Preparation method of wet process mixed natural rubber material

A natural rubber, wet mixing technology, applied in the direction of rolling resistance optimization, road transportation emission reduction, etc., can solve the problems of poor processing performance, insufficient dispersion, production environment pollution, etc., to achieve low rolling resistance, processing Simple process and the effect of reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

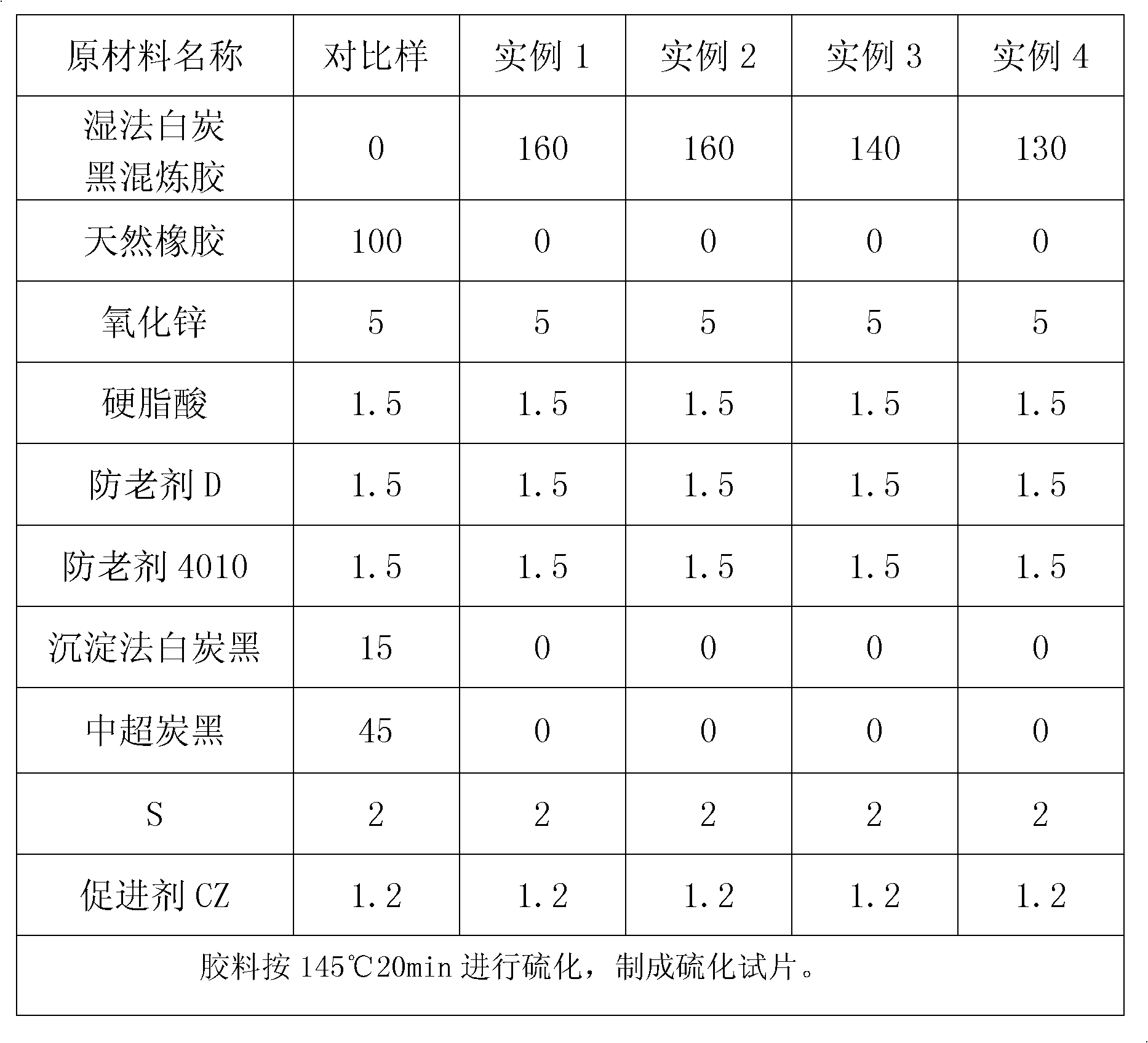

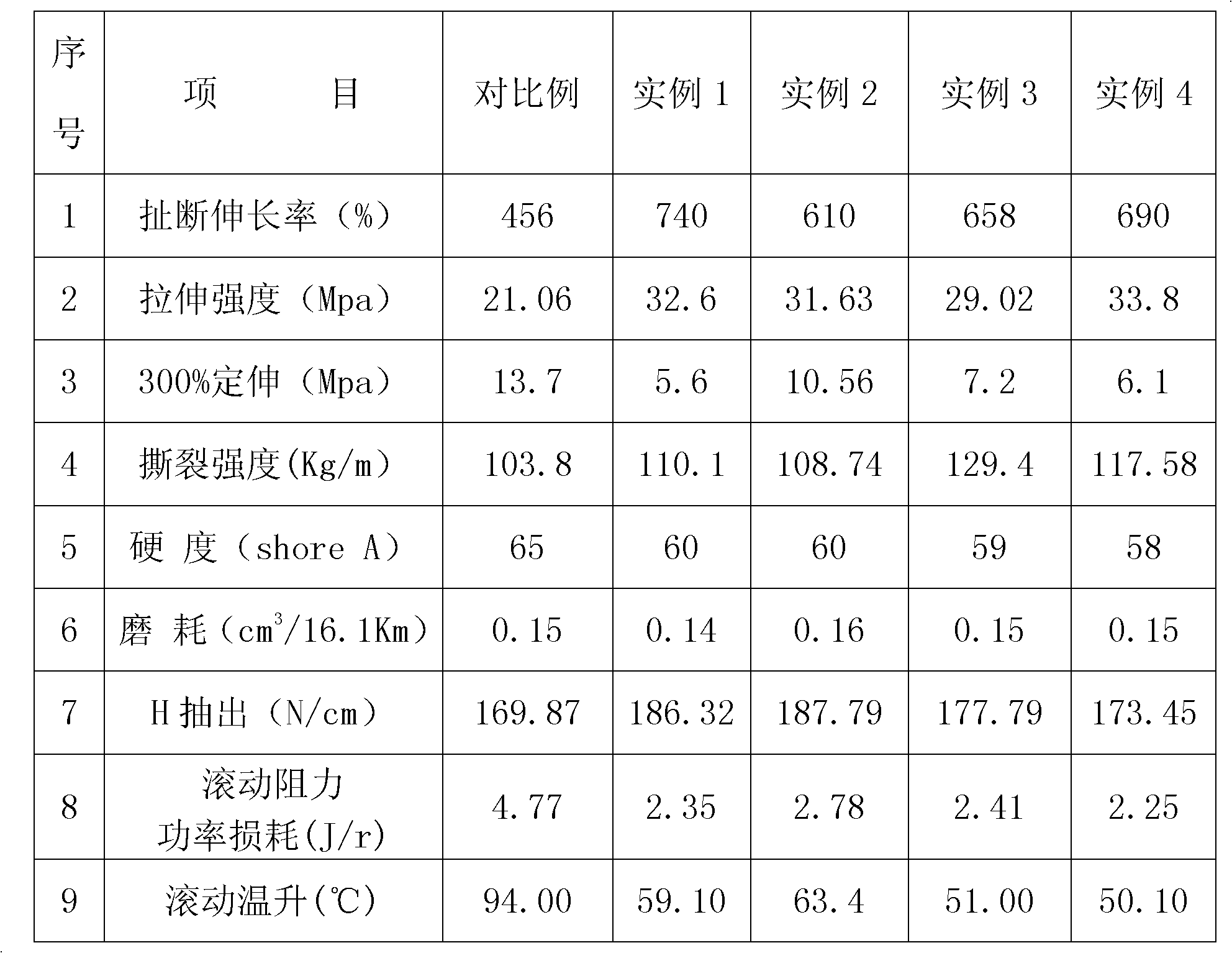

Examples

Embodiment 1

[0034] Concentrated natural rubber latex by centrifugal

[0035] A. Preparation of slurry

[0036] 1. Take 120 grams of precipitated white carbon black, dissolve it in 280 grams of deionized water, and soak for 3 hours;

[0037] 2. Add 4.8 grams of silane coupling agent γ-aminotriethoxysilane and 0.6 grams of surfactant sodium dodecylbenzenesulfonate, stir and mix evenly to make white carbon black slurry;

[0038] B. Grinding

[0039] The above-mentioned silica slurry was added to a high-shear disperser and ground for 20 minutes to prepare a silica dispersion with a sedimentation capacity of 60 mg / h.

[0040] C. Preparation of latex mixture

[0041] 1. Take 334 grams of centrifugally concentrated natural rubber latex with dry rubber content of 60%;

[0042] 2. Add the prepared silica water dispersion into 334 grams of latex, stir at room temperature for 30 minutes, and mix to make a latex mixture;

[0043] D. Flocculation, gel washing and dehydration

[0044] 1) Add 7 gr...

Embodiment 2

[0049] Field natural rubber latex

[0050] A. Preparation of slurry

[0051] 1. Take 120 grams of precipitated white carbon black, dissolve it in 280 grams of deionized water, and soak for 3 hours;

[0052] 2. Add 3.6 grams of silane coupling agent γ-aminotriethoxysilane and 1.4 grams of surfactant sodium dodecylbenzenesulfonate, stir and mix to make white carbon black slurry;

[0053] B. Grinding

[0054] The above-mentioned white carbon black slurry was added to a high-shear disperser and ground for 20 minutes to make a water dispersion of white carbon black with a sedimentation capacity of 50 mg / h;

[0055] C. Preparation of latex mixture

[0056] 1. Take 666.66 grams of field natural latex with a dry rubber content of 30%;

[0057] 2. Add the prepared white carbon black aqueous dispersion into 666.66 grams of natural rubber latex, stir at room temperature for 30 minutes and evenly mix to form a latex mixture;

[0058] D. Flocculation, gel washing and dehydration

[0...

Embodiment 3

[0064] Concentrated natural rubber latex by centrifugal

[0065] A. Preparation of slurry

[0066] 1. Take 80 grams of precipitated white carbon black, dissolve it in 320 grams of deionized water, and soak for 5 hours;

[0067] 2. Add 6.4 grams of silane coupling agent γ-aminotriethoxysilane and 0.8 grams of surfactant sodium dodecylbenzenesulfonate, stir and mix to make a white carbon black slurry;

[0068] B. Grinding

[0069] The above-mentioned white carbon black slurry was added to a high-shear disperser and ground for 20 minutes to make a water dispersion of white carbon black with a sedimentation capacity of 50 mg / h;

[0070] C. Preparation of latex mixture

[0071] 1. Take 334 grams of field natural rubber latex with dry rubber content of 60%;

[0072] 2. Add the prepared silica water dispersion into 334 g of natural rubber latex, stir at room temperature for 30 minutes and evenly mix to form a latex mixture.

[0073] D. Flocculation, gel washing and dehydration

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com