Patents

Literature

12801results about How to "Improve working environment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

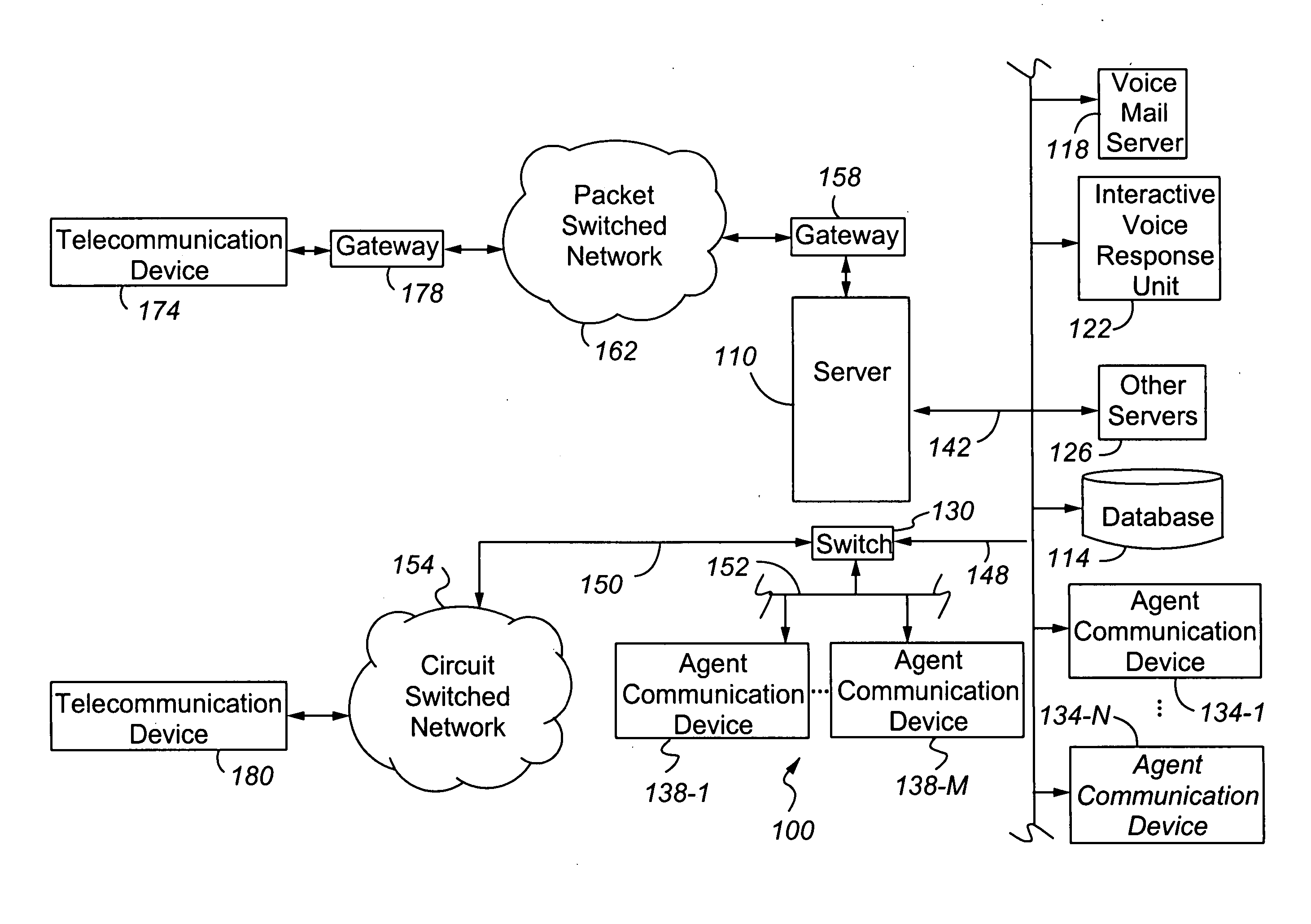

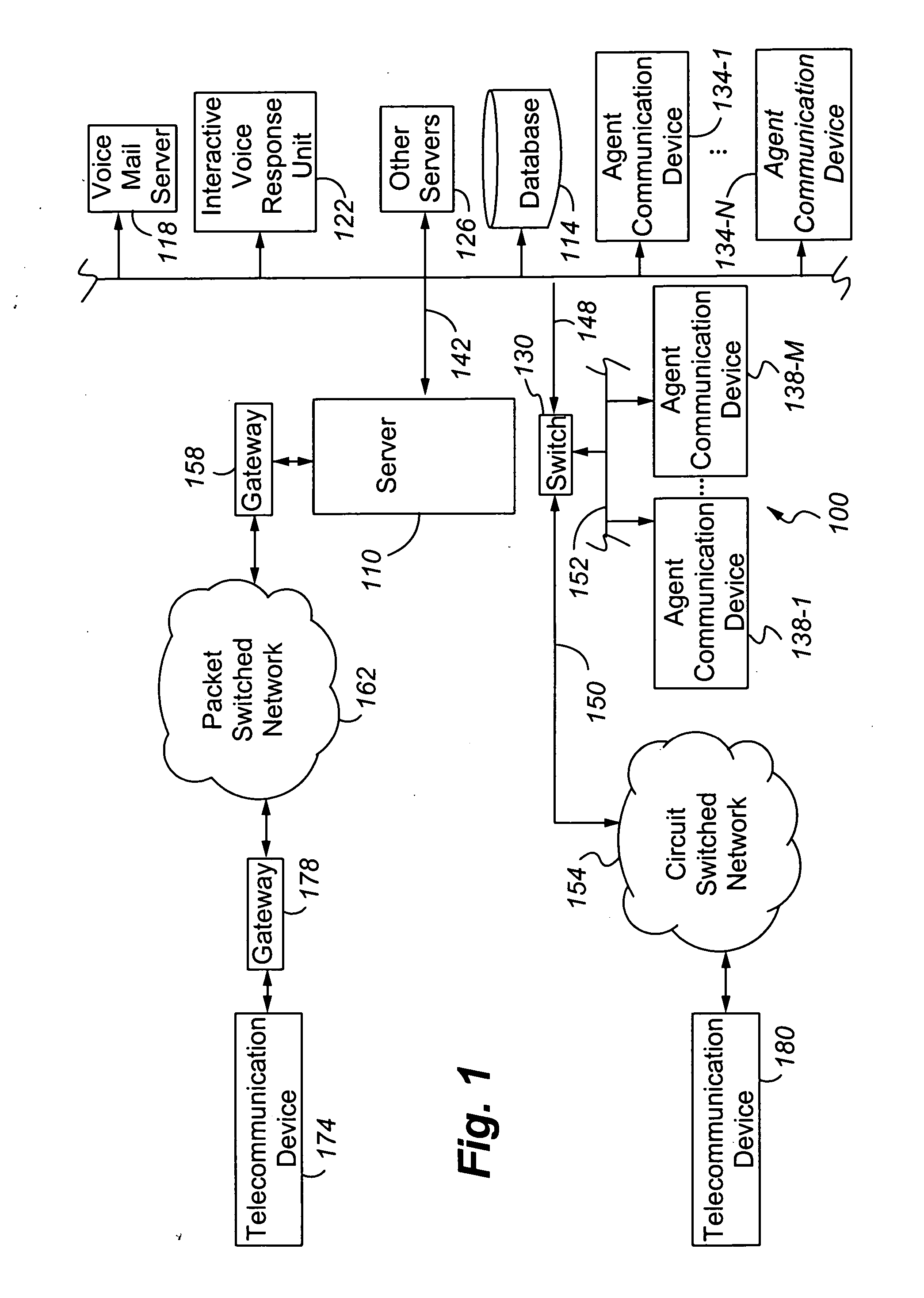

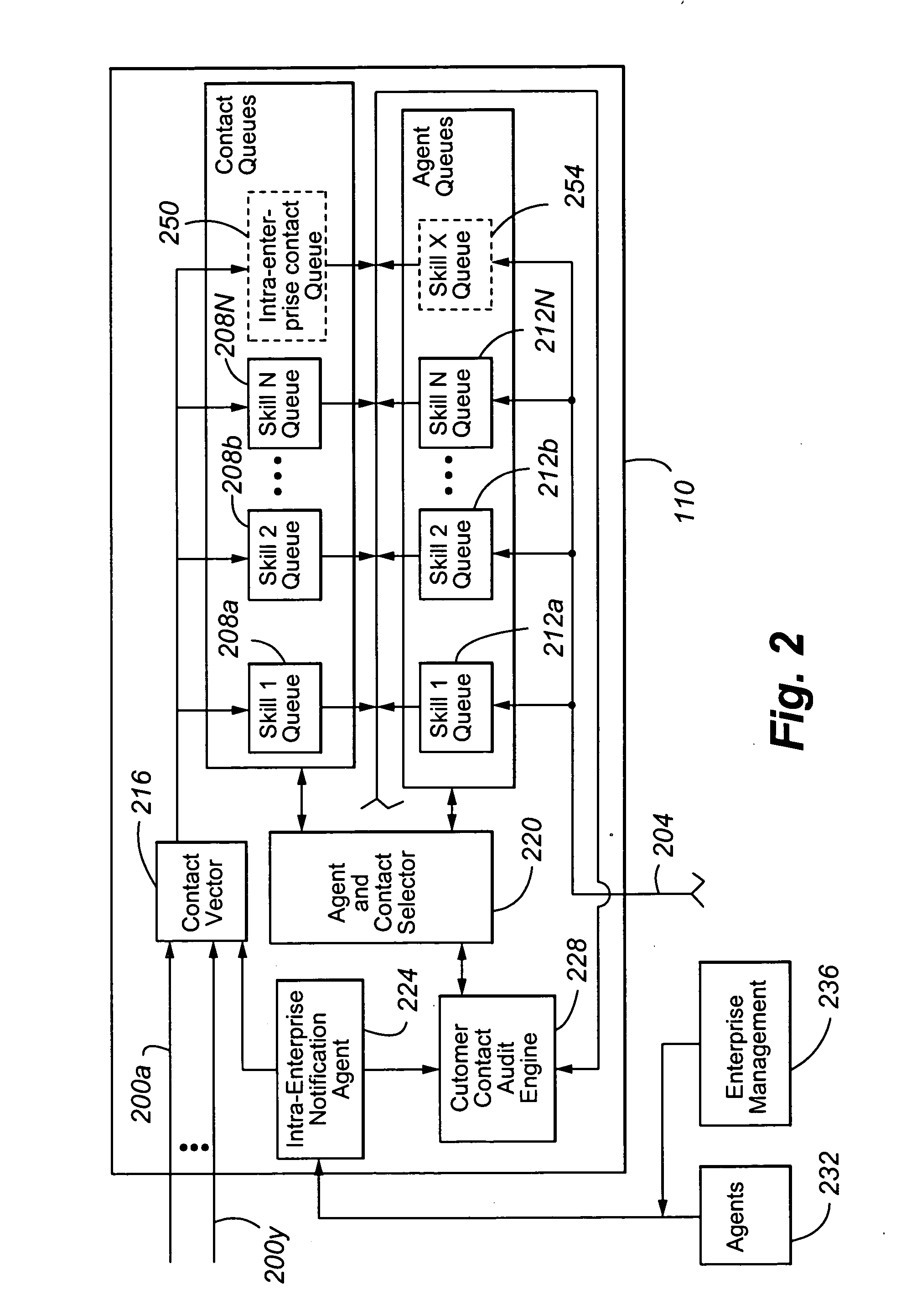

Method and apparatus for the automated delivery of notifications to contacts based on predicted work prioritization

ActiveUS20070071222A1Improved customer serviceImproved contact center effectivenessSpecial service for subscribersManual exchangesContact centerComputer science

In one embodiment, a contact center is provided that includes: (a) a work item queue 208, 250 comprising an intra-enterprise contact associated with at least first and second internal endpoints of an enterprise; and (b) a selector operable to select and assign a work item to an agent. In selecting the work item, the selector considers both a customer contact and the intra-enterprise contact. The intra-enterprise contact, for example, can be a training notification.

Owner:AVAYA INC

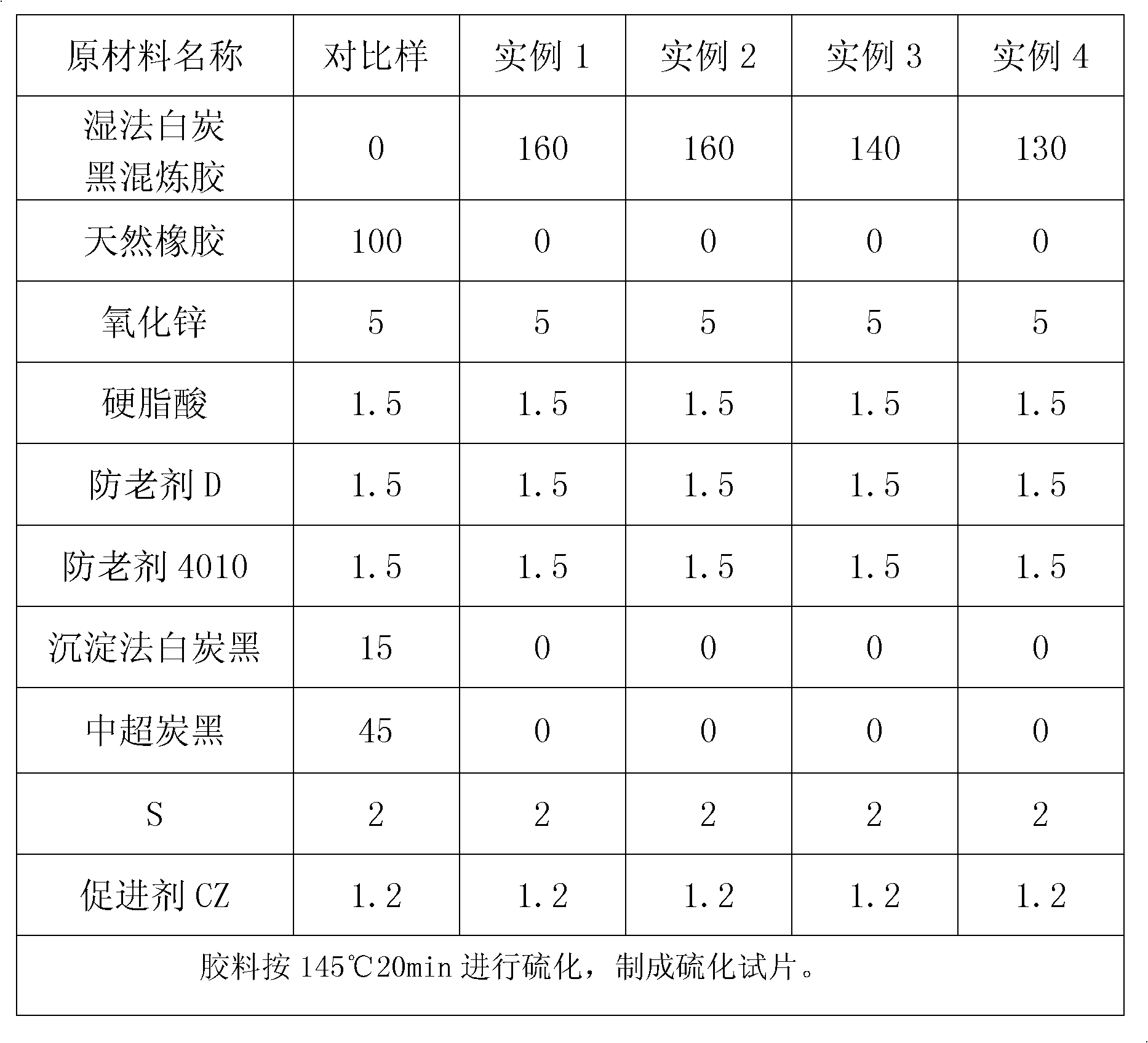

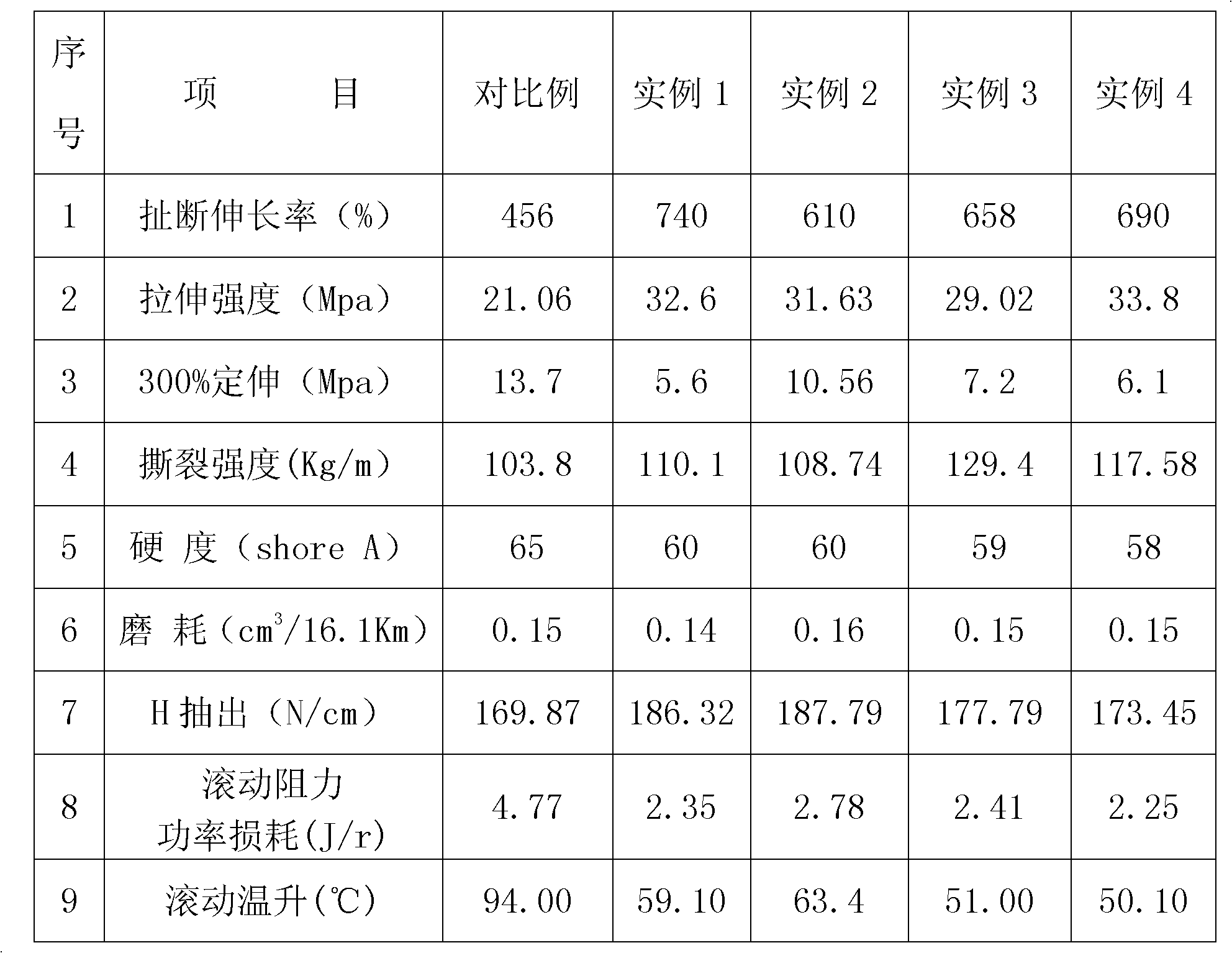

Preparation method of wet process mixed natural rubber material

ActiveCN102153792AGood dispersionImprove uniformityRolling resistance optimizationRubber materialPolymer science

The invention relates to a preparation method of a wet process mixed natural rubber material. The method comprises the following steps of: preparing slurry and soaking 15-40 percent of dry white carbon black in 60-85 percent of deionized water; adding a coupling agent and a surfactant, uniformly mixing, grinding, preparing latex mixed liquor, extracting natural latex and adding white carbon black water dispersoid into the latex; stirring and mixing to obtain a latex mixed liquor, flocculating and adding acetic acid into the mixed liquor; performing rubber washing and dehydration by using a rubber washing machine and feeding to a rubber pelletizer for pelletizing; and feeding rubber particles into a box drying cabinet for drying. The preparation method has the advantages of simple machining process, small equipment investment, realization of various ideal performances with the most ordinary white carbon black, low dust pollution in the entire production process and energy saving. A tire manufactured with the method has small rolling resistance, low heat generation, high tensile strength, high tearing strength and high rubber material ageing resistance. Mixing of the white carbon black is performed in a liquid phase, so that the dispersivity and uniformity are enhanced.

Owner:ZHUZHOU ANBAOLINFENG NEW MATERIALS

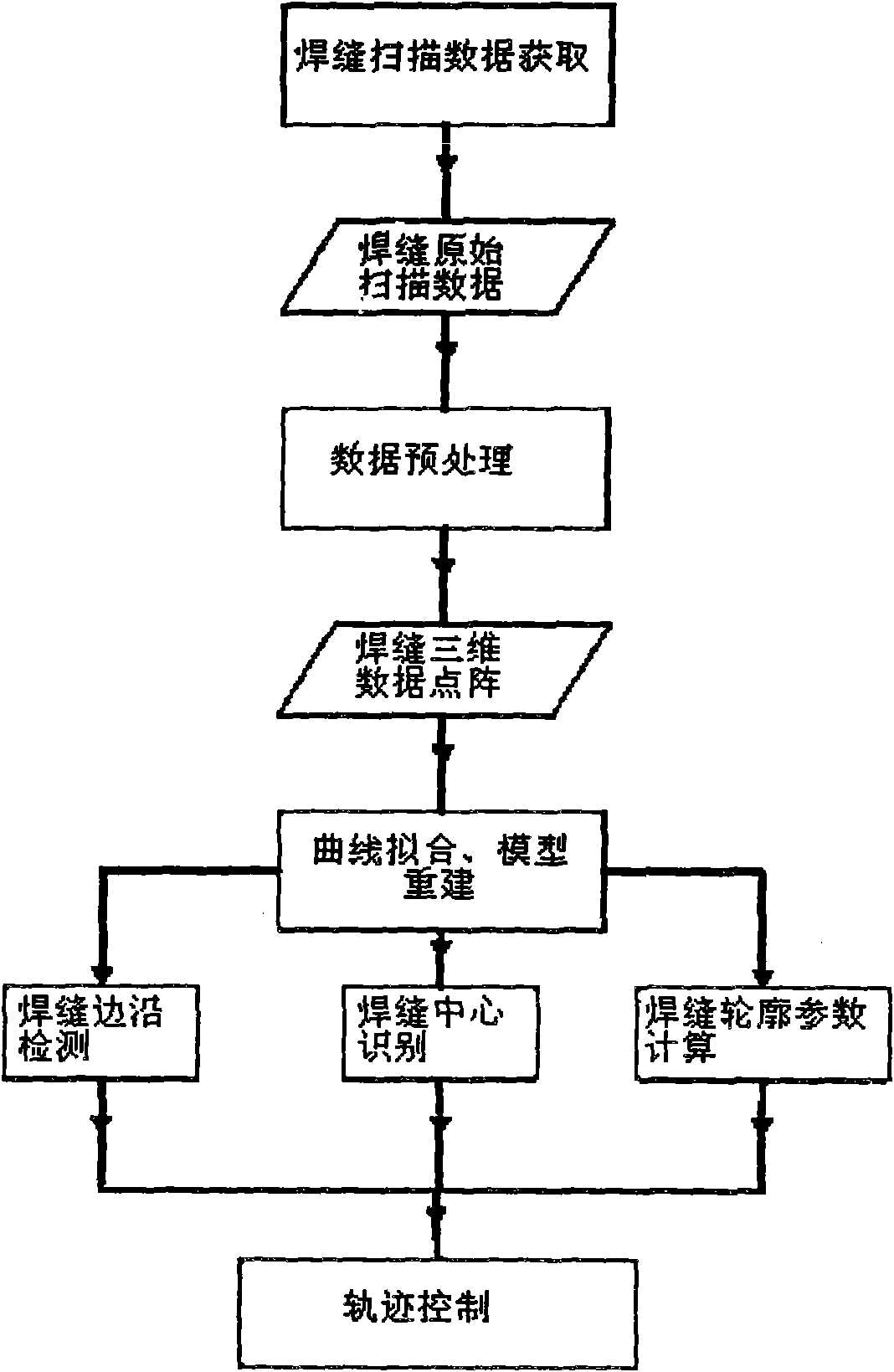

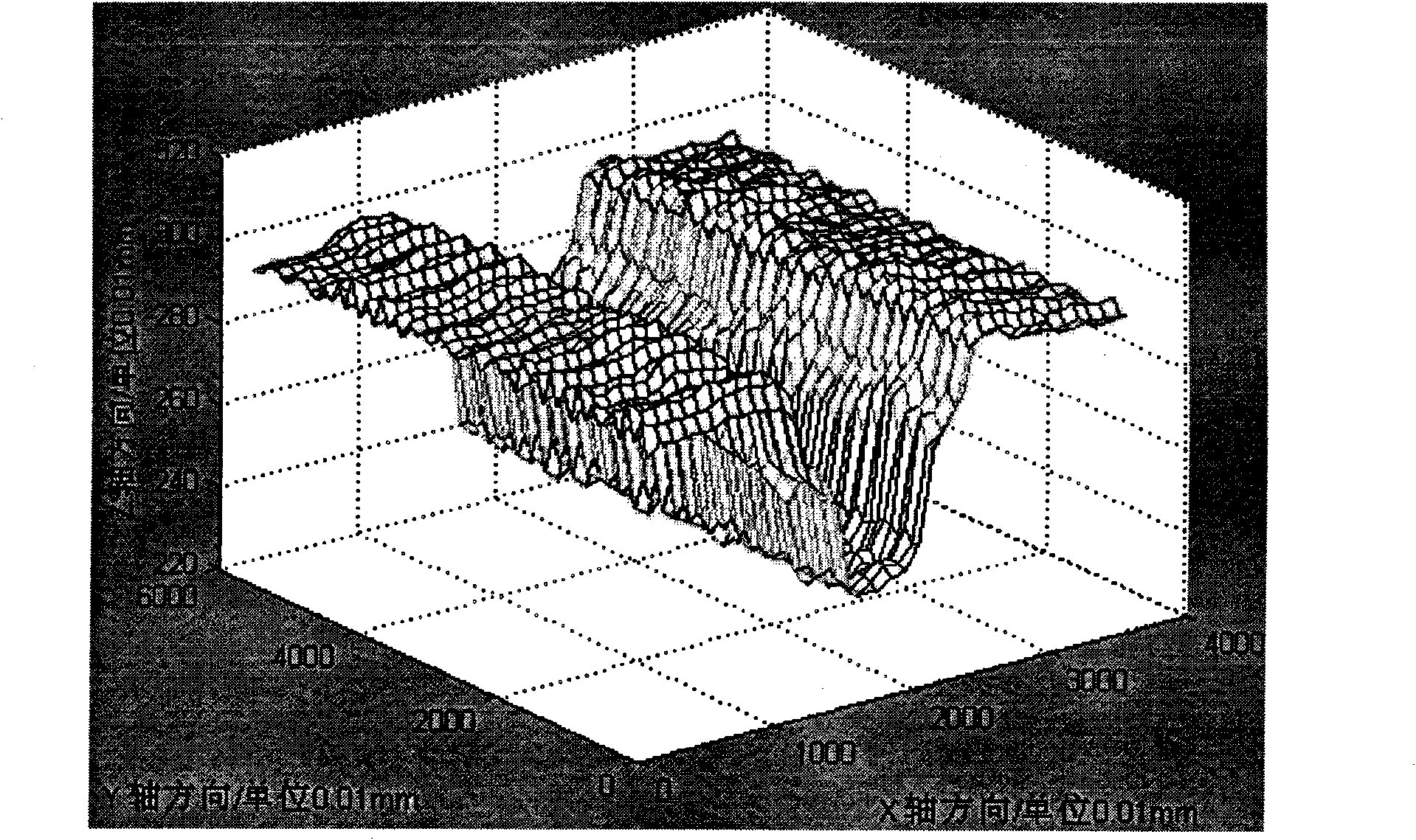

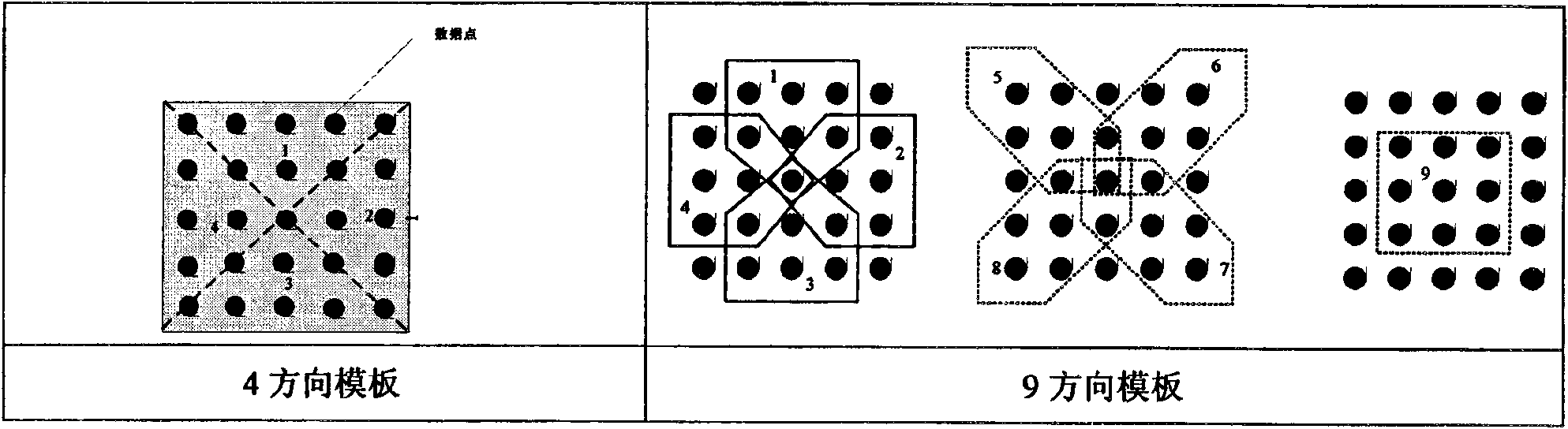

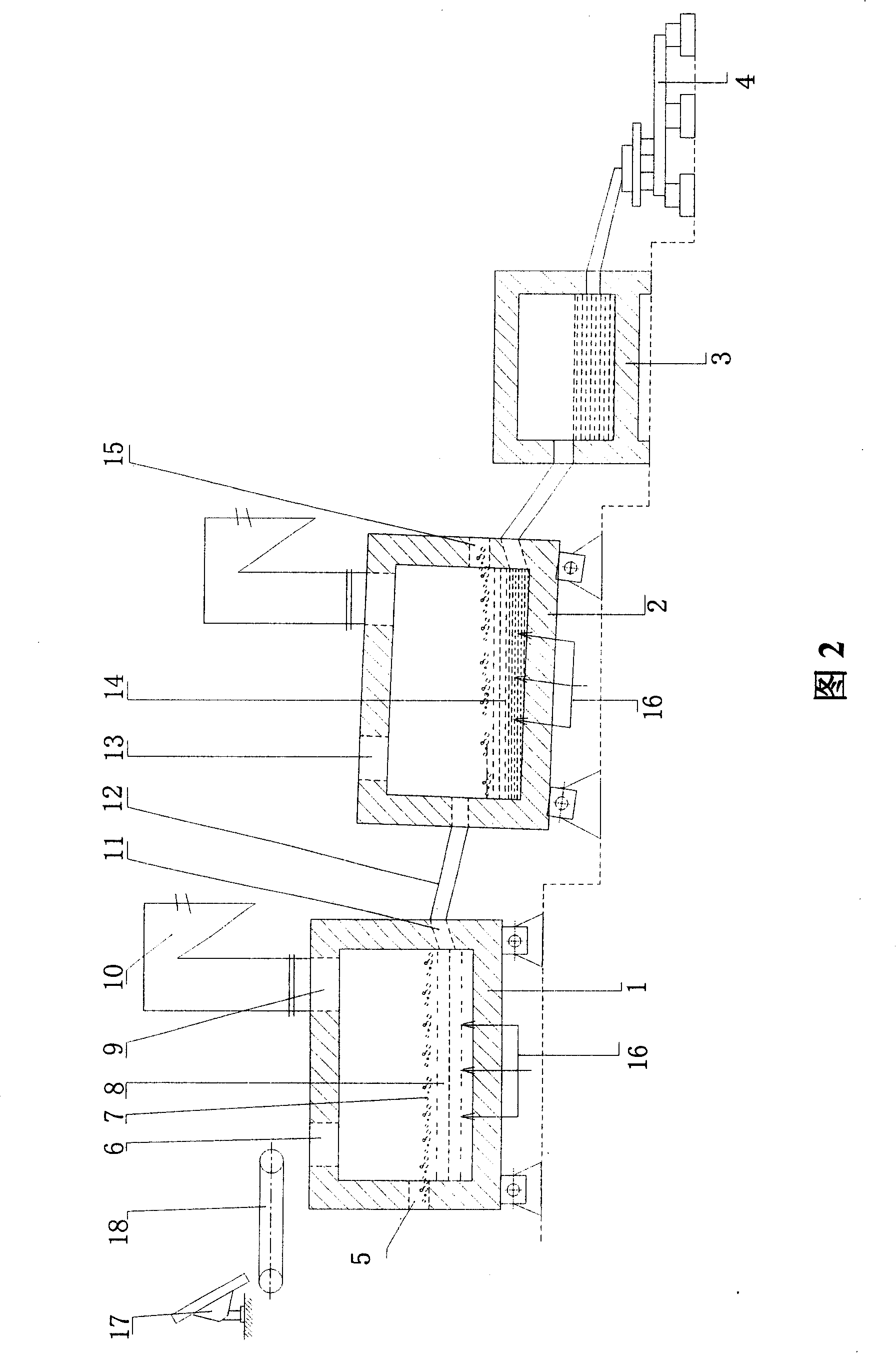

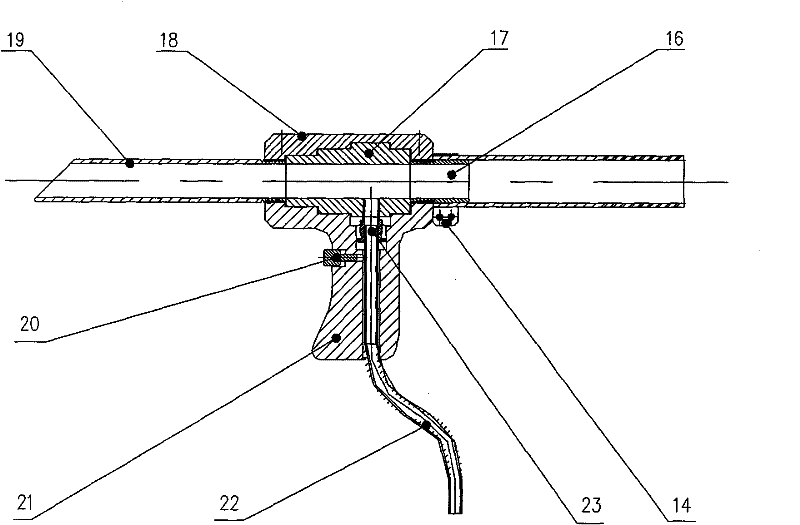

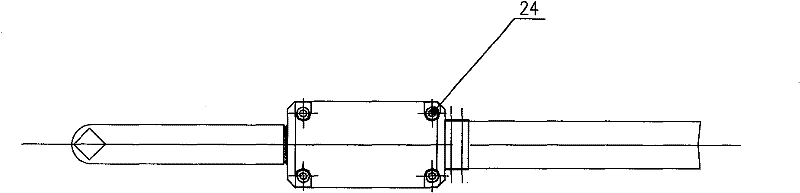

Welding track detection and control method of plate butt weld based on laser ranging

InactiveCN101559512ATo achieve the purpose of seam trackingTo achieve the purpose of trackingArc welding apparatusNumerical controlLaser rangingField tests

The invention relates to a welding track detection and control method of plate butt weld based on laser ranging, including the following steps: A. track detection is carried out; B. track identification and extraction are carried out; C. track control is carried out; D. the relative position relation between a welding gun and a welding seam is adjusted at last by performing mechanism actions. In the invention, the information of welding seam profile is obtained by transverse scanning of a laser sensor, and welding seam is rebuilt after effective wave filtering treatment to realize three-dimensional detection of the welding seam; simultaneously, the welding track curve is obtained by fit while detecting welding seam by using dynamic B spline fit algorithm, and the track control is carried out in combination with constant speed B spline track interpolation algorithm, thereby fundamentally solving the problem of track detection and control in automatic welding of plate butt weld. By using the method in the invention, the field test welding has welding profile identification precision of 0.15mm and welding track identification precision of 0.2mm, and the welding speed is more than four times of common manual welding.

Owner:SHANDONG UNIV

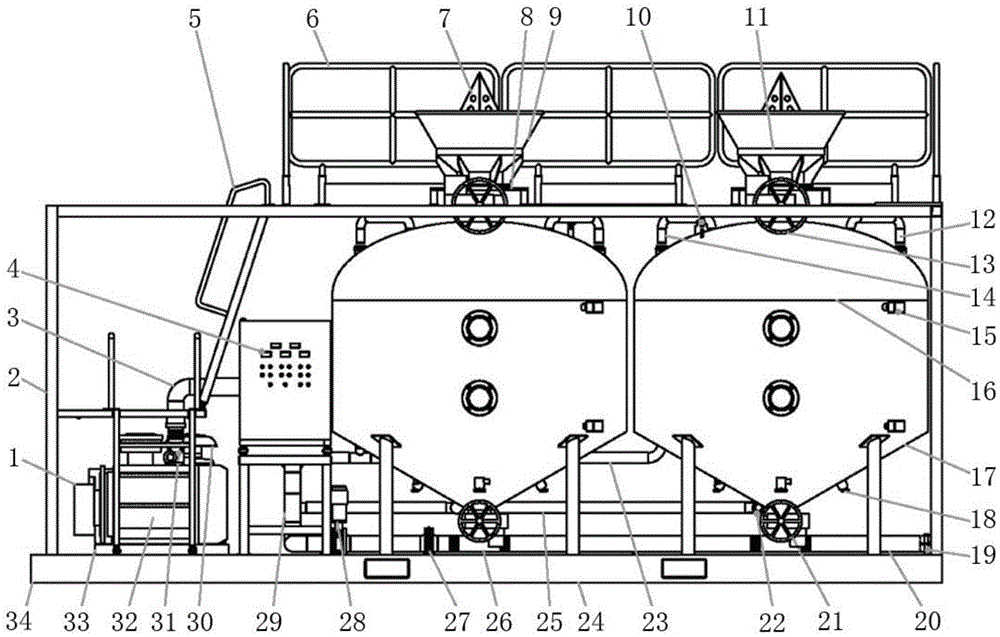

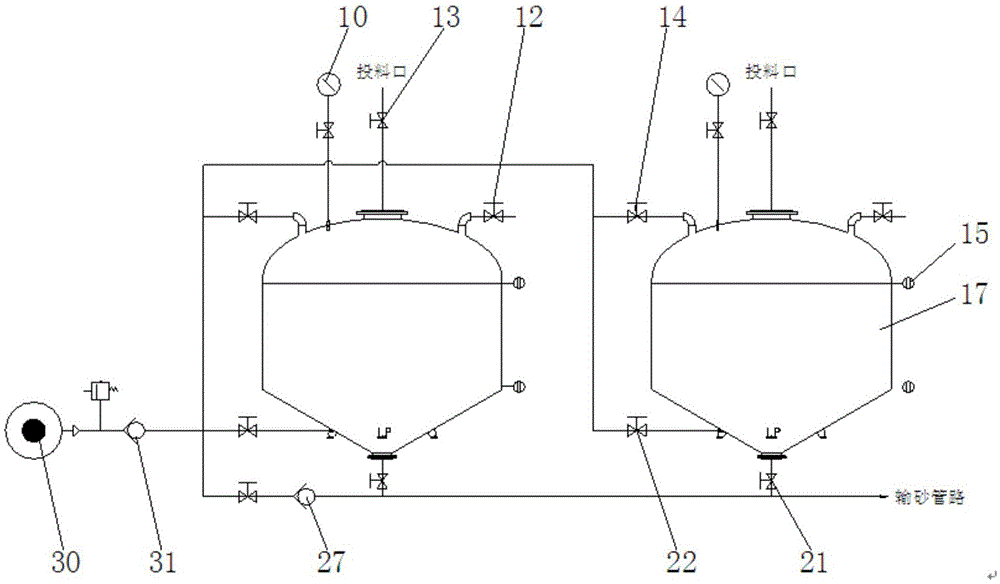

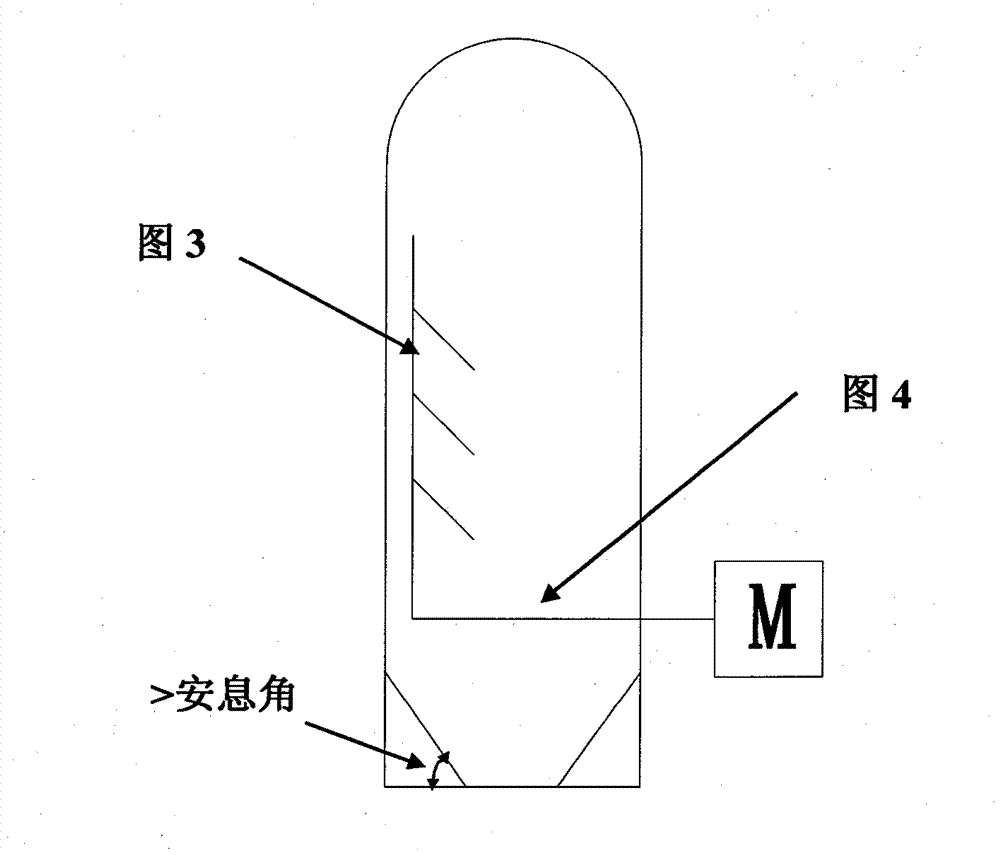

A positive pressure pneumatic conveying skid for oil field fracturing proppant

ActiveCN104340682BImprove securityReduce the difficulty of homeworkBulk conveyorsPositive pressureControl system

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

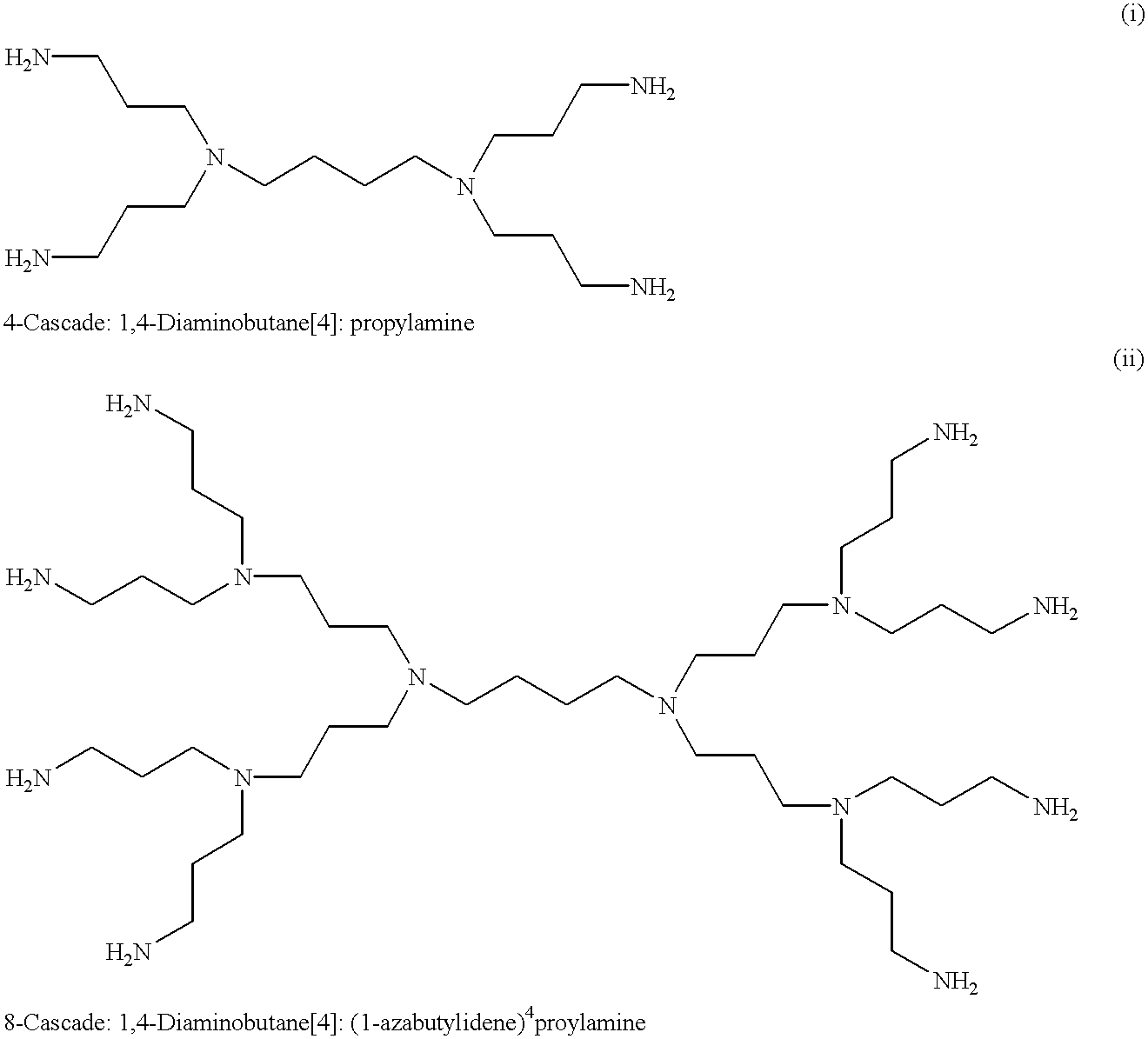

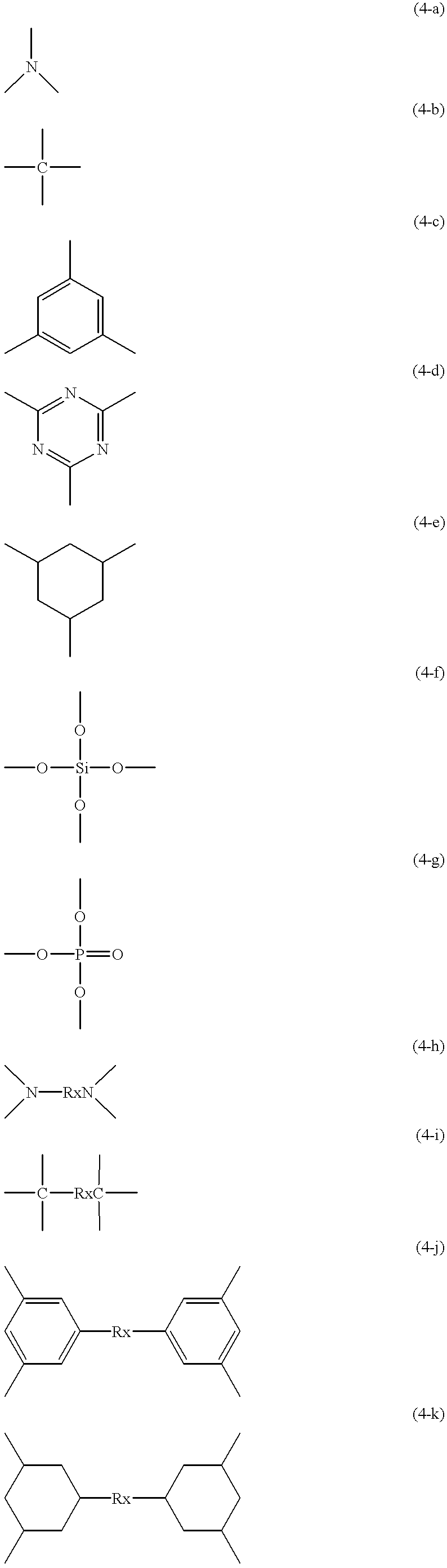

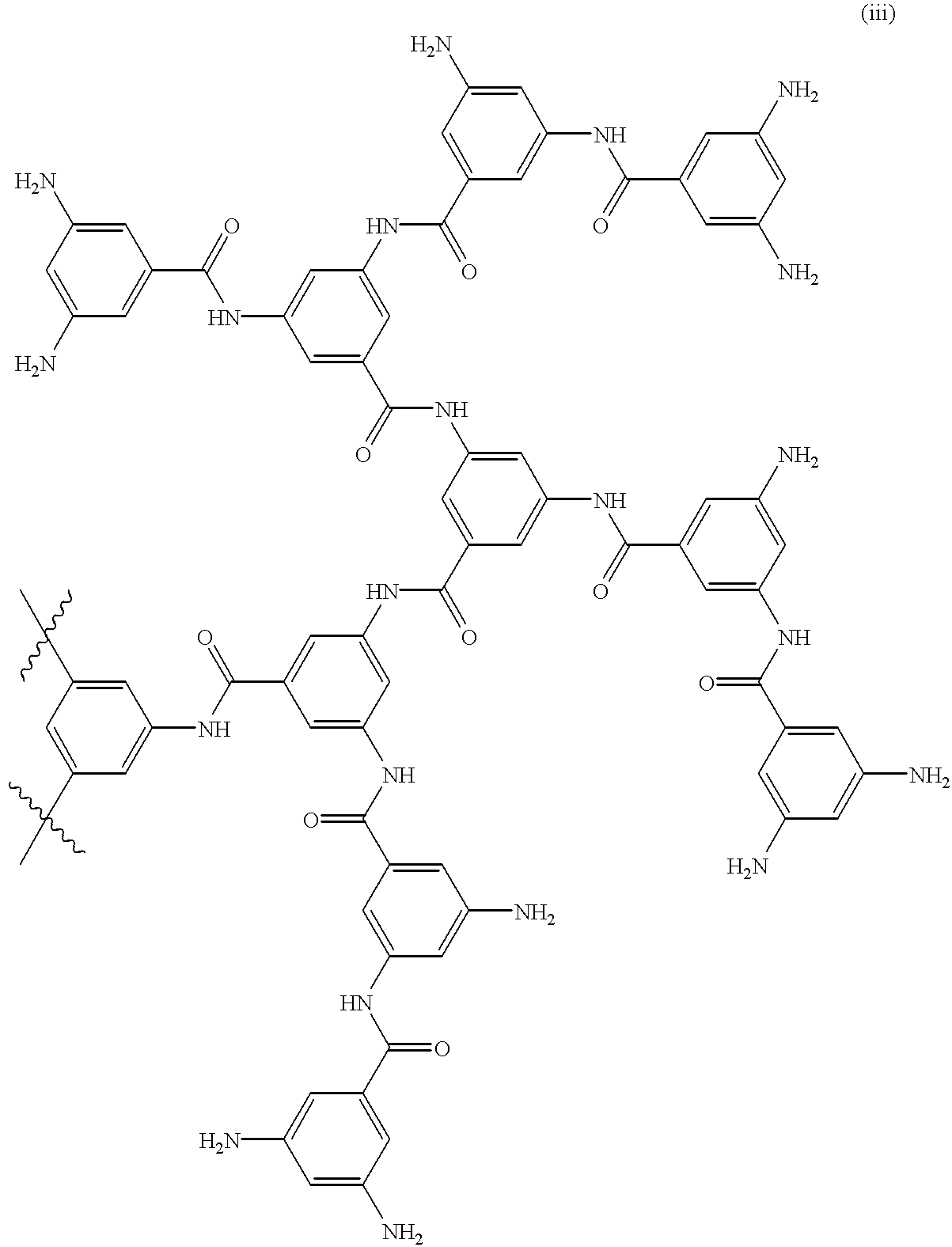

Vinyl-group-containing dendrimer and curable composition

A vinyl-group-containing dendrimer useful in coating and printing and is curable by any one of conventional triggers such as heating, ultraviolet light, infrared light, electron beams and gamma rays, the composition comprising a vinyl-group-containing dendrimer (A) comprising a core portion, branching portions, branches and at least 4 terminal portions and having a vinyl group as a terminal portion and a long-chain group and a curable unsaturated-group-containing compound (B), and the composition comprising a vinyl-group-containing dendrimer (A) obtained by reacting a polyfunctional compound (a) having at least three active-hydrogen-containing groups in a terminal per molecule and having at least five active hydrogen atoms per molecule with a long-chain-group-containing compound (b) having a functional group reactive with an active hydrogen atom so as to leave part of the active hydrogen atoms, thereby obtaining a long-chain-group-containing multi-branched compound (X), and reacting the long-chain-containing multi-branched compound (X) with a vinyl-group-containing compound (c) having a functional group reactive with an active hydrogen atom and a curable unsaturated-group-containing compound (B).

Owner:TOYO INK SC HOLD CO LTD

Preparation of 2,2-bi-[4-(4-aminophenoxy)phenyl]propane

InactiveCN1472193AEasy to operateImprove working environmentOrganic compound preparationAmino-hyroxy compound preparationActivated carbonAlcohol

A process for preparing 2,2-bis-[4-(4-aminophenyloxy)phenyl] propane includes such steps as reflux reacting between 4,4'-dihydroxydiphenyl propane (BPA), 1-chloro-4-nitrobenzene (CNB) and salting agent in the mixture of non-protonic transferring polar solvent and dewatering agent at 110-150 deg.C to obtain 2,2-bis-[4-(4-nitrophenyloxy)phenyl] propane (BNPP), and reducing in alcohol as solvent under action of hexahydrated iron chloride, activated carbon and hydrazine hydrate. Its advantages are simple process, low cost and high quality and output rate of product.

Owner:TANSUO SCI & TECH NANTONG CITY

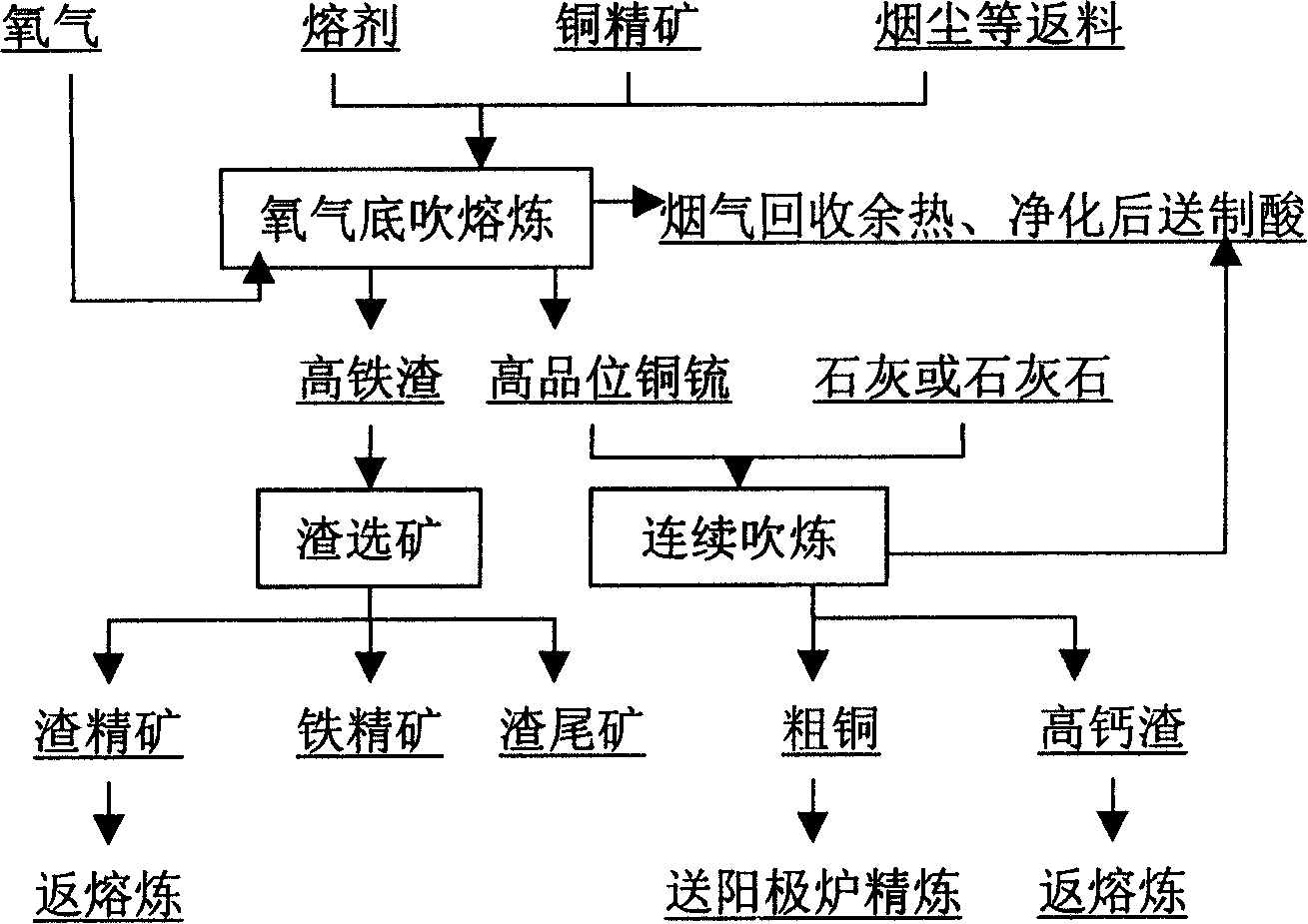

Technique for continuously smelting copper by employing oxygen bottom converter and device thereof

ActiveCN101165196AReduce loadHigh smelting yieldProcess efficiency improvementAutomatic controlSmelting process

The present invention relates to continuous copper-smelting oxygen bottom blowing furnace process and apparatus. The continuous copper-smelting process includes smelting high grade copper matte in an oxygen bottom blowing furnace, smelting coarse copper product with the high grade copper matte in one other bottom blowing furnace, producing high iron slag, dressing the furnace slag to obtain copper concentrate and returning to smelting furnace, separating out iron concentrate product and obtaining tailings. The process has short flow path, low investment, low power consumption, low cost, environment friendship and other advantages.

Owner:CHINA ENFI ENGINEERING CORPORATION

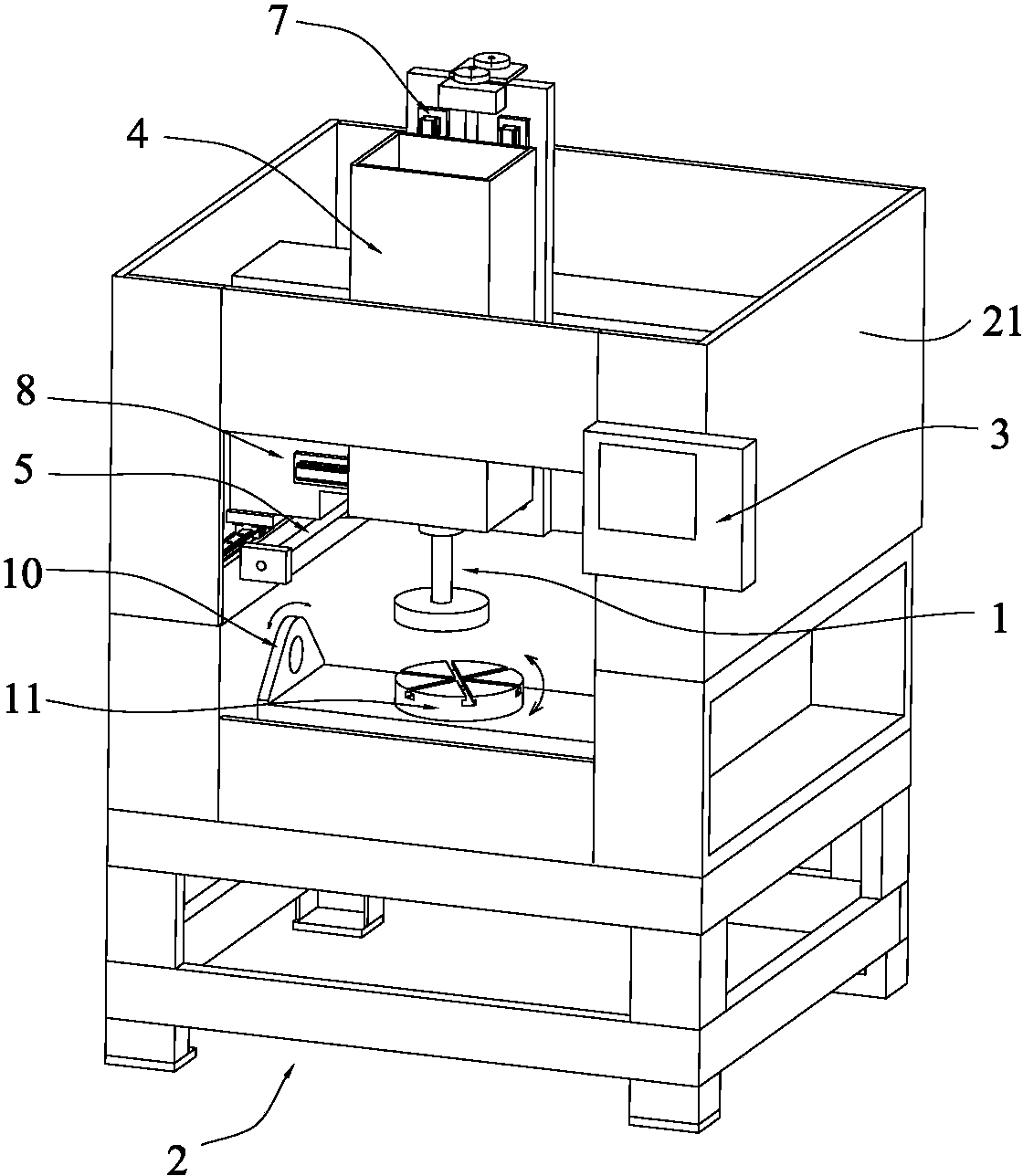

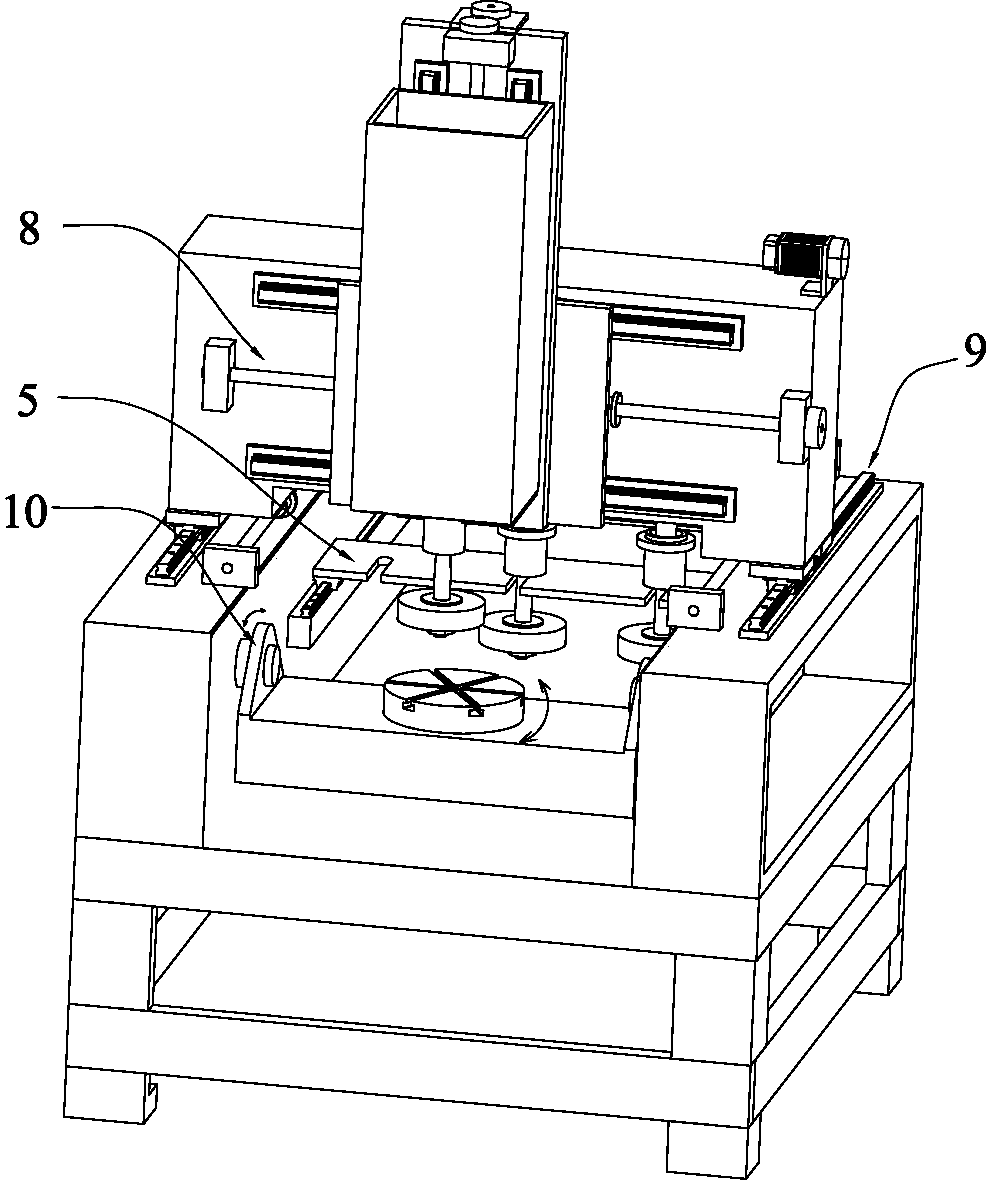

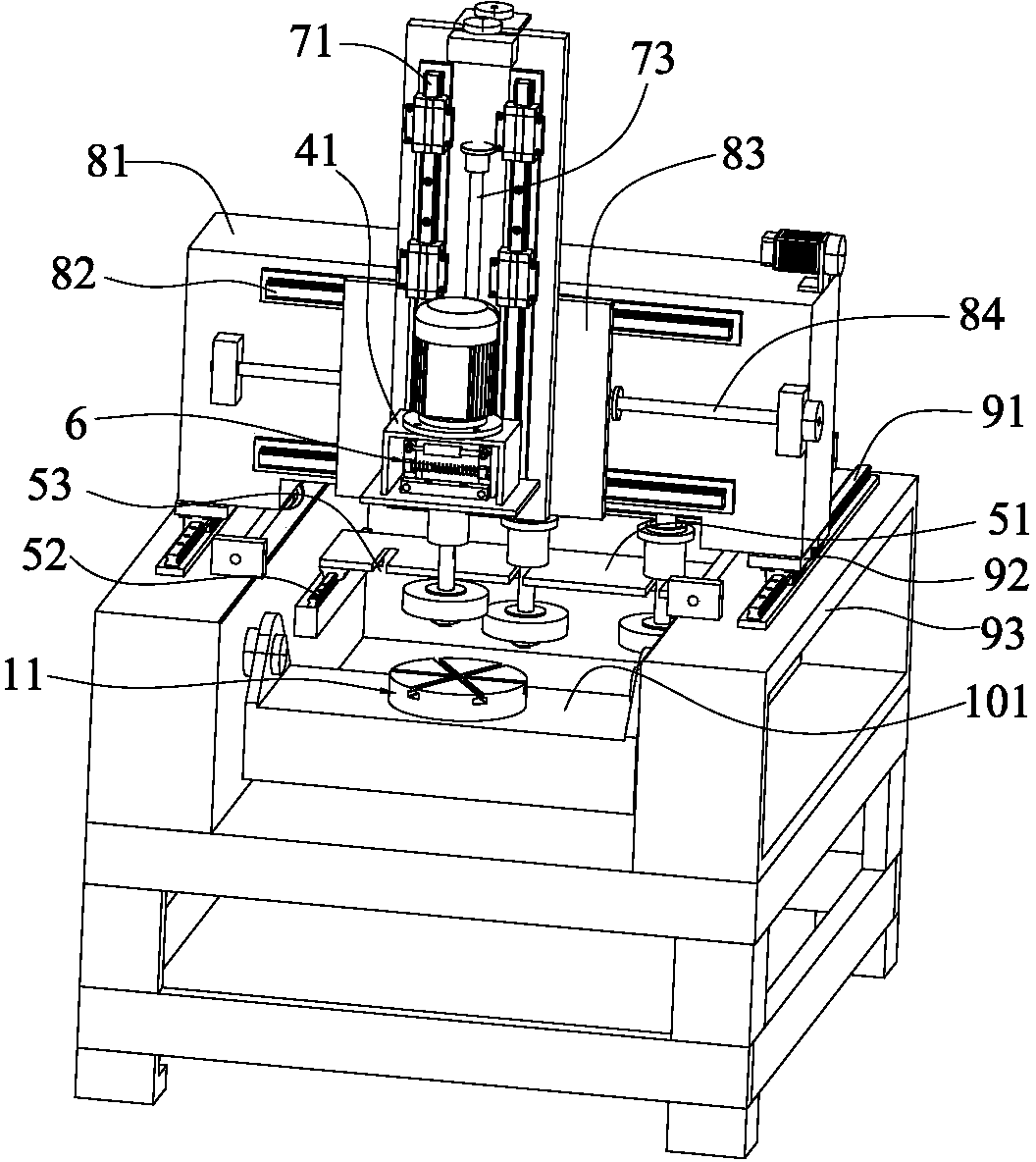

Five-axis numerical control polishing machine capable of changing grinding heads automatically

InactiveCN103465145AAutomatic replacementReduce labor intensityPolishing machinesNumerical controlCurve shape

The invention discloses a five-axis numerical control polishing machine capable of changing grinding heads automatically. The five-axis numerical control polishing machine comprises a plurality of semi-axis grinding heads, a machine body frame, a controller, a polishing head, a grinding head supply mechanism, a spindle clamping device, a Z-axis drive mechanism, an X-axis drive mechanism, a Y-axis drive mechanism, an A-axis rotary workbench and a C-axis rotating mechanism. The polishing head, the grinding head supply mechanism, the spindle clamping device, the Z-axis drive mechanism, the X-axis drive mechanism, the Y-axis drive mechanism, the A-axis rotary workbench and the C-axis rotating mechanism are respectively connected with the controlled and controlled by the same. The five-axis numerical control polishing machine capable of changing grinding heads automatically has the advantages that the polishing machine is ingenious and reasonable in structural design, high in automation level, convenient and fast to operate, high in flexibility by the five-axis linkage structure, and widely applicable; multiple polishing procedures such as rough polishing, fine polishing and mirror polishing can be completed at one-step clamping, clamping time is saved, machining efficiency and precision are increased greatly, polishing effect is guaranteed, work efficiency is increased, labor intensity of workers is lowered, enterprise competitiveness is increased effectively, and polishing of surfaces of complex curve shapes can be achieved.

Owner:东莞市钜铧机械有限公司

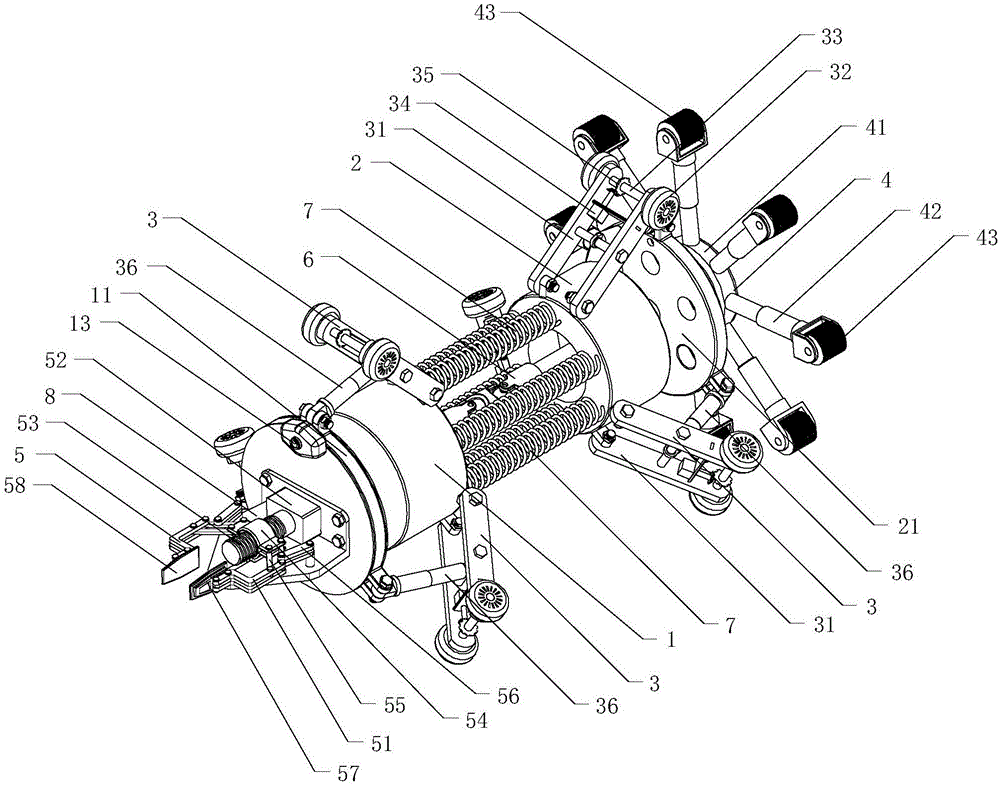

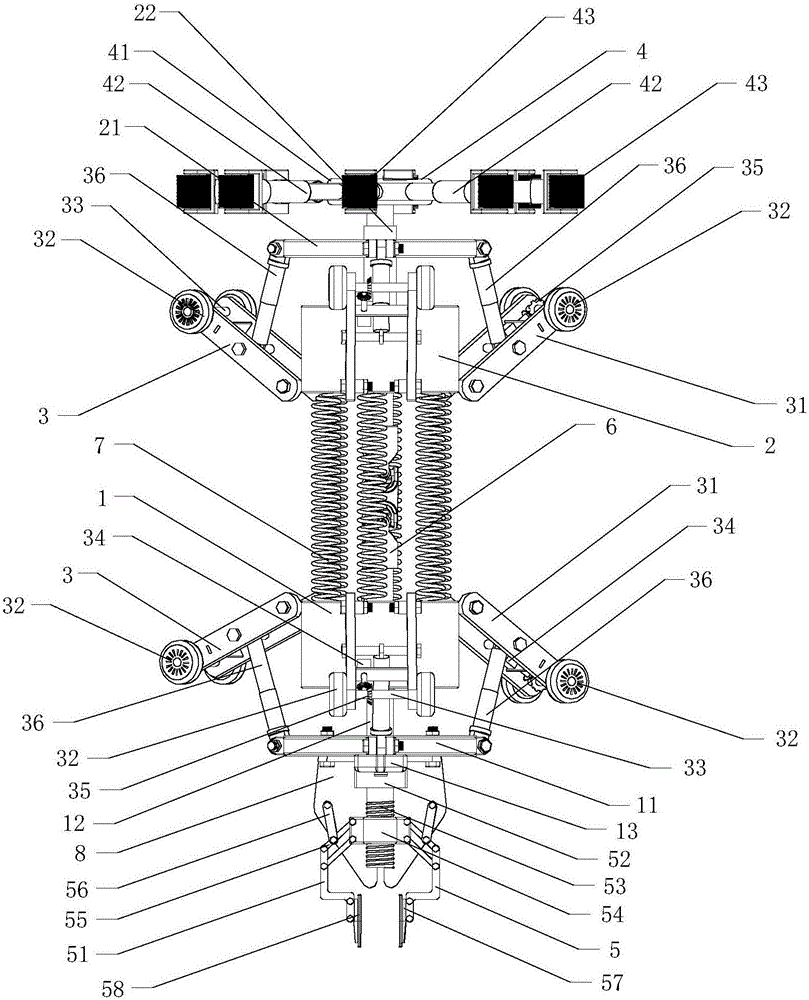

Novel telescopic pipeline cleaning robot

ActiveCN106623296AImprove working environmentEliminate sanitary cornersHollow article cleaningCouplingEngineering

The invention discloses a novel telescopic pipeline cleaning robot which comprises a first body, a second body, two traveling mechanisms, a cleaning device and a mechanical arm. The first body and the second body are arranged in the front-back direction and connected through a double-joint universal coupler. The traveling mechanisms are arranged on the outer side of the first body and the outer side of the second body correspondingly. The cleaning device is arranged on the rear side of the second body and comprises a cleaning disc and a plurality of telescopic rods. The cleaning disc is connected with a first motor arranged inside the second body. The multiple telescopic rods are evenly arranged on the edge of the cleaning disc in an annular mode. One end of each telescopic rod is fixedly connected with the cleaning disc, and a cleaning wheel is arranged at the other end of each telescopic rod. A bracket is arranged on the front side of the first body, and the mechanical arm is installed on the bracket. When the novel telescopic pipeline cleaning robot is used for cleaning different pipelines, the inner walls of the pipelines with different diameters and curvature degrees can be cleaned by adjusting the lengths of the telescopic rods, the novel telescopic pipeline cleaning robot is suitable for variable-diameter pipelines of complex structures, the adaptability is high, and the cleaning efficiency is high.

Owner:SHANDONG UNIV OF SCI & TECH

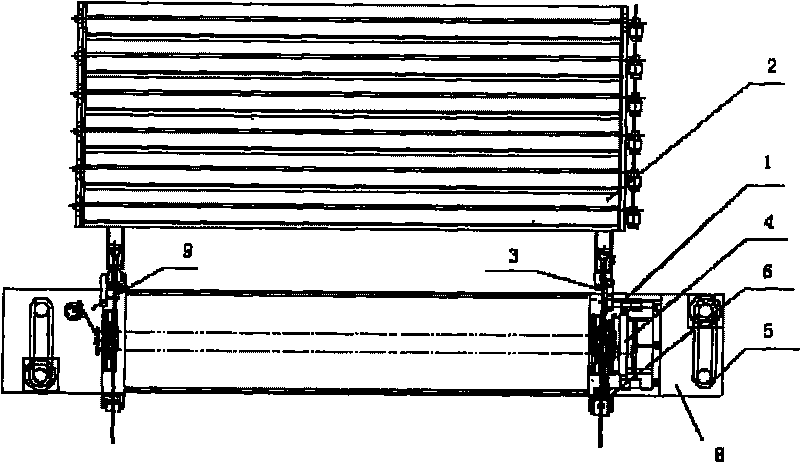

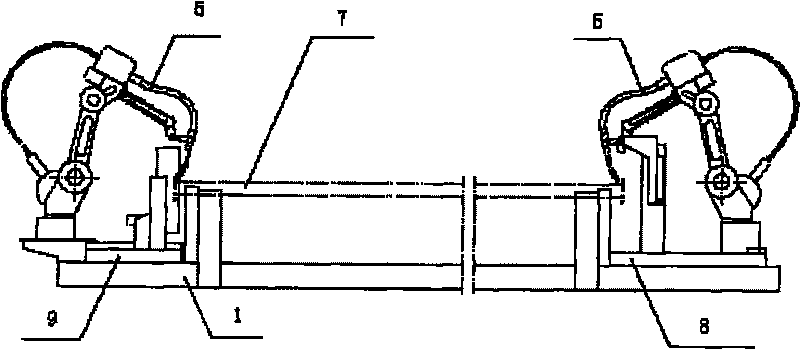

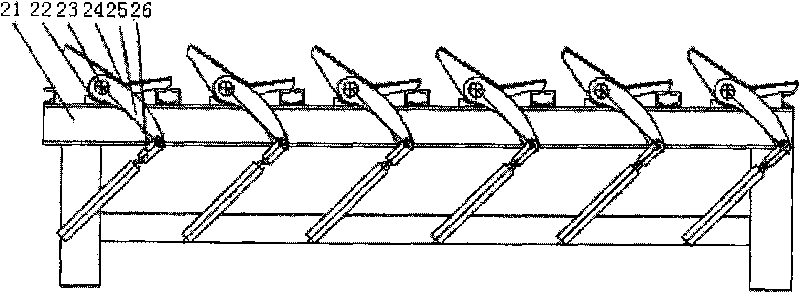

Pipe-flange automatic welding equipment

ActiveCN101733593AReduce labor intensityIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesManufacturing technologyWorking environment

The invention discloses pipe-flange automatic welding equipment, which comprises a machine frame. The pipe-flange automatic welding equipment is characterized in that the machine frame is provided with a rack conveyor and also provided with a feeding positioning device, a clamping rotating device, a discharging device and a welding device. In the invention, the conventional welding processing mode which is operated manually and performs production discretely is converted into the automatic welding production mode which runs in a continuous production line, so the production efficiency and the welding quality of the product are improved, the working environment is improved, the labor intensity of workers is reduced and the level of ship-manufacturing technology can be improved.

Owner:上海中船临港船舶装备有限公司 +1

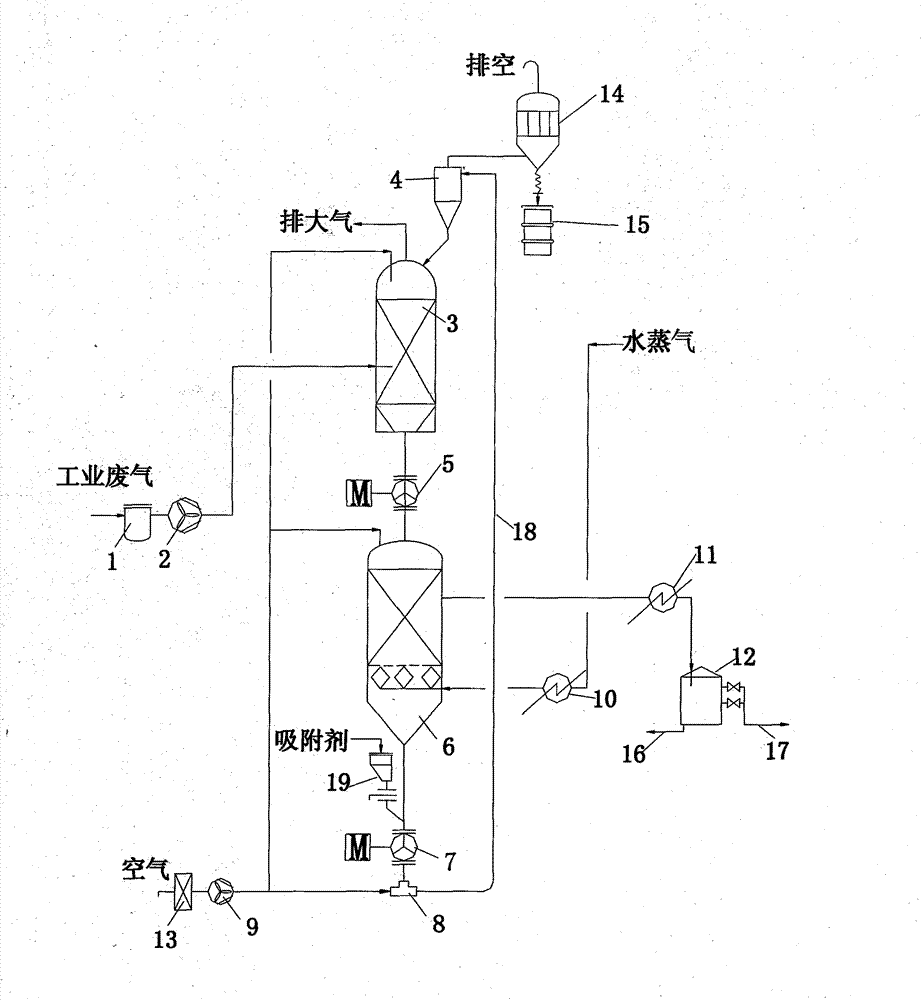

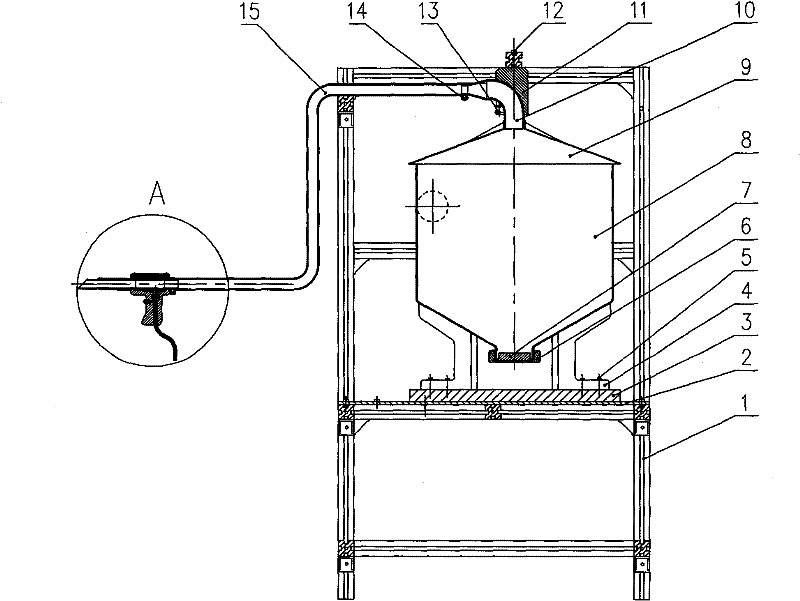

Device for continuously adsorbing and desorbing organic waste gas by using active carbon

ActiveCN102772981AFully furnishedImprove stabilityDispersed particle separationBenzeneActivated carbon

The invention relates to the technical field of industrial waste gas treatment and particularly relates to a treatment technology for continuously adsorbing an organic solvent in the industrial waste gas and continuously desorbing the solvent. The invention provides a device for continuously adsorbing and desorbing organic waste gas by using active carbon. The device comprises an adsorbing tower (3), a desorbing tower (6), an active carbon fluidization system, and an organic solvent recycling system. The organic waste gas, including methylene dichloride, methylbenzene, dimethylbenzene, benzene and the like, is continuously adsorbed by using the active carbon. The device has the outstanding characteristics that the adsorbing process and the desorbing process can be continuously and synchronously carried out. The organic waste gas and the active carbon are in inverse contact; the gas distribution is uniform; and the particle mobility is good. The active carbon is circularly used in a dense phase pneumatic transmission manner. The device provided by the invention has a simple and stable technique; and the labor intensity of staff and the environment pollution caused by the powder active carbon can be greatly reduced.

Owner:甘肃银光聚银化工有限公司 +1

Pipeline inner wall rust removal device

ActiveCN104723223AAvoid pollutionReduce direct damageGrinding machinesAbrasive machine appurtenancesPneumatic motorPollution

The invention discloses a pipeline inner wall rust removal device, belonging to the technical field of polishing units. The device comprises a first end cover and a second end cover which are hermetically installed at two ends of the pipeline, a rust removal trolley is arranged in the pipeline, the dust removal trolley comprises a pneumatic motor with dual output shafts, a shell of the pneumatic motor is provided with a plurality of support shafts, the end part of each support shaft is provided with a roller wheel, a grinding disc is fixedly installed on the output shaft of the pneumatic motor, close to the first end cover, and is provided with a plurality of support rods in the radial direction, the end part of each support rod is provided with an abrasive disc, the output shaft of the pneumatic motor, close to the second end cover, is connected with a shot-blasting machine in a transmission manner; the end part of the grinding disc is connected with a traction rope, the traction rope extends out of the first end cover, one end of the shot-blasting machine, close to the second end cover, is connected with a shot feeding pipe, the pneumatic motor is connected with a gas inlet pipe, the shot feeding pipe and the gas inlet pipe extend out of the second end cover. The pipeline inner wall rust removal device can be used for solving the technical problems that the pipeline inner wall is serious in rust removal pollution and the rust removal effect is poor, and can be widely applied to pipeline cleaning.

Owner:SHANGHAI HONGPU STEEL STRUCTURE ENG

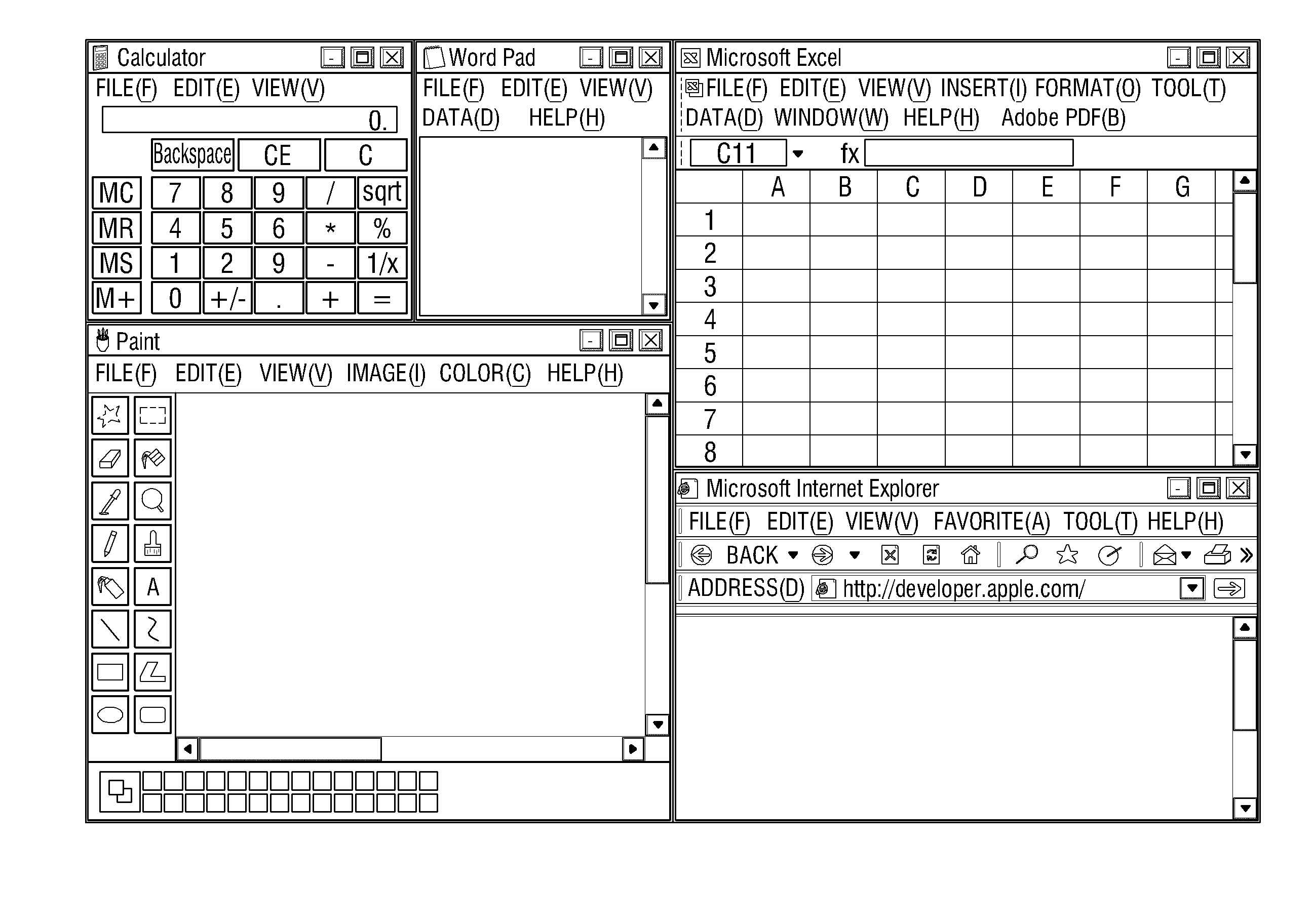

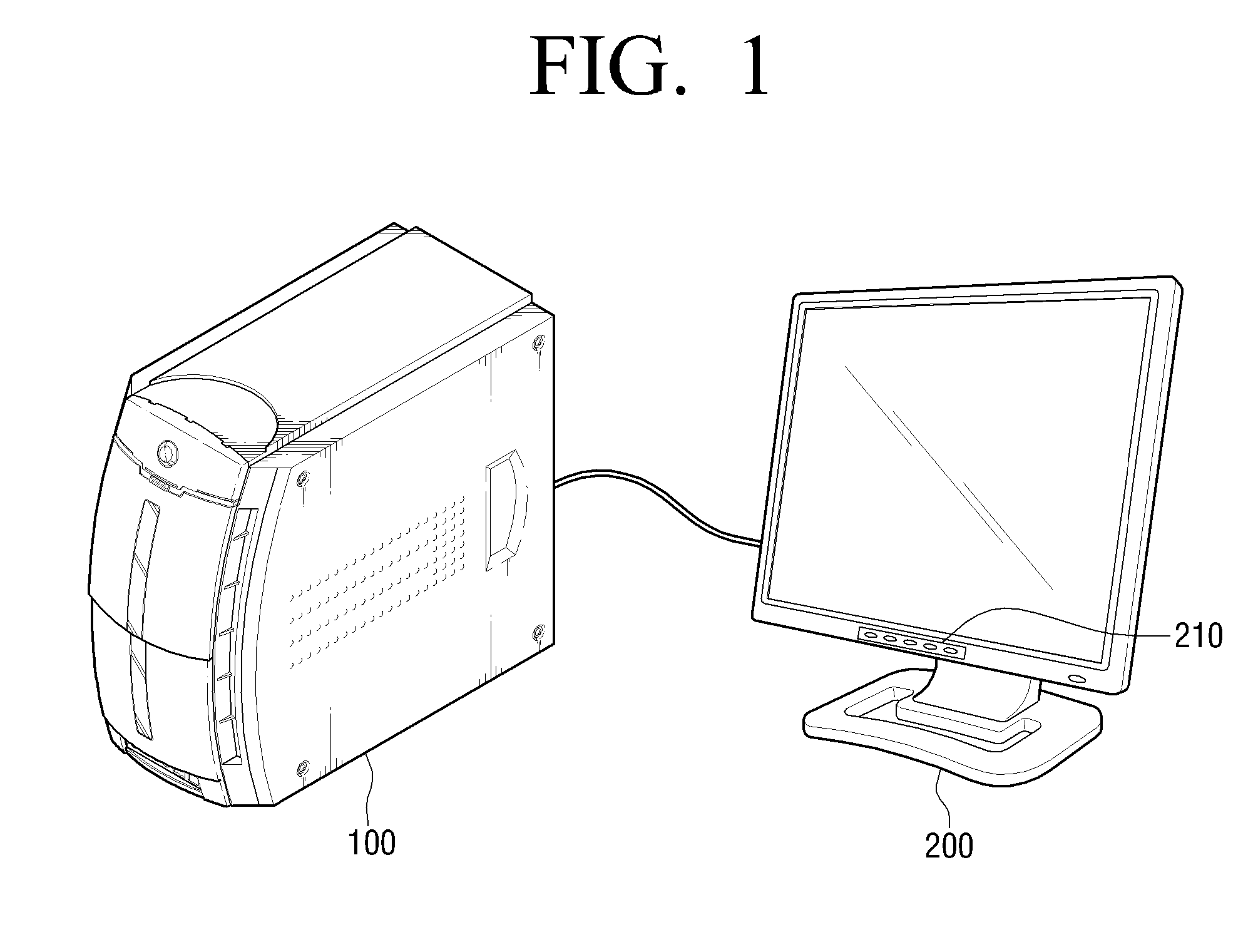

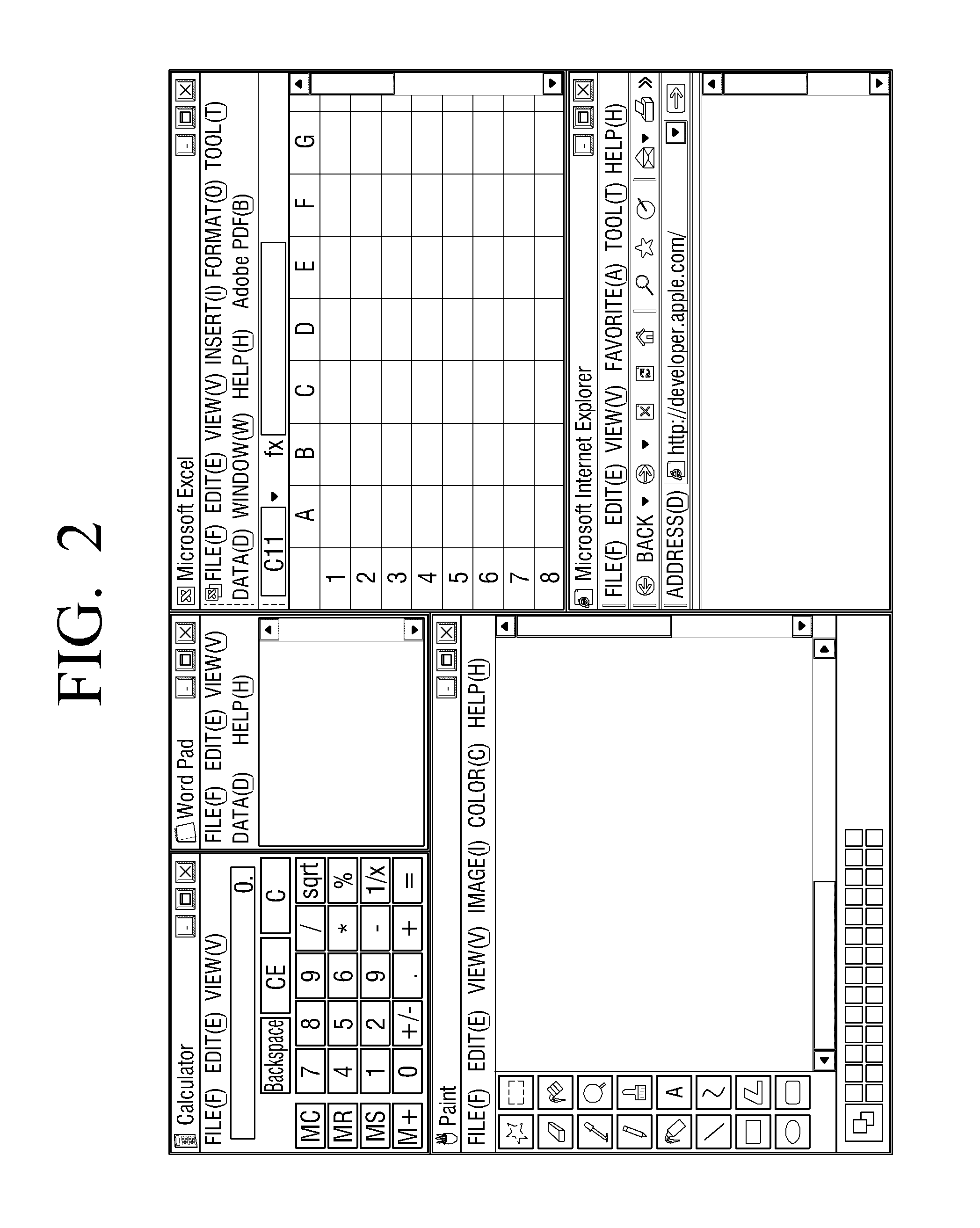

Method for displaying screen, method for generating screen, method for operating application, and electronic device using the same

InactiveUS20100313154A1Convenience to workImprove working environmentDigital computer detailsImage data processing detailsWorking environmentComputer science

A method for displaying a screen, a method for generating a screen, a method for operating an application, and an electronic device using the same are provided. The method for displaying a screen of the present invention stores information regarding display state of the screen and displays the screen according to the stored information. Accordingly, a user can be provided with a desired working environment more conveniently and rapidly.

Owner:SAMSUNG ELECTRONICS CO LTD

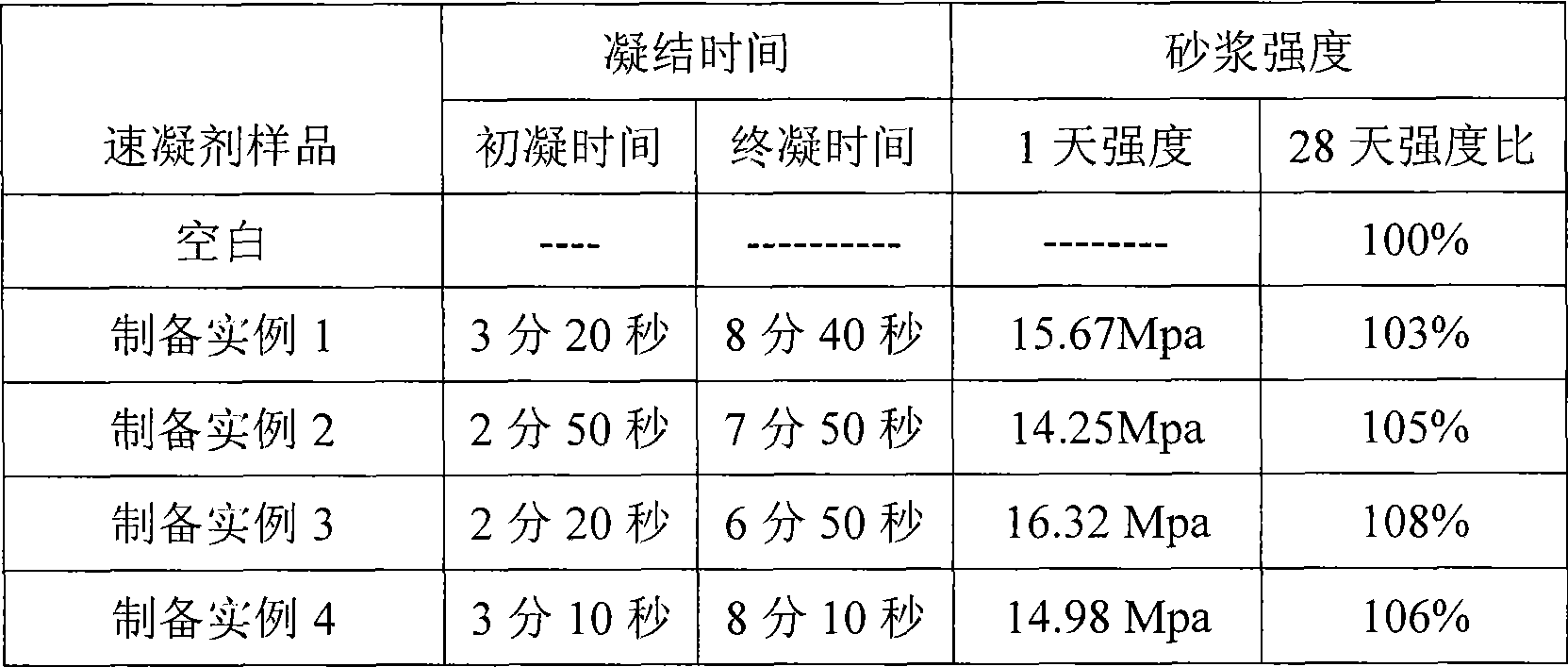

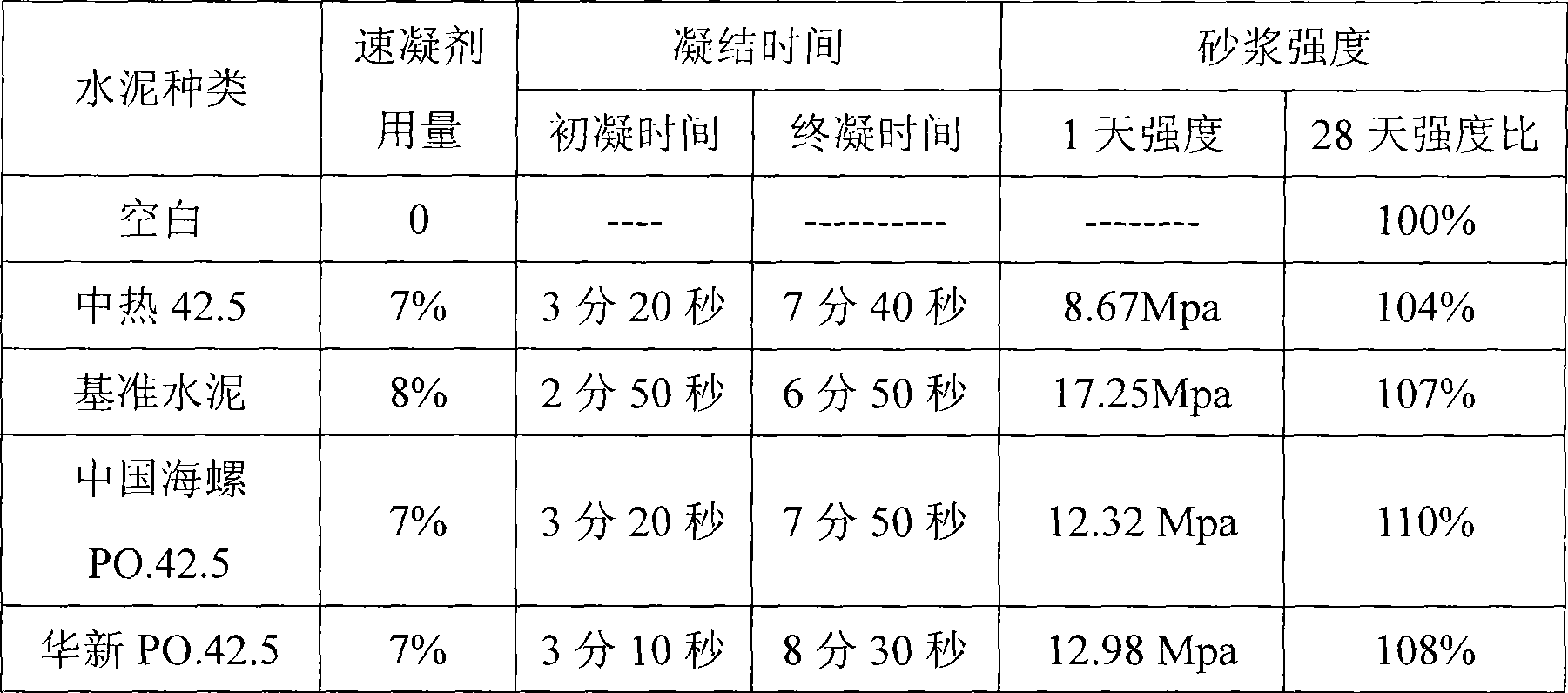

Liquid accelerator for sprayed concrete and preparation thereof

The invention relates to a liquid accelerator for shotcrete and a method for preparing the same. The liquid accelerator is prepared from the following components in percentage by weight: 25 to 70 percent of aluminum sulfate, 0 to 8 percent of metal fluoride, 1 to 10 percent of amine substance, 0.5 to 7 percent of pH regulator, 0.01 to 1 percent of thickening agent, and the balance being water. The method for preparing the liquid accelerator comprises the following steps: firstly, dissolving the fluoride into the water; secondly, adding the amine substance to the mixture and heating the solution to a temperature of between 40 and 80 DEG C; thirdly, adding the aluminum sulfate to the solution to perform heat preservation reaction until the solution becomes a uniform liquid; and fourthly, adding the pH regulator and the thickening agent to the uniform liquid and stirring the mixture evenly to finally obtain a uniform liquid substance which is the liquid accelerator for the shotcrete. The liquid accelerator is free from corrosion, has no penetrating odor, has good storage stability so that the phenomena of deposition, crystallization and the like do not appear after the storage of more than 6 months at a temperature of between 0 and 35 DEG C, and does not influence the effect in practice. Using the liquid accelerator with lower mixing proportion (5 to 8 percent), cement can be initially set within 4 minutes and finally set within 10 minutes, and the strength of cement mortar within one day is more than 10 MPa and the storage rate of the strength within 28 days is more than 100 percent.

Owner:JIANGSU SUBOTE MATERIAL

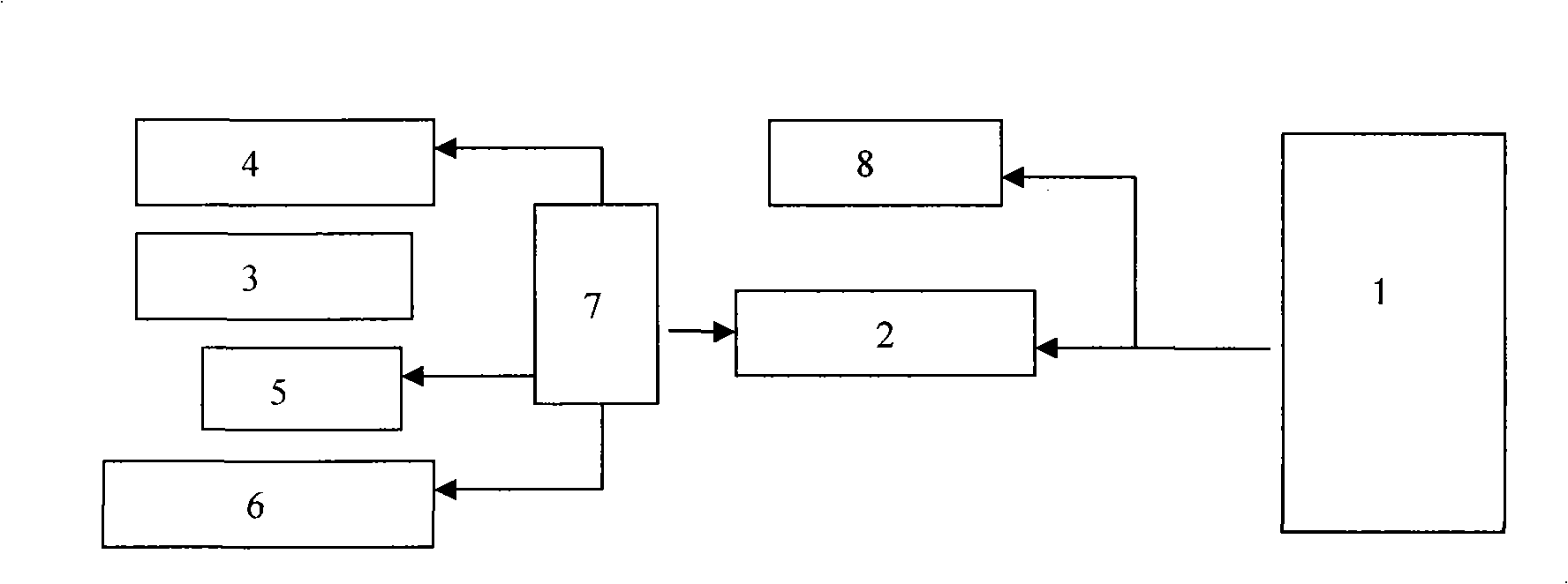

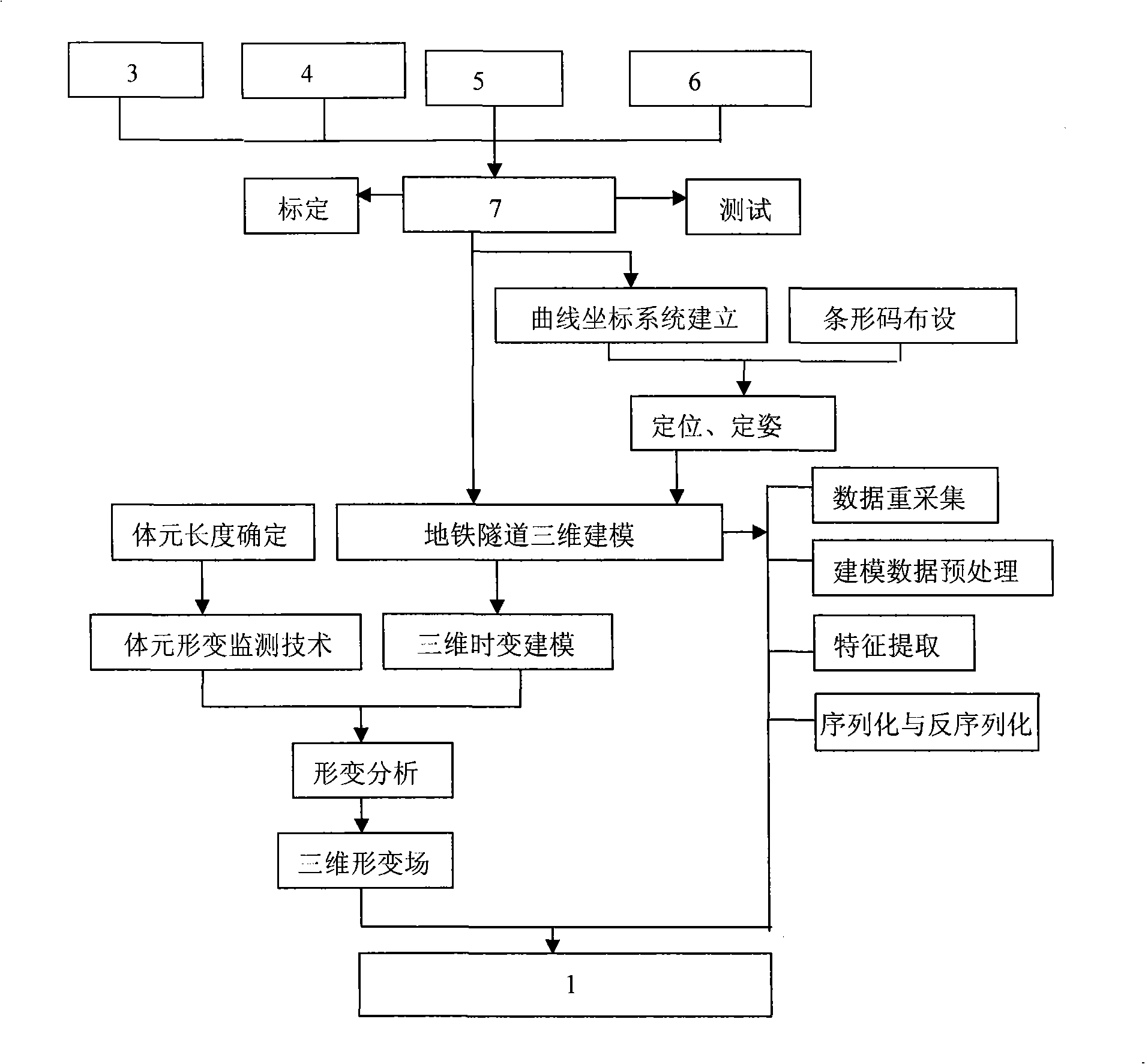

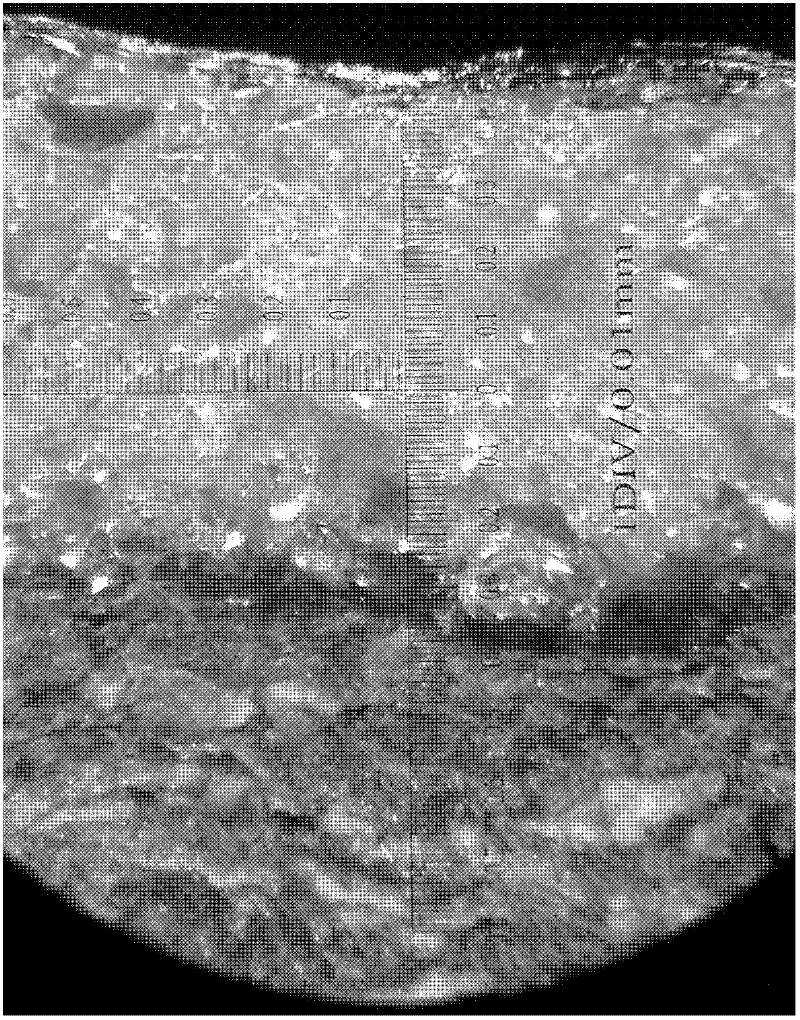

Tunnel volume element deformation movable monitoring system and method

InactiveCN101408410AQuick collectionDynamic acquisitionUsing optical meansProfile tracingPoint cloudMonitoring system

The invention discloses a tunnel body form deformation mobile monitoring system and a monitoring method thereof. The hardware comprises a laser scanner, a CCD camera, a speed meter, an inertial navigator, a central control unit and bar codes. The central operation control unit leads the hardware of each sensor to be synchronous, stores the data of each sensor and carries out the corresponding position and stature calculation so as to process the obtained point cloud data of the tunnel sections; the bar codes are distributed at the positions on the tunnel surface where the CCD camera can shoot and the storage position information of the bar codes is adopted as the position reference of moving carriers and sensors. The hardware of the tunnel body form deformation mobile monitoring system provided by the invention is helpful for quickly and dynamically collecting space data and for further carrying out the body form deformation analysis through three dimensional modeling and reconstruction of models so as to monitor the deformation process continuously.

Owner:SHANDONG UNIV OF SCI & TECH

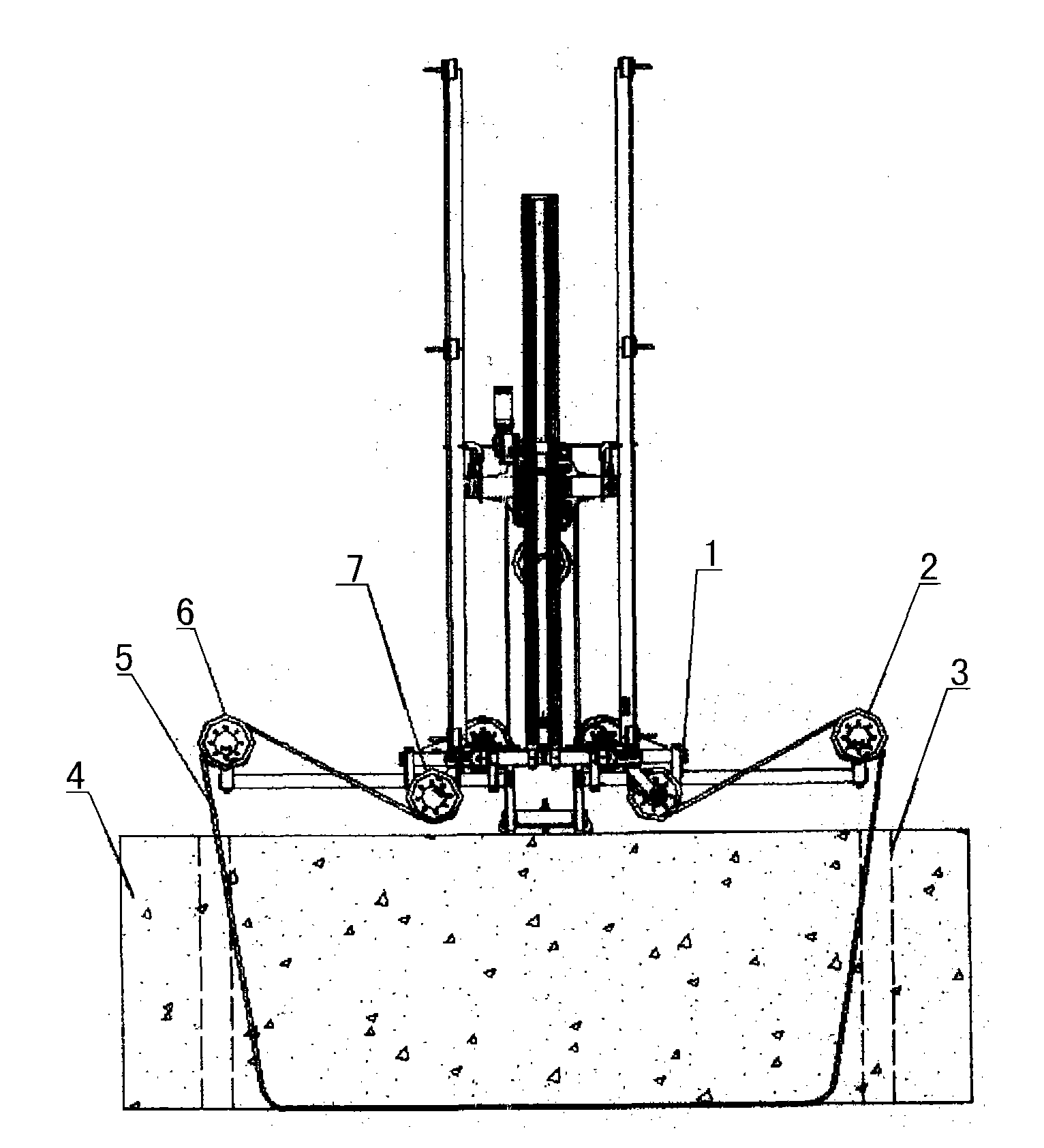

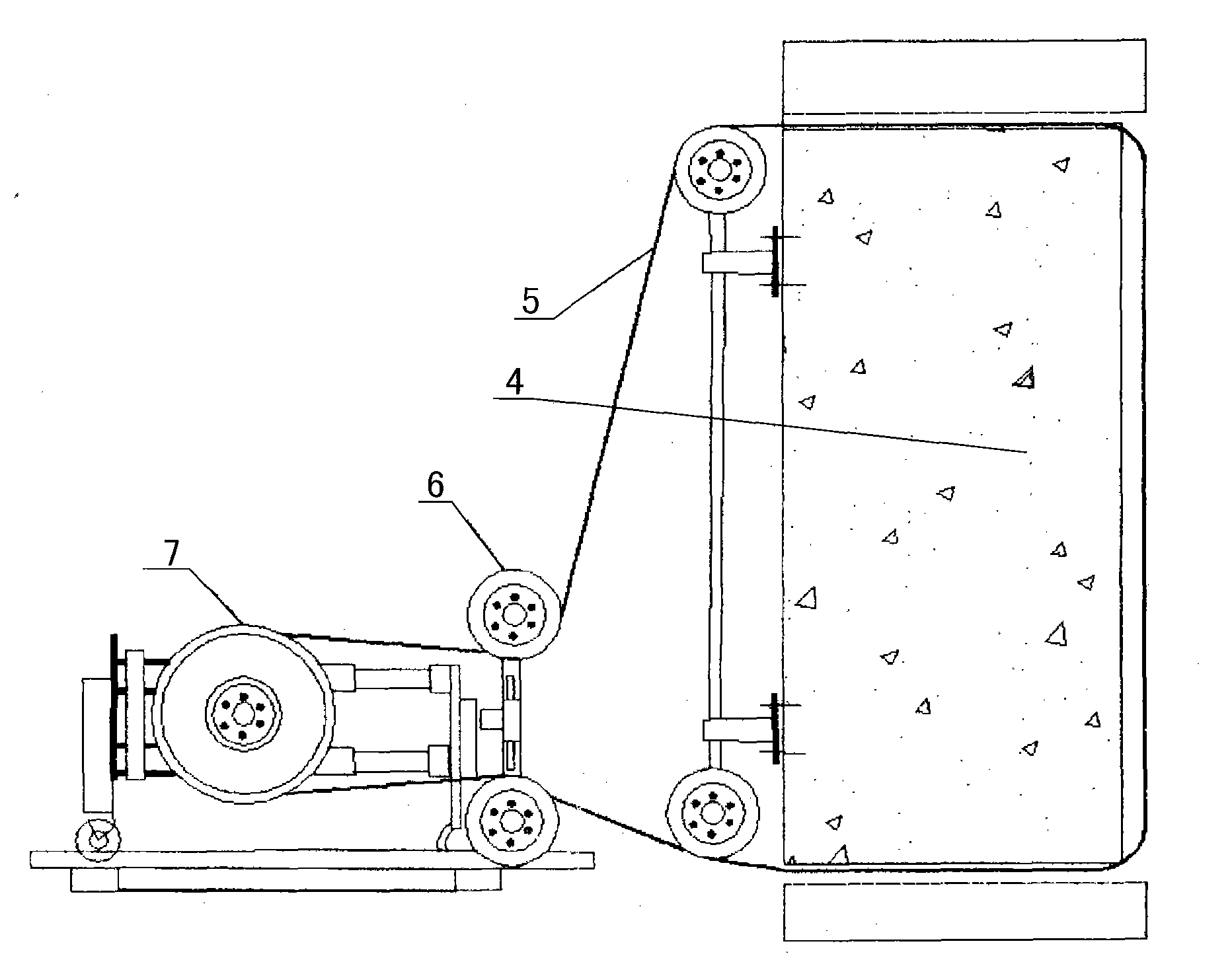

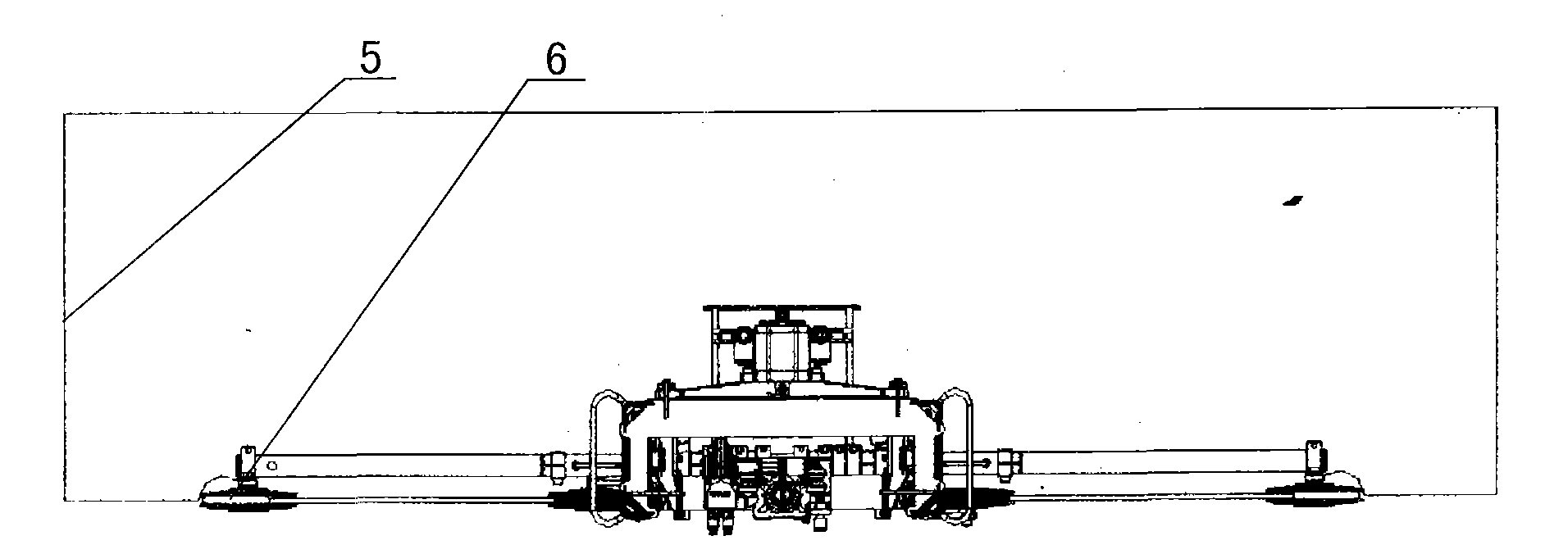

Diamond rope saw static force cutting method

InactiveCN101768926AImprove cutting efficiencySimple construction processBuilding repairsGrinding machinesHydraulic motorReinforced concrete

The invention provides a diamond rope saw static force cutting method, relating to a diamond cutting method. In the invention, an adopted hydraulic pressure diamond rope saw is driven by an hydraulic motor to move at a high speed around the cut surface of a cutting object (4) so as to cut the cutting object (4); the grinding material of diamond rope saw (5) is diamond particles, so the diamond rope saw can be used for cutting stone, reinforced concrete or other hard materials; the power source of the cutting is the hydraulic motor, a hydraulic pump is driven by the hydraulic motor to operate smoothly; and the hydraulic motor can be distantly controlled by a high-pressure oil pipe to reduce vibration and noise in cutting process and enable the cutting object (4) is cut and separated stably. The invention has the advantages of high safety and efficiency and environment protection.

Owner:CHINA RAILWAY TUNNEL GROUP CO LTD +1

Method for Deuteration of an Aromatic Ring

ActiveUS20070255076A1Improve working environmentAmino preparation from aminesOrganic compound preparationNickel catalystHydrogen

The present invention relates to a method for deuteration of a compound having an aromatic ring, using an activated catalyst, and the method comprises reacting a compound having an aromatic ring with heavy hydrogen source in the presence of an activated catalyst selected from a platinum catalyst, a rhodium catalyst, a ruthenium catalyst, a nickel catalyst and a cobalt catalyst.

Owner:FUJIFILM WAKO PURE CHEM CORP

Method for producing synthetic leather by using solvent-free double-component polyurethane scraping and coating method

The invention discloses a method for producing synthetic leather by using a solvent-free double-component polyurethane scraping and coating method and the synthetic leather produced by using the same. The method comprises the following steps: (1) controlling the flow of a material loading machine so that an M material and an N material are mixed in the mixing chamber of the material loading machine and then poured, scraped and coated to release paper coated with an isolation layer, drying so as to obtain a foamed material layer, wherein the coating amount of scraping and coating is 50-2000g / m<2>; (2) pressing and compounding the foamed material layer, heating and solidifying; and (3) coiling, curing, and separating out the release paper at last, so as to obtain the synthetic leather finished product. According to the invention, an organic solvent and water are not used in the synthesis and mixing of polyurethane resin on a foaming layer and a bonding layer and in the various links of embarkation. Compared with the method for producing the foaming layer with a water-based polyurethane composite material, the method disclosed by the invention can greatly reduce energy consumption; and the synthetic leather has good property and excellent hand feeling.

Owner:佛山市飞凌皮革化工有限公司

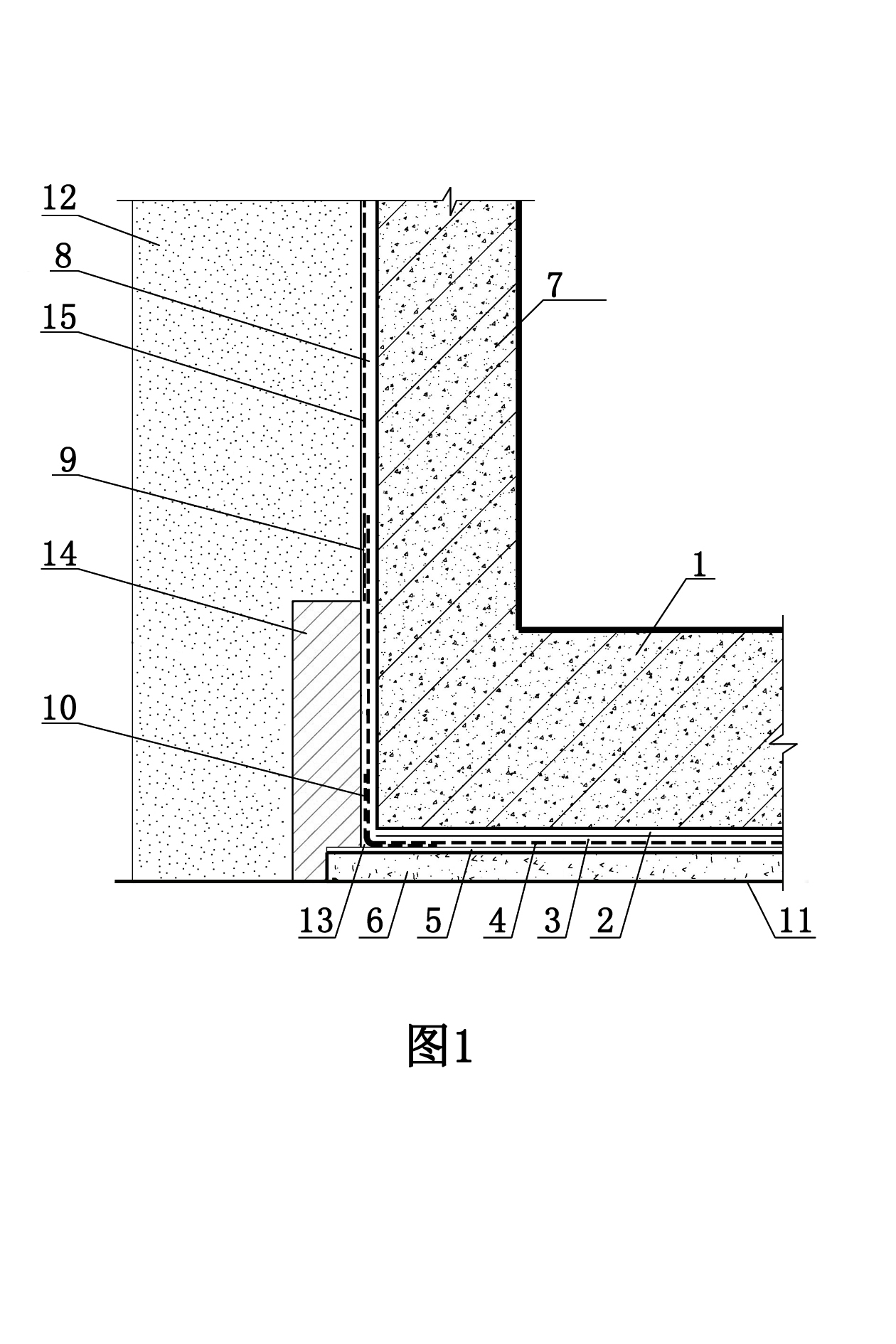

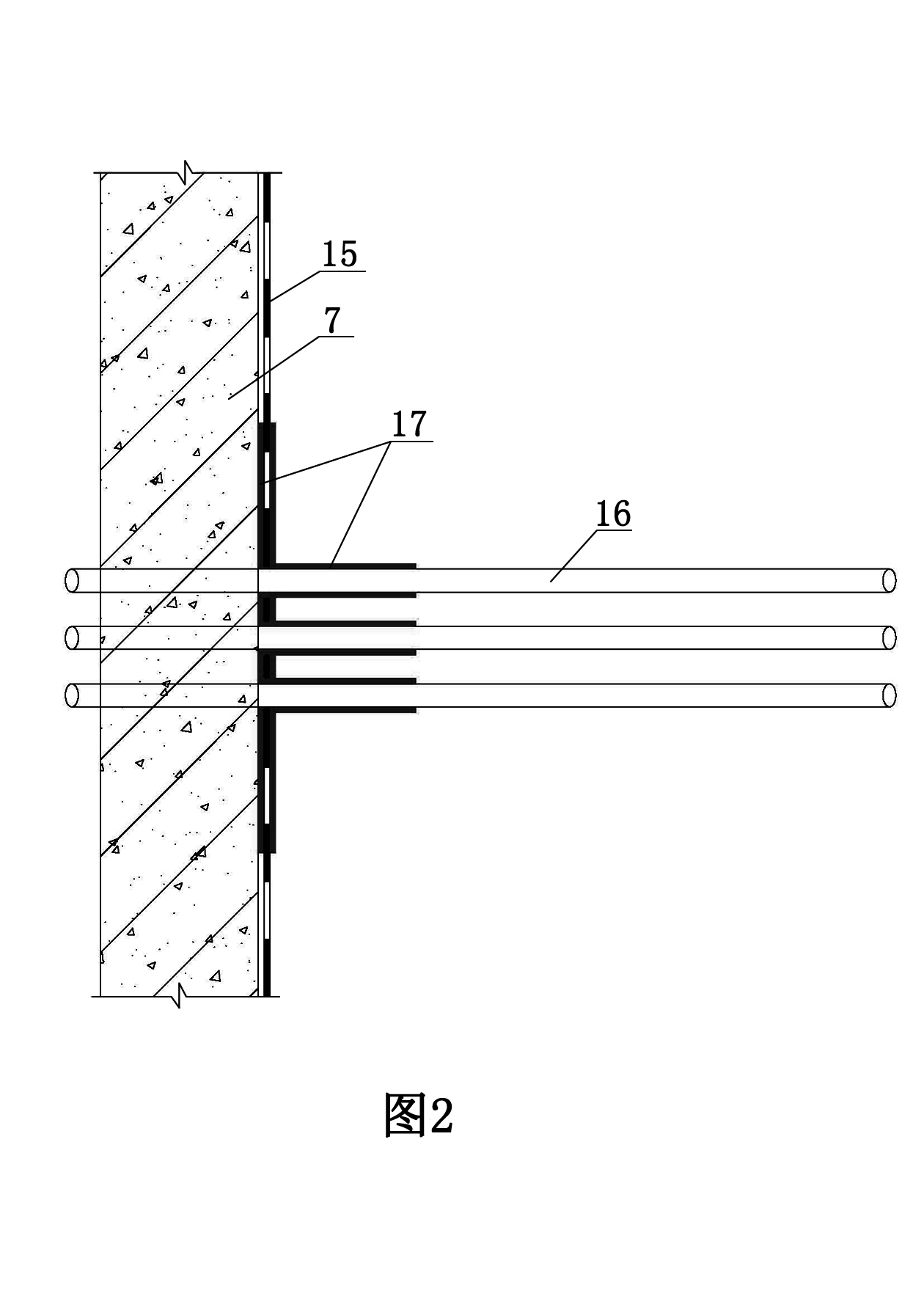

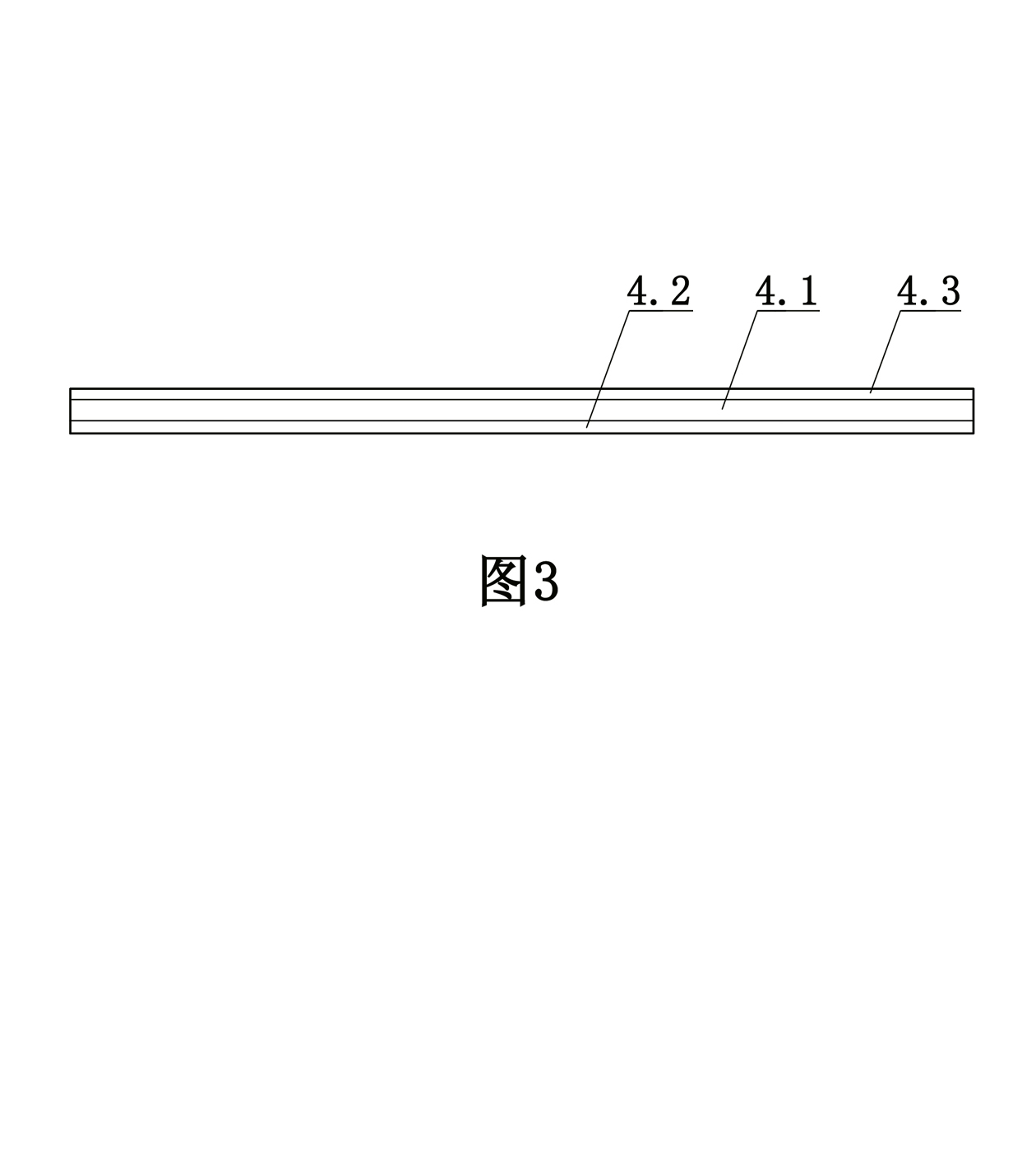

Waterproof system for basement bottom board and wall surface and construction method thereof

InactiveCN101914927AReduce weightHigh tensile strengthArtificial islandsBuild-up roofsBasementBituminous waterproofing

The invention relates to a waterproof system for a basement bottom board and a wall surface and a construction method thereof. The construction method comprises the steps of: horizontally spreading and pasting a self-adhesive rubber bituminous waterproof sheet material on a concrete base layer, and building up a brick permanent protection wall outside a preset position of a basement wall surface, wherein the bottom of the brick permanent protection wall is vertically connected with the concrete base layer, the self-adhesive rubber bituminous waterproof sheet material spreads over corners of the basement wall surface and then is upward folded to be spread and pasted on the water attaining surface of the brick permanent protection wall, then the self-adhesive rubber bituminous waterproof sheet material is lapped with another self-adhesive rubber bituminous waterproof sheet material pasted above the brick permanent protection wall, a self-adhesive rubber bituminous waterproof sheet material is pasted on an outer vertical surface of the basement wall surface. The construction method has the advantages of strong construction continuity, fast speed, good construction environment, low cost and the like, eliminates the hidden danger of fire since the heating is avoided in the construction process, is safe and reliable, completely changes and improves the traditional waterproof construction environments and the waterproof construction technology. The waterproof system can be widely applied in basements, underground structures and roofs.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

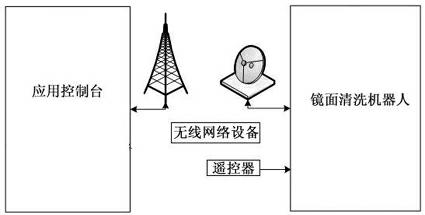

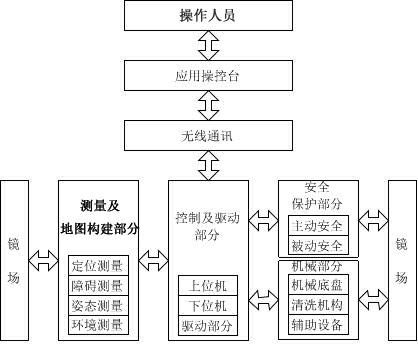

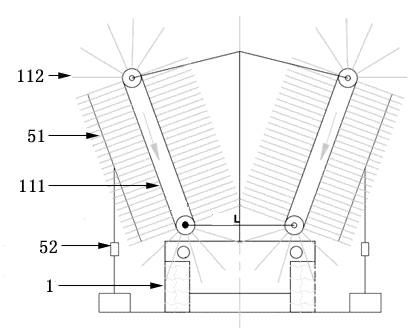

Solar mirror surface cleaning robot system

InactiveCN102426455AAuto-bootReduce work intensityPosition/course control in two dimensionsRobotic systemsObstacle avoidance

The invention discloses a solar mirror surface cleaning robot system comprising a mirror surface cleaning robot and an application console, wherein the mirror surface cleaning robot is connected with the application console, the mirror surface cleaning robot is provided with a laser detector and a gyro which are used for realizing autonomous positioning and an automatic direction steering mechanism and a brake control mechanism which are used for automatic steering and braking, and is also provided with an infrared anticollision antenna, an ultrasonic wave sensor, a collision switch, a car body stop button and other safety protection devices, and the equipment or sensor and driving parts complete autonomous navigation and automatic obstacle stopping and obstacle avoidance under association control. The solar mirror surface cleaning robot system disclosed by the invention can automatically clean a mirror surface in a designated mirror field according to predetermined setting in a hostile environment, has higher automation level and can complete cleaning on the designated mirror surface without human control; and meanwhile, the robot is used for replacing a person to complete cleaning on the mirror surface in a photo-thermal generating mirror field, the working strength of field staff can be greatly reduced, and the working environment of the staff can be improved.

Owner:ZHEJIANG SUPCON RES

High-efficiency blocking coal shovel

The invention relates to coal mining equipment and specially, relates to a high-efficiency blocking coal shovel. The high-efficiency blocking coal shovel comprises a shovel body. The shovel body comprises a frame. The high-efficiency blocking coal shovel also comprises an impulsion shovel mechanism. The impulsion shovel mechanism comprises a shovel head and an impulsion device. The shovel head comprises shovel teeth and a fixing part. The shovel teeth are installed on the fixing part. A rear part of the fixing part is provided with an impulsion stroke guiding mechanism. The impulsion stroke guiding mechanism is sildingly connected to a guiding sleeve. The guiding sleeve is arranged on the impulsion device and / or the frame. The impulsion device impacts the impulsion stroke guiding mechanism. Only through one impulsion process, the shovel head can complete both coal falling and surface cleaning. The impulsion shovel mechanism is arranged on the shovel body. The shovel body drives the whole high-efficiency blocking coal shovel to walk. Coal mined by the high-efficiency blocking coal shovel is not broken fully. The high-efficiency blocking coal shovel has a high blocking rate and low power consumption, produces a small quantity of coal dust, provides a good work environment, realizes continuous coal mining, synchronously completes both coal falling and surface cleaning, and saves a mass of energy.

Owner:刘素华

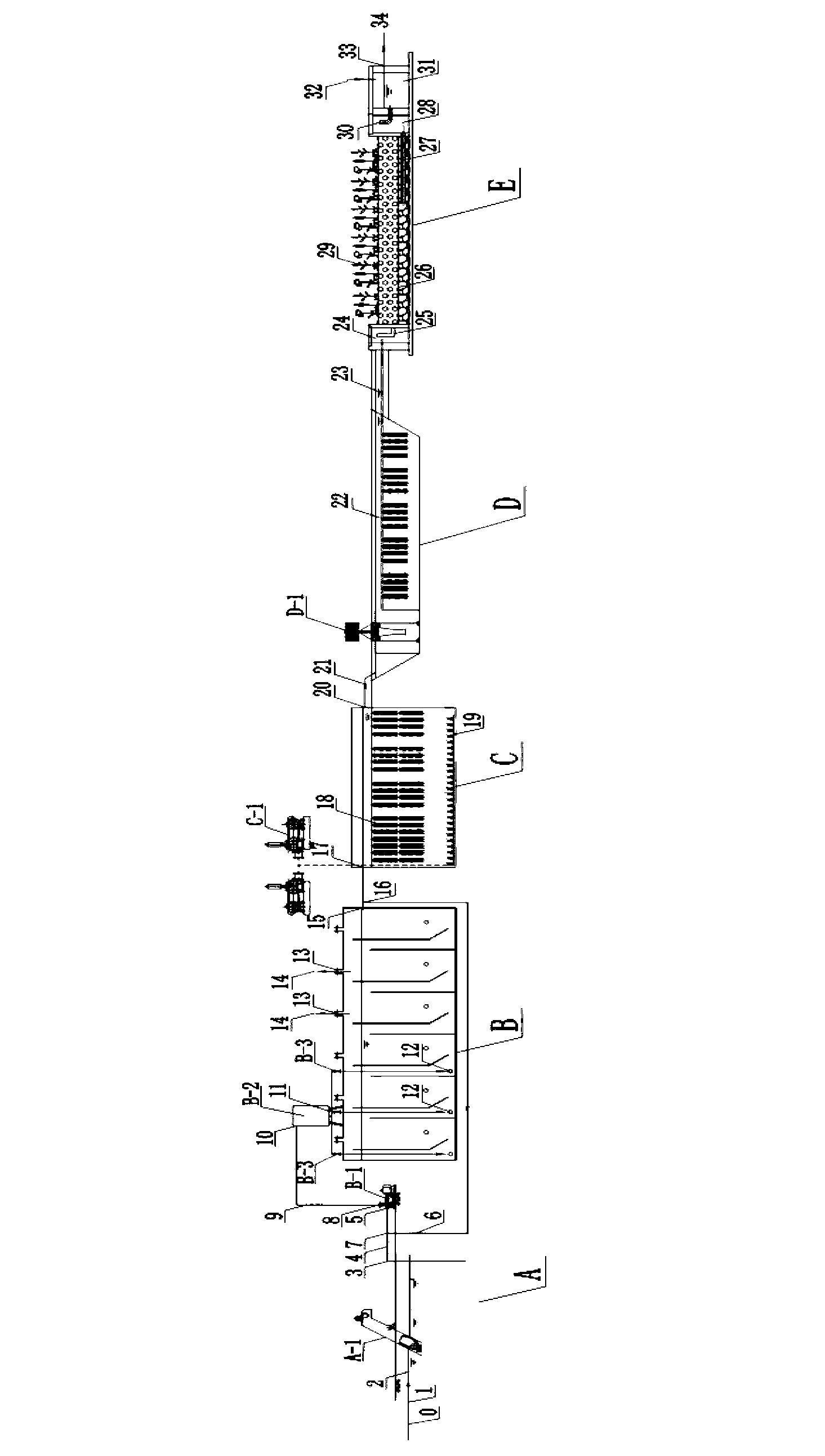

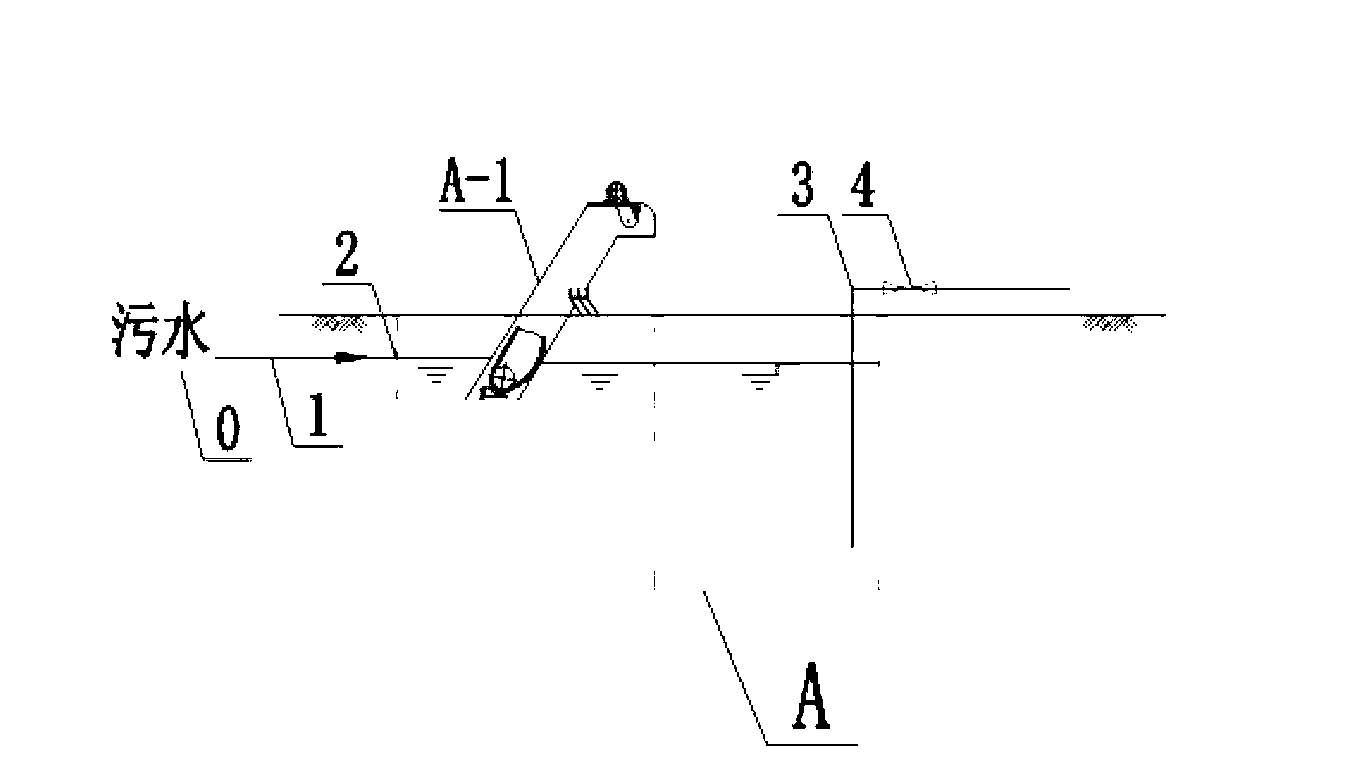

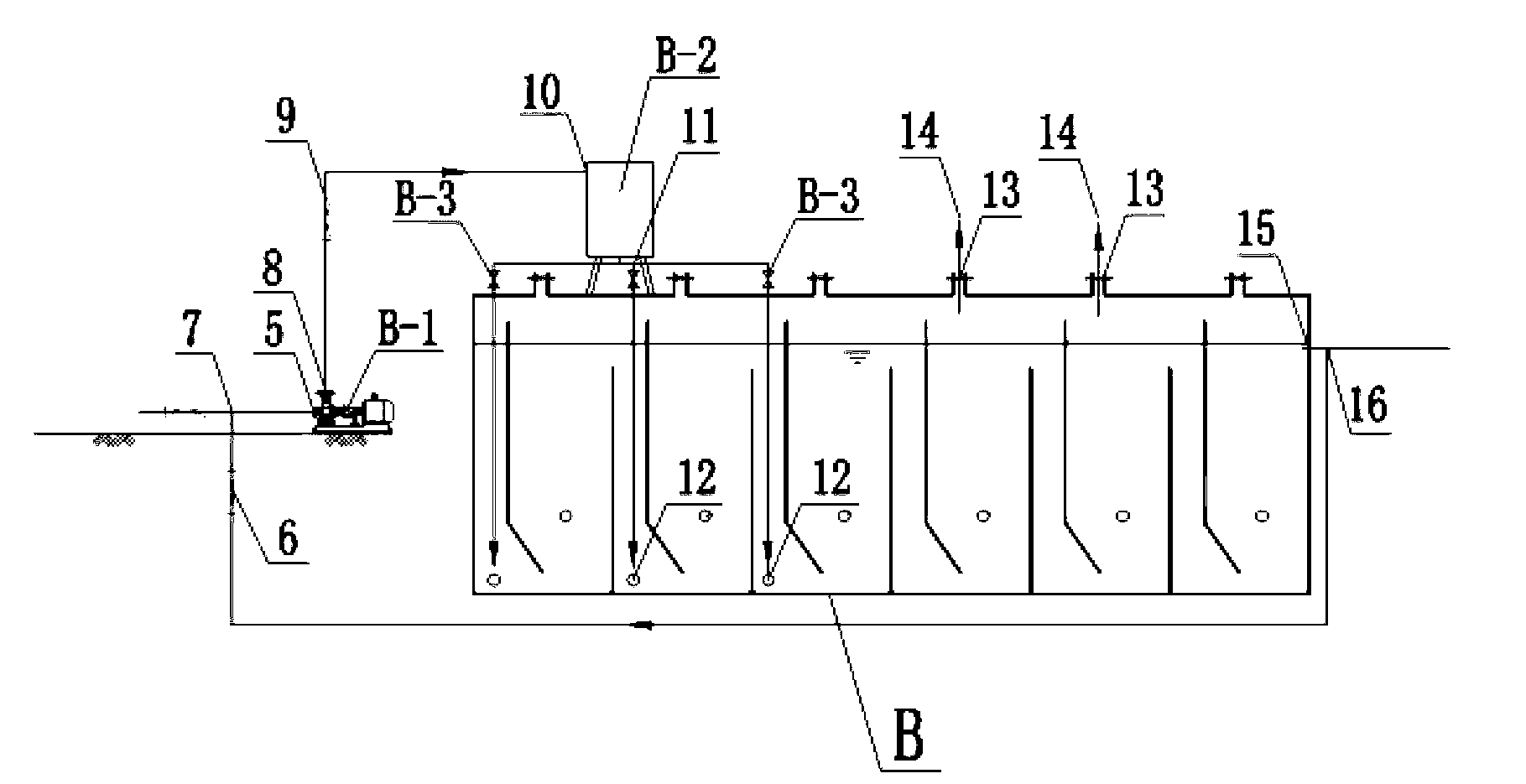

Low-energy-consumption low-carbon-emission economical energy-saving urban sewage treatment method

ActiveCN102701521AEasy to handleReduce load ratioEnergy based wastewater treatmentMultistage water/sewage treatmentConstructed wetlandRural area

The invention discloses a low-energy-consumption low-carbon-emission economical energy-saving urban sewage treatment method. The method comprises the steps that: 1, the to-be-treated wastewater is collected by a sewage pipe network and then is filtered by lattices, and is lifted by a pump to enter a pulse water distribution pot of a novel efficient turn-back anaerobic biochemical pool (ABR); 2, the swage subjected to the treatment in step 1 flows into a circulation-flow biological oxidization pool; 3 the effluent water from the step 2 flows into an artificial reinforced biological contact oxidization pool reconstructed by a water body from natural tunnels and reservoirs; and 4, the effluent water from the step 2 or the step 3 flows into constructed wetlands. After the sewage is treated by the above steps, the most pollutants in the water are effectively removed and the treated effluent water reaches the standard first-grade A in GB 18918-2002 ''Discharge standard of pollutants for municipal sewage treatment plant''. The energy-saving sewage treatment purification process with low cost, low energy consumption, low carbon emission and low operating cost is particularly suitable for the sewage treatment in small towns or rural areas.

Owner:武汉昌宝环保工程有限公司

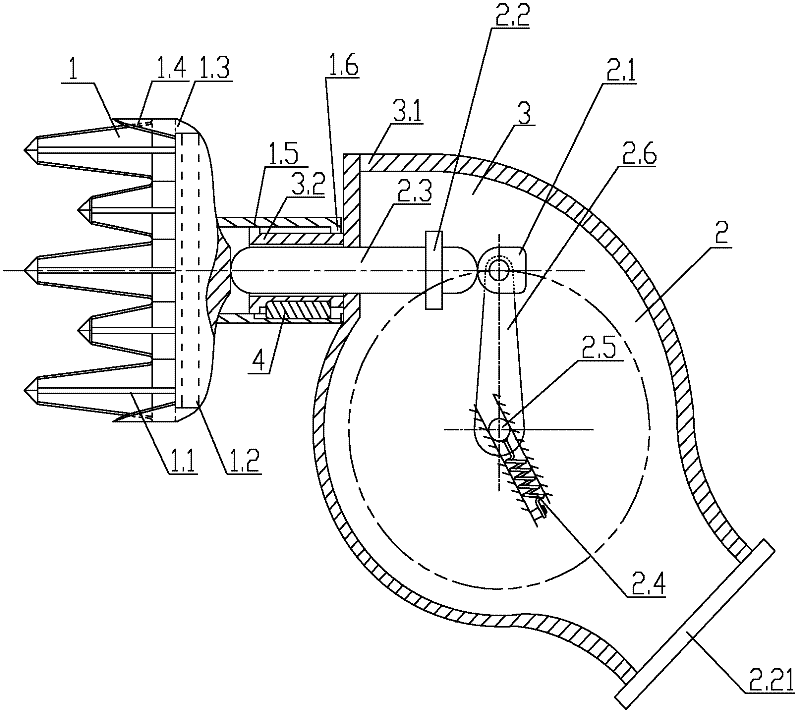

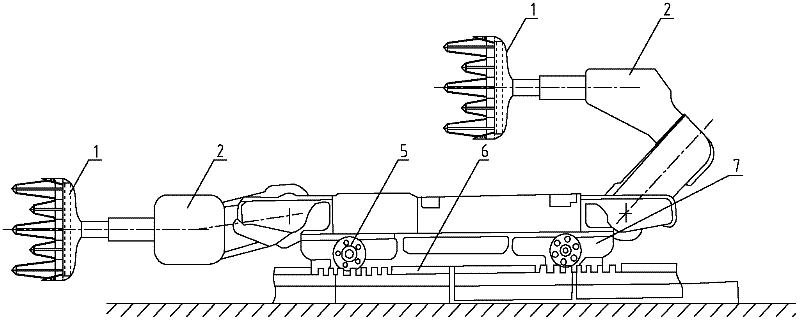

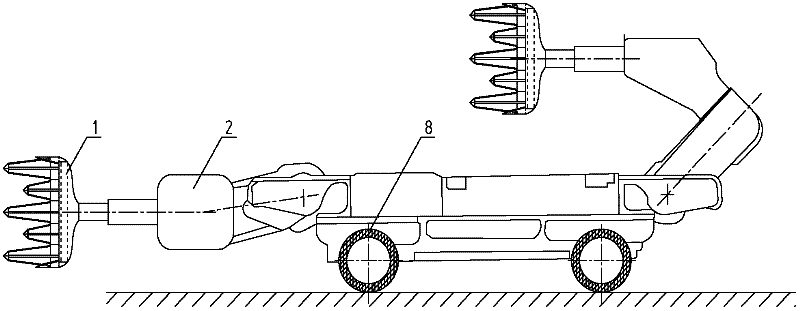

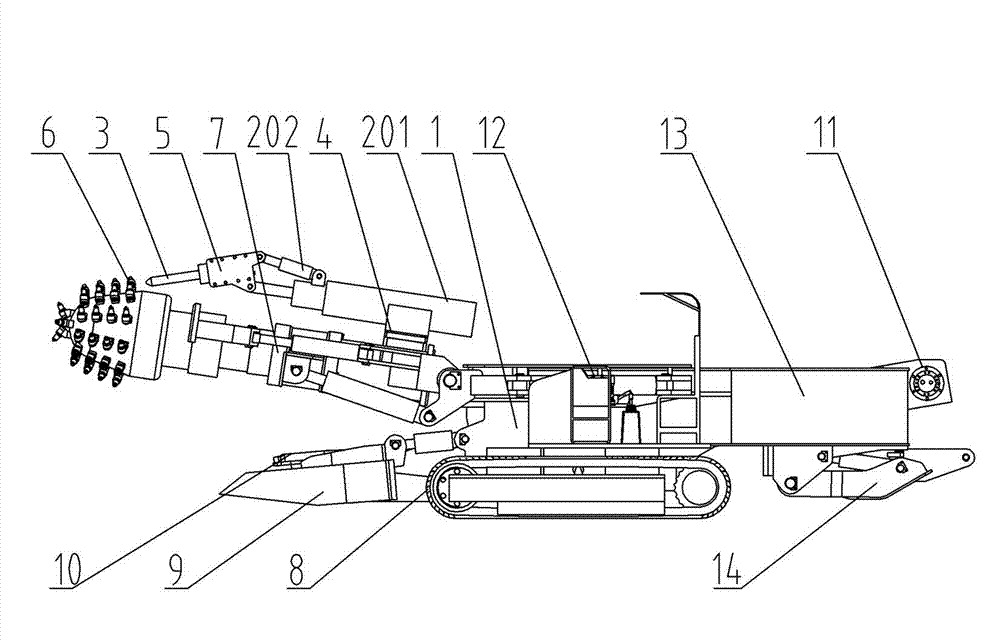

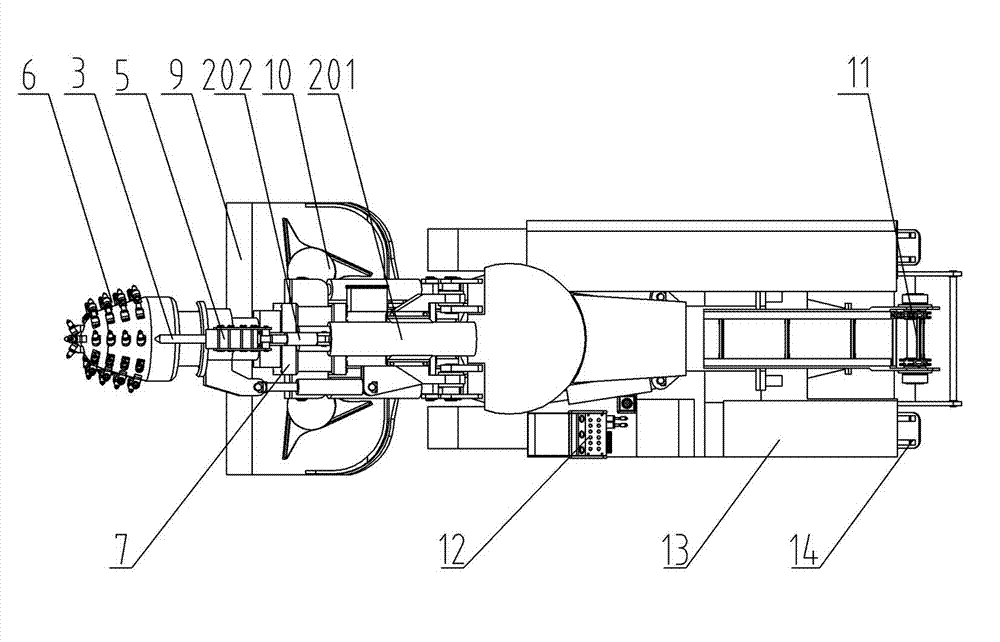

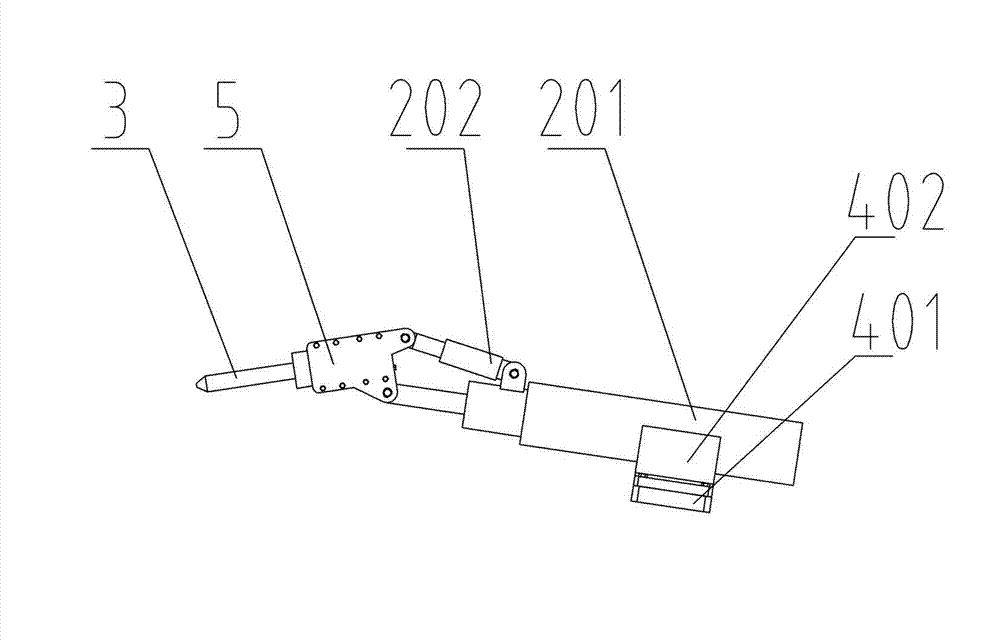

Compound cantilever excavator

InactiveCN102733803AImprove drilling abilityImprove work efficiencySlitting machinesCutting machinesHydraulic cylinderClassical mechanics

The invention relates to an excavating machine, and especially relates to a compound cantilever excavator. The excavator comprises an excavator body, an excavating mechanism, a travelling mechanism, a hydraulic system, an electrical system, a conveying mechanism and a dedusting system, wherein the excavating mechanism comprises cutting heads and a cutting arm, the cutting heads are positioned on the top of the cutting arm, and the lower part of the cutting arm is movably fixed on the body of the excavator; the travelling mechanism comprises a power machine and a crawler belt positioned under two sides the body of the excavator; and the upper part of the excavating mechanism is provided with an impact fragmenting mechanism, and the impact fragmenting mechanism comprises a hydraulic cylinder and a fragmenting hammer positioned on the top of the hydraulic cylinder. According to the compound cantilever excavator of the invention, service lives of cutting teeth can be prolonged, so the cost of the whole excavator is reduced; the working environment of workers is improved, so the body health of the workers is protected; and the application range of the cantilever excavator is substantially widened, so the cantilever excavator has a wide market prospect.

Owner:CHINA RAILWAY ENGINEERING EQUIPMENT GROUP CO LTD

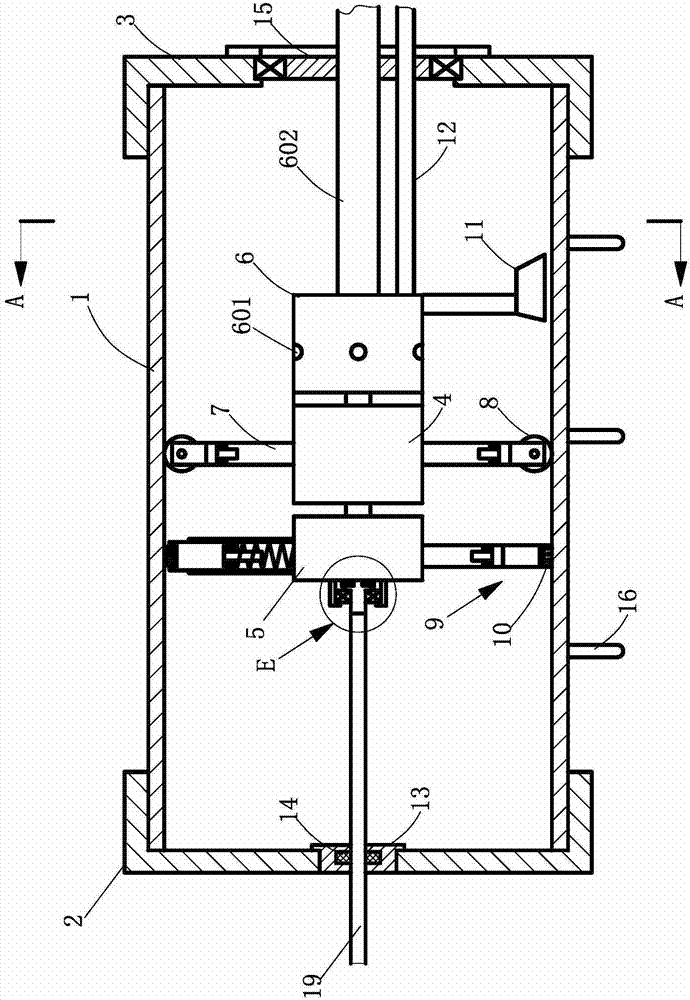

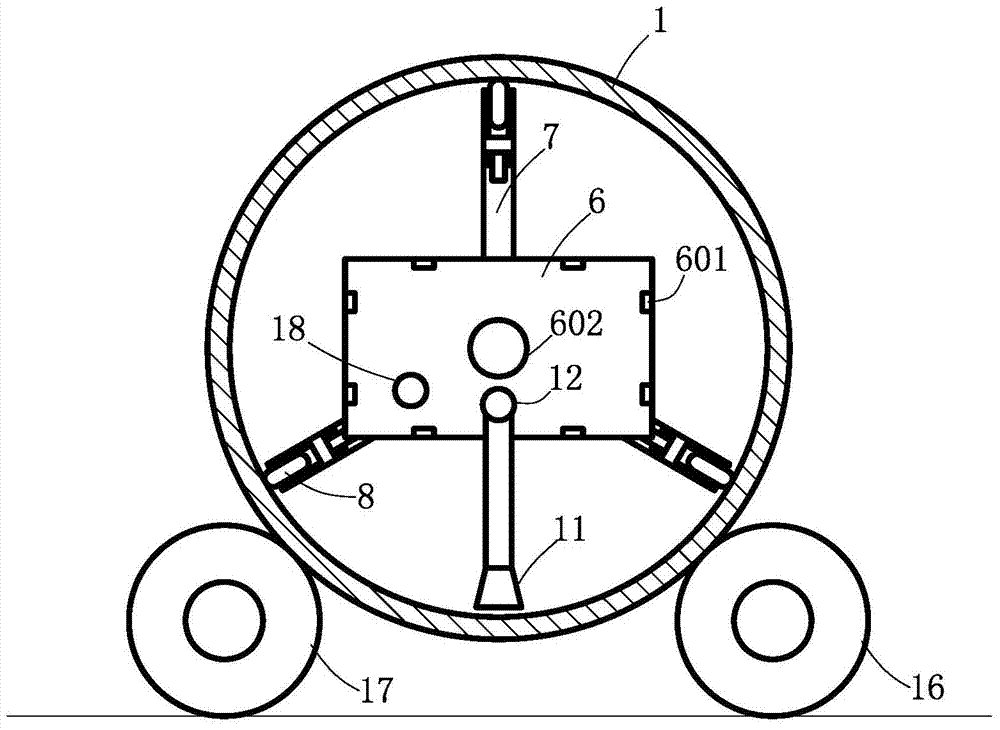

Automatic quantitative down-filling machine

InactiveCN101779837BImprove down filling efficiencyRealize quantitative weighingUpholstery manufactureClothes making applicancesAutomatic controlSolenoid valve

Owner:CHINA JILIANG UNIV

Aerogel composite material with surface subjected to dust-free treatment and preparation method

The invention relates to an aerogel composite material with a surface subjected to dust-free treatment and a preparation method thereof, in particular to a method using an aerogel felt, an aerogel plate, an aerogel cylinder and an aerogel shaped piece as the base material and coating the substrate surface with compact coating so as to avoid shedding of aerogel surface dust. The method is simple and practicable, can effectively solve the problem of easy generation of dust on the aerogel surface, significantly improves the working environment, and can satisfy the use condition of aerogel in clean space. By adopting different ratios, a rigid coating and a flexible coating can be obtained, high temperature and low temperature application can also be achieved, compound proportioning of an inorganic film-forming agent and an organic film-forming agent also can give consideration to flexibility and fire resistance, and significantly improves the adaptability of the coating paste to different types of aerogel materials. The aerogel subjected to dust-free treatment can be applied to heat preservation of various industrial equipment and pipeline, and also can be applied to thermal insulation of high speed rail, vessels, electronics and pharmaceutical workshops and building field.

Owner:浙江圣润纳米科技有限公司

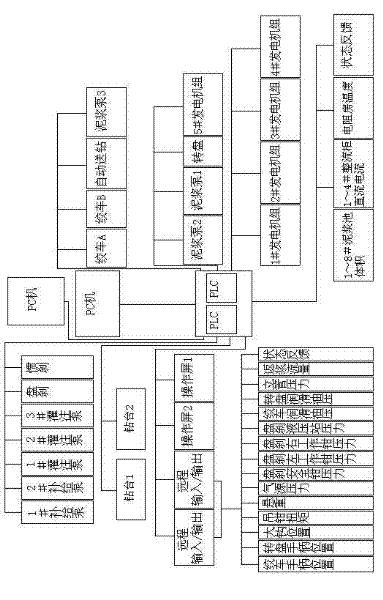

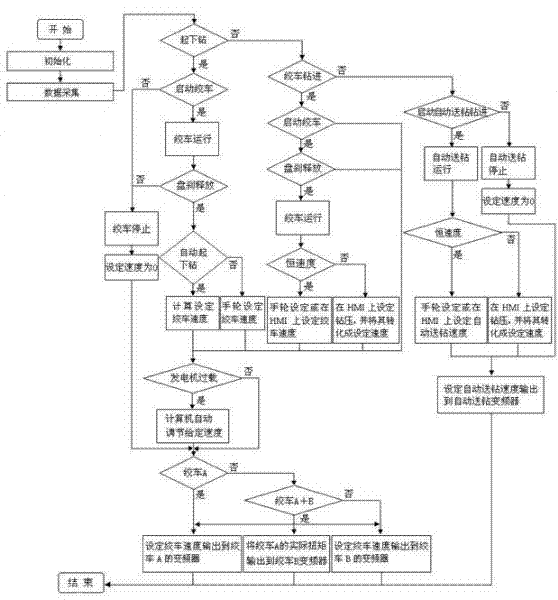

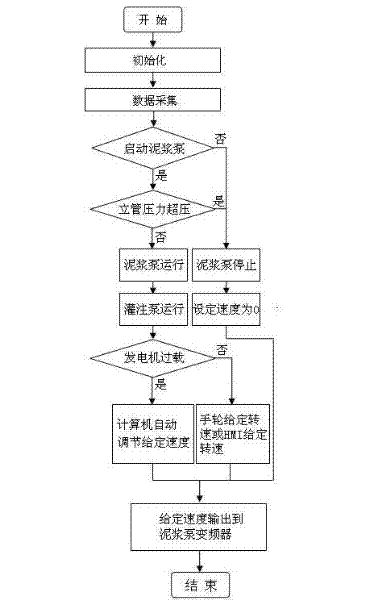

Automatic control system and method of petroleum drilling machine

ActiveCN102305059AEasy to operateRealize centralized controlFlushingAutomatic control for drillingAutomatic controlAutomatic train control

The invention relates to the field of oil-field drilling operation and provides an automatic control system and method of a petroleum drilling machine. The automatic control system comprises a master station and a plurality of slave stations, wherein a winch, an automatic driller, a rotary table and a mud pump are centrally controlled so that processes of well drilling operation can be dynamically, accurately and automatically controlled and good operation environment and work environment are provided for operating personnel.

Owner:四机赛瓦石油钻采设备有限公司

Superhigh strength thick steel plate capable of large-line energy welding and its manufacturing method

ActiveCN1676656AReduce manufacturing costGood welding performanceHigh intensityUltimate tensile strength

This is a super intensive thick steel board which can be welded with jug line power. It contains 0.01-0.06%C, 0.10-0.50%Si, 1.00 -1.40%Mn, 0.010-0.050%Nb, 0.040-0.090%V, 0.60-1.00%Cu, 0.20-0.50%Cr, 0.20-0.50%Mo, 0.50-0.80%Ni, 5ppm-30ppmB, 0.005-0.020%Ti, 0.040-0.070%Als, and remained Fe and inevitable impurity: 0.065<=(%Cu*%V)<=0.085. The producing method includes: casting technique, slab heating, hot rolling, which is asynchronous rolling in austenite non-crystallized area, strain relaxation and direct cooling by quenching. This invention associates well the steel board's high intensity, high ductility and good weldability. It decreases the quantity of alloying agent and reduces the cost for steel board's production. It can as well improve the low-temperature flexibil ity and welability of the steel board, as it realizes welding with jug line power. As a result, it needs no pre-heating to weld steel board above 0 degree Centigrade.

Owner:BAOSHAN IRON & STEEL CO LTD

Chemical deplating solution and deplating method suitable for removing tin-nickel coating on surface of brass

InactiveCN101775601AImprove the status quo of low dissolution rateImprove work efficiencyWater bathsTin

The invention discloses a deplating solution and a deplating method thereof for tin-nickel coating (commonly called plated scrap) on the surface of brass. The deplating solution comprises oxidizer, accelerator, complexing agent and inhibitor, and the deplating solution is prepared by adding water to the reagents, stirring, dissolving, then putting in a water bath and slowly heating. The oxidizer adopts 65-68% nitric acid, the accelerator adopts 36-38% hydrochloric acid, the complexing agent adopts citric acid and the inhibitor adopts benzotriazole. After being deplated by the deplating solution of the invention, the surface of the brass is bright, the color of the substrate is basically unchanged, and the brass has no pinholes and small corrosion amount.

Owner:HEFEI UNIV OF TECH

Waterborne polyurethane coating transfer synthetic leather and manufacturing method

InactiveCN101666043ASimple production processExpand technical routeSynthetic resin layered productsTextiles and paperOrganic solventSolvent based

The invention relates to waterborne polyurethane coating transfer synthetic leather and a manufacturing method, belonging to the technical field of synthetic leather and manufacturing methods. The manufacturing method of the waterborne polyurethane coating transfer synthetic leather is characterized in that the waterborne polyurethane coating transfer synthetic leather is manufactured by sequentially including the following steps: base cloth, surface formation by dry coating transfer, curing, separation of paper and leather, inspection and storage. Compared with solvent based polyurethane, thewaterborne polyurethane coating transfer synthetic leather has equivalent physical properties of the product, meets the requirement of application, uses the environmentally friendly waterborne polyurethane so that organic solvent which is harm to environmental protection is not contained in the product, and simplifies the production process because the working procedure of DMF recycling needed bysolvent-based products is reduced in a production process, thereby saving energy, protecting environment, meeting the restrictive requirements of foreign countries on the environmentally friendly polyurethane leather, reducing the quantity demand on production personnel, alleviating harm to human bodies, lowering the production cost and enabling the market competitiveness of the product to be strong.

Owner:烟台万华超纤股份有限公司

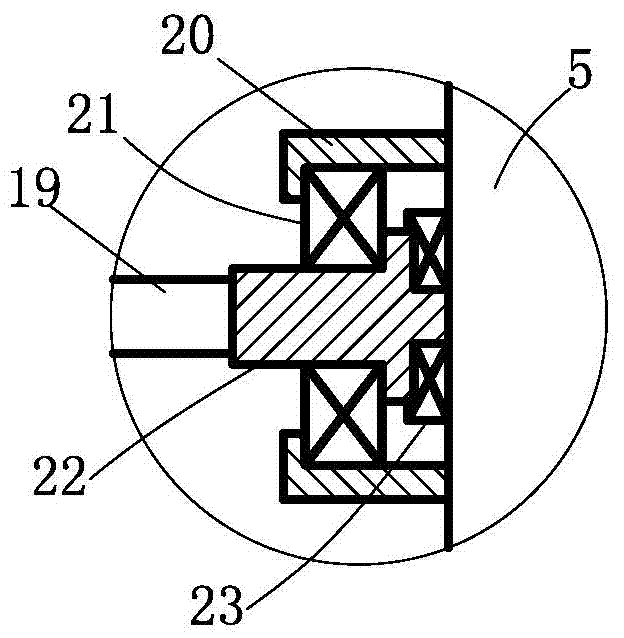

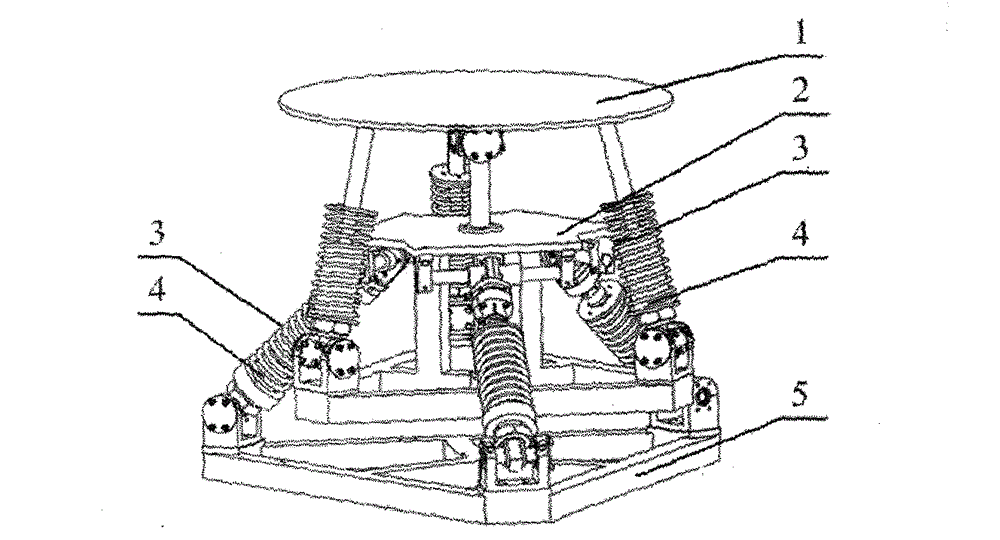

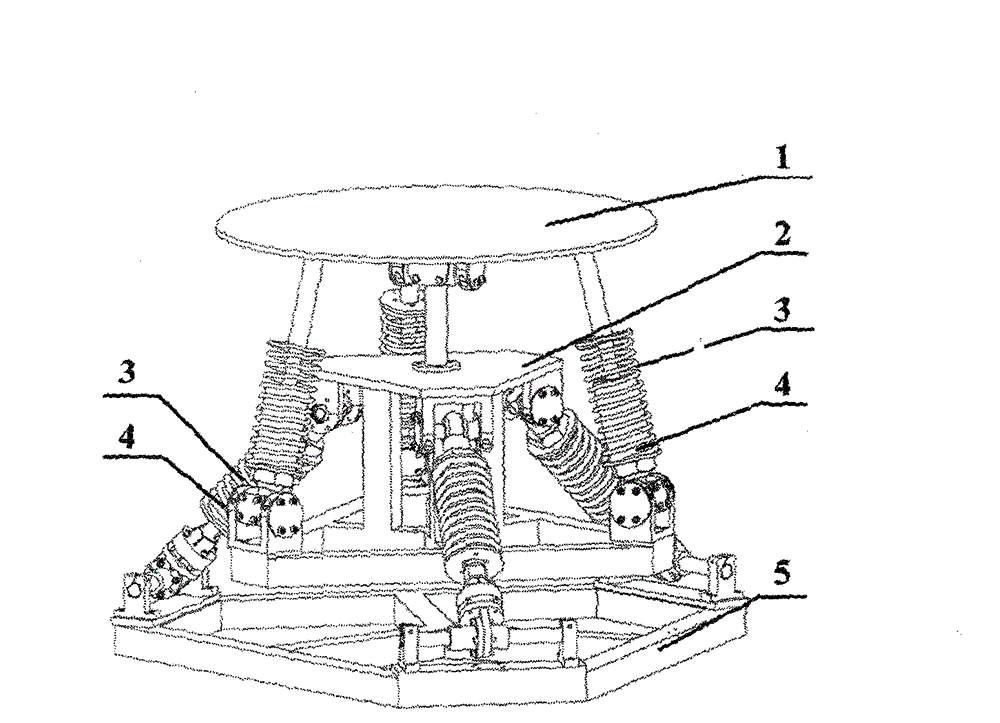

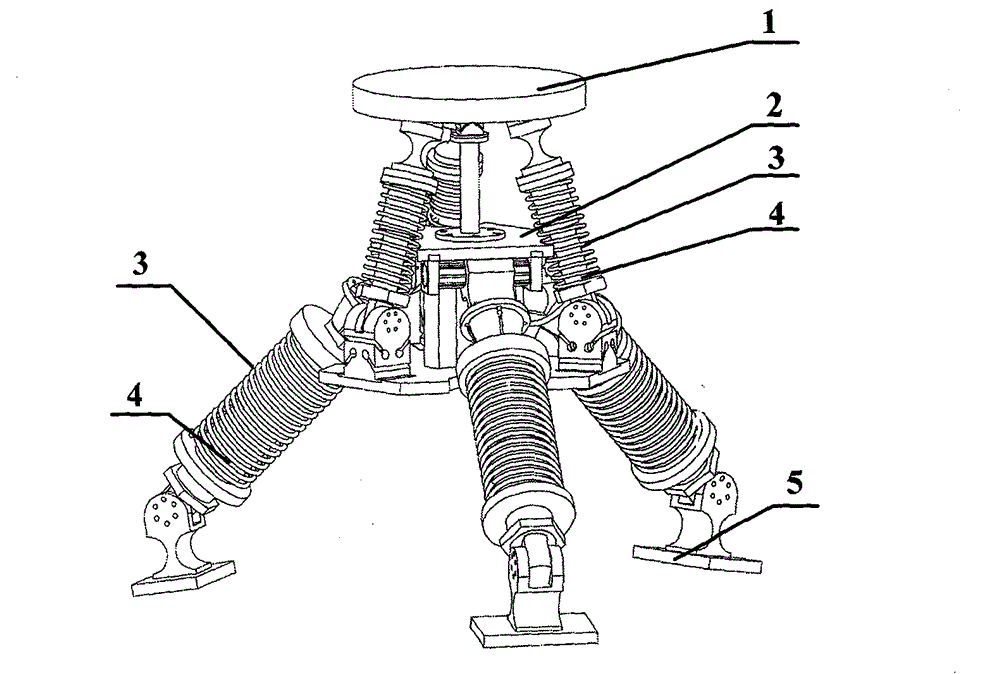

Hybrid mechanism-based five-dimensional vibration isolation platform

ActiveCN102865328AImprove the dynamic environmentImprove working environmentNon-rotating vibration suppressionDamping factorEngineering

The invention relates to a five-dimensional vibration isolation device which is suitable for equipment arranged on a dynamic carrier. Aiming at the problem of five-dimensional vibration of the equipment on the dynamic carrier, one hybrid mechanism-based vibration isolation platform is arranged between an equipment mounting platform and a carrier connecting platform to realize five-dimensional vibration isolation. The vibration isolation platform consists of the equipment mounting platform (1), a middle platform (2), the carrier connecting platform (5), six branched chains comprising vibration isolation subsystems and a constraint branch containing no vibration isolation subsystem, so that vibration isolation along spatial three-movement two-rotation directions can be realized. Each vibration isolation subsystem in each branched chain is formed by connecting a linear spring (3) and a magneto-rheological damper (4) in parallel; and control over the entire platform is realized by changing a damping coefficient of the magneto-rheological damper. Since the movement and the rotation of a hybrid mechanism are fully decoupled, the control of the system is relatively simple. Experiments prove that the vibration isolation platform using the five-dimensional vibration isolation device enables that a vibration signal transferred to the equipment by the carrier is obviously weakened, so that the vibration isolation platform has the advantage of effectively and reliably improving the dynamic environment of the equipment of the dynamic carrier.

Owner:HARBIN INST OF TECH SHENZHEN GRADUATE SCHOOL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com