Patents

Literature

174results about How to "Realize filling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

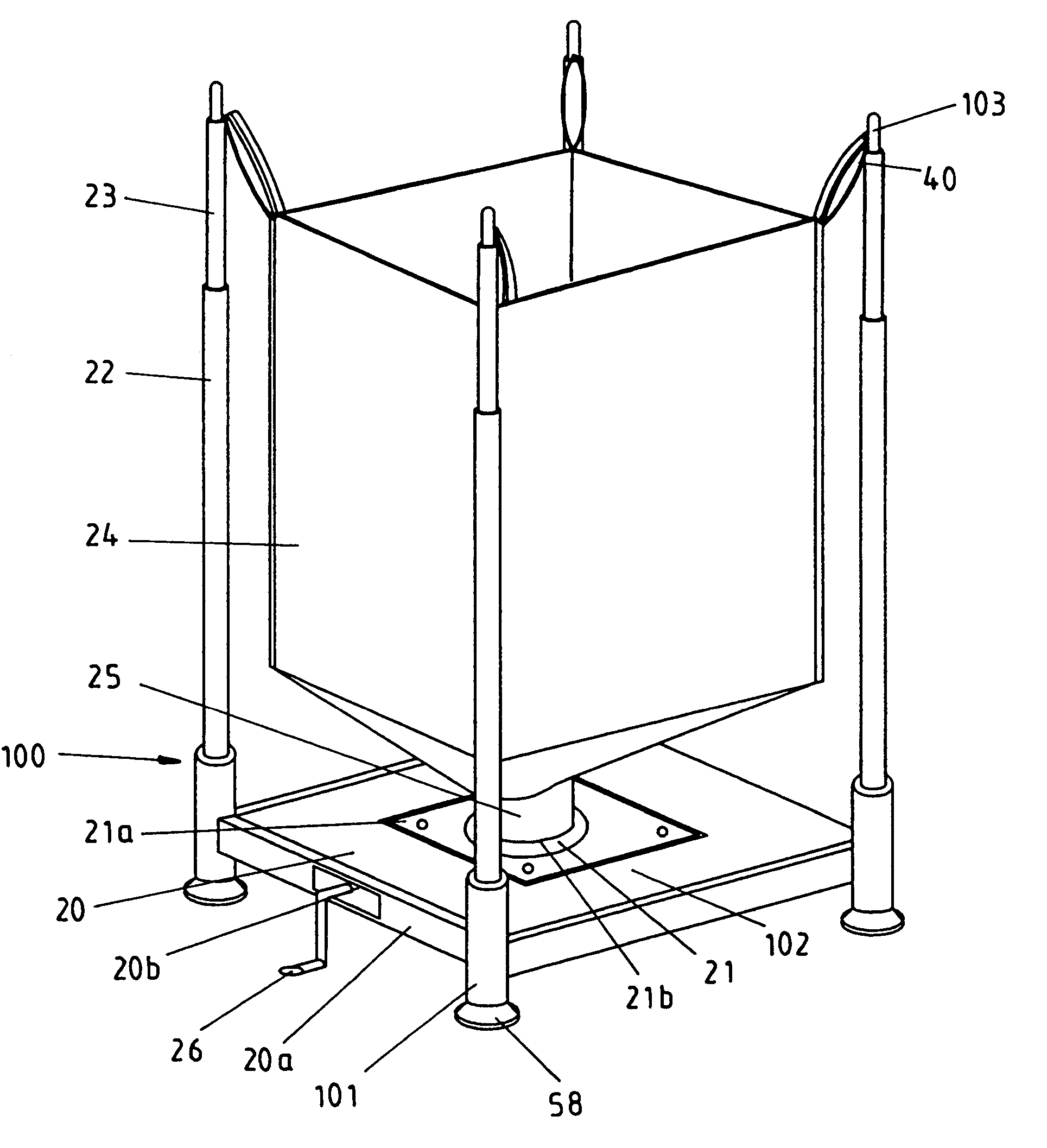

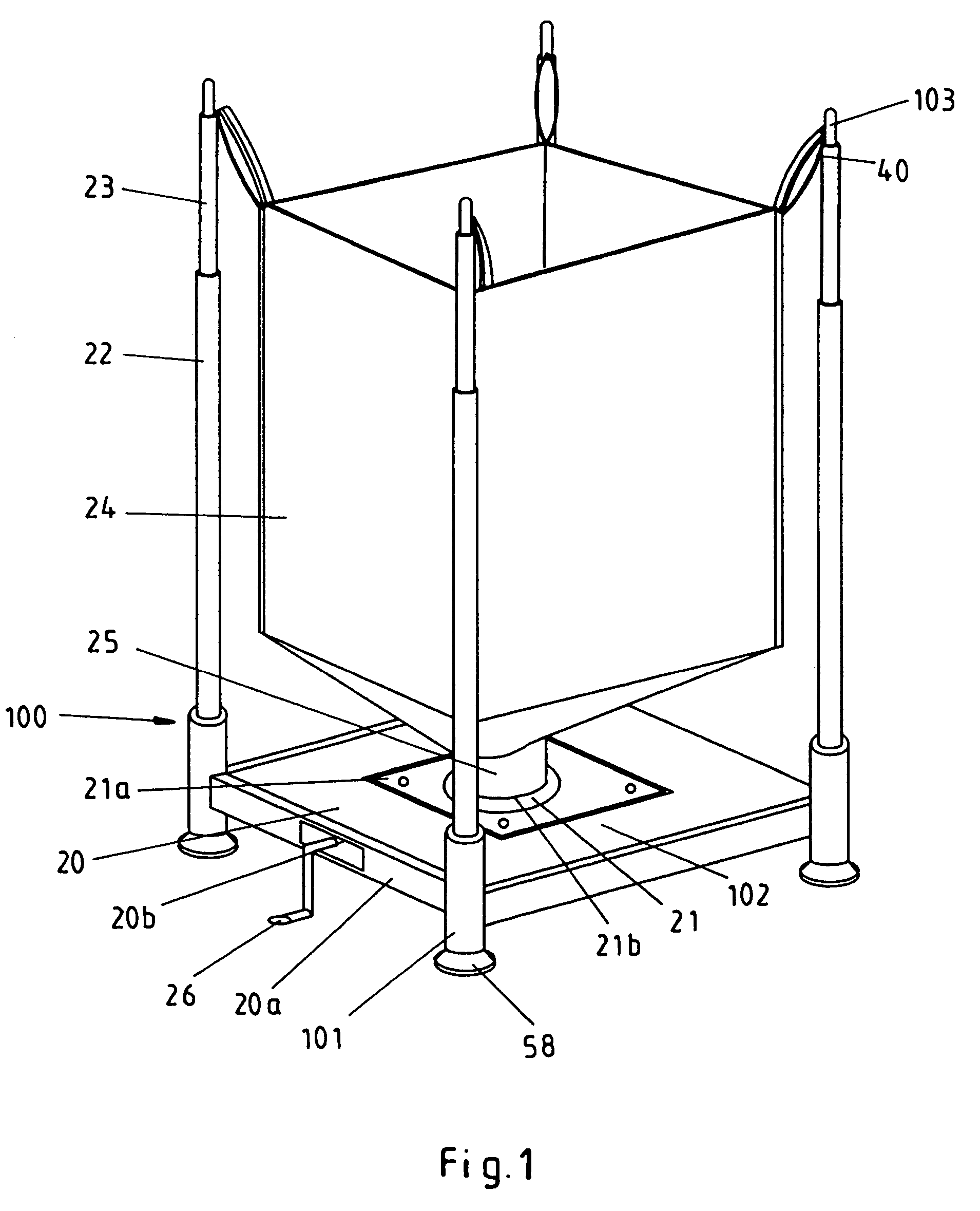

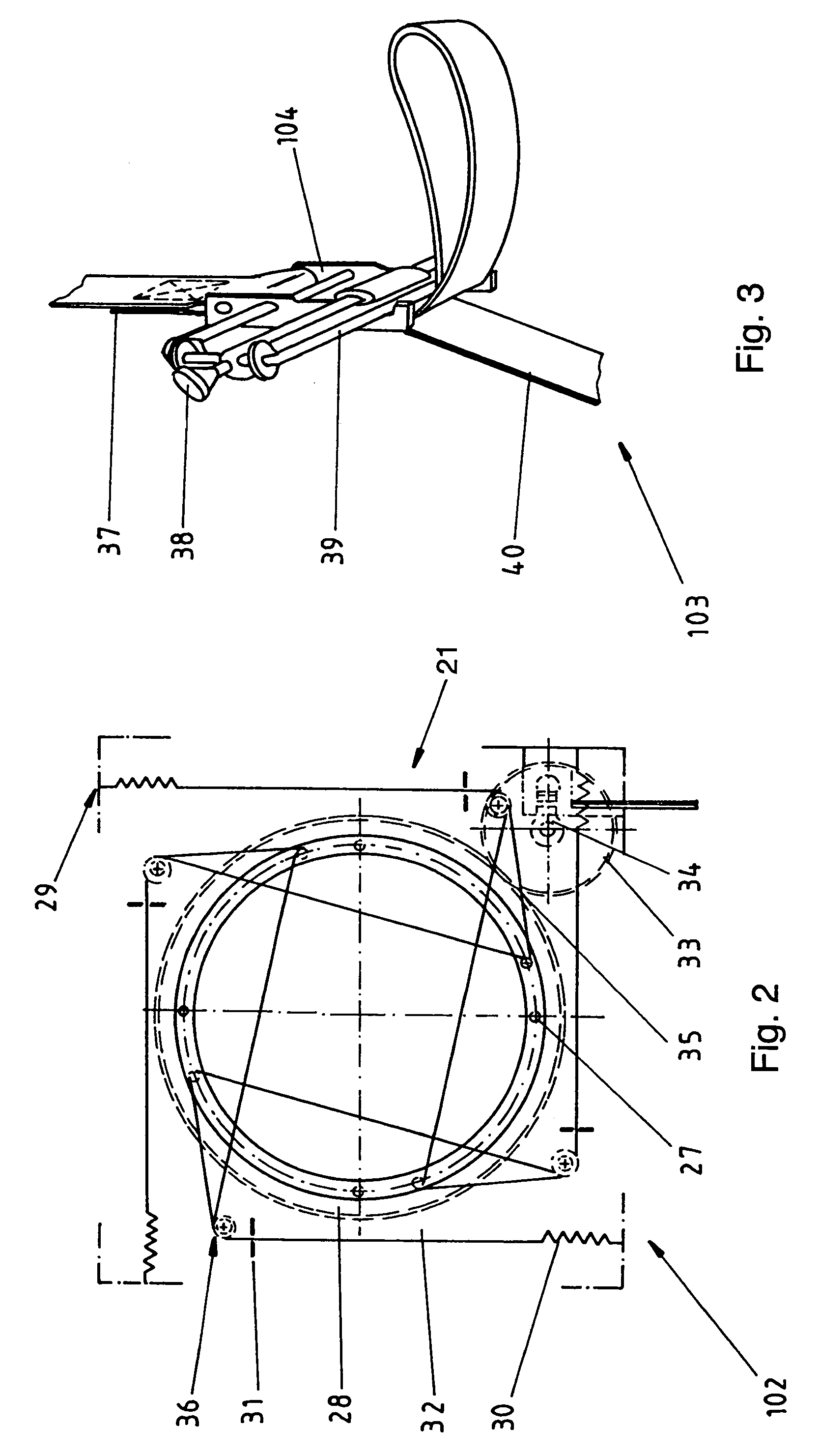

Device for large-volume containers

InactiveUS7140516B2Easy to fillSimple fashionFlexible bulk container emptying systemsClosuresMechanical engineeringLarge capacity

The invention pertains to an emptying device for large-volume receptacles which consists of an auxiliary transport apparatus that is composed of at least four uprights, on the lower ends of which one respective stacking leg is arranged and in the lower end of which one respective lifting mechanism is arranged. This lifting mechanism can be connected to the carrying straps of the large-volume receptacle by means of carrying strap holders, wherein the uprights are respectively connected to one another by means of transverse braces in their lower region in order to accommodate a bottom plate. The bottom plate contains a central opening for accommodating a shutter mechanism with a shutter that is situated in a base plate arranged on the bottom plate and can be actuated by means of a hand crank.

Owner:BOTHOR KERIM PATRICK +1

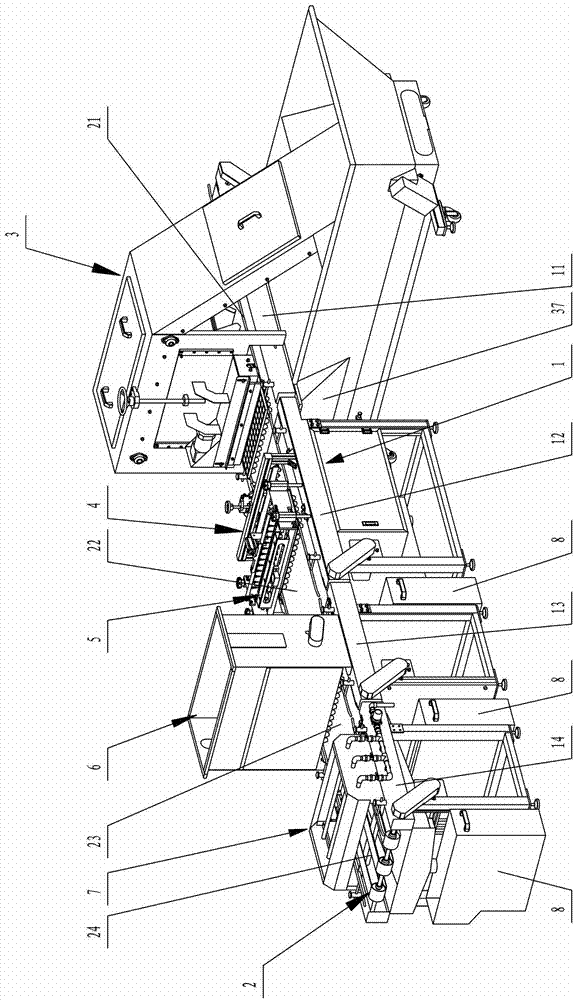

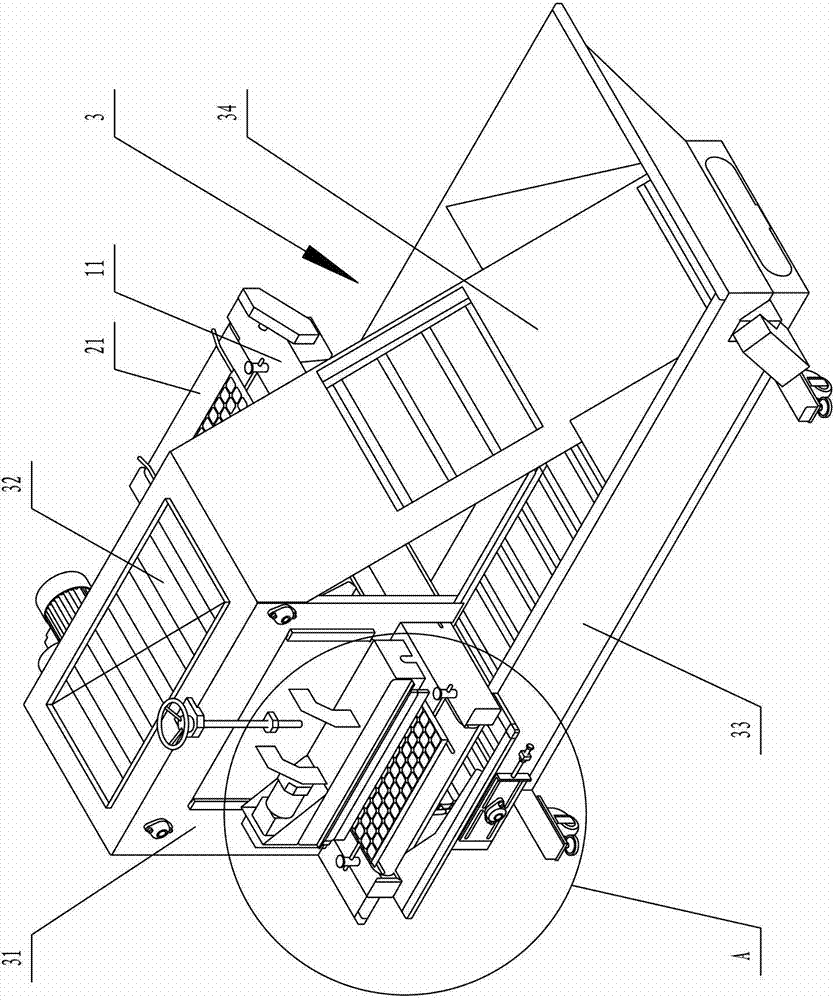

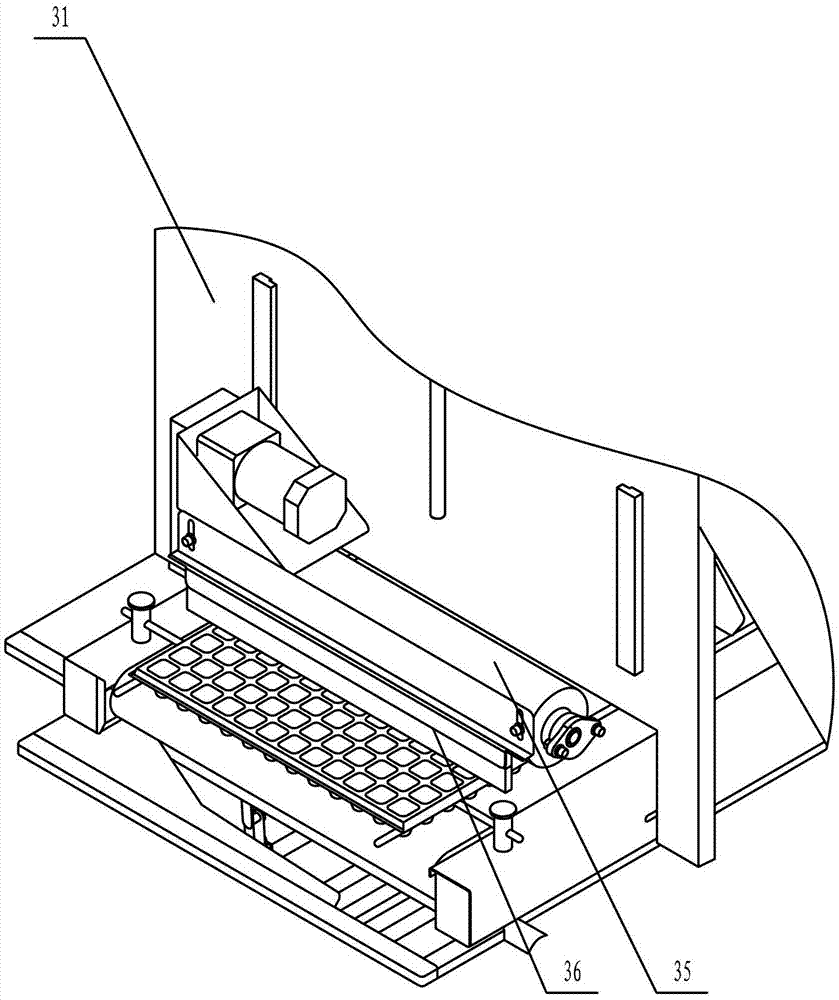

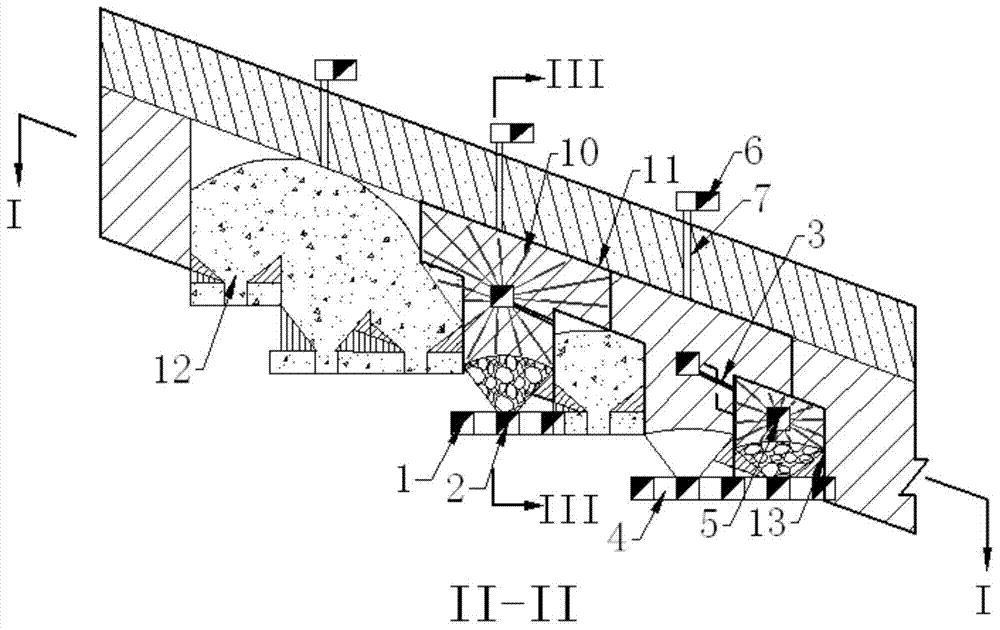

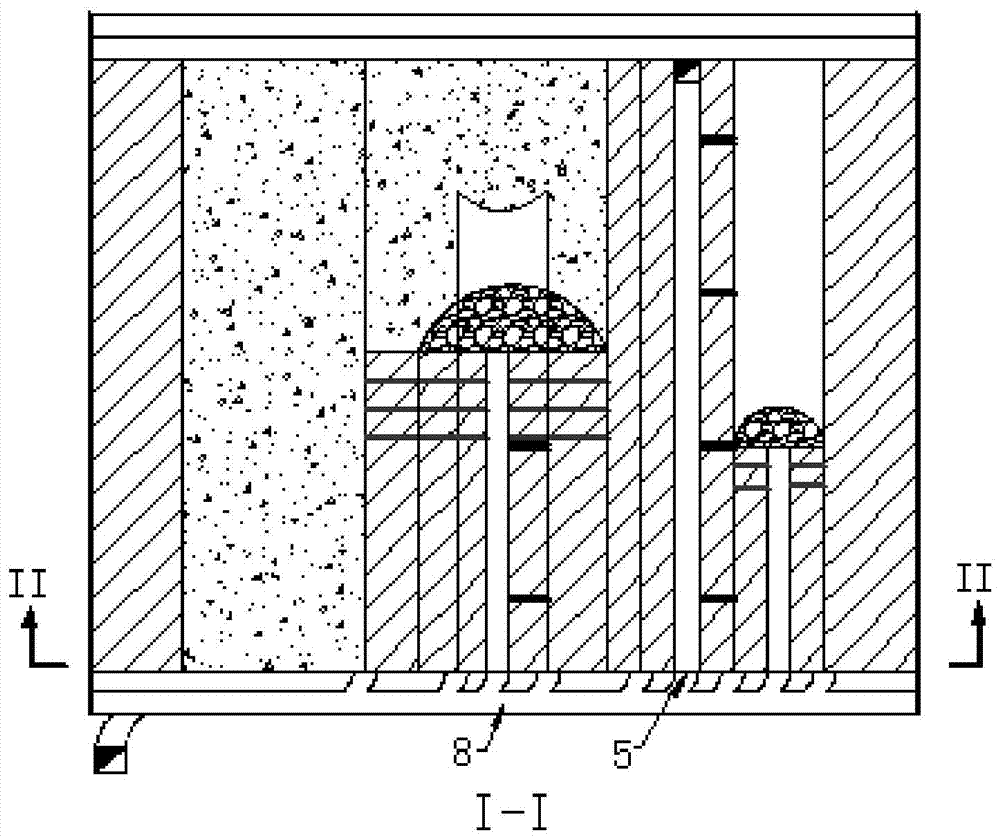

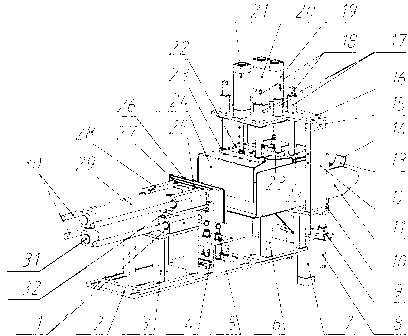

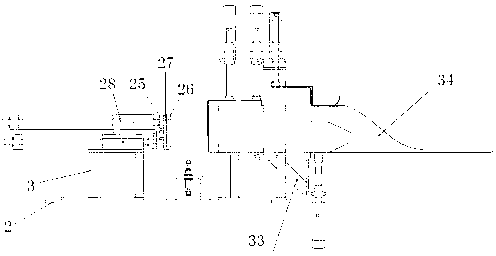

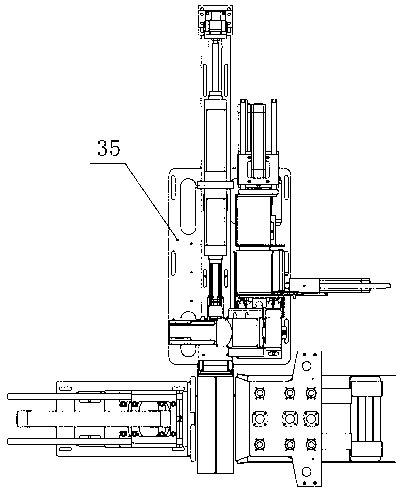

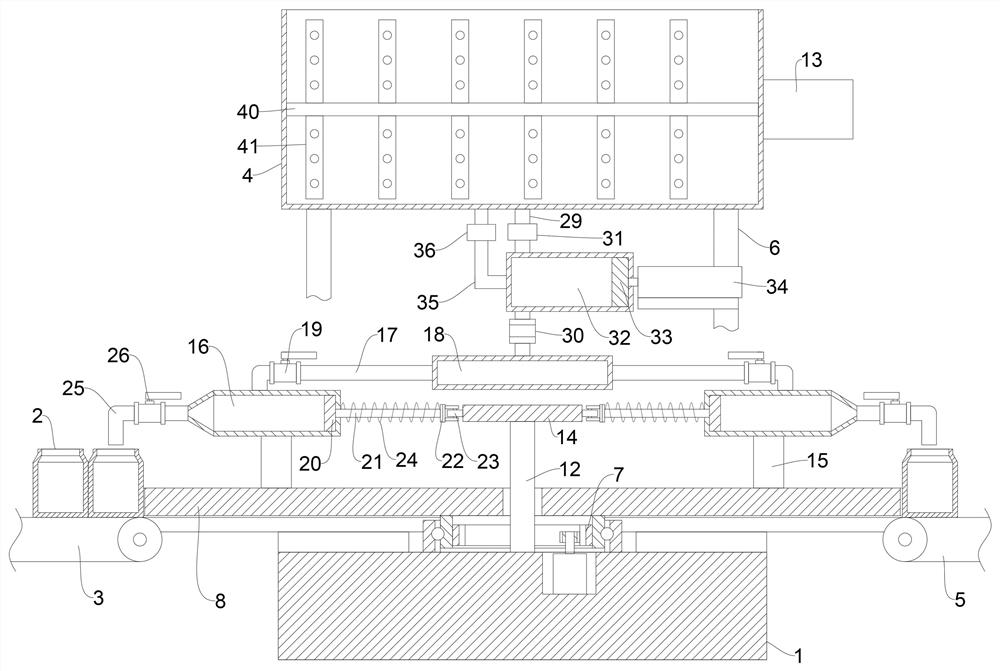

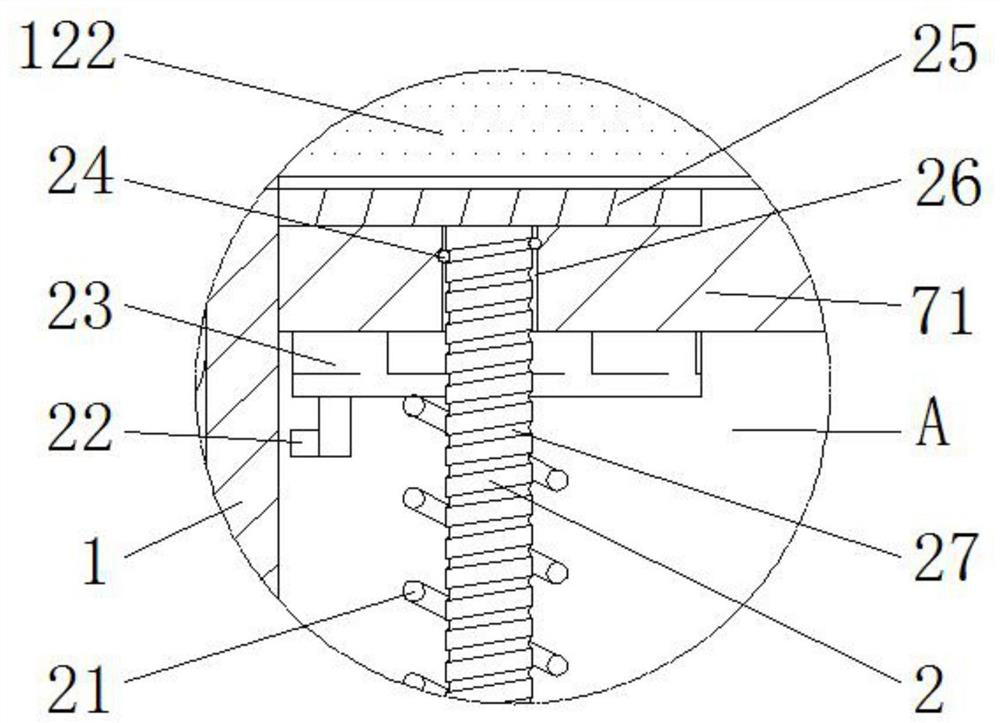

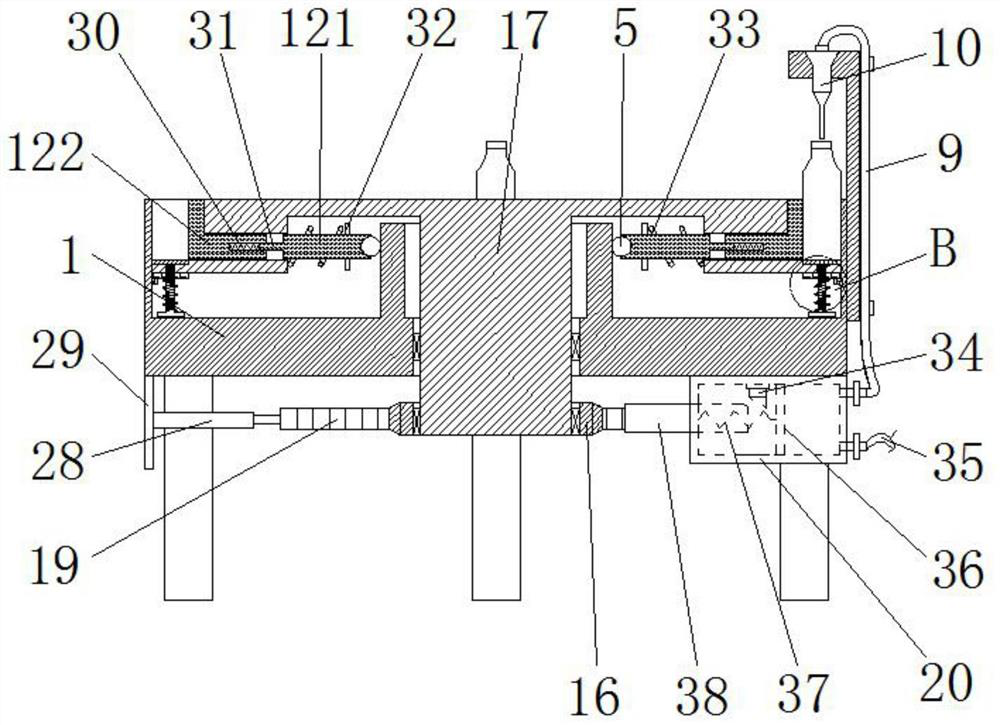

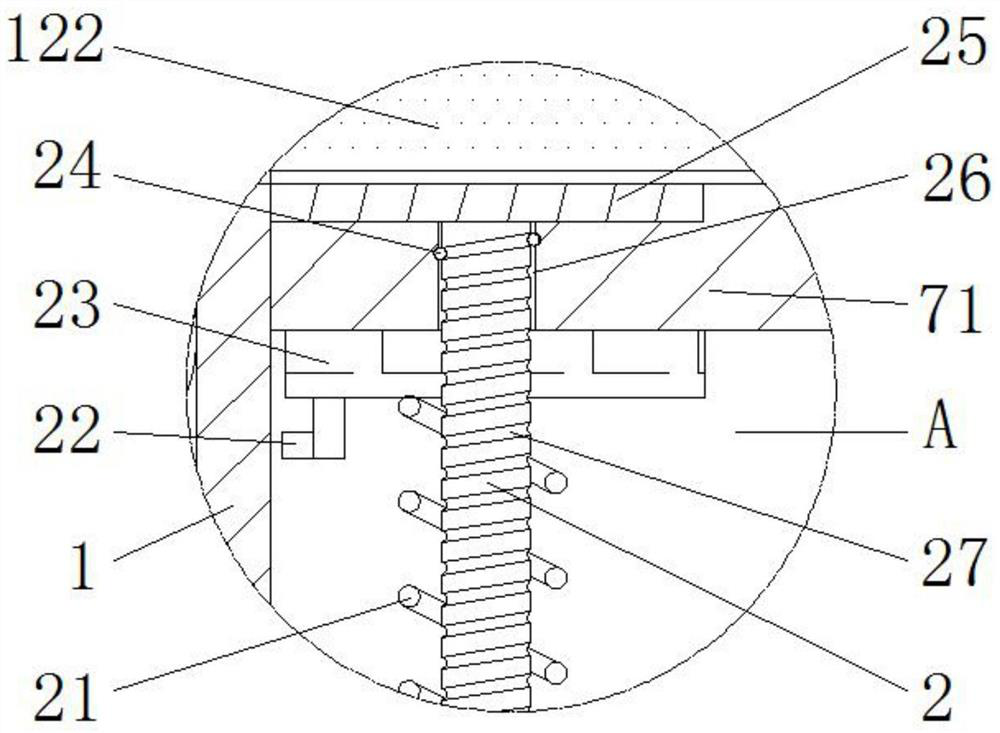

Seedling and seeding machine and seedling and seeding method

ActiveCN102960101AImprove work efficiencyRealize automatic controlCultivating equipmentsSeed depositing seeder partsProduction linePunching

The invention provides a seedling and seeding machine. The seedling and seeding machine comprises a rack, and a conveying device at the top of the rack, wherein a subsoil filling device, a punching device, a needle type tray seeding device, a soil covering device and a watering device are sequentially arranged on the conveying device along the conveying direction of the conveying device. According to the seedling and seeding machine provided by the invention, the subsoil filling device, the punching device, the needle type tray seeding device, the soil covering device and the watering device which are sequentially arranged on the conveying device are used for conveying trays, filling the subsoil, punching, seeding, filling trays and covering the soil, and watering, so that the whole work of seedling and seeding can be carried out on one production line, and as a result, the working efficiency in seedling and seeding can be effectively improved. The invention also provides a seedling and seeding method. The seedling and seeding method comprises the following steps in sequence: conveying trays, filling the subsoil, punching, seeding, filling trays and covering the soil, and watering; and by adopting the method, the working efficiency in seedling and seeding can be effectively improved.

Owner:四川川龙拖拉机制造有限公司

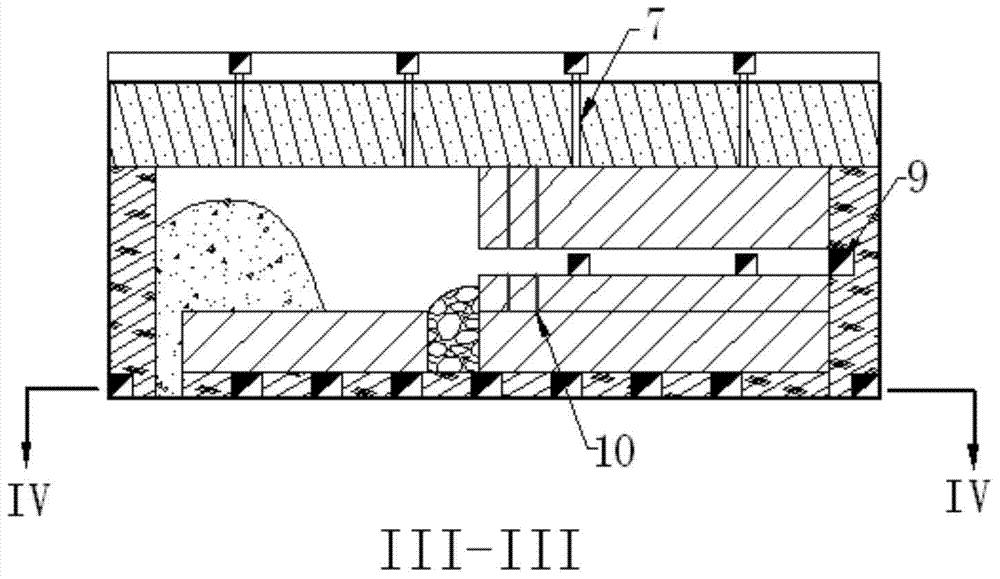

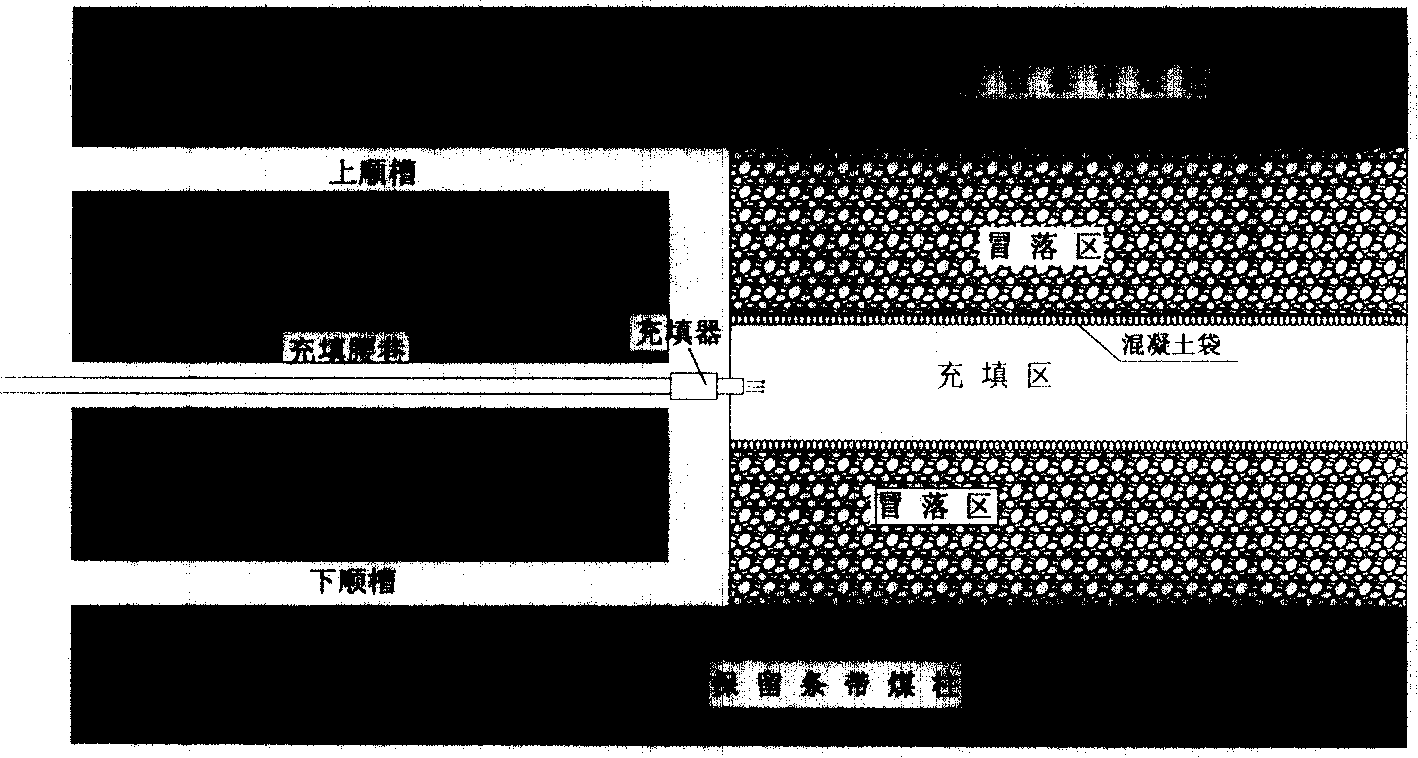

Subsection-studding all-open-stoping backfilling collaborative mining method

ActiveCN103615250AControl limit exposure areaGuarantee mining safetyUnderground miningSurface miningLarge sizeProtection layer

The invention discloses a subsection-studding all-open-stoping backfilling collaborative mining method. A panel ore block is divided into primary studdings and secondary studdings; a retrusive mining working mode that the mining is carried out out at intervals, the secondary studdings are mined and then the primary studdings are stoped is adopted; when each secondary studding is stoped, a certain thickness of an ore body is reserved on the top of the ore body and is used as a temporary protection layer; a drilling drift is arranged in each primary studding and is used for drilling the top ore body and the ore body of the primary studding; meanwhile, the drilling drift has a function of filling the drift, the function of filling the drift is achieved by a goaf of a low-level secondary studding; a filling hole is formed in the wall of the drift and is used for immediately filling the goaf of each secondary studding; a large-size stope structure parameter is designed in the ore body; a production mode of mechanical mining work is adopted; a drill jumbo is used for drilling, and a scraper discharges ores, so that the safety and high-efficiency mining is realized. The subsection-studding all-open-stoping backfilling collaborative mining method disclosed by the invention is high in ore recycling rate and high in safety under the condition that a roof surrounding rock is unsteady.

Owner:CENT SOUTH UNIV +1

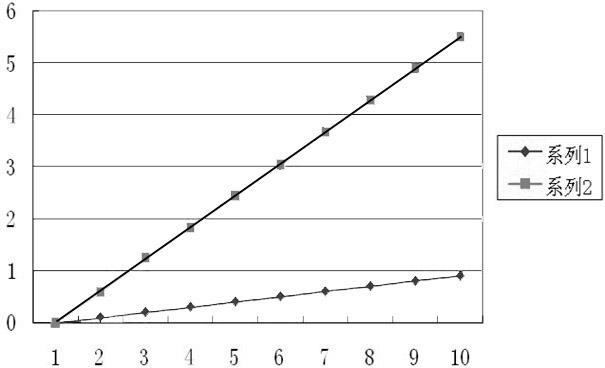

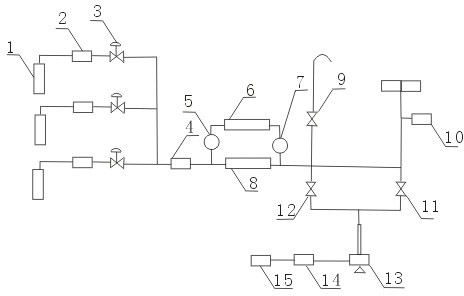

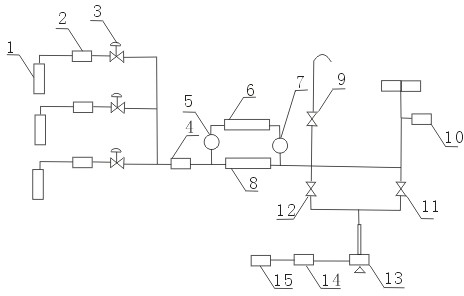

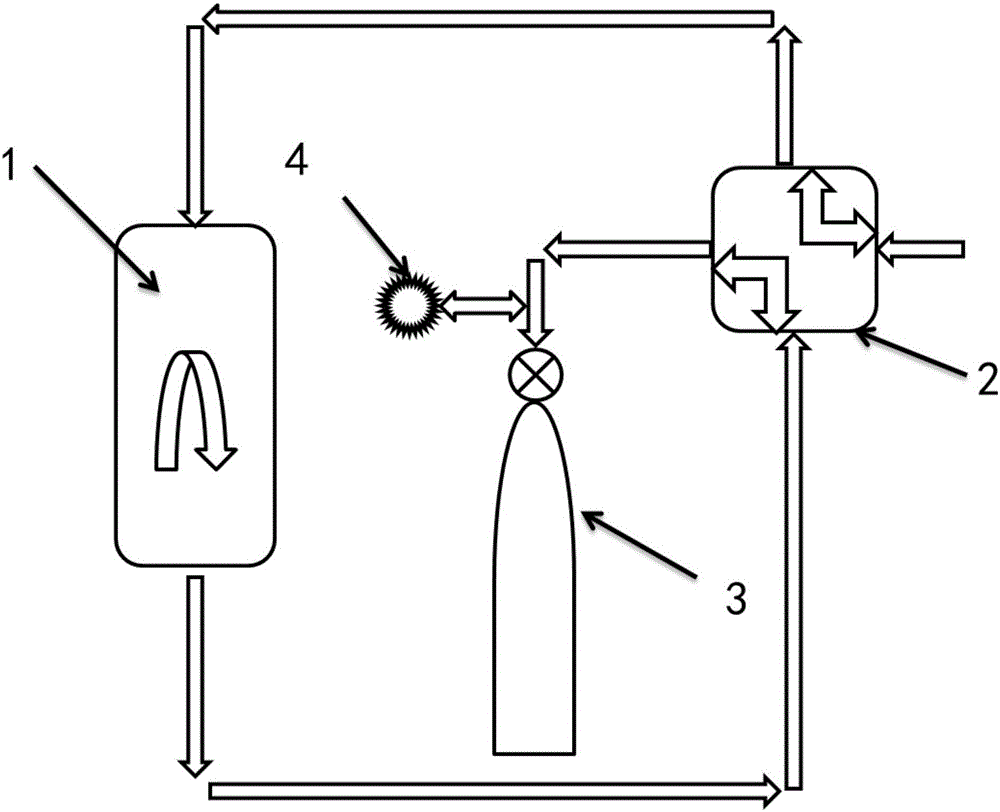

Novel device for distributing standard gas

ActiveCN102500253ARealize fillingAchieve fixed valuePreparing sample for investigationMixer accessoriesData processing systemChemical reaction

The invention discloses a novel device for distributing standard gas. In the whole set of device, a raw material gas cylinder is filtered by a filter and then is connected with a raw material control valve; the raw material control valve is connected with a high-pressure adjusting system; the high-pressure adjusting system is connected with a pressure sensor I and then is connected with a low-pressure adjusting system; the low-pressure adjusting system is connected with a pressure sensor II and then is connected with a product control valve, an air release control valve and a vacuum pump valve respectively; a product is placed on an electronic balance; signals of the pressure sensor I and the pressure sensor II and data of the balance are accessed into a signal processing system; and the signal processing system is connected with a data processing system, the air release control valve and a vacuum pump interlocking device respectively. The device can intuitively display the component mass and proportioning, greatly simplifies the gas distribution process and improves work efficiency and weighing accuracy. The system can directly give warning according to the gas distribution components which may cause safety accidents and chemical reaction, so that operation simplicity, safety and quickness of the equipment are greatly improved.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

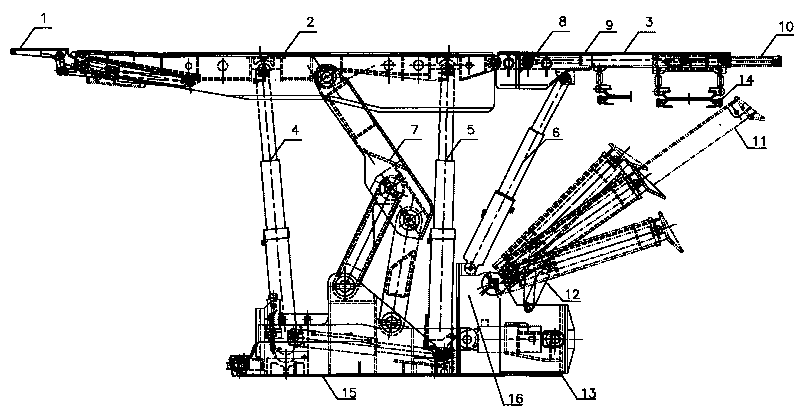

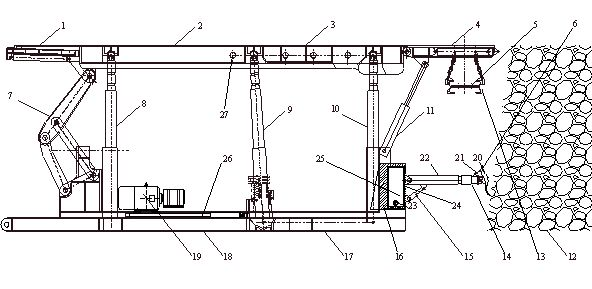

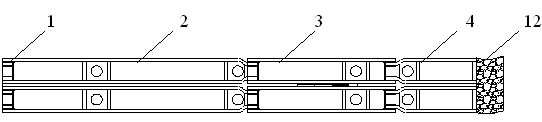

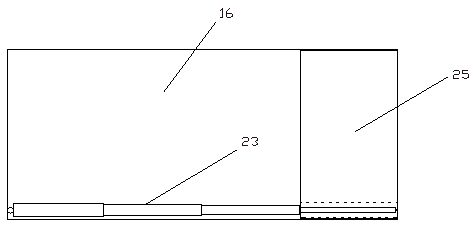

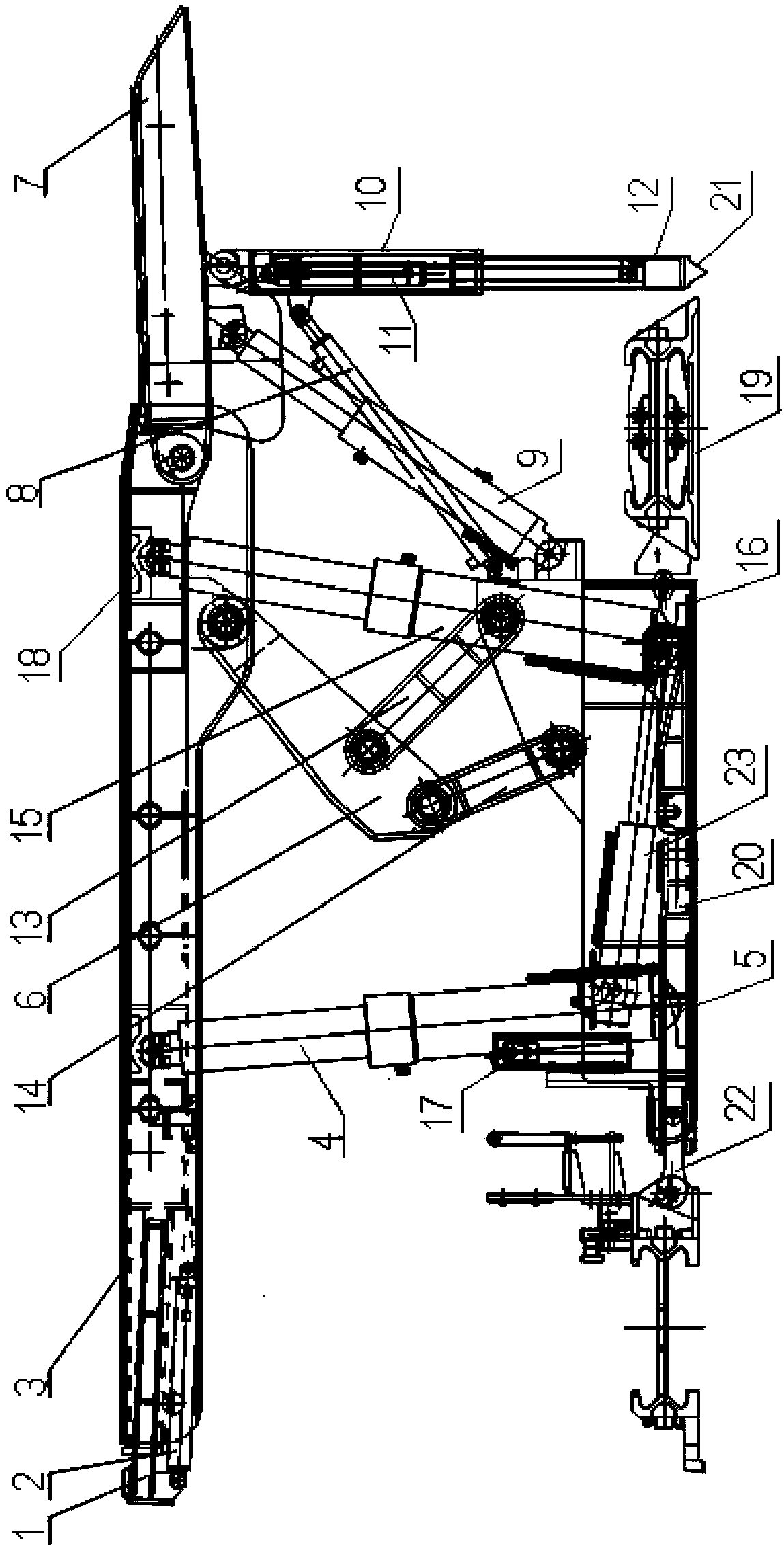

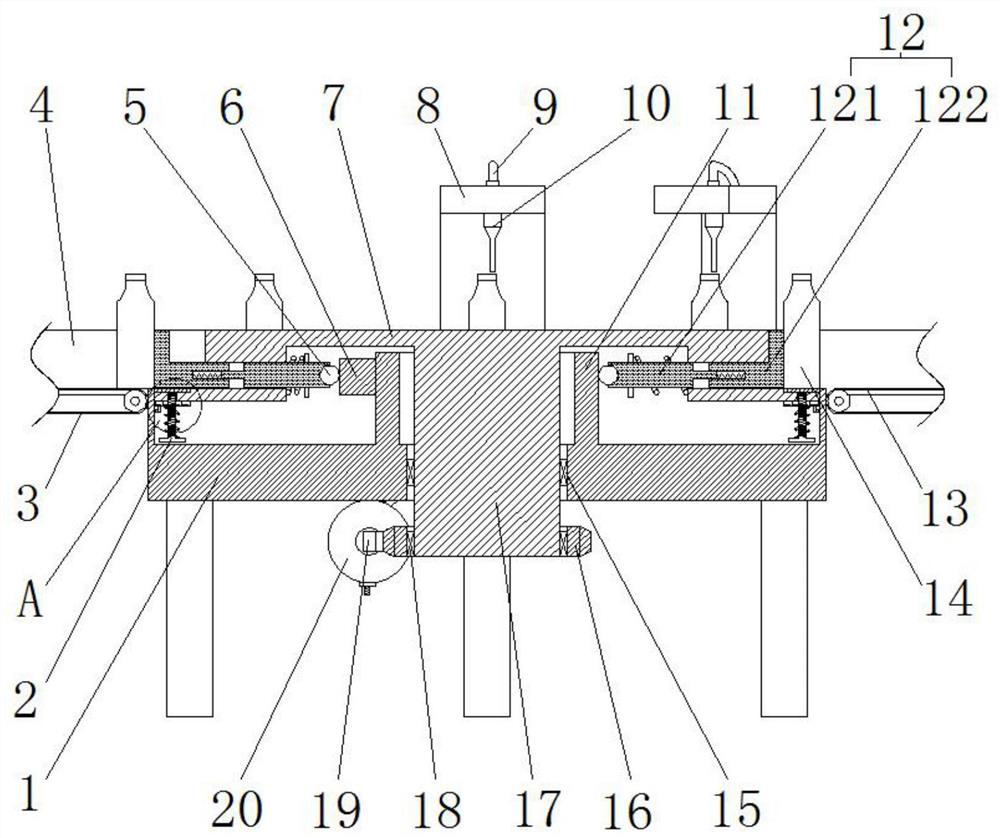

Hexastyle supporting type coal mining and filling hydraulic bracket

InactiveCN101725365ARealize fillingAchieve compactionMaterial fill-upMine roof supportsEngineeringWork space

The invention relates to a hexastyle supporting type coal mining and filling hydraulic bracket which comprises a telescopic girder, a front top girder, a rear top girder, a front upright post, a middle upright post, a rear upright post, a four bar mechanism, a middle upper part compaction mechanism, a height-regulating jack, a lower box type compaction mechanism, a slide way, a pulling jack, a rear-inserting type top protection device, a filling and mining conveyer and a base, wherein the front top girder is supported through the front upright post and the middle upright post and maintains the balance through the four bar mechanism; the rear top girder is mutually hinged with the front top girder and supported through the rear upright post, bears the pressure of a top plate, controls the deflection of the top plate before filling and can overhang the filling and mining conveyer to realize filling solid fillers in a goaf; and the rear top girder is provided with the slide way and can maintain a working space for normal mining of a working surface, realize the full filling of the goaf and meanwhile compact the fillers by clean mining within a high range. The hexastyle supporting type coal mining and filling hydraulic bracket has compact structure, strong supporting force, convenient operation and good filling effect on the goaf and can adapt to the filling and the mining under a complicated geological condition.

Owner:CHINA UNIV OF MINING & TECH

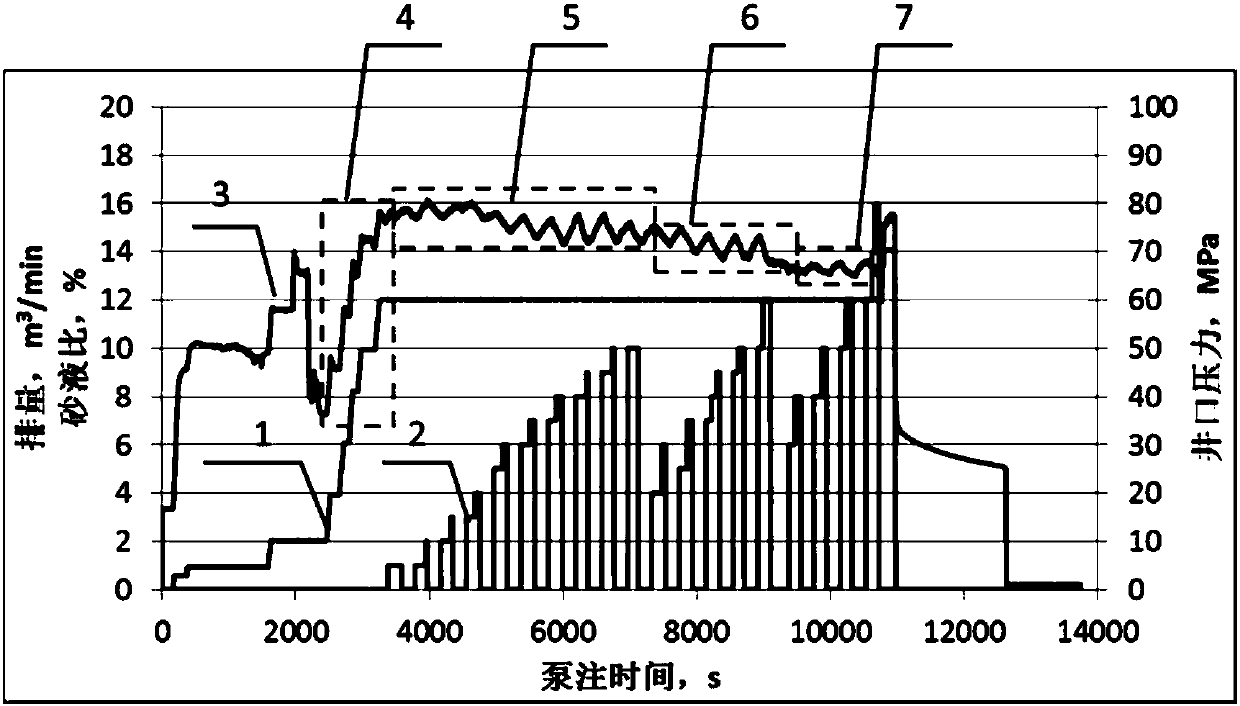

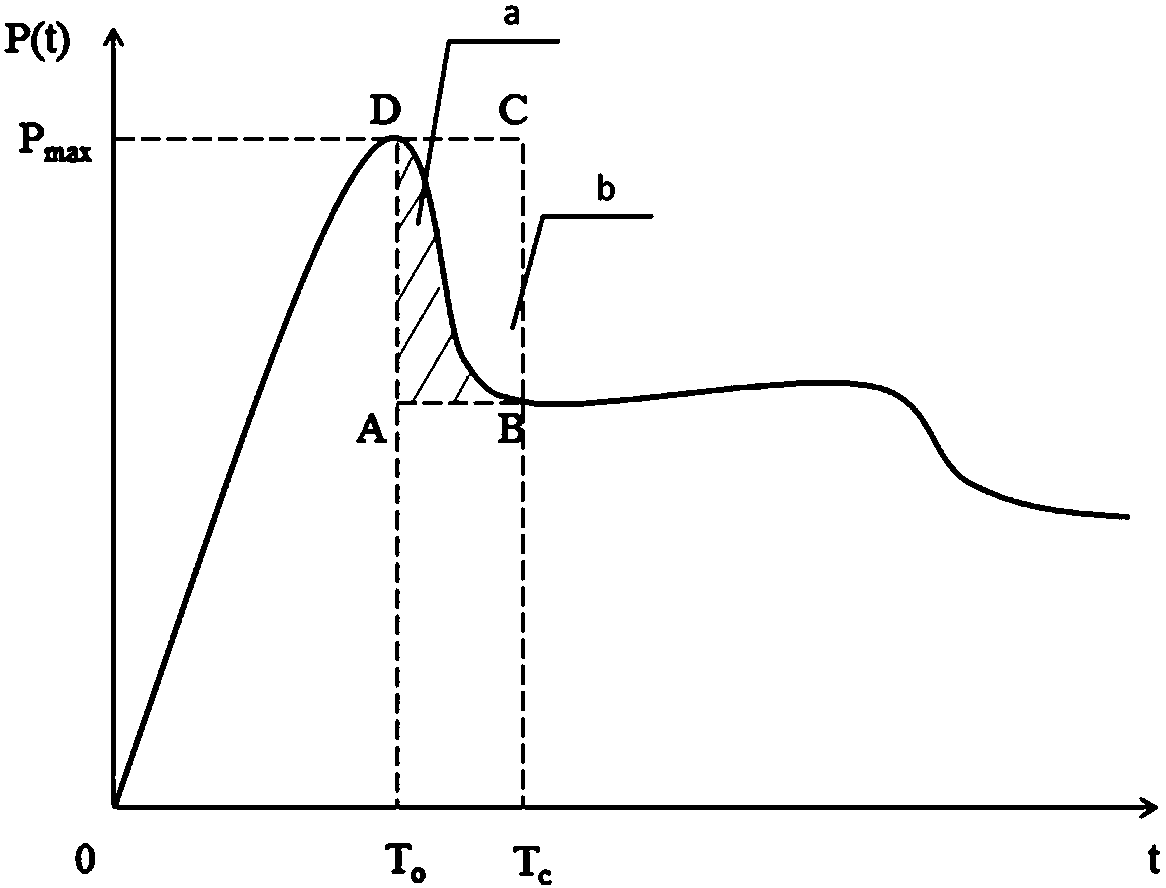

Multi-particle-size proppant mixed fracturing method

ActiveCN109751032AConstruction pressure rises steadilyGuaranteed compatibilityFluid removalHorizontal stressComputer science

The invention discloses a multi-particle-size proppant mixed fracturing method. The method comprises the following steps: (1) evaluating brittleness, natural cracks and horizontal stress difference; (2) injecting low-viscosity slickwater into a pre-formed joint; (3) injecting a 70-140 mesh proppant or 140-210 mesh proppant; (4) conducting mixed injection of the 70-140 mesh proppant and 40-70 meshproppant; and (5) injecting a mixture of a 30-50 mesh proppant and a 40-70 mesh proppant or a mixture of a 30-50 mesh proppant, a 40-70 mesh proppant and a 70-140 mesh proppant. Different proppant particle size combinations are optimized, proppants with various particle sizes enter multi-scale cracks matched with the proppant particle sizes in sequence, filling and supporting of different-scale cracks of main cracks and micro cracks in the fracturing process are achieved, and the effectiveness of a fracturing and cracking system is further improved. The effective coverage of cracks on an oil-gas reservoir is increased, the yield is improved, and progressive decrease is delayed.

Owner:CHINA PETROLEUM & CHEM CORP +1

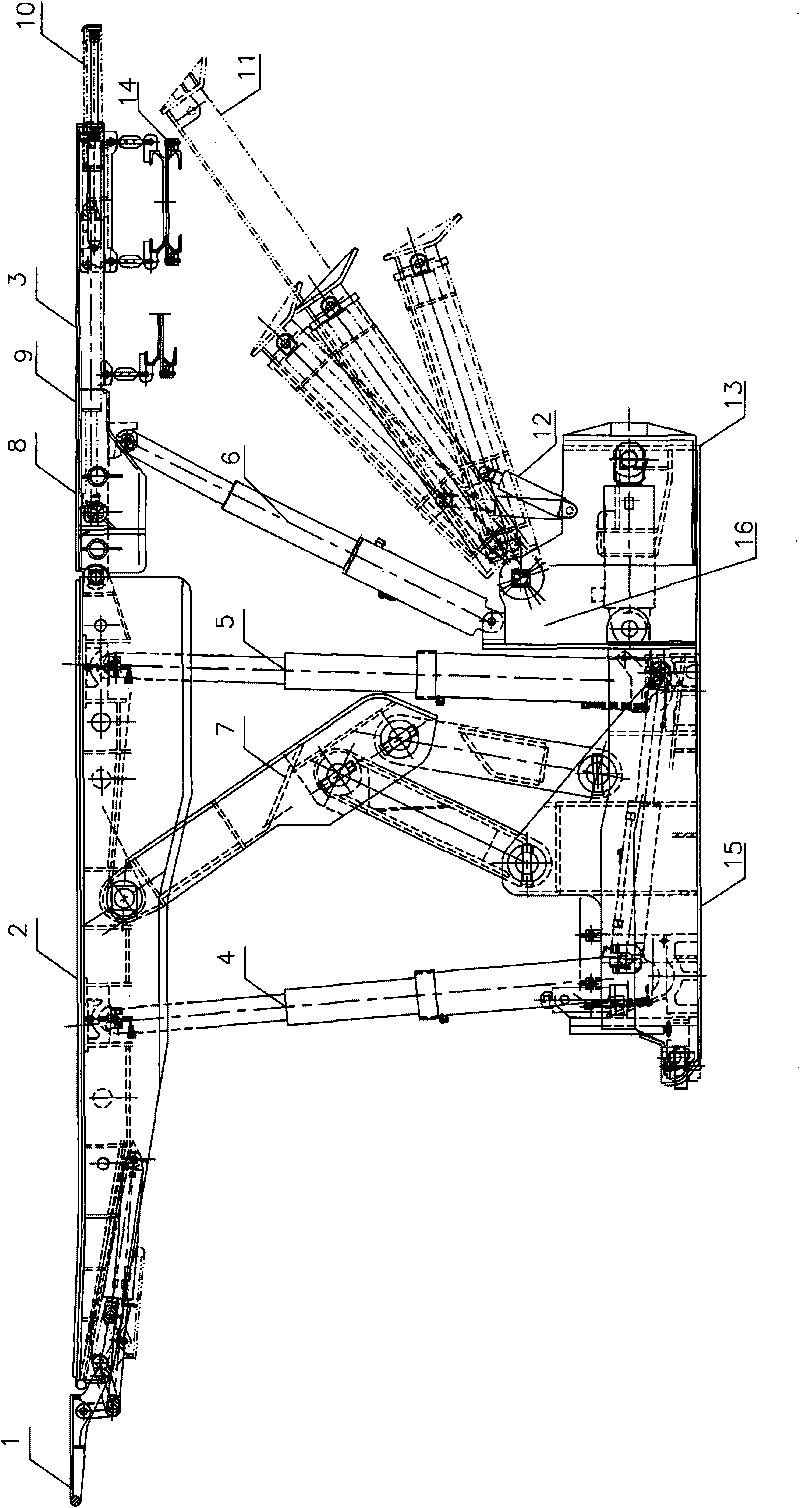

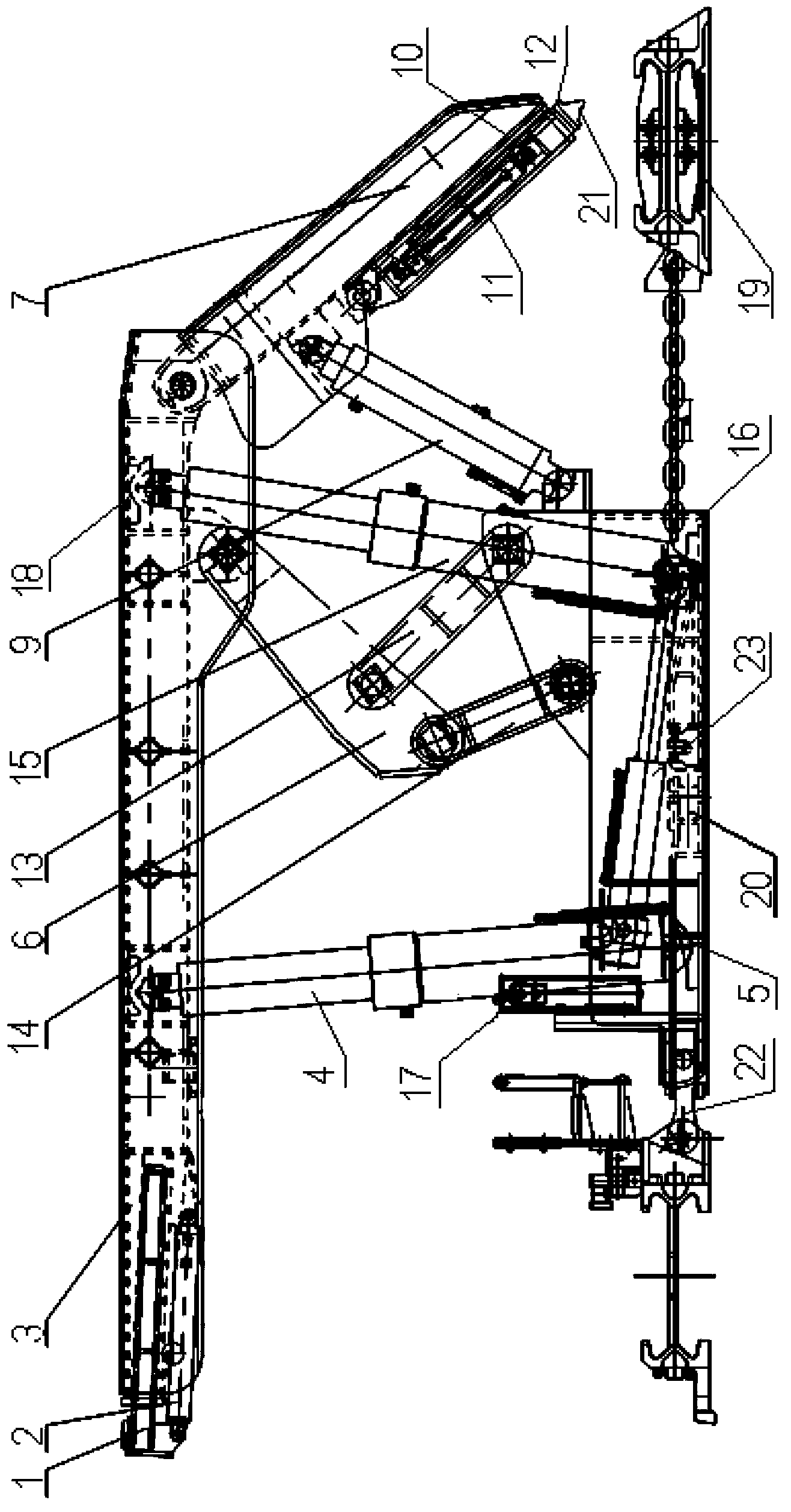

Hydraulic bracket for end of comprehensive mechanized filling coal face

ActiveCN102094664AEffective supportReduce manual labor intensityMaterial fill-upMine roof supportsEngineeringMechanical engineering

The invention relates to a hydraulic bracket for the end of a comprehensive mechanized filling coal face. The bracket comprises top beams, an upright post, a connecting rod mechanism, a head sliding oil cylinder and bases, wherein the connecting rod mechanism is reversely supported on the lower part of a front top beam; a scraper conveyor head installing and moving space is reserved and the head sliding oil cylinder is arranged on a middle base; a pushing device is arranged below a rear front beam jack and comprises a case fixed on a rear base; a sliding block and a sliding block pushing oil cylinder for pushing the sliding block to horizontally move are arranged in the case; the sliding block is hinged with a telescopic pushing oil cylinder; the lower part of the telescopic pushing oil cylinder is connected with a tamping adjustment jack of which the base is hinged to the lower part of the sliding block; the front part of the telescopic pushing oil cylinder is provided with a vibration generator; the head of the vibration generator is provided with a pushing plate direction adjusting oil cylinder and a pushing plate; the pushing plate is an arc plate with a small upper part and alarge lower part; and the arc surface of the pushing plate is provided with a nail-shaped compaction block. The bracket can realize the advance support and full cross section dense filling of the endof a fully mechanized mining face, and matched equipment movement simultaneously, and overcomes the defects at the end of the conventional filling working face.

Owner:CHINA UNIV OF MINING & TECH

Hydraulic support capable of realizing top coal caving and filling operation

ActiveCN103410545AImprove stabilitySolve the problem that the filling operation cannot be realizedMaterial fill-upMine roof supportsFilling materialsEngineering

The invention discloses a hydraulic support capable of realizing top coal caving and filling operation. The hydraulic support is a support filling device used for mining unexploited coal 'below a building, a railway and water and above pressure-bearing water', the hydraulic support comprises two groups of bases and top beams, the bases are hinged to the top beams through four vertical columns, a tail beam is hinged to the rear end of each top beam, the angle of each tail beam is changed by a tail beam jack, a baffle is hinged below each tail beam, the baffles and the tail beams can be closed, and an inserting plate and an inserting plate jack are arranged on the inner side of each baffle. The top of a gob can be supported, and the top beams and the tail beams further can serve as top coal caving channels when a top coal bed is minded. When the gob needs to be filled, the tail beams can function in supporting the top of the gob, the tail beams, the baffles and the inserting plates jointly function as a box plate, and the hydraulic support is used for filling water rapid-solidifying materials and other filling materials.

Owner:JIZHONG ENERGY MACHINERY EQUIP XINGTAI MACHINERY FACTORY

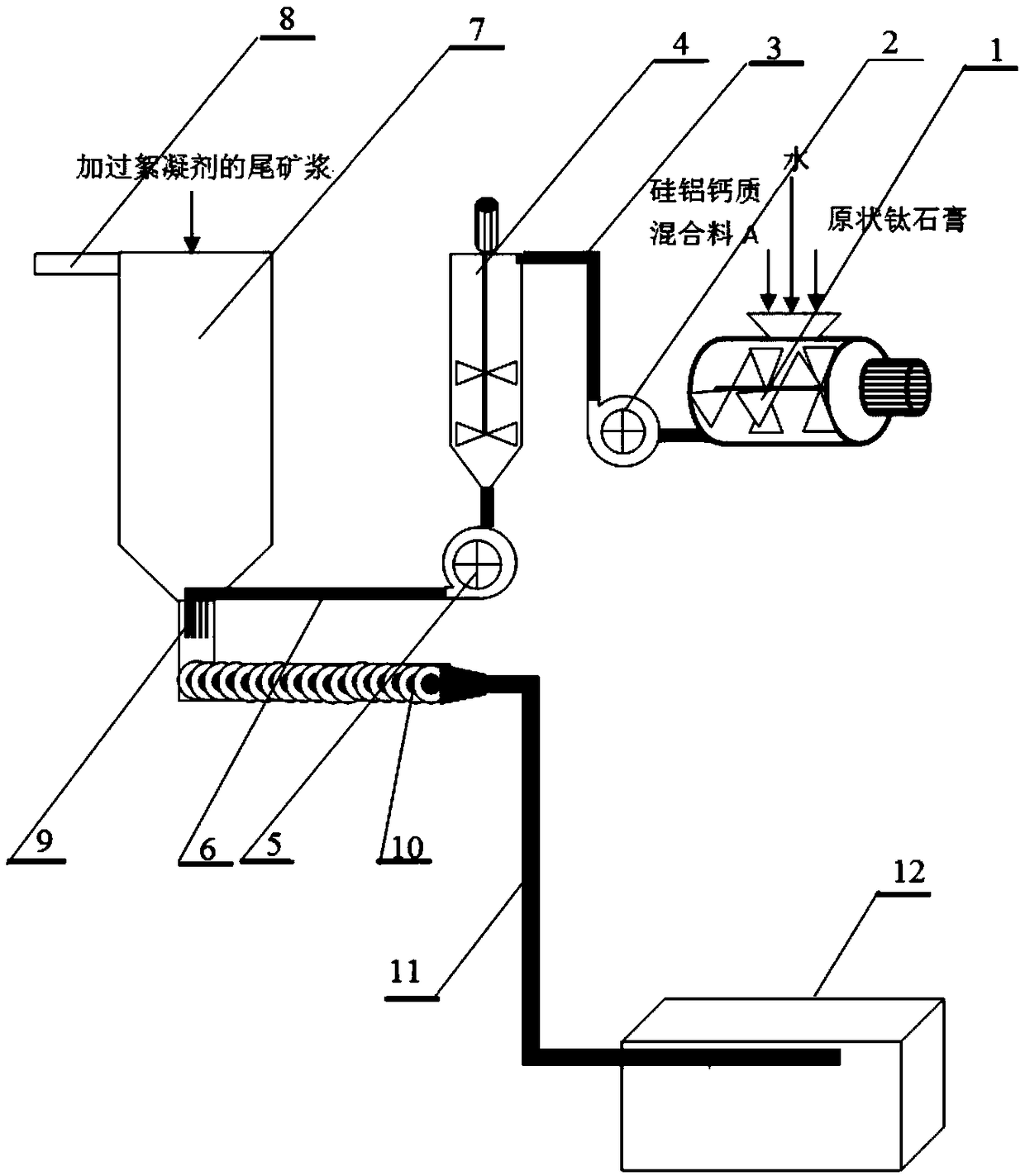

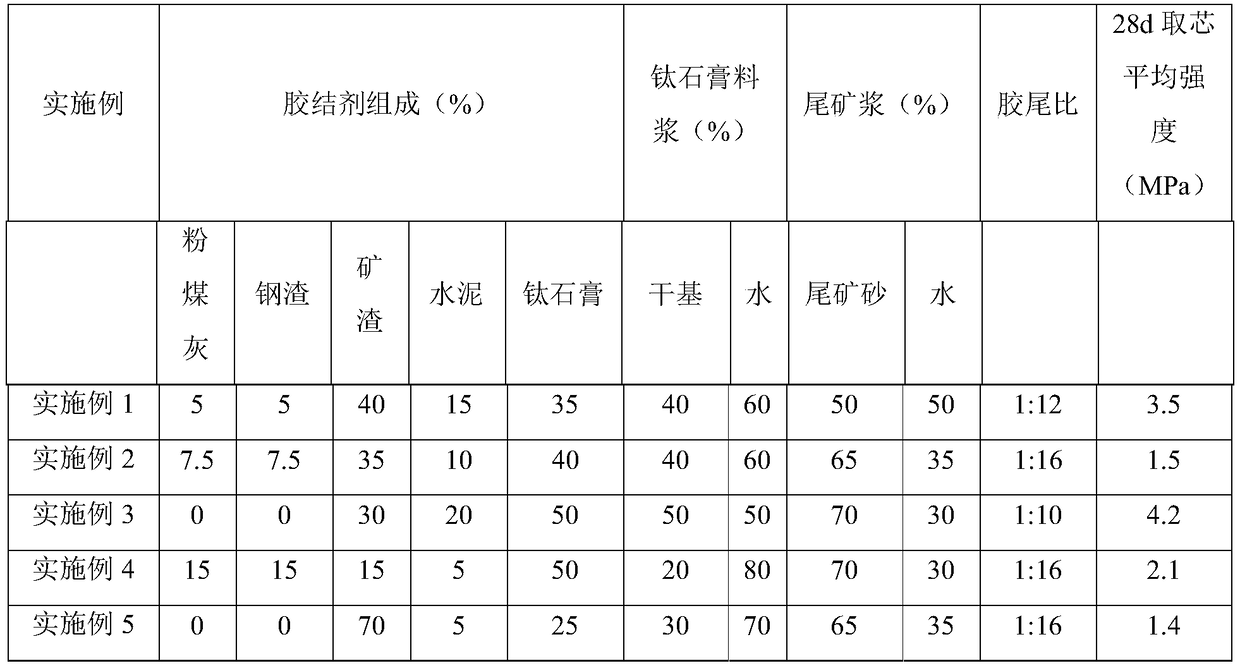

Mine filling material, preparation device and preparation method of mine filling material, cementing agent slurry for mine filling

InactiveCN109265120AReduce manufacturing costHigh strengthMaterial fill-upMixing operation plantResource utilizationSlag

The invention discloses a mine filling material, a preparation device and a preparation method of the mine filling material, cementing agent slurry for mine filling, and belongs to the technical fieldof mining engineering and building materials. The cementing agent slurry for mine filling is formed by mixing premixed powder of silicon aluminum and calcium raw materials and titanium gypsum slurry;concretely, the cementing agent slurry dry basis is prepared from the following ingredients in percentage by weight: 0 to 15 percent of fly ash, 15 to 70 percent of ore slag micro powder, 0 to 15 percent of steel slag micro powder, 5 to 20 percent of cement and 25 to 50 percent of industrial byproduct titanium gypsum. The mine filling material is formed by mixing tailings slurry formed by full tailing sand and water and the cementing agent slurry through stirring and mixing. When the technical scheme is used, the intensity of a mine filling body can be effectively improved; the effective resource utilization on industrial waste residue, particularly titanium gypsum is realized; the preparation process of the mine filling cementing material is simple; the filling of the full tailing sand can be realized.

Owner:深圳市颐泰中和科技有限公司

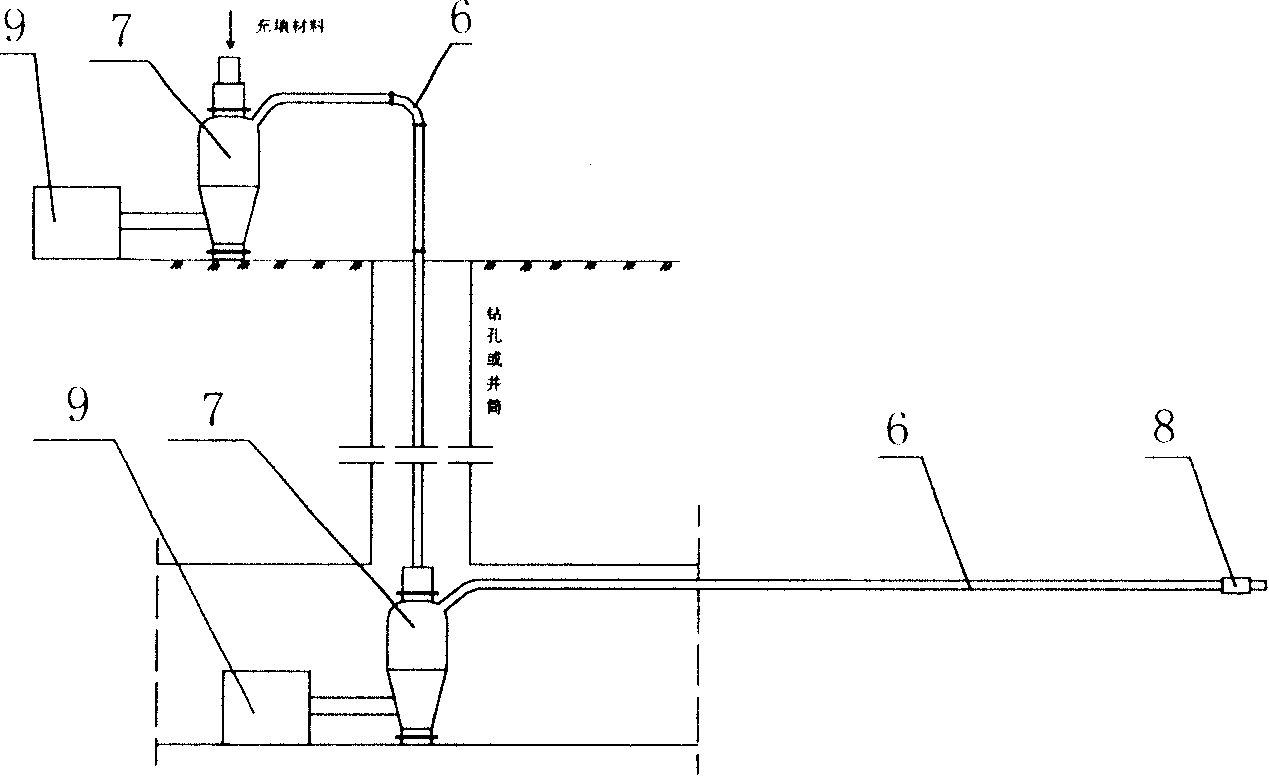

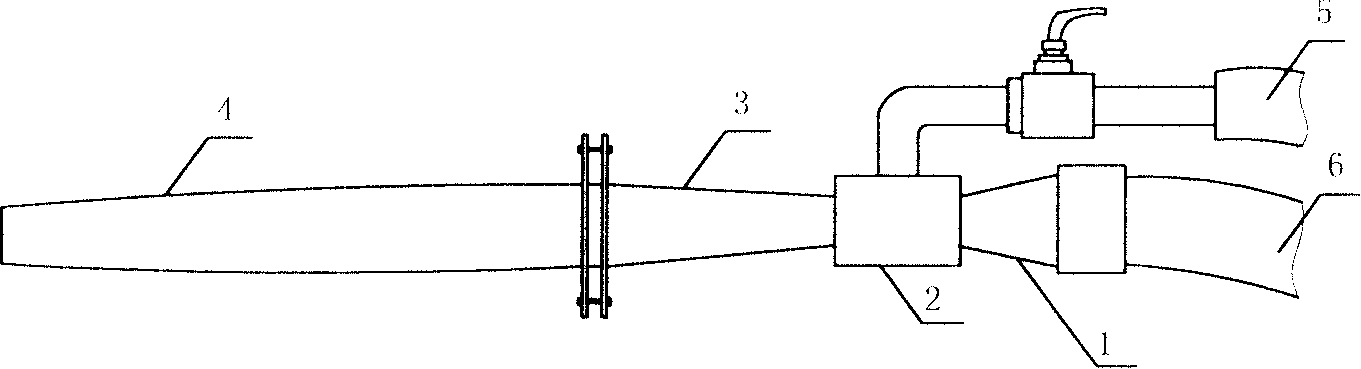

Filling device and method for filling down-hole goaf by same

The filling apparatus include one compressor, one storehouse pump, one ash conveying pipeline and one filling unit. After the compressor feeds compressed air to the storehouse pump, the filling material is conveyed through the ash conveying pipeline from the storehouse pump to the filling unit and jetted to the filled region. The filling unit includes one convergent pipe, one throat pipe, one diverging pipe, one rifling pipe and one water pipe. The filled region is first separated out from waste area in the mine and then filled with the filling material while mining coal in the working face. The present invention is simple, practical, low in cost and suitable for filling of various kinds of mine, especially coal mine.

Owner:CHINA UNIV OF MINING & TECH (BEIJING) +1

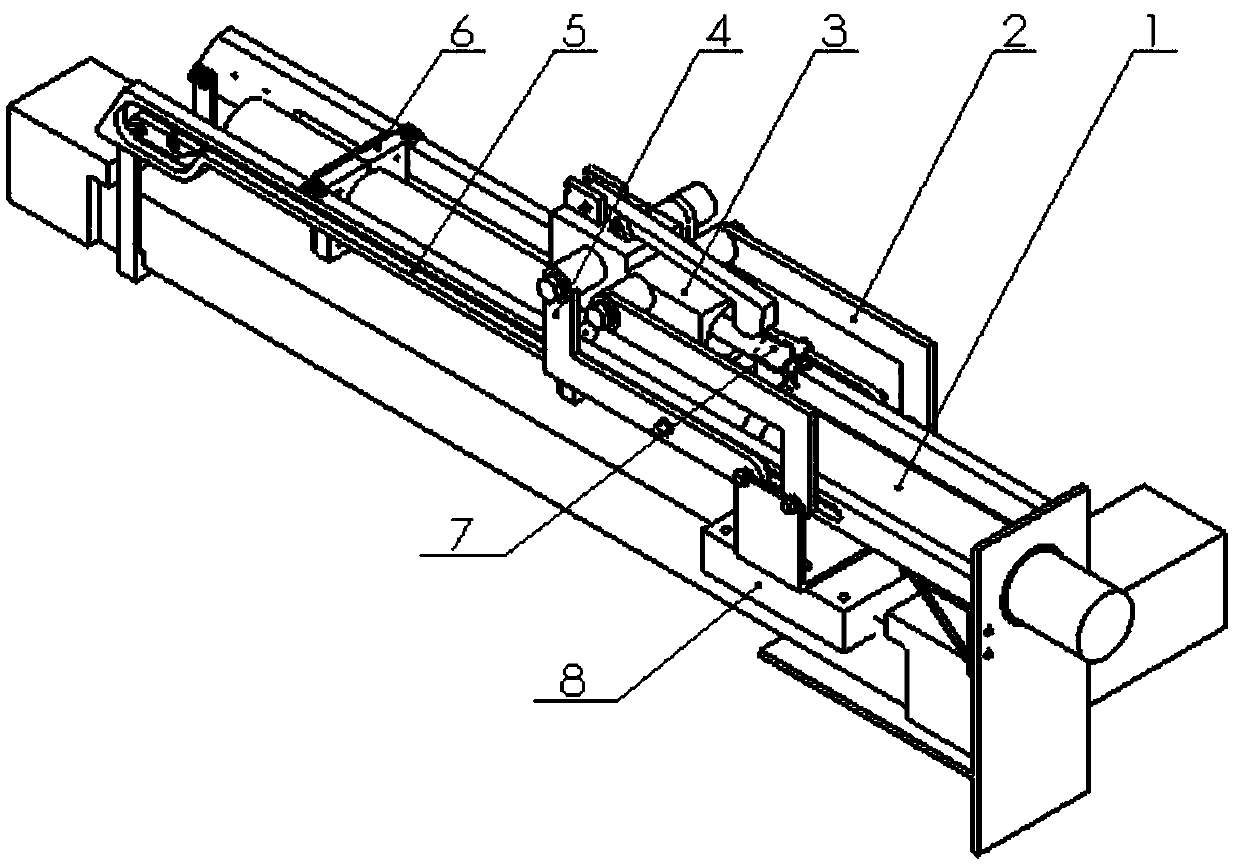

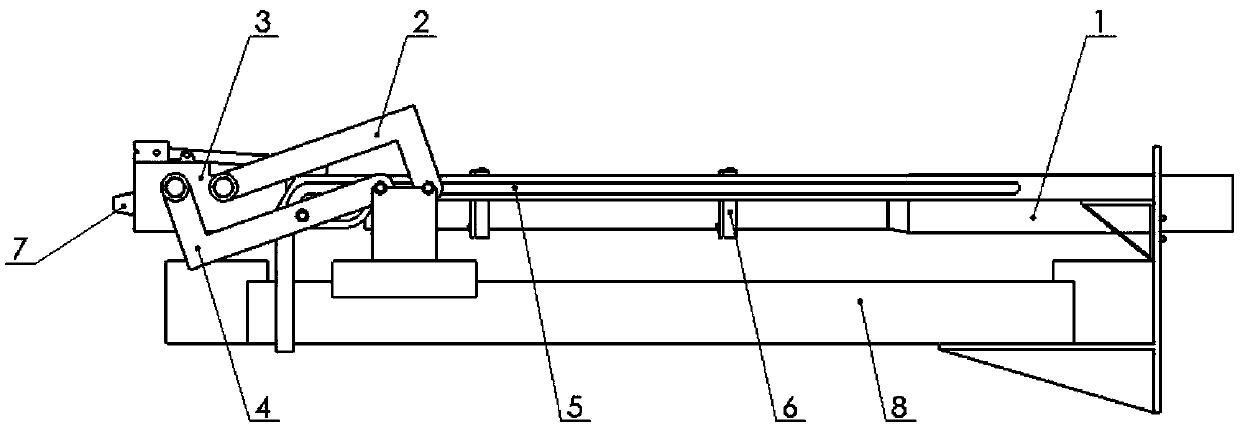

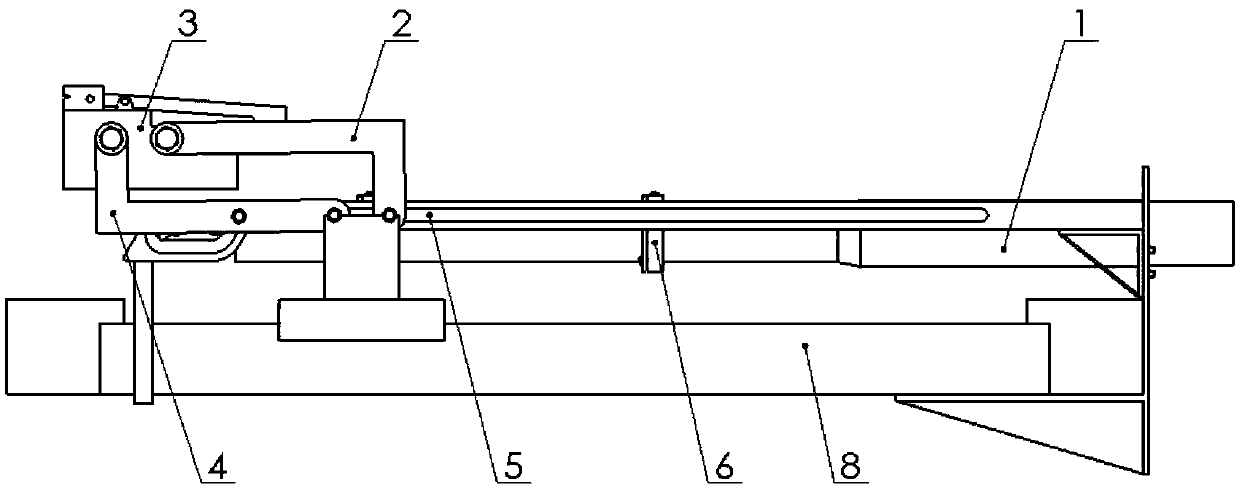

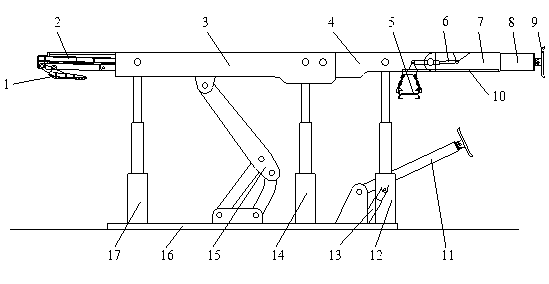

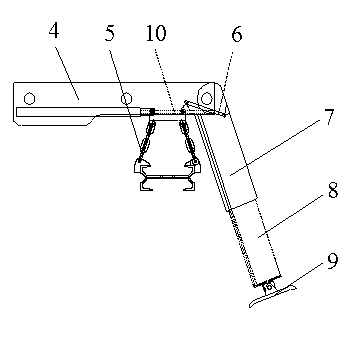

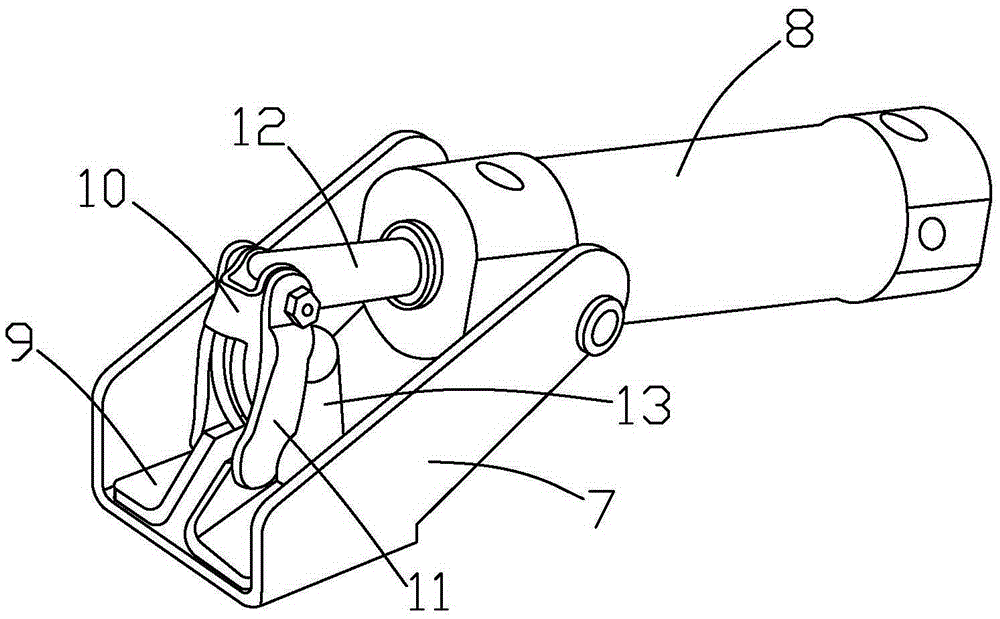

Mine thrower automatic front loading device and loading method thereof

The invention discloses a mine thrower automatic front loading device and a loading method thereof. The mine thrower automatic front loading device is used for achieving automatic loading of mine thrower shells and comprises a driven arm, a shell supporting device, a driving arm, a guide rail and a power system. The shell supporting device is used for clamping shells. The power system is used fordriving the front driven arm to move on the guide rail, and therefore the shell supporting device is driven to convey shells to a muzzle, and a curved trough on the guide rail is used for controllinga swing arm to complete loading. By means of the mine thrower automatic front loading device, mine thrower loading automation can be achieved, reliability is high, stability is good, manpower is saved, shells are supplied rapidly, the device can be used for replacing manual loading, the fighting efficiency is improved, and the hurt to personnel can be reduced.

Owner:NANJING UNIV OF SCI & TECH

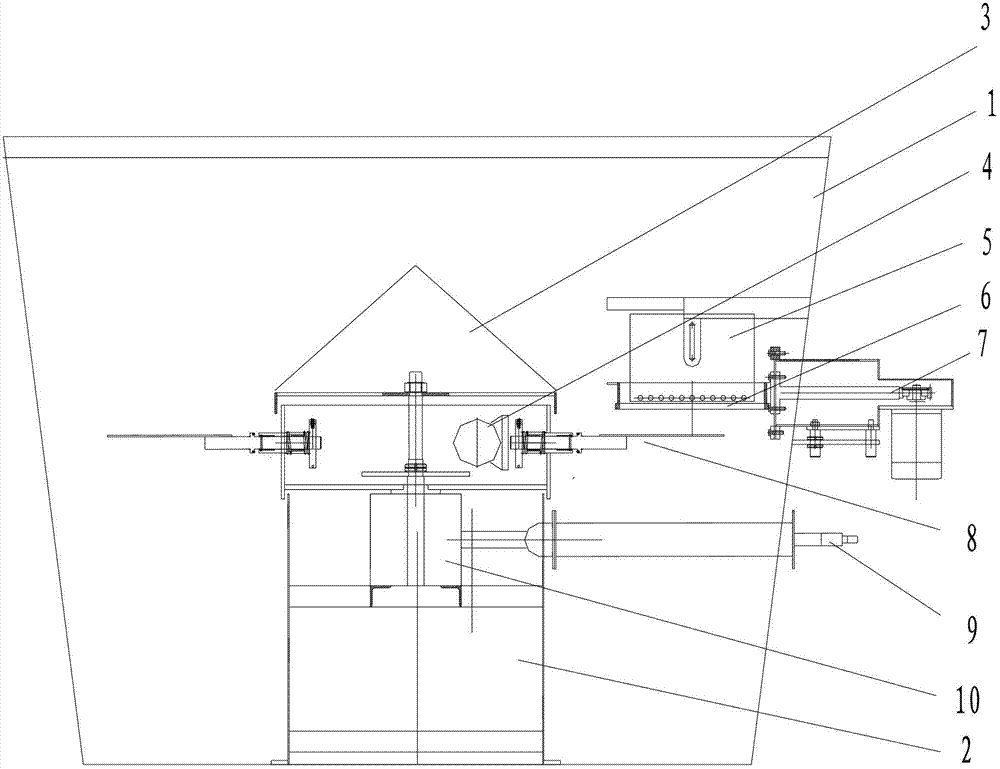

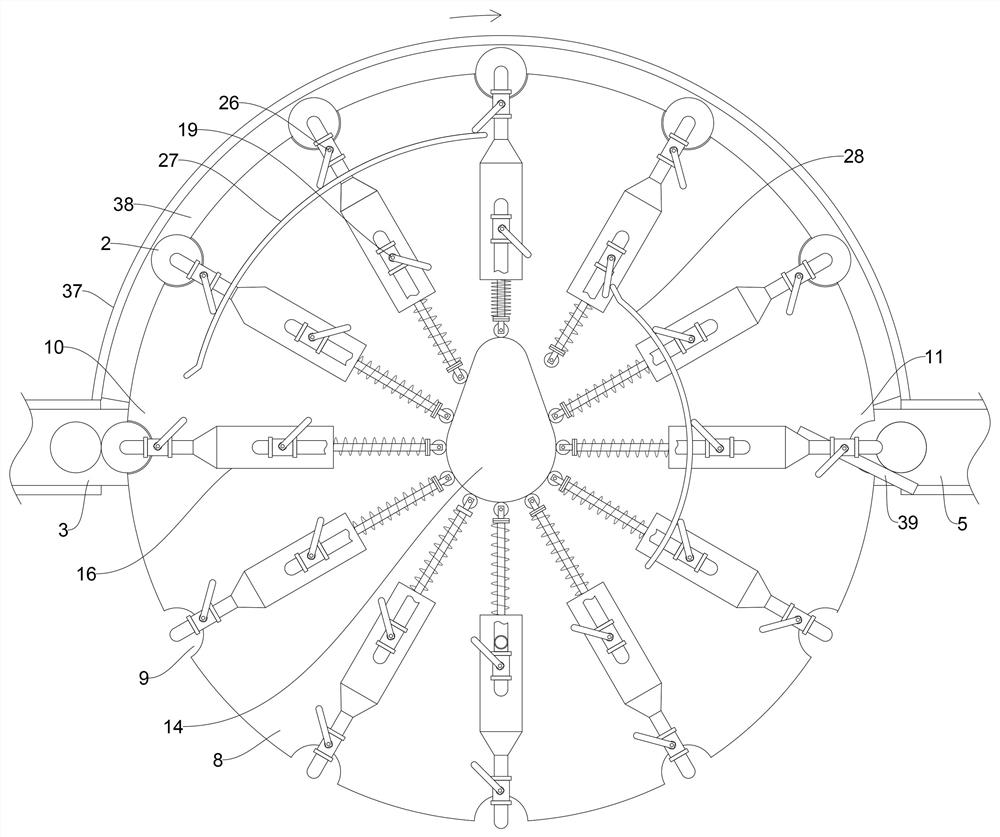

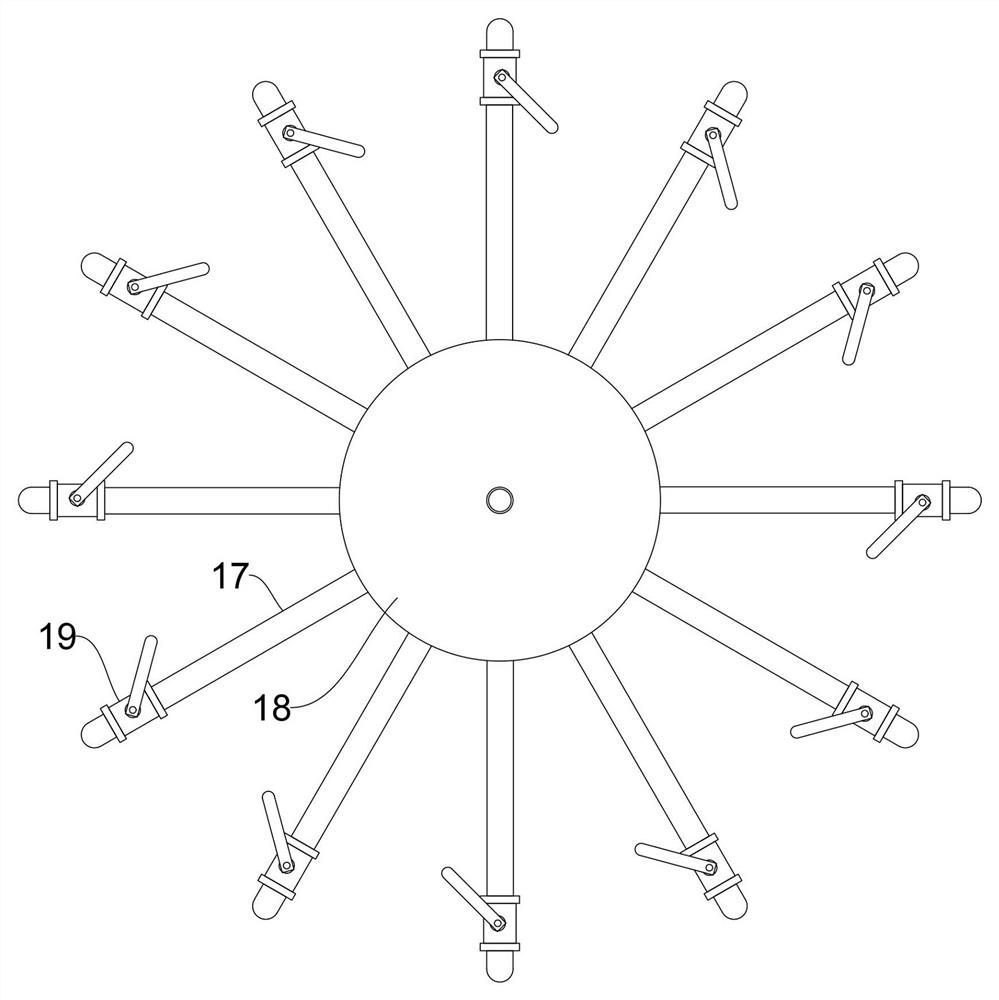

Machine for automatically charging gunpowder into firecrackers

The invention discloses a machine for automatically charging gunpowder into firecrackers. A turntable (16) is arranged on a frame (2); at least one workpiece tray unit (8) is arranged at the periphery of the turntable (16); a feeding station, a gunpowder charging station, a vibrating and residual gunpowder removing station and a discharging station are at least arranged on the frame (2) in sequence; a feeding conveying device and a conveying cylinder are butted with the feeding station; and a discharging conveying device is butted with the discharging station. The machine for automatically charging the gunpowder into the firecrackers is high in production efficiency, safety and measuring accuracy.

Owner:吴伟

Automatic bag-clamping filling device

ActiveCN103213699AImprove filling stabilityCompact structureIndividual articlesEngineeringMechanical engineering

Owner:WUHAN RENTIAN PACKAGING TECH

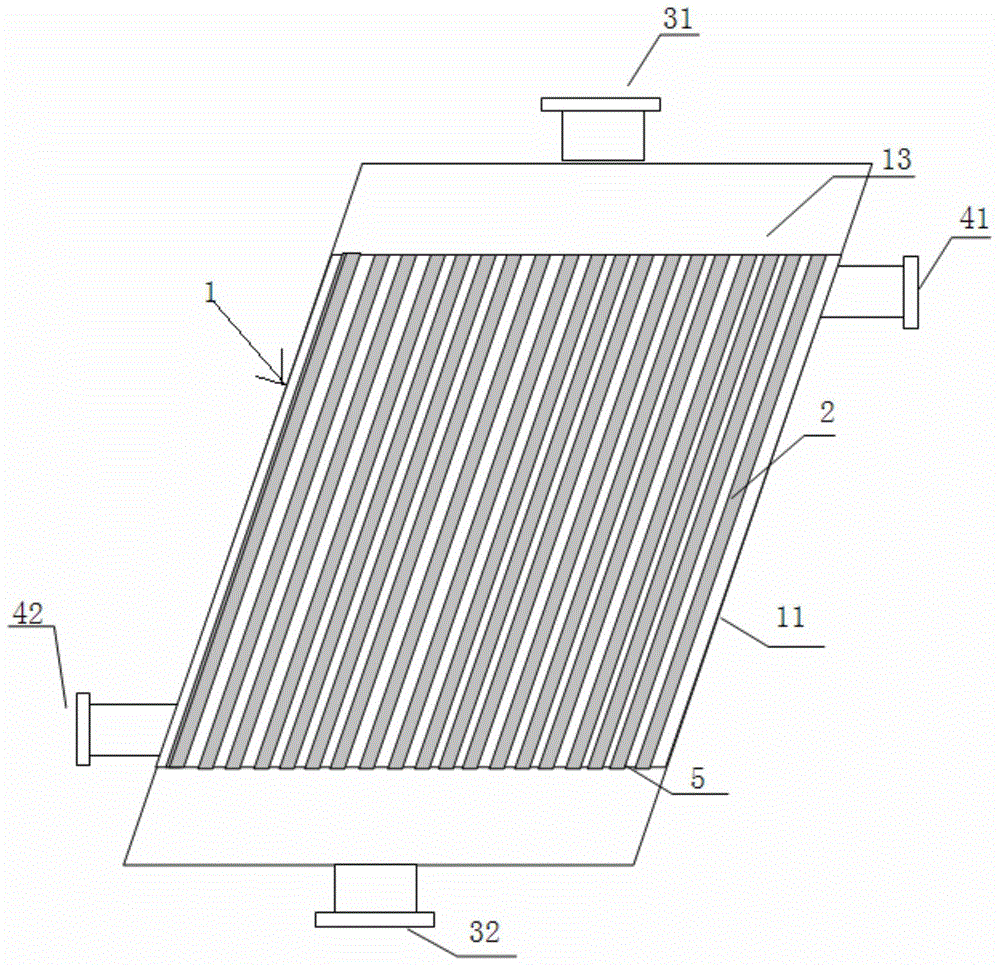

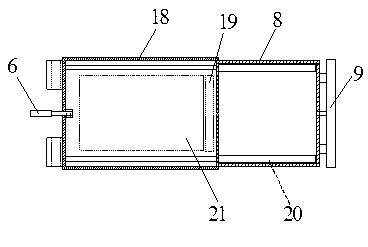

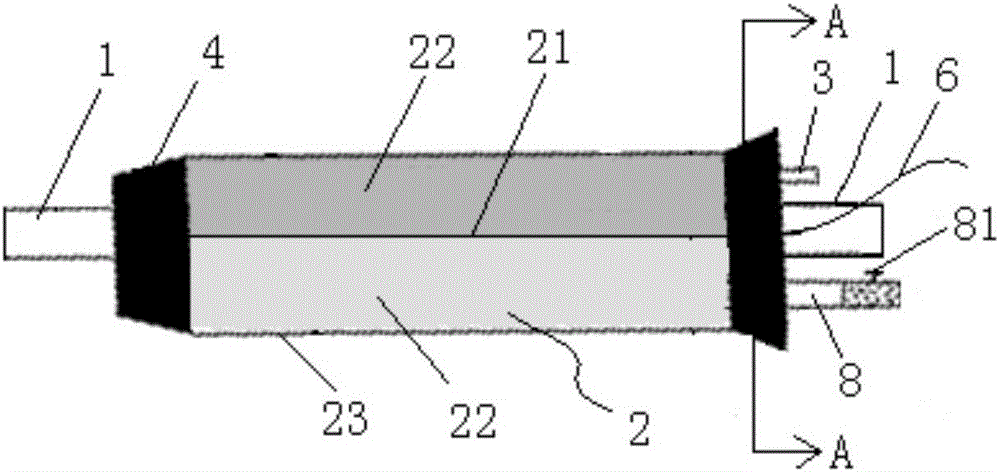

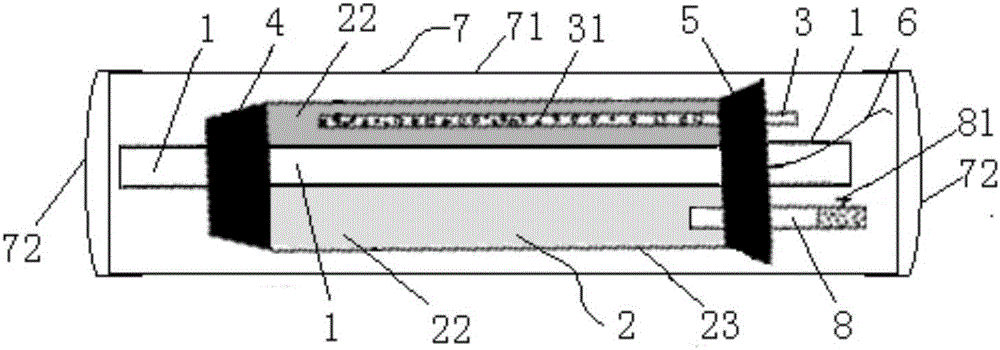

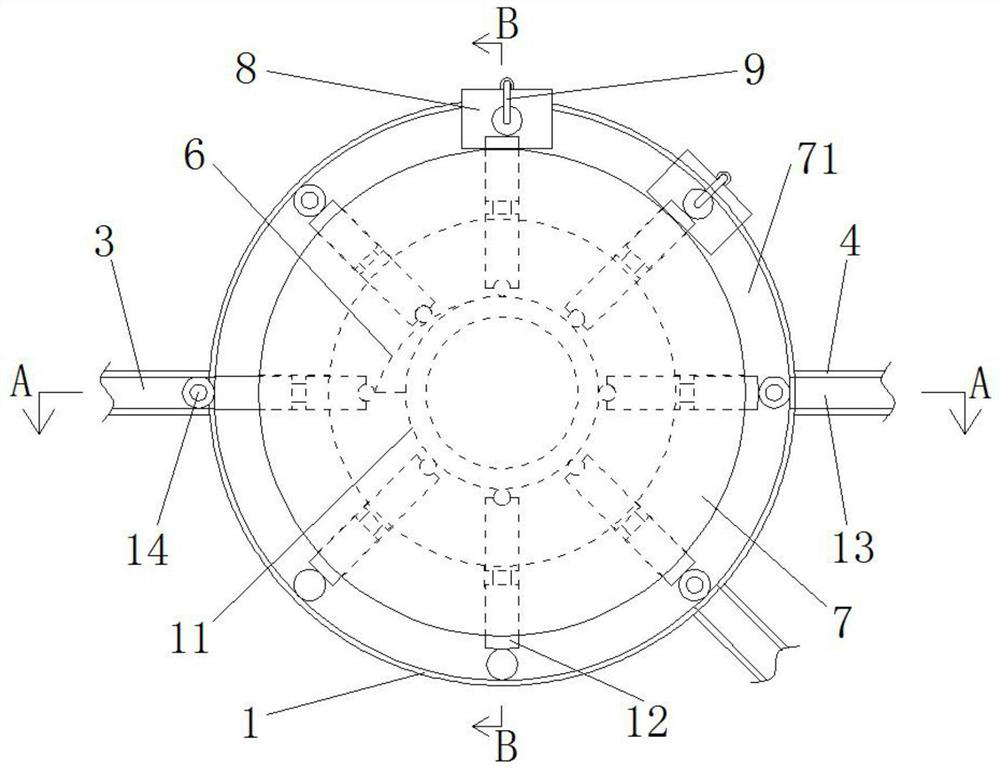

Tubular reactor

ActiveCN104368281AImprove heat transfer performanceGuarantee safety and reliabilityChemical/physical processesProcess engineeringExothermic reaction

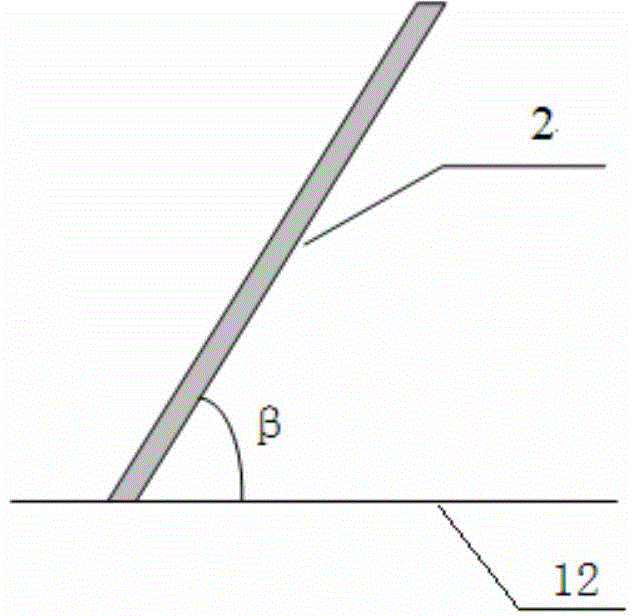

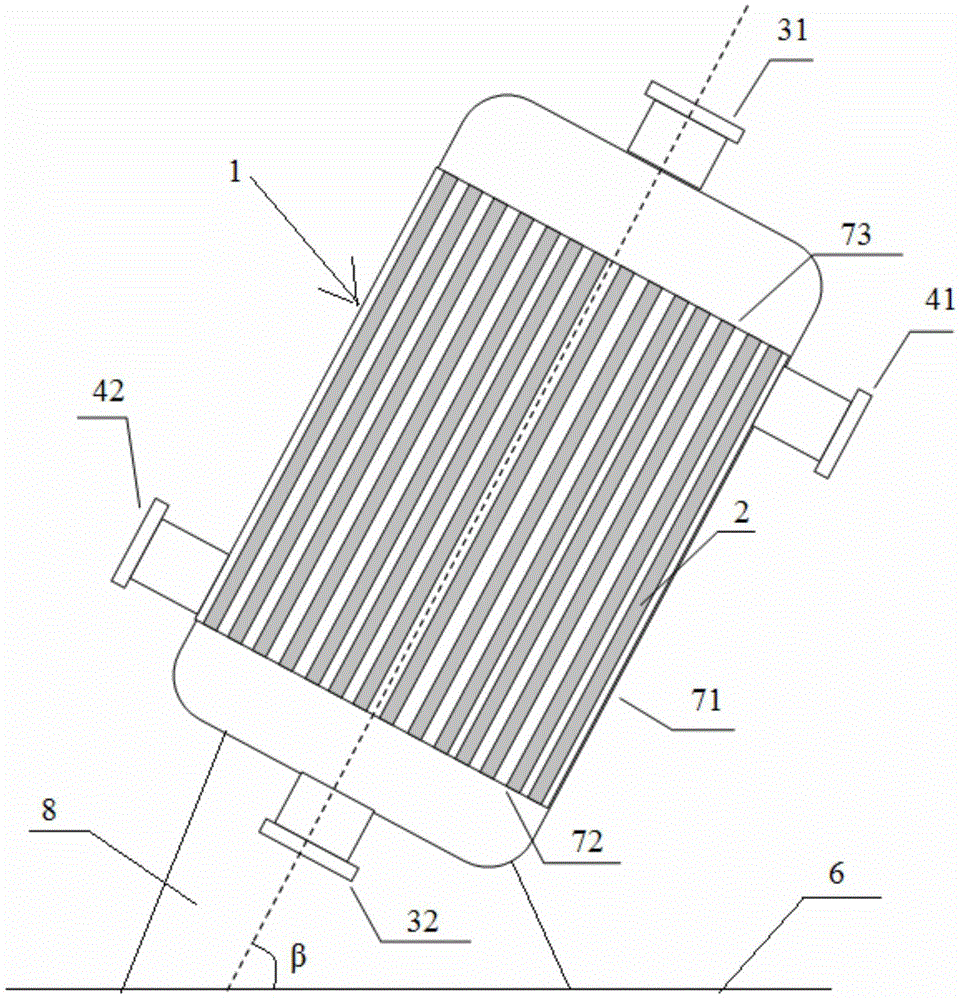

The invention discloses a tubular reactor which comprises a reactor cabinet and a plurality of tubulations arranged in the reactor cabinet at intervals, wherein the reactor cabinet comprises a cabinet body and a horizontal base fixed at the bottom of the cabinet body, and the reactor cabinet is also provided with a reaction material inlet and a reaction product output which are communicated with the plurality of tubulations, wherein at least one tubulation is obliquely arranged relative to the horizontal base. As at least one tubulation in the tubular reactor provided by the invention is obliquely arranged relative to the horizontal base, in the process of filling catalyst, the catalyst can slowly slide in the tubulations with the help of the weight of the catalyst relatively, so that the uniformity of catalyst filler can be provided, the fluidity of the reaction fluid can be improved, the pressure drop can be reduced, the problem of gas attachment generated in the operation of exothermic reaction can be solved, and the heat transfer of the tubulations can be improved, and then the security and reliability of the reactor can be ensured.

Owner:CHINA PETROLEUM & CHEM CORP +1

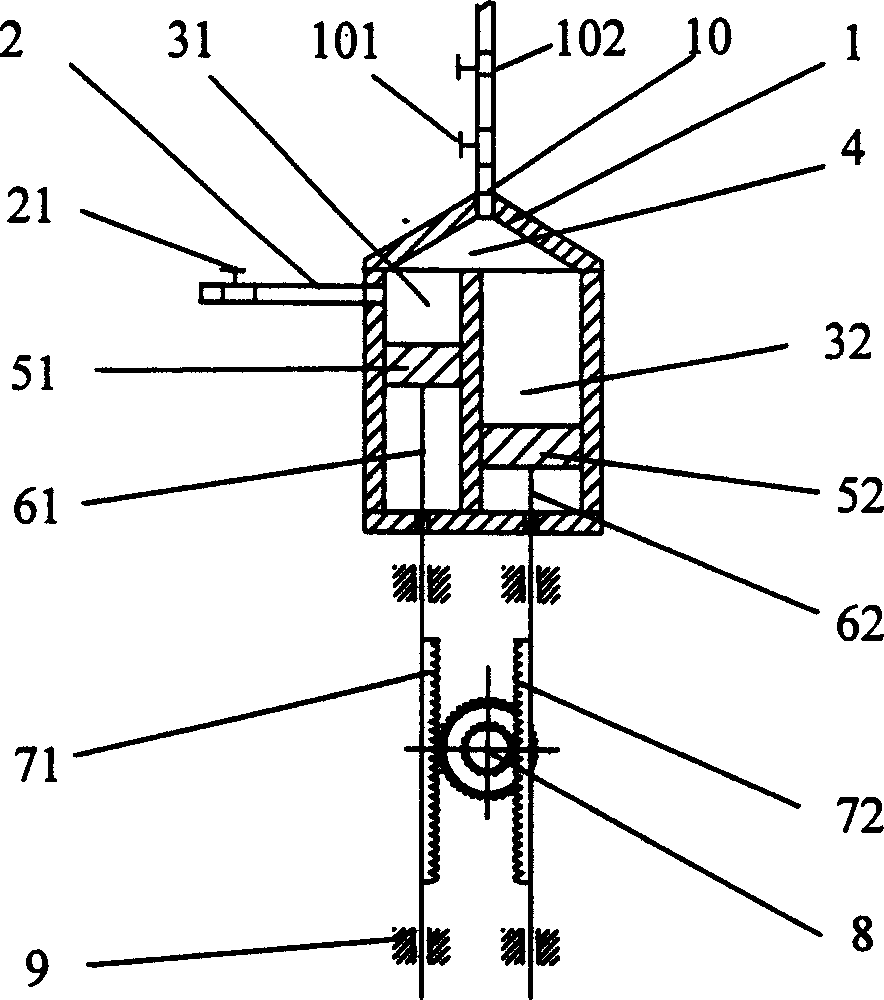

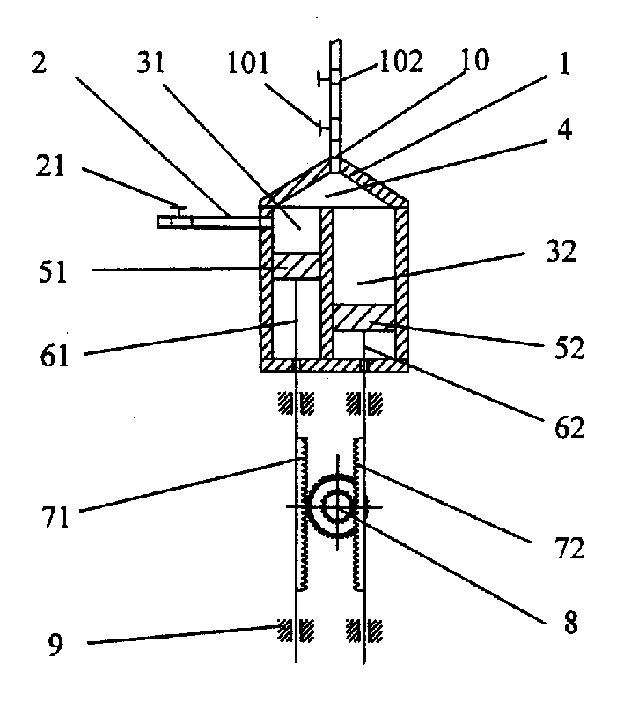

Device capable of qualitatively filling liquid

InactiveCN1537806AAccurate measurementRealize fillingLiquid flow controllersLiquid transferring devicesEngineeringMechanical engineering

A filling apparatus for quantitatively filling liquid is composed of a cylindrical body for containing liquid in it and a liquid outlet channel. In said cylindrical body, there are the first and the second piston cavities, a capc avity communicated with said piston cavities, two pistons in said piston cavities (one for one), and two rigid piston rods extended out of the piston cavities. Said filling apparatus has also a linkage mechanism connected to two piston rods to make them move in reverse directions and a measuring element for directly measuring the quantity of filled liquid. Its advantage is high accuracy.

Owner:中科微槽群(北京)节能技术开发有限公司

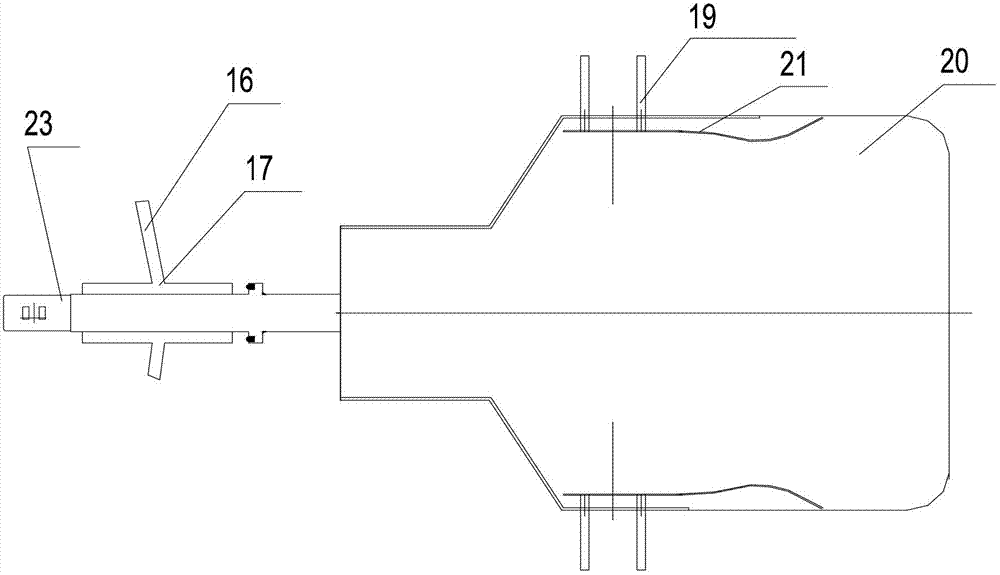

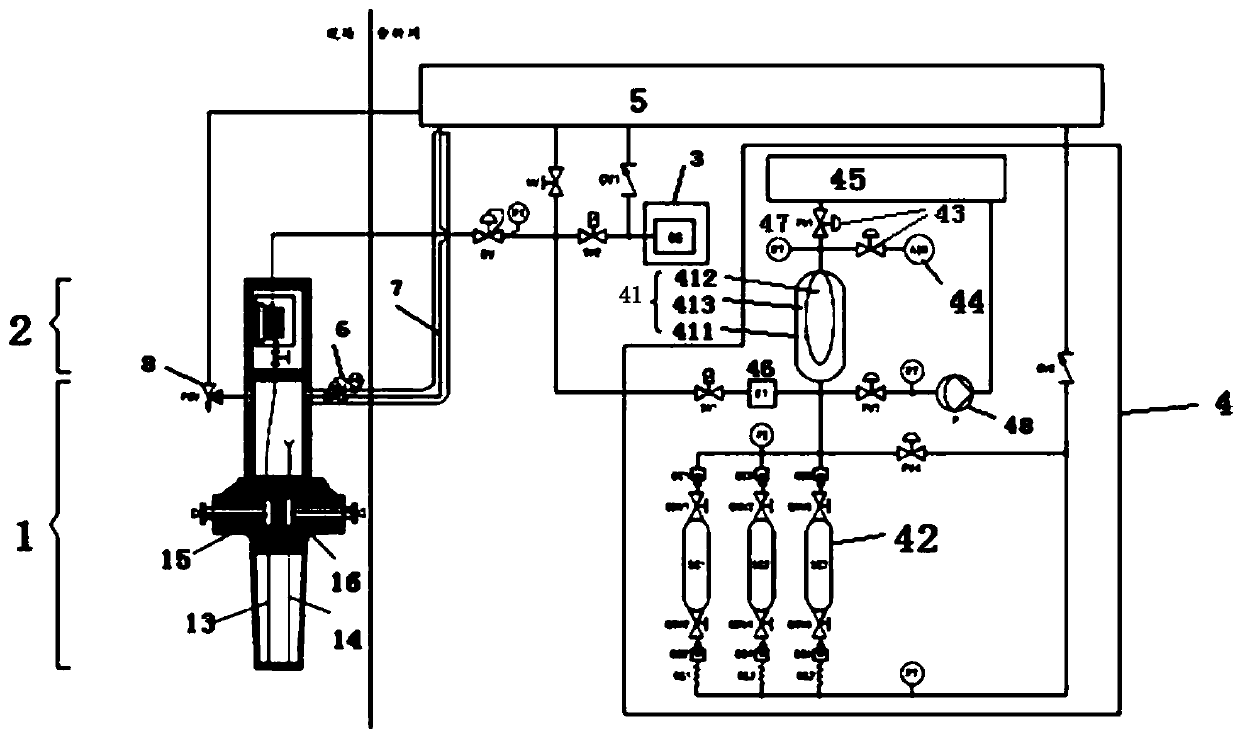

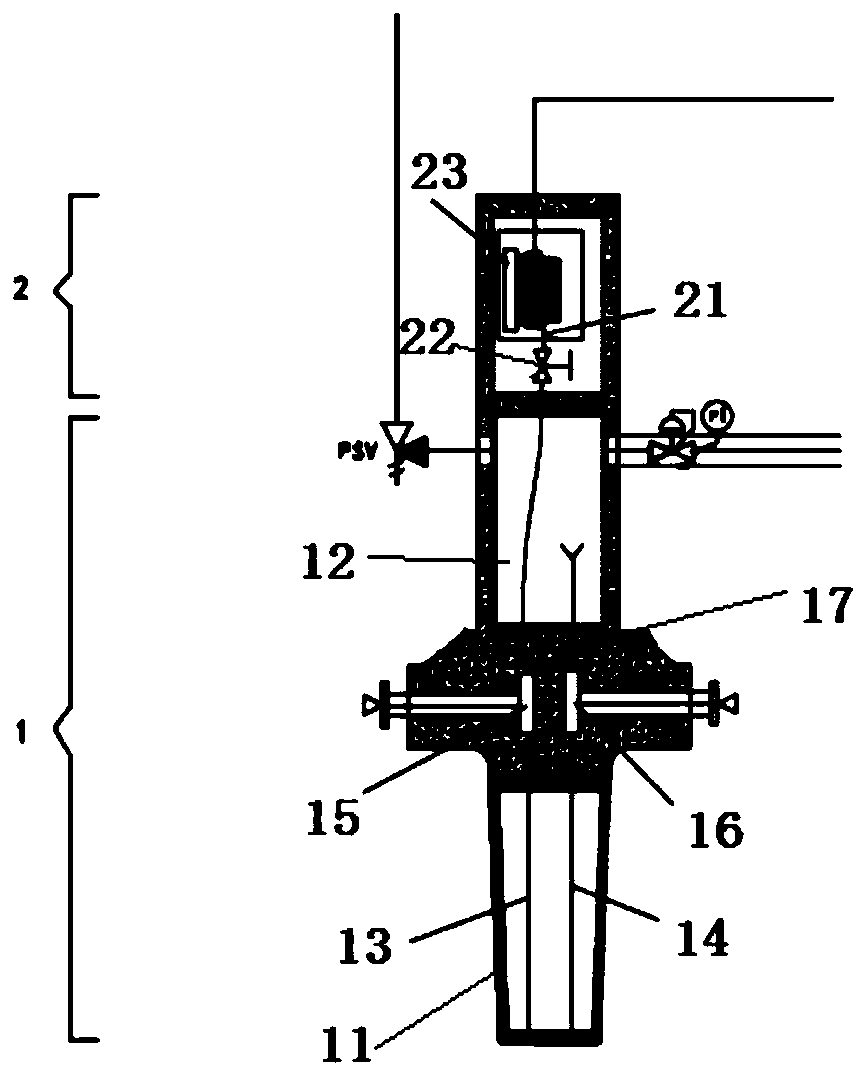

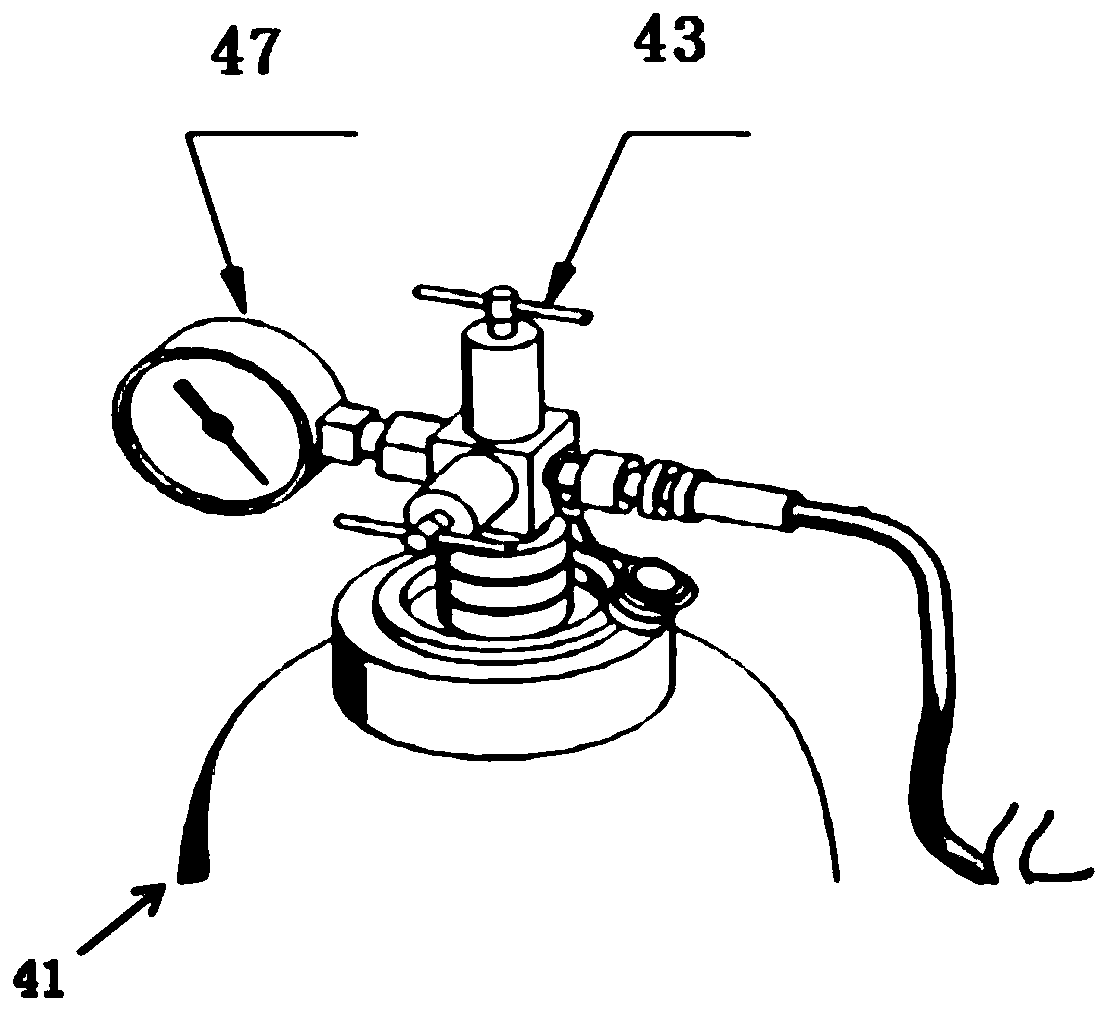

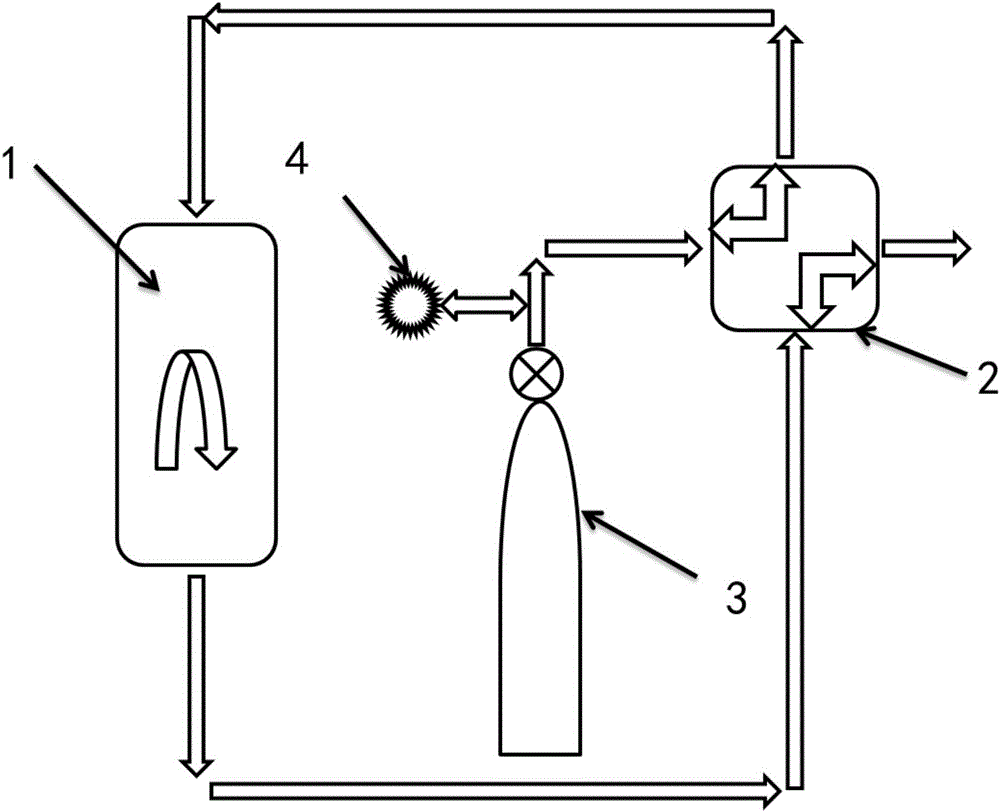

Liquefied natural gas sampling and continuous collecting device

PendingCN110045041AAvoid fractionationInhibition of premature gasificationComponent separationVessel geometry/arrangement/sizeLine tubingCollection system

The invention discloses a liquefied natural gas sampling and continuous collecting device, which comprises a sampling system, a gasification system, an on-line analysis system and a continuous collecting system, wherein the sampling system comprises an LNG sampling probe, a sampling pipeline and an LNG filling pipeline; a closed deep cooling cavity is formed at the front end of the LNG sampling probe; the sampling pipeline is arranged in the LNG sampling probe in a penetrating manner; the LNG filling pipeline is arranged in the LNG sampling probe in a penetrating mode and communicates with a closed deep cooling cavity; one end of the sampling pipeline penetrates through the closed deep cooling cavity and is connected to the gasification system; the gasification system is used for gasifyingan LNG sample conveyed by the sampling pipeline; the on-line analysis system is connected to an outlet of the gasification system and is used for carrying out on-line analysis on a gasified natural gas sample and providing gas component parameters; and the continuous collecting system is connected to the outlet of the gasification system and is used for continuously collecting the gasified natural gas samples.

Owner:CNOOC GAS & POWER GRP

Miniaturized sample collecting device used for gas sampling

InactiveCN105954071ARealize cleaning pretreatmentRealize fillingWithdrawing sample devicesDiaphragm pumpGas cylinder

The invention provides a miniaturized sample collecting device adopting the combination of a diaphragm pump and a four-way ball valve. The miniaturized sample collecting device is composed of the diaphragm pump, the four-way ball valve, a sampling gas bottle and a gas pipeline. A positive and negative pressure dual-purpose gas pump is adopted as the diaphragm pump, and the diaphragm pump can be used for generating the vacuum low-pressure condition and obtaining high-pressure gas. The four-way ball valve is connected with a gas inlet of the diaphragm pump, a gas outlet of the diaphragm pump, the sampling gas bottle and a sample gas connector through clamping sleeve connectors capable of achieving fast connection. A national standard all-metal gas spray pot is adopted as the sampling gas bottle, and the miniaturized sample collecting device is small, light, low in cost and free of pollution. Gas pipelines are all connected through clamping sleeve connectors. The working states of the diaphragm pump are switched by means of the four-way ball valve to carry out air exhaust and air inflation on the sampling gas bottle. By means of circulating switching, cleaning pretreatment of the sampling gas bottle is achieved, and finally, high-pressure sample gas is filled into the sampling gas bottle.

Owner:PLA PEOPLES LIBERATION ARMY OF CHINA STRATEGIC SUPPORT FORCE AEROSPACE ENG UNIV

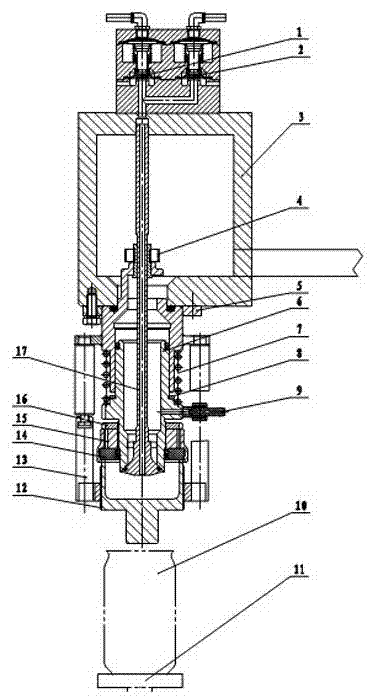

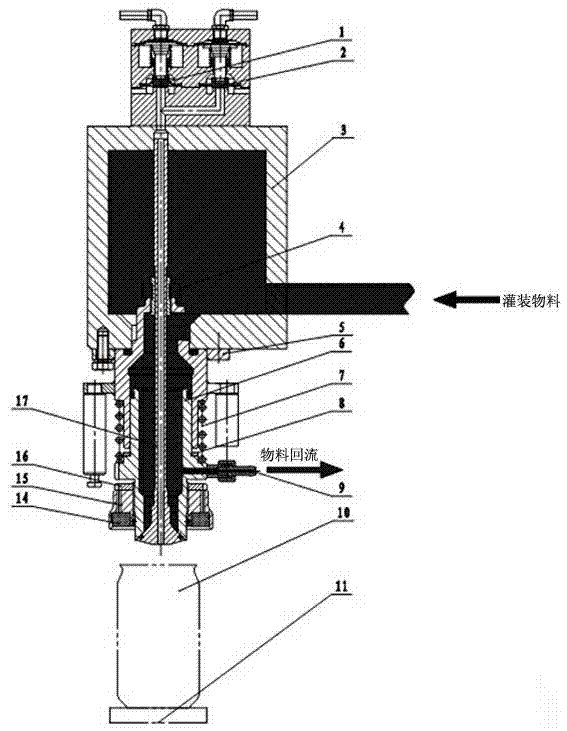

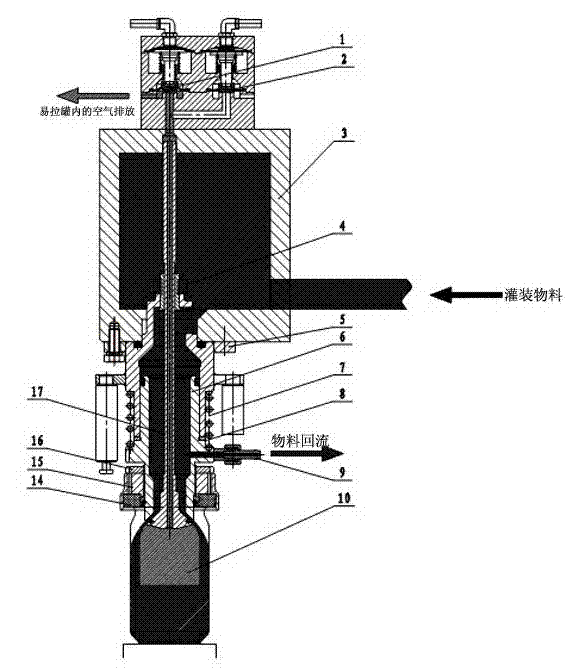

Filling valve for fruit-containing zip-top can beverage

The invention discloses a filling valve for fruit-containing zip-top can beverage. The filling valve is characterized in that the bottom of an annular filling cylinder is fixedly provided with a valve base, a valve body is inserted in the valve base from the lower part, and can slide relative to the valve base, dynamic seal can be achieved at the sliding part and a pressure spring is arranged between the valve base and the valve body so as to provide resilience force; the annular filling cylinder, the valve base and the valve body internally form a communicated logistics channel, a long-rod-shaped valve core is fixed in the logistics channel, and the valve core is internally provided with an air return hole; and the bottom end of the valve core is radially extruded and can form a sealing structure with the bottom end of the valve body, the outer edge of the bottom of the valve body is provided with a can port sealing ring, the top of the annular filling cylinder is provided with an air release valve and a compressed air valve, which are parallel to each other, and both the air release valve and the compressed air valve are connected with the air return hole of the valve core. According to the filling valve provided by the invention, an air return pipe of the valve core of the filling valve is connected with the compressed air valve for introducing external compressed air so as to sweep to remove the solid fruit in the air return pipe, so that the air return is smooth, and the filling of the fruit-containing zip-top can beverage is achieved.

Owner:南京保立隆包装机械有限公司

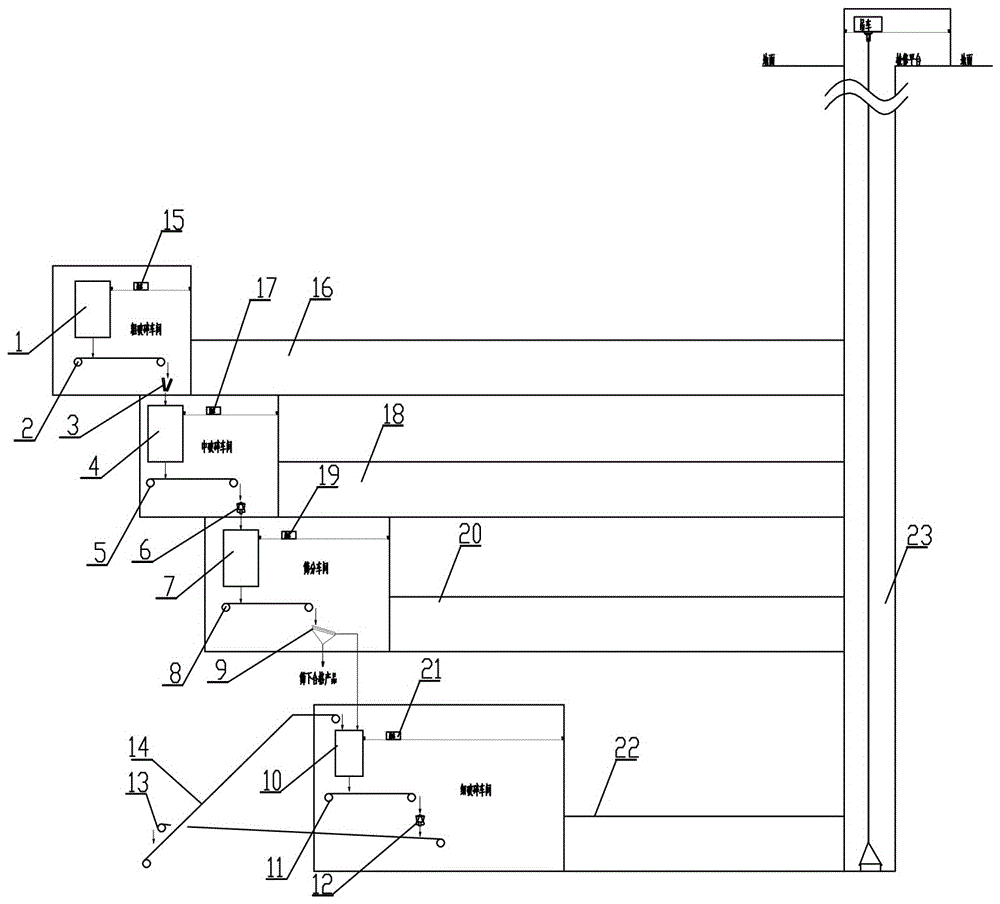

Crushing system for iron mine underground mill and crushing process

The invention relates to a crushing system for an iron mine underground mill and a crushing process. The crushing system for the iron mine underground mill is characterized in that the crushing system is mainly composed of a coarse crushing plant, a medium crushing plant, a screening plant, a fine crushing plant and an overhaul system; and the coarse crushing plant, the medium crushing plant, the screening plant and the fine crushing plant are arranged in a stair-step mode from top to bottom in the vertical direction of a mining factory travelling roadway according to the operation sequence. The crushing process includes the steps that after mined lump ore with the particle size being 600mm-1000mm is crushed by a coarse crushing machine, a medium crushing machine and a fine crushing machine, the ore grain size is turned to be 20mm-30mm; and then the undersize product of a vibrating screen is fed into roughing flotation operation of a grinding flotation system through a pump. The crushing system is low in energy consumption, no earth surface land is occupied, environmental protection is achieved, and qualified raw materials can be provided for the subsequent grinding flotation system.

Owner:MCC NORTH (DALIAN) ENG TECH CO LTD

Full-mechanized filling and coal-mining hydraulic support

ActiveCN102704976AAchieve dense fillingMaintain workspaceMaterial fill-upMine roof supportsHydraulic cylinderSpelunking

The invention discloses a full-mechanized filling and coal-mining hydraulic support. The ull-mechanized filling and coal-mining hydraulic support mainly comprises a face guard, a front canopy, a front top beam, a middle top beam, a rear top beam, a front upright post, a middle upright post, a rear upright post, a four-bar mechanism, a cut and fill mining conveyor, an adjusting jack and a base. The rear end of the middle top beam is hinged with the rear top beam for drawing coal; a rail for the cut and fill mining conveyor to slide forwards and backwards is arranged on the bottom ends of the middle top beam and the rear top beam; a pushing and pulling oil cylinder for raising or dropping the rear top beam is arranged between the middle top beam and the rear top beam; the rear top beam comprises a box body, wherein a drawing and pulling box matched with the box body is arranged inside the box body; a hydraulic cylinder which is connected with the inside of the box body is symmetrically arranged inside the drawing and pulling box; a drawing and pulling plate is arranged on the box body; a coal carving machine is arranged on the drawing and pulling plate; and a pushing and pressing plate is arranged on the front end of the rear top beam. The device not only can support the fully-mechanized caving and mining surfaces, but also can completely fill normal coal caving and milling regions of the bracket, so that coal caving and filling cannot affect each other. The bracket has simple structure, strong adaptability and operability, good filling effects, and extensive practicability.

Owner:CHINA UNIV OF MINING & TECH

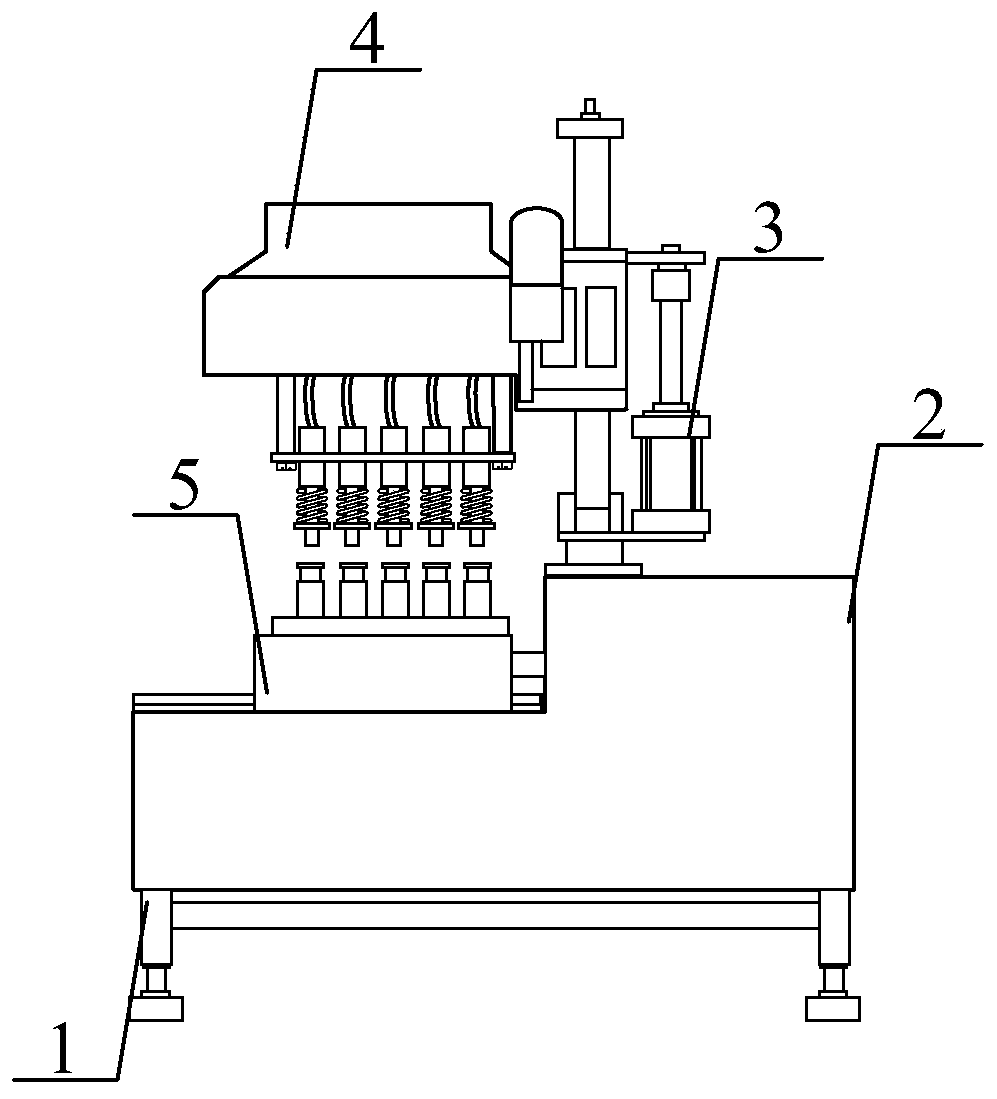

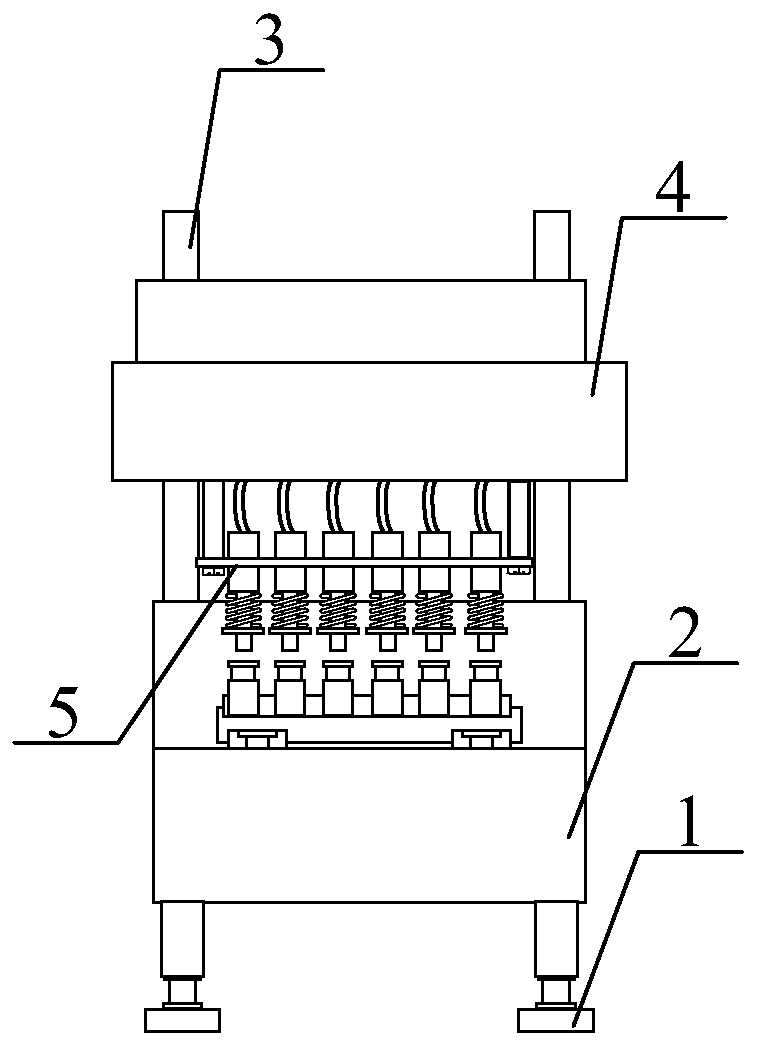

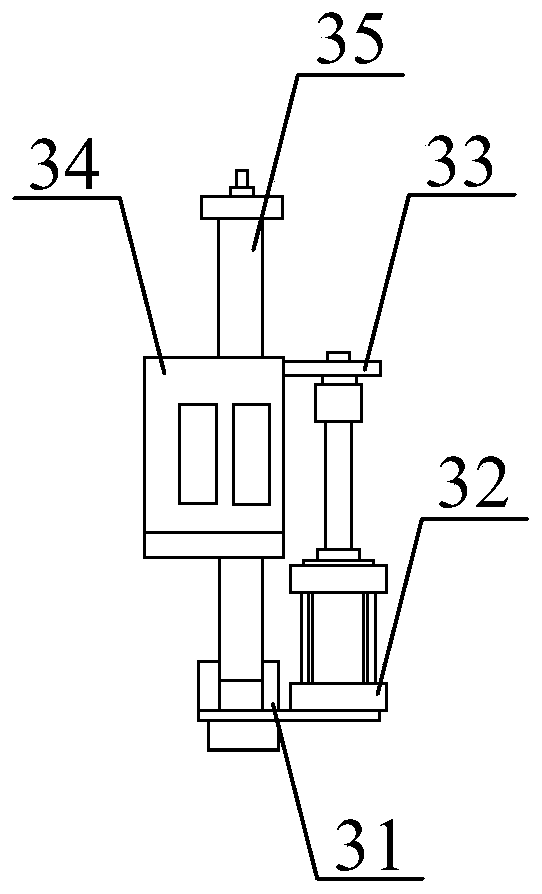

Antiviral oral liquid filling machine

InactiveCN111071510AMeet the usageRealize fillingLiquid materialLiquid bottlingEngineeringMechanical engineering

The invention discloses an antiviral oral liquid filling machine, which comprises regulating supporting legs, a case body, a lifting mechanism, a filling mechanism and a feeding mechanism. By arranging filling nozzles, the antiviral oral liquid filling machine is simple in structure and flexible in starting and stopping, the filling amount of oral liquid can be guaranteed, and the situation of excessive filling or insufficient filling is avoided; by arranging the feeding mechanism, a push rod of an air cylinder retracts to drive a sliding seat to move rightwards on sliding rails, so that oralliquid bottles are placed under the filling nozzles, the tedious step of manual alignment is omitted, the manual labor intensity is reduced, and the filling efficiency is greatly improved; and by arranging the filling mechanism, the oral liquid bottles can be filled once, so that the filling efficiency of the oral liquid is effectively improved.

Owner:徐国华

Automatic bottled chili sauce filling device

The invention discloses an automatic bottled chili sauce filling device. The automatic bottled chili sauce filling device comprises a filling table, bottle bodies used for containing chili sauce, an empty bottle conveying belt used for conveying empty bottle bodies to a feeding station, sauce containing tanks used for storing the chili sauce and a sauce bottle conveying belt used for outputting the full-loaded chili sauce bottle bodies, wherein the filling table is provided with a hollow electric turntable, the hollow electric turntable is provided with a filling turntable, and the filling turntable is clamped with the bottle bodies at the feeding station through notches at the edges of the filling turntable, and the bottle bodies filled with the chili sauce are output to the sauce bottleconveying belt at a discharging station; quantitative sauce bins corresponding to the notches in one-to-one correspondence are fixed on the filling turntable through a fixing frame, a distributing pipe is communicated with the upper end of the middle of each quantitative sauce bin, a rotary distributing bin is communicated with the other ends of the distributing pipes, and a feeding mechanism forconveying the chili sauce in the sauce containing tanks to the rotary distributing bin is further included. According to the automatic bottled chili sauce filling device, quantitative material distribution and quantitative filling can be carried out in the moving process of the bottle bodies, and the filling rate can be obviously improved.

Owner:河北世轩科技有限公司

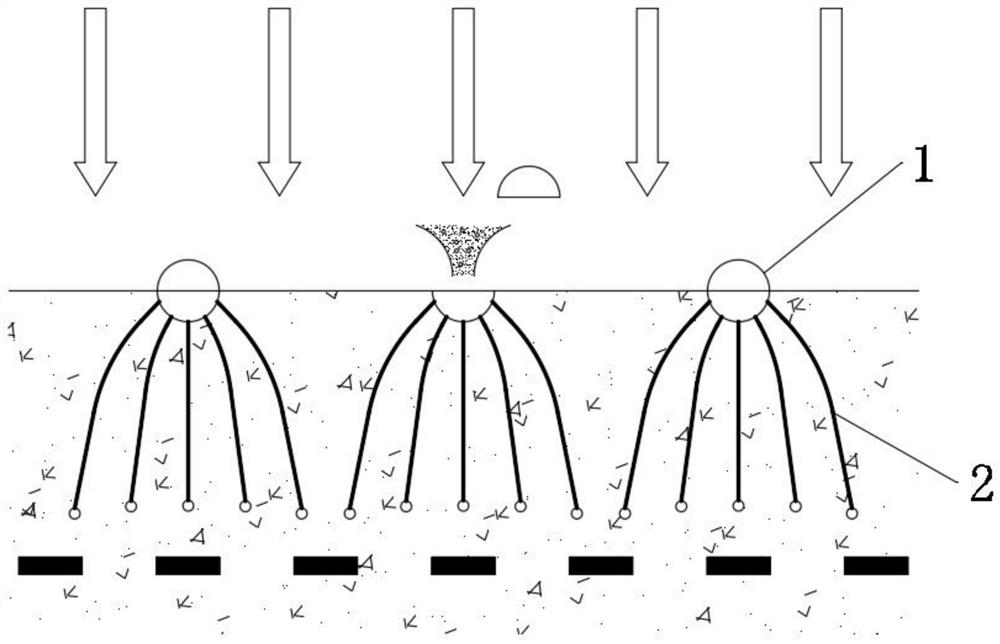

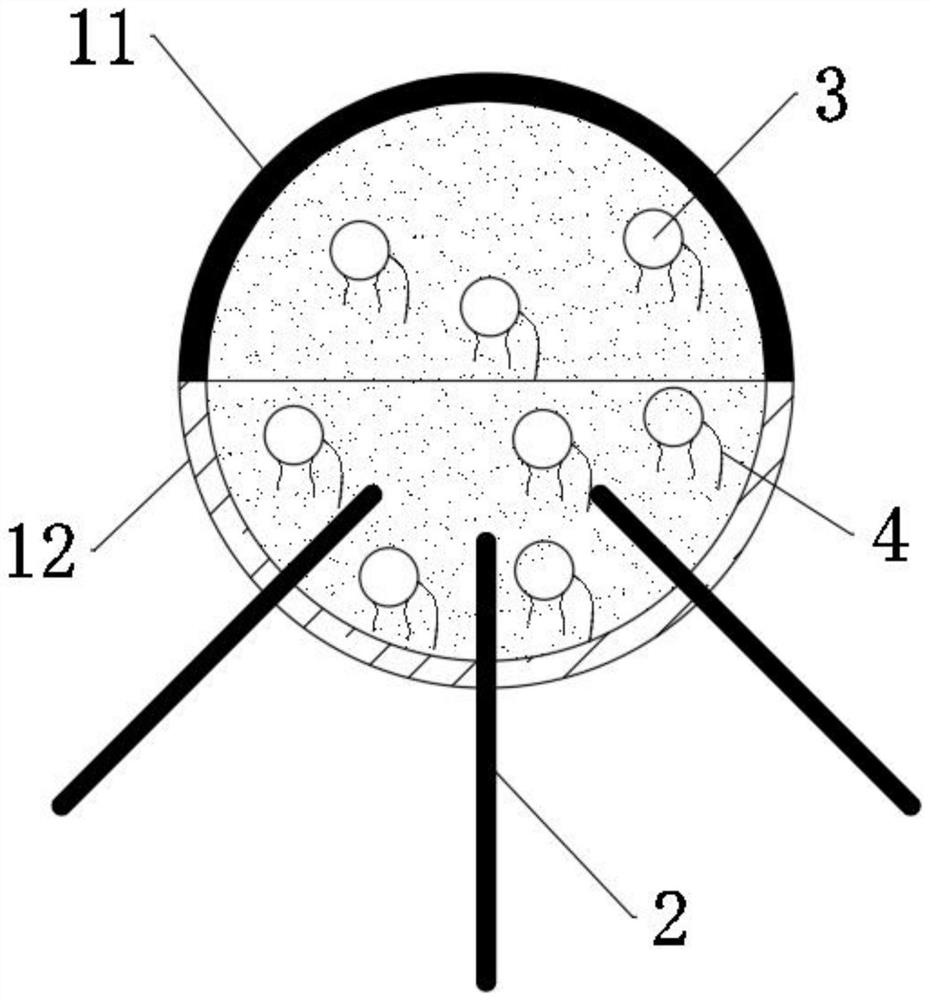

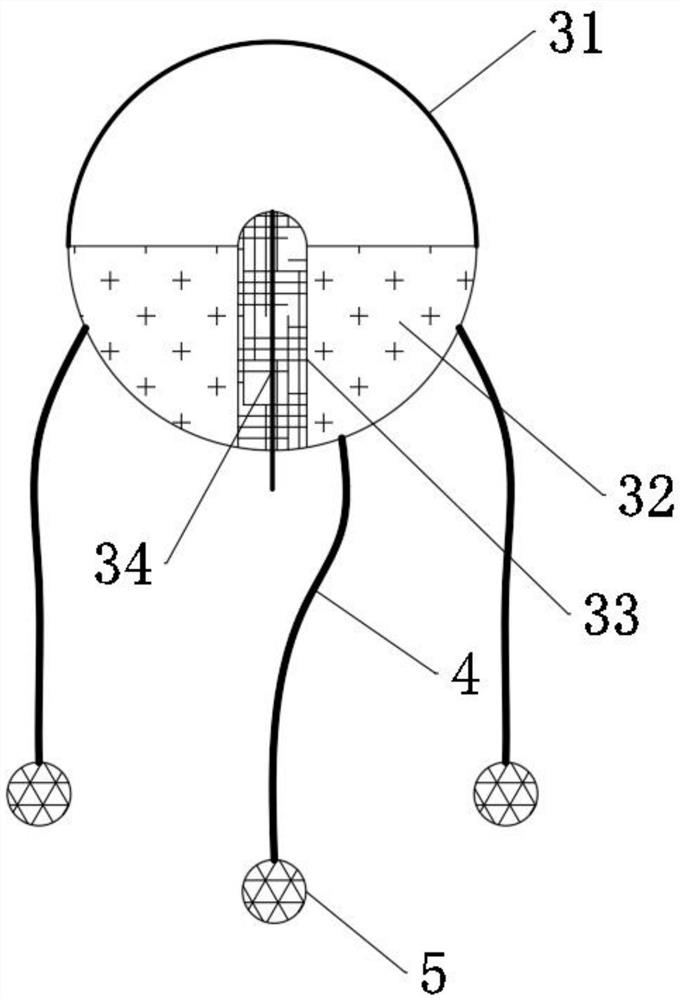

Replacement type rapid remediation method for saline-alkali soil

ActiveCN113056980AImprove soil qualityEfficient repairSoil lifting machinesOrganic fertilisersSoil scienceAlkali soil

The invention discloses a replacement type rapid remediation method for saline-alkali soil, and belongs to the technical field of soil governance. According to the replacement type rapid remediation method for the saline-alkali soil, a plurality of uniformly distributed magnet blocks are embedded in the soil of the saline-alkali soil, then semi-extending semi-embedded replacement balls are embedded in the surface of the soil, and water delivery lines on the semi-embedded replacement balls are magnetically attracted by the magnet blocks, so that the water delivery lines are forced to be vertically distributed in the soil and spread downwards; the semi-embedded replacement ball is filled with the replacement soil subjected to modification treatment, and finally remediation liquid is scattered into the soil, so that on one hand, the remediation liquid repairs the soil and improves the soil quality, and on the other hand, the remediation liquid is absorbed by the water delivery lines and conveyed into the semi-embedded replacement balls after salt and alkali are dissolved; then metal cations such as sodium ions are adsorbed through the replacement soil, and efficient adsorption is accelerated by promoting the movement of replacement moving balls in the replacement soil, so that the metal ions are transferred in a mode of actively replacing the metal ions from the soil, and rapid and efficient remediation is realized.

Owner:大安市中科佰澳格霖农业发展有限公司

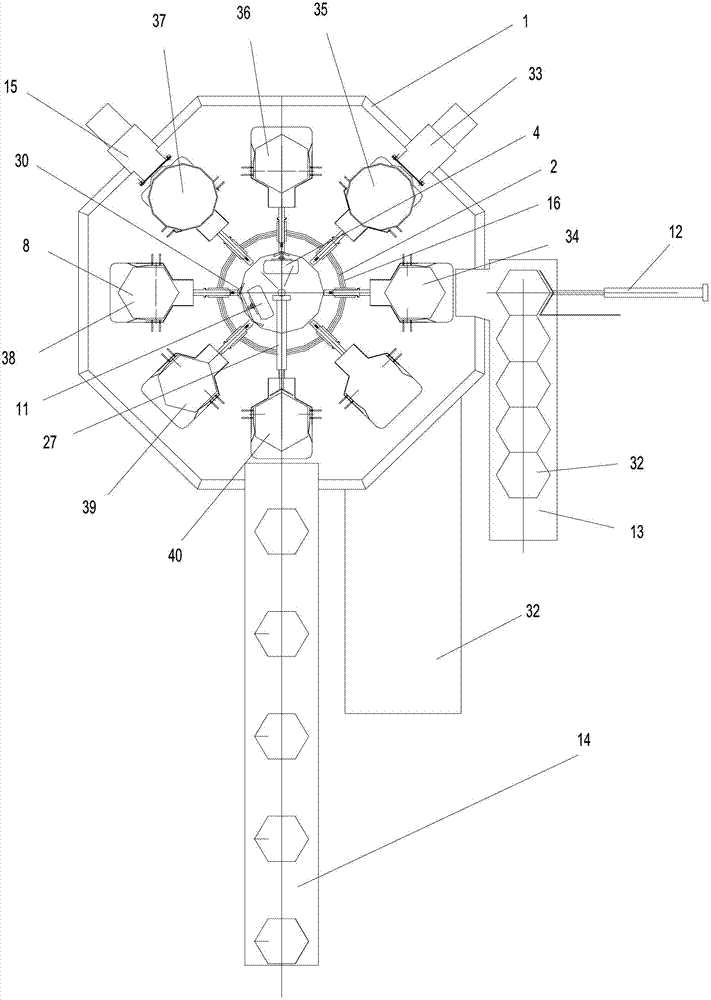

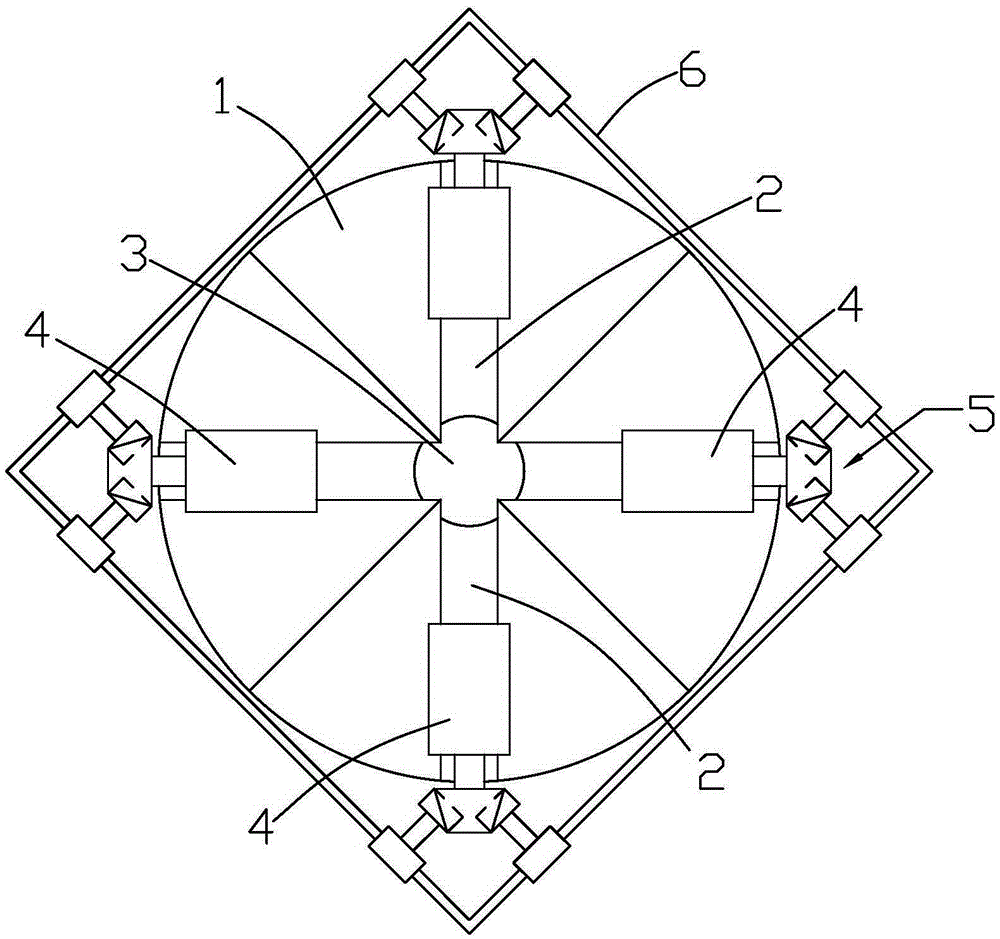

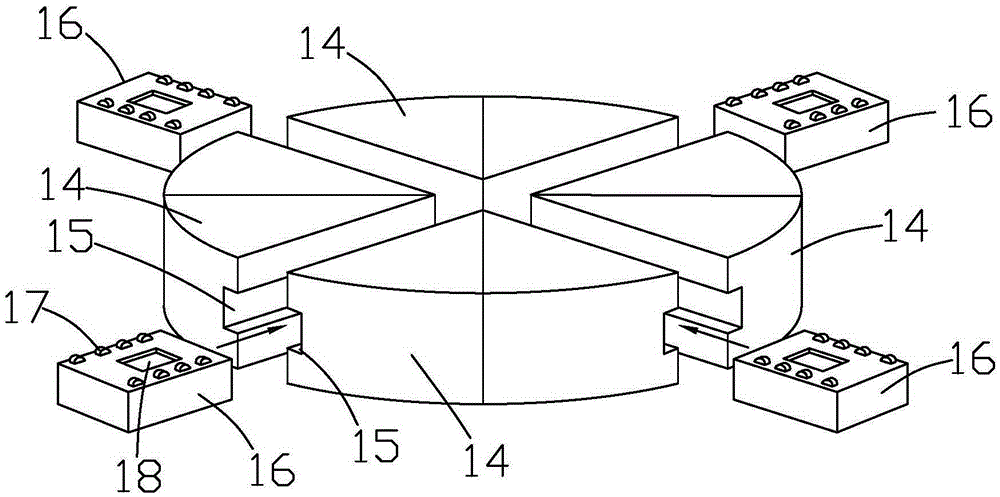

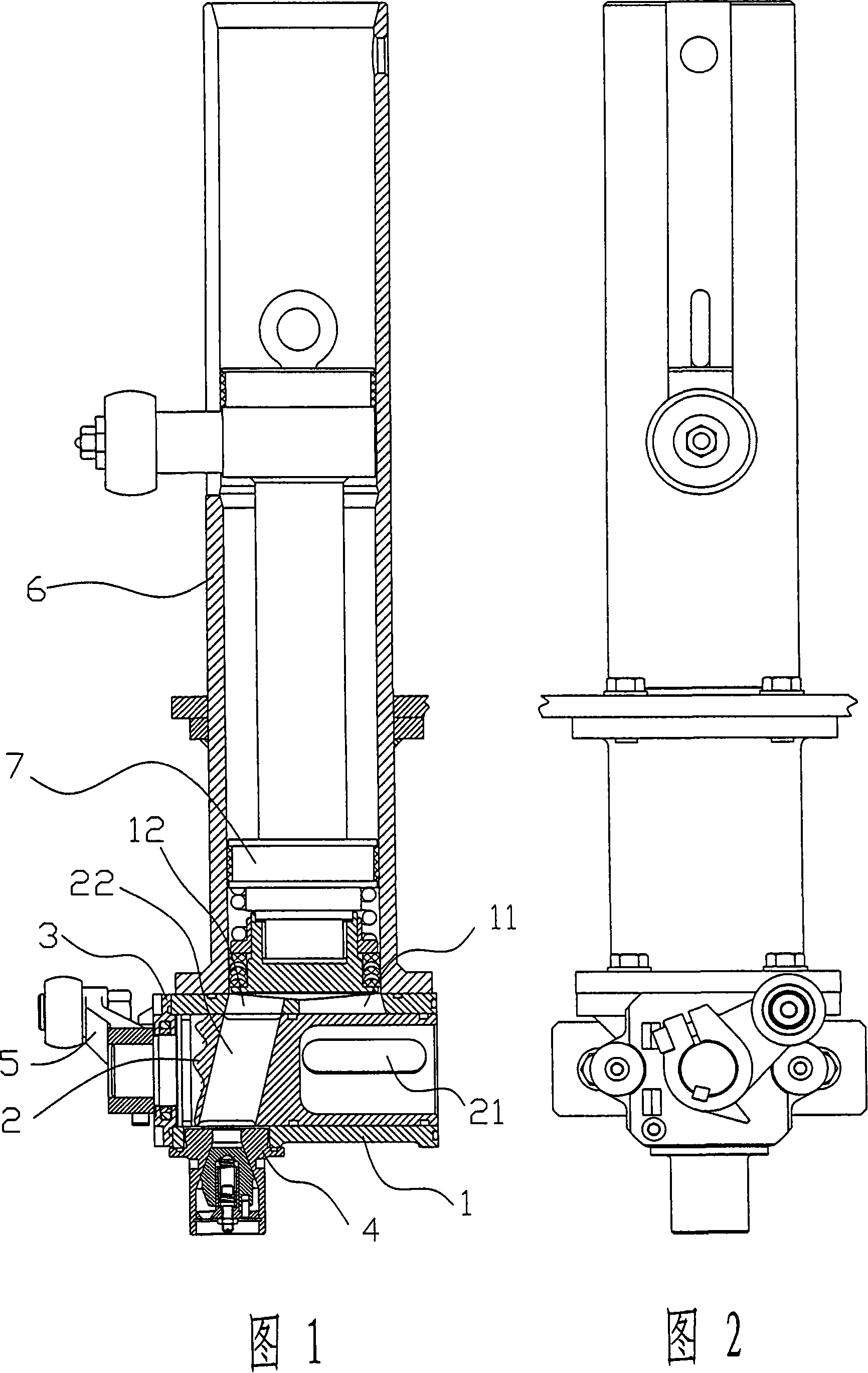

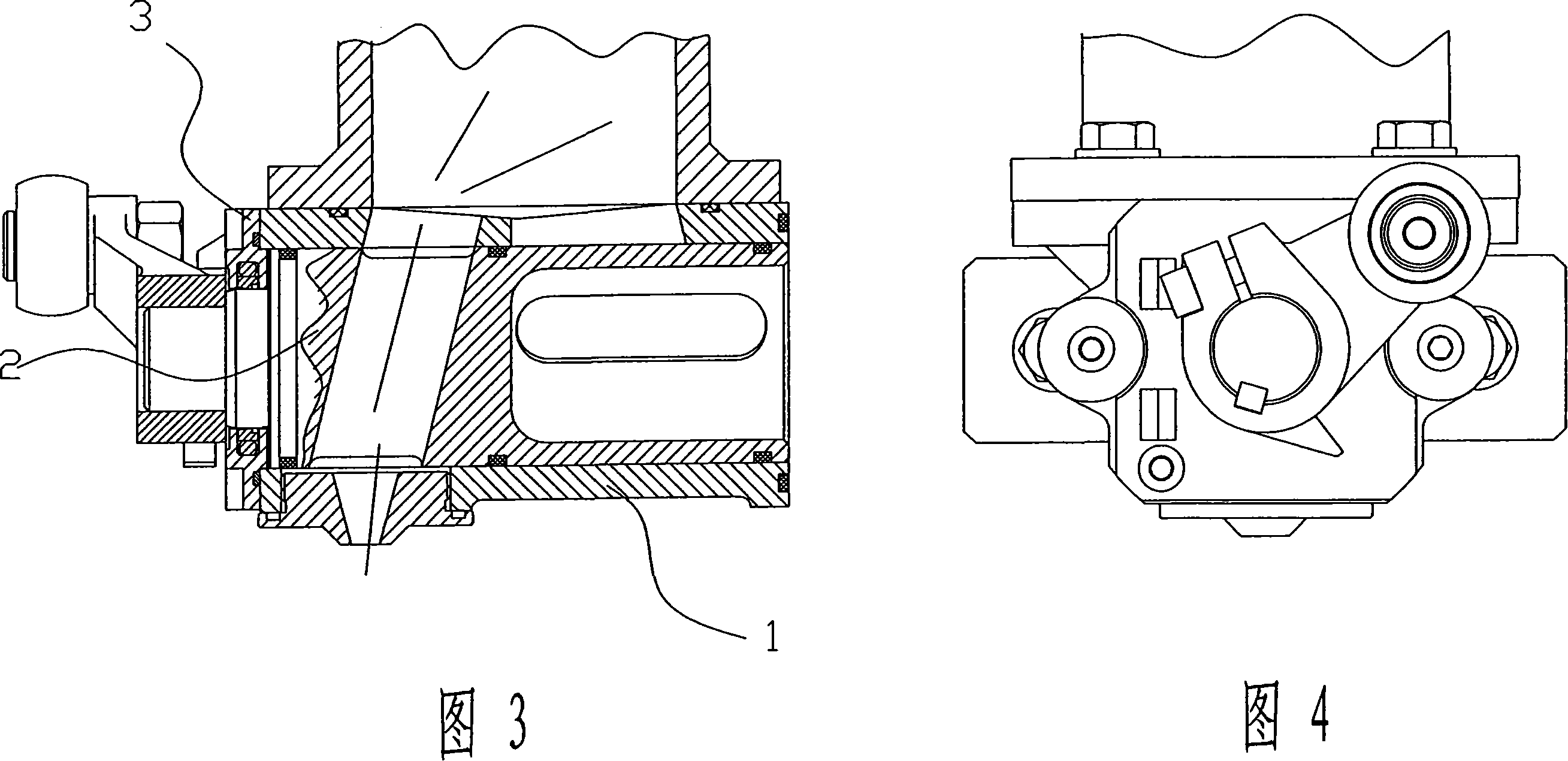

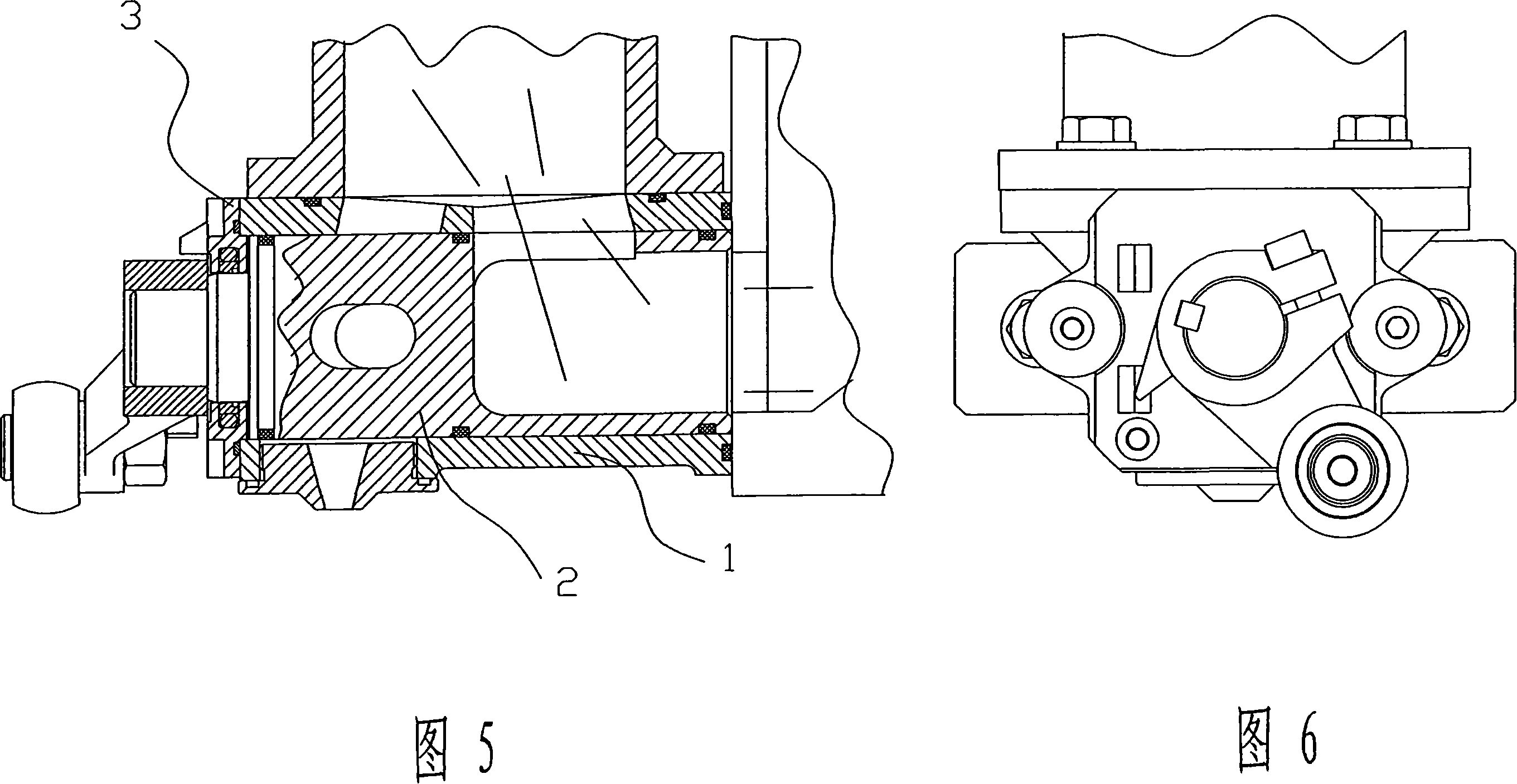

Telescopic aluminum strip positioning and compressing device for hollow glass molecular sieve filling machine

The invention discloses a telescopic aluminum strip positioning and compressing device for a hollow glass molecular sieve filling machine. The device comprises a turning table, a hydraulic ejecting and extending device and a positioning and compressing mechanism, wherein the turning table consists of four fan-shaped expansion plates, a positioning guide groove is arranged between every two adjacent fan-shaped expansion plates, limiting sliding grooves which are mutually parallel are arranged in the positioning guide grooves, the limiting sliding grooves are respectively located at the side surfaces of every two adjacent fan-shaped expansion plates, synchronous sliding blocks are connected into the limiting sliding grooves in a sliding manner, the top surfaces of the synchronous sliding blocks are provided with catching grooves, the hydraulic ejecting and extending device is connected to the turning table through the synchronous sliding blocks in a moving manner, the positioning and compressing mechanism is connected to the end part of the hydraulic ejecting and extending device, and every two opposite fan-shaped expansion plates are provided with one group of synchronous travel mechanisms. The device provided by the invention is simple in structure and high in practicability, not only is the molecular sieve filling of aluminum strip frames of different shapes and sizes met, but also the clamping and positioning can be automatically realized, the filling of each through hole of molecular sieve is realized, and the working efficiency of the filling machine is improved.

Owner:SHENGZHOU HUANDING GLASS TECH CO LTD

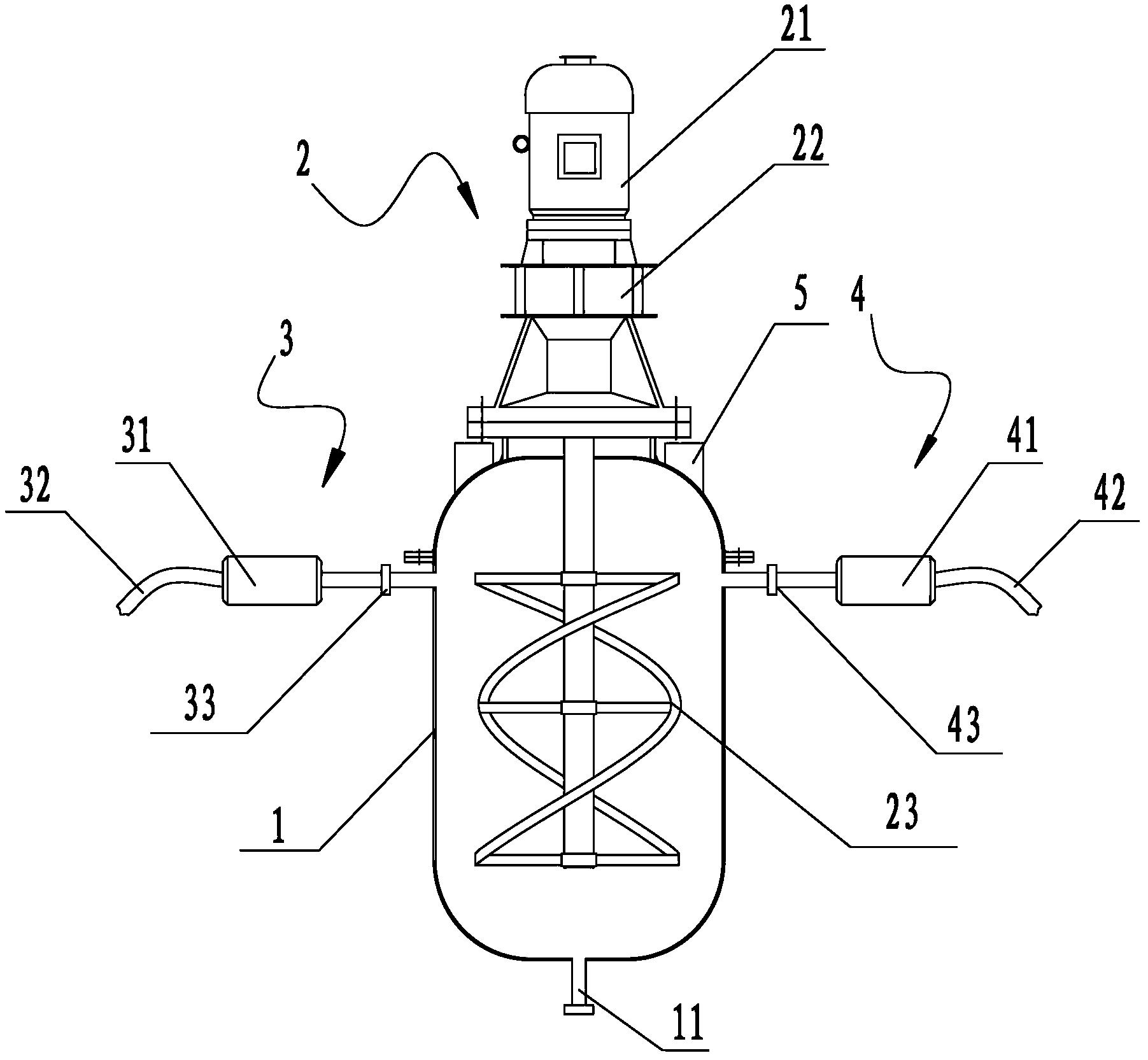

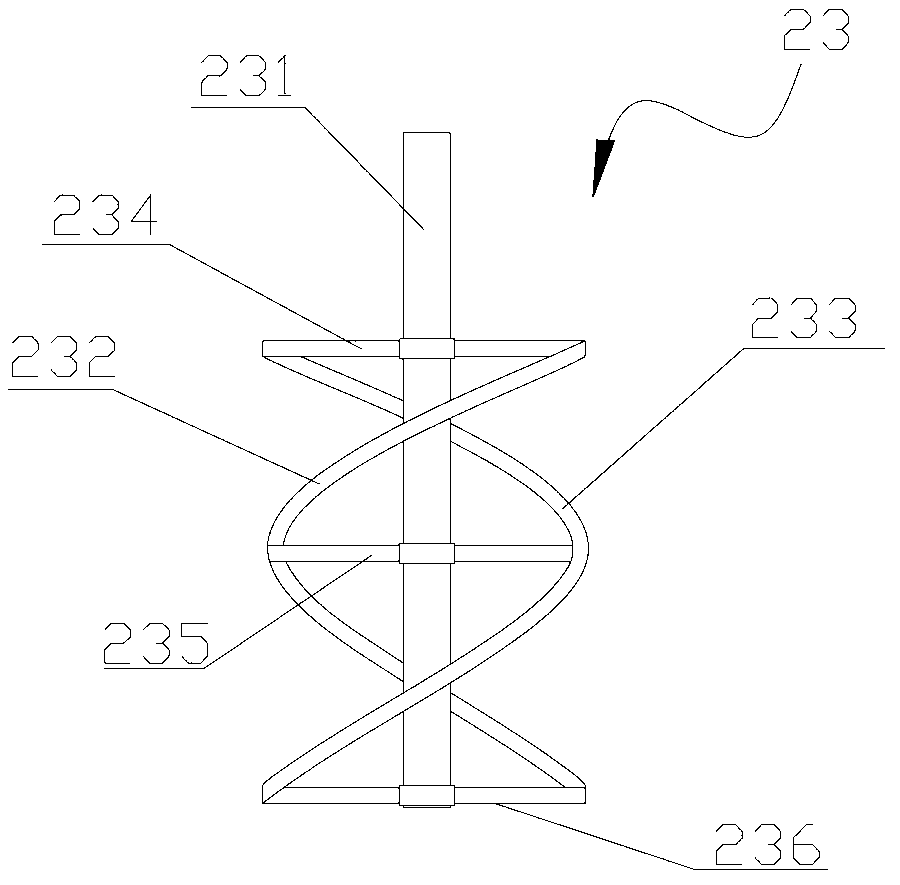

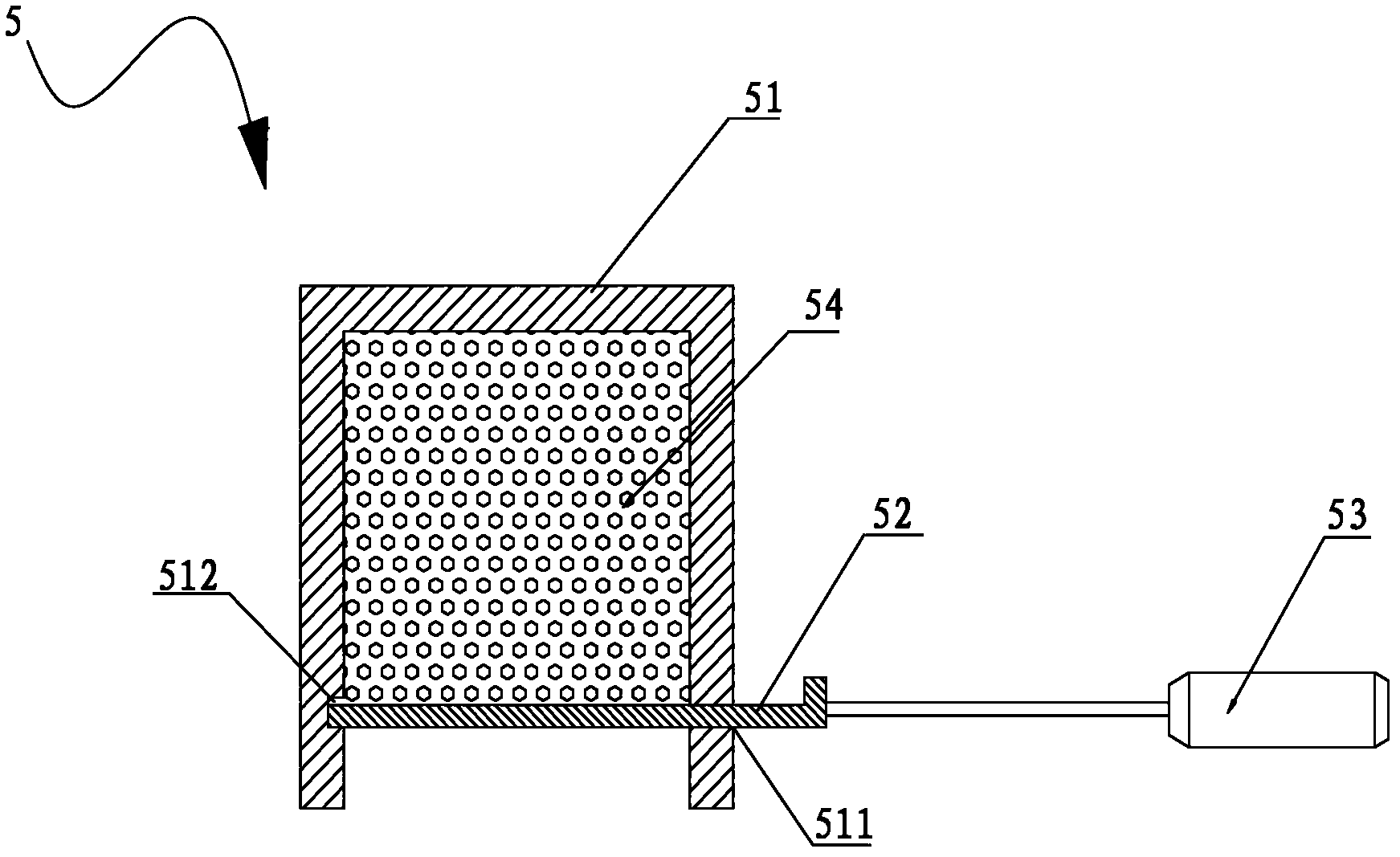

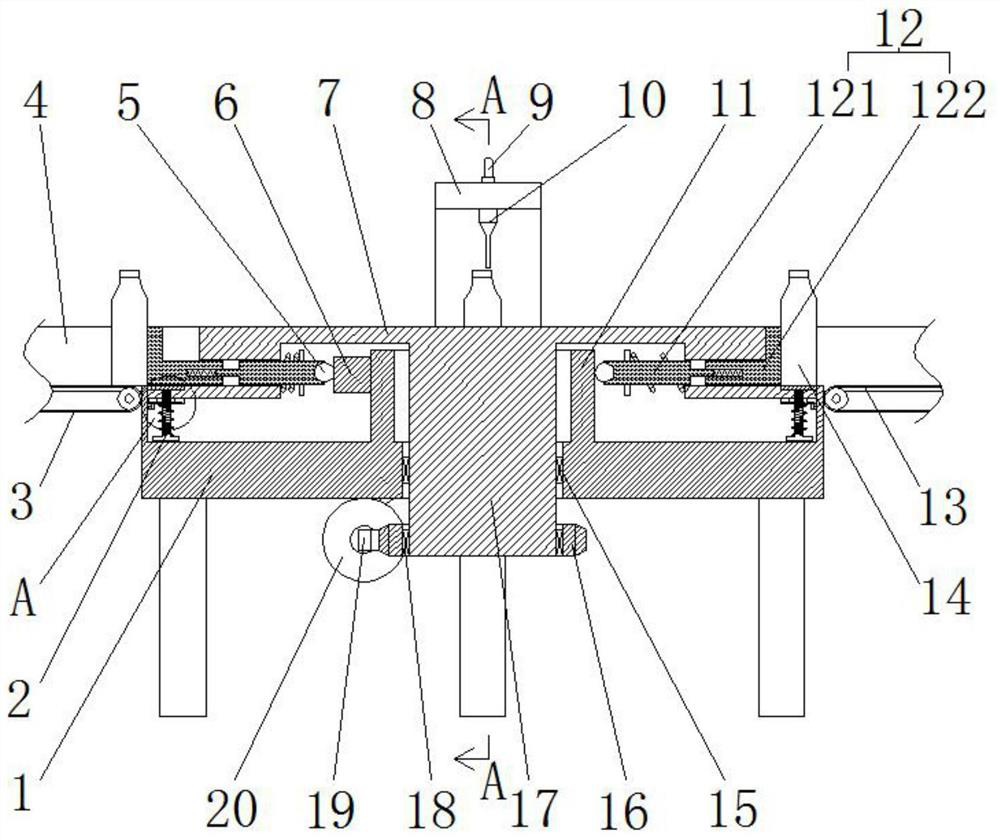

Automatic material mixing device

ActiveCN103301774AWell mixedFully automatedRotary stirring mixersMixing methodsEngineeringSolid material

The invention discloses an automatic material mixing device. The automatic material mixing device comprises a stirring kettle for containing two or more than two materials, at least one fluid delivery device, at least one solid filling device and a control device, wherein a liquid feed port and a solid feed port are formed in the stirring kettle, and the stirring kettle is internally provided with a stirring device for stirring the material; the fluid delivery device and the liquid feed port of the stirring kettle are connected so as to deliver a liquid material into the stirring kettle, and the solid filling device is used for filling a solid material into the stirring kettle through the solid feed port of the stirring kettle; the control device is connected with the stirring device, the fluid delivery device and the solid filling device so as to control the delivery of the liquid material and the solid material. The automatic material mixing device provided by the invention overcomes the defects that the mixing of the existing material mixing machine is not uniform, the liquid material and the solid material can not be mixed together, and the automatic material mixing device can uniformly mix the liquid material and the solid material through stirring.

Owner:北京北机机电工业有限责任公司

Filling device for cosmetic production

The invention discloses a filling device for cosmetic production, and belongs to the field of cosmetic production equipment. The filling device comprises a conveying mechanism and a filling mechanism,wherein the filling mechanism comprises a storage barrel and a filling head communicated with the storage barrel; the conveying mechanism comprises a fixed supporting table and a rotating table; a feeding notch, a filling station and a discharging notch are sequentially formed in the three sides of the fixed supporting table, carrier plates used for bearing filling bottles are arranged on the rotating table at equal intervals, and lifting rods are fixed to the bottoms of the carrier plates and are connected with a rotating lifting driving mechanism; the outlet end of the filling head is aligned with the eccentric part of a bottle opening of a filling bottle at the filling station; pushing assemblies in one-to-one correspondence with the carrier plates are arranged on the rotating table, and arc-shaped protruding blocks which are gradually widened are fixed to the outer side face of the supporting barrel. A large amount of foam can be prevented from being generated in the filling bottle, so that insufficient filling amount caused by foam accumulation in the filling bottle can be avoided, and the reliability of the filling procedure is guaranteed; and automatic feeding, filling anddischarging can be achieved, and the working efficiency is high.

Owner:济宁高新文化创意园服务有限公司

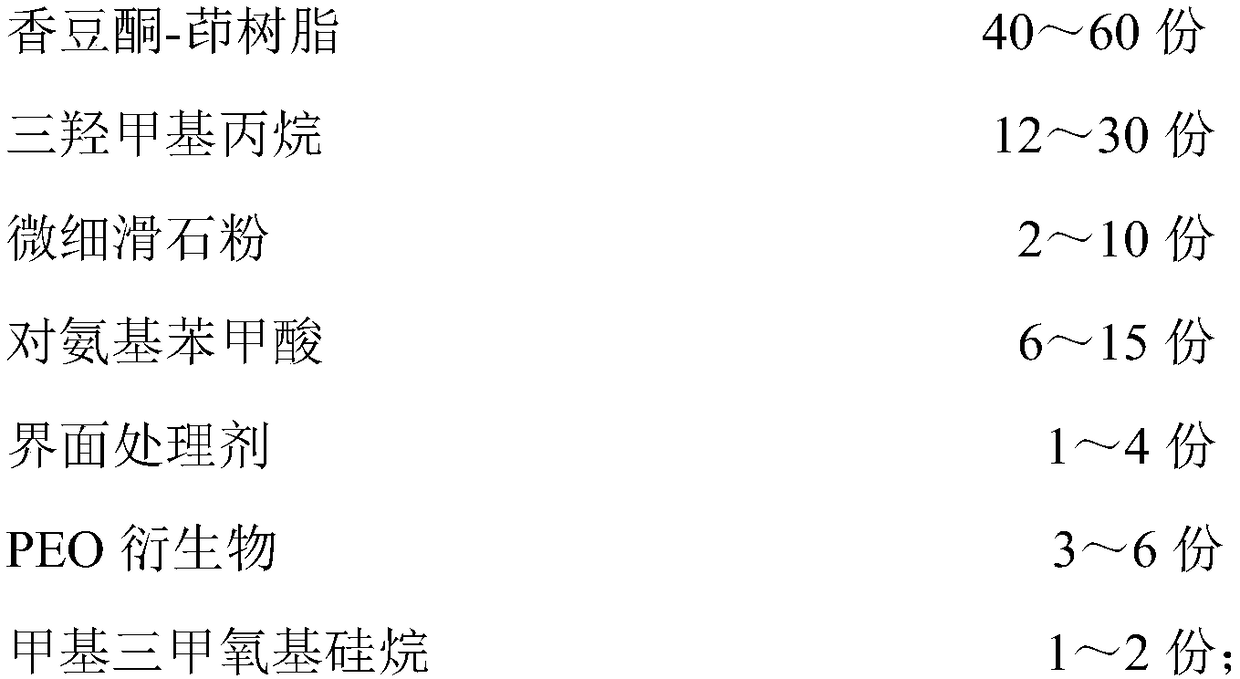

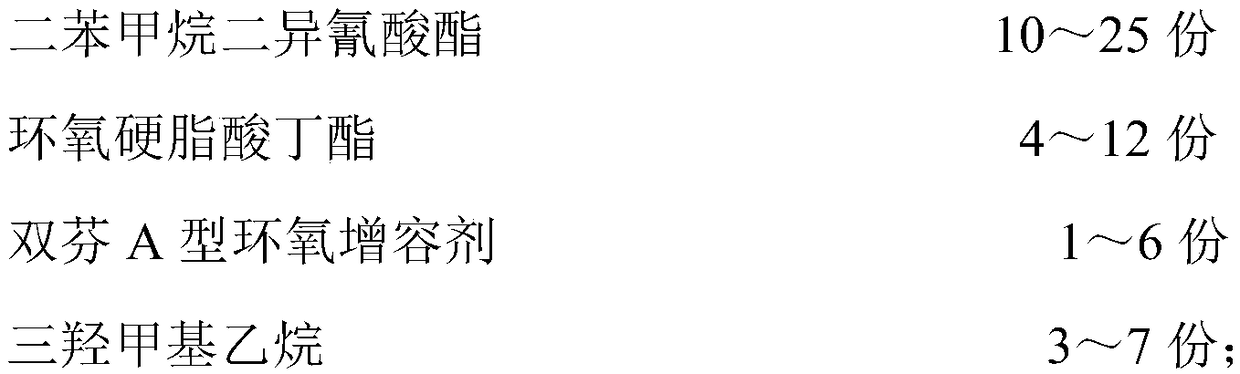

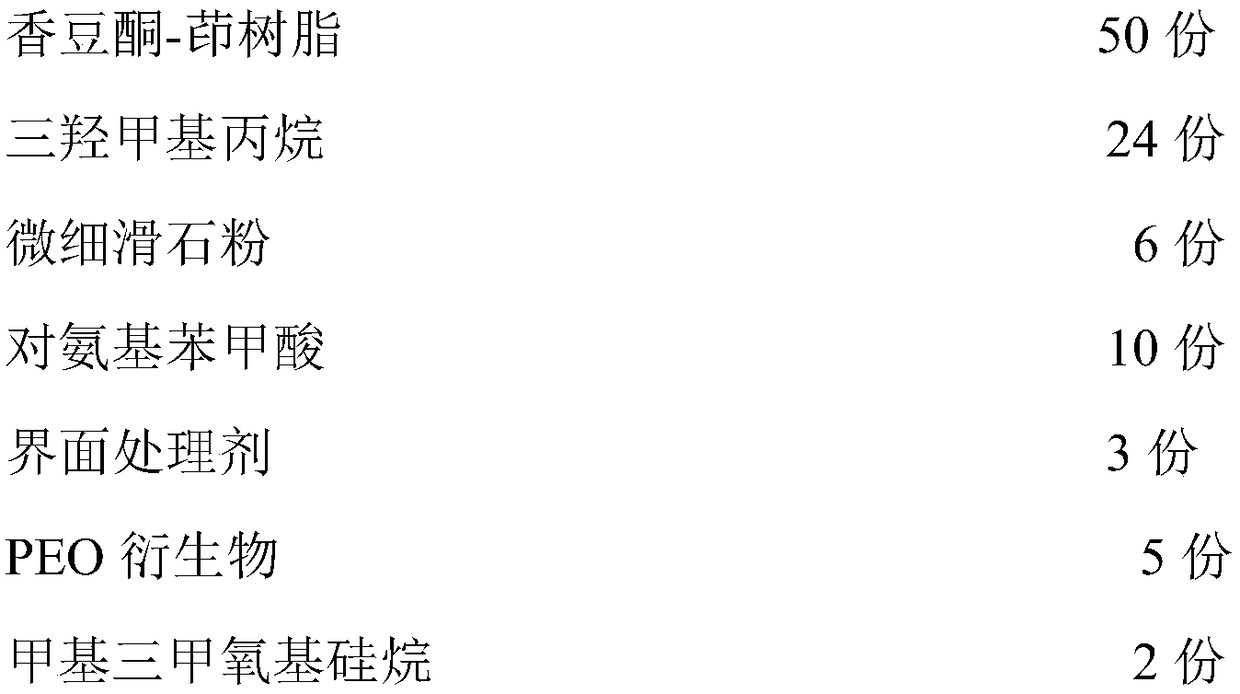

Compound multifunctional asphalt pavement sealant and preparation process thereof

ActiveCN108913093AImprove adhesionIncreased durabilityNon-macromolecular adhesive additivesBituminous material adhesivesSodium BentonitePolymer science

The invention discloses a compound multifunctional asphalt pavement sealant and a preparation process thereof. The main components of the sealant include: 100 parts of mixed modifier-modified asphaltwith 35 percent of 40-mesh rubber powder, 45 percent of 60-mesh rubber powder and 20 percent of 80-mesh rubber powder; 15 to 30 parts of functional component agent A; 10 to 35 parts of functional component agent B; and 5 to 25 parts of functional component agent C. The main components of the functional component agent A are coumarone-indene resin, trimethylolpropane, fine talcum powder, p-aminobenzoic acid and the like. The main components of the functional component agent B are diphenylmethane diisocyanate, butyl epoxy stearate, bisphenol-A epoxy compatibilizer, trimethylolethane and the like. The main components of the functional component agent C are microcapsules, vinyl glass flake mortar, polyvinyl alcohol-modified high-sodium bentonite particles and the like. According to the invention, after the functional component agents A, B and C are prepared, proportion is designed to carry out compounding, and the compounded sealant not only can fill cracks, but also can seal the cracks. The invention is applicable to different types of cracks, and according to causes of crack formation, different amounts of functional component agents A, B and C can be added. The sealant compounded bythe invention has high bonding strength, good sealing property and waterproofness and excellent high-temperature stability and low-temperature bonding property, having high application and popularization values.

Owner:CHONGQING JIAOTONG UNIVERSITY

Sauce and juice dual-purpose pour-in valve

InactiveCN101139076ARealize fillingEasy to assemble and disassembleLiquid bottlingEngineeringDual purpose

The present invention discloses a dual-use filling valve for sauce and juice and comprises a main valve body and a main valve core which can rotate relatively in the main valve body, the upper part of the main valve body is provided with a material absorption port and a material outlet, the lower part of the main valve body is provided with a sauce filling port, the main valve core is provided with a material absorption channel and a filling channel, the absorption channel can selectively communicate the material absorption port of the main valve body with a material storage tank or be closed when the main valve core rotate, meanwhile, the filling channel can be closed or communicate the material outlet of the main valve body and the sauce filling port, the internal surface of the main valve body matches with the outer surface of the valve core in a liquid sealing way, the main valve core out of the main valve body is provided with a sealing cover, the sealing cover is connected with the main valve body fixedly, the surrounding of the sauce filling port on the lower part of the main valve body is provided with a connection body, and a juice filling valve is connected with the upper part of the connection body conveniently; the present invention not only can be used for filling of sauce material, but also for filling of juice material, meanwhile, the present invention has the characteristics of simple structure, convenient installation and detachment, and high stability.

Owner:GUANGZHOU NANLIAN IND

Hole sealing device for drilled hole

InactiveCN105822255AAvoid generation and developmentEasy to operateGas removalSealing/packingDrill holeMechanical engineering

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

Quantitative filling device for cosmetic production

The invention discloses a quantitative filling device for cosmetic production, and belongs to the field of cosmetic production equipment. The device comprises a conveying mechanism and a filling mechanism. The filling mechanism comprises a storage barrel body and a filling head communicating with the storage barrel body. The conveying mechanism comprises a fixed supporting table and a rotating table; a feeding notch, a filling station and a discharging notch are sequentially arranged on three sides of the fixed supporting platform, carrier plates are arranged on the rotating table at equal intervals, lifting rods are fixed at the bottoms of the carrier plates, and the lifting rods are connected with a rotating lifting driving mechanism; and the filling head is aligned with the eccentric position of a bottle mouth of a filling bottle below the filling head; a limiting rod is arranged in the storage barrel body, a screw rod penetrating through the storage barrel body is fixed on the limiting rod, an adjusting port is formed in the position, through which the screw rod penetrates, of the storage barrel body, and the screw rod is sleeved with a locking nut. Insufficient filling quantity caused by foam accumulation in the filling bottle can be avoided, and the reliability of the filling process is guaranteed; the primary filling amount of the filling mechanism is adjustable, so thatquantitative filling can be realized; and automatic feeding, filling and discharging can also be realized.

Owner:泉州市创智工业设计服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com