Liquid alkali-free chloride-free accelerating agent as well as methods for preparing and using same

An accelerator and liquid technology, applied in the field of shotcrete, can solve the problems of corrosion of steel bars, affecting the quality and service life of concrete, and achieve the effects of less dust pollution, low rebound rate and good performance

Inactive Publication Date: 2013-02-13

北京冶建特种材料有限公司 +1

View PDF3 Cites 54 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

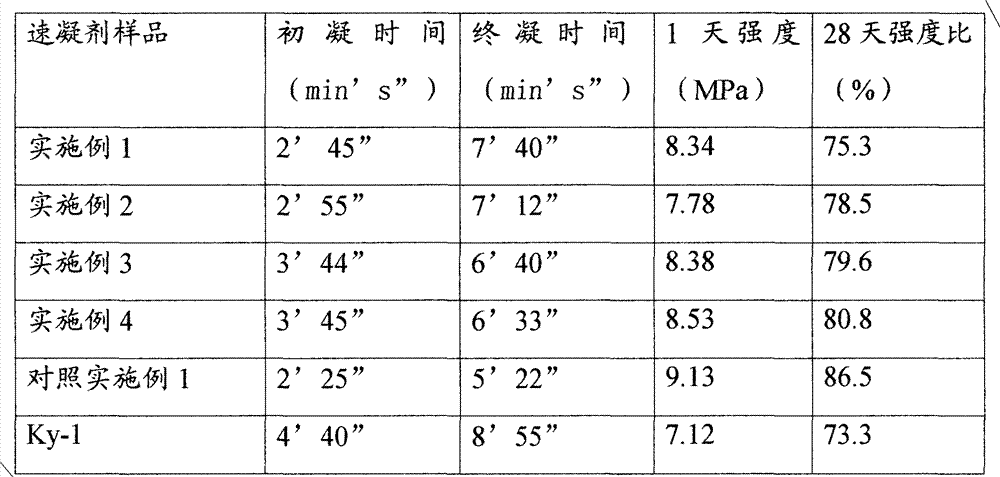

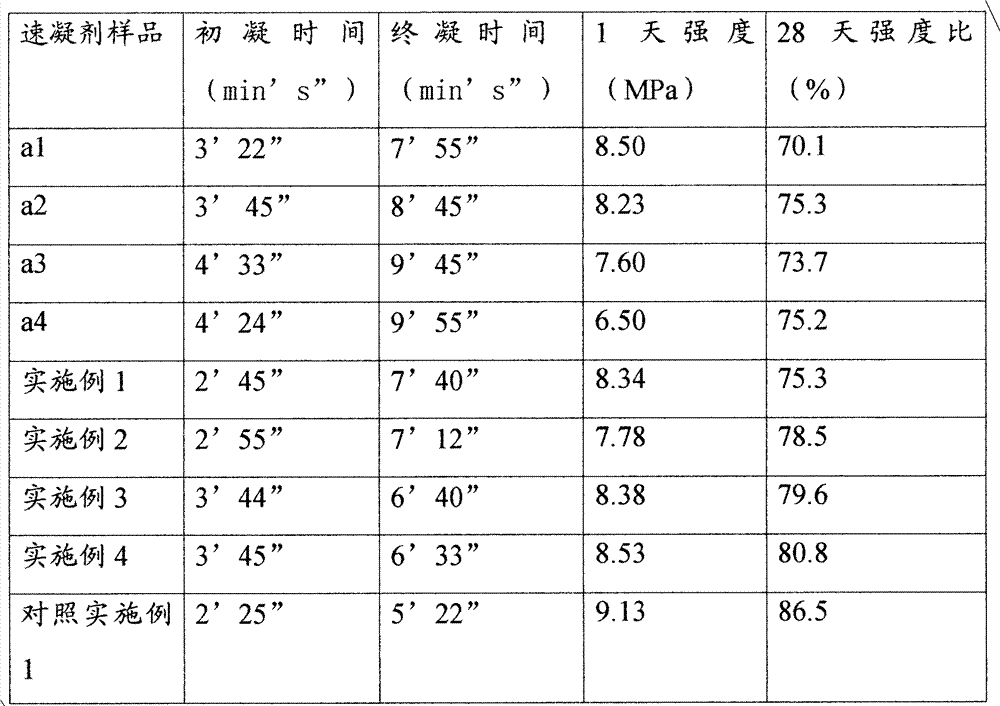

Effect test

Embodiment 1

[0041] Water: 50

[0042] Aluminum sulfate: 38

[0043] Diethanolamine: 2

[0045] Magnesium Fluorosilicate: 10

Embodiment 2

[0047] Water: 30

[0048] Aluminum sulfate: 60

[0049] Magnesium sulfate heptahydrate: 5

[0050] Triethanolamine: 2

[0051] Calcium sulfate: 3

Embodiment 3

[0054] Water: 25

[0055] Aluminum sulfate: 45

[0056] Magnesium sulfate heptahydrate: 20

[0057] Diethanolamine: 5

[0059] Magnesium Fluoride: 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a liquid alkali-free chloride-free accelerating agent and methods for preparing and using the same. Raw materials for preparing the accelerating agent include one or a plurality of the following components of aluminum sulfate, magnesium sulfate, hydramine, an early strength agent, a synergist and water. The aluminum sulfate is the purchasable industrial-grade aluminum sulfate hydrate Al2(SO4)3.18H2O and has the solid content of 51%-52%. The magnesium sulfate is MgSO4.7H2O with the solid content of 48%-49%. The hydramine is one or a plurality of mono ethanol amine, diethanolamine, triethanolamine or isopropoxide. The early strength agent is one or a plurality of calcium sulfate, calcium formate or calcium nitrite. The synergist is magnesium fluosilicate and / or magnesium fluoride. The liquid alkali-free chloride-free accelerating agent provided by the invention has the characteristics of good adaptability, low price, low mixing amount, good performance, good stability and the like; and moreover, the liquid alkali-free chloride-free accelerating agent is added into the concrete to be used as sprayed concrete, has the characteristics of low resilience, small dust pollution and the like and can satisfy the requirements of the 'JC477-2005 sprayed concrete accelerating agent' standard.

Description

technical field [0001] The invention relates to the technical field of concrete additive materials chemical industry, in particular to a liquid alkali-free quick-setting agent and its preparation, and the use of shotcrete in engineering, civil construction, tunnels and the like. Background technique [0002] Cement accelerator (hereinafter referred to as accelerator), also known as accelerator, is a chemical admixture that can promote the rapid setting of cement or concrete. widely used in engineering. [0003] Shotcrete support technology has been widely used in underground and tunnel engineering. At the same time, higher requirements are also put forward for the performance of shotcrete, such as avoiding the spray layer slipping during spraying, increasing the thickness of one shot concrete as much as possible, reducing concrete rebound, and reducing dust pollution. In order to meet the above requirements, the spraying construction of concrete is developing to the wet sp...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C04B24/12C04B103/14

Inventor 任雪梅郝挺宇涂玉波曹擎宇侯学力

Owner 北京冶建特种材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com