Tail end-capped polylactic acid fiber with high heat resistance and water resistance and preparation method thereof

A polylactic acid fiber, polylactic acid technology, applied in the direction of melt spinning, single-component polyester rayon, etc., can solve the problems of no friction resistance improvement, polylactic acid water resistance can not be improved, etc., to improve friction resistance. good abrasion resistance, improve the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

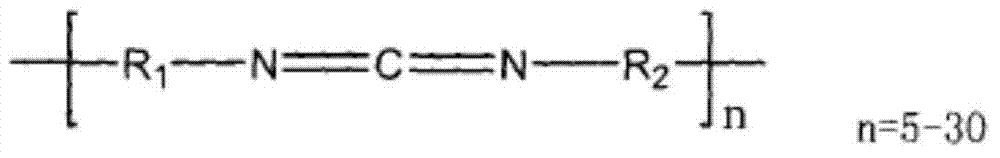

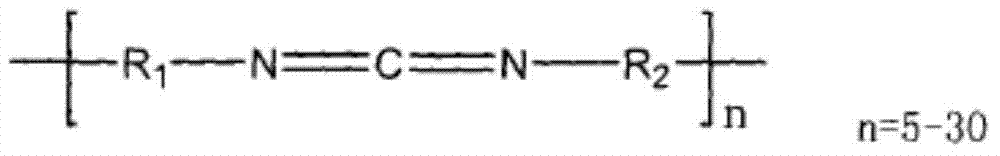

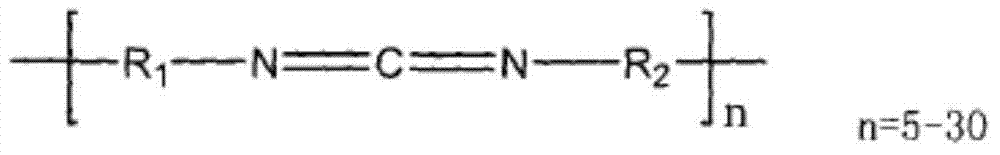

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The polylactic acid slices are vacuum-dried until the water content is 100ppm, and the dried polylactic acid slices are mixed with 10% polycarbodiimide compound Stabaxol P200 (Germany Rheinland company product) equivalent to the weight of the polylactic acid and an amount equivalent to the weight of the polylactic acid. 7.5% EBS (ethylene bis stearamide, its melting point is 144 DEG C) mixed evenly, melt blending, extruding granulation with a twin-screw extruder, the extrusion temperature is 200 DEG C, the screw speed is 250rpm, obtained Masterbatch slices. Then the masterbatch slices are dried to make the masterbatch slice moisture reach 120ppm, then the dried polylactic acid slices 60% by weight and the masterbatch slices by 40% by weight are prepared through melt spinning, and the concentration is 15% spinning oil emulsion is coated on the fiber, and the spinning oil emulsion is by containing 40% weight fatty acid ester lubricant (20% weight isotridecyl stearate+20% ...

Embodiment 2

[0037] The polylactic acid slices are vacuum-dried until the moisture content is 80ppm, and the dried polylactic acid slices are mixed with 12% polycarbodiimide compound Stabaxol P200 (Germany Rheinland company product) equivalent to the weight of polylactic acid and equivalent to the weight of polylactic acid. 10% EBS (ethylene bis stearamide, its fusing point is 144 DEG C) mixed evenly, melt blending, extrusion granulation with twin-screw extruder, extrusion temperature is 190 DEG C, screw speed is 300rpm, obtained Masterbatch slices. Then the masterbatch slices are dried to make the masterbatch slice moisture reach 100ppm, and then the dried polylactic acid slices 65% by weight and the masterbatch slices by 35% by weight are prepared through melt spinning, and the concentration is 15% spinning oil emulsion is coated on the fiber, and the spinning oil emulsion is by containing 40% weight fatty acid ester lubricant (20% weight isotridecyl stearate+20% weight Octyl palmitate)...

Embodiment 3

[0039]The polylactic acid slices are vacuum-dried until the moisture content is 120ppm, and the dried polylactic acid slices are mixed with 2% polycarbodiimide compound Stabaxol P200 (product of German Rheinland Co., Ltd.) equivalent to the weight of polylactic acid and equivalent to the weight of polylactic acid. 0.5% EBS (ethylene bis stearamide, its fusing point is 144 DEG C) components are uniformly mixed, melt blended, extruded, pelletized with a twin-screw extruder, the extrusion temperature is 200 DEG C, and the screw speed is 250rpm. Then the chips obtained are dried to make the moisture content of the chips reach 150ppm, prepared by melt spinning, and the spinning oil emulsion with a concentration of 15% is coated on the fiber by an oiling yarn guide, and the spinning oil emulsion is made of Containing 40% by weight of fatty acid ester lubricants (20% by weight of isotridecyl stearate+20% by weight of octyl palmitate) spinning oil mixed with water, so that the final oi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com