Low-hardness solvent-proof polyurethane elastomer and preparation method thereof

A technology of polyurethane elastomer and low hardness, which is applied in the field of printing products and can solve problems such as low mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

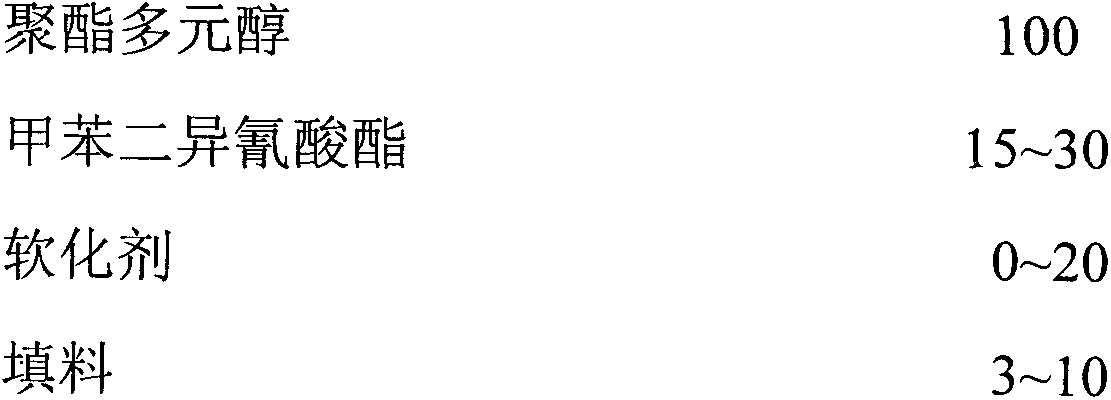

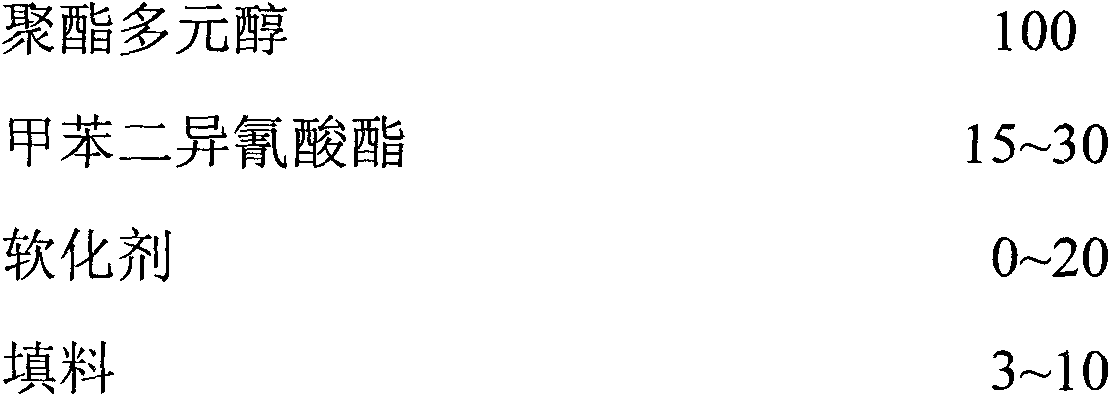

Method used

Image

Examples

Embodiment 1

[0029] Synthesis of component A: first mix 1000g of polyester polyol LM2856 and 30g of talc powder, then add colloid mill (the minimum adjustment distance of the grinding disc is 0.01mm) for secondary mixing and dispersion, then take 515g into the reactor, heat to 125°C, vacuum Dehydration was carried out for 2 hours, the material temperature was lowered to 70°C, 100g of TDI was added, and the reaction was carried out at 95°C under nitrogen protection for 1.5h.

[0030] Synthesis of component B: 92gGLY, 191gTIPA, 75gTEA, 0.07g bismuth carboxylate and 0.7g defoamer were added to the reactor for stirring and mixing, and the temperature was controlled at 50°C for 1 hour.

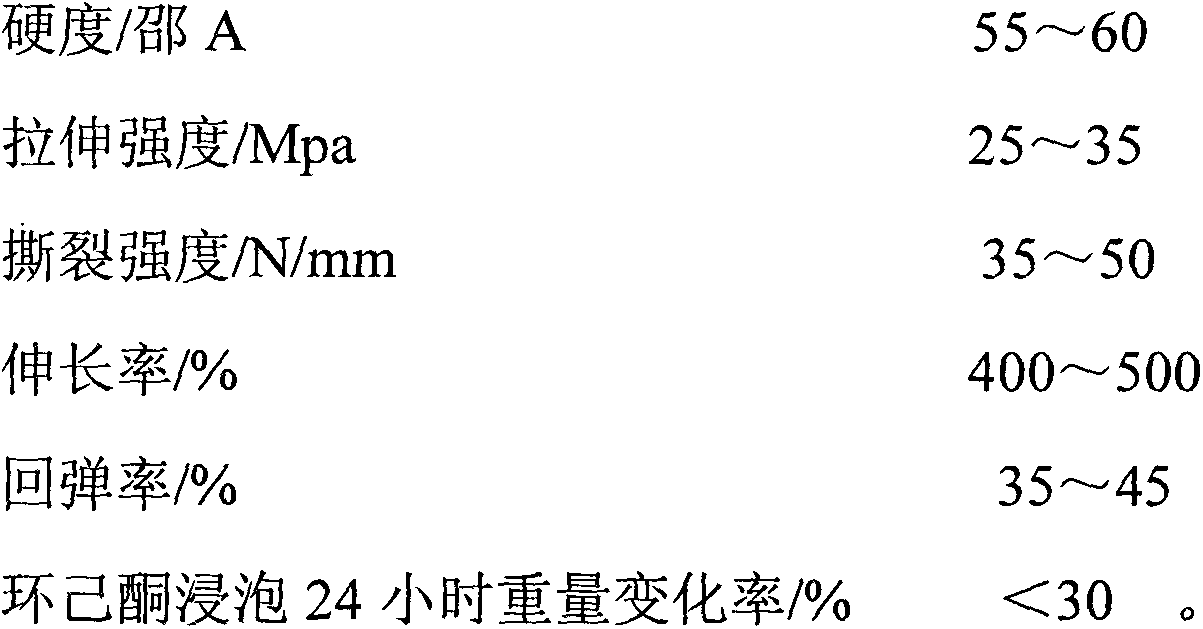

[0031] Elastomer preparation: Mix A and B according to the mass ratio of 100 / 9.2, defoam, pour into a 2mm mold at 130°C, demould for 60 minutes, vulcanize for 20 hours at 125°C, and measure performance after 7 days at room temperature. The properties of the obtained materials are shown in Table 2. Example 2

Embodiment 2

[0032] Synthesis of component A: first mix 1000g of polyester polyol LM7510, 200g of DEP and 60g of calcium carbonate, add colloid mill for secondary mixing and dispersion, then take 630g into the reactor, heat to 125°C, dehydrate under vacuum for 2h, The temperature was lowered to 70°C, 150g of TDI was added, and the reaction was carried out at 75°C under nitrogen protection for 2h.

[0033] Synthesis of component B: Add 134g TMP, 19.1gTIPA, 23gTEA, 0.1g bismuth isooctanoate and 0.6g defoamer into the reactor for stirring and mixing, the temperature is controlled at 70°C and the mixing time is 1h.

[0034] Preparation of elastomer: Mix A and B at a mass ratio of 100 / 6, defoam, pour into a 2mm mold at 110°C, demould for 90 minutes, vulcanize at 120°C for 20 hours, and measure performance after 7 days at room temperature. The properties of the obtained materials are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com