Liquid accelerator for sprayed concrete and preparation thereof

A technology of shotcrete and accelerator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

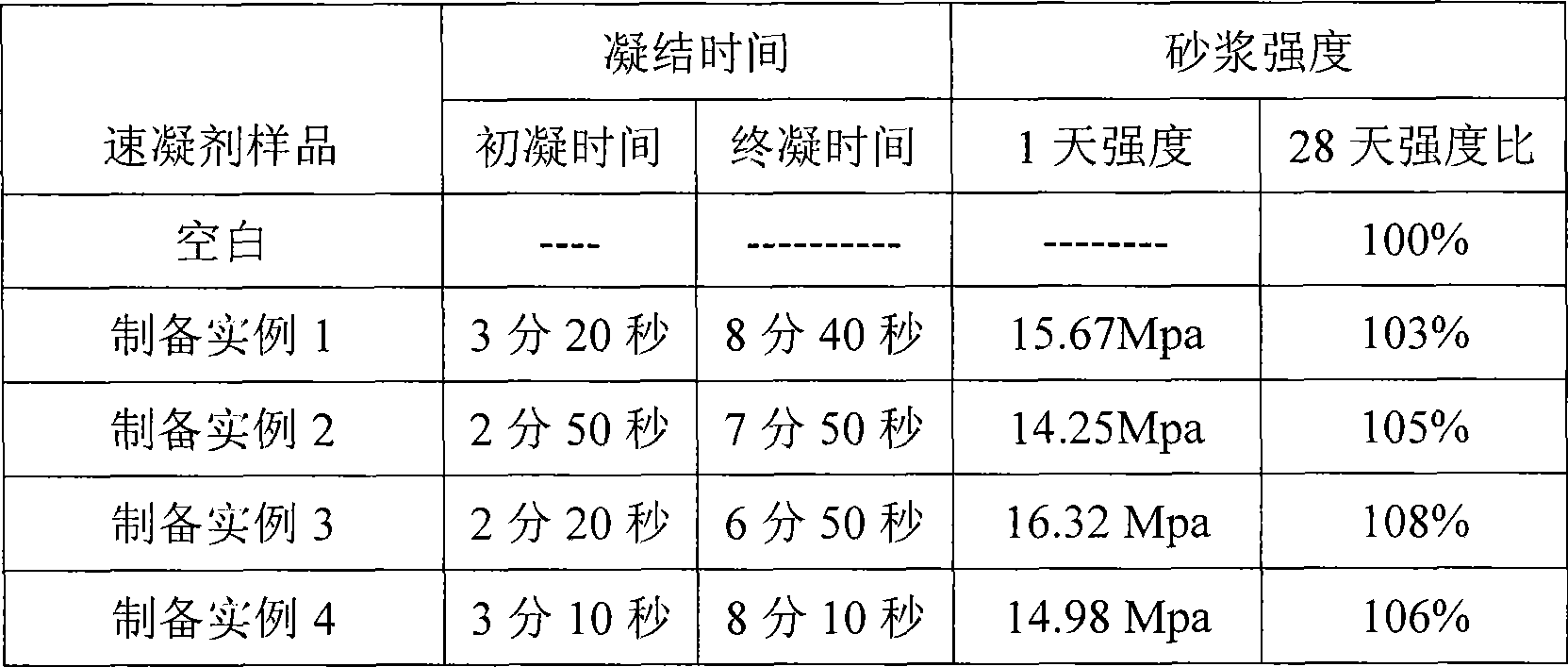

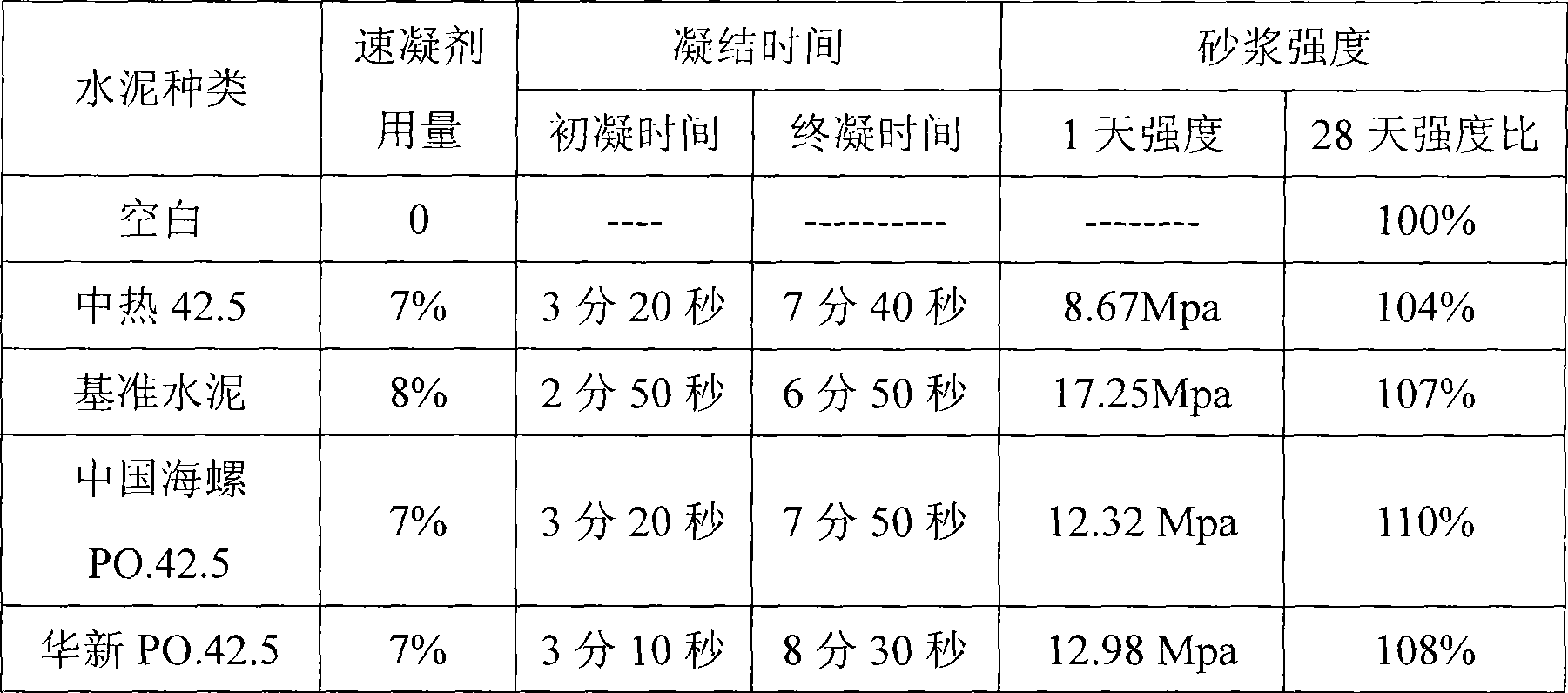

Examples

preparation Embodiment 1

[0024] A quick-setting admixture for shotcrete, in weight:

[0025] Aluminum sulfate (Al 2 O 3 15.8%) 50%

[0026] Diethanolamine 6%

[0028] Phosphoric acid 1.5%

[0029] Attapulgite 0.5%

[0030] Water 37%

[0031] The preparation method of the liquid accelerator for sprayed concrete is specifically as follows:

[0032] 1) Weigh the said weight ratio of sodium fluoride and add it to water to dissolve it. This process needs to be realized at 40-100°C; then diethanolamine is added; finally aluminum sulfate is added and stirred until the system becomes a clear solution or micro Suspension, this process needs to maintain the above temperature in the previous step.

[0033] 2) Add phosphoric acid and stir well.

[0034] 3) Add the attapulgite diagram and stir evenly, and lower the temperature to obtain the required liquid accelerator for sprayed concrete.

preparation Embodiment 2

[0036] Aluminum sulfate (Al 2 O 3 15.8%) 54%

[0037] Diethanolamine 6%

[0038] Sodium fluoride 5%

[0039] Phosphoric acid 1%

[0040] Formic acid 0.5%

[0041] Attapulgite 0.8%

[0042] Water 32.7%

[0043] The preparation method is similar to the embodiment. Phosphoric acid and formic acid can be pre-mixed before adding, or can be added separately and sequentially.

preparation Embodiment 3

[0045] Aluminum sulfate (Al 2 O 3 15.6%) 60%

[0046] Diethanolamine 4%

[0047] Sodium fluoride 4%

[0048] Phosphoric acid 1.5%

[0049] Sepiolite magnesium silicate 0.5%

[0050] Water 30%

[0051] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com