Patents

Literature

33 results about "Triphenylmethane triisocyanate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waterproof antibacterial polyurethane adhesive

InactiveCN107903868ANon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMethacrylatePolyester

The invention discloses a waterproof antibacterial polyurethane adhesive, which is prepared from the following raw materials in parts by weight: 100 parts of polyurethane prepolymer, 0.1-1.5 parts ofnano-silver, 5-12 parts of modified filler, 3-12 parts of hexadecyltrimethoxysilane modified nano-zinc oxide, 1-3.5 parts of dihydromethyl propionic acid, 2-7 parts of 1,6-hexanediamine, 0.3-1.5 partsof triethylamine, 0.1-1 part of dibutyltin dilaurate, 1-3.5 parts of plasticizer, 0.2-1.3 parts of polrvinyl benzene, 5-20 parts of glycol dimethyl ether, 0.3-1.2 parts of 2,4,4-trichlorine-2-hydroxy-diphenyl ether and 2-5 parts of dodecafluoroheptyl methacrylate, wherein the polyurethane prepolymer is obtained in a way that diferrocenyl alcohol, hydroxyl-terminated polybutadiene, polyester polyol, triphenylmethane triisocyanate and p-phenylene diisocyanate react. The waterproof antibiosis polyurethane adhesive which is put forward by the invention has the advantages of high binding strength,good antibacterial property and excellent water-proof performance.

Owner:阜阳市龙建包装材料有限公司

Adhesive containing ultra-fine aluminum silicate for packaging and preparation method thereof

ActiveCN103265911AGood compatibilityEasy to bendNon-macromolecular adhesive additivesStarch derivtive adhesivesPolyvinyl alcoholAdhesive

The present invention discloses an adhesive containing ultra-fine aluminum silicate for packaging and a preparation method thereof. The adhesive comprises the components in parts by weight of 25-30 parts of chloroprene rubber (SN24), 50-60 parts of cyclohexane, 120-160 parts of methylbenzene, 20-30 parts of acetic ether, 10-15 parts of trichloromethane, 20-25 parts of phenolic resin 2402, 5-10 parts of terpene resin, 8-12 parts of polyvinyl alcohol, 2-4 parts of vinyltriethoxysilane, 0.3-0.5 parts of morpholine, 1-2 parts of tri-phenyl methane tri-isocyanate, 4-6 parts of chlorinated paraffinss, 0.2-0.3 parts of Span-60, 8-12 parts of butadiene styrene rubber (SBR1502), 4-8 parts of butyl rubber (BBK232), 1-2 parts of activated zinc oxide, 2-3 parts of active magnesium oxide, 0.5-1 parts of sulphur, 4-6 parts of ultra-fine aluminum silicate, and 2-4 parts of light calcium carbonate, etc. The adhesive provided by the present invention has excellent resistance to high-and-low temperature, good abrasion resistance, high bonding strength, waterproof property, moisture resistance, good storage stability, environmental protection property, good effect and convenient usage.

Owner:ANHUI FENGHUANGSONG PACKAGING

High-etherification modified high-performance adhesive and preparation process thereof

The invention discloses a high-etherification modified high-performance adhesive and a preparation process thereof, wherein the adhesive comprises, by weight, 100 parts of natural rubber, 45-80 partsof a melamine formaldehyde resin, 25-40 parts of triphenyl methane triisocyanate, 4-12 parts of mineralized nanometer powder, 2-7 parts of magnesium oxide, 1-3 parts of an initiator, 1-3 parts of an anti-aging agent, 1-3 parts of an antioxidant, and 870-960 parts of a solvent. According to the present invention, the adhesive has improved bonding activity, improved aging resistance and improved tear strength so as to improve the wear resistance and the safety of the tire.

Owner:JIANGSU GUOLI CHEM TECH

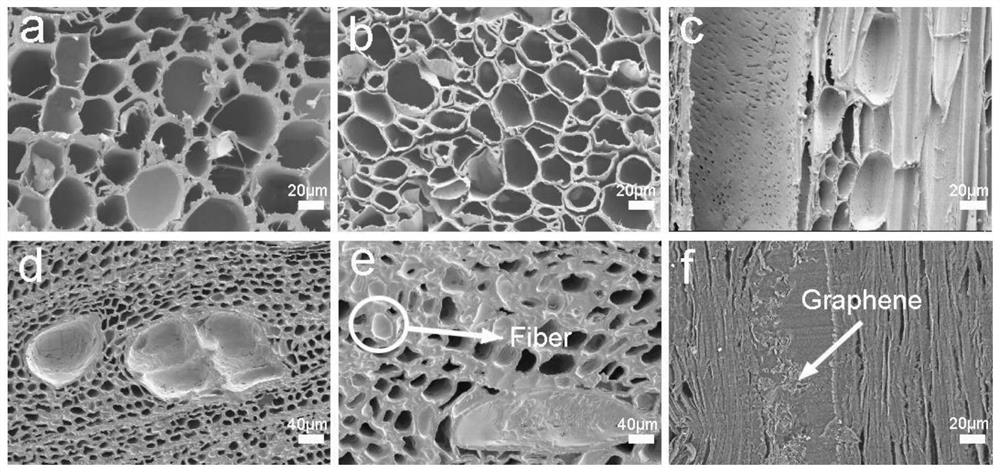

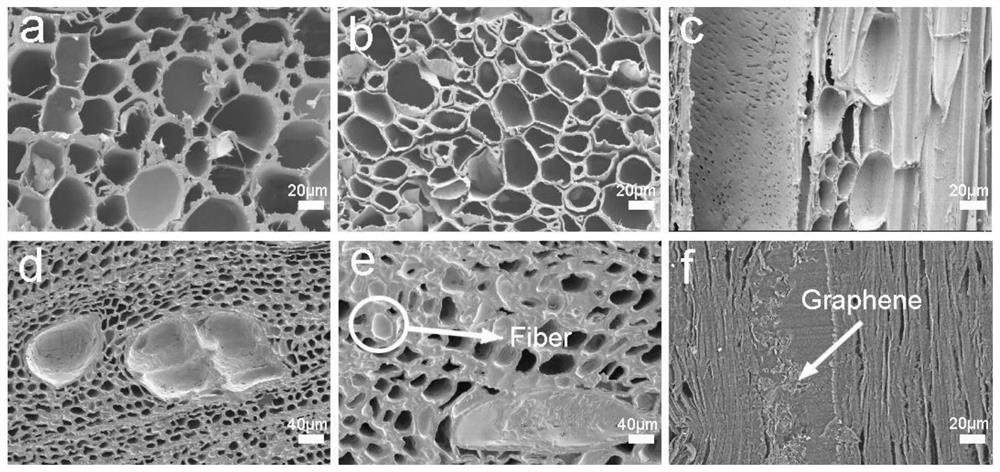

Nanoparticle reinforced self-lubricated cast nylon composite shaft sleeve and manufacturing method thereof

A nanoparticle reinforced self-lubricated cast nylon composite shaft sleeve is prepared from components including a caprolactam monomer, sodium hydroxide, triphenylmethane triisocyanate, nano graphite fluoride and mica powder in a weight ratio being 100:(0.15-0.45):(0.3-0.6):(0.4-0.5):(2.0-4.0). The manufacturing method of the composite shaft sleeve comprises preparation of reaction melts, preparation of a dispersion liquid as well as molding and demolding, the centrifugal casting method is adopted in the casting process, so that more nano graphite fluoride and mica powder are centralized and distributed on the outer surface of the shaft sleeve, the shaft sleeve has better bearing capacity and more excellent anti-friction and wear-resistance properties, the wear of the shaft sleeve is reduced, and the service life of the shaft sleeve is prolonged.

Owner:HENAN UNIV OF SCI & TECH

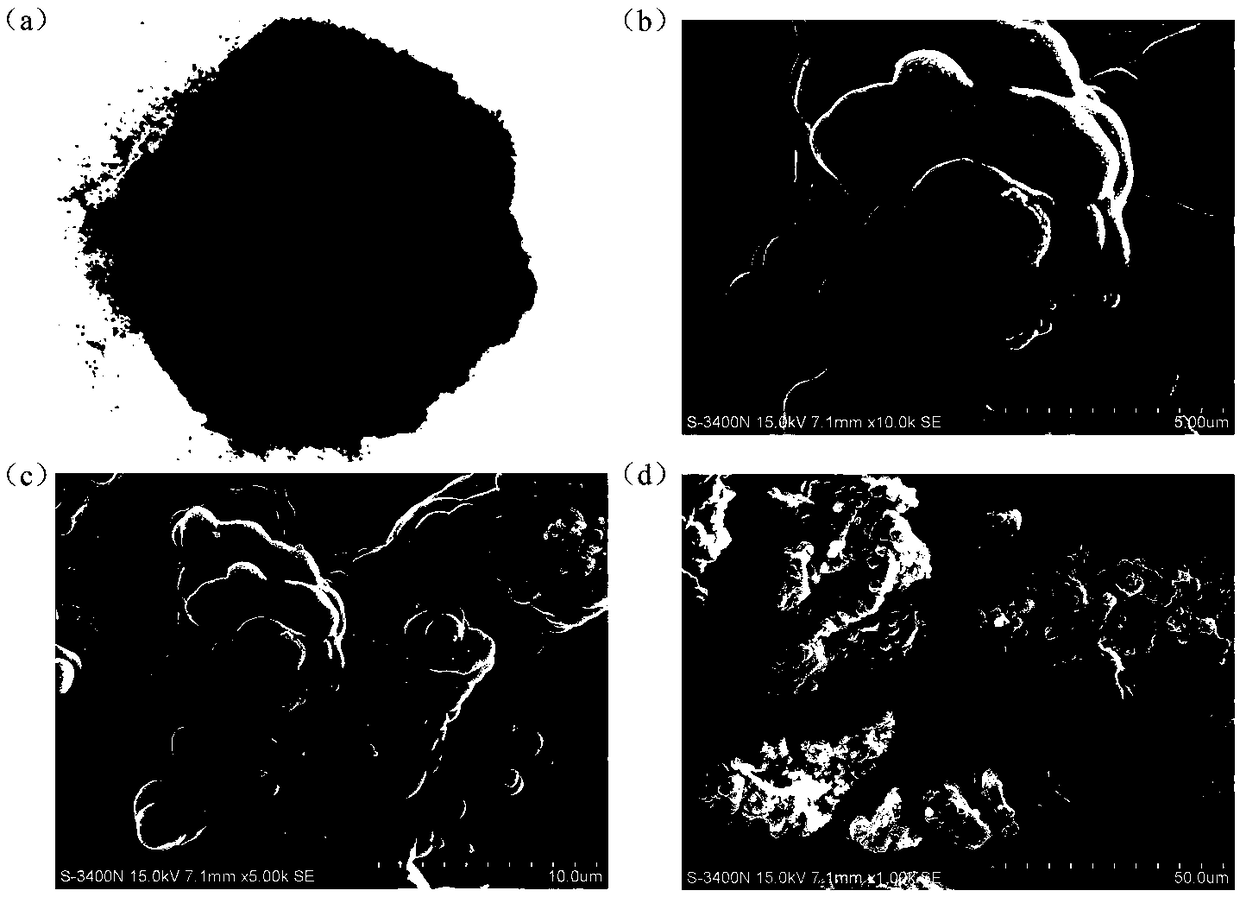

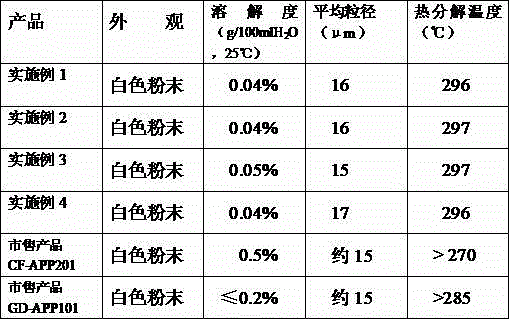

Micro/nano size beta-cyclodextrin polymer powder as well as preparation method and application thereof

InactiveCN108484800AImprove adsorption efficiencyWith micro/nano dimensionsWater contaminantsWater/sewage treatment by sorptionCross-linkPolymer science

The invention discloses micro / nano size beta-cyclodextrin polymer powder as well as a preparation method thereof and application thereof. The preparation method comprises the following steps: dispersing a beta-cyclodextrin in a butanone solvent; using triphenylmethane triisocyanate as a cross-linking agent; heating, stirring and reacting for 2-10 hours without adding a catalyst or adding differentkinds of catalysts; then, washing with acetone and hot water to obtain a polymer powder product; and drying at 60 DEG C for 24 hours to obtain the micro / nano size beta-cyclodextrin polymer powder, wherein the polymer powder can be used as an adsorbing material for extraction and recovery of chlorophenol in wastewater. The method has advantages that the preparation process is simple, and the obtained beta-cyclodextrin polymer powder has a micro / nano size and has high adsorbing efficiency for chlorophenol.

Owner:GUANGXI UNIV

Resin self-hardening core sand for casting train iron castings and preparing method of resin self-hardening core sand

The invention discloses a resin self-hardening core sand for casting train iron castings and a preparing method of the resin self-hardening core sand. The resin self-hardening core sand is prepared from, by weight, 160-180 parts of sea sand, 20-30 parts of carborundum, 16-20 parts of refiring magnesia, 10-14 parts of paper clay, 6-8 parts of chalk soil, 10-15 parts of furan resin, 12-14 parts of cashew nut shell oil modified phenolic resin, 4-6 parts of polyimide, 3-5 parts of rare earth tailing, 5-7 parts of pandermite, 8-10 parts of waste foam glass, 3-5 parts of ferro silicon nitride, 1-2 parts of N-(beta-aminoethyl)-gamma-aminopropyl triethoxy silane, 2-4 parts of p-toluenesulfonic acid, 3-5 parts of phosphoric acid, 4-6 parts of castor oil maleic anhydride acid esters, 8-10 parts of triphenylmethane triisocyanate and 2-4 parts of styrene. According to the furan resin self-hardening sand, mixed resin is adopted, the method of adding single resin is changed, mutual effects between different kinds of resin including the furan resin, the cashew nut shell oil modified phenolic resin, the polyimide and the like are adopted for enabling the core sand to have the beneficial effects of being high in strength, small in gas-forming amount, low in thermal expansivity, good in breathability, good in collapsibility and the like, and the produced castings are high in degree of precision and good in surface quality.

Owner:江阴联华铸造有限公司

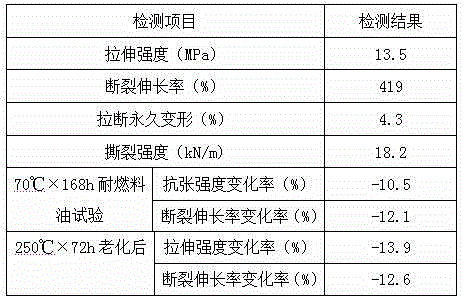

Oil resistant silicone rubber material and preparation method thereof

The invention discloses an oil resistant silicone rubber material and a preparation method thereof. The material consists of the following raw materials by weight: 75-95 parts of methyl vinyl trifluoropropyl silicone rubber, 40-60 parts of polyethylene naphthalate, 4-8 parts of dihydroxy polydimethylsiloxane, 5-10 parts of nano titanium boride, 3-6 parts of methyl silicone oil, 2-3 parts of aluminum naphthenate, 4-6 parts of lead silicate white, 2-3 parts of triphenylmethane triisocyanate, 10-15 parts of precipitated barium sulfate, 3-6 parts of candelilla wax, 5-10 parts of hydroxyl terminated liquid nitrile rubber, 2-3 parts of dibenzoylquinone dioxime, 1.5-2.5 parts of N,N'-1,3-phenylene bismaleimide, 1-2 parts of polytrimethyldihydroquinoline, 0.5-1.5 parts of TNPP and 3-5 parts of an additive. The silicon rubber material provided by the invention has the advantages of good oil resistant performance, heat resistance, high mechanical strength, tear resistance and aging resistance, can work in the oil medium for a long time, is not easy to age, and has long service life, good processing performance, low cost and broad application prospects.

Owner:天长市荣盛有机硅科技有限公司

Novel composite new material high-strength rubber sound insulation pad and preparation method thereof

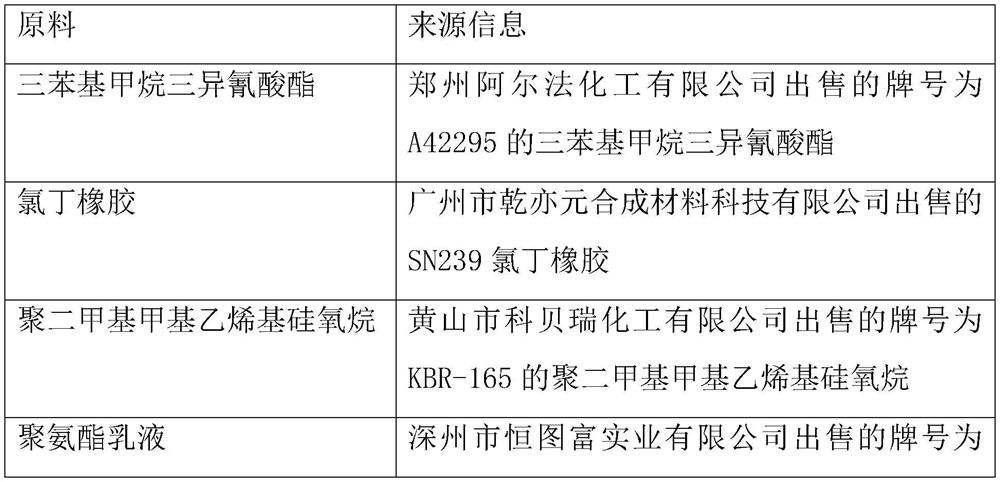

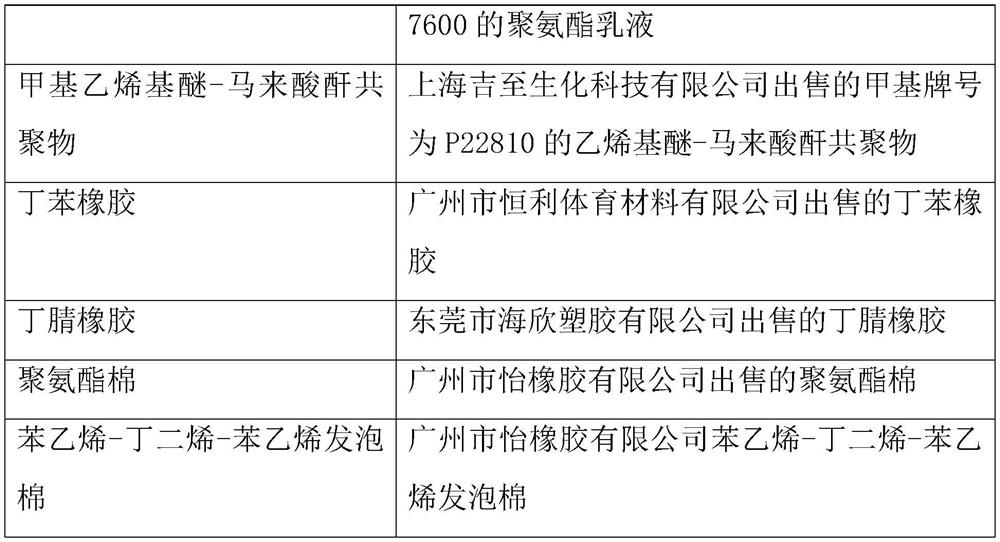

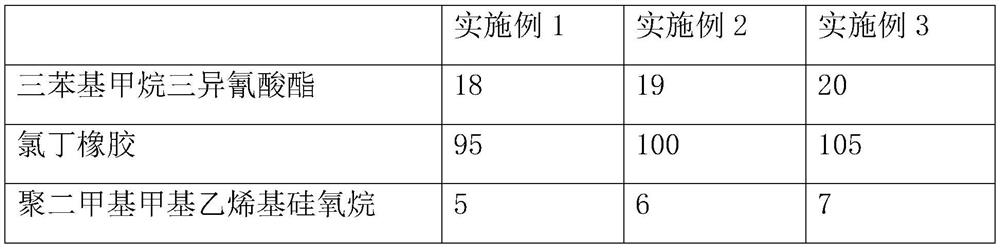

The invention relates to a novel composite new material high-strength rubber sound insulation pad and a preparation method thereof. The novel composite new material high-strength rubber sound insulation pad comprises the following components in parts by mass: 35-45 parts of rubber; 65 to 75 parts of foam cotton; 10 to 20 parts of an adhesive; the adhesive comprises the following components in parts by mass: 18-20 parts of triphenylmethane triisocyanate; 95 to 105 parts of chloroprene rubber; 5 to 7 parts of polydimethylvinylsiloxane; 2-4 parts of a polyurethane emulsion; 5-7 parts of a methylvinyl ether-maleic anhydride copolymer; 4-6 parts of zinc oxide; 3-5 parts of magnesium oxide; and 300 to 340 parts of an organic solvent. The rubber sound insulation pad has the effect of improving the noise reduction capability of the rubber sound insulation pad.

Owner:广州宝来声学材料有限公司

Polyurethane adhesive and manufacturing method and application method thereof

InactiveCN104031595ALow costGood adhesionPolyureas/polyurethane adhesivesAdhesive processes with surface pretreatmentAdhesive cementPolymer science

The invention discloses a polyurethane adhesive which is composed of a component A and a component B. The component A comprises, by mass, 65 parts of triphenyl methane tri-isocyanate and 4 parts of zinc chloride. The component B comprises, by mass, 110 parts of chloroprene rubber, 4 parts of calcium oxide, 3 parts of N-phenyl-2-naphthylamine, 90 parts of methylbenzene and 60 parts of ethyl acetate. The polyurethane adhesive contains isocyanate groups with strong polarity, so the polyurethane adhesive has excellent adhesive properties and excellent mechanical properties such as bending resistance and impact resistance and has the advantages of high peeling strength, acid and alkali resistance, solvent resistance, water resistance, mould prevention and the like. The polyurethane adhesive still has good adhesion strength at a low temperature and especially can keep constant adhesion strength at an ultralow temperature, and the usage temperature range of the polyurethane adhesive is from minus 30 DEG C to 50 DEG C. The invention further provides a manufacturing method and application method of the polyurethane adhesive.

Owner:罗静

Preparation process of polyurethane-based thermal insulation type multi-layer composite waterproof coiled material

InactiveCN111574782AImprove insulation effectEfficient Flame RetardancyPolymer scienceTriphenylmethane triisocyanate

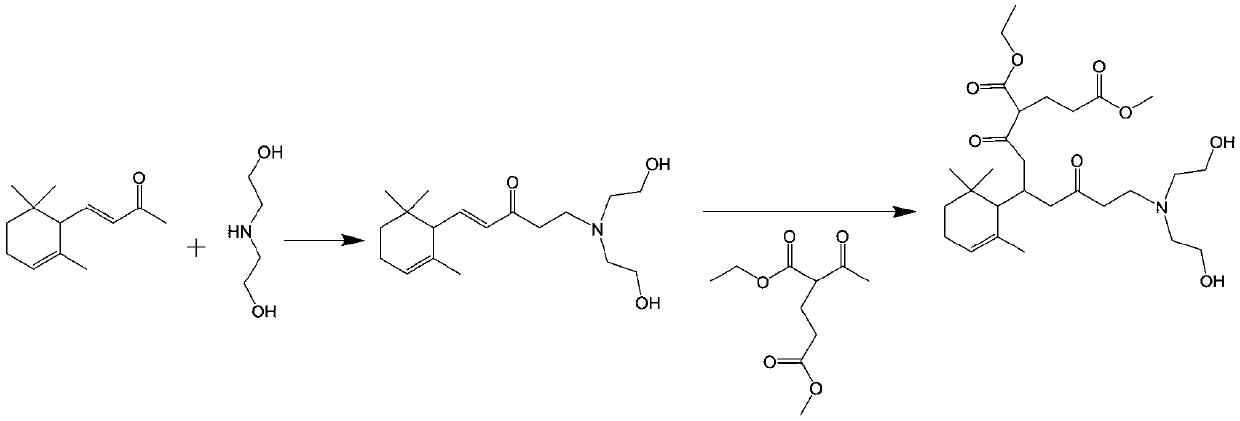

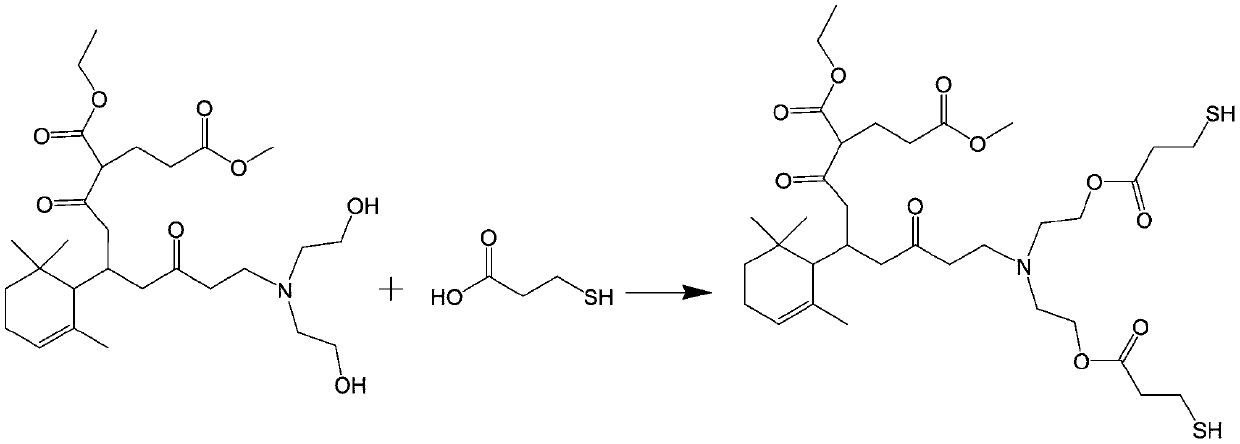

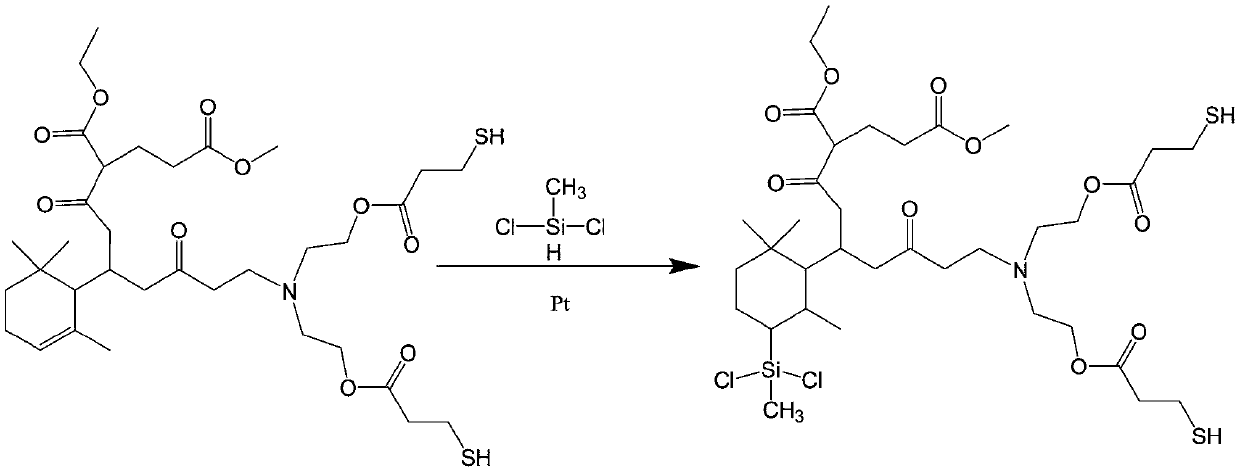

The invention discloses a preparation process of a polyurethane-based thermal insulation type multi-layer composite waterproof coiled material. The specific preparation process of the preparation process includes the following steps of: simultaneously adding polyphosphooxy polyamine, dibutyl dilaurate, diisopropanolamine and water into a stirring kettle; performing stirring and mixing, then addingtriphenylmethane triisocyanate into the stirring kettle; performing stirring and mixing, pouring an obtained mixture into a mold so as to subject the mixture to foaming and shaping; rolling obtainedpolyurethane foam for multiple times; and adhering a layer of polyvinyl chloride sheet to each of the upper surface and the lower surface of a polyurethane foam sheet to obtain the thermal insulationtype multi-layer composite waterproof coiled material. The toughening modifier prepared by the preparation method disclosed by the invention contains two sulfydryl groups which can react with chlorineatoms on a PVC chain, so that the toughening modifier can be introduced on the PVC chain; the toughening modifier contains a large amount of ester groups, so that Van der Waals' force among polyvinylchloride molecules can be weakened, the mobility of polyethylene molecular chains is improved, the crystallinity of the polymer molecular chains is reduced, the viscosity of the polymer is reduced, and flexibility is enhanced.

Owner:徐磊

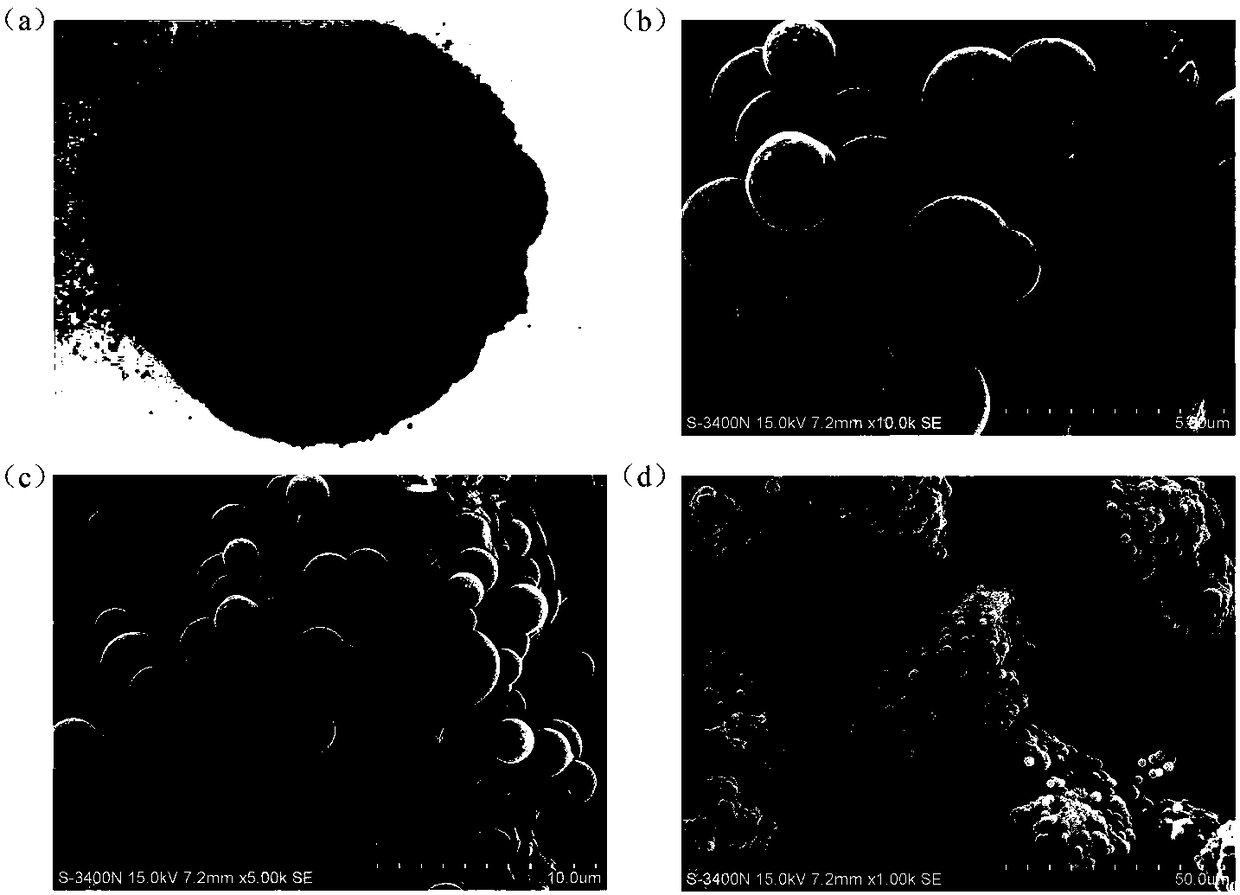

Preparation method of thermally induced flexible phase change energy storage wood

ActiveCN113319956AImprove permeabilityEasy to manufactureClimate change adaptationWood treatment detailsPolymer scienceTriphenylmethane triisocyanate

The invention discloses a preparation method of thermally induced flexible phase change energy storage wood, which comprises the following steps of: a, preparing 50 to 70 parts of 0.05 to 0.2 mol / L triethanolamine solution and 40 to 60 parts of 0.1 to 0.4 mol / L triphenylmethane triisocyanate solution by taking N,N-dimethylformamide as a solvent; b, adding the triethanolamine solution in the step a into the triphenylmethane triisocyanate solution, and conducting stirring at 60-80 DEG C for 10-15 hours to obtain a prepolymer; c, adding 10-20 parts of polyethylene glycol-1500 into the prepolymer, and conducting stirring for 20-30 hours at the temperature of 60-80 DEG C to obtain a solid-solid phase change material; and d, putting the delignified wood into the solid-solid phase change material, carrying out vacuum impregnation for 20-40 minutes, and then conducting drying to obtain a finished product. The prepared phase change energy storage wood has the heat and energy storage capacity and is good in flexibility.

Owner:ZHEJIANG FORESTRY UNIVERSITY

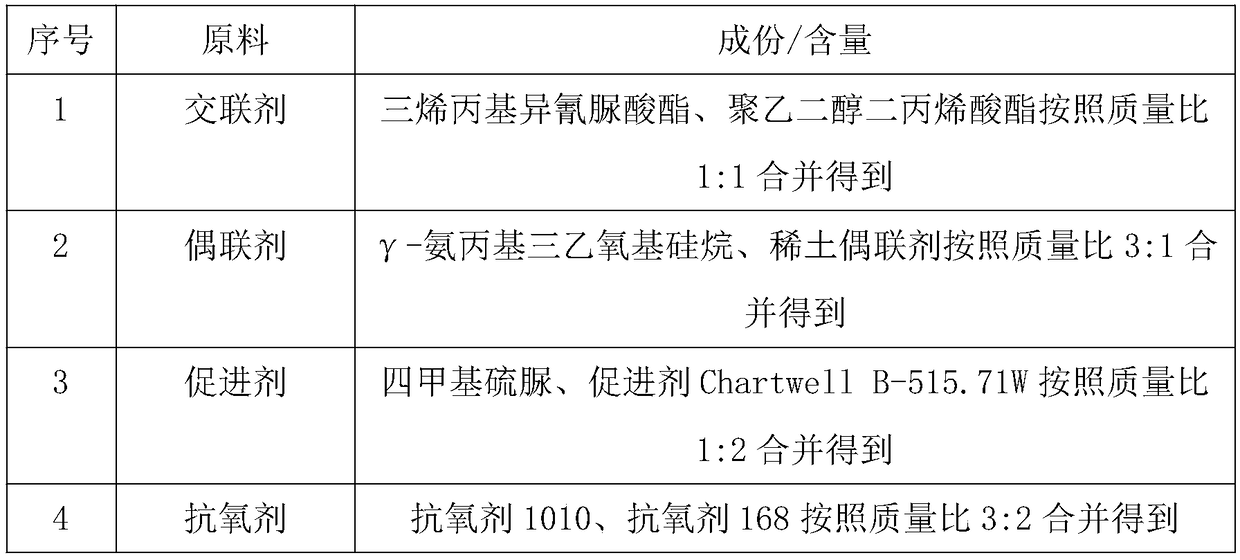

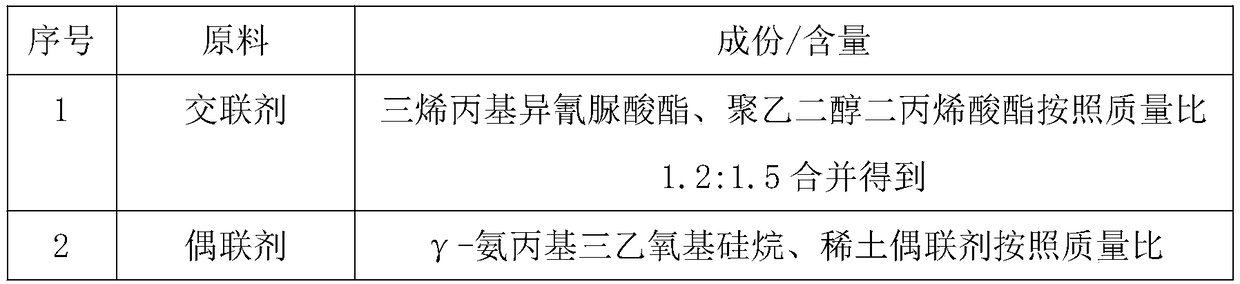

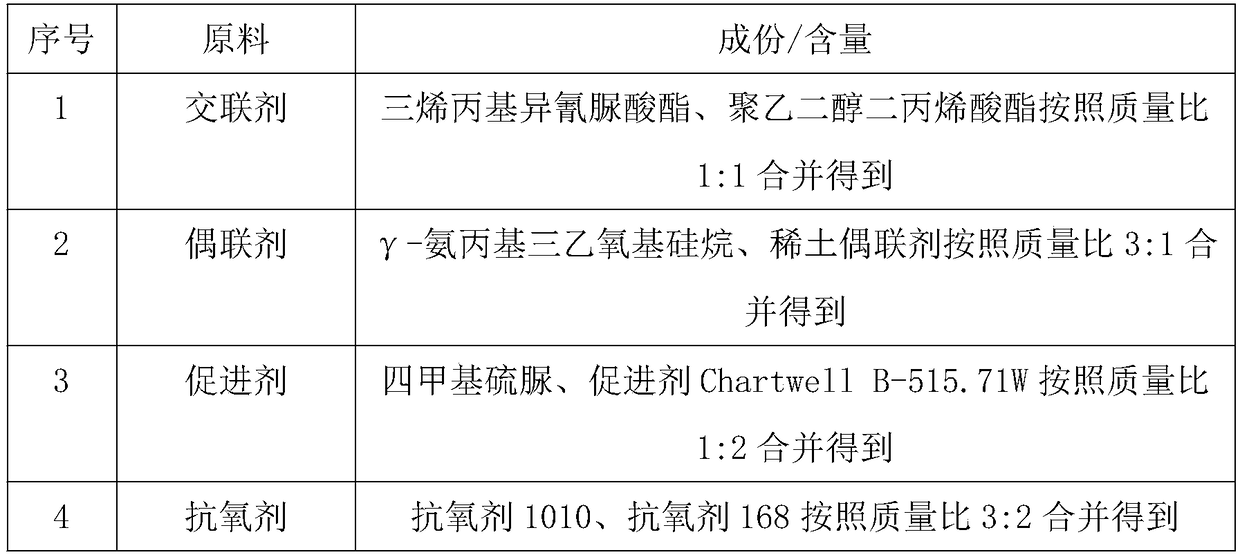

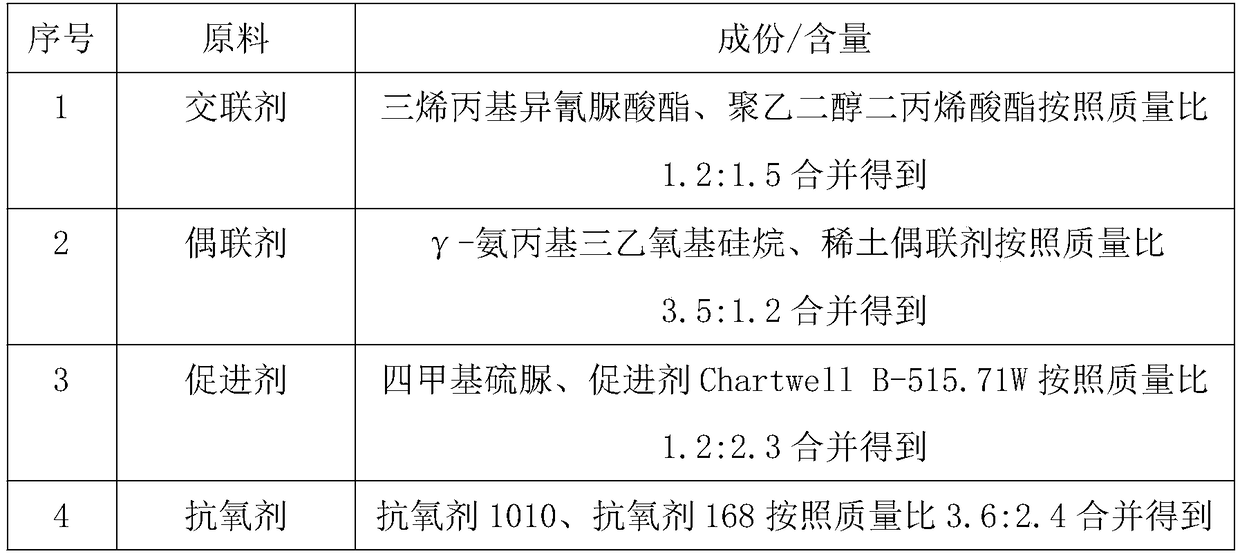

Flame-retardant, high-viscosity and environmental-protection sealant

InactiveCN109021872AThree-dimensional cross-linked dense and stableDoes not affect adhesionNon-macromolecular adhesive additivesMacromolecular adhesive additivesAntioxidantPhosphate

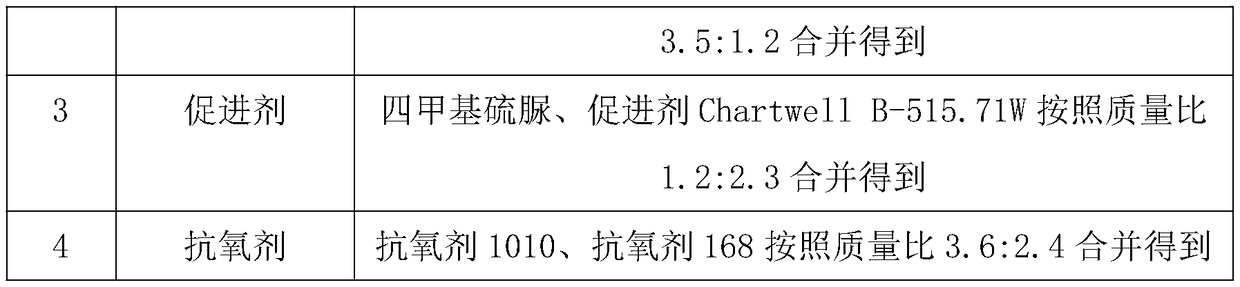

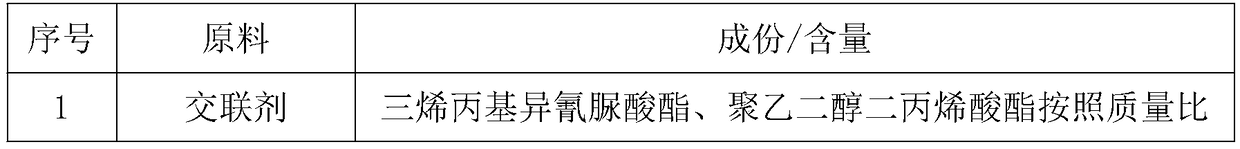

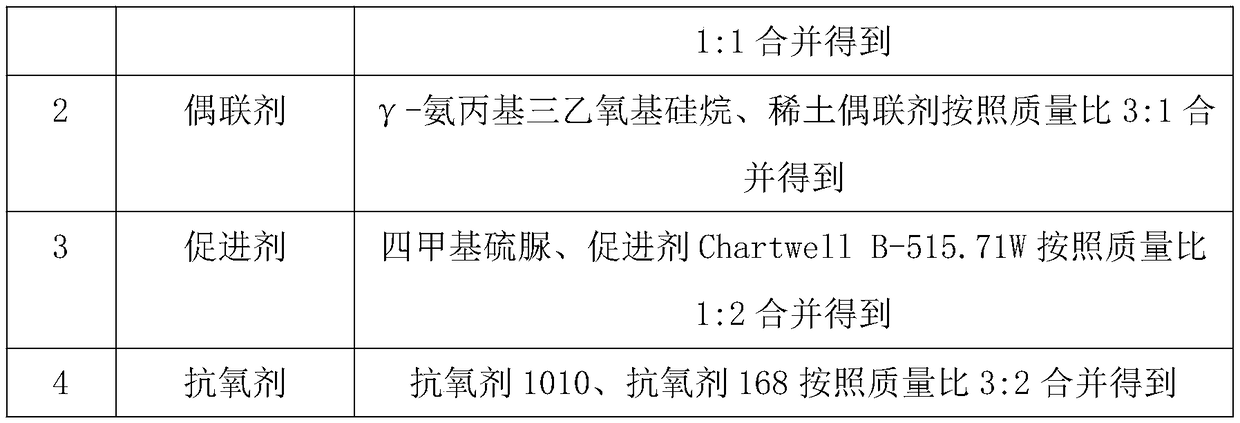

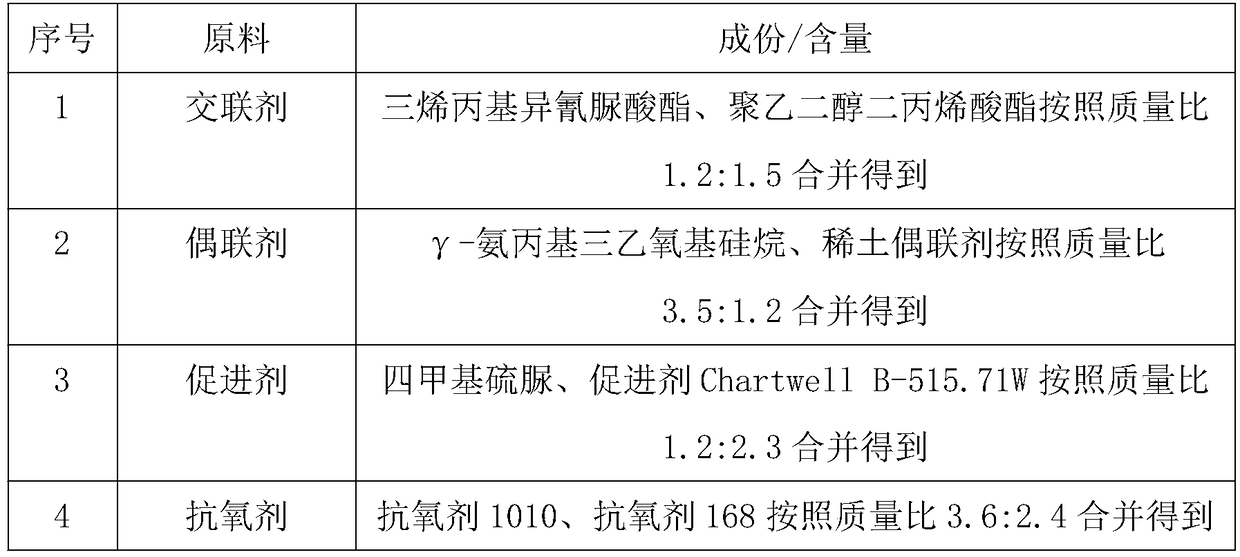

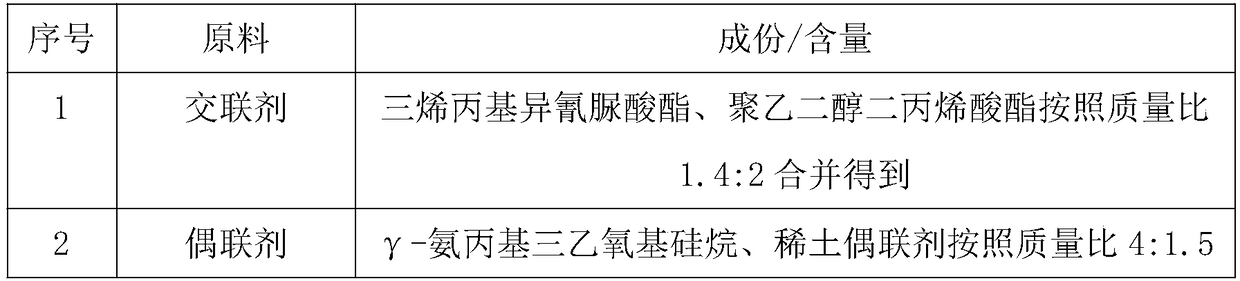

The invention discloses a flame-retardant, high-viscosity and environmental-protection sealant, and relates to the technical field of building sealant, wherein the sealant includes the following raw materials: a vinyl chloride-acrylate copolymer, tert-butyl phenolic tackifying resin, illite powder with a particle size of 20-30 [mu]m, methyl isothiazolinone, flocking powder with a particle size of15-30 [mu]m, triphenylmethane triisocyanate, flaxseed gum, tris(butoxyethyl)phosphate, a dispersant FT-78, a crosslinking agent, an accelerator, an antioxidant, and a coupling agent. The sealant has the advantages of simple and convenient preparation, fast surface drying speed, compact and stable cross-linking structure of an adhesive layer, good tensile bonding performance, flame retardancy, highand low temperature resistance, water prevention and weather resistance, heat preservation, sound insulation, insect expelling and mildew resistance, green energy saving and environmental protection,wide application occasion fields and long service life.

Owner:HEFEI LONGYANG AGRI TECH CO LTD

Building sealant composition and application thereof

InactiveCN108728019AThree-dimensional cross-linked dense and stableFast dryingNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesTriphenylmethane triisocyanatePhosphate

The invention discloses a building sealant composition and application thereof and relates to the technical field of building sealants. The building sealant composition is prepared from the followingraw materials including a vinyl chloride-acrylate copolymer, tert-butyl phenolic tackifying resin, illite powder with the particle size being 20-30 microns, methylisothiazolinone, villus powder with the particle size being 15-30 microns, triphenylmethane triisocyanate, flaxseed gum, tris(butoxyethyl)phosphate, a dispersant FT-78, a crosslinking agent, an accelerator, an antioxidant and a couplingagent. The sealant provided by the invention is simple and convenient to prepare, rapid in surface drying speed, compact and stable in rubber layer crosslinking structure and good in stretching adhesive performance, is flame retardant, resists high-low temperature, water and weather, preserves heat, insulates sound, expels parasites, resists mould, is green and environmentally friendly, saves theenergy and is wide in application places and fields and long in service life.

Owner:HEFEI LONGYANG AGRI TECH CO LTD

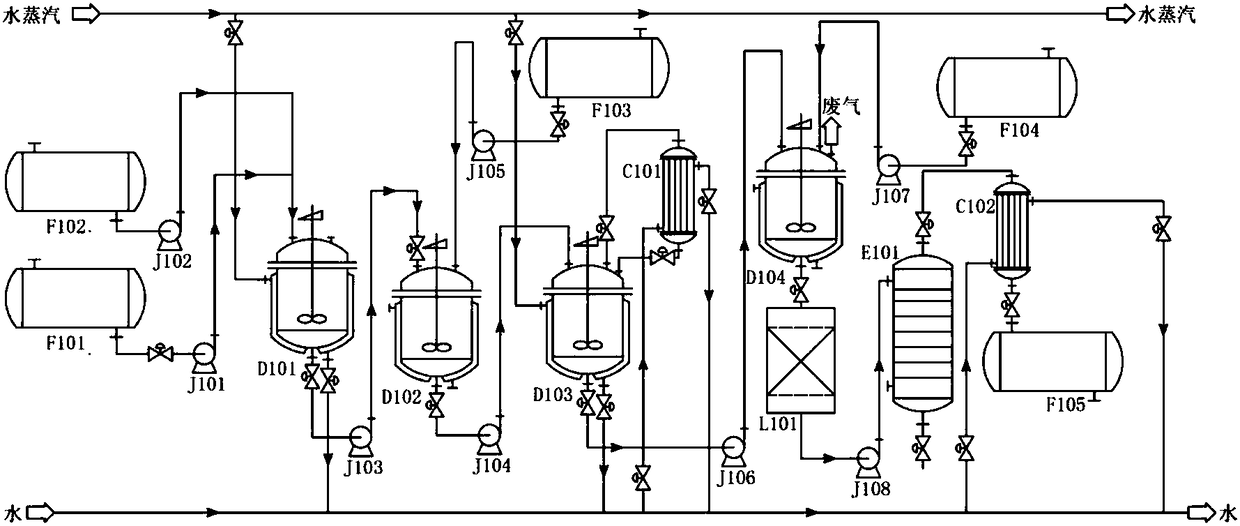

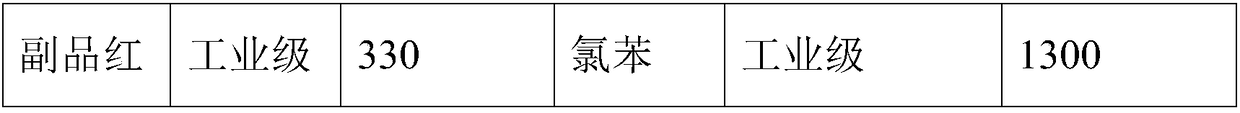

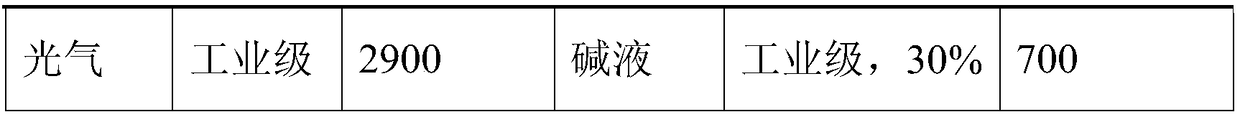

Production device of triphenylmethane triisocyanate

InactiveCN108238980AReduction of intermediate links in the reactionLow reaction temperatureIsocyanic acid derivatives preparationOrganic compound preparationTriphenylmethane triisocyanateChlorobenzene

The invention relates to a production device of triphenylmethane triisocyanate. The production device mainly comprises a low-temperature photochemical kettle (D102), a raw material pump (J101), a rawmaterial pump (J102), a high-temperature photochemical kettle (D103), conveying pumps (J103, J104, J106 and J108), a storage tank (F103), condensers (C101 and C102), a gas expelling kettle (D104), vacuum pump (J105 and J107), a filter (L101), a distillation column (E101), a storage tank (F104), a finished product receiving tank (F105), a storage tank (F101), a storage tank (F102) and a suspensionpreparation kettle (D101), wherein the storage tank (F103) is used for storing phosgene, the storage tank (F104) is used for storing nitrogen, the storage tank (F101) is used for storing chlorobenzene, the storage tank (F102) is used for storing parafuchsin, and the diameter of a water inlet of the raw material pump (J102) is 230-250mm.

Owner:成都麦克贝恩科技有限公司

Microencapsulation ammonium polyphosphate fire retardant and preparation method thereof

ActiveCN103252200BGood dispersionGood compatibilityFibre treatmentMicroballoon preparationMethyl palmoxirateHydroxymethyl

The invention relates to a microencapsulation ammonium polyphosphate fire retardant and a preparation method thereof. The microencapsulation ammonium polyphosphate fire retardant is prepared from the following raw materials in percentage by weight: 100%-102% of crystal phase APP II (Ammonium Polyphosphate II), 4%-4.5% of melamine, 11%-11.5% of MDI (Diphenylmethane Diisocyanate), 0.4%-0.5% of triphenylmethane triisocyanate, 5%-5.5% of dicyclohexylcarbodiimide, 0.5%-0.8% of trimethylolethane, 120%-125% of acetone and 27%-29% of methylbenzene and is prepared through a double-layer coating process procedure. The microencapsulation ammonium polyphosphate fire retardant disclosed by the invention has the characteristics of easiness for dispersion, good compatibility, high stability, low hygroscopicity and high fire-retardant property.

Owner:LIAONING FIXED STAR FINE CHEM

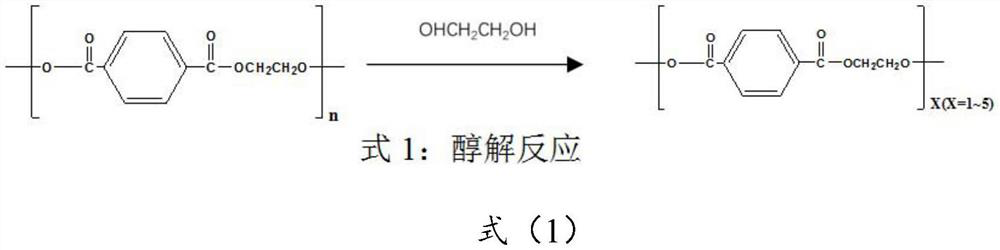

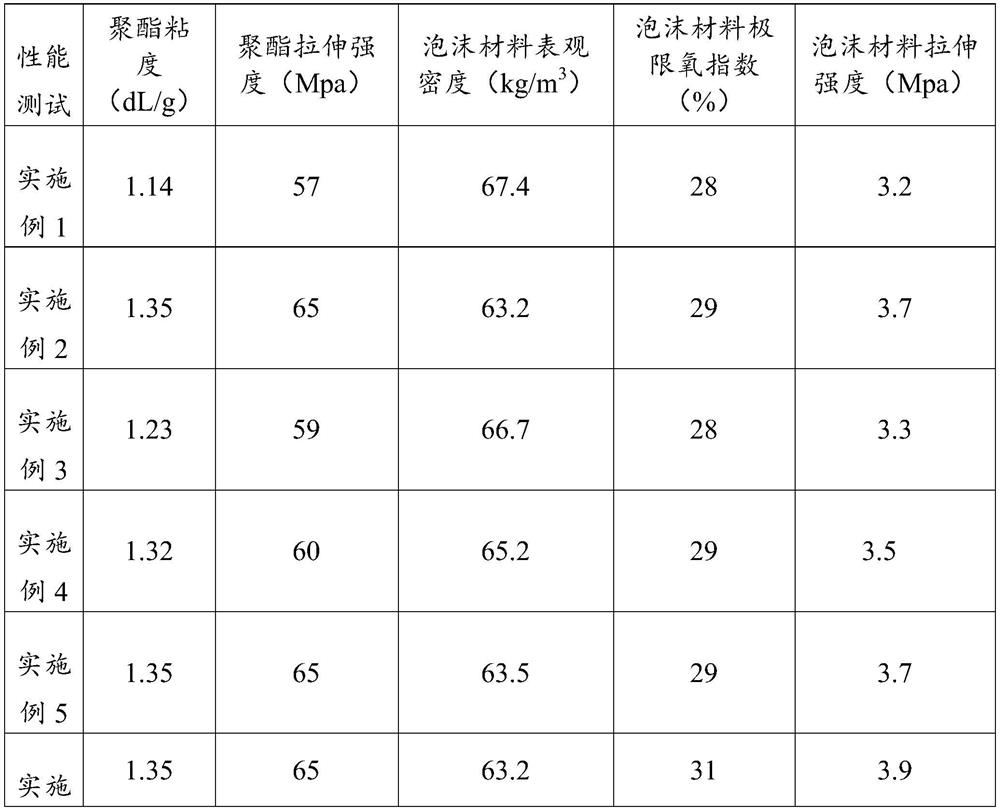

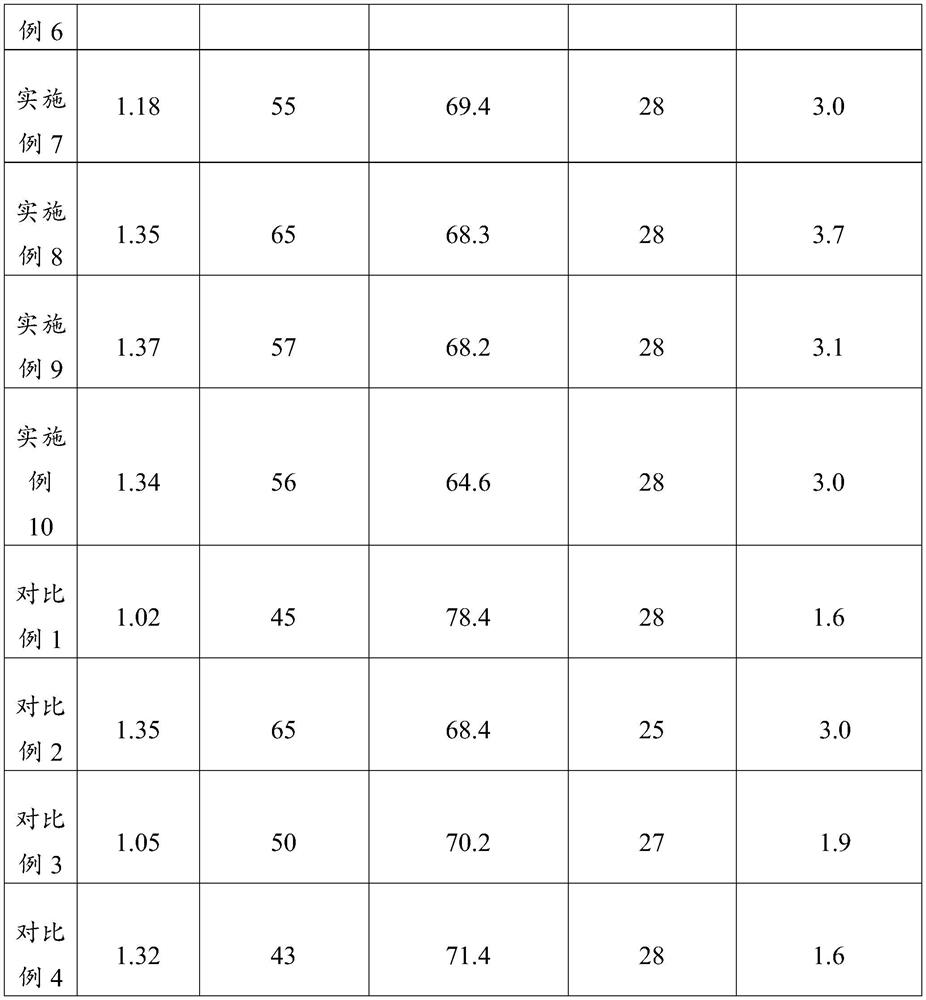

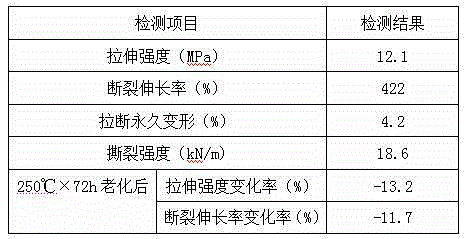

Regenerated PET polyester, regenerated flame-retardant PET foam material and preparation method of regenerated flame-retardant PET foam material

The invention discloses regenerated PET polyester, a regenerated flame-retardant PET foam material and a preparation method thereof, and relates to the technical field of engineering plastics. The invention provides regenerated PET polyester. The regenerated PET polyester is prepared from the following components in parts by weight: 5 to 50 parts of recycled PET polyester, 40 to 85 parts of terephthalic acid, 30 to 45 parts of ethylene glycol, 0.01 to 0.1 part of a catalyst, 0.01 to 1 part of a stabilizer, 0.2 to 4 parts of a nucleating agent, 0.01 to 0.5 part of an antioxidant and 0.02 to 0.15 part of a branching agent, wherein the branching agent is selected from at least two of triphenylmethane triisocyanate, triphenyl isocyanate thiophosphate, tri (4-aminophenyl) amine, pyromellitic dianhydride, pentaerythritol, bisphenol A diglycidyl ether and triglycidyl isocyanurate. The invention also provides a regenerated flame-retardant PET foam material containing the regenerated PET polyester and a flame retardant, the prepared foam material not only has flame retardant property, but also can ensure the melt uniformity and various stable properties of the material, and the preparation process is safe, reliable, environment-friendly and pollution-free.

Owner:CHINA RESOURCES PACKAGING MATERIALS CO LTD

Flame retardant coating adhesive and preparation method thereof

InactiveCN109836984AIncrease elasticityCorrosion resistanceFireproof paintsPolyurea/polyurethane coatingsAdhesivePhosphate

Belonging to the technical field of coating adhesives, the invention in particular relates to a flame retardant coating adhesive and a preparation method thereof. The flame retardant coating adhesiveis prepared from the following raw materials by weight: 80-120 parts of a waterborne matrix emulsion, 20-35 parts of a polyurethane coating adhesive, 18-22 parts of cyclic phosphate, 10-15 parts of isocyanate, 10-16 parts of tripentaerythritol, 20-26 parts of antimony trioxide, 10-22 parts of ammonium polyphosphate, 8-16 parts of a flame retardant synergist, 5-10 parts of toluene, 5-8 parts of diphenylmethane diisocyanate, 3-8 parts of water-borne blocked isocyanate, 2-5 parts of triphenylmethane triisocyanate and 1-5 parts of trimethylolethane. The flame retardant coating adhesive provided bythe invention has the advantages of good elasticity, corrosion resistance, good flame retardance and the like.

Owner:沈阳邦正科技有限公司

Anti-UV irradiation silicone rubber compound and preparation method thereof

InactiveCN104312153AImprove Radiation PerformanceImprove thermal stabilityPolymer scienceAluminum magnesium silicate

The invention discloses an anti-UV irradiation silicone rubber compound and a preparation method thereof. The rubber compound consists of the following raw materials by weight: 40-60 parts of high phenyl silicone rubber, 25-45 parts of methyl MQ silicon resin, 1.5-2.5 parts of 4,4',4''-triphenylmethane triisocyanate, 5-10 parts of aluminum magnesium silicate, 3-6 parts of white factice, 2-3 parts of cobalt 2-ethylhexanoate, 2-3 parts of octamethyl cyclotetrasiloxane, 3-4 parts of tert-Butyl hydroperoxide, 3-6 parts of ethyleneglycol dimethacrylate, 2-4 parts of N,N'-dicyclohexylcarbodiimide, 10-15 parts of waste tire rubber powder, 2-3 parts of Di-t-butoxydiacetoxysilane, 8-14 parts of light calcium carbonate, 5-10 parts of glycerol tribenzoate, 4-8 parts of dipropylene glycol monosalicylate, 1-2 parts of 4-tert-butylphenol 2-hydroxy-4-methoxybenzophenone-5-sulfonic acid and 2-4 parts of an assistant. The silicone rubber compound provided by the invention has excellent anti-ultraviolet irradiation performance, good thermal stability to ultraviolet, and can be used for a long time under sunlight; and the rubber compound has excellent mechanical strength, high and low temperature resistance, corrosion resistance, electrical insulation property, long service life, wide application range and low cost.

Owner:天长市荣盛有机硅科技有限公司

A kind of low temperature resistant rubber and plastic product and preparation method thereof

The invention belongs to the technical field of rubber and plastic products, and proposes a low-temperature-resistant rubber and plastic product and a preparation method thereof, comprising the following components in parts by weight: 15 to 20 parts of nitrile rubber, 2 to 3 parts of butadiene rubber, polyvinyl chloride 4-7 parts of resin, 4-7 parts of foaming agent, 3-5 parts of carbon black, 10-13 parts of rubber process oil, 4-7 parts of low-temperature modifier, 0.3-0.5 parts of active agent, 0.1-0.1 parts of stearic acid 0.3 parts, 5-9 parts of aluminum tripolyphosphate, 3-5 parts of barium metaborate, 10-12 parts of filler, 3-5 parts of protective wax, 2-4 parts of accelerator, 0.1-0.3 parts of vulcanizing agent, the low temperature The modifier consists of the following components in parts by weight: 5-8 parts of dioctyl sebacate, 3-5 parts of polydimethylsiloxane, 0.5-1 part of N-methylpyrrolidone, triphenylmethane 2.5-4 parts of isocyanate. Through the above technical solution, the problem that the minimum service temperature of the rubber and plastic products in the prior art can only reach -20°C and the low temperature resistance is poor is solved.

Owner:HEBEI SHENZHOU THERMAL INSULATION BUILDING MATERIAL GRP CO LTD

Preparation method of rural experience type light-storing luminescent material

InactiveCN111961364AIncrease the function of light storage and light emissionHard to quenchLuminescent paintsPolyurea/polyurethane coatingsTriphenylmethane triisocyanateWeather resistance

The invention provides a preparation method of a rural experience type light-storing luminescent material. The preparation method comprises the following specific steps: dehydrating a mixed solution of dihydric alcohol and trihydric alcohol at 100-110 DEG C under the vacuum condition of 0.05-0.2 MPa for 3-5 hours; adding an aliphatic ketone solution and an organic tin solution into the dehydratedalcohol solution, mixing, heating to 70-80 DEG C, adding triphenylmethane triisocyanate, and carrying out heat preservation reaction for 1.5-2.5 hours at 70-80 DEG C; and adding the light-storing luminescent material into the catalytic reaction, and continuing the heat preservation reaction to obtain the single-component light-storing polyurethane luminescent material. According to the luminescentmaterial prepared by the method, the light-storing and light-emitting functions of the coating are improved, the problems of the traditional fluorescent coating are solved, and the obtained luminescent material has the advantages of increased light-emitting stable strength, difficulty in migration, lasting and stable maintenance of a light-emitting group, excellent glossiness and weather resistance, difficulty in quenching and typical light-storing and light-emitting enhancement effect.

Owner:FUJIAN SPRING ECOLOGICAL TECH CO LTD

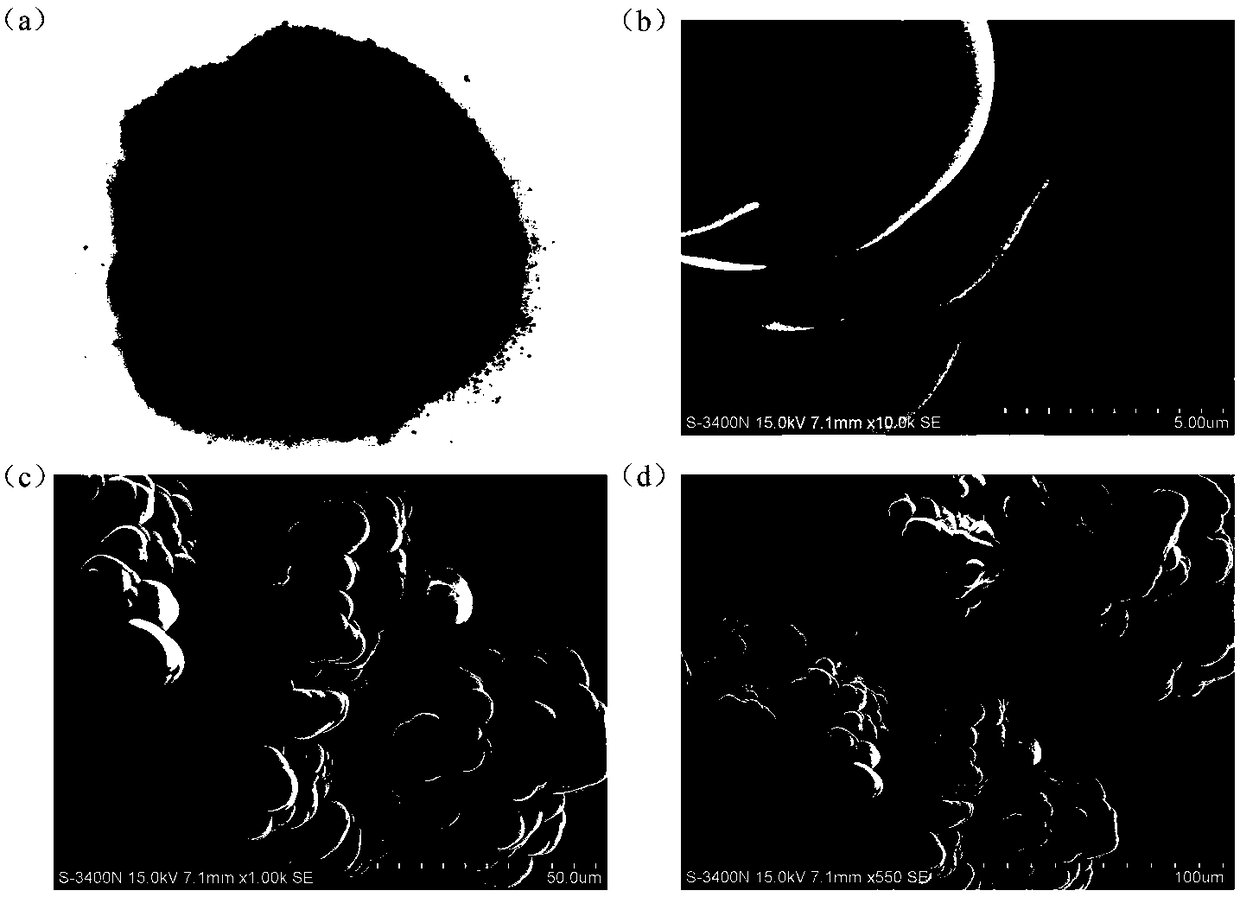

A nanoparticle reinforced self-lubricating cast nylon composite shaft sleeve and its manufacturing method

A nanoparticle reinforced self-lubricated cast nylon composite shaft sleeve is prepared from components including a caprolactam monomer, sodium hydroxide, triphenylmethane triisocyanate, nano graphite fluoride and mica powder in a weight ratio being 100:(0.15-0.45):(0.3-0.6):(0.4-0.5):(2.0-4.0). The manufacturing method of the composite shaft sleeve comprises preparation of reaction melts, preparation of a dispersion liquid as well as molding and demolding, the centrifugal casting method is adopted in the casting process, so that more nano graphite fluoride and mica powder are centralized and distributed on the outer surface of the shaft sleeve, the shaft sleeve has better bearing capacity and more excellent anti-friction and wear-resistance properties, the wear of the shaft sleeve is reduced, and the service life of the shaft sleeve is prolonged.

Owner:HENAN UNIV OF SCI & TECH

LED (Light-emitting diode) encapsulating material with high hardness and excellent bonding strength and preparation method of LED encapsulating material

InactiveCN107502259AHigh hardnessHigh bonding strengthNon-macromolecular adhesive additivesMacromolecular adhesive additivesDiphenylmethaneRefractive index

The invention discloses an LED (light-emitting diode) encapsulating material with high hardness and excellent bonding strength. The LED encapsulating material is prepared from the following raw materials in parts by weight: 45 to 49 parts of cycloaliphatic epoxy resin, 20 to 24 parts of diamino diphenylmethane tetraglycidylamine, 6 to 10 parts of terminal carboxyl liquid nitrile rubber, 2 to 5 parts of polyimide, 8 to 12 parts of methyl-ethyloxy silicone oil, 1 to 3 parts of triphenyl methane triisocyanate, 0.3 to 0.7 part of yttrium isopropoxide and 2 to 3 parts of modified titanium sol. The invention also discloses a preparation method of the LED encapsulating material with high hardness and excellent bonding strength. The encapsulating material prepared by the invention has relatively high hardness and bonding strength; the refractive index can meet the market requirement, the quality of an LED can be ensured, and the service life of the LED can be prolonged.

Owner:陈贤尧

Anti-stripping agent as well as preparation method and application thereof

ActiveCN114479218AEnhanced resistance to peelingReduce peelingClimate change adaptationTriphenylmethane triisocyanateEngineering

The invention discloses an anti-stripping agent as well as a preparation method and application thereof. The anti-stripping agent comprises the following raw materials: styrene butadiene rubber, triphenylmethane triisocyanate, a p-phenylenediamine compound, a coupling agent and aromatic oil. The preparation method comprises the following steps: uniformly mixing the materials, mixing and extruding to obtain the anti-stripping agent. The asphalt anti-stripping agent is pasty and does not need to be cured in the using process, the production time of anti-stripping asphalt is shortened, and the working efficiency is improved. The anti-stripping agent disclosed by the invention is used in airport asphalt, can remarkably improve the adhesion strength of the asphalt and improve the anti-stripping performance, and has relatively strong adaptive capacity to a high-temperature wake flow environment of an airplane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing PBT (polybutylene terephthalate) resin with anti-bacterial function

ActiveCN104804178APermanent antibacterial functionSimple processing methodPolytetramethylene terephthalateReaction temperature

The invention provides a method for preparing PBT (polybutylene terephthalate) resin with an anti-bacterial function. The method comprises steps as follows: 100 parts of PTA pure terephthalic acid, 50-100 parts of 1,4-BDO (butanediol) and 0.2-2 parts of a composite titanium catalyst are added to an esterification reaction kettle, are stirred uniformly and react for 60-270 min at the esterification temperature of 205-225 DEG C under the normal pressure to obtain an esterification reaction product (BHBT); the esterification reaction product (BHBT) is introduced into a polycondensation reaction tank, the reaction temperature is controlled in a range from 250 DEG C to 260 DEG C, a reaction is performed for 1 h under the normal pressure, 1-5 parts of a TTI (triphenylmethane triisocyanate) modified negative ion powder chain extender are added, and the mixture reacts for 1 h under the condition of low vacuum (under the pressure reduced from 50 kPa to 2.5 kPa) and then reacts for 4-7 h under the condition of high vacuum (under the pressure reduced from 133 Pa to 33 Pa) until the power of a stirring paddle shaft is not increased. According to the method, negative ion mineral powder is organically combined in the PBT molecular chain, so that the product has the permanent anti-bacterial function.

Owner:QUANZHOU NAISI MATERIAL TECH

A preparation method of thermally induced flexible phase change energy storage wood

ActiveCN113319956BEasy to integrateImprove permeabilityClimate change adaptationWood treatment detailsN dimethylformamideTriphenylmethane triisocyanate

The invention discloses a method for preparing heat-induced flexible phase change energy storage wood, which is carried out according to the following steps: a. Using N,N dimethylformamide as a solvent, prepare 0.05-0.2mol / L triethanolamine solution 50- 70 parts and 40-60 parts of 0.1-0.4mol / L triphenylmethane triisocyanate solution; b, adding the triethanolamine solution in step a to the triphenylmethane triisocyanate solution, stirring at 60-80°C for 10- 15 hours to obtain a prepolymer; c, adding 10-20 parts of polyethylene glycol-1500 to the prepolymer, stirring at 60-80°C for 20-30 hours to obtain a solid-solid phase change material; d, adding The delignified wood is put into the solid-solid phase change material, vacuum impregnated for 20-40 minutes and then dried to obtain the finished product. The phase change energy storage wood prepared by the invention not only has the ability to store heat and store energy, but also has good flexibility.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Method for preparing polyurethane-polydiphenylamine antistatic material

The invention discloses a method for preparing a polyurethane-polydiphenylamine antistatic material, and the polyurethane-polydiphenylamine antistatic material is prepared from diphenylamine, sodium dodecyl benzene sulfonate, (NH4) 2S2O8, triphenylmethane triisocyanate, ethanol, propylene glycol and other raw materials by combination of vacuum distillation, ice water bath, acid treatment and other methods. The material prepared by the method has very good antistatic performance.

Owner:徐州乐泰机电科技有限公司

Waterproof and weatherproof building sealant

InactiveCN109021871AThree-dimensional cross-linked dense and stableFast dryingNon-macromolecular adhesive additivesAldehyde/ketone condensation polymer adhesivesTriphenylmethane triisocyanateWeather resistance

The invention discloses a waterproof and weatherproof building sealant, and relates to the technical field of building sealant, wherein the waterproof and weatherproof building sealant includes the following raw materials: a vinyl chloride-acrylate copolymer, tert-butyl phenolic tackifying resin, illite powder with the particle size of 20-30 [mu]m, methyl isothiazolinone, flocking powder with theparticle size of 15-30 [mu]m, triphenylmethane triisocyanate, flaxseed gum, tris(butoxyethyl)phosphate, a dispersant FT-78, a crosslinking agent, an accelerant, an antioxidant, and a coupling agent. The sealant has the advantages of simple and convenient preparation, fast surface drying speed, compact and stable cross-linking structure of an adhesive layer, good tensile bonding performance, flameretardancy, high and low temperature resistance, water prevention and weather resistance, heat preservation, sound insulation, insect expelling and mould resistance, green energy saving and environmental protection, wide application occasion fields and long service life.

Owner:HEFEI LONGYANG AGRI TECH CO LTD

Asphalt anti-stripping agent as well as preparation method and application thereof

ActiveCN114479486AEnhanced resistance to peelingReduce peelingClimate change adaptationBuilding insulationsTriphenylmethane triisocyanateEngineering

The invention discloses an asphalt anti-stripping agent as well as a preparation method and application thereof. The asphalt anti-stripping agent comprises the following raw materials: butadiene styrene rubber, triphenylmethane triisocyanate, a p-phenylenediamine compound and a coupling agent. The preparation method of the asphalt anti-stripping agent comprises the following steps: uniformly mixing the materials, mixing and granulating to obtain the asphalt anti-stripping agent. The asphalt anti-stripping agent disclosed by the invention is granular, is used in airport asphalt, can remarkably improve the adhesion strength of the asphalt and improve the anti-stripping performance, and has relatively strong adaptive capacity to a high-temperature wake flow environment of an airplane.

Owner:CHINA PETROLEUM & CHEM CORP +1

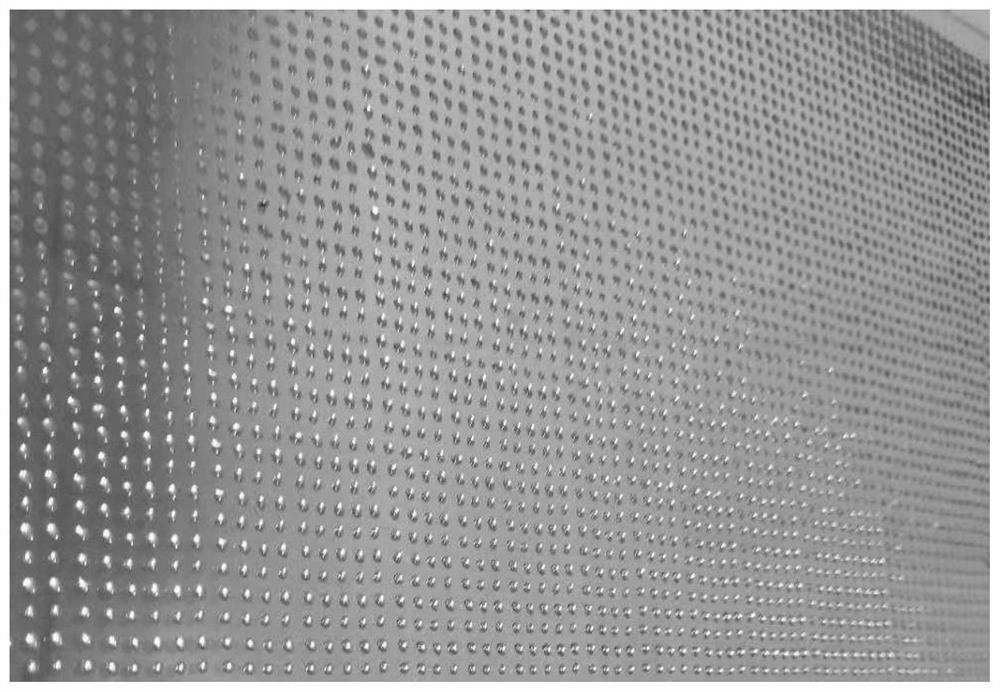

Glass coated with metal refractive raindrops on surface, and preparation process thereof

ActiveCN113387594AHigh transparencyGood transition connectionEpoxy resin coatingsPolymer scienceFirming agent

The invention relates to the technical field of glass production processes, and concretely relates to a glass coated with metal refraction raindrops on the surface, and a preparation process THEREOF. The glass coated with metal refraction raindrops on the surface comprises a glass plate, a transition layer is arranged on the glass plate, and metal refraction raindrops formed by shrinking and curing an epoxy composition are arranged on the transition layer. The epoxy composition is prepared from, by weight, 10 to 15 parts of brominated bisphenol A type epoxy resin, 8 to 12 parts of novolac epoxy resin, 5 to 10 parts of triphenylmethane triisocyanate, 7 to 12 parts of tetrafunctional epoxy resin, 8 to 15 parts of an organic solvent, 0.8 to 1.2 parts of a curing accelerator and 1 to 1.5 parts of a curing agent. By preparing the epoxy resin composition, the epoxy resin composition can be smoothly shrunk to form metal refraction raindrops, and the raindrops also have relatively strong adhesion ability and relatively good scratch resistance and weather resistance, so that metal-like raindrops are formed on the surface of glass, and a relatively strong artistic decoration effect is achieved.

Owner:YIWU HUAHONG CULTURE CREATIVE CO LTD

Reactive polyurethane adhesive for bonding and preparation method thereof

ActiveCN114874739AIncrease the degree of cross-linkingHigh strengthPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention relates to a reactive polyurethane adhesive for bonding. The adhesive is prepared from the following raw materials in parts by weight: 39.6 to 175.8 parts of diisocyanate, 0.2 to 5 parts of triphenylmethane triisocyanate, 5 to 50 parts of polyester diol, 100 to 400 parts of polyether diol, 0.5 to 10 parts of polyether triol, 10 to 40 parts of chain extender, 0.1 to 1 part of silane coupling agent, 0.2 to 2 parts of latent curing agent and 0.01 to 0.5 part of catalyst. The invention also discloses a preparation method of the adhesive. The obtained reactive polyurethane adhesive has the advantages of being good in initial adhesion, moderate in use temperature, easy to coat, free of blistering and high in curing speed, and can be widely applied to adhesion of decorative layers and base materials such as solid wood, composite boards and fiberboards with different densities.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com