Compound multifunctional asphalt pavement sealant and preparation process thereof

A technology for asphalt pavement and potting glue, which is applied in the direction of asphalt material adhesives, adhesives, and other rubber adhesives. It can solve the problems of high temperature stability and low temperature flexibility, and achieve excellent performance and interface adhesion. And the effect of excellent durability and good bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

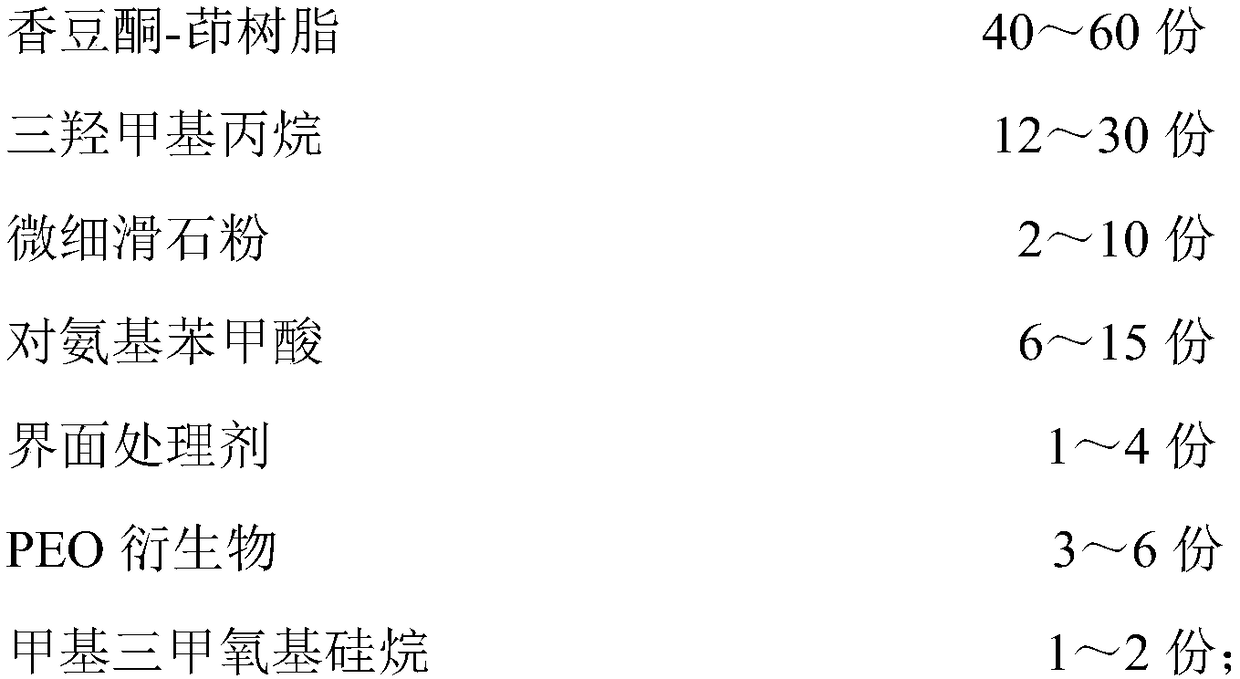

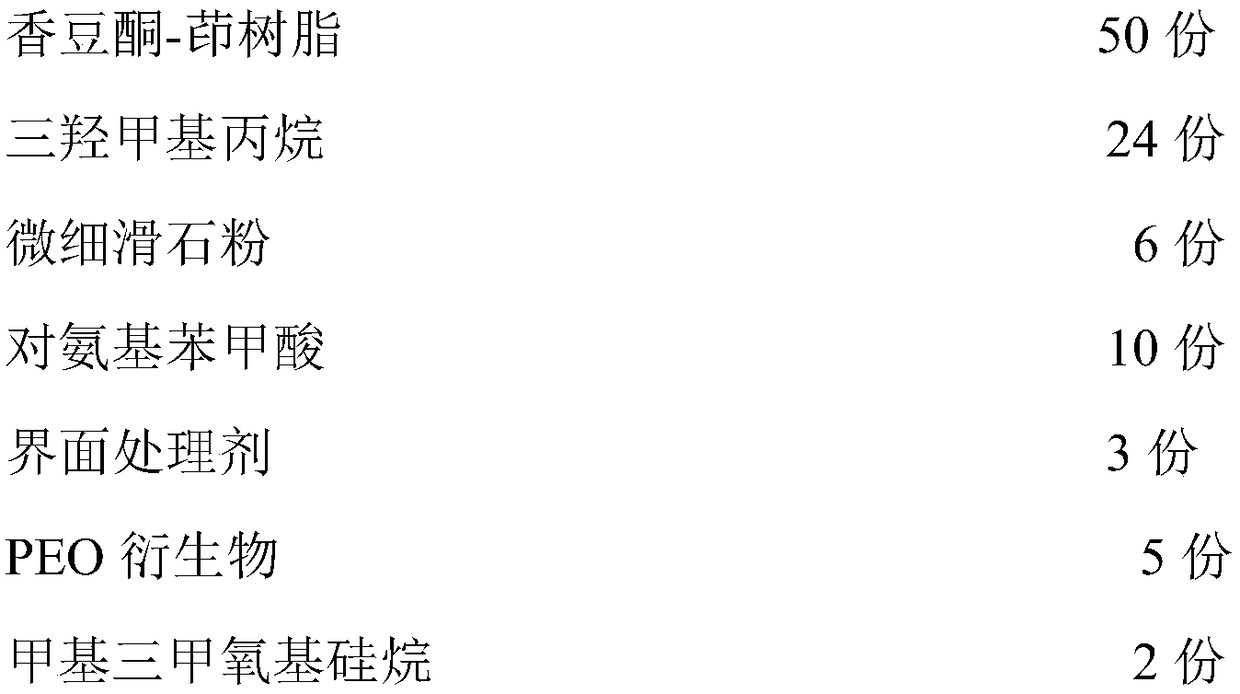

[0035] Configuration of functional group preparation A: weigh the corresponding components according to the following composition ratio configuration,

[0036]

[0037] Stir at a temperature of 80-100°C for 52 minutes, vacuum dehydrate for 1.8 hours, and package for later use;

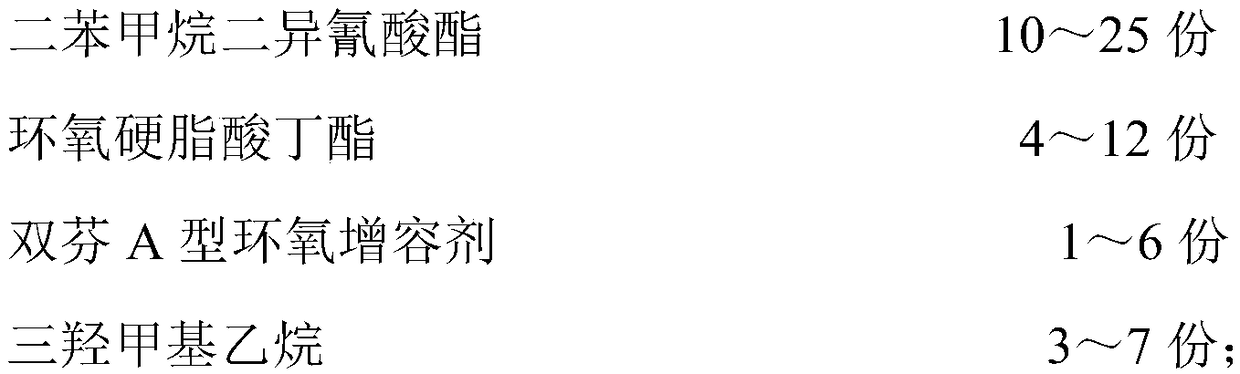

[0038] Configuration of functional group agent B: Weigh 18 parts of diphenylmethane diisocyanate, 8 parts of epoxy butyl stearate, and 5 parts of trimethylolethane, stir for 45 minutes at a temperature of 110°C, and vacuum dehydrate for 2.5 h, add 4 parts of bisphen-A epoxy compatibilizer, stir at the same temperature for 45 minutes, vacuum dehydrate for 0.75 hours, and package for later use;

[0039] Configuration of functional group agent C: Weigh 10 parts of microcapsules, 8 parts of vinyl glass flake cement, and 3 parts of polyvinyl alcohol-modified high-sodium bentonite particles, stir at room temperature for 35-60 minutes, vacuum dehydrate for 0.5-1 hour, and package spare;

[0040] The conf...

Embodiment 2

[0056] Embodiment 2: the repair of temperature crack

[0057] Using the potting glue prepared in Example 1, base asphalt, and conventional equivalent rubber modified joint glue to seal and fill the temperature cracks respectively, the performance index test of the road surface at the sealed and filled place after sealing and filling is shown in Table 3.

[0058]

[0059] Table 3 The performance comparison between the present invention and base asphalt and conventional grouting glue

Embodiment 3

[0060] Embodiment 3: Repair of pavement load cracks

[0061] The potting glue prepared in Example 1, matrix asphalt, and conventional equivalent rubber-modified asphalt joint glue were used to seal and fill the cracks under load on the pavement respectively.

[0062]

[0063]

[0064] Table 4 The performance comparison between the present invention and base asphalt and conventional grouting glue

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com