Abrasion-resistant epoxy mortar and preparation method thereof

An epoxy mortar and anti-abrasion technology, which is applied in the field of hydraulic construction materials, can solve the problems of low epoxy resin strength, high epoxy resin specific gravity, and poor workability, and achieve excellent anti-abrasion performance, The effect of simple preparation method, good toughness and bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: the preparation of epoxy resin slurry

[0038] (1) Preparation of curing agent: Add 10 parts by weight of triethylenetetramine, 1 part by weight of γ-aminopropyltriethoxysilane and 1 part by weight of 2,4,6-tris(dimethylamino)phenol Into the reactor, slowly add 10 parts by weight of 1,4-butanediol diglycidyl ether into the reactor at 15°C, and react for 2 hours to obtain curing agent I.

[0039] (2) Preparation of activator (obtained by referring to Chinese invention patent 201110237100.2): Mix 25 parts by mass of diethylenetriamine, 20 parts by mass of p-methoxyphenol and 20 parts by mass of formaldehyde (37% by mass), and add 0.65 Parts by mass of NaOH, heated to 40° C. for 20 h under stirring, and then fully dehydrated by decompression to obtain a high-efficiency furfural-acetone activator for grouting materials.

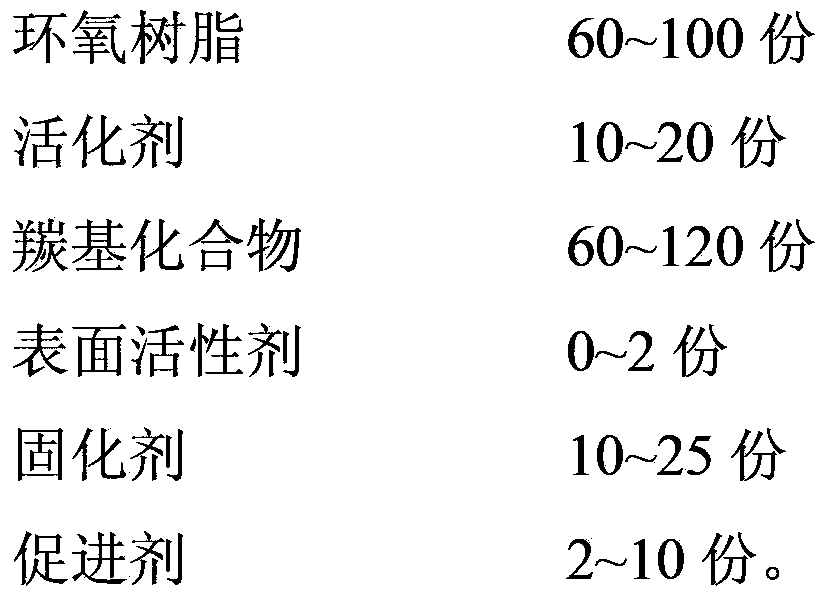

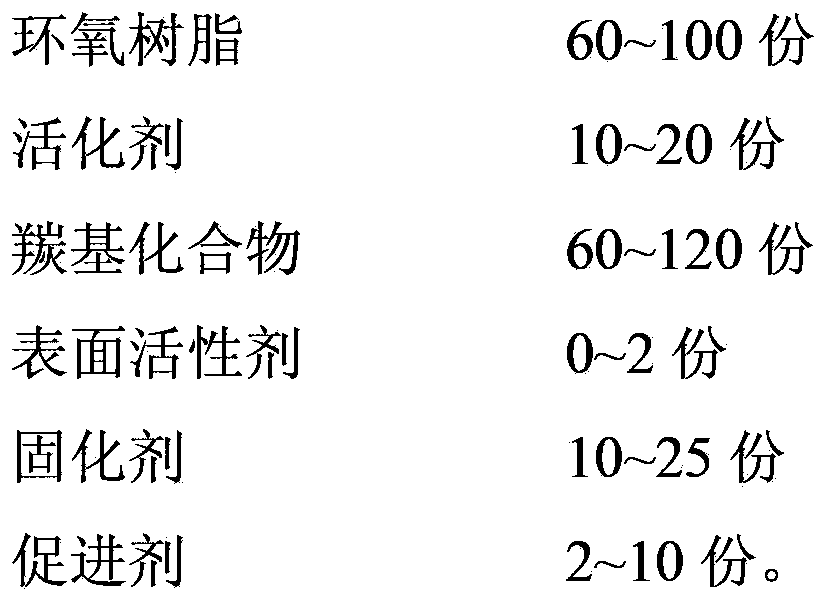

[0040] (3) Preparation of epoxy resin slurry: 60 parts by weight of epoxy resin E-44, 10 parts by weight of the activator prepared in step ...

Embodiment 2

[0041] Embodiment 2: the preparation of epoxy resin slurry

[0042] (1) Add 15 parts by weight of polyethylene polyamine, 3 parts by weight of γ-aminopropyltrimethoxysilane and 2 parts by weight of 2,4,6-tris(dimethylamino)phenol into the reactor, Slowly add 5 parts by weight of 1,6-hexanediol diglycidyl ether into the reactor at 40°C and react for 4 hours to obtain curing agent II.

[0043] (2) The preparation of the activator is the same as in Example 1.

[0044] (3) 100 parts by weight of epoxy resin E-51, 20 parts by weight of the activator prepared in step (2), 50 parts by weight of acetone, 40 parts by weight of furfural, 30 parts by weight of benzaldehyde, 16 parts by weight of step (1) The prepared curing agent II, 2 parts by weight of fatty acid glyceride, 5 parts by weight of 2,4,6-tris(dimethylamino)phenol, and 5 parts by weight of triethanolamine were mixed to obtain epoxy resin slurry II.

Embodiment 3

[0045] Embodiment 3: the preparation of epoxy resin slurry

[0046] (1) 14 parts by weight of isophorone diamine, 2.5 parts by weight of N-β-(aminoethyl)-γ-aminopropylmethyldimethoxysilane and 2 parts by weight of 2,4,6- Tris(dimethylamino)phenol was added into the reactor, and 8 parts by weight of ethylene glycol diglycidyl ether was slowly added into the reactor at 25° C., and reacted for 3 hours to obtain curing agent III.

[0047] (2) The preparation of the activator is the same as in Example 1.

[0048] (3) 80 parts by weight of epoxy resin E-44, 12 parts by weight of the activator prepared in step (2), 30 parts by weight of acetone, 50 parts by weight of furfural, 20 parts by weight of butanone, 25 parts by weight of step (1) The prepared curing agent III, 2 parts by weight of Tween, 6 parts by weight of 2,4,6-tris(dimethylamino)phenol, and 3 parts by weight of diphenylformylhydrazide were mixed to obtain epoxy resin slurry III.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Bond strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com