Novel electric cable reinforced core and preparation method thereof

A technology for reinforcing cores and cables, which is applied in the direction of cable/conductor manufacturing, insulated cables, cables, etc. It can solve problems such as longitudinal cracking, composite cable core damage, and reduced mandrel life, so as to reduce arc sag, increase tensile strength, The effect of increasing the safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

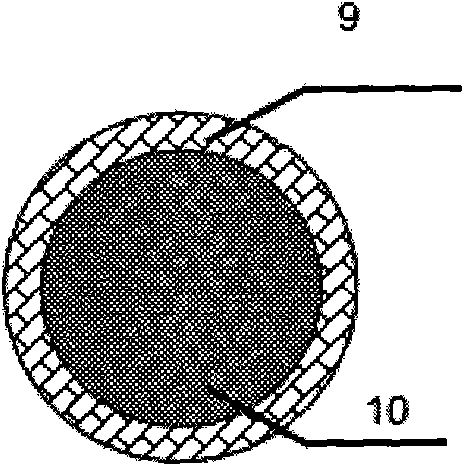

[0026] The fiber composite core adopts epoxy resin system, and the inner fiber of the reinforcing core adopts carbon fiber, wherein the strength of carbon fiber is 4900MPa, and the modulus is 230GPa. The outer weaving fiber adopts basalt fiber, and the strength of basalt fiber is 3000MPa and the modulus is 90GPa. The mandrel adopts pultrusion molding method, the mandrel diameter is 9.5mm, the tensile strength of the fiber composite mandrel can reach 2300MPa, the modulus can reach 100GPa, and the mandrel density is 1.7~1.9g / cm 3 .

Embodiment 2

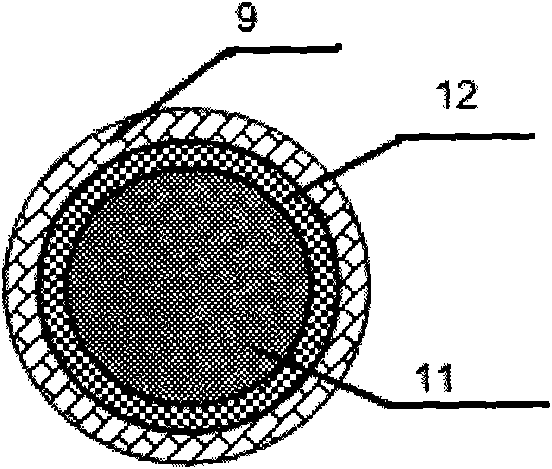

[0028] The fiber composite core adopts epoxy resin system, and the inner fiber of the reinforced core adopts basalt fiber and carbon fiber. The strength of basalt fiber is 3000MPa and the modulus is 90GPa; the strength of carbon fiber is 3300MPa and the modulus is 220GPa. The outer weaving fiber is made of carbon fiber, the strength of carbon fiber is 3300MPa, and the modulus is 220GPa. The mandrel adopts pultrusion-braiding molding method, the fiber gradually transitions from carbon fiber to basalt fiber from the inside to the outside, the outer layer is made of braided basalt fiber, the mandrel diameter is 9.5mm, the tensile strength of the fiber composite mandrel can reach 1900MPa, the modulus Can reach 100GPa, mandrel density is 1.8~2.0g / cm 3 .

Embodiment 3

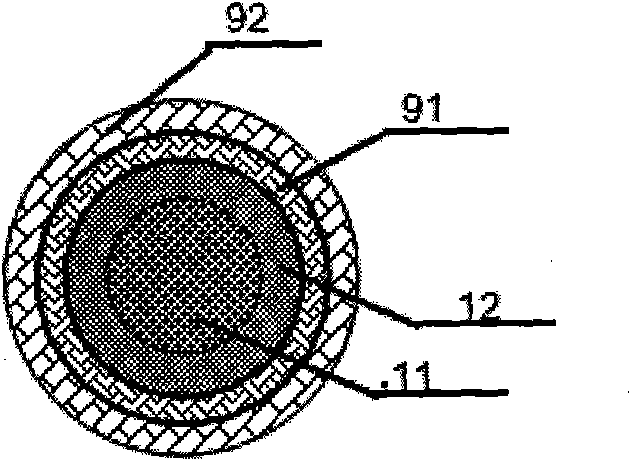

[0030] The composite core adopts a vinyl resin system, and the inner fiber of the reinforcing core adopts aramid fiber and carbon fiber. The strength of the aramid fiber is 3200MPa and the modulus is 70GPa; the strength of the carbon fiber is 3300MPa and the modulus is 220GPa. The braided fiber of the outer layer of the reinforcing core is aramid fiber, the strength of the aramid fiber is 3200MPa, and the modulus is 70GPa. The mandrel adopts the pultrusion-braiding method, and the fiber gradually transitions from carbon fiber to aramid fiber from the inside to the outside, and then transitions to the braided aramid fiber on the outer layer. The diameter of the overall composite mandrel is 7.8mm, and the fiber composite The tensile strength of the mandrel can reach 1960MPa, the modulus can reach 120GPa, and the mandrel density is 1.5~1.7g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com