Patents

Literature

9142results about How to "Improve aging resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

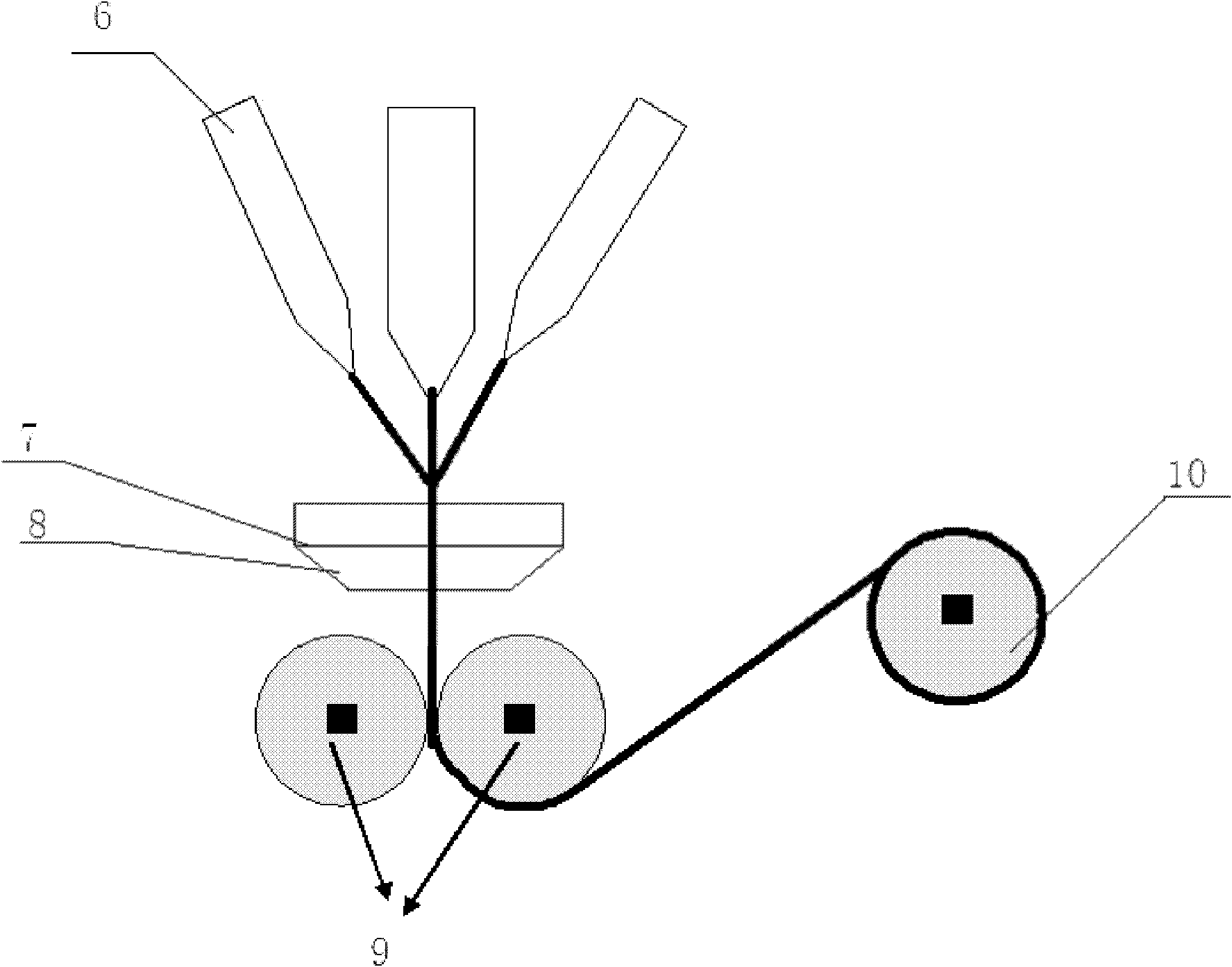

Preparation method of wet process mixed natural rubber material

ActiveCN102153792AGood dispersionImprove uniformityRolling resistance optimizationRubber materialPolymer science

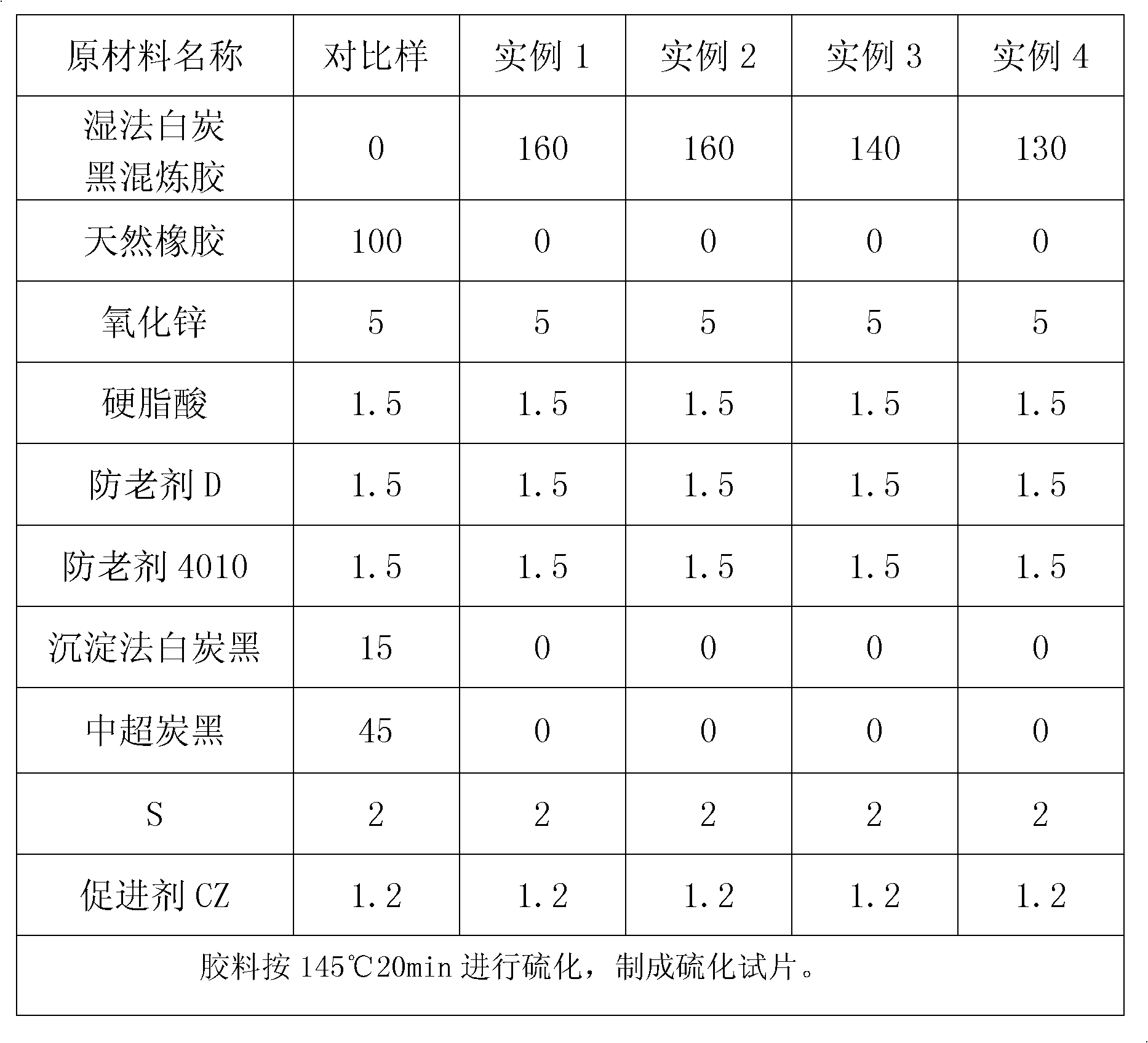

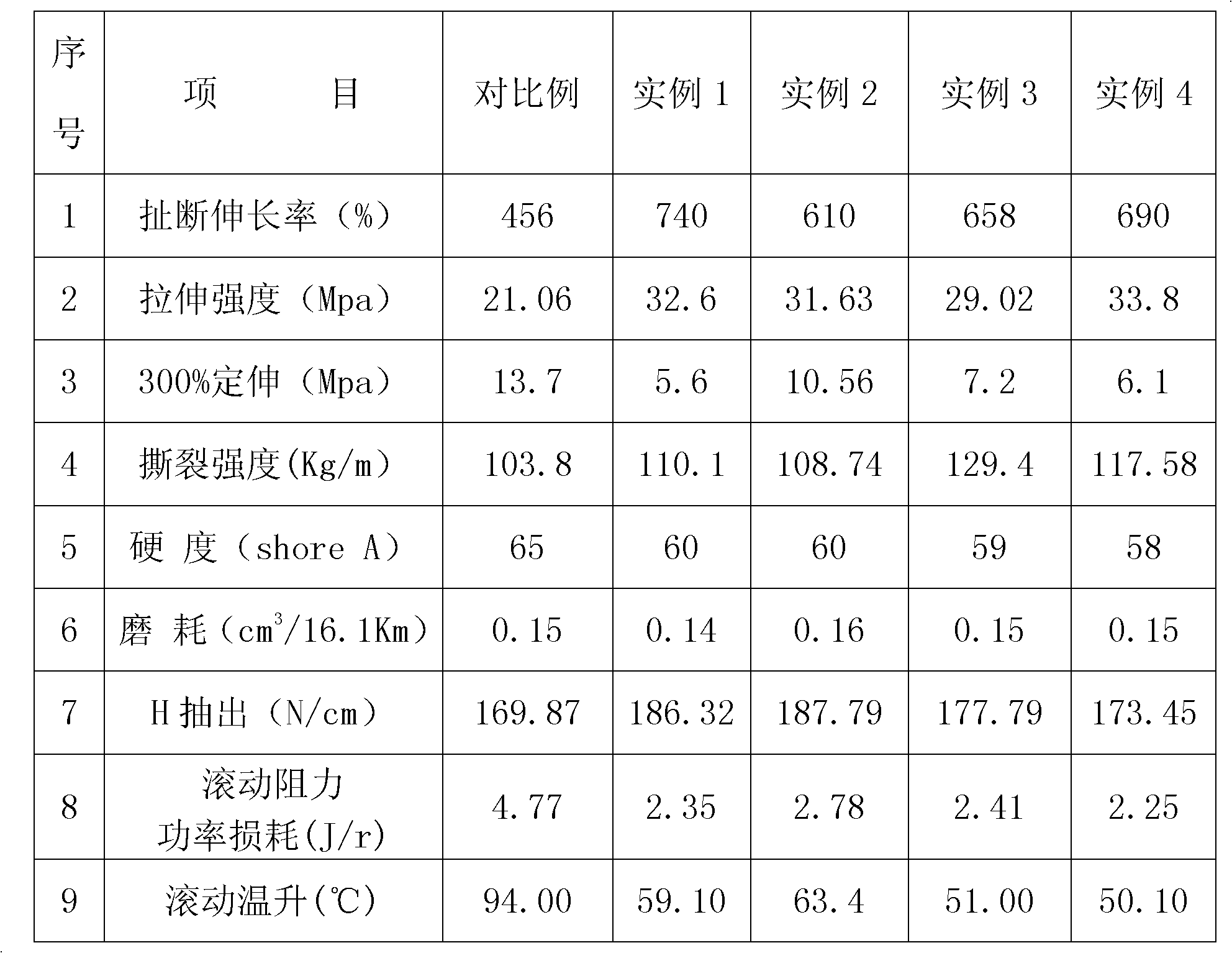

The invention relates to a preparation method of a wet process mixed natural rubber material. The method comprises the following steps of: preparing slurry and soaking 15-40 percent of dry white carbon black in 60-85 percent of deionized water; adding a coupling agent and a surfactant, uniformly mixing, grinding, preparing latex mixed liquor, extracting natural latex and adding white carbon black water dispersoid into the latex; stirring and mixing to obtain a latex mixed liquor, flocculating and adding acetic acid into the mixed liquor; performing rubber washing and dehydration by using a rubber washing machine and feeding to a rubber pelletizer for pelletizing; and feeding rubber particles into a box drying cabinet for drying. The preparation method has the advantages of simple machining process, small equipment investment, realization of various ideal performances with the most ordinary white carbon black, low dust pollution in the entire production process and energy saving. A tire manufactured with the method has small rolling resistance, low heat generation, high tensile strength, high tearing strength and high rubber material ageing resistance. Mixing of the white carbon black is performed in a liquid phase, so that the dispersivity and uniformity are enhanced.

Owner:ZHUZHOU ANBAOLINFENG NEW MATERIALS

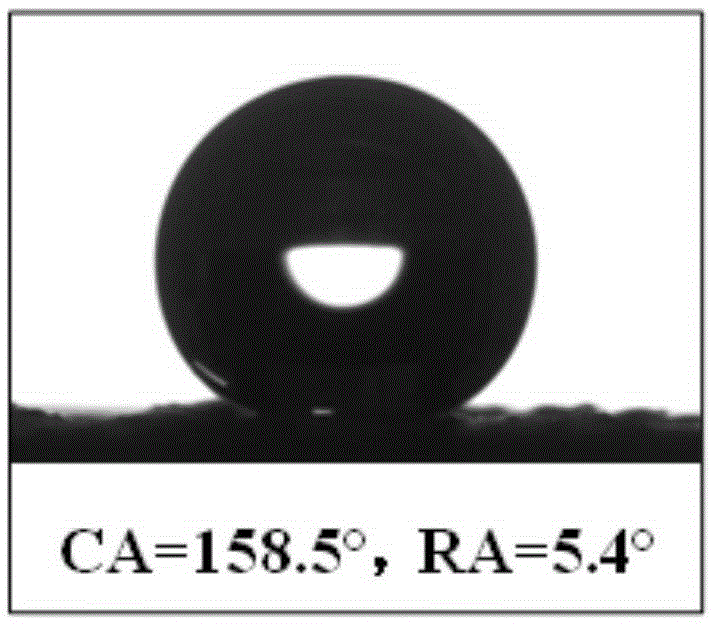

Highly-wear-resistant super-hydrophobic composite coating and preparation method thereof

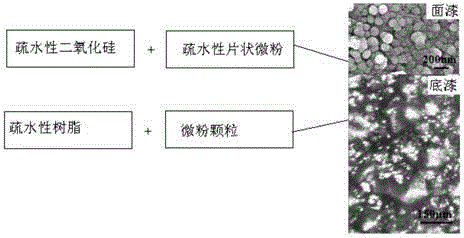

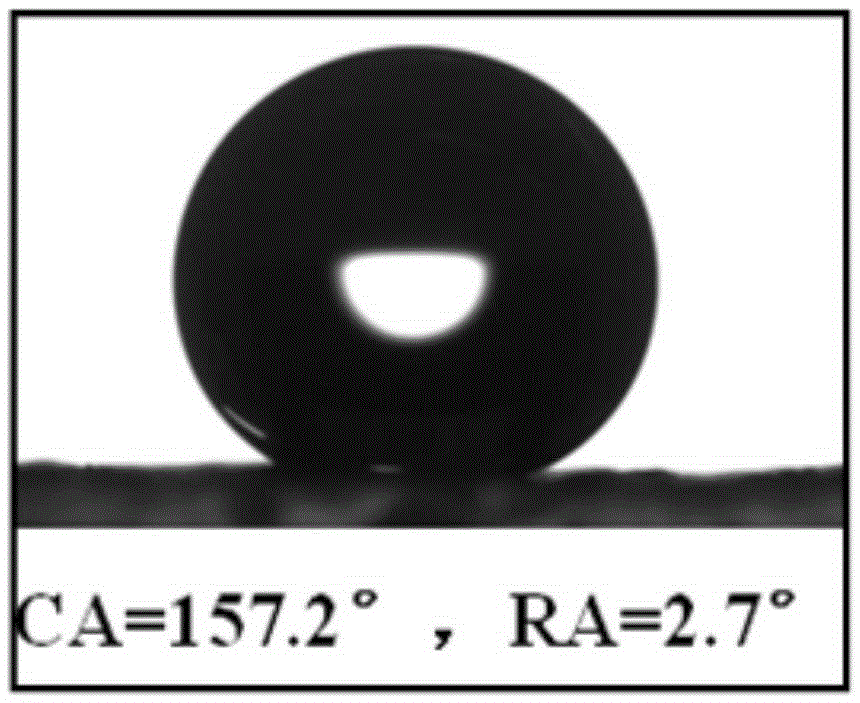

The invention discloses a highly-wear-resistant super-hydrophobic composite coating and a preparation method thereof. The preparation method includes the steps that the surface of a base is coated with hydrophobic resin primer containing compound micropowder through a brush coating or spray coating method, the surface of the resin primer is sprayed with hydrophobic organic / inorganic hybrid nano-paint after semi-curing, and the highly-wear-resistant super-hydrophobic composite coating is obtained after complete curing. The highly-wear-resistant super-hydrophobic composite coating and the preparation method thereof have the advantages that equipment and the process are simple, operation is easy and cost is low, and have the industrial mass production prospect. The prepared super-hydrophobic composite coating can be applied to various hard / soft bases such as glass, copper, aluminum, stainless steel, exterior wall tiles, wood, paper and cloth and can bear damage of external force such as sanding.

Owner:SOUTHEAST UNIV

High-abrasion resistant ultraviolet light solidifying fingerprint resistant coating

InactiveCN101701129AGood hardness and wear resistanceMeet wear resistancePolyurea/polyurethane coatingsSolventFingerprint

The invention relates to a light solidifying high-abrasion resistant fingerprint resistant coating which is used for the surfaces of plastic shells of portable electronic products, such as mobile phones, MP3, digital cameras, handheld computers, and the like and comprises the following components: 10-35 percent of high-functionality urethane acrylate, 5-25 percent of bifunctional urethane acrylate, 0.01-20 percent of acrylic ester monomer, 5-20 percent of high-functionality acrylic ester, 5-40 percent of fluorin-contained acrylic ester, 0.01-10 percent of nano inorganic powder filler, 1-5 percent of light initiating agent, 0.01-5 percent of auxiliary agent and 5-30 percent of solvent. The invention improves the fingerprint resistant capability of a coating film by the enrichment and microphase separation of a fluorin-contained group added into the coating on the surface of a coating surface, provides excellent abrasion resistance and hardness by using the polyurethane structure in the coating and the added nano abrasion resistant filler and meets the requirements of abrasion resistance, scratch resistance and fingerprint resistance of the portable electronic products.

Owner:武汉嘉特利佰联创科技有限公司

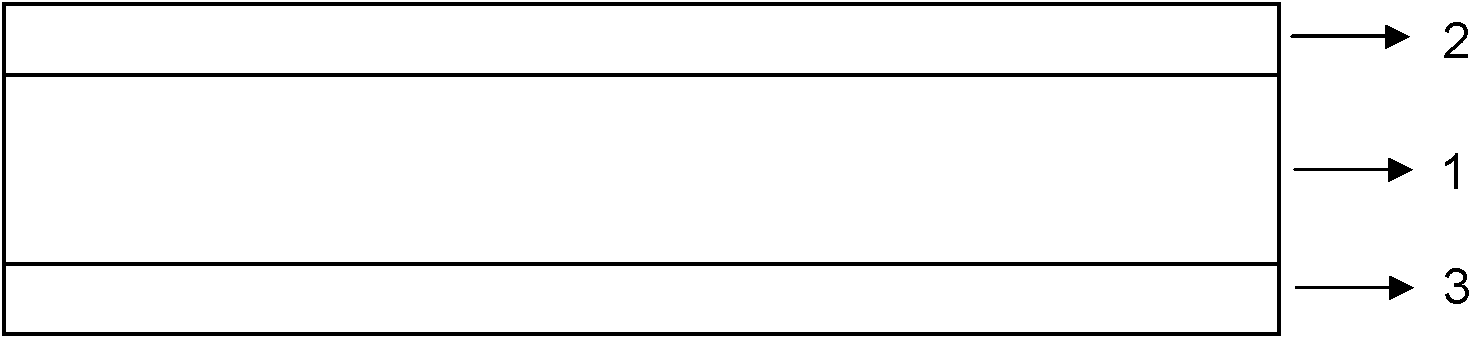

Solar cell assembly backplane and preparation method thereof

ActiveCN102738275AReduce usageExcellent formabilityFinal product manufactureSynthetic resin layered productsSolar technologyElectrical battery

The invention provides a solar cell assembly backplane, belonging to the technical field of solar energy. The solar cell assembly backplane comprises a base film layer as well as a second film layer and a third film layer arranged at two sides of the base film layer. The solar cell assembly backplane is characterized in that: the base film layer as well as the second film layer and the third film layer arranged at two sides of the base film layer are directly composited into one film through a melting co-extrusion process. At the same time, the invention also provides a preparation method of the solar cell assembly backplane. According to the invention, the use of an adhesive is avoided; and the preparation process of the solar cell assembly backplane can be completed by a single step with simple and efficient techniques; and the solar cell assembly backplane is advantaged in improved processing-shaping performance, mechanical properties, barrier properties and aging resistance performance.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

Production method for liner gloves aqueous polyurethane coating connection material

InactiveCN101328383ABreathableGood moisture permeabilityPolyurea/polyurethane coatingsWater basedPropanoic acid

The invention discloses a production method for insert gloves water-based polyurethane coating bonding materials. The method comprises the following steps of: under the protection of dry nitrogen, adding polyether glycols (including polyether diatomic alcohol and / or polyether triatomic alcohol) having undergone vacuum dewatering and isocyanate into a reaction vessel; heating the mixture up to between 80 and 100 DEG C for reaction after even mixing; then adding a hydrophilic chain extender such as dihydromethyl propionic acid (DMPA) and a catalyst for reaction at a temperature of between 80 and 100 DEG C; finally adding the chain extender and a solvent into the mixture for reaction at a temperature of between 55 and 65 DEG C until the NCO content of the isocyanate group does not change; discharging the reactant after temperature reduction to obtain an ionomer; neutralizing a preformed polymer with triethylamine or diethanolamine or triethanolamine and then adding water the mixed solution for emulsification to obtain water-based polyurethane latex; and carrying out reduced pressure distillation to remove the solvent and obtain the product. The synthesized water-based polyurethane resin which serves as a gloves coating has the advantages of good air and moisture permeability, excellent mechanical performance, solvent resistance, ageing resistance, resistance to corrosion caused by chemical mediators, oil resistance, resistance to hooking, cutting and piercing, excellent abrasion resistance, odorlessness, innocuous and nondestructive for contacting with skin, etc.

Owner:ANHUI UNIVERSITY +1

Light diffusion master batch for transparent plastics and preparation method thereof

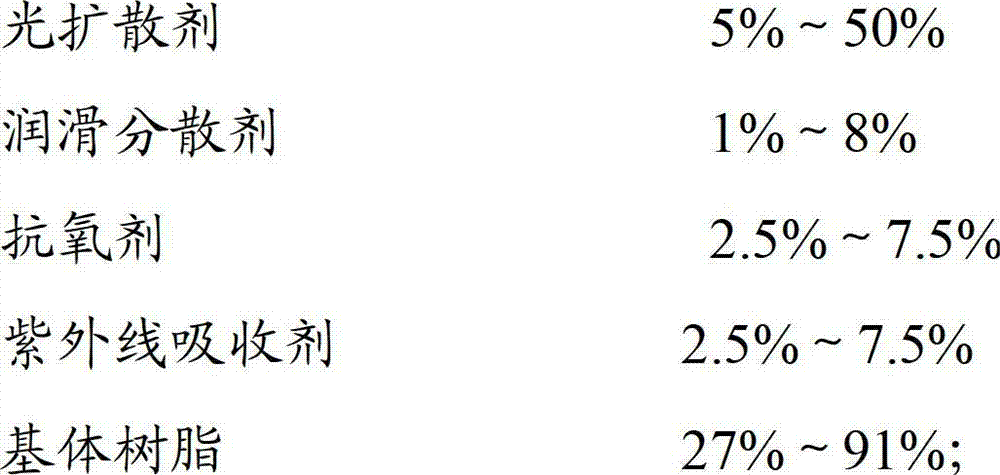

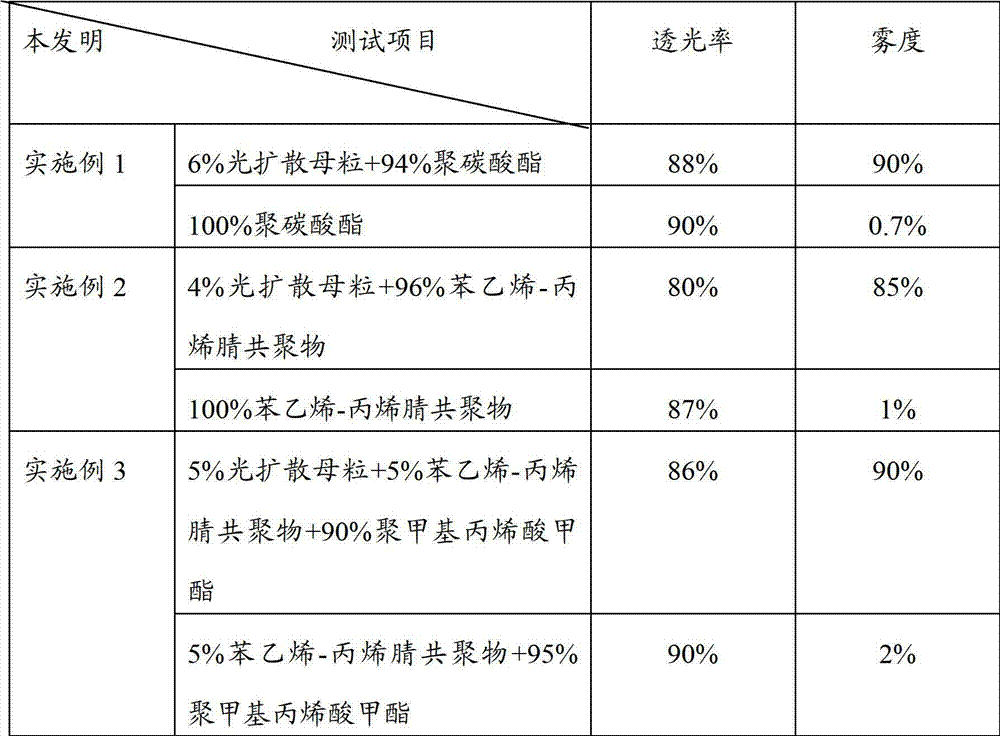

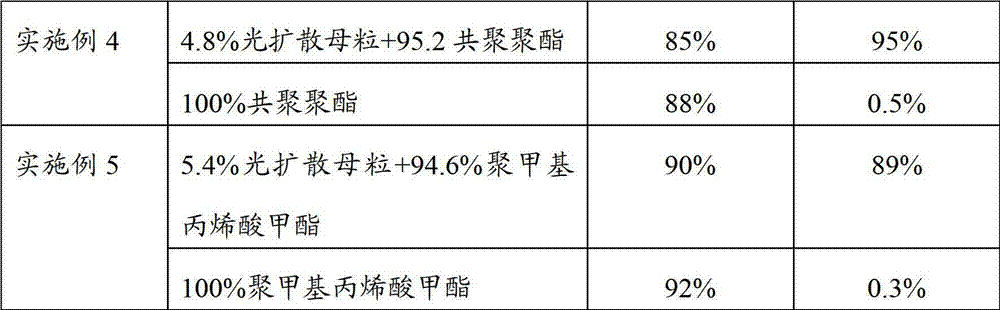

ActiveCN103073867ASolve the problem of fragmentationAvoid the disadvantages of physical property degradationHigh concentrationAging resistance

The invention relates to the technical field of functional master batches, in particular to a light diffusion master batch for transparent plastics and a preparation method thereof. The light diffusion master batch comprises the following components in percentage by weight: 5-50% of light diffusant, 1-8% of lubrication dispersant, 2.5-7.5% of antioxidant, 2.5-7.5% of ultraviolet light absorber and 27-91% of matrix resin; after being mixed, the components are placed in an extruder for being molten and extruded; and the extruded materials are cooled, pelletized and dried to prepare the product of light diffusion master batch. The light diffusion master batch has stable properties, high transparency and high haze; and as the master batch contains a light stabilizing agent and a heat stabilizing agent with high concentrations, plastic products produced thereby have excellent ageing resistance, and are suitable for long-time use in locations of natural illumination or manual illumination.

Owner:东莞市普凯塑料科技有限公司

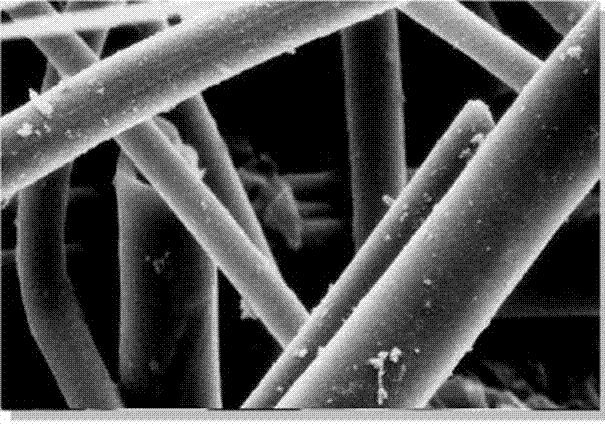

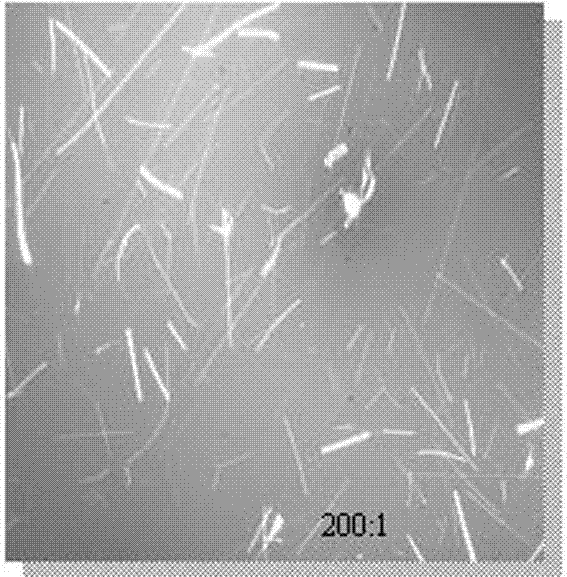

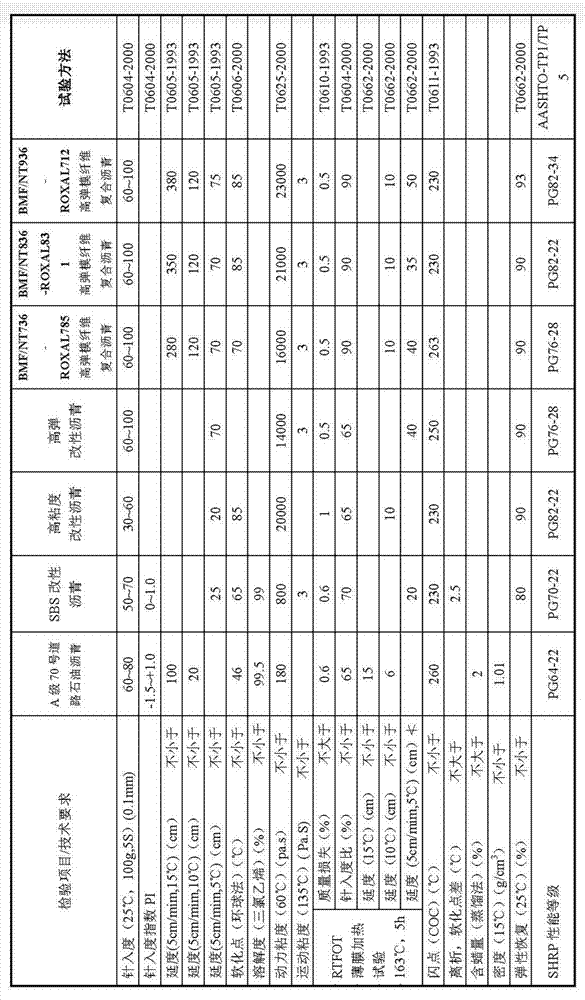

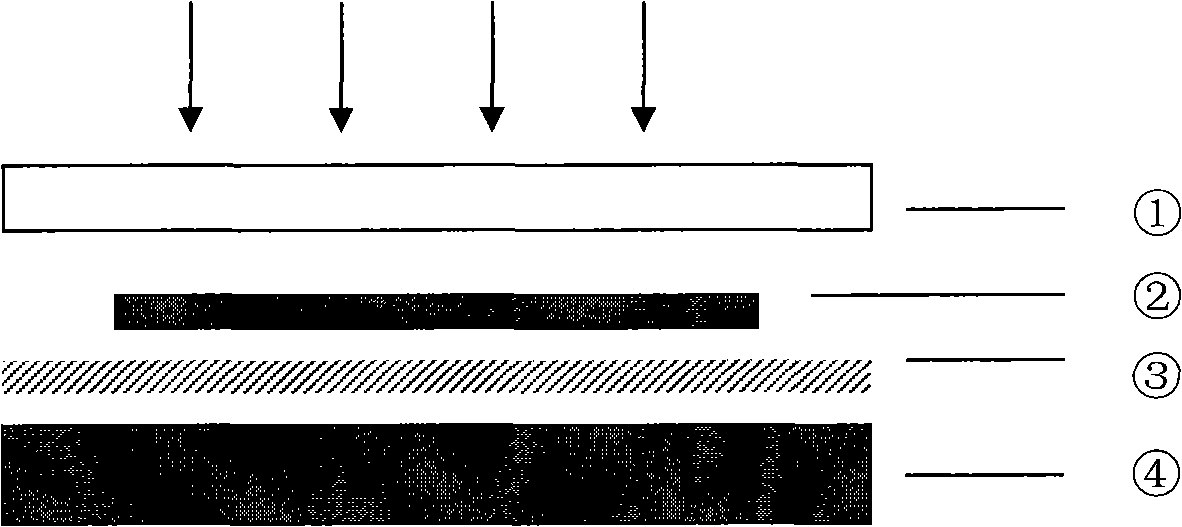

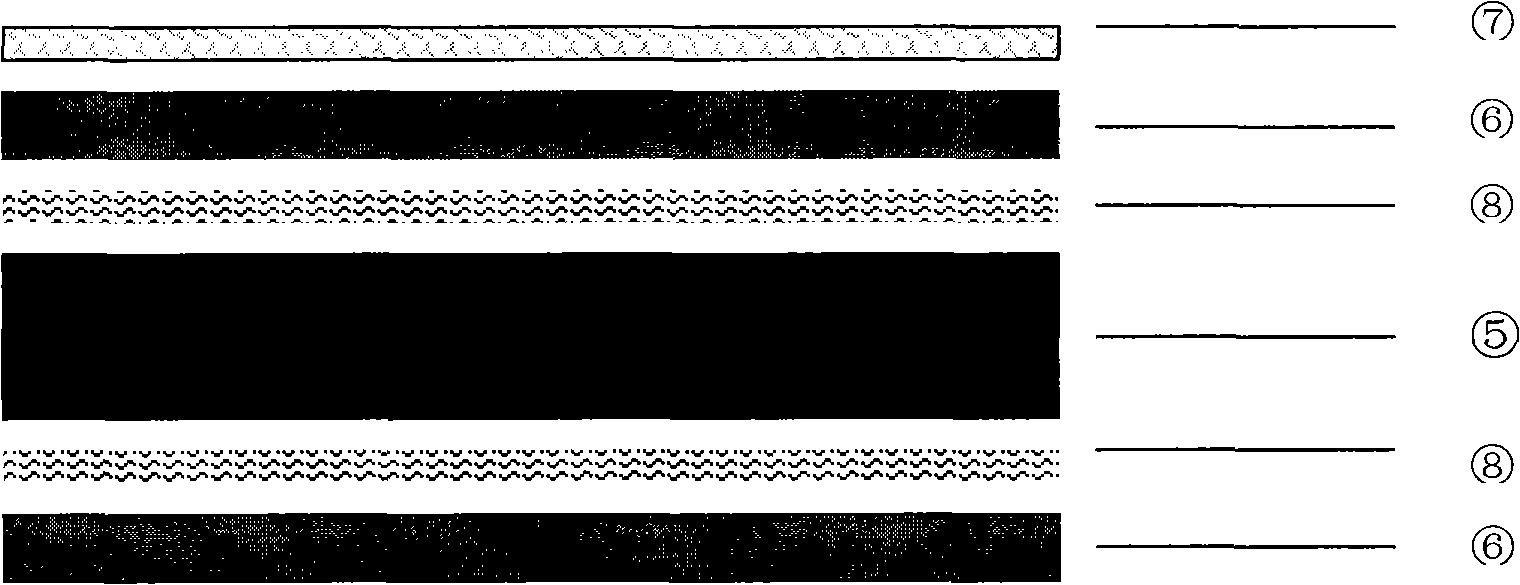

Composite material containing modified basalt fiber and polymer and preparation method thereof

The invention provides composite material containing a modified basalt and a polymer and a preparation method thereof, wherein the main components of the composite material contains: 1200-1300 parts of polymer, 700-800 parts of modified basalt fiber, and 5-50 parts of surfactant coupling agent. The method, by means of the mechanical force, supersonic wave and electromagnetic force synthetic effect of the surfactant or coupling agent, comprises: uniformly dispersing the polymer and the modified basalt fiber into a solvent to prepare a uniform and stabile mixture, adding another solvent into the mixture, implementing the cladding or wrapping to the modified basalt fiber while precipitating the polymer from the mixture, and then forming the composite material of the modified basalt fiber containing polymer. The composite material can be used for preparing asphalt with excellent performances, the method has the advantages of low cost, simple operation and easy enlargement, and the method makes it easy for the modified basalt fiber to be uniformly dispersed in the polymer.

Owner:长沙北美孚新材料科技有限公司

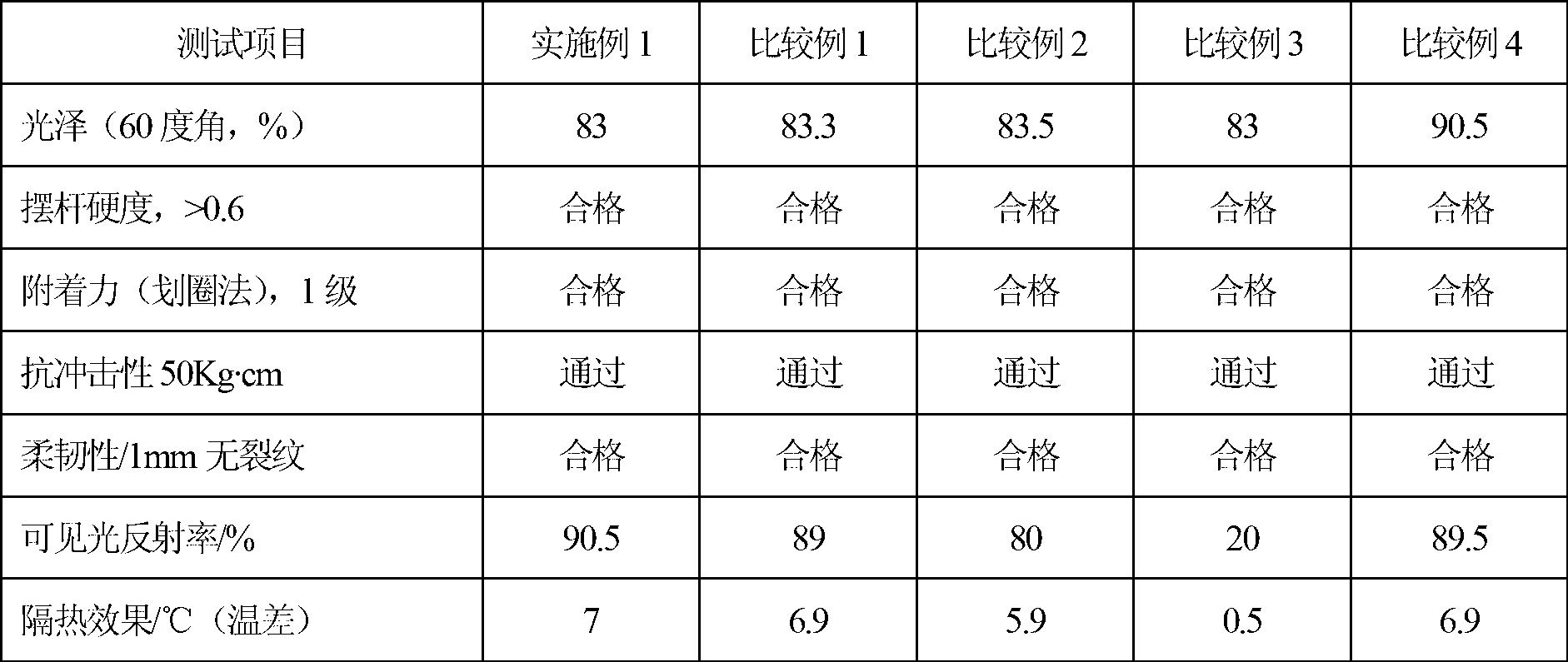

Heat-insulating energy-saving paint for vehicle and method for producing the same

InactiveCN101195725AIncrease reflectionInsulate heat radiationFireproof paintsPolyester coatingsRadiant heatAbsorption rate

The invention relates to heat insulating and energy saving coating used for the vehicle, and the preparation method thereof. The invention takes organic resin film forming material as the main material, the coating at least includes infrared reflection pigment, hollow ceramic micro-spheres and silicon dioxide aerogel, an organic resin film having low sunlight absorption rate is formed in the coating through the organic resin film forming material with high transparency, the visible light and the near infrared ray in the sunlight are reflected through the infrared reflection pigment, the rutile type titanium dioxide and the hollow ceramic micro-spheres, and simultaneously a compact vacuum layer and an inert gas layer are formed on the surface of a coated object through the hollow ceramic micro-spheres and the silicon dioxide aerogel, so as to effectively isolate the radiant heat of the sun, and to reduce the heat conduction of air, and finally the heat insulating and energy saving coating used for the vehicle is formed, which not only can effectively reflect the energy in the sunlight, but also can effectively isolate the radiant heat of the sun and reduce the heat conduction of air, and simultaneously has good weather resistant performance, chemicals resistant performance, mechanical property and decorative property.

Owner:ZHUZHOU FEILU ADVANCED MATERIAL TECH CO LTD

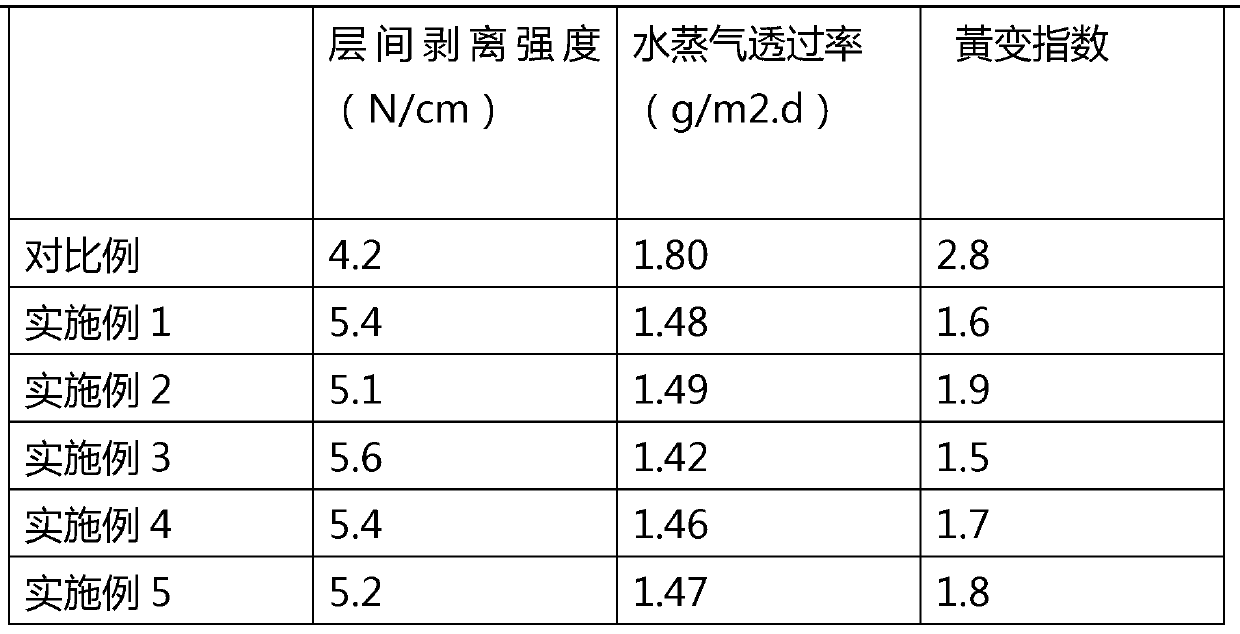

Back film of solar cell and preparing technique thereof

InactiveCN101290950AAvoid Bubble ProblemsAvoid stickingSynthetic resin layered productsPretreated surfacesWeather resistanceMass ratio

The invention discloses a solar panel back film and a technique for manufacturing the same. The back film comprises a PET film substrate with thickness of between 100 and 350 micrometers, wherein, fluoropolymer coatings with thickness of between 15 and 30 micrometers are coated on both sides of the substrate; an adhesive layer with thickness of between 0.5 and 5 micrometers is coated on the fluoropolymer coating on one side; the fluoropolymer coatings are obtained by direct coating of mixed latex which is obtained through mixture of various raw material compositions according to the mixture ratio and subsequent grinding treatment on the PET film substrate; the compositions by mass ratio of the raw materials of the fluoropolymer coatings are 30 to 55 percent of fluoride coating materials, 20 to 40 percent of solvent, 2 to 6 percent of cross-linking agent and curing agent and 15 to 40 percent of filling. The technique greatly improves the bonding strength between a back film layer and a layer, improves the ageing resistance, the weathering resistance of products, simultaneously improves the insulativity and the vapor permeability resistance due to the design of a multilayered structure and also can design and modify the performance and the appearance of the products as required.

Owner:ZHEJIANG VENTURA PHOTOVOLTAIC MATERIALS +2

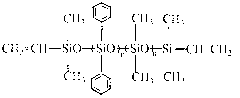

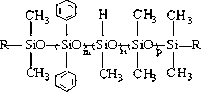

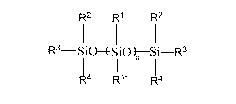

Silicon rubber with high refractive index and high transparency for optical encapsulation and preparation method thereof

ActiveCN103122149AHigh refractive indexImprove mechanical propertiesSemiconductor devicesHydrogenPolymer science

The invention relates to silicon rubber with high refractive index and high transparency for optical encapsulation and a preparation method thereof. The silicon rubber is prepared from a phenyl vinyl polysiloxane component A, a silicon resin component B containing phenyl vinyl, a phenyl component C containing hydrogen polyoxyalkylene, a platinum catalyst component D, a catalytic inhibitor component E, a modified polysiloxane component F, and a water remover component G in a mixing manner. The silicon rubber not only has over 1.50 of refractive index, but also is good in transparency, excellent in adhesion, and stable in performance, can resist heat and ultraviolet radiation for a long period of time, can meet various requirements of LED (light-emitting diode) encapsulation, and is an ideal encapsulation material of the LED. The silicon rubber can be packaged into a bi-component product; the product has good storage stability; and high transparency is still kept after the product is stored for over 6 months.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

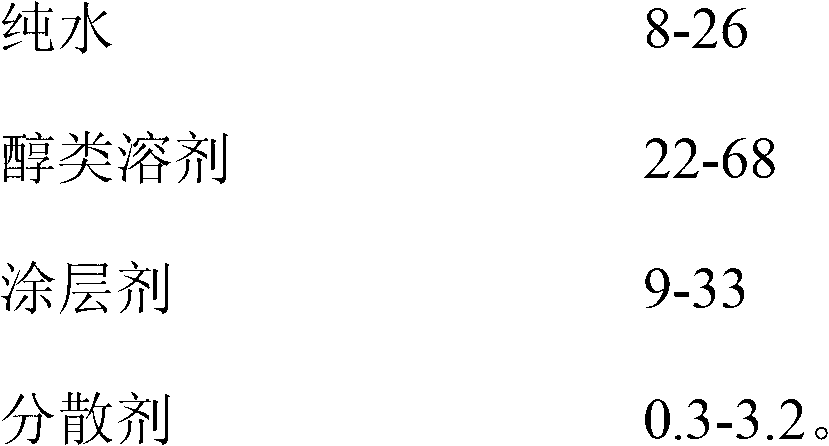

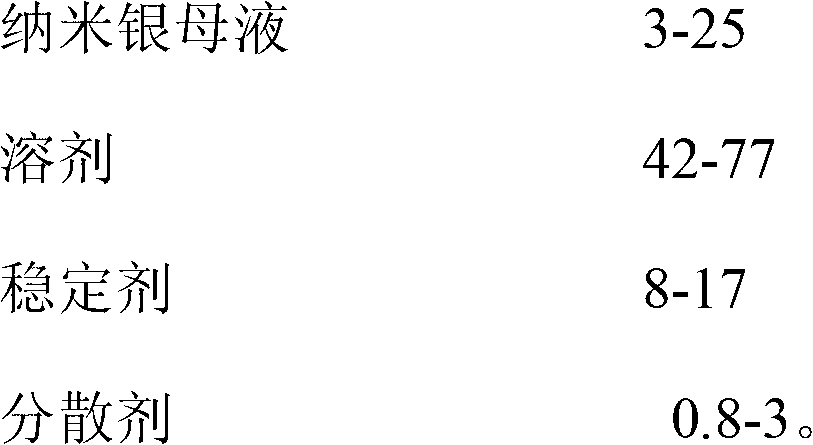

Anti-bacterial water-based paint and preparation method thereof

InactiveCN102702889AImprove aging resistanceImprove the pulverization performanceBiocideAntifouling/underwater paintsWater basedEscherichia coli

The invention relates to anti-bacterial water-based paint and a preparation method thereof. The paint comprises the following components in parts by weight: 0.2-11 parts of anti-bacterial agent, 8-33 parts of nano material, 23-64 parts of water-based resin dispersoid and 0.75-18 parts of adhesive resin or plasticizer. The preparation method comprises the following steps: firstly preparing a nano silver anti-bacterial agent; mixing deionized water, the anti-bacterial agent, a wetting agent, a dispersing agent and a defoaming agent and uniformly mixing, adding the nano material, uniformly dispersing to obtain the water-based dispersoid; adding the obtained water-based dispersoid to the mixed emulsion or water-based resin dispersoid, then adding the adhesive resin or plasticizer and various conventional assistants, stirring and dispersing evenly; adding pigments or colorant; and supplementing water to obtain the anti-bacterial water-based paint. The long-acting broad-spectrum antibacterial water-based paint has high fungicidal efficiency (more than 99%) on escherichia coli, staphylococcus aureus, black varietas of bacillus subtilis and the like and can reduce the high concentrate of organic matters of formaldehyde to the range of specified concentration index.

Owner:ANHUI JINDUN PAINT

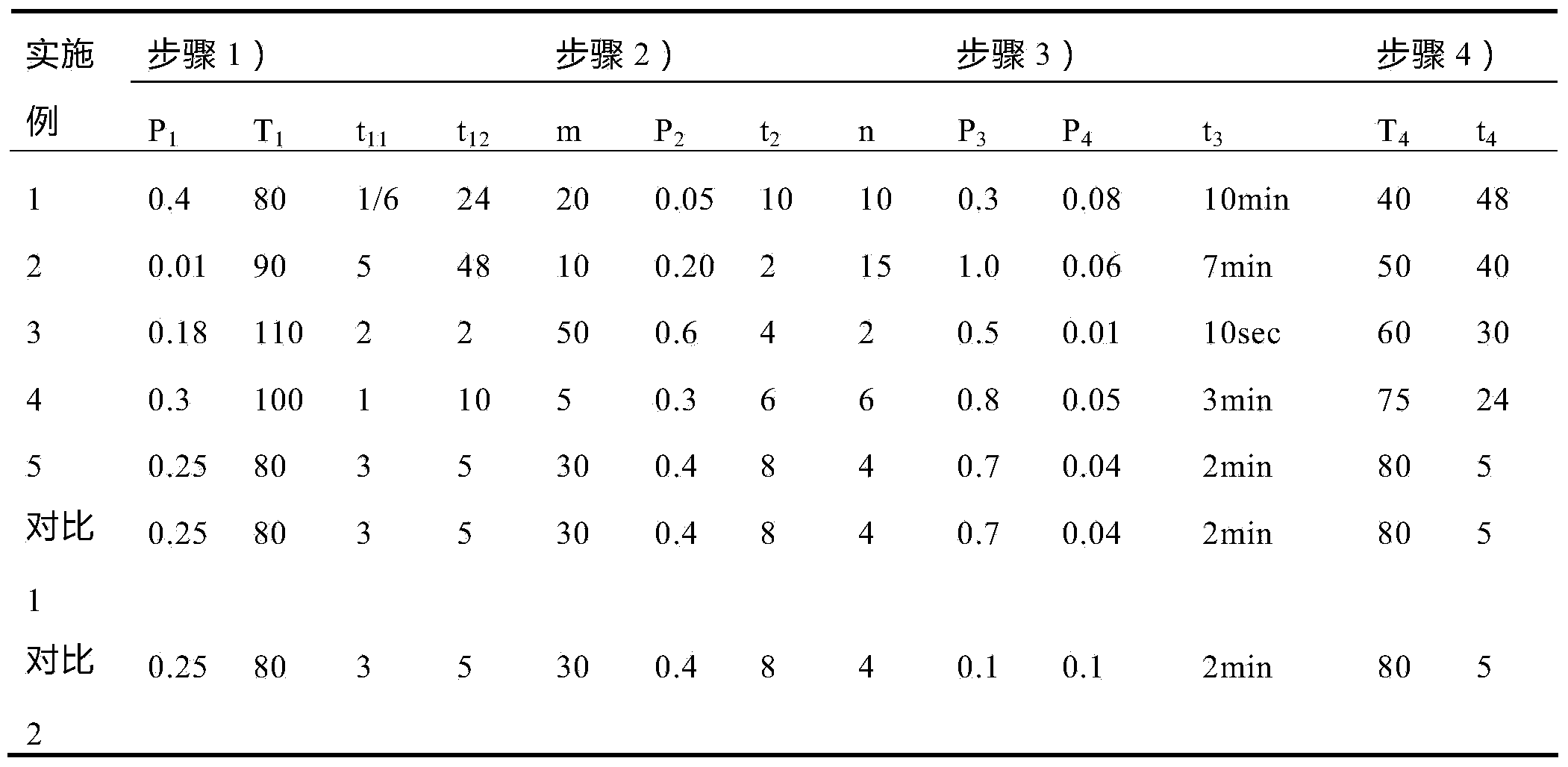

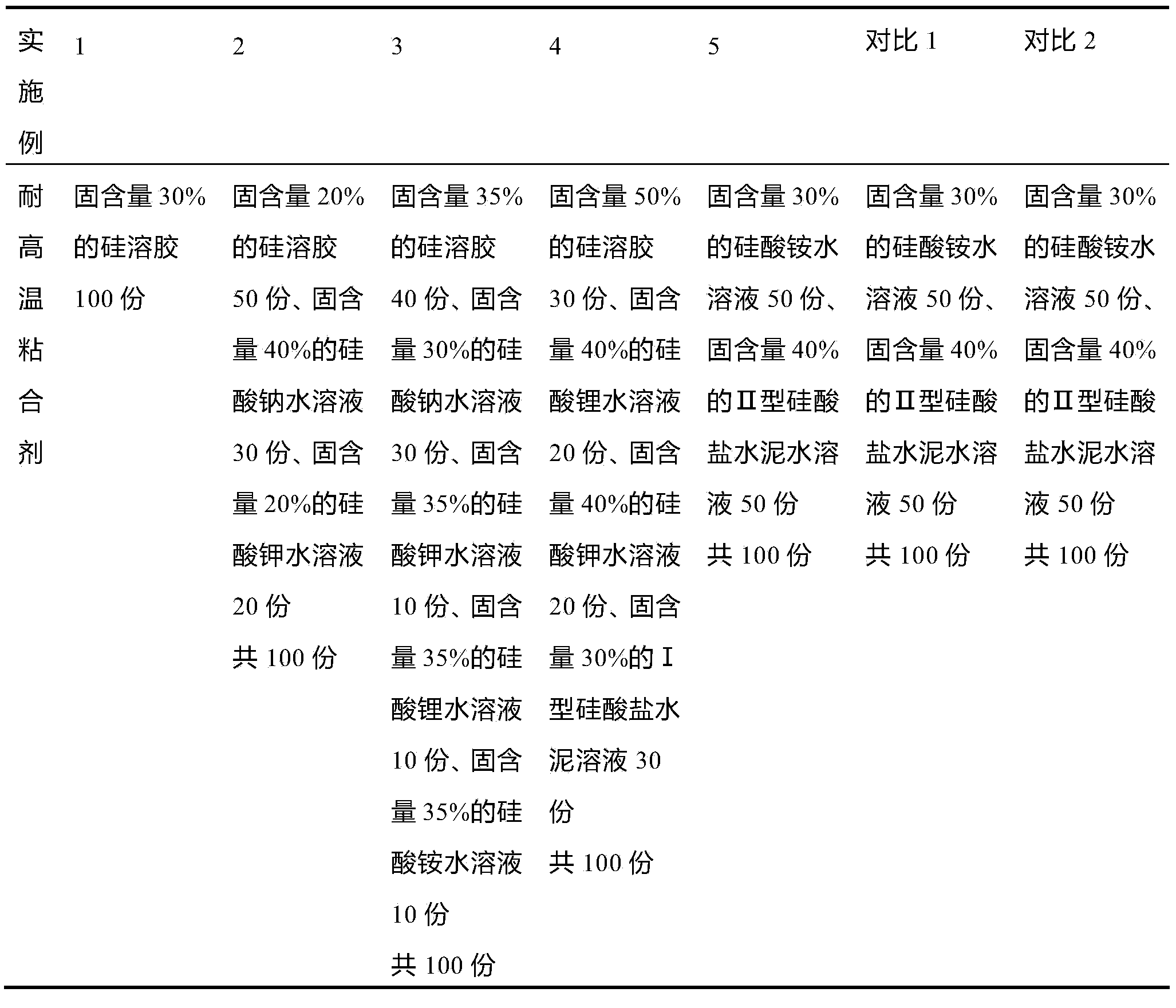

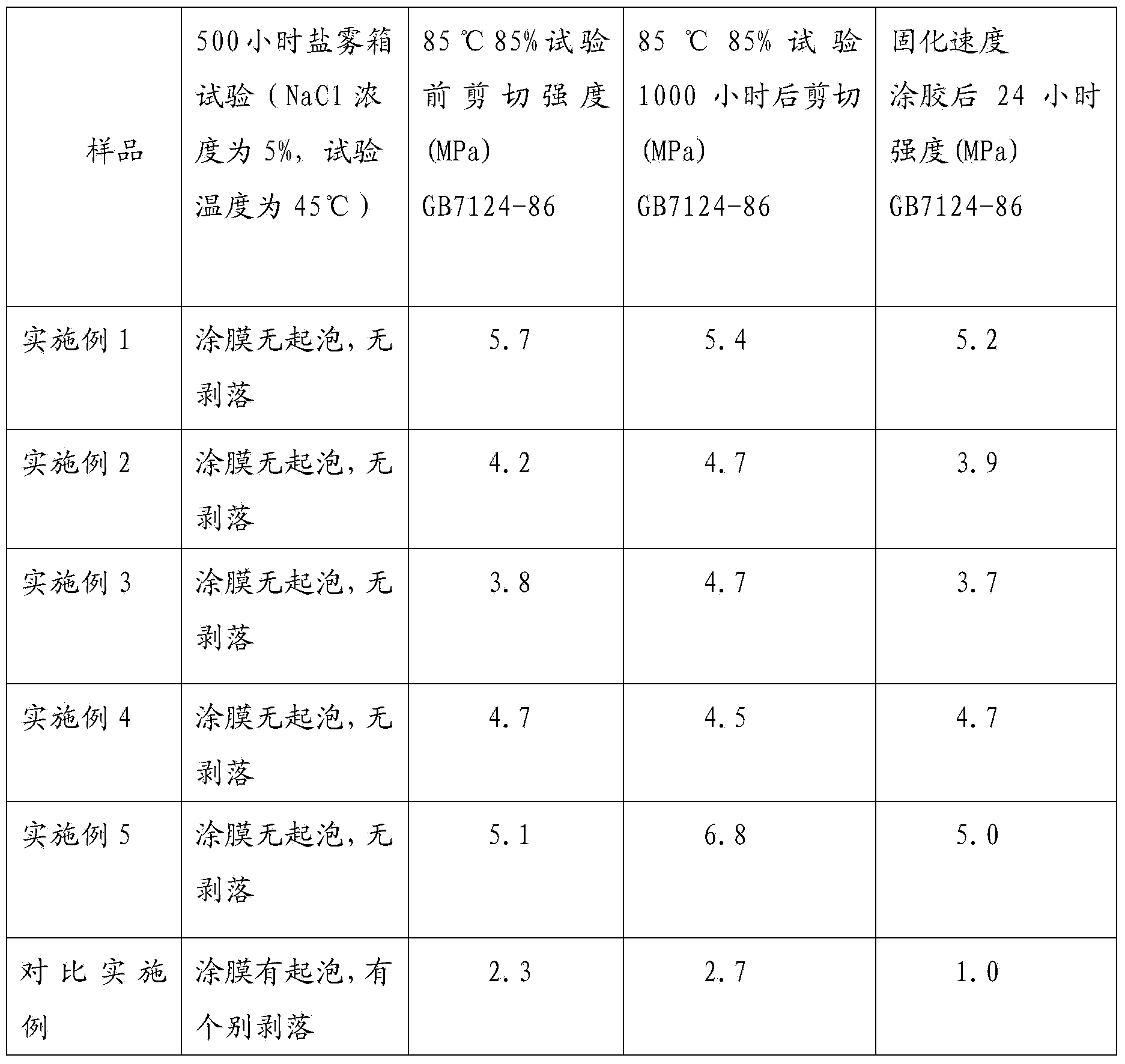

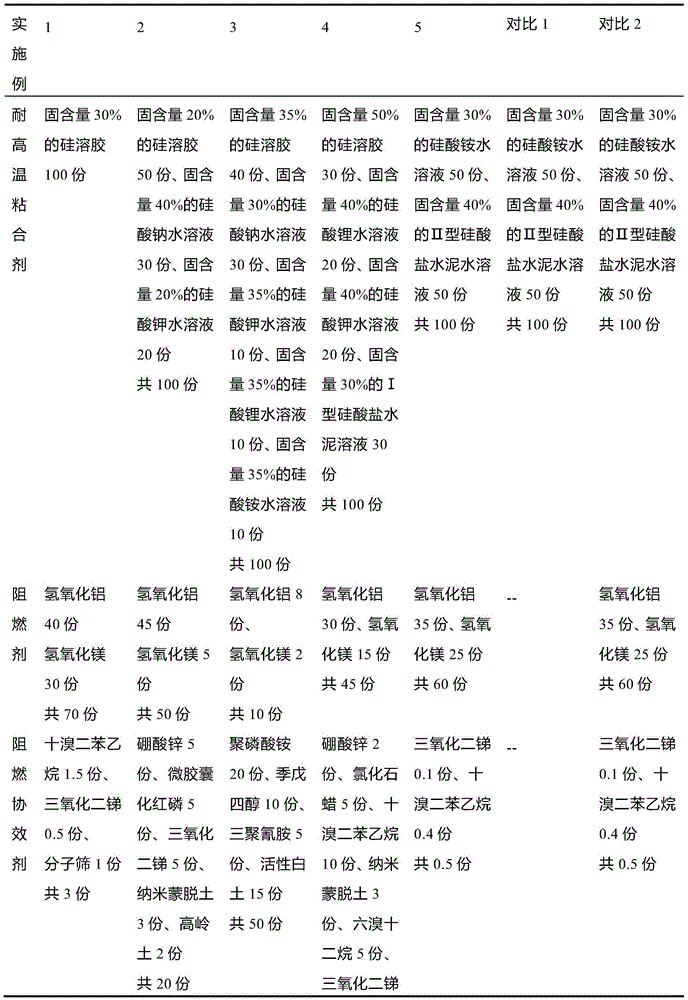

Fire-proof adhesive and application thereof

ActiveCN104099028AReduce total calorific valueImprove thermal conductivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesCombustionAdhesive

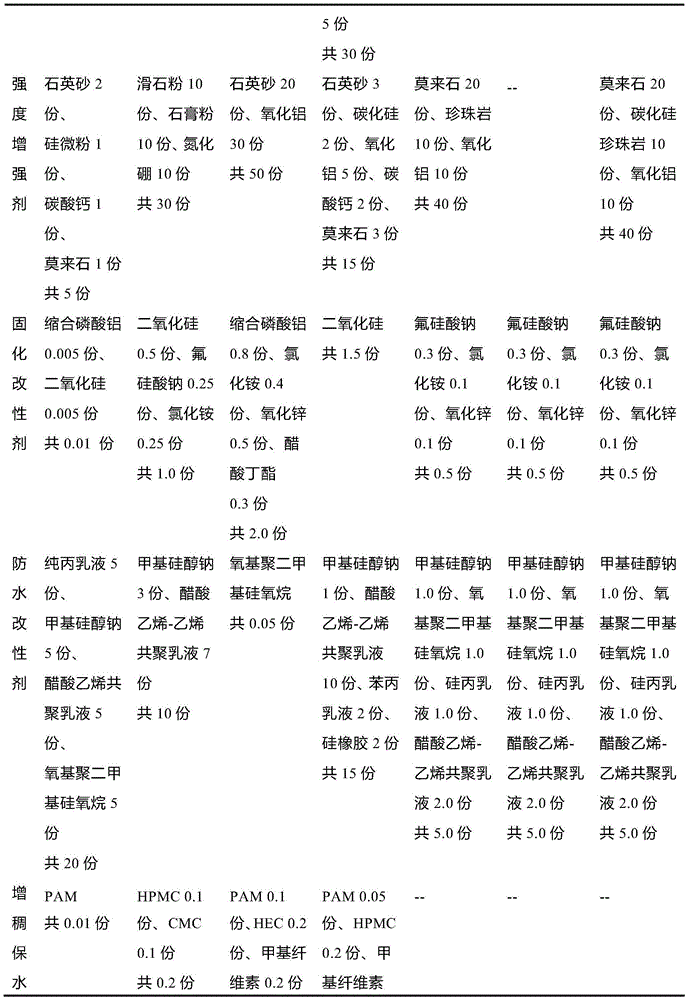

The invention discloses a fire-proof adhesive and application thereof. The fire-proof adhesive comprises the following components by parts: 100 parts of high-temperature bonding agent, 10-70 parts of fire retardant, 0.5-50 parts of flame retardant synergist, 5-50 parts of strength enhancer, 0.05-20.0 parts of water-proof modifying agent and 0.01-2.0 parts of curing modifying agent. By adopting the fire-proof adhesive and a preparation method of a fire-retardant EPS (Expandable Polystyrene) foam heat-insulating plate, the combustion performance and physicochemical performance of the fire-retardant EPS foam heat-insulating plate can be improved remarkably. For example, the heat-conducting coefficient can be lowered below 0.055w / m.k, the specific gravity can be lower than 150Kg / M<3>, the compressive strength is higher than 150KPa, and the heat value is less than 3MJ / kg.

Owner:应急管理部四川消防研究所

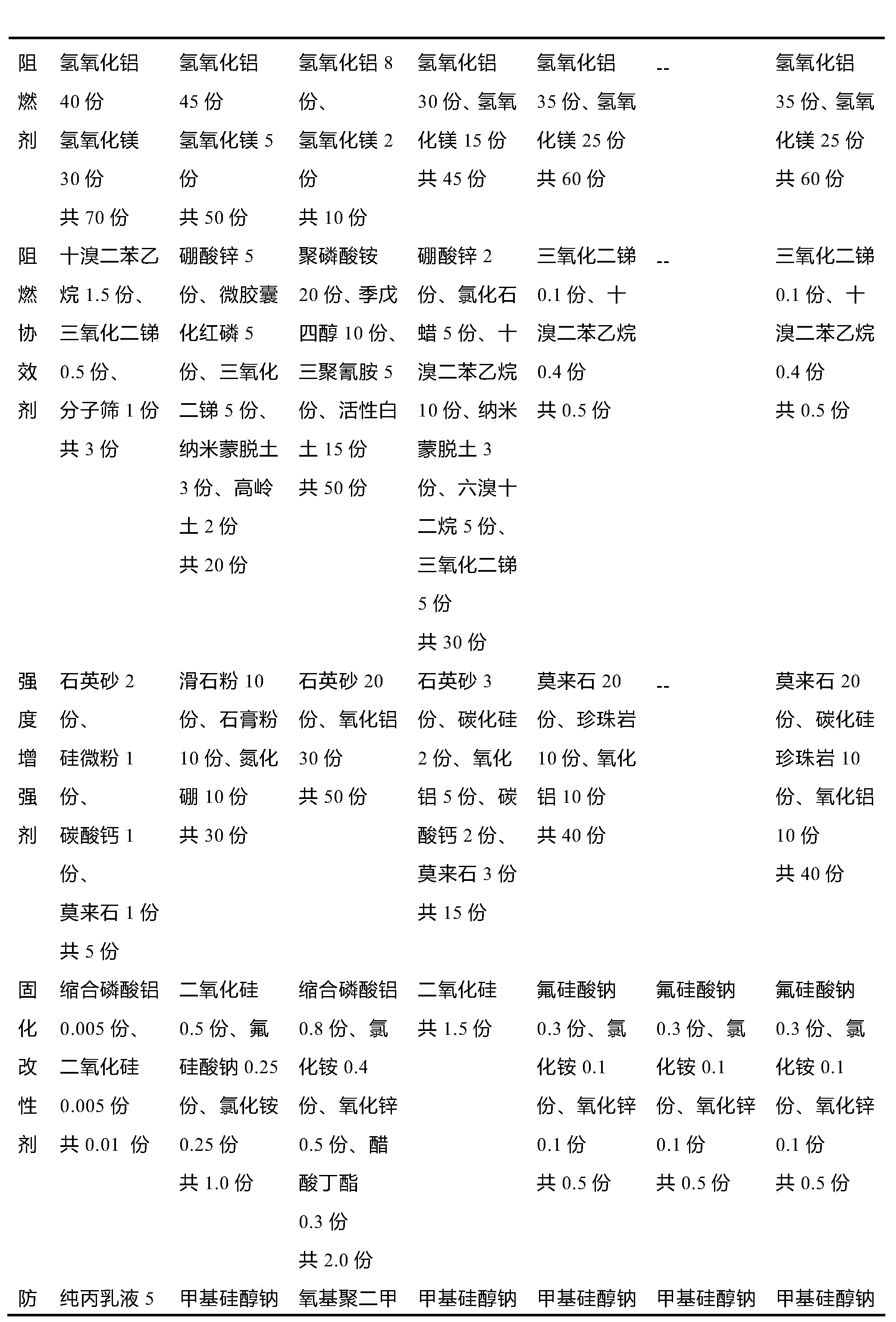

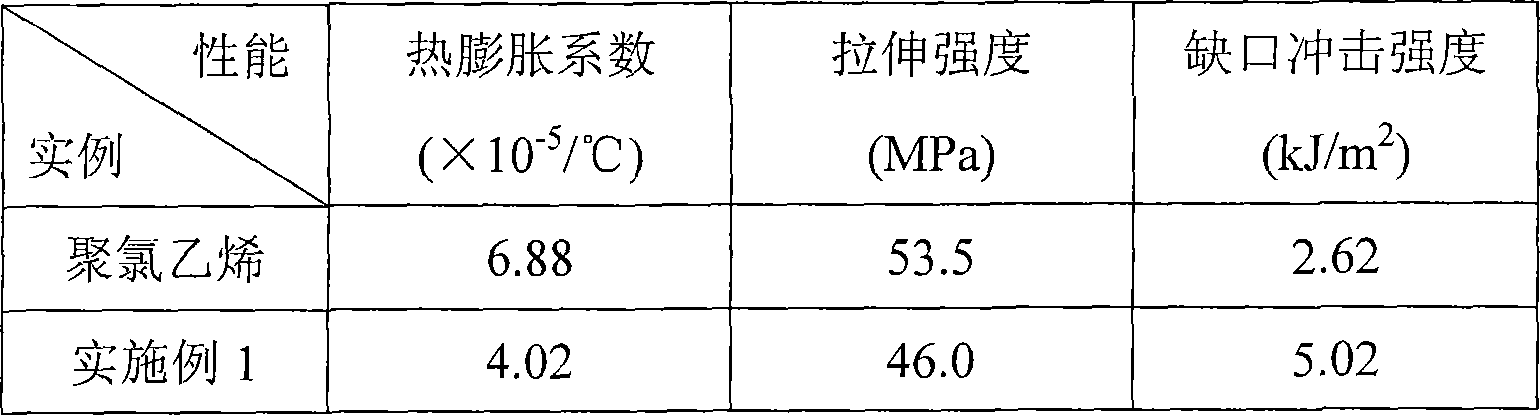

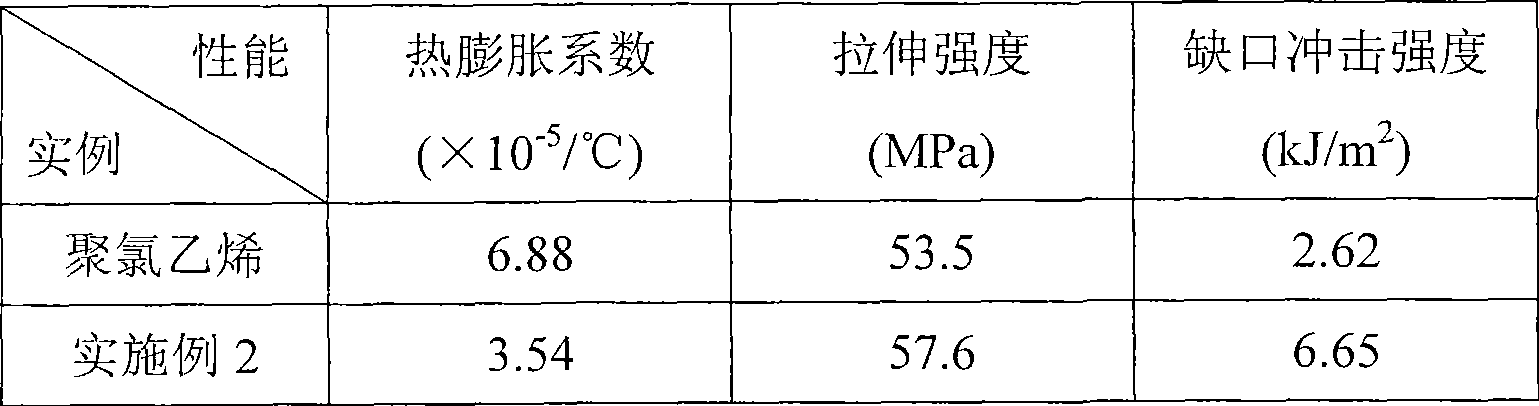

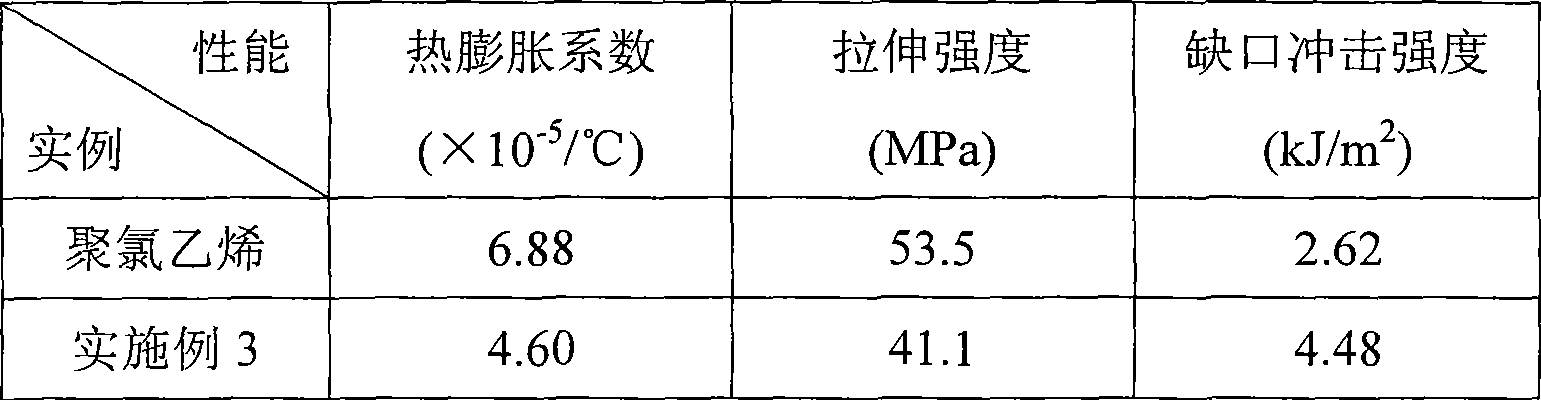

Low-expansion coefficient polyvinyl chloride alloy material and manufacturing method thereof

The invention provides a low-expansion coefficient polyvinyl chloride alloy material and a manufacturing method thereof. The ingredients of raw materials of the alloy material comprise a polyvinyl chloride substrate, a heat-resistant modifier, a heat stabilizer, a lubricator, a filler and a processing agent, and the alloy material is manufactured by a melt blending technique. The processing agent and the filler in the ingredients of the raw materials of the invention are the processing agent that is subjected to modification by a new method and the filler that is subjected to organic treatment, and by means of a mechanochemical reaction, self-plastification, toughening and reinforcement of the PVC can be combined organically to improve compatibility and dispersity of the polyvinyl chloride, the filler and heat-resistant resin, thus settling the problem about the contraction between the improvement of heat expansion performance and heat resistance of the PVC, and processing performance, strength and toughness of the PVC; the polyvinyl chloride engineering plastic with low expansion coefficient, high heat resistance, high strength, high toughness, excellent aging resistance and outstanding processing performance is manufactured; the invention has extensive industrial market prospect and the manufacturing method thereof is simple in technology, convenient in operation and control, stable in quality and high in production efficiency.

Owner:SICHUAN UNIV

Nitrogen-containing compound luminescent material, manufacturing method and illuminating device used thereof

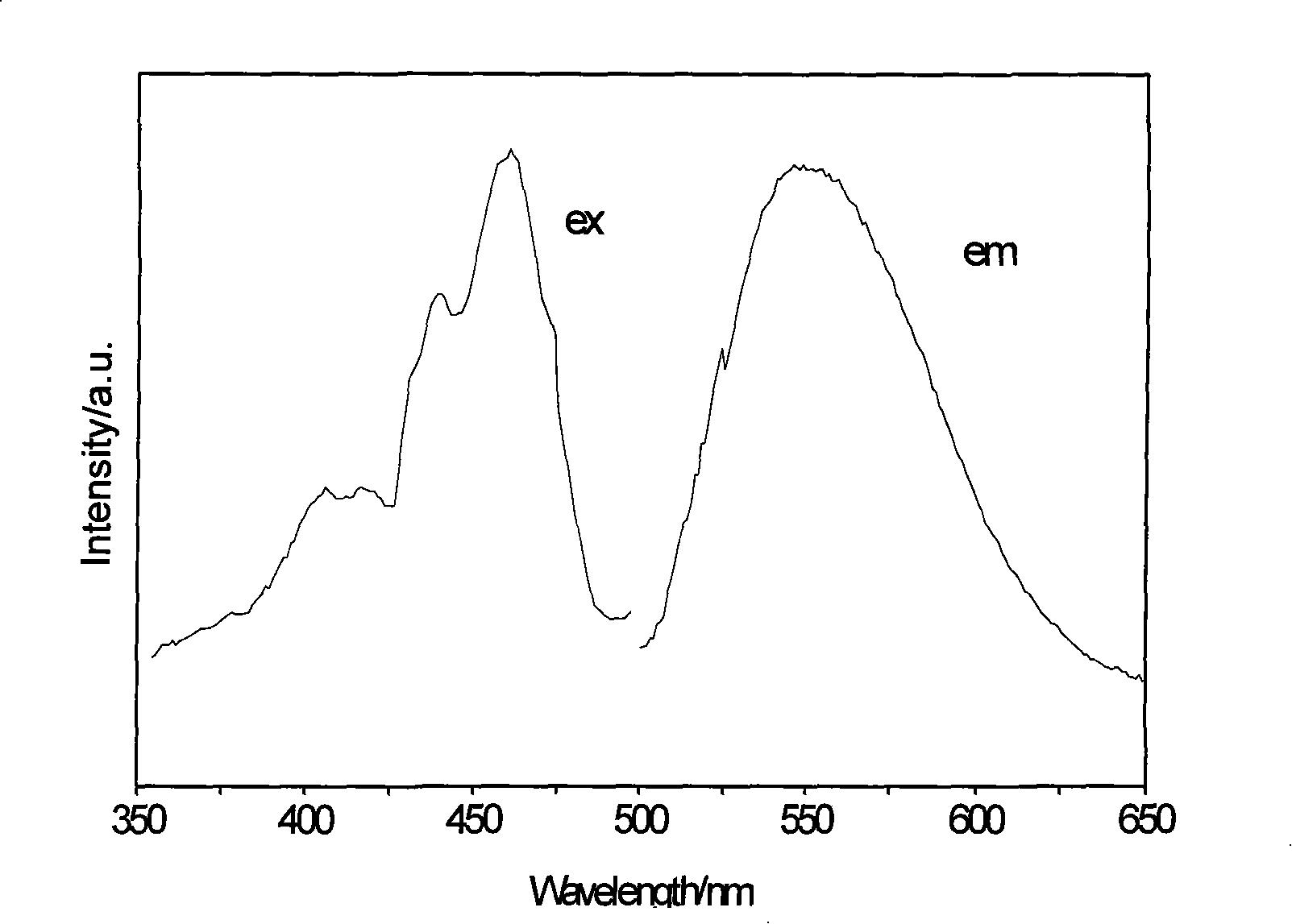

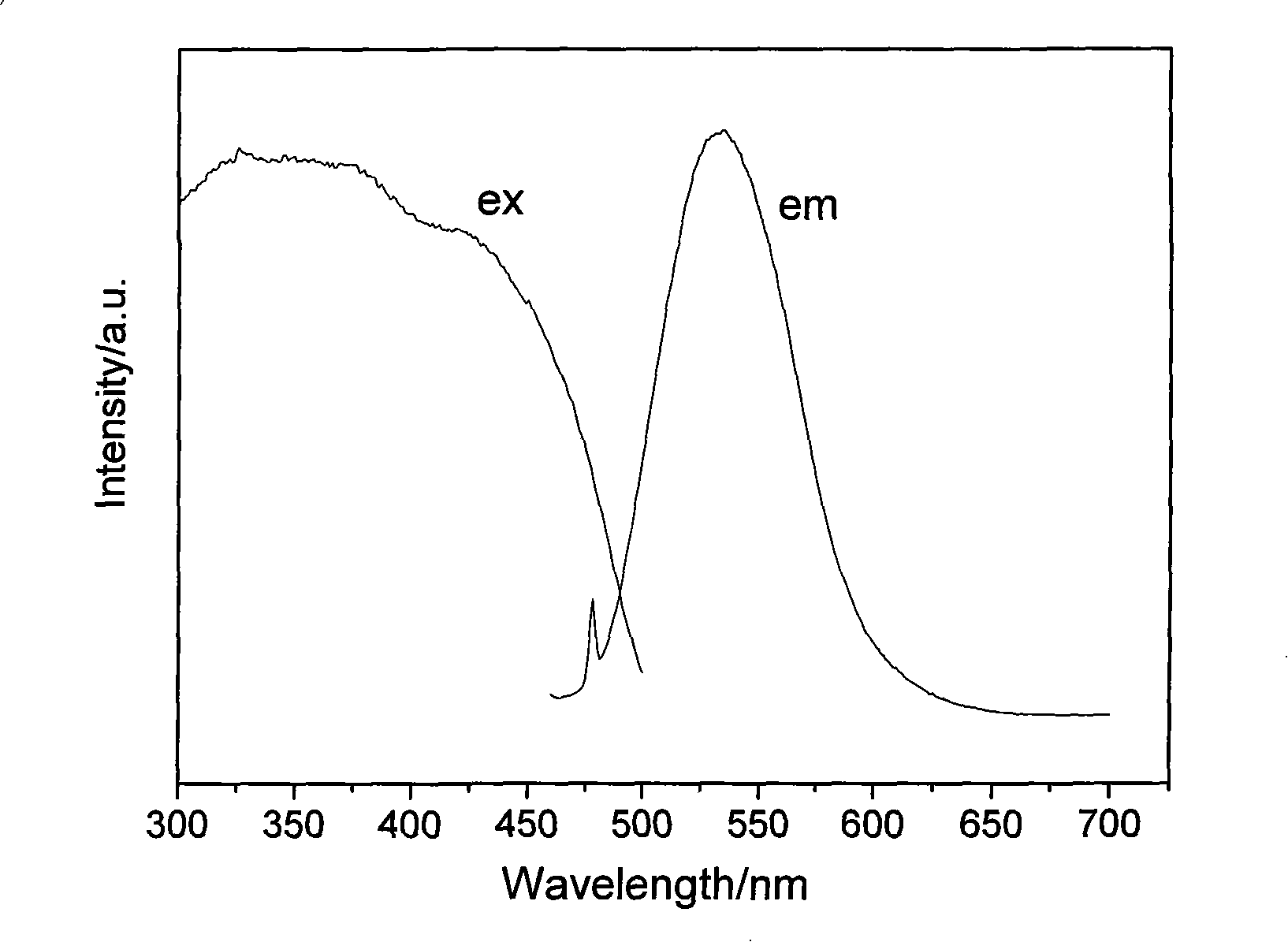

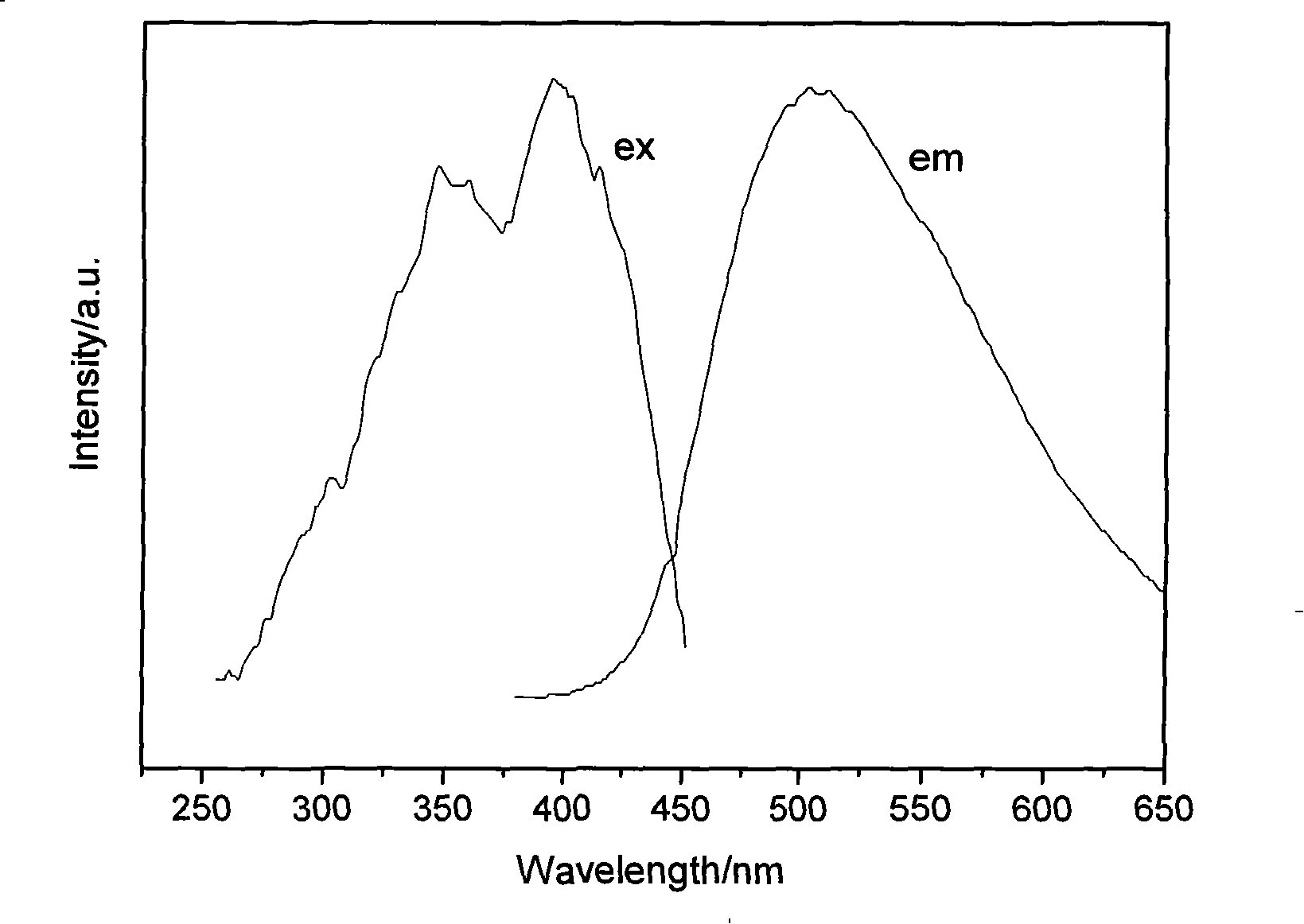

InactiveCN101195744AImprove thermal stabilityGood chemical stabilityLuminescent compositionsSemiconductor devicesAlkaline earth metalFluorescence

The invention relates to fluorescent material including nitrogen compound. The fluorescent material can be stimulated through ultraviolet-blue green light, the general formula is MaAbQcOdNe:Ref, R1g and R2h, wherein, the M is selected from at least one of alkali metal, alkaline earth metal element of Zn, Lu, La, Y and Gd, the A is one element of B, Al, Ga, In, Y, Sc, P, As, Sb and Bi, the Q is one element of C, Si, Ge, Sn, Ti, Hf, Mo, W, P and Zr, the O is oxygen element, and the N is nitrogen element. The Re is at least one element selected from Eu, Nd, Dy, Ho, Tm, La, Ce, Er, Pr, Bi, Sm, Yb, Lu, Gd, Sb, Tb and Mn. The R1 is an ion selected from halogen, the R2 is an ion selected from NH4<+>, Au<+>, Ag<+>, Cu<+>, Li<+>, Na<+> and K<+>. The a, the b, the c, the d, the e, the f, the g and the h are mole coefficient.

Owner:DALIAN LUMINGLIGHT SCIENCE & TECHNOLOGY CO LTD

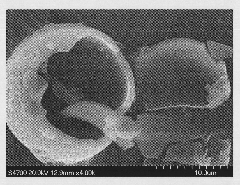

Composite phase-change energy storage material for microcapsule and preparation method thereof

InactiveCN101824307ANo leaksPlay the role of self-control temperature controlHeat-exchange elementsMicroballoon preparationCrack resistanceSolvent

The invention discloses a composite phase-change energy storage material for microcapsules and a preparation method thereof. The coating of the microcapsule is made of silicon dioxide, and the core of the microcapsule is made of a phase-change energy storage material, wherein the phase-change energy storage material is a paraffin organic solid-liquid phase-change energy storage material. 0.2 to 0.5 wt.% of dispersed emulsifier, 52.5 to 62.5 wt.% of solvent water, 18.75 to 31.5 wt.% of phase-change energy storage material and 15.5 to 18.75 wt.% of inorganic silica source are matched and put into a reactor for stirring for 5 to 8 hours; the mixture is uniformly dispersed and emulsified at the temperature 3 to 8 DEG C higher than that for solid-liquid phase change; hydrochloric acid aqueous solution catalyst with the pH value of 0.93 to 4.07 or sodium hydroxide aqueous solution catalyst with the pH value of 8.0 to 12.0 is added into the emulsion; the reacting solution is naturally cooled to room temperature and precipitation solution is obtained; the precipitate is washed with the combination of water and petroleum ether, wherein the mass percent of the petroleum ether is 30 wt.%; then the precipitate is washed with deionized water and is filtered, and the product is naturally aired. The invention improves the technology of phase-change energy storage and conservation, and has the function of automatic temperature regulation, favorable physical and chemical stability, crack resistance, flame retardancy, wear resistance and high thermal conductivity.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing organosilicon and nano-silicon dioxide modified acrylic resin soap-free emulsion

InactiveCN101735412AIncreased stability and solids contentImproves water resistance and adhesionSolventEmulsion

The invention relates to a method for preparing an organosilicon and nano-silicon dioxide modified acrylic resin soap-free emulsion. According to the method, a reactive emulsifier is used to replace a conventional emulsifier, and the method comprises the steps of: performing soap-free emulsion polymerization on acrylic ester monomers, (methyl) acrylic acid, vinyl silicone oil and alkoxy silane containing double bonds; and then adding ethyl orthosilicate for a sol-gel reaction to obtain the organosilicon and nano-silicon dioxide modified acrylic resin soap-free emulsion. The organosilicon and nano-silicon dioxide modified acrylic resin soap-free emulsion is suitable to be taken as a leather finishing agent. The method can completely eliminate the adverse effect of a small molecular emulsifier on an acrylic resin emulsion finishing agent, introduce good characteristics of organosilicon and nano-silicon dioxide into an acrylic resin, overcome the disadvantages of hot sticking and cold shortness, poor waterproof performance and poor solvent resistance and the like of the acrylic resin, and improve the mechanical property, adhesive force and wear resistance of the acrylic resin.

Owner:山西佳宇丰化工科技有限公司

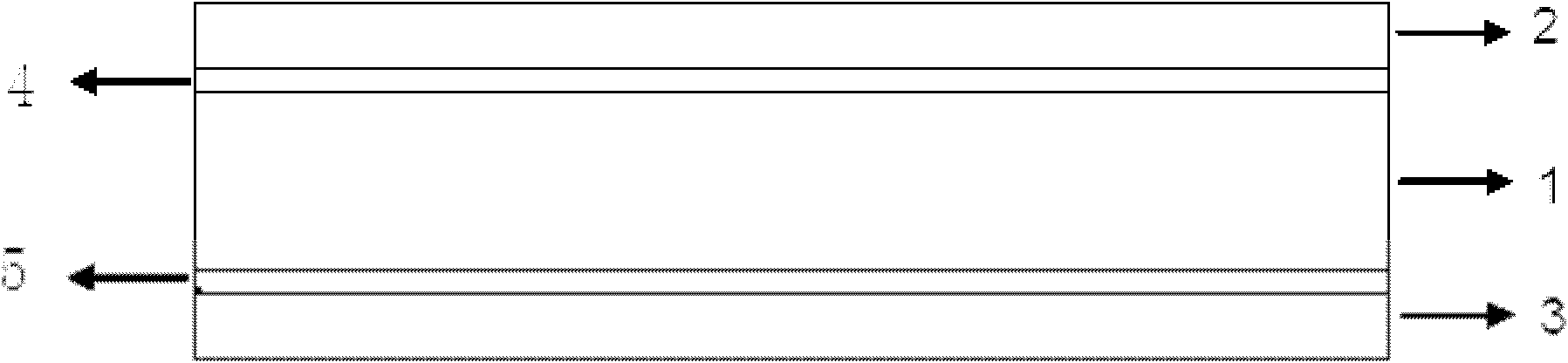

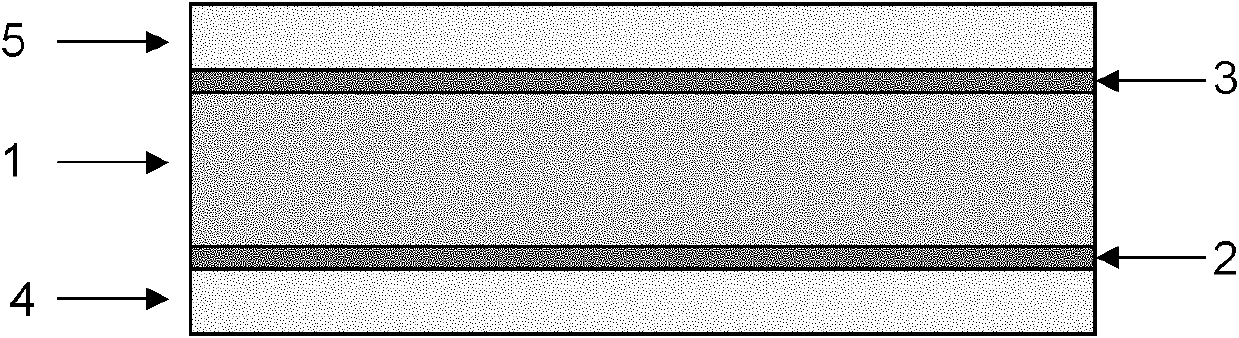

Polymer back panel of solar battery assembly and manufacture method of polymer back panel

ActiveCN102569452AExtend your lifeHigh bonding strengthSynthetic resin layered productsCoatingsPolymer alloyPolyethylene terephthalate glycol

The invention provides a polymer back panel of a solar battery assembly. The polymer back panel comprises a base film layer, binding layers on both sides of the base film layer, a fourth thin film layer and a fifth thin film layer on the other two sides of the binding layers, wherein the base film layers contain at least one of the following components: polyamide polymers, polypropylene and acrylic polymers, polyethylene and ethylene polymers, polyvinylidene chloride, styrene polymers, ABS (acrylonitrile butadiene styrene) resins, liquid crystal polymers, acrylic acid polymers, polyphenyl ether, polycarbonate and polymer alloy of polycarbonate and poly(C2-6 alkal terephthalate). In addition, the invention also provides a manufacture method of the back panel. By adopting a thin film structure made of one or more of the above polymers to substitute for the conventional PET (polyethylene terephthalate) layer, the polymer back panel has excellent processing formation performance, material mechanical performance, barrier performance and anti-aging performance; and a back panel laminated film can be prepared by molten co-extrusion or extrusion composite process, with the advantages of significantly improved bonding strength between the films and simplified production process.

Owner:DSM SUNSHINE SOLAR TECH (SUZHOU) CO LTD

Glass fibre reinforced nylon colorful heat insulation stripe for al-alloy door & window and method for preparing same

InactiveCN101307147ADifficult to disperseSolve easy discolorationDoors/windowsMasterbatchGlass fiber

The invention discloses a glass fiber reinforced nylon colored insulated strip used for an aluminum alloy door and window. The compositions by weight portion of the glass fiber reinforced nylon colored insulated strip are: 100 portions of nylon resin, 5 to 50 portions of glass fibers, 0 to 50 portions of inorganic filler, 5 to 25 portions of toughening agent, 0.3 to 5 portions of coupling agent, 0.3 to 5 portions of dispersing lubricant, 0.2 to 5 portions of antioxidant, 0.1 to 1 portion of light stabilizer, 0.1 to 1 portion of heat stabilizer and 2 to 10 portions of colored masterbatch. The invention also discloses a method for preparing the colored insulated strip. The glass fiber reinforced nylon colored insulated strip solves the problems that the masterbatch and the filler are difficult to disperse and nylon 66 is easy to change color during the processing procedure; the insulated strip products have various colors, superior performance and beautiful appearance; and the glass fiber reinforced nylon colored insulated strip realizes perfect matching with the window color, can achieve the beautility effect, meets and enlarges the demand of clients and the market, and is favorable for promotion, use and development of the glass fiber reinforced nylon 66 insulated strip.

Owner:FOSHAN NANHAI YILE ENG PLASTICS

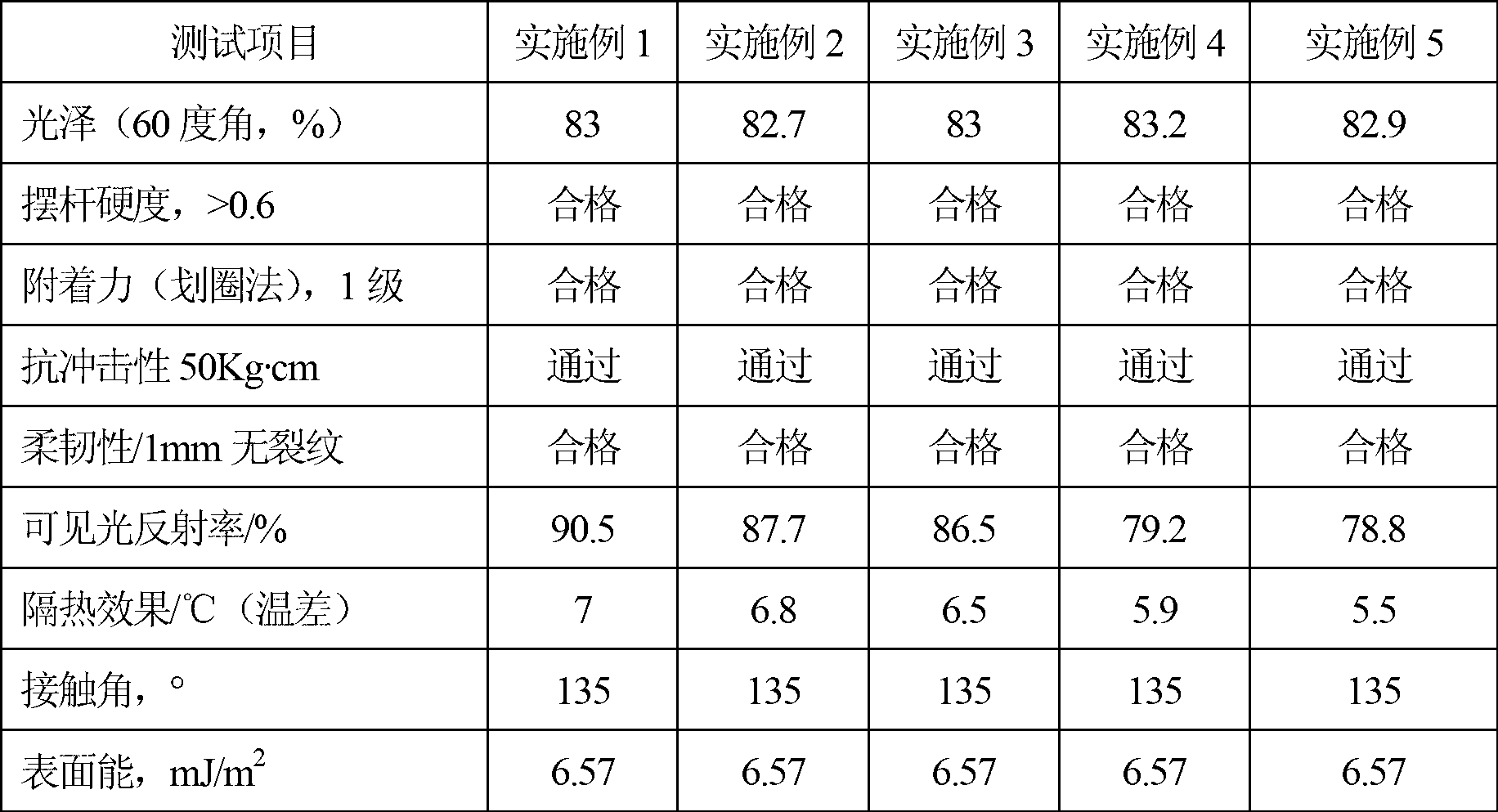

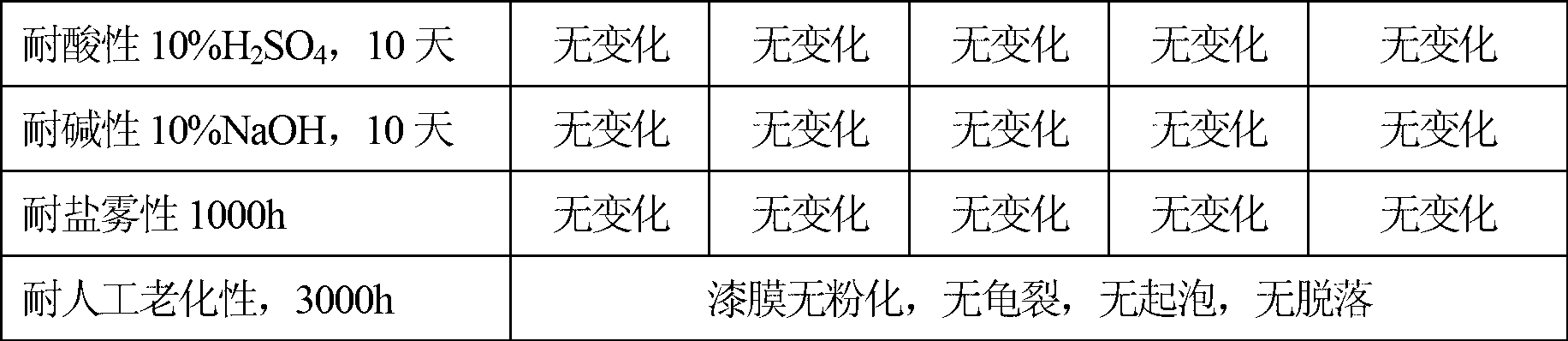

Fluorocarbon nanometer solar heat-insulation reflective paint, preparation method and using method thereof

ActiveCN103013241AImprove reflectivityImprove anti-corrosion performanceReflecting/signal paintsCross-linkInfrared

The invention relates to a fluorocarbon nanometer solar heat-insulation reflective paint, a preparation method thereof and a using method thereof. The paint can be used for roofs and glass curtain walls of the building industry, offshore drilling platforms, oil tanks and petroleum pipelines of the petroleum industry, the surfaces of cars and trains of the transportation industry, hulls and decks of the ship-building industry, and the tanks and warships of the weapon and aerospace industry. The fluorocarbon nanometer solar heat-insulation reflective paint comprises a component A and a component B, wherein the component A comprises the following materials in percentage by weight: 40%-70% of fluorocarbon resin, 1%-10% of nanometer TiO2 concentrated slurry, 10%-30% of infrared-ray reflective pigment, 3%-10% of hollow micro beads, 1%-5% of auxiliaries and 10%-20% of organic solvent; and the component B is cross-linking agent. The preparation method for the fluorocarbon nanometer solar heat-insulation reflective paint comprises the following steps: 1) preparing, dispersing and grinding the materials of the component A in proportion until the fineness is lower than 30 microns; and 2) mixing and curing the component A and the component B to prepare the fluorocarbon nanometer solar heat-insulation reflective paint. The fluorocarbon nanometer solar heat-insulation reflective paint provided by the invention is suitable for normal-temperature drying or low-temperature baking and drying; moreover, a coating film formed by the paint has the characteristics such as high reflectivity, a good heat-insulation effect, high corrosion prevention, high weather resistance, high self-cleanness, low friction and the like.

Owner:大连佳秀百隆新材料股份有限公司

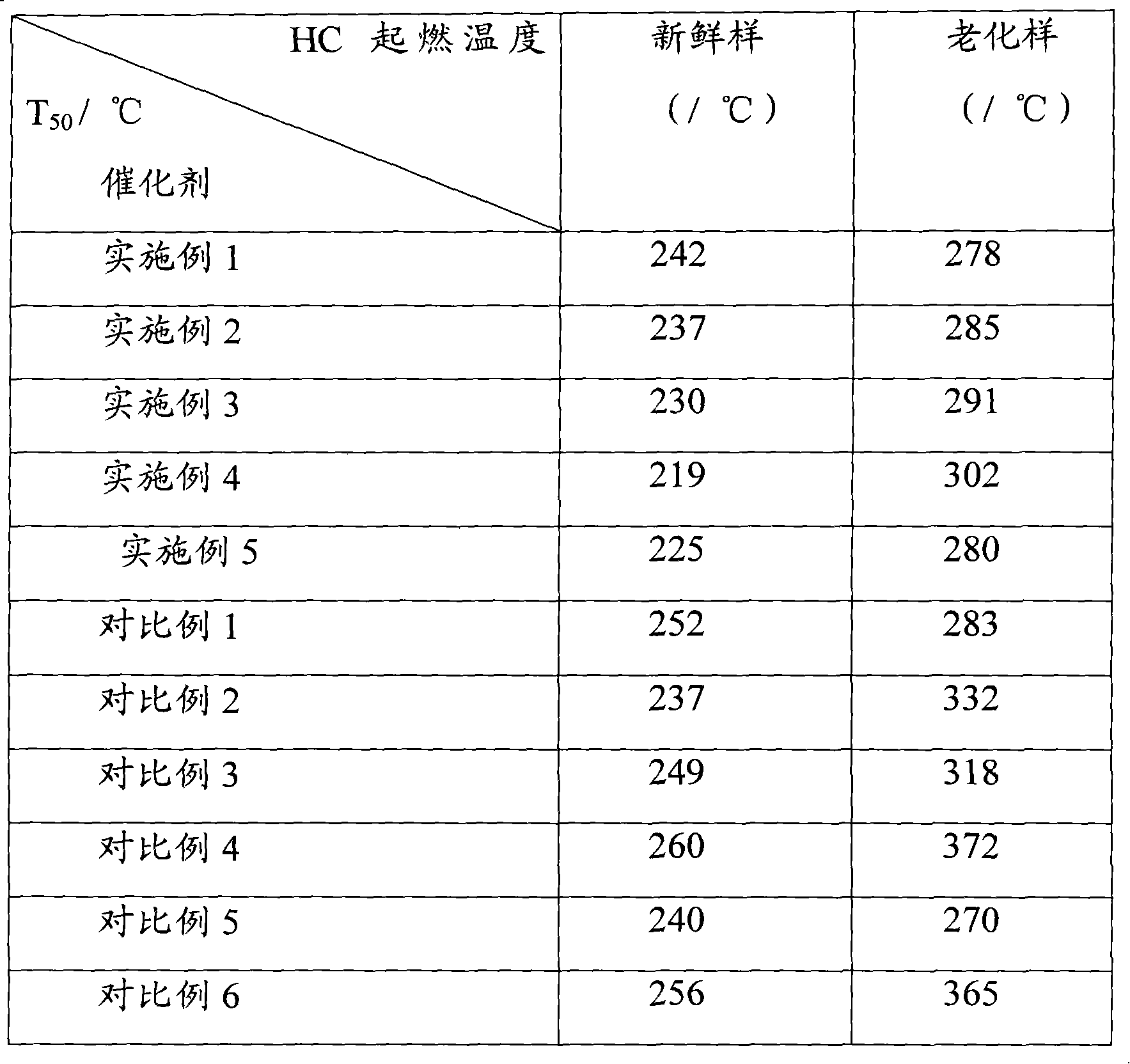

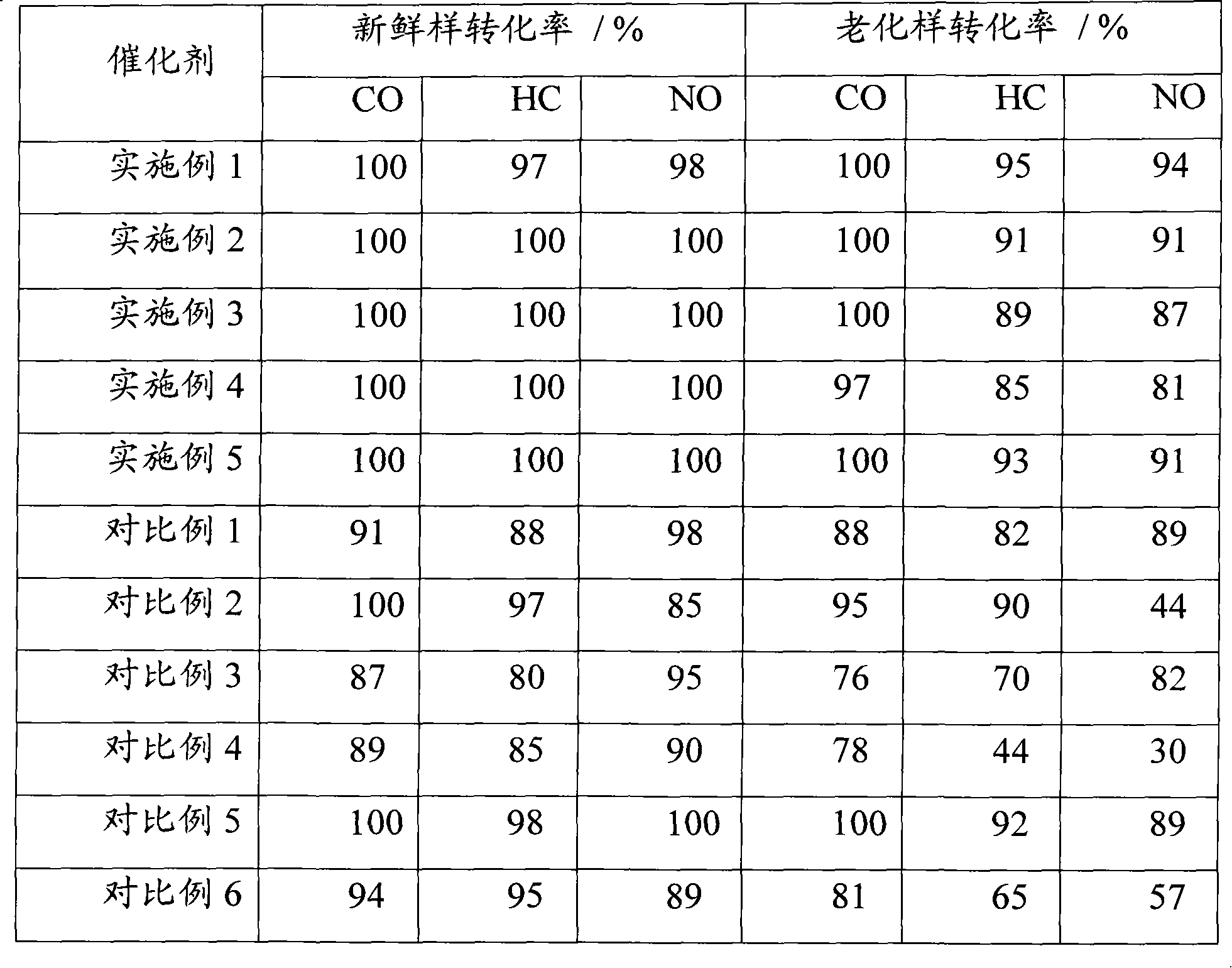

Automobile exhaust purifying catalyst and preparation method thereof

ActiveCN101601999AGood low temperature ignition activityGood aging resistanceDispersed particle separationCatalyst activation/preparationLayered structureChemistry

The invention provides an automobile exhaust purifying catalyst and a preparation method thereof. Honeycomb ceramics are used as a carrier, activated aluminum oxide and an oxygen storage material are used as a coating, noble metals of palladium and rhodium are used as activated components of the catalyst; the coating is of a double-layered structure, wherein a first-layer load is loaded on the carrier, and contains the activated aluminum oxide and the oxygen storage material; a second-layer load is loaded on the first coating and contains the activated aluminum oxide along with or without the oxygen storage material; the activated components of the noble metals of palladium and rhodium are respectively loaded on different materials; a metal and / or oxide load of rhodium is loaded on the first-layer oxygen storage material, and a metal and / or oxide load of palladium is loaded on the second-layer activated aluminum oxide. The automobile exhaust purifying catalyst has the advantages of good low-temperature combustion activity and good anti-aging performance and can satisfy the requirement for low emission.

Owner:常熟华虞环境科技有限公司

Anti-soiling aging-resisting stainless steel paint and preparation method thereof

ActiveCN101215438AImprove aging resistanceImproves UV resistanceLiquid surface applicatorsAntifouling/underwater paintsEpoxyWater based

The invention relates to anti-pollution anti-aging rustless steel coating material and a process for preparation, and coating material comprises acroleic acid resin, film forming matter, filling material, dissolvent and auxiliary agent which are mixed, the film forming matter comprises fluoro containing resin, water-based polyurethane and epoxide resin, the filling material comprises nanometer silicon oxide. The process comprises dissolving acroleic acid resin in dissolvent, further adding film forming matter, filling material, and auxiliary agent, balling to evenly mix. The rustless steel coating material of the invention adopts nanometer silicon oxide and fluoro containing resin to modify acroleic acid coating material, utilizes the ultraviolet screening performance of nanometer silicon oxide, the particle diameter of nanometer-grade particle and low surface tension of fluoro containing resin to lead the anti-aging capability and anti-ultraviolet performance of acroleic acid resin which is prepared to be greatly enhanced, the invention has longer life span than the existing normal acroleic acid resin coating material, which has better fingerprint resisting effect, and the quality and the level are greatly improved, the scope of application is further enlarged.

Owner:HAIMEN SENDA DECORATION MATERIAL CO LTD +1

Solar panel back film and manufacturing technology thereof

ActiveCN103346182AImprove bindingStrong bonding between layersFinal product manufactureSynthetic resin layered productsPolyesterManufacturing technology

A solar panel back film comprises a PET film matrix with the thickness of 100-350 micrometers. Fluorine-containing polymer coatings of 15-30micrometers cover the two faces of the matrix, and the fluorine-containing polymer coatings are formed by mixing raw material components according to a proportion to obtain mixed emulsion and coating the PET film matrix by the mixed emulsion which is swollen under the temperature between 80 DEG C and 200 DEG C, wherein raw materials of the fluorine-containing polymer coatings comprise, by mass, polyester PET powder, fluorine-containing resin, solvent, a cross-linking agent, padding and ethylene glycol. The polyester PET powder is polyester PET powder with grain size smaller than 25 micrometers, wherein the polyester PET powder is formed by smashing precipitate obtained by dissolving in phenol-carbon tetrachloride mixed solvent. The fluorine-containing resin is fluorine-containing macromolecule resin. The solar panel back film is easy to process, tearing resistant and superior in electrical insulation performance and weather fastness.

Owner:ZHEJIANG VENTURA PHOTOVOLTAIC MATERIALS

Waxy Hot Melt Adhesives and Disposable Absorbent Articles

ActiveCN102277112AGood adhesionPrevent over-migrationMineral oil hydrocarbon copolymer adhesivesSynthetic resin layered productsWaxHot-melt adhesive

1) Wax-containing hot melt adhesive comprising 1 to 40 % of a styrenic block copolymer (a), 3 to 15 % of a modified thermoplastic elastomer (b) comprising -COO- groups, and 5 to 25 % of a wax (c). 2) Disposable absorbent article employing said hot melt adhesive. The article bonded by the hot melt adhesive of the present invention has excellent creep resistance and aging resistance.

Owner:BOSTIK FENDELI CHINA ADHESIVE CO LTD

Preparation method of high temperature and high pressure resistant rubber sealing material

InactiveCN101824172AImprove mechanical propertiesImprove heat resistanceSealing/packingPolymer scienceVulcanization

The invention belongs to the technical field of rubber sealing material, and relates to a preparation method of a high temperature and high pressure resistant rubber sealing material which can be applied to an oilfield deep oil production engineering process; first, 100 parts of hydrogenated nitrile rubber is weighed by parts in weight, put into a mixing mill to be plasticated; and then 2 to 20 parts of metal oxide, 1 to 5 parts of stearic acid, 5 to 100 parts of acrylate, 10 to 70 parts of carbon black, 1 to 6 parts of aging inhibitor, 5 to 30 parts of plasticizer, 2 to 10 parts of antiscorcher, 2 to 10 parts of vulcanizer and 2 to 10 parts of vulcanization aid are sequentially added into the mixing mill to be mixed uniformly; mixing rubber is vulcanized primarily in a plate vulcanizing press, the vulcanizing temperature is controlled to be 150 to 180DEG C, the vulcanizing time is 20 to 40min, and the vulcanizing pressure is 10 to 20MPa; after being taken out from the plate vulcanizing press, the rubber is secondarily vulcanized at 150 to 180DEG C to obtain vulcanized rubber with excellent performance; and the preparation method of the high temperature and high pressure resistant rubber sealing material has the advantages of simple process, convenient operation and use, low preparation cost, excellent mechanical performance, and in particular better high-temperature mechanical performance.

Owner:QINGDAO UNIV OF SCI & TECH +1

Method for preparing organosilicon modified acrylic resin

The invention relates to a method for preparing organosilicon modified acrylic resin. An organosilicon unit is introduced into an acrylic polymer chain segment, and polyorganosiloxane is grafted to an acrylate chain segment through the organosilicon unit. The resin comprises raw materials such as a vinyl-containing micromolecular organosilicon monomer, styrene, a (methyl) acrylate monomer, hydroxyl-containing polyorganosiloxane, a solvent, an initiator and a catalyst, wherein the vinyl-containing micromolecular organosilicon monomer and the acrylate monomer are subjected to prepolymerization under the action of the initiator; and prepolymer and the hydroxyl-containing polyorganosiloxane are polymerized to form the resin under the action of the catalyst. The resin has high gloss and weather resistance and is suitable to be used as decorative finishing paint, and high mechanical property of the acrylic resin is kept.

Owner:中山大桥化工集团有限公司

Reactive polyurethane hot melt adhesive and preparation method thereof

ActiveCN103627362AHigh bonding strengthGood flexibilityMineral oil hydrocarbon copolymer adhesivesPolyureas/polyurethane adhesivesChemistryPolyester

The invention relates to a reactive polyurethane hot melt adhesive, consisting of the following raw materials in parts by weight: 10-30 parts of polyether polyol, 30-50 parts of polyester polyol, 12-16 parts of isocyanate, 6-20 parts of tackifying resin, 8-20 parts of reactive plasticizer, 1-3 parts of latent curing agent and 0.1-0.5 part of catalyst. The reactive polyurethane hot melt adhesive prepared by the invention has good bonding strength, flexibility, hot and cold shock resistance, water resistance and aging resistance, and the curing speed is improved to greatly perfect the performance of PUR (Polyurethane) adhesive.

Owner:YANTAI DARBOND TECH

Activated waste rubber powder and preparation method thereof as well as modified asphalt and preparation method thereof

InactiveCN101817946AGood compatibilityGood storage stabilityBuilding insulationsPolymer scienceWaste rubber

The invention relates to activated waste rubber powder and a preparation method thereof. The activated waste rubber powder is prepared from a mixture containing waste rubber powder, a softener and / or a rubber activating agent. The invention also relates to a waste rubber powder modified asphalt and a preparation method thereof. The waste rubber powder modified asphalt is prepared from a mixture containing base asphalt and the activated waste rubber powder. The activated waste rubber powder and the base asphalt have favorable compatibility, and the modified asphalt containing the activated waste rubber powder can have favorable storage stability, high temperature property and ageing-resistant performance and lower cost. In addition, the preparation methods of the activated waste rubber powder and the modified asphalt are simple in process and convenient to operate.

Owner:RES INST OF HIGHWAY MIN OF COMM

Thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and preparation method thereof

ActiveCN103122097ADoes not affect physical and mechanical propertiesDoes not affect processabilityInsulated cablesPigment treatment with macromolecular organic compoundsCrack resistanceDimethyl methylphosphonate

The invention discloses a thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables and a preparation method thereof. The thermoplastic low-smoke halogen-free flame-retardant environment-friendly sheath material for power cables comprises the following components in parts by weight: 60-80 parts of EVA (ethylene-vinyl acetate), 20-30 parts of HDPE (high-density polyethylene), 10-15 parts of EPDM (ethylene-propylene-diene monomer), 15-25 parts of compatiblizing agent, 100-150 parts of halogen-free flame retardant, 0.5-1 part of antioxidant 1035, 0.5-1 part of antioxidant DSTP, 1-2 parts of ethylene bis stearamide, 3-5 parts of DCP (dicumyl peroxide), 2-4 parts of zinc oxide, 1-2 parts of calcium stearate, 10-20 parts of dimethyl methyl phosphonate, 30-40 parts of nano kaolin, 2-3 parts of stearic acid and 0.5-1 part of isopropyl tri(dioctylpyrophosphate)titanate. The sheath material disclosed by the invention has the advantages of excellent physical and mechanical properties, excellent flame retardancy, favorable high / low temperature resistance, favorable oil resistance, favorable solvent resistance, favorable wear resistance, favorable ozone resistance, favorable aging resistance, high flexibility, crack resistance and the like, is very durable, environment-friendly and pollution-free, and can completely satisfy the requirements for modern power cables.

Owner:ANHUI HUAJIN CABLE GROUP

Aqueous acrylic acid-modified alkyd resin and preparation method thereof

ActiveCN103554379AImprove water resistanceImprove aging resistanceCoatingsBenzoic acidPolymer science

The invention discloses aqueous acrylic acid-modified alkyd resin and a preparation method thereof. Basic alkyd resin of the aqueous acrylic acid-modified alkyd resin is prepared from an unsaturated fatty acid, benzoic acid, trimethylolpropane, pentaerythritol, maleic anhydride, isophthalic acid, ethylene glycol monobutyl ether and butanol. The aqueous acrylic acid-modified alkyd resin is prepared by adding styrene, methyl methacrylate, butyl acrylate, acrylic acid, a silane coupling agent, benzoyl peroxide, tert-butyl hydroperoxide, ethylene glycol monobutyl ether and a mixing neutralizer into the basic alkyd resin. According to the aqueous acrylic acid-modified alkyd resin and the preparation method thereof, the advantages of alkyd resin and acrylic resin are integrated, and a product has high gloss retention, color retention and weather resistance; a production process is simple, the raw materials are readily available, and the production cost is low; a paint production process is simple, water is used as a diluting agent, and safety and convenience in construction are ensured.

Owner:西北永新涂料有限公司

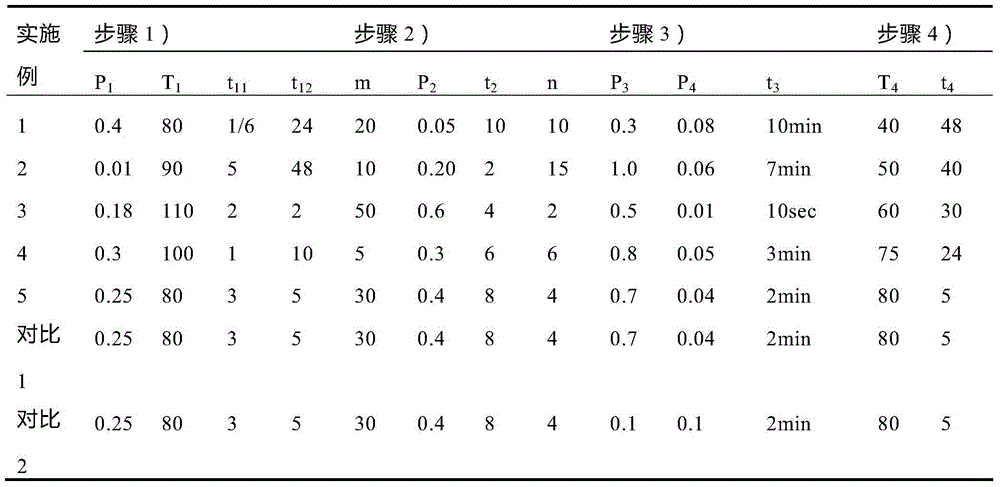

Flame-retardant EPS (expandable polystyrene) foam thermal-insulation board and preparation method thereof

The invention discloses a flame-retardant EPS (expandable polystyrene) foam thermal-insulation board and a preparation method thereof. The method comprises the following steps: 1) preparing flame-retardant EPS prefoaming granules; 2) preparing a flame-retardant EPS foam board; 3) carrying out coating modification on the flame-retardant EPS foam board: adding a fireproof adhesive into a polystyrene board modification device, in which the flame-retardant EPS foam board is arranged, under the high pressure of 0.3-1.0 MPa, and standing under the pressure of 0.01-0.08 MPa for 10 seconds-10 minutes until the fireproof adhesive penetrates into the flame-retardant EPS foam board, thereby achieving the goal of coating modification; and 4) drying and curing to form. The heat conductivity coefficient of the flame-retardant EPS foam thermal-insulation board is lower than 0.055 w / m.k, the specific gravity is down to 150 Kg / m<3> below, the compression strength is greater than 150 KPa, and the heat value is less than 3 MJ / kg.

Owner:应急管理部四川消防研究所

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com