Patents

Literature

2894 results about "Diethanolamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diethanolamine, often abbreviated as DEA or DEOA, is an organic compound with the formula HN(CH₂CH₂OH)₂. Pure diethanolamine is a white solid at room temperature, but its tendencies to absorb water and to supercool mean it is often encountered as a colorless, viscous liquid. Diethanolamine is polyfunctional, being a secondary amine and a diol. Like other organic amines, diethanolamine acts as a weak base. Reflecting the hydrophilic character of the secondary amine and hydroxyl groups, DEA is soluble in water. Amides prepared from DEA are often also hydrophilic. In 2013, the chemical was classified by the International Agency for Research on Cancer as "possibly carcinogenic to humans" (Group 2B).

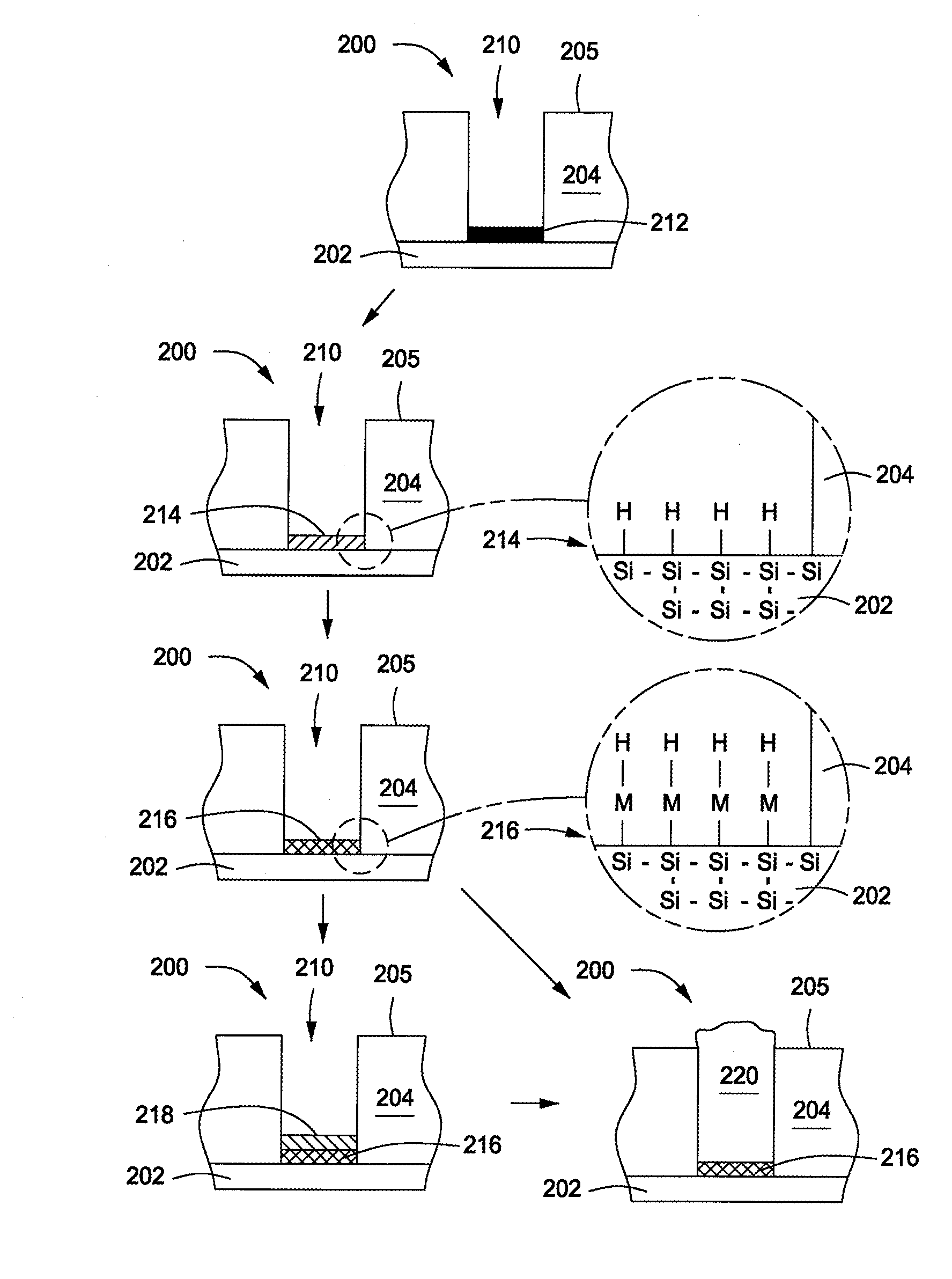

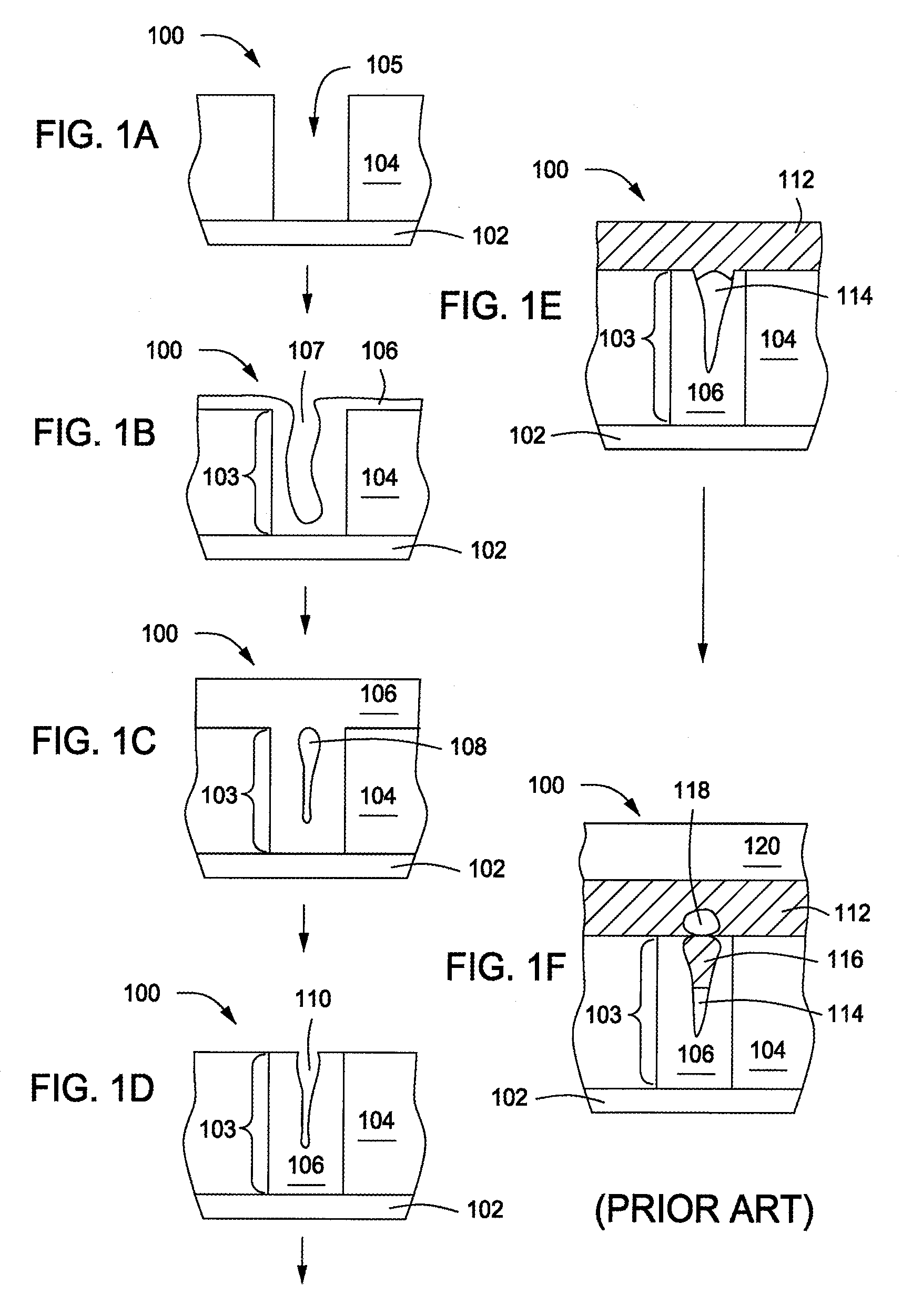

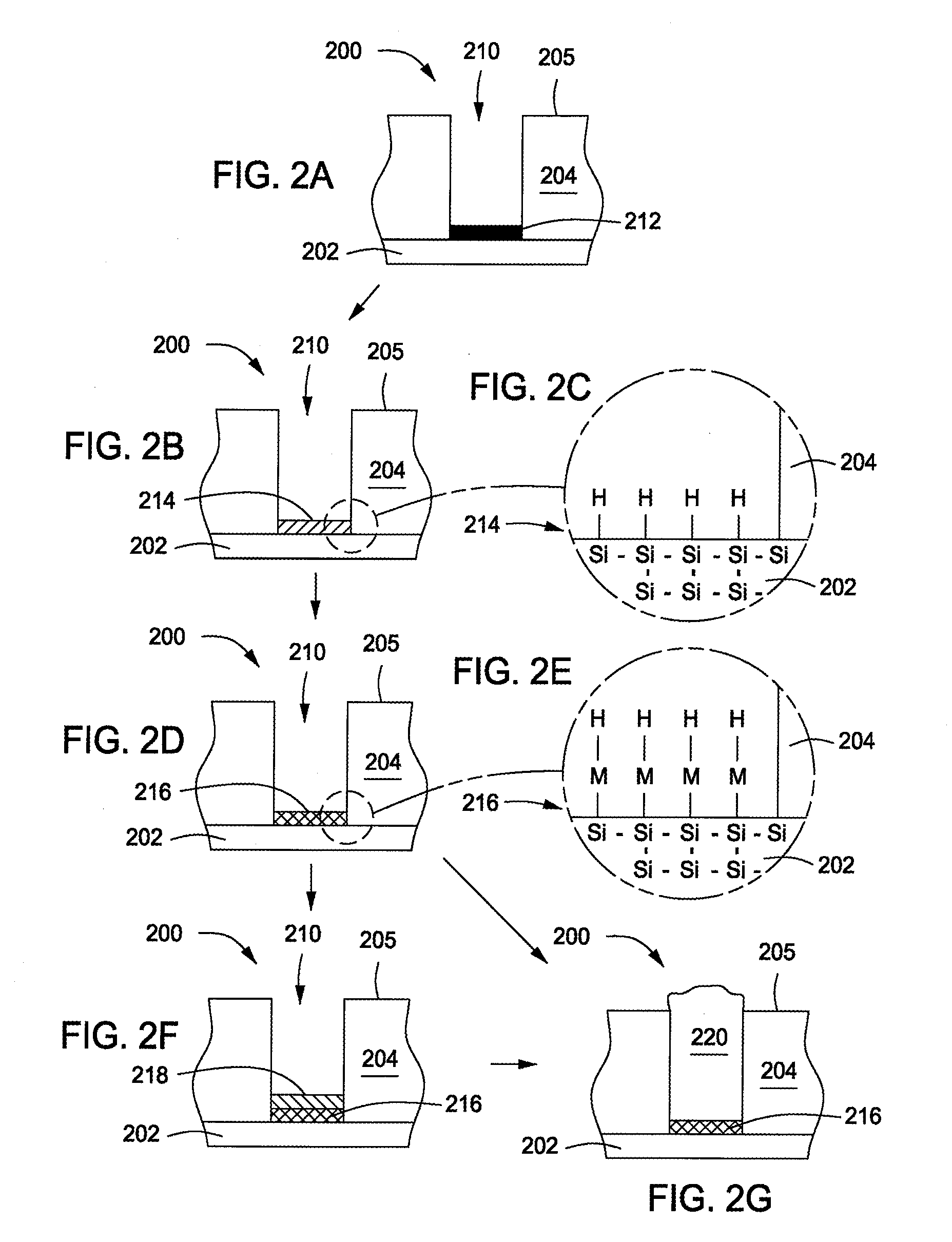

Method of selectively depositing a thin film material at a semiconductor interface

InactiveUS20070108404A1Detergent mixture composition preparationSemiconductor/solid-state device manufacturingDevice formMetal silicide

Embodiments of the invention provide processes to form a high quality contact level connection to devices formed on a substrate. In one embodiment, a method for depositing a material on a substrate is provided which includes exposing the substrate to a buffered oxide etch solution to form a silicon hydride layer during a pretreatment process, depositing a metal silicide layer on the substrate, and depositing a first metal layer (e.g., tungsten) on the metal silicide layer. The buffered oxide etch solution may contain hydrogen fluoride and an alkanolamine compound, such as ethanolamine diethanolamine, or triethanolamine. The metal silicide layer may contain cobalt, nickel, or tungsten and may be deposited by an electroless deposition process. In one example, the substrate is exposed to an electroless deposition solution containing a solvent and a complexed metal compound.

Owner:APPLIED MATERIALS INC

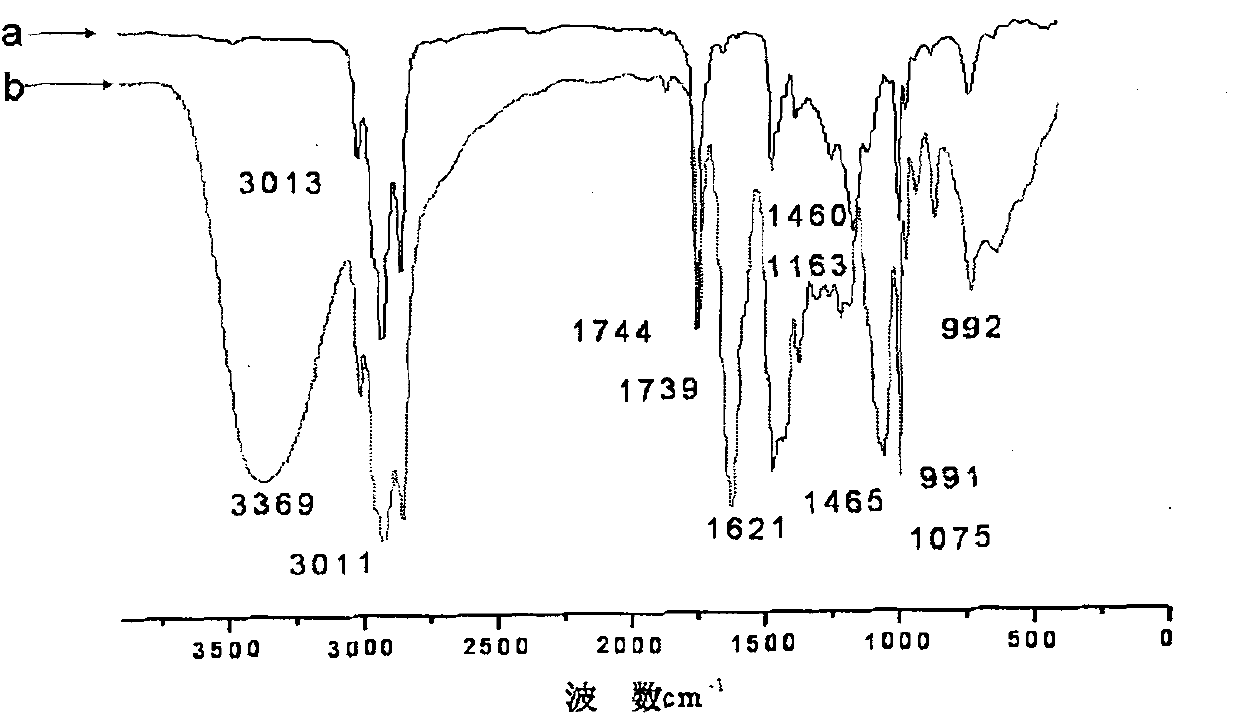

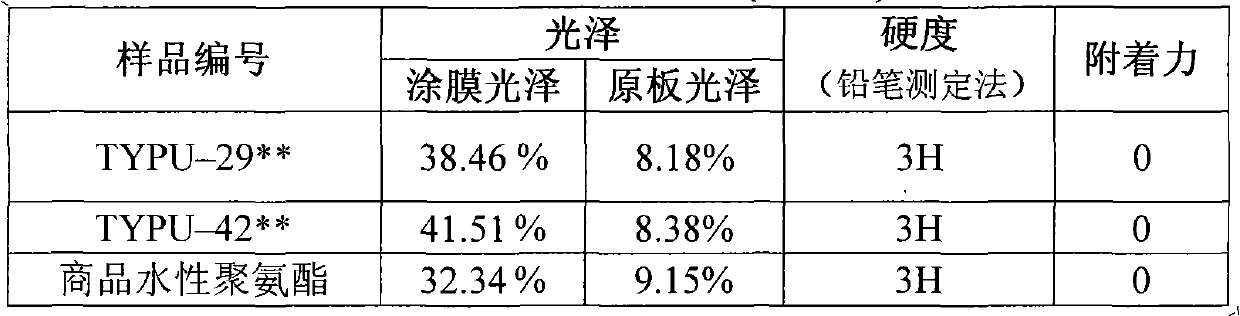

Production method for liner gloves aqueous polyurethane coating connection material

InactiveCN101328383ABreathableGood moisture permeabilityPolyurea/polyurethane coatingsWater basedPropanoic acid

The invention discloses a production method for insert gloves water-based polyurethane coating bonding materials. The method comprises the following steps of: under the protection of dry nitrogen, adding polyether glycols (including polyether diatomic alcohol and / or polyether triatomic alcohol) having undergone vacuum dewatering and isocyanate into a reaction vessel; heating the mixture up to between 80 and 100 DEG C for reaction after even mixing; then adding a hydrophilic chain extender such as dihydromethyl propionic acid (DMPA) and a catalyst for reaction at a temperature of between 80 and 100 DEG C; finally adding the chain extender and a solvent into the mixture for reaction at a temperature of between 55 and 65 DEG C until the NCO content of the isocyanate group does not change; discharging the reactant after temperature reduction to obtain an ionomer; neutralizing a preformed polymer with triethylamine or diethanolamine or triethanolamine and then adding water the mixed solution for emulsification to obtain water-based polyurethane latex; and carrying out reduced pressure distillation to remove the solvent and obtain the product. The synthesized water-based polyurethane resin which serves as a gloves coating has the advantages of good air and moisture permeability, excellent mechanical performance, solvent resistance, ageing resistance, resistance to corrosion caused by chemical mediators, oil resistance, resistance to hooking, cutting and piercing, excellent abrasion resistance, odorlessness, innocuous and nondestructive for contacting with skin, etc.

Owner:ANHUI UNIVERSITY +1

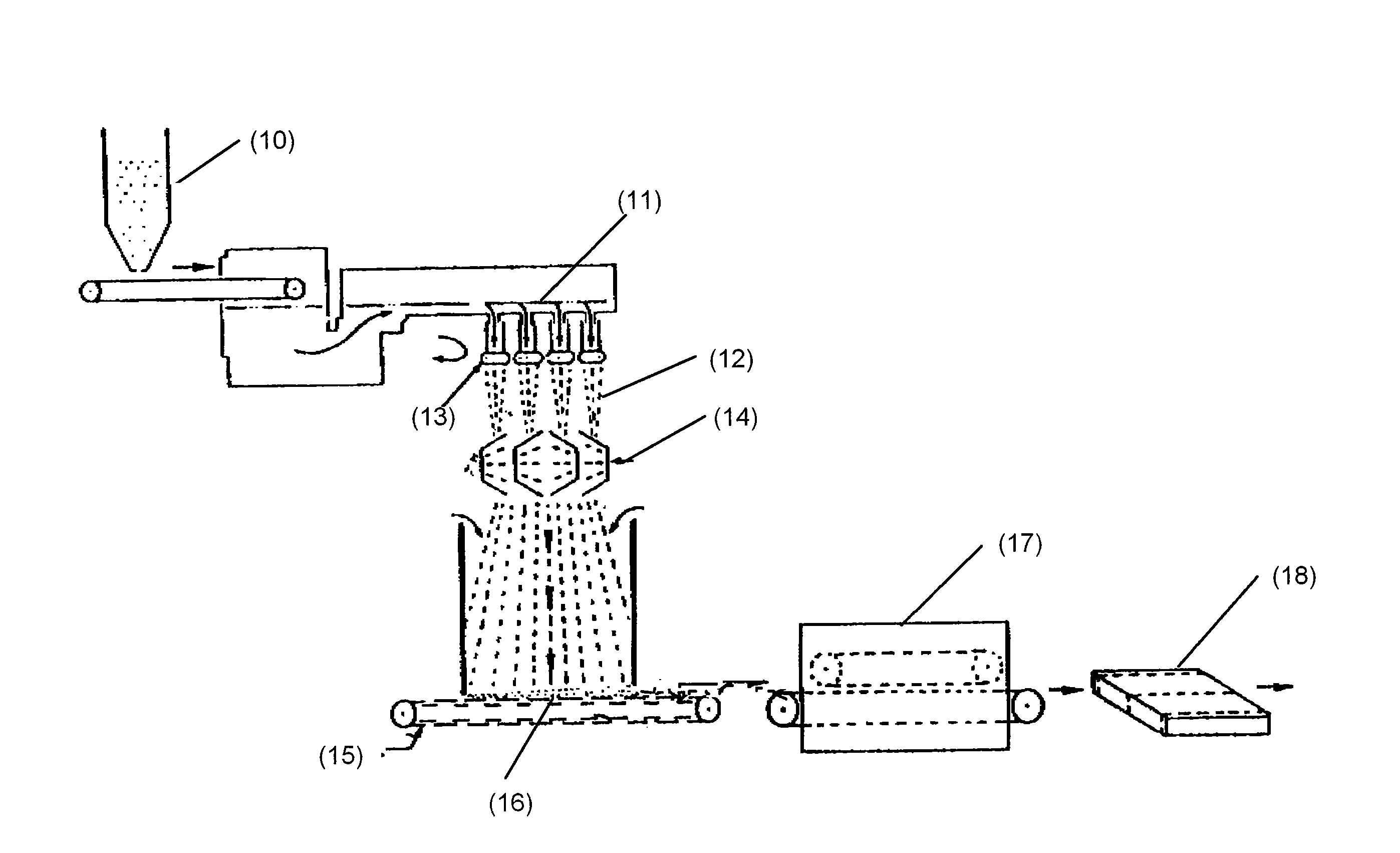

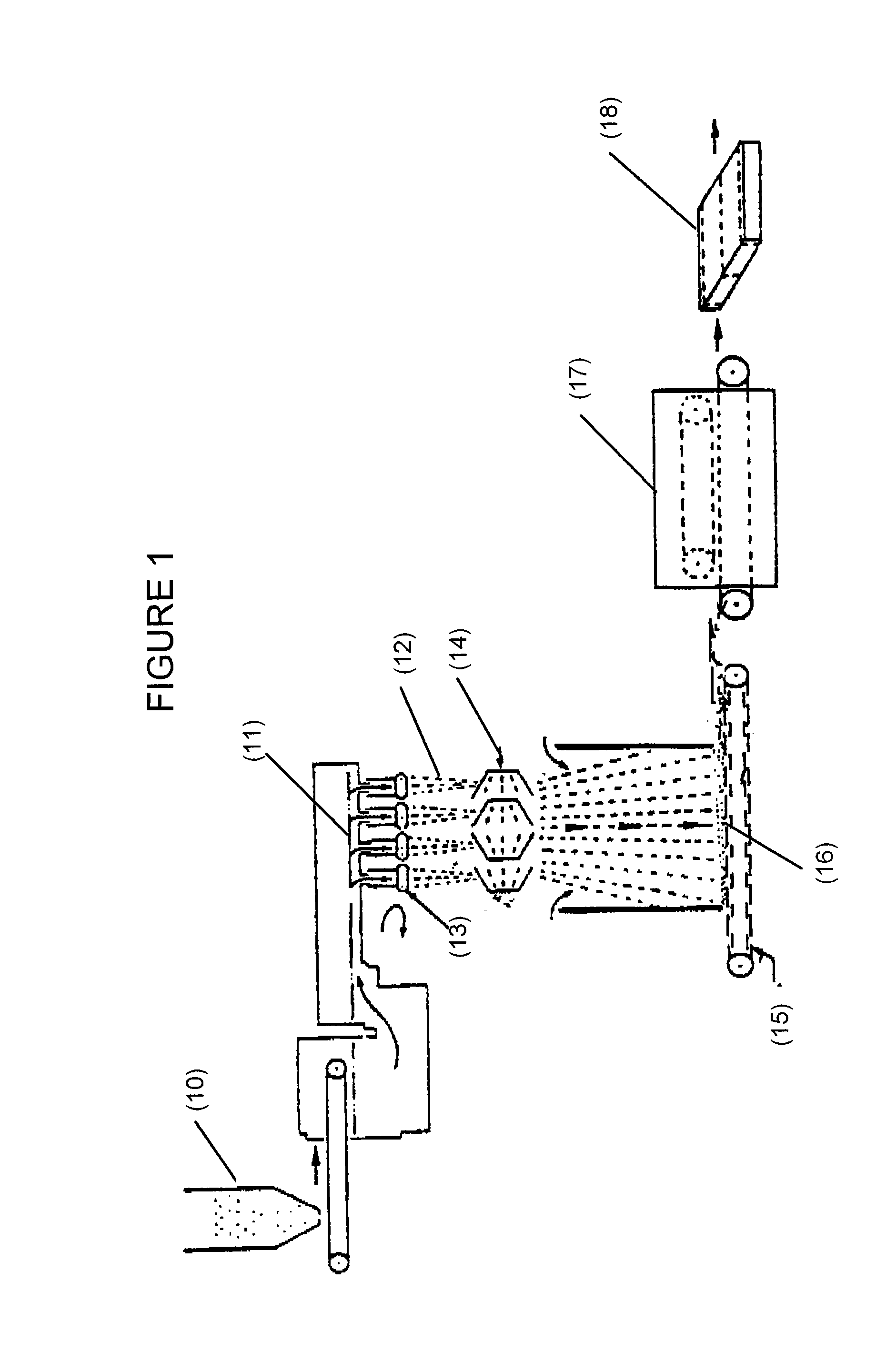

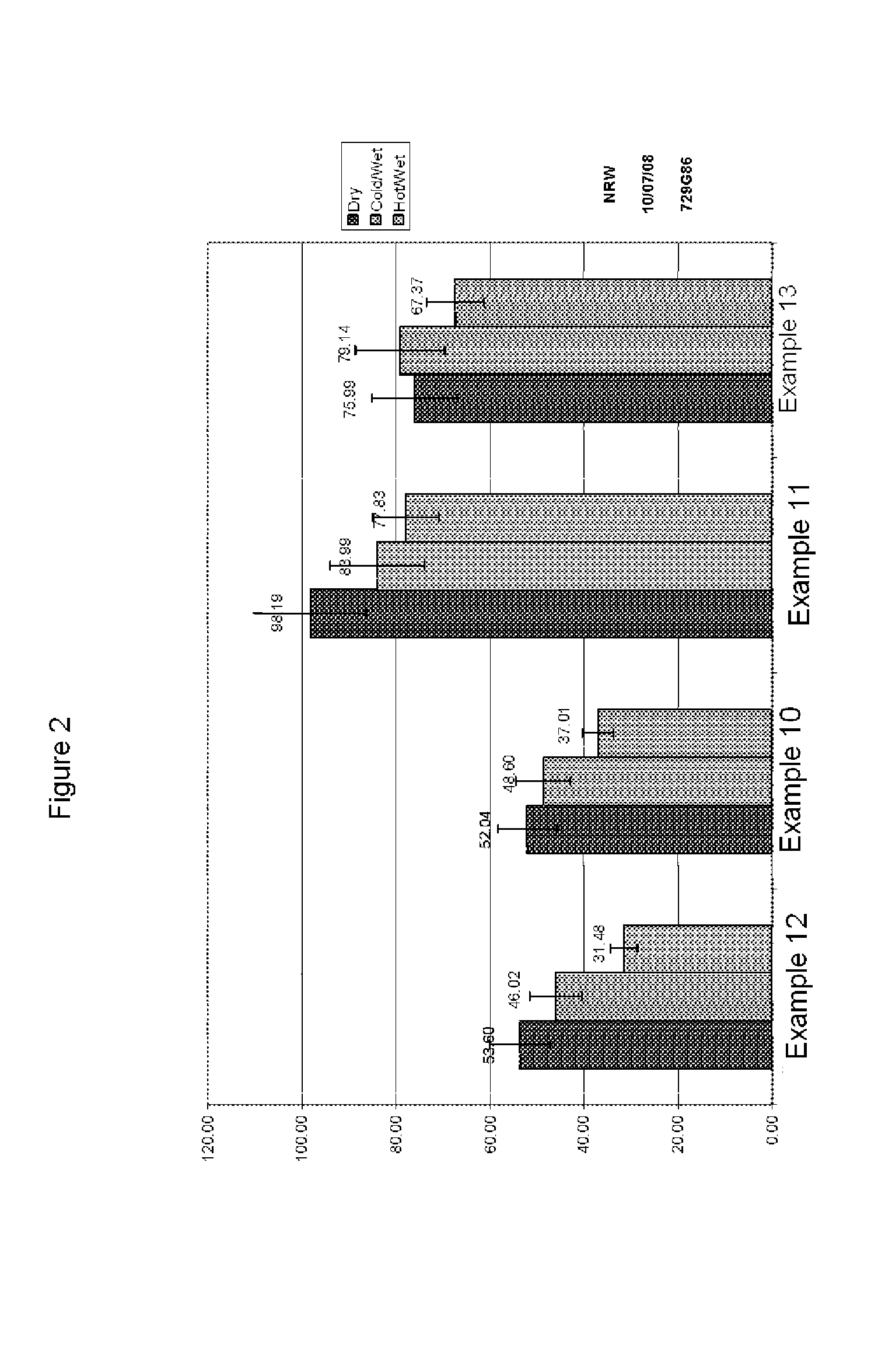

Formaldehyde free binder

An aqueous binder composition, useful for making fiber products, especially fiberglass insulation, comprising an aqueous substantially alkaline (pH of at least 5.0) solution of a polyol and a hydrolyzed (solubilized) copolymer of maleic anhydride and a vinyl aromatic compound, preferably styrene (i.e., a SMA copolymer); the copolymer is solubilized using ammonia, a secondary alkanolamine (preferably diethanolamine (DEA)), a tertiary alkanolamine (preferably triethanolamine (TEA)), or a mixture thereof and the binder composition is cured as a consequence of cross-linking, esterification reactions between pendant carboxyls on the solubilized (hydrolyzed) copolymer (SMA) chains and hydroxyl groups of the polyol, including the diethanolamine and / or triethanolamine preferably used in the solubilization of the SMA.

Owner:GEORGIA PACIFIC CHEM LLC

Formaldehyde free binder

An aqueous binder composition, useful for making fiber products, especially fiberglass insulation, comprising an aqueous substantially alkaline (pH of at least 5.0) solution of a polyol and a hydrolyzed (solubilized) copolymer of maleic anhydride and a vinyl aromatic compound, preferably styrene (i.e., a SMA copolymer); the copolymer is solubilized using ammonia, an ammine, a primary alkanolamines (preferably monoethanolamine), a secondary alkanolamine (preferably diethanolamine (DEA)), a tertiary alkanolamine (preferably triethanolamine (TEA)), or a mixture thereof and the binder composition is cured as a consequence of cross-linking, esterification reactions between pendant carboxyls on the solubilized (hydrolyzed) copolymer (SMA) chains and hydroxyl groups of the polyol, including the diethanolamine and / or triethanolamine preferably used in the solubilization of the SMA.

Owner:GEORGIA PACIFIC CHEM LLC

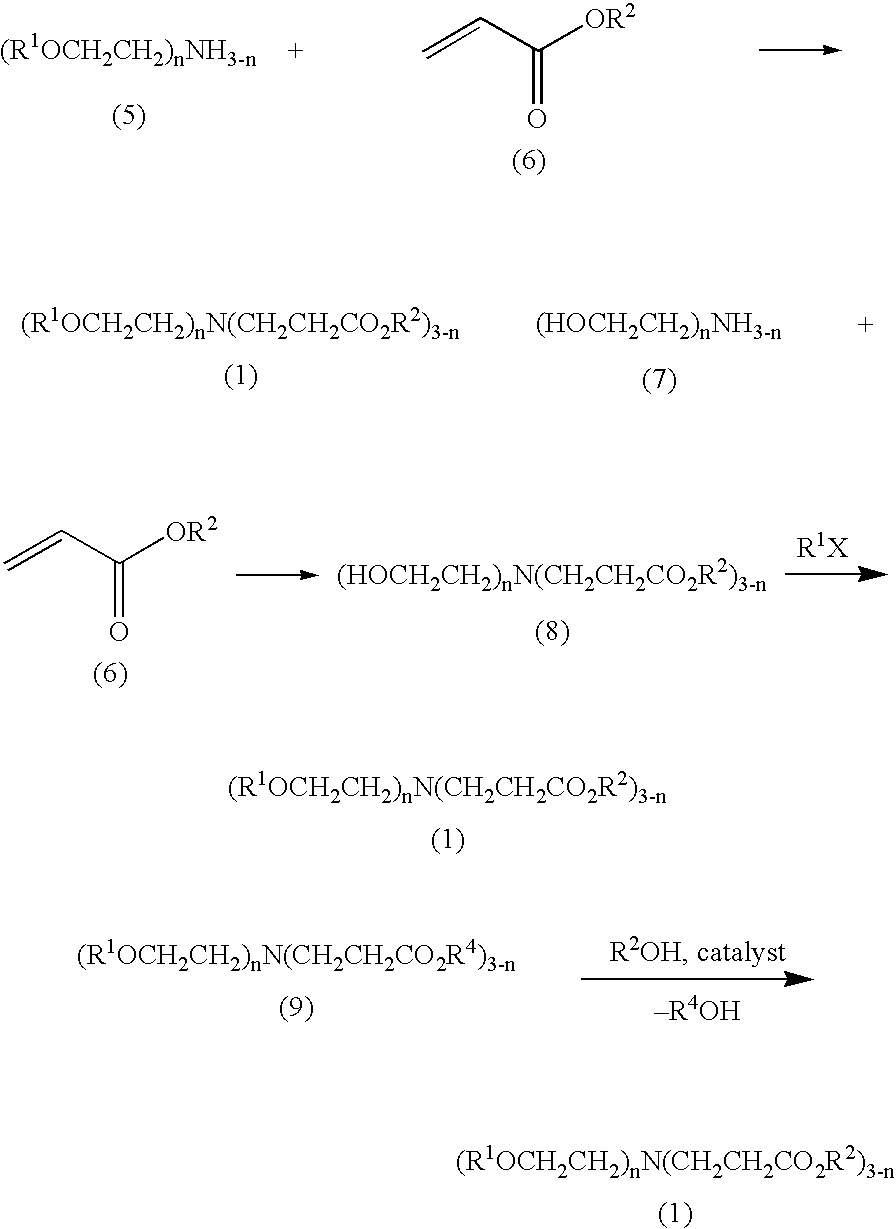

Tertiary amine compounds having an ester structure and processes for preparing same

InactiveUS7084303B2Preventing a film lossIncrease contrastOrganic chemistryOrganic compound preparationChemical amplificationPhotolithography

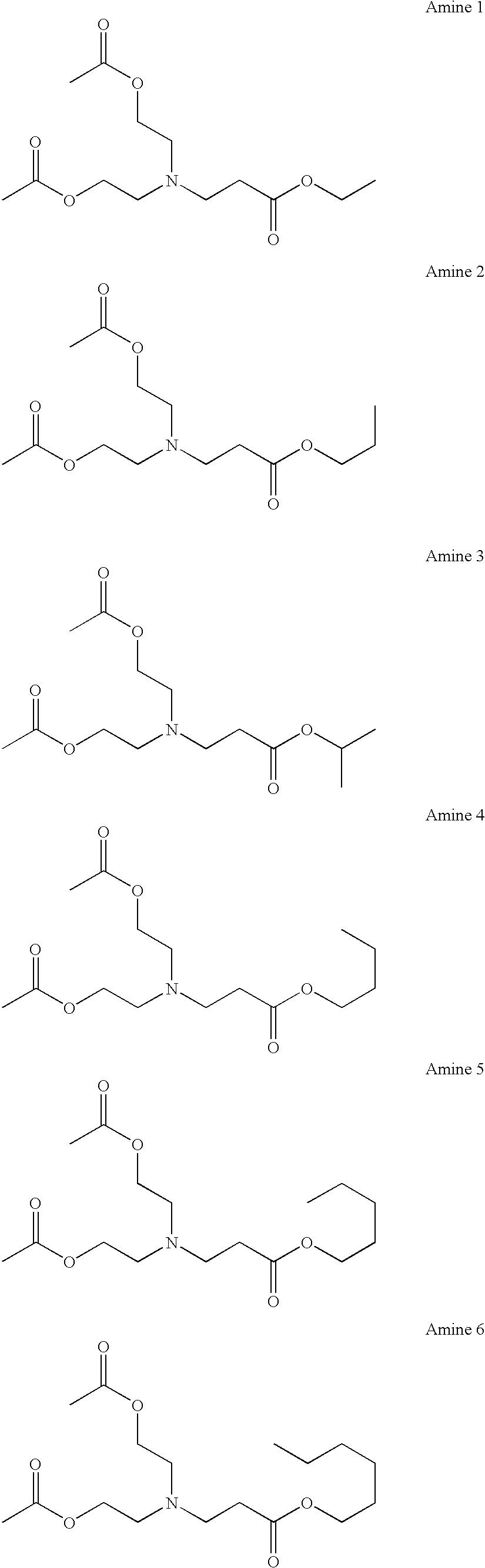

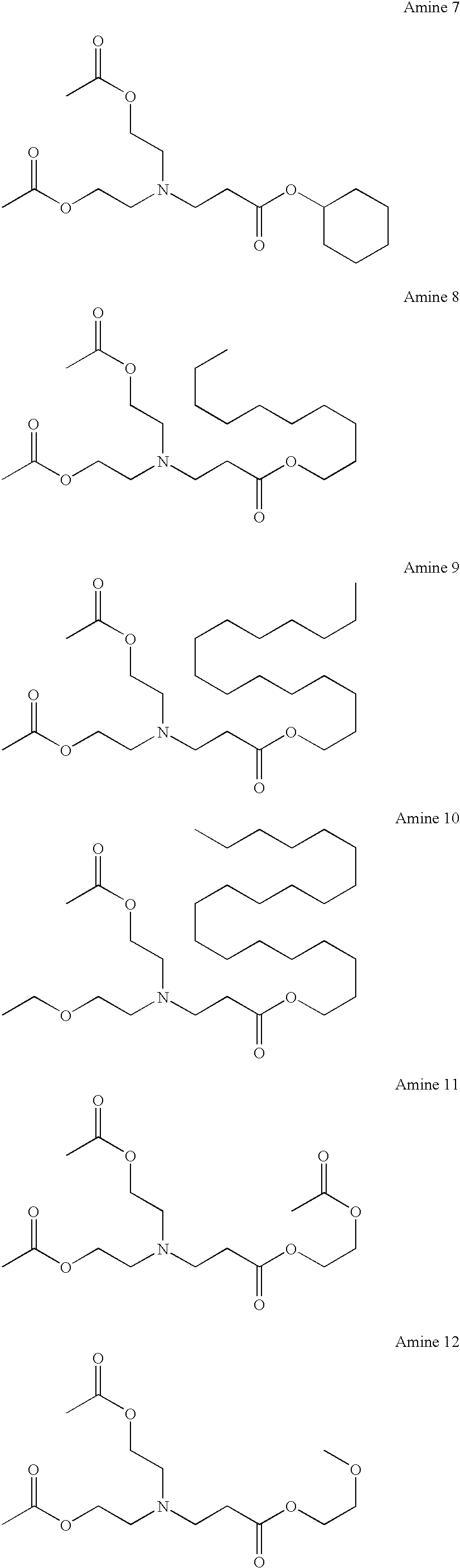

The present invention provides ester group-containing tertiary amine compounds of the formula (R1OCH2CH2)nN(CH2CH2CO2R2)3-n which, when used as additives in chemical amplification photolithography, can yield photoresists having a high resolution and an excellent focus margin. The present invention also provides a process comprising the step of subjecting a primary or secondary amine compound to Michael addition to an acrylic ester compound; a process comprising the steps of subjecting monoethanolamine or diethanolamine to Michael addition to an acrylic ester compound so as to form an ester group-containing amine compound and introducing a R1 group to the resultant ester group-containing amine compound; and a process comprising the step of effecting the ester exchange reaction of an ester group-containing tertiary amine with R2OH.

Owner:SHIN ETSU CHEM IND CO LTD

Non-halide cleaning-free welding flux for leadless solder

InactiveCN101062536AImprove solderabilityHigh insulation resistanceWelding/cutting media/materialsSoldering mediaSurface-active agentsAmino acid

The invention relates to a lead free soldering clean free soldering flux with the mass percentage of organic acid activating agent 1. 5-3. 5%, surface active agent 0. 04-0. 6%, organic amine and derivant 2. 0-5. 0%, with the rest being film forming matter. The said organic acid could be one or more of the aliphatic acid mono acid or bi-acid, aromatic acid, or amino acid. The said surface active agent is one or more of the nonion surface active agent, and the said organic amine and the derivant being ethanediamine, tetramethylenediamine, diethyl ethanolamine and so on, with the said film forming material being diethyl ethanolamine or resin. The soldering flux does not have halogen, being environmental protective, good in welding, welding spot being full and luminous, without residue, no corrosion, high in isolation resistance.

Owner:CENT SOUTH UNIV

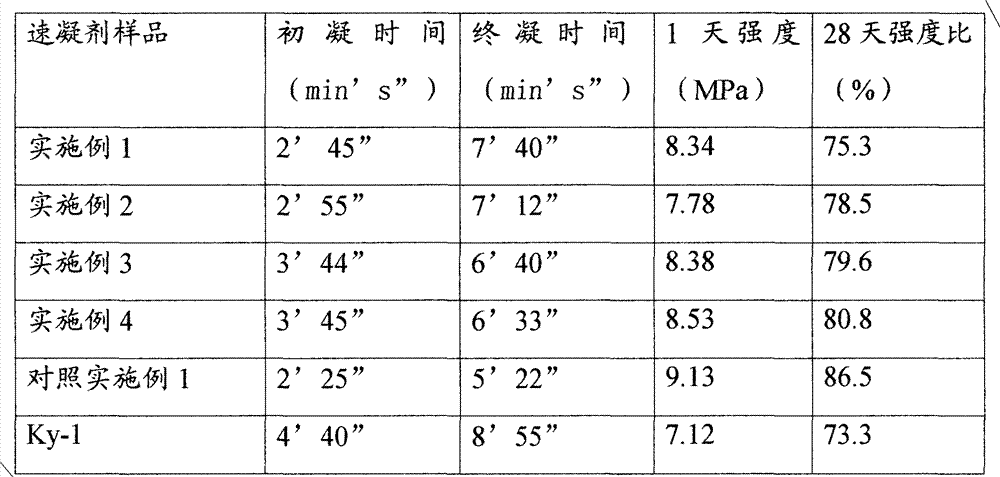

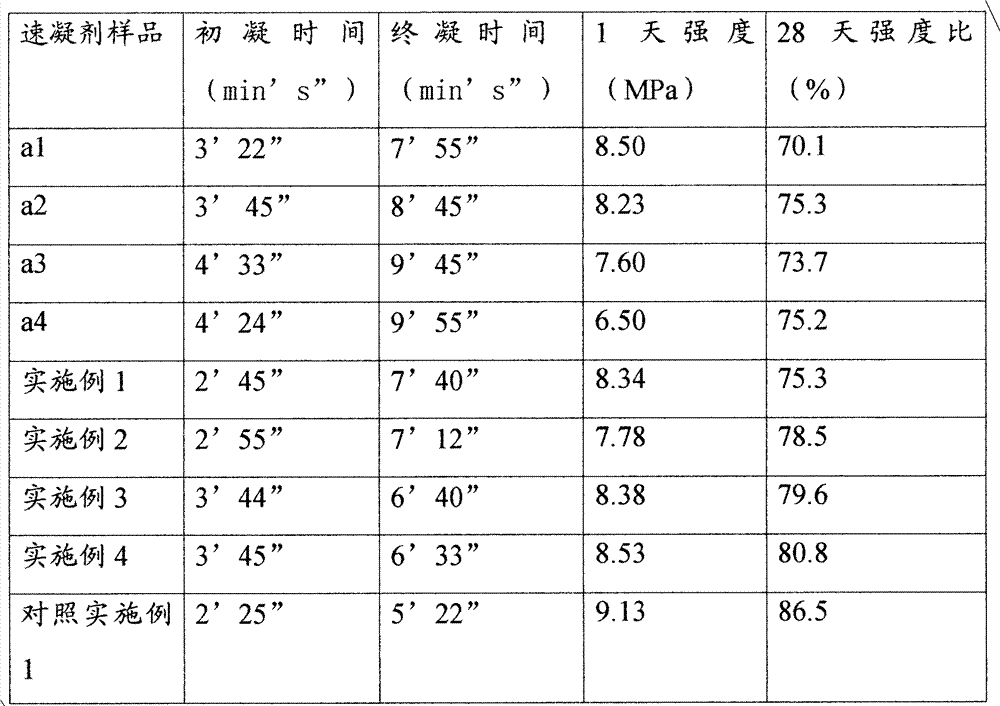

Liquid alkali-free chloride-free accelerating agent as well as methods for preparing and using same

The invention discloses a liquid alkali-free chloride-free accelerating agent and methods for preparing and using the same. Raw materials for preparing the accelerating agent include one or a plurality of the following components of aluminum sulfate, magnesium sulfate, hydramine, an early strength agent, a synergist and water. The aluminum sulfate is the purchasable industrial-grade aluminum sulfate hydrate Al2(SO4)3.18H2O and has the solid content of 51%-52%. The magnesium sulfate is MgSO4.7H2O with the solid content of 48%-49%. The hydramine is one or a plurality of mono ethanol amine, diethanolamine, triethanolamine or isopropoxide. The early strength agent is one or a plurality of calcium sulfate, calcium formate or calcium nitrite. The synergist is magnesium fluosilicate and / or magnesium fluoride. The liquid alkali-free chloride-free accelerating agent provided by the invention has the characteristics of good adaptability, low price, low mixing amount, good performance, good stability and the like; and moreover, the liquid alkali-free chloride-free accelerating agent is added into the concrete to be used as sprayed concrete, has the characteristics of low resilience, small dust pollution and the like and can satisfy the requirements of the 'JC477-2005 sprayed concrete accelerating agent' standard.

Owner:北京冶建特种材料有限公司 +1

Method for finishing wool fabric by compositing chitosan/TiO2

ActiveCN103981694AImprove the efficiency of grafting reactionGood antibacterialLiquid/gas/vapor removalUltrasonic/sonic fibre treatmentCooking & bakingPollution

The invention provides a method for finishing wool fabric by compositing chitosan / TiO2, which comprises the following steps: A)pretreating fabric; B)preparing composite finishing liquor, taking butyl titanate and dissolving in ethanol, adding diethanolamine, uniformly stirring and adding mixed liquor mixed by ethanol and water, heating, stirring under a backflow state to form nano TiO2 sol; adding chitosan, citric acid and sodium hypophosphate in the nano TiO2 sol, uniformly stirring to obtain the composite finishing liquor; C)finishing wool fabric, placing wool fabric in the composite finishing liquor, dipping and padding twice, wherein mangle expression is 85% and padding temperature is 50-65%; D)predrying; E)baking; F)washing; and G)drying. According to the finishing method, chitosan and nano TiO2 sol are employed as the composite finishing liquor, the finished wool fabric has good antibiosis, shrinkproof, ultraviolet resistance and anti-insolation performances; the finishing method generates no pollution on human body and environment, and the finished wool fabric has good hand feeling.

Owner:ZHEJIANG ZHONGXIN DYEING & FINISHING CO LTD

Formaldehyde free binder

An aqueous binder composition, useful for making fiber products, especially fiberglass insulation, comprising an aqueous substantially alkaline (pH of at least 5.0) solution of a polyol and a hydrolyzed (solubilized) copolymer of maleic anhydride and a vinyl aromatic compound, preferably styrene (i.e., a SMA copolymer); the copolymer is solubilized using ammonia, a secondary alkanolamine (preferably diethanolamine (DEA)), a tertiary alkanolamine (preferably triethanolamine (TEA)), or a mixture thereof and the binder composition is cured as a consequence of cross-linking, esterification reactions between pendant carboxyls on the solubilized (hydrolyzed) copolymer (SMA) chains and hydroxyl groups of the polyol, including the diethanolamine and / or triethanolamine preferably used in the solubilization of the SMA.

Owner:GEORGIA PACIFIC CHEM LLC

Sulfur removal agent suitable for production of oil-gas well

InactiveCN102698576ASimple recipeAffect normal productionDispersed particle separationPropanolAlcohol

The invention relates to a sulfur removal agent suitable for the production of an oil-gas well. The sulfur removal agent comprises the following components in percentage by mass: 10 to 25 percent of hexahydro-1,3,5-tris(hydroxyethyl)-s-triazine, 5 to 20 percent of alcohol amine, 5 to 20 percent of small molecular alcohol and the balance of water. The alcohol amine is one or a mixture of more thantwo of monoethanolamine, ethyleneglycol amine, diisopropanolamine, methyldiethanolamine and triethanolamine; and the small molecular alcohol is one or a mixture of more than two of methanol, ethanol and propanol. The sulfur removal agent has a simple formula, can be soluble with water, and can effectively reduce the content of hydrogen sulfide in crude oil or natural gas; simultaneously, productsgenerated by the sulfur removal agent and the hydrogen sulfide are water-soluble, and cannot block a mineshaft and influence the normal production of the oil-gas well; and the sulfur removal agent can achieve effects at the temperature of 30 to 120 DEG C and can be quickly reacted with the hydrogen sulfide.

Owner:SOUTHWEST PETROLEUM UNIV

Method for absorbing SO2 gas by alcoholamine carboxylate ion liquid

This invention relates to a method of absorbing SO2 gas by the hydramine carboxylate ion liquid, which belongs to the chemical field. In the normal temperature, the aminoethyl alcohol, diethylehthanolamine, triethanolamine, and the diglycol have neutralization reaction with the acetic acid, lactic acid or the acid with similar structure, and then create a series of corresponding alkaline ion liquor. It cost small balancing time through using that ion liquor or loaded in the carrier to absorb the acid gas SO2.

Owner:北京中科艾内茵科技有限公司

Preparation method for self-emulsified cationic epoxy emulsion

InactiveCN103497617ANarrow molecular weight distributionGood flexibilityPolyurea/polyurethane coatingsPaints for electrolytic applicationsEmulsionCarbon chain

The invention discloses a preparation method for self-emulsified cationic epoxy emulsion. The method mainly comprises: using bisphenol A, dodecylphenol and ethoxylatedbisphenol A to perform chain extension on low-molecular-weight epoxy resin to obtain medium-molecular-weight chain-extended epoxy resin; using diethanolamine and N, N-dimethylpropylamine to perform ring-opening amination on chain-extended epoxy resin; and taking a totally-enclosed modified MDI as a curing agent, neutralizing with lactic acid, and emulsifying in deionized water to obtain the self-emulsified cationic epoxy emulsion. According to the epoxy emulsion, tertiary / quaternary amine cationic epoxy resin is taken as the resin main body, and the molecules of the tertiary / quaternary amine cationic epoxy resin have both hydrophobic carbon chains and hydrophilic cationic chain segments, so that the resin molecules have self-emulsifying function, and can be stably emulsified in water without the help of emulsifiers. The provided self-emulsified cationic epoxy emulsion is applicable to preparation of cathodic electrophoretic coatings which has excellent coating performance.

Owner:ZHAOQING UNIV

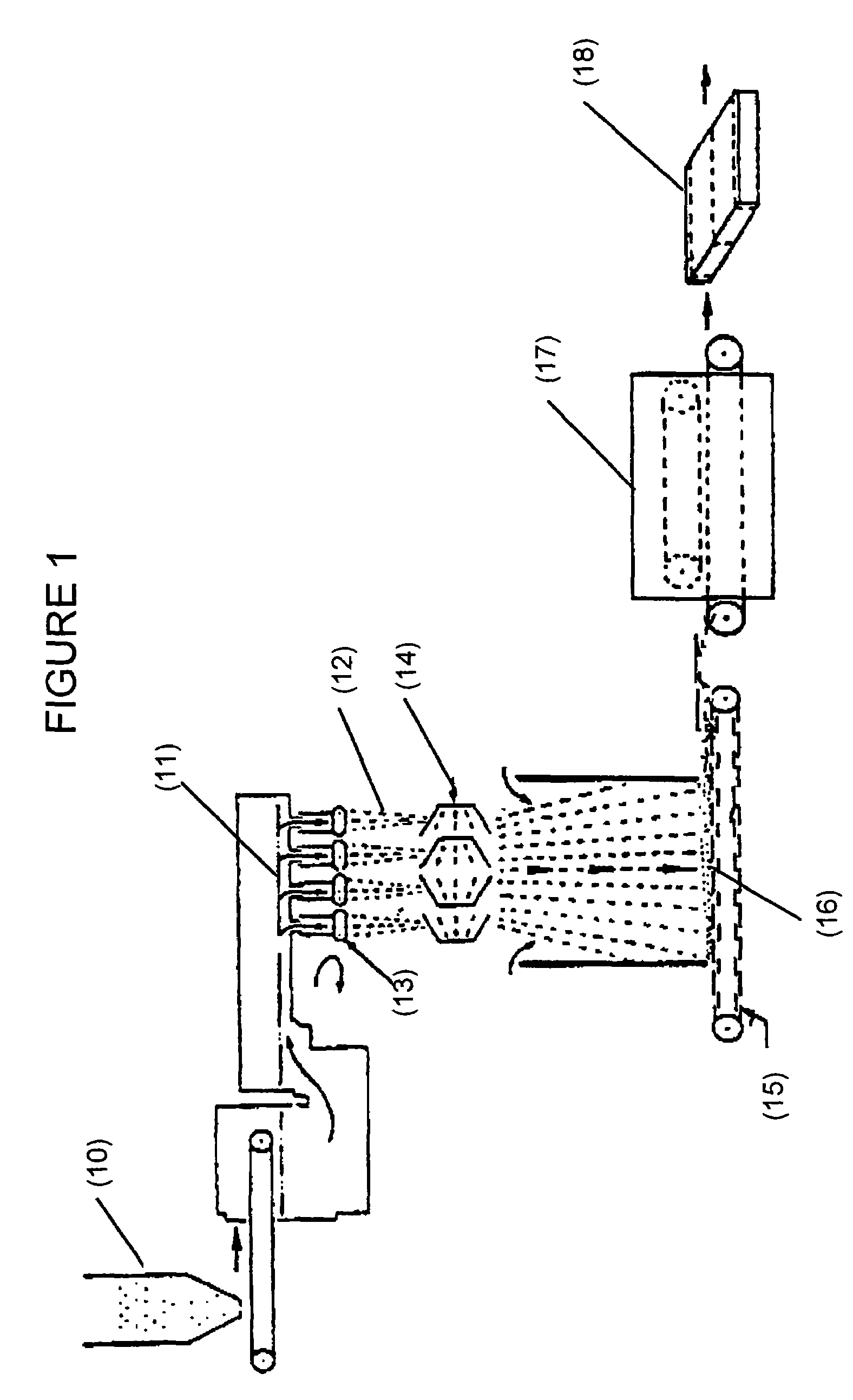

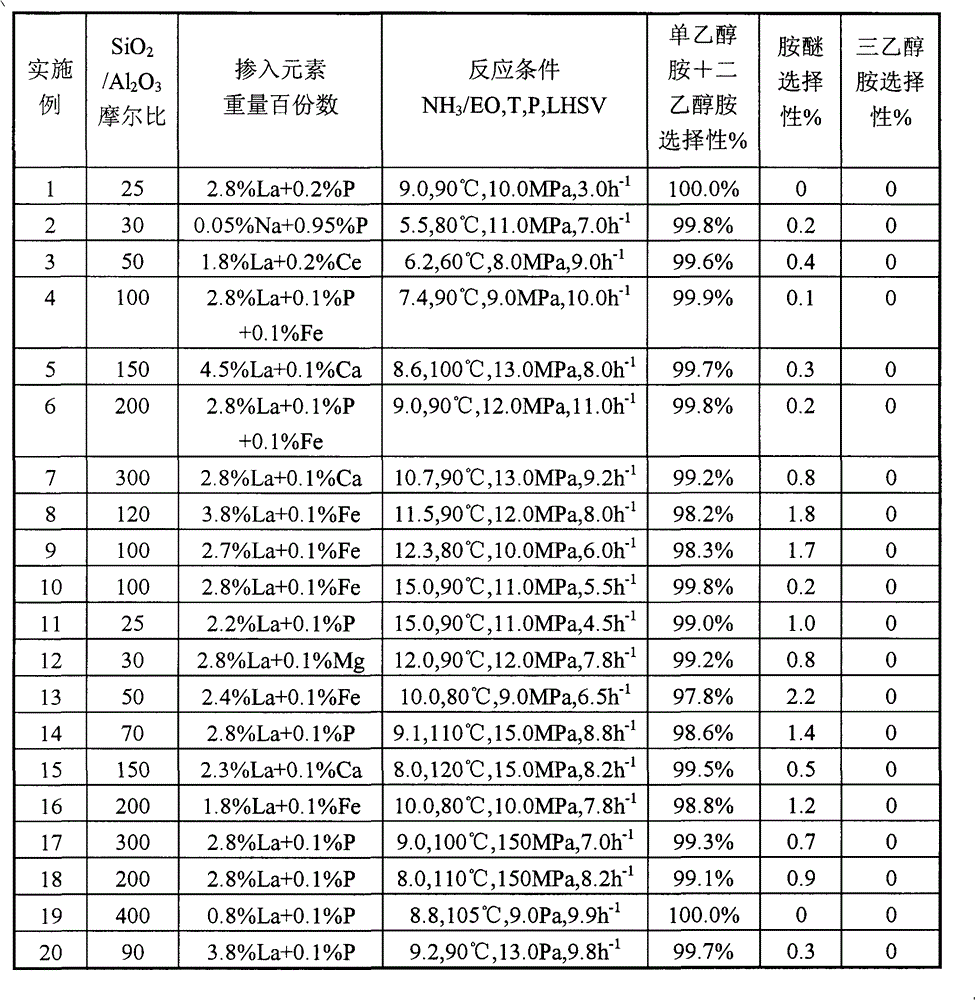

Method for production of monoethanolamine and diethanolamine

ActiveCN102746167ATriethanolamine content is smallMolecular sieve catalystsOrganic compound preparationMolecular sieveZSM-5 zeolite

The invention relates to a method for production of monoethanolamine (MEA) and diethanolamine (DEA), and aims to mainly solve the problem that triethanolamine (TEA) is generated as a byproduct in production of monoethanolamine in the prior art. According to a technical scheme adopted by the method of the invention, a binder-free ZSM-5 zeolite molecular sieve catalyst containing SiO2 and Al2O3 that are in a mole ratio of 10-500 by weight is employed, and raw materials contact with the catalyst to generate triethanolamine-free products. The technical scheme well solves the problem, and can be applied in the industrial production of monoethanolamine (MEA) and diethanolamine.

Owner:CHINA PETROLEUM & CHEM CORP +1

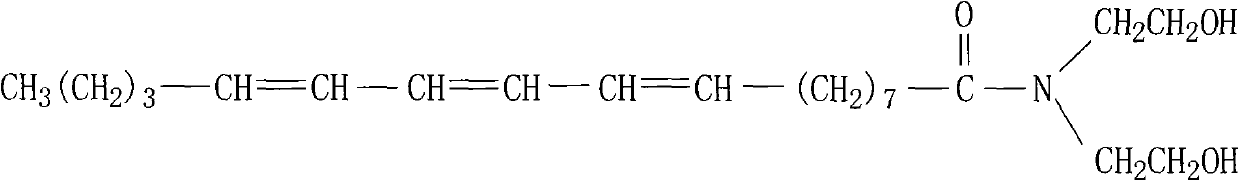

Hydroxylated tung oil and ester group-aminated preparation method thereof

InactiveCN101845367AIncrease profitReduce dependenceFatty acid chemical modificationChemical synthesisPetroleum product

The invention discloses a hydroxylated tung oil and an ester group-aminated preparation method, belonging to the technical field of organic chemosynthesis. In the method, under a certain condition, ester groups in the tung oil and diethanol amine are subjected to aminolysis reaction on the premise of reserving conjugated double bonds, thus the tung oil is hydroxylated to mainly produce a compound containing terminated hydroxyl and three conjugated double bonds. The structural formula of the compound is shown in the specification. The aminolysis reaction product plays an important role in developing and producing processes of leading the tung oil into waterborne polyurethane, not only can combine the advantages of the tung oil and the polyurethane, but also can improve the utilization ratio of tung oil resources as special local products in China and decrease the dependence on petroleum products; and simultaneously, the method has the advantages of simplicity, practicability, high conversion rate and convenience in industrialized production.

Owner:HIGH & NEW TECH RES CENT OF HENAN ACAD OF SCI

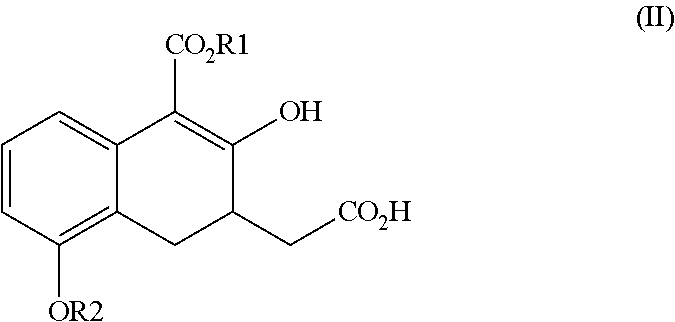

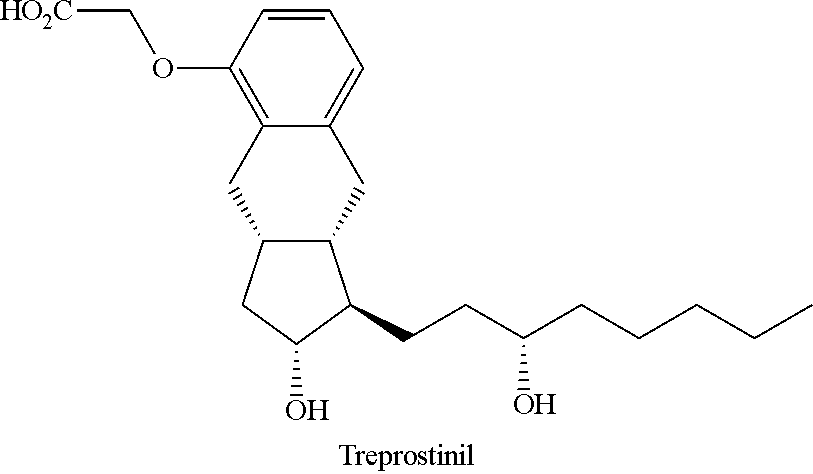

Novel intermediate for synthesizing treprostinil diethanolamine and method for preparing the same

ActiveUS20160152548A1High optical purityHigh purityOrganic compound preparationPreparation by ester-hydroxy reactionCombinatorial chemistryEthanolamine synthesis

The present invention relates to a method for treprostinil diethanolamine synthesis. The present invention also relates to a novel intermediate used in the method for treprostinil diethanolamine synthesis. The novel intermediate is shown in the following formula (II):wherein R1 and R2 are described in the description.

Owner:EVERLIGHT CHEMICAL INDUSTRIAL CORPORATION

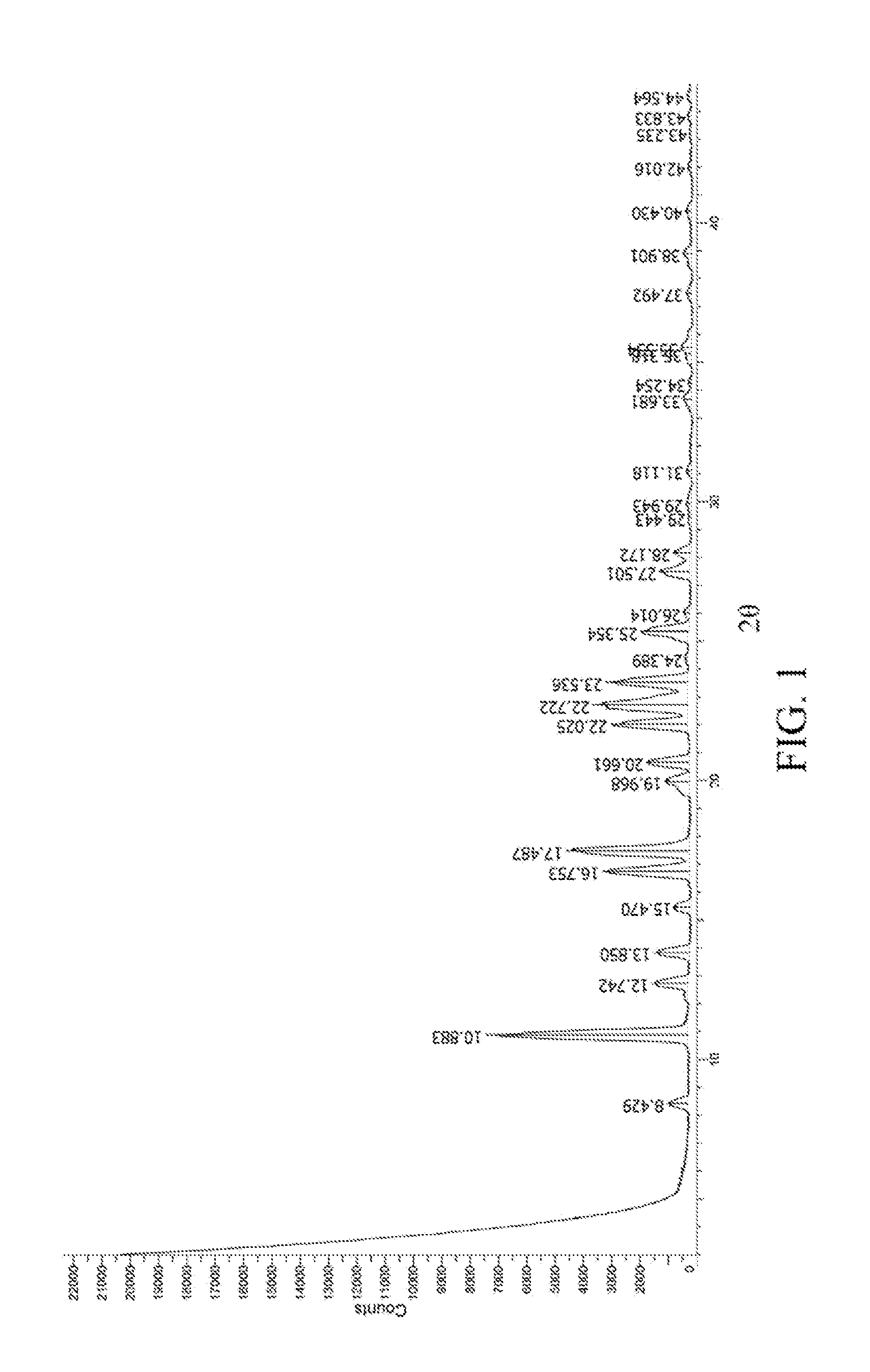

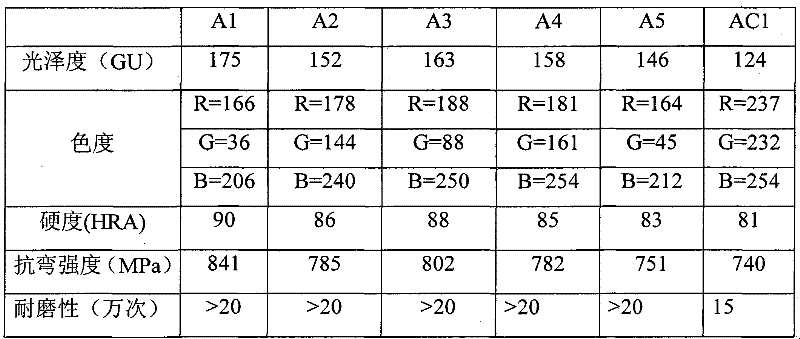

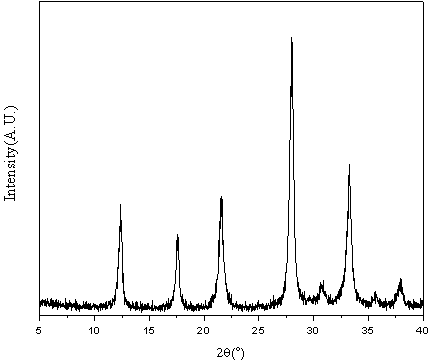

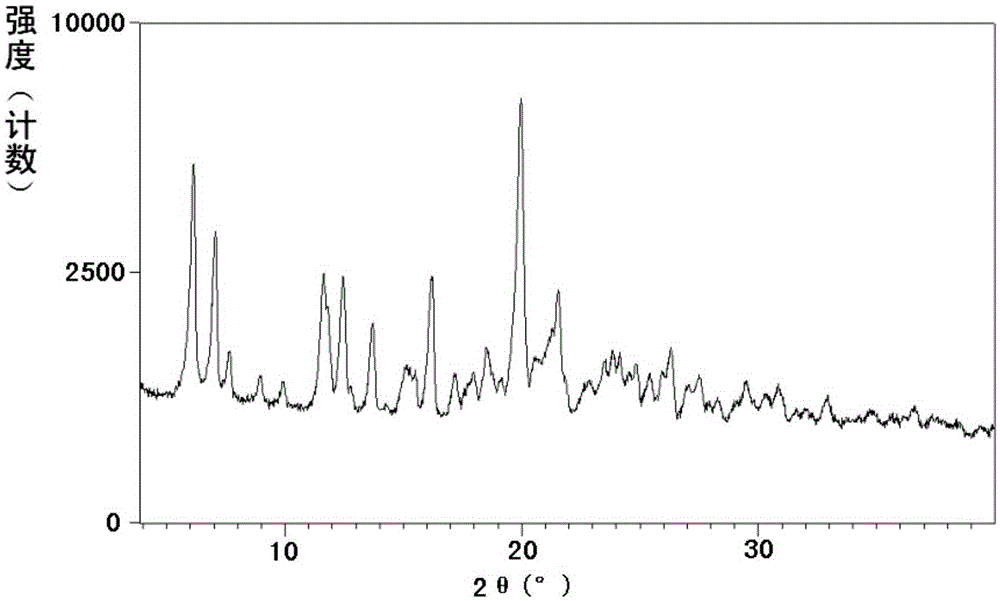

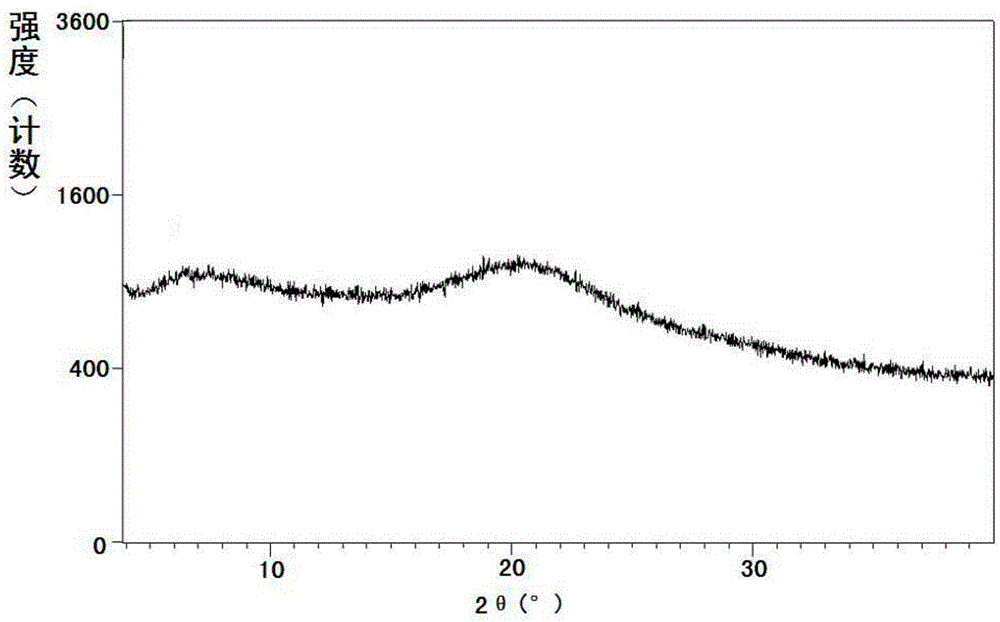

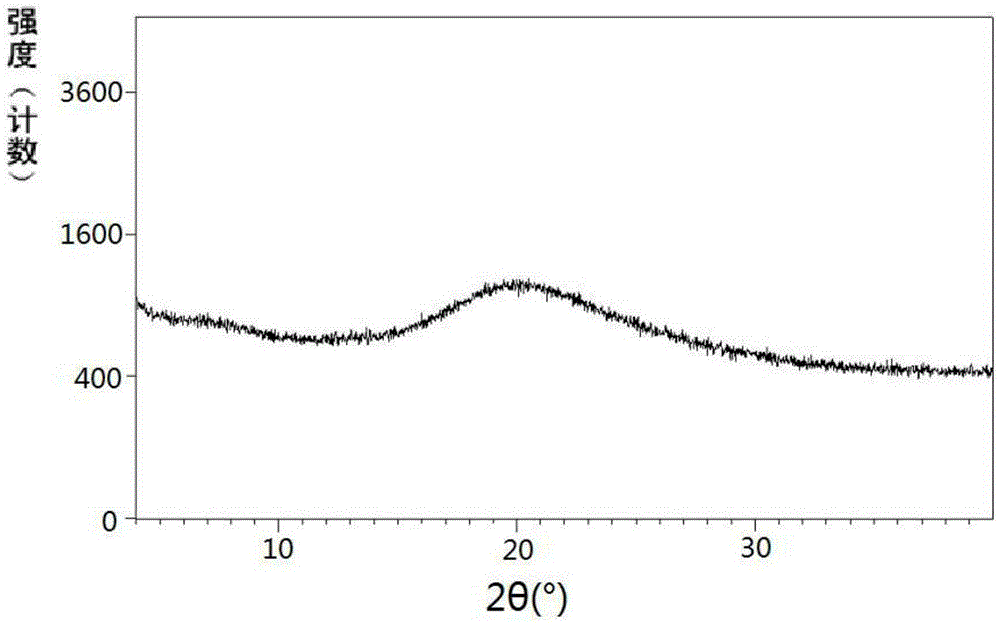

A kind of zirconia ceramic and its preparation method

The invention, belonging to the technical field of zirconia ceramic, discloses a zirconia ceramic and a preparation method thereof. The ceramic comprises matrix, sintering aid, neodymium oxide and additive, wherein, the matrix is yttria stabilized zirconia, the additive is selected from one or more of zinc oxide, barium carbonate and calcium fluoride, and the diffraction peak of the XRD appears when the 2 theta is 34.8-36.2 degrees. The zirconia ceramic has stable and beautiful purple. The preparation method comprises the following steps: adding neodymium oxide particles in a diethanolamine solution for soaking, then carrying out solid-liquid separation; carrying out ball mill mixing of the matrix, processed neodymium oxide particles, sintering aid and additive, then carrying out die forming and high temperature sintering. The preparation method provided by the present invention is simple and easy, and is suitable for large-scale industrial production.

Owner:HUAWEI TEHCHNOLOGIES CO LTD

Premixed liquid monopropellant solutions and mixtures

Nondetonable, or low detonation sensitivity, substantially nontoxic liquid monopropellants are provided. The liquid propellants are formed from aqueous solutions of solid oxidizers in liquid oxidizers and water soluble liquid fuels and formulated to have a freezing point less than −10° C. Liquid oxidizers may be inorganic or organic aqueous solutions, with hydrogen peroxide being preferred. Preferred solid oxidizers are water soluble nitrates including ammonium dinitramide, aminoguanidine dinitrate, ammonium nitrate, hydroxylamine nitrate, hydrazine nitrate, guanidine nitrate and aminoguanidine nitrate. Preferred liquid fuels are water soluble alcohols, amines and amine nitrates, hydroxyethyl hydrazine, hydroxyethylhydrazine nitrate, cyanoguanidine, guanidines, aminoguanidines, triaminoguanidines, and their nitrate salts, ethanolamine dinitrate, ethylenediamine dinitrate, polyvinyl nitrate, and aziridine.

Owner:AEROJET GENERAL CORP

Process for the preparation of rice bran oil low in phosphorous content

InactiveUS6706299B2Simple and economical and fast processReduce processing stepsFatty-oils/fats refiningCheese manufacturePhosphoric acidPulp and paper industry

Owner:COUNCIL OF SCI & IND RES

Method for preparing P type molecular sieve by using coal ash as raw material

InactiveCN104291349AInhibition of dissolutionCause dissolutionCrystalline aluminosilicate zeolitesMolecular sieveSodium aluminate

The invention relates to a method for preparing a P type molecular sieve by using coal ash as a raw material. The method for preparing the P type molecular sieve by using coal ash as the raw material comprises the following steps: I, pre-treating and activating coal ash; II, preparing sodium silicate and sodium metaaluminate by using activated coal ash; and III, synthesizing the P type molecular sieve: firstly, uniformly mixing a sodium silicate solution with a sodium salt, then, dropwise adding the sodium metaaluminate solution into the mixed liquid, and finally, adding an organic steric hindering agent and a proper amount of deionized water to form a reaction mixture, wherein the molar ratios of the reaction mixture are as follows: SiO2 / Al2O3=0.4-1.8, M / Al2O3=1-5, Na2O / Al2O3=2-4 and H2O / SiO2=20-150 and the organic spatial steric hindering agent is at least one of ethanol amine, diethanol amine and triethanol amine; packing the mixed materials in a polytetrafluoroethylene container, stirring, then putting in a stainless steel reaction kettle, and carrying out hydro-thermal synthesis for 2-8 hours; and taking out products in the reaction kettle, carrying out centrifugal separation and washing by deionized water, and drying to obtain the P type molecular sieve. The method provided by the invention is short in synthetic cost, short in crystallization time and high in yield of the P type molecular sieve.

Owner:NORTHEAST GASOLINEEUM UNIV

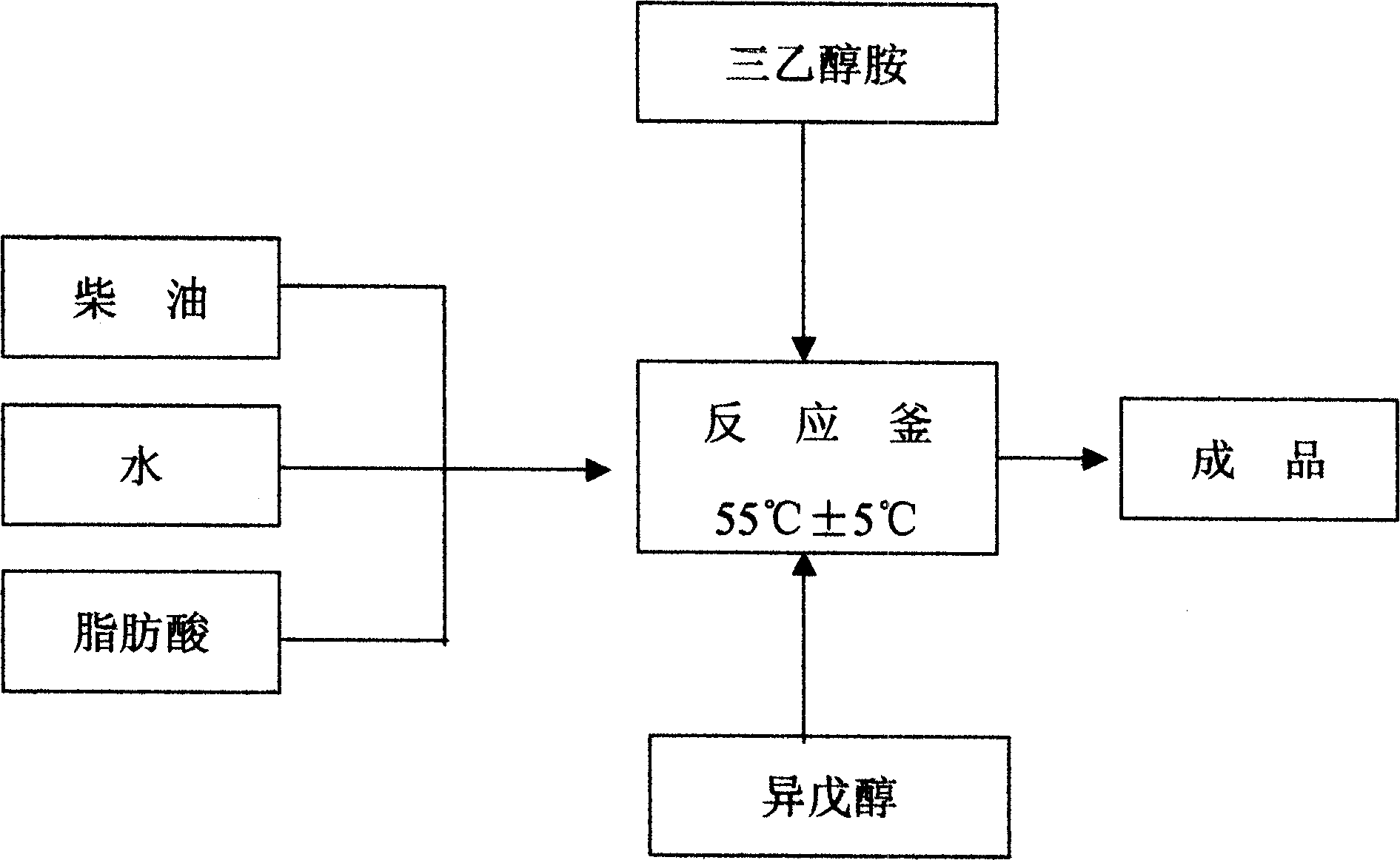

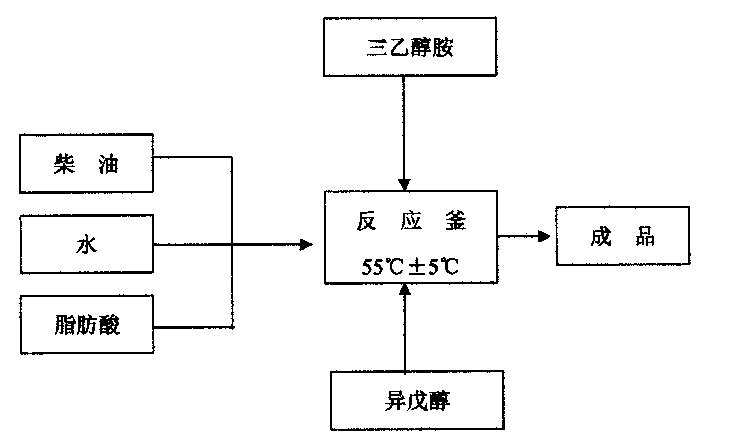

Production technology and formulation of microemulsion fuel oil

InactiveCN1410514AWide variety of sourcesTake advantage ofRefining by water treatmentFuel oilMicroemulsion

A microemulsified fuel oil is prepared from fatty acid (or oleic acid) (15 vol.%), triethanolamine (or biethanolamine) (2 vol.%), isopentanol (3 vol.%), water (20 vol.%) and diesel oil (60 vol.%). Its advantages are low cost, little harmful gas, and long service life of diesel engine.

Owner:季忠

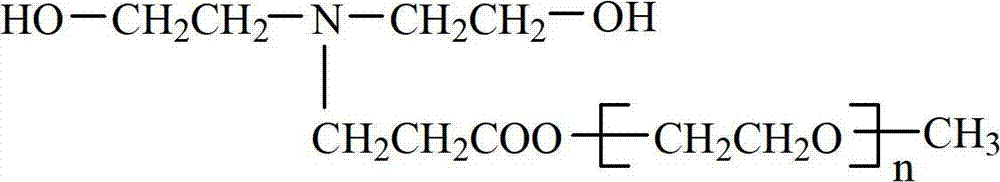

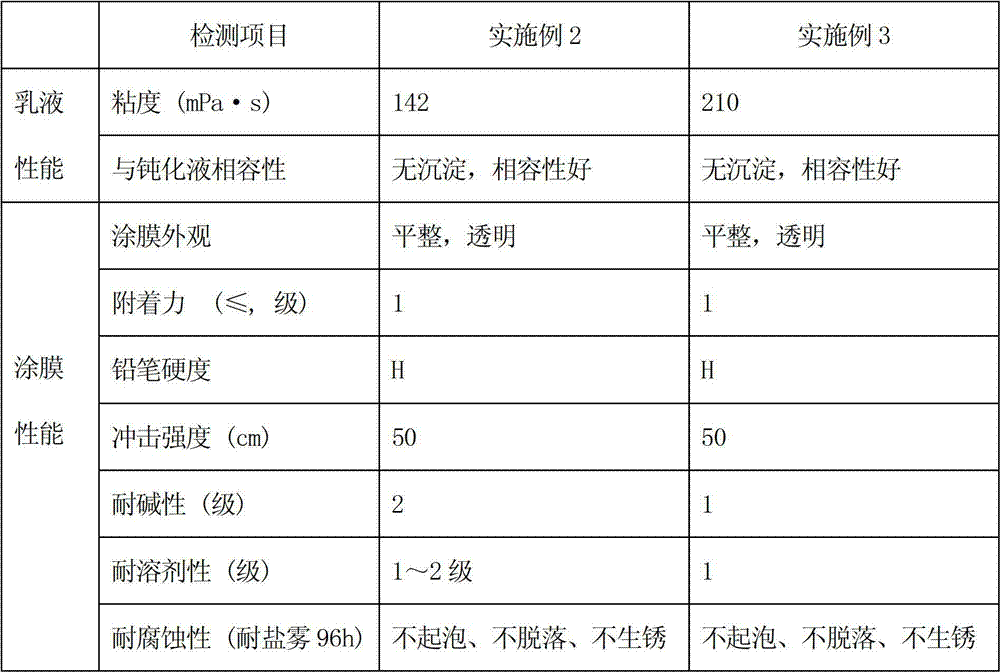

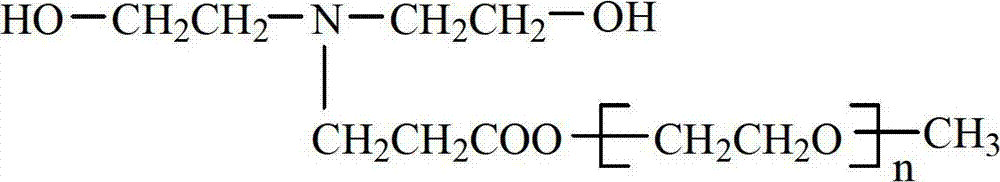

Cation-nonionic mixed aqueous polyurethane emulsion and preparation method thereof

ActiveCN102775578AGood chemical resistanceImprove corrosion resistancePolyurea/polyurethane coatingsChromium freePropanoic acid

The invention relates to a cation-nonionic mixed aqueous polyurethane emulsion and a preparation method thereof. The emulsion is aqueous polyurethane which has a cation hydrophilic group and a nonionic hydrophilic side chain. The preparation method comprises the steps of firstly introducing the nonionic hydrophilic side chain by using a specific nonionic hydrophilic chain extender; and introducing the cation hydrophilic group by using a cation hydrophilic chain extender, wherein the amounts of the nonionic hydrophilic chain extender and the cation hydrophilic chain extender respectively account for 1-10 percent and 1-8 percent according to the total weight of the raw materials, and the specific nonionic hydrophilic chain extender is 3-(N,N-dihydroxyethyl) amino-propionic acid polyethyleneglycol monomethyl ether ester which is prepared by heating and reacting methoxy polyethylene glycol single methyl acrylate and diethanol amine in a molar ratio of 1:1. By using the emulsion, the defect of the existing emulsion is overcome, and the requirement of zinc-plating steel plate chromium-free passivation pretreatment on aqueous polyurethane resins are met, so that the cost is reduced.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

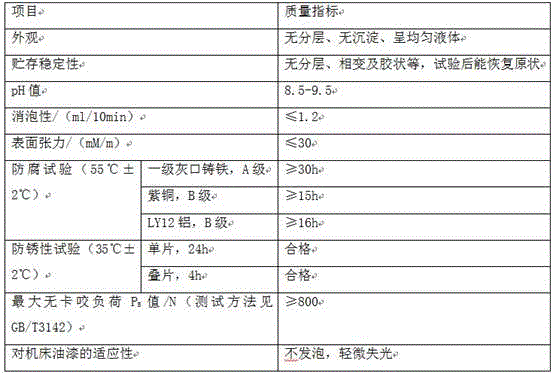

Aluminium alloy cutting liquid with long service life and preparation method thereof

ActiveCN106118834AReduce dosageExtended service lifeLubricant compositionDefoaming AgentsMineral oil

The invention relates to the field of metal cutting liquids, in particular to an aluminium alloy cutting liquid with a long service life and a preparation method thereof. The semi-synthetic cutting liquid provided by the invention is prepared from 10 to 30 percent of mineral oil, 5 to 15 percent of alcohol amine, 5 to 12 percent of an emulsifying agent, 3 to 8 percent of an anti-rusting agent, 3 to 10 percent of a lubricating agent, 1 to 4 percent of a corrosion inhibitor, 1 to 4 percent of an extreme pressure agent, 0.5 to 1 percent of a defoaming agent, and 1 to 3 percent of a sterilizing agent. According to the formula of the aluminium alloy cutting liquid, conventional monoethanolamine, diethanol amine and triethanolamine serving as pH regulating agents are abandoned, and through a special compounding mode, the aluminium alloy cutting liquid has higher stability, and the cost is reduced. Secondly, the using amount of the extreme pressure agent is reduced by regulating the using amounts of various raw materials; moreover, excellent corrosion preventing and lubricating effects of the cutting liquid are maintained; the cutting liquid can be used for a long time; the replacement period of the cutting liquid provided by the invention is about one year; the cutting liquid is environment-friendly and has extremely low damage to a human body.

Owner:东莞市科泽润滑油有限公司

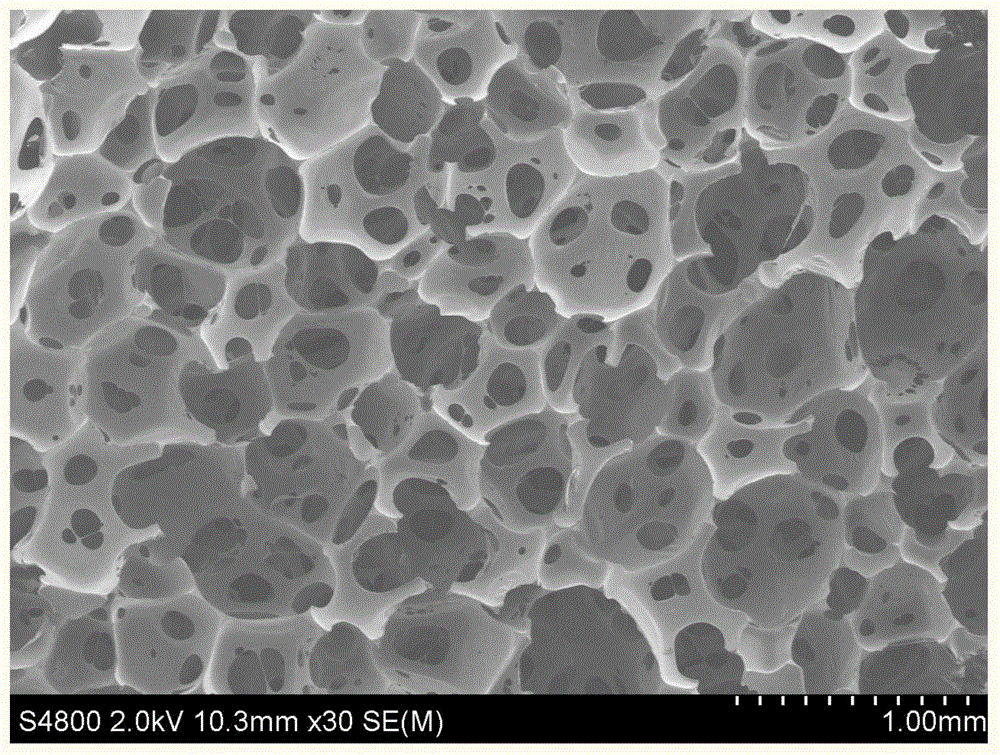

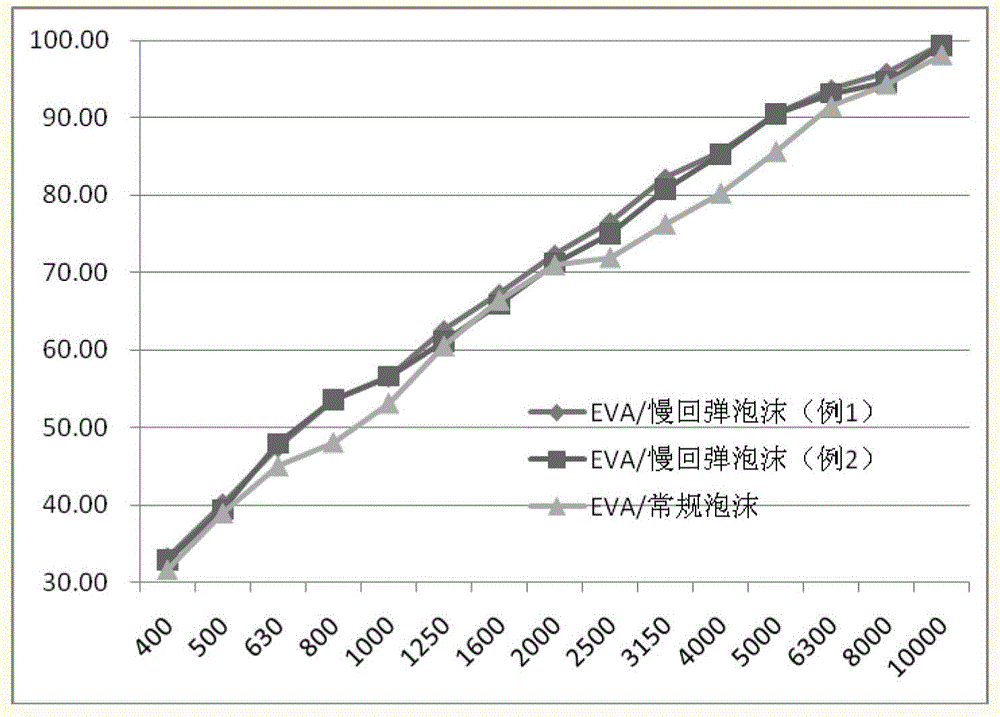

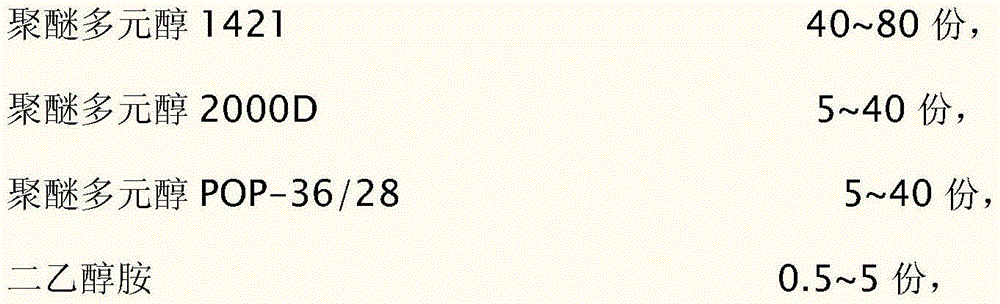

Vehicle-used slowly-springback polyurethane foam composite material

ActiveCN104149455AHigh reactivityGood physical propertiesSynthetic resin layered productsEnvironmental resistanceSilicone oil

The invention discloses a vehicle-used slowly-springback polyurethane foam composite material which is compounded from slowly-springback polyurethane foam and an ethylene-vinyl acetate copolymer. The slowly-springback polyurethane foam is prepared from following components including, by weight, an A material: 40-80 parts of a polyether polyol 1421, 5-40 parts of a polyether polyol 2000D, 5-40 parts of a polyether polyol POP-36 / 28, 0.5-5 parts of diethanolamine, 1-6 parts of water, 0.1-1.5 parts of a catalyst EF-600, 0.1-0.5 parts of a catalyst ZF-10 and 1-6 parts of a silicone oil L-580; a B material: 40-80 parts of a modified MDI. During preparation of the slowly-springback polyurethane foam, a weight usage amount ratio of the A material to the B material is 100:40-80. The vehicle-used slowly-springback polyurethane foam is high in reaction activity, is low in toxicity, is environmental-protective, is high in damp loss factor, is high in sound-insulation performance and is free of addition of a foam-forming agent.

Owner:NINGBO TUOPU GROUP CO LTD

Adhesive remover and preparation method thereof

ActiveCN101899365ASmall smellEasy to removeOrganic detergent compounding agentsNon-ionic surface-active compoundsSilanesAlkylphenol

The invention relates to an adhesive remover and a preparation method thereof. The basic composition of the adhesive remover formula is as follows in percentage by weight: 12-25% of fatty alcohol-polyoxyethylene ether sodium sulfate and fatty alcohol-polyoxyethylene ether silane, 20-30% of alkylphenol polyoxyethylene ether, 4-5% of ethylene oxide / propane segmented copolymer, 5-7.9% of sodium chloride, 10-12% of triethyl phosphate and dimethyl adipate, 5-10% of tricarboxyl triethylamine, triethylamine, diethanol amine, EDTA, urea, triethanolamine and hexamethylene tetramine, 2-10% of ethylene glycol, butyl cellosolve, propylene glycol methyl ether, ethanol, isopropanol, benzyl alcohol and methyl isoamyl ketone and 0.1-42% of deionized water. Compared with the prior art, the invention has the advantages that the adhesive remover is aqueous and low irritating, is wide in application range, can rapidly remove various trade mark adhesives, eliminate adhesiveness, degrease, remove adhesive and deliquate adhering oil stain in the aspect of removing advertising posters on the surfaces of glass, ceramics, marbles, stainless steel, etc. The invention also provides an environment-friendly and safe method for preparing the adhesive remover.

Owner:NINGBO PASCO UNITED IND

Metal anti-rust agent

The invention relates to a metal anti-rust agent which is characterized by comprising the following components in parts by weight: 10-20 parts of inositol hexaphosphate, 8-15 parts of acrylamide, 6-14 parts of diethanol amine, 5-10 parts of a polymer film-forming agent, 4-8 parts of sodium molybdate, 1-3 parts of cresyl triazole, 0.5-1.5 parts of a surfactant and the balance amount of water. The metal anti-rust agent has the characteristics of wide application range, stable anti-rust effect, convenience in use, high efficiency, safety, environmental friendliness and the like.

Owner:GUANGXI DOCTOR HAIYI INFORMATION TECH

Method for producing o-chloroaniline

InactiveCN101333169AHigh yieldLow costOrganic compound preparationAmino compound preparationEthylenediamineO-nitrochlorobenzene

An o-chloroaniline production method takes o-nitrochlorobenzene as raw material and is characterized in that the o-nitrochlorobenzene is dissolved in alcohol solvent in the presence of catalyst and additive and reacted with hydrogen at 10-120 DEG C and under 0.3-4.0 MPa; the reaction process is continuous reaction; after the completion of the reaction, the o-chloroaniline is obtained through treatment, wherein, the catalyst can be selected from one of the following: Ni / Al2O3, Raney Ni, Pt / C and Pd / C; while the additive can be selected from one, or two, or three of the following compounds: cyclohexylamine, ethylenediamine, ethanolamine, diethanolamine, triethanolamine, pyridine, liquid ammonia, ammonium bicarbonate, ammonium carbonate, sodium carbonate, sodium bicarbonate, potassium bicarbonate, potassium carbonate, potassium hydrogen phosphate, potassium dihydrogen phosphate, sodium hydrogen phosphate and sodium dihydrogen phosphate; the dosage of the catalyst takes up 0.05% to 20% of the mass of the o-nitrochlorobenzene; the dosage of the additive takes up 0. 5% to 20% of the mass of the o-nitrochlorobenzene; the alcohol can be methanol or ethanol; the dosage of alcohol takes up 30% to 150% of the dosage of the o-nitrochlorobenzene; the continuous reaction is realized through 1 to 6 tank reactors which are connected in series.

Owner:淮安嘉诚高新化工股份有限公司

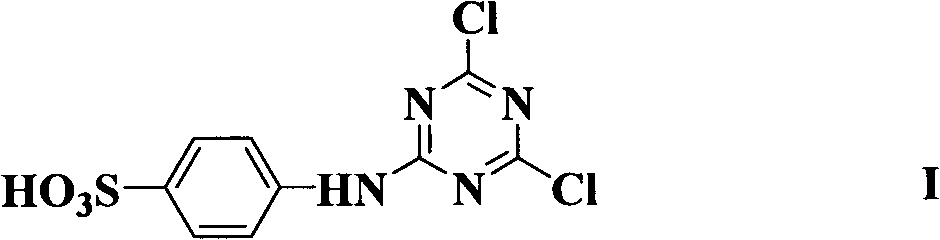

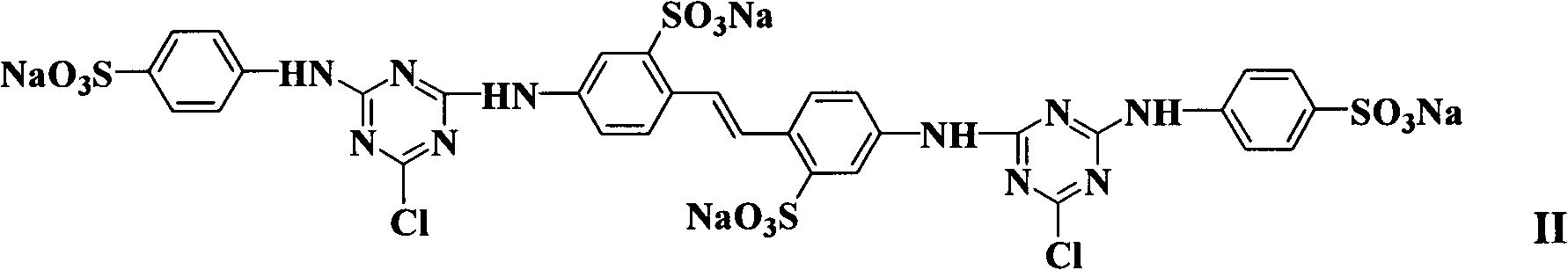

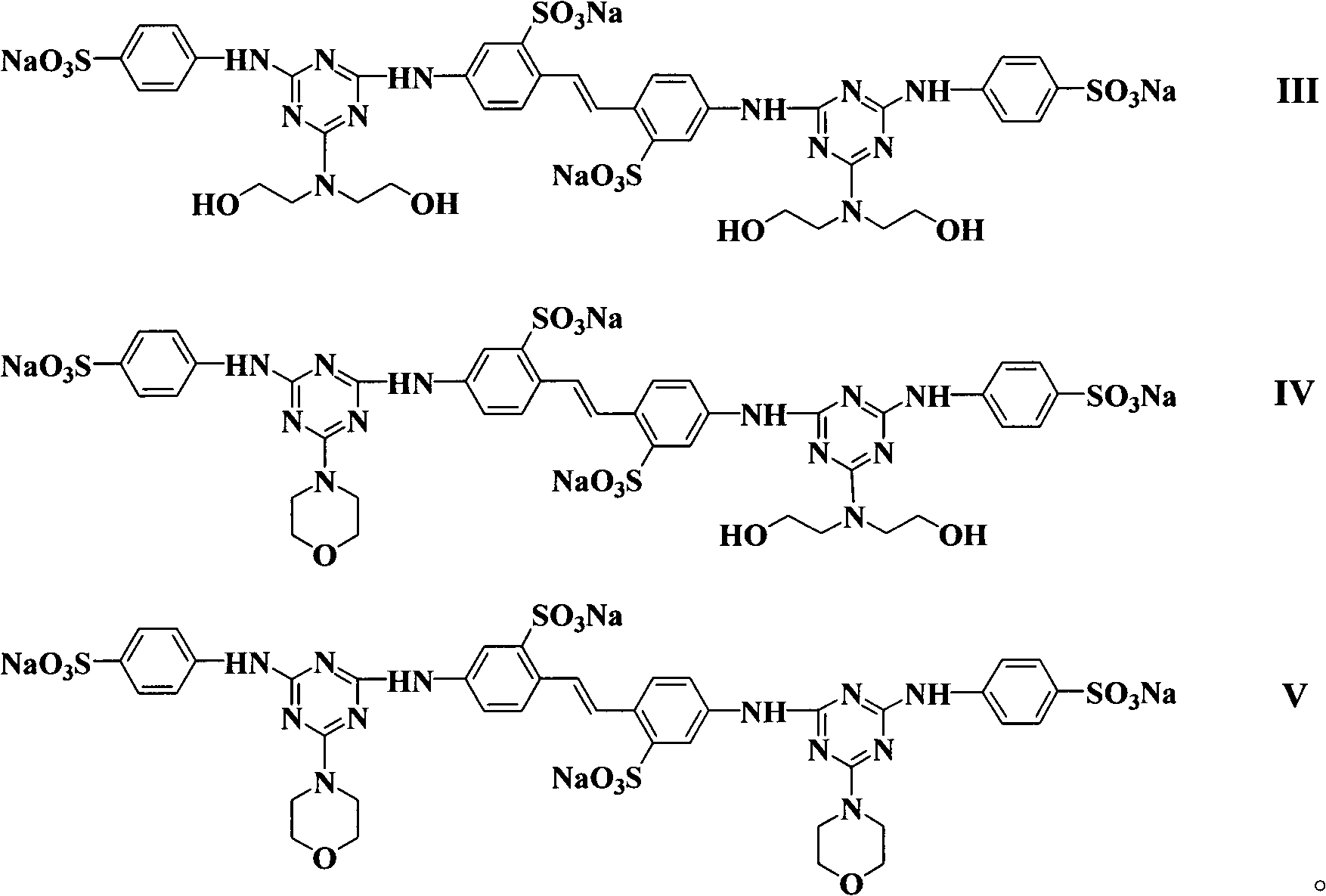

Preparation method of toluylene triazine liquid fluorescent brightener composite

InactiveCN101654894AReduce salt contentGood storage stabilityOrganic chemistryNon-macromolecular organic additionSulfanilic acidMorpholine

The invention provides a preparation method of symmetric and asymmetric toluylene triazine liquid fluorescent brightener composite expressed by the structural formulas (III), (VI) and (V), comprisingthe following steps: taking cyanuric chloride, sulfanilic acid, 4, 4-diaminobenzil-2, 2-disulfonic acid, morpholine and diethanol amine as raw materials; synthesizing by the three steps of reaction; and desalinating and filtering by means of nanofiltration membrane filtration. The liquid fluorescent brightener composite has a built synergistic effect and better brightening effect than a single composite; and the method not only can improve the quality of the fluorescent brightener, but also can reduce the consumption of amounts of raw materials, and greatly elevates product yield and quality.

Owner:山西晋光化工有限公司

Sacubitril derivatives and medicine compositions, preparation methods and application thereof

ActiveCN105693543AEasy to prepareCrystal form controllableAmino compound purification/separationOrganic compound preparationEthylenediamineArginine

The invention provides sacubitril derivatives and medicine compositions, preparation methods and application thereof and belongs to the fields of medicine compounds and preparation thereof. The sacubitril derivatives comprise sacubitril lithium salt, sacubitril kali salt, sacubitril magnesium salt, sacubitril calcium salt, sacubitril strontium salt, sacubitril zinc salt, sacubitril ferric salt, sacubitril ammonium salt, sacubitril diethylamine salt, sacubitril ethylenediamine salt, sacubitril piperazine salt, sacubitril N-(2-ethoxyl)-pyrrolidine salt, sacubitril choline salt, sacubitril cholamine salt, sacubitril diethanol amine salt, sacubitril triethanolamine salt, sacubitril tromethamine salt, sacubitril meglumine salt, sacubitril diisopropylamine salt, sacubitril tert-butylamine salt, sacubitril N, N'-bis-benzyl ethylenediamine salt, sacubitril L-lysine salt, sacubitril L-arginine salt or sacubitril L-histidine salt.

Owner:SICHUAN HAISCO PHARMA CO LTD

Method for preparing loaded nano titanium dioxide photocatalysis film

InactiveCN1634653AHigh catalytic activityImprove photocatalytic activityCatalyst activation/preparationChemical reactionTitanic acid

This invention relates to a sol to gel method to process load nanometer titania effective light catalyzer thin film process method, which belongs to light catalyzer materials chemical technique field and comprises the following steps: using the pure titanic acid butonate and absolute ethyl alcohol, aminoethyl alcohol, water, poly-glycol 600 as materials; getting transparent stable light yellow titania sol through common temperature chemical reaction; then adopting the dipping and lifting method to load titania thin film on metal wire surface; finally burning in Muffle furnace under temperature of 450íµ to 550íµ to get the light catalyzer thin film.

Owner:SHANGHAI UNIV

Dispersant for wet grinding of heavy calcium carbonate and preparation method thereof

InactiveCN101230209ALow viscosityLow aging stabilityPigment treatment with organosilicon compoundsPigment physical treatmentOrganic basePotassium hydroxide

The invention provides a dispersant used for wet grinding of heavy calcium carbonate and the preparation method thereof. The dispersant is composed of Alpha and Beta-unsaturated carboxylic acid of 80 to 100 parts by weight, and other monomers of 0 to 20 parts by weight, which are polymerized together, and a neutralizing agent in the polymer is selected from one or two of inorganic base ammonium hydroxide, sodium hydroxide, potassium hydroxide, calcium hydroxide, etc., or organic base diethylamine, triethylamine, mono ethanolamine, diethanolamine, triethanolamine, etc. The dispersant of the invention is used for grinding calcium carbonate pulp with high solid content, low viscosity and good time efficiency and stability.

Owner:SHANGHAI DONGSHENG NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com