Patents

Literature

2944results about How to "Increased shear strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Structural and other composite materials and methods for making same

InactiveUS20050281999A1High strength-to-weight ratioEasy to manufactureSynthetic resin layered productsLaminationPolymer scienceHigh intensity

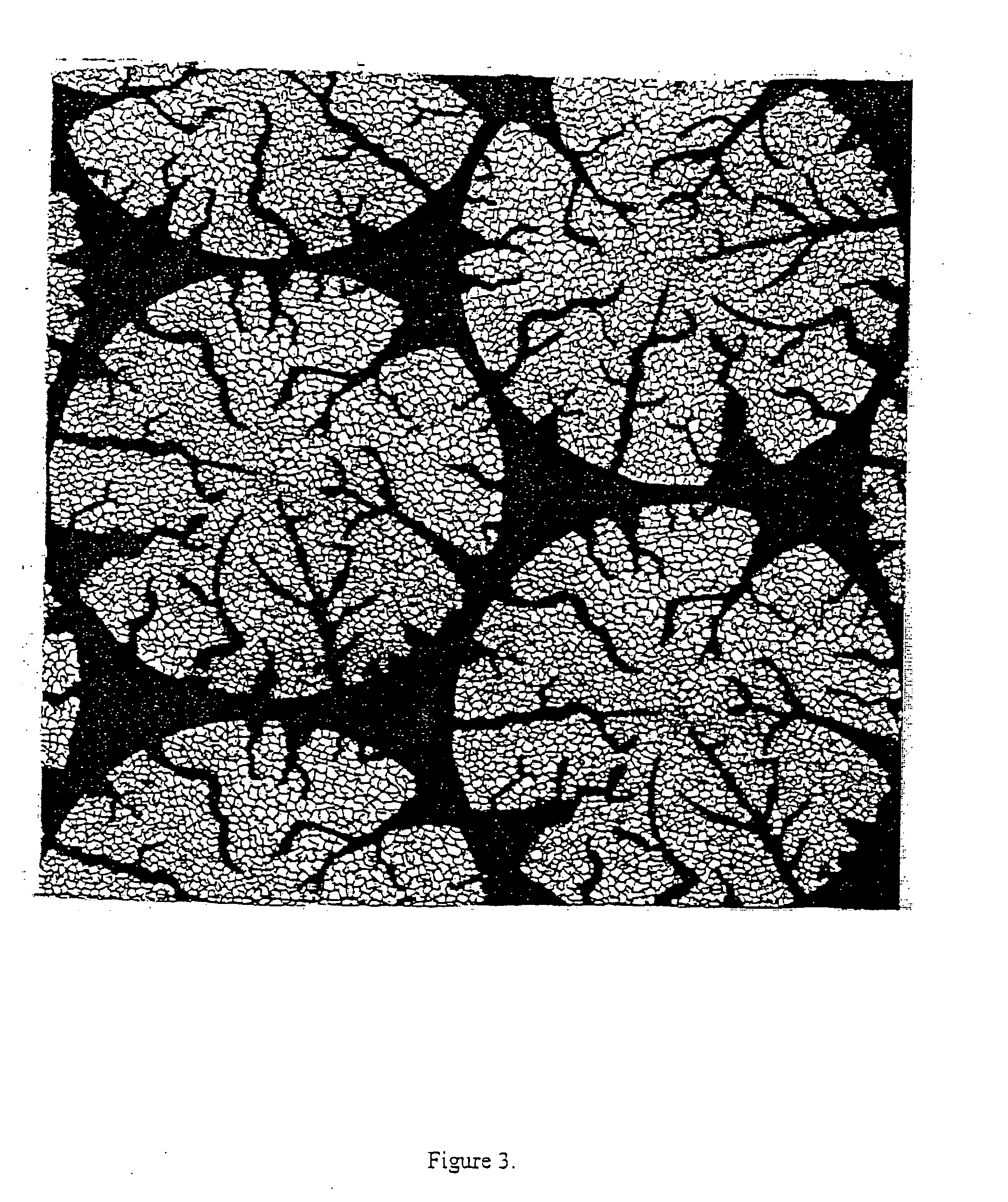

In accordance with the present invention, structural and other composite materials have been developed which have superior performance properties, including high compressive strength, high tensile strength, high shear strength, and high strength-to-weight ratio, and methods for preparing same. Invention materials have the added benefits of ease of manufacture, and are inexpensive to manufacture. The superior performance properties of invention materials render such materials suitable for a wide variety of end uses. For example, a variety of substances can be applied to invention materials without melting, dissolving or degrading the basic structure thereof. This facilitates bonding invention materials to virtually any surface or substrate. Moreover, the bond between invention materials and a variety of substrates is exceptionally strong, rendering the resulting bonded article suitable for use in a variety of demanding applications. Invention materials can be manufactured in a wide variety of sizes, shapes, densities, in multiple layers, and the like; and the performance properties thereof can be evaluated in a variety of ways.

Owner:PETRITECH

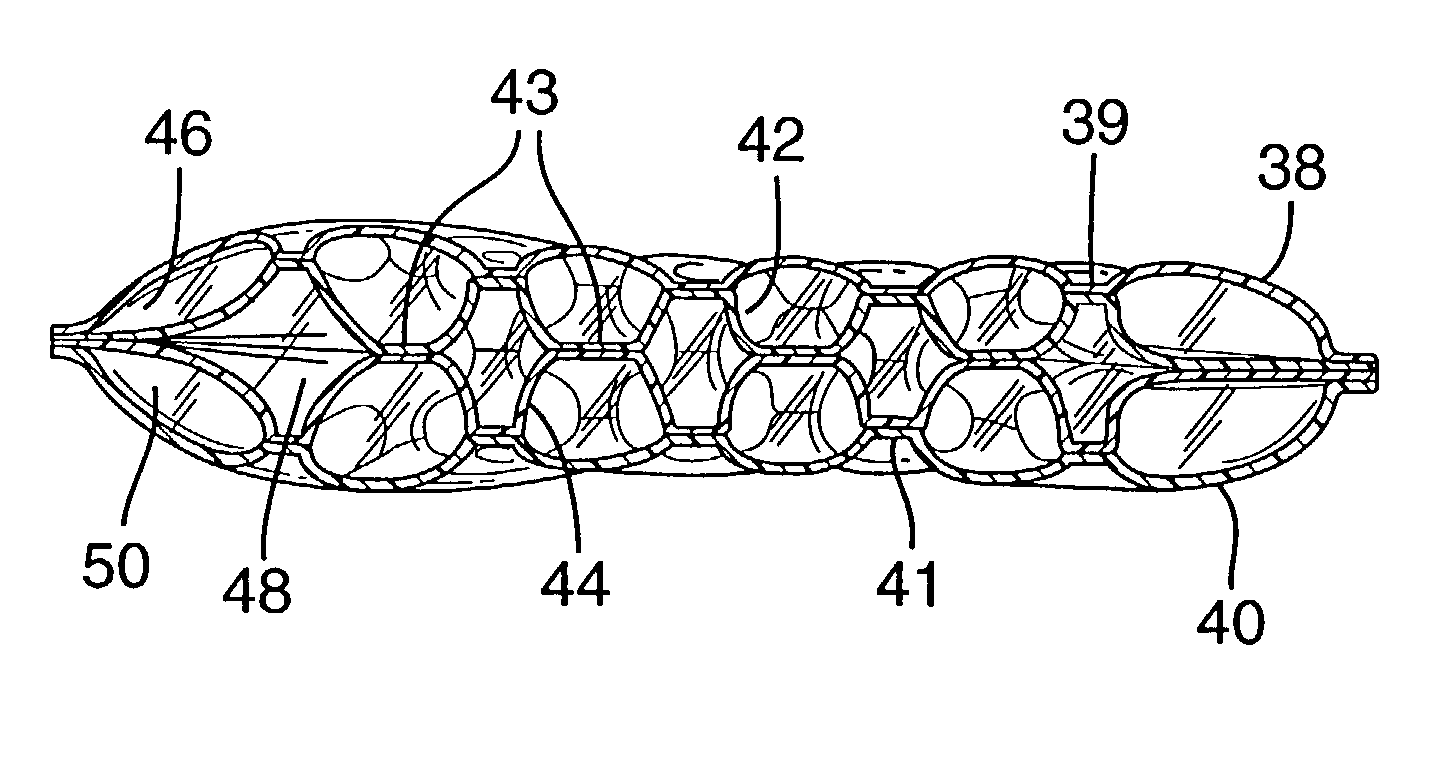

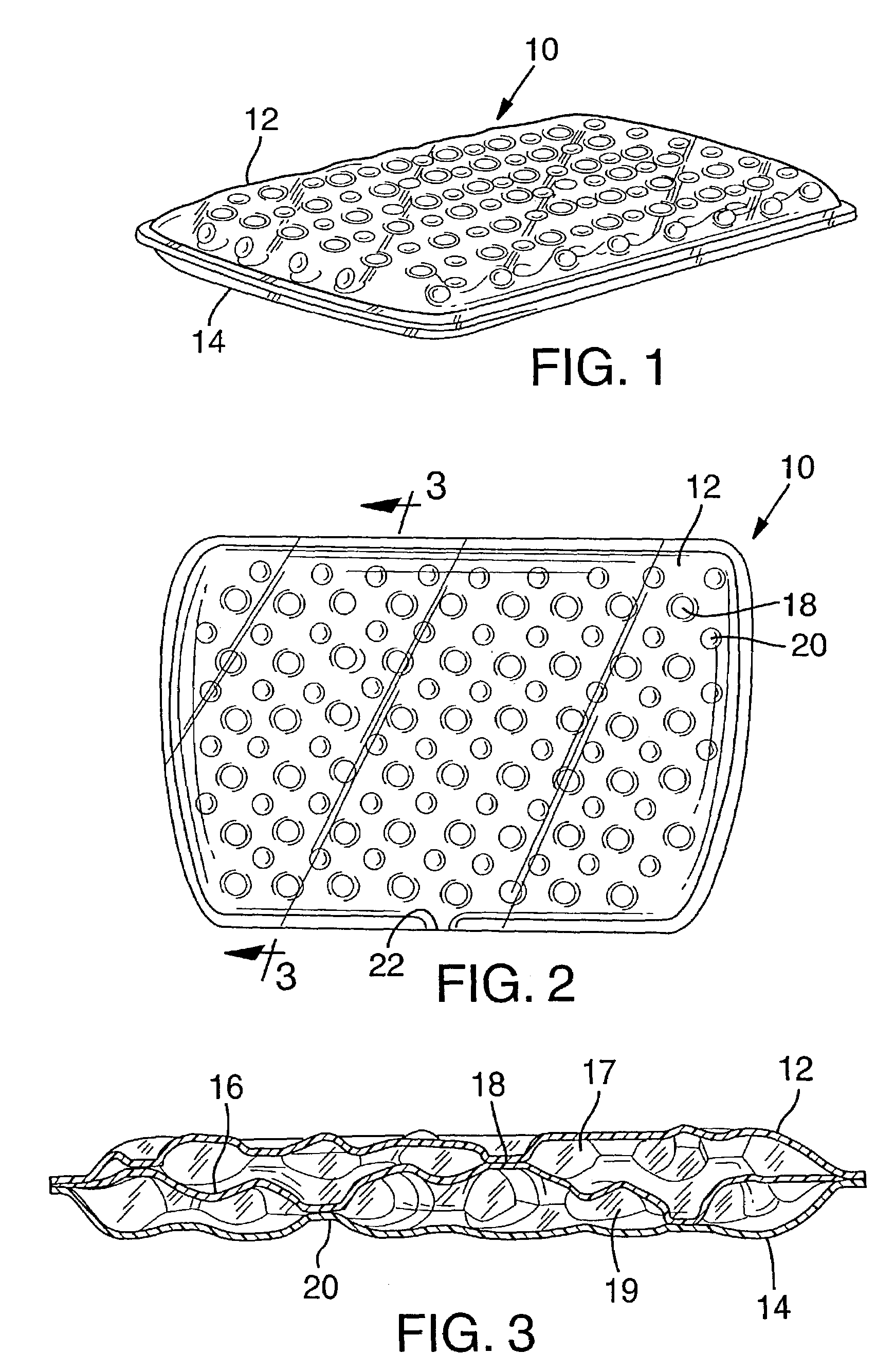

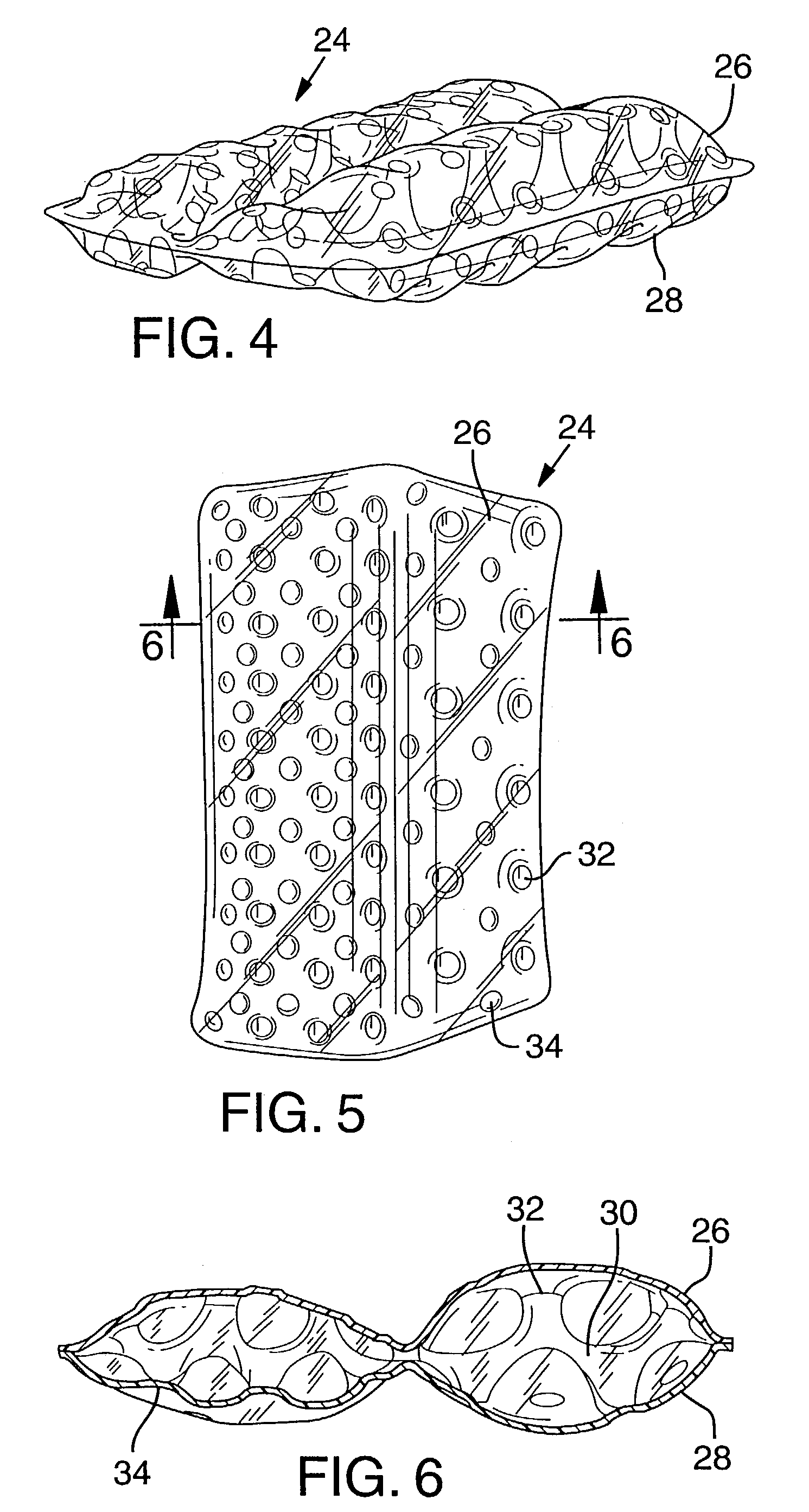

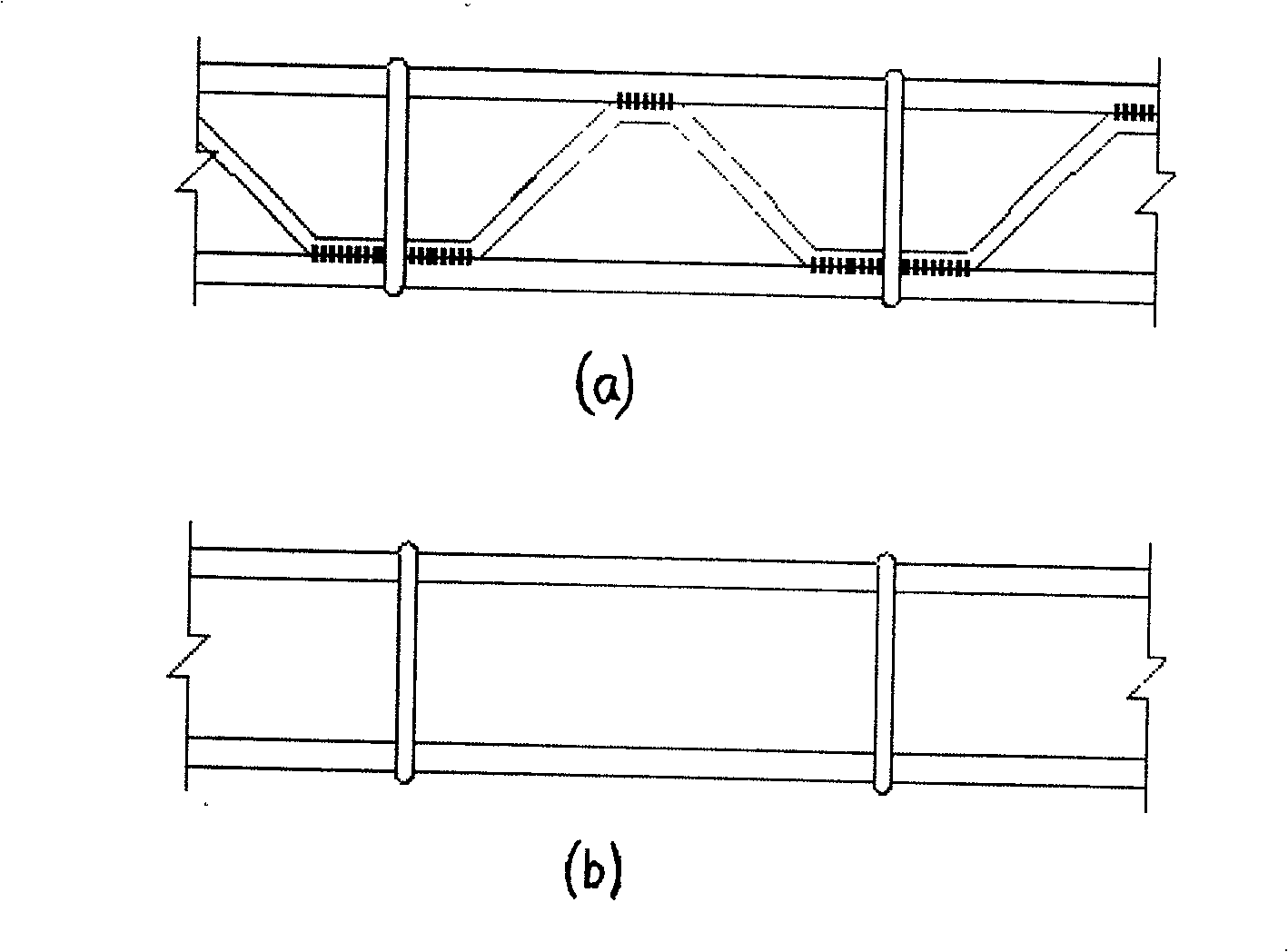

Bladder with multi-stage regionalized cushioning

InactiveUS7132032B2Overcome problemsEnhances cushioning responseSolesHollow inflatable ballsCushioningEngineering

A bladder which is particularly useful for a sole assembly of a shoe is formed of multiple layers of barrier film to provide multiple pressurized layers of cushioning fluid or gas when the bladder is filled. A multiple gas layer bladder enhances cushioning response by relying more on the response characteristics of the gas and reducing the amount of foam and the dependence on foam as a cushioning material. The internal film layers provide a truss-like geometry in cross section and act as tensile members to impart a generally smooth surface contour to the bladder. The bladder is constructed to provide complex regionalized cushioning profiles which are coupled to the anatomy of the foot and expected loads at known points.

Owner:NIKE INC

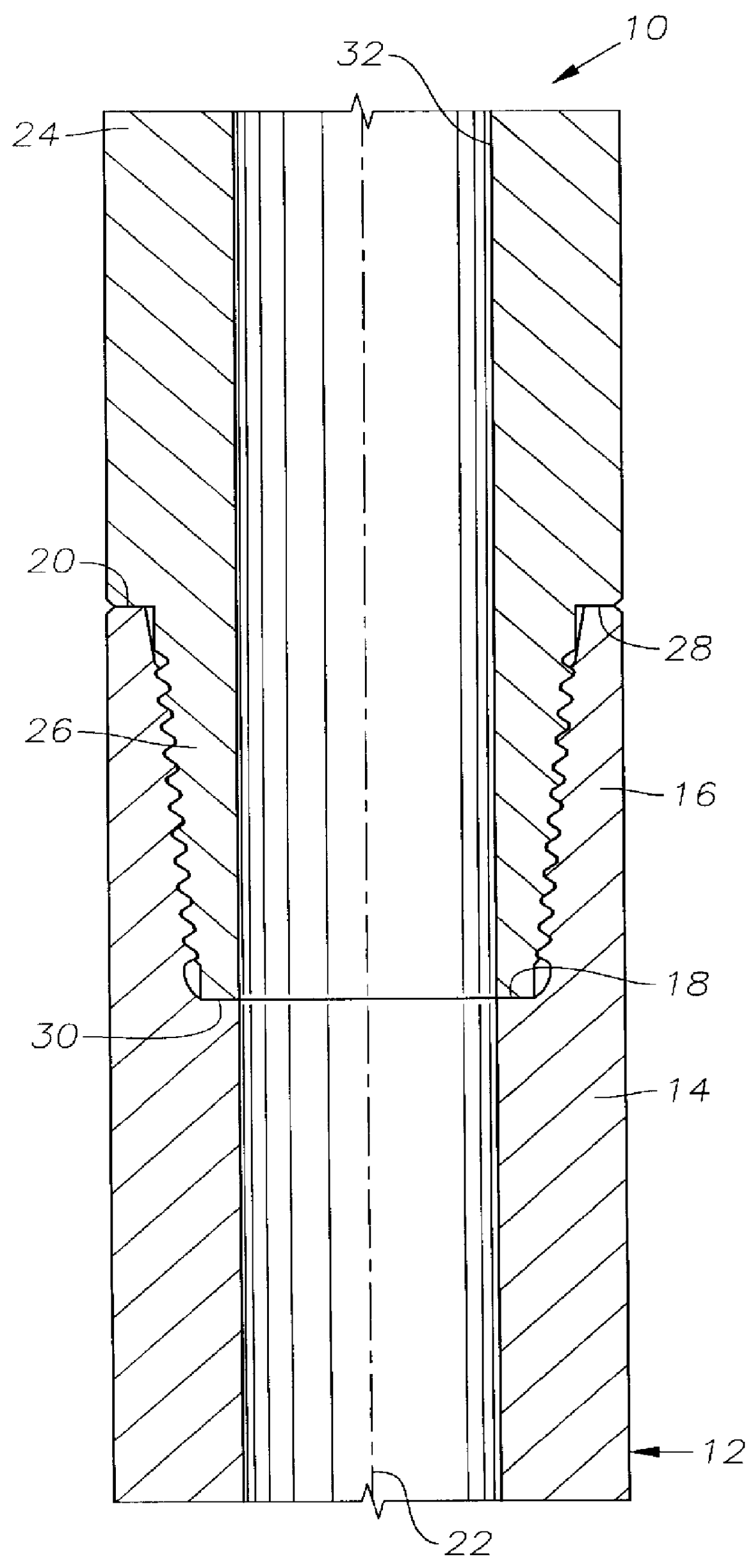

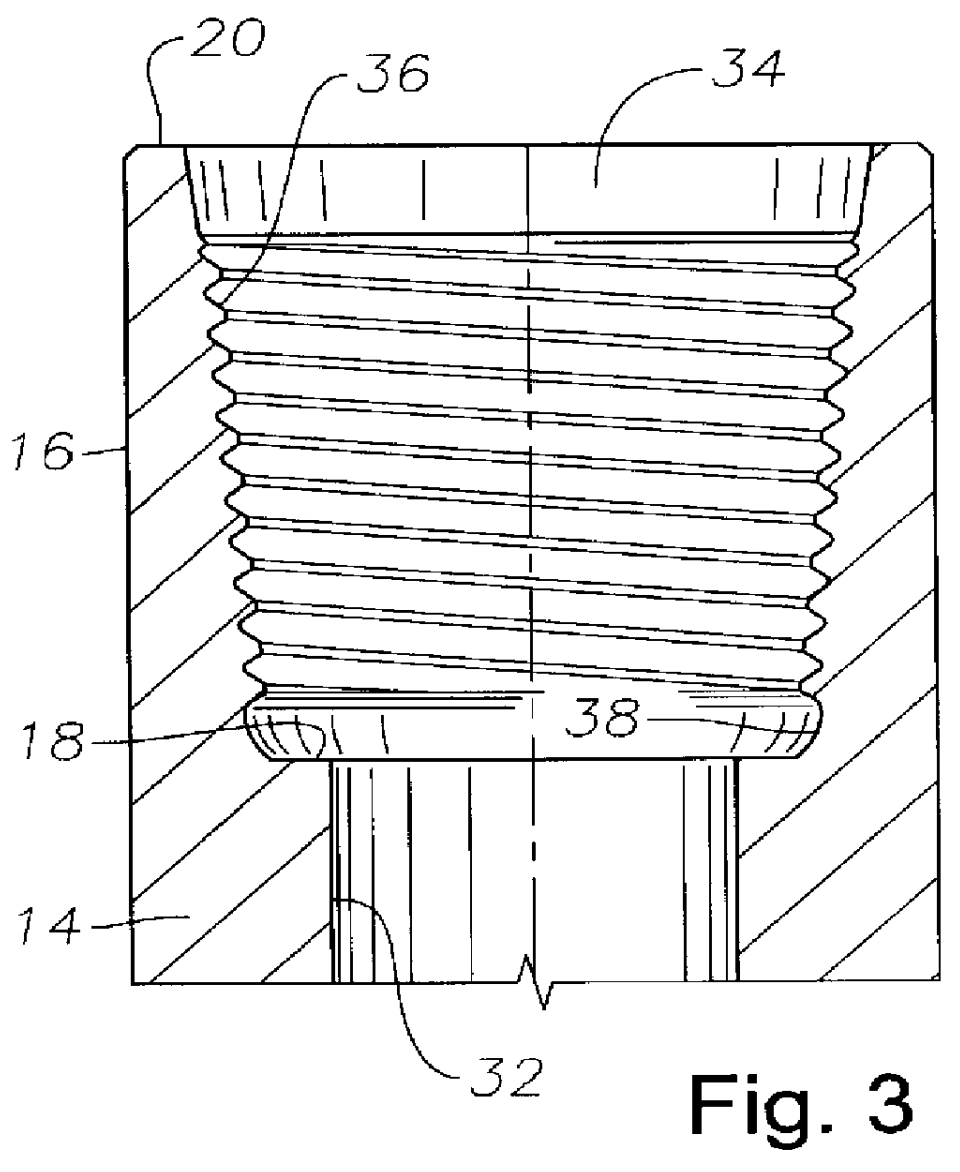

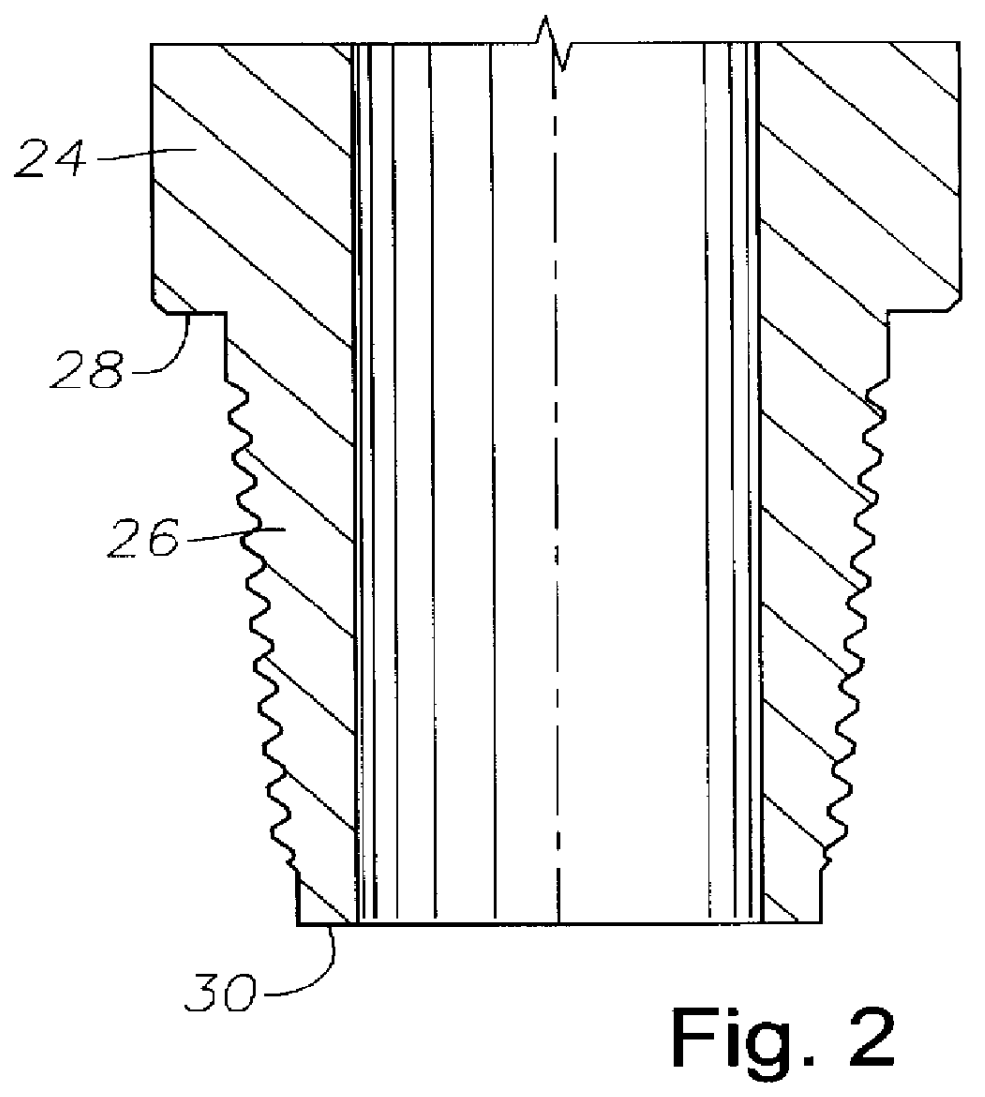

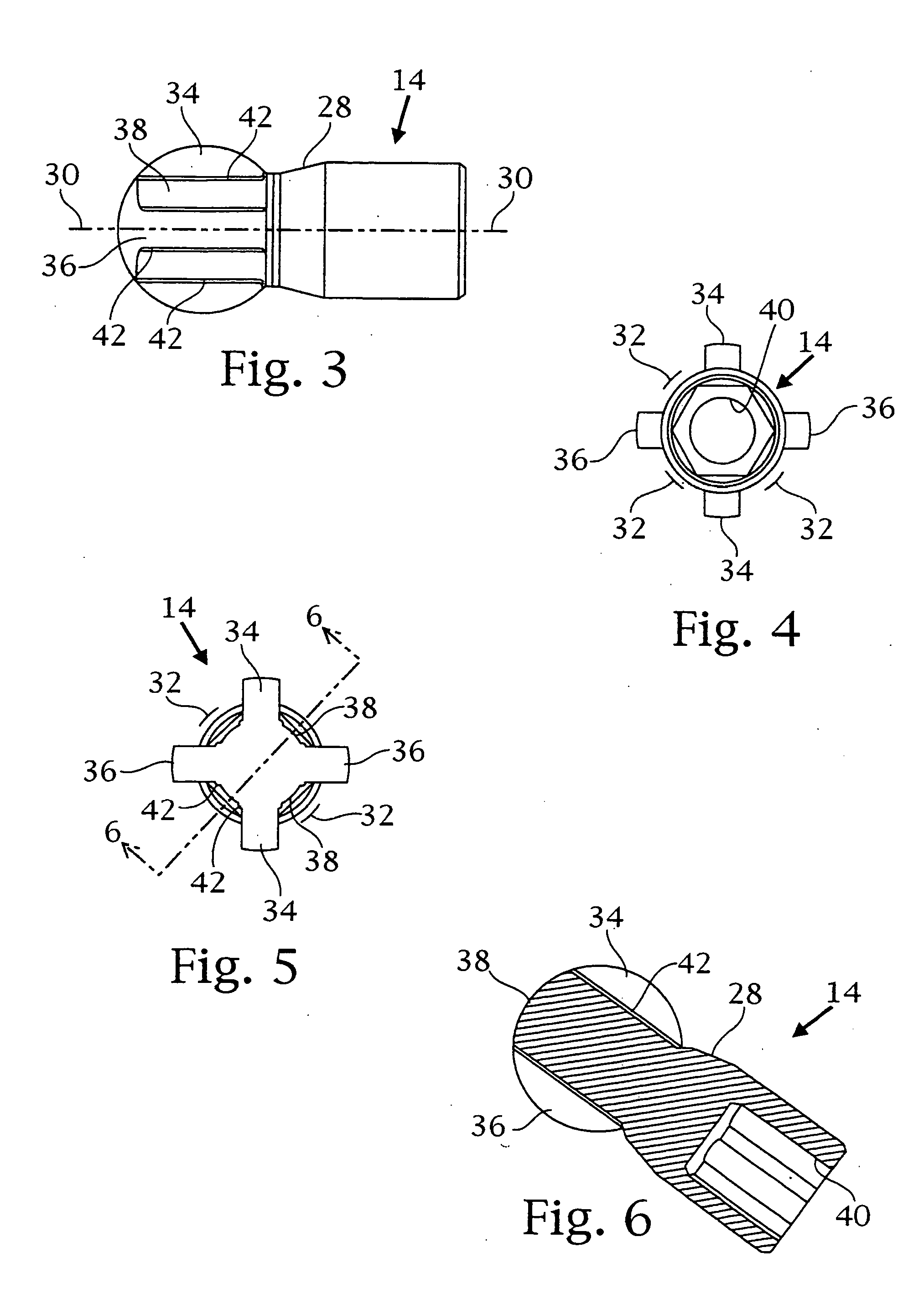

High torque threaded tool joint for drill pipe and other drill stem components

InactiveUS6030004AIncrease torqueEnhancing the torque resisting characteristicsDrilling rodsNutsStress concentrationRoot surface

A double shouldered high torque resistance threaded connection for drill stem components having enhanced resistance to torque forces, tensile loads and material stress and fatigue is disclosed. The tool joint is provided with threads having a 75 DEG included angle between the thread flanks thereof and with generally elliptical root surfaces to minimize material stress and fatigue during operation under high torque and high tensile loads. When made up, the double intrerengaging shoulders of the threaded tool joint are in firm face to face engagement permitting torque forces and tensile loads to propagate through the tool joint in a manner that minimizes bending forces and minimizes high stress concentration so that the resulting service life of the tool joint is significantly enhanced.

Owner:VALLOUREC OIL & GAS FRANCE SAS

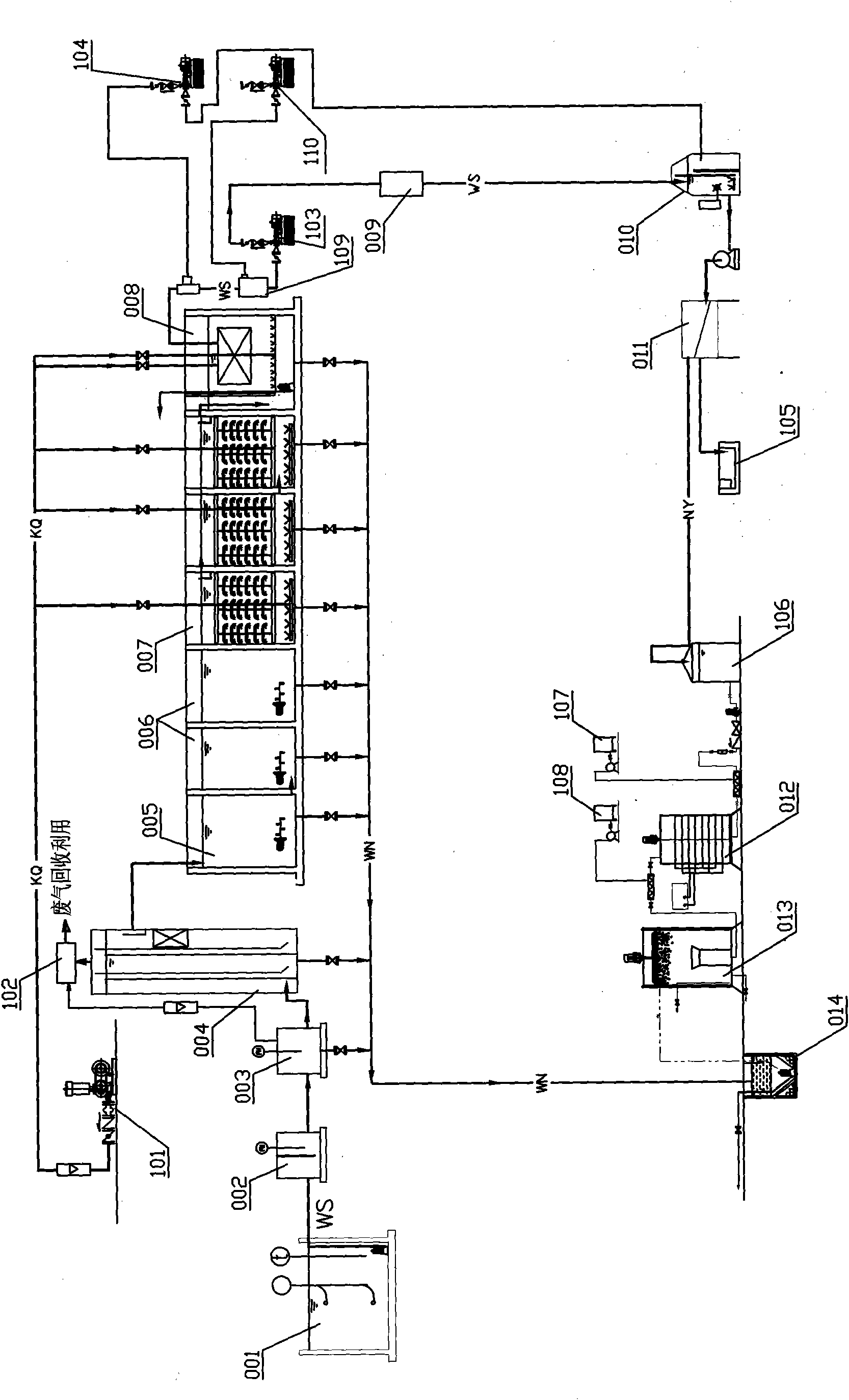

Ultrasonic combined waste water treatment process and system of refuse leachate

InactiveCN102139990ASimple processCompact structureWater/sewage treatment with mechanical oscillationsMultistage water/sewage treatmentEmission standardCatalytic oxidation

The invention relates to an ultrasonic combined waste water treatment process of refuse leachate, relating to the technical field of waste water treatment and recycling of resources and environmental protection. The ultrasonic combined waste water treatment process of the refuse leachate comprises the following steps of: enabling waste water to enter a regulating pond; treating colloids, amphoteric substances and heavy metals in a coagulation sedimentation pond; eliminating ammonia nitrogen in an ultrasonic catalytic oxidation pond; sequentially sedimentating through biological treatment in an ABR (Acrylate Butadience Rubber) baffle plate anaerobic pond, a hydrolytic pond, a facultative pond and an aerobic pond; filtering in a CMBR (Chatter Membrane Bioreactor); eliminating waste gases and stench in a carbon filter pond; disinfecting in a contact disinfection pond; and filtering in an RO (Reverse Osmosis) membrane reverse osmosis system so as to obtain water meeting the requirements for emission standards. The invention also provides a treatment system for the ultrasonic combined waste water treatment process. The ultrasonic combined waste water treatment process and system can obtain the outflow water with stable quality by treating the refuse leachate; the treatment system has the advantages of small size and occupying area, high efficiency, low energy consumption and easy realization for mechanical-electrical integration control and management; and in addition, the invention is beneficial to the protection of the original landscapes of a construction party by adopting a non-buried type structure and also reduces the influence of the operation of the treatment system on an office area.

Owner:深圳市万山红环保实业有限公司

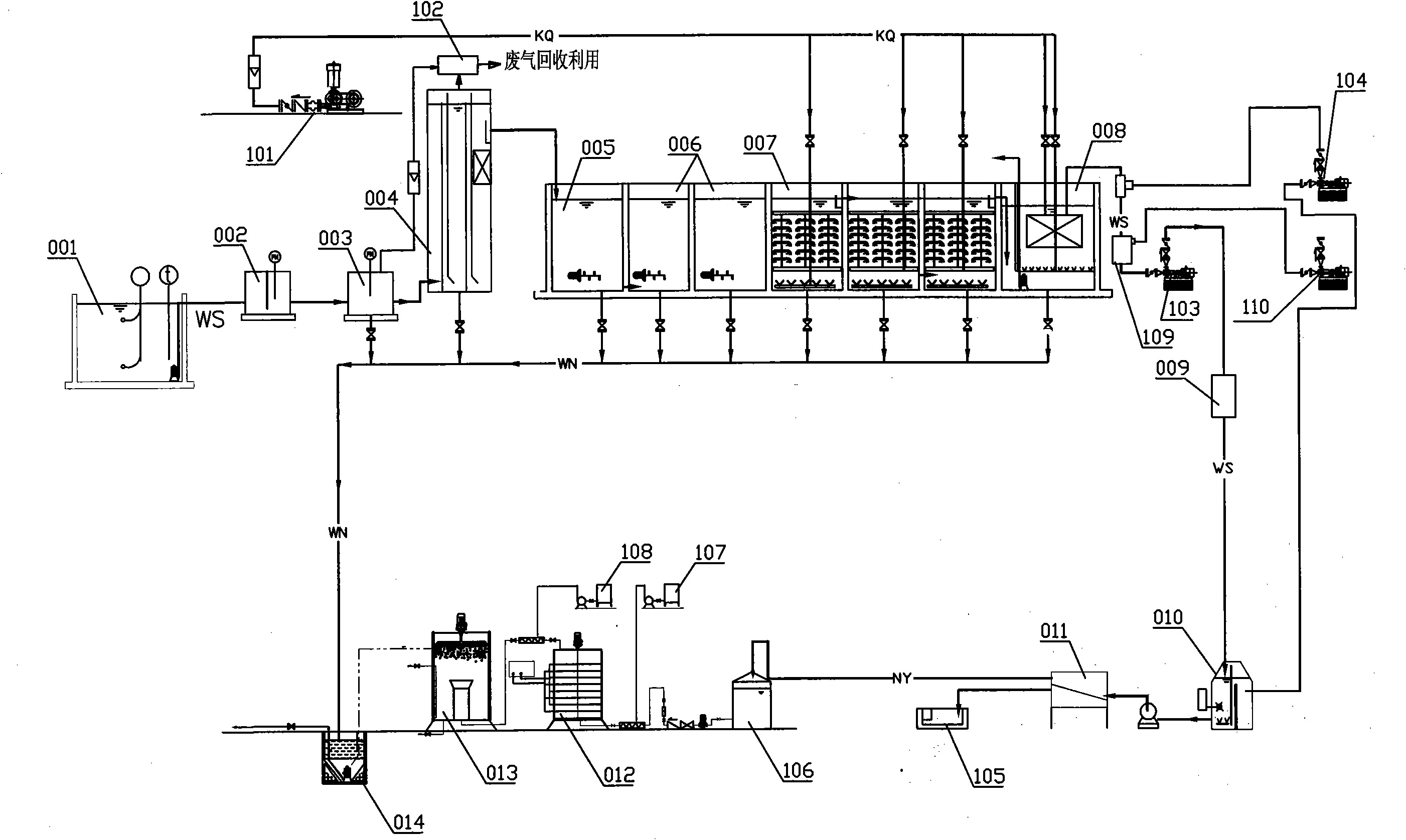

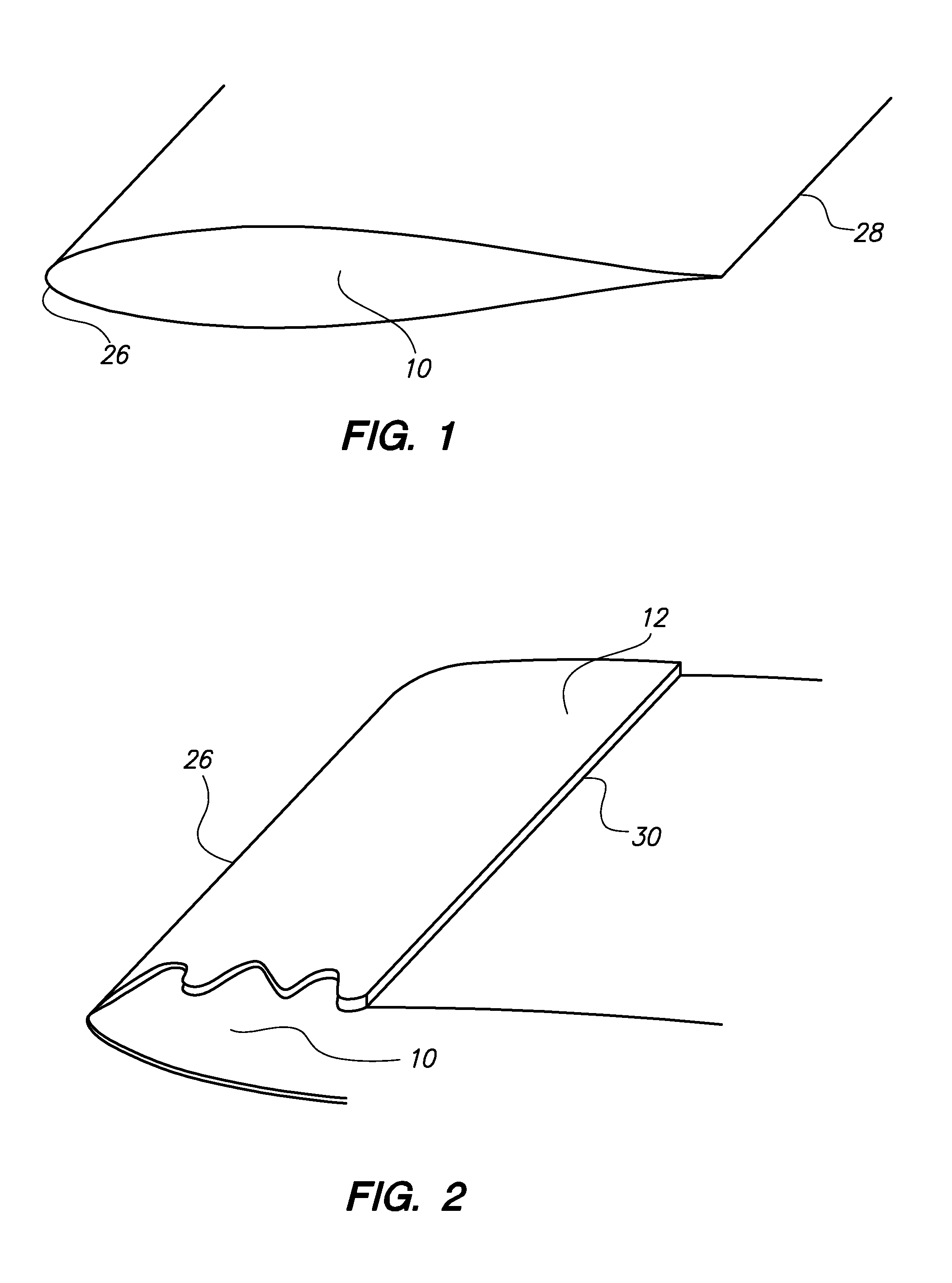

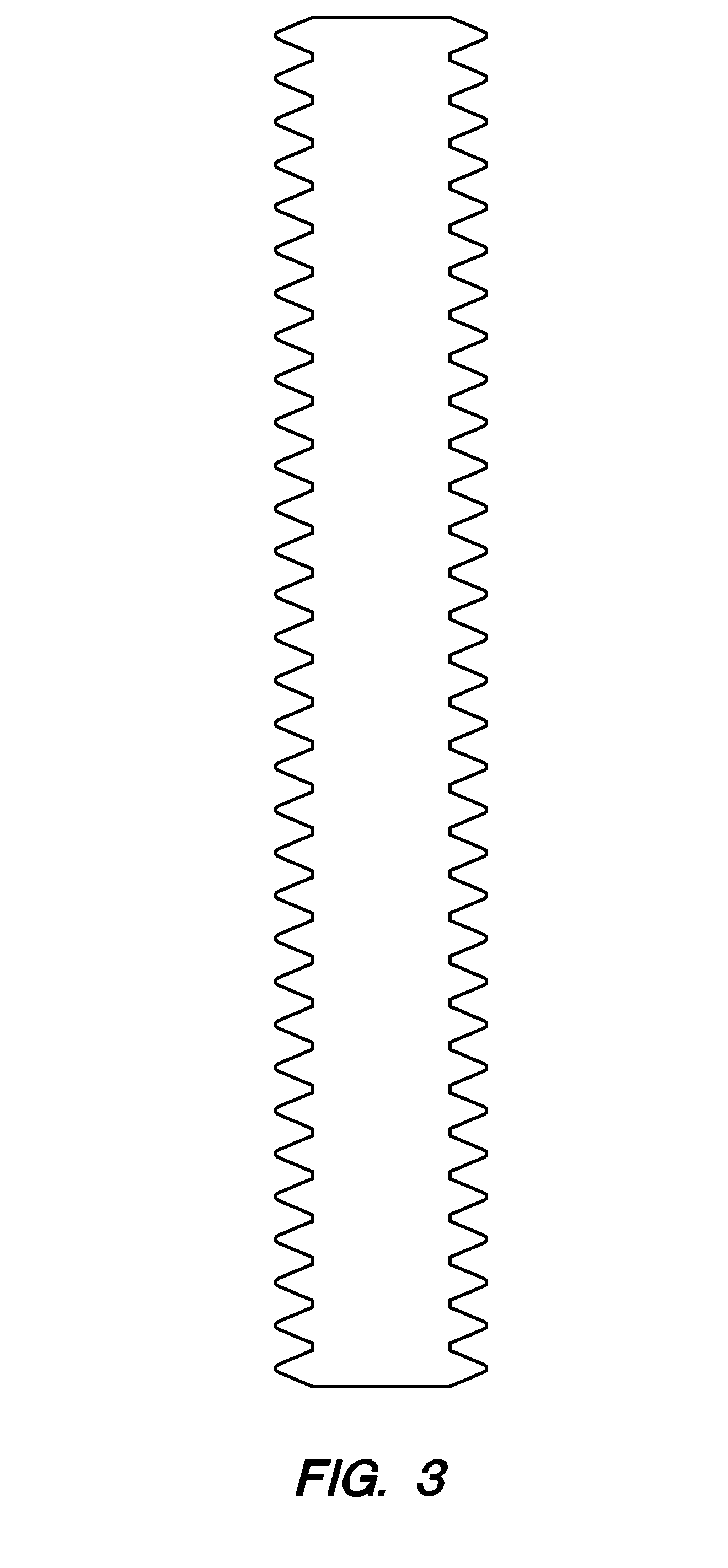

Application of conformal sub boundary layer vortex generators to a foil or aero/ hydrodynamic surface

InactiveUS20110006165A1Easy to liftImproving drag ratioInfluencers by generating vorticesWingsStream flowEngineering

A method of improving aerodynamic performance of foils by the application of conformal, low drag vortex generators. A film of erosion protection material or other conformal material is placed on the foil to provide a medium for the incorporation of planform edge vortex generators. The form edge is shaped to achieve submerged vortex generating shapes of chevron or ogival planforms, extending primarily chordwise on the foil surface. The vortex generators promote improved boundary layer dynamics by mixing free stream flow into the boundary layer while minimising separation and fluid losses. At the trailing edge, the shape formed with the chevrons applied apex forward, acts as a vented gurney tab series and additionally as disruptors to the Von Karman Street wake, delaying sheet rollup into the tip vortice.

Owner:IRELAND PETER

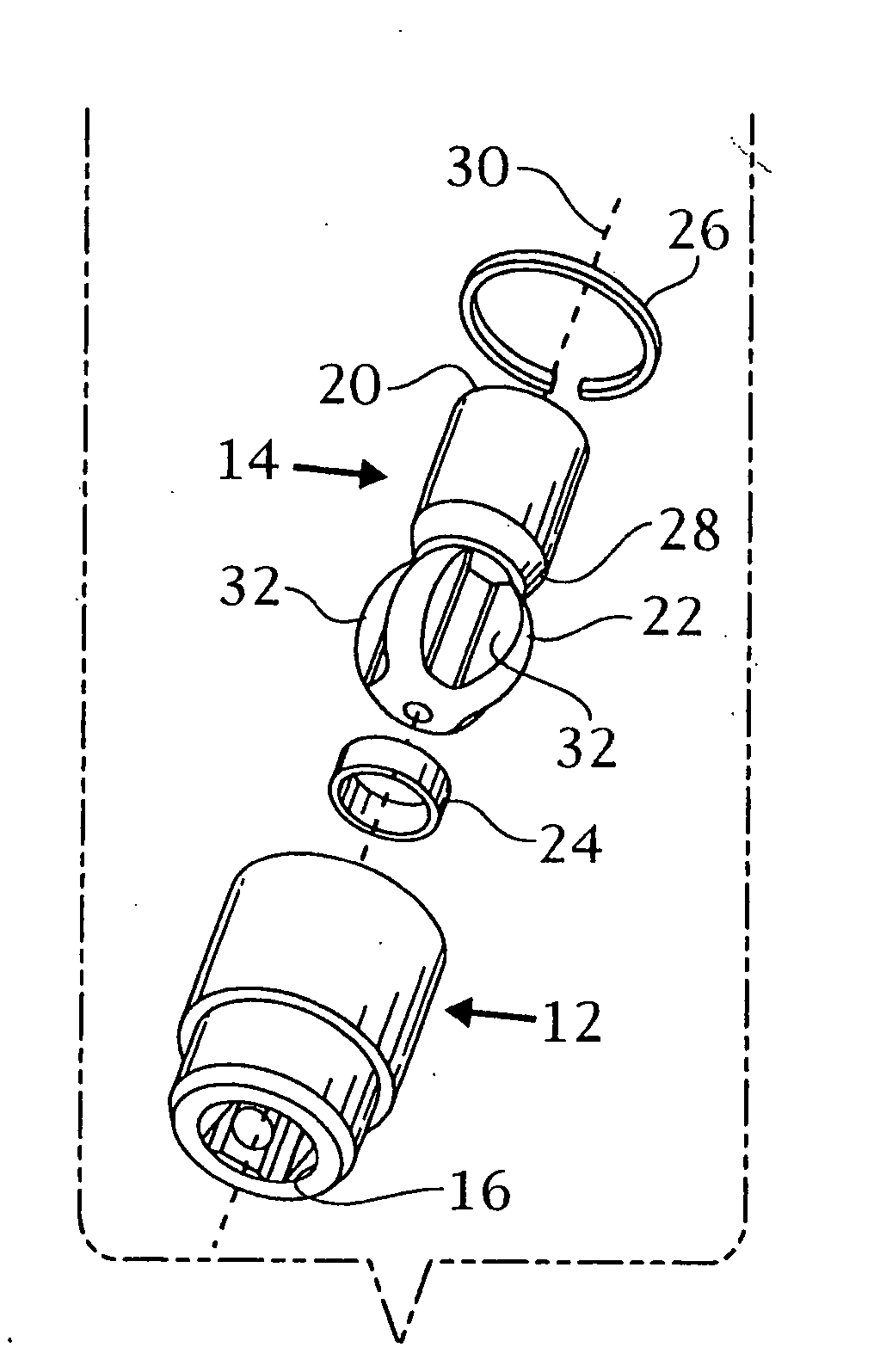

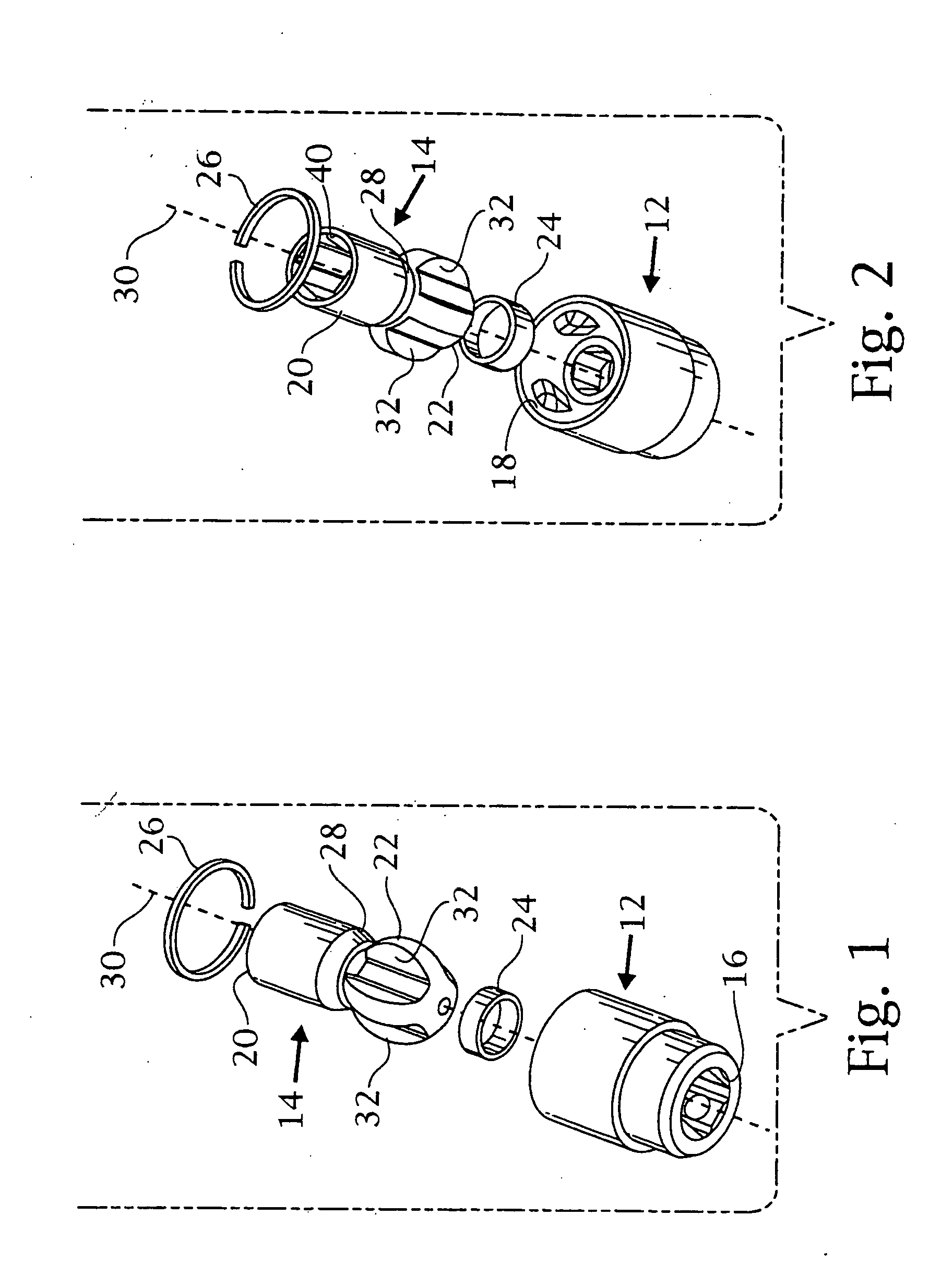

Universal joint

InactiveUS20050143179A1Increase in sizeIncreased shear strengthYielding couplingSpannersUniversal jointEngineering

Owner:APEX BRANDS

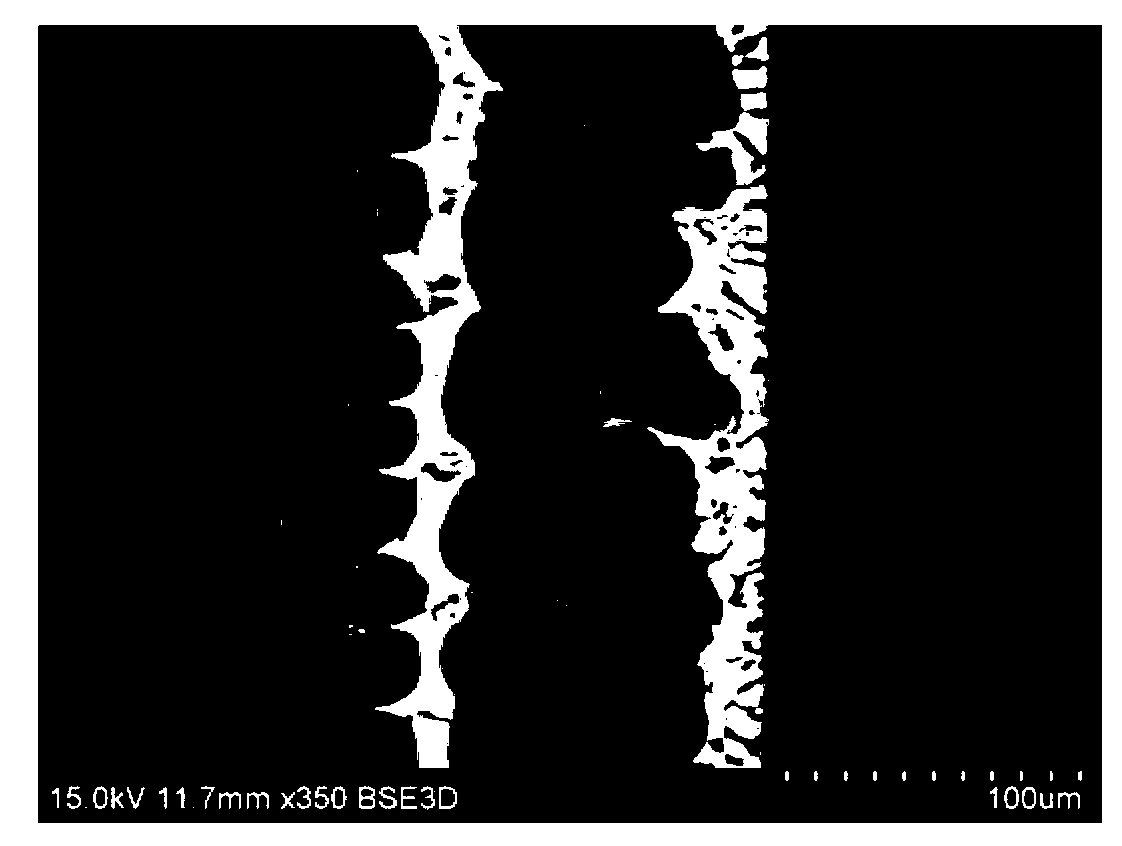

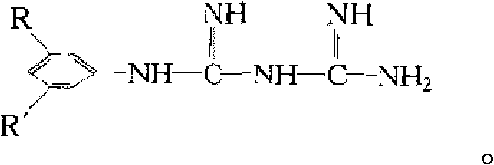

Flexible composite middle layer brazing alloy and method of utilizing brazing ceramic and metal

InactiveCN102699558AEnables direct brazingIncreased shear strengthWelding/cutting media/materialsSoldering mediaHeating furnaceUltimate tensile strength

The invention discloses flexible composite middle layer brazing alloy and a method of utilizing brazing ceramic and metal, and relates to the composite brazing alloy and the method of utilizing the brazing ceramic and metal. The flexible composite middle layer brazing alloy and the method aim at solving the problems that the conventional method is high in cost and the forming of brittle compound of a joint can not be restrained. The flexible composite middle layer brazing alloy is prepared from upper layer brazing alloy, a flexible middle layer and lower layer brazing alloy. The brazing method comprises the steps of: cleaning greasy dirt and impurity on a pre-welding surface; processing the upper-layer brazing alloy, the flexible middle layer and the lower-layer brazing alloy into small sheets; and ultrasonically cleaning and airing ceramic to be welded, metal to be welded, the upper layer brazing alloy, the flexible middle layer and the lower layer brazing alloy by acetone, assembling a workpiece to be welded, and putting the workpiece to be welded into a vacuum heating furnace to braze. According to the method disclosed by the invention, the operation is simple; the residual stress of the joint is released by adding the flexible middle layer; and the forming of the brittle compound of the joint is restrained, and the shearing strength of the joint is improved by 30-109%. The method disclosed by the invention is used for brazing the ceramic and the metal.

Owner:HARBIN INST OF TECH

Room-temperature curing epoxy structural adhesive composition and preparation method thereof

InactiveCN101818037AIncreased shear strengthHigh T-peel strengthEpoxy resin adhesivesNitrile rubberAdhesive

The invention relates to a room-temperature curing epoxy structural adhesive composition, which comprises a component A and a component B, wherein the component A comprises bisphenol A epoxy resin, toughness modified bisphenol A epoxy resin, silane coupling agent, thixotropic agent and colorant; and the component B comprises polyamide, polyether amine, a filler and a curing accelerator; the toughness modified bisphenol A epoxy resin is liquid nitrile rubber-modified bisphenol A epoxy resin and / or polymer-toughened bisphenol A epoxy resin with a nuclear shell structure; meanwhile, the invention also provides a method for preparing the room-temperature curing epoxy structural adhesive compositiion. The structural adhesive of the invention has the advantages of good toughness, strong high-temperature strength, short curing time, simple preparation method, and the like.

Owner:HENKELCHINAINVESTMENT

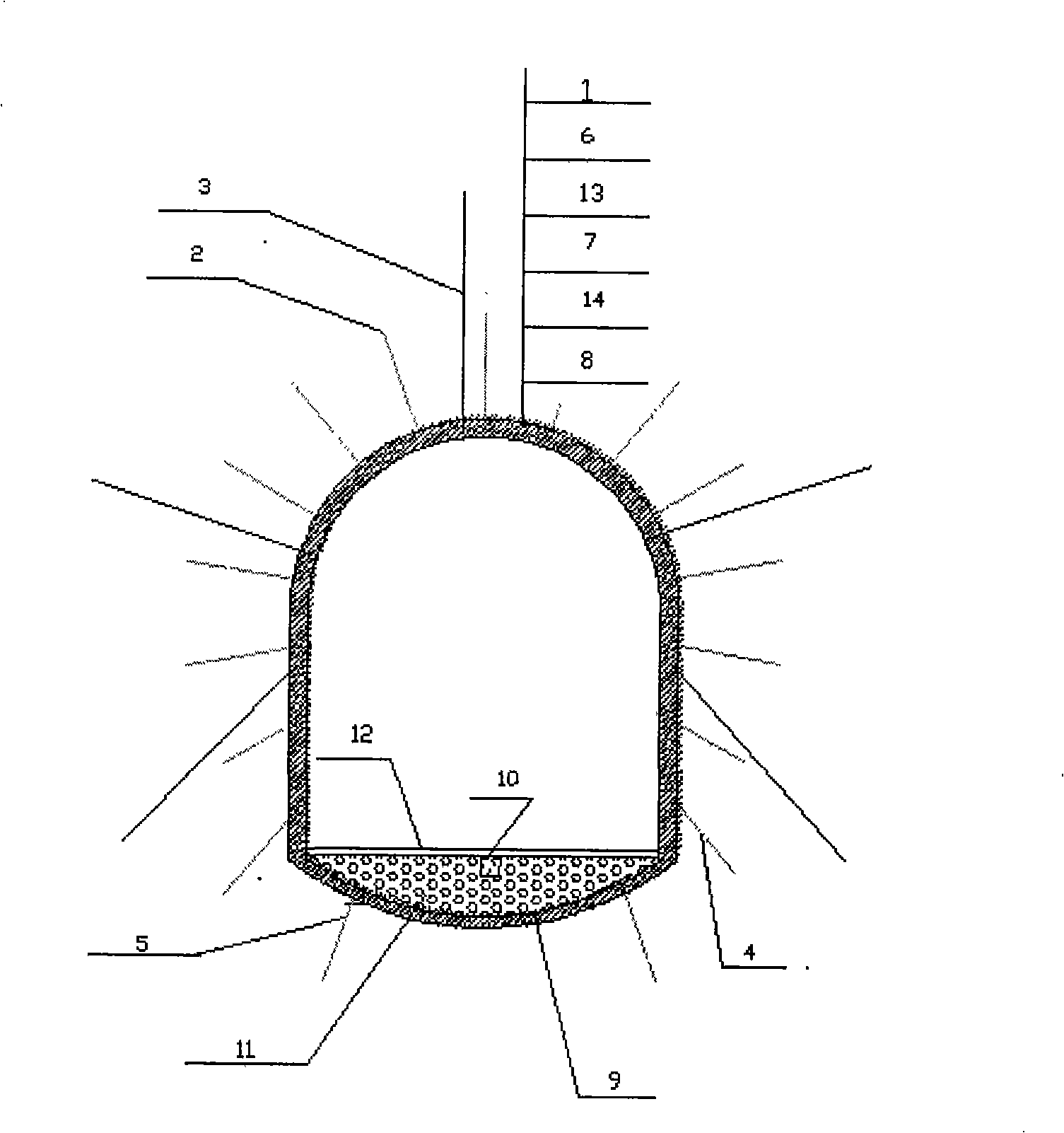

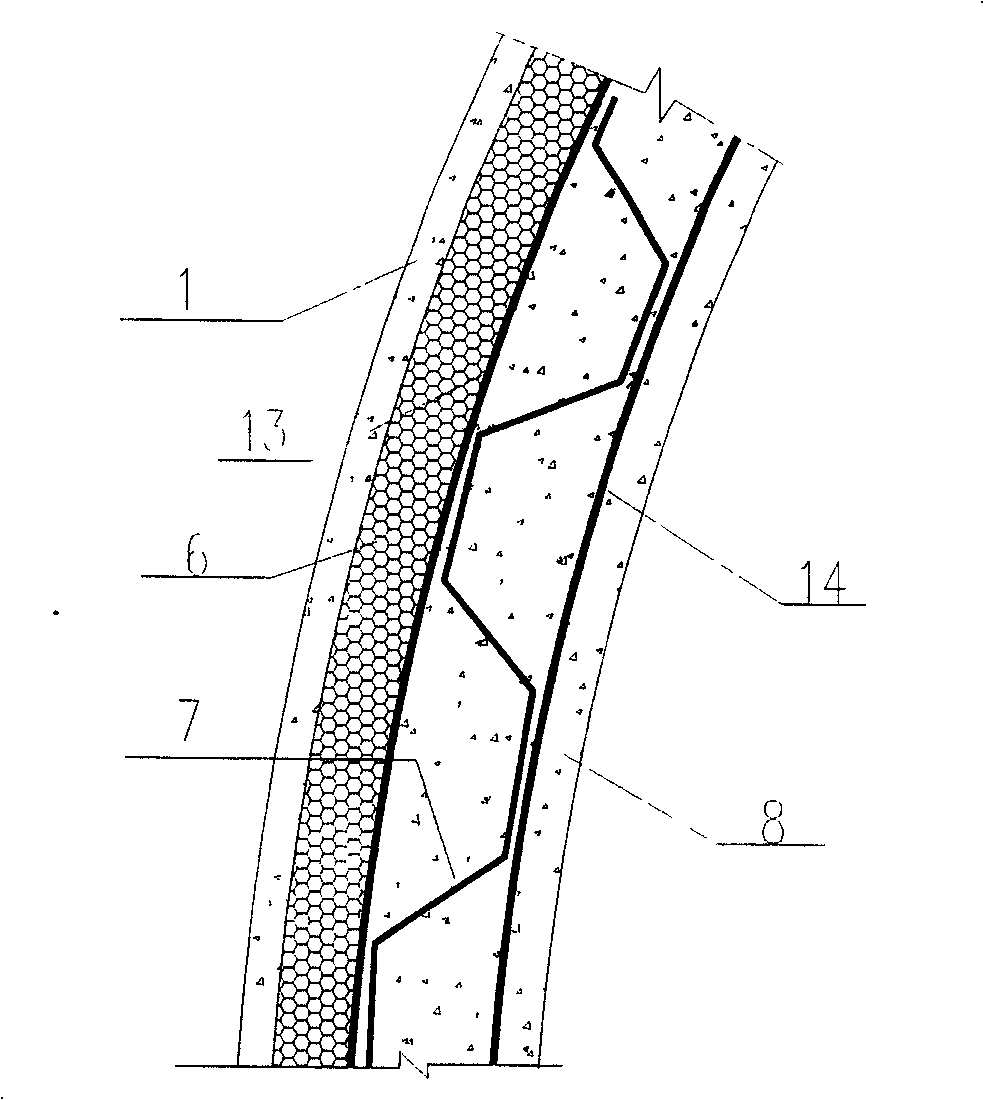

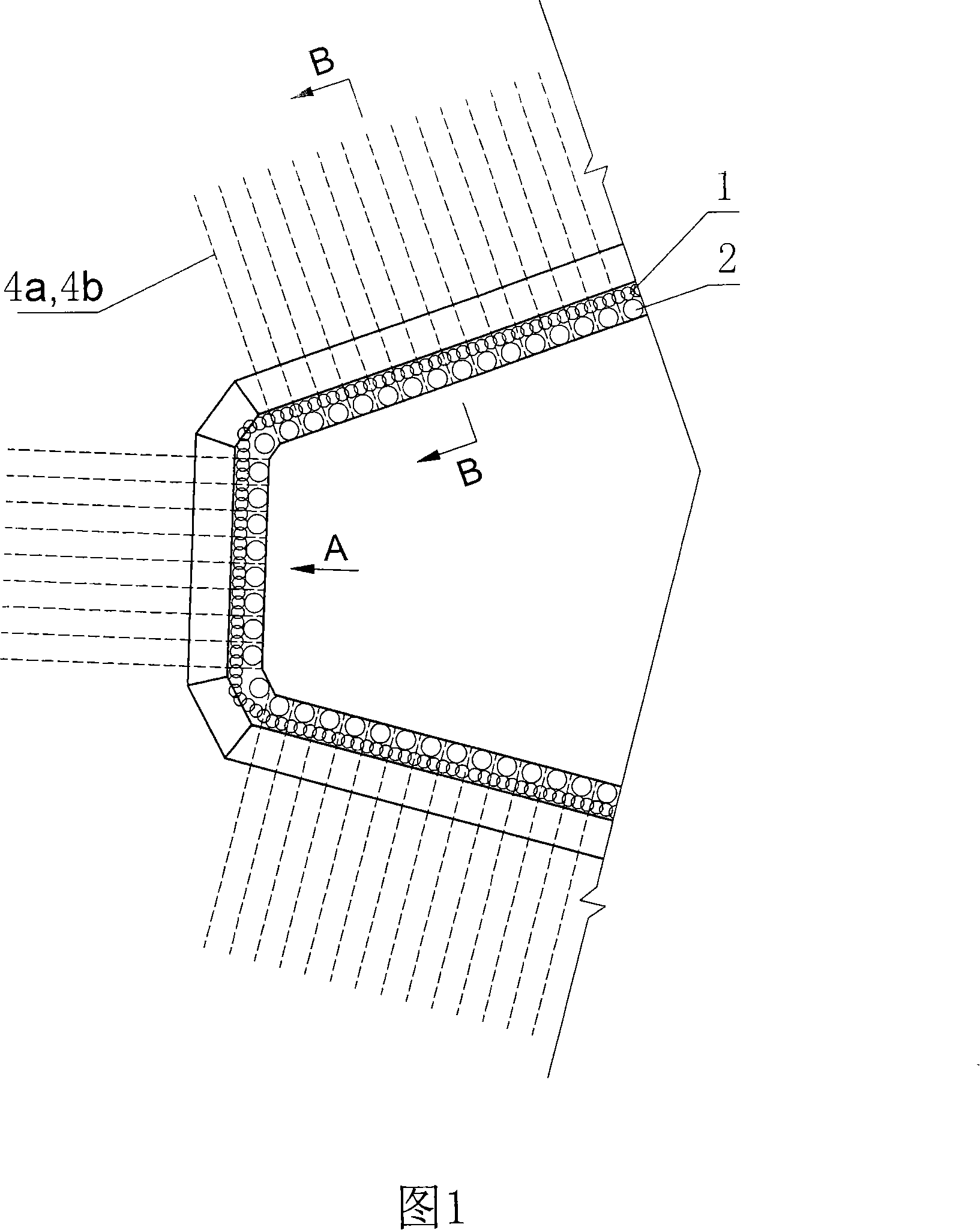

Soft expansion type wall rock tunnel support method

InactiveCN101493011AIncreased shear strengthImprove stabilityUnderground chambersTunnel liningCushionLower intensity

The invention discloses a support method of a weak expansion type surrounding rock laneway, comrprising the following steps: A. the laneway is excavated according to the sectional form, an arc pit is excavated on a bottom board of the laneway, and full face injection of a thick concrete leveling course is carried out; B. high-strength prestressed anchor and prestressed anchor cable are used for supporting the surrounding rock, an anchor rod and an anchor cable are constructed, a high-strength prestressed anchor rod uses a laevo rod body without longitudinal bar and is arranged in plum blossom shape; C. a foam cushion is laid, and the full face of the laneway is tightly stuck and paved with an initial ejection leveling course, and a gap is added and preserved in case of laneway deformation; D. a first layer of reinforcement mat is hung and tightly stuck to the foam cushion, a full face sealed type steel bar grid arching is constructed, the main bar inside the grid is bonded with the first layer of reinforcement mat, and the second layer of reinforcement mat is hung on the sealed type steel bar grid arching; E. the bottom board is constructed, a cast-in-place concrete gutter is constructed at the center part of a positive arching, and rubbles are paved at the both sides of the gutter. The method solves the problems of low intensity of surrounding rock laneway, water expansion and floor heave, thereby avoiding reclamation work of the laneway and having low cost.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

Preparation method of stainless steel-carbon steel composite board

ActiveCN102069289ASolve oxidationImprove service life and application rangeElectron beam welding apparatusWelding/soldering/cutting articlesCarbon steelFlat panel

The invention relates to a preparation method of a stainless steel-carbon steel composite board, which belongs to the technical field of material and comprises the following steps: (1) removing and cleaning rusted layers and oxidative layers of stainless steel board material and carbon steel board material; (2) alternately stacking the stainless steel board material and the carbon steel board material; (3) arranging a composite blank between two metal panels to constitute a clamped composite blank, or welding two composite blanks together by electric welding to constitute a combined structure of the composite blank, a blocker and the composite blank, and arranging the combined structure between two metal panels to constitute a clamped composite blank; (4) welding the peripheries of contact surfaces of two adjacent steel boards under a vacuum condition; (5) arranging the composite board in a resistor furnace for heating and heat preservation; and (6) rolling the composite board by a rolling mill. The method disclosed by the invention prolongs the service life and enlarges the application scope of the stainless steel-carbon steel composite board. Compared with an explosive compounding method, the method causes small environmental pollution, and has low requirements on the production environment, in addition, the shape of the board is flat, and the product yield is high.

Owner:沈阳科安捷材料技术有限公司

Supporting material for medical purposes

InactiveUS6555730B1High elastic modulusHigh strengthWeft knittingSynthetic resin layered productsEngineeringMedical treatment

The invention relates to the use of a non-woven fabric which is over-stitched by means of stitching threads as a supporting material for medical purposes. The invention is characterized in that the maximum tensile force of supporting material is equal to at least 30 N / cm and at least one side of the supporting material is partially or completely coated with a self-adhesive mass.

Owner:BEIERSDORF AG

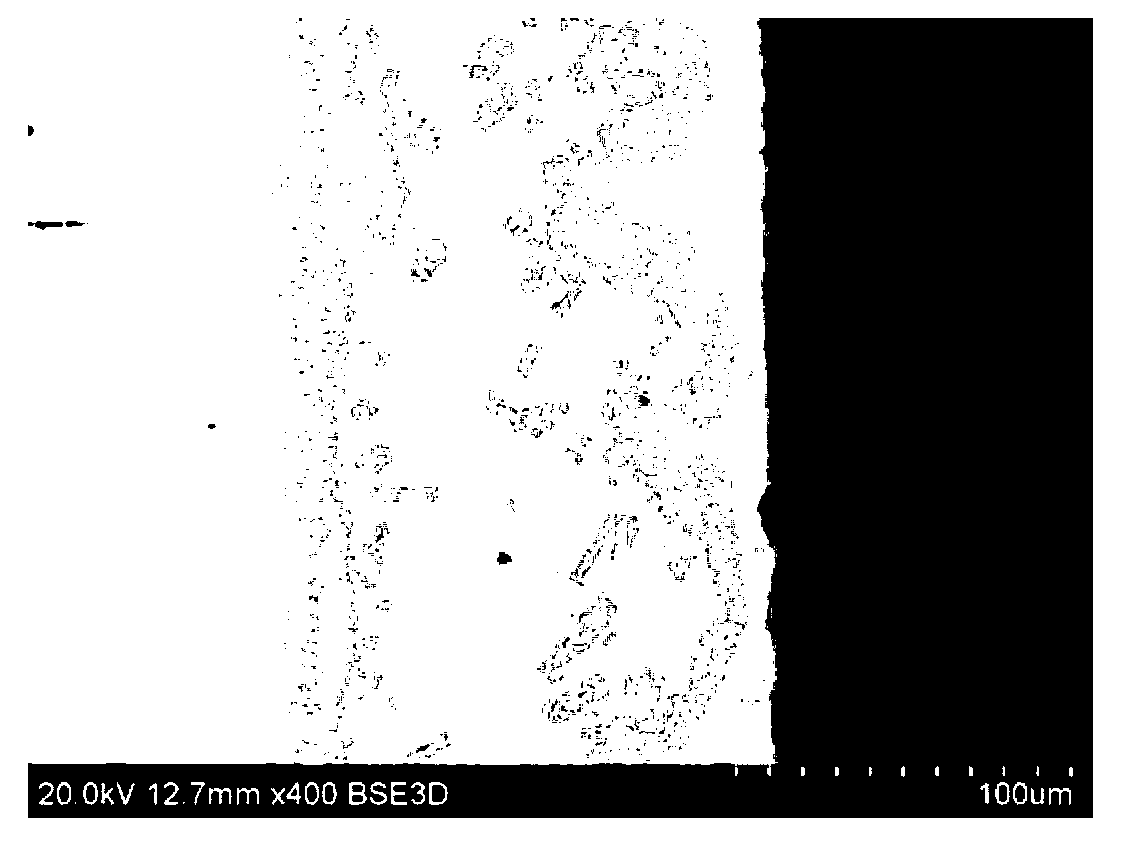

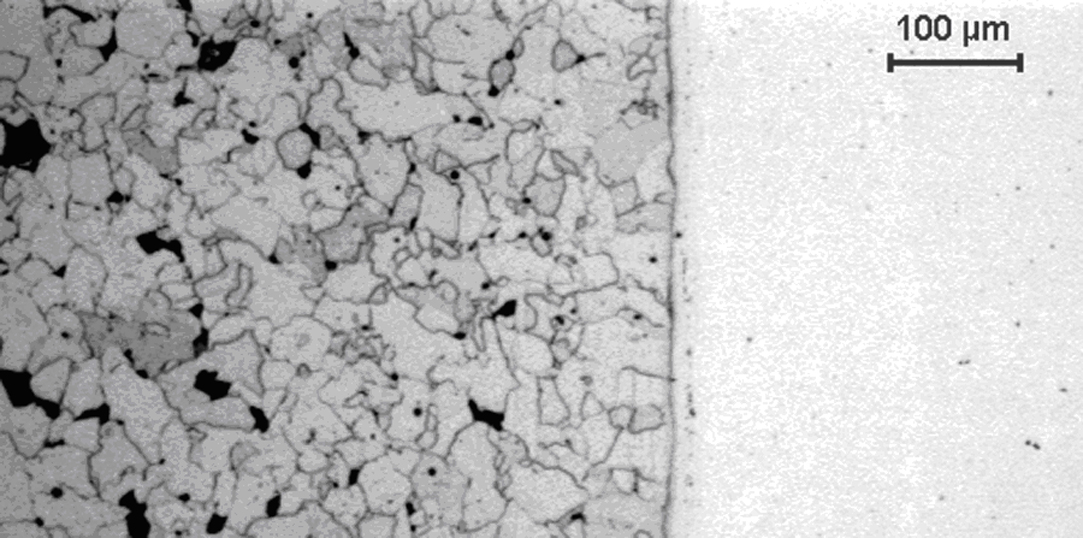

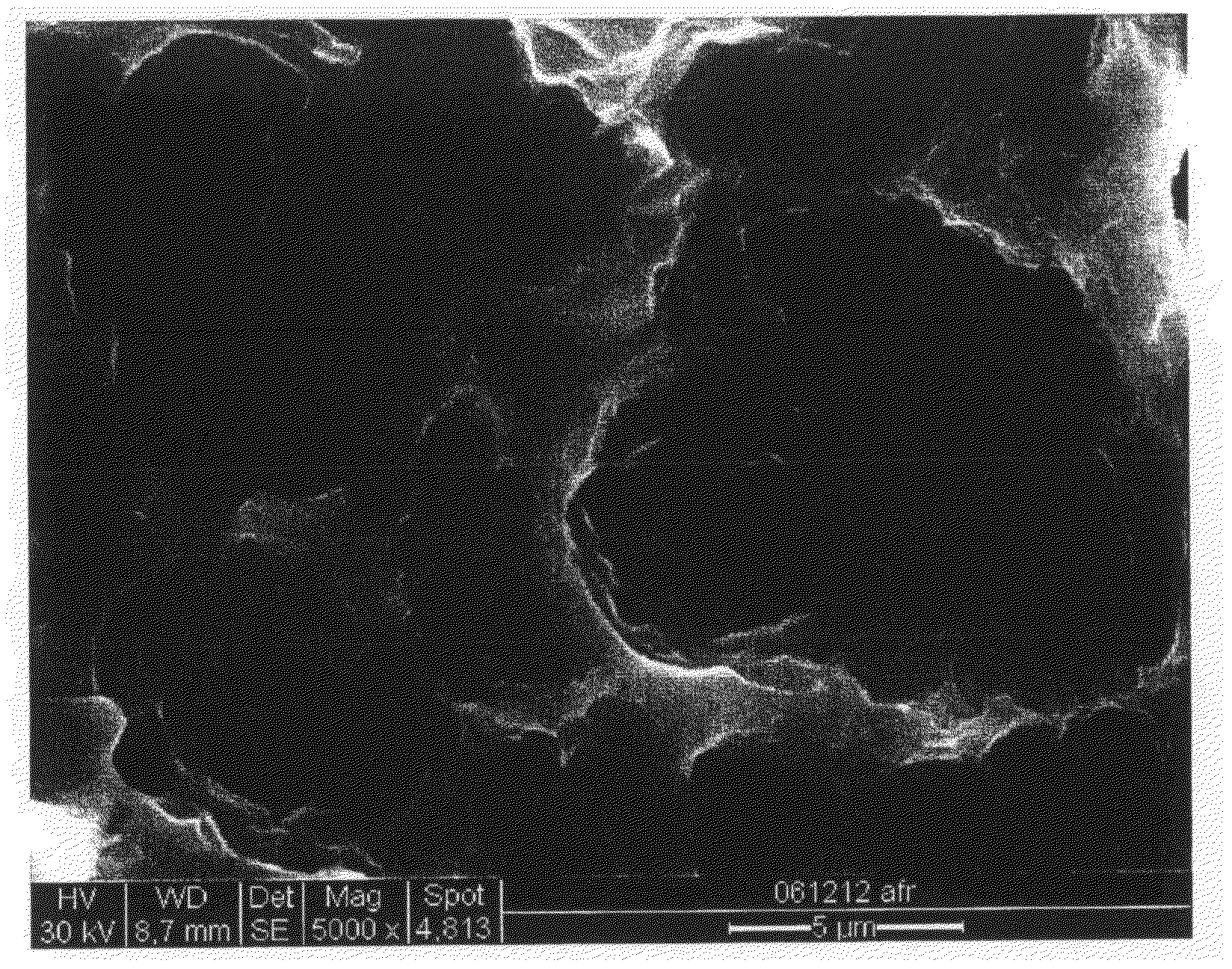

Nanosurface

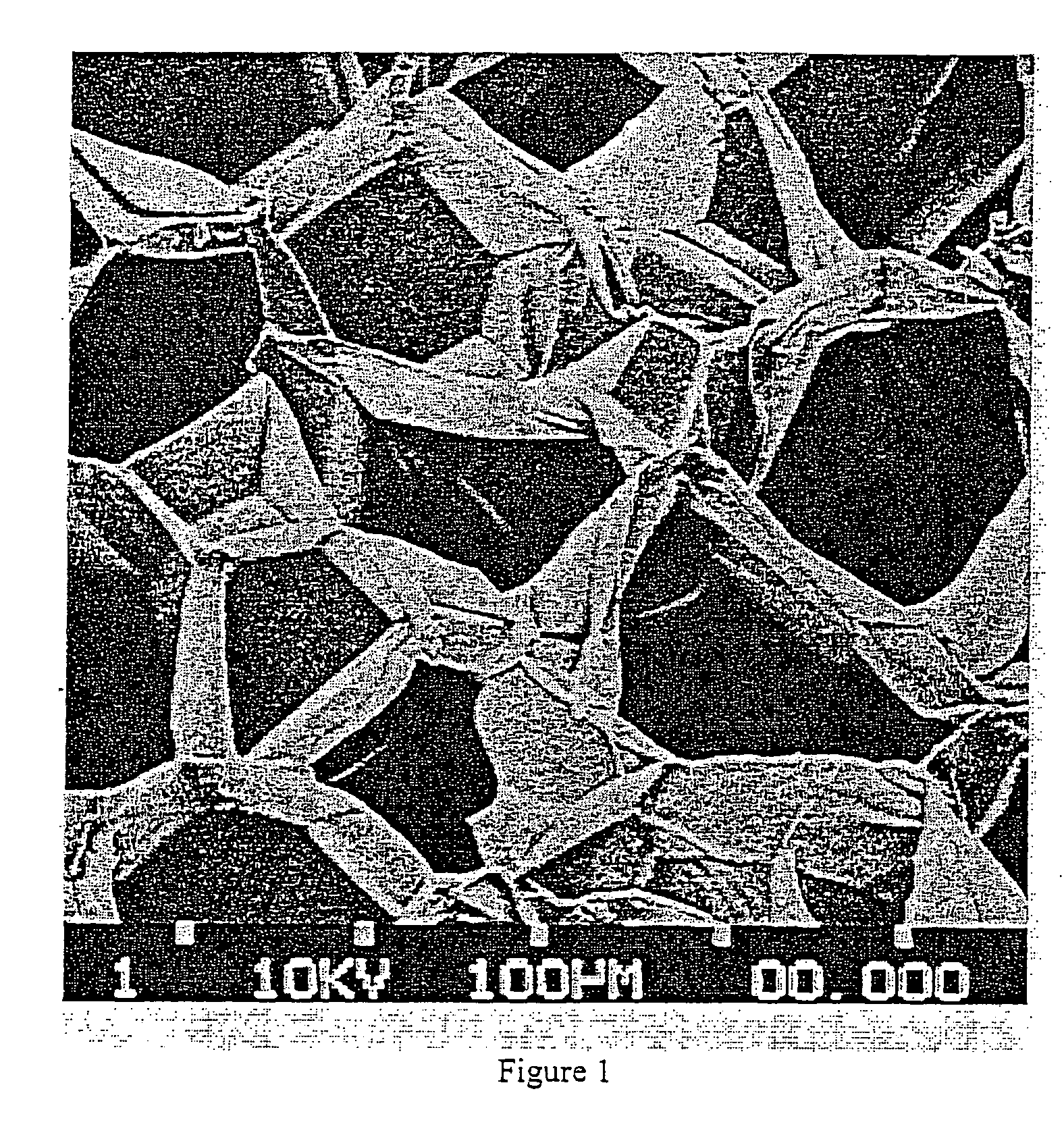

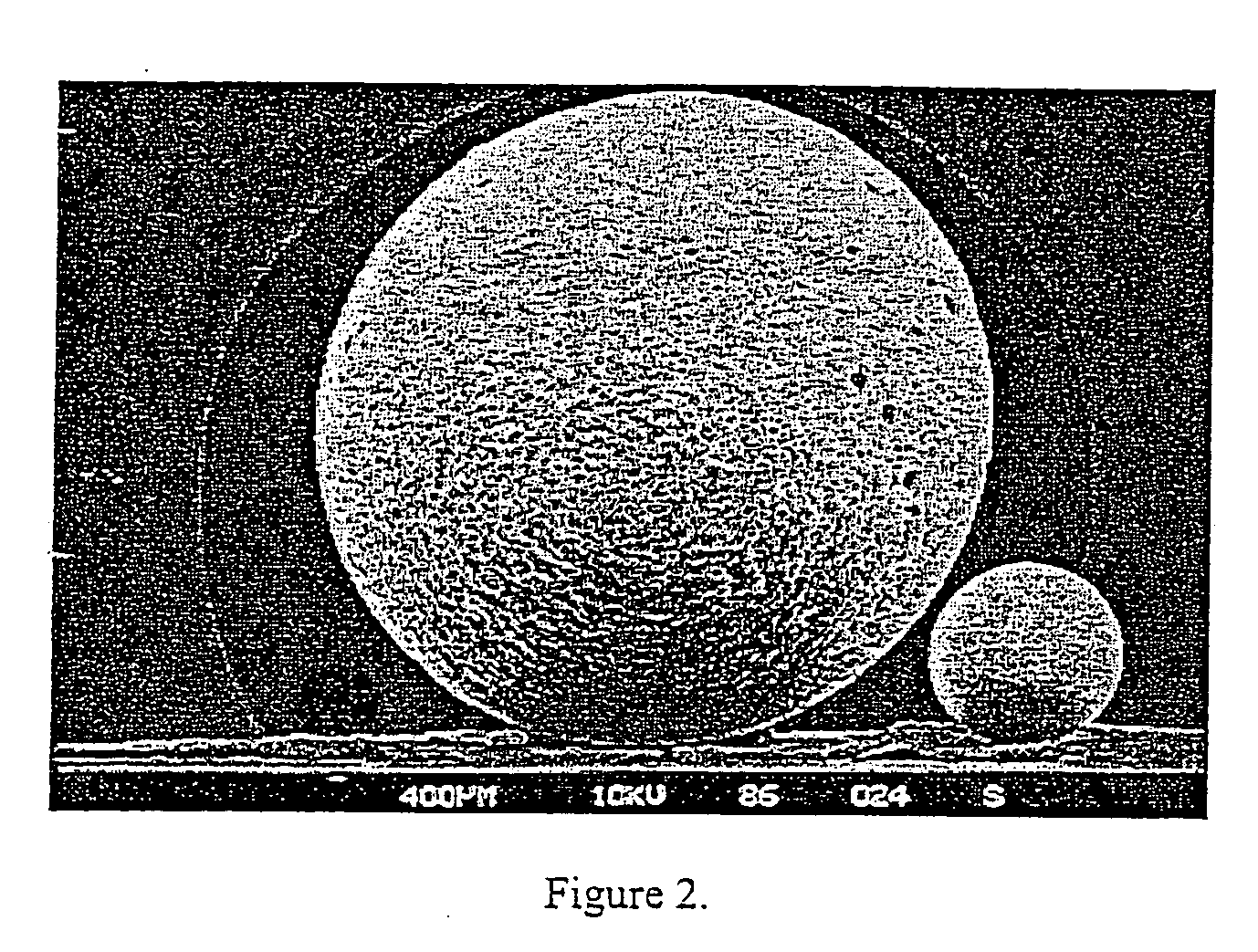

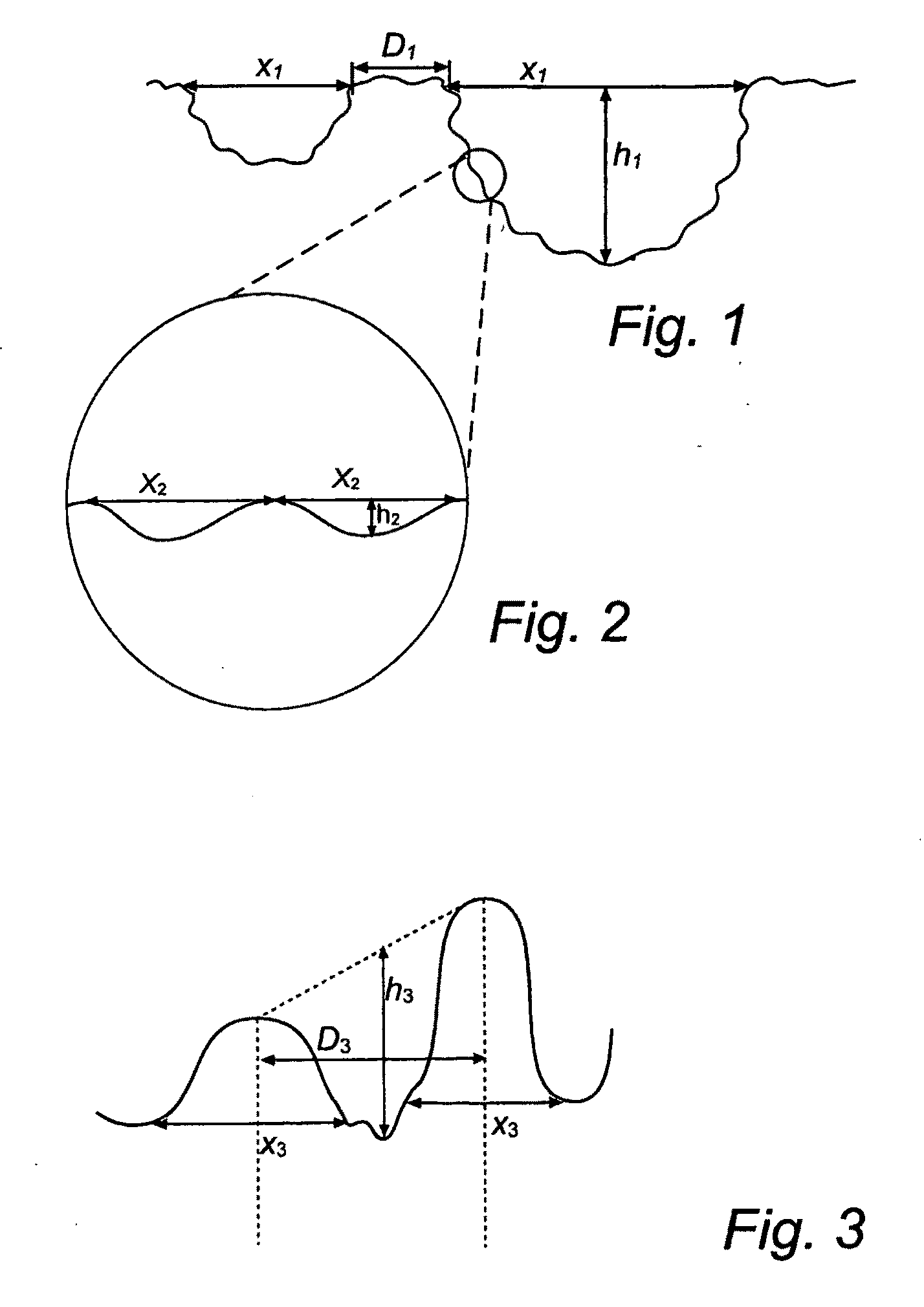

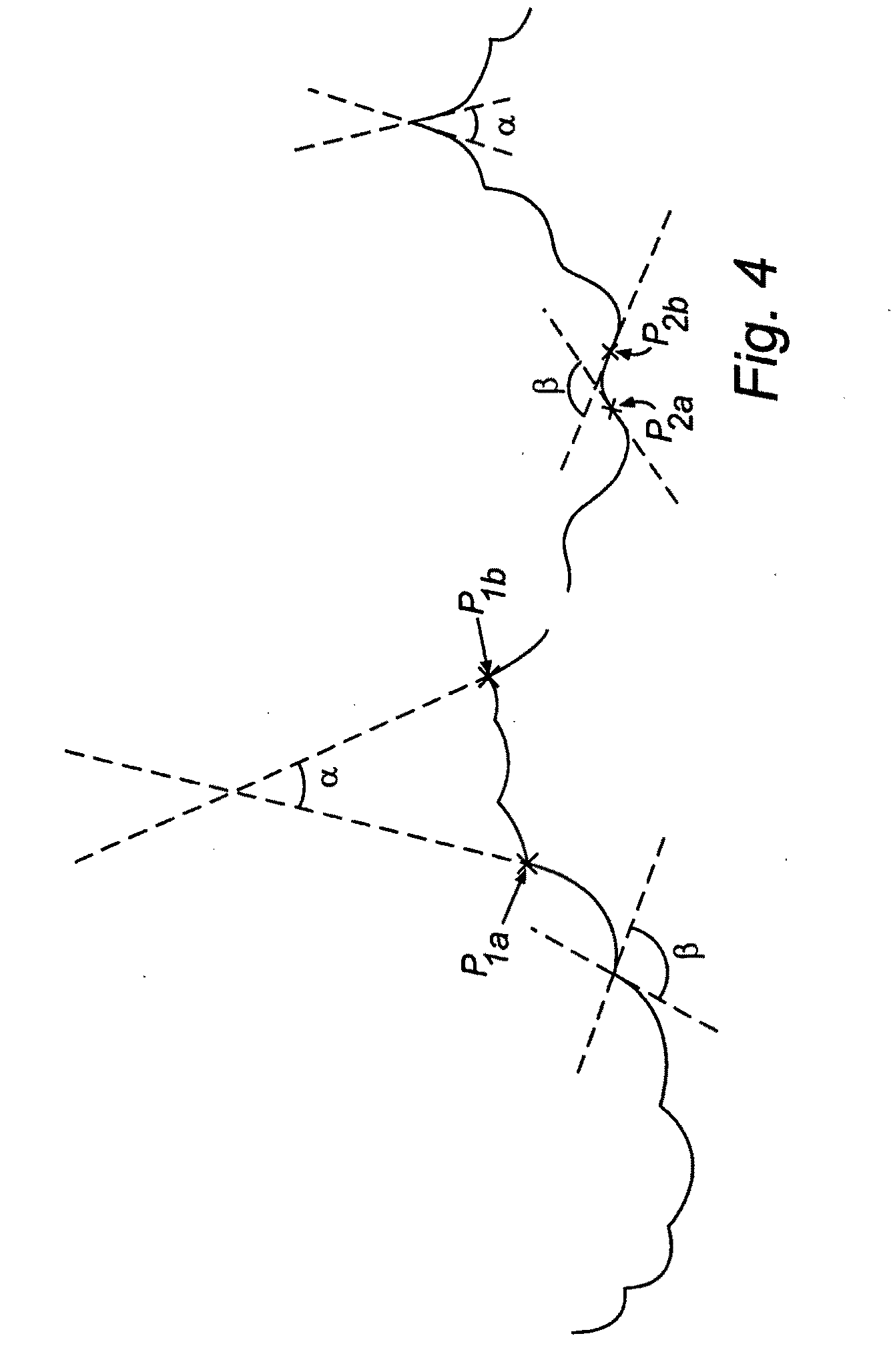

ActiveUS20100173264A1Reduced strengthReduce the amount requiredMaterial nanotechnologyDental implantsNanostructureOxalic acid

The invention relates to a method for modification of a biocompatible component comprising the steps of a) providing a biocompatible component at least partly covered by metallic oxide; and b) treating at least a part of said component, which part is covered by said metallic oxide, with an aqueous composition comprising oxalic acid; whereby a modified metallic oxide is obtained. The invention also relates to a biocompatible component comprising a substrate having a surface comprising a) a microstructure comprising pits separated by plateus and / or ridges; and b) a primary nanostructure being superimposed on said microstructure, said primary nanostructure comprising depressions arranged in a wave-like formation.

Owner:ASTRA TECH SE

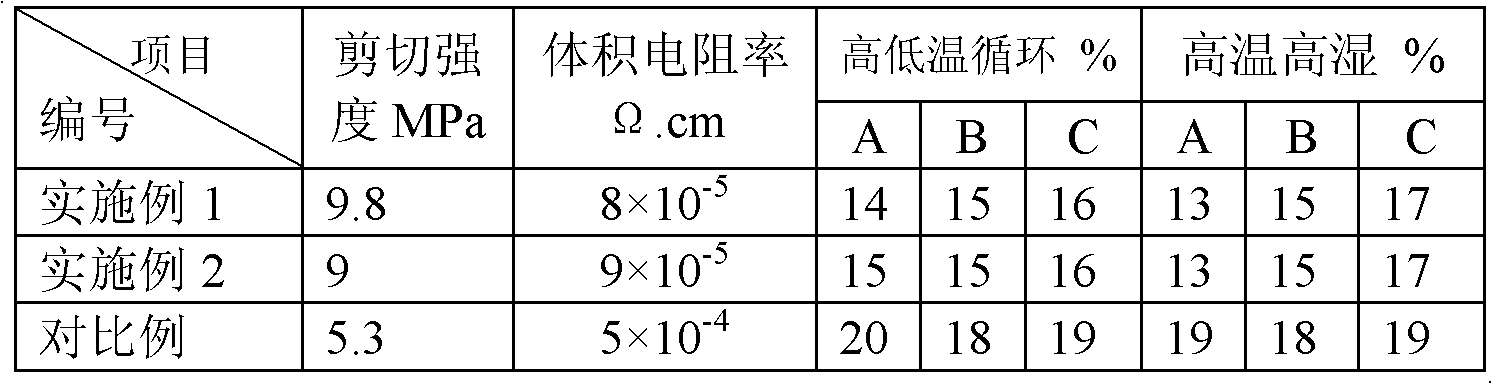

Conductive silver paste for microelectronic packaging and preparation method thereof

InactiveCN102086364AIncrease contactReduce bulk resistivityNon-macromolecular adhesive additivesSemiconductor/solid-state device detailsEpoxySilver paste

The invention discloses a conductive silver paste for microelectronic packaging, which contains the following components in parts by mass: 10-12 parts of liquid epoxy resins, 9-10 parts of diluents, 10-13 parts of spherical silver powder, 50-57 parts of platy silver powder, 0.5-1.5 parts of latent curing agents, 0.2-0.8 part of curing promoter, 1-2 parts of coupling agents, 0.5-1 part of conductive promoters, 0.5-1 part of aging resister and 1.5-2.3 parts of toughening agents. The body resistivity of the conductive silver paste prepared by the invention reaches 10-5 omega.cm, the shear strength is greater than 9MPa, and the conductive silver paste has stable contact resistance; and after low-temperature circulation, high-temperature humidity aging tests and other aging tests, the shear strength, the impact-resistant toughness and the contact resistance change are all less than 18%. The prepared conductive silver paste is suitable for microelectronic packaging and has the advantages of stable contact resistance and strong impact resistance.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

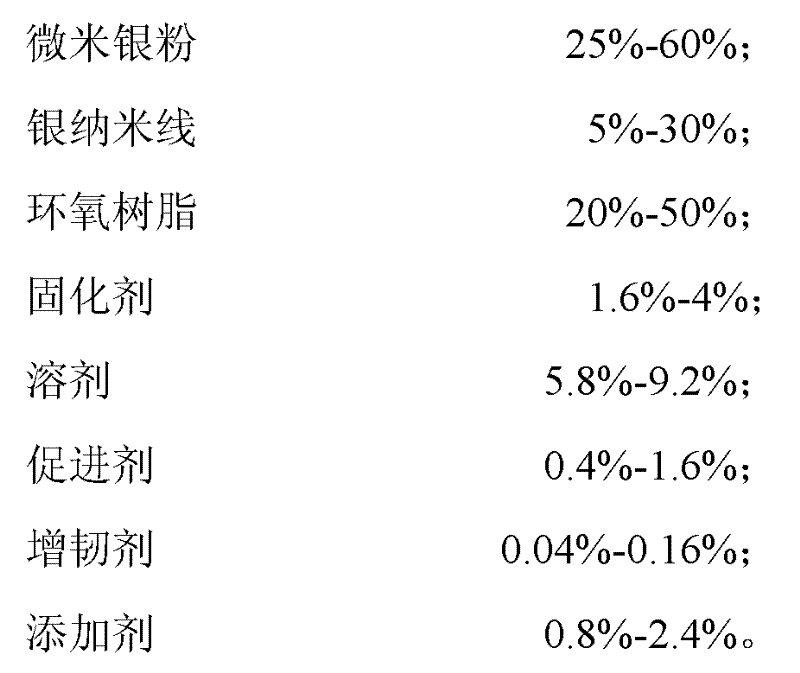

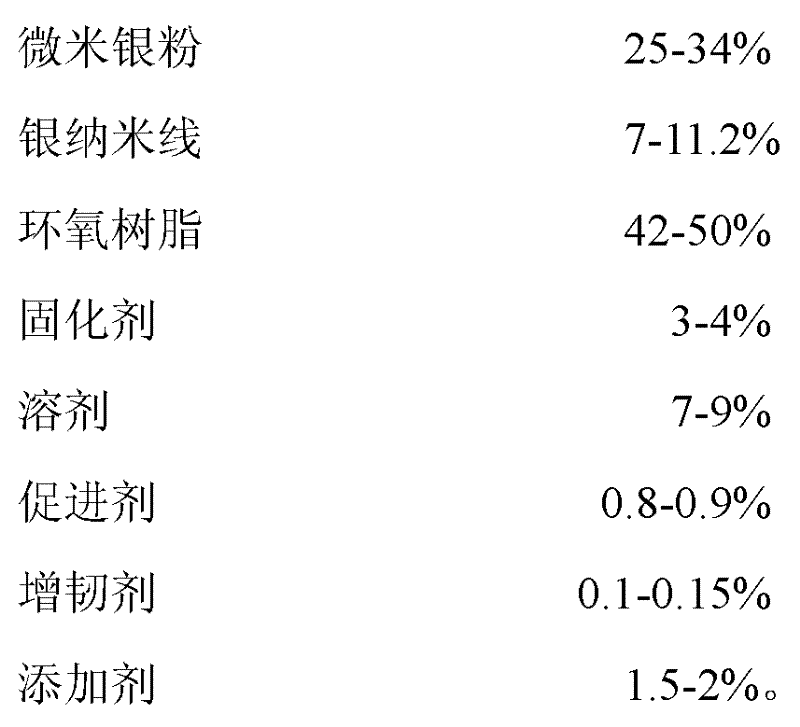

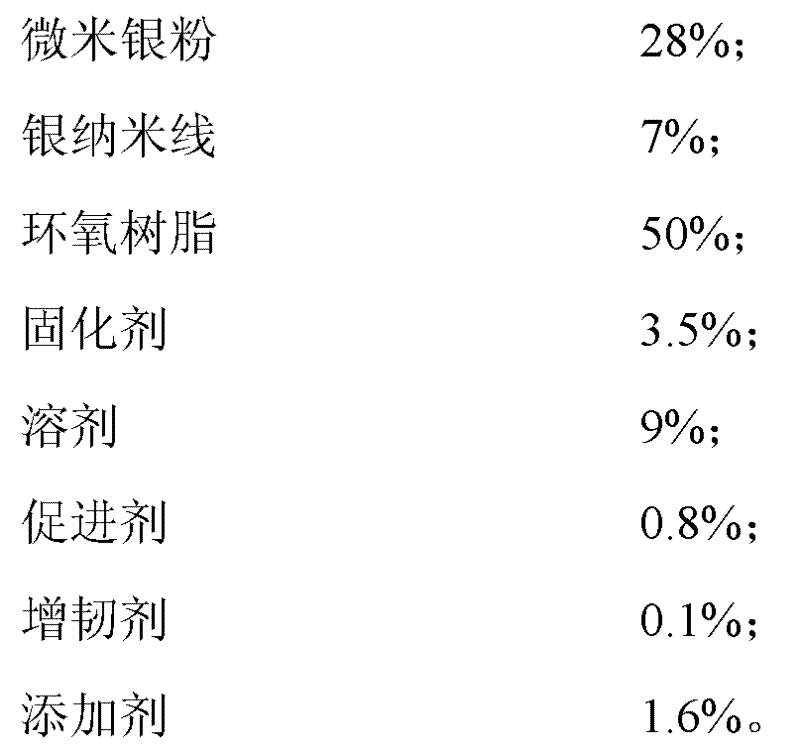

Silver nanowire doped conductive silver colloid and preparation method thereof

InactiveCN102676102AImprove electrical performanceReduce silver contentNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyWorking temperature

The invention relates to the field of semiconductor electronic materials, and in particular relates to a silver nanowire doped conductive silver colloid and a preparation method thereof. The raw materials of the silver nanowire doped conductive silver colloid provided by the invention comprise the following components in percentage by weight: 25-60% of micrometer silver powder, 5-30% of silver nanowires, 20-50% of epoxy resin, 1.6-4% of curing agent, 5.8-9.2% of dissolvent, 0.4-1.6% of accelerant, 0.04-0.16% of toughening agent and 0.8-2.4% of additive. The conductive silver colloid is prepared by mixing and doping single-crystal silver nanowires and silver granules, thus, the total silver doping amount is reduced to 35-45%, and the conductive silver colloid has a favorable conductive effect, high shear strength, low working temperature and good ageing-resistant performance, and the cost of the conductive silver colloid is reduced. The silver nanowire doped conductive silver colloid can be widely applied to the fields of solar cell (film, crystal silicon) conductive colloids, conductive colloid LED (Light-Emitting Diode) package and the like.

Owner:SHANGHAI FUXIN NEW ENERGY TECH

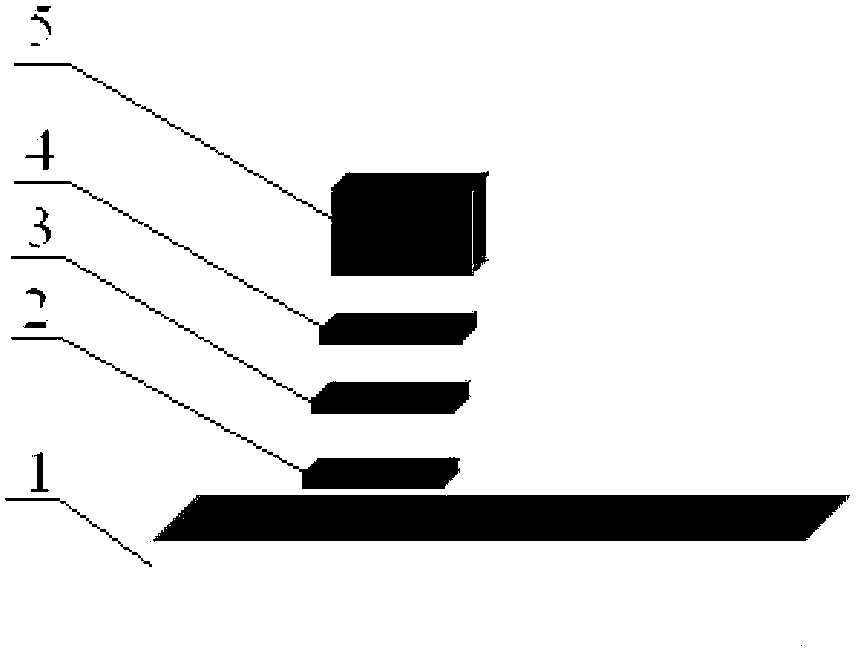

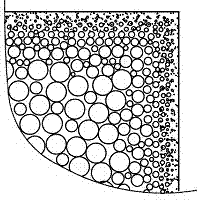

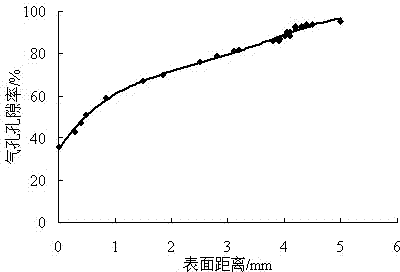

Functionally-graded cellular-concrete thermal-insulating material and preparation method thereof

ActiveCN102561532AOvercoming the Interface Breaking DilemmaImprove bending strengthHeat proofingCeramicwareFoam concreteThermal insulation

The invention relates to a functionally-graded cellular-concrete thermal-insulating material and a preparation method thereof. The functionally-graded cellular-concrete thermal-insulating material comprises a cellular-concrete thermal-insulating core, a plurality of air holes are uniformly distributed in the thermal-insulating material, and the surface of the cellular-concrete thermal-insulating core is wrapped with a functionally-graded layer; in the air holes of the functionally-graded cellular-concrete thermal-insulating material, the air hole in the cellular-concrete thermal-insulating core has a maximum diameter, then, the diameters and porosities of the air holes from the cellular-concrete thermal-insulating core to the outside are in a continuous graded change in a descending order, the thickness of the functionally-graded layer is 0.1-20 mm, the porosities of the air holes are in a continuous graded change in a range of 1- 95%, and the diameters of the air holes are in a continuous graded change in a range of 0.1-8 mm. According to the invention, the interior of the material is porous and thermal-insulating, and the surface of the material is high in density and strength, the mechanical strength of the material is gradually improved from the inside to the outside, and the thermal conductivity factor of the material is gradually reduced front the outside to the inside, thereby achieving an effect of integrating light weight, high strength, thermal insulation and fire prevention.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Aqueous acrylic emulsion, aqueous adhesive for pearlized film composite materials and preparation method thereof

InactiveCN101717467AGood adhesionImprove the level ofEster polymer adhesivesFunctional monomerMetal foil

The invention discloses an aqueous acrylic emulsion, an aqueous adhesive for pearlized film composite materials and a preparation method thereof, and belongs to the field of preparation of adhesive. The acrylic emulsion is polymerized from 20-40 wt% of acrylic acid hard monomer and 55-70 wt% of acrylic acid soft monomer and 1-5 wt% of acrylic acid functional monomer under the action of water, an emulsifying agent, an initiator, a buffering agent and a pH regulator. The invention also provides an aqueous adhesive and a preparation method thereof. The molecule segment of the film forming matter (acrylate copolymer) in the aqueous acrylic emulsion has various chemical groups, such as -OH, -COOH, -NH and the like; and the chemical groups can form various chemical bonds and hydrogen bonding acting force, and thereby having favorable adhering force for various composite substrates (plastic films, aluminum plating films, metal foils and the like). The polymer obtained by polymerization has higher molecular weight, lower coating viscosity and favorable levelling property; and thus, the polymer has high shear strength and initial strength and can achieve the best bonding strength without curing for a long time.

Owner:BEIJING COMENS NEW MATERIALS

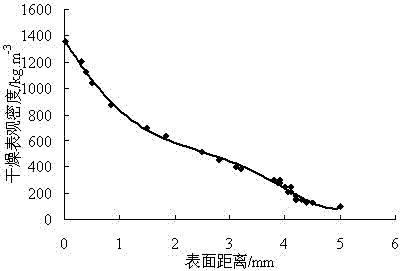

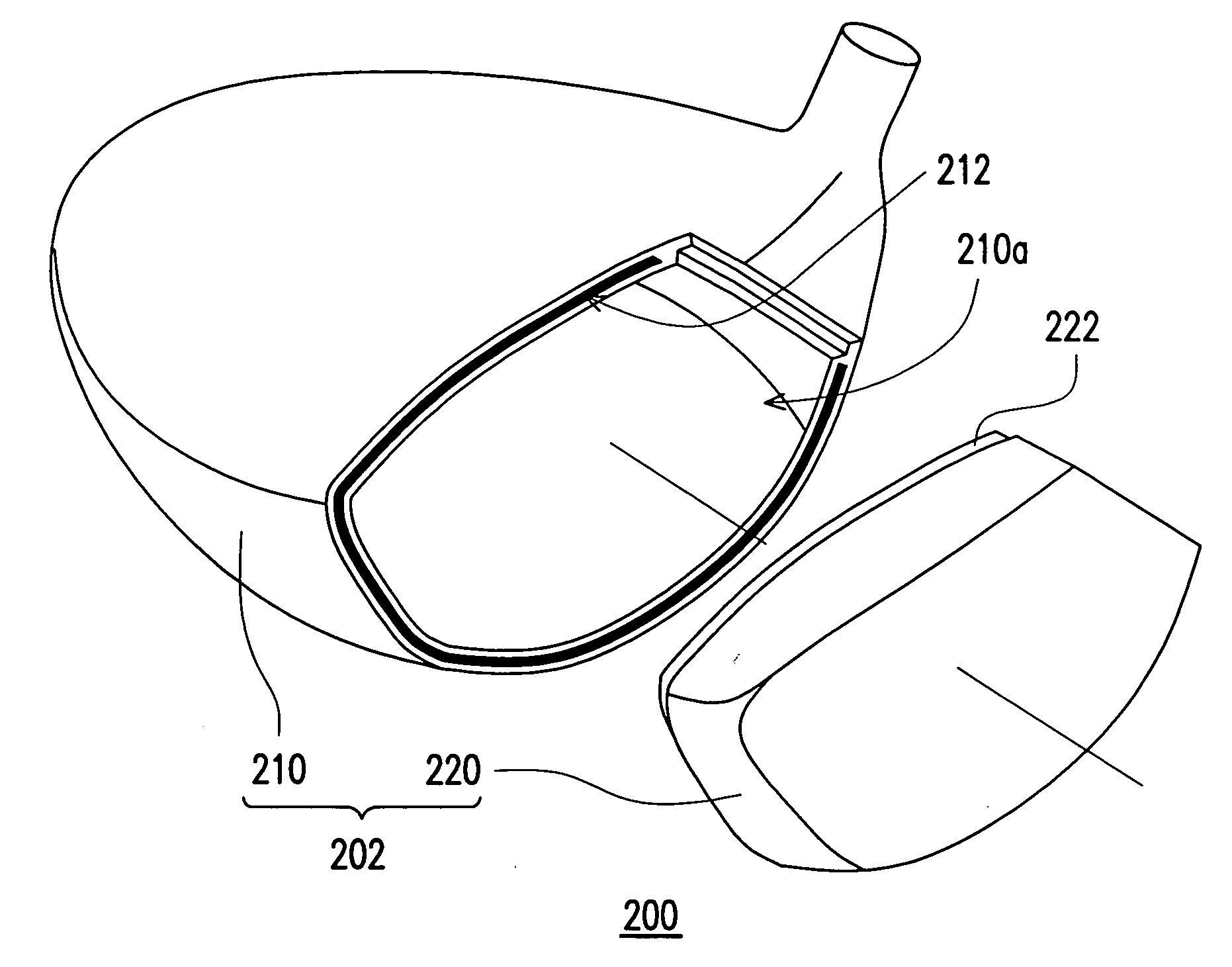

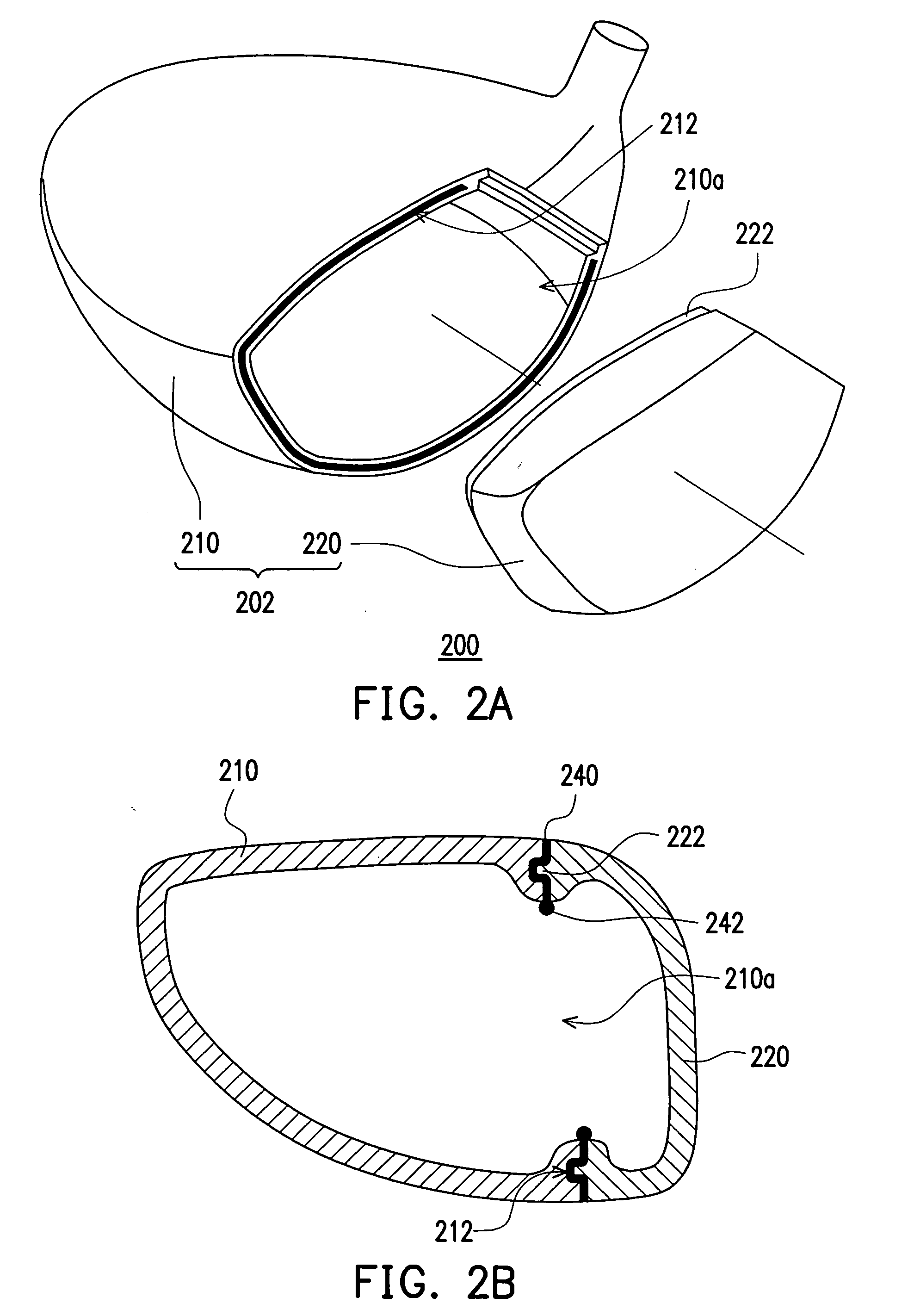

Golf club head

A golf club head which mainly includes a shell and a striking plate is provided. In which, the shell has an opening, and a portion of the edge of the opening of the shell has a first engagement portion. Furthermore, the striking plate is located at the opening, and with the shell forms a golf club head. A portion of the edge of the striking plate has a second engagement portion, which is corresponding to the first engagement portion. The shell and the striking plate are mutually engaged respectively using the first engagement portion and the second engagement portion. The golf club head has superior structural strength and manufacturing yield.

Owner:FUSHENG IND CO LTD

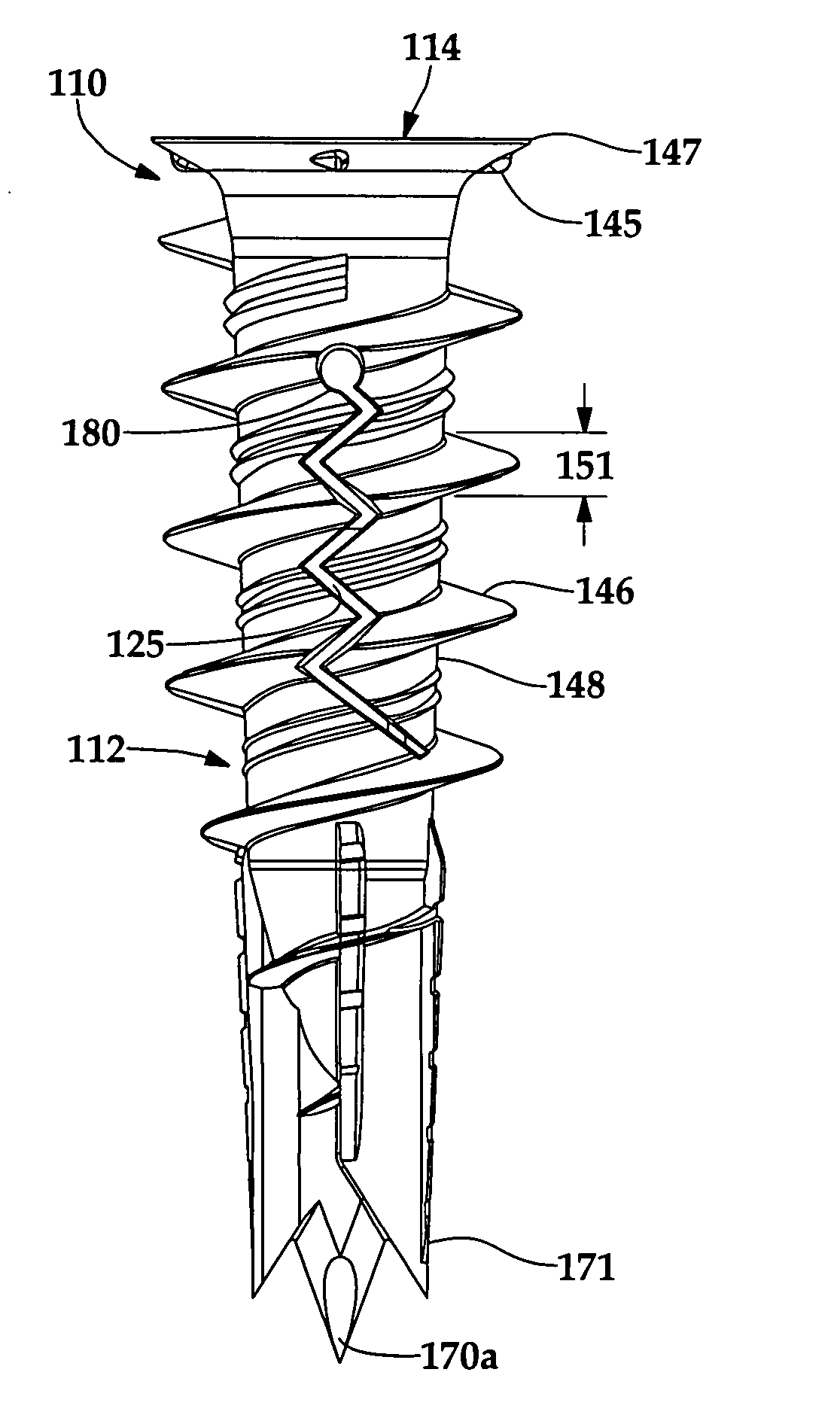

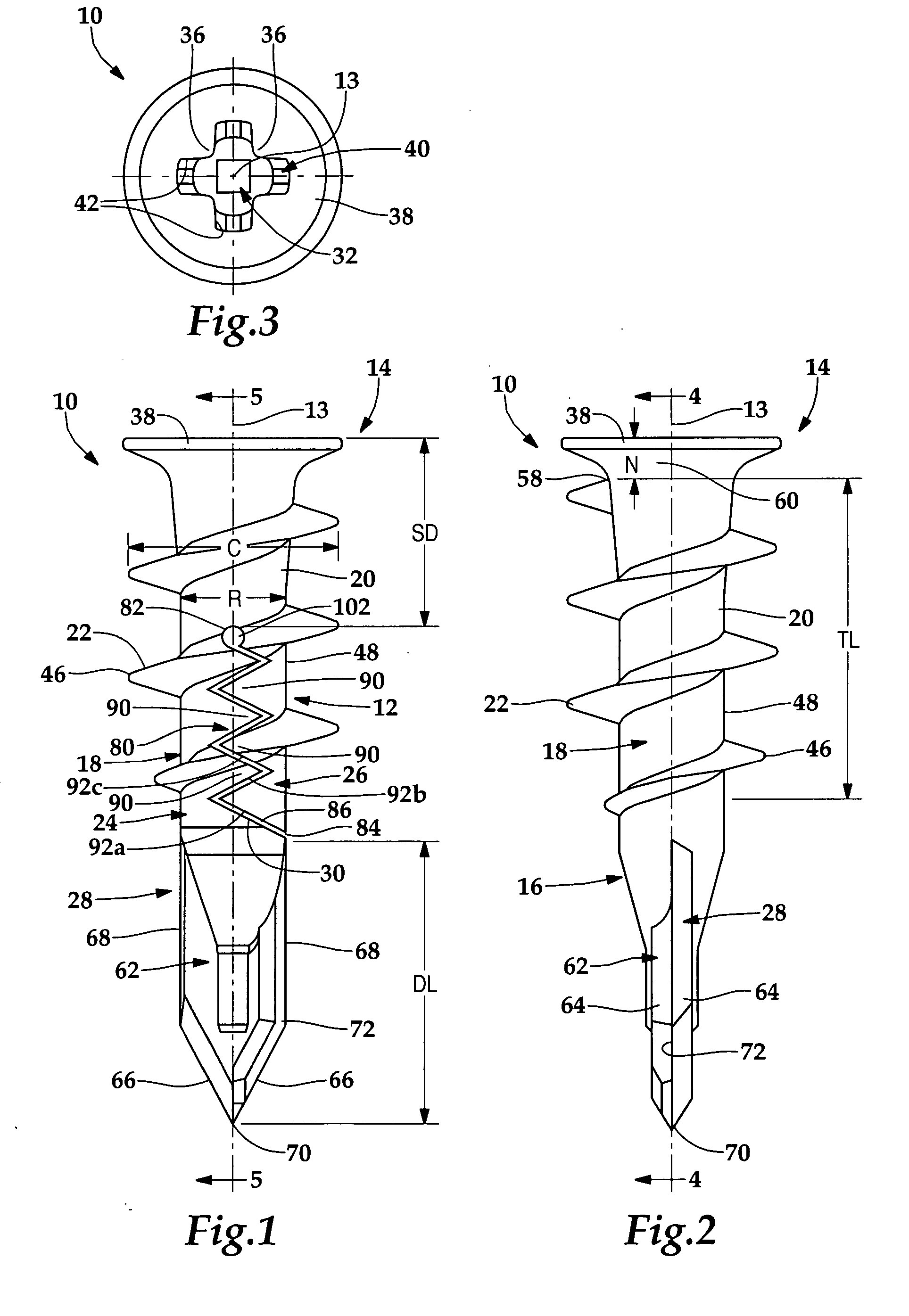

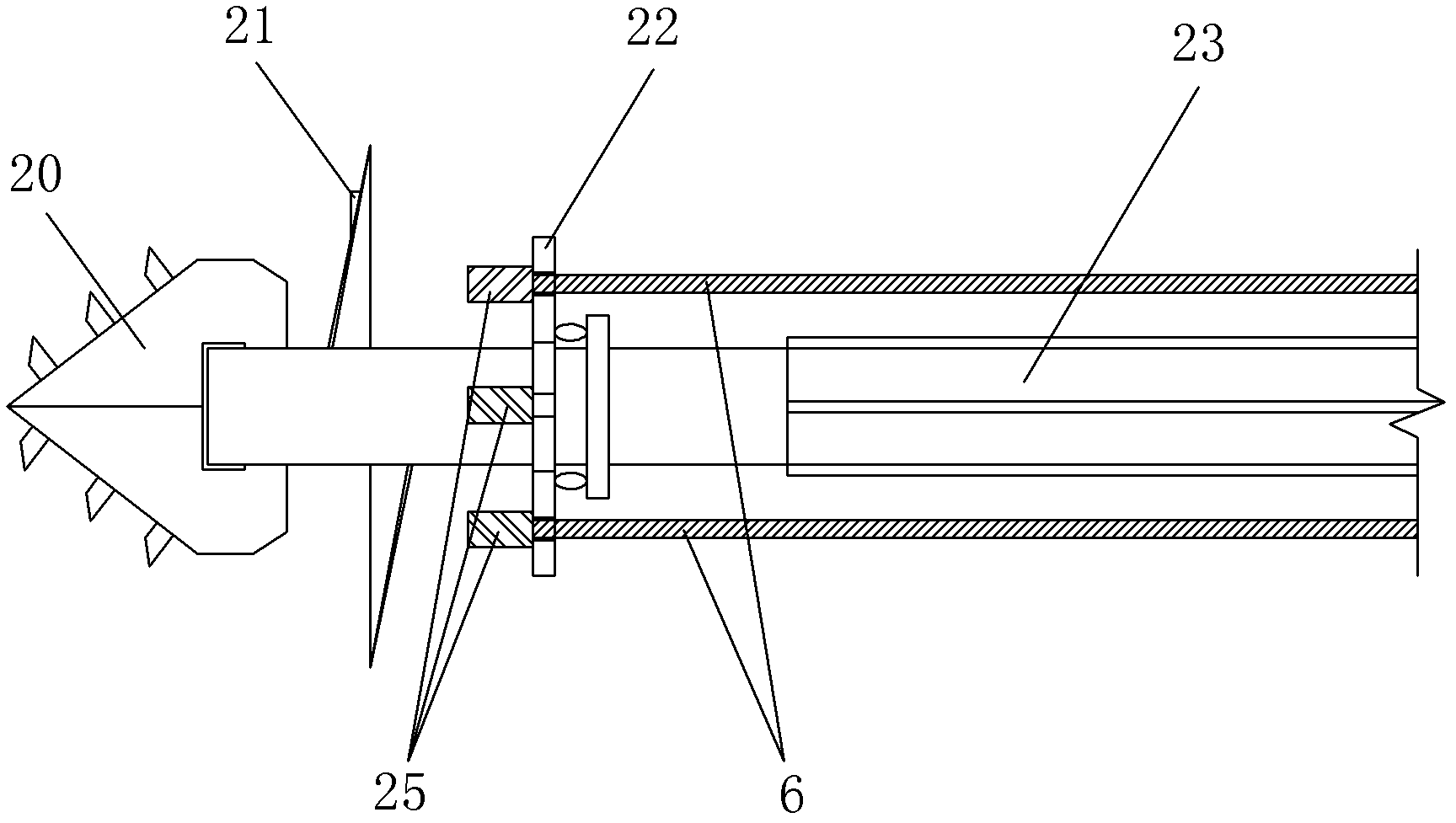

Anchor

A self-drilling anchor for use in a friable material comprises a body having an axis, a flanged rear end, a drilling front end and a generally cylindrical portion therebetween having an outer surface with a thread disposed thereon, wherein the body forks, beginning at a predetermined distance from the flanged rear end, into a first leg and a second leg, the first leg extending forwardly into a drilling tip and having a generally rearward facing shoulder angled obtusely outwardly with respect to the axis, wherein the body has an axial bore for receiving an elongate fastener, the axial bore extending substantially through the flanged end and the generally cylindrical portion and leading to the generally rearward facing shoulder, wherein the anchor has a drilling mode wherein the second leg nests behind the generally rearward facing shoulder of the first leg, and an anchoring mode wherein the legs are pivoted apart from one another.

Owner:ILLINOIS TOOL WORKS INC

High-temperature resistant and expediting setting dealcoholized type room temperature vulcanized silicone rubber adhesive and preparation method thereof

The invention discloses a high-temperature resistant and expediting setting dealcoholized type room temperature vulcanized silicone rubber adhesive and a preparation method thereof. The adhesive is prepared from the following components by weight: 100 parts of hydroxyl-terminated polydimethylsiloxane with the viscosity ranging from 4000 to 12000 Pa.s, 3 to 20 parts of fumed silica, 0.1 to 6 parts of viscosity increasers, 1 to 7 parts of cross-linking agents, 0.1 to 1 part of catalysts, 2 to 8 parts of titanium dioxide and 0.1 to 5 parts of hydroxy finishing agent, and is prepared by the following methods: (1) the hydroxyl-terminated polydimethylsiloxane, the fumed silica and the titanium dioxide are uniformly mixed to obtain a mixture, and the mixture is led into a vacuum drying chamber and then is dried and defoamed; and (2) under the dry environment, the hydroxy finishing agent, the viscosity increaser, the catalyst and the cross-linking agent are added to the mixture and stirred with under vacuum at room temperature, thereby preparing the adhesive. The adhesive of the invention has the advantages of high and adjustable setting speed, excellent mechanical property, favorable resistance to high temperature and strong bonding force.

Owner:TIANJIN UNIV

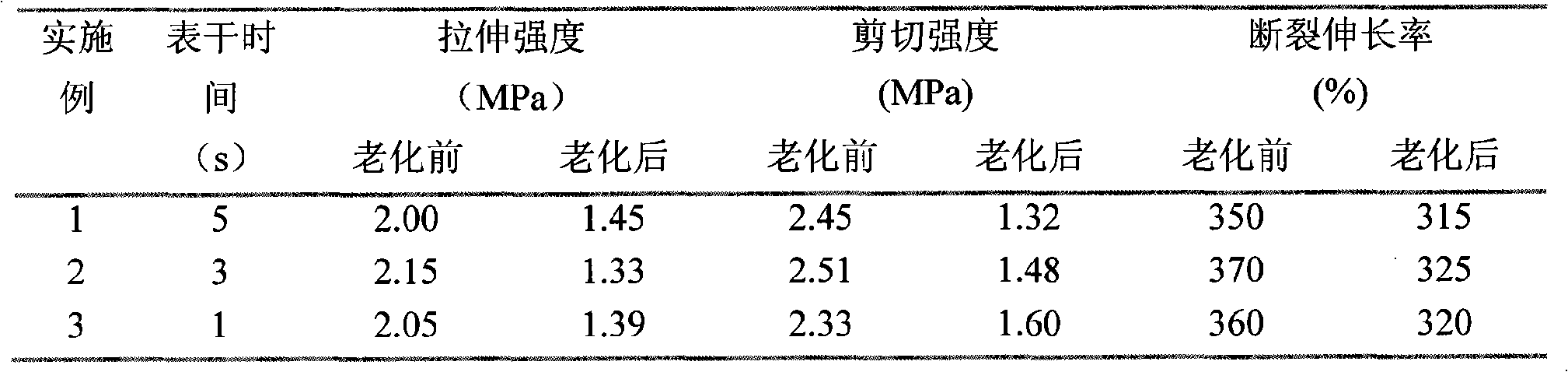

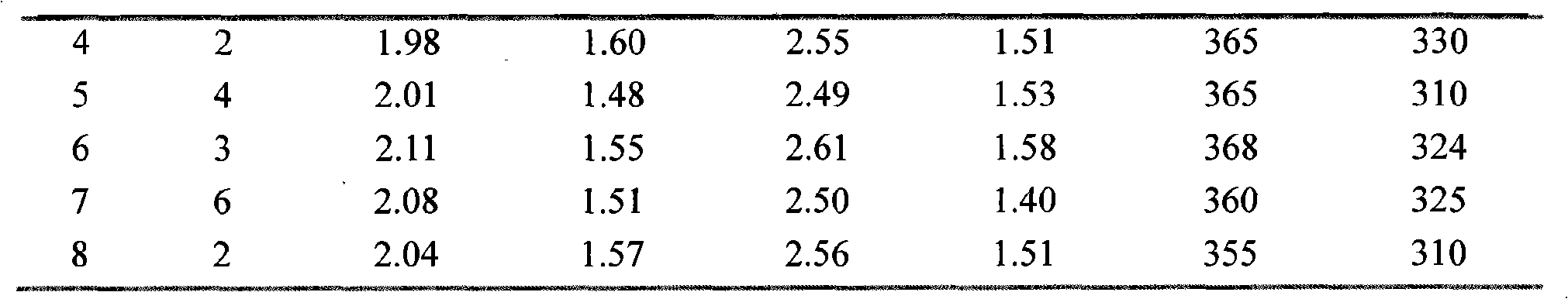

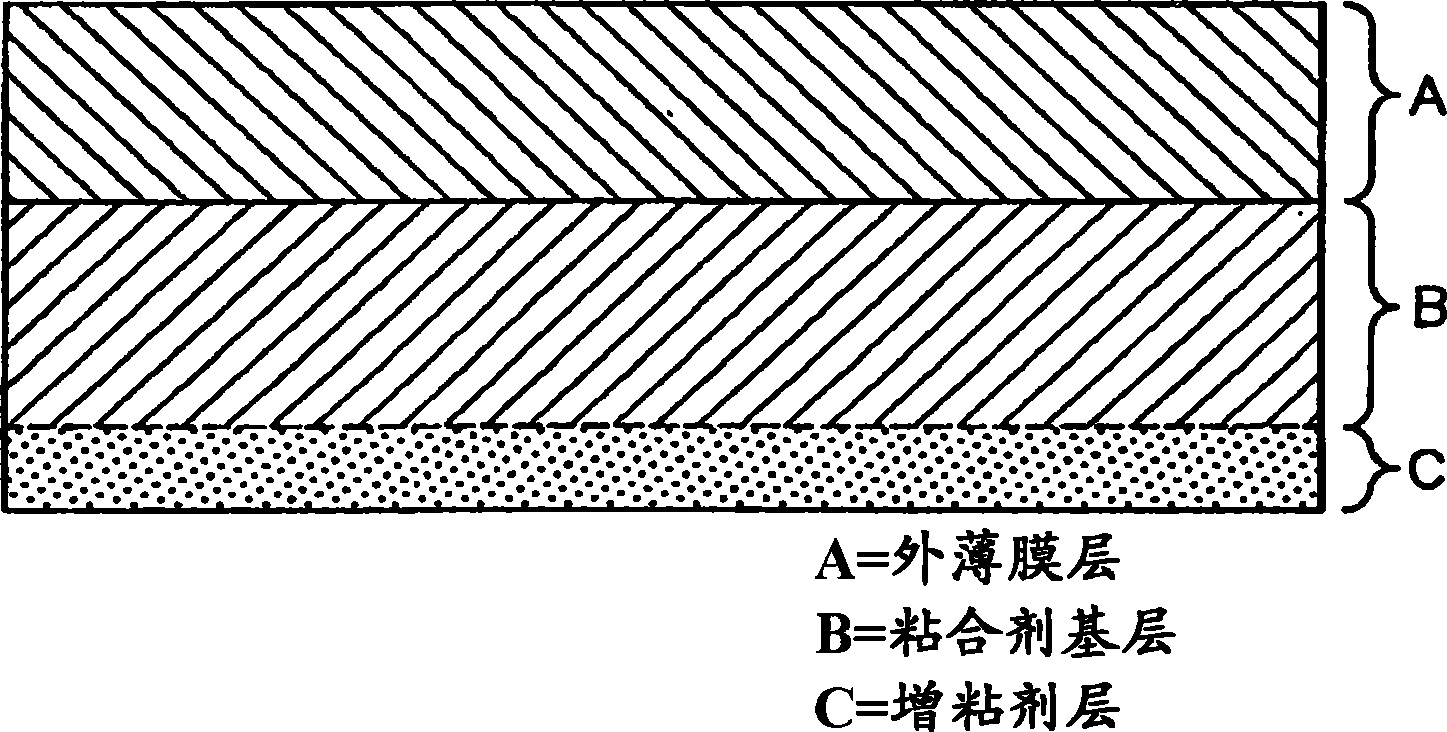

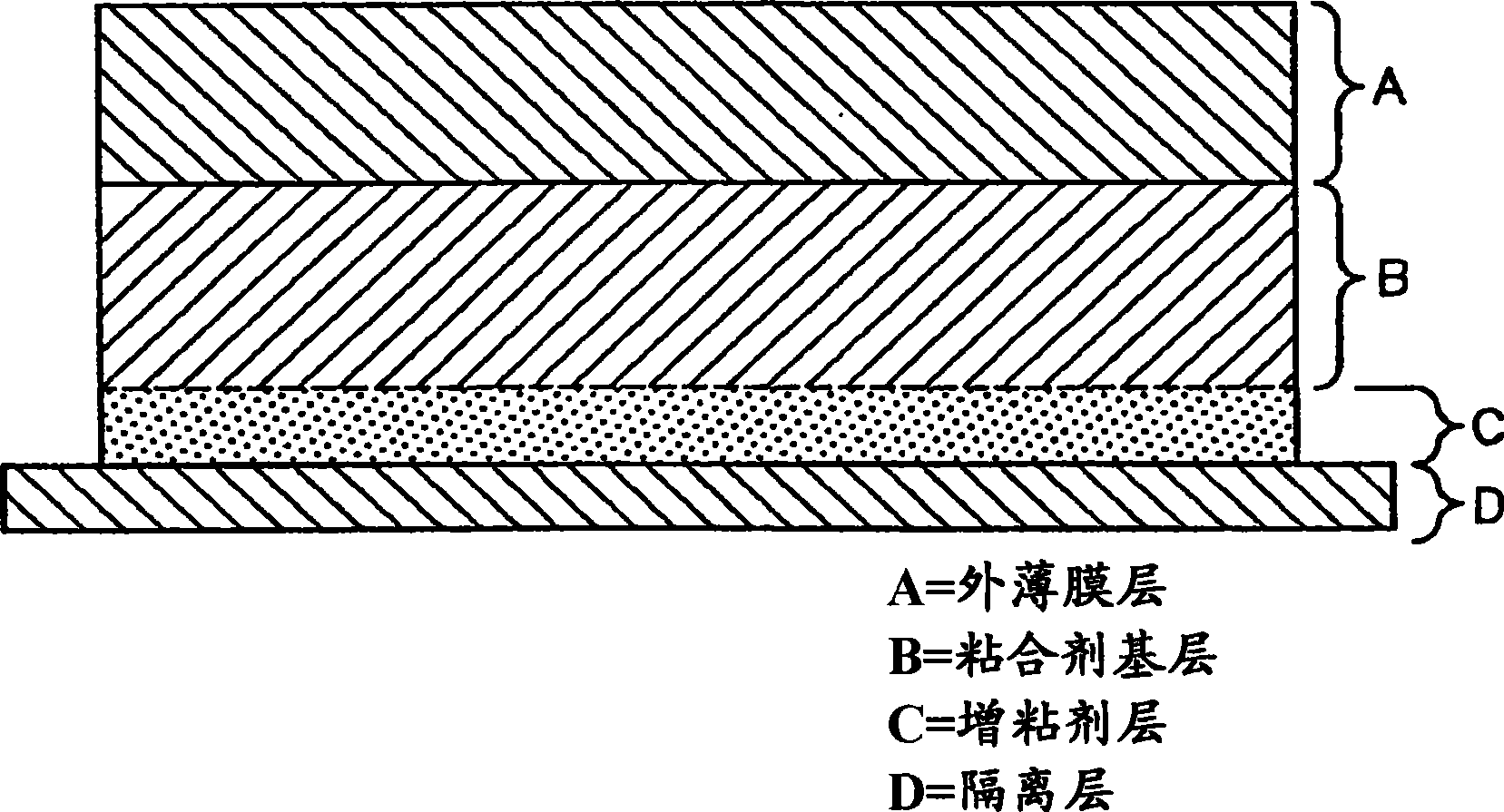

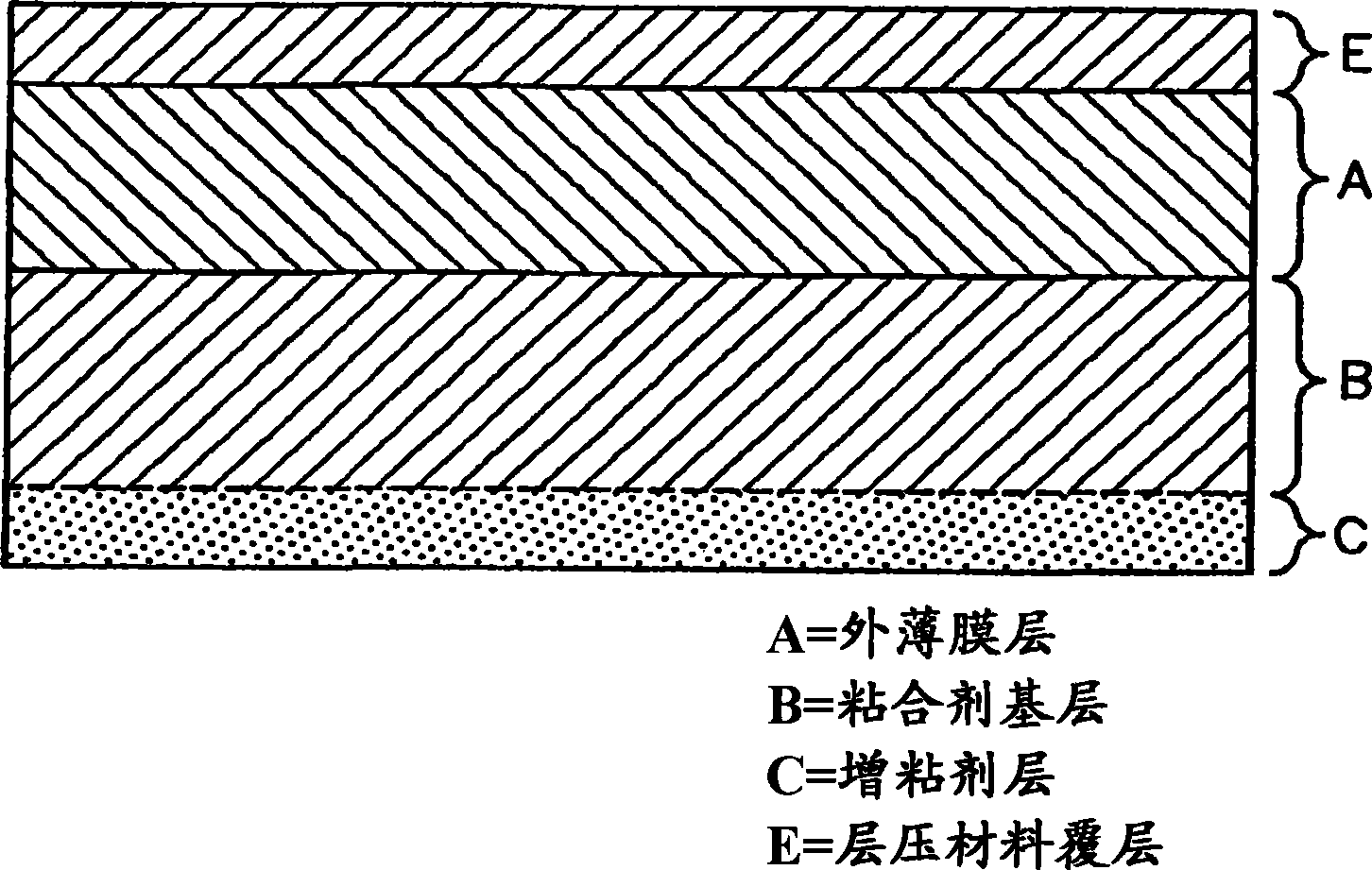

Pressure sensitive adhesive (psa) laminates

InactiveCN101454416AManufacturing Method ImprovementsCoating temperature is lowFlat articlesThin material handlingPolymer scienceTackifier

A PSA laminate is provided comprising at least one non-adhesive laminate and at least one tackifier layer; wherein the non-adhesive laminate comprises at least one facestock layer and at least one adhesive base layer; wherein the facestock layer comprises at least one facestock material; wherein the adhesive base layer comprises at least one adhesive base polymer; wherein the tackifier layer comprises at least one tackifier; wherein the tackifier composition is not a PSA; and wherein the tackifier layer is applied to the adhesive base layer side of the non-adhesive laminate to produce the PSA laminate. Processes for producing the PSA laminate are also provided as well as articles comprises the PSA laminates.

Owner:EASTMAN CHEM CO

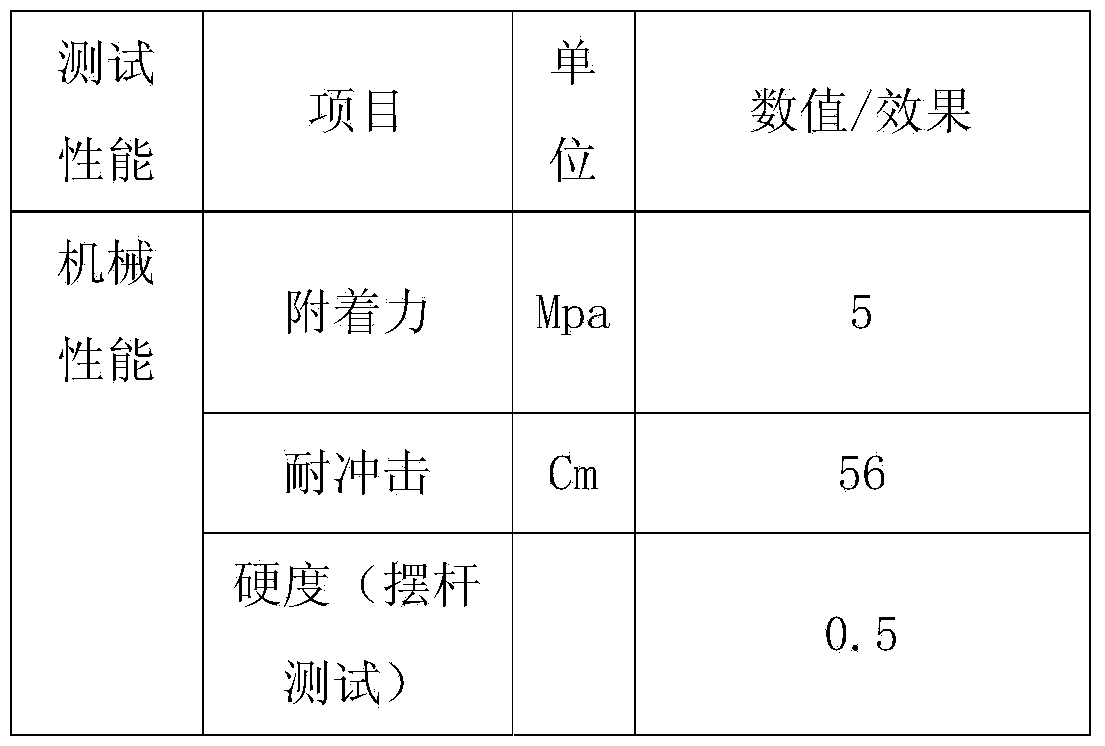

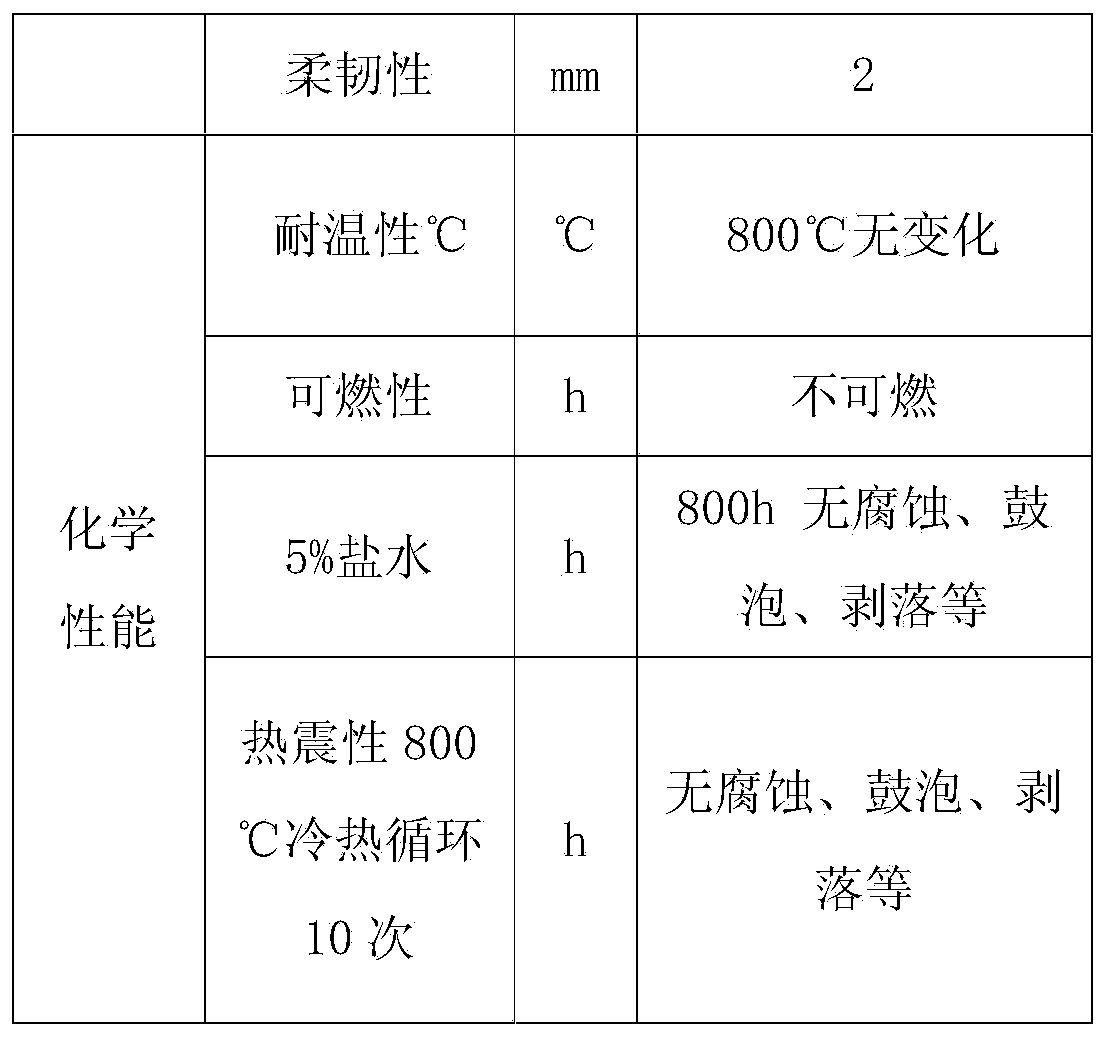

Boron-modified organic silicon resin high-temperature-resistant coating and preparation method thereof

The invention discloses a boron-modified organic silicon resin high-temperature-resistant coating which comprises the following components in percentage by mass: 45%-58% of boron-modified organic silicon resin, 35%-45% of heat-resisting pigment fillers and 2%-4% of auxiliary agents, wherein the boron-modified organic silicon resin is boric-acid-modified organic silicon resin or epoxy-modified silicon-boron resin; and the mass ratio of nanometer silicon dioxide to barrier function fillers to aluminum powder which are contained in the heat-resisting pigment fillers is 1.5:1:1. The invention also discloses a preparation method of the boron-modified organic silicon resin high-temperature-resistant coating. The preparation method disclosed by the invention can be implemented on an existing coating preparation production line without increasing equipment investment; the prepared high temperature-resistant organic silicon coating can be coated by adopting a spray coating process and constructed by adopting a roll coating process, can be subjected to high temperature of 800 DEG C for a long time and has corrosion-resistant property.

Owner:JIANGSU MARINE VICTORY COATING

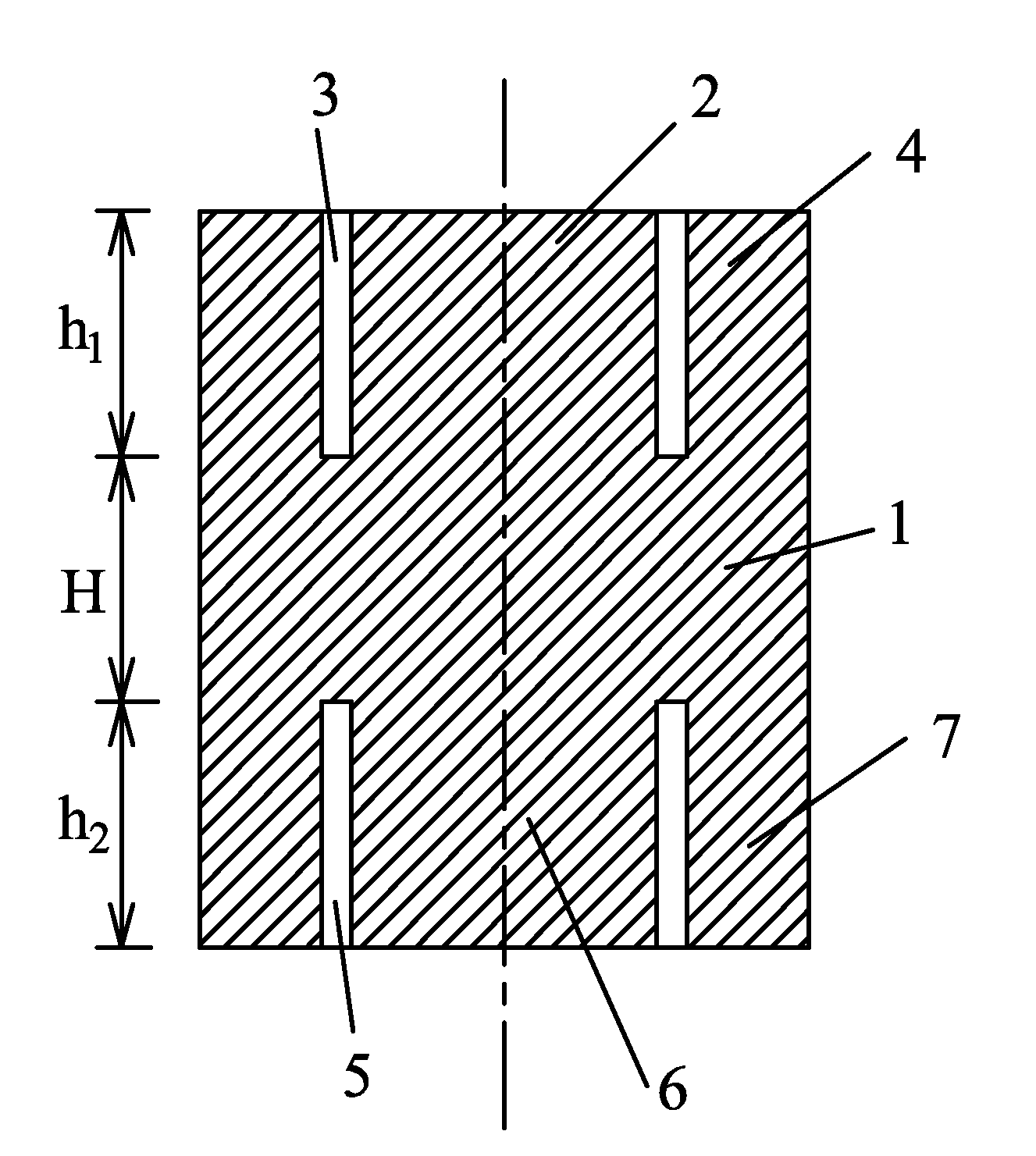

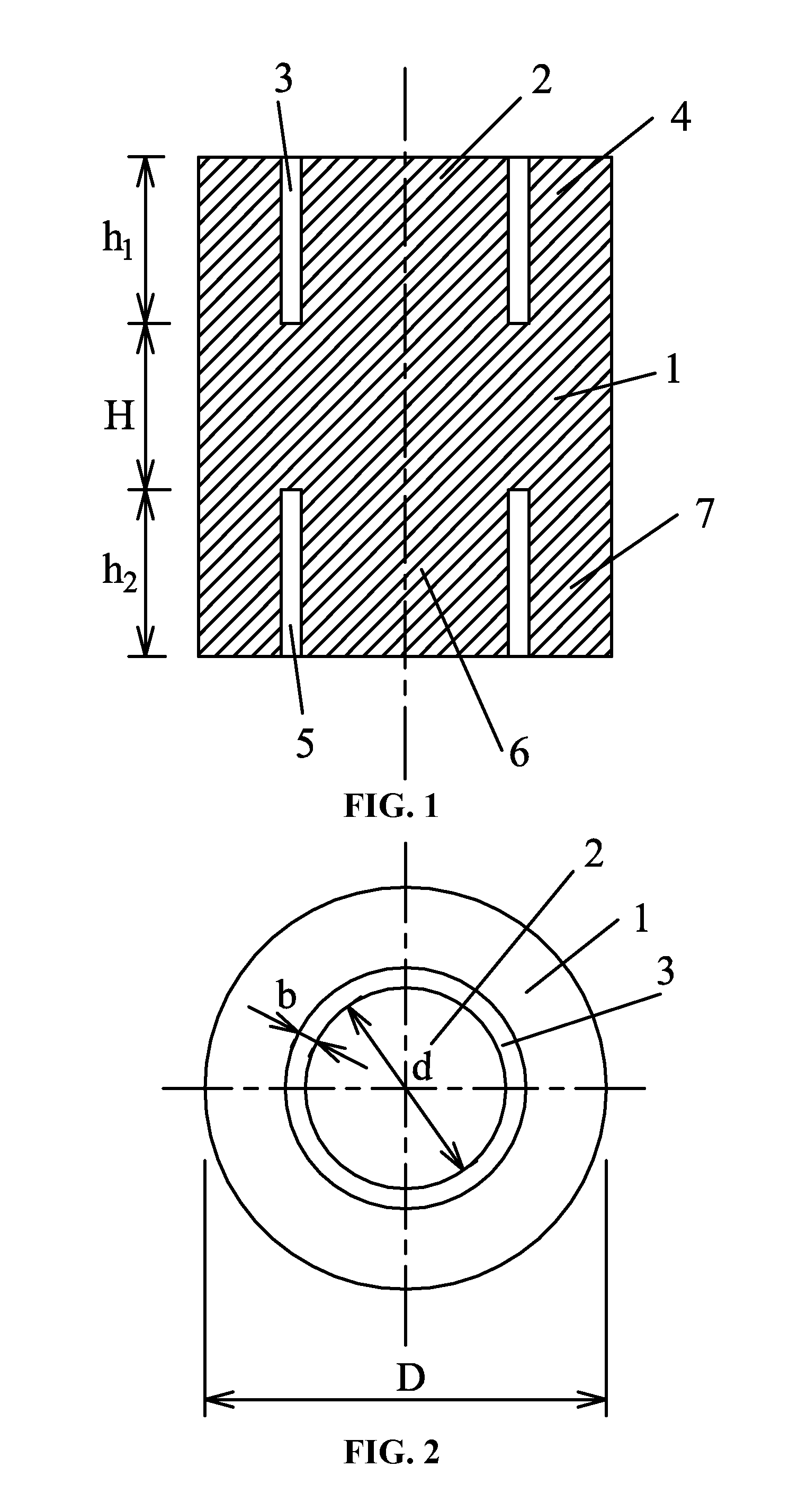

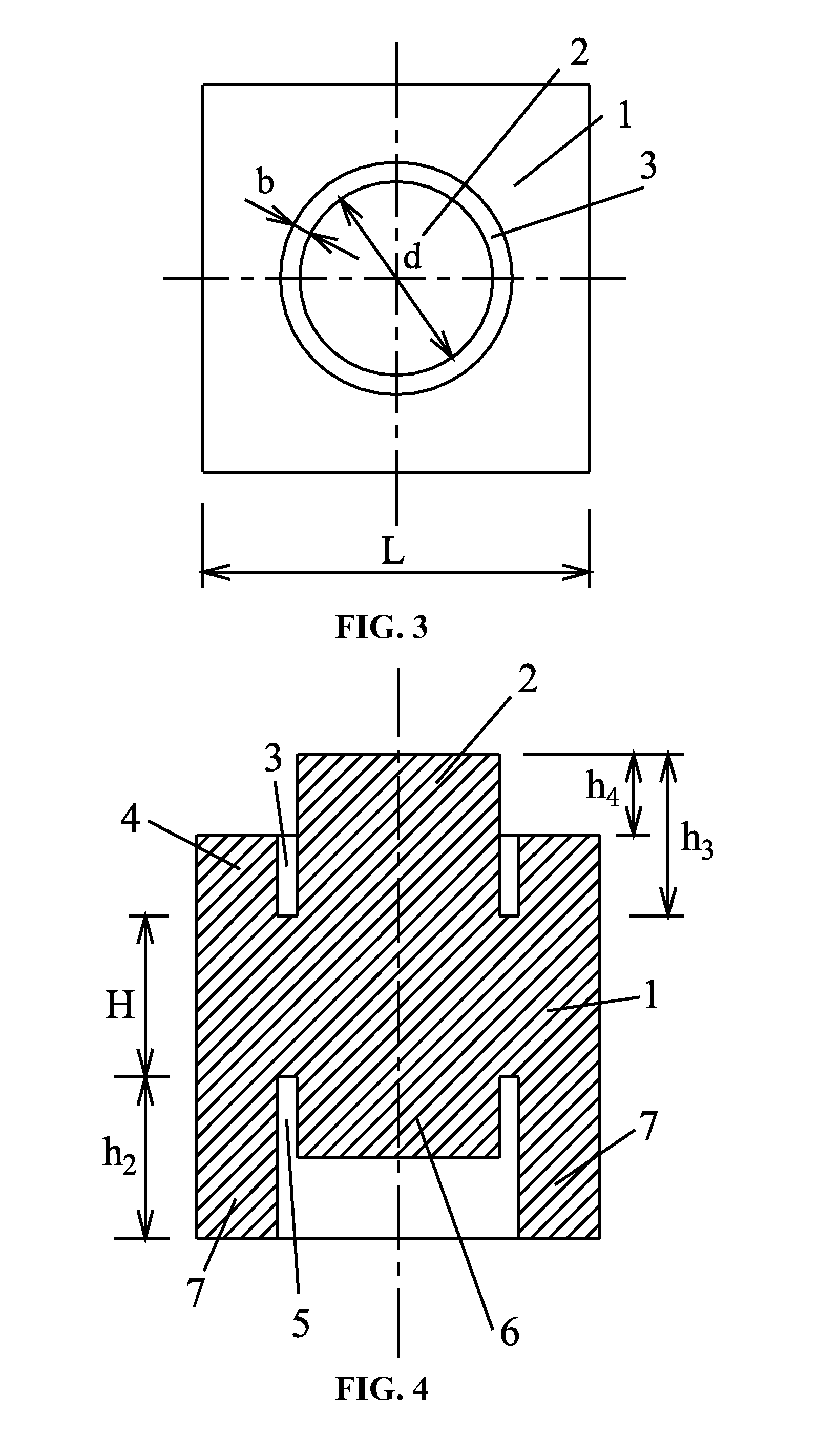

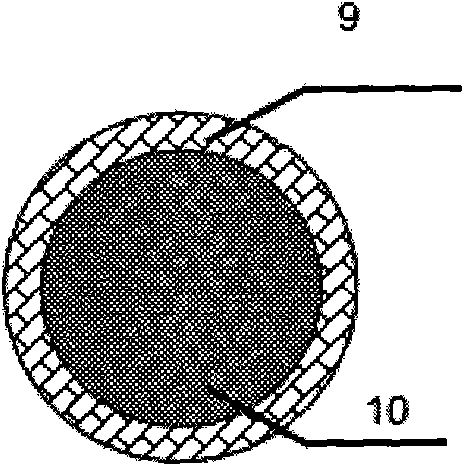

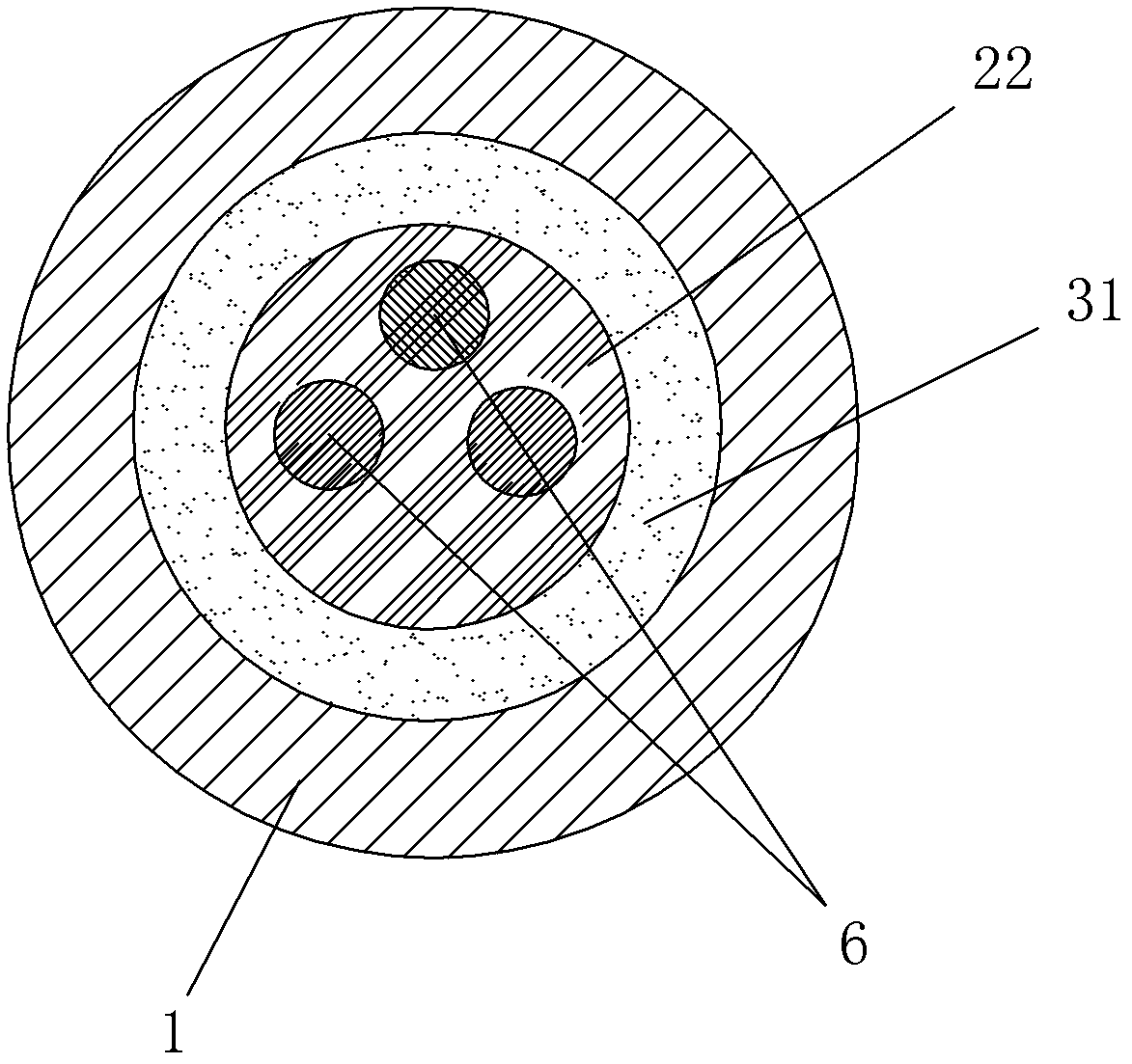

Rock specimen and method for testing pure shear of the same

ActiveUS20160103049A1Easy to measureSolve the real problemEarth material testingMaterial strength using steady shearing forcesPure shearTest bench

A rock specimen, including a rock body. The rock body includes: an upper part, an upper end face, a first circular groove, a first cylinder, a first circular body, a lower part, a lower end face, a second circular groove, a second cylinder, and a second circular body. The first circular groove is disposed on the upper end face of the rock body and has a circle center coinciding with a center of the upper end face. A method for testing pure shear of the rock specimen, includes: 1) disposing the rock specimen on a test bench of a rock mechanics testing system, allowing the end face of the second circular body to contact the test bench; and 2) operating the rock mechanics testing system, loading a pressure on the rock specimen via the end face of the first cylinder and the end face of the second circular body.

Owner:SICHUAN UNIV

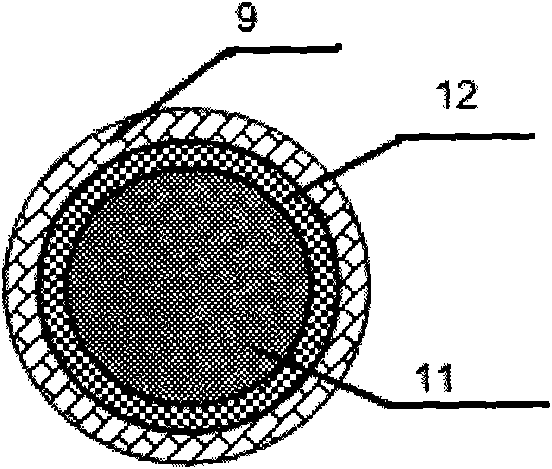

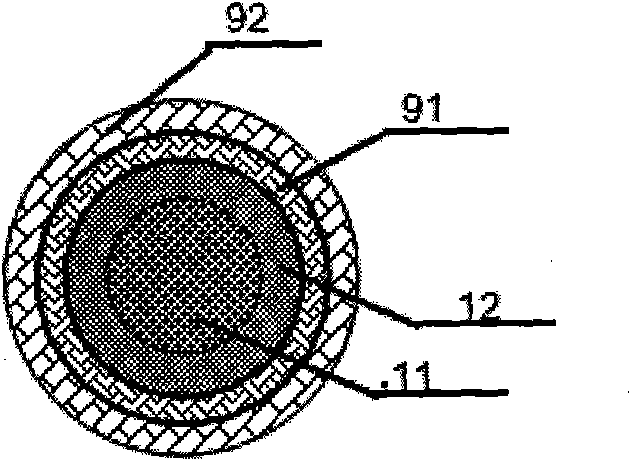

Novel electric cable reinforced core and preparation method thereof

InactiveCN101740161ASmall sagHigh tensile strengthNon-insulated conductorsPlastic/resin/waxes insulatorsFiber-reinforced compositeFiber type

The invention discloses a novel electric cable reinforced core, which is composed of a fiber reinforced composite material, the fiber reinforced composite material comprises at least a reinforced fiber type which has longitudinal orientation in the resin and is basically continuous and is used as an inner layer composite material core; the fiber reinforced composite material further comprises a braided or twined reinforced protective outer layer around the inner layer composite material core, the reinforced protective outer layer comprises at least a reinforced fiber type which is braided in the resin and is basically continuous. The longitudinal fiber and the braided fiber are composited in the invention, thereby having the advantages that the longitudinal tensile strength, the resist compression strength, the bending resistance and the shearing resistance of the electric cable reinforced core in the longitudinal direction are increased, and the safety factor are increased, and the loss of the mechanical performance caused by defects owning to external abrasion or impact in the transportation process, the laying and installing process and the operation process is avoided.

Owner:SHANGHAI ELECTRIC CABLE RES INST

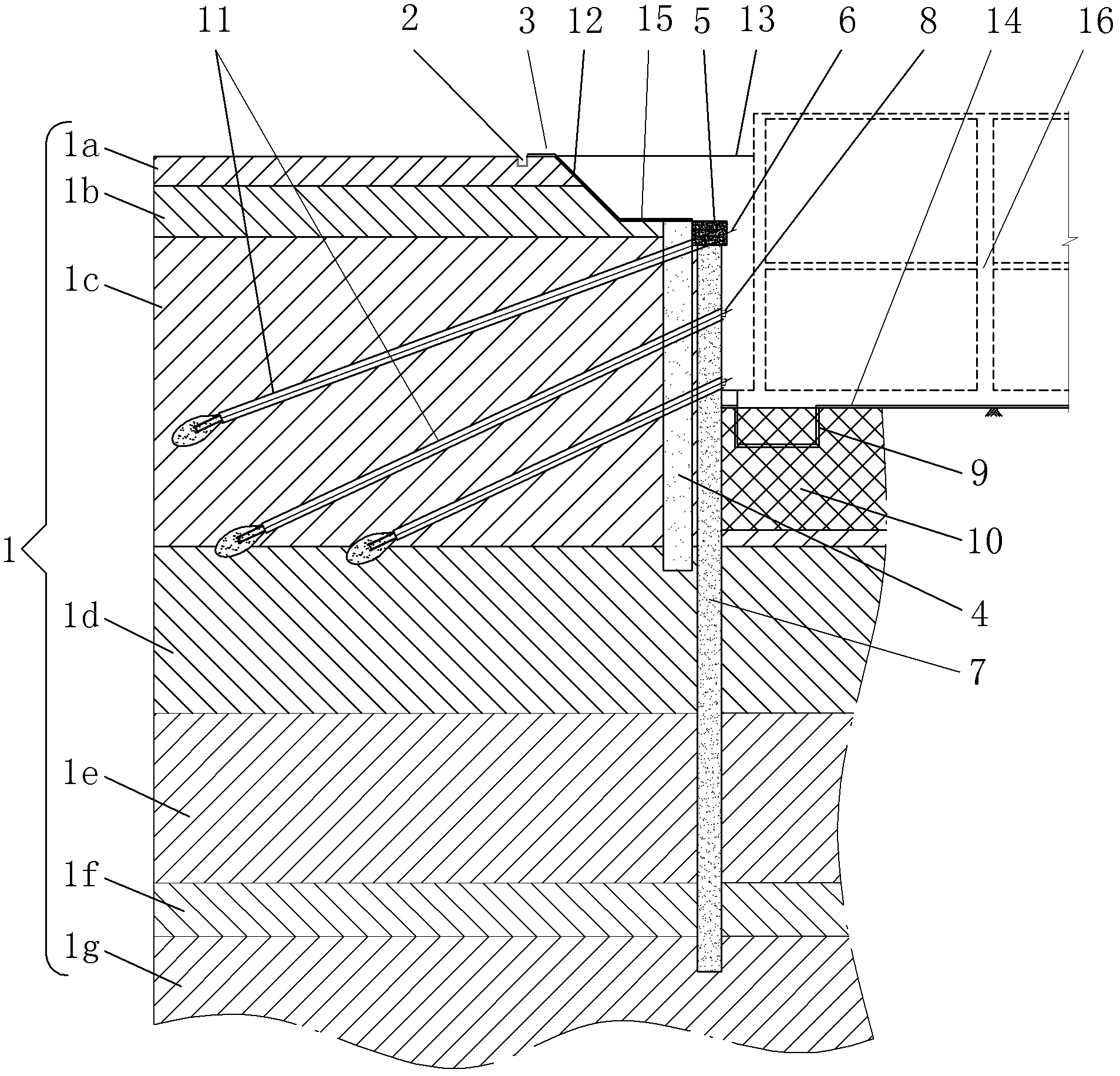

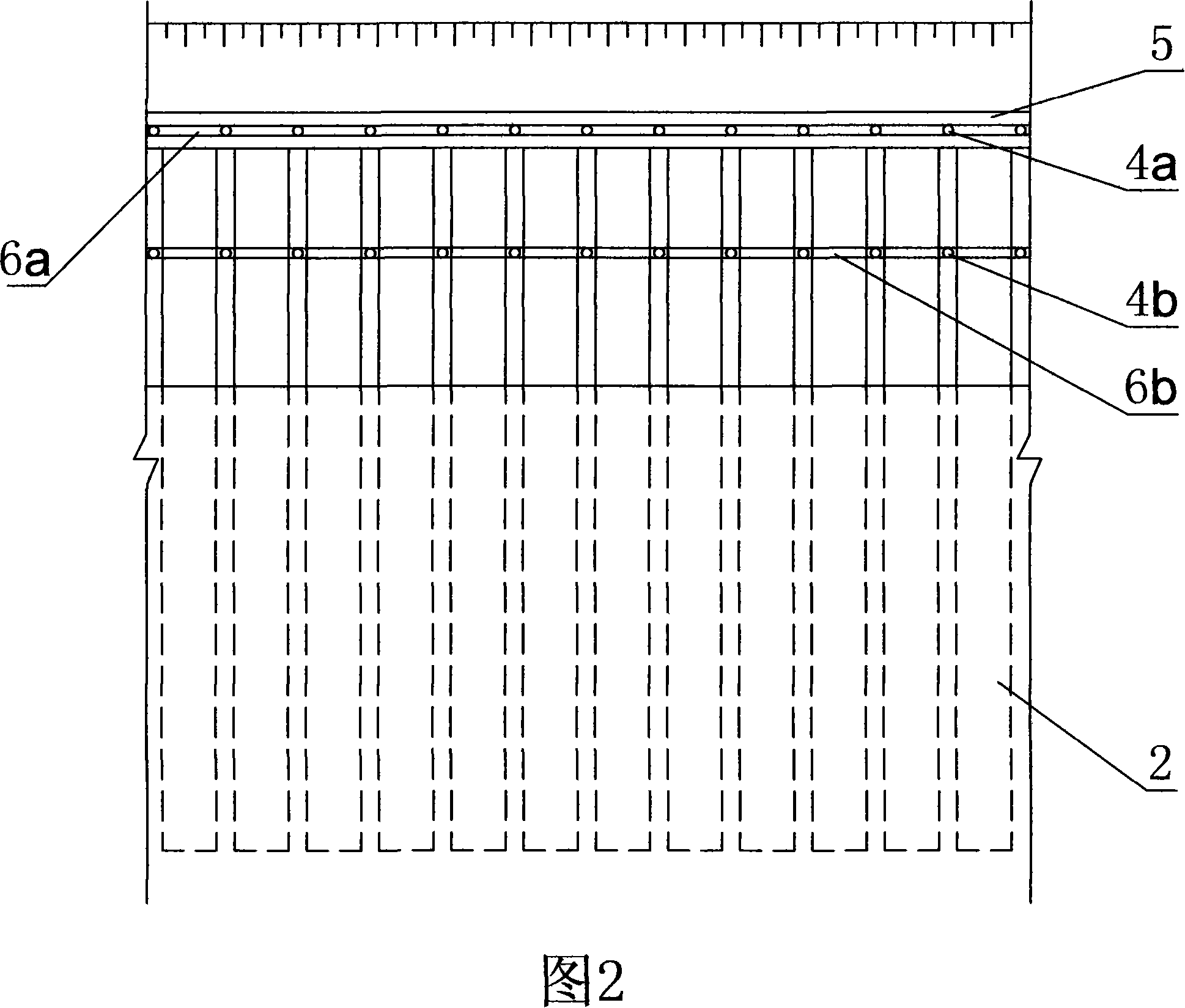

Foundation pit support construction method combining horizontal rotary jet-grouting soil bolting and bore concrete piles

ActiveCN102518135AOutstanding and Beneficial Technical EffectsControl deformation valueExcavationsBulkheads/pilesEngineeringDeformation control

The invention belongs to the technical field of foundation pit supporting for high-rise buildings, in particular to a foundation pit support construction method combining horizontal rotary jet-grouting soil bolting and bore concrete piles, which includes steps: firstly, constructing water-stop mixed piles and bored concrete piles according to a preset foundation pit; and secondly, performing soil excavation and soil bolting layer by layer and section by section. The foundation pit support construction method has the advantages that the foundation pit support constructed by the method is high in deformation control performance and stability and especially applicable to projections with high requirements on foundation pit deformation, and the method is applicable to mega-area foundation pit supporting in soft soil areas with failure of using internal support structures, limited slope reduction conditions and excavation depth limited within 15m, and meets the requirement that development and utilization of urban underground space continue to develop.

Owner:BIAOLI CONSTR GROUP

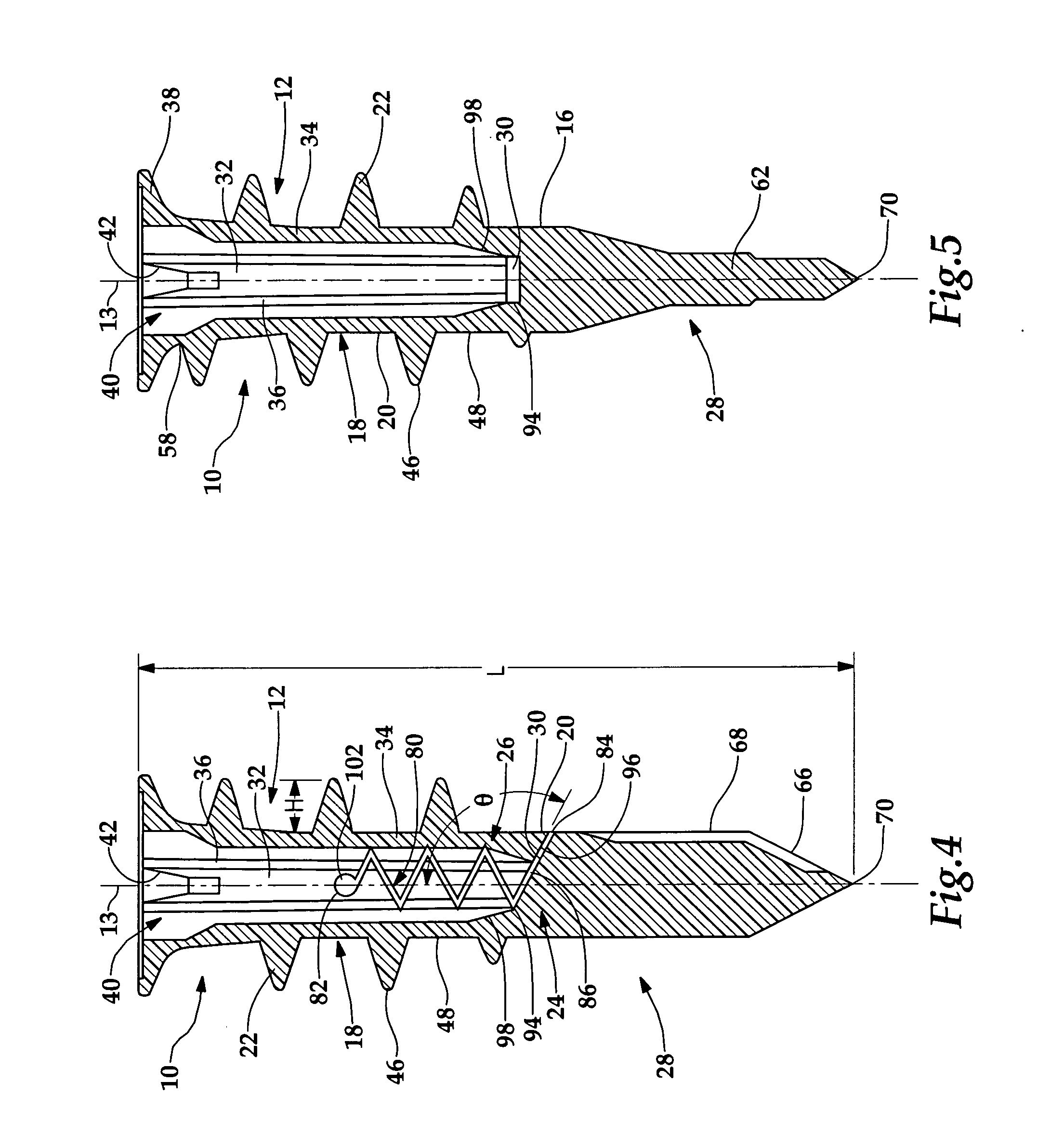

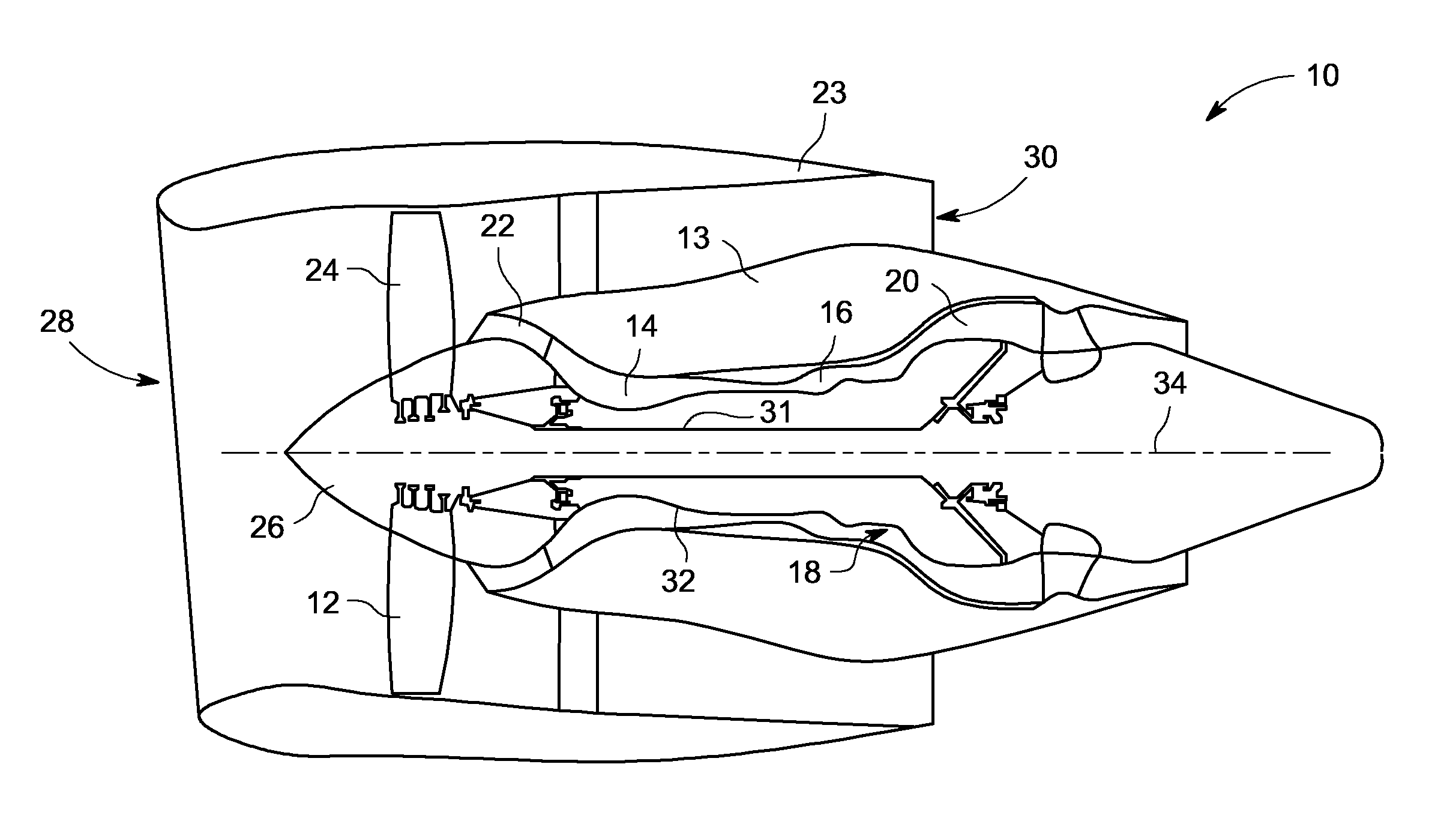

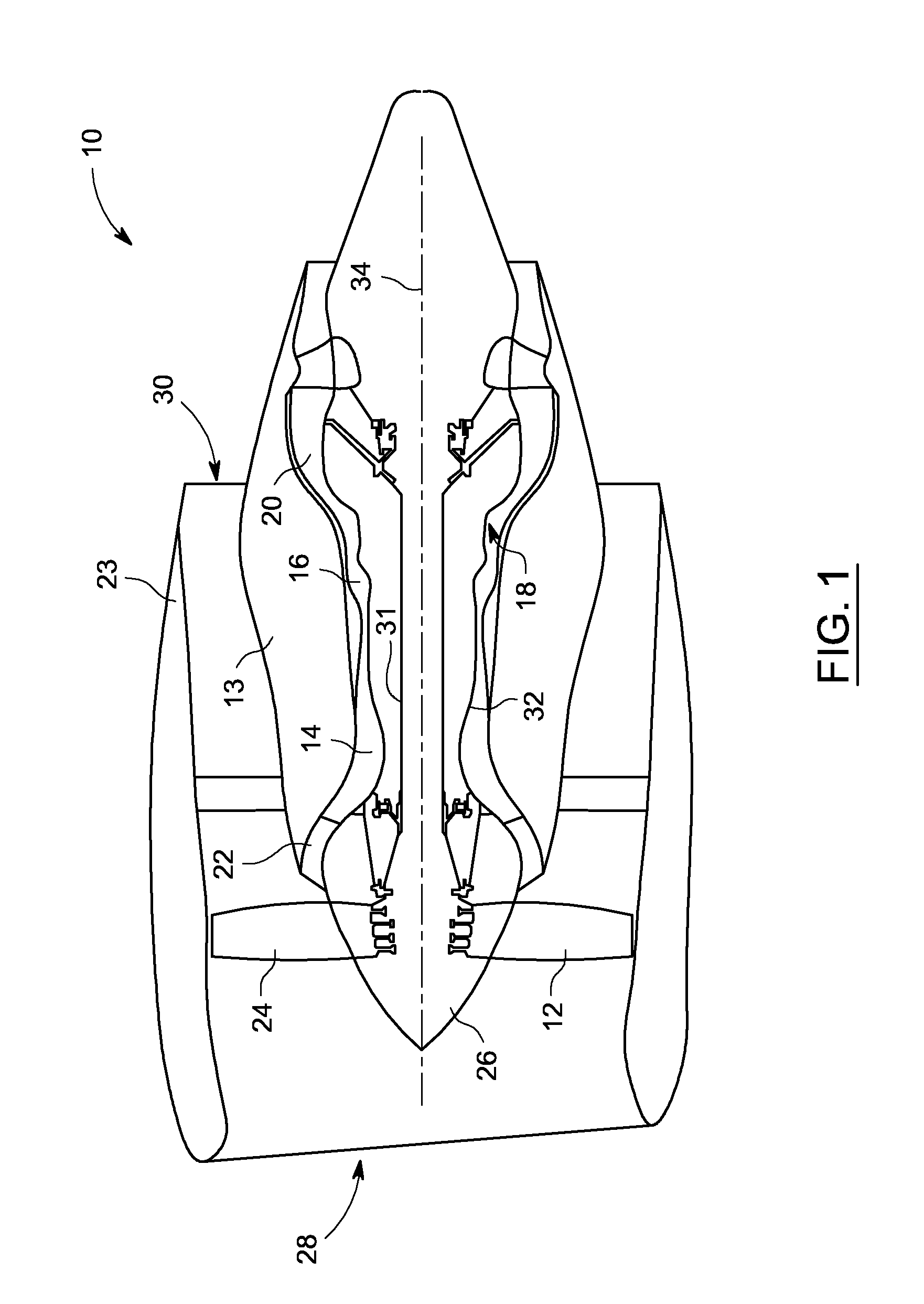

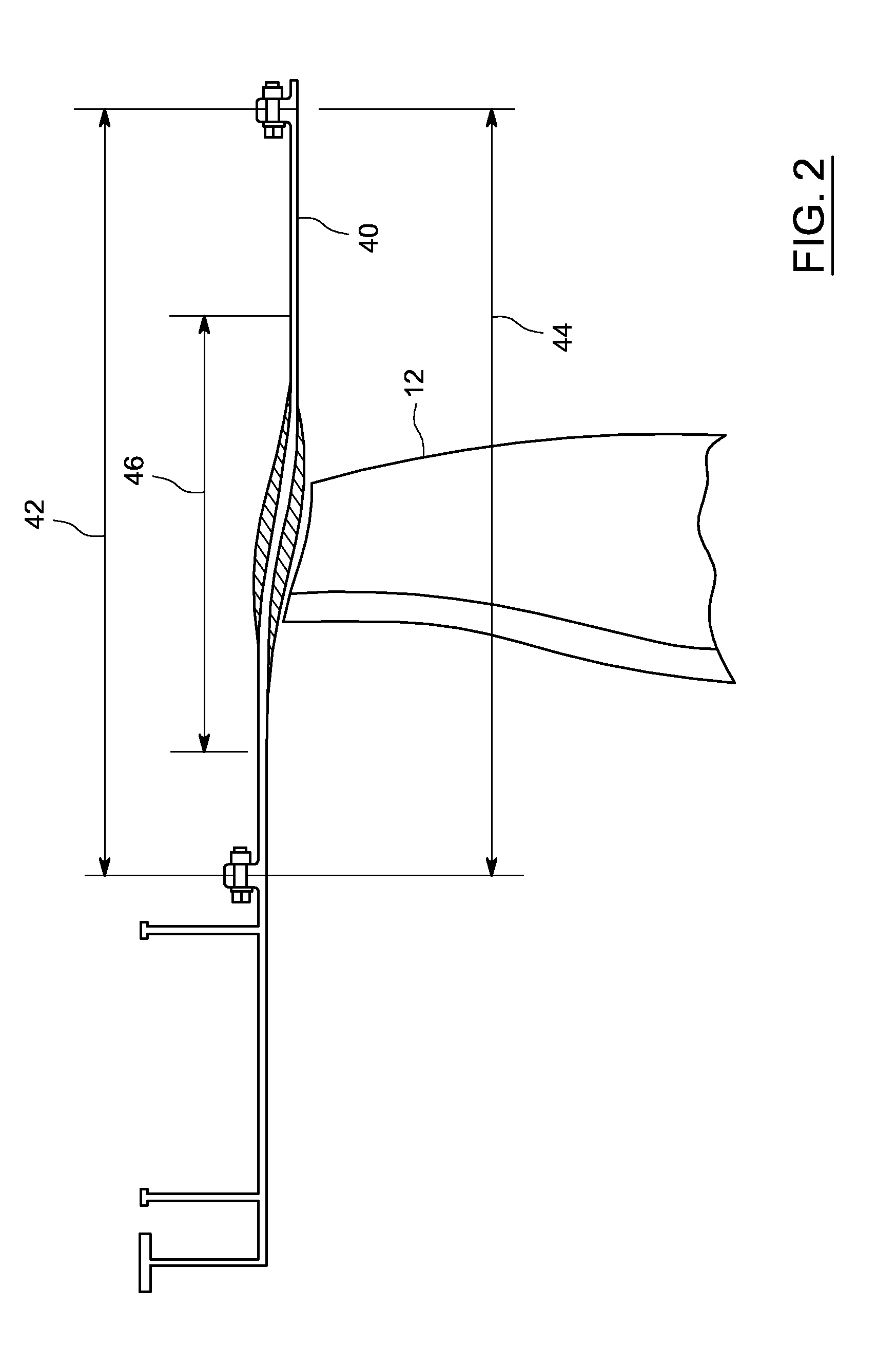

Containment case and method of manufacture

ActiveUS20130153456A1Increased shear strengthLower resistanceBlade accessoriesEfficient propulsion technologiesIn planeUltimate tensile strength

A containment case comprises a composite core, with an inner and outer surface, at least one puncture resistant layer bonded to the inner surface of the composite core and at least one energy capture layer bonded to the outer surface of the composite core. The puncture resistant layer having a high through-thickness shear strength and high interlaminar toughness at impact. The energy capture layer having a high in-plane tensile strength and low resistance to delamination and fiber-matrix debonding at impact. A method of fabricating a containment case includes the steps of disposing one or more layers of a puncture resistant material on a layup mandrel, disposing one more layers of a structural composite material on an exterior surface of the puncture resistant material, disposing one or more layers of an energy capture material on an exterior surface of the structural material and curing a resin in the plurality of layers.

Owner:GENERAL ELECTRIC CO

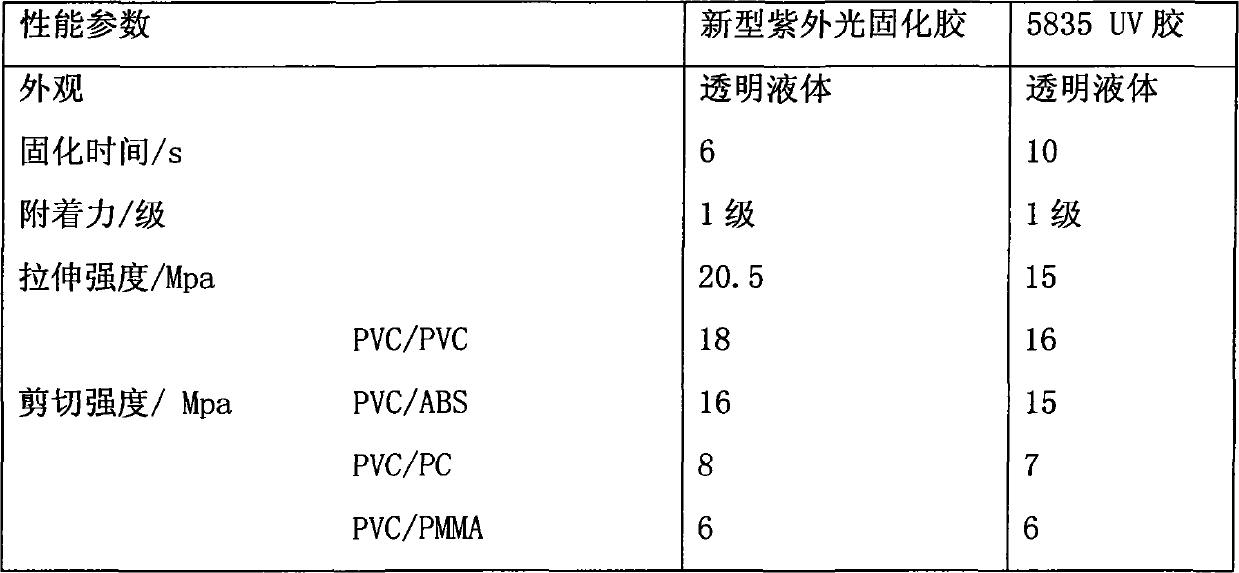

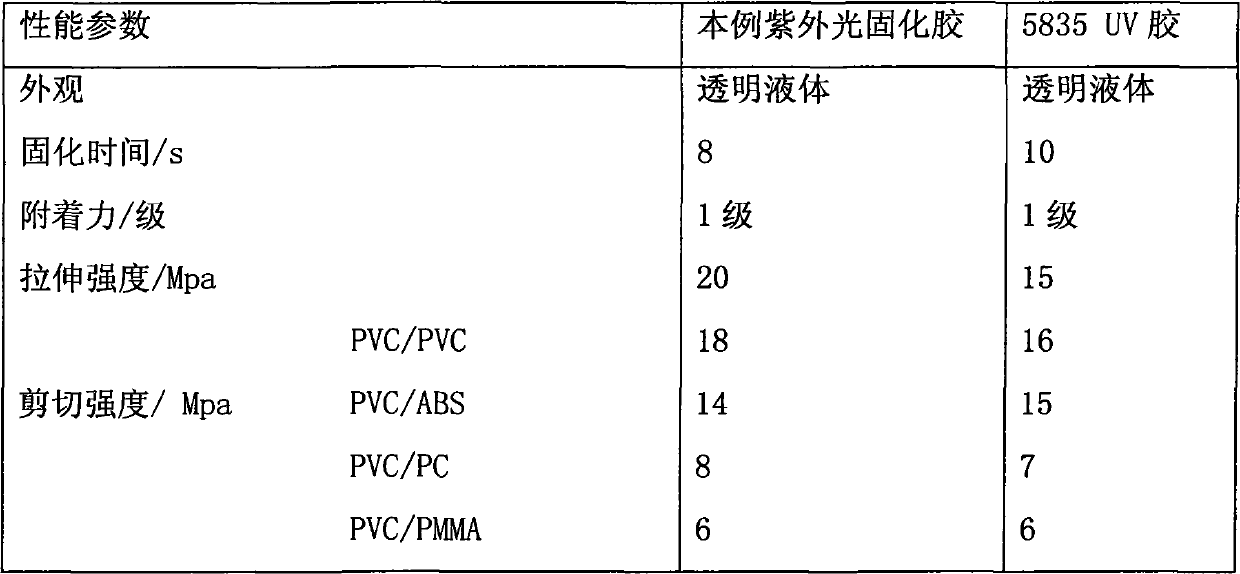

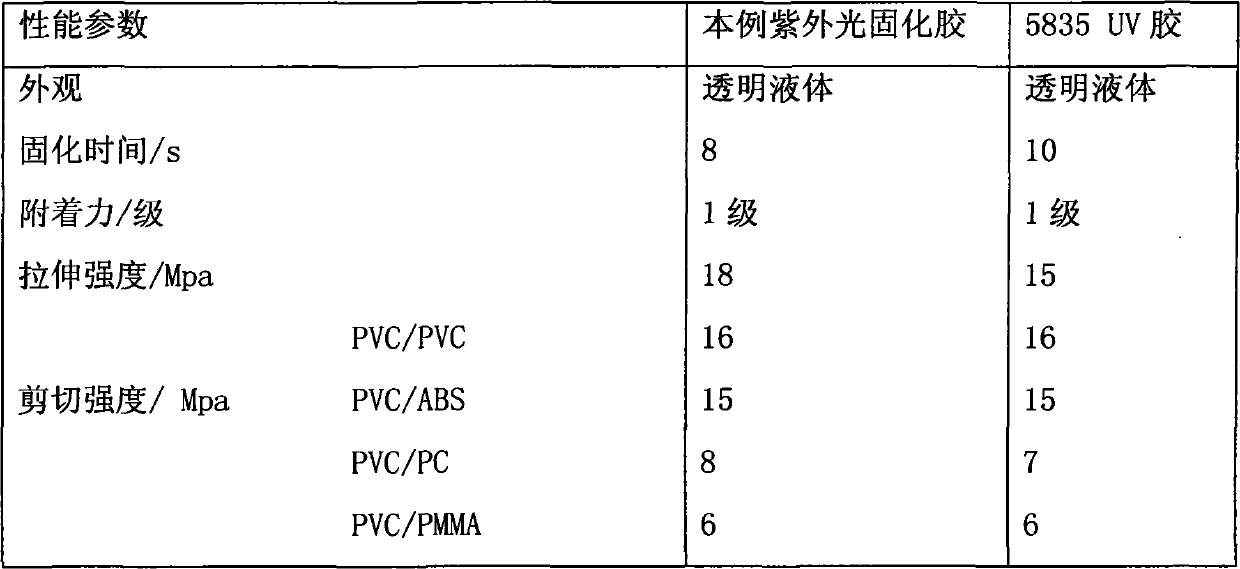

UV-cured adhesive for plastic and preparation method thereof

InactiveCN101906284AImprove flexibilityImprove curing speedPolyureas/polyurethane adhesivesModified epoxy resin adhesivesAdhesiveDiluent

The invention discloses a novel UV-cured adhesive for plastic and a preparation method thereof. The UV-cured adhesive is prepared by the following steps of: adding polyurethane acrylate and a monomer diluent into an epoxy acrylate resin, stirring at the constant temperature of between 50 and 55 DEG C for 3 to 4 hours, and adding a photoinitiator, an accelerating agent and a polymerization inhibitor; and regulating the temperature to between 60 and 70 DEG C, stirring at the constant temperature for 1 to 2 hours and discharging to prepare the novel UV-cured adhesive. The UV-cured adhesive comprises the following components in percentage by weight: 30 to 60 percent of polyurethane acrylate, 10 to 30 percent of epoxy acrylate resin, 4 to 5 percent of photoinitiator, 25 to 65 percent of monomer diluent, 0.1 to 0.9 percent of accelerating agent and 0 to 0.2 percent of polymerization inhibitor. The product is mainly applied to adhesion of PVC, ABS, PC, PMMA and other plastics, and has the advantages of no solvent, simple and easy operation and suitability for mass production.

Owner:SOUTH CHINA UNIV OF TECH

Pile-anchor foundation ditch supporting construction method

ActiveCN101225661AOpen working surfaceImprove construction progressExcavationsBulkheads/pilesBasementEngineering

The invention discloses a foundation pit support method with pile and anchor, belonging to an external staying support technique field of the supporting structural retaining of the foundation pit, comprising that: a. bored piles are constructed to form a retaining wall, after lofting of the pile location according to the planar graph of the pile location; b. the soil is excavated to the bottom elevation of the top beam; c. the bored piles are chiseled to the design elevation; d. the first row of anchors are constructed in the soil layer between the adjacent bored piles; e. the top beams are constructed; f. the soil is excavated to the constructing position of the second row of anchors; g. the second row of anchors are constructed; h. the processes of f and g can be repeated until to the last row of anchors, according to different design conditions; i. the soil is excavated to the bottom of the foundation pit. The foundation pit support method with pile and anchor has the advantages of avoiding a lot of inner supports, providing an open working face for soil excavation, creating a good condition for mechanized construction, increasing the construction progress, needing not to treat the water stop of supporting, bracing substitution, dismantling support during the subsequent construction of the basement, convenient construction, increasing the progress, reducing the construction cost.

Owner:浙江环宇建设集团有限公司

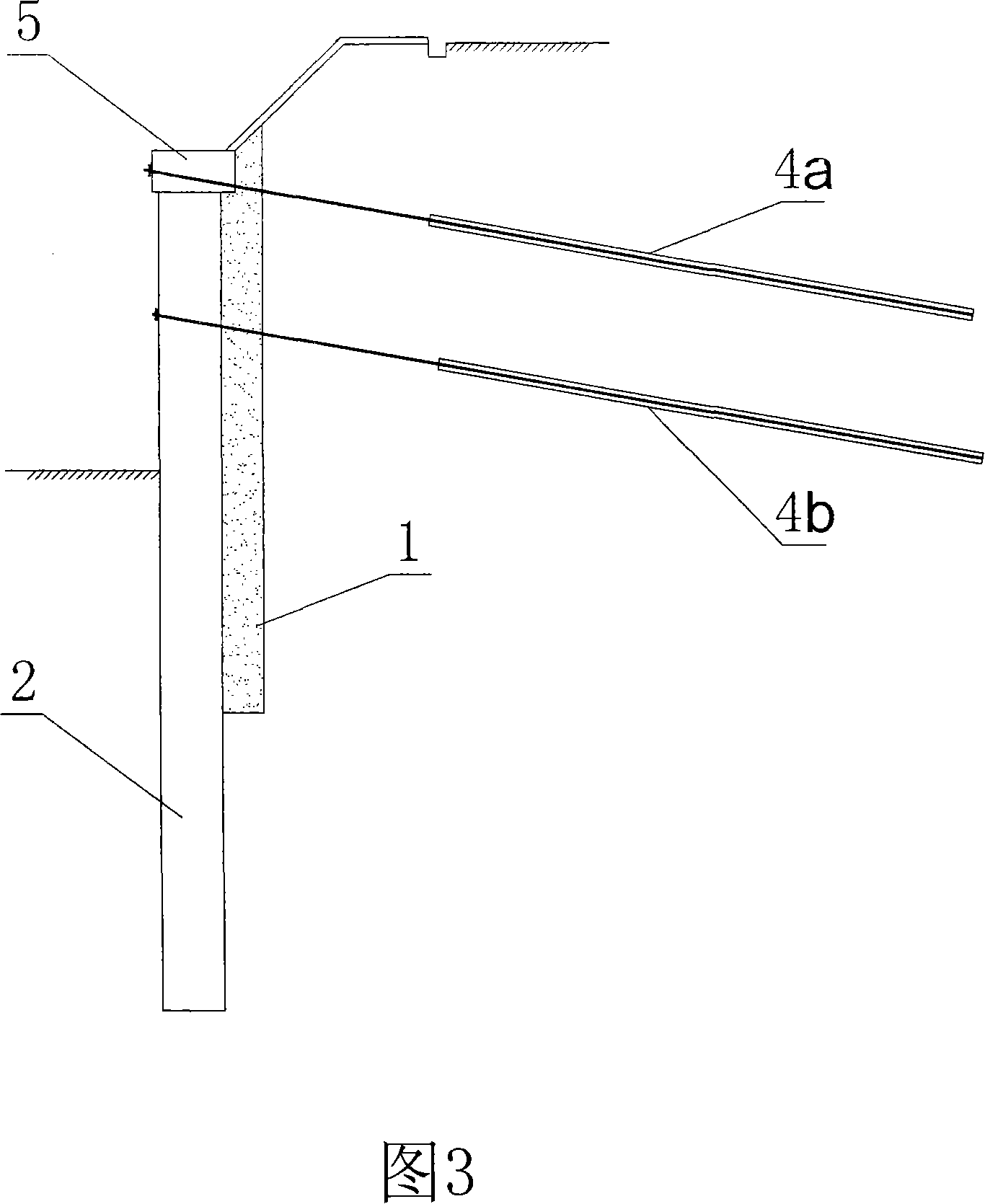

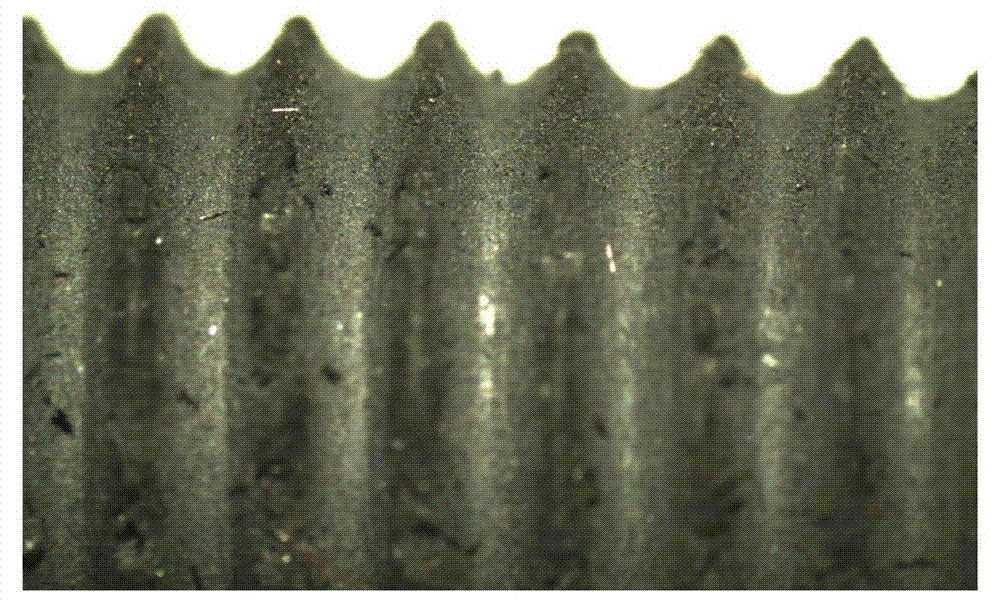

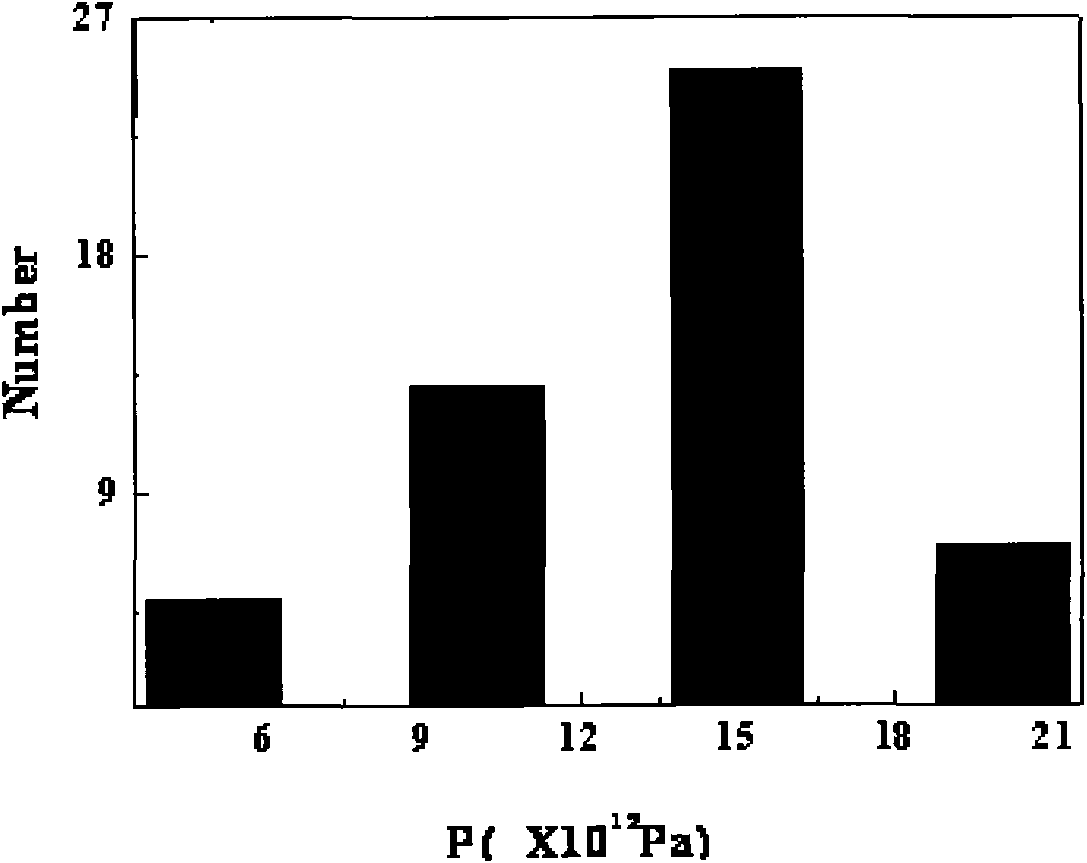

Preparation method of three-dimensional needling carbon/carborundum composite material bolt

ActiveCN102775176AIncreased shear strengthReduce wearScrewsChemical vapor infiltrationMaterials science

A preparation method of a three-dimensional needling carbon / carborundum composite material bolt adopts a three-dimensional needling fiber prefabrication body to prepare the composite material bolt. Pyrolytic carbon is deposited on the prefabrication body, carborundum substrates are deposited through chemical vapor infiltration (CVI), and a bolt bar blank and a bolt cap blank are obtained. The carborundum substrates of the bolt bar blank and the bolt cap blank which are obtained through machining are deposited through the CVI, a carborundum anti-oxidation coating is deposited through the CVI, and a three-dimensional needling C / SiC composite material bolt end product with the shear strength being 80-100MP is obtained. Compared with the prior art, the preparation method has the advantages that the number of times for getting into a furnace is reduced by 6-10, the densifying period is shorter, and the production cost is reduced. By means of a test of a CK6180-3000 numerically controlled lathe, the preparation method is small in diamond grinding wheel abrasion, hour norm for machining 30 bolt threads is reduced by about 10 hours, and as the abrasion of a grinding wheel is less, the working accuracy is improved, and industrialized batch production is achieved.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

Environment-friendly heat conduction insulating glue used by high-power LEDs and preparation method

ActiveCN101812280AImprove cooling effectImprove work efficiencyNon-macromolecular adhesive additivesEpoxynovolac adhesivesEpoxyWorking temperature

The invention relates to an environment-friendly heat conduction insulating glue used by high-power LEDs, which is characterized by being prepared from the following raw materials in percentage by weight: 50-68 percent of micro-grade high-thermal conductive powder, 18-30 percent of epoxy resin, 4-10 percent of curing agent, 7-15 percent of solvent, 0.6-1.5 percent of accelerator and 1-2 percent of additive; and the micro-grade high-thermal conductive powder is selected from a mixture formed by one or more of micro-grade aluminum powder, palladium powder, platinum powder, gold powder, C powder, AlN powder and SiC powder. The invention also relates to a preparation method of the heat conduction insulating glue. The environment-friendly heat conduction insulating glue used by high-power LEDsis obtained by optimizing the matching ratio and the modification of the raw materials and improving and simplifying the preparation process. Besides high resistivity, the heat conduction insulating glue also has high thermal conductivity, higher working temperature, strong viscosity, high cutting strength and fine performance index.

Owner:连云港市昭华光电科技有限公司

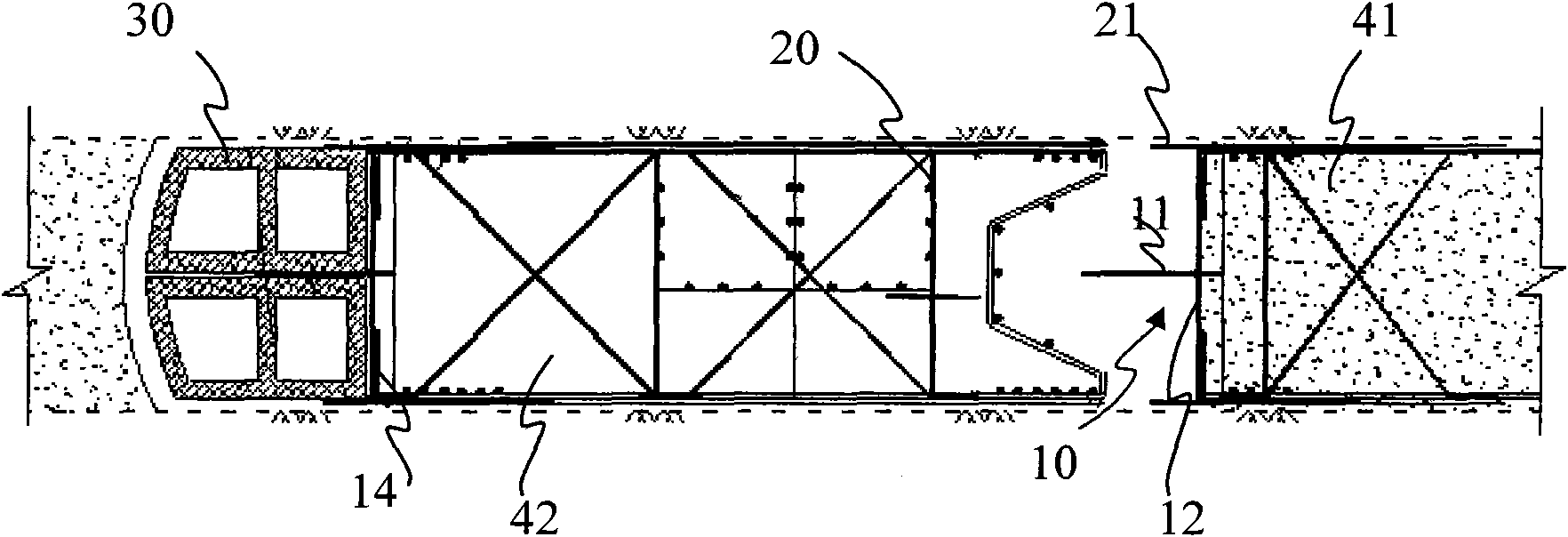

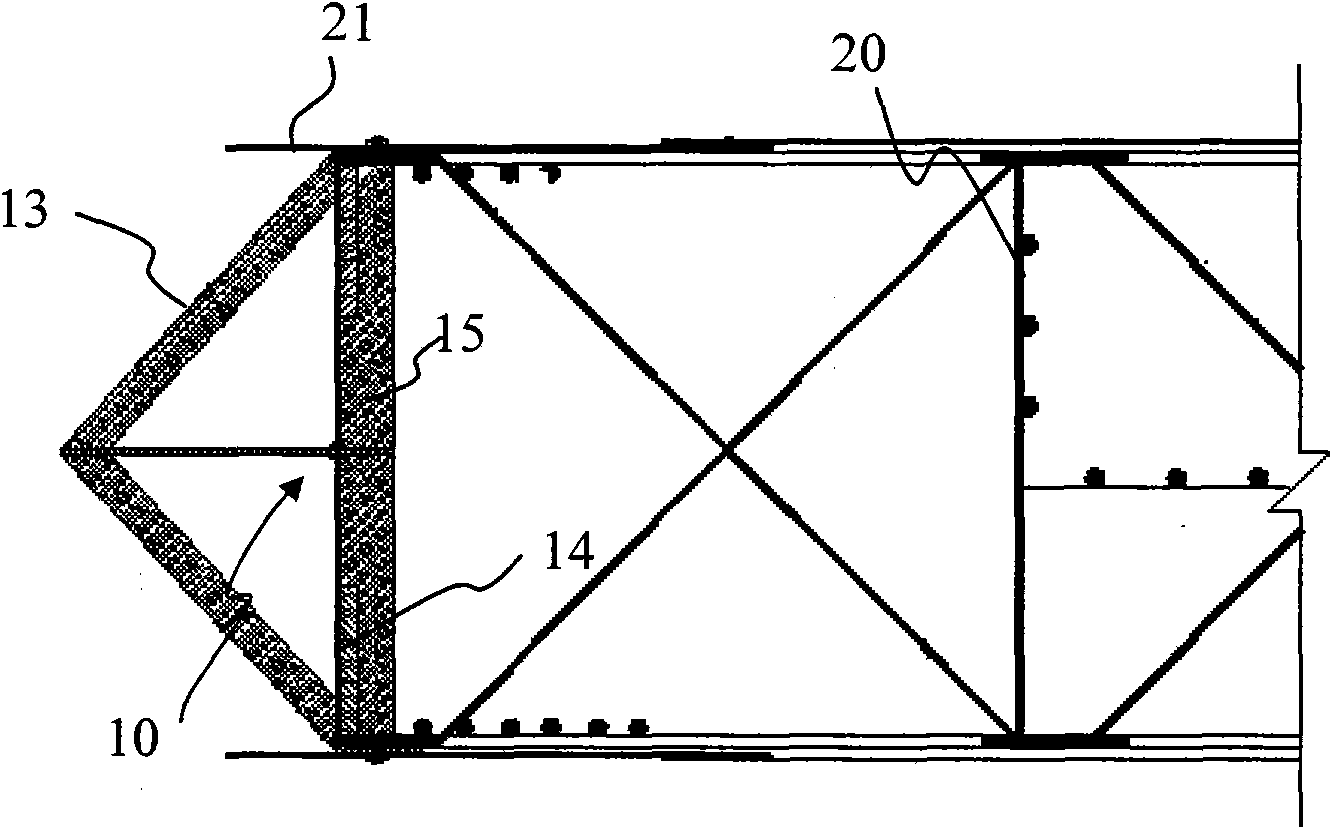

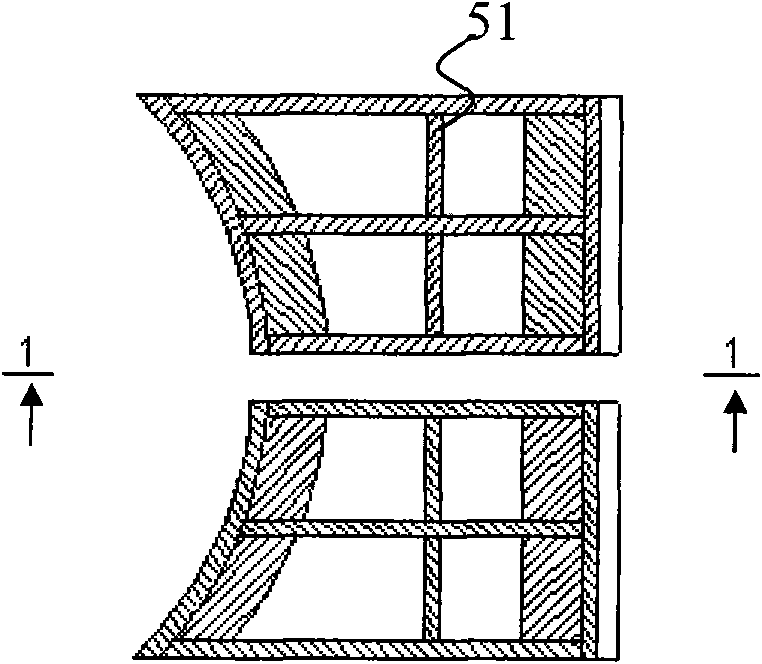

Cross steel plate water-stopping joint continuous concrete wall and joint construction method thereof

InactiveCN101608447AIncreased shear strengthImprove integrityArtificial islandsUnderwater structuresSlurry wallCement slurry

The invention provides a cross steel plate water-stopping joint of a continuous concrete wall and a joint construction method thereof. The cross steel plate joint comprises a longitudinal water-stopping steel plate and a horizontal head steel plate, wherein the longitudinal water-stopping steel plate is about 35-50 cm long, a detouring flow line of cement slurry is lengthened, the impermeability of the joint of the continuous concrete wall is enhanced, the bottom of the horizontal head steel plate extends to the tank bottom level or is inserted into the soil by 20 cm, and the detouring flow line of concrete and sand pulp along the bottom of the head steel plate is blocked; during constructing, a cross steel plate and a steel reinforcement cage are welded into a whole which is then deposited into a tank section so that the joint and a wall body have better integrity; a counterforce box is deposited at the back of the cross steel plate and is impacted to enter soil by over + / -30 cm, and then carpolite or clay are backfilled at the back for sealing; the concrete is cast in the tank section; the counterforce box is pulled out, then a flushing or shoveling tool corresponding to the cross steel plate in structure is adopted to remove the attachment at the part so as to ensure the water-stopping effect and the joint intensity of the cross steel plate.

Owner:SHANGHAI TUNNEL ENGINEERING CO. LTD.

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com