Anti-icing automatic deicing anti-galling special-shaped overhead wire

An overhead wire, anti-galling technology, applied in the direction of power cables, electrical components, circuits, etc., can solve problems such as power supply difficulties, loss, and unstable hydrophobic performance, and achieve the effect of ensuring safe operation and preventing galloping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The application of the present invention will be described in detail below in conjunction with the accompanying drawings.

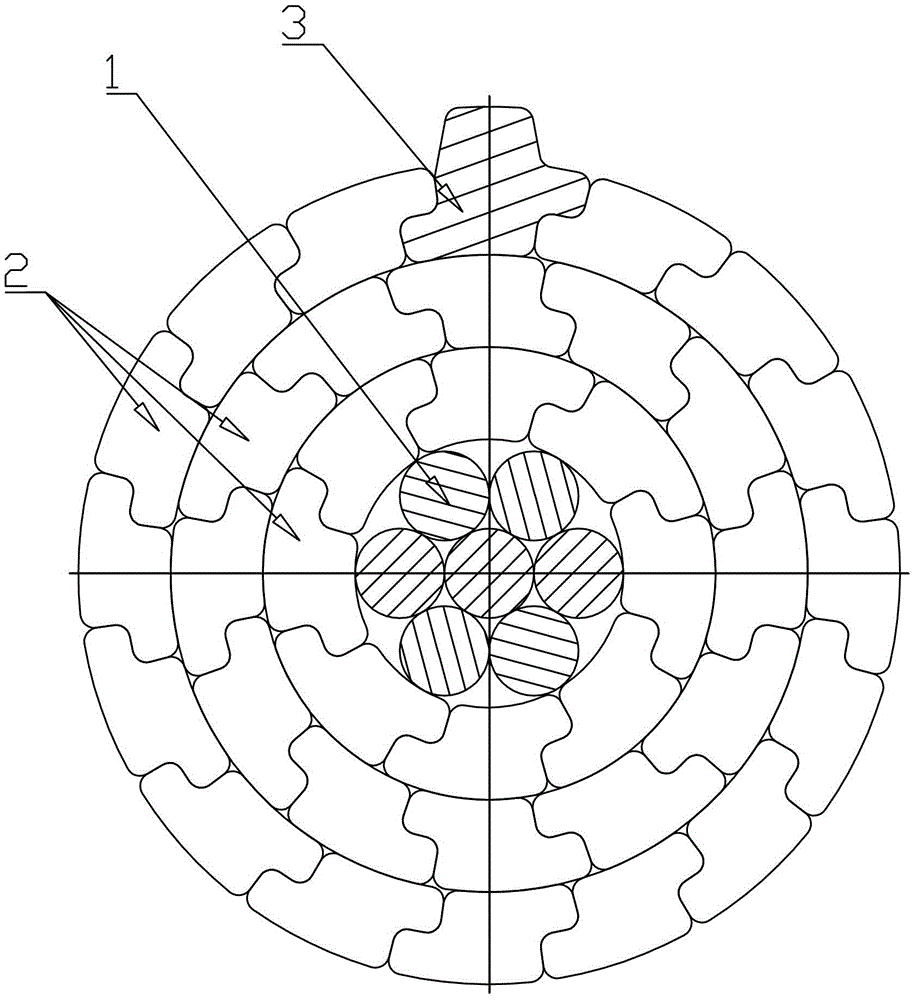

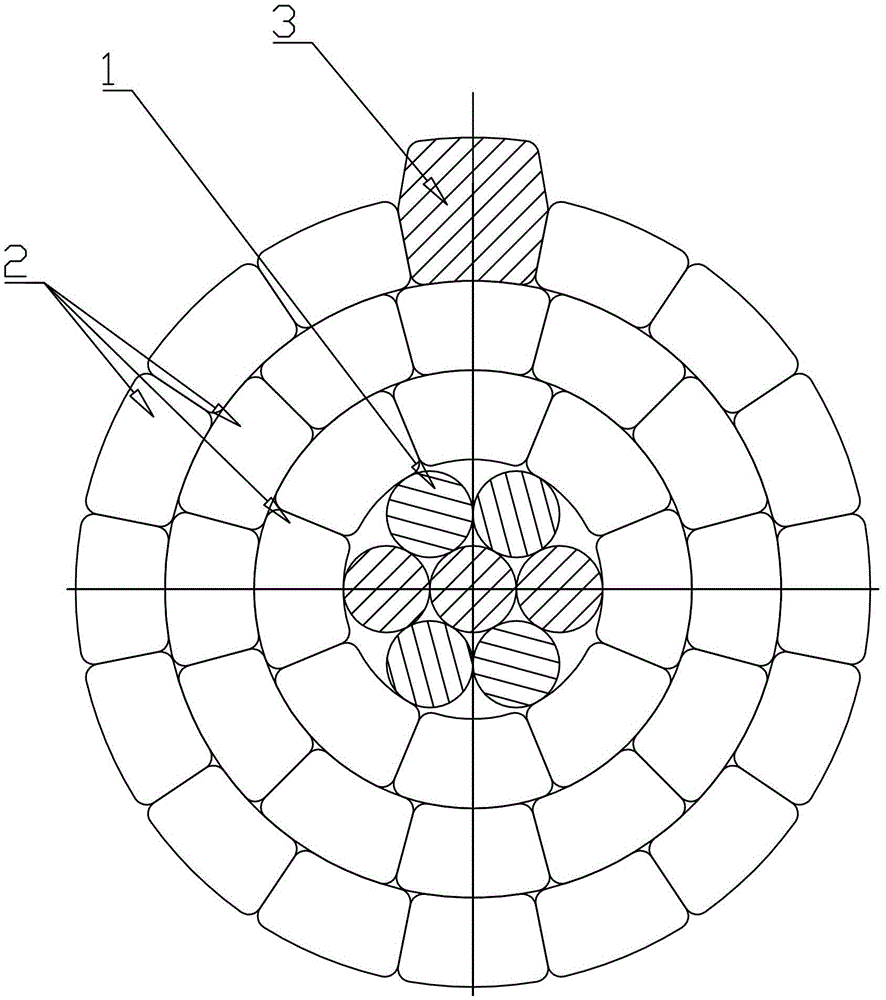

[0018] refer to Figure 1 ~ Figure 2 , an anti-icing, automatic deicing and anti-galling special-shaped overhead wire, which includes a core 1, and the outer surface of the core 1 is wrapped with several layers, and a plurality of metal strands 2 are twisted together to form a cylindrical conductive layer with a smooth outer surface , the adjacent conductive layers are pressed against each other and can rotate relative to each other. Each layer of conductive layer forms a tube ring, and the two layers are in close contact, so that the overhead wire has greater strength; when the wind blows, due to the different parts between the two layers The natural frequency of the overhead wire is different, so resonance cannot occur; at the same time, the relative rotation between the two adjacent conductive layers will occur, heat and noise will be generated,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com