Polybutadiene-based non-slip wear-resistant sole rubber and preparation method thereof

A polybutadiene rubber and polybutadiene technology, which is applied in the directions of soles, footwear, and applications, can solve the problems of poor elasticity of rubber soles, high rubber density, and hard shoes, so as to improve the degree of mutual integration, Strong elasticity and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] A polybutadiene-based anti-slip and wear-resistant rubber for soles, calculated in parts by weight, comprising the following components:

[0061] 60 parts of polybutadiene rubber, 40 parts of thermoplastic elastomer SBS, 30 parts of modified borosite composite particles, 2.8 parts of terpene phenol resin, 0.5 part of silane coupling agent KH-792, 1.5 part of antioxidant TMQ, sulfur 3.8 parts and Accelerator M 1.4 parts.

[0062] The number average molecular weight of the thermoplastic elastomer SBS is 18000-20000, the particle size of the modified boronite composite particles is 200 μm, and the softening point of the terpene phenol resin is 135°C.

[0063] Wherein, the preparation method of modified boschite composite particles includes:

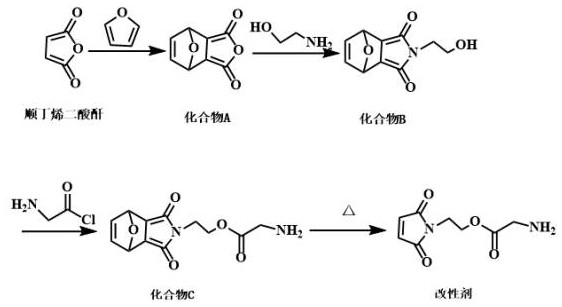

[0064] The first step is to prepare the modifier:

[0065] S1, weigh maleic anhydride and furan and mix them in a reaction vessel containing acetone, the mass ratio of maleic anhydride, furan and acetone is 2.8:4.1:100, after fully ...

Embodiment 2

[0079] A polybutadiene-based anti-slip and wear-resistant rubber for soles, calculated in parts by weight, comprising the following components:

[0080] 60 parts of polybutadiene rubber, 32 parts of thermoplastic elastomer SBS, 26 parts of modified borosite composite particles, 1.5 parts of terpene phenol resin, 0.2 parts of silane coupling agent KH-550, 1.2 parts of antioxidant MB, sulfur 2.3 parts and Accelerator M 1.1 parts.

[0081] Among them, the number average molecular weight of the thermoplastic elastomer SBS is 18000-20000, the particle size of the modified boronite composite particles is 100 μm, and the softening point of the terpene phenol resin is 125°C.

[0082] Wherein, the preparation method of modified boschite composite particles includes:

[0083] The first step is to prepare the modifier:

[0084] S1, weigh maleic anhydride and furan and mix them in a reaction vessel equipped with acetone, fully stir at room temperature for 16 h, filter out the solid, rin...

Embodiment 3

[0098] A polybutadiene-based anti-slip and wear-resistant rubber for soles, calculated in parts by weight, comprising the following components:

[0099] 60 parts of polybutadiene rubber, 48 parts of thermoplastic elastomer SBS, 35 parts of modified borosite composite particles, 3.6 parts of terpene phenol resin, 0.8 parts of silane coupling agent KH-560, 1.8 parts of antioxidant DNP, sulfur 4.6 parts and accelerator TETD 1.6 parts.

[0100] Among them, the number average molecular weight of the thermoplastic elastomer SBS is 18000-20000, the particle size of the modified boronite composite particles is 300 μm, and the softening point of the terpene phenol resin is 150°C.

[0101] Wherein, the preparation method of modified boschite composite particles includes:

[0102] The first step is to prepare the modifier:

[0103] S1, weigh maleic anhydride and furan and mix them in a reaction vessel equipped with acetone. After fully stirring at room temperature for 24 h, filter out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com