Patents

Literature

469results about How to "Improve abrasion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

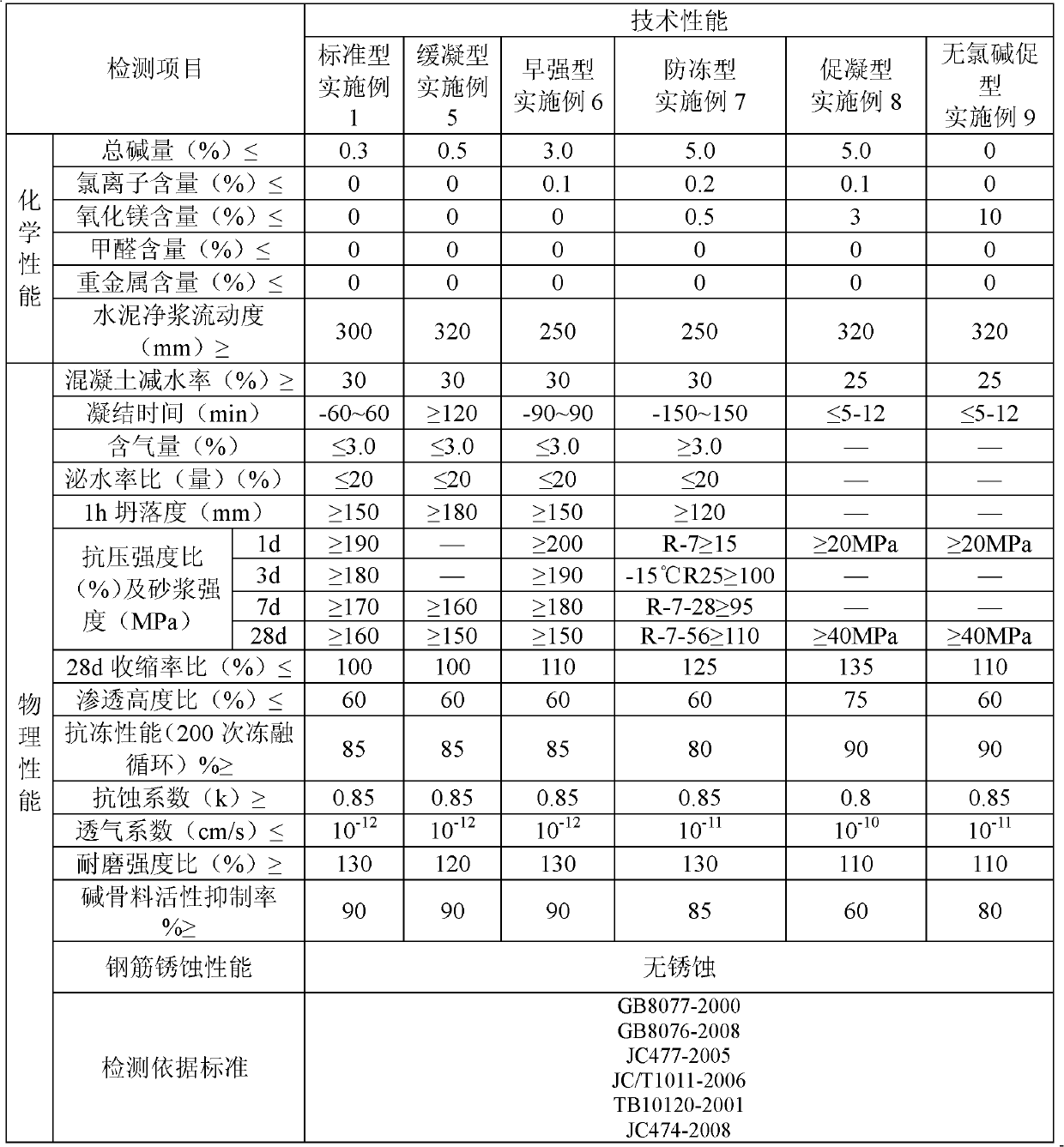

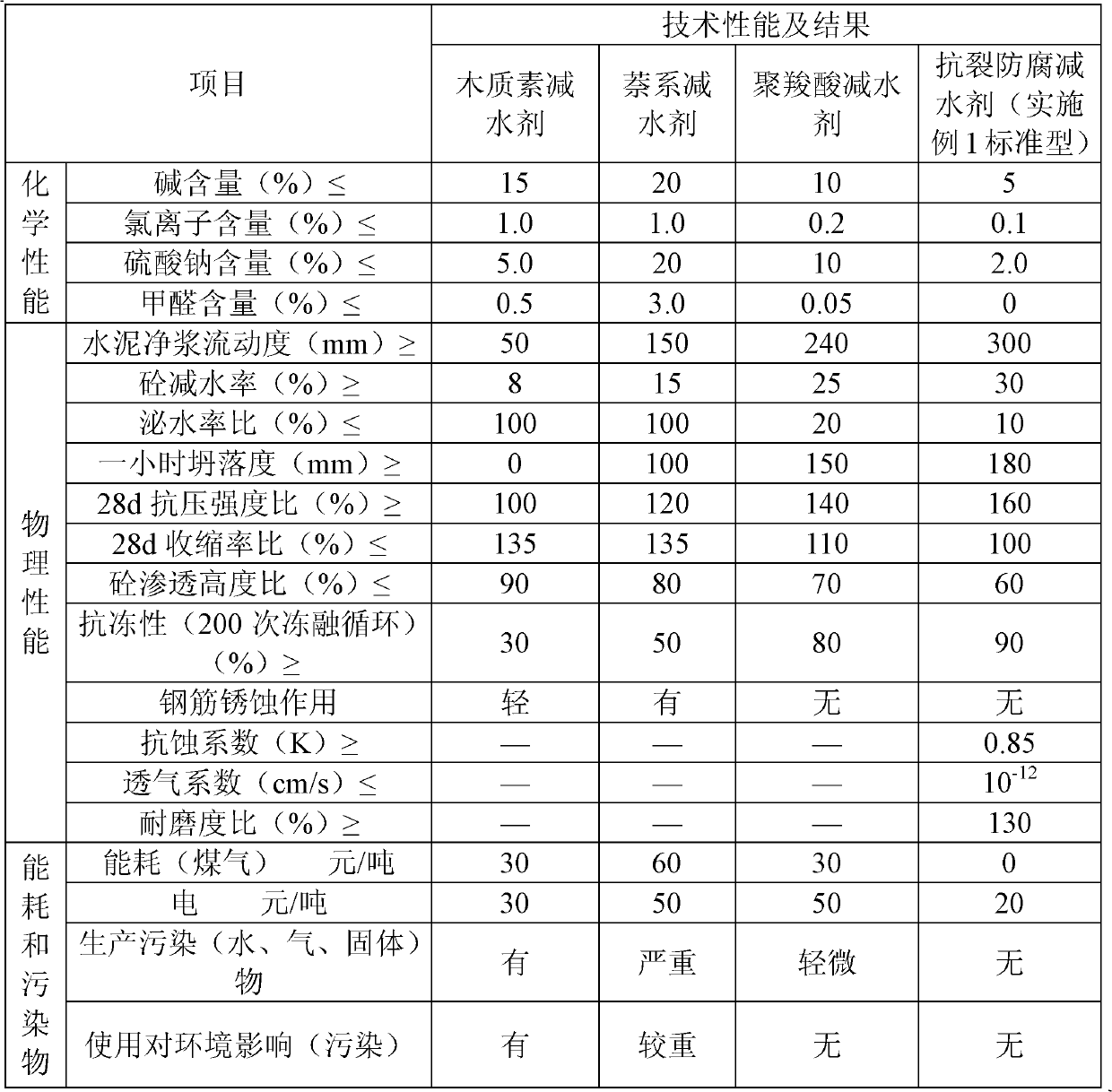

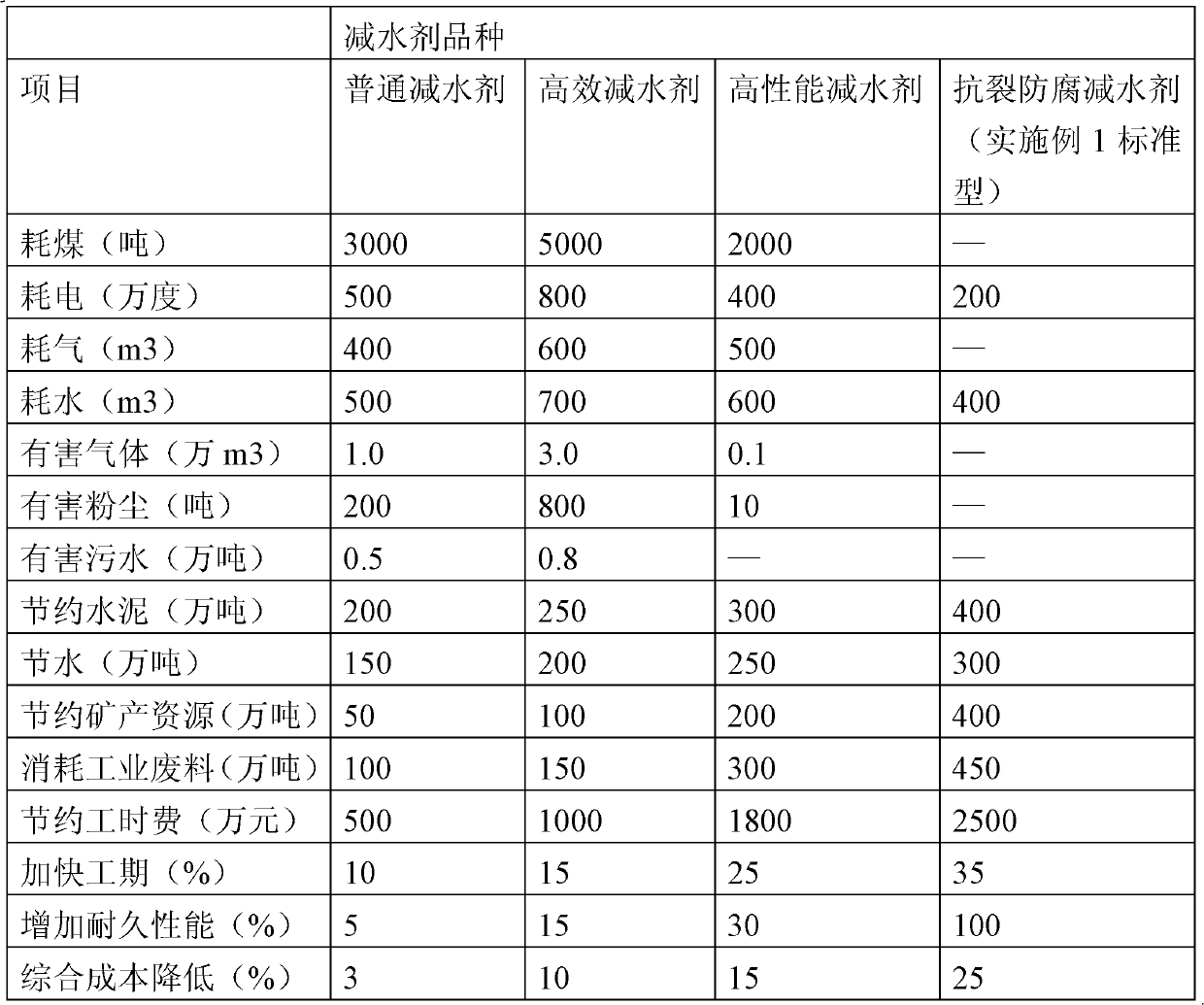

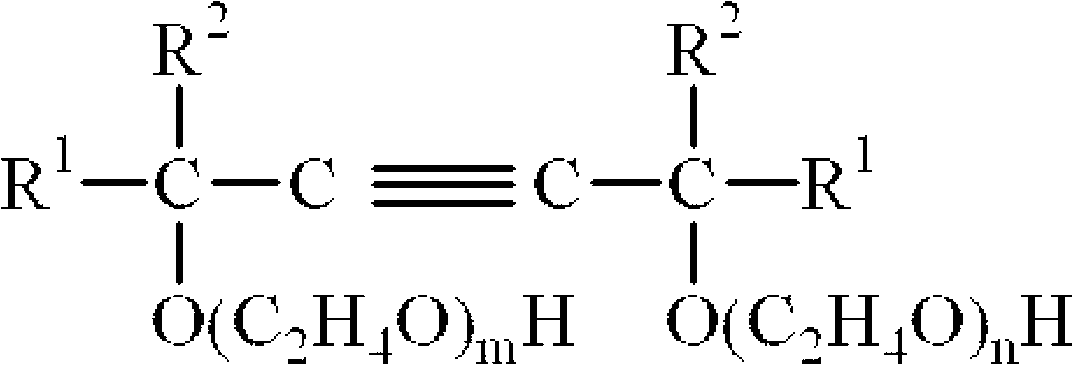

High-performance anti-cracking anticorrosive water reducing agent composition and preparation method thereof

The invention relates to a high-performance anti-cracking anticorrosive water reducing agent composition and a preparation method thereof. The anti-cracking anticorrosive waterproof anti-frost property of the water reducing agent composition is improved while the water-reducing rate of the water reducing agent composition is increased. Compared with a water reducing agent in the prior art, the water reducing agent composition has excellent combination property and an anti-cracking anticorrosion effect. When the water reducing agent composition is prepared, low energy is consumed, and when the water reducing agent composition is used, little pollution is caused.

Owner:苏琳

Preparation method and construction process of waterborne marble-imitated multicolor paint

ActiveCN101693800AGood water and rub resistanceGood environmental performanceMulticolor effect coatingsChemistryDispersed media

The invention discloses a preparation method and the construction process of a waterborne marble-imitated multicolor paint, in particular to a compounding technology and the construction process of the water-in-water type multicolor external wall paint. The paint consists of a disperse phase and a disperse medium, wherein the waterborne multicolor dispersoid containing water-soluble colloid is taken as the disperse phase and the water is taken as the disperse medium, namely the multicolor dispersoid is uniformly dispersed in the water-dispersed medium containing the film-forming substance. The wall paint has excellent wall decoration and protection performance and high performance-to-price ratio; and as the coating is thin and light and has elasticity and stain resistance, the paint can be applicable to the high-rise external walls and the external heat-preservation coating decoration, thus solving the problem that the self-weight is large in the practical application process of the marbles, the wall bricks and the glass curtain walls. In the invention, the wall paint solves the construction localization that the special spraying gun is only used for the waterborne multicolor paint, the normal spraying gun for building can be used, therefore, the construction is convenient and is easy for operation, and the wall paint has wider application prospect.

Owner:鳄鱼尼卡(上海)新材料有限公司

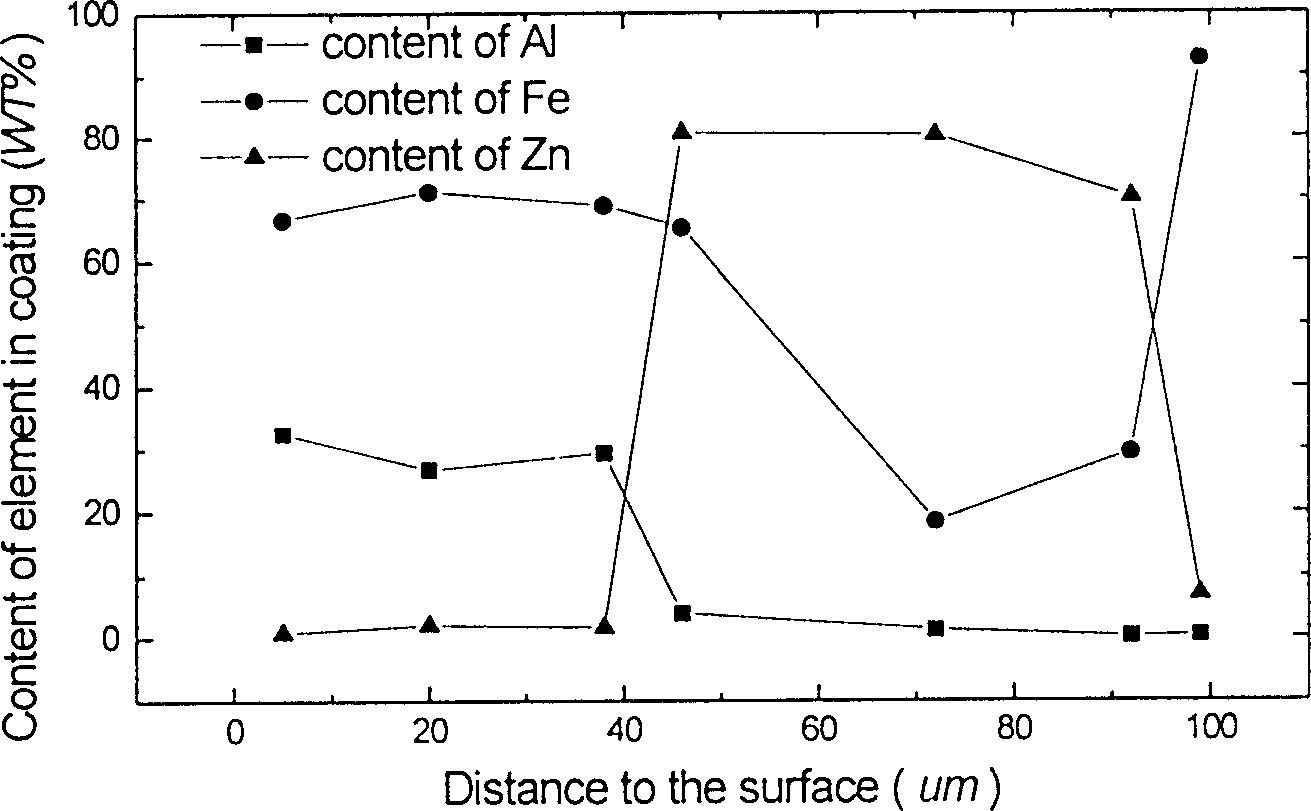

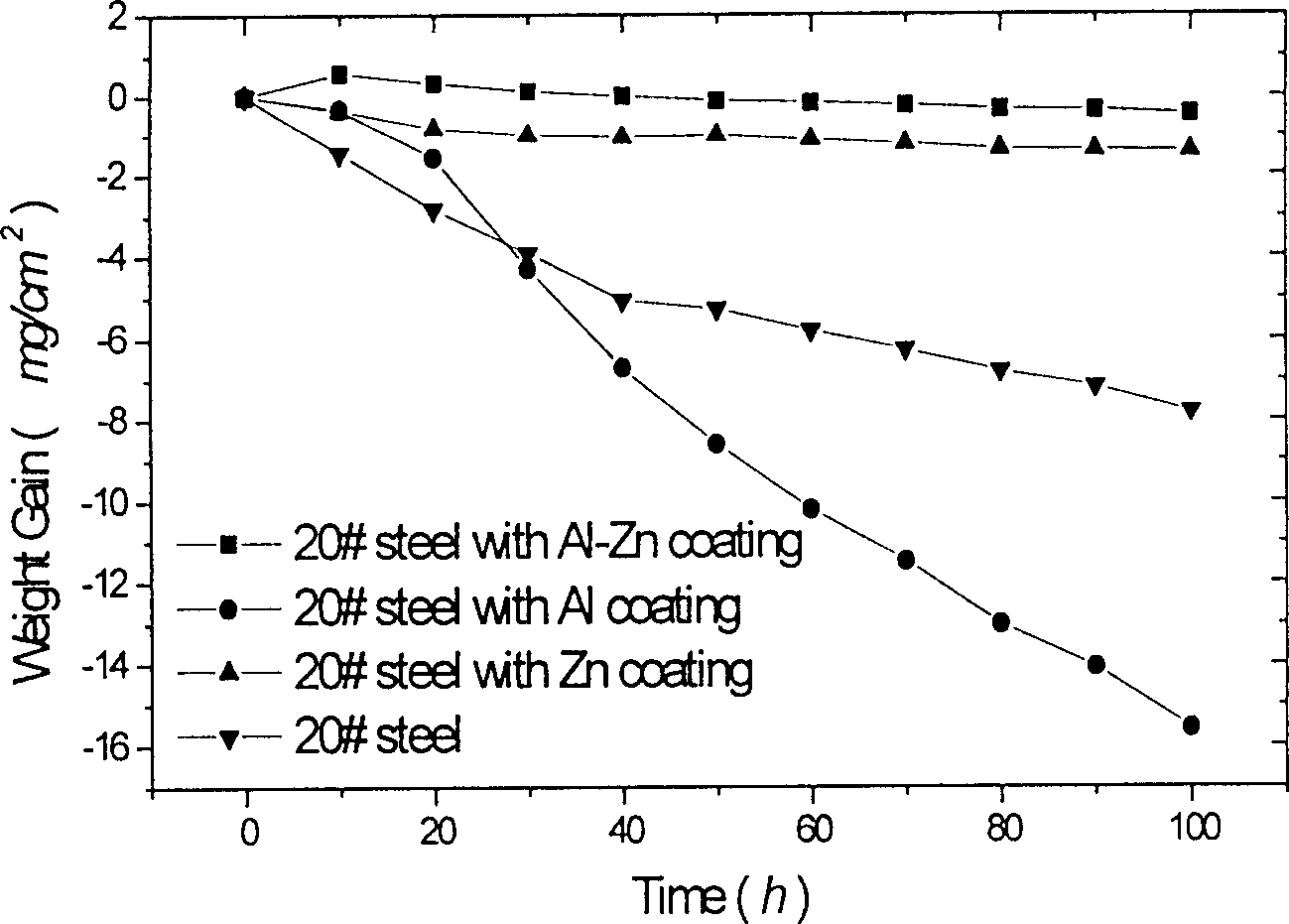

Zinc-aluminium embedding co-penetrating method for iron and steel products and its penetrant

InactiveCN1428454AImprove corrosion resistanceImprove abrasion resistanceSolid state diffusion coatingMaterials scienceZinc aluminium

The present invention relates to a zinc-aluminium embedding copenetrating method of iron and steel products and its penetrant. Its method includes the following steps: embedding iron or steel product in the penetrant, heat-insulating treatment for 3-10 hr at 400 to 600 deg.C, then a zinc-aluminium copenetrated layer with double-layer structure whose external layer is enriched with aluminium and internal layer is enriched with zinc is formed on the surface of iron or steel product, so that the iron or steel product can have more excellence anticorrosion property and resistance to abrasion.

Owner:中国石油乌鲁木齐石油化工有限公司 +1

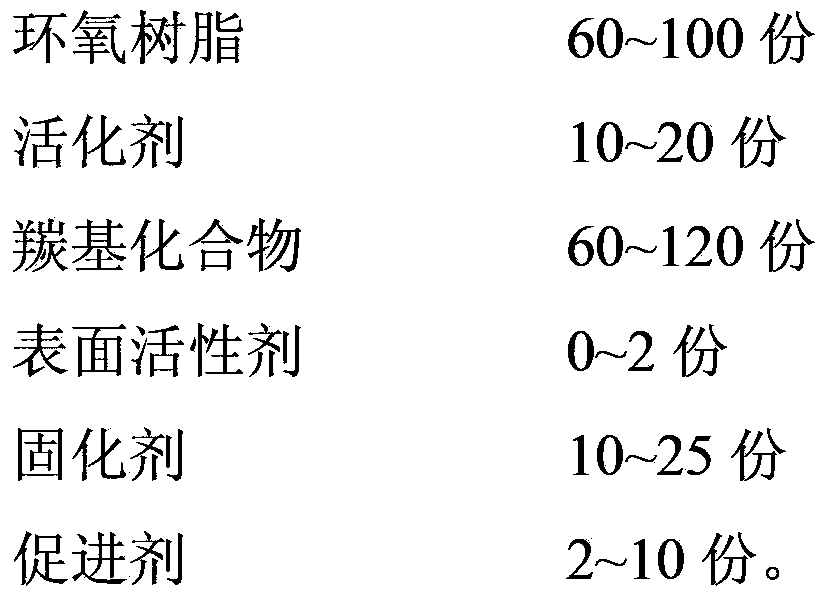

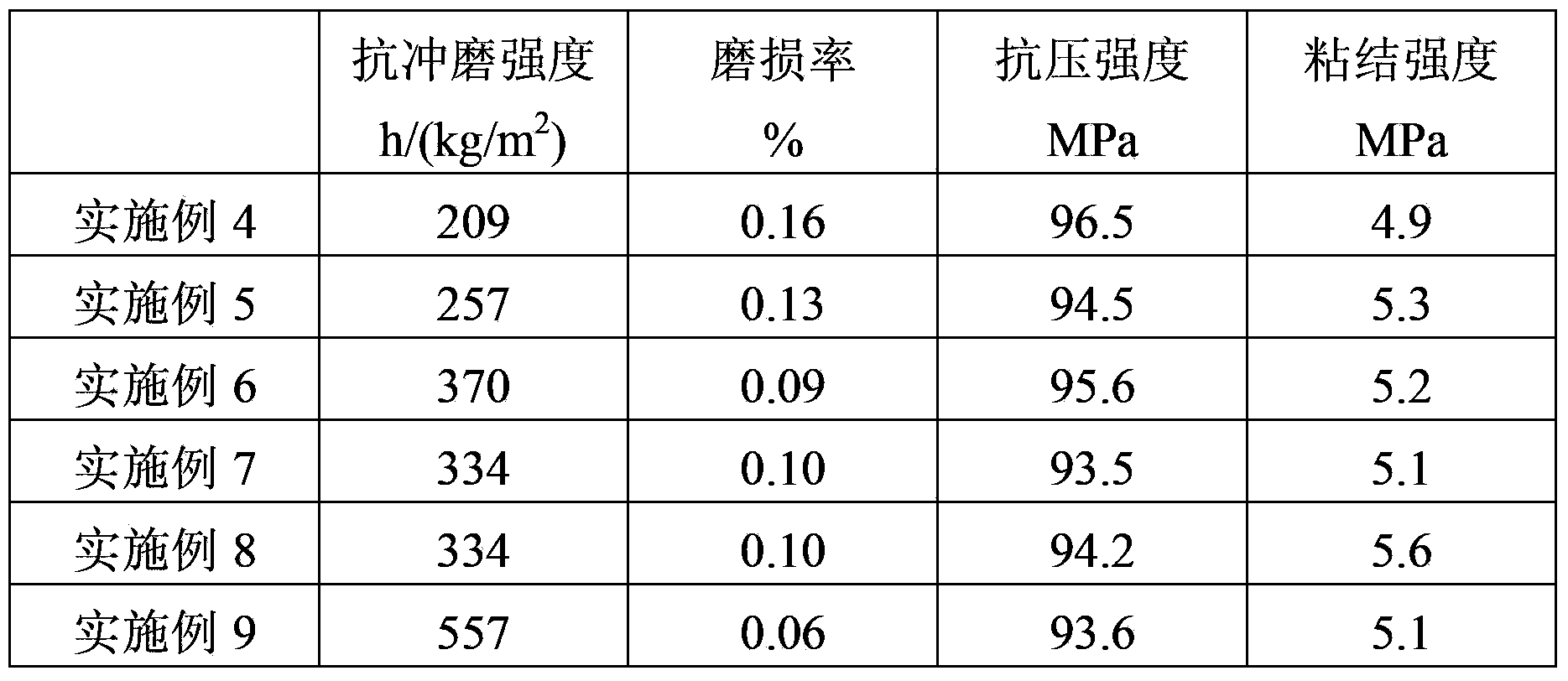

Abrasion-resistant epoxy mortar and preparation method thereof

InactiveCN103359977AImproved impact and abrasion resistance and durabilityGood abrasion resistanceBuilding materialBonding strength

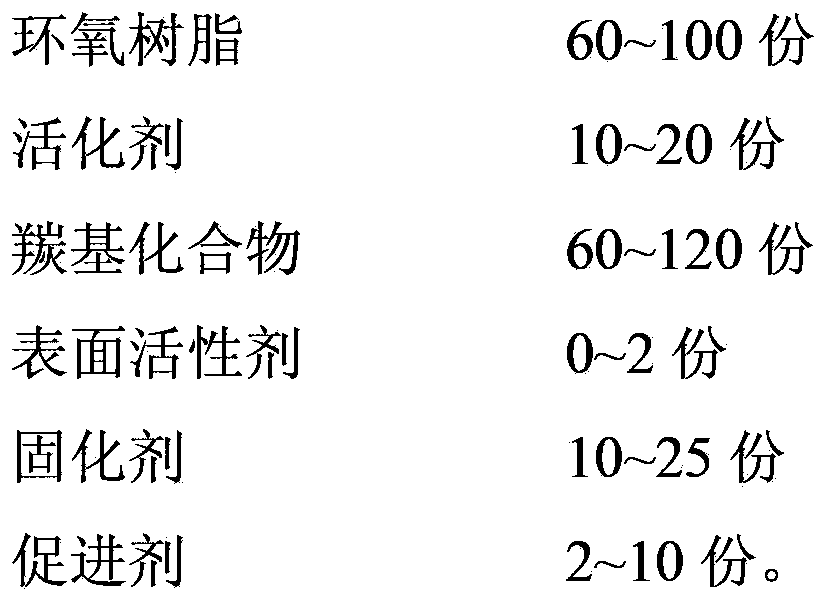

The invention belongs to the technical field of hydraulic structure construction materials and discloses abrasion-resistant epoxy mortar and a preparation method thereof. The abrasion-resistant epoxy mortar consists of the following components in parts by weight: 80-100 parts of sand, 25-40 parts of powder and 18-26 parts of epoxy resin slurry, wherein the epoxy resin slurry consists of the following components in parts by weight: 60-100 parts of epoxy resin, 10-20 parts of activating agent, 60-120 parts of carbonyl compound, 0-2 parts of surfactant, 10-25 parts of curing agent and 2-10 parts of accelerant. The abrasion-resistant epoxy mortar has excellent abrasion resistance (over 200h / (kg / m<2>) and low wear rate (below 0.16 percent), the compressive strength is over 90MPa, the bonding strength is over 4.9MPa, and the abrasion-resistant epoxy mortar can serve as an abrasion-resistant material and is applied to the field of hydraulic structure buildings.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI

Active powder concrete for railroad bridge cover plate

The invention discloses an active powder concrete for a railroad bridge cover plate, which is prepared by evenly mixing cement, silica powder, quartz sand, admixture, steel fiber, additive and water according to the weight ratio of 650-700:170-200:1,150-1,200:160-250:140-150:30-40:135-160, wherein the admixture is fly ash or slag, and the additive is a non-air-entraining type high-efficiency water reducing agent. The active powder concrete has the advantages of superior lasting quality, high-grade compression strength and rupture strength and simple preparation process, and a footway cover plate processed from the active powder concrete can completely satisfy the design requirement on special lines for passenger trains in China and has small workloads of later-period maintenance.

Owner:CHINA RAILWAY FIRST GRP CO LTD

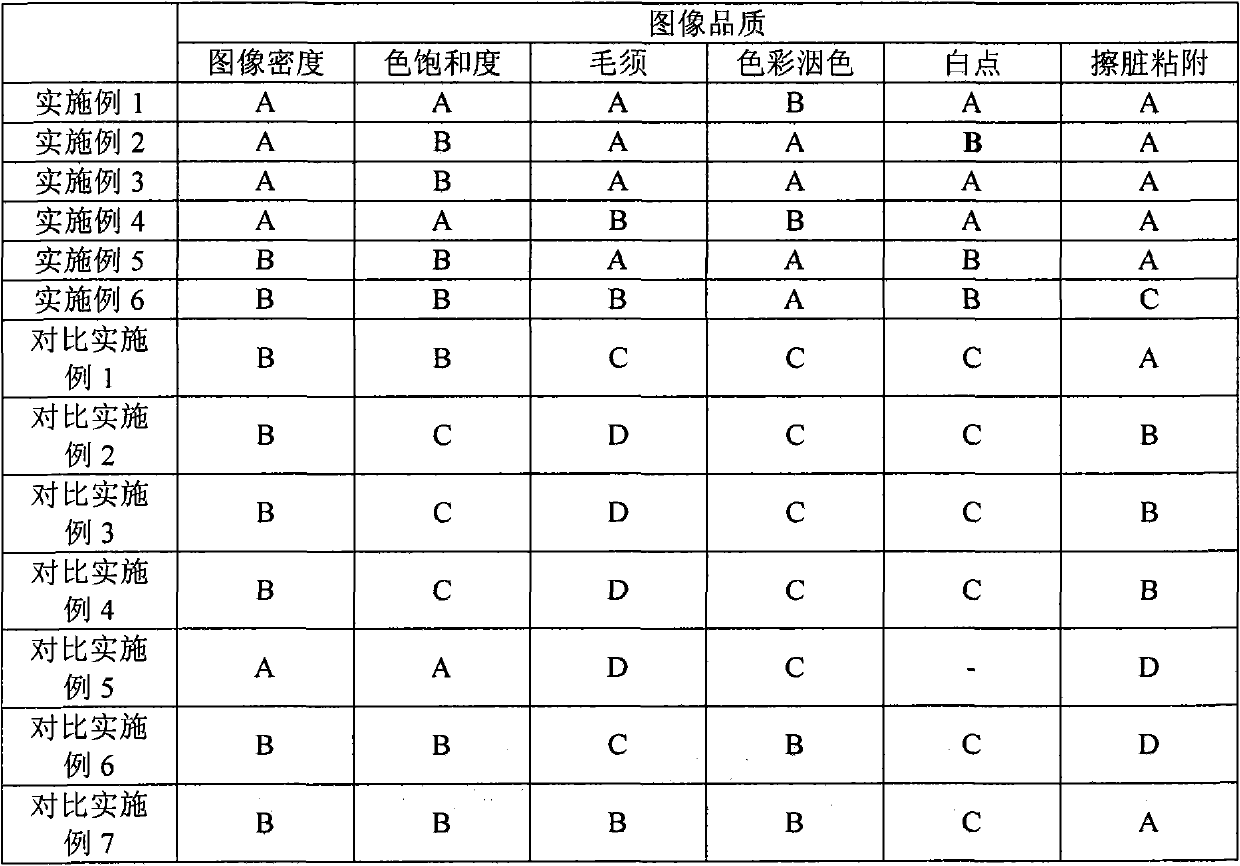

Image forming method and image formed record

InactiveCN101909898AHigh image qualityImprove satisfactionDuplicating/marking methodsInksOrganic acidWater dispersible

An image forming method of the present invention including applying a pretreatment liquid to a recording medium, and discharging an inkjet recording ink dropwise according to an image signal to form an image on the recording medium on which the pretreatment liquid has been applied, wherein the recording medium is regular paper which has no coat layer, the pretreatment liquid contains a cationic polymer compound, a surfactant A, water and a water-soluble organic acid, and the inkjet recording ink contains a water-dispersible colorant, a water-soluble organic solvent, a surfactant B, a penetrating agent and water, and wherein the pretreatment liquid has a static surface tension of 20 mN / m to 30 mN / m.

Owner:RICOH KK

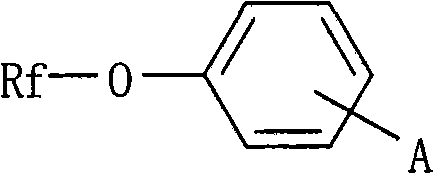

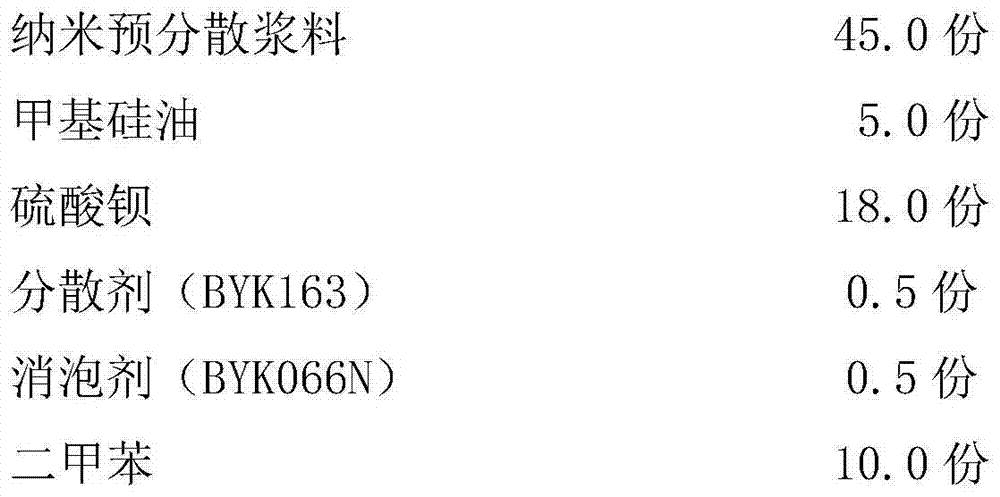

Nanometer reinforced, non-transition-layer, organosilicone and low-surface-energy type antifouling paint and preparation method thereof

ActiveCN104231919AEasy to buyEasy to synthesizeAntifouling/underwater paintsPaints with biocidesMaricultureSlurry

The invention discloses a novel nanometer reinforced, non-transition-layer, organosilicone and low-surface-energy type antifouling paint which can be directly coated to a base material and an epoxy primer without an intermediate transition layer. The antifouling paint comprises the following components in parts by weight: 10 to 20 parts of A, 2 to 10 parts of B, and 0.1 to 2 parts of C, wherein the component A comprises the following materials in parts by weight: 25.0 to 50.0 parts of nanometer pre-dispersed slurry, and 0.5 to 5.0 parts of silicone oil; the component B comprises the following materials in parts by weight: 3.0 to 50.0 parts of crosslinking curing agent, and 1.0 to 10.0 parts of silane coupling agent; the component C comprises the following materials in parts by weight: 0.1 to 3.0 parts of catalyst. The coating has the advantages of being high in intensity, high in attaching force, easy to be constructed, and high in recoatability, and can be applied to various ships, offshore oil platforms, ocean structures and facilities, and mariculture nets and the like.

Owner:DALIAN MARITIME UNIVERSITY

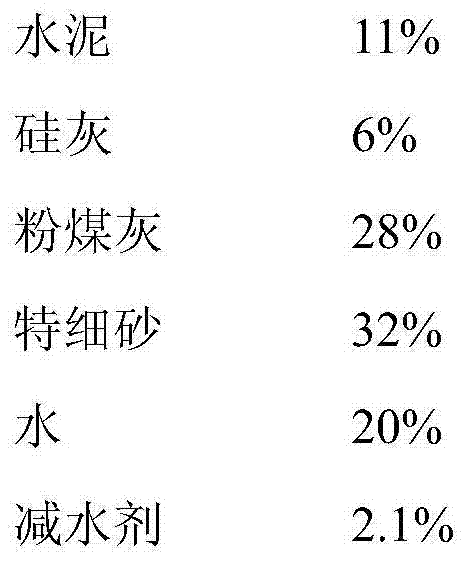

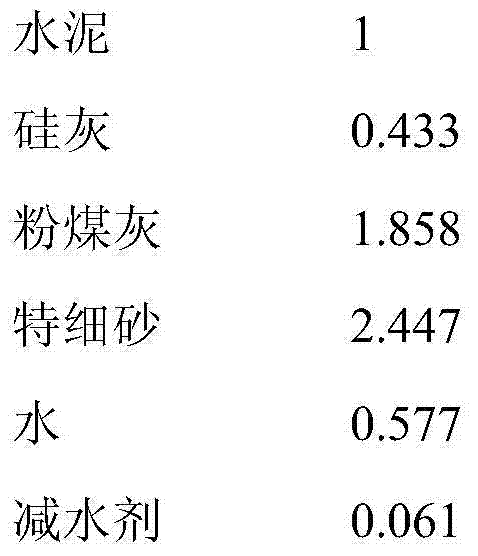

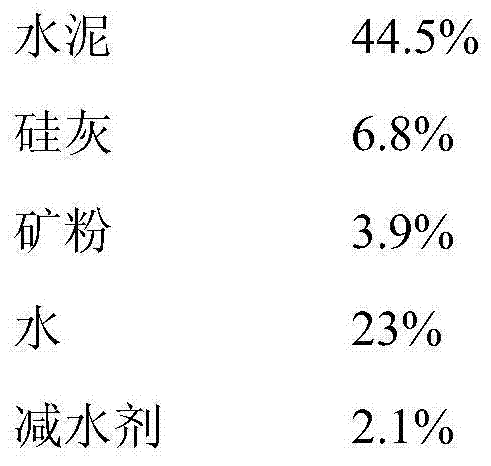

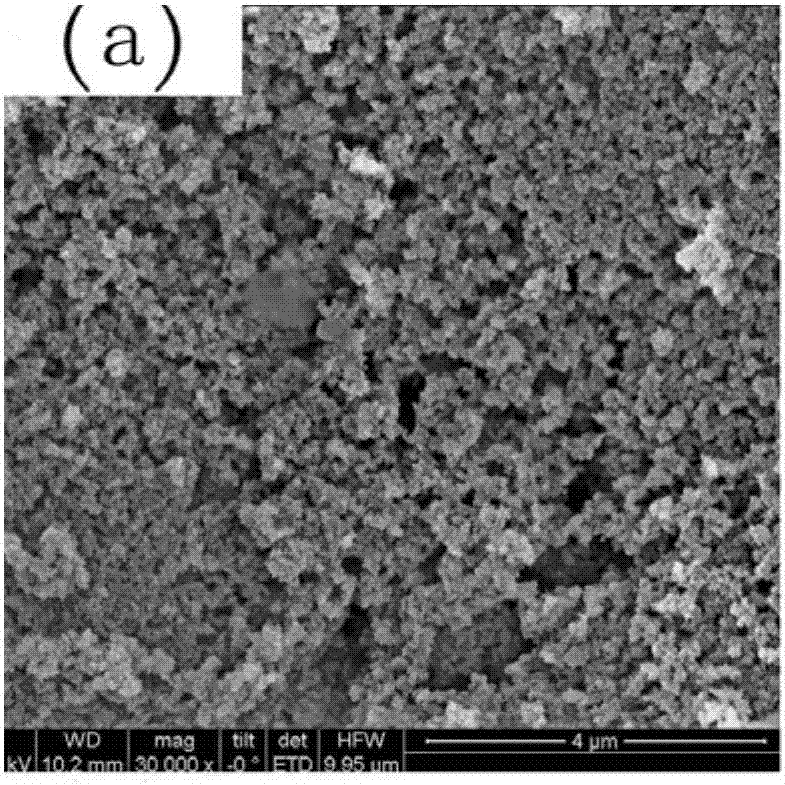

Ultra-high performance cement-based impact wear resistant material

The invention relates to an ultra-high performance cement-based impact wear resistant material. By optimizing the grain gradation of a multi-element cementing material and the grain gradation of an aggregate, and using a water reducing agent and other chemical admixtures, the material provided by the invention can be employed to perform surface coating on a newly constructed concrete structure or an impact wear damaged old concrete structure, and the impact wear resistance of a hydraulic structure can be improved by means of the high impact wear resistance of the material itself and the good adhesion of a concrete substrate. The material has the technical advantages that: the impact wear resistance is significantly superior to that of ordinary concrete; the weatherability and durability are significantly superior to those of an organic impact wear resistant coating material; by optimizing the grain gradation of the cementing material and the grain gradation of the aggregate, the material can meet the construction liquidity requirements under a low water-binder ratio; under standard curing conditions, the material can reach high strength of more than 150MPa after 28 days; and the anti-permeability, carbonization resistance, chloride ion penetration resistance, freezing-thawing cycle resistance and other properties are superior to those of ordinary concrete.

Owner:SHANGHAI LUOYANG NEW MATERIAL TECH

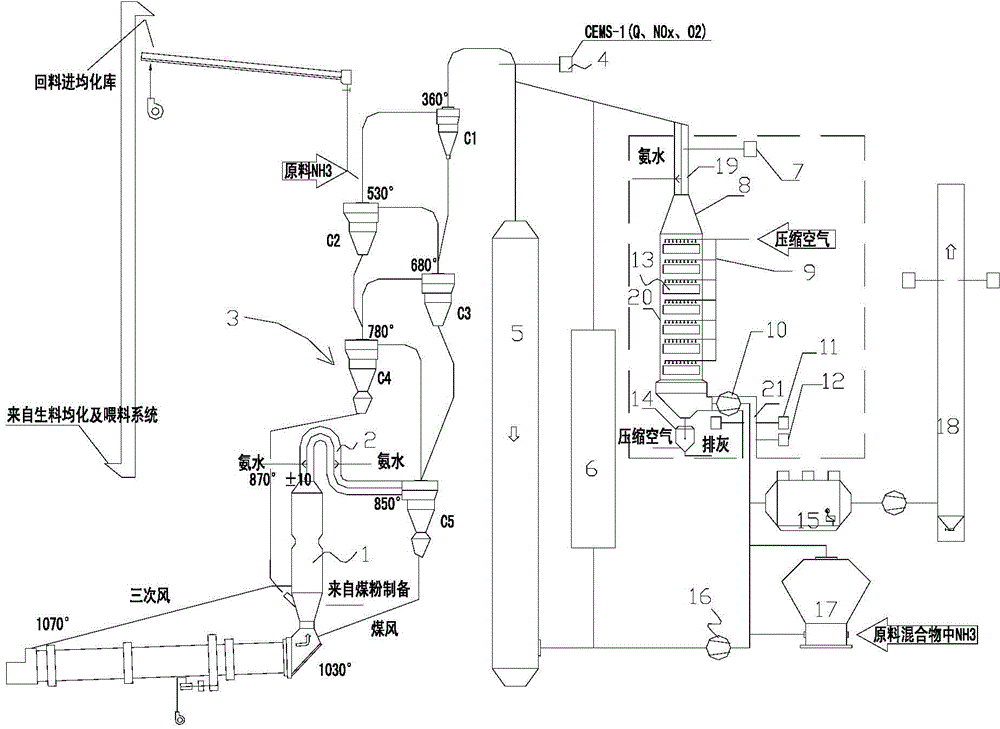

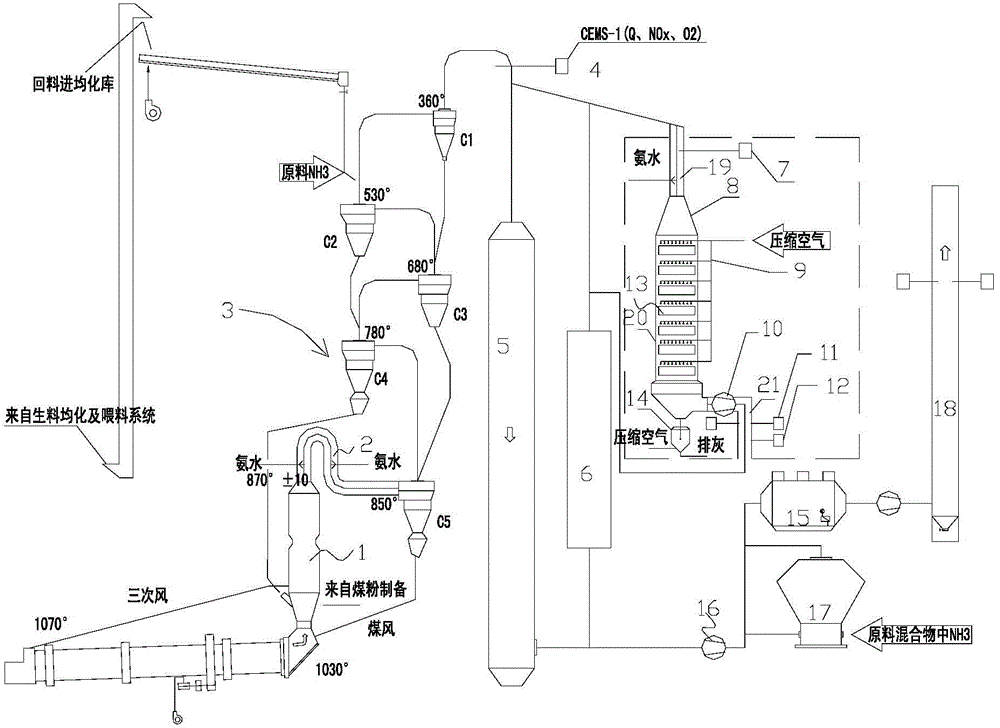

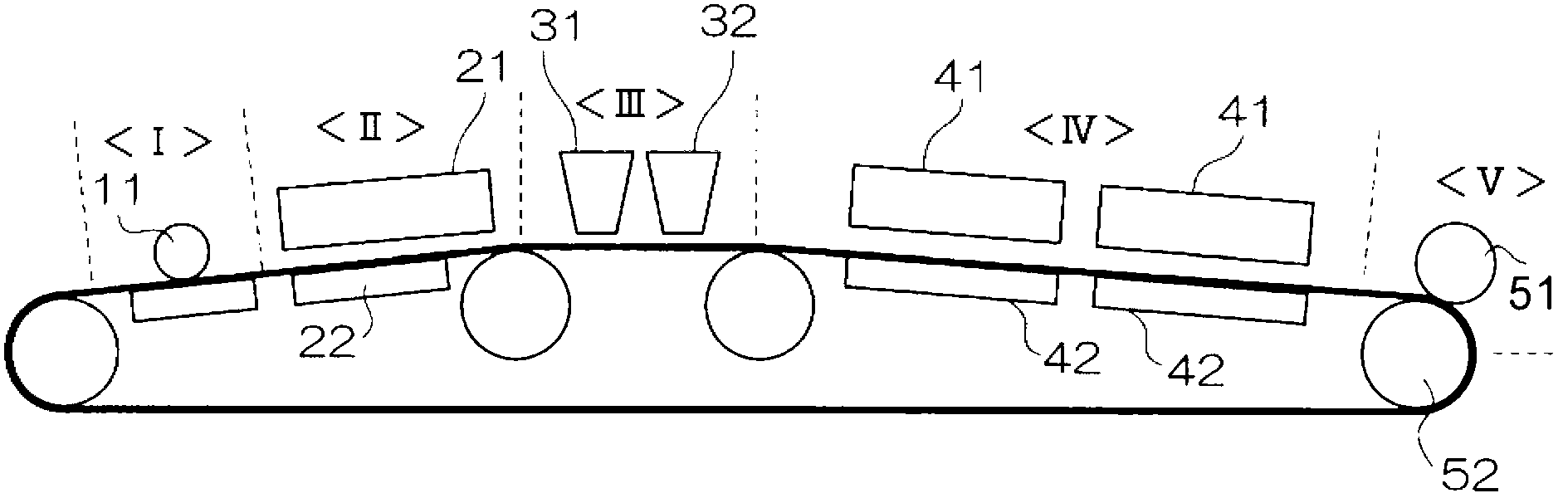

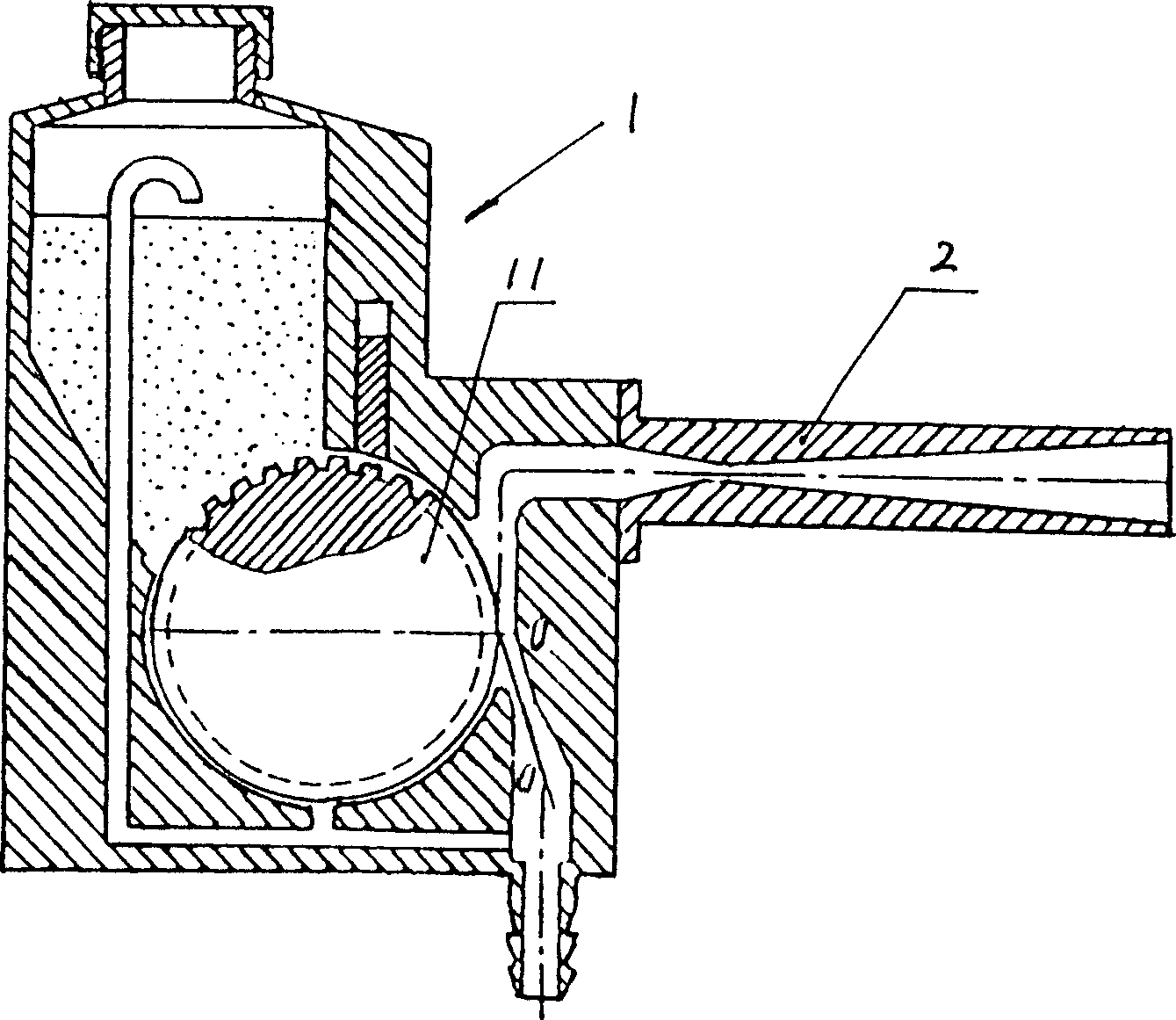

SCR denitration device and method applied to high-dust-content smoke from kiln tail of cement clinker production line

ActiveCN104645828AFlow field stabilityDoes not affect thermal efficiencyNitrous oxide captureDispersed particle separationProduction lineSprayer

The invention discloses an SCR (selective catalytic reduction) denitration device and an SCR denitration method applied to high-dust-content smoke from a kiln tail of a cement clinker production line. The device comprises a cement kiln decomposing furnace, a preheater, an afterheat boiler, a raw mill, an electric dust remover and a kiln tail chimney which are connected in sequence along the smoke direction, and further comprises an SCR reactor, wherein the SCR reactor comprises a reactor shell; an inlet divergent section is arranged at the top of the reactor shell, and an ash bucket is arranged at the bottom of the reactor shell; an inlet flue of the SCR reactor is connected with the preheater and the inlet divergent section and is provided with a reducer sprayer; a plurality of catalyst layers are arranged in the reactor shell in sequence from top to bottom; a plurality of steam ash blowers correspond to the catalyst layers one to one and are arranged above the corresponding catalyst layers; an outlet flue of the SCR reactor is connected with the bottom of the reactor shell and an upstream flue or a downstream flue of the afterheat boiler and is additionally provided with a high-temperature fan. On the basis that a high-temperature dust remover is not arranged, the SCR denitration device can handle with the smoke characteristics of high NOx load fluctuation, temperature fluctuation and high dust content.

Owner:ENVIRONMENTAL SCI RES & DESIGN INST OF ZHEJIANG PROVINCE +1

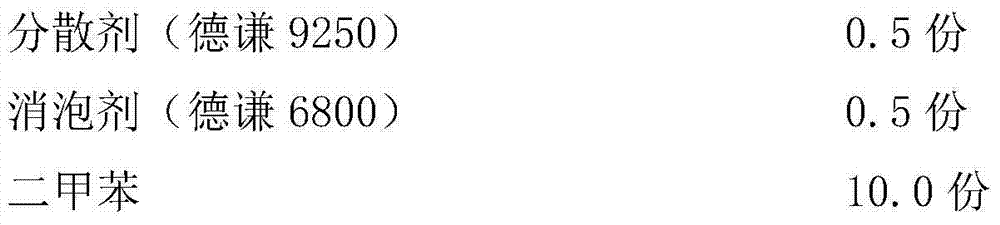

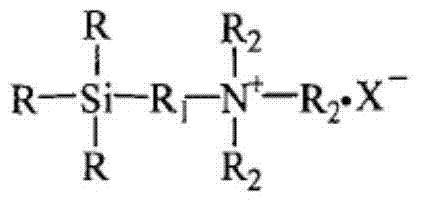

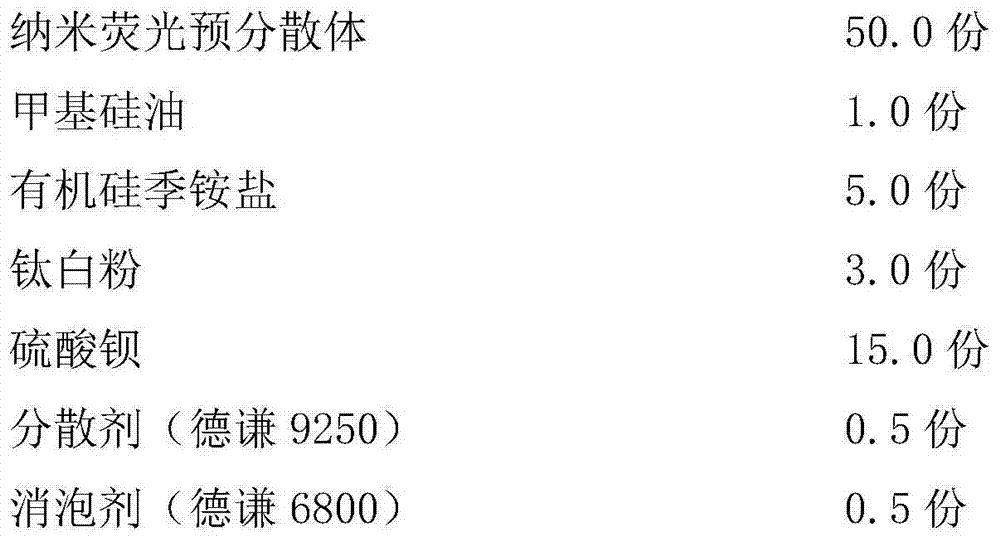

Nano-antibacterial low-surface energy organosilicon luminescence anti-fouling paint and preparation method thereof

ActiveCN104327721AEasy to buyEasy to synthesizeAntifouling/underwater paintsLuminescent paintsMarine aquacultureFluorescence

The invention discloses a nano-antibacterial low-surface energy organosilicon luminescence anti-fouling paint, which comprises the following components by weight: 25-35 parts of component A, 2-5 parts of component B and 1 part of component C; the component A comprises 25.0-50.0 parts of nano fluorescence pre-dispersion, 5-25.0 parts of organosilicon quaternary ammonium salt and 0.5-5.0 parts of silicone oil; the component B comprises 3.0-50.0 parts of crosslinking curing agent and 1.0-10.0 parts of silane coupling agent; The component C comprises 0.1-3.0 parts of catalyst; and the catalyst is at least one of stannous octoate, dibutyl tin diacetate and dibutyltin dilaurate. The paint has long persistence luminescent performance, has can prevent pollution by depending on fluorescence and enables contact sterilization, and has advantages of excellent antifouling performance, high strength and high adhesive force, can be used for various ships, sea petroleum platforms, marine structure and facility, marine aquaculture nets.

Owner:DALIAN MARITIME UNIVERSITY

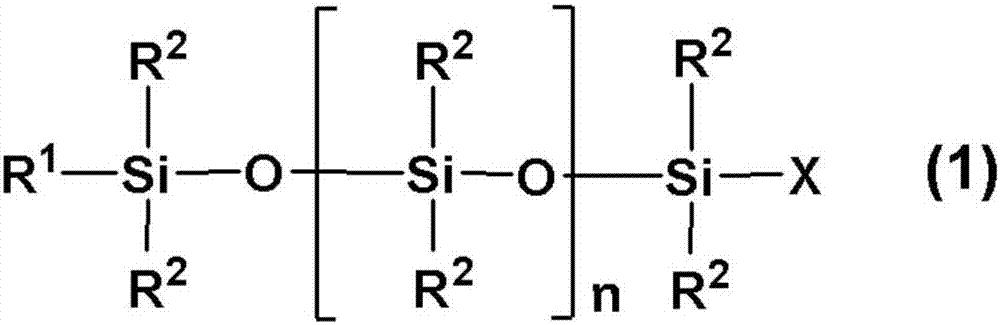

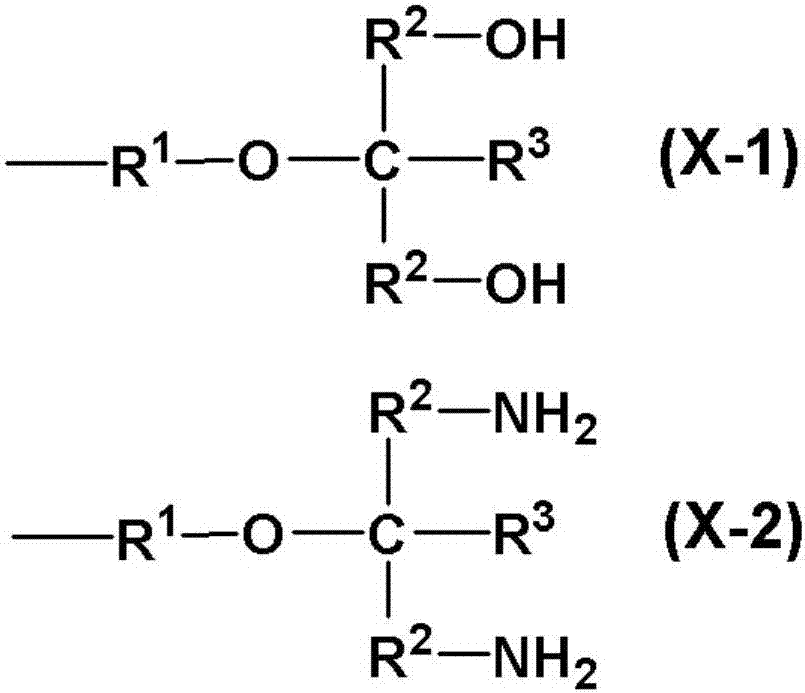

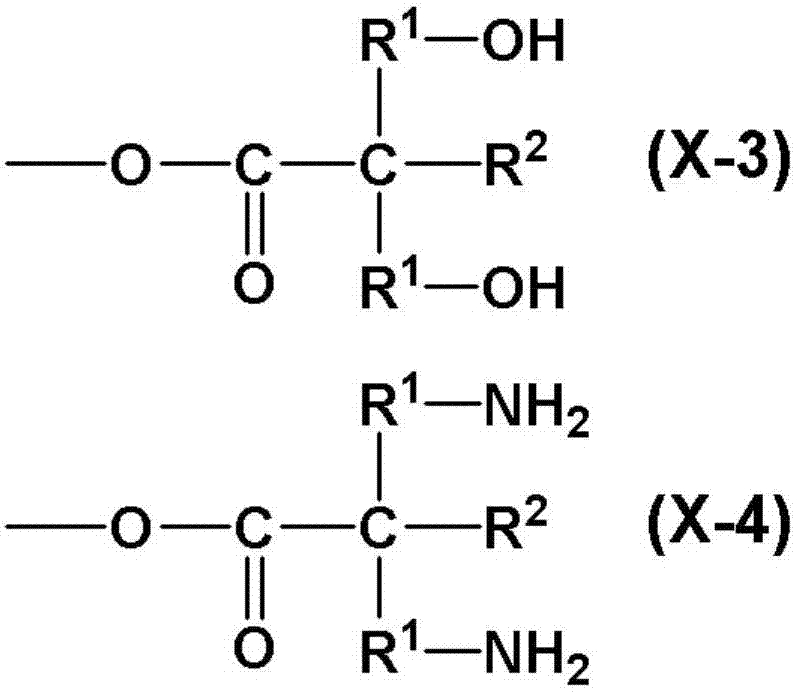

Water-based urethane resin composition and synthetic leather

PendingCN107531861AImprove abrasion resistanceImprove water resistanceFurniture partsFootwearPolymer sciencePolyol

The present invention provides a water-based urethane resin composition characterized by comprising: a urethane resin (A) which is a reaction product obtained from starting materials indispensably comprising a polyol (a1), a reactive silicone (a2) having a number-average molecular weight of 4,000 or higher and having a functional group that reacts with an isocyanate group, and a polyisocyanate (a3); and an aqueous medium (B). The present invention further provides a synthetic leather characterized by including a skin layer and / or surface treatment layer formed from the water-based urethane resin composition. The problem to be solved by the invention is to provide a water-based urethane resin composition excellent in terms of wear resistance and hydrolytic resistance. The water-based urethane resin composition of the present invention is suitable for use as the skin layers or surface treatment layers of synthetic leathers.

Owner:DIC CORPORATION

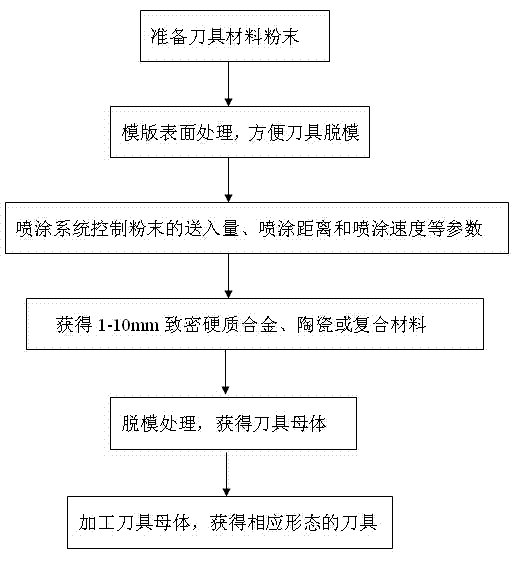

Preparation method of mechanical machining tool

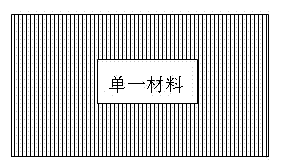

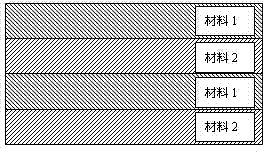

ActiveCN104498859AReduce joinHigh hardnessMolten spray coatingManufacturing technologyThermal spraying

The invention discloses a preparation method of a mechanical machining tool, and belongs to the technical field of manufacturing of mechanical machining tools. The preparation method comprises the following steps of preparing a hard alloy type tool or a ceramic tool with the thickness of 1mm-10mm by adopting a thermal spraying technique. By adopting a thermal spraying technique, the mechanical machining tool meeting the tool development trend can be prepared with high efficiency and low cost, and also the hard alloy type tool or the ceramic tool with an uniform tissue structure, high abrasion resistance and oxidation resistance and good high-temperature red hardness can be prepared on a corresponding template, wherein the material of the obtained tool can be formed by a single material, and also can be prepared from multiple layers of different materials in a combined spraying mode; the obtained tool can be subjected to corresponding secondary thermal treatment (such as carburization, nitridation, high-temperature sintering) or subjected to coating cladding, or can be obtained by directly processing. The tool prepared by the technique has good self-lubricating capability and self-chipping property as well as relatively high hardness and toughness, thereby prolonging the service life of the tool and improving the machining efficiency of the tool.

Owner:KUNMING UNIV OF SCI & TECH

Scuff resistant compositions comprising ethylene acid copolymers and polyamides

ActiveCN1833004AHigh crystalline melting temperatureImprove abrasion resistanceProtective equipmentSynthetic resin layered productsTectorial membraneAlkaline earth metal

Disclosed are compositions of ethylene acid copolymers and polyamides that are useful for fabricating films, sheets and molded articles for scuff and scratch resistant material and their application as decorative and protective films, comprising (1) from about 30 to about 65 weight % of a polyamide; and (2) from about 70 to about 35 weight % of a copolymer of (a) ethylene; (b) from about 5 weight % to about 15 weight % of an alpha,ss unsaturated C3-C8 carboxylic acid; (c) from about 0.5 weight % to about 12 weight % of at least one comonomer that is an ethylenically unsaturated dicarboxylic acid; and (d) from 0 weight % to about 30 weight % of monomers selected from alkyl acrylate and alkyl methacrylate, wherein the alkyl groups have from one to twelve carbon atoms; at least partially neutralized by one or more alkali metal, transition metal, or alkaline earth metal cations. Articles prepared from these compositions, such as films, show high toughness, good mechanical properties, excellent scratch and scuff resistance and, most importantly, good optical properties. More particularly, the compositions of ethylene copolymers and polyamides of the present invention can be used as protective coatings or layers on scuff- and scratch-exposed objects.

Owner:DOW GLOBAL TECH LLC

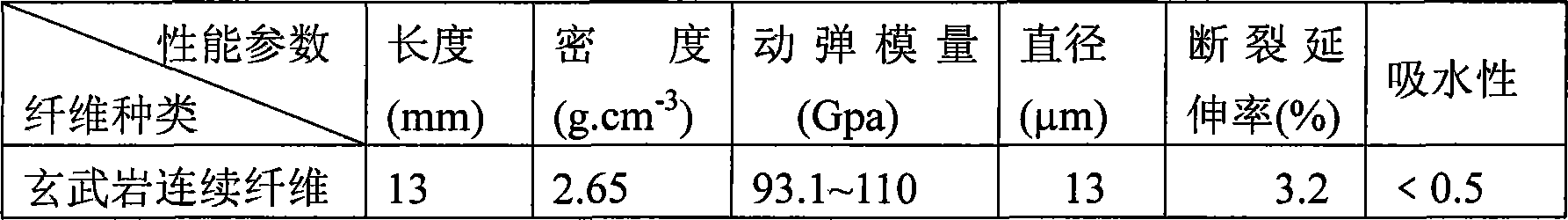

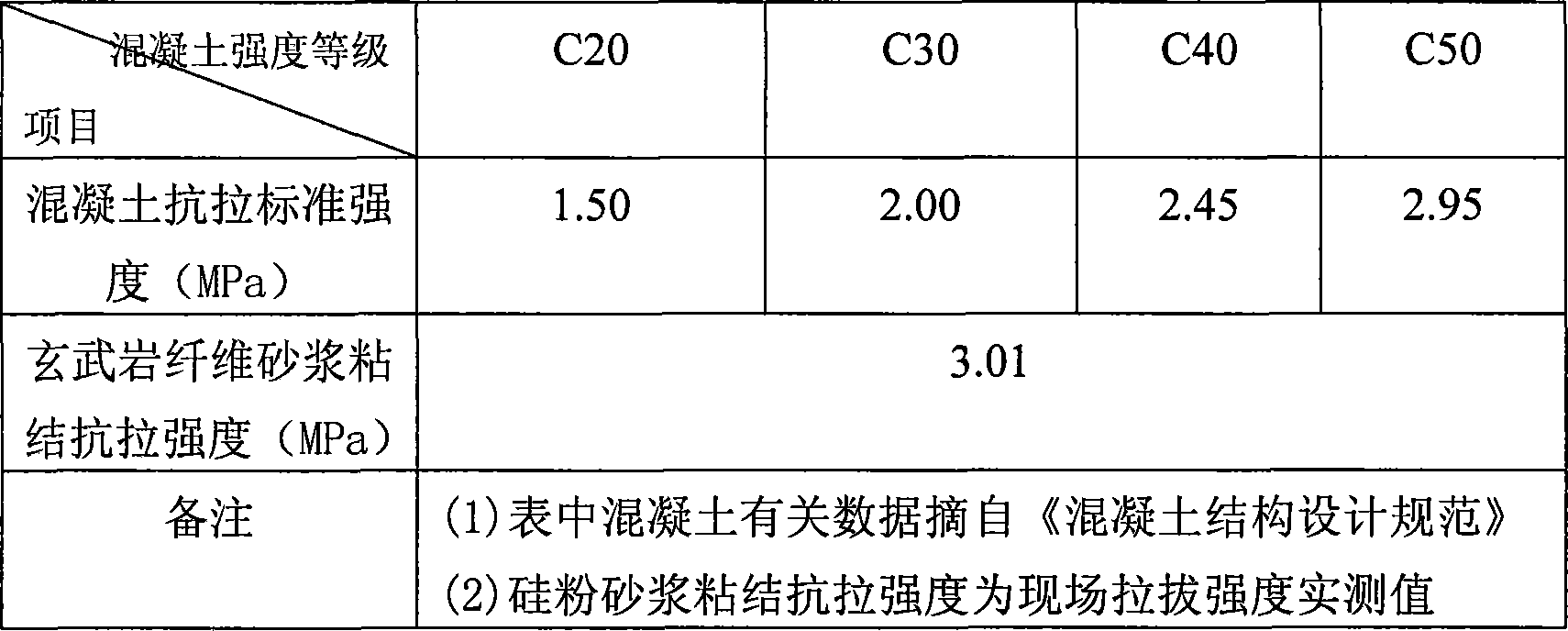

Method for rehabilitating concrete surface injury using high-strength abrasion-proof basalt fibre mortar

InactiveCN101235673AHigh tensile strengthHigh modulus of elasticityBuilding repairsHydraulic engineering apparatusAnti freezingHydraulic structure

The invention discloses a process for repairing the surface wounds of concrete with basalt fiber plaster which is high strength and abrasion resistance. The repairing steps comprise firstly conducting chiseling, cleaning and curing moisture holding for the repair surface, and then brushing binding agent on the repair surface, then brushing basalt fiber plaster after slightly drying, and finally conducting the curing. The invention primarily proposes a process for repairing the large area wound such as surface concrete aging, carbonizing and peeling and cracking and the like on the hydraulic structure such as locks, dams and bridges and the like through preparing basalt fiber plaster which is high strength and abrasion resistance with chopped basalt fiber. The experiment shows that the surface concrete of hydraulic structure which is repaired has excellent mechanic property, impact abrasion resistance and excellent durability such as permeability resistance and anti-freezing, and favorable binding property, can meet the technical requirements of high speed sand inclusion current abrasion and corrosion resistance and ship attack and the like. And the repairing process has simple technology, low cost and excellent effect.

Owner:HOHAI UNIV

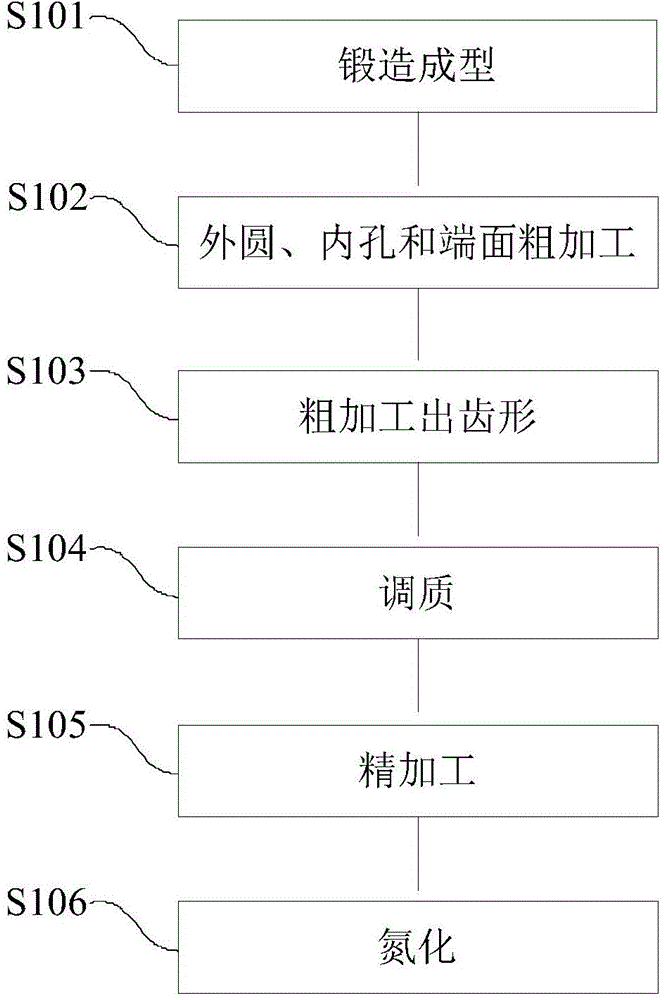

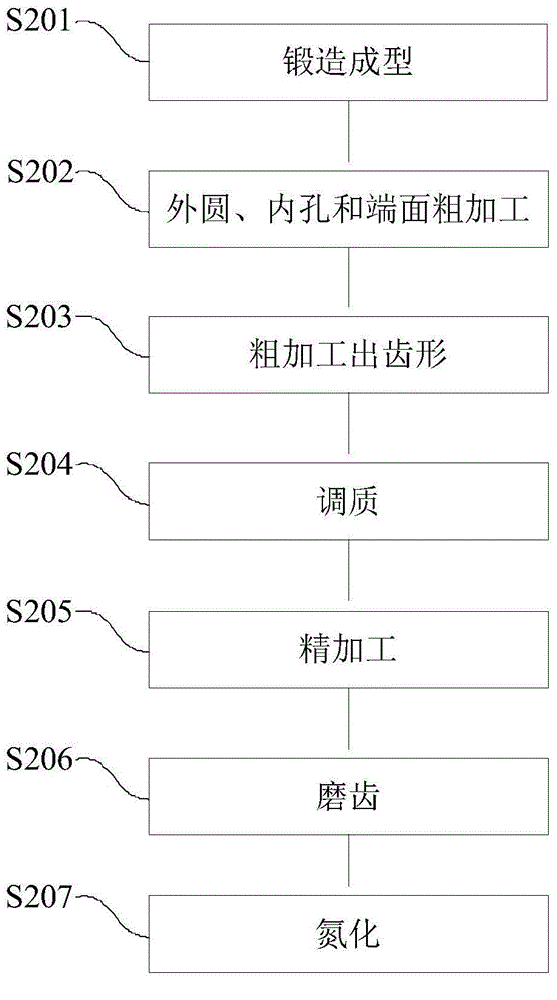

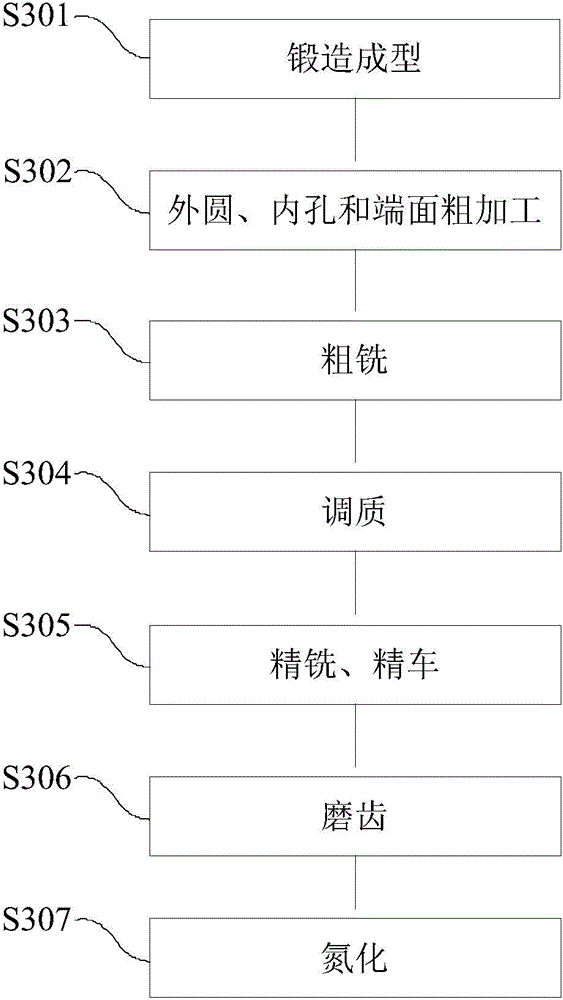

Method for machining large inner gear ring of wind turbine gear box

The invention discloses a method for machining a large inner gear ring of a wind turbine gear box. The method includes the steps that 1, an inner gear ring blank is formed in a forging forming mode according to the specification and forging standard of the inner gear ring; 2, outer circle rough machining, inner hole rough machining and end face rough machining are conducted on the inner gear ring blank, the outer circle, an inner hole and an end face are primarily formed, and allowance is reserved; 3, rough machining is conducted on the inner gear ring obtained after outer circle rough machining, inner hole rough machining and end face rough machining are conducted to enable the inner gear ring to be in a tooth shape; 4, quenching and tempering are conducted on the tooth-shaped inner gear ring obtained after rough machining is conducted; 5, the profile and the inner hole of the inner gear ring obtained after quenching and tempering are machined through finish machining; 6, nitrogen treatment is conducted on the inner gear ring obtained after finishing machining is conducted. By means of the method for machining the large inner gear ring of the wind turbine gear box, quenching and tempering are conducted on the inner gear ring which is machined to be in the tooth shape through rough machining, the quenching and tempering effects on the tooth top, the tooth root and the tooth surface are the same, the uneven quenching and tempering effect caused by the limited quenching and tempering hardenability is avoided, and the comprehensive mechanical performance of the interior of the inner gear ring is improved; meanwhile, working allowance of follow-up finishing machining is lowered, and machining deformation is reduced.

Owner:CHONGQING GEARBOX

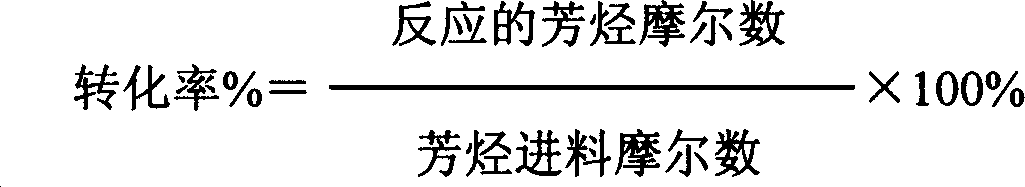

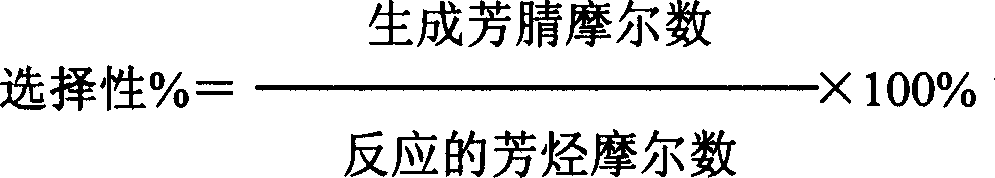

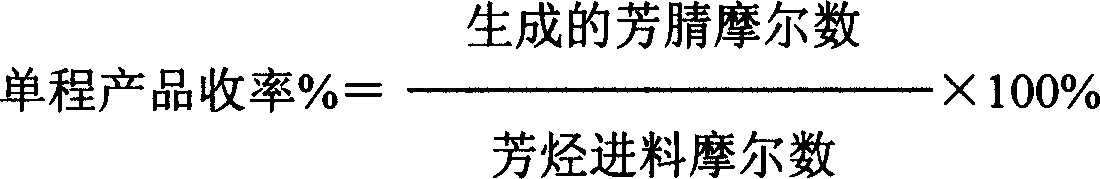

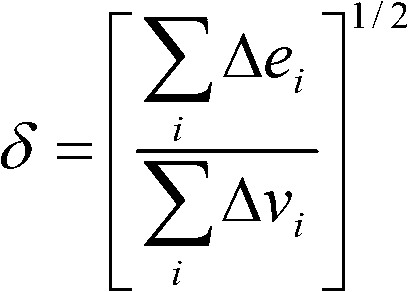

Fluid-bed catalyst for ammoxidation of aromatic hydrocarbon

InactiveCN1490080AHigh activityHigh selectivityPreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsAlkaline earth metalFluidized bed

A granular fluidized-bed catalyst for ammoxidizing arylhydrocarbon to preparing arylnitrile has a chemical formula: V1.0CraTibAcBdCeOx, where A is chosen from P, B, Bi, Sb and As, B is chosen from alkali metals and alkali-earth metals, and C is choosen from Mn, Ni, Co, Sn, Pb, Fe, Mo, W and ER. Its advantage is high output rate.

Owner:CHINA PETROLEUM & CHEM CORP +1

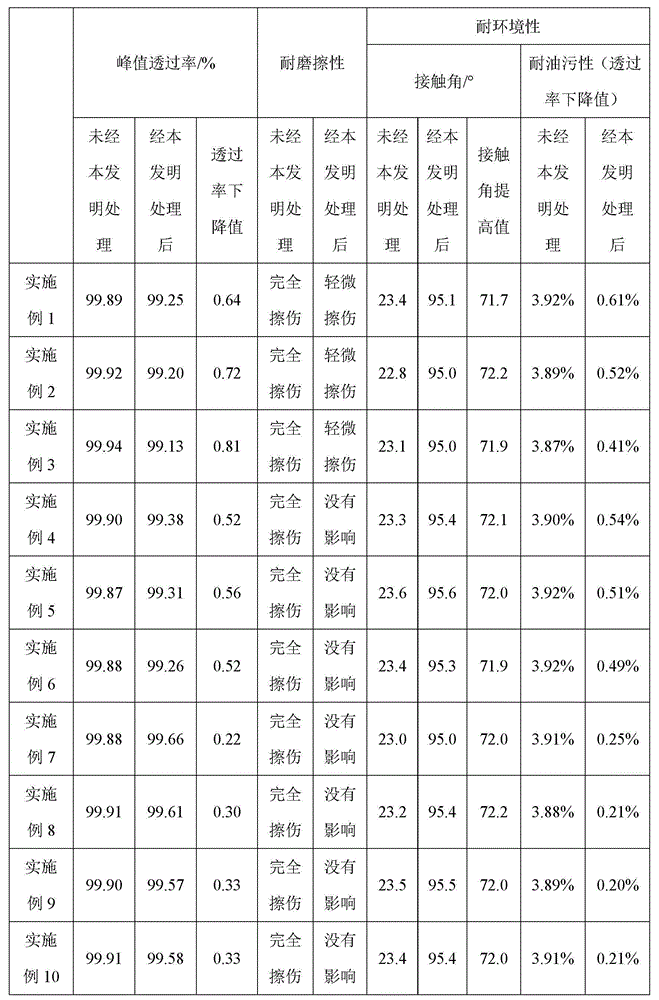

Silicon dioxide anti-reflection film for surface ultrafast hydrophobic treatment and preparation method thereof

InactiveCN102875033AImprove abrasion resistanceFast processingCoatingsOptical elementsChemistryTransmittance

The invention discloses a silicon dioxide anti-reflection film for surface ultrafast hydrophobic treatment. The silicon dioxide anti-reflection film is characterized in that the peak transmittance drop-out valve of the anti-reflection film which is subjected to the surface ultrafast hydrophobic treatment is 0.21-0.61 percent; after the anti-reflection film which is subjected to the surface ultrafast hydrophobic treatment is scrubbed by ethanol-stained absorbent cotton for 30 times, the surface has slight scratches or no scratches; the rise value of a contact angle is 71.7-72.2; and after the silicon dioxide anti-reflection film is placed in an oil-containing atmosphere formed by dimethyl silicone oil volatilization for one week, the drop-out value of the peak transmittance of the silicon dioxide anti-reflection film is 0.22-0.81. The invention also discloses a preparation method of the silicon dioxide anti-reflection film. The silicon dioxide anti-reflection film provided by the invention has the advantages of not only simultaneously improving the wear resistance and the environment resistance but also having no influence on the transmittance of the peak value basically, and can be widely applied to the fields such as a strong laser system, a solar battery and a solar heat collection pipe. The method has the advantages of quick treatment process, simple process, easiness in operation and high easiness for realizing large-scale application in industry.

Owner:SICHUAN UNIV

Method for preparing activated kaolin by washing kaolin with water

ActiveCN104045092AOptimizing the firing temperatureOptimize dwell timeSilicon compoundsRebarChemistry

The invention belongs to the technical field of the production process of activated kaolin and in particular relates to a method for preparing activated kaolin by washing kaolin with water. The method comprises the steps of preparing a kaolin filter cake, preparing kaolin dry powder, thermally activating kaolin, and preparing activated kaolin by performing depolymerization and modification on the thermally activated kaolin. Deep treatment is performed on kaolin resources by use of processes such as appropriate-temperature calcination, efficient depolymerization and dispersion and modification on the basis of the traditional treatment process of washing the kaolin with water, therefore, the activated kaolin having the characteristics of volcanic ash can be prepared; the activated kaolin can be applied to the fields such as a high-grade concrete additive, a cable filler, a water-based coating and the like, and has the characteristics of short setting time, high early strength, shrinkage compensation, no corrosion to reinforcements, high resistivity and the like; as a result, the valued added of the kaolin resources can be increased, and the activated kaolin has enormous market space potential.

Owner:北海高岭科技有限公司

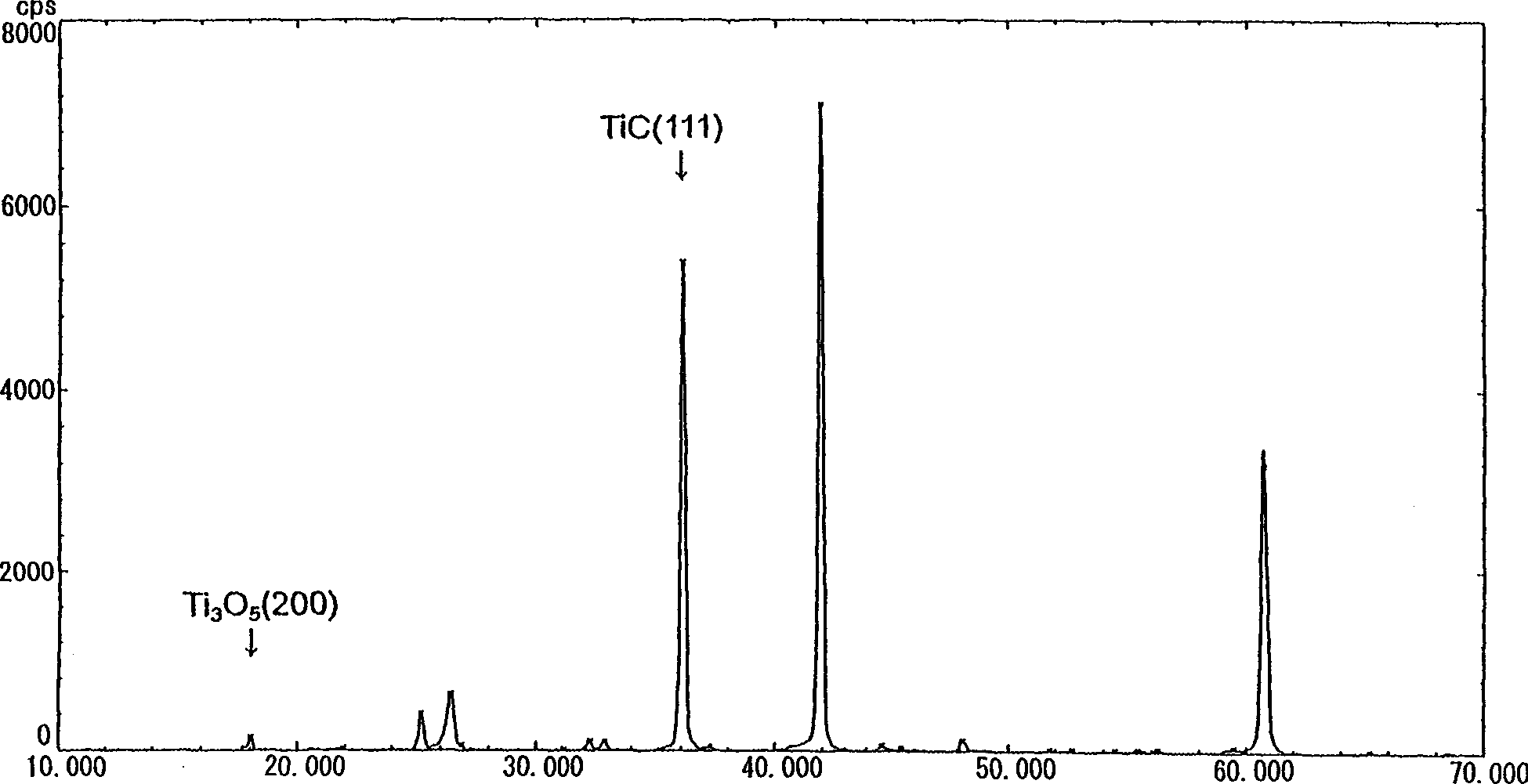

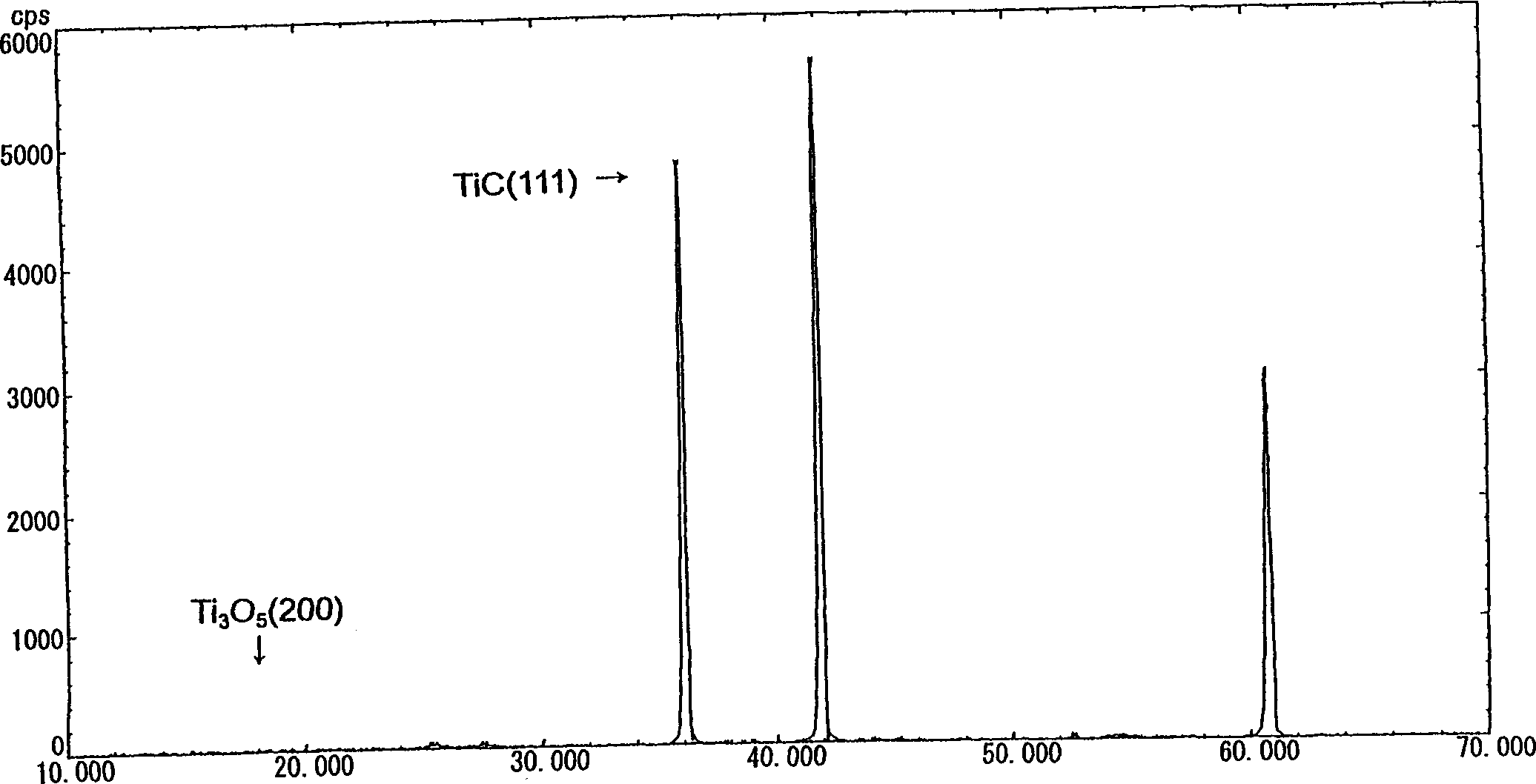

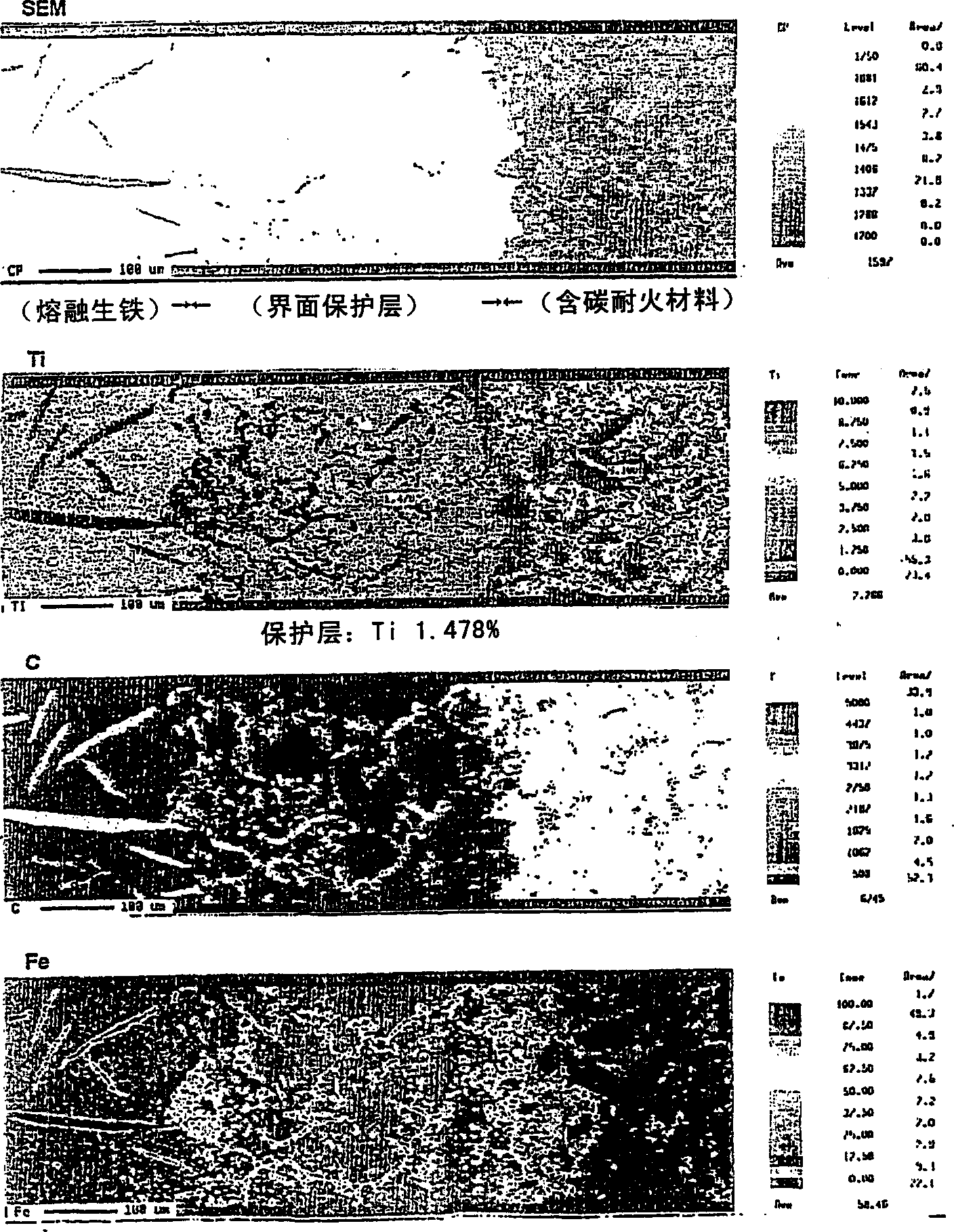

Carbonaceous refractory and method for preparing same

InactiveCN1366515AEasily wets molten ironImprove corrosion resistanceBlast furnace detailsCooling devicesTitanium nitrideCoke

Owner:NIPPON STEEL CORP +1

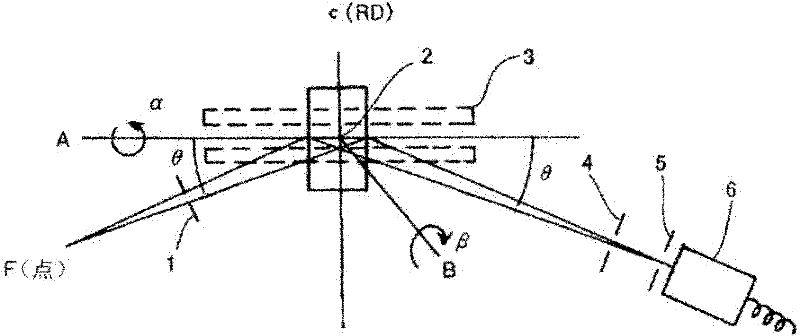

Coated member

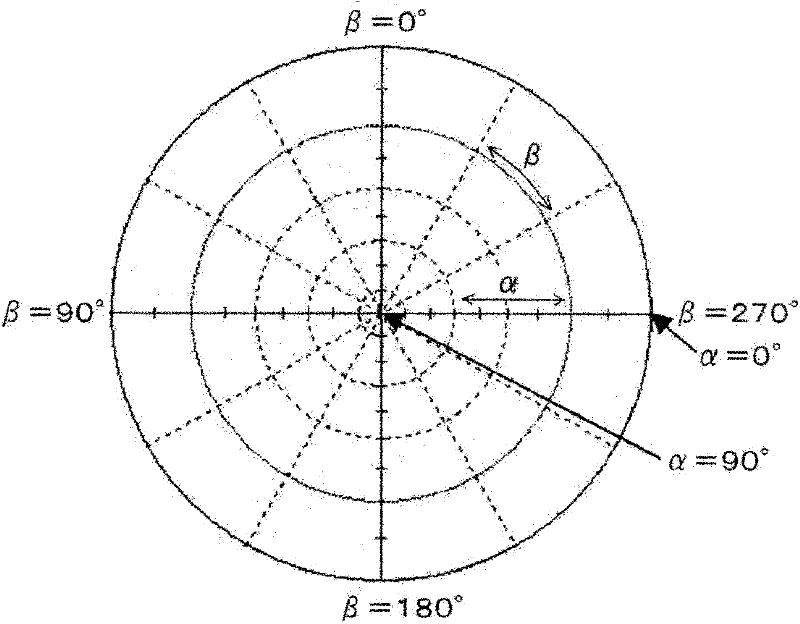

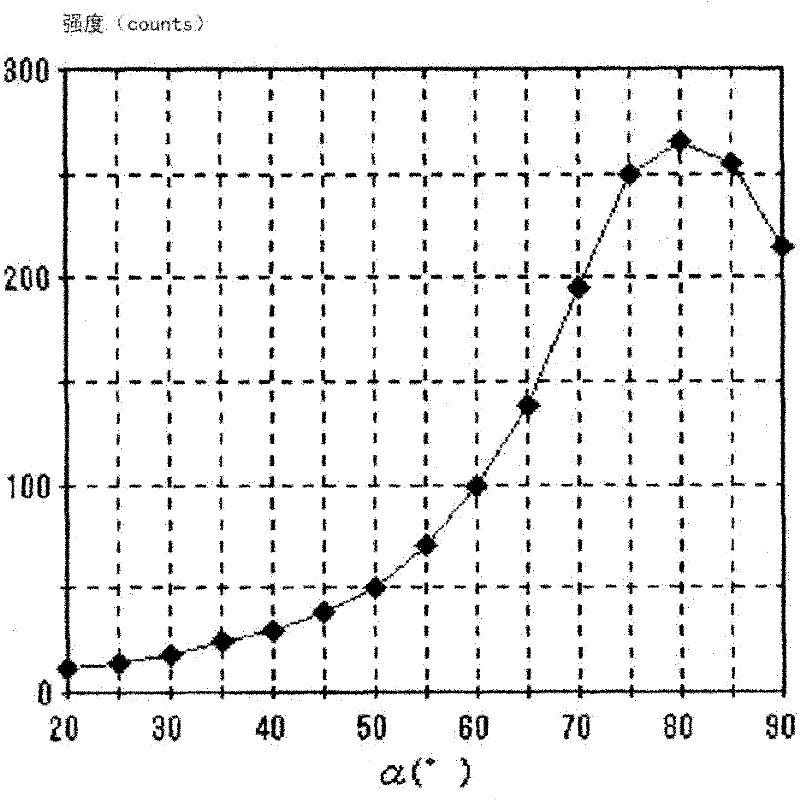

ActiveCN102099138AStrong adhesionImprove abrasion resistanceMilling cuttersVacuum evaporation coatingX-rayHardness

The invention provides a coated member for cutting tools which renders a long life possible under severe cutting conditions as in high-speed processing, high-feed-rate processing, cutting of works having enhanced hardness, and cutting of works difficult to cut. The coated member comprises a base having a surface coated with one or more coating films. At least one of the coating films is a hard film of a cubic metallic compound comprising at least one metallic element (M) selected from Al, Si, Ti, Zr, Hf, V, Nb, Ta, Cr, Mo, and W and at least one element (X) selected from C, N, and O. In the pole figure for the (111) plane of the hard film, the X-ray intensity distribution in the alpha axis has a maximum intensity in the alpha-angle range of 75-90 DEG. In the pole figure for the (220) plane of the hard film, the X-ray intensity distribution in the alpha axis has a maximum intensity in the alpha-angle range of 75-90 DEG .

Owner:TUNGALOY CORP

Environment-friendly water-based nano anti-aging exterior wall coating

InactiveCN102827521AImprove abrasion resistanceStrong ability to resist wind and sand impactAntifouling/underwater paintsPaints with biocidesSodium aluminateDefoaming Agents

The invention relates to an environment-friendly water-based nano anti-aging exterior wall coating which comprises the components by weight percent: 15-30% of polyacrylic acid emulsion, 1-5% of film-forming additive, 0.1-0.3% of defoaming agent, 0.5-1% of dispersing agent, 0.1-0.5% of wetting agent, 2-5% of flatting agent, 1-6% of emulsifying agent, 15-25% of titanium dioxide, 2-5% of precipitated calcium carbonate, 0.5-3.5% of mica, 1-3% of zinc oxide, 3-7% of sodium silicoaluminate, 1.5-4.5% of talcum powder, 0.5-1% of thickening agent, 0.3-0.5% of mildew preventive, 10-30% of water, 2-5% of environment-friendly additive and 1-3% of water-based nano anti-aging agent. The environment-friendly water-based nano anti-aging exterior wall coating is good in scuff resistance, high in sandstorm impact resistance and even in coating without crack, can be used for blade coating, roller coating and spraying, has the functions of inhibiting bacteria, dispelling peculiar smell and cleaning air, and is remarkable in anti-man-made aging performance.

Owner:WUJIANG WUHUA HARDWARE PROD

Solar back panel transparent polyurethane paint and preparation method thereof

ActiveCN104356914AStrong adhesionImprove aging resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsAcrylic resinUltraviolet

The invention relates to the technical field of solar cell back panels, particularly a solar back panel transparent polyurethane paint and a preparation method thereof. The transparent polyurethane paint is a double-component system. The component A is prepared from the following raw materials in parts by weight: 5-50 parts of acrylic resin, 30-70 parts of fluororesin, 10-20 parts of organic solvent, 1-3 parts of catalyst, 1-3 parts of ultraviolet absorbent and 1-2 parts of defoaming agent. The component B is an aliphatic polyisocyanate curing agent, and the aliphatic polyisocyanate curing agent comprises at least one of hexamethylene diisocyanate biuret, hexamethylene diisocyanate tripolymer and isophorone diisocyanate tripolymer. The components A and B are mixed according to the NCO / OH ratio of 0.9-1.2 to obtain the transparent polyurethane paint. The transparent polyurethane paint has the advantages of lower cost, accessible raw materials, excellent weather resistance, excellent corrosion resistance, excellent adhesive force, excellent ultraviolet resistance and excellent hydrolysis resistance.

Owner:MING CROWN ADVANCED MATERIAL CO LTD

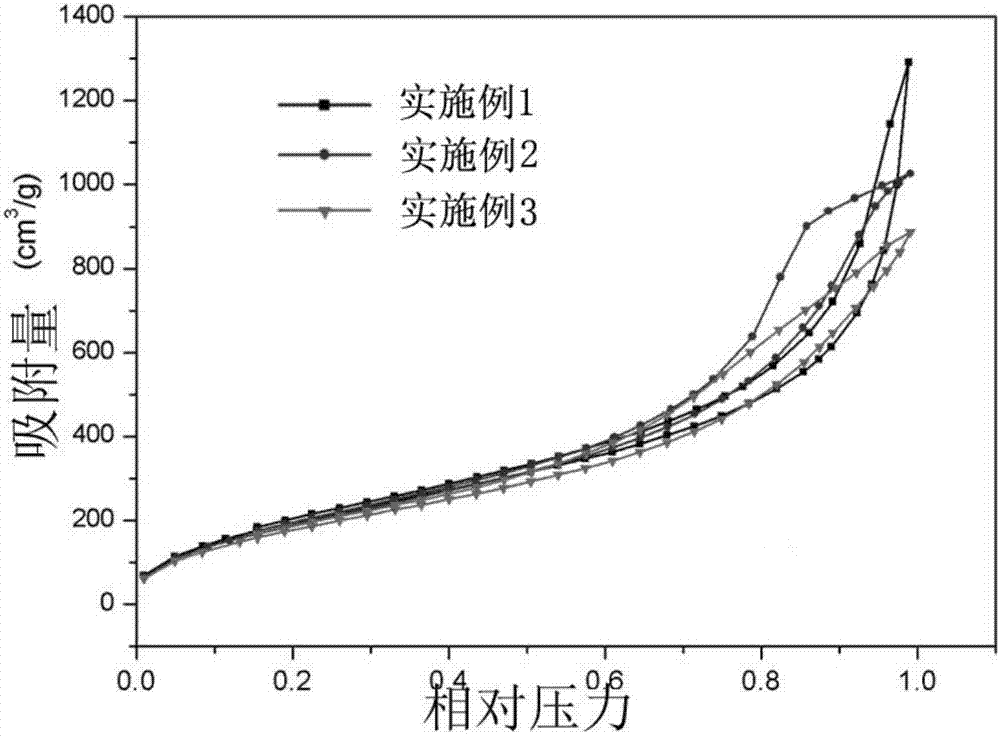

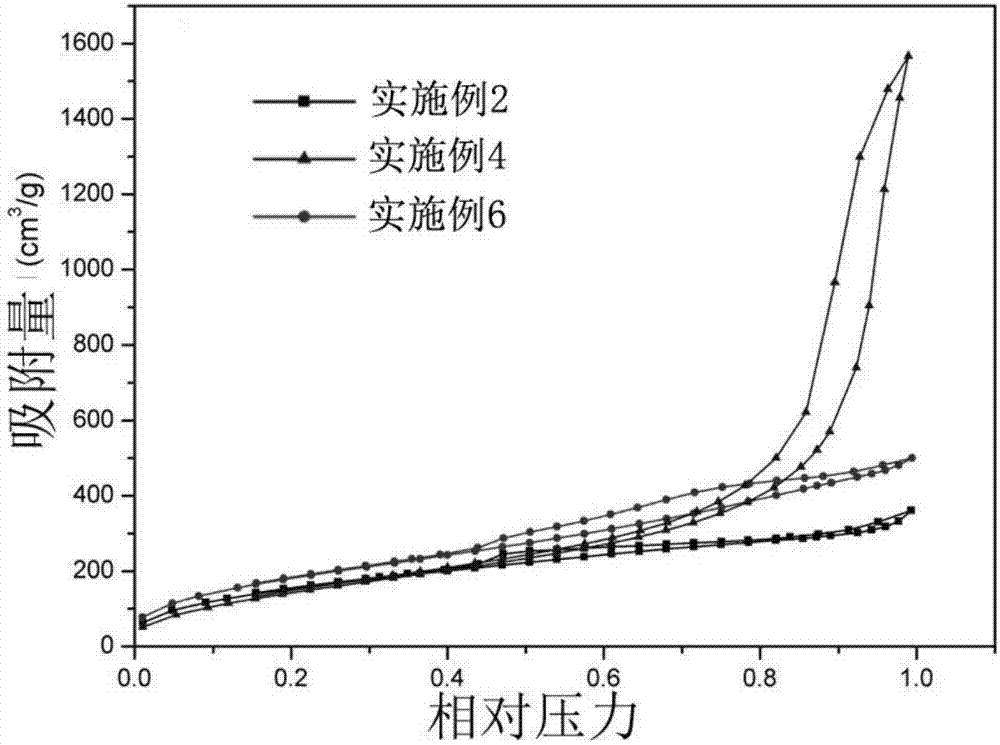

Superhydrophobic silicon dioxide aerogel micropowder, and preparation method and application thereof

ActiveCN107364871AExempt replacement processSimple processSilicaWater contaminantsOrganic solventOil water

The invention discloses superhydrophobic silicon dioxide aerogel micropowder, and a preparation method and application thereof. The preparation method comprises the following steps: uniformly mixing a silicon source, a low-surface-tension organic solvent, a hydrophobic modifier and an alkali catalyst to form a mixed solution, performing standing to form a silicon dioxide organogel, and performing aging; and pulverizing the obtained silicon dioxide organogel, and performing drying under normal pressure conditions to obtain the superhydrophobic silicon dioxide aerogel micropowder. The superhydrophobic silicon dioxide aerogel micropowder has a porous structure; the pore size of pores in the porous structure is 1-50nm; and the specific surface area of the superhydrophobic silicon dioxide aerogel micropowder is 500-1000 m<2> / g, the pore volume is 0.5-3 cm<3> / g, the contact angle with water is greater than 140 degrees, and the particle size is 500nm-50 mu m. The method does not need any solvent for replacement, has the advantages of simple technique, short production cycle and low cost, implements continuous quick production of the silicon dioxide aerogel micropowder, and implements the application of the aerogel micropowder in the fields of oil-water separation, superhydrophobic modification of object surfaces and the like.

Owner:SUZHOU INST OF NANO TECH & NANO BIONICS CHINESE ACEDEMY OF SCI

Ink composition, ink set, and image forming method

ActiveCN102827511AImprove abrasion resistanceGood ink jetting characteristicsDuplicating/marking methodsInksOrganic solventWater soluble

An ink composition is disclosed which includes a pigment, self-dispersing resin particles including a hydrophilic constituent unit and a hydrophobic constituent unit, at least two nonionic surfactants including (a) a nonionic surfactant having an HLB of from 15 to 19 and (b) a nonionic surfactant having an HLB of from 10 to less than 15, a water-soluble organic solvent, and water. An ink set and an image forming method are also disclosed.

Owner:FUJIFILM CORP

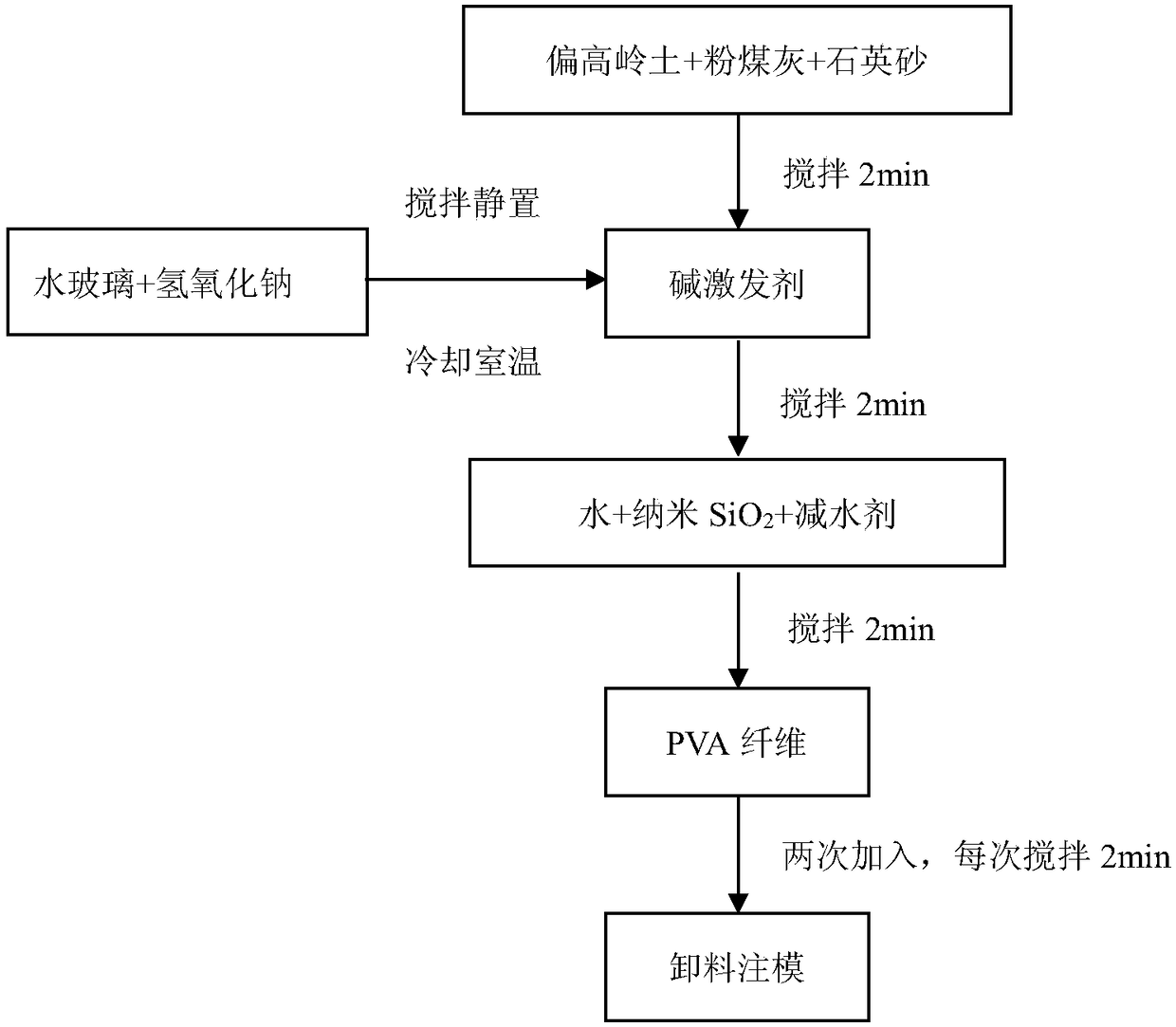

Method for preparing nano-SiO2 and PVA fiber reinforced polymer mortar

The invention discloses a method for preparing nano-SiO2 and PVA fiber reinforced polymer mortar, belonging to the field of inorganic polymer materials. The method comprises the following steps: stirring pre-treated metakaolin, pulverized fuel ash and quartz sands in a stirrer for 2 minutes; adding alkali-activator under a constant stirring state; continuously stirring for 2 minutes; adding a nano-SiO2 mixed solution, continuously stirring for 2 minutes; and adding PVA fibers twice under a constant stirring situation, stirring for 2 minutes each time to obtain the nano-SiO2 and PVA fiber reinforced polymer mortar. The nano-SiO2 and PVA fiber reinforced polymer mortar has excellent mechanical performance and excellent adhesion characteristic, and has a broad application prospect in the fields of construction, road and bridges, hydraulic engineering, military science and the like.

Owner:ZHENGZHOU UNIV

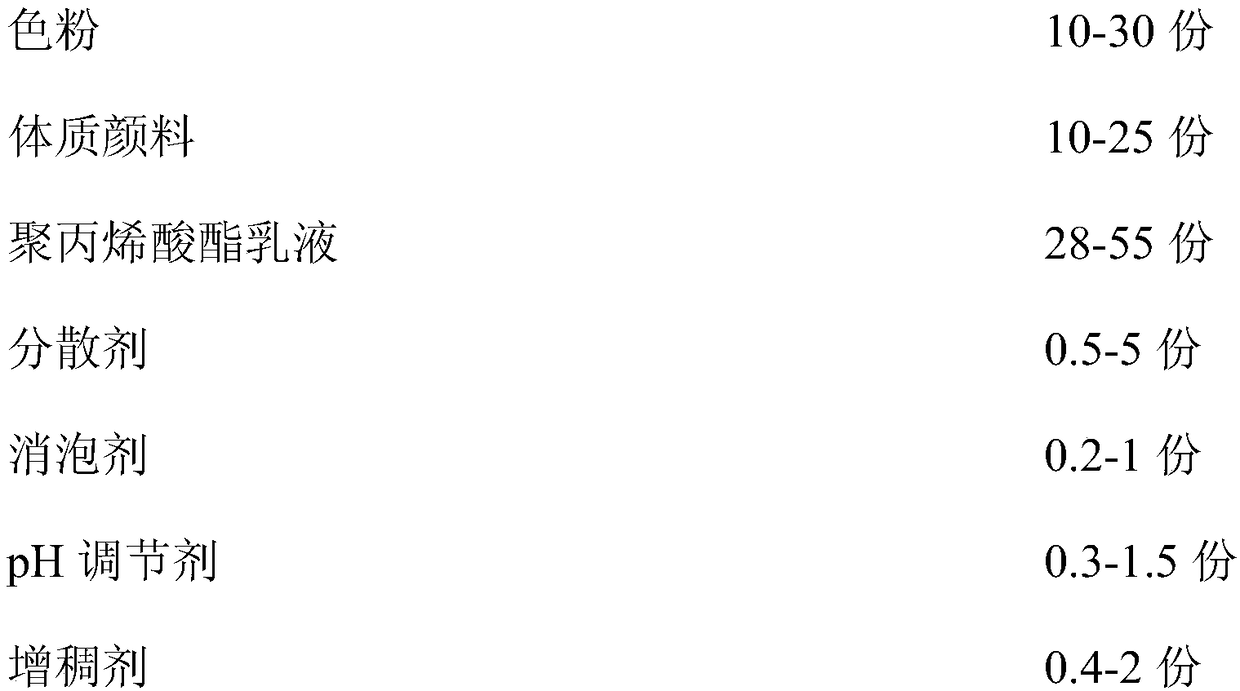

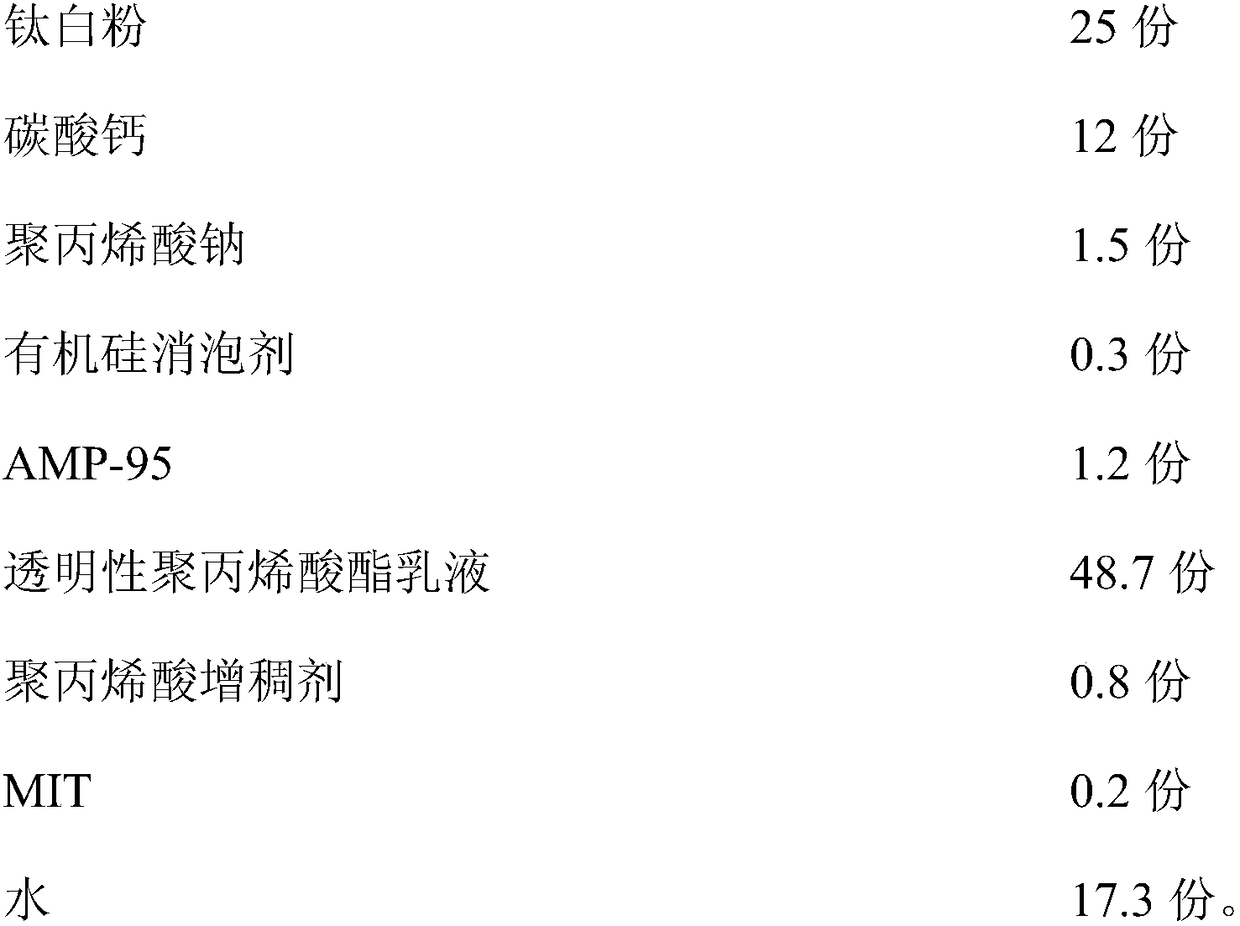

Pigment composition and preparation method and application thereof

ActiveCN108285710AGood fastnessGood adhesionArtist's paintsDyeing processPigment compositionWeather resistance

The invention provides a pigment composition. The pigment composition is prepared from, by weight, 10-30 parts of colored powder, 10-25 parts of extender pigments and 28-55 parts of polyacrylate emulsion. The invention also provides a preparation method of the pigment composition. The color display degrees of the provided pigment composition in a wet state and a dry state are both equal, a chromatic aberration phenomenon cannot occur, and an anti-yellowing effect is achieved when the pigment composition is used outdoors; even if the pigment composition is placed at 50 DEG C for one month or exposed under the blazing sun for eight hours, a yellowing situation does not occur; meanwhile, the pigment composition also has great fastness, water resistance, scuff resistance and weather resistance, and especially when the pigment composition is used in a textile, the adhesive force is high; when the textile is soaked in water after the textile is baked at the high temperature of 50 DEG C for one hour, the pigments totally do not permeate into the water, and the textile can still keep soft and resistant to washing, so that the pigment composition has a high application value.

Owner:上海马利画材股份有限公司

Dam concrete surface abrasion-resistant coating and coating method thereof

ActiveCN102925032AWon't fall offProtect safe operationLiquid surface applicatorsSynthetic resin layered productsEpoxySurface layer

The invention provides dam concrete surface abrasion-resistant coating and a coating method of the dam concrete surface abrasion-resistant coating. The coating is composed of three layers of coating namely a bottom layer, a middle layer and a surface layer from the surface of concrete outwards, wherein the coating at the bottom layer is epoxy cement gum with the thickness of 1-3 mm, the coating at the middle layer is low-viscosity epoxy resin adhesive with the thickness of 0.1-0.5 mm, the coating at the surface layer is polyaspartic acid ester polyurea which is 0.3-0.5 mm thick and is modified from nanometer materials, and the viscosity of the low-viscosity epoxy resin adhesive is 50-200 mPa.s. The dam concrete surface abrasion-resistant coating is resistant against the abrasion and damage of high-speed silt carrying water flow and bed load, effectively protects a dam to run normally, prolongs the safe service life of the dam, and protects the surface of dam concrete from fading or being pulverized and falling off. Meanwhile, the dam concrete surface abrasion-resistant coating is economical and practical, has good abrasion-resistant performance, adaptability and weather resistance, thereby meeting the requirements for abrasion-resistance of the surface of the dam concrete.

Owner:CHANGJIANG RIVER SCI RES INST CHANGJIANG WATER RESOURCES COMMISSION

Metal-surface supersonic stress peening method

InactiveCN1438332ALess corrosion resistanceImprove mechanical propertiesRoom temperatureMetallic materials

The invention refers to the intensifying technology of metal surface, especially is metal surface supersonic velocity blasting shot intensifying method, the character is that it uses compressed air to carry metal or nonmetal pills, accelerates the pills to speed of 300-1100 m / s, and the pills strikes the metal surface continuously, forms a remnants tress layer on the surface of the metal, the craft parameters is: the ejecting distance 55-100mm, the pressure of air 2.2-3.0 MPa, the air temperature is room temperature, the flux of air 26-30 g / s, the pills sending voltage 20-30 V, the diameter of pill 50-200 micron.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Low-VOC (volatile organic compound) photocuring laser transfer paint and preparation method thereof

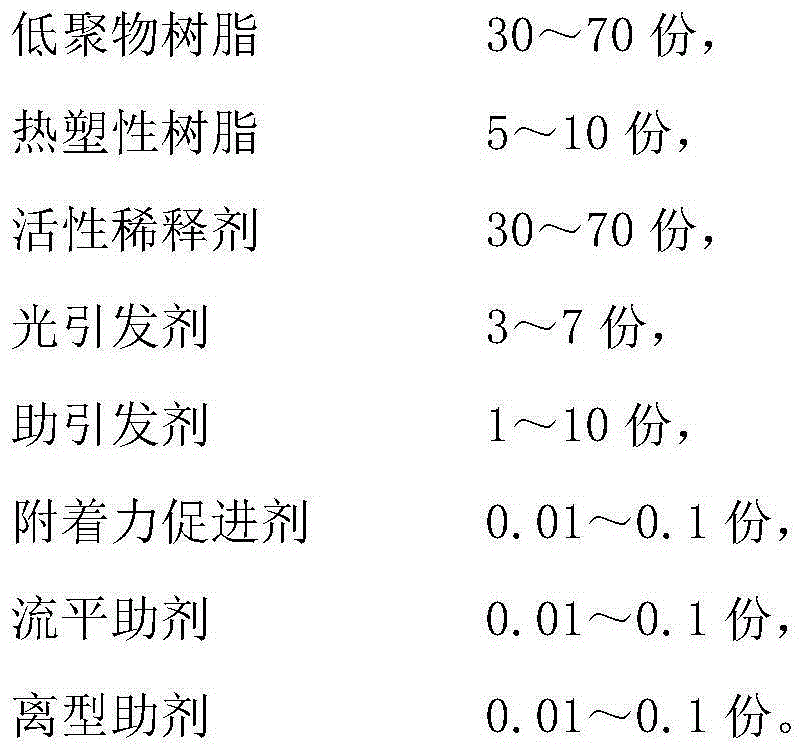

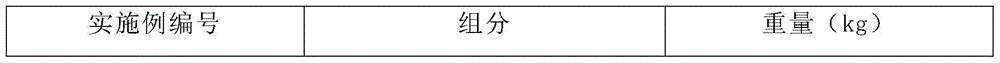

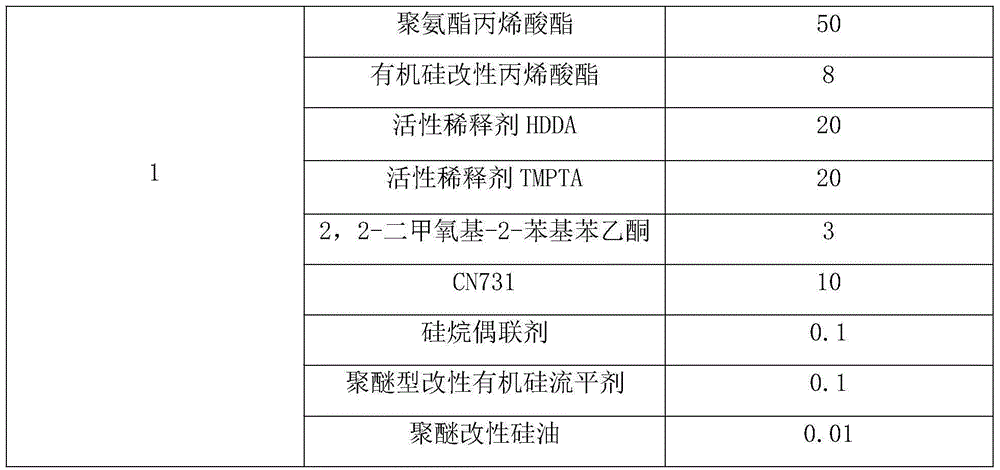

The invention discloses a low-VOC (volatile organic compound) photocuring laser transfer paint and a preparation method thereof. The transfer paint comprises 30-70 parts of low-polymer resin, 5-10 parts of thermoplastic resin, 30-70 parts of reactive diluent, 3-7 parts of photoinitiator, 1-10 parts of auxiliary initiator, 0.01-0.1 part of adhesion promoter, 0.01-0.1 part of leveling assistant and 0.01-0.1 part of release assistant. The preparation method comprises the following steps: respectively dissolving the low-polymer resin and thermoplastic resin in the reactive diluent; adding the photoinitiator and auxiliary initiator, and uniformly mixing; and adding the leveling assistant, adhesion promoter and release assistant, uniformly mixing and cooling. The photocuring laser transfer paint does not release any organic solvent, and almost does not have any harmful VOC residue. The low-VOC photocuring laser transfer paint has the advantages of excellent rubbing resistance, wide application range and high die pressing yield, can be used for die pressing to obtain micron-sized laser holographic patterns, and does not need to previously coat any release layer.

Owner:SHANGHAI WEIKAI CHEM

Self-compacting high-performance concrete and preparation method thereof

The invention discloses a self-compacting high-performance concrete and a preparation method thereof. The concrete is prepared from the following raw materials by weight: a gelling material, fine aggregate, coarse aggregate, water, polypropylene fiber, a nanometer photocatalysis material, an expanding agent and a high-efficiency water reducer. The preparation method comprises the following steps: step 1, preparation of the nanometer photocatalysis material: (1) with chitosan as a matrix, subjecting chitosan and chloropropylene oxide to cross-linking modification so as to obtain cross-linked chitosan and mixing the cross-linked chitosan with active carbon fiber so as to obtain a mixed loading material; (2) preparing nanometer titanium dioxide sol by using a sol-gel method; and (3) mixing the nanometer titanium dioxide sol with the loading material prepared in (1) and carrying out ultrasonic vibration so as to the nanometer photocatalysis material; and step 2, weighing the gelling material, fine aggregate and polypropylene fiber in a weight ratio, stirring the weighed materials in a forced stirrer for 40 s, then adding the coarse aggregate, water, the nanometer photocatalysis material, the expanding agent and the high-efficiency water reducer and continuing stirring for 90 s so as to obtain the self-compacting high-performance concrete.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com