Patents

Literature

64results about How to "Small sag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

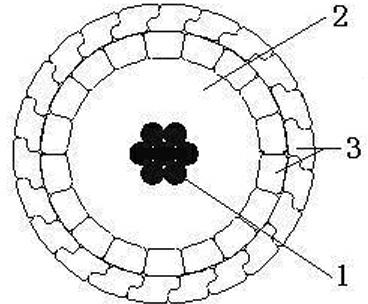

Novel electric cable reinforced core and preparation method thereof

InactiveCN101740161ASmall sagHigh tensile strengthNon-insulated conductorsPlastic/resin/waxes insulatorsFiber-reinforced compositeFiber type

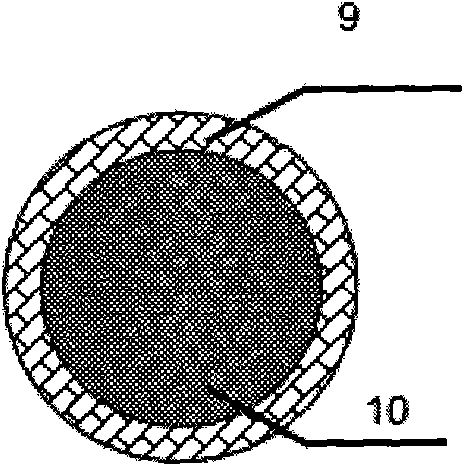

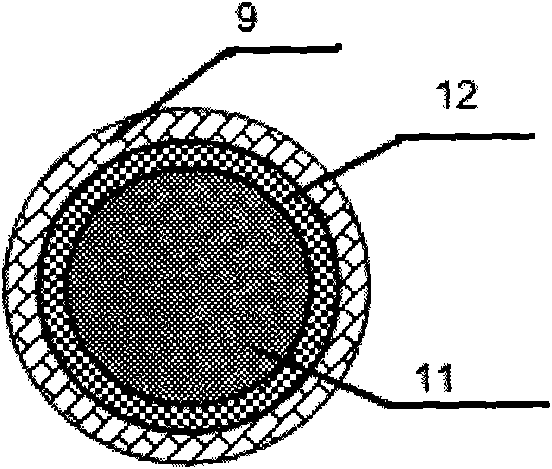

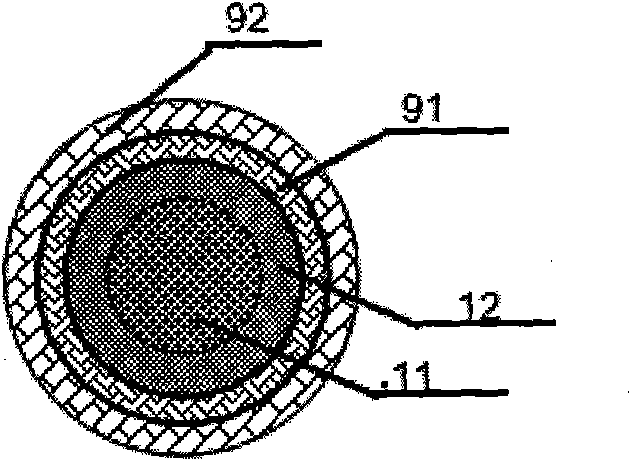

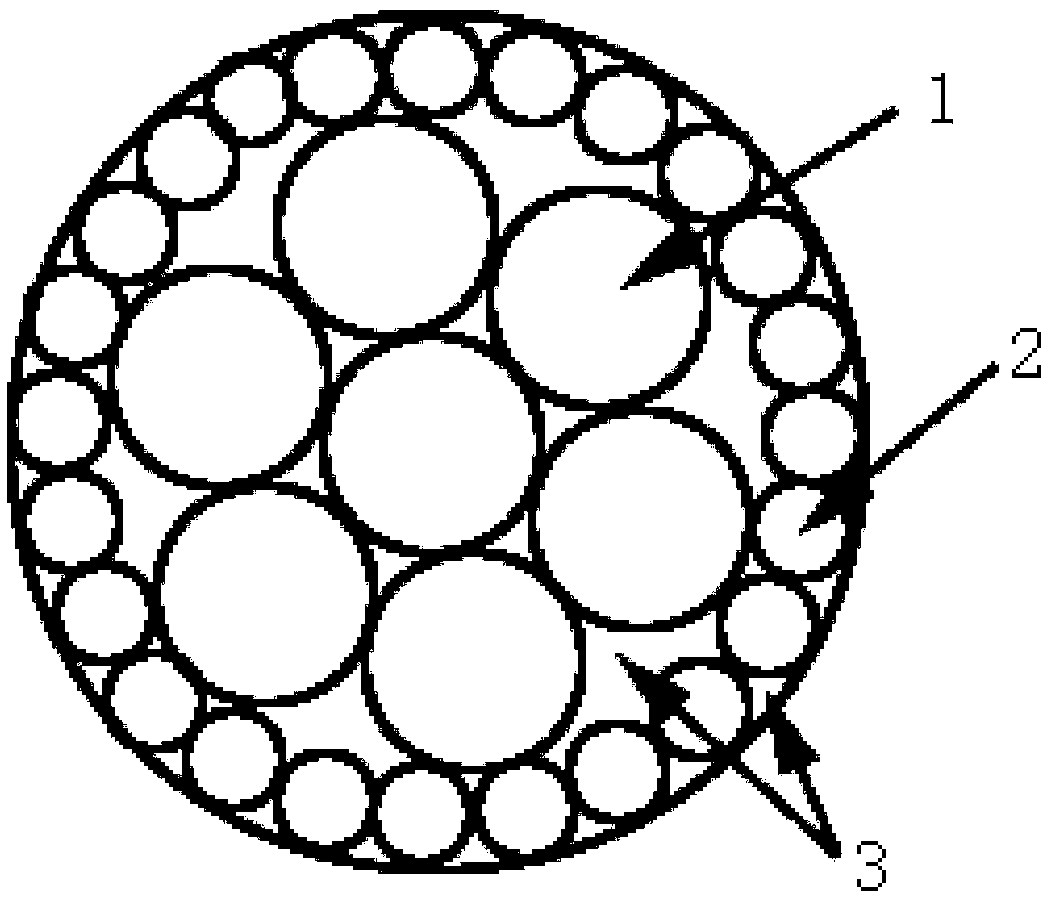

The invention discloses a novel electric cable reinforced core, which is composed of a fiber reinforced composite material, the fiber reinforced composite material comprises at least a reinforced fiber type which has longitudinal orientation in the resin and is basically continuous and is used as an inner layer composite material core; the fiber reinforced composite material further comprises a braided or twined reinforced protective outer layer around the inner layer composite material core, the reinforced protective outer layer comprises at least a reinforced fiber type which is braided in the resin and is basically continuous. The longitudinal fiber and the braided fiber are composited in the invention, thereby having the advantages that the longitudinal tensile strength, the resist compression strength, the bending resistance and the shearing resistance of the electric cable reinforced core in the longitudinal direction are increased, and the safety factor are increased, and the loss of the mechanical performance caused by defects owning to external abrasion or impact in the transportation process, the laying and installing process and the operation process is avoided.

Owner:SHANGHAI ELECTRIC CABLE RES INST

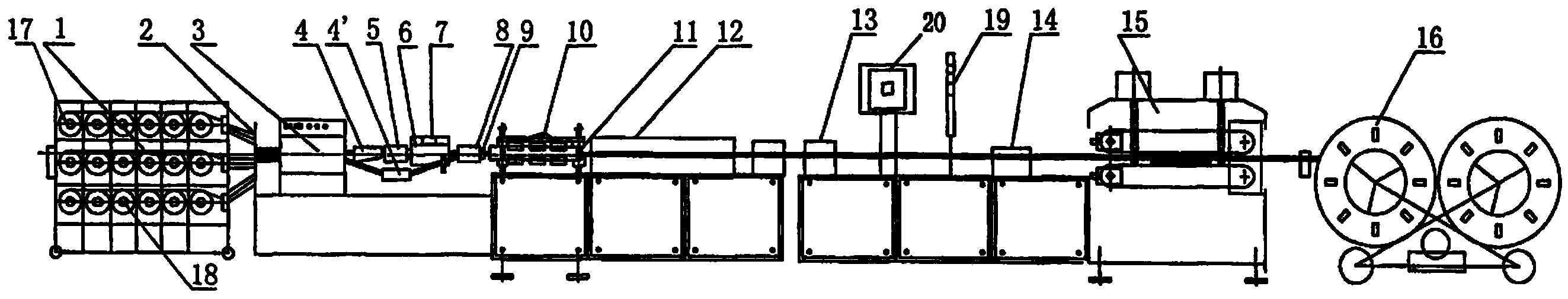

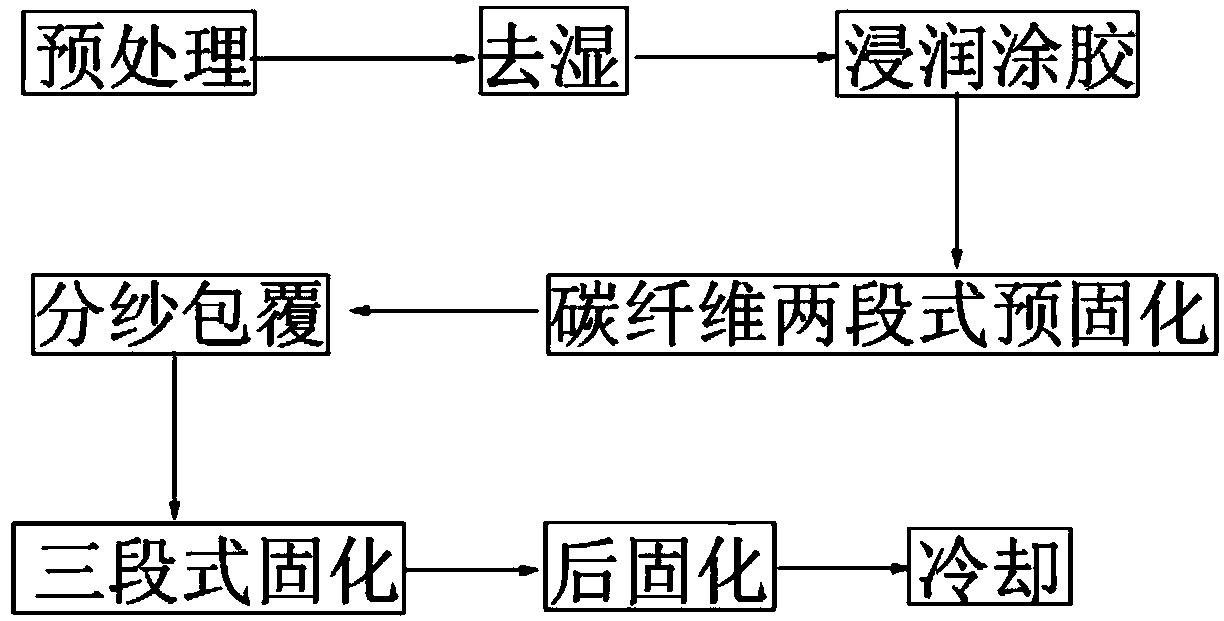

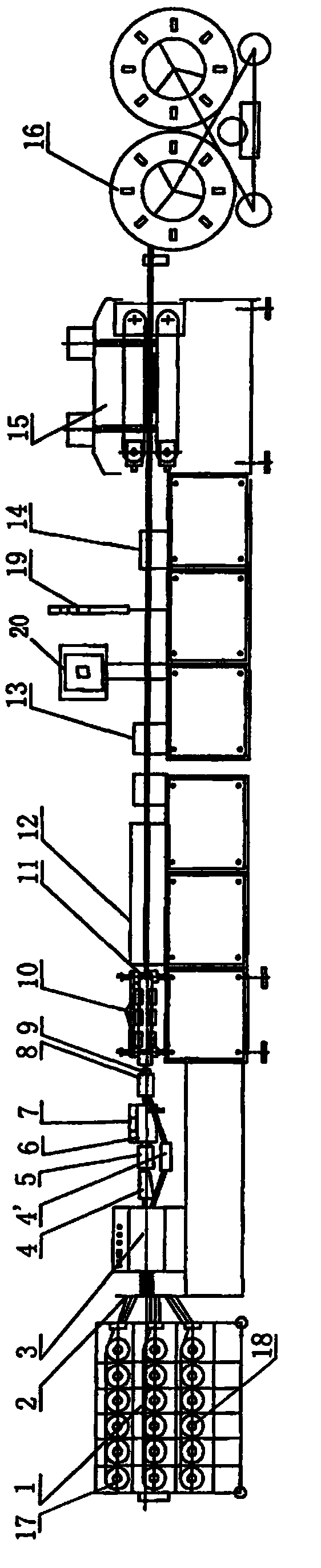

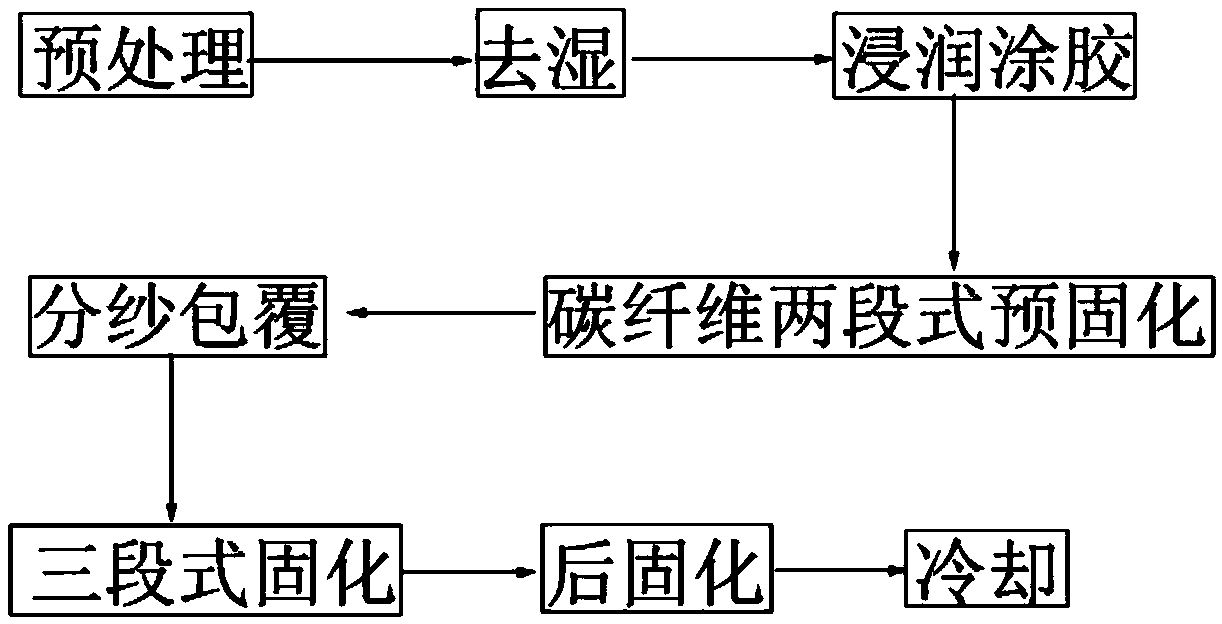

Electric transmission line carbon fiber composite core manufacturing method

InactiveCN103413629AImprove conductivityImprove performanceCable/conductor manufactureElectric power transmissionBasalt fiber

An electric transmission line carbon fiber composite core manufacturing method mainly includes the following steps of conducting preprocessing, dehumidification and glue infiltration, pre-hardening carbon fibers in a two-section heating mode, enabling high-strength glass fibers or basalt fibers to cover a pre-hardened carbon fiber core according to certain rules, hardening the carbon fiber core covered by the high-strength glass fibers or the basalt fibers in a three-section mode, and conducting post curing and cooling, wherein consumed epoxy resin is high-temperature-resistant special type pultrusion epoxy resin which is prepared by adding modified anhydride compounds in the glue infiltration process. The electric transmission line carbon fiber composite core manufacturing method has the advantages that the carbon fibers are preformed in a pultrusion mode to be in a semi-hardened state after being infiltrated, heating temperature sections are controlled so that the carbon fiber core with excellent performance can be obtained, particularly, heating and hardening are conducted in the three-section mode in the final covering and forming process, therefore, the rigidity of final products is ensured, the smoothness of production and production efficiency are improved, and the carbon fiber composite core produced through combination can completely meet the requirements of electric power transmission.

Owner:SUZHOU SUYUE NEW MATERIAL

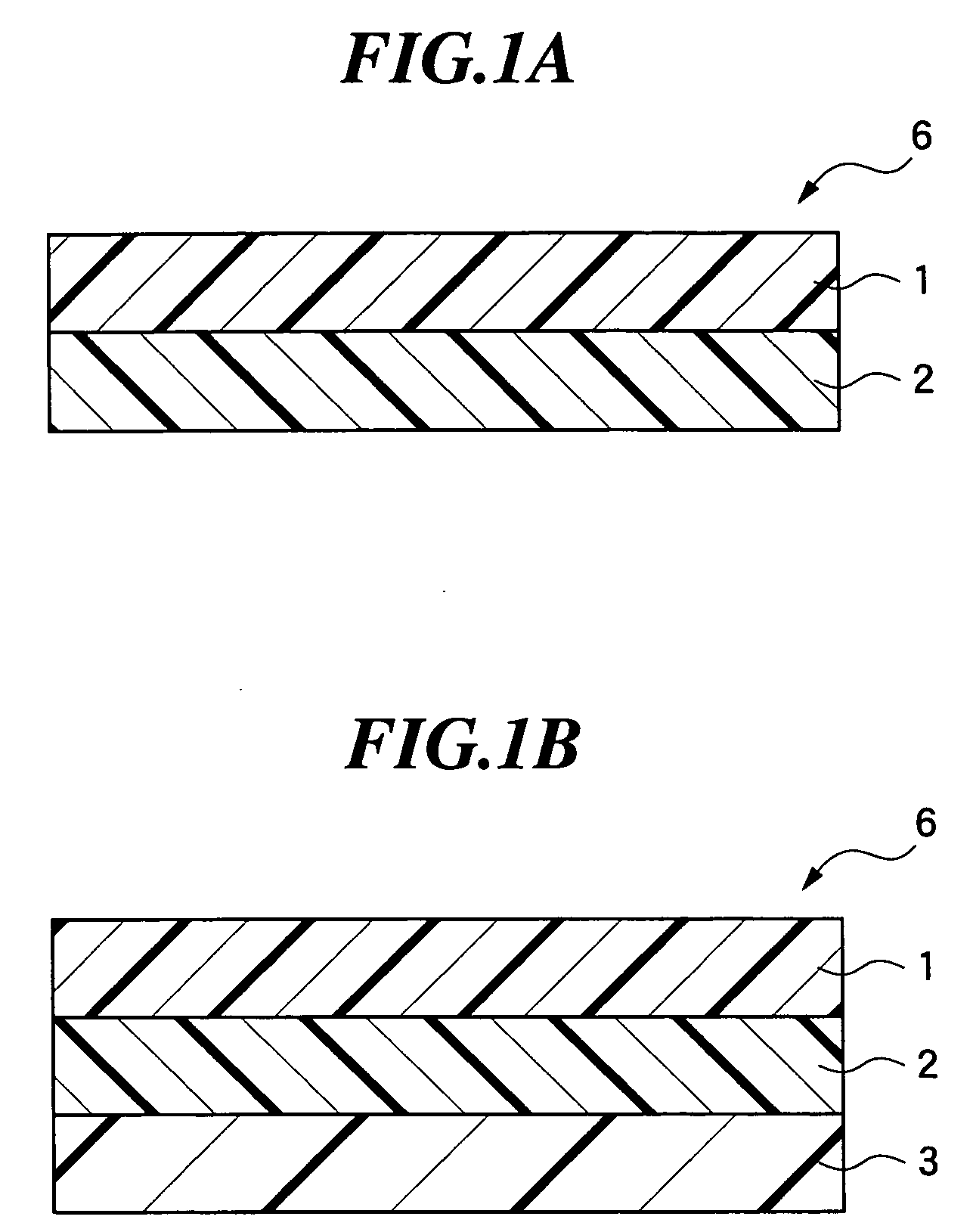

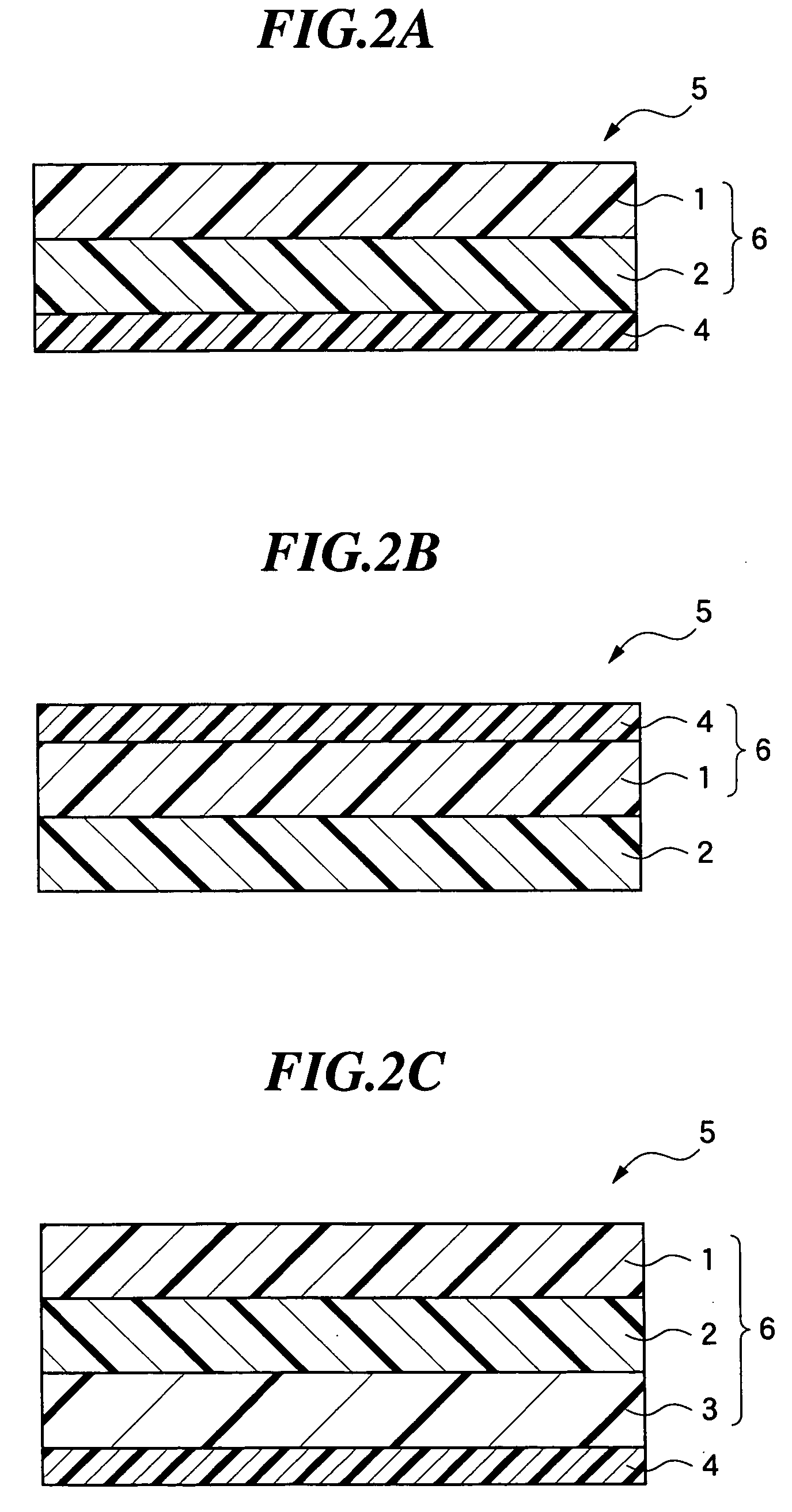

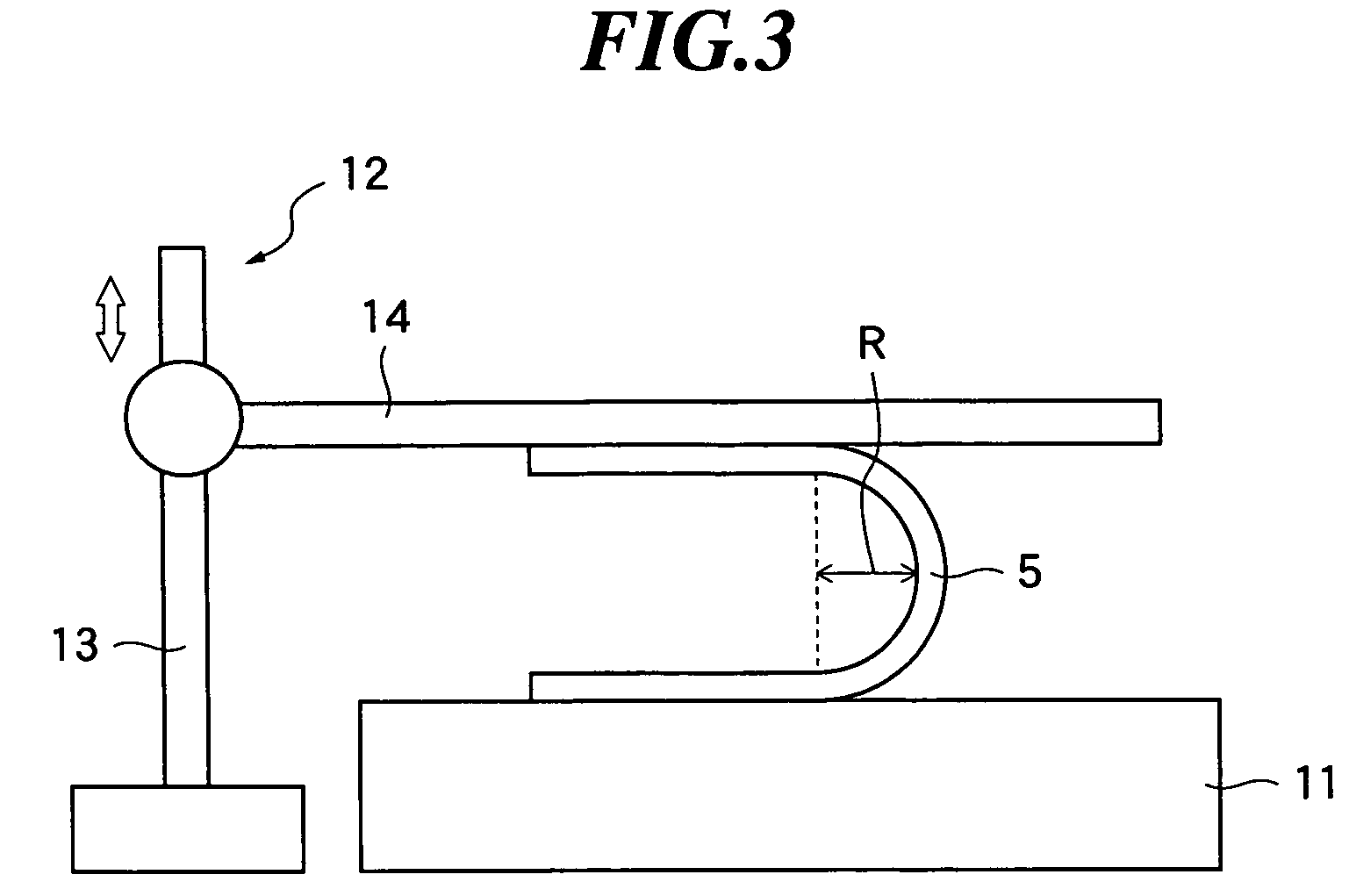

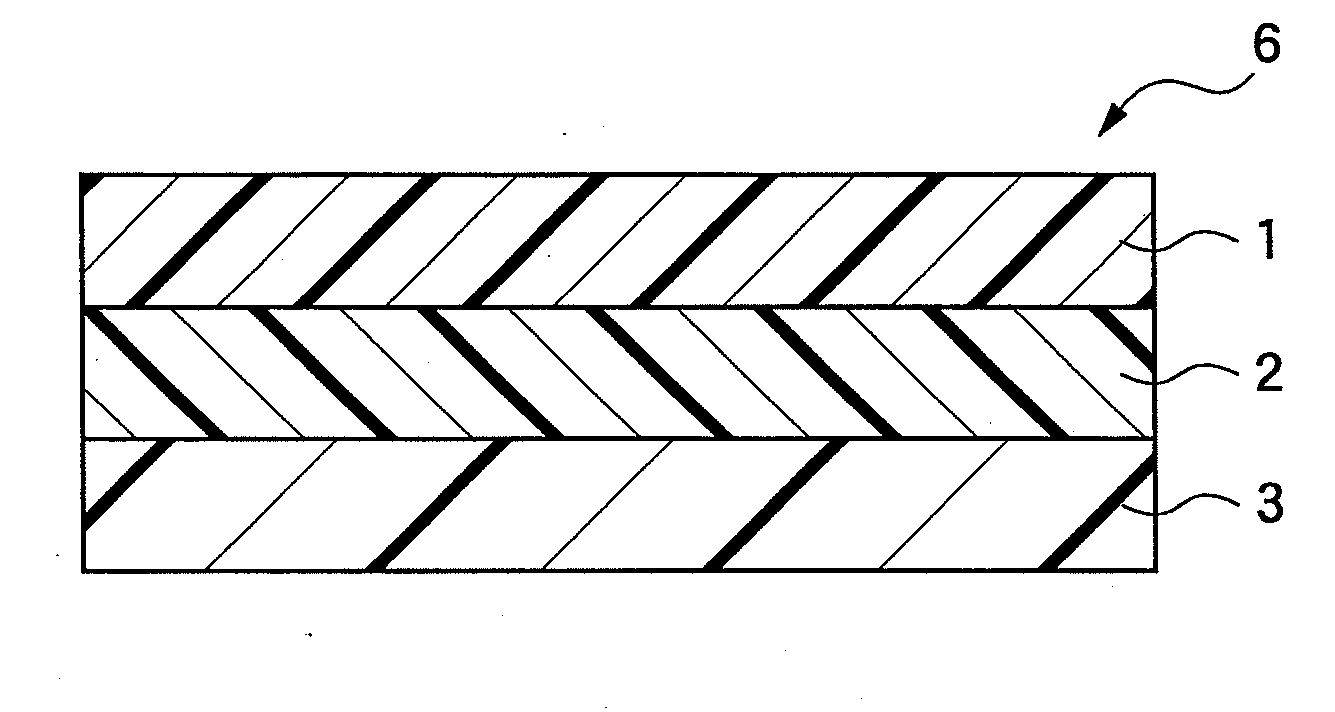

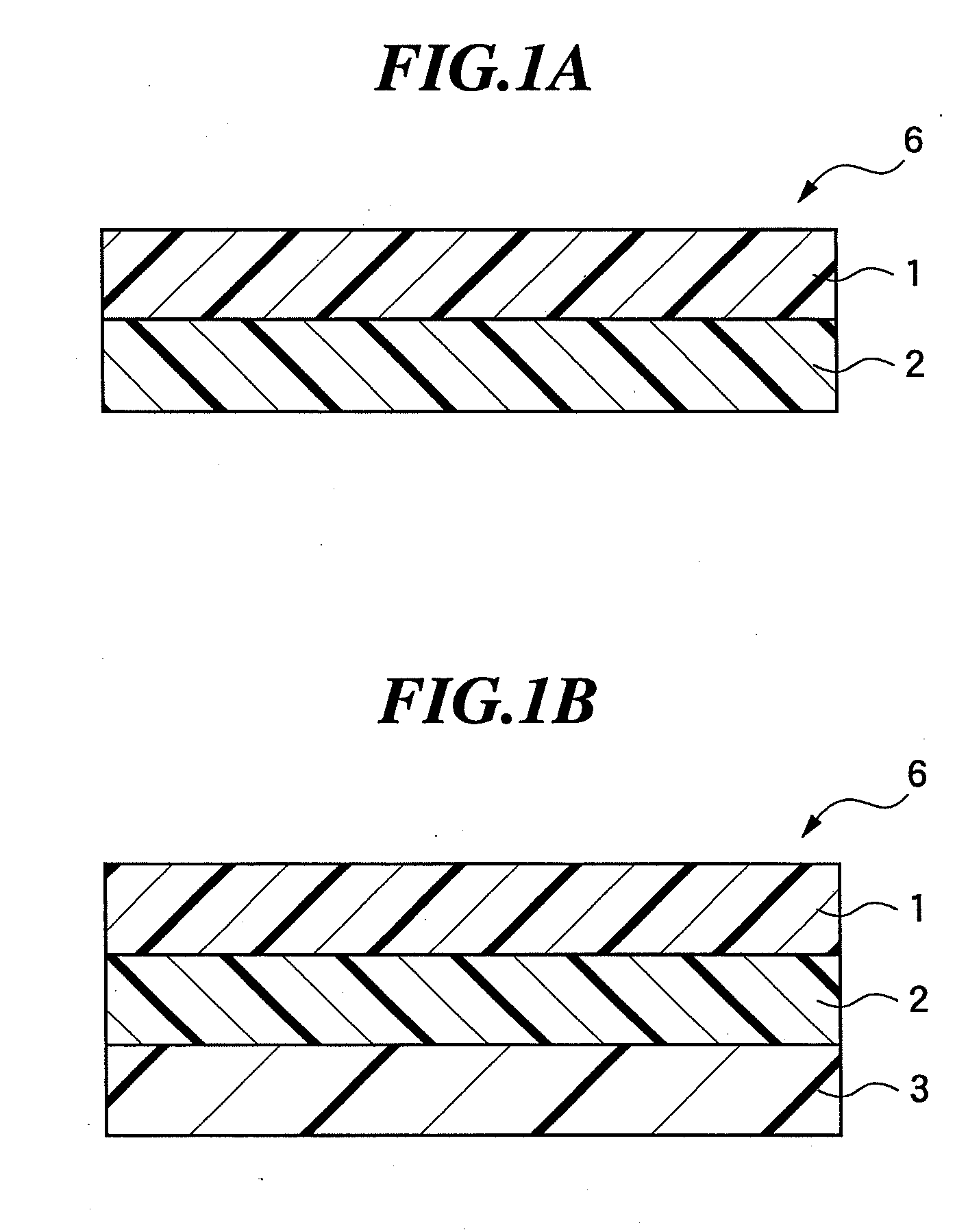

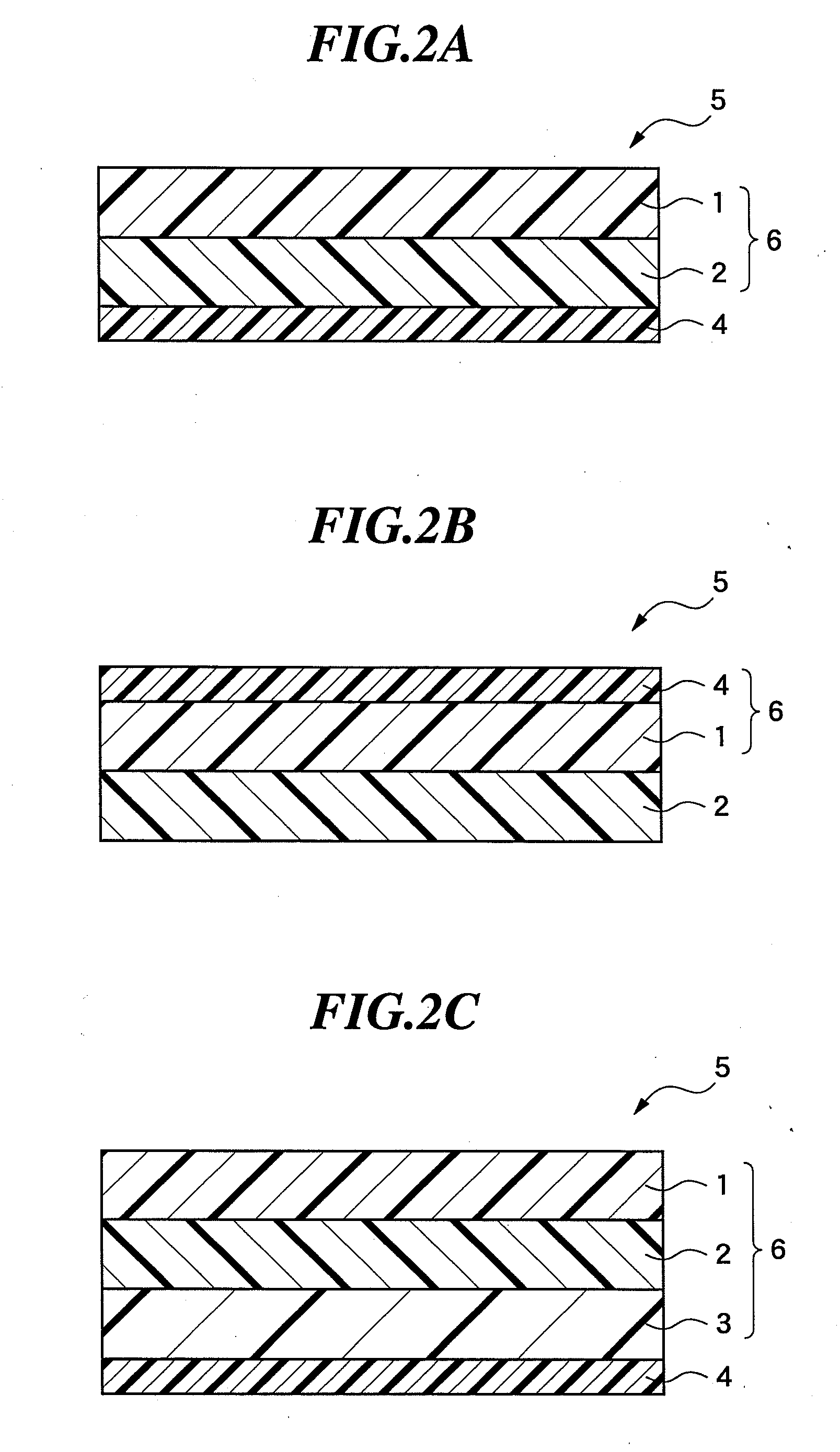

Pressure-sensitive adhesive sheet, method for producing the same and method for using the same as well as a multi-layer sheet for use in the pressure-sensitive adhesive sheet and method for producing the same

InactiveUS20050153129A1Less curlMade smallFilm/foil adhesivesAdhesive articlesAdhesive cementWafering

Disclosed is a pressure-sensitive adhesive sheet for use in processing a product such a semiconductor wafer. To provide a pressure-sensitive adhesive sheet that provides a minimized number of broken semiconductor wafers during the process of polishing them and that produces a less curl of the wafer due to the residual stress of the pressure-sensitive adhesive sheet, the pressure-sensitive adhesive sheet includes a composite film formed from a composition containing a urethane polymer and a vinyl polymer as effective components, a first film comprising a material different from that of the composite film, and a pressure-sensitive adhesive layer. It is preferable that the pressure-sensitive adhesive sheet has a modulus of 9 N / mm2 or more and 250 N / mm2 or less when an oblong piece of the pressure-sensitive adhesive sheet with a width of 20 mm is bent at a radius of curvature of 3.0 mm.

Owner:NITTO DENKO CORP

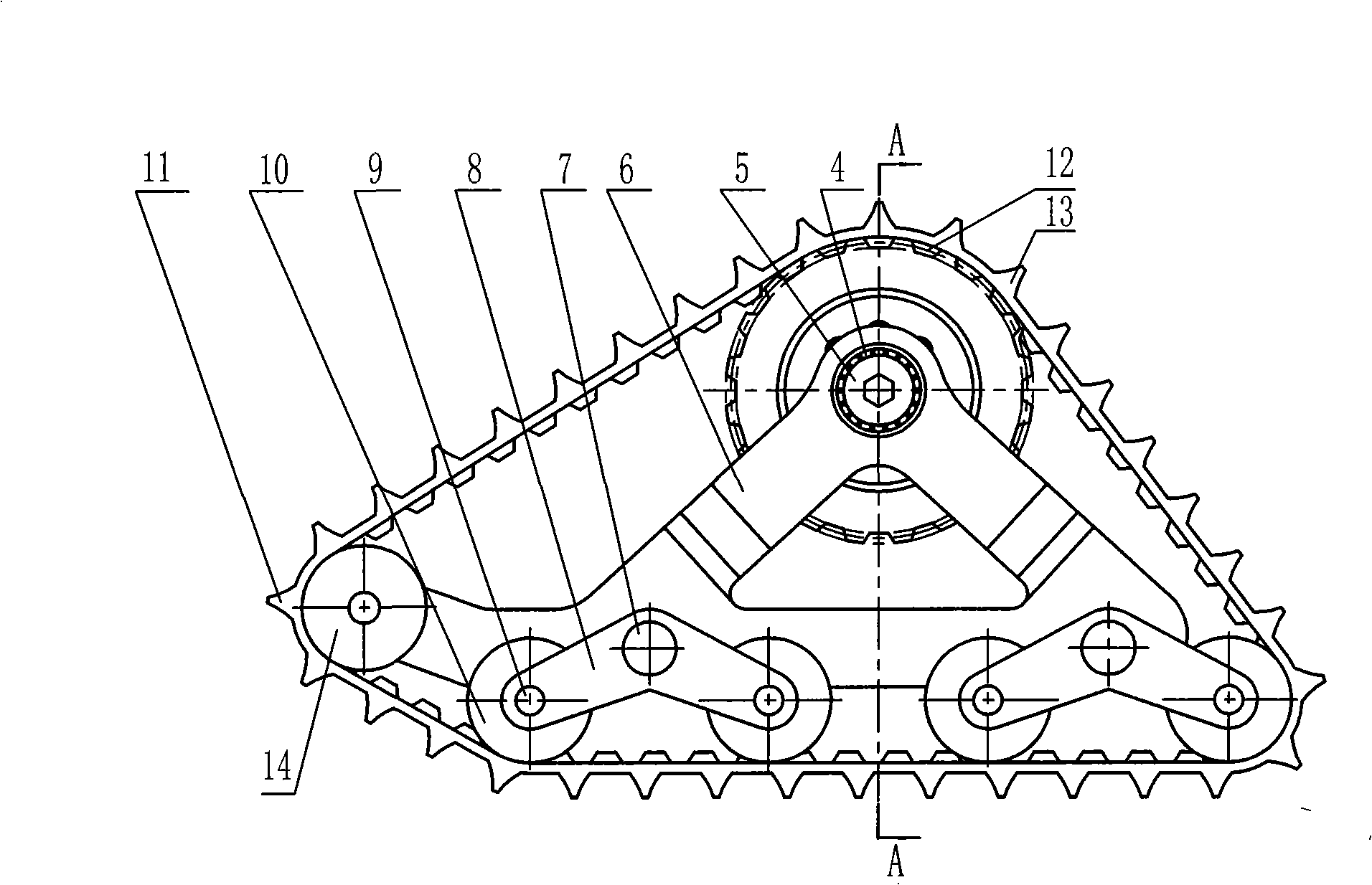

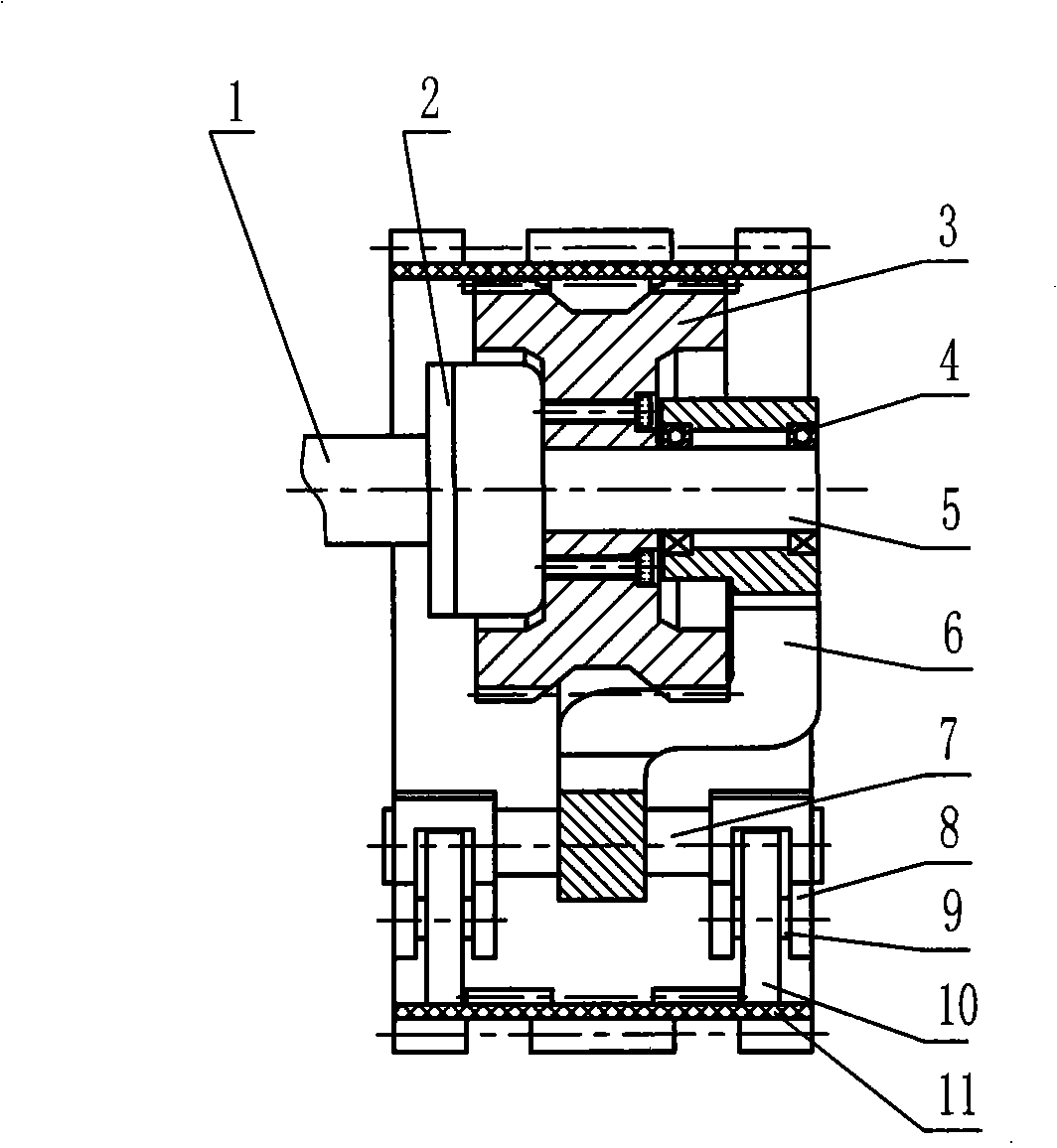

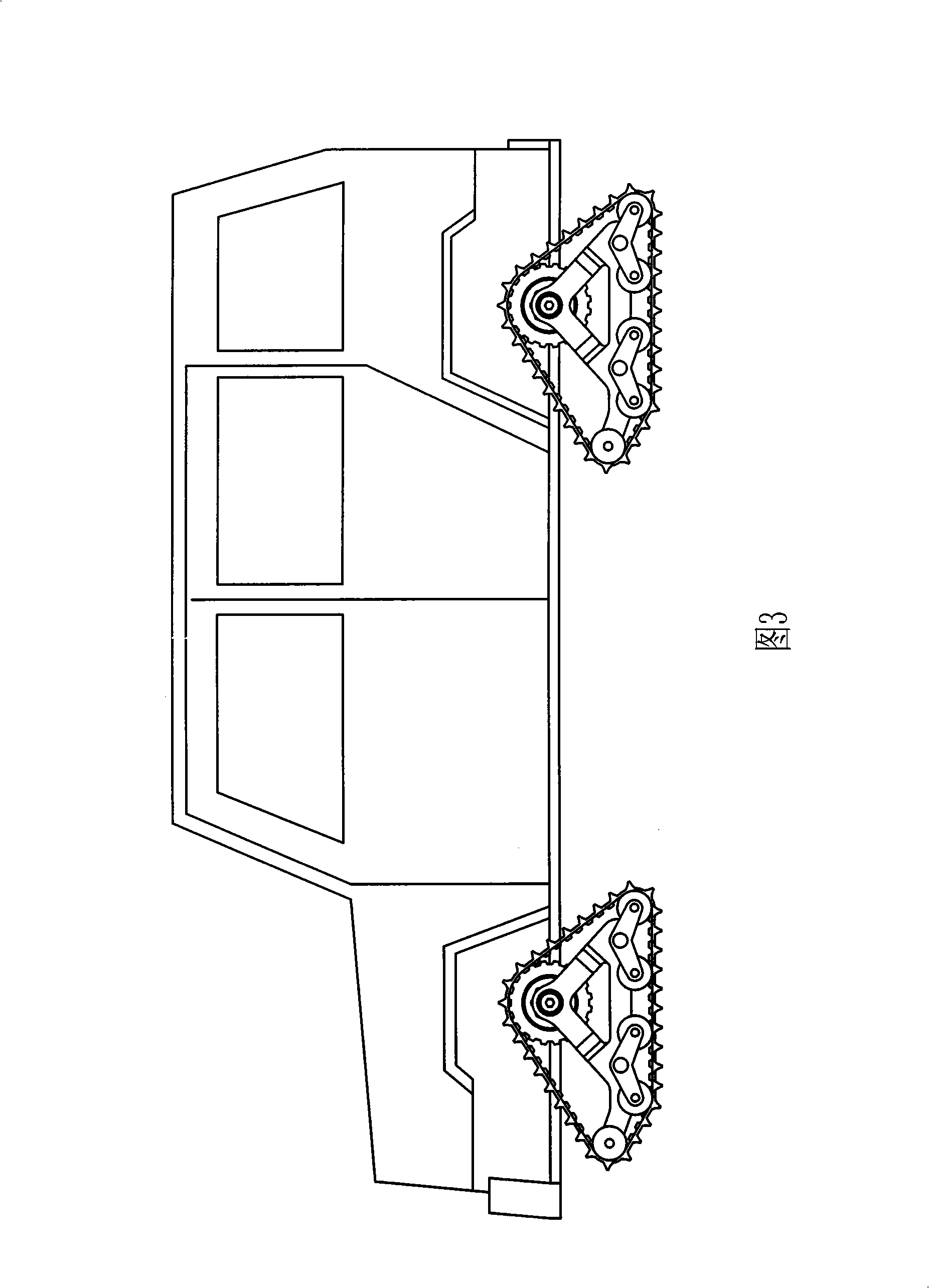

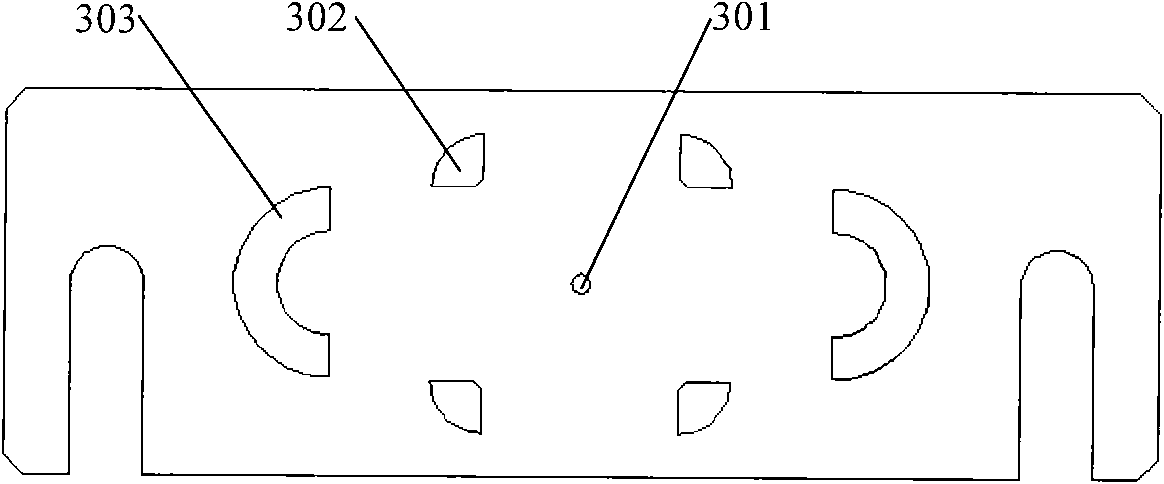

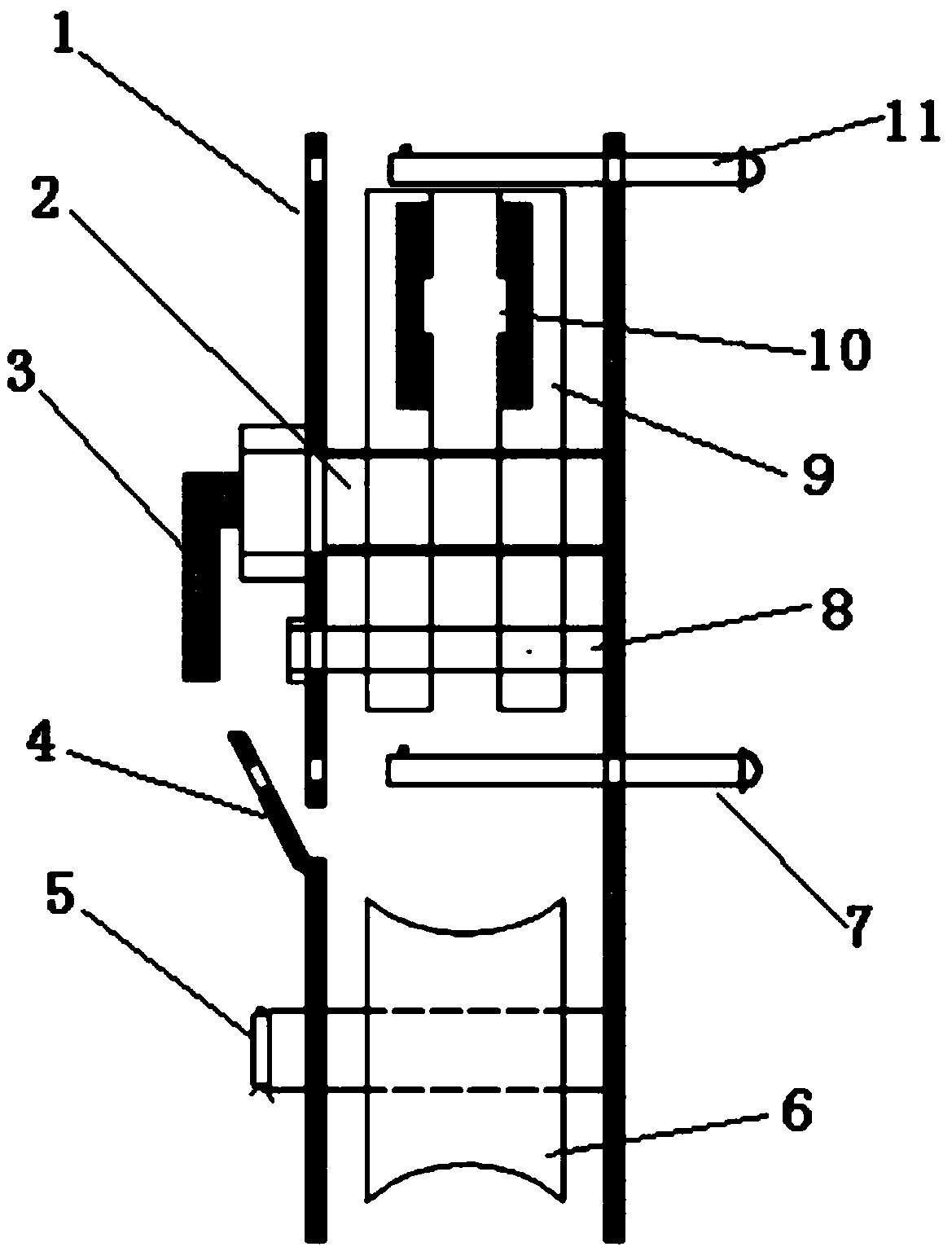

Independent caterpillar walking mechanism

InactiveCN101293540AIncrease ground areaReduce pressureEndless track vehiclesEngineeringSteering system

The invention discloses an independent crawler running mechanism, comprising a driving wheel (3), a crawler (11), a bracket (6) and a swing frame (8); the driving wheel (3) is connected with a brake drum / disc (2) of a motor vehicle; the external side of the driving wheel (3) is provided with a bracket shaft (5); the bracket (6) is arranged on the bracket shaft (5); the bottom of the bracket (6) is provided with the swing frame (8); the lower part of the swing frame (8) is provided with a loading wheel (10); the external round of the driving wheel (3) is provided with grousers (12) which are matched with the crawler (11); the loading wheel (10) is arranged on the crawler (11). The crawler running mechanism of the invention is an independent whole part and requires no reconstruction to the original suspension, braking and steering system and requires to only design the bolt connection hole on the driving wheel to be consistent with the hole of a hub when being applied to the existing off-road vehicles; the independent crawler running mechanism can lead the motor vehicle to run on the ground with accumulated snow, mud water and desert, etc.

Owner:高鹏

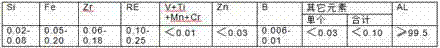

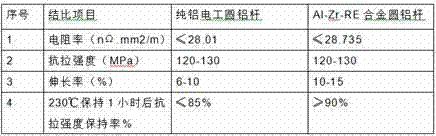

Preparation method of Al-Zr-RE alloy round aluminum rod

The invention relates to a preparation method of an Al-Zr-RE alloy round aluminum rod and belongs to the technical field of aluminum alloy materials. In the production of the round aluminum rod, according to the preparation method, a proper amount of zirconium and rare earth is added to the smelting process of pure aluminum liquid to obtain an Al-Zr-RE alloy; the Al-Zr-RE alloy is formed into the aluminum alloy round rod by virtue of the production process of smelting, standing, casting, rolling and the like; an aluminum alloy conductor formed by use of the aluminum alloy round rod by drawing is extremely low in sag when working at a relatively high temperature for a long time because the tensile strength retention rate of the conductor is kept above 90%, and therefore, the conductor can be used as a long-span overhead conductor; besides, the power transmission capacity of the conductor is greatly improved, the utilization rate of the aluminum is increased and the construction cost is relatively saved.

Owner:YUNNAN ALUMINUM

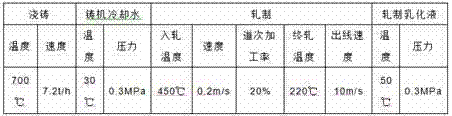

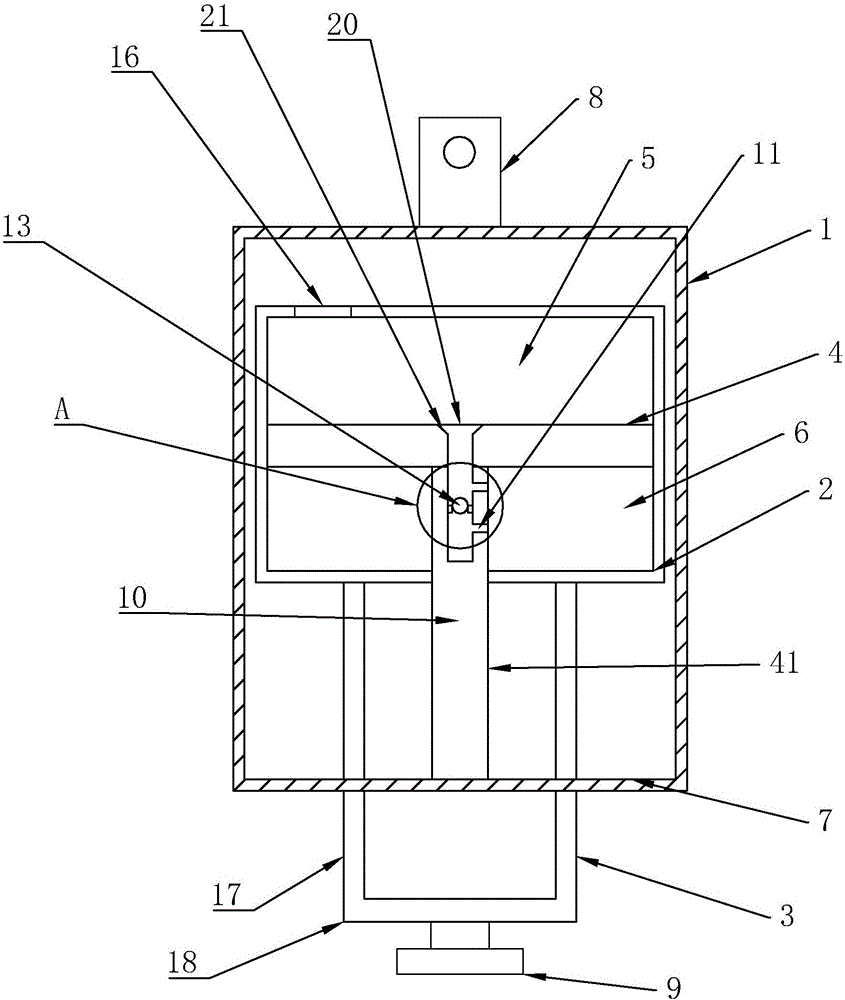

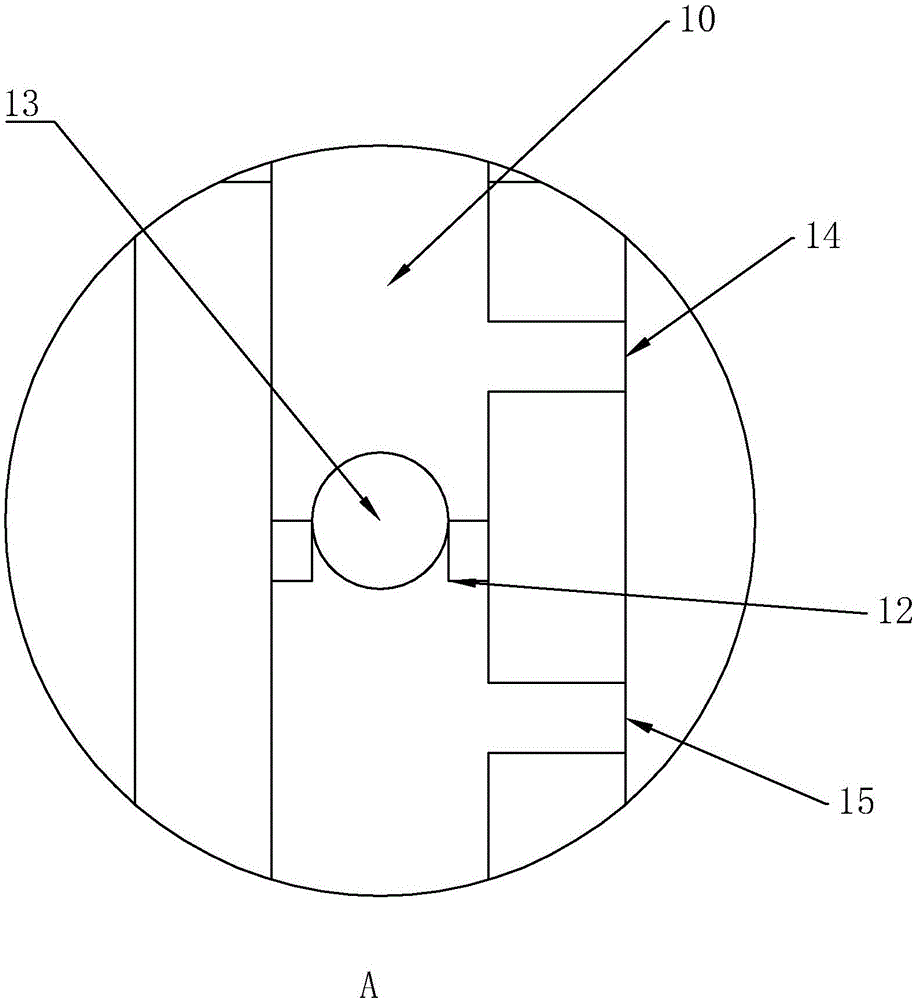

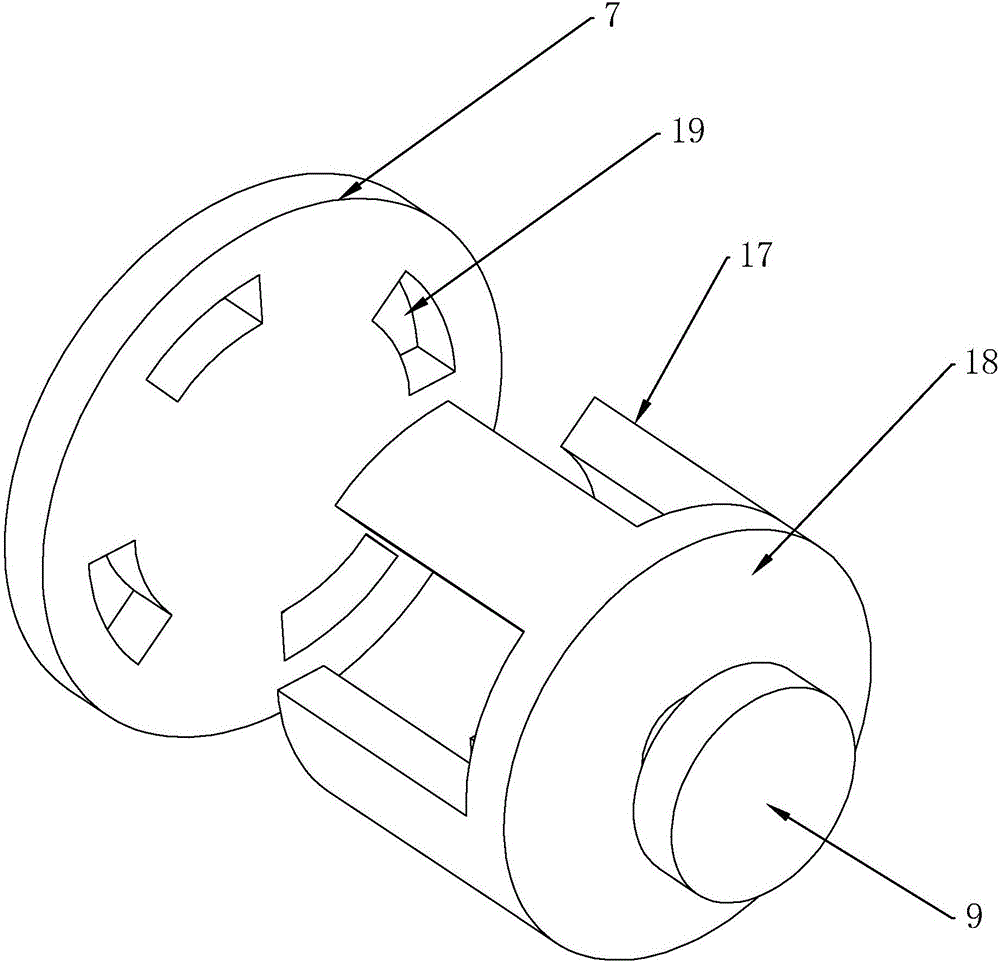

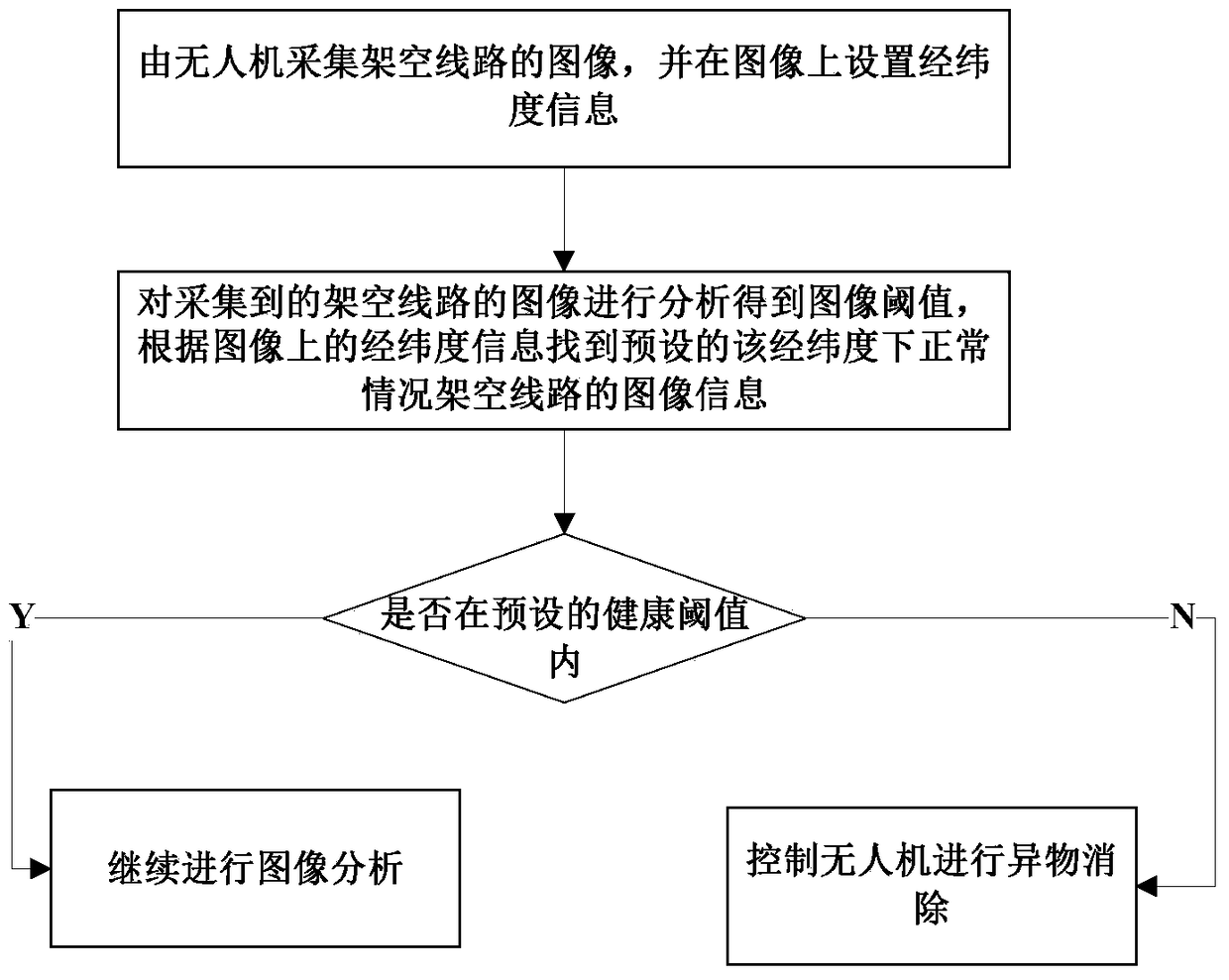

Foreign matter eliminating method for overhead line

InactiveCN105322464AImprove efficiencyImprove securityApparatus for overhead lines/cablesAircraftsForeign matterImaging analysis

The invention relates to the technical field of power transmission lines, in particular to a foreign matter eliminating method for an overhead line. The method comprises the following steps: collecting an image of the overhead line by an unmanned plane, and setting longitude and latitude information on the image; carrying out analysis on the image of the collected overhead line to obtain an image threshold, finding out preset image information of the overhead line at the longitude and latitude in a normal condition according to the longitude and latitude information on the image; if the image information exceeds the preset health threshold, controlling the unmanned plane to carry out foreign matter elimination; and if the image information is within the preset health threshold range, further carrying out image analysis. Aiming at the foreign matters of kites, packaging bags and the like on the overhead line, by the methods that the unmanned plane enters an electric field in a charged manner and charged elimination is carried out, the efficiency and the safety are improved; and the labor intensity is reduced.

Owner:STATE GRID HENAN ELECTRIC POWER COMPANY ZHENGZHOU POWER SUPPLY +2

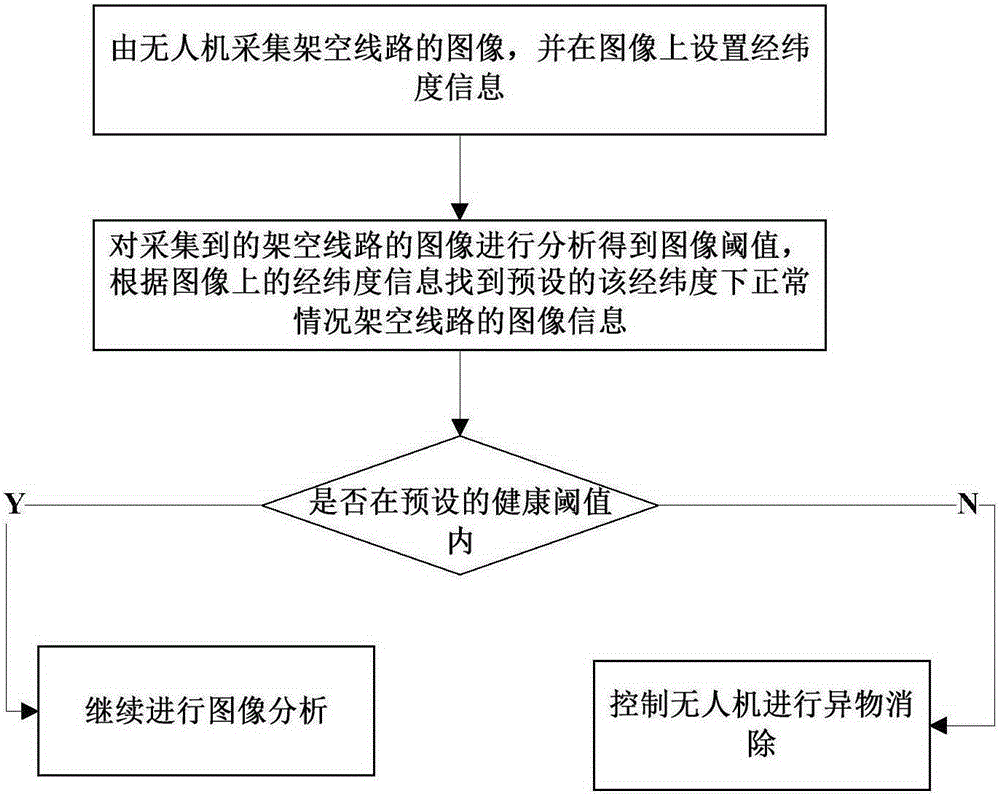

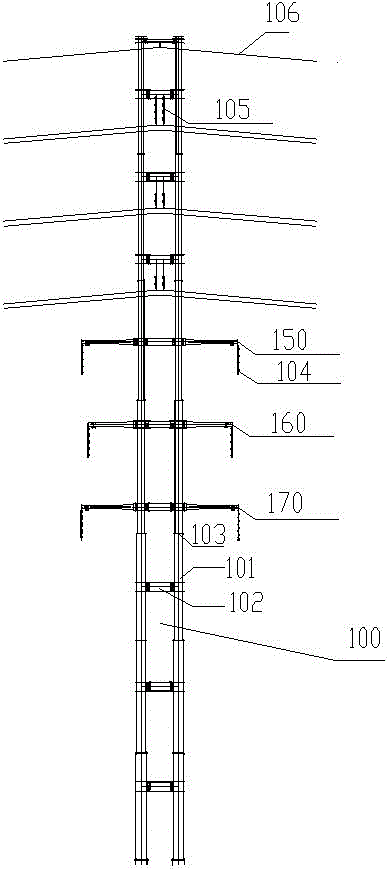

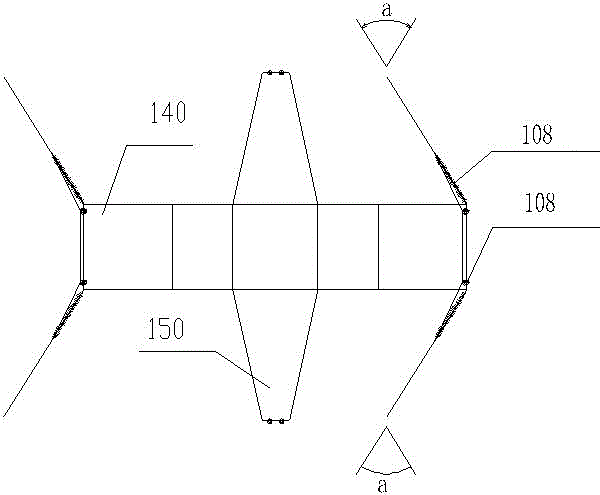

Multi-loop crisscross-spanning steel pipe pole

The invention relates to a multi-loop crisscross-spanning steel pipe pole which comprises a common pole body, lower-layer loop cross arms, upper-layer loop cross arms and a ground wire cross arm. The lower-layer loop cross arms, the upper-layer loop cross arms and the ground wire cross arm are crisscross, two sides of the common pole body are respectively provided with one circuit transmission line, and the common pole body consists of four vertical steel pipes which are provided with no knick point and connected through flanges. Compared with conventional iron towers, the rigid frame steel pole structure in rigid connection with the cross arms is small in foot distance, the line corridor width is decreased, accordingly the demolition and vegetation deterioration are decreased, and resource saving and environmental protection are facilitated. A traversing tower and a spanning tower are integrated on the combined steel pipe pole, the engineering investment is saved, the power outage time is shortened, a traversing mode is simple and easily implemented in an urban area, line channels and the tower-occupied area are decreased, the overall appearance is attractive, and the multi-loop crisscross-spanning steel pipe pole meets the appearance requirement of urban power transmission lines.

Owner:STATE GRID CORP OF CHINA +2

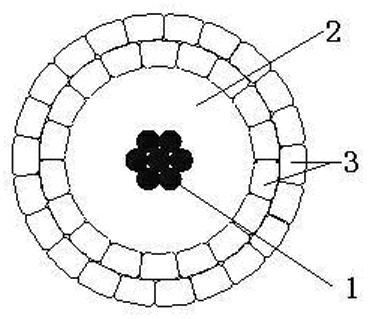

Carbon fiber compound core of power transmission circuit

InactiveCN103426558ACorrosion resistantExtended service lifeInsulated cablesPower cablesEpoxyCarbon fibers

A carbon fiber compound core of a power transmission circuit comprises an inner core body and an outer core body. The outer core body wraps the periphery of the inner core body, wherein the inner core body is carbon fibers prepared by carbonizing polyacrylonitrile fibers, the outer core body is high-strength glass fibers or basalt fibers, the inner core body and the outer core body are fixed and formed by heating cured resin, the cured resin is high-temperature-resistant special pultrusion epoxy resin prepared by adding modified anhydride compounds, the carbon fiber inner core body is of a straight-line type, and the high-strength glass fibers or basaltic fibers are of a twist increasing bundling type. The strength of a compound wire produced by the carbon fiber compound core is twice higher than the strength of an existing wire of the same type, the electric conductivity is higher, magnetic loss and heat loss are not generated, energy can be saved by more than 6%, the sag is lower due to the fact that the weight of the wire is reduced by 10-20%, and the compound core further has the advantages of being wearproof and long in service life.

Owner:SUZHOU SUYUE NEW MATERIAL

Production method for long span aluminum clad steel stranded wires

InactiveCN103578653ALong transmission distanceLight loadCable/conductor manufactureElectric power transmissionContact network

The invention discloses a production method for long span aluminum clad steel stranded wires. the method comprises the following steps that steel wire rods are bent and peeling is conducted on the steel wire rods; constraint coating and drawing are conducted; steel wire surface processing is conducted; steel wire ultrasonic wave cleaning is conducted; steel wire induction heating is conducted; aluminum rod surface pre-processing is conducted; short groove distance continuous squeezing is conducted; dual metal rapid synchronous deformation is conducted; aluminum clad steel wire compound wound is conducted; the steel stranded wires are wrapped by aluminum. According to the production method for the long span aluminum clad steel stranded wires, the continuous short groove distance continuous squeezing technology and the dual metal rapid synchronous deformation technology are adopted; compared with traditional aluminum clad steel stranded wires, the long span aluminum clad steel stranded wires manufactured by the production method have the advantages of being long in conveying distance, low in bearing load, small in sagging, high in conductive rate, good in corrosion resisting performance, long in service life, high in intensity, good in thermal stability, capable of being widely applied to ground wires for electric power transmission lines, long span conductive lines, carrier cables for electrified railway contact networks and overhead electric conductive lines used in special environments such as coastal areas.

Owner:HUANGSHAN CHUANGXIANG SCI & TECH

Pressure-sensitive adhesive sheet, method for producing the same and method for using the same as well as a multi-layer sheet for use in the pressure-sensitive adhesive sheet and method for producing the same

InactiveUS20080193728A1Less curlMade smallFilm/foil adhesivesSynthetic resin layered productsComposite filmSemiconductor

Disclosed is a pressure-sensitive adhesive sheet for use in processing a product such a semiconductor wafer. To provide a pressure-sensitive adhesive sheet that provides a minimized number of broken semiconductor wafers during the process of polishing them and that produces a less curl of the wafer due to the residual stress of the pressure-sensitive adhesive sheet, the pressure-sensitive adhesive sheet includes a composite film formed from a composition containing a urethane polymer and a vinyl polymer as effective components, a first film comprising a material different from that of the composite film, and a pressure-sensitive adhesive layer. It is preferable that the pressure-sensitive adhesive sheet has a modulus of 9 N / mm2 or more and 250 N / mm2 or less when an oblong piece of the pressure-sensitive adhesive sheet with a width of 20 mm is bent at a radius of curvature of 3.0 mm.

Owner:NITTO DENKO CORP

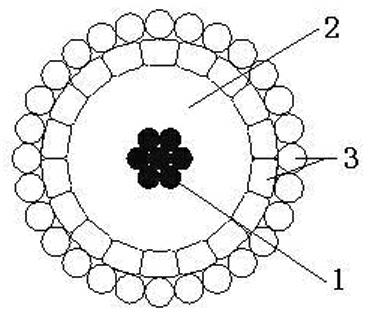

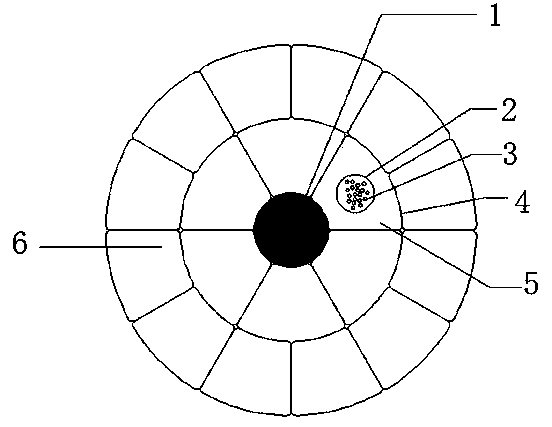

Unbraced expanded steel-cored aluminum stranded wire

InactiveCN102610300AGood self-damping performanceHigh tensile strengthNon-insulated conductorsPower cables with screens/conductive layersHigh voltageMaterials science

The present invention relates to an unbraced expanded steel-cored aluminum stranded wire, belonging to the technical field of overhead transmission lines. The unbraced expanded steel-cored aluminum stranded wire is suitable for severe using environments such as high voltage, high altitude and bold wind and has the characteristics of saved material, reduced corona, reduced energy consumption, reduced vibration and prolonged service life. The unbraced expanded steel-cored aluminum stranded wire comprises an outer aluminum stranded wire layer, a hollow structure layer and a center reinforced steel stranded wire, wherein the hollow structure layer is arranged between the outer aluminum stranded wire layer and the center reinforced steel stranded wire. The hollow structure layer is annular. The outer aluminum stranded wire layer is composed of an inner aluminum conduction wire layer and an outer aluminum conduction wire layer. The inner aluminum conduction wire layer uses a T-shaped wire; and the outer aluminum conduction wire layer uses a T shaped wire, a Z-shaped wire, an S-shaped wire or a round wire. The inner aluminum conduction wire layer of the outer aluminum stranded wire is stranded leftwards, and the outer aluminum conduction wire layer of the outer aluminum stranded wire is stranded rightwards. The unbraced expanded steel-cored aluminum stranded wire is an expanded conduction wire with the characteristics of large expanding rate, stable structure, simple manufacturing process, high tensile strength of the conduction wire, and excellent self-damping performance.

Owner:SHANGHAI ZHONGTIAN ALUMINUM WIRE

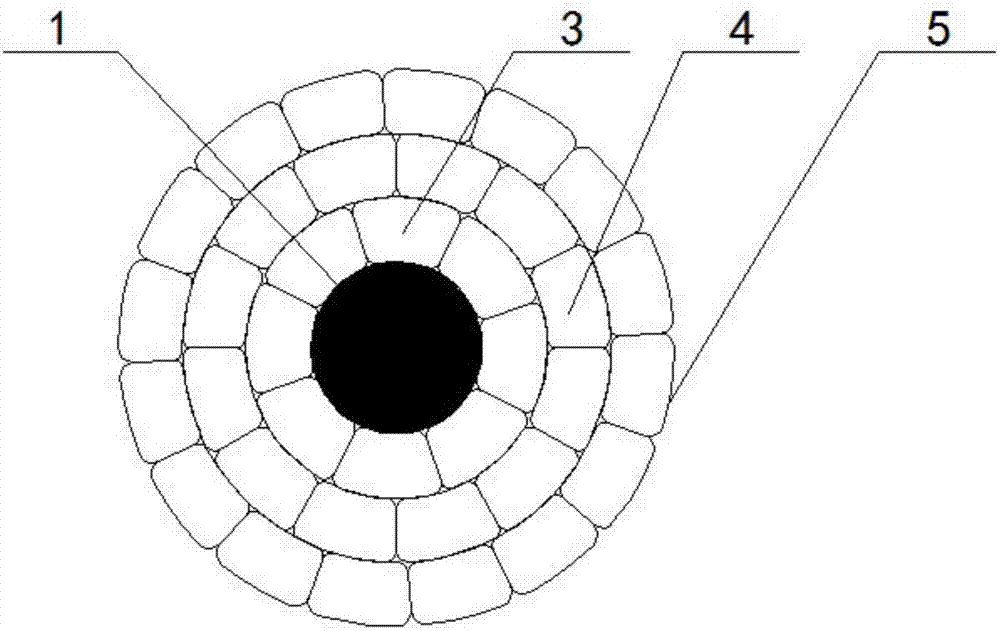

Carbon fiber composite lead wire core and preparation method thereof

The invention discloses a carbon fiber composite lead wire core, a preparation method thereof and a lead wire comprising same. The carbon fiber composite lead wire core comprises an aluminum alloy cylinder and carbon fibers which are uniformly distributed in the aluminum alloy cylinder and provided with silica coating. The lead wire core obtained in the invention is high in strength, has the tensile strength higher than that of a common steel core by about one time and higher than that of a high-strength steel core by 40%, is low in line loss and high in conductivity, has no magnetic loss thermal effect caused by a steel wire material, and has lower operating temperature under the condition of conveying the same load to reduce power transmission loss by about 6%, is small in sag, has significant low sag characteristics compared with a conventional lead wire, and high allowable working temperature, is high in current-carrying capacity, has the aluminum product section of the lead wire with the carbon fiber core being 1.29 times that of a conventional ACSR (Aluminum Conductor Steel Reinforced) under the condition of same quality, is light in weight, has the density of the carbon fibers and the aluminum alloy being 1.8 g / cubic centimeter and 2.7 g / cubic centimeter respectively, and corrosion resistant, with long service life.

Owner:JIANGSU BURGEREE NEW TECH MATERIALS

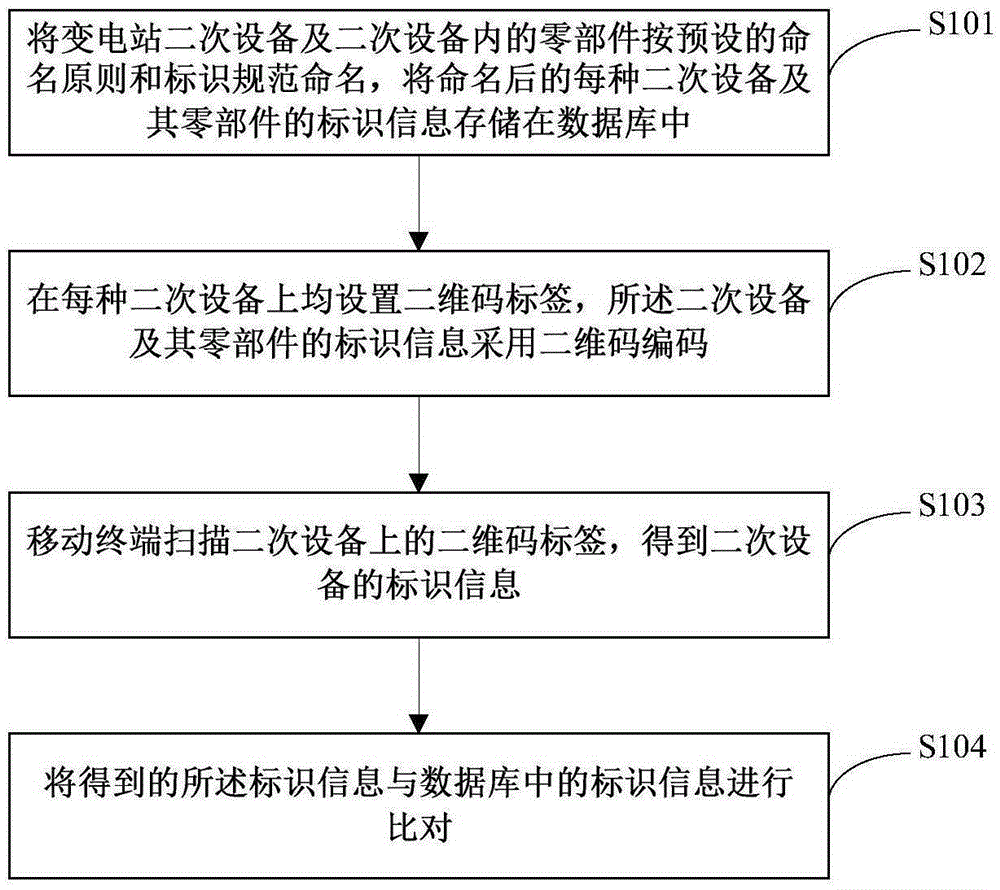

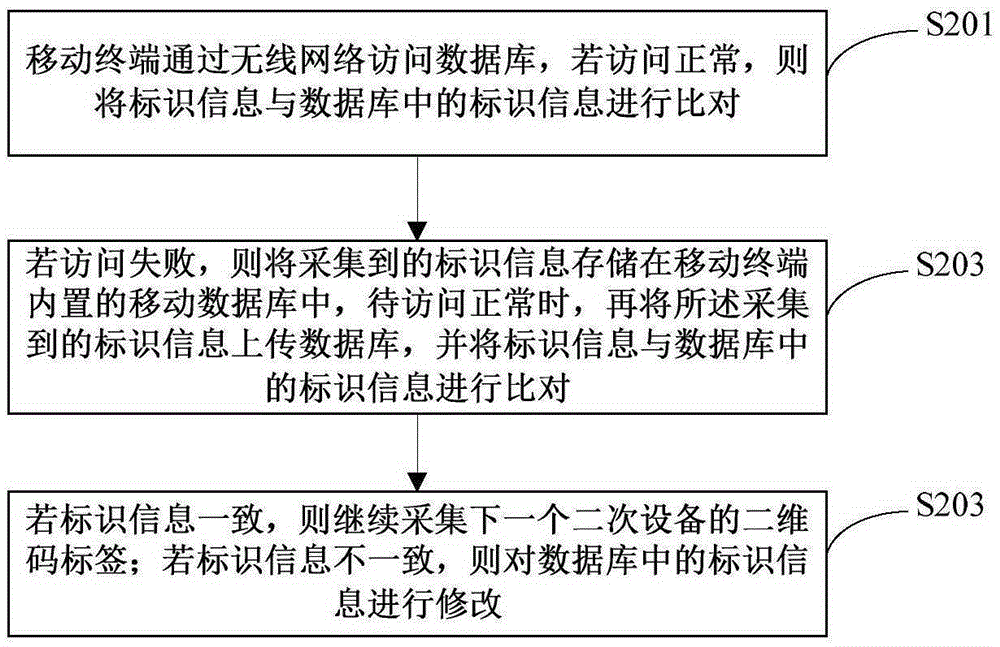

Intelligent substation secondary equipment information collection method

InactiveCN105427048AImprove operating conditionsGuaranteed uptimeResourcesInformation technology support systemSmart substationWorkload

The invention provides an intelligent substation secondary equipment information collection method. The method comprises: naming substation secondary equipment and parts in the secondary equipment according to preset naming principles and identifier specifications, and storing identifier information of the named secondary equipment and the named parts of the equipment in a database; setting two-dimensional code tags for the secondary equipment, wherein the identifier information of the secondary equipment and the parts of the equipment is coded by adopting two-dimensional codes; scanning the two-dimensional code tags on the secondary equipment by a mobile terminal to obtain the identifier information of the secondary equipment; comparing the obtained identifier information with identifier information in the database, and if the identifier information is the same, continuing to collect a two-dimensional code tag of next secondary equipment; and if the identifier information is not the same, modifying the identifier information in the database. The method is used for analyzing and managing intelligent substation secondary equipment information, so that the problem of high workload of operation and maintenance personnel caused by an increase in equipment quantity is effectively solved.

Owner:STATE GRID HENAN ELECTRIC POWER COMPANY ZHENGZHOU POWER SUPPLY +1

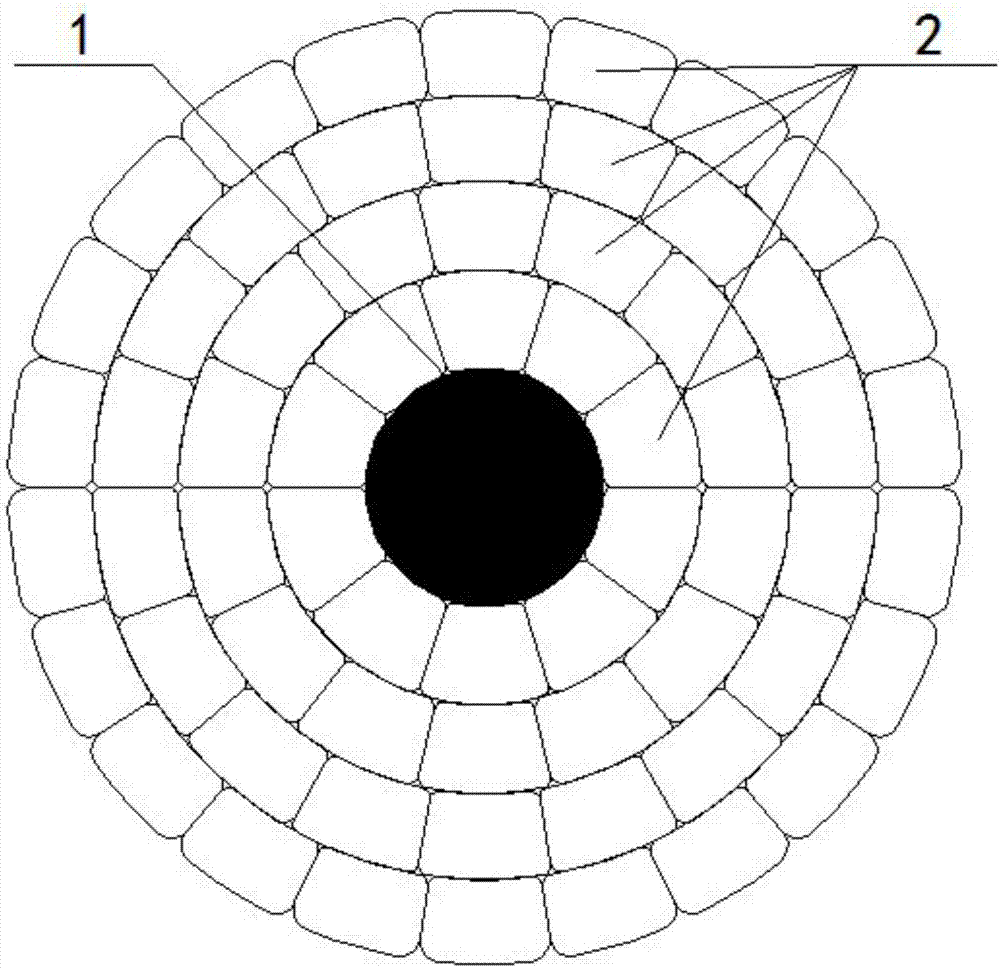

Composite material reinforcing lead and production method thereof

InactiveCN101814338AGuaranteed mechanical propertiesGuaranteed service lifeNon-insulated conductorsPlastic/resin/waxes insulatorsGlass fiberManufacturing technology

The invention relates to a composite material lead and a production method thereof, in particular to a lead for overhead power transmission and a production method thereof. The lead comprises a composite material reinforcing rib encircled by a conducting material. The production method relates to a composite material pultrusion process. The lead comprises the reinforcing rib and a long-bar shaped conductive body distributed vertically along the reinforcing rib. The reinforcing rib comprises a continuous carbon fiber reinforced composite material carrier and a glass fiber mat reinforced composite material protective body. The reinforcing rib of the invention is produced by the pultrusion process including a die opening and closing technology and an induction heating technology. The reinforcing rib is wound with the conductive body outside to form the lead which can be used for overhead power transmission. The lead provided by the invention has the advantages of long service life, low cost, low sag and high transmission efficiency. The production method of the reinforcing rib has fast pultrusion speed and even internal and external heating of materials and can eliminate residual heat stress during solidification.

Owner:JIANGSU AOSHENG COMPOSITE MATERIALS HI TECH +1

Large-cross-section carbon-fiber-composite-core semi-hard aluminum lead

InactiveCN107358995AReduce in quantityPromote coordinated developmentNon-insulated conductorsPower cables for overhead applicationSocial benefitsGlass fiber

The invention relates to a large-cross-section carbon-fiber-composite-core semi-hard aluminum lead comprising a carbon-fiber composite core rod and a plurality of semi-hard aluminum wire layers twisted outside the carbon-fiber composite core rod. The carbon-fiber composite core rod includes a composite-material inner core and a glass-fiber composite material layer coating the composite-material inner core. The semi-hard aluminum lead has advantages of high carrying capacity, high strength, low sag, and low usage cost; and the tower number is reduced. The large-cross-section carbon-fiber-composite-core-included semi-hard aluminum lead applied to a large-cross-section carbon-fiber composite core widely is capable of creating great economic and social benefits to build the strong smart grid, realizing cleaning replacement, and promoting energy conservation and environment protection. With development of the ultra-high-voltage grid, the semi-hard aluminum lead has the great significance in stimulating the domestic demand and economic growth, leading the transformation and upgrading of the equipment manufacturing industry, promoting coordinated development between the western and eastern regions, increasing employment, and treating the atmospheric contamination.

Owner:ZHONGFU CARBON FIBER CORE CABLE TECH

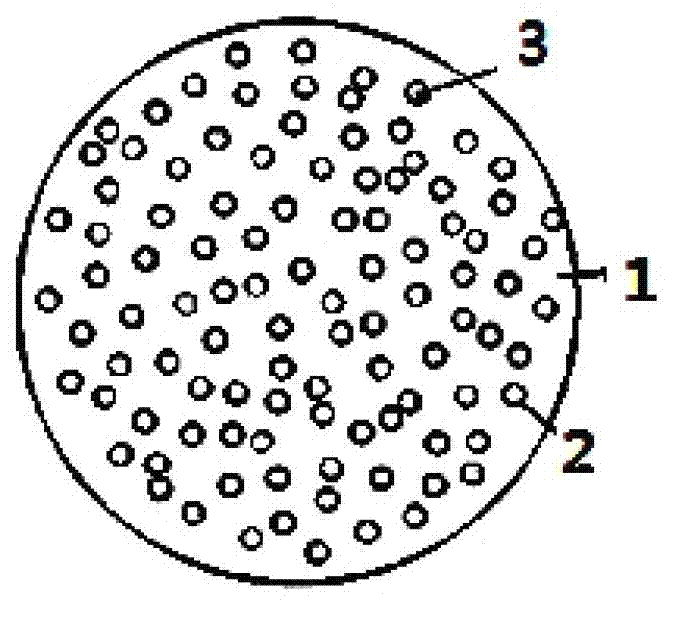

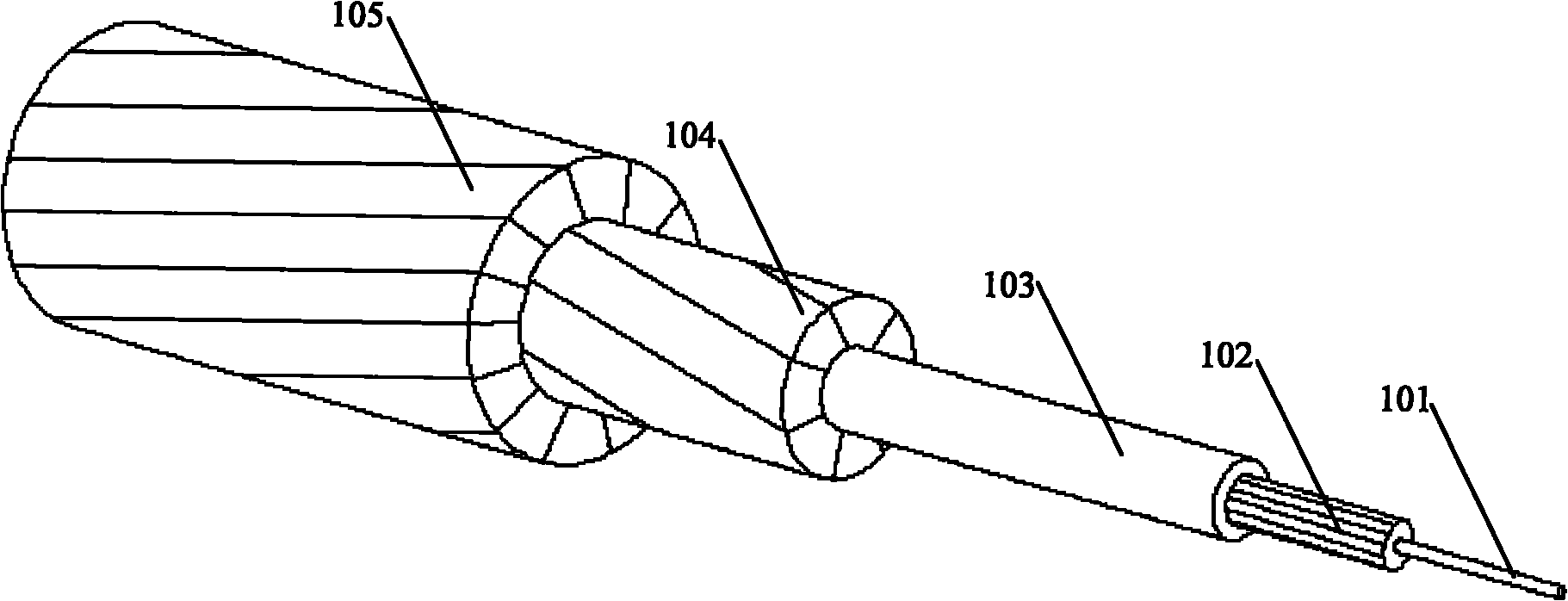

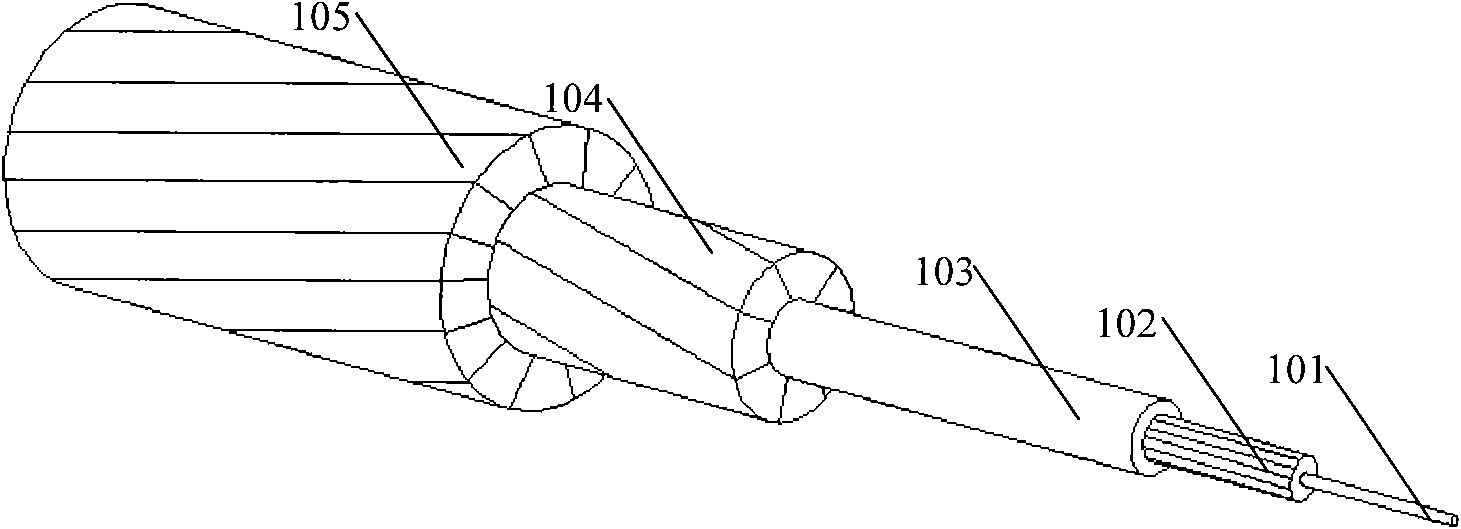

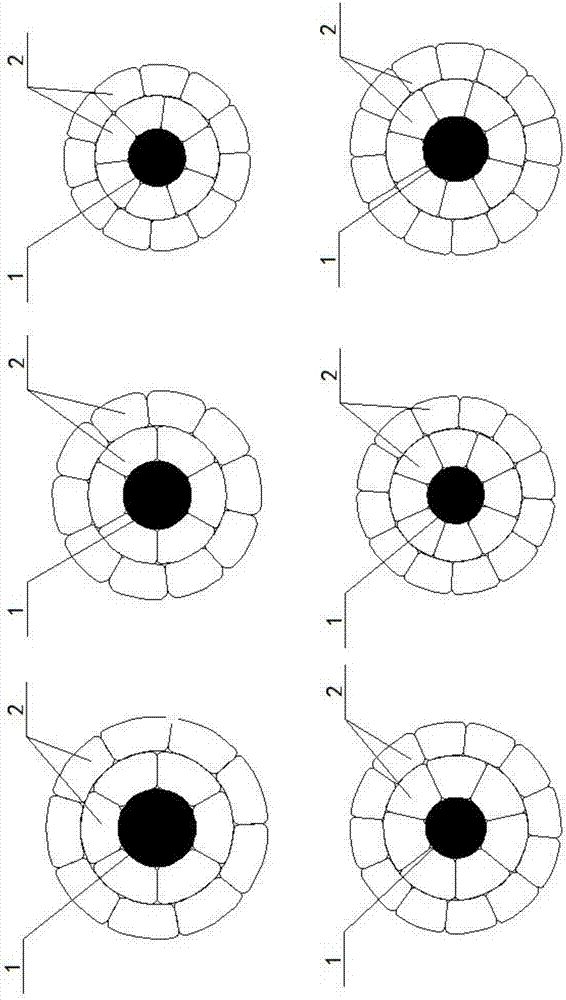

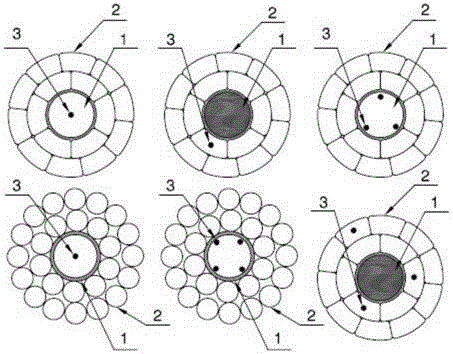

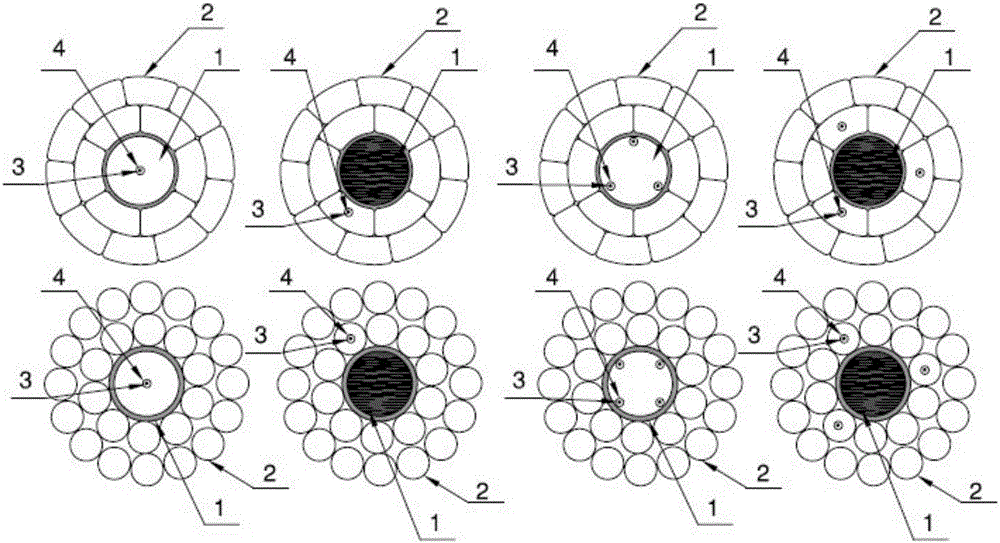

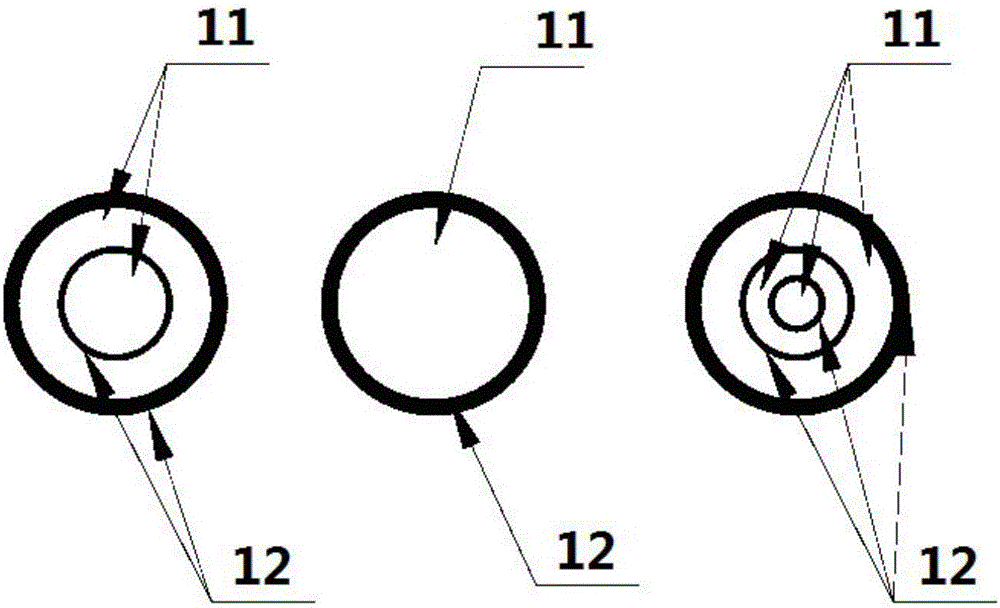

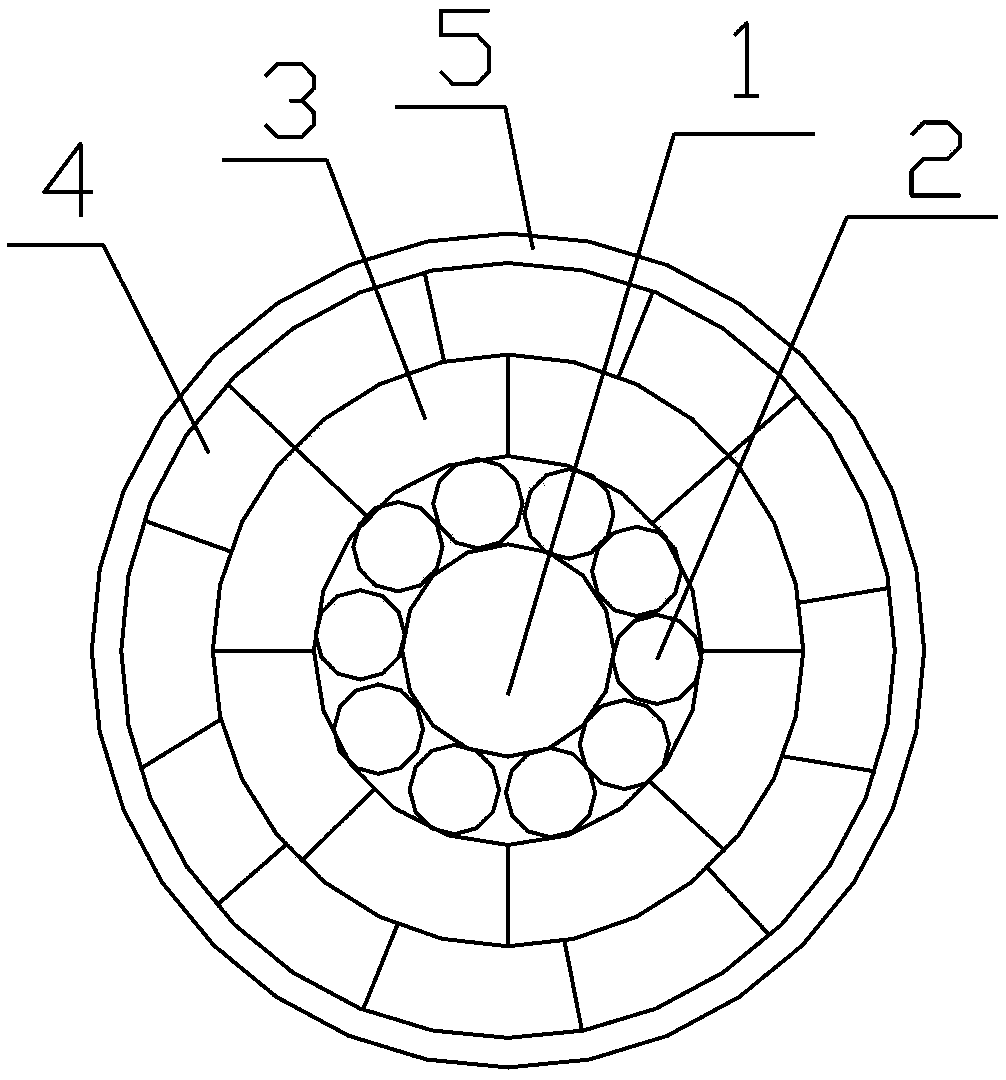

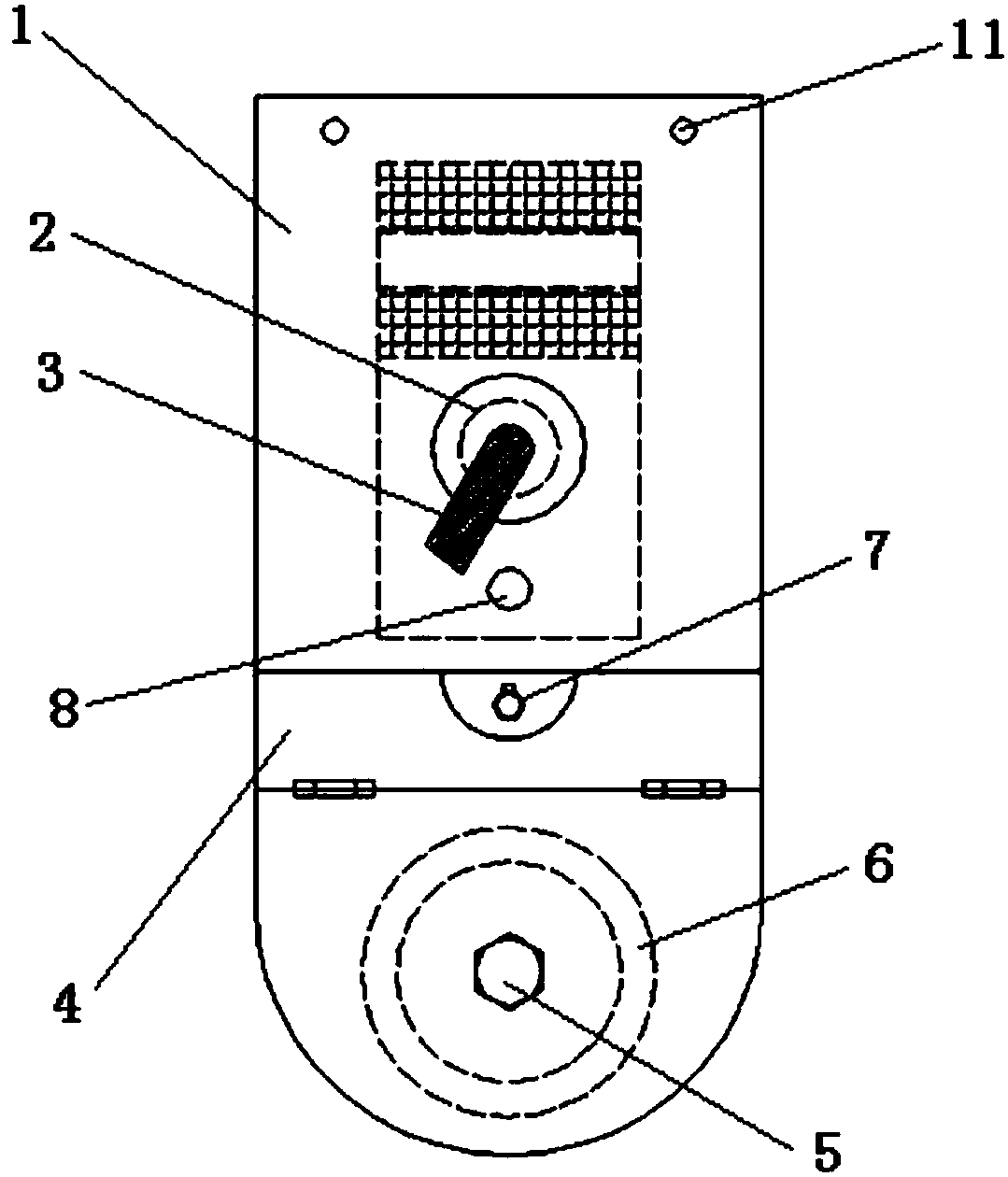

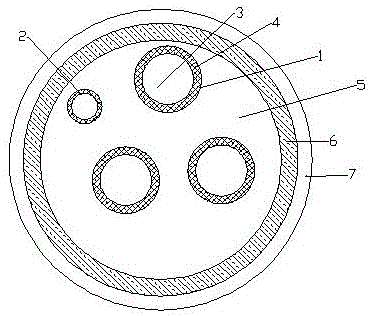

Intelligent composite material core wire and preparation method thereof

ActiveCN105825945AReasonable structural designHigh temperature resistantNon-insulated conductorsPower cables including optical transmission elementsCarrying capacityAging resistance

The invention discloses an intelligent composite material core wire and a preparation method thereof. The intelligent composite material core wire includes a composite material core (1) and single conductor wires (2) stranded at the periphery of the composite material core (1), wherein the composite material core (1) or the single conductor wires (2) are internally provided with optical fibers (3) or optical fiber protection pipes (4) for communication or monitoring; and the optical fibers (3) are arranged in the optical fiber protection pipes (4). The preparation method of the intelligent composite material core wire includes the steps of preparing the composite material core and stranding the single conductor wires (2) at the periphery of the composite material core (1). The preparation method of the intelligent composite material core wire has the advantages of being high in operability, being higher in production efficiency, being able to save a lot of manpower and material resources, and being low in production cost; the prepared composite material core has the advantages of being high in linearity and roundness, having no bending, being high in color consistency, being high in intensity, being long in the service life, having no eccentricity, and being high in aging resistance; and the prepared intelligent composite material core wire has the advantages of being higher in the wire compactness and filling rate, being resistant to high temperature, being high in current-carrying capacity and being small in sag.

Owner:ZHONGFU CARBON FIBER CORE CABLE TECH

Sag damping cable

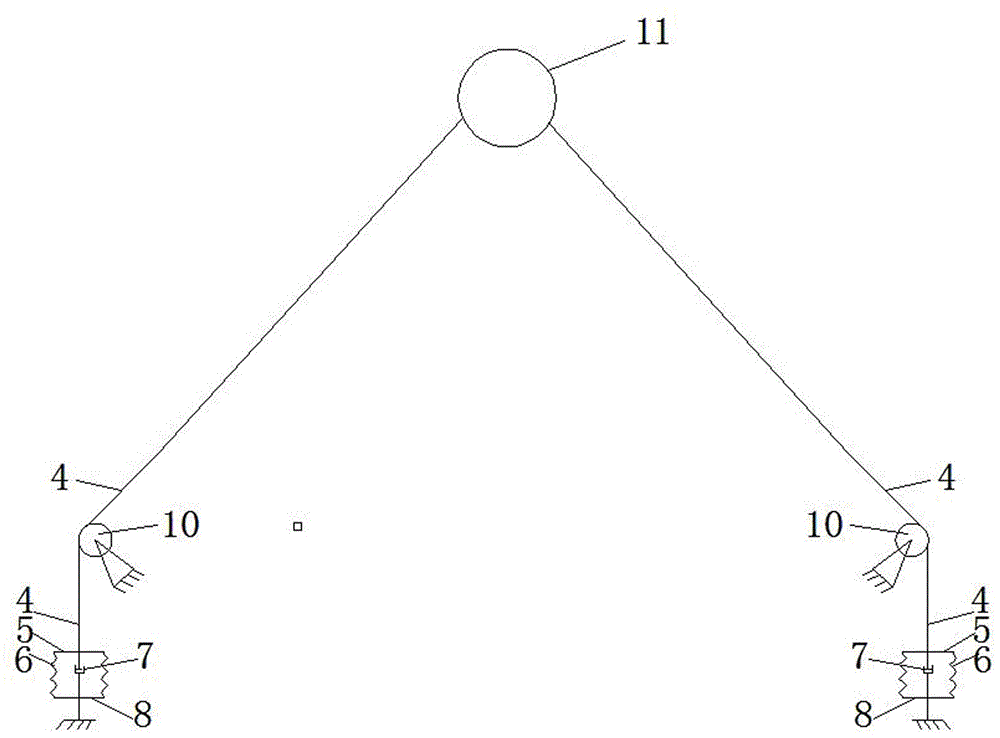

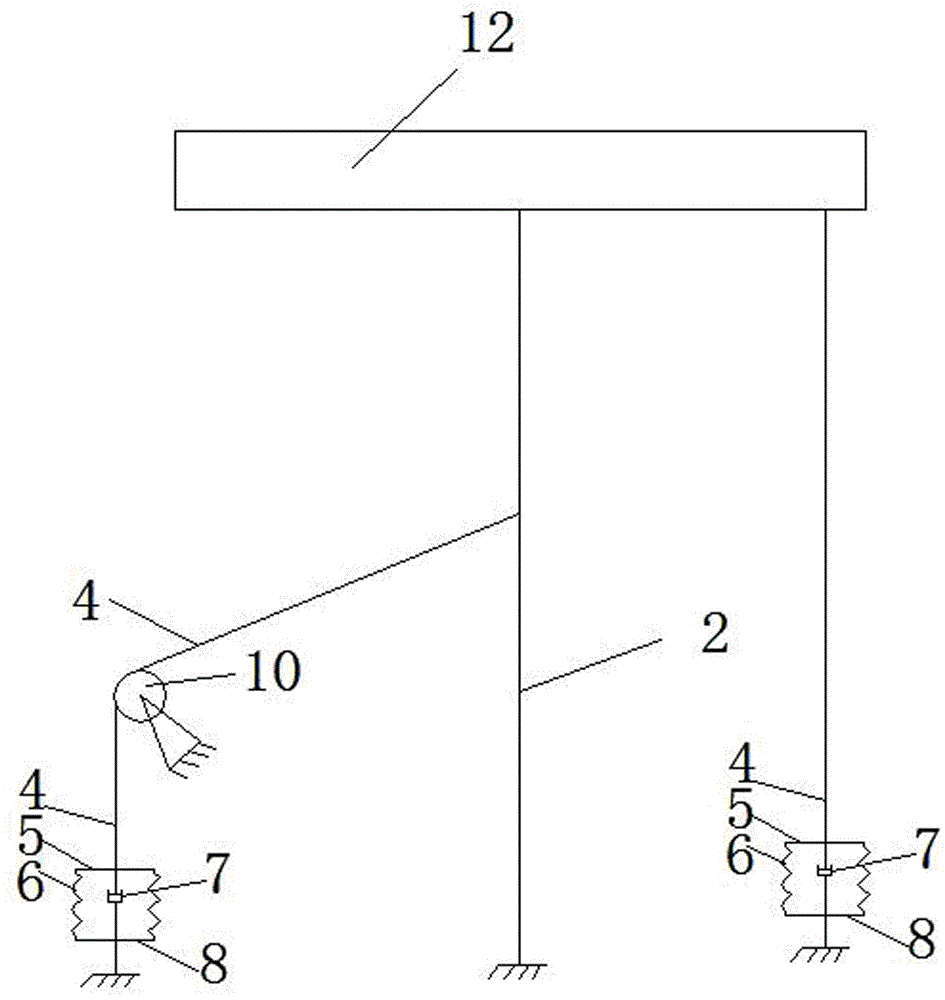

ActiveCN106368343AEasy to installImprove energy consumptionProtective buildings/sheltersShock proofingEngineeringStructural vibration

The invention discloses a sag damping cable which comprises a main cable. The upper end of the main cable is connected with an upper anchoring point fixedly connected with a structure, the lower end of the main cable is connected with an anchor fixed to the ground, a suspension cable is fixedly connected in the main cable and is roughly perpendicular to the main cable, and the lower end of the suspension cable is connected with an upper beam. A lower beam is fixedly connected with the ground through another suspension cable or directly connected with the ground. A damper is installed between the upper beam and the lower beam. The form of combining the single main cable, the suspension cable and the damper is adopted, the main cable vibrates through structural vibration, the sag of the main cable varies periodically with the structural vibration, the damper is driven to consume energy by utilizing periodic variations of the sag of the main cable, and thus the structural vibration is restrained.

Owner:HUNAN UNIV OF SCI & TECH

Carbon fiber copper core alloy wire spiral wrapping cable

InactiveCN103354114AHigh tensile strengthHigh elongationInsulated cablesInsulated conductorsFiberInsulation layer

The invention discloses a carbon fiber copper core alloy wire spirally-wrapping cable including a conductor and an insulation layer. The insulation layer wraps the conductor. The conductor includes an inner core and two alloy wire layers. The inner core is composed of a carbon fiber core wire in the center and copper leads surrounding the carbon fiber core wire. The two alloy wire layers are formed by wrapping the inner core with a plurality of alloy wires in a spiral manner. Materials of the two alloy wire layers are the same and the spiral directions of the two alloy wire layers outside the inner core are the same. The spiral angels of climb of the two alloy wire layers are in a range between 25 degrees and 45 degrees. According to the invention, the carbon fiber copper core alloy wire spiral wrapping cable is high in tensile strength, good in ductility, low in DC resistance, good in electric conductivity, low in line loss and comparatively low in sag.

Owner:JINYUAN ELECTRIC GRP

Manufacturing method for low-sag soft-aluminum-wire optical fiber composite overhead phase line

InactiveCN103426550AExtended service lifeNo significant effect on strengthPower cables with screens/conductive layersCable/conductor manufacturePhysical chemistrySteel casing pipe

The invention discloses a manufacturing method for a low-sag soft-aluminum-wire optical fiber composite overhead phase line. The method comprises the following steps that 1) optical fibers are arranged in a stainless steel casing pipe; 2) a fan-shaped aluminum cladding layer is extruded on the outer surface of the stainless steel casing pipe to form an optical fiber unit; 3) fan-shaped soft aluminum wires and the optical fiber unit are simultaneously intertwisted outside a carbon fiber composite core; 4) and at least one layer of fan-shaped soft aluminum wires are intertwisted on an outermost layer.

Owner:HENAN KOSEN CABLE

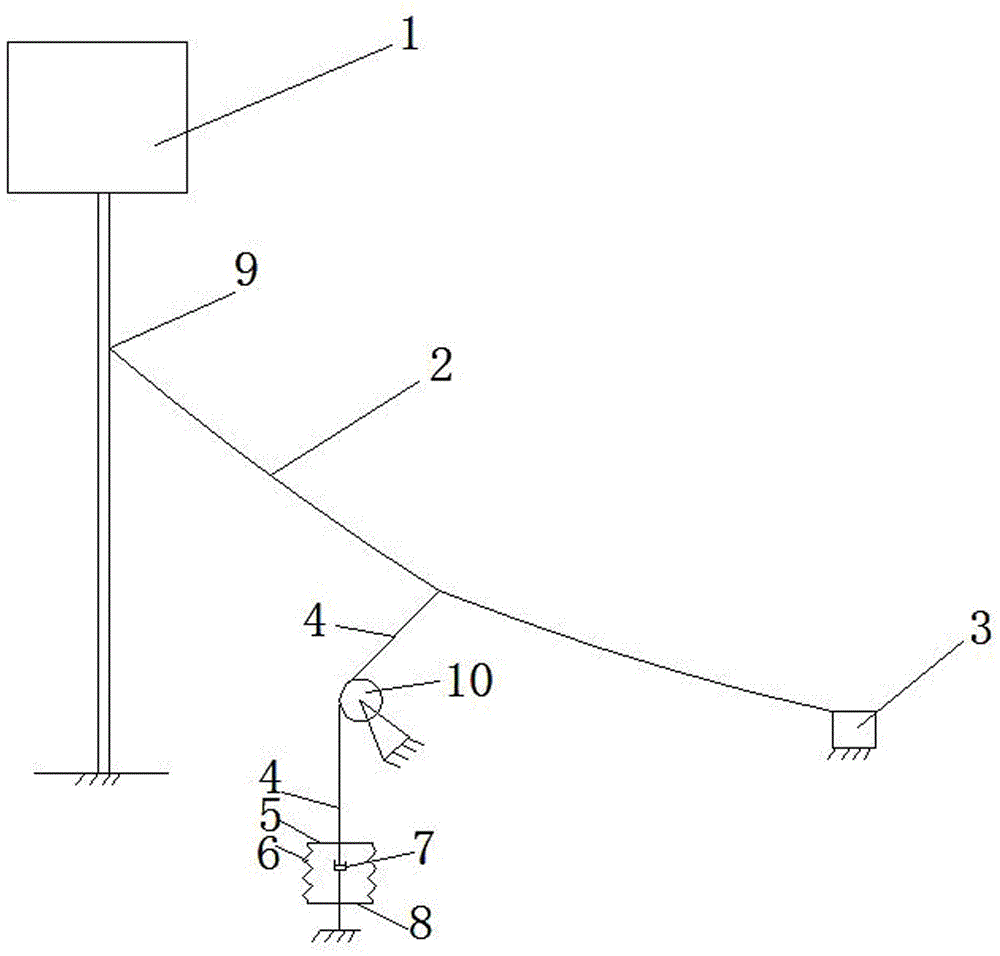

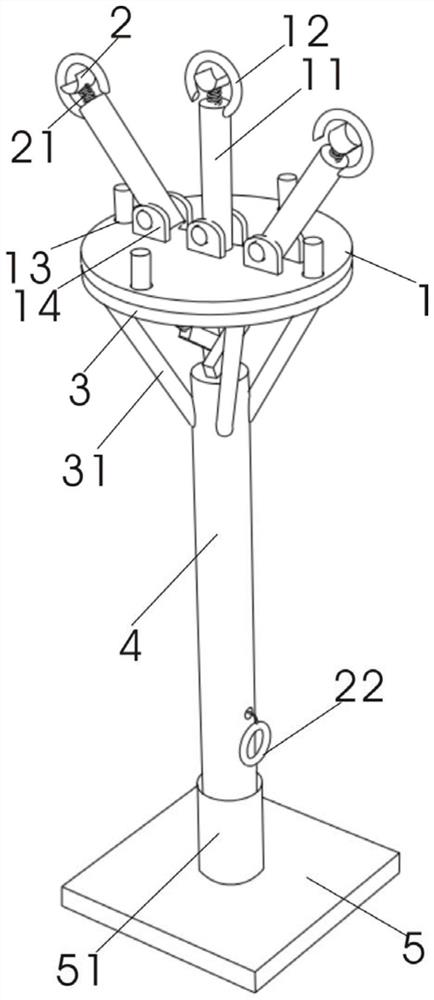

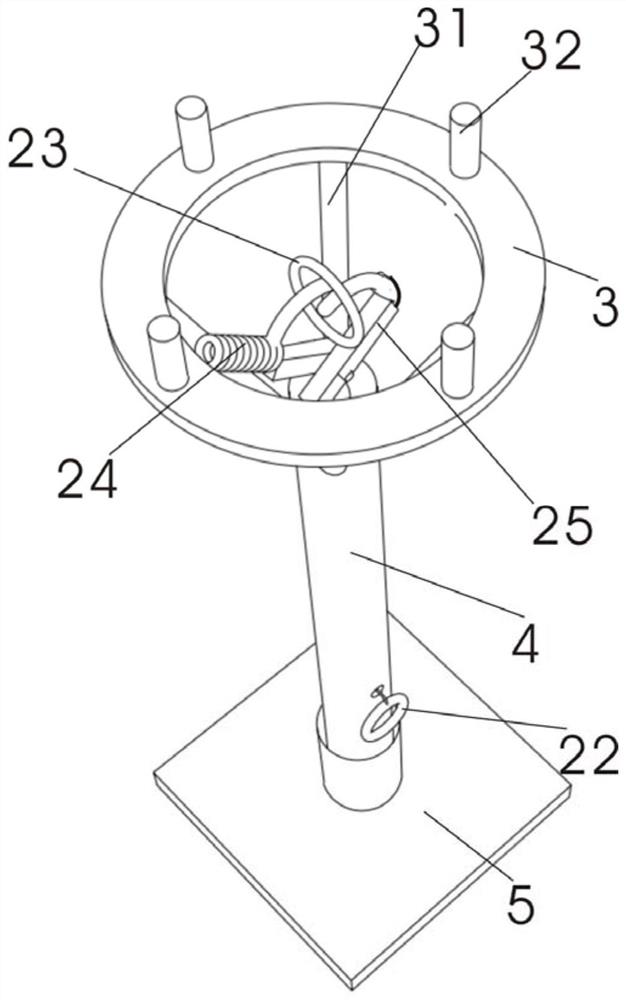

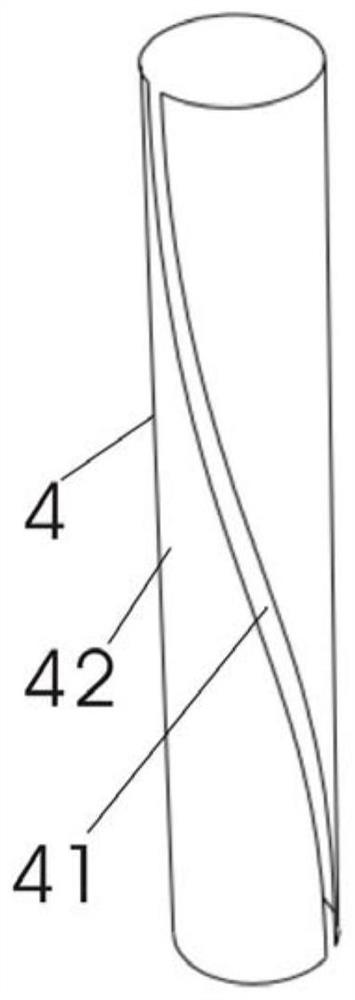

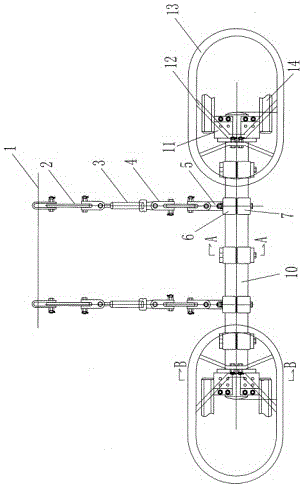

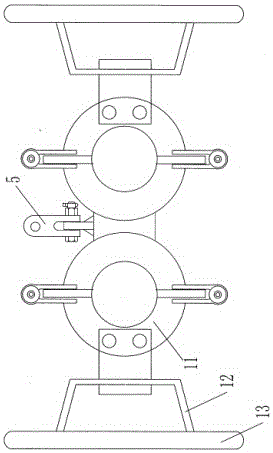

A transmission line erecting device for electric power engineering

ActiveCN112186636BSmall sagImprove construction efficiencyApparatus for overhead lines/cablesCable trayPower engineering

The invention discloses a power transmission line erecting device for electric power engineering, which comprises a mounting base, a support rod, a pressing mechanism and several hooks, the several hooks are respectively connected to the mounting base through extension rods, the extension rod is a hollow structure, and the pressing mechanism It includes a thread support plate, a guide rod and a first spring arranged in the hook, the thread support plate is connected with the extension rod through the first spring, the guide rod is arranged inside the first spring, one end of which is fixedly connected with the thread support plate, and the other end is connected with the extension rod. The extension rod is slidingly connected; there is a pull ring under the mounting seat, the pull ring is connected to the guide rod through the first pull wire, a vertical support rod is provided under the mounting seat, a clip is provided on the top of the support rod, and a second spring is provided on the clip. The clip is connected to the pull handle through the second pull wire. The hook is hooked on the erected transmission line, and the transmission line is pressed by the compression mechanism. The support rod supports the mounting seat to reduce the sag of the transmission line. construction efficiency.

Owner:国网山东省电力公司惠民县供电公司

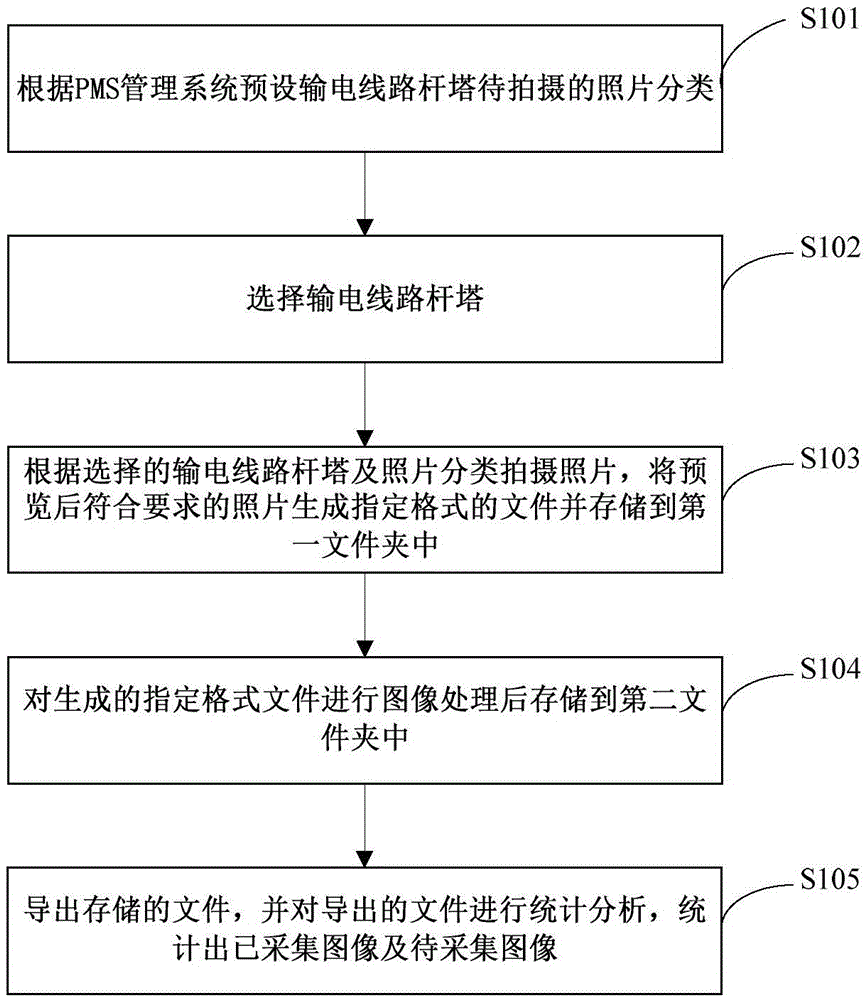

Standardized line data acquisition method

InactiveCN105488152ASmall sagReduce transmission lossData processing applicationsFile access structuresPower transmissionStandardization

The invention provides a standardized line data acquisition method. The method comprises: presetting the categories of to-be-shot photos of a power transmission line tower according to a PMS; selecting the power transmission line tower manually or automatically; according to the selected power transmission line tower and the photo categories, shooting the photos, generating a file in a specified format by the previewed photos meeting the requirements, and storing the file into a first folder; performing image processing on the generated file in the specified format and storing the processed file into a second folder; and exporting the stored file, performing statistic analysis on the exported file, and making statistics on acquired images and to-be-acquired images. The method is used for quickly acquiring tower information and superposing the acquired tower information with tower longitude and latitude information and shooting time, thereby facilitating later management and maintenance.

Owner:STATE GRID HENAN ELECTRIC POWER COMPANY ZHENGZHOU POWER SUPPLY +1

Oil gas damping ant-galloping device

ActiveCN106356792AGood at absorbing vibrationPrevent broken stockDevices for damping mechanical oscillationsApparatus for overhead lines/cablesMechanical engineeringPiston rod

The invention discloses an oil gas damping anti-galloping device which comprises a sleeve, a rod barrel and an outer cylinder barrel, wherein the rod barrel is positioned inside the sleeve; a piston is arranged in the rod barrel; the piston divides the rod barrel into a gas filling cavity for filling a gas and an oil filling cavity for filling damping oil; a piston rod is arranged on the piston, goes through one end of the rod barrel and is positioned in the oil filling cavity; a communication channel communicating the gas filling cavity with the oil filling cavity is arranged on the piston rod; a bottom plate is also arranged on the sleeve; the piston rod is fixedly connected with the bottom plate; the outer cylinder barrel extends into the sleeve from the bottom plate and is fixedly connected with the rod barrel; a hanging plate connected with an insulator string ball is arranged at the top of the sleeve; and a connection end connected with a wire is arranged on the outer cylinder barrel. The anti-galloping device disclosed by the invention can effectively absorb external force to reduce wire galloping; by coating the surfaces of the sleeve, the outer cylinder barrel and the hanging plate with a hydrophobic insulating coating, an anti-icing effect is realized, the damage of a transmission line caused by icing aggravated galloping is avoided, and the safe and reliable operation of the transmission line is guaranteed.

Owner:WENZHOU ELECTRIC POWER DESIGN

Ultrahigh-conductivity aluminum-clad steel stranded wire and production method thereof

ActiveCN111816349ALess investmentReduce lossNon-insulated conductorsConductive materialSiluminElectric power industry

The invention belongs to the technical field of overhead transmission conductors in the power industry, and discloses an ultrahigh-conductivity aluminum-clad steel stranded wire. The steel wire section of the aluminum-clad steel stranded wire is 15.17%, and the tension-weight ratio is 11.1%. The invention also discloses a production method of the ultrahigh-conductivity aluminum-clad steel strandedwire. The preparation method comprises the following steps: selecting 82A steel wires as steel wire blanks, paying off the steel wires, straightening the steel wires, cleaning the steel wires, heating the steel wires, finely rolling the end parts through a pointing rolling machine, and drawing the steel wires in a die under the action of a wire drawing machine and a die wall; cladding: cladding the drawn steel wires with an aluminum rod by using a cladding machine to obtain aluminum-clad steel single wire blanks; carrying out one-die micro-deformation drawing on the aluminum-clad steel singlewire blanks to improve the surface smoothness; and stranding the aluminum-clad steel single wires in a cage stranding machine to obtain the aluminum-clad steel stranded wire. By limiting the steel wire material and the arrangement mode and changing the processing mode, the produced ultrahigh-conductivity aluminum-clad steel stranded wire can replace a high-strength aluminum alloy stranded wire.

Owner:HENAN TONG CABLE

Methods of Eliminating Foreign Objects in Overhead Lines

InactiveCN105322464BImprove efficiencyImprove securityApparatus for overhead lines/cablesAircraftsForeign matterImaging analysis

Owner:STATE GRID HENAN ELECTRIC POWER COMPANY ZHENGZHOU POWER SUPPLY +2

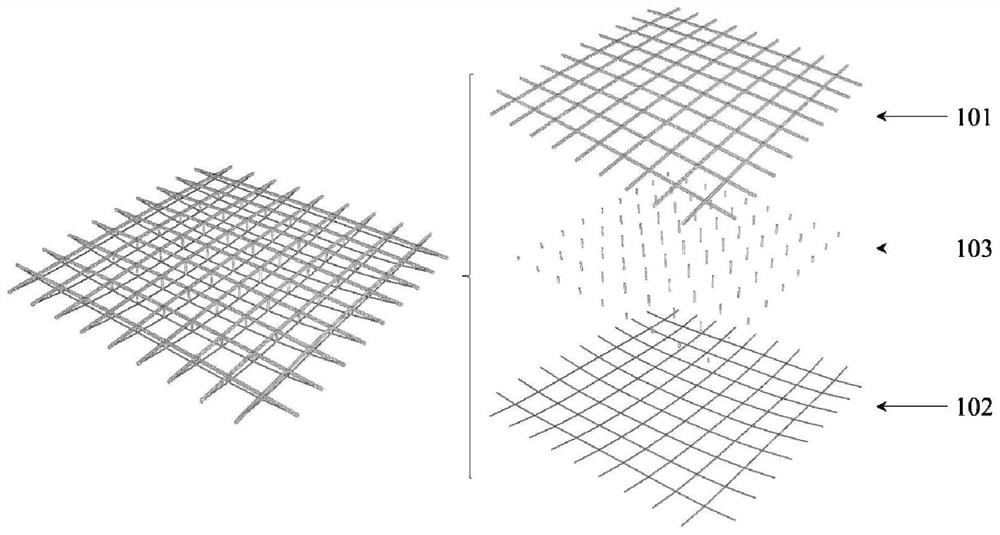

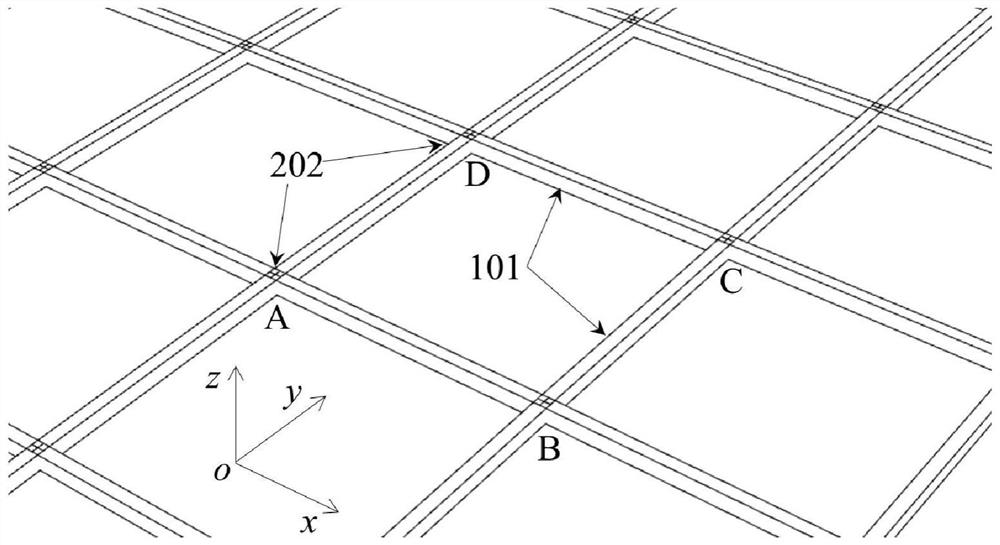

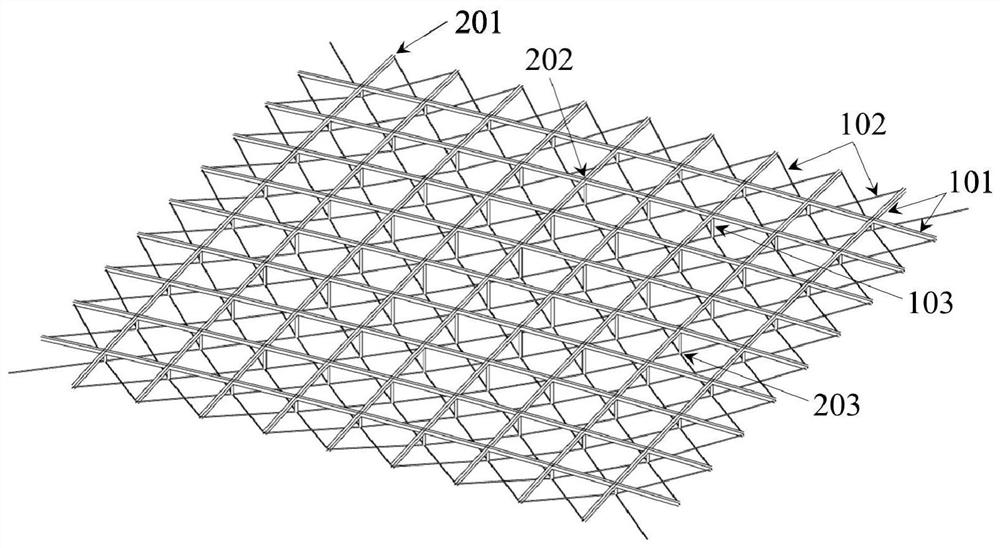

Bidirectional beam string structure of rectangular plane

PendingCN113605600AEasy to processEasy to installGirdersJoistsStructural engineeringMechanical engineering

The invention discloses a bidirectional beam string structure of a rectangular plane. The bidirectional beam string structure comprises an upper-layer beam system, a lower-layer cable system and a supporting rod, wherein the upper-layer beam system is formed by connecting two groups of beam systems with orthogonal horizontal projections, an upper-layer beam system node is formed at the intersection of the two groups of beam systems, the horizontal projections of the two groups of beam systems are respectively parallel to two groups of opposite sides of the rectangular plane of the structure, and the beam end node and the upper-layer beam system node are positioned on an elliptical paraboloid; the lower-layer cable system is composed of two groups of cable systems with inclined horizontal projections, the horizontal projections of the two groups of cable systems are respectively parallel to the directions of two diagonal lines of the rectangular plane of the structure, a lower-layer cable system node is formed at the intersection of the two groups of cable systems, and the lower-layer cable system node coincides with the horizontal projection of the corresponding upper-layer beam system node; and the supporting rod is connected with the lower-layer cable system node and the corresponding upper-layer beam system node. According to the bidirectional beam string structure, each upper-layer grid is a plane quadrangle, so that the machining and mounting difficulty of a roof unit is reduced, and additionally, the stress efficiency of all string cables is equivalent, so that the rigidity and stability of side truss string beams are improved.

Owner:BEIJING INST OF ARCHITECTURAL DESIGN

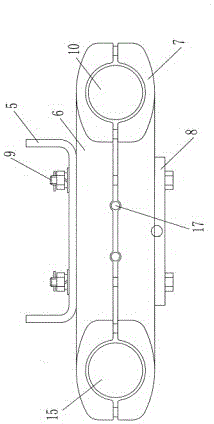

Rope sag adjusting pulley for ground wire

InactiveCN109494613ASmall sagReduce overhangApparatus for overhead lines/cablesUltra high voltageEngineering

The invention, belonging to the technical field of overhead ground wire maintenance tools for ultra-high voltage and extra-high voltage transmission lines, discloses a rope sag adjusting pulley for aground wire. The pulley comprises a clamping device for clamping a ground wire, a control device for adjusting opening or closing of the clamping device, and a roller being connected with the clampingdevice and being arranged below the clamping device. The roller is in rotation connection relative to the central shaft at the center; an arc surface recessed inwardly is formed at the outer wheel surface of the roller; and the arc surface cooperates with a rope. Therefore, a technical problem of a large working risk caused by the large galloping rope sag in the prior art is solved; and thus technical effects of reducing the rope sagging and ensuring the working safety are realized.

Owner:STATE GRID CORP OF CHINA +1

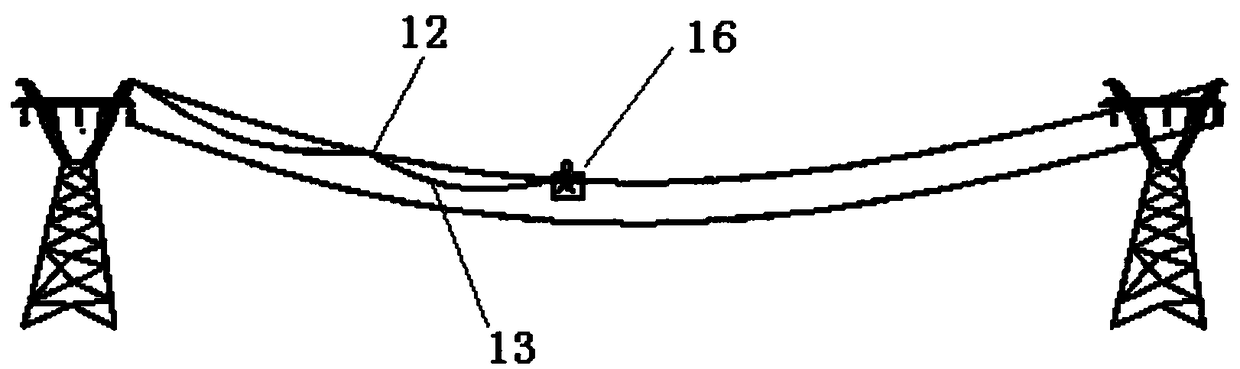

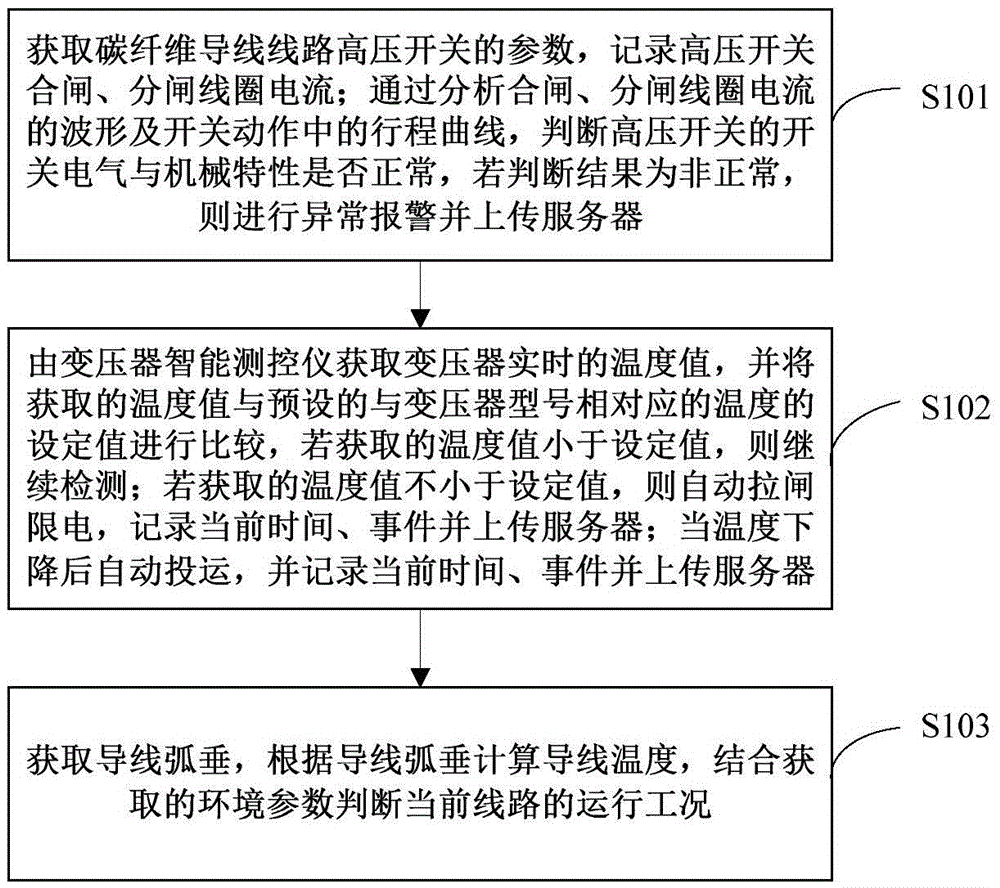

Line fault detection method based on carbon fiber conductor

InactiveCN105486947AReduce transmission lossIncrease unit delivery capacityMachine part testingCircuit interrupters testingConductor sagEngineering

The invention provides a line fault detection method based on a carbon fiber conductor. The method comprises the following steps: obtaining parameters of a carbon fiber conductor line high-voltage switch, and recording closing and opening coil current of the high-voltage switch; by analyzing waveform of the closing and opening coil current and stroke curve in the switching actions, judging whether switch electrical and mechanical characteristics of the high-voltage switch are normal; obtaining a real-time temperature value of a transformer through a transformer intelligent measurement and control instrument, and comparing the obtained temperature value with a preset value of the temperature corresponding to the model of the transformer; and obtaining a conductor sag, calculating the conductor temperature according to the conductor sag, and judging the operation condition of the current line with the obtained environment parameters being taken into consideration. The method realizes on-line automatic detection and control of the operation condition of the power transmission line.

Owner:STATE GRID HENAN ELECTRIC POWER COMPANY ZHENGZHOU POWER SUPPLY +2

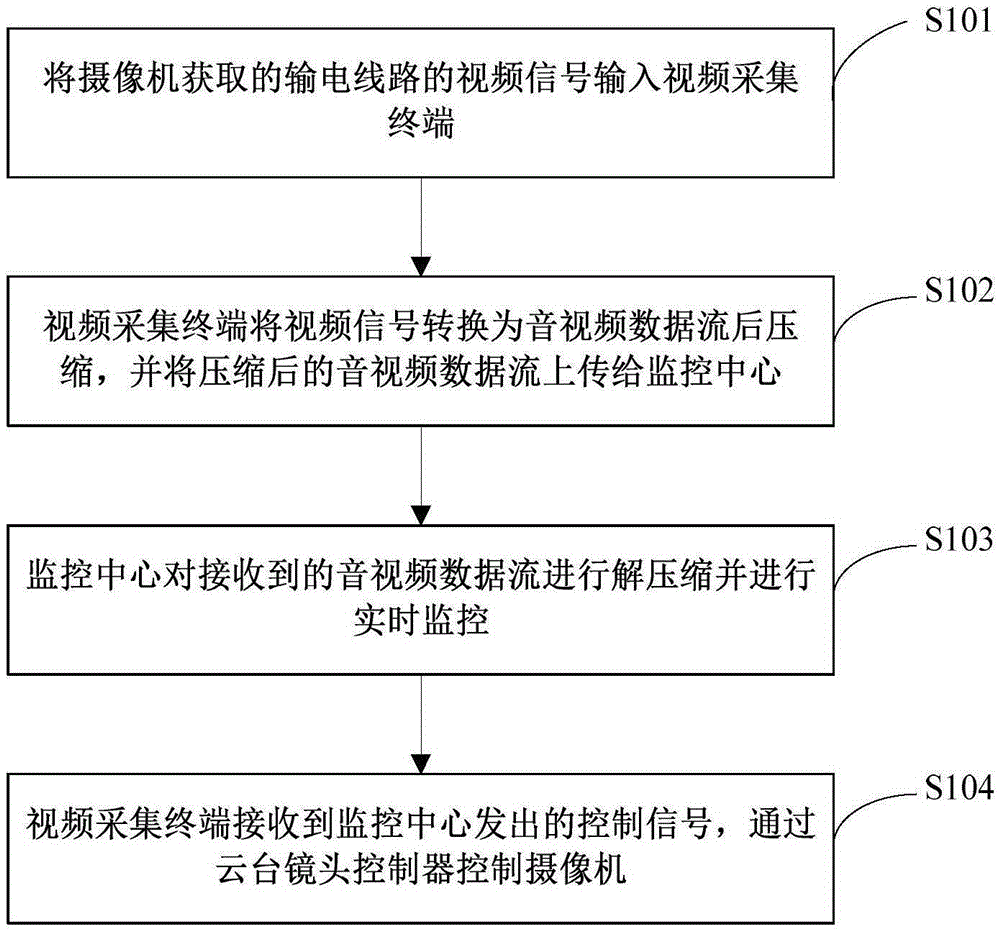

Remote monitoring method for power transmission line

InactiveCN105357486ARealize remote video monitoring functionImprove monitoring efficiencyTelevision system detailsPower distribution line transmissionLens ControllerData stream

The invention relates to a remote monitoring method for a power transmission line. The method includes following steps: video signals of the power transmission line obtained by a camera are inputted to a video acquisition terminal; the video acquisition terminal converts the video signals to audio and video data streams for compressing and uploads the compressed audio and video data streams to a monitoring center, and the monitoring center decompresses the received audio and video data streams and performs real-time monitoring. According to the method, remote on-line monitoring is realized at a mobile terminal, and the monitoring efficiency is improved; and the acquisition terminal receives control signals emitted by the monitoring center, and the camera is controlled via a holder lens controller.

Owner:STATE GRID HENAN ELECTRIC POWER COMPANY ZHENGZHOU POWER SUPPLY +1

Cross-linking insulated tin-plated copper wire power cable resistant to high temperature and under 35kV

ActiveCN106128624ALow wire lossImprove conductivityConductive materialPower cables with screens/conductive layersCross-linkInsulation layer

The invention relates to a cross-linking insulated tin-plated copper wire power cable resistant to a high temperature and under 35kV, and belongs to the technical field of power equipment. The cross-linking insulated tin-plated copper wire power cable comprises wire cores and a power connection core, wherein the three wire cores and the power connection core are arranged in the cable and are both internally structured with tin-plated copper wires, insulation layers wrap the tin-plated copper wires, a shielding layer encircles the wire cores and the power connection core, a filling layer is arranged among the shielding layer, the wire cores and the power connection core, and a rubber sheath wraps the shielding layer. The cable disclosed by the invention is applied to high-voltage power engineering and has the characteristics of low line loss of the wire cores, high conductivity and small sag; and compared with a conventional wire, the wire has the characteristics of remarkable low relaxation degree and has the advantages of high allowable working temperature, large carrying capacity, light weight and corrosion resistance.

Owner:GUANGDONG HERUN PRECISION METAL MATERIALS CO LTD

Aluminum tube wire jumper device used on double-loop transposition tower

InactiveCN105762741AImprove flexibilityStrong wind resistanceDevices for damping mechanical oscillationsDouble loopTransposition tower

The invention discloses an aluminum tube wire jumper device used on a double-loop transposition tower, and solves the problems of an existing wire jumper device that an end part is liable to discharge and the capability for overcoming the wind swinging is poor. The aluminum tube wire jumper device is characterized in that a hanging interval rod U-shaped plate (5) is connected with an aluminum tube upper hoop (6) and an aluminum tube lower hoop (7); a fixing bolt (9) successively penetrates through the hanging interval rod U-shaped plate (5), the aluminum tube upper hoop (6), the aluminum tube lower hoop (7) and a lower pad (8) to buckle the aluminum tube upper hoop (6) with the aluminum tube lower hoop (7); an aluminum tube (10) penetrates through a hole formed by the aluminum tube upper hoop (6) and the aluminum tube lower hoop (7); and wire jumper connection seats (11) are fixedly arranged on two ends of the aluminum tube (10), the wire jumper connection seats (11) are provided with grading ring support seats (12), and grading rings (13) are arranged on the grading ring support seats (12). According to the invention, the requirement of electric intervals is met, the machining is simple, and the installation is convenient.

Owner:CEEC SHANXI ELECTRIC POWER EXPLORATION & DESIGN INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com