Unbraced expanded steel-cored aluminum stranded wire

A steel-cored aluminum stranded wire, unsupported technology, applied in conductors, electrical components, power cables with shielding layer/conductive layer, etc. The problems of poor structural stability and low strength of hollow expanded diameter conductors achieve the effects of low noise, simple manufacturing process and excellent self-damping performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

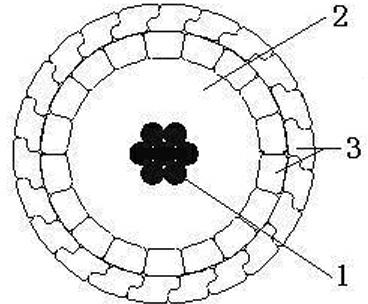

[0029] Embodiment one: if figure 1 As shown, the unsupported expanded diameter steel-cored aluminum strand of the present invention includes a central reinforced steel strand 1, a hollow structural layer 2 and an outer aluminum strand layer 3, wherein the central reinforced steel strand 1 is used as the core wire and is in the hollow structural layer 2 and the inside of the outer aluminum strand layer 3, between the outer aluminum strand layer 3 and the central reinforced steel strand 1 is a hollow structural layer 2, and the hollow structural layer is circular.

[0030] The central reinforced steel strand 1 is galvanized steel wire, aluminum-clad steel wire, etc., and the outer aluminum strand layer 3 is the inner aluminum conductor layer and the outer aluminum conductor layer respectively, and the inner aluminum conductor layer and the outer aluminum conductor layer are ordinary Aluminum wire, heat-resistant aluminum alloy wire, aluminum-magnesium-silicon alloy wire. The in...

Embodiment 2

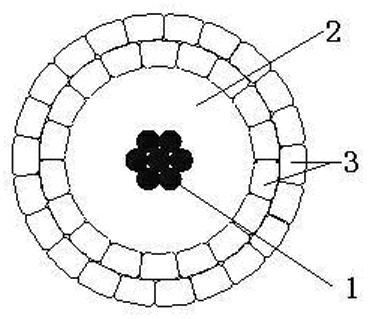

[0033] Embodiment two: if figure 2 As shown, the unsupported expanded diameter steel-cored aluminum strand of the present invention includes a central reinforced steel strand 1, a hollow structural layer 2 and an outer aluminum strand layer 3, wherein the central reinforced steel strand 1 is used as the core wire and is in the hollow structural layer 2 and the inside of the outer aluminum strand layer 3, between the outer aluminum strand layer 3 and the central reinforced steel strand 1 is a hollow structural layer 2, and the hollow structural layer is circular.

[0034] The central reinforced steel strand 1 is galvanized steel wire, aluminum-clad steel wire, etc., and the outer aluminum strand layer 3 is the inner aluminum conductor layer and the outer aluminum conductor layer respectively, and the inner aluminum conductor layer and the outer aluminum conductor layer are ordinary Aluminum wire, heat-resistant aluminum alloy wire, aluminum-magnesium-silicon alloy wire. The i...

Embodiment 3

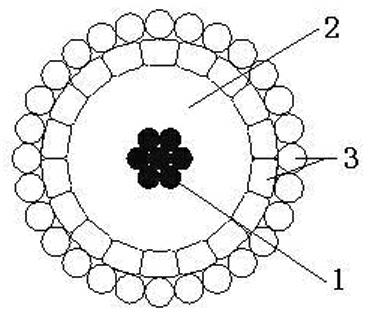

[0037] Embodiment three: as image 3 As shown, the unsupported expanded diameter steel-cored aluminum strand of the present invention includes a central reinforced steel strand 1, a hollow structural layer 2 and an outer aluminum strand layer 3, wherein the central reinforced steel strand 1 is used as the core wire and is in the hollow structural layer 2 and the inside of the outer aluminum strand layer 3, between the outer aluminum strand layer 3 and the central reinforced steel strand 1 is a hollow structural layer 2, and the hollow structural layer is circular.

[0038] The central reinforced steel strand 1 is galvanized steel wire, aluminum-clad steel wire, etc., and the outer aluminum strand layer 3 is the inner aluminum conductor layer and the outer aluminum conductor layer respectively, and the inner aluminum conductor layer and the outer aluminum conductor layer are ordinary Aluminum wire, heat-resistant aluminum alloy wire, aluminum-magnesium-silicon alloy wire. The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com