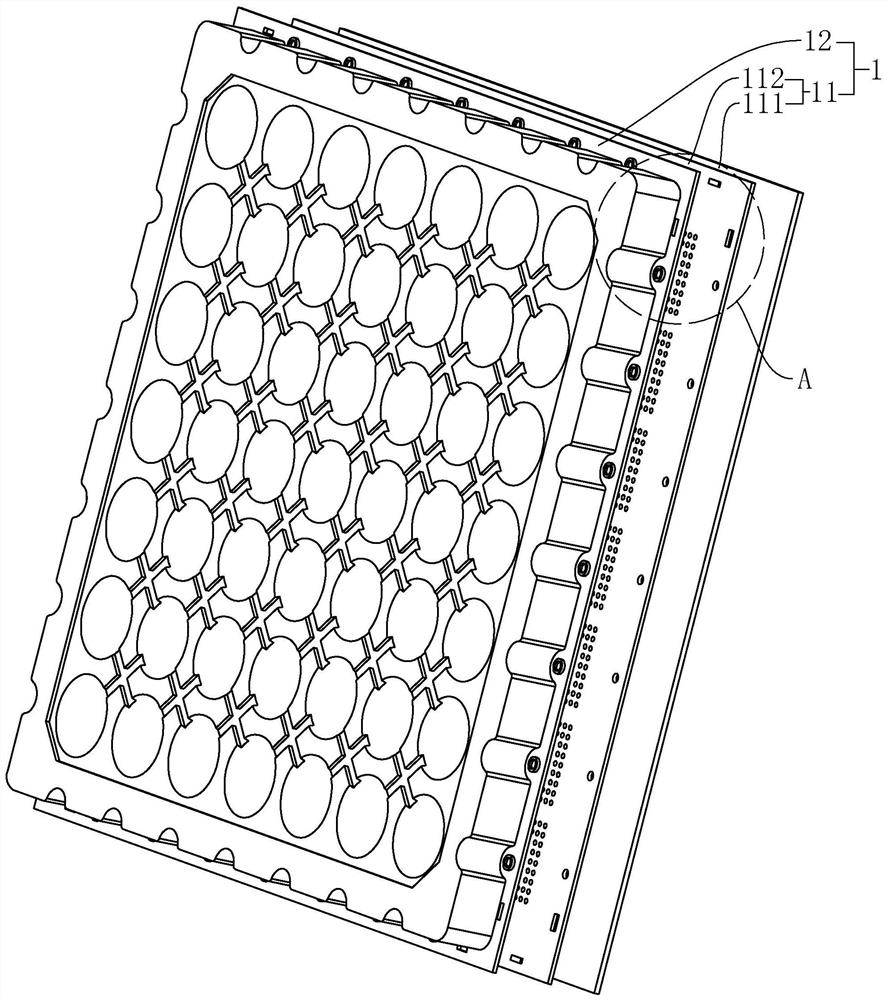

Wireless charging system for electric bicycle

ActiveCN103326447AImprove battery lifeRealize smart wireless chargingBatteries circuit arrangementsElectromagnetic wave systemElectricityEngineering

The invention provides a wireless charging system for an electric bicycle. The wireless charging system for the electric bicycle comprises a wireless charging reception module installed on the electric bicycle and used for converting a received magnetic signal to an electric signal and charging a battery of the electric bicycle, a wireless charging transmission module for converting the electric signal to a magnetic signal and transmitting the magnetic signal to the wireless charging reception module, and a position detection module for obtaining the condition of the magnetic signal received by the wireless charging reception module and giving a prompt according to the condition of the magnetic signal. The wireless charging system for the electric bicycle provided by the invention is capable of realizing wireless charging for the electric bicycle so as to ensure the maximum cruising power of the electric bicycle; simultaneously, as a charging cable carried in the bicycle is omitted, the electricity loss of the battery can be avoided, and an effect of prolonging the service life of the battery can be achieved, so that the electric bicycle has a new selling point, and the market competitiveness of the electric bicycle is enhanced.

Owner:BEIJING AUTOMOBILE RES GENERAL INST

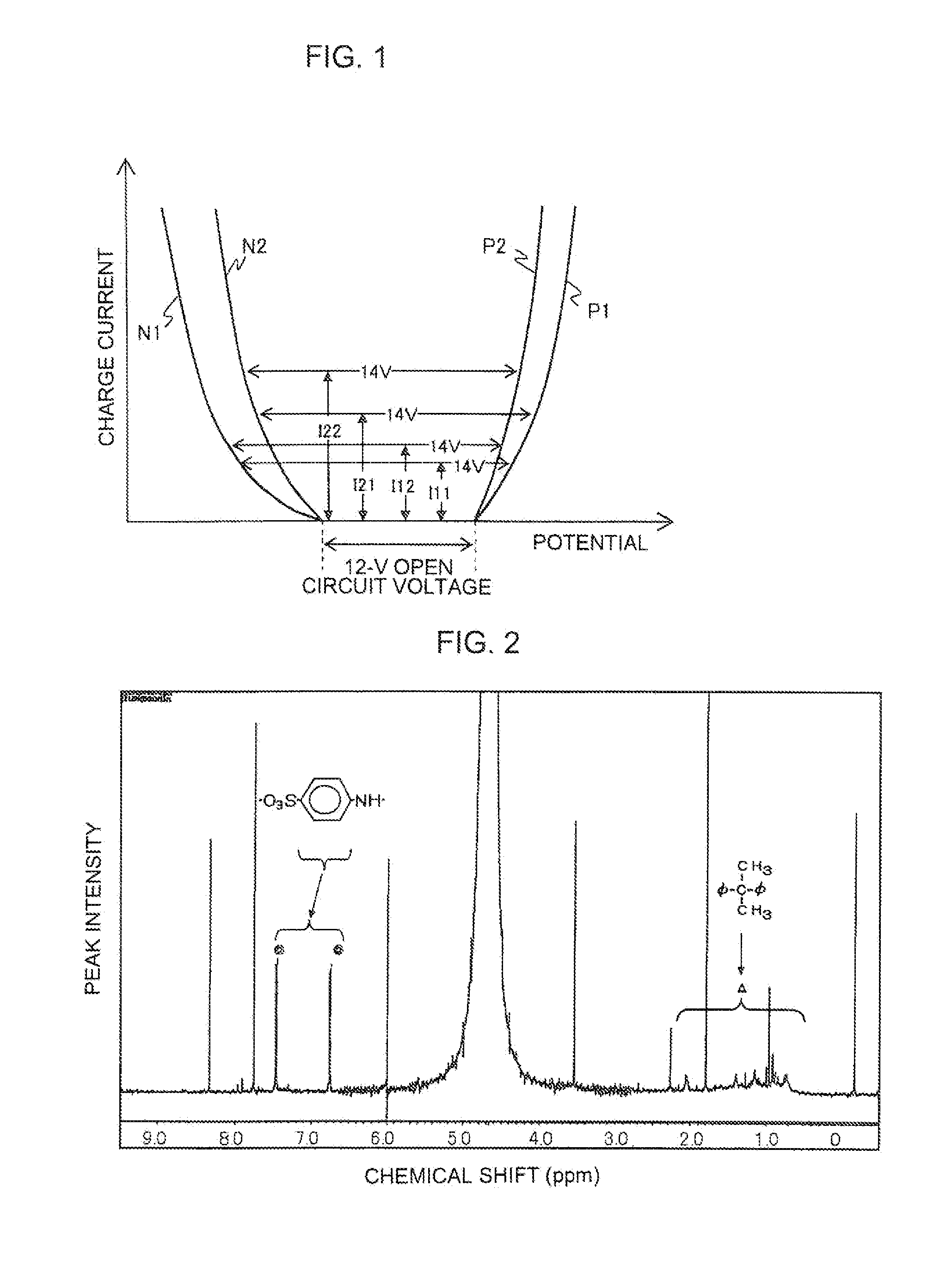

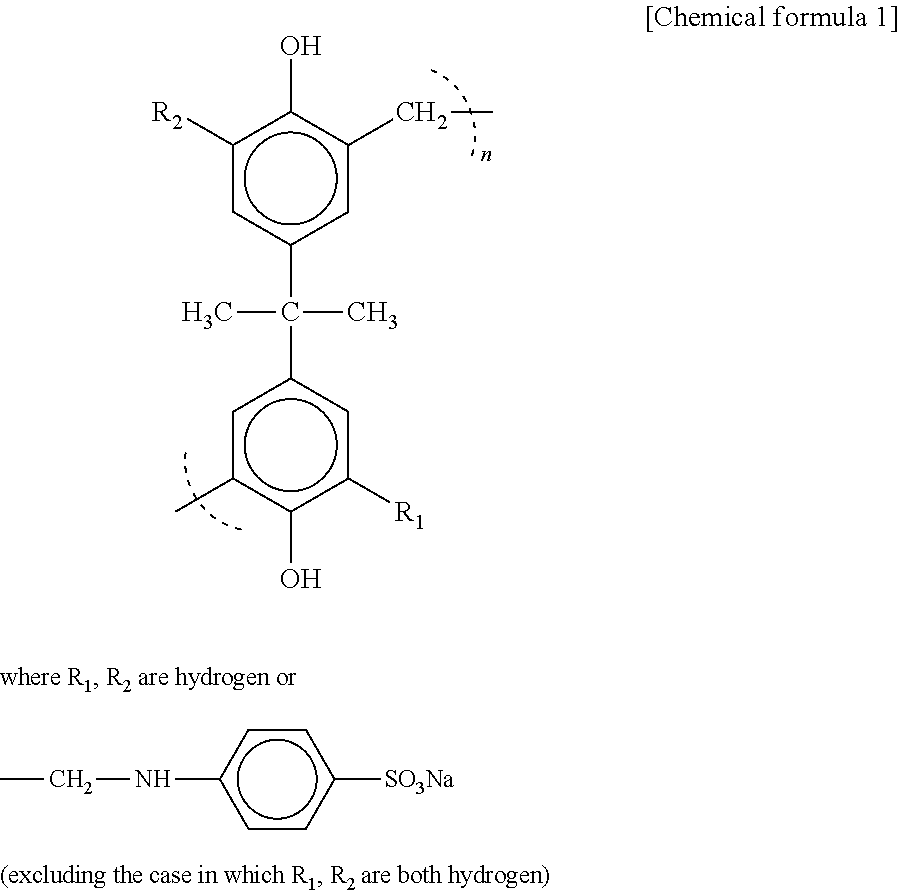

Lead acid storage battery

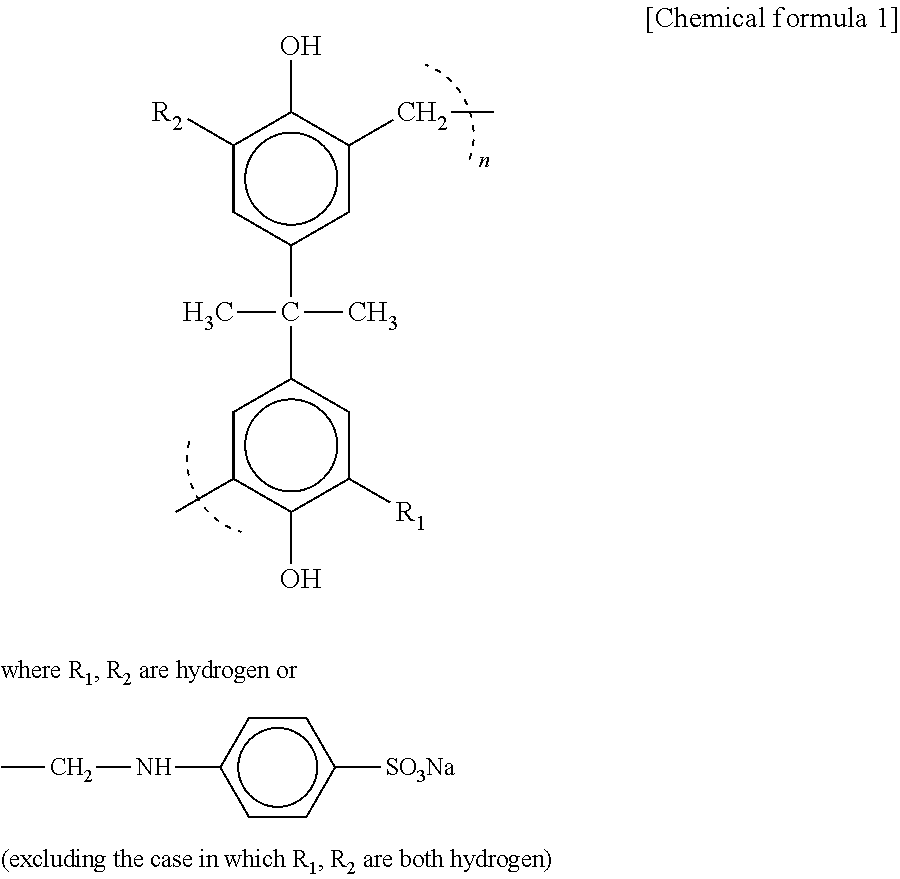

InactiveUS20130022860A1Improve service life effectHigh acceptanceLead-acid accumulatorsCell seperators/membranes/diaphragms/spacersPolyolefinState of charge

A flooded-type lead acid storage battery in which charging is intermittently carried out in a short period of time and high-efficiency discharge to a load is carried out in a partial state of charge, wherein the charge acceptance and service life characteristics are improved by using a positive plate in which the specific surface area of the active material is set to 6 m2 / g or more; a negative plate with improved charge acceptance and service life performance obtained by adding a carbonaceous electrically conductive material, and a bisphenol aminobenzenesulfonic acid formaldehyde condensate to the negative active material; and a separator formed from a nonwoven in which the surface facing the negative plate is composed of material selected from glass, pulp, and polyolefin.

Owner:SHIN KOBE ELECTRIC MASCH CO LTD

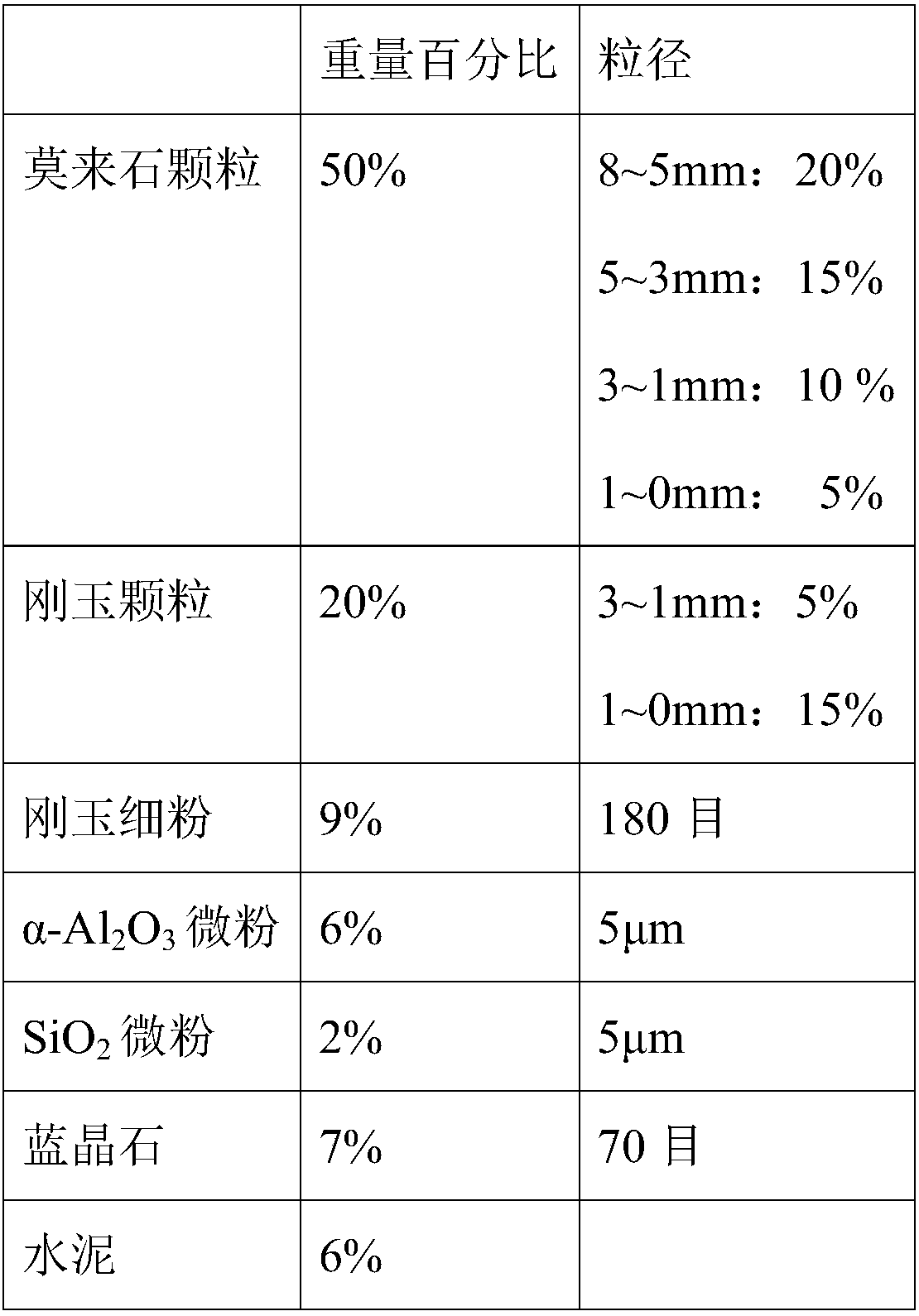

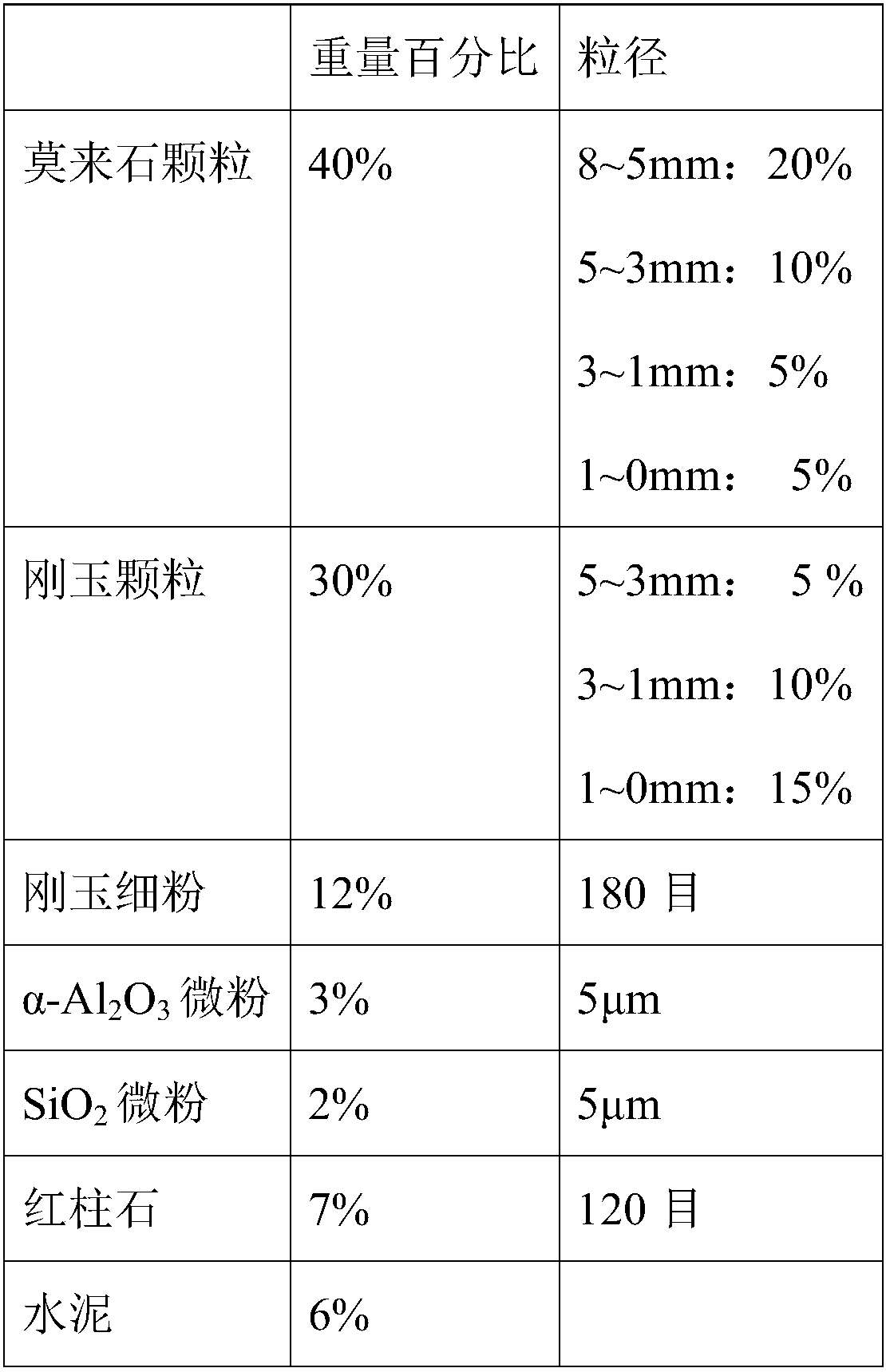

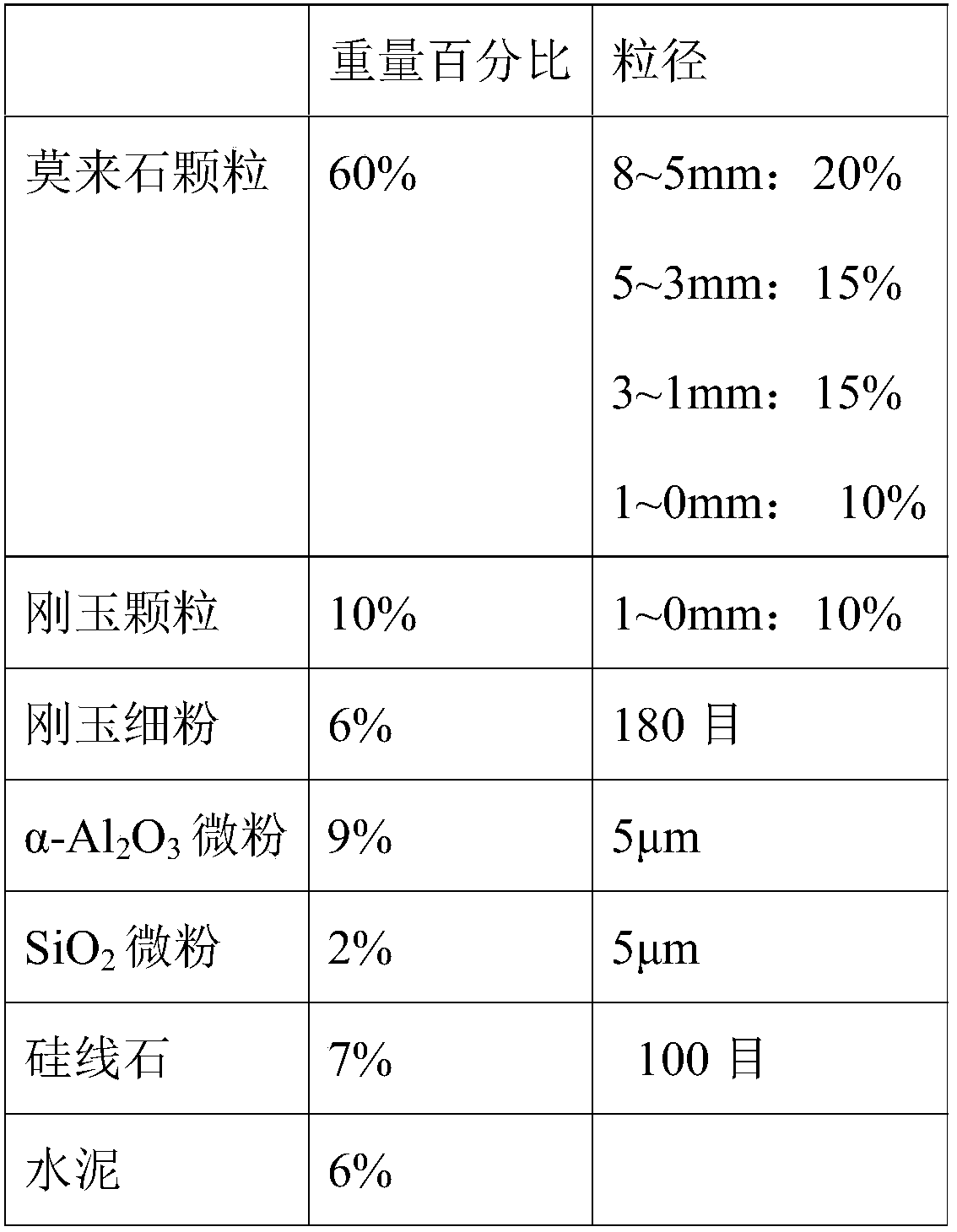

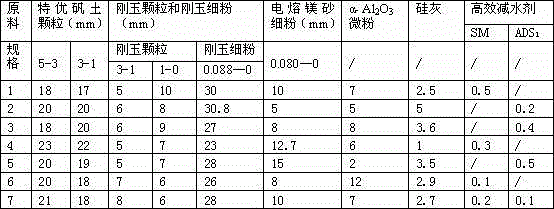

Mullite-based castable used for tundish cover and production method thereof

The invention discloses a mullite-based castable used for a tundish cover and a production method thereof. The mullite-based castable used for a tundish cover is prepared from main materials and additives, wherein the main materials include the following components in weight percentage: 40-60% of mullite particles, 10-30% of corundum particles, 5-20% of corundum fine powder, 2-10% of alpha-AI203 micropowder, 1-5% of SiO2 micropowder, 5-10% of raw material (kyanite, sillimanite and andalusite), and 3-10% of cement. The additives include the following components in weight percentage: 1-3% of No.446 steel fiber, 0.5-2.0% of a water reducing agent, 0.02-0.5% of aluminium powder, 0.05-0.5% of organic anti-explosion fiber, and 5.5-6.5% of water. A tundish cover produced by using the castable ishigh in normal and high temperature strength, good in thermal shock stability, remarkable in the effect of prolonging the service life of the tundish cover, and obvious in economic benefit.

Owner:瑞泰马钢新材料科技有限公司 +1

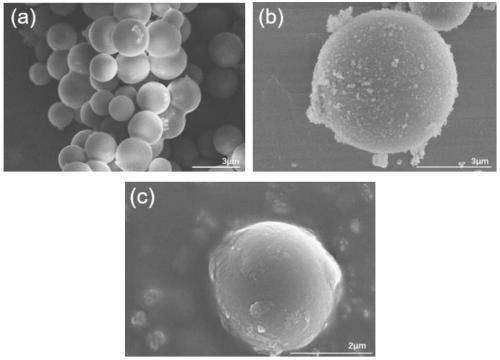

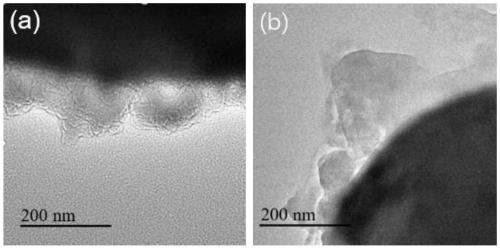

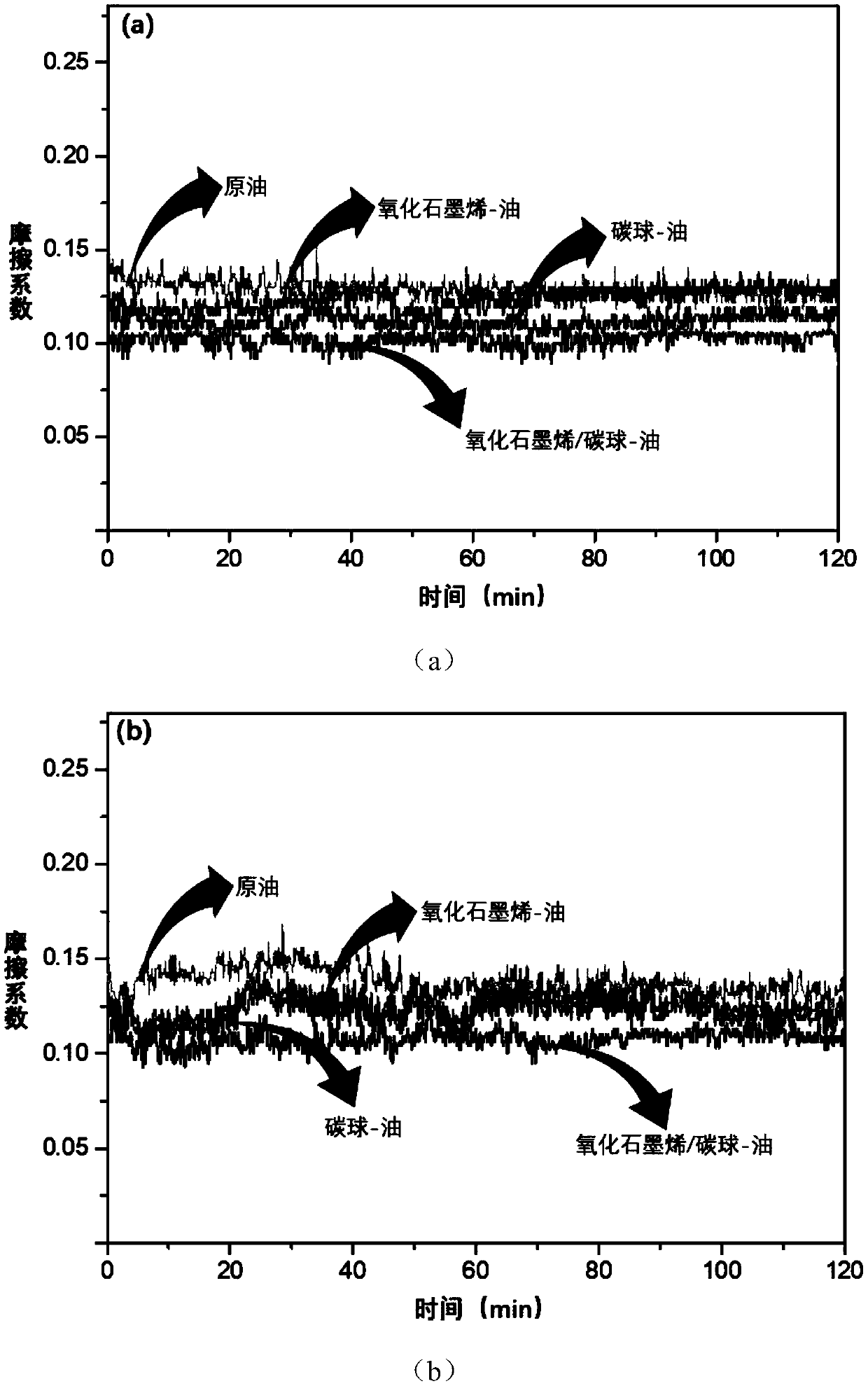

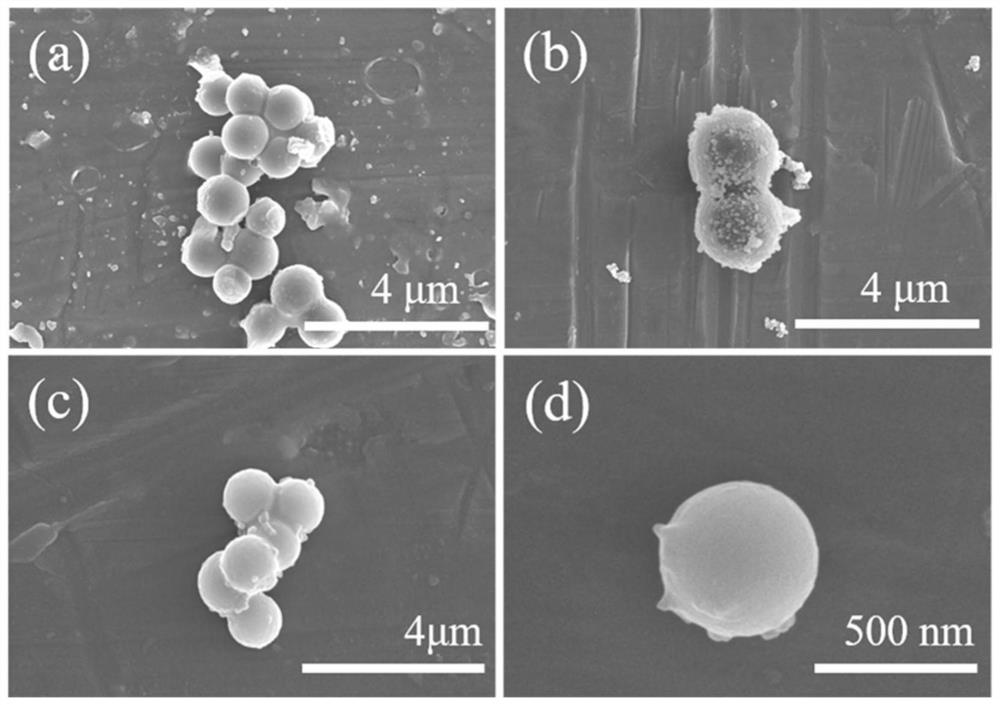

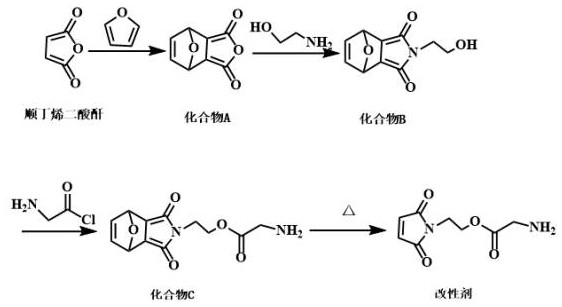

Preparation method of graphene oxide coated carbon microsphere composite material

The invention discloses a preparation method of a graphene oxide coated carbon microsphere composite material. The method comprises the following steps: preparing a dextrose solution as a carbon source; performing hydrothermal reaction under an acidic condition; washing the obtained product in a plurality of times; performing suction filtering; drying to obtain carbon microspheres; dissolving thecarbon microspheres in a mixed solution consisting of water and absolute ethyl alcohol; then adding a mixed solution of a silane coupling agent and the absolute ethyl alcohol; performing condensing and reflowing under a room temperature or a heating condition; washing the obtained product in a plurality of times; performing suction filtering; drying to obtain modified carbon microspheres; adding graphene oxide to DMF; then adding an activating agent; ultrasonically treating to obtain a graphene oxide solution; adding the modified carbon microspheres to the graphene oxide solution; ultrasonically processing to obtain an uniform mixed solution A; adding a catalyst to the mixed solution A; performing condensing and reflowing under a heating condition; washing the obtained product in a plurality of times; and performing suction filtering and drying to obtain the graphene oxide coated carbon microsphere composite material.

Owner:SHAANXI UNIV OF SCI & TECH

Rotor blade arrangement and gas turbine

InactiveUS8951015B2High deformationSimple producibilityPropellersRotary propellersGas turbinesEngineering

A rotor blade arrangement (20), especially for a gas turbine, which can be fastened on a blade carrier (19) and includes in each case a blade aerofoil element (10) and a platform element (14), wherein the platform elements (14) of a blade row form a continuous inner shroud. With such a blade arrangement, a mechanical decoupling, which extends the service life, is achieved by the blade aerofoil element (10) and the platform element (14) being formed as separate elements and by being able to be fastened in each case separately on the blade carrier (19).

Owner:ANSALDO ENERGIA IP UK LTD

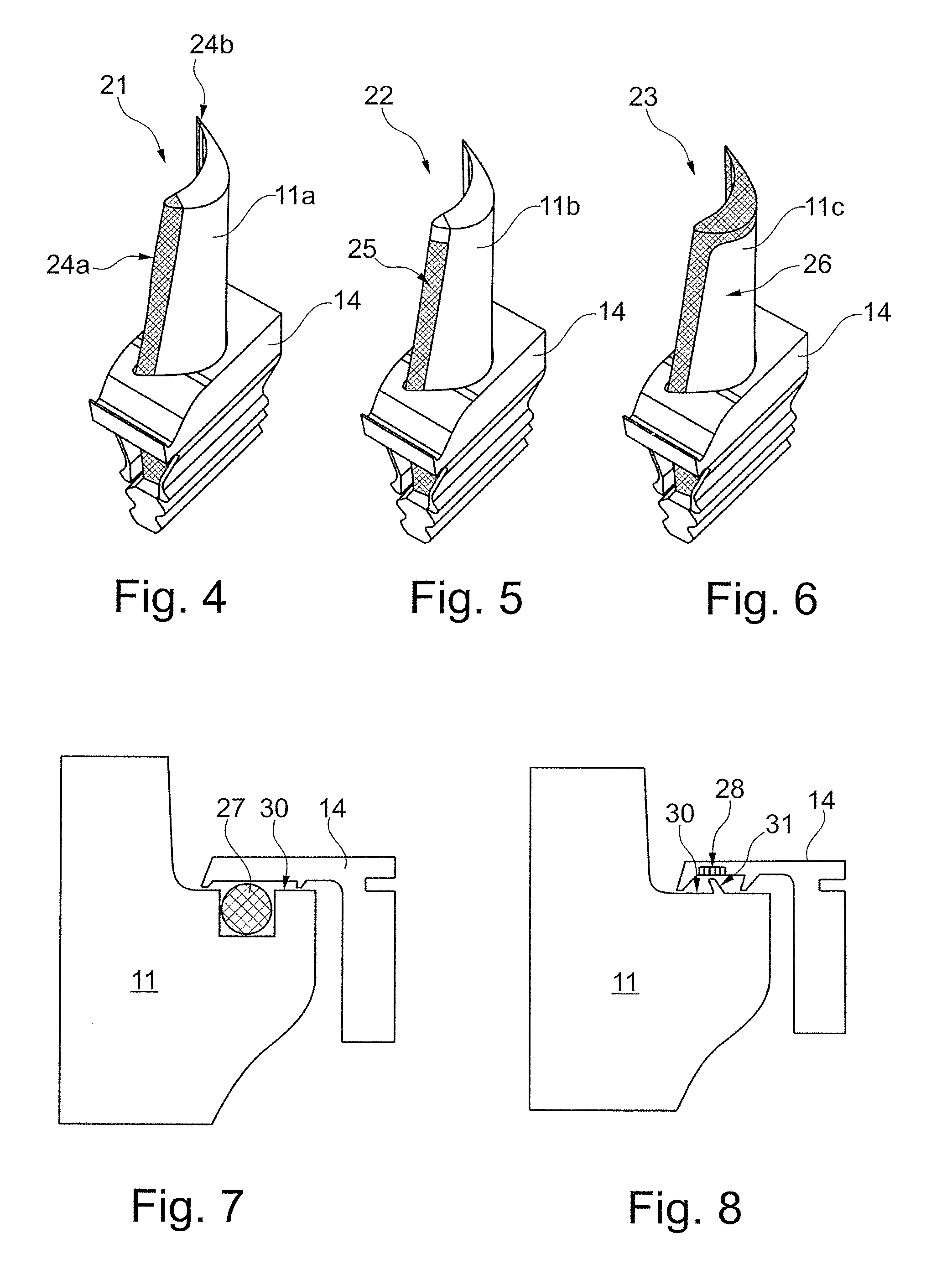

Cold state integral repairing material with high adhesiveness for wall of steel ladle

The invention discloses a cold state integral repairing material with high adhesiveness for a wall of a steel ladle. The material comprises the components in percentage by weight as follows: 35-45% of extra-superior alumina particles, 35-45% of corundum particles and fine powder, 5-15% of fused magnesite fine powder, 2-12% of alpha-Al2O3 micro-powder, 1-5% of silica fume and 0.1-0.5% of additive. The additive is an efficient water reducer. The extra-superior alumina particles are processed by extra-superior alumina which is processed to 5-3mm and 3-1mm grades by a crushing and screening device. The corundum particles consist of 3-1mm and 1-0mm corundum materials. The granularity of the corundum fine powder is 0.088-0mm. The proportional region of the corundum particles to corundum fine powder is 1: (1.8-2.2). Field actual application of the cold state integral repairing material with high adhesiveness for the wall of the steel ladle shows that the material is good in adhesiveness due to less bounce, nearly free from falling after being roasted, remarkable in effect of prolonging the service life of the steel ladle liner and remarkable in economic benefit. In addition, the material is nearly free from falling after being roasted, so that the safety of the steel lade during use is greatly improved.

Owner:瑞泰马钢新材料科技有限公司 +2

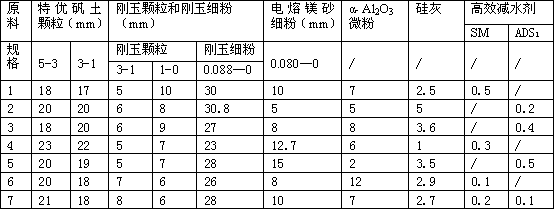

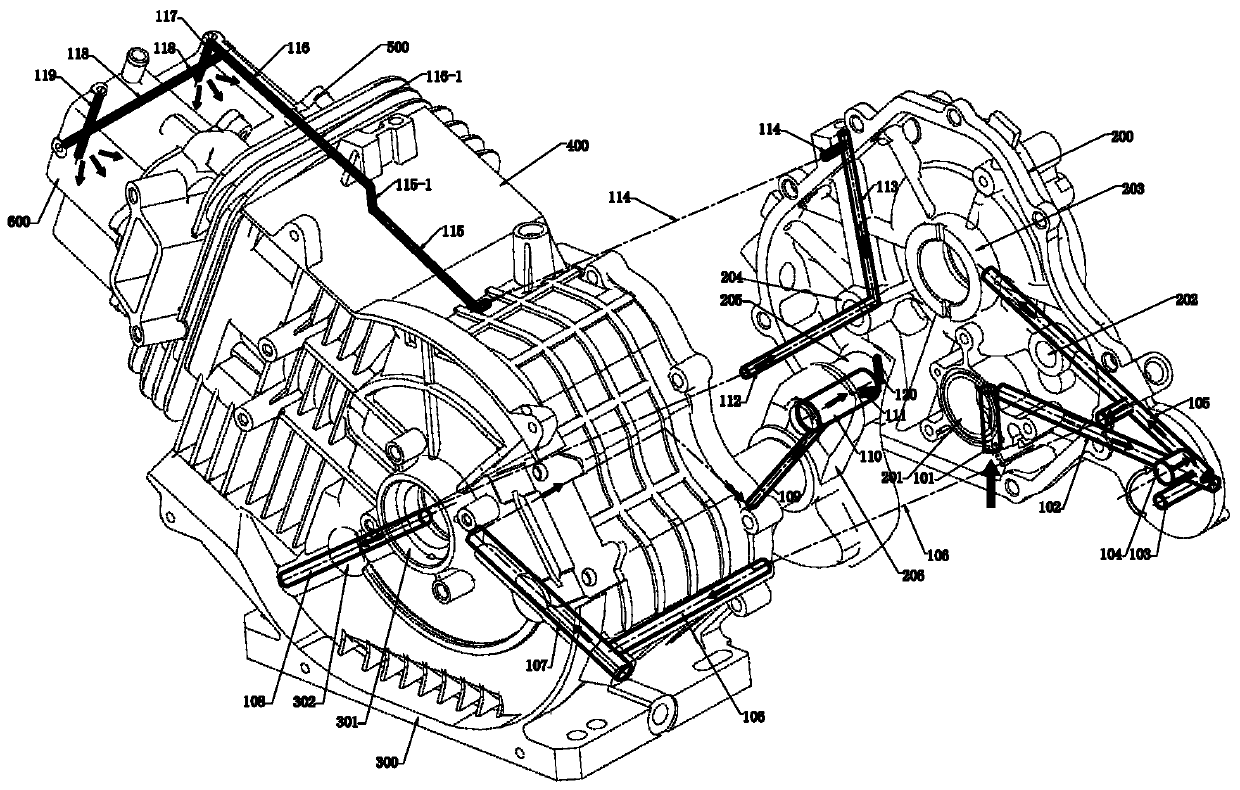

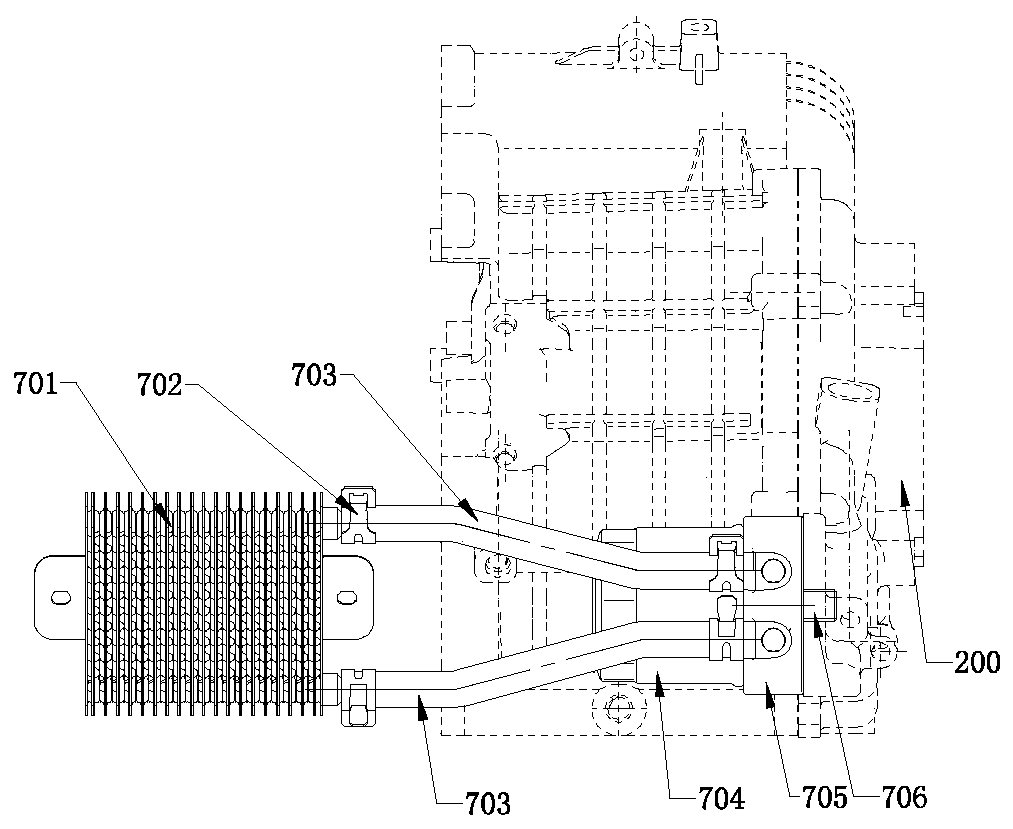

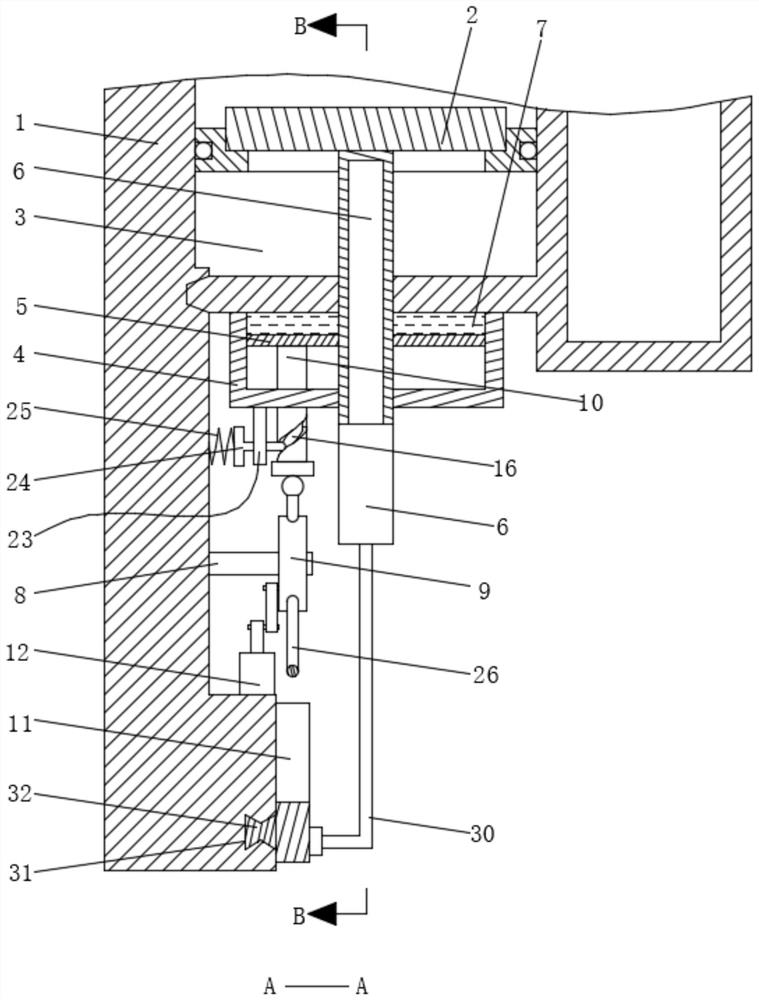

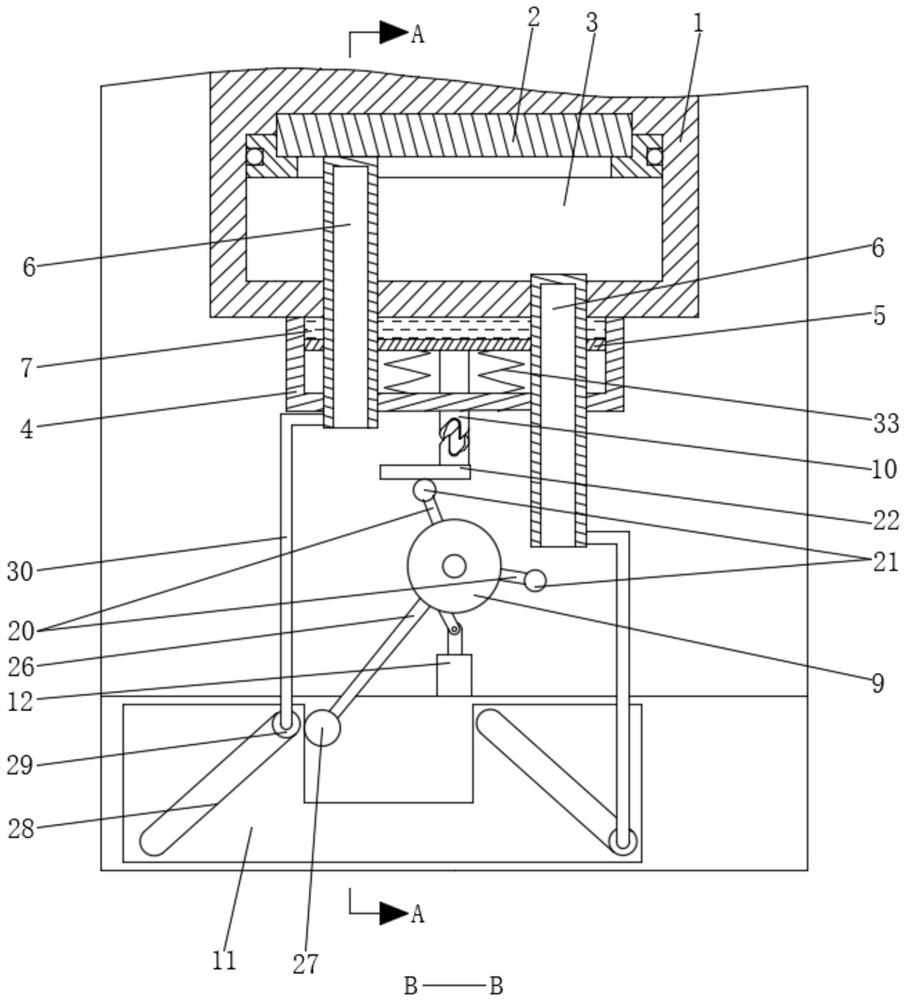

Forced lubrication oil way system for engine

PendingCN109707477AClosely connectedEasy to processCasingsLubrication of auxillariesCylinder headCrankcase

The invention discloses a forced lubrication oil way system for an engine. The forced lubrication oil way system for the engine comprises a plurality of straight oil ways. The oil ways start from thebottom of a crankcase cover and flow back into a shaft hole of the crankcase cover for lubrication after filtering and cooling, meanwhile, the oil ways are provided with branches and flow to a shaft hole of a crankcase body, a camshaft of the crankcase body and a crank module for lubrication and cooling; and finally, the oil ways enter into a cylinder head cover through an oil passage externally arranged on the outer wall of a cylinder body, and lubricate and cool all parts in the cylinder head cover through a plurality of oil outlets. The forced lubrication oil way system for the engine can improve the overall lubrication performance of the engine, all moving parts in the engine can be lubricated to the greatest extent, the frictional work of the engine is reduced, the power of the engineis improved, and the service life of the engine is prolonged.

Owner:浙江康思特动力机械有限公司

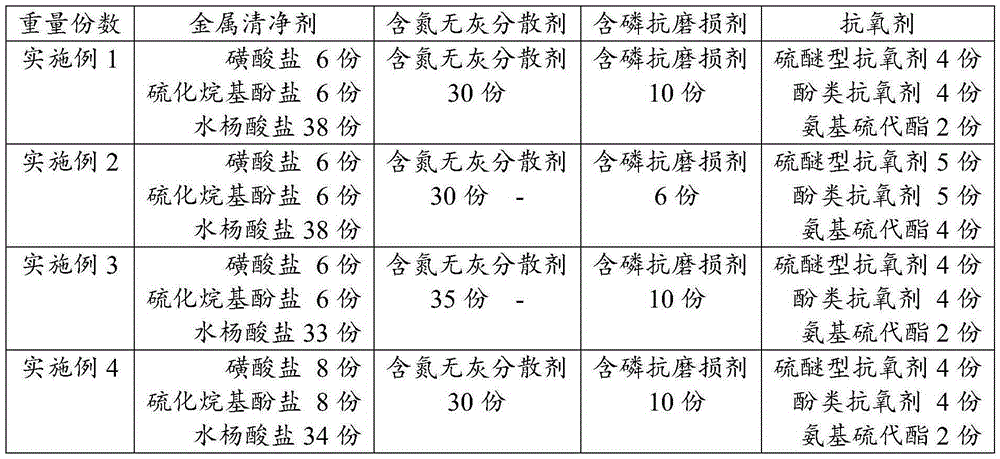

Railroad internal combustion engine car oil complexing agent composition and application thereof

The invention relates to a railroad internal combustion engine car oil complexing agent composition and application thereof. The railroad internal combustion engine car oil complexing agent composition is prepared from, by weight, 20-70 parts of metal detergent, 10-50 parts of nitrogen-contained ash-free dispersing agent, 5-30 parts of phosphorus-contained anti-wear preservatives and 5-30 parts of complex antioxidant, wherein metal detergent is prepared from sulfonate, sulfurated alkyl phenate and salicylate, and the complex antioxidant is prepared from aryl sulfide antioxidant, phenolic antioxidant and amino thio ester. The composition can be used for industrially producing railroad internal combustion engine car oil.

Owner:CHINA PETROLEUM & CHEM CORP

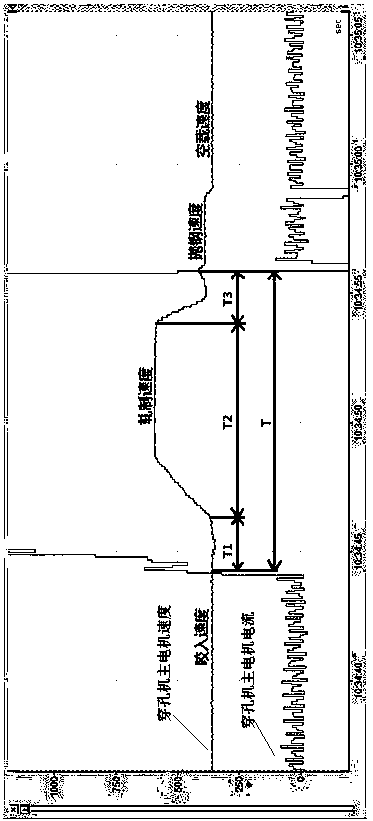

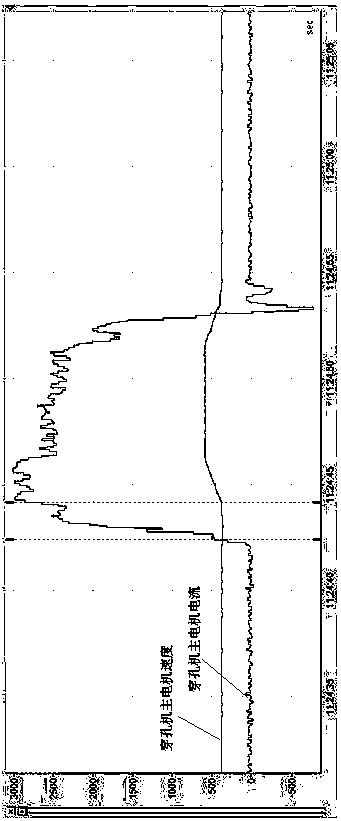

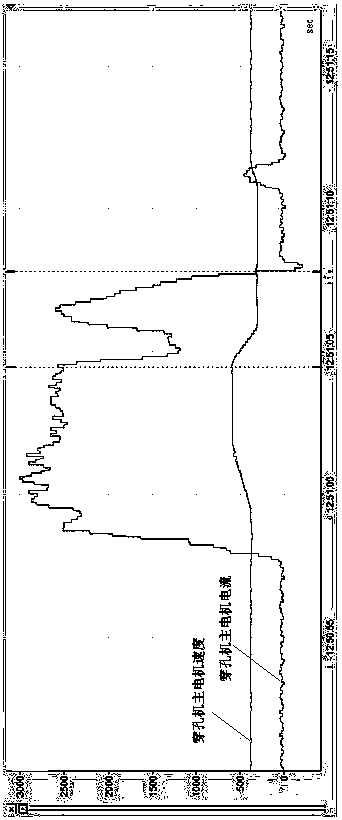

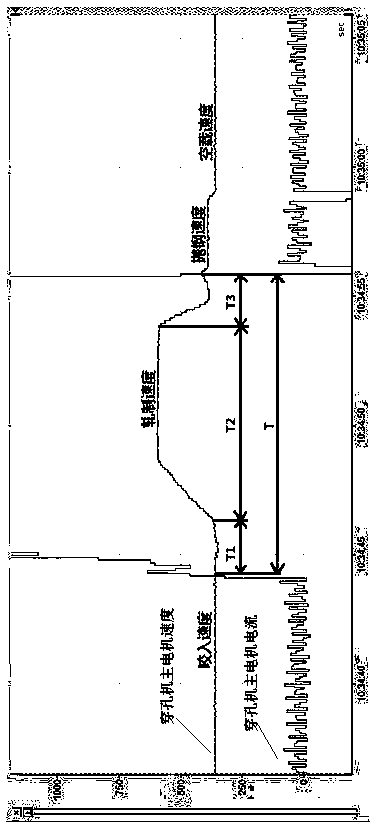

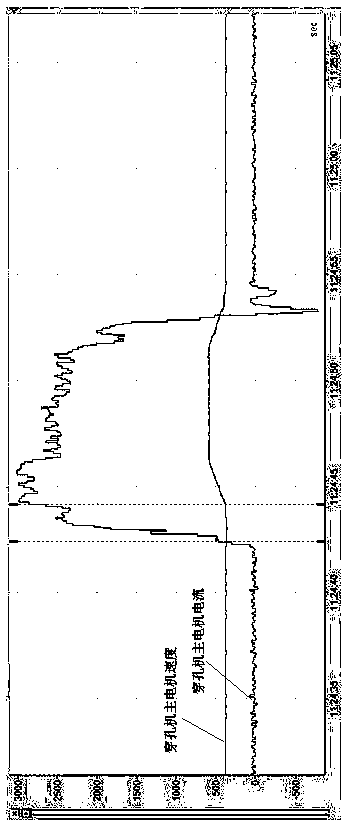

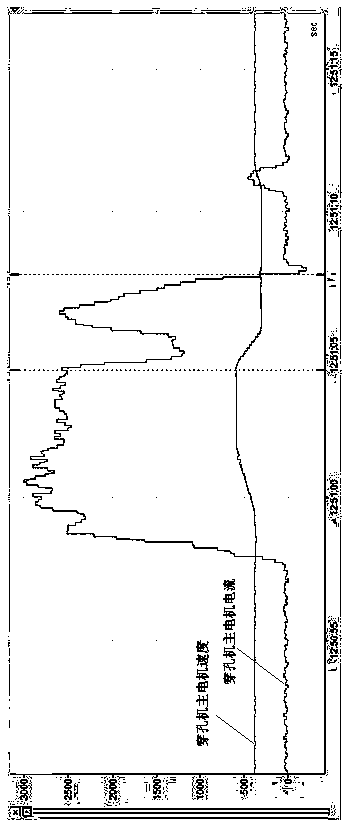

Automatic control method of tubular billet tail ring of perforating machine

ActiveCN107790497AEffective in normal useImprove service life effectRolling mill drivesMetal rolling arrangementsAutomatic controlEngineering

The invention provides an automatic control method of a tubular billet tail ring of a perforating machine. The automatic control method is characterized by comprising the following steps that 1, a perforating unit roller operates in a no-load speed state and is bitten into a pipe blank; 2, after time is delayed for T1, the speed is increased to the rolling speed at an accelerated speed I; 3, whenthe current pipe blank is rolled, high-speed rolling time T2 of the current tubular billet is calculated according to rolling time of a former steel pipe, and T2 is equal to T2 upper + (T3 upper-T3 setting)*V3 / V2; 4, in the steel polishing process, the speed is decreased to the steel polishing speed at an accelerated speed II; and 5, after steel polishing is completed, time is delayed for T4, andthe roller speed is restored to the steel biting speed. According to the method, the tubular billet tail ring after perforating is eliminated basically, and the problem that due to the tubular billettail ring, the surface of a core bar is damaged is solved basically. By the adoption of the automatic control program, the problem of the tubular billet tail ring generated by the perforating machinecan be well controlled, the technology can meet the site production requirement, and the effects on stability of the production quality and normal use of the core bar are remarkable.

Owner:LINZHOU FENGBAO PIPE

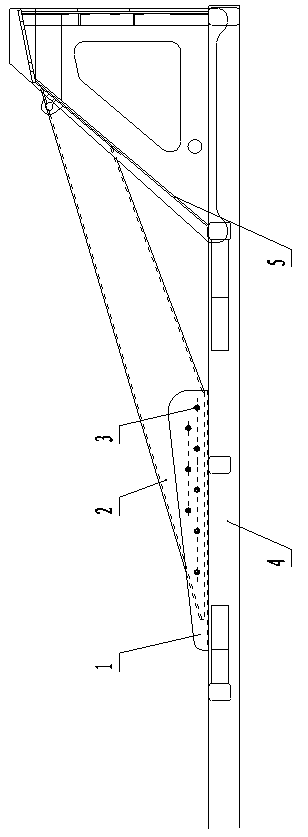

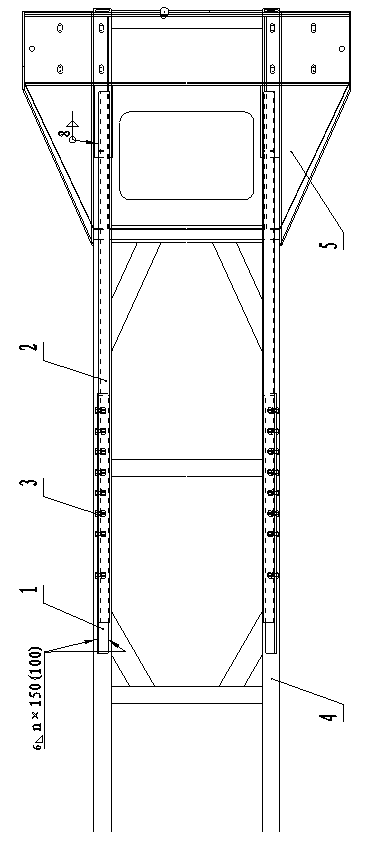

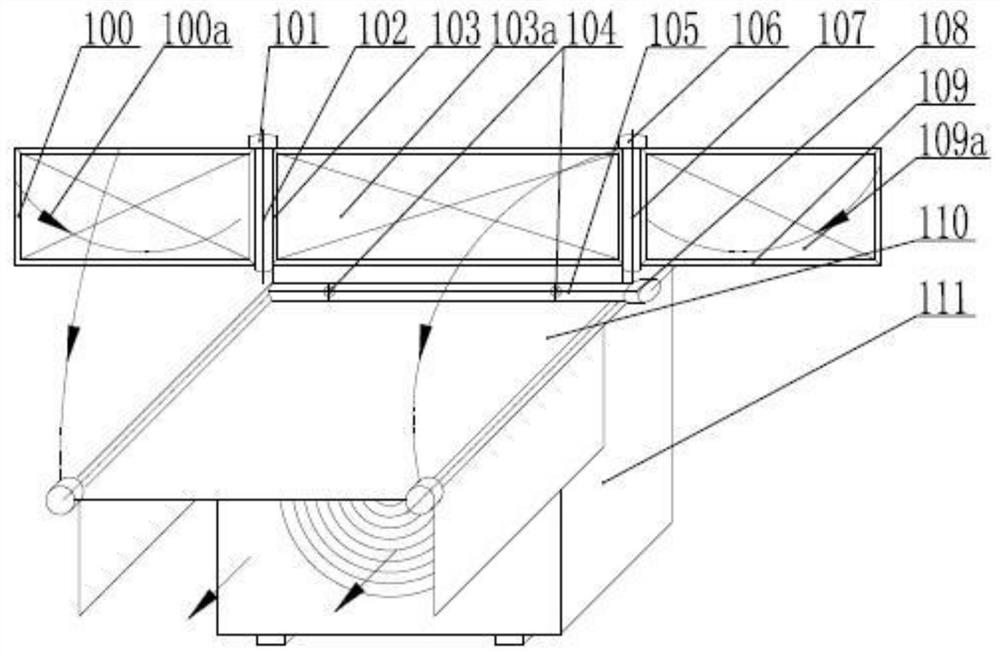

Cable-stayed beam assembly of concrete mixer truck frame

InactiveCN103010075AReduce distortionAvoid breakageConcrete transportationStress concentrationVehicle frame

The invention discloses a cable-stayed beam assembly of a concrete mixer truck frame, relating to the technical field of transit mixer trucks. The cable-stayed beam assembly comprises a cable-stayed plate welded on a front closure plate of a back platform and a cable-stayed plate support welded on longitudinal beams of the frame, and the cable-stayed plate is connected and fixed with the cable-stayed plate support through bolts. The cable-stayed beam assembly enables the longitudinal beams of the frame to have reasonable stress, prevents the stress concentration of a chassis longitudinal beam, and reduces the welding deformation of the chassis longitudinal beam, so the chassis longitudinal beam can meet the assembling requirement.

Owner:SINOTRUK LIUZHOU YUNLI SPECIAL PURPOSE VEHICLES

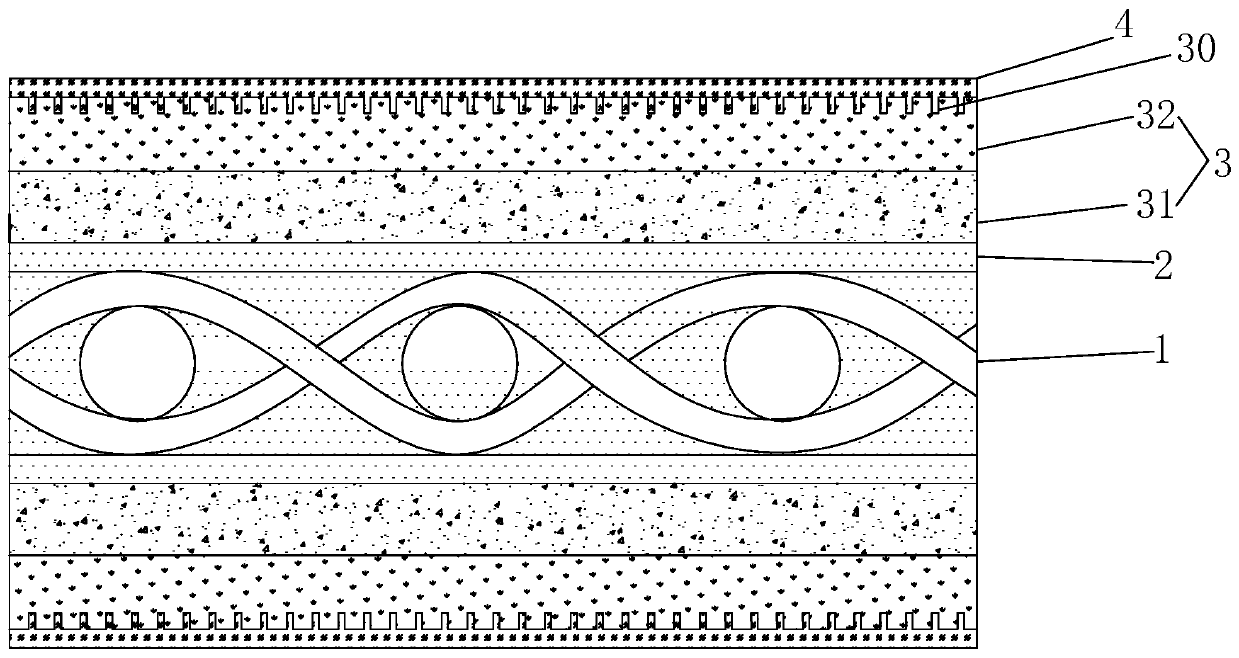

Self-cleaning membrane structure and preparation method thereof

ActiveCN111441178AImprove flame retardant performanceHigh tear strengthFibre typesCoatingsPolyesterPolymer science

The invention discloses a self-cleaning membrane structure and a preparation method thereof, and belongs to the field of building membrane materials. The self-cleaning membrane structure comprises a high-strength polyester fabric core layer, a strengthening layer, a polyvinyl chloride (PVC) function layer and a self-cleaning layer, wherein the PVC function layer comprises a creep-resistant layer and an anti-aging layer; and the strengthening layer is prepared from the following raw materials in parts by weight: 100 parts of polyvinyl chloride paste resin, 5 to 15 parts of polystyrene resin, 140 to 160 parts of dioctyl-phthalate (DOP), 2 to 8 parts of liquid rare-earth stabilizer, 2 to 6 parts of liquid isocyanate cross-linking agent, 6 to 15 parts of flame retardant, 1 to 5 parts of octylphenol polyoxyethylene ether, and 5 to 15 parts of OS-20 diluent. The self-cleaning membrane structure has the effects of better creep resistance, a better mechanical property and longer service life.The preparation method of the self-cleaning membrane structure comprises the steps of preparing raw materials; preparing the membrane layers: sequentially forming the strengthening layer, the creep-resistant layer and the anti-aging layer, and then plastifying; embossing; carrying out surface treatment to form the self-cleaning layer; embossing; and cooling to obtain the product. The product hasthe effects of better tear resistance and tension resistance, and higher membrane material peeling strength.

Owner:海宁市明德新材料有限公司

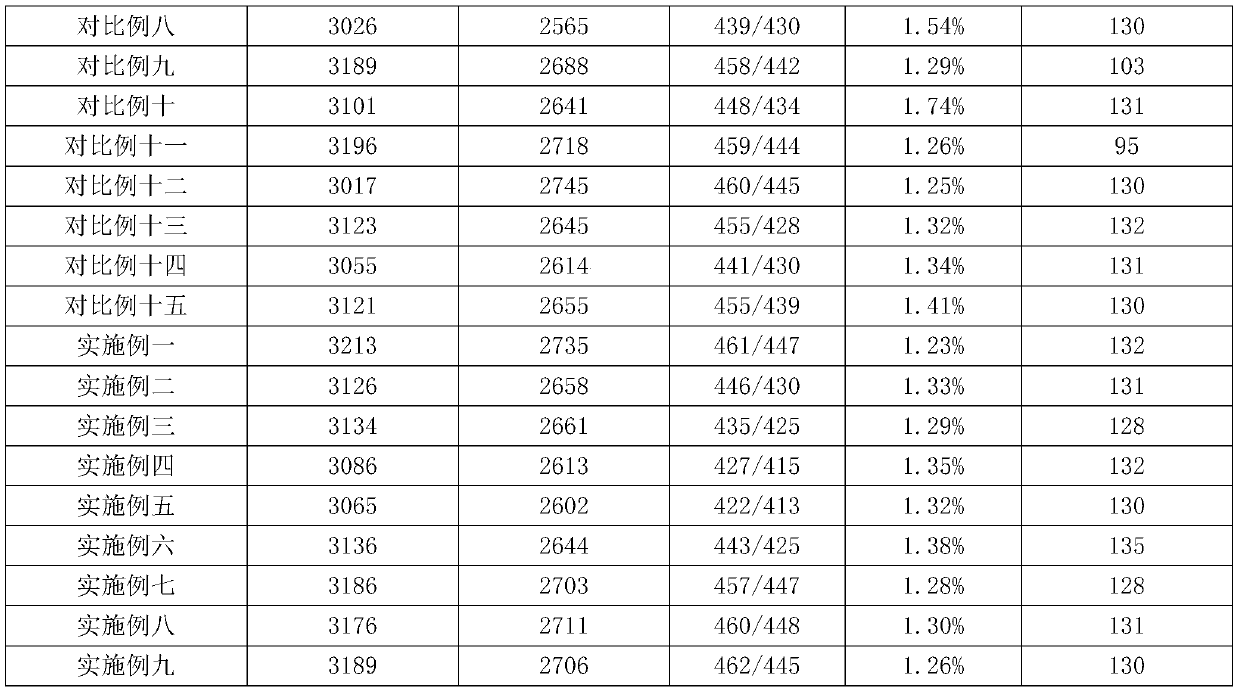

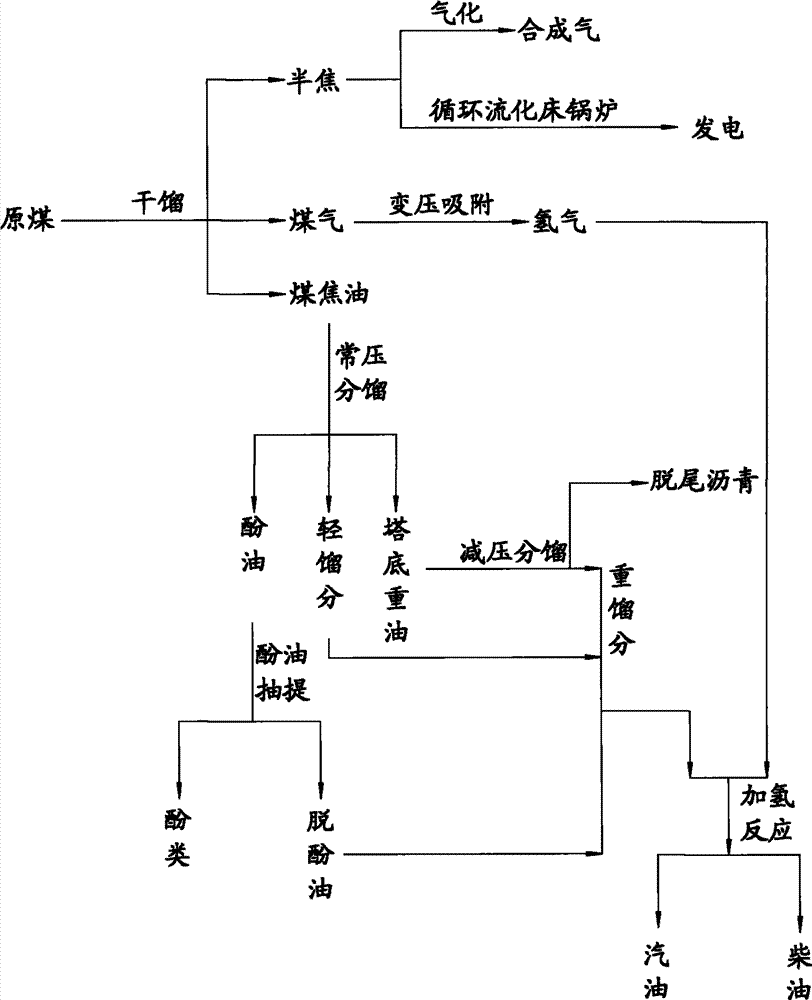

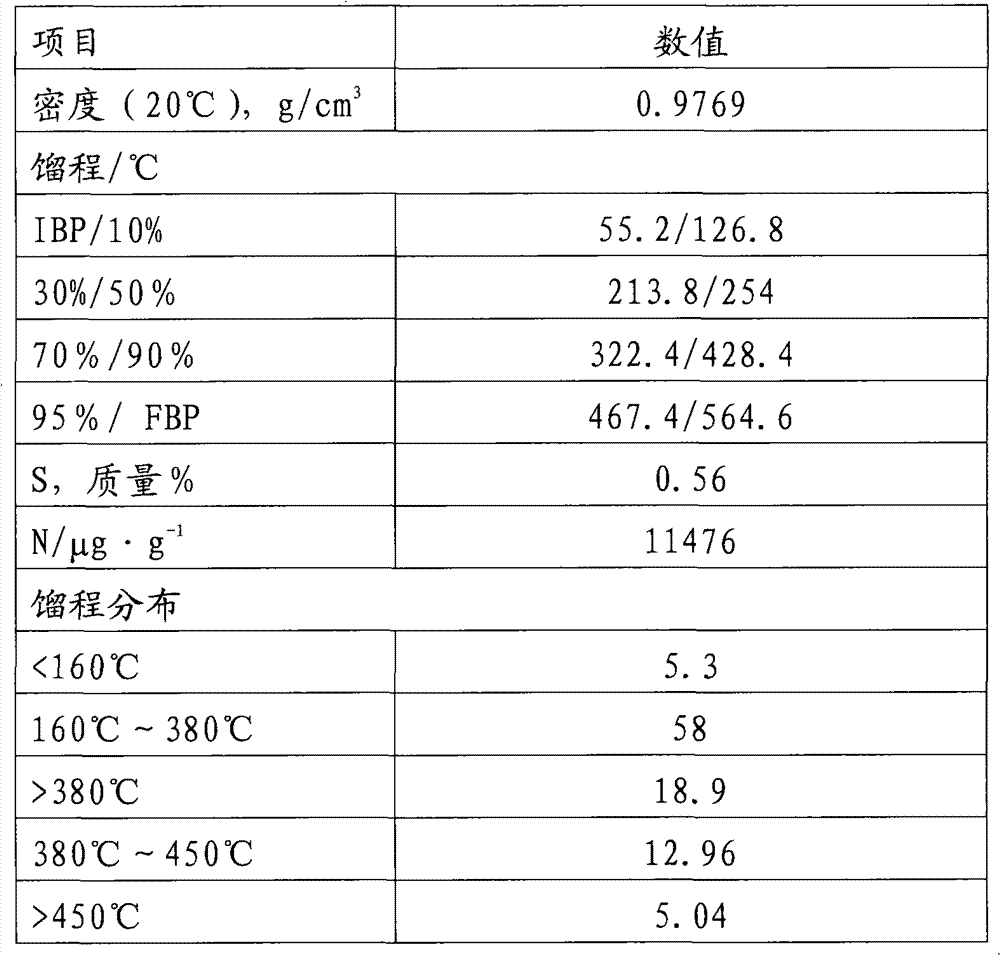

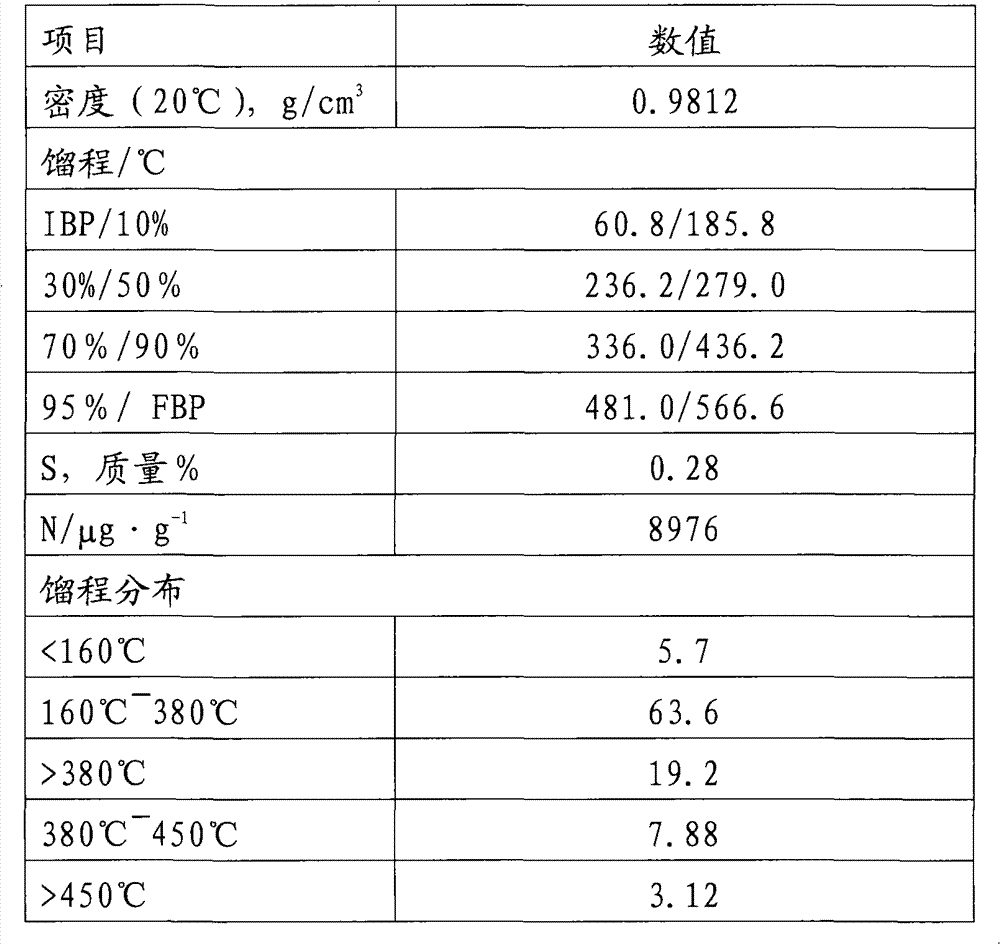

Processing technology of non-caked coal or weakly caking coal

InactiveCN101643654BImprove service life effectThorough responseWorking-up pitch/asphalt/bitumen by distillationHydrogen separation using solid contactWater vaporFractionation

The invention discloses a processing technology of non-caked coal or weakly caking coal, comprising the following steps: a) performing low medium temperature dry distillation reaction to non-caked coal or weakly caking coal to generate coal gas, semicoke and coal tar; b1) extracting hydrogen from the coal gas by pressure swing adsorption; b2) sending the semicoke into a gas generator, ensuring that semicoke, oxygen and water vapour react to generate synthesis gas and coal ash in the gas generator, wherein, the synthesis gas comprises carbon monoxide and hydrogen, or sending the semicoke into acirculating fluidized bed boiler for generating electricity; b3) performing constant pressure fractionation to the coal tar to obtain light fraction, carbolic oil and tower bottom heavy oil, wherein,the tower bottom heavy oil removes trailing asphalt via vacuum distillation to obtain heavy fraction; obtaining phenols and dephenollized phenol oil by extracting phenol oil; and c) performing hydrogenation to light fraction, dephenollized phenol oil, heavy fraction and hydrogen. The technology can prolong the service life of hydrogenation catalyst, can improve the yield of the final product andbrings more products with excellent quality.

Owner:CHINA COAL ENERGY HEILONGJIANG COAL CHEM +1

High-performance alloy material and strap-shape composite material for micromotor electric bush and producing method thereof

The invention relates to a high-performance alloy material and a strap-shape composite material for a micromotor electric bush and a producing method thereof. The high-performance alloy material for the micromotor electric bush is prepared from, by weight, 40-50wt% of Ag, 0.3-0.5 wt% of Pt, 35-45 wt% of Pd and the balance copper. The strap-shape composite material comprises the high-performance alloy material for the micromotor electric bush and a copper alloy base material. The high-performance alloy material for the micromotor electric bush is compounded in a groove body in the surface of the copper alloy base material. The performance of the alloy material is substantially improved, the Vickers hardness of the material where solid solution aging treatment is performed can be improved about by 50, and abrasion resistance is also greatly improved. The strap-shape composite material is low in production cost, the micromotor electric bush made from the strap-shape composite material is installed and tested, and performance is remarkably improved in a high-temperature and high-humidity environment or under the condition of large torque.

Owner:SHANGHAI LONGSUN ALLOY CO LTD

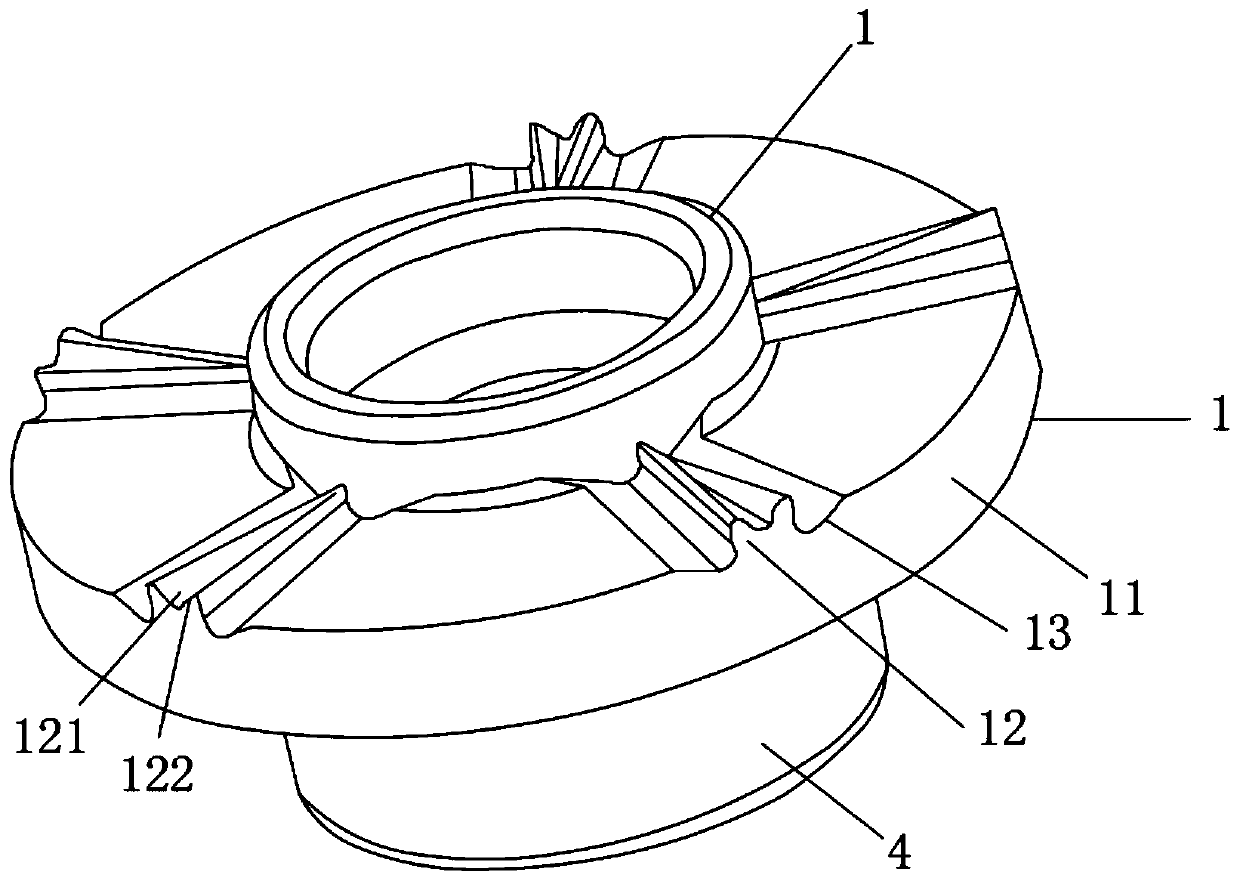

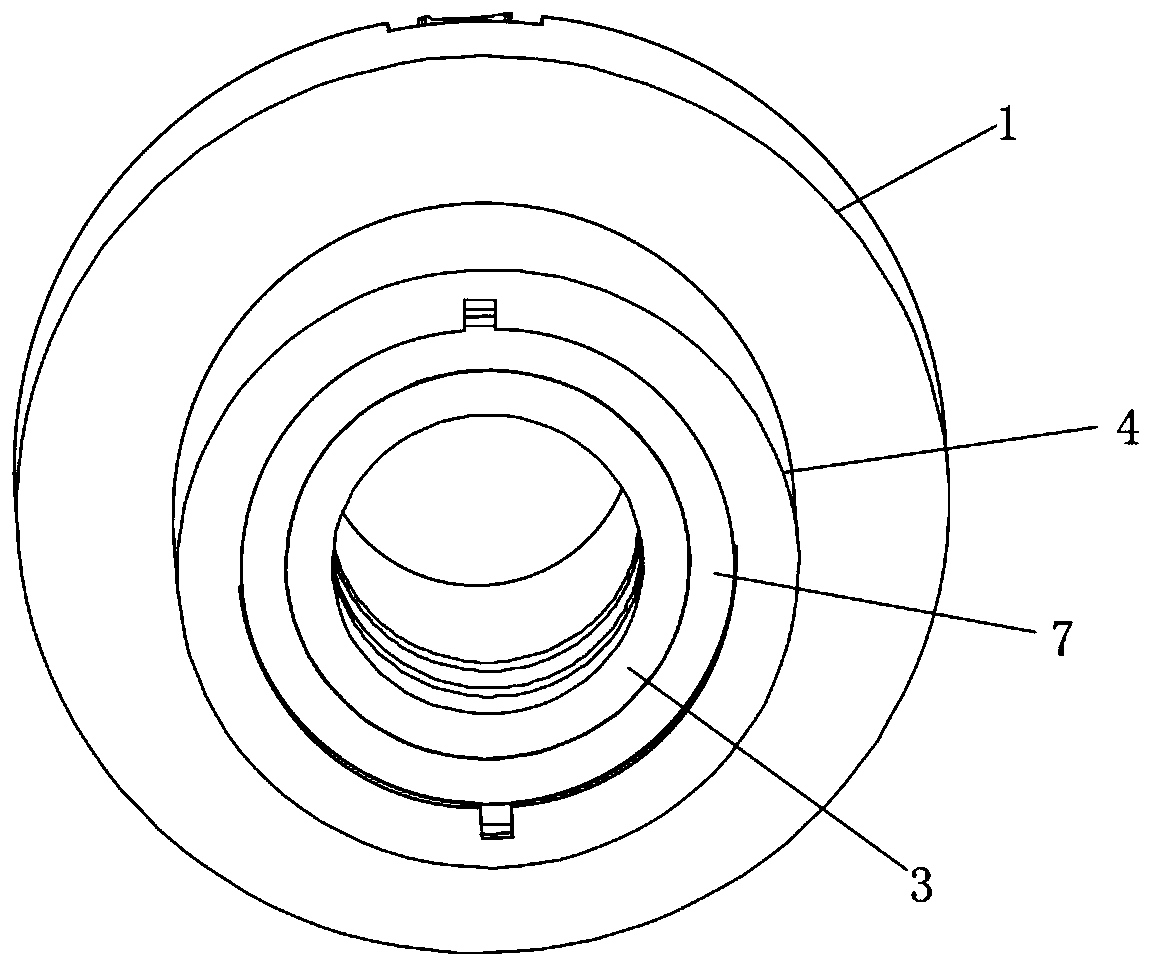

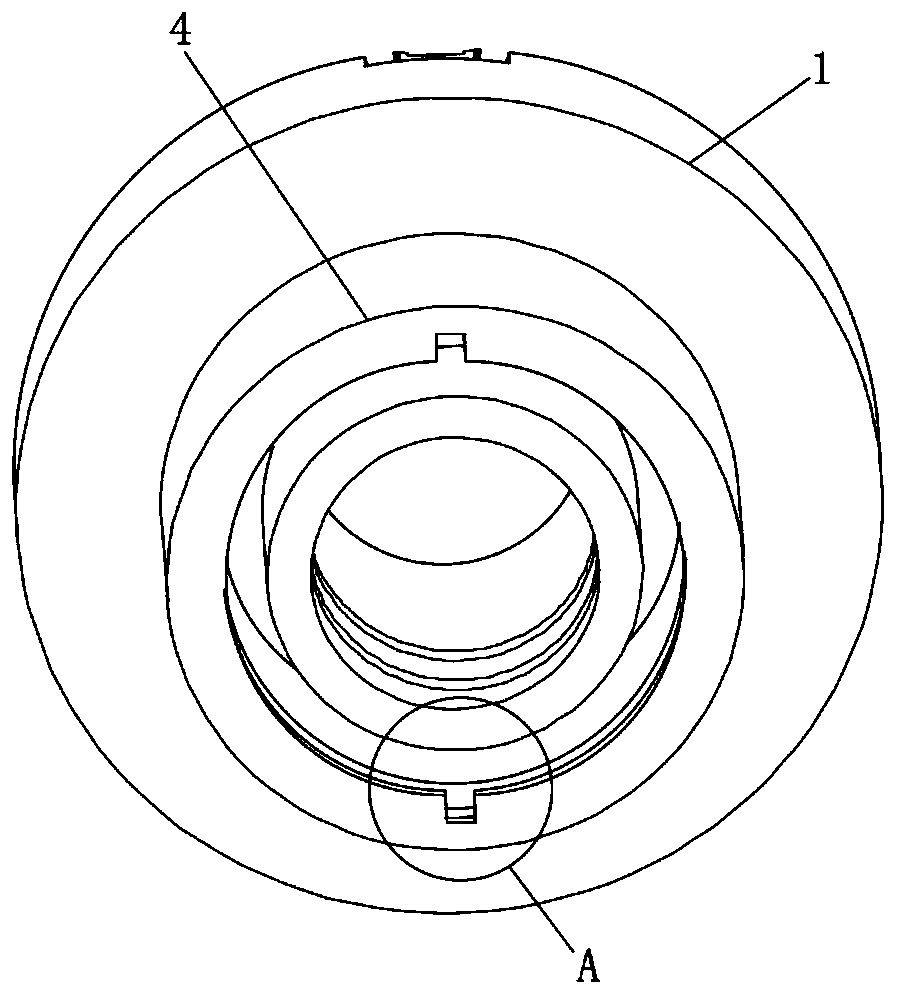

Anti-falling safety pressure pressing rivet nut

The invention relates to the technical field of nuts, and discloses an anti-falling safety pressing rivet nut. The anti-falling safety pressing rivet nut comprises a supporting plate, a rollover riveting ring, a nut block, a supporting outer plate, a reset spring, a rotating block and a rotating plate, wherein the supporting plate comprises a supporting plate shell, flange riveting claws and sunkcave deformed material accumulating grooves, wherein the lower surface of the rollover riveting ring is fixedly connected with the upper surface of the supporting plate shell, the lower surfaces of the flange riveting claws are fixedly connected with the upper surface of the supporting plate shell, a riveting claw grooves are formed in the upper surfaces of the flange riveting claws, the upper surface of the nut block is fixedly connected with the lower surface of the supporting plate, two limiting holes are formed in the lower surface of supporting outer plate shell, the supporting outer plate comprises a rotating groove, the limiting holes and the supporting outer plate shell, the nut block is positioned in the supporting outer plate shell, a rotating groove is formed in the upper surface of a rotating plate shell, the rotating block is inserted into the rotating groove, and the rotating block is movably connected with a rotating plate. The pressing rivet nut has the advantages thatthe after the pressing rivet nut is pressed and riveted on a dissimilar material, a thin sheet metal and a high-strength steel sheet, a bolt can be stably fixed on the sheet metal.

Owner:上海纳特汽车标准件有限公司

Resin grinding wheel capable of cutting and grinding

InactiveCN109202751ATightly boundImprove heat resistanceBonded abrasive wheelsGlass fiberFiberglass mesh

The invention discloses a resin grinding wheel capable of cutting and grinding. The resin grinding wheel capable of cutting and grinding comprises a cutting and grinding wheel housing, a transition hole, a slicing plate and a grinding plate, wherein the grinding plate is fixedly connected into the cutting and grinding wheel housing; a circular assembling hole is connected into a positioning ring in a penetrating manner; heat dissipating strips are closely clung to the front surface of the cutting and grinding wheel housing; the transition hole is connected to the front surface of the cutting and grinding wheel housing in a penetrating manner; glass fiber gridding cloth layers are fixedly connected to the peripheries of resin fibers in the second layer; the resin fibers are compressed and combined by the glass fiber gridding cloth layers utilizing inner fiber nets in order to enable close and compact inner part of the grinding wheel; the circular assembling hole is capable of fixing a device into the grinding wheel through an own encircling hole; the transition hole on the basis of own width is combined with peripheral thick and fine grinding wheels to form a clearance so as to realize the transition effect; and meanwhile, the heat dissipating strips on the grinding wheel are capable of dispersing heat produced by the grinding wheel through concave strips; and the grinding wheelcapable of cutting and grinding has a wide application prospect.

Owner:DIAMOND GRINDING WHEEL CO LTD IN ANHUI TOBE

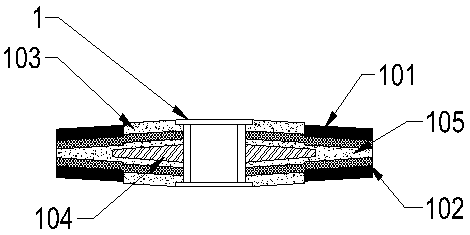

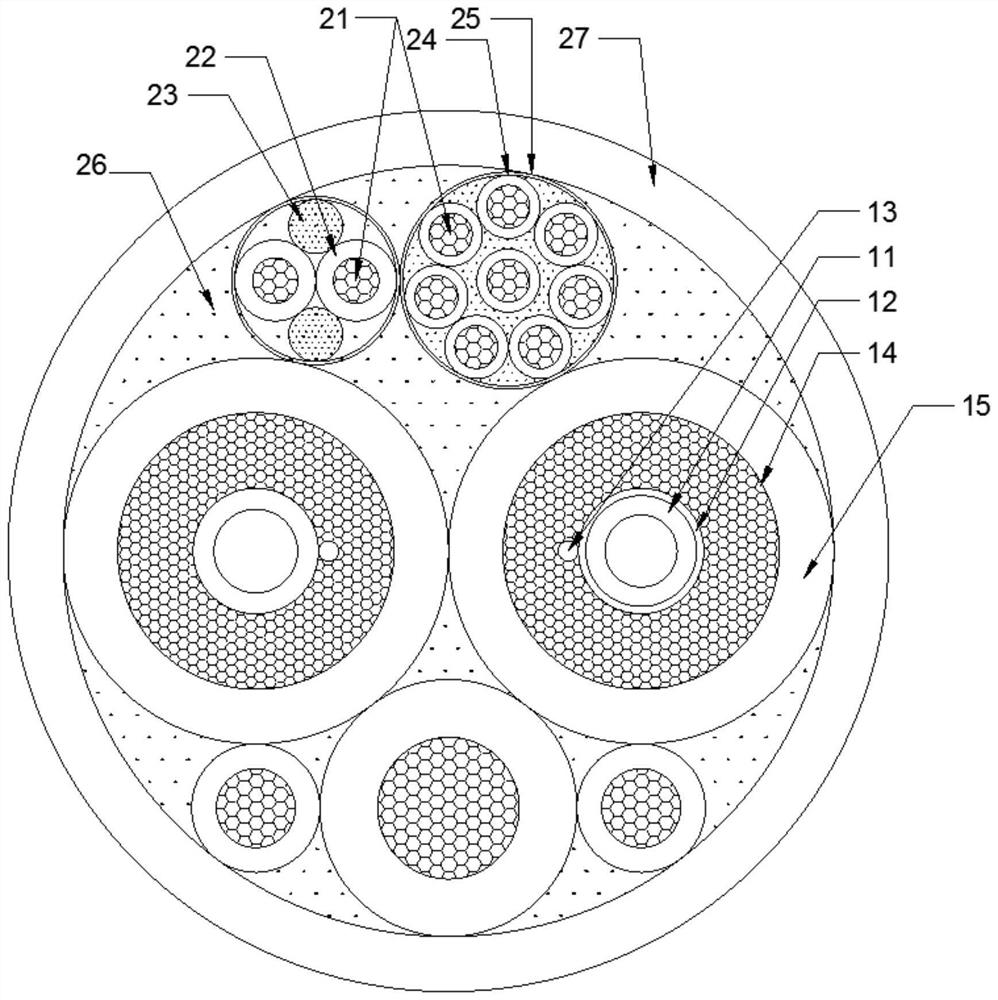

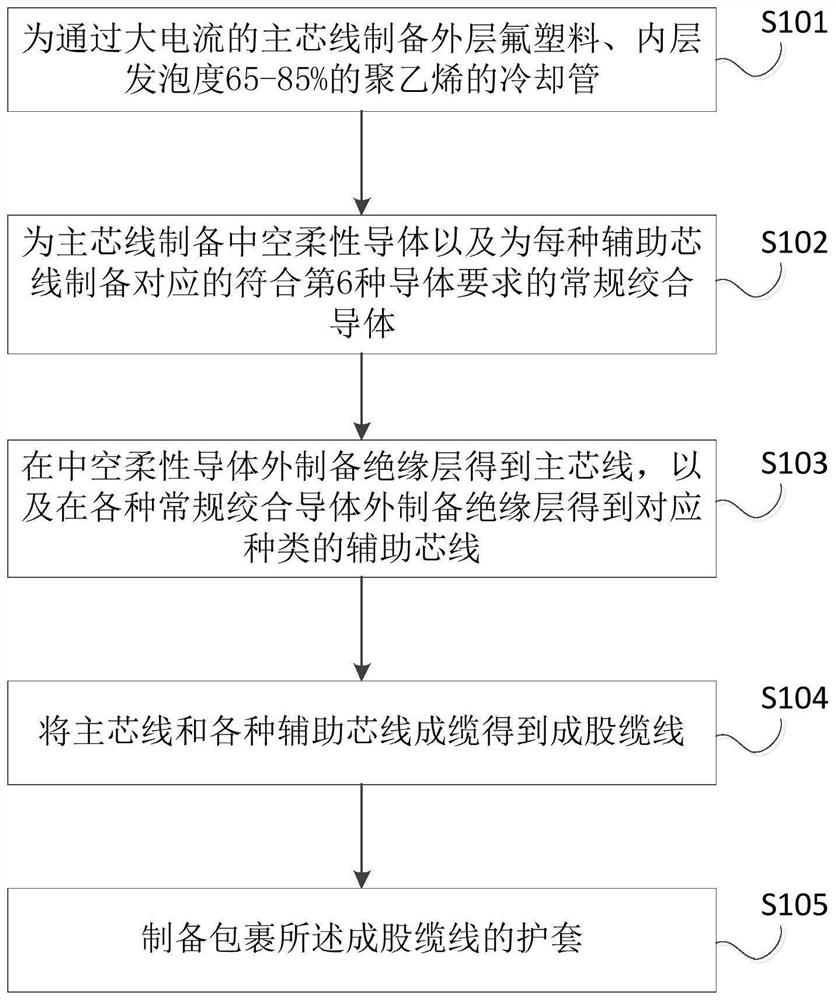

Quick-charging external connection cable for large-current soft charging pile and preparation method of quick-charging external connection cable

PendingCN114005614AGood flexibilityFast chargingPower cables including communication wiresPower cables with screens/conductive layersStructural engineeringAmpacity

The invention discloses a quick-charging external connection cable for a large-current soft charging pile and a preparation method of the quick-charging external connection cable. According to the invention, outer fluoroplastic of a cooling pipe of a main core wire has temperature resistance and insulation effects, and inner foamed polyethylene with a foaming degree of 65-85% increases the volume of cooling liquid and also has an effective supporting effect; more importantly, when a hollow flexible conductor of the main core wire is prepared, the compression resistance of the cooling pipe is improved, so after all conductor wires are grouped and bundled, the cooling pipe can be used as a support and then stranded to form the cable, the flexibility of the cable can be effectively improved, and compared with a cable of a conventional cooling device, the cable is easier to install, small in bending radius and large in current-carrying capacity; in addition, an temperature-sensitive optical fiber is added when the hollow flexible conductor is formed, and the flow rate of cooling liquid can be controlled according to feedback temperature, so the temperature of the cable is constant; and thus, the charging speed of the cable is greatly improved, the heating problem of the cable is greatly improved, an insulation aging speed is effectively reduced, the service life of the cable is prolonged, and product flexibility is better.

Owner:ANHUI LIANJIAXIANG SPECIAL CABLE

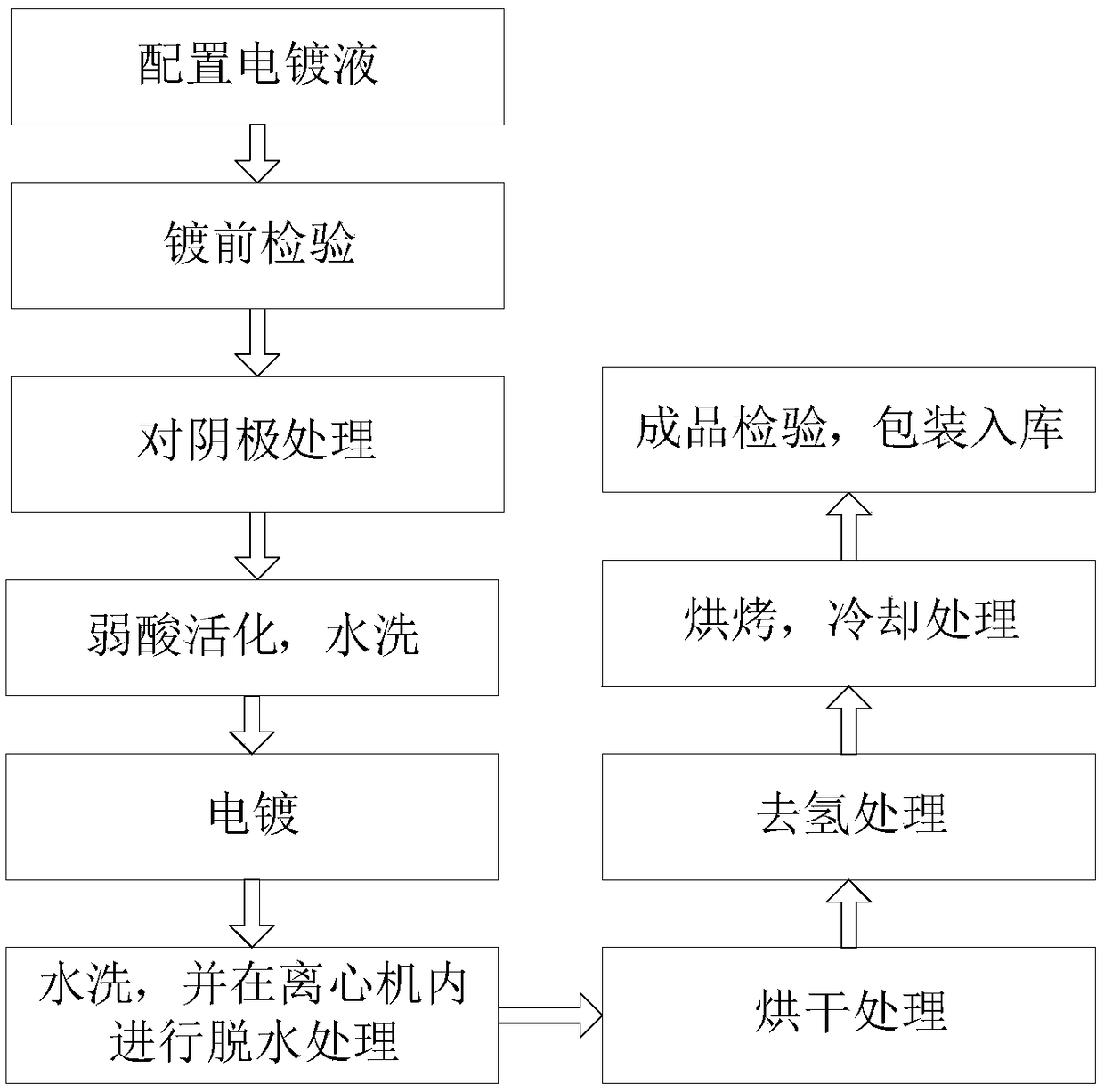

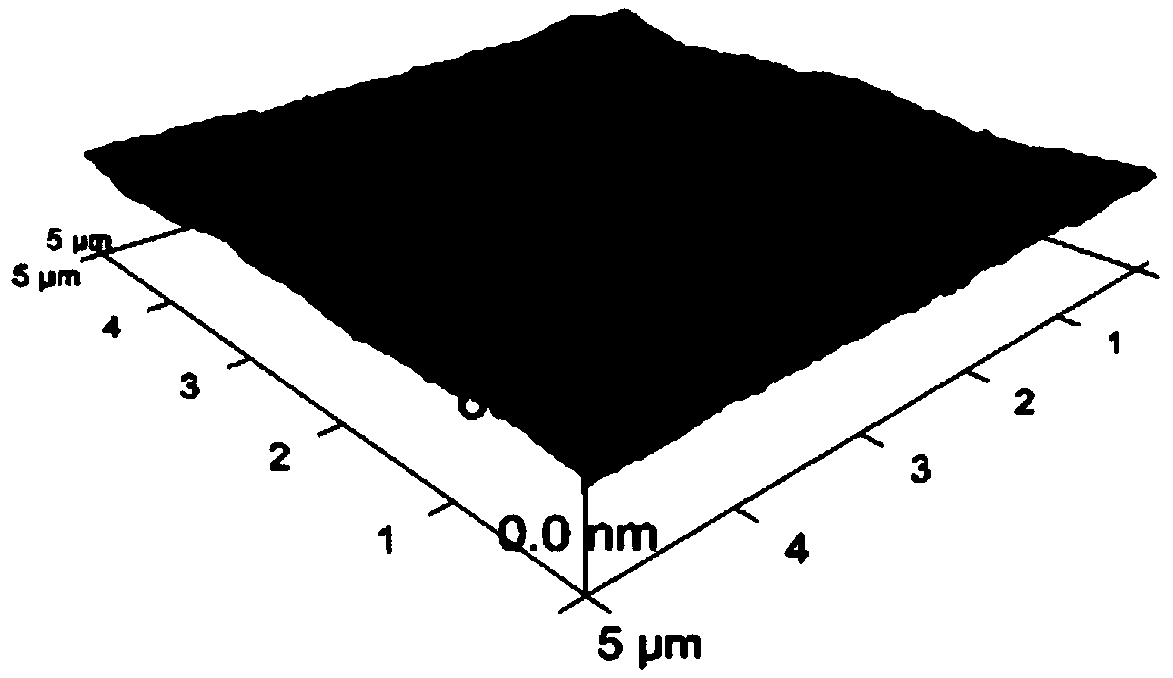

Formula and treatment method of abrasion-resisting, anti-friction and life-prolonging nano plating layer of mechanical parts

InactiveCN109023451AReduce internal stressIncrease internal stressElectrolytic coatingsNanotechnologySulfideSlurry

The invention discloses a formula and treatment method of an abrasion-resisting, anti-friction and life-prolonging nano plating layer of mechanical parts. The formula of an electroplating solution comprises 150-650g / l of ammonia nickel methane sulfonate, 1-50g / l of cobalt chloride, 15-60g / l of boric acid, 2-80g / l of nano tungsten sulfide plating slurry, 0.5-3g / l of cerous sulfate and 0.5-3g / l of 1-2-3-benzotriazole, and the lamellar particle size of the nano tungsten sulfide plating slurry is 40-70 nm. According to the treatment method of the abrasion-resisting, anti-friction and life-prolonging nano plating layer of the mechanical parts, through the electroplating solution with the ammonia nickel methane sulfonate as the main component, the nano tungsten sulfide plating slurry is added toform the electroplating solution, the plating layer has high mechanical properties after electroplating, the ductility, uniformity and corrosion resistance are all greatly improved, the effects of abrasion-resisting, anti-friction and prolonging of the service life are achieved, and good application prospects are achieved.

Owner:苏州润纳斯纳米科技有限公司

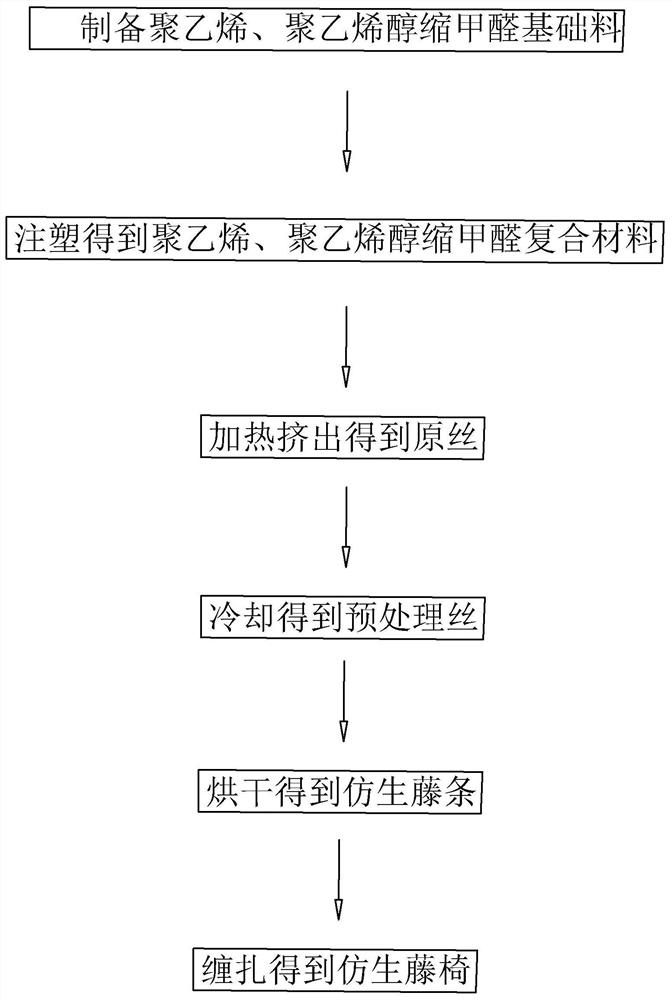

Polyethylene and polyvinyl formal composite material, preparation method thereof, and bionic rattan chair

PendingCN113372639AGood chemical stabilityImprove the environmentChairsPolymer chemistryPolyvinyl alcohol

The invention relates to the technical field of leisure household articles, and especially relates to a polyethylene and polyvinyl formal composite material, a preparation method thereof, and a bionic rattan chair. The polyethylene and polyvinyl formal composite material is prepared from, by weight, 40-50 parts of polyethylene, 30-40 parts of polyvinyl formal, 14-22 parts of color master batch and 5-9 parts of a fiber material. The preparation method of the polyethylene and polyvinyl formal composite material comprises the following steps: (1) preparing a polyethylene and polyvinyl formal base material; and (2) performing injection molding to obtain the polyethylene and polyvinyl formal composite material. The polyethylene and polyvinyl formal composite material and the preparation method thereof have the effects of improving the aging resistance of the bionic rattan chair and prolonging the service life of the bionic rattan chair.

Owner:杭州汉普塑料制品有限公司

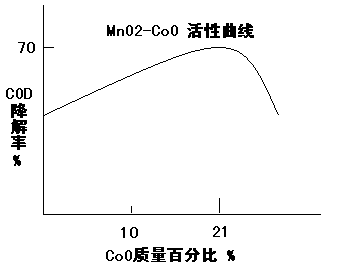

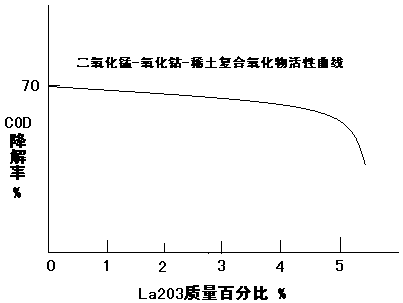

Protective Agent for Ozone Oxidation Catalyst Used in Degradation of Organic Wastewater

ActiveCN105772110BImprove service life effectHigh removal rateCatalyst protectionHeterogenous catalyst chemical elementsPapermakingRare earth

Owner:JIANGXI HUIHUA TECH CO LTD

A floor with non-damageable edges and a pavement structure using the same

ActiveCN112982883BReduce wearImprove service life effectResiliently-mounted floorsClassical mechanicsEngineering

The present application relates to a floor whose edges are not easy to be damaged and a floor paving structure using the floor. It relates to the field of flooring, which includes a floor body, edge strips are provided at the edge of the floor body, and openings are provided on the side strips facing the floor body. The edge of the floor body is inserted into the open groove, and the hardness of the edge strip is lower than that of the floor body. The present application has the effect of reducing the possibility of direct contact with other objects at the edge of the floor body, thereby reducing the possibility of abrasion at the edge of the floor body, and improving the service life of the floor body.

Owner:江苏辉映地板科技有限公司

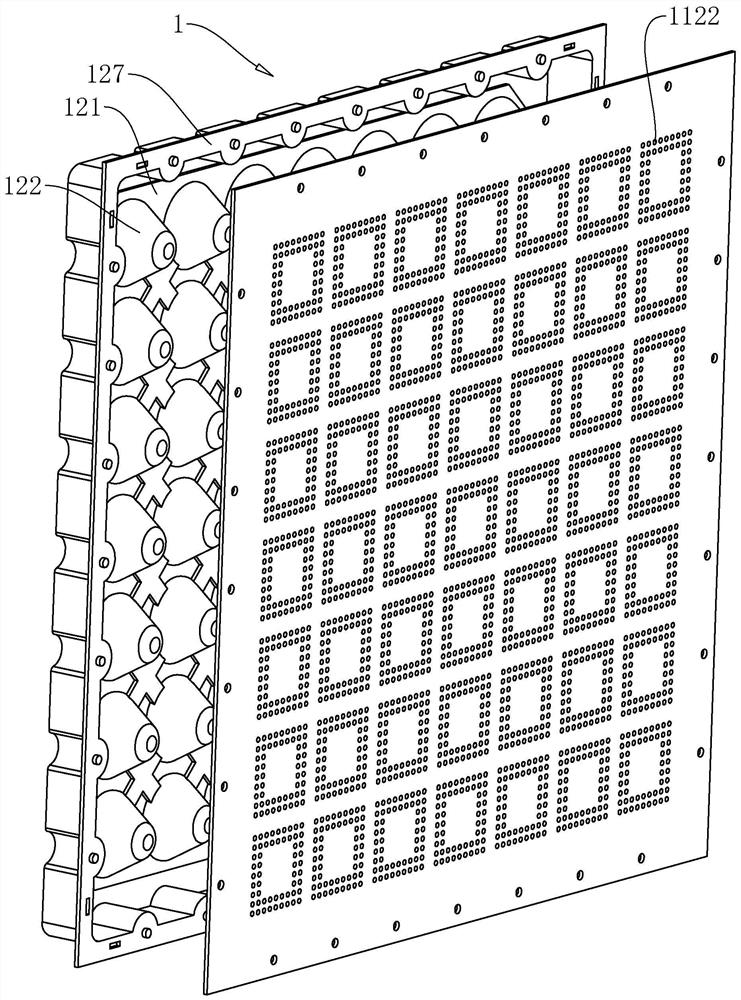

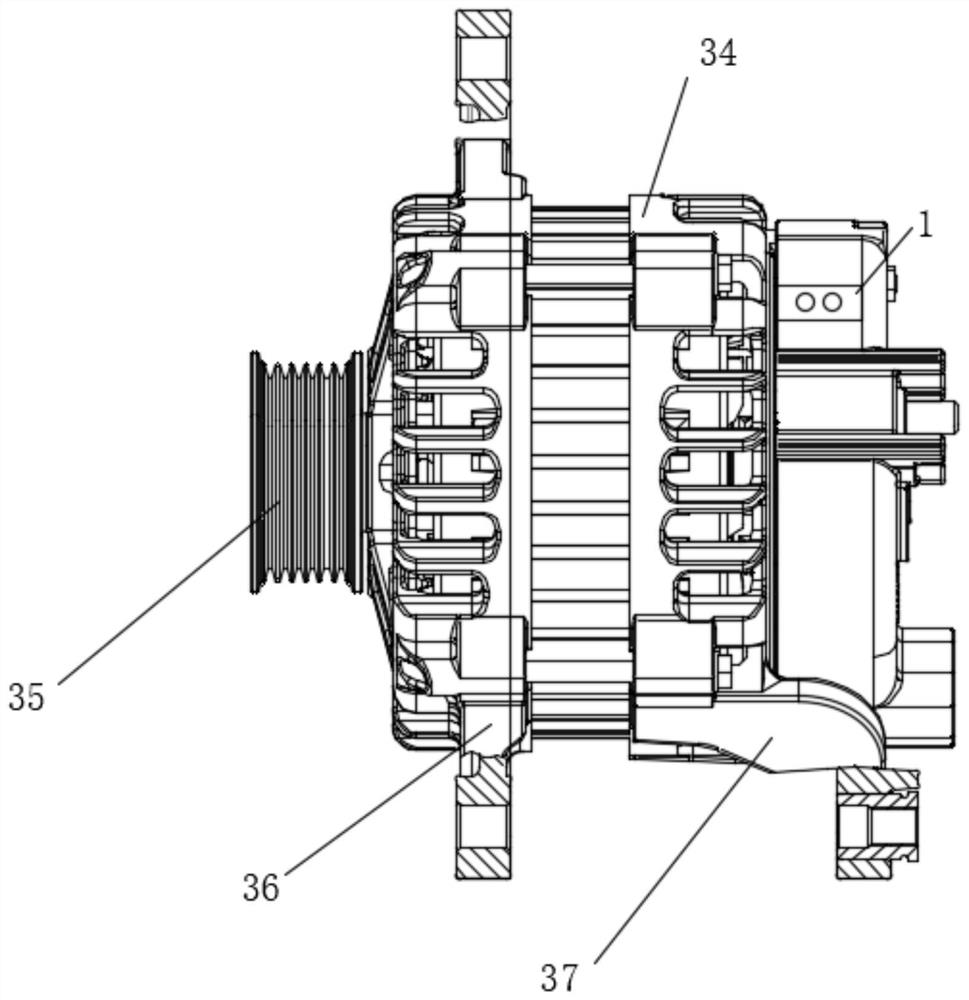

A kind of automobile alternator and its application

ActiveCN111327144BExtended service lifeImprove service life effectCooling/ventillation arrangementSupports/enclosures/casingsEngineeringHeat sink

The invention discloses an automobile alternator, which relates to the technical field of auto parts, and comprises a carbon brush mounting seat body, a semiconductor refrigerating sheet and a cooling water cavity. A piston cylinder is fixedly connected to the outer wall of the carbon brush mounting seat body, and the piston The inner wall of the cylinder is sealed and slidably connected up and down with a piston plate, the cavity wall of the cooling water chamber, the cylinder wall of the piston cylinder and the plate wall of the piston plate are jointly connected with a radiating cylinder in an alternately up and down sealing and sliding connection, and the upper part of the piston plate The surface and the cavity formed by the inner wall of the piston cylinder jointly store the mercury medium, and the outer wall of the carbon brush mounting seat body is fixedly connected with a support shaft. Through the good cooperation between the above-mentioned structures, the present invention has the ability to replace a single heat dissipation column with two heat dissipation cylinders, and when the temperature of any one of the heat dissipation cylinders is too high, the two heat dissipation cylinders can be replaced alternately. On the one hand, the effect and efficiency of heat dissipation are improved, and on the other hand, the effect of prolonging the service life of the heat dissipation object.

Owner:浙江安美德汽车配件有限公司

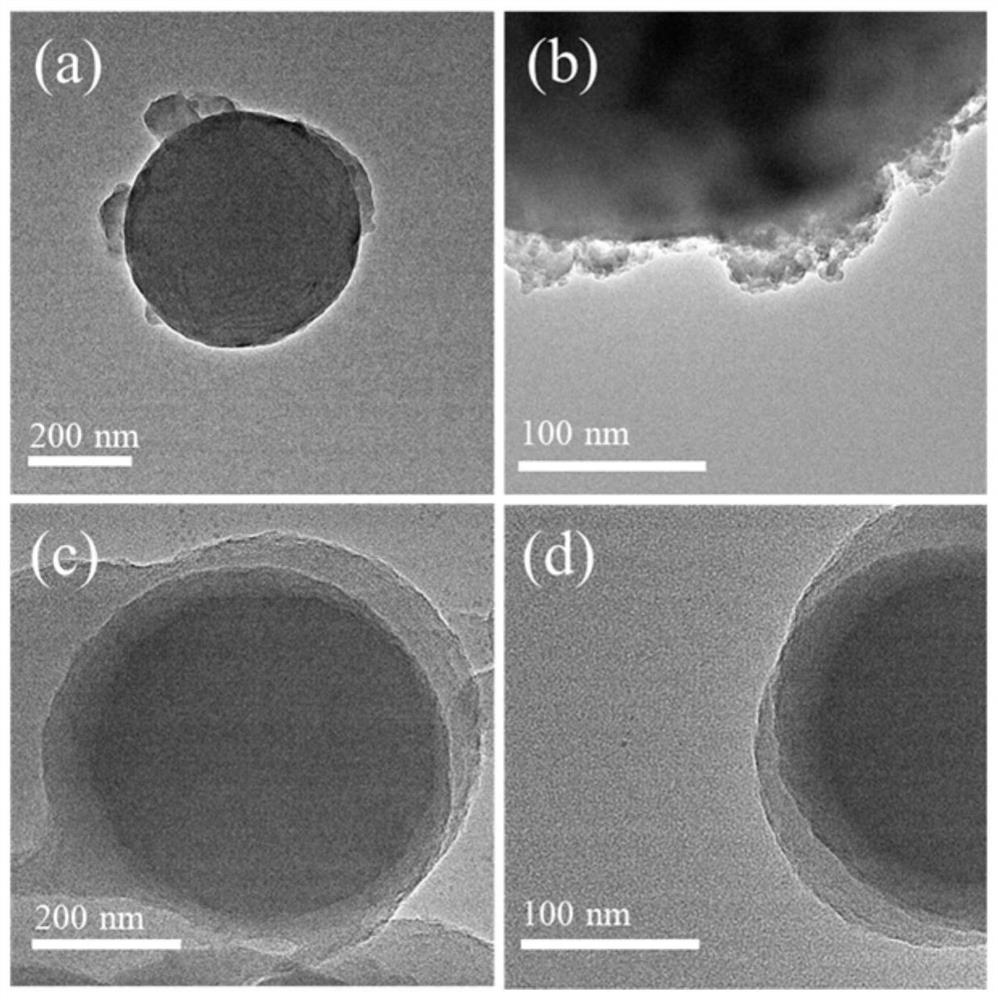

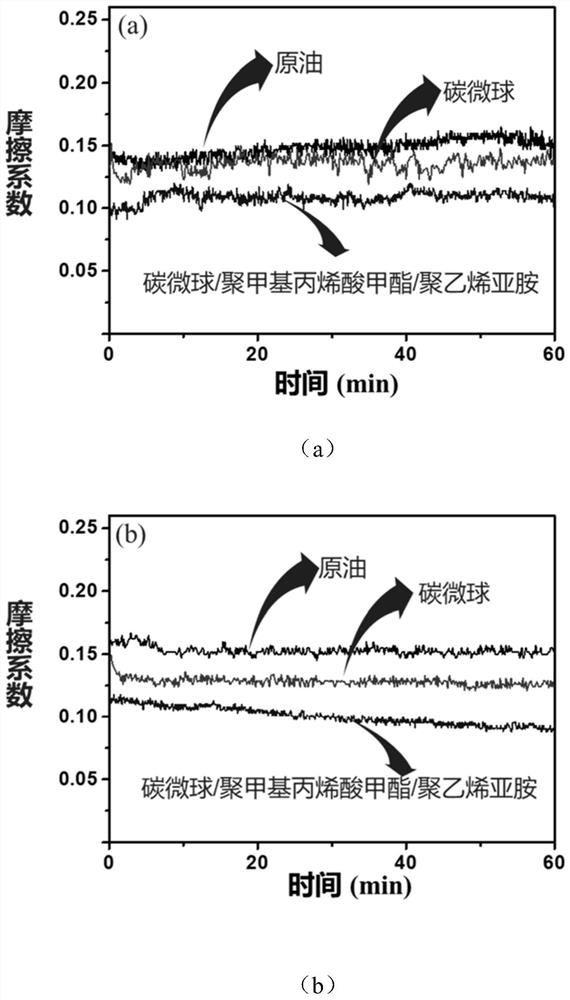

Preparation method of carbon microsphere/polymethyl methacrylate/polyethyleneimine nanocomposite with double shell-core structure

The invention discloses a preparation method of a carbon microsphere / polymethyl methacrylate / polyethyleneimine nanocomposite material with a double shell-core structure. The carbon microsphere is obtained by hydrothermal reaction using glucose solution as a carbon source Dissolve carbon microspheres in a mixed solution of water and absolute ethanol, add a mixed solution of silane coupling agent and absolute ethanol, and react under condensing and reflux heating conditions to obtain modified carbon microspheres; Microspheres, water and methyl methacrylate are made into a solution, which is called solution A; the mixed aqueous solution of polymethyl methacrylate and polyethyleneimine is prepared, which is called solution B; solution B is added to solution A to obtain Solution C; tert-butyl hydroperoxide is added to solution C and heated for reaction; after the reaction is completed, the product is filtered, centrifuged, washed and dried to obtain carbon microspheres / polymethacrylic acid with a double shell-core structure Methyl ester / polyethyleneimine nanocomposites.

Owner:SHAANXI UNIV OF SCI & TECH

Automatic control method of capillary tail ring of perforator

ActiveCN107790497BEffective in normal useImprove service life effectRolling mill drivesMetal rolling arrangementsAutomatic controlPolishing

The invention provides an automatic control method of a tubular billet tail ring of a perforating machine. The automatic control method is characterized by comprising the following steps that 1, a perforating unit roller operates in a no-load speed state and is bitten into a pipe blank; 2, after time is delayed for T1, the speed is increased to the rolling speed at an accelerated speed I; 3, whenthe current pipe blank is rolled, high-speed rolling time T2 of the current tubular billet is calculated according to rolling time of a former steel pipe, and T2 is equal to T2 upper + (T3 upper-T3 setting)*V3 / V2; 4, in the steel polishing process, the speed is decreased to the steel polishing speed at an accelerated speed II; and 5, after steel polishing is completed, time is delayed for T4, andthe roller speed is restored to the steel biting speed. According to the method, the tubular billet tail ring after perforating is eliminated basically, and the problem that due to the tubular billettail ring, the surface of a core bar is damaged is solved basically. By the adoption of the automatic control program, the problem of the tubular billet tail ring generated by the perforating machinecan be well controlled, the technology can meet the site production requirement, and the effects on stability of the production quality and normal use of the core bar are remarkable.

Owner:LINZHOU FENGBAO PIPE

Polybutadiene-based non-slip wear-resistant sole rubber and preparation method thereof

The invention discloses a polybutadiene-based rubber for a non-slip wear-resistant shoe sole and a preparation method of the polybutadiene-based rubber for the non-slip wear-resistant shoe sole. Comprising the following components in parts by weight: 60 parts of polybutadiene rubber, 32 to 48 parts of thermoplastic elastomer SBS, 26 to 35 parts of modified szaibelyite composite particles, 1.5 to 3.6 parts of terpene-phenolic resin, 0.2 to 0.8 part of a silane coupling agent, 1.2 to 1.8 parts of an anti-aging agent, 2.3 to 4.6 parts of sulfur and 1.1 to 1.6 parts of an accelerant. The anti-slip wear-resistant sole rubber based on polybutadiene prepared by the invention not only has wear resistance and skid resistance, but also has the advantages of light weight and strong elasticity, and in addition, the ageing resistance is also well improved.

Owner:BIEM L FDLKK GARMENT CO LTD

Electrochromic material and preparation method thereof

PendingCN112662389AImprove physical and chemical propertiesImprove service life effectTenebresent compositionsPolymer scienceOrganic chemistry

The invention relates to the technical field of electrochromic material preparation, and discloses an electrochromic material and a preparation method thereof. The electrochromic material is of a multi-layer hollow sphere structure, the outer diameter of the electrochromic material is 50-180 microns, the outer surface layer of the electrochromic material is a high-molecular polymerization product electrochromic material, iron is doped in the high-molecular polymerization product electrochromic material, the inner layer is made of a high-molecular polymerization product non-electrochromic material, and the thickness of the inner layer is 7-15 microns. A layer of inorganic metal film is plated on the surface of the high-molecular polymerization product electrochromic material, so that the physical and chemical properties of the high-molecular polymerization product electrochromic material are improved on the premise of not changing the electrochromic properties of the high-molecular polymerization product electrochromic material, the service life of the high-molecular polymerization product electrochromic material is prolonged, and the market competitiveness of the electrochromic material is improved.

Owner:SHENZHEN HUAKE COMM TECH CO LTD

High adhesion ladle wall cold overall repair material

Owner:瑞泰马钢新材料科技有限公司 +2

A method for microwave treatment of aged rum oak barrels

InactiveCN104560624BImprove breathabilityImprove aging qualityAlcoholic beverage preparationVenting devicesMicrowaveEngineering

The invention relates to a method for treating a rum-aging oak barrel in microwaves. The method comprises the following steps: (1), after an oak barrel ages rum for one month, performing a first microwave treatment on the rum-aging oak barrel by using microwave with the frequency of 50-30,000 MHz and the power of 1-12 kW, and during later five months, performing once microwave treatment to the rum-aging oak barrel by using the microwave with the frequency of 50-30,000 MHz and the power of 1-12 kW in every month; (2), during 6-18 months when the oak barrel ages the rum, performing once microwave treatment on the rum-aging oak barrel by using the microwave with the frequency of 50-30,000 MHz and the power of 12-24 kW in every month; (3), after the oak barrel ages the rum for 18 months, performing once microwave treatment to the rum-aging oak barrel by using the microwave with the frequency of 50-30,000 MHz and the power of 24-60 kW in every month. According to the method for treating the rum-aging oak barrel in the microwaves, micropores in the inner wall of the oak barrel are abundant, the blockage during aging is prevented, and the purposes of improving the rum aging quality, accelerating the rum aging and prolonging the service life of the oak barrel are finally achieved.

Owner:南宁海酩威科技有限公司 +1

Silicon-magnesium material modified solid-wood fiber board

The invention belongs to the field of decorative boards, and particularly relates to a silicon-magnesium material modified solid-wood fiber board which consists of a forming agent, wood reinforced fibers, a water-retaining agent and a modifier. The silicon-magnesium material modified solid-wood fiber board is characterized in that a silicon material and magnesium chloride is further added, and themodifier is a strong acid solution with mass percentage concentration of 5%-30%.

Owner:陈发江

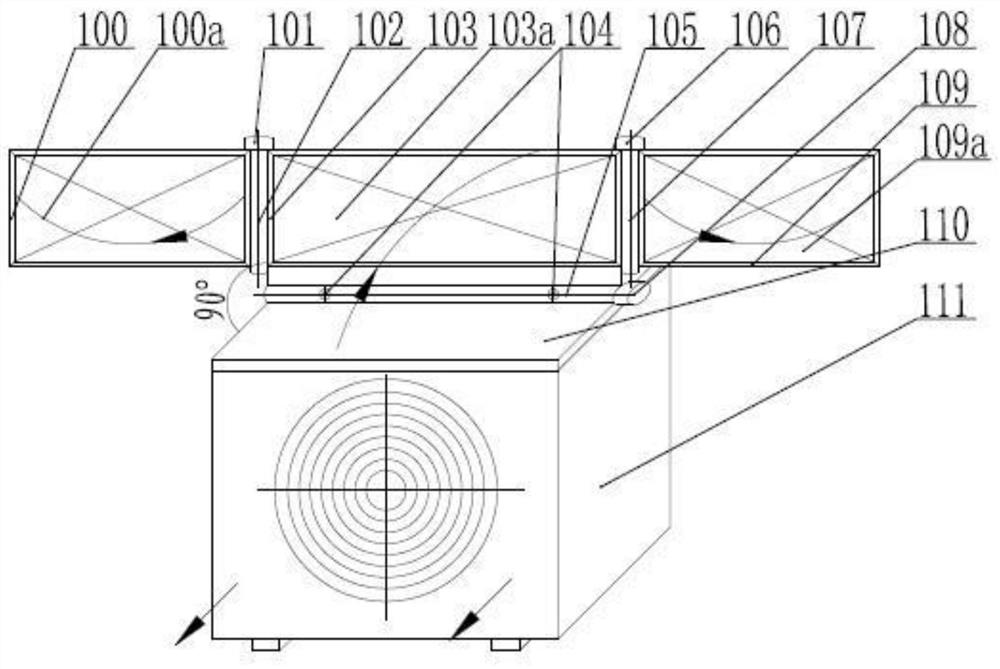

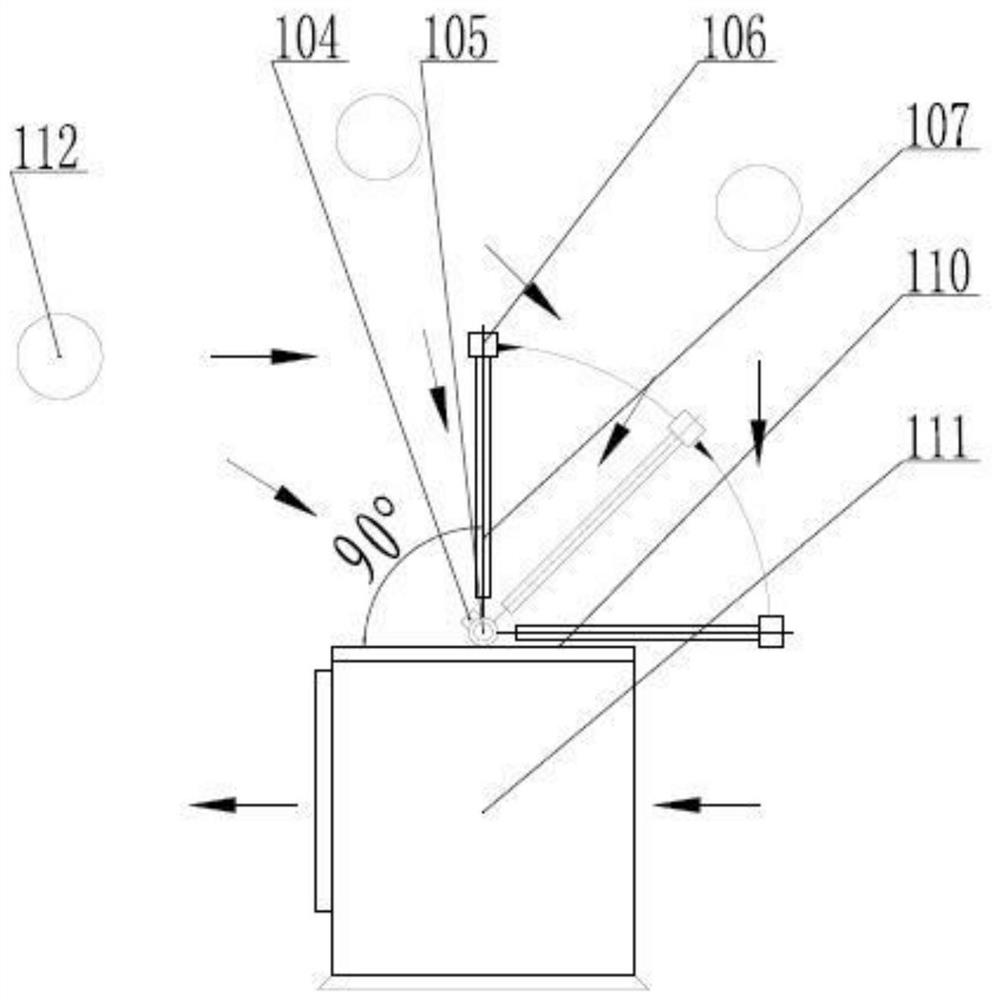

A solar air conditioner outdoor unit and battery panel connection device

ActiveCN110749009BThe effect of improving heat exchange efficiencyAvoid destructionPhotovoltaic supportsSolar heating energyElectric machineDrive motor

The invention discloses a connection device between an outdoor unit of a solar air conditioner and a battery panel, comprising an outdoor unit of an air conditioner, a main support, a sub-support, and a solar battery panel. The upper part of the cover is provided with a main rotating shaft device, and the lower part of the main bracket is connected with the top cover of the air conditioner outdoor unit through the main rotating shaft device. The sub and main rotating shaft devices are respectively rotated forward and reverse by the driving motor, and are adjusted and fixed on the sub bracket and the main bracket. The solar panel can receive solar energy at a suitable angle of attack after deployment, and form an auxiliary air duct for the air outlet of the air conditioner outdoor unit when retracted. The invention not only simplifies the installation, but also can adjust the angle according to the position of the sun at different times to improve the power generation efficiency through the unfolding and folding of the solar panel integrally fixed on the bracket on the top cover of the external unit of the air conditioner, and the wind generated by the air outlet of the external unit when folded To prevent the blown air from short-circuiting and directly flowing back to the air inlet, reducing the heat exchange efficiency.

Owner:HANGZHOU YAOYAO PHOTOVOLTAIC TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com