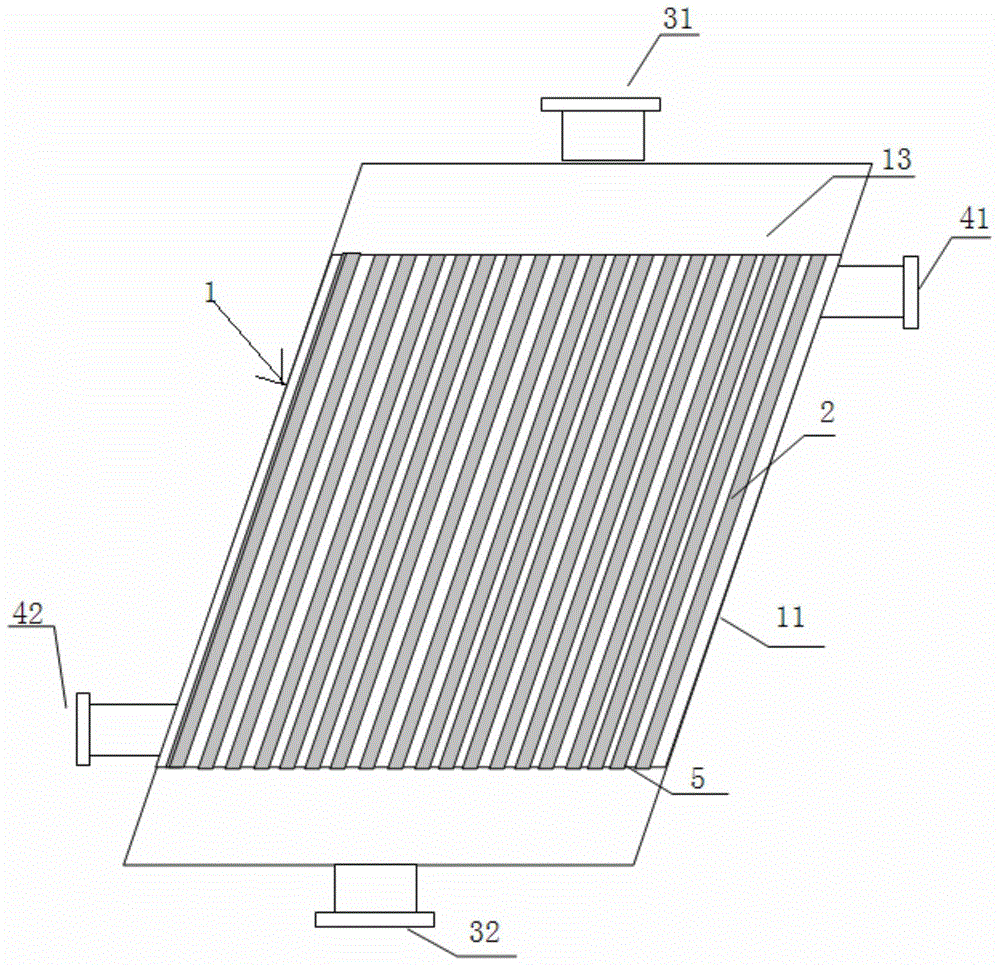

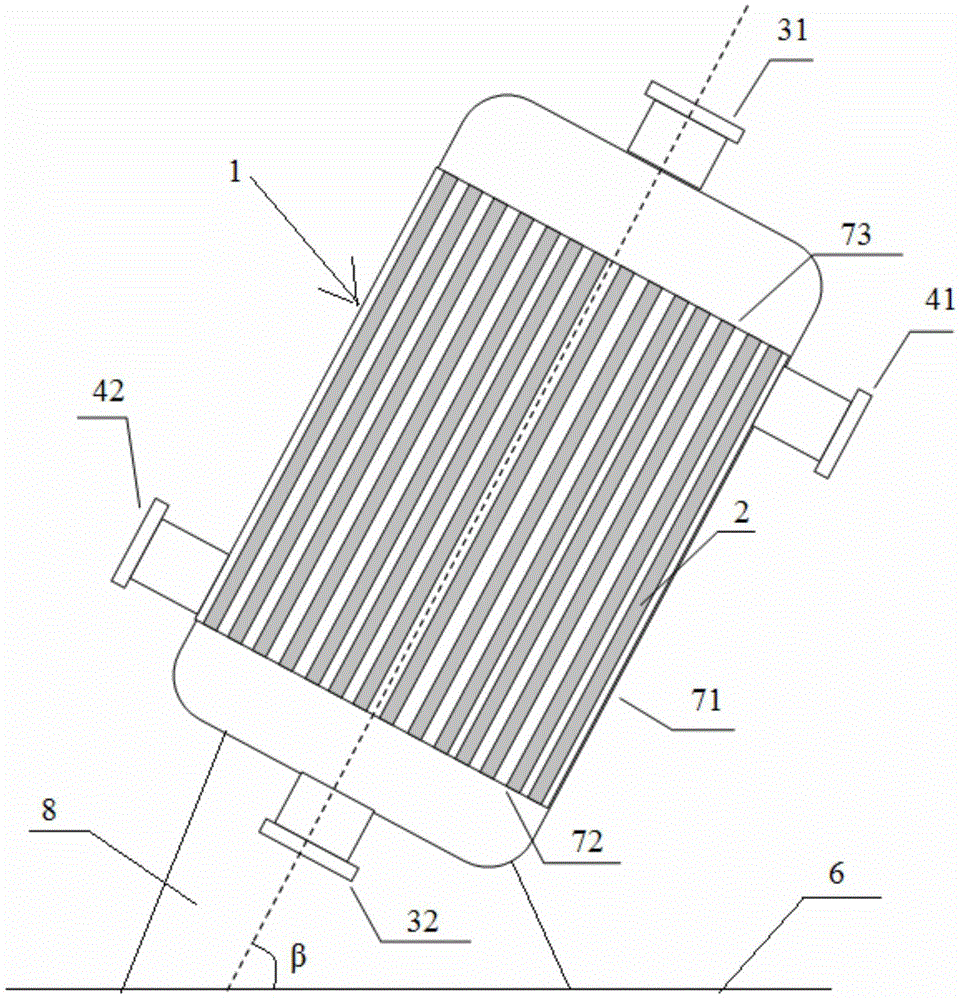

Tubular reactor

A tube-and-tube reactor and reactor technology, applied in the field of reactors, can solve problems affecting the safety of reactors, affecting the reaction performance of chemical production processes, and difficult heat transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

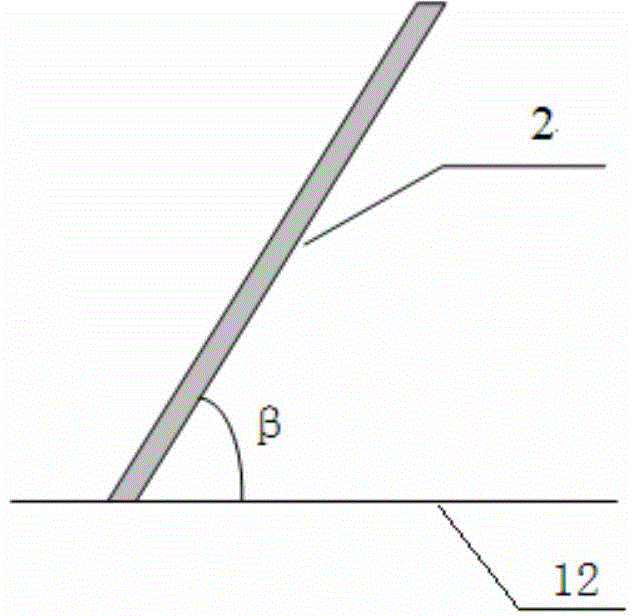

[0060] Embodiment 1. Select 10m-long, 5.15cm stainless steel tubes in the tube-and-tube reactor, and make it have an included angle of 30° with the horizontal direction during the reaction.

Embodiment 2

[0061] Example 2. Select a stainless steel tube with a length of 10 m and an inner diameter of 5.15 cm in the tube-and-tube reactor, and make it have an included angle of 45° with the horizontal direction during the reaction.

Embodiment 3

[0062] Example 3. In the tubular reactor, a stainless steel tubular tube with a length of 10 m and an internal diameter of 5.15 cm was selected, and during the reaction, it had an angle of 60° with the horizontal.

[0063] Wherein embodiment 1-3 makes the mode that column tube is inclined can be realized by adopting the reactor provided by the present invention also can adopt the assembly method provided by the present invention to realize, gained reaction result is listed in Table 1, can find out that the present invention It has obvious advantages in reducing the pressure drop at both ends of the reaction equipment.

[0064] Table 1

[0065]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com