Patents

Literature

110 results about "Trimethylolethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Trimethylolethane (TME) is the organic compound with the formula CH₃C(CH₂OH)₃. This colorless solid is a triol, as it contains three hydroxy functional groups. More specifically, it features three primary alcohol groups in a compact neopentyl structure. Its esters are known for their resistance to heat, light, hydrolysis, and oxidation. More important than TME and closely related is trimethylolpropane (TMP).

Ink for ink jet recording, ink set for ink jet recording, method for ink jet recording, ink cartridge for ink jet recording, ink jet recording apparatus and recorded article

InactiveUS6695443B2Excellent ejection stabilityGood storage stabilityMeasurement apparatus componentsInksPolyolImaging quality

An ink for ink jet recording and an ink jet recording method which realize an image quality of laser printer on a plain paper in a one-pass printing mode under conditions of a volume of an ink droplet ejected being 5 to 43 Pico liter, a velocity of an ink droplet being 6 to 20 m / sec, frequency of 1 kHz and resolution of 300 dpi or more. The ink for ink jet recording is a penetrating type ink which includes (1) at least one humectant selected from glycerin, 1,3-butandiol, triethyleneglycol, 1,6-hexanediol, propyleneglycol, 1,5-pentanediol, diethyleneglycol, dipropyleneglycol, trimethylolpropane and trimethylolethane, (2) colorant contained in the amount of 6% by weight or more, (3) a polyol having 8 to 11 carbon atoms and glycolether, and an anionic surfactants or non-ionic surfactants, the ink has viscosity of 5 mPa.s or more at 25° C. and a surface tension of 40 mN / m or less.

Owner:RICOH KK

Ink for ink jet recording, ink set for ink jet recording, method for ink jet recording, ink cartridge for ink jet recording, ink jet recording apparatus and recorded article

InactiveUS20030107632A1Excellent ejection stabilityGood storage stabilityMeasurement apparatus componentsInksImaging qualityEngineering

An ink for ink jet recording and an ink jet recording method which realize an image quality of laser printer on a plain paper in a one-pass printing mode under conditions of a volume of an ink droplet ejected being 5 to 43 Pico liter, a velocity of an ink droplet being 6 to 20 m / sec, frequency of 1 kHz and resolution of 300 dpi or more. The ink for ink jet recording is a penetrating type ink which comprises (1) at least one humectant selected from glycerin, 1,3-butandiol, triethyleneglycol, 1,6-hexanediol, propyleneglycol, 1,5-pentanediol, diethyleneglycol, dipropyleneglycol, trimethylolpropane and trimethylolethane, (2) colorant contained in the amount of 6 % by weight or more, (3) a polyol having 8 to 11 carbon atoms and glycolether, and an anionic surfactants or non-ionic surfactants, the ink has viscosity of 5 mPa.s or more at 25° C. and a surface tension of 40 mN / m or less.

Owner:RICOH KK

Polyolefin fibers and method for the production thereof

InactiveUS6811716B1Poor propertyPoor processabilityOther chemical processesFibre typesFiberPolyolefin

A method for producing hydrophobic polyolefin-containing fibers or filaments, in particular cardable staple fibers, using spin finishes applied after spinning and stretching, that comprise at least one water-insoluble ester of a mono-, di-, tri- or tetrahydric alcohol with a molecular weight not exceeding 500 and a branched or straight chain fatty acid with between 12 and 30 carbon atoms, e.g. a water-insoluble ester of ethylene or propylene glycol, glycerol, neopentyl glycol, trimethylolethane or trimethylolpropane and at least one saturated or unsaturated fatty acid residue having 12-24 carbons atoms, an anionic or nonionic antistatic agent preferably being applied after crimping; fibers produced by the method; and nonwovens produced from such fibers.

Owner:FIBERVISIONS LP

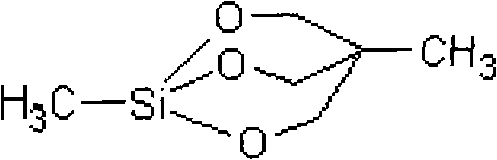

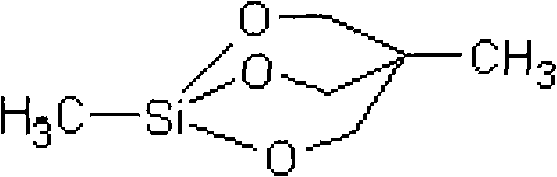

Cage-shaped organic silicon flame retardant charring agent and preparation method thereof

ActiveCN102146093ACompact and stable structureStrong insulationGroup 4/14 element organic compoundsCoatingsMethyltrimethoxysilanePhysical chemical

The invention relates to a cage-shaped organic silicon flame retardant charring agent, i.e. a 1,4-dimethyl-1-sila-2,6,7-trioxabicyclo[2,2,2]-octane compound, and a preparation method thereof. The compound has a structure shown as the following formula in the specification. The preparation method comprises the step of: reacting methyl trichlorosilane or methyltrimethoxysilane with trimethylolethane in an organic solvent to prepare 1,4-dimethyl-1-sila-2,6,7-trioxabicyclo[2,2,2]-octane. The cage-shaped organic silicon flame retardant charring agent is a novel halogen-free non-toxic flame retardant charring agent, which has high flame retardant performance and good charring performance, can effectively prevent the melting and the dropping of high polymer during combustion, and is stable in physical and chemical properties, good in compatibility with macromolecular materials, high in raw material availability, simple in process and easy for industrial production.

Owner:SUZHOU UNIV OF SCI & TECH

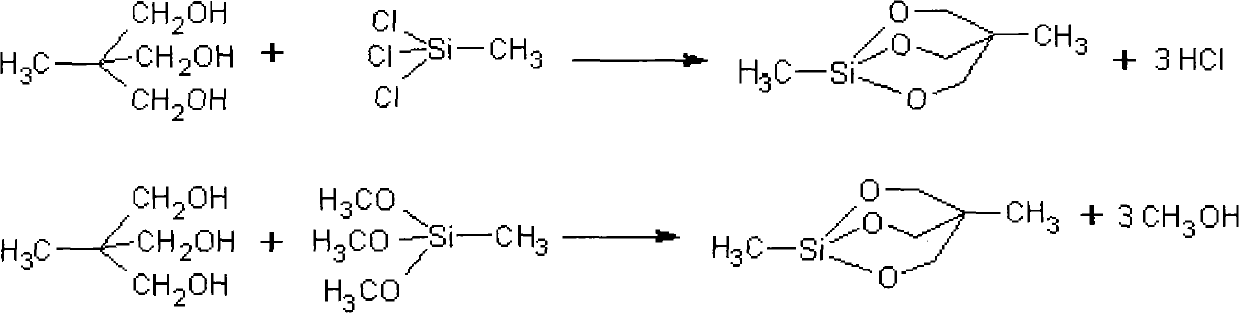

Low-hardness solvent-proof polyurethane elastomer and preparation method thereof

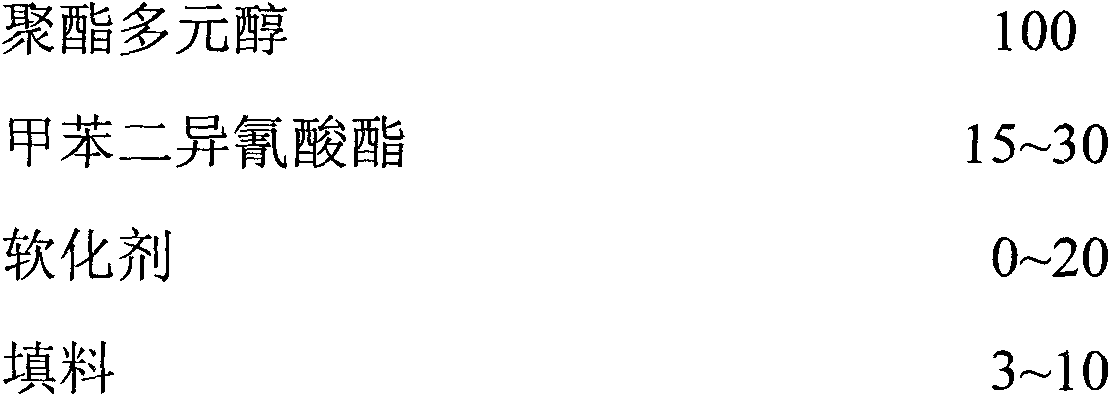

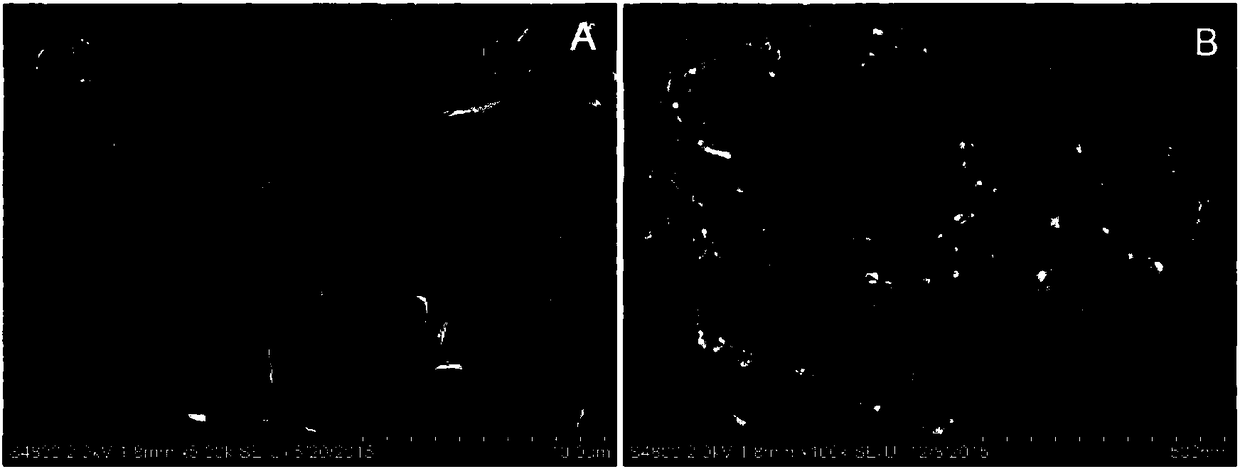

The invention discloses a low-hardness solvent-proof polyurethane elastomer and a preparation method thereof. The raw material of the low-hardness solvent-proof polyurethane elastomer comprises two parts including a component A and a component B, wherein the component A comprises 100 parts of polyester polyatomic alcohol, 15 to 30 parts of toluene diisocyanate, 0 to 20 parts of soften flux, and 3 to 10 parts of filling material; the component B comprises 100 parts of chain extendor, 0 to 0.5 part of foam killer, and 0.02 to 0.05 part of catalyst. The chain extendor is composed of an alcohol amine chain extendor and a three-functionality alcohol chain extendor, wherein the alcohol amine chain extendor adopts a mixture of TIPA (triisopropanolamine) and DEA (diethanol amine) or TEA ( triethavolamine), and the mixture molar ratio is 1 to 0.5-1.5; the three-functionality alcohol chain extendor is made of GLY (glycerine),TMP (trimethylolpropane) or TME (trimethylolethane); the molar ratio of the three-functionality alcohol chain extendor to the alcohol amine mixture is 1 to 0.25-1.5. The material has a better mechanical property, and better solvent resisting performance and cutting machinability, and can be used in the fields of color coating and the like.

Owner:LIMING RES INST OF CHEM IND

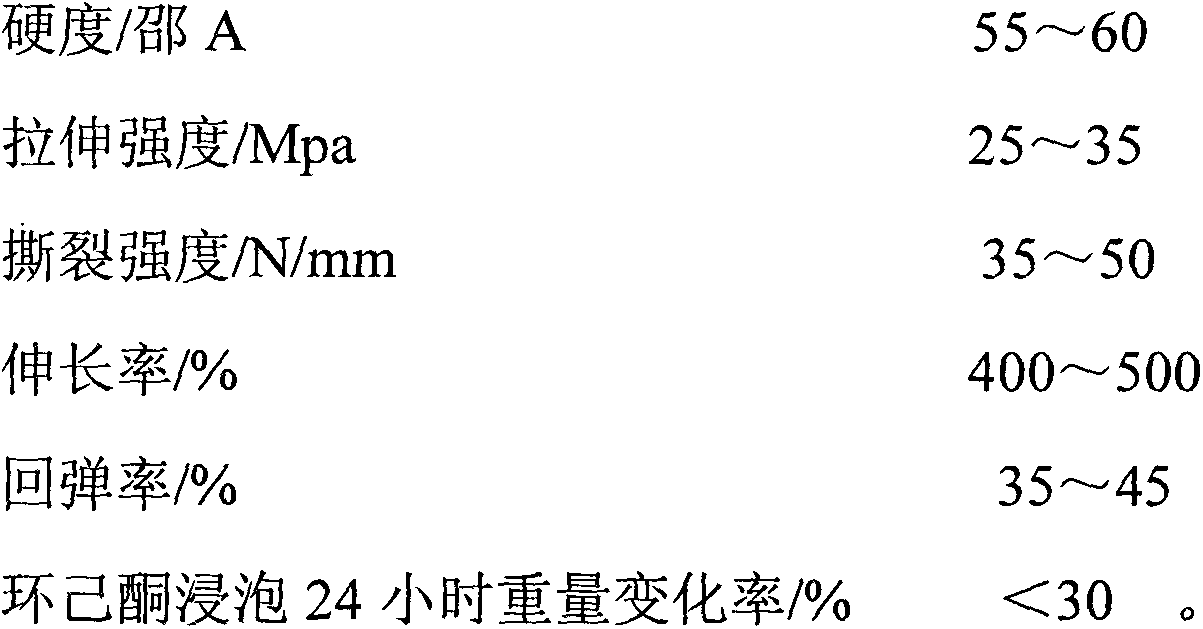

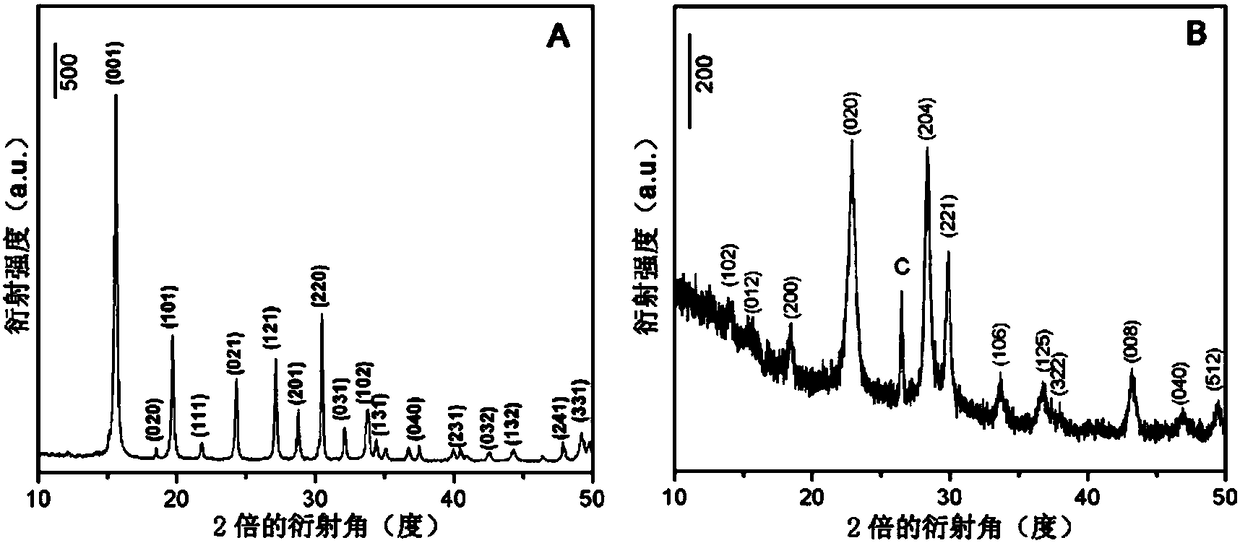

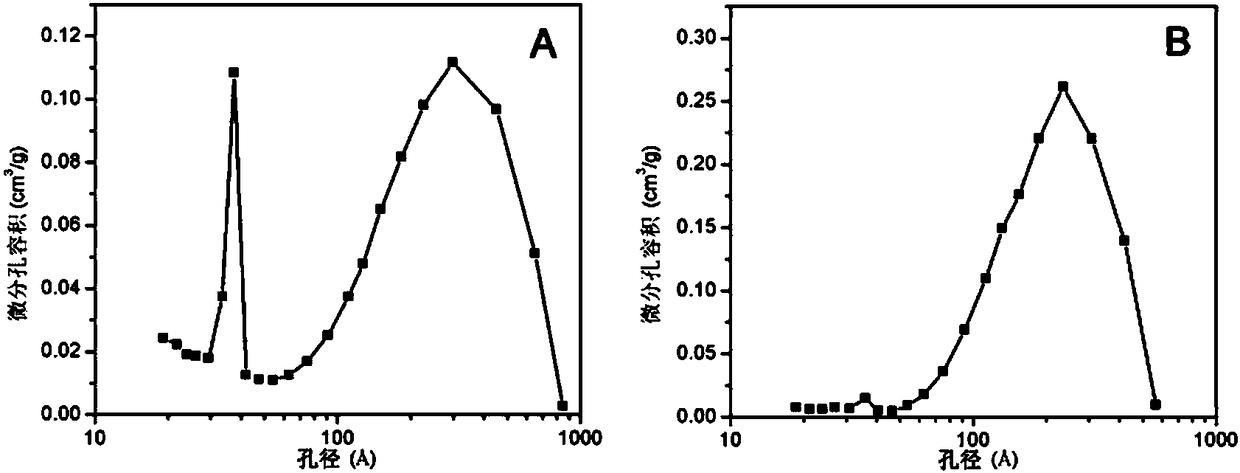

Vanadium phosphorus oxide catalyst for preparing maleic anhydride from n-butane through oxidation and preparation method thereof

ActiveCN108339558AImprove responseHigh yield of maleic anhydridePhysical/chemical process catalystsOrganic chemistryPhthalic anhydrideButane

The invention provides a vanadium phosphorus oxide catalyst for preparing maleic anhydride from n-butane through oxidation. The vanadium phosphorus oxide catalyst is prepared by treating a vanadium phosphorus oxide catalyst matrix with a pore-enlarging agent; the mass content of elemental vanadium in the catalyst is 28 to 35%; the mass content of elemental phosphorus in the catalyst is 15 to 25%;and the pore-enlarging agent comprises one or more selected from a group consisting of 1,1,1-trimethylolethane, trimethylolpropane, phthalic anhydride, maleic anhydride, tartaric acid, and citric acidor In many cases, and a mass ratio of the pore-enlarging agent to the vanadium phosphorus oxide catalyst matrix is (5-20): (80-95). According to the invention, the pore-enlarging agent is added and the removal process of the pore-enlarging agent is controlled in the post-treatment process of the catalyst, so the specific surface area and the pore structure of the treated catalyst can be controlled and improved; and thus, the activity of the catalyst in catalysis of the selective oxidation of butane and the selectivity of produced maleic anhydride are improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

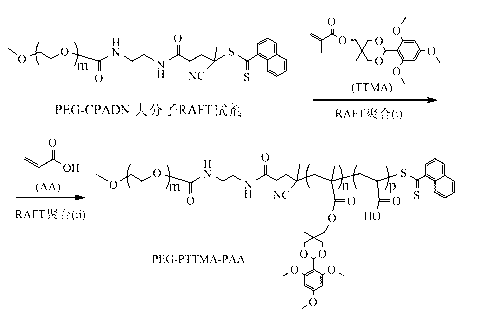

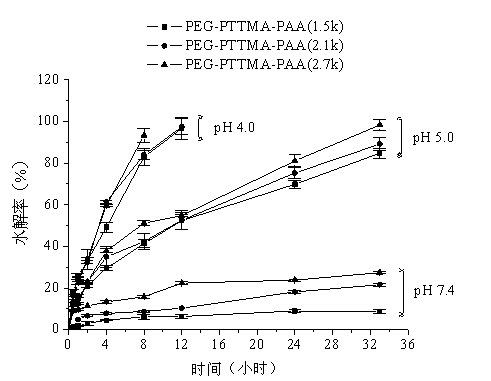

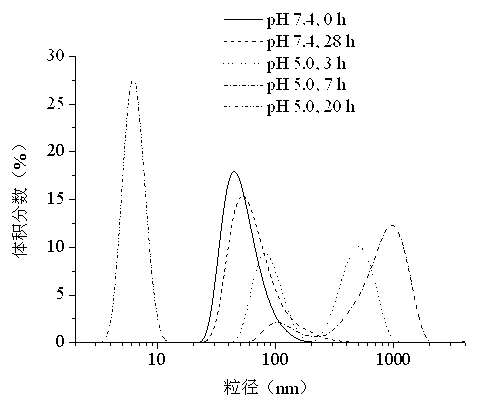

Acid-sensitive degradable polymer vesicle and preparation and application thereof

ActiveCN102911326AQuick releaseImprove colloidal stabilityPharmaceutical non-active ingredientsMicrocapsulesMethacrylatePolymer science

The invention discloses an acid-sensitive degradable polymer vesicle and preparation and application of the polymer vesicle. The polymer vesicle is formed by an A-B-C type block polymer, wherein the block A is polyethylene glycol and distributed on the external surface of the vesicle; the block B is hydrophobic pH-sensitive degradable polymer poly(trimethoxy benzaldehyde acetal-trimethylolethane-methacrylate) and forms a film core of the vesicle; and the block C is polyelectrolyte selected from one of polyacrylic acid, polymethacrylic acid, dimethylaminoethyl polymethacrylate, diethylaminoethyl polymethacrylate and diisopropylaminoethyl polymethacrylate, distributed on the inner wall of the vesicle film, and used for efficiently loading medicaments with opposite charges. The pH-sensitive degradable vesicle is simple in preparation method, can efficiently load micromolecular hydrophile anticancer medicaments, therapeutic protein medicaments, polypeptide medicaments and nucleic acid medicaments.

Owner:SUZHOU UNIV

Alkali-free liquid setting accelerator containing cellulose and preparation method of alkali-free liquid setting accelerator

The invention discloses an alkali-free liquid setting accelerator containing cellulose and a preparation method of the alkali-free liquid setting accelerator. The alkali-free liquid setting accelerator comprises components in parts by mass as follows: 30-60 parts of aluminum sulfate, 5-10 parts of calcium formate, 5-10 parts of calcium fluoride, 0.8-1.6 parts of sulfosalicyclic acid, 1.0-3.5 parts of hydroxyethyl cellulose, 0.8-1.5 parts of polyacrylamide, 0.2-1.0 part of ethylenediamine tetraacetic acid, 1-3 parts of triisopropanolamine, 0.15-1.2 parts of polypropylene glycol, 0.10-1.12 parts of dimethyl silicone, 0.5-1.5 parts of phosphoric acid, 0.5-1.5 parts of hydrofluoric acid, 3-8 parts of magnesium sulfate, 1-3 parts of sodium fluoride, 1-4 parts of trimethylolethane, 2-6 parts of aluminum hydroxide and 30-60 parts of water.

Owner:徐明

Multifunctional liquid fertilizer capable of degrading pesticide residues and preparation method thereof

InactiveCN107698330AQuick killingHazard preventionMagnesium fertilisersAlkali orthophosphate fertiliserInsect pestCatalase

The invention discloses a multifunctional liquid fertilizer capable of degrading pesticide residues and a preparation method thereof. The multifunctional liquid fertilizer is prepared from the following components in parts by weight: 5-10 parts of a nitrogen-containing component, 10-20 parts of a phosphorus-containing and potassium-containing component, 2-3 parts of a chelated medium and trace element component, 3-5 parts of amino acid, 8-10 parts of an organic matter, 10-15 parts of humic acid, 10-15 parts of a pesticide detoxifying enzyme, 0.5-2 parts of antifreezing protein, 0.5-1.5 parts of antibacterial peptides and 35-42 parts of water, wherein the pesticide detoxifying enzyme is prepared by mixing protease, cellulase, pectinase, catalase, amylase, glycerin, trimethylolethane, pentaerythritol, xylitol, sorbitol and water. The multifunctional liquid fertilizer can effectively degrade the pesticide residues and reduce the using amounts of pesticides, and can prevent plant diseasesand insect pests and maintain the balance of agroecological environment, so that the agricultural yield and the agricultural income are increased, the quality of agricultural products is improved andthe agricultural production environment is improved; the multifunctional liquid fertilizer has the advantages of comprehensive and balanced nutrition, high plant absorption and utilization rate, wideapplication range, simple preparation technology, economic benefit, high efficiency, environmental protection and the like.

Owner:中山国晟生物工程有限公司

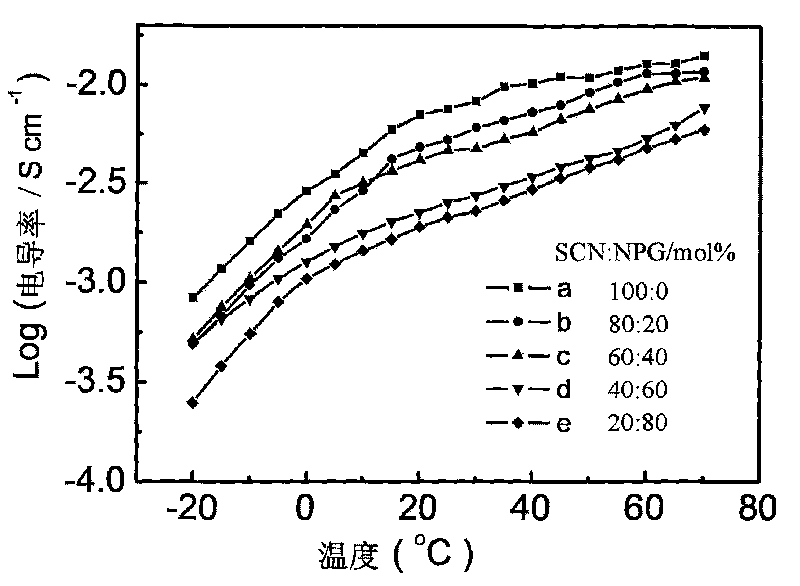

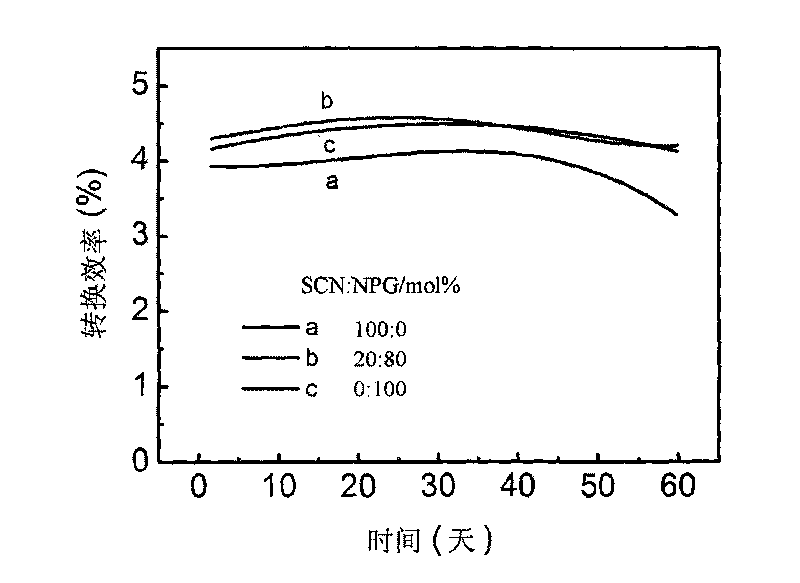

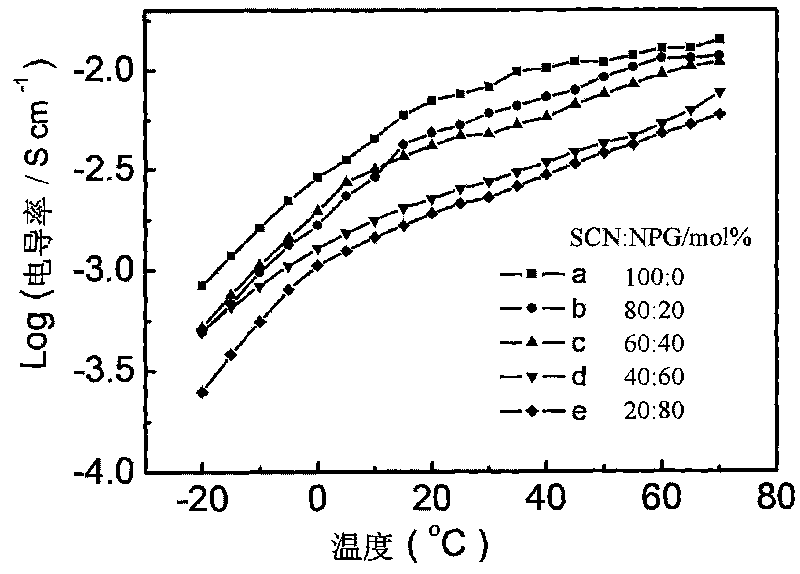

All-solid-state organic alloy electrolyte for dye-sensitized solar battery

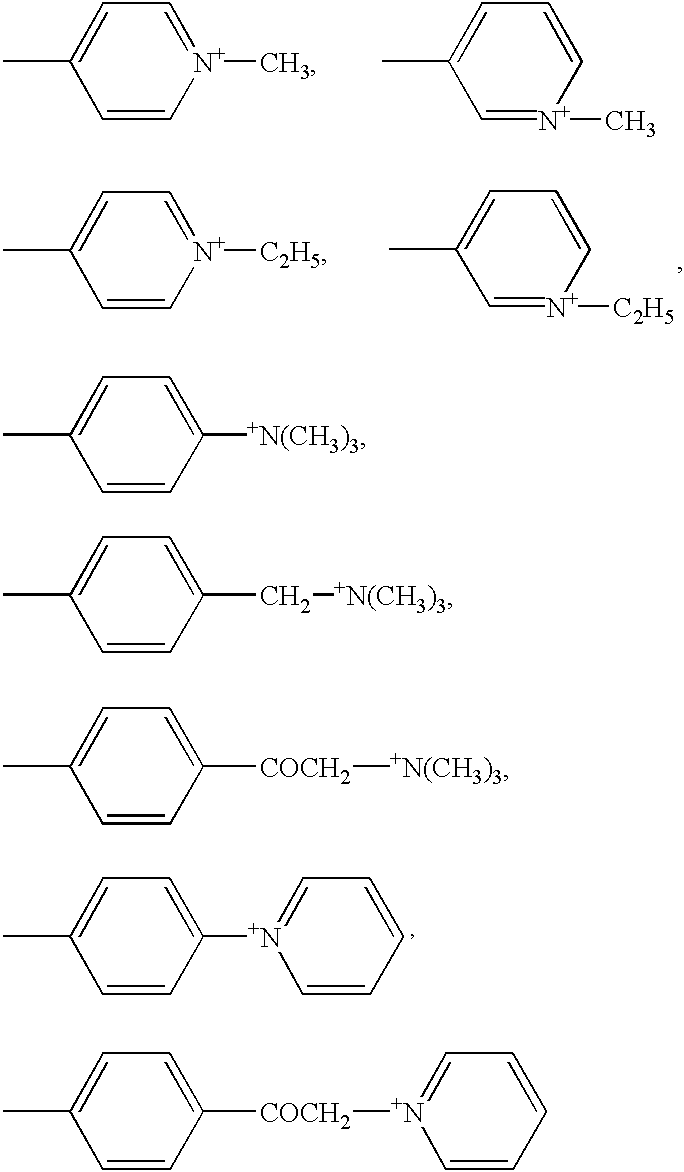

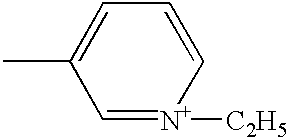

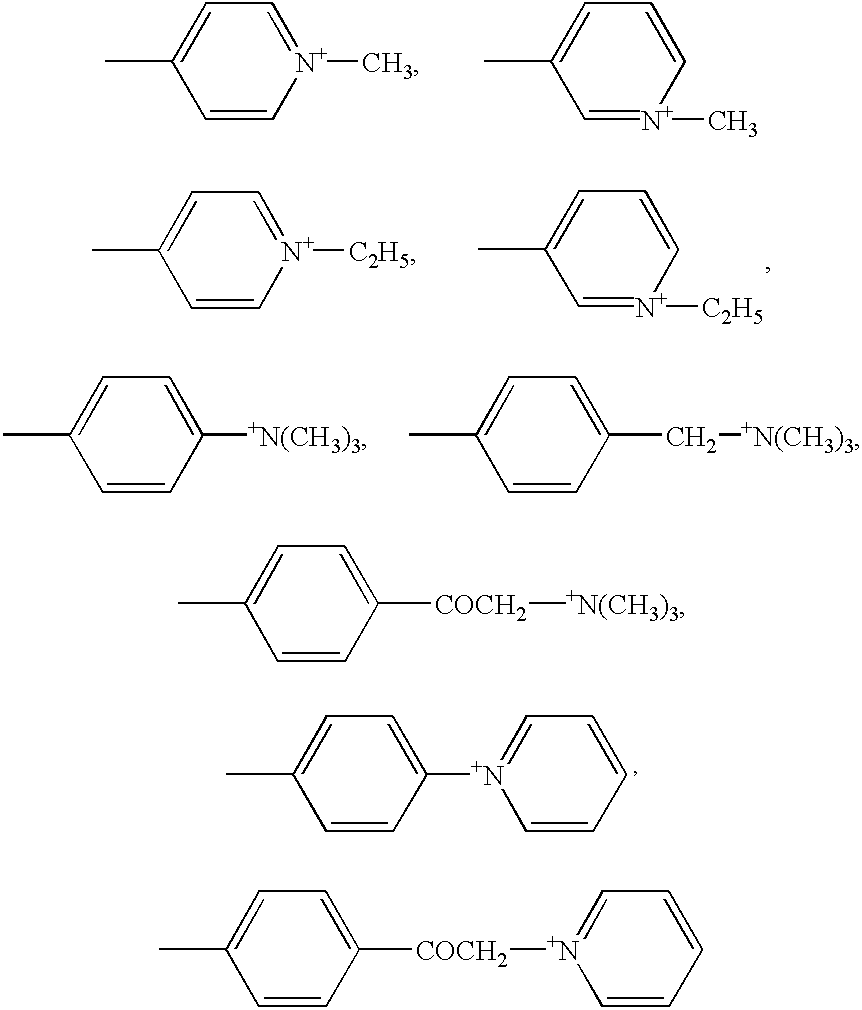

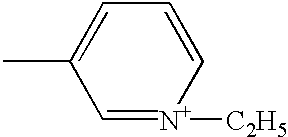

ActiveCN101719427AWell mixedImprove photoelectric conversion efficiencyLight-sensitive devicesSolid-state devicesPlastic crystalQuaternary ammonium cation

The invention discloses an all-solid-state organic alloy electrolyte for a dye-sensitized solar battery and a preparation method thereof. The electrolyte comprises an organic alloy material prepared from more than two or three plastic crystals selected from succinonitrite, neopentyl glycol, trimethylolethane, pentaerythritol, camphor, imidazole and the derivative quaternary ammonium salt thereof and pyridine and the derivative quaternary ammonium salt thereof, iodine accounting for 1-5 percent of the amount of substance of the organic alloy, lithium iodide or potassium iodide or sodium iodide accounting for 1- 10 percent of the amount of substance of the organic alloy and one or more of methyl ethyl imidazole iodine, tert-butyl pyridine, LiTFSI and LiBF4 conducting salt, which account for 1- 10 percent of the amount of substance of the organic alloy. The prepared electrolyte has a high melting point (more than 80 DEG C) and equivalent electrical conductivity with a liquid electrolyte, and the dye-sensitized solar battery (DSSCs) prepared from the electrolyte has high photoelectric transformation efficiency and stability.

Owner:常熟紫金知识产权服务有限公司

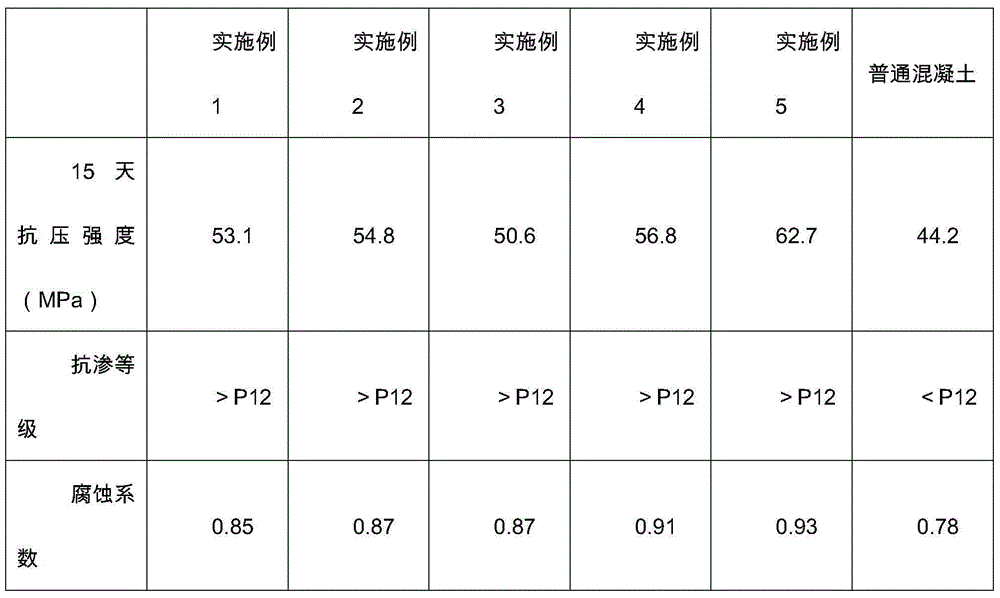

Anti-corrosion concrete material and preparation method thereof

The invention discloses an anti-corrosion concrete material and a preparation method thereof. The anti-corrosion concrete material comprises components in parts by weight as follows: 150-180 parts of Portland cement, 40-60 parts of fly ash, 8-18 parts of mineral cotton, 120-180 parts of gravel, 80-160 parts of glass flakes, 80-120 parts of fine sand, 12-36 parts of calcium chloride, 12-25 parts of magnesium silicate, 1-8 parts of barium silicate, 1-8 parts of sodium benzoate, 8-16 parts of calcium silicate, 4-12 parts of aluminum dihydrogen phosphate, 6-16 parts of strontium oxide, 4-12 parts of brucite powder, 2-10 parts of zinc dust, 10-20 parts of zinc oxide, 2-10 parts of sodium metaaluminate, 2-10 parts of polyvinyl alcohol, 15-30 parts ofdihydrate gypsum, 1-4 parts of aluminum tripolyphosphate, 1-4 parts of potassium tripolyphosphate, 1-4 parts of monopotassium phosphate, 6-8 parts of bisphenol A epoxy acrylate, 1-3 parts of trimethylolethane, 2-10 parts of polyacrylamide, 1-3 parts of xylitol, 1-4 parts of triethyl phosphate, 1-4 parts of butyl methacrylate, 1-4 parts of acrylonitrile, 2-4 parts of triethoxyisobutylsilane, 6-10 parts of sodium allylsulfonate, 4-16 parts of calcium lignosulphonate, 1-6 parts of a water reducing agent and 60-100 parts of water.

Owner:广东盈坚实业集团有限公司

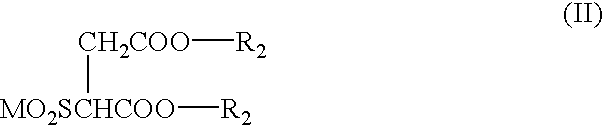

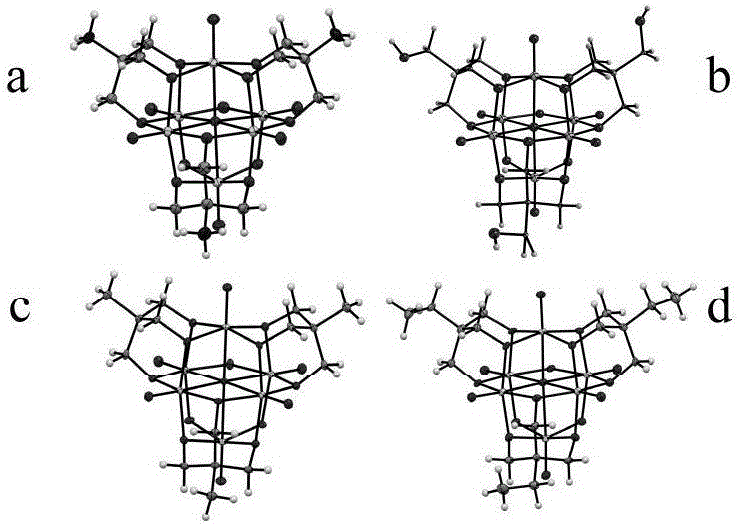

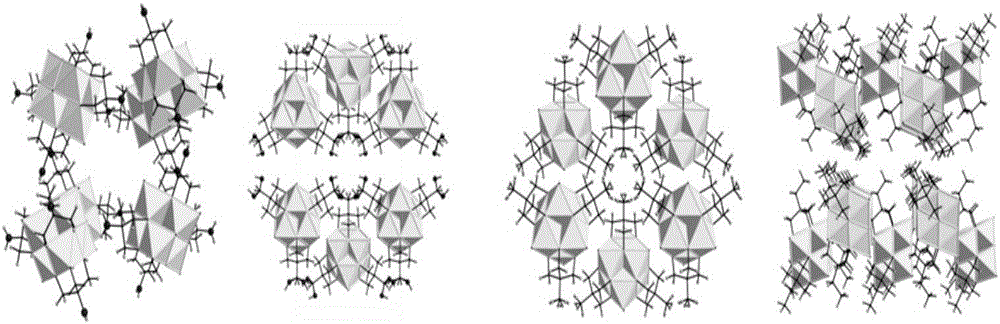

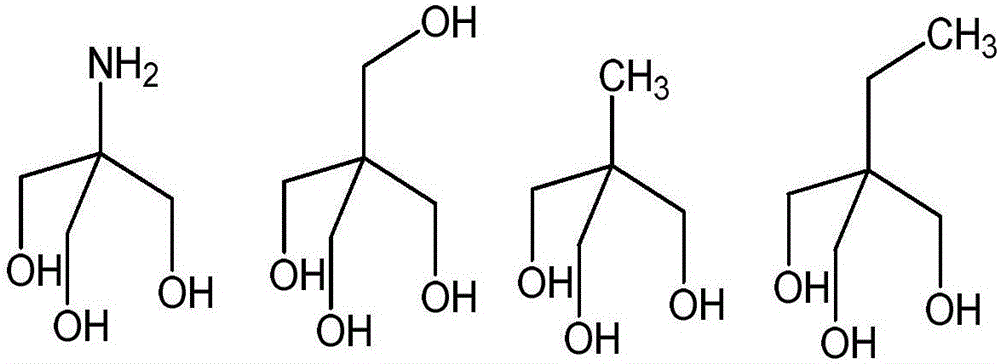

Mixed-valence hexavanadate alkoxyl derivative and preparation method thereof

InactiveCN106831854ASimple structureUnique magneticCell electrodesGroup 5/15 organic compounds without C-metal linkagesHybrid materialHydroxy group

The invention relates to a mixed-valence hexavanadate alkoxyl derivative and a preparation method thereof and belongs to the technical field of organic-inorganic hybrid materials. According to the structure of the alkoxyl derivative, three bridging oxygen atoms arranged to form a planar triangle on a Linqivist hexavanadate framework are substituted by three hydroxyl oxygens of a tri-hydroxymethyl compound molecule, three tri-hydroxymethyl compounds are adjacently distributed on the hexavanadate framework, and all vanadium is tetravalent vanadium or tetravalent and pentavalent vanadium distributed in a mixed mode. The tri-hydroxymethyl compounds are tri-hydroxymethyl aminomethane, pentaerythritol, trimethylolethane or trimethylolpropane. The tri-substituted hexavanadate alkoxyl derivative and a post-modification product thereof possibly have unique magnetism, catalytic activity and other properties. The properties make them have unique advantages on the aspect of the organic-inorganic hybrid materials rich in construction structure and property.

Owner:HUBEI UNIV OF TECH

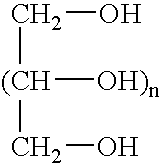

Refrigerator lubricating oil and mixed composition for refrigerator

InactiveCN107406799AInhibit swellingCompressorCompression machines with non-reversible cyclePolyolPolyolester

The refrigerator lubricating oil includes: a base oil, the main component of which is a polyol ester (A) of C3-C18 fatty acids (a1) and of a polyol (a2) that is selected from among neopentyl glycol, trimethylolethane, trimethylolpropane, trimethylolbutane, pentaerythritol, and dipentaerythritol; and a disulfide and / or trisulfide compound (B). The blended amount of the disulfide and / or trisulfide compound (B)is, in terms of sulfur, 30-10000 mass ppm with respect to the total amount of the refrigerator lubricating oil.

Owner:IDEMITSU KOSAN CO LTD

Chromium-free photo-sensitive resist for rotary screen printing

The invention relates to chromium-free photo-sensitive resist for rotary screen printing, which comprises the following components: polyvinyl alcohol (30%), gelatin, p-diazodiphenylamine paraformaldehyde condensate, polyisocyanate blocks, silicone modified polyurethane resins, trimethylolethane, 3-6 parts of stilbazole dimethyl sulfate salt, hydroquinone, curing agents, polyethyleneimine, ethylamine boron trifluoride salt, benzyl dimethylamine, aluminum chloride hexahydrate, solvents, aluminum chloride hexahydrate, silicone defoaming agents and vitamin E. The chromium-free photo-sensitive resist has the advantages of strong binding force of the high-precision photo-sensitive resist for a rotary printing screen and the rotary printing screen, excellent chemical resistance and abrasion resistance, and high press run; plate making and developing of the rotary printing screen are clear and mesh holes cannot be stopped; through adding the silicone modified polyurethane resin, the tensile property of the rotary printing screen in a printing process is improved, and the service life of the rotary printing screen is prolonged.

Owner:陈国荣

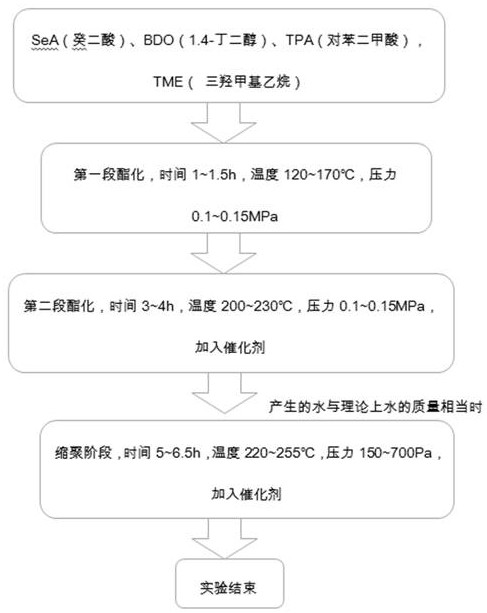

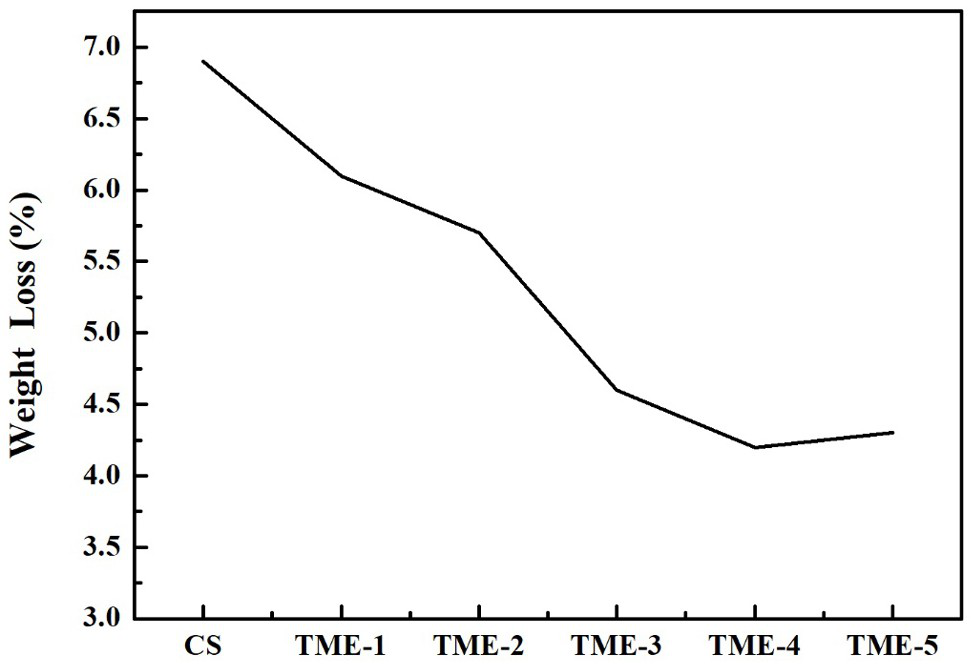

Tear-resistant environment-friendly PBSeT copolyester material and preparation method thereof

The invention relates to the field of high polymer materials, and concretely relates to a tear-resistant environment-friendly PBSeT copolyester material and a preparation method thereof. The material is prepared from, by mole, 5 parts of sebacic acid, 10 parts of 1, 4-butanediol, 5 parts of terephthalic acid, 0-0.1 part (0 exclusive) of trimethylolethane and 0-0.06 part (0 exclusive) of tetrabutyl titanate. The preparation method comprises the following steps: blending sebacic acid, 1, 4-butanediol, terephthalic acid and trimethylolethane according to a molar ratio under the condition of not adding a catalyst, and then starting first-stage esterification; and starting second-stage esterification, raising the temperature to a certain temperature, adding a catalyst tetrabutyl titanate for esterification, starting a polycondensation stage when the mass of generated water is equivalent to that of theoretical water, adding the catalyst tetrabutyl titanate, raising the temperature to a certain temperature and then performing polycondensation, and finishing polycondensation when torque on equipment is not changed. The synthesis method provided by the invention greatly improves the tearing property of the environment-friendly PBSeT copolyester material.

Owner:ZHONGBEI UNIV

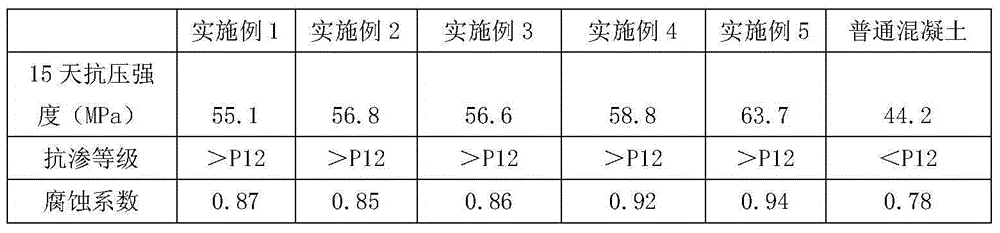

High-strength, anti-seepage and anti-corrosion concrete material and preparation method thereof

InactiveCN105198326AHigh compressive strengthImprove impermeabilityCalcium silicatePolyvinyl alcohol

The invention discloses a high-strength, anti-seepage and anti-corrosion concrete material and a preparation method thereof. The concrete material comprises components in parts by weight as follows: 180-200 parts of portland cement, 10-20 parts of mineral cotton, 150-200 parts of macadam, 100-150 parts of glass flakes, 100-130 parts of fine sand, 10-30 parts of calcium chloride, 10-20 parts of magnesium silicate, 1-8 parts of barium silicate, 1-8 parts of sodium benzoate, 8-16 parts of calcium silicate, 4-12 parts of dialuminum hydrogen phosphate, 6-16 parts of strontium oxide, 4-12 parts of brucite powder, 2-10 parts of zinc powder, 10-20 parts of zinc oxide, 2-10 parts of sodium metaaluminate, 2-10 parts of polyvinyl alcohol, 15-30 parts of dihydrate gypsum, 1-4 parts of aluminum tripolyphosphate, 1-4 parts of potassium tripolyphosphate, 1-4 parts of potassium dihydrogen phosphate, 6-8 parts of bisphenol A epoxy acrylate, 1-3 parts of trimethylolethane, 2-10 parts of polyacrylamide, 1-3 parts of xylitol, 1-4 parts of triethyl phosphate, 1-4 parts of butyl methacrylate, 1-4 parts of acrylonitrile, 2-4 parts of triethoxyisobutylsilane, 6-10 parts of sodium allysulfonate, 4-16 parts of calcium lignosulphonate, 1-6 parts of a water reducer and an appropriate amount of water.

Owner:徐光武

High-bonding cracking-resistant wallboard

ActiveCN105153983AImprove film formationImprove mechanical propertiesNon-macromolecular adhesive additivesLayered productsFiberMethacrylate

The invention discloses a high-bonding cracking-resistant wallboard which comprises a base layer, a bonding layer, a fireproof layer, a waterproof layer, an emulsion layer and a decorative coating arranged sequentially from inside to outside, wherein the bonding layer is prepared by using an aqueous adhesive; the aqueous adhesive comprises the raw materials in parts by weight: 20-30 parts of bisphenol F epoxy resin, 5-10 parts of hydrogenated bisphenol A epoxy resin, 20-30 parts of modified phenolic resin, 0.5-1.5 parts of a curing agent, 1-2 parts of a silane coupling agent KH-550, 1.2-1.5 parts of a diluent, 1-3 parts of a softener, 10-15 parts of 2-ethyl methacrylate, 5-12 parts of tricresyl phosphate, 1-3 parts of trimethylolethane, 10-12 parts of propylene glycol, 1-4 parts of xylitol, 4-8 parts of short fiber and 20-30 parts of water. Even if in a humid environment, the bonding property of the wallboard is extremely excellent, and the wallboard is prevented from deforming and cracking as a result of different amounts of expansion and contraction.

Owner:安徽复材科技有限公司

High-performance glass fiber impregnating agent

InactiveCN106242319AImprove protectionConducive to the number of episodesEpoxyTemperature resistance

The invention discloses a high-performance glass fiber impregnating agent. The high-performance glass fiber impregnating agent is prepared from, by weight, 30-40 parts of epoxy dicyclopentadiene epoxy resin, 20-30 parts of cyclopentanediol, 10-20 parts of trimethylolethane, 5-10 parts of polyvinyl acetate, 5-8 parts of castor oil, 3-5 parts of a coupling agent, 0.5-2 parts of a lubricant, 0.5-1 part of an antiseptic, 0.5-1 part of a pH regulator, 0-0.5 parts of an antistatic agent, 0.5-1 part of a compatilizer, and a proper amount of water. Epoxy dicyclopentadiene epoxy resin, cyclopentanediol, trimethylolethane and polyvinyl acetate are adopted as a film forming agent, so the impregnating agent has excellent high temperature resistance and excellent electric performances, can tolerate the temperature reaching 300 DEG C or above, has high stiffness, high toughness, high tensile strength, high bending strength, high adhesion stress, good film forming property and good protection property, is in favor of realizing protection and bundling of glass fibers in the high speed injecting and rolling process, increases the production efficiency, improves the mechanical performances of the glass fibers, and makes the glass fibers have good cutting property, dispersibility, lubricity, antistatic property, weaving property and fluidity.

Owner:TONGCHENG GLASS FIBER OF ANHUI DANFENG GROUP

High-performance glass fiber wetting agent and preparation method thereof

The invention discloses a high-performance glass fiber wetting agent and a preparation method thereof. The high-performance glass fiber wetting agent is prepared from the following raw materials in parts by weight: 45-55 parts of epoxy resin, 30-40 parts of polyoxyethylene glycol, 5-10 parts of trimethylolethane, 10-20 parts of an acrylate emulsion, 5-7 parts of potato starch, 5-7 parts of corn starch, 4-6 parts of cotmar, 0.1-1.2 parts of a softening agent, 7-9 parts of grease paraffin, 3-5 parts of a coupling agent, 0.5-1 part of a lubricating agent, 0.5-1 part of a preservative, 0.1-0.5 part of an organic tin bactericide, 0.3-0.5 part of a de-foaming agent and 60-80 parts of water. According to the invention, the physical and chemical properties of an electronic spinning yarn of glass fiber are comprehensively improved, the stiffness is within 50-80, the tensile strength reaches up to 52CN / TEX or above and the problems of yarn break and fluffing in the spinning process can be effectively solved.

Owner:ANHUI DANFENG ELECTRONICS MATERIAL

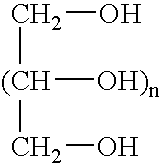

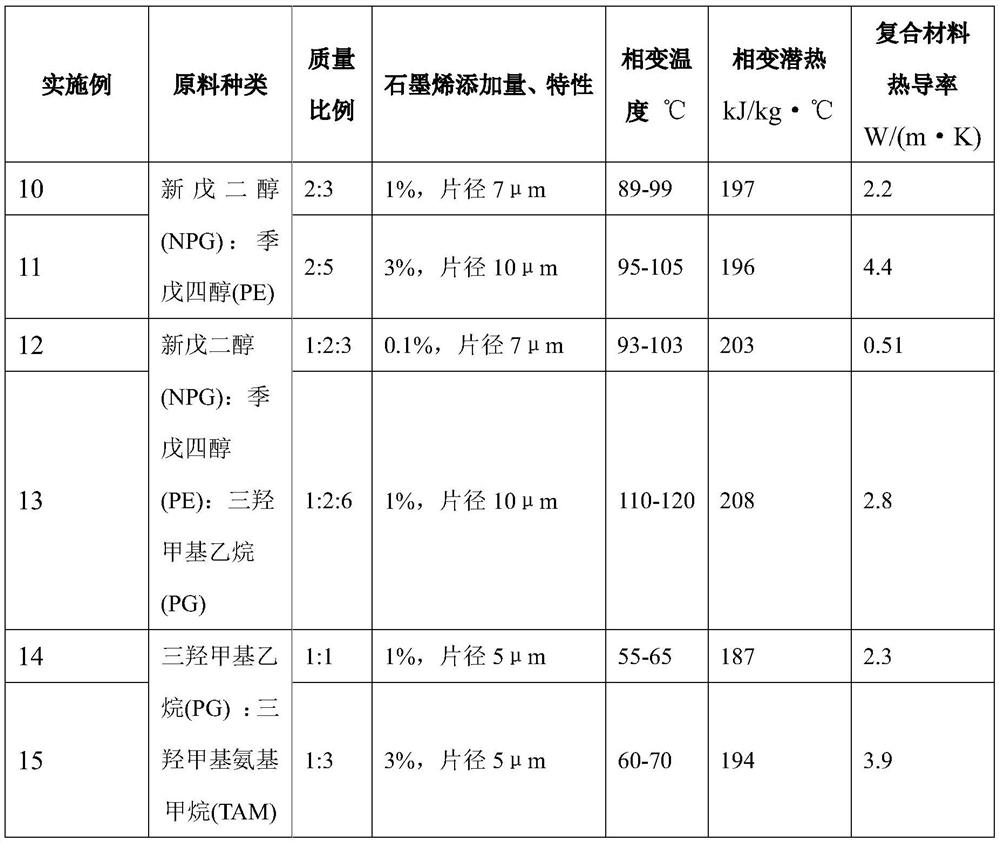

Method for preparing graphene composite solid-solid phase change material

InactiveCN112574715AReduce supercoolingImprove thermal conductivityHeat-exchange elementsMolten statePolyol

The invention discloses a method for preparing a graphene composite solid-solid phase change material, which comprises the following steps: (1) preparing graphene powder with the sheet diameter of 5-10 [mu]m; (2) heating a mixture of two or more of pentaerythritol (PE), trimethylolethane (PG), neopentyl glycol (NPG), 2-amino-2-methyl-1,3-propylene glycol (AMP) and trimethylol aminomethane (TAM) toa molten state, then adding graphene powder with the weight percentage of 0.1%-10%, and conducting mixing and uniform stirring to prepare graphite polyol composite slurry; and (3) extruding the graphite polyol composite slurry in the molten state to form the graphene composite solid-solid phase change material plate with the thickness of 2-10mm.

Owner:江苏烯泰石墨烯应用技术研究院有限公司 +1

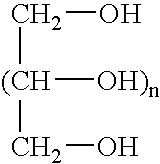

Preparation method for improving enzyme activity of pichia pastoris fermentation lipase and yield of methanol protein

A preparation method for improving the enzyme activity of a pichia pastoris fermentation lipase and the yield of a methanol protein comprises the steps of: culture of primary seeds, culture of secondary seeds, high-density fermentation, induction for enzyme production, enzyme extraction, spray drying of enzymatic liquid and obtaining of the single-cell methanol protein; in the stage of induction for enzyme production, the seeds in the high-density fermentation stage are cultured until the dissolved oxygen rebounds, the seeds are continuously and hungrily cultured for 2-3 h; the seeds enter themethanol-polyol induction stage, the polyol is one of pentaerythritol, glycerin, trimethylolethane, xylitol and sorbitol; the polyol MPC is added to methanol in a volume ratio of 0.5-2:1, and the substances are fed together; the stirring speed is constant, methanol-polyol containing 12 mL / L of PTM1 is fed at a constant speed and is used for feeding induction; the concentration of methanol-polyolis increased in a gradient manner, from 1 mL / L / h-6 mL / L / h, and the concentration is increased by 1 mL / L / h per hour; the dissolved oxygen is controlled to be 10%-20%. With the preparation method provided by the invention, the enzyme activity of the pichia pastoris fermentation lipase can be improved and meanwhile the yield of the methanol protein is increased.

Owner:JIANGSU YIMING BIOLOGICAL SCI & TECH

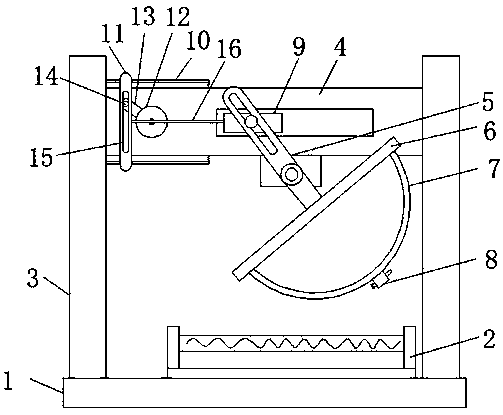

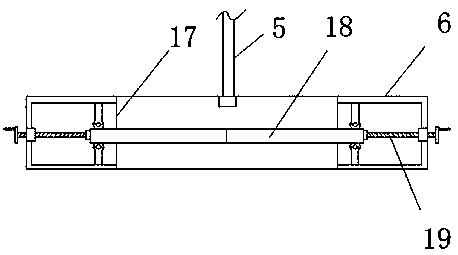

Drying equipment for trimethylolethane

InactiveCN108253760AAchieve swingFlipDrying machines with non-progressive movementsDrying solid materialsArchitectural engineeringTrimethylolethane

The invention discloses drying equipment for trimethylolethane. The drying equipment comprises a base plate, supporting plates are welded to the top of the base plate, electric heating bars are fixedly mounted on the top of the base plate, a transverse plate is welded between the two supporting plates, a swinging rod is hinged to the bottom of the transverse plate, and a cover plate is welded to the bottom of the swinging rod; the bottom of the cover plate is fixedly connected with a drying pot, the bottom of the drying pot is provided with a discharging pipe, and a reciprocating block is slidably mounted on the transverse plate; and guiding rods are welded to the top and the bottom of the transverse plate correspondingly, vertically-arranged reciprocating rods are slidably mounted on theguiding rods, a rotating disc is rotatably mounted on the transverse plate, a connecting rod is welded to the rotating disc, a cylindrical block is welded to the connecting rod, the reciprocating rodsare provided with track holes, and cylindrical block is slidably connected with the track holes. According to the drying equipment for the trimethylolethane, drying of the trimethylolethane is achieved, an overturning mechanism is additionally arranged, uniform heating of the trimethylolethane is ensured, the drying effect is good, the efficiency is high, using is convenient, and popularization is easy.

Owner:XIANGSHUI MODERN CHEM CO LTD

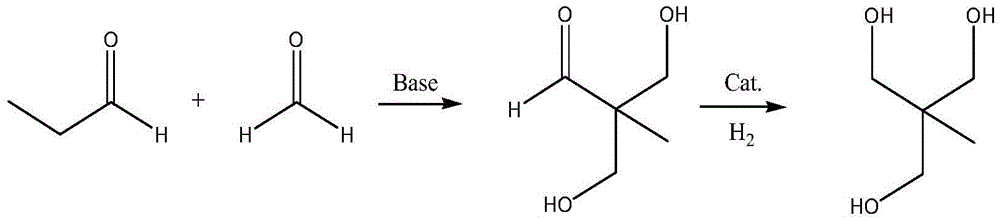

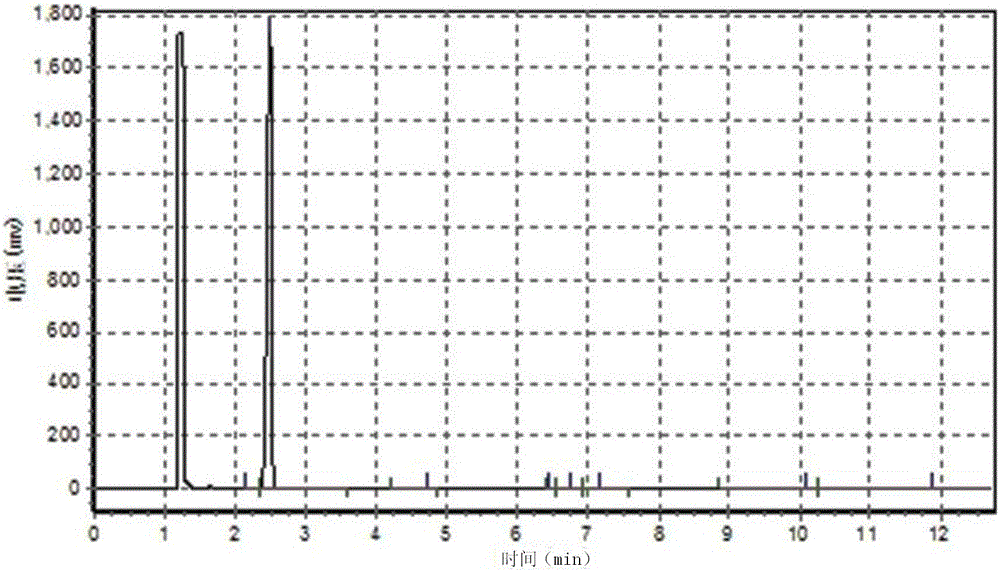

Preparation method of trimethylolethane

ActiveCN105669370AHigh activityReduce consumptionOrganic compound preparationHeterogenous catalyst chemical elementsFormateDisproportionation

The invention discloses a preparation method of trimethylolethane. The method comprises the following steps: carrying out aldol condensation reaction on propanal and formalin to form a 2,2-dihydroxymethylpropanal-containing solution, and carrying out hydrogenation reaction on the 2,2-dihydroxymethylpropanal-containing solution and hydrogen gas under the action of a hydrogenation catalyst to obtain a solution containing the product trimethylolethane, wherein the 2,2-dihydroxymethylpropanal-containing solution contains 0.5-3 wt% of 2-aldomethyl-2-hydroxymethylpropylmethyl ether. Compared with the traditional technique for preparing trimethylolethane by aldol condensation and Cannizzaro disproportionation reaction, the method disclosed by the invention has the advantages of less wastewater, no coproduct formate and the like, has the characteristics of high conversion rate for the coproduct trimethylolethane acetals in the condensation step in the trimethylolethane hydrogenolysis treatment process, simple process and the like, and can obviously enhance the trimethylolethane yield.

Owner:JIANGSU QINGQUAN CHEM CO LTD

Antiflaming coating adhesive for textiles and preparation method thereof

ActiveCN103215818AEfficient flame retardantLow hygroscopicityFibre treatmentMicroballoon preparationPhosphoric Acid EstersPolymer science

The invention discloses an antiflaming coating adhesive for textiles and a preparation method thereof. The microencapsulation polyphosphoric acid is prepared from the following raw materials in parts by weight: 100-102 parts of crystal phase II polyphosphoric acid amine, 4-4.5 parts of tripolycyanamide, 11-11.5 parts of diphenylmethane diisocyanate, 0.4-0.5 part of triphenyl methane three isocyanate, 5-5.5 parts of dicyclohexyl carbodiimide, 0.5-0.8 part of trimethylolethane, 120-125 parts of acetone and 27-29 parts of methylbenzene; and the antiflaming coating adhesive is prepared from the following raw materials in parts by weight: 200-300 parts of microencapsulation polyphosphoric acid amine, 600-800 parts of a solvent type coating adhesive, 20-30 parts of ring-shaped phosphate FR-CU, and 60-80 parts of antimonous oxide. The antiflaming coating adhesive provided by the invention has the advantage that the hygroscopicity is low, can resist washing and is environment-friendly and is efficient and antiflaming.

Owner:LIAONING FIXED STAR FINE CHEM

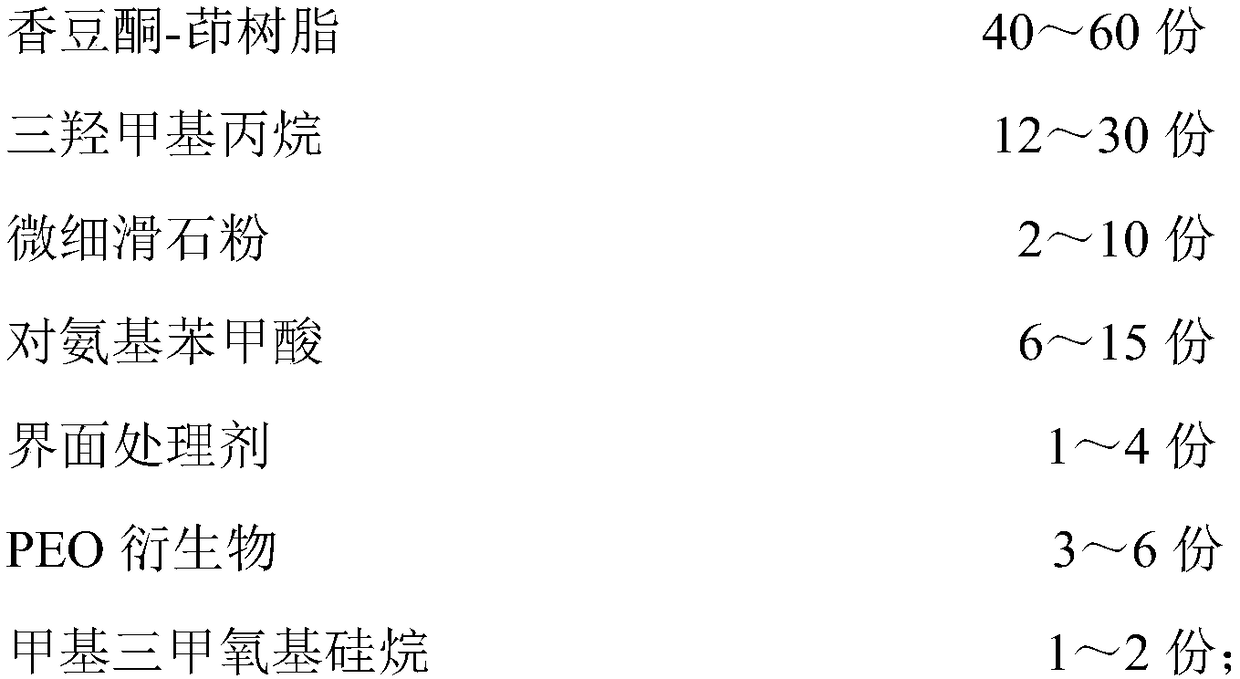

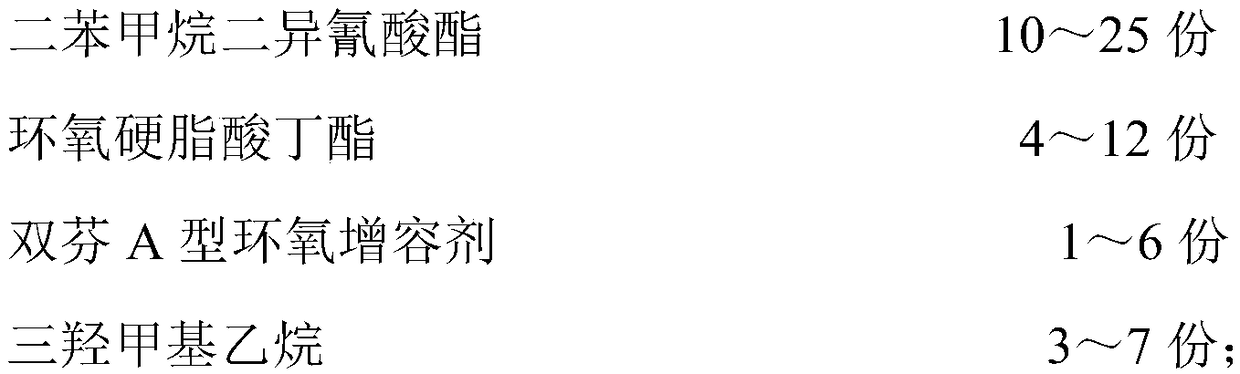

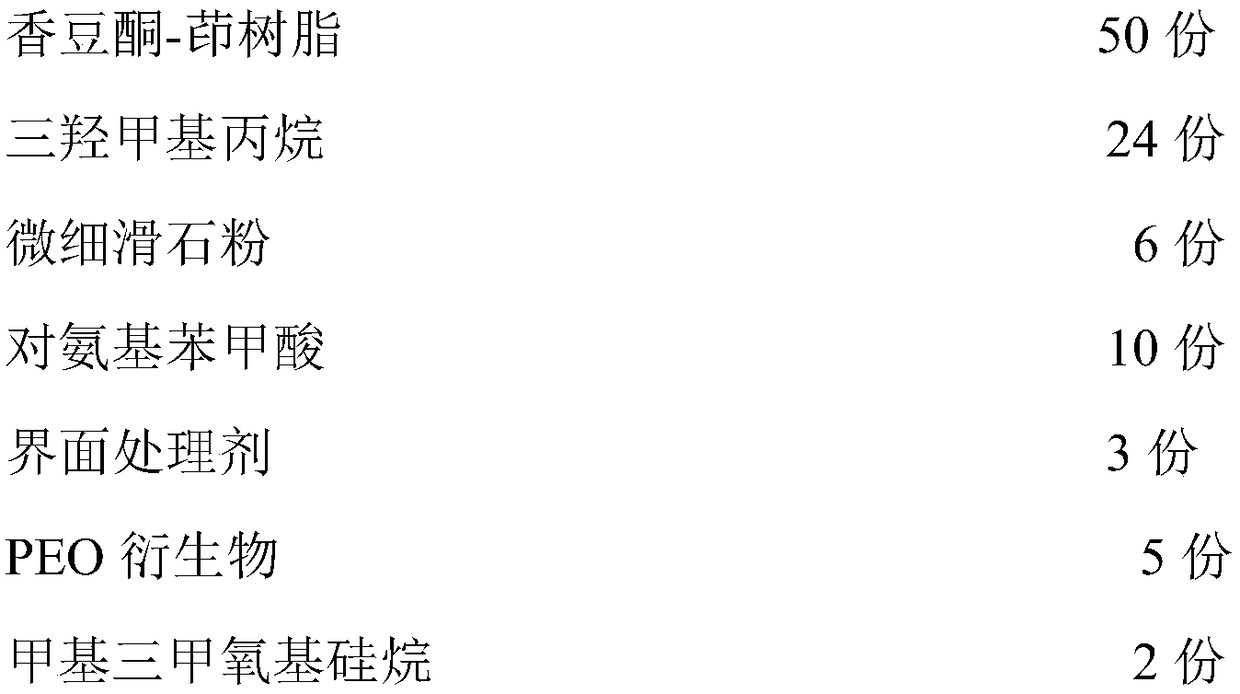

Compound multifunctional asphalt pavement sealant and preparation process thereof

ActiveCN108913093AImprove adhesionIncreased durabilityNon-macromolecular adhesive additivesBituminous material adhesivesSodium BentonitePolymer science

The invention discloses a compound multifunctional asphalt pavement sealant and a preparation process thereof. The main components of the sealant include: 100 parts of mixed modifier-modified asphaltwith 35 percent of 40-mesh rubber powder, 45 percent of 60-mesh rubber powder and 20 percent of 80-mesh rubber powder; 15 to 30 parts of functional component agent A; 10 to 35 parts of functional component agent B; and 5 to 25 parts of functional component agent C. The main components of the functional component agent A are coumarone-indene resin, trimethylolpropane, fine talcum powder, p-aminobenzoic acid and the like. The main components of the functional component agent B are diphenylmethane diisocyanate, butyl epoxy stearate, bisphenol-A epoxy compatibilizer, trimethylolethane and the like. The main components of the functional component agent C are microcapsules, vinyl glass flake mortar, polyvinyl alcohol-modified high-sodium bentonite particles and the like. According to the invention, after the functional component agents A, B and C are prepared, proportion is designed to carry out compounding, and the compounded sealant not only can fill cracks, but also can seal the cracks. The invention is applicable to different types of cracks, and according to causes of crack formation, different amounts of functional component agents A, B and C can be added. The sealant compounded bythe invention has high bonding strength, good sealing property and waterproofness and excellent high-temperature stability and low-temperature bonding property, having high application and popularization values.

Owner:CHONGQING JIAOTONG UNIVERSITY

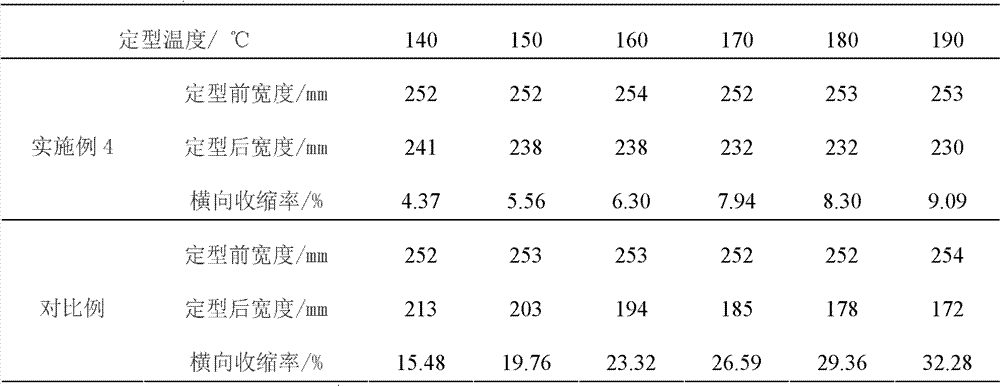

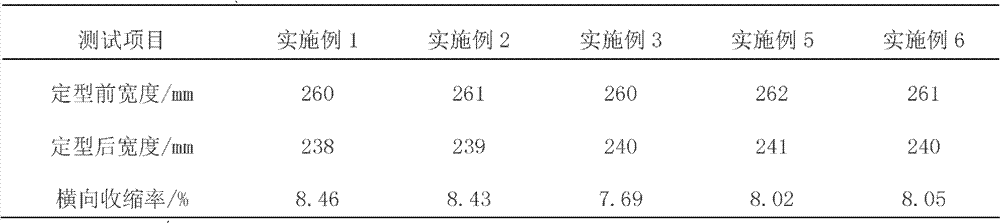

Chromophilous copolyester fiber protective agent of cationic dye, preparation method of chromophilous copolyester fiber protective agent and shaping method of fabric

InactiveCN103361972AAvoid plasticizationEffective protectionFibre typesHeating/cooling textile fabricsFiberSulfolane

The invention relates to a chromophilous copolyester fiber protective agent of a cationic dye and a preparation method of the chromophilous copolyester fiber protective agent. The protective agent is prepared from calcium carbonate filled high-density polyethylene composites, trimethylolethane, trihytdroxy methyl-aminomethane, tetramethylolmethane, ethanol, sulfolane and water. The invention also relates to a shaping method using the chromophilous copolyester fiber protective agent of the cationic dye. The chromophilous copolyester fiber protective agent of the cationic dye is similar to a heat insulating layer of a fiber, so that the phenomenon that chromophilous copolyester fiber of the cationic dye is heated to result in plastifying is avoided, fiber fabrics are effectively protected, and the change of hand feeling after heat shaping is prevented.

Owner:SHANGHAI WEAVING SCIENCE RESEARCH INSTITUTE CO LTD

Refrigerator lubricating oil and mixed composition for refrigerator

ActiveUS20180044608A1Properly suppressing the swelling of various rubber membersCompressorCompression machines with non-reversible cycleTO-18Polyolester

The refrigerator lubricating oil of the present invention contains: a base oil containing, as a major component, a polyol ester (A) of a fatty acid (a1) that is a fatty acid having a number of carbon atoms of from 3 to 18 and a polyol (a2) that is selected from neopentyl glycol, trimethylolethane, trimethylolpropane, trimethylolbutane, pentaerythritol, and dipentaerythritol; and a disulfide and / or trisulfide compound (B), and the disulfide and / or trisulfide compound (B) is blended in an amount of from 30 to 10,000 ppm by mass in terms of sulfur equivalent based on the total amount of the refrigerator lubricating oil.

Owner:IDEMITSU KOSAN CO LTD

Method for preparing trimethylolethane through continuous condensation hydrogenation method

InactiveCN106278817AQuality improvementShort processOrganic compound preparationHydroxy compound preparationLiquid solidAldol condensation

The invention relates to a method for preparing trimethylolethane through a continuous condensation hydrogenation method. According to the method, a condensation reaction still for achieving a continuous hydroxy aldehyde addition reaction of an impinging stream reactor, a gas-liquid-solid three-phase drip bed hydrogenation reactor and a bubbling type fluidized bed hydrogenation reactor are involved, and the two hydrogenation reactors are operated in series and contain a novel nickel hydrogenation catalyst and a main ingredient copper-chrome-aluminum-zinc catalyst respectively. It is guaranteed that formaldehyde and propionaldehyde stably generate a 2,2-dihydroxy methyl propyl aldehyde intermediate under organic weak alkali through the continuous impact steam aldol condensation reactor, generated byproducts are reduced, two hydrogenation reactions of different structures have the advantages of being high in conversion rate, simple in process, high in product purity, good in high temperature stability and the like, and the final yield of trimethylolethane can reach 95% or above.

Owner:湖北泰元新材料科技有限公司

Moisture curing type leather polishing coating agent

InactiveCN102477698AExcellent low temperature bending resistanceIncrease brightnessFibre treatmentOrganic groupTergallic acid

The invention discloses a moisture curing type leather polishing coating agent. The moisture curing type leather polishing coating agent comprises, by weight, 34-43% of tolylene diisocyanate, 9-36% of trimethylolethane, 14-22% of dibenzoyl peroxide, 9-16% of trichloroethylene, 2-6% of dibasic lead stearate, 4-10% of organic group modified polysiloxane, and 1-5% of propyl gallate. Compared to the prior art, with the present invention, the moisture curing type leather polishing coating agent has excellent low temperature flexing resistance; after the moisture curing type leather polishing coating agent is coated on the leather, characteristics of high brightness, strong crystal sense, and strong three-dimensional effect are achieved, and the good visual effect is provided.

Owner:周志昌

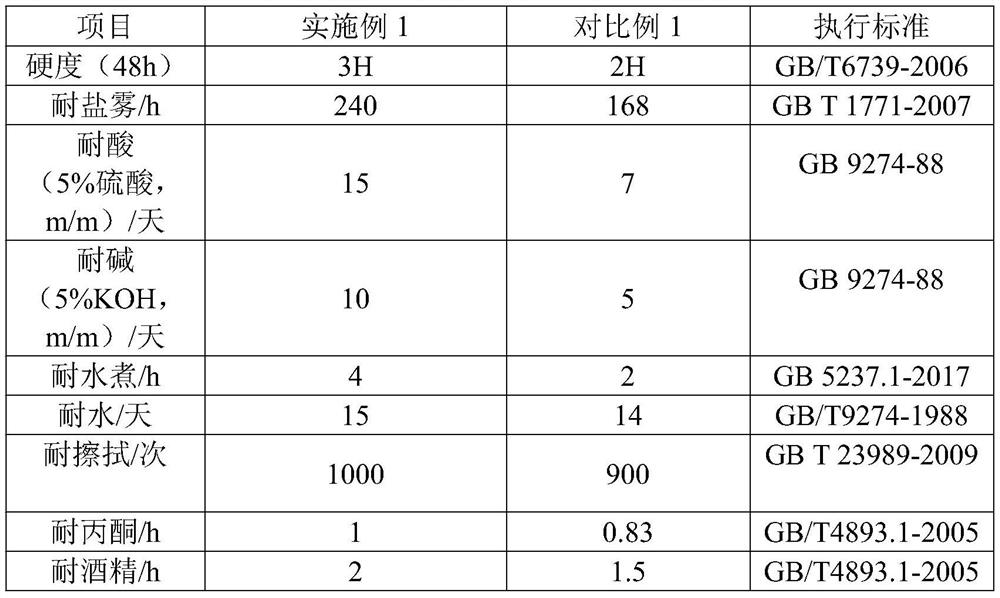

Multi-curing polyurethane latent curing agent and preparation method thereof

The invention relates to a multi-curing polyurethane latent curing agent. The multi-curing polyurethane latent curing agent is prepared from the following raw materials: diisocyanate, polymer polyol, a multi-hydroxyl monomer and hydroxyl-containing acrylate, the polyhydroxy small molecules are selected from one or more of trimethylolpropane, trimethylolethane, trimethylolmethane, 1,4-butanediol, 1,3-propylene glycol and 1,5-pentanediol. The invention also discloses a preparation method of the multi-curing polyurethane latent curing agent. The multi-curing polyurethane latent curing agent disclosed by the invention has relatively high hardness and chemical corrosion resistance after being cured, and has excellent water resistance, solvent corrosion resistance and wiping resistance.

Owner:韶关东森合成材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com