Ultra-high performance cement base composite material

An ultra-high performance, composite material technology, applied in the field of concrete, can solve the problems of not reaching ultra-high strength, weakening the compressive strength of concrete, and improving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

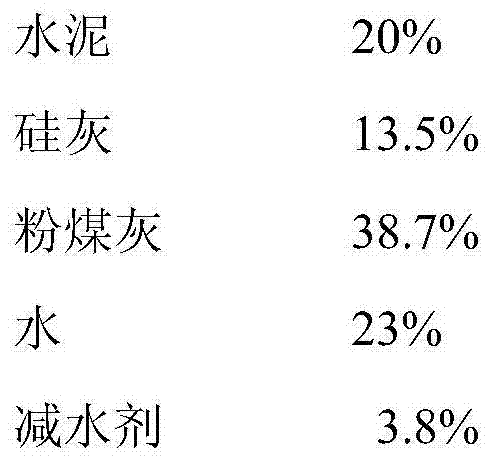

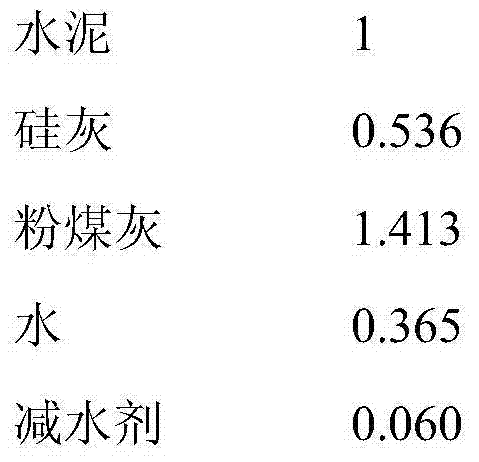

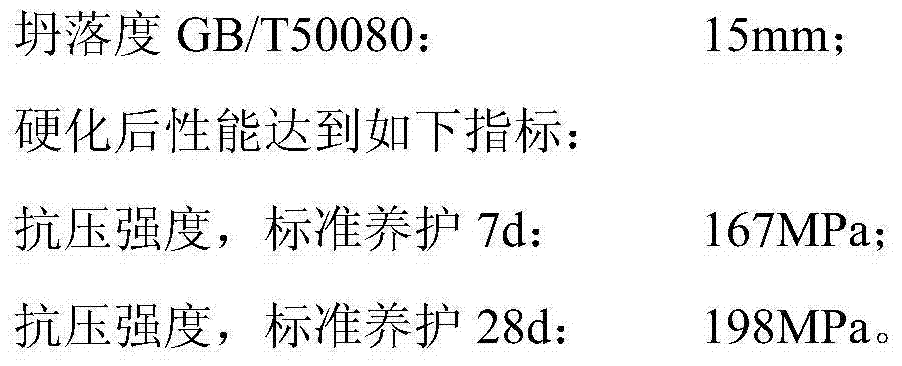

[0086] Ultra-high performance cement-based composite material, including cementitious material, water and water reducer, the volume of cement accounts for 20%, the cement is P·I cement with a strength grade of 52.5, and the mineral admixture is silica fume and powder Coal ash accounts for 52.2% by volume.

[0087] The ratio fraction of cement, silica fume and fly ash is numerically analyzed and calculated through the ideal accumulation curve and its particle size cumulative distribution curve;

[0088] 1) The ideal stacking curve formula is:

[0089] P sd 100 / max / ;

[0090] Among them, P sd is the percentage of particles passing through the sieve, A is an empirical constant, d is the diameter of the sieve, D max is the maximum particle size of the particle;

[0091] The value of the empirical constant A is determined by the formula according to the design slump or design expansion requirements of ultra-high performance cement-based composite materials:

[0092] Slu...

Embodiment 2

[0110] Ultra-high performance cement-based composite material, including cementitious material, water, water reducer, defoamer and early strength agent, the volume of cement accounts for 57%, the cement is P·O cement with a strength grade of 52.5, and the mineral The admixture is silica fume and fly ash, accounting for 12.5% by volume. Each component distribution fraction of gelling material is by the calculation mode of embodiment 1, gets X c =0.820,X sf =0.101 and X fa =0.079. The water-to-binder ratio W / B=0.132, the admixture uses polycarboxylate superplasticizer solution, the dosage is 1.1% of the mass of the gelling material, and the silicone defoamer is used, and the dosage is 0.1% of the mass of the gelling material. Triethanolamine early strength agent, the dosage is 0.03% of the mass of the gelling material.

[0111] The volume percentage of the main materials used in ultra-high performance cement-based composites is as follows:

[0112]

[0113] The dosage ...

Embodiment 3

[0118] Ultra-high-performance cement-based composite materials, including cementitious materials, water and water reducing agent, the volume of cement accounts for 49%, the cement is P·I cement with a strength grade of 62.5, and the mineral admixtures are silica fume, powder Coal ash and slag powder account for 18% by volume; the proportions of each component of the cementitious material are by the calculation method of embodiment 1, get X c =0.731,X sf =0.104,X fa =0.094 and X bs =0.070. The water-binder ratio W / B=0.143, the admixture uses the polycarboxylate superplasticizer solution, and the dosage is 2.1% of the mass of the gelling material.

[0119] The volume percentage of the main materials used in ultra-high performance cement-based composites is as follows:

[0120]

[0121]

[0122] The dosage and quality ratio of each material of ultra-high performance cement-based composite materials are as follows:

[0123]

[0124] Ultra-high-performance cement-base...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com