Patents

Literature

129 results about "Chemical admixture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical Admixtures. A chemical admixture is any chemical additive to the concrete mixture that enhances the properties of concrete in the fresh or hardened state. It does not typically include paints and protective coatings (for steel or concrete).

Chemical Admixtures for Hydraulic Cements

InactiveUS20130074736A1Improve propertiesImprove economySolid waste managementChemical admixtureHardness

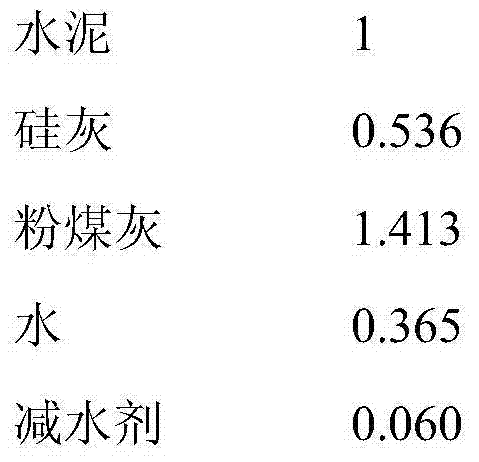

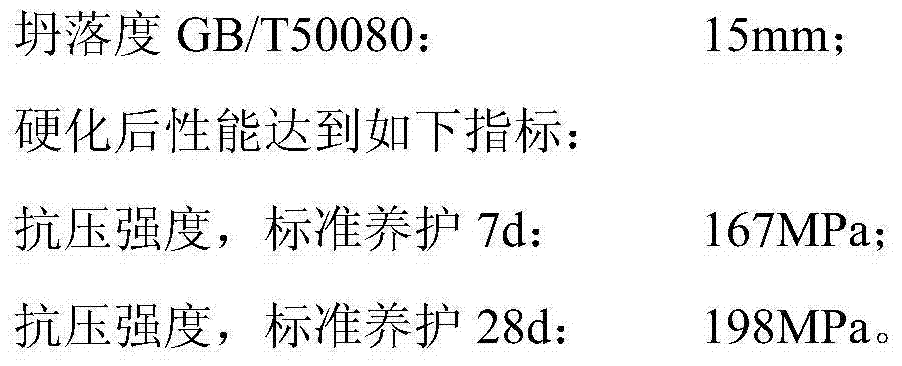

This invention relates to a new class of chemical admixtures for hydraulic cement compositions such as pastes, mortars, grouts and concretes. The cement compositions are comprised of ordinary Portland cement, blended cements, or non-Portland cements made with Supplementary Cementitious Materials. The admixtures contain complexes of metals with derivatives of hydroxycarboxylic acids, and improve properties of cement compositions, including setting, hardness, compressive strength, shrinkage, and freeze-thaw resistance. The invention discloses a method for improving the properties of hydraulic cements by adding the disclosed chemical admixtures to cement compositions, and also discloses methods of preparing said admixtures.

Owner:GILL IQBAL

Fiber reinforced high-strength mortar used for concrete structure repair

ActiveCN101580369AExcellent structural repair comprehensive performanceIncreasing the thicknessSolid waste managementChemical admixtureCement mortar

The invention relates to a fiber reinforced high-strength mortar used for concrete structure repair, belonging to the technical field of building materials. The mortar is characterized in that the mortar is formed by mixing cement, activated and inert mineral admixtures, expanding agents, micro steel fibers, chemical admixtures, sand and the like based on a certain proportion. At the constructionfields or concrete batching plants, the mortar is added with right amount of water and the mixture is stirred evenly, transported to the construction sites and poured by hand spreading or pumping. Thefiber reinforced high-strength mortar has high strength, good volume stability and durability and large deformability, can be free of vibrating and self-leveling construction, and is convenient, fastand flexible in construction. The structure repair combination property of the fiber reinforced high-strength mortar is greatly superior to that of the current commonly used fine gravel concrete or steel wire mesh-polymer cement mortar system.

Owner:TSINGHUA UNIV

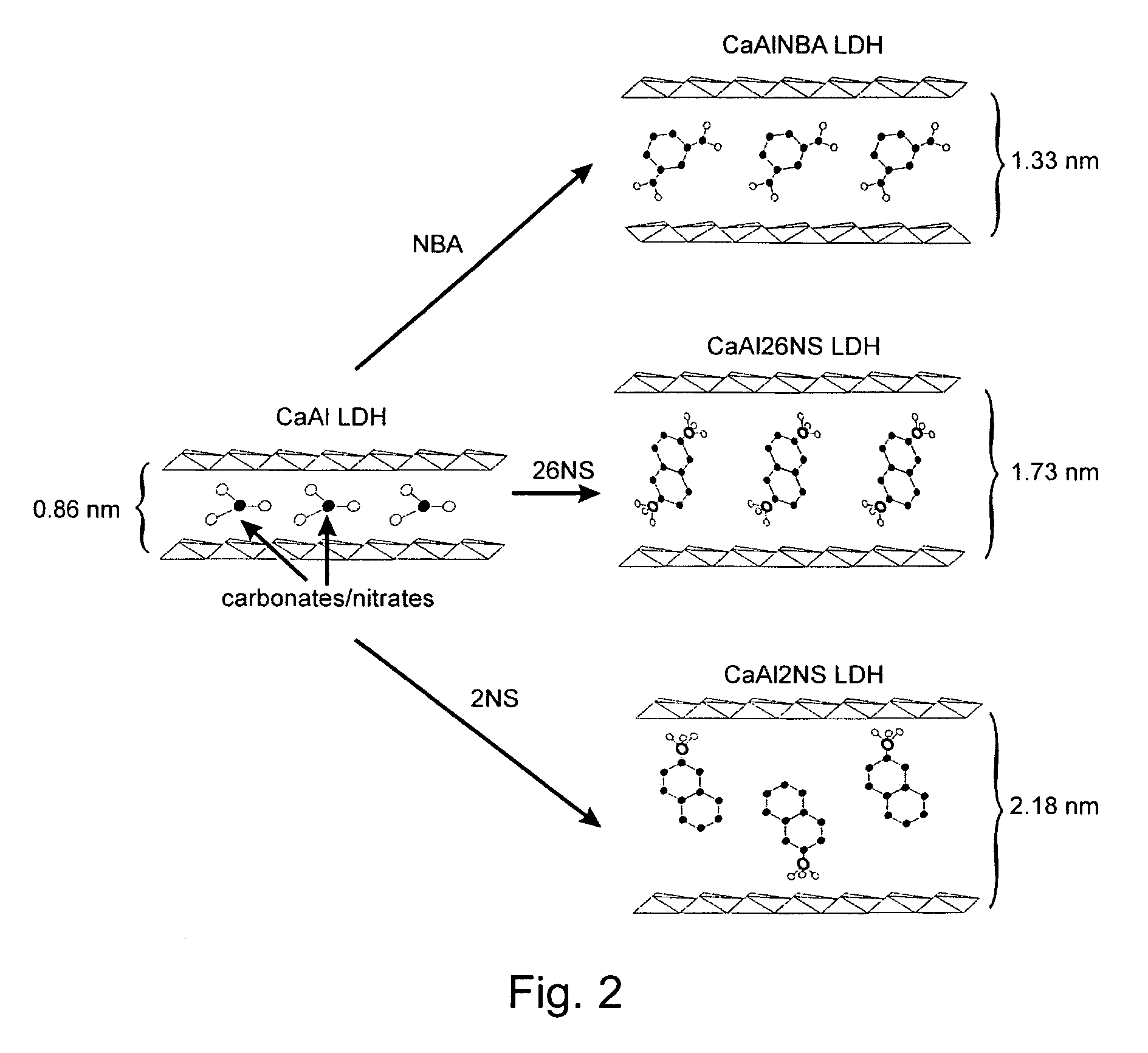

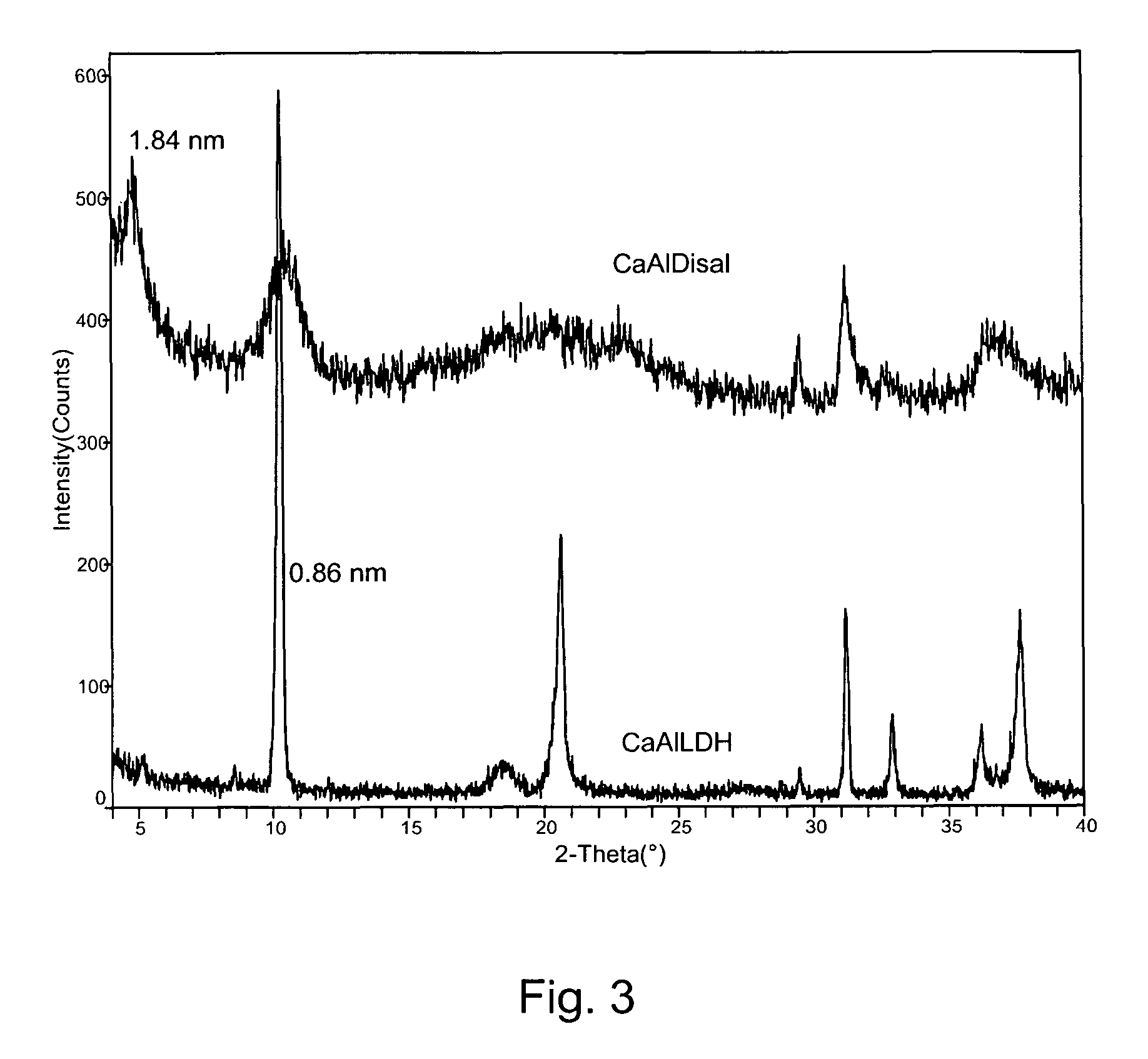

Controlled release of chemical admixtures

InactiveUS7879146B2Improved modulation of slump lossImprove performanceSolid waste managementChemical admixtureSuperplasticizer

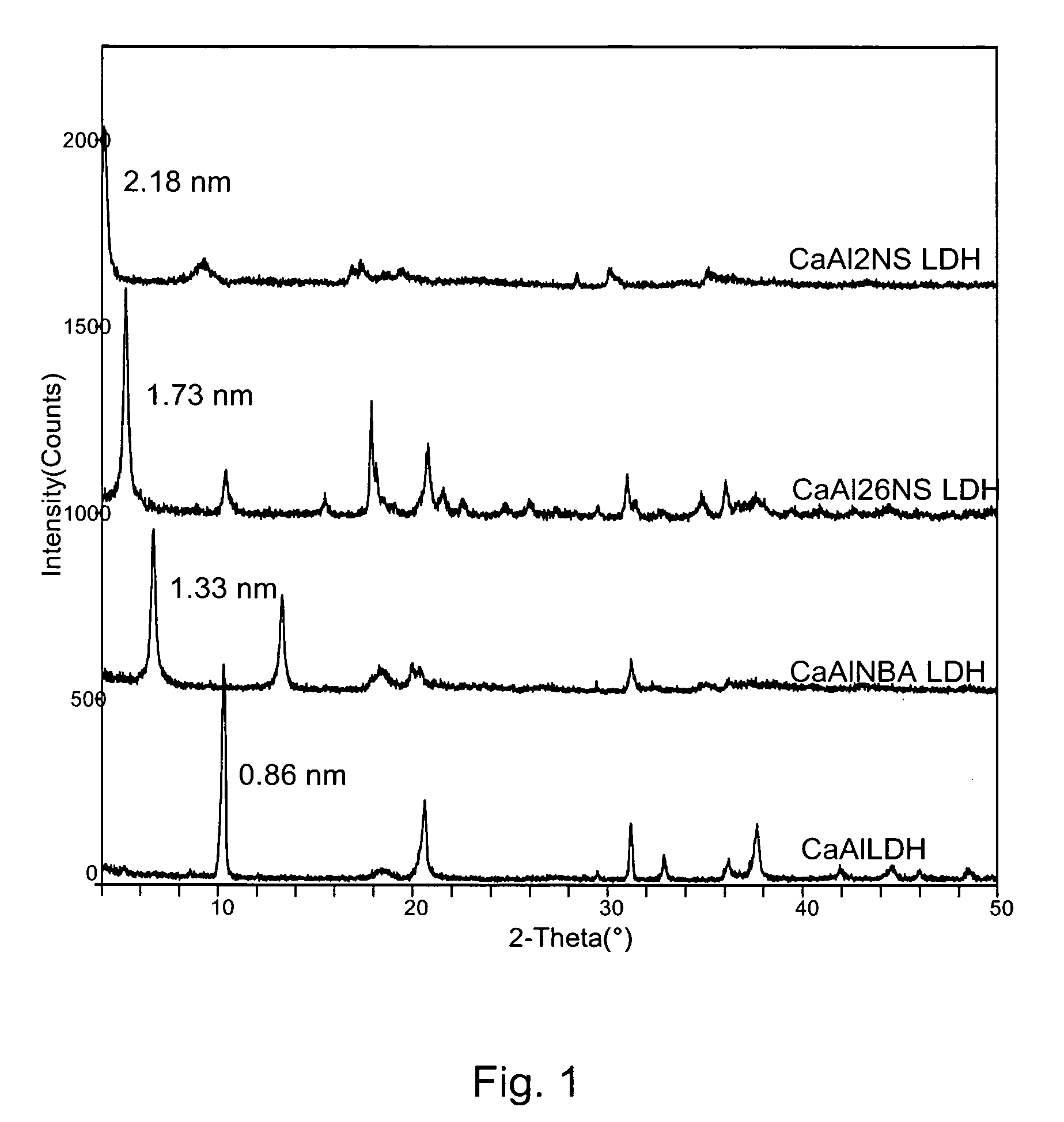

A controlled release formulation for a cement-based composition can be produced by intercalating an admixture (e.g. an accelerator, a set retarder, a superplasticizer) for the cement-based composition into a layered inorganic material (e.g. a layered double hydroxide (LDH)). A cement-based composition containing a cement-based material (e.g. cement, mortar or concrete) and such a controlled release formulation has better workability, especially in respect of slump-loss characteristics. With such a formulation release of an admixture in a cement-based composition may be controlled.

Owner:NAT RES COUNCIL OF CANADA

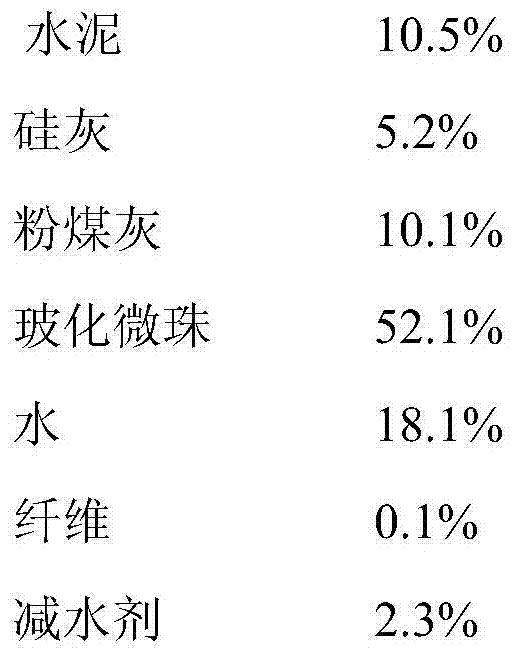

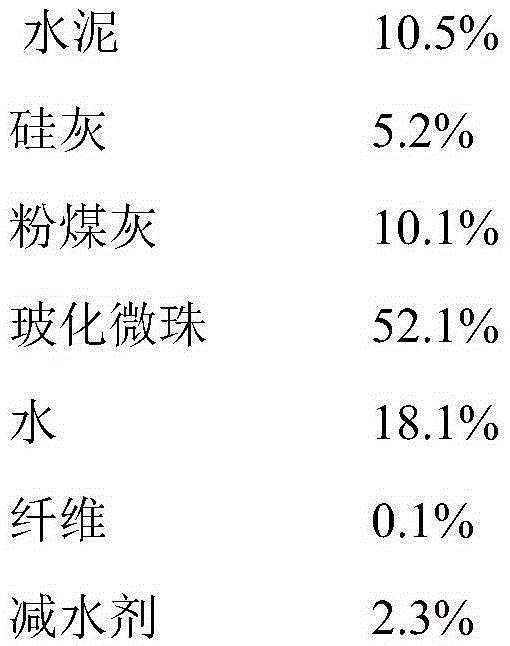

Lightweight high-strength cement based composite material

InactiveCN103896527AMeet the requirements of construction mobilityThe material surface is denseSolid waste managementChemical admixtureUltimate tensile strength

The invention relates to a lightweight high-strength cement based composite material. The grain composition of a multivariate cementing material and grain composition of aggregate are optimized, anddue to use of additives such as water reducing agent and thickener, the material can obtain high compressive strength of over 20MPa while obtaining the unit weight which is significantly lower than that of common concrete. The material has the technical advantages that the compressive strength of 28d standard curing is greater than or equal to 20MPa when the unit weight is smaller than or equal to 1650kg / m<3>; the requirements of the construction liquidity can be met by grain composition of the optimized gel material and the grain composition of the aggregate; the hardened material has a dense surface, and has excellent endurance performances such as anti-permeability, carbonation resistance, resistance to chloride ion erosion and the like.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

High fluidization micro expansive high-strength grouting material

ActiveCN104402345AReduce physical water consumptionImprove early strengthSolid waste managementChemical admixtureSlag

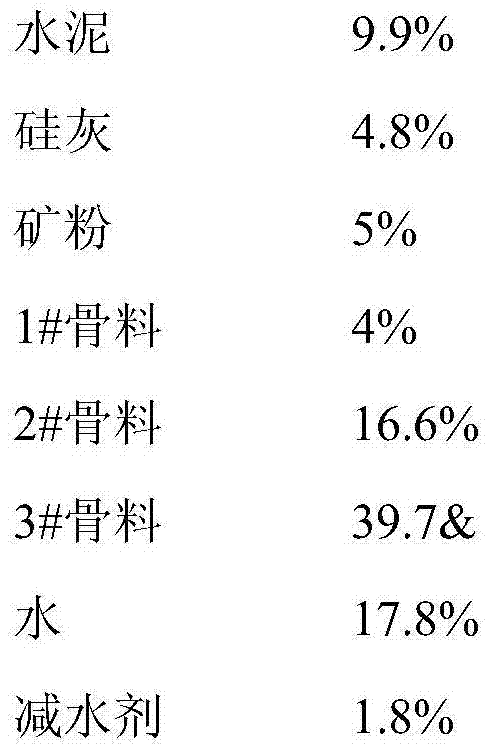

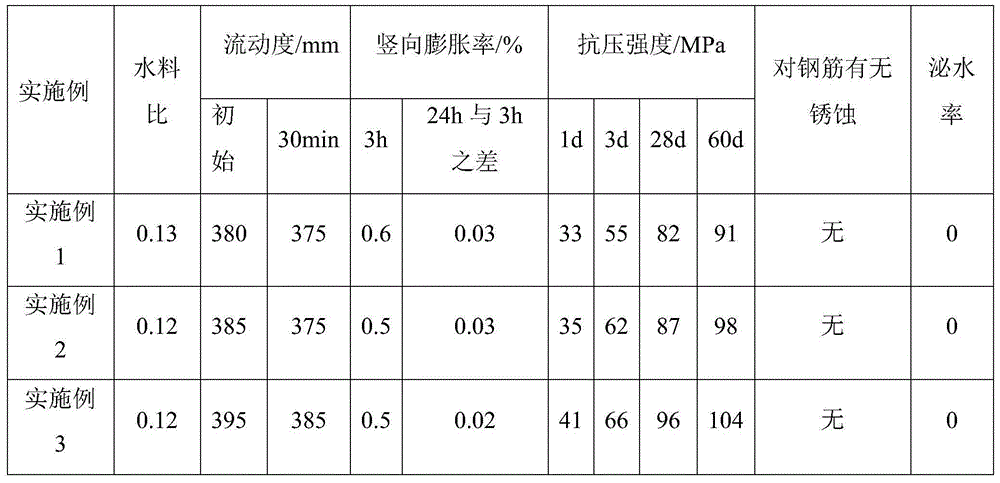

The invention discloses a high fluidization micro expansive high-strength grouting material which comprises the following raw materials by mass percentage: 23-34% of cement, 3-5% of microbead, 5-7.5% of phosphorus slag composite powder, 2.5-3.5% of silica fume, 2.5-3.5% of quartz powder, 46-55% of fine aggregate, 0.7-1% of water reducer, 0.01-0.03% of defoaming agent, 2.5-3.5% of expanding agent and 0.5-1% of early strength agent. The grouting material has the advantages of high strength in the early stage and later stage, good flowing property and adjustable expansiveness by taking the cement as a major binding material and employing the silica fume, the microbead and the phosphorus slag composite powder with different hydration activities together with a chemical additive matched with a binding material system and an aggregate system with reasonable gradation, and is particularly applicable to high precision equipment mounting, secondary grouting of an equipment foundation, bolt anchoring, crack repairing, duct grouting and the like.

Owner:中建西部建设西南有限公司

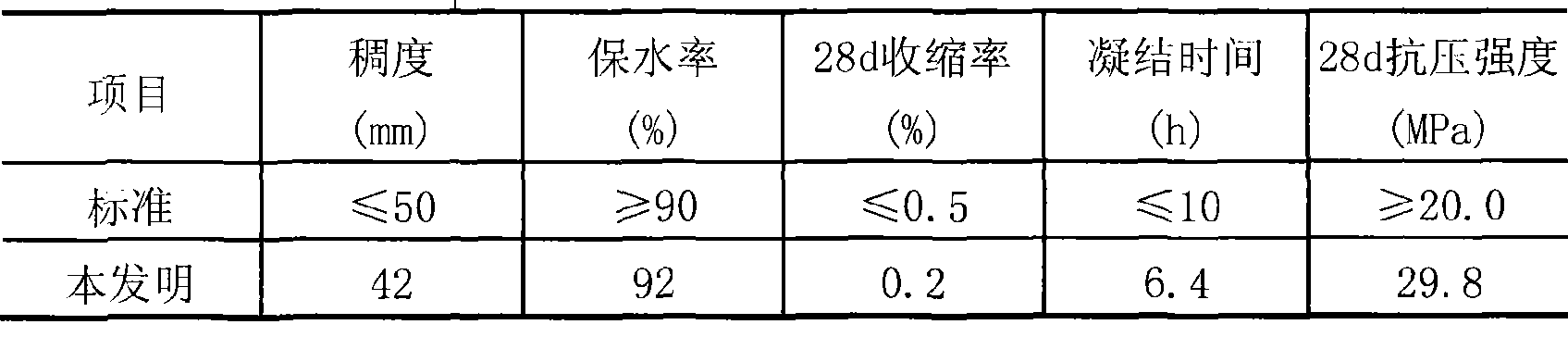

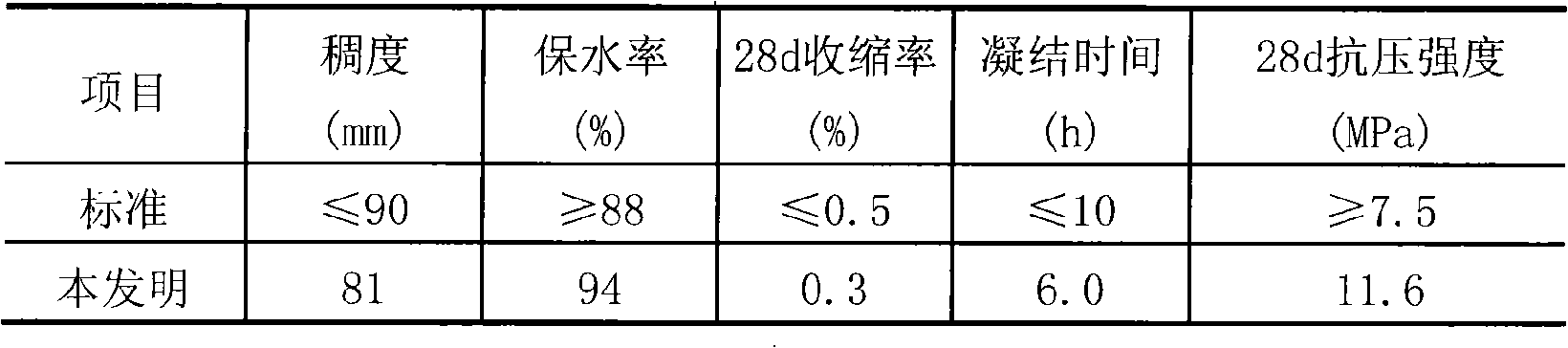

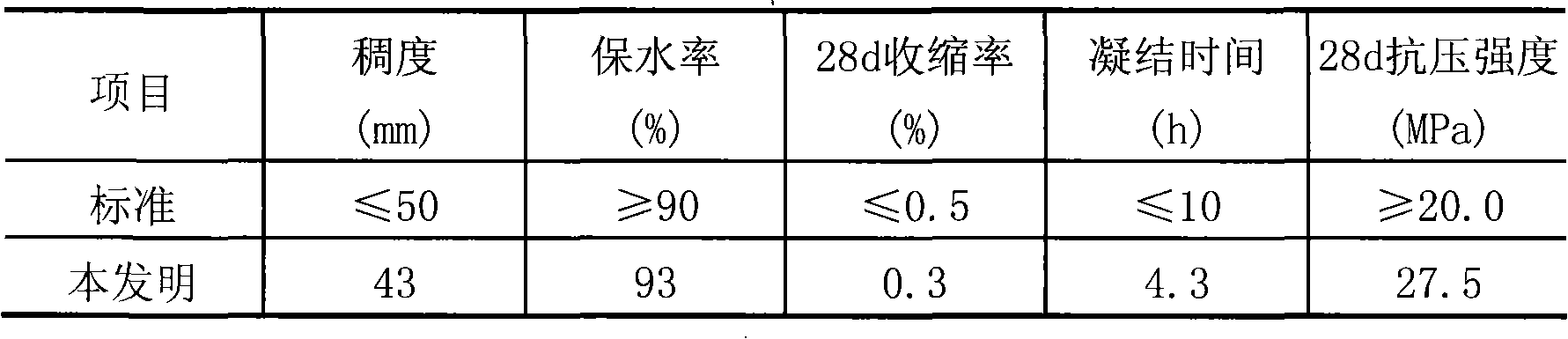

Gypsum base hydraulicity building mortar and preparation method thereof

The invention belongs to the technical field of building material, in particular to building mortar for the laying, plastering and paving for a building and a method for preparing the same. The gypsum based hydraulicity building mortar is characterized in that the mortar is formed by the mixing and stirring of a mixed material and water, and the weight ratio of the mixed material to water is between 1:0.20 and 0.85; the mixed material comprises the following materials in weight percentage: 60 to 80 percent of quartz sand, 6.0 to 20.0 percent of gypsum powder, 6 to 20 percent of slag powder, 0.01 to 10 percent of limestone powder, 0.01 to 3 percent of mineral admixture and 0 to 0.1 percent of chemical additive; the chemical additive is one or a mixture of the two of plasticizing agent and thickener at any blending ratio. The invention has the characteristics of low cost, high strength and low energy consumption, and the method has the advantages of simple process and easy operation.

Owner:WUHAN UNIV OF TECH +1

Ecological nanoparticle reinforced cement based composite material and preparation method thereof

ActiveCN103319129ASimple compositionSimple structureChemical admixtureEnvironmental resource management

The invention discloses an ecological nanoparticle reinforced cement based composite material and a preparation method thereof. High-strength and high-elastic spherical nanoparticles in industrial waste residues are adopted for largely replacing cement, and a high-performance admixture with a water-reducing rate of over 50% and high-strength superfine coppered steel fibers are used, and through the effective and efficient application of cement, the ecological nanoparticles, the chemical admixtures, the steel fibers and multi-element composite techniques thereof, the composition and structure optimization of concrete materials is greatly promoted, and an effect that the advantages of the components are superposed, and components are complementary is achieved. According to the invention, the problem that under standard curing and steam curing conditions, the compressive strength of an existing cement-based composite material can not reach over 300 Mpa and the bending strength can not reach over 60 Mpa is solved, the highly efficient regeneration and utilization rate and core technological value of the industrial waste residues are greatly enhanced, and the application amount of cement clinkers in the cement-based composite material is reduced, and therefore, the composite material is suitable for being used as a large civil engineering structure material with a designed concrete compressive strength of 300 Mpa.

Owner:河北蓝科悦拼建筑科技有限公司

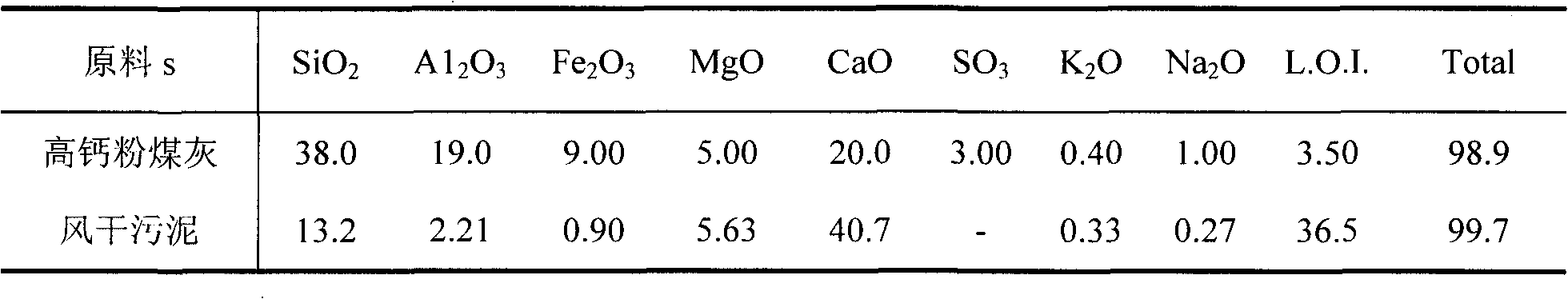

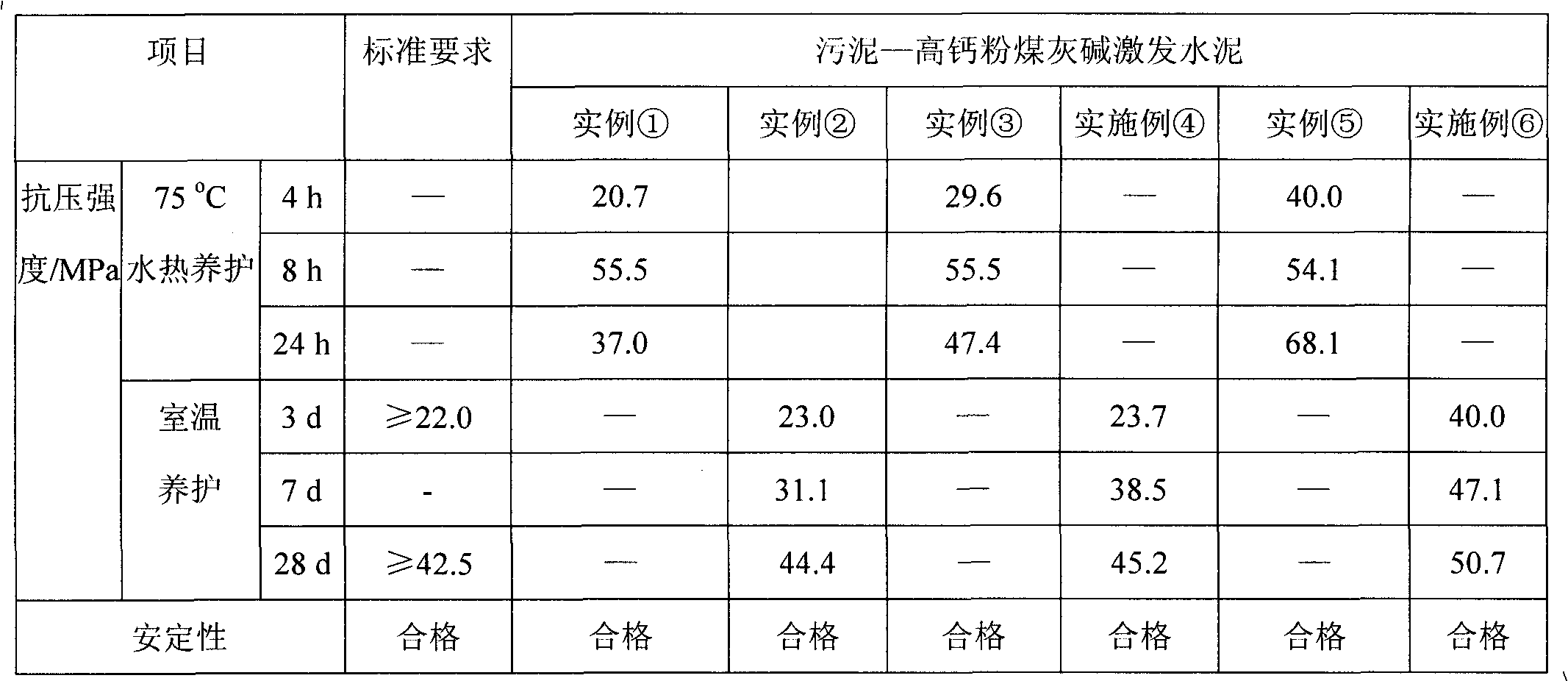

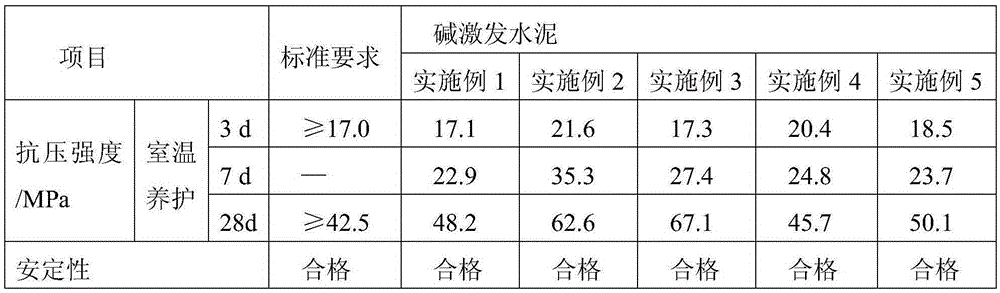

Sludge-high calcium fly ash alkali-excited cement and preparation method thereof

InactiveCN101830653AImprove performanceReduce the burden onCement productionActivated sludgeChemical admixture

The invention discloses sludge-high calcium fly ash alkali-excited cement and a preparation method thereof. The alkali-excited cement uses high calcium fly ash as a main raw material, thermally activated sludge as a mineral additive and solution prepared from sodium hydroxide and liquid sodium silicate as a composite chemical additive and makes the system have good performance in a certain curing environment. The method alleviates the environmental burden, and reduces the cost and resource consumption by using industrial waste such as high calcium fly ash and sludge; and the novel alkali-excited cement only has little emission of greenhouse gas, is a low-carbon emission, green and environment-friendly gel material, meets the trend of current social development, and has good economic and social benefits.

Owner:TONGJI UNIV

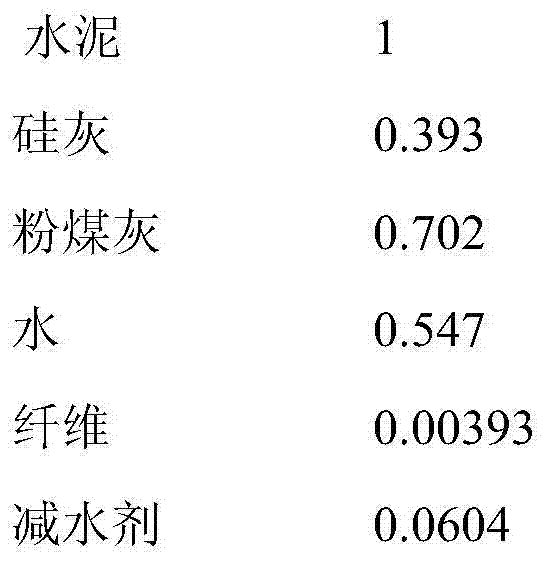

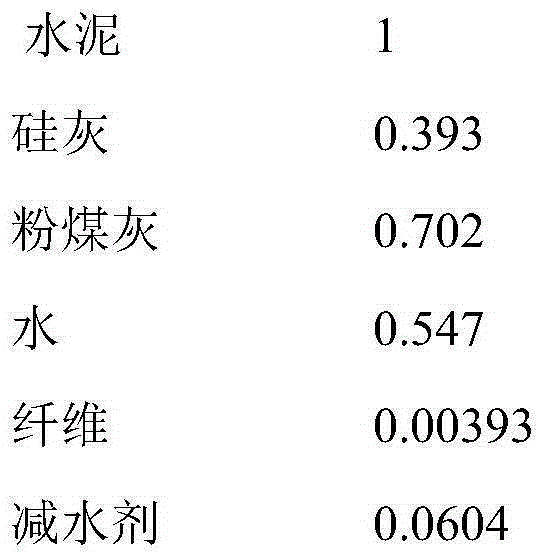

Ultra-high performance cement base composite material

InactiveCN103922662AMeet the requirements of construction mobilityHigh strengthChemical admixtureCarbonization

The present invention relates to a light weight and high strength cement base composite material. According to the present invention, particle size distribution of a multi-component cementing material and particle size distribution of an aggregate are optimized, and a reducing agent, a thickener and other chemical admixtures are used to make the material can concurrently achieve bulk density of significantly lower than bulk density of the ordinary concrete and a compressive strength of more than 20 MPa; the technical advantages of the material comprise that: in the case of the bulk density of less than or equal to 1650 kg / m<3>, the 28 d standard maintenance compressive strength of more than or equal to 20 MPa is achieved, and the construction fluidity requirements can be met in the case of the low water-binder ratio by optimizing the particle size distribution of the cementing material and the particle size distribution of the aggregate; and the hardened material has characteristics of compact surface, excellent impermeability, excellent carbonization resistance, chloride ion erosion resistance, and other durable performances.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

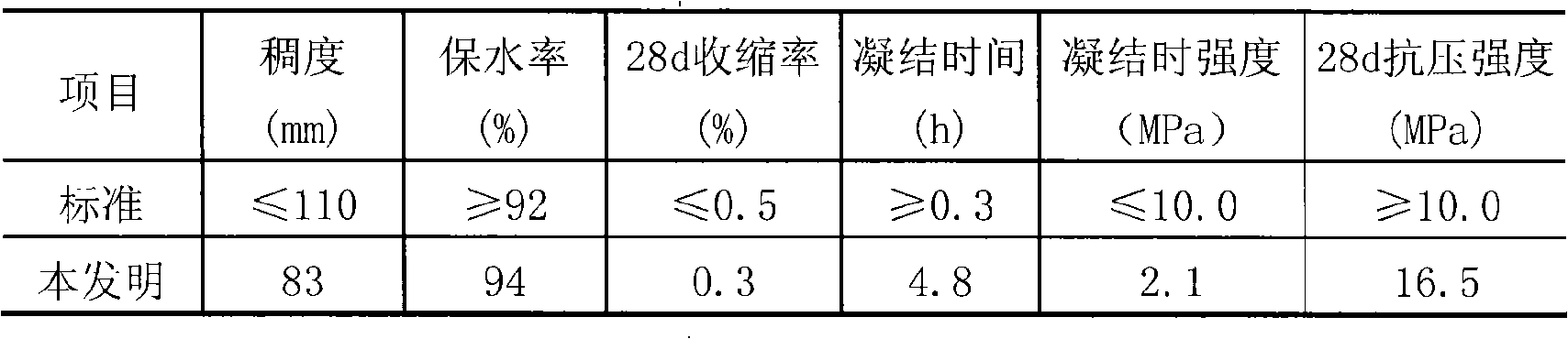

Building mortar and method for preparing same

The invention belongs to the technical field of a constructional material, in particular relates to building used mortar used for masonry and plastering of buildings and ground, and a preparation method thereof. The building mortar is characterized in that the building motor is prepared with a dry material and water though mixing according to the ratio of 1 to 0.03 to 0.35 by weight; the dry material is prepared with 60 to 80 percent of quartz sand, 7 to 30 percent of ground limestone, 1 to 20 percent of powdered industrial residue, 0.1 to 4 percent of land plaster, 0.1 to 8 percent of mineral admixture, and 0 to 0.1 percent of chemical additives by weight. The additive is any of or the mixture of a plasticizer and a gelatinizer at a discretionary ratio. The building mortar has the characteristics of low cost, high strength, and low dissipation of energy. The preparation method is operated easily.

Owner:WUHAN UNIV OF TECH +1

Mortar for heat preservation and thermal insulation of building outer wall

The invention belongs to a mortar used for the heat insulation of external walls of buildings, which consists of fibers and a plurality of functional chemical admixtures added in the organic light heat insulation mortar. The functional chemical admixtures consists essentially of hydrophobic agent taking hydrophobic effect, such as SEAL80 of organic silicon, zinc stearate, etc. cellulose ether and guar gum taking water retention and viscosity-phobic effects, polyvinyl alcohol taking thickening and foam stabling effects, re-dispensable latex powder taking water resistant and flexibility increasing effects and a little amount of air-entraining agent for lowering the volume and the density and reducing the thermal conductivity. With the common functions of the admixtures, the construction performance, the water resistant performance and the bond strength of the heat insulation mortar are improved. The invention can be used for the heat insulation of the external walls.

Owner:韩玉霞

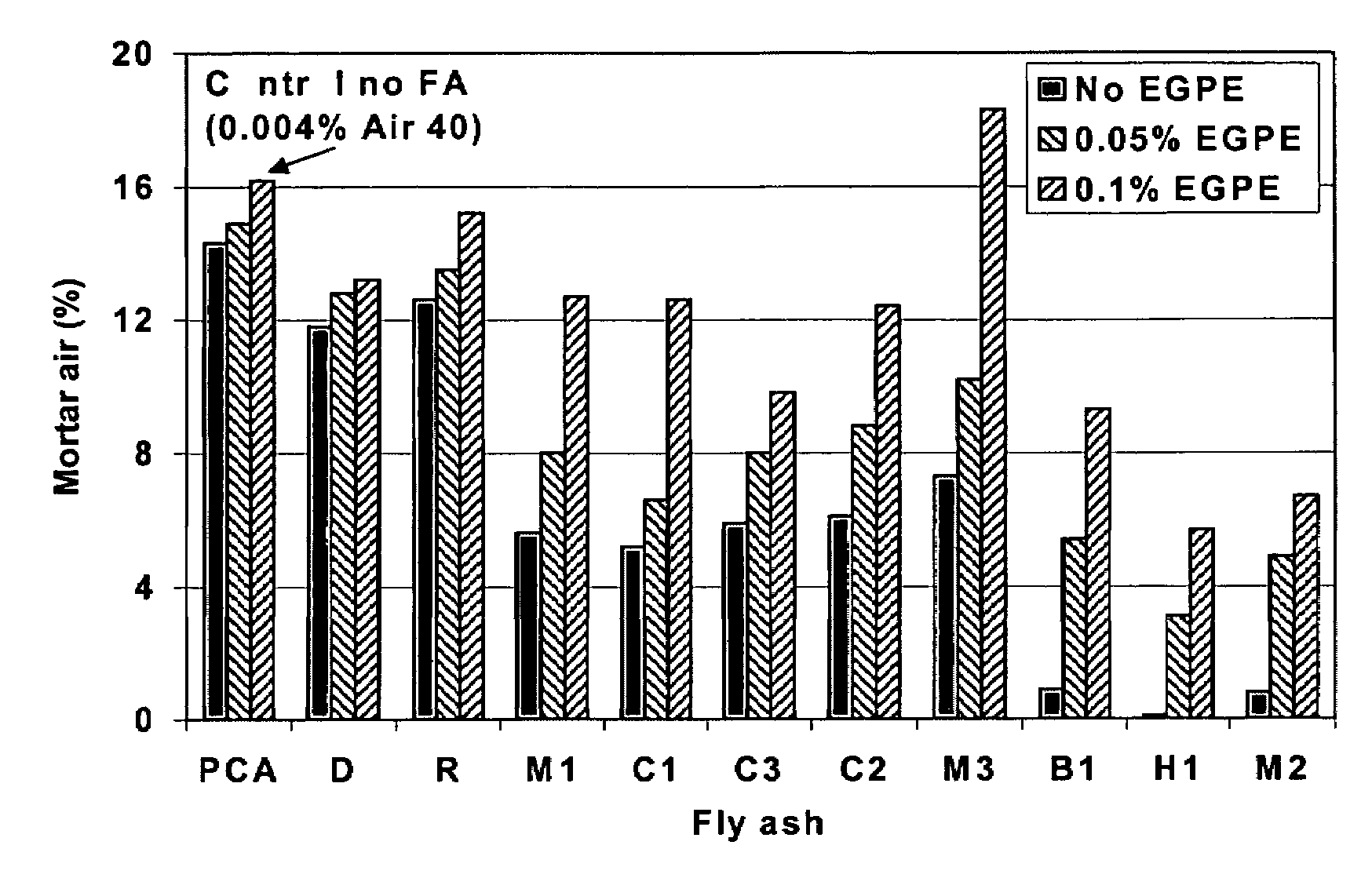

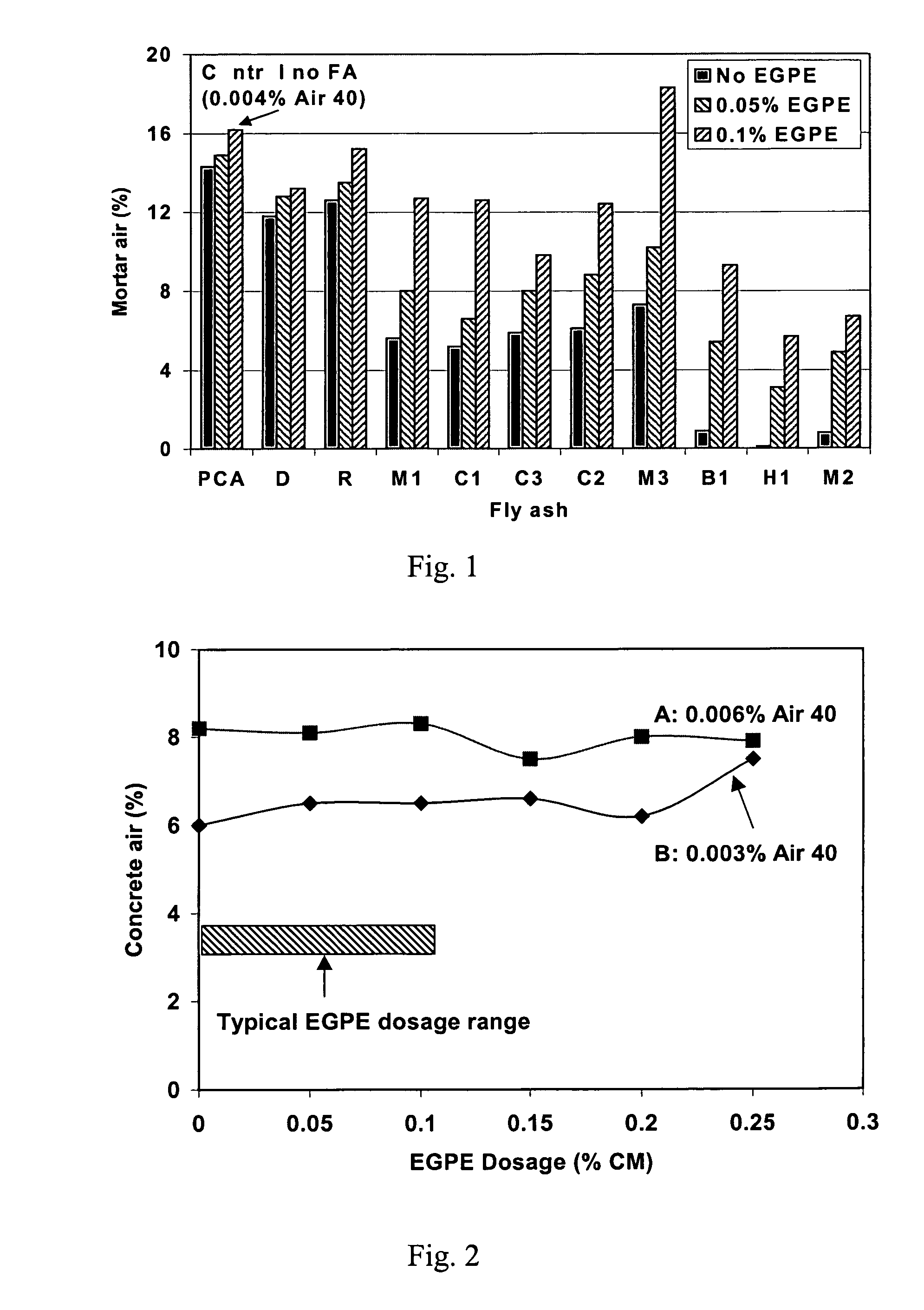

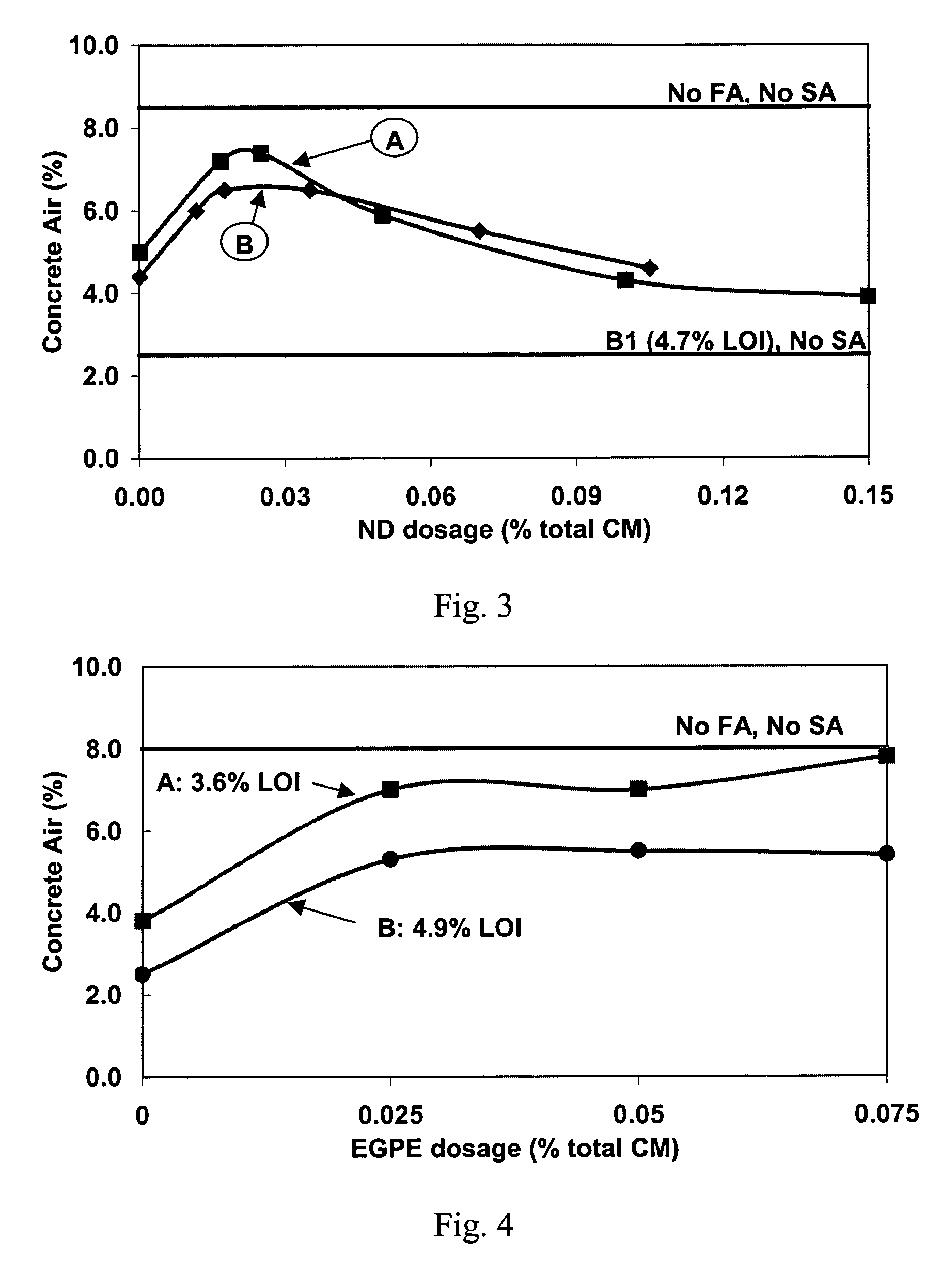

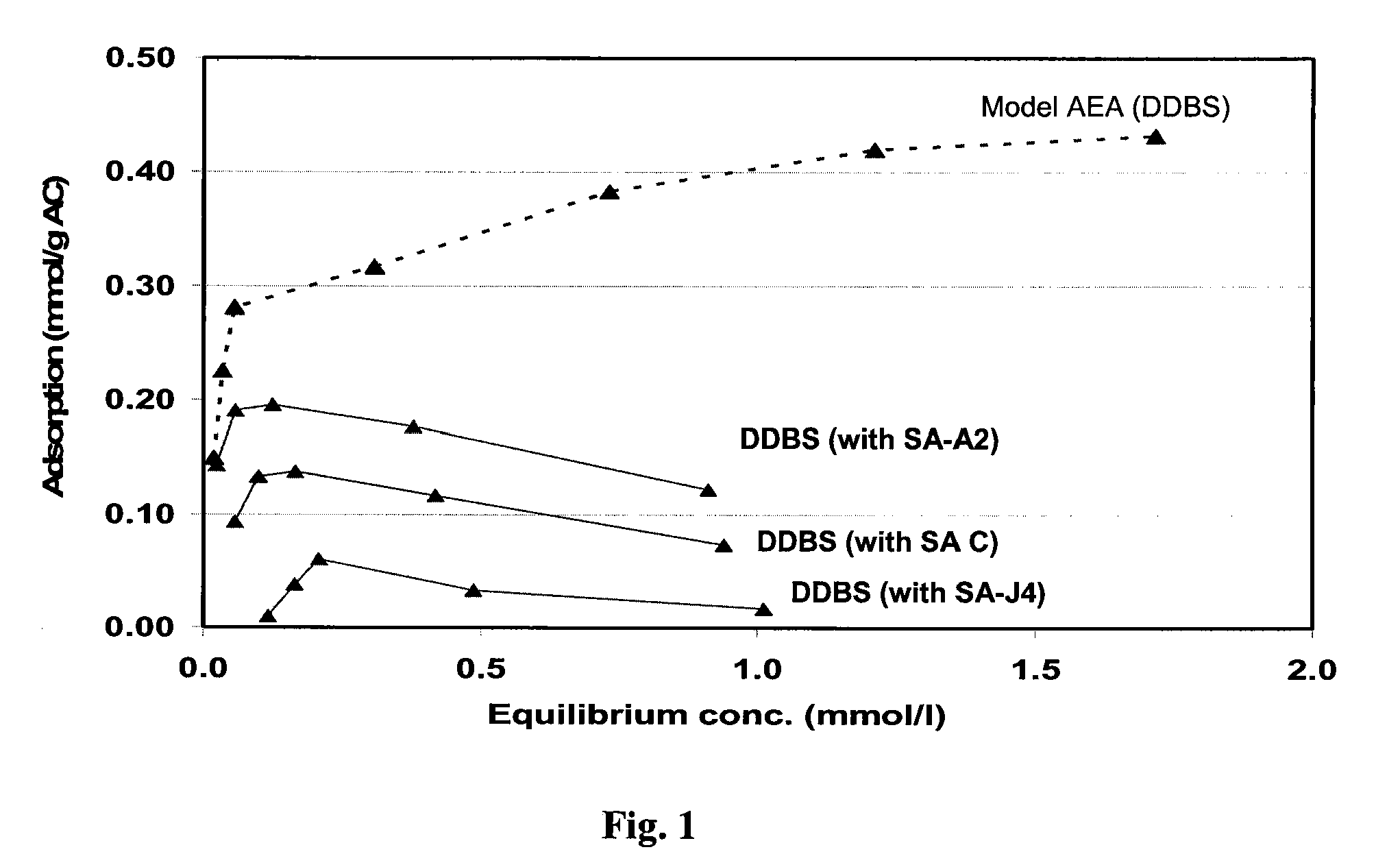

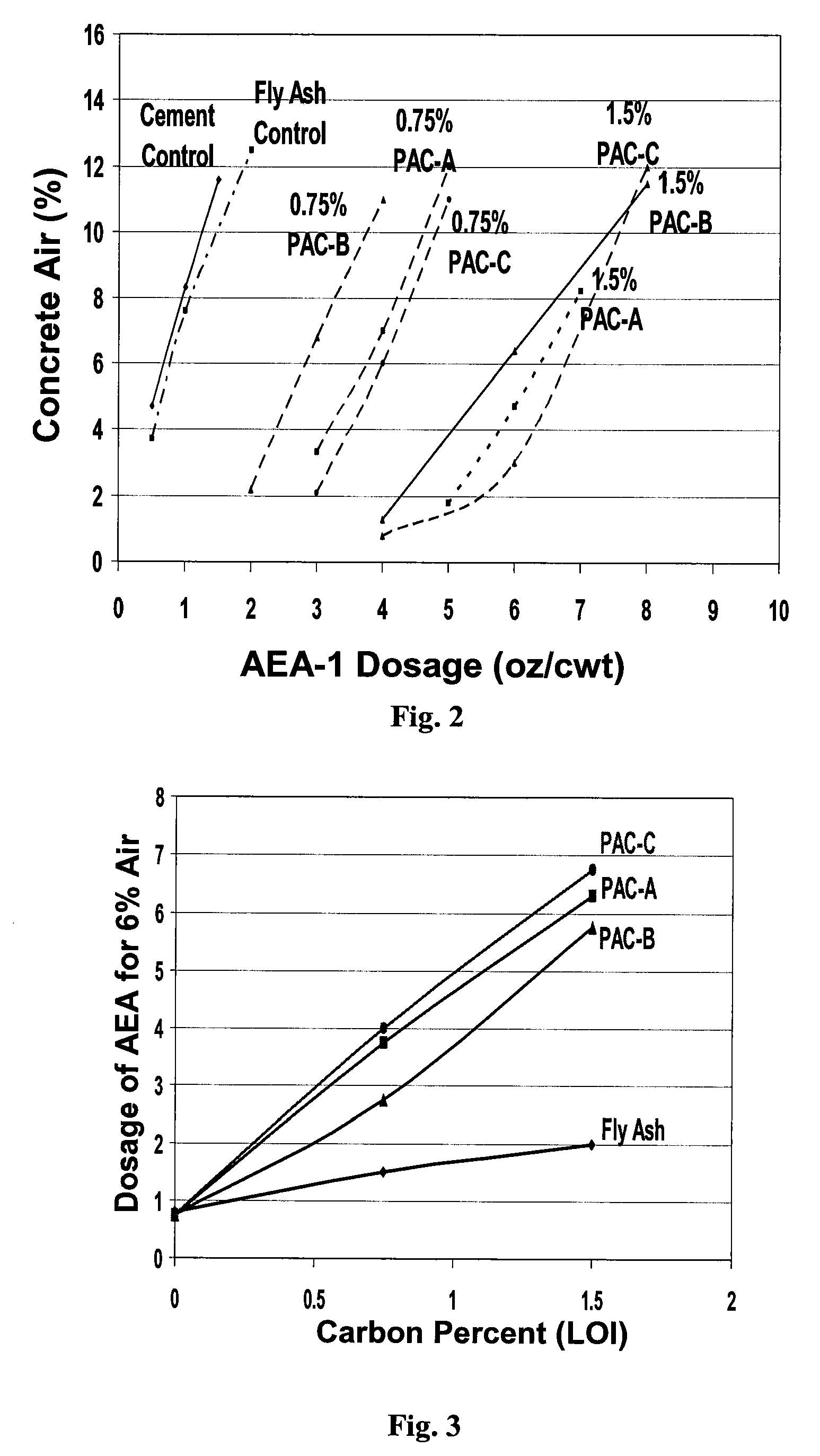

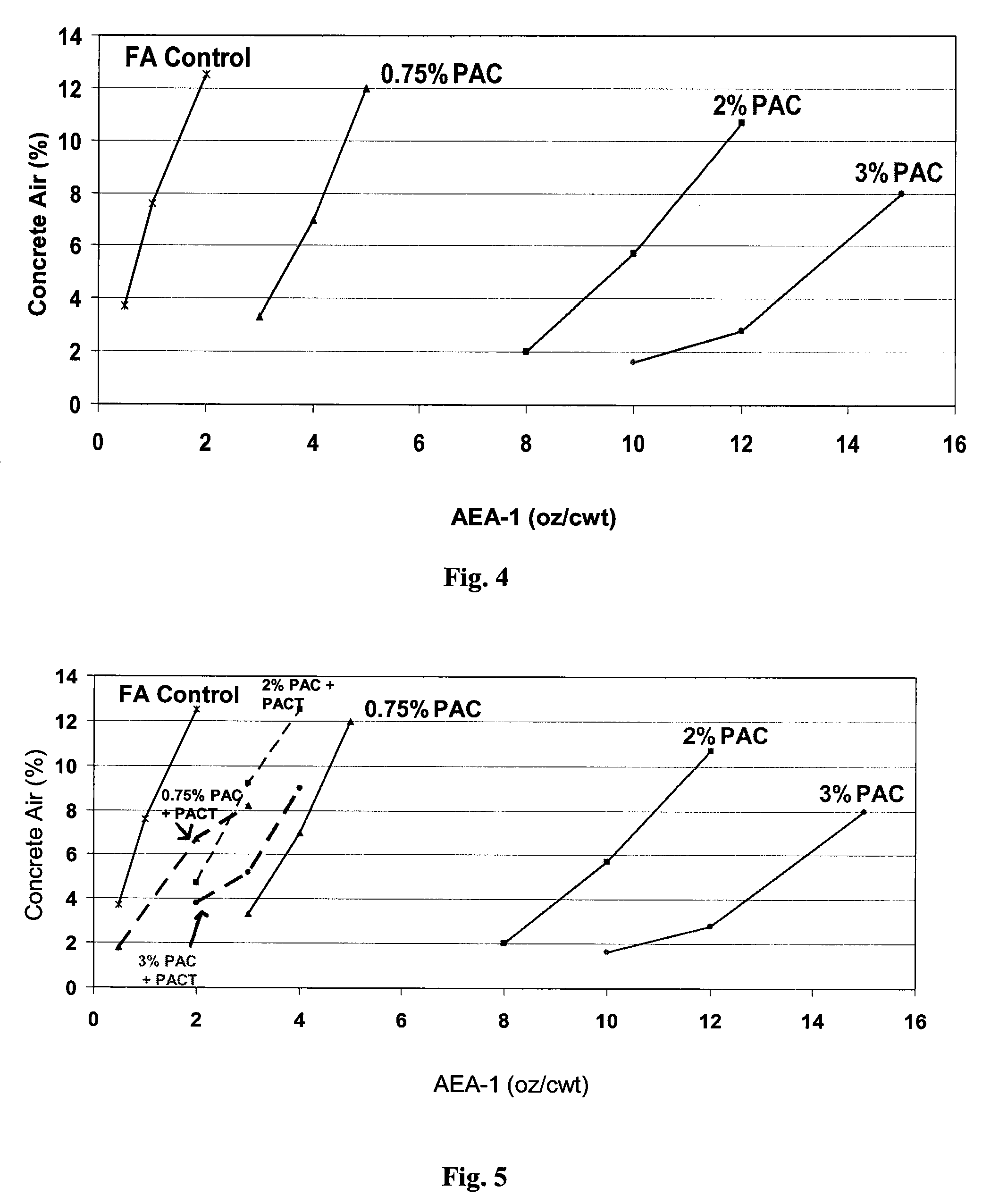

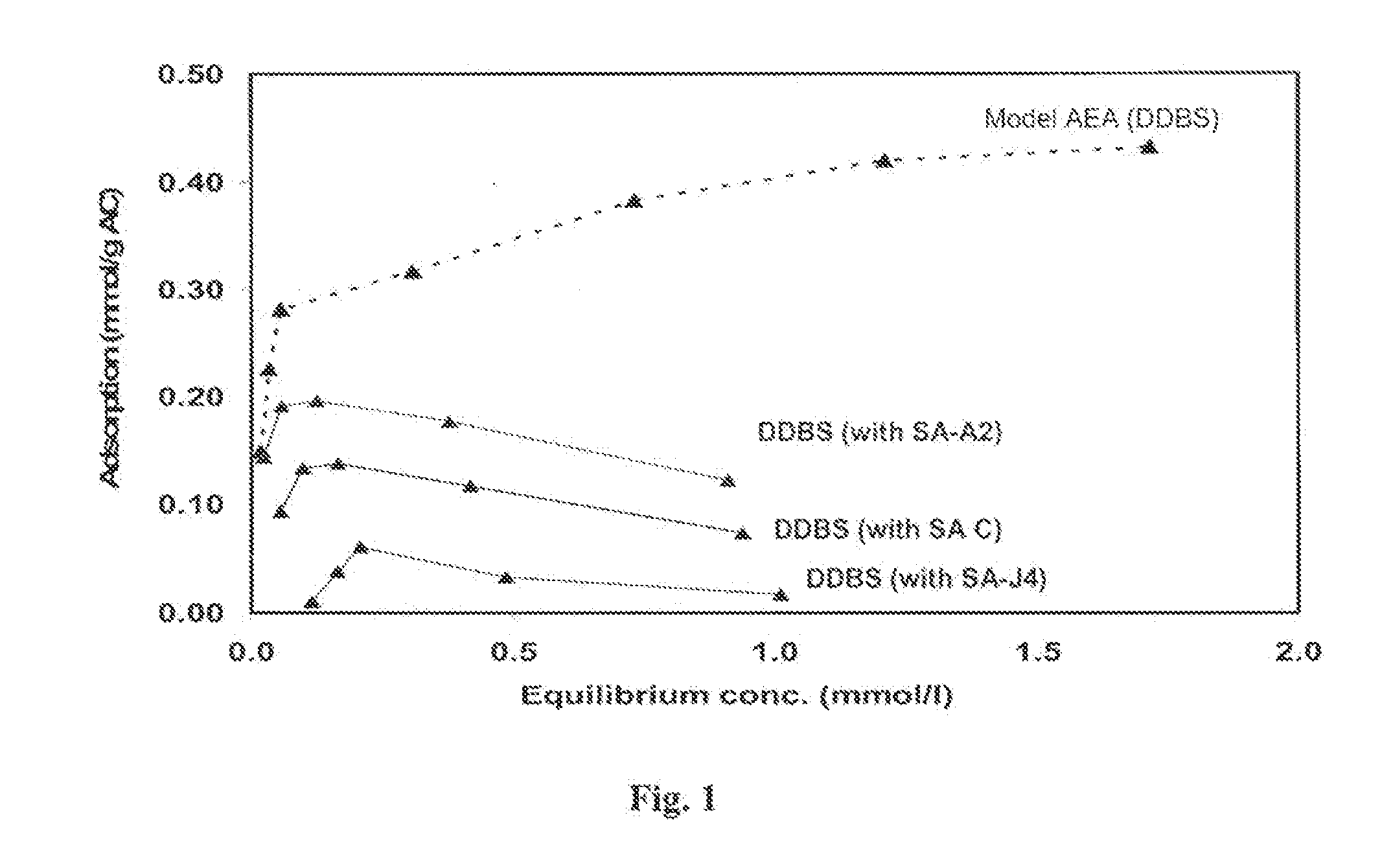

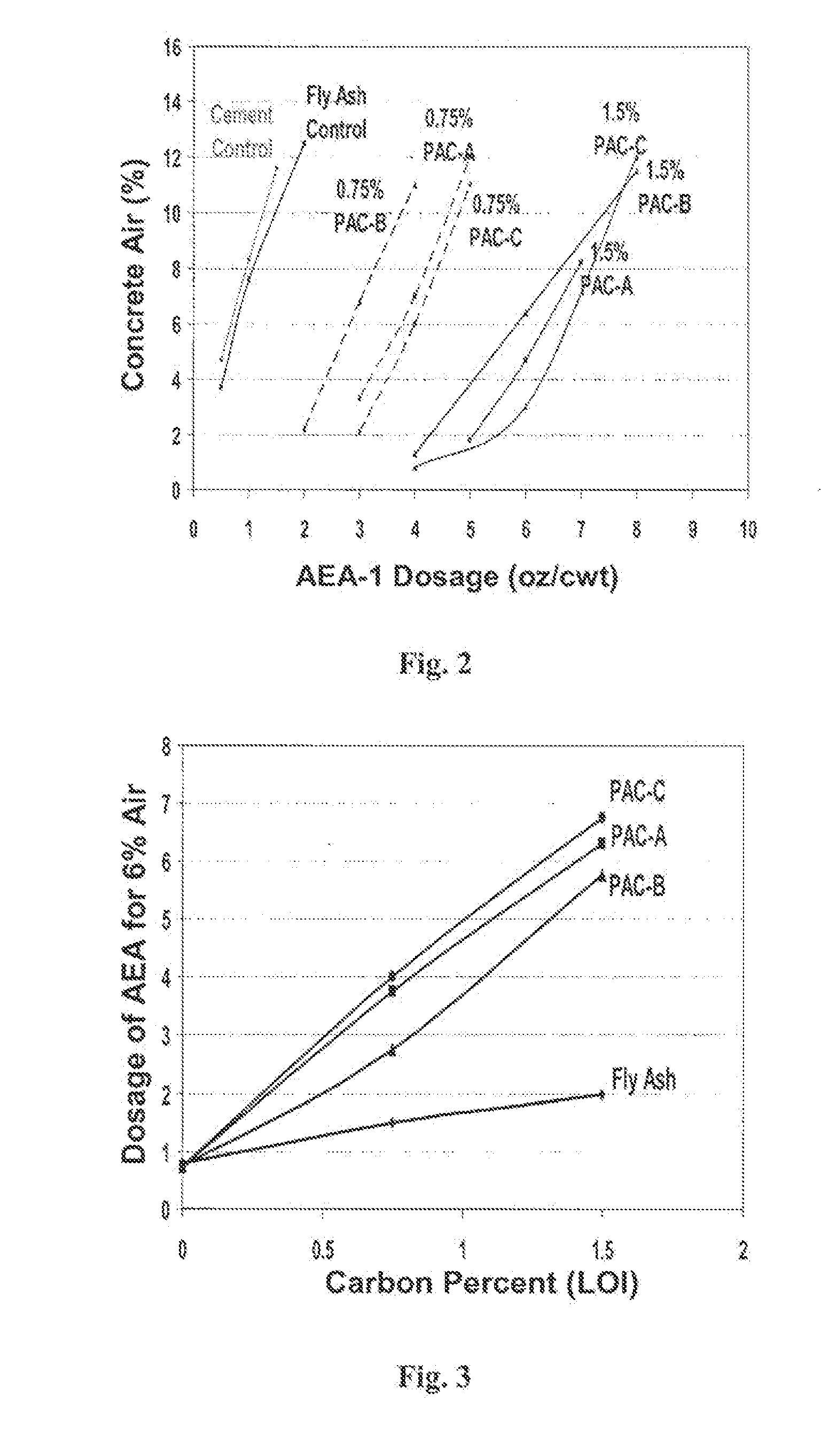

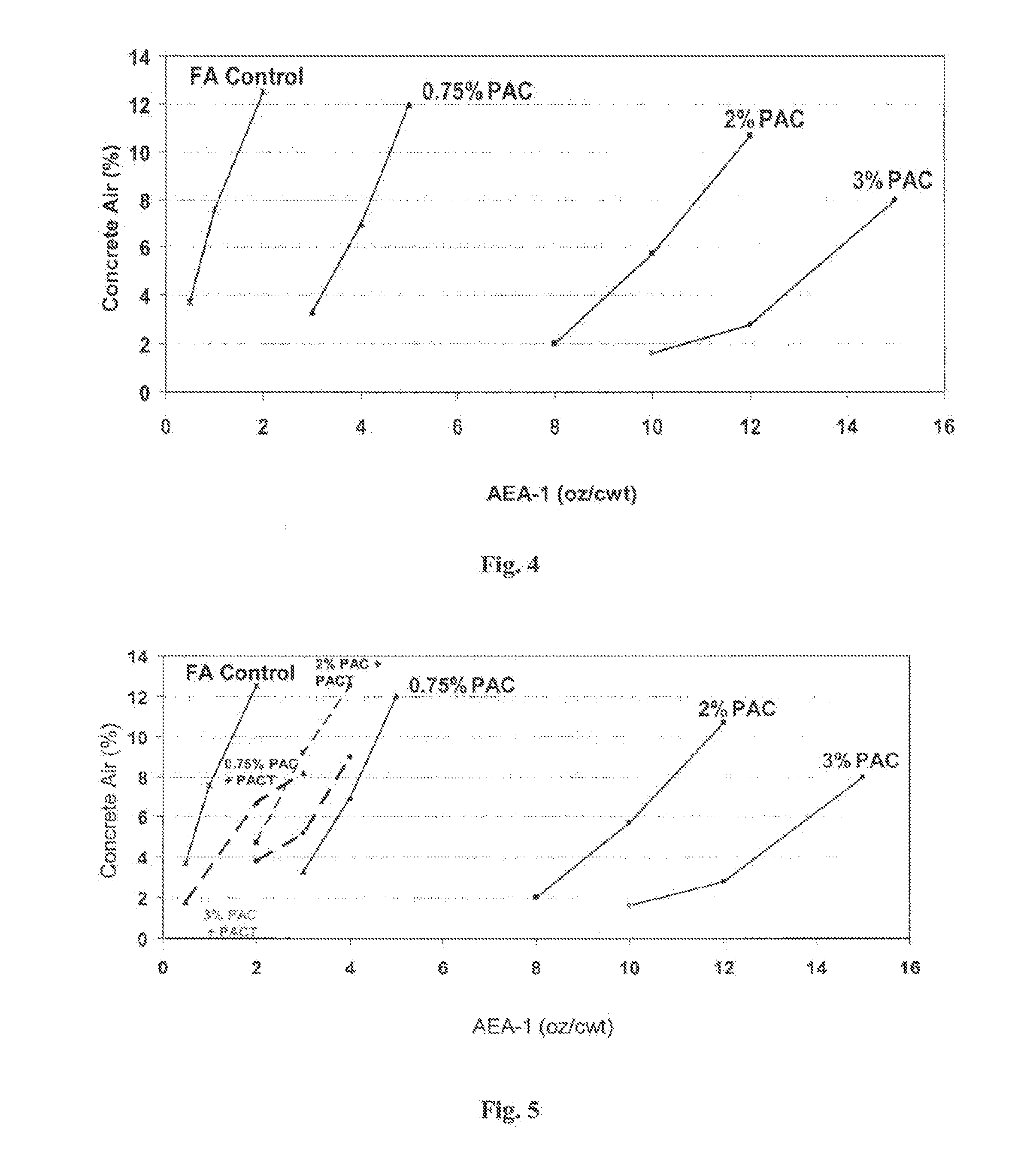

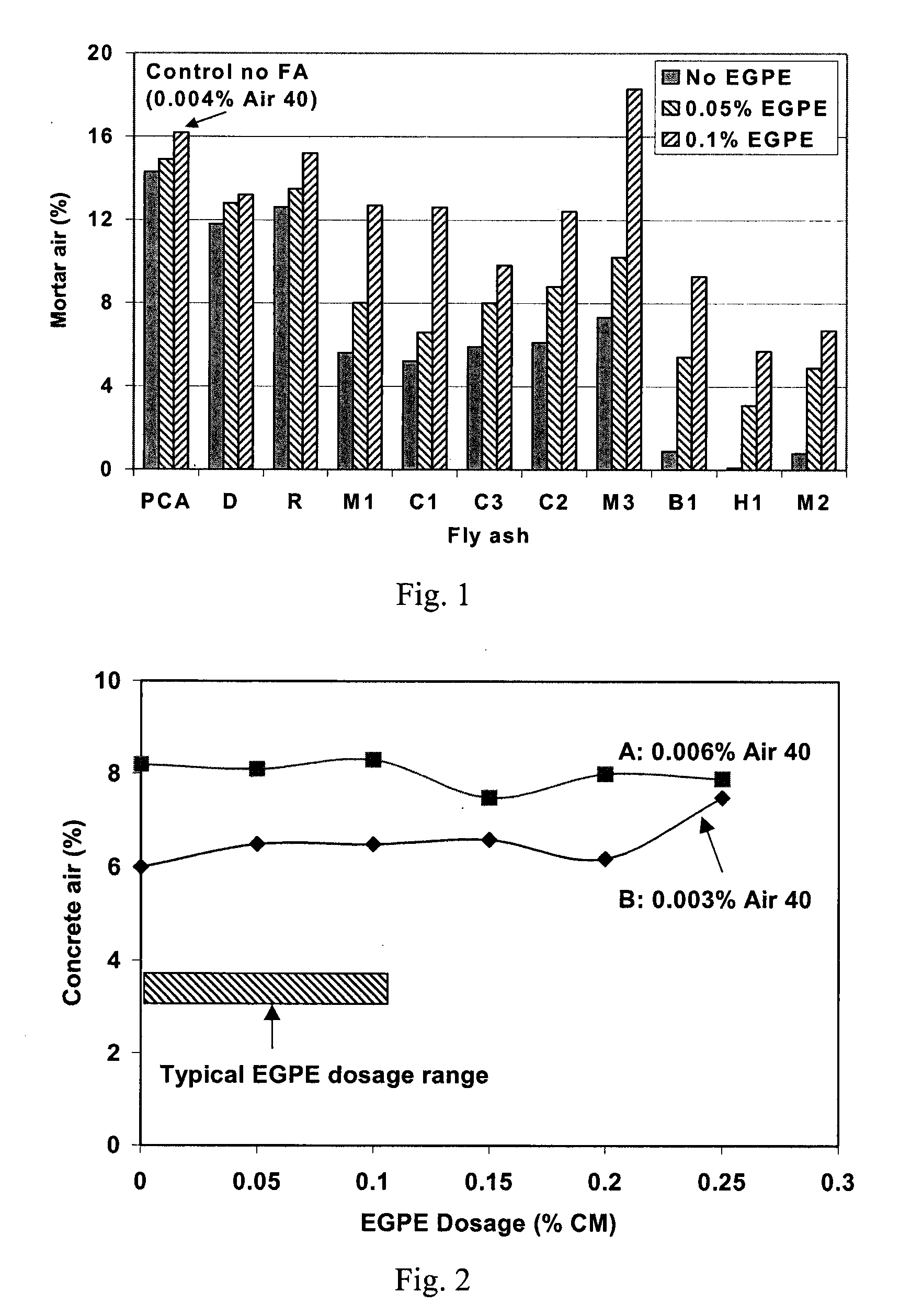

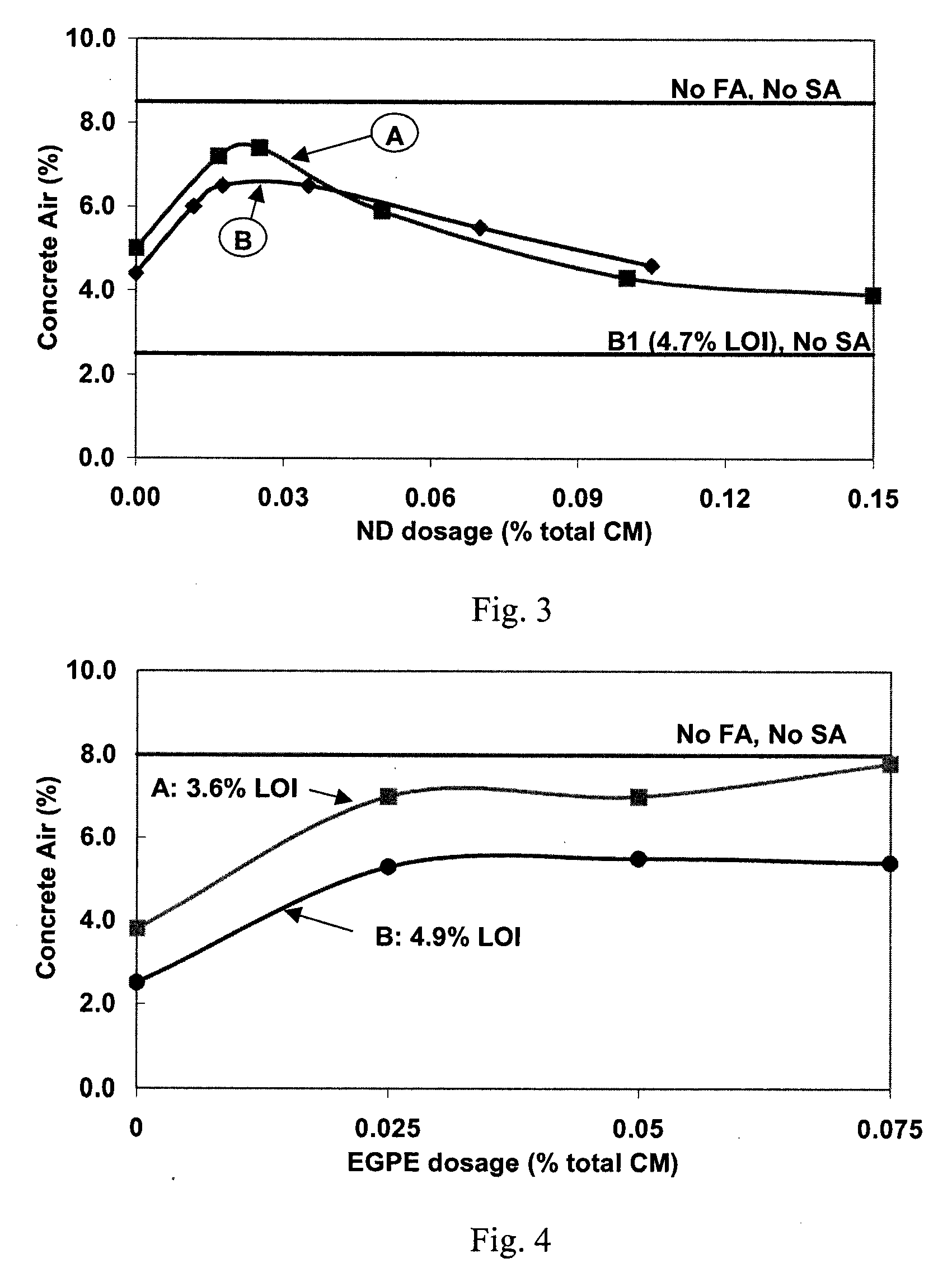

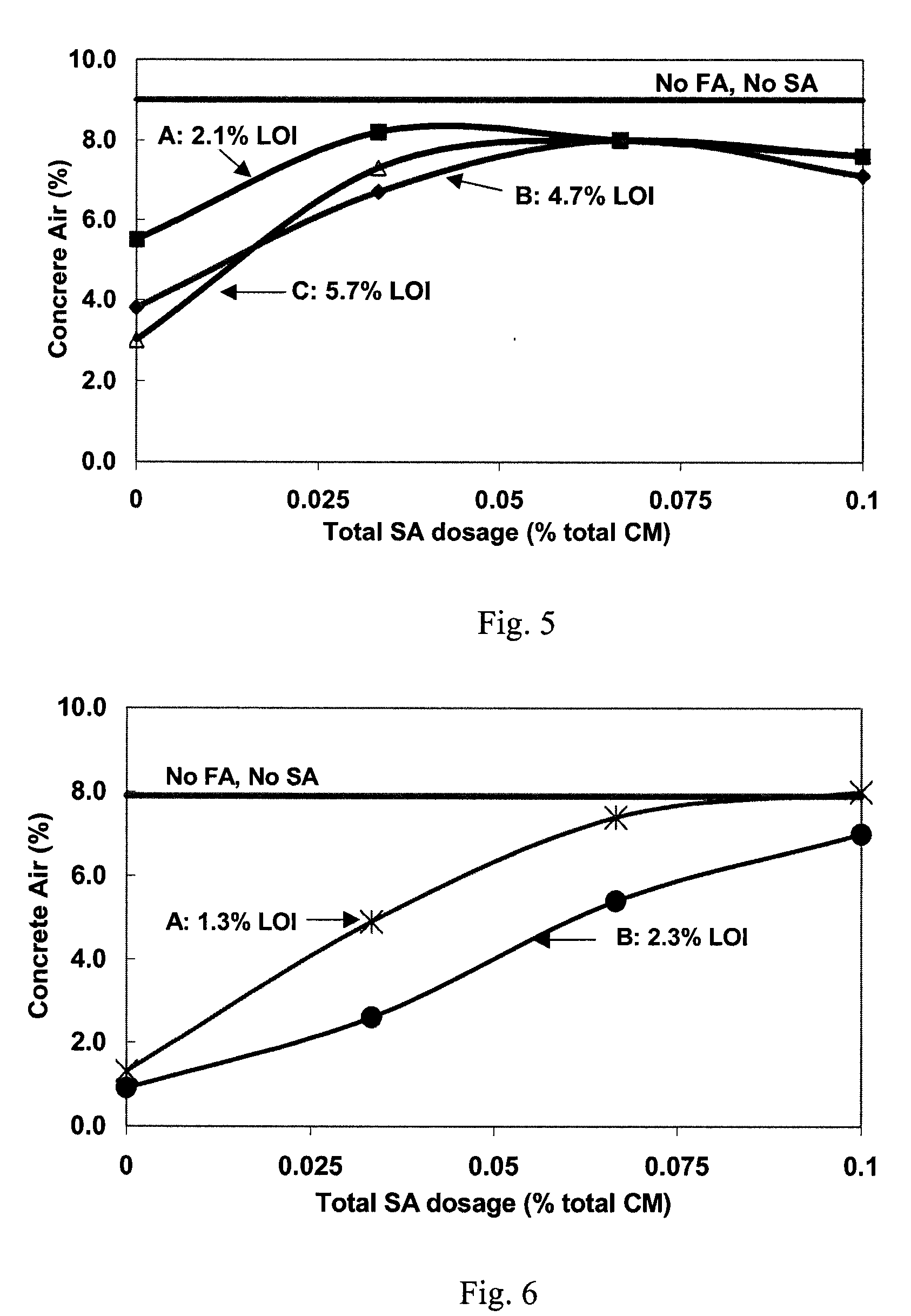

Sacrificial agents for fly ash concrete

ActiveUS7485184B2Facilitate spraying procedureBeneficial effect is somewhat lowSolid waste managementCoatingsChemical admixtureAgent Combination

A method of producing cementitious mixtures containing fly ash as one of the cementitious components, under air entrainment conditions. The method involves forming a mixture comprising water, cement, fly ash, optionally other cementitious materials, aggregate, conventional chemical admixtures, and an air entrainment agent and agitating the mixture to entrain air therein. Additionally, at least one sacrificial agent is also included in the mixture. The sacrificial agent is a material or mixture of materials that is not required to act as an air entrainment agent but interacts preferentially with components of the fly ash that otherwise neutralize, repress or depress the activity of the air entrainment agent. The invention includes cementitious mixtures and hardened concretes resulting from the method and fly ash treated with sacrificial agent, or air entrainment agent / sacrificial agent combinations, and processes for selecting suitable sacrificial agents.

Owner:HANDY CHEM

Light-weight high-strength cement-based composite material

InactiveCN105272004AMeet the requirements of construction mobilityThe material surface is denseSolid waste managementChemical admixtureCarbonization

The invention relates to a light-weight high-strength cement-based composite material. By optimizing grain composition of a multi-component cementitious material and grain composition of aggregates and utilizing chemical additives such as a water reducing agent, a thickening agent and the like, the volume weight of the material can be obviously lower than that of ordinary concrete, and the compression resistive strength of 20MPa or more can be obtained. The light-weight high-strength cement-based composite material has technical advantages that under the volume weight less than or equal to 1650kg / m<3>, the compression resistive strength is greater than or equal to 20MPa after the material is standard cured for 28 days; by optimizing the grain composition of the cementing material and the grain composition of the aggregates, the construction mobility requirement can be met under a low water-binder ratio; the surface of the hardened material is compact, and the hardened material has durable performance such as permeation resistance, carbonization resistance, chlorine ion erosion resistance and the like.

Owner:浙江宏日泰耐克新材料科技有限公司

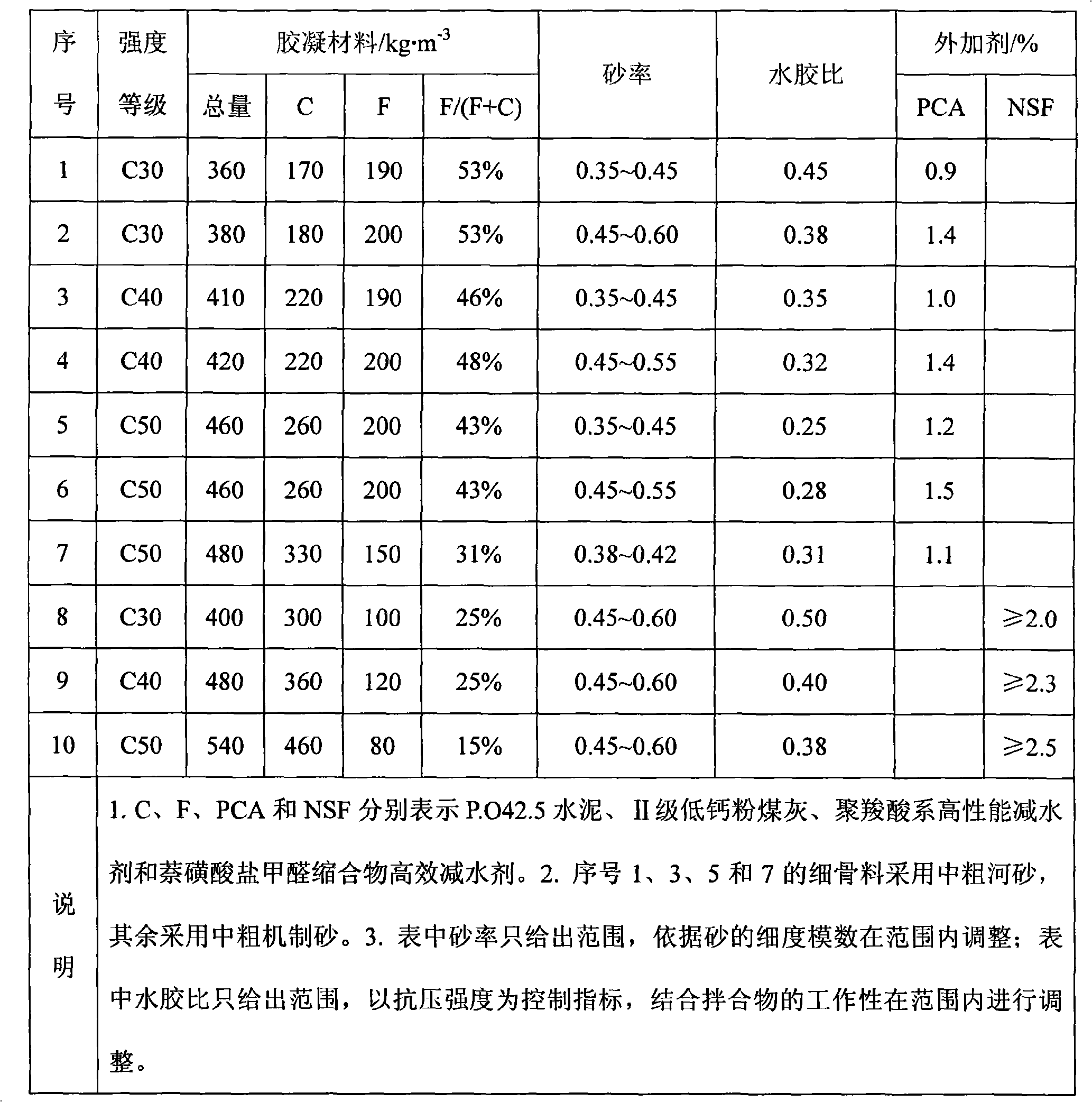

High fly ash commercial concrete or ready-mixed concrete

InactiveCN101525223AHigh water reduction rateImprove work performanceSolid waste managementChemical admixtureFrost

The invention relates to high fly ash commercial concrete or ready-mixed concrete or a preparation method thereof. The high fly ash commercial concrete or ready-mixed concrete is made from gelled material, aggregate, chemical additive and water; wherein, the gelled material comprises cement and fly ash; the aggregate comprises fine aggregate and coarse aggregate; and the chemical additive is polycarboxylate-based high performance water reducer. The usage of the gelled material is 360-480kg / m<3>concrete; wherein, the concrete is 47%-69wt% of the total gelled material; and the fly ash is 31%-53wt% of the total gelled material. The concrete has good workability, suitable strength and strength development, lower hydration temperature rising, higher volume stabilization, higher cracking resistance, impermeability, frost resistance, corrosion stability, resistance to carbonizing, alkali-resistant-aggregate reaction and chloride-resistant diffusibility.

Owner:WUHAN UNIV

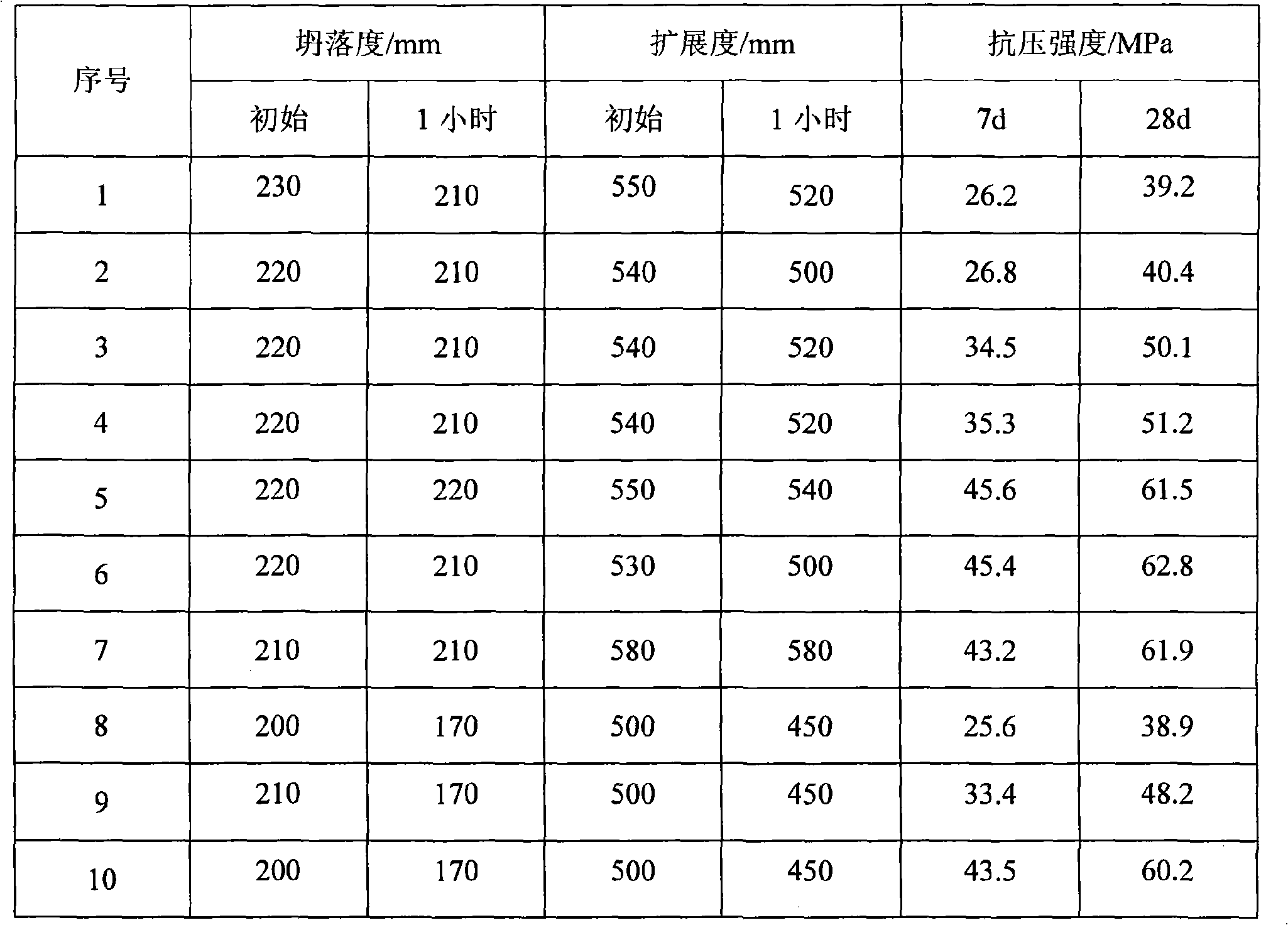

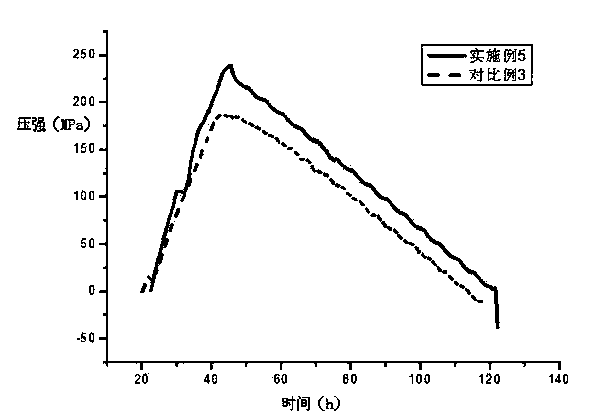

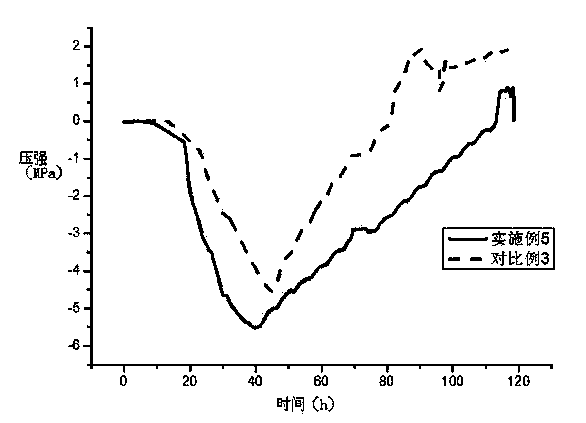

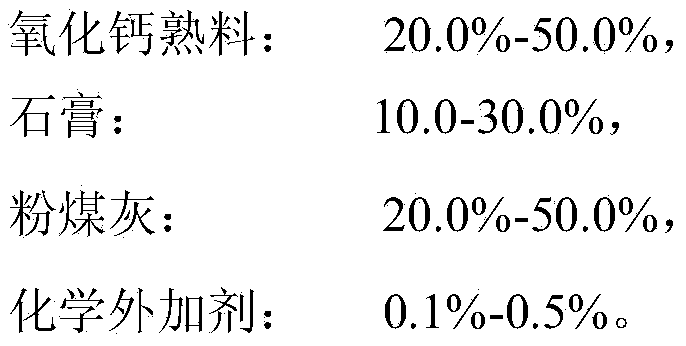

Chemical admixture capable of improving effectiveness of concrete expanding agent under restrictive condition

The invention provides a chemical admixture capable of improving the effectiveness of a concrete expanding agent under a restrictive condition. The chemical admixture accounts for 0.1-0.5% of the total weight of the concrete expanding agent, and the concrete expanding agent comprises the rest components as follows: 20.0-50.0% of calcium oxide clinker, 10.0-30.0% of gypsum and 20.0-50.0% of fly ash. The chemical admixture has the benefits as follows: when the adding amount of the chemical admixture is the same, the effect of the concrete expanding agent in a cement-based material under a free condition is remarkably improved and the free expanding rate is increased; the effect of the concrete expanding agent in the cement-based material under the restrictive condition is remarkably improved and the effective expanding rate is increased, so that the chemical admixture is more suitable for a sidewall, a roof and other solid structures with relatively strong constraints; mechanical properties and durability of the cement-based material are slightly affected, so that actual control and use are facilitated.

Owner:悉地(苏州)勘察设计顾问有限公司 +1

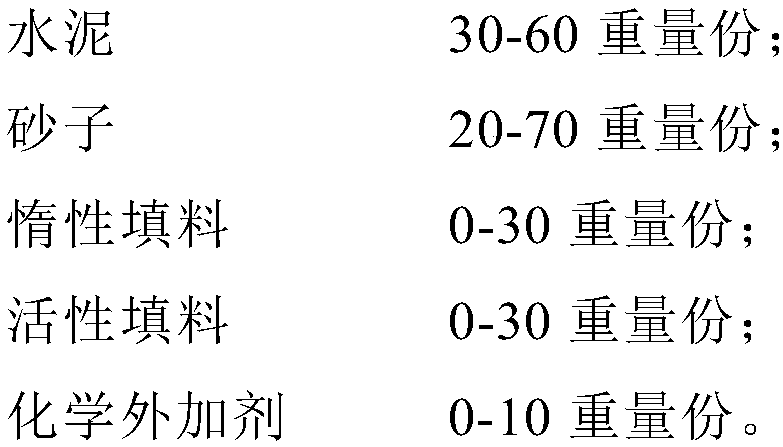

Environmentally-friendly odor removing dual-component cement-based waterproof material

InactiveCN107686297APromote environmental protectionGood physical propertiesChemical admixtureAmmonia

The invention discloses an environmentally-friendly odor removing dual-component cement-based waterproof material, which is prepared from the following ingredients in parts by weight: 1 part of liquidmaterial ingredient and 1-6 parts of powder material ingredient, wherein the powder material ingredient comprises cement, sand, inert filler, active filler and chemical additive; the liquid materialingredient comprises polymer emulsion, defoamer, bactericide and water. The environmentally-friendly odor removing dual-component cement-based waterproof material has the characteristics of extremelylow ammonia content, odor removal, good environment protection performance, good physical performance, good construction hand feeling and convenience in use and is suitable for various construction technologies including spraying, rolling and brushing, and VOC (volatile organic compounds), formaldehyde and harmful heavy metal powder can not be detected.

Owner:NIPPON PAINT CHINA

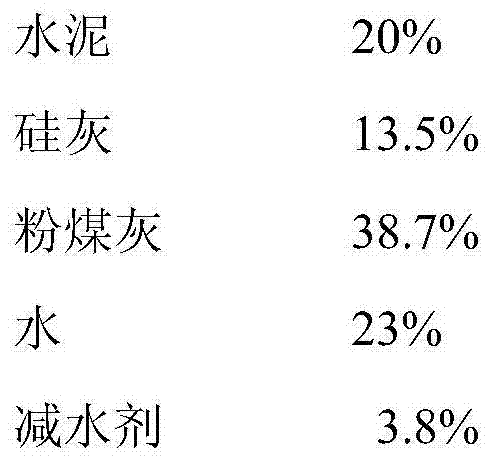

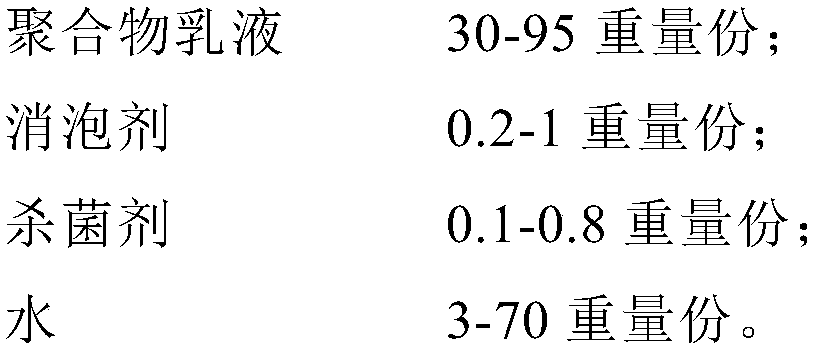

Fiber reinforced cement based mixed material

ActiveUS20140326168A1Small amount of shrinkageRapid early strength developmentSolid waste managementChemical admixturePolymer science

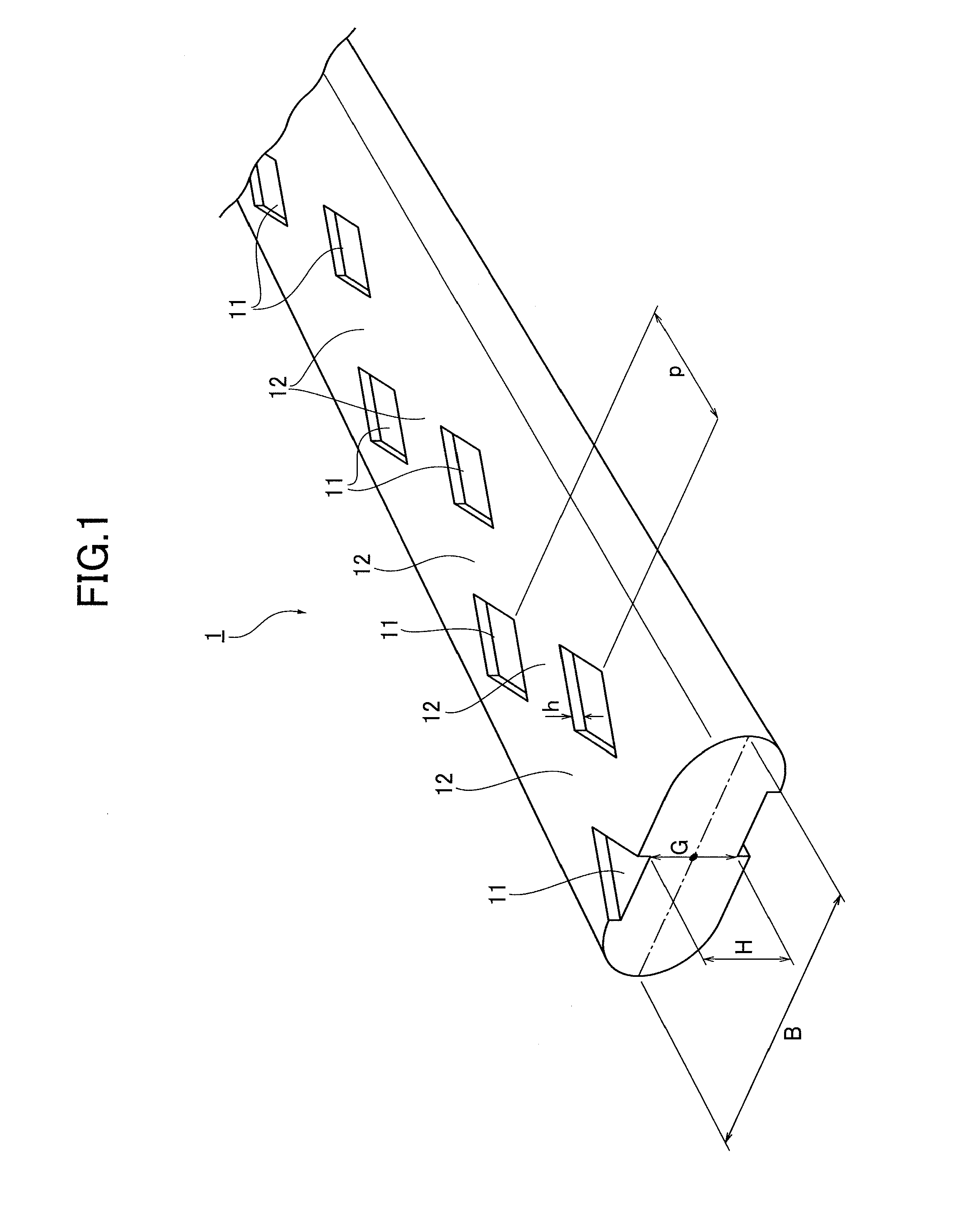

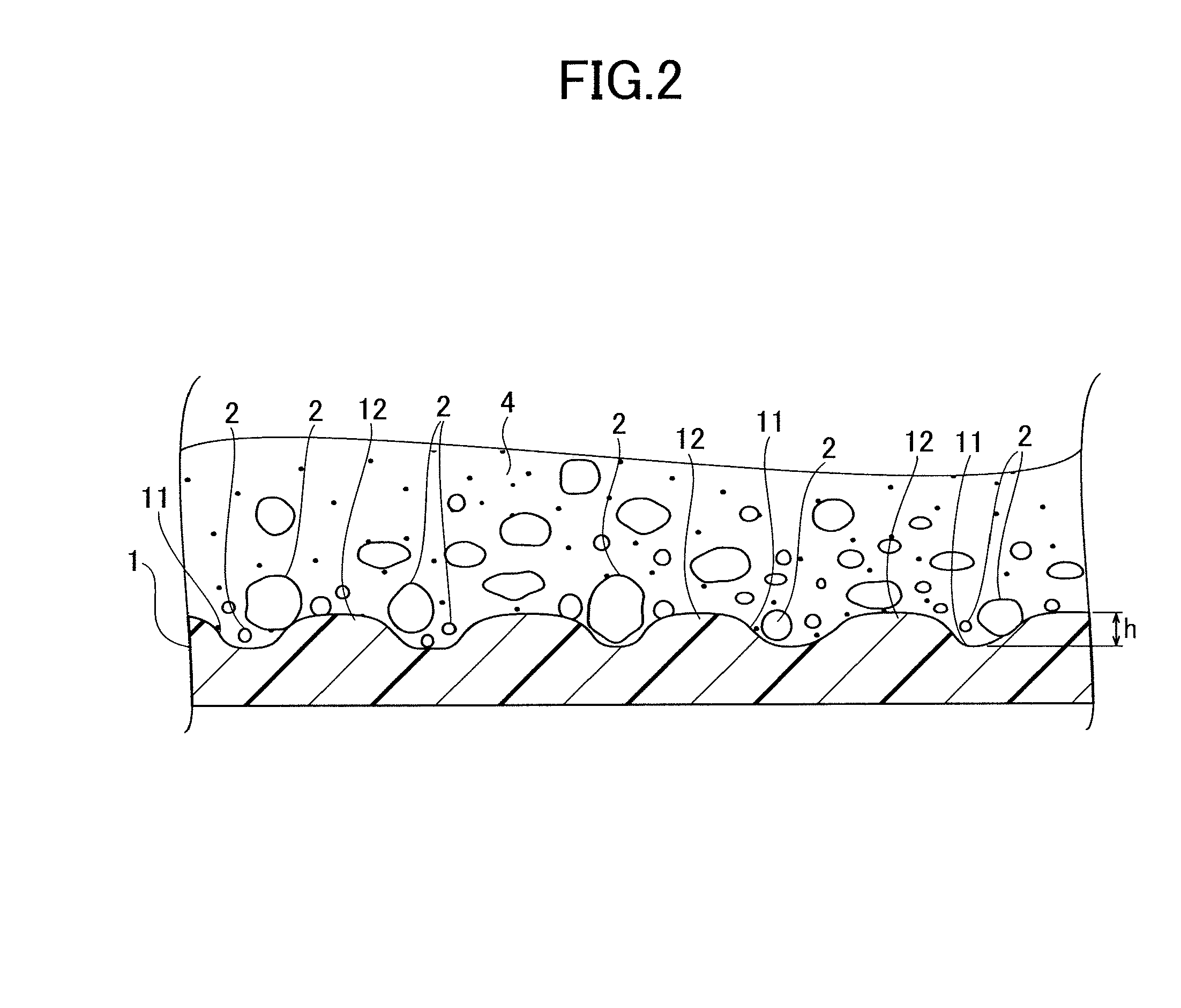

Provided is a fiber reinforced cement based mixed material having high tensile strength and high toughness, the mixed material comprising a cementitious composition with fast development of early strength; a small hydration heat temperature; and a small shrinkage during curing. The fiber reinforced cement based mixed material contains 100 wt. parts of cement, 5-30 wt. parts of silica fume, 30-80 wt. parts of at least one pozzolanic material excluding the silica fume, 5-25 wt. parts of limestone powder, at least one chemical admixture, water, 70-150 wt. parts of aggregate having a largest aggregate diameter of 1.2-3.5 mm, and fibers, wherein at least some of the fibers comprise a fiber having asperities formed in the surface, the fiber having asperities being formed such that a ratio (h / H) of a depth h of each of recessed portions among the asperities to a smallest cross-sectional diameter H thereof is 0.05-0.8.

Owner:TAISEI CORP

Mortar partner and its use

A composite modifier for mortar in building engineering consists of lime mountain flour 50-85wt%, latex powder 8-30wt%, cellulose ether 0.5-14wt%, inducer 0-0.3wt%, starch ether 0-0.2wt%, hydrophobic agent 0-5wt%, inorganic pigment 0-3wt% and organic fibre 0-18wt%. It has excellent thermal-insulating, water-proofing and anti-stain functions and be used for decorative and waterproofing materials, polystyrene foaming board, concrete wall and air-entrained concrete.

Owner:TONGJI UNIV

Amine Sacrificial Agents and Methods and Products Using Same

InactiveUS20100286312A1Promote formationFacilitate air entrainmentSolid waste managementCeramicwareChemical admixtureAgent Combination

A method of producing cementitious mixtures containing fly ash as one of the cementitious components, under air entrainment conditions is described. The method involves forming a mixture comprising water, cement, fly ash, optionally other cementitious materials, aggregate, conventional chemical admixtures, and an air entrainment agent and agitating the mixture to entrain air therein. Additionally, at least one amine sacrificial agent is included in the mixture. The cementitious mixtures and hardened concretes resulting from the method and fly ash treated with sacrificial agent, or air entrainment agent / sacrificial agent combinations, are also described.

Owner:RUETGERS POLYMERS LTD

Amine sacrificial agents and methods and products using same

InactiveUS20120085264A1Promote formationFacilitate air entrainmentSolid waste managementCeramicwareChemical admixtureAgent Combination

A method of producing cementitious mixtures containing fly ash as one of the cementitious components, under air entrainment conditions is described. The method involves forming a mixture comprising water, cement, fly ash, optionally other cementitious materials, aggregate, conventional chemical admixtures, and an air entrainment agent and agitating the mixture to entrain air therein. Additionally, at least one amine sacrificial agent is included in the mixture. The cementitious mixtures and hardened concretes resulting from the method and fly ash treated with sacrificial agent, or air entrainment agent / sacrificial agent combinations, are also described.

Owner:RUETGERS POLYMERS LTD

Application of carbide slag solid wastes as raw materials for preparing mineral filling gel material, filling gel material and filling material

InactiveCN106698984AHigh compressive strengthAchieve resource utilizationCement productionChemical admixtureResource utilization

The invention provides application of carbide slag solid wastes as raw materials for preparing a mineral filling gel material. The activities of fly ash and blast furnace slag are activated by using carbide slag; under the situation of the high-content fly ash, the volcanic ash effects of the fly ash and the blast furnace slag are activated through supplementing the carbide slag with chemical admixtures; the hydraulic gel material is generated and plays a mutually-complementary synergetic effect in function, so that the compressive strength of the mineral filling gel material achieves an ideal effect, the purposes of resource utilization of industrial waste residues such as carbide slag and effective filling in a mine are achieved, and a new way is sought for the resource utilization of the carbide slag solid waste.

Owner:SHANDONG UNIV OF SCI & TECH

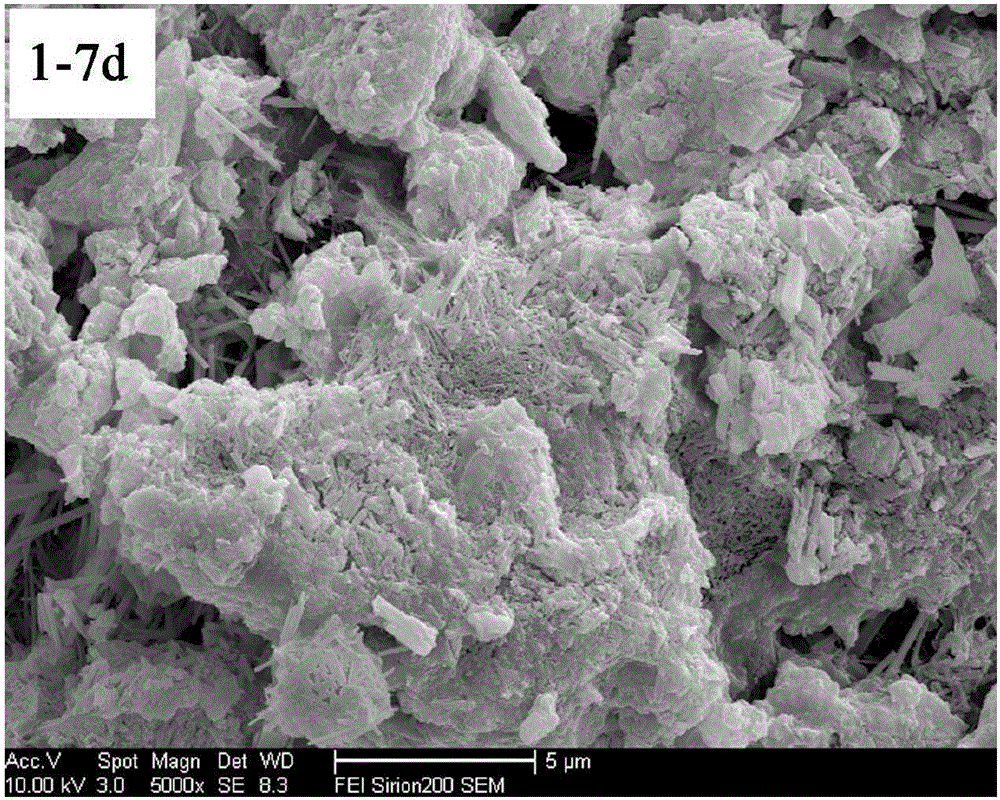

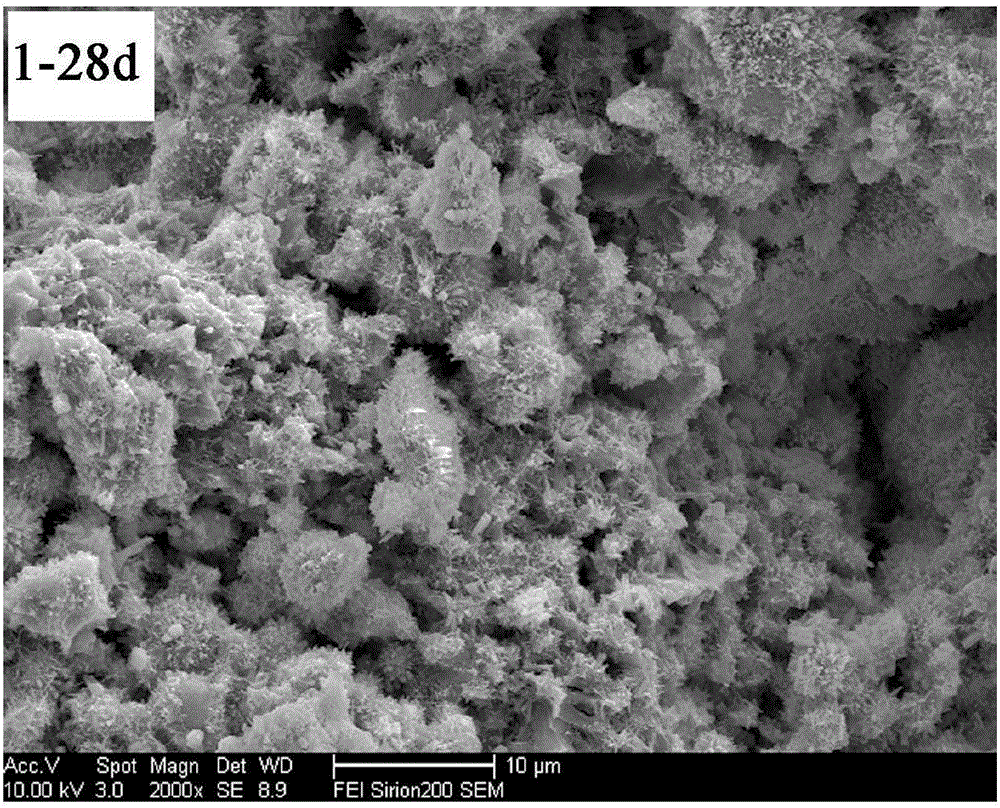

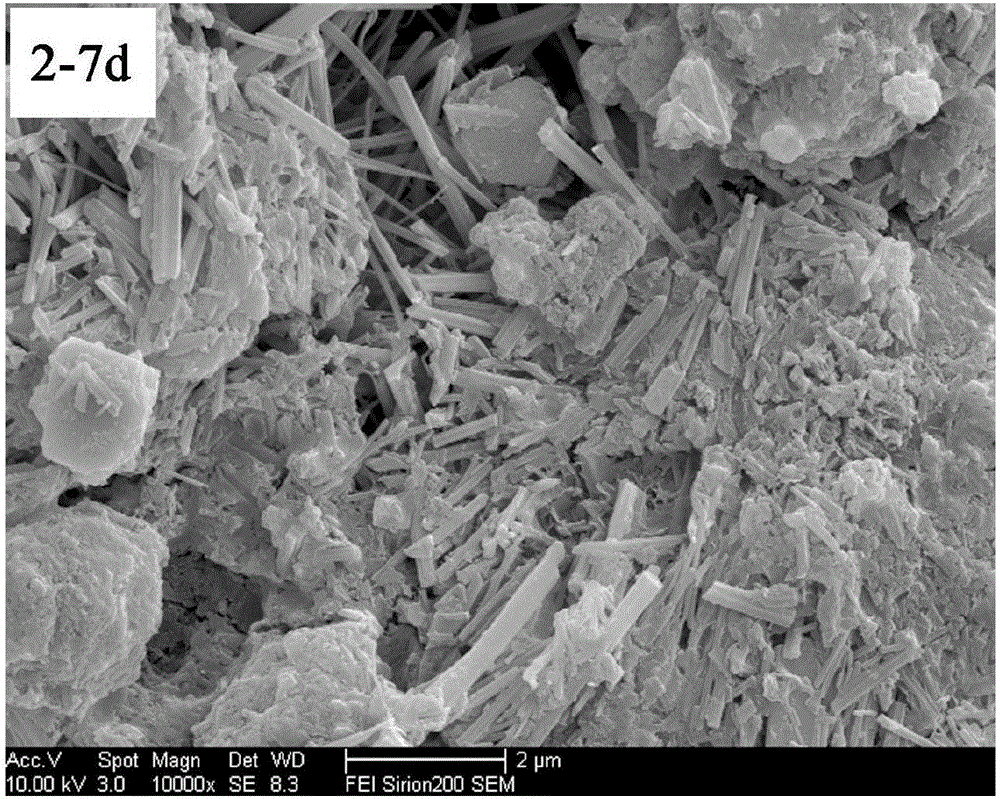

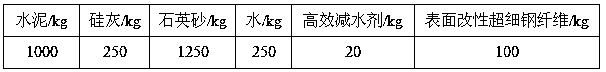

Surface-modified ultrafine steel fiber reinforced high-impedance ultrahigh-performance concrete and preparation method thereof

The invention discloses surface-modified ultrafine steel fiber reinforced high-impedance ultrahigh-performance concrete and a preparation method thereof, and belongs to the technical field of buildingmaterials. The ultrahigh-performance concrete comprises the following components in parts by mass: 50-300 parts of surface-modified ultrafine steel fiber, 500-1500 parts of cement, 50-500 parts of amineral admixture, 1000-1800 parts of fine aggregate, 5-40 parts of a chemical admixture and 150-650 parts of water. The preparation method comprises the following steps: preparing a nanometer silicondioxide modifier; performing surface modification on ultrafine steel fiber; stirring and curing concrete. Through modification of growing SiO2 on the surface of the ultrafine steel fiber, morphologically, the surface roughness is improved and a friction coefficient between the fiber and a matrix is increased, and chemically, by virtue of high volcanic ash activity of nanometer SiO2, secondary hydration is performed on the nanometer SiO2 and a cement hydration product Ca(OH)2 to produce calcium silicate hydrate gel C-S-H so as to improve a weak interfacial region; the flexural strength of thesurface-modified ultrafine steel fiber reinforced high-impedance ultrahigh-performance concrete reaches 25MPa or above, and the electrical resistivity thereof reaches 20,000 ohm.cm or above.

Owner:HARBIN INST OF TECH

Acid rain corrosion resisting concrete additive and preparation method thereof

InactiveCN101851080AImproved particle size distributionHigh activitySolid waste managementFiberChemical admixture

The invention relates to an acid rain corrosion resisting concrete additive and a preparation method thereof. The acid rain corrosion resisting concrete additive is characterized by mainly comprising the following materials in parts by weight: 100 parts of grounded furnace slag, 150-300 parts of high-lime fly ash, 10-50 parts of siliceous dust, a polymer, organic fiber and a function intensifyingcomponent, and the addition quantities of the polymer, the organic fiber and the function intensifying component respectively account for 3-5%, 0.5-2.5% and 3-8% of the total mass of the grounded furnace slag, the high-lime fly ash and the siliceous dust, wherein the function intensifying component is a chemical additive prepared by compounding an exciting agent and a dispersing agent in the massratio of 1:0.02-0.08. The acid rain corrosion resisting concrete additive is applied to concrete in acid rain environment, can obviously increase the acid rain corrosion resistance of the concrete, can extend the service life of concrete structures, and is low in price.

Owner:EAST CHINA JIAOTONG UNIVERSITY

Activated waste slay composite powder and its application in cement, concrete and bake free brick

InactiveCN1493541ANon-proliferationImproved pozzolanic propertiesCement productionBuilding componentsChemical admixtureMineral Sources

An activated composite waste dregs powder used for cement, concrete and non-calcine brick is prepared from acidified zeolite powder, lead or copper dregs, carbonate stone powder, phosphate dregs (ardealite), lime dregs and powdered coal ash as basic materials. Its advantages are high property and low cost.

Owner:吴发辉

Alkali-activated cement utilizing abandoned clay brick powder and preparation method thereof

The invention discloses alkali-activated cement. The alkali-activated cement comprises a basic component and a compound chemical additive, wherein the basic component is prepared from the following components by mass percent: 10-30% of abandoned clay brick powder and 70-90% of high-calcium fly ash, and amount of added compound chemical additive accounts for 10-15% of the mass of the basic component metered by content of introduced Na2O. The invention also discloses a preparation method of the alkali-activated cement. The preparation method of the alkali-activated cement comprises the following steps: mixing the abandoned clay brick powder with the mass percentage of 10-30% with the high-calcium fly ash with the mass percentage of 70-90%, adding the compound chemical additive accounting for 10-15% of the sum of the mass of the abandoned clay brick powder and high-calcium fly ash, controlling water-solid ratio of a system to be 0.28-0.32, and mixing, so that the alkali-activated cement is obtained. The alkali-activated cement disclosed by the invention has the beneficial effects that industrial waste, namely the high-calcium fly ash and the abandoned clay brick powder, are utilized, an approach is provided for utilization of the waste, and cost is reduced.

Owner:TONGJI UNIV

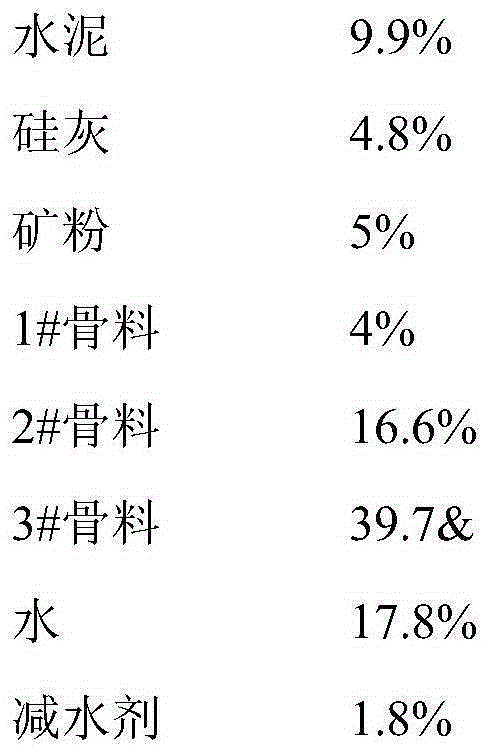

Profundity sterilization borehole face high-strength high-performance concrete

InactiveCN101152977AImprove carrying capacityStrong water sealingSolid waste managementChemical admixtureSlag

The present invention discloses a concrete with high strength and high performance for deeply and thickly frozen well wall. The double-doping technology of milled slag as the main mineral doping and different chemical doping is used; the invention is prepared after optimized combination and blending of mixture. The concrete is made by mixing P.0.42.5cement, machine-made sand, limestone rubble, milled rubble, I-level powder coal ash, TK-M intensifier, J851-D early strengthening high-early-strength water reducing agent, JQ-D anti-crack intensifying agent, high-efficiency water reducing agent of liquid polycarboxylic salt, and water. The present invention has the characteristics of the low preparation cost, the simple operation process, the applicability to engineering of the inside of a deeply and thickly frozen and a well wall on the outer layer, and so on.

Owner:盛天宝 +2

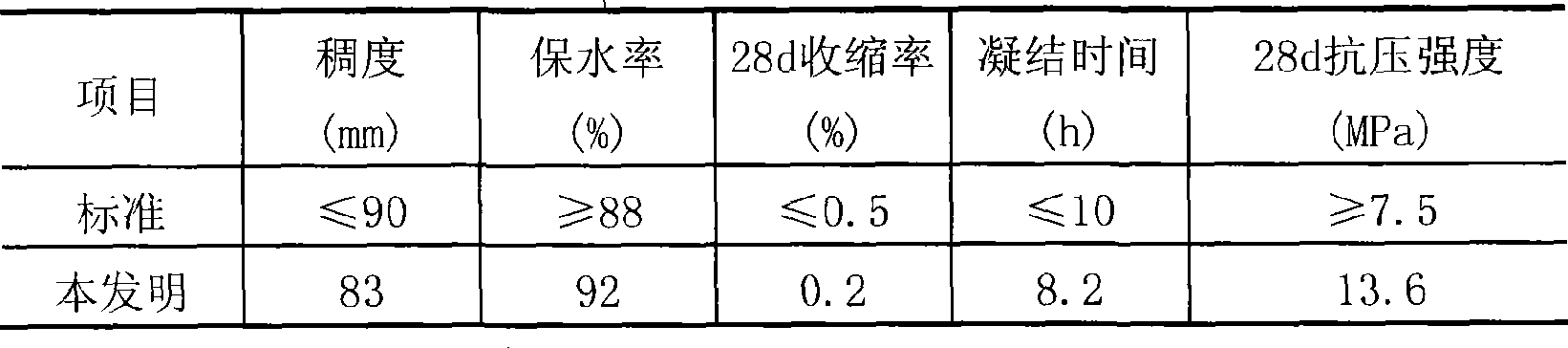

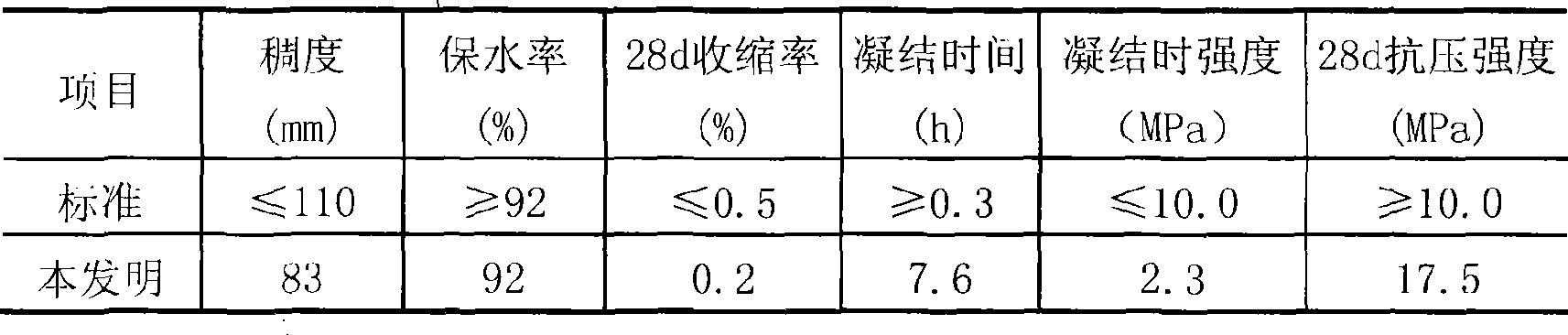

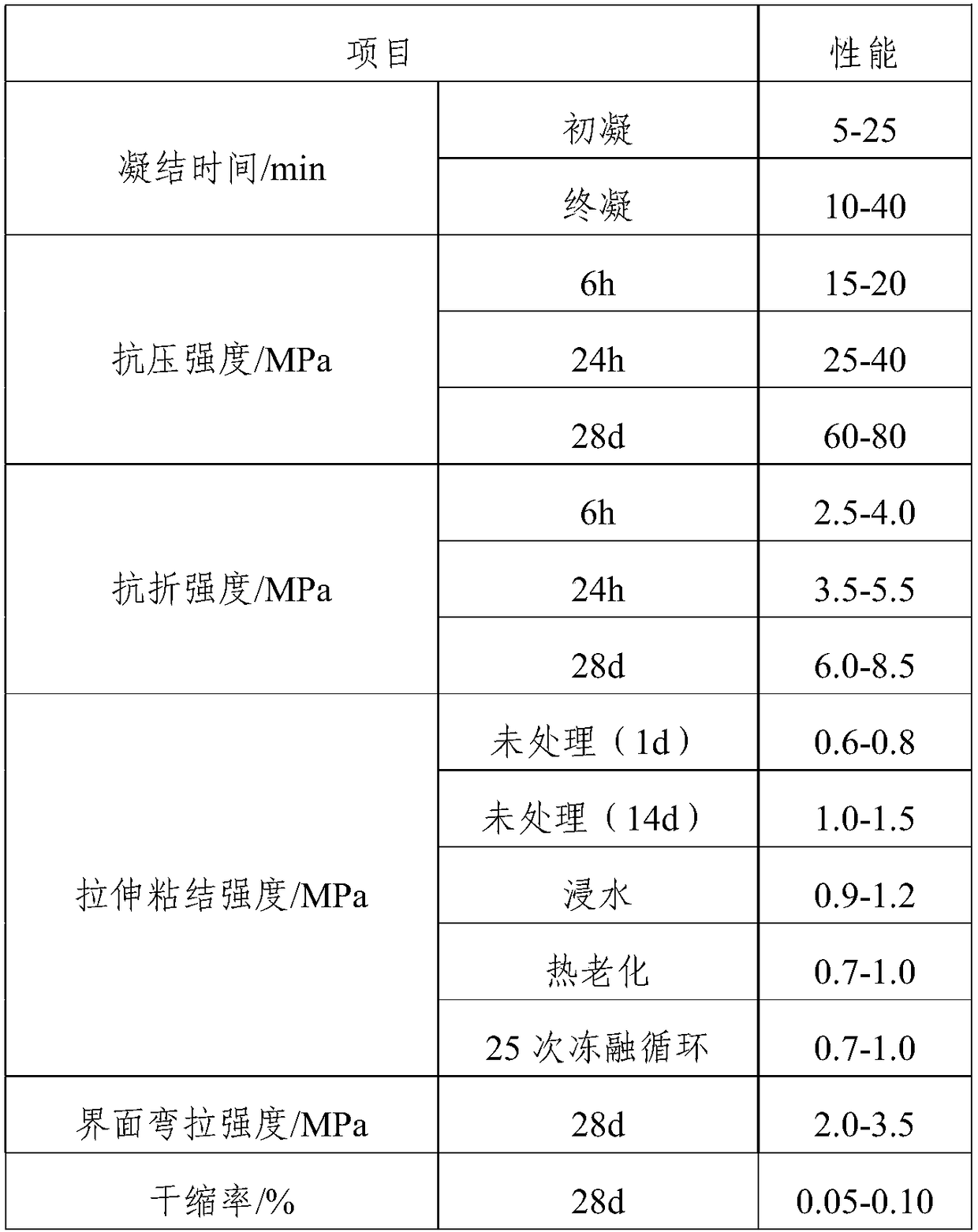

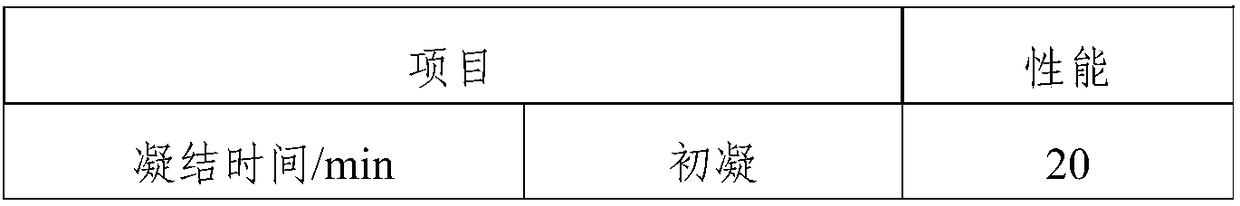

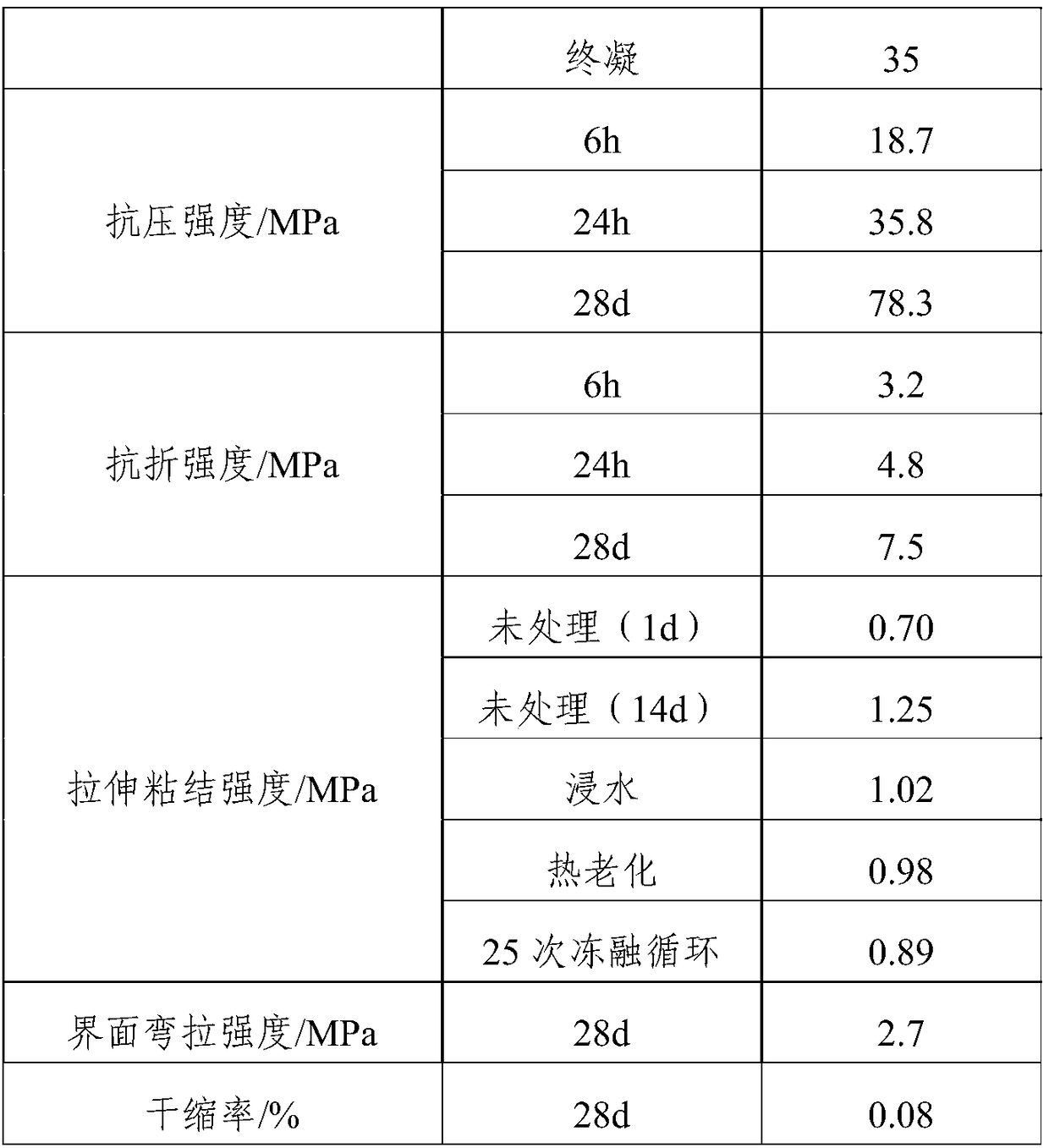

Coal ash and mineral powder-based geopolymer quick setting type rigid repair mortar and preparation method thereof

ActiveCN108585649AReduce production energy consumptionImprove performanceCement productionSolid componentChemical admixture

The invention provides quick setting type rigid repair mortar prepared from industrial byproducts such as coal ash, mineral powder and tailing fine sand as well as a preparation method of quick setting type rigid repair mortar. The coal ash and mineral powder-based geopolymer quick setting type rigid repair mortar consists of a solid component material and a liquid component liquid; the solid component material is formed by combining the coal ash, the mineral powder, the tailing fine sand and a chemical additive according to a certain proportion; the liquid component material is formed by mixing a sodium hydroxide solution with a certain concentration, waster glass and water according to a certain proportion; and the solid component material and the liquid component material are stirred completely and uniformly according to a certain proportion, and the quick setting type rigid repair mortar can be used. The coal ash and mineral powder-based geopolymer quick setting type rigid repair mortar prepared by the method has excellent performance and completely meets each perform index requirement of JC / T 2381-2016. The main raw materials of the coal ash and mineral powder-based geopolymerquick setting type rigid repair mortar are industrial byproducts such as the coal ash, the mineral powder and the tailing fine powder and belong to environment-friendly materials.

Owner:BEIJING BUILDING MATERIALS ACADEMY OF SCI RES +1

Non-shrinkage cement-based roofing material

The invention relates to a non-shrinkage cement-based roofing material, belonging to the technical field of building materials. The roofing material is formed by mixing cement, activated and inert mineral admixtures, plaster, expanding agents, glass fibers and organic synthesis fibers, chemical admixtures, sand and the like based on a certain proportion. At the construction field, right amount of water is added and stirred evenly, and is constructed by hand spreading or spraying. Regarding constructed roofing, the thickness of the waterproof layer is 35-50mm and the area of the separate bin is 50-300m. The non-shrinkage roofing material has high strength, good volume stability and excellent waterproof property, can be used for thin layer construction and is convenient, fast and flexible in construction. The roofing material is low in cost, convenient in production and changeable in production scale, and is applicable to the requirements of construction of villages and small towns. In addition, the roofing material utilizes a substantial proportion of industrial residues, thus not only reducing cost but also conducing to environment protection.

Owner:TSINGHUA UNIV

Composite soil solidifying agent, and preparation and application thereof

The invention relates to a composite soil solidifying agent, and a preparation method thereof. According to the invention, ore slag, nickel slag, cement, and chemical additives are mixed according to a certain ratio, such that the soil solidifying agent is obtained. When the solidifying agent with a proper amount is doped in weak soil, a substantial enhancing effect can be obtained. Especially, soil water resistance and corrosion resistance can be improved. The solidifying effect is substantially better than that of Portland cement. Industrial waste slag is adopted as main raw materials, such that cost is reduced, and environment protection is benefited.

Owner:NANJING UNIV OF TECH

Sacrificial Agents for Fly Ash Concrete

InactiveUS20090199743A1Easy to useExceeding amountSolid waste managementCoatingsChemical admixtureAgent Combination

A method of producing cementitious mixtures containing fly ash as one of the cementitious components, under air entrainment conditions. The method involves forming a mixture comprising water, cement, fly ash, optionally other cementitious materials, aggregate, conventional chemical admixtures, and an air entrainment agent and agitating the mixture to entrain air therein. Additionally, at least one sacrificial agent is also included in the mixture. The sacrificial agent is a material or mixture of materials that is not required to act as an air entrainment agent but interacts preferentially with components of the fly ash that otherwise neutralize, repress or depress the activity of the air entrainment agent. The invention includes cementitious mixtures and hardened concretes resulting from the method and fly ash treated with sacrificial agent, or air entrainment agent / sacrificial agent combinations, and processes for selecting suitable sacrificial agents.

Owner:HANDY CHEM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com