Nanocomposite ice-coating-proof paint having properties of superhydrophobicity and low adhesive strength

A nano-composite, low-adhesion technology, applied in coatings and other directions, can solve the problems of anti-icing effect, water absorption and water absorption rate, limited hydrophobic performance and deicing performance, and limited anti-icing life. Anti-icing effect is remarkable, anti-icing effect, remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Mix 15 grams of perfluorooctyl ethyl acrylate, 10 grams of 2-hydroxyethyl methacrylate, 35 grams of methyl methacrylate, 25 grams of isooctyl acrylate, and 15 grams of lauryl acrylate and add them to the reactor In the process, the temperature was slowly raised to 65° C. under nitrogen gas, and 0.5 g of initiator 2,2′-azobisisobutyronitrile was added to react for 8 hours to obtain a fluorine-containing polyacrylate copolymer.

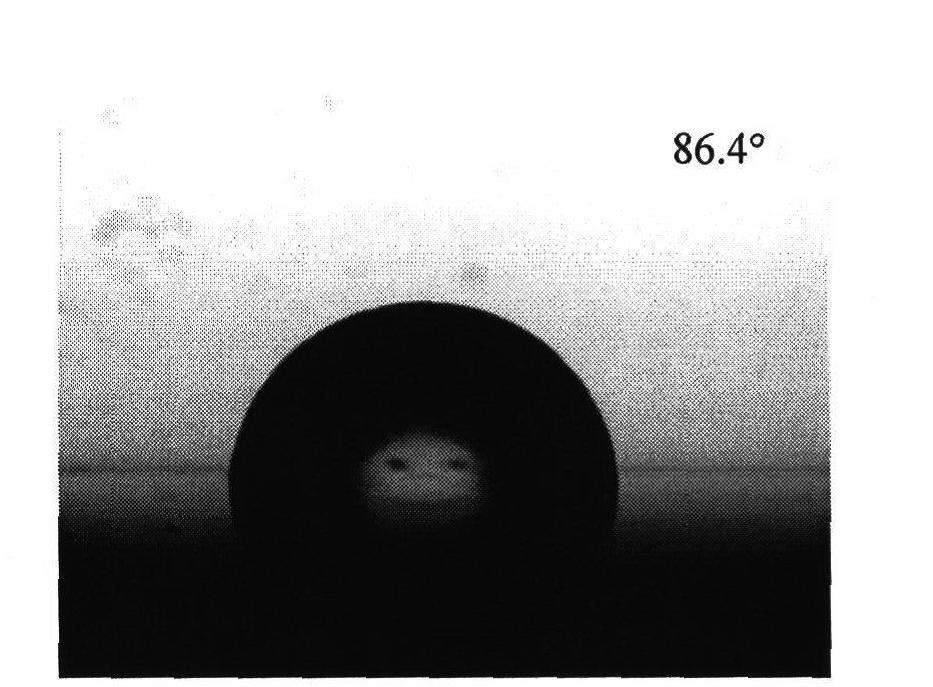

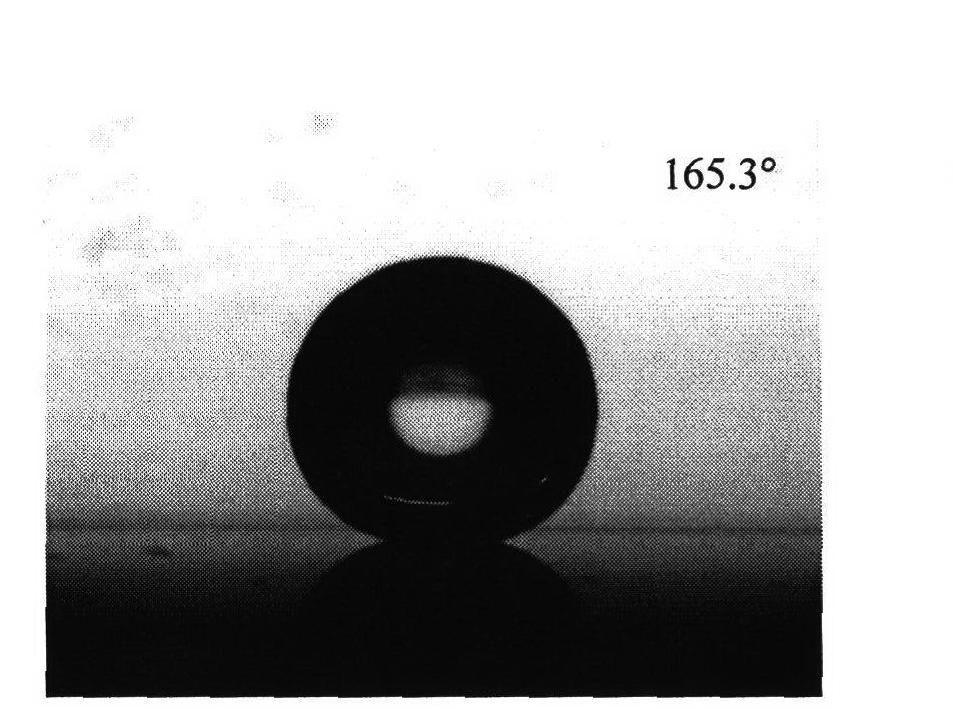

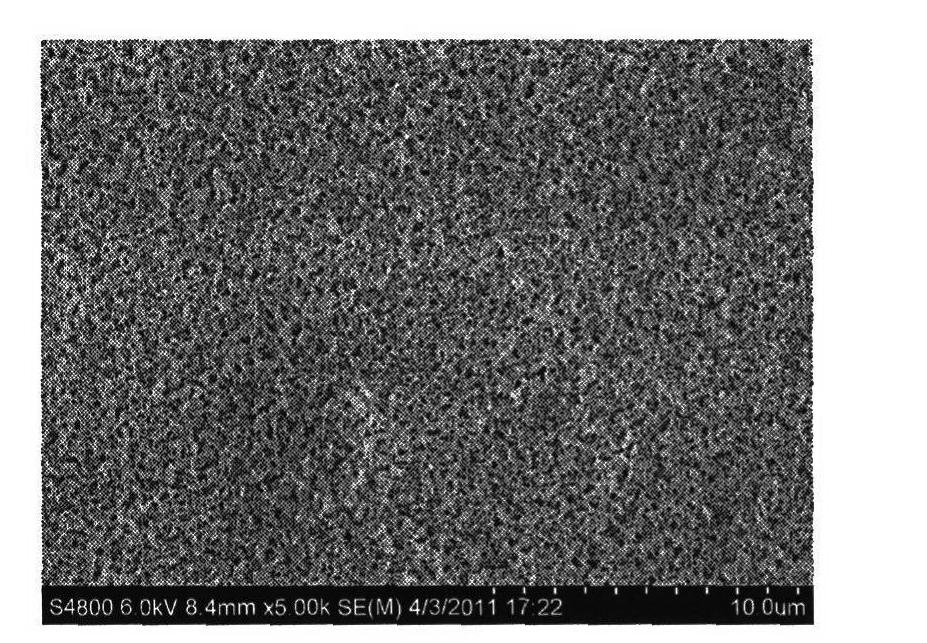

[0033] 10 grams of the above fluorine-containing polyacrylate copolymer, 0.05 grams of BYK-070 defoamer, 0.3 grams of organic bentonite, 35 grams of ethyl acetate, 35 grams of butyl acetate, 10 grams of xylene, 4 grams of nano-silica, Stir at room temperature to prepare a mixed solution, add 6 grams of amino resin into the mixed solution and stir for 1 to 2 hours, and discharge to prepare the super-hydrophobic, low-adhesion nanocomposite anti-icing coating. The paint is directly coated on the aluminum sheet, and after drying, it is put into an ov...

Embodiment 2

[0035] 20 grams of perfluorohexyl ethyl acrylate, 10 grams of glycidyl methacrylate, 30 grams of methyl methacrylate, 25 grams of butyl methacrylate, and 15 grams of octadecyl acrylate are mixed and added to the reaction kettle. Slowly heat up to 80° C. under nitrogen gas, add 0.5 g of initiator benzoyl peroxide, and react for 10 hours to obtain a fluorine-containing polyacrylate copolymer.

[0036] Prepare 20 grams of the above-mentioned fluorine-containing polyacrylate copolymer, 0.1 grams of BYK-054 defoamer, 0.5 grams of modified polyamide wax powder, 40 grams of butyl acetate, 30 grams of xylene, and 6 grams of nano-zinc oxide at room temperature. into a mixed solution. Add 4 grams of epoxy resin into the mixed solution and stir for 1 to 2 hours, and discharge to prepare the super-hydrophobic, low-adhesion nanocomposite anti-icing coating. The paint is directly coated on an aluminum sheet, and after drying, it is placed in an oven for 30 minutes with hot air at 150°C to ...

Embodiment 3

[0038] Mix 20 grams of perfluorooctyl sulfonyl acrylate, 20 grams of 2-hydroxyethyl acrylate, 25 grams of methyl methacrylate, 25 grams of butyl methacrylate, and 10 grams of isooctyl methacrylate before adding to the reaction In the kettle, the temperature was slowly raised to 80° C. under the condition of feeding nitrogen, and 1 g of initiator benzoyl peroxide was added, and reacted for 12 hours to obtain a fluorine-containing polyacrylate copolymer.

[0039] 15 grams of the above-mentioned fluorine-containing polyacrylate copolymer, 0.05 grams of BYK-057 defoamer, 0.5 grams of organic bentonite, 30 grams of butyl acetate, 20 grams of n-butanol, and 20 grams of xylene were stirred at room temperature to prepare a mixed solution. Add 5 grams of nano-alumina into the mixed solution and stir for 1-2 hours, then add 10 grams of polyurethane and discharge to prepare the super-hydrophobic, low-adhesion nano-composite anti-icing coating. The paint is directly coated on the aluminum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com