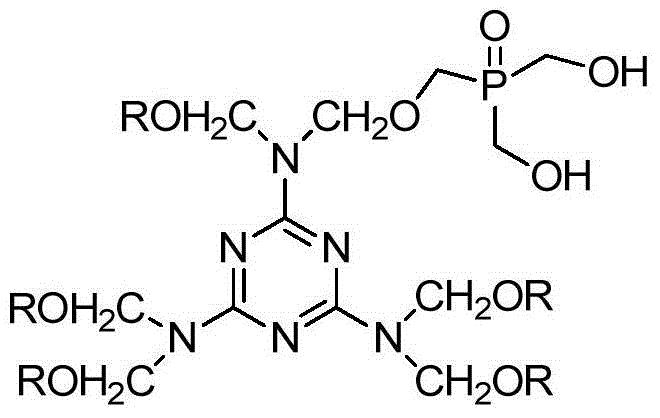

Phosphorus-nitrogen synergistic flame-retardant polyalcohol and preparation method thereof

A synergistic flame retardant and polyol technology, applied in chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc. Inexpensive, practical and easy to operate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of trihydroxymethylphosphine oxide (THPO)

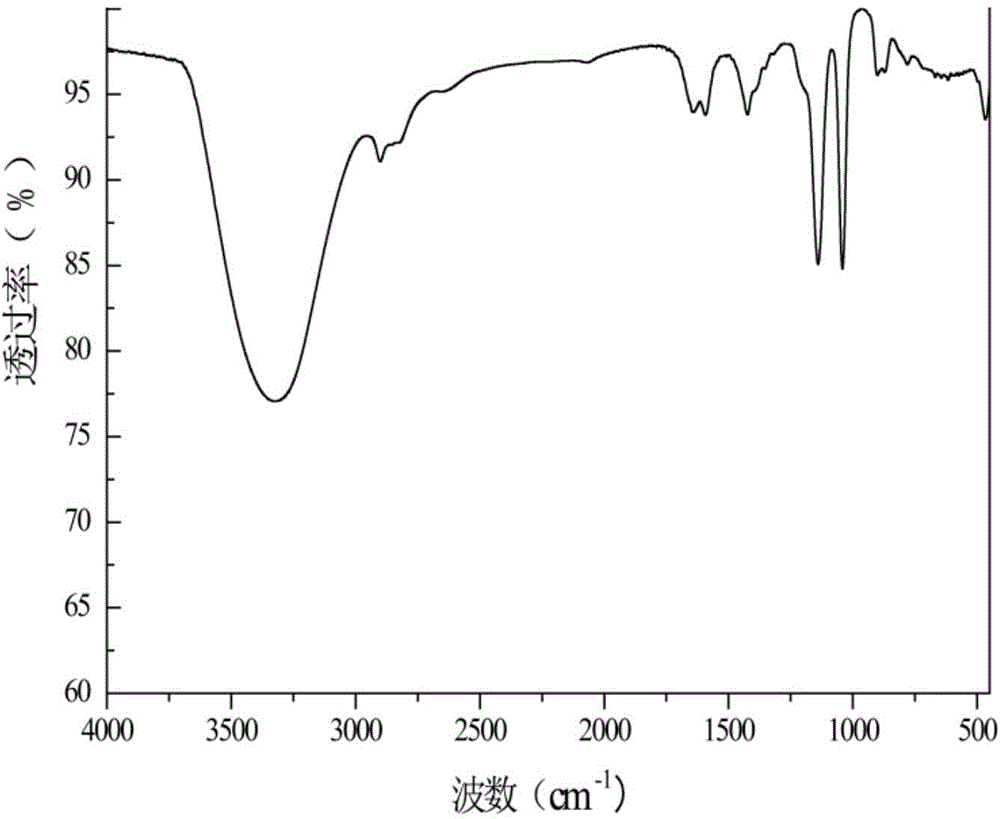

[0032] In a 1L three-necked flask equipped with a stirrer, a constant pressure dropping funnel, and a condenser, add 40.0 g (1 mol) of NaOH and 400 mL of distilled water, and stir to completely dissolve the alkali. After it was cooled to room temperature, 190.1 g (1 mol) of tetrakishydroxymethylphosphonium chloride solution was added dropwise through a constant pressure funnel. Dropping time 1h, 50 ℃ reaction 5h. After the reaction, slowly add HCl solution dropwise to the solution, after adjusting the pH to neutral, add 19mL HCl solution 2 o 2 After reacting for 2 hours, use a rotary evaporator to evaporate most of the water, then pour it into a 1L beaker containing 400mL of ethanol, and let it stand overnight until the salt is fully separated, then filter it with suction. The solvent is spin-dried to obtain the product THPO. And carried out infrared characterization, such as figure 1 shown.

[0033] (2) ...

Embodiment 2

[0036] (1) Preparation of trihydroxymethylphosphine oxide

[0037] Add 85.5g (0.5mol) Ba(OH) 2 , and add 300mL of distilled water, stir to dissolve the base completely. After it was cooled to room temperature, 190.1 g (1 mol) of tetrakishydroxymethylphosphonium chloride solution was added dropwise through a constant pressure funnel. Dropping time 1h, 70 ℃ reaction 4h. After the reaction was completed, HCl solution was slowly added dropwise to the solution to adjust the pH to neutral. Add 19mLH 2 o 2 After reacting for 2 hours, use a rotary evaporator to evaporate most of the water, then pour it into a 1L beaker containing 300mL of ethanol, and let it stand overnight until the salt is fully separated, then filter it with suction. The solvent is spin-dried to obtain the product.

[0038] (2) Preparation of Phosphorus Nitrogen Synergistic Flame Retardant Polyols

[0039] Experimental procedure 2 is the same as embodiment 1.

Embodiment 3

[0041] (1) Preparation of trihydroxymethylphosphine oxide

[0042]In a 1L three-necked flask equipped with a stirrer, a constant pressure dropping funnel, and a condenser, add 40.0 g (1 mol) of NaOH and 400 mL of distilled water, and stir to completely dissolve the alkali. After it was cooled to room temperature, 190.1 g (1 mol) of tetrakishydroxymethylphosphonium chloride solution was added dropwise through a constant pressure funnel. Dropping time 1h, 60 ℃ reaction 5h. After the reaction was completed, HCl solution was slowly added dropwise to the solution to adjust the pH to neutral. Add 19mLH 2 o 2 After reacting for 2 hours, use a rotary evaporator to evaporate most of the water, then pour it into a 1L beaker containing 400mL of ethanol, and let it stand overnight until the salt is fully separated, then filter it with suction. The solvent was spin-dried to obtain the product.

[0043] (2) Preparation of Phosphorus Nitrogen Synergistic Flame Retardant Polyols

[0044...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com